Municipal administration comprehensive pipe rack hydraulic trolley and construction method thereof

A technology of integrated pipe gallery and hydraulic trolley, which is applied in artificial islands, earthwork drilling, water conservancy projects, etc., can solve the problem of difficult demoulding, save labor, reduce the difficulty of demolition, and speed up the construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

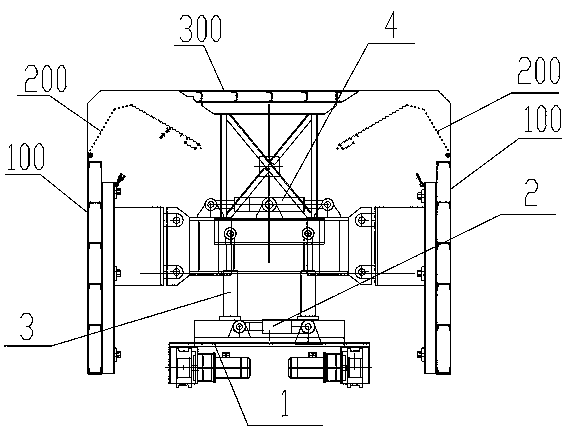

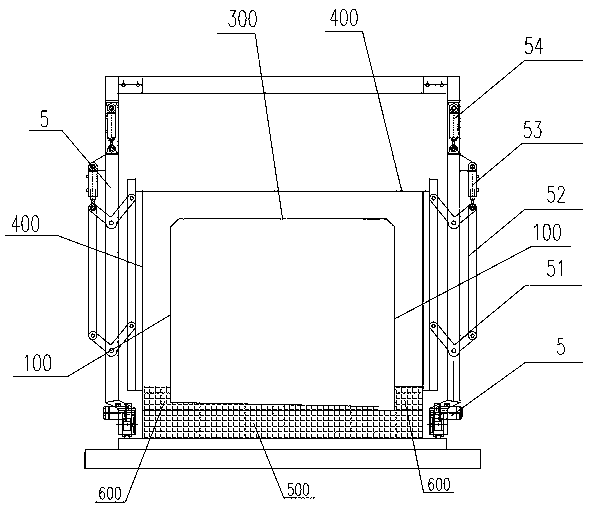

[0046] Please refer to image 3 As shown, the hydraulic trolley of the municipal comprehensive pipe gallery includes: an inner mold, an outer mold, and a pouring area for pouring the wall and roof of the municipal comprehensive pipe gallery is formed between the inner mold and the outer mold. It also includes: setting under the inner mold The inner formwork trolley 1, the inner formwork support assembly for supporting the inner mold, the outer formwork trolley 5 arranged under the outer mold, the inner mold trolley track for the inner formwork trolley 1 to walk, and the outer formwork trolley 5 to walk The outer mold trolley track;

[0047] The inner formwork support assembly is arranged on the inner formwork trolley 1, and the inner formwork support assembly is used to remove or support the inner formwork;

[0048] The track of the inner formwork trolley is laid on the bottom plate of the pipe gallery that has been poured, the track of the outer formwork trolley is located o...

Embodiment 2

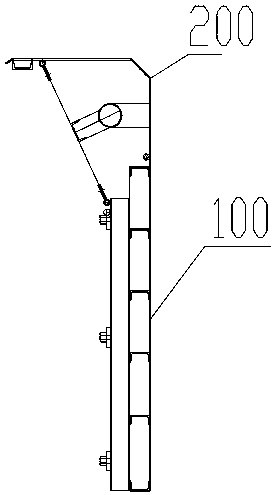

[0063] In this embodiment, an integral hydraulic formwork trolley is used for construction, and the wall and roof of the comprehensive pipe gallery are poured and formed at one time. The inner mold is composed of 5 templates: 2 side molds 100+2 chamfering molds 200+1 top mold 300, the outer mold is a whole large template, the integrity of the template is good, the installation and disassembly efficiency is high, safe and practical, the inner mold The panel adopts composite stainless steel panel, which improves the appearance quality of the inner wall of the comprehensive pipe gallery. The length of the hydraulic trolley for the municipal comprehensive pipe gallery is designed to be 5m. The hydraulic trolley for the municipal comprehensive pipe gallery is divided into inner formwork trolley 1 and outer formwork trolley 5. The hydraulic trolley for the municipal comprehensive pipe gallery includes the walking system, the main body of the bench, the hydraulic system, Inner mold, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com