Patents

Literature

71results about How to "Realize the installation work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

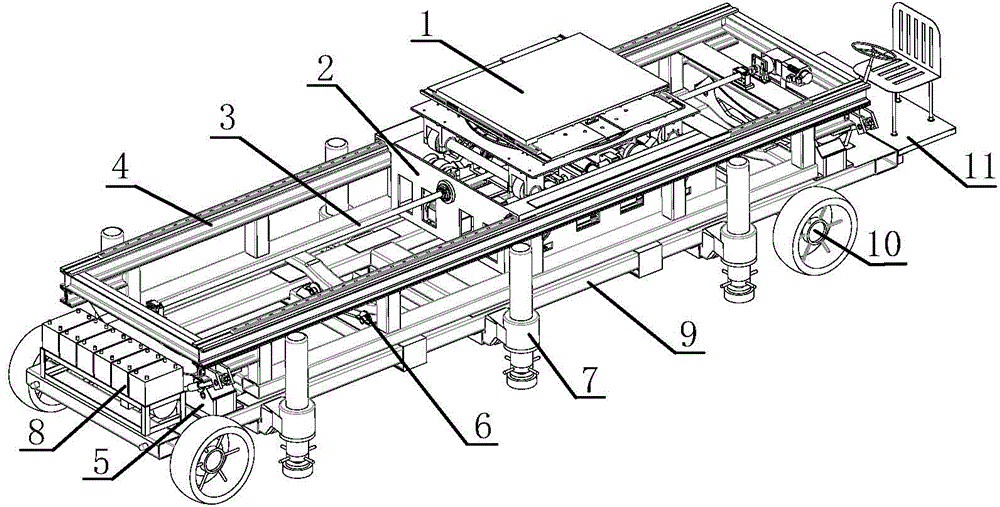

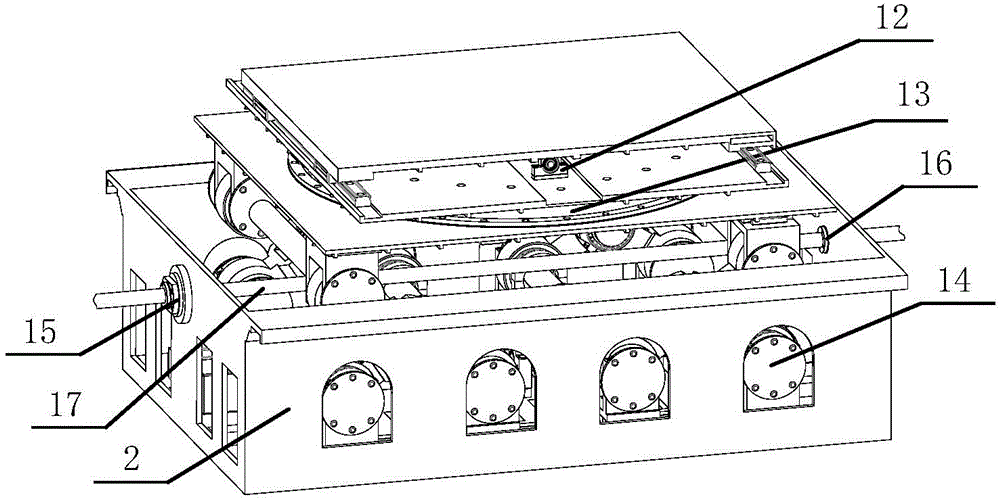

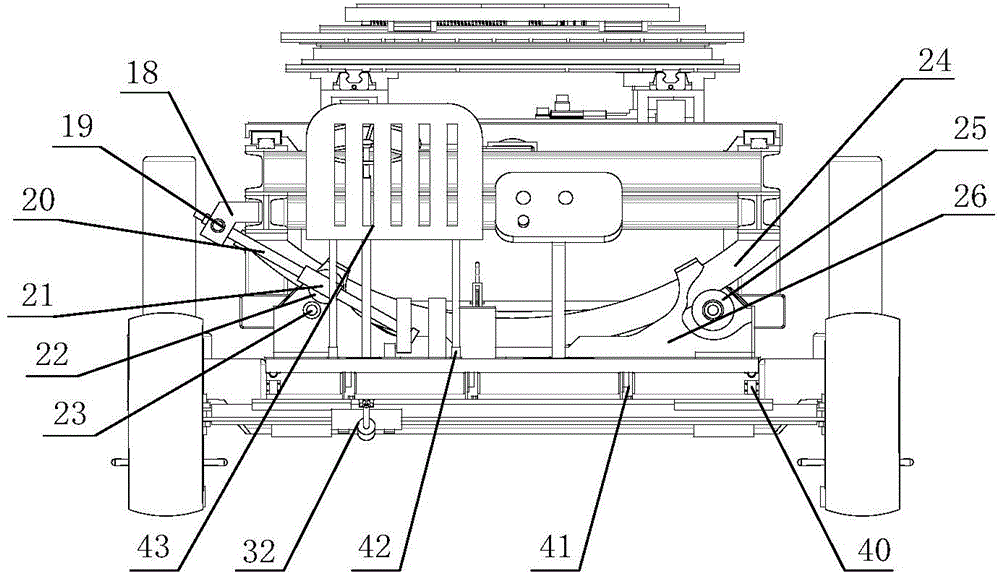

Numerical-control electric frame truck for airplane engine mounting

InactiveCN103204248ARealize the installation workEnable mobilityAircraft assemblyNumerical controlDrive wheel

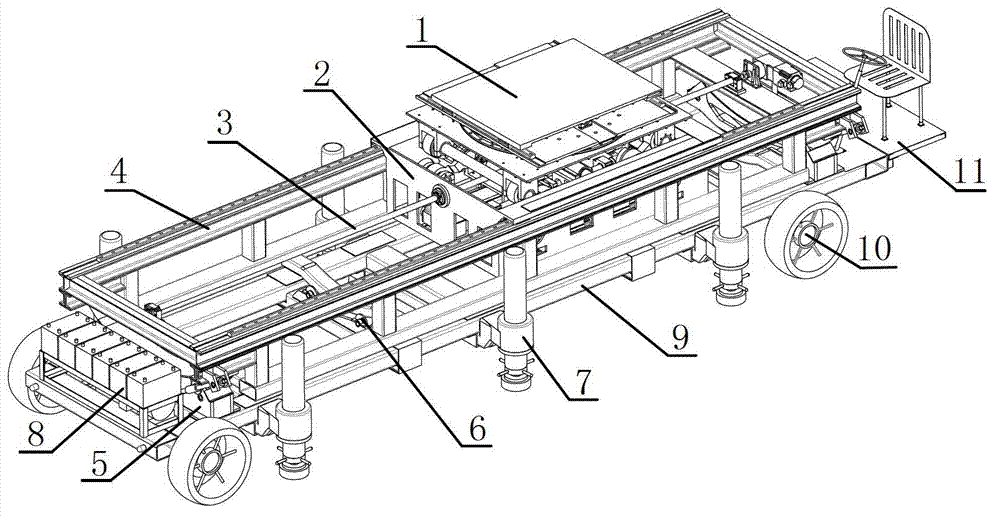

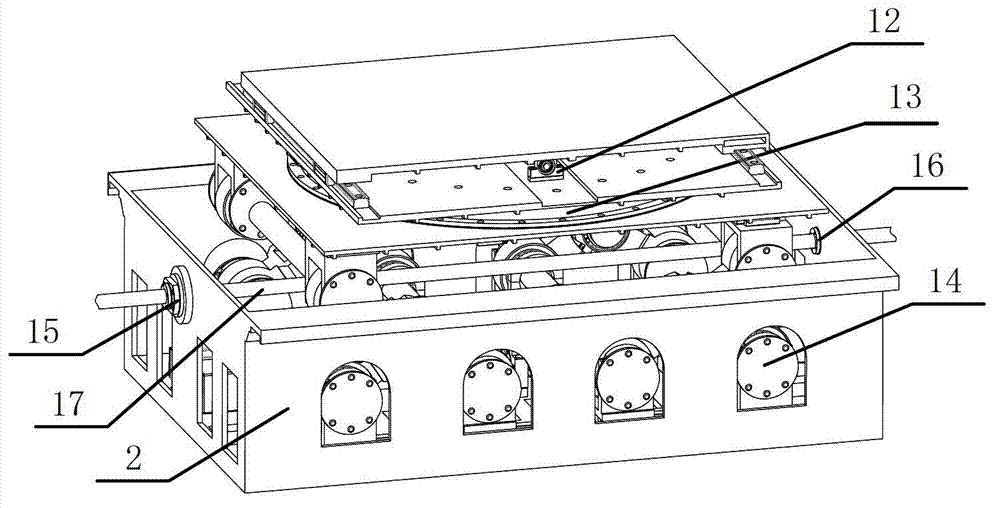

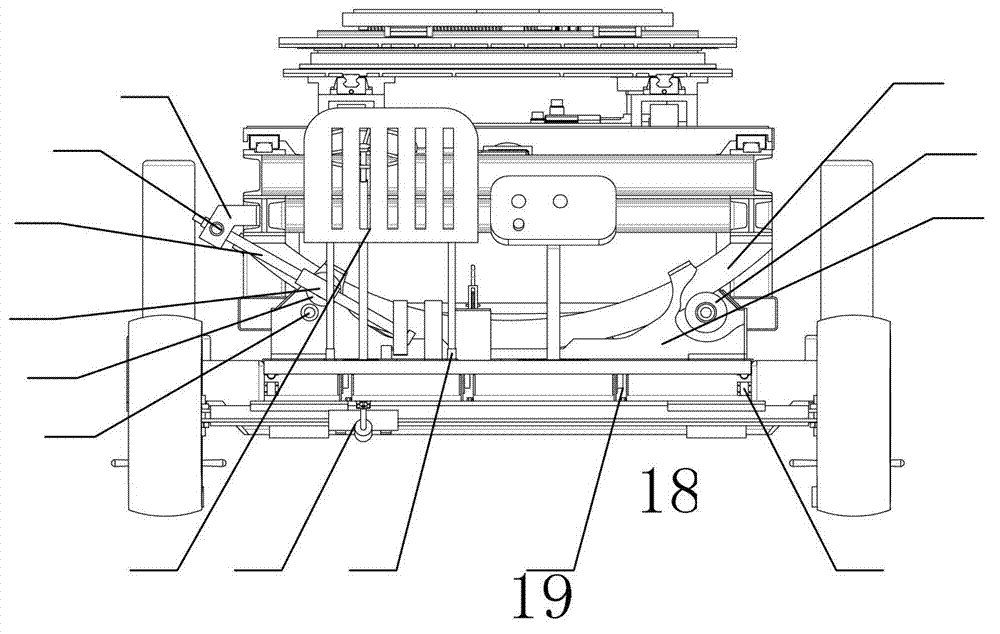

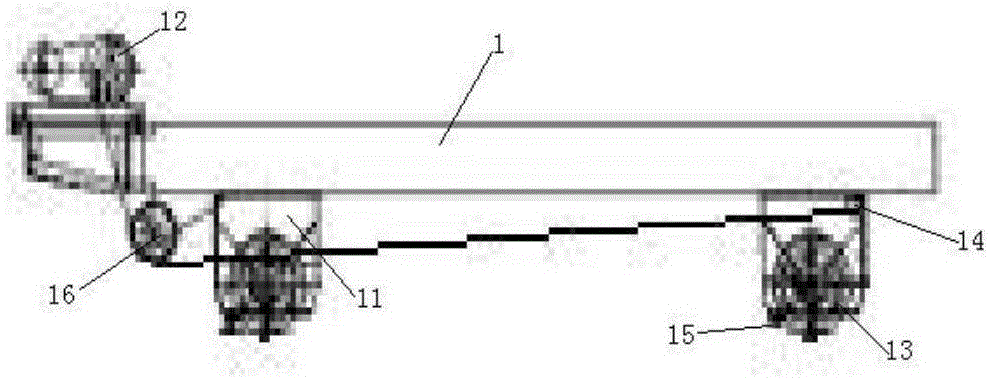

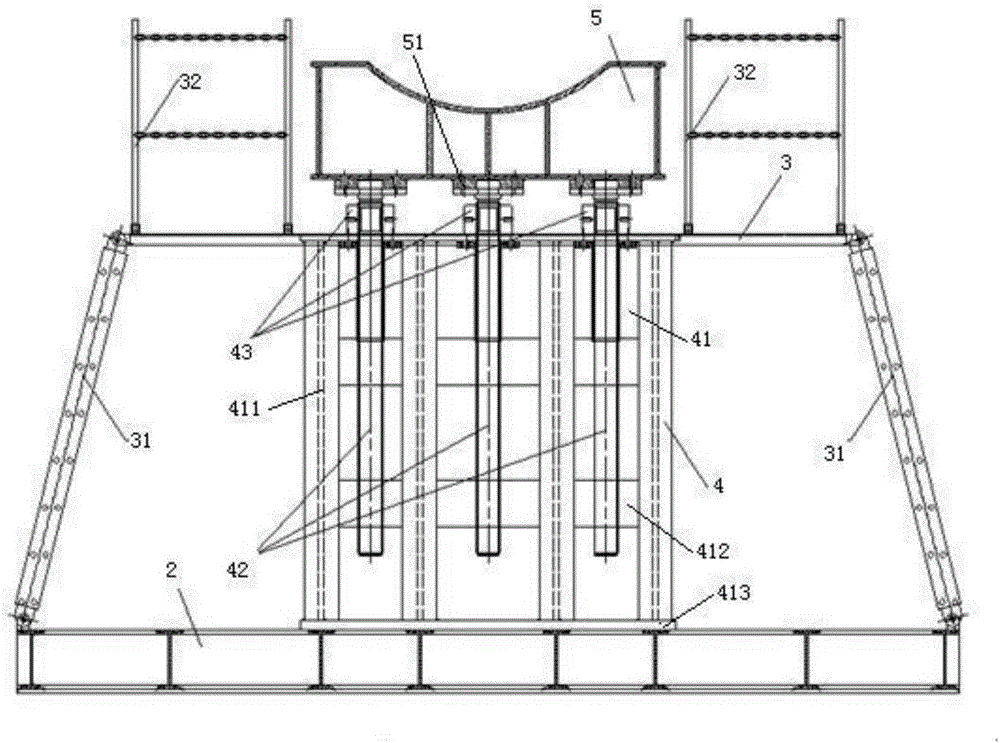

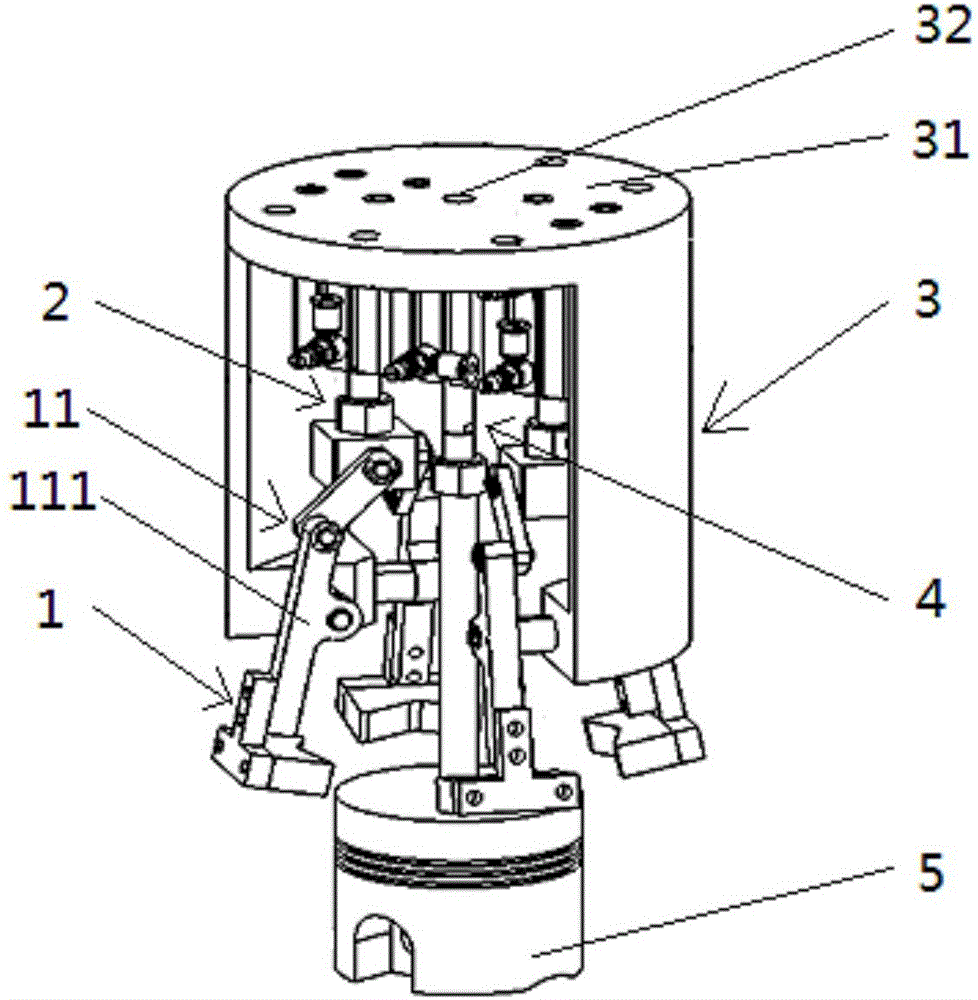

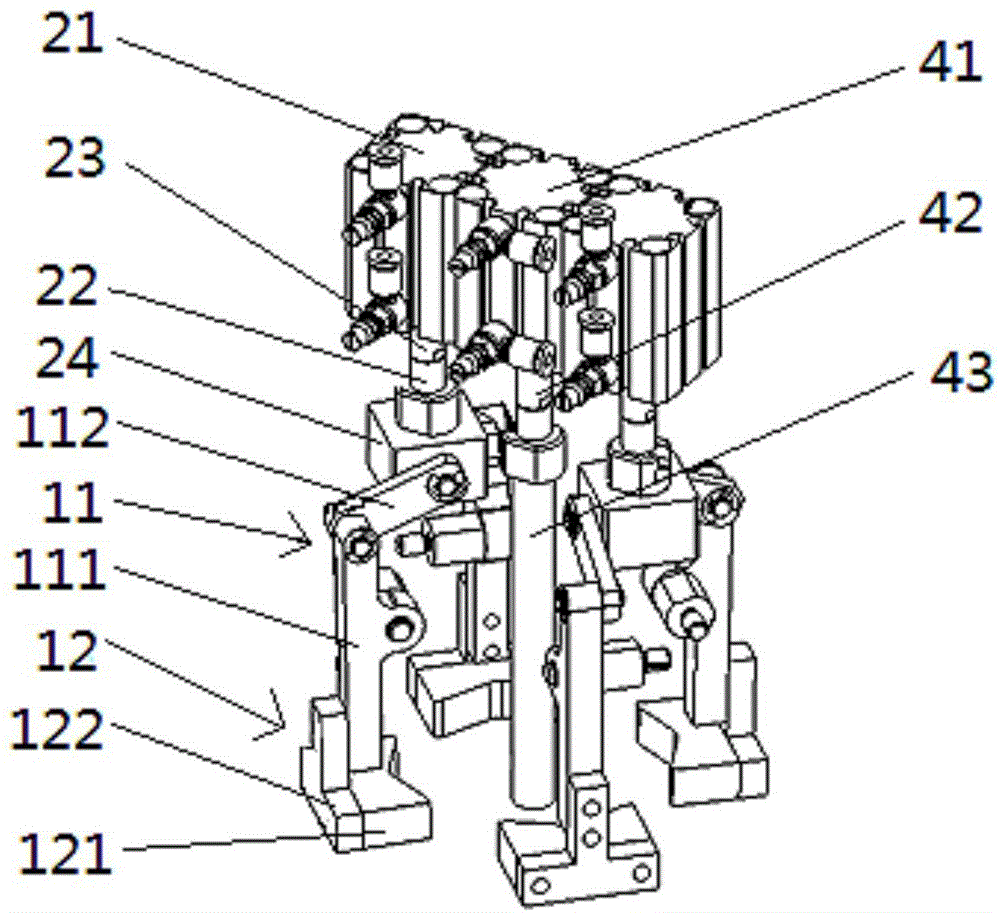

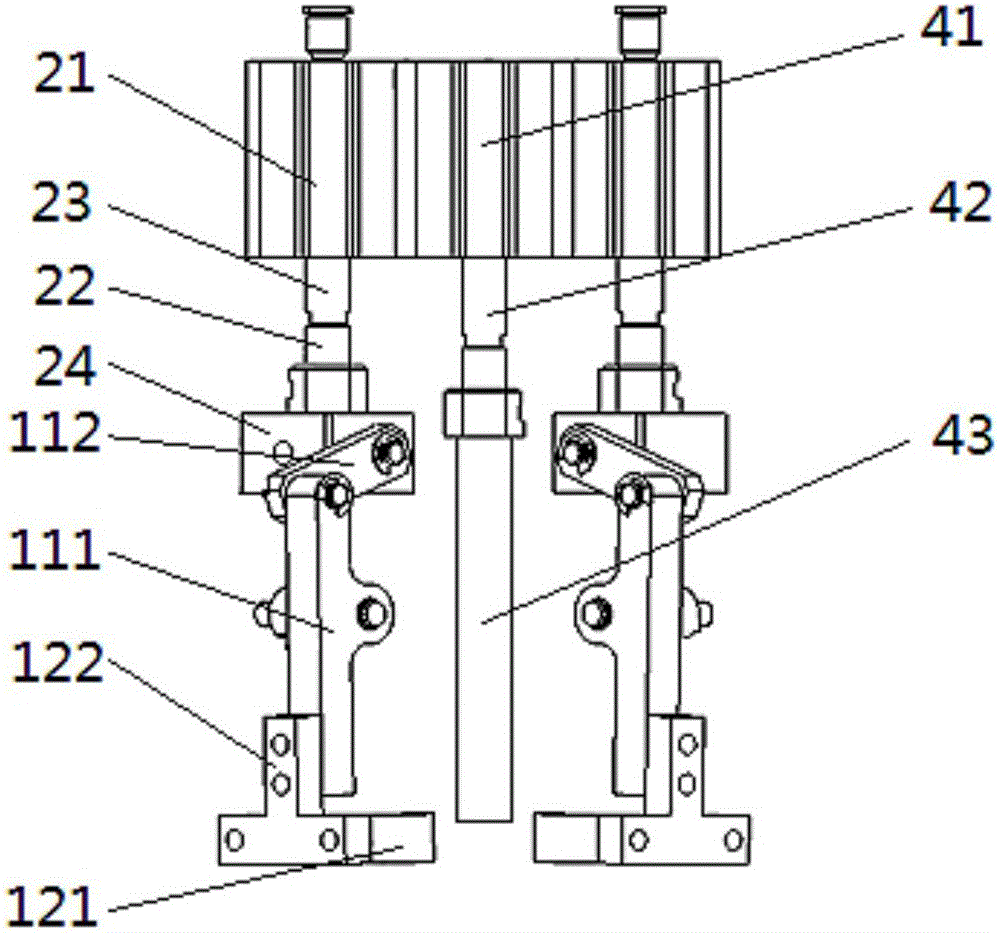

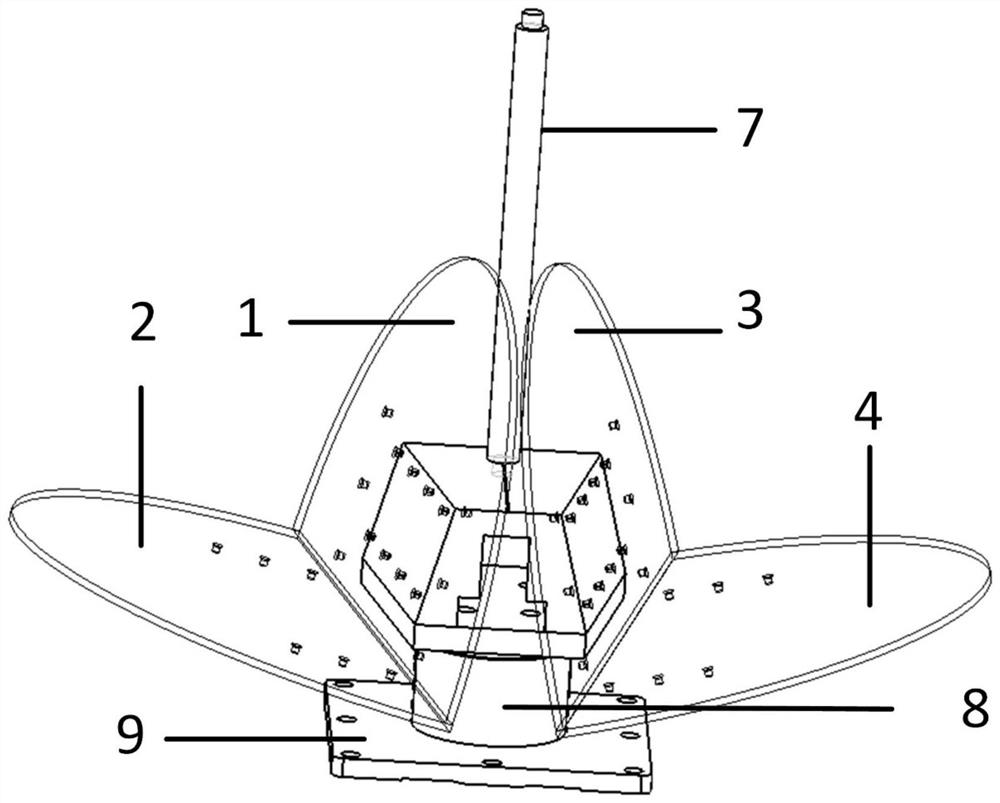

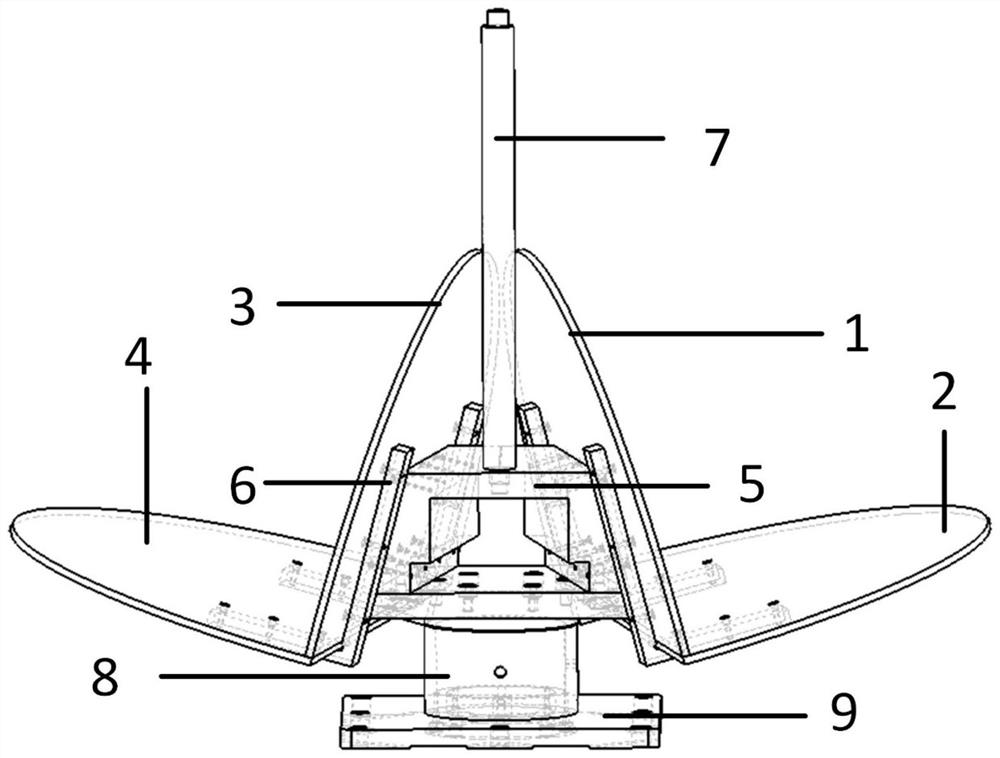

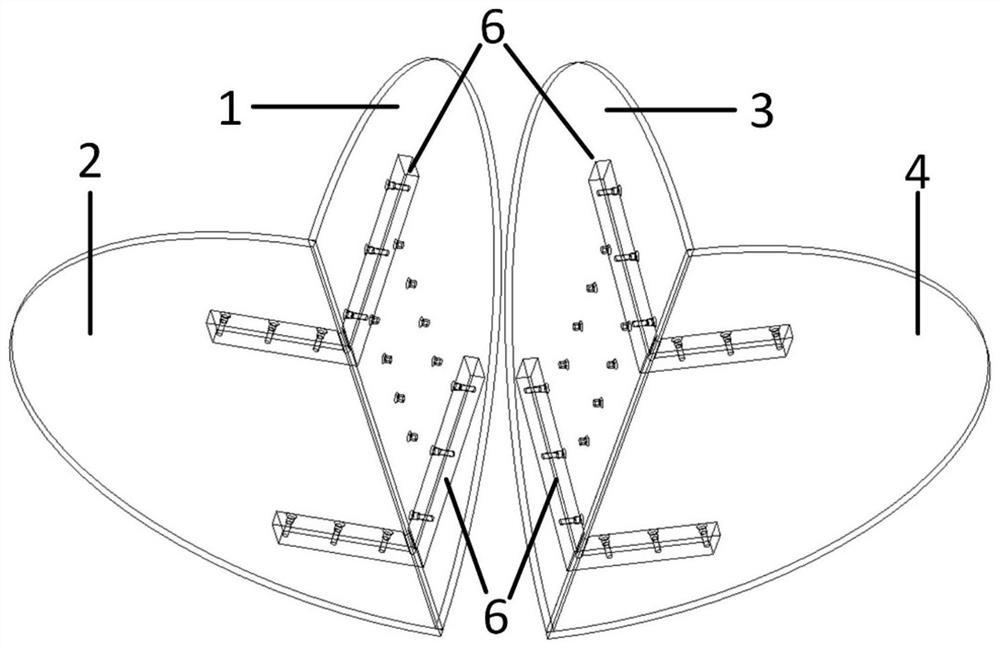

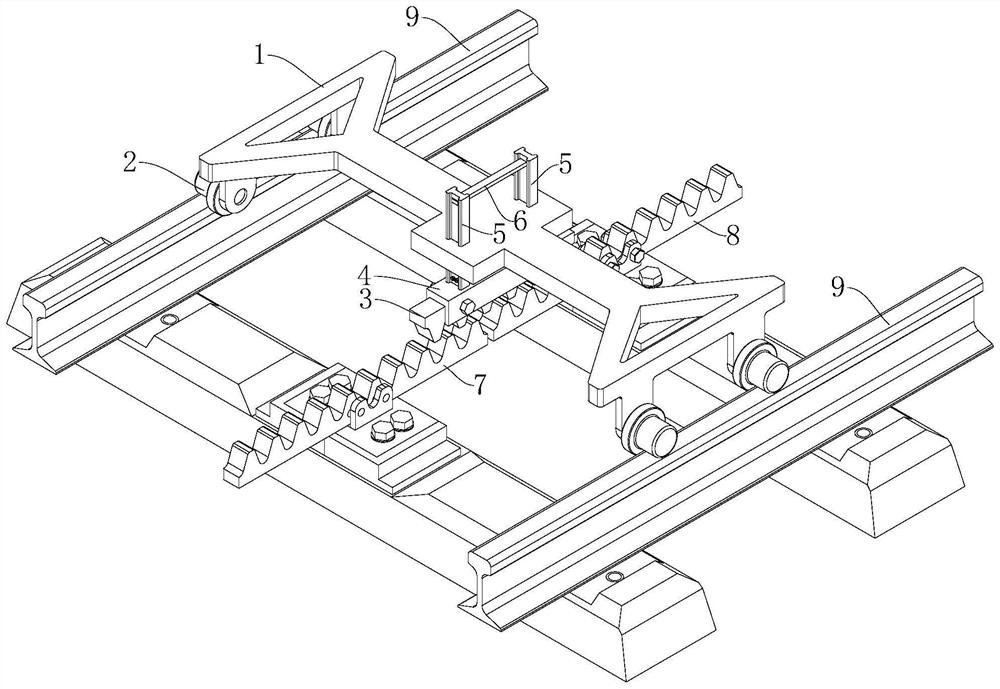

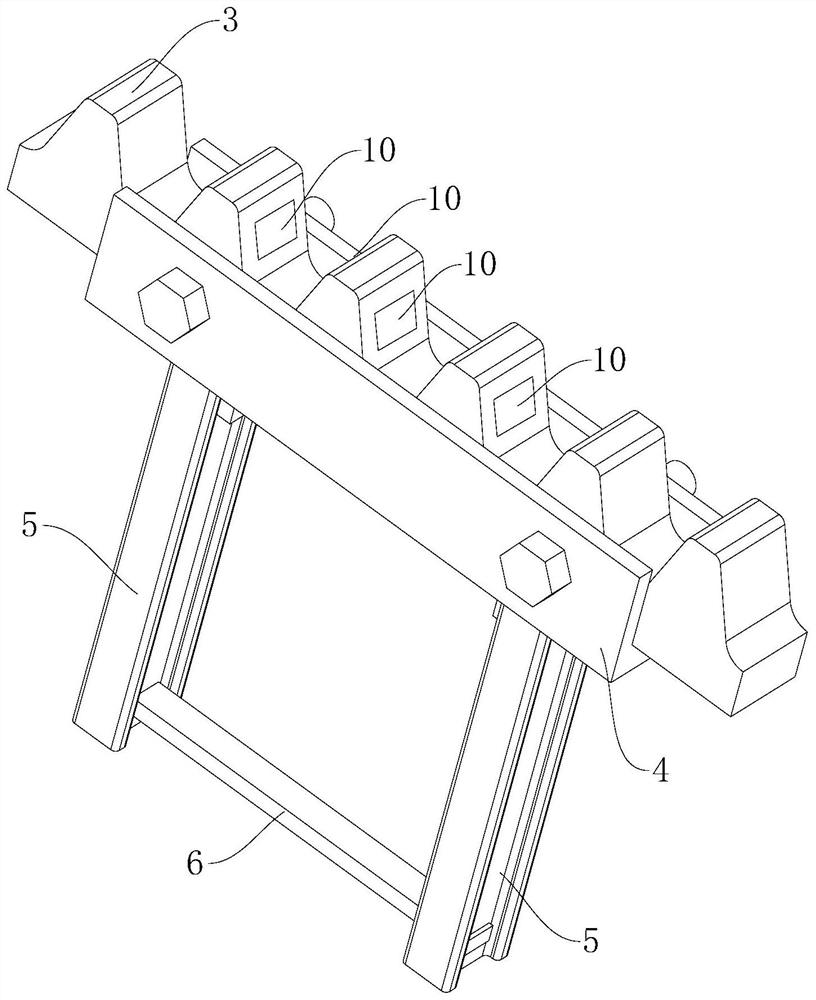

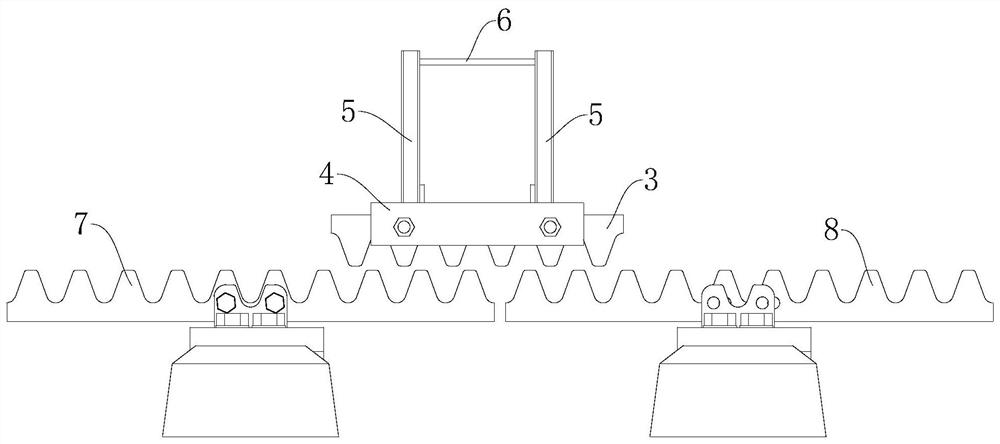

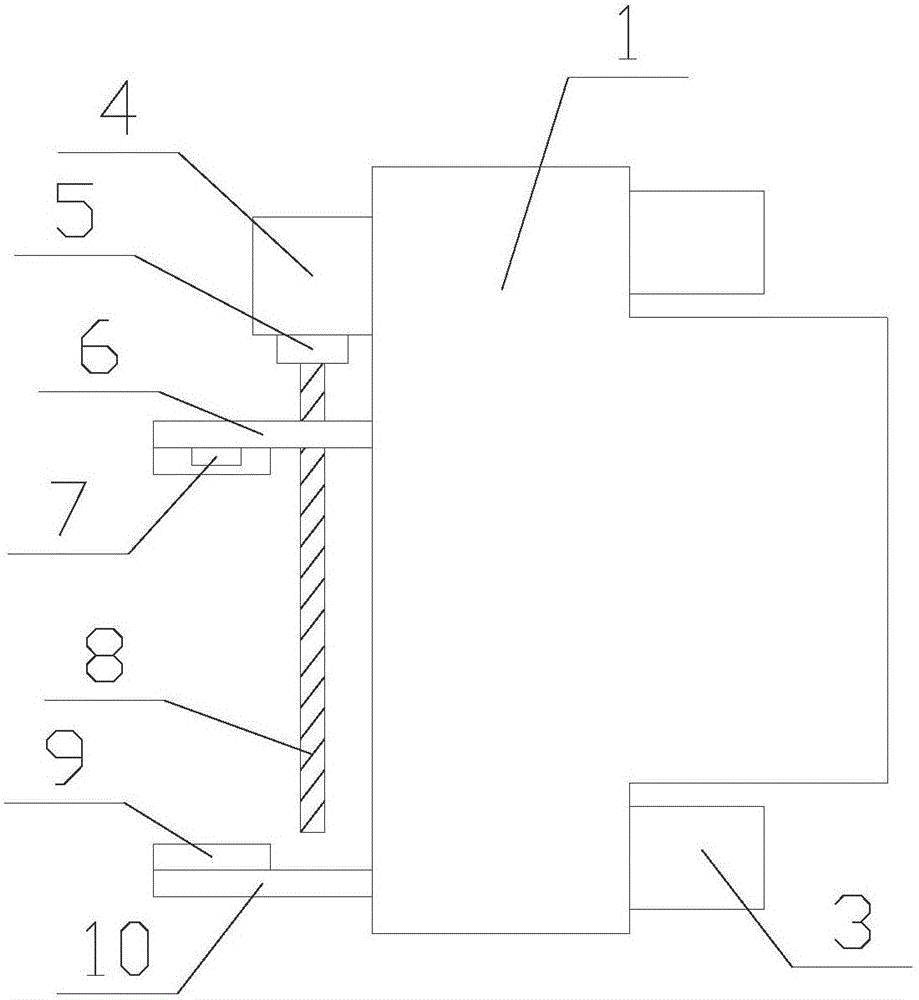

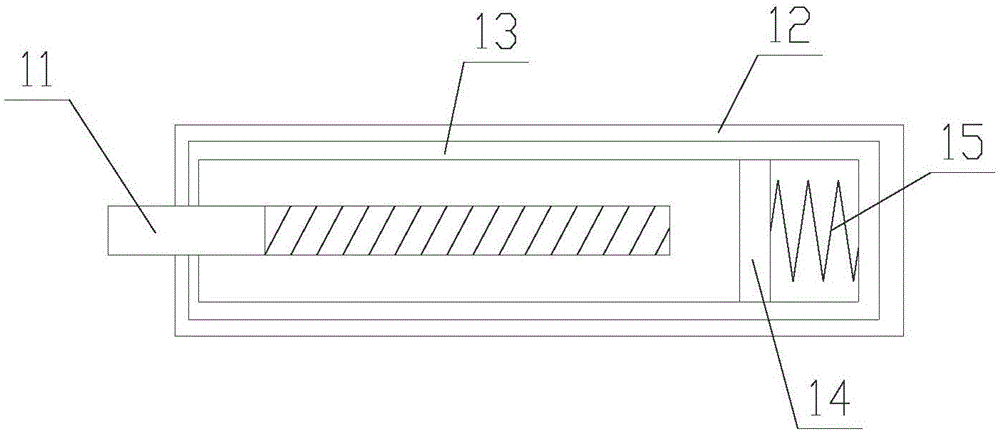

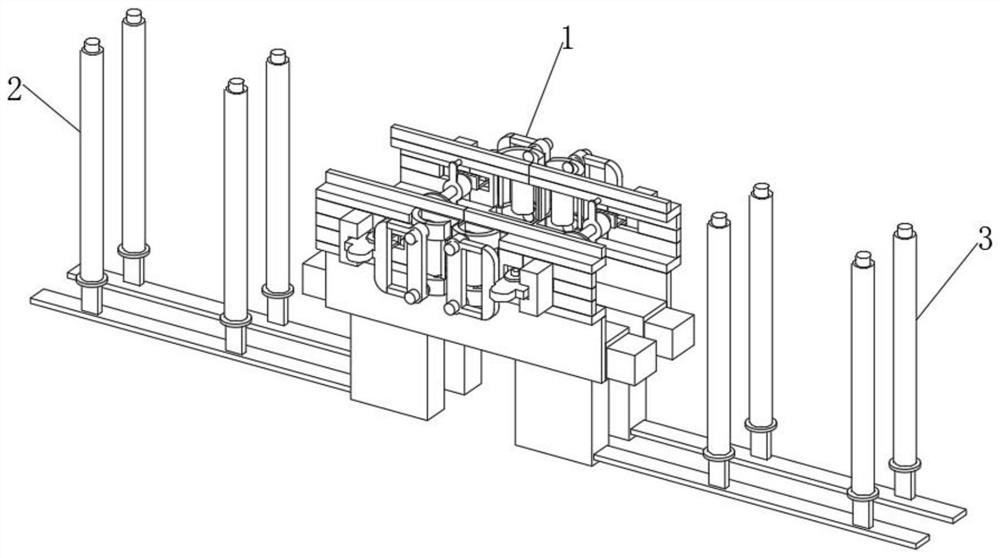

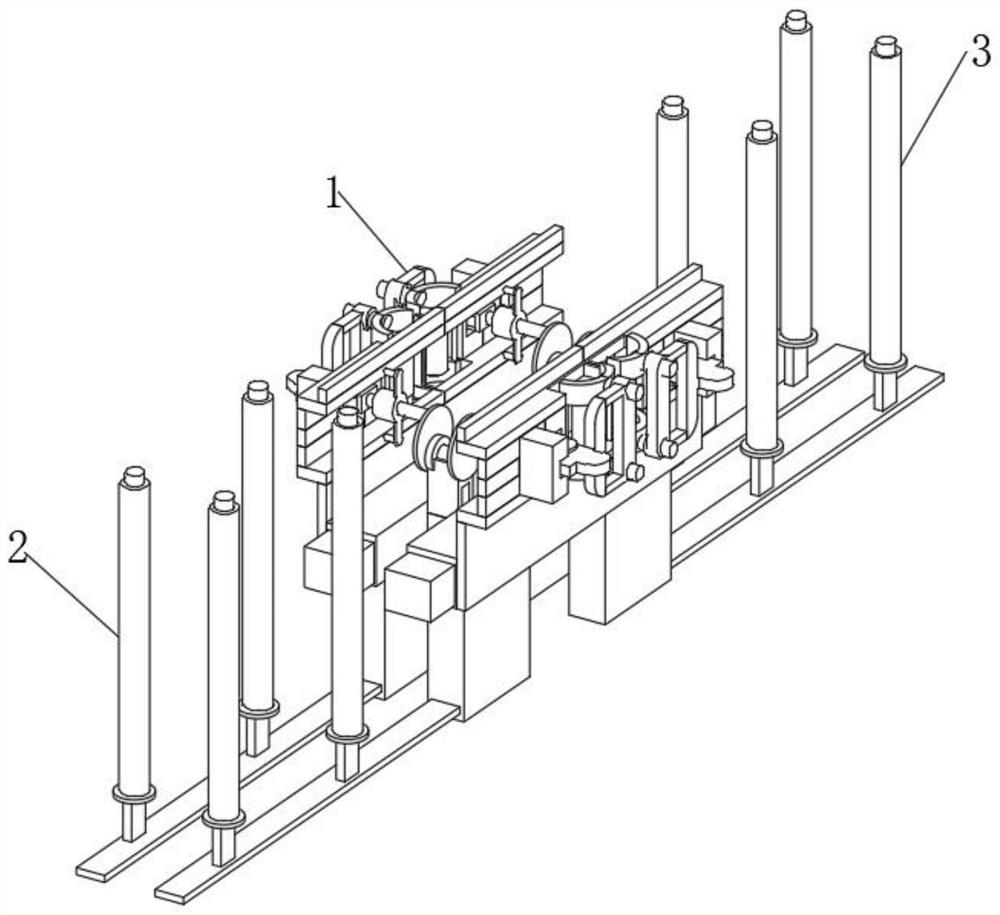

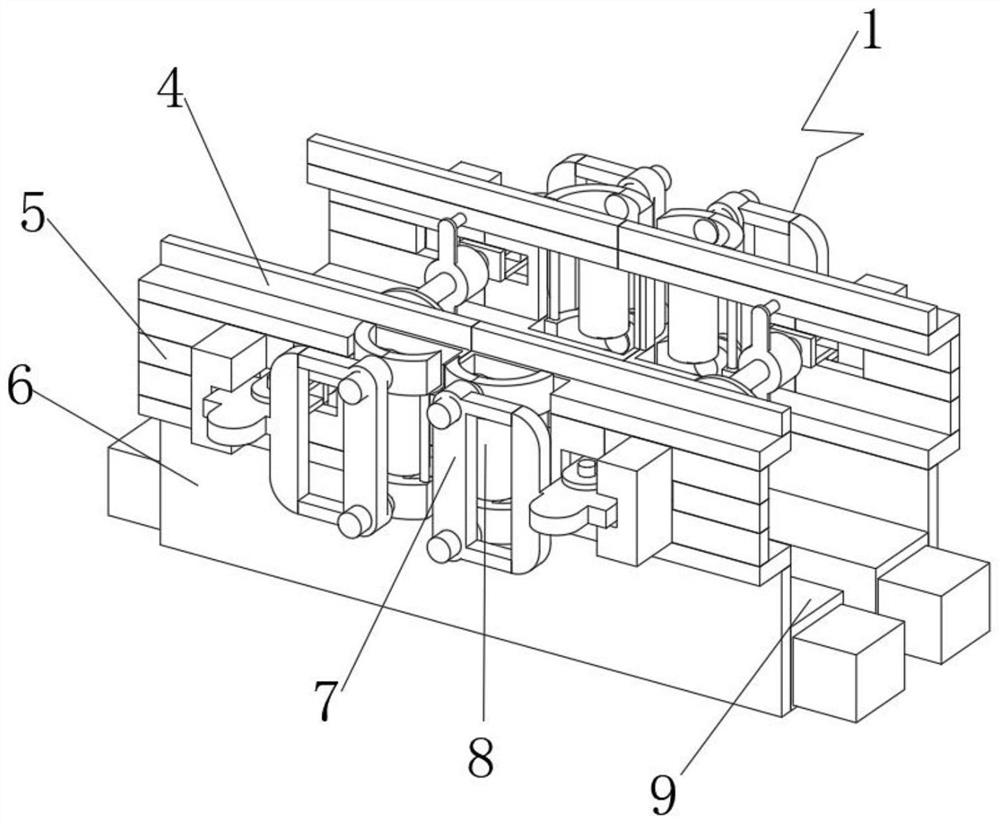

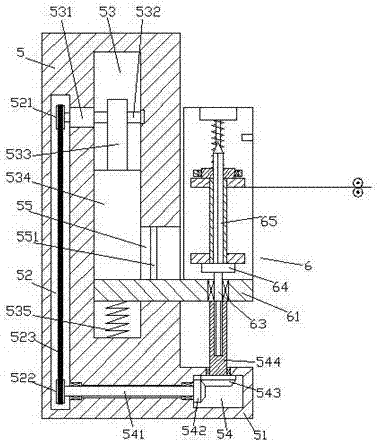

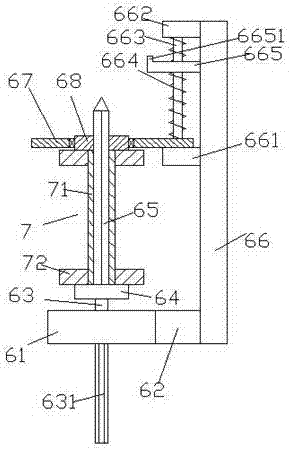

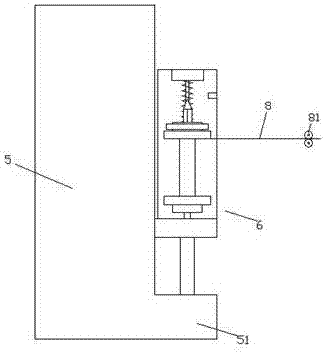

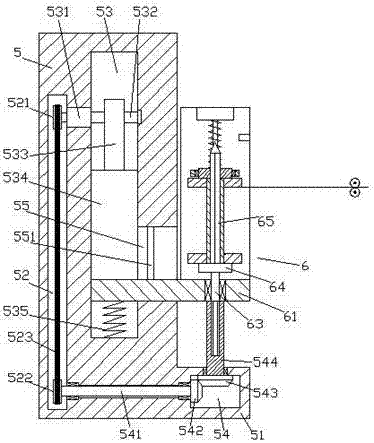

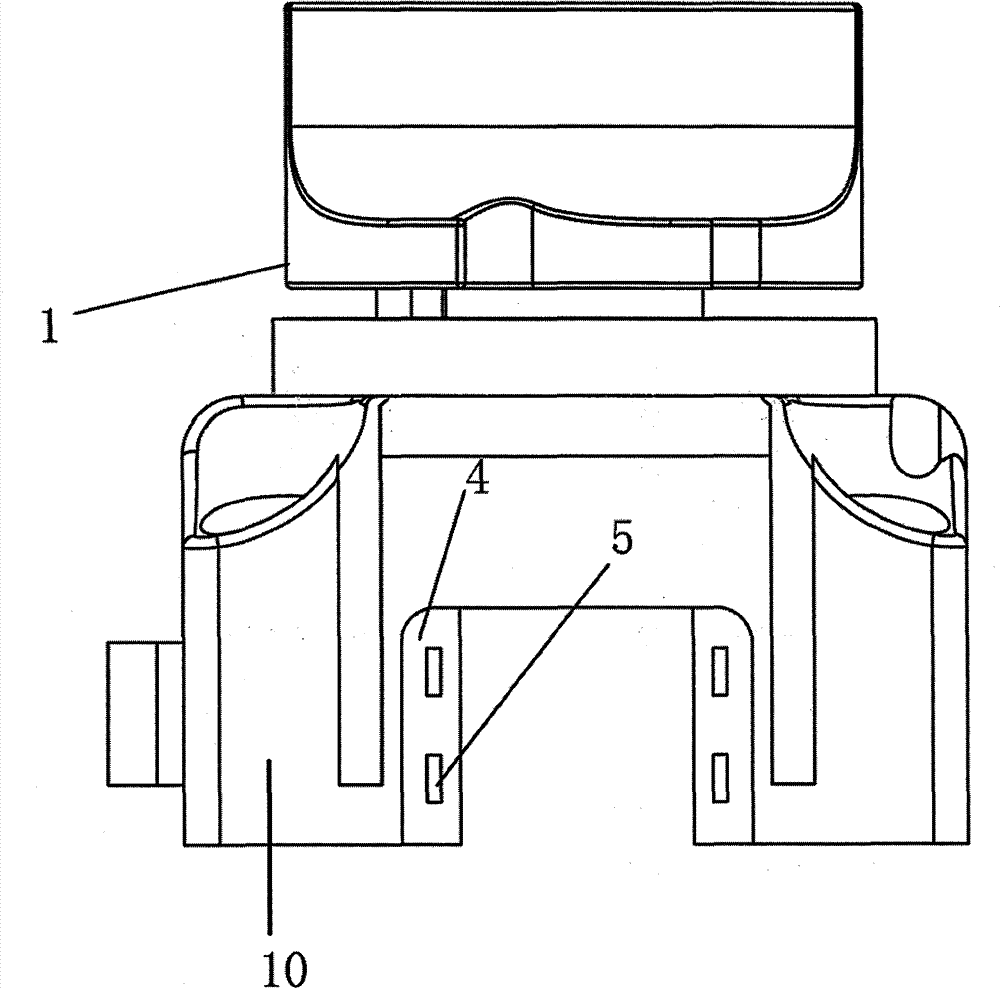

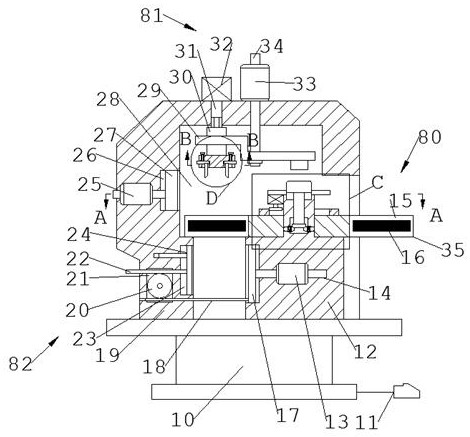

The invention relates to a numerical-control electric frame truck for airplane engine mounting and belongs to the technical field of assembly automation. The numerical-control electric frame truck is characterized by comprising a multi-shaft posture adjusting platform (1), a posture adjusting platform frame (2), a long-shaft feed mechanism (3), a truck body frame (4), left and right rotation mechanisms (5), an auxiliary support mechanism (6), hydraulic support legs (7), a driving wheel system (8), a truck body underframe (9), steering wheel systems (10), a driving cab (11), a hydraulic control system and a servo control system. Posture of five shafts is driven and adjusted by a servo motor, and posture of the rest one shaft is manually adjusted. Travelling of the frame truck is driven by the mode of electric vehicle. The numerical-control electric frame truck has the advantages that positioning accuracy is high, maneuverability is good, stability is high, engine mounting efficiency is improved, and labor intensity of operators is reduced. Besides, the numerical-control electric frame truck is applicable to automatic mounting operation of heavy complicated shaft parts requiring multi-shaft posture adjustment.

Owner:DALIAN UNIV OF TECH +1

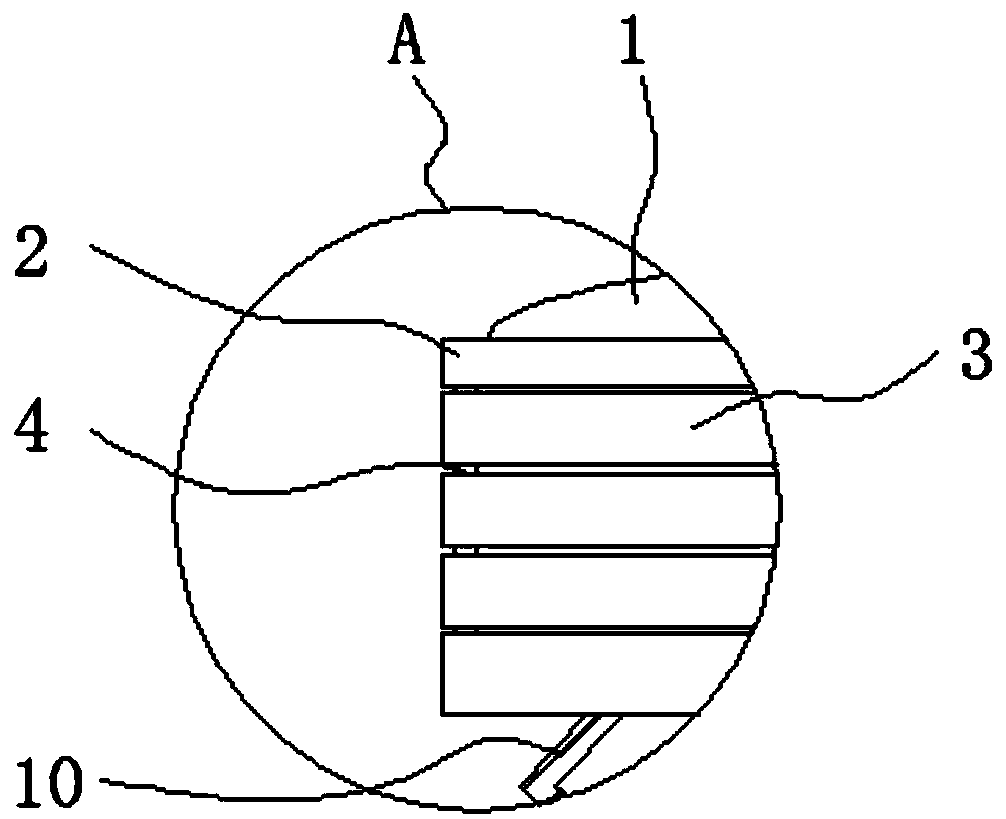

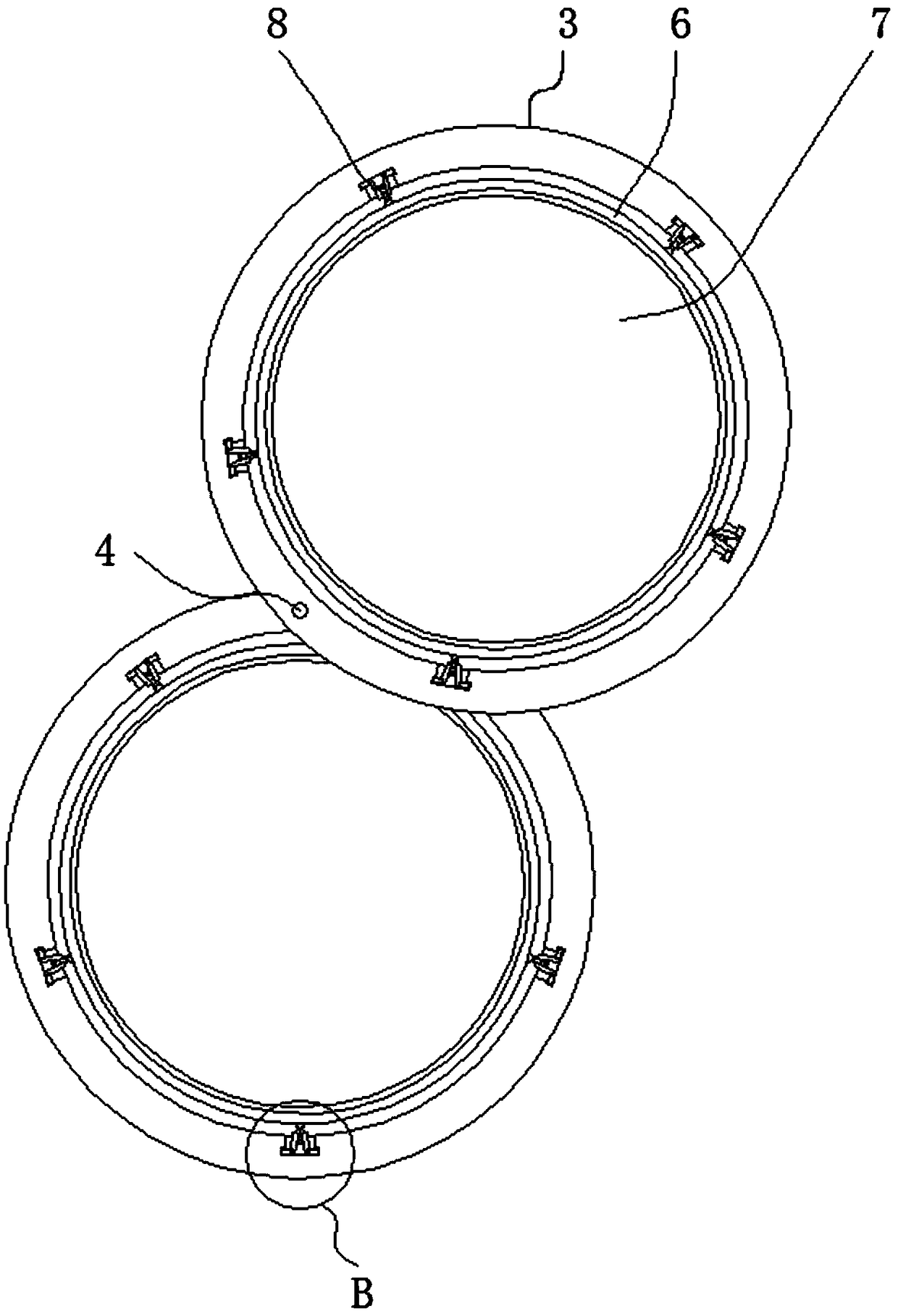

Rudder-propeller tooling car and rudder-propeller installation process

InactiveCN106564565ARealize the installation workEasy to operateVessel designingPropellerMechanical engineering

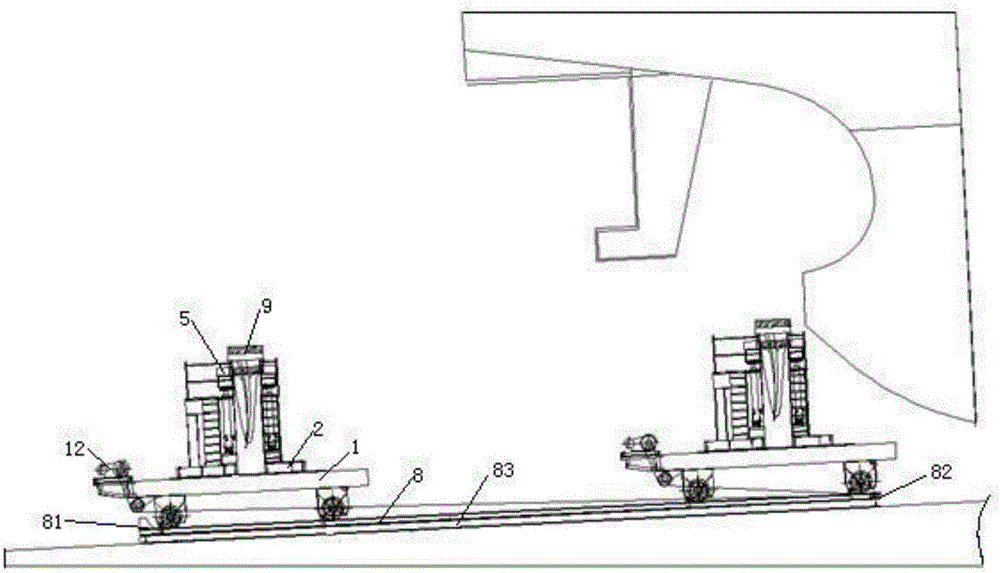

The invention discloses a rudder-propeller tooling car which comprises a mobile car body, a propeller installation frame and a rudder blade installation frame. The propeller installation frame and the rudder blade installation frame are detachably installed on the mobile car body, the bottom face of the mobile car body is provided with a wheel set, and the side face is provided with a winding engine; the propeller installation frame comprises a supporting platform, an operation platform, a jacking assembly and a propeller supporting bracket. The jacking assembly comprises a jacking bracket, at least two sets of lead screws and nuts matched with the lead screws, the jacking bracket is fixed between the supporting platform and the operation platform, and one end of each lead screw penetrates through a hole of the operation platform to be connected with the propeller supporting bracket; the rudder blade installation frame comprises at least two layers of racks, and each layer of rack is provided with a cavity for storing a rudder blade. The invention discloses a rudder-propeller installation process, the mobile car body moves back and forth on a track through the winding engine, the height position of the rudder blade is adjusted through the lead screws, and installation is conducted by determining the installation position of a propeller blade or the rudder blade. The rudder-propeller tooling car is easy to manufacture, time and labor are saved, energy consumption is lowered, and worker safety can be guaranteed.

Owner:TAIZHOU SANFU SHIP ENG CO LTD

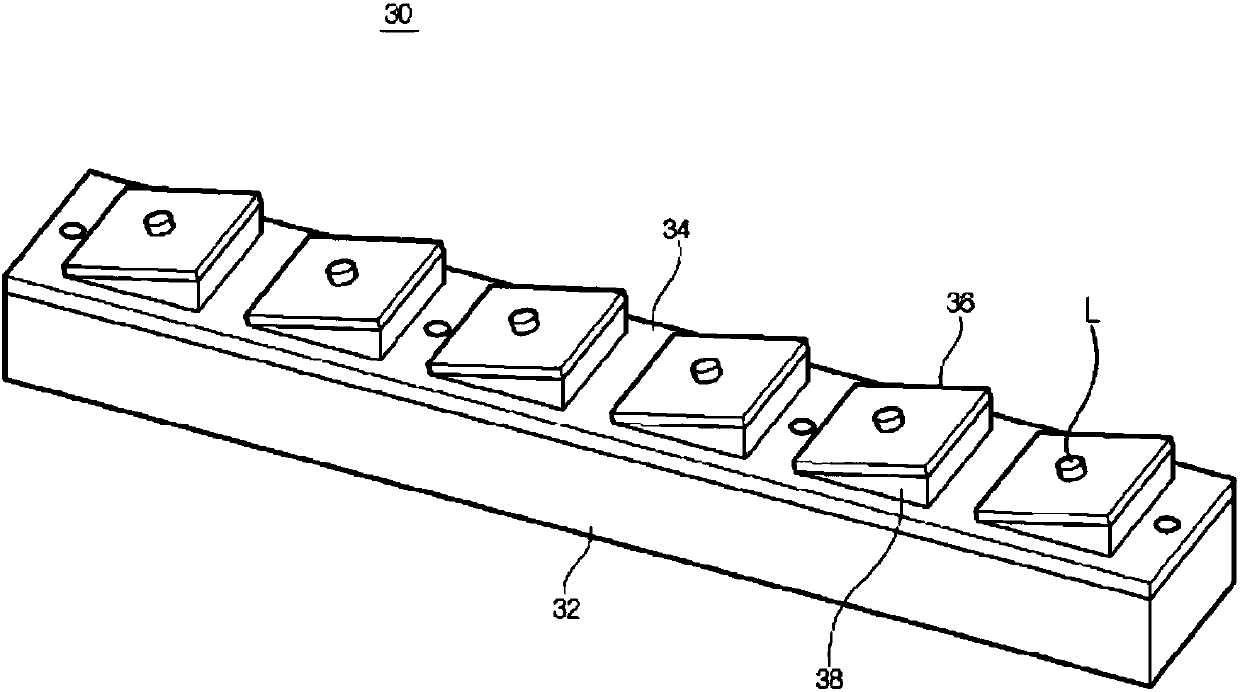

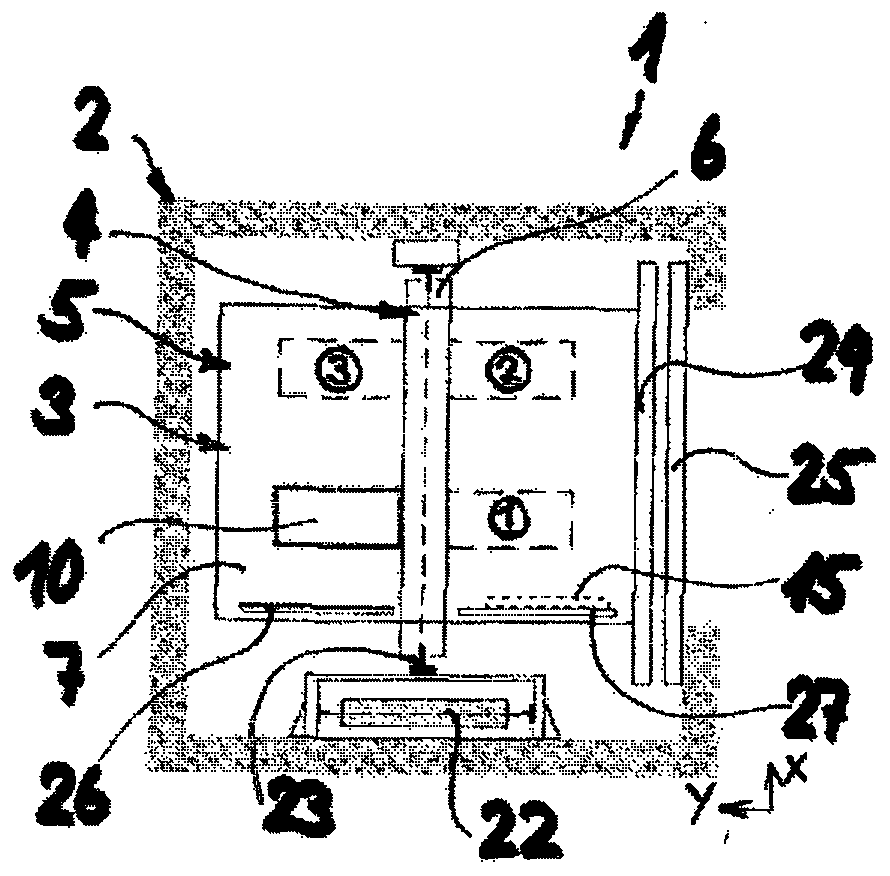

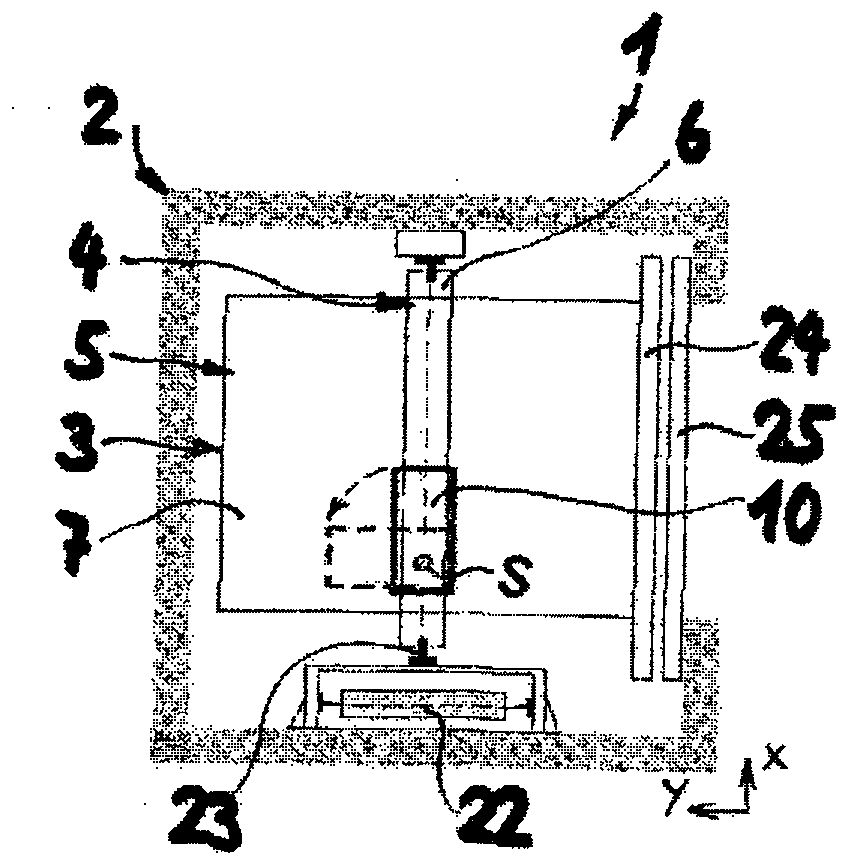

Metal PCB, headlight module having metal PCB applied thereto, and method for assembling headlight module

ActiveCN107690716AHighly integratedAchieve permutationSemiconductor/solid-state device detailsSolid-state devicesMetallic materialsLight-emitting diode

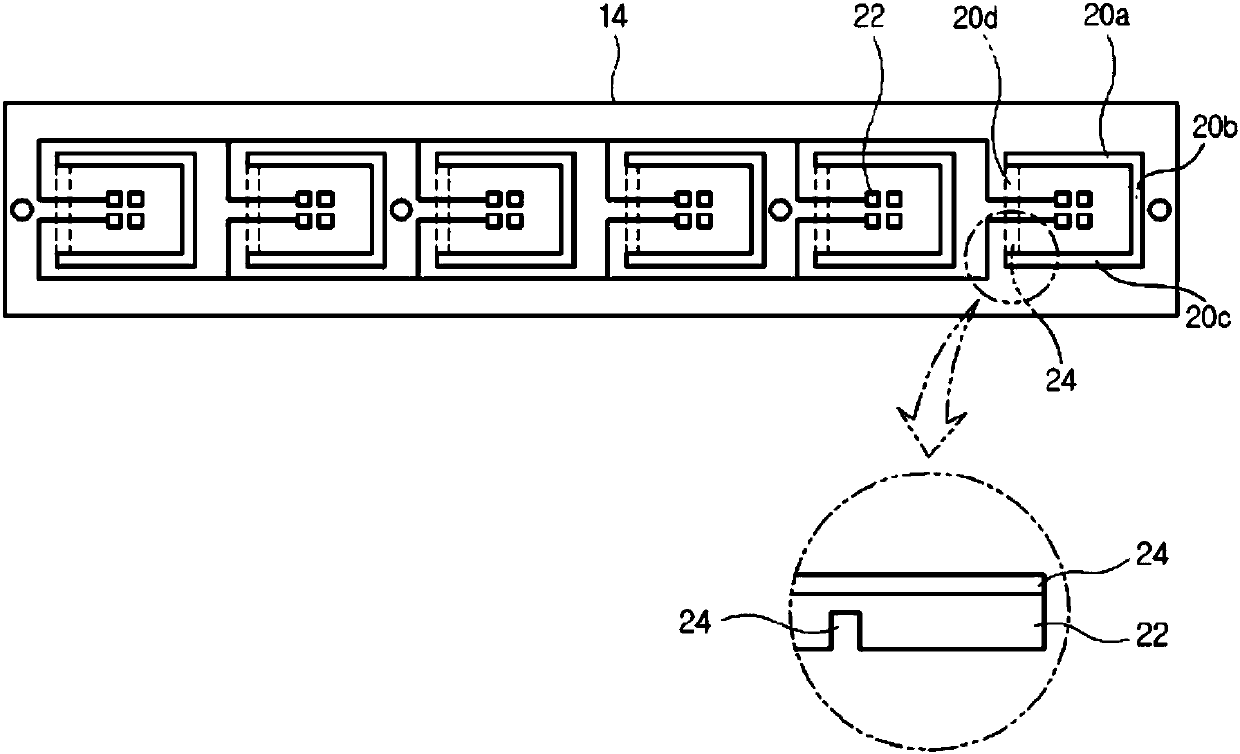

The present invention relates to a metal PCB, a headlight module having the metal PCB applied thereto, and a method for assembling the headlight module, wherein the metal PCB has a base made of a metal material and configured as a thin plate, or the base has a predetermined thickness and is bent in a desired direction through a bending groove formed on the rear surface thereof, and the base has aplurality of chip mounting portions integrally formed thereon such that one or more LED chips are mounted thereon, the chip mounting portions being spaced at a predetermined interval and having at least two parts of incision surfaces formed on one side of the base such that the chip mounting portions are inclined and installed to have a predetermined angle with regard to the base.

Owner:WENDENG AIKE WIRE HARNESS CO LTD

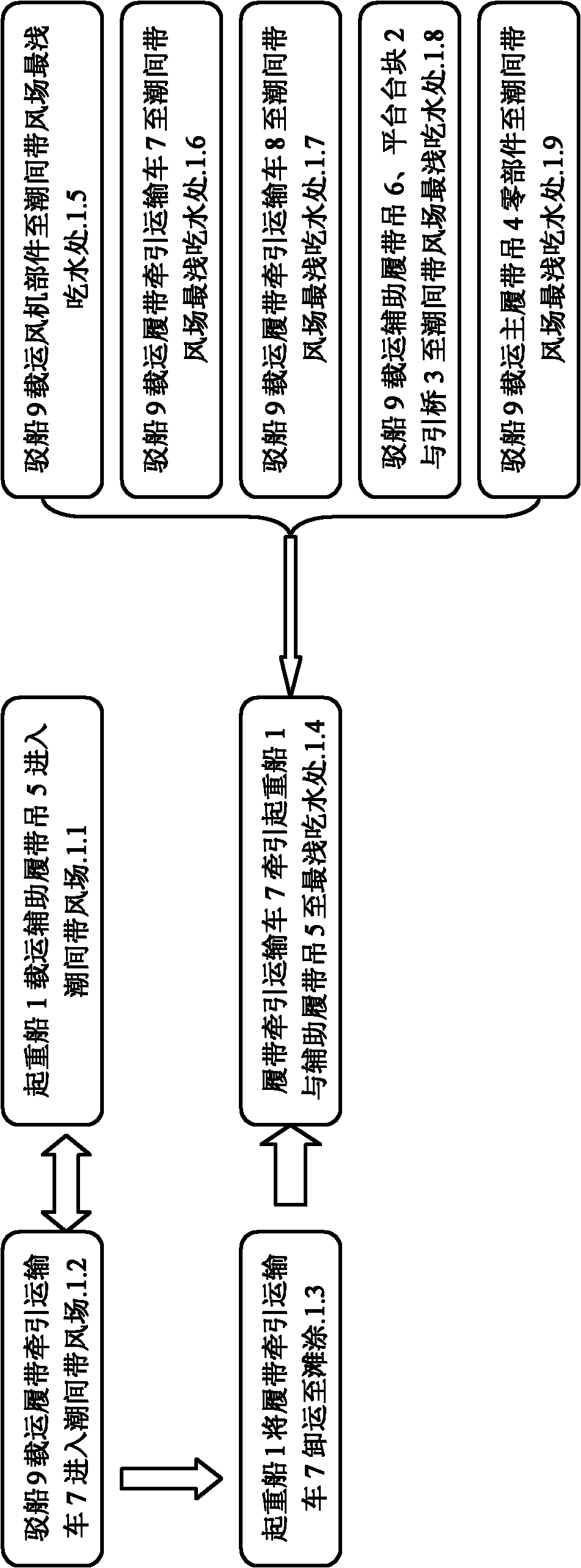

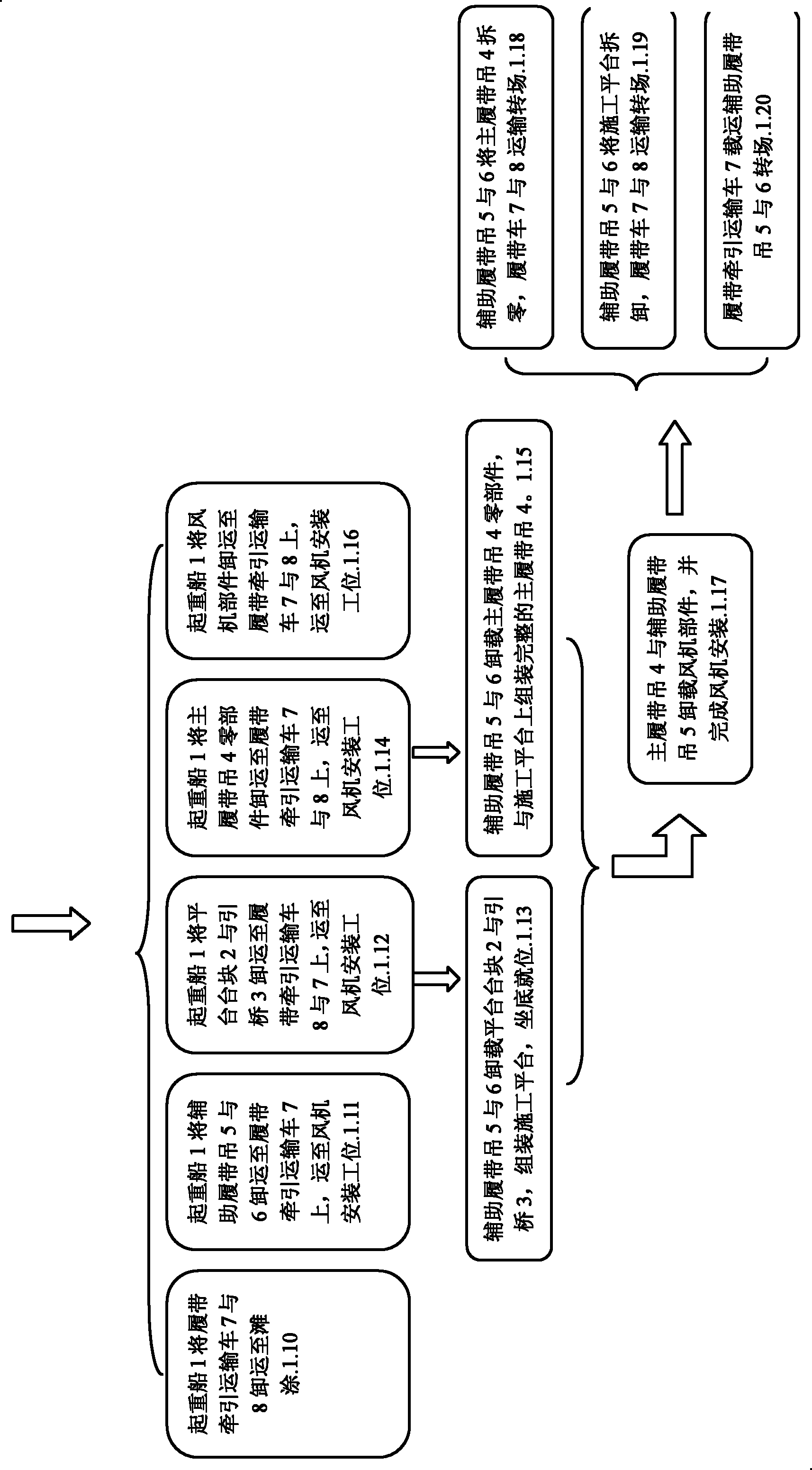

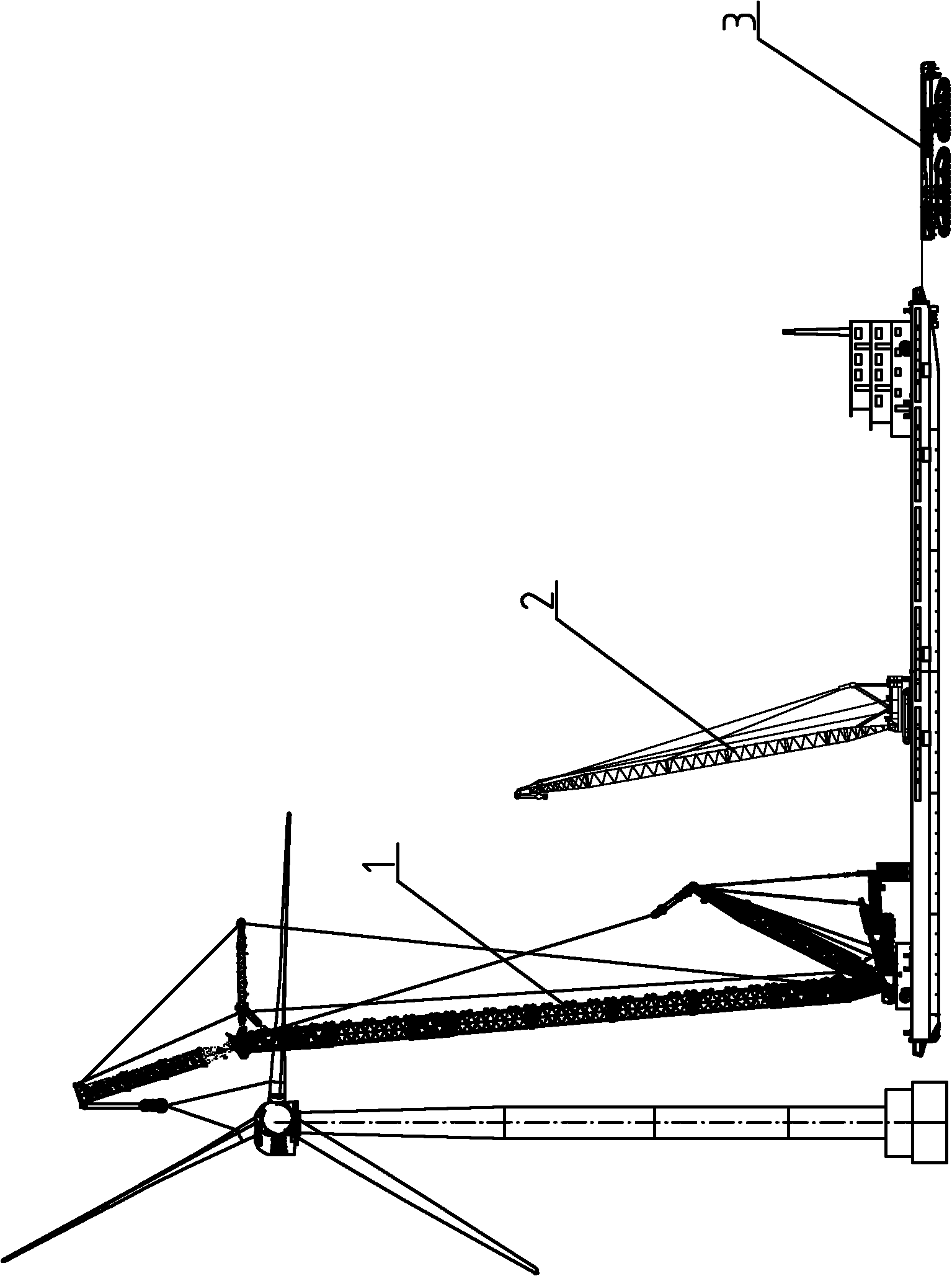

Method for arranging wind power generation equipment in shallow water of intertidal zone

InactiveCN102092645ASuitable for bulk installationImprove installation efficiencyWind energy generationCranesEngineeringBARGE

The invention discloses a method for arranging wind power generation equipment in the shallow water of an intertidal zone, which aims to solve the problems of equipment arrangement by adopting a construction method skillfully combining tracked carriers, crawler cranes, a crane ship, a barge and the like. The method is characterized by comprising the following steps that: the crane ship carries anauxiliary crane, and automatically voyages to a position with the smallest draught; the barge transports equipment comprising fan parts, the tracked carriers, platform blocks, approach bridges, a main crawler crane, an auxiliary crawler crane and the like to the position with the smallest draught; the tracked carriers transport the fan parts, the platform blocks, the approach bridges and the maincrawler crane part to a fan mounting station; the auxiliary crawler crane finishes the assembly of a construction platform at the fan mounting station and the complete main crawler crane; the main crawler crane and the auxiliary crawler crane finish the assembly and hoisting of the fan parts; and after the steps are finished, the auxiliary crawler crane disassembles the main crawler crane and theconstruction platform to a transportable weight, and the tracked carriers transport the main crawler crane and the construction platform to the next fan mounting station.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

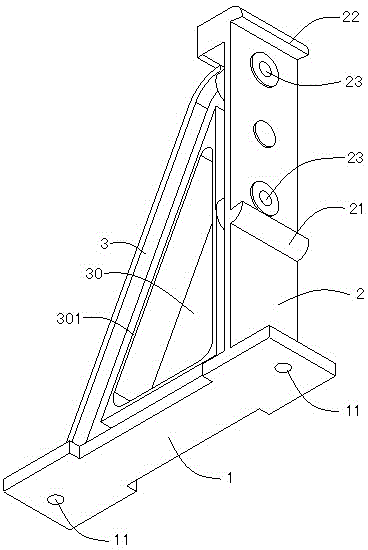

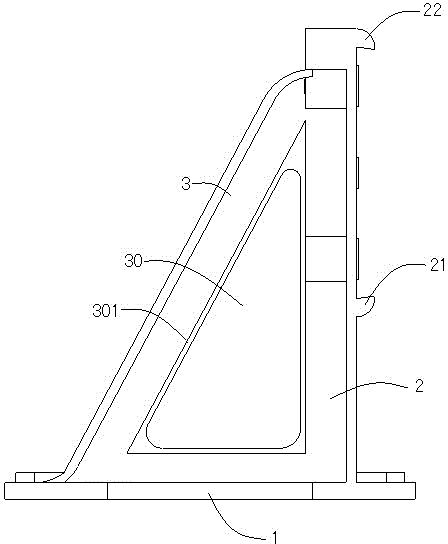

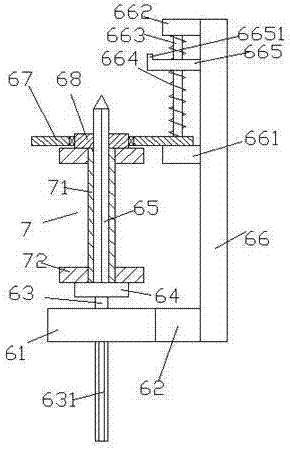

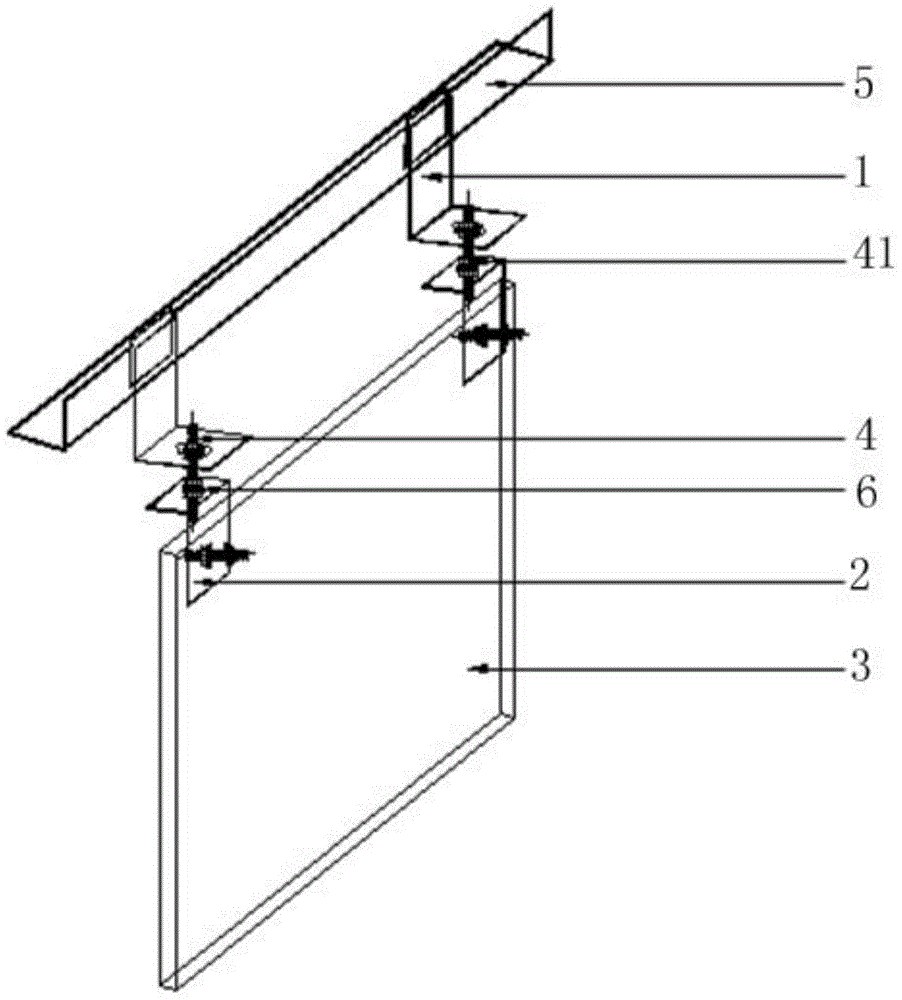

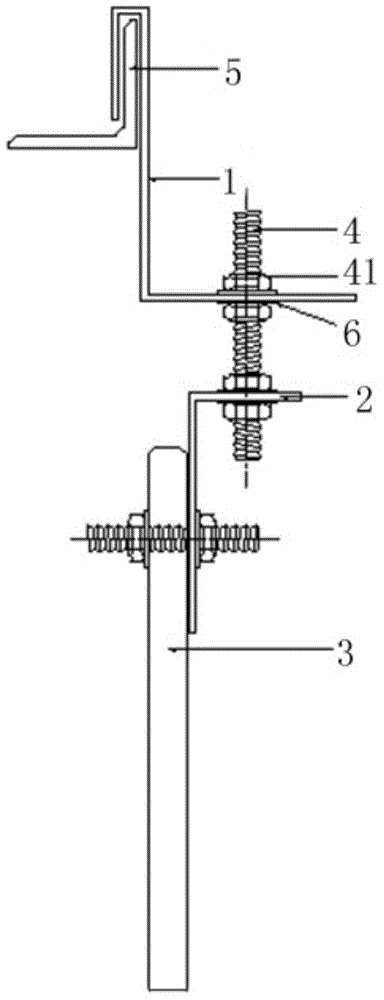

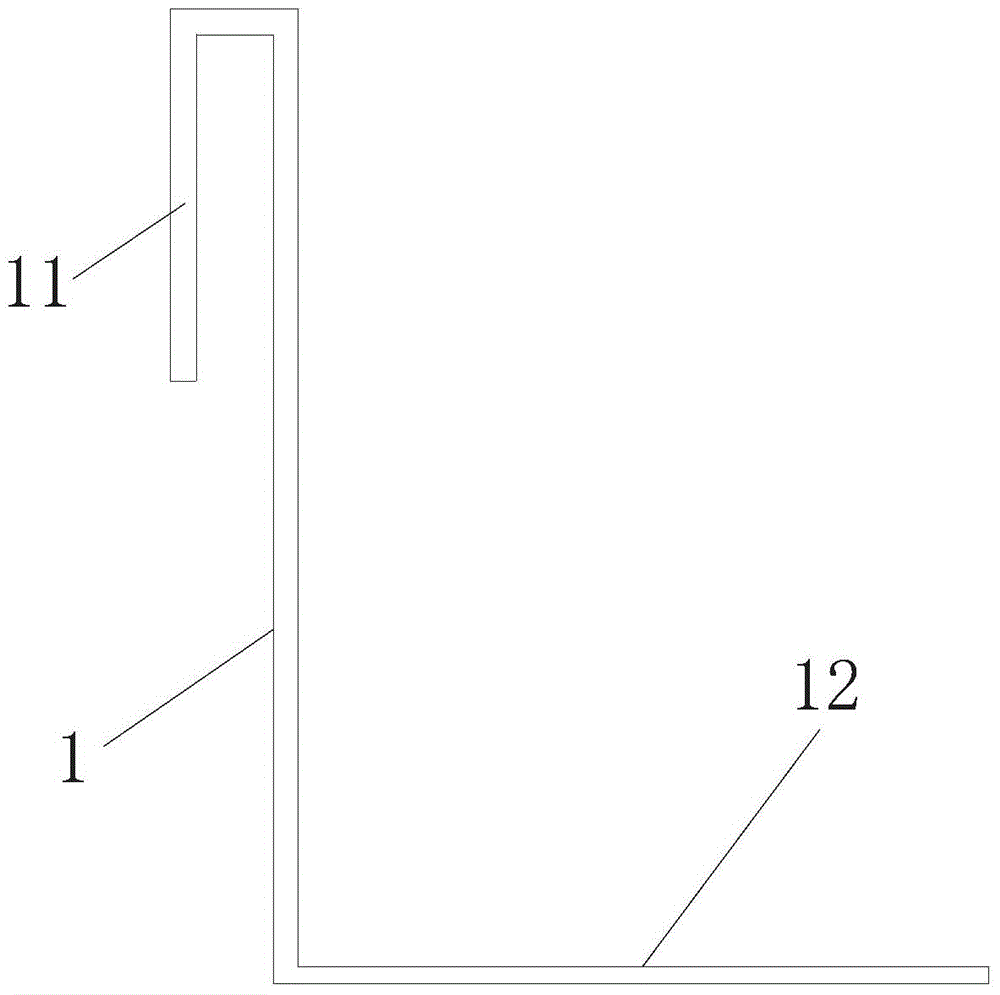

Support device for outdoor curtain wall billboard

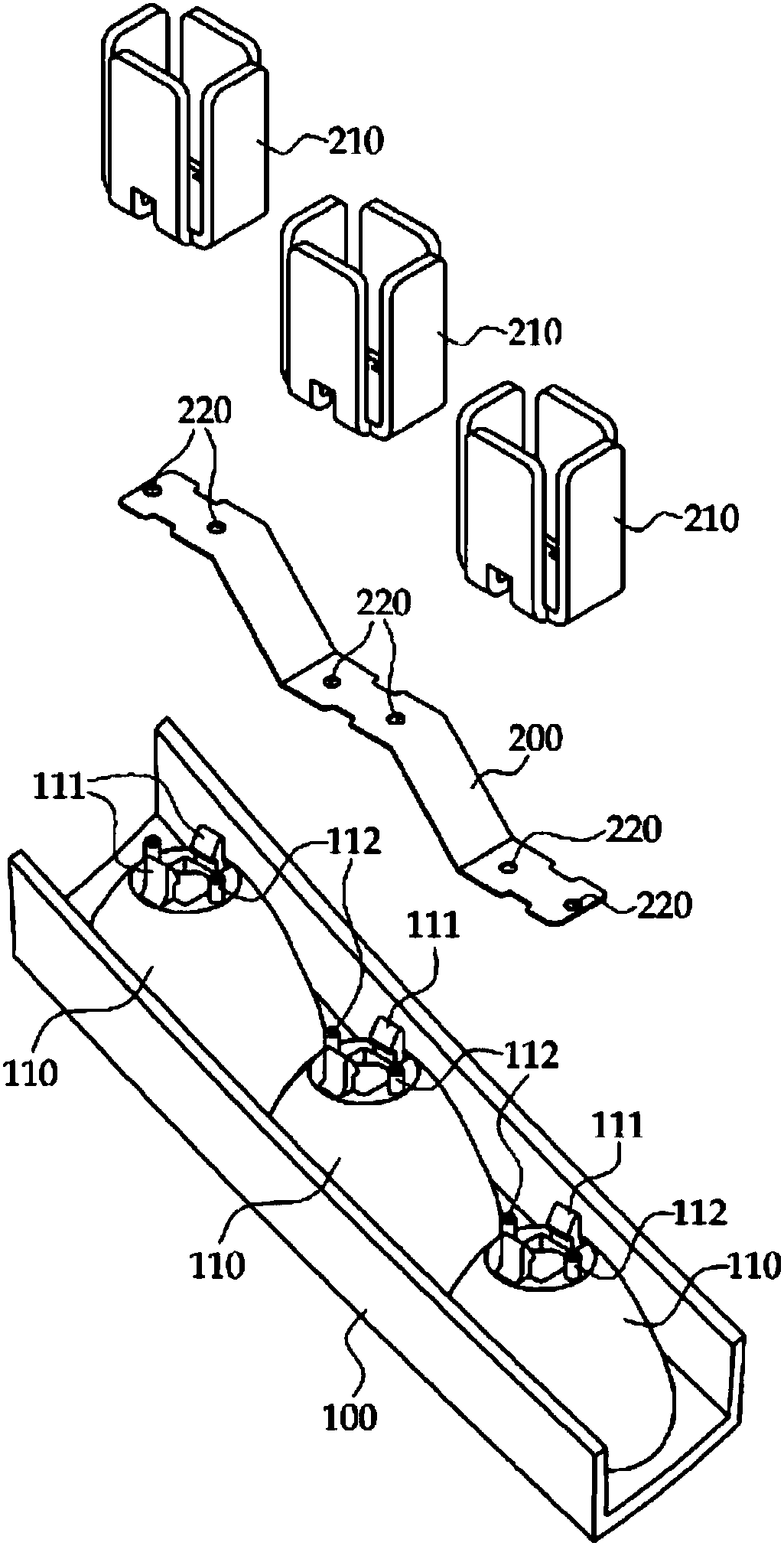

The invention discloses a support device for an outdoor curtain wall billboard. The support device comprises a base (1) and a curtain wall billboard hanging beam (2) which are integrally connected to be L-shaped, wherein the base (1) is provided with at least two mounting holes (11), the curtain wall billboard hanging beam (2) is provided with a lower supporting seat (21) and an upper supporting seat (22) which are oppositely arranged, and connecting screw hole (23) are formed in the curtain wall billboard hanging beam (2) between the lower supporting seat (21) and the upper supporting seat (22). The support device for the outdoor curtain wall billboard has the advantages of realization of standardized installation operation, firm and reliable connection, strong stress capability, simple structure, recyclability, and convenience and rapidness in installation.

Owner:GUANGZHOU BRANDSTAND EXHIBITION EQUIP CO LTD

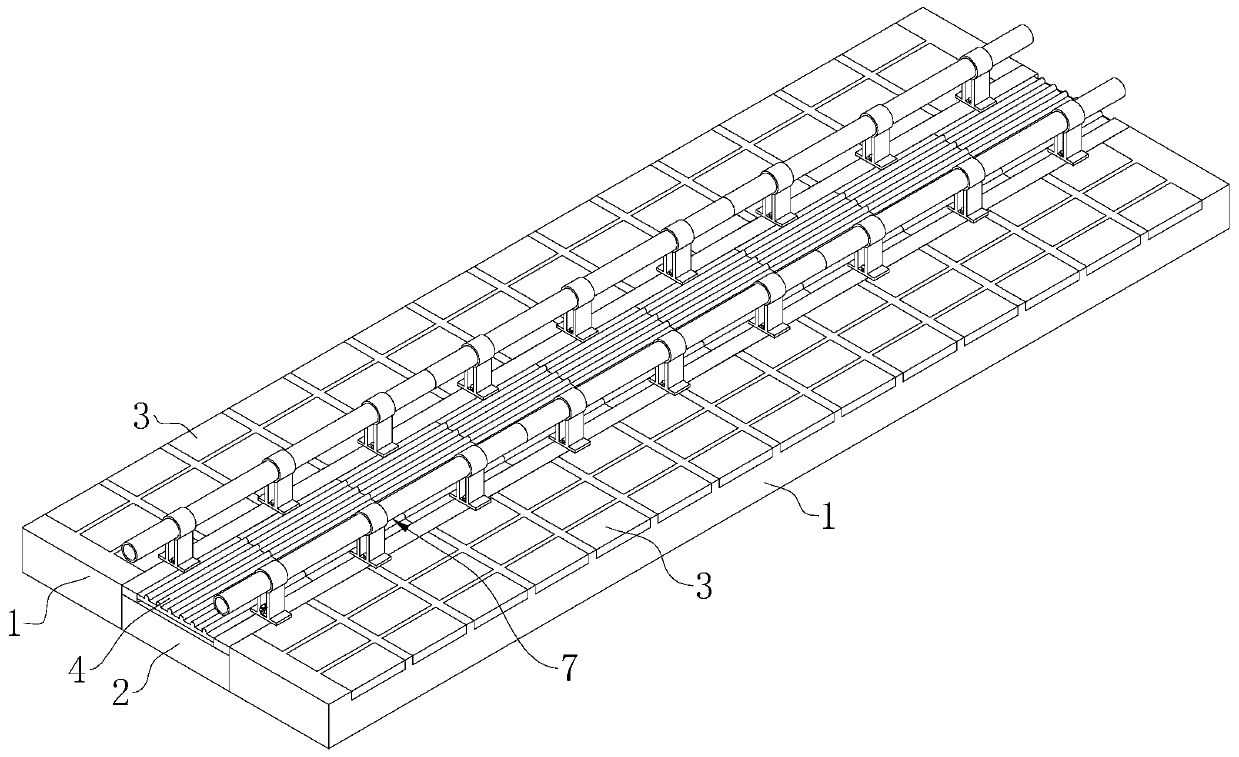

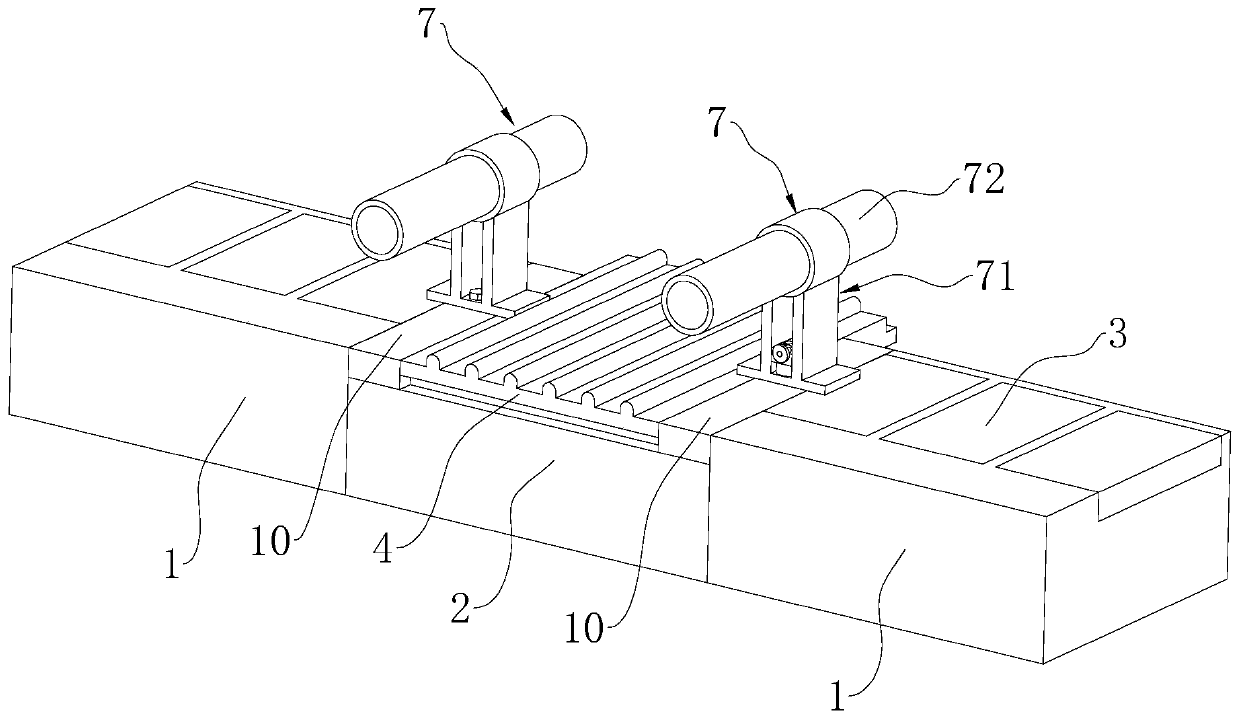

Road structure and construction method thereof

InactiveCN110387779ARealize the installation workEasy constructionSingle unit pavingsSidewalk pavingsBrickStructural engineering

Owner:东莞市金建达建筑有限公司

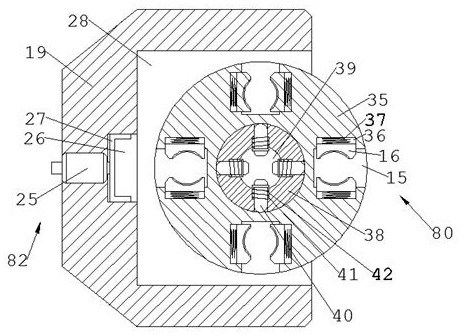

Mechanical hand for grabbing pistons

PendingCN106737811ARealize the installation workCompact structureGripping headsProduction lineEngineering

The invention belongs to the field of mechanical automation, particularly provides a mechanical hand for grabbing pistons, and aims to solve the problems that engine piston assembly in an automation engine production line is high in cost and low in efficiency. The mechanical hand for grabbing the pistons comprises grabbing assemblies, driving assemblies and an outer shell, and is further provided with a push rod assembly, wherein the grabbing assemblies and the driving assemblies are rotatably connected with the outer shell; the driving assemblies are fixedly connected with the outer shell; the driving assemblies can drive the grabbing assemblies to rotate relative to the outer shell to grab or release the pistons; the push rod assembly is arranged in the middle of the four grabbing assemblies; and after the grabbing assemblies grab and place the pistons, the push rod assembly can knock the pistons. The mechanical hand has the advantages that the structure is simple and compact, the occupied space is small, driving depends on air power, pollution is avoided, the manufacturing cost is low, and the assembly quality is high.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

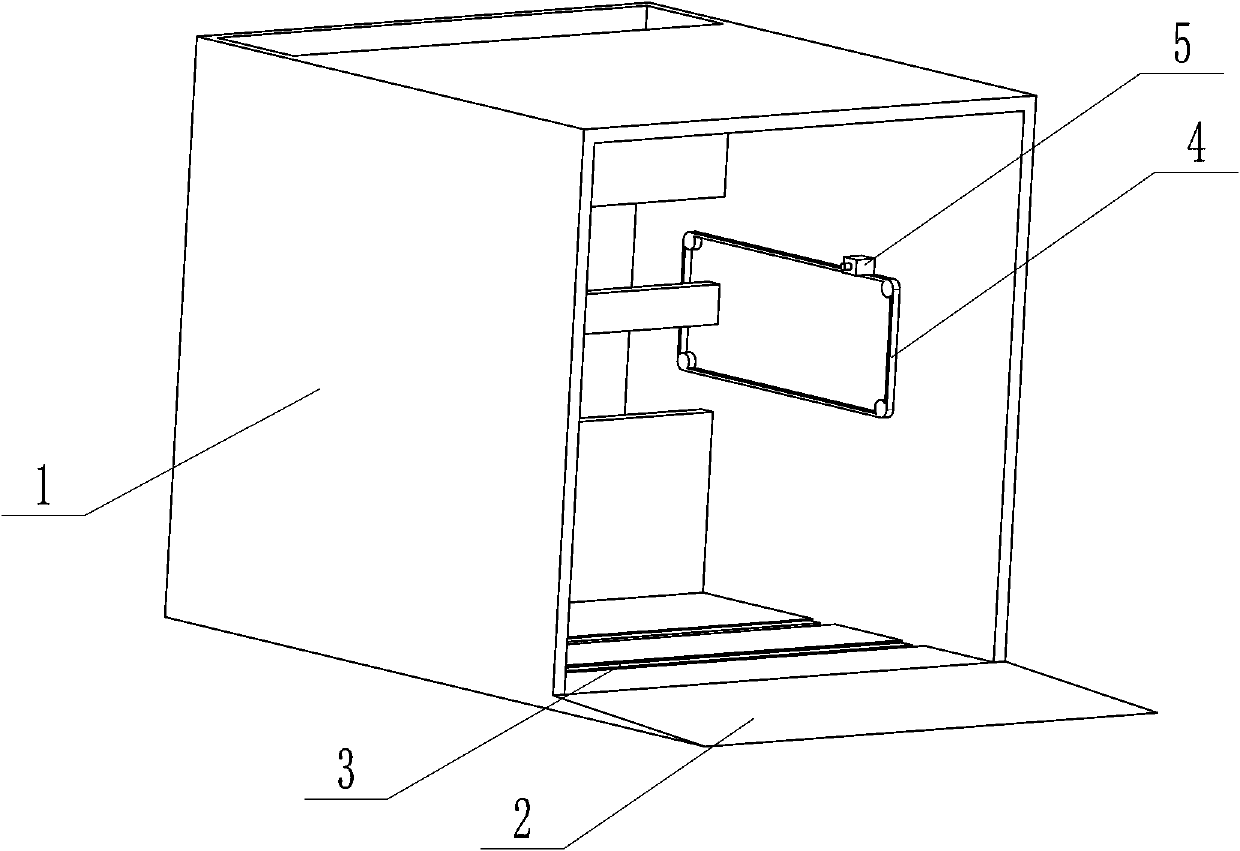

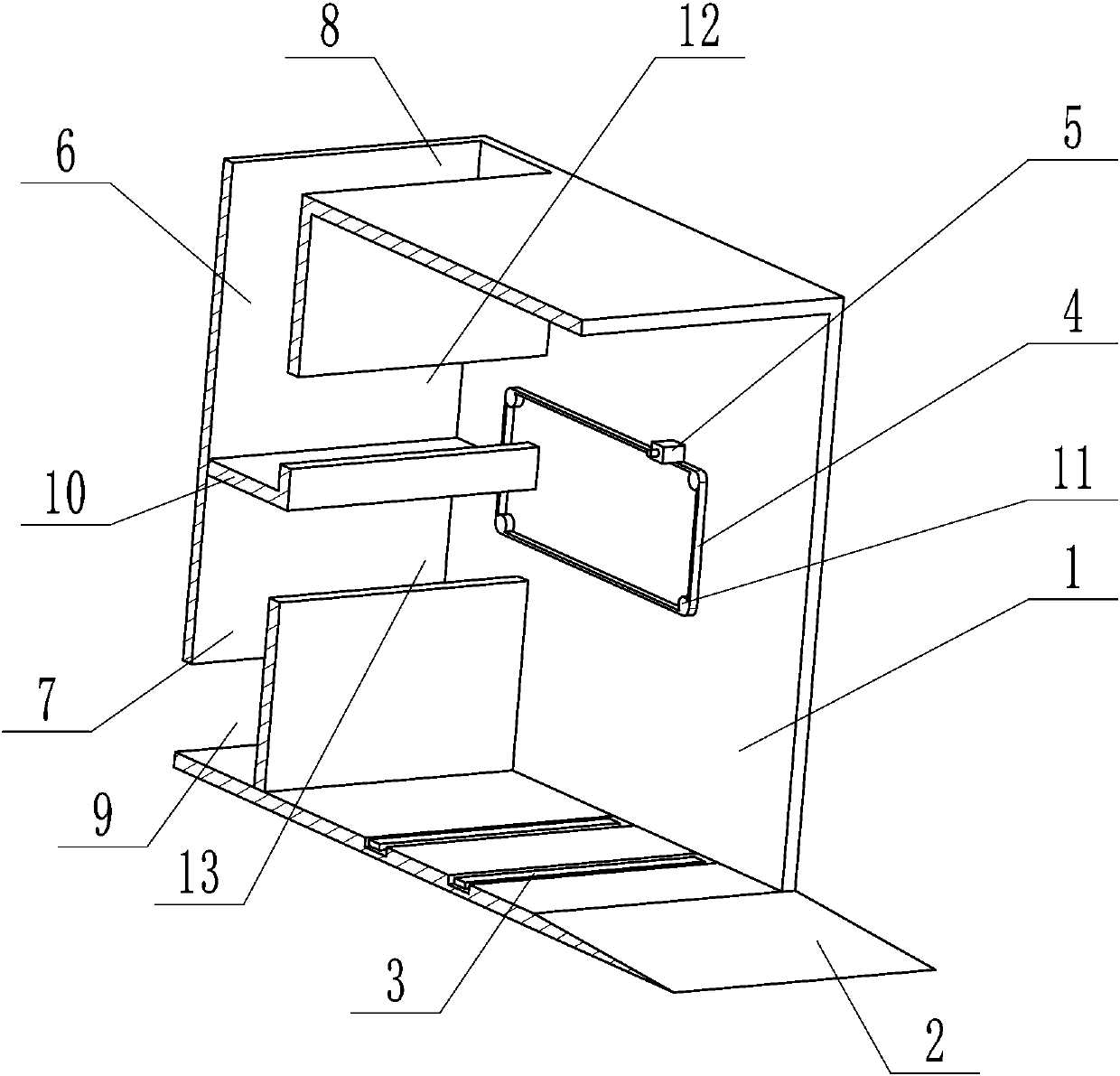

Automatic brush replacement device for floor sweeping robot

PendingCN110558898AImprove practicalityAvoid manual replacement operationsMachine detailsFloor sweeping machinesEngineeringRobot

The invention relates to an automatic brush replacement device for a floor sweeping robot. The device comprises a shell, a new brush bin, an old brush bin, a bracket used for supporting the floor sweeping robot, and a conveying device used for dismounting an old brush on the floor sweeping robot, putting the old brush into the old brush bin, taking a new brush from the new brush bin and replacingthe new bush on the floor sweeping robot, wherein the new brush bin and the old brush bin are arranged on the rear side of the shell. According to the device, the conveying device is used for dismounting the old brush on the floor sweeping robot, conveying the old brush into the old brush bin, taking the new brush from the new brush bin and finally mounting the new brush on the floor sweeping robot, so that operation of automatically replacing the brush for the floor sweeping robot is realized, manual replacement operation is completely avoided, it is only ensured that the new brush bin has sufficient new brushes, manual operation is greatly reduced, and the practicability of the sweeping robot is improved.

Owner:高殷沛

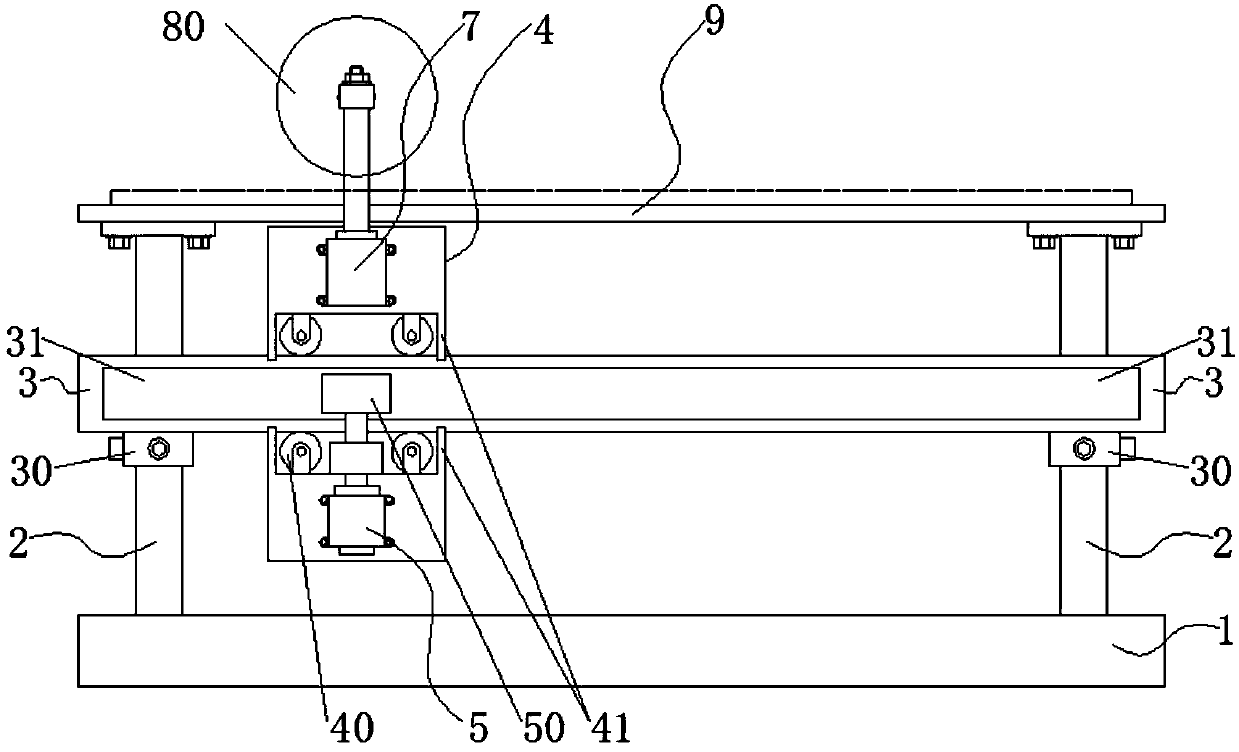

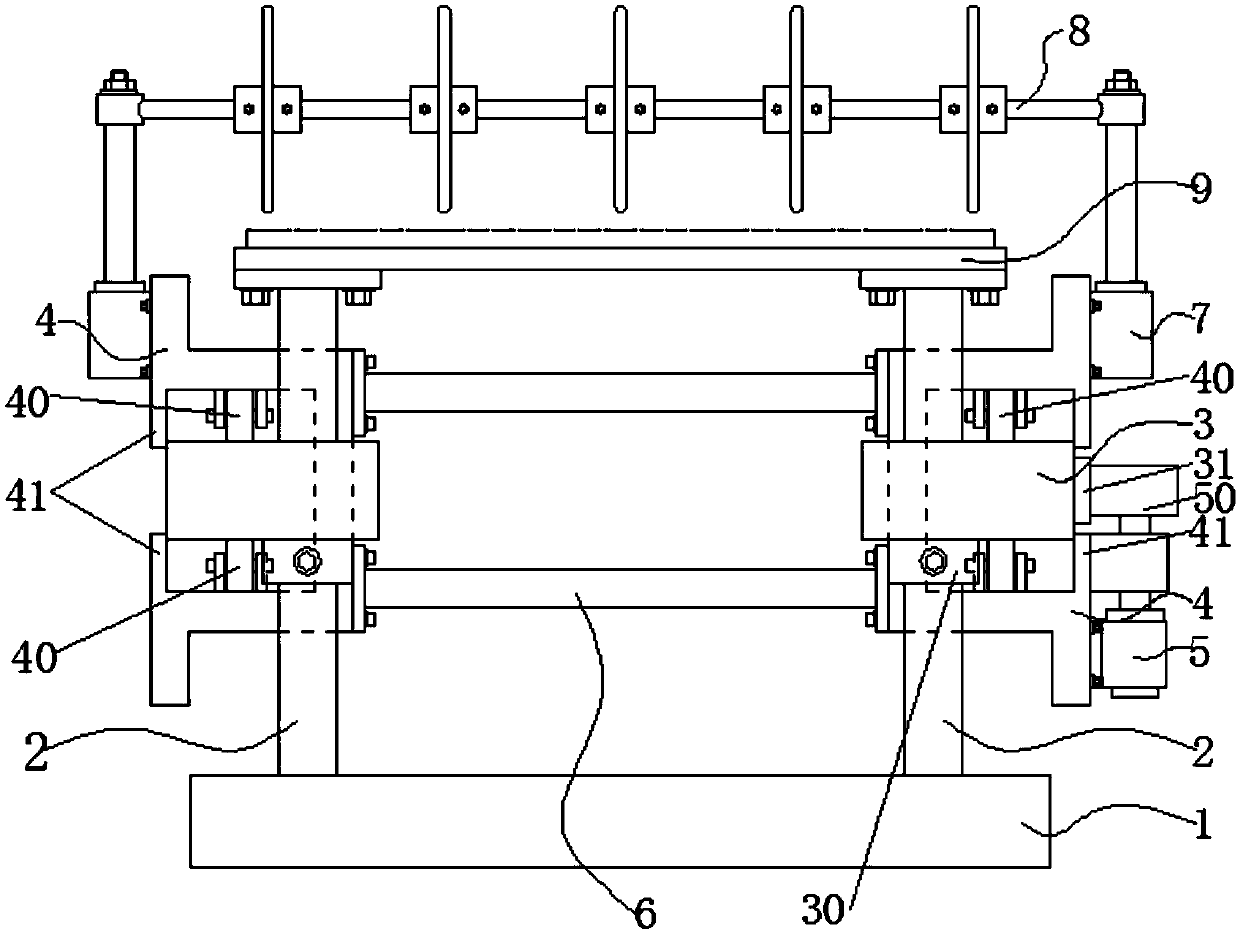

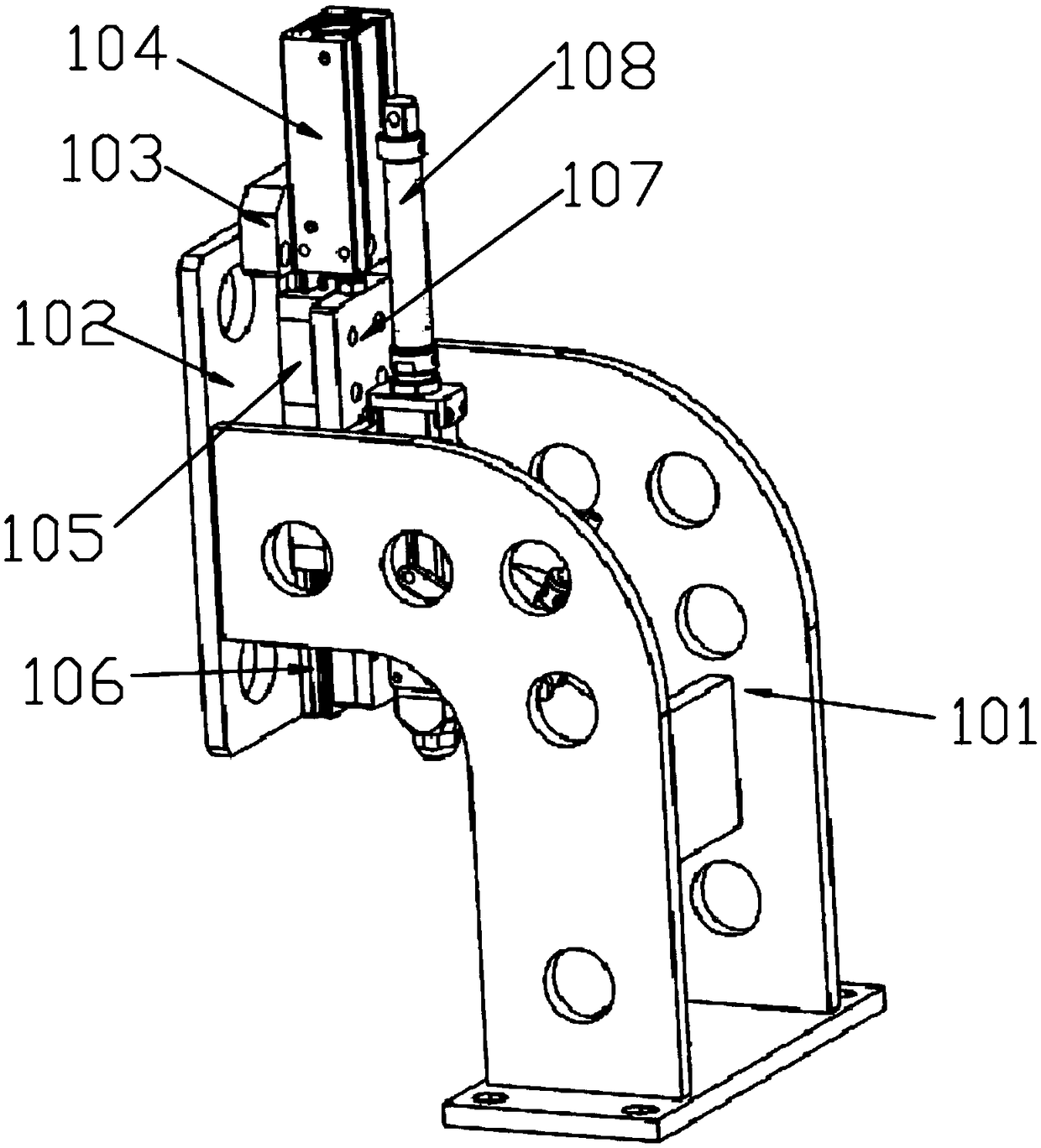

Paperboard folding-line making device

InactiveCN109834989ARealize indentation operationChange depthBox making operationsPaper-makingProduction linePaperboard

The invention discloses a paperboard folding-line making device. The paperboard folding-line making device comprises a base, stand columns, sliding tables, sliding bases, a servo motor, supporting rods, air cylinders, a folding-line making shaft and a workbench, wherein four stand columns and four supporting rods are arranged, two sliding tables, two sliding bases and two air cylinders are arranged, the lower ends of the stand columns are fixedly connected with the base, connecting sleeves are arranged at the lower ends of the sliding tables, the sliding tables are connected with the middles of the stand columns in a locking mode through the connecting sleeves, racks are arranged on the side faces of the sliding tables, a pair of rollers are arranged in each sliding base, the sliding basesare in rolling connection with the sliding tables through the rollers, the servo motor is connected with the side faces of the lower ends of the sliding bases, a gear is arranged on an output shaft of the servo motor, the gear is meshed with the racks, the two sliding bases are connected into a whole through the supporting rods, the air cylinders are connected with the side face of the upper endsof the sliding bases, the two ends of the folding-line making shaft are respectively connected with the end parts of piston rods of the two air cylinders, and the worktable is connected with the topsof the stand columns, so that the folding-line making operation of a paperboard on a production line of the paperboard is realized, the traditional manual rolling and pressing operation is avoided, and the requirements of an automatic production line are met.

Owner:安徽祥欣新材料科技有限公司

High-precision calibration positioning device for radar satellites and GNSS satellites

PendingCN111624637ARealize the installation workRealize horizontal deformation monitoringUsing electrical meansElectrical/magnetic solid deformation measurementVertical planeEngineering

The invention discloses a high-precision calibration positioning device for a radar satellite and a GNSS satellite. The high-precision calibration positioning device comprises: a bottom plate; a basewhich is fixed on the bottom plate and can rotate; a mounting table which is fixed on the base, wherein the top of the mounting table is provided with a GNSS antenna mounting structure, the tangent lines of the first side face and the second side face with the horizontal plane are consistent with the flight direction of the lifting orbit radar satellite, and the included angles between the first side face and the vertical plane and between the second side face and the vertical plane are matched with the local incident angles of the lifting orbit radar satellite; the two dihedral corner reflectors are used for reflecting radar satellite signals, are fixed on the first side surface and the second side surface of the mounting table, are respectively parallel to the direction of a radar lifting rail and are respectively adapted to the local incident angles of the radar signals of the lifting rail. According to the calibration positioning device, the RCS theoretical maximum value of radar satellite signal two-side right-angle reflection is achieved, and the calibration positioning device can be used for satellite-borne SAR radiation calibration and InSAR deformation monitoring and synchronously achieve GNSS positioning.

Owner:WUHAN UNIV

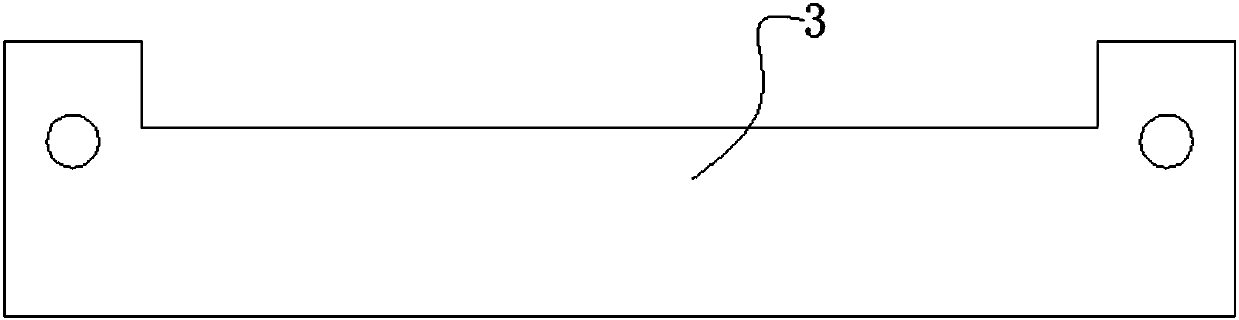

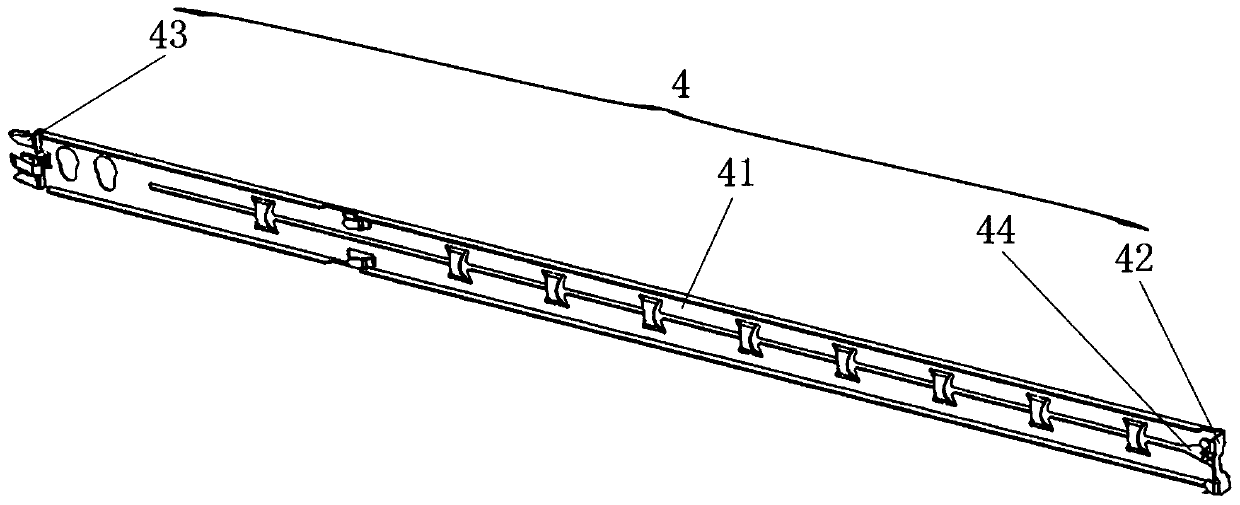

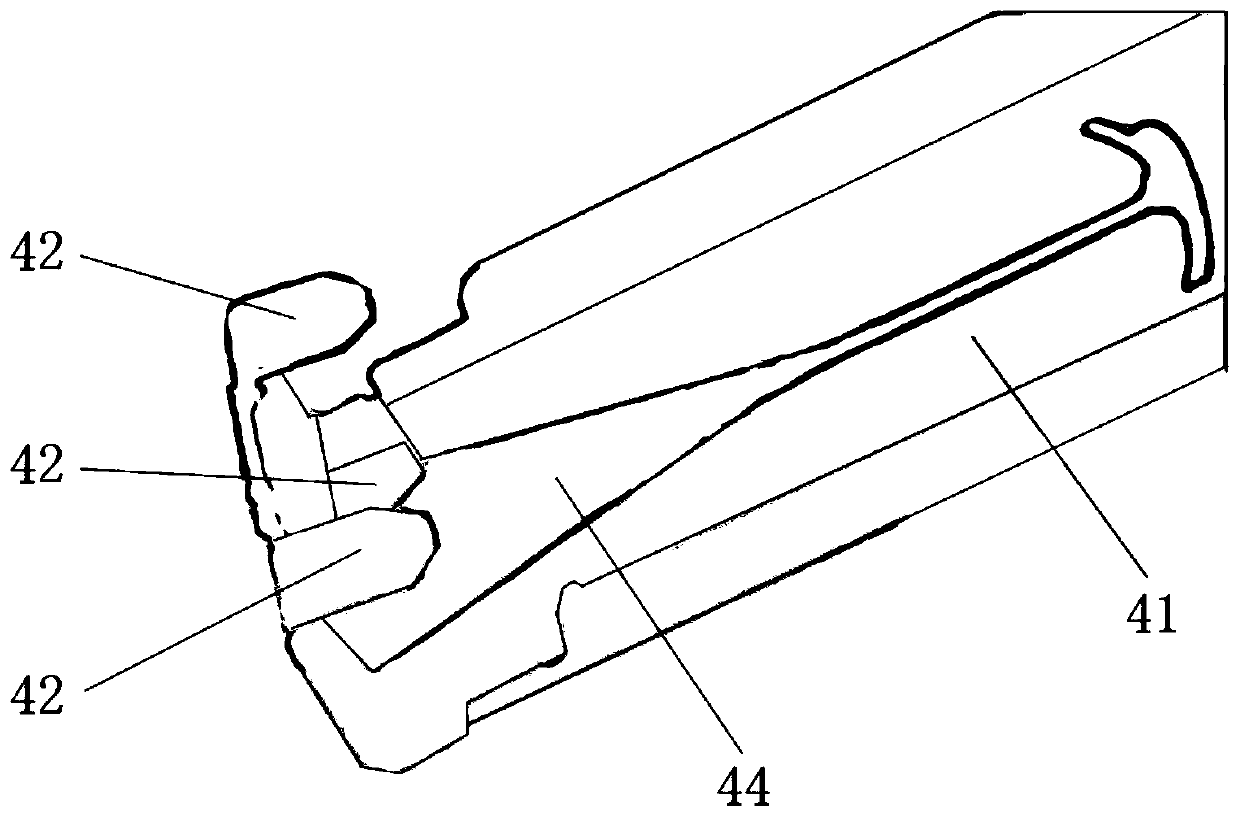

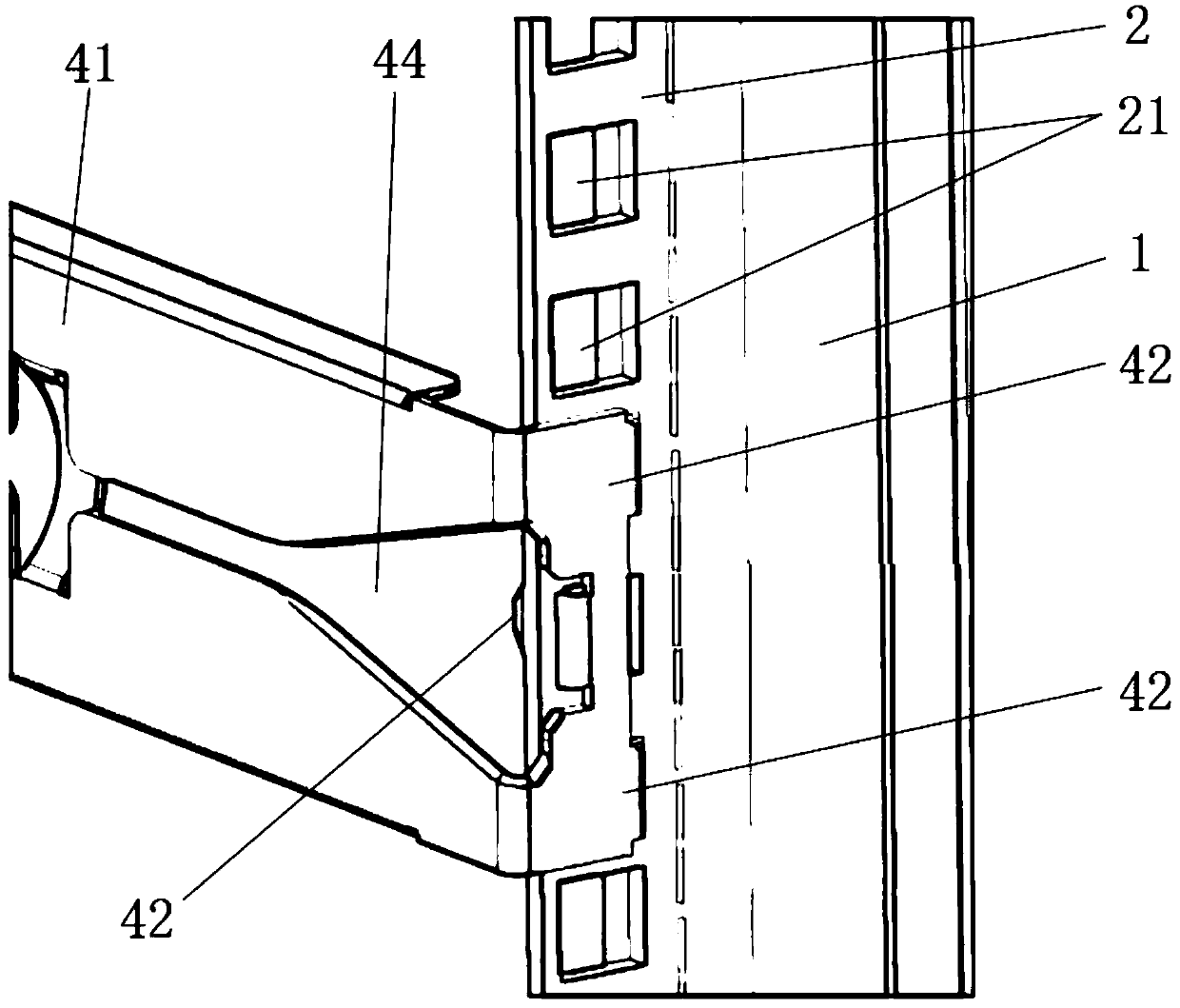

Server cabinet and fastening-free disassembly and assembly sliding installation structure thereof

ActiveCN110996604ARealize the installation workImprove the efficiency of disassembly and assembly operationsServersData center roomsIndustrial engineeringServer

The invention discloses a fastening-free disassembly and assembly sliding installation structure. The structure comprises a front installation plate which is arranged on the side wall of the front endof a cabinet body and extends in the vertical direction, a rear installation plate which is arranged on the side wall of the rear end of the cabinet body, extends in the vertical direction and is right opposite to the front installation plate, and a sliding rail which is connected between the front installation plate and the rear installation plate in the transverse direction and used for allowing a server case to be installed in a sliding mode. The front end of the sliding rail is connected with the front installation plate in a clamped mode, and the rear end of the sliding rail is connectedwith the rear installation plate in a clamped mode. According to the fastening-free disassembly and assembly sliding installation structure, when disassembly and assembly operation is conducted on the sliding rail, the disassembly and assembly operation of the sliding rail on the server cabinet can be conveniently and efficiently achieved without screwing fasteners, the disassembly and assembly operation efficiency of the sliding rail is improved, the disassembly and assembly operation process is simplified, and the disassembly and assembly operation burden of workers is reduced. The invention also discloses a server cabinet, and the beneficial effects of the server cabinet are as described above.

Owner:INSPUR BUSINESS MACHINE CO LTD

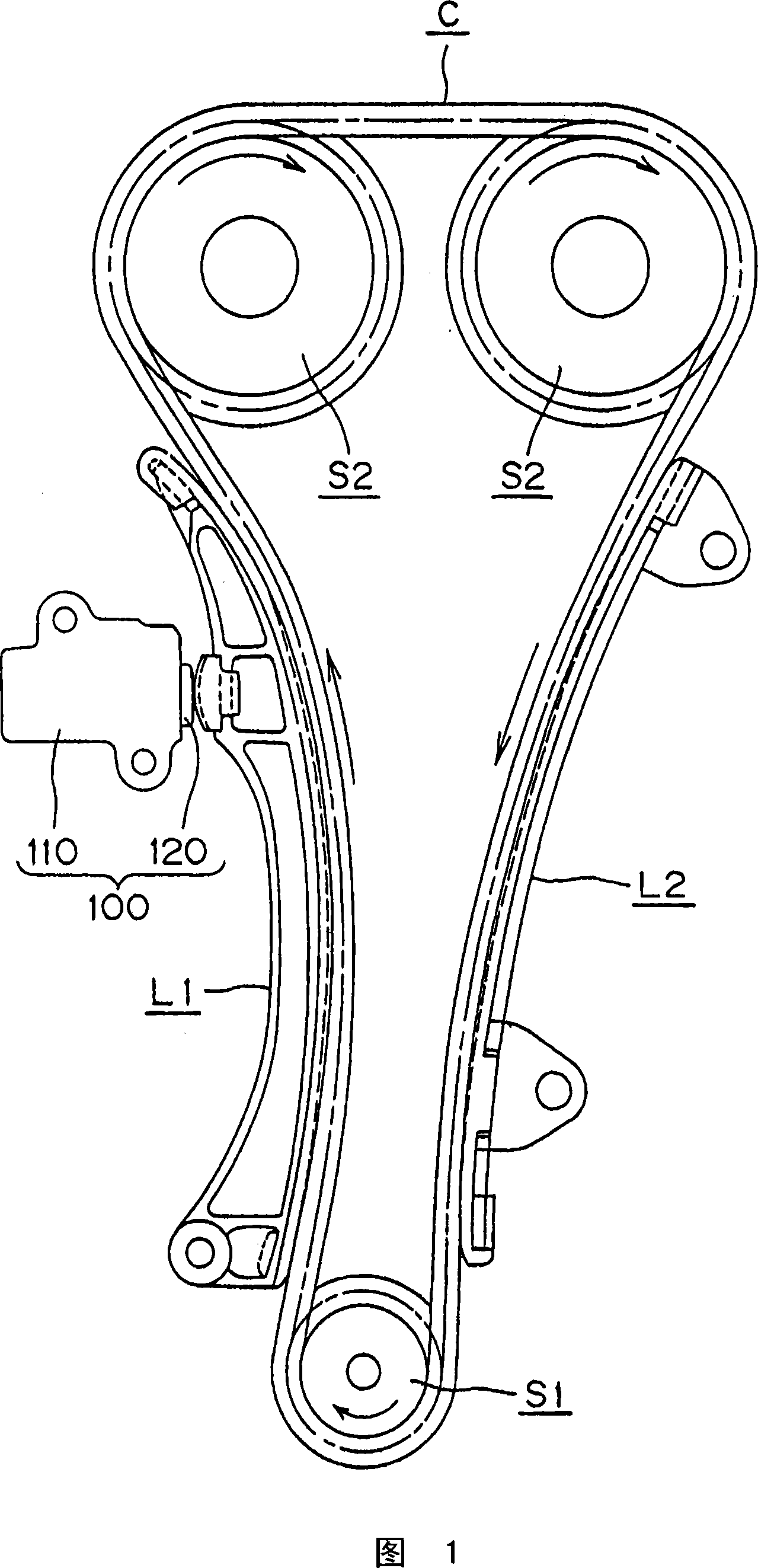

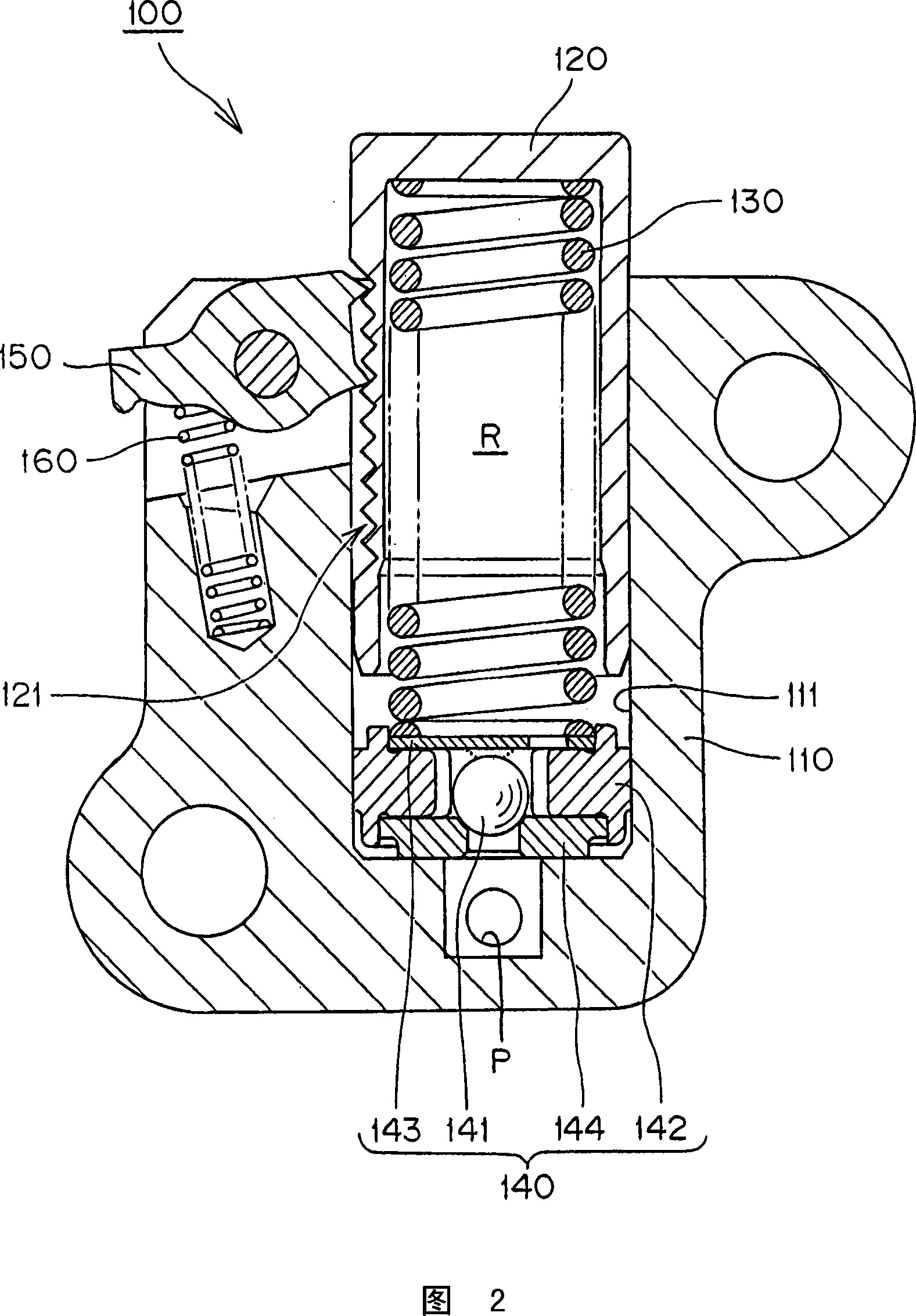

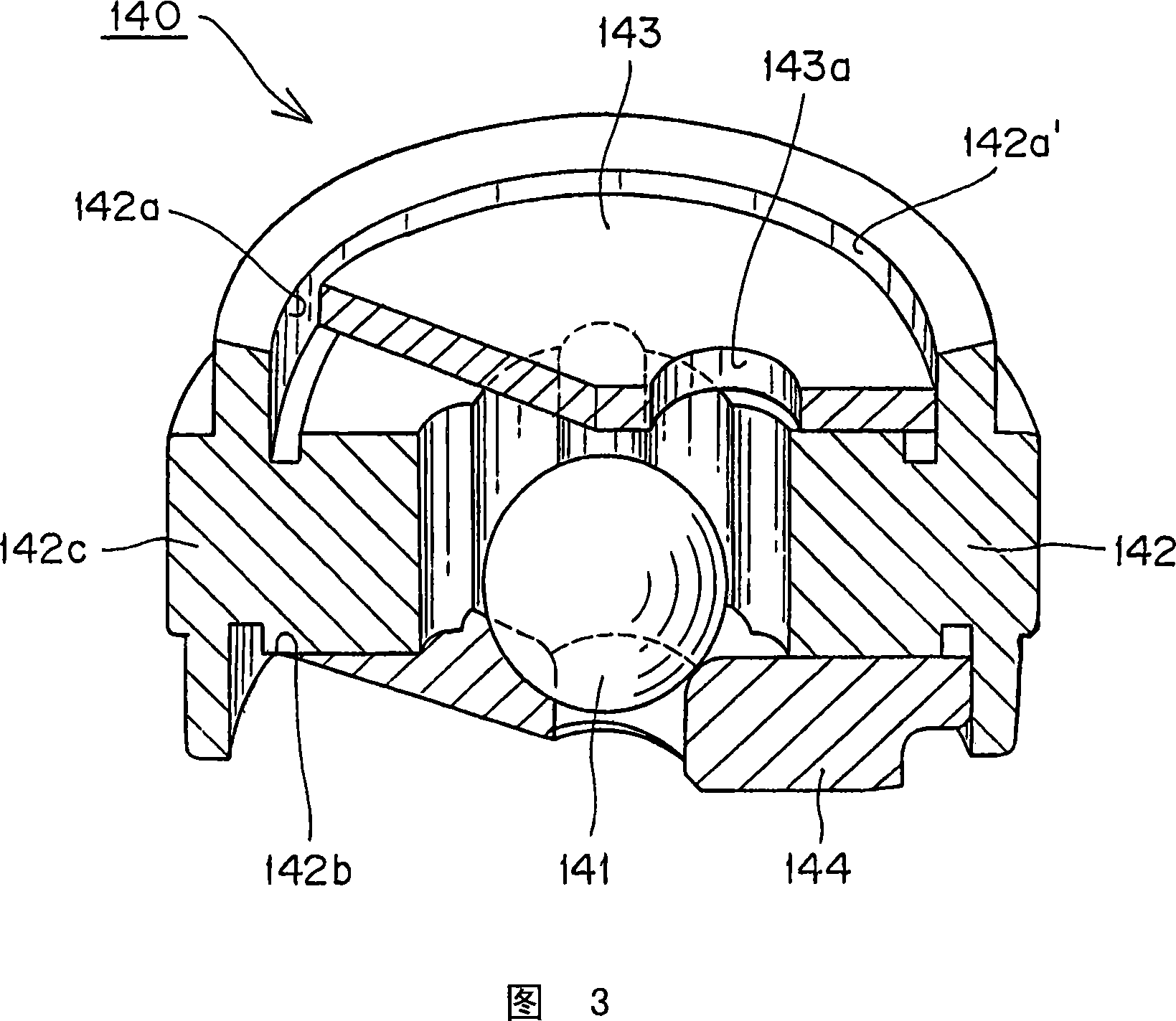

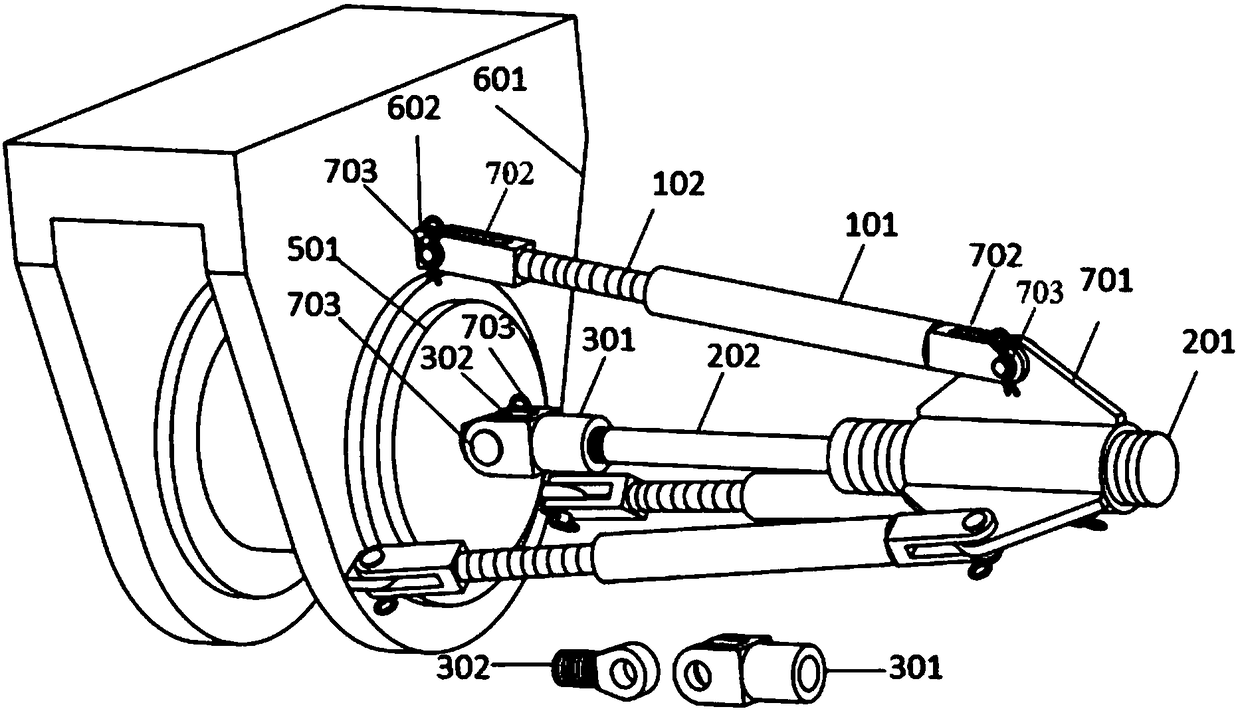

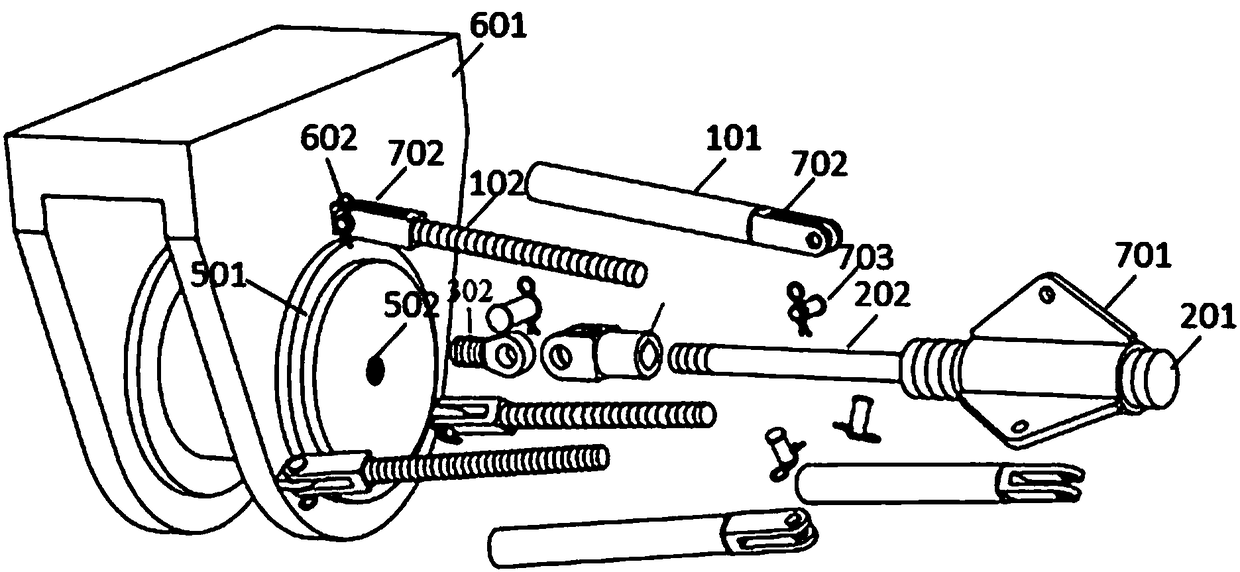

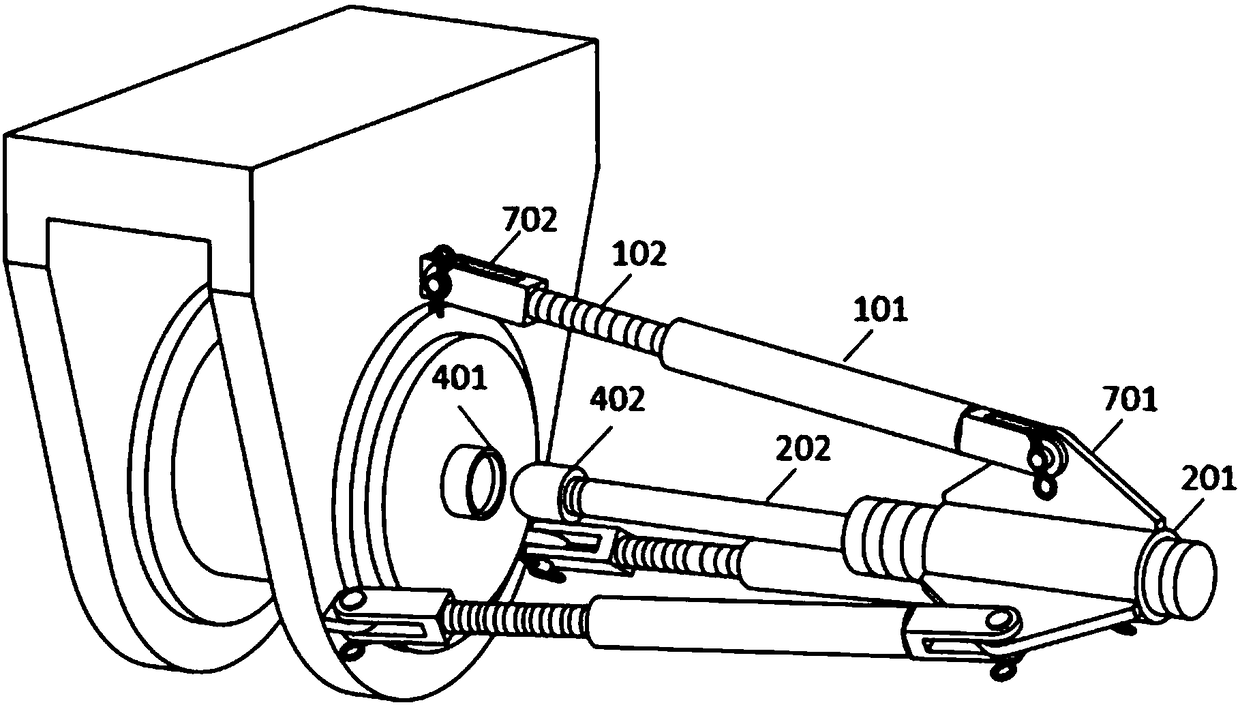

Hydraulic tensioner

The invention provides a hydraulic tensioner. A check valve unit has no elastic deformation or expansion caused by high-pressure in high-pressure oil chamber or high-temperature change in engine indoor, and can play a role of a check valve, furthermore, the check valve unit can be simply and firmly mounted on a case mainbody. The check valve unit (140) in a hydraulic tensioner (100) comprises: a check ball (141) allowing a limited range of pressure oil flow; a steel ball guide (142) having an inner wall allowing movement of a ball non-return valve; a steel retainer (143) attached to the high pressure oil chamber side of the ball guide (142); and a steel ball seat (144) attached to the oil supply side of the ball guide (142); bulged portions (142c) formed on an outer surface of the ball guide (142) are press-fit into the plunger-accommodating hole 111 of the tensioner.

Owner:TSUBAKIMOTO CHAIN CO

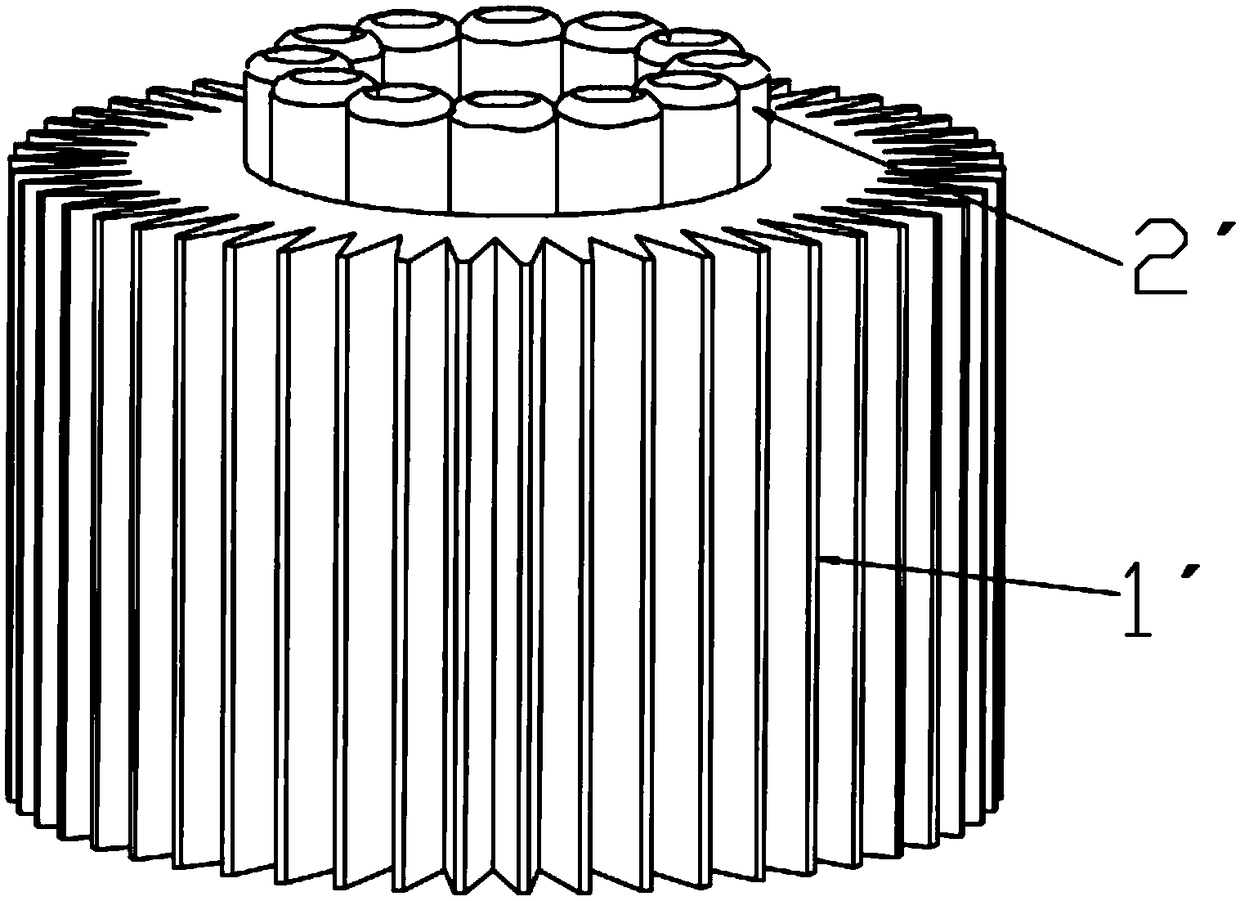

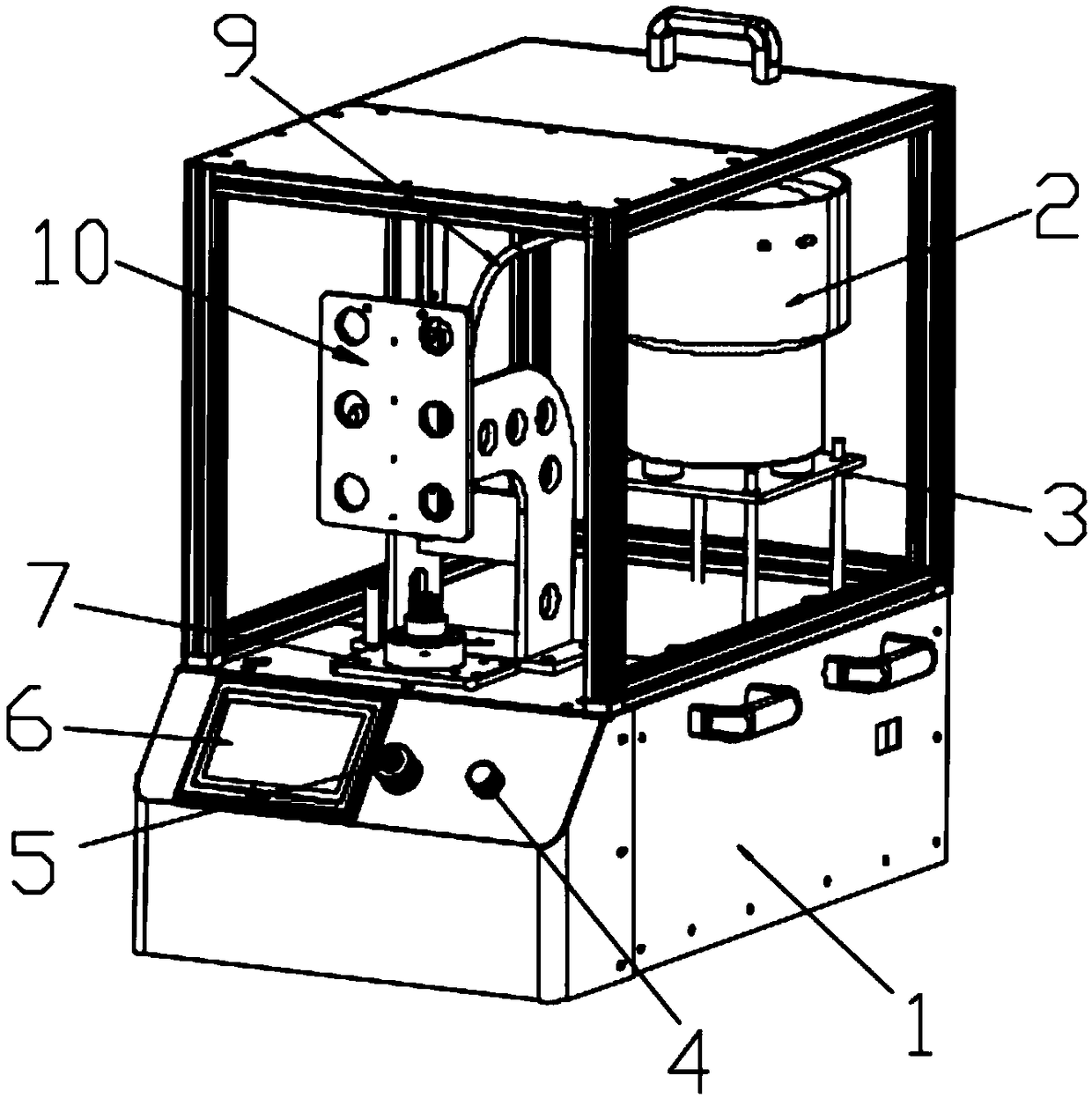

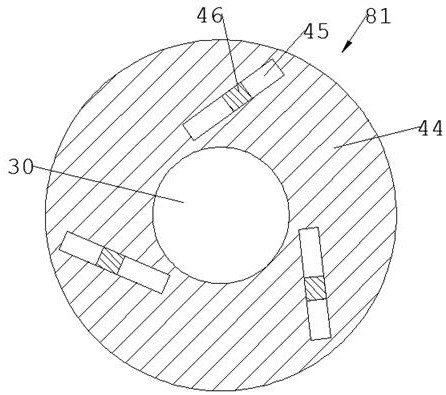

An automatic assembly apparatus for a gear needle of a planetary reducer

InactiveCN108890258AEasy to operateImprove assembly efficiencyLubricant transferMetal working apparatusGear wheelEngineering

The invention discloses an automatic assembling device for a gear needle of a planetary reducer, comprising a base with a working platform, an electric control cabinet for controlling the operation ofthe assembling device is arranged on the base inside or outside of the base, and an operation interface connected with the electric control cabinet is arranged on the base. As that gear bear is arranged on the work platform, and a gear bearing placing mechanism capable of rotating the gear bearing 360 degrees, wherein a latch mechanism capable of placing a gear roller needle in the gear bearing is arranged on a working platform on the outer side of the gear bearing placing mechanism, and the feed end of the latch mechanism is connected with the discharge end of the feeder through a conveyingpipe. It adopts mechanical linkage mode to put the gear needle into the gear bearing, which has the characteristics of simple operation and high assembly efficiency.

Owner:王福州 +1

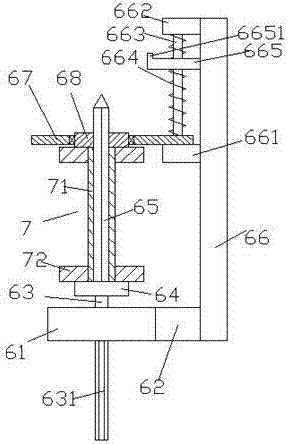

Large equipment pin shaft installing and dismantling device

PendingCN108262602ARealize disassembly workRealize the installation workMetal working apparatusEngineeringSupport plane

Owner:SHANGHAI ZHENHUA HEAVY IND

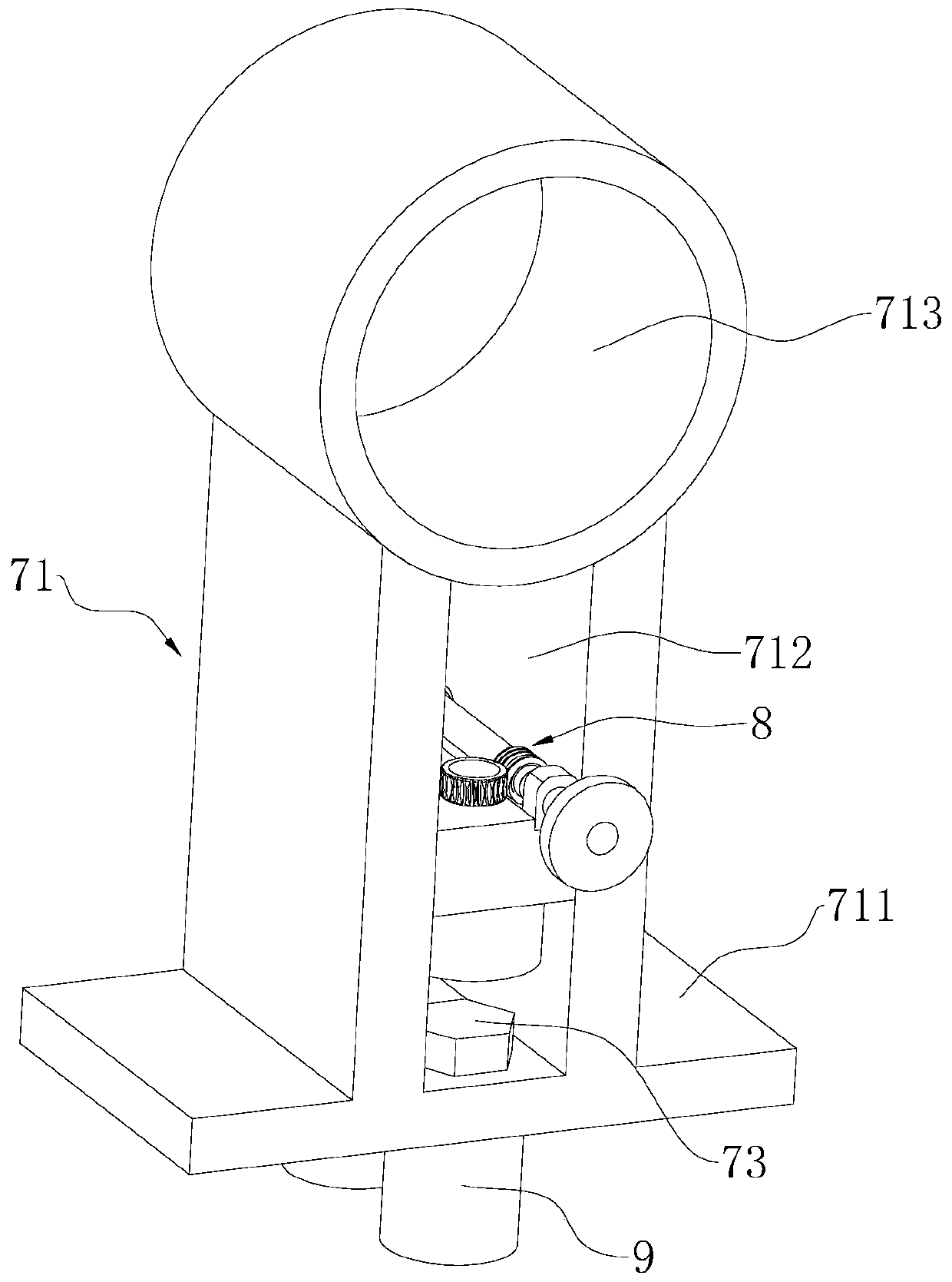

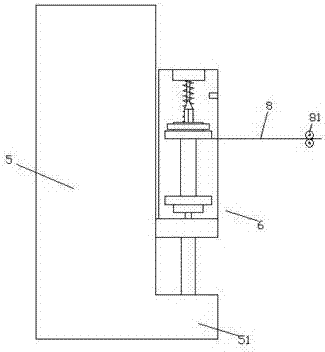

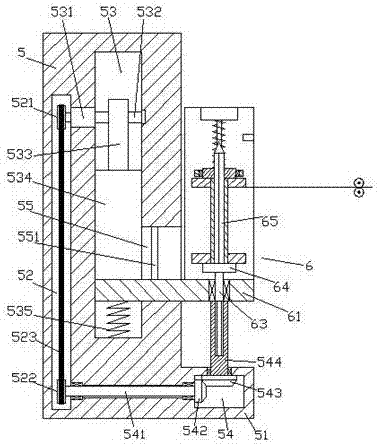

Adjacent rack rail mounting and adjusting appliance for rack rail railway

ActiveCN112962371AEasy to installFully consider the installation position deviationTrack superstructureRailway track constructionEngineeringMechanical engineering

The invention relates to the field of rack rail detection, in particular to an adjacent rack rail mounting and adjusting appliance for a rack rail railway, which comprises a rack slidably connected with steel rails on two sides and a working module positioned below the rack, the working module comprises a meshing rack, a base and a guide rail, the guide rail is slidably connected with the rack up and down, and the guide rail is fixedly connected to the base; the base is detachably connected with a meshing rack, the meshing rack is used for being meshed with a rack rail to be installed, and the guide rail is used for recognizing the relative height between the meshing rack and the rack; according to the invention, quick longitudinal positioning can be realized, and the longitudinal pitch between two adjacent toothed rails can be adjusted in an auxiliary manner, so that the two adjacent toothed rails can be flatly mounted, the mounting position height meets the travelling crane requirement, the construction is quick and efficient, the positioning is accurate, and the construction efficiency can be improved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

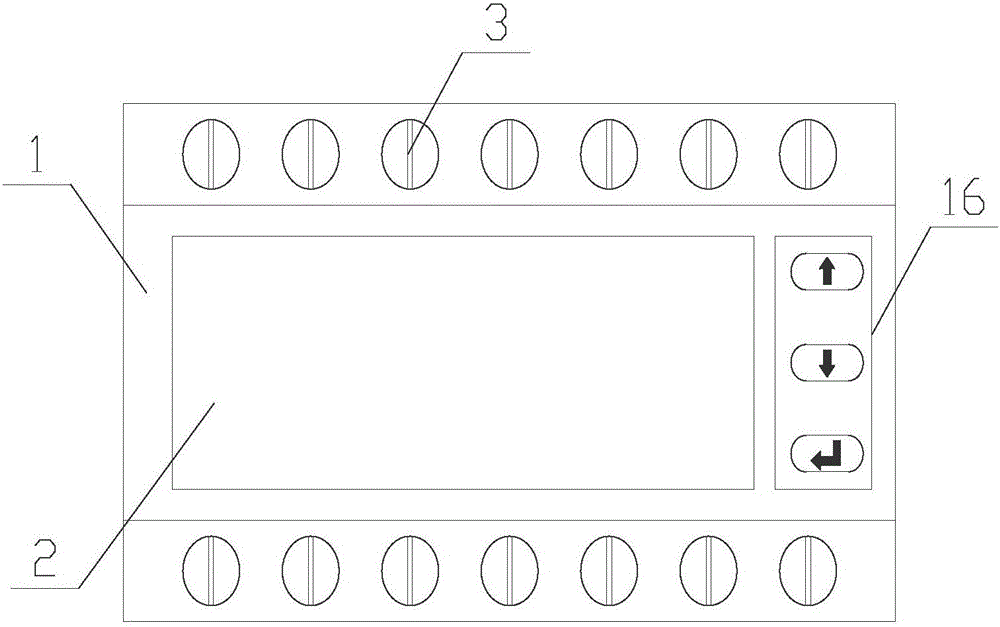

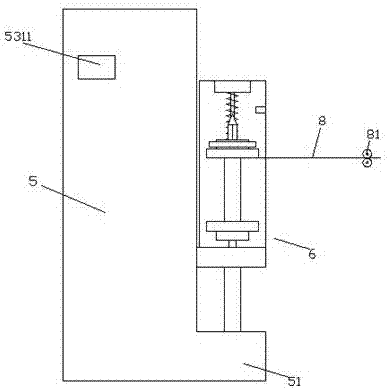

Intelligent guide rail meter based on wireless monitoring

InactiveCN105842497AEasy to fixRealize the installation workTransmission systemsTime integral measurementElectricityElectric machine

The invention relates to an intelligent guide rail meter based on wireless monitoring. The intelligent guide rail meter comprises a body and a fixed mechanism which is arranged at the back surface of the body. The body is provided with a display screen, a control panel and multiple wiring units. According to the intelligent guide rail meter based on wireless monitoring, a screw rod is driven to rotate by a driving motor arranged in the fixed mechanism so that a moving clamp pin is enabled to be away from or close to a fixed clamp pin, and installation and disassembling work of the guide rail meter can be realized. Installation and fixing of the guide rail meter are enabled to be reliable by the fixed mechanism, and disassembling operation is convenient and rapid. Besides, an electrical oscillation signal is converted into an ultrasonic signal by a frequency oscillator formed by an ultrasonic sensor, a first triode and a second triode in an ultrasonic transmitting circuit in the body, and conventional components are adopted so that reliable ultrasonic transmission can be guaranteed, production cost can be reduced and the practical value of the device can be enhanced.

Owner:徐帆

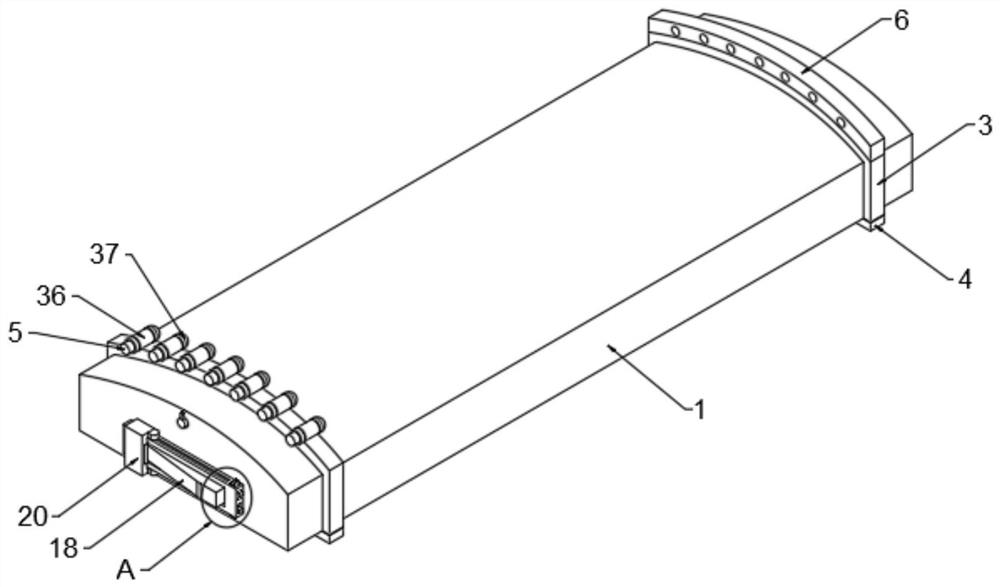

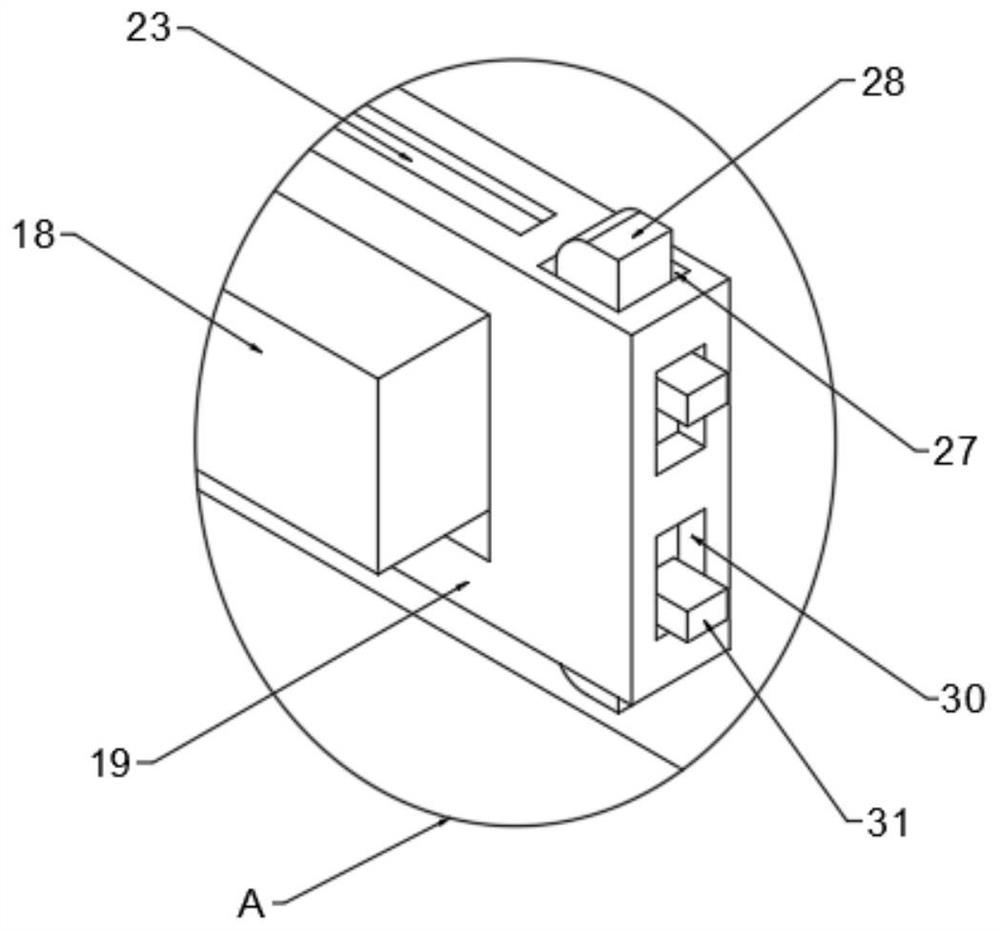

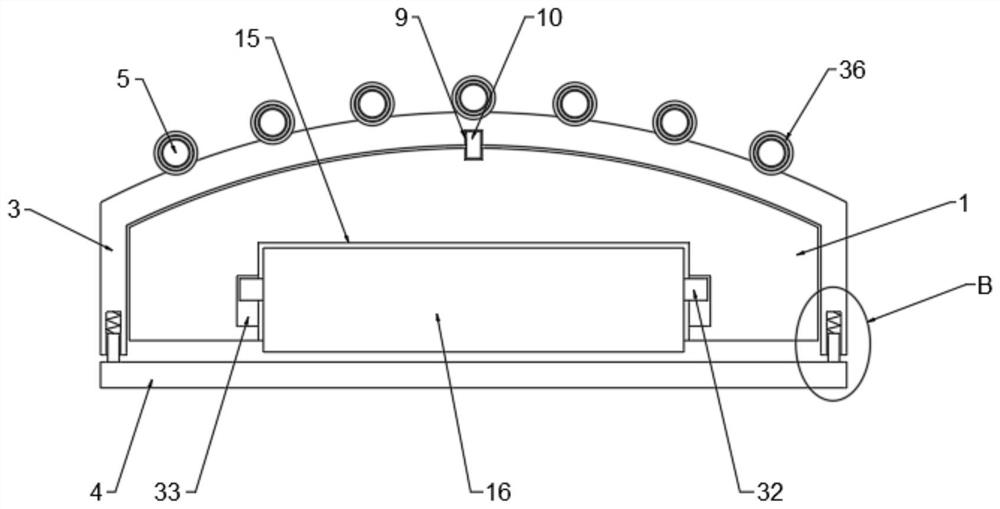

Geological disaster monitoring, predicting and early warning equipment based on artificial intelligence and use method thereof

InactiveCN114724340AAchieve extrusionRealize the installation workHuman health protectionStands/trestlesDisaster monitoringStructural engineering

The invention relates to the technical field of geological disaster monitoring equipment, in particular to geological disaster monitoring, predicting and early warning equipment based on artificial intelligence and a using method thereof.The geological disaster monitoring, predicting and early warning equipment comprises a centralized pressurization monitoring structure, a first laying monitoring structure and a second laying monitoring structure; the other end of the centralized pressurization monitoring structure communicates with a second laying monitoring structure, the centralized pressurization monitoring structure comprises a connecting frame, a supporting plate frame, a limiting guide plate, a stable connecting frame, an arc-shaped guide frame and a communicating groove pipe, the lower end of the connecting frame is fixedly connected with the supporting plate frame, and the lower end of the supporting plate frame is fixedly connected with the limiting guide plate; the rear end of the limiting guide plate is fixedly connected with a communicating groove pipe, and the center position of the supporting plate frame is fixedly connected with the stable connecting frame and the arc-shaped guide frame. Through the arrangement of the centralized pressurization monitoring structure, the first laying monitoring structure and the second laying monitoring structure, geological disaster monitoring and early warning work is achieved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

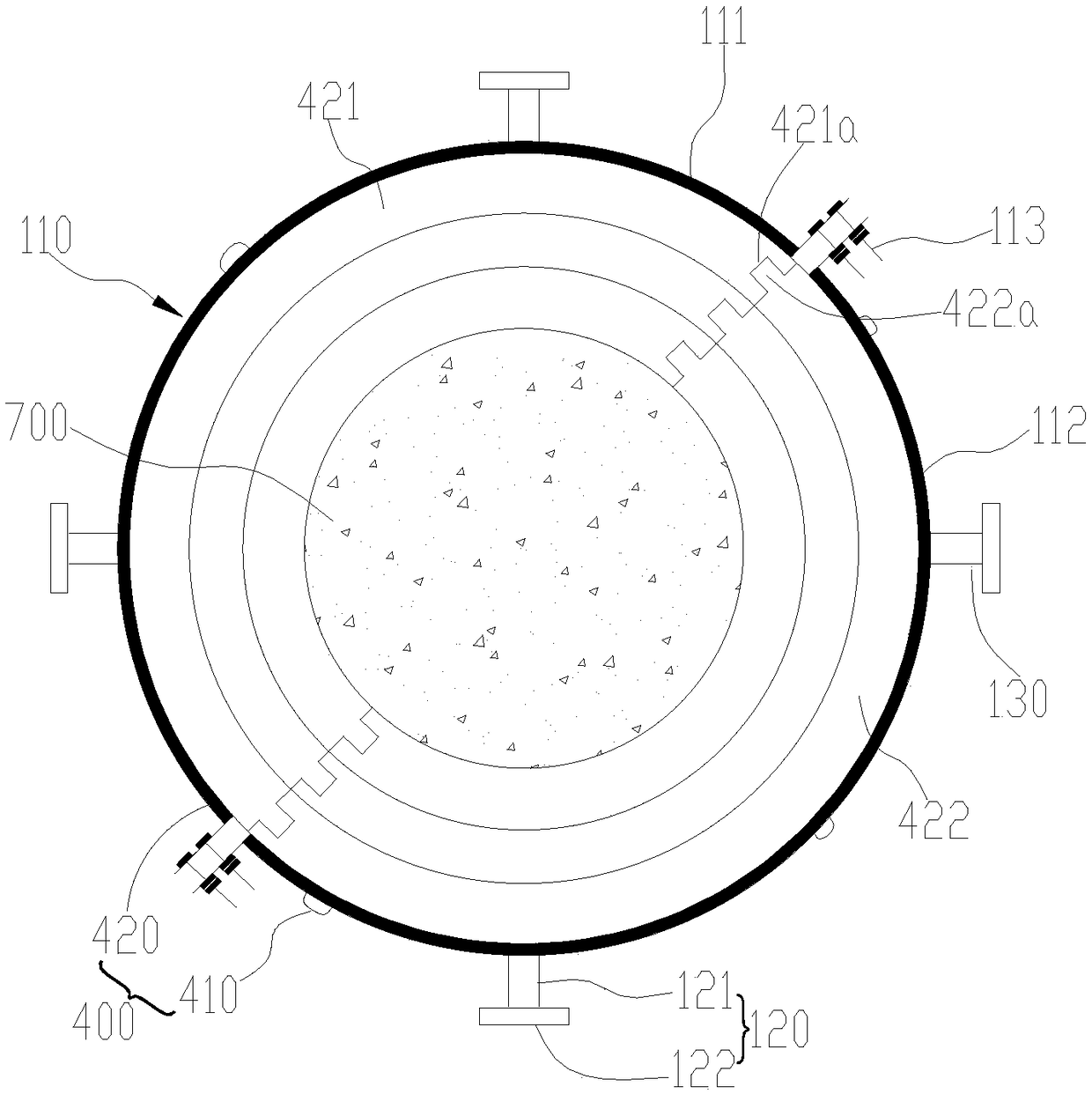

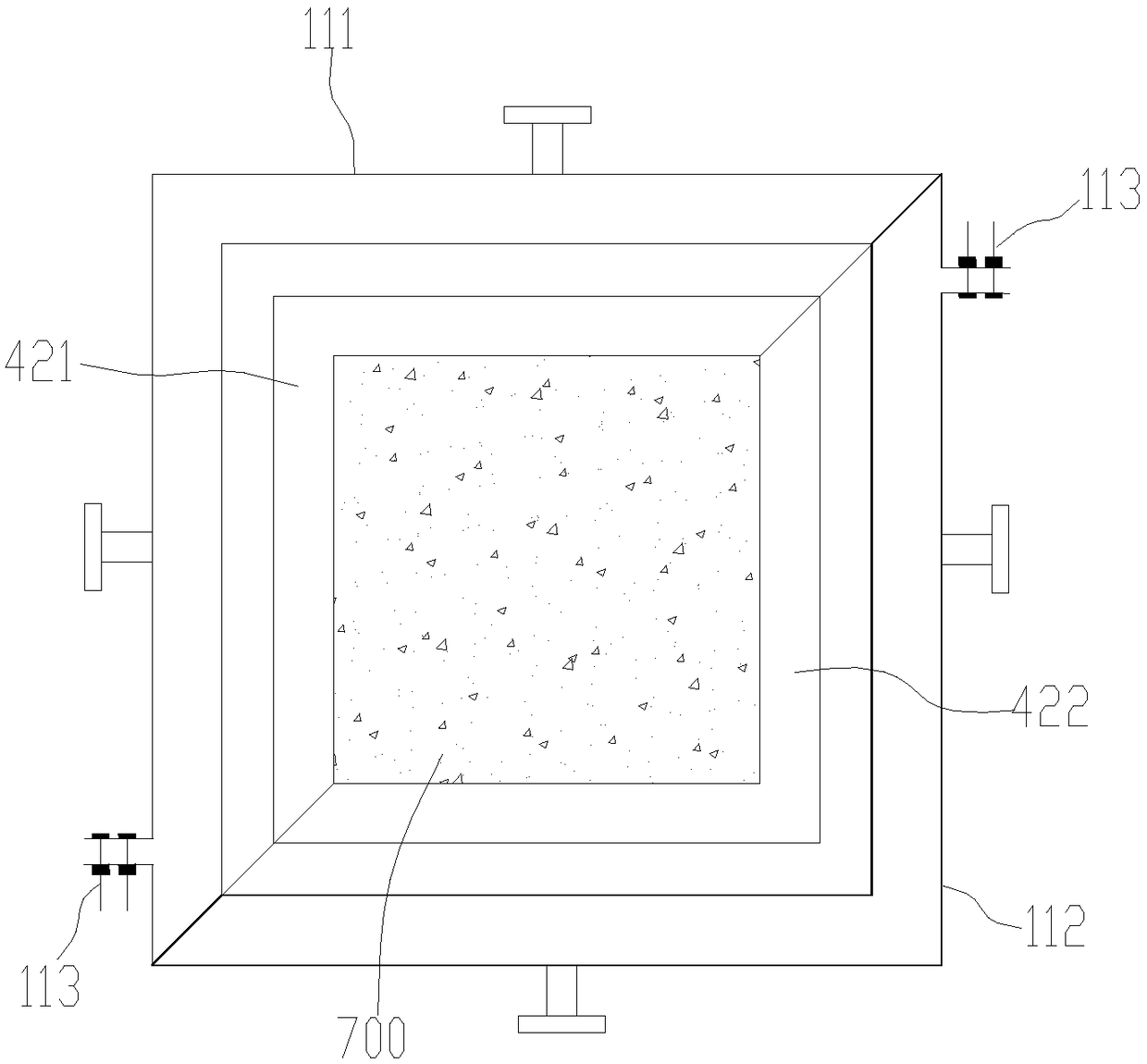

Formwork automatic disassembly and assembly device

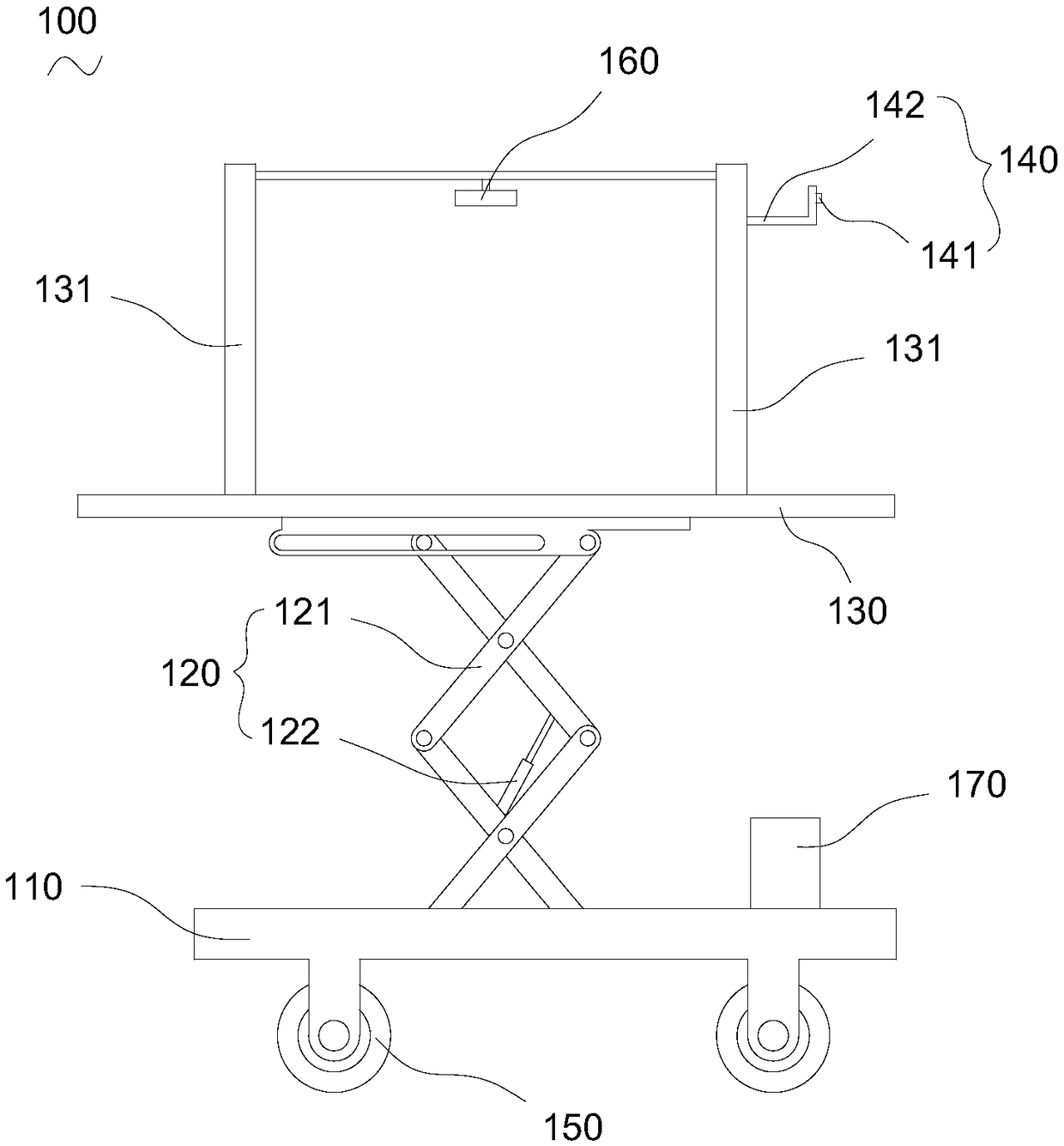

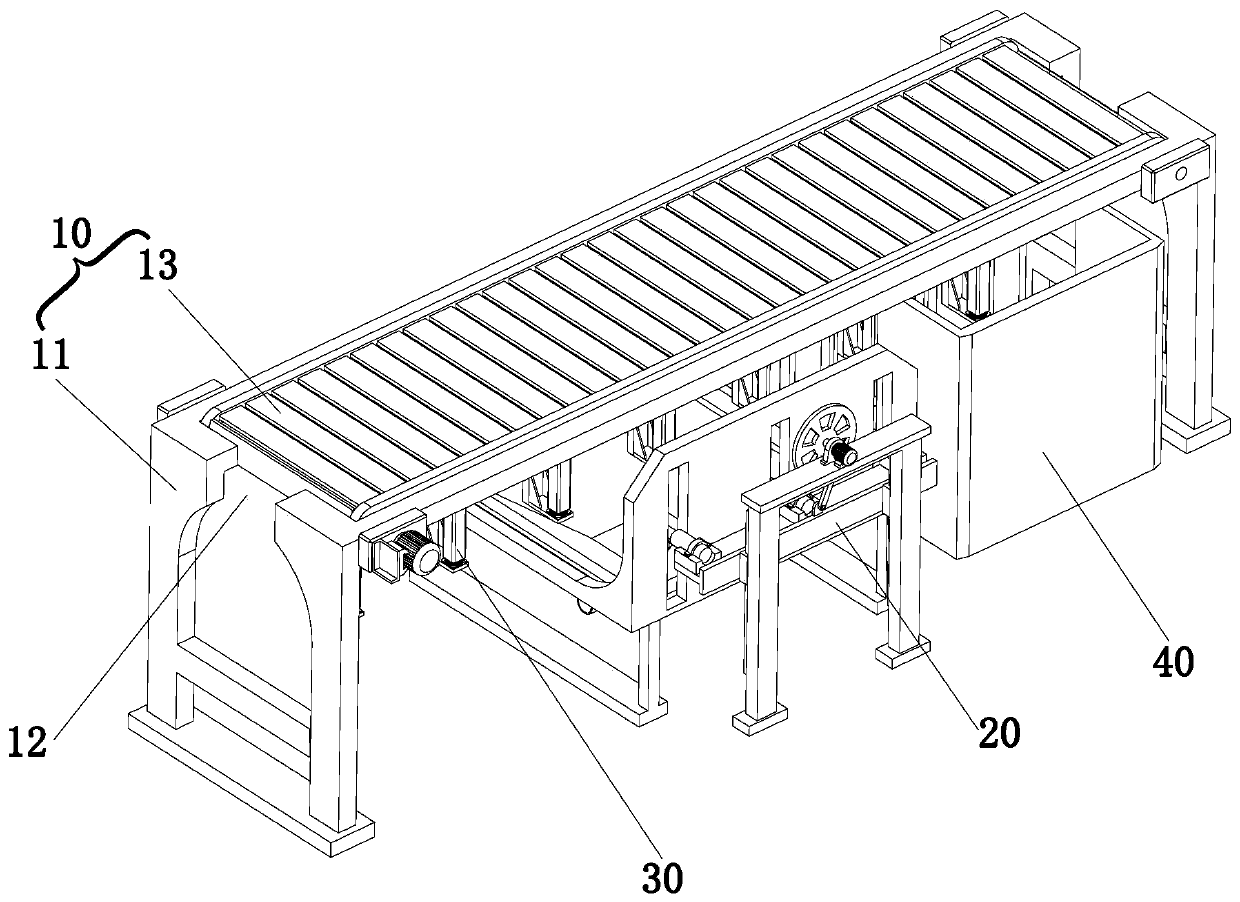

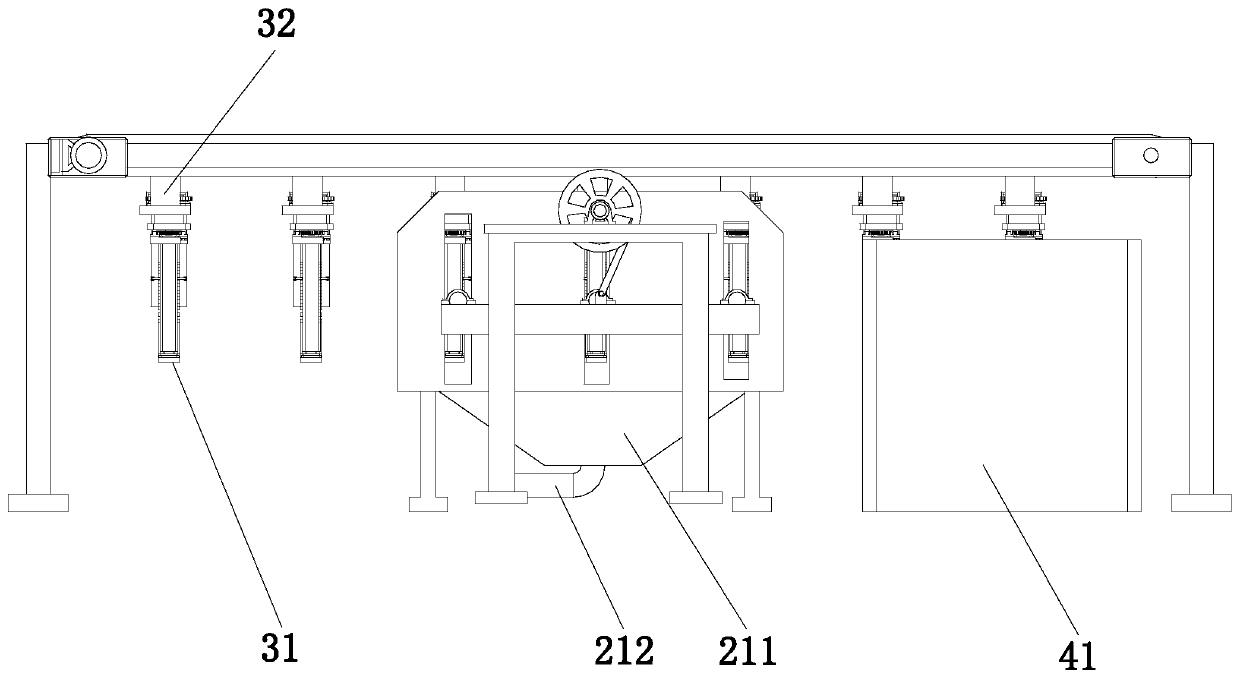

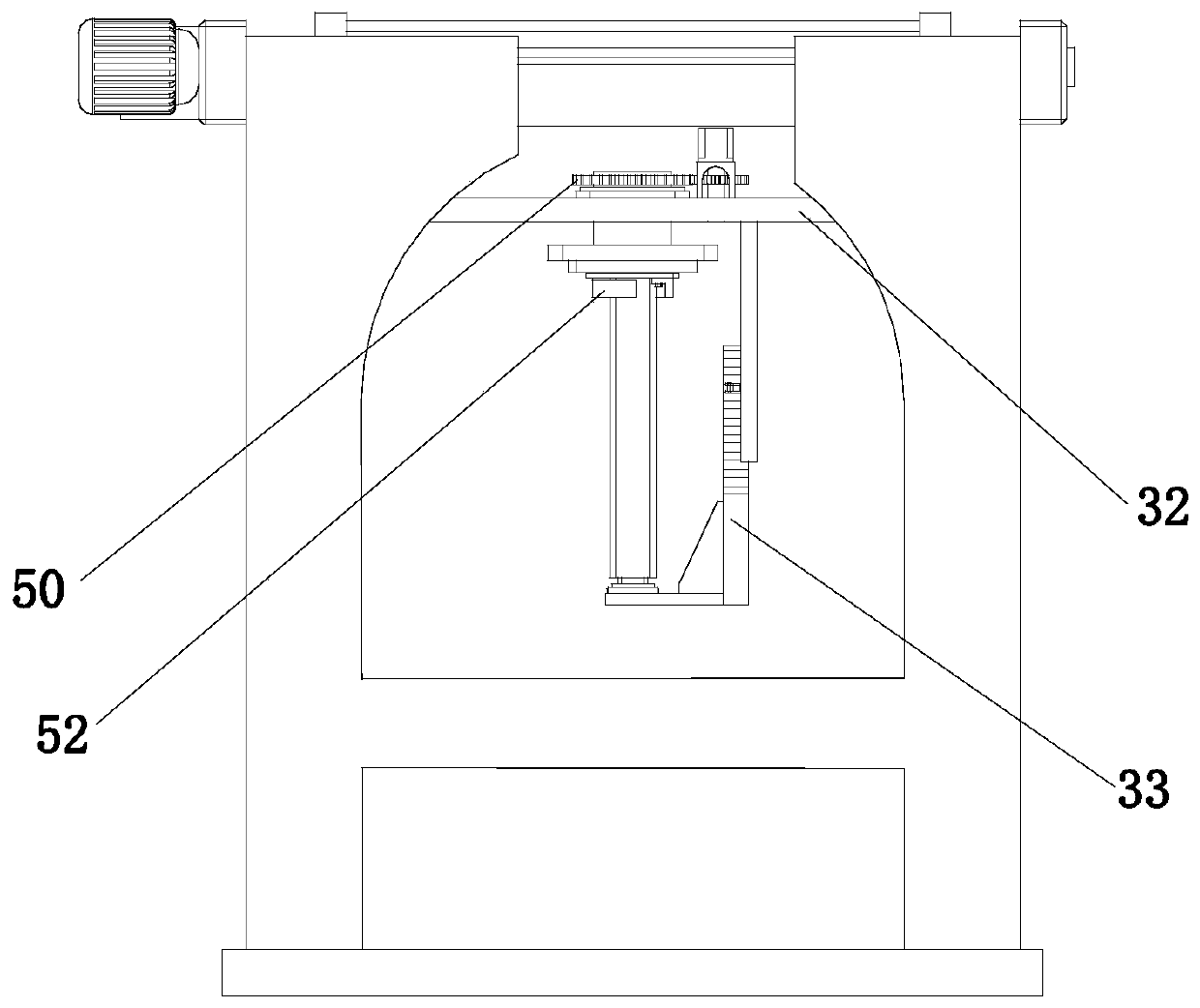

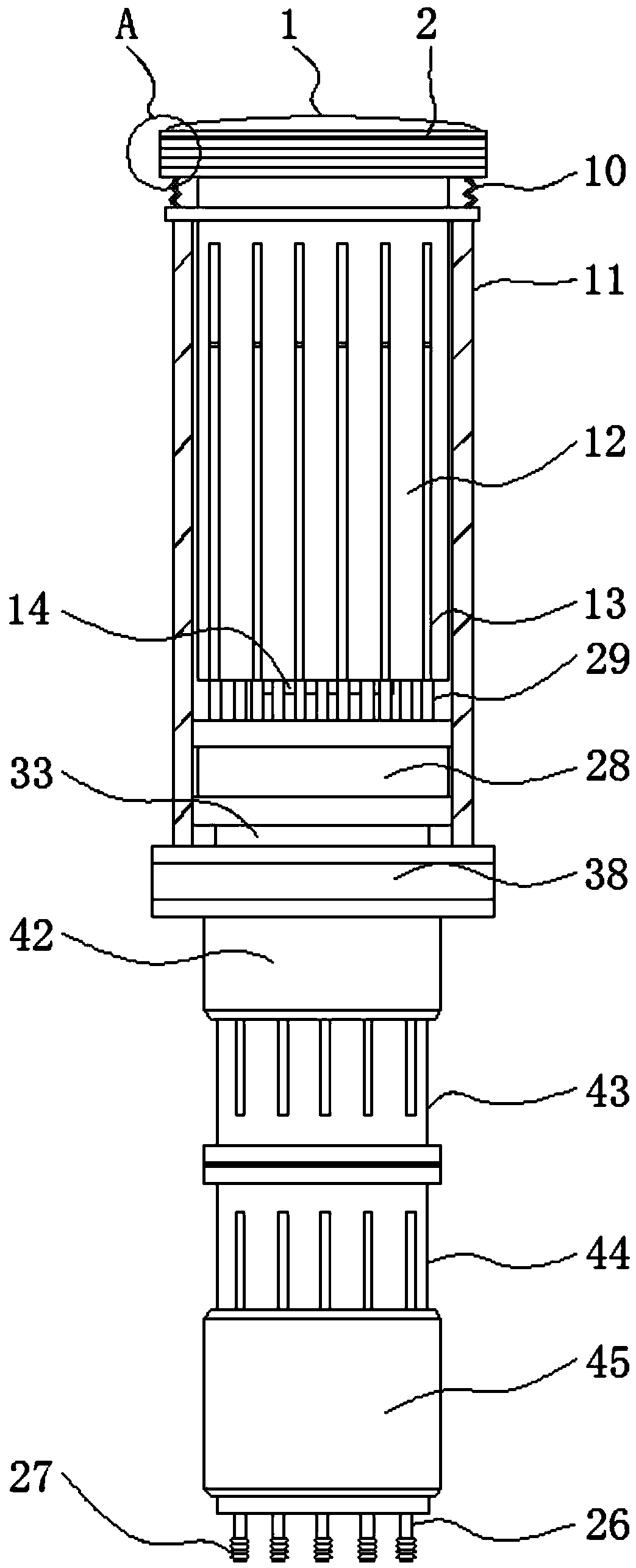

ActiveCN109262547ARealize the installation workRealize disassembly workWork benchesMetal-working hand toolsCounter rotationEngineering

The invention relates to a formwork automatic disassembly and assembly device. The device comprises a base, a lifting assembly, a working platform, a rotating assembly and a cutting machine. One end of the lifting assembly is disposed on the surface of the base. The working platform is disposed at one end of the lifting assembly away from the base, and the lifting assembly can drive the working platform to move up and down in a direction perpendicular to the surface of the base. The rotating assembly includes a rotator. The rotator is rotatably mounted on the working platform. The rotator candrive a fixing nut to rotate forward or reversely. The cutting machine is rotatably mounted on the working platform. The cutting machine is used for cutting a fixing screw. Therefore, when a formworkneeds to be assembled or disassembled, the formwork automatic disassembly and assembly device can be moved to a designated working area to achieve vertical transportation and automatic disassembly andassembly of the formwork. The input of an operator during disassembly and assembly of the formwork is reduced, and the formwork is more convenient and quick to assemble and disassemble.

Owner:湖南易兴建筑有限公司

Wire wrapping device for spinning

The invention discloses a wire wrapping device for spinning. The wire wrapping device comprises a machine body and guide transmission wheels which are arranged at the right side of the machine body and are symmetrically arranged up and down, wherein a lug boss part is arranged on the bottom of the end surface at the right side of the machine body; a wire wrapping mechanism is arranged above the lug boss part; the wire wrapping mechanism comprises a bottom plate which extends left and right, a connecting block which is fixedly arranged at the rear side of the right side of the bottom plate, a straight plate which is fixedly arranged at the rear side end of the connecting block and extends upwards, and a wire wrapping base arranged above the bottom plate; the bottom of the wire wrapping base is fixedly equipped with a first rotary shaft; the bottom of the first rotary shaft penetrates through the bottom plate and is rotatably connected with the bottom plate in a matched mode; the bottom of the first rotary shaft is fixedly equipped with an outer spline shaft which extends downwards; a single spline shaft is fixedly arranged on the top of the wire wrapping base; a first transmission cavity is arranged in the lug boss part; and an inner spline rotary shaft which extends towards upper and lower sides is rotatably matched and connected in the top wall in the first transmission cavity. The wire wrapping device is simple in structure, realizes automatically controlling upper and lower movable wire wrapping work, improves wire wrapping uniformity, realizes quickly dismounting a bobbin and improves wire wrapping stability.

Owner:惠州市骏鹏织造有限公司

Laser string with interaction effect

PendingCN113436592AHigh precisionImprove convenienceElectrophonic musical instrumentsLight beamEngineering

The invention discloses a laser string with an interaction effect. The laser string comprises a mounting base and two calibration mechanisms, wherein an outer wall of the mounting base is symmetrically provided with arc-shaped mounting grooves, inner cavities of the two arc-shaped mounting grooves are both provided with U-shaped mounting rings, two calibration mechanisms are symmetrically arranged on the two sides of the mounting base, each calibration mechanism comprises a threaded hole, a telescopic hole is formed in one side of the inner wall of the threaded hole, a calibration hole is formed in one side of the U-shaped mounting ring, an inner cavity of the threaded hole is in threaded connection with a threaded rod, and one end of the threaded rod is rotationally connected with a calibration rod. Through the arrangement of the threaded hole, the threaded rod, the telescopic hole, the calibration hole and the calibration rod, the threaded rod in the threaded hole is rotated, so the calibration rod is driven to move in the telescopic hole and be inserted into the calibration hole, the alignment work of the two U-shaped mounting rings is completed, and meanwhile, the work that a laser emits light beams to be aligned with a photoelectric receiver is completed; and precision of laser string installation is improved.

Owner:广州新起典文旅科技有限公司

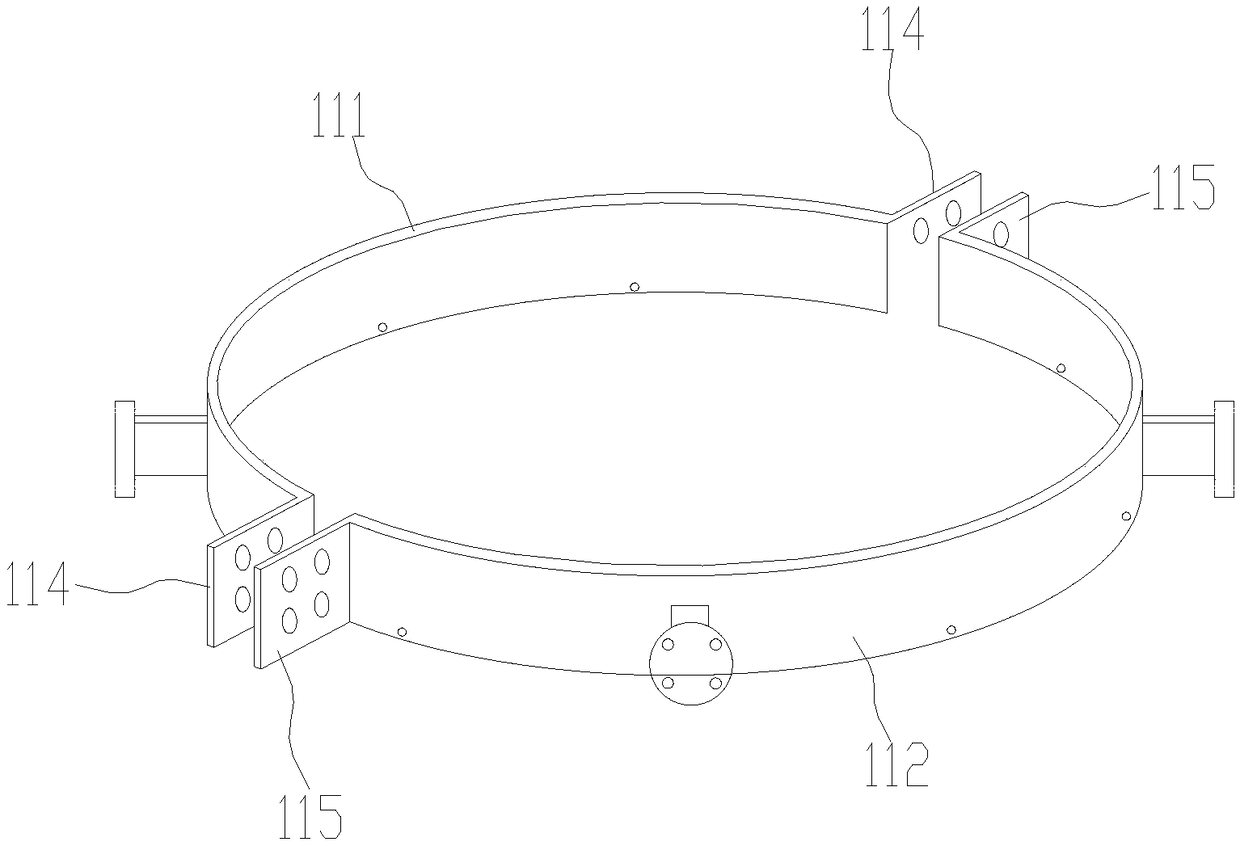

Detachable iron tower coupling beam and transmission tower

The invention discloses a detachable iron tower coupling beam and a transmission tower. The detachable iron tower coupling beam and the transmission tower comprises at least three tower legs embracinghoops, at least six first adjustable locking assemblies and at least three straight-side coupling beams, wherein the tower leg embracing hoops comprise an embracing hoop body connected with each of the tower legs in a fastening and fixing mode one by one, and at least two first fixed connecting seats arranged on the embracing hoop body at intervals; the first adjustable locking assemblies are connected with the first fixed connecting seats in a fastening and fixing mode one by one; and second fixed connecting seats are arranged on the two ends of each of the straight-side coupling beams, thesecond fixed connecting seats are connected with the first adjustable locking assemblies in a fastening and fixing mode one by one. The installation work of the coupling beam can be quickly achieved,the construction steps are simple and convenient, the use for support of damaged tower legs can be quickly put into, the disassembly can be achieved to facilitate the circulation use, and energy saving and environmental protection are achieved; and at the same time, by the trimming of the first adjustable locking assemblies, tower leg supports with different foot distance sizes in a certain rangecan be achieved, and universality and economy are good.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

Spinning wire winding device

InactiveCN108002134AWork fasterRealize the installation workFilament handlingAutomatic controlBobbin

The invention discloses a spinning wire winding device. The spinning wire winding device comprises a machine body, and guide wheels arranged on the right side of the machine body and symmetrically arranged in an up-and-down mode; a boss part is arranged at the bottom of the right side end surface of the machine body; a wire winding mechanism is arranged above the boss part; the wire winding mechanism comprises a baseplate extending left and right, a connecting block fixed on the back side of the right side of the baseplate, a straight plate fixed at the back side end of the connecting block and upwards extending, and a wire winding base arranged above the baseplate; a first rotating shaft is fixedly arranged at the bottom of the wire winding base; the bottom of the first rotating shaft penetrates through the baseplate for rotary cooperating connection; an outer spline shaft downwards extending is fixedly arranged at the bottom of the first rotating shaft; a single key shaft is fixedlyarranged at the top of the wire winding base; a first transmission cavity is formed in the boss part; and an inner spline rotating shaft extending to the upper and lower sides is in rotary cooperatingconnection into the inner top wall of the first transmission cavity. The spinning wire winding device is simple in structure, realizes automatic control of up-down movable wire winding work, improvesthe wire winding uniformity, realizes quick disassembly of bobbins, and improves the wire winding stability.

Owner:扬州市青山环保科技有限公司

Anti-knotting spinning wire winding device

InactiveCN108002125AWork fasterRealize the installation workFilament handlingBobbinAutomatic control

The invention discloses an anti-knotting spinning wire winding device. The anti-knotting spinning wire winding device comprises a machine body, and guide wheels arranged on the right side of the machine body and symmetrically arranged up and down; a boss part is arranged at the bottom of the right side end surface of the machine body; a wire winding mechanism is arranged above the boss part; the wire winding mechanism comprises a baseplate extending left and right, a connecting block fixed on the back side of the right side of the baseplate, a straight plate fixed at the back side end of the connecting block and upwards extending, and a wire winding base arranged above the baseplate; a first rotating shaft is fixedly arranged at the bottom of the wire winding base; the bottom of the firstrotating shaft penetrates through the baseplate for rotary cooperating connection; an outer spline shaft downwards extending is fixedly arranged at the bottom of the first rotating shaft; a single keyshaft is fixedly arranged at the top of the wire winding base; a first transmission cavity is formed in the boss part; and an inner spline rotating shaft extending to the upper and lower sides is inrotary cooperating connection into the inner top wall of the first transmission cavity. The anti-knotting spinning wire winding device is simple in structure, realizes automatic control of up-down movable wire winding work, improves the wire winding uniformity, realizes quick disassembly of bobbins, and improves the wire winding stability.

Owner:CIXI QICHENG MACHINERY TECH CO LTD

Hanging mounting structure for smoke glass

InactiveCN104436468AAchieve connectionRealize adjustment workFire rescueBuilding constructionsEngineeringVertical distance

The invention discloses a hanging mounting structure for smoke glass. The hanging mounting structure comprises first connecting elements, second connecting elements and the smoke glass which are arranged vertically and sequentially, wherein each first connecting element comprises a hanging part arranged at the top end and a connecting part arranged at the bottom, the connecting part is connected with the corresponding second connecting element, and the vertical distance after the second connecting element is connected with the connecting element is adjustable; and the smoke glass is connected with the second connecting elements. With adoption of the hanging mounting structure for the smoke glass, both vertical and horizontal adjustment of the mounted smoke glass can be realized, further, the mounting is convenient, the operation is easy, and the mounting efficiency of the smoke glass is increased.

Owner:GOLD MANTIS CONSTR DECORATION

Automatic plastic spraying system for traffic guardrail production

ActiveCN110076057ARealize automatic feeding processUniform plastic sprayingPretreated surfacesCoatingsChain typeEngineering

The invention discloses an automatic plastic spraying system for traffic guardrail production and belongs to the technical field of guardrail plastic spraying. The automatic plastic spraying system comprises a guardrail feeding mechanism, a plastic spraying mechanism, a guardrail installation mechanism and a baking mechanism. The guardrail feeding mechanism is arranged above the plastic spraying mechanism. The baking mechanism is arranged at the right end of the plastic spraying mechanism. The guardrail feeding mechanism comprises an installation frame and a plate chain type conveying belt. The guardrail installation mechanism comprises multiple guardrail fixing assemblies, and each guardrail fixing assembly comprises an installation frame, a guardrail limiting part and a rotating part. Bymeans of the automatic plastic spraying system for traffic guardrail production, fixing work on the top end of a guardrail can be achieved through the guardrail fixing assemblies, meanwhile, the guardrail can rotate under the effect of the rotating parts, plastic spraying work can be conducted on the four side walls of the guardrail through the plastic spraying mechanism, three plastic spraying guns can move in a reciprocating manner in the vertical direction through the plastic spraying mechanism, and the plastic spraying guns can conduct plastic spraying work evenly on the guardrail entering a plastic spraying box.

Owner:浙江富瑞新材料有限公司

Device capable of preventing and treating shortsightedness

The invention discloses a device capable of preventing and treating shortsightedness, and relates to the technical field of shortsightedness prevention and treatment. The device specifically comprisesan image light source disk, a pipe sleeve and a driving disk, a color mixing disk set is arranged below the image light source disk, a folding cylinder is fixedly connected to the lower surface of the color mixing disk set, the pipe sleeve is connected to the lower end of the folding cylinder, slots are formed in the outer wall of a movable sleeve at equal intervals, a set building pipe cylindervertically penetrates into the movable sleeve, a limiting loop is placed below the movable sleeve, insertion rods are integrally arranged at the upper surface of the limiting loop, the insertion rodsare inserted into the slots, an air heating disk is fixedly connected to the lower surface of the limiting loop, and the driving disk is integrally connected to the lower end of the pipe sleeve. According to the device capable of preventing and treating shortsightedness, due to a light source inside the image light source disk, light of proper brightness for a viewing image is supplied to the whole device, image paper of a unique image can be placed on the image light source disk for human eye viewing, and the view focal length is determined.

Owner:连云港市一明医疗科技有限公司

Numerical-control electric frame truck for airplane engine mounting

InactiveCN103204248BRealize the installation workEnable mobilityAircraft assemblyNumerical controlDrive wheel

The invention relates to a numerical-control electric frame truck for airplane engine mounting and belongs to the technical field of assembly automation. The numerical-control electric frame truck is characterized by comprising a multi-shaft posture adjusting platform (1), a posture adjusting platform frame (2), a long-shaft feed mechanism (3), a truck body frame (4), left and right rotation mechanisms (5), an auxiliary support mechanism (6), hydraulic support legs (7), a driving wheel system (8), a truck body underframe (9), steering wheel systems (10), a driving cab (11), a hydraulic control system and a servo control system. Posture of five shafts is driven and adjusted by a servo motor, and posture of the rest one shaft is manually adjusted. Travelling of the frame truck is driven by the mode of electric vehicle. The numerical-control electric frame truck has the advantages that positioning accuracy is high, maneuverability is good, stability is high, engine mounting efficiency is improved, and labor intensity of operators is reduced. Besides, the numerical-control electric frame truck is applicable to automatic mounting operation of heavy complicated shaft parts requiring multi-shaft posture adjustment.

Owner:DALIAN UNIV OF TECH +1

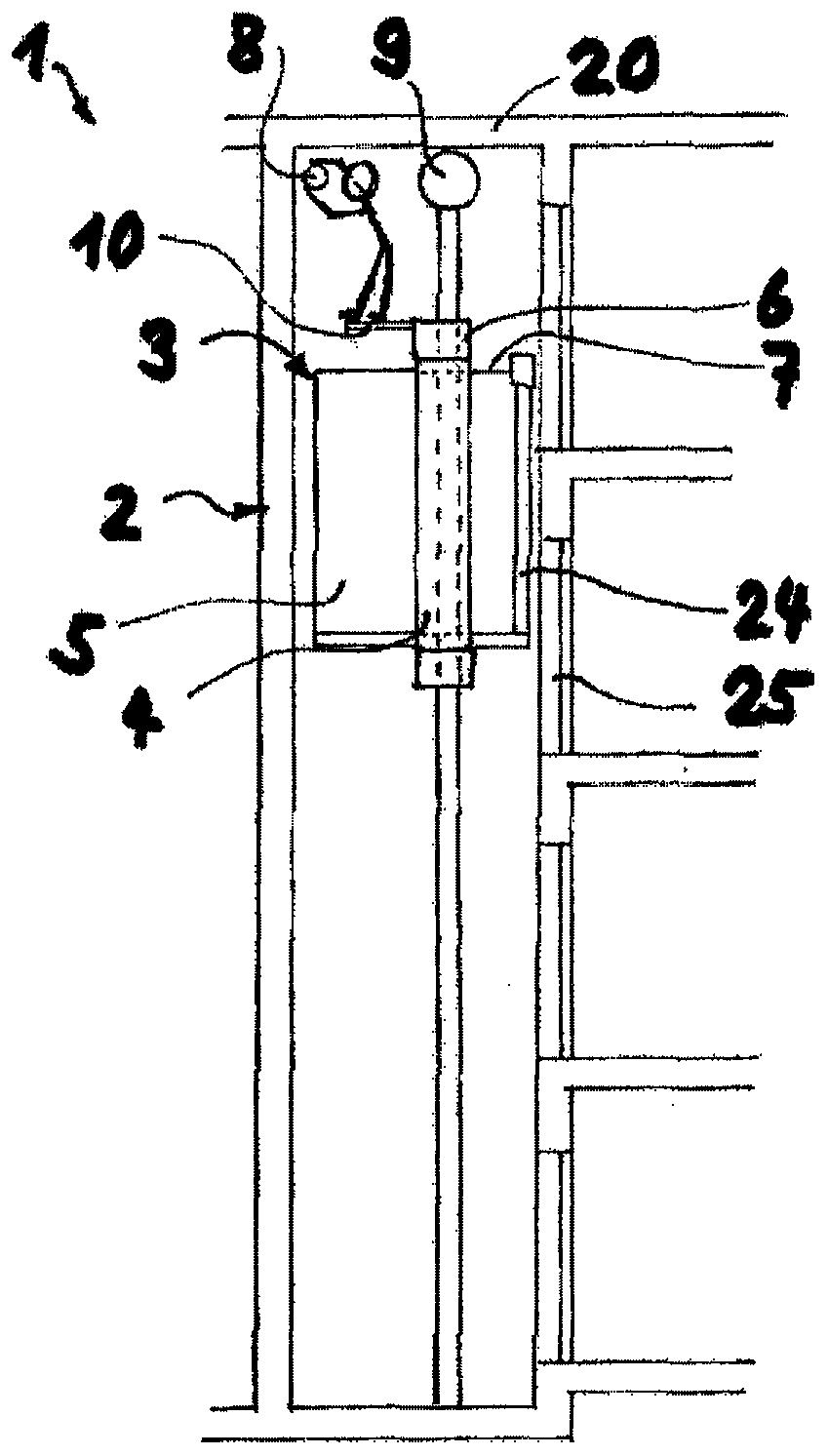

Maintenance platform for elevator car

Owner:INVENTIO AG

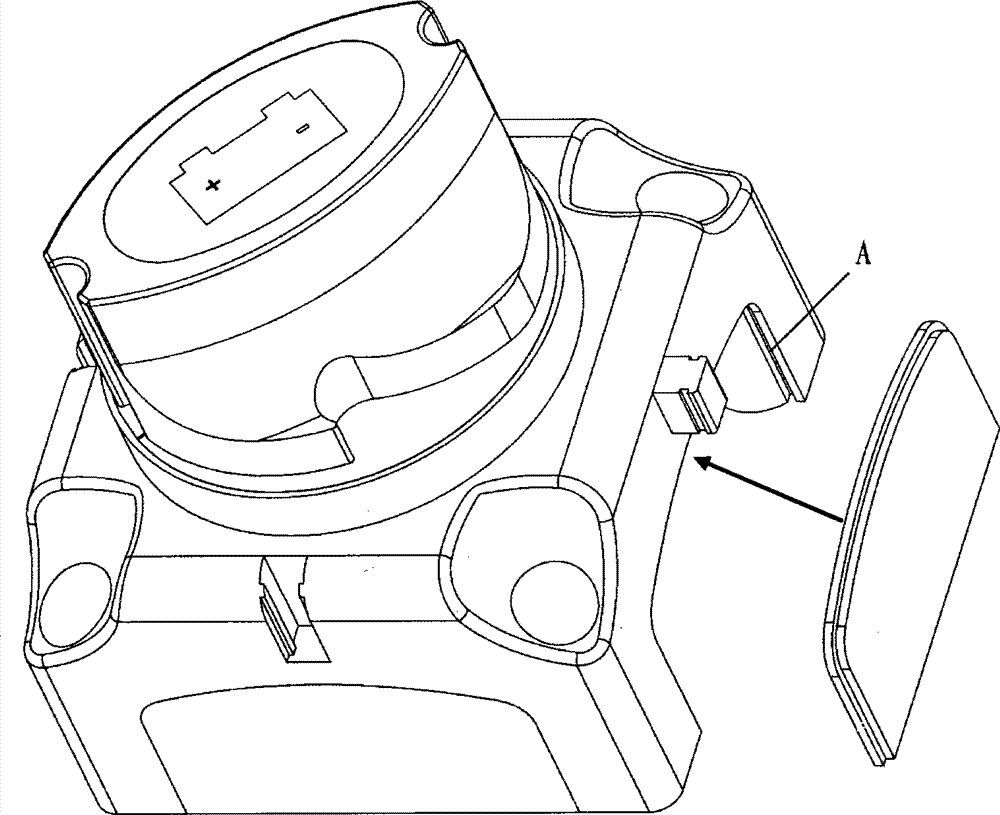

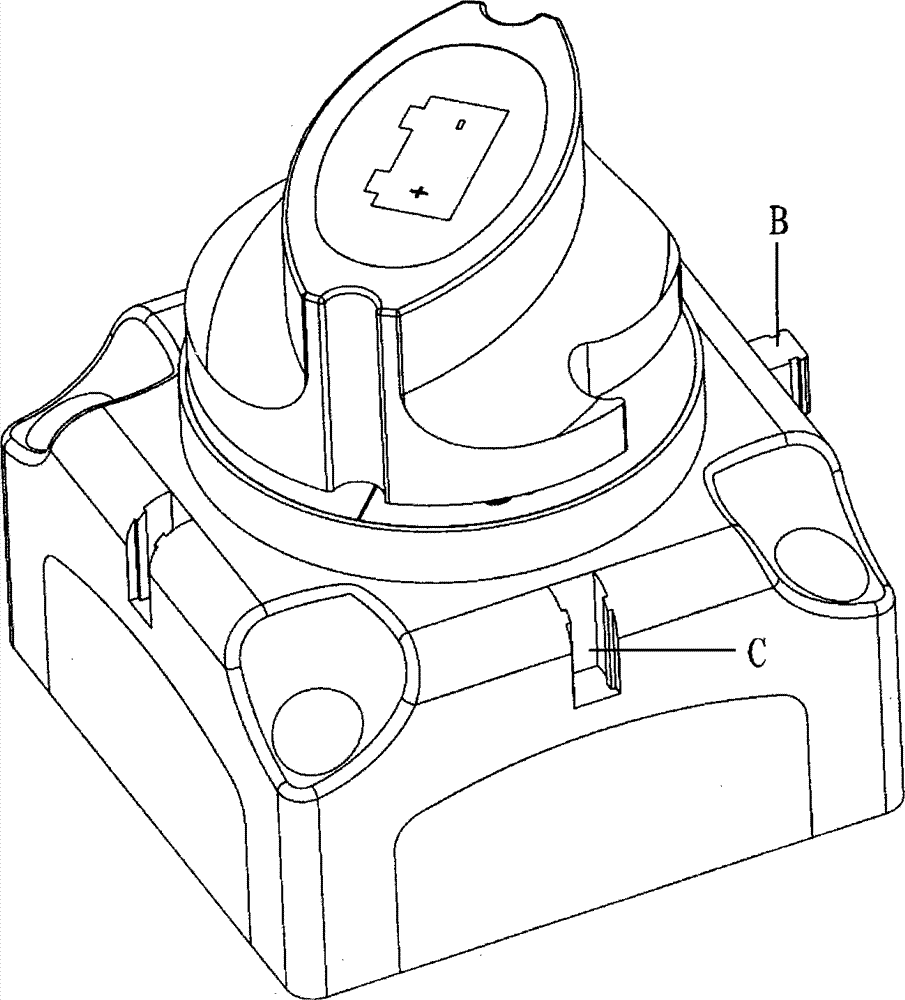

An electrical control switch structure

InactiveCN102254722BGood choiceRealize the installation workElectric switchesState of artEngineering

The invention relates to an electrical appliance control switch structure, comprising an electrical appliance control switch and a cover plate which is arranged on a first side face of the electrical appliance control switch, wherein the cover plate is provided with a bayonet post; the first side face of the electrical appliance control switch is provided with a bayonet face; the bayonet face is provided with a bayonet groove; the bayonet groove is matched and connected with the bayonet post; grooves are arranged at the left and right sides of the first side face of the electrical appliance control switch respectively; and a second side face of the electrical appliance control switch is provided with a bolt which is matched and connected with the groove. A pressing buckle type switch and a threading groove structure are used to solve the defects in the prior art, thus avoiding unrecoverable misoperation and solving the unreasonable post-installation adjustment in a certain range. The composite structure of electrical appliance control switch expansion modules is used to solve the problem that the structure between the body and an expansion unit is incompact and unstable.

Owner:SUZHOU AOPEIKE AUTOMOBILE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com