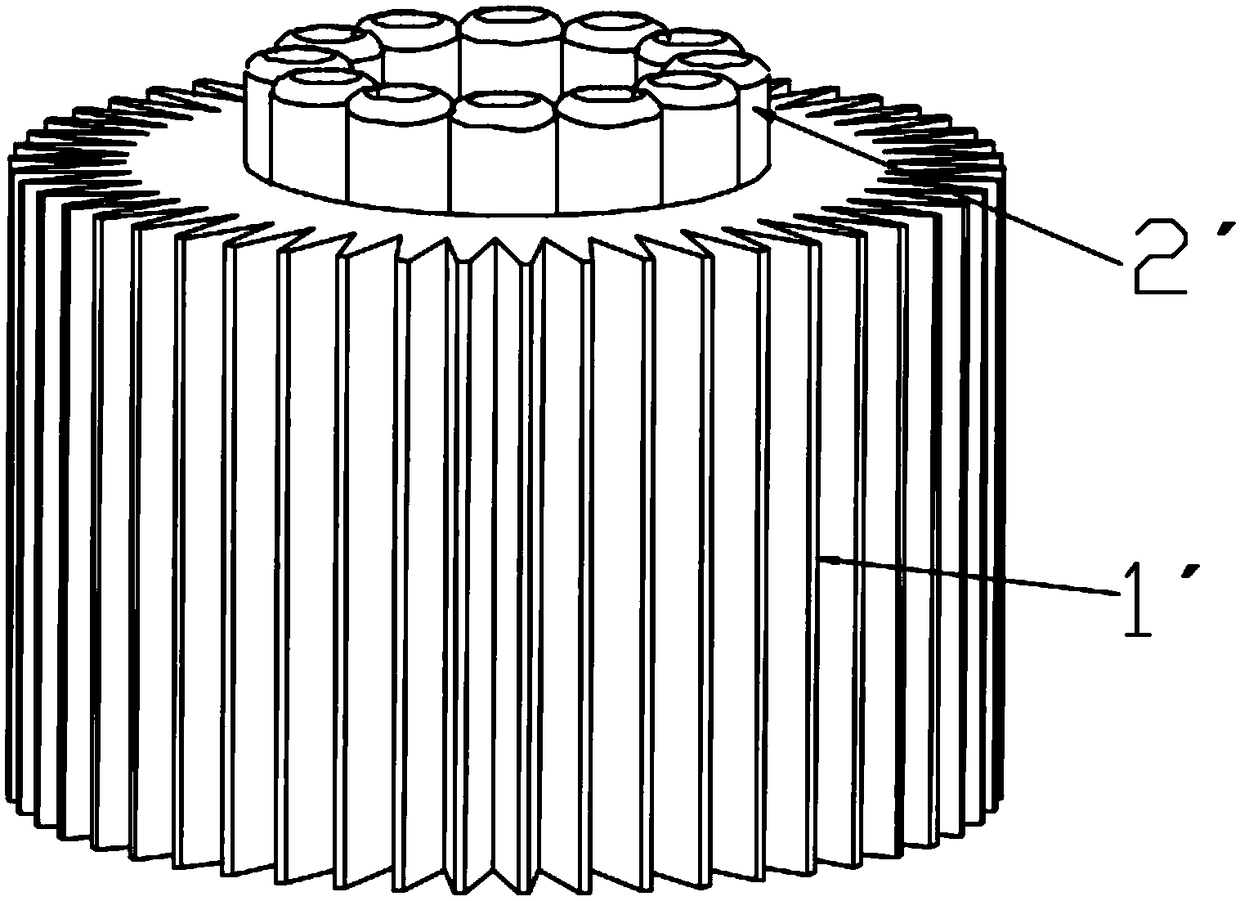

An automatic assembly apparatus for a gear needle of a planetary reducer

A planetary reducer and assembly equipment technology, which is applied in the direction of mechanical equipment, engine lubrication, metal processing equipment, etc., can solve the problem of low installation efficiency, and achieve the effect of high assembly efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

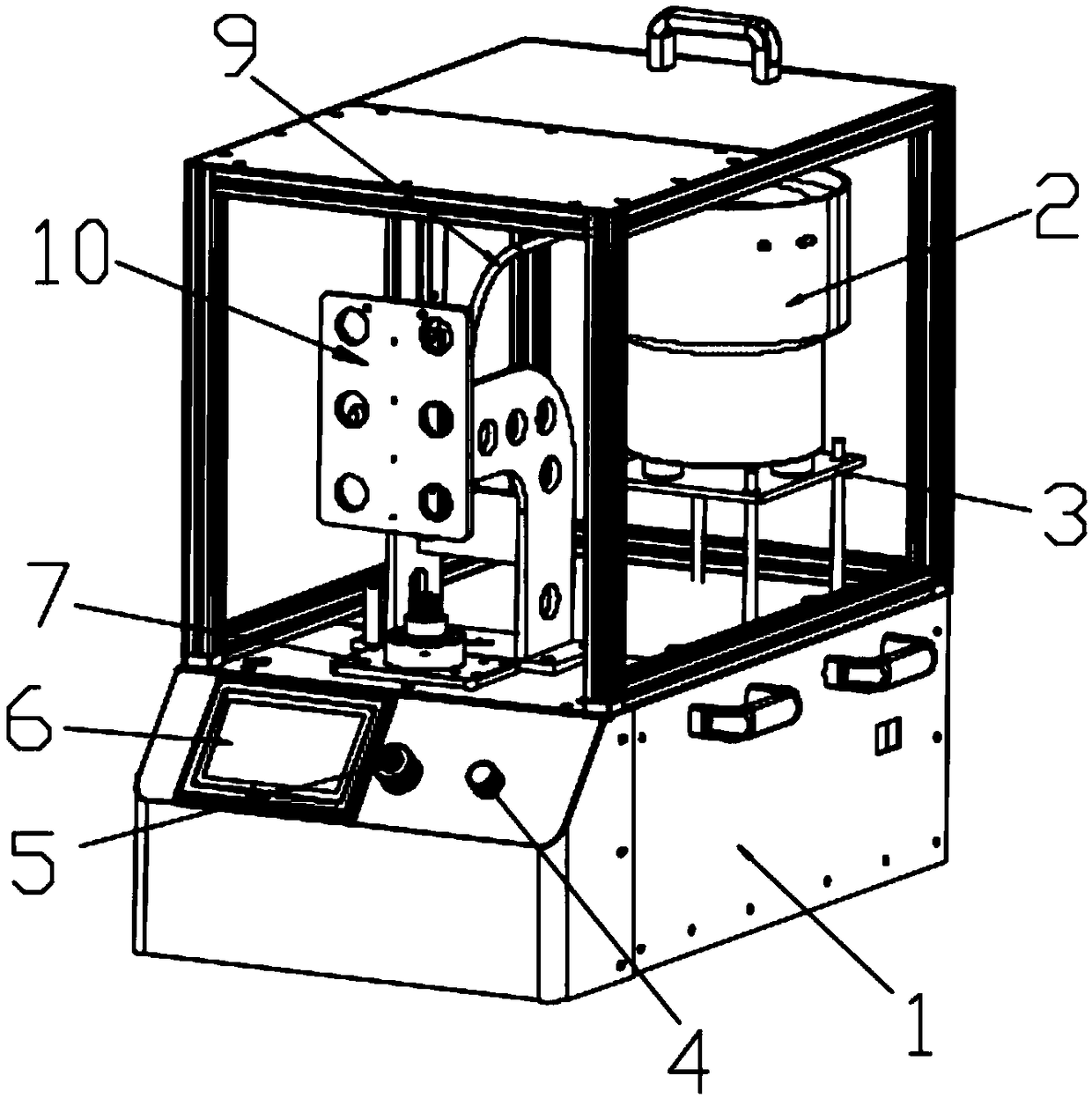

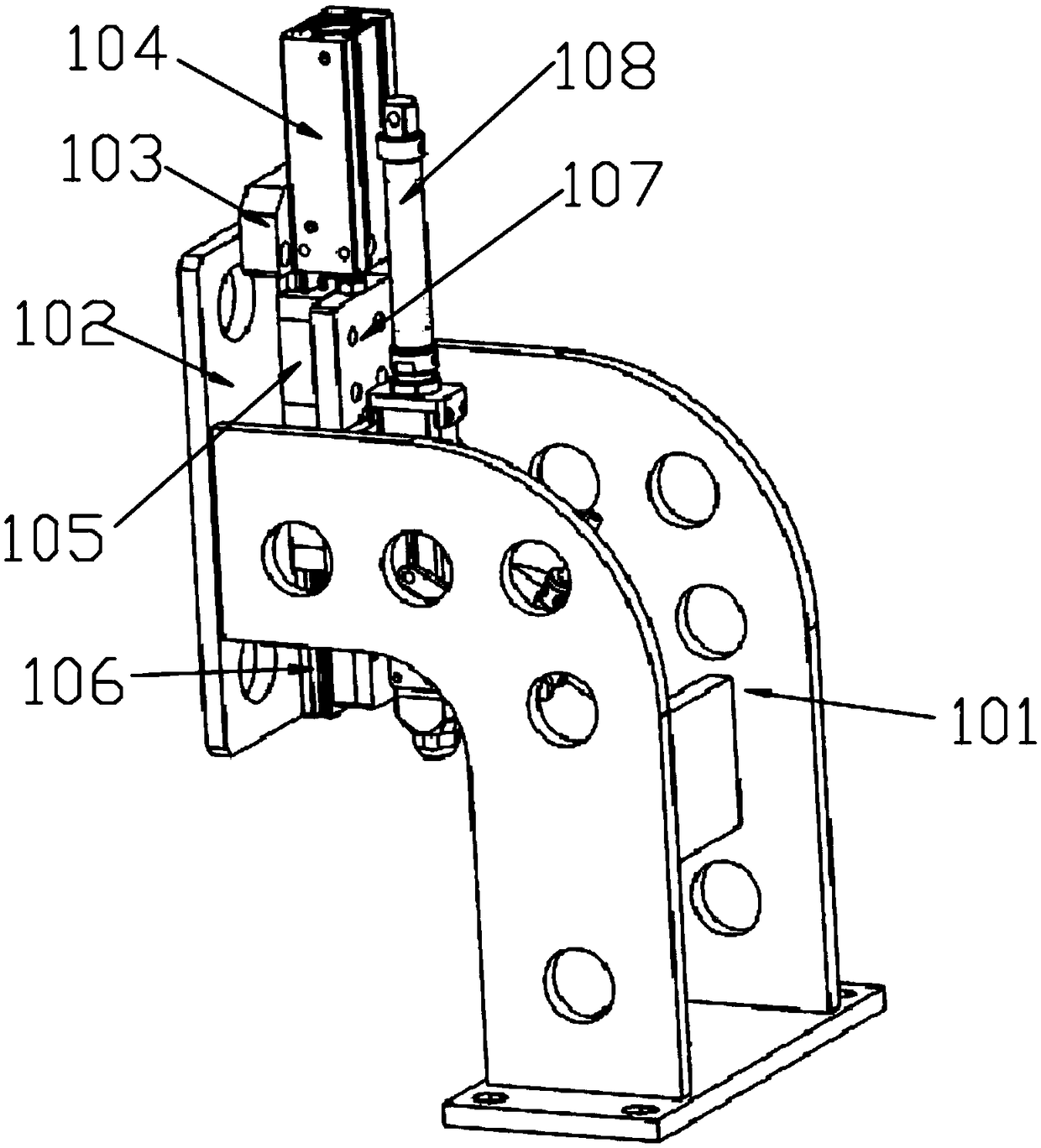

[0028] See attached figure 2 As shown, in this embodiment, an automatic assembly equipment for gear needle rollers of planetary reducers, a base 1, a working platform is arranged on the base 1, and on the base 1 where one side of the working platform is located An operation panel (emergency button 5 , operation button 4 and operation panel 6 ) is provided, and the above-mentioned emergency button 5 , operation button 4 and operation panel 6 are all connected to the electrical control cabinet located in the base 1 . A gear bearing placing mechanism 7 is installed on the working platform near the side of the operation panel 6 for placing the gear bearing. A latch mechanism 10 is provided above the gear bearing placement mechanism 7 for inserting the gear needle into the gear bearing. On the working platform, a vibrating disc support frame 3 is also provided, on which a vibrating disc 2 (feeder) is arranged, and the discharge port of the vibrating disc 2 is connected to the fee...

Embodiment 2

[0036] This embodiment provides an automatic assembly equipment for gear needle rollers of planetary reducers. Its structure is basically the same as that of Embodiment 1, the difference is that on the basis of Embodiment 1, the method of injecting grease into the gear bearing is added. Oil injection mechanism, the oil injection mechanism is connected with the original electrical control cabinet to realize linkage operation. At present, the butter on the inner wall of the central shaft hole of the gear bearing is manually applied externally and placed on the gear bearing placement mechanism. The oiling mechanism in this embodiment can replace the manual operation of injecting butter on the inner wall of the central shaft hole of the gear bearing. The implemented structure is as follows:

[0037] There is a butter barrel on the working platform, and a hydraulic cylinder-driven squeeze plate is arranged inside the butter barrel. The edge of the squeeze plate is in contact with t...

Embodiment 3

[0039] This embodiment provides an automatic assembly equipment for gear needle rollers of planetary reducers. Its structure is basically the same as that of Embodiment 2, the difference is that on the basis of Embodiment 2, it is used to grab the gear bearing , and place the gear bearing on the mechanical claw on the gear bearing placement mechanism, which is connected with the electrical control cabinet. The implemented structure is as follows:

[0040] A conveyor belt specially designed to place gear bearings is designed on the outside of the base. The above conveyor belt can only be transmitted by a single gear bearing. When the gear bearing is transported to the end of the conveyor belt, the sensor A set at the end of the conveyor belt will detect Gear bearings, and stop the transmission of the conveyor belt, waiting for the mechanical claws to grab the gear bearings. A sensor B is also arranged outside the gear bearing placement mechanism for sensing whether there is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com