Patents

Literature

66results about How to "High degree of peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance halogen-free flame retardant ABS modified resin and preparation method thereof

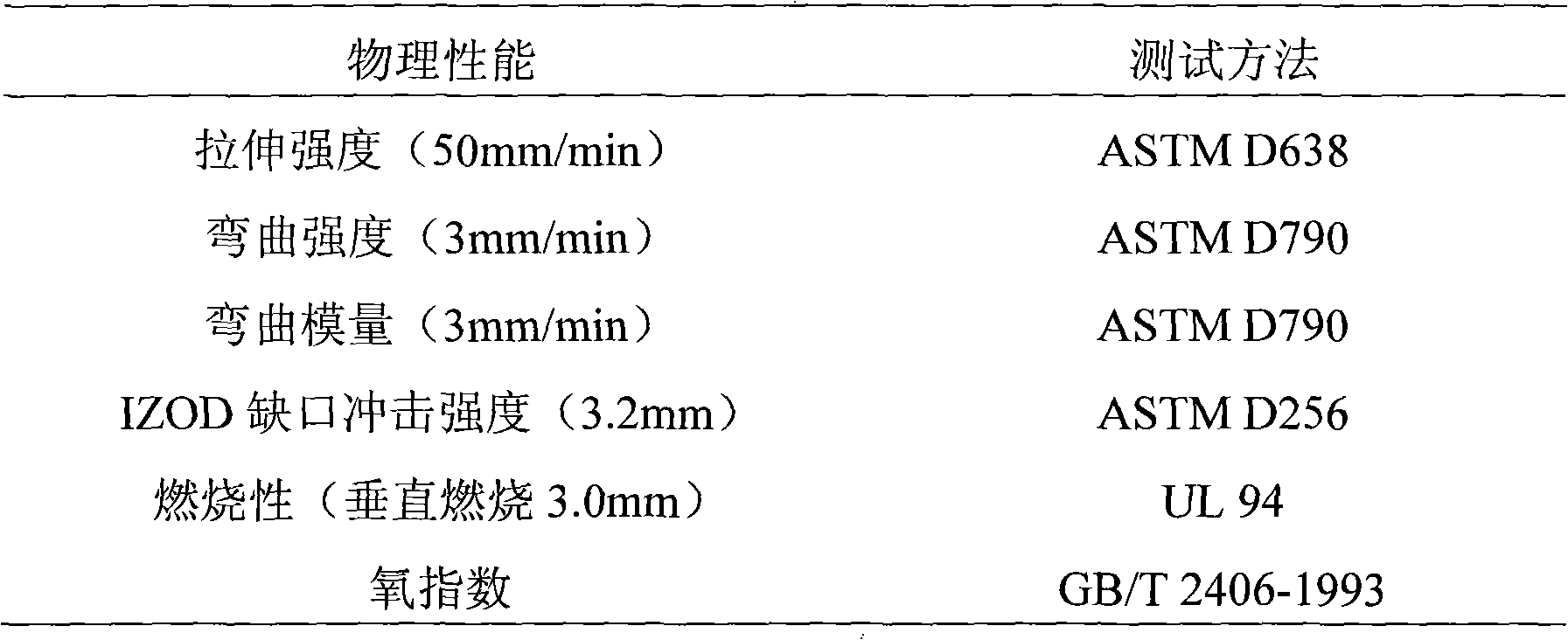

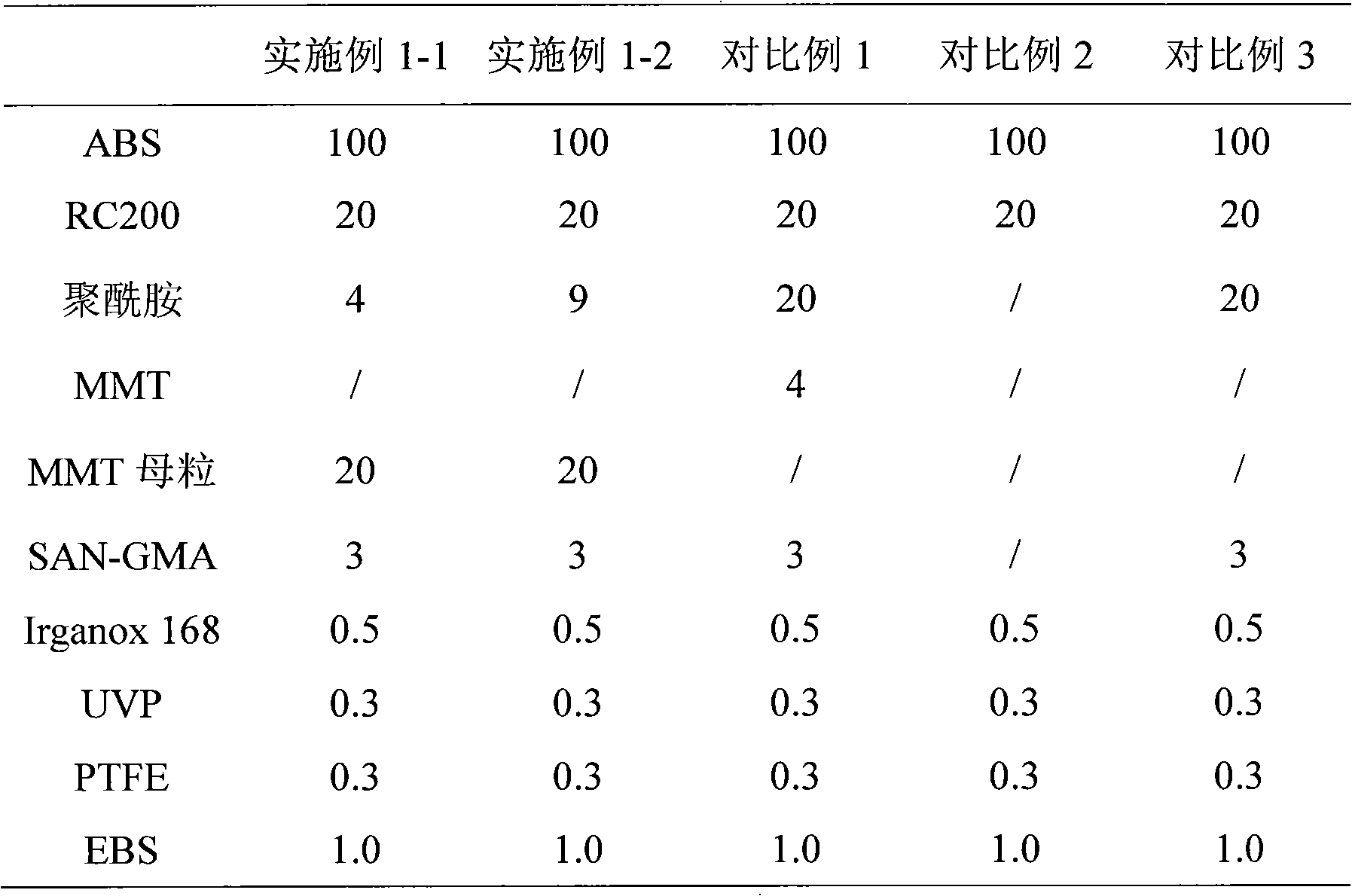

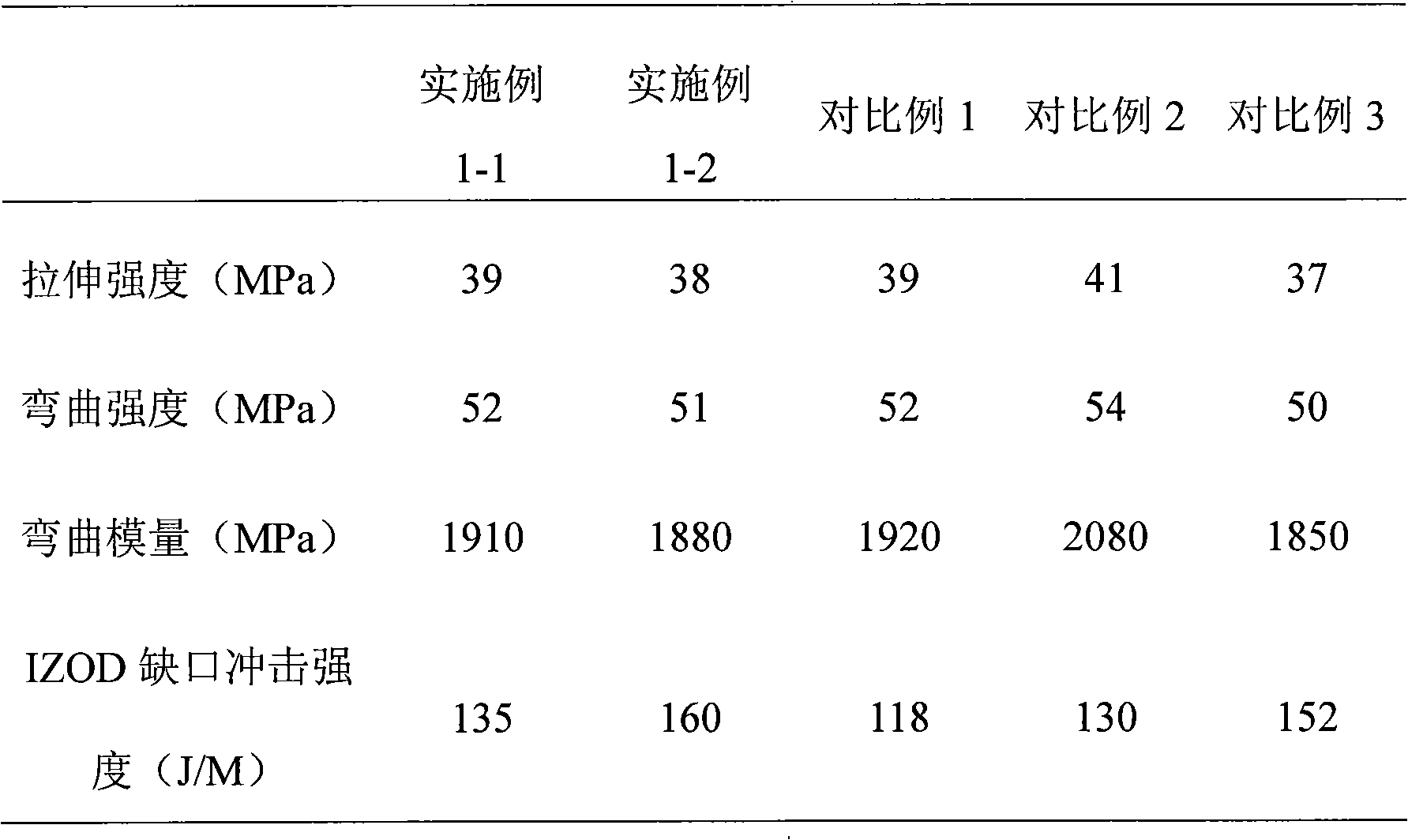

The invention relates to a high-performance halogen-free flame retardant ABS modified resin and a preparation method thereof. The resin comprises the following components with the content (in parts by weight): 100 ABS resin, 4-30 polyamide, 5-25 phosphate fire retardant, 0.1-0.5 anti-drippage agent, 5-10 toughening agent, 1-5 nano filler, 1-5 compatilizer, 0.2-1 antioxidant, 0.1-0.5 light stabilizer and 1-5 processing agent. Compared with the prior art, the invention has reasonable technique, and overcomes the defects of poor flame retardant property and low impact strength of the existing halogen-free flame retardant ABS; and the invention adopts a novel high-efficiency halogen-free flame retardant compounding synergism technology, a novel polyamide coal-forming agent, the high-efficiency synergism between organic and inorganic fire retardants, and the master batch method processing technique, thus endowing the resin with high fire resistance on the basis of improving the original good performances (especially the impact performance) of the ABS resin, and having wide application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

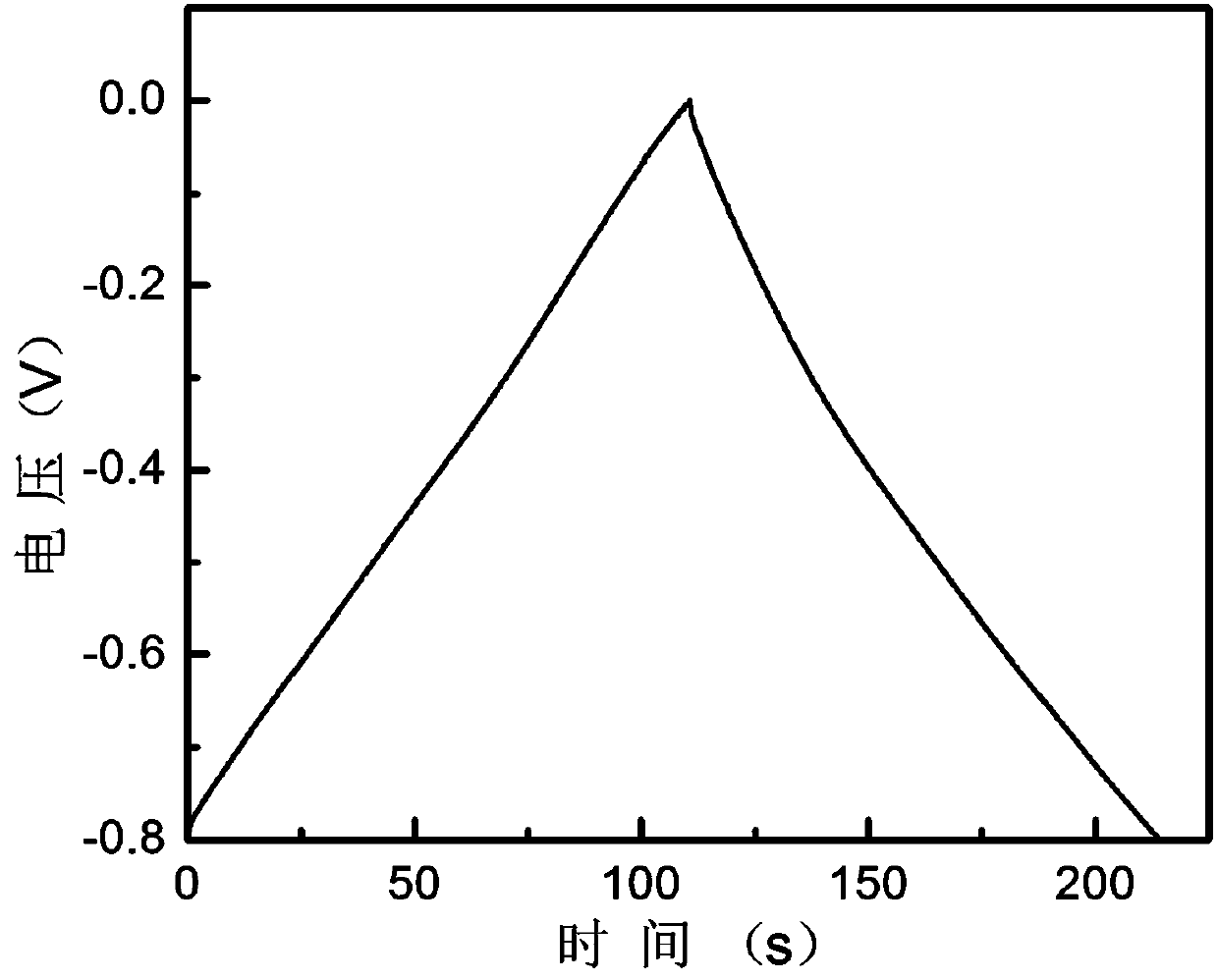

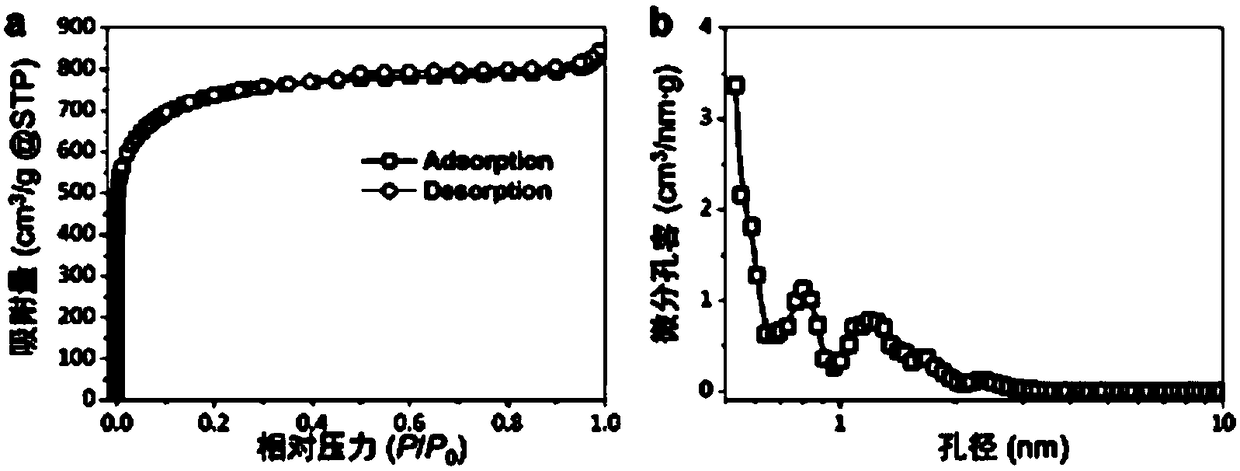

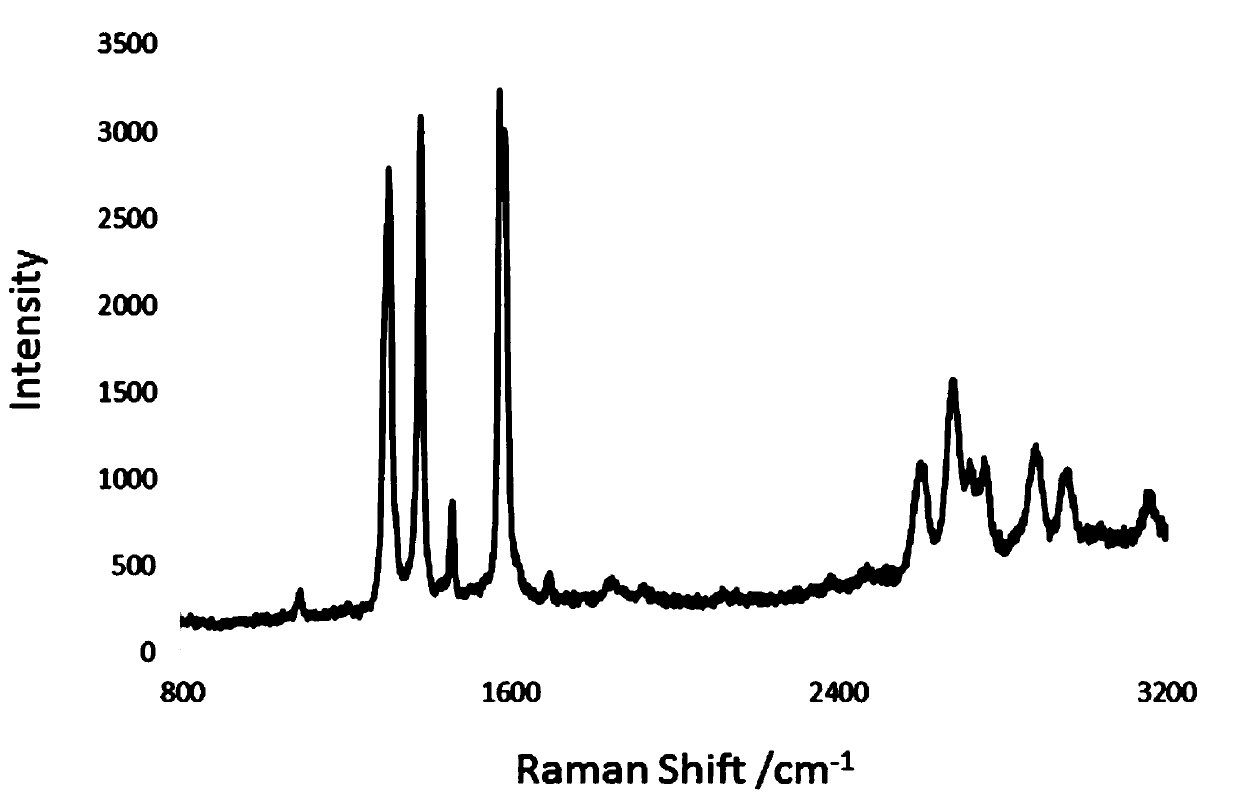

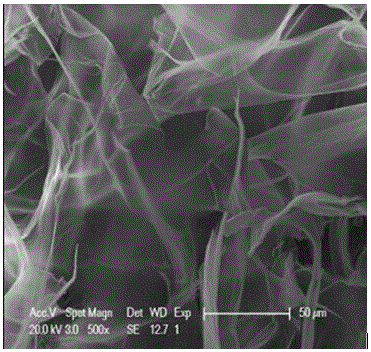

Preparation method of porous graphene

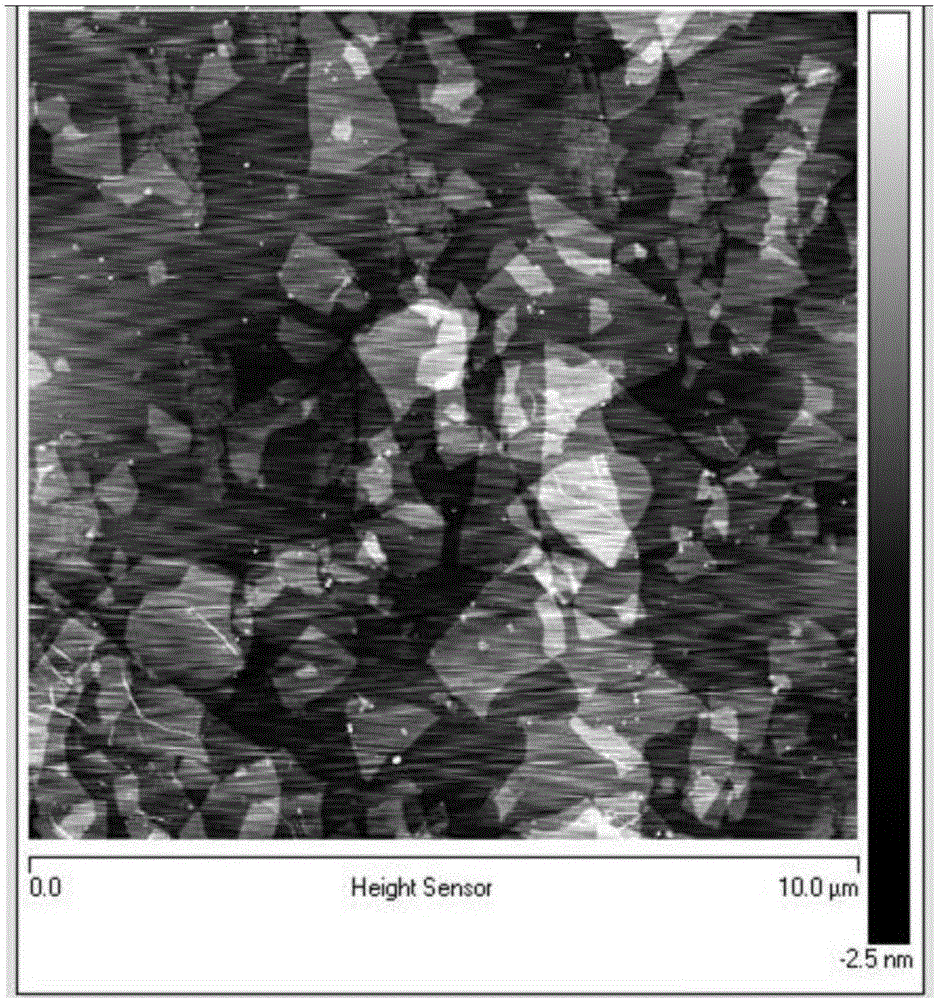

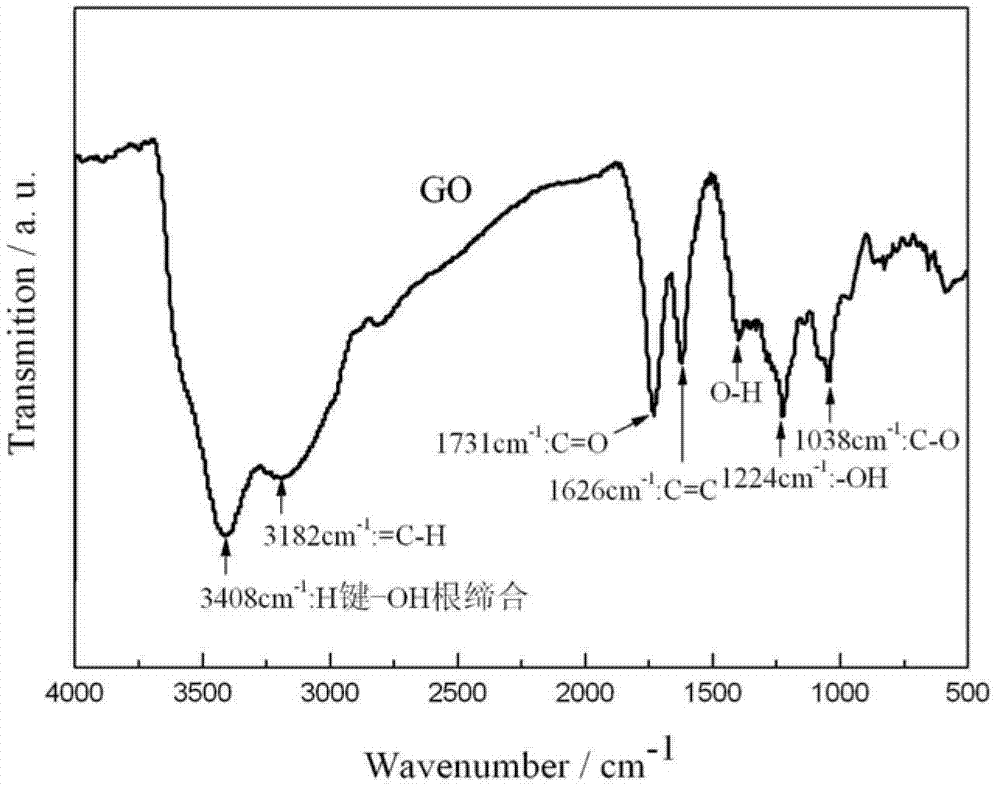

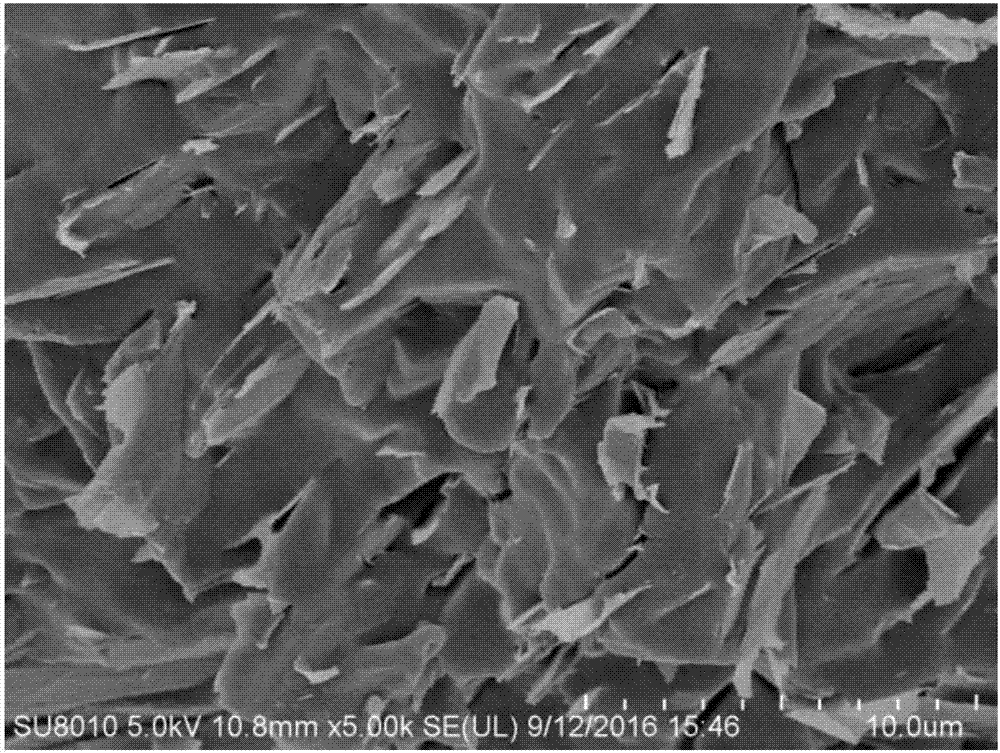

InactiveCN103466604AInhibit high temperature agglomeration effectHigh degree of peelingCarbon compoundsPorous grapheneCapacitance

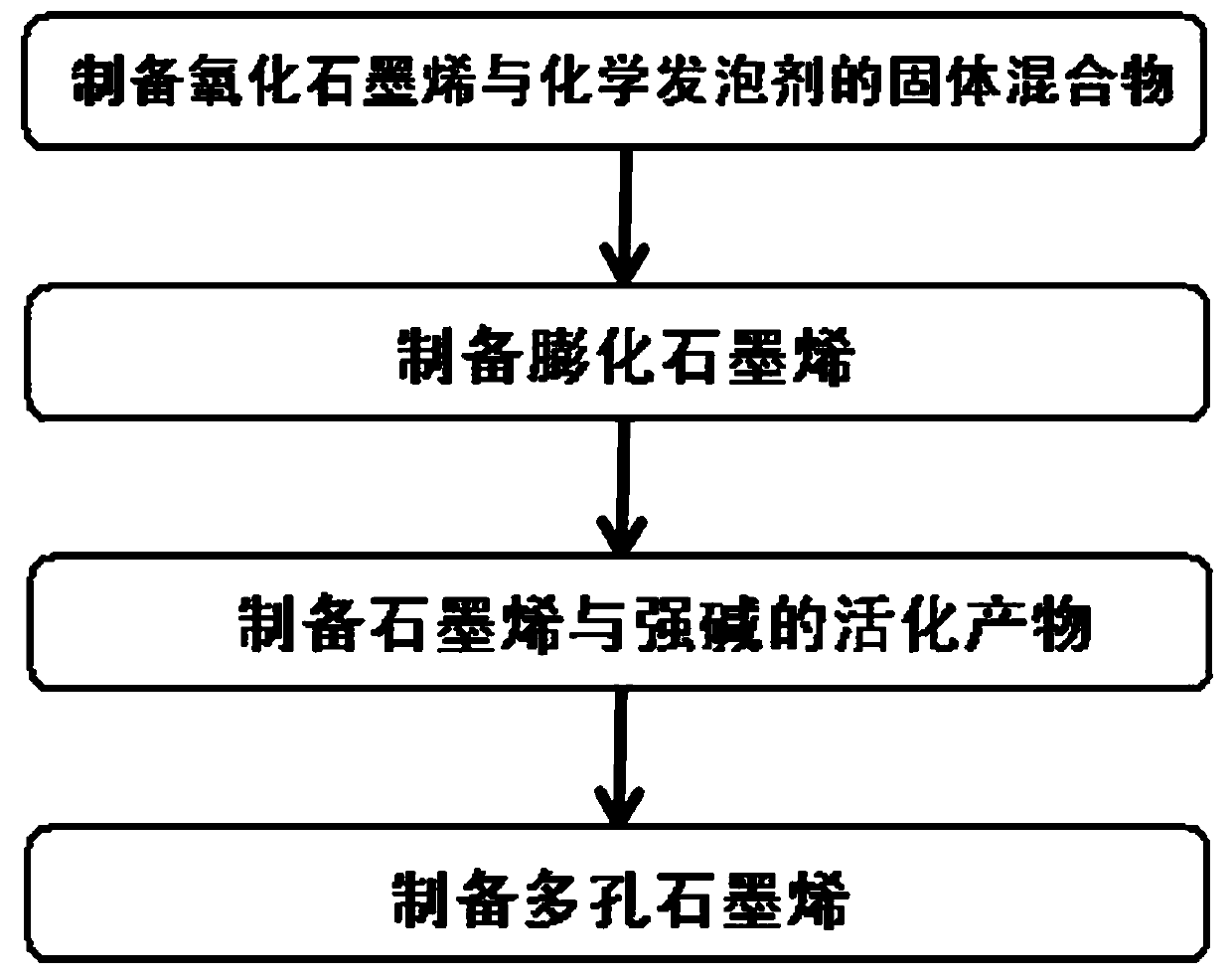

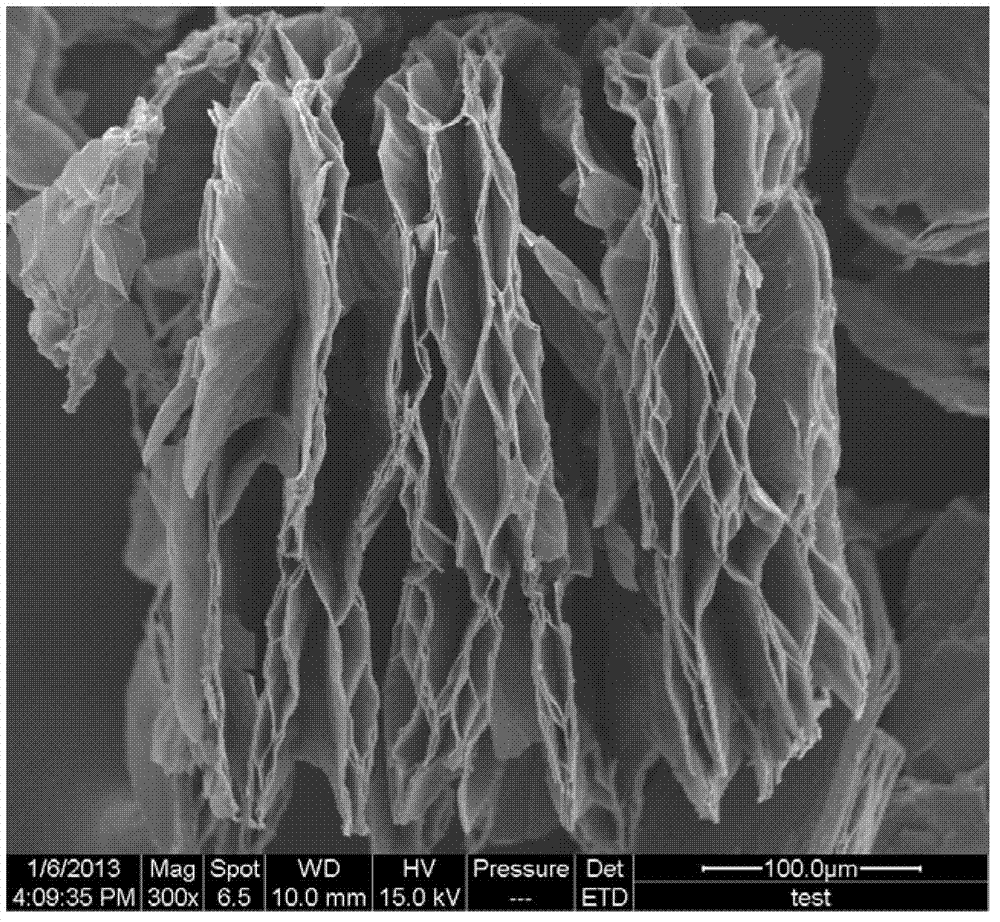

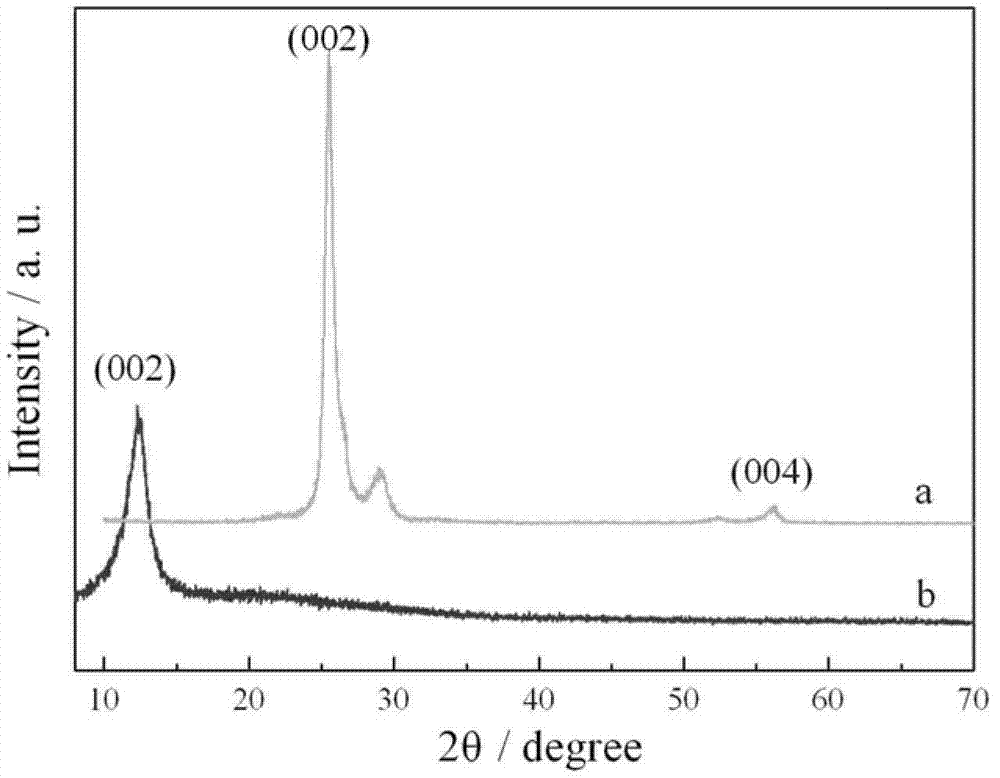

The invention discloses a preparation method of porous graphene. The method comprises the steps of: (1) stripping graphite oxide in a water / ethanol mixed solution with pH of 9-10, adding a chemical foaming agent and mixing them uniformly, carrying out filtering and drying to obtain a solid mixture; (2) placing the mixture in a reducing atmosphere, and performing heating expansion reduction to obtain expanded graphene; (3) blending the expanded graphene with strong base, and conducting high temperature activation; and (4) washing the product with hydrochloric acid and deionized water, and performing drying so as to obtain porous grapheme. The porous graphene prepared by the method involved in the invention has a specific surface area up to 2075m<2> / g, a pore volume up to 1.8cm<3> / g, and an average pore size of 1-7nm. As a supercapacitor electrode material, the specific capacitance can reach 155F / g under a current density of 1Ag<-1>. As a porous graphene electrode, the specific capacitance can reach 84.4% along with the increase of current density from 0.2Ag<-1> to 20Ag<-1>. The porous graphene has high specific capacitance and cycle stability. The preparation method disclosed in the invention has the advantages of simple process, low cost, and easy scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

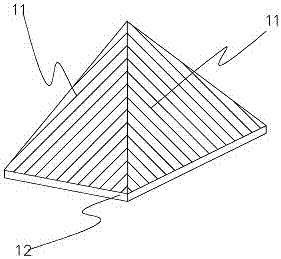

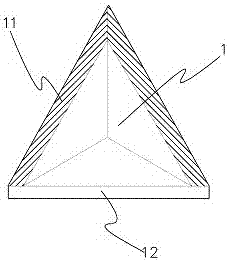

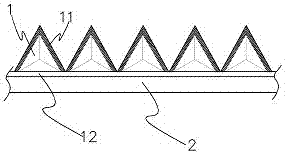

Micron order prism pyramid monomer and manufacturing method thereof

PendingCN107144903AAvoids the phenomenon of sedimentation at the bottom of the fluidImprove reflective effectOptical elementsMicron scalePolymer science

The invention relates to the light reflection material technology field and provides a micron order prism pyramid monomer and a manufacturing method thereof. The prism pyramid is capable of accommodating both the light flashing and light reflecting effects, and can exist independently without being attached to a carrier film. Only with adhesive glue, oil painting, hair glue and nail polishing oil and other colorless or colored transparent fluid or liquid media, it is possible to let the prism pyramid monomer to be attached on objects such as films, cloth, wires and plates requiring to be added with light or to realize light flash so that these materials can present the lighting effect. The monomer can be applied widely in great practical use, and the manufacturing method for the monomer is also simple and easy to implement. Therefore, with the method, batched monomer can be produced and used.

Owner:YEAGOOD INC

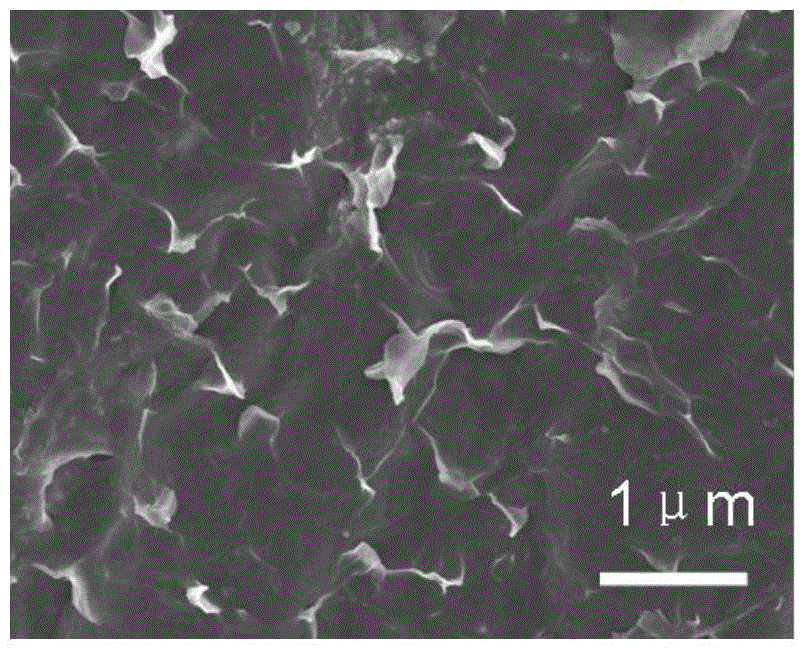

Preparation method of high quality graphene conductive film

Owner:QINGDAO UNIV OF SCI & TECH

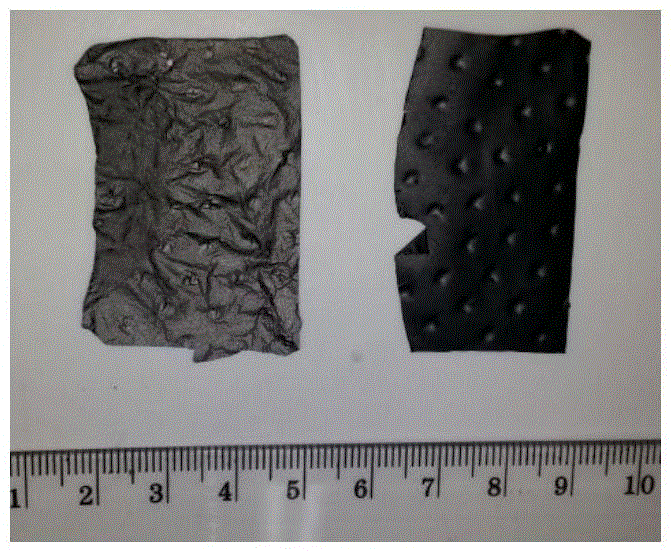

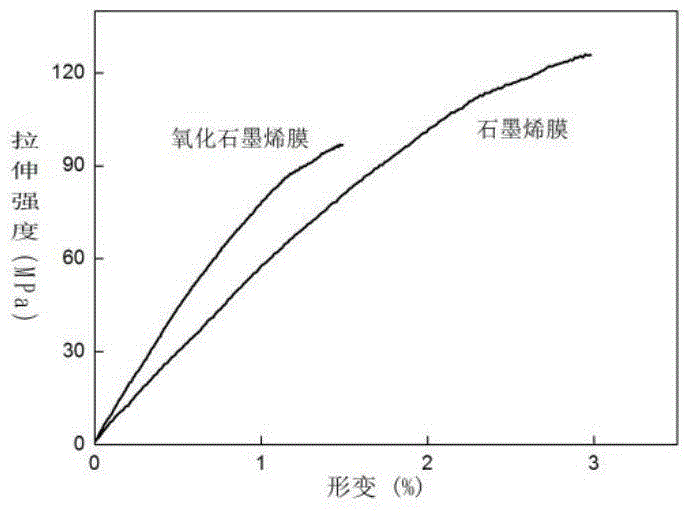

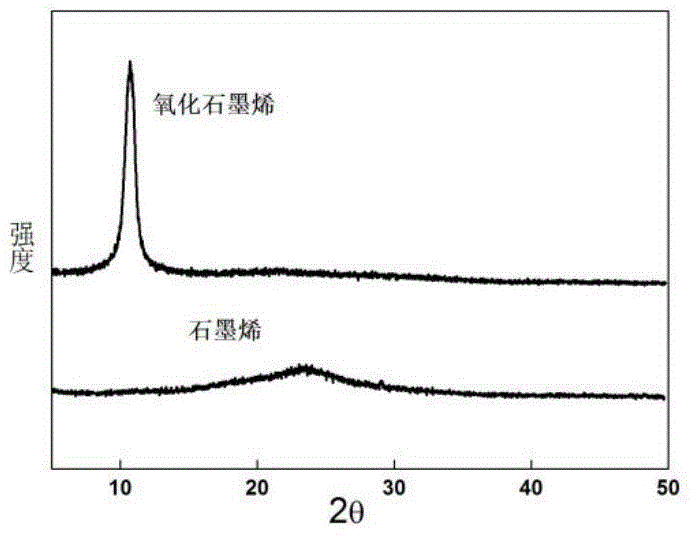

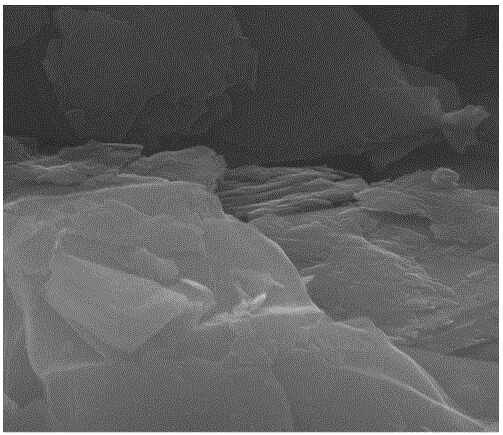

Preparation method of high-conductivity graphene membrane

The invention belongs to the technical field of preparation of graphene materials, and particularly relates to a preparation method of a high-conductivity graphene membrane. The preparation method comprises the following steps: preparing graphene oxide through an improved Hummer method in the presence of phosphoric acid protective agent, filtering through a polyester fiber filter membrane to obtain a graphene oxide membrane, and reducing the obtained graphene oxide membrane in a hydriodic acid-ethanol mixed solution to obtain the graphene membrane. The preparation method is simple and convenient to operate, has simple requirements for equipment and technology, and is cheap in raw materials and low in cost; and the prepared graphene membrane has few defects and high conductivity. The preparation method is easy to realize large-scale industrial production.

Owner:QINGDAO UNIV OF SCI & TECH

Method for preparing graphene

InactiveCN106006613AResidue reductionMeet the requirements of green environmental protectionGrapheneSodium bicarbonateOxidation state

A kind of method for preparing graphene of the present invention, concrete process is: with halogen, hydrochloric acid, hydrogen bromide, hydrogen iodide, ammonium nitrate, zinc chloride, ferric chloride, ammonium carbonate, sodium carbonate, potassium carbonate or ammonium bicarbonate , sodium bicarbonate, potassium bicarbonate and other high-temperature, easy-to-evaporate, sublime, and easily-decomposed substances are used as intercalation agents, and the raw materials for preparing graphene, such as expanded graphite, layered graphite, and carbon paper, are pretreated. , the pretreated raw material is electrochemically oxidized under a certain voltage to obtain an oxidized precursor, and the oxidized material is further blasted and peeled off under the action of ultrasound and stirring to obtain flaky graphene oxide, and then after heat treatment Graphene oxide will be reduced to graphene. The method of the invention is simple to operate and convenient to prepare, and can prepare high-quality graphene or graphene oxide on a large scale, and can be used to solve the problems of high cost, low product quality, complicated operation and large pollution in the current graphene preparation technology.

Owner:GUANGZHOU TINGYU ENERGY TECH CO LTD

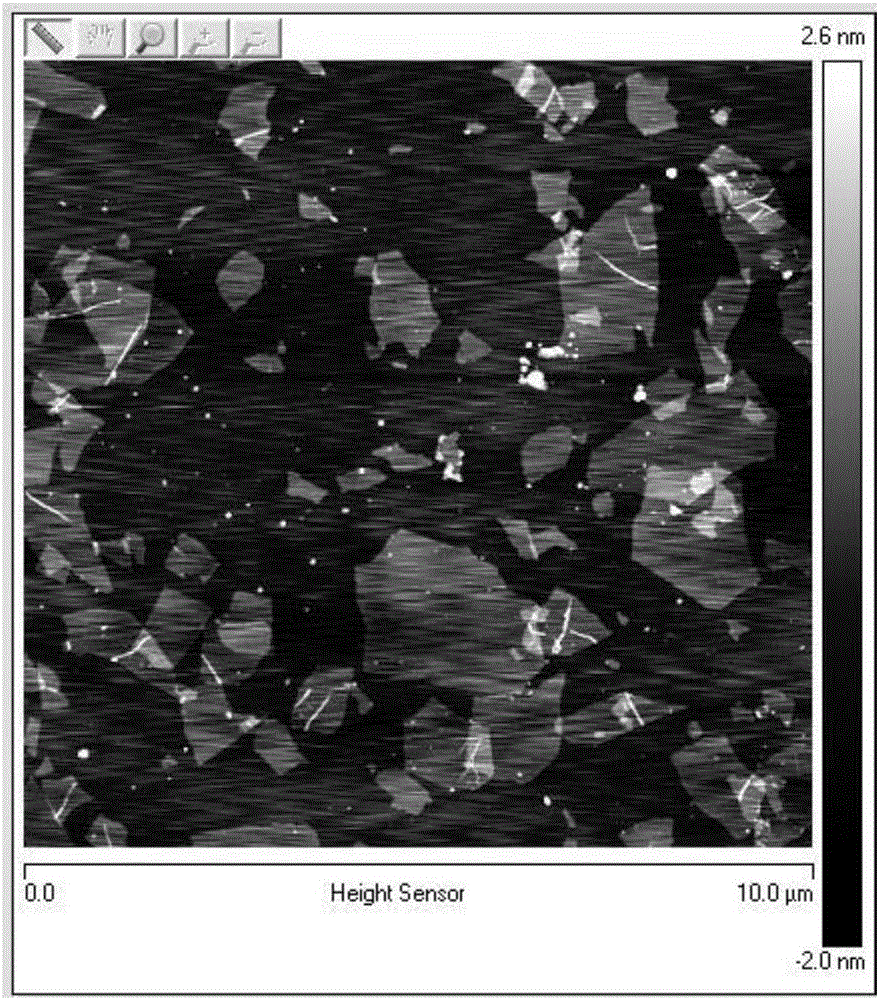

Preparation method of graphene powder

ActiveCN106744894AImprove the recovery peeling degreeHigh degree of peelingCarbon compoundsLithiumReduction treatment

The invention relates to the technical field of preparation of nanophase materials, and in particular relates to a preparation method of graphene powder. The preparation method comprises the following steps: (1) preparing a graphene oxide solution; (2) adding organic small molecules to the graphene oxide solution, stirring and drying to obtain graphite oxide containing the organic small molecules; and (3) carrying out heat reduction treatment on the dried graphite oxide containing the organic small molecules to obtain graphene powder. The graphene powder prepared by the method provided by the invention has the characteristics of high degree of peeling, thin sheets, few structural defects, good degree of order and excellent electric conductivity, and has great application prospects in the fields of lithium-ion batteries, supercapacitors and the like.

Owner:BEIJING SINEVA MATERIAL TECH CO LTD +2

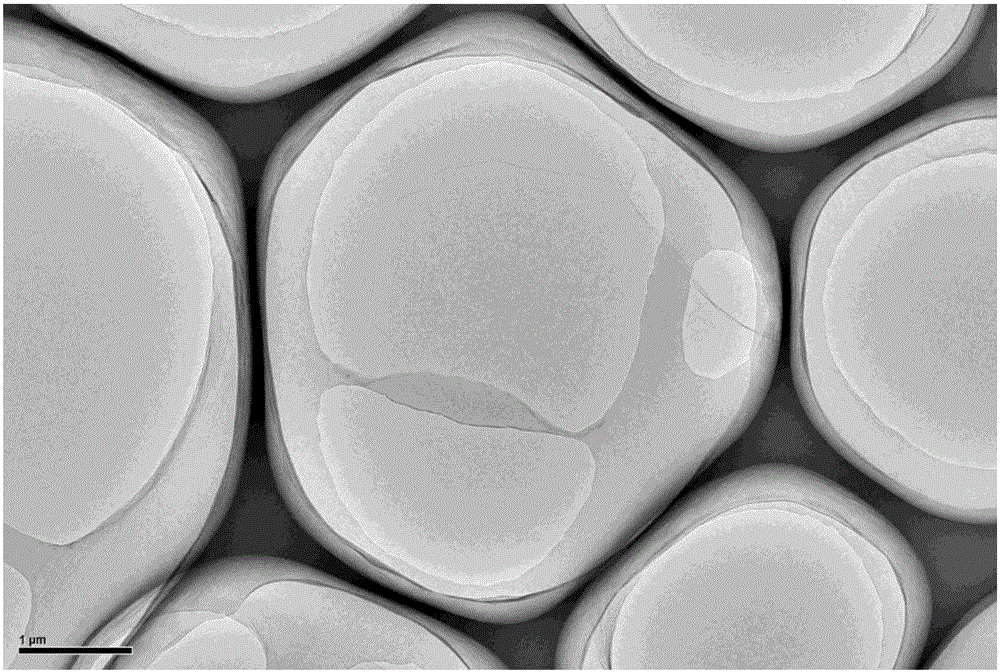

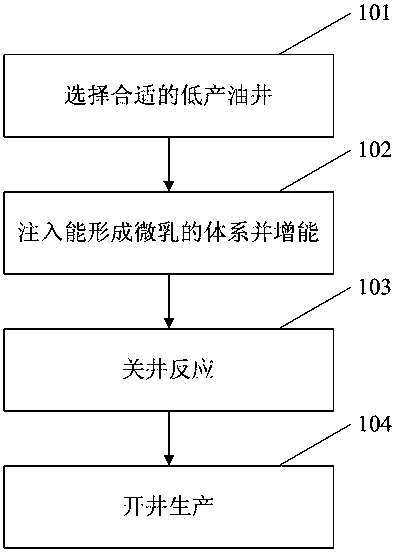

Production increase method for increasing single-well productivity of oil well

InactiveCN107859507AIncrease production capacityHigh degree of peelingFluid removalDrilling compositionMicroemulsionWell control

The invention provides a production increase method for increasing the single-well productivity of an oil well. The production increase method for increasing the single-well productivity of the oil well comprises the steps that 1, the suitable low-productivity oil well is selected; 2, a system capable of forming microemulsion is injected into the low-productivity oil well, and energization is conducted on the low-productivity oil well; 3, the low-productivity oil well is subjected to a well closing reaction, the reaction of an injected fluid and crude oil is met, and it is ensured that after sufficiently reacting, the crude oil in a reservoir stratum is dissolved into the injected microemulsion system and an energization system at the maximum quantity; and 4, well opening for production isconducted. According to the production increase method for increasing the single-well productivity of the oil well, through the microemulsion and an oil layer protection assistant, an oil flow channel can be dredged, damage is removed, the production increase purpose is achieved, the stripping extent of the crude oil can be greatly increased, effective flowing of the oil of the single-well controlled reserve volume is increased in an auxiliary energization mode, and thus the single-well yield is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polypropylene modified sound insulation composite material and preparation method thereof

ActiveCN107793637AImprove sound absorptionImprove sound insulationBulk chemical productionAntioxidantAcoustic wave

The invention discloses a polypropylene modified sound insulation composite material and a preparation method thereof. The polypropylene modified sound insulation composite material comprises, in weight percent, 33.8%-88.8% of polypropylene, 10%-60% of modified talcum powder, 0.2% -2% of antioxidants and 1%-6% of additives. The composite material mainly takes the modified talcum powder as a raw material, the modified talcum powder after intercalation modification in a supercritical carbon dioxide state is of a laminated structure in a polypropylene substrate, polymer macromolecules easily enter in the production process of the modified talcum powder, the stripping degree of the modified talcum powder in polypropylene is greatly improved, the reflection frequency of the same weight parts oftalcum powder for sound waves is increased, the composite material has excellent sound insulation effects and better stiffness increasing effects, and sound absorption and sound insulation performances of the composite material are improved.

Owner:中广核俊尔(上海)新材料有限公司

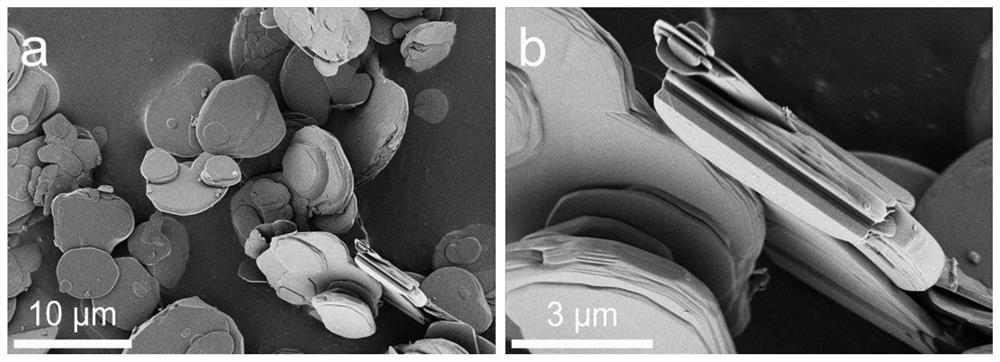

Mechanical stripping method of functionalized boron nitride nanosheet

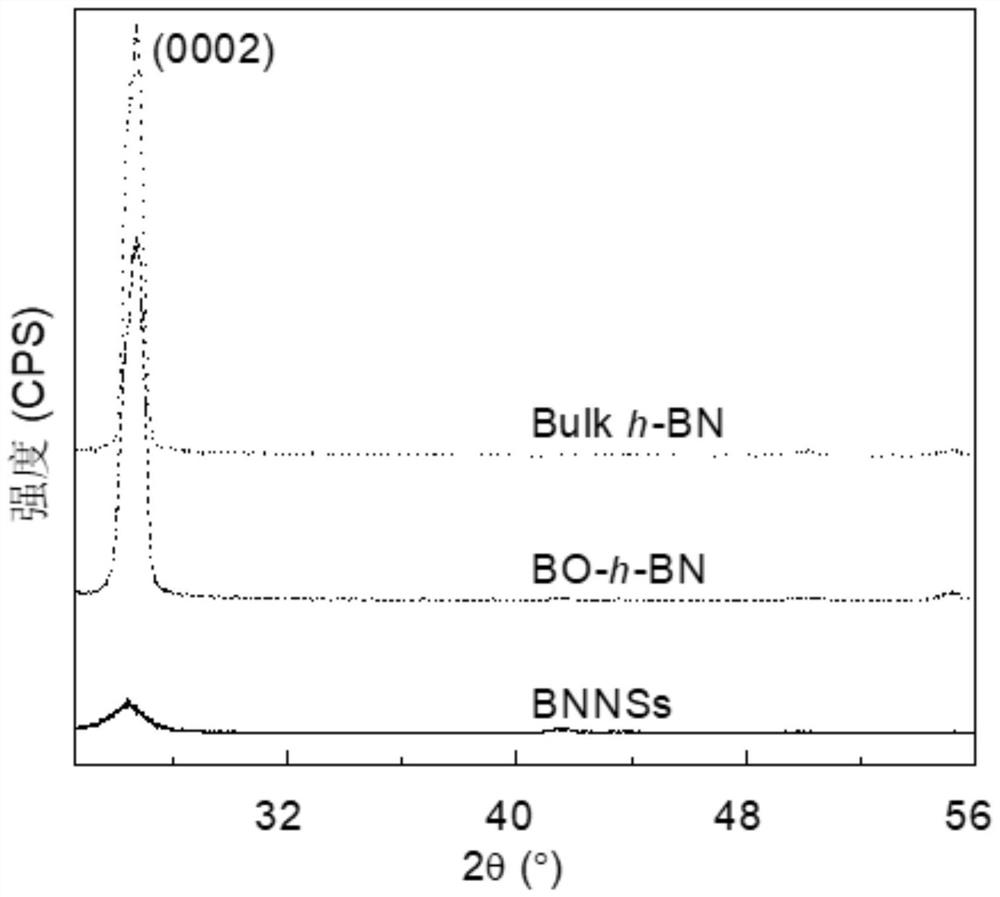

ActiveCN111717900ADiffraction peak intensity of apparent crystal planeEfficient strippingNitrogen compoundsNanotechnologyLiquid productHexagonal boron nitride

The invention relates to a mechanical stripping method of a functionalized boron nitride nanosheet. The method adopts boric acid and commercial bulk hexagonal boron nitride as raw materials, and comprises the following three steps: uniformly mixing boric acid and commercial hexagonal boron nitride in a mortar, and carrying out high-temperature pretreatment to make the commercial bulk hexagonal boron nitride eroded by dehydrated boric acid and fixed by boron oxide in order to obtain a uniformly reacted solid mixture; roughly grinding the solid mixture obtained after the reaction, putting the ground solid mixture into a ball milling tank, and carrying out mechanical ball milling treatment; and dissolving and dispersing white powder obtained after ball milling into deionized water, and carrying out repeated washing multiple times to ensure that free boric acid is completely washed away so as to obtain a functionalized boron nitride nanosheet dispersion liquid product; or drying a productobtained by centrifugal washing to obtain a functionalized boron nitride nanosheet powder product. The method is simple to operate, harsh experimental conditions are not needed, boric acid and deionized water can be recycled, and the obtained products are high in crystallinity and functionalization degree.

Owner:HEBEI UNIV OF TECH

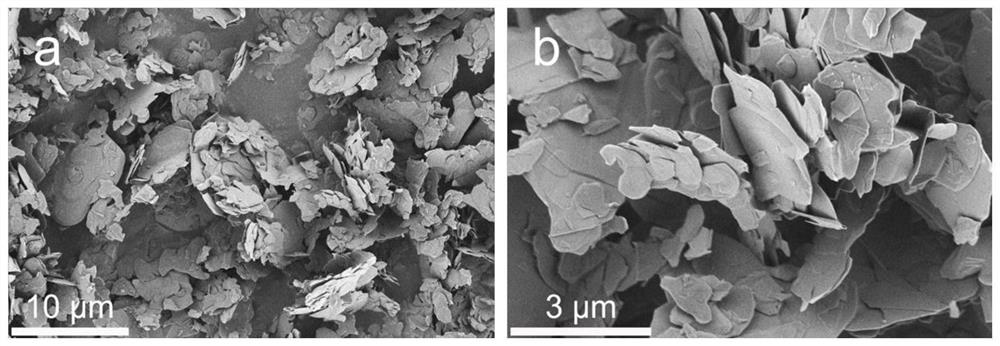

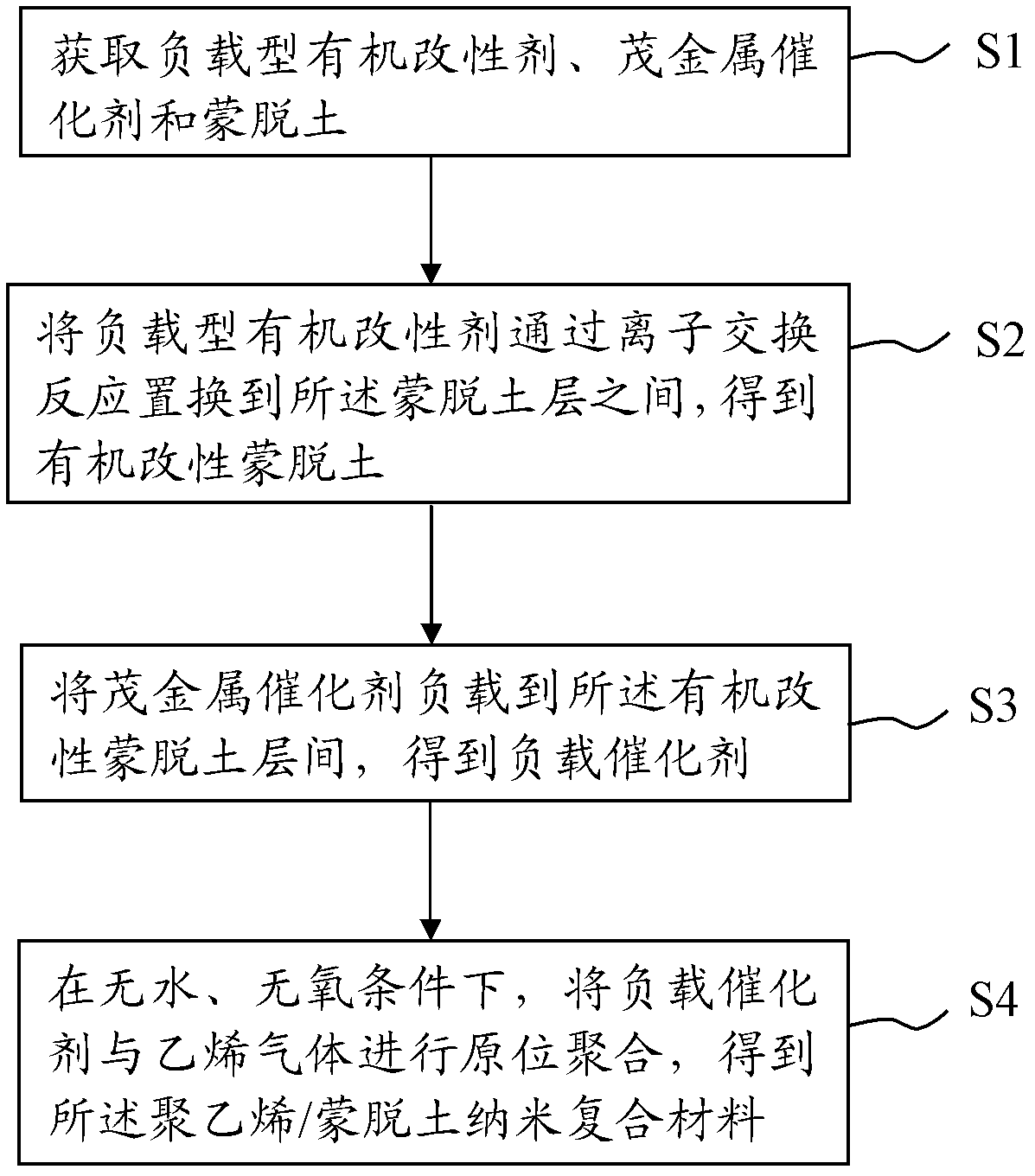

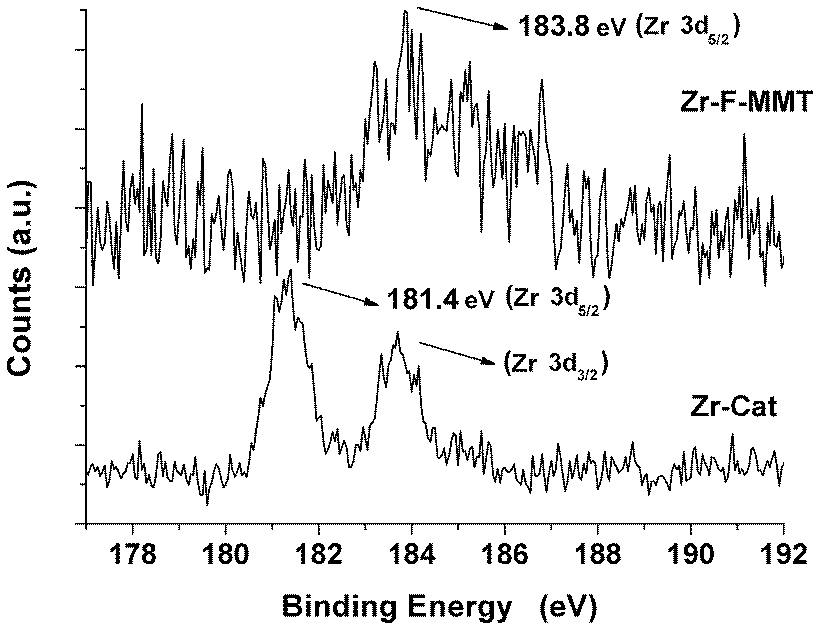

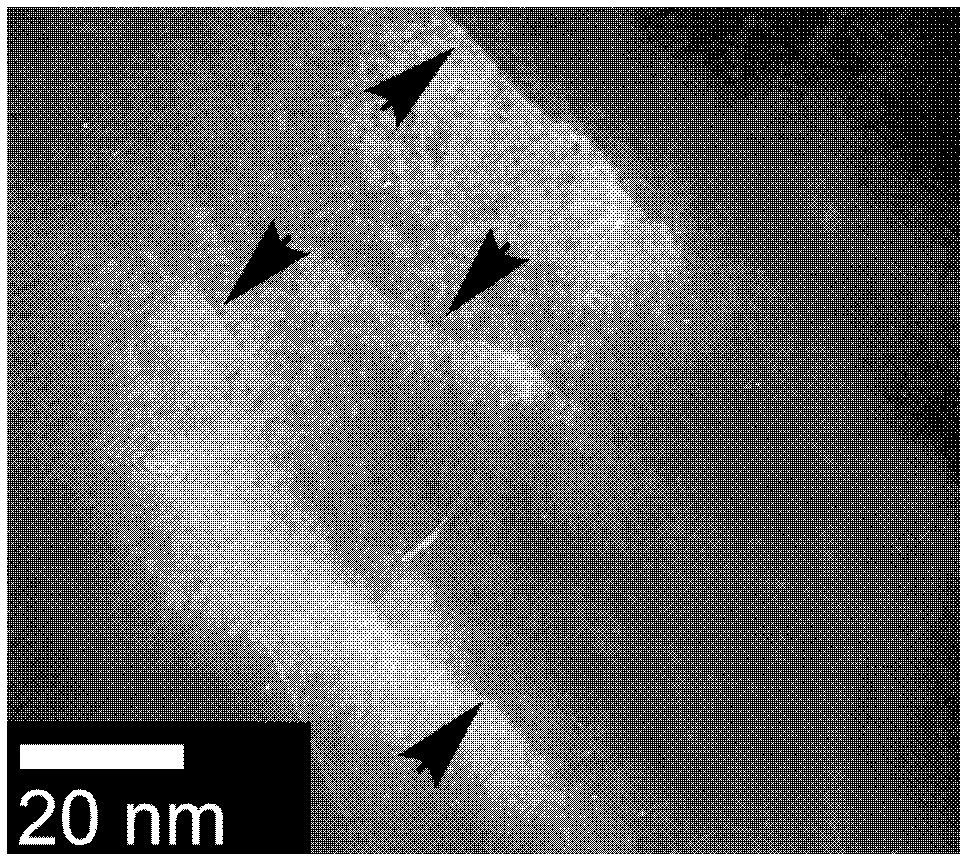

Polyethylene/montmorillonite nanometer composite material and method for preparing same by in-situ polymerization

The invention discloses a polyethylene / montmorillonite nanometer composite material and a method for preparing the same by in-situ polymerization. The method for preparing the polyethylene / montmorillonite nanometer composite material by in-situ polymerization includes the following steps of: obtaining a supported organic modifier, a metallocene catalyst and montmorillonite; displacing the supported organic modifier into interlayers of the montmorillonite through ion exchange reaction to obtain organically modified montmorillonite; loading the metallocene catalyst into interlayers of the montmorillonite to obtain a supported catalyst; and carrying out in-situ polymerization on the supported catalyst with ethylene gases under the water-free and oxygen-free condition to obtain the polyethylene / montmorillonite nanometer composite material. The method for preparing the polyethylene / montmorillonite nanometer composite material by in-situ polymerization effectively reduces the catalyst amount and production cost, improves the production efficiency, and has moderate reaction condition, low requirements for equipment and simple operation, and is suitable for industrialization production.

Owner:SHENZHEN KEJU NEW MATERIAL

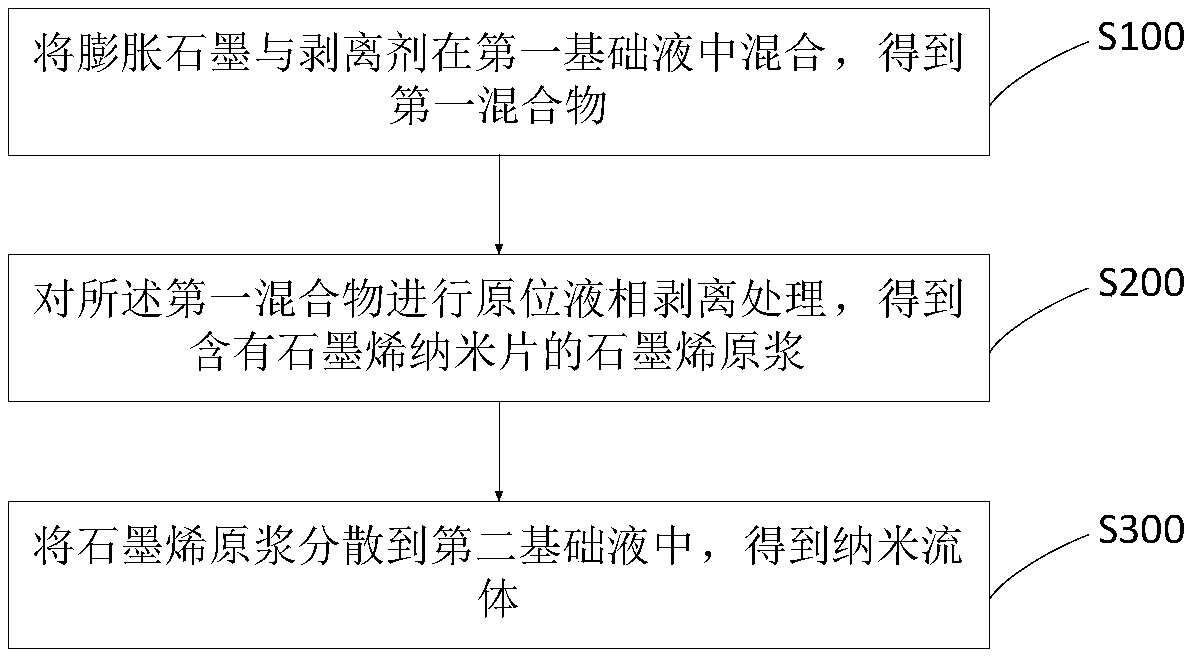

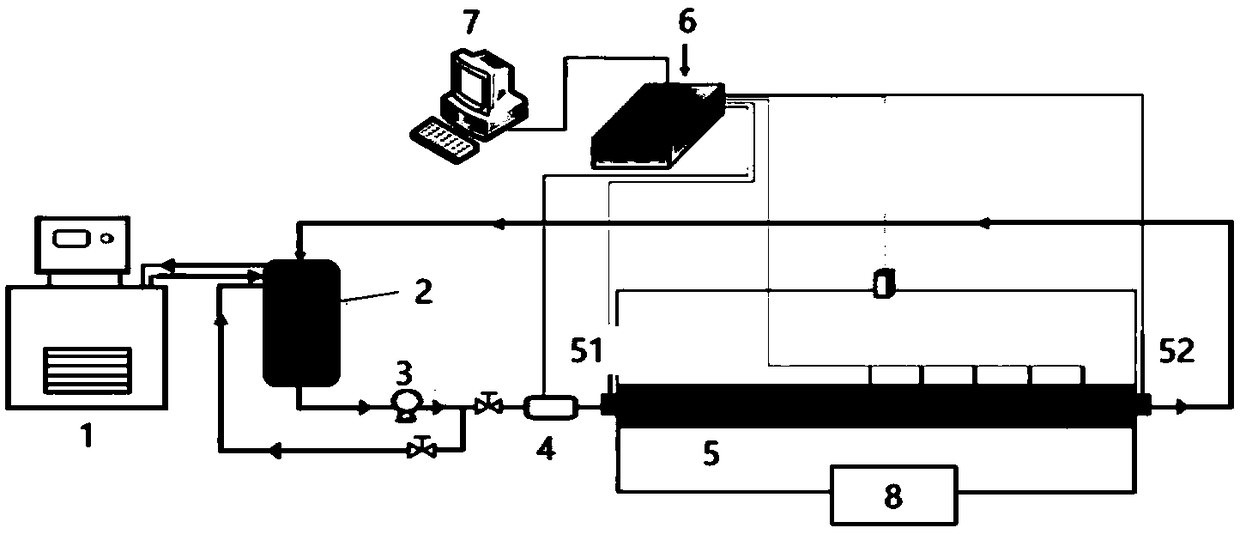

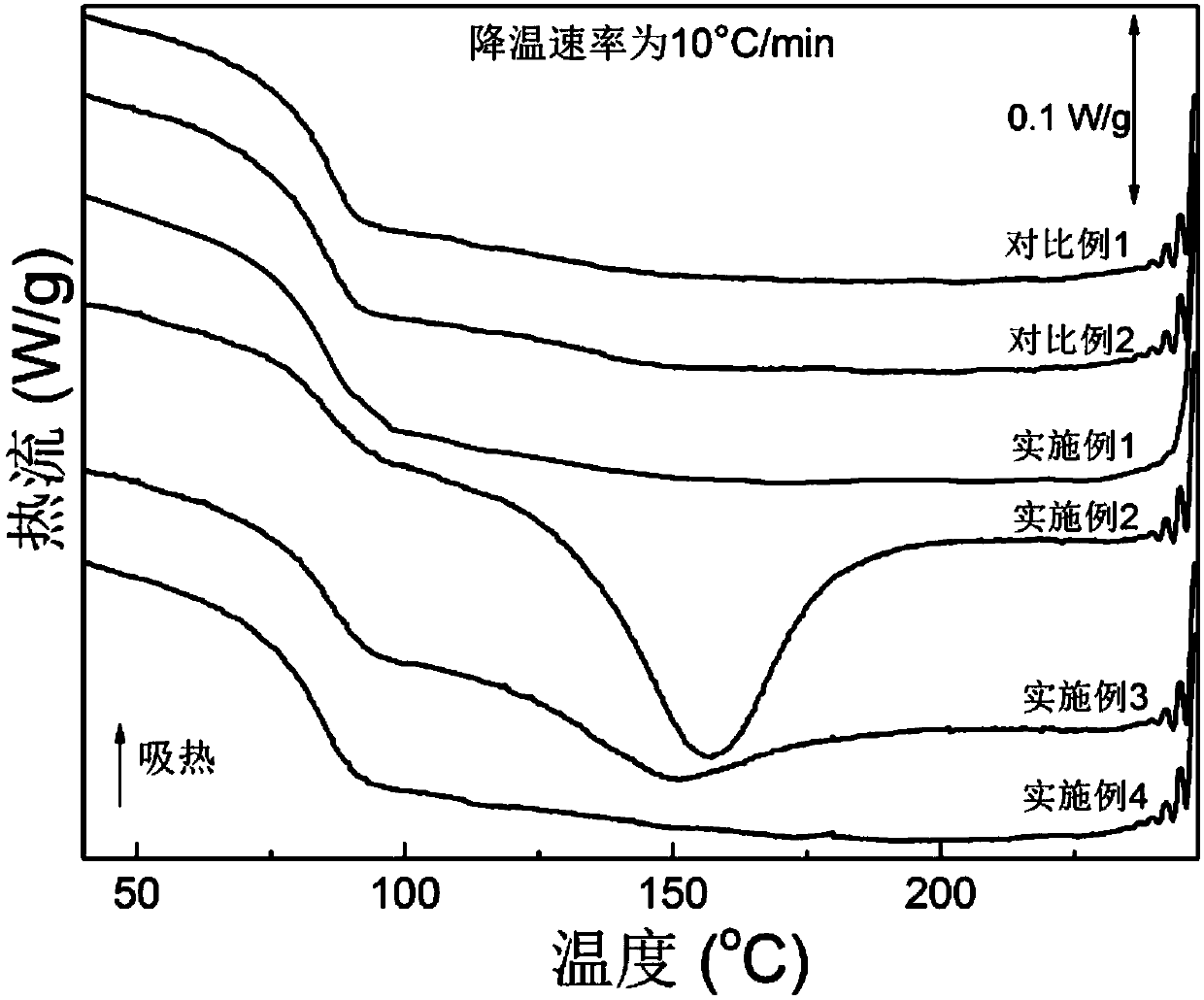

Nano-fluid for efficient heat transfer fluid, preparation method thereof and heat exchange device

The invention provides a nano-fluid, a preparation method thereof and a heat exchange device. The preparation method of the nano-fluid comprises the following steps: mixing expanded graphite with a stripping agent in a first base fluid to obtain a first mixture, and performing in-situ liquid phase stripping treatment on the first mixture to obtain a raw graphene stock containing graphene nano-sheets; and uniformly dispersing the raw graphene stock into a second base fluid to obtain the nano-fluid. The inventors have found that the method is simple and convenient to operate, facilitates large-scale production, is safe and environment-friendly, and can obtain the nano-fluid with high heat transfer coefficient, high thermal conductivity, low flow resistance and long-term stable dispersion.

Owner:ENN GRAPHENE TECH CO LTD

Extrusion stretching type pre-coating film and preparation method thereof

ActiveCN104497901AHigh mechanical strengthHigh degree of peelingFilm/foil adhesivesPolymer scienceBoPET

Owner:ANHUI GUOFENG PLASTIC

Improved process for clean production of xylose

InactiveCN106498001AReduce the adhesion of impuritiesSteam explosion time shortenedSugar derivativesSugar derivatives preparationAgricultural residueChemistry

The invention discloses an improved process for clean production of xylose. The process comprises the steps that forestry and agricultural residues are subjected to pretreatment of raw material, enzymolysis, solid-liquid separation, concentration, pre-decoloration and chromatographic separation and purification, and then refining and crystallization of xylose are achieved and purification and crystallization of arabinose are achieved. The improved process for clean production of xylose has the advantages that the steam explosion temperature is relatively low, and a continuous production is achieved through a steam explosion technology; xylan in the raw materials are transformed to xylose and the transformation rate reaches 95% or above; moreover, impurities in a xylose solution are reduced, the steam explosion time is greatly shortened, water consumption is reduced, chromatographic separation resin is protected, the service life of the resin is prolonged, steam is effectively saved and the steam explosion cost is reduced.

Owner:FUTASTE PHARM CO LTD

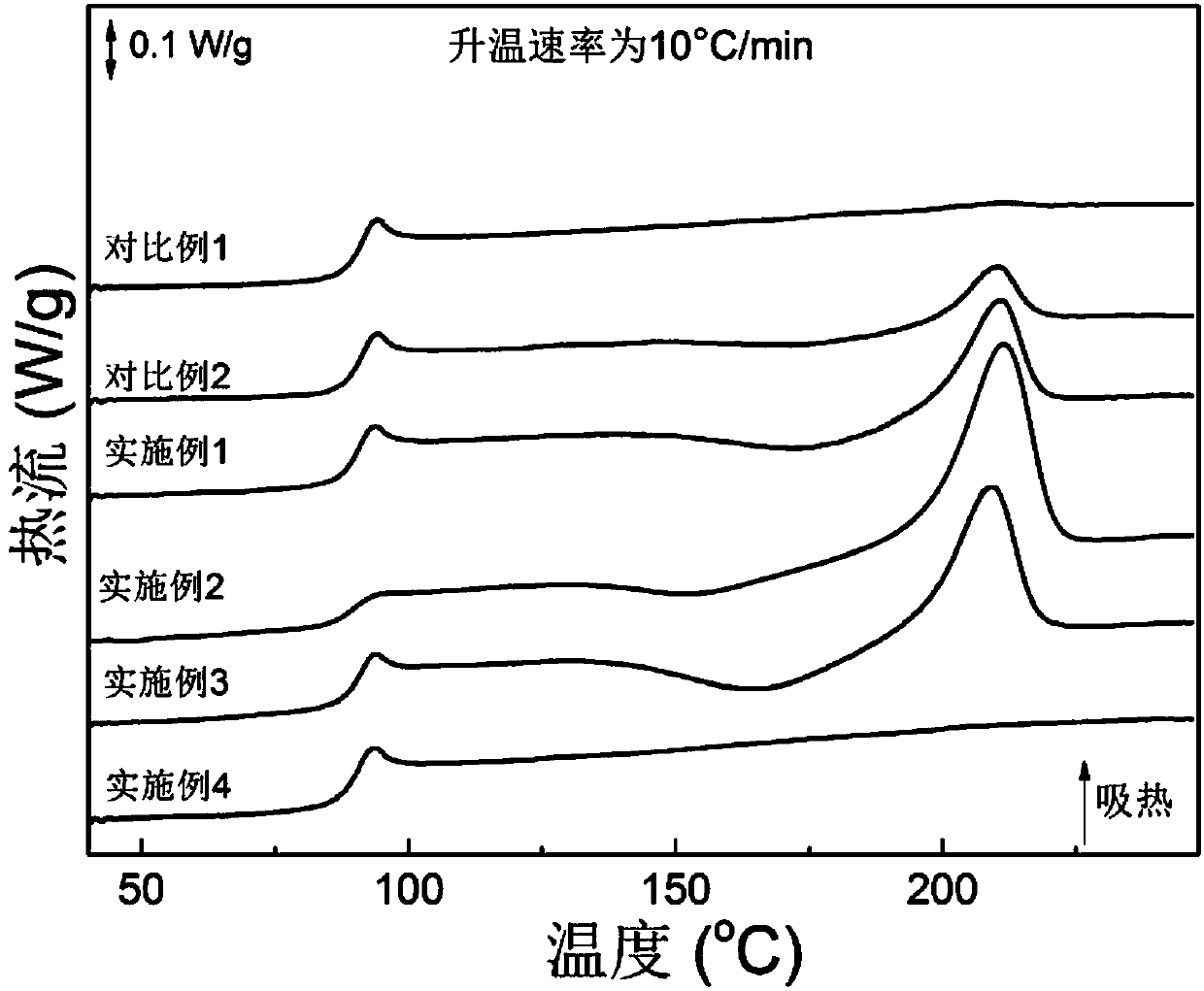

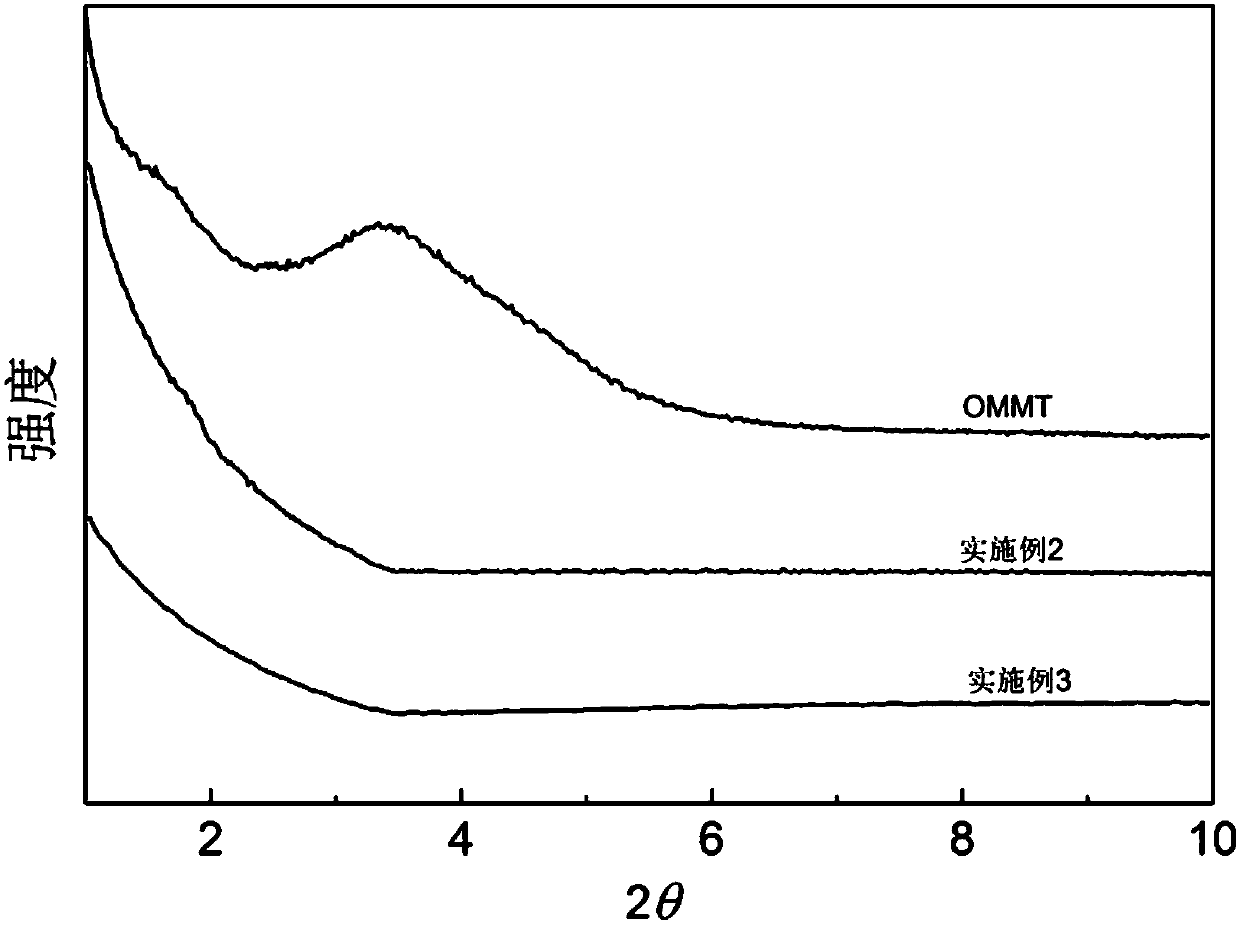

2, 5-furan dicarboxylic polyester/layered silicate nano-composite material, preparation method thereof and application of material

The invention discloses a 2, 5-furan dicarboxylic polyester / layered silicate nano-composite material, a preparation method thereof and an application of the material. The composite material comprises2, 5-furan dicarboxylic polyester and layered silicate and is prepared by an in-situ polymerization method, the stripping degree of the organically-treated layered silicate in an acquired product substrate is high, the molecular weight of the organically-treated layered silicate is high, the tensile strength of the organically-treated layered silicate is high, and the organically-treated layered silicate has a certain crystallization property. The preparation method is simple and feasible and solves the problem of slow crystallization rate of the2, 5-furan dicarboxylic polyester, applicationsof the preparation method can further be widened in the high-resistance air packaging market, and a good foundation is provided for subsequent industrialization.

Owner:ZHEJIANG UNIV

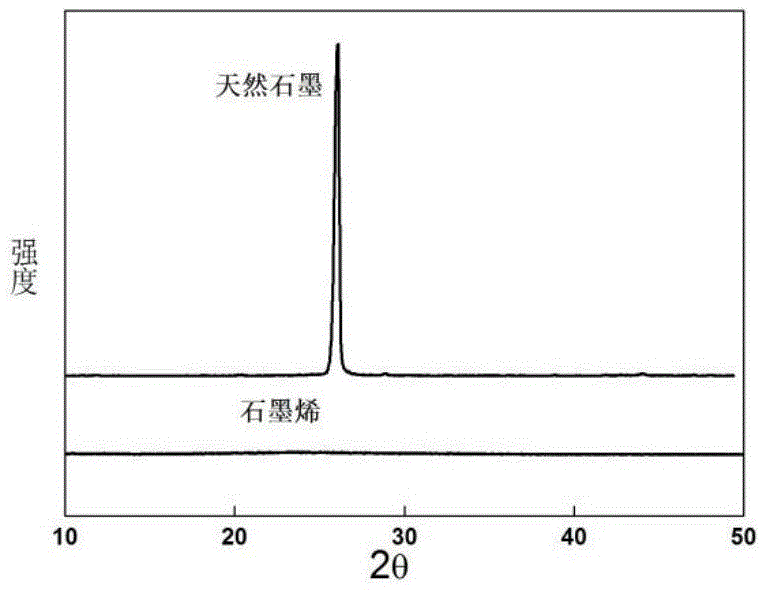

Preparation method for oxidized grapheme in large sheet

ActiveCN103408000BImprove oxidation efficiencyHigh degree of peelingCarbon compoundsIce waterStrong acids

The invention relates to a preparation method for oxidized graphene in a large sheet. The method comprises the following steps: uniformly mixing natural scale graphite with the mixed acid of concentrated nitric acid or nitric acid and sulfuric acid in a reactor; adding hydrogen peroxide from the bottom of the reactor; reacting under mixing for 10-60 min; washing with water and drying to obtain layered graphite; mixing the layered graphite with strong acid; adding strong oxidant slowly; performing ultrasound-assisted oxidation reaction in an ice-water bath for 30-60 min after uniform mixing; heating the reaction mixture to 50-60 DEG C and continuing mixing for 6-12 h; adding deionized water and performing ultrasound-assisted mixing reaction for 10-30 min; cleaning the obtained product first with mixed solution of diluted hydrochloric acid and hydrogen perhydrol, then with deionized water; performing centrifugal separation to obtain oxidized graphene. The method provided by the invention is simple in operation, high in oxidation efficiency and free from environment pollution; the prepared oxidized graphene has a high peeling rate and a high specific surface area.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

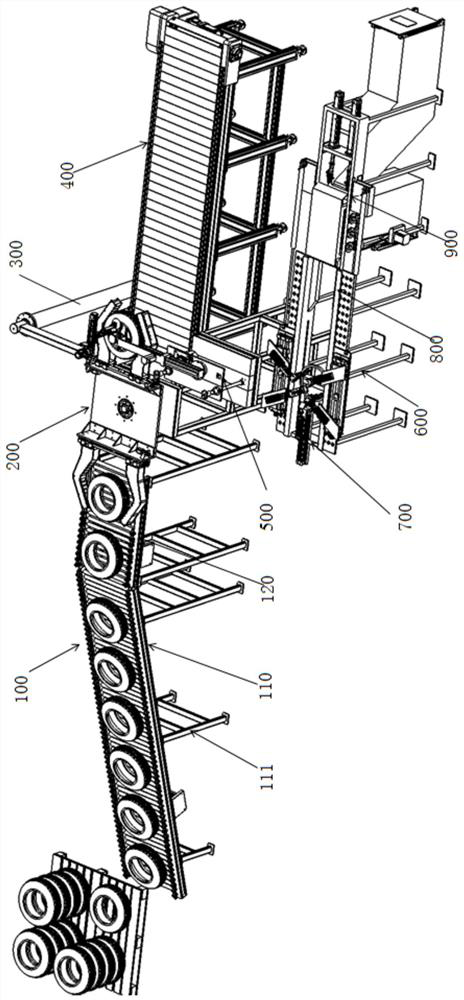

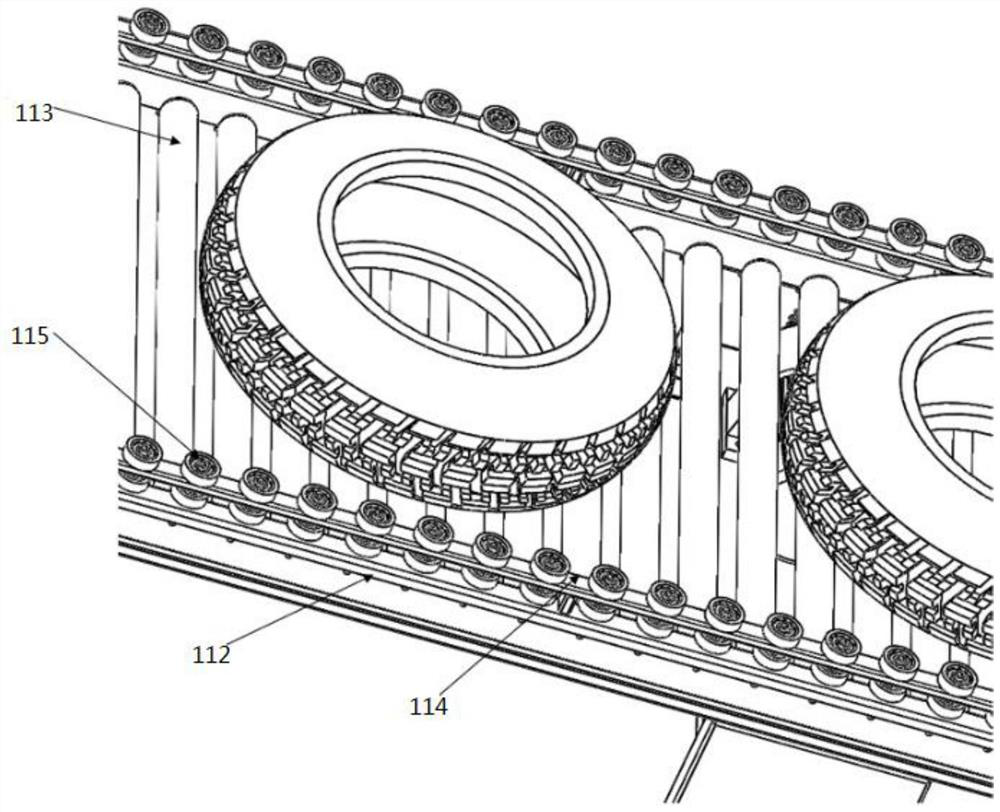

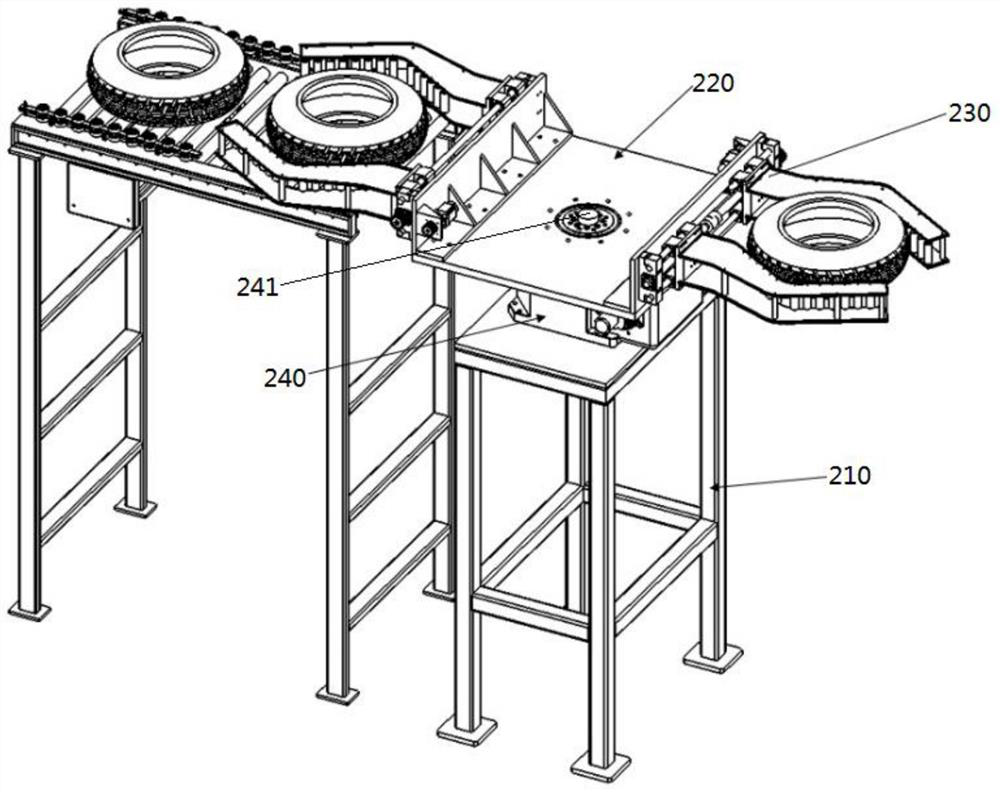

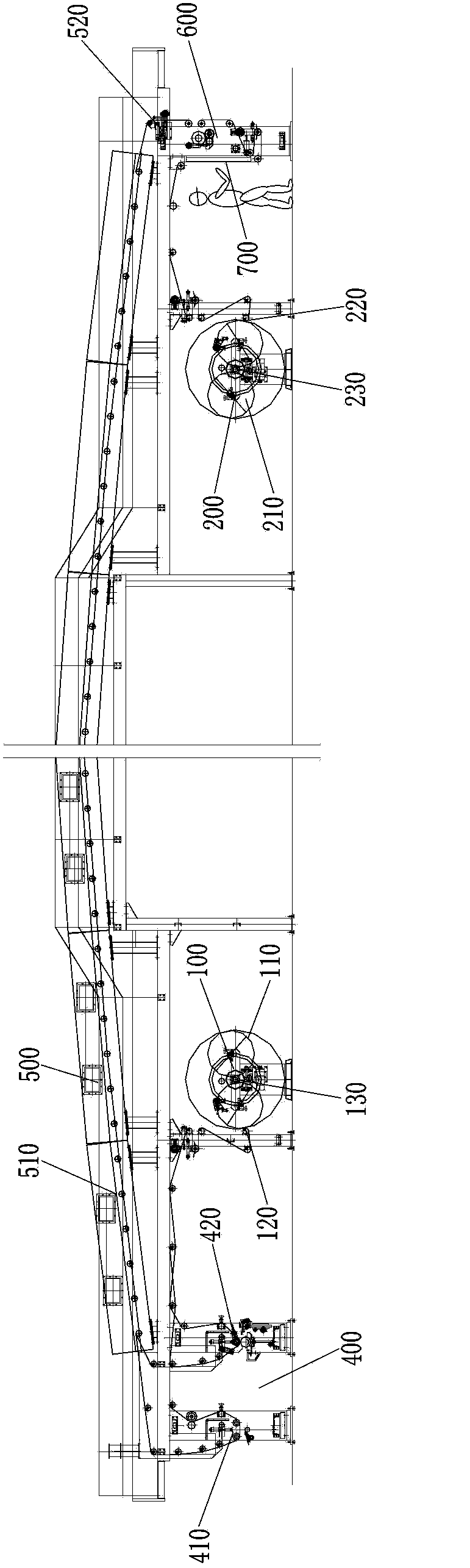

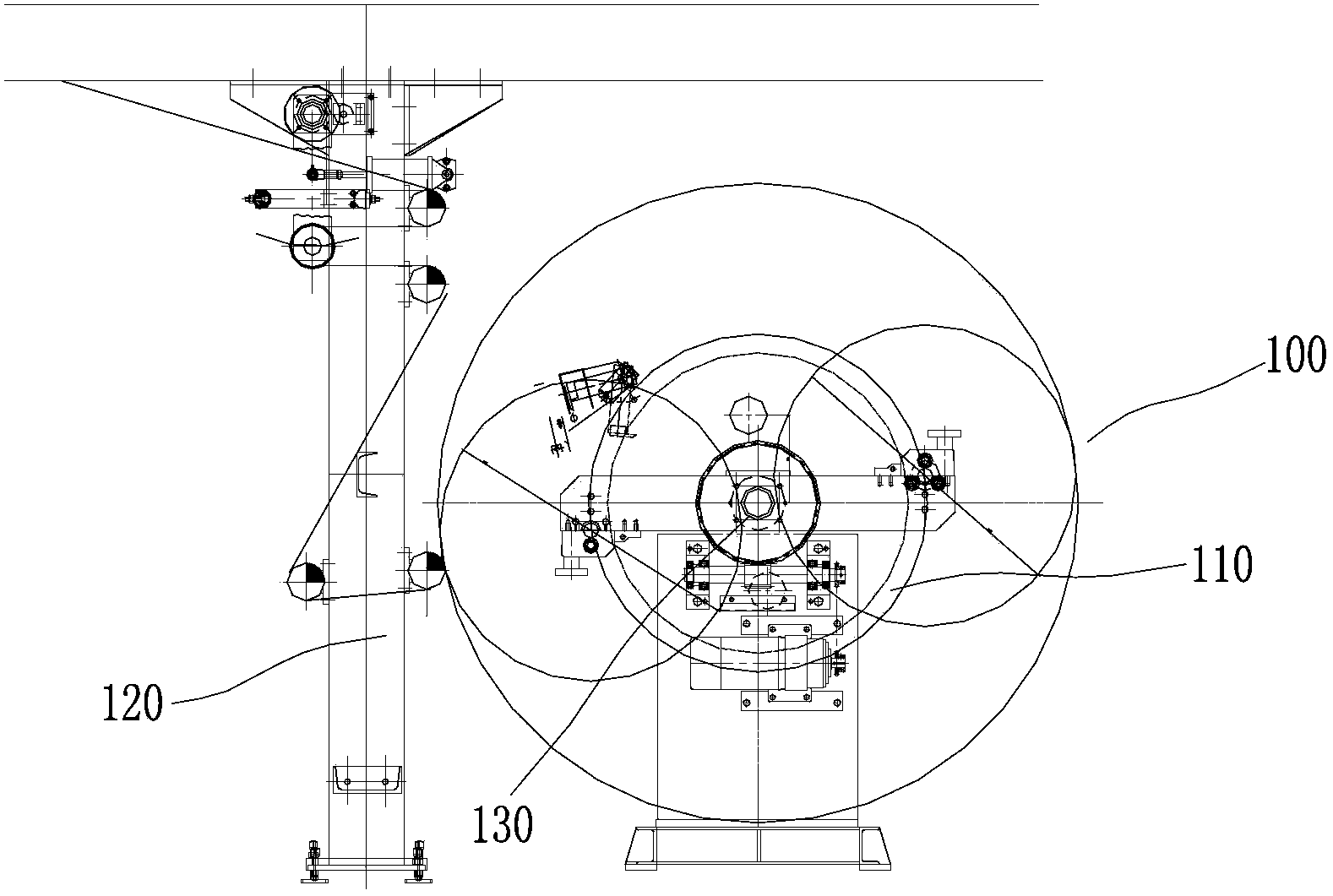

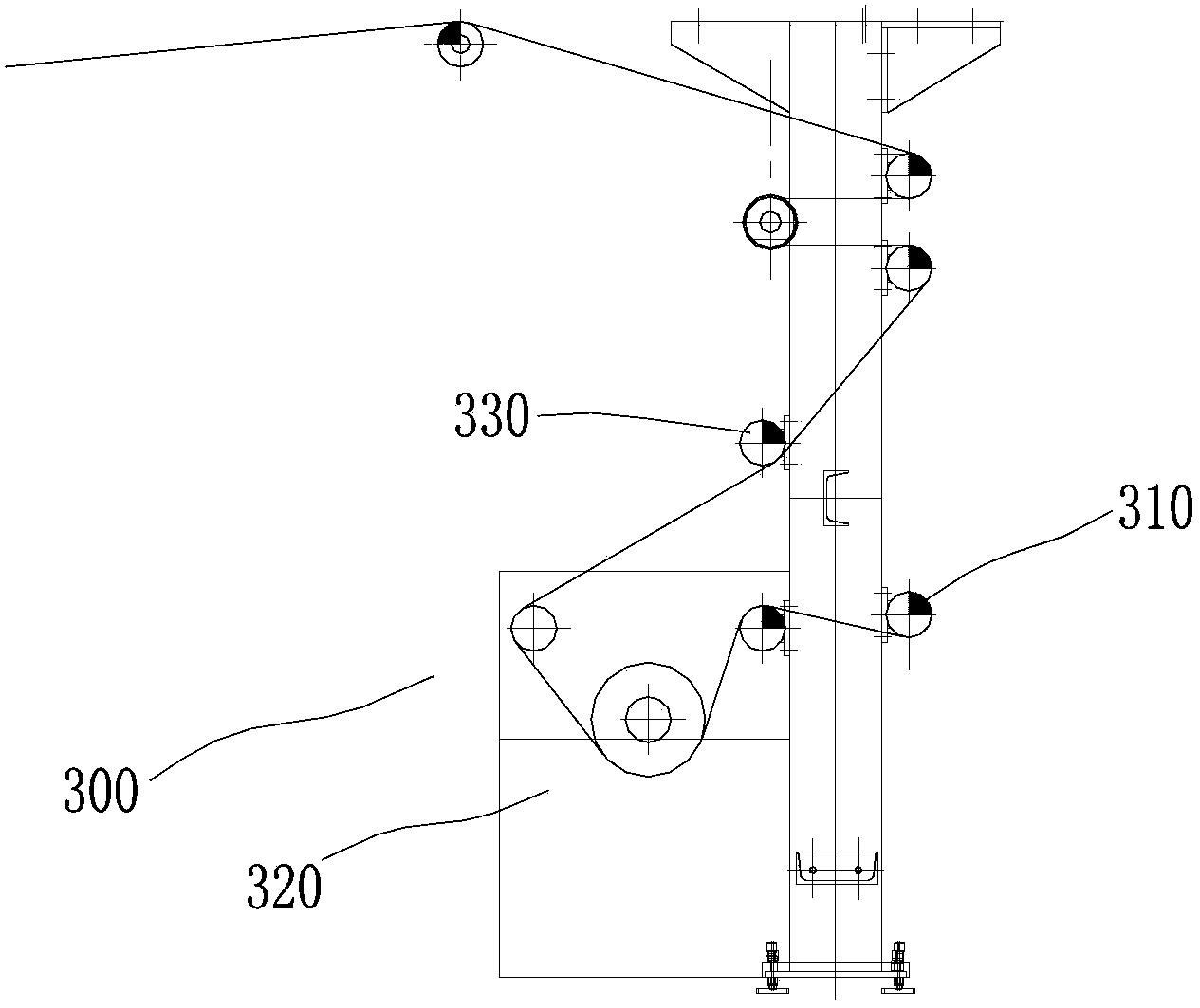

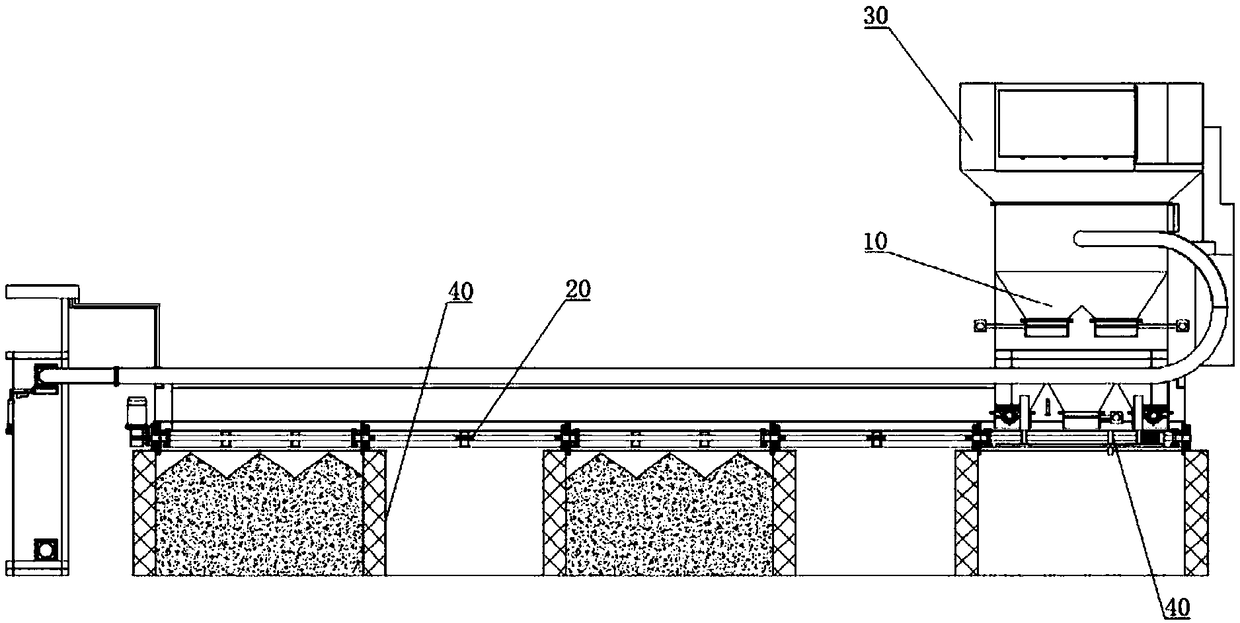

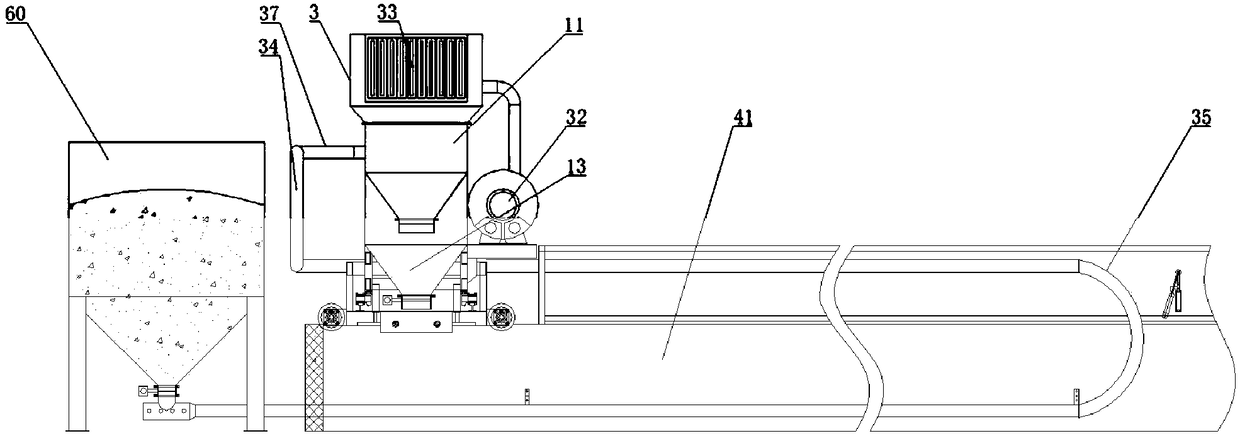

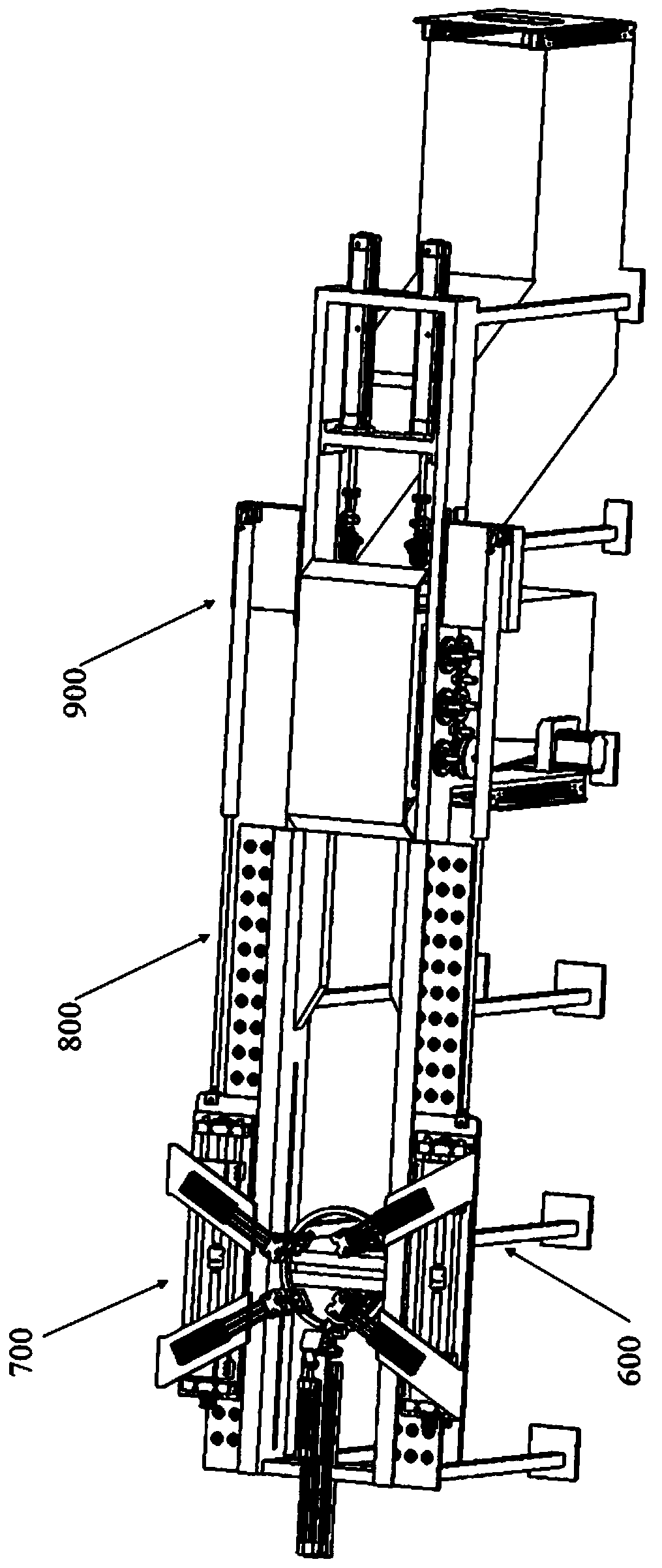

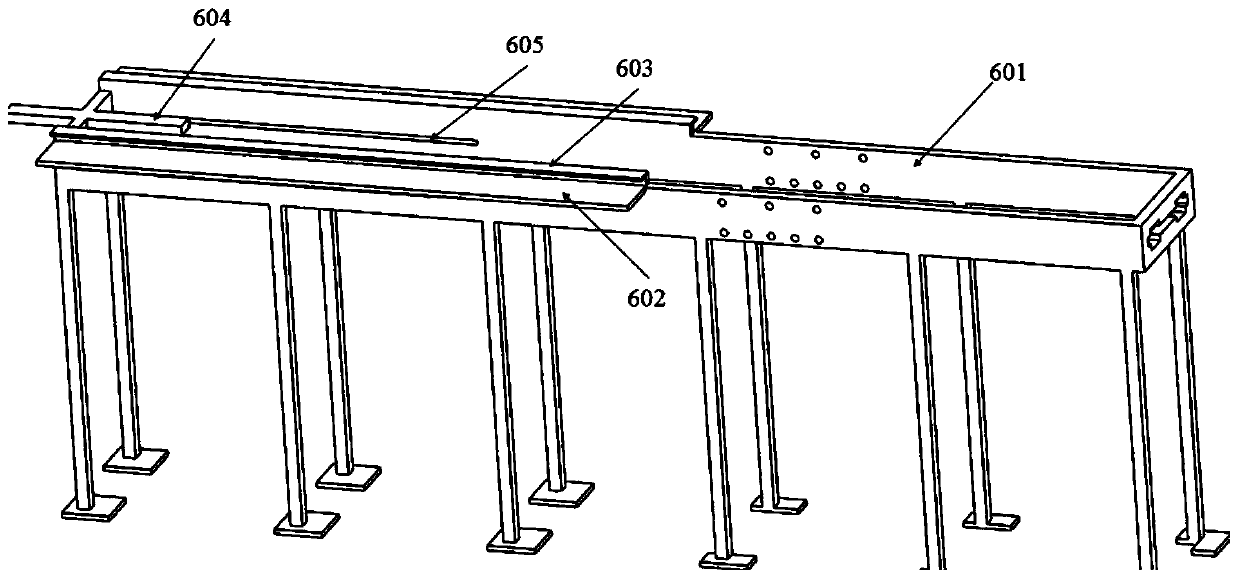

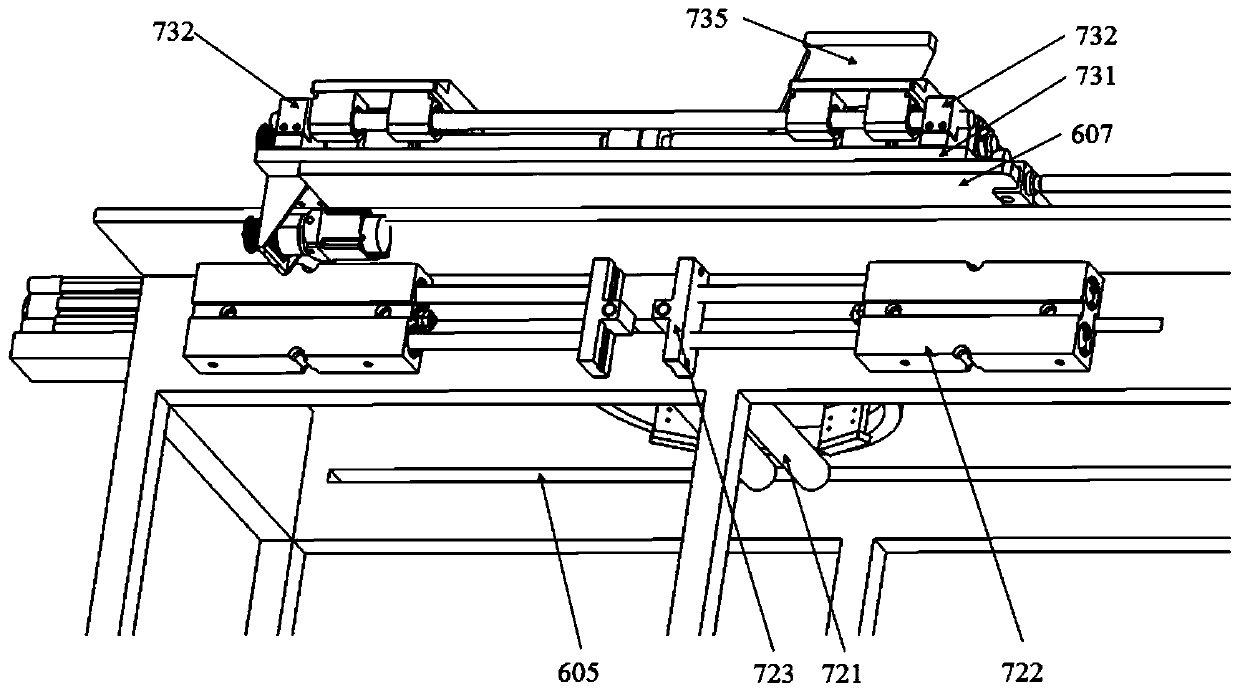

Full-automatic waste tire circular-cutting and tire bead cutting and wire stripping system and method

PendingCN111619039ARealize comprehensive utilizationMeet processingPlastic recyclingGrain treatmentsTire beadProcess engineering

The invention relates to a full-automatic waste tire circular-cutting and tire bead cutting and wire stripping system. The system comprises a tire circular-cutting and conveying device, a tire bead carrying device and a tire bead cutting and wire stripping device; the tire circular-cutting and conveying device comprises a front-end conveying mechanism, a rotating carrying mechanism for carrying and assisting in circular cutting, a tire bead circular-cutting mechanism for cutting off tire beads of waste tires and a back-end conveying mechanism for conveying out the waste tires with the tire beads cut; the tire bead carrying device is arranged on one side of a tire bead circular-cutting device, assists the tire bead circular-cutting device in tire bead cutting and conveys the tire beads cuteach time to a tire bead cutting and wire stripping module; the tire bead cutting and wire stripping device comprises a workbench mechanism, a tire bead cutting mechanism, a tire bead pulling mechanism and a tire bead wire stripping mechanism; the tire bead cutting mechanism is arranged on the workbench mechanism and is used for cutting off and leveling the tire beads; the tire bead pulling mechanism is used for conveying the cut and leveled tire beads to the tire bead wire stripping mechanism; and the tire bead wire stripping mechanism is used for stripping steel wires out of the tire beads.The system has the beneficial effects that a relatively perfect waste tire processing system and manner is provided and has the relatively high scientificity and logicality.

Owner:SAILUN GRP CO LTD +1

Production method and device of coating leather-imitated synthesized leather

InactiveCN103660496AGood weather resistanceHigh degree of peelingLamination ancillary operationsLaminationProduction lineWrinkle skin

The invention aims at disclosing a production method and device of coating leather-imitated synthesized leather. The production device comprises a first discharging unit, a second pretreatment unit, a third coating unit, a fourth drying unit, a fifth traction unit and a sixth collection unit, wherein the output end of the discharging unit is sequentially connected with the pretreatment unit, the coating unit, the drying unit and the collection unit, and the discharging unit, the pretreatment unit, the coating unit, the drying unit and the collection unit are communicated with one another in a traction manner through the traction unit. Compared with the prior art, the production device has the advantages that a production line is formed by the discharging unit, the pretreatment unit, the coating unit, the drying unit and the collection unit in sequence, lining injection paper in an imitated finished product is split, and then the imitated product is packaged to obtain the final product, and the high-imitated leather synthesized leather product can be produced and has excellent properties of high weather resistance, ultraviolet resistance, high stripping degree, wear resistance, wrinkle resistance, water resistance, contaminant resistance, high-temperature resistance, environmental protection and the like.

Owner:SHANGHAI LONGYI NEW MATERIAL TECH CO LTD

Preparation method of high-strength anti-aging sodium polyacrylate water-absorbing resin

The invention relates to the field of synthesis of polymer materials and discloses a preparation method of high-strength anti-aging sodium polyacrylate water-absorbing resin. The preparation method comprises: A) preparation of organically modified vermiculite powder: adding lactose and dodecyl dimethyl benzyl ammonium chloride into water, carrying out heating for a reaction, carrying out reduced pressure distillation, cleaning the product, drying the product to obtain modified lactose, calcining and grinding vermiculite, preparing a suspension liquid, heating the suspension liquid, adding themodified lactose into the suspension liquid, carrying out stirring for a heat preservation reaction, and carrying out centrifugation, filtration and drying, B) neutralization: adding acrylic acid andacrylamide into water and then neutralizing the solution with sodium hydroxide until the pH is 5-5.5, C) polymerization: adding organically modified vermiculite and bacterial cellulose, adding triallyl ammonium chloride and an initiator and carrying out a reaction process to obtain a viscous liquid, and D) drying and pulverization for forming a sodium polyacrylate water-absorbent resin. The sodiumpolyacrylate resin contains organically modified vermiculite powder so that the strength and aging resistance of the resin are effectively improved.

Owner:深圳市新拓普新材料有限公司

Electric-conduction ink containing graphene complex, and preparation method thereof

The invention relates to the field of inks, and discloses an electric-conduction ink containing a graphene complex, and a preparation method thereof, wherein the electric-conduction ink contains a specially-made graphene complex, the graphene complex is prepared by using a special graphene stripping agent, and has high peeling strength, and the electric-conduction ink made of the graphene complexhas significantly excellent electric conductivity compared with the electric-conduction ink containing the existing graphene and the derivative thereof.

Owner:ZHEJIANG MARINE DEV RES INST

Peeling method of graphene nanoplatelets and application

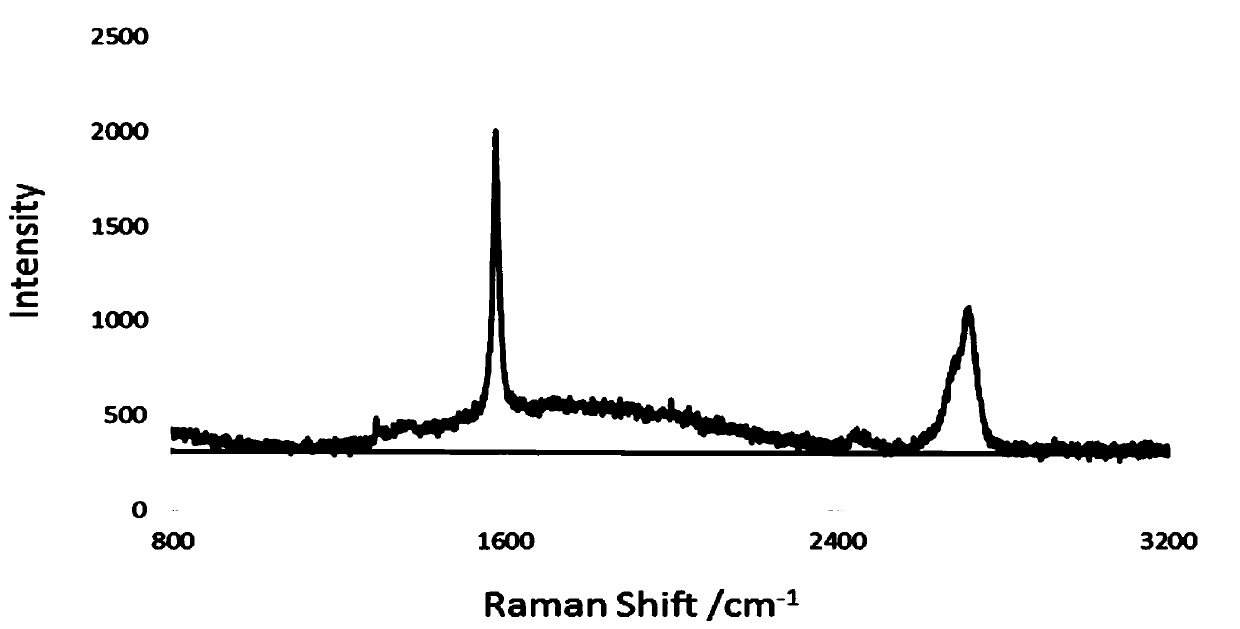

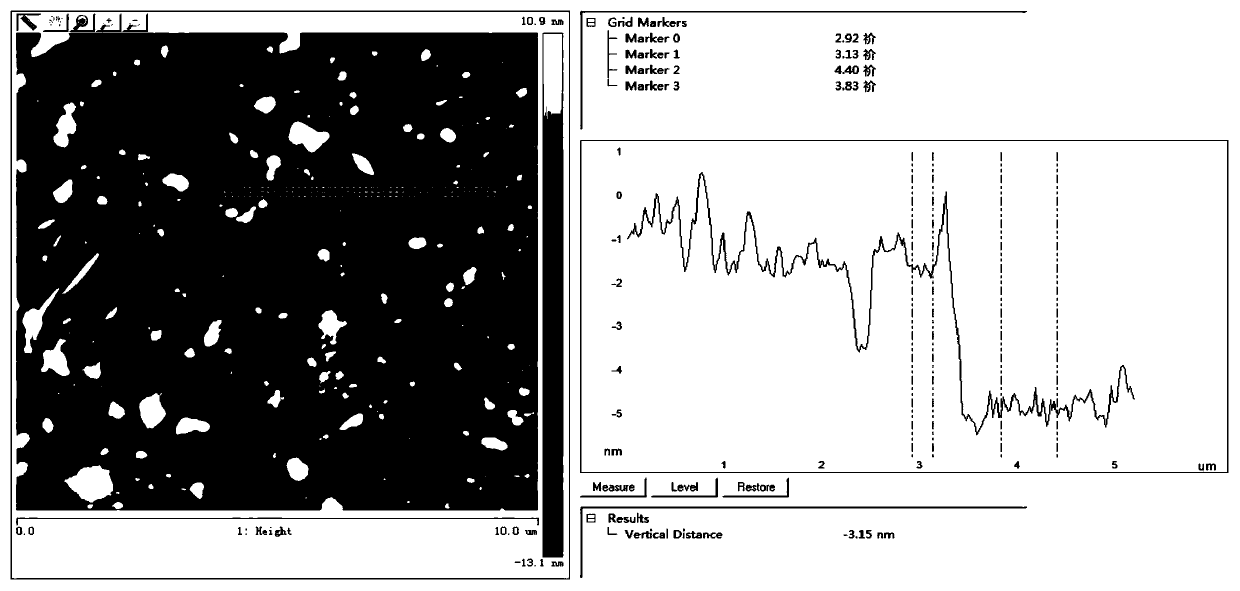

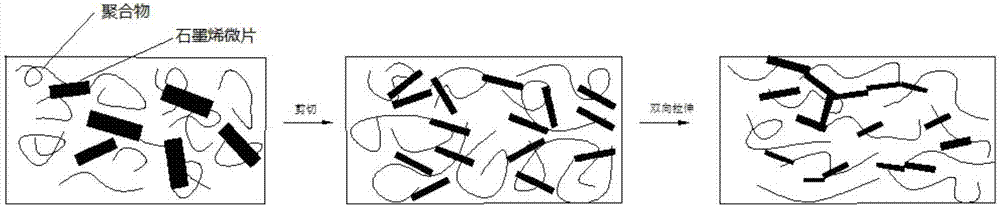

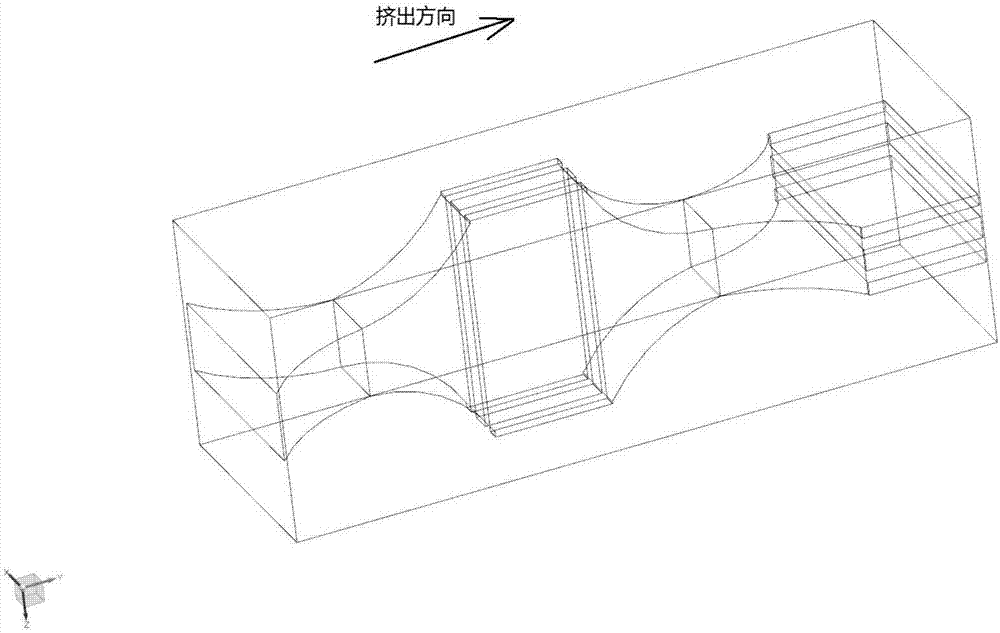

ActiveCN107312200AHigh degree of peelingNo loss of excellent performanceShear stressPolymer composites

The invention provides a peeling method of graphene nanoplatelets. The method comprises the following steps: (a) mixing polymers, graphene nanoplatelets and coupling agents to obtain a reaction mixture; and (b) melting and mixing the reaction mixture obtained in the step (a), then extruding to obtain the peeled graphene nanoplatelets, wherein the shearing stress of melting and mixing is 0.14-0.2MPa, and the staying time lasts for 250-600 seconds; the extruding process is carried out in a force field which is firstly sheared and subsequently stretched in two ways. Compared with the prior art, the technical problem of unsatisfactory dispersion effect of a melting and mixing method for compounding the graphene nanoplatelets in the polymers can be solved; the specific melting and mixing condition is matched with a specific extrusion field; the peeling degree of the graphene nanoplatelets is obviously improved, so that the dispersion effect of the graphene nanoplatelets in the polymers is improved on the basis that the excellent properties of the graphene nanoplatelets are not reduced. The peeling method can be used for preparing graphene nanoplatelet / polymer composites and plays an important role in improvement of the properties of the products.

Owner:GUANGDONG UNIV OF TECH

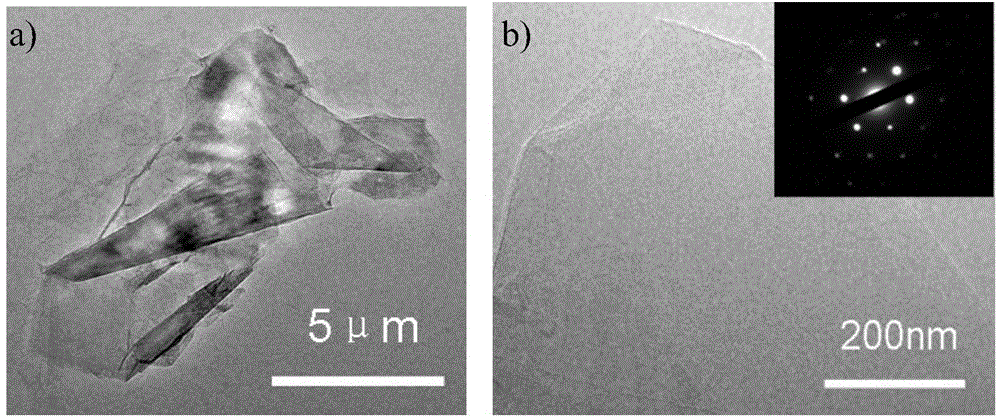

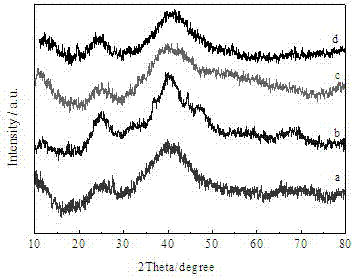

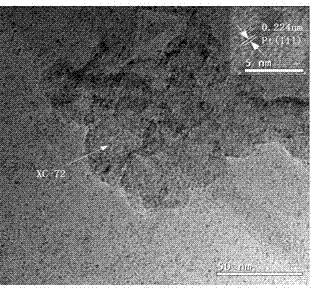

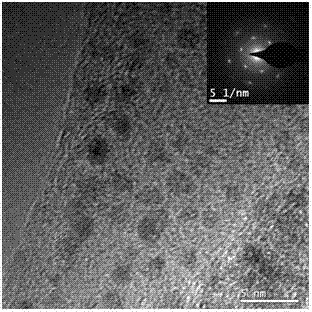

Preparation method of Pt-Co/C-single-layer graphene for fuel cell

ActiveCN103456969BGood physical propertiesLarge specific surface areaCell electrodesGrapheneChemical synthesisSingle layer graphene

The invention discloses a preparation method of Pt-Co / C-single-layer graphene for a fuel cell, belongs to the chemical synthesis field, and relates to a preparation method of graphene. The Pt-Co / C-single-layer graphene for the fuel cell is prepared by the following steps: (1), preparation of graphite oxide; (2), pre-treatment of active carbon XC-72; and (3), preparation of an rGO-XC-72 composite carrier-loaded Pt-Co alloy nano particle. The metal alloy nano particle-graphene and XC-72 active carbon composite catalyst prepared by utilizing a microwave ethylene glycol auxiliary reduction method is simple and easy to implement, and is high in efficiency. Moreover, the obtained graphene has a single-layer structure and the alloy particle has uniform particle diameter distribution and an average particle diameter of 1.5 nm. The catalytic activity of the nano particle can be improved by interaction with the XC-72 active carbon as well as electronic modification to the metal nano particle. And obtained catalyst has excellent oxygen-reduction electro-catalysis performances.

Owner:HARBIN INST OF TECH

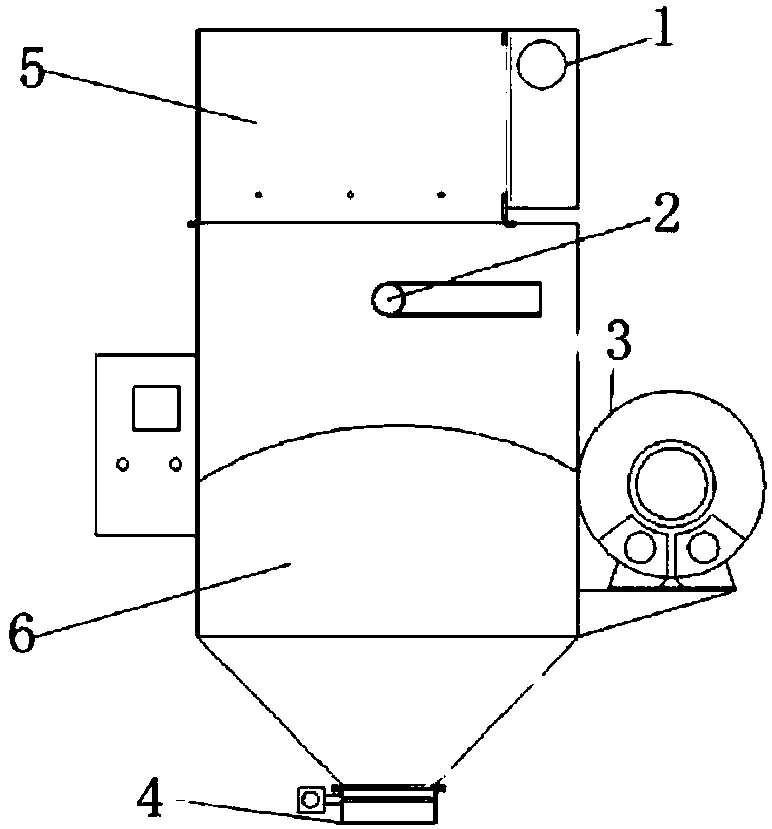

Intelligent transverse and longitudinal cloth machine

ActiveCN108220116AIncrease the feeding speedIncrease productivityVinegar preparationEngineeringBrewing

The invention discloses an intelligent transverse and longitudinal cloth machine, belongs to the field of automatic vinegar brewing equipment and aims to solve the problems of slow feeding speeds andlow production efficiency in the prior art. The machine comprises a double-chamber feeding machine, wherein the double-chamber feeding machine comprises a sucking chamber I; a feeding hole is formed in the sucking chamber I; a sucking chamber II is formed below the sucking chamber I; the sucking chamber I and the sucking chamber II are communicated through discharge holes; outlet holes are formedin the sucking chamber II; discharge devices are arranged in both the outlet holes and the discharge holes. By adopting the machine, material cloth for brewing vinegar can be put into a fermentation tank.

Owner:LUZHOU JIANGXU MACHINERY MFG

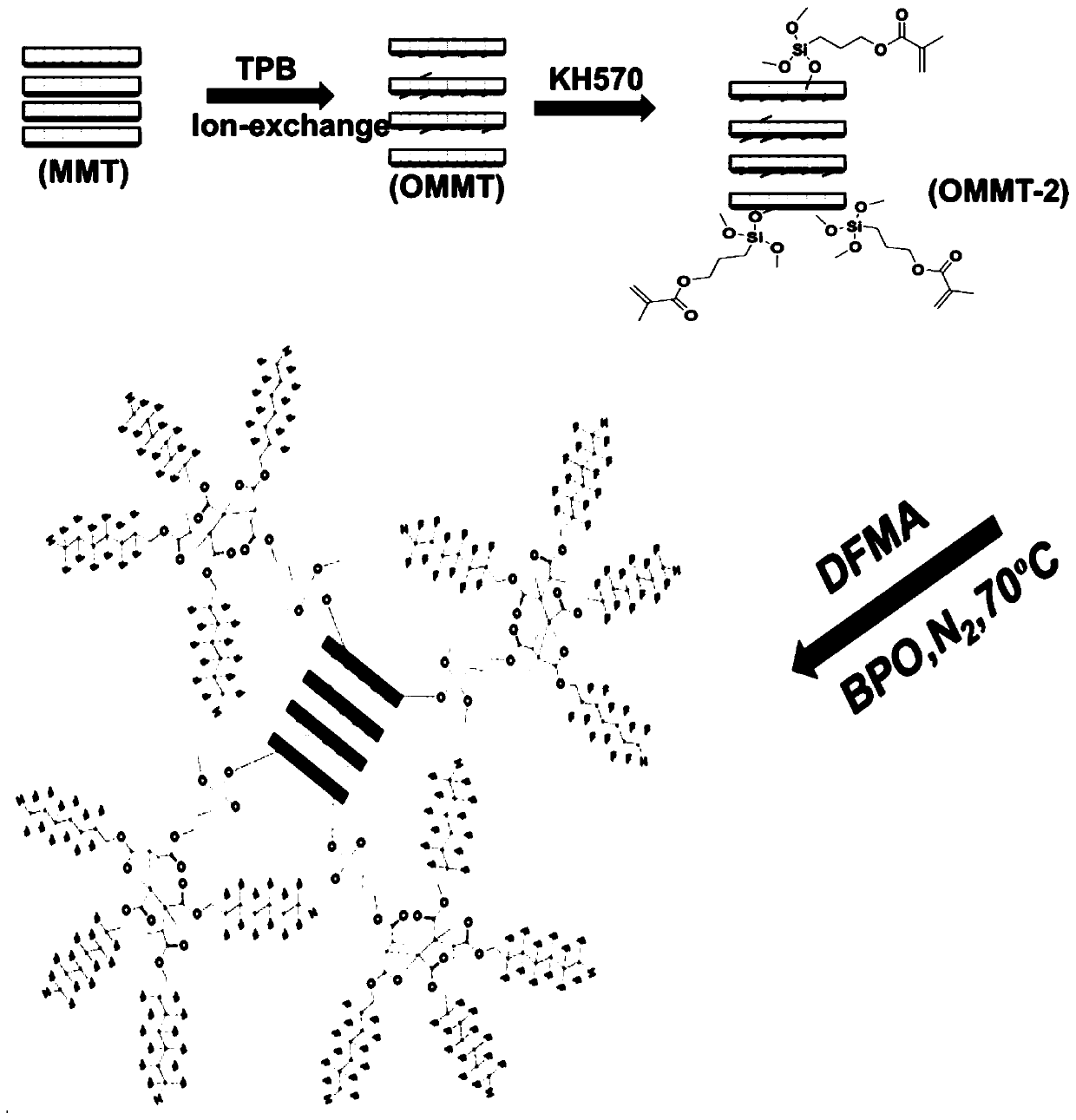

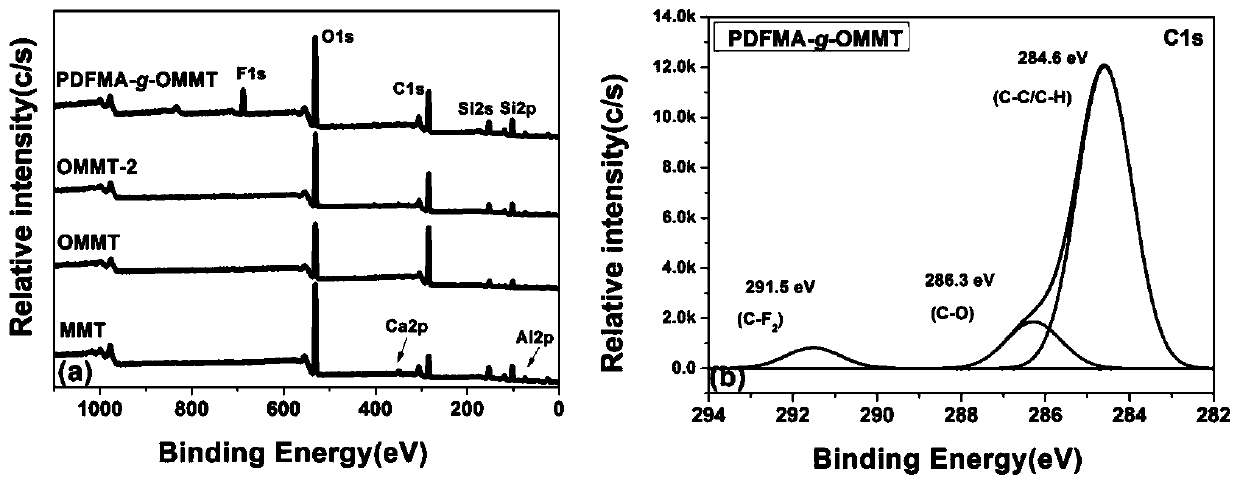

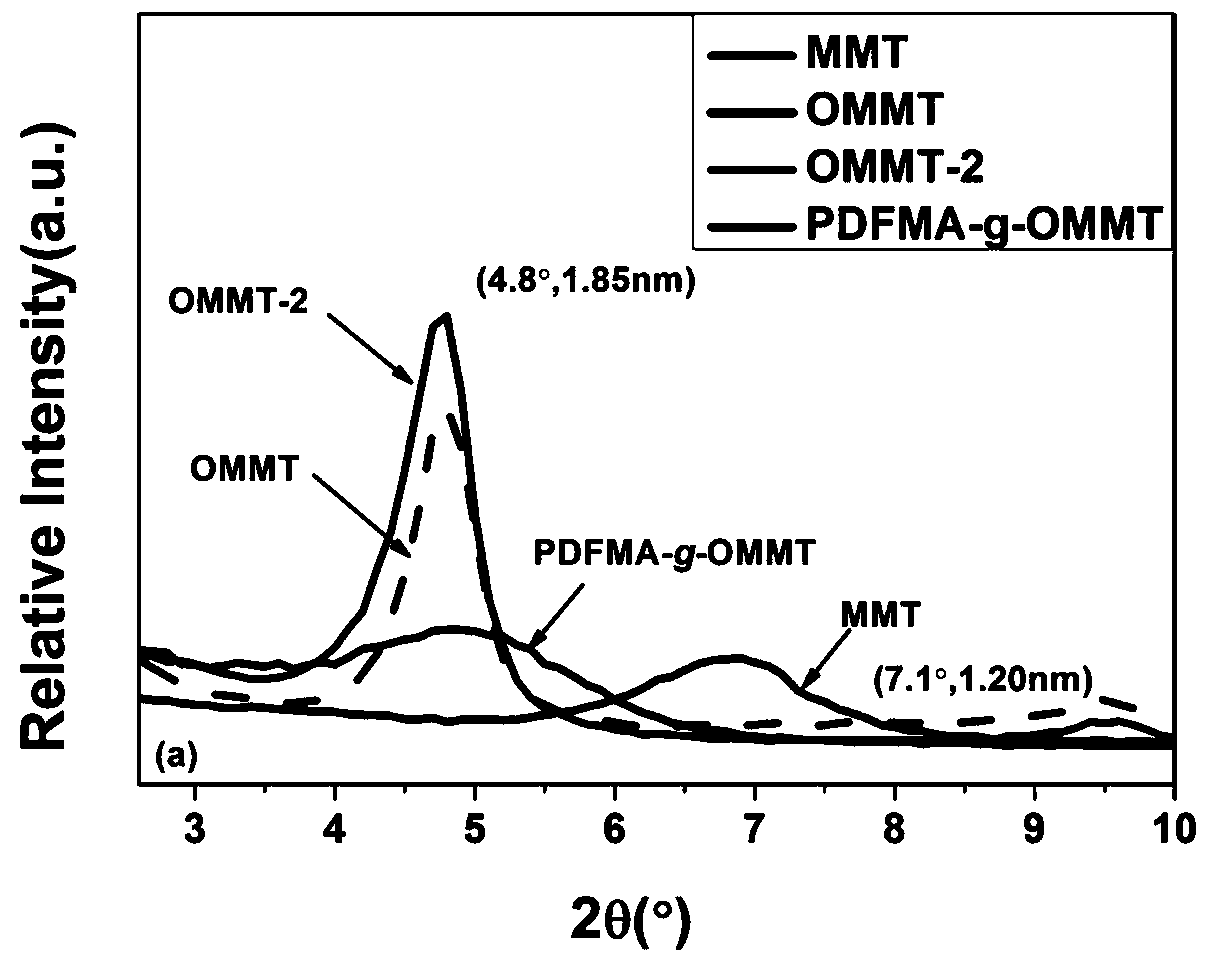

Compatible ethylene-tetrafluoroethylene copolymer nano-composite material and preparation method thereof

The invention provides a compatible ethylene-tetrafluoroethylene copolymer nano-composite material and a preparation method thereof. The method comprises the following steps: pretreating montmorillonite nanoparticles (MMT) with an organic quaternary phosphonium salt to obtain OMMT; carrying out activation modification on the surface of the OMMT by adopting a silane coupling agent to obtain activated OMMT; grafting a fluorine-containing monomer onto the activated OMMT so as to obtain fluorinated modified OMMT; mixing the fluorinated modified OMMT with an ethylene-tetrafluoroethylene copolymer and polyvinylidene fluoride, and carrying out extrusion granulation and compression molding to obtain the compatible ethylene-tetrafluoroethylene copolymer nano-composite material, wherein the mass ratio of the fluorinated modified OMMT to the ethylene-tetrafluoroethylene copolymer to the polyvinylidene fluoride is (0.1-4):(88-92):(8-12). The nano-composite material has good mechanical properties;and the composite system has a stable homogeneous structure.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Tire bead cutting and wire stripping device and method

PendingCN111590787ARealize the delivery workConvenient stripping and strippingPlastic recyclingGrain treatmentsTire beadCutting tool

The invention relates to a tire bead cutting and wire stripping device and method. The device comprises a workbench mechanism, a tire bead cutting mechanism, a tire bead hauling mechanism and a tire bead wire stripping mechanism; the tire bead cutting mechanism comprises a cutting tool assembly installed at the end part of the workbench mechanism, a moving roller assembly with adjustable clearanceinstalled on the workbench, horizontal moving slide rail assemblies installed on two sides of the workbench mechanism, and clamping assemblies installed on the horizontal moving slide rail assemblies; the tire bead hauling mechanism is installed on the workbench mechanism and positioned at the rear side of the tire bead cutting mechanism, and is used for transporting a cut tire bead to the tire bead wire stripping mechanism; and the tire bead wire stripping mechanism is installed on the workbench mechanism, and comprises a tire bead wire stripping assembly, a debris storage box positioned right below the tire bead wire stripping assembly, a steel wire hauling assembly positioned on the rear side of the tire bead wire stripping assembly, and a steel wire storage box positioned below the steel wire hauling assembly. The tire bead cutting and wire stripping device and method has the beneficial effects that, cutting and wire stripping operation of the tire bead can be completed, the degree of automation is high, the level of mechanism linkage and integration is high, and operation ability of a system is improved.

Owner:SAILUN GRP CO LTD +1

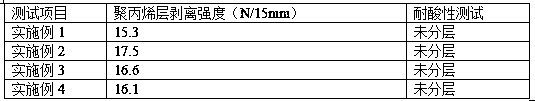

Production technology for package composite film

ActiveCN110039805AGood chemical stabilityAccelerated corrosionFlat articlesComposite filmFree cooling

The invention provides a production technology for a package composite film. The production technology comprises the following steps that firstly, an aluminum plating film is immersed in a treating agent I, ultrasonic treatment is conducted, temperature rise is conducted to 30-35 DEG C, a treating agent II is added, the ultrasonic reaction is conducted, then, temperature rise is conducted to 35-45DEG C, a treating agent III is added, after stirring is conducted to be uniform, ultrasonic dispersion is conducted, natural cooling is conducted to the room temperature, clean water is adopted for flushing, and aluminum plating film surface pretreatment is finished after drying; secondly, the inner surface of the treated aluminum plating film is coated with a sizing material, and a sizing material layer is formed; thirdly, a polypropylene film is formed on the face, away from the aluminum plating film, of the sizing material layer in a curtain coating manner, then a hot press is utilized forconducting hot pressing on the curtain coating polypropylene layer, and after hot pressing is finished, natural cooling is conducted to the room temperature; and fourthly, a pattern is printed on theside, away from the polypropylene layer, of the aluminum plating film, then drying is conducted, and the package composite film is obtained. According to the provided production technology, operationis simple, acid resistance is good, the service life is long, and good mechanical performance is achieved.

Owner:广东中兴塑料纸类印刷有限公司

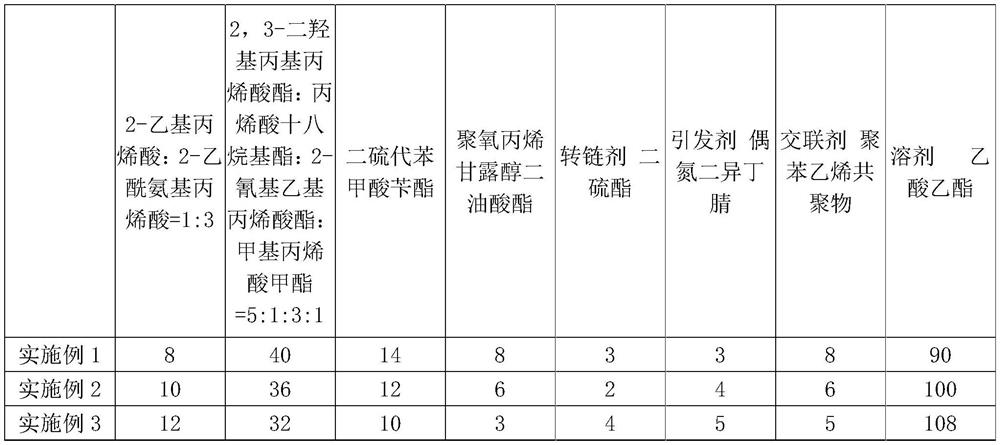

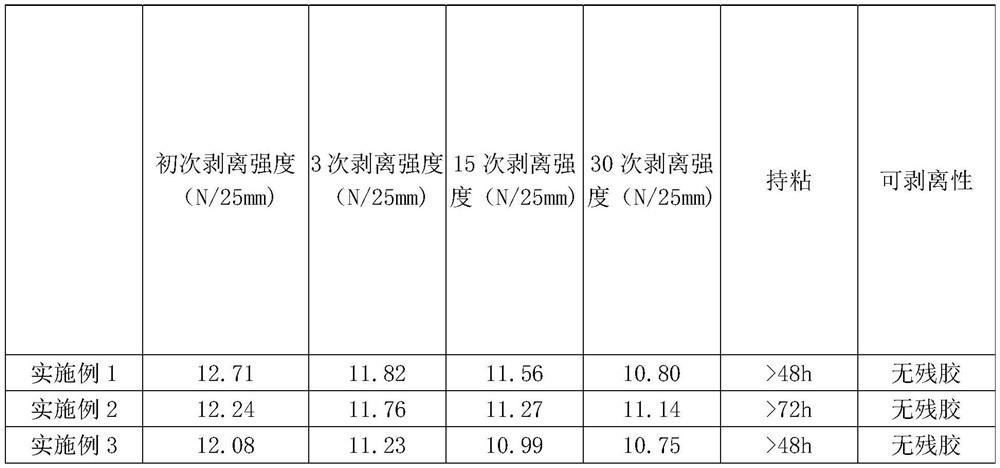

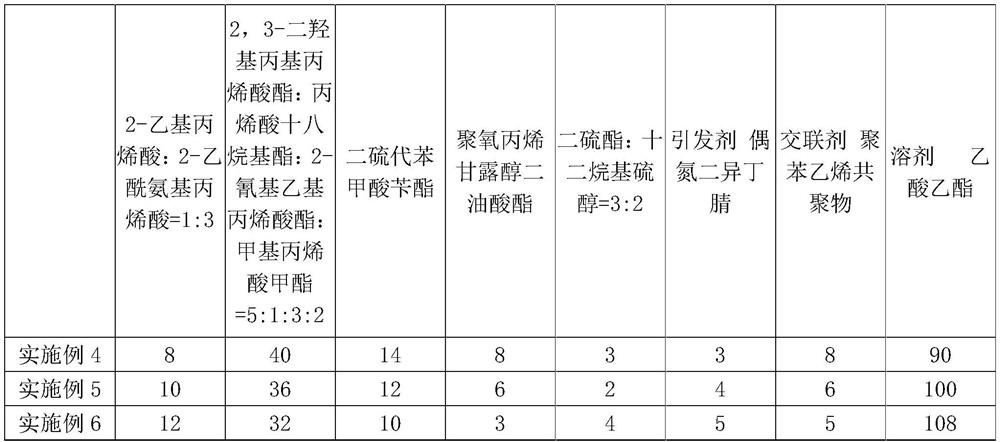

Easily stripped pressure-sensitive adhesive and preparation method thereof

PendingCN114214010AHigh degree of peelingStrong cohesionMacromolecular adhesive additivesPressure sensitive film/foil adhesivesBenzoic acidPolymer science

The invention provides an easy-to-peel pressure-sensitive adhesive. The easy-to-peel pressure-sensitive adhesive comprises 8-12 parts by weight of an acrylic monomer, 30-42 parts by weight of an acrylate monomer, 10-15 parts by weight of benzyl dithiobenzoate, 3-10 parts by weight of polyoxypropylene mannitol dioleate, 2-6 parts by weight of a chain transfer agent, 3-5 parts by weight of an initiator, 5-8 parts by weight of a cross-linking agent and 88-110 parts by weight of a solvent. The easy-to-peel pressure-sensitive adhesive disclosed by the invention is relatively high in peeling degree at normal temperature, keeps initial viscosity after being continuously used for multiple times, and does not have any adhesive residue after being peeled for multiple times.

Owner:安徽富印新材料股份有限公司

Preparation method of sodium polyacrylate water-absorbing fibers

ActiveCN109023583AImprove water retentionHigh strengthMonocomponent synthetic polymer artificial filamentArtifical filament manufactureViscous liquidFiber

The invention relates to the field of synthesis of polymer materials and discloses a preparation method of sodium polyacrylate water-absorbing fibers. The preparation method comprises: A) preparationof organically modified vermiculite powder: adding lactose and dodecyl dimethyl benzyl ammonium chloride into water, carrying out heating for a reaction, carrying out reduced pressure distillation, cleaning the product, drying the product to obtain modified lactose, calcining and grinding vermiculite, preparing a suspension liquid, carrying out heating, adding the modified lactose into the suspension liquid, carrying out stirring under thermal insulation for a reaction, and carrying out centrifugation, filtration and drying, B) neutralization: adding acrylic acid and acrylamide into water, andthen neutralizing the solution with sodium hydroxide until the pH is 5-5.5, C) polymerization: adding organically modified vermiculite and bacterial cellulose into the solution, and adding a triallylammonium chloride and an initiator into the solution for a reaction so that a viscous liquid is obtained, and D) wet spinning: preparing sodium polyacrylate fibers. The organically modified vermiculite powder in the sodium polyacrylate fibers can effectively improve the strength and aging resistance of fibers.

Owner:深圳市金利源绝缘材料有限公司

A kind of method for preparing graphene oxide by ultrasonic-assisted method

ActiveCN106477572BIncrease layer spacingShort manufacturing timeCarbon compoundsSorbentPhosphoric acid

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for preparing graphene oxide through ultrasonic-assisted process

ActiveCN106477572AIncrease layer spacingShort manufacturing timeCarbon compoundsSorbentPhosphoric acid

The invention provides a method for preparing graphene oxide through an ultrasonic-assisted process. The method comprises the following steps: in a low temperature stage, subjecting natural flake graphite to complete ultrasonic dispersion in a mixed acid solution of concentrated sulfuric acid and concentrated phosphoric acid, slowly adding a small amount of potassium permanganate in the process of stirring, and carrying out preoxidation under an ultrasonic condition; and in the high temperature stage, continuously adding potassium permanganate under stirring, carrying out deep oxidation so as to obtain graphite oxide, then carrying out centrifugal washing until the graphite oxide is neutral, and ultrasonically exfoliating the graphite oxide so as to obtain the graphene oxide. The method provided by the invention uses the ultrasonic-assisted process to prepare the graphene oxide, so the preparation time can be effectively saved; energy is saved; meanwhile, the interlamellar spacing of the graphite oxide is effectively improved. The graphene oxide prepared by using the method provided by the invention can be used for preparation of high-strength lightweight composite materials, catalyst carriers, adsorbent carriers, etc. The graphene obtained by reduction can be used for preparation of graphene composite materials like energy storage materials, sensors and super-capacitors.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com