Production method and device of coating leather-imitated synthesized leather

A production method and artificial leather technology, applied in lamination auxiliary operations, chemical instruments and methods, lamination, etc., can solve the problems of high weather resistance, ultraviolet resistance, high peeling degree, wear resistance, pleat resistance, waterproof, and antifouling. and high temperature resistance, environmental protection, insufficient performance and quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

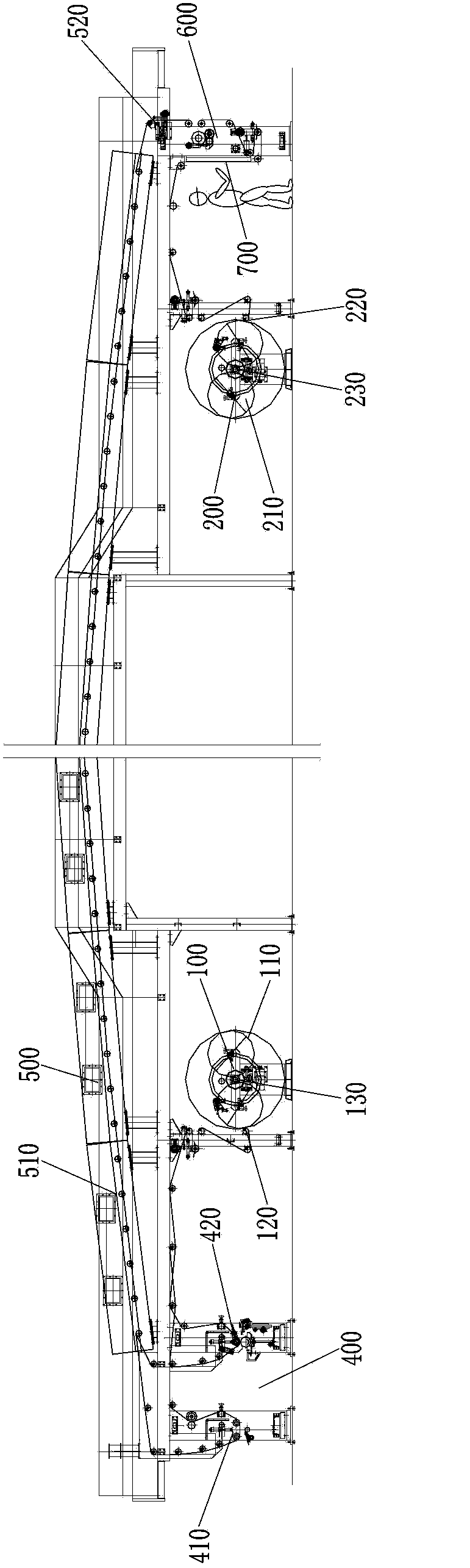

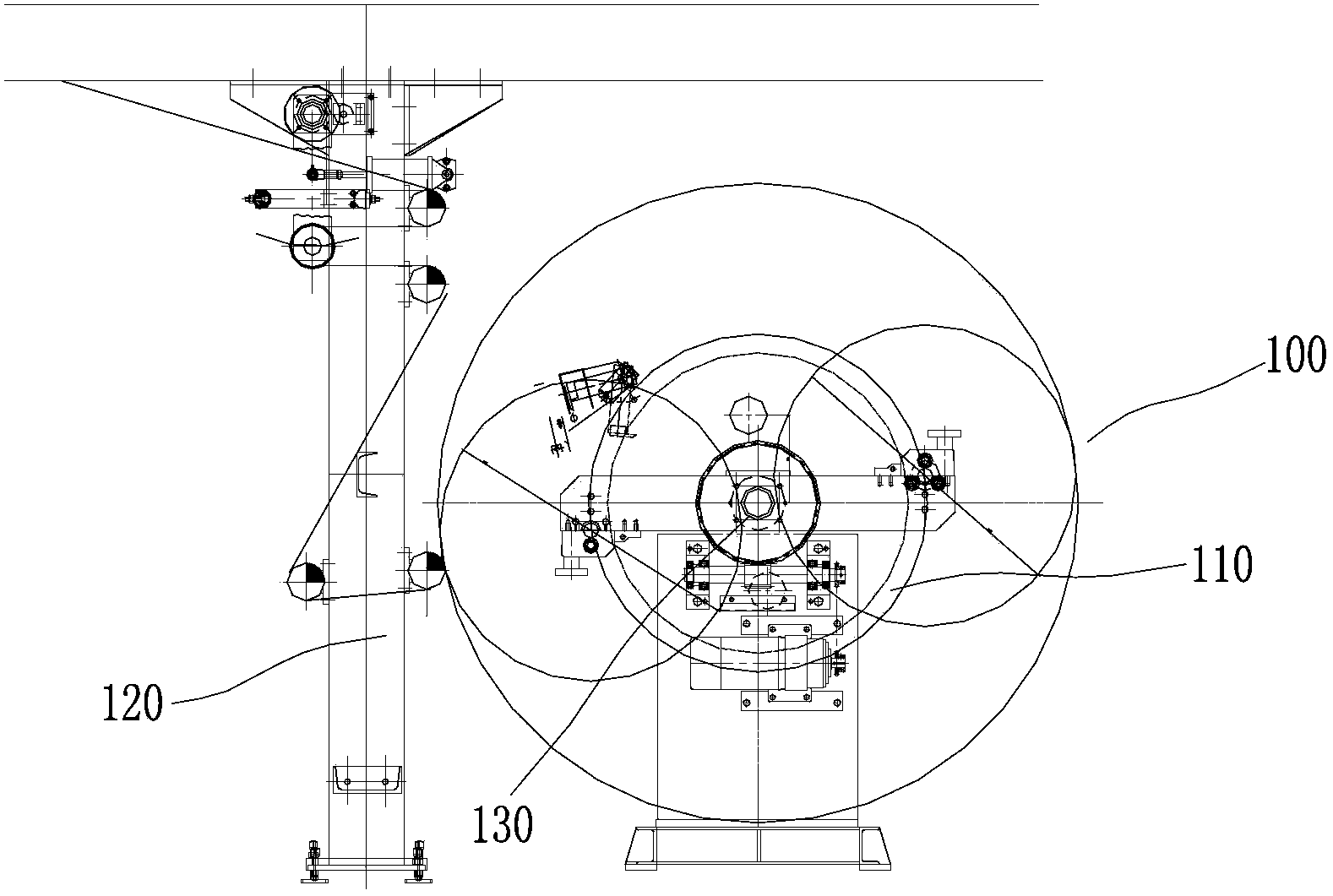

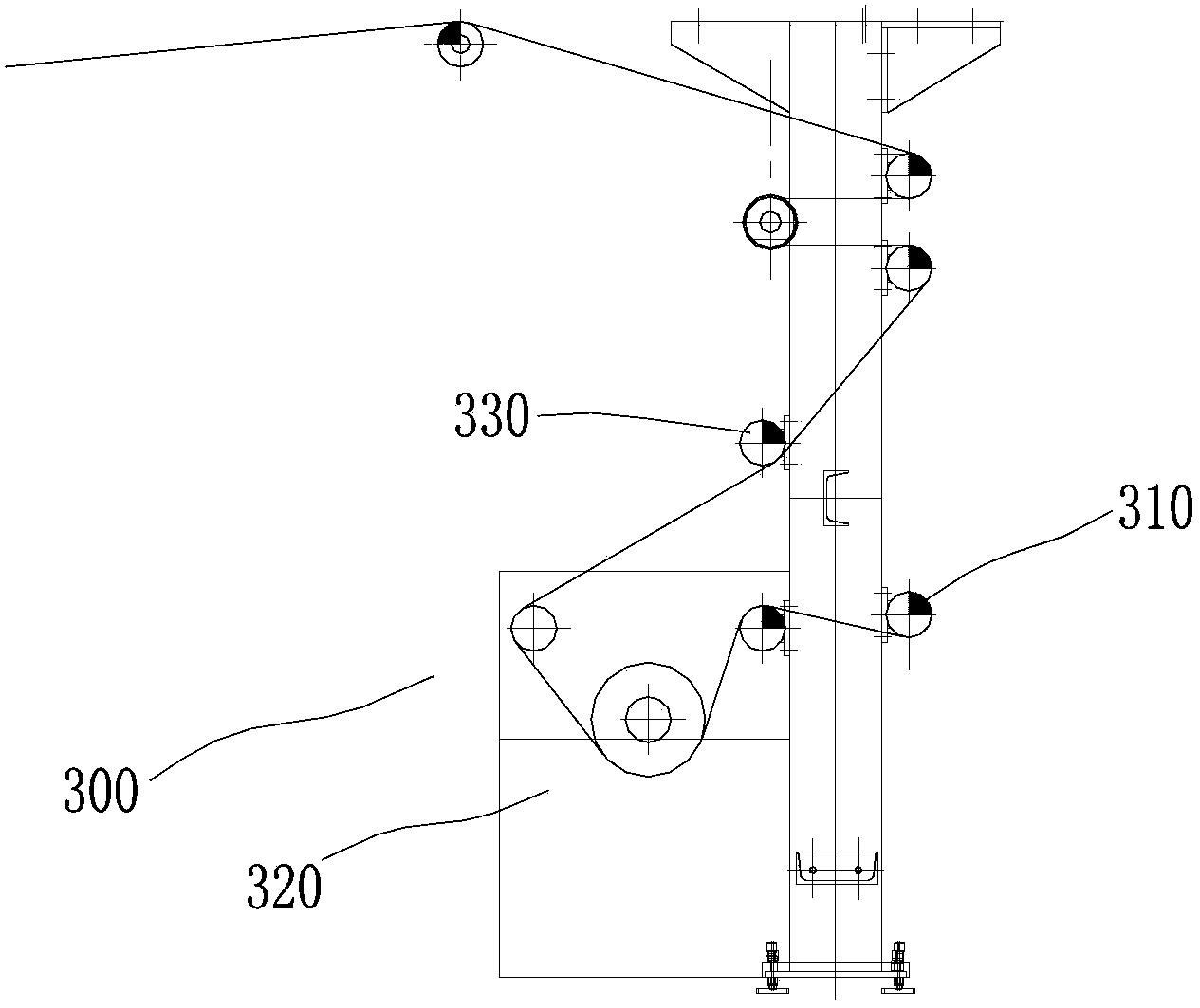

[0052] Such as figure 1As shown, the present invention provides a kind of manufacturing equipment of coating imitation leather synthetic leather, and it comprises six big steps: the first discharging unit 100, the second pretreatment unit 300, the third coating coating unit 400, the fourth drying Unit 500, the fifth traction unit 600, the sixth receiving unit 200; the output end of the discharging unit 100 is sequentially connected to the pretreatment unit 300, the coating coating unit 400, the drying unit 500 and the receiving unit 200, The discharging unit 100 , the pretreatment unit 300 , the coating unit 400 , the drying unit 500 and the receiving unit 200 are pulled and communicated with each other through the pulling unit 600 .

[0053] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com