Patents

Literature

35results about How to "Realize disassembly work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-altitude lamp replacing device

ActiveCN104217922AHigh degree of automationEliminate potential safety hazardsElectrical apparatusEngineeringElectric motor

Owner:STATE GRID CORP OF CHINA +1

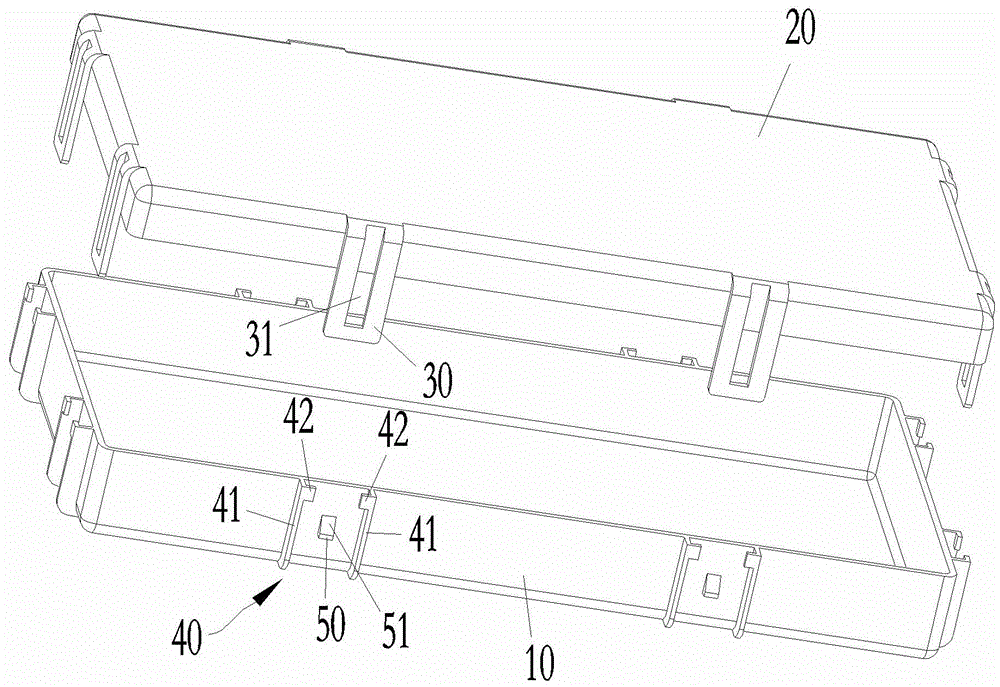

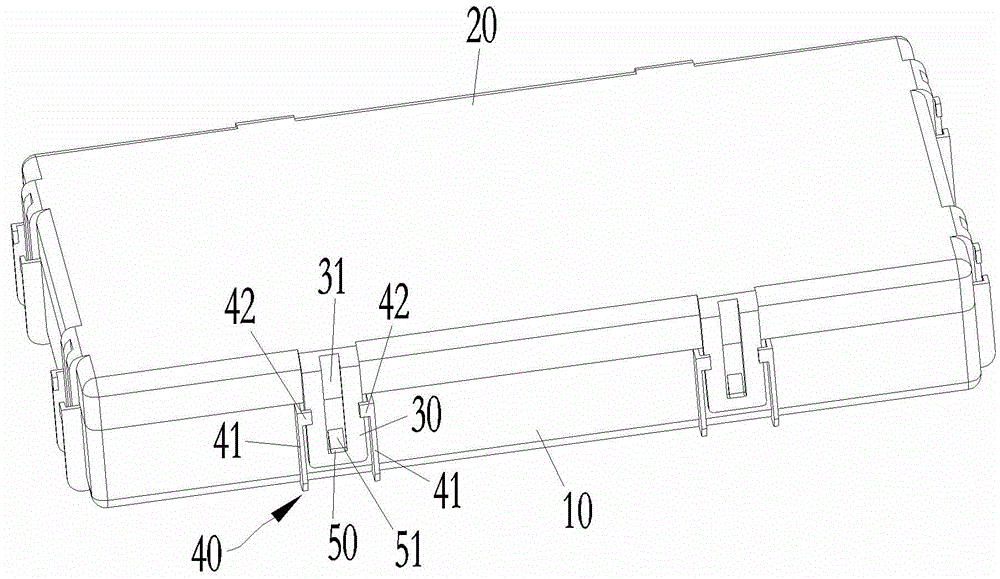

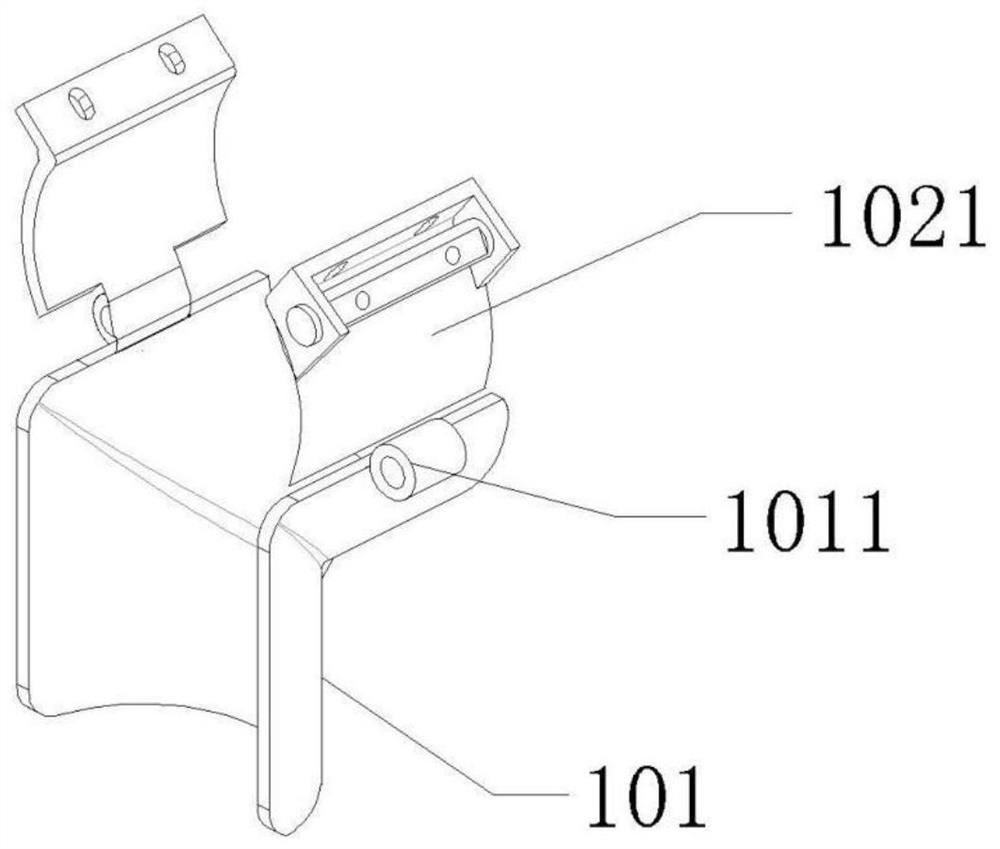

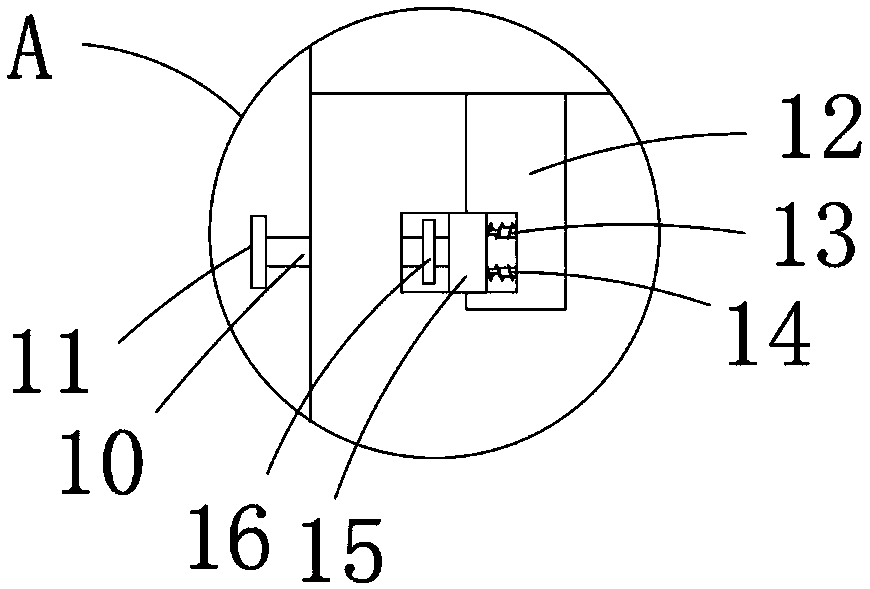

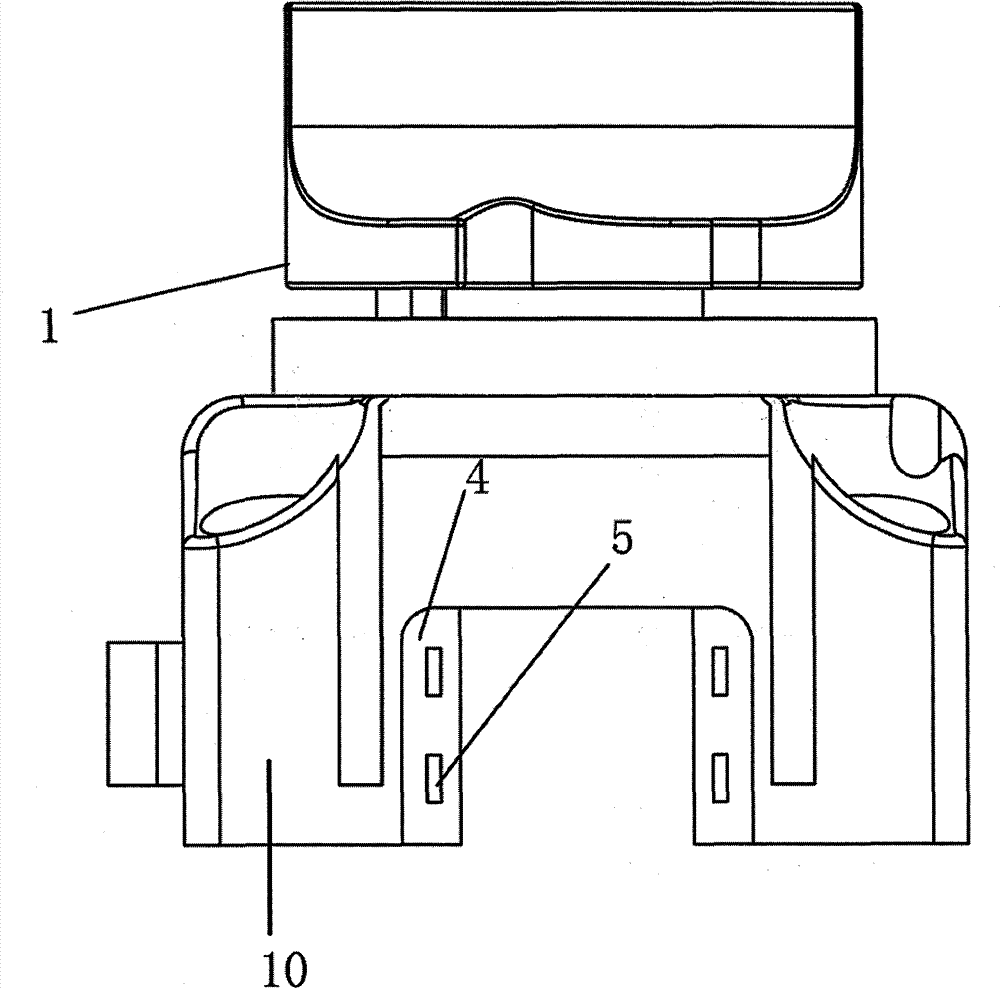

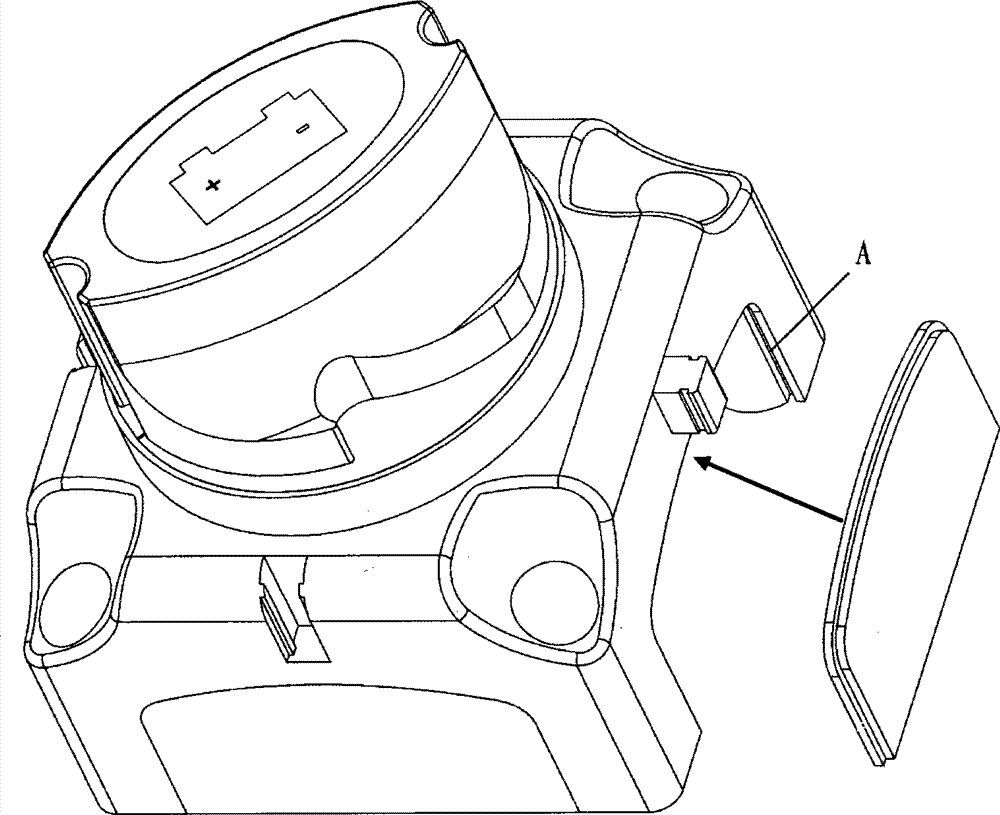

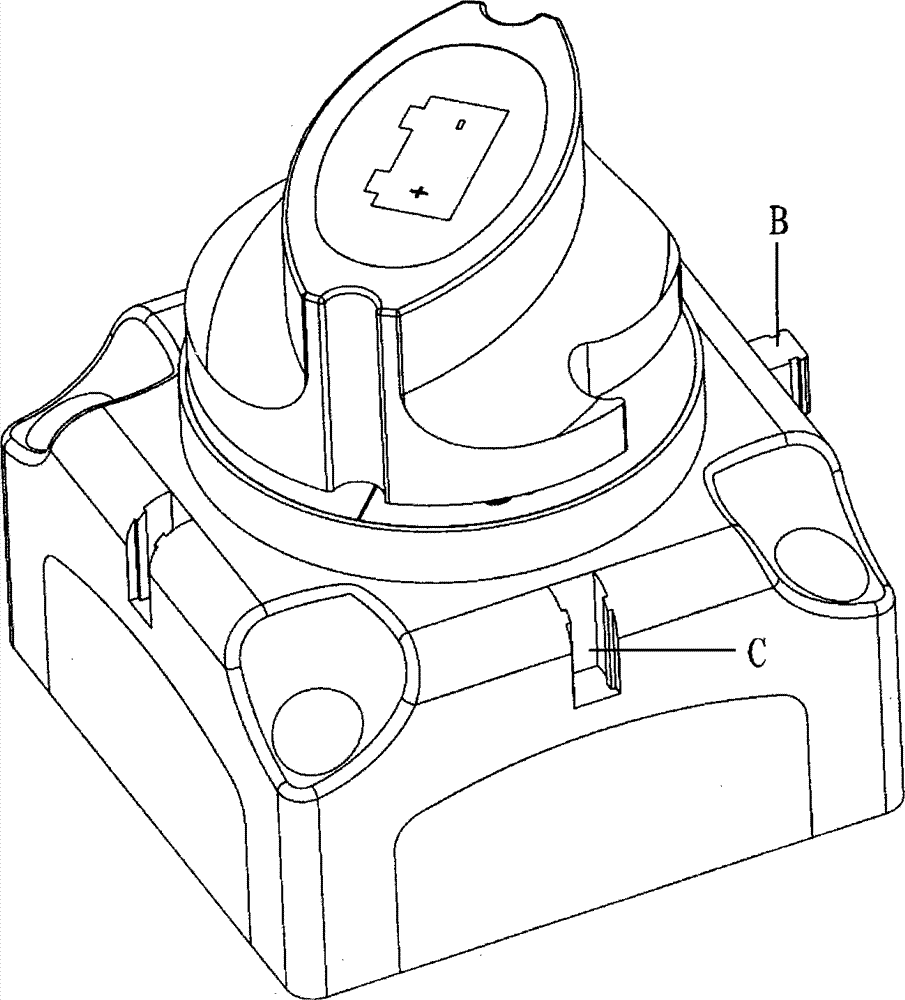

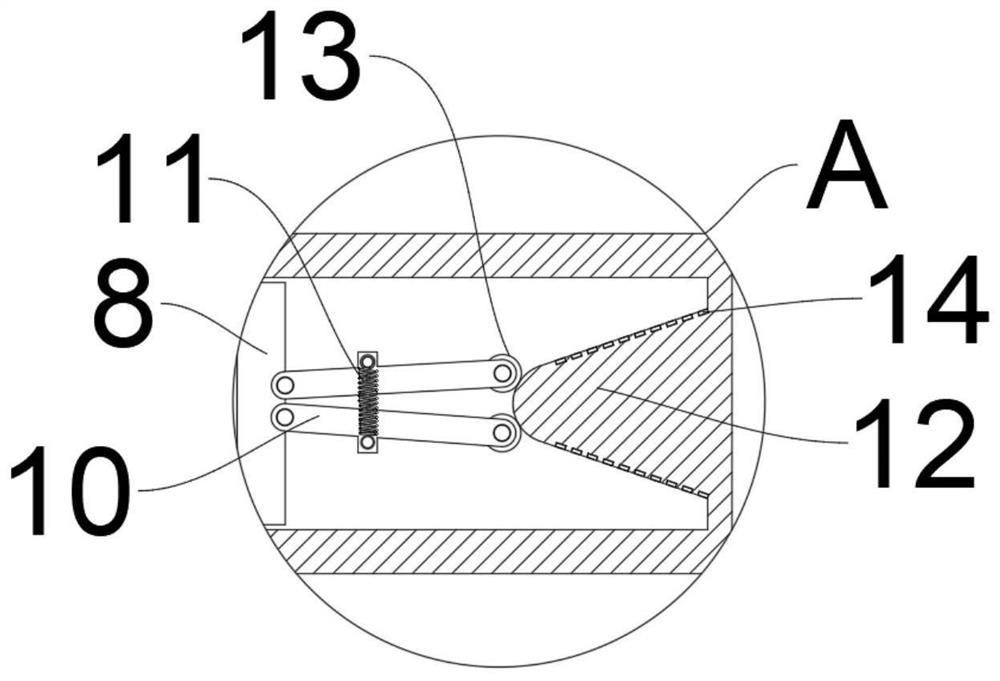

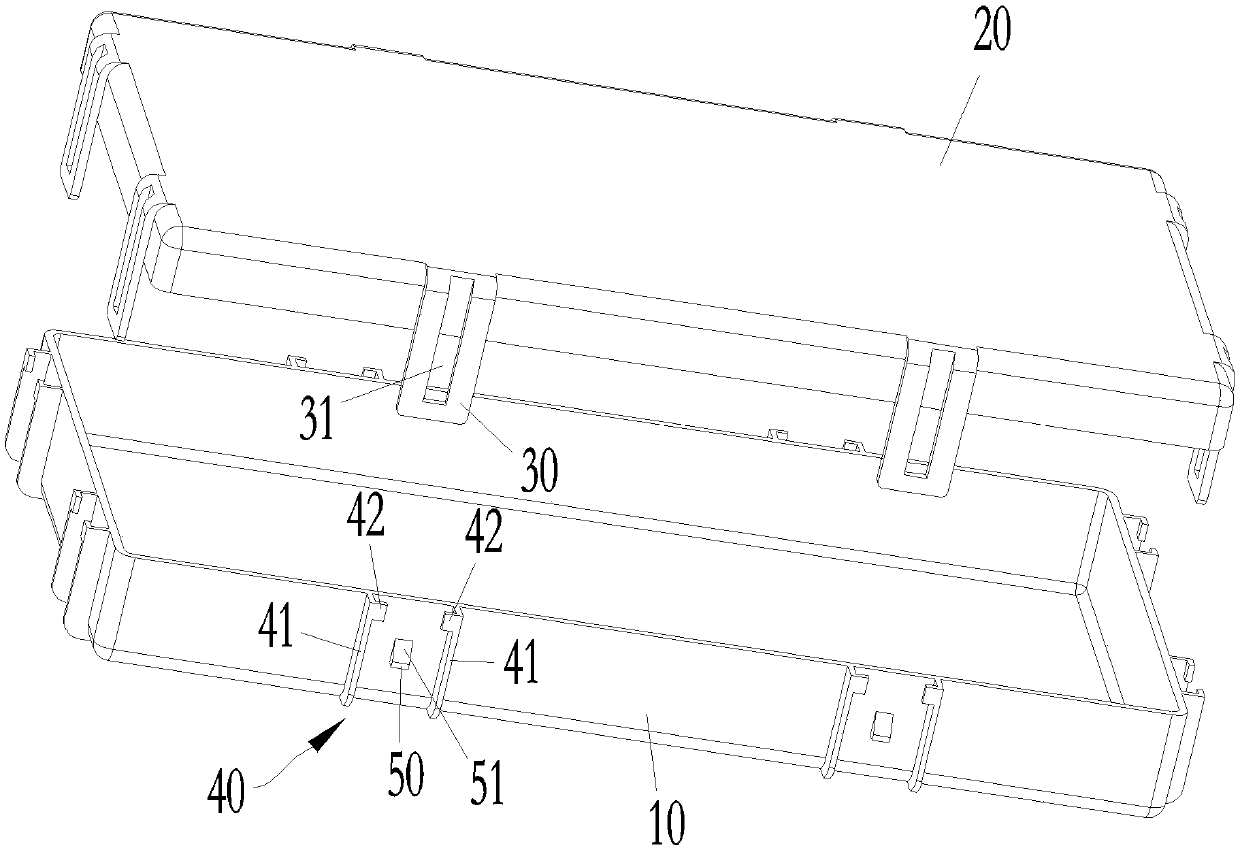

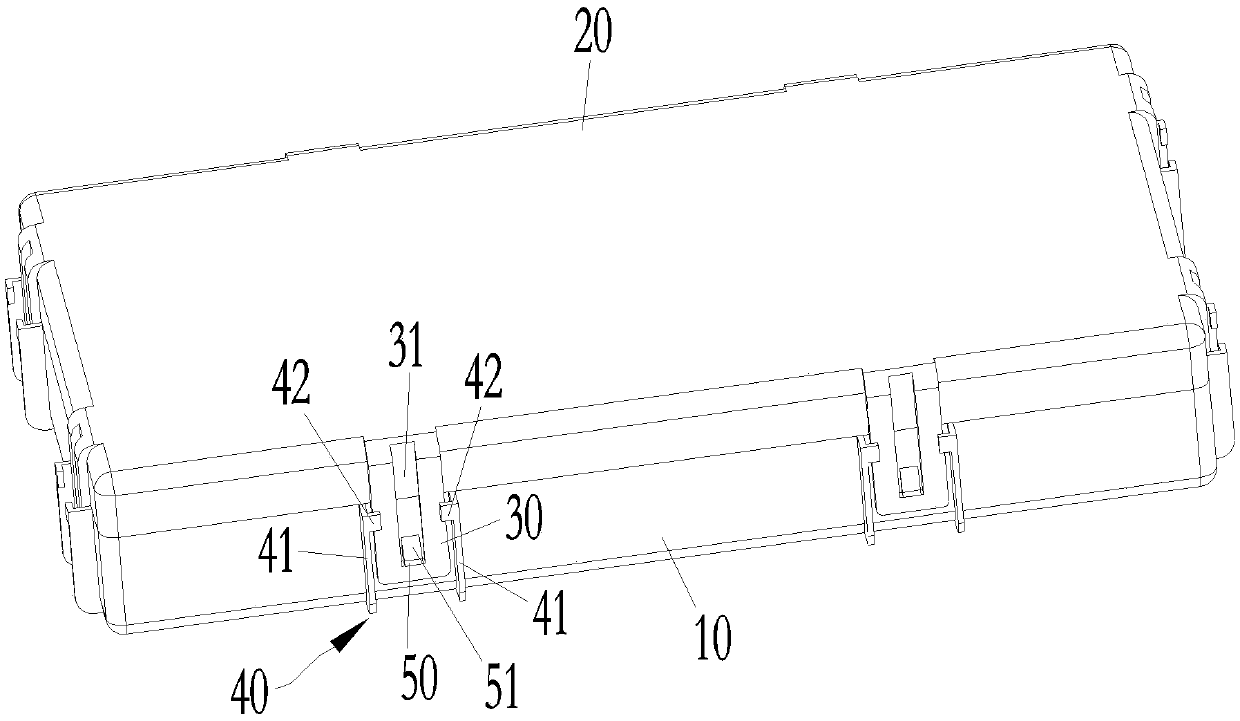

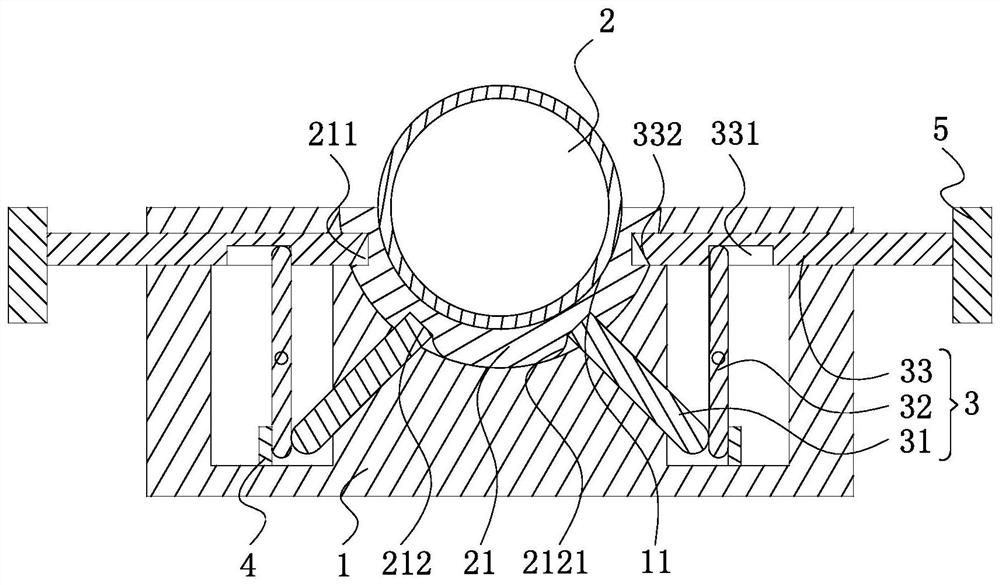

Device for detaching snap structures

ActiveCN104481991ARealize disassembly workStructure labor savingSheet joiningMechanical engineeringWedge shape

Owner:MARELLI AUTOMOBILE ELECTRONIS GUANGZHOU CO LTD

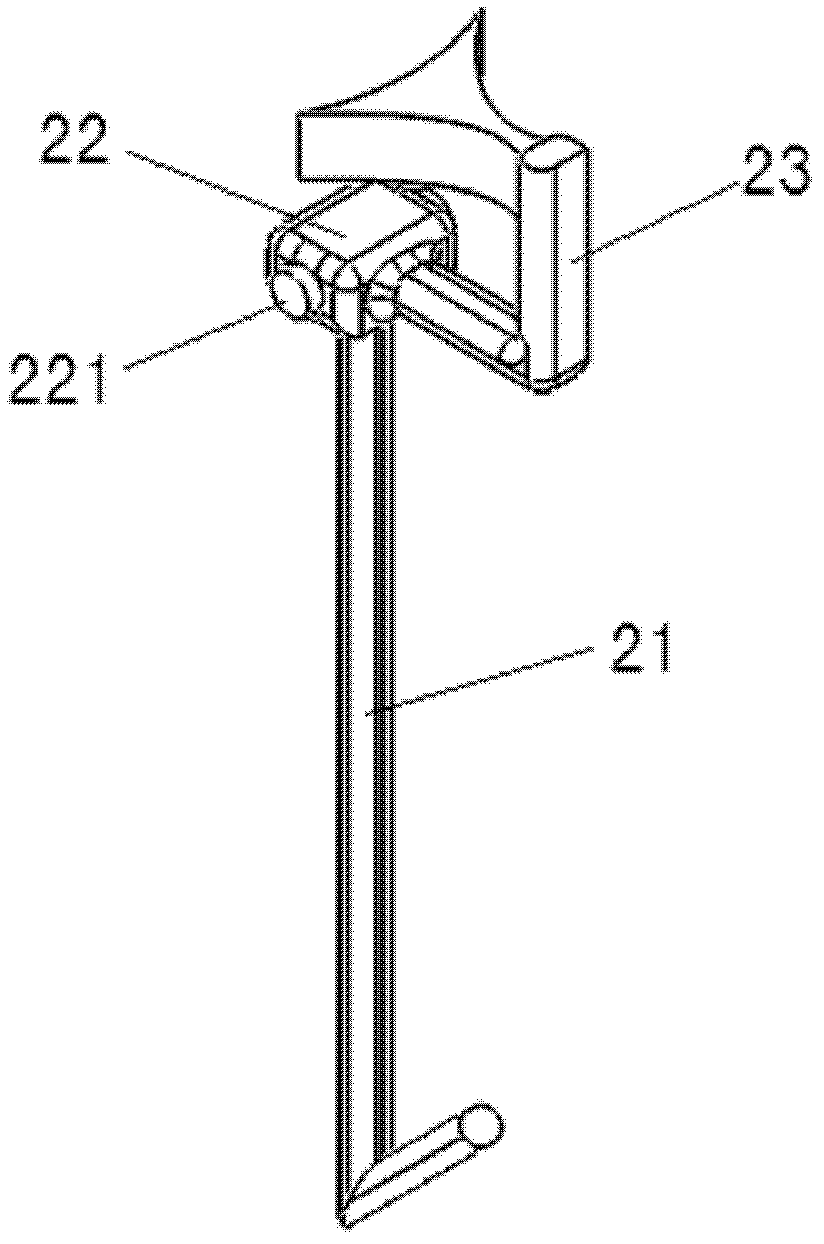

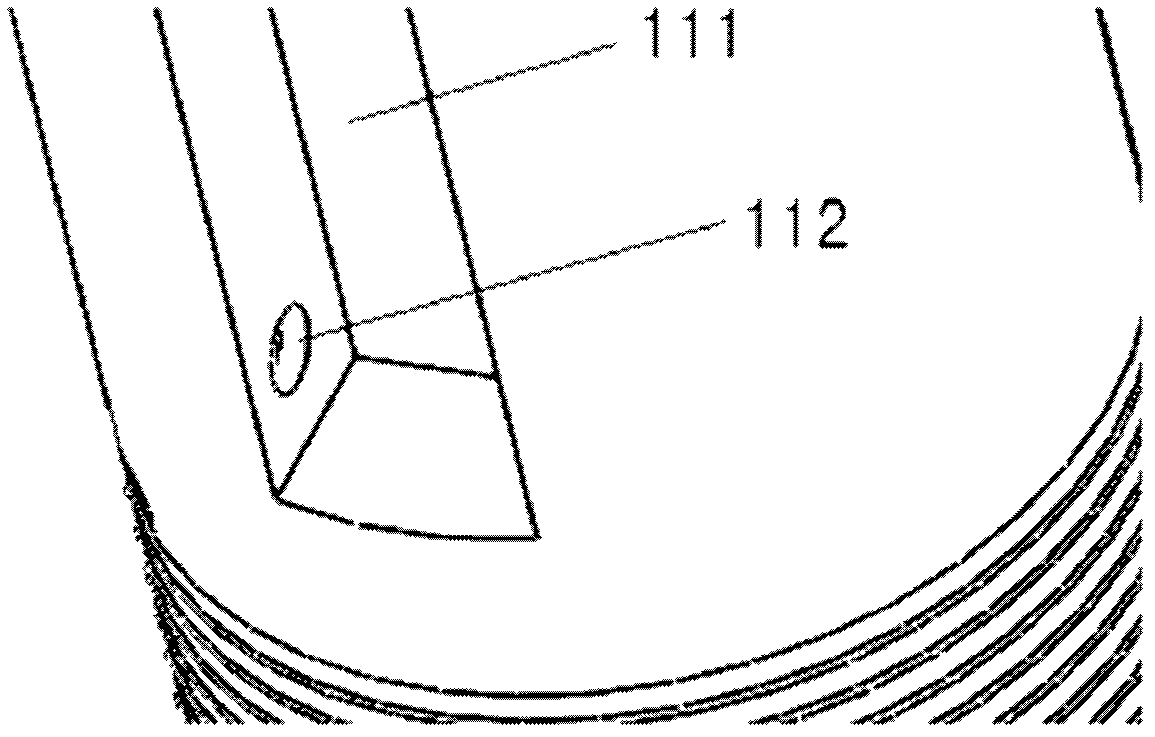

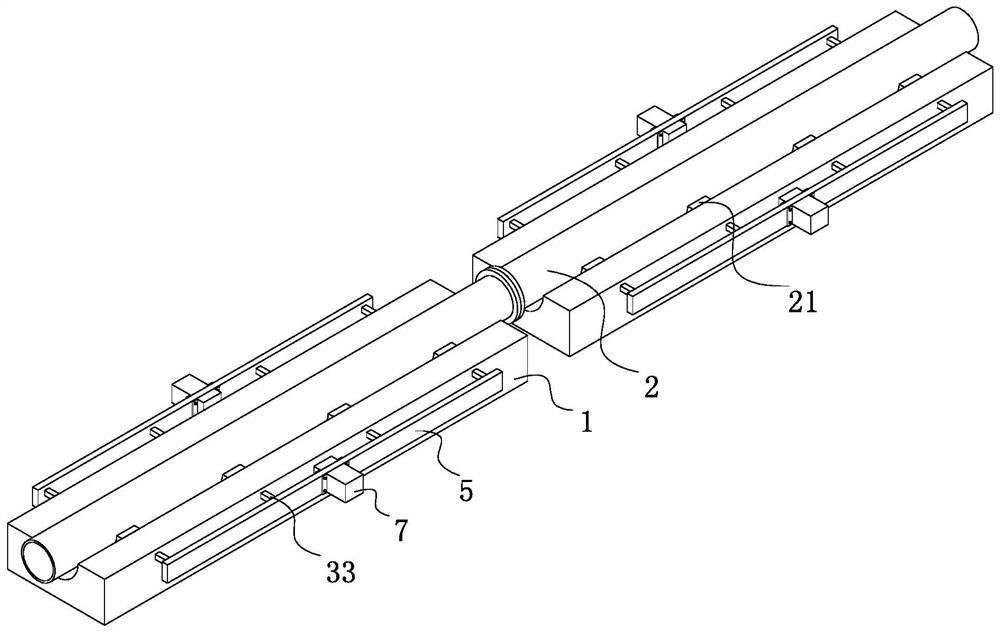

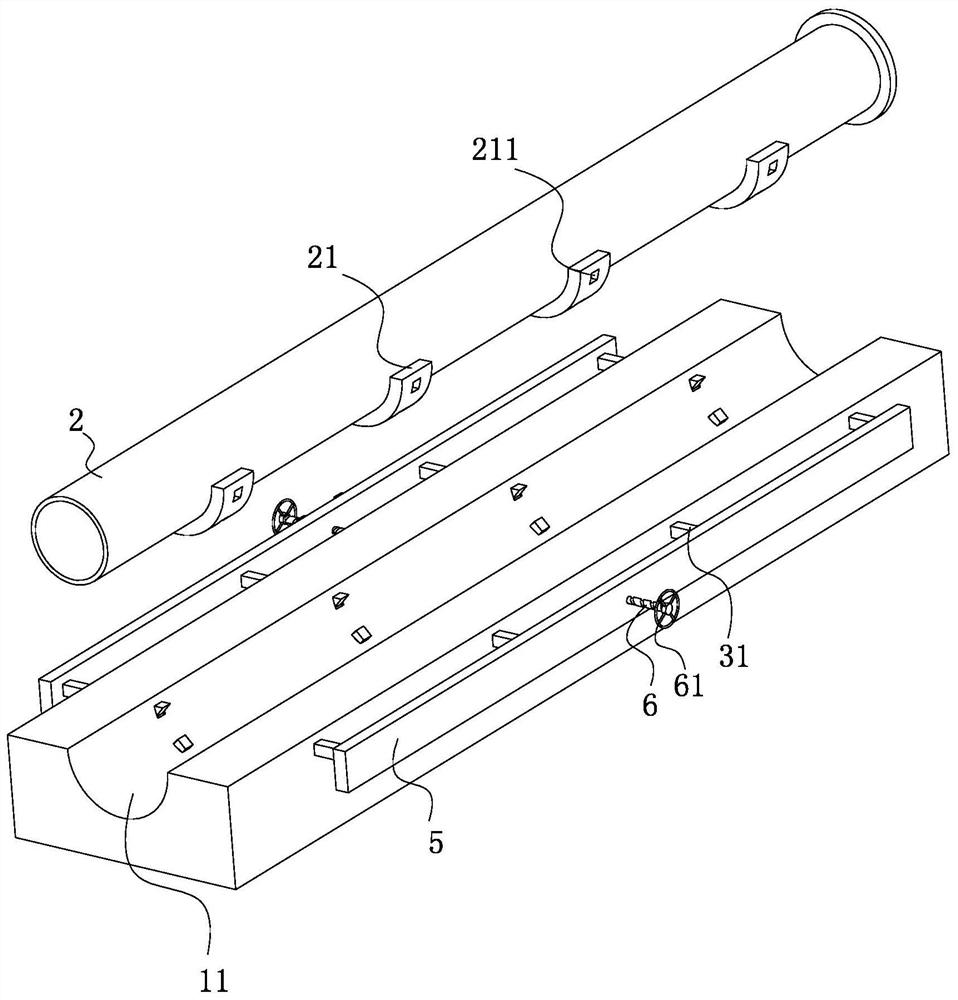

Large equipment pin shaft installing and dismantling device

PendingCN108262602ARealize disassembly workRealize the installation workMetal working apparatusEngineeringSupport plane

Owner:SHANGHAI ZHENHUA HEAVY IND

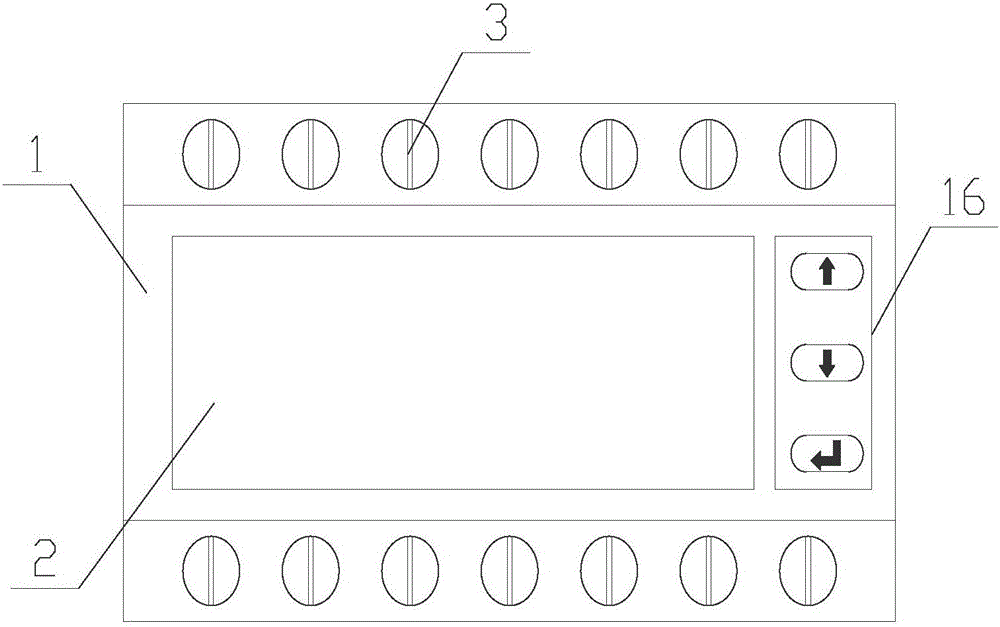

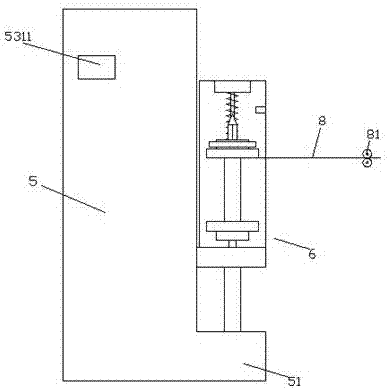

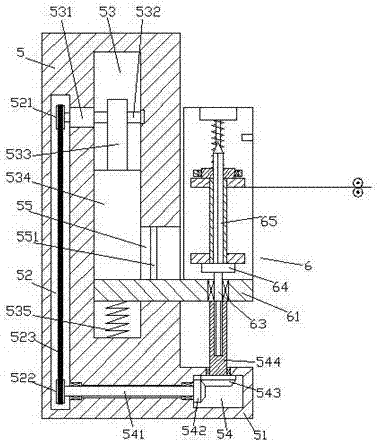

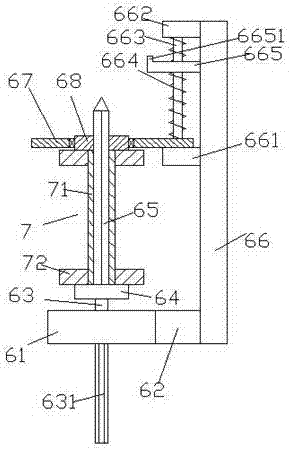

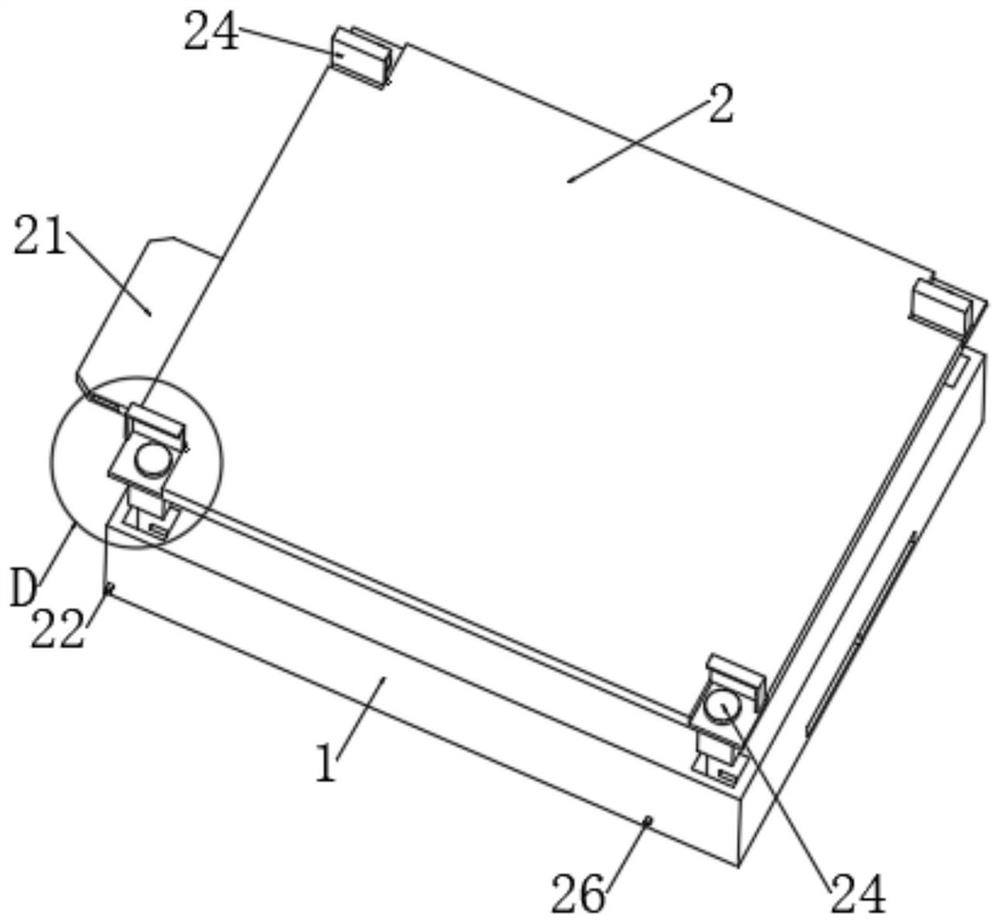

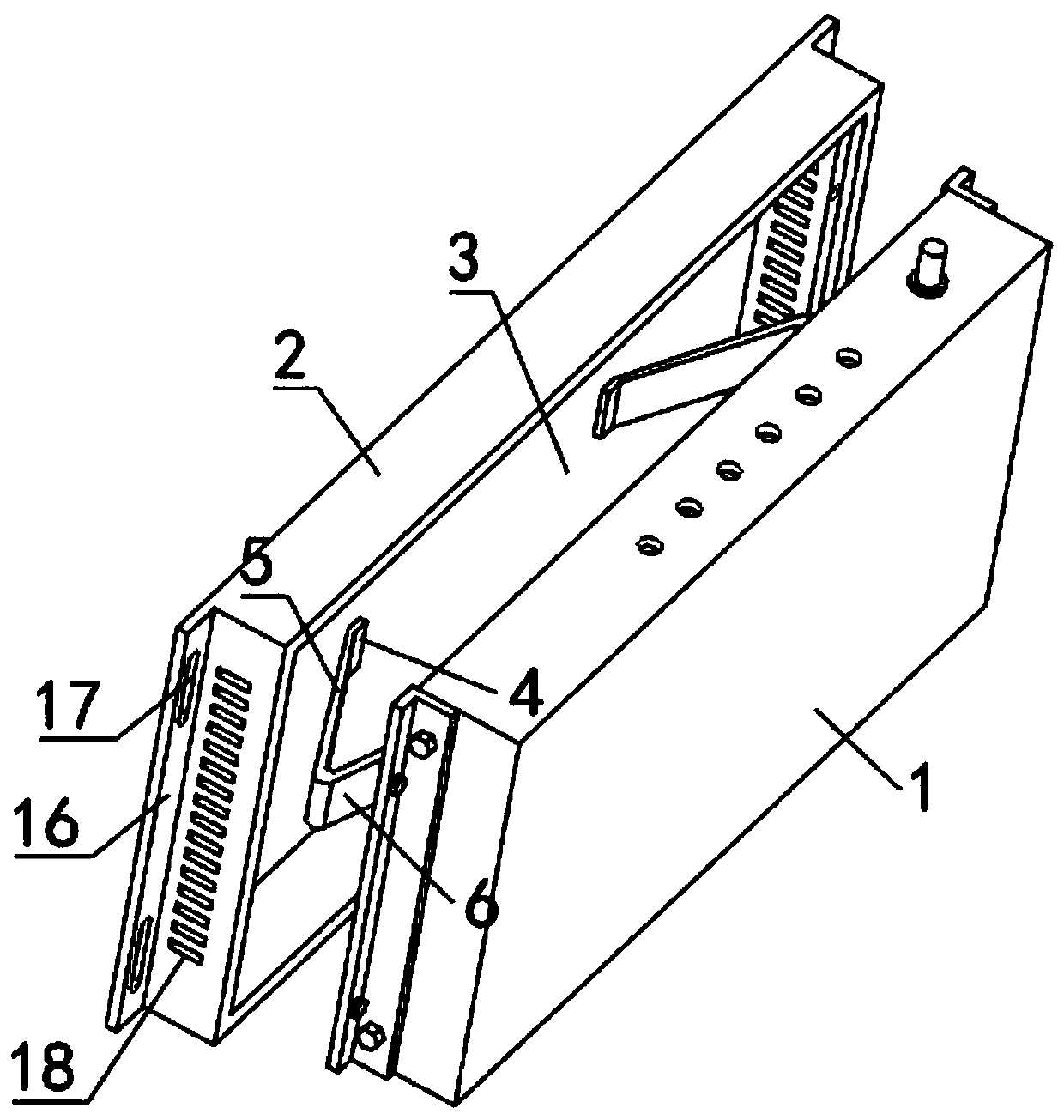

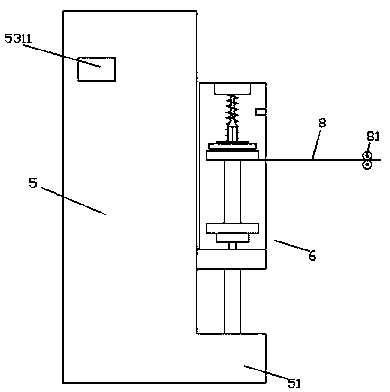

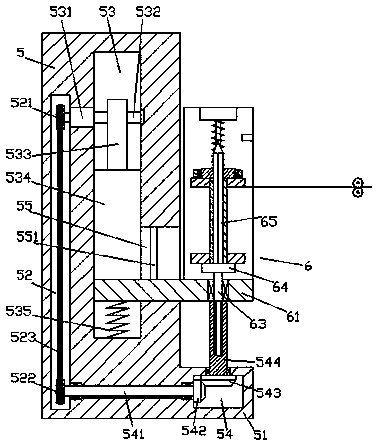

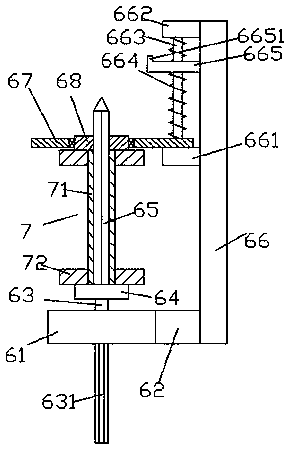

Intelligent guide rail meter based on wireless monitoring

InactiveCN105842497AEasy to fixRealize the installation workTransmission systemsTime integral measurementElectricityElectric machine

The invention relates to an intelligent guide rail meter based on wireless monitoring. The intelligent guide rail meter comprises a body and a fixed mechanism which is arranged at the back surface of the body. The body is provided with a display screen, a control panel and multiple wiring units. According to the intelligent guide rail meter based on wireless monitoring, a screw rod is driven to rotate by a driving motor arranged in the fixed mechanism so that a moving clamp pin is enabled to be away from or close to a fixed clamp pin, and installation and disassembling work of the guide rail meter can be realized. Installation and fixing of the guide rail meter are enabled to be reliable by the fixed mechanism, and disassembling operation is convenient and rapid. Besides, an electrical oscillation signal is converted into an ultrasonic signal by a frequency oscillator formed by an ultrasonic sensor, a first triode and a second triode in an ultrasonic transmitting circuit in the body, and conventional components are adopted so that reliable ultrasonic transmission can be guaranteed, production cost can be reduced and the practical value of the device can be enhanced.

Owner:徐帆

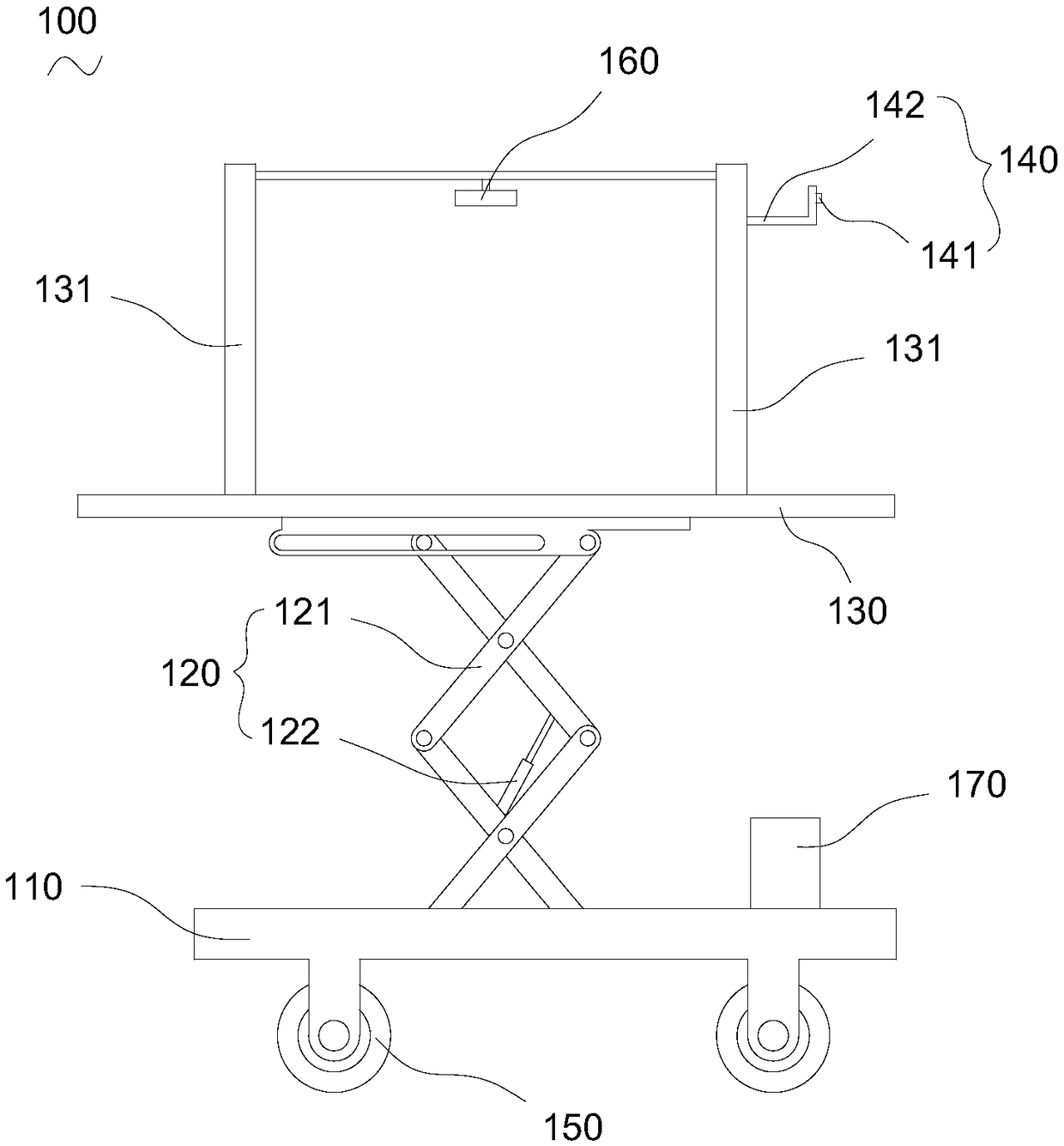

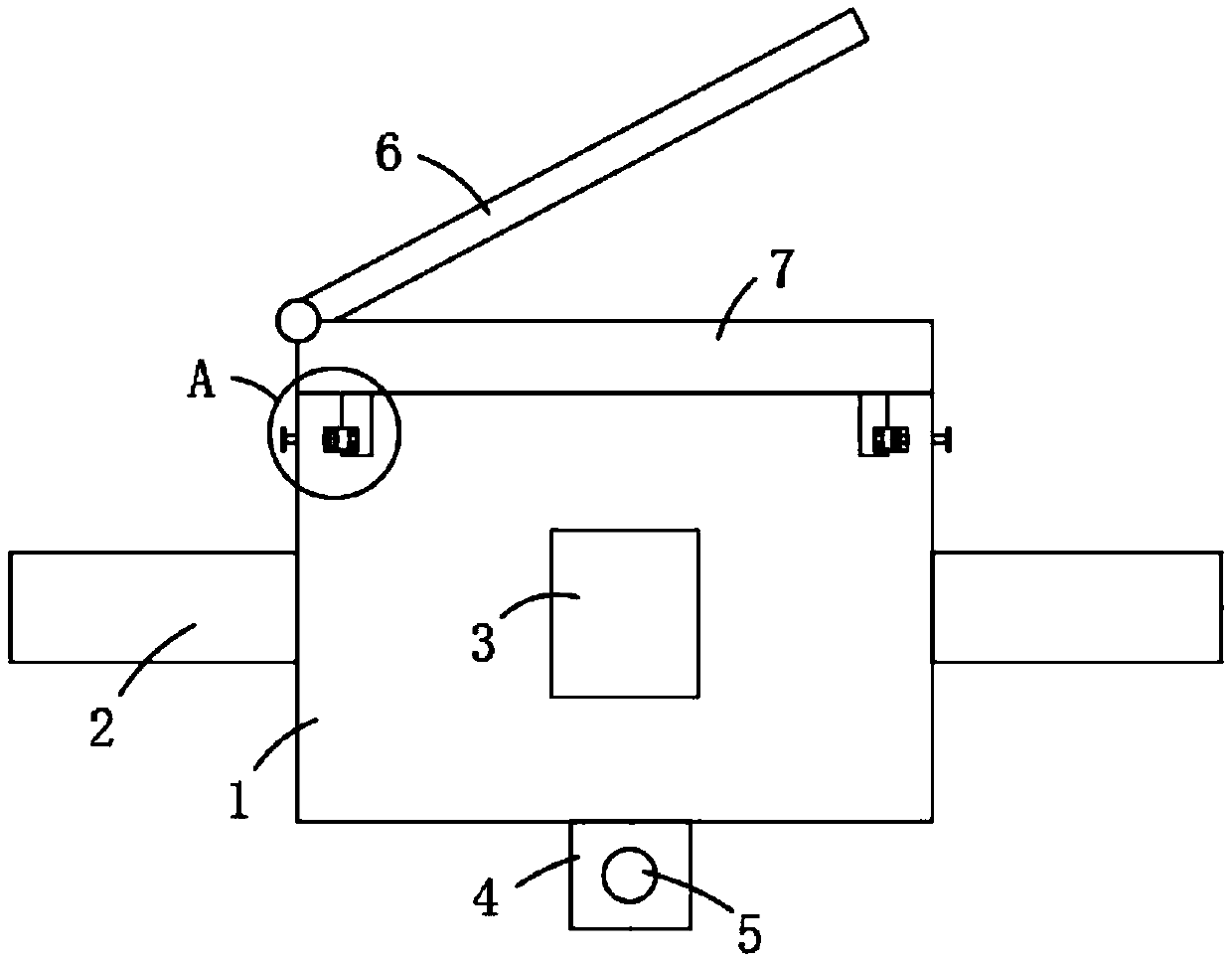

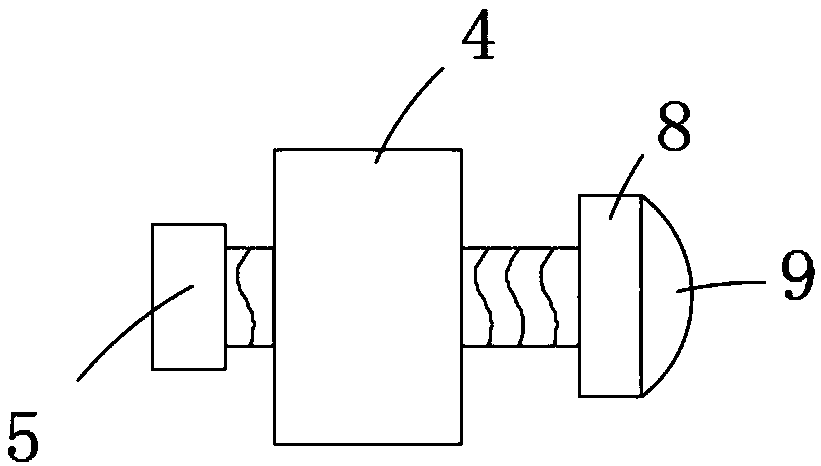

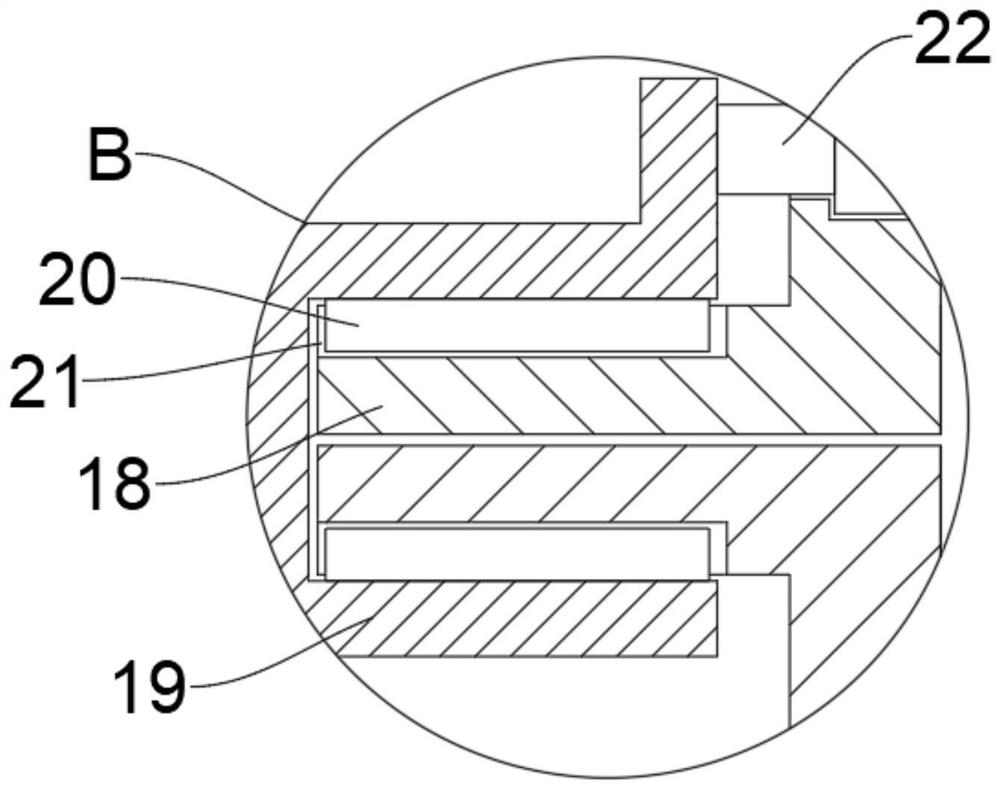

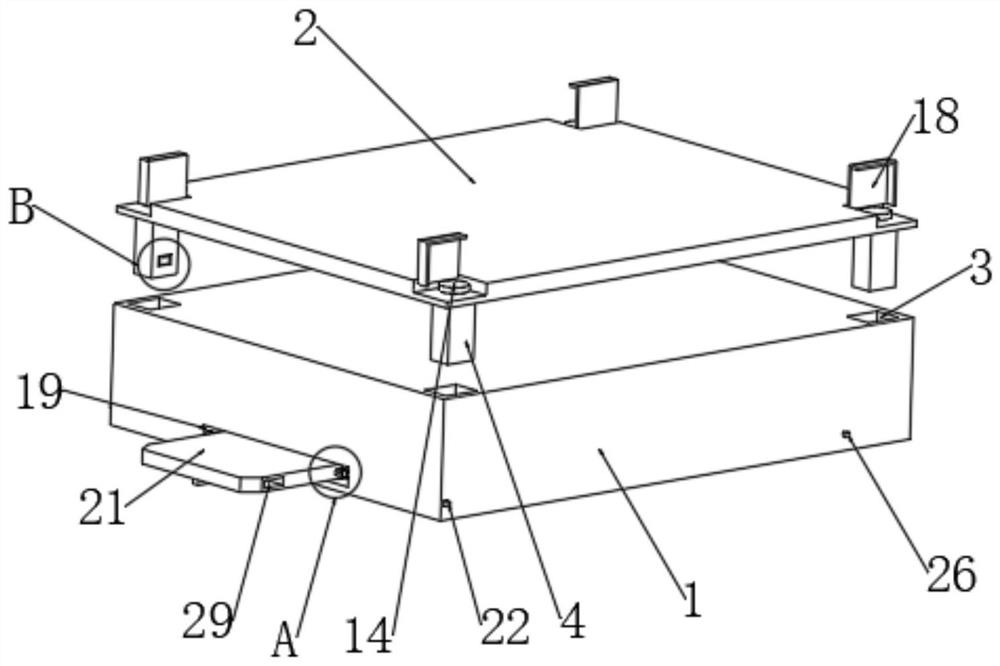

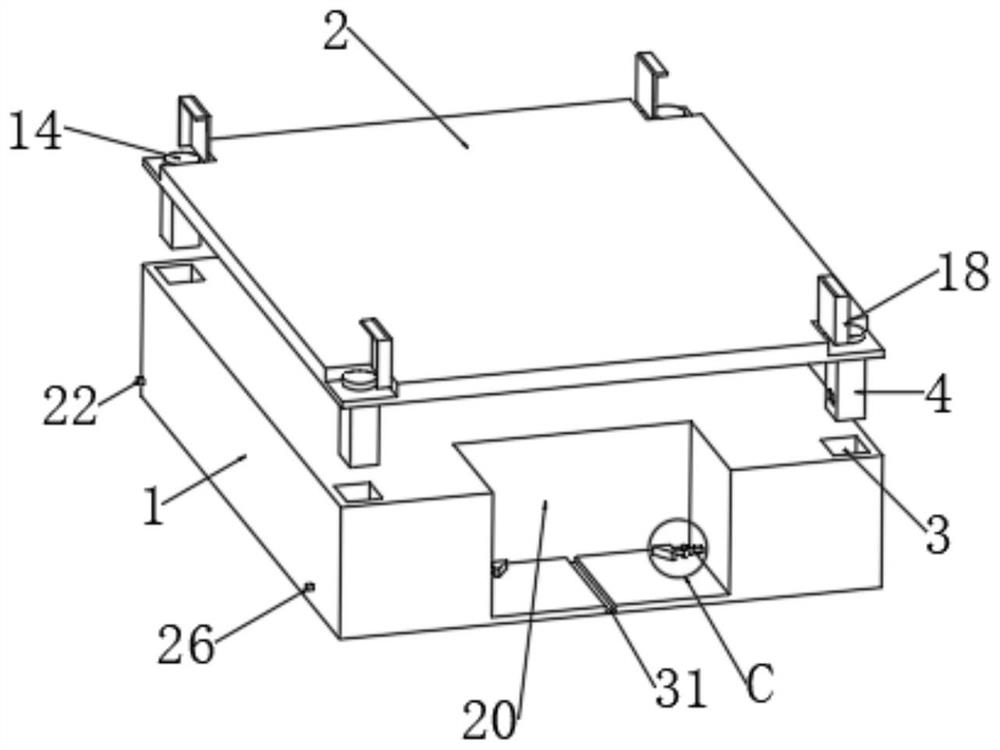

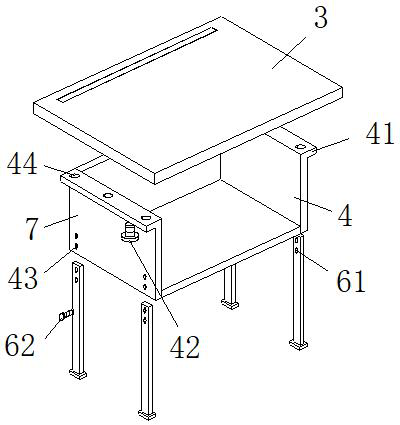

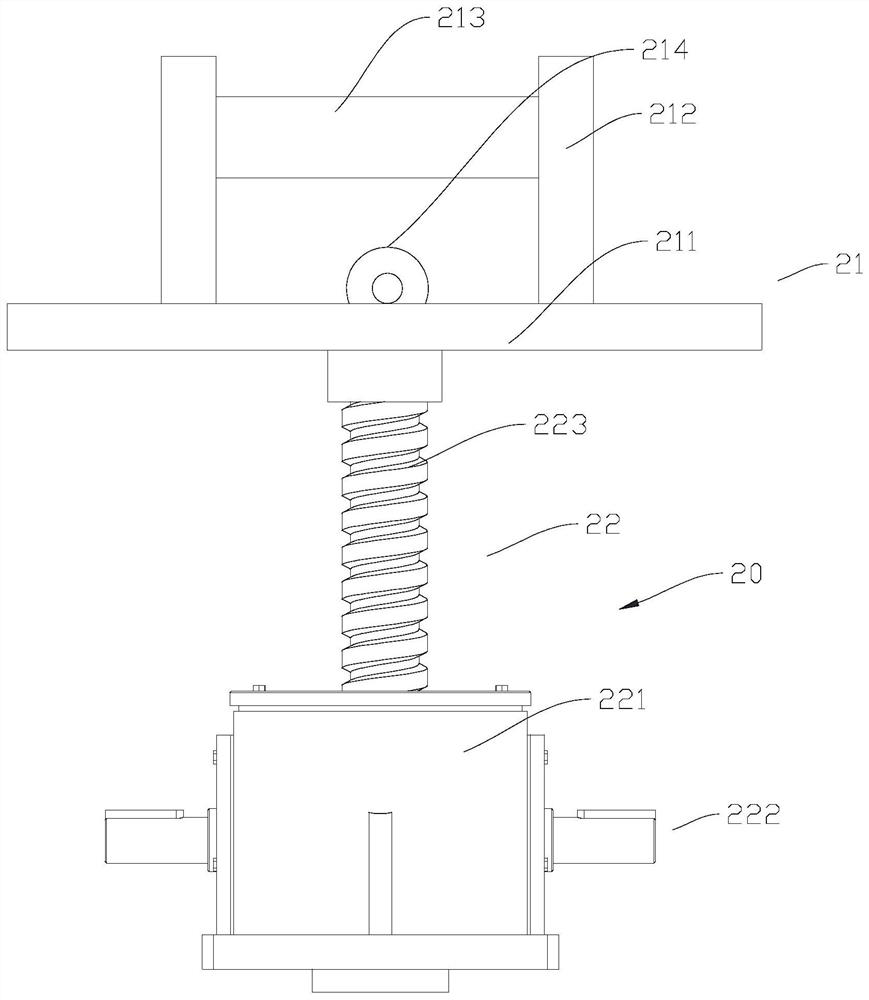

Formwork automatic disassembly and assembly device

ActiveCN109262547ARealize the installation workRealize disassembly workWork benchesMetal-working hand toolsCounter rotationEngineering

The invention relates to a formwork automatic disassembly and assembly device. The device comprises a base, a lifting assembly, a working platform, a rotating assembly and a cutting machine. One end of the lifting assembly is disposed on the surface of the base. The working platform is disposed at one end of the lifting assembly away from the base, and the lifting assembly can drive the working platform to move up and down in a direction perpendicular to the surface of the base. The rotating assembly includes a rotator. The rotator is rotatably mounted on the working platform. The rotator candrive a fixing nut to rotate forward or reversely. The cutting machine is rotatably mounted on the working platform. The cutting machine is used for cutting a fixing screw. Therefore, when a formworkneeds to be assembled or disassembled, the formwork automatic disassembly and assembly device can be moved to a designated working area to achieve vertical transportation and automatic disassembly andassembly of the formwork. The input of an operator during disassembly and assembly of the formwork is reduced, and the formwork is more convenient and quick to assemble and disassemble.

Owner:湖南易兴建筑有限公司

Wire wrapping device for spinning

The invention discloses a wire wrapping device for spinning. The wire wrapping device comprises a machine body and guide transmission wheels which are arranged at the right side of the machine body and are symmetrically arranged up and down, wherein a lug boss part is arranged on the bottom of the end surface at the right side of the machine body; a wire wrapping mechanism is arranged above the lug boss part; the wire wrapping mechanism comprises a bottom plate which extends left and right, a connecting block which is fixedly arranged at the rear side of the right side of the bottom plate, a straight plate which is fixedly arranged at the rear side end of the connecting block and extends upwards, and a wire wrapping base arranged above the bottom plate; the bottom of the wire wrapping base is fixedly equipped with a first rotary shaft; the bottom of the first rotary shaft penetrates through the bottom plate and is rotatably connected with the bottom plate in a matched mode; the bottom of the first rotary shaft is fixedly equipped with an outer spline shaft which extends downwards; a single spline shaft is fixedly arranged on the top of the wire wrapping base; a first transmission cavity is arranged in the lug boss part; and an inner spline rotary shaft which extends towards upper and lower sides is rotatably matched and connected in the top wall in the first transmission cavity. The wire wrapping device is simple in structure, realizes automatically controlling upper and lower movable wire wrapping work, improves wire wrapping uniformity, realizes quickly dismounting a bobbin and improves wire wrapping stability.

Owner:惠州市骏鹏织造有限公司

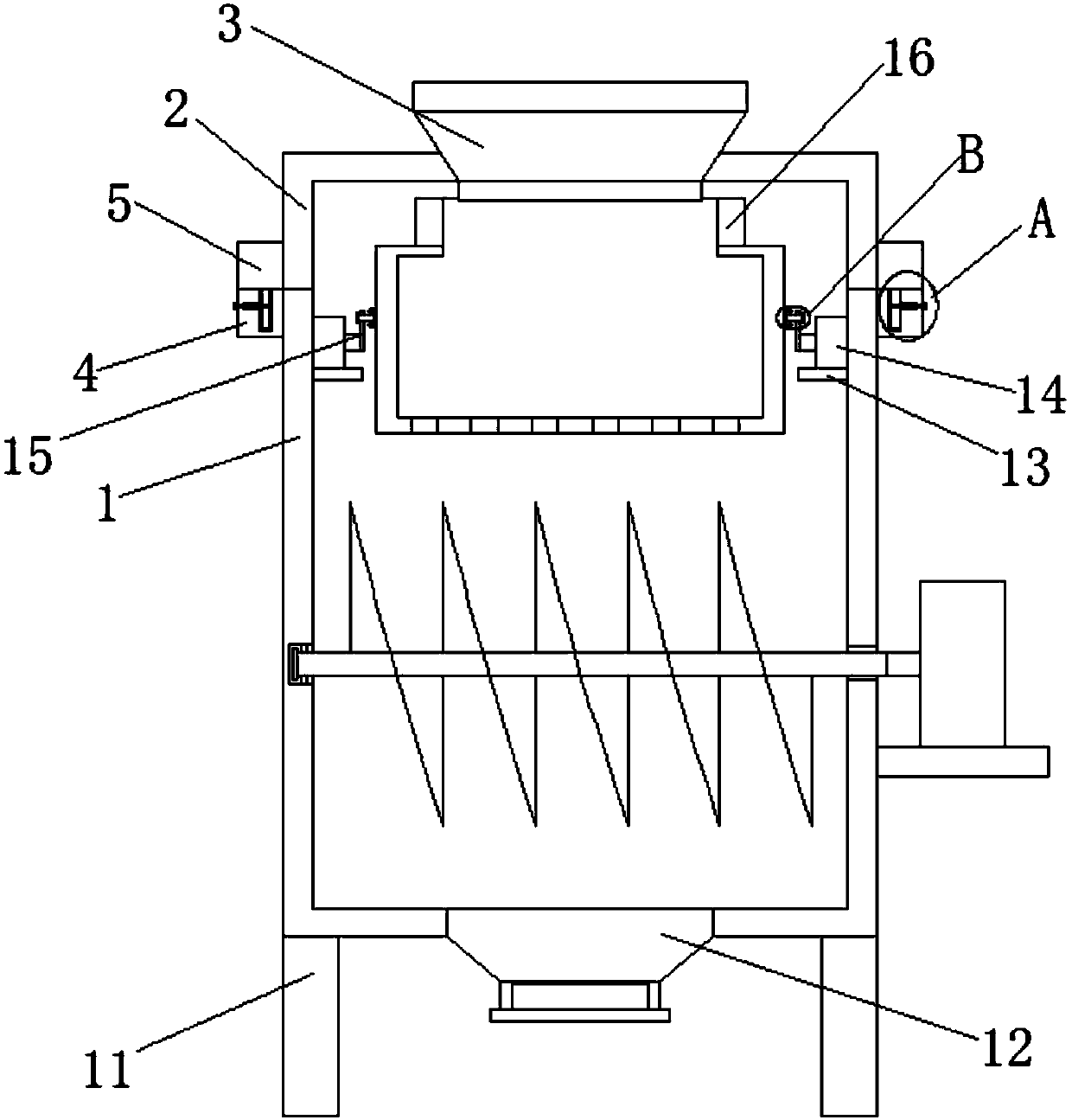

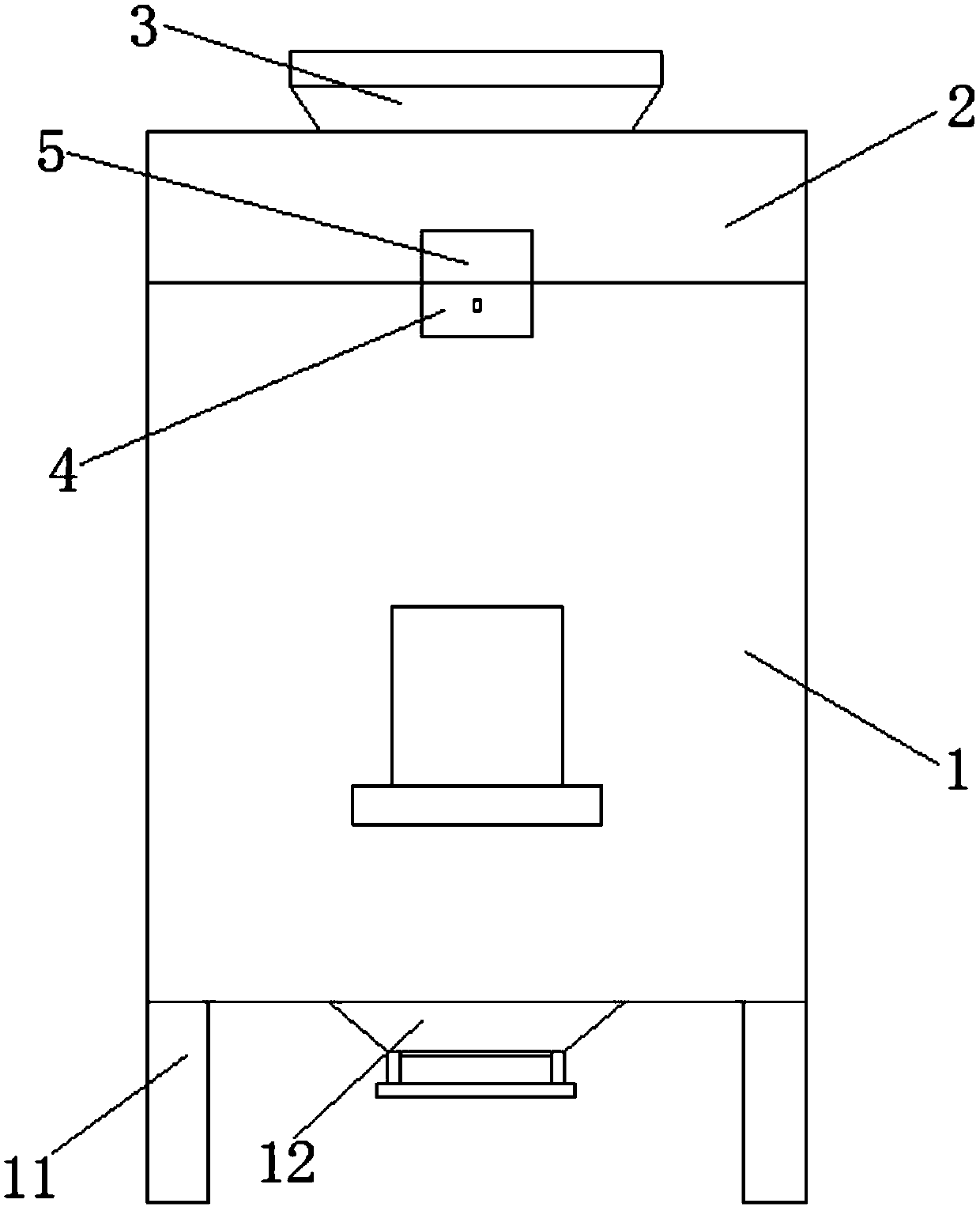

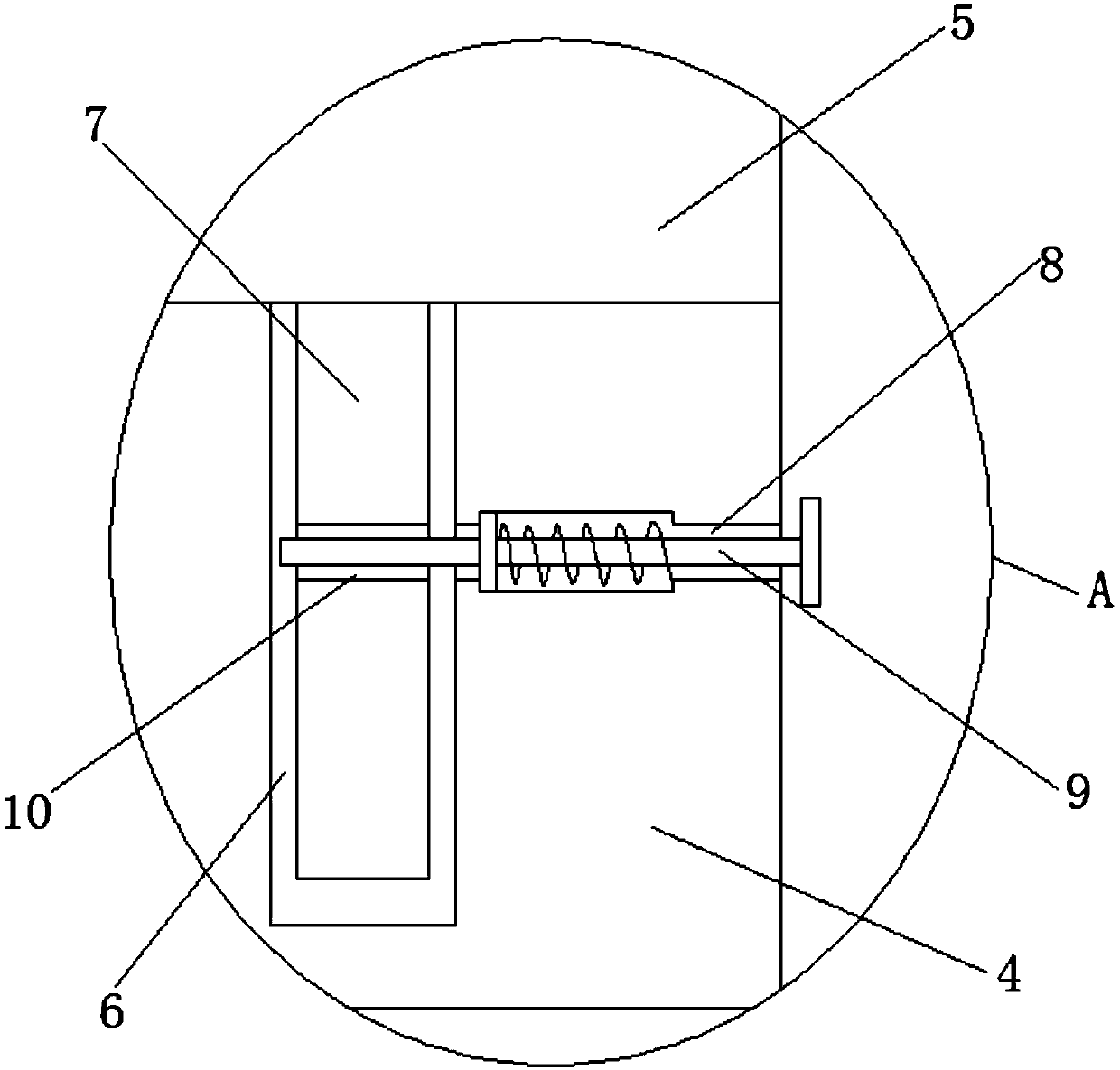

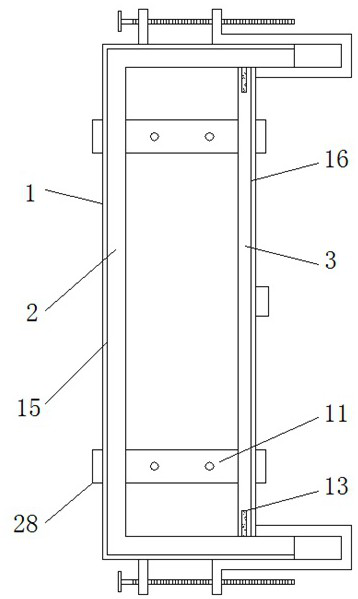

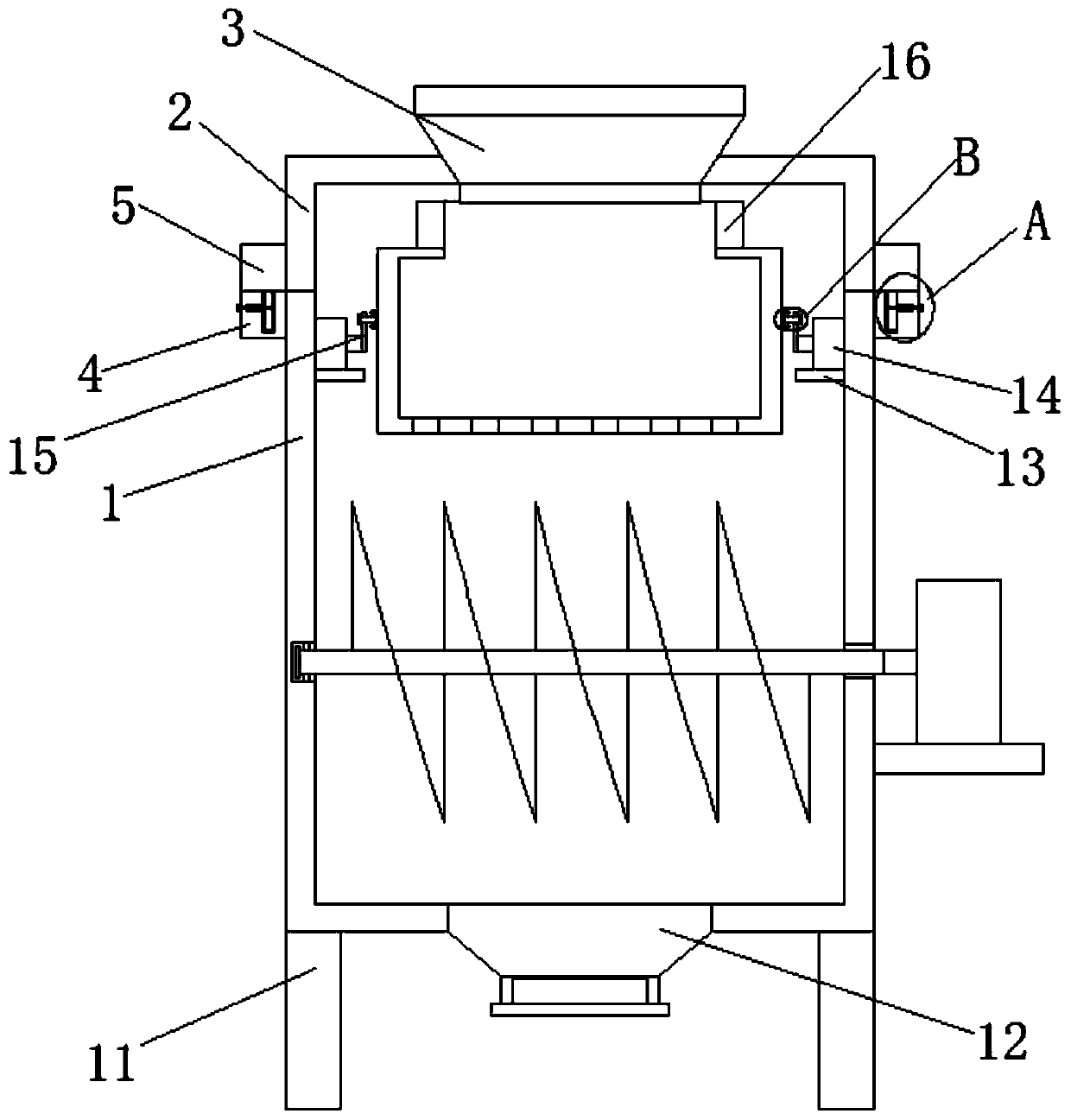

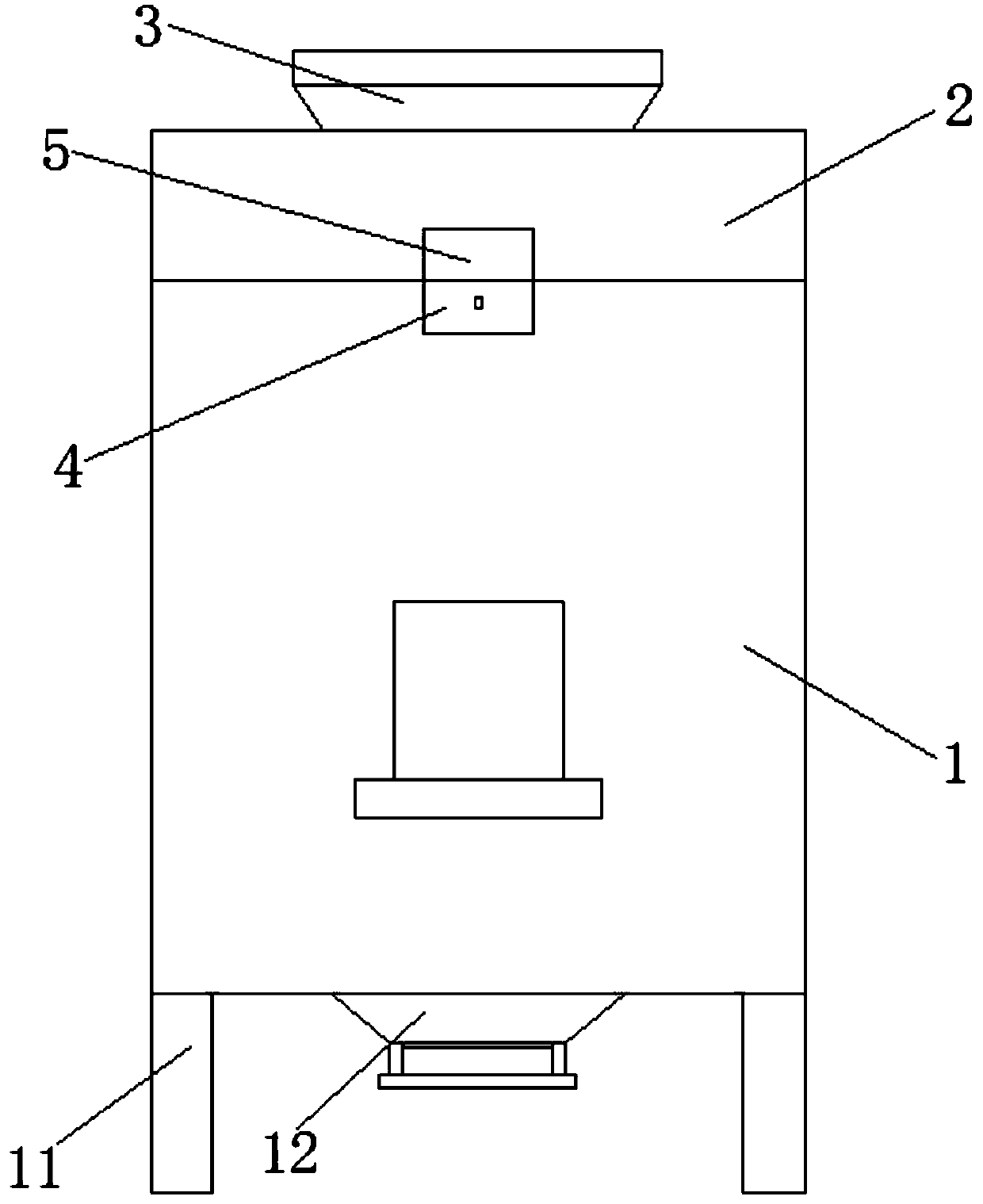

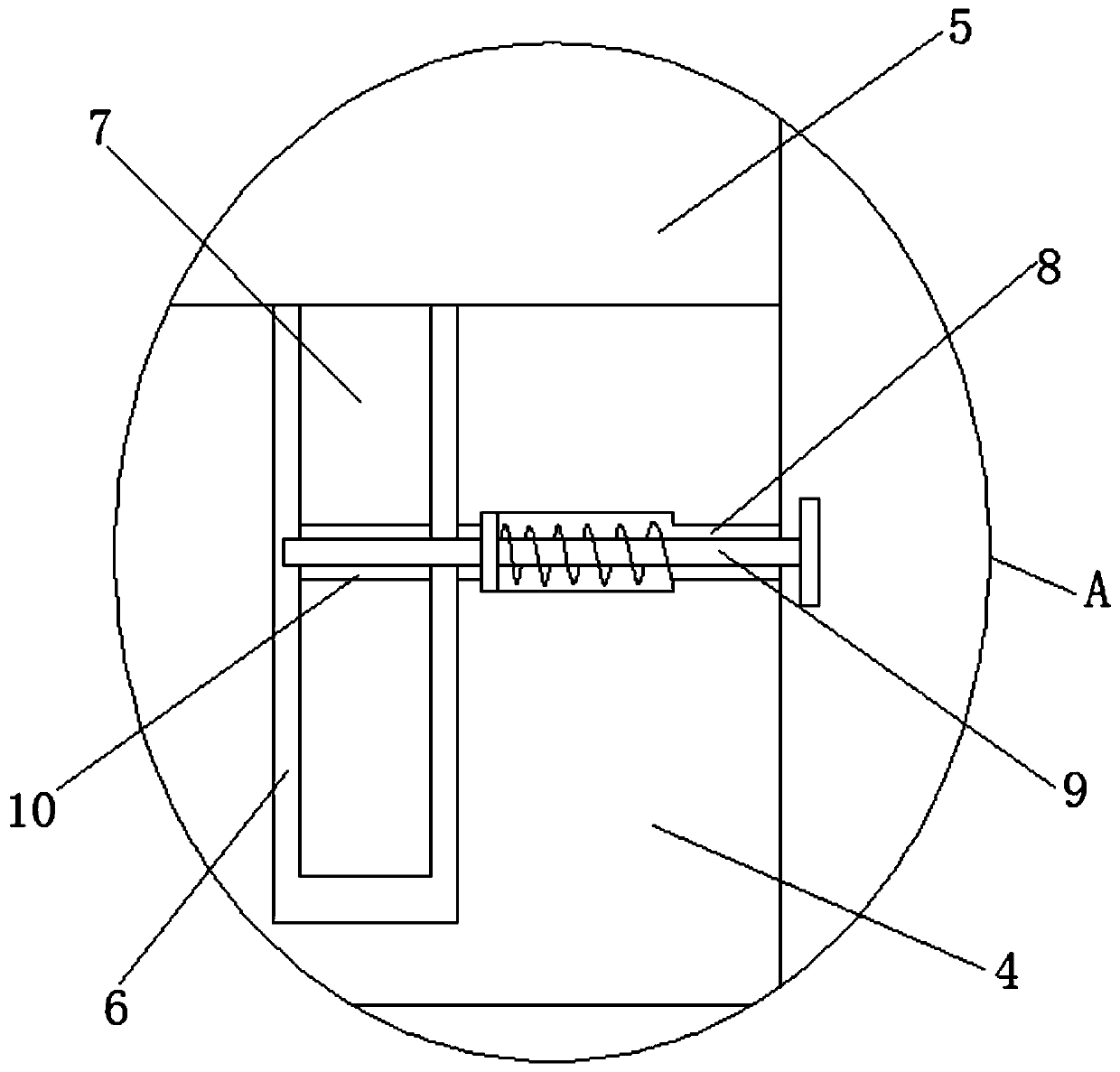

Rotating mixer for biological garbage collection

ActiveCN107626565ARealize disassembly workEasy to assemble and disassembleSievingScreeningEngineering

The invention discloses a rotating mixer for biological garbage collection. The rotating mixer comprises a mixer barrel body and a mixer barrel cover located on the upper portion of the mixer barrel body; a feeding hopper is fixedly mounted at the top end of the mixer barrel cover and communicates with the inside of the mixer barrel cover; first fixing blocks are welded to the two sides of the mixer barrel body correspondingly; second fixing blocks are welded to the two sides of the mixer barrel cover correspondingly; the first fixing blocks are provided with first fixing modules used for being connected with the mixer barrel body and the mixer barrel cover; supporting feet are welded to the bottom end of the mixer barrel body; and a discharging hopper is fixedly mounted at the bottom endof the mixer barrel body. The rotating mixer for biological garbage collection is simple in structure and convenient to use, a filtering device is additionally arranged on the rotating mixer, and thenthe mixer equipment is better protected; and meanwhile a filtering box is convenient to disassemble and assemble, so that cleaning and maintaining are facilitated, the service life of the equipment is prolonged, operation is simple, and the working efficiency is improved.

Owner:徐州淘沙生态农业有限公司

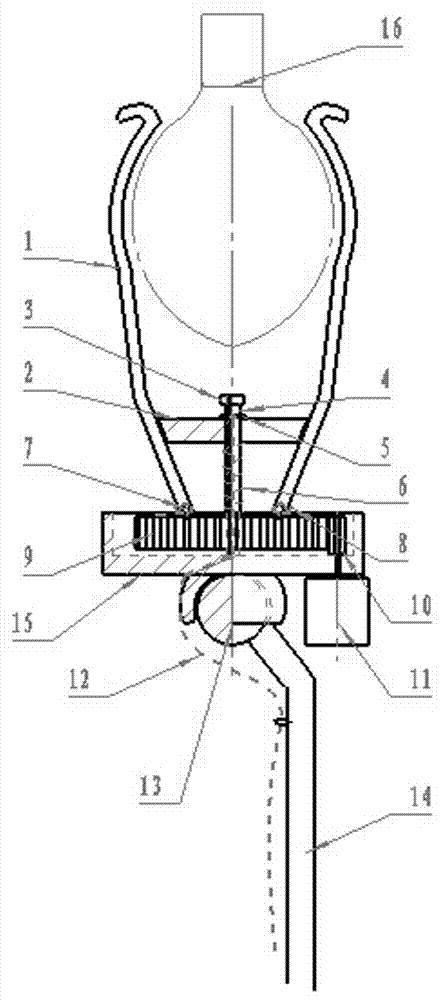

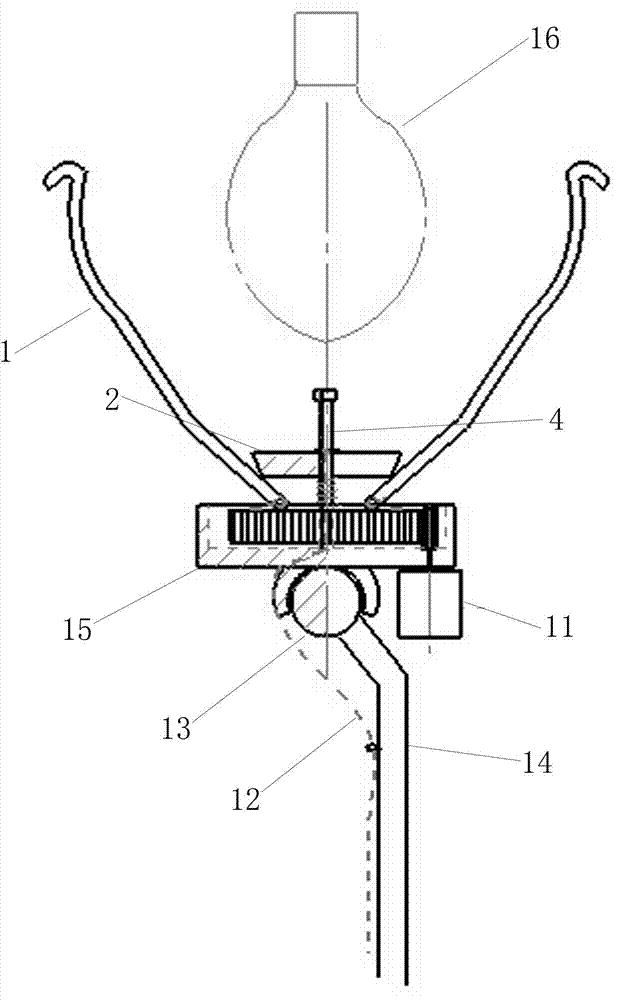

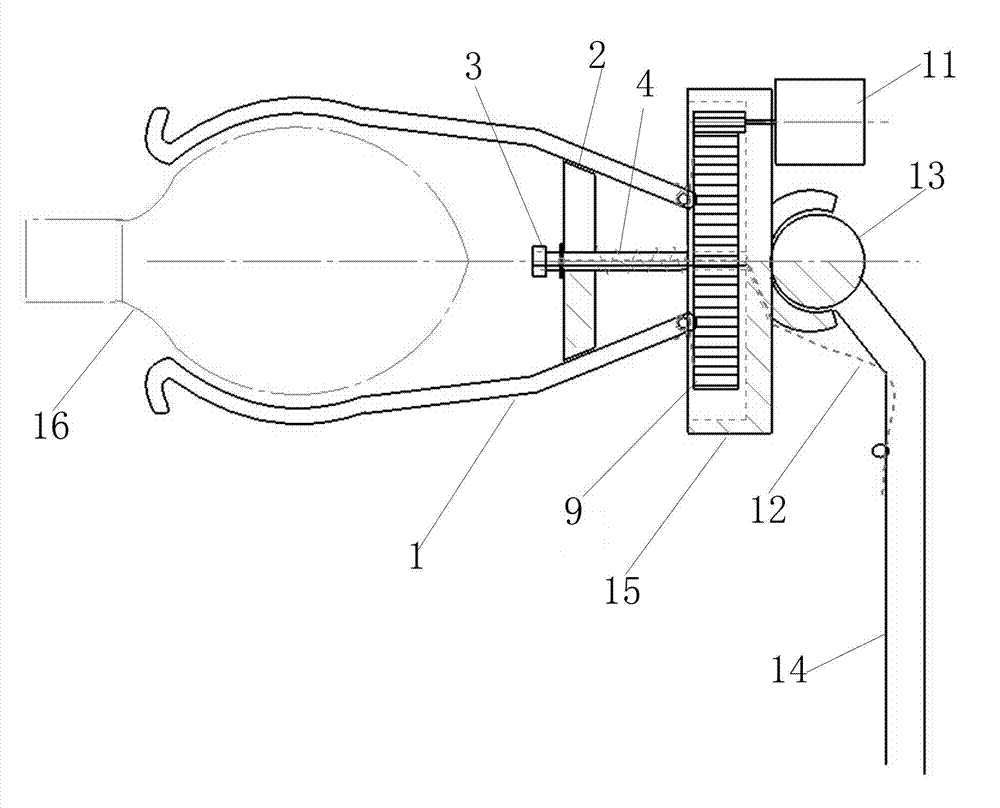

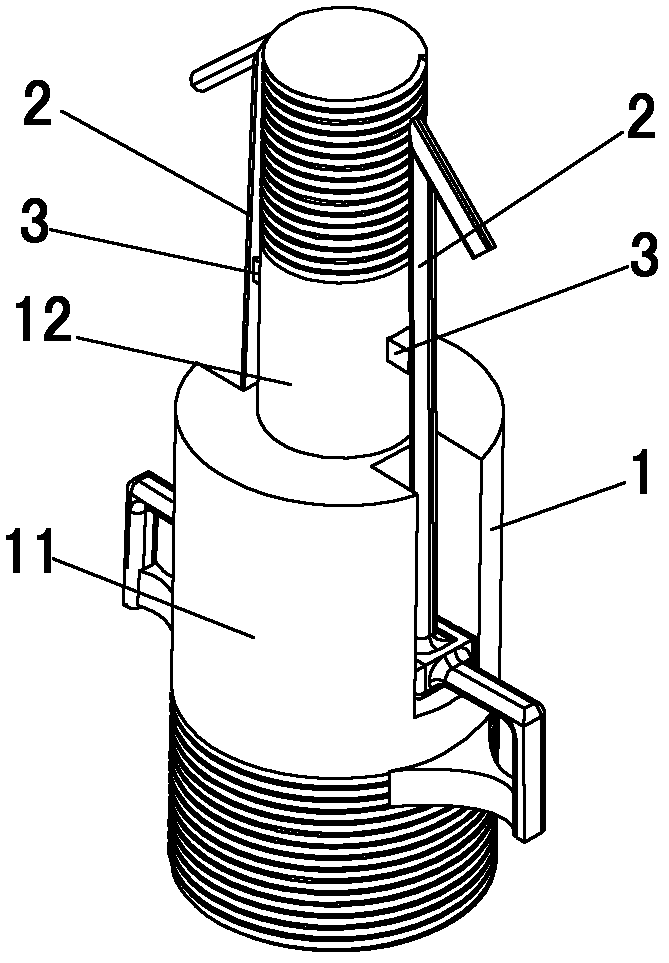

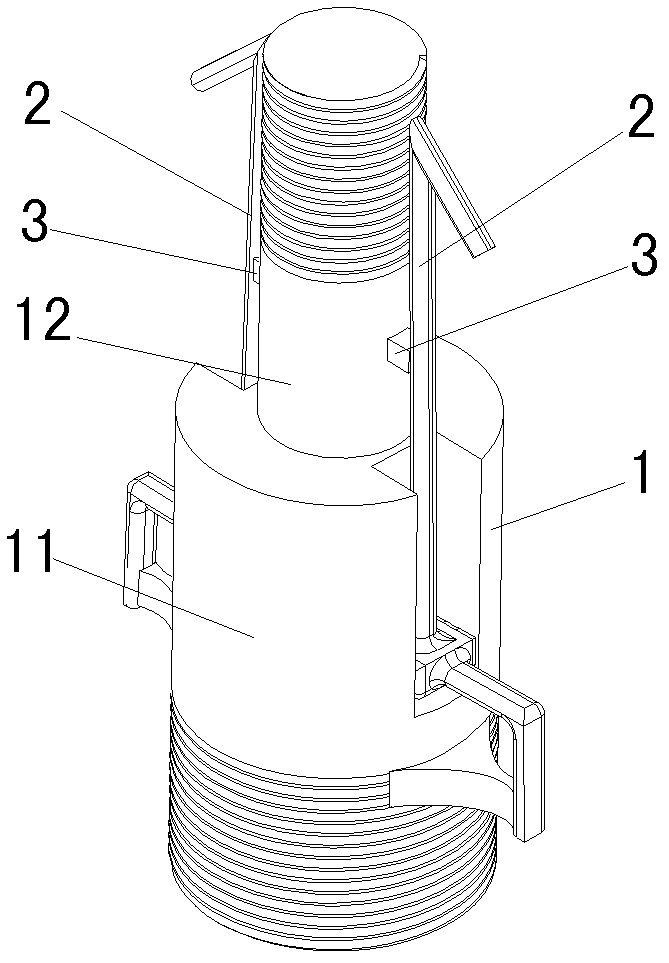

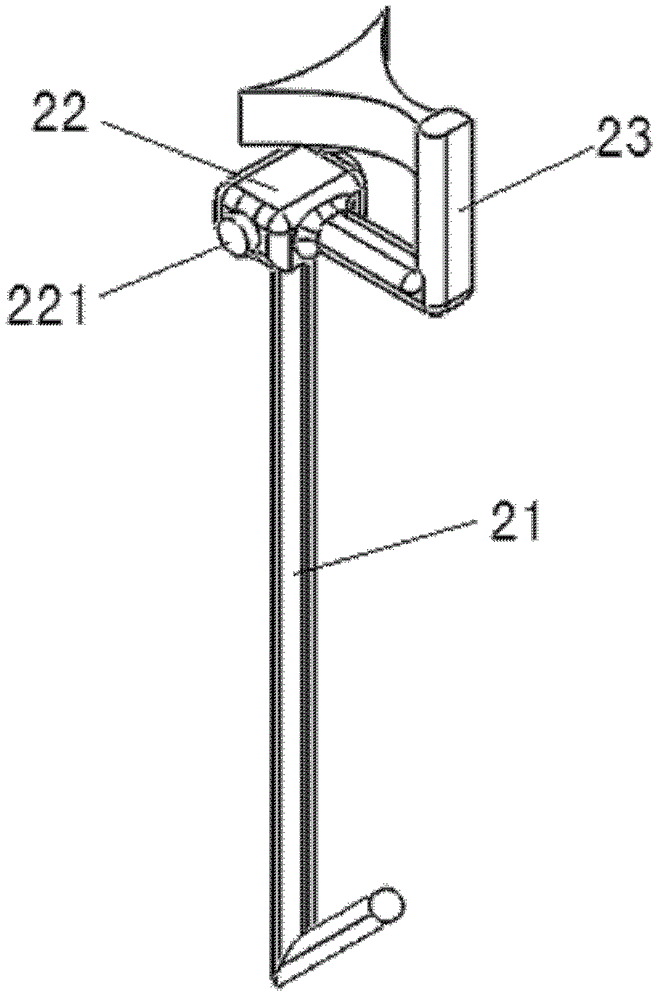

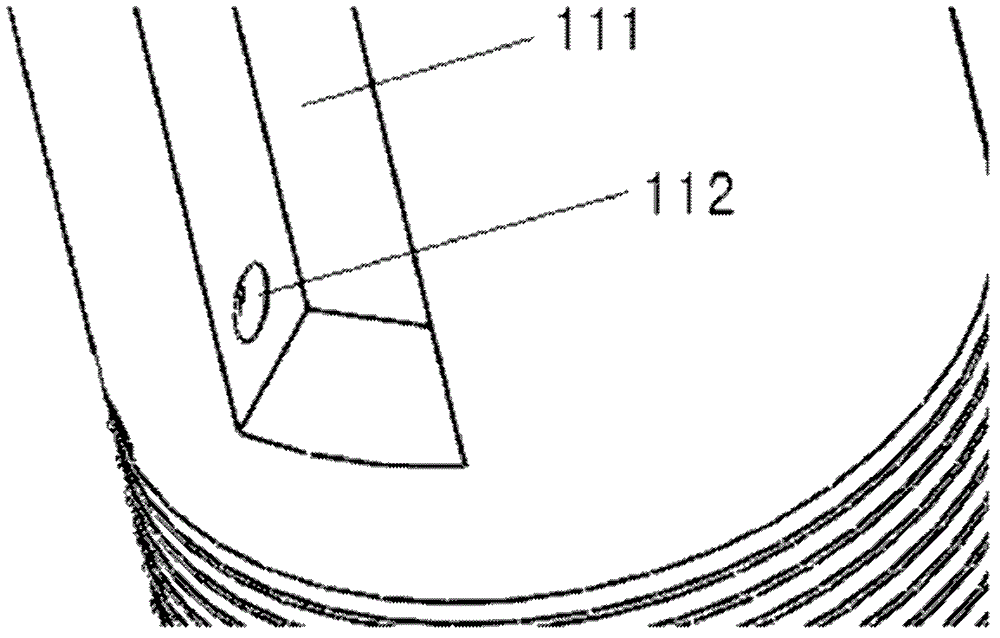

Detachable dental crown implant

InactiveCN103284806ARealize disassembly workEasy to break awayDental implantsTooth crownGreatest Diameter

The invention provides a detachable dental crown implant. The detachable dental crown implant comprises a spiral implant, detachable barb assemblies and tensioning mechanisms, wherein the spiral implant is in a different-diameter column-shaped body structure and comprises a lower part spiral body with a greater diameter and an upper part spiral body with a smaller diameter; the bottom of the lower part spiral body is provided with a thread section for planting a tooth root; the top of the upper part spiral body is provided with a thread section for screwing a dental crown. Two sets of the detachable barb assemblies are symmetrically arranged at the two sides of the spiral implant. The two tensioning mechanisms correspond to the two sets of the detachable barb assemblies and are respectively mounted on the upper part spiral body to be respectively collided and connected with the two sets of the detachable barb assemblies. According to the detachable dental crown implant disclosed by the invention, in a planting process, only the dental crown is half screwed in to have the reinforcing and anti-falling effects. In a detaching process, only designed detaching pliers need to be used and a connection body of a detachable barb is forcedly and upwardly pulled so that a barb can be released from a clamping groove in the dental crown; therefore, the dental crown can be very easily released from the implant. The detachable dental crown implant is convenient to use and simple to operate.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

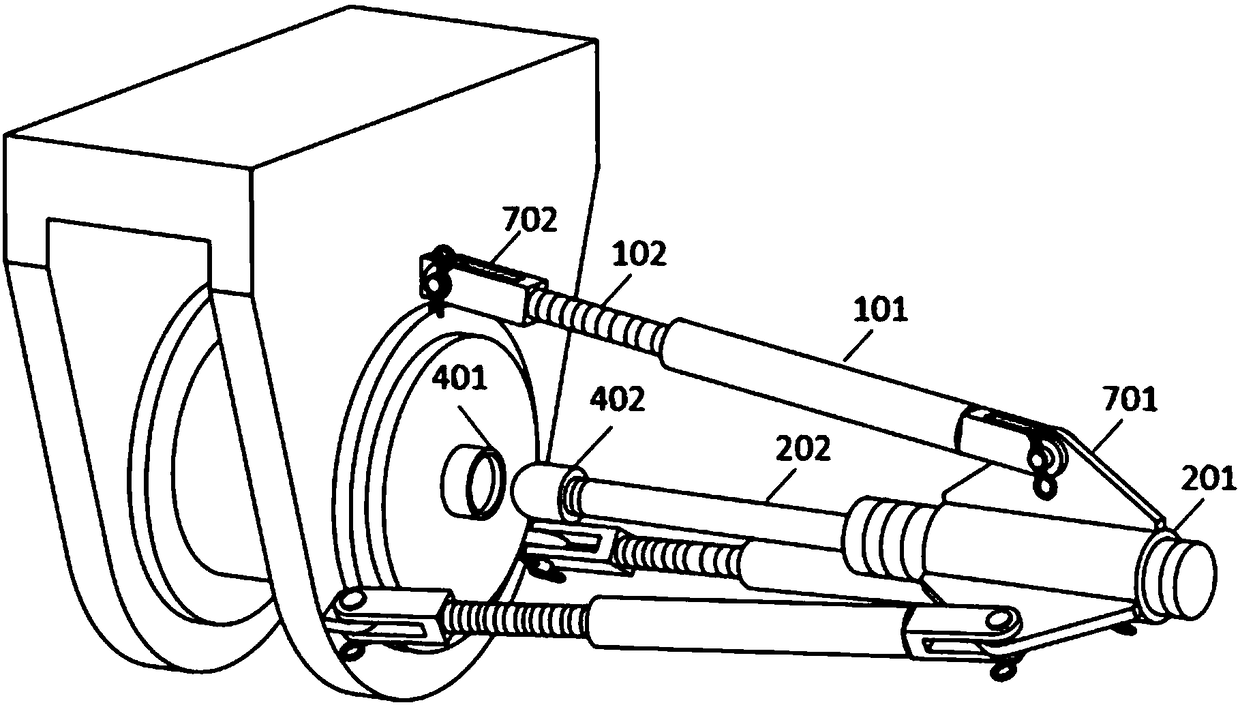

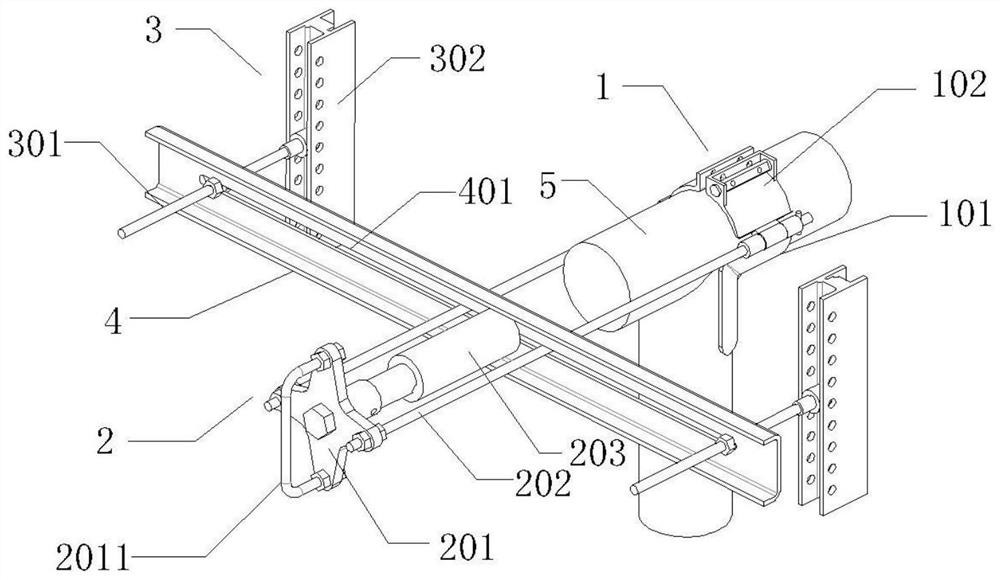

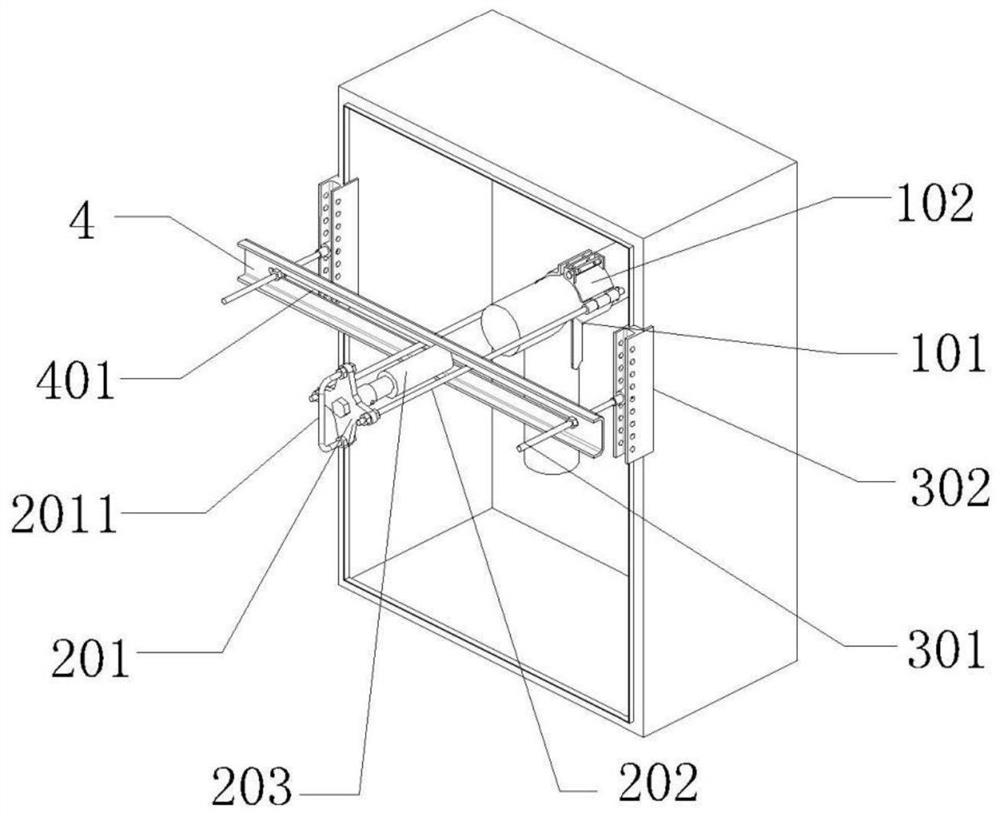

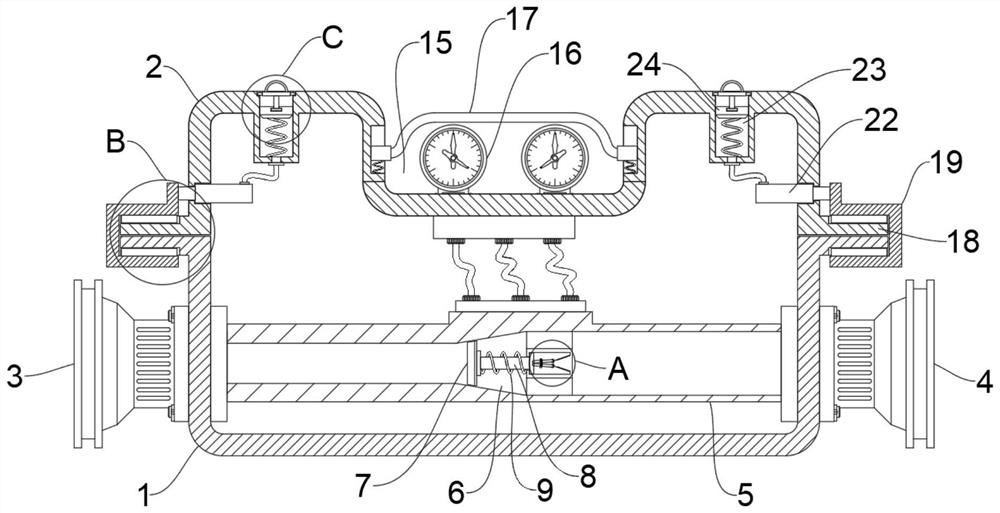

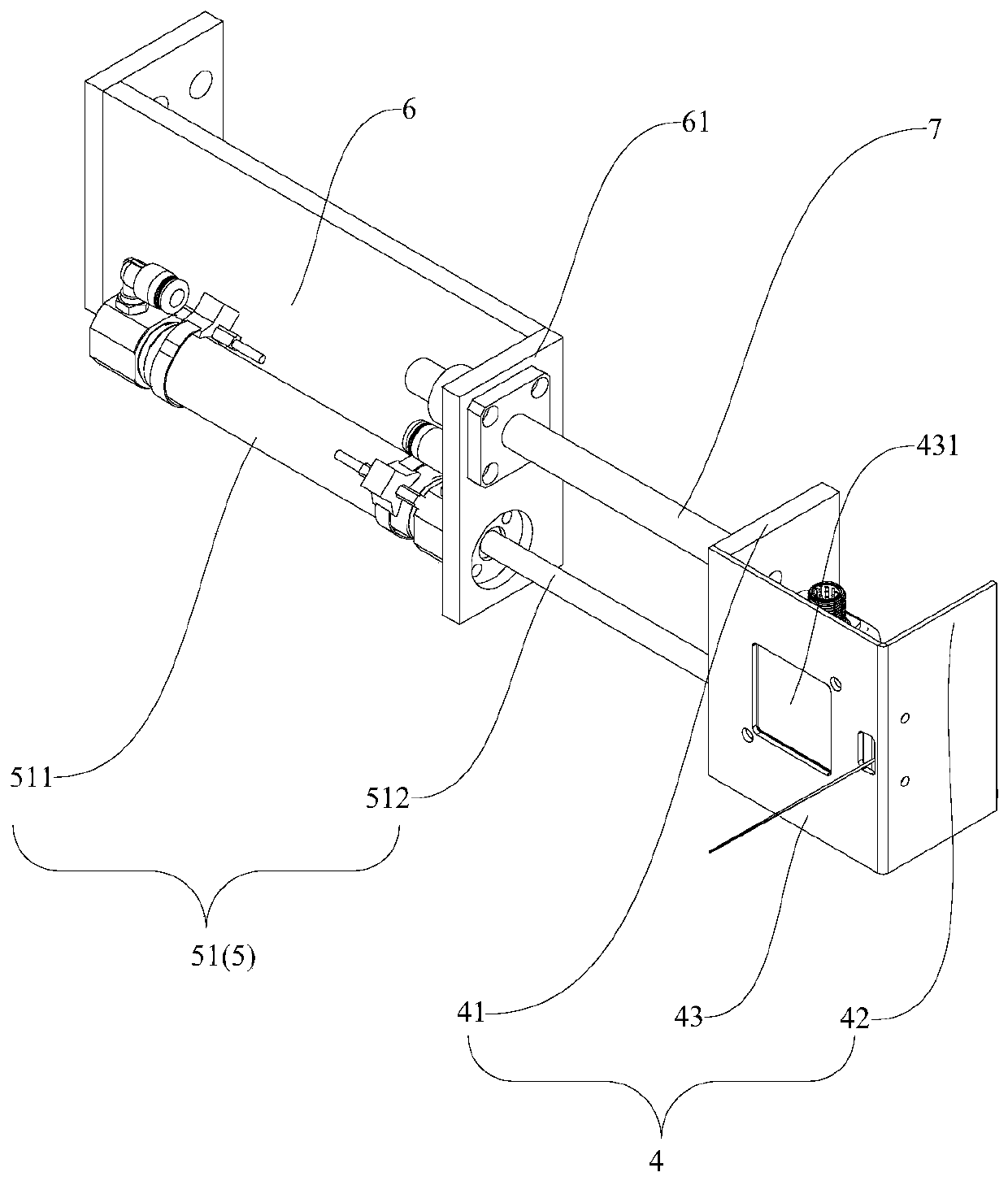

Rapid pulling-out device for elbow type cable head and using method of rapid pulling-out device

ActiveCN113241649AReduce the difficulty of dismantlingReduce labor intensityApparatus for joining/termination cablesSwitchgearStructural engineeringMechanical engineering

The invention discloses a rapid pulling-out device for an elbow type cable head and a using method of the rapid pulling-out device. The rapid pulling-out device comprises a fixing mechanism, a driving mechanism and a supporting mechanism, wherein the fixing mechanism comprises a first fixing piece and a second fixing piece, the top end of the first fixing piece is hinged to the bottom end of the second fixing piece, and the upper portion of the first fixing piece forms a cylinder matched with the horizontal part of the elbow type cable head; the driving mechanism comprises a mounting plate, the center of the end face of the mounting plate is fixedly connected with the top end of a hydraulic device, pull rods are symmetrically arranged on the two sides of the hydraulic device respectively, the top ends of the pull rods are fixedly connected with the mounting plate, and the bottom ends of the pull rods are detachably and fixedly connected with the first fixing piece; the supporting mechanism comprises supports which are parallel to the pull rods and arranged on the two sides of the hydraulic device respectively, and the bottom ends of the supports are connected with support bases which are connected with a box body of a power distribution cabinet; and a connecting plate is arranged between the two supports, and the bottom end of the hydraulic device is connected with the connecting plate in a sliding mode. With the rapid pulling-out device, cable head dismounting difficulty and the labor intensity of workers are reduced, working efficiency is improved, and the cable head and the box body of the power distribution cabinet are prevented from being damaged.

Owner:GUIZHOU POWER GRID CO LTD

Spinning wire winding device

InactiveCN108002134AWork fasterRealize the installation workFilament handlingAutomatic controlBobbin

The invention discloses a spinning wire winding device. The spinning wire winding device comprises a machine body, and guide wheels arranged on the right side of the machine body and symmetrically arranged in an up-and-down mode; a boss part is arranged at the bottom of the right side end surface of the machine body; a wire winding mechanism is arranged above the boss part; the wire winding mechanism comprises a baseplate extending left and right, a connecting block fixed on the back side of the right side of the baseplate, a straight plate fixed at the back side end of the connecting block and upwards extending, and a wire winding base arranged above the baseplate; a first rotating shaft is fixedly arranged at the bottom of the wire winding base; the bottom of the first rotating shaft penetrates through the baseplate for rotary cooperating connection; an outer spline shaft downwards extending is fixedly arranged at the bottom of the first rotating shaft; a single key shaft is fixedlyarranged at the top of the wire winding base; a first transmission cavity is formed in the boss part; and an inner spline rotating shaft extending to the upper and lower sides is in rotary cooperatingconnection into the inner top wall of the first transmission cavity. The spinning wire winding device is simple in structure, realizes automatic control of up-down movable wire winding work, improvesthe wire winding uniformity, realizes quick disassembly of bobbins, and improves the wire winding stability.

Owner:扬州市青山环保科技有限公司

Anti-knotting spinning wire winding device

InactiveCN108002125AWork fasterRealize the installation workFilament handlingBobbinAutomatic control

The invention discloses an anti-knotting spinning wire winding device. The anti-knotting spinning wire winding device comprises a machine body, and guide wheels arranged on the right side of the machine body and symmetrically arranged up and down; a boss part is arranged at the bottom of the right side end surface of the machine body; a wire winding mechanism is arranged above the boss part; the wire winding mechanism comprises a baseplate extending left and right, a connecting block fixed on the back side of the right side of the baseplate, a straight plate fixed at the back side end of the connecting block and upwards extending, and a wire winding base arranged above the baseplate; a first rotating shaft is fixedly arranged at the bottom of the wire winding base; the bottom of the firstrotating shaft penetrates through the baseplate for rotary cooperating connection; an outer spline shaft downwards extending is fixedly arranged at the bottom of the first rotating shaft; a single keyshaft is fixedly arranged at the top of the wire winding base; a first transmission cavity is formed in the boss part; and an inner spline rotating shaft extending to the upper and lower sides is inrotary cooperating connection into the inner top wall of the first transmission cavity. The anti-knotting spinning wire winding device is simple in structure, realizes automatic control of up-down movable wire winding work, improves the wire winding uniformity, realizes quick disassembly of bobbins, and improves the wire winding stability.

Owner:CIXI QICHENG MACHINERY TECH CO LTD

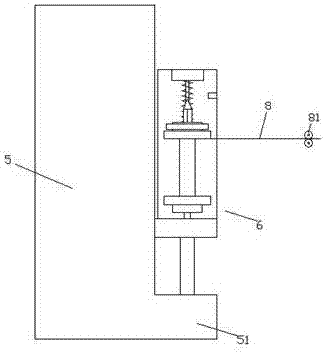

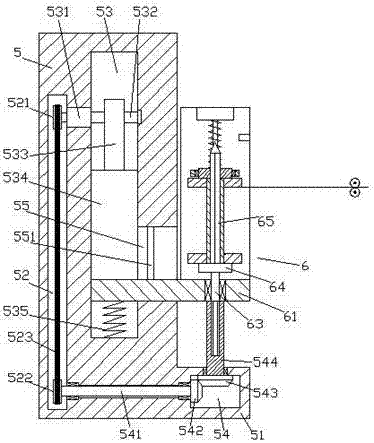

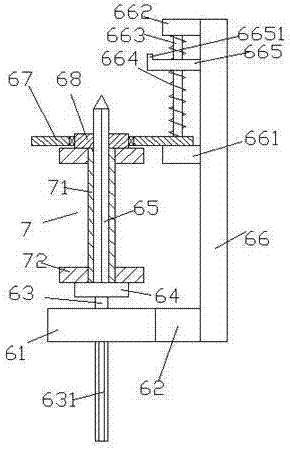

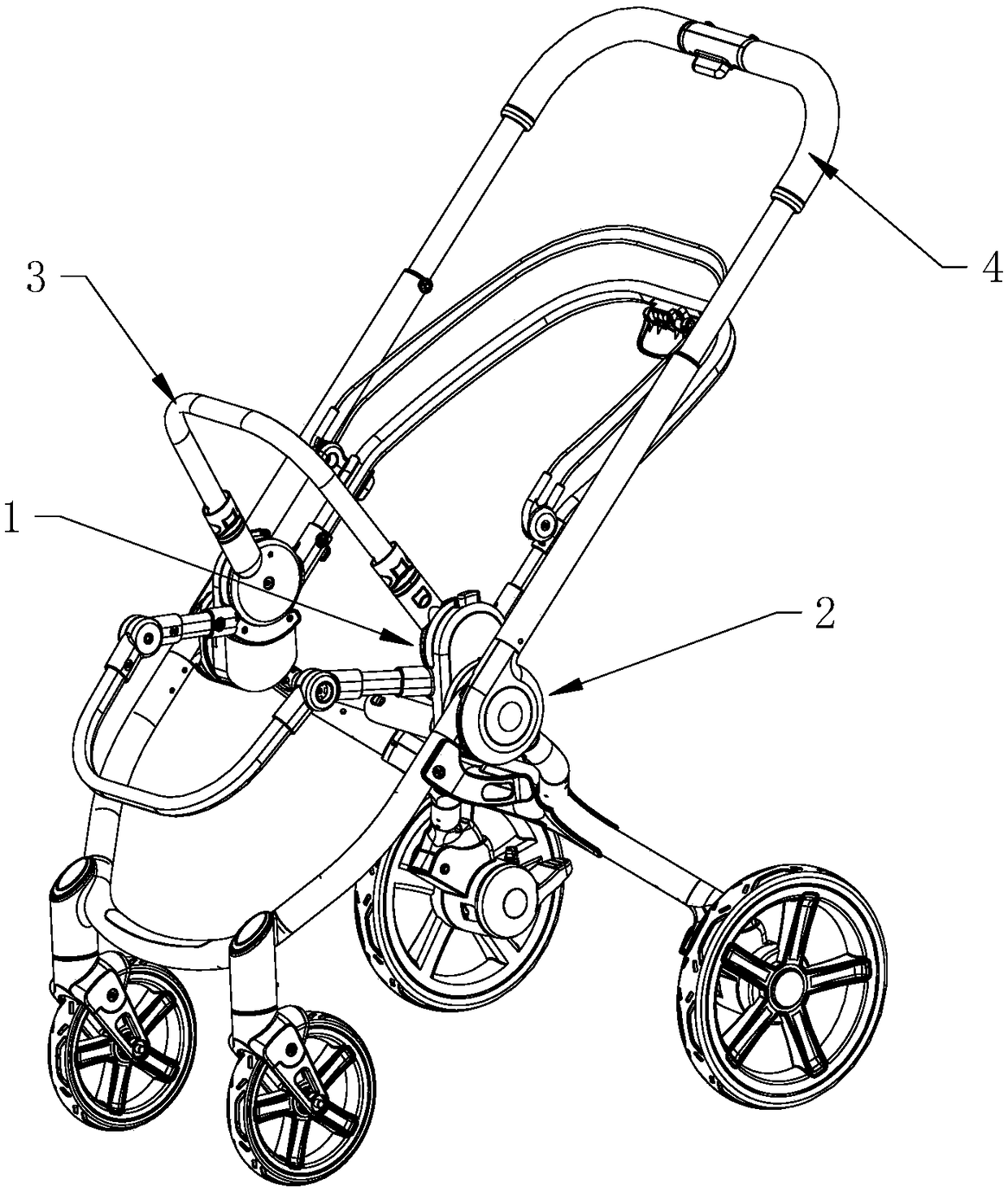

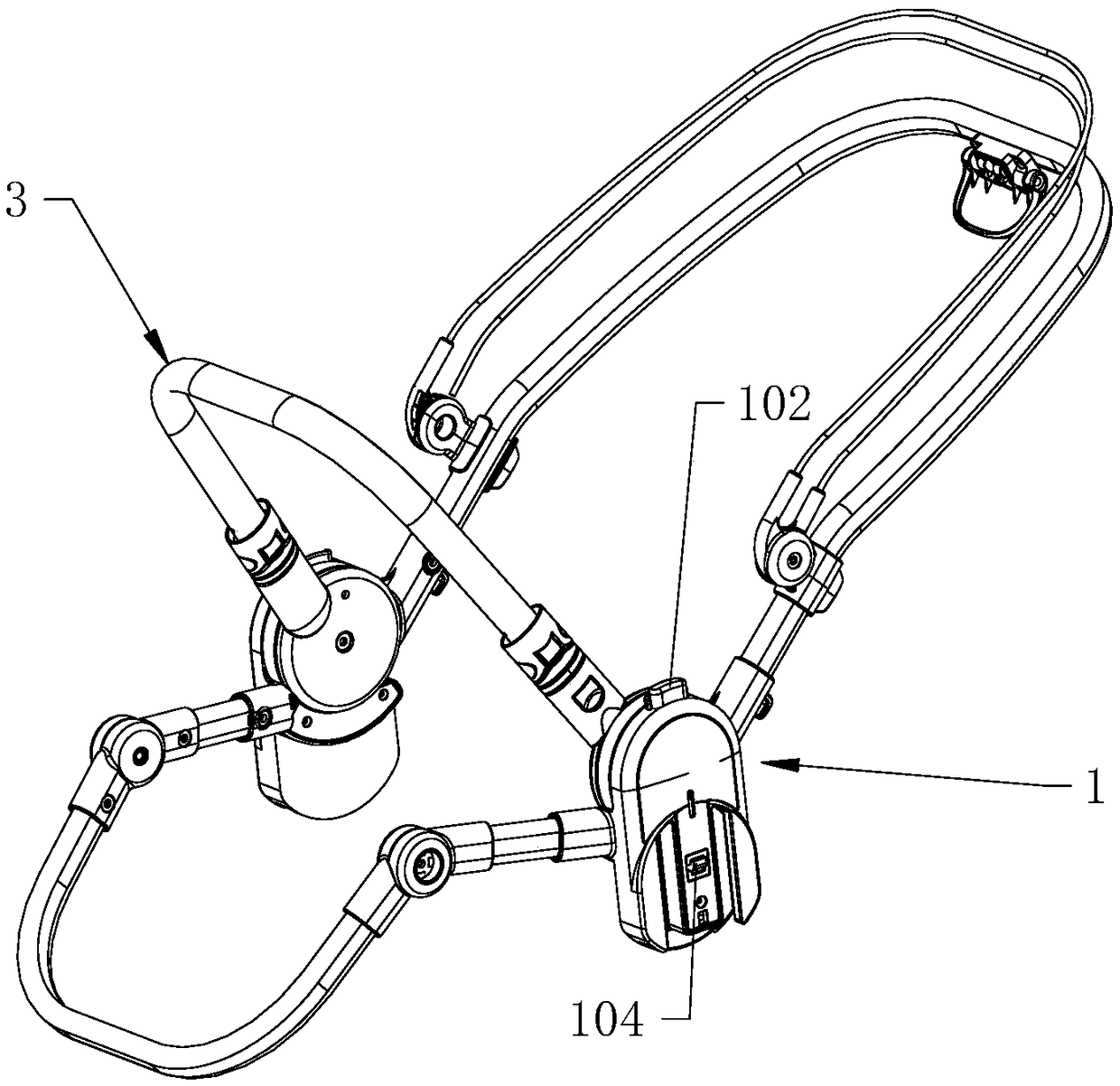

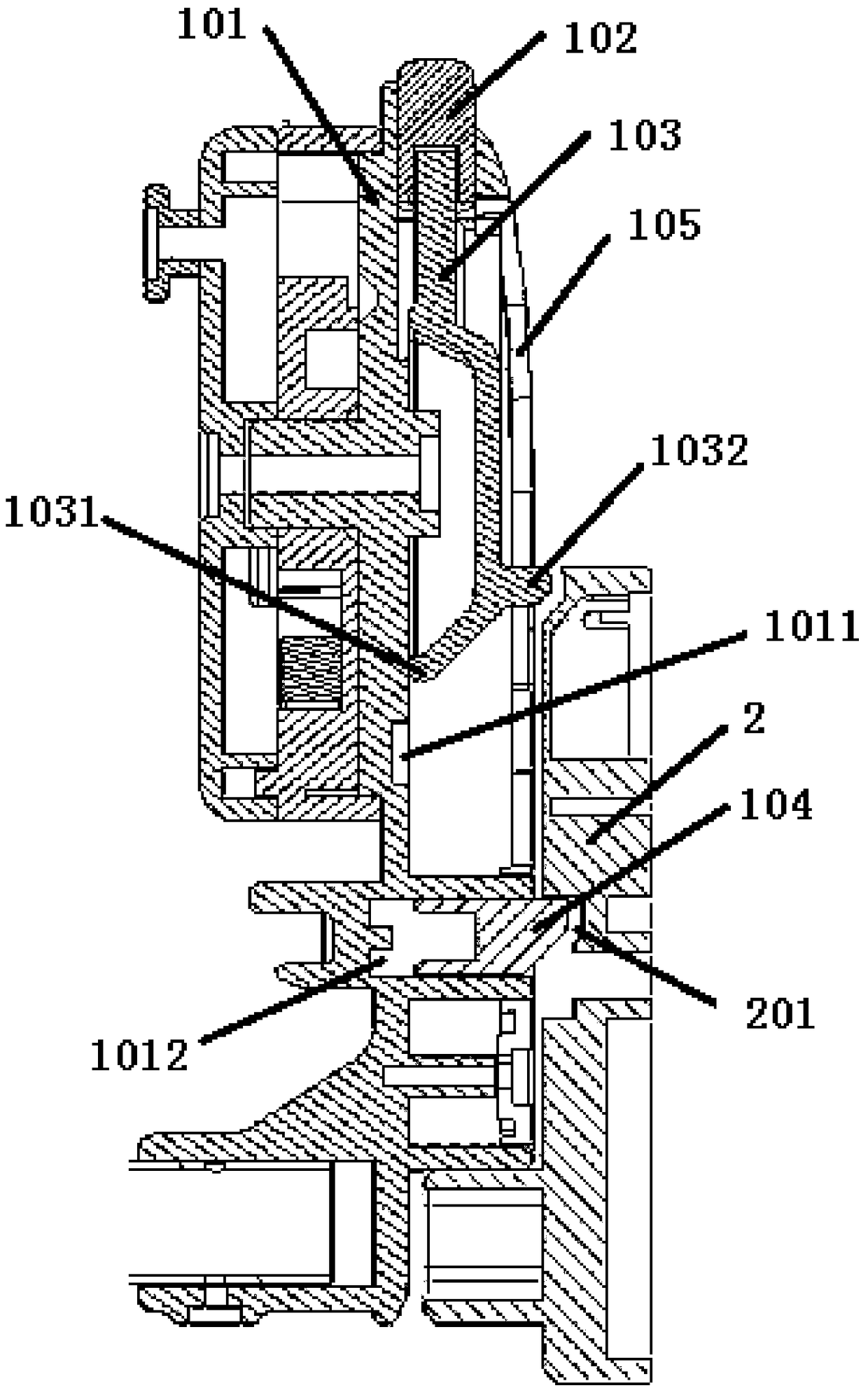

A locking connection structure and a baby carriage

PendingCN109204430ARealize disassembly workEasy to disassembleCarriage/perambulator accessoriesVehicle frameEngineering

The invention relates to the technical field of infant articles, in particular to a locking connection structure and a baby carriage. The locking connection structure comprises a first connection partfor fixing on a chair frame and a second connection part for fixing on a vehicle frame. The first connection part includes a positioning plate the middle of which is provided with a hook groove; a hook plate one side of which close to the positioning plate is provided with a sliding hook for hooking the hook groove; and a latch, wherein one side of the latch close to the positioning plate is connected with the positioning plate through a spring, one side of the latch far away from the positioning plate is connected with the hook plate, and when the sliding hook is close to the hook groove, the latch compresses the spring under the driving of the hook plate. The second connecting part includes a bolt hole into which the spring drives the latch to insert when the chair frame and the vehicleframe are connected. The locking connection structure and the baby carriage provided by the invention are convenient for parents to realize the disassembly work of the seat and the carriage frame with one hand.

Owner:东莞市铭心科技服务有限公司

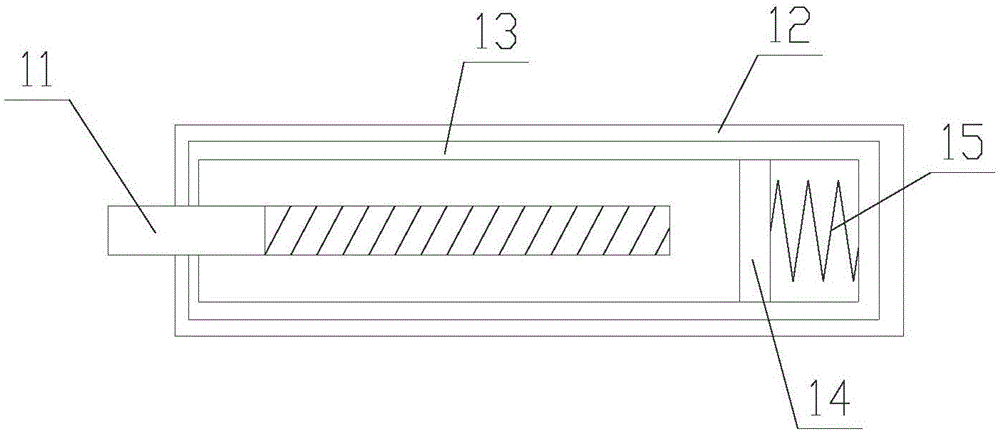

Novel water meter shell

InactiveCN111141357ARealize disassembly workEasy maintenanceVolume meteringEngineeringStructural engineering

The invention discloses a novel water meter shell, which comprises a shell body, a cover body is arranged on the upper side wall of the shell body; the lower side wall of the cover body is fixedly connected with two inserting blocks which are symmetrically arranged; two symmetrically arranged slots are formed in the upper side wall of the shell body; the inserting blocks are inserted into the inserting grooves; and a installation groove is formed in one side of the inserting groove, a clamping groove is formed in the side wall of the side, close to the installation groove, of the inserting block, two telescopic mechanisms are arranged on the inner wall of the clamping groove, the other ends of the two telescopic mechanisms are jointly and fixedly connected with a clamping block, a sleeve plate is arranged on the inner wall of the installation groove, and an inserting rod is fixedly inserted into the sleeve plate. By arranging the insertion rod, the push plate, the insertion block, thetelescopic rod, the spring, the clamping block and the sleeve plate, when the cover body and the shell body need to be detached, the push plate is pushed, the push plate drives the insertion rod to move, the insertion rod drives the clamping block to enter the clamping groove, then the cover body is pulled, the insertion block is moved out of the insertion groove, detaching work is achieved, and overhauling is convenient.

Owner:XIAN TRIONES DIGITAL INFORMATION

An electrical control switch structure

InactiveCN102254722BGood choiceRealize the installation workElectric switchesState of artEngineering

The invention relates to an electrical appliance control switch structure, comprising an electrical appliance control switch and a cover plate which is arranged on a first side face of the electrical appliance control switch, wherein the cover plate is provided with a bayonet post; the first side face of the electrical appliance control switch is provided with a bayonet face; the bayonet face is provided with a bayonet groove; the bayonet groove is matched and connected with the bayonet post; grooves are arranged at the left and right sides of the first side face of the electrical appliance control switch respectively; and a second side face of the electrical appliance control switch is provided with a bolt which is matched and connected with the groove. A pressing buckle type switch and a threading groove structure are used to solve the defects in the prior art, thus avoiding unrecoverable misoperation and solving the unreasonable post-installation adjustment in a certain range. The composite structure of electrical appliance control switch expansion modules is used to solve the problem that the structure between the body and an expansion unit is incompact and unstable.

Owner:SUZHOU AOPEIKE AUTOMOBILE ELECTRONICS

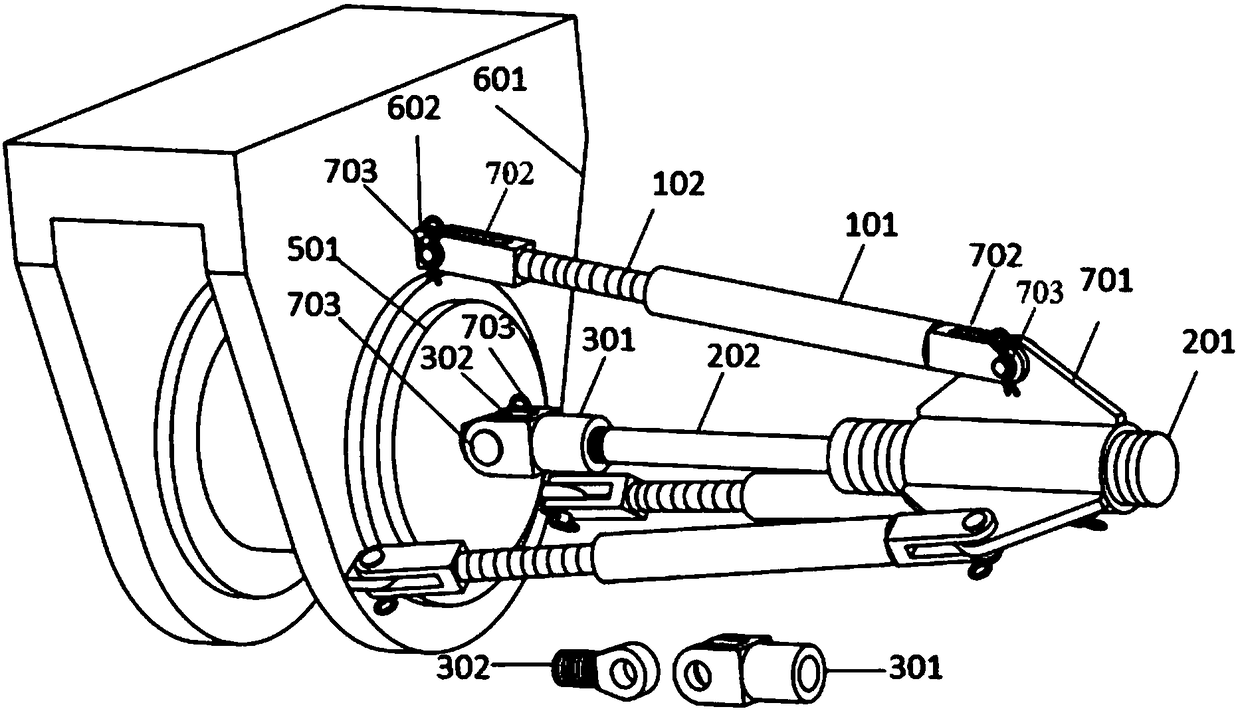

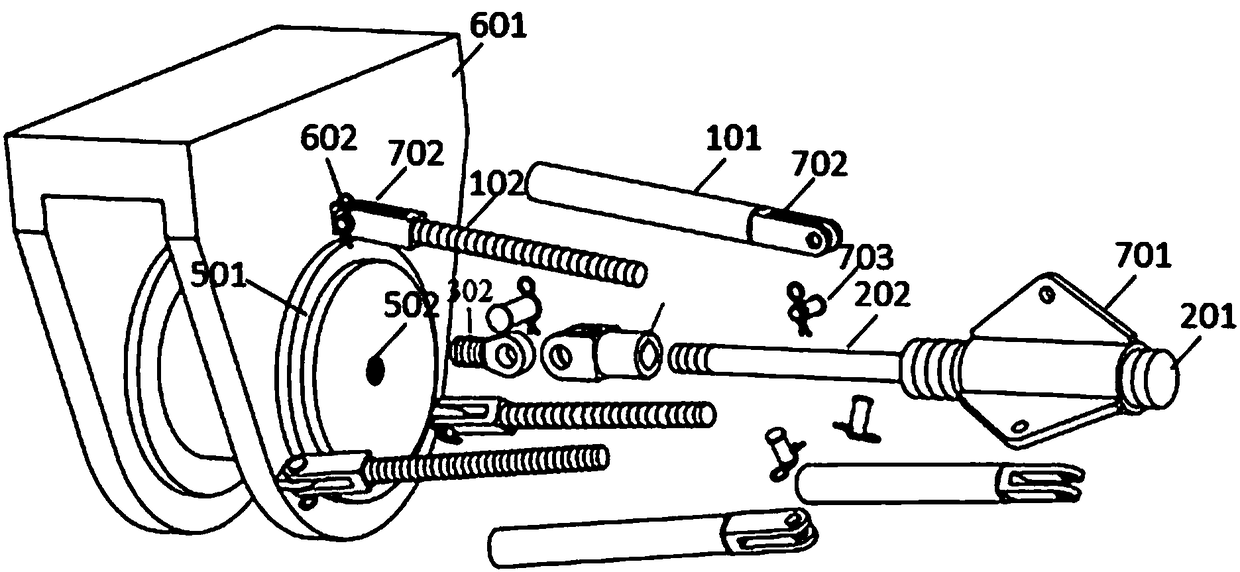

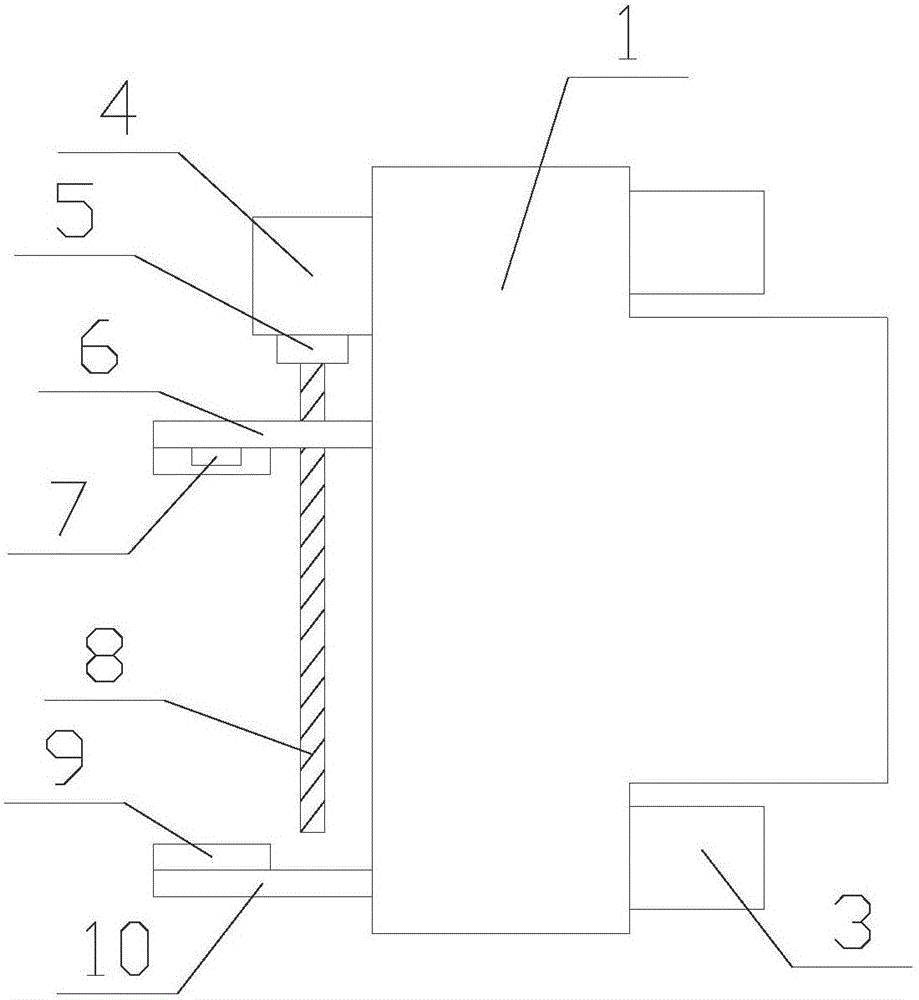

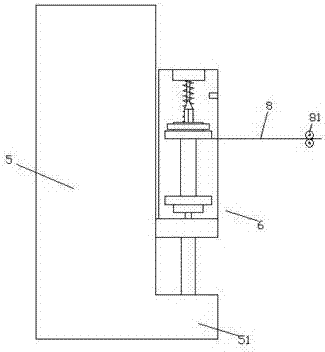

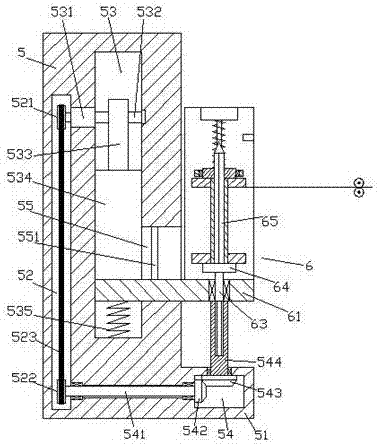

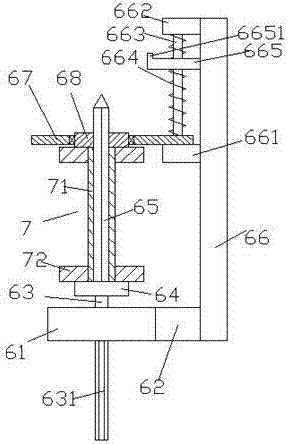

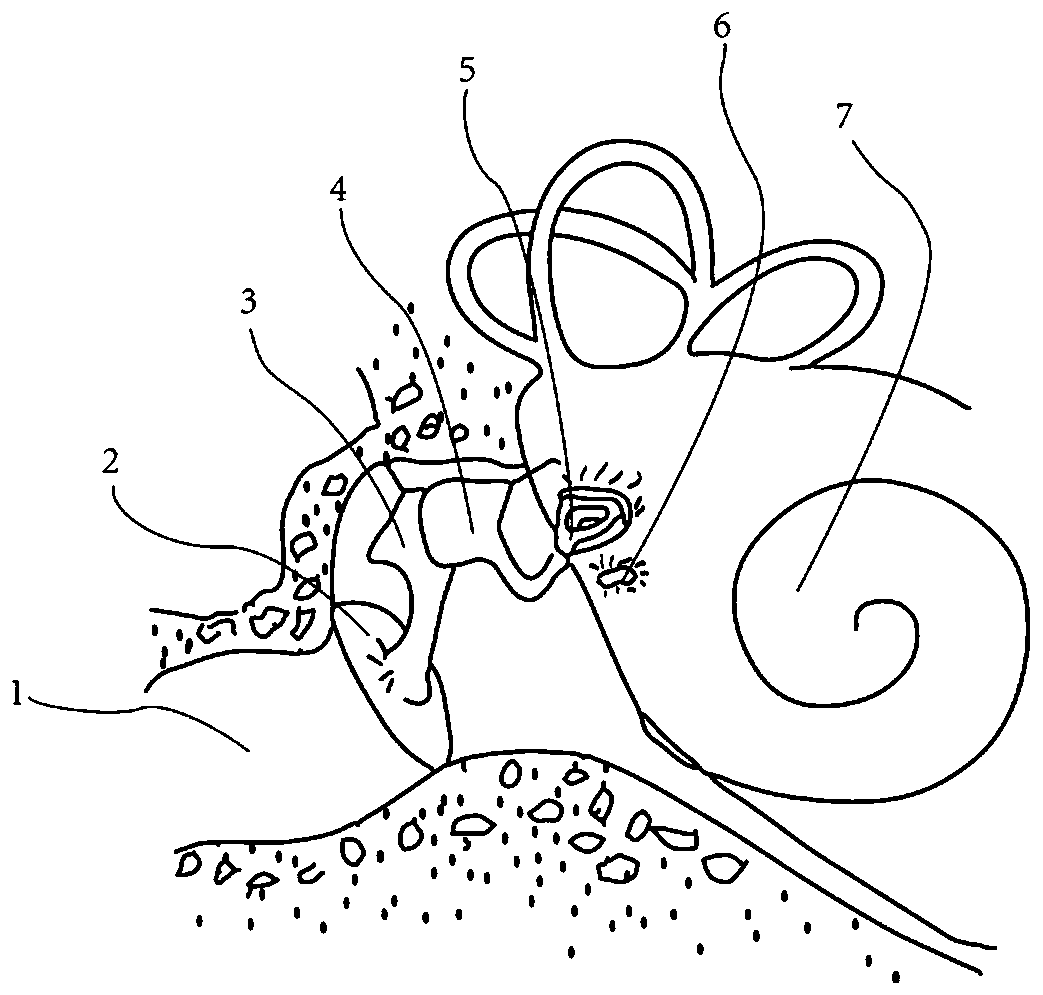

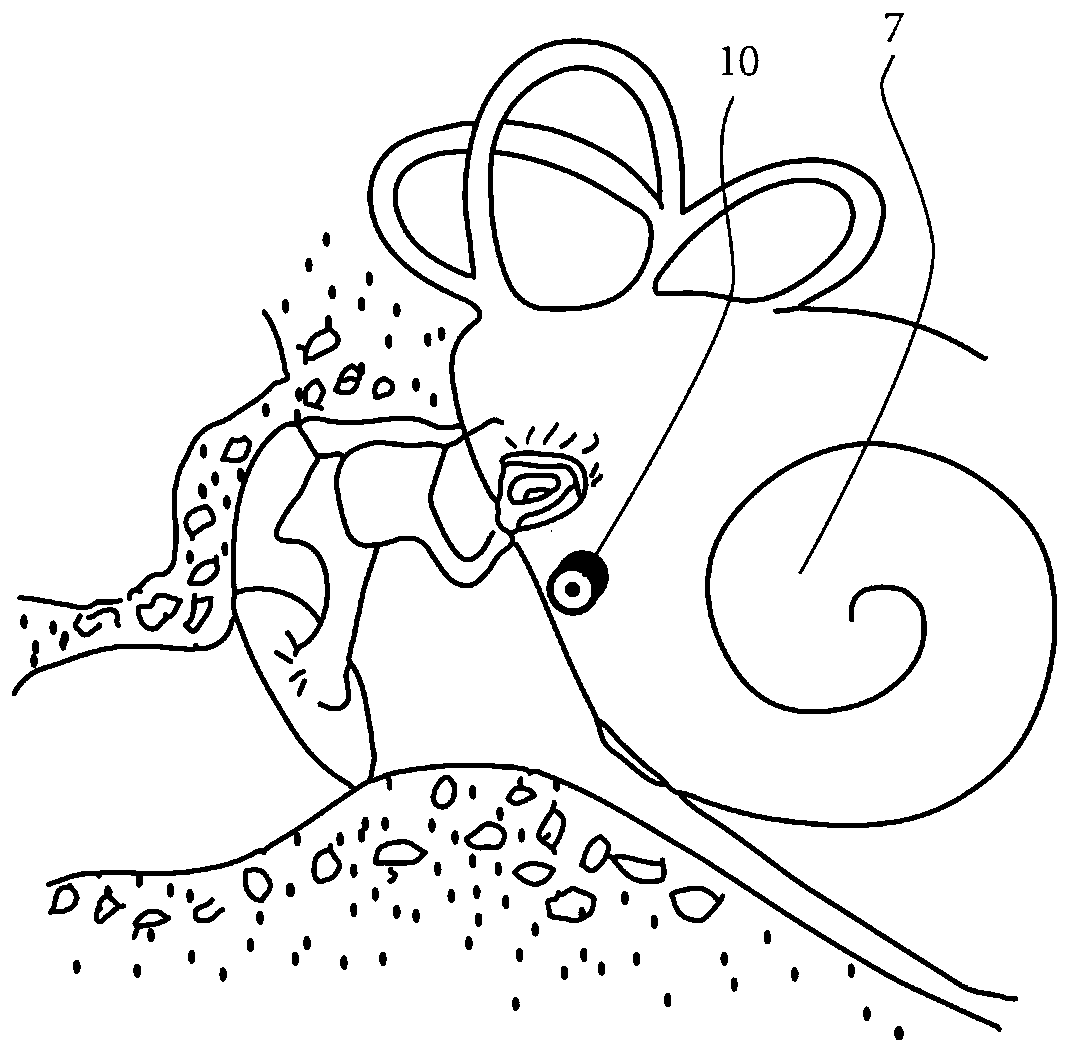

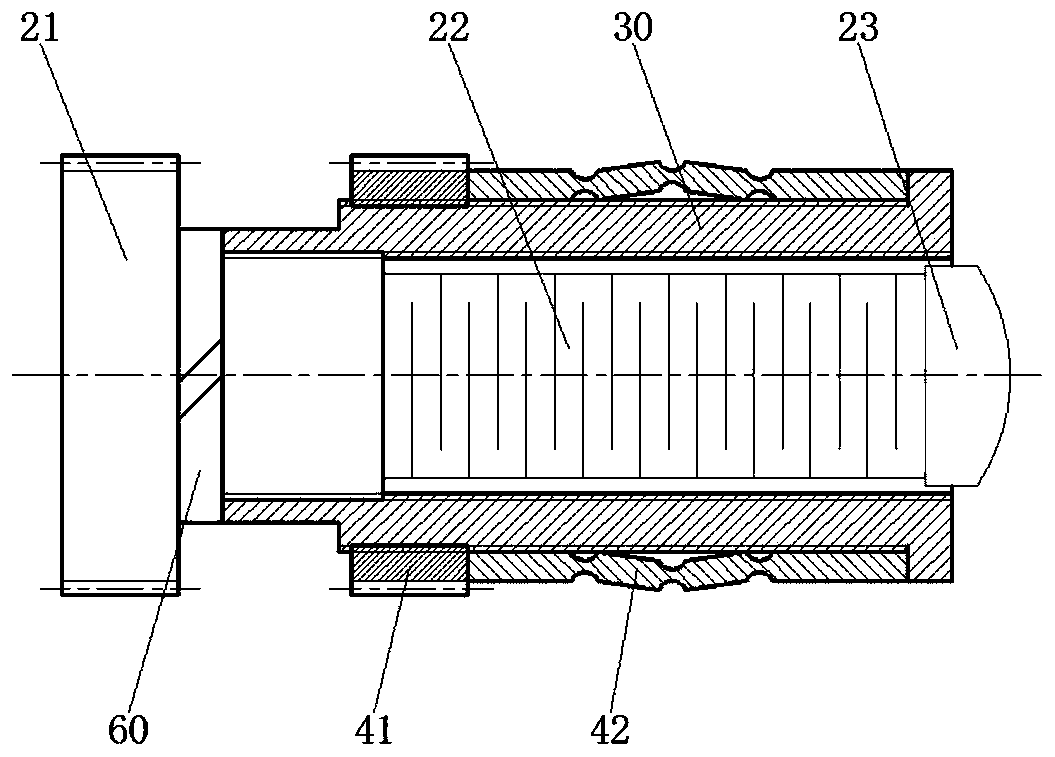

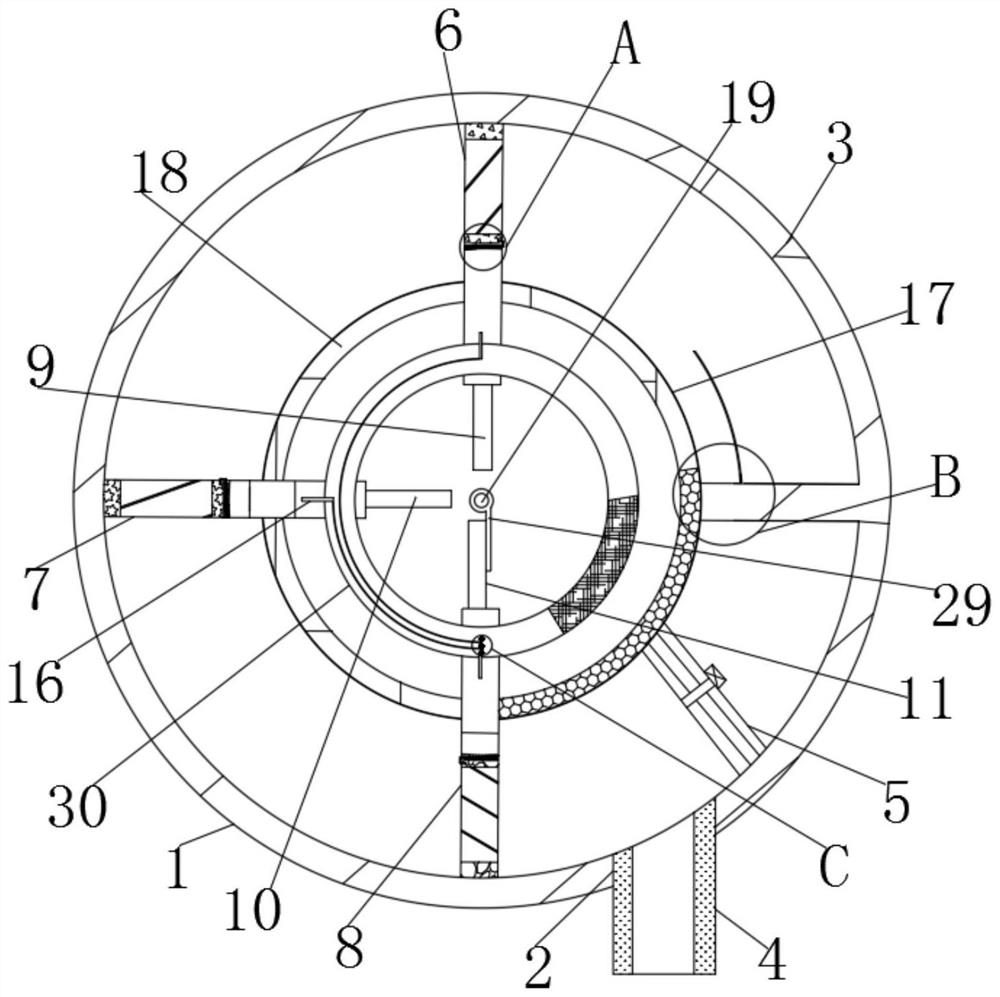

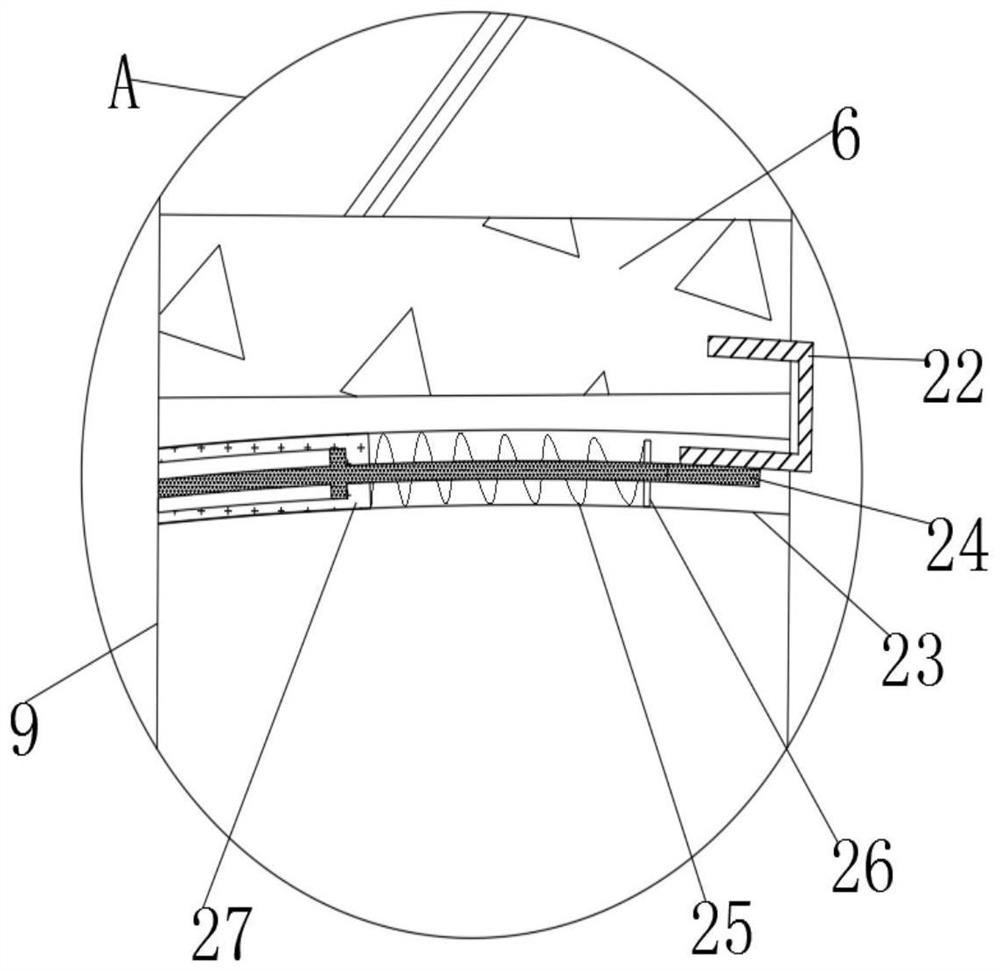

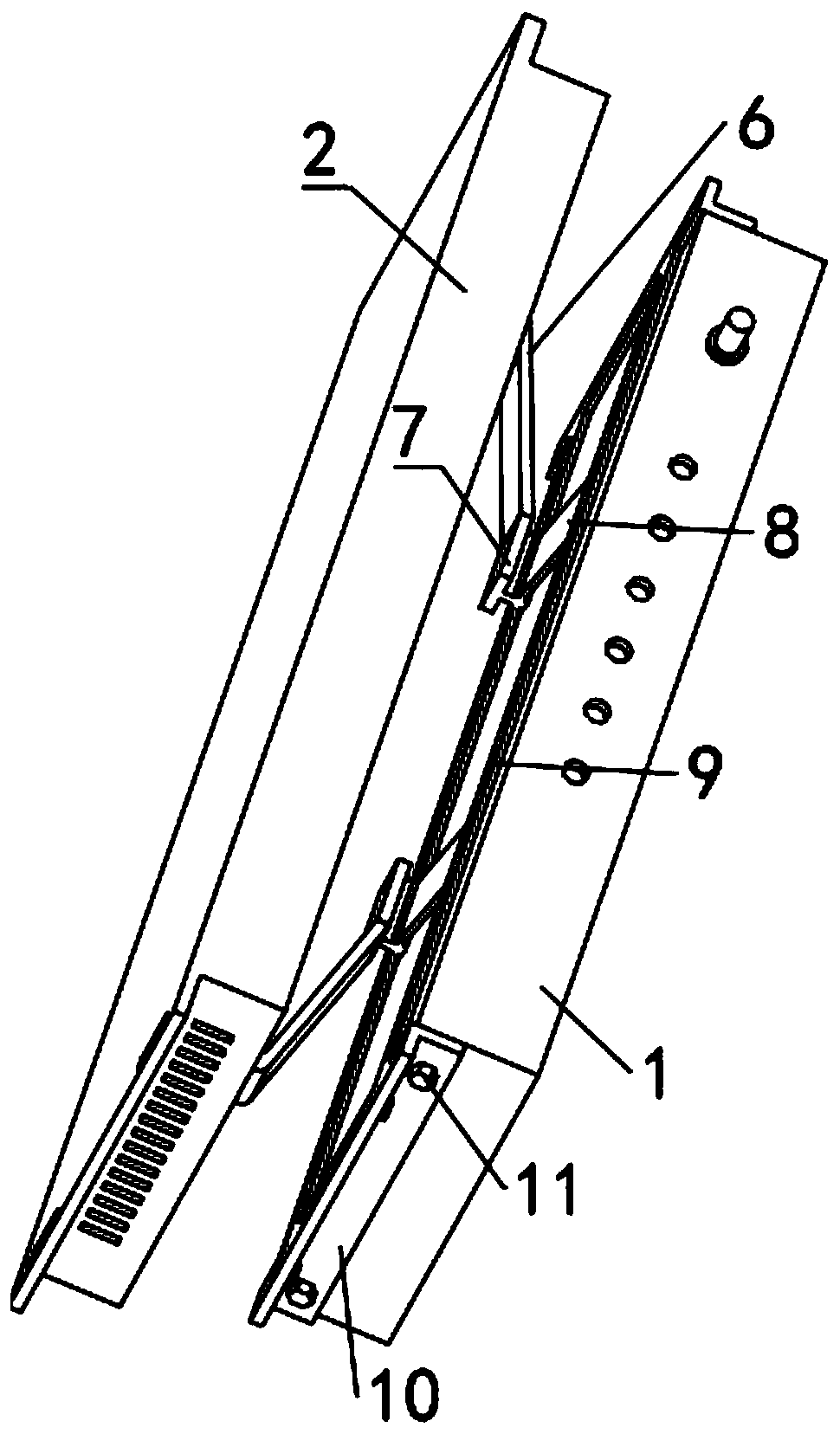

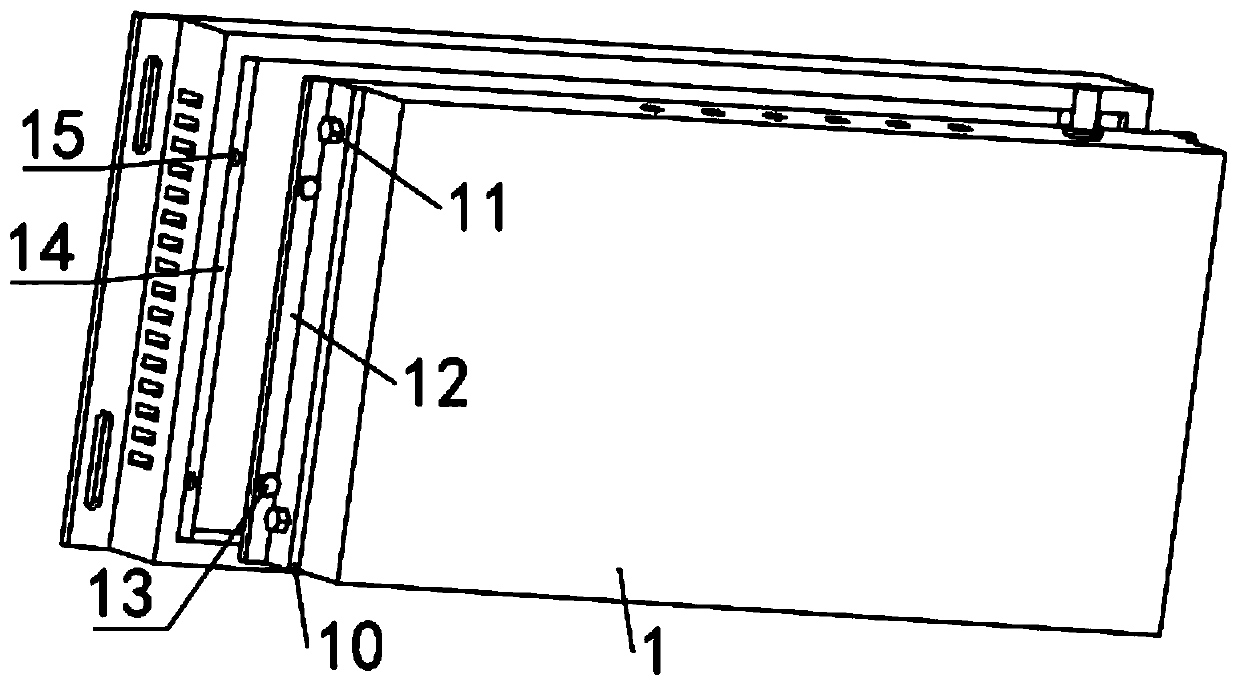

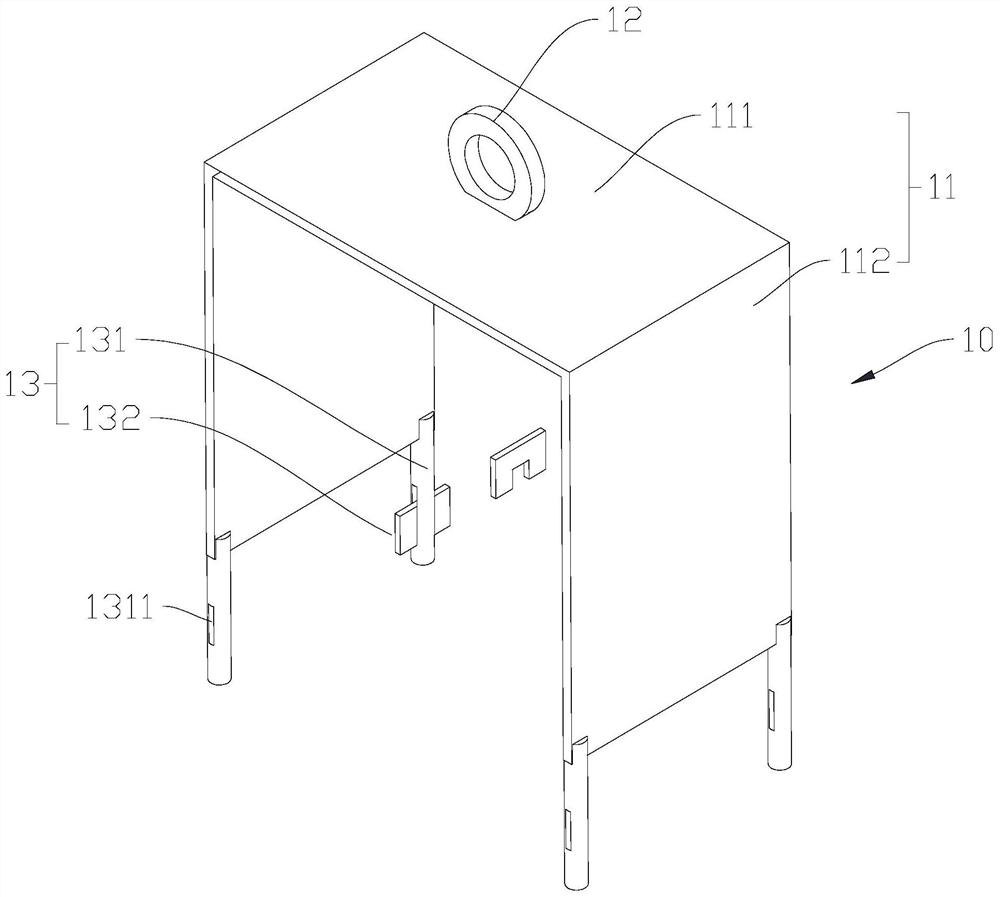

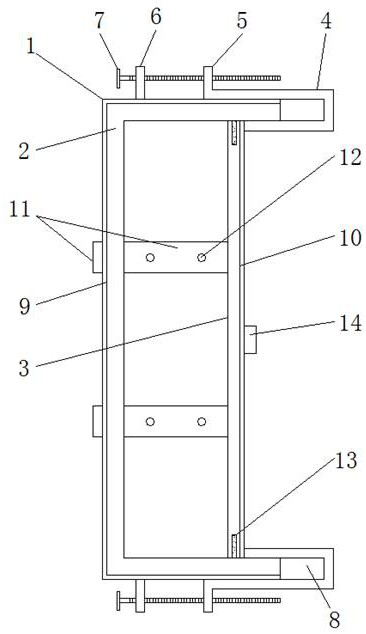

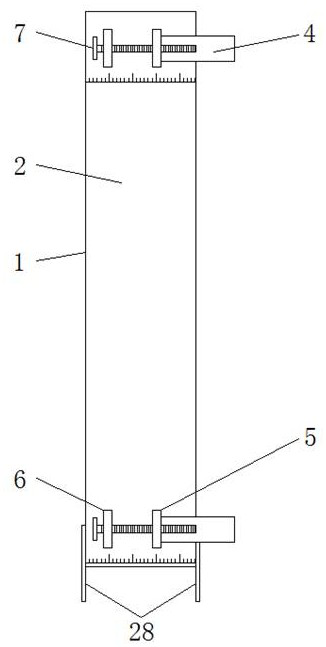

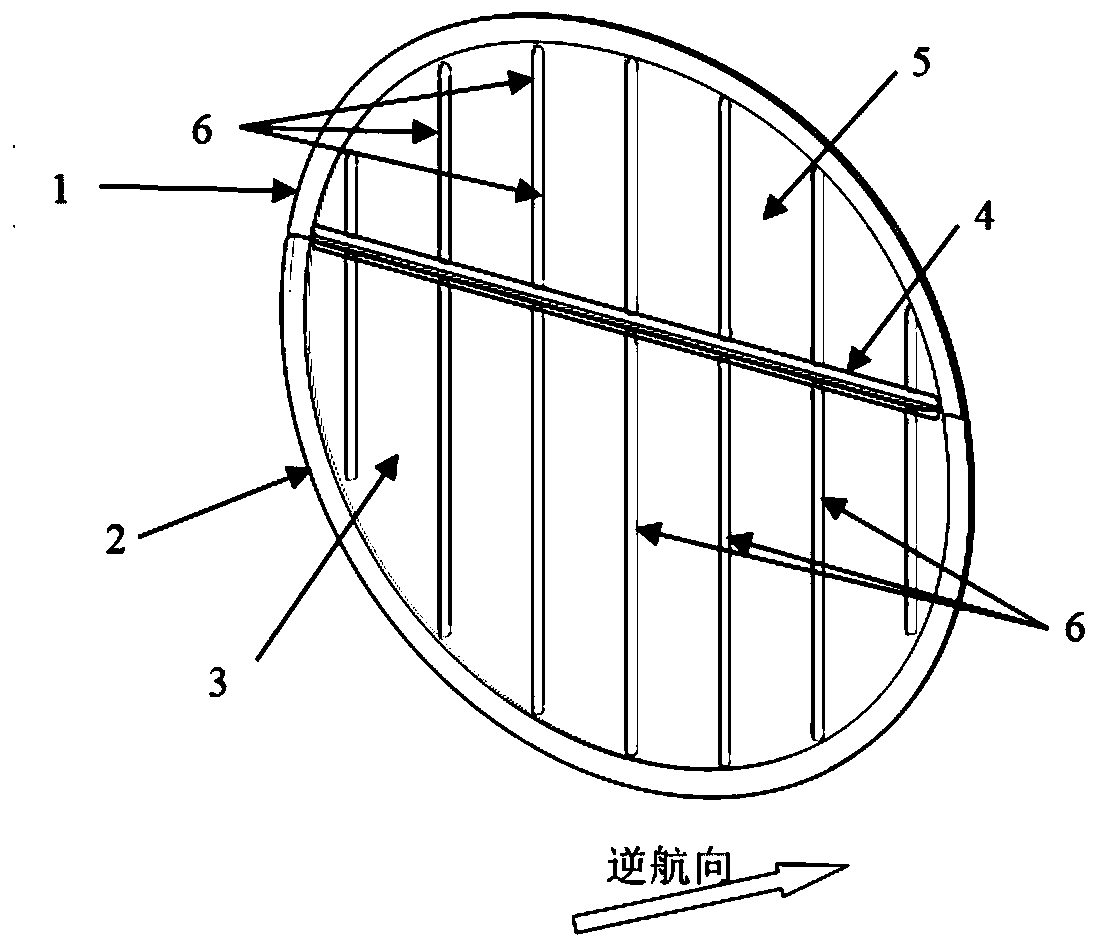

A fixed actuator in a round window niche and its fixing device

ActiveCN109068252BImprove support stiffnessImprove hearing compensation effectHearing aid design aspectsGear wheelEngineering

The invention relates to a fixed actuator in a round window niche, comprising a sleeve, a fixing support device and a telescoping device. The front end of the sleeve is provided with a circumferentialpartition plate and the rear end is provided with a clamping table. The fixing support device comprises an expansion sleeve and a position fixing nut arranged on the outer side of the sleeve, whereinthe position fixing nut is screwed with the sleeve through a screw pair, one end of the expansion sleeve abuts against a partition plate located at the front end of the sleeve, and the other end abuts against the position fixing nut; The telescopic device comprises a position adjusting bolt, a telescopic device and an excitation film arranged on the inside of the sleeve. The invention also relates to a fixing device for the fixed actuator in a round window niche, including a box, a first knob, a second knob, a clamping arm, a tightening wheel, a rotating shaft, feet and a reduction gear set,andbeing used for fixing the actuator at the round window niche of the use object, thereby solving the problems of the existing round window excitation actuator, such as the implantation difficulty, the small support rigidity, the unstable support and the uncontrollable initial pressure, and can be widely applied to the technical field of hearing aid equipment.

Owner:CHINA UNIV OF MINING & TECH

Current measuring box convenient to overhaul

PendingCN114609409ARealize disassembly workEasy to disassembleMeasuring open water movementSpeed/acceleration/shock instrument detailsLocking mechanismControl cell

Owner:YINCHUAN INAUTO AUTOMATION

Wear-resistant plastic floor

PendingCN114635540AFast realization of disassembly workRealize disassembly workFlooringEngineeringLocking plate

The wear-resistant plastic floor comprises a floor body, and a wear-resistant layer is arranged on the upper surface of the floor body; four inserting grooves are vertically formed in the upper surface of the plate body, and four inserting rods used for being inserted into the four inserting grooves are vertically and fixedly installed on the lower surface of the wear-resisting layer. A locking assembly is arranged in the inserting rod, the locking assembly comprises a spring rod and an L-shaped locking plate fixedly installed at one end of the spring rod, and a locking groove used for allowing the locking plate to be inserted therein is formed in one groove wall of the inserting groove; a driving part is arranged in the inserting rod and used for providing driving force for the locking plate to move. A user can quickly realize the disassembly and assembly work between the wear-resistant layer and the plate body through the matching between the locking assembly and the driving part, heating and bonding are not needed, the operation is convenient and quick, and the flatness of the wear-resistant layer after replacement can be ensured.

Owner:河南省皮革塑料研究所有限公司

High-energy ion air purification equipment matched with municipal facilities

InactiveCN114526528ARealize disassembly workAchieve disassemblyHuman health protectionMechanical apparatusAir purificationIndustrial engineering

The invention relates to the technical field of purification equipment, and discloses high-energy ion air purification equipment matched with municipal facilities, the high-energy ion air purification equipment comprises a purifier shell, an air inlet and an air outlet, and a motor is started to rotate clockwise to drive a third filter plate, a second filter plate and a first filter plate to rotate to the air outlet; an arc-shaped ejector rod enables an arc-shaped composite rod to be separated from a U-shaped magnet block, and a third filter plate, a second filter plate and a first filter plate are loosened, so that the filter plates needing to be replaced or cleaned can be manually taken out through an air outlet, all the filter plates do not need to be disassembled and taken out, the disassembly is convenient, and the efficiency is high. The rotating direction of the motor is manually changed to enable the motor to rotate anticlockwise, the arc-shaped composite rod and the U-shaped magnet block are fixed through adsorption force when making contact, then the filter plate is installed, manual disassembly is not needed in the whole process, the operation difficulty is lowered, the disassembly and installation speed is increased, and then the replacement speed is increased.

Owner:SHANGHAI JINGRUI ENVIRONMENT PROTECTION ENG CO LTD

A disassembly device with buckle structure

ActiveCN104481991BRealize disassembly workStructure labor savingSheet joiningEngineeringMechanical engineering

Owner:MARELLI AUTOMOBILE ELECTRONIS GUANGZHOU CO LTD

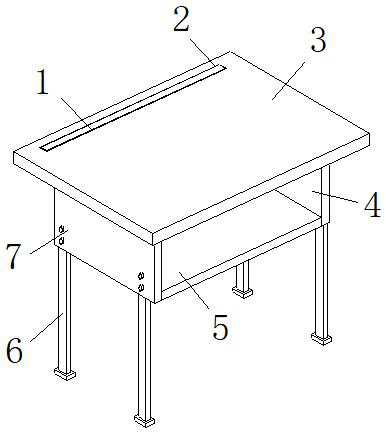

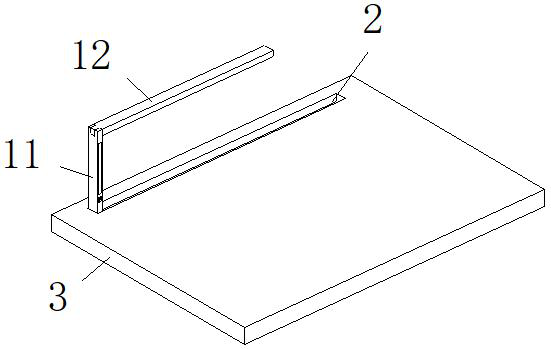

Multifunctional combined desk

PendingCN111685486AGuarantee normal useEasy to assemble and disassembleDomestic lightingLighting elementsStructural engineeringDesk

The invention discloses a multifunctional combined desk which comprises a desk plate, a containing groove is formed in one side of the desk plate, an illuminating lamp assembly is arranged in the containing groove, a right side plate is arranged on one side of the lower portion of the desk plate, a left side plate is arranged on the other side of the lower portion of the desk plate, and a bottom plate is arranged at the bottom between the right side plate and the left side plate; the desk is composed of a desk plate, a left side plate, a right side plate, a protection plate, a bottom plate andsupporting legs. During mounting, the left side plate and the right side plate are fixedly connected with the table plate through first limiting bolts; the protection plate and the bottom plate are fixedly connected with the left side plate and the right side plate through the limiting grooves and the limiting blocks, the left side plate and the right side plate are fixedly connected with the supporting legs through the second limiting bolts, normal use of the combined desk can be guaranteed through the installation mode, later assembly and disassembly can be facilitated, and the combined desk has market competitiveness.

Owner:SIAS INTERNATIONAL UNIVERSITY

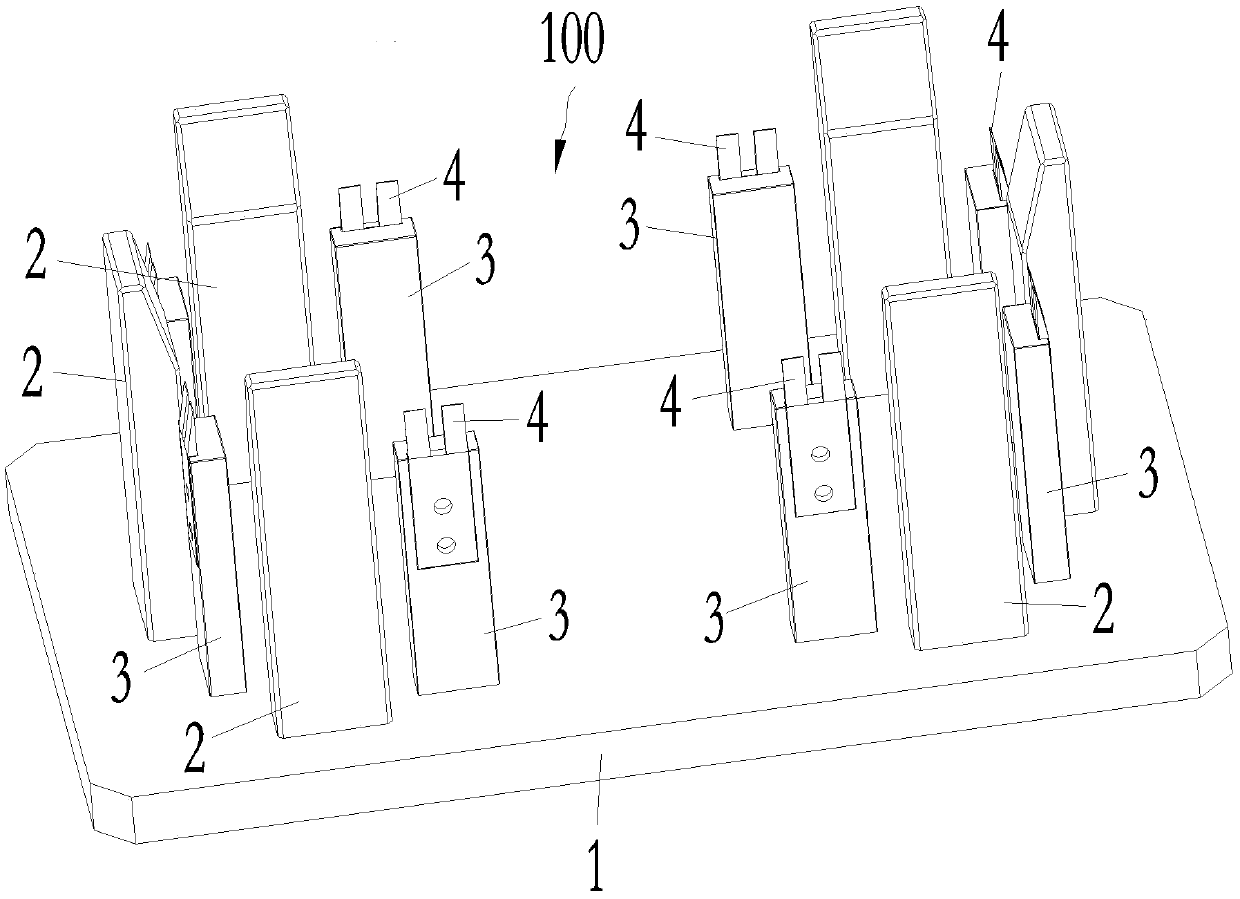

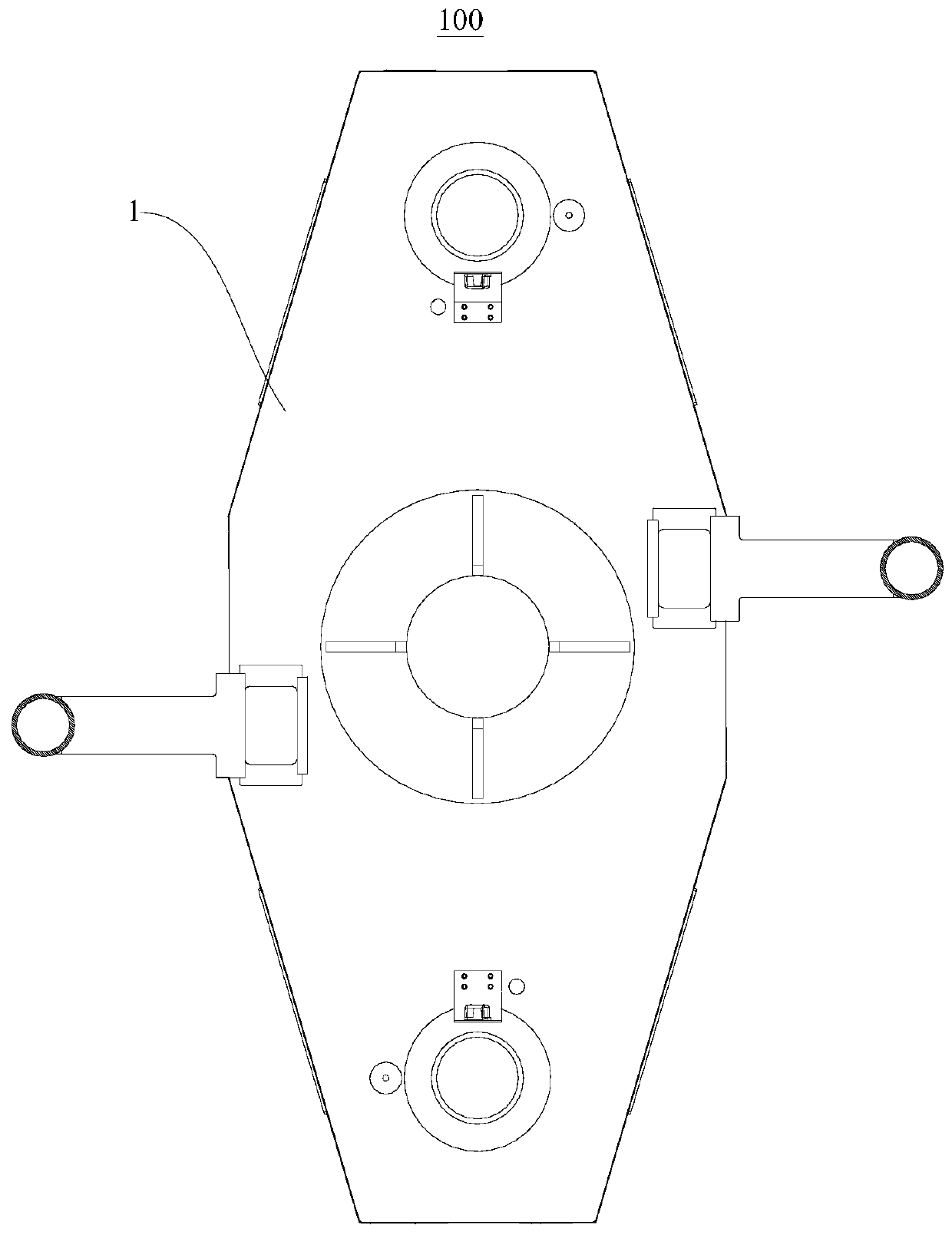

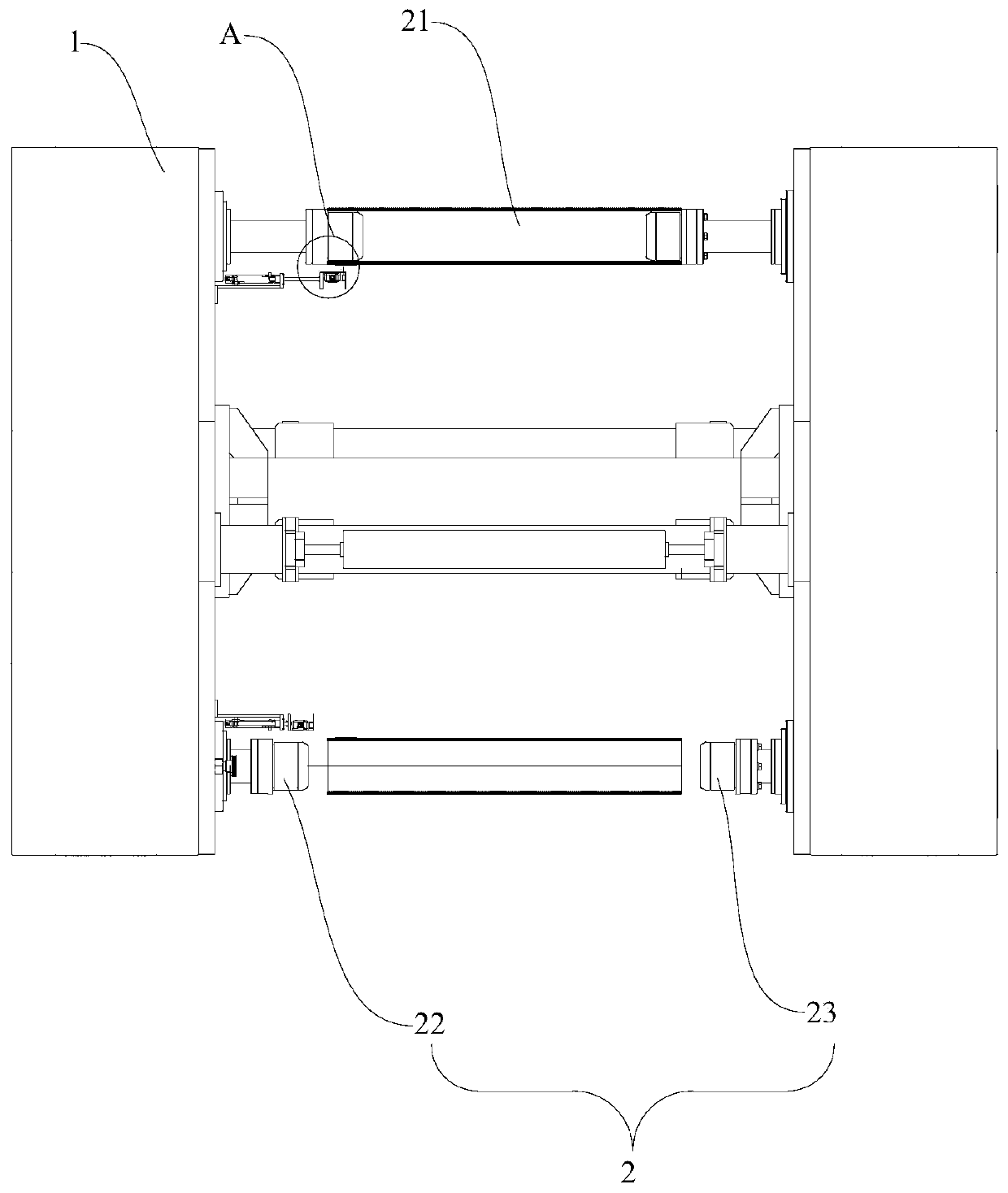

Battery pole piece winding and unwinding structure

The invention discloses a battery pole piece winding and unwinding structure. The structure comprises a rack; a mounting chuck is arranged on the rack and is suitable for fixing a winding and unwinding winding drum, the mounting chuck can move upwards in the mounting axial direction of the winding and unwinding winding drum relative to the rack, and a data storage label is arranged on the windingand unwinding winding drum; and a data reader-writer is arranged on the rack and is suitable for performing data reading and writing on a data storage label. According to the battery pole piece winding and unwinding structure disclosed by the embodiment of the invention, the winding and unwinding winding drum can be quickly fixed and disassembled through the mounting chuck, so that the automationdegree of the battery pole piece winding and unwinding structure can be improved, the winding and unwinding winding drum can be automatically fixed and disassembled, the labor consumption is reduced,and the working efficiency is improved. The data reader-writer can read and write the data of the data storage label, can accelerate the reading, writing and transmission of information on the data storage label of the winding and unwinding reel part, enables the whole device to be automatic and informational, and improves the work efficiency.

Owner:昆山聚创新能源科技有限公司

RFID antenna device

ActiveCN111029716ARealize disassembly workRealize the installation workAntenna supports/mountingsRadiating element housingsTelecommunicationsEmbedded system

The invention discloses an RFID antenna device in the technical field of antenna installation. The RFID antenna device comprises an RFID antenna body and an antenna storage box, and an inner side wallof the antenna storage box is provided with a storage groove for the RFID antenna body. A stretching connection mechanism used for pulling the RFID antenna body out of an outer side of the storage groove and an adjusting mechanism used for enabling the RFID antenna body to rotate up and down are connected between an inner side wall of the storage groove and one side of the RFID antenna body. According to the invention, an RFID antenna can be dismounted and mounted conveniently, and the signal coverage range of the RFID antenna can be adjusted by pulling out the RFID antenna and adjusting therotation angle when the RFID antenna works.

Owner:重庆壹城桥慧科技有限公司

A textile winding device

InactiveCN108002134BWork fasterRealize the installation workFilament handlingBobbinAutomatic control

The invention discloses a spinning wire winding device. The spinning wire winding device comprises a machine body, and guide wheels arranged on the right side of the machine body and symmetrically arranged in an up-and-down mode; a boss part is arranged at the bottom of the right side end surface of the machine body; a wire winding mechanism is arranged above the boss part; the wire winding mechanism comprises a baseplate extending left and right, a connecting block fixed on the back side of the right side of the baseplate, a straight plate fixed at the back side end of the connecting block and upwards extending, and a wire winding base arranged above the baseplate; a first rotating shaft is fixedly arranged at the bottom of the wire winding base; the bottom of the first rotating shaft penetrates through the baseplate for rotary cooperating connection; an outer spline shaft downwards extending is fixedly arranged at the bottom of the first rotating shaft; a single key shaft is fixedlyarranged at the top of the wire winding base; a first transmission cavity is formed in the boss part; and an inner spline rotating shaft extending to the upper and lower sides is in rotary cooperatingconnection into the inner top wall of the first transmission cavity. The spinning wire winding device is simple in structure, realizes automatic control of up-down movable wire winding work, improvesthe wire winding uniformity, realizes quick disassembly of bobbins, and improves the wire winding stability.

Owner:扬州市青山环保科技有限公司

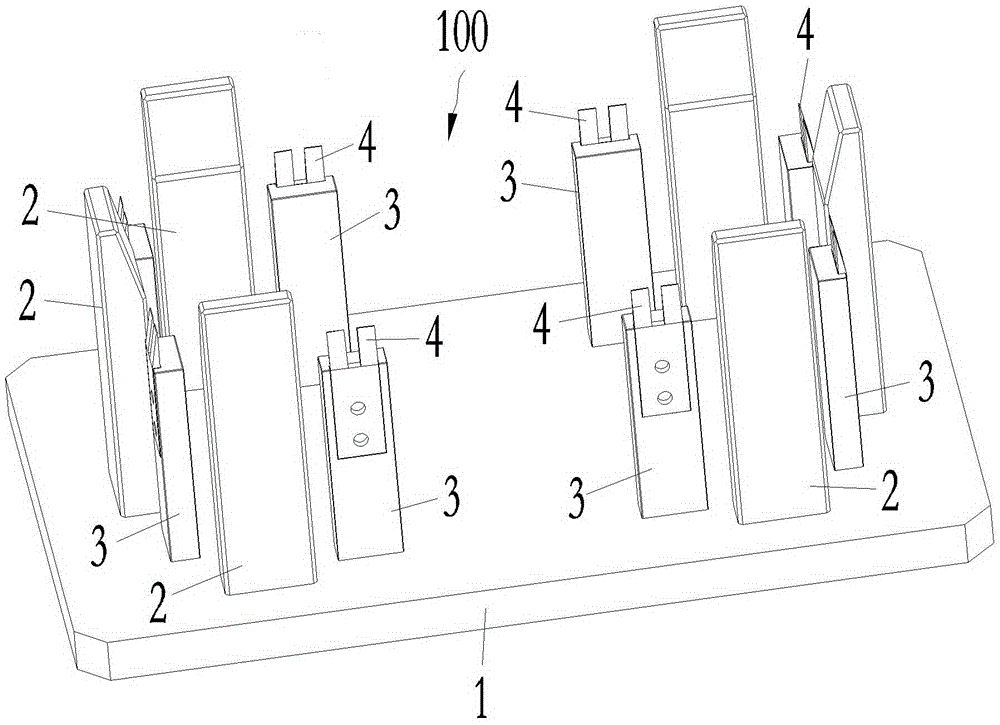

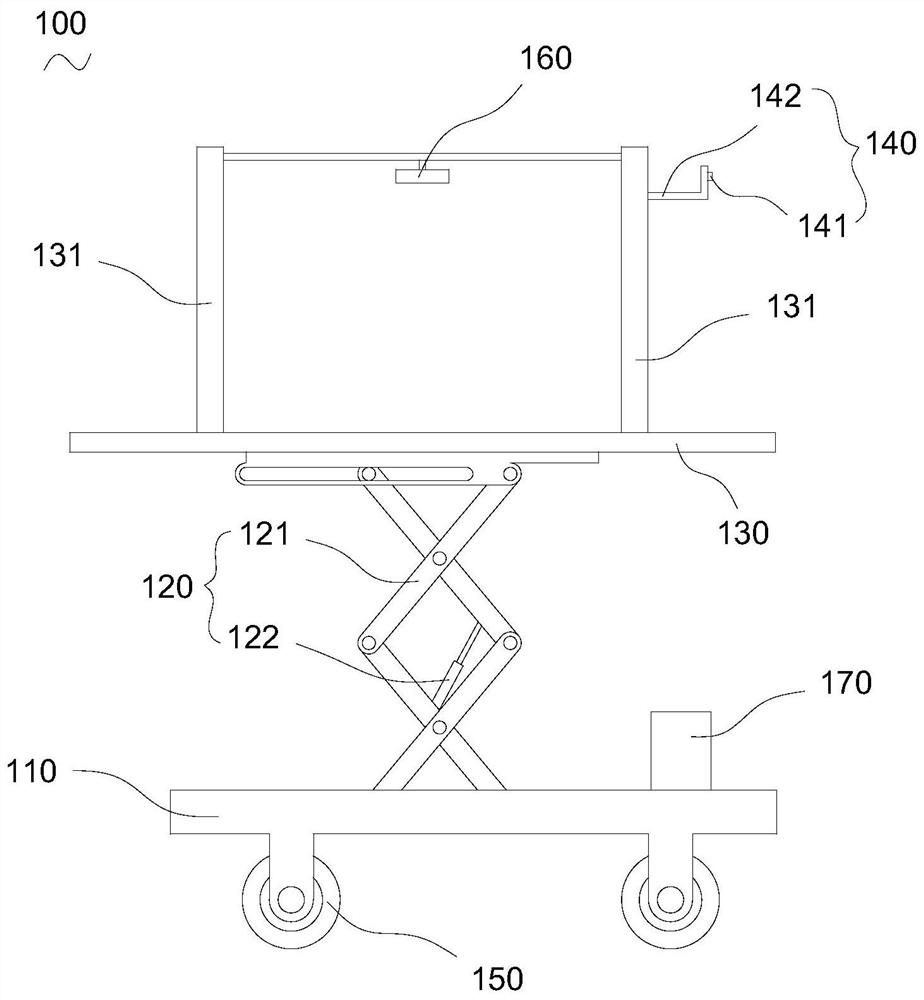

Disassembling and assembling tool for clamping jaw of loading and unloading machine

ActiveCN112938745ARealize disassembly workShorten working timeLifting framesLoad-engaging elementsStructural engineeringMachine

The invention discloses an disassembling and assembling tool for a clamping jaw of a loading and unloading machine. The disassembling and assembling tool comprises a lifting appliance and a base, wherein the lifting appliance is detachably connected to the upper portion of the clamping jaw of the loading and unloading machine and used for lifting the clamping jaw of the loading and unloading machine, and the base is detachably installed on the lower portion of the clamping jaw of the loading and unloading machine and used for bearing the clamping jaw of the loading and unloading machine. The base comprises a base body and a lifting mechanism, wherein the base body is detachably connected with the clamping jaw of the loading and unloading machine and used for bearing the clamping jaw of the loading and unloading machine, and the lifting mechanism is connected with the base body to drive the base body to ascend and descend so as to adjust the position of the clamping jaw of the loading and unloading machine. The disassembling and assembling tool for the clamping jaw of the loading and unloading machine can quickly and safely realize the disassembling and assembling work of the clamping jaw of the loading and unloading machine, reduce the working time of personnel and reduce the exposure dose of the personnel.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +2

Mold base automatic disassembly equipment

ActiveCN109262547BRealize the installation workRealize disassembly workWork benchesMetal working apparatusStructural engineeringMachine

The invention relates to a formwork automatic disassembly and assembly device. The device comprises a base, a lifting assembly, a working platform, a rotating assembly and a cutting machine. One end of the lifting assembly is disposed on the surface of the base. The working platform is disposed at one end of the lifting assembly away from the base, and the lifting assembly can drive the working platform to move up and down in a direction perpendicular to the surface of the base. The rotating assembly includes a rotator. The rotator is rotatably mounted on the working platform. The rotator candrive a fixing nut to rotate forward or reversely. The cutting machine is rotatably mounted on the working platform. The cutting machine is used for cutting a fixing screw. Therefore, when a formworkneeds to be assembled or disassembled, the formwork automatic disassembly and assembly device can be moved to a designated working area to achieve vertical transportation and automatic disassembly andassembly of the formwork. The input of an operator during disassembly and assembly of the formwork is reduced, and the formwork is more convenient and quick to assemble and disassemble.

Owner:湖南易兴建筑有限公司

Pouring-size-adjustable modular pouring formwork for concrete plate manufacturing

InactiveCN113681691AGood versatilityRealize disassembly workMouldsWall plateArchitectural engineering

Owner:汪开锁

A rotary mixer for biowaste recycling

ActiveCN107626565BRealize disassembly workEasy to assemble and disassembleSievingScreeningEngineeringBiological waste

The invention discloses a rotary mixer for recycling biological waste, which comprises a mixer cylinder body and a mixer cylinder cover located above the mixer cylinder body, a feeding funnel is fixedly installed on the top end of the mixer cylinder cover, and The feed funnel communicates with the inside of the mixer cover, the first fixing block is welded on both sides of the mixer barrel, the second fixing block is welded on both sides of the mixer cover, and the first fixing block is provided for connecting The mixer cylinder and the first fixing module of the mixer cylinder cover, the bottom end of the mixer cylinder is welded with feet, and the bottom end of the mixer cylinder is fixedly installed with a discharge funnel. The invention is simple in structure, easy to use, adds a filtering device to the rotary mixer, and better protects the mixer equipment. At the same time, the filter box is easy to disassemble, which is beneficial to cleaning and maintenance, increases the service life of the equipment, and is simple to operate and improves work efficiency.

Owner:徐州淘沙生态农业有限公司

Removable Crown Implants

The invention provides a detachable dental crown implant. The detachable dental crown implant comprises a spiral implant, detachable barb assemblies and tensioning mechanisms, wherein the spiral implant is in a different-diameter column-shaped body structure and comprises a lower part spiral body with a greater diameter and an upper part spiral body with a smaller diameter; the bottom of the lower part spiral body is provided with a thread section for planting a tooth root; the top of the upper part spiral body is provided with a thread section for screwing a dental crown. Two sets of the detachable barb assemblies are symmetrically arranged at the two sides of the spiral implant. The two tensioning mechanisms correspond to the two sets of the detachable barb assemblies and are respectively mounted on the upper part spiral body to be respectively collided and connected with the two sets of the detachable barb assemblies. According to the detachable dental crown implant disclosed by the invention, in a planting process, only the dental crown is half screwed in to have the reinforcing and anti-falling effects. In a detaching process, only designed detaching pliers need to be used and a connection body of a detachable barb is forcedly and upwardly pulled so that a barb can be released from a clamping groove in the dental crown; therefore, the dental crown can be very easily released from the implant. The detachable dental crown implant is convenient to use and simple to operate.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

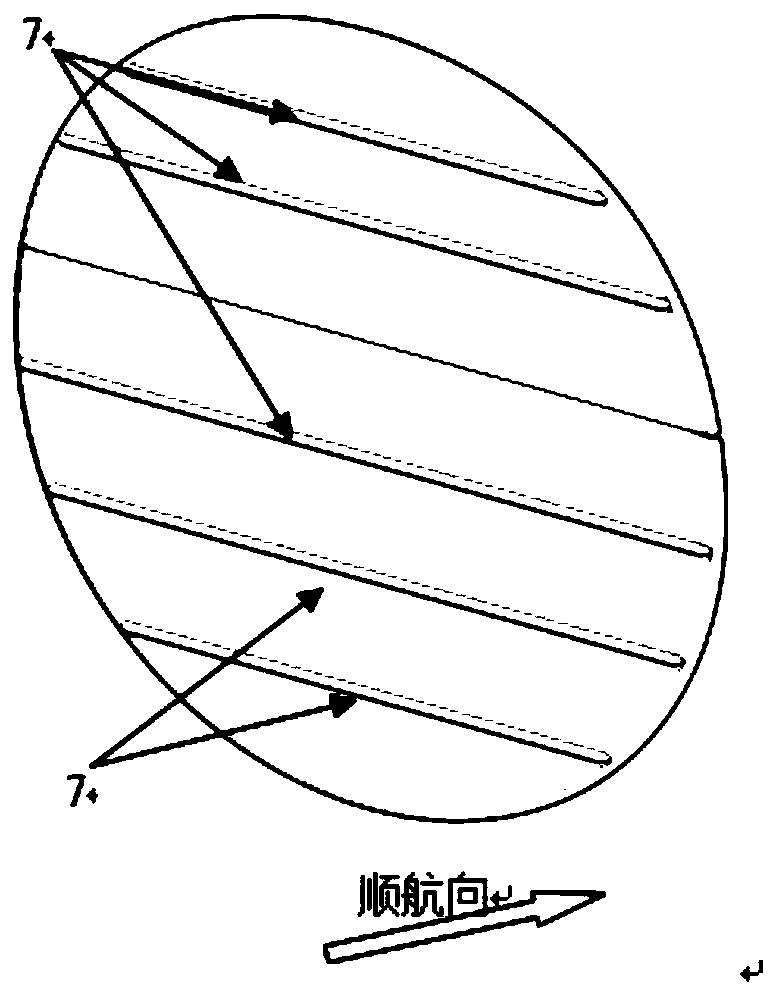

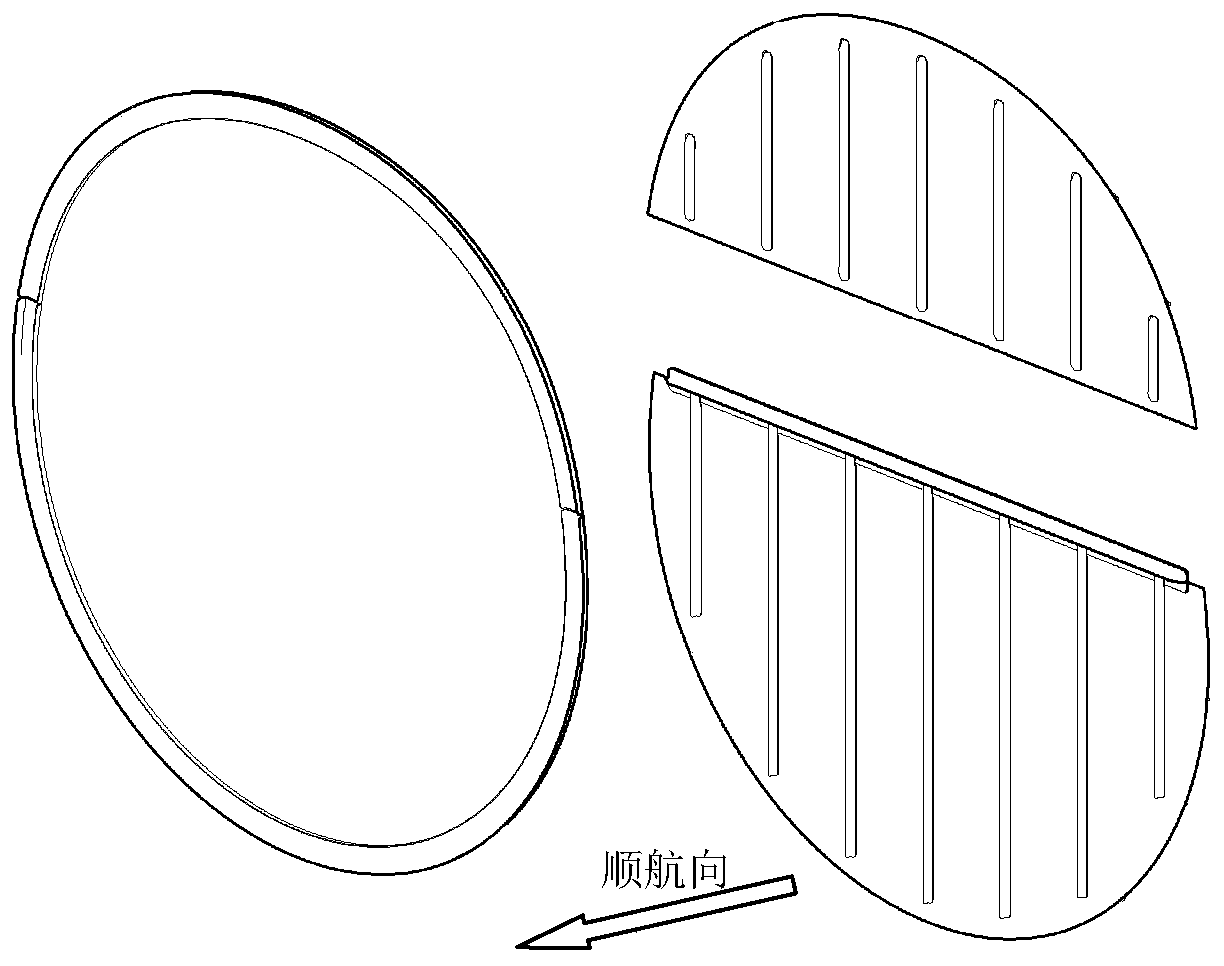

Compact passenger plane detachable firewall and usage method thereof

PendingCN110920858ARealize disassembly workEasy to disassembleFuselage insulationWeight reductionEngineeringAirframe

The invention relates to a firewall structure on an airplane, in particular to a compact passenger plane detachable firewall structure which comprises an upper half frame connected with an airplane body and a lower half frame connected with the airplane body. The upper half frame and the lower half frame are respectively connected with the airliner body through permanent fasteners; the detachablelower firewall panel is connected with the lower half frame through a detachable fastener; the detachable upper firewall panel is connected with the upper half frame through a detachable fastener; thedetachable upper firewall panel and the detachable lower firewall panel are detachably connected with the two sides of the firewall butt joint assembly respectively. The device is easy to disassemble, the maintenance time is shortened, and the maintenance cost is reduced.

Owner:AVIC SAC COMML AIRCRAFT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com