New Jersey guard bar structure convenient to disassemble and construction method

A guardrail structure and easy-to-remove technology, which is applied to bridge parts, erection/assembly bridges, bridges, etc., can solve the problems of broken concrete blocks splashing, time-consuming and labor-intensive construction, and affecting driving safety, etc. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

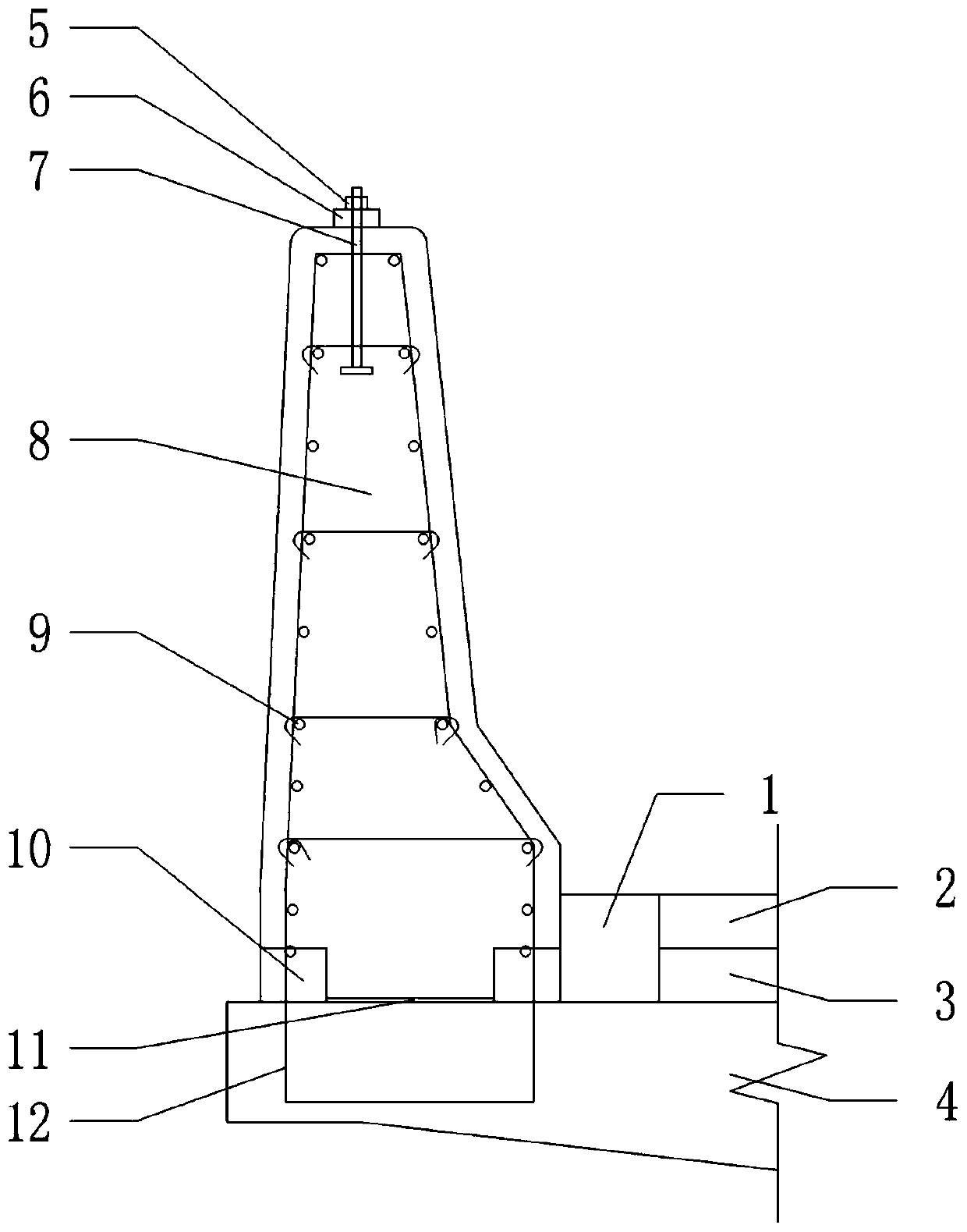

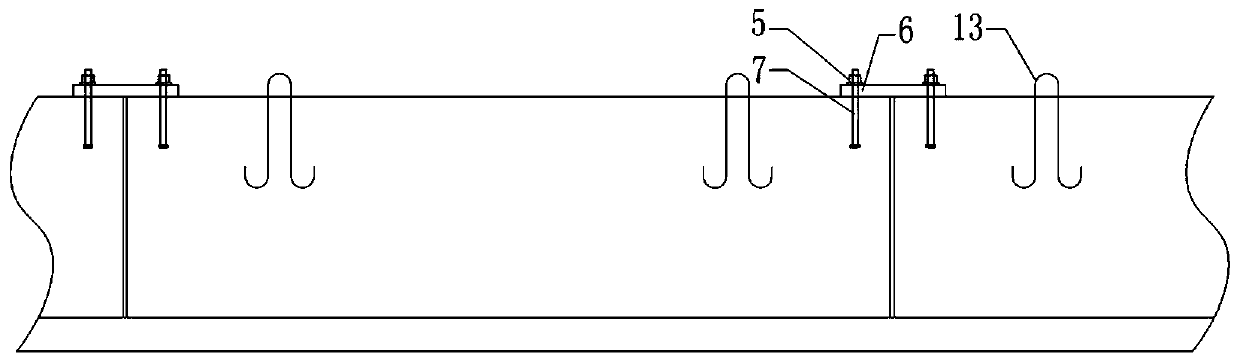

[0045]An easy-to-remove guardrail structure in New Jersey, comprising a prefabricated box girder 4 and a guardrail steel skeleton 9, characterized in that the prefabricated box girder 4 is installed on the lower surface of the external bridge deck integration layer 3, and the bridge deck integration layer The upper surface of the bridge deck 3 is laid with a bridge deck asphalt pavement layer 2, and the inside of the prefabricated box girder 4 is equipped with a prefabricated box girder pre-embedded guardrail reinforcement 12, and the guardrail reinforcement skeleton 9 is located above the prefabricated box girder 4. The bottom of the guardrail reinforcement skeleton 9 is fixedly connected with the prefabricated box girder pre-embedded guardrail reinforcement 12, and the left and right joints of the prefabricated box girder 4 and the guardrail reinforcement skeleton 9 are correspondingly poured with sulfur mortar belts 10, and the left and right sulfur An anti-adhesive film 11 ...

Embodiment 2

[0062] An easy-to-remove guardrail structure in New Jersey, comprising a prefabricated box girder 4 and a guardrail steel skeleton 9, characterized in that the prefabricated box girder 4 is installed on the lower surface of the external bridge deck integration layer 3, and the bridge deck integration layer The upper surface of the bridge deck 3 is laid with a bridge deck asphalt pavement layer 2, and the inside of the prefabricated box girder 4 is equipped with a prefabricated box girder pre-embedded guardrail reinforcement 12, and the guardrail reinforcement skeleton 9 is located above the prefabricated box girder 4. The bottom of the guardrail reinforcement skeleton 9 is fixedly connected with the prefabricated box girder pre-embedded guardrail reinforcement 12, and the left and right joints of the prefabricated box girder 4 and the guardrail reinforcement skeleton 9 are correspondingly poured with sulfur mortar belts 10, and the left and right sulfur An anti-adhesive film 11...

Embodiment 3

[0079] An easy-to-remove guardrail structure in New Jersey, comprising a prefabricated box girder 4 and a guardrail steel skeleton 9, characterized in that the prefabricated box girder 4 is installed on the lower surface of the external bridge deck integration layer 3, and the bridge deck integration layer The upper surface of the bridge deck 3 is laid with a bridge deck asphalt pavement layer 2, and the inside of the prefabricated box girder 4 is equipped with a prefabricated box girder pre-embedded guardrail reinforcement 12, and the guardrail reinforcement skeleton 9 is located above the prefabricated box girder 4. The bottom of the guardrail reinforcement skeleton 9 is fixedly connected with the prefabricated box girder pre-embedded guardrail reinforcement 12, and the left and right joints of the prefabricated box girder 4 and the guardrail reinforcement skeleton 9 are correspondingly poured with sulfur mortar belts 10, and the left and right sulfur An anti-adhesive film 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com