Patents

Literature

53results about How to "Realize assembly work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

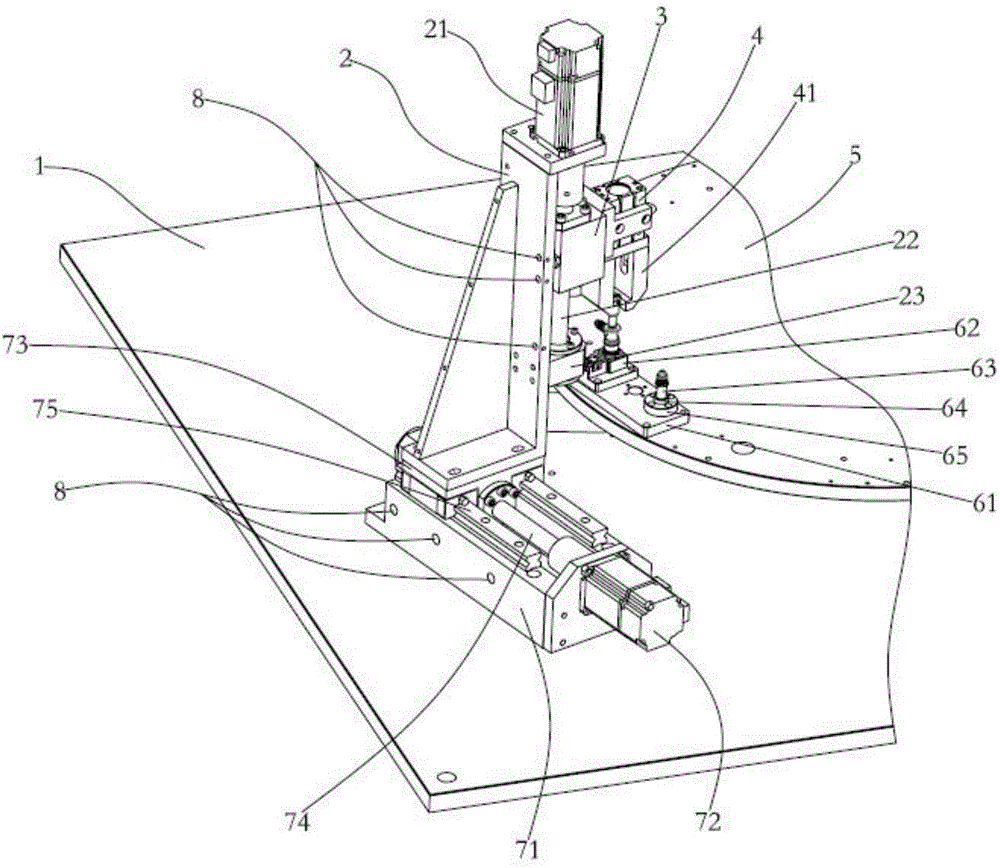

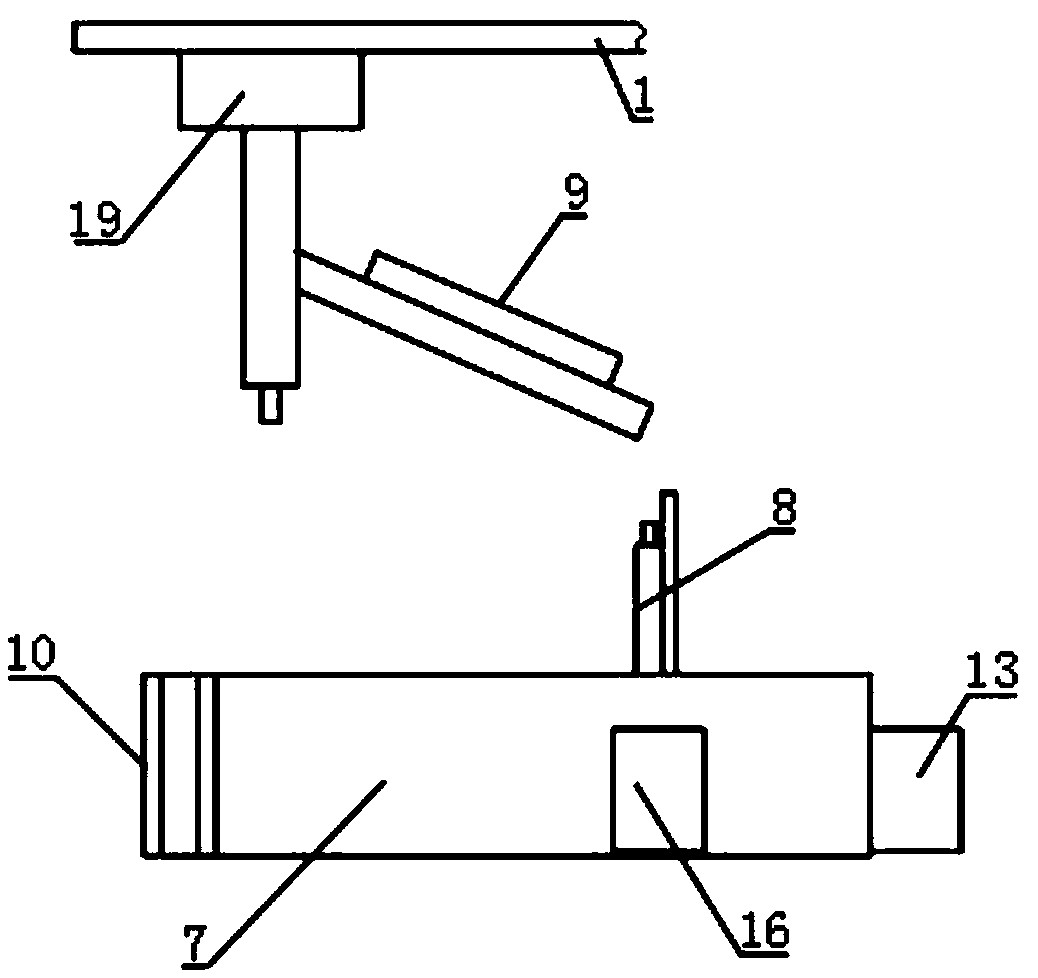

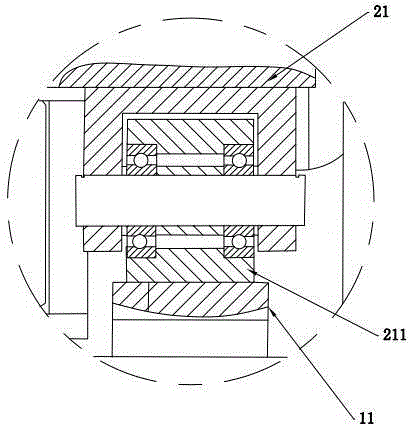

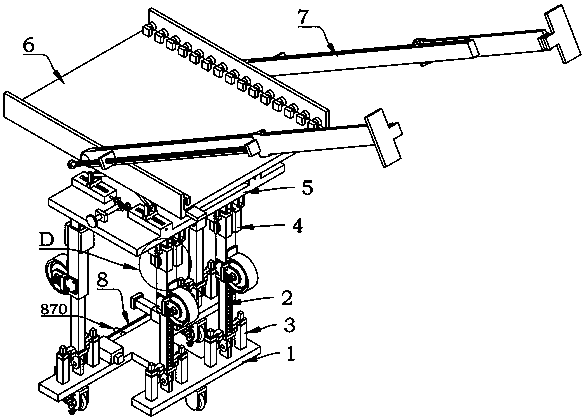

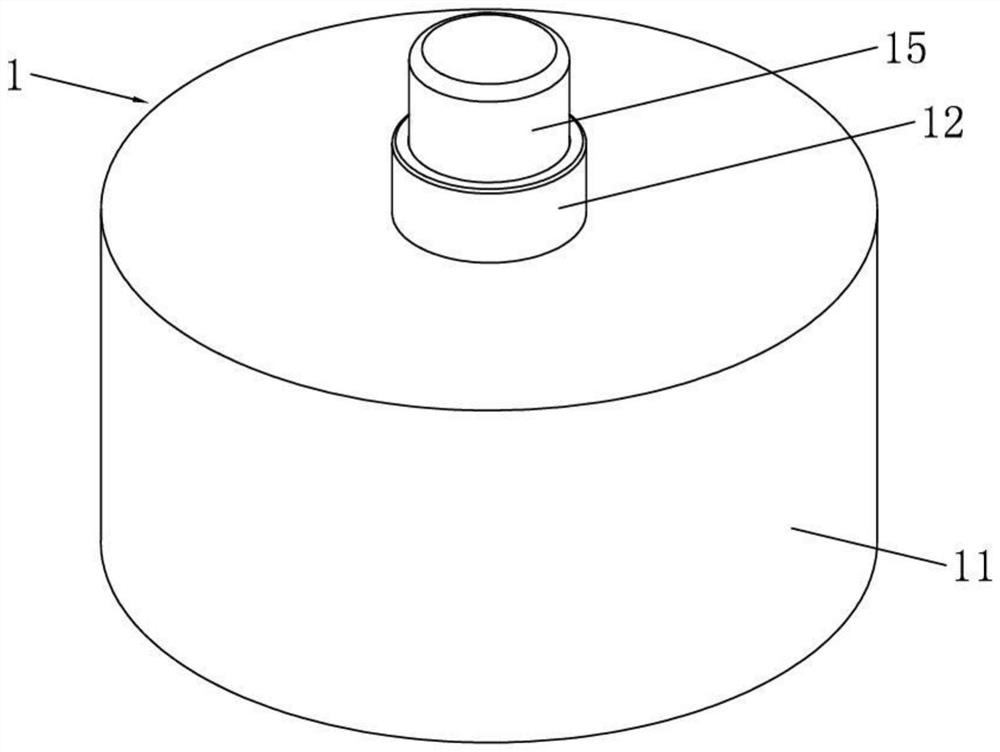

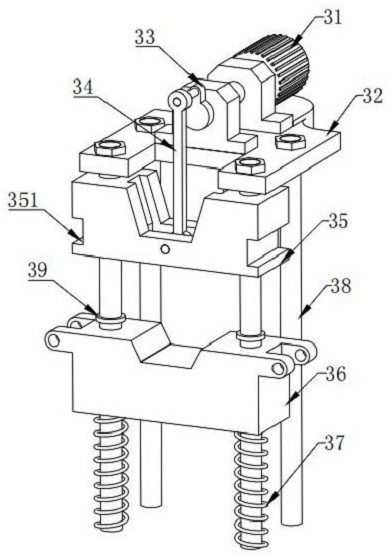

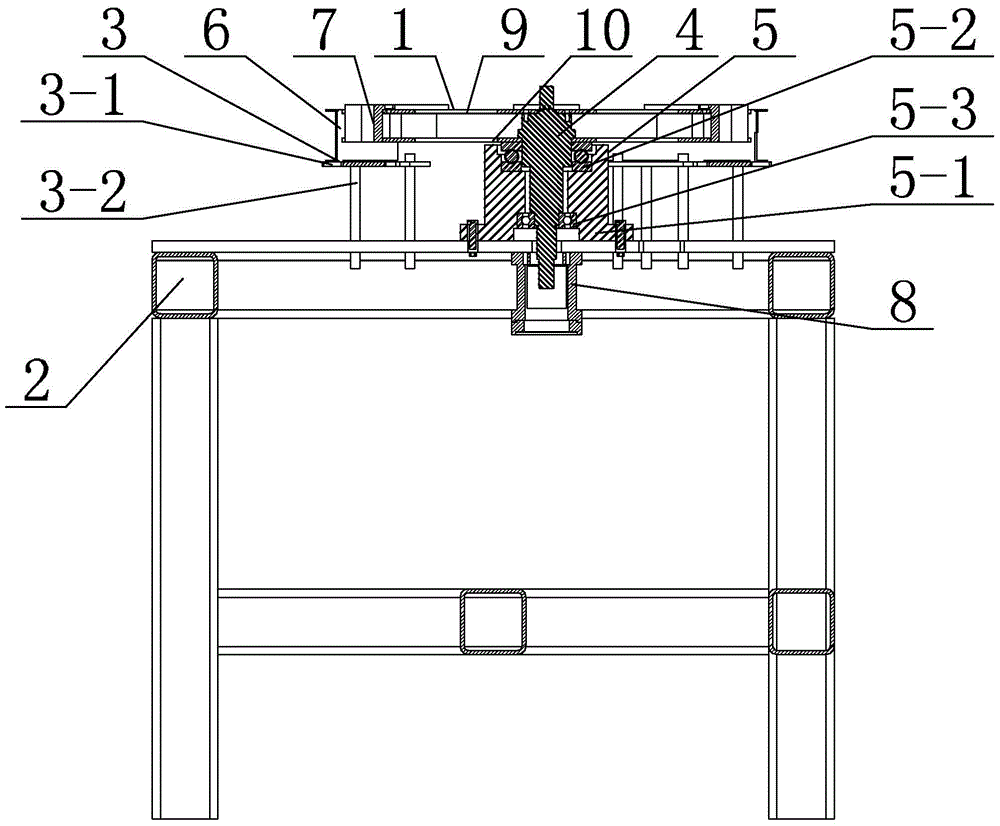

Seal ring assembly machine

ActiveCN104858636AGuaranteed accuracy requirementsRealize assembly workAssembly machinesMetal working apparatusCircular discBiochemical engineering

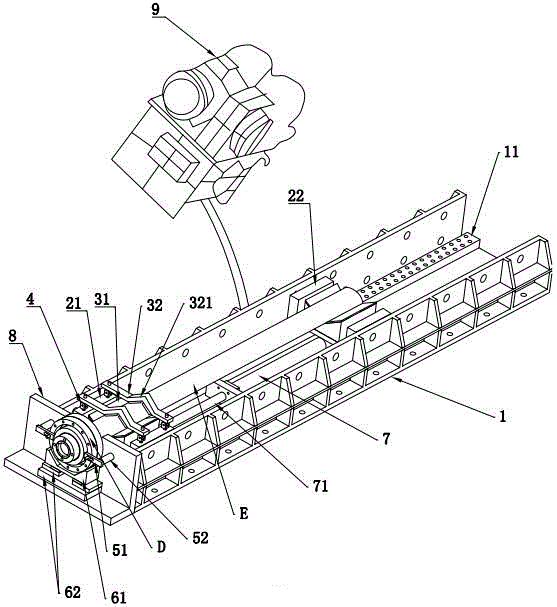

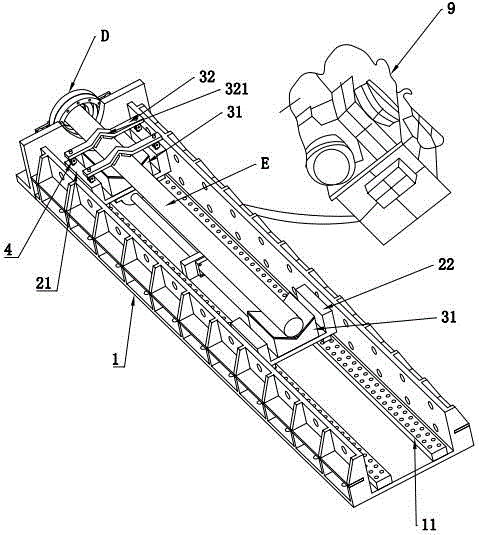

The invention discloses a seal ring assembly machine which comprises a worktable (1), wherein a transverse moving device is arranged on the worktable (1), a support seat (2) is arranged on the transverse moving device, a first servo motor (21) is arranged on the support seat (2), a first screw rod (22) is arranged at the lower end of the first servo motor (21), a fixing block (3) is arranged on the first screw rod (22) in a penetrating manner, a clamping jaw cylinder (4) is fixed on the fixing block (3), and a clamping jaw (41) is arranged at the lower end of the clamping jaw cylinder (4); an index plate (5) is arranged in the middle of the worktable (1), and a plurality of joint mounting check clamps are arranged on the index plate (5). Relevant parts are driven by the servo motors to move transversely or longitudinally, the assembly work of joint sealing pieces is realized, the structure is simple, the operation is convenient, the automation degree is high, the reliability of assembly of the sealing pieces is improved, and the production quality is improved effectively.

Owner:CHONGQING SULIAN AUTO PARTS

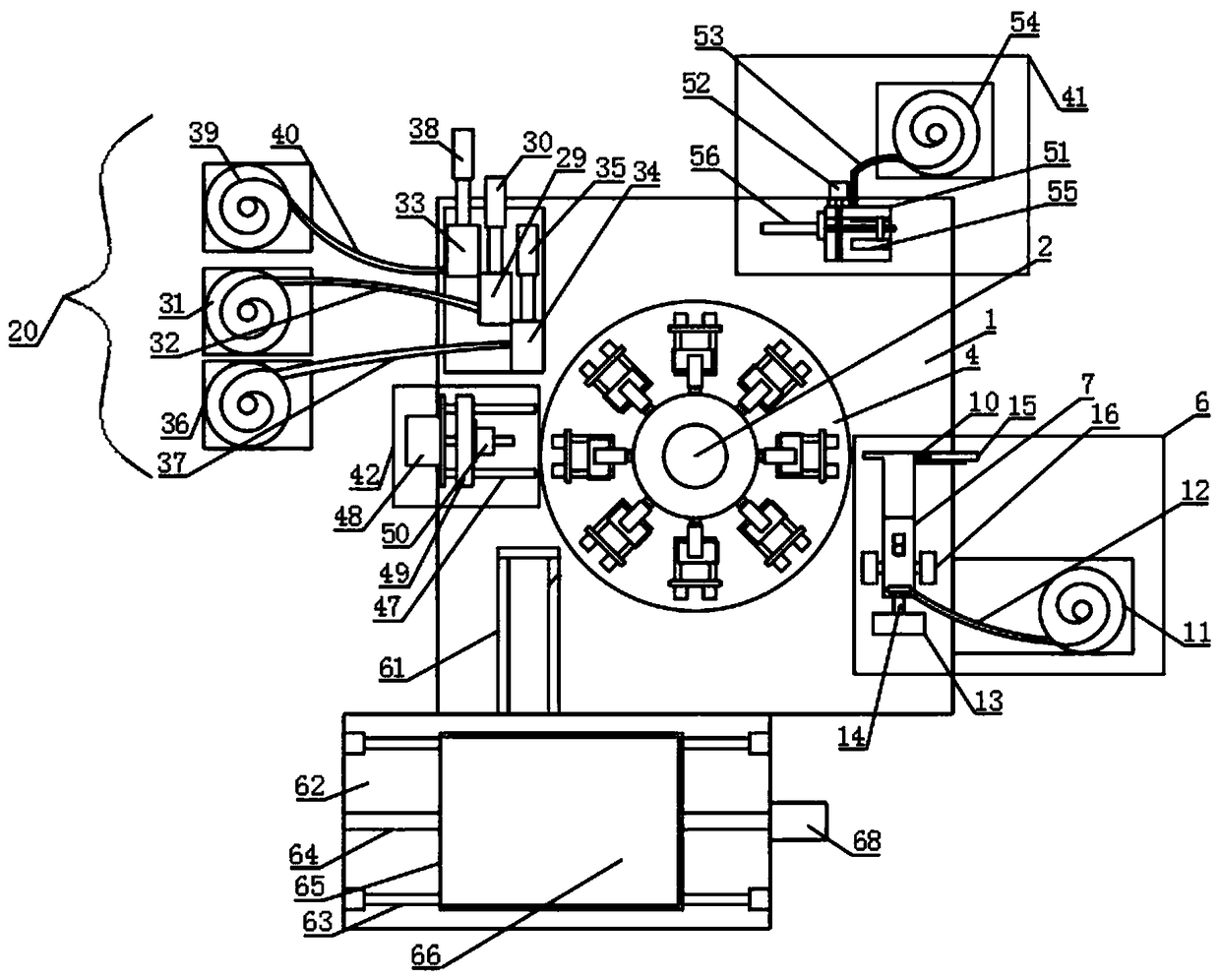

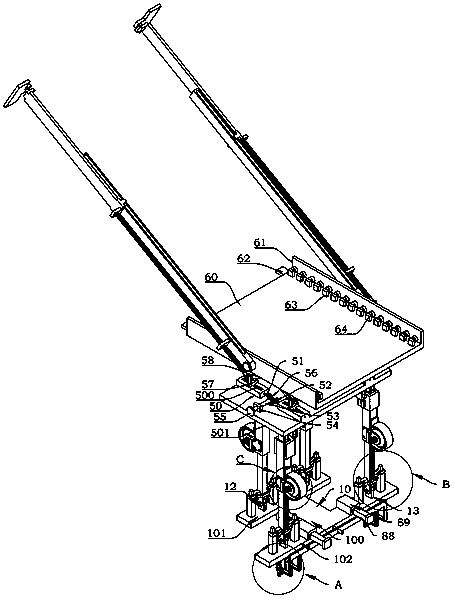

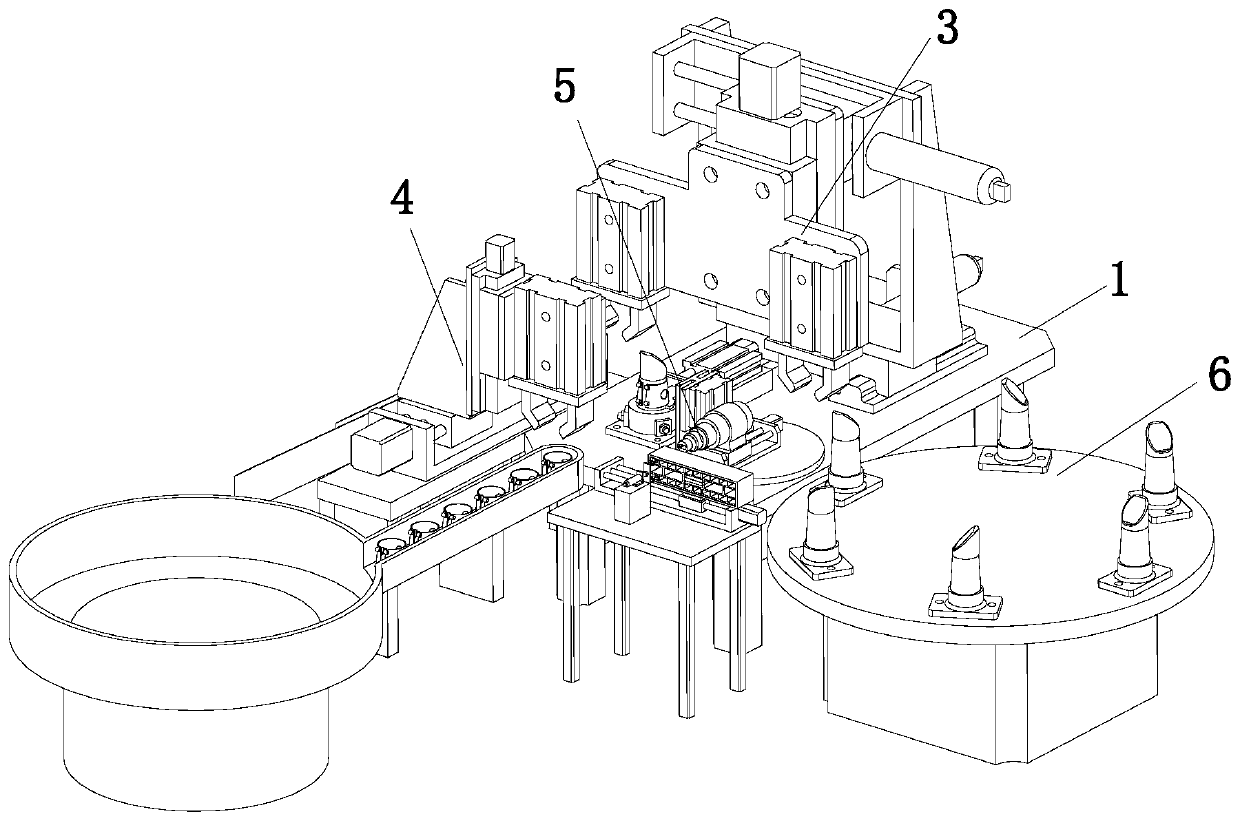

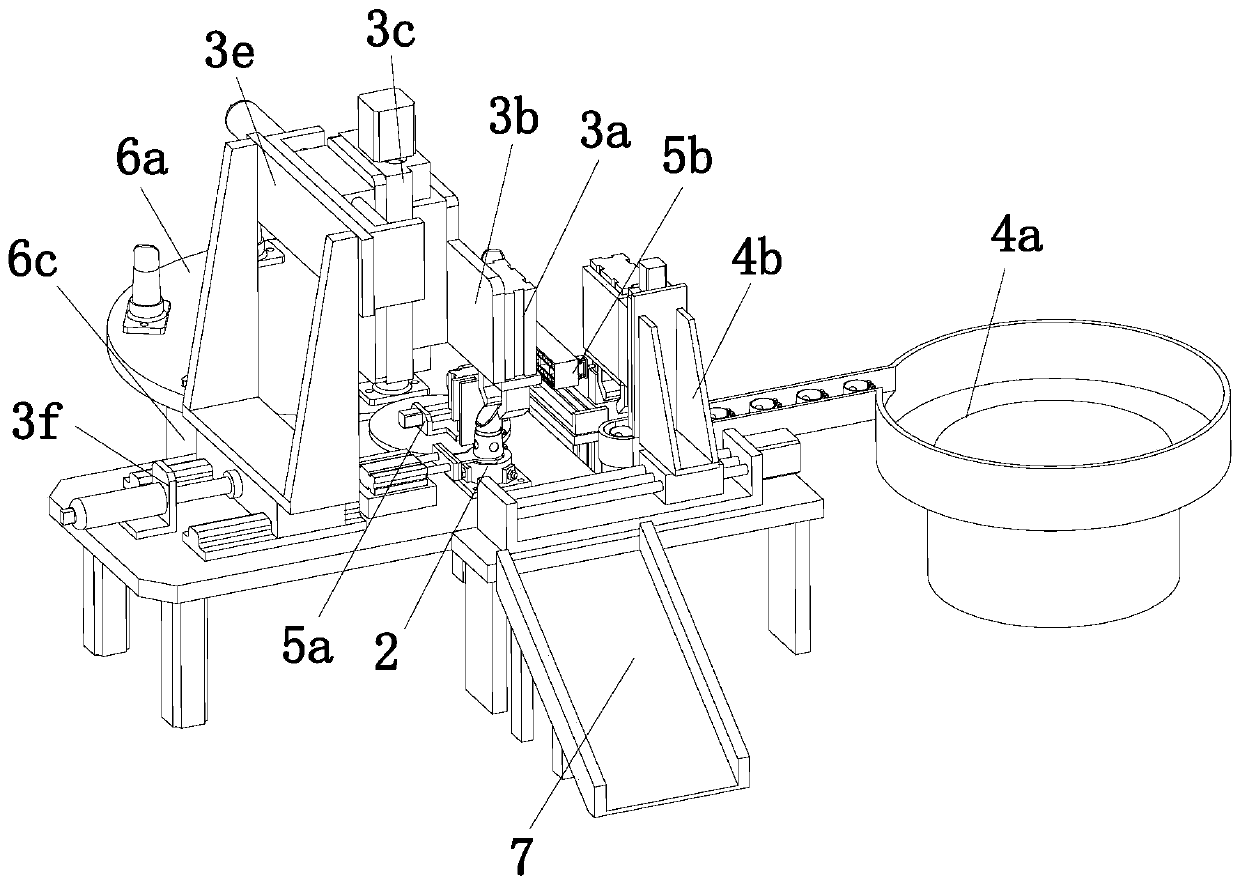

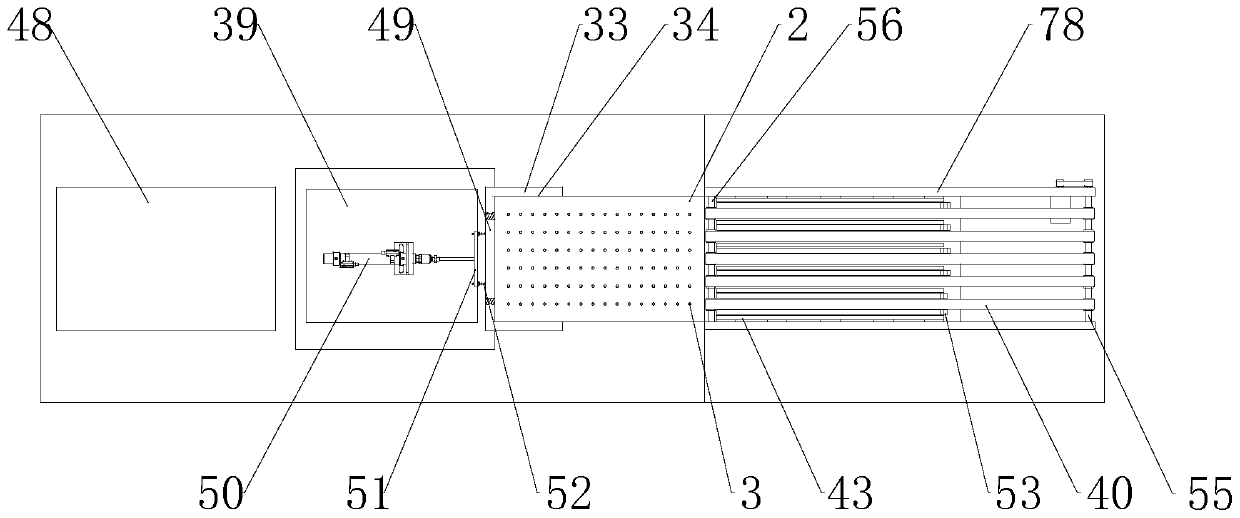

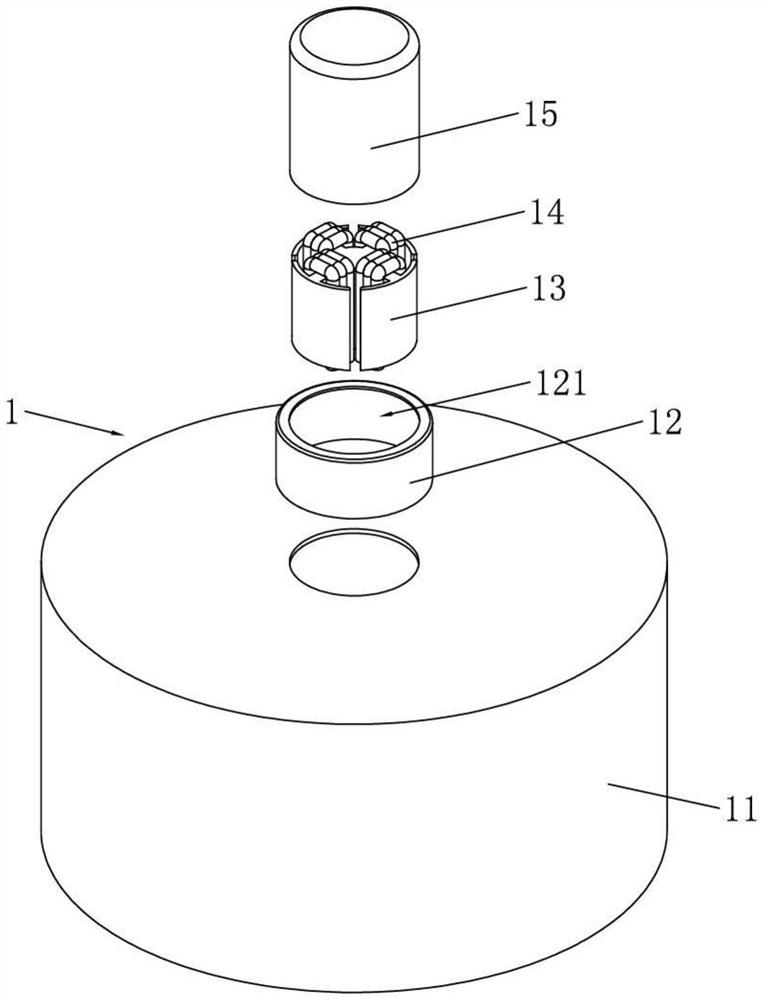

Full-automatic assembling system for adjusting pin of cupboard

InactiveCN104526339AScientific and reasonable structure designFast assemblyMetal working apparatusCouplingEngineering

The invention provides a full-automatic assembling system for an adjusting pin of a cupboard, relates to an assembling system, and aims at solving the problems that when an existing adjusting pin is assembled by a manual manner, the manual assembling is low in efficiency, costs lots of time and force and is high in cost, and meanwhile, a large length difference occurs when manually assembling and screwing a T-shaped part into a cylindrical part, the standardization and unification cannot be reached, and as a result, the packaging and transportation are difficult. The full-automatic adjusting system for the adjusting pin of the cupboard is characterized in that a cylindrical part lifting machine is positioned at one side of an overturning mechanism; a discharging opening in the cylindrical part lifting machine is formed above a conveyor belt in the overturning mechanism; a four-shaft coupling assembling device is positioned at the other side of the overturning mechanism, and a clearance exists between the four-shaft coupling assembling device and the overturning mechanism; two conveyor belts of a T-shaped part arranging machine are positioned at one side of the double-shaft coupling assembling device and a clearance exists between the conveyor belts and a rotating plate mechanism in the four-shaft coupling assembling device; the overturning mechanism and the four-shaft coupling assembling device are respectively electrically connected with a system controller. The full-automatic adjusting system for the adjusting pin of the cupboard is used for assembling the T-shaped part and the cylindrical part.

Owner:HARBIN INST OF TECH

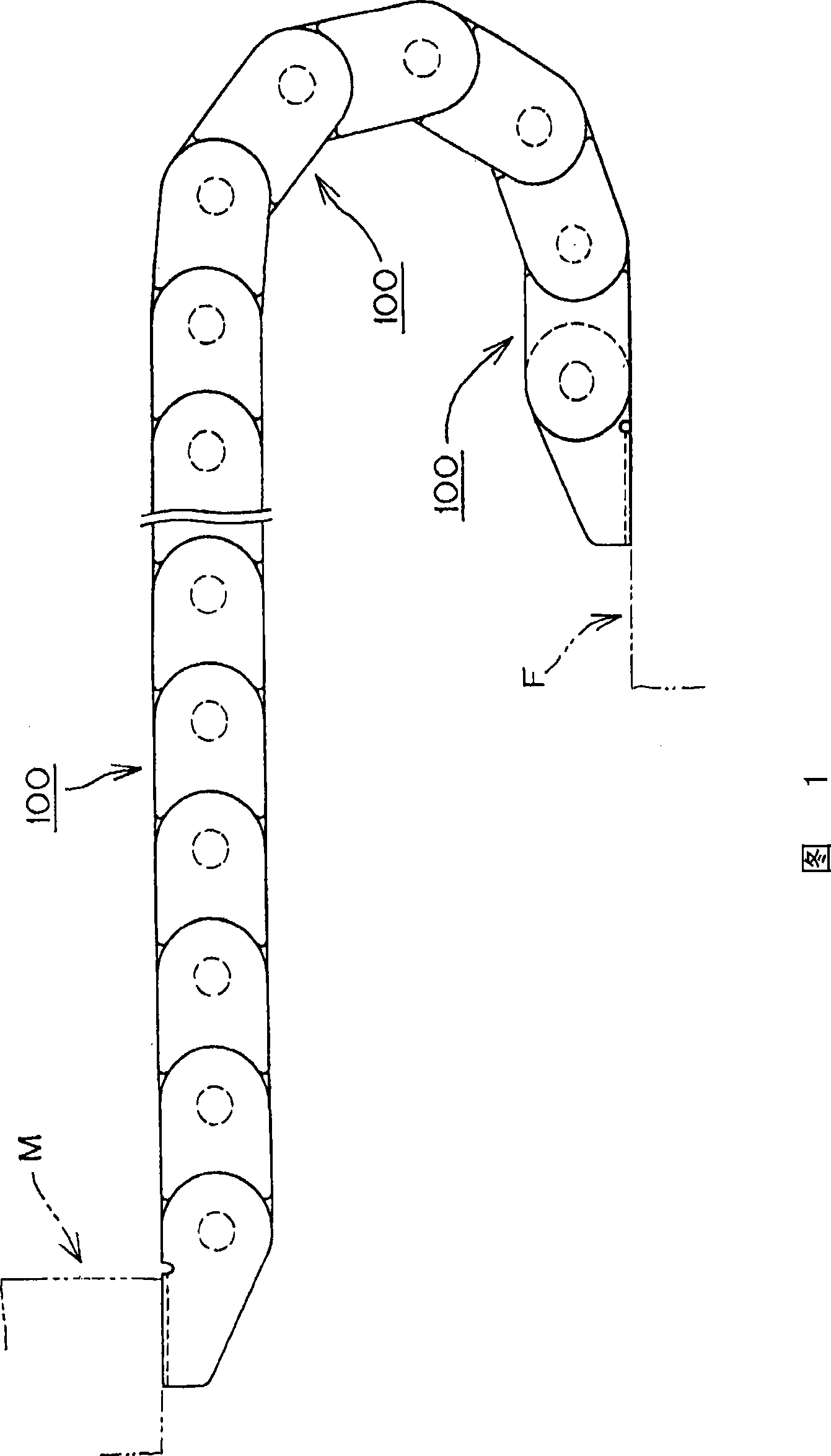

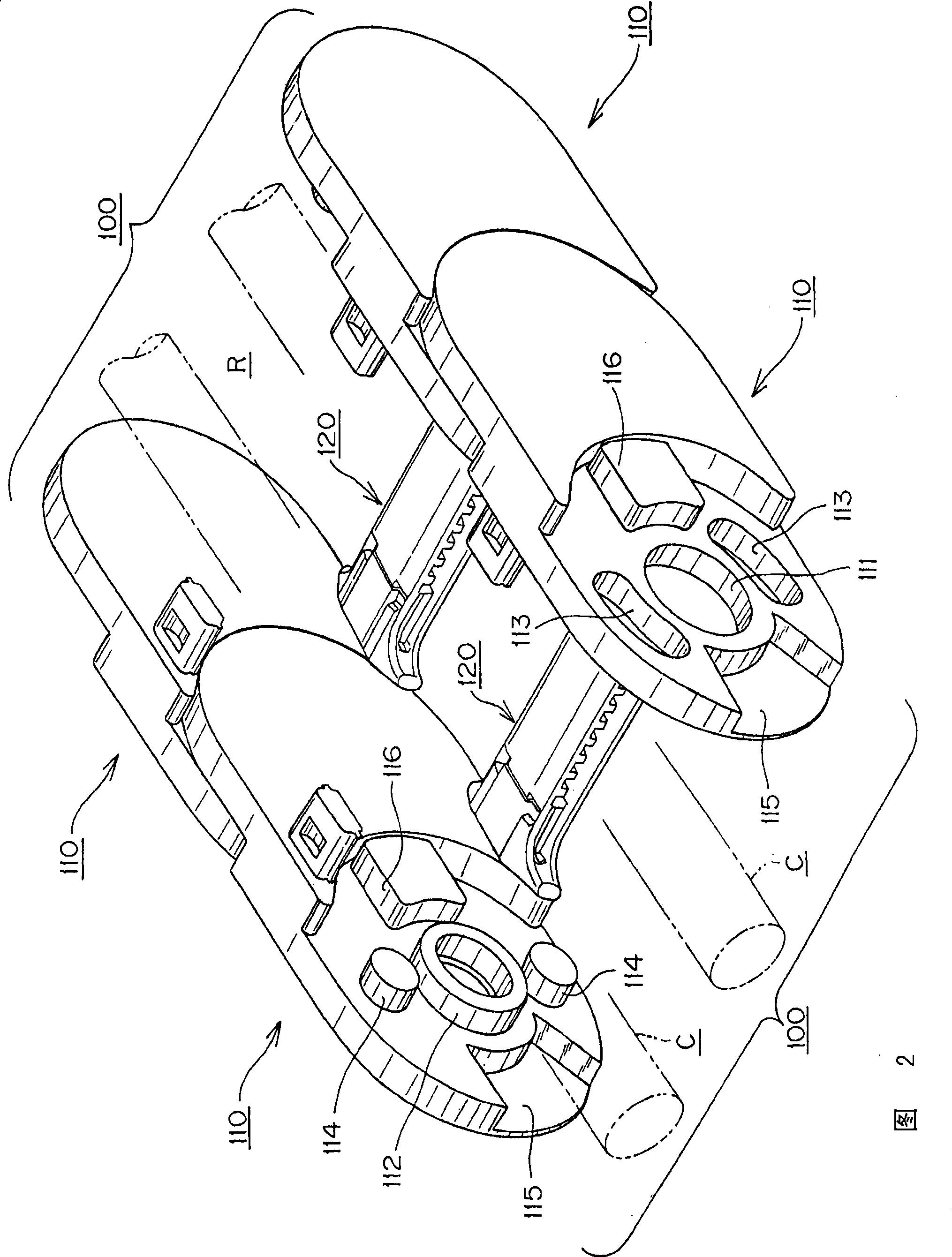

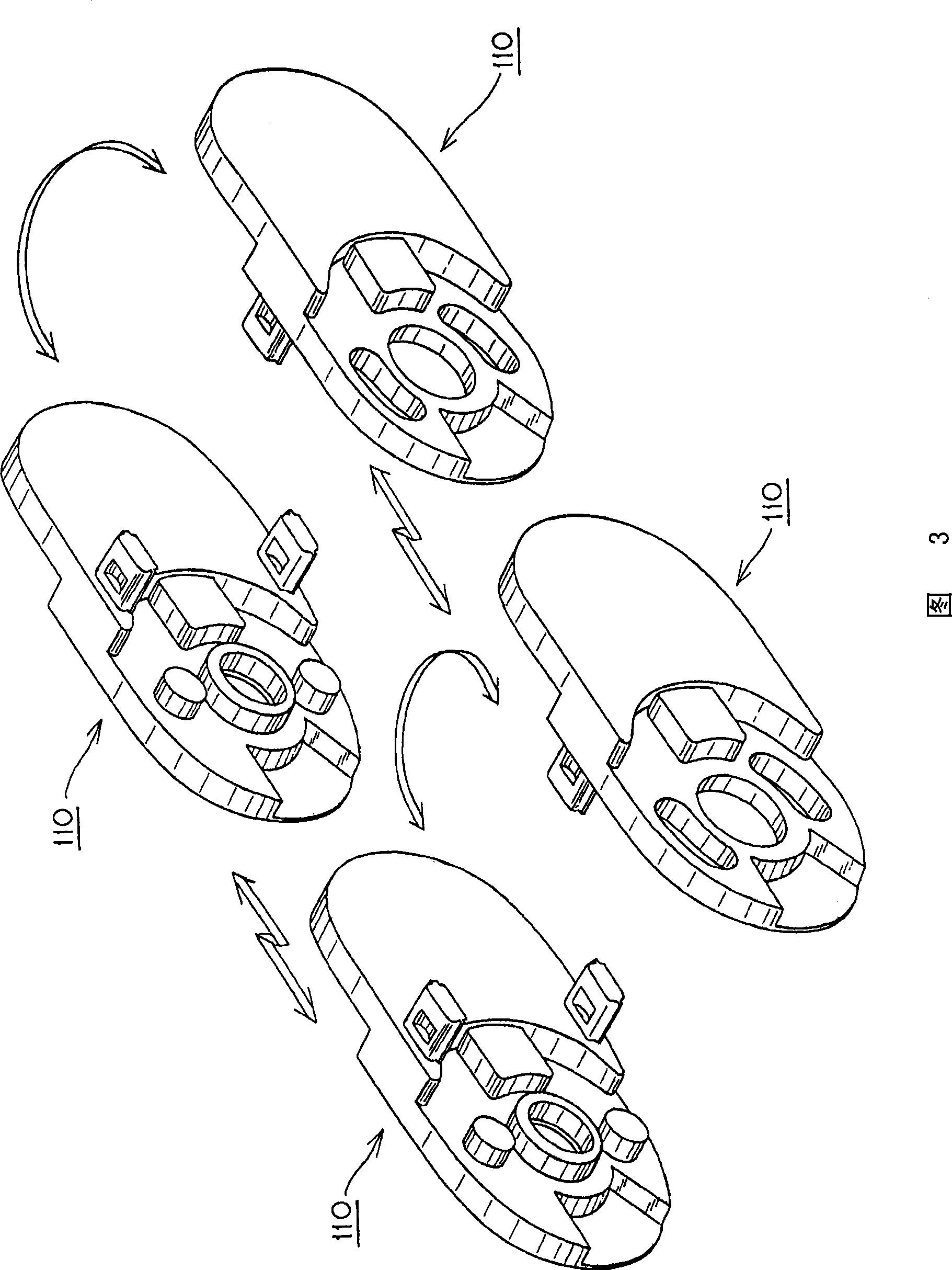

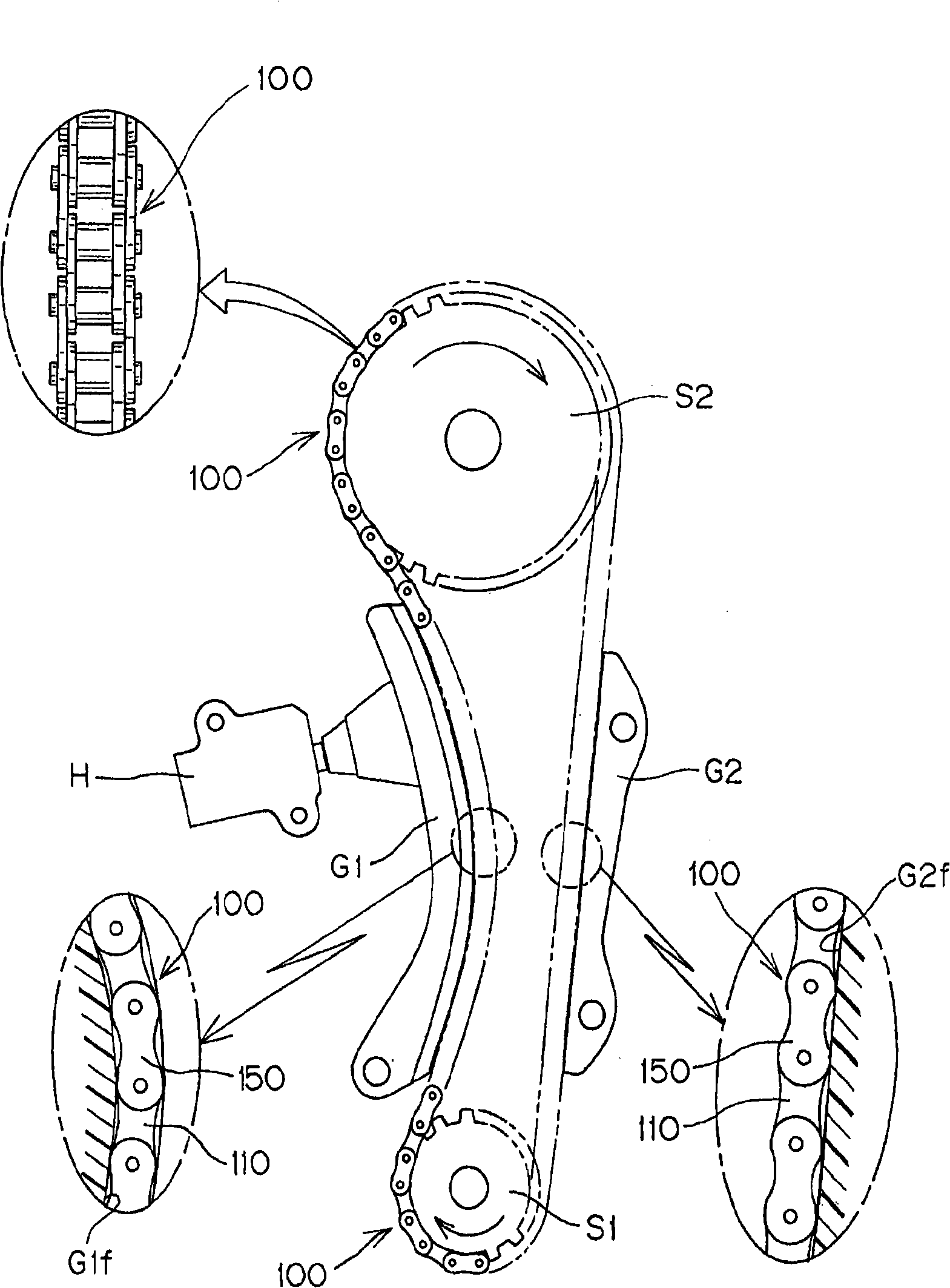

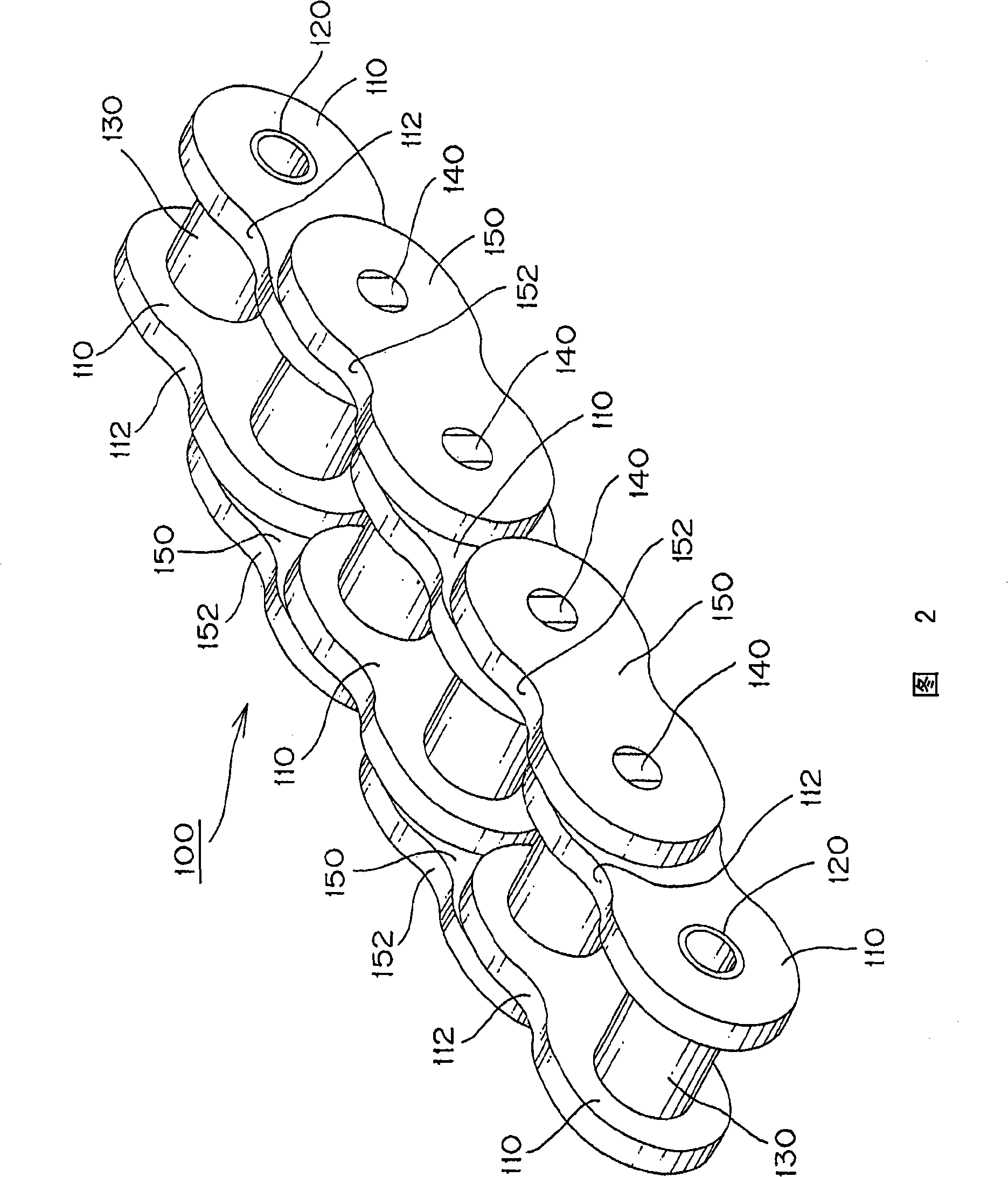

Cable protection and guide device

ActiveCN101363504AProduction cost halvedLow production costHauling chainsHoisting chainsEngineeringSingle plate

The present invention provides a cable protection and guide device. The manufacturing cost for a single link plate used in the cable protection and guide device is reduced by half, link plates have no manufacturing error when connected and assembled and can be assembled randomly at front, back, left and right sides, and the component supply and management is convenient. In the cable protection and guide device (100), connecting plates (120) are arranged cross the curved inner circumference and the curved outer circumference of the right and left spaced link plates (110, 110), and a cable accommodating space (R) protects and guides cables (C) under connection state, wherein a plurality of link plates are connected by curving connecting pins and connecting pin openings at the eccentric positions of the front side portion and the rear side portion along the longitudinal direction of cables. The link plate forms a single plate, such that the link plate can be configured at the front, back, left and right sides of the longitudinal direction of cables.

Owner:TSUBAKIMOTO CHAIN CO

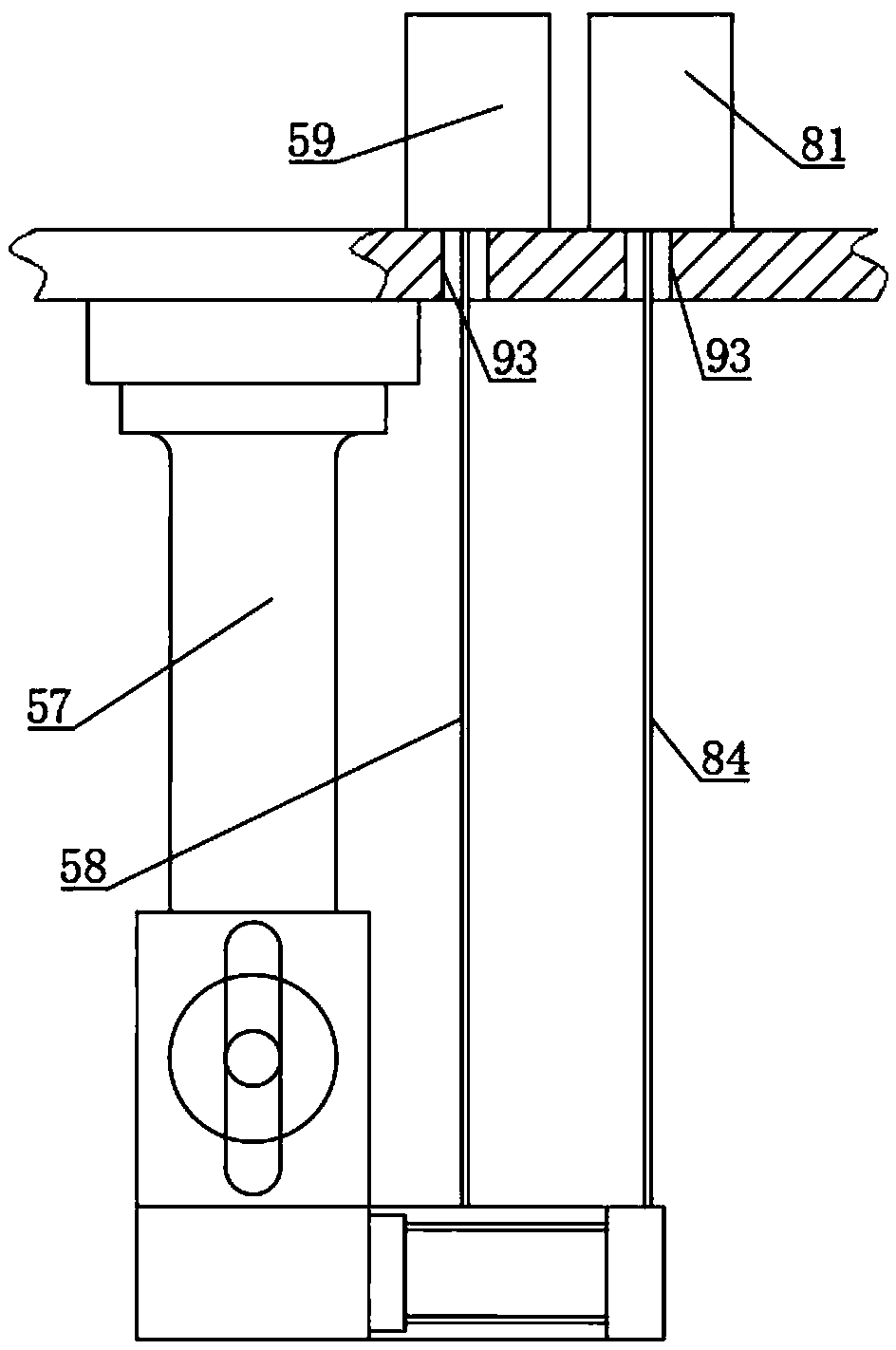

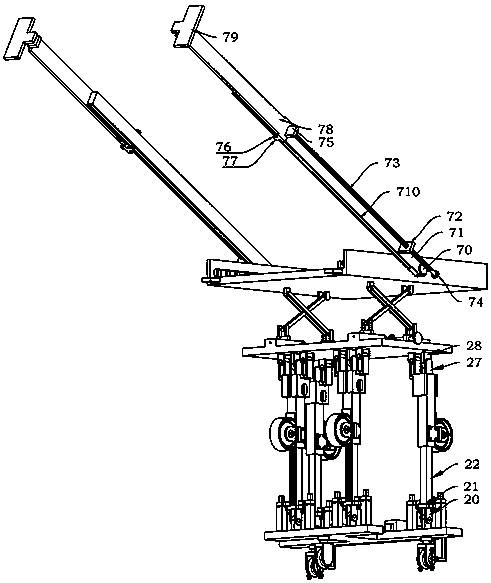

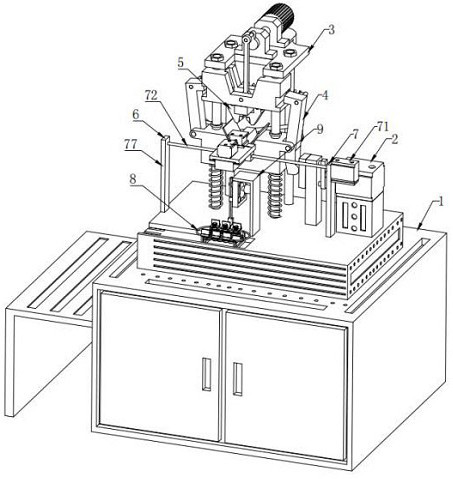

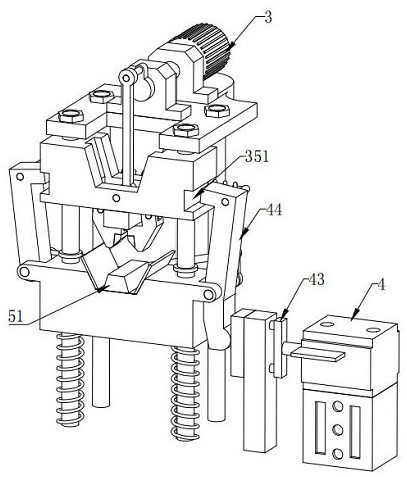

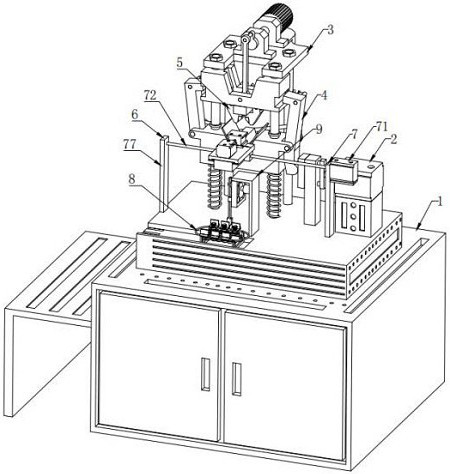

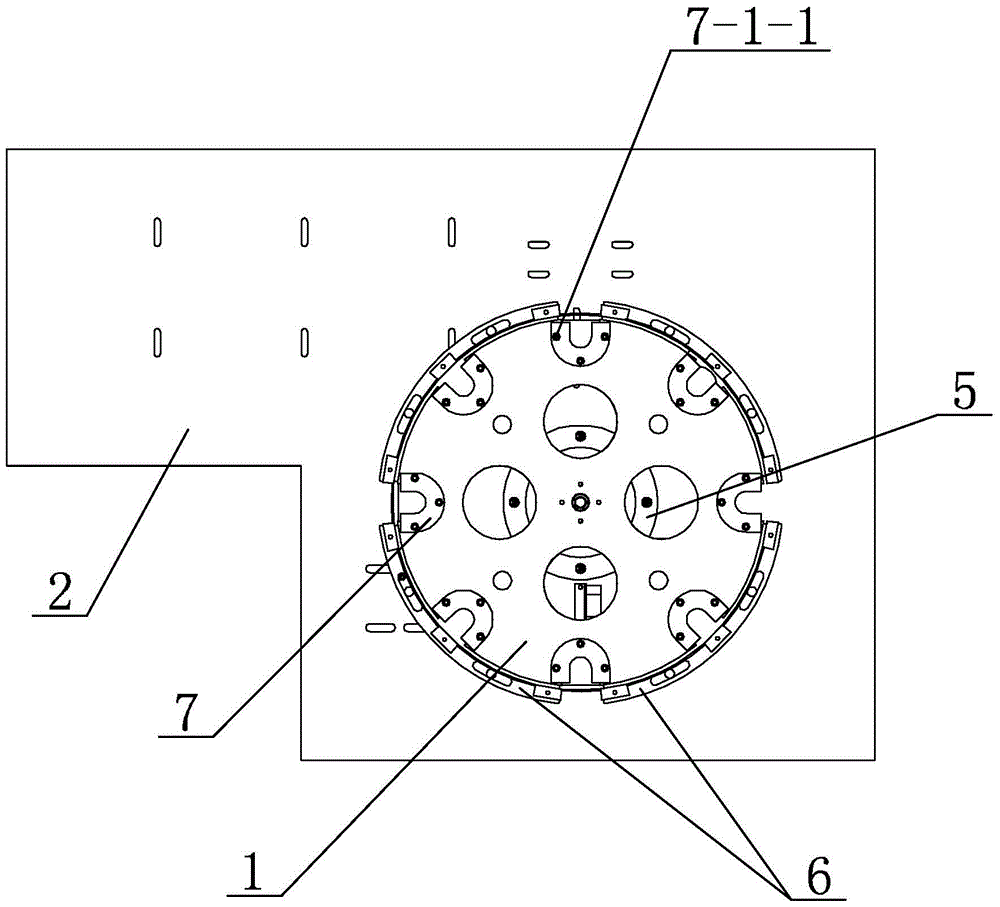

Efficient lock body and spring bolt assembling device

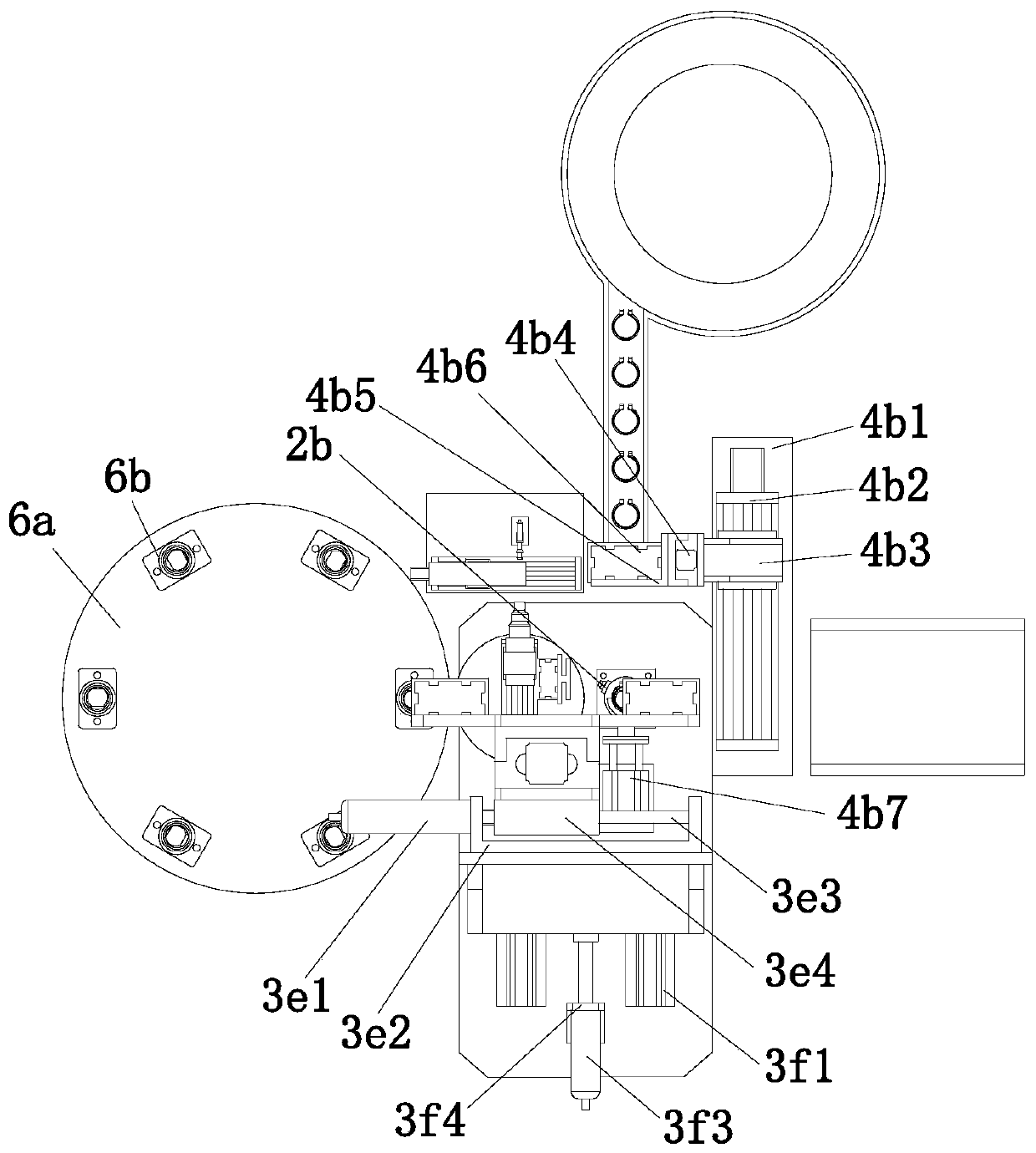

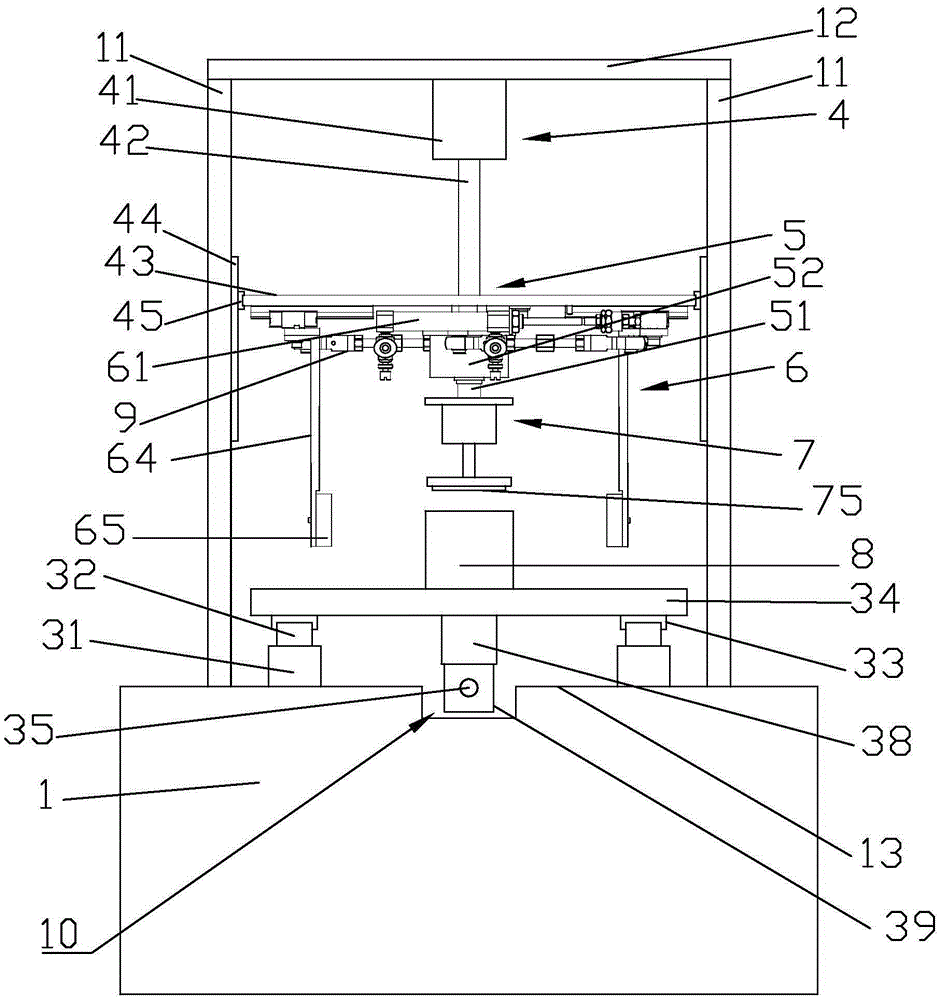

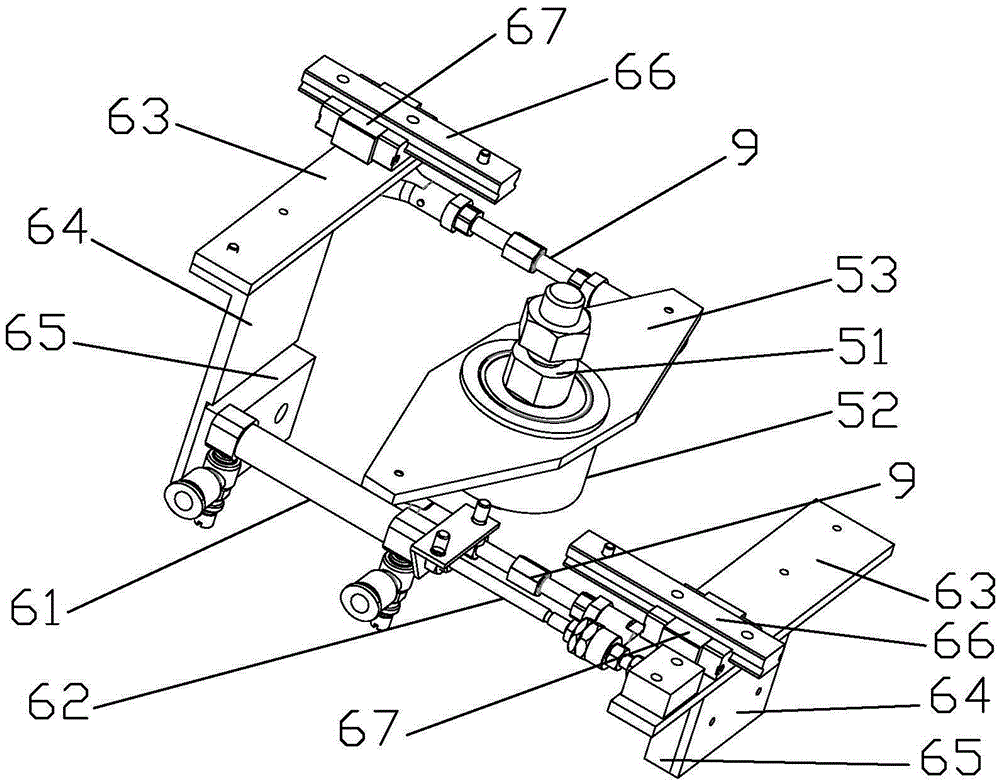

PendingCN109227123ASmall footprintReduce labor intensityAssembly machinesMetal working apparatusSmall footprintRotating disc

The invention discloses an efficient lock body and spring bolt assembling device. The device comprises a supporting frame (1), and a rotating main shaft (2) is arranged in the middle of the supportingframe (1); a servo motor (3) is arranged at one end of the rotating main shaft (2), a multi-station rotating disc (4) is installed on the rotating main shaft (2), and a plurality of annularly and uniformly distributed rotating disc clamps (5) are arranged on the multi-station rotating disc (4); a plurality of machining stations are arranged on the supporting frame (1), and the machining stationsare annularly distributed at the periphery of the multi-station rotating disc (4). The working efficiency can be improved, and the device has the advantages of being low in labor intensity, small in floor area, low in defective percentage, low in labor cost, convenient to use, long in service life, high in installing accuracy and wide in application range.

Owner:黄斌辉

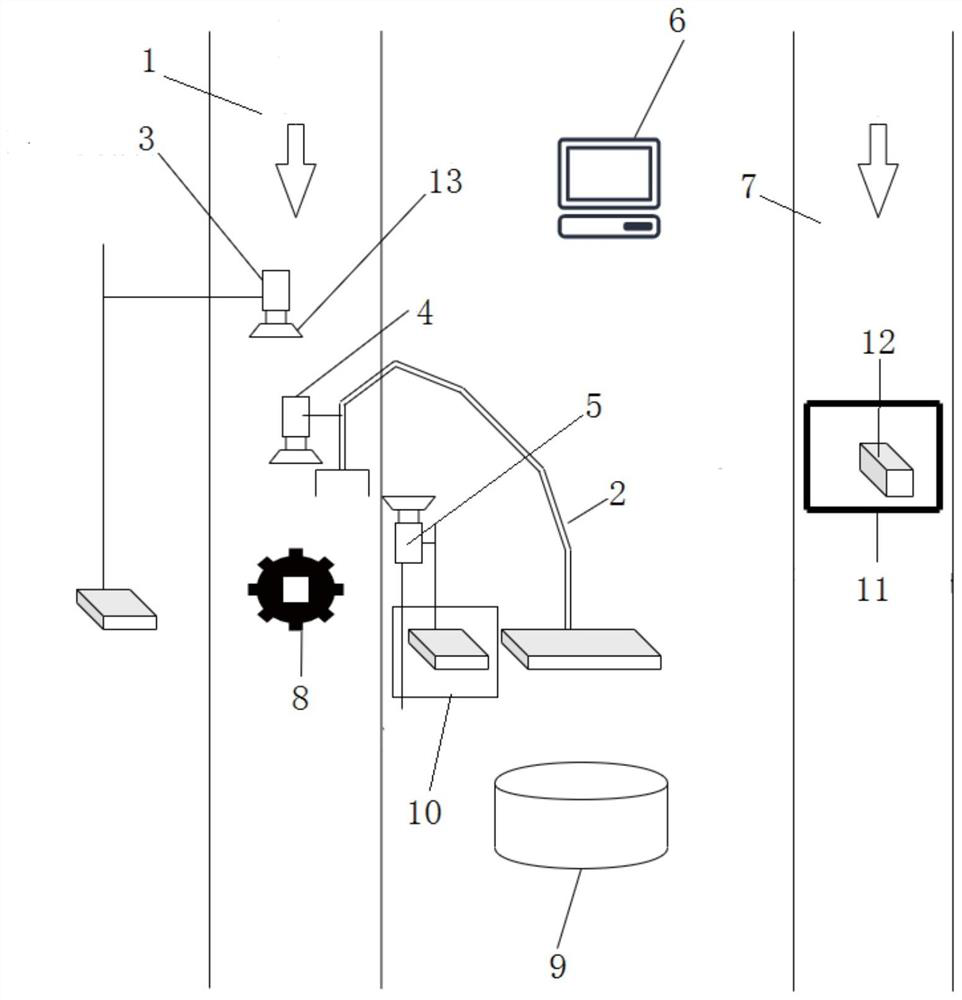

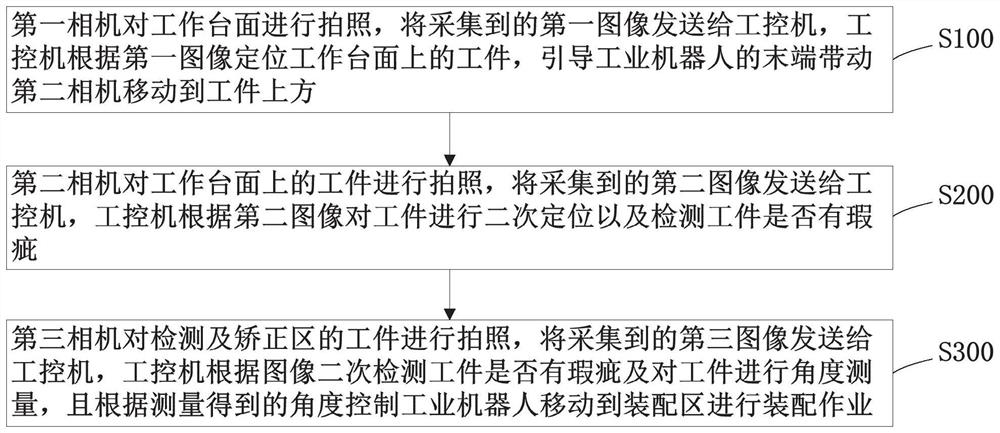

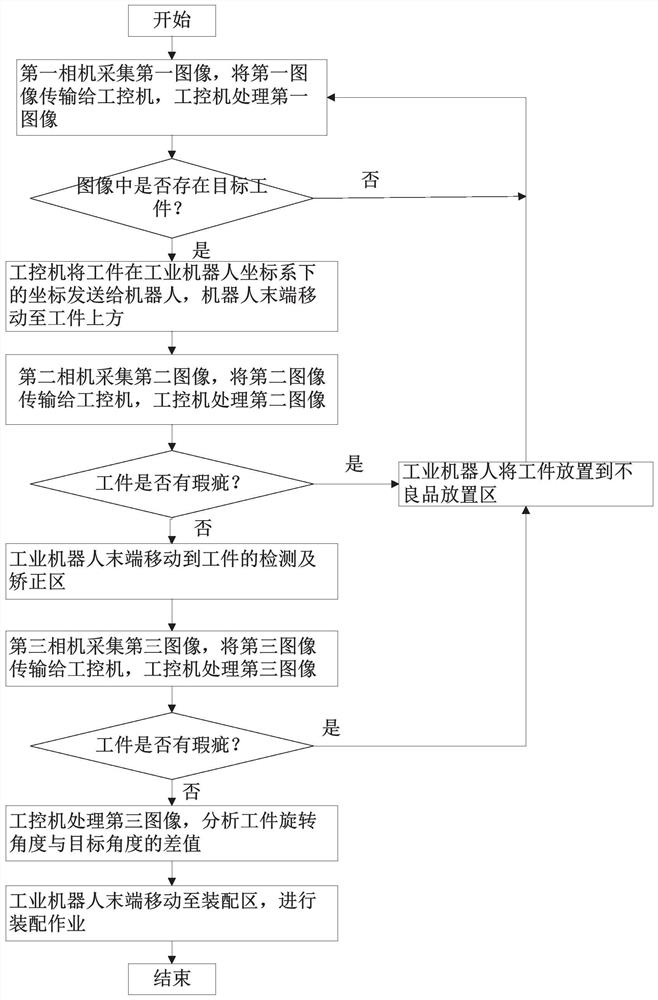

Multi-vision-based detection and assembly system and method

ActiveCN113146172AImprove intelligenceEasy to detectSortingMetal working apparatusMachine visionControl engineering

The invention discloses a multi-vision-based detection and assembly system and method. The system comprises an industrial robot, a first camera, a second camera, a third camera and an industrial personal computer, wherein, the industrial personal computer is connected with the industrial robot and used for positioning a workpiece on a working table according to a first image shot by the first camera, and guiding the tail end of the industrial robot to drive the second camera to move above the workpiece; used for carrying out secondary positioning on the workpiece according to a second image shot by the second camera and detecting whether the workpiece has flaws; and used for secondarily detecting whether the workpiece has flaws or not according to a third image shot by the third camera, carrying out angle measurement on the workpiece and controlling the industrial robot to move to an assembly area to carry out assembly operation according to the measured angle. According to the system, workpiece detection and assembly are automatically completed by combining machine vision with the industrial robot, the production efficiency is improved, and the defective rate is reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

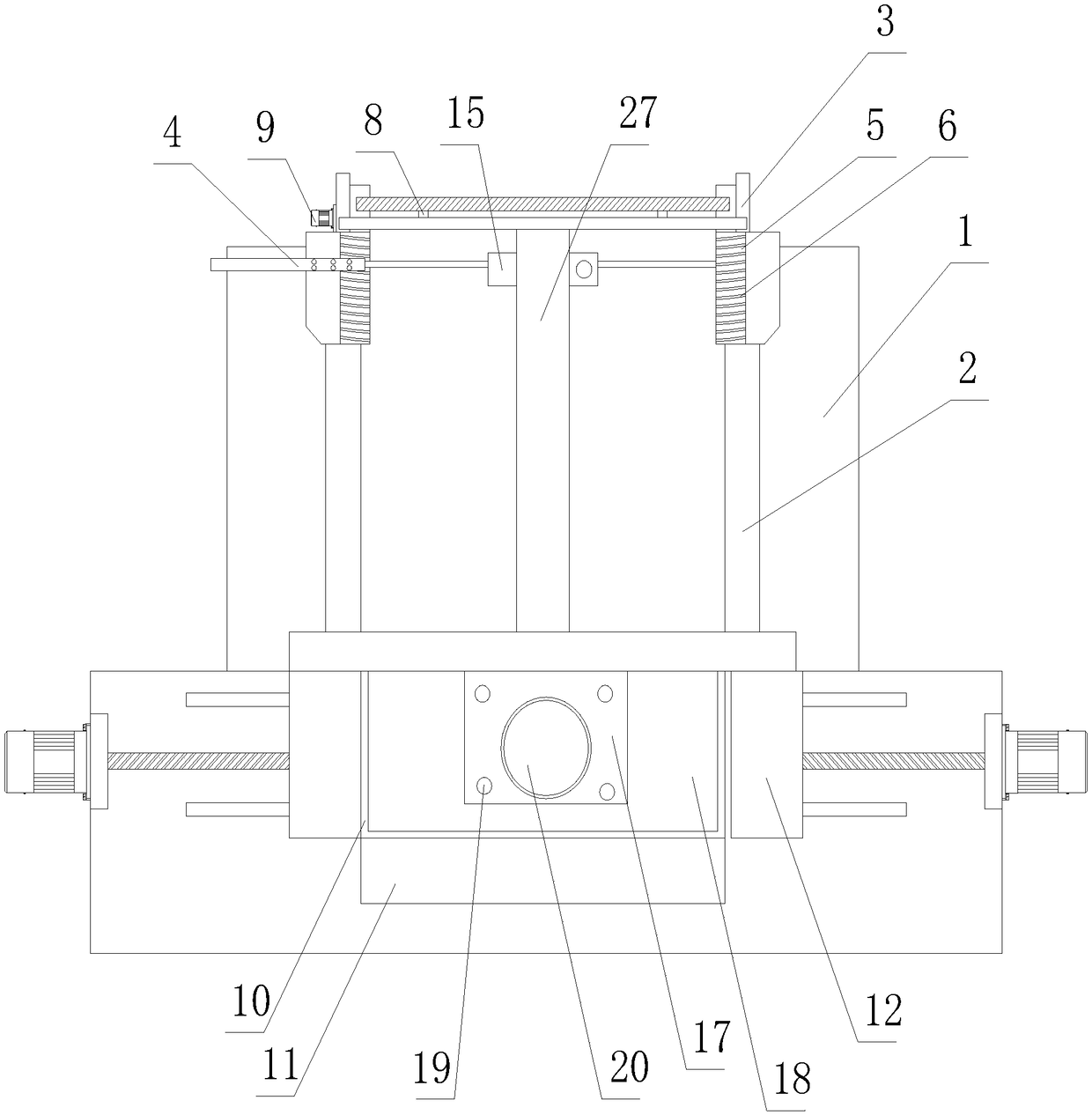

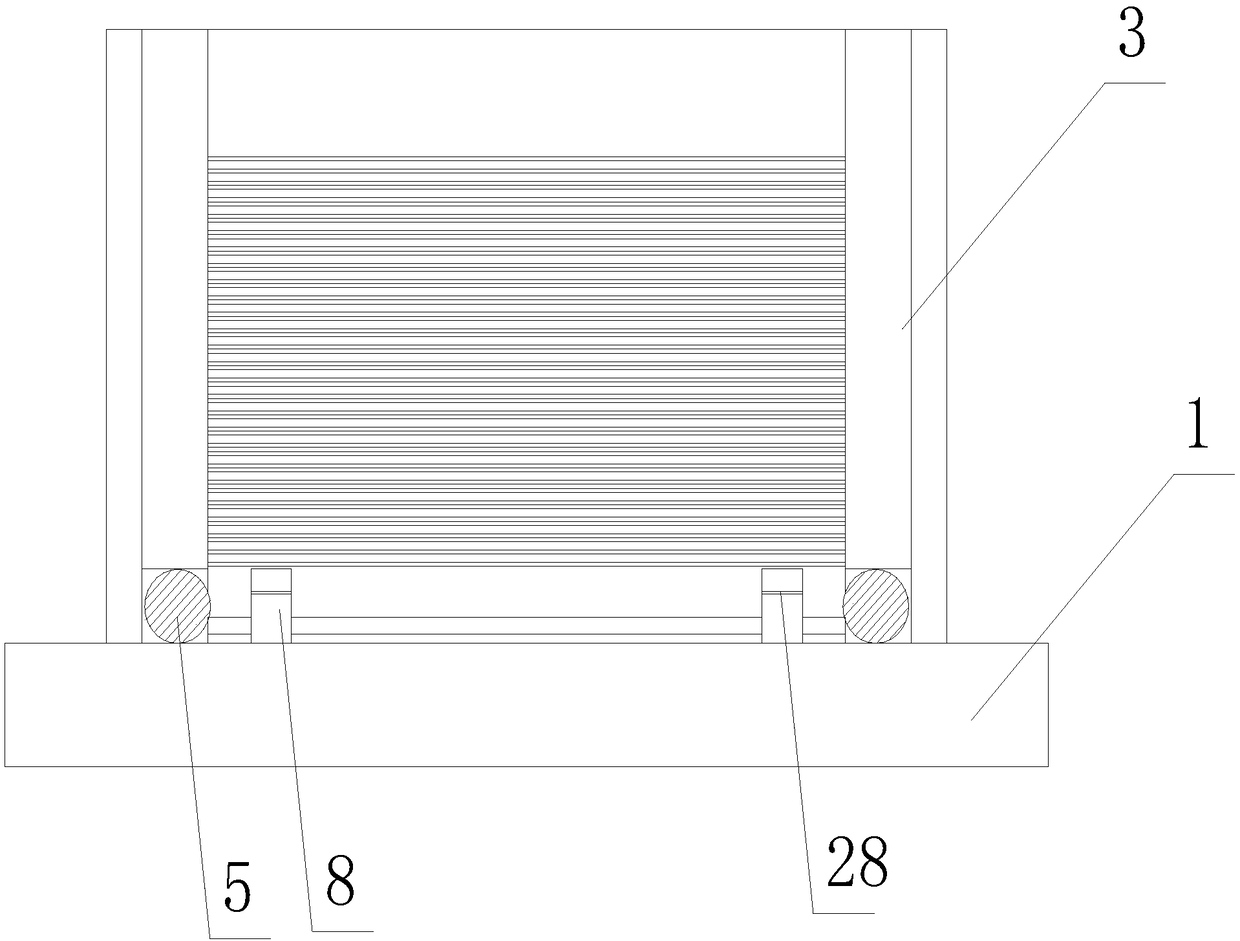

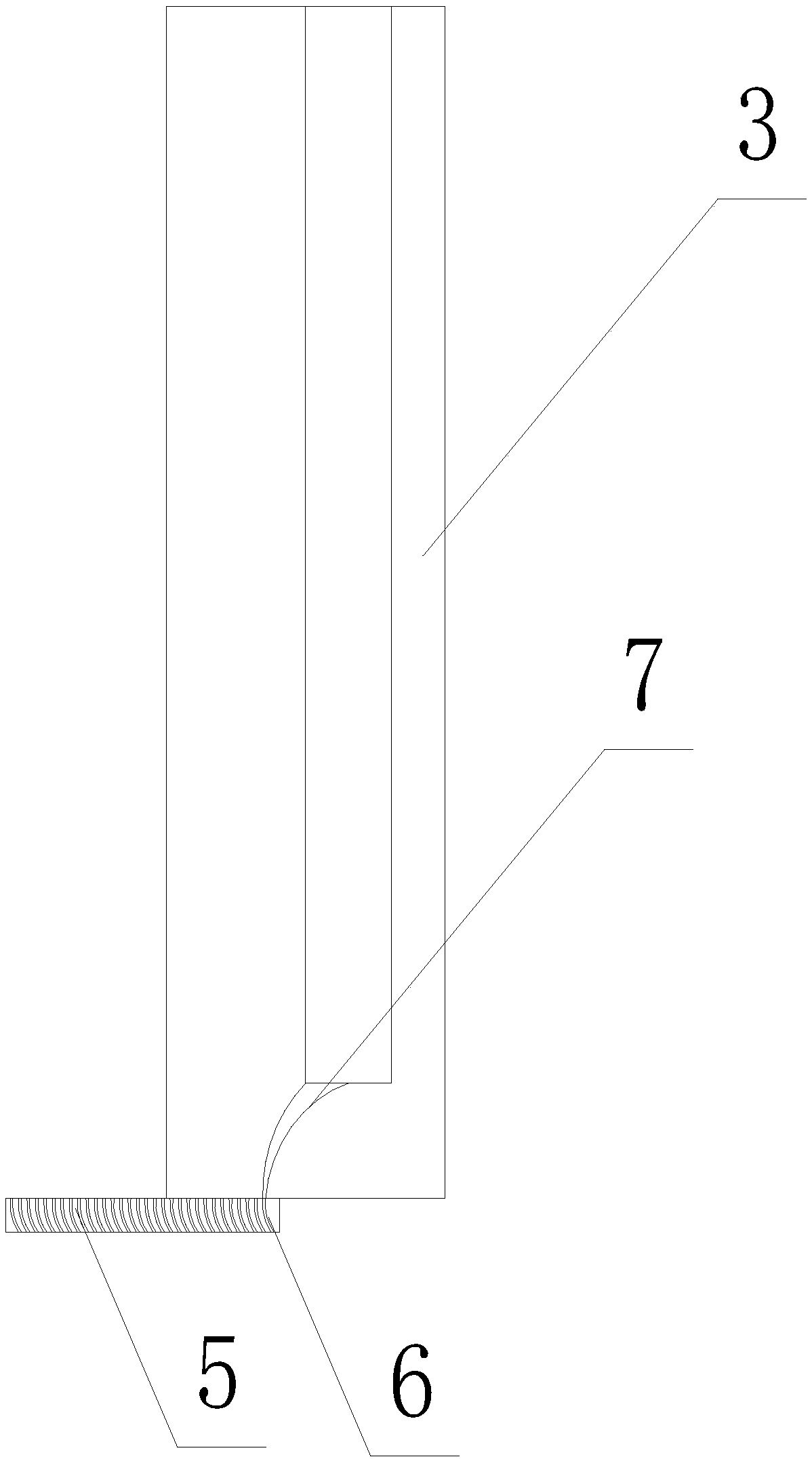

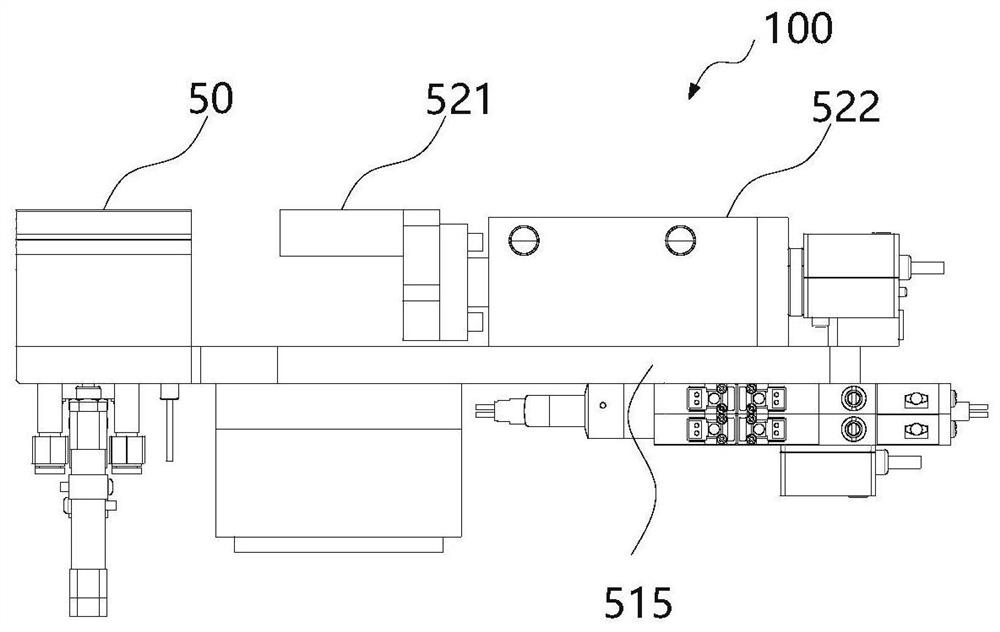

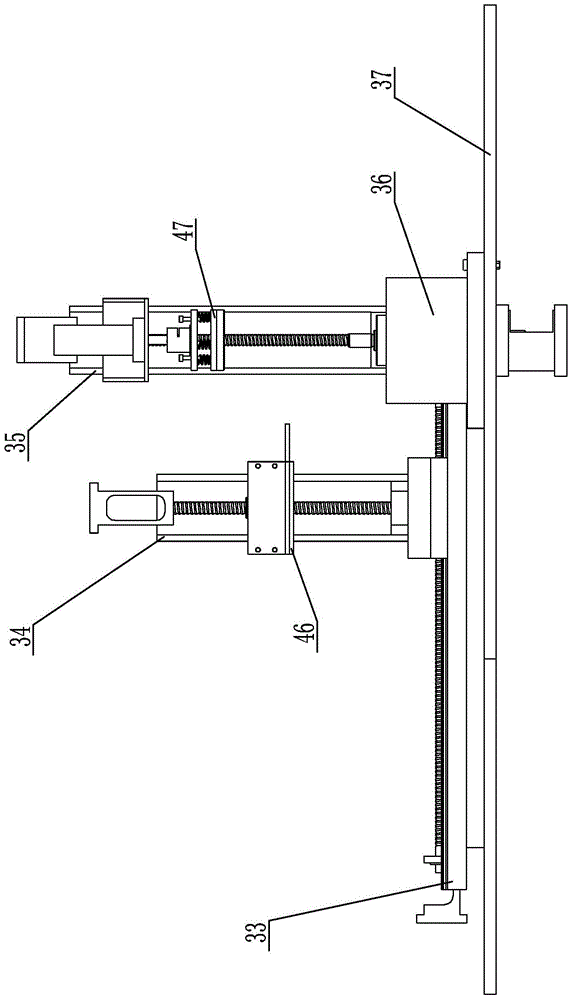

Automatic assembly device for assembling die-locking oil cylinder

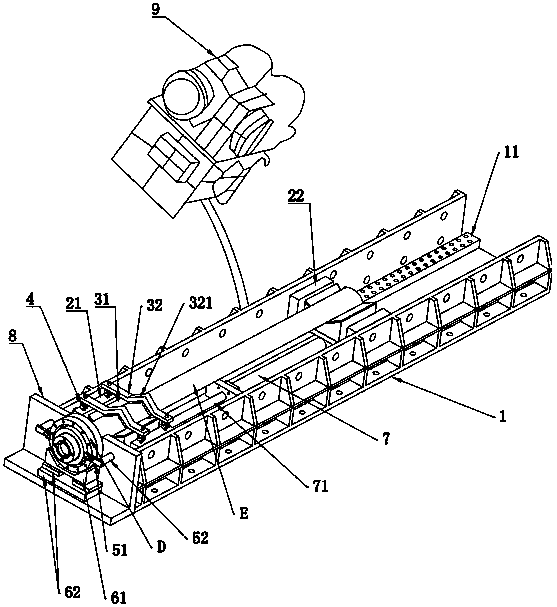

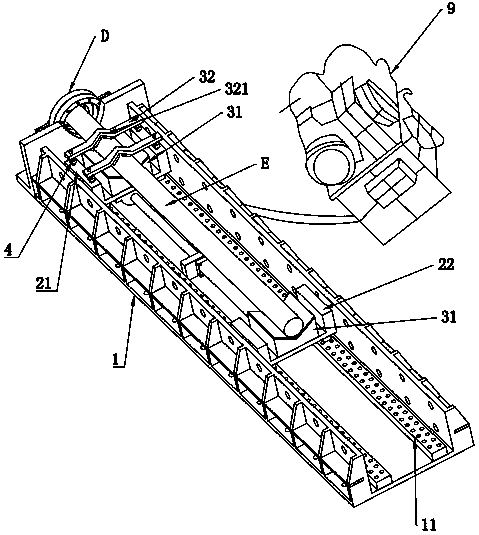

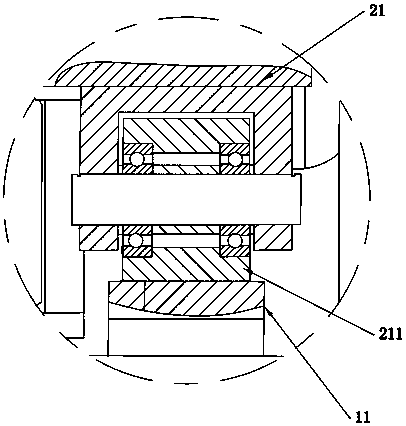

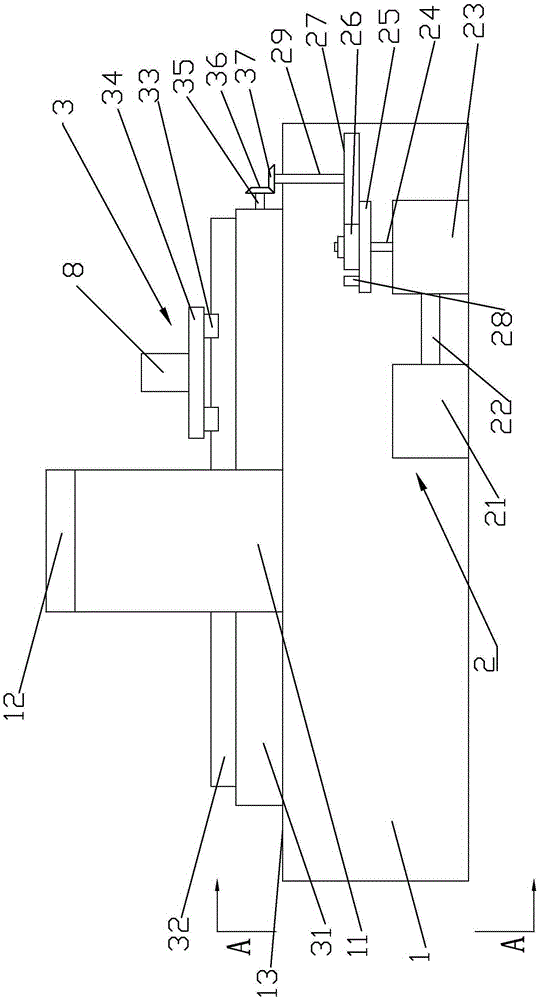

ActiveCN105345437ARealize assembly workRealize safe operationMetal working apparatusPush pullEngineering

The invention discloses an automatic assembly device for assembling a die-locking oil cylinder. The automatic assembly device comprises a rack, wherein one end of the rack is detachably connected with the die-locking oil cylinder; the other end of the rack is provided with a feed mechanism for assembling a pull rod of the die-locking oil cylinder; the feed mechanism comprises a slide mechanism slidably connected with the rack; the slide mechanism is controlled by a drive mechanism which is arranged on the rack; and the pull rod is fixed on the slide mechanism. Slide of the slide mechanism on the rack is realized through the drive mechanism, thus assembly work for the pull rod of the die-locking oil cylinder fixed on the rack is realized; and the existing manner of enabling the pull rod to penetrate through the die-locking oil cylinder by virtue of oblique-pulling of a travelling crane and pushing-pulling of a forklift is replaced by the manner, thus a safe operation in assembly for the pull rod of the die-locking oil cylinder is realized, the labour is reduced, and the effect of increasing the working efficiency is achieved.

Owner:HAITIAN PLASTICS MACHINERY GRP

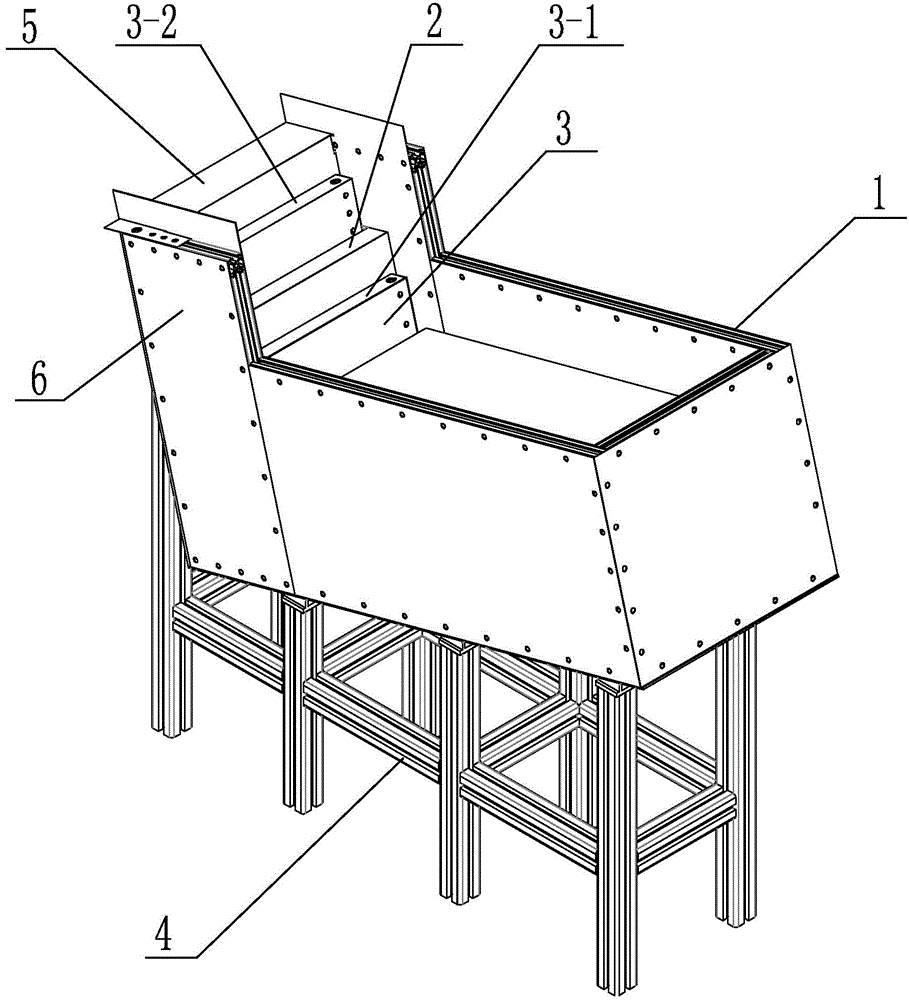

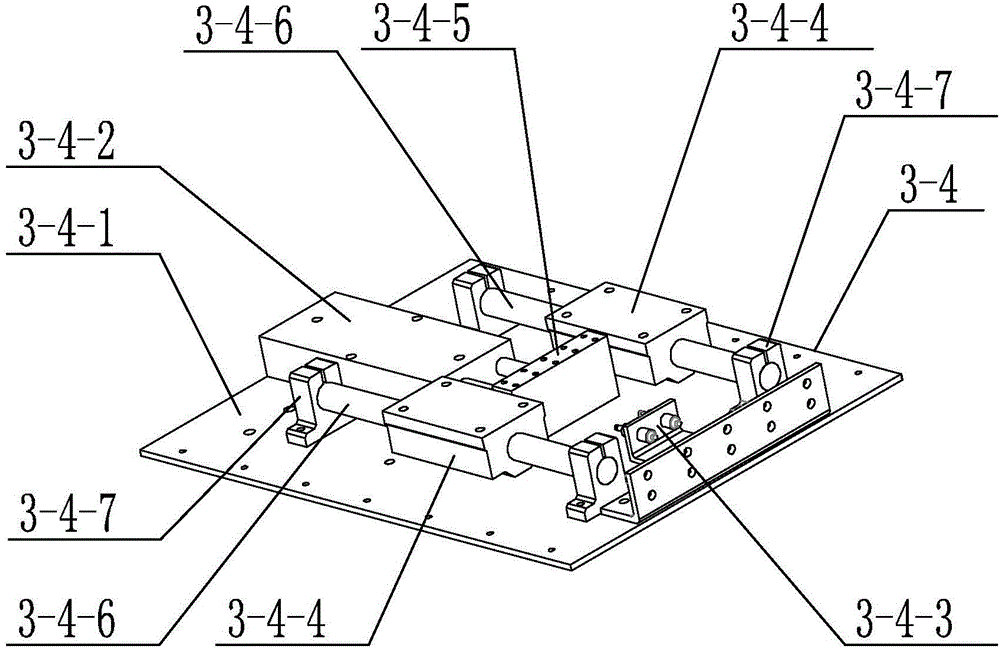

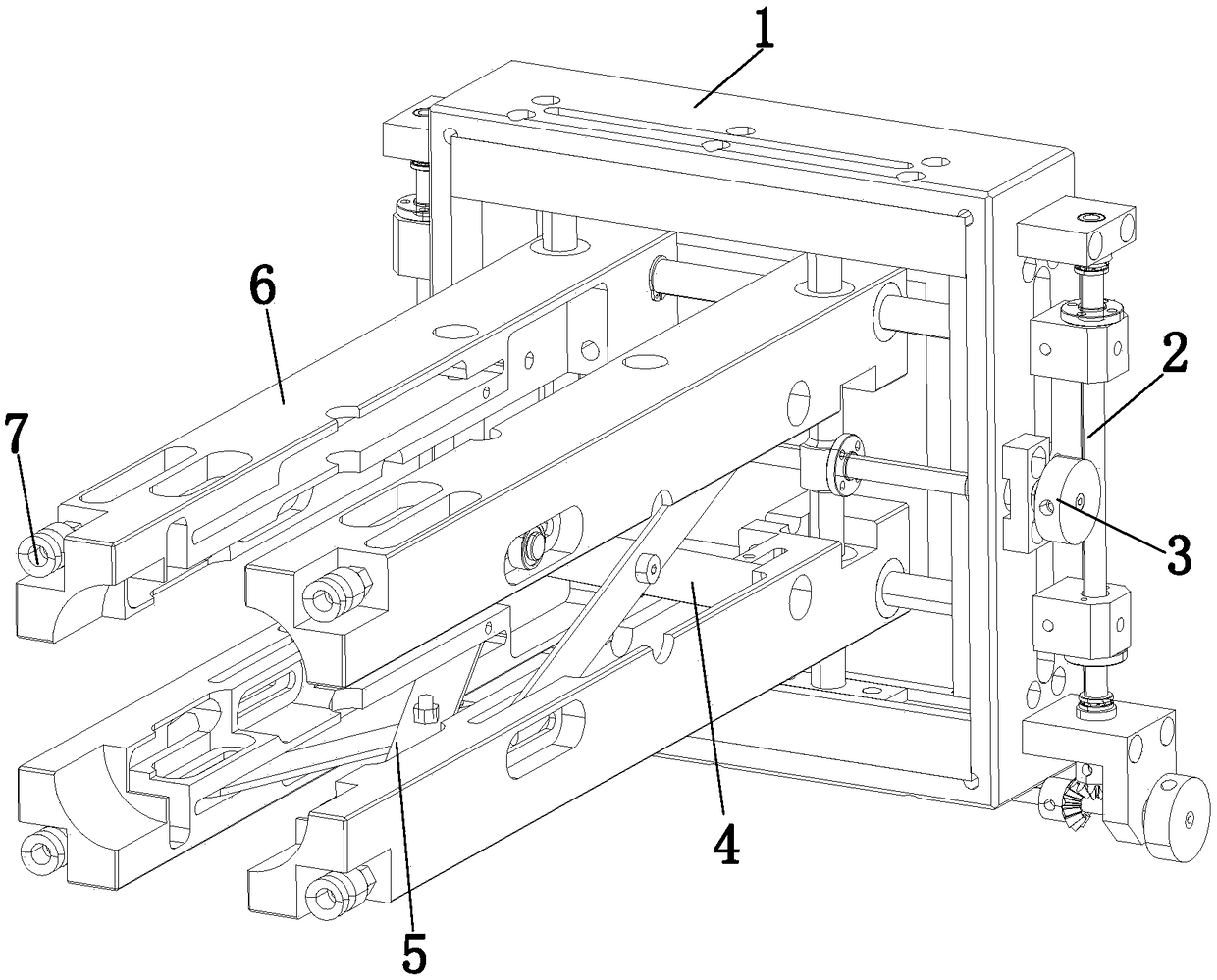

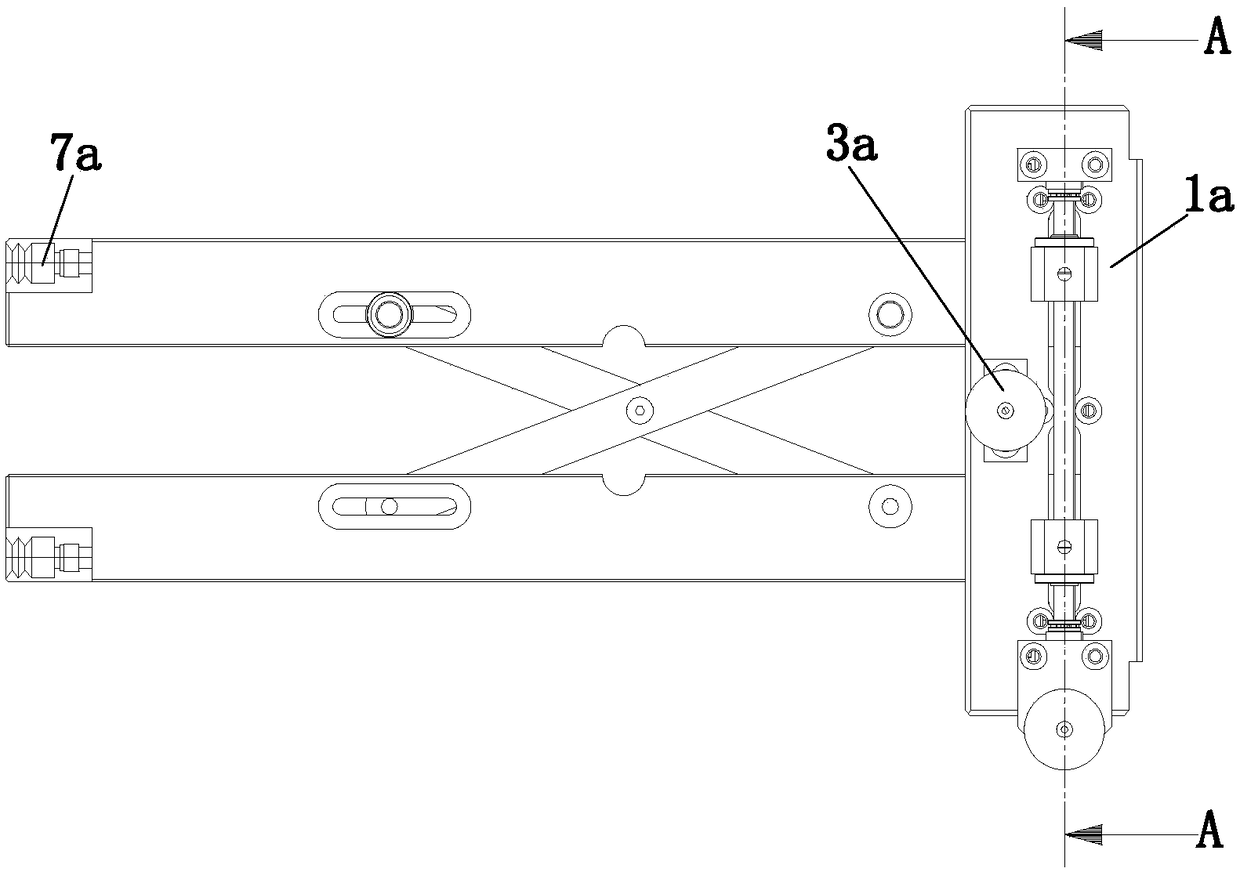

Adjusting mould for fixing to-be-assembled barrel boxes

PendingCN109094111AShorten the timeRealize assembly workPaper-makingBox making operationsEngineeringMechanical engineering

The invention relates to the technical field of processing and packaging equipment, in particular to an adjusting mould for fixing to-be-assembled barrel boxes. The adjusting mould comprises a positioning device, longitudinal adjusting devices, transverse adjusting devices, a longitudinal telescopic device, a transverse telescopic device and a limiting forming device, wherein the end portions of the longitudinal adjusting devices and the transverse adjusting devices can be movably arranged on the positioning device, the longitudinal telescopic device is arranged between the longitudinal adjusting devices in a vertical state, the transverse telescopic device is arranged between the transverse adjusting devices in a horizontal state, one end of the limiting forming device can be slidably arranged on the longitudinal adjusting devices and the transverse adjusting devices, and a material suction device is arranged at the end, far away from the positioning device, of the limiting forming device. According to the adjusting mould for fixing the to-be-assembled barrel boxes, assembly operation of different assembling packaging boxes is realized, the mould can be adjusted by screw rods leftand right and up and down, the time and the cost are saved for customers, and mould changing is more convenient and faster.

Owner:亚晟(东莞)自动化设备科技有限公司

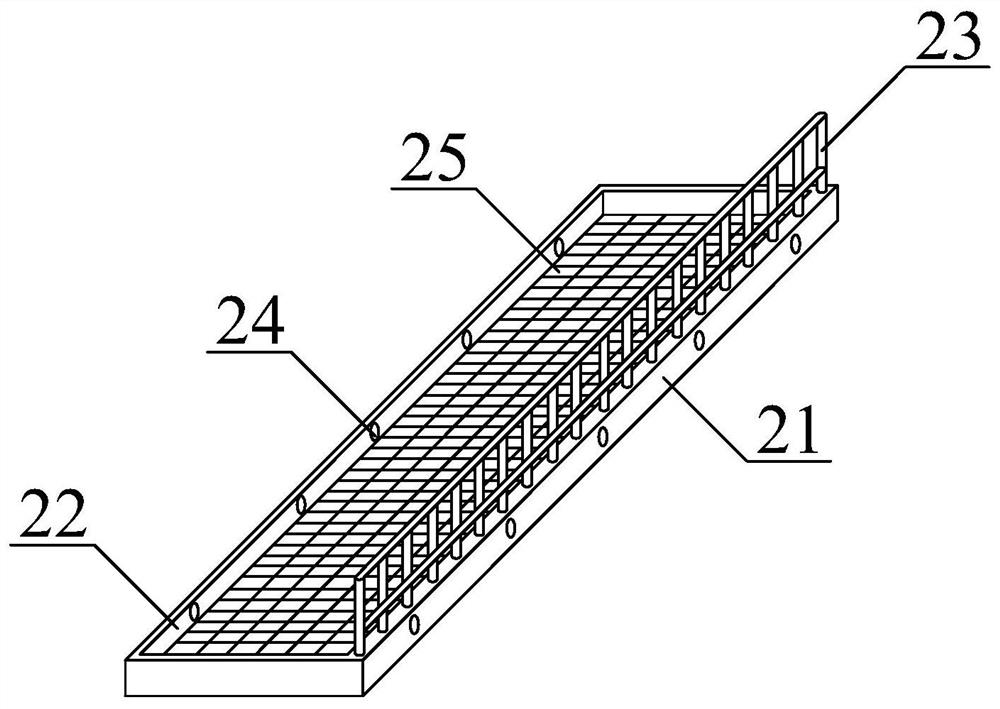

Modular electric control cabinet assembling vehicle

ActiveCN111313300AEasy to realize folding operationIncrease flexibilitySwitchgearLow voltageStructural engineering

The invention discloses a modular electric control cabinet assembling vehicle which comprises a sliding unit, a telescopic unit, a lifting unit and a locking unit used for locking the lower end of thetelescopic unit so that the telescopic unit can be perpendicular to an I-shaped bottom plate. The modular electric control cabinet assembling vehicle further comprises a clamping and locking unit which is used for locking the upper end of the telescopic unit to enable the telescopic unit to be perpendicular to an upper plate, a placing table which is used for placing an electric control cabinet assembling module, a traction unit which is used for locking the position between an electric control cabinet and an assembling vehicle, a sliding locking unit which is used for locking the sliding assembly, a telescopic unit which is used for coarse adjustment of the height of the placing table, and a lifting unit which is used for fine adjustment of the placing table. Short-distance transportation of high-low voltage control modules can be carried out; the assembling vehicle can be used as an assembling platform when high-low voltage control modules are assembled; transportation and assembling of high-low voltage control modules are facilitated; folding can be performed; on-site assembling operation of the electric control cabinet is well achieved; the assembling efficiency of the electric control cabinet is improved; the assembling vehicle can adapt to assembling operation of electric control cabinets of different heights; and the application range is expanded.

Owner:CHINA NUCLEAR ELECTRICAL CO LTD

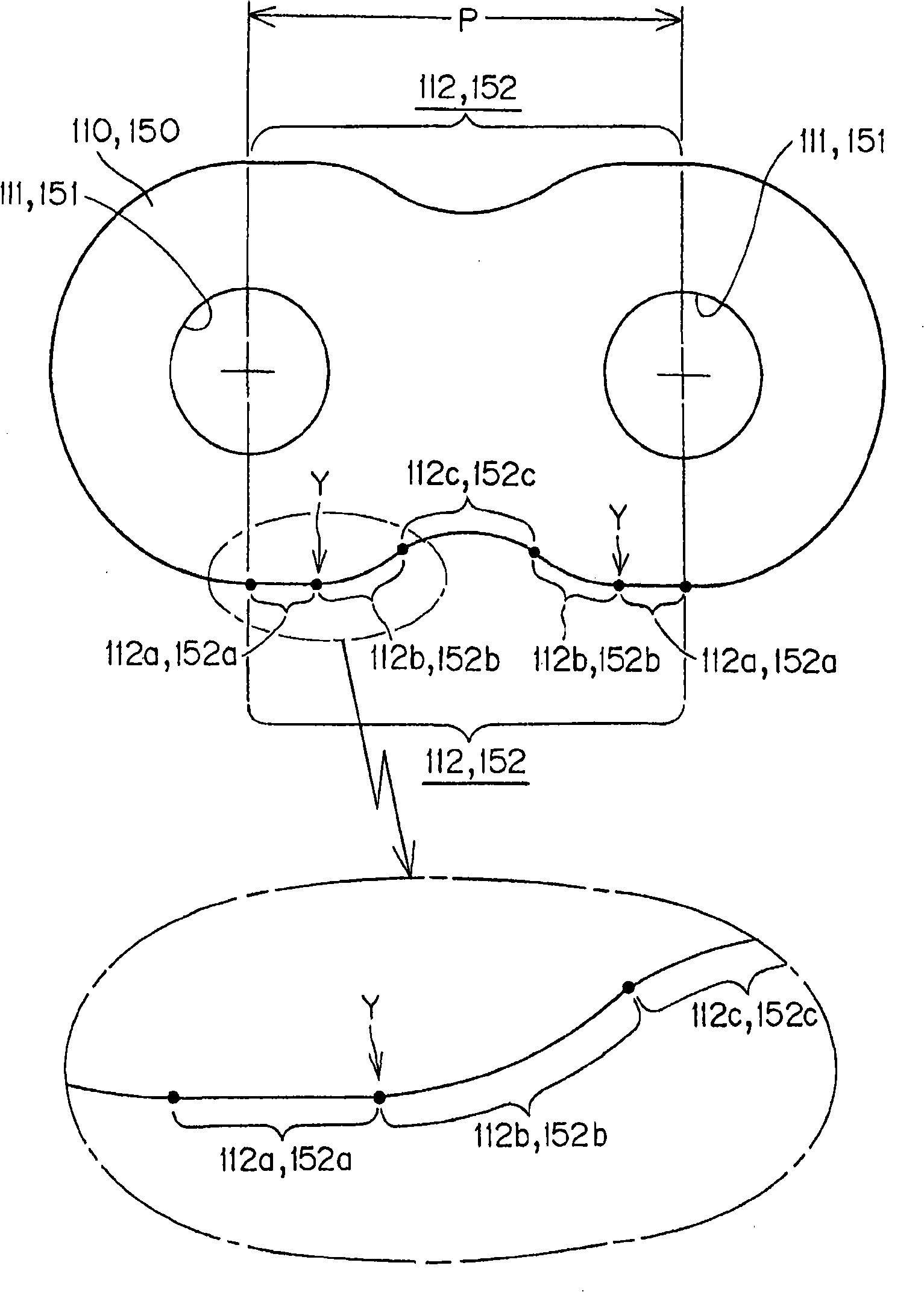

Transmission chain for use in engine

provided is a transmission chain for an engine, which alleviates plunge relative to a hump bending guide surface to cause an orbit stable, and increases intension of a plate meeting with fatigue ruption caused by easy concentration of strengthening force of the chain, and saves lubricating oil reliably between a chain guide and the plate to bring into play excellent durability. The transmission chain for an engine (100) is disclosed, wherein sliding contact parts (112, 152) of a guide of an inner plate (110) and an outer plate (150) are composed of a pair of front and rear flat surfaces (112a, 152a), a pair of front and rear plate hump curved surfaces (112b, 152b) and an lubricating oil holding curved surfaces (112c, 152c). Arrangement interval in a plate length direction of a boundary (Y) of the plate flat surfaces (112a, 152a) and the plate hump curved surfaces (112b, 152b) is set shorter than a chain interval (P).

Owner:TSUBAKIMOTO CHAIN CO

Automatic clarinet mouthpiece production process

ActiveCN111002022AIngenious process designSmooth connectionAssembly machinesMetal working apparatusProcess engineeringMachine

The invention relates to the field of music accessory production processes, in particular to an automatic clarinet mouthpiece production process. The process comprises the following steps of 1, clamping a mouthpiece onto an adjusting and positioning device; 2, completing assembly of a mouthpiece clamp and the mouthpiece; 3, inserting two fastening screws; and 4, carrying out automatic discharging.The process is ingenious in design, smooth in connection and high in automation degree, manual labor is reduced, the production efficiency is improved, compared with the prior art, one person can watch multiple machines, 80% or above of labor can be saved, the efficiency is improved by 8 times-10 times or above, the yield reaches 99.99% or above, 24-hour continuous production can be realized, andthe market competitiveness is high.

Owner:杜方萍

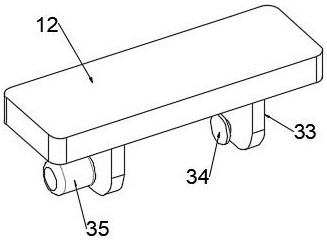

Vertical gasket taking whole machine robot

ActiveCN108994599AGuaranteed surface qualityImprove stabilityMetal working apparatusFlangingEngineering

The invention discloses a vertical gasket taking whole machine robot. The vertical gasket taking whole machine robot comprises a feeding assembly and a rotary feeding mechanism, wherein the feeding assembly comprises a fixing block, a feeding sliding groove, a sliding ejection block, a reset spring and a spring cover; the inner flanging of the feeding sliding groove is arranged, one end of the reset spring is connected with the sliding ejection block, and the other end of the reset spring is connected with the spring cover; and the rotary emptying mechanism comprises a turnover plate, a guidepart and a double-shaft air cylinder, the turnover plate sleeves the guide part, the double-shaft air cylinder is connected with one end of the turnover plate, the two ends of the guide part are provided with vacuum suction heads, circular grooves are formed in the vacuum suction heads, and vacuum suction holes are formed in the circular ring grooves. According to the vertical gasket taking wholemachine robot, the vacuum suction heads are adopted to suck a gasket in a vacuum state, so that the gasket can be grabbed, the gasket is better protected, and the stability of the gasket is more durable; the vacuum suction heads are arranged on the guide part, so that the assembling work of the gasket can be realized through the turnover of the turnover plate; and meanwhile, the grabbing and assembling of the gasket are combined together, so that the efficiency is higher.

Owner:东莞市智赢智能装备有限公司

Automobile air conditioner condenser integrated assembling forming device

InactiveCN108817895ARealize assembly workRealize continuous processing and productionMetal working apparatusAutomobile air conditioningEngineering

The invention discloses an automobile air conditioner condenser integrated assembling forming device. The device comprises a rack and a limiting frame which is arranged on the rack and provided with asliding cavity; a placement frame for containing a flat pipe is arranged at one end of the limiting frame, a flat pipe discharge mechanism is arranged at the bottom of the placement frame, a flat pipe arranging mechanism is arranged at one side of the flat pipe discharge mechanism, the flat pipe discharge mechanism can convey flat pipes in the placement frame into the flat pipe arranging mechanism and flat pipes can be evenly arranged at intervals; a conveying assembly for conveying fins is arranged on the flat pipe arranging mechanism, the conveying assembly can convey the fins into the intervals of the flat pipes, the machine frame is provided with a material shifting assembly located above the limiting frame, a collecting pipe installing mechanism is arranged at the other end of the limiting frame, and the material shifting assembly can push the flat pipes and the fins in the length direction of the limiting frame and convey the flat pipes to the collecting pipe installing mechanism; compared with the prior art, the working efficiency and precision are improved, and continuous machining and production are achieved.

Owner:ZHEJIANG CHUANGXIN AUTO AIR CONDITIONER

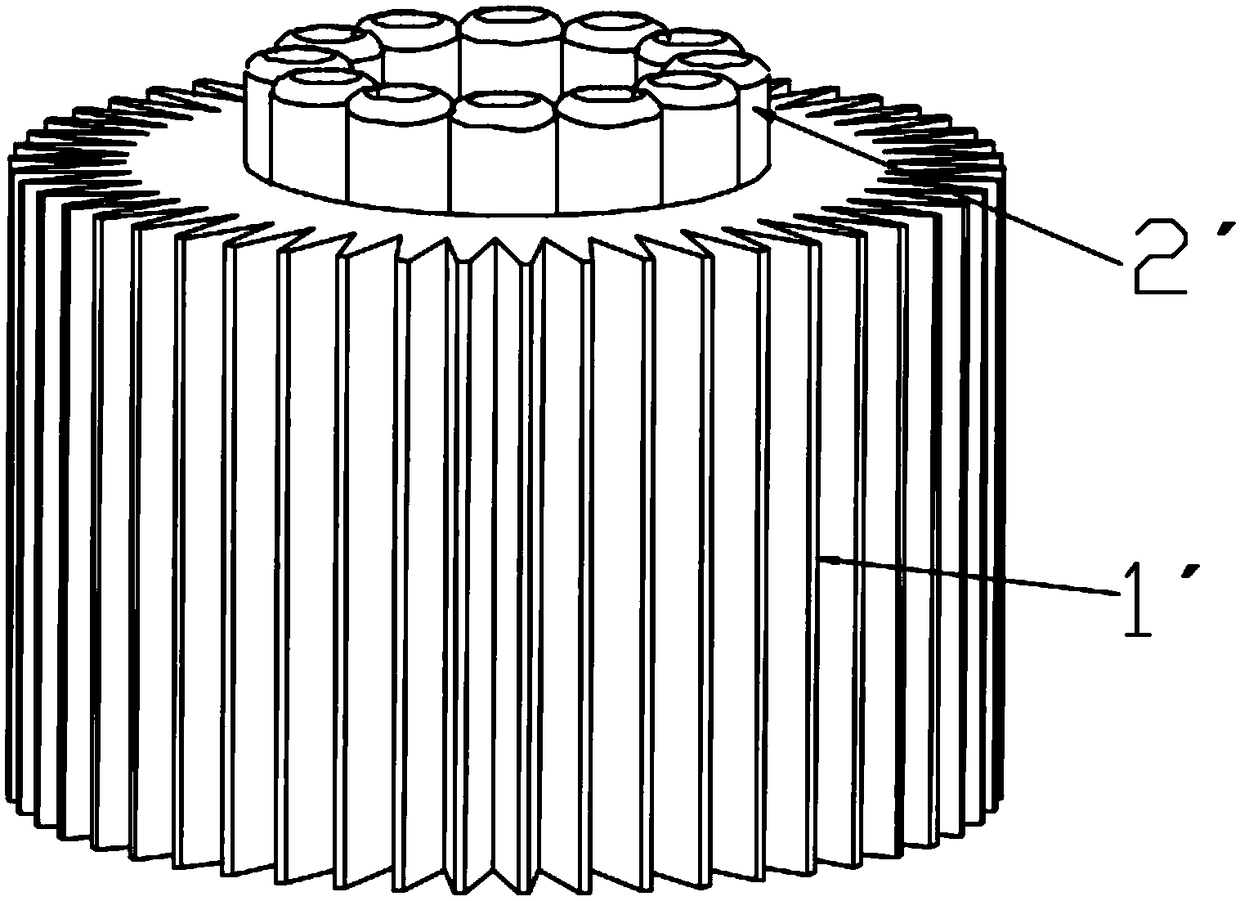

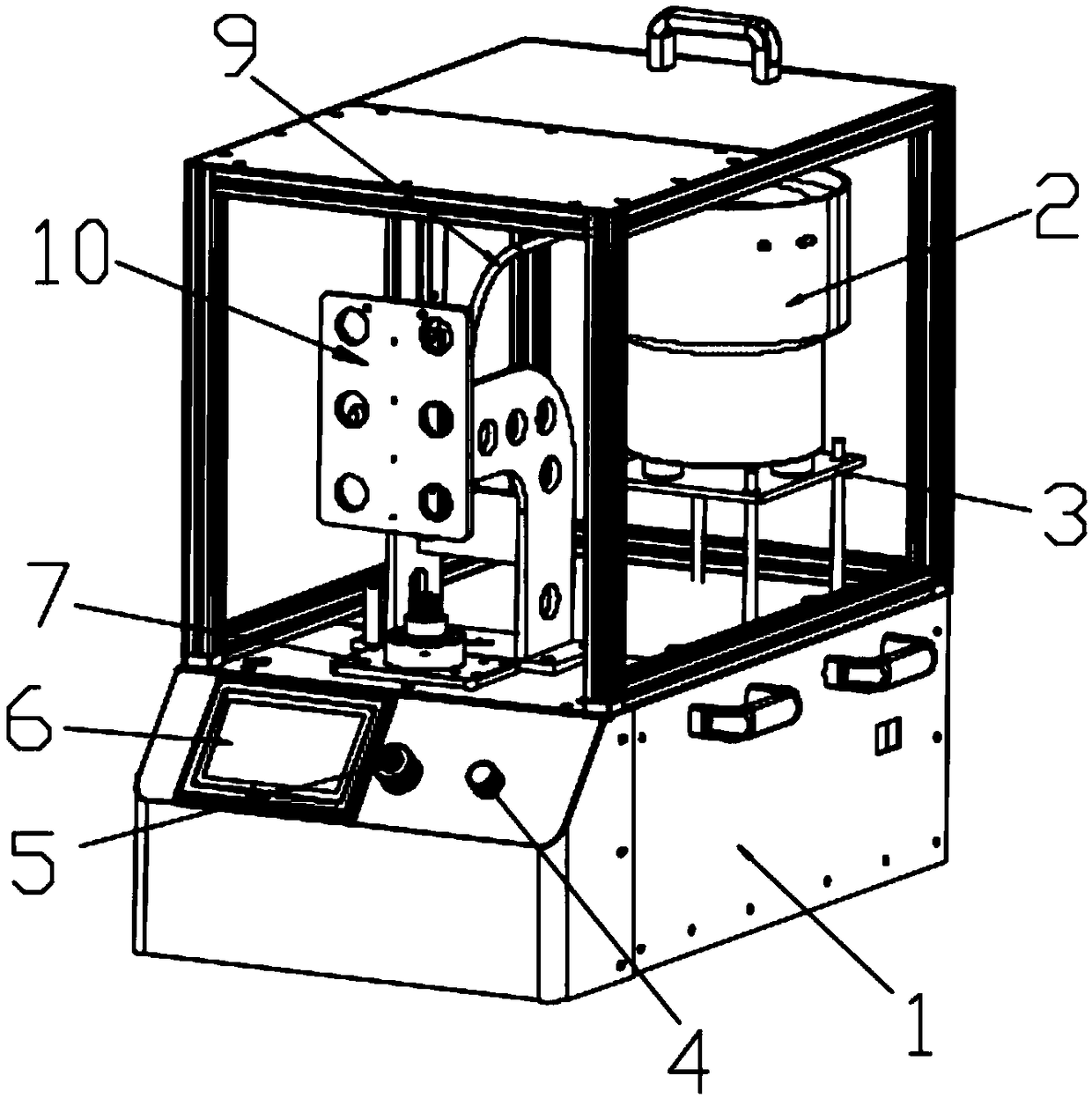

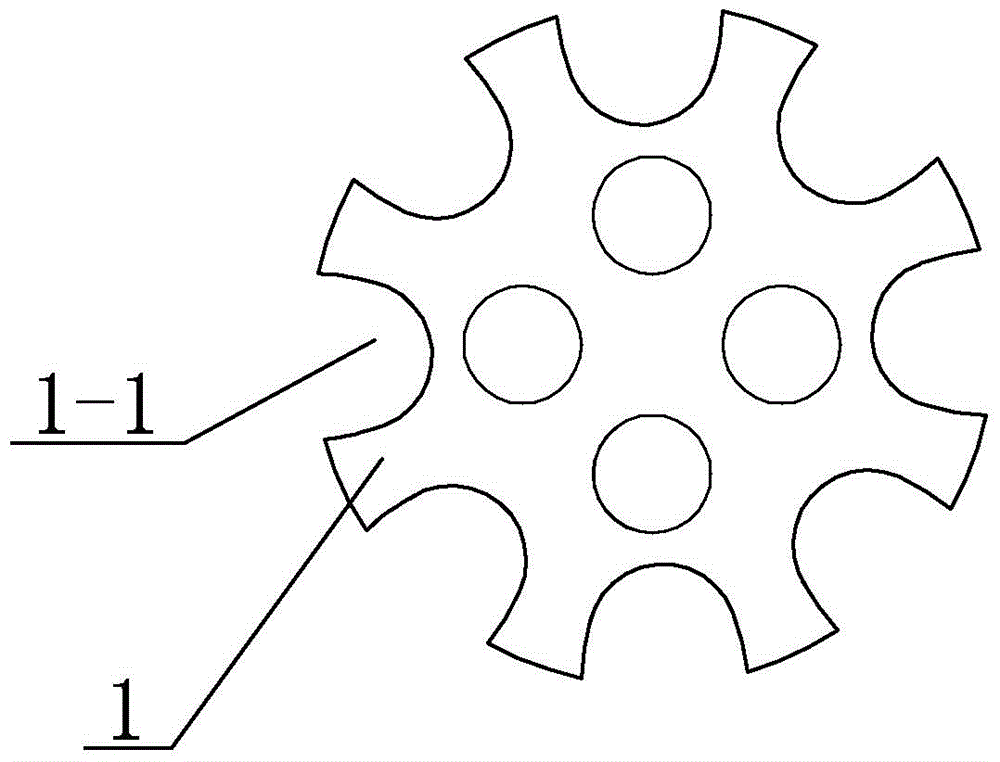

An automatic assembly apparatus for a gear needle of a planetary reducer

InactiveCN108890258AEasy to operateImprove assembly efficiencyLubricant transferMetal working apparatusGear wheelEngineering

The invention discloses an automatic assembling device for a gear needle of a planetary reducer, comprising a base with a working platform, an electric control cabinet for controlling the operation ofthe assembling device is arranged on the base inside or outside of the base, and an operation interface connected with the electric control cabinet is arranged on the base. As that gear bear is arranged on the work platform, and a gear bearing placing mechanism capable of rotating the gear bearing 360 degrees, wherein a latch mechanism capable of placing a gear roller needle in the gear bearing is arranged on a working platform on the outer side of the gear bearing placing mechanism, and the feed end of the latch mechanism is connected with the discharge end of the feeder through a conveyingpipe. It adopts mechanical linkage mode to put the gear needle into the gear bearing, which has the characteristics of simple operation and high assembly efficiency.

Owner:王福州 +1

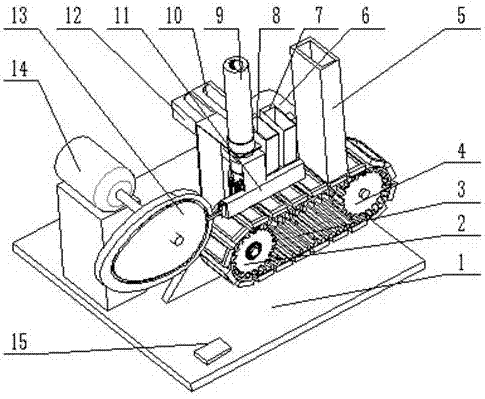

Crawler-type medical thinprep clamp automatic assembly robot

InactiveCN107186733AImplement automatic assemblyAchieve continuous supplyManipulatorHydraulic cylinderGear wheel

The invention relates to a crawler-type medical thinprep clamp automatic assembly robot, and belongs to the field of medical machines. The crawler-type medical thinprep clamp automatic assembly robot is composed of a rack, a gear set, a crawler set, gears, a base channel, sheet grooves, a rotating column, hydraulic cylinders, a rack set, a hydraulic cylinder base, a cam, stepping motors and a controller. The crawler-type medical thinprep clamp automatic assembly robot is characterized in that the controller, the hydraulic cylinder base, the stepping motor, the rotating column, the base channel, the stepping motor and the gear set are installed on the rack, the gears are installed on the stepping motors, the crawler set is installed on the gear set and the gears, the sheet grooves are fixed to the hydraulic cylinder base, the two hydraulic cylinders are installed on the hydraulic cylinder base, the rack set is fixed to the rotating column through a fixing plate on the rack set, one end of the rack is matched with a groove in the cam, and the cam is installed on one stepping motor. The crawler-type medical thinprep clamp automatic assembly robot has the beneficial effects that under cooperation of all devices, automatic assembling of a thinprep clamp can be achieved, continuous supply of a thinprep clamp base can be achieved through crawlers, downward pressing and rotating motions of a barrel can be achieved through the rotating column, and therefore assembly work is achieved.

Owner:柴传程

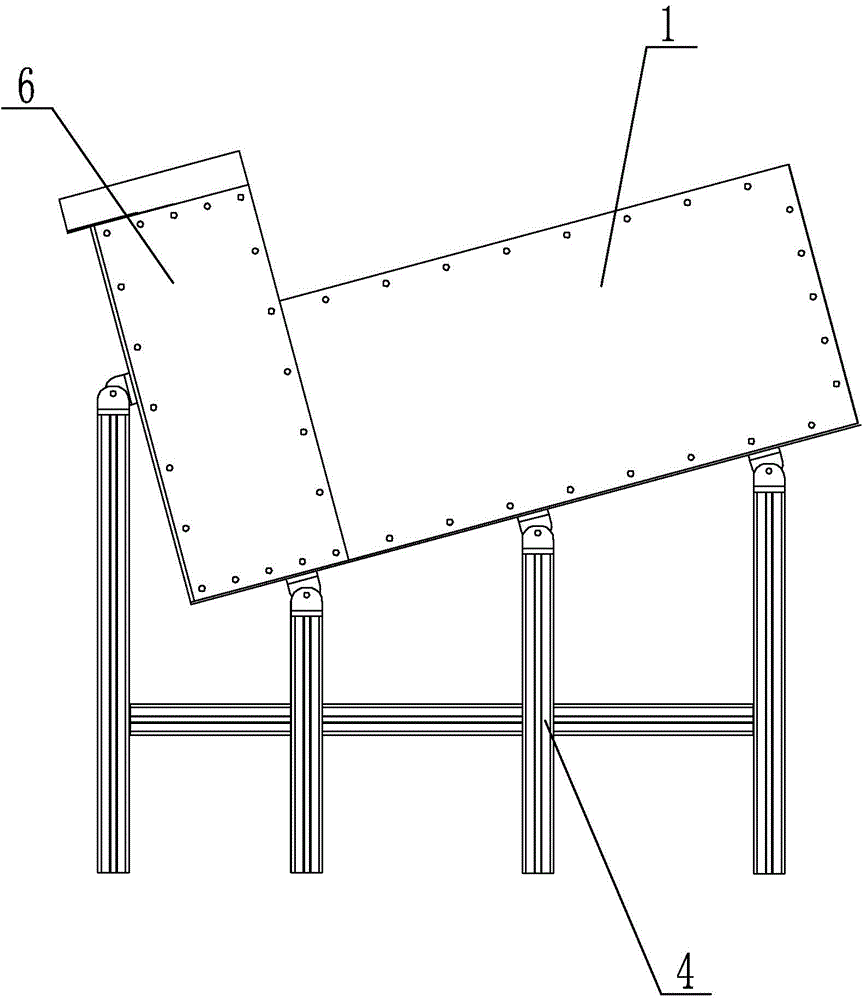

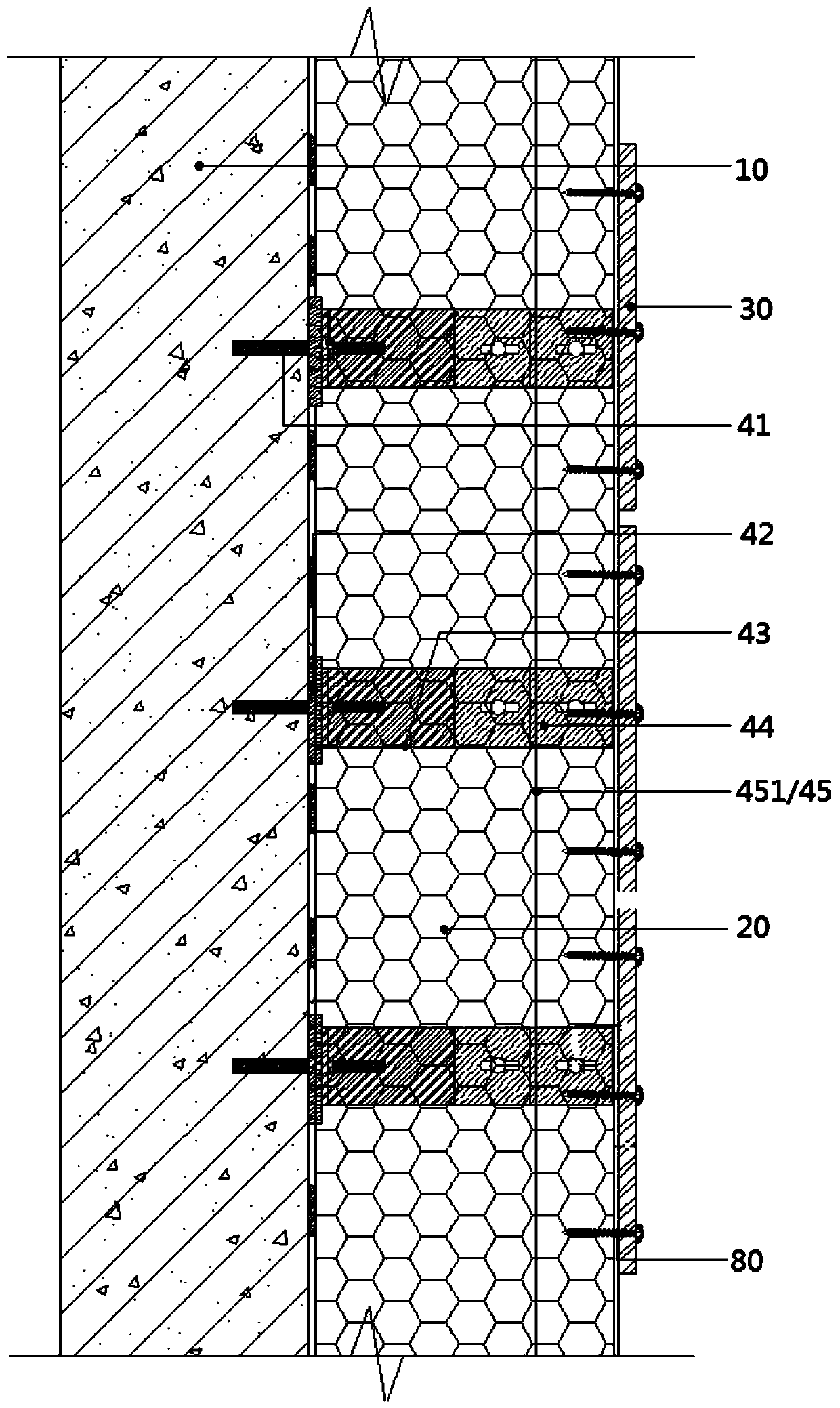

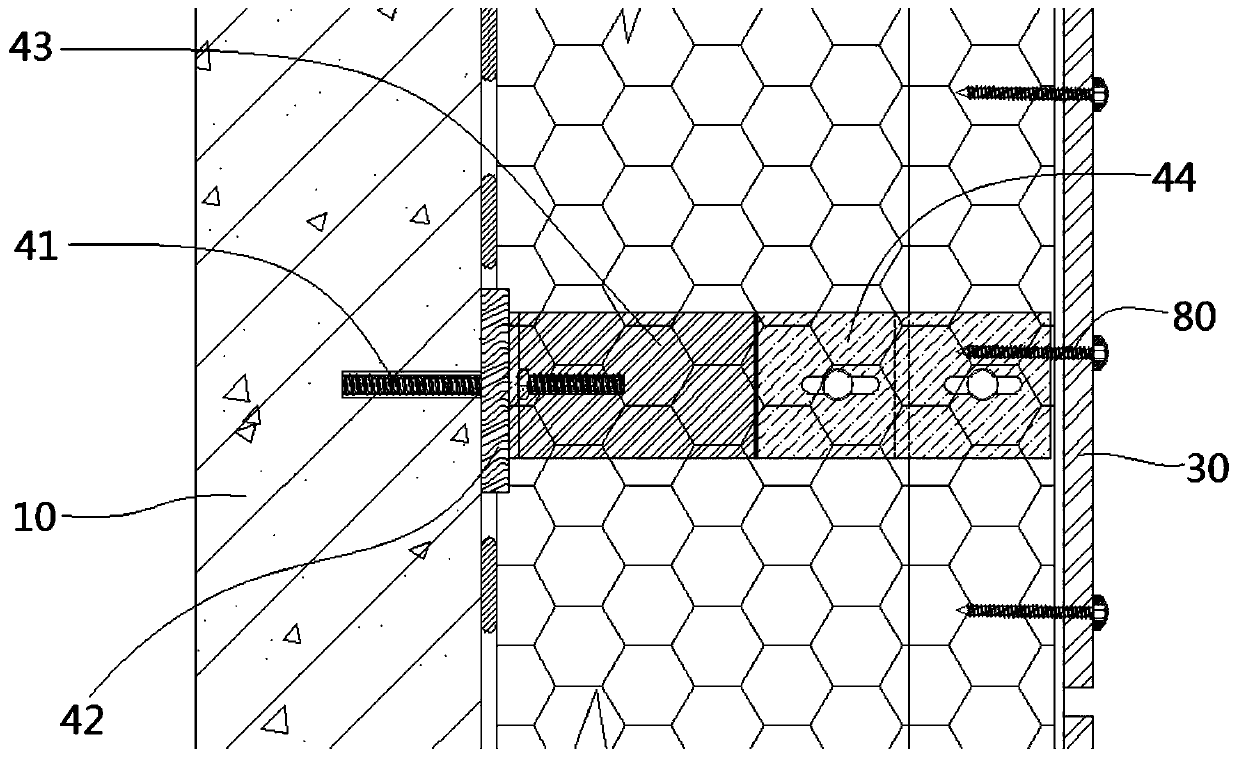

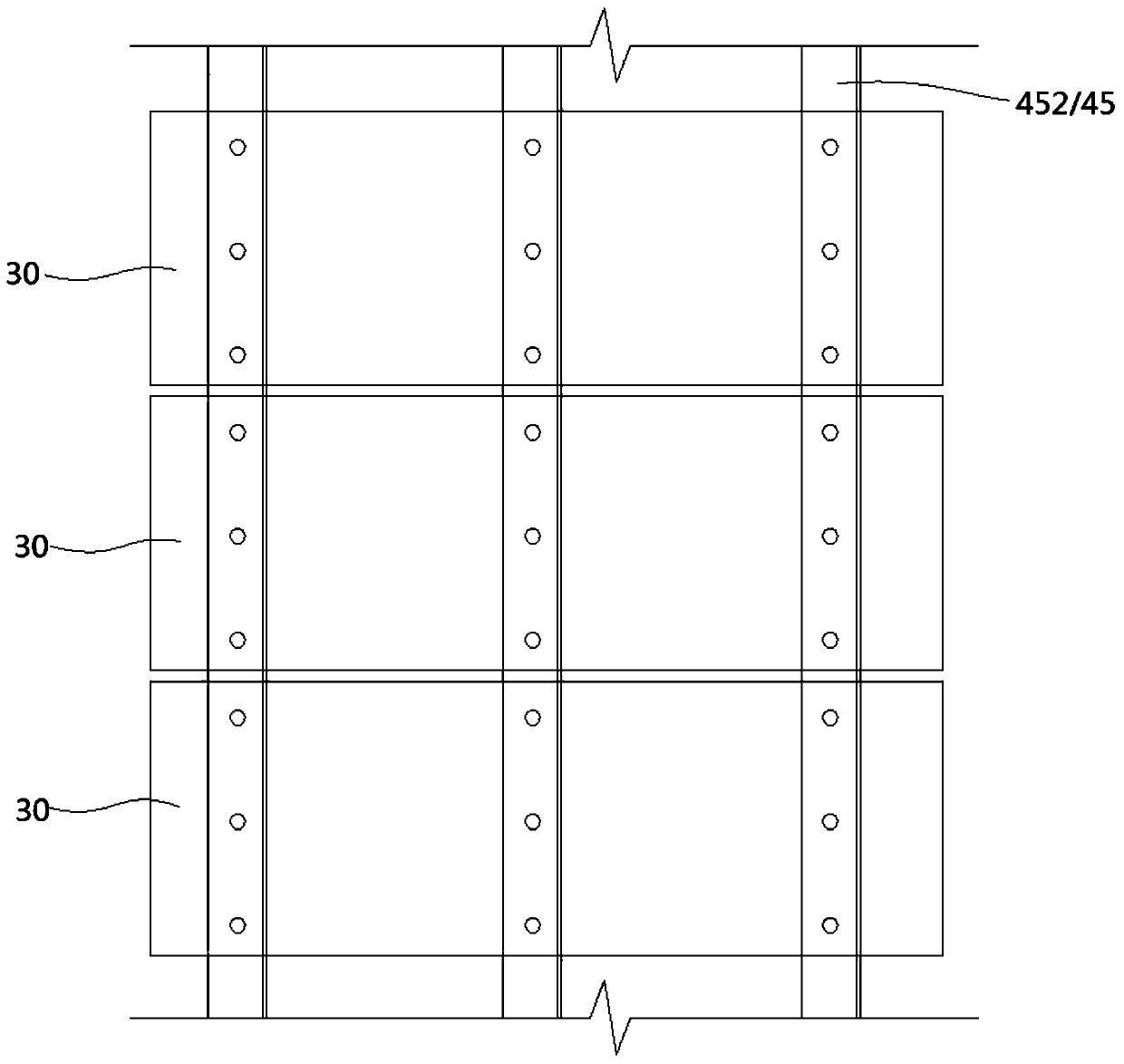

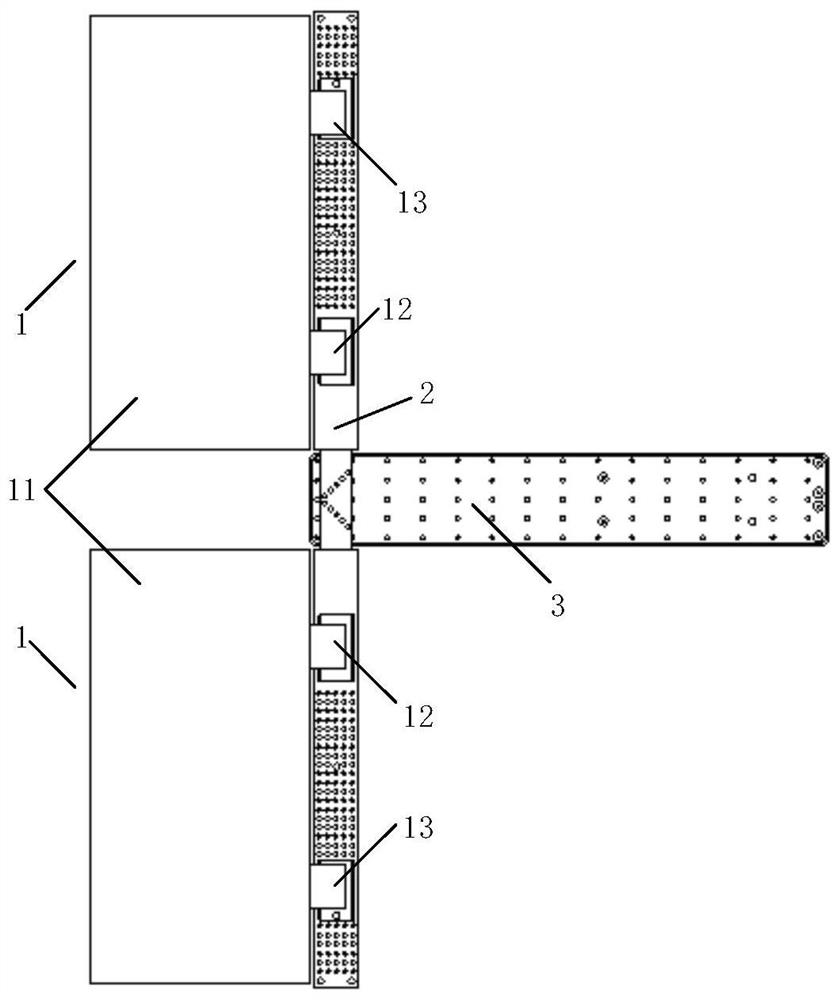

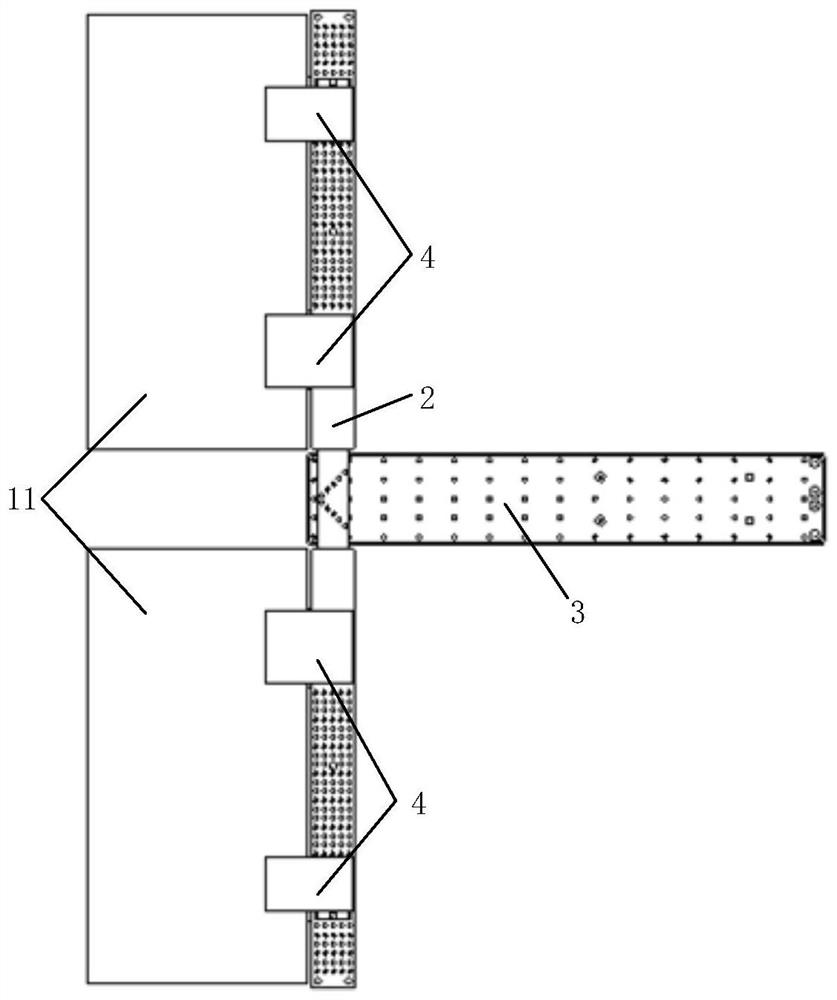

Building external wall insulation system and construction method thereof

InactiveCN110499842ARealize assembly workGuaranteed forceCovering/liningsWallsInsulation layerCoating system

The invention discloses a building external wall insulation system and a construction method thereof. The building external wall insulation system includes an insulation layer fixed to the wall surface of a base layer wall body and a decorative plate arranged on the outer surface of the insulation layer, a composite connection member is further included, the composite connection member includes afirst connection assembly and a second connection assembly, the inner end of the first connection assembly is fixedly inserted into the base layer wall body, the outer end of the first connection assembly is fixedly connected with the second connection assembly, and the second connection assembly is used for fixing the decorative plate; the insulation layer is fixedly connected with the base layerwall body; and the insulation layer and the decorative plate are prefabricated parts correspondingly. According to the building external wall insulation system, field wet construction can be completely avoided, assembly operation of an insulation coating system is realized, the construction efficiency can be improved, and the construction cost is lowered.

Owner:曹德军

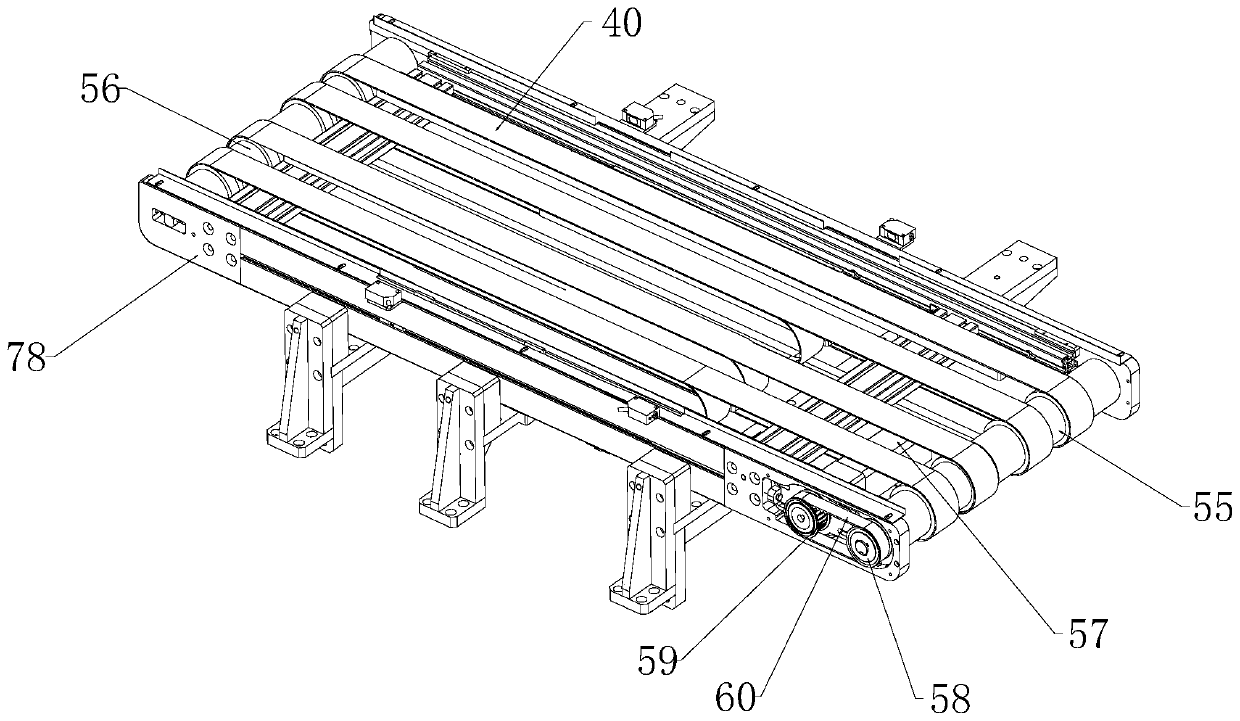

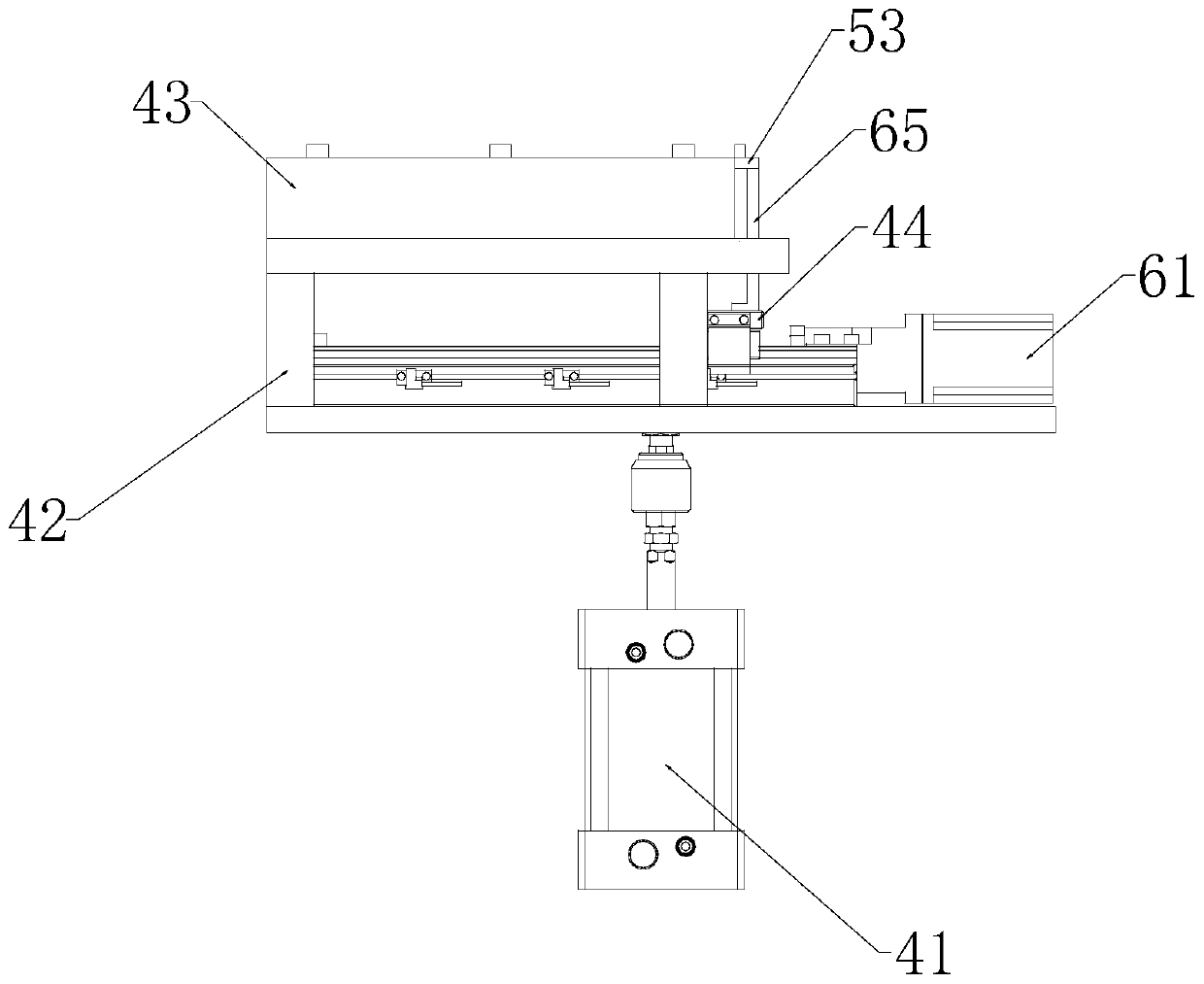

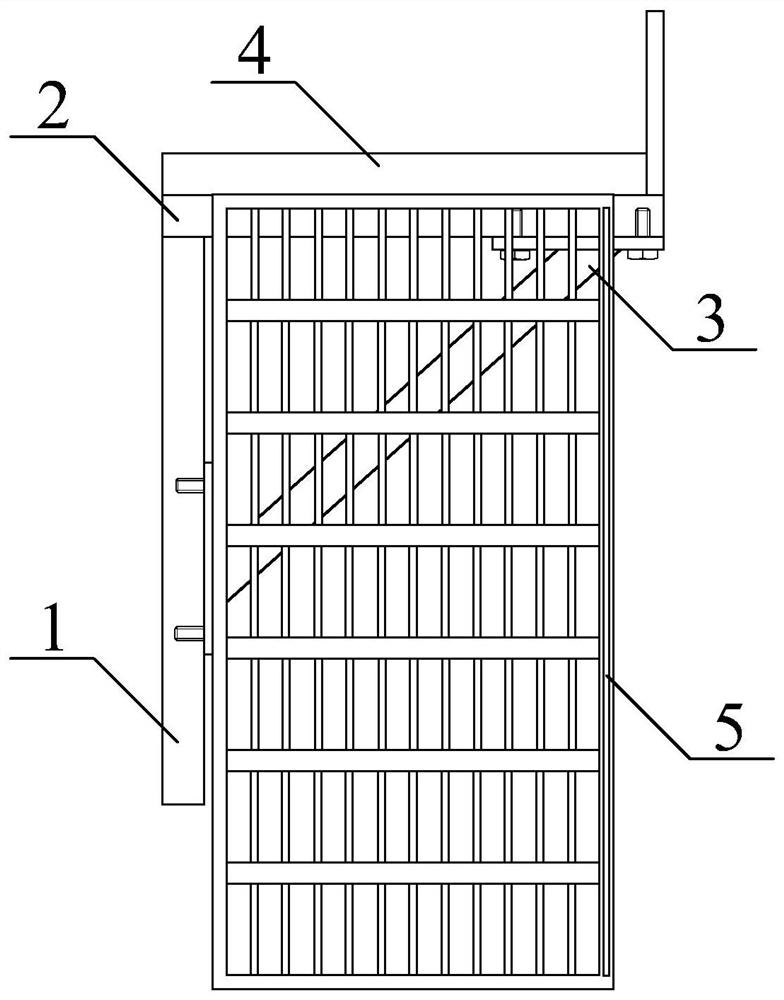

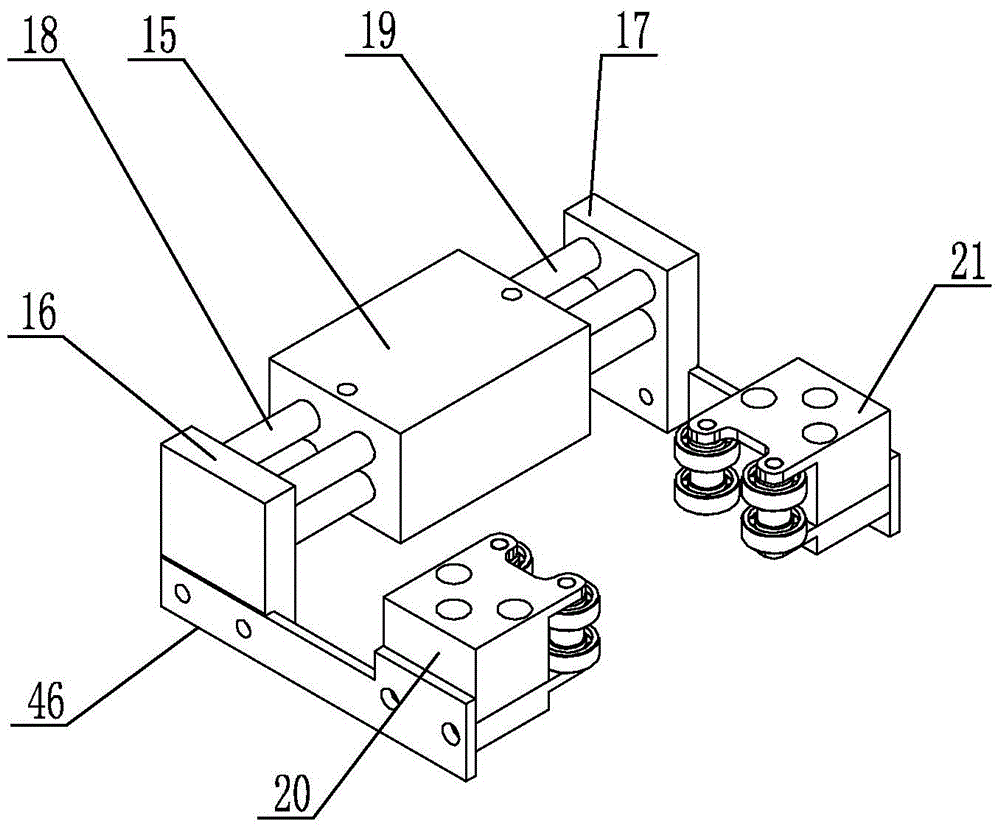

Conveying structure for keyboard middle plate and assembling device with conveying structure

ActiveCN111524738ARealize the delivery workRealize assembly workElectric switchesEngineeringFriction force

The invention discloses a conveying structure for a keyboard middle plate and an assembling device with the conveying structure. The conveying structure comprises a supporting base. A middle plate conveying frame is installed on the supporting base, and a plurality of conveying belts are arranged on the middle plate conveying frame in a transmission mode. A feeding supporting driving device is further installed on the supporting base, and the output end of the feeding supporting driving device is connected with a feeding supporting frame; a plurality of feeding supporting rods are arranged onthe feeding supporting frame; a feeding power driving device is further arranged on the feeding supporting frame, and the output end of the feeding power driving device is connected with a feeding power frame. Through cooperation of the feeding supporting frame and the middle plate conveying frame, conveying work of a middle plate can be achieved; and the assembling work of the middle plate can berealized. Through the arrangement of the feeding supporting rod and the slipping layer of the feeding supporting rod, it can be guaranteed that the middle plate can be located at the same height as akeyboard cavity, meanwhile, the friction force between the middle plate and the supporting structure can be reduced, and the keyboard middle plate can be conveniently, stably and rapidly pushed intothe keyboard shell.

Owner:重庆保时鑫电子科技有限公司

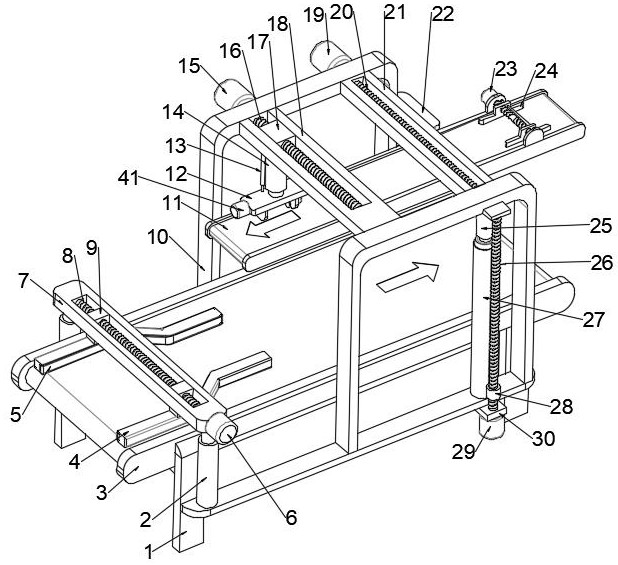

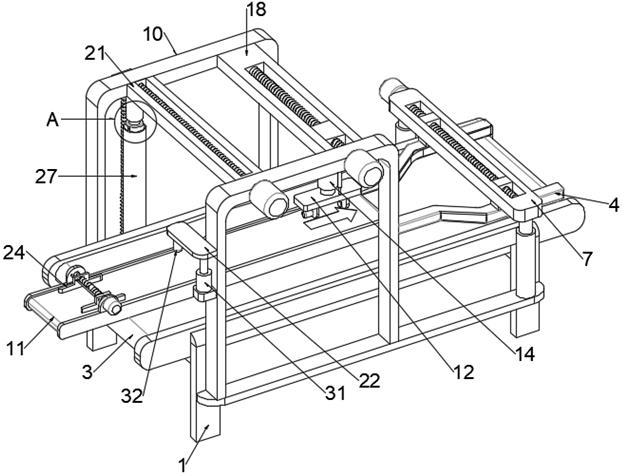

Loudspeaker production assembly equipment with automatic feeding function and assembly method

ActiveCN114268895ARealize assembly workAvoid product qualityElectrical transducersConveyorsEngineeringLoudspeaker

The invention relates to the technical field of loudspeaker production equipment, and discloses loudspeaker production assembly equipment with an automatic feeding function, the loudspeaker production assembly equipment comprises a support base and a U-shaped frame located on the support base, and the support base is further provided with a first conveying belt; a first conveying belt is arranged on the support base, a first guide assembly used for adjusting the position of a loudspeaker front cover on the first conveying belt is further arranged on the support base, a second conveying belt is further arranged on the U-shaped frame, a second guide assembly used for adjusting the position of a loudspeaker body component is further arranged on the second conveying belt, and a gluing assembly is further arranged on the U-shaped frame. A membrane feeding assembly is further arranged on the support base, a conveying and assembling assembly used in cooperation with the membrane feeding assembly is arranged on the U-shaped frame, an adjusting assembly is further arranged on the U-shaped frame, and a clamping assembly is connected to the adjusting assembly. The structure is innovative, and the production quality of the loudspeaker can be improved.

Owner:常州诚铭电子科技有限公司

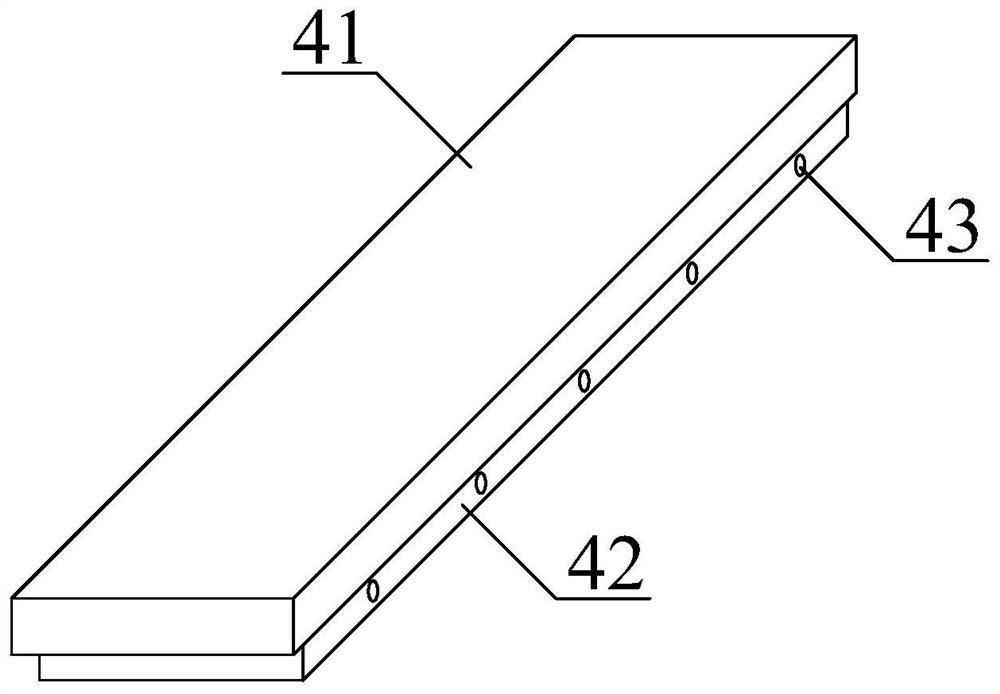

Evacuation platform system based on composite material

PendingCN111608724ARealize assembly workEasy to installSafety equipmentsLaddersStructural engineeringUltimate tensile strength

The invention provides an evacuation platform system based on a composite material. The system comprises an installation plate, a supporting assembly, a stabilizing rod, a platform assembly and a climbing assembly. According to the arrangement of the supporting assembly and the platform assembly, an embedded plate is embedded in an embedding groove and bolts screwed into a first installation holeand a second installation hole to realize assembly operation of the platform system, installation of the platform system is convenient, a lot of labor force and time are saved, and installation efficiency of the platform system is improved; according to the arrangement of the platform assembly, a platform body and the embedded plate are made of the composite material which is a material of excellent dynamic performance, five times steel in strength, resistant to a high temperature of 2000 DEG C, one fifth of the steel in specific gravity, and excellent in flame retardant performance, so stability of the platform system is improved, phenomenon of collapse or crack is avoided, and safety performance of the platform system is improved; and the evacuation platform system based on the compositematerial is simple in structure, convenient and rapid in operation, and convenient for market promotion and application.

Owner:SHANDONG DINGCHANG COMPOSITE MATERIAL CO LTD

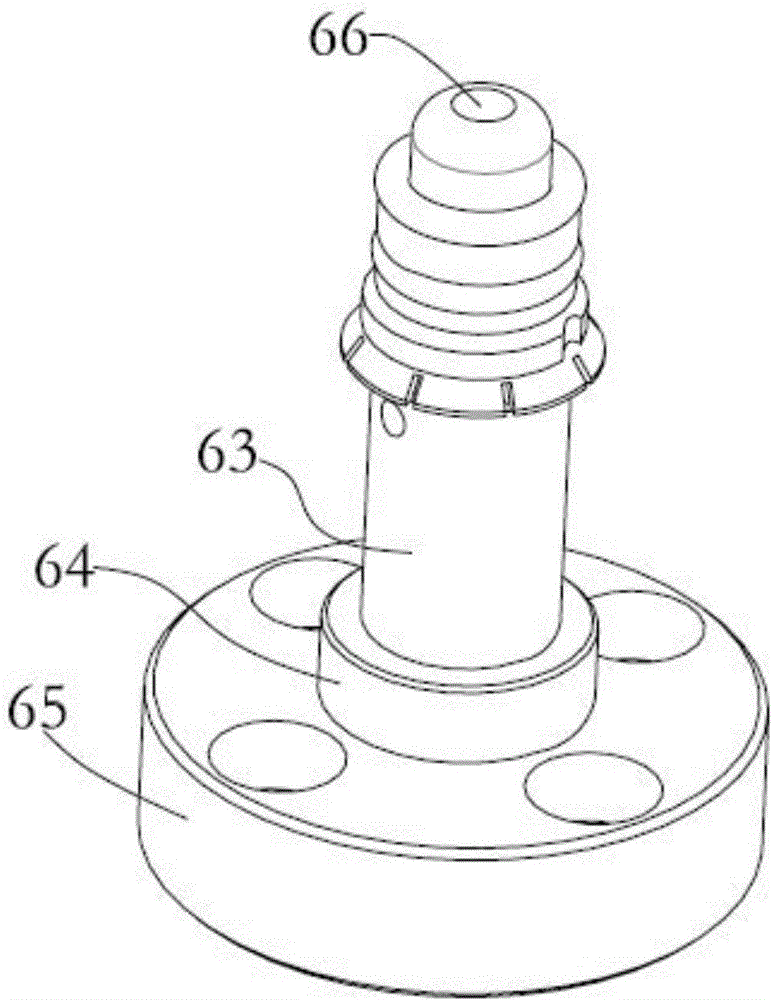

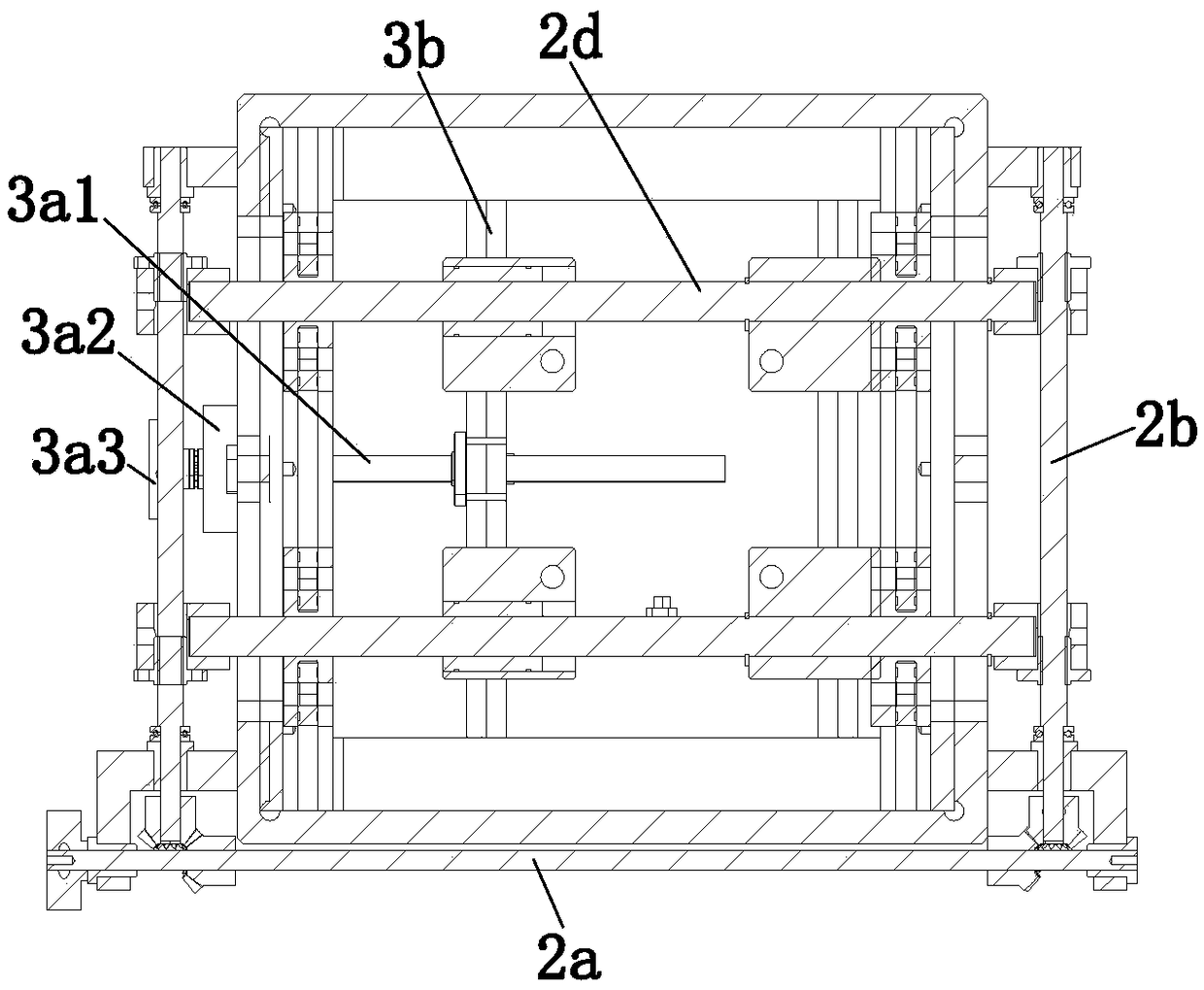

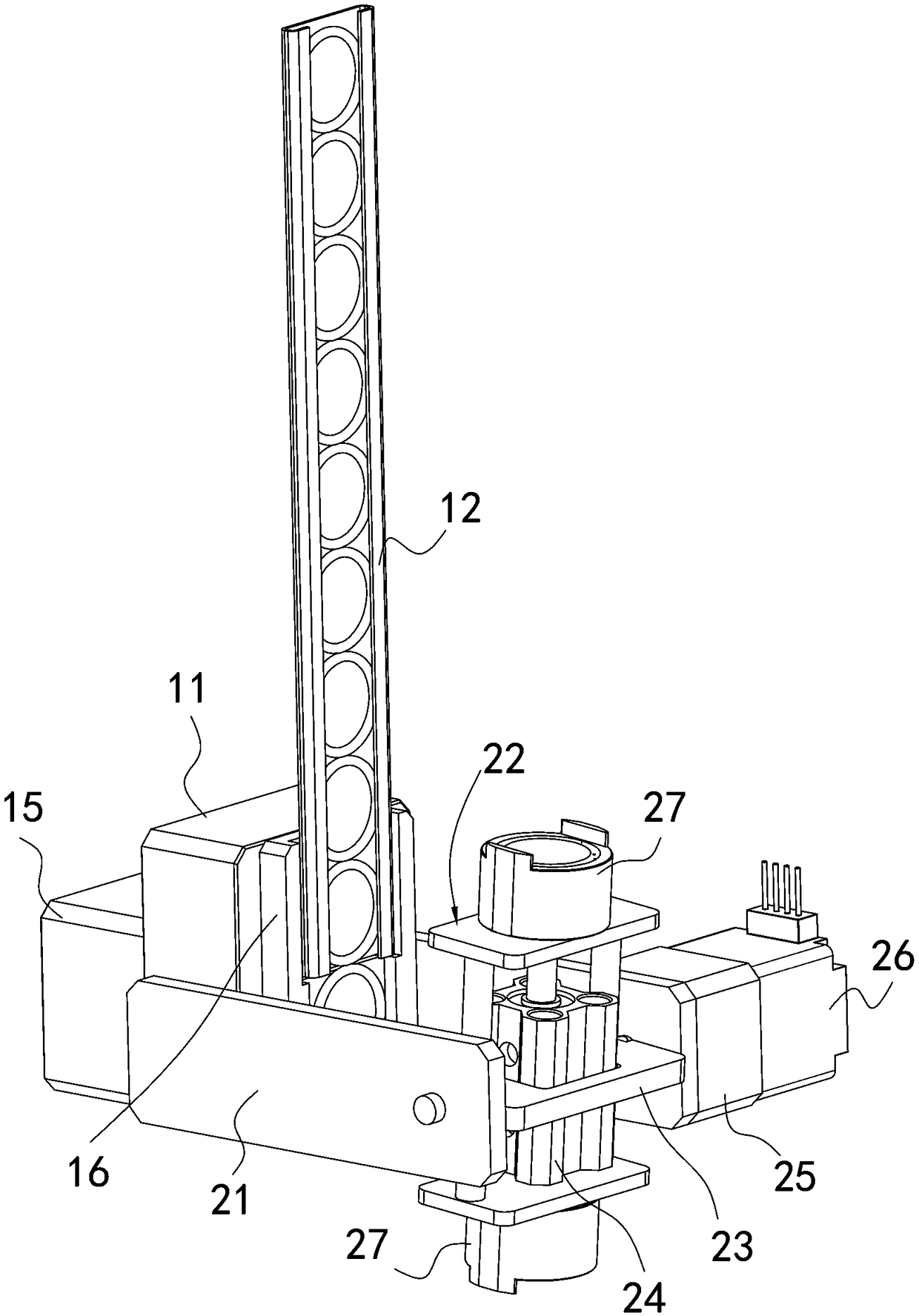

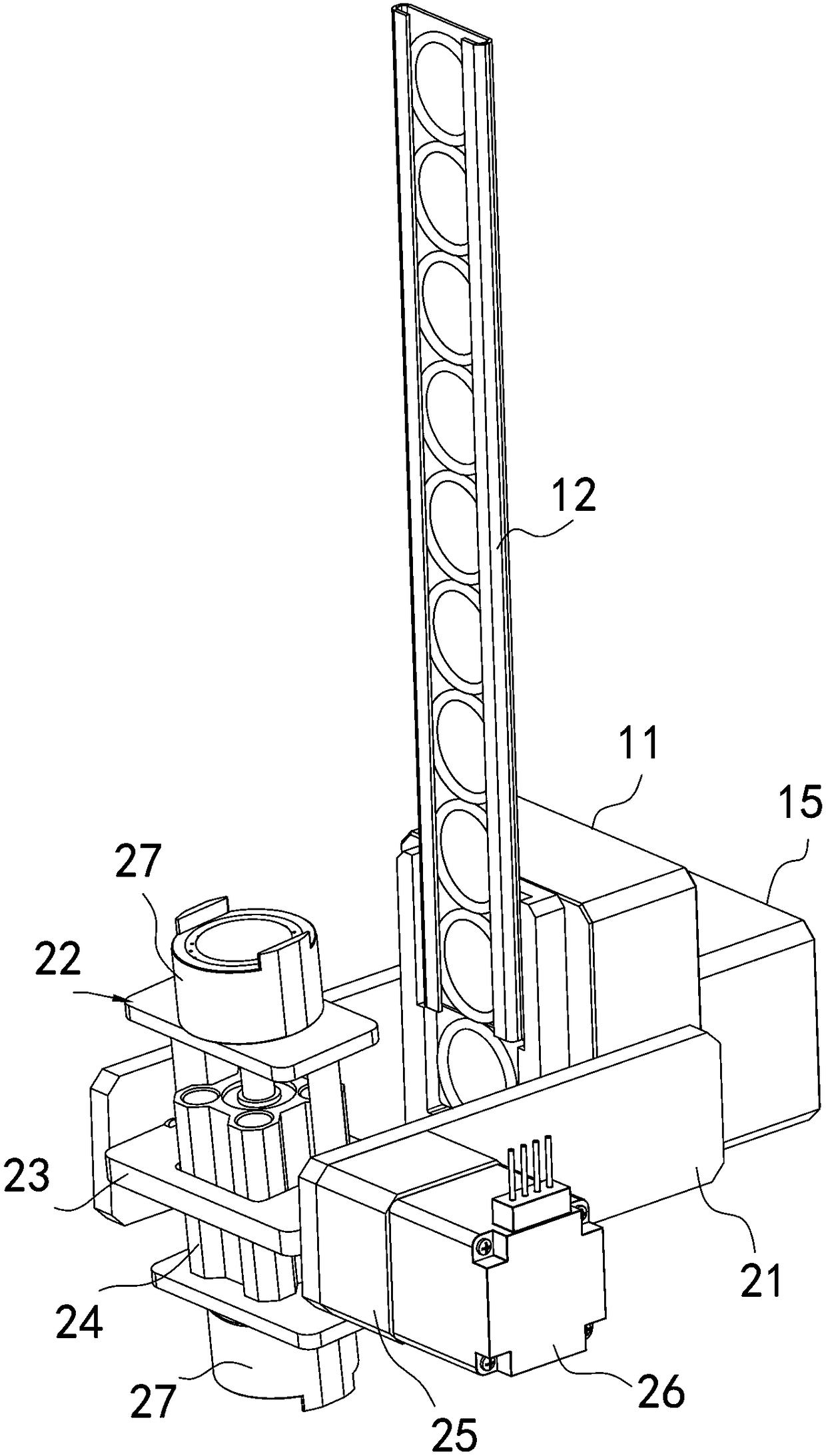

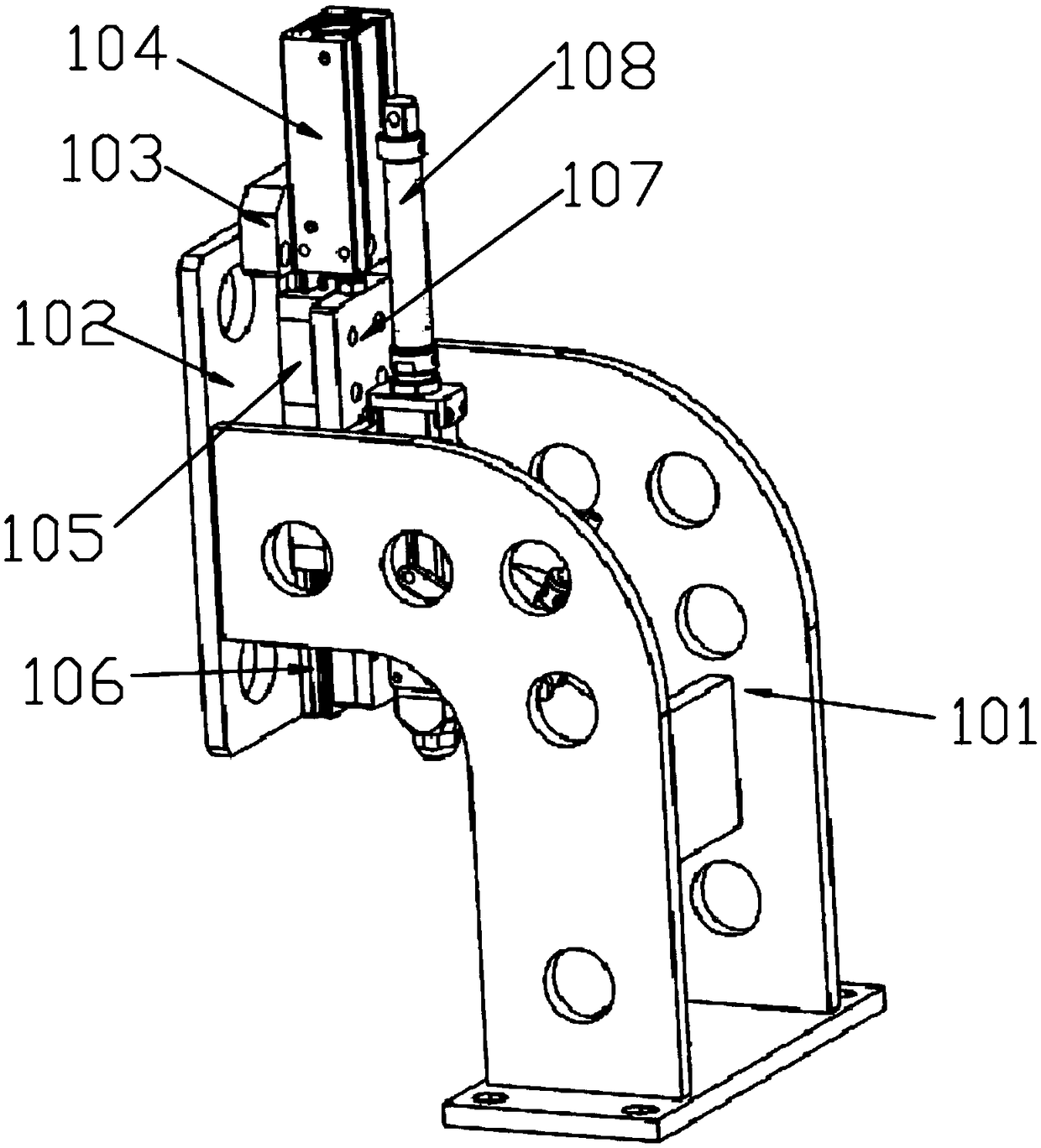

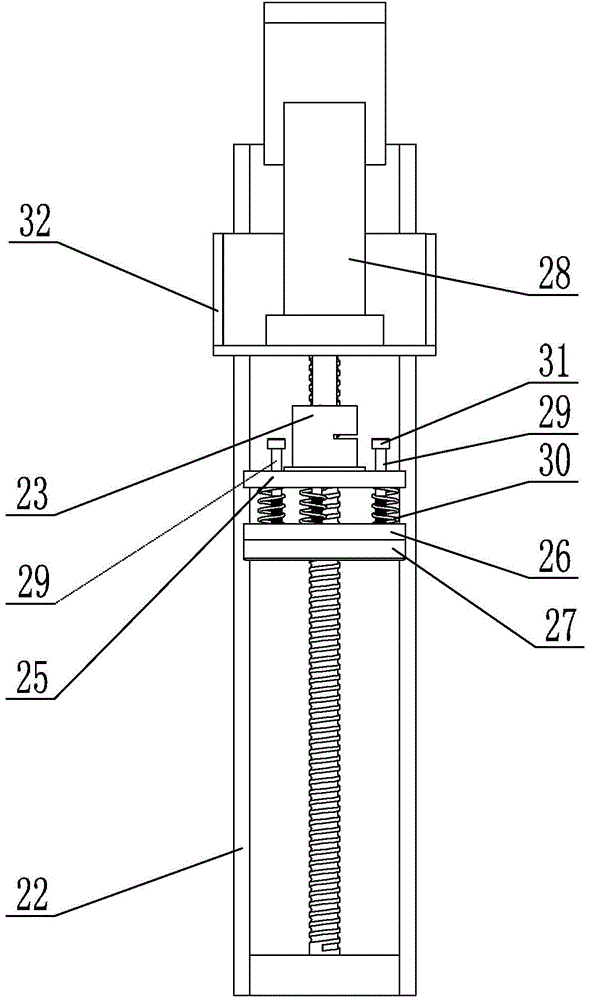

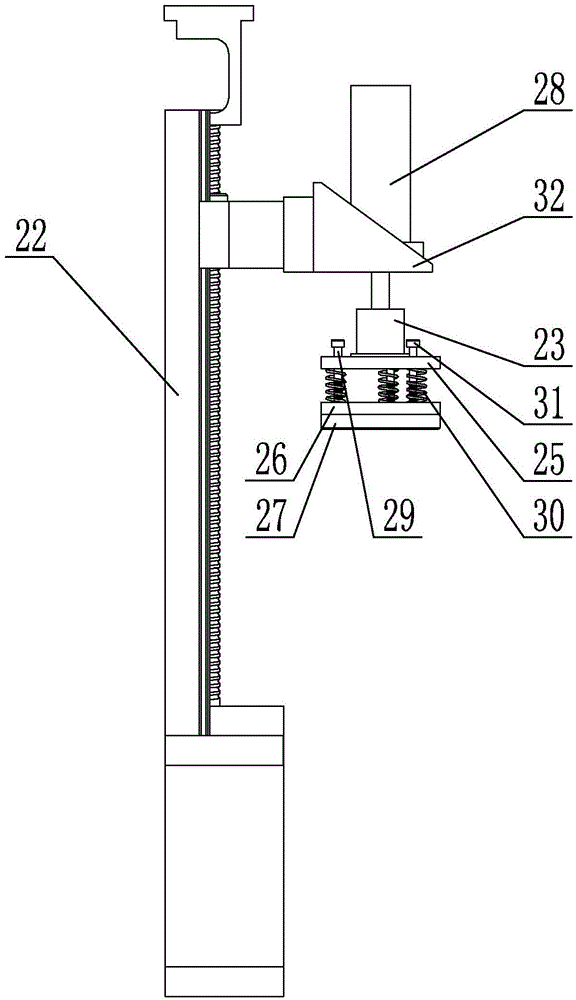

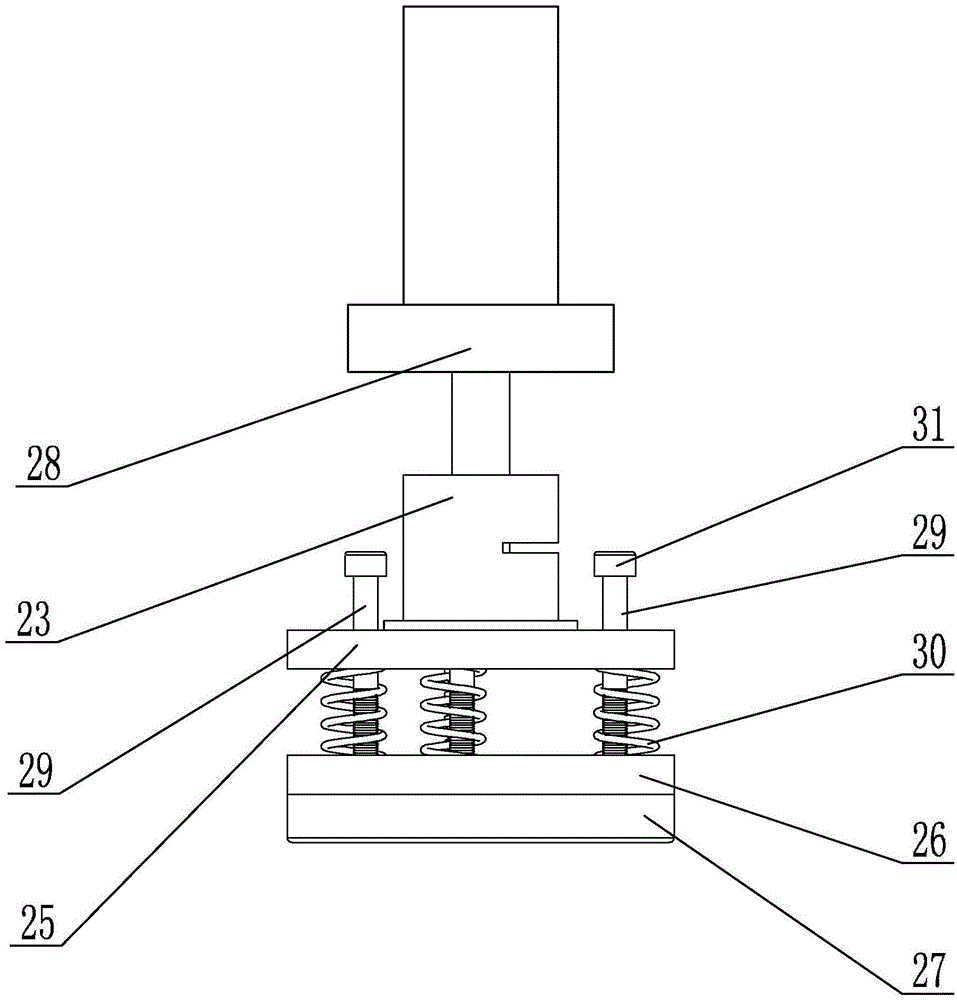

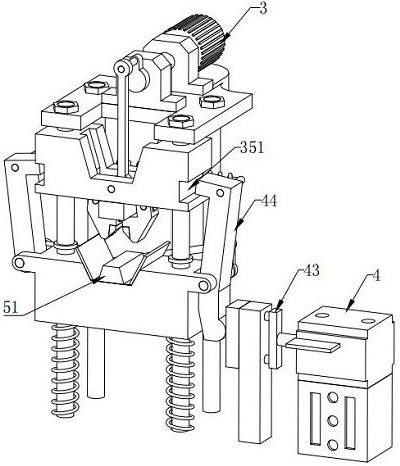

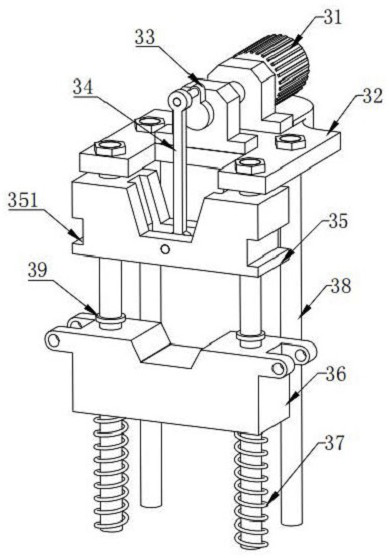

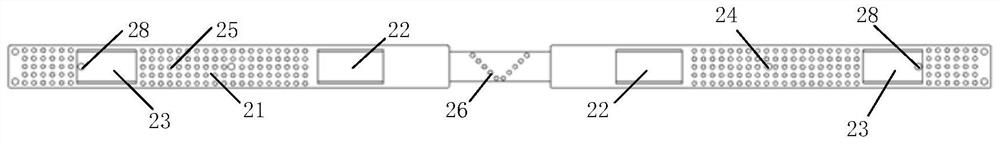

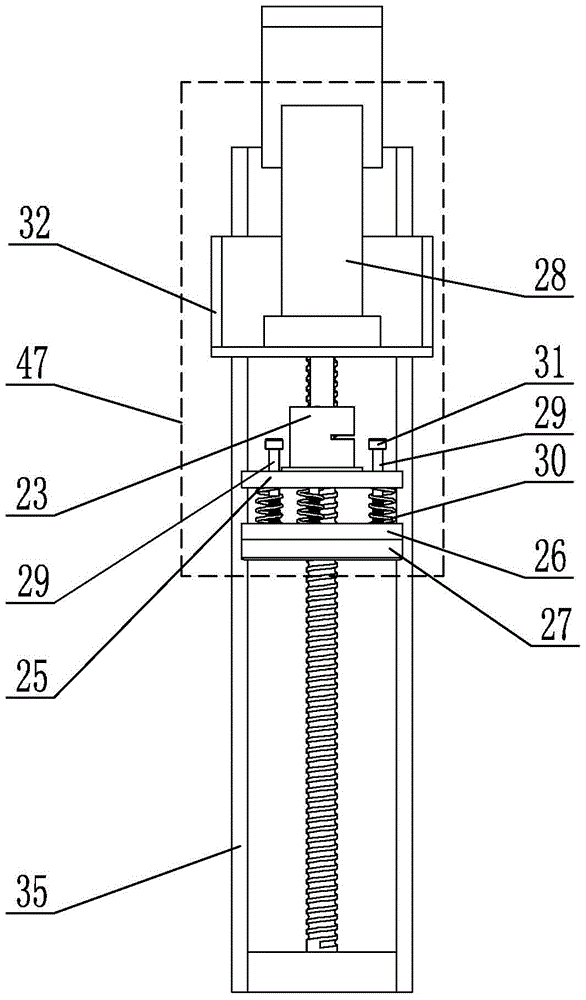

Elastic screwing mechanism in full-automatic assembly system for adjusting pin of cupboard

InactiveCN104690541AAdjustable distanceRealize assembly workMetal working apparatusCouplingEngineering

The invention relates to an elastic screwing mechanism in a full-automatic assembly system for an adjusting pin of a cupboard, and relates to an elastic screwing mechanism. Threads of different specifications of adjusting pins have different thread pitches, different adjusting pins with different thread pitches cannot be assembled in a conventional device, and when a T-shaped part and a cylindrical part in the adjusting pin are assembled, the accuracy of coaxiality of an axis of the T-shaped part and an axis of the cylindrical part is not ideal because of manufacturing errors, positioning errors and movement errors. A motor is fixedly connected to one side of a movable slider in a linear sliding table, an output shaft of the motor penetrates through a coupler to be fixedly connected with a screwing cap upper cap body, a screwing cap lower cap body is arranged below the screwing cap upper cap body, and a plurality of guide pillars are vertically arranged and glidingly connected between the screwing cap upper cap body and the screwing cap lower cap body; each guide pillar is sleeved with a spring, and a buffer cushion is fixedly connected to the lower end surface of the screwing cap lower cap body. The mechanism is used for assisting in coaxial assembly of the T-shaped part and the cylindrical part.

Owner:HARBIN INST OF TECH

Motor shell assembling and magnetizing process

PendingCN113783380ARealize assembly workReduce electromagnetic soundMagnetic bodiesManufacturing stator/rotor bodiesMechanical engineeringDirect current

The invention discloses a motor shell assembling and magnetizing process, which comprises the following steps that a, a triangular waveform magnetizing head is prepared, specifically, the magnetizing head comprises a fixing base and a magnetizing assembly, and the magnetizing assembly comprises a fixing sleeve, a magnetic conduction steel reel, a coil winding and an insulating glue layer; b, the magnetic strip is installed in the motor shell, and the magnetic feeding procedure is completed, the magnetic strip and the motor shell are automatically assembled through a magnetic feeding jig assembly, and the magnetic feeding jig assembly comprises a magnetic strip bending die, a magnetic strip push broach, a motor shell positioning jig, a lifting die core and a die core lifting driving mechanism; c, the magnetic strip in the motor shell is magnetized through a magnetizing head so as to enable the magnetic strip to generate a triangular wave curve effect; and d, detection is conducted. The motor shell and magnetic strip assembling operation can be effectively achieved, the magnetic strips in the motor shell can be effectively magnetized, the assembled and magnetized motor shell finished product can effectively reduce electromagnetic sound generated in the operation process of the brushless direct current fan, and the mute effect of the brushless direct current fan is improved.

Owner:深圳市庆源电子五金有限公司

Machining mechanism of aluminum electrolytic capacitor

ActiveCN113305538ALabor savingImprove work efficiencyMetal working apparatusAluminium electrolysisEngineering

The invention discloses a machining mechanism for an aluminum electrolytic capacitor, and belongs to the technical field of aluminum electrolytic capacitor machining. The machining mechanism comprises a machining table, wherein the machining table is placed on a horizontal plane, and a machining device is further arranged at the top of the machining table. The machining device comprises a driving assembly, an adjusting assembly and a pressing assembly, wherein the driving assembly is installed at the top of the machining table, the adjusting assembly is installed on the machining table and matched with the driving assembly in a hinged mode, and the pressing assembly is fixedly installed on the driving assembly. The driving assembly and the pressing assembly can cooperate to wrap guide pins with gold foil paper to complete assembling, work efficiency of assembling is improved, when guide pins of different specifications are assembled, the adjusting assembly is matched with the gold foil paper feeding assembly to feed gold foil paper of different specifications, the gold foil paper of the corresponding specifications can be freely switched for assembly when the machining device assemblies the guide pins of different specifications with the gold foil paper, and the working efficiency of overall assembly is improved.

Owner:NANTONG CHUANGJIA ELECTROMECHANICAL

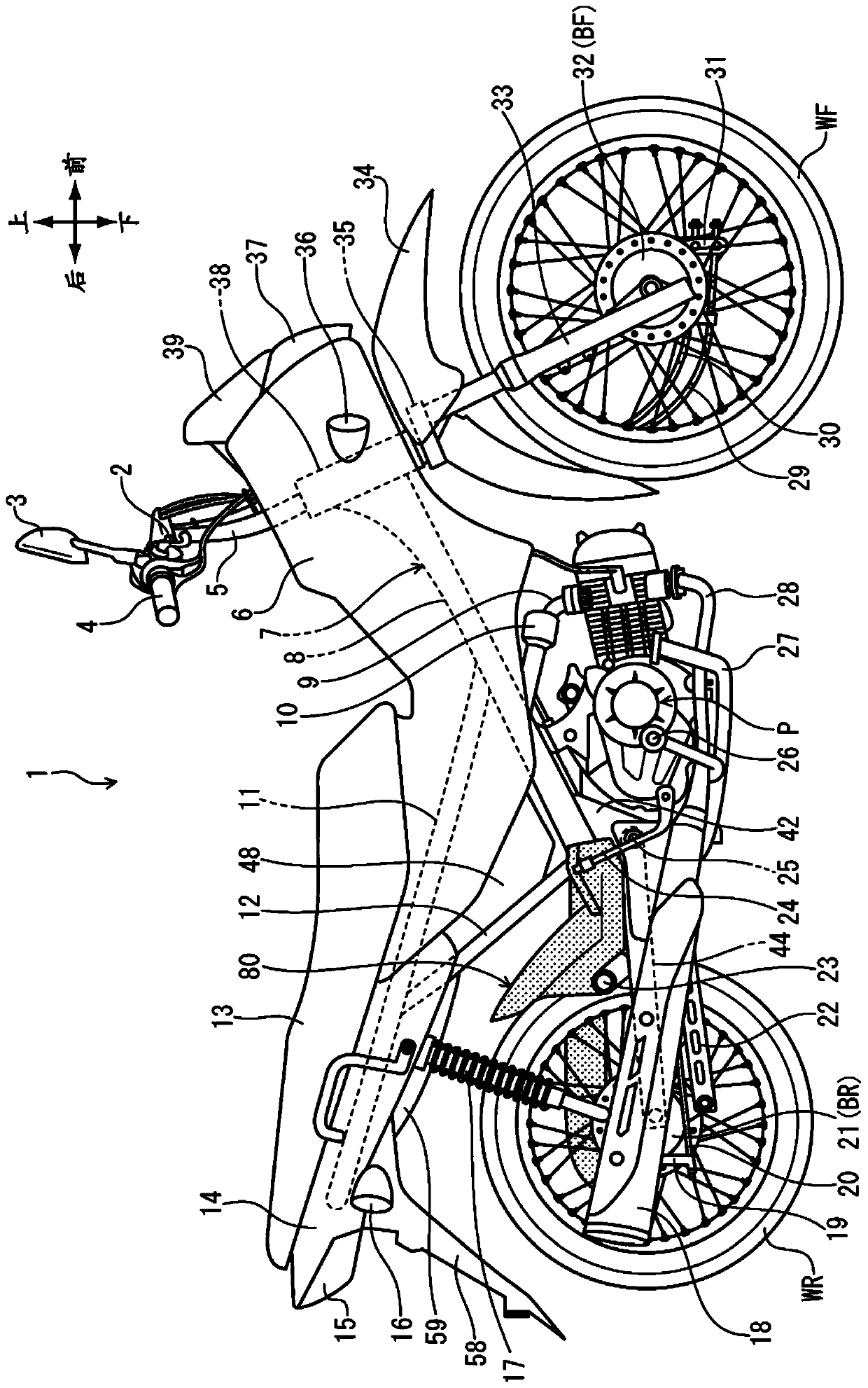

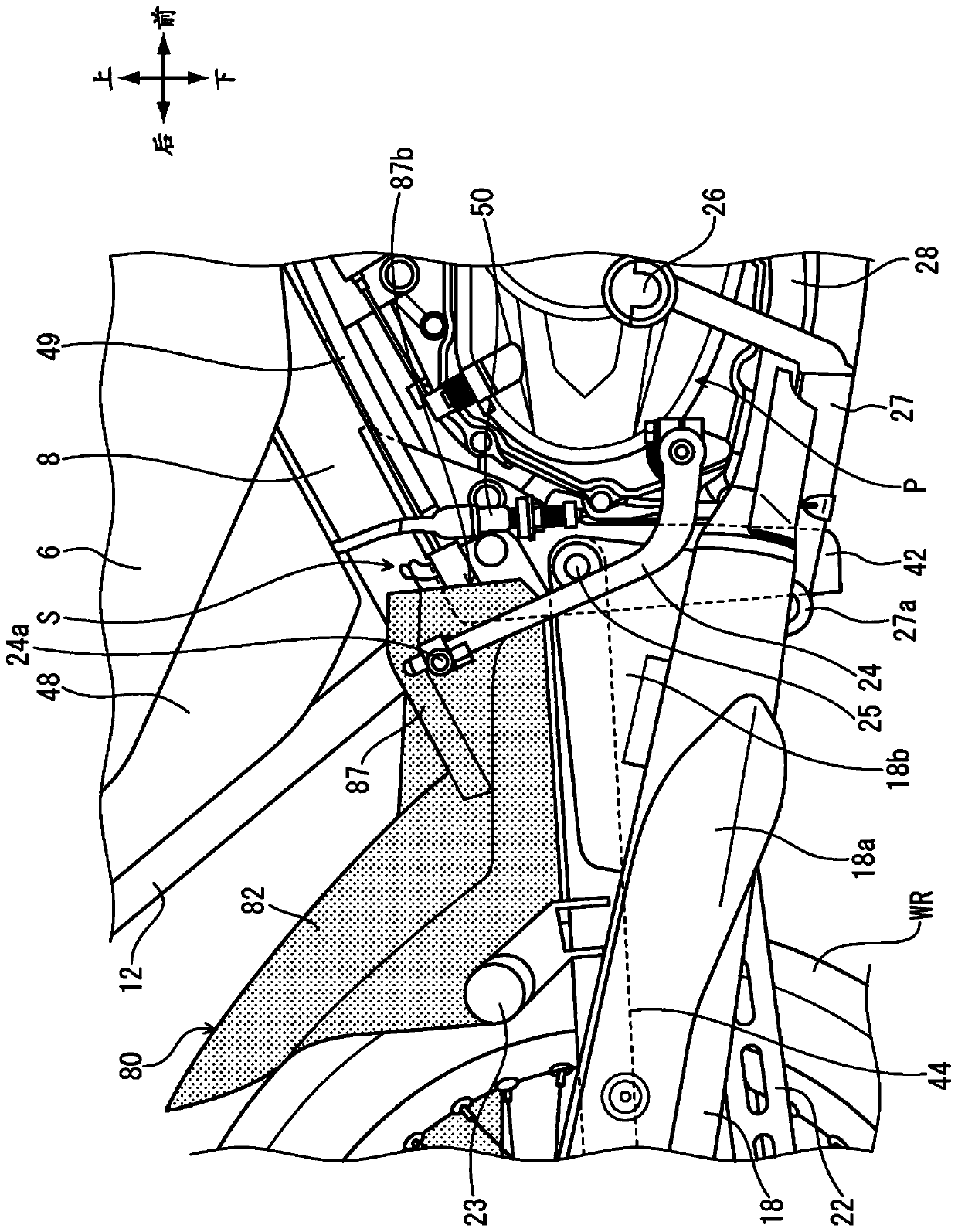

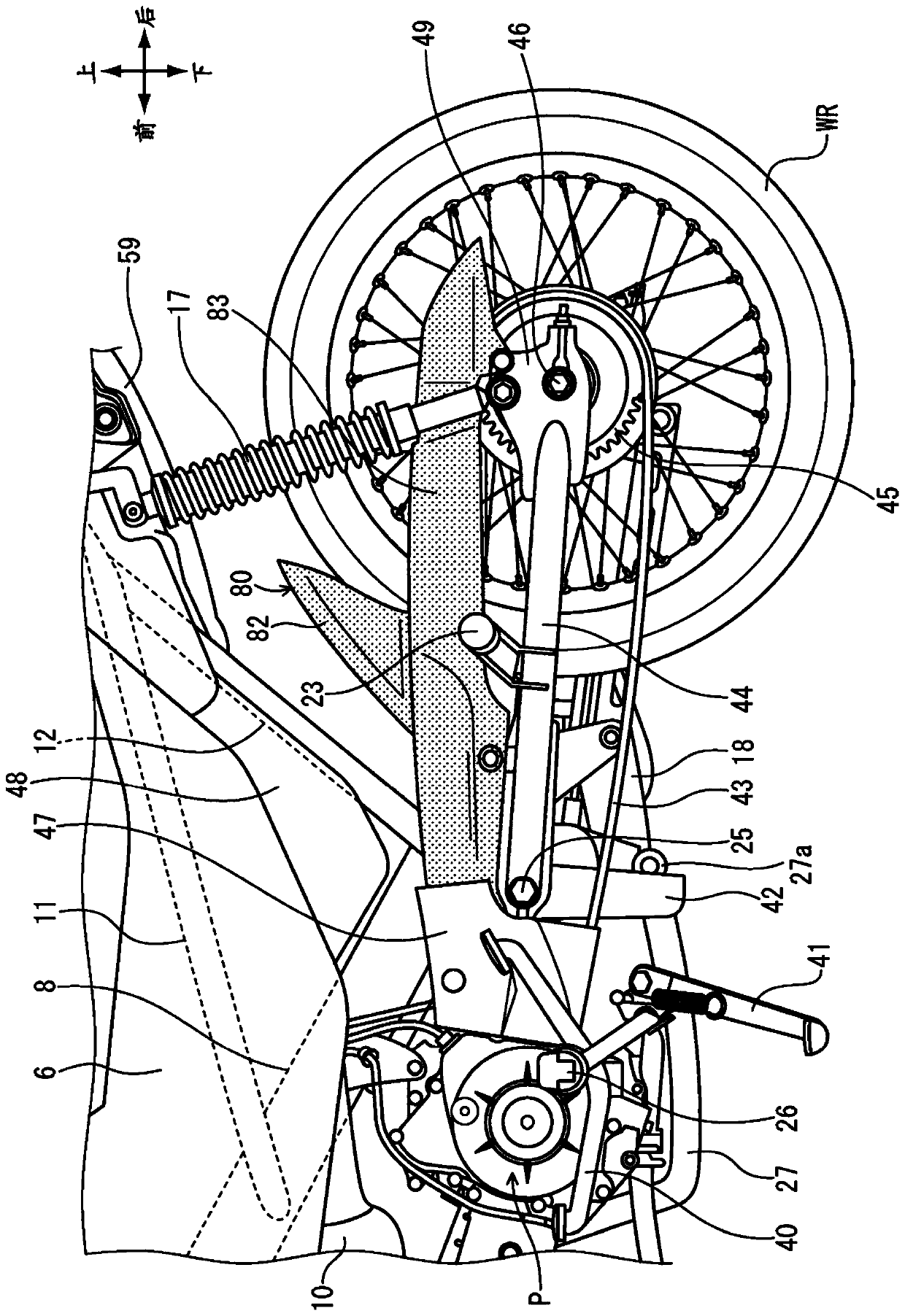

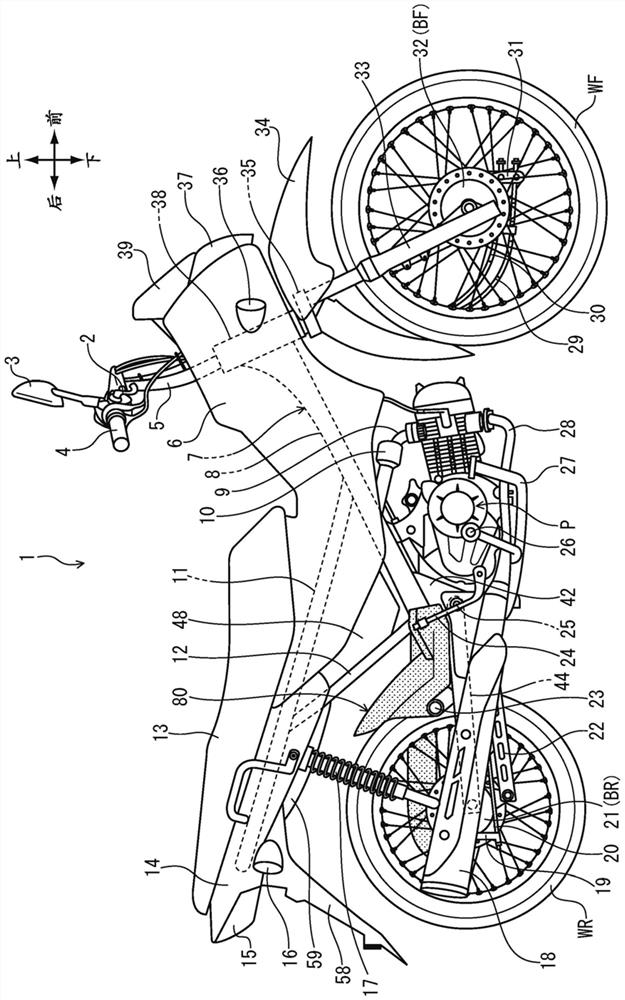

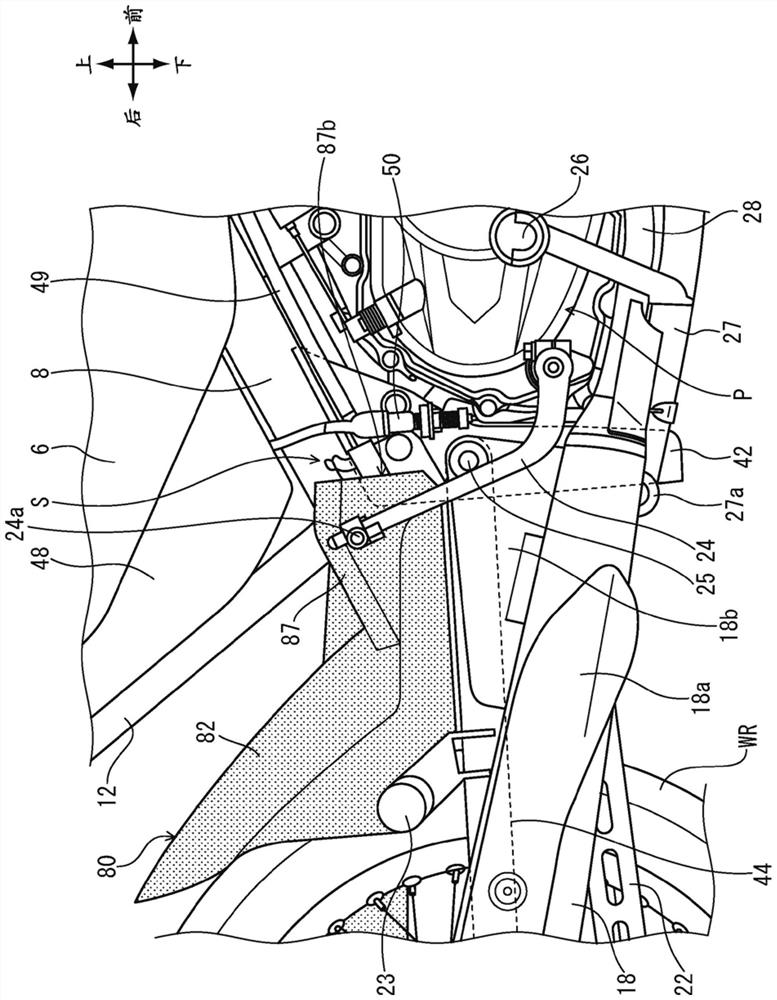

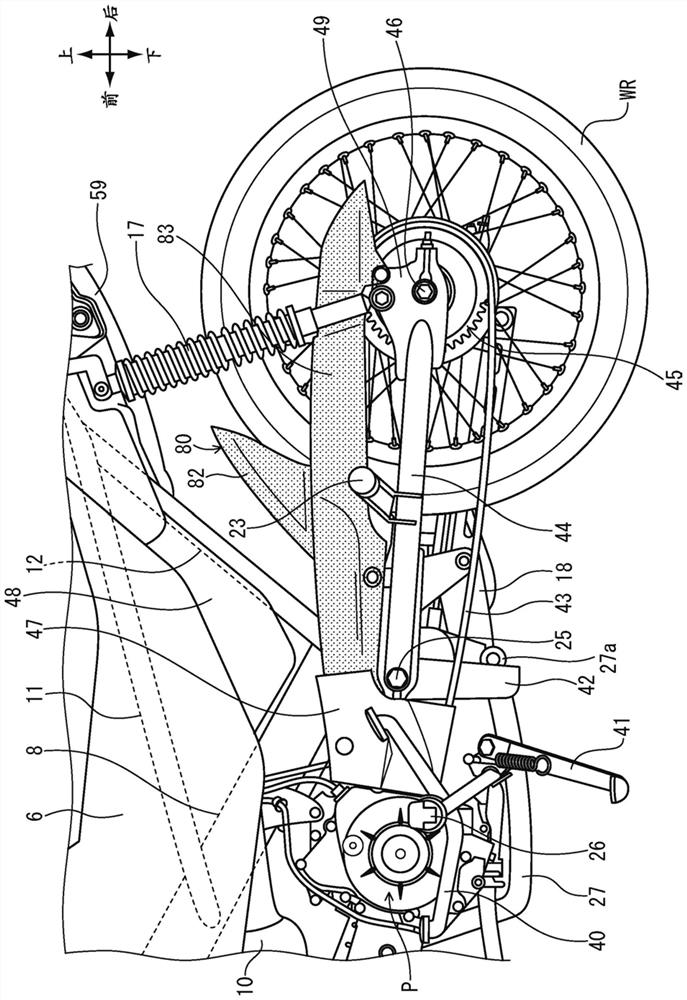

Straddle-type vehicle

The invention provides a straddle-type vehicle. The straddle-type vehicle is provided with a cover component for protecting a linkage mechanism of a front-and-back linkage brake system connected witha brake pedal. The straddle-type vehicle (1) is provided with: a linkage mechanism (S) that is connected to a brake pedal (27) in order to interlock a front wheel brake (BF) and a rear wheel brake (BR); a swing arm (44) which is pivotally supported by a vehicle body frame (7) so as to be capable of swinging, and which pivotally supports a rear wheel (WR) so as to be rotatable; and a cover member (80) attached to the upper part of the swing arm (44), the cover member (80) including a rear fender portion (82) covering the front upper part of the vehicle body of the rear wheel (WR) and a protective cover portion (87) covering at least a part of the linkage mechanism (S) from above the vehicle body and on the side of the vehicle body. A wall member (81) is provided on the rear surface side ofthe cover member (80) at a position between the protective cover portion (87) and the rear fender portion (82).

Owner:HONDA MOTOR CO LTD

An automatic assembly device for assembling the clamping cylinder

ActiveCN105345437BRealize assembly workRealize safe operationMetal working apparatusMechanical engineeringSafe operation

The invention discloses an automatic assembly device for assembling a die-locking oil cylinder. The automatic assembly device comprises a rack, wherein one end of the rack is detachably connected with the die-locking oil cylinder; the other end of the rack is provided with a feed mechanism for assembling a pull rod of the die-locking oil cylinder; the feed mechanism comprises a slide mechanism slidably connected with the rack; the slide mechanism is controlled by a drive mechanism which is arranged on the rack; and the pull rod is fixed on the slide mechanism. Slide of the slide mechanism on the rack is realized through the drive mechanism, thus assembly work for the pull rod of the die-locking oil cylinder fixed on the rack is realized; and the existing manner of enabling the pull rod to penetrate through the die-locking oil cylinder by virtue of oblique-pulling of a travelling crane and pushing-pulling of a forklift is replaced by the manner, thus a safe operation in assembly for the pull rod of the die-locking oil cylinder is realized, the labour is reduced, and the effect of increasing the working efficiency is achieved.

Owner:HAITIAN PLASTICS MACHINERY GRP

Stator and rotor mounting machine applied to motor production and assembling

ActiveCN105429383ASave installation spaceReasonable installation layoutManufacturing stator/rotor bodiesAssembly lineEngineering

The invention discloses a stator and rotor mounting machine applied to motor production and assembling. The stator and rotor mounting machine comprises a rack and a rack platform; the rack platform is positioned on the rack; the rack platform is provided with a material conveying flat plate and a mounting frame; the material conveying flat plate is connected with an interval material conveying apparatus; the interval material conveying apparatus comprises a material conveying mechanism and an interval transmission mechanism; the material conveying mechanism is connected with the interval transmission mechanism; the mounting frame comprises two mounting vertical frames and a mounting transverse frame; the mounting transverse frame is provided with a lifting mounting apparatus; the lifting mounting apparatus is connected with a centering apparatus; the centering apparatus comprises a centering rotating shaft, a centering disk and a centering rotating table; the centering rotating shaft is mounted below the lifting mounting apparatus; the centering disk and the centering rotating table are mounted on the centering rotating shaft; and a mounting assembly is mounted under the centering rotating table. The stator and rotor mounting machine is simple in structure, scientific and convenient, highly targeted, high in automation degree, and capable of realizing assembly line assembling of the motor stators and rotors and well solving the problem existing in the assembling of the motor stators and rotors.

Owner:安徽创研新材料有限公司

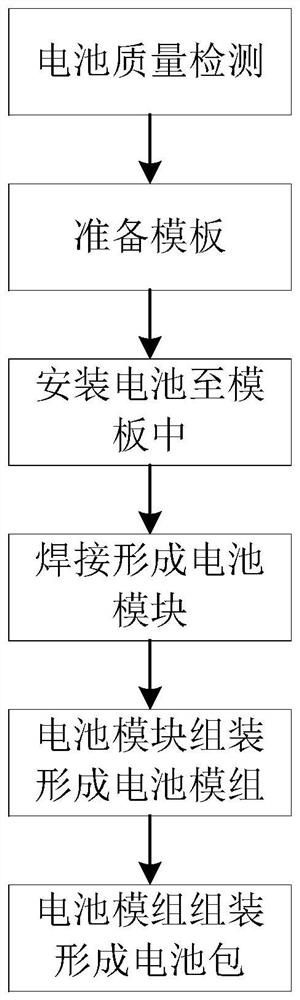

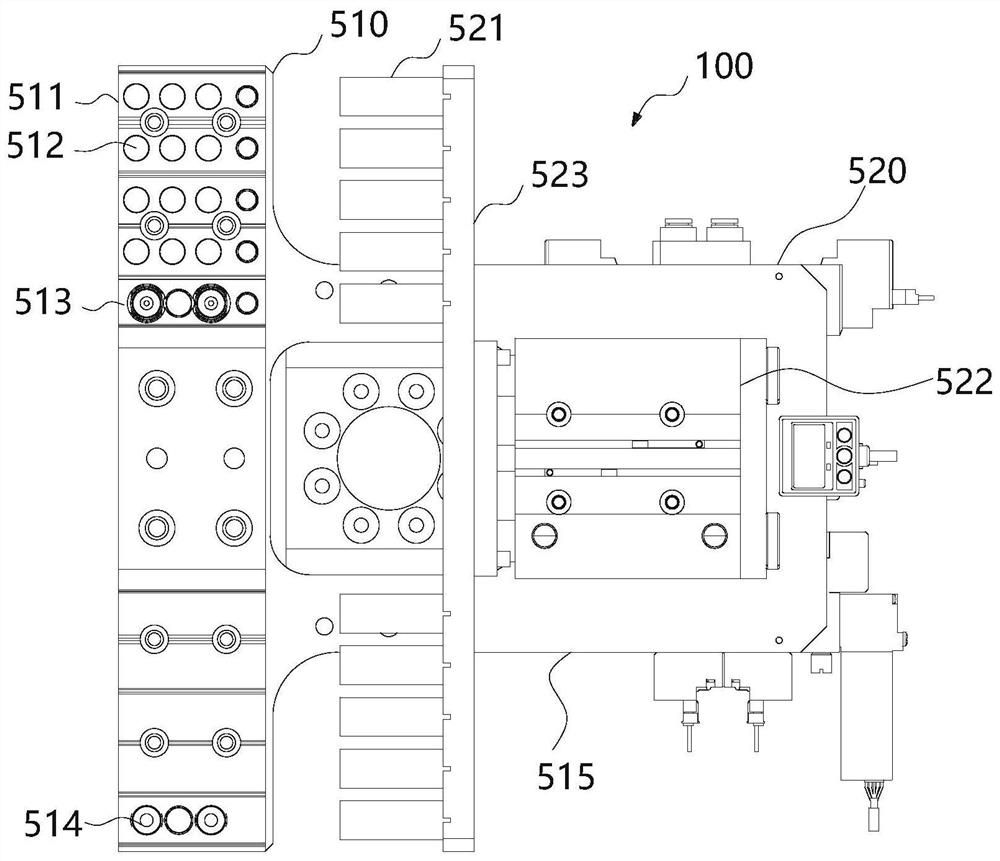

Power battery production system

ActiveCN108075167BRealize assembly workRealize mechanical automation operationAssembling battery machinesFinal product manufacturePower batteryElectrical battery

Owner:AULTON NEW ENERGY AUTOMOTIVE TECHNOLOGY GROUP +1

A processing mechanism for aluminum electrolytic capacitors

ActiveCN113305538BLabor savingImprove work efficiencyMetal working apparatusEngineeringMechanical engineering

The invention discloses a processing mechanism for aluminum electrolytic capacitors, which belongs to the technical field of processing aluminum electrolytic capacitors, and comprises a processing table, which is placed on a horizontal plane, and a processing device is arranged on the top of the processing table, and the processing device It includes a driving assembly, an adjusting assembly and a pressing assembly, the driving assembly is installed on the top of the processing table, the adjusting assembly is installed on the processing table and hingedly fitted with the driving assembly, the pressing assembly is fixedly installed on the driving assembly, The present invention can wrap the guide pin nails with gold foil paper to complete the assembly through the driving component and the pressing component, which improves the working efficiency of the assembly. The standard gold foil paper is loaded, so that the processing device can freely switch the gold foil paper assembly of the corresponding specification when assembling the gold foil paper of guide pins of different specifications, which improves the work efficiency of the overall assembly.

Owner:NANTONG CHUANGJIA ELECTROMECHANICAL

Multi-roll-core structure of lithium battery and assembly method of multi-roll-core structure

PendingCN114156608ASimple structureAvoid the risk of short circuitsFinal product manufactureVent arrangementsStructural engineeringLithium-ion battery

The invention discloses a multi-roll-core structure of a lithium battery and an assembly method of the multi-roll-core structure, and relates to the technical field of lithium ion batteries. Comprising a plurality of roll core assemblies, a connecting assembly, a cover plate assembly and an aluminum shell, the roll core assembly comprises a pole lug, the connecting assembly comprises a stand column and a bending hole, the cover plate assembly comprises a pole, and a pole hole is formed in the pole; the connecting assembly and the cover plate assembly are fixed through the upright post and the pole post hole in the pole post, the connecting assembly and the pole lug on the roll core assembly are fixed, and the connecting assembly is bent through the bending hole; the roll core assembly, the connecting assembly and the cover plate assembly are combined and then placed in the aluminum shell, and the cover plate assembly is fixed to the aluminum shell. The problem that in the prior art, a large amount of metal dust generated when a connecting piece and a cover plate are welded enters roll cores, and consequently the lithium battery is short-circuited can be solved, and assembling work of any number of roll cores of the lithium battery can be achieved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A four-axis linkage assembly device in a fully automatic assembly system for cabinet adjustment feet

InactiveCN104625700BScientific and reasonable structure designLow costAssembly machinesMetal working apparatusIndustrial engineeringAssembly systems

Owner:HARBIN INST OF TECH

A turntable mechanism in a fully automatic assembly system for cabinet adjustment legs

InactiveCN104526337BReusableScientific and reasonable structure designMetal working apparatusEngineeringMechanical engineering

Owner:HARBIN INST OF TECH

straddle vehicle

The present invention provides a saddled vehicle including a cover member for protecting a linkage mechanism of a front-rear linkage brake system connected to a brake pedal. The straddle type vehicle (1) includes: a linkage mechanism (S), which is connected to a brake pedal (27) in order to link the front wheel brake (BF) and the rear wheel brake (BR); a swing arm (44) , which is pivotally supported on the vehicle body frame (7) in a swingable manner, and pivotally supports the rear wheel (WR) in a freely rotatable manner; and a cover member (80), which is installed on the swing arm (44) In the upper part, the cover member (80) includes a rear fender portion (82) covering the upper front of the vehicle body of the rear wheel (WR) and a protective cover portion ( 87) and integrally formed. A wall member (81) is provided on the back side of the cover member (80) and at a position between the protective cover portion (87) and the rear fender portion (82).

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com