Large equipment pin shaft installing and dismantling device

A large-scale equipment and pin technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low efficiency of pin assembly and disassembly, and achieve the effect of disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

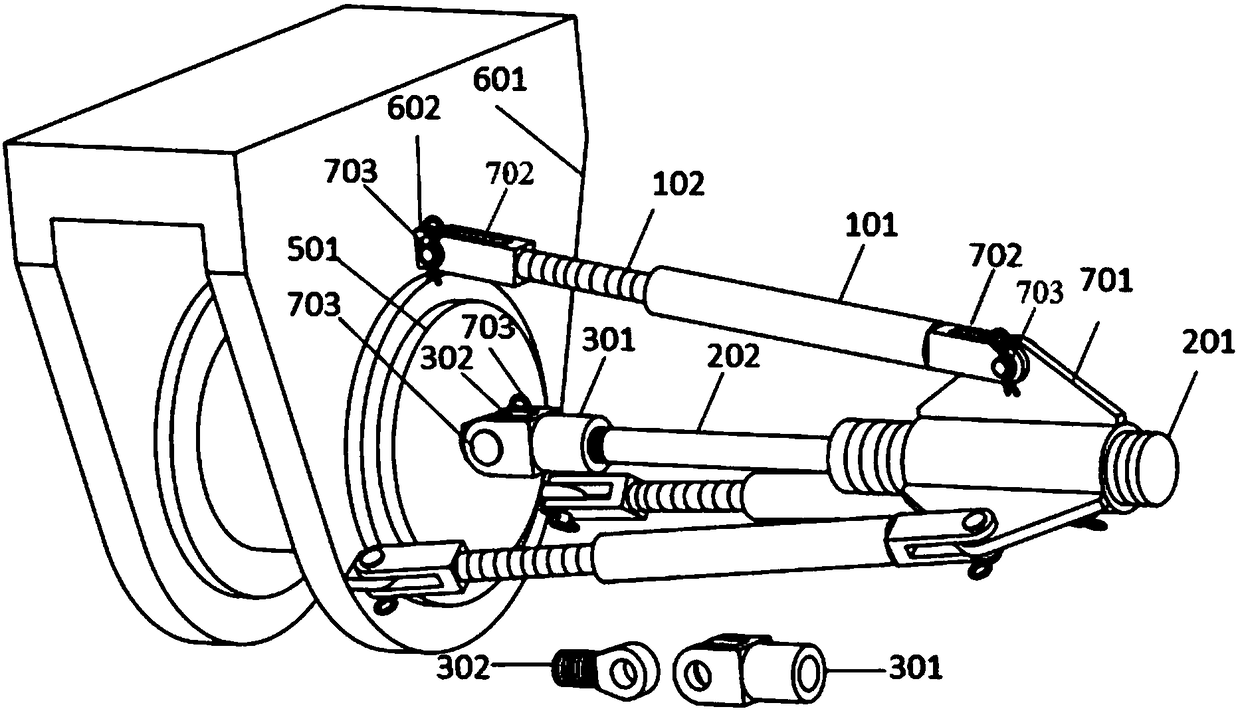

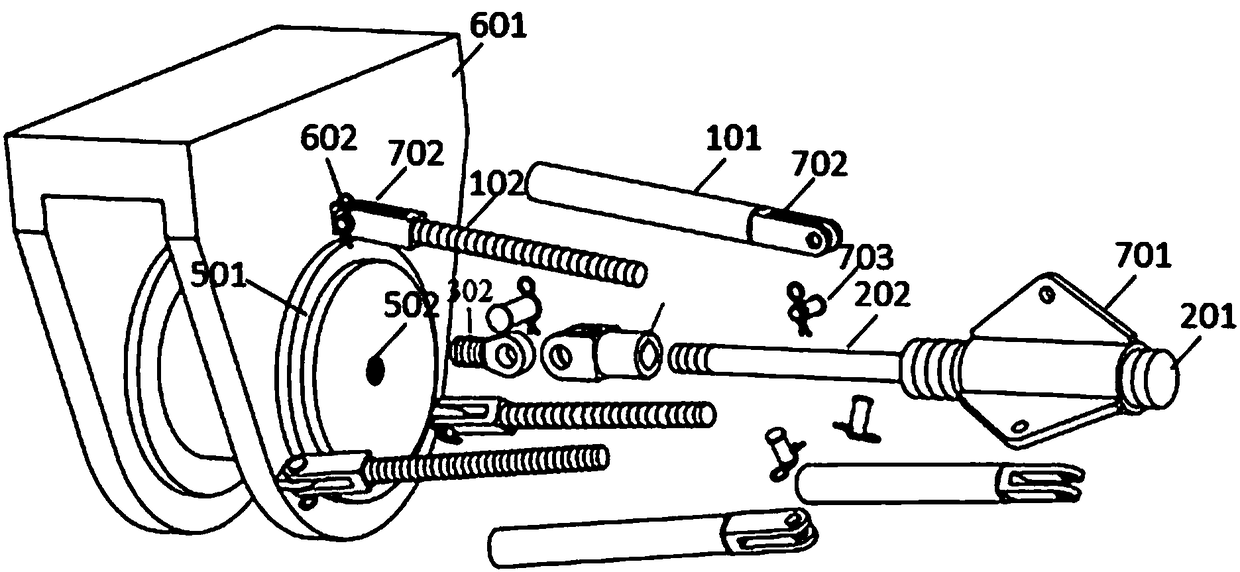

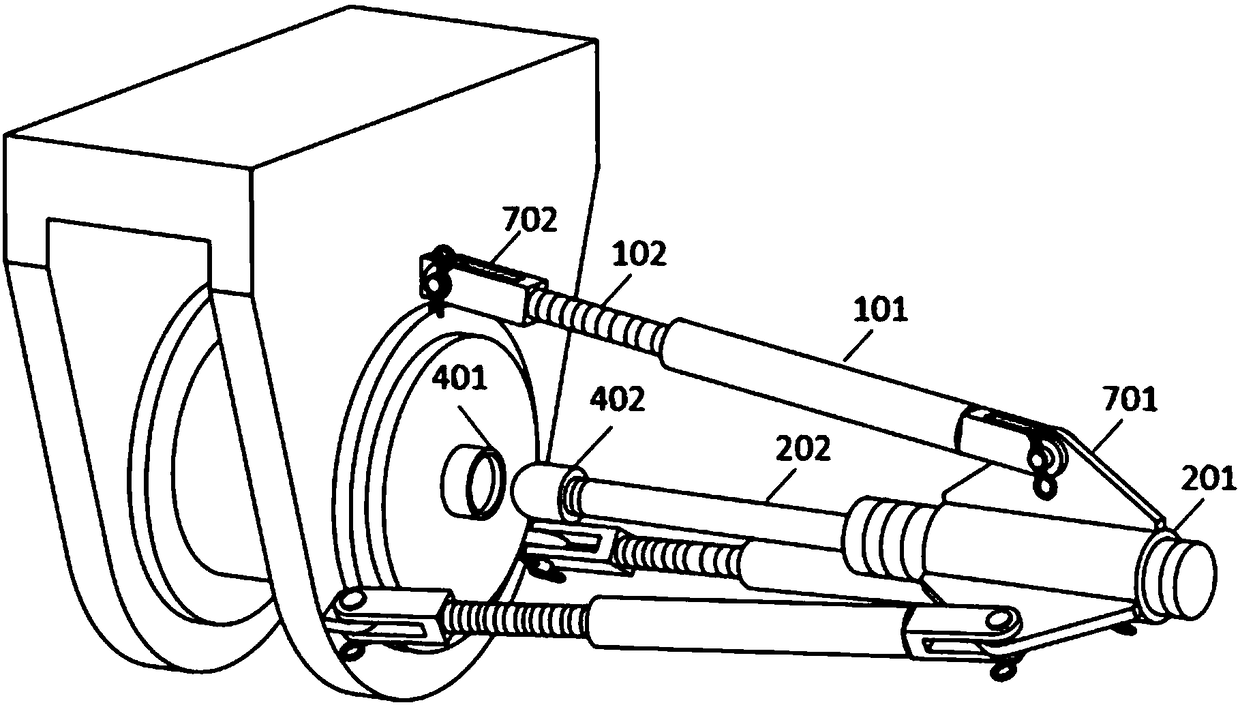

[0026] As a typical articulated connection, the pin connection has clear force transmission and simple structure, and is widely used in large modern steel structure projects and plays an important role. This involves the installation and disassembly of pin shafts. For the pin shafts used in large steel structures, special tools are often used for their installation and disassembly, otherwise it is difficult to achieve.

[0027] The existing pin disassembly tools commonly used are separate assembly and disassembly tools, that is, the pin installation tool cannot realize the disassembly operation of the pin shaft, and the pin shaft removal tool cannot realize the installation operation of the pin shaft, because the disassembly and assembly of the pin shaft must Different tools are replaced, which reduces the working efficiency of pin shaft disassembly.

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com