Patents

Literature

43results about How to "Reduce the difficulty of dismantling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

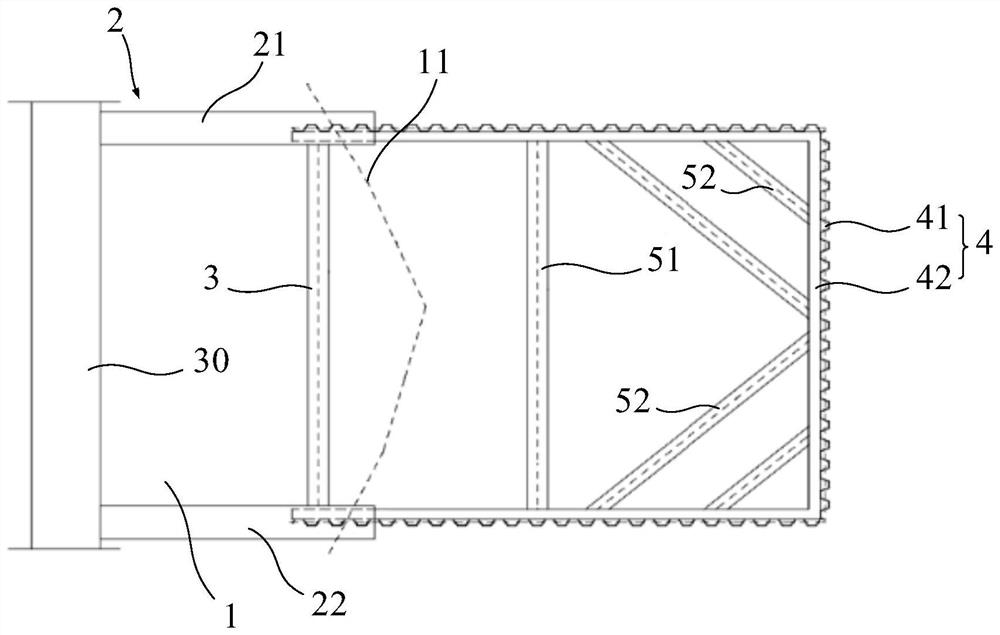

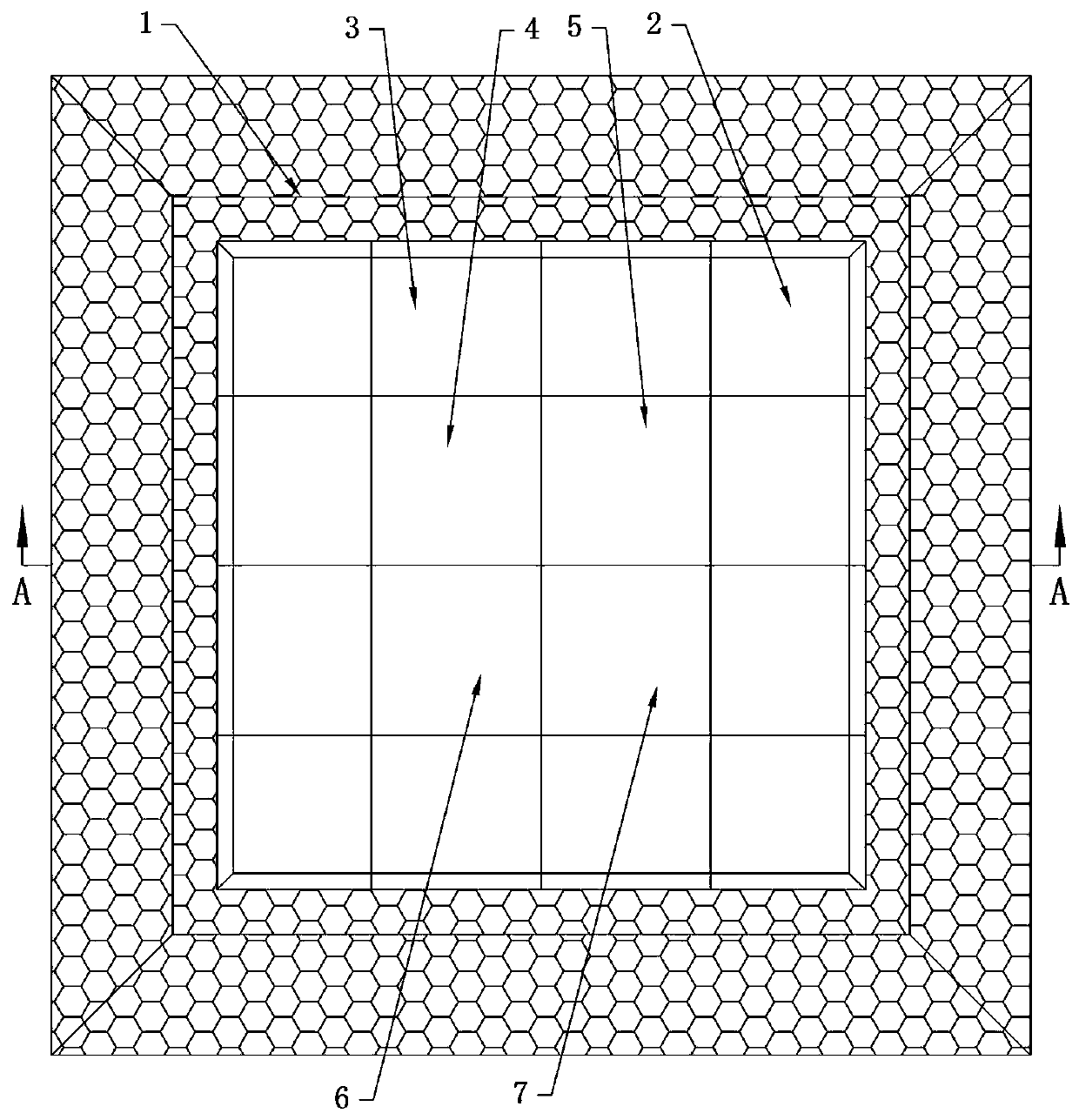

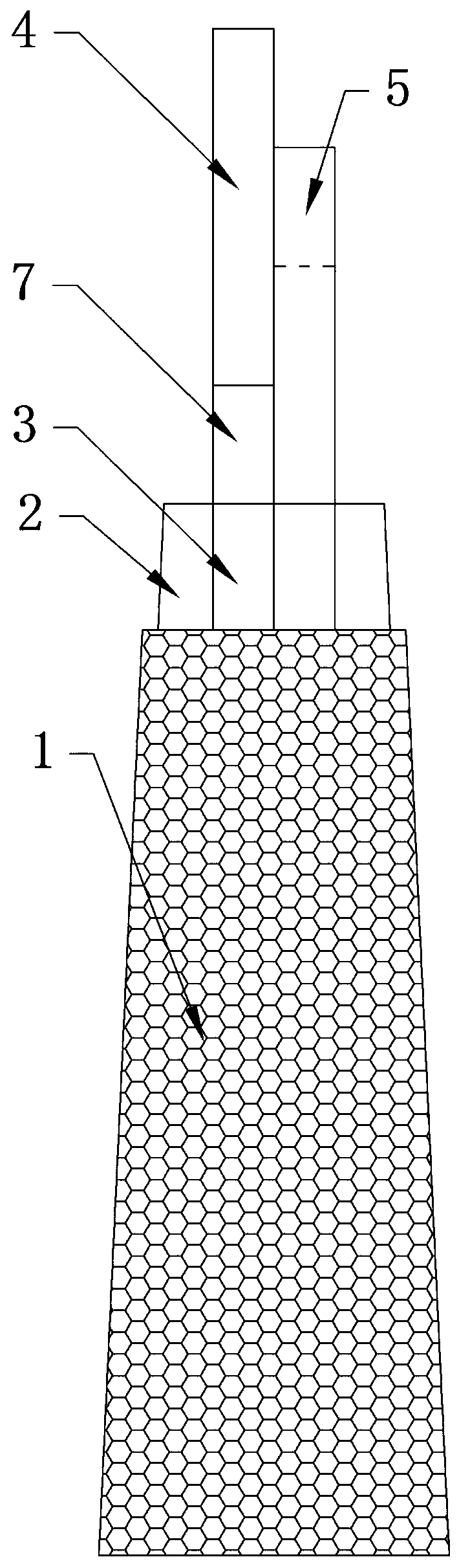

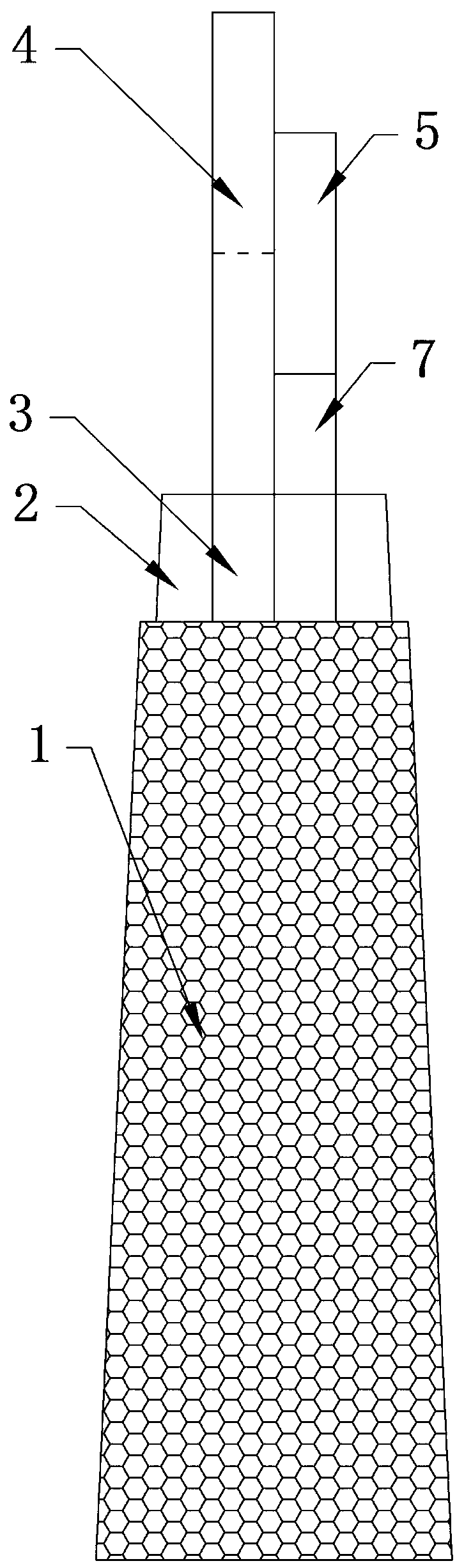

Supporting module for fused deposition modeling three-dimensional printing and generating method of supporting module

InactiveCN105058798AReduce the difficulty of dismantlingReduce spacingAdditive manufacturing apparatusFixation pointComputer module

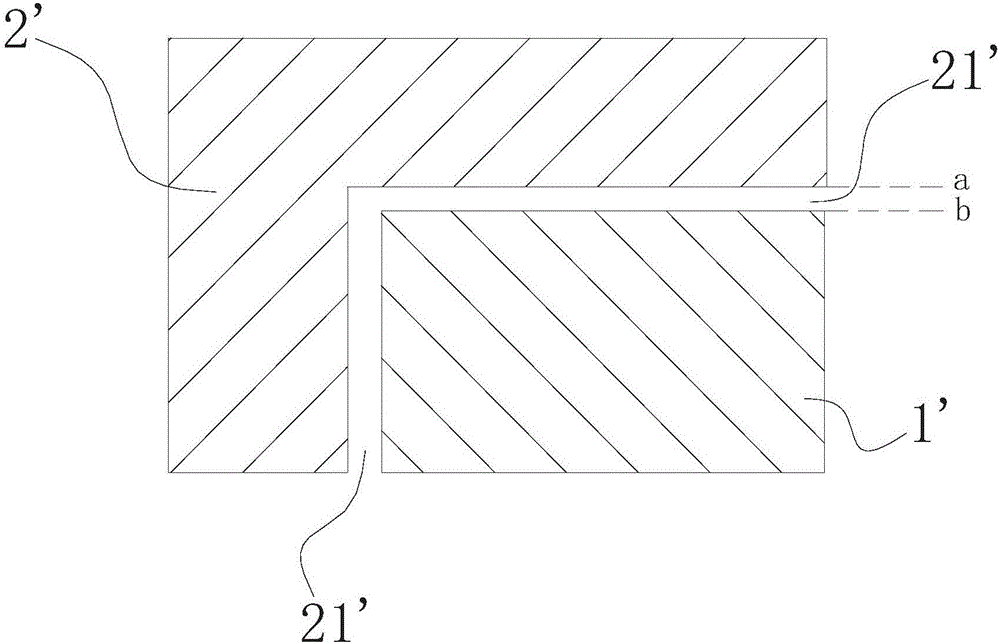

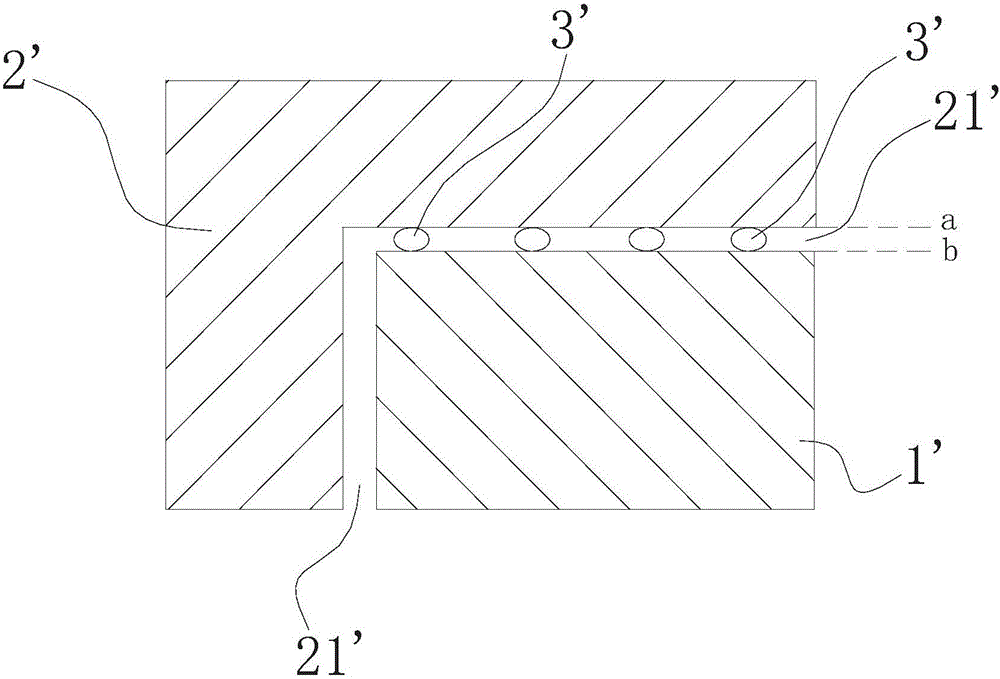

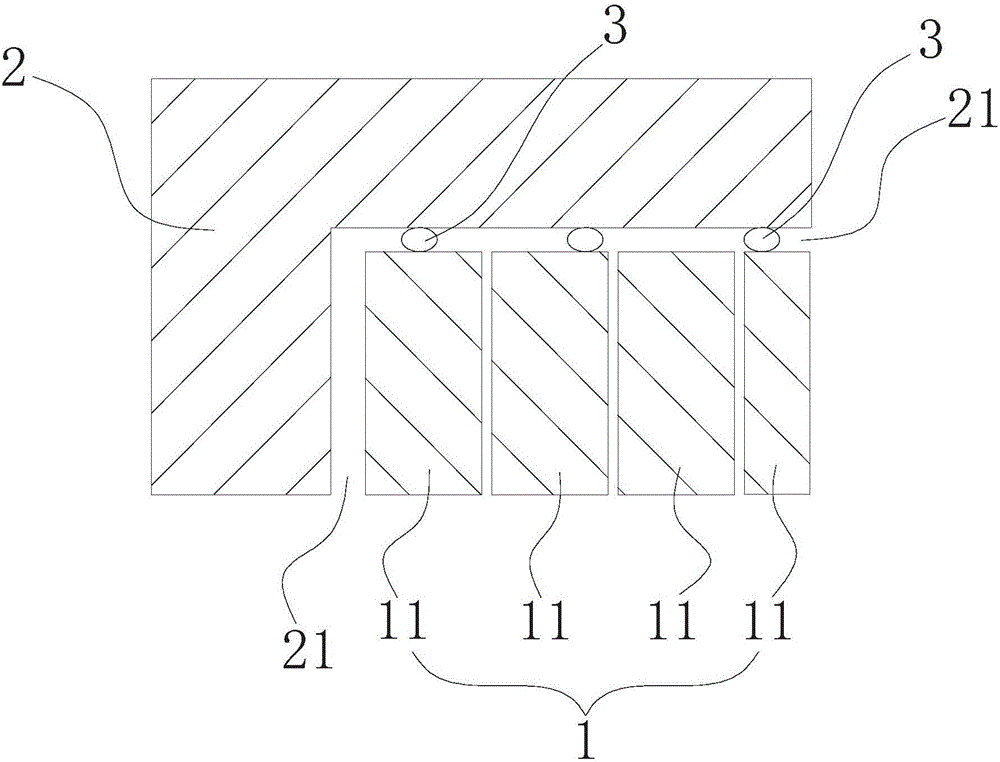

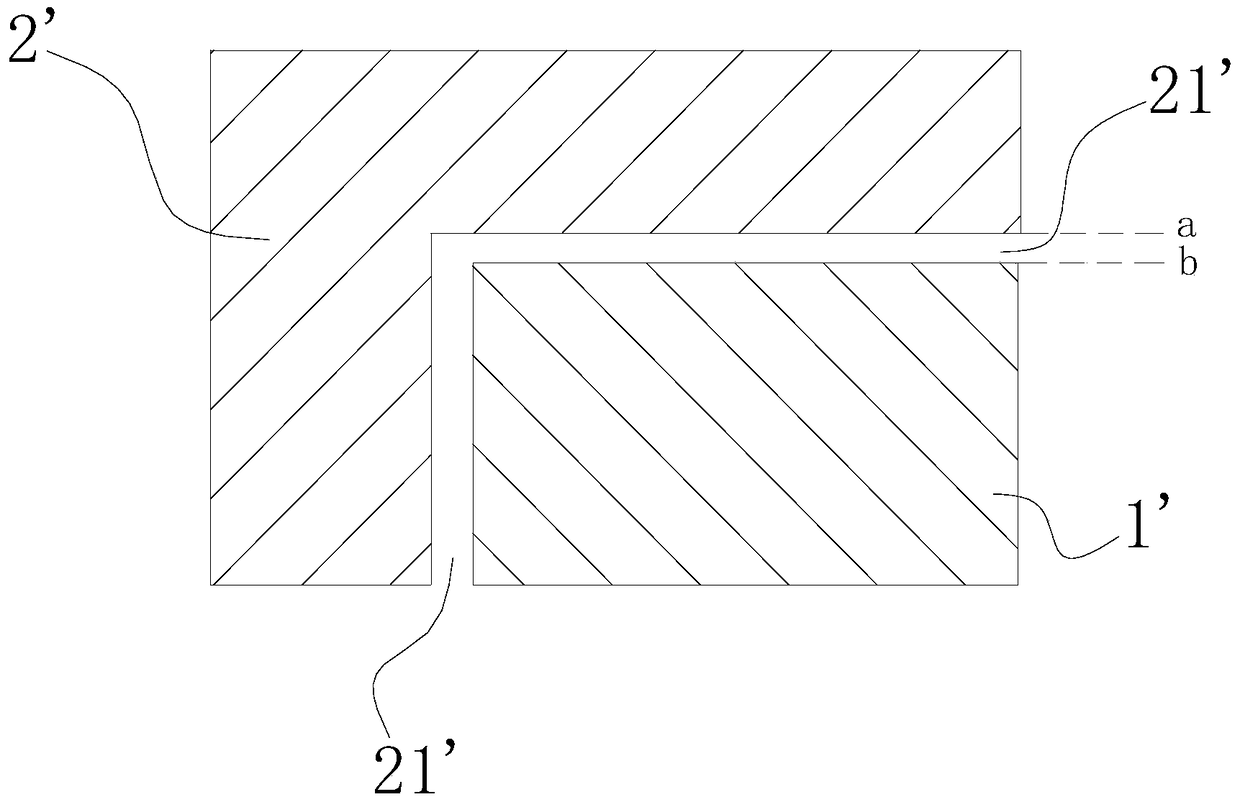

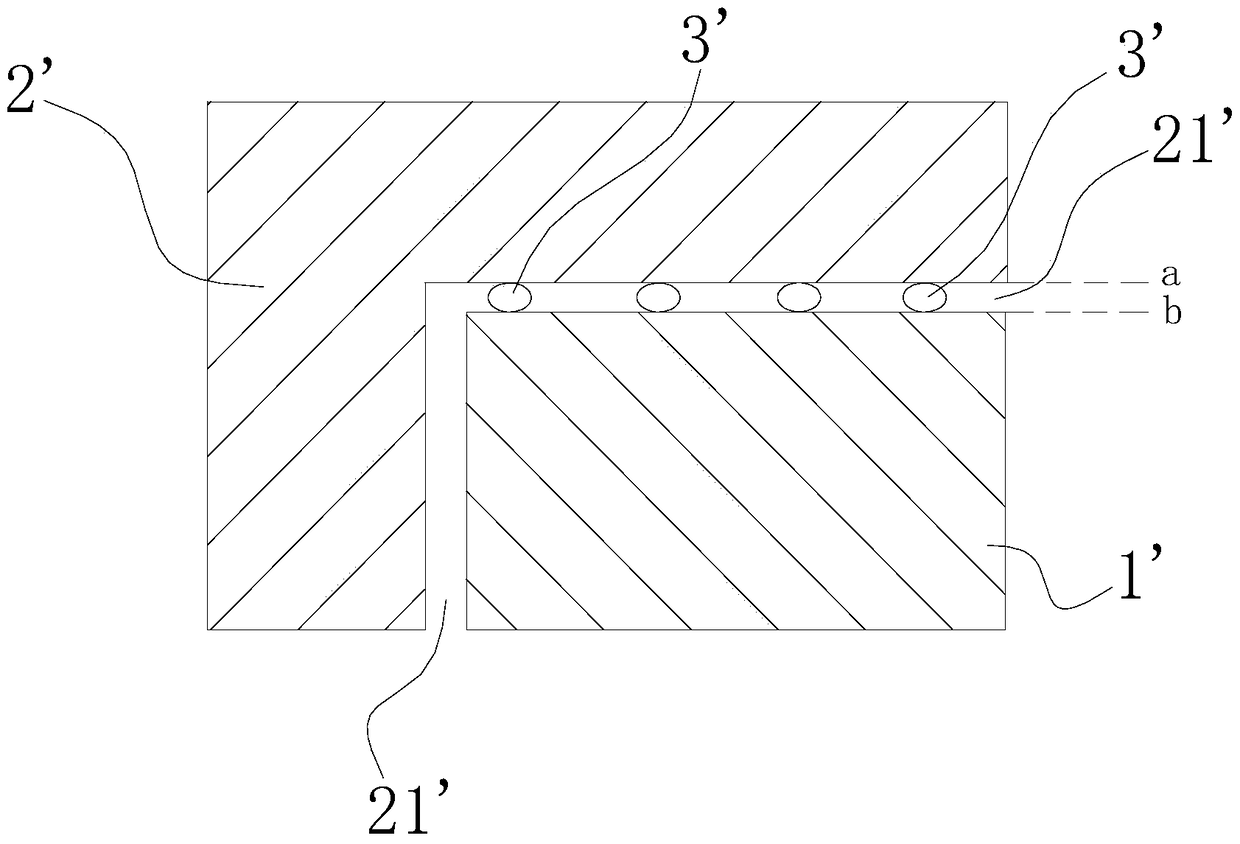

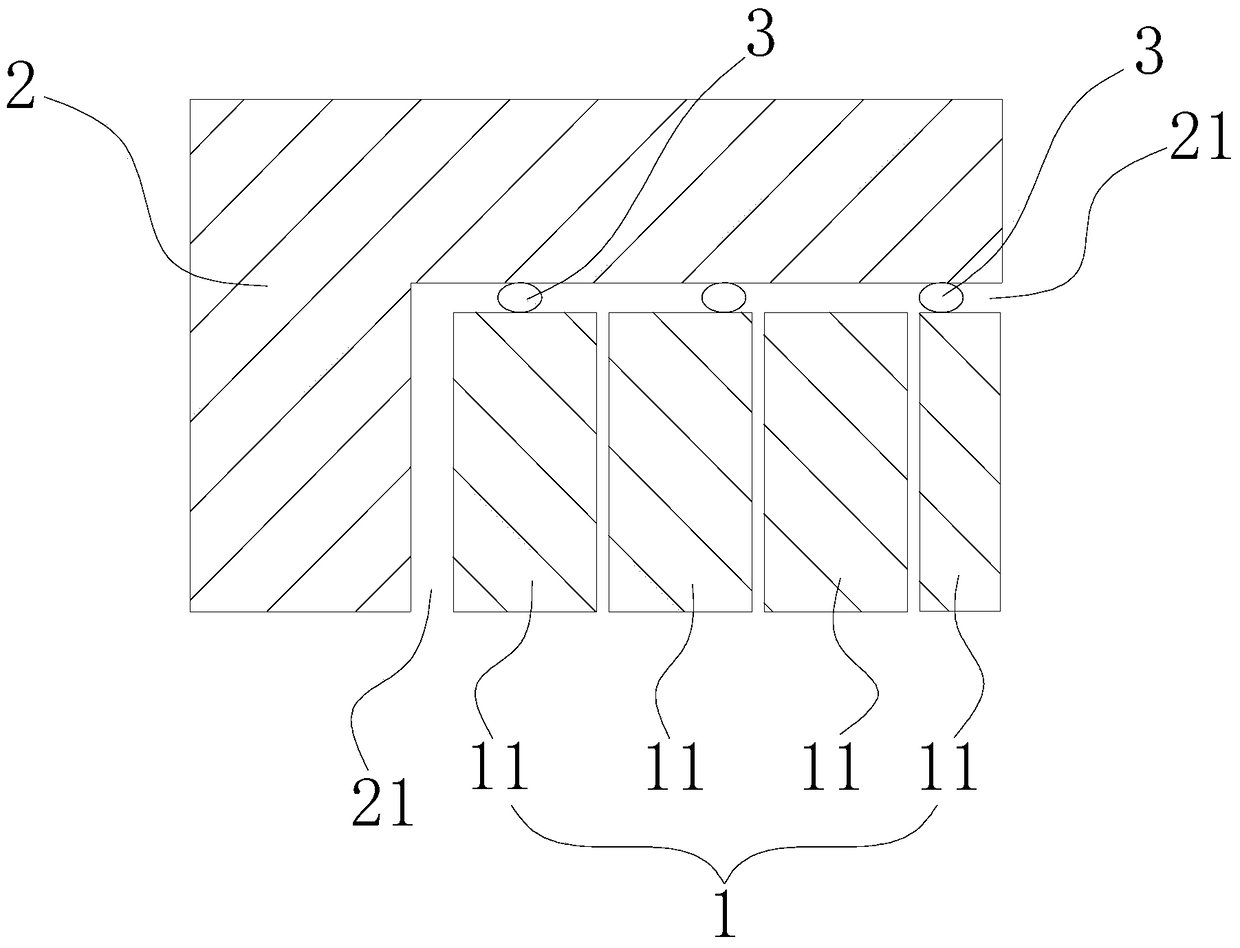

The invention discloses a supporting module for fused deposition modeling three-dimensional printing and a generating method of the supporting module. The supporting module is used for supporting the suspended portion of a model needing three-dimensional printing. The supporting module comprises multiple supporting units arranged at intervals to provide multiple fixation points for the suspended portion. Compared with an original supporting module, the supporting module can be more easily removed from the suspended portion of the model while the supporting performance is kept.

Owner:PANOWIN TECH

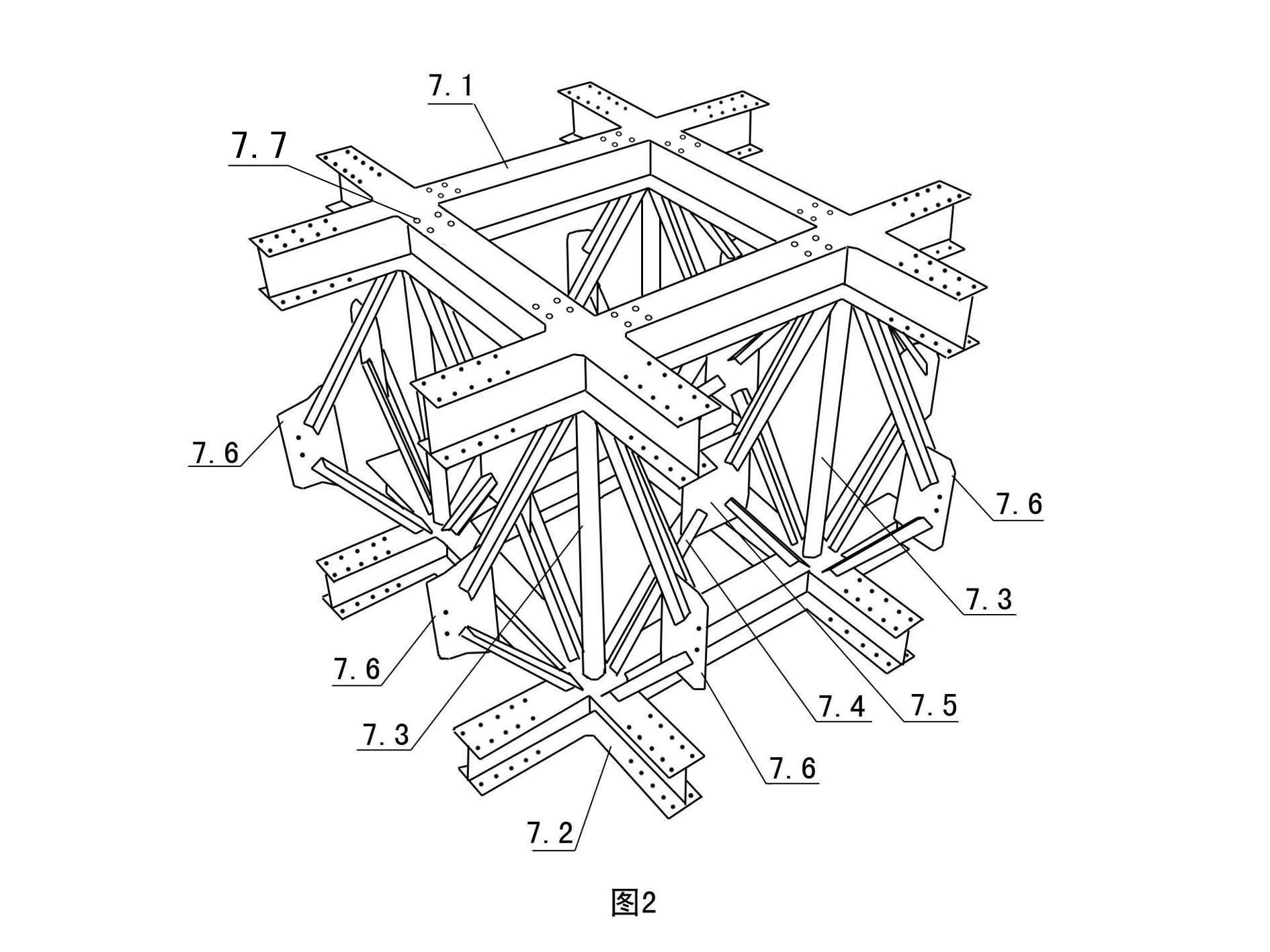

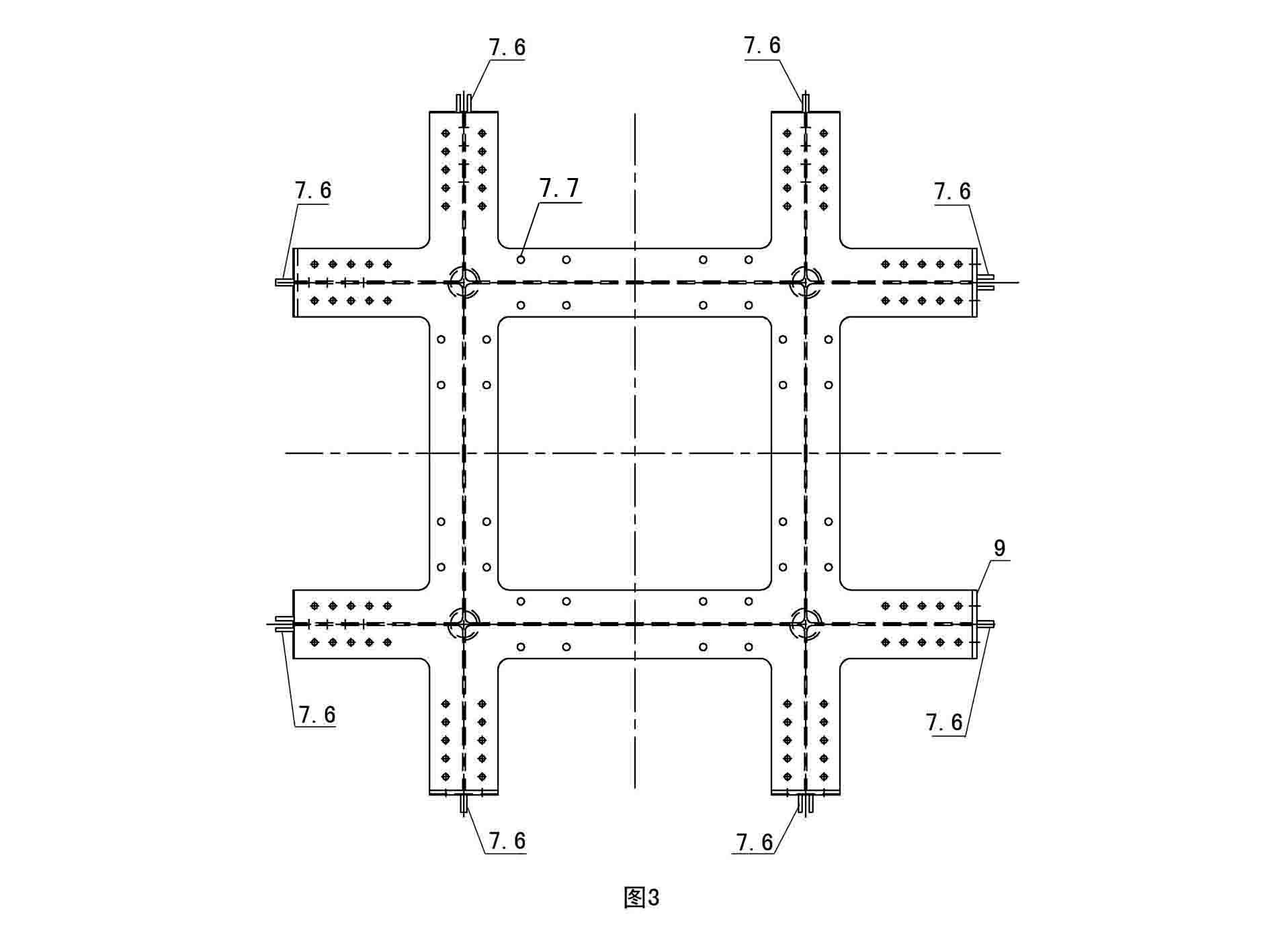

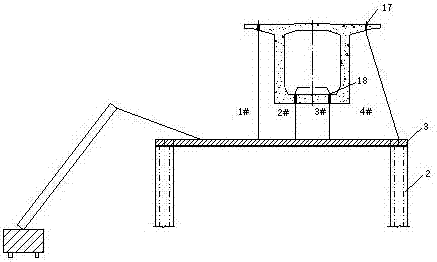

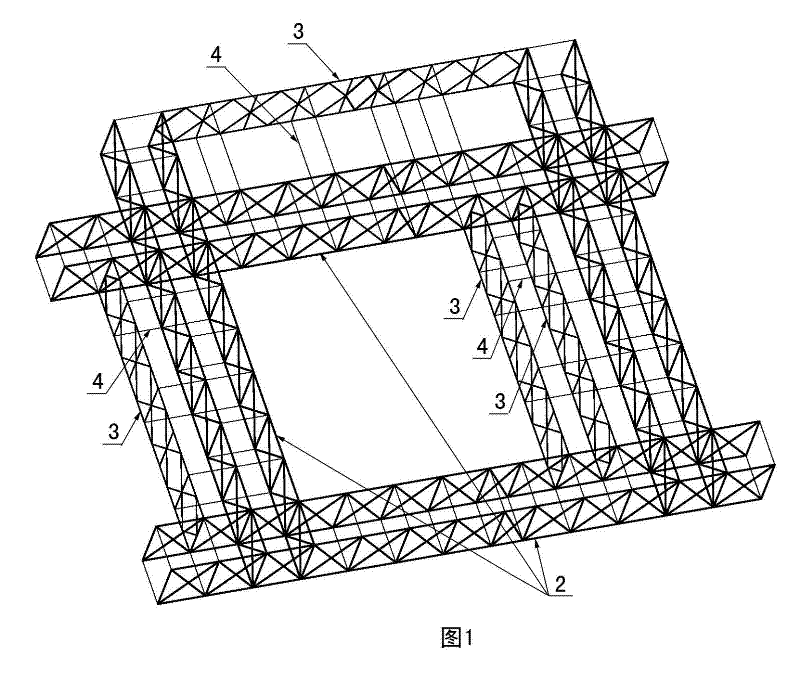

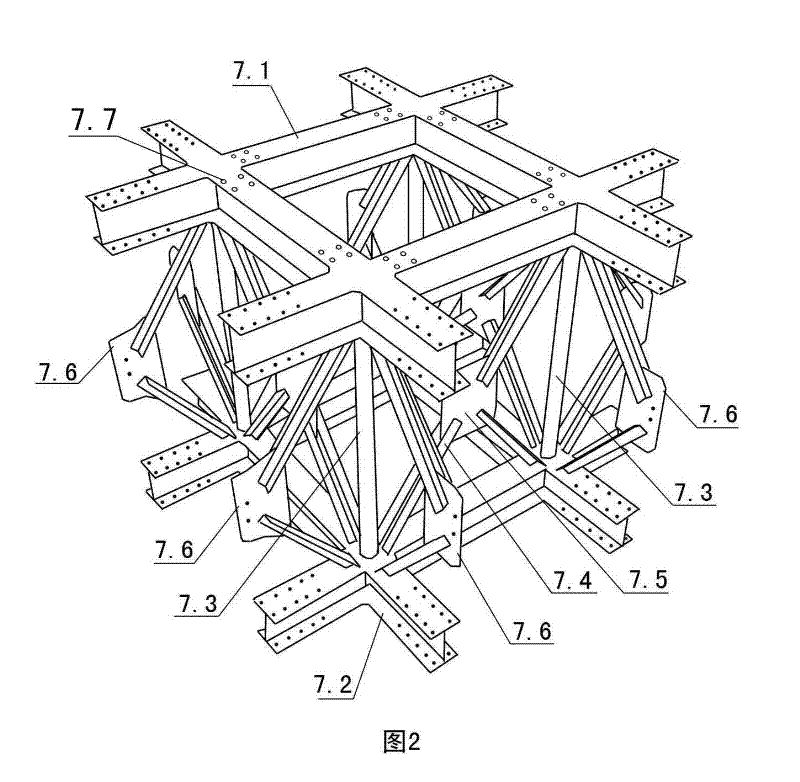

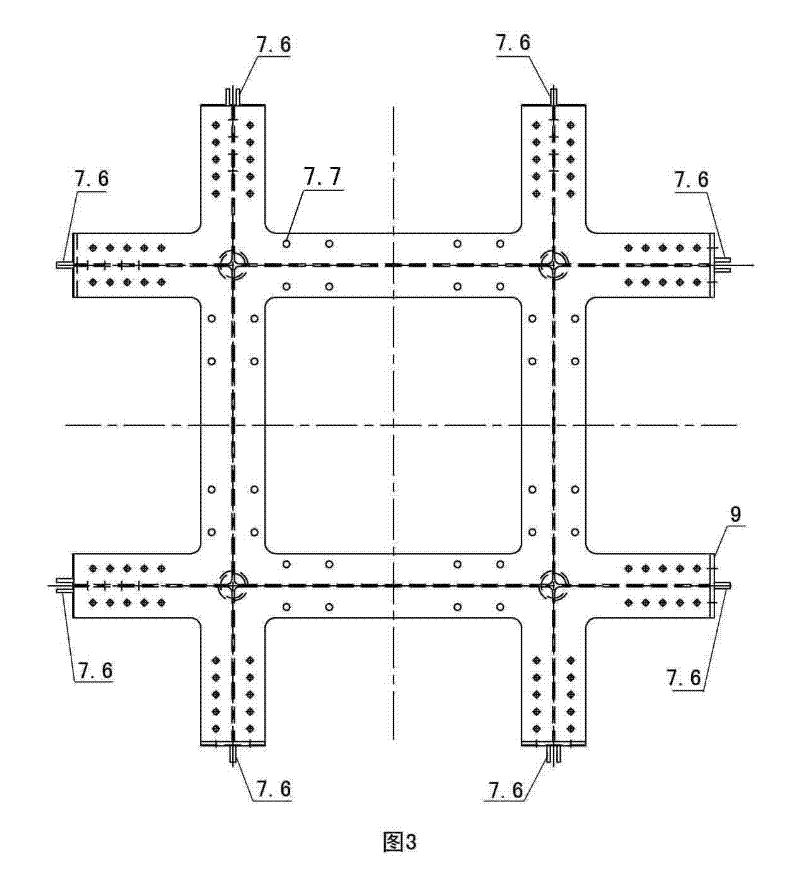

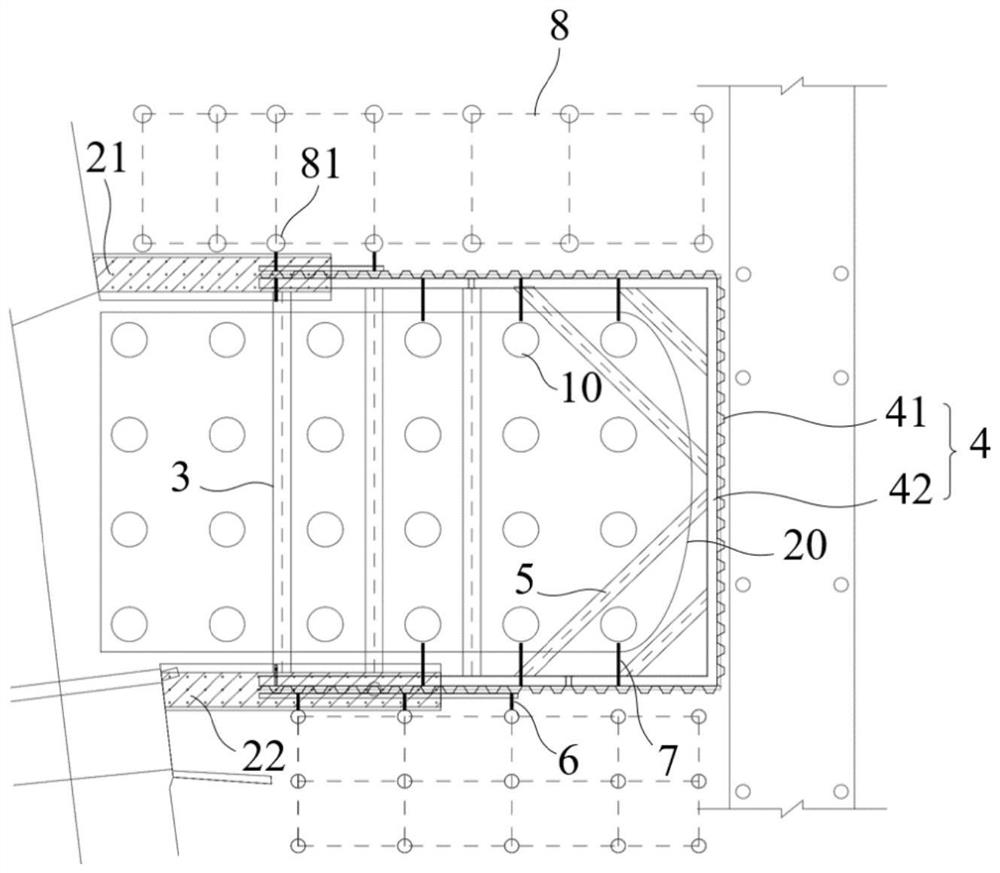

Assembly type variable steel girder platform, distribution method and assembly method thereof

ActiveCN101824905AEasy to set upSpeed up the construction periodBuilding support scaffoldsWork periodDistribution method

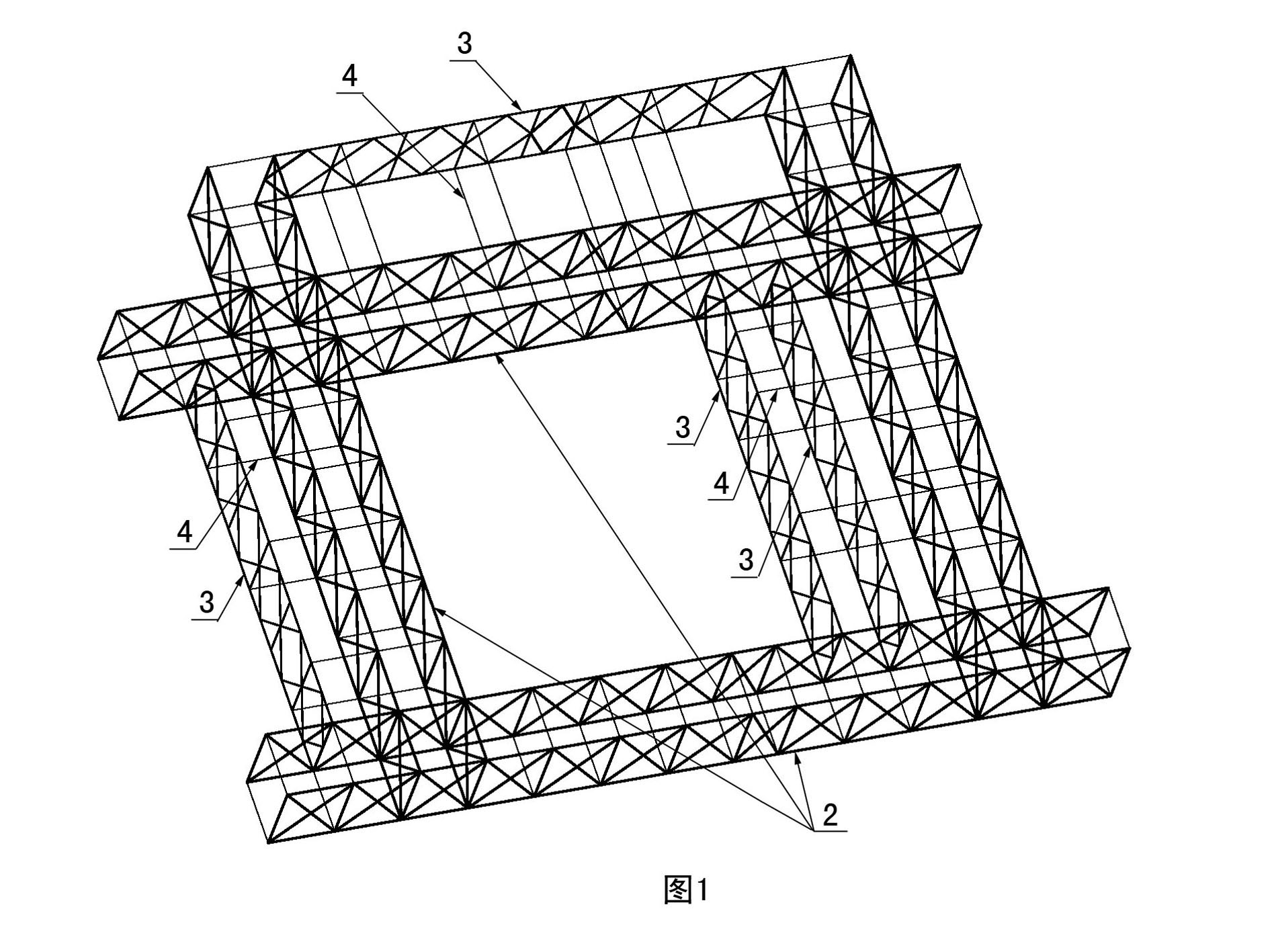

The invention relates to an assembly type variable steel girder platform, a distribution method and an assembly method thereof. The platform is supported on a core tube, and is formed by sectional steel grinders through being fixedly connected, and the sectional steel grinders mainly consist of main stress grinders, sub stress grinders and support rods between grinders, wherein the main stress grinders are formed by main grinder standard nodes and main grinder groined node standard nodes through being dismountably connected via node plates with bolt holes, end sealing plates with bolt holes and screw bolts, the sub stress grinders are formed by sections of sub grinder standard sections through being dismountably connected end to end, and in addition, the sub stress grinders are dismountably connected between two main stress grinders. The platform can be applied to template lifting construction of high and superhigh building core tube steel platforms, and can also be used as platforms for large-area spanning construction operation and construction machine pile carrying and placement, the construction is very easy, the work period of the construction is greatly accelerated, and the construction cost is reduced.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +1

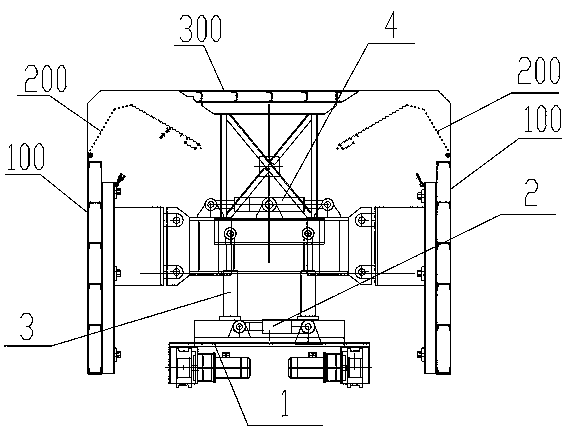

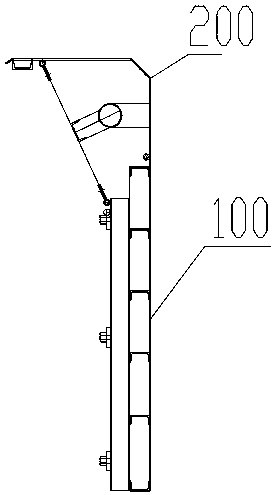

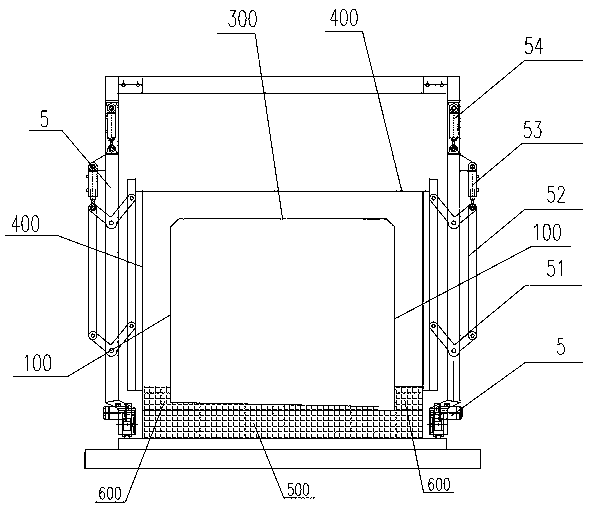

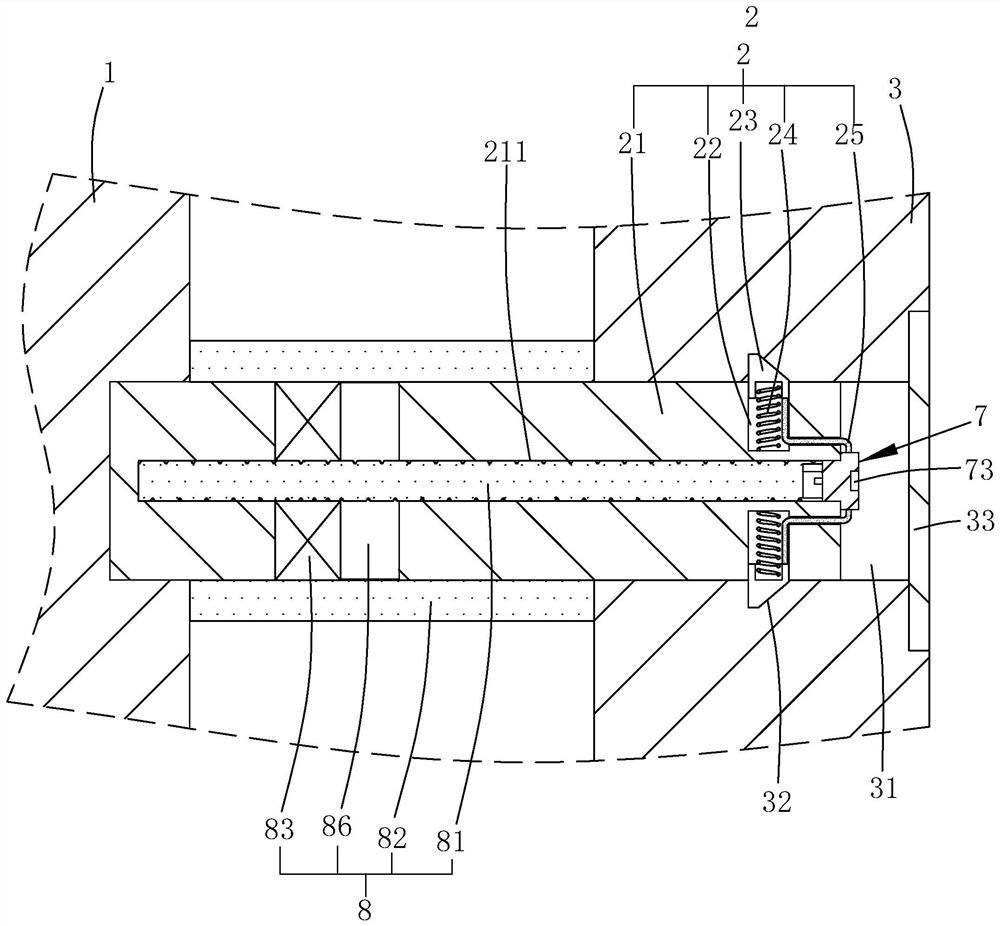

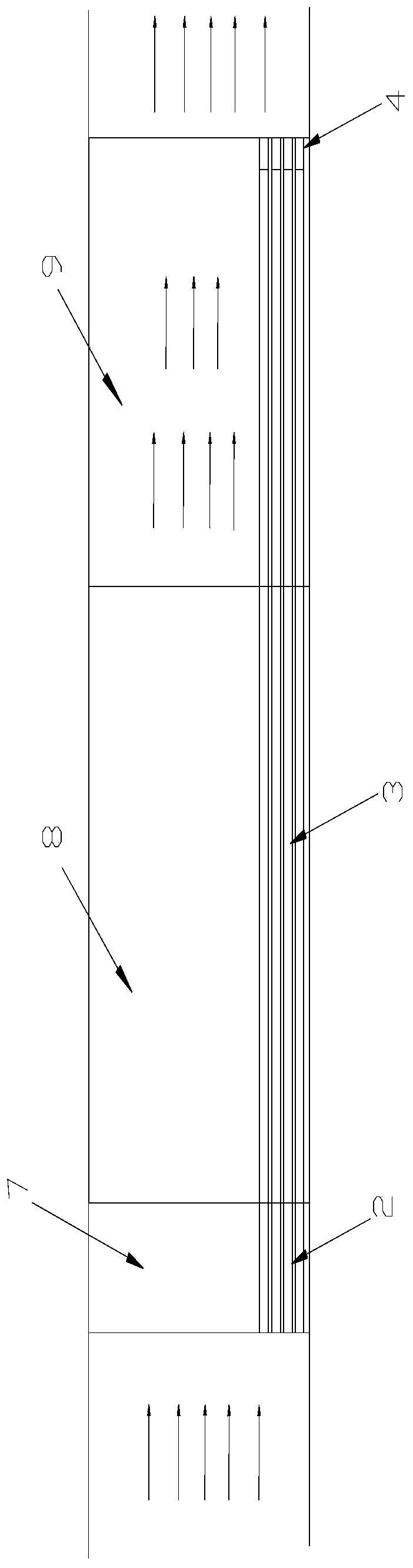

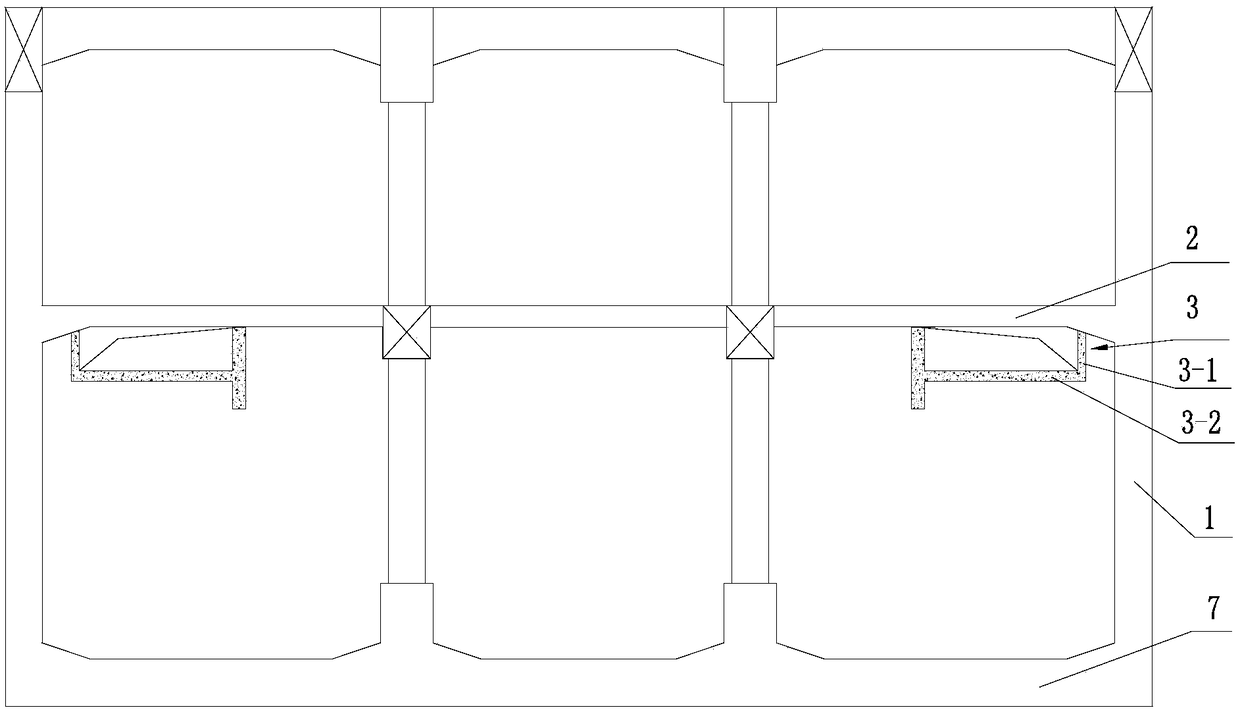

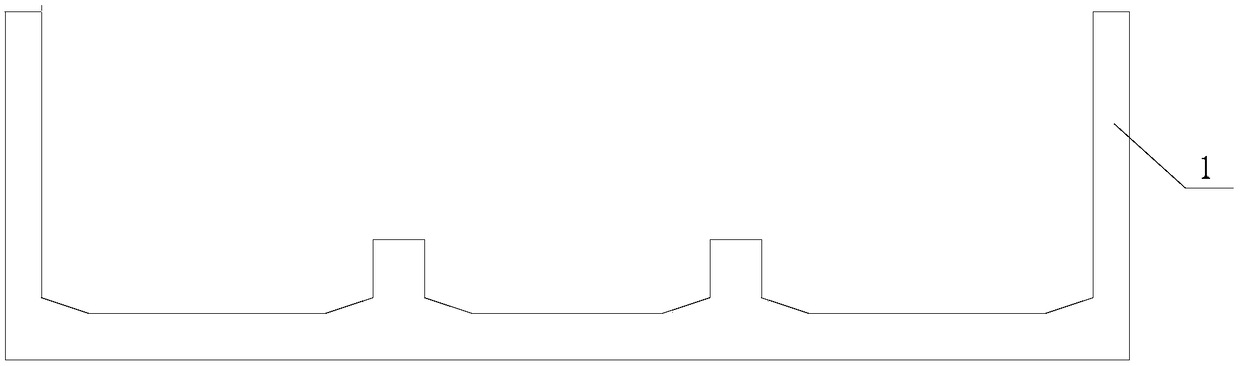

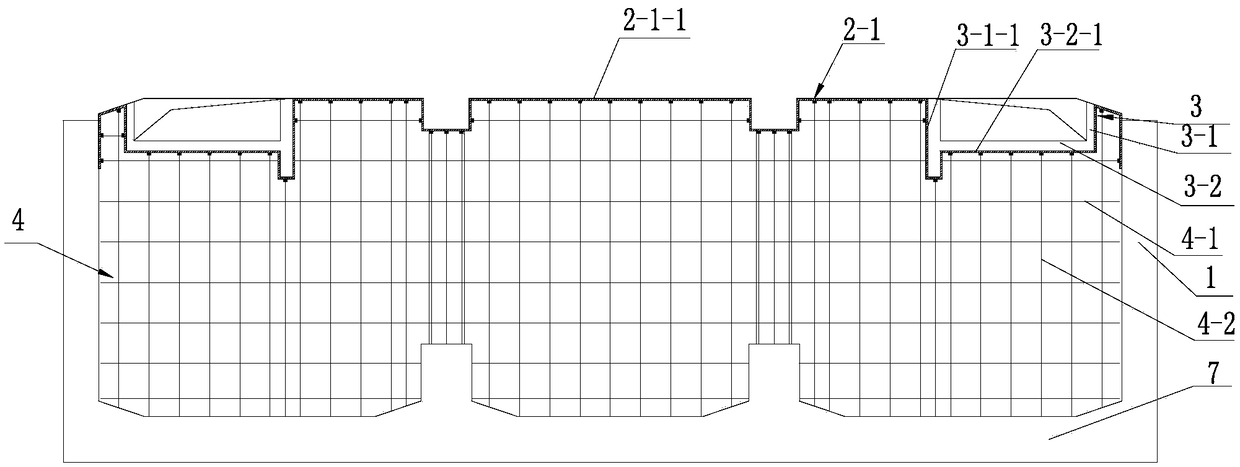

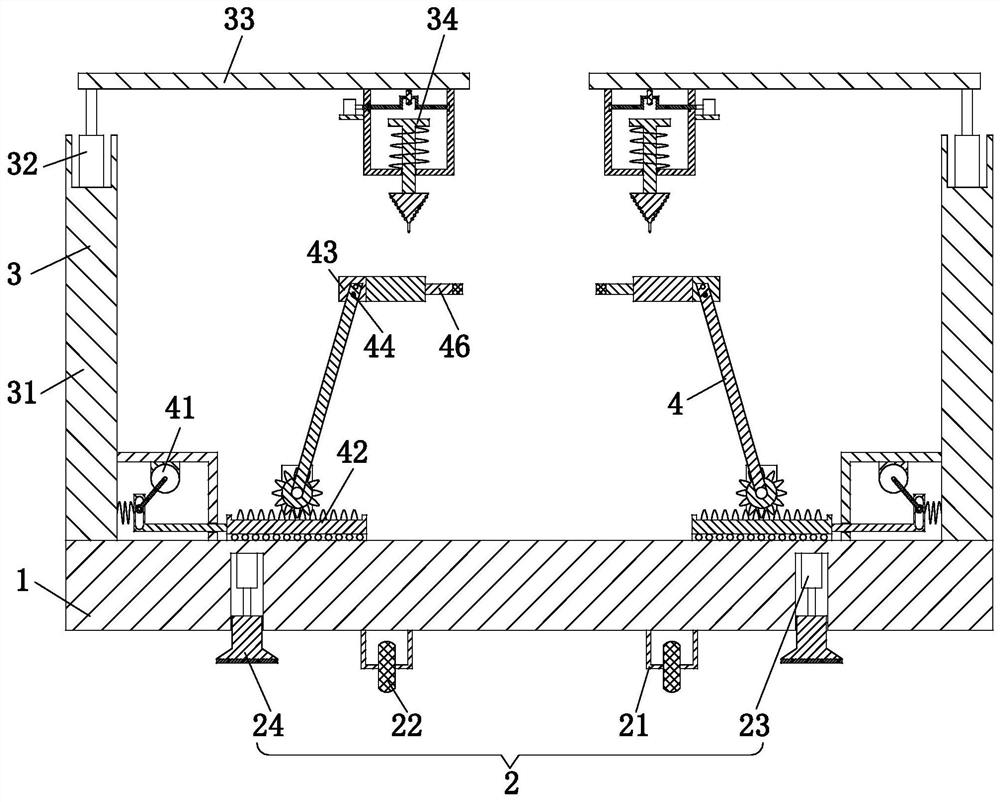

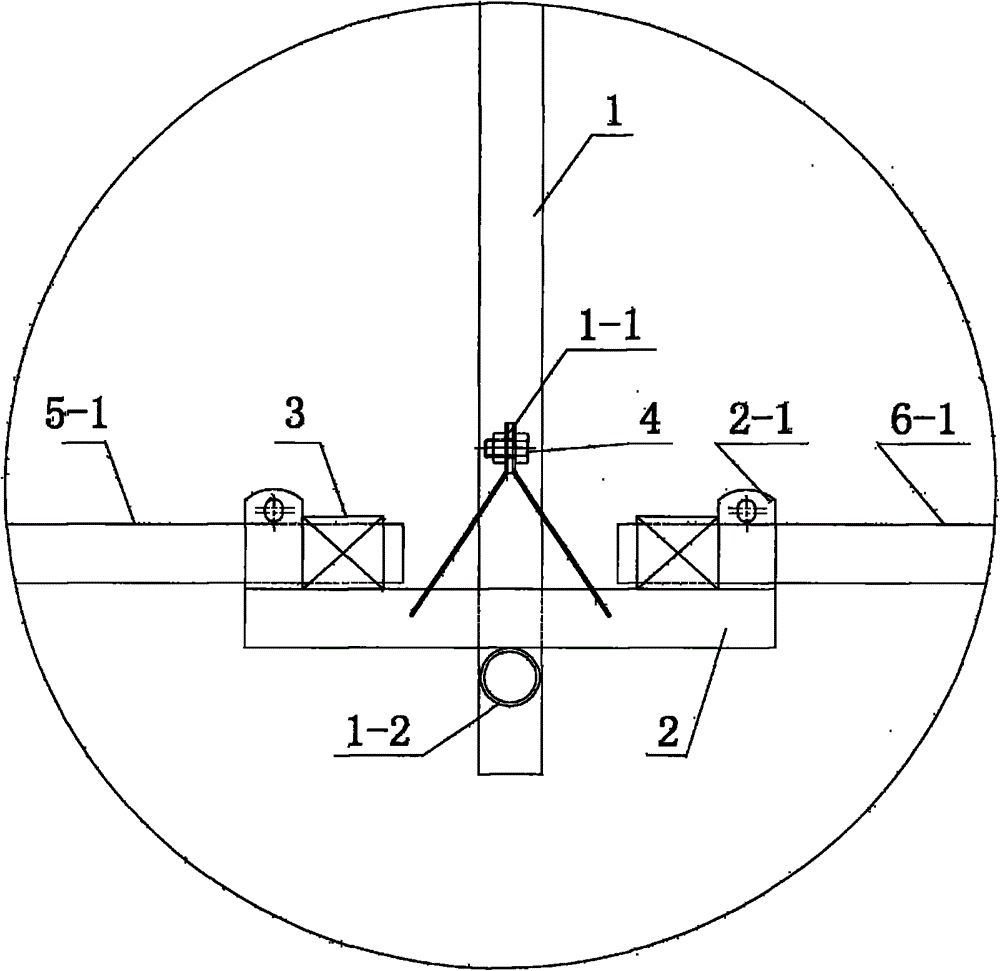

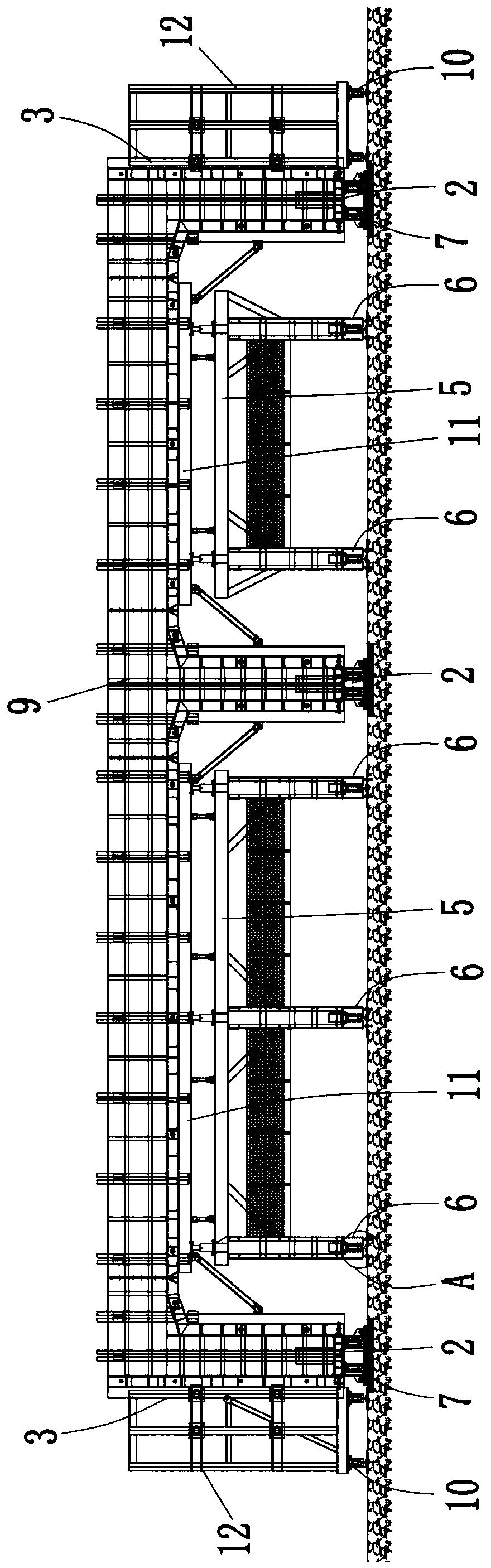

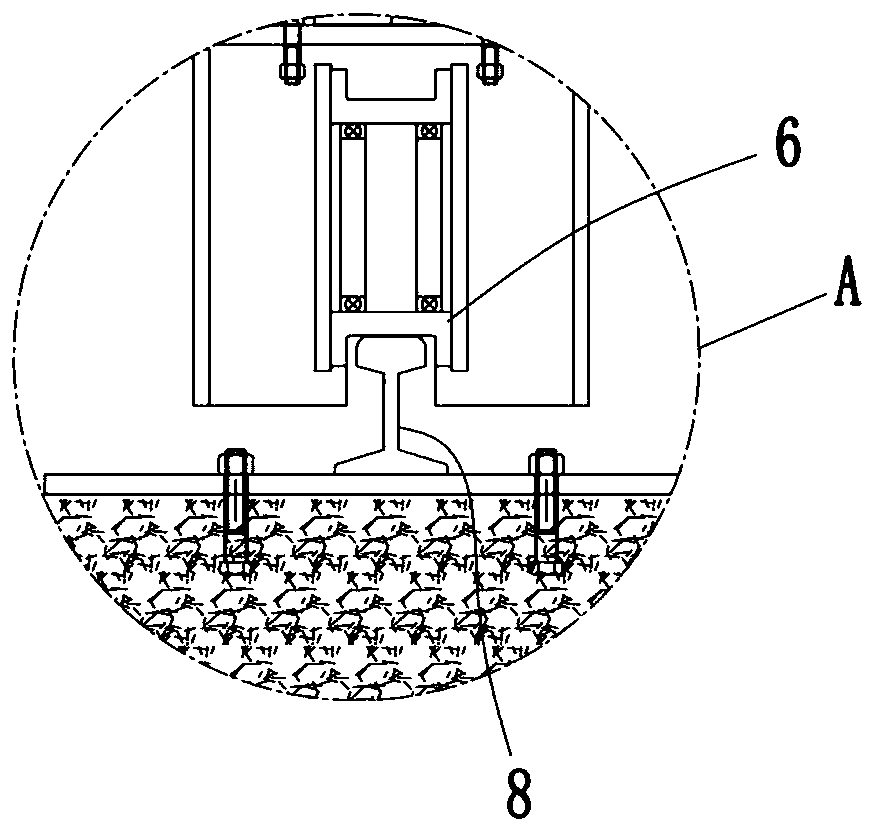

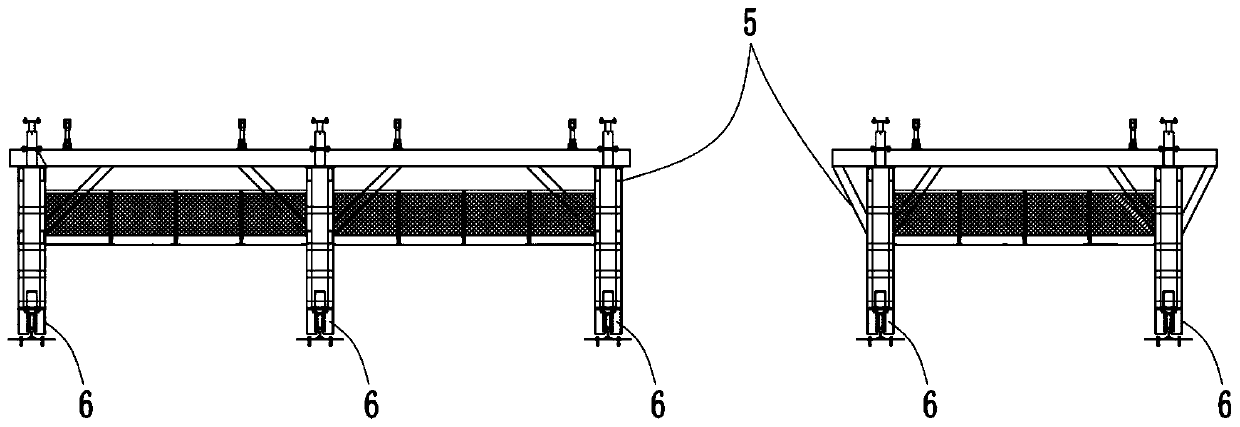

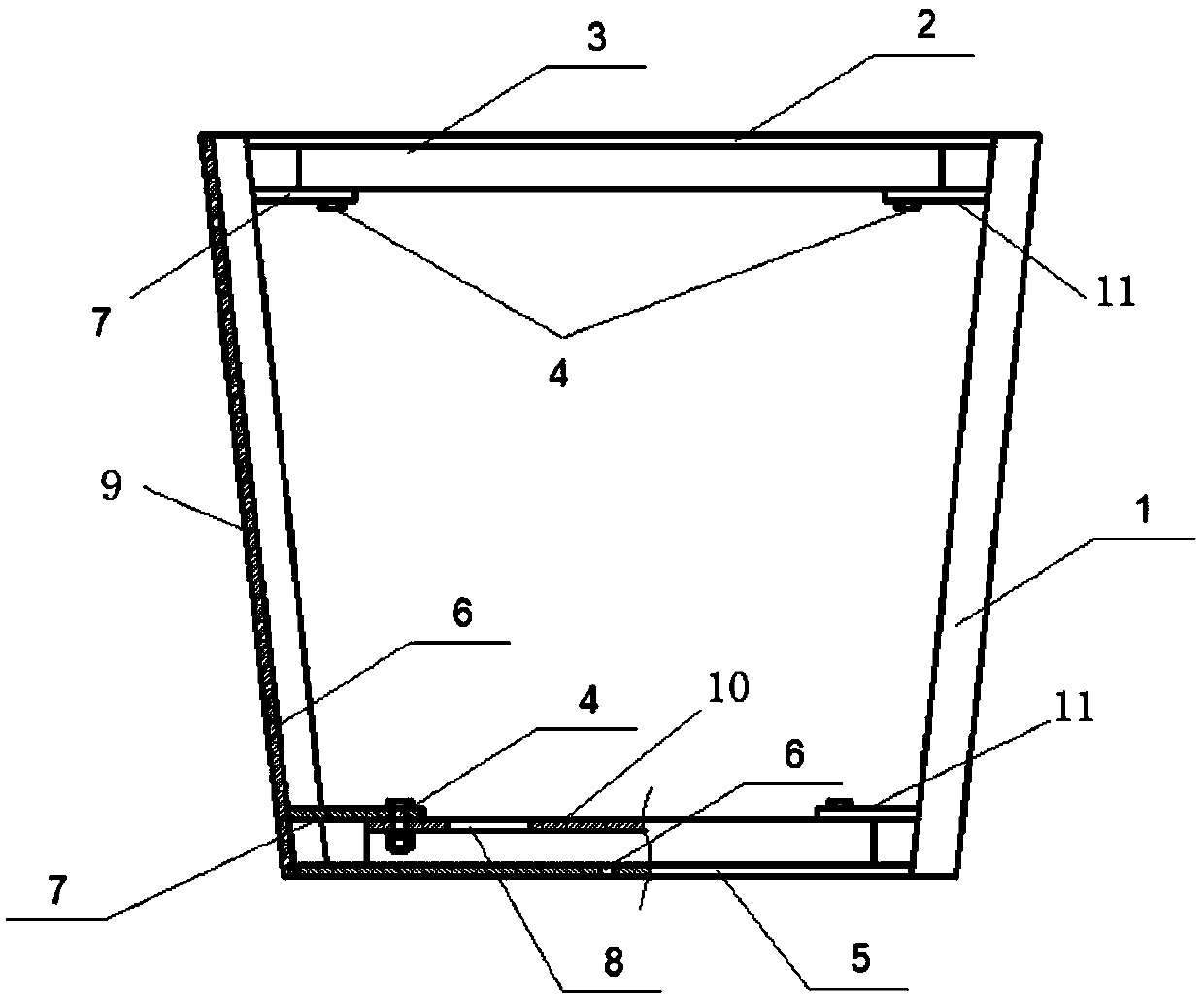

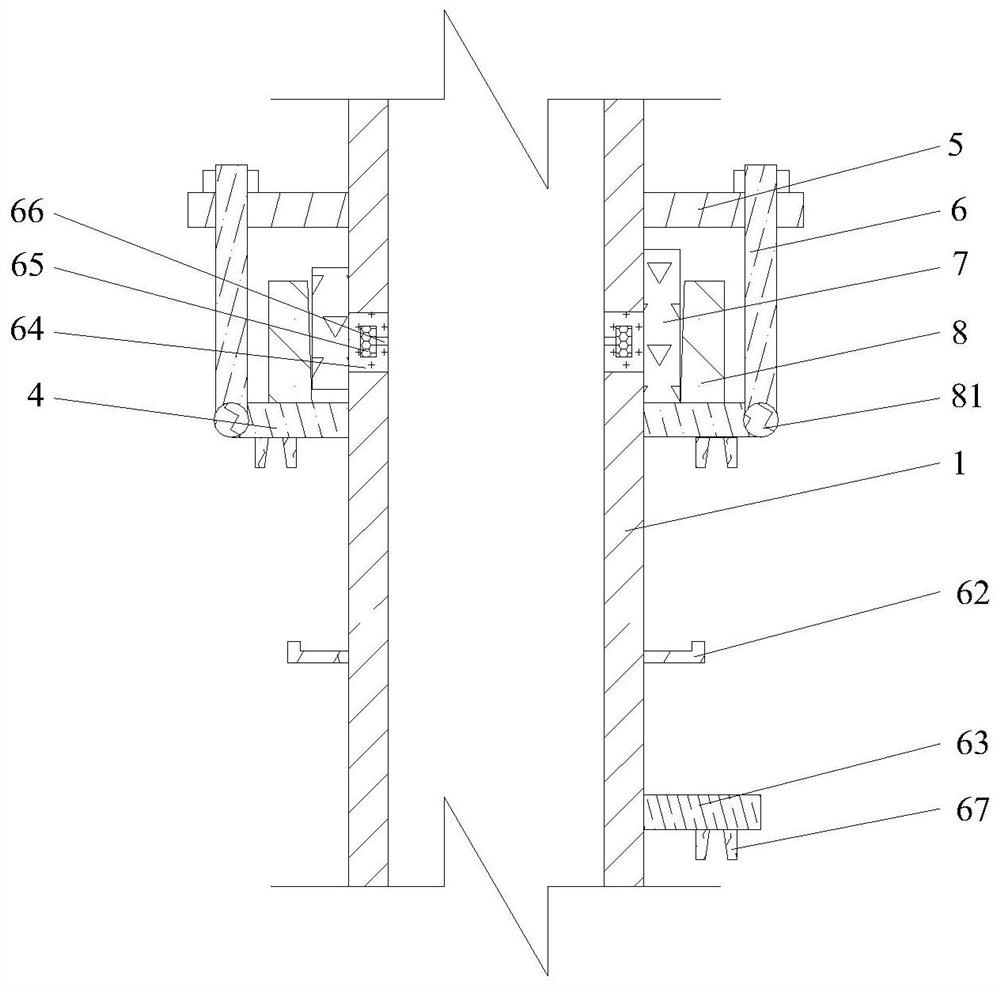

Municipal administration comprehensive pipe rack hydraulic trolley and construction method thereof

InactiveCN109137976AReduce the difficulty of dismantlingImprove securityArtificial islandsUnderground chambersGroutEngineering

The invention provides a municipal administration comprehensive pipe rack hydraulic trolley and a construction method thereof. The hydraulic trolley comprises an internal model, an external model, internal formwork trolleys arranged below the internal model, an internal formwork supporting assembly used for supporting the internal model, external formwork trolleys arranged below the external model, internal model trolley tracks for running of the internal formwork trolleys and external model trolley tracks for running of the external formwork trolleys; the internal formwork supporting assemblyis arranged on the internal formwork trolleys, and the internal formwork supporting assembly is used for dismantling or supporting the internal model; and the internal model trolley tracks are pavedon a pipe rack base plate which is subjected to pouring, the external model trolley tracks are located on the two sides of the pipe rack base plate, the external formwork trolleys are arranged on thepipe rack base plate in a straddling mode, and the external model is arranged on the external formwork trolleys. The construction method is applied to the hydraulic trolleys. Compared with the traditional assembled formwork, the municipal administration comprehensive pipe rack hydraulic trolleys and the construction method thereof solve the common quality problems that the formwork has many edge joints and small integral rigidity, grout leakage and model swelling are prone to appearing and the like, and moreover, the difficulty of removing the roof formwork and the safety hazards are greatly reduced.

Owner:CCCC SHEC DONGMENG ENG CO LTD

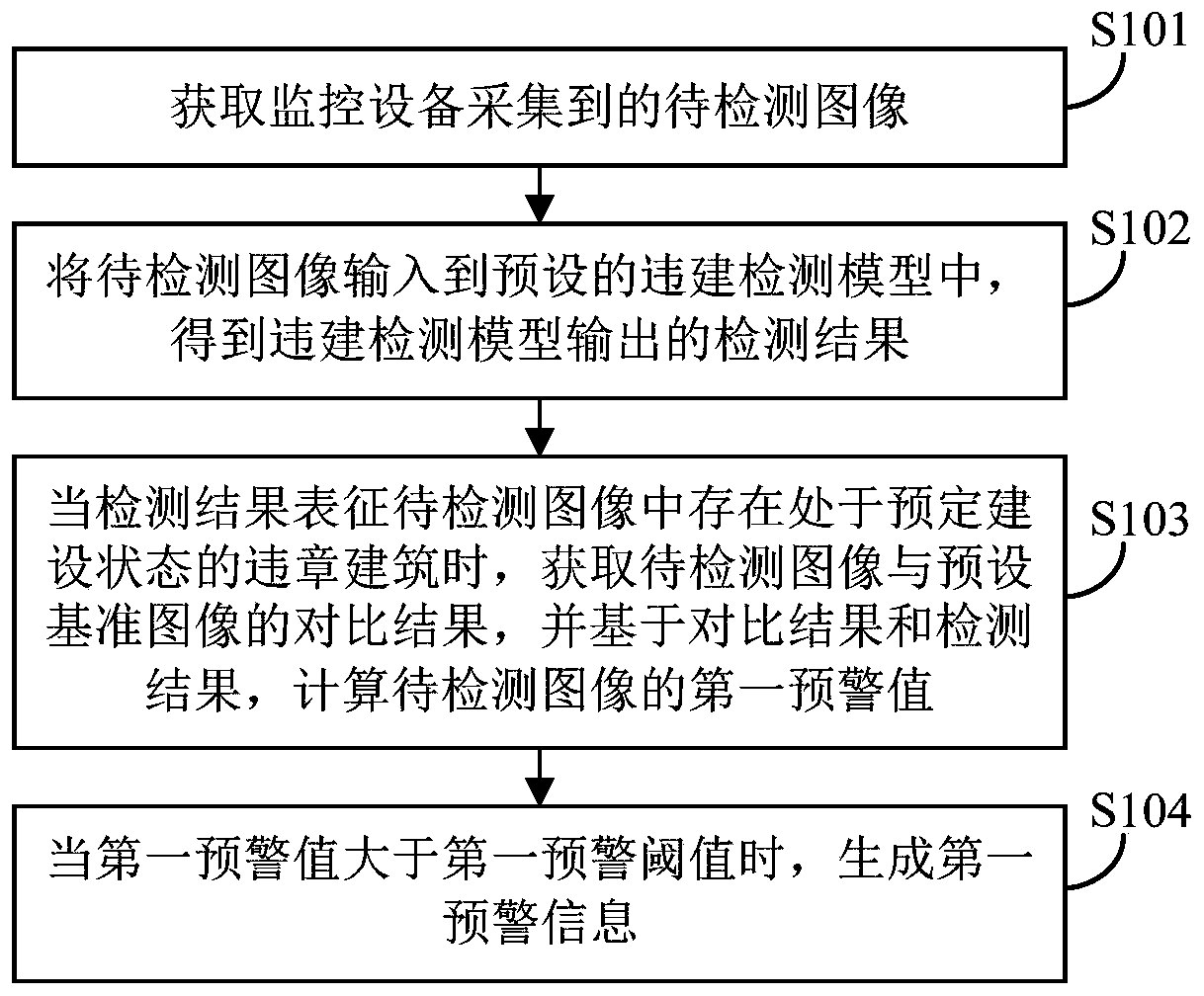

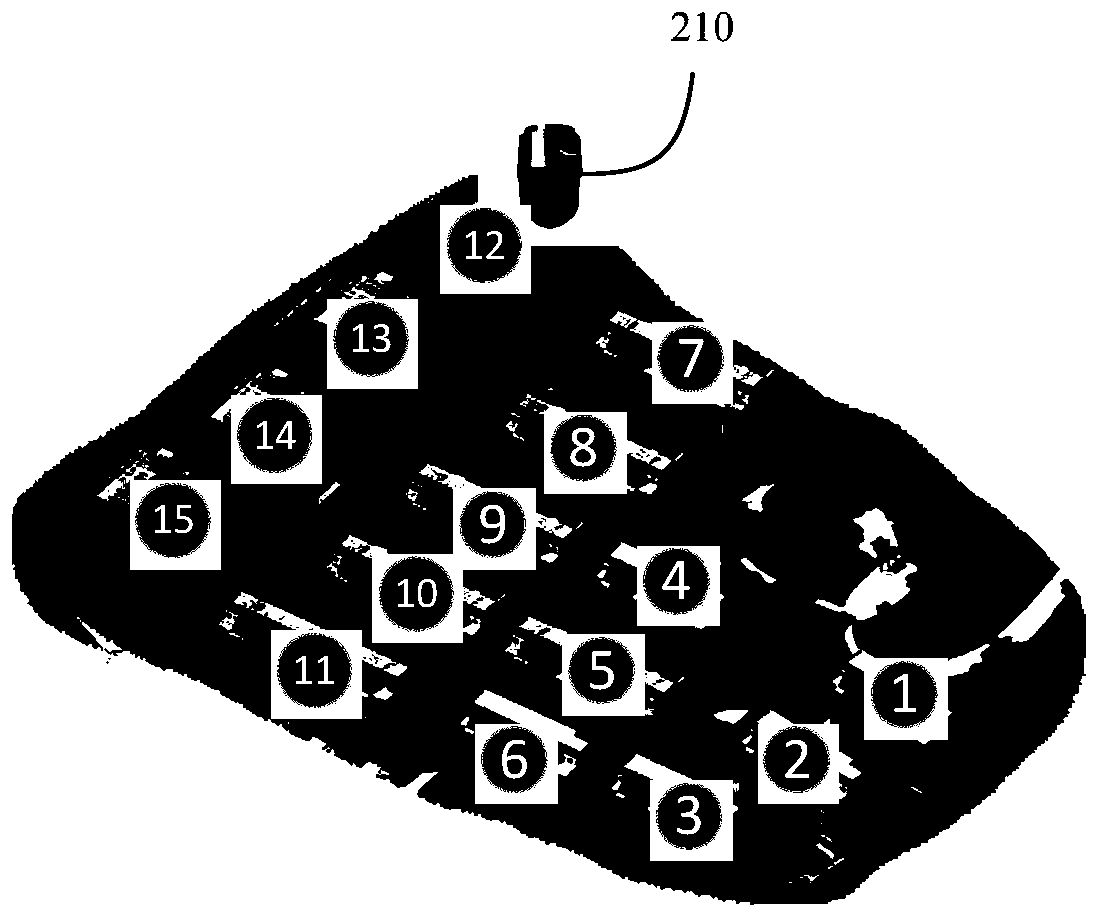

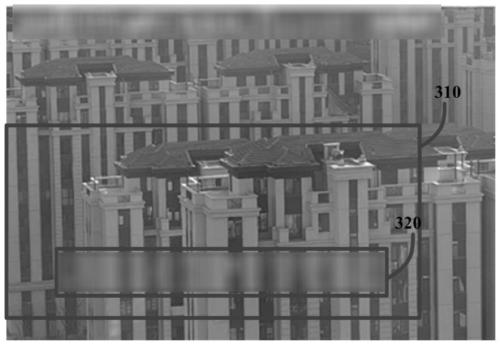

Illegal building early warning method and device and electronic equipment

PendingCN111368615AReduce the difficulty of dismantlingReduce demolition costsData processing applicationsCharacter and pattern recognitionReference imageMonitor equipment

The embodiment of the invention provides a violation illegal building early warning method and device and electronic equipment. The method comprises the following steps: acquiring a to-be-detected image acquired by monitoring equipment; inputting the to-be-detected image into a preset illegal building detection model to obtain a detection result output by the illegal building detection model; whenthe detection result represents that the illegal building in the predetermined construction state exists in the to-be-detected image, obtaining a comparison result of the to-be-detected image and a preset reference image, and calculating a first early warning value of the to-be-detected image based on the comparison result and the detection result; and when the first early warning value is greater than the first early warning threshold, generating first early warning information. Compared with the prior art, by applying the scheme provided by the embodiment of the invention, illegal buildingsexisting on actual buildings can be discovered in time, and effective early warning can be carried out on the illegal buildings in a predetermined construction state.

Owner:HANGZHOU HIKVISION SYST TECH

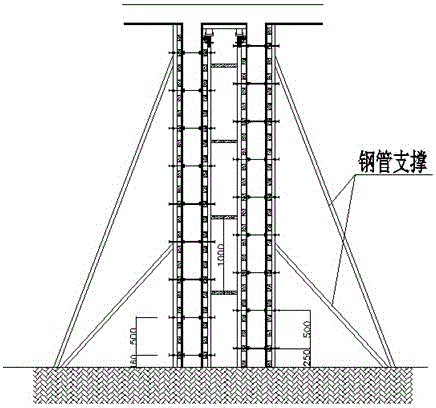

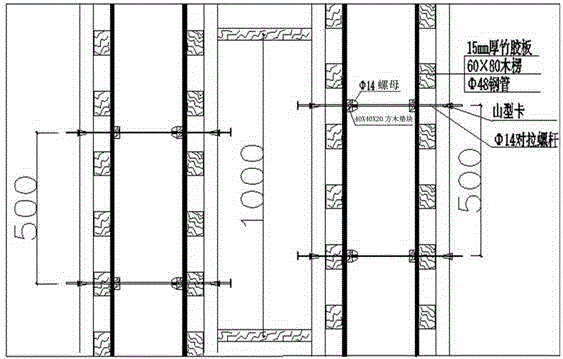

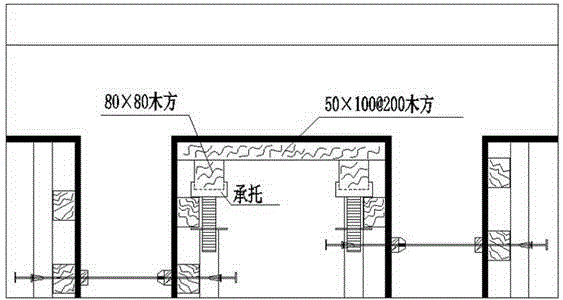

Vault shear wall anti-explosion and drilling-resistant formwork erecting construction method

InactiveCN106437140AReduce supportReduce the difficulty of dismantlingForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksShear wallBuilding construction

The invention relates to a vault shear wall anti-explosion and drilling-resistant formwork erecting construction method. The construction method comprises the following steps that (1) materials are selected; (2) ambulatory wall formworks are erected; (3) ambulatory cast-in-place slab formworks are erected; and (4) the formworks are dismounted. During formwork design, fixing inner nuts are used on the inner sides, and left split bolts and right split bolts are staggered up and down. The method has the advantages that through the vault shear wall anti-explosion and drilling-resistant formwork erecting construction method, the formwork erecting and dismounting difficulty is lowered, and thus the construction quality is well ensured.

Owner:JIANGSU JIANGZHONG GROUP

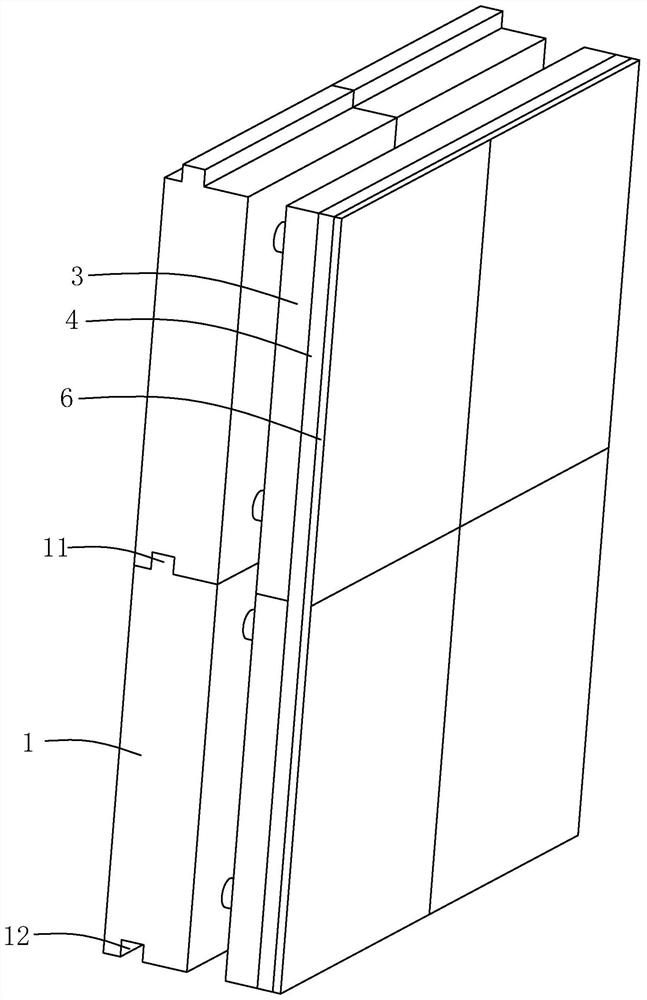

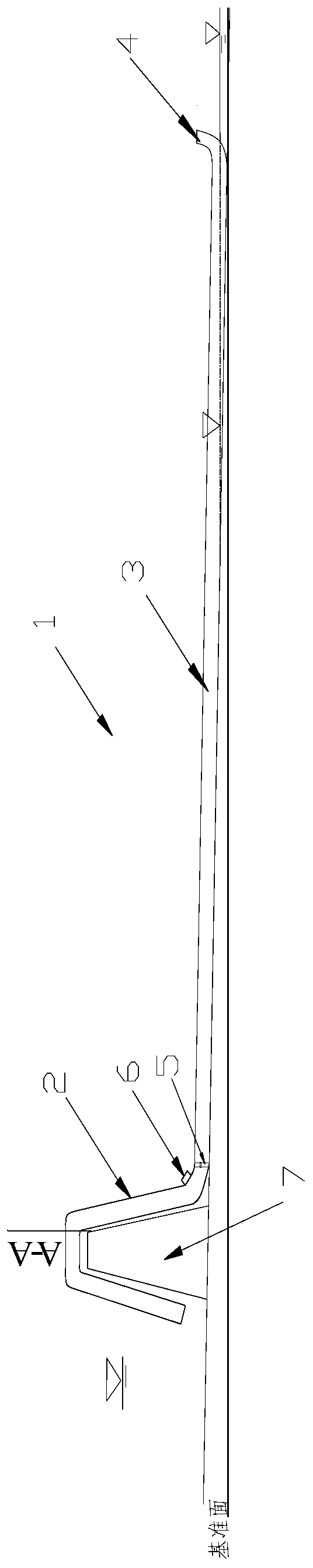

Fabricated outer wall structure based on BIM technology

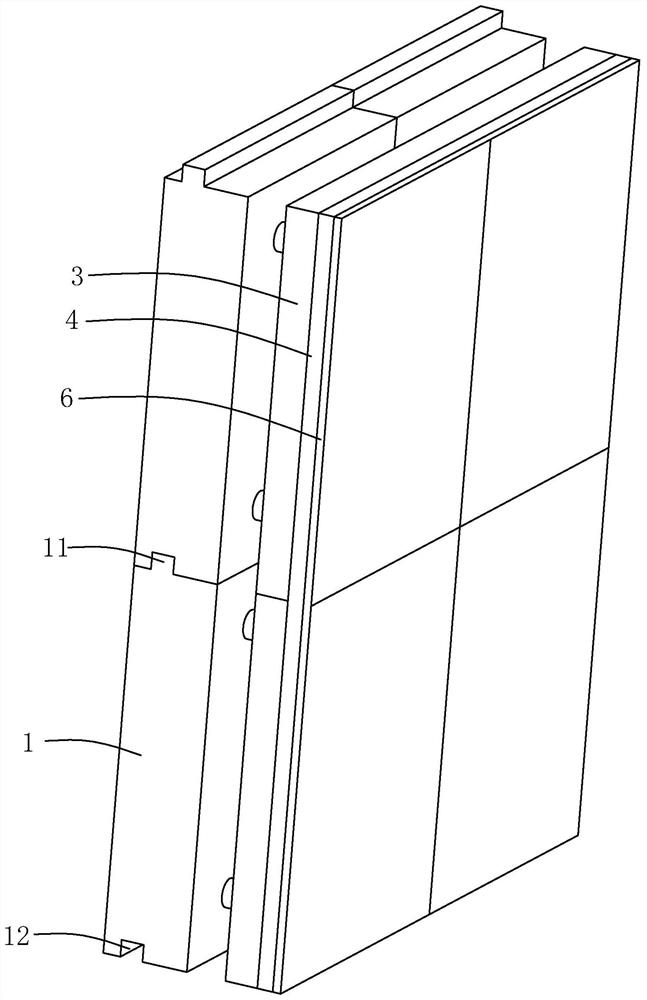

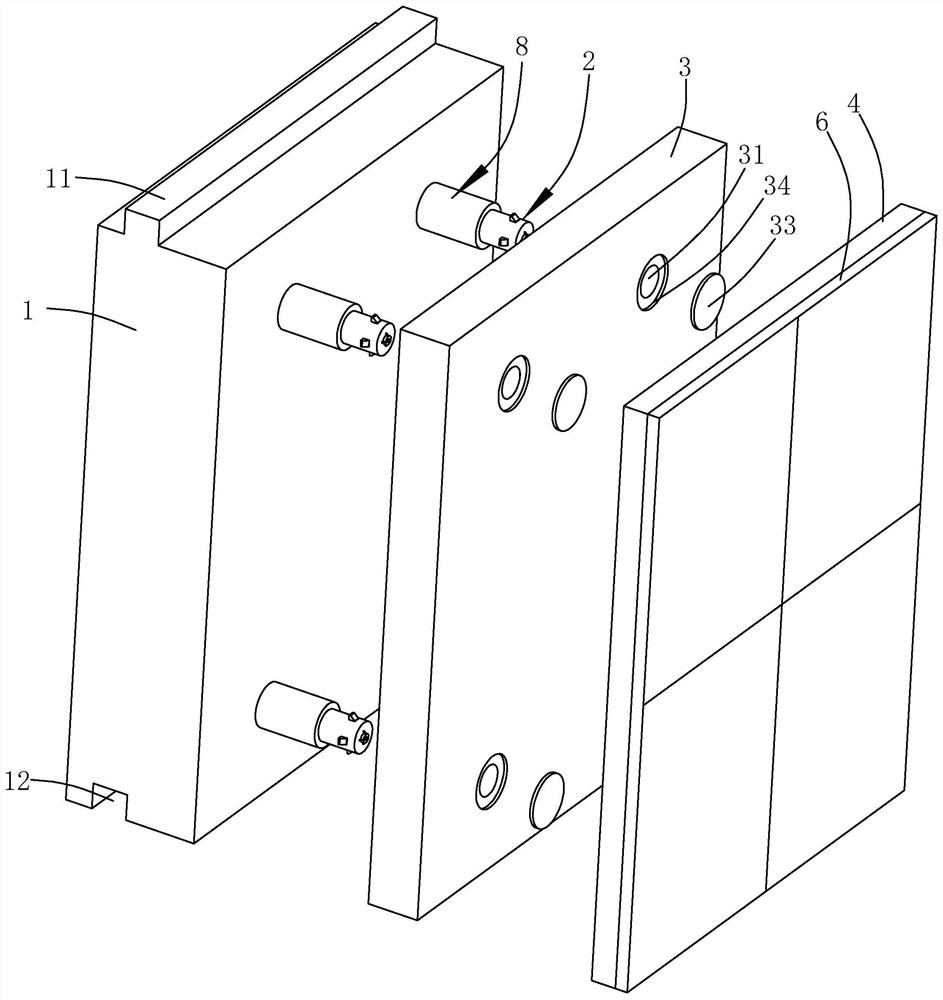

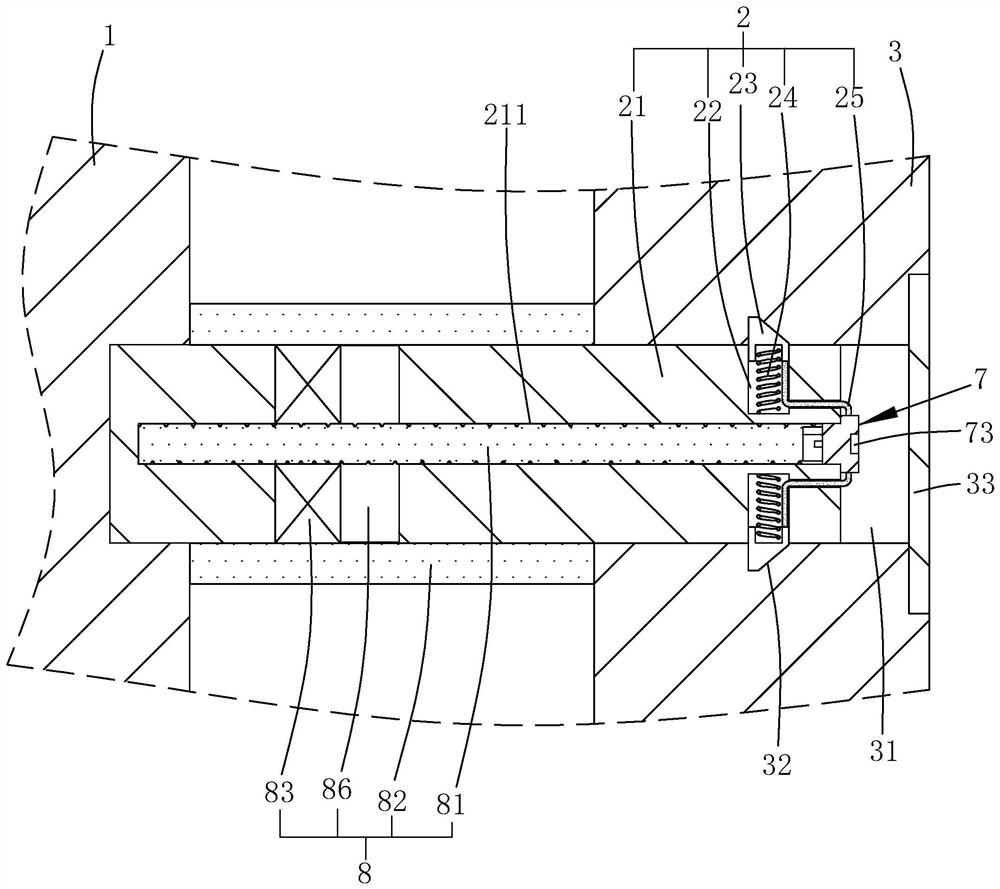

ActiveCN111691577AReduce the difficulty of dismantlingNot easy to damageCovering/liningsWallsStructural engineeringExternal cladding

The invention relates to a fabricated outer wall structure based on a BIM technology. The fabricated outer wall structure comprises an outer wall body formed by splicing a plurality of outer wallboards. Waterproof flashings are integrally formed at the upper ends of the outer wallboards. The lower ends of the outer wallboards are provided with positioning grooves matched with the waterproof flashings. Connecting boards are arranged on the outer sides of the outer wallboards. Waterproof layers and facing layers are sequentially fixed to the sides, away from the outer wallboards, of the connecting boards. A plurality of suspension assemblies are mounted on one sides, facing the connecting boards, of the outer wallboards. Through holes are formed in the positions, corresponding to the suspension assemblies, on the connecting boards. The suspension assemblies extend into the through holes and are detachably connected with the connecting boards. The connecting boards are suspended on the outer wallboards through the suspension assemblies. Fragile pieces are fixed to one ends, away from the outer wallboards, of the through holes. The fabricated outer wall structure has the advantages that the difficulty of removing the facing layers during later maintenance is greatly reduced, and damage to the outer wall body of a building is not easily caused when the facing layers are removed.

Owner:深圳市创远天成建筑设计有限公司

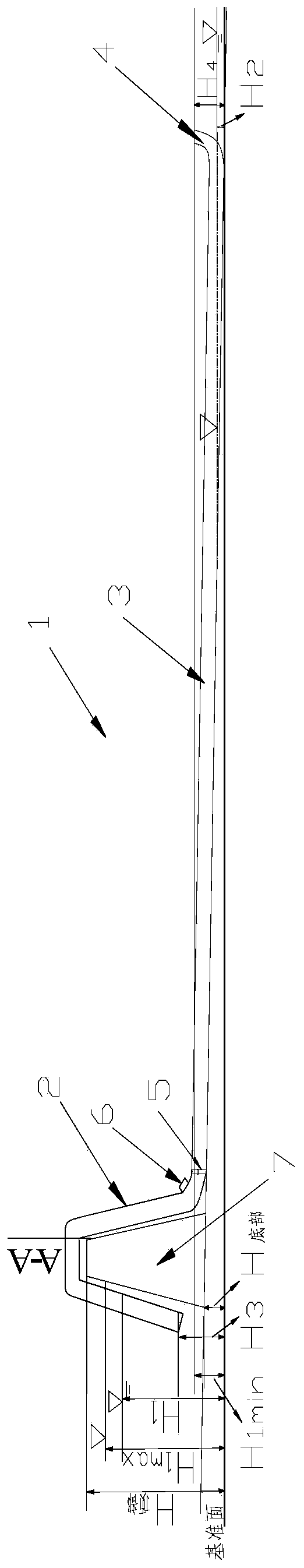

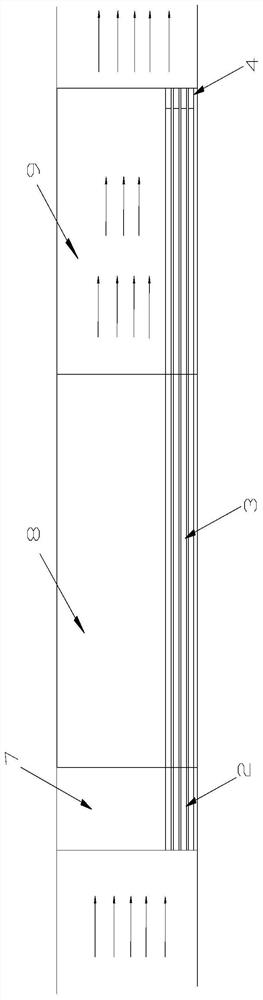

Method for manufacturing river channel dry land construction conditions by using flow self-adjusting siphoning type construction flow guide pipe

ActiveCN110378024AEasy to operateReduce stepsGeometric CADClimate change adaptationEngineeringStreamflow

The invention provides a method for manufacturing river channel dry land construction conditions by using a flow self-adjusting siphoning type construction flow guide pipe, which comprises the following steps of: marking a river channel area of the river channel dry land construction conditions to be manufactured as a construction drying area which is positioned at the downstream of a water retaining building of a river channel; determining a water return area at the downstream of the construction drying area, wherein the water return area is adjacent to the construction drying area; installing a siphoning type construction flow guide pipe used for conveying water on the upstream of the water retaining building to the downstream of the water return area at the water retaining building; andcreating a vacuum condition for the siphoning type construction flow guide pipe so that water in front of the water retaining building can be conveyed to the downstream of the water return area through the siphoning type construction flow guide pipe, and when water in the target area flows out of the target area, forming a riverway dry land construction condition in the construction drying area.The method can significantly reduce the engineering investment, simplify the manufacturing operation of river dry land construction conditions, avoid the hidden danger of flood discharge, and also has the characteristic of being more environmentally friendly.

Owner:SICHUAN UNIV

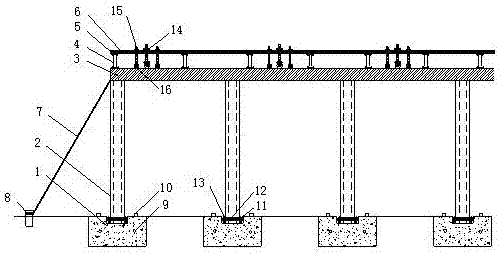

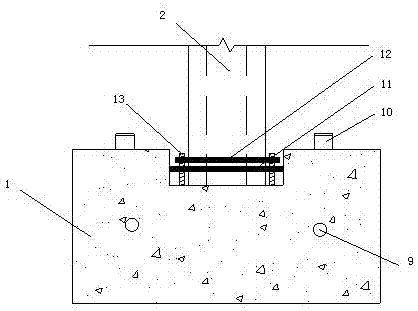

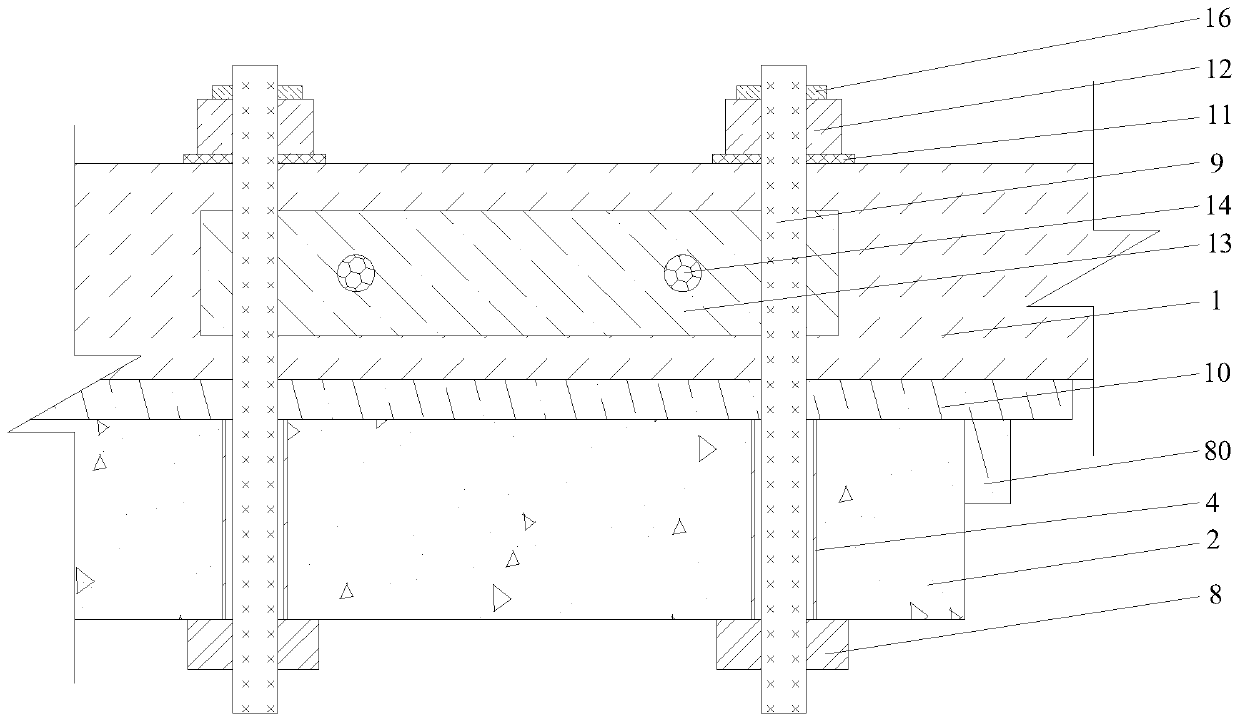

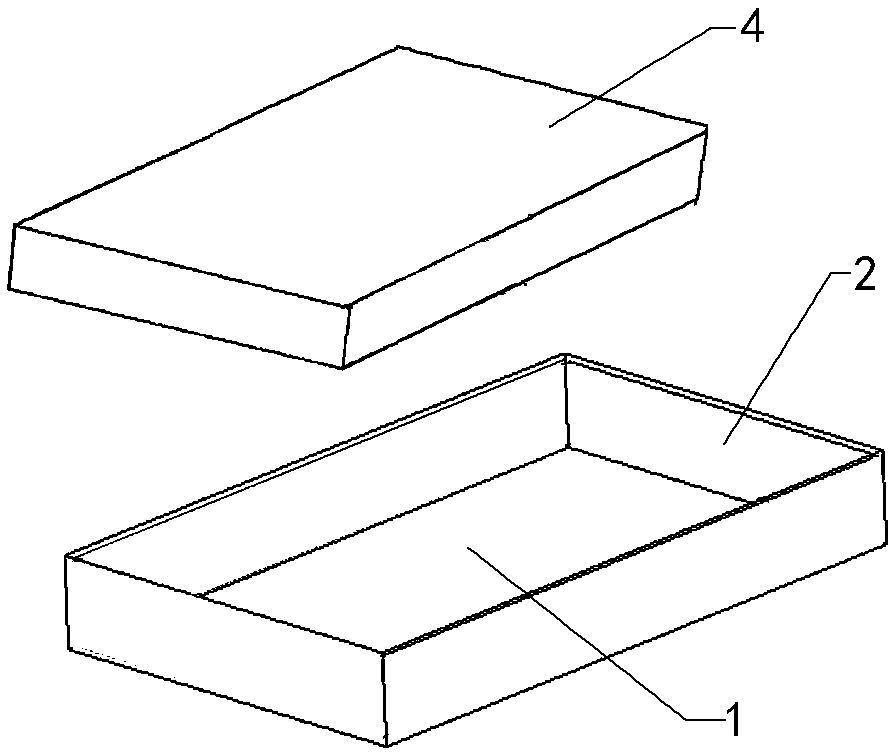

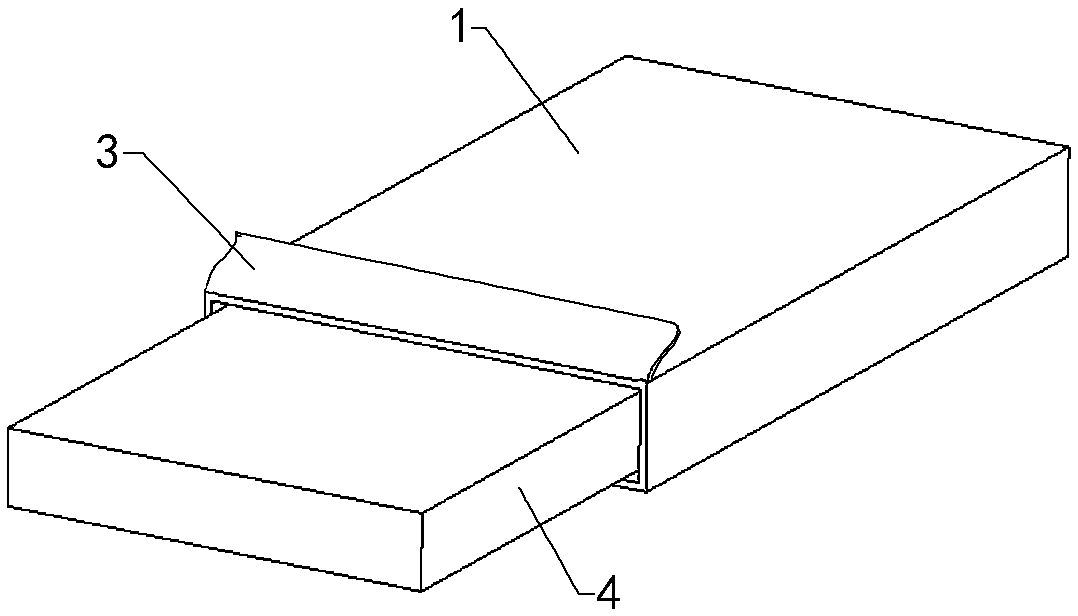

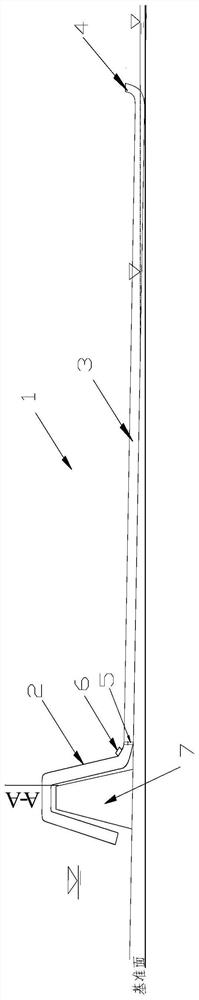

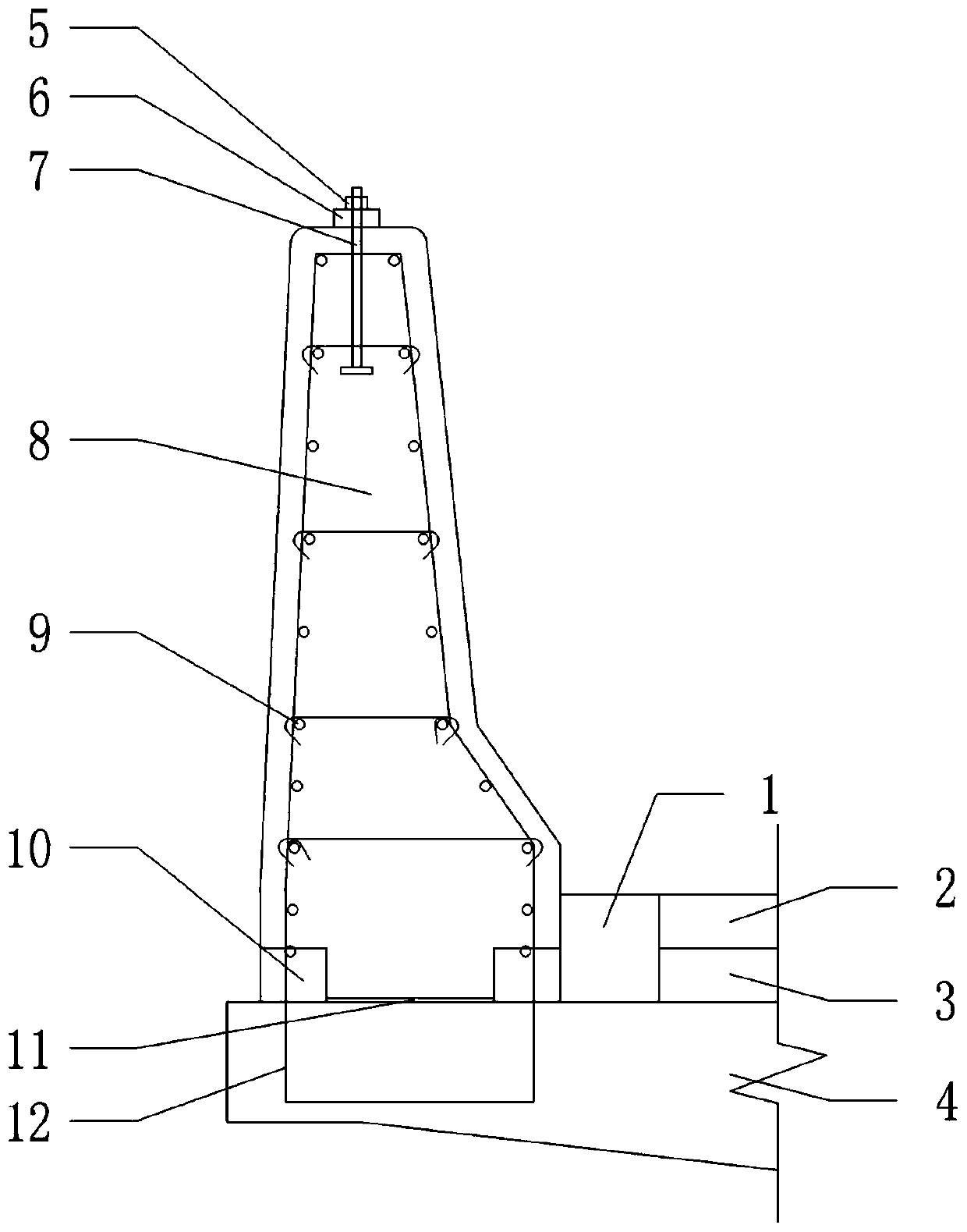

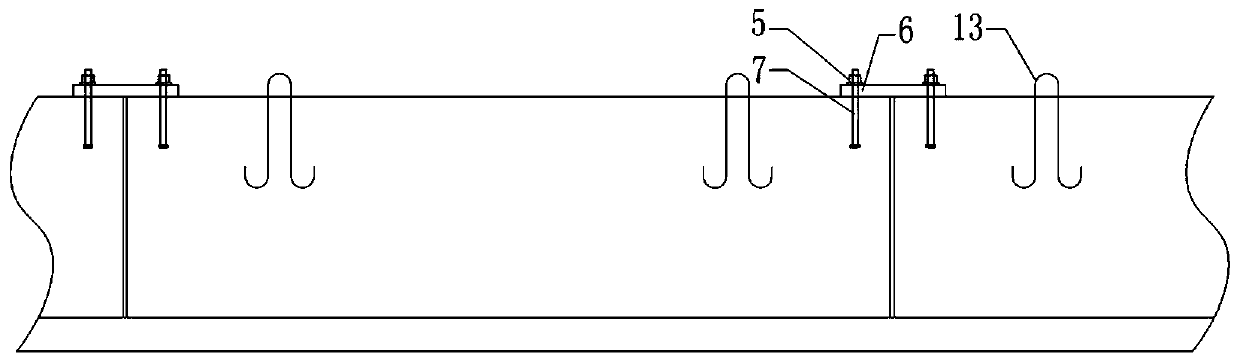

Protective shed structure for continuous girder crossing on-active-duty highway and construction method of protective shed structure

InactiveCN107269013ASolve the difficulty of constructionSolve the problem of high safety factorBuilding material handlingBuilding construction

The invention discloses a protective shed structure for a continuous girder crossing an on-active-duty highway and a construction method of the protective shed structure. The protective shed structure comprises strip-shaped bases, stand columns and transverse load distributing girders, wherein the stand columns are fixedly arranged on the strip-shaped bases, and the transverse load distributing girders are set up on the stand columns; a set of longitudinal load distributing girders are arranged on each transverse load distributing girder, a waterproof board is arranged above the longitudinal load distributing girders, and steel pipe piles are fixedly arranged on the positions, at the two sides of the transverse load distributing girders, of the ground; and hawsers are arranged on the steel pipe piles, one ends of the hawsers are fixedly connected with the steel pipe piles, and the other ends of the hawsers are fixedly connected with the tops of the corresponding stand columns at the two sides of the transverse load distributing girders. The protective shed structure has the following characteristics and beneficial effects that the problem of large construction difficulty is solved by integrally hoisting and splicing the bases, the transverse girders and a longitudinal girder top layer, the problem of a high requirement for a safety factor is solved by building auxiliary facilities, and relatively good technical and economical benefits are achieved; and the transverse girders are removed by adopting the method of traction hoisting, and therefore the removing difficulty is reduced.

Owner:HANGZHOU JIANGRUN TECH LIMITED

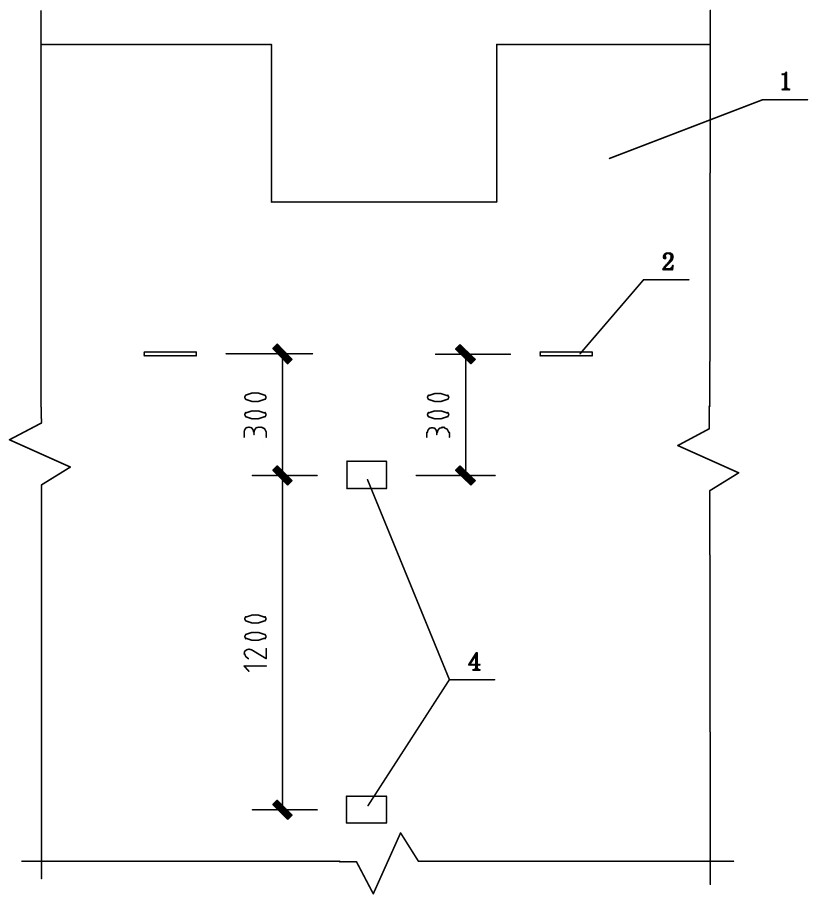

Construction method for simultaneously pouring metro rail top air passages and middle plate

InactiveCN109137977ALarge space for construction workGuarantee the pouring qualityArtificial islandsUnderwater structuresArchitectural engineeringRebar

The invention discloses a construction method for simultaneously pouring metro rail top air passages and a middle plate, and belongs to the field of tunneling. Construction of a middle plate lower side wall of a station is firstly carried out, and concrete pouring and form removal are completed; and then construction of the rail top air passages and the middle plate is carried out. The rail top air passages and the middle plate are constructed according to the following steps that a, construction of the rail top air passages, a middle plate support except the corresponding position of the railtop air passages, base plate templates and external templates of rail top air passage vertical walls is carried out; b, reinforcing bars of the middle plate base plates except the corresponding position of the rail top air passages, the rail top air passage vertical walls and the rail top air passage base plates are manufactured and installed; c, construction of interior templates of the rail topair passage vertical walls, the base plate templates and middle plate supports of the rail top air passage positions is carried out; d, construction of reinforcing bars of the middle plate is carriedout; e, concrete pouring of the rail top air passages and the middle plate is carried out; and f, form removal is carried out. According to the construction method for simultaneously pouring the metro rail top air passages and the middle plate, the quality of concrete pouring of the rail top air passage vertical wall is ensured, and integrality of concrete bonding of the rail top air passage vertical wall and the middle plate is enhanced.

Owner:POWERCHINA RAILWAY CONSTR

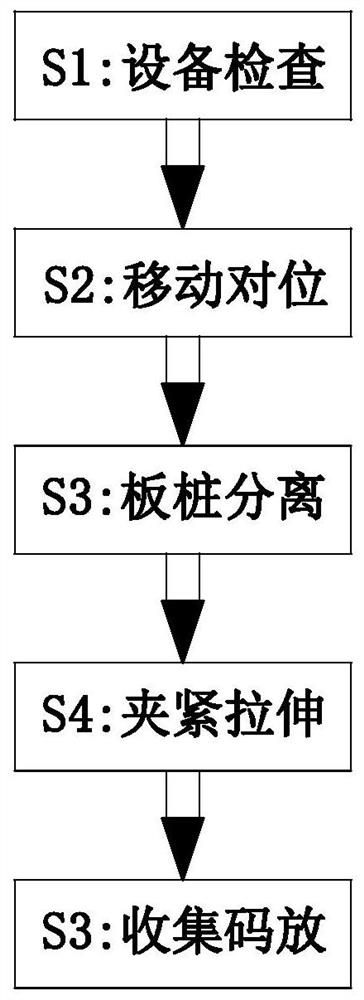

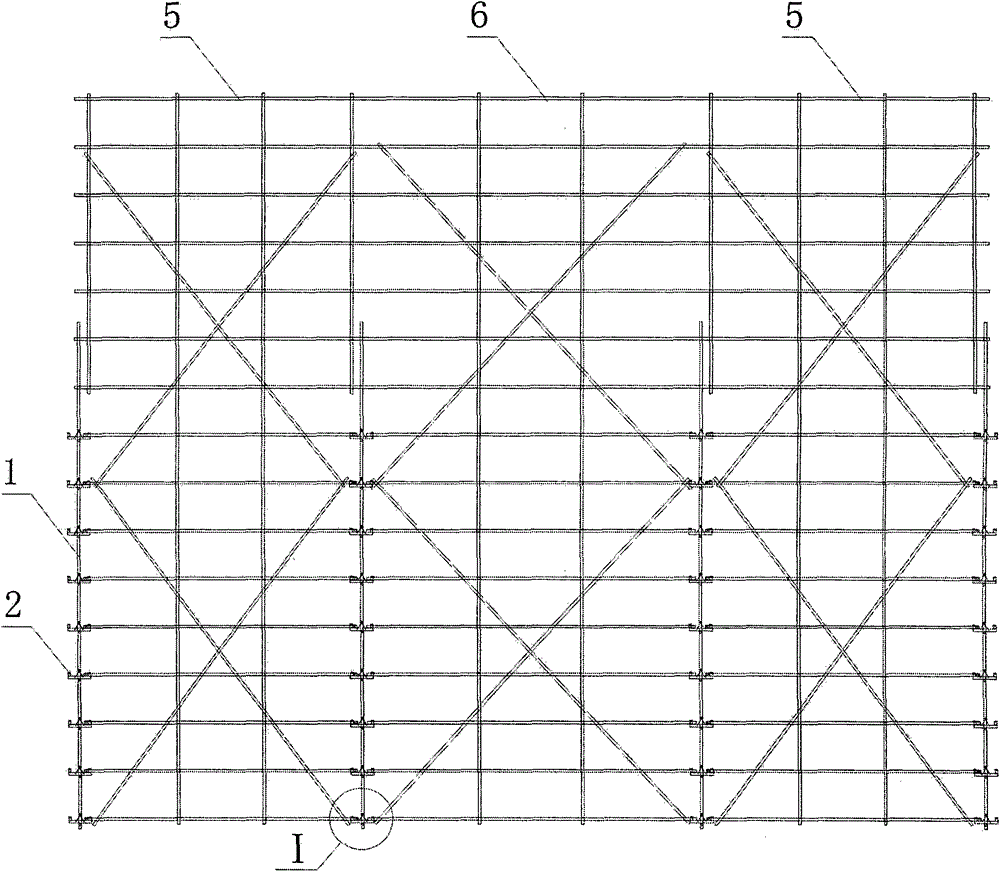

Building construction formwork dismantling method

InactiveCN112709433ALow costReduce investmentForm treatmentArchitectural engineeringPersonal security

The invention relates to a building construction formwork dismantling method. A bottom plate, a moving device, a dismantling device and stretching devices are included, wherein the moving device is arranged at the lower end of the bottom plate; and the stretching devices are symmetrically arranged at the left end and the right end of the upper end face of the bottom plate and symmetrically mounted on the inner side of the dismantling device. The building construction formwork dismantling method can solve the following problems that in the actual operation process of an existing building construction formwork dismantling method, a building construction formwork is dismantled manually, the mechanical strength is large, dismantling is difficult, and consequently the dismantling efficiency is low; and b, manual dismantling is adopted, the input labor force is large, the building construction formwork needs to be supported manually in the dismantling process, and certain harm may be caused to the personal safety of dismantling workers.

Owner:盐城墨攻建筑工程有限公司

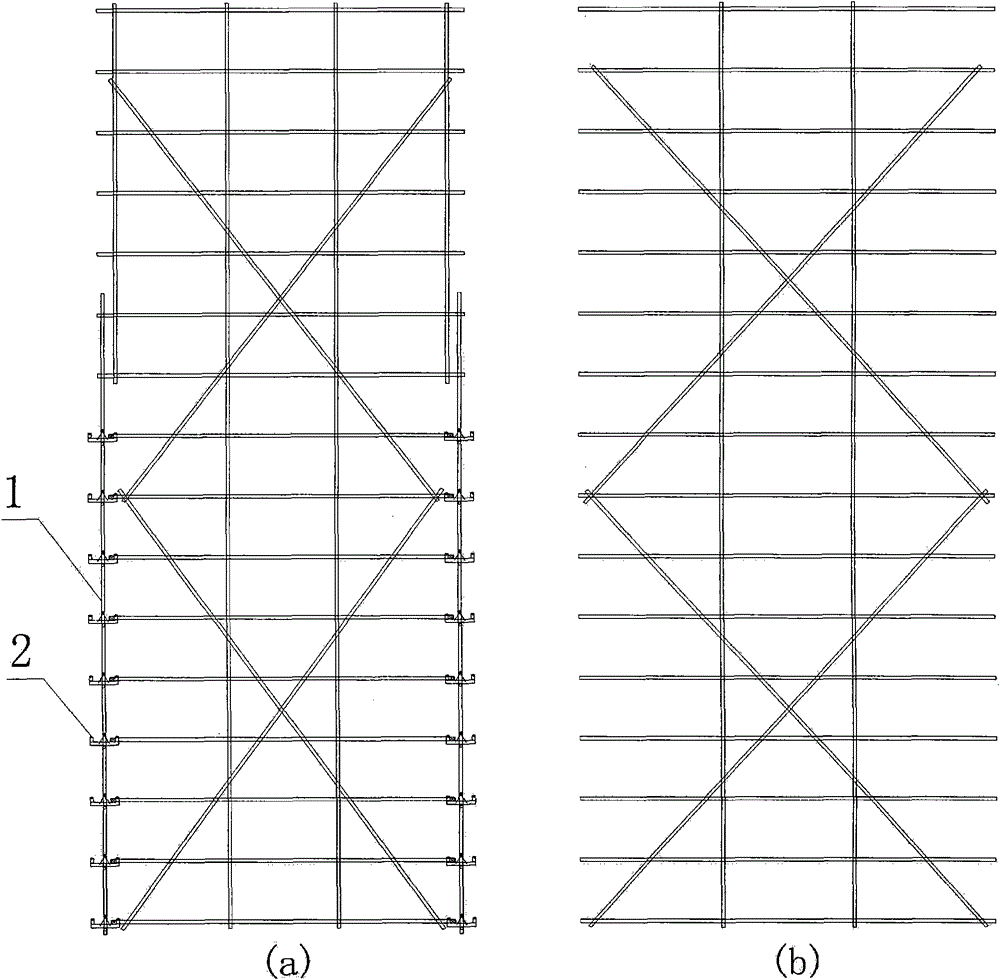

Building scaffold and detachment method thereof

InactiveCN104631807ASimple structureEasy to install and disassembleScaffold connectionsBuilding support scaffoldsEngineeringLifting equipment

The invention discloses a building scaffold and a detachment method of the building scaffold. The building scaffold comprises a sub-piece connecting device, a main framework, a frame body, lifting equipment and an attached supporting device and is characterized in that the sub-piece connecting device is fixed to the main framework, the frame body is divided into basic units of different lengths, the basic units include a stress unit and a closed unit which are fixedly connected through the sub-piece connecting device, and an integrated structure connected end to end is formed on the periphery of a building. The detachment method of the building scaffold is characterized in that in the detachment process, the sub-piece connecting device is removed, and the stress unit and the closed unit are lifted to the ground to be detached through the lifting equipment. The frame body is arranged unit by unit, each unit is lifted to the ground to be detached through the lifting equipment, overhead detachment of workers at the height of scores of floors is completely avoided, risks are reduced, and safety of lives and properties of the workers is guaranteed.

Owner:姚磊

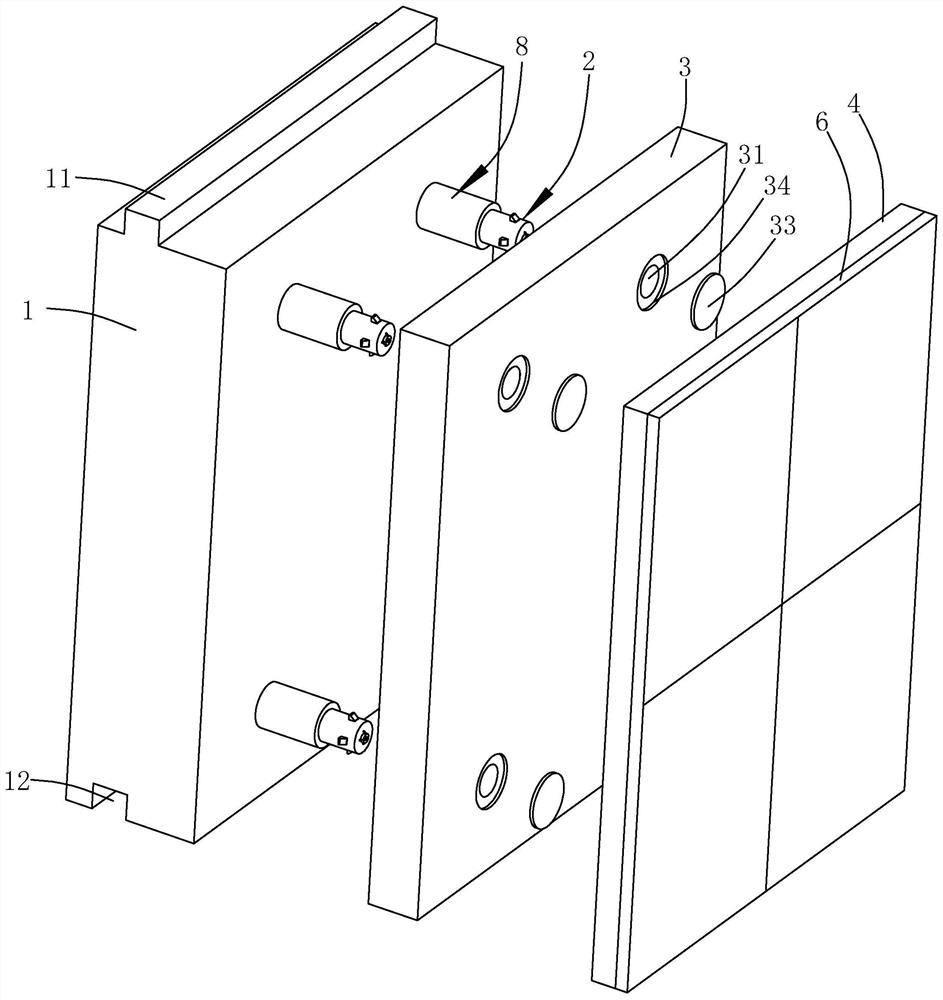

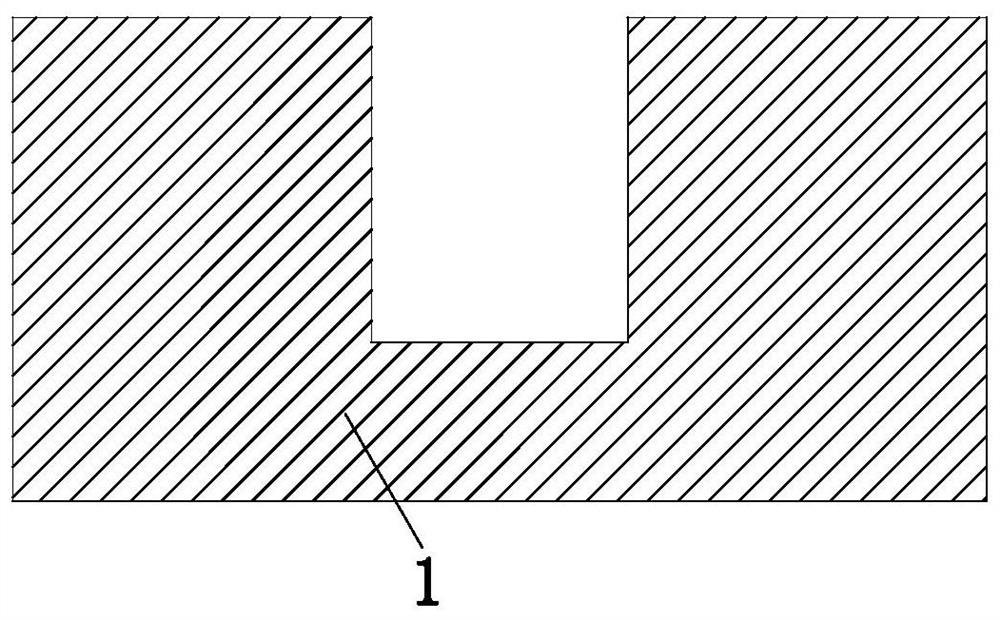

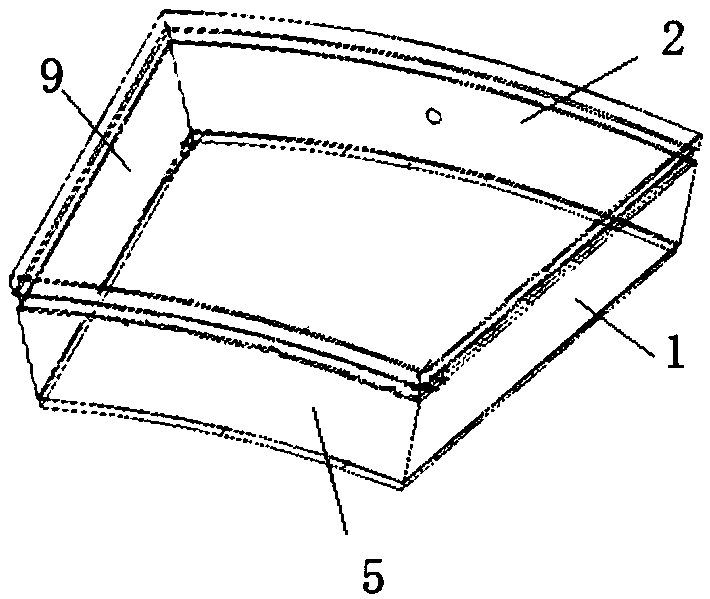

Mold suitable for producing fabricated undercrossing channel frame through long-line matching method and prefabrication method

ActiveCN110497511AAvoid the risk of deformationReduced strength requirementsMouldsEngineeringLine matching

The invention relates to the technical field of building engineering, in particular to a mold suitable for producing a fabricated undercrossing channel frame through a long-line matching method and aconstruction method. The mold comprises bottom mold assemblies matched with the bottom of a frame segment, inner mold assemblies matched with the inner wall of the frame segment, side mold assembliesmatched with the outer walls of the two sides of the mold segment and end mold assemblies matched with the two ends of the mold frame. The mold further comprises an inner mold support used for supporting the inner mold assemblies. A drive device used for driving the inner mold assemblies to be switched between a pouring position and a separation position is arranged on the inner mold support. First walking assemblies are further arranged on the inner mold support and are used for proving movement in the length direction of the frame for the inner mold support.

Owner:成都城投城建科技有限公司

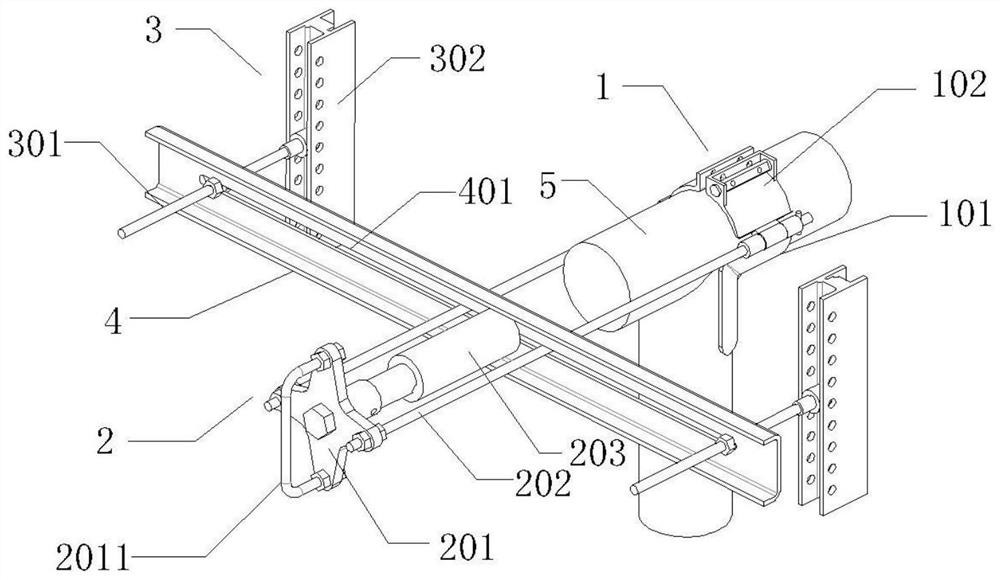

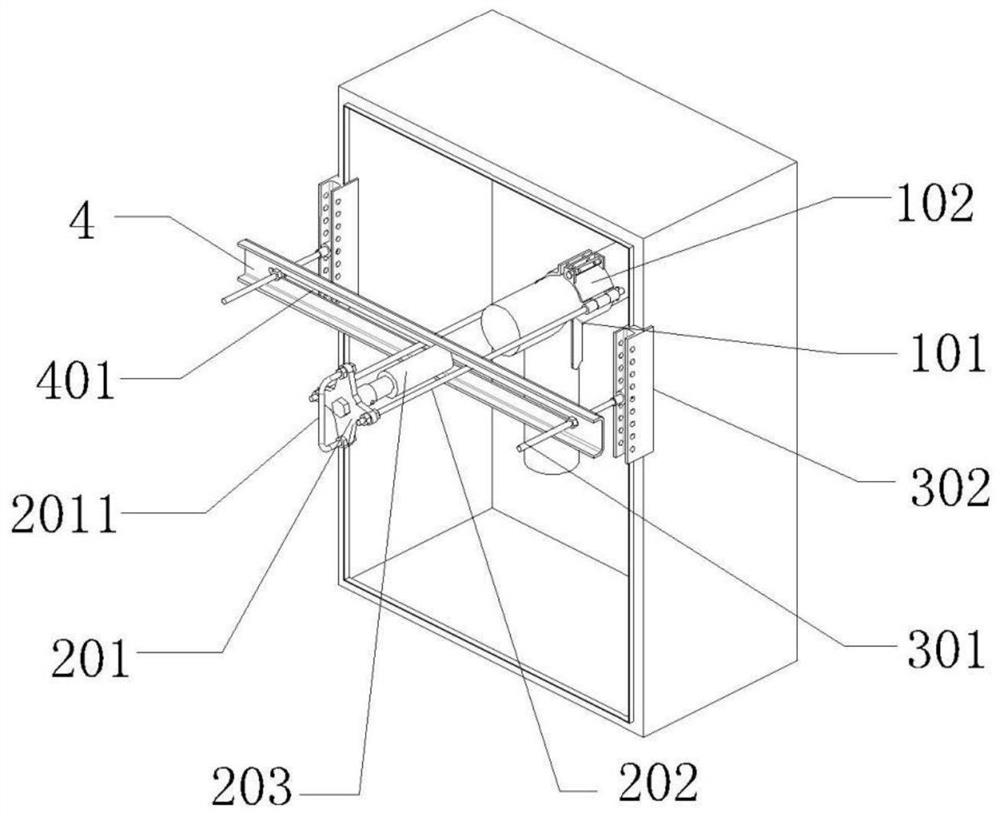

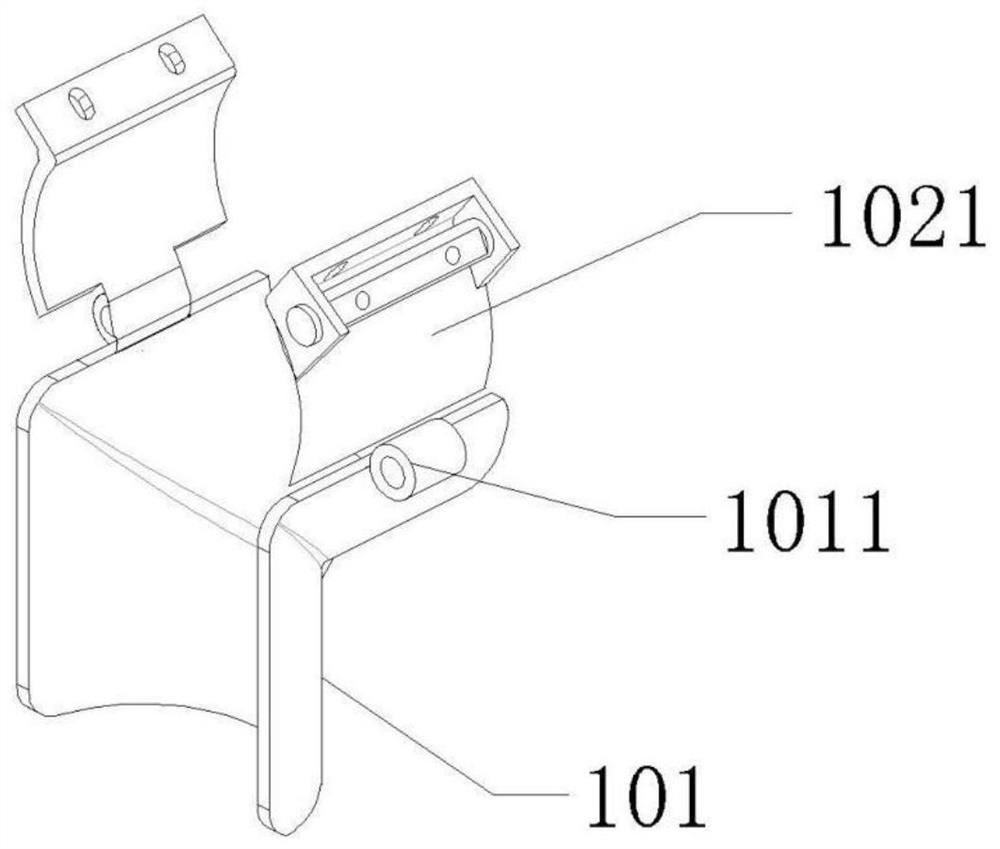

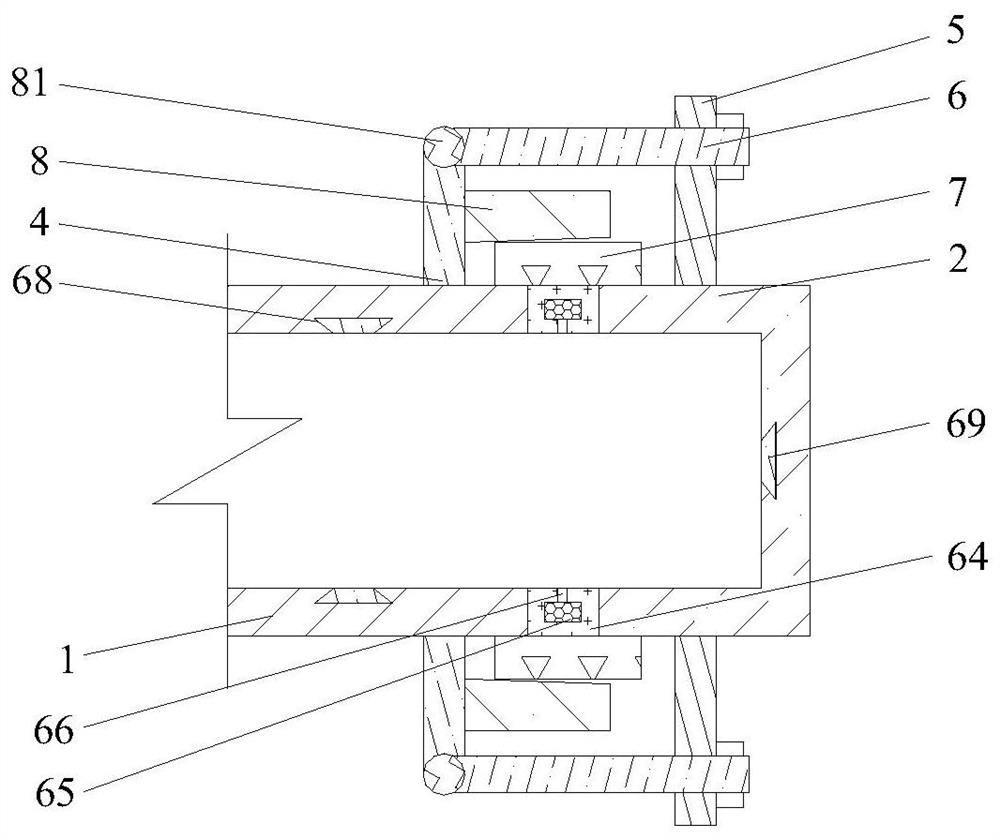

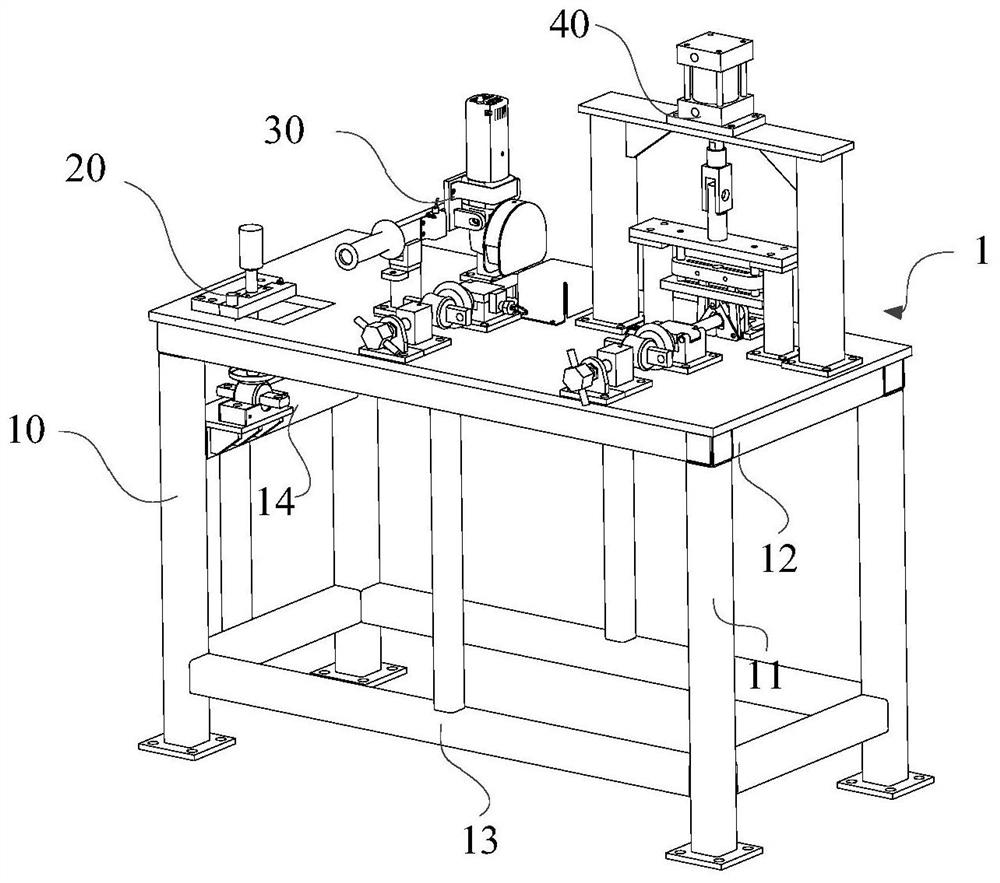

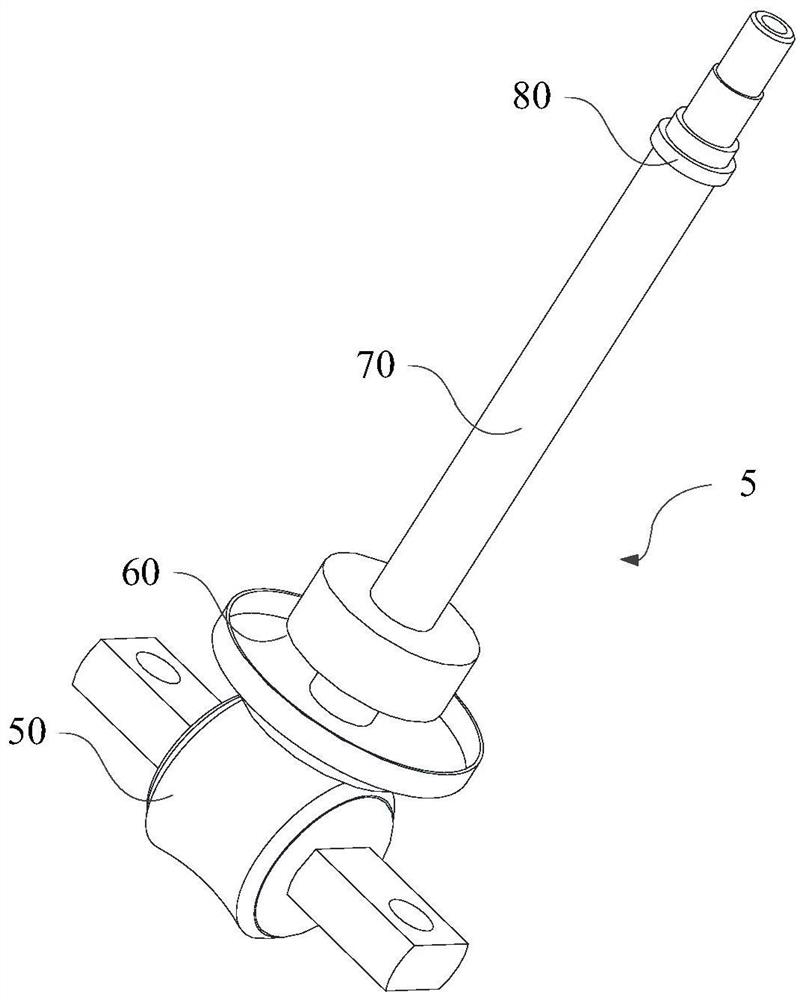

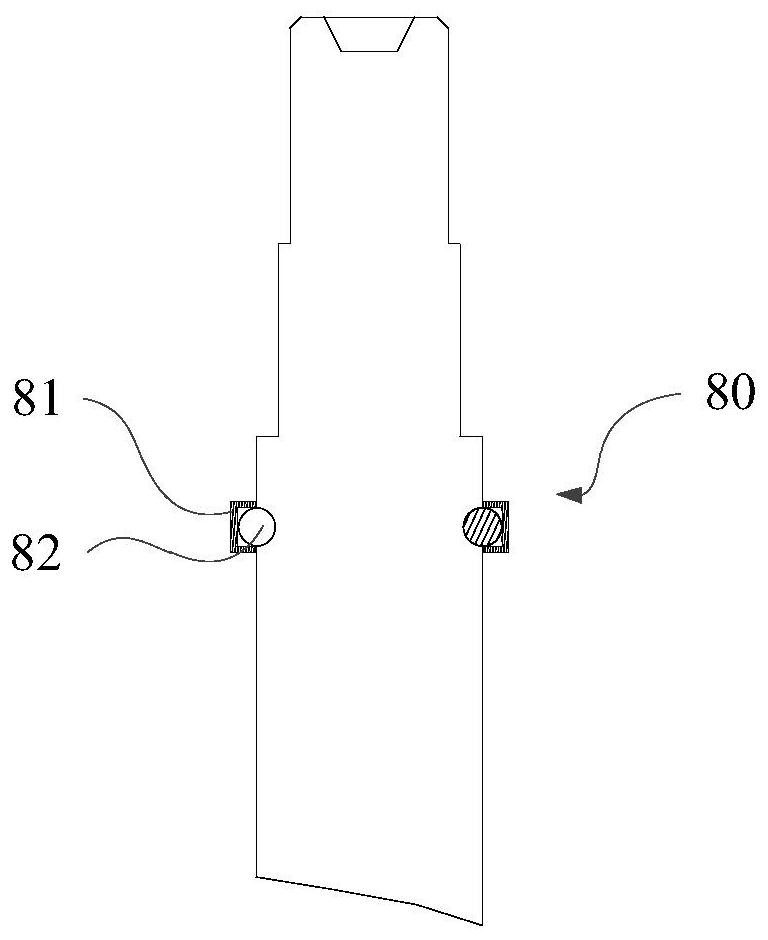

Rapid pulling-out device for elbow type cable head and using method of rapid pulling-out device

ActiveCN113241649AReduce the difficulty of dismantlingReduce labor intensityApparatus for joining/termination cablesSwitchgearStructural engineeringMechanical engineering

The invention discloses a rapid pulling-out device for an elbow type cable head and a using method of the rapid pulling-out device. The rapid pulling-out device comprises a fixing mechanism, a driving mechanism and a supporting mechanism, wherein the fixing mechanism comprises a first fixing piece and a second fixing piece, the top end of the first fixing piece is hinged to the bottom end of the second fixing piece, and the upper portion of the first fixing piece forms a cylinder matched with the horizontal part of the elbow type cable head; the driving mechanism comprises a mounting plate, the center of the end face of the mounting plate is fixedly connected with the top end of a hydraulic device, pull rods are symmetrically arranged on the two sides of the hydraulic device respectively, the top ends of the pull rods are fixedly connected with the mounting plate, and the bottom ends of the pull rods are detachably and fixedly connected with the first fixing piece; the supporting mechanism comprises supports which are parallel to the pull rods and arranged on the two sides of the hydraulic device respectively, and the bottom ends of the supports are connected with support bases which are connected with a box body of a power distribution cabinet; and a connecting plate is arranged between the two supports, and the bottom end of the hydraulic device is connected with the connecting plate in a sliding mode. With the rapid pulling-out device, cable head dismounting difficulty and the labor intensity of workers are reduced, working efficiency is improved, and the cable head and the box body of the power distribution cabinet are prevented from being damaged.

Owner:GUIZHOU POWER GRID CO LTD

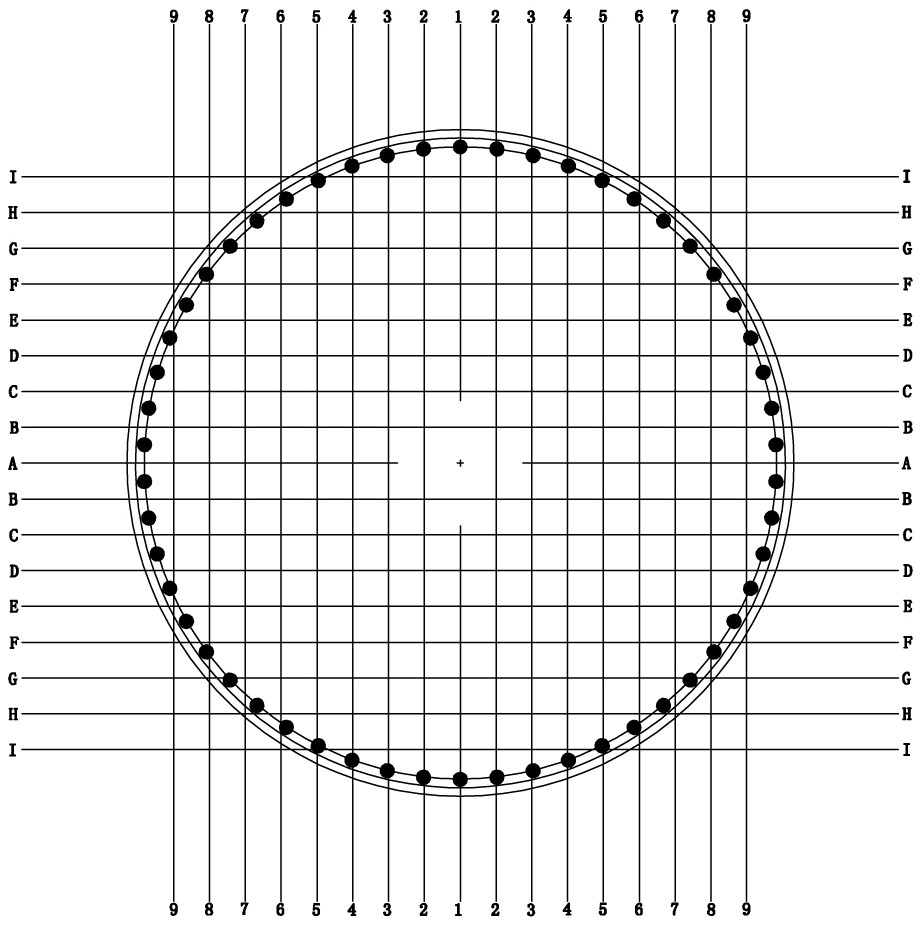

Construction method of large silo dome concrete

PendingCN112554534AShorten the construction periodReduce investmentBuilding support scaffoldsRebarSteel tube

The invention relates to the field of building construction, in particular to a construction method of large silo dome concrete. The large silo dome concrete comprises the following steps: 1) when a silo wall is constructed to an elevation, pre-burying a plurality of pull rings at a certain distance from the lower part of a top beam of the silo wall, and mounting steel suspension cables on the pull rings, so that all the steel suspension cables are arranged into a steel cable net in a criss-cross manner; 2) prefabricating a central net rack and a fan-shaped net rack; 3) hoisting and fixing thecentral net rack and the fan-shaped net rack on the steel cable net; 4) erecting formwork supporting scaffolds on the net racks; 5) measuring downwarp amount of the steel cable net after performing pre-compaction for a period of time based on weight of cast-in-situ reinforced concrete at a silo dome, and adjusting stretching height of a supporting vertical rod based on the downwarp amount after dismantling; 6) erecting a dome formwork; (7) pouring dome concrete; and (8) disassembling a steel pipe supporting frame and the dome formwork. According to the construction method, the construction efficiency is greatly improved, the construction period is shortened, and the construction cost is lowered.

Owner:CHINA NO 15 METALLURGICAL CONSTR GRP

Combined steel structure capping block and segment

PendingCN108678773AEasy accessFacilitate internal and external communicationUnderground chambersTunnel liningEngineeringSafety risk

The invention discloses a combined steel structure capping block and a segment and solves the problem of inconvenience in internal and external contact when shield whole ring erection segments pass through an air shaft or structures similar to the air shaft through no-load pushing. The capping block can be reused, hoop stress among negative ring segments can be relieved during dismounting of firstblocks, and the dismounting difficulty and safety risk are greatly reduced. The technical scheme is as follows: the capping block comprises a first arc-shaped end plate and a second arc-shaped end plate, first ends of the first arc-shaped end plate and the second arc-shaped end plate are connected through a first side connecting plate, seconds ends of the first arc-shaped end plate and the secondarc-shaped end plate are connected through a second side connecting plate, and the first arc-shaped end plate, the second arc-shaped end plate, the first side connecting plate and the second side connecting plate define a frame type structure with a cavity.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD +3

A support module for deposition molding 3D printing and its generation method

InactiveCN105058798BReduce the difficulty of dismantlingReduce spacingAdditive manufacturing apparatus3D object support structuresFixation pointComputer module

The invention discloses a supporting module for fused deposition modeling three-dimensional printing and a generating method of the supporting module. The supporting module is used for supporting the suspended portion of a model needing three-dimensional printing. The supporting module comprises multiple supporting units arranged at intervals to provide multiple fixation points for the suspended portion. Compared with an original supporting module, the supporting module can be more easily removed from the suspended portion of the model while the supporting performance is kept.

Owner:PANOWIN TECH

Assembly type variable steel girder platform, distribution method and assembly method thereof

ActiveCN101824905BEasy to set upImprove construction periodBuilding support scaffoldsWork periodDistribution method

The invention relates to an assembly type variable steel girder platform, a distribution method and an assembly method thereof. The platform is supported on a core tube, and is formed by sectional steel grinders through being fixedly connected, and the sectional steel grinders mainly consist of main stress grinders, sub stress grinders and support rods between grinders, wherein the main stress grinders are formed by main grinder standard nodes and main grinder groined node standard nodes through being dismountably connected via node plates with bolt holes, end sealing plates with bolt holes and screw bolts, the sub stress grinders are formed by sections of sub grinder standard sections through being dismountably connected end to end, and in addition, the sub stress grinders are dismountably connected between two main stress grinders. The platform can be applied to template lifting construction of high and superhigh building core tube steel platforms, and can also be used as platforms for large-area spanning construction operation and construction machine pile carrying and placement, the construction is very easy, the work period of the construction is greatly accelerated, and the construction cost is reduced.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +1

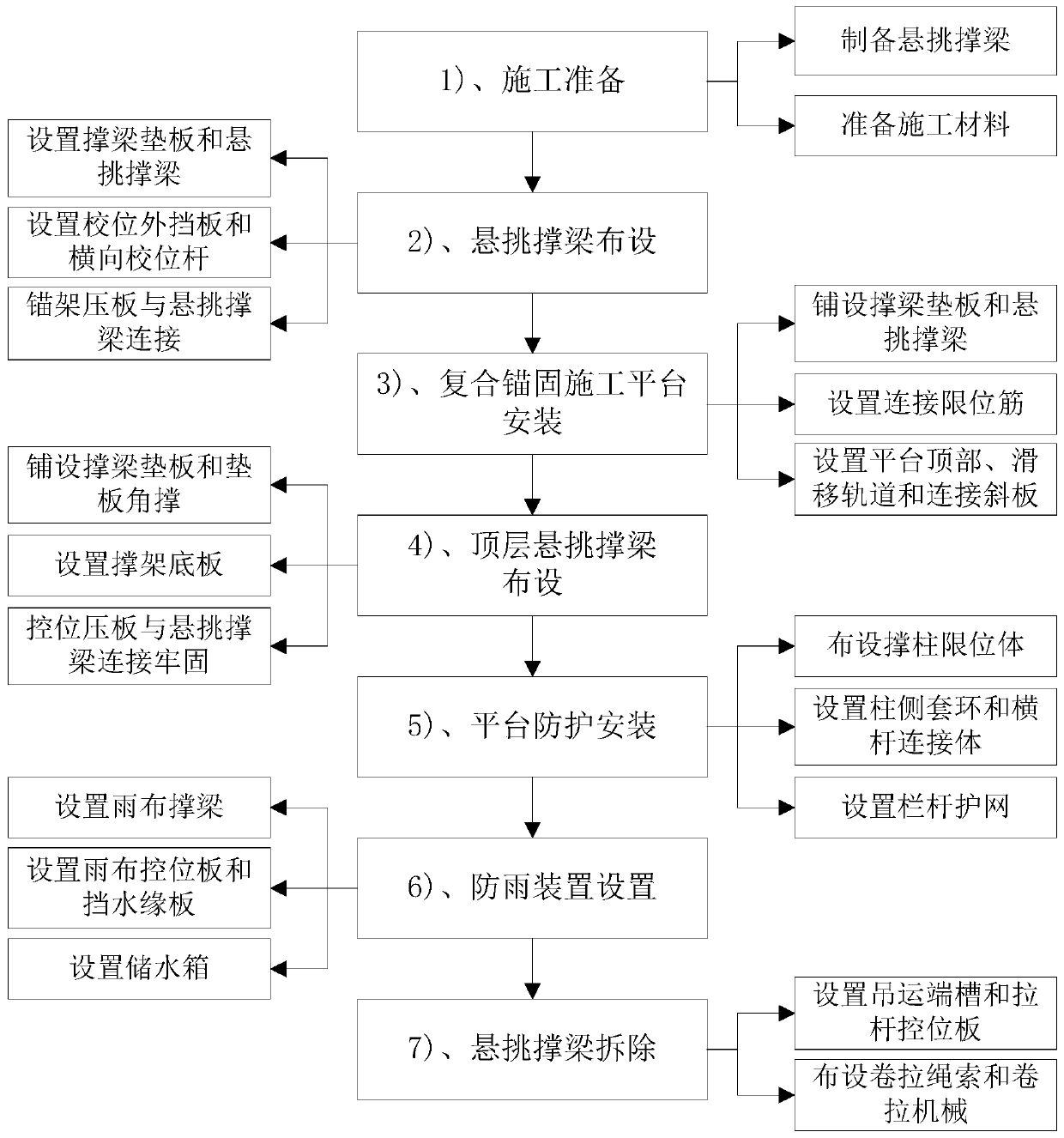

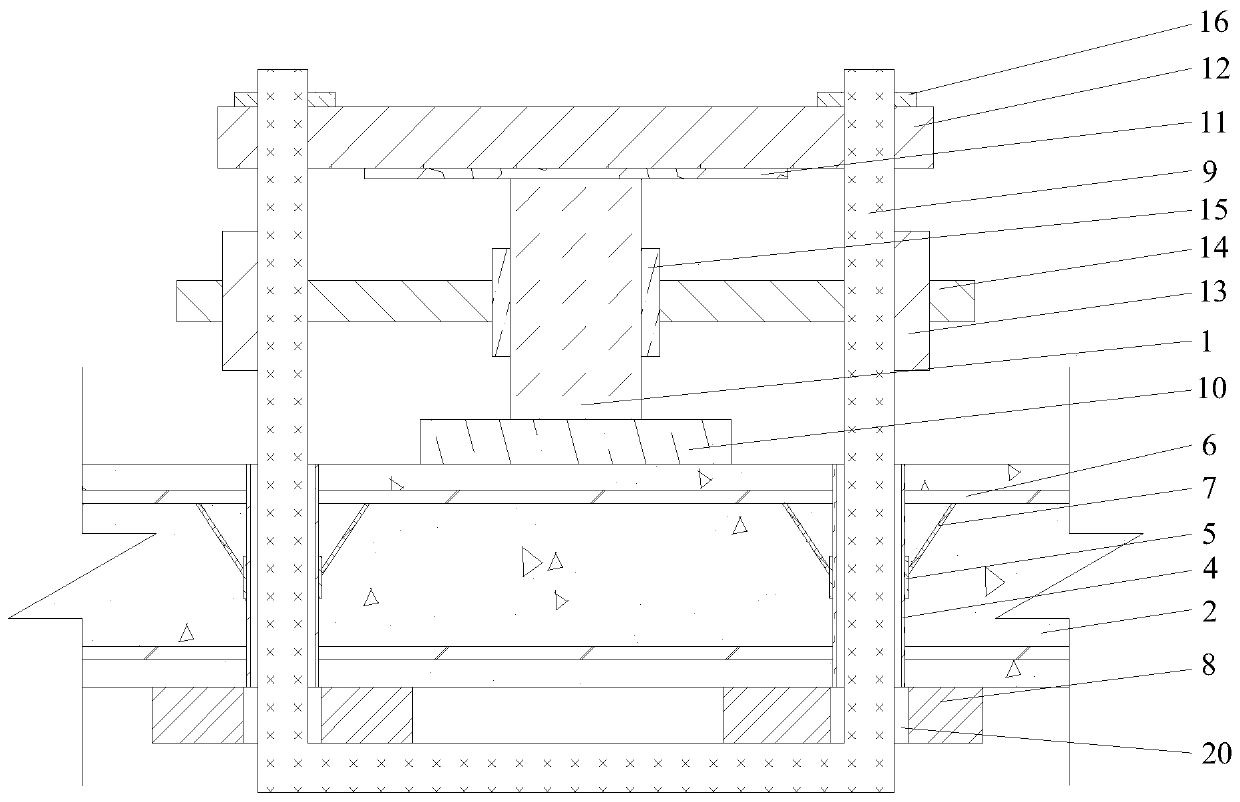

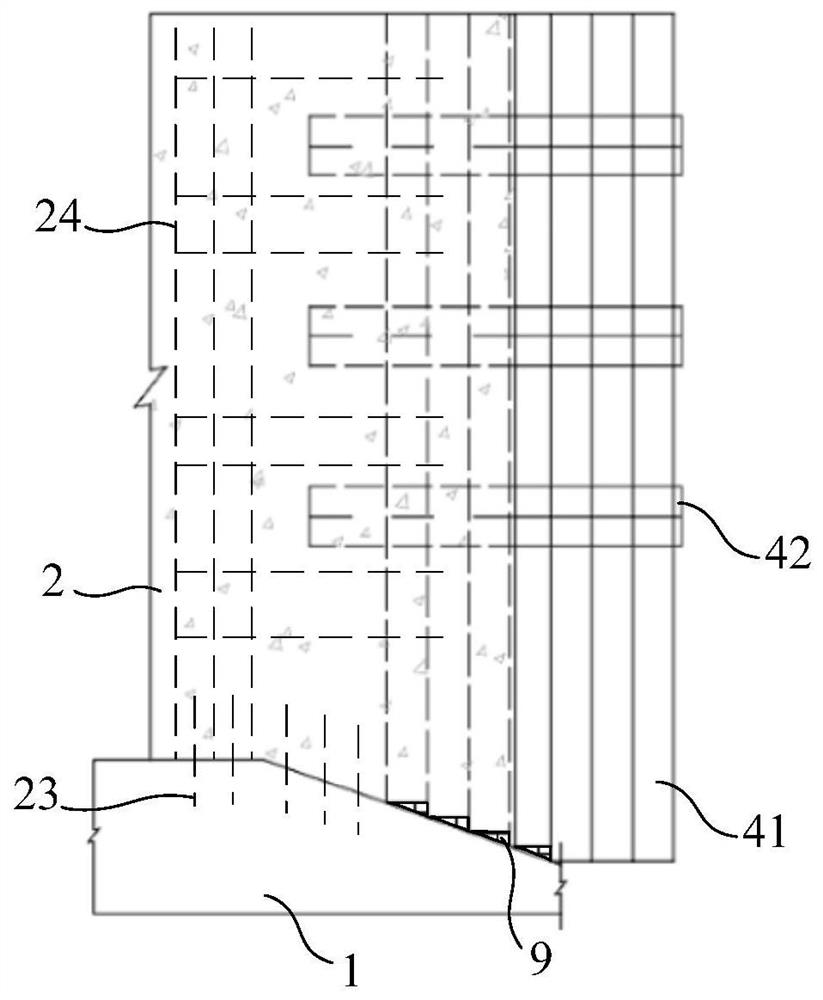

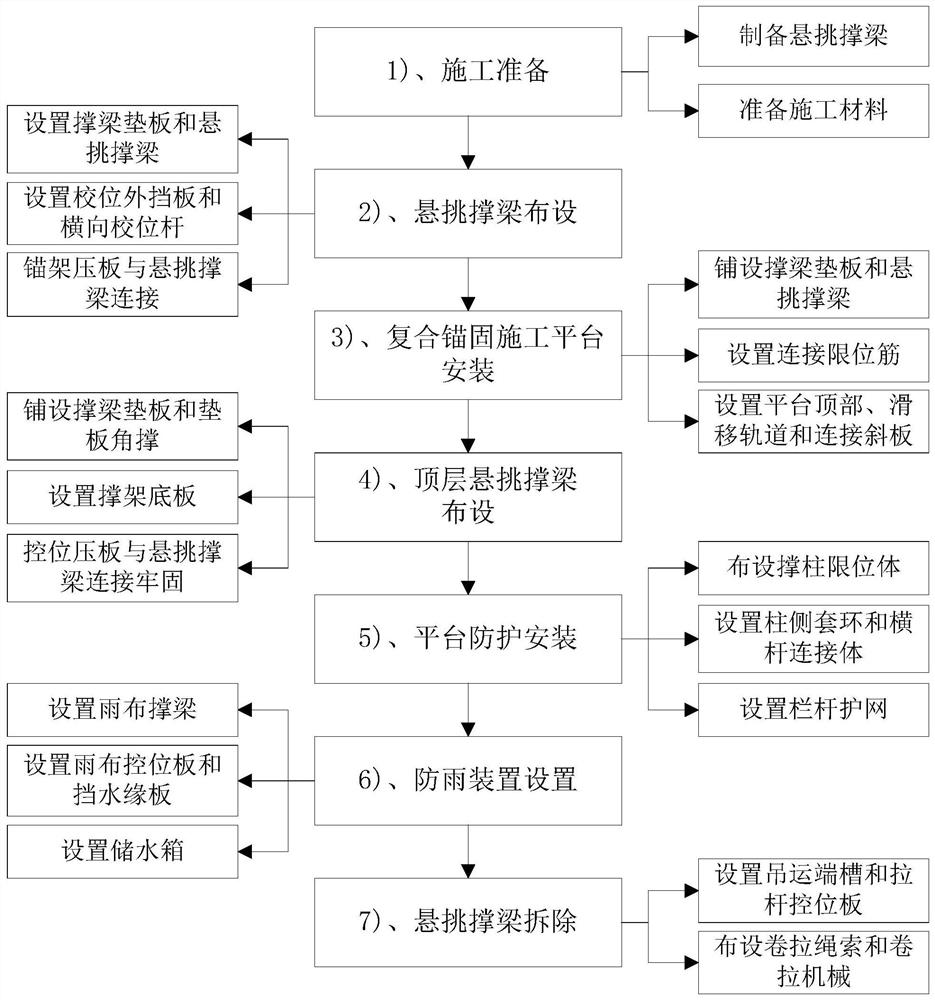

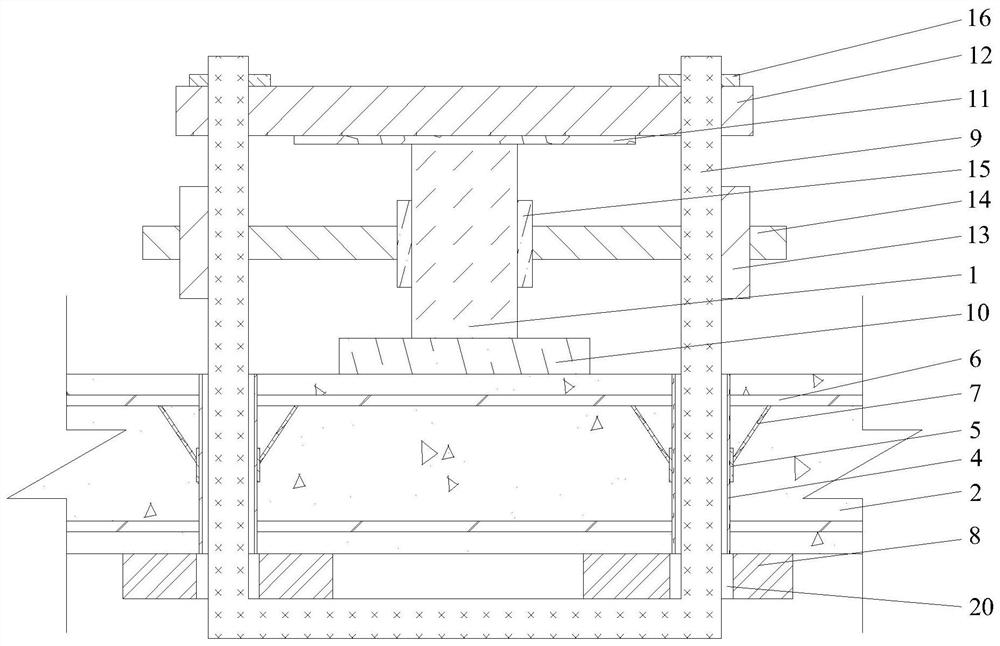

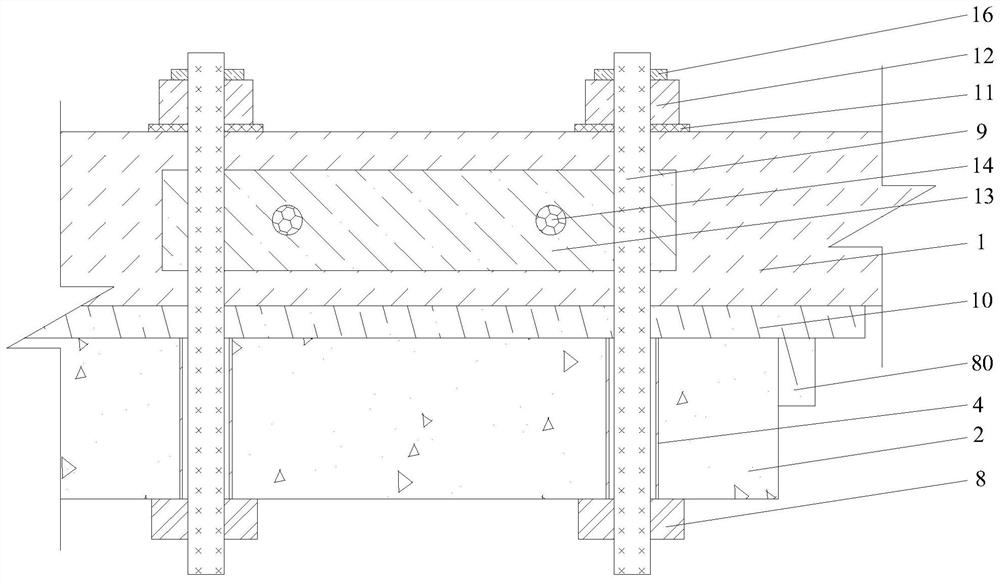

Circulation type composite anchor discharging platform and construction method thereof

ActiveCN110130656AAvoid damageMeet the needs of accurate alignmentBuilding material handlingEngineeringCantilever

The invention provides a circulation type composite anchor discharging platform and a construction method thereof. The construction method comprises the steps that a supporting beam base plate and a cantilever supporting beam are sequentially arranged on a supporting floor plate, and the position of the cantilever supporting beam is corrected by a lateral alignment rod; a limiting groove plate, asupporting column limiting body and a beam top connecting plate are arranged on the cantilever supporting beam, and a sliding material vehicle is arranged on a sliding rail; a supporting frame bottomplate is arranged on the supporting floor plate of the lower layer, and a bottom plate adjustable supporting rod, a bottom plate fixing supporting rod and a built-in ejector rod are arranged on the supporting frame bottom plate; cross bar connecting bodies are arranged on the vertical supporting columns, and a vertical pull rod is arranged between the beam top connecting plate and a horizontal connecting rod; an elastic control position body and a limit connecting rod are arranged between two rain cloth control position plates relative to mirror image; and a lifting pull rod sequentially penetrates through an end groove hanging plate, a pull rod control position plate and a pull rod guide body, the lifting pull rod is connected with a winding tow rope through a conversion baffle, the installation and construction efficiency of the discharging platform can be increased, the rainproof performance of the platform can be improved, and the construction difficulty in demolition of the cantilever supporting beam is reduced.

Owner:WENZHOU ZHONGSHUN BUILDING ENG

Composite polyolefin skin for surface of construction formwork, and preparation and use method of composite polyolefin skin

InactiveCN110527184AImprove protectionReduce the difficulty of disassemblyForming/stuttering elementsPolymer sciencePolyolefin

The invention relates to the technical field of construction formworks, and discloses a composite polyolefin skin for the surface of a construction formwork, and a preparation and use method of the composite polyolefin skin. The composite polyolefin skin is arranged to be in contact with the surface of the construction formwork, and is prepared from the following components in parts by weight: 80-90 parts of polyolefin, 15-25 parts of a controllable transfer assistant, 15-25 parts of filler, 5-15 parts of a flame retardant, 0.1-5 parts of an antioxidant, 0.1-5 parts of an anti-ultraviolet absorbent and 0.1-5 parts of a dispersant. The composite polyolefin skin adheres to the external surface of an existing construction formwork for use, demoulding performance is good, waterproof performance is good, and the composite polyolefin skin can be reused.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

The method of using siphon construction diversion pipe to make the construction conditions of river dry land

ActiveCN110378024BEasy to operateReduce stepsGeometric CADClimate change adaptationSiphonRiver routing

The invention provides a method for using a siphon-type construction diversion pipe to manufacture dry river construction conditions, the steps are as follows: record the river area where the construction conditions for river dry land are to be manufactured as the construction dry area, and the construction dry area is located at the water retaining area of the river Downstream of the building; determine the backwater area downstream of the construction dry area, and the back water area is adjacent to the construction dry area; install a siphon construction at the water-retaining building to transport the water upstream of the water-retaining building to the downstream of the backwater area Diversion pipe: Create a vacuum condition for the siphon construction diversion pipe to transport the water in front of the water-retaining building to the downstream of the backwater area through the siphon construction diversion pipe. When the water in the target area flows out of the target area, the construction The dry area forms the construction conditions of river dry land. The method can significantly reduce the project investment, simplify the manufacturing operation of the construction conditions of the river dry land, avoid the hidden danger of flooding, and has the characteristics of being more environmentally friendly.

Owner:SICHUAN UNIV

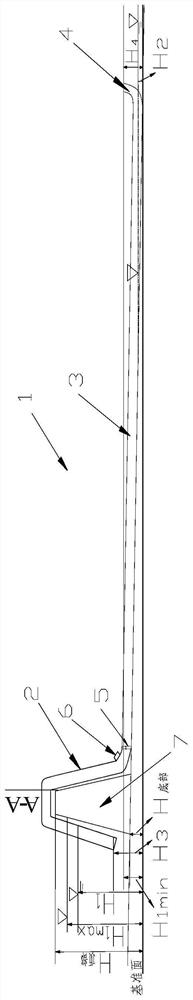

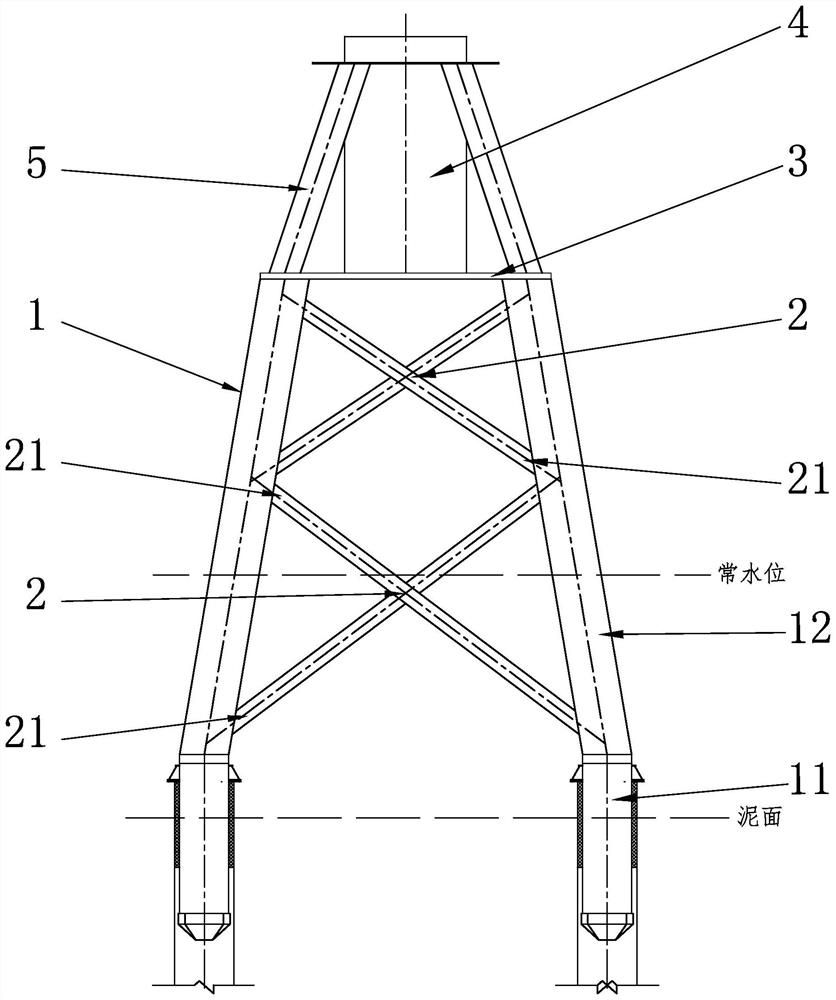

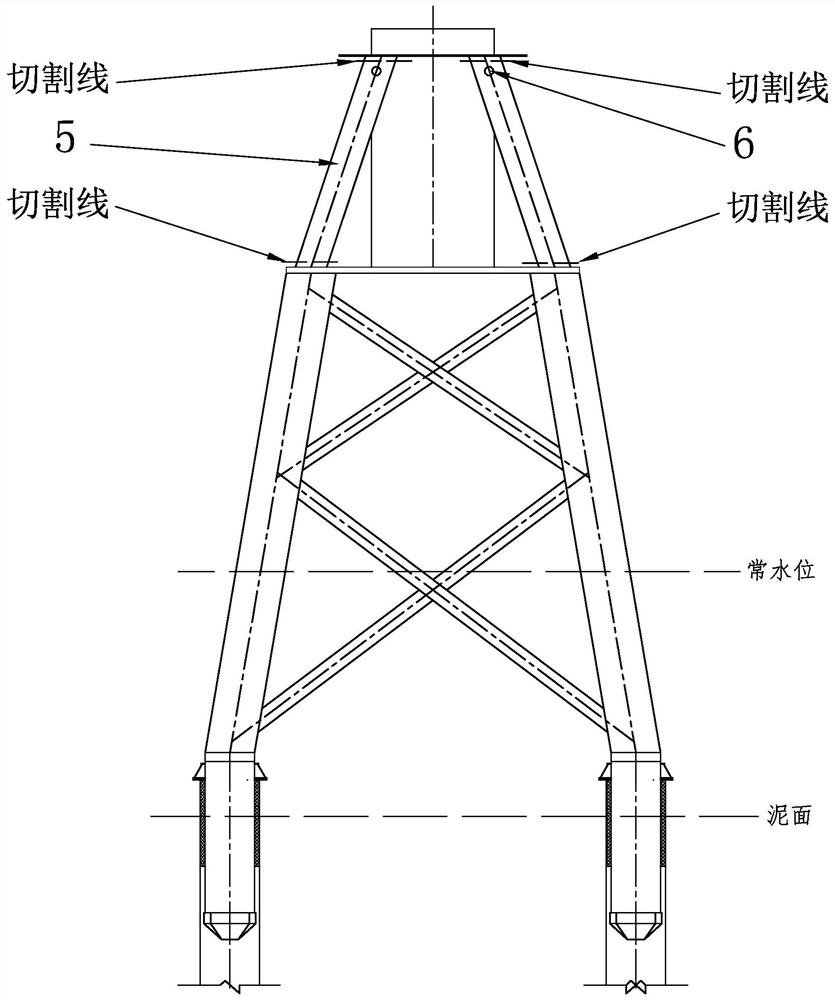

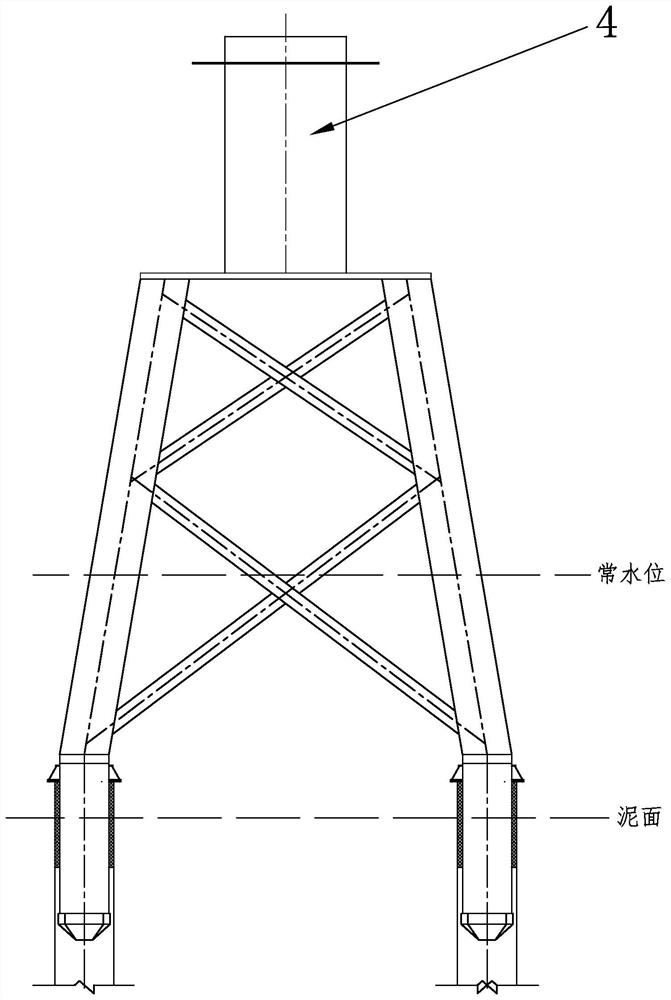

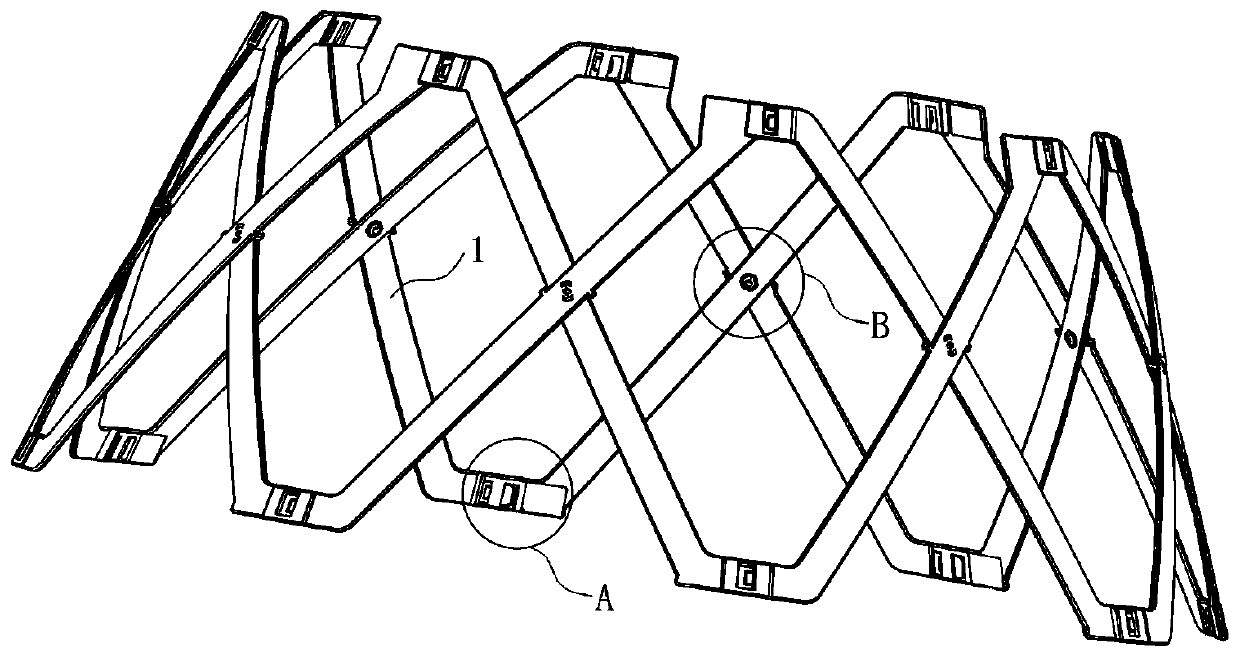

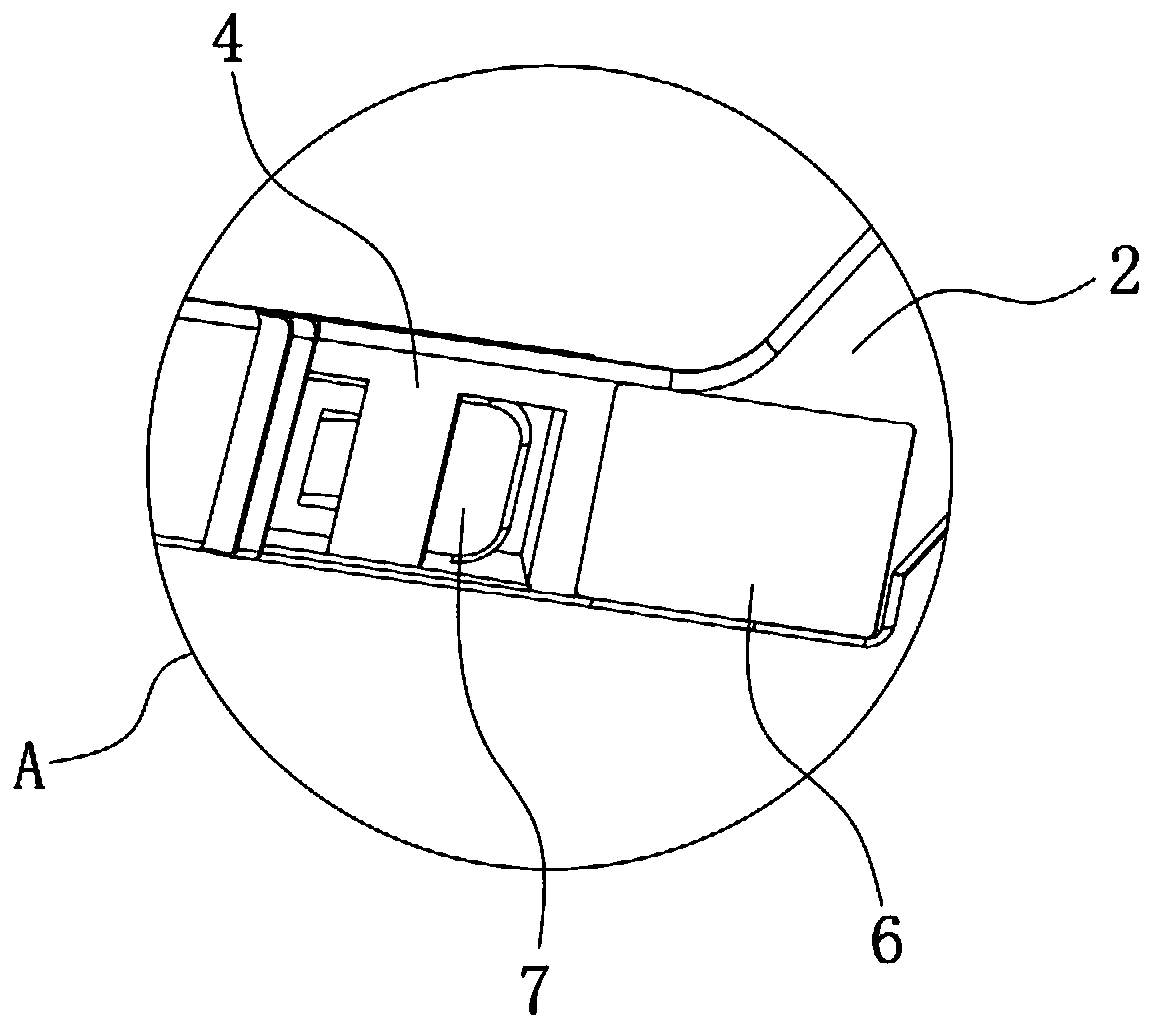

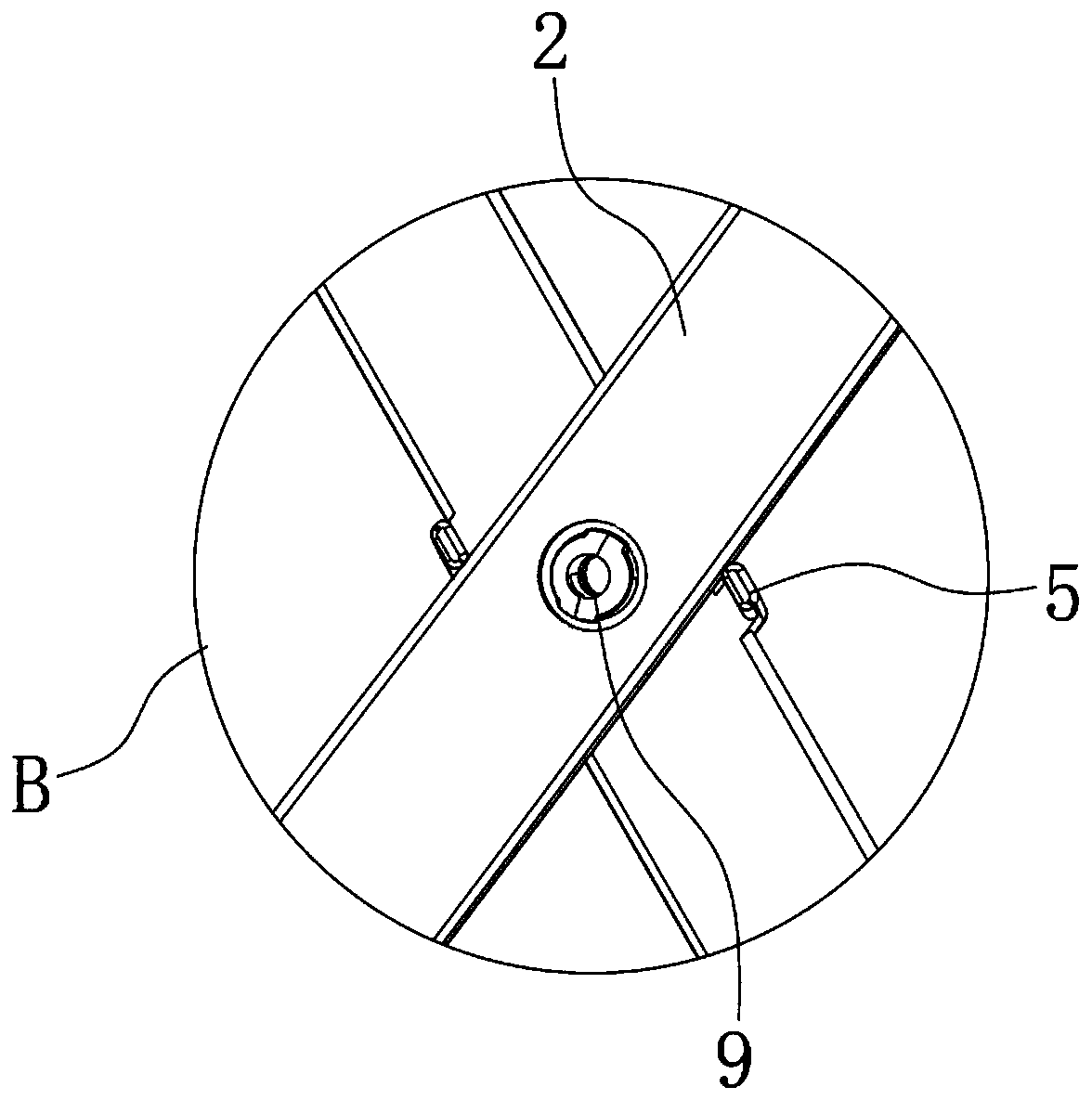

A method for removing the foundation of an offshore wind power jacket

ActiveCN110965804BAvoid safety hazardsReduce volumeBuilding repairsElectrical conductorMarine engineering

The invention relates to the technical field of offshore wind power engineering, and discloses a method for dismantling the foundation of an offshore wind power jacket, including construction preparation, dismantling of the diagonal bracing of the transition section, dismantling of the transition section, dismantling of the steel platform, dismantling of the reinforcing support, steel The dismantling of the upper part of the pipe pile and the dismantling of the lower part of the steel pipe pile are carried out by dismantling in sections and layers from top to bottom, which makes the selection of marine machinery and equipment more flexible for construction and avoids dependence on large-scale proprietary equipment; In addition, segmental lifting points are set to prevent safety accidents caused by unbalance in the dismantling process. The cutting of underwater steel pipe piles adopts the method of first pumping mud and then cutting steel pipe piles, so as to ensure the accuracy requirements after completion and the navigation requirements of sea areas; Potential safety hazards during the demolition process of the jacket foundation, accurately control the accuracy of the demolition process, and ensure the normal operation and safe navigation of the wind farm during and after the demolition.

Owner:南方海上风电联合开发有限公司 +1

Cross type tree skirt frame

InactiveCN111527959AEasy to assemble and disassembleReduce the difficulty of assemblyMachine supportsFlower holdersEngineeringStructural engineering

Owner:CENTRESKY CRAFTS (SHANTOU) CO LTD

A mold and prefabrication method suitable for producing assembled underpass tunnel frames by long-line matching method

ActiveCN110497511BAvoid the risk of deformationReduced strength requirementsMouldsMechanical engineeringLine matching

Owner:成都城投城建科技有限公司

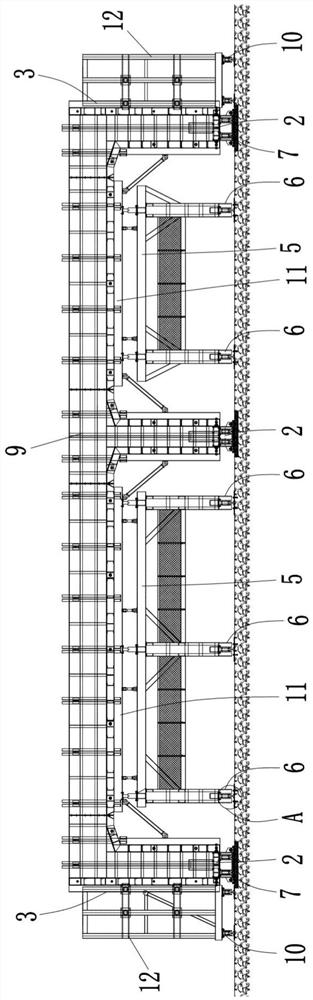

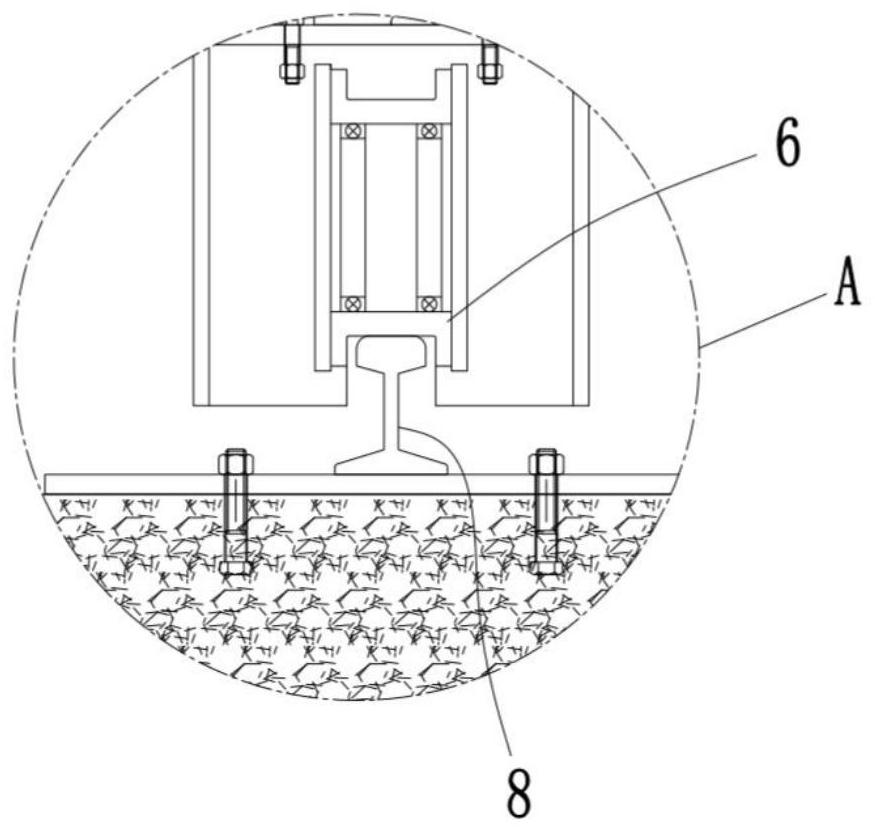

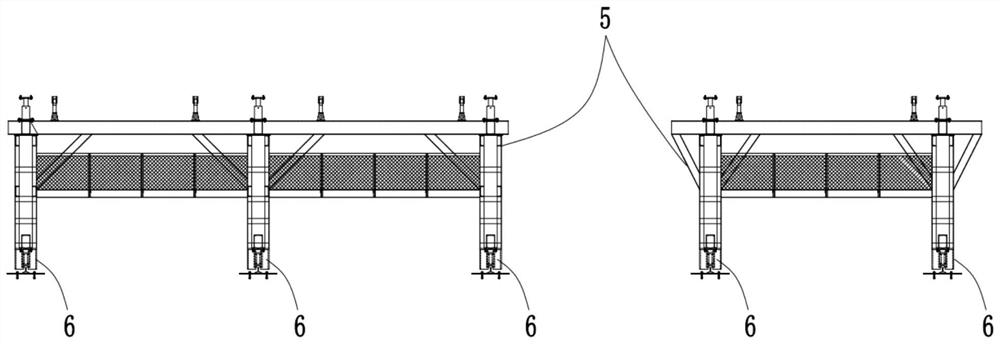

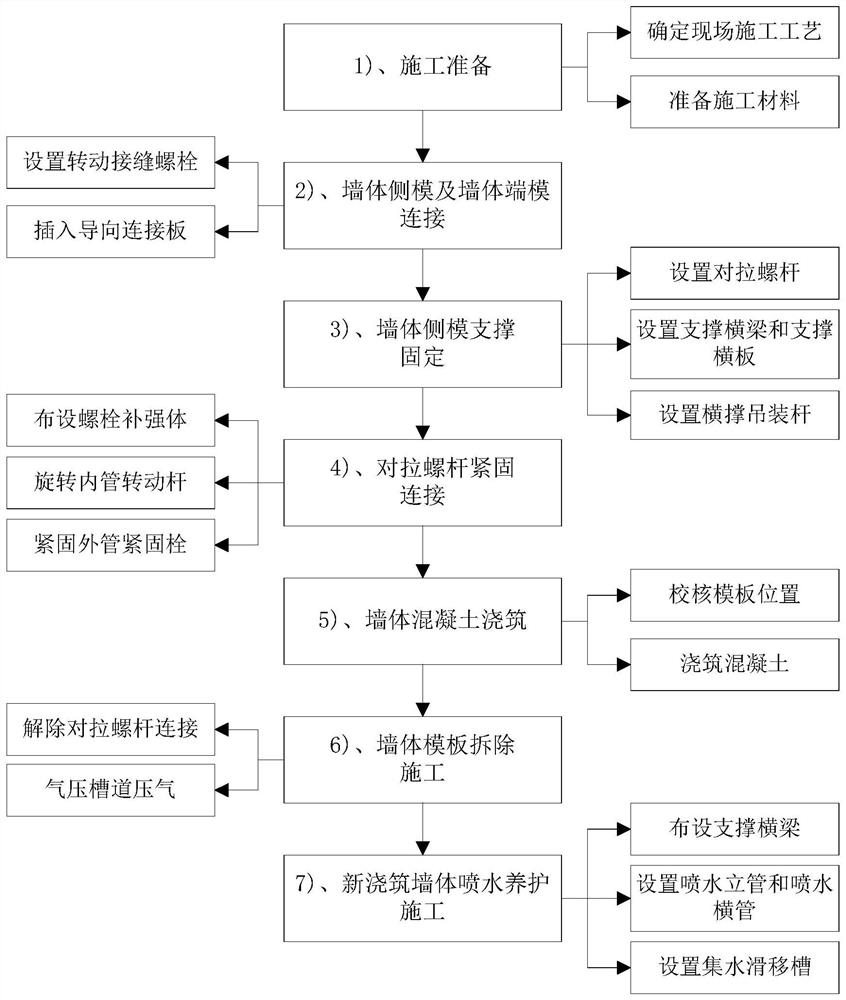

Integral assembly of large formwork narrow space wall and construction method

ActiveCN110424722BImprove airtightnessImprove connection strengthForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringStructural engineering

The invention relates to an integrally assembled large formwork narrow space wall and a construction method. An expansion control body is arranged in the joint strip of the wall side formwork; a joint is provided between the wall side formwork and the joint between the wall body formwork and the wall end formwork Groove plate, guide connecting plate and rotating joint bolts; a horizontal support composed of supporting outer tube and supporting inner tube is set between the wall side formwork and the external wall; after the hoisting connection falcon is connected with the hoisting connection groove, through The formwork lifting rod is used for hoisting construction of the side formwork of the wall; the pull screw is composed of a fastening outer tube, a retractable inner tube, an outer tube fastening bolt and a protective sleeve, and is connected with the bolt reinforcement; through the position control sling The vertical height of the maintenance bearing plate is controlled, and a sliding water collection tank is set at the lower part of the maintenance bearing plate, and elastic sealing ribs are set between the support plate at the bottom of the plate and the sealing body on the side of the tank. The invention can improve the supporting quality of the formwork of the wall, reduce the construction difficulty of formwork supporting and concrete maintenance, improve the mechanical performance of the construction structure and protect the construction environment.

Owner:倡创(上海)咨询管理事务所

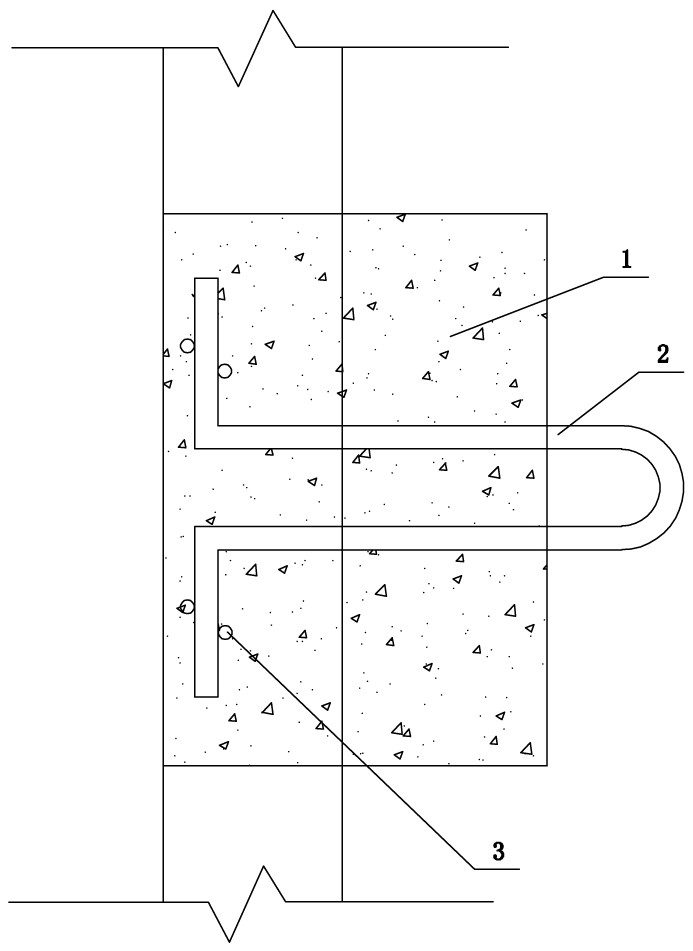

Steel sheet pile and concrete wall combined cofferdam structure and construction method

The invention relates to the technical field of underwater foundation construction, in particular to a steel sheet pile and concrete wall combined cofferdam structure and a construction method. The steel sheet pile and concrete wall combined cofferdam structure comprises a wall body assembly built on bedrock on a shore, the wall body assembly comprises a first wall body and a second wall body and a steel sheet pile assembly. The first wall body and the second wall body are oppositely arranged, and a first supporting rod is arranged between the first wall body and the second wall body; at least part of the steel sheet pile assembly is located in water, one end of the steel sheet pile assembly is arranged in the first wall body, and the other end of the steel sheet pile assembly is arranged in the second wall body. According to the steel sheet pile and concrete wall combined cofferdam structure, the cofferdam structure is formed by arranging the wall body assembly, the steel sheet pile assembly and the first supporting rod arranged between the first wall body and the second wall body, the structural strength of the wall body assembly is improved, and therefore the overall structural strength of the cofferdam structure is improved, and the steel sheet pile and concrete wall combined cofferdam structure is simple in structure. The construction and dismantling difficulty of the cofferdam structure is reduced, the construction efficiency of the cofferdam structure is effectively improved, and the cost is effectively reduced.

Owner:CHINA RAILWAY 19TH BUREAU GRP FIFTH ENG CO LTD +1

Turnaround Composite Anchor Unloading Platform and Construction Method

ActiveCN110130656BAvoid damageMeet the needs of accurate alignmentBuilding material handlingFloor slabArchitectural engineering

The invention provides a turnover type composite anchoring unloading platform and a construction method, in which a support beam backing plate and a cantilever support beam are sequentially arranged on the support floor, and the position of the cantilever support beam is corrected by a horizontal calibration rod; Set the limit groove plate, the support column limit body and the beam top connecting plate, and set the sliding material truck on the slip track; set the support bottom plate on the lower support floor, and set the bottom plate on the support floor Adjustable struts, bottom plate fixed struts and built-in ejector rods; horizontal bar connectors are set on the vertical struts, and vertical tie rods are set between the beam top connecting plate and the horizontal connecting rods; An elastic position control body and a limit connecting rod are set between the plates; the hoisting pull rod passes through the end groove hanging plate, the pull rod position control plate and the pull rod guide in turn, and is connected with the coiled rope through the conversion baffle, which can lift the unloading The installation and construction efficiency of the platform can be improved, and the rainproof performance of the platform can be improved, and the difficulty of dismantling the cantilever beam can be reduced.

Owner:WENZHOU ZHONGSHUN BUILDING ENG

A prefabricated exterior wall structure based on bim technology

ActiveCN111691577BReduce the difficulty of dismantlingNot easy to damageCovering/liningsWallsExternal claddingMechanical engineering

A prefabricated exterior wall structure based on BIM technology, including an exterior wall body formed by splicing several exterior wall panels. Adapted positioning slots; a connection plate is provided on the outer side of the exterior wall panel, and a waterproof layer and a decorative layer are sequentially fixed on the side of the connection plate facing away from the exterior wall panel; the side of the exterior wall panel facing the connection plate is installed There are several suspension components, and through holes are opened on the corresponding positions of the suspension components on the connecting plate. On the exterior wall panel, a fragile part is fixed at the end of the through hole away from the exterior wall panel. The invention has the advantages of greatly reducing the difficulty of removing the facing layer during later maintenance, and not easily causing damage to the exterior wall body of the building when the facing layer is removed.

Owner:深圳市创远天成建筑设计有限公司

Dismantling device

ActiveCN113458751ALow demolition efficiencyReduce the difficulty of dismantlingVehicle dissasembly recoveryOther manufacturing equipments/toolsEngineeringWorkbench

The invention provides a dismantling device. The dismantling device comprises a workbench, a disassembling unit, a cutting unit and a dismantling unit; the disassembling unit comprises a first fixing base and a disassembling piece, the first fixing base is used for fixing a shock absorber, and the disassembling piece is used for abutting against the end face of a hoop and applying impact force to the hoop so as to separate the hoop from a clamping ring; the cutting unit comprises a second fixing base and a cutting tool, the second fixing base is used for fixing the shock absorber with the hoop removed, and the cutting tool can move relative to the second fixing base so as to be used for cutting the clamping ring on a connecting rod; and the dismantling unit is provided with a dismounting clamping hook assembly, the dismounting clamping hook assembly comprises two clamping hooks capable of being oppositely opened and closed, and the clamping hooks are used for separating the cut clamping ring when being opened so as to dismantle the clamping ring from the connecting rod. The dismantling device has high dismantling efficiency when dismantling a mechanical stop assembly.

Owner:CRRC TANGSHAN CO LTD

Equipment foundation reserved hole core convenient to dismantle and construction method thereof

Owner:CHINA ELEVENTH CHEM CONSTR

New Jersey guard bar structure convenient to disassemble and construction method

InactiveCN109750598AReasonable constructionEasy constructionBridge structural detailsBridge erection/assemblyEngineeringRebar

The invention provides a New Jersey guard bar structure convenient to disassemble and a construction method. The New Jersey guard bar structure comprises a precast box beam and a guard bar rebar skeleton. The construction method comprises the steps that construction are arranged; measuring and setting-out are conducted; pre-embedded rebars arrangement is conducted; a sulphur mortar area is poured;rebars are machined and mounted; templates are mounted; concrete is poured; template disassembling and curing are conducted; a mortar protection layer is poured; blocks are connected; and when disassembling is conducted, firstly, a mortar protection layer is crushed, then the sulphur mortar area and the guard bar rebar skeleton are cut off, after nuts among the blocks, steel fasteners and pre-embedded screw rods on the top surface are disassembled, the blocks are hung away one by one, tools are picked up, and field is cleaned.According to the New Jersey guard bar structure convenient to disassemble and the construction method, the technology is reasonable, construction of the New Jersey guard bar with a cast-in-situ structure is simple, in the premise of not reducing the protection effectof the guard bar, the New Jersey guard bar structure convenient to disassemble is adopted, use of large-scale disassembling equipment is avoided, disassembling difficulty is lowered, fast disassembling of the cast-in-situ guard bar is achieved, thus the disassembling efficiency is improved, meanwhile the condition of concrete crushed-block splashing is reduced, and traffic safety is not influenced.

Owner:CCCC FIRST HARBOR ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com