Patents

Literature

43results about How to "Realize the delivery work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

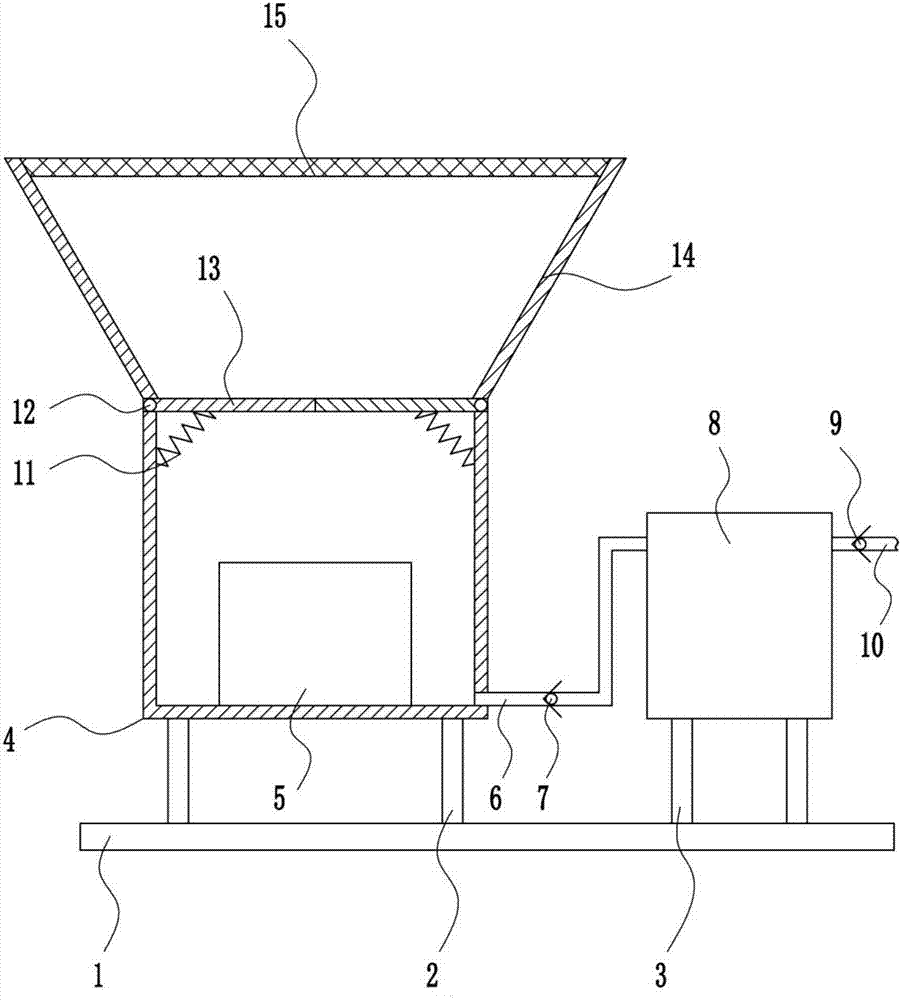

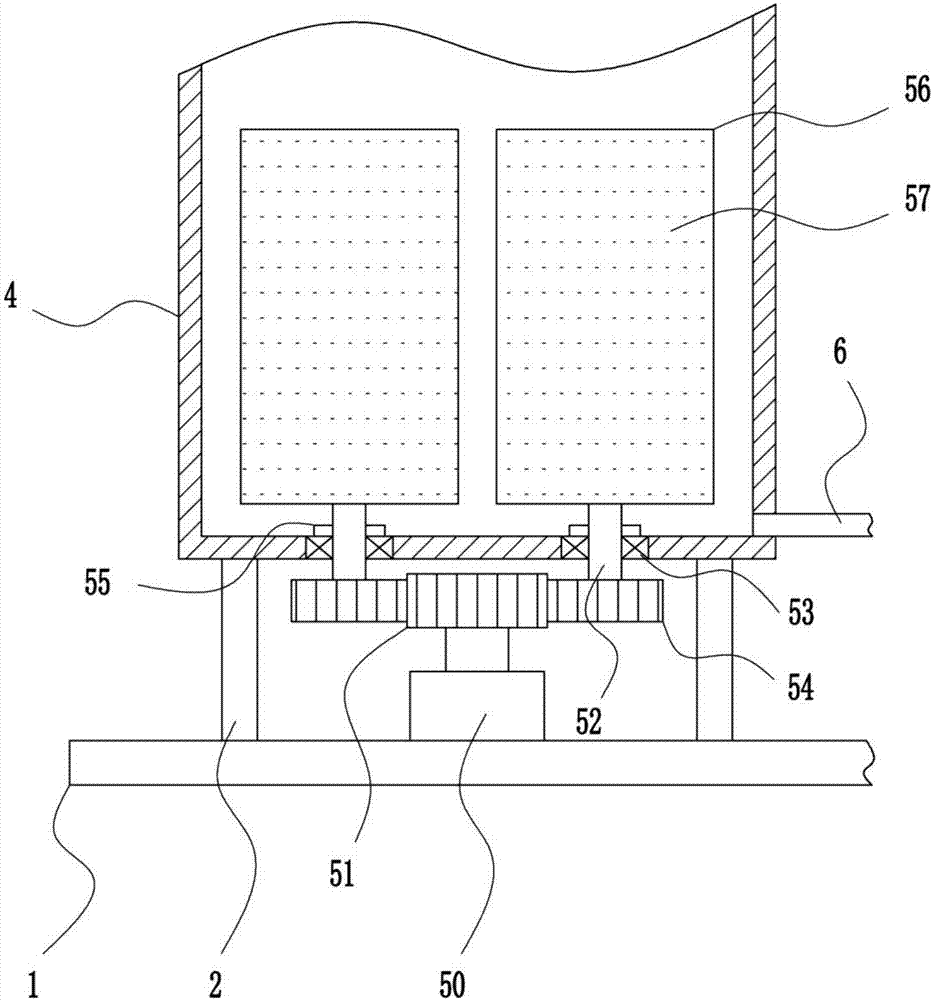

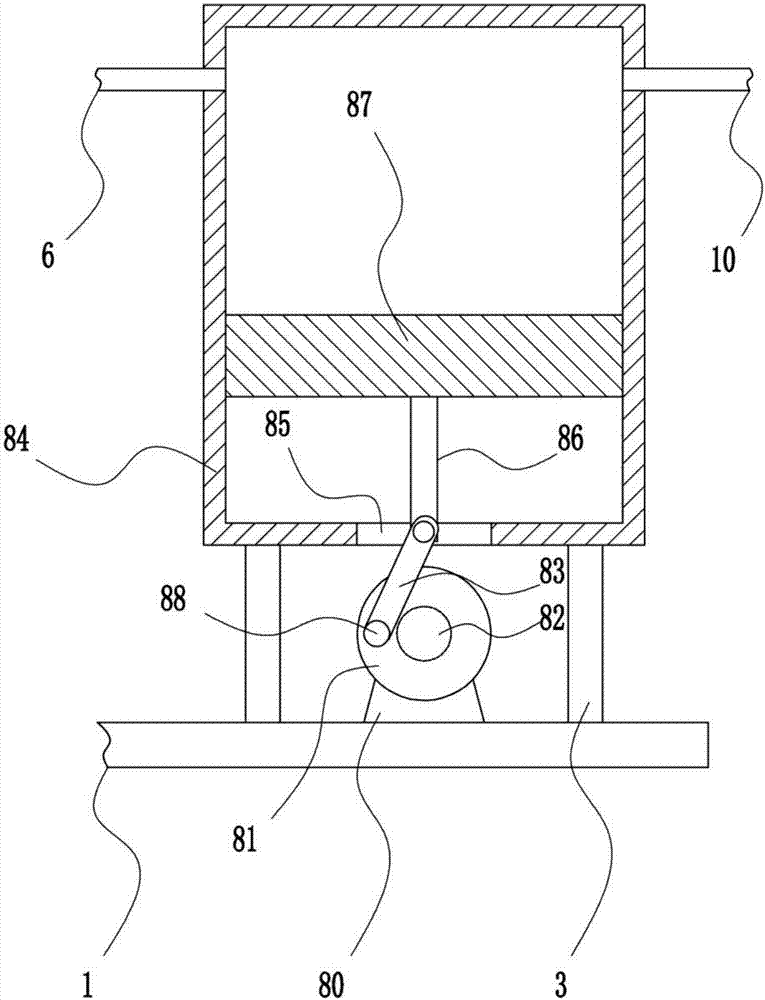

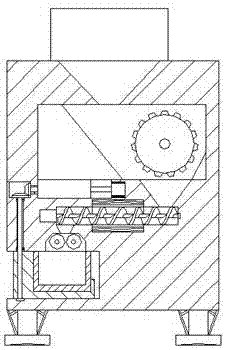

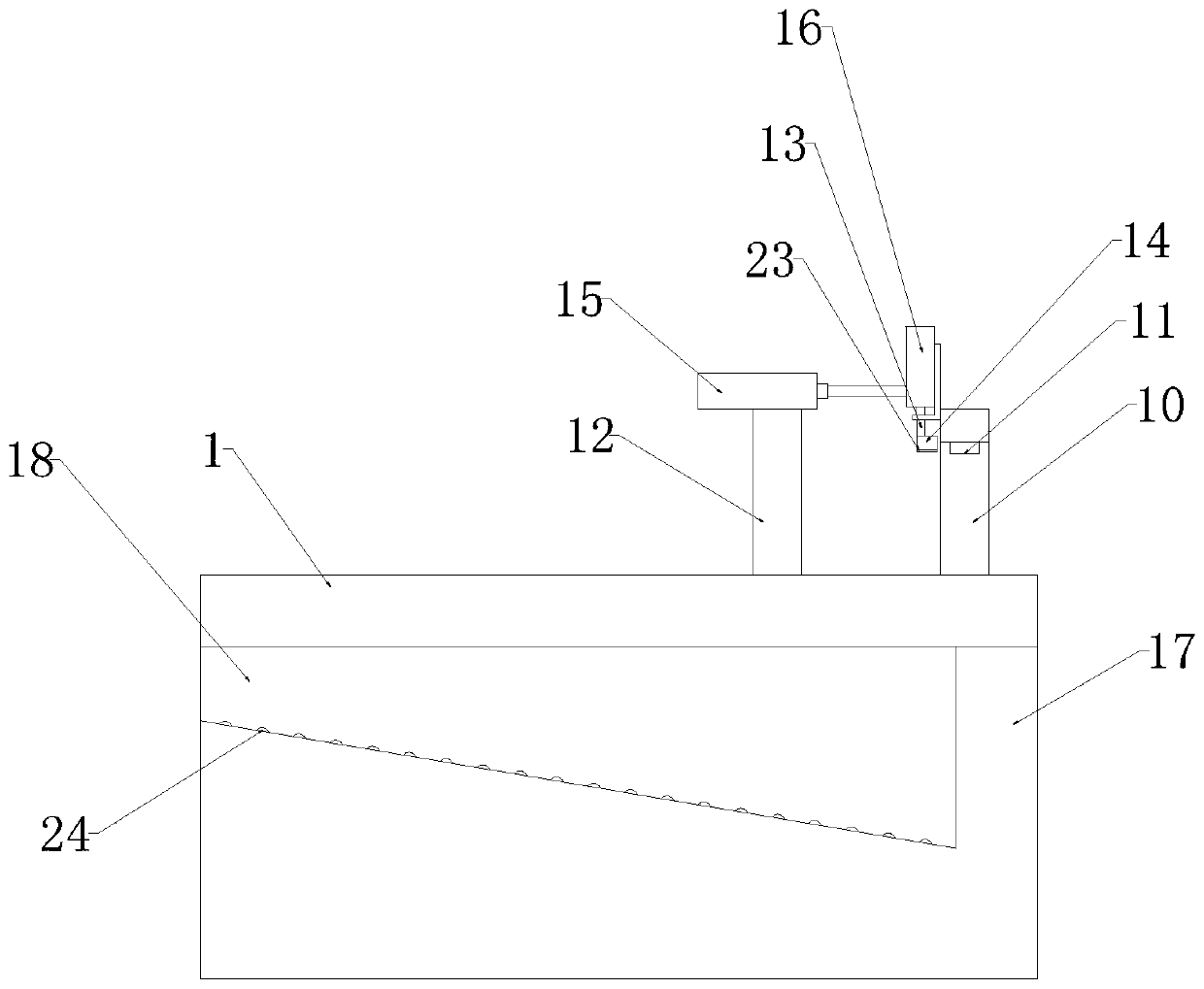

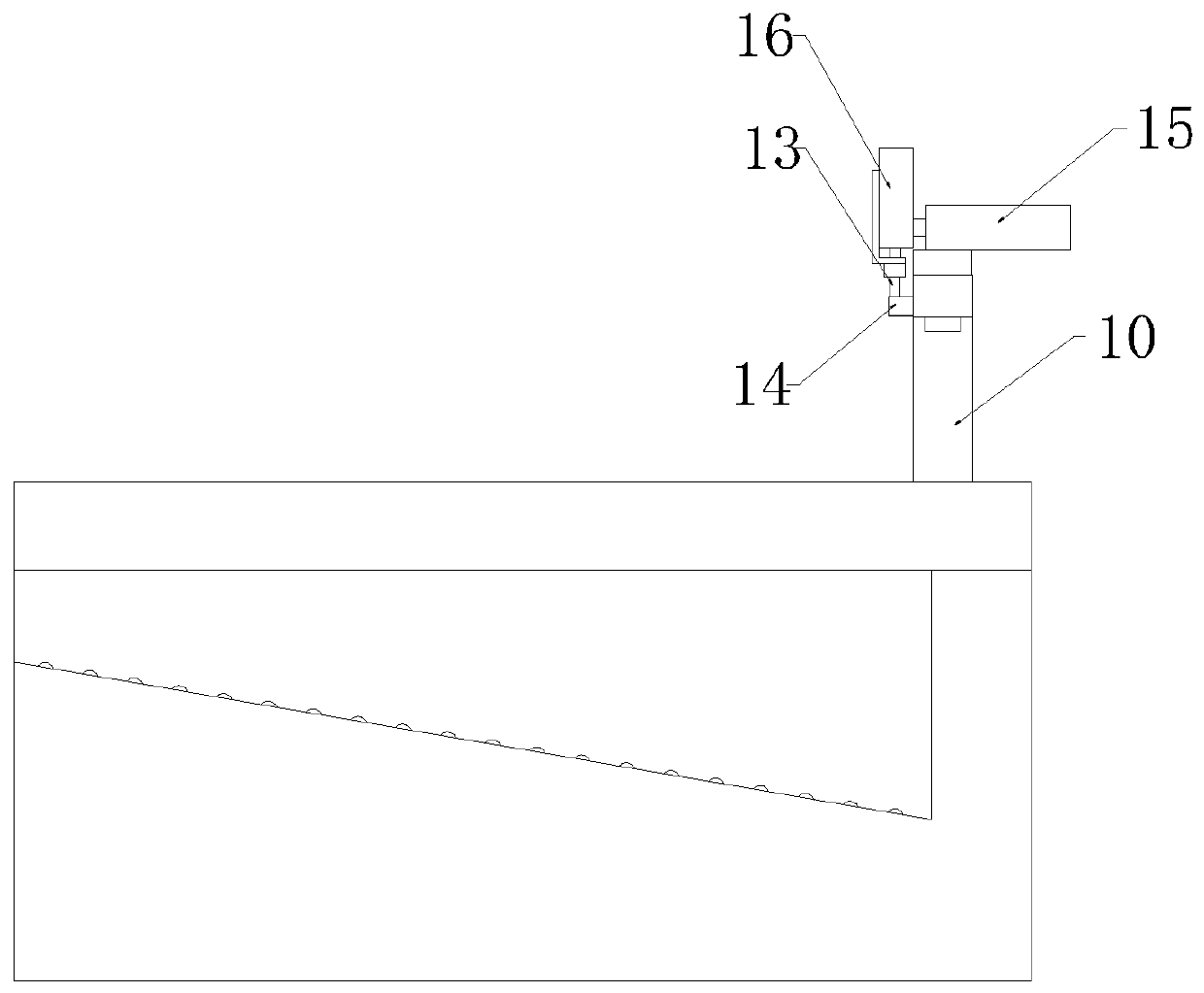

Filtering equipment for rainwater collection

InactiveCN107419771AFast filtering effectQuick purificationGeneral water supply conservationFiltration circuitsMotor driveRainwater harvesting

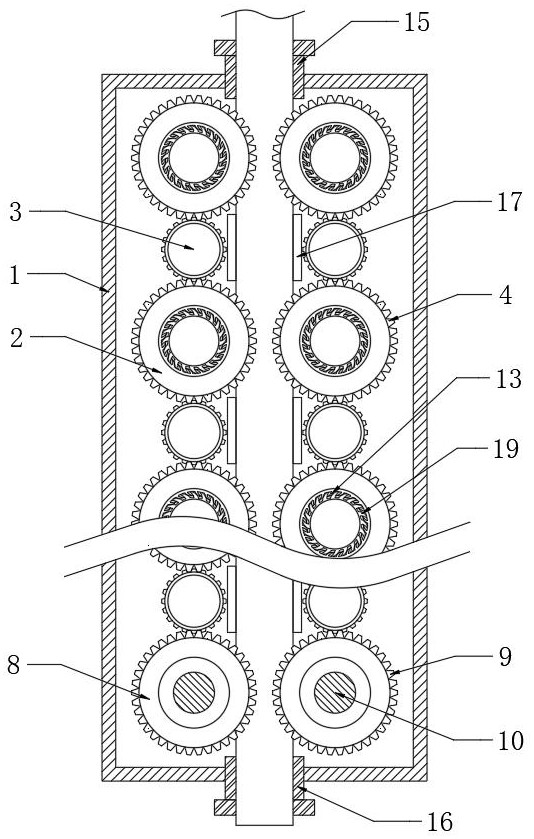

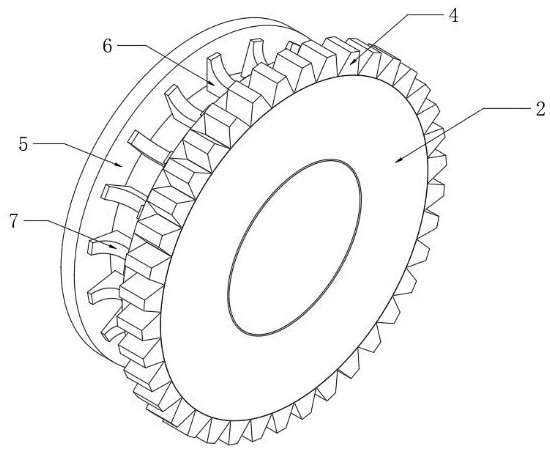

The invention relates to filtering equipment, in particular to filtering equipment for rainwater collection. The invention aims to solve the technical problem of providing the filtering equipment for rainwater collection which is novel in structure, convenient to use and capable of filtering rainwater. To solve the technical problem, the invention provides the filtering equipment for rainwater collection, comprising a base plate, first support rods, second support rods, a water collection tank, a filtering device, a first pipeline, a first one-way valve, a water delivery device, a second one-way valve, a second pipeline and the like; and the first support rods are symmetrically welded to the left side of the top of the base plate, the water collection tank is welded to the upper ends of the first support rods, a water collection cover is welded to the top end of the water collection tank, and a filter net is welded to the top in the water collection cover. A first motor is controlled to rotate, the first motor drives a second gear to rotate through a first gear, finally a filter net cover is made to rotate, and the rotation of the filter net cover can make active sand in sufficient contact with rainwater.

Owner:王金鑫

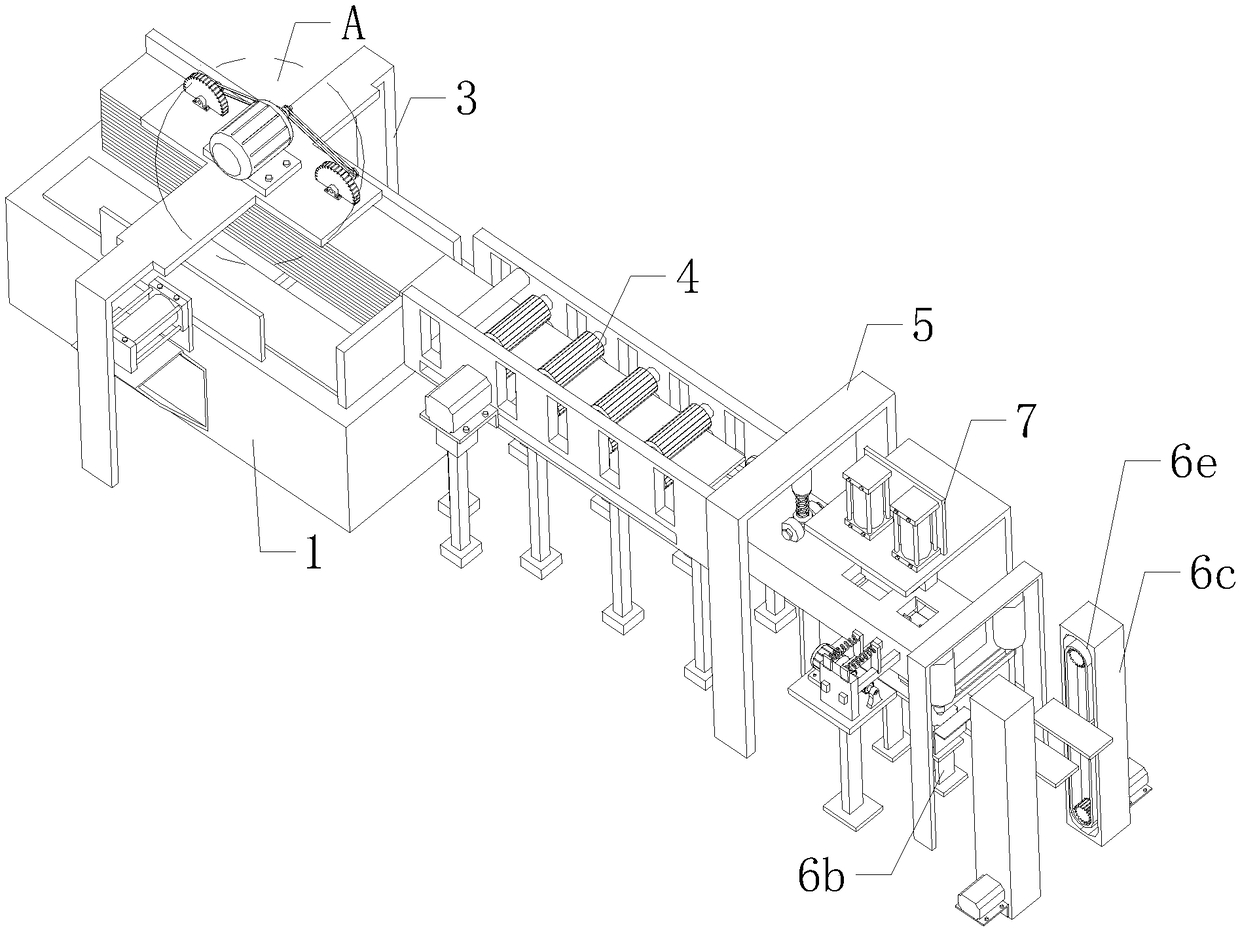

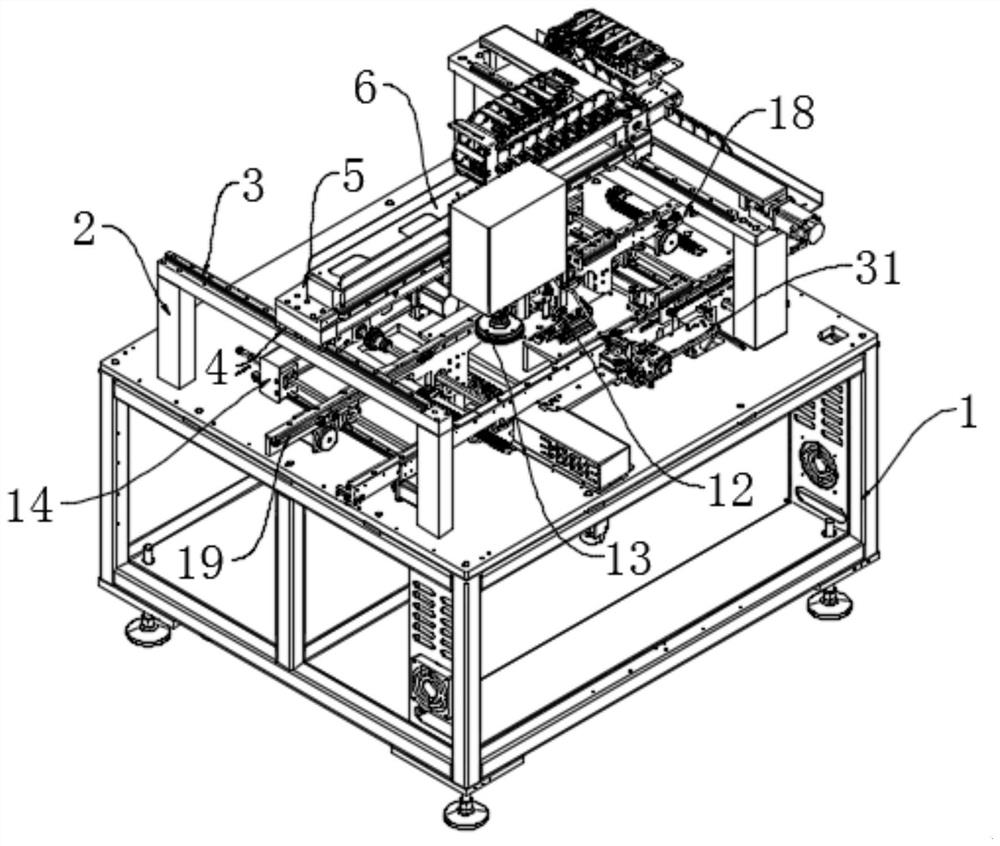

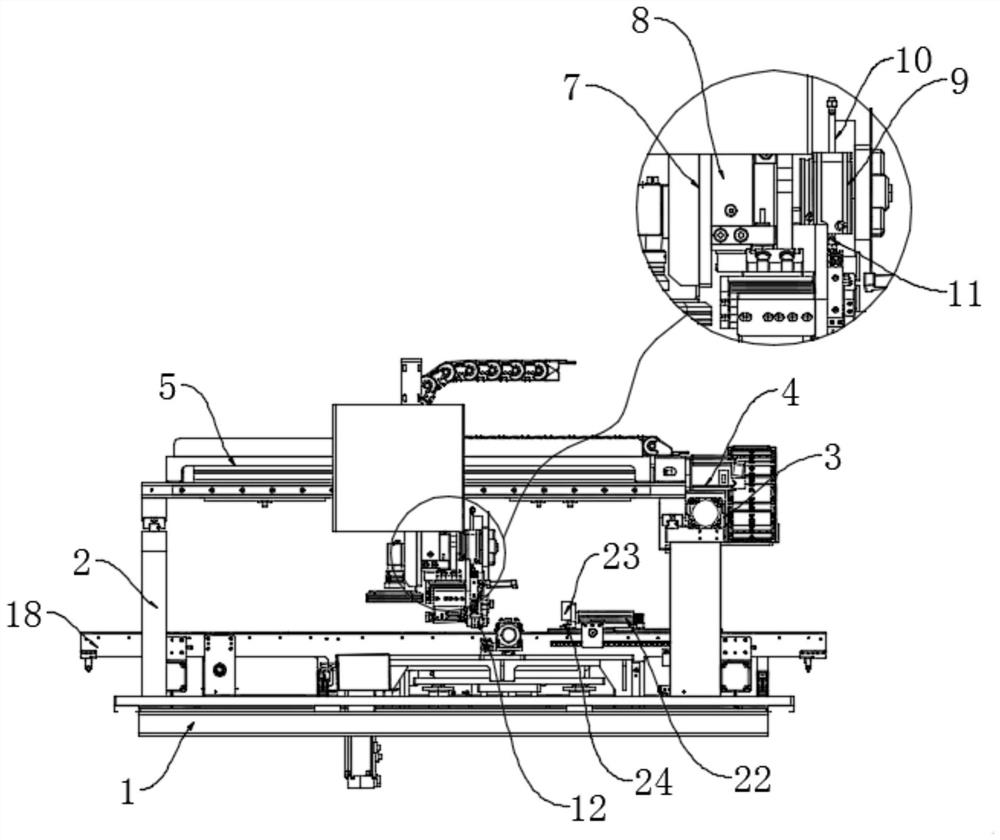

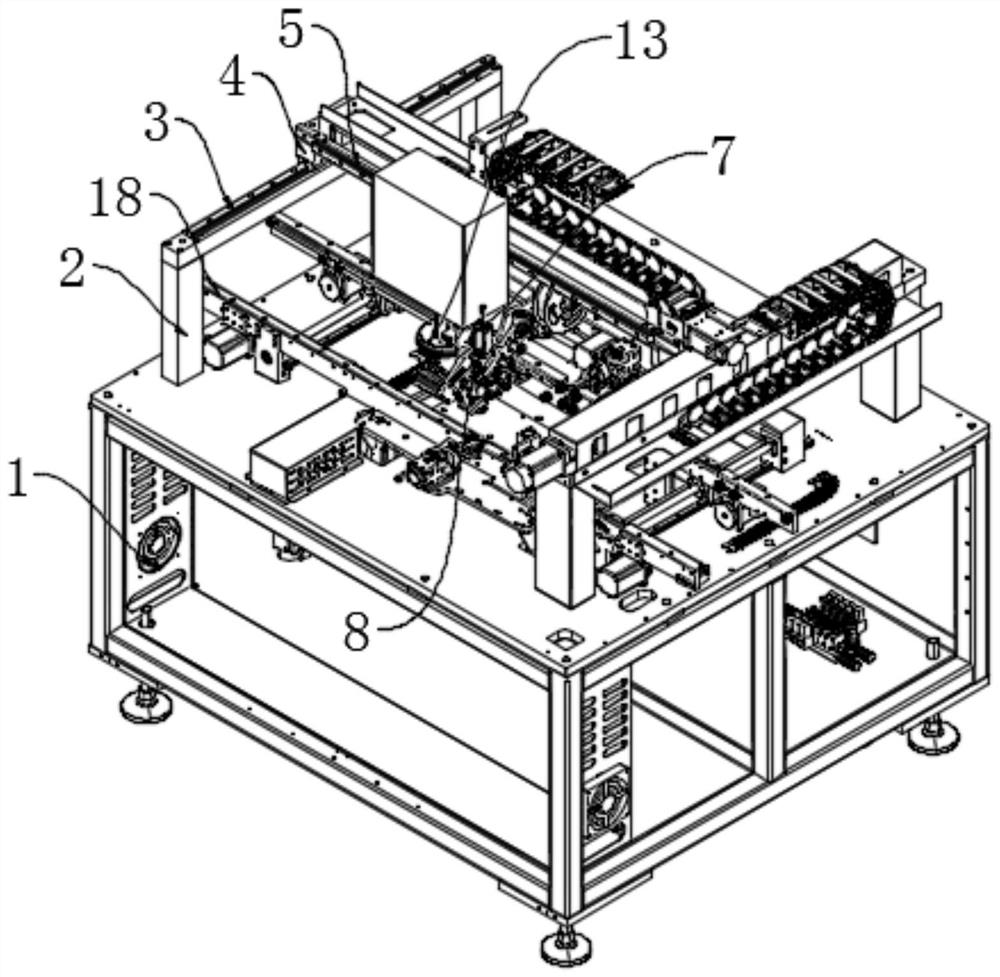

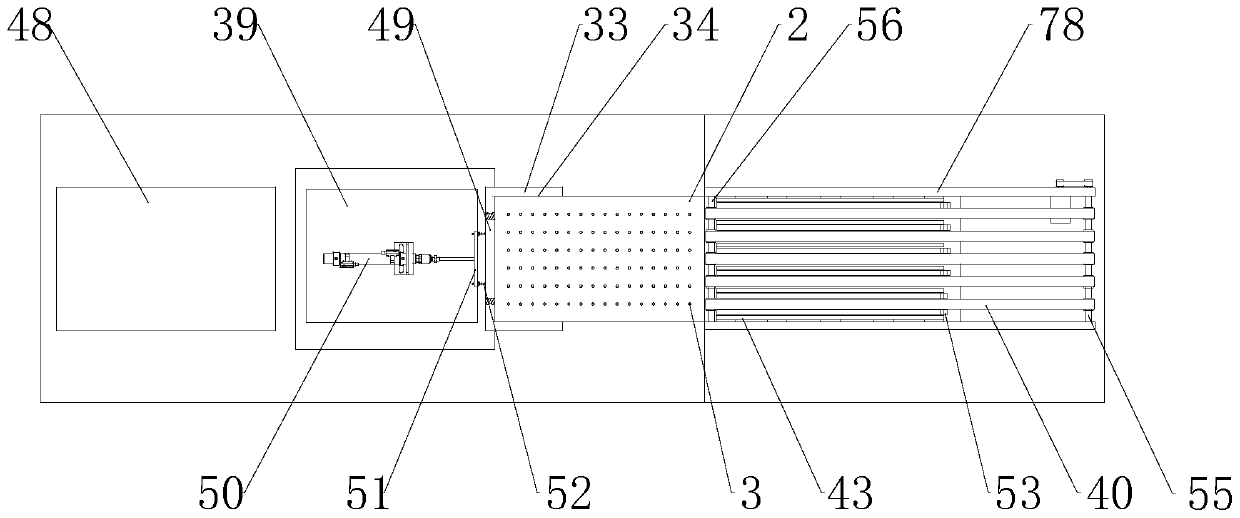

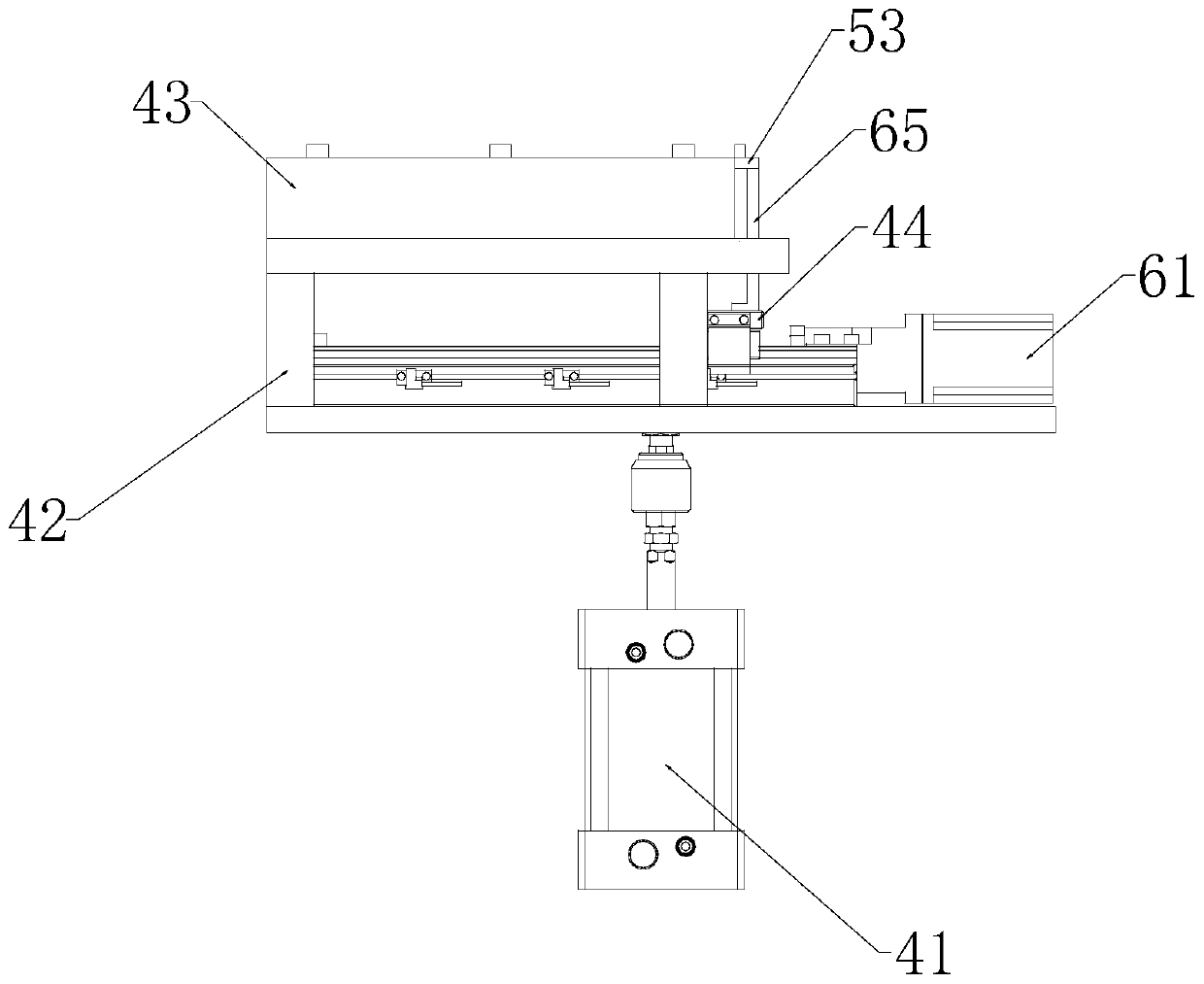

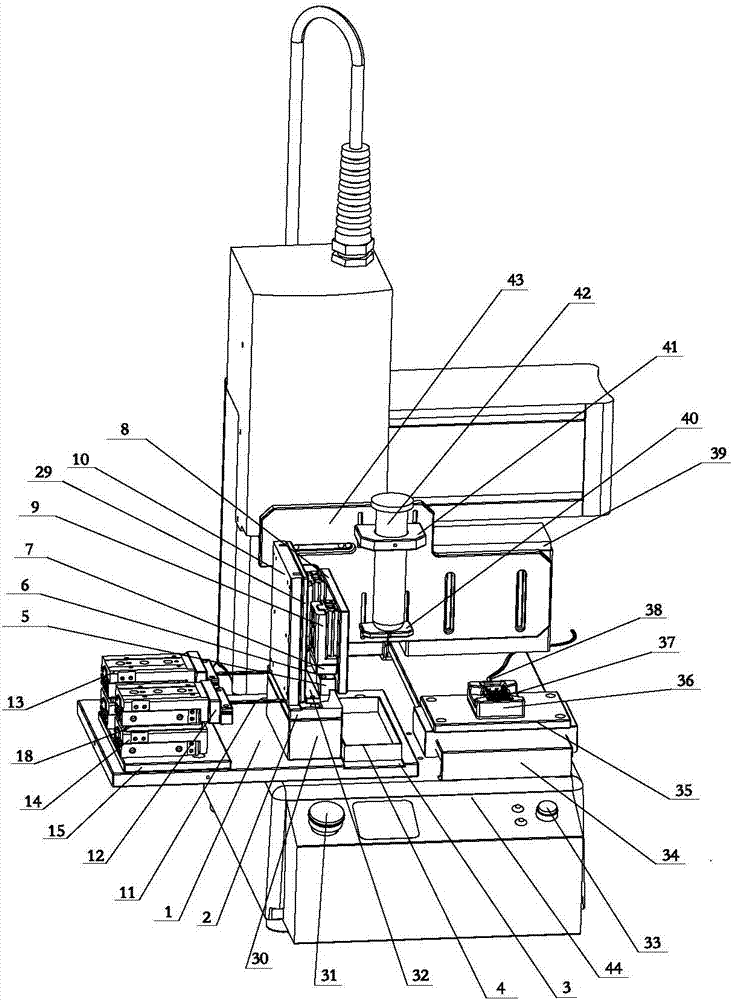

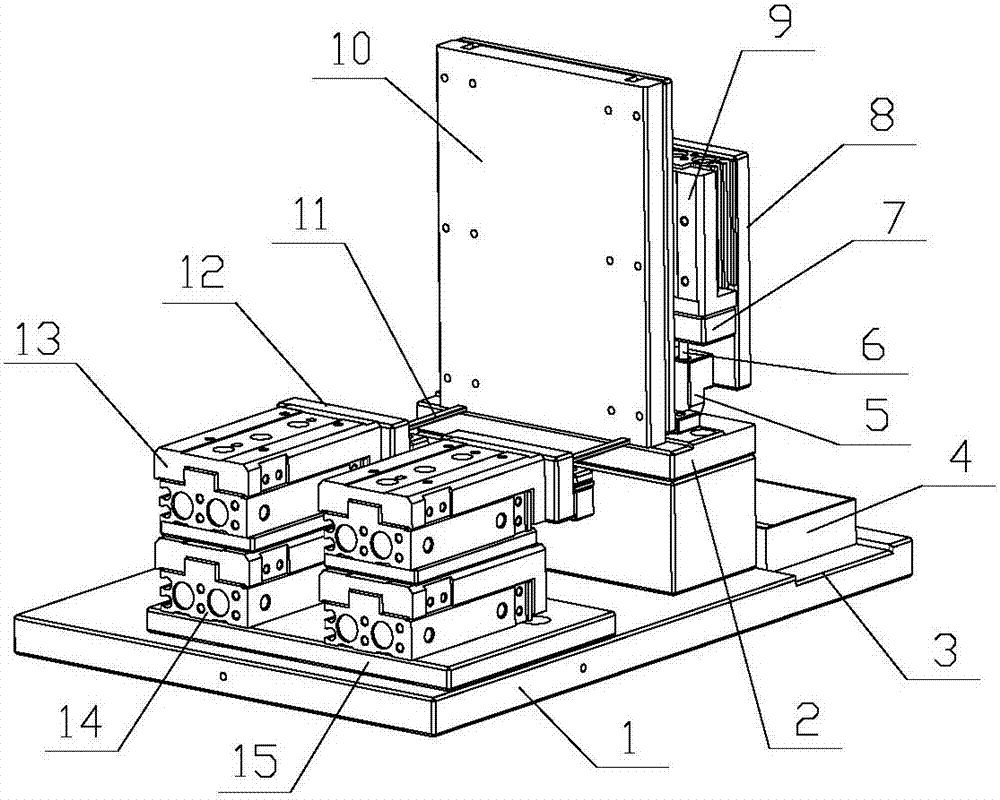

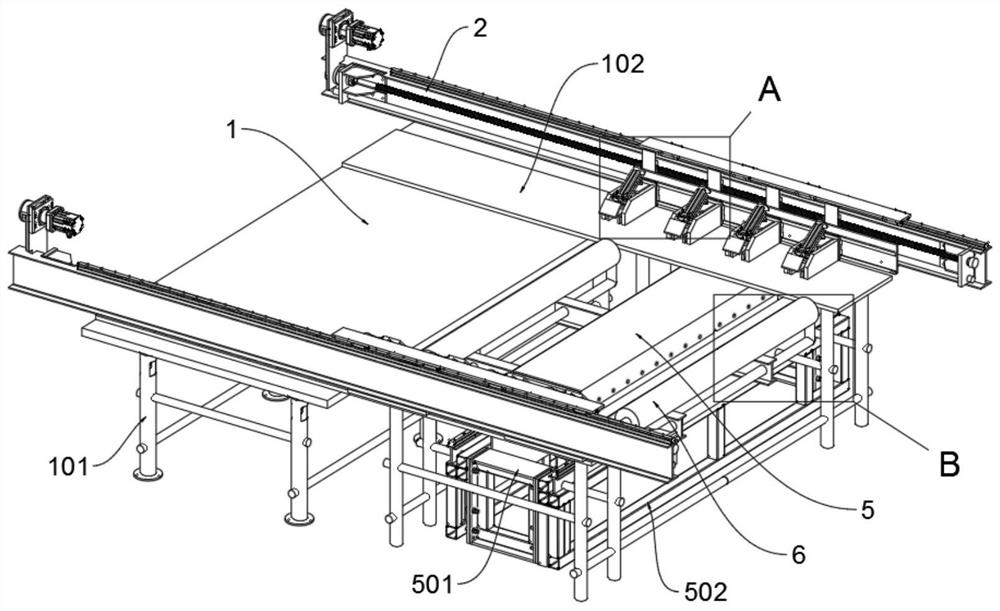

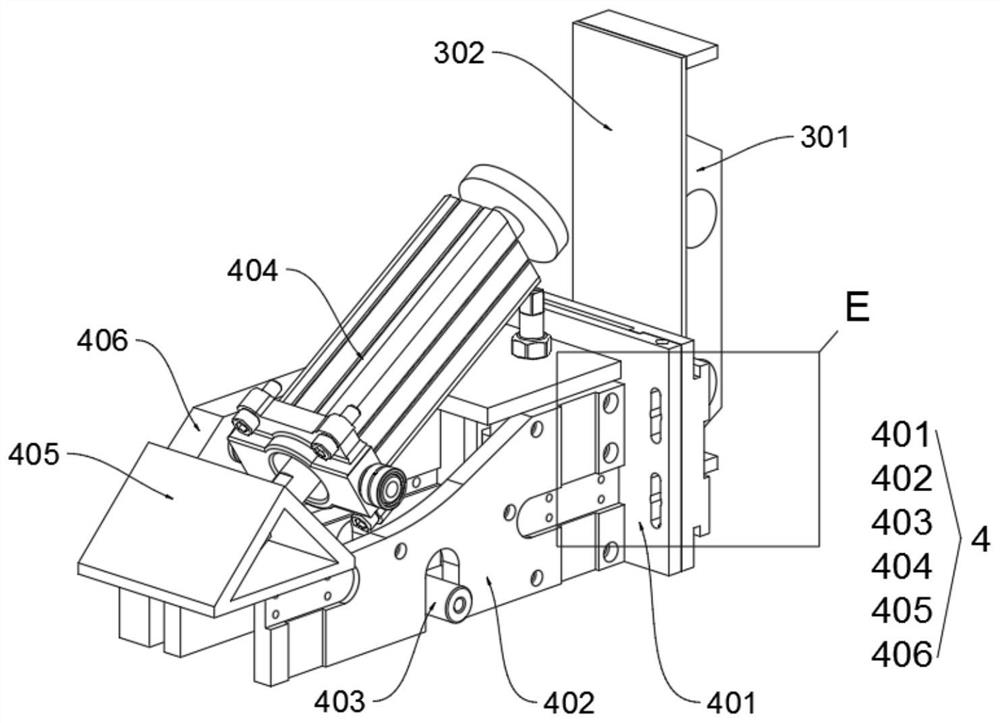

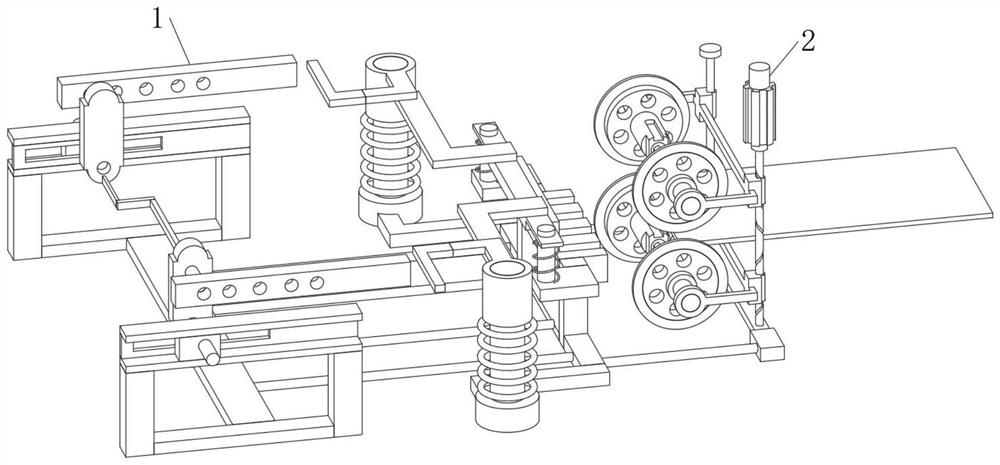

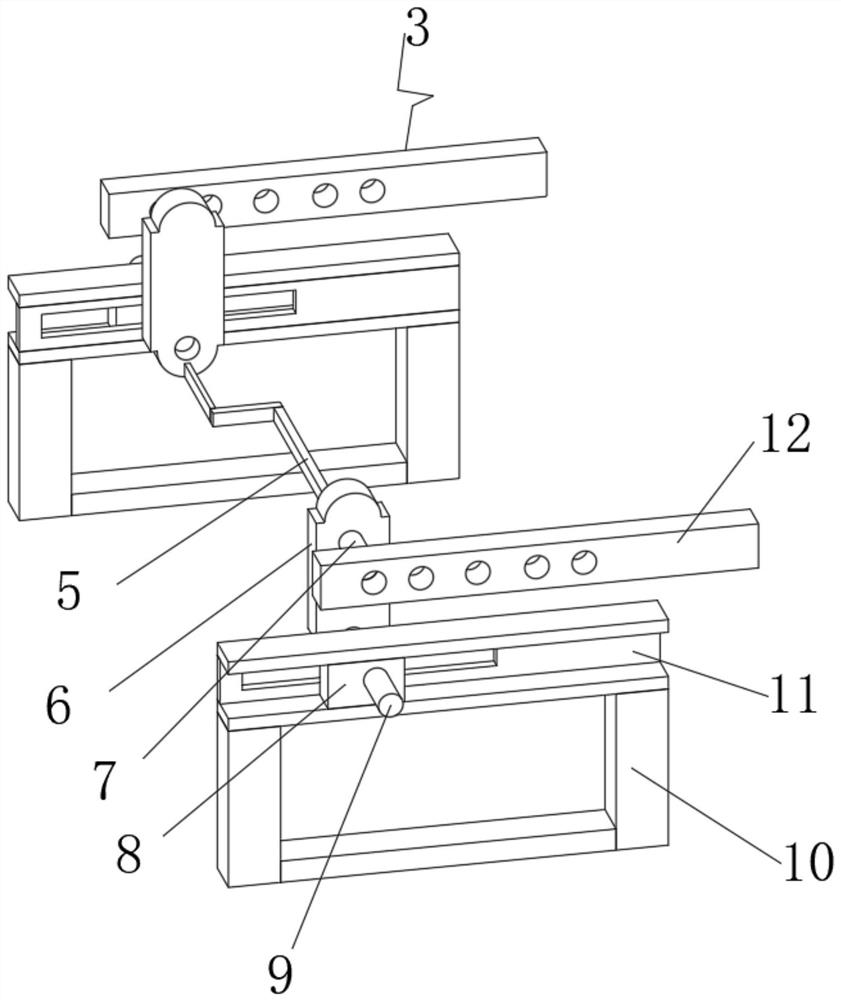

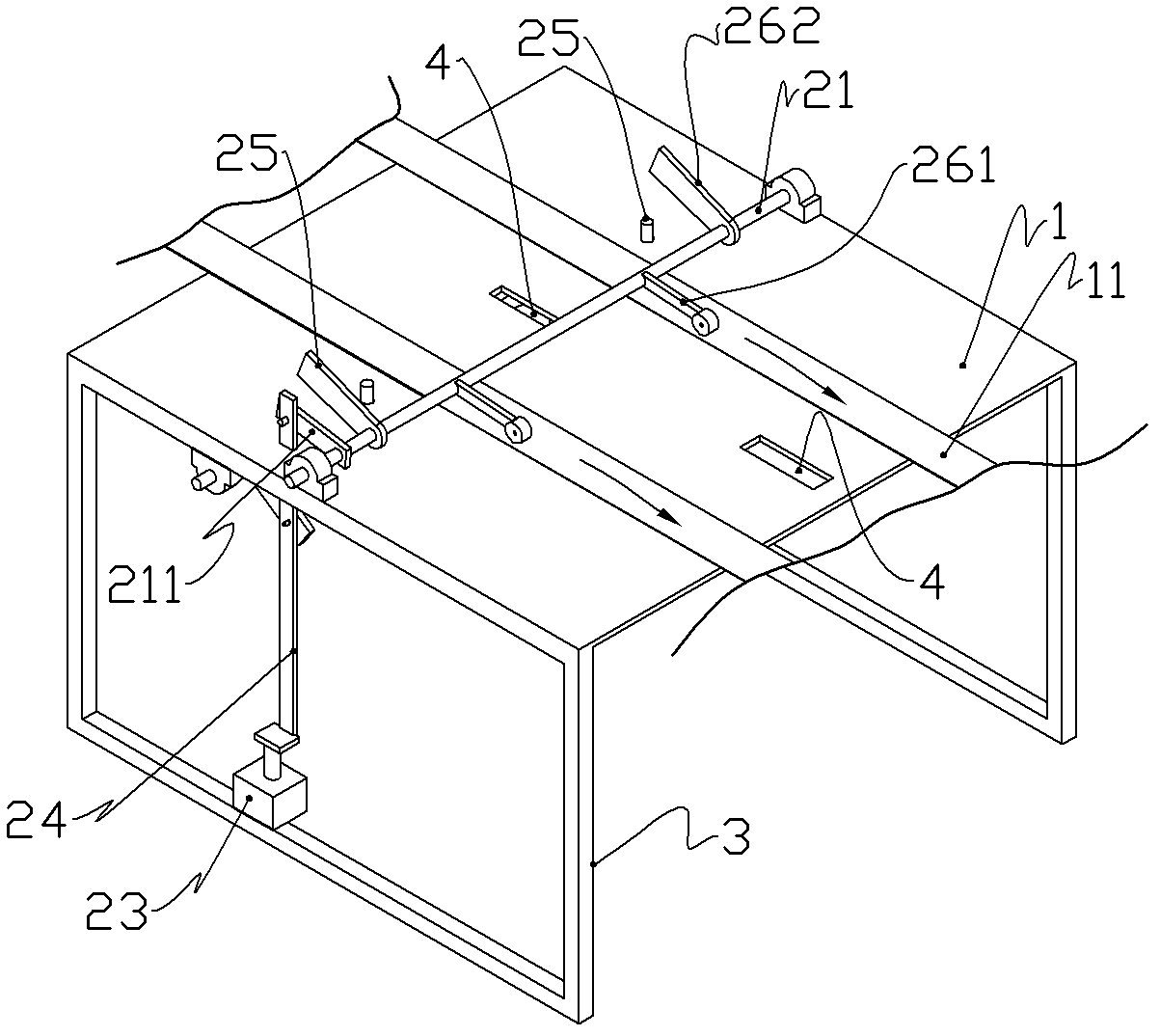

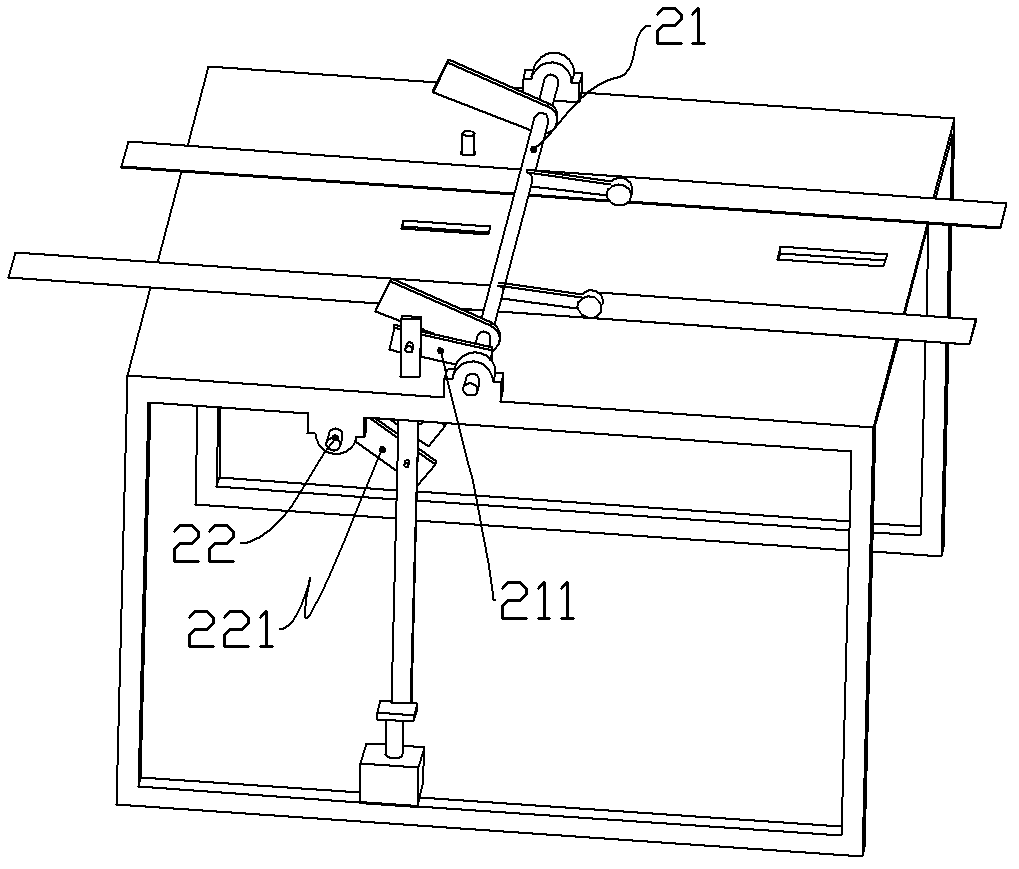

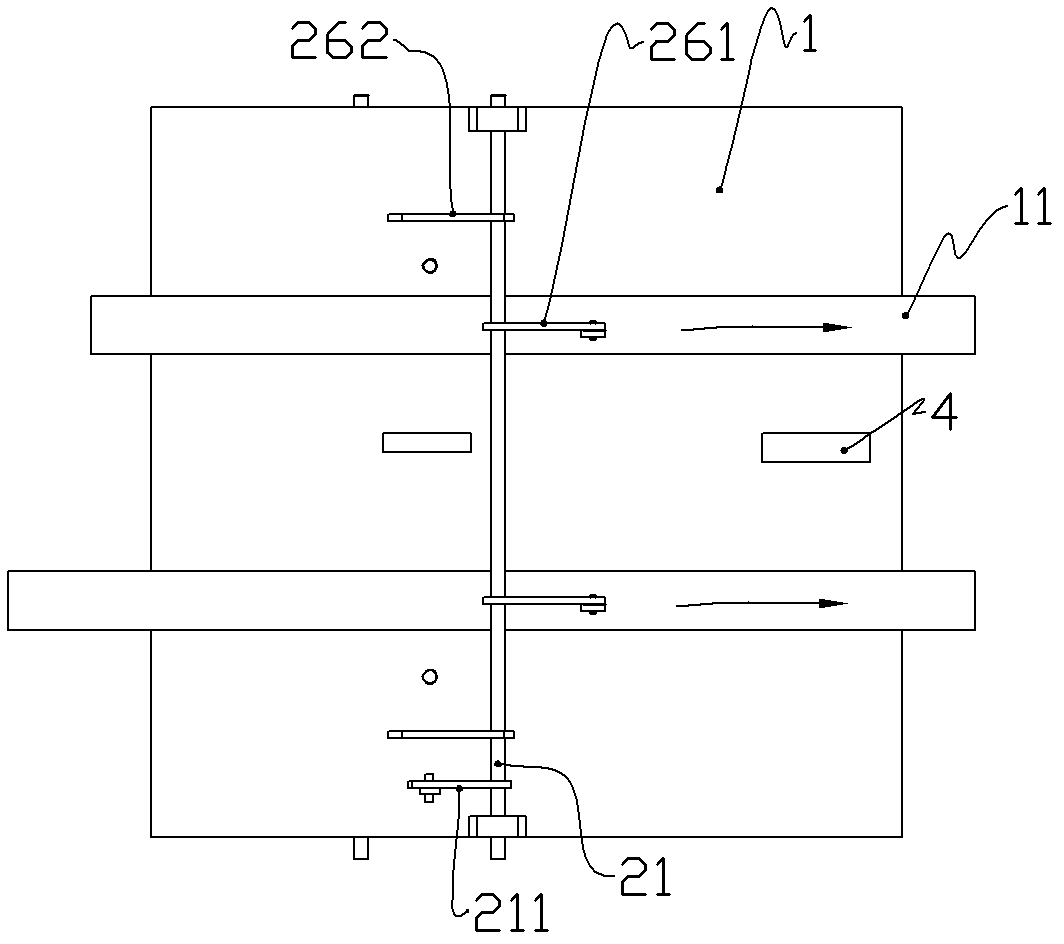

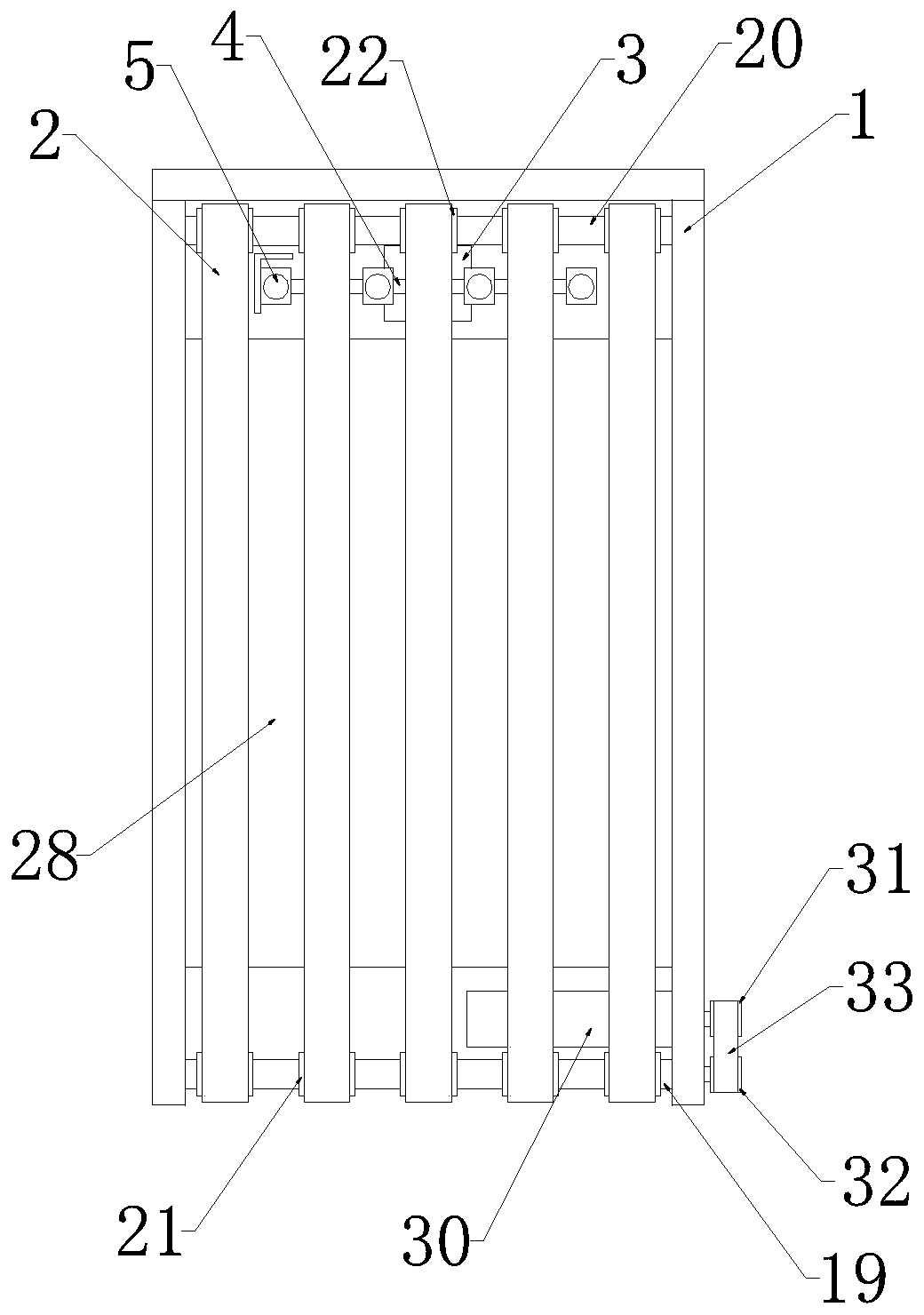

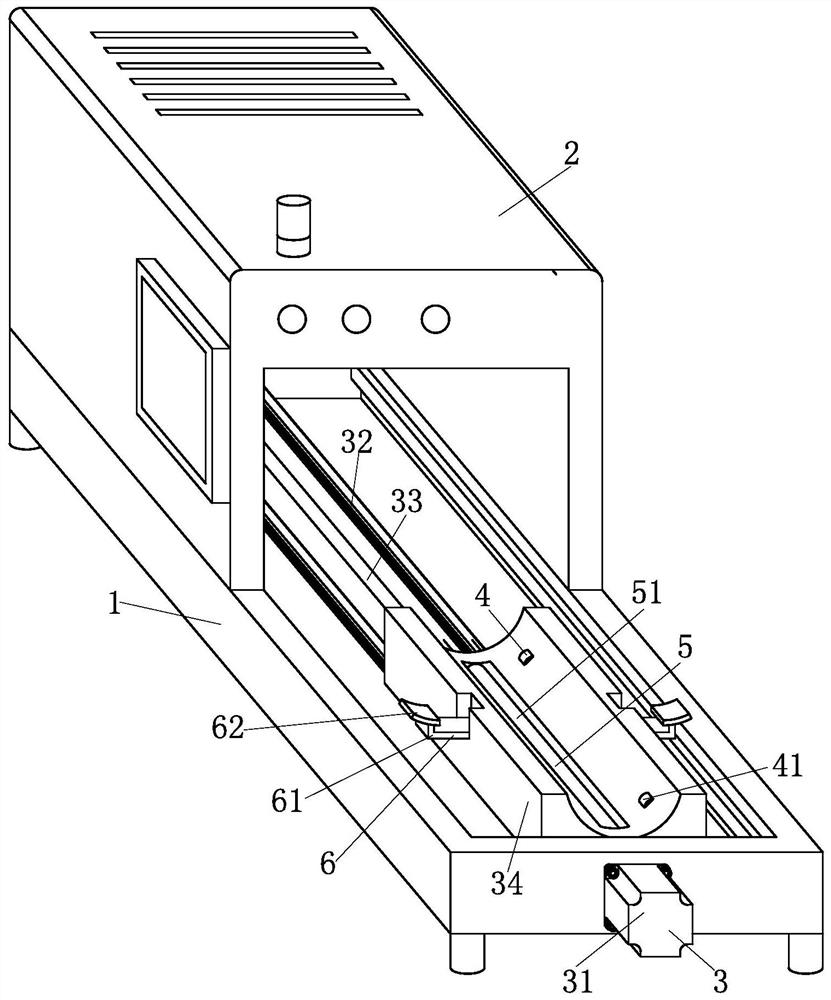

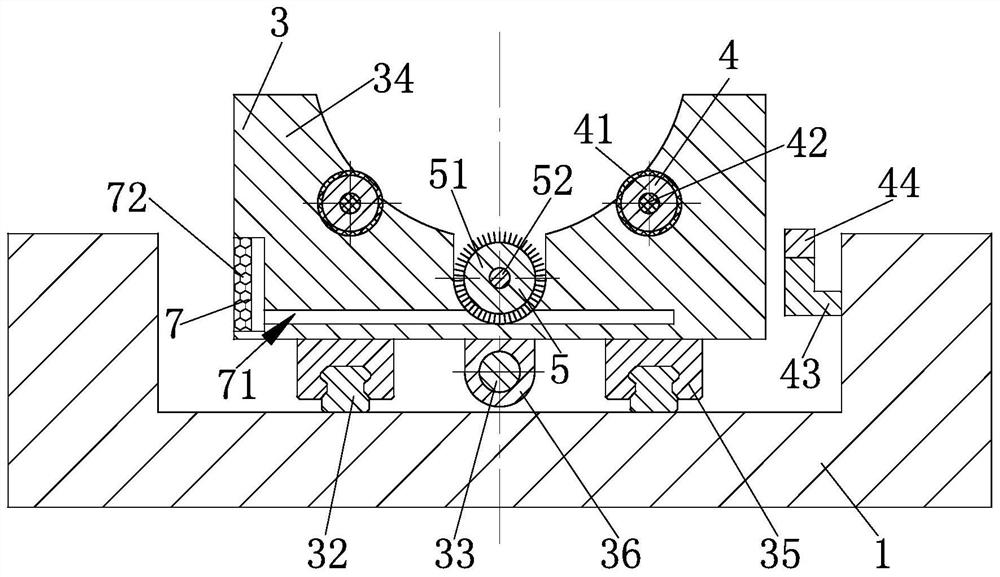

Automatic shrapnel forming machine

ActiveCN108723182ARealize bending workRealize the delivery workMetal-working feeding devicesPositioning devicesPunchingEngineering

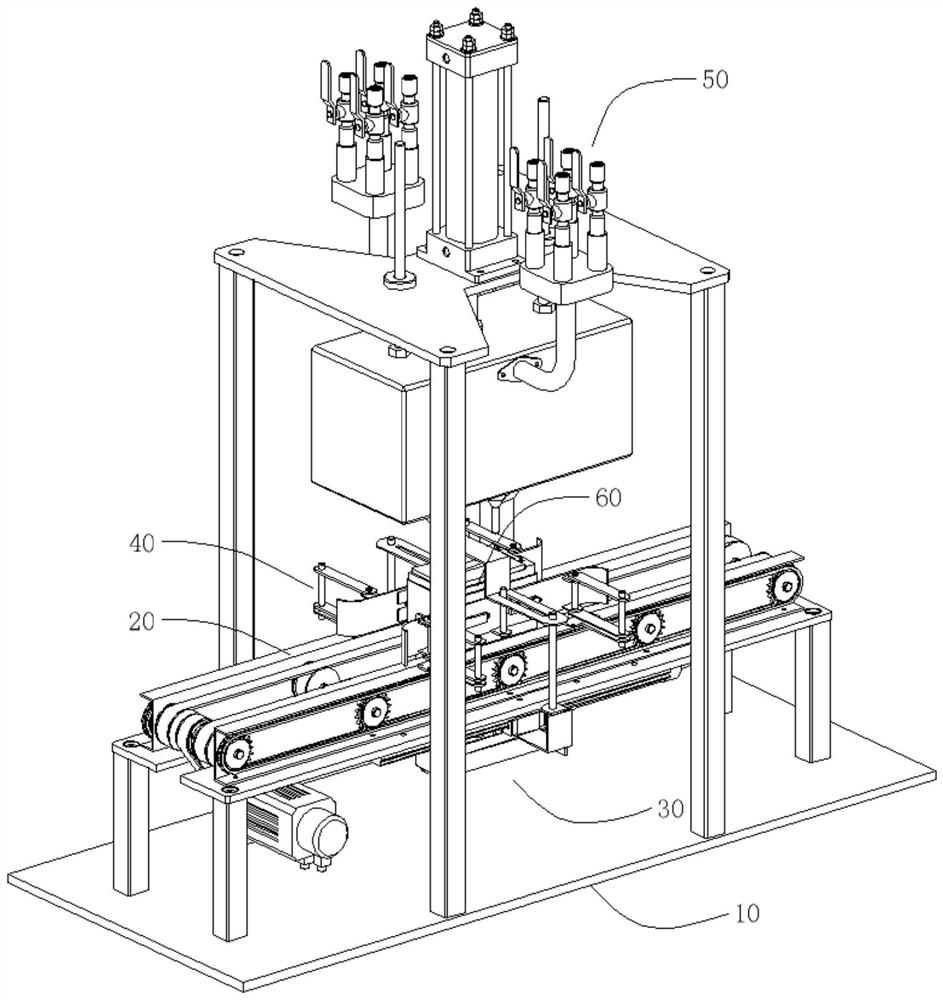

The invention relates to the field of shrapnel machining, in particular to an automatic shrapnel forming machine. The machine comprises a feeding device, a punching and bending device and a waste discharging device which are arranged in a straight line in sequence. The feeding device comprises a transfer stock bin, an uplifting assembly which is located in the transfer stock bin and used for supporting a plurality of metal sheets, a delivery assembly which is located beside the transfer stock bin and used for pushing the metal sheets to a position above the uplifting assembly one by one, and atravelling assembly which is located above the uplifting assembly. A traction assembly is arranged at the discharging end of the transfer stock bin, a punching table is arranged on the down stream ofthe traction assembly, an elastic limit assembly is arranged at the end, close to the traction assembly, of the punching table, and the waste discharging device comprises a leading-out assembly and alifting assembly which are arranged at the other end of the punching table. By means of the automatic shrapnel forming machine, automatic feeding and conveying work of the metal sheets can be effectively achieved and cooperate with subsequent punching and bending work, and the production efficiency is improved.

Owner:深圳市科成精密五金有限公司

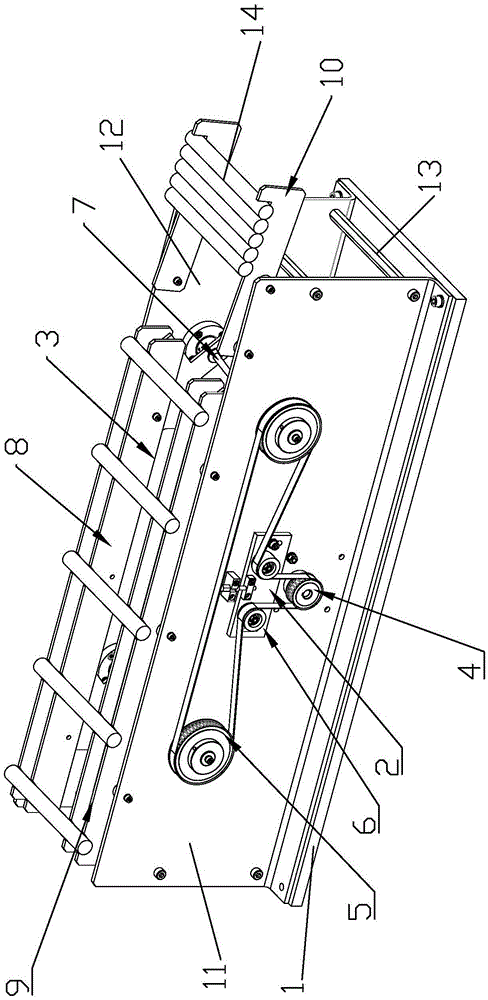

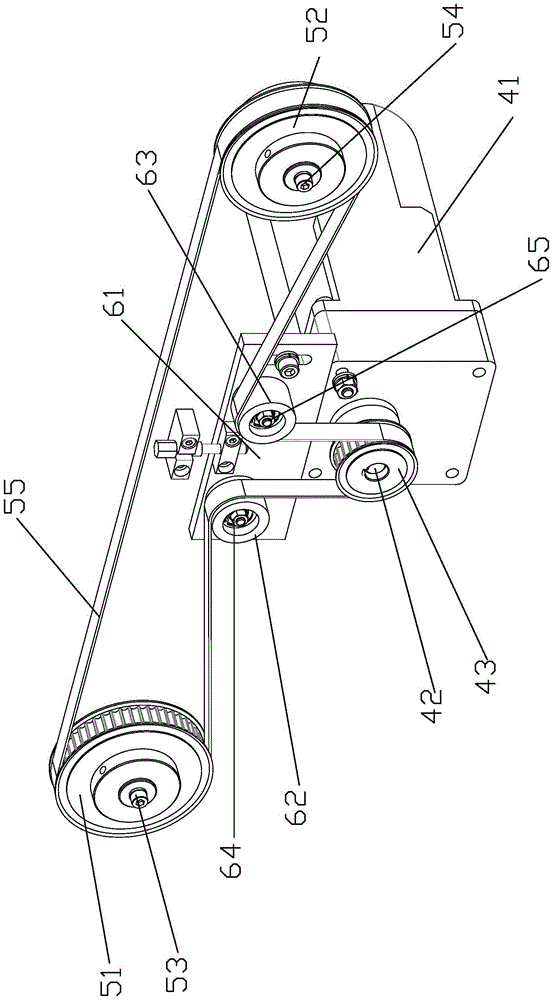

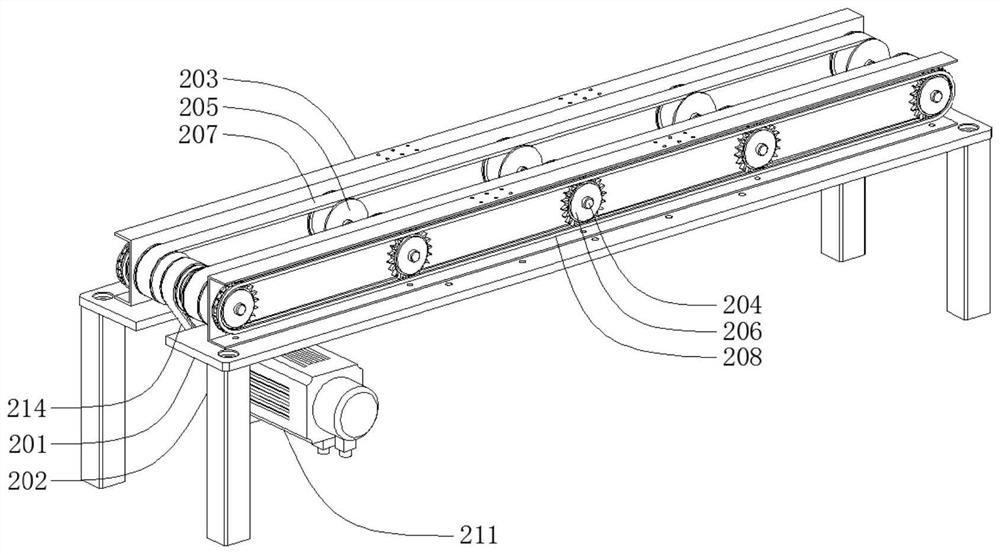

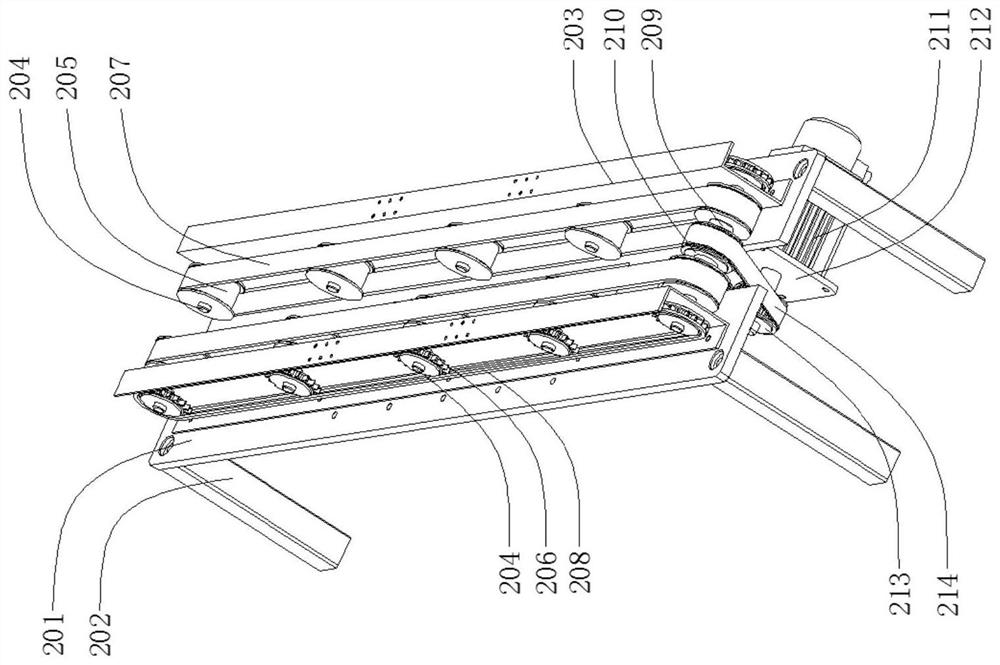

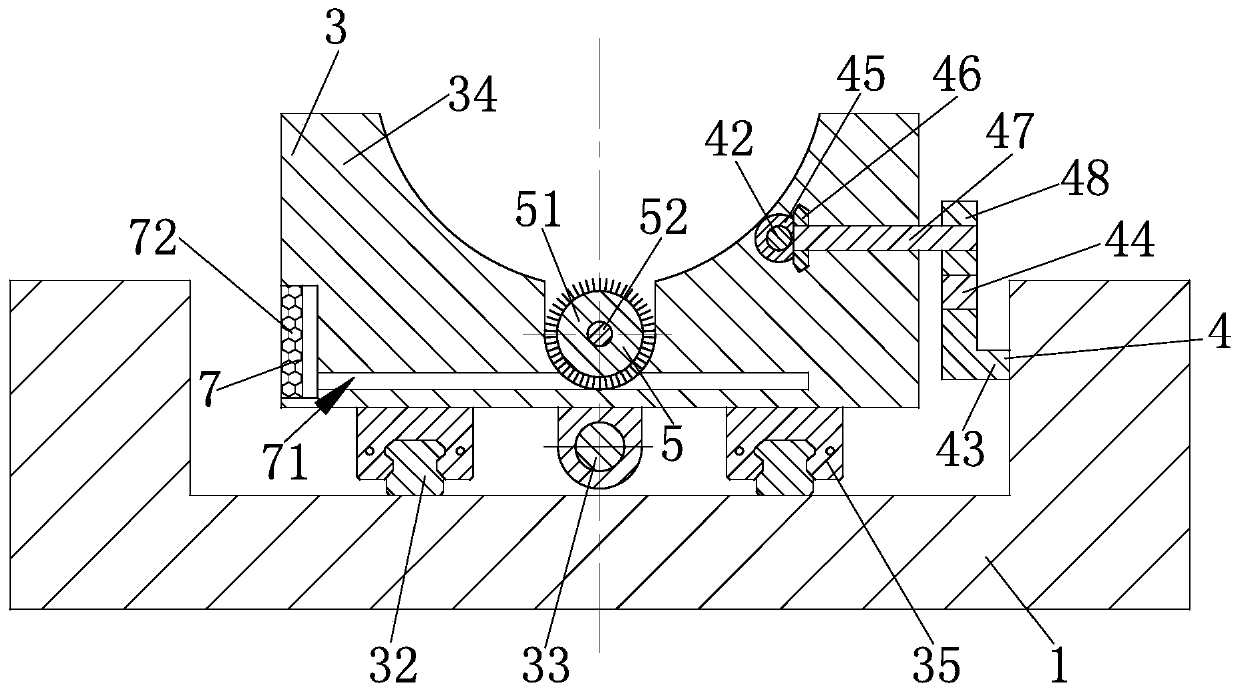

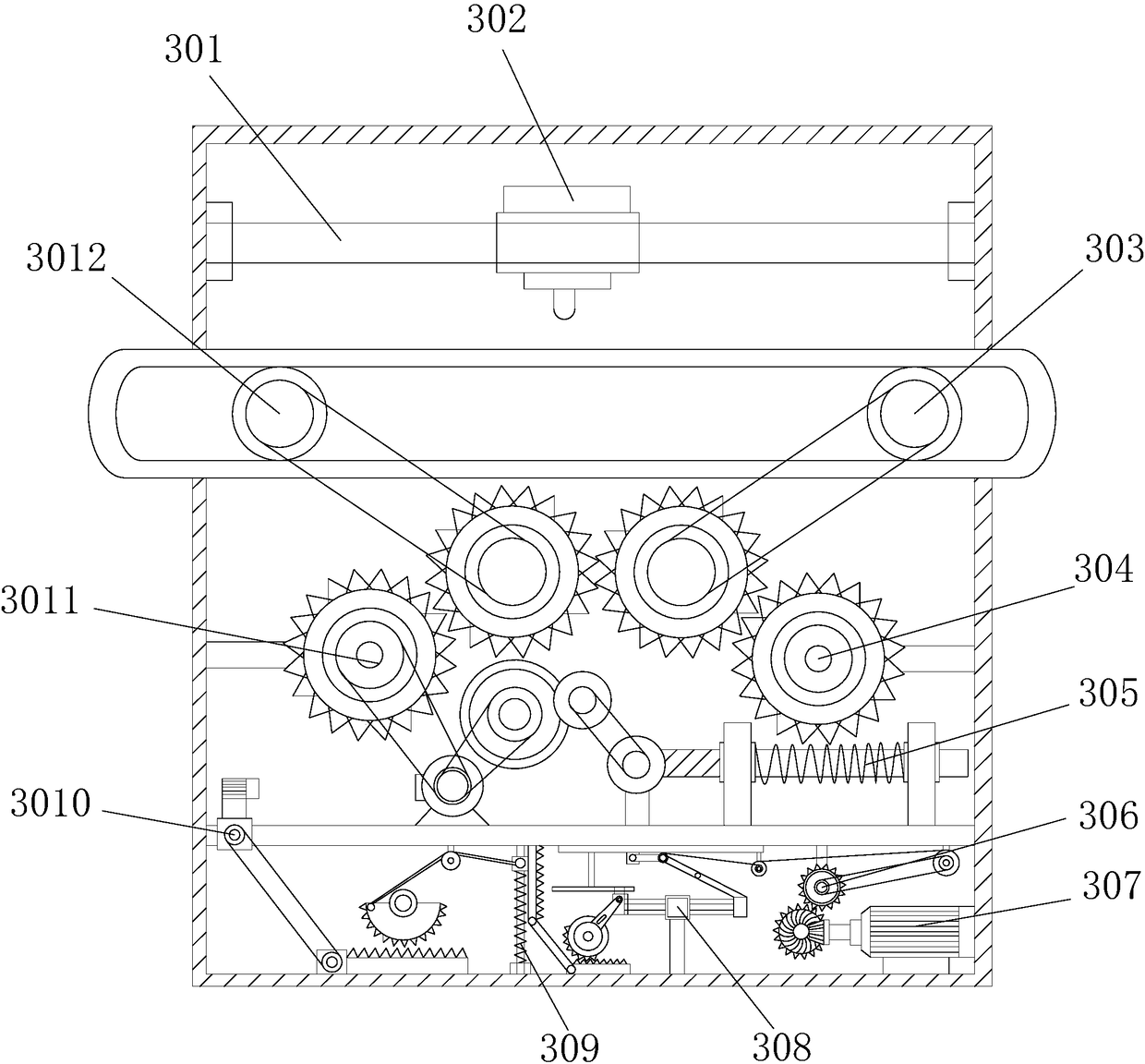

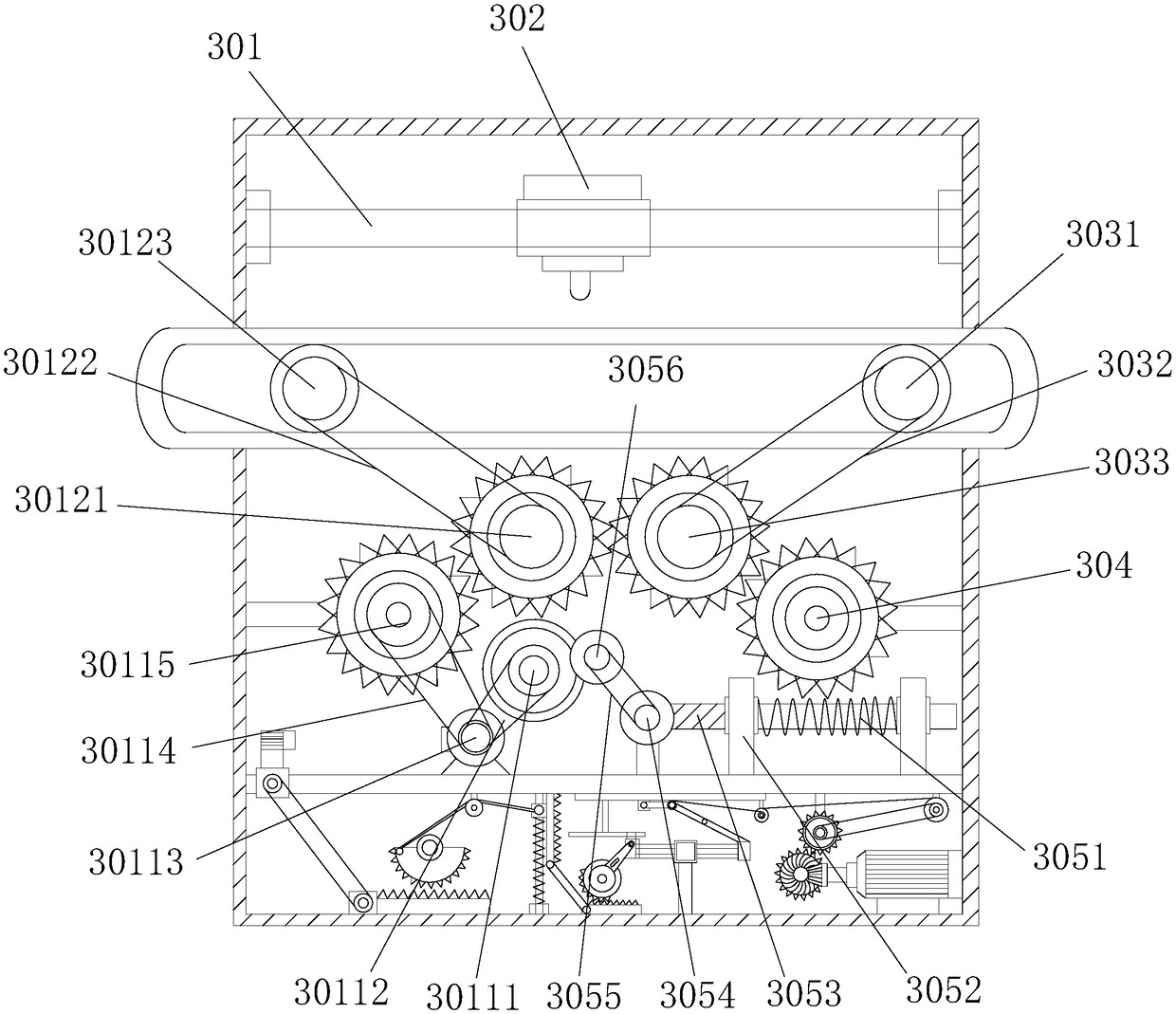

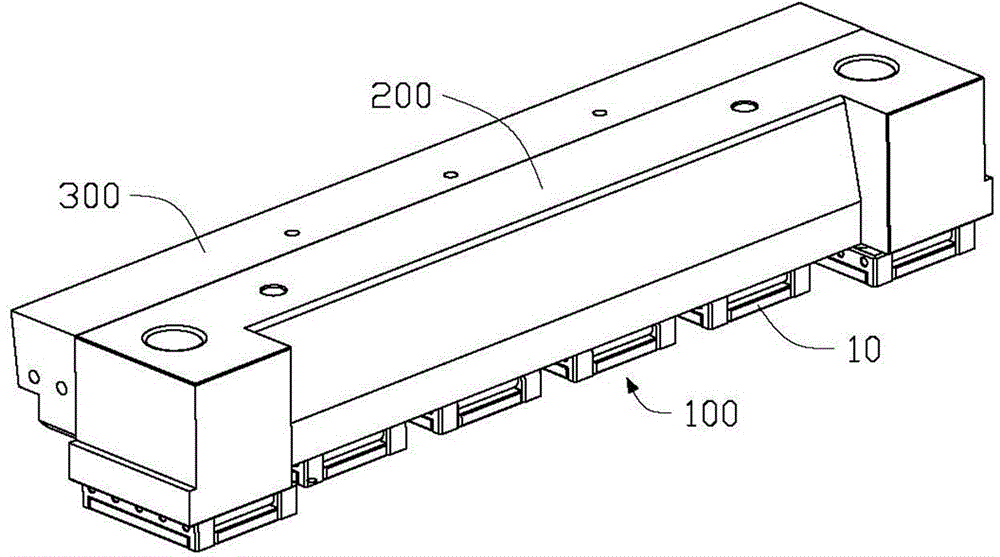

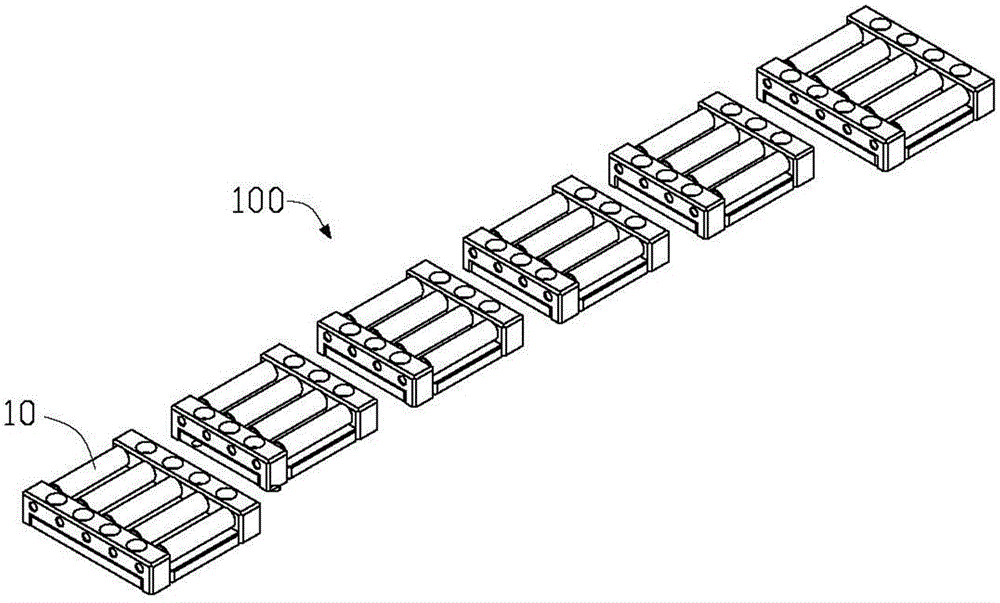

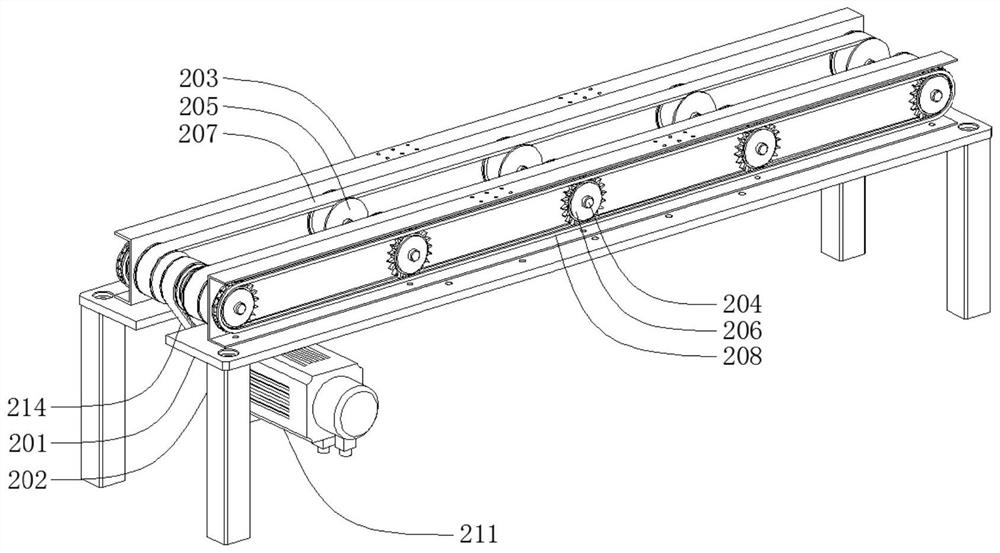

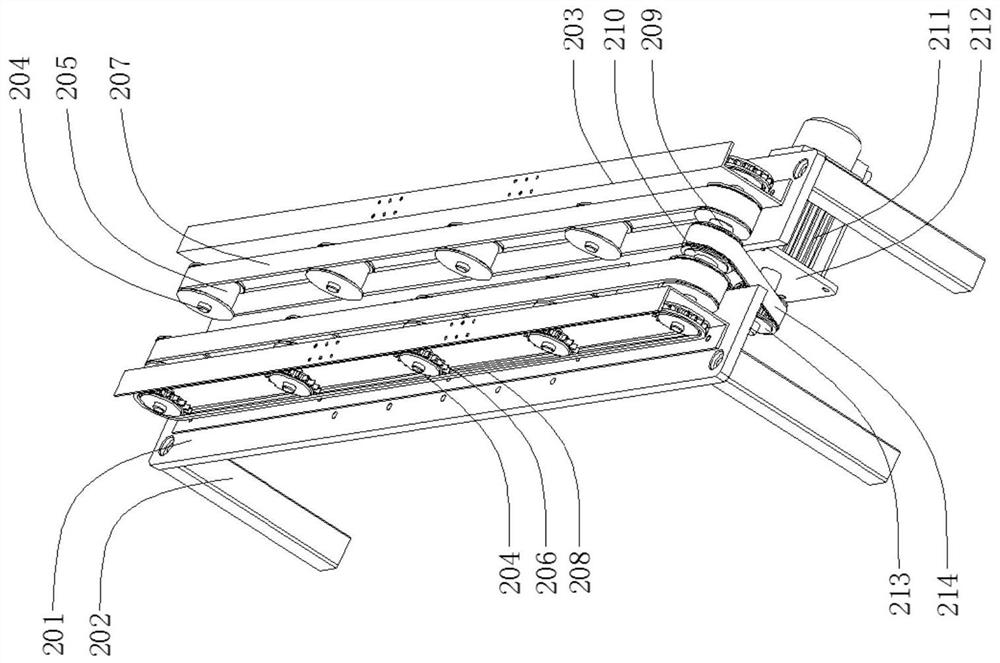

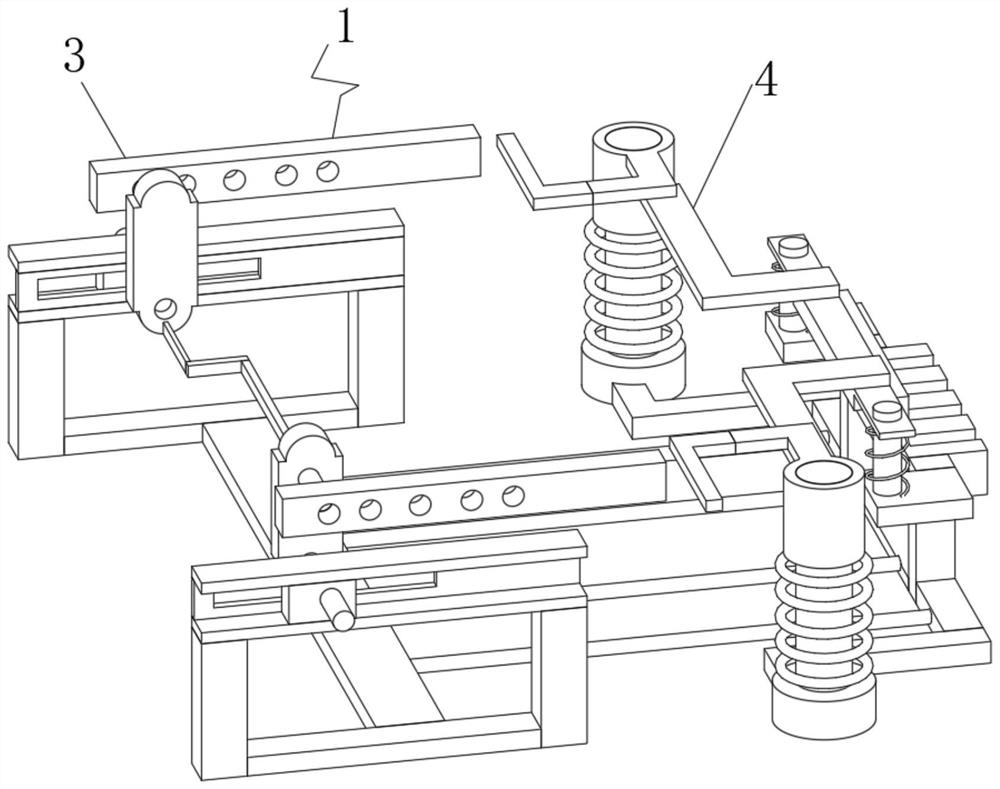

Uniform conveying device used for pin shaft parts

The invention discloses a uniform conveying device used for pin shaft parts. The uniform conveying device comprises a conveying base, a conveying drive mechanism and a conveying mechanism. The conveying base is provided with the conveying drive mechanism. The conveying drive mechanism is connected with the conveying mechanism. The conveying base is provided with a conveying frame which comprises a first conveying frame body and a second conveying frame body. The first conveying frame body is provided with the conveying drive mechanism, and the conveying mechanism is arranged between the first conveying frame body and the second conveying frame body. The conveying drive mechanism comprises a drive assembly, a guide wheel tensioning assembly, a belt transmission assembly and an eccentric transmission assembly. The drive assembly is connected with the belt transmission assembly. The belt transmission assembly is connected with the eccentric transmission assembly and the guide wheel tensioning assembly. The conveying mechanism comprises a conveying lifting assembly and a conveying moving assembly. The uniform conveying device can be used for conveying and machining of pin shaft parts and cylindrical workpieces and is very wide in application range, high in work efficiency, easy to operate and capable of greatly increasing the working efficiency and the finished product qualification rate.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

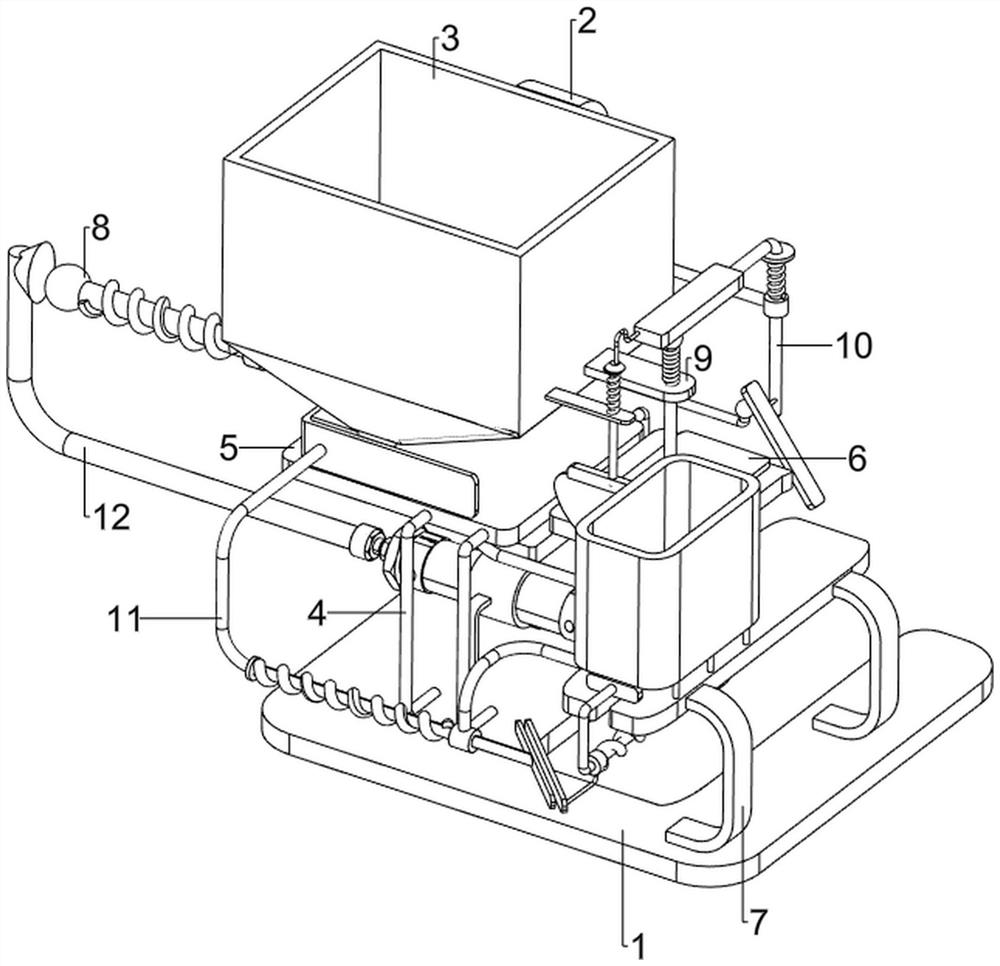

Novel glue conveying equipment for shoemaking

InactiveCN106983237ARealize the delivery workPrevent solidificationLiquid surface applicatorsCoatingsInterference fitCam

The invention relates to glue conveying equipment, in particular to novel glue conveying equipment for shoemaking. The novel glue conveying equipment for shoemaking aims at solving the technical problem of providing the novel glue conveying equipment for shoemaking capable of preventing glue from solidifying of which the conveying efficiency is high. In order to solve the technical problem, the invention provides the novel glue conveying equipment for shoemaking. The equipment comprises a bottom plate, a mounting base, a cam, a support, a pressing plate, a cylinder, a feed pipe, a first one-way valve, a lifting rod, a spring, a piston, a baffle plate, a seal ring, mixing blades and the like; the middle of the top of the bottom plate is welded to the mounting base, the upper end of the mounting base is connected with a first motor in a bolt connection mode, and an output shaft of the front side of the first motor is connected with the cam in an interference fitting mode. According to the novel glue conveying equipment for shoemaking, the cam is driven to rotate through the first motor, the cam is matched with the spring, and therefore the pressing plate drives the piston to move downwards through the lifting rod, and the conveying work of glue is achieved.

Owner:陈波平

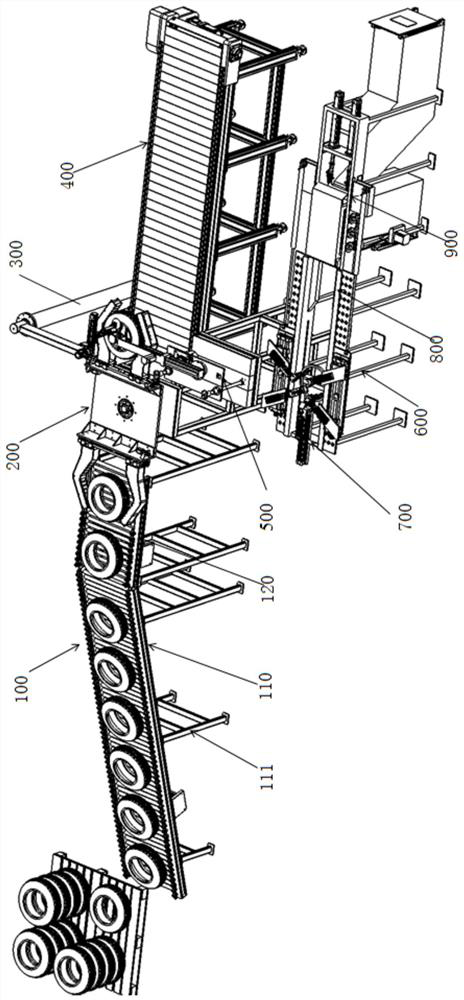

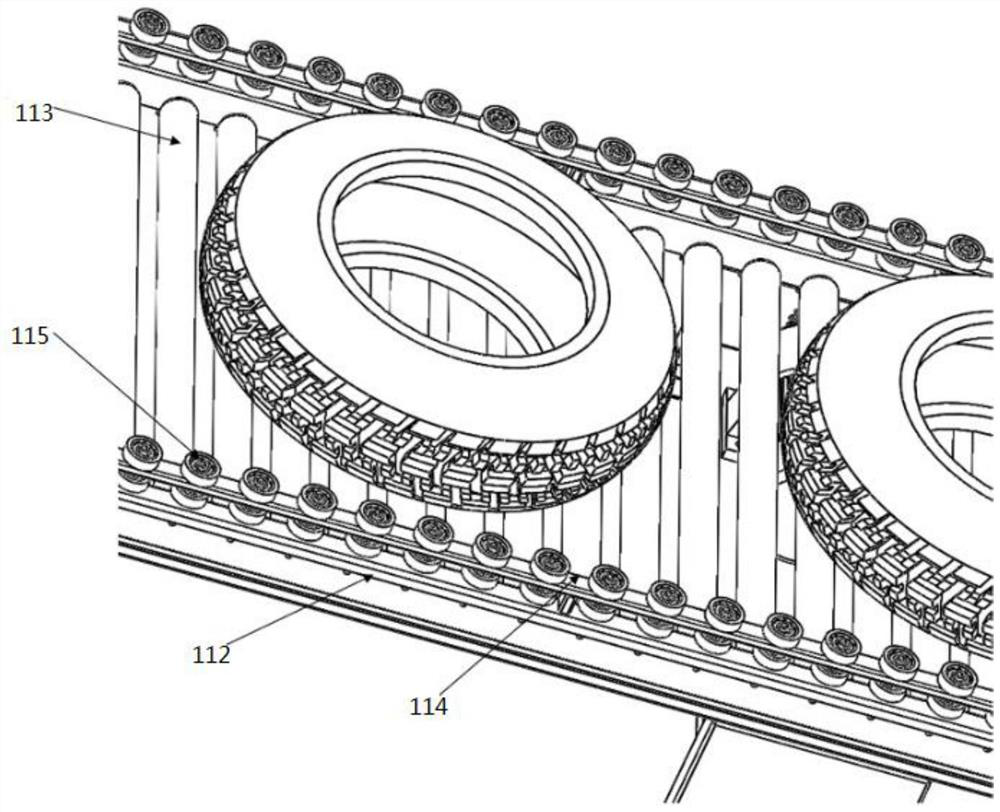

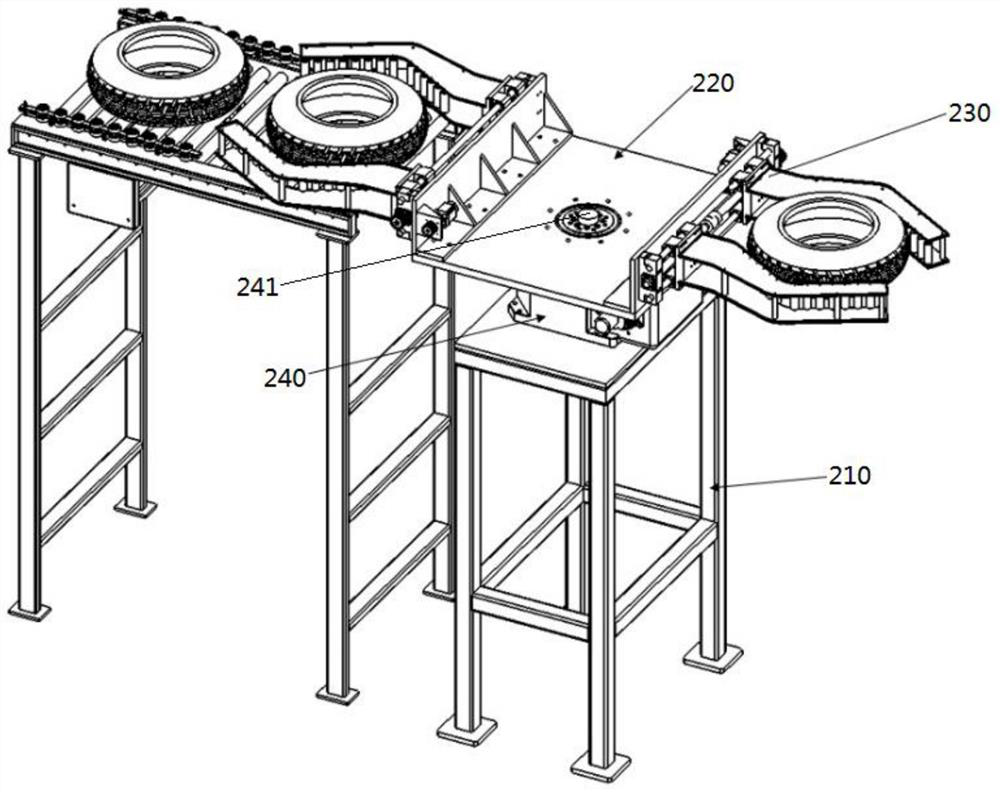

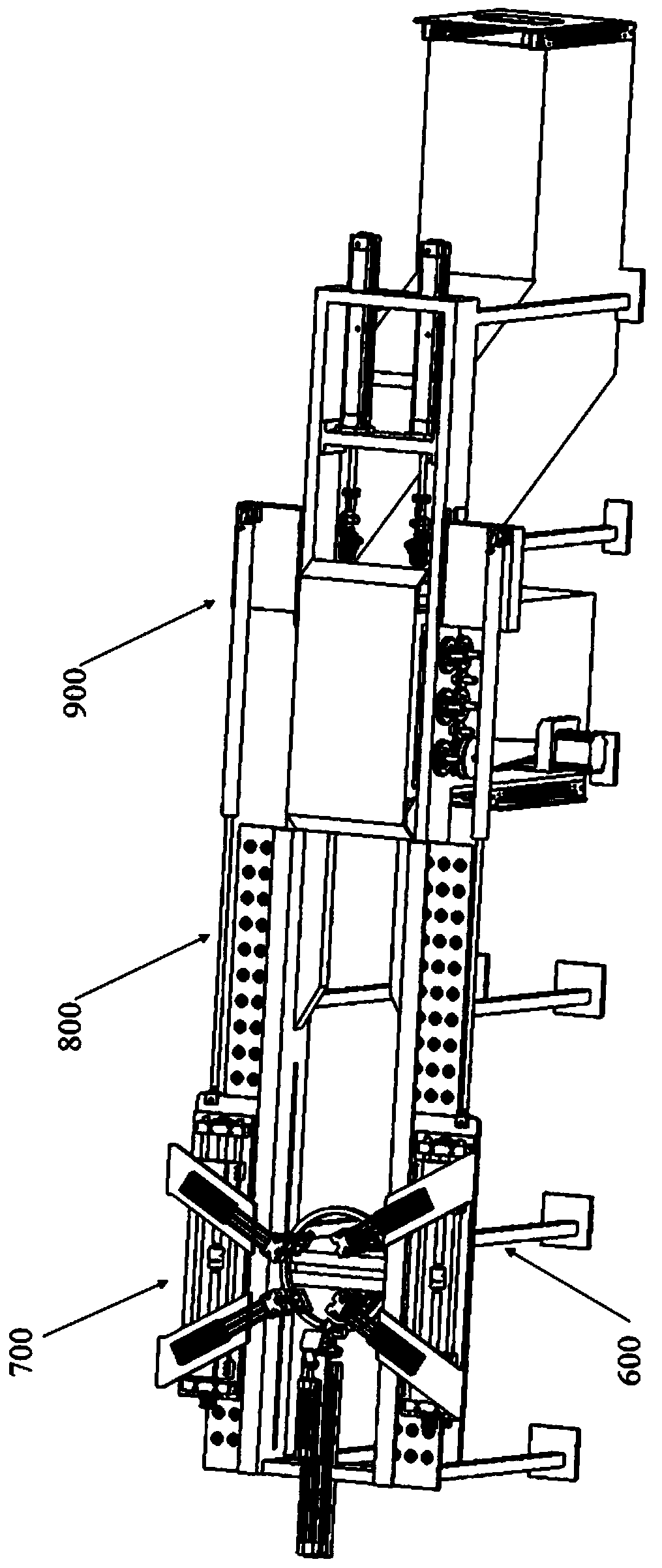

Full-automatic waste tire circular-cutting and tire bead cutting and wire stripping system and method

PendingCN111619039ARealize comprehensive utilizationMeet processingPlastic recyclingGrain treatmentsTire beadProcess engineering

The invention relates to a full-automatic waste tire circular-cutting and tire bead cutting and wire stripping system. The system comprises a tire circular-cutting and conveying device, a tire bead carrying device and a tire bead cutting and wire stripping device; the tire circular-cutting and conveying device comprises a front-end conveying mechanism, a rotating carrying mechanism for carrying and assisting in circular cutting, a tire bead circular-cutting mechanism for cutting off tire beads of waste tires and a back-end conveying mechanism for conveying out the waste tires with the tire beads cut; the tire bead carrying device is arranged on one side of a tire bead circular-cutting device, assists the tire bead circular-cutting device in tire bead cutting and conveys the tire beads cuteach time to a tire bead cutting and wire stripping module; the tire bead cutting and wire stripping device comprises a workbench mechanism, a tire bead cutting mechanism, a tire bead pulling mechanism and a tire bead wire stripping mechanism; the tire bead cutting mechanism is arranged on the workbench mechanism and is used for cutting off and leveling the tire beads; the tire bead pulling mechanism is used for conveying the cut and leveled tire beads to the tire bead wire stripping mechanism; and the tire bead wire stripping mechanism is used for stripping steel wires out of the tire beads.The system has the beneficial effects that a relatively perfect waste tire processing system and manner is provided and has the relatively high scientificity and logicality.

Owner:SAILUN GRP CO LTD +1

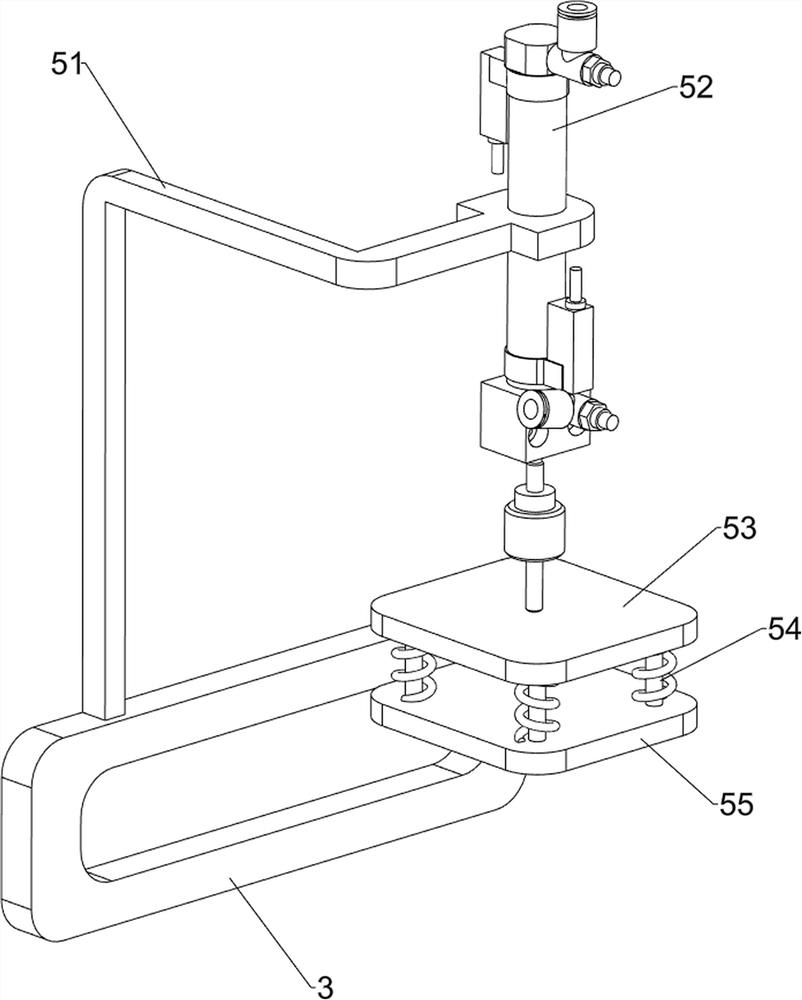

Liquid injection device for producing lithium ion battery

ActiveCN113381138ARealize the delivery workRealize positioning workCell component detailsElectric machineryEngineering

The invention discloses a liquid injection device for producing a lithium ion battery, and belongs to the technical field of lithium battery production. The liquid injection device comprises a workbench, a conveying mechanism, a positioning mechanism and a clamping mechanism; the workbench is horizontally arranged; the conveying mechanism is arranged on the upper side of the workbench and used for conveying lithium batteries before and after liquid injection; the conveying mechanism specifically comprises a supporting plate, a supporting column, a mounting strip, a connecting shaft and a driving motor; the positioning mechanism is arranged on the lower side of the conveying mechanism and used for positioning during liquid injection of the lithium batteries; and the positioning mechanism specifically comprises a telescopic air cylinder, a first hinge strip, a second hinge strip and a positioning strip; the clamping mechanism is arranged on the upper side of the conveying mechanism and used for clamping the lithium batteries during liquid injection; the clamping mechanism specifically comprises an overhanging strip, a clamping plate, a third hinge strip, a linkage column and a linkage strip. In conclusion, the liquid injection device has the advantages of reasonable design, ingenious structure and convenient use, and can achieve automatic conveying, automatic positioning and automatic clamping of the lithium batteries.

Owner:WUHU ETC BATTERY LTD

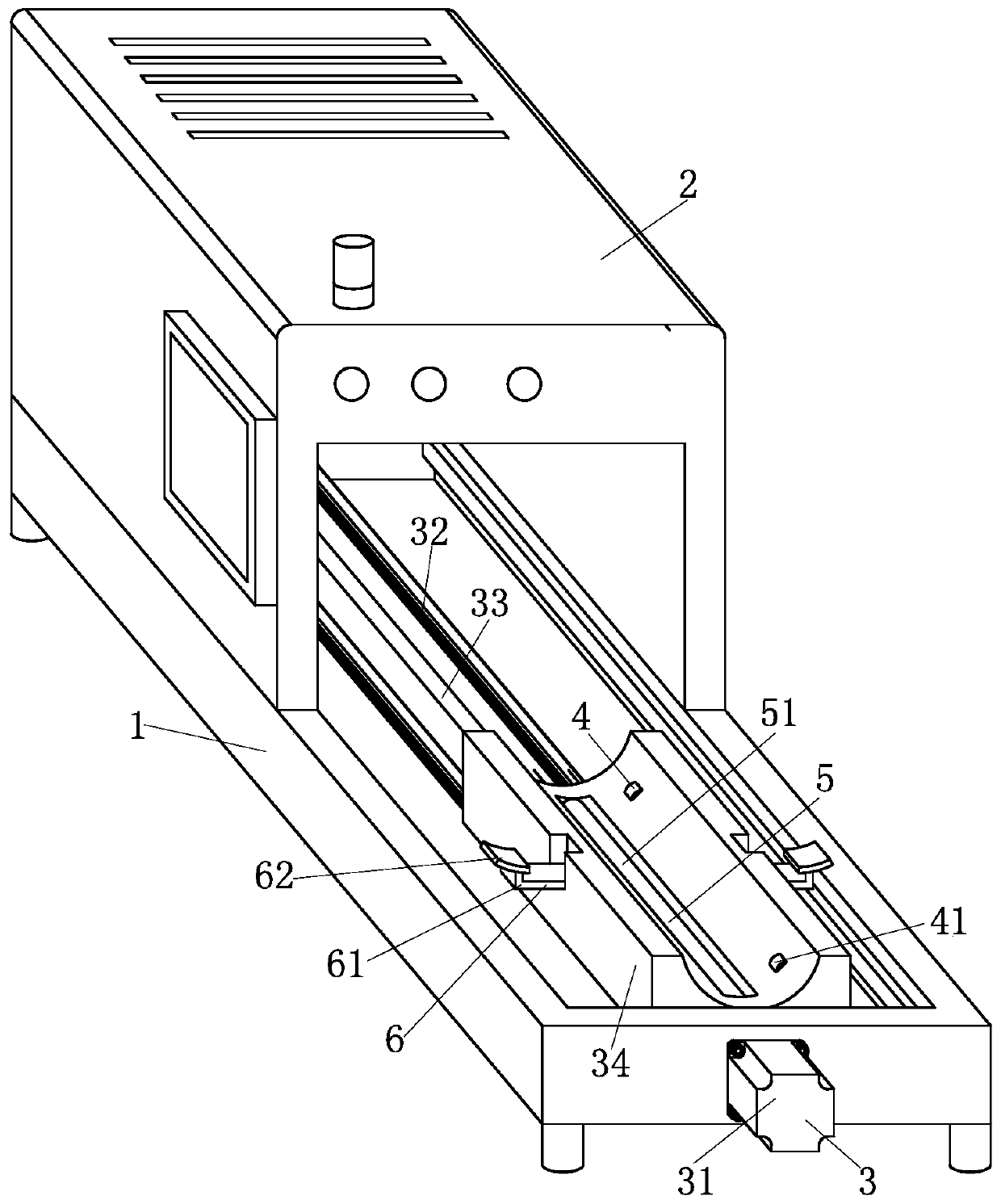

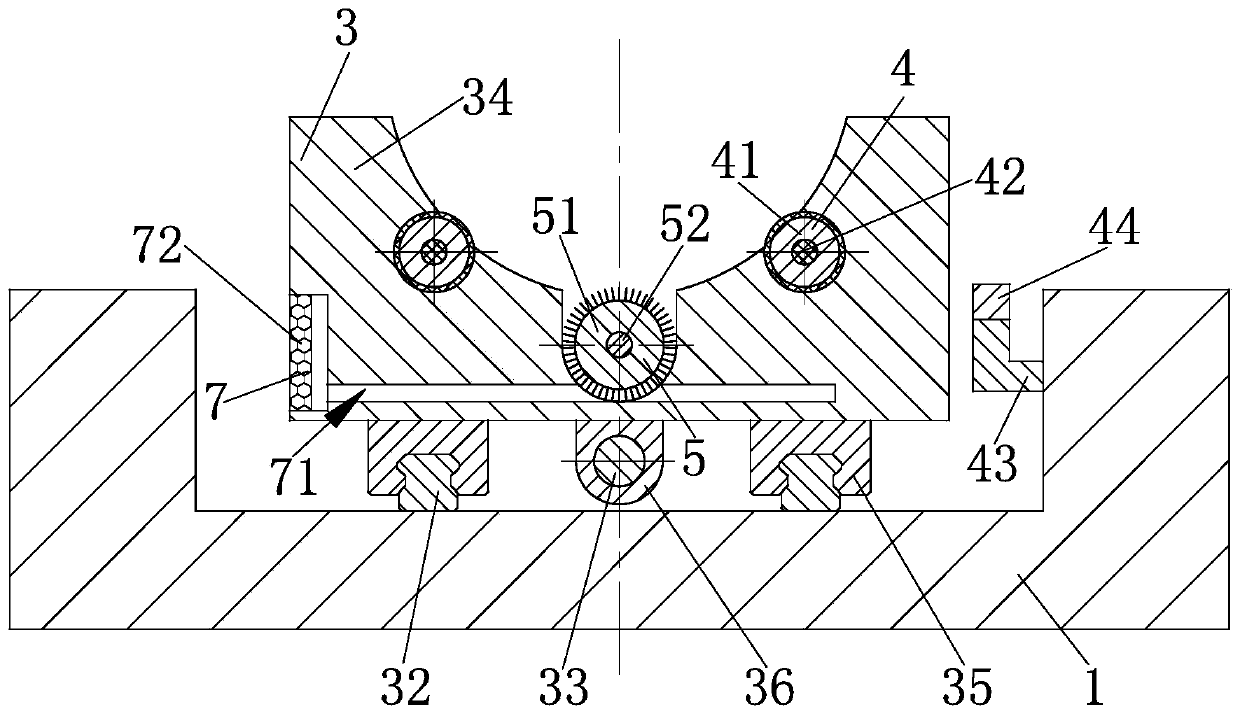

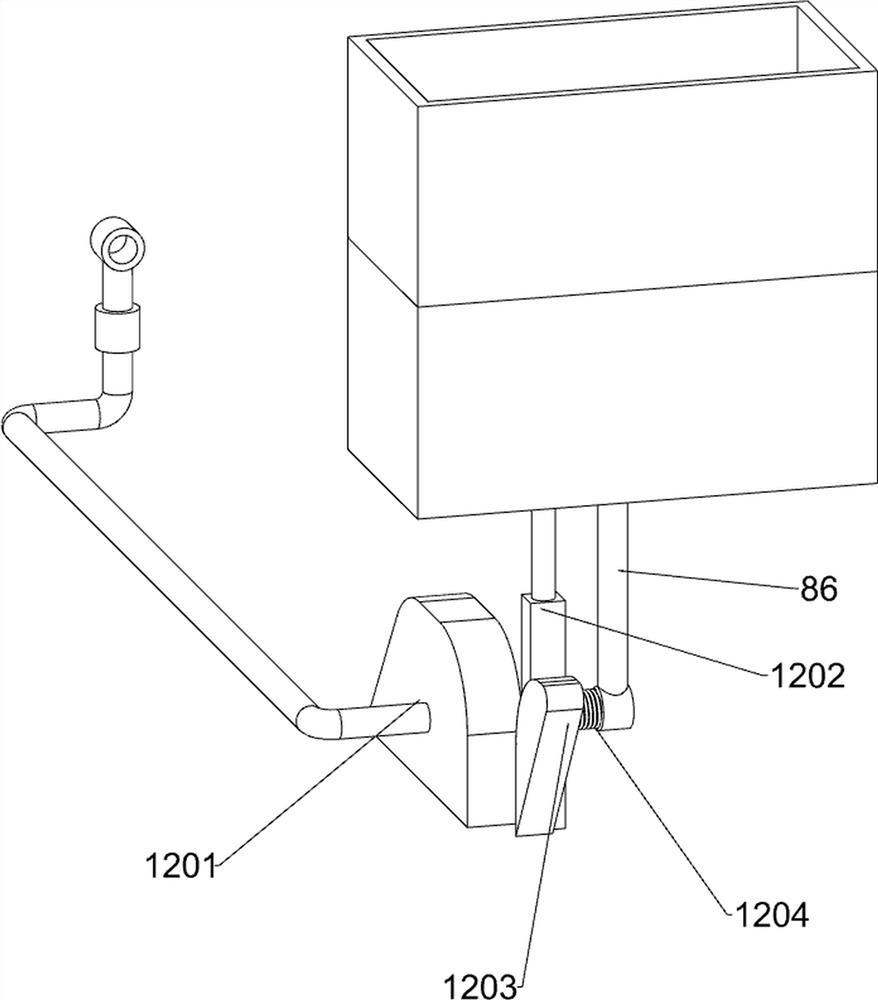

Steel pipe nondestructive testing feeding device

ActiveCN111591741ACases to prevent slippingImprove stabilityConveyorsCleaning using toolsPipeMechanical engineering

The invention relates to the field of steel pipe nondestructive testing devices, in particular to a steel pipe nondestructive testing feeding device which comprises a base, a flaw detector, a feedingstructure, a rotating structure, a sweeping structure, a clamping structure and a cleaning structure. Through the arrangement of the clamping structure, the side wall of the upper half part of a steelpipe can be clamped and fixed by utilizing the gravity of the steel pipe, and therefore the steel pipe can be prevented from slipping off in the detection process, and the detection quality is improved; through work of the feeding structure, the steel pipe needing to be detected can be automatically conveyed to a detection area to be detected, time and labor can be saved, and meanwhile the detection precision effect can be improved; and when the feeding structure works, the rotating structure can be synchronously driven to work, through work of the rotating structure, rotation of the steel pipe can be achieved while the steel pipe is fed, and therefore all-around detection of the steel pipe can be conducted, the detection effect is improved, and the rotating structure can synchronously drive the sweeping structure to work while working.

Owner:山东中正钢管制造有限公司

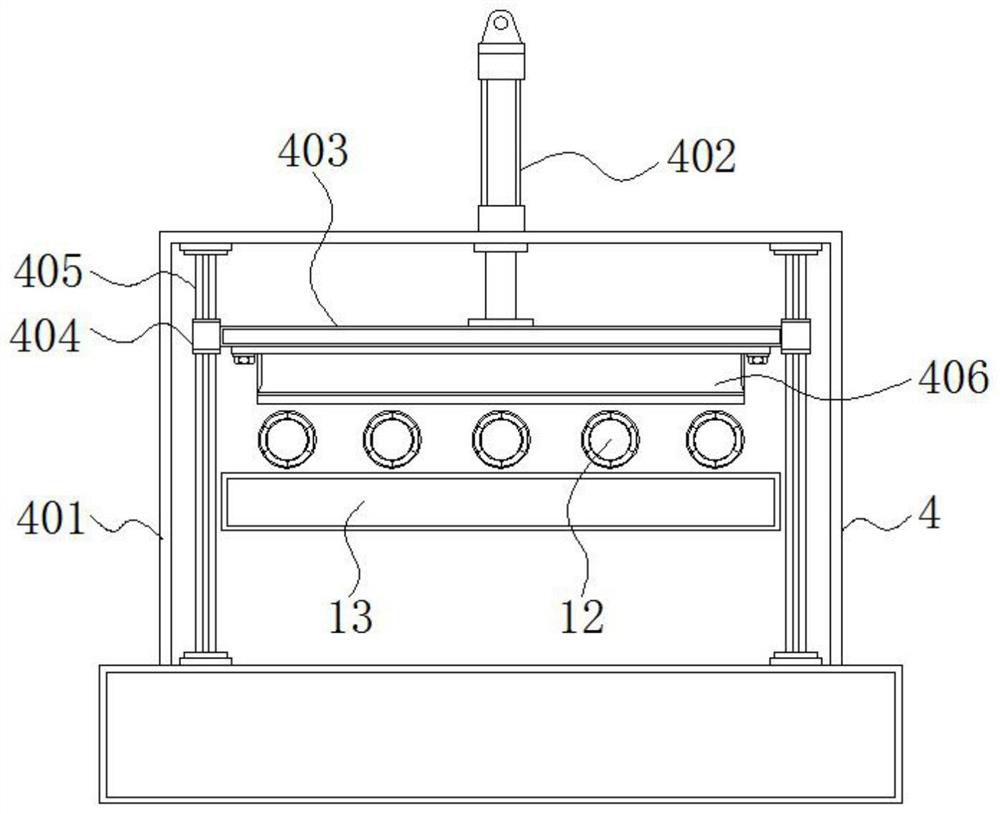

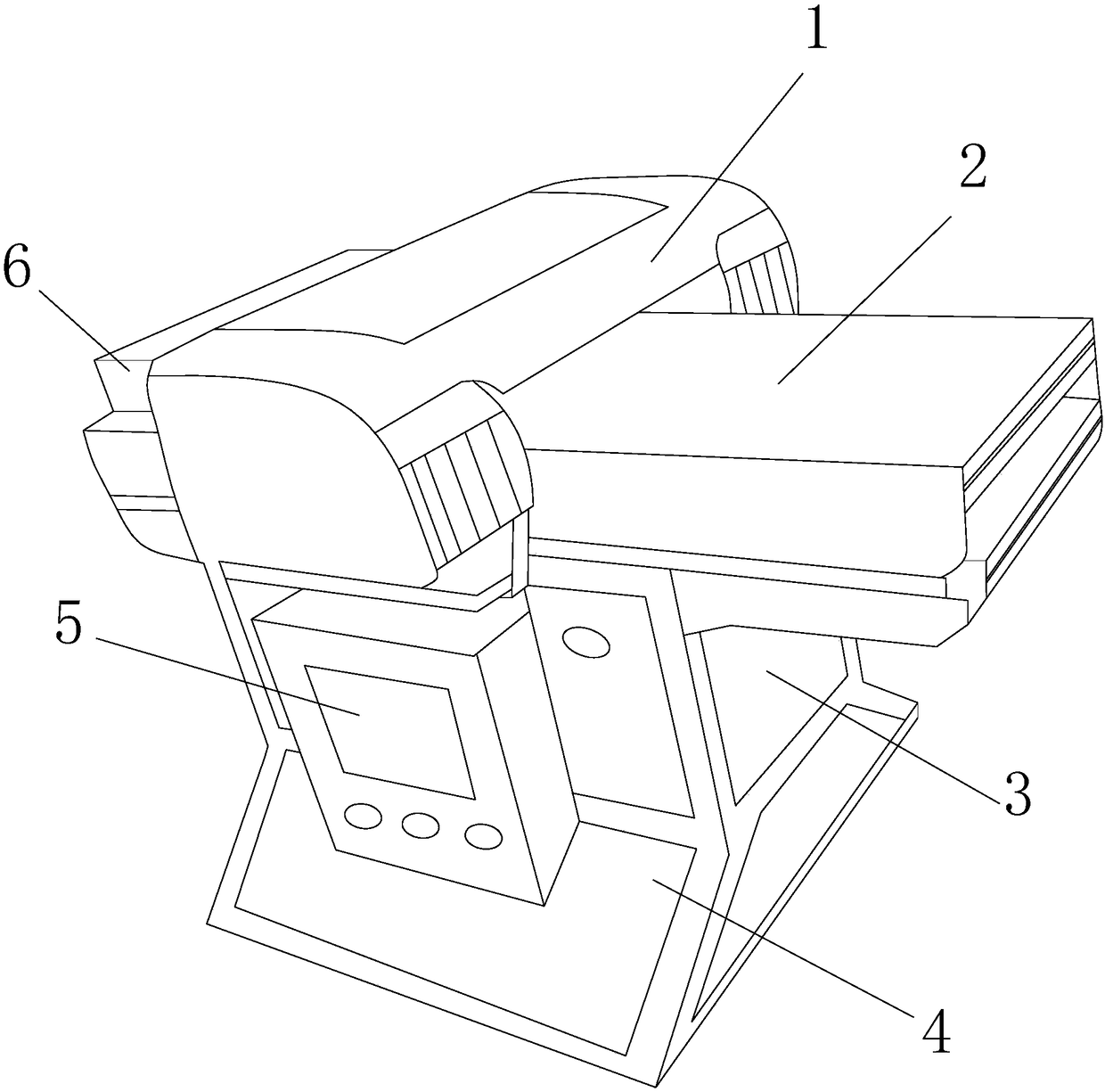

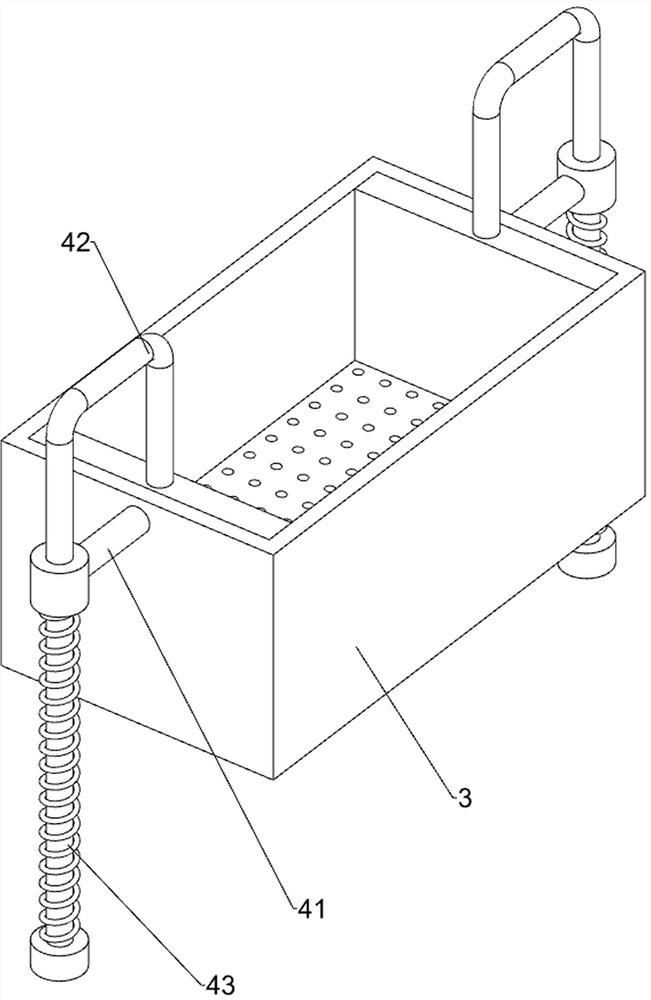

Medical ultrasonic cleaning machine

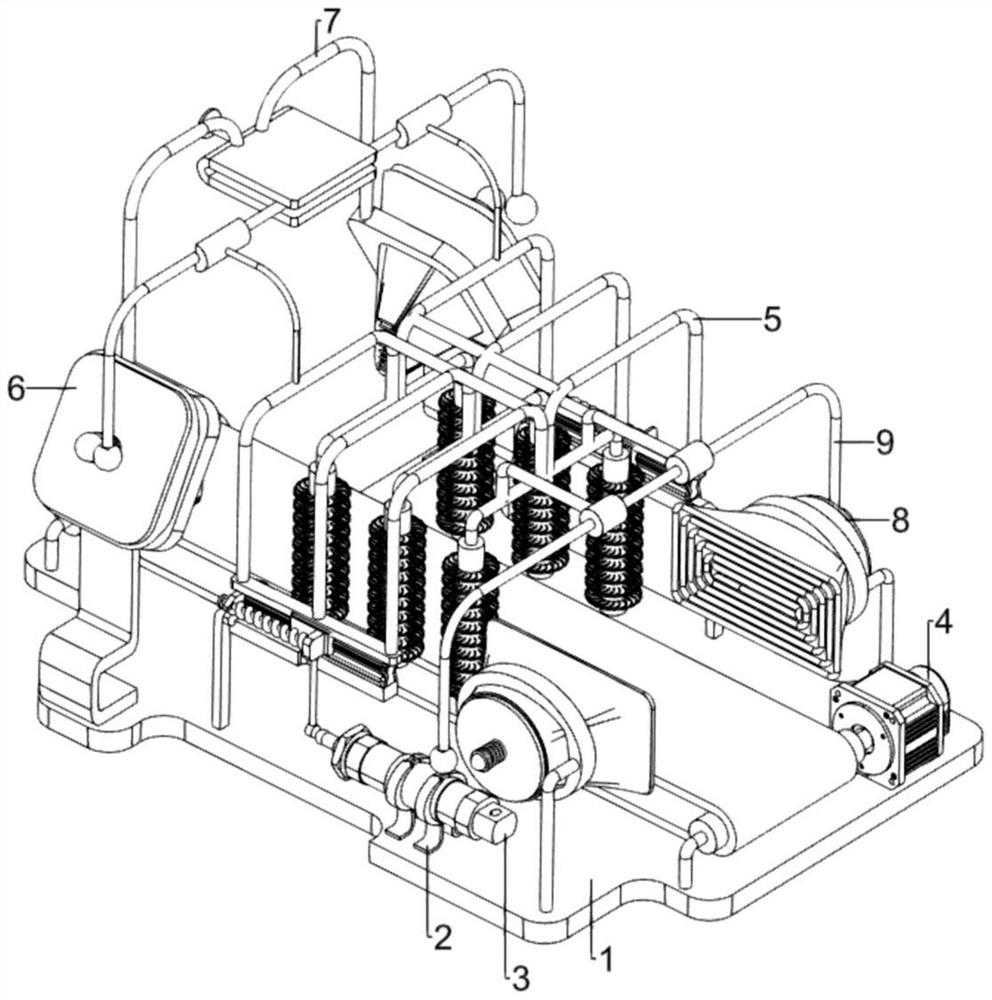

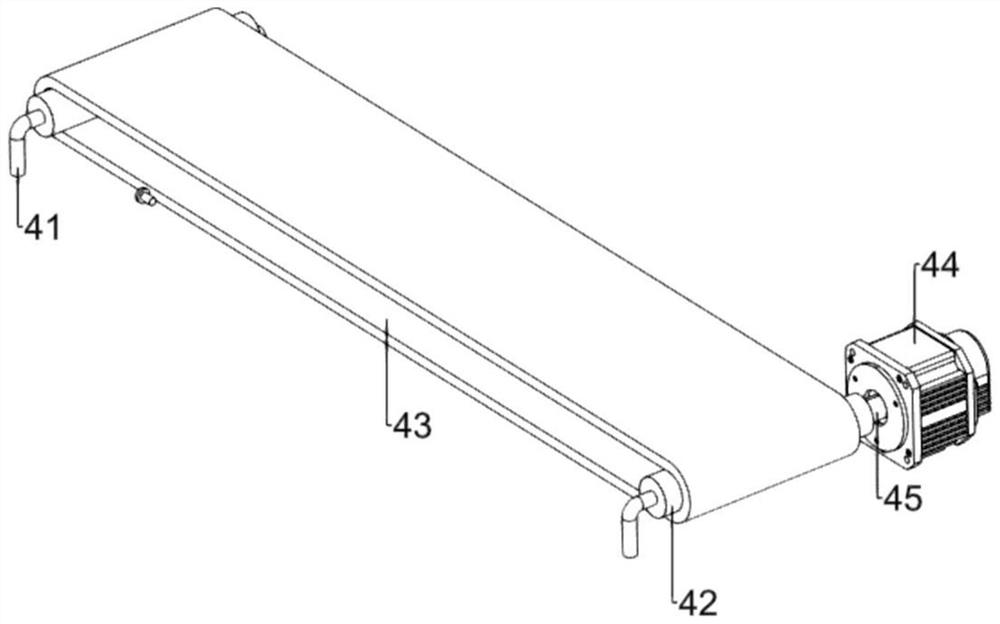

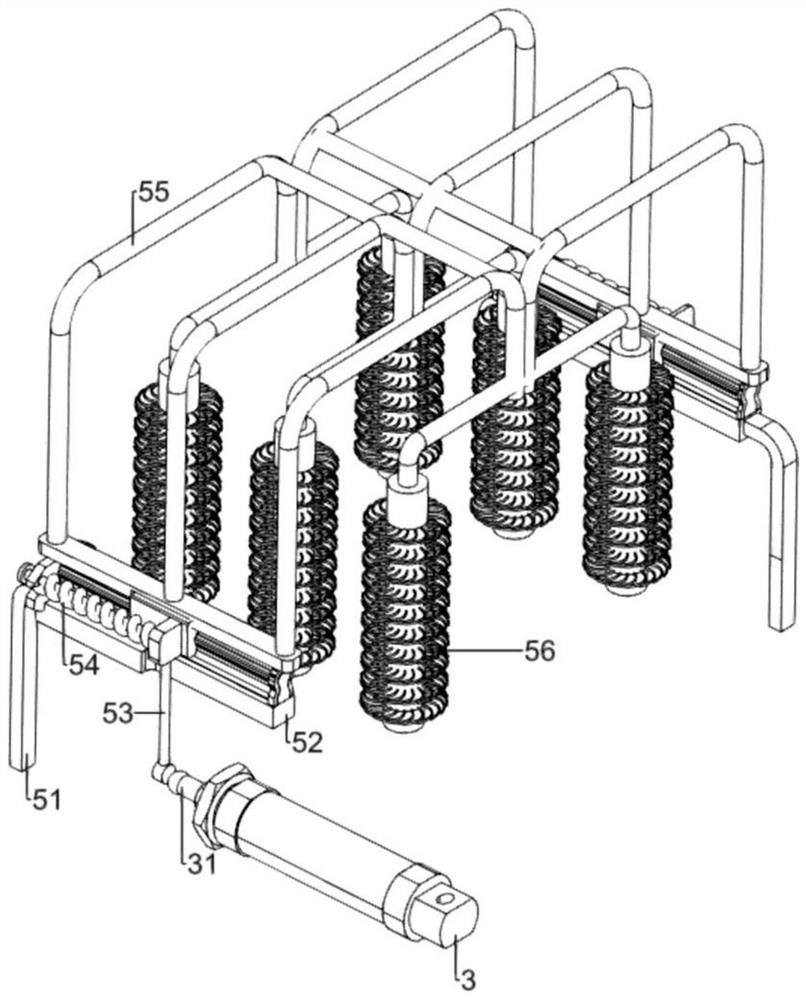

ActiveCN112246719AImplement wipeRealize the delivery workDrying solid materials without heatCleaning using toolsMedicineMegasonic cleaning

The invention relates to a cleaning machine, in particular to a medical ultrasonic cleaning machine. The invention provides the medical ultrasonic cleaning machine capable of transmitting medical ultrasonic waves and cleaning the medical ultrasonic waves. The medical ultrasonic cleaning machine comprises a bottom plate, a first supporting seat and an air cylinder. The first supporting seat is mounted at the top of the bottom plate. The air cylinder is fixedly connected into the first supporting seat through a bolt. A conveying mechanism is arranged and is matched with a cleaning mechanism, andthus wiping and conveying work of the medical ultrasonic waves can be achieved. The cleaning mechanism is matched with the air cylinder and a pushing shaft, and a brush can move forwards and backwards to wipe the medical ultrasonic waves. A water sprinkling mechanism is matched with a water sprinkling auxiliary mechanism so that a proper amount of water in a water outlet tank can flow onto the medical ultrasonic waves, and thus the cleaning efficiency of the medical ultrasonic waves is improved.

Owner:江西怡中堂生物科技有限公司

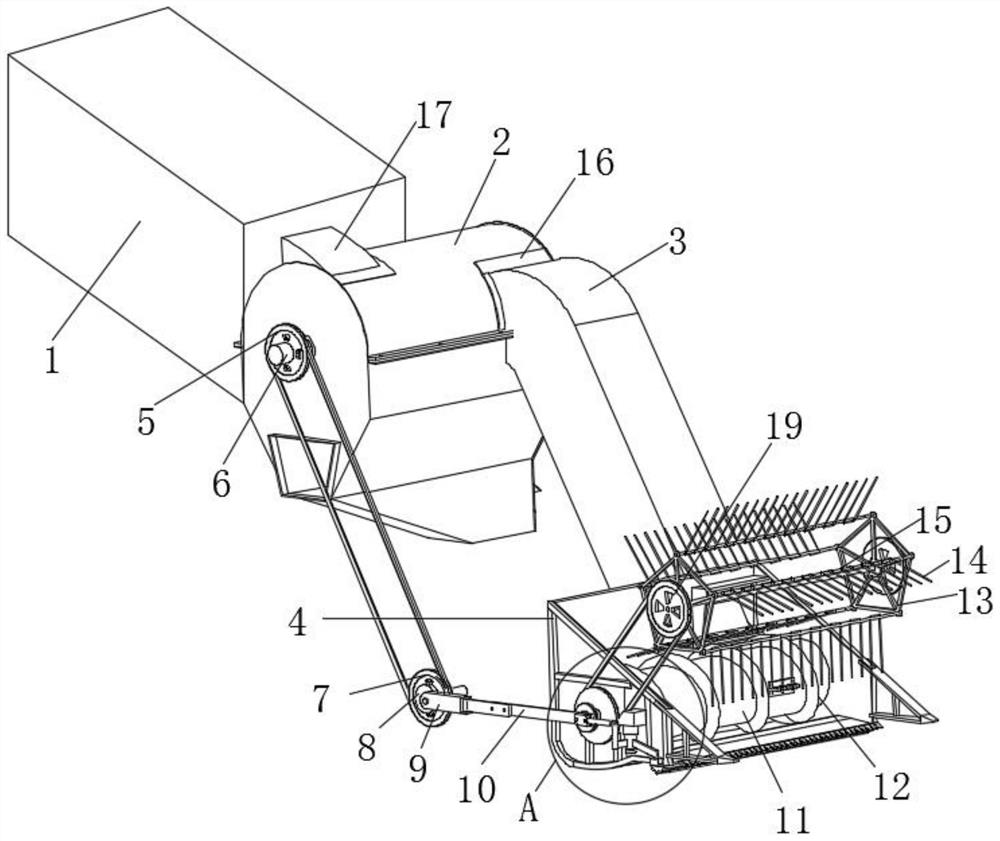

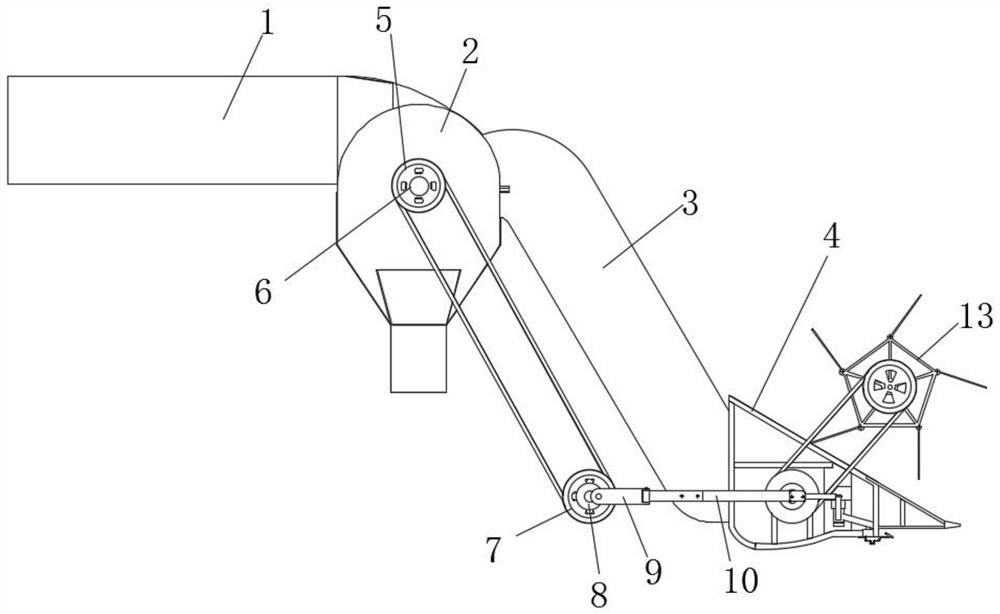

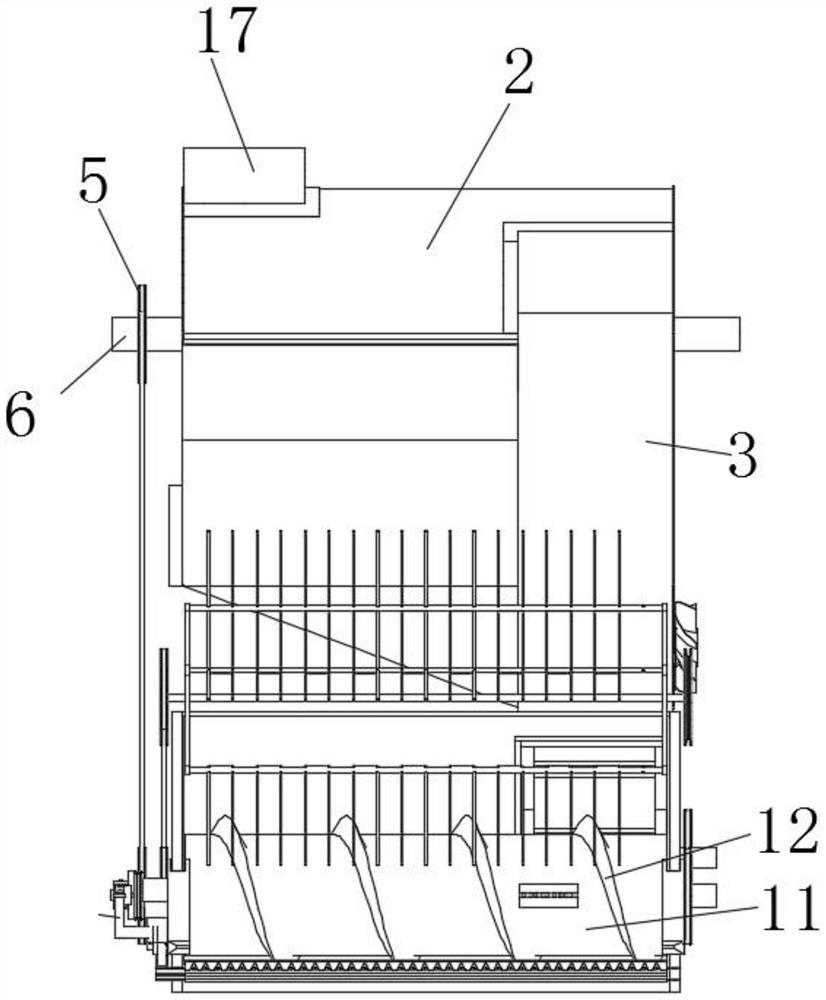

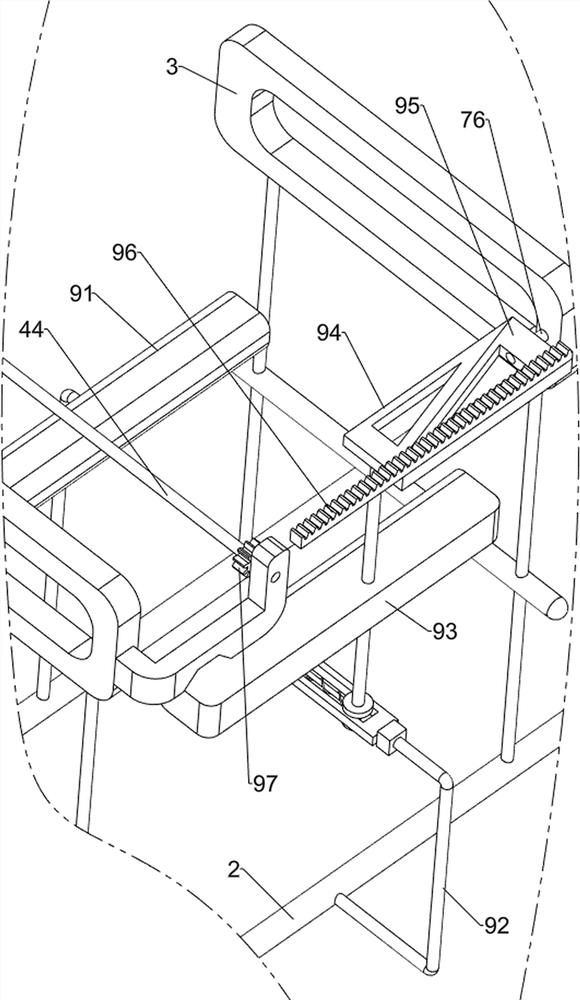

Crop straw harvesting and bundling machine and working method thereof

ActiveCN112425350ATo achieve the purpose of cuttingRealize the delivery workReaper-bindersAgricultural scienceAgricultural engineering

The invention discloses a crop straw harvesting and bundling machine. The machine comprises a crushed material bundling box and a material collecting box, a crushed material pipe is arranged at one end of the top of the material collecting box, the crushed material bundling box is arranged at one side of the material collecting box, the material collecting box communicates with the crushed material bundling box through the crushed material pipe, and a feeding port is formed at the side wall of one end of the material collecting box; and a conveying frame is arranged at one side of the bottom of the feeding port, after crop straw enters the material collecting box, a driving wheel drives a crushing wheel to rotate through a belt, a crushing shaft is driven to rotate through rotation of thecrushing wheel, the crop straw entering the material collecting box is crushed, and fruits and straw are separated. The fruits leak out through a leaking plate and are collected, the straw enters thecrushed material bundling box through the crushed material pipe to achieve bundling work, straw collecting and bundling work is conducted while the crop straw and the fruits are separated, straw scattering is avoided, straw centralized treatment is facilitated, and the phenomenon that traditional straw is not easy to treat and incinerate on site is avoided.

Owner:ANHUI DENGSHI MACHINERY MFG

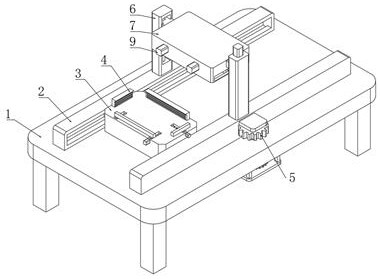

Automatic detection equipment for electrical control panel

PendingCN114779055AReduce testing costsIncrease contact areaCoupling contact membersWork benchesElectrical controlElectrically conductive

The invention provides an electrical control panel automatic detection device, and relates to the technical field of electrical control panel detection, and the electrical control panel automatic detection device comprises a workbench, the two sides of the upper surface of the workbench are fixedly provided with installation plates, and a placement table is movably installed between the two installation plates; a workpiece positioning mechanism used for fixing a workpiece is arranged on the upper surface of the containing table, and a driving mechanism used for driving the containing table to move is arranged on one side of the workbench. Through the wavy design of the annular metal connecting sheet, the annular metal connecting sheet can be changed according to the shape of the spherical contact on the surface of the circuit board under the connection action of the auxiliary spring, so that the contact area between the annular conductive block and the contact on the circuit board and the contact between the annular metal connecting sheet and the contact on the circuit board can be larger; contact breaking conditions can be effectively reduced, detection work can be better facilitated, and the detection contact can be suitable for detection contacts of different sizes on electrical control panels of different models due to the change of the overall shape of the annular metal connecting piece.

Owner:XIAN JIAOTONG UNIV CITY COLLEGE

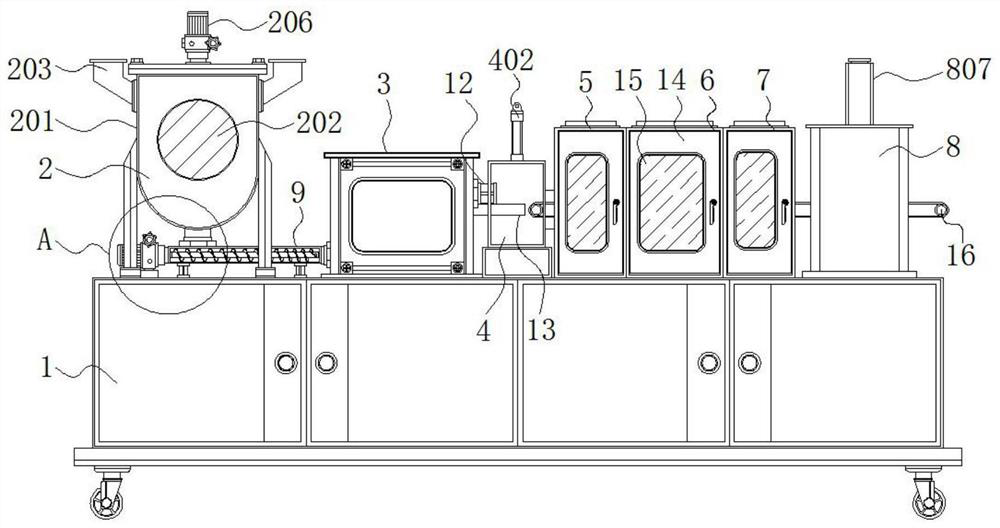

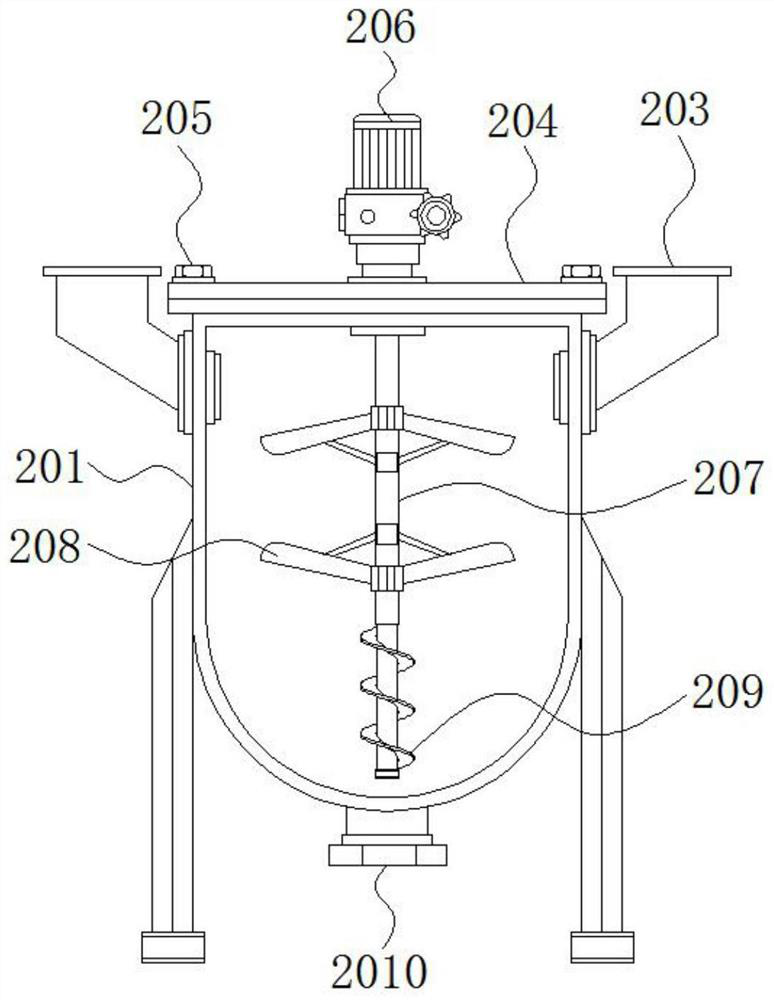

Oat bread formula and production equipment thereof

InactiveCN112385674AEasy to cleanRealize the delivery workDough treatmentMixing/kneading structural elementsProcess engineeringFermentation

The invention discloses an oat bread formula and production equipment thereof, and relates to the technical field of oat bread production. The oat bread production equipment comprises a bearing base,a conveying pipe and a temperature-resistant conveying belt, and a stirring mechanism, a puffing fermentation assembly, a cutting mechanism, a preheating baking box, a heating baking box, a low-heat baking box and an oil coating mechanism are sequentially arranged at the upper end of the bearing base from left to right. Through the preheating baking box, the heating baking box and the low-heat baking box which are distributed in parallel, cut fermentation raw materials are sequentially conveyed into the preheating baking box, the heating baking box and the low-heat baking box through the temperature-resistant conveying belt to complete the baking of bread. Through the arrangement of the preheating baking box, the heating baking box and the low-heat baking box, the quality of baked bread isguaranteed, the situation of bread scorching caused by directly entering high temperature baking is avoided, and the internal situation of the three baking boxes can be checked in real time through arranged heat insulation glass so as to ensure the continuity and effectiveness of baking work.

Owner:南通梦桦食品有限公司

Adhesive tape attaching machine for PCB (printed circuit board) processing

PendingCN114126252ARealize the delivery workRapid positioningConveyorsNon-metallic protective coating applicationAdhesive beltEngineering

The invention discloses an adhesive tape attaching machine for PCB (printed circuit board) processing, which comprises a rack, two groups of reinforcers, an adjusting assembly, an attaching assembly and a feeding assembly, the reinforcers are symmetrically locked and mounted on two sides of the upper surface of the rack, the adjusting assembly is mounted on the reinforcers, and the attaching assembly is mounted on the adjusting assembly. Through the adjusting assembly, comprehensive adjustment of the adhesive tape attaching unit in the X-axis direction, the Y-axis direction, the Z-axis direction and the R-axis direction is achieved, a circuit board can be covered and attached, the situation of adhesive tape attaching dead angles is avoided, workers can operate and use the adhesive tape attaching device conveniently, under clamping of the feeding assembly, the adhesive tape attaching device can adapt to circuit boards with different widths and conduct conveying work, and the working efficiency is improved. The servo motor is used for enabling the lifting rack to ascend on one side of the transverse plate, a space is provided for lifting of the lifting plate and the rotary clamping jaw air cylinder and overturning of the circuit board, then the rotary clamping jaw air cylinder is started for overturning, the circuit board is driven to conduct overturning work, and comprehensive adhesive tape attaching work can be conducted on the circuit board.

Owner:SUZHOU WISETECH AUTOMATION TECH CO LTD

Rapid laser material packaging device for intelligent manufacturing

InactiveCN113043585AEncapsulation worksRealize the delivery workMechanical engineeringSmart manufacturing

The invention relates to a packaging device, in particular to a rapid laser material packaging device for intelligent manufacturing. The invention provides a rapid laser material packaging device for intelligent manufacturing, capable of covering a laser material with a film for packaging, replacing the laser material at intervals, finishing material control work of the laser material, and positioning the laser material to avoid movement. The packaging device, in particular to a rapid laser material packaging device for intelligent manufacturing comprises a base, a supporting frame and a first fixed frame, wherein the supporting frame is symmetrically arranged on the two sides of the top of the base, and the first fixed frame is welded to the two sides of the supporting frame. For the rapid laser material packaging device for intelligent manufacturing, by arranging a film winding mechanism to be matched with a packaging mechanism, packaging work of the laser material can be realized; a moving mechanism is matched with the supporting frame, and conveying work of the laser material can be achieved; a discharging mechanism is matched with the material control mechanism, and interval material control work of the laser material can be achieved; and the positioning mechanism is matched with the discharging mechanism, so that clamping work of the laser material can be realized.

Owner:王华

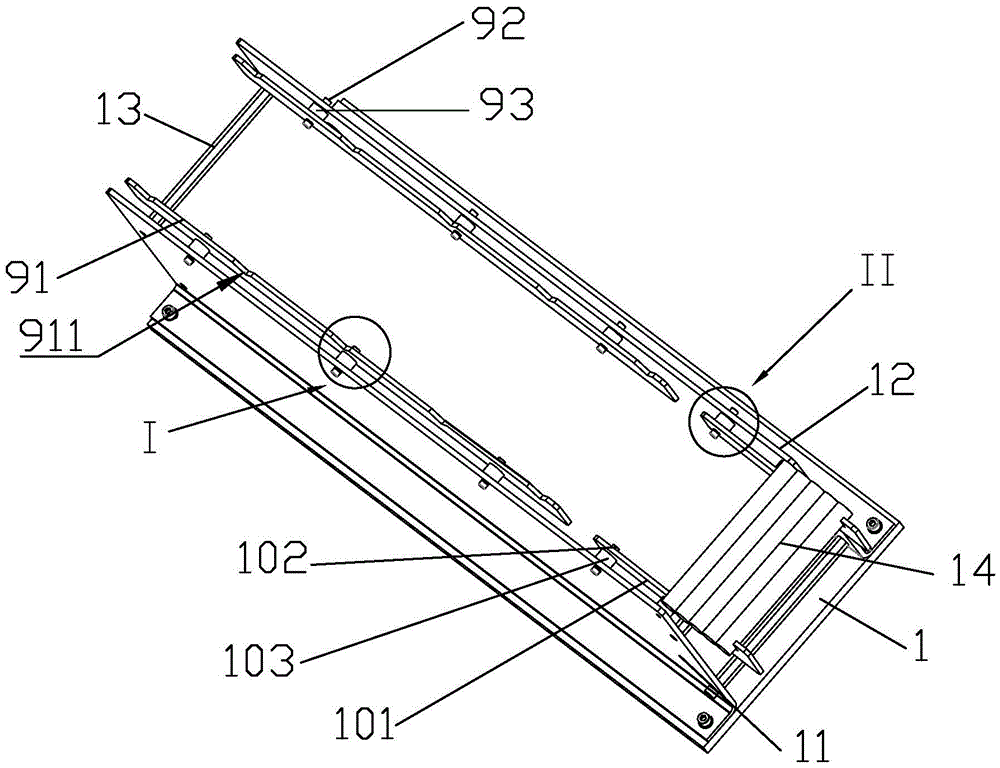

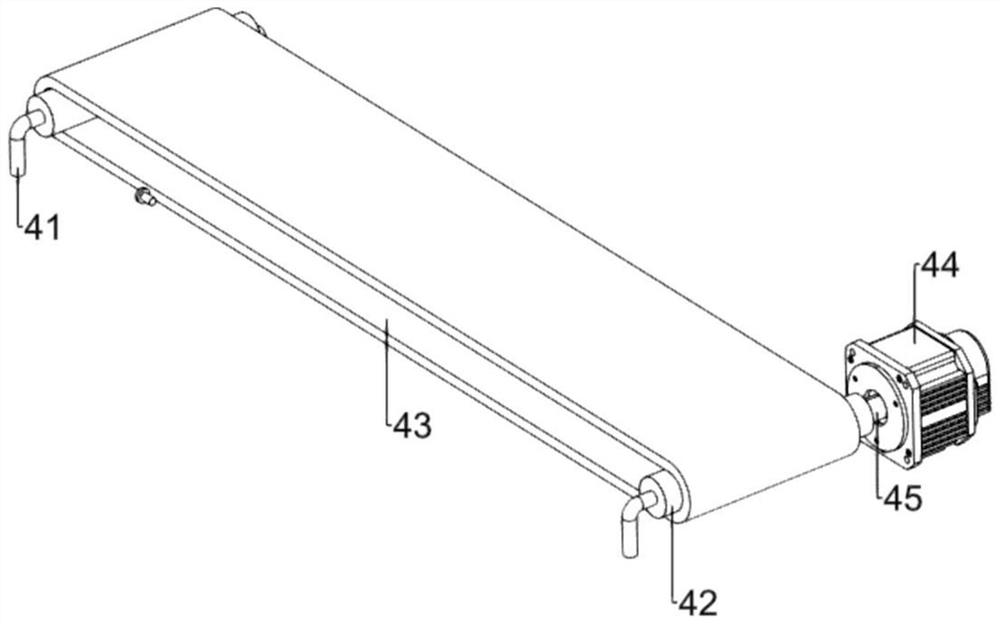

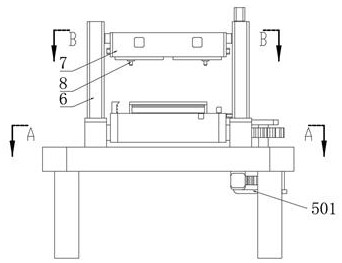

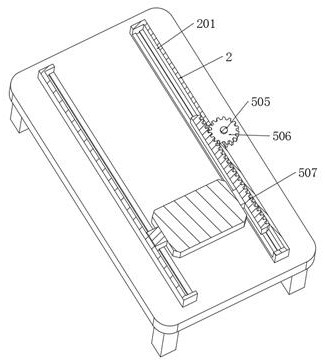

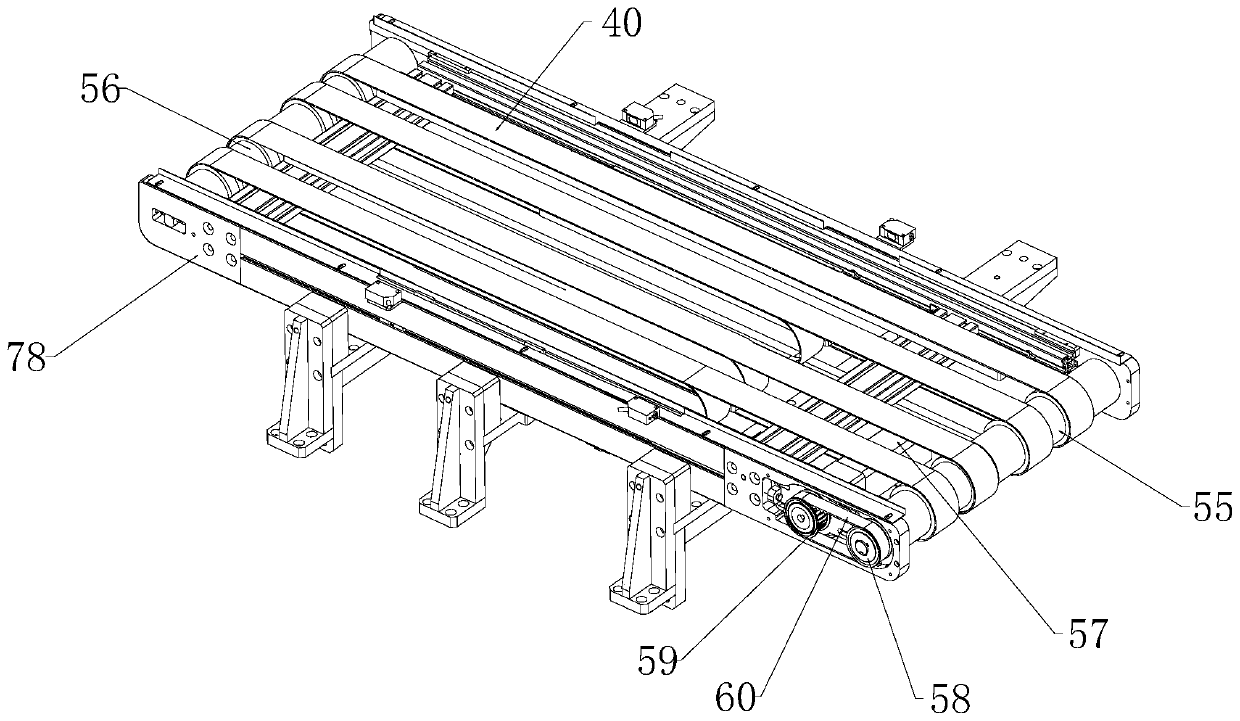

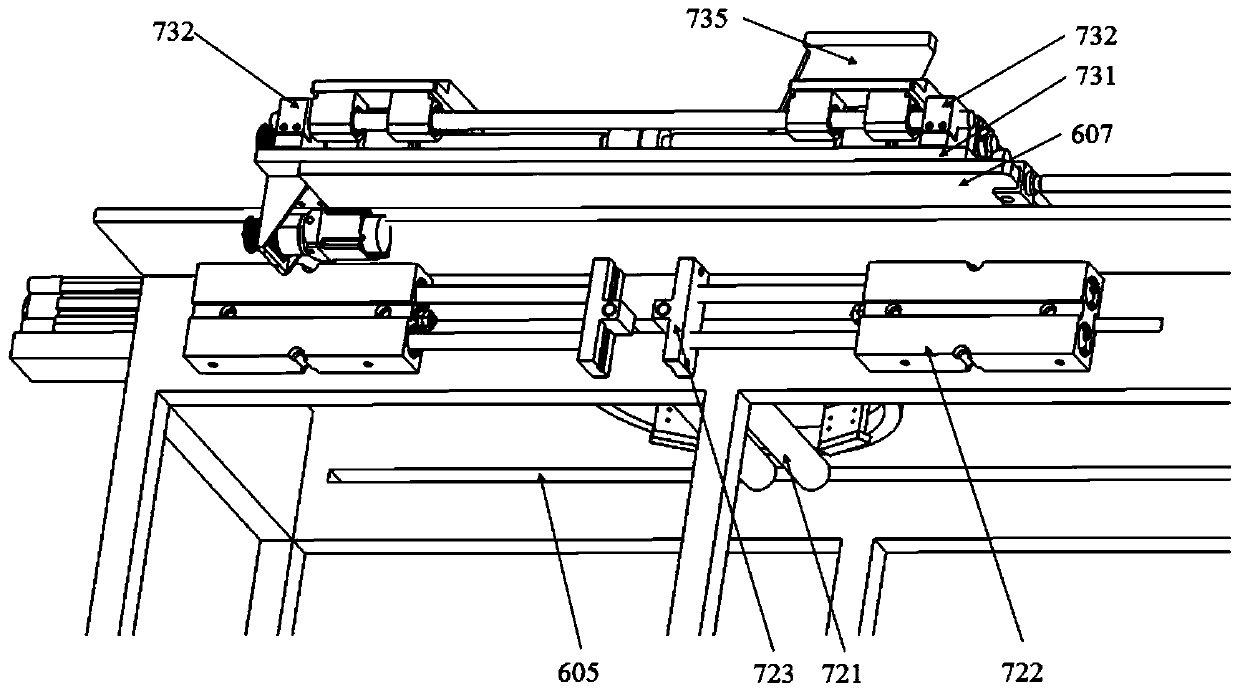

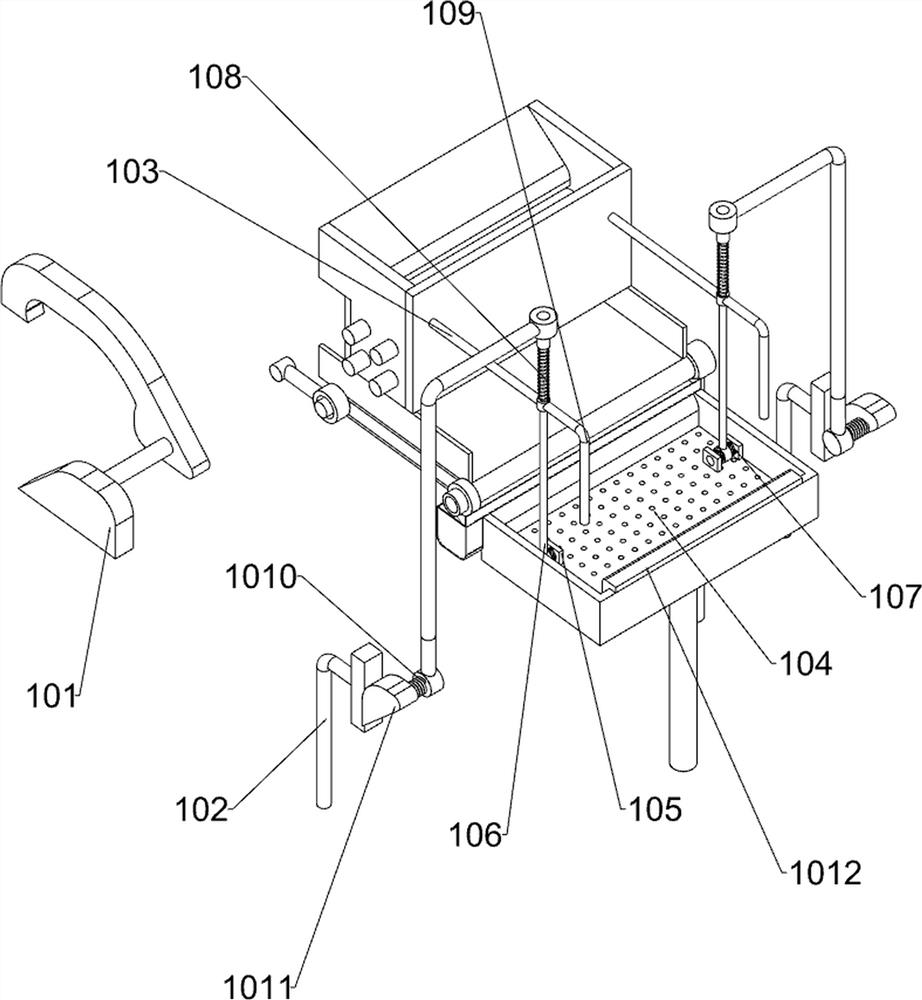

Conveying structure for keyboard middle plate and assembling device with conveying structure

ActiveCN111524738ARealize the delivery workRealize assembly workElectric switchesEngineeringFriction force

The invention discloses a conveying structure for a keyboard middle plate and an assembling device with the conveying structure. The conveying structure comprises a supporting base. A middle plate conveying frame is installed on the supporting base, and a plurality of conveying belts are arranged on the middle plate conveying frame in a transmission mode. A feeding supporting driving device is further installed on the supporting base, and the output end of the feeding supporting driving device is connected with a feeding supporting frame; a plurality of feeding supporting rods are arranged onthe feeding supporting frame; a feeding power driving device is further arranged on the feeding supporting frame, and the output end of the feeding power driving device is connected with a feeding power frame. Through cooperation of the feeding supporting frame and the middle plate conveying frame, conveying work of a middle plate can be achieved; and the assembling work of the middle plate can berealized. Through the arrangement of the feeding supporting rod and the slipping layer of the feeding supporting rod, it can be guaranteed that the middle plate can be located at the same height as akeyboard cavity, meanwhile, the friction force between the middle plate and the supporting structure can be reduced, and the keyboard middle plate can be conveniently, stably and rapidly pushed intothe keyboard shell.

Owner:重庆保时鑫电子科技有限公司

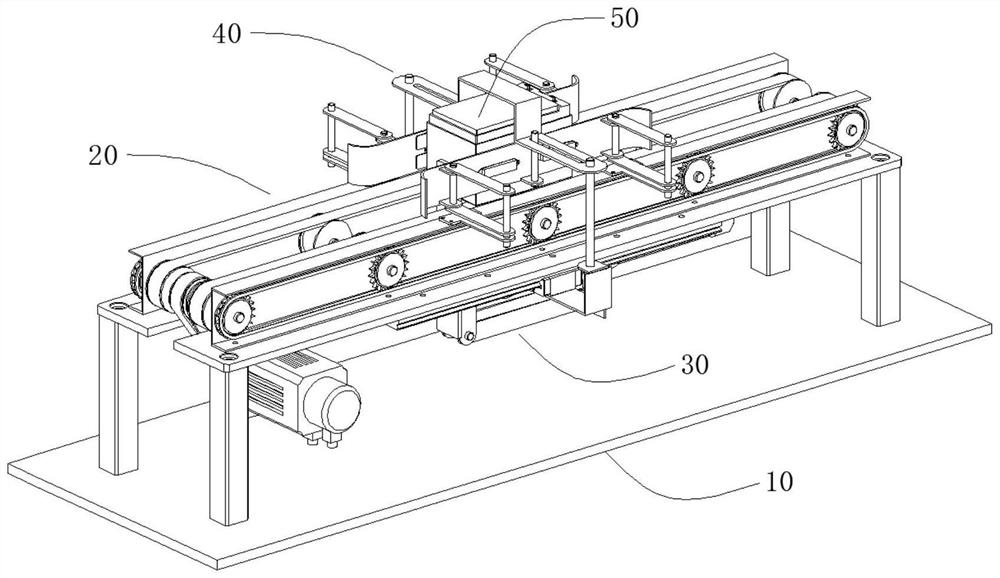

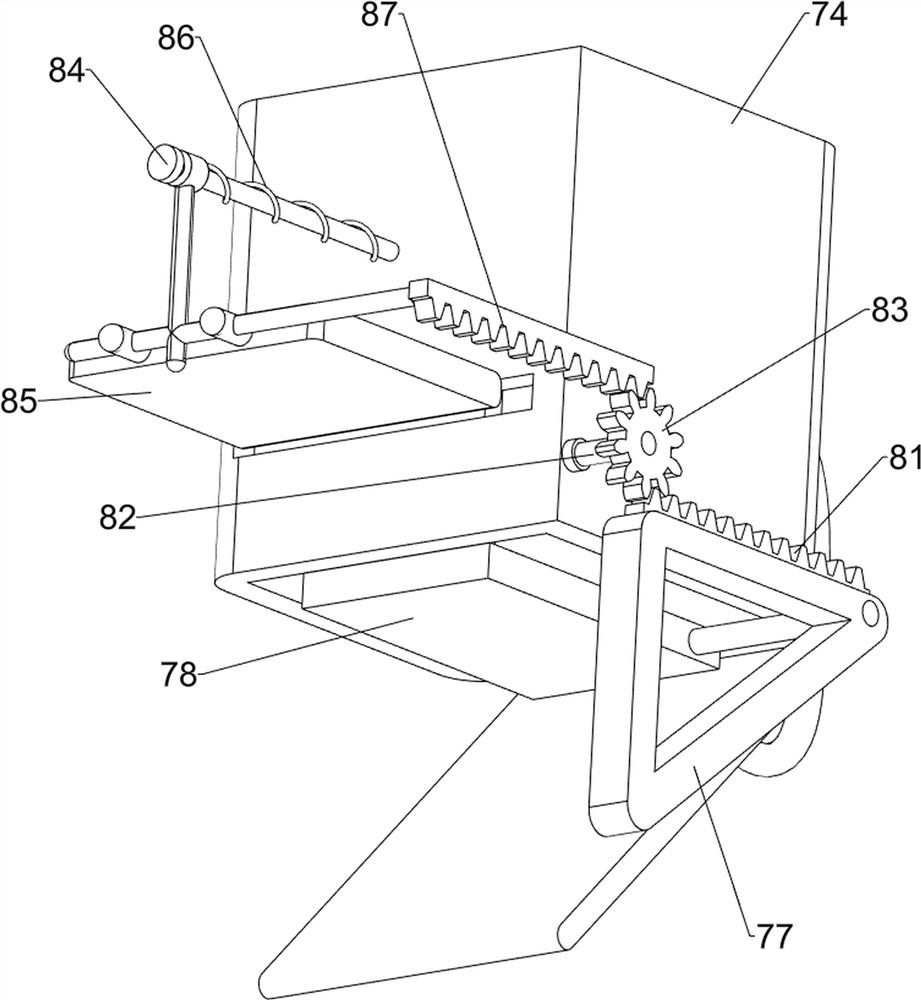

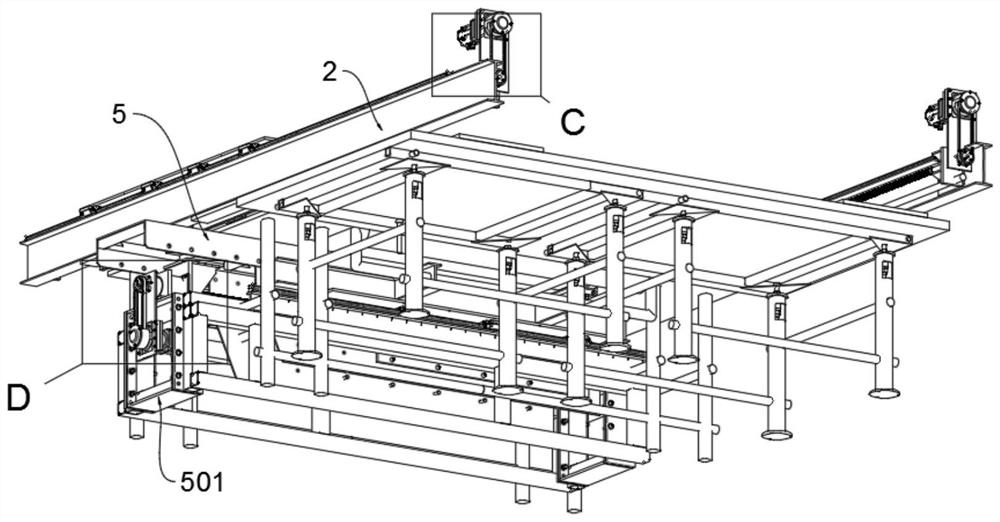

Tire bead cutting and wire stripping device and method

PendingCN111590787ARealize the delivery workConvenient stripping and strippingPlastic recyclingGrain treatmentsTire beadCutting tool

The invention relates to a tire bead cutting and wire stripping device and method. The device comprises a workbench mechanism, a tire bead cutting mechanism, a tire bead hauling mechanism and a tire bead wire stripping mechanism; the tire bead cutting mechanism comprises a cutting tool assembly installed at the end part of the workbench mechanism, a moving roller assembly with adjustable clearanceinstalled on the workbench, horizontal moving slide rail assemblies installed on two sides of the workbench mechanism, and clamping assemblies installed on the horizontal moving slide rail assemblies; the tire bead hauling mechanism is installed on the workbench mechanism and positioned at the rear side of the tire bead cutting mechanism, and is used for transporting a cut tire bead to the tire bead wire stripping mechanism; and the tire bead wire stripping mechanism is installed on the workbench mechanism, and comprises a tire bead wire stripping assembly, a debris storage box positioned right below the tire bead wire stripping assembly, a steel wire hauling assembly positioned on the rear side of the tire bead wire stripping assembly, and a steel wire storage box positioned below the steel wire hauling assembly. The tire bead cutting and wire stripping device and method has the beneficial effects that, cutting and wire stripping operation of the tire bead can be completed, the degree of automation is high, the level of mechanism linkage and integration is high, and operation ability of a system is improved.

Owner:SAILUN GRP CO LTD +1

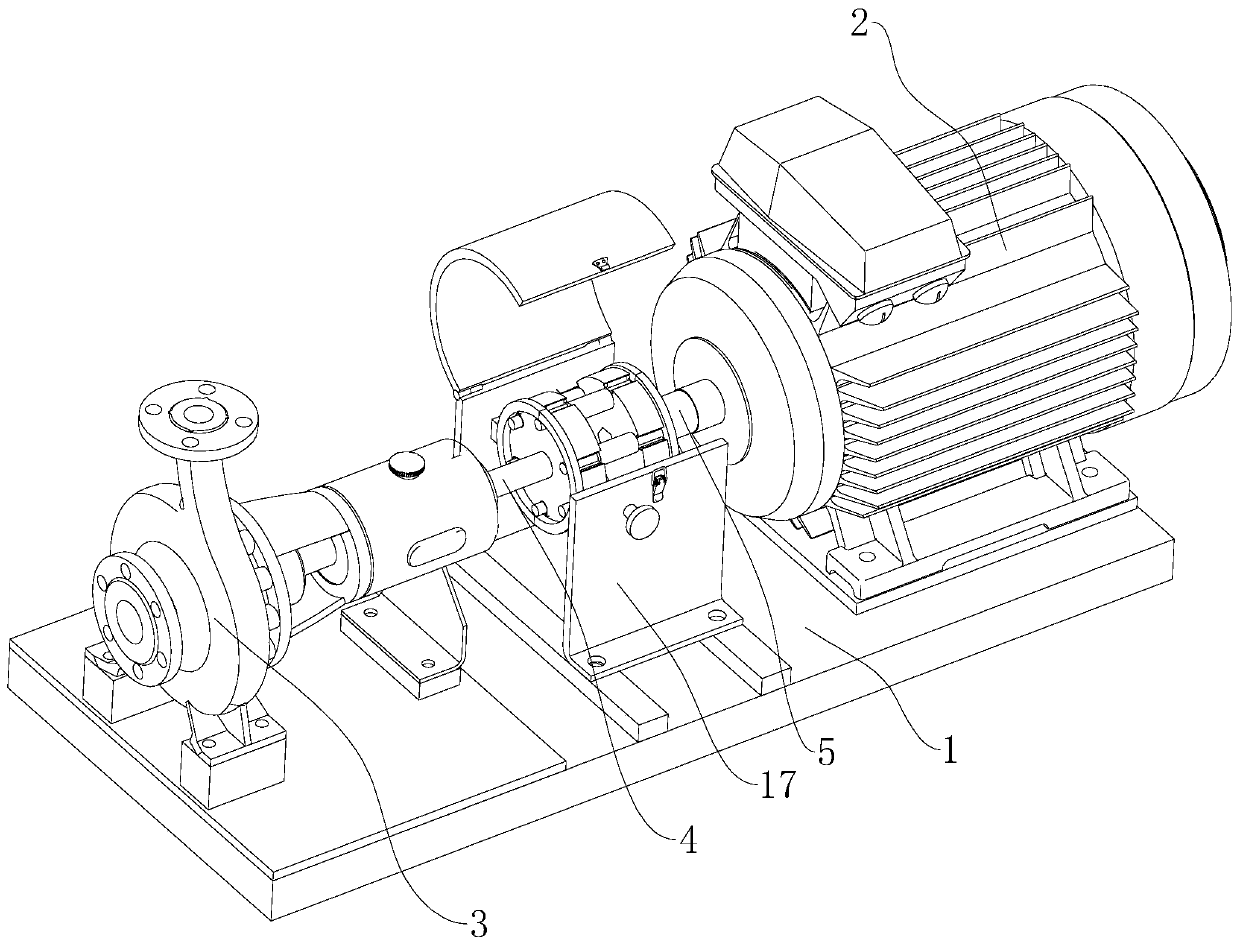

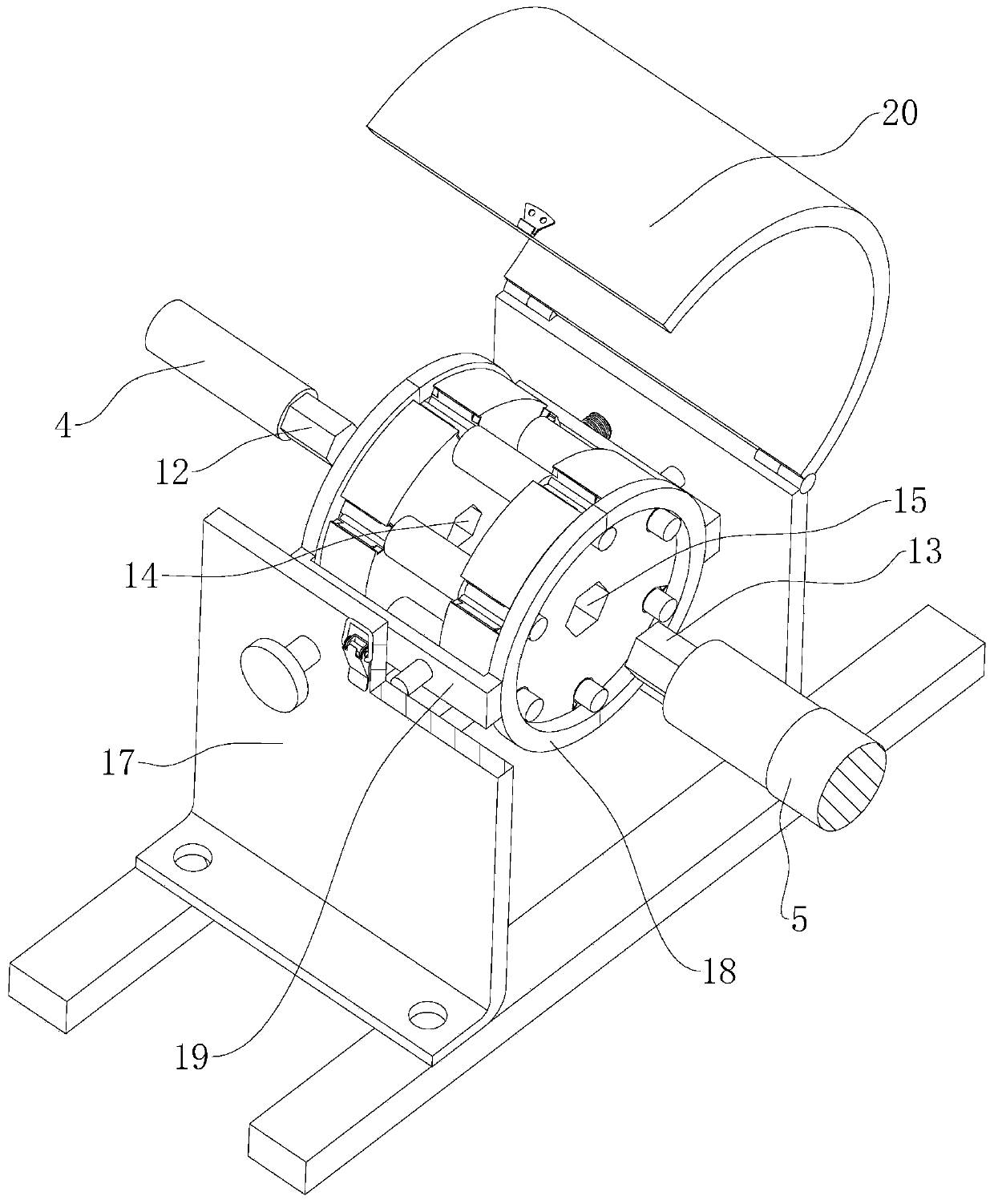

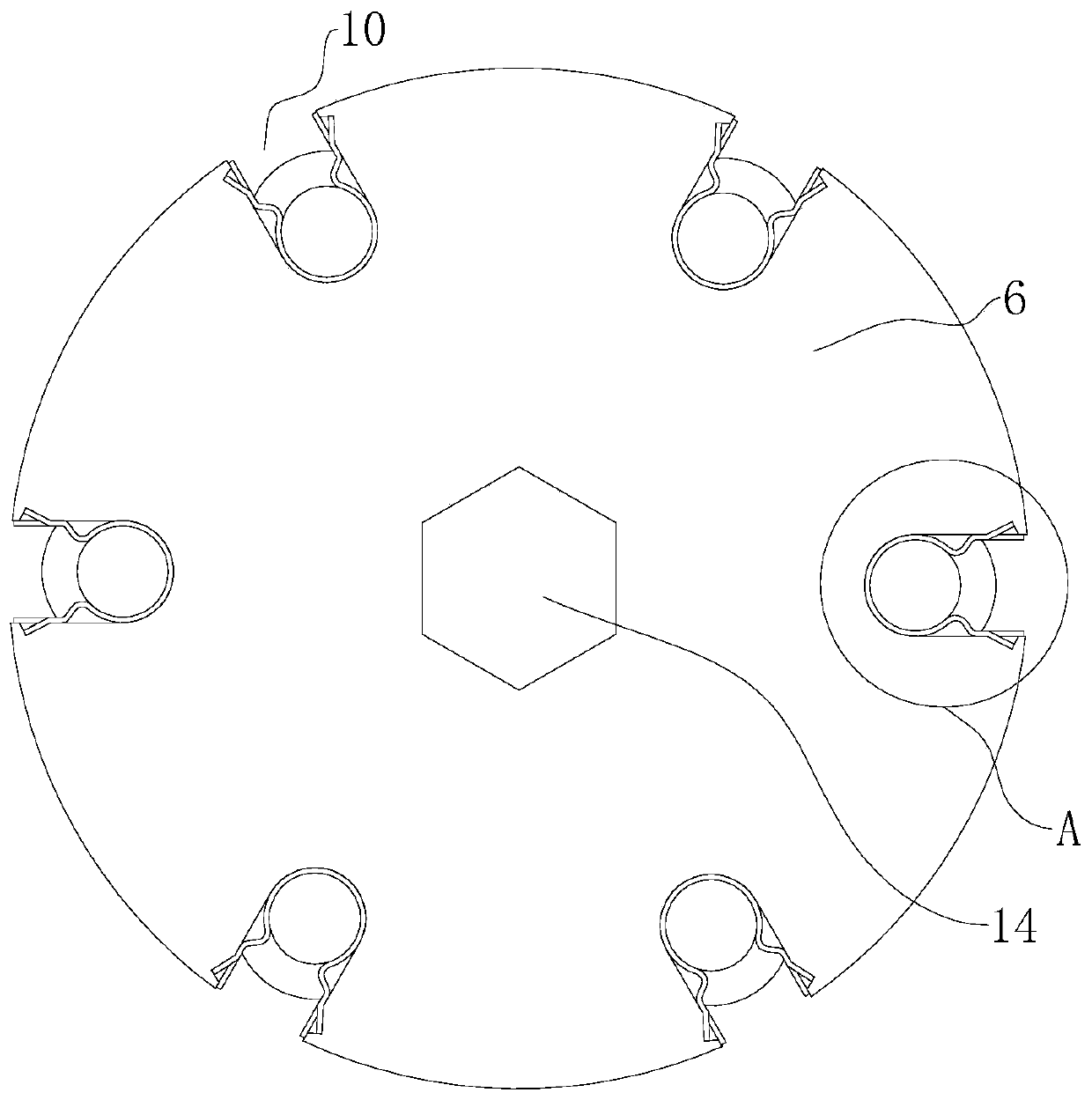

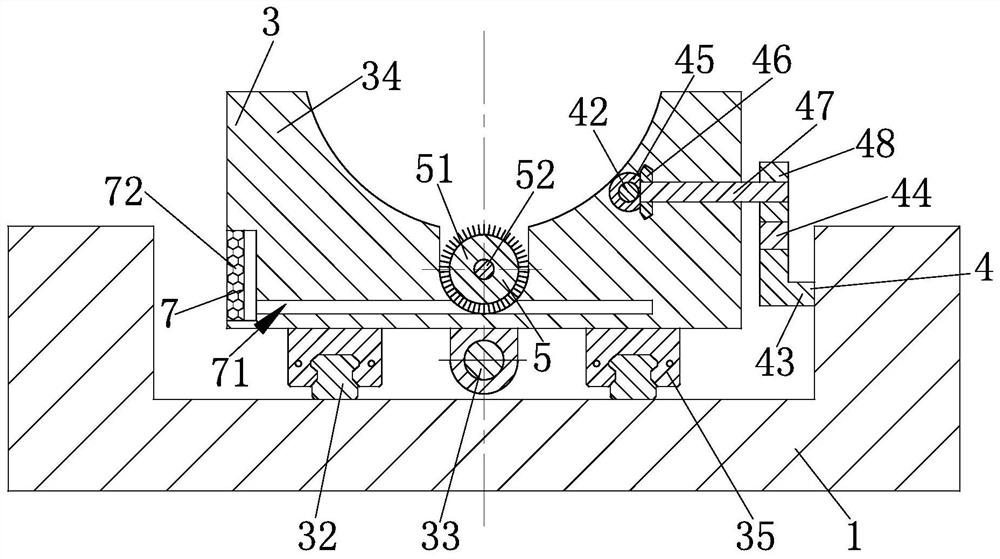

Strong drainage pump for soft foundation treatment

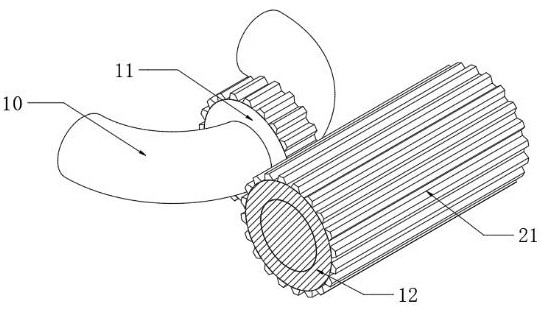

ActiveCN110259695ARealize turning workRealize the delivery workPump componentsPump installationsImpellerEngineering

The invention relates to a strong drainage pump for soft foundation treatment. The strong drainage pump comprises a base, a motor arranged on the base, a pump housing and an impeller arranged in the pump housing, wherein the impeller is coaxially fixedly provided with a pump shaft, a fixing disc I and a fixing disc II are separately coaxially arranged on the pump shaft and an output shaft of the motor, multiple groups of limiting holes are separately correspondingly formed in the fixing disc I and the fixing disc II, nylon bars are inserted into the corresponding limiting holes of the fixing disc I and the fixing disc II, the nylon bars are parallel with the pump shaft, and limiting components for limiting the nylon bars are further arranged in the limiting holes. The strong drainage pump has the advantages that when blockage occurs, the connection of the motor and the pump shaft is cut off, and the motor is protected from damage.

Owner:东莞市金建达建筑有限公司

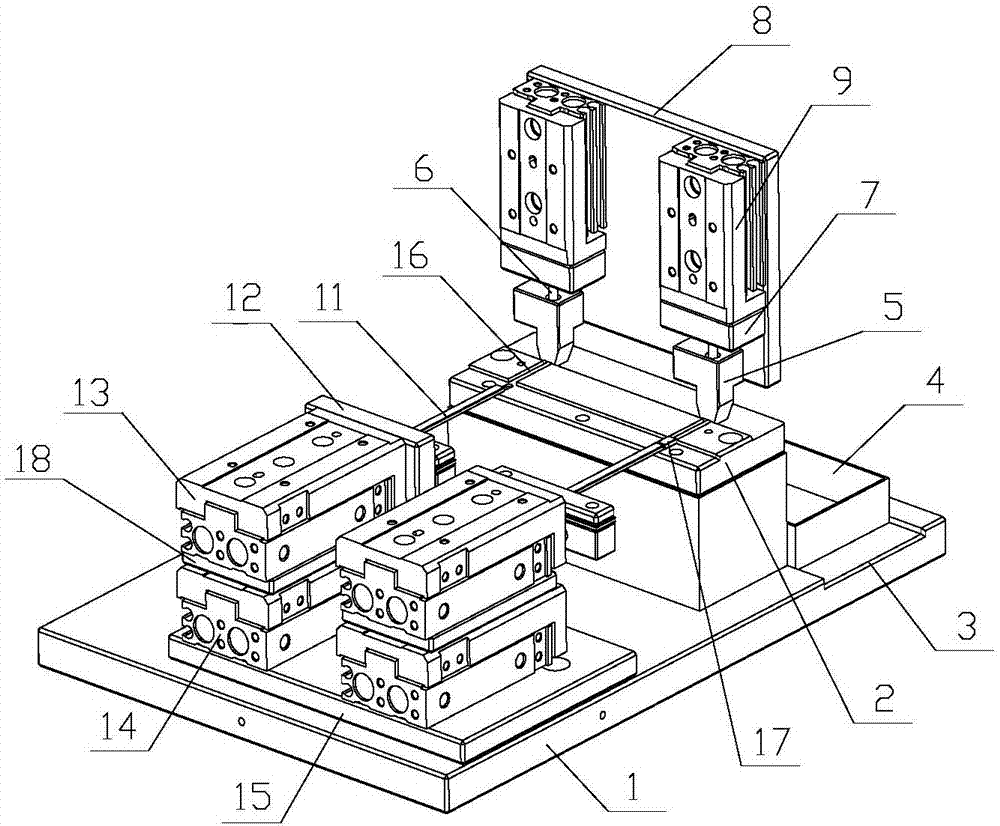

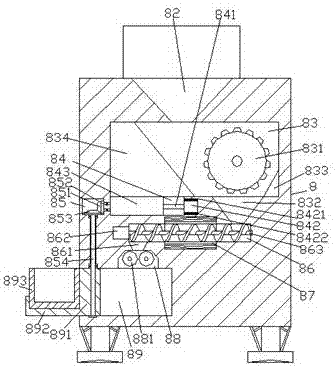

Magnetic material assembling device

ActiveCN107257619AAchieving separation of workRealize the delivery workElectrical componentsEngineeringMechanical engineering

A magnetic material assembling device provided by the present invention comprises a product fixing base, a separating mechanism and a dispensing mechanism. The product fixing base is installed on a Y-axis motion mechanism, the dispensing mechanism is installed on a Z-axis motion mechanism, and the separating mechanism comprises a separation fixing base. A feed bin is arranged above the separation fixing base, a discharging port is arranged at the bottom of the feed bin, and a discharging gap is formed between the discharging port and the separation fixing base. A separation ejecting block is arranged at one side of the feed bin, and a horizontal push mechanism is arranged at the other side of the feed bin. The horizontal push mechanism and the separation ejecting block are located at the relative two sides of the feed bin respectively, and the horizontal push mechanism and the Z-axis motion mechanism are arranged on an X-axis motion mechanism separately. The magnetic material assembling device of the present invention separates the magnetic materials, the horizontal push mechanism transports the magnetic materials to a product on the product fixing base to assemble, and the dispensing mechanism fixes the assembled materials, thereby separating, transporting and assembling the magnetic materials, being convenient to operate and easy to separate, being high in assembly efficiency and strong in reliability.

Owner:GEER TECH CO LTD

Wooden board size rapid detection device for building monitoring

InactiveCN108444384ARealize the delivery workImprove efficiencyUsing optical meansEngineeringElectric control

The invention discloses a wooden board size rapid detection device for building monitoring. The structure comprises an operating bench, a conveyor belt, a work bench, a work bench support seat, an electric control box and a dust cover. A laser measurer arranged in the operating bench is used for realizing the measurement of a wooden board size. Compared with manual measurement, realized laser measurement possesses advantages of high efficiency, high accuracy and high comprehensive performance. Through cooperating with the conveyor belt, wooden boards can be continuously placed on the conveyorbelt, the wooden boards pass through the laser measurer through a driving effect so as to realize rapid detection, and a detected value can be displayed through the screen of an electric cabinet. Thedevice can be used for large scale detection places. During the transmission process of the conveyor belt, a first driven belt wheel and a second driven belt wheel adopt different driving mechanisms so that when one belt wheel is damaged, the operation of equipment is not influenced, and equipment practicality is effectively increased.

Owner:卢渭彬

Weight conveying device

InactiveCN105523333ARealize the delivery workLabor savingManual conveyance devicesEngineeringMechanical engineering

A weight conveying device is used for moving a weight and comprises a plurality of conveying assemblies arranged side by side. Each conveying assembly comprises a bottom plate, a supporting part arranged on the bottom plate and a rolling mechanism. Each rolling mechanism is used for making direct contact with the weight needing to be moved, freely rotates or rolls under the action of external force and is limited between the corresponding supporting part and the corresponding bottom plate. According to the weight conveying device, not only is manpower saved, but also conveying efficiency is high.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

A high-altitude erection device for power cables

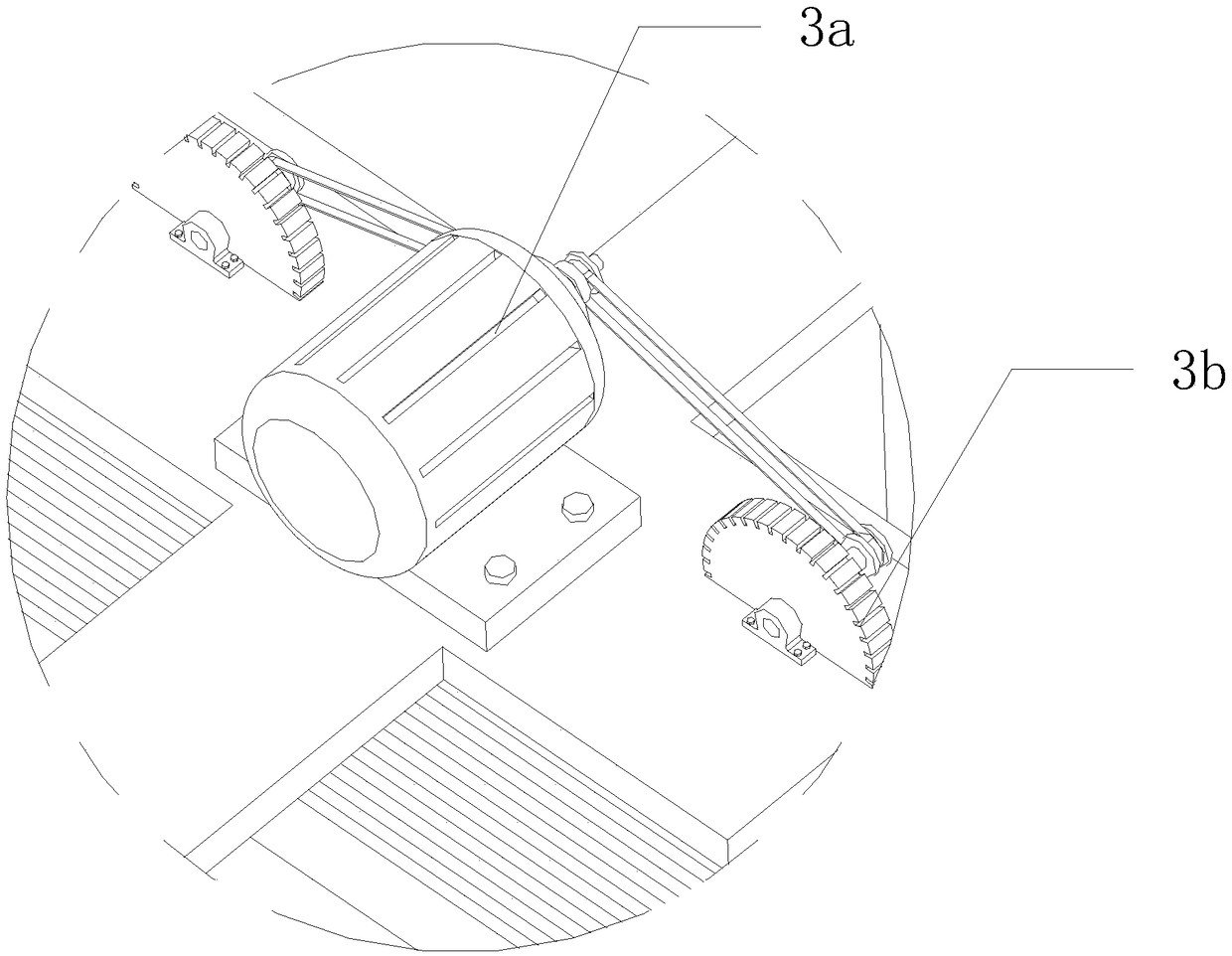

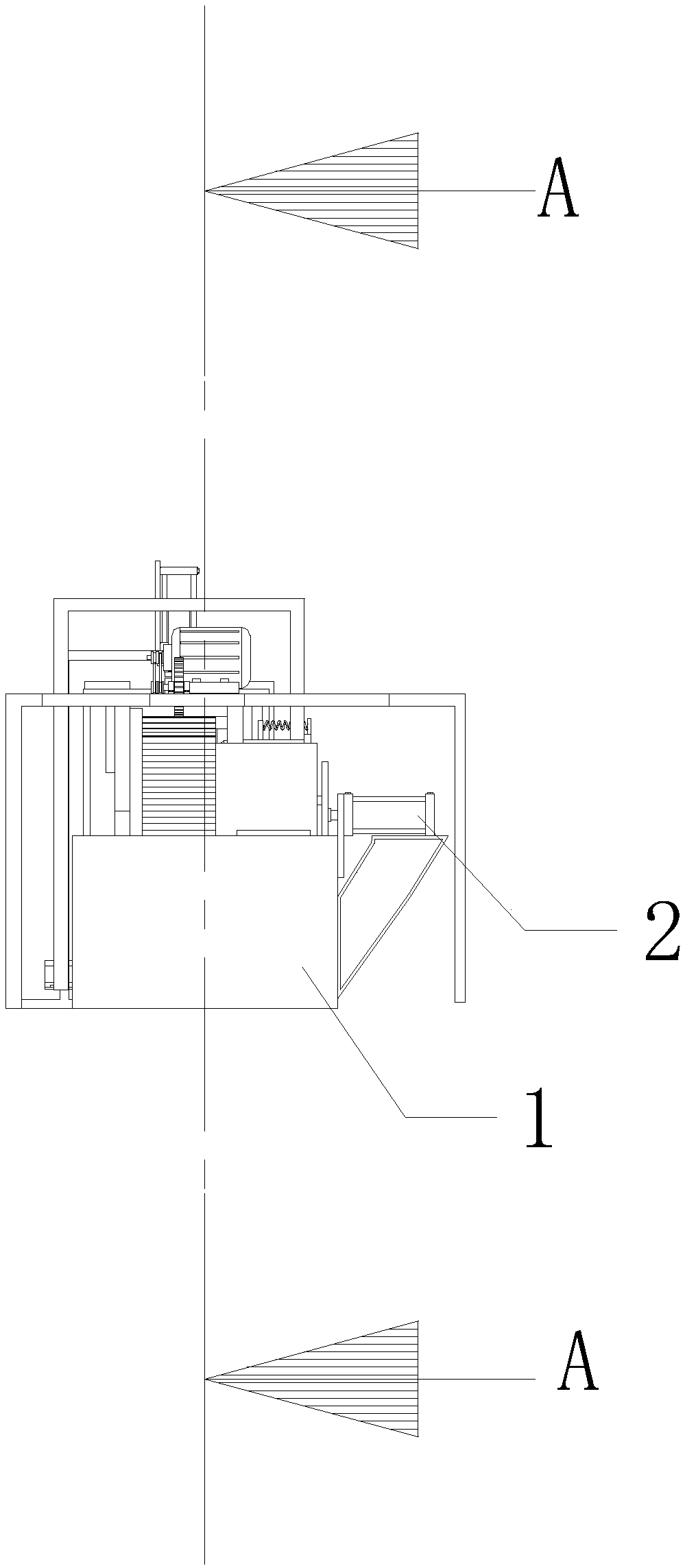

ActiveCN112670899BRealize the delivery workAvoid injuryFilament handlingApparatus for overhead lines/cablesRatchetPower cable

The invention is applicable to the technical field of electric power engineering cable laying, and provides a power cable high-altitude erection device, comprising: a conveying frame, a rotating wheel and an input pipe, two clamping components are installed in the conveying frame, and the clamping The assembly includes a rotating wheel and a first gear, the rotating wheel is provided with a clamping cavity, and a plurality of clamping blocks arranged at equal angles are installed in the clamping cavity, and each clamping block is provided with a clamping cavity. There is a clamping groove, the two rotating wheels are driven by the drive assembly, and the rotation directions of the two rotating wheels are opposite, the input pipe is installed coaxially with the output pipe installed on the top of the conveyor, the rotating wheel rotates and conveys the cable upward, avoiding In the case of cable damage or personal injury caused by manual climbing and conveying, multiple conveyors are clamped and fixed on the fixed box, which can convey multiple cables at the same time, which increases the cable conveying efficiency. The engagement between the pawl and the ratchet prevents the rotating wheel Rotation occurs to prevent the problem of cable damage caused by the falling of the cable.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN +1

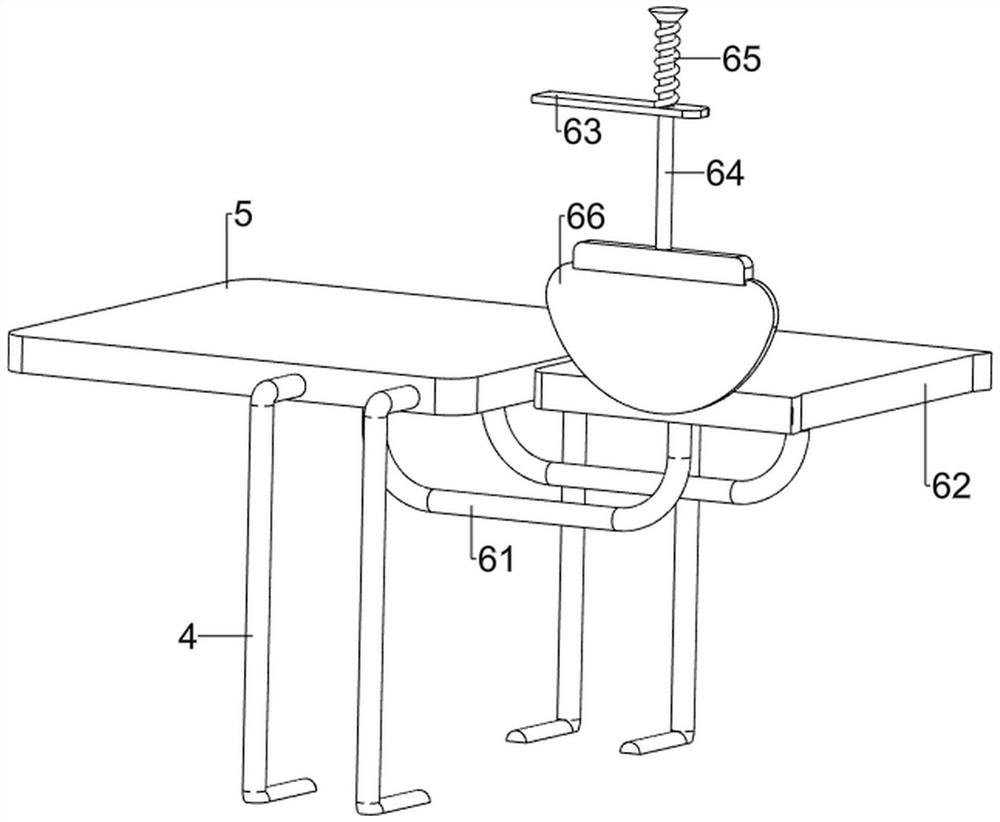

Electrolyte injection device in a lithium-ion battery

ActiveCN113270698BRealize the delivery workRealize positioning workFinal product manufactureCell component detailsHydraulic cylinderElectric machinery

The invention discloses an electrolyte injection device in a lithium ion battery, relates to the technical field of lithium battery production, and includes a workbench, a conveying mechanism, a positioning mechanism, a clamping mechanism and a liquid injection mechanism, wherein the conveying mechanism is arranged on the workbench The upper side is used to realize the delivery before and after the lithium battery injection. The delivery mechanism includes a support plate and a drive motor. The positioning mechanism is located on the lower side of the delivery mechanism and is used to realize the positioning of the lithium battery injection. The positioning mechanism includes a telescopic cylinder. , Hinge strip 1, Hinge strip 2, and positioning strip. The clamping mechanism is located on the upper side of the conveying mechanism and is used to clamp the lithium battery when liquid is injected. The clamping mechanism includes an overhang strip, a clamping plate, and a hinge strip 3. , a linkage column and a linkage strip. The liquid injection mechanism is arranged on the upper side of the clamping mechanism and is used to realize the liquid injection of the lithium battery. The liquid injection mechanism includes a hydraulic cylinder and an electrolyte tank. In summary, the present invention can realize automatic delivery, automatic positioning, automatic clamping and automatic filling of lithium batteries.

Owner:WUHU ETC BATTERY LTD

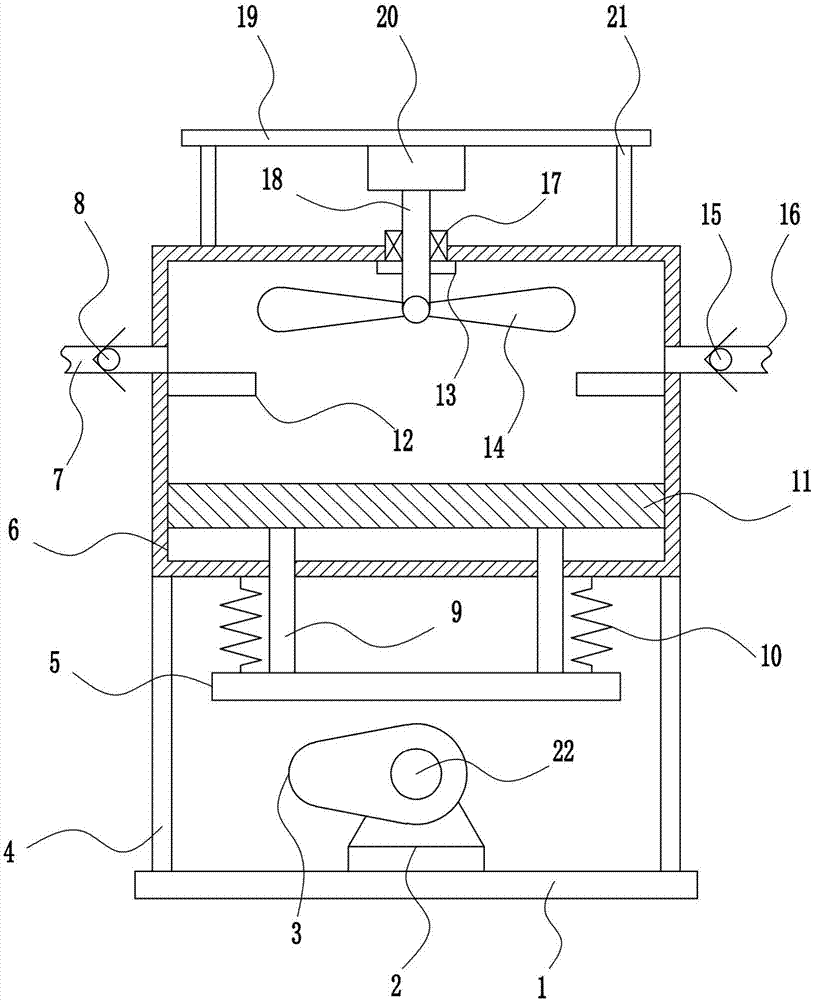

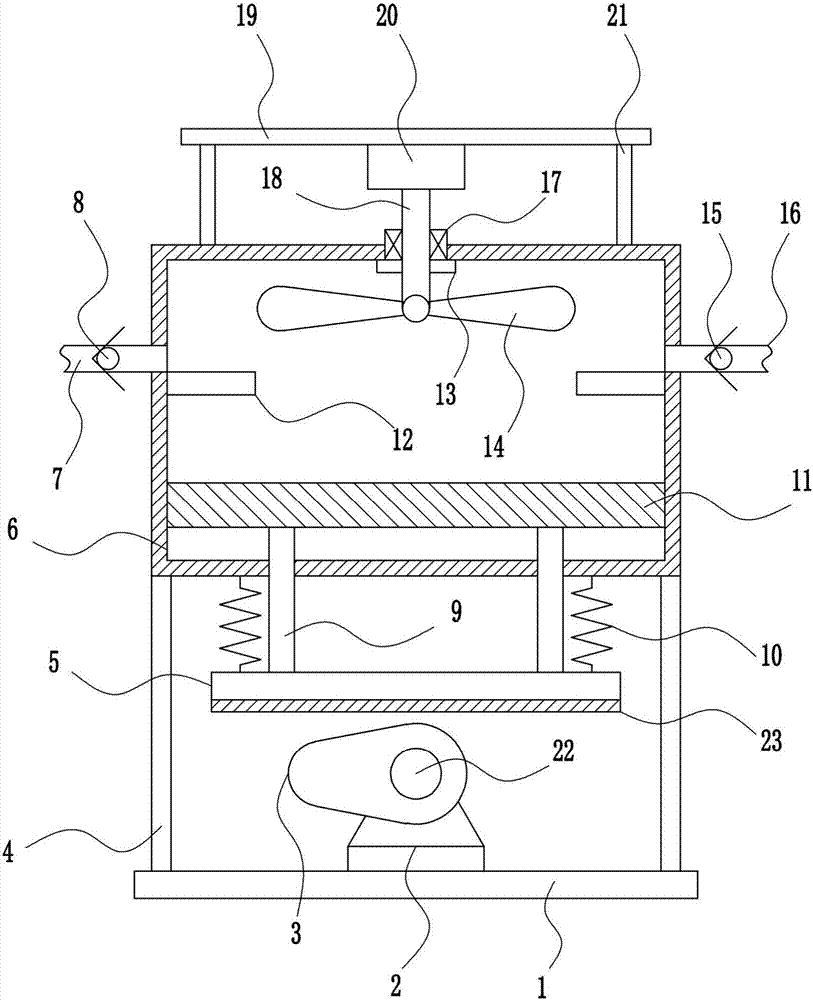

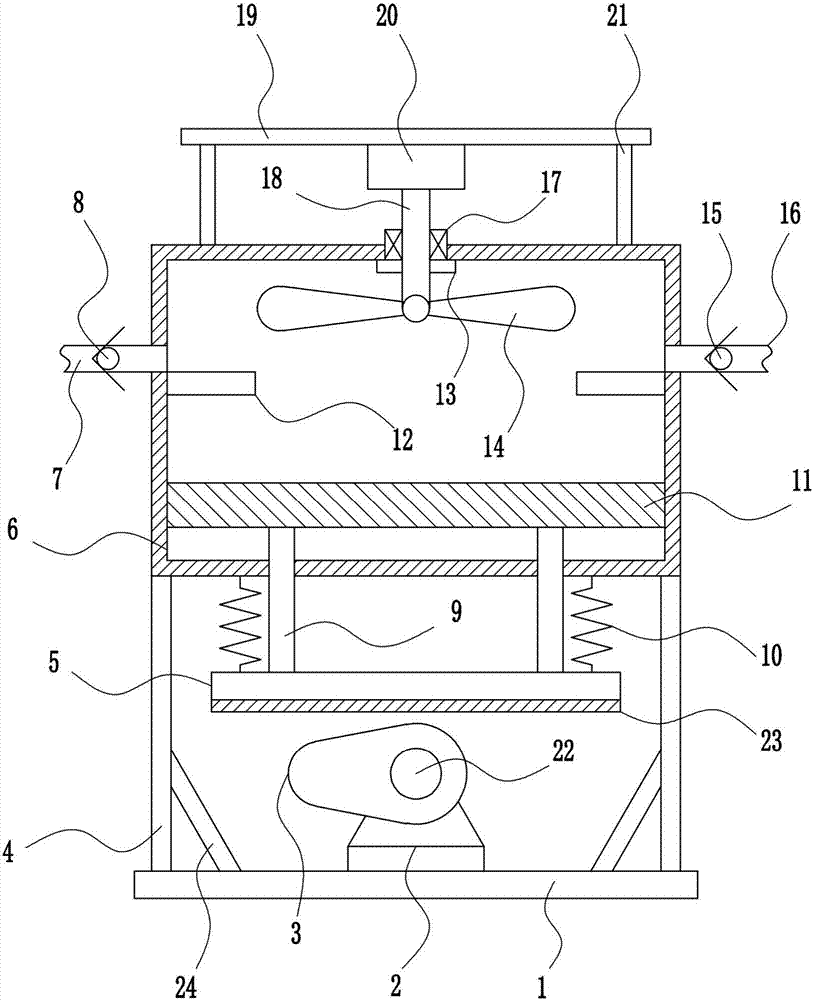

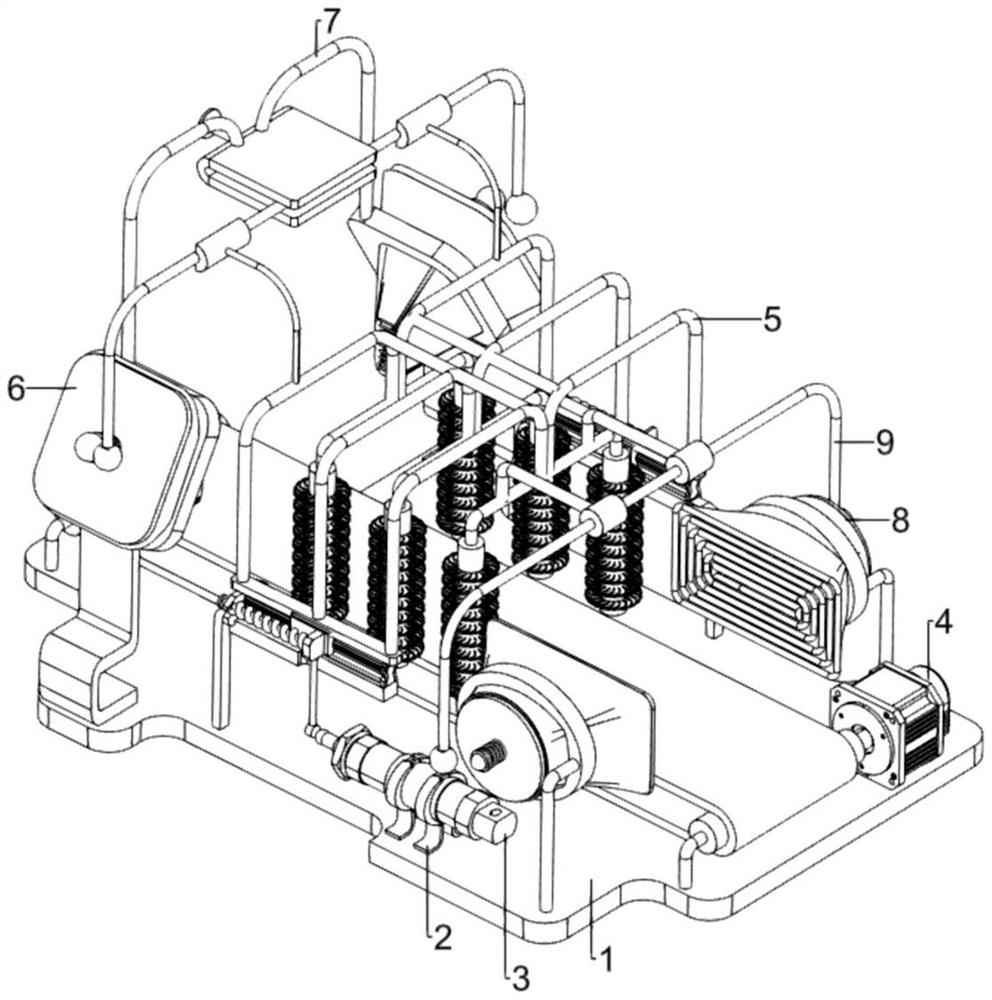

Novel medicinal material crushing and drying machine

InactiveCN107999194AImprove processing speedImprove processing qualityGrain treatmentsPulp and paper industryFuselage

The invention discloses a novel crushing and drying machine for medicinal materials. The crushing and drying machine comprises a machine body, wherein a conical groove is formed in the top surface ofthe machine body, and the bottom of the conical groove communicates with a first crushing chamber extending leftwards and rightwards; a first crushing device is arranged in an extension part at the right side of the first crushing chamber, and a slope block is slidably connected to the left side of the first crushing chamber in a matching mode; a guide groove is formed in the position, at the bottom part of the slope block, of the bottom wall of the interior of the first crushing chamber, a spiral rod extending leftwards and rightwards is arranged in the guide groove, and the tail part of theright side of the spiral rod is connected with a first motor in a matched mode; a spiral thread on the spiral rod is connected with a guide block in a matched mode, and the top part of the guide blockis fixedly connected with the left side of the bottom part of the slope block; and a transmission cavity is formed in the position, on the left side of the guide groove, of the interior of the machine body, and a first rotating piece extending leftwards and rightwards is connected to the part, between the transmission cavity and the guide groove, of the machine body in a rotary mode. The crushingand drying machinehas the advantages of being simple in structure and convenient to operate, so that the medicine entering work in the later stage is facilitated, and the utilization rate of the medicinal materials is improved.

Owner:广州一德智能科技有限公司

Processing equipment for fireproof layer of fireproof plate

ActiveCN114263066ARealize the delivery workAddresses an issue where teleporting jobs could not be done while clampedPhysical paper treatmentEngineeringControl circuit

The invention provides processing equipment for a fireproof layer of a fireproof plate, and relates to the technical field of fireproof plate processing. The top face of the main table body is fixedly connected with a fixing support, and the bottom face of the main table body is fixedly connected with a round rod support. The opposite sides of the fixing supports are movably connected with connecting pieces. The inner side of the connecting piece is movably connected with a pressing device in a clamped mode. The pressing device is electrically connected with an external control circuit of the main table body, after the pressurizer is started, pressure is applied to the pressing block downwards, after the front end of the pressing block is attached to the top face of the auxiliary table face, pressurization continues to enable the bottom face of the pressing block to be completely attached to the top face of the auxiliary table face, the pressing block rotates through a shaft at the tail end of the pressurizer, and the pressurizer rotates through a rotating rod. After a pressing block is tightly attached to the top face of the auxiliary table top, kraft paper can be pressurized, a pressing device can move left and right on the inner side of a sliding groove plate through an external control circuit, kraft paper conveying work is achieved, and the problem that conveying work cannot be conducted during clamping is solved.

Owner:响水海智科技有限公司

A medical ultrasonic cleaning machine

ActiveCN112246719BRealize the delivery workMake the wipe workDrying solid materials without heatDrying machines with progressive movementsMedicineMegasonic cleaning

The invention relates to a cleaning machine, in particular to a medical ultrasonic cleaning machine. The invention provides a medical ultrasonic cleaning machine capable of transmitting medical ultrasonic waves and cleaning medical ultrasonic waves at the same time. A medical ultrasonic cleaning machine, comprising: a bottom plate and a first support seat, the first support seat is installed on the top of the bottom plate; an air cylinder, the first support seat is fixedly connected with the air cylinder by bolts. The invention is equipped with a conveying mechanism, and the conveying mechanism cooperates with the cleaning mechanism to realize the wiping and conveying work of the medical ultrasonic wave; the cleaning mechanism cooperates with the cylinder and the push shaft to realize the wiping work of the medical ultrasonic wave by moving the brush back and forth; sprinkling water The mechanism cooperates with the sprinkler auxiliary mechanism to realize that an appropriate amount of water in the water outlet tank will flow to the medical ultrasonic wave, thereby improving the cleaning efficiency of the medical ultrasonic wave.

Owner:江西怡中堂生物科技有限公司

Swing mechanism of plate shearing machine

InactiveCN114101774ARealize the phenomenon of streamlined continuous processingConvenience for inner touch continuous cuttingShearing machinesShearing machine accessoriesScrew threadElectric motor

The invention discloses a plate shearing machine swing mechanism which comprises a contact conduction device, the side end position of the contact conduction device is fixedly connected with a connection transmission device, the contact conduction device comprises a contact structure and a shearing structure, the contact structure is arranged on one side of the inner end of the contact conduction device, and the shearing structure is arranged on one side of the inner end of the contact conduction device. The shearing structure is fixedly connected to the side end position of the contact structure, the connecting transmission device comprises a first lantern ring, a first rotating ring, a transmission rod, a second lantern ring, a second rotating ring, a first threaded sleeve rod, a threaded guide rod, a motor, a second threaded sleeve rod and a smooth rod, and the motor is installed at the top of one side of the inner end of the connecting transmission device; the lower end of the motor is connected with a threaded guide rod in an inserted mode, and the top of the threaded guide rod is in threaded connection with a second threaded sleeve rod. According to the swing mechanism of the plate shearing machine, through the arrangement of the contact conduction device, the purpose of inner end contact conduction is achieved.

Owner:张建成

Regular shearing and packaging equipment for fiber material for manufacturing masks

The invention relates to packaging equipment, in particular to regular shearing and packaging equipment for a fiber material for manufacturing masks. According to the regular shearing and packaging equipment for the fiber material for manufacturing the masks, the fiber material can be sheared into uniform specifications, and meanwhile, the fiber material can be pressed and packaged. The regular shearing and packaging equipment for the fiber material for manufacturing the masks comprises a bottom plate and a first supporting rod, wherein the first supporting rod is fixedly connected to the topof the bottom plate. By arranging a shearing mechanism, the shearing mechanism is matched with a packaging mechanism, and shearing and packaging of the fiber material can be achieved; a feeding mechanism is matched with the shearing mechanism, so that the feeding work of the fiber material can be realized, and workers do not need to manually push the fiber material onto a second table plate; a pressing auxiliary mechanism is matched with the shearing mechanism and can press the fiber material; and a packaging auxiliary mechanism is matched with the packaging mechanism and can continuously eject out packaging boxes.

Owner:山东康斌医疗科技有限公司

Feed mechanism of valve bag capping machine

The invention discloses a feed mechanism of a valve bag capping machine. The feed mechanism comprises a stockpiling platform, a belt conveying device and a feeding component, wherein the feeding component comprise a cylinder, a push rod, a first rotating shaft, a second rotating shaft, an ejector rod and front and rear compression rods; the two rotating shafts are respectively arranged on the upper side and the lower side of the stockpiling platform back and forth; a front compression rod is sleeved and a rear compression rod is fixed on the first rotating shaft respectively; the second rotating shaft is fixedly provided with a second suspension arm rod; the ejector rod is sleeved in a through hole of the stockpiling platform; the lower end of the ejector rod is hinged with a connecting rod; the other end of the connecting rod is fixed on the second rotating shaft; the upper part and the middle part of the push rod are hinged with a first suspension arm rod and the second suspension arm rod respectively; and the lower end of the push rod is fixed on a piston rod of the cylinder. According to the feed mechanism, all actions can be controlled only by one cylinder in coordination with a control system; and in the feeding process, the compression rods are matched with the ejector rod, so that the feeding operation of a single valve bag can be realized.

Owner:JINAN LIYU MACHINERY TECH

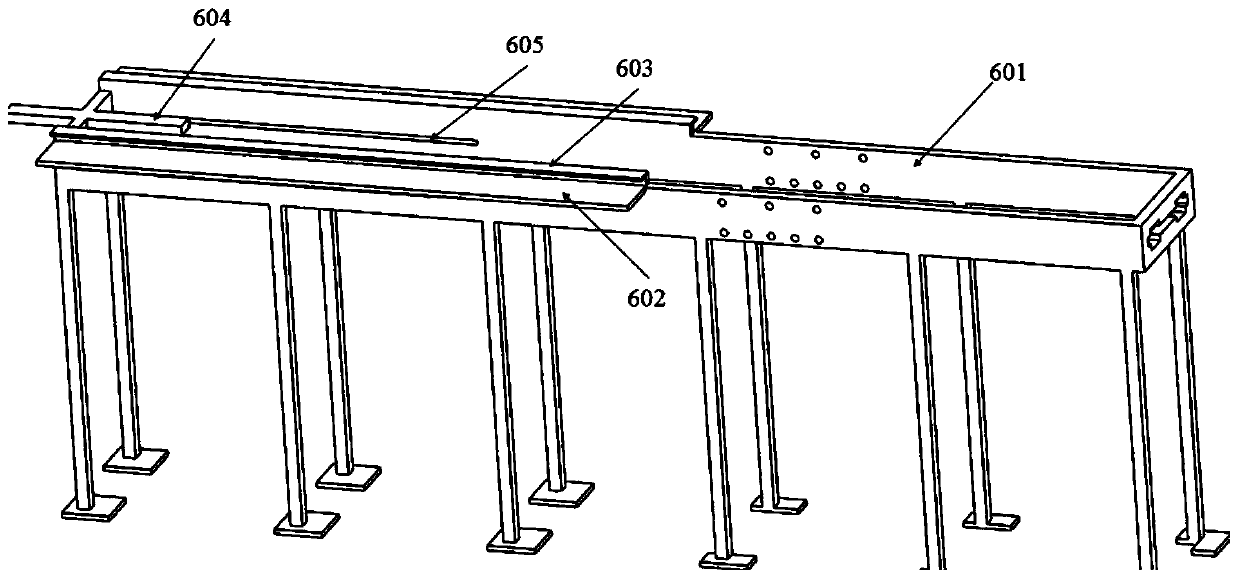

Discharging conveying device for packaging bag making machine

PendingCN111099063ARealize positioning receiving workRealize the delivery workPaper article packagingStructural engineeringIndustrial engineering

The invention discloses a discharging conveying device for a packaging bag making machine. A conveying frame is included; a plurality of conveying belts arranged at intervals are arranged on the conveying frame in a transmission manner, and a belt driving assembly used for driving the conveying belts for transmission is further installed on the conveying frame; a jacking driving device is installed on the conveying frame, and the output end of the jacking driving device is connected with a jacking positioning frame which is provided with a plurality of jacking positioning rods, and the jackingpositioning rods and the conveying belts are arranged in a staggered manner; the jacking driving device acts on the jacking positioning frame so that the jacking positioning rods can move up and downrelative to the conveying frame; and positioning suction nozzles located beside the jacking positioning rods are further connected to the jacking positioning rods through installing bases. Accordingto the discharging conveying device for the packaging bag making machine, due to cooperation of the jacking positioning rods and the conveying belts, the positioning material receiving work of circulating boxes can be achieved, the conveying work of the circulating boxes can also be achieved, in this way, the workload of operators can be effectively reduced, and the production efficiency and quality are improved.

Owner:重庆巧琢工贸发展有限公司

A feeding device for non-destructive testing of steel pipes

ActiveCN111591741BCases to prevent slippingImprove stabilityConveyorsCleaning using toolsPipeMechanical engineering

The invention relates to the field of non-destructive testing devices for steel pipes, in particular to a feeding device for non-destructive testing of steel pipes, including a base, a flaw detector, a feeding structure, a rotating structure, a cleaning structure, a clamping structure and a cleaning structure; the setting of the clamping structure, The steel pipe's own gravity can be used to clamp and fix the upper part of the side wall of the steel pipe, so as to prevent the steel pipe from slipping during the inspection process, thereby improving the inspection quality. The steel pipe is sent to the detection area for detection, which can not only save time and effort, but also improve the effect of detection accuracy. While the feeding structure is working, it can also drive the rotating structure to work synchronously. Through the work of the rotating structure, it can be in the steel pipe feeding At the same time, the rotation of the steel pipe is realized, so that the steel pipe can be inspected in all directions, thereby improving the detection effect. While the rotating structure is working, it can also synchronously drive the cleaning structure to work.

Owner:山东中正钢管制造有限公司

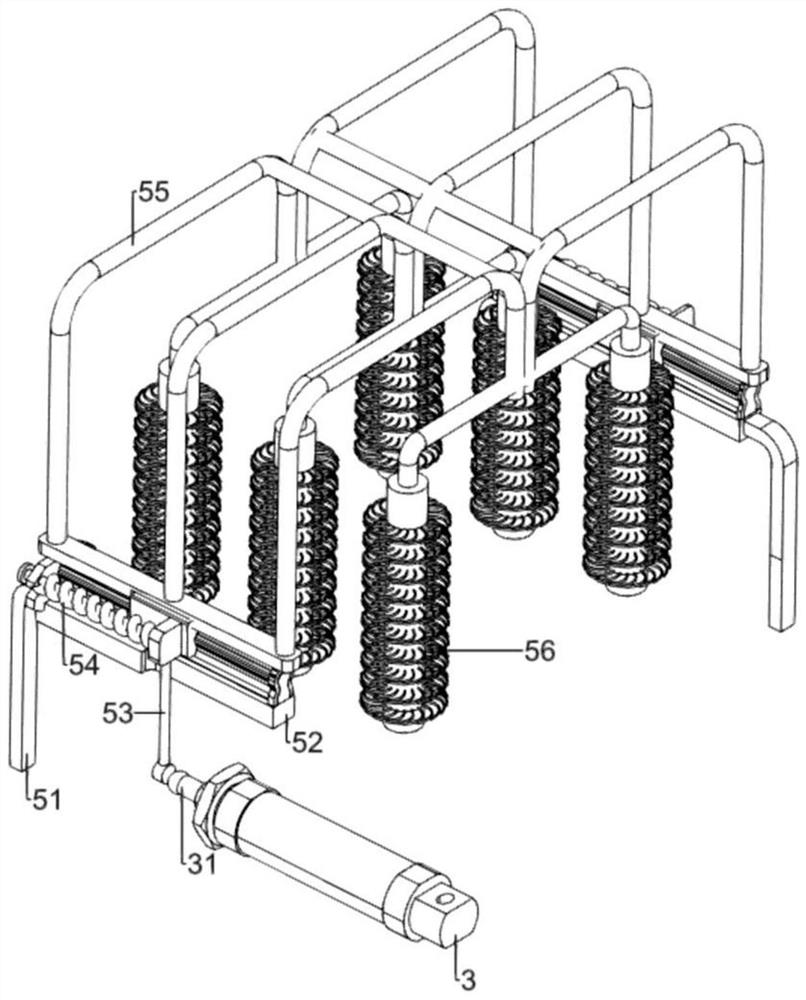

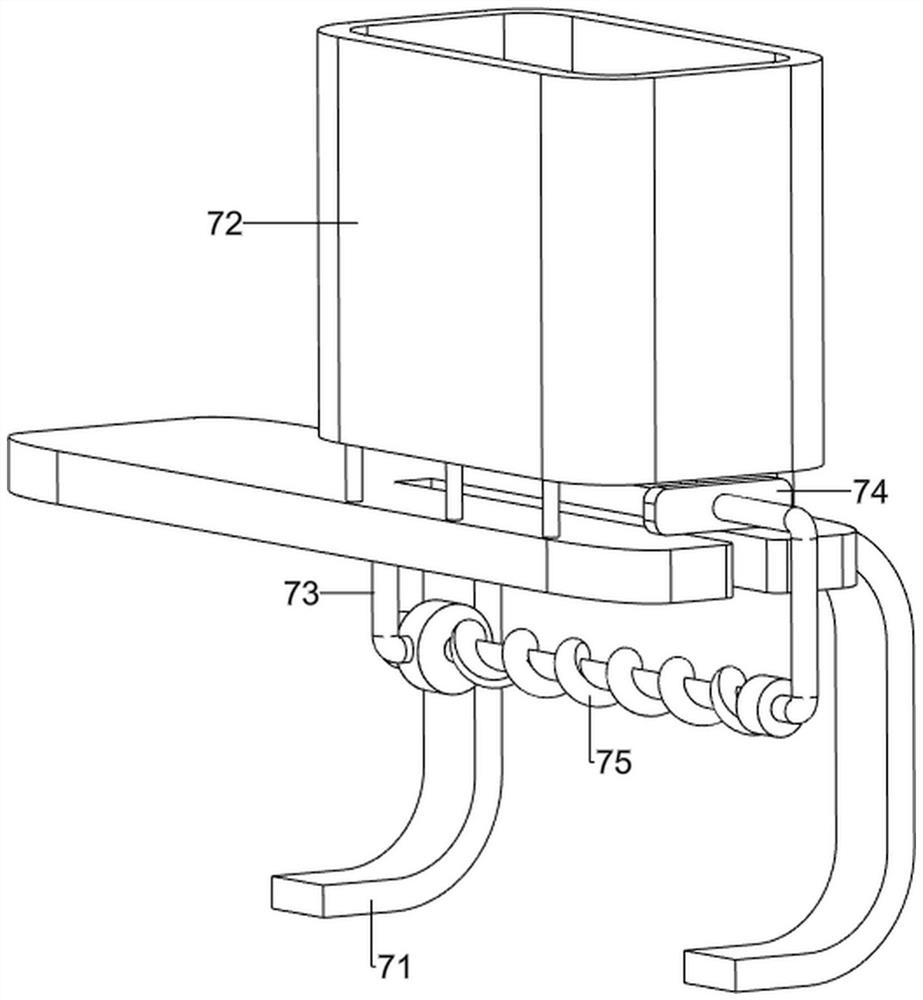

Environment-friendly oil immersion device for chain production

ActiveCN112495883ATo achieve the work of wipingRealize the delivery workCharge manipulationCleaning using toolsEngineeringFishing

The invention relates to an oil immersion device, in particular to an environment-friendly oil immersion device for chain production. The environment-friendly oil immersion device for the chain production is capable of derusting a chain, wiping off water on the chain, conveying the chain to a designated position, immersing the chain in oil and fishing up the chain, and comprises a base, first supporting rods and a storage frame, wherein the first supporting rods are symmetrically and fixedly connected to the top of the base; the storage frame is connected between the two first supporting rods;and the shape of the storage frame is square. According to the environment-friendly oil immersion device for the chain production, a fishing mechanism soaked by rust remover is arranged and matched with an automatic fishing, wiping, conveying and rotating mechanism, so that the chain in the storage frame is fished out; and a water wiping mechanism is matched with the automatic fishing, wiping, conveying and rotating mechanism, so that the rust remover on the chain is wiped.

Owner:青岛奥格机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com