Patents

Literature

503 results about "Mooring line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

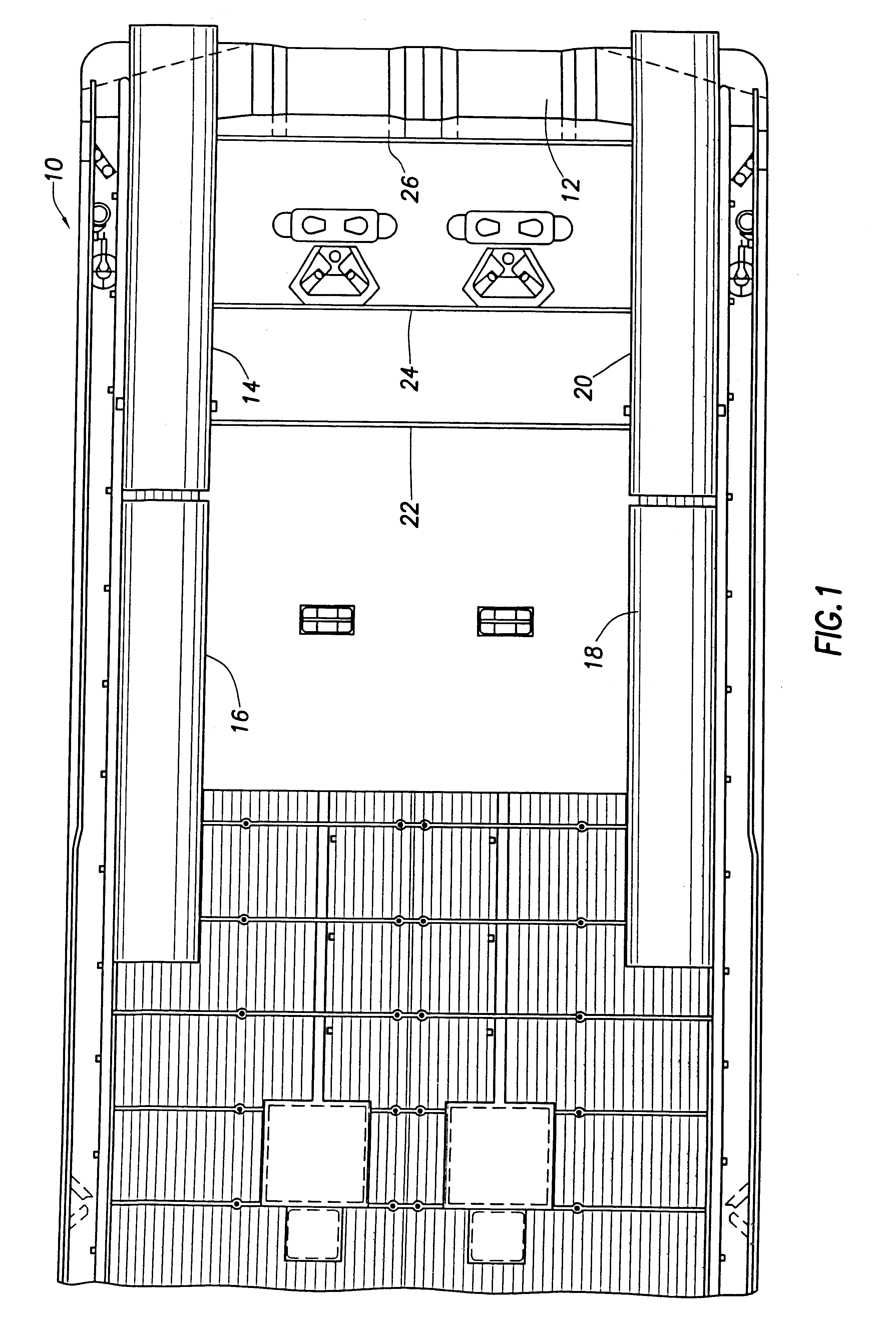

Offshore floating production, storage, and off-loading vessel for use in ice-covered and clear water applications

InactiveUS20090126616A1Reduces dynamic amplificationReduce resonanceProtective foundationMovement controllersResonanceBuoy

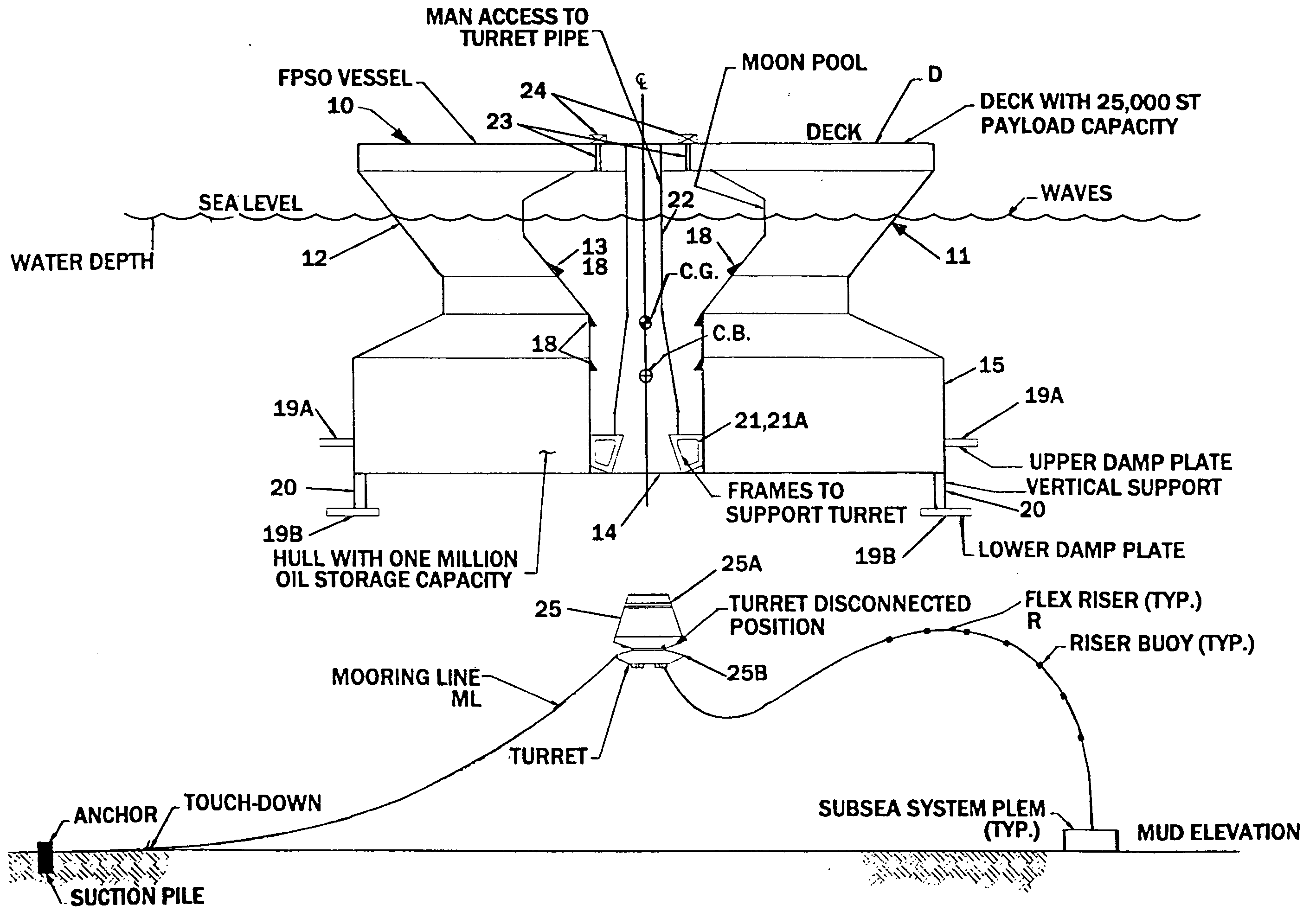

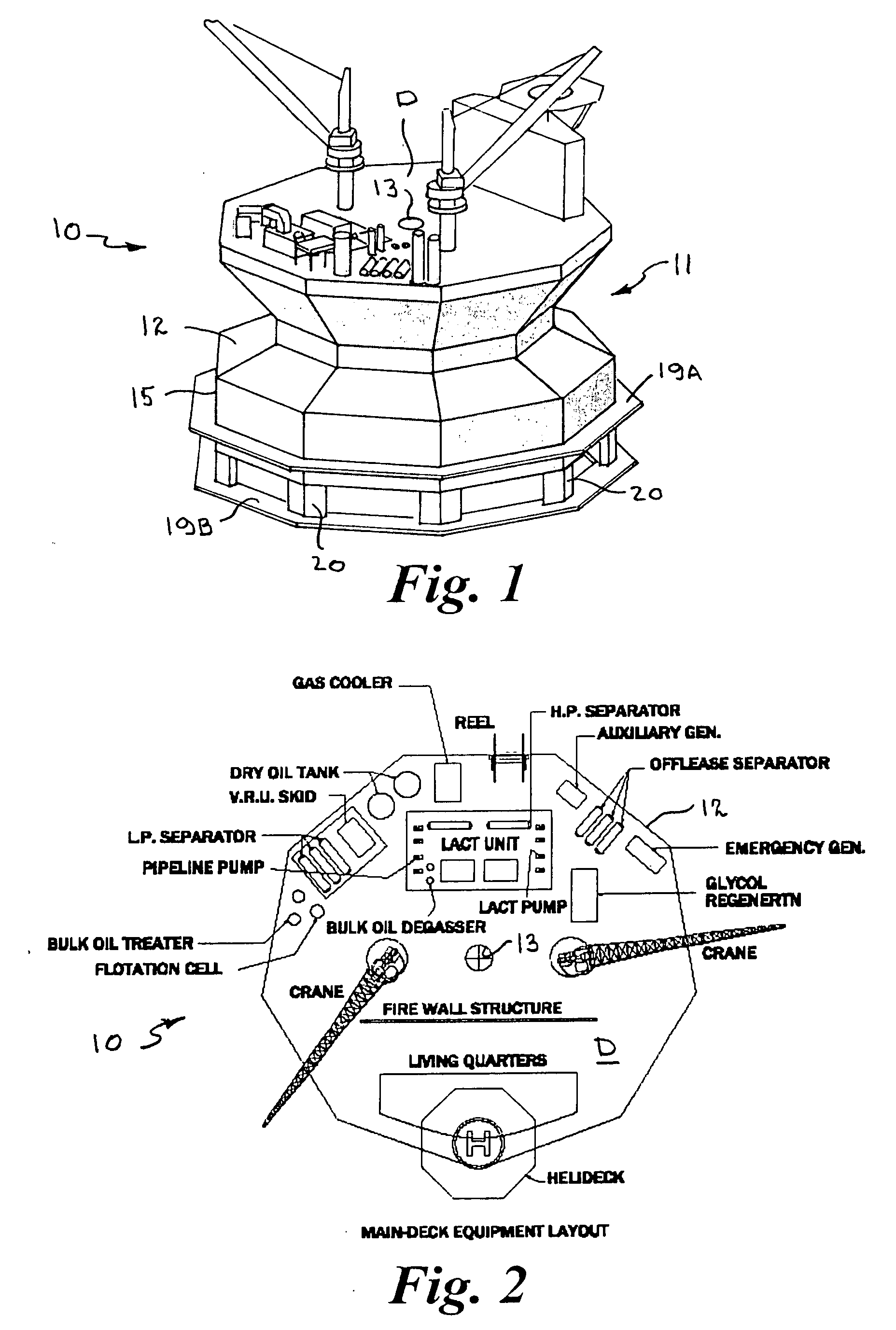

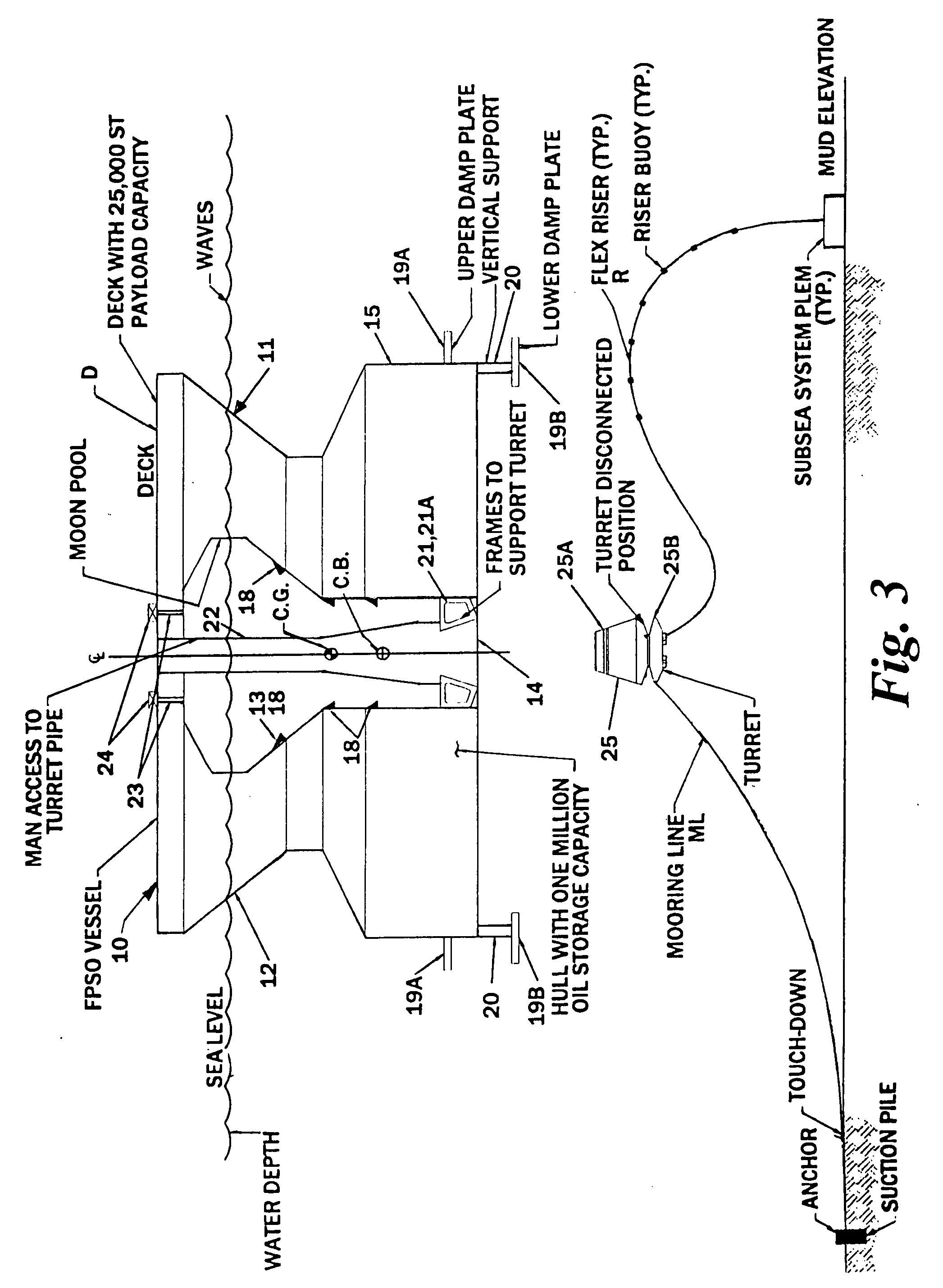

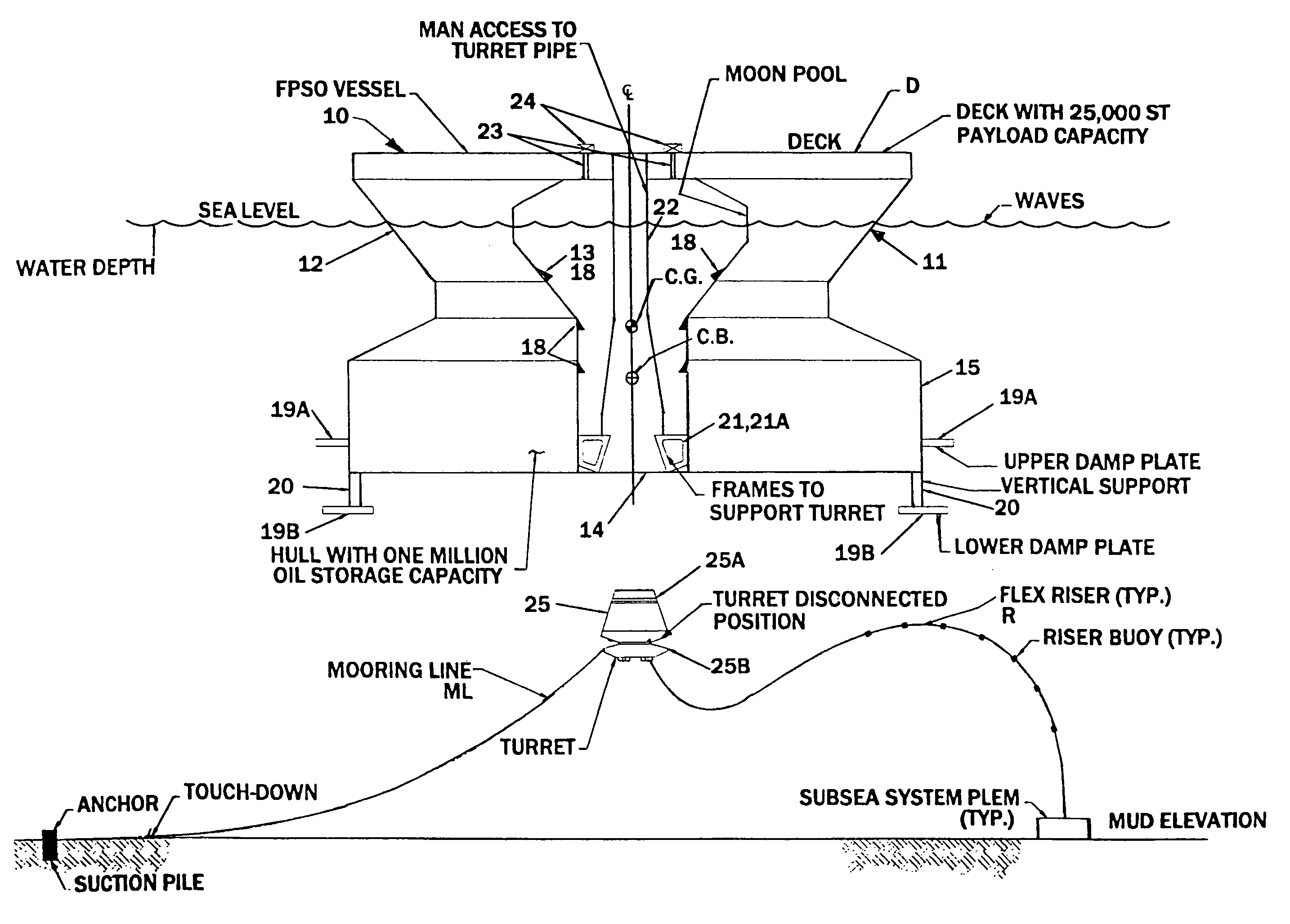

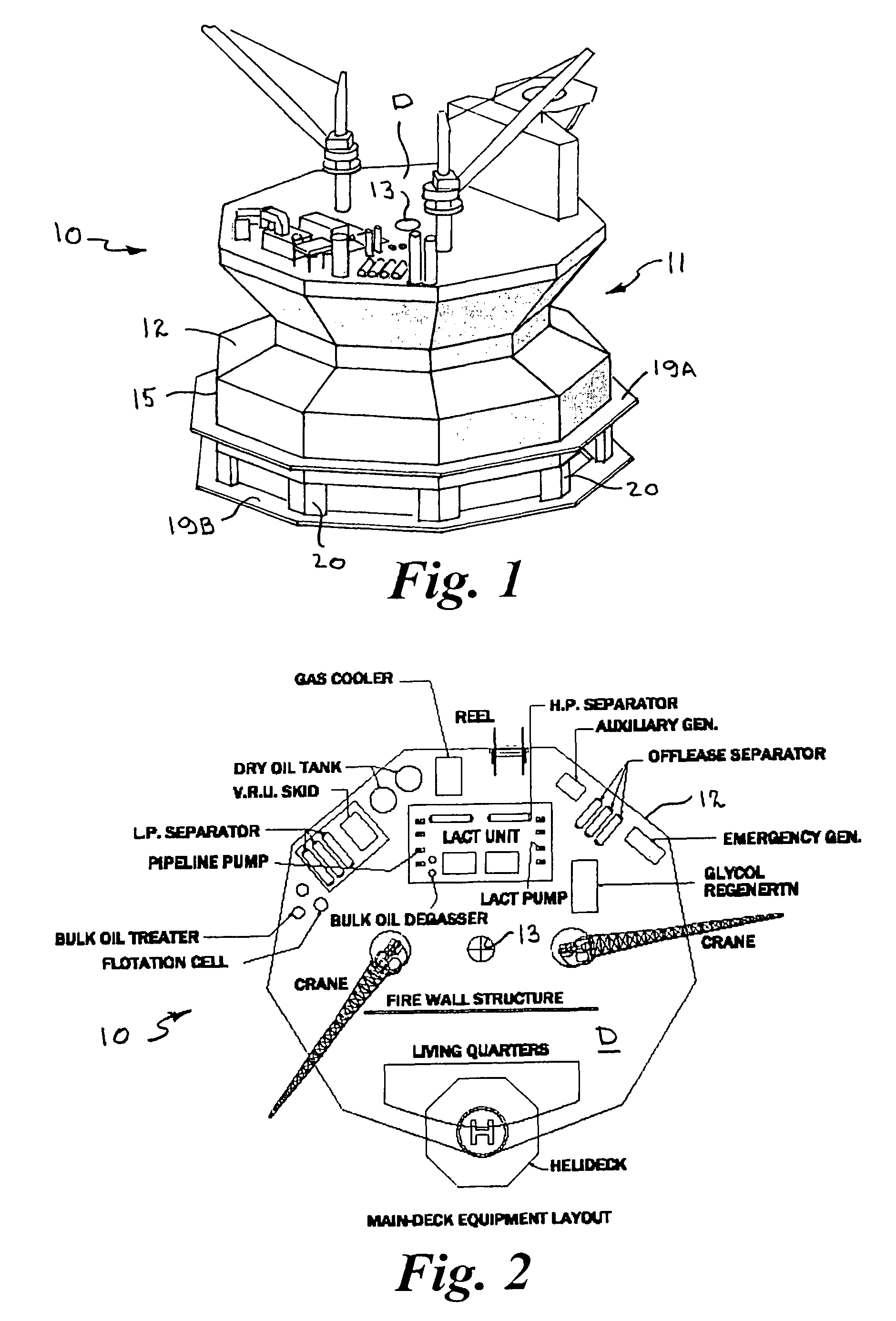

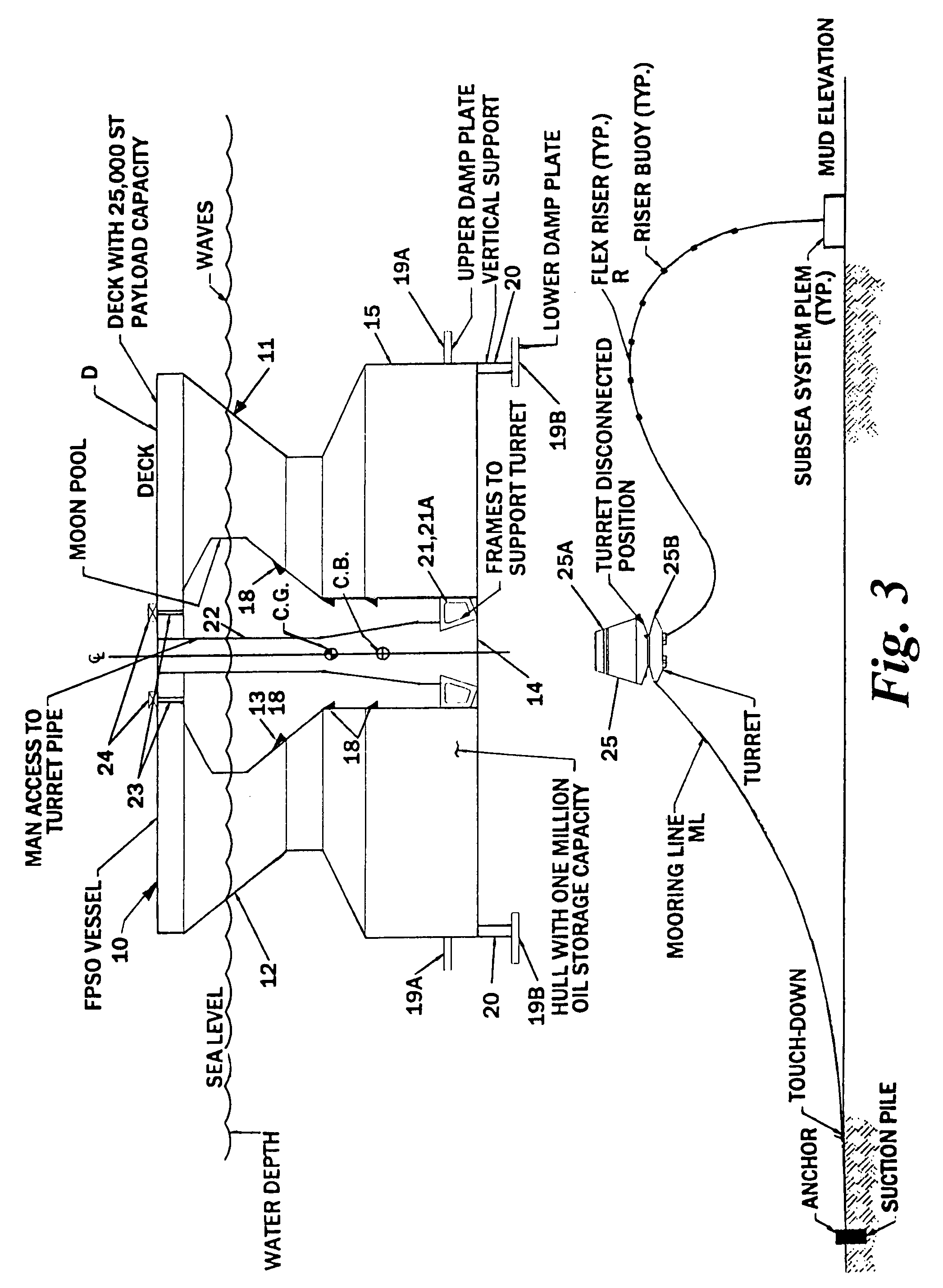

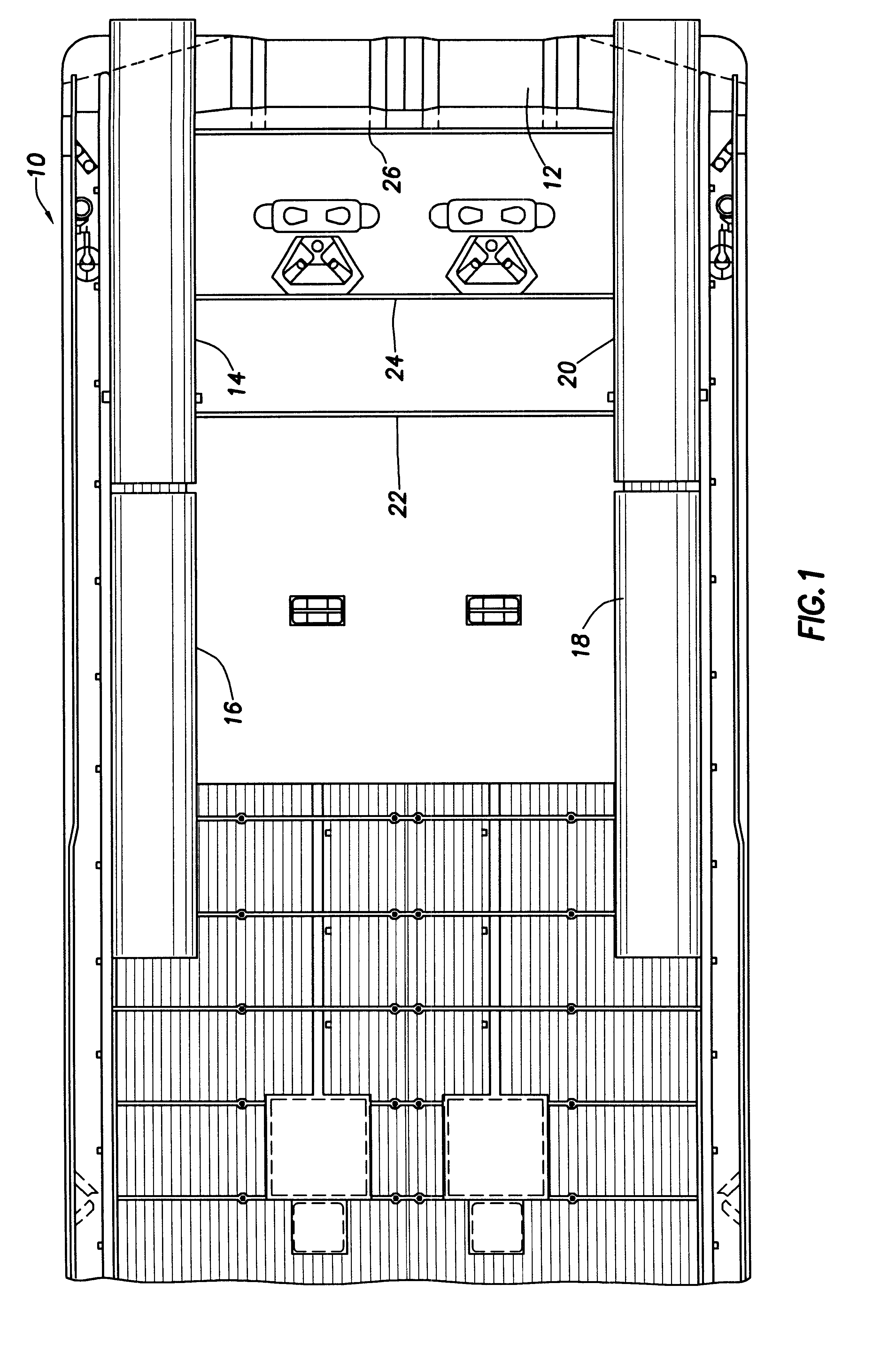

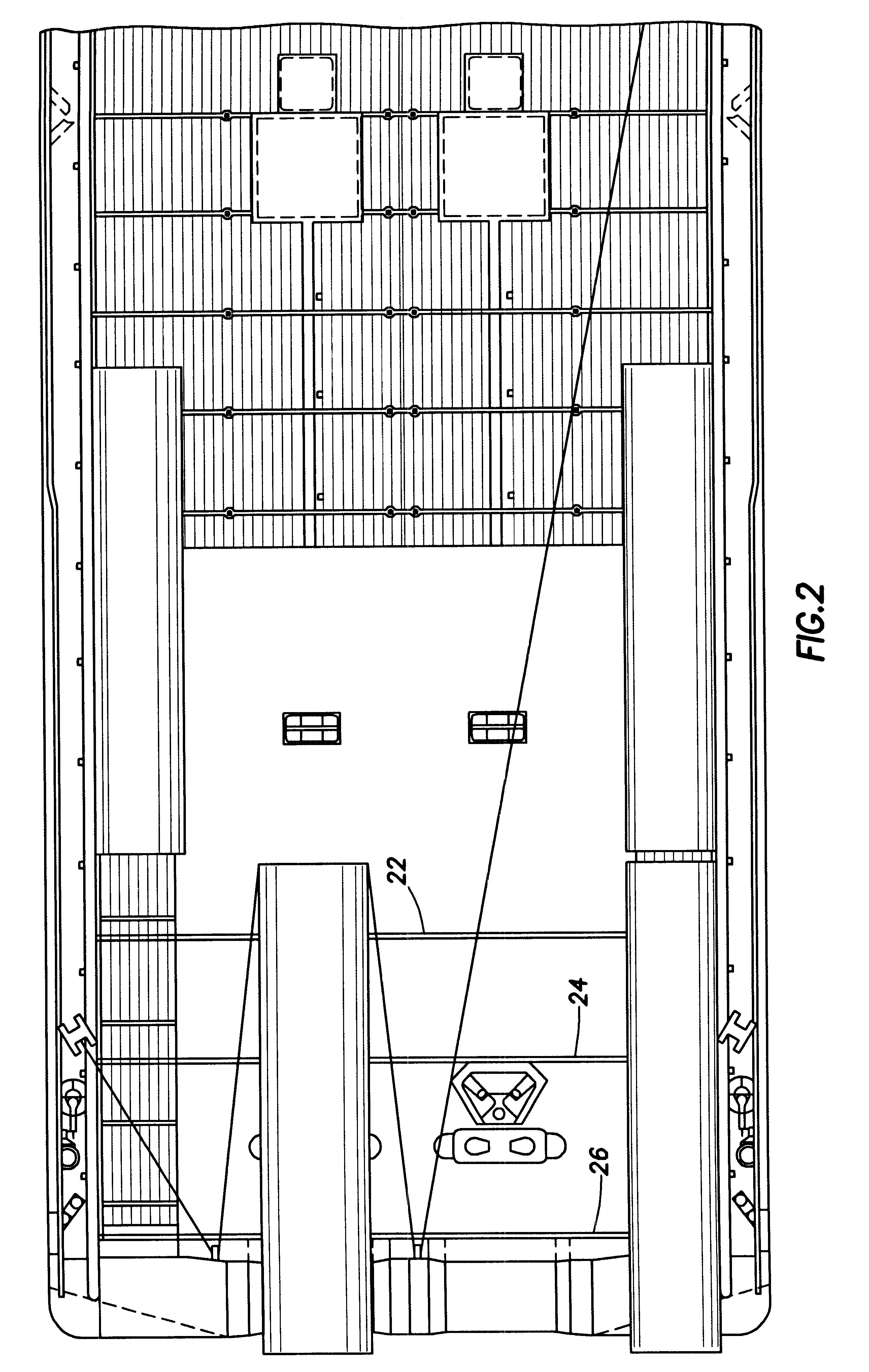

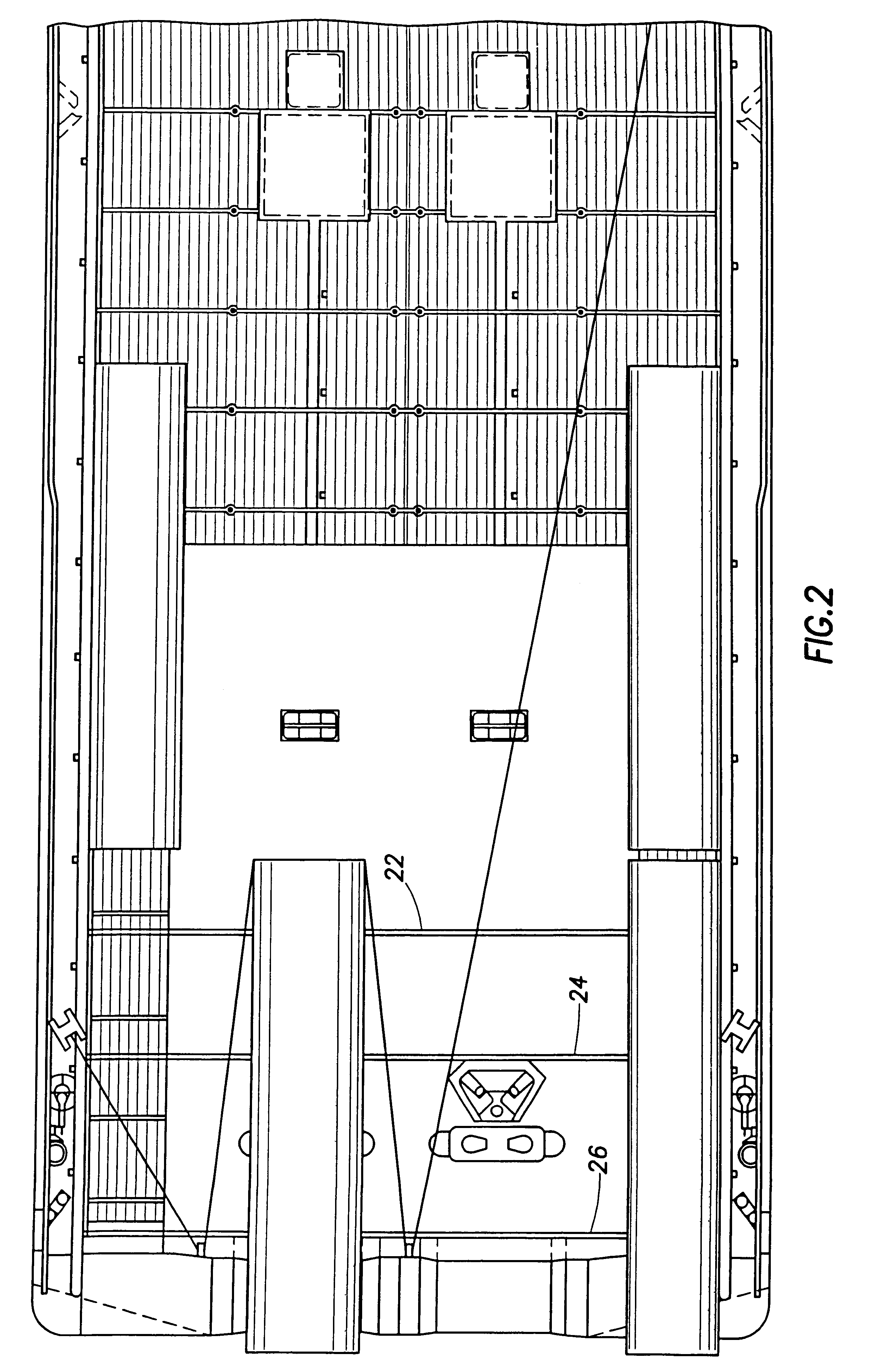

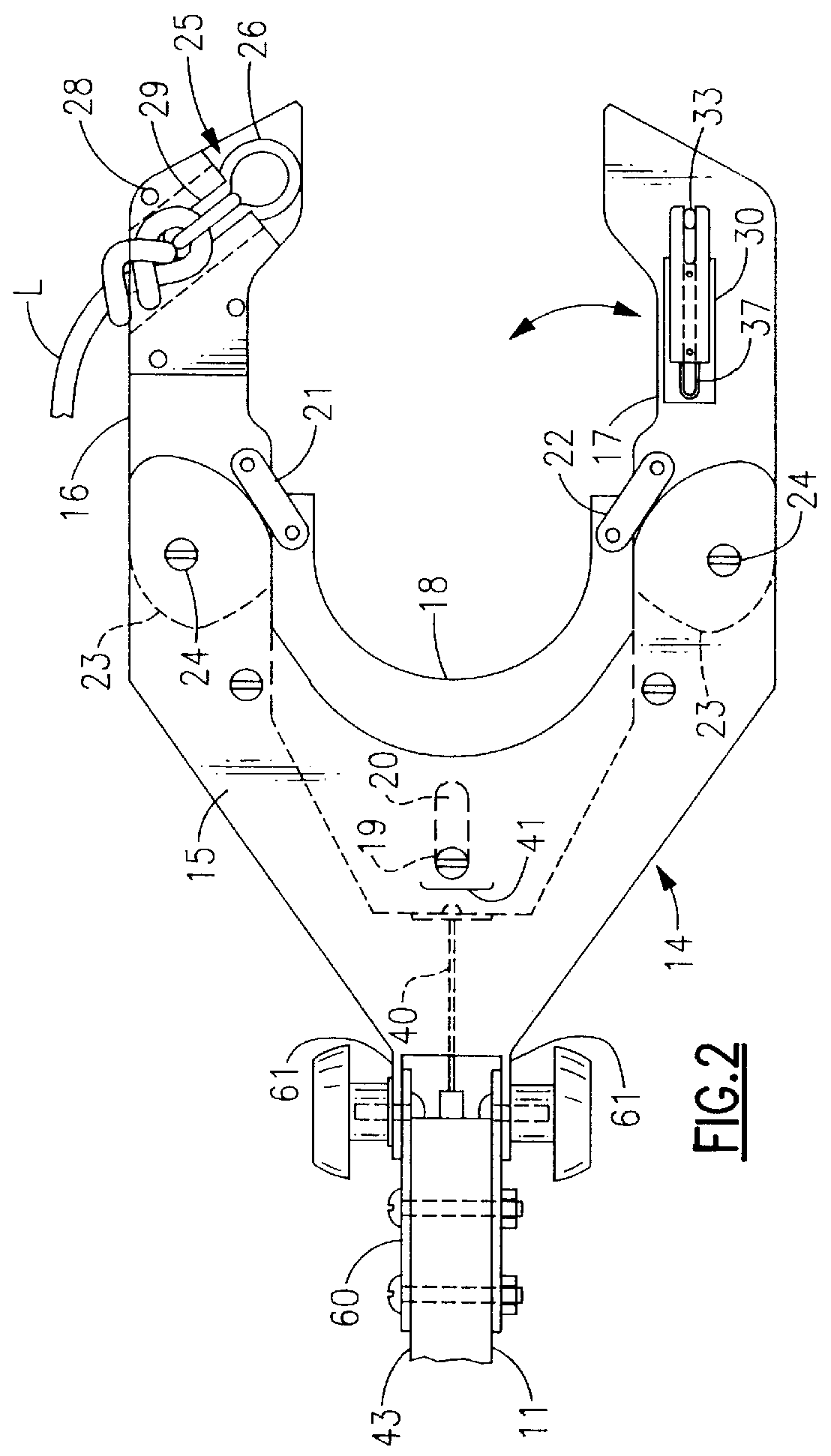

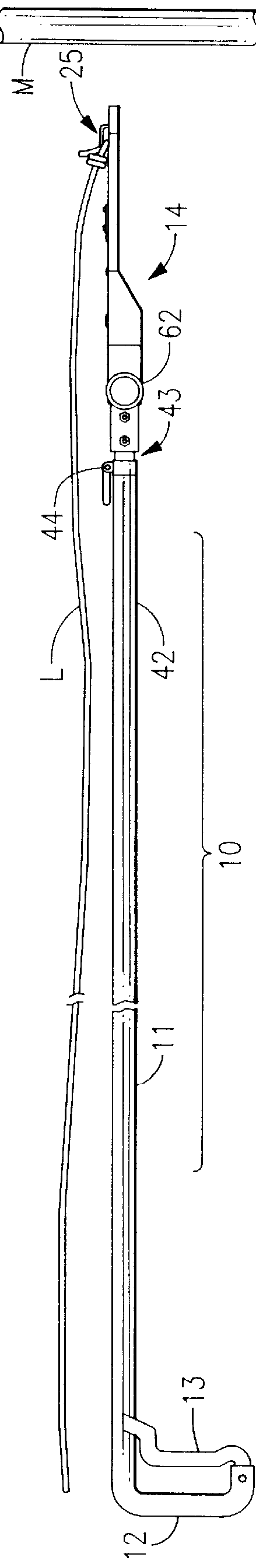

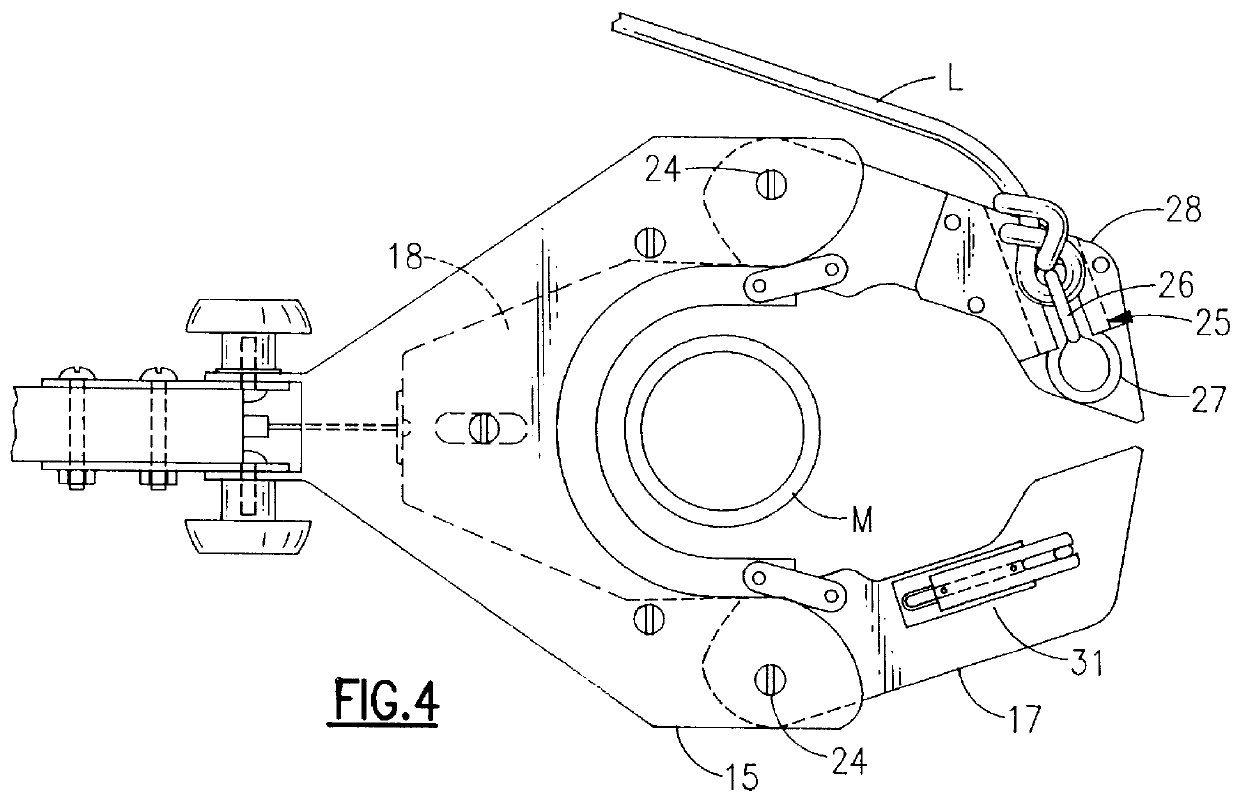

An offshore floating production, storage, and off-loading vessel has a monolithic non ship-shaped hull of polygonal configuration surrounding a central double tapered conical moon pool and contains water ballast and oil storage compartments. The exterior side walls of the hull have flat surfaces and sharp corners to cut ice sheets, resist and break ice, and move ice pressure ridges away from the structure. An adjustable water ballast system induces heave, roll, pitch and surge motions of the vessel to dynamically position and maneuver the vessel to accomplish ice cutting, breaking and moving operations. The moon pool shape and other devices on the vessel provide added virtual mass capable of increasing the natural period of the roll and heave modes, reducing dynamic amplification and resonance due to waves and vessel motion, and facilitate maneuvering the vessel. The vessel may be moored by a disconnectable turret buoy received in a support frame at the bottom of the moon pool and to which flexible well risers and mooring lines are connected.

Owner:SRINIVASAN NAGAN

Offshore floating production, storage, and off-loading vessel for use in ice-covered and clear water applications

InactiveUS7958835B2High strengthProtective foundationMovement controllersClassical mechanicsPressure ridge

An offshore floating production, storage, and off-loading vessel has a hull of generally cylindrical or polygonal configuration surrounding a central double tapered conical moon pool and contains water ballast and oil and / or liquefied gas storage compartments. The exterior side walls of the polygonal hull have flat surfaces and sharp corners to cut ice sheets, resist and break ice, and move ice pressure ridges away from the structure. An adjustable water ballast system induces heave, roll, pitch and surge motions of the vessel to dynamically position and maneuver the vessel to accomplish ice cutting, breaking and moving operations. The moon pool shape and other devices on the vessel provide added virtual mass for increasing the natural period of the roll and heave modes, reducing dynamic amplification and resonance due to waves and vessel motion, and facilitate maneuvering the vessel. A disconnectable turret buoy at the bottom of the moon pool connects risers and mooring lines.

Owner:SRINIVASAN NAGAN

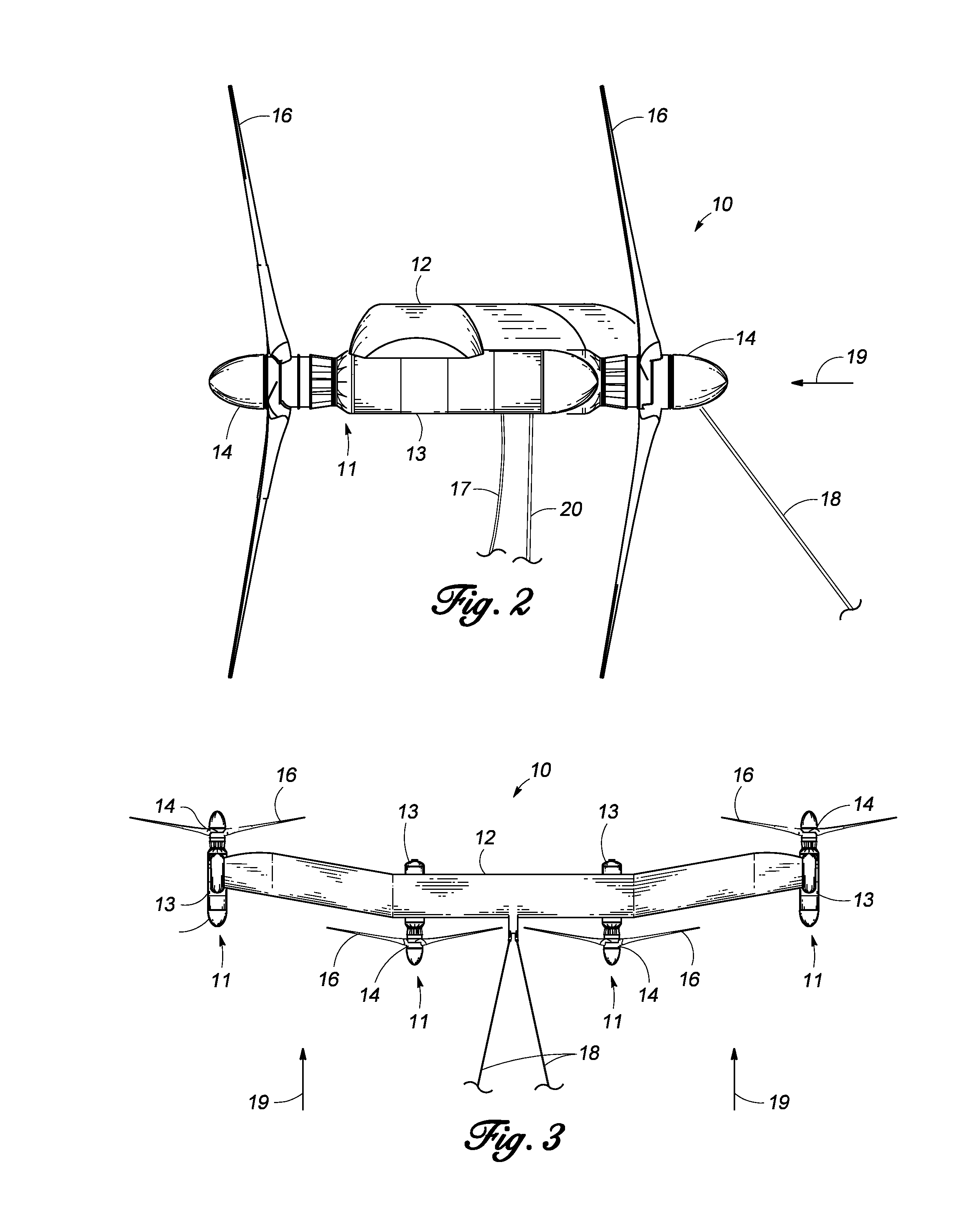

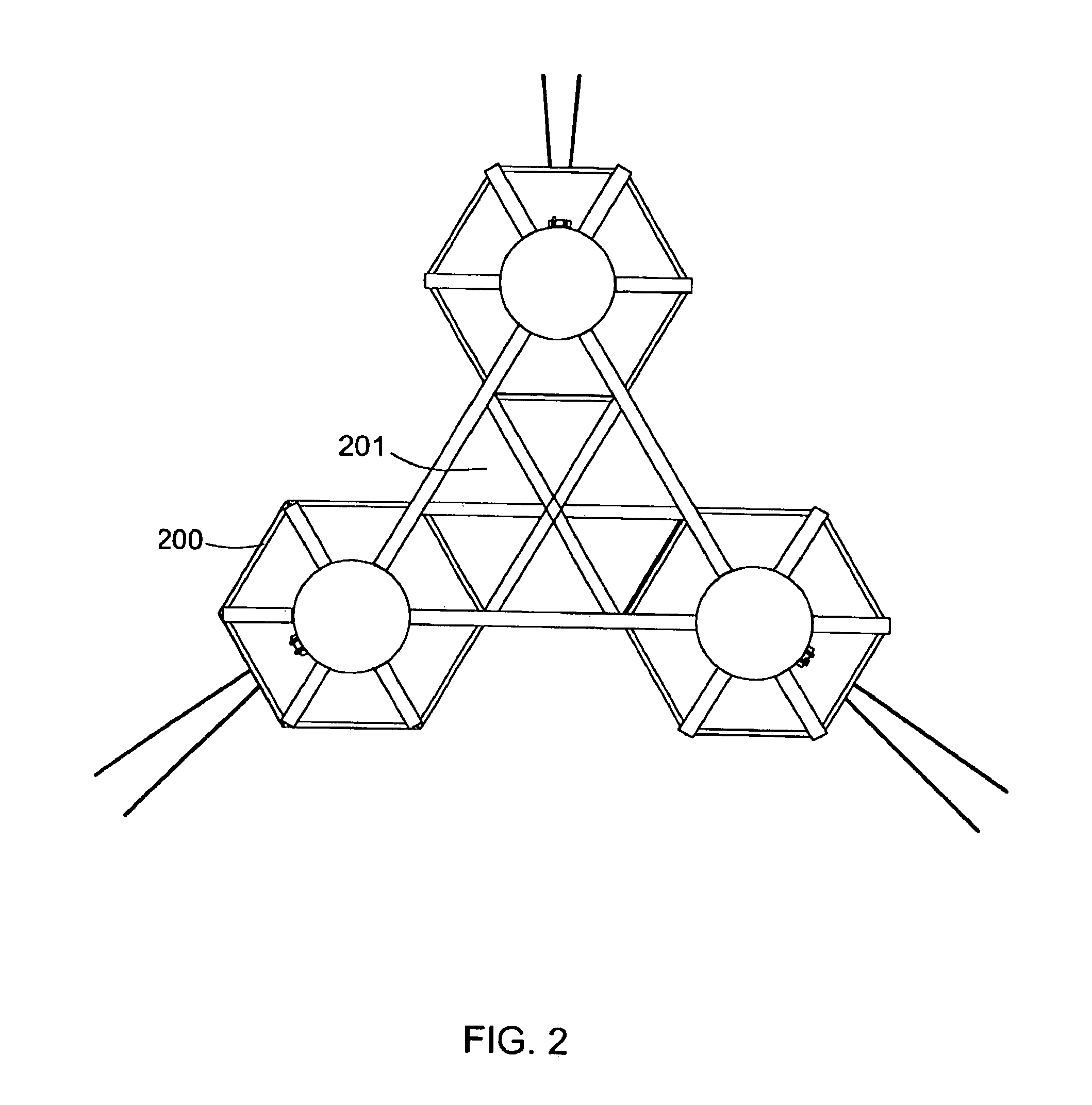

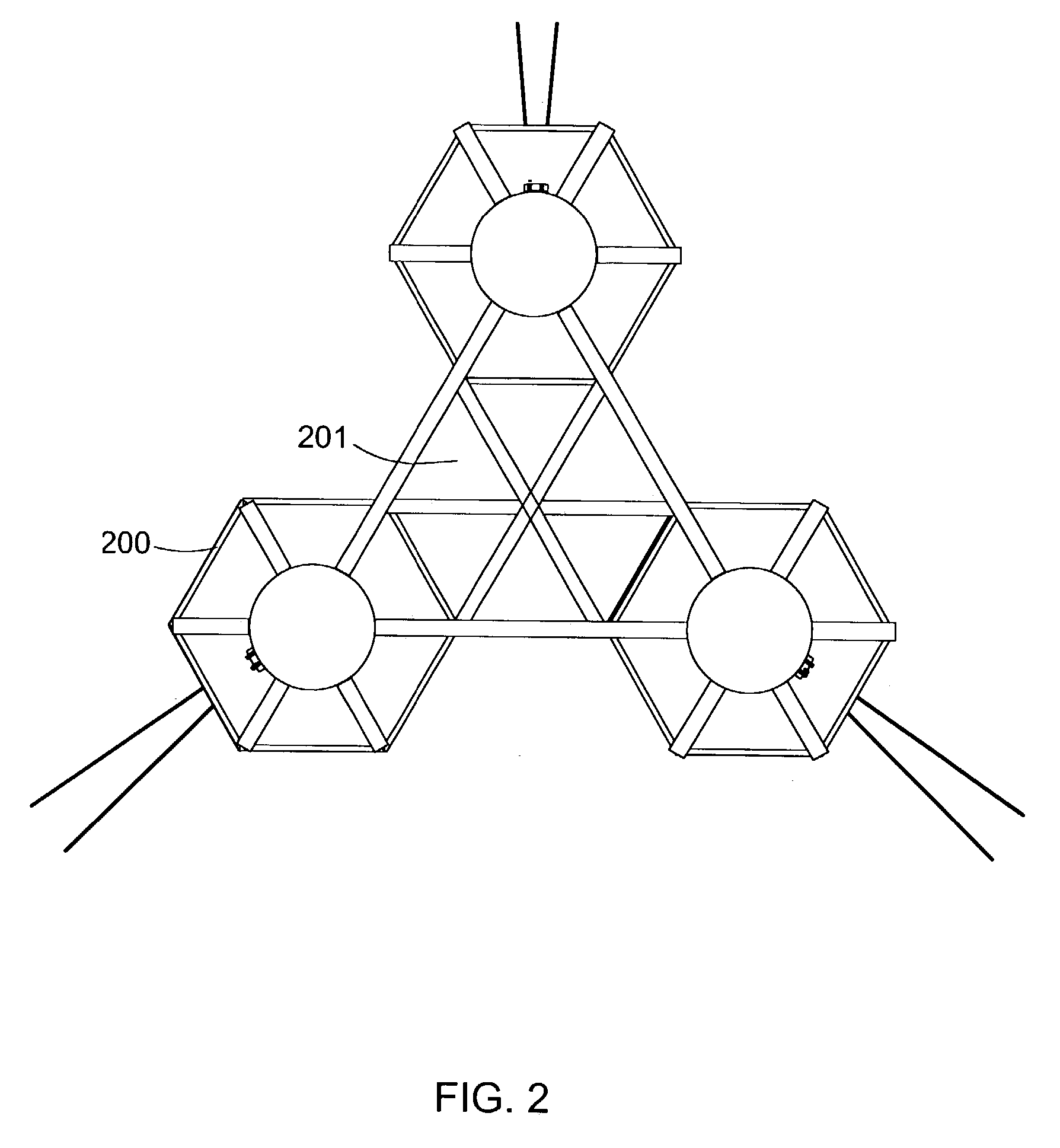

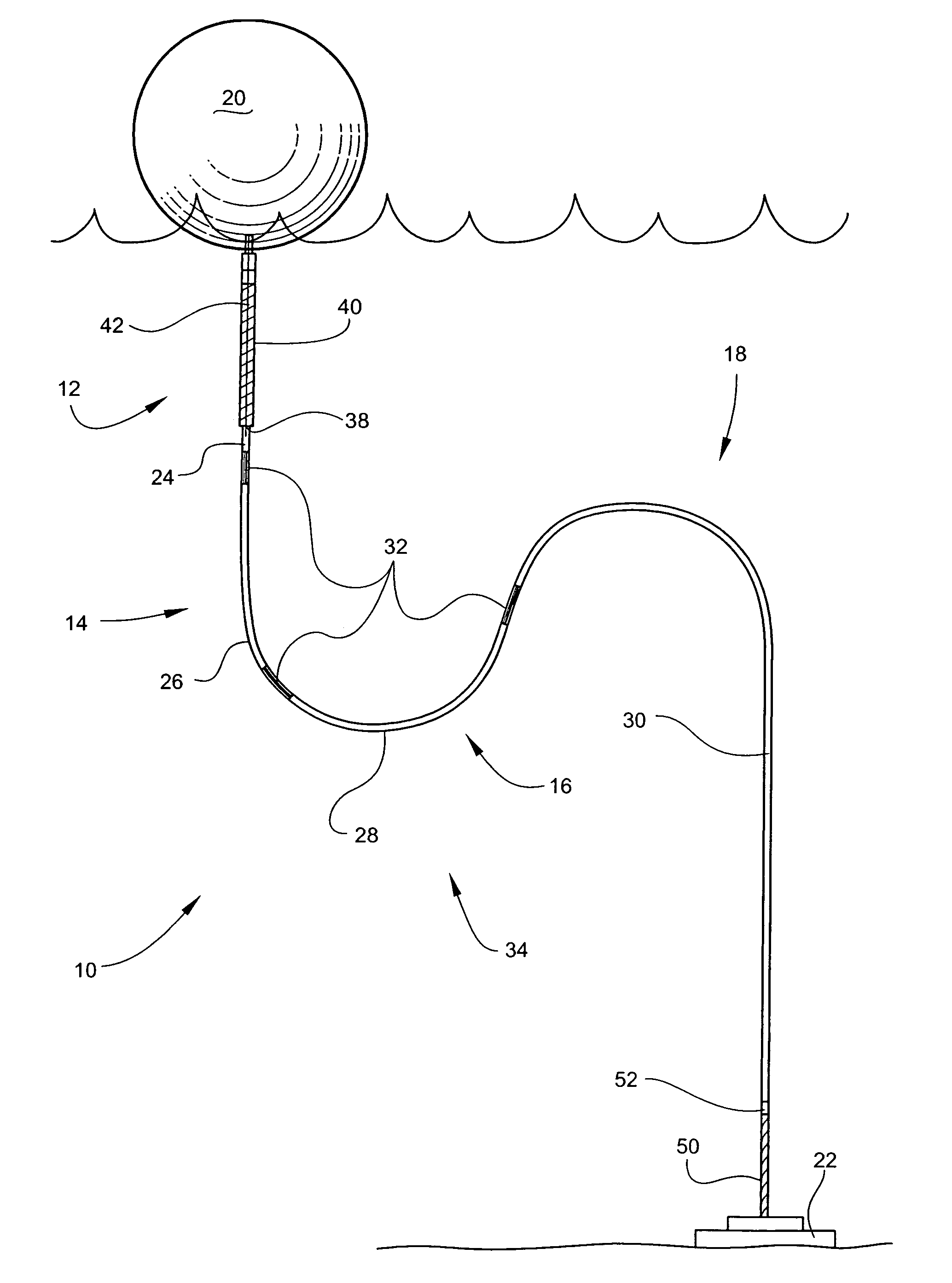

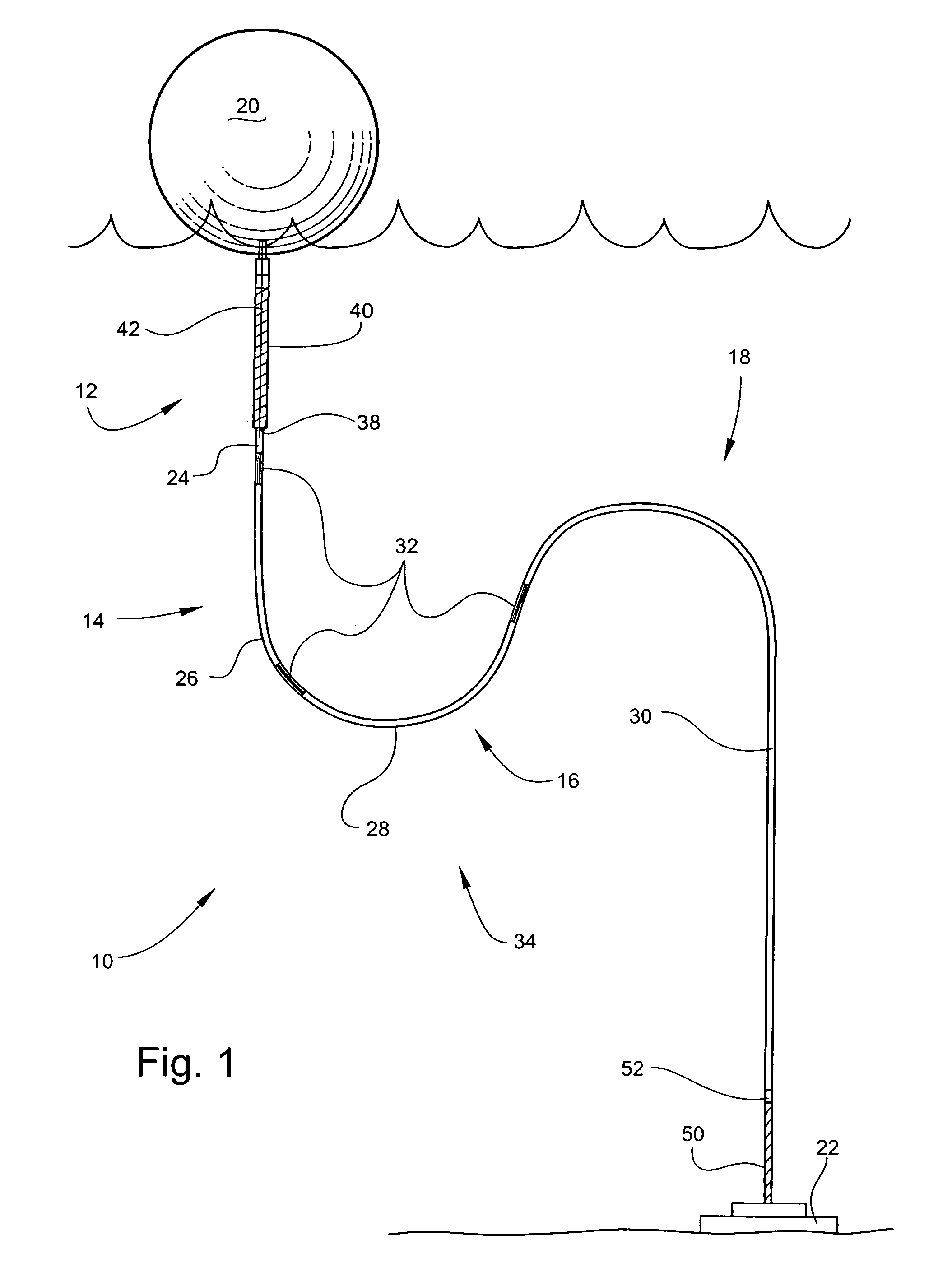

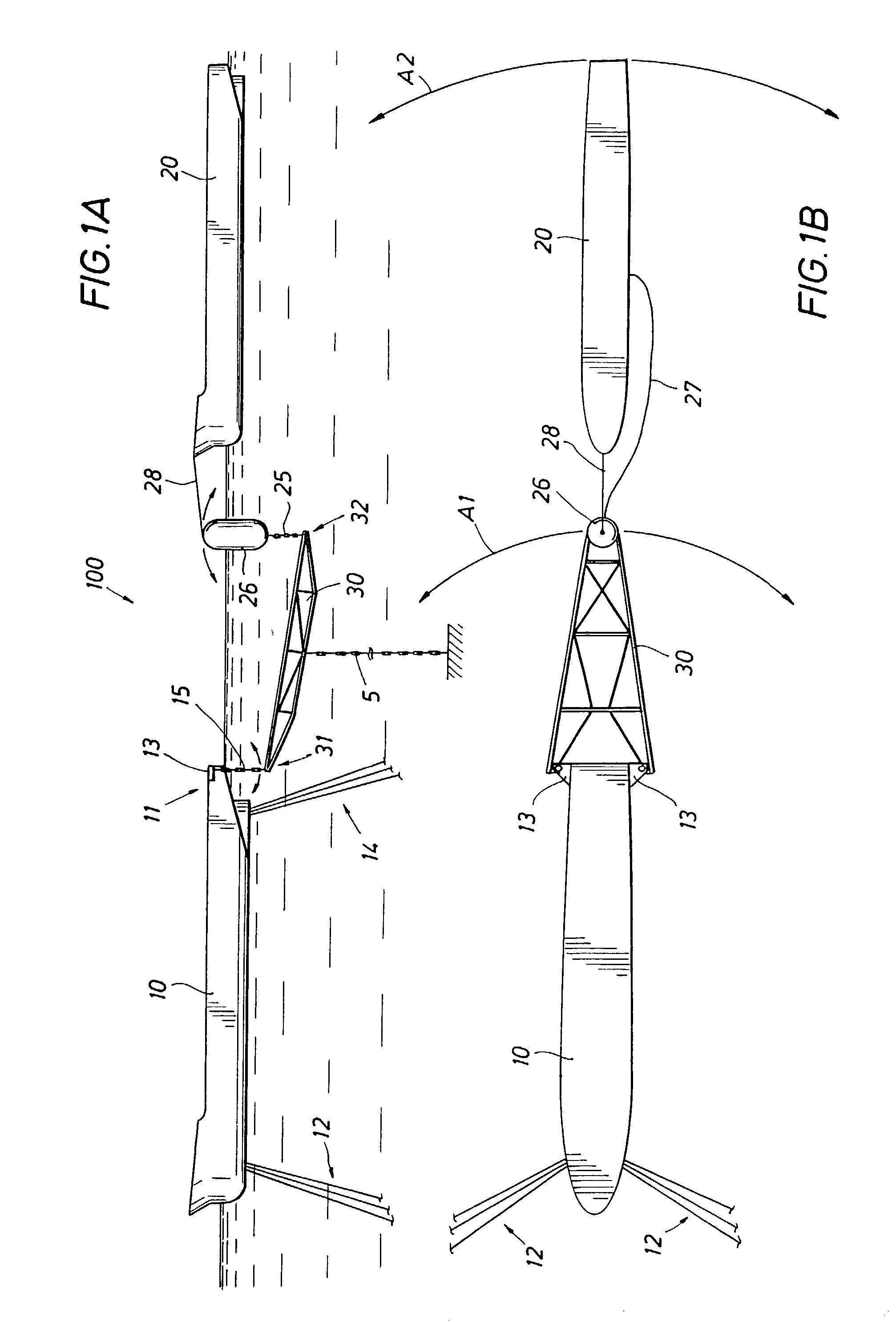

Multi-Megawatt Ocean Current Energy Extraction Device

InactiveUS20130106105A1Counteract buoyancyReduce the average velocityEngine fuctionsBuoyancy controlOcean bottomDrivetrain

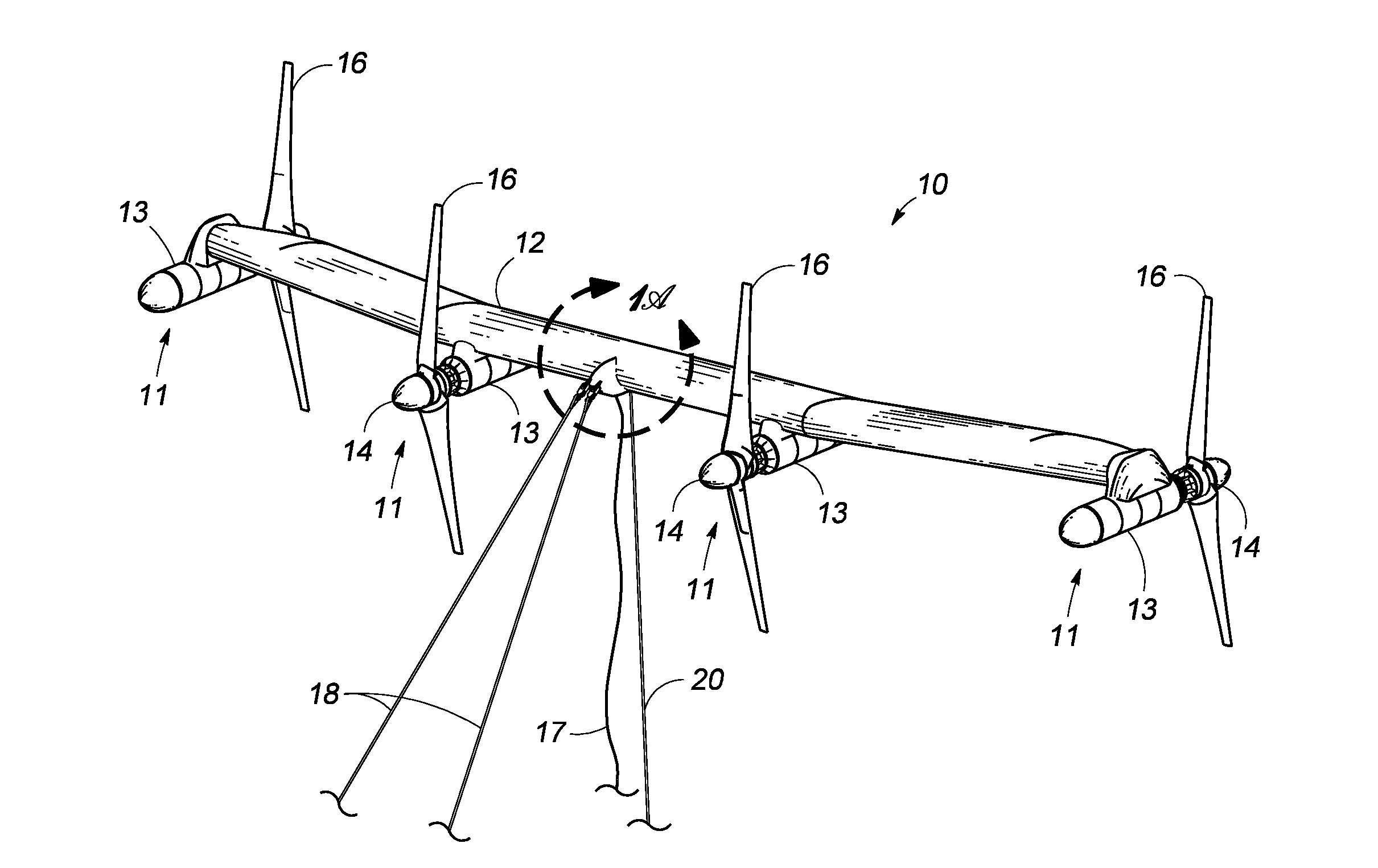

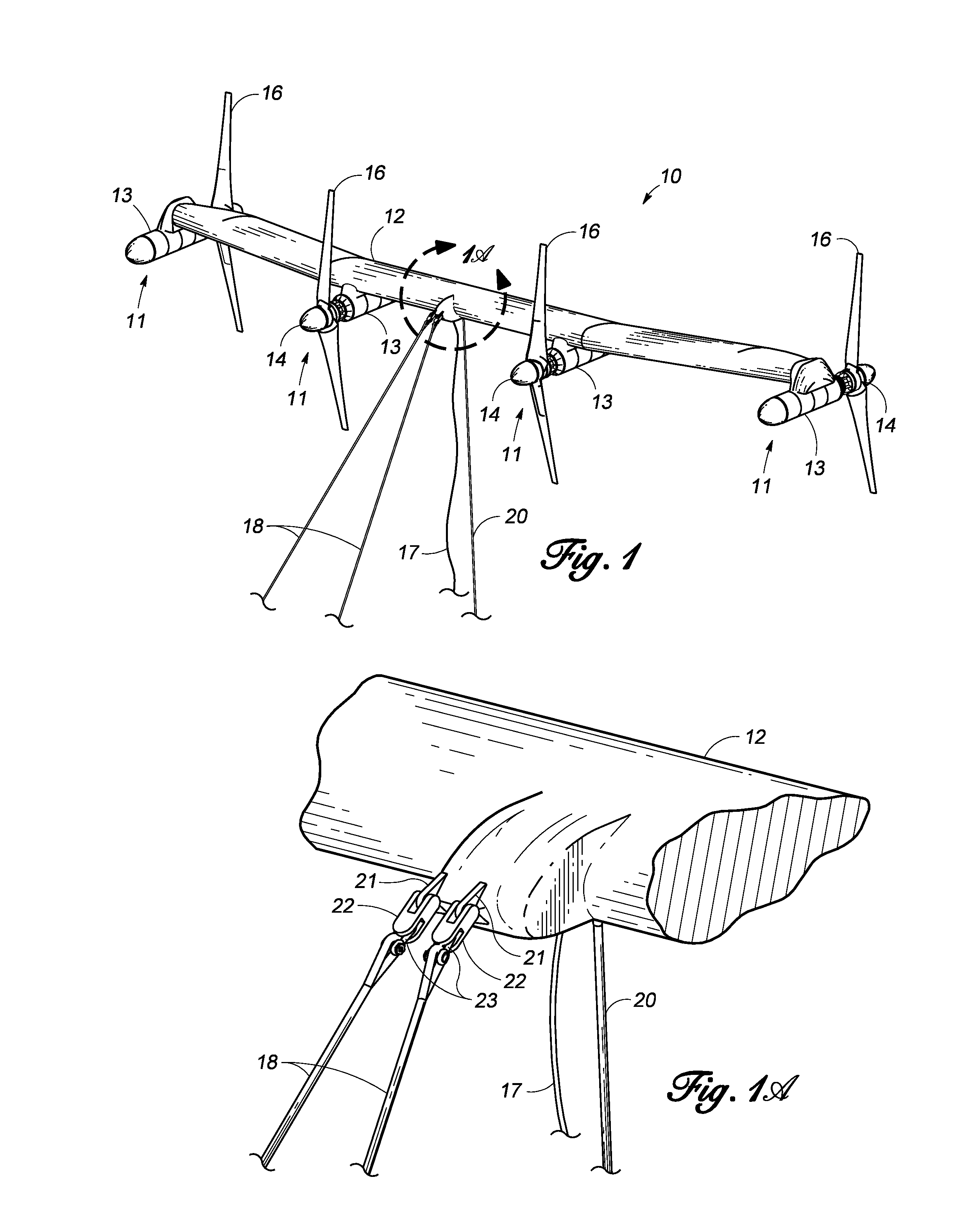

An underwater apparatus for generating electric power from ocean currents and deep water tides. A submersible platform including two or more power pods, each having a rotor with fixed-pitch blades, with drivetrains housed in pressure vessels that are connected by a transverse structure providing buoyancy, which can be a wing depressor, hydrofoil, truss, or faired tube. The platform is connected to anchors on the seafloor by forward mooring lines and a vertical mooring line that restricts the depth of the device in the water column. The platform operates using passive, rather than active, depth control. The wing depressor, along with rotor drag loads, ensures the platform seeks the desired operational current velocity. The rotors are directly coupled to a hydraulic pump that drives at least one constant-speed hydraulic-motor generator set and enables hydraulic braking. A fluidic bearing decouples non-torque rotor loads to the main shaft driving the hydraulic pumps.

Owner:AQUANTIS

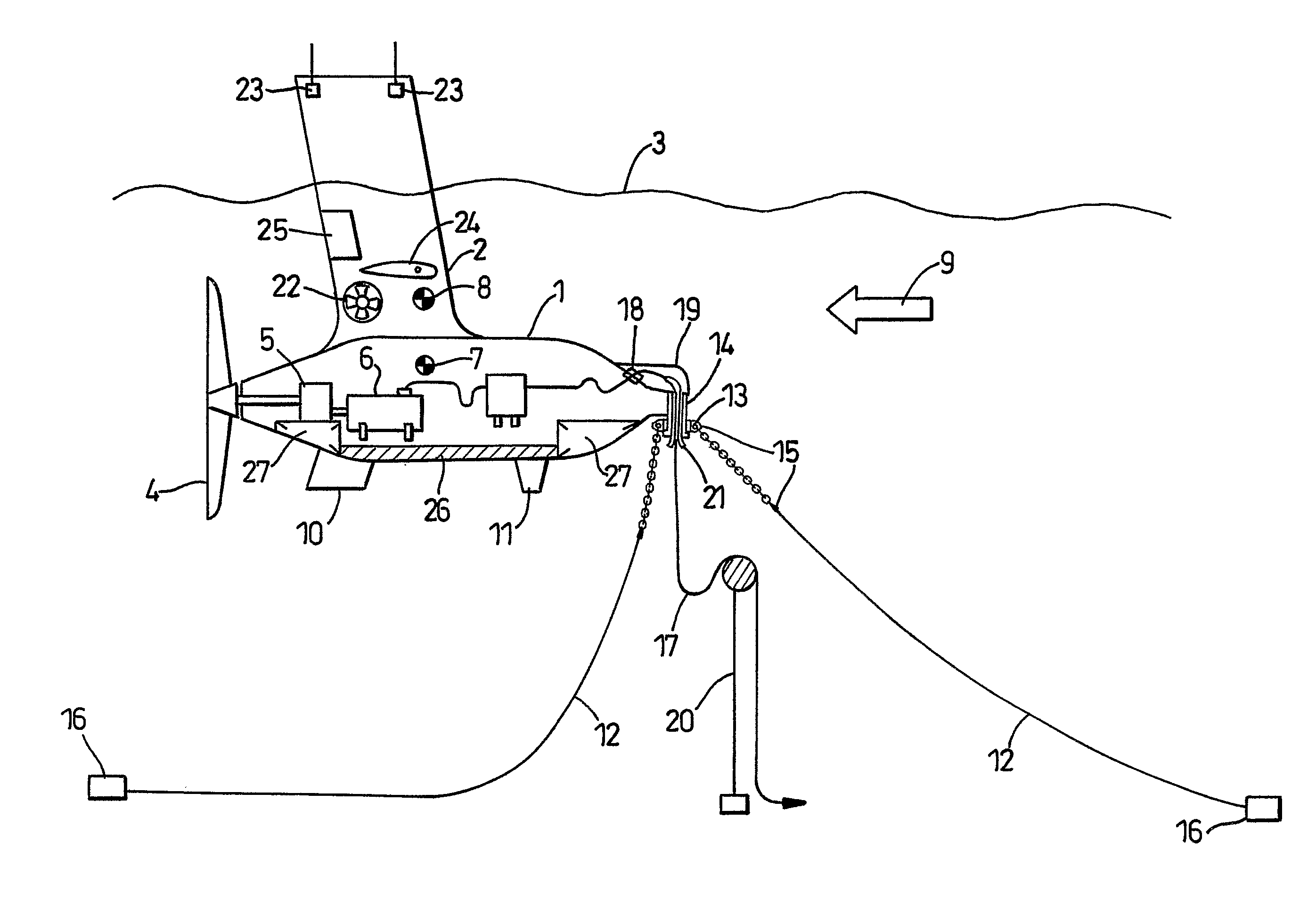

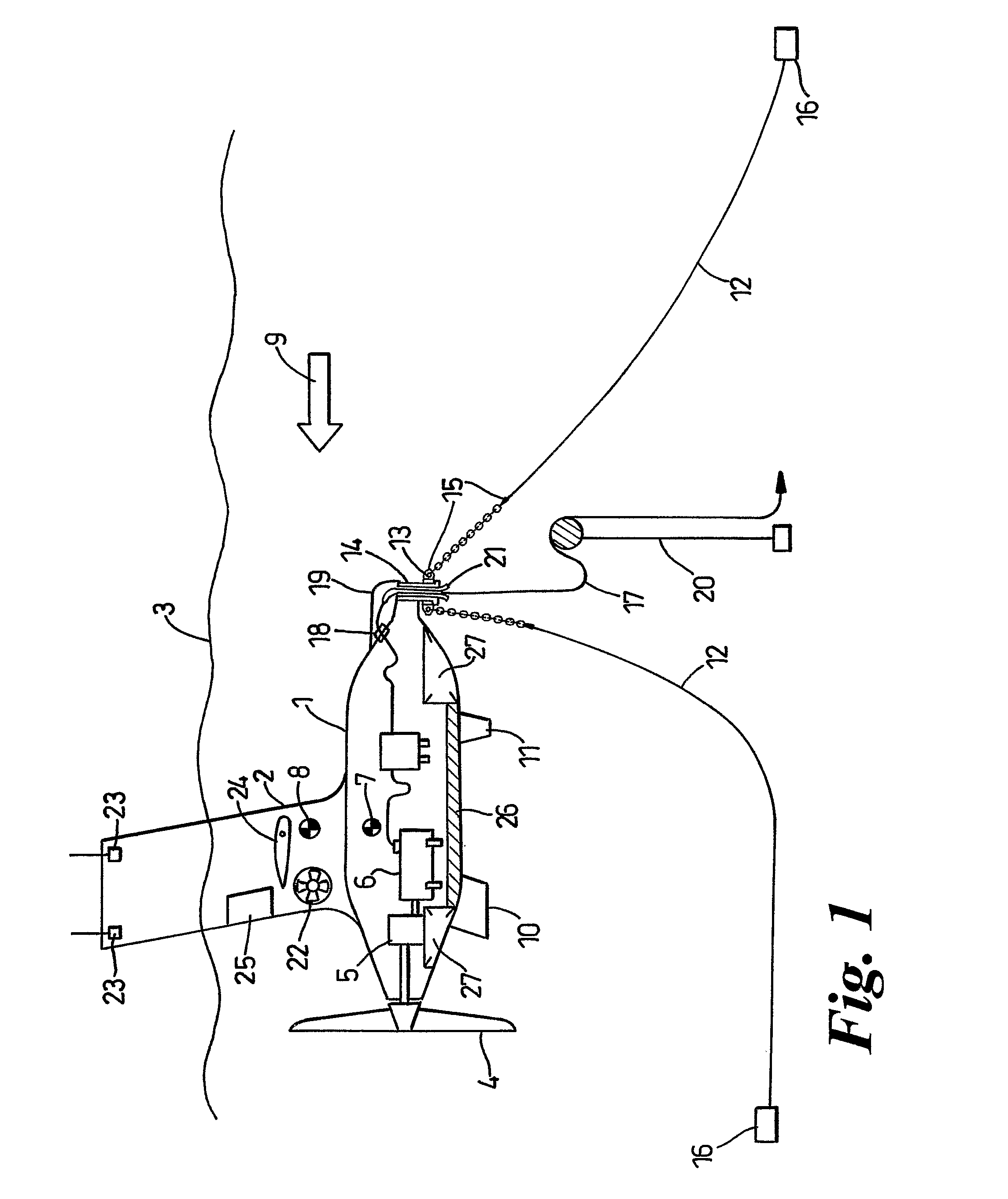

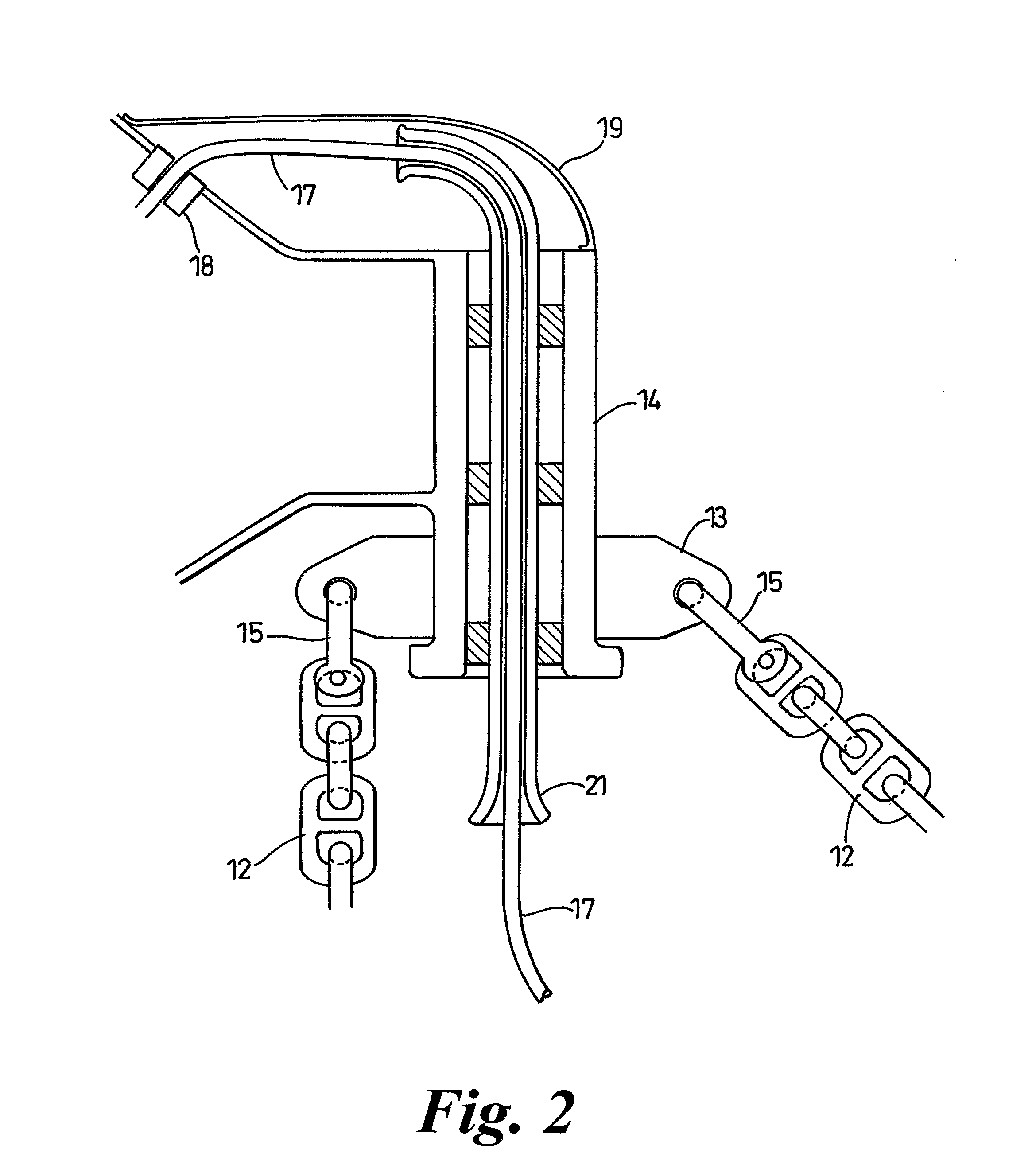

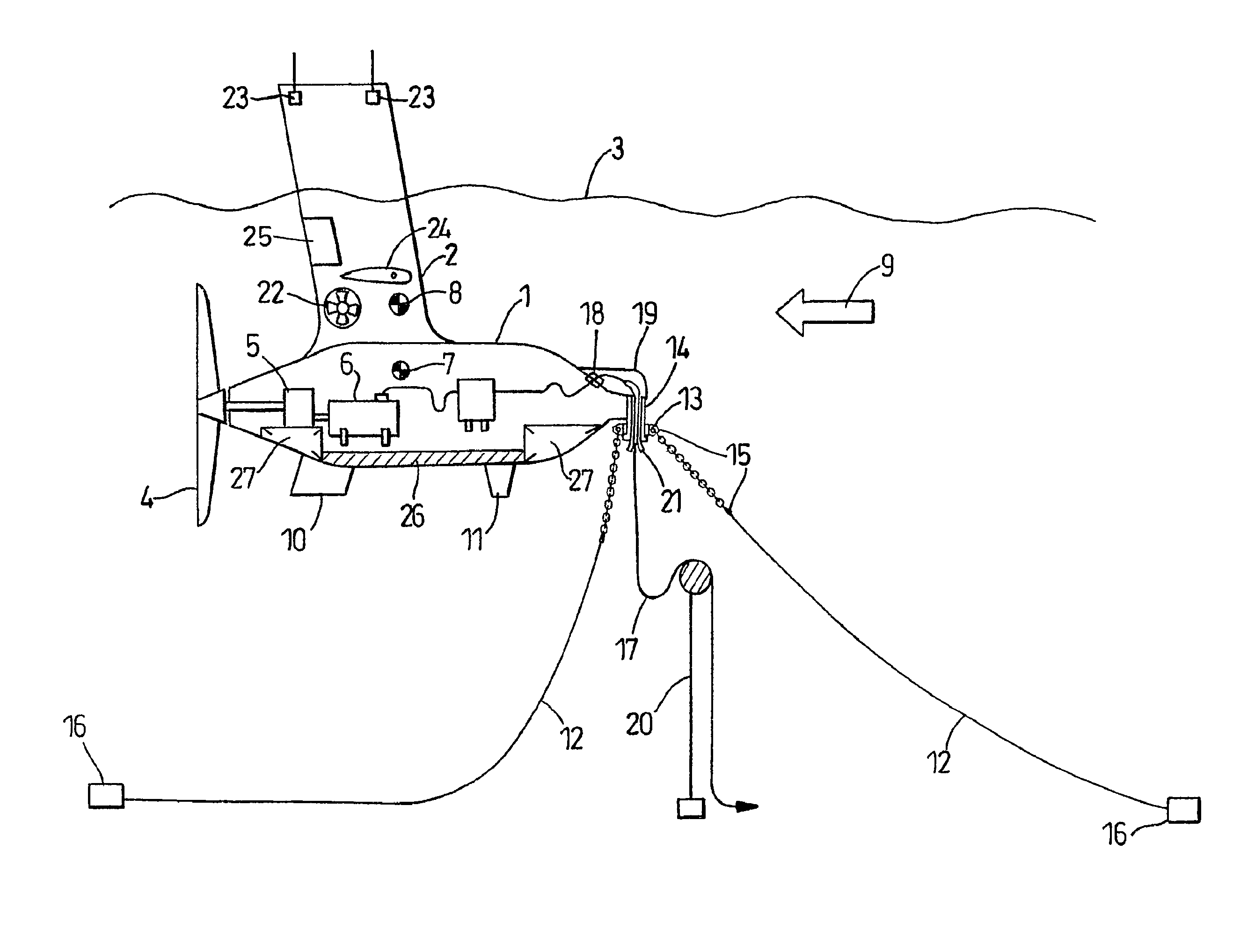

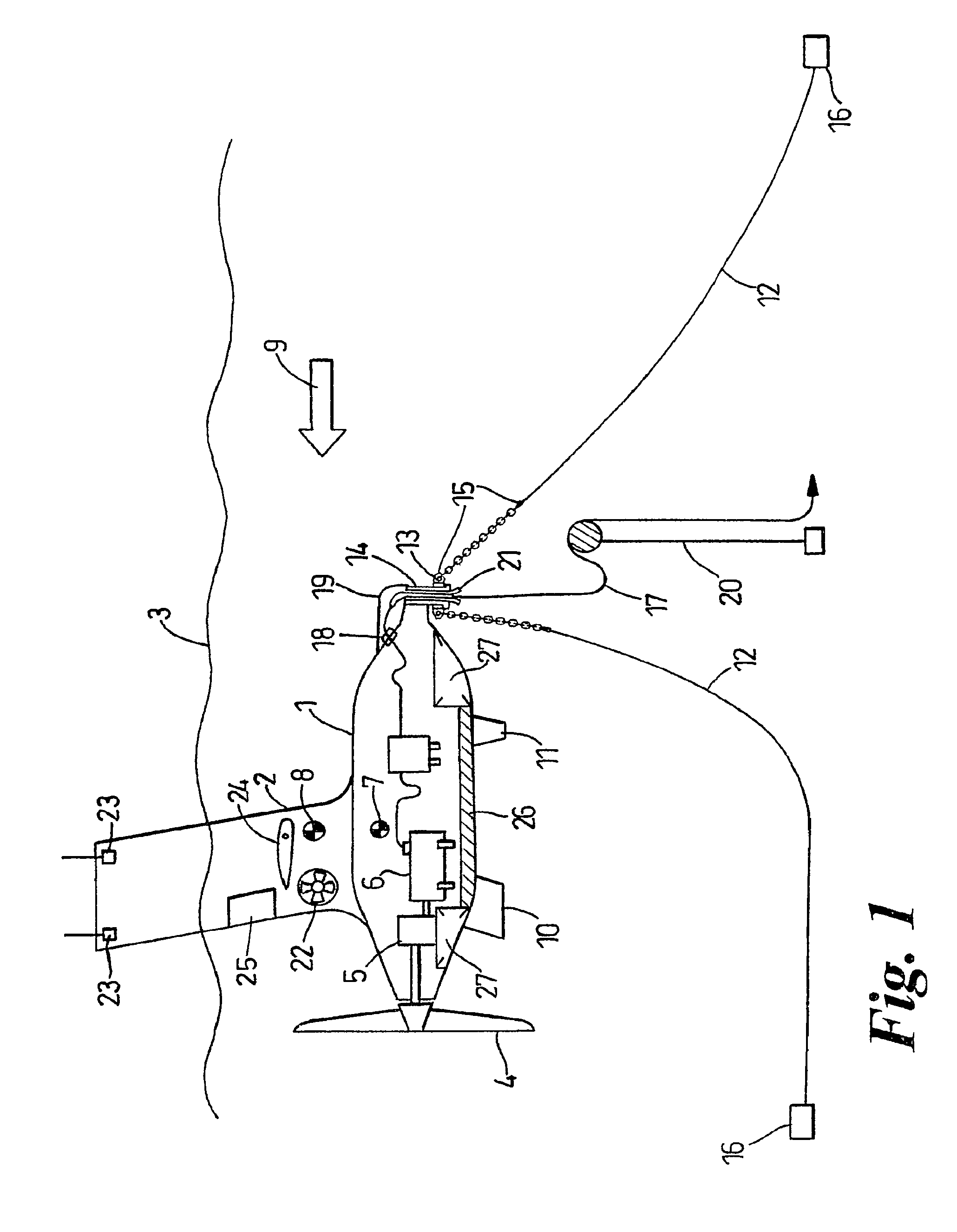

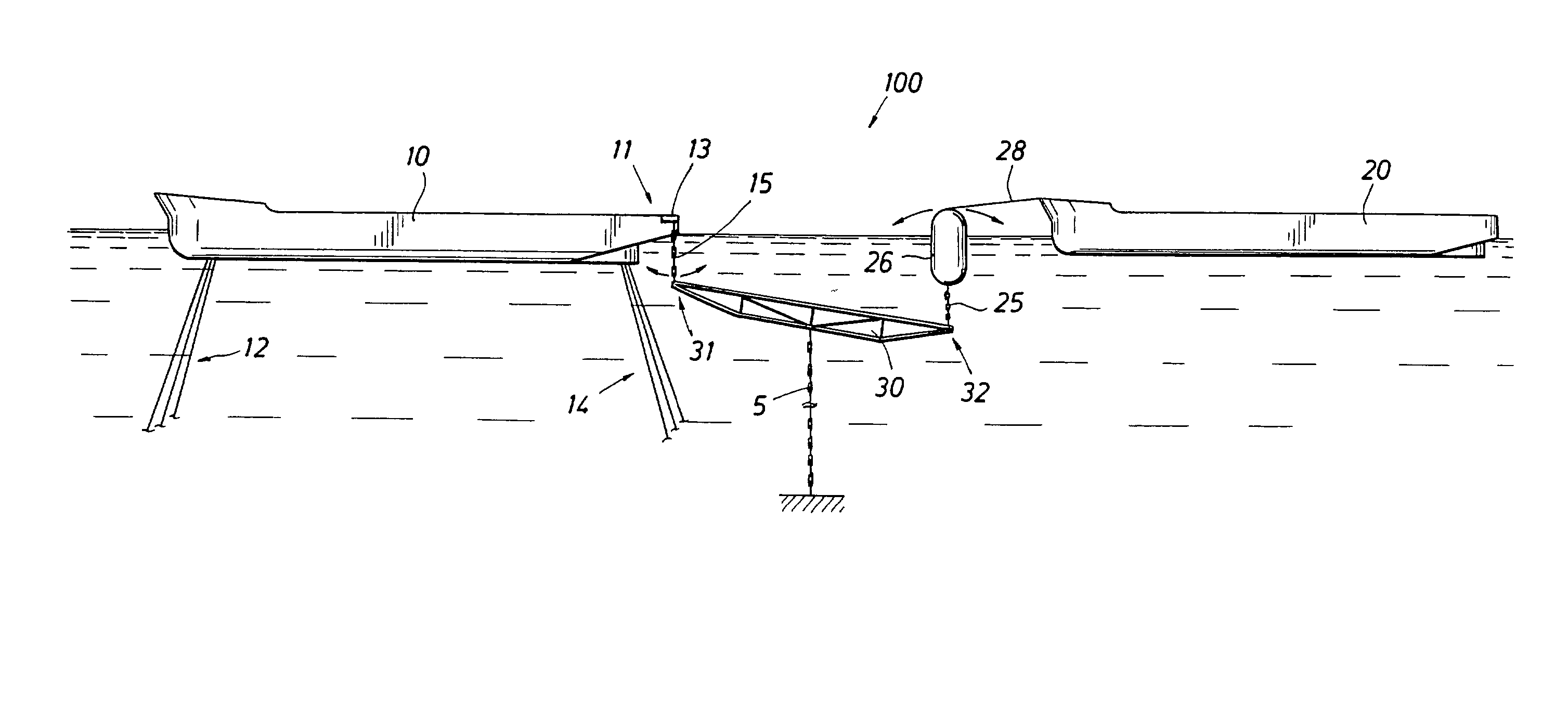

Floating Apparatus for Deploying in Marine Current for Gaining Energy

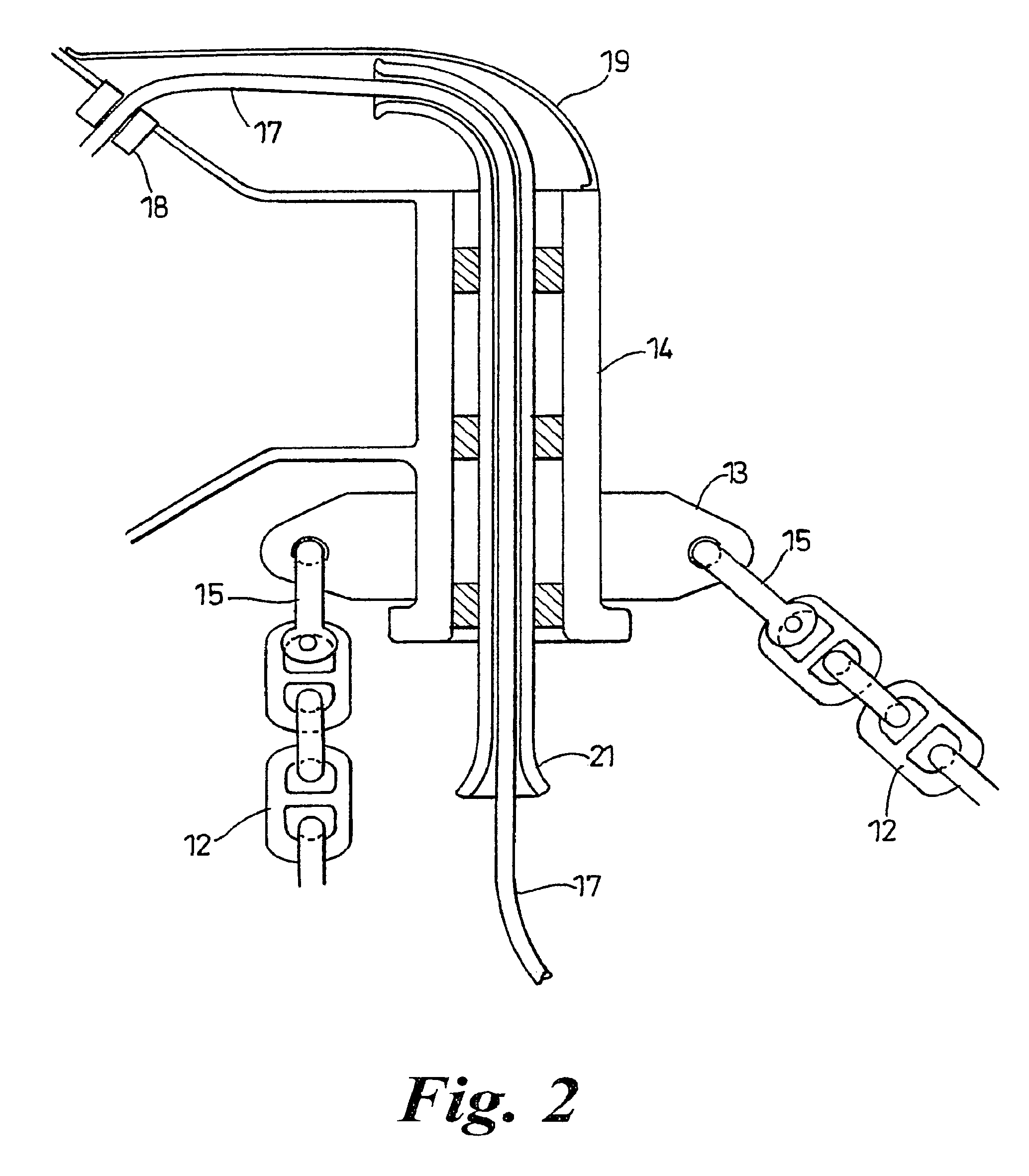

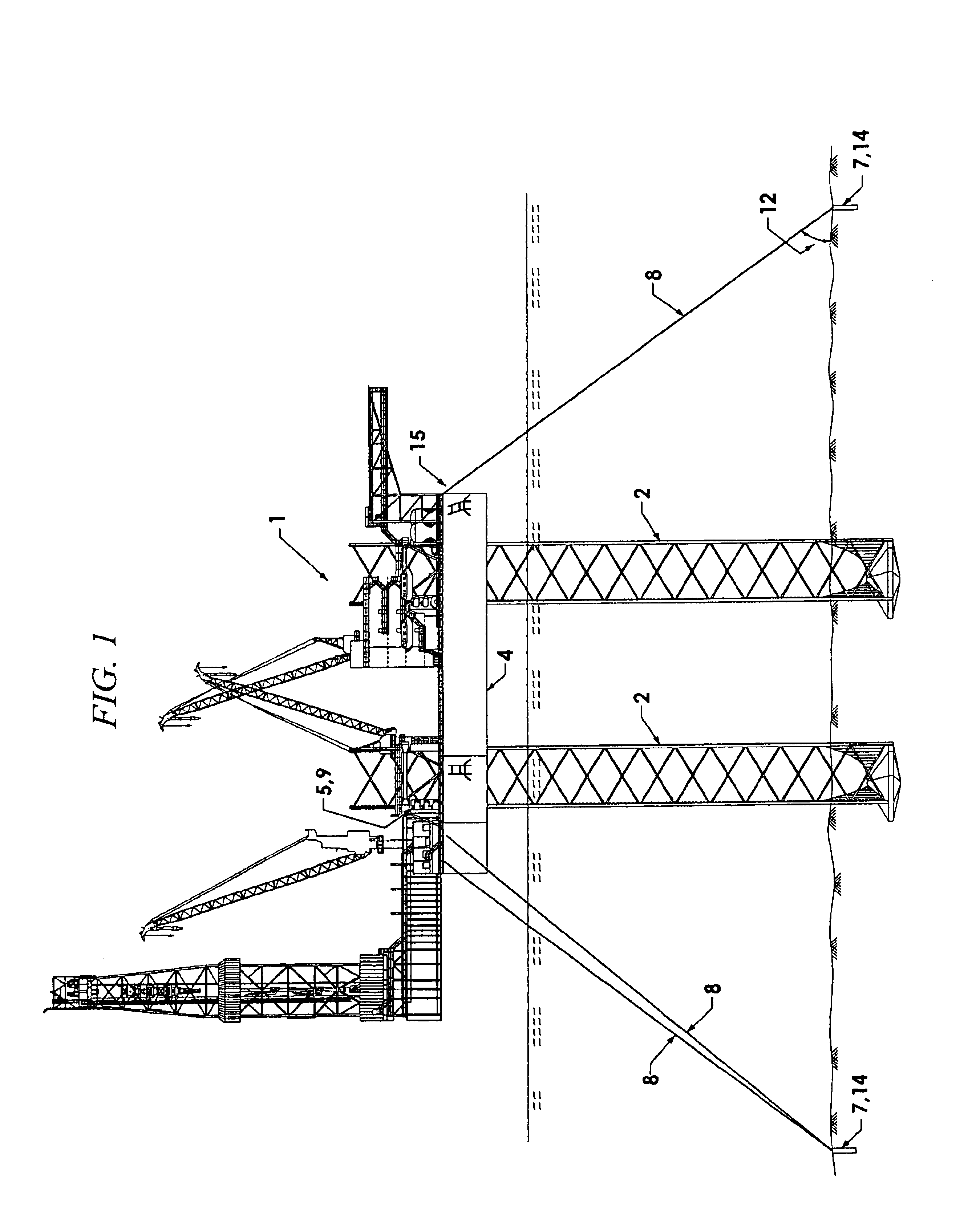

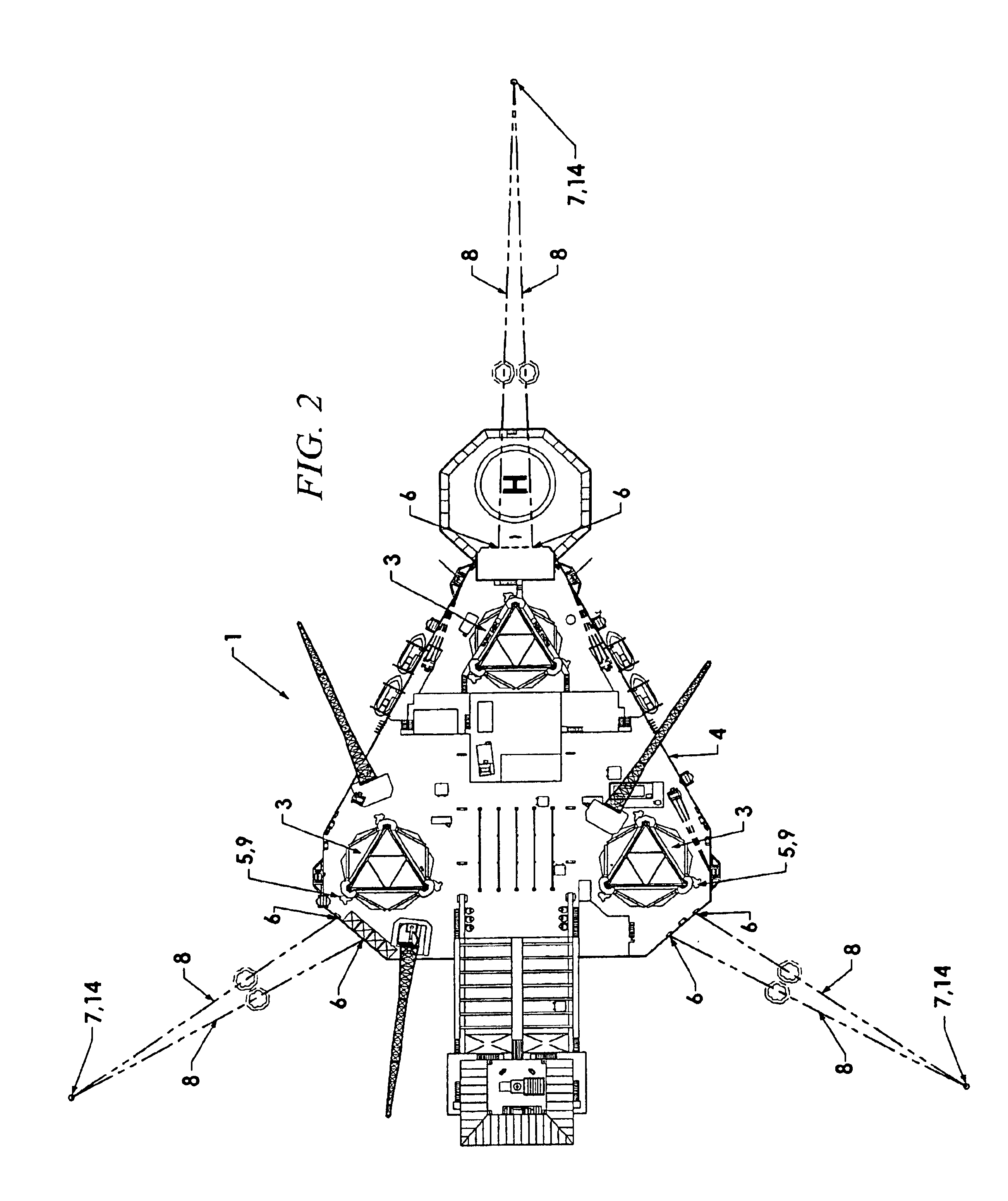

ActiveUS20080050993A1Effective supportHigh suppression characteristicsArtificial islandsWaterborne vesselsHorizontal axisRudder

A floating, semi-submerged, tethered device that supports a horizontal axis turbine and power generation equipment for extracting kinetic energy from a tidal stream or ocean current. A submerged body (1) is supported by surface piercing struts (2) of small water plane area (FIG. 6). The device is tethered to the seabed by a spread of mooring lines (12) that are deployed both into and away from the direction of the tidal current. A horizontal axis turbine (4) harnesses energy from the water flow and drives a generator housed within the body. A horizontal strut hydrofoil (24) corrects the trim of the device when subject to varying loads from the mooring system and can also be used to dampen pitch motion. Rudder flaps in the struts (25) can be used to counteract roll motion. Power is exported from the device to the seabed by an umbilical (17). A thrusters (22) can be used to constrain the rotation of the device about its mooring system to prevent excessive twist building up between the mooring lines and the power export umbilical.

Owner:OCEAN FLOW ENERGY

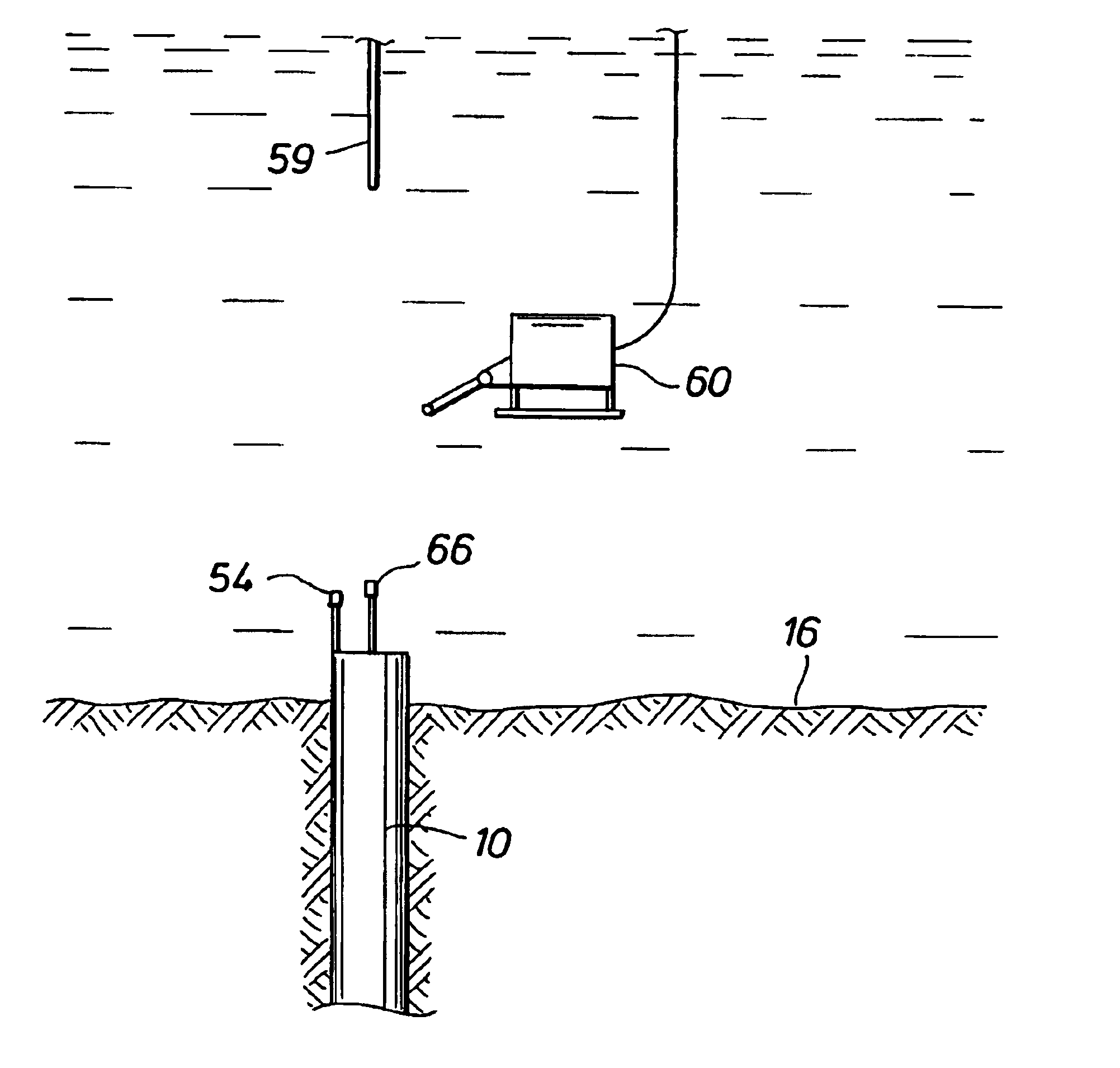

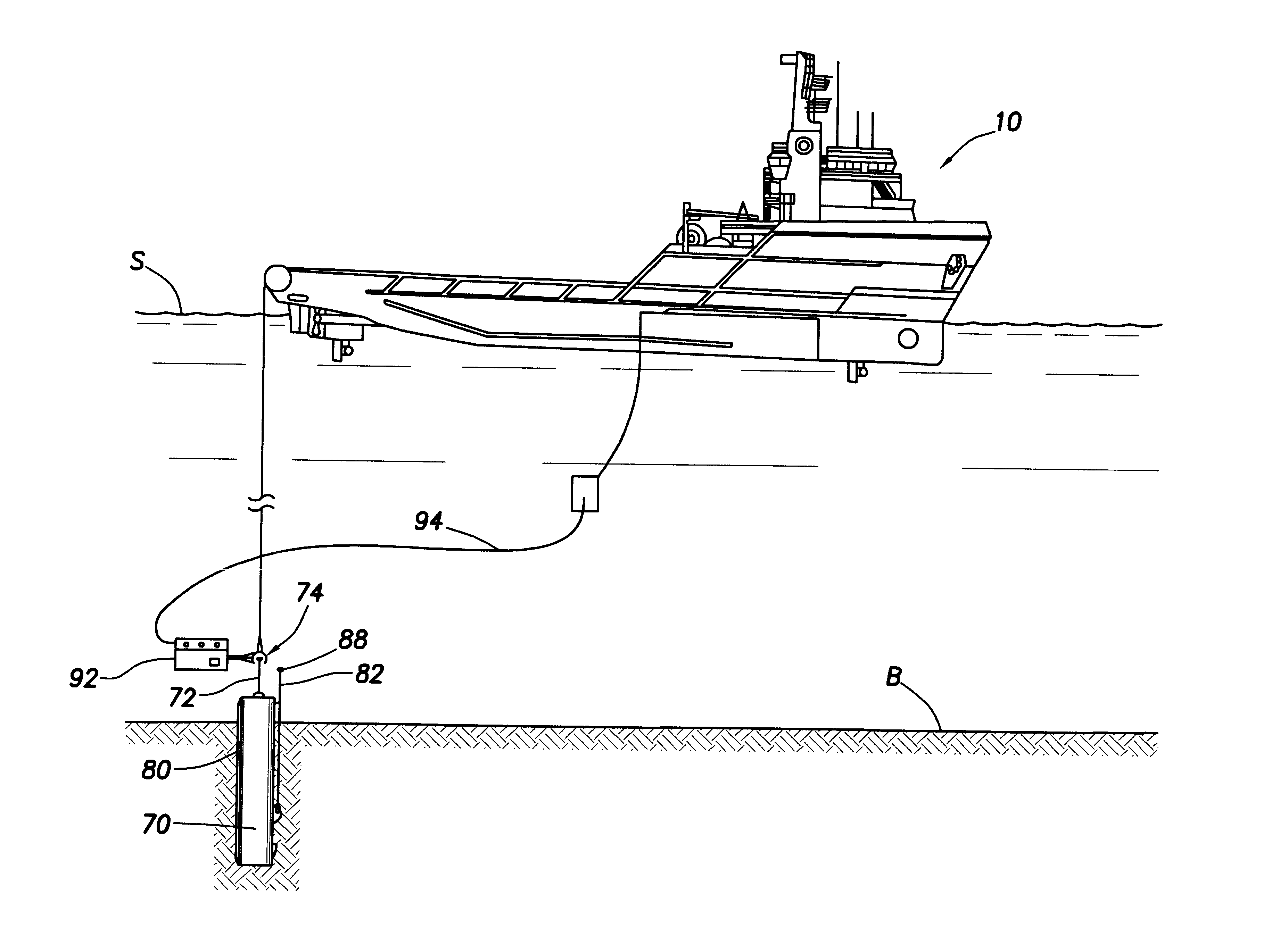

ROV installed suction piles

A method is disclosed for deploying a suction pile anchor in which flood valves are opened on the top of a suction pile and the suction pile anchor is off loaded from the anchor boat and lowered it to the sea floor. The suction pile anchor is set down and the rate of feed is adjusted to match the rate of self-penetration. An ROV with pump capability closes the flood valves on the top of the suction pile and attaches to the pumping port of the suction pile. The pump of the ROV operates to draw down the suction pile to full depth and brings the first load line connection and the attached first end of the load line well below the mudline while the second load connection at the second end of the load line is supported above the mudline. The ROV disconnects from the pump port and connects a mooring line to second the load connection. Another aspect of the present invention is a suction pile system having a suction pile with an ROV compatible pressure port and a flood valve at the top. A load support system includes a first load connection on the side of the suction pile with a load line connected to the first load connection. A second, ROV accessible load connection is provided at the distal end of the load line.

Owner:SHELL OIL CO

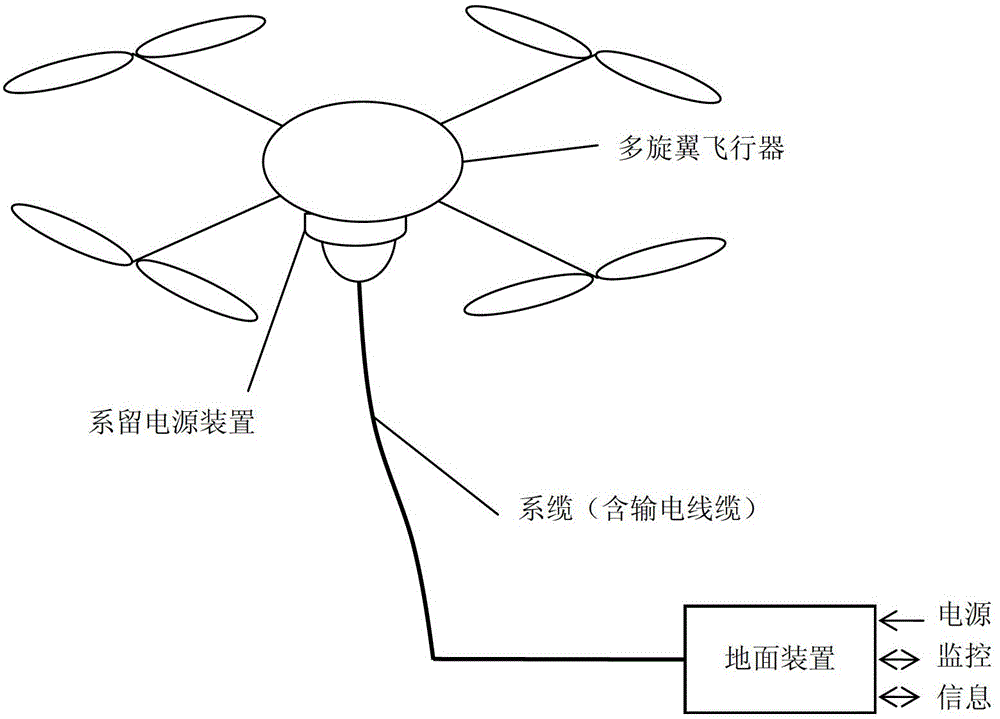

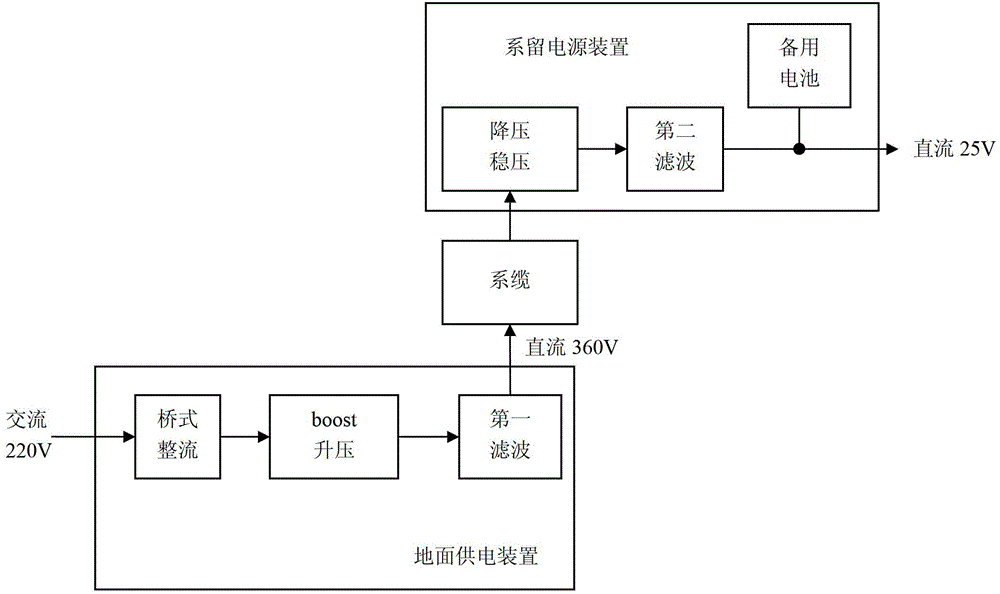

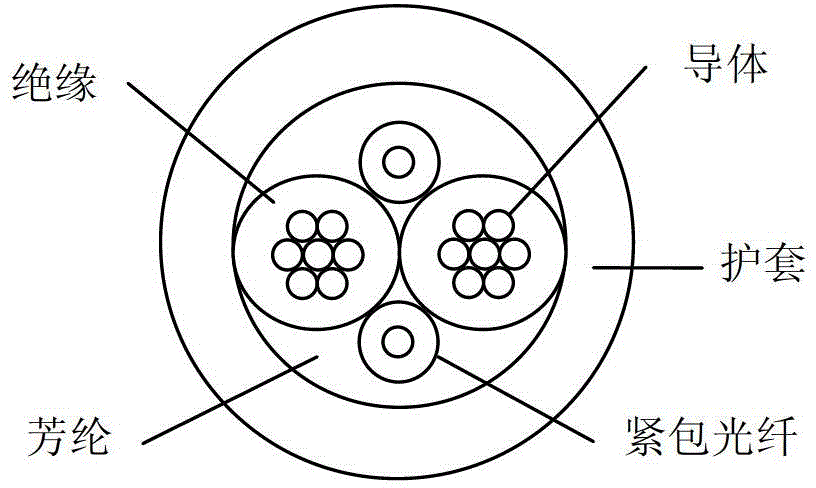

Multi-rotor-wing unmanned aerial vehicle mooring system

ActiveCN103144779ASimple structureImprove reliabilityPower cablesFor captive aircraftsMooring systemFlight vehicle

The invention discloses a multi-rotor-wing unmanned aerial vehicle mooring system, which comprises a multi-rotor-wing unmanned aerial vehicle serving as a mooring platform, a mooring line and a ground device, wherein the mooring line is connected with the multi-rotor-wing unmanned aerial vehicle and the ground device; the multi-rotor-wing unmanned aerial vehicle comprises a mooring supply unit; the mooring line comprises a power transmission cable; the ground device comprises a ground power supply device; and the mooring supply unit is connected with the ground power supply device via the power transmission cable in the mooring line. The multi-rotor-wing unmanned aerial vehicle mooring system disclosed by the invention has the characteristics of simple structure, high reliability, stability in hovering, convenience in use and low cost, the mooring mode is applied to the multi-rotor-wing unmanned aerial vehicle, and the problems of the mooring platform on the aspects of stability, erection convenience, use flexibility and use cost are solved. In addition, through the power transmission cable in the mooring line, a ground power supply can continuously supply power to the mooring platform, and the long-time hovering flight of the aerial vehicle is realized.

Owner:CHINA ELECTRONICS TECH GRP NO 7 RES INST

Floating apparatus for deploying in marine current for gaining energy

A floating, semi-submerged, tethered device that supports a horizontal axis turbine and power generation equipment for extracting kinetic energy from a tidal stream or ocean current. A submerged body (1) is supported by surface piercing struts (2) of small water plane area (FIG. 6). The device is tethered to the seabed by a spread of mooring lines (12) that are deployed both into and away from the direction of the tidal current. A horizontal axis turbine (4) harnesses energy from the water flow and drives a generator housed within the body. A horizontal strut hydrofoil (24) corrects the trim of the device when subject to varying loads from the mooring system and can also be used to dampen pitch motion. Rudder flaps in the struts (25) can be used to counteract roll motion. Power is exported from the device to the seabed by an umbilical (17). A thrusters (22) can be used to constrain the rotation of the device about its mooring system to prevent excessive twist building up between the mooring lines and the power export umbilical.

Owner:OCEAN FLOW ENERGY

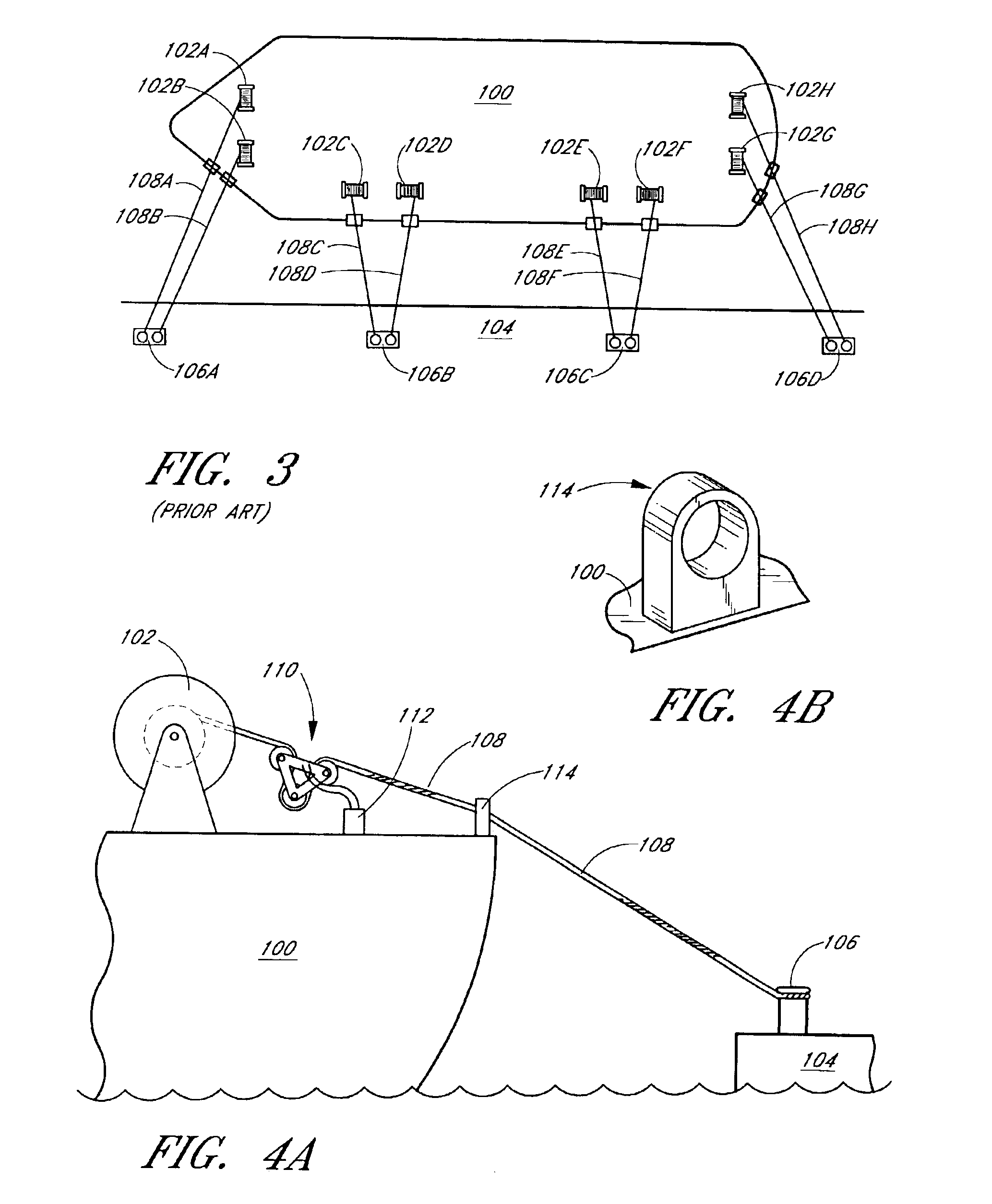

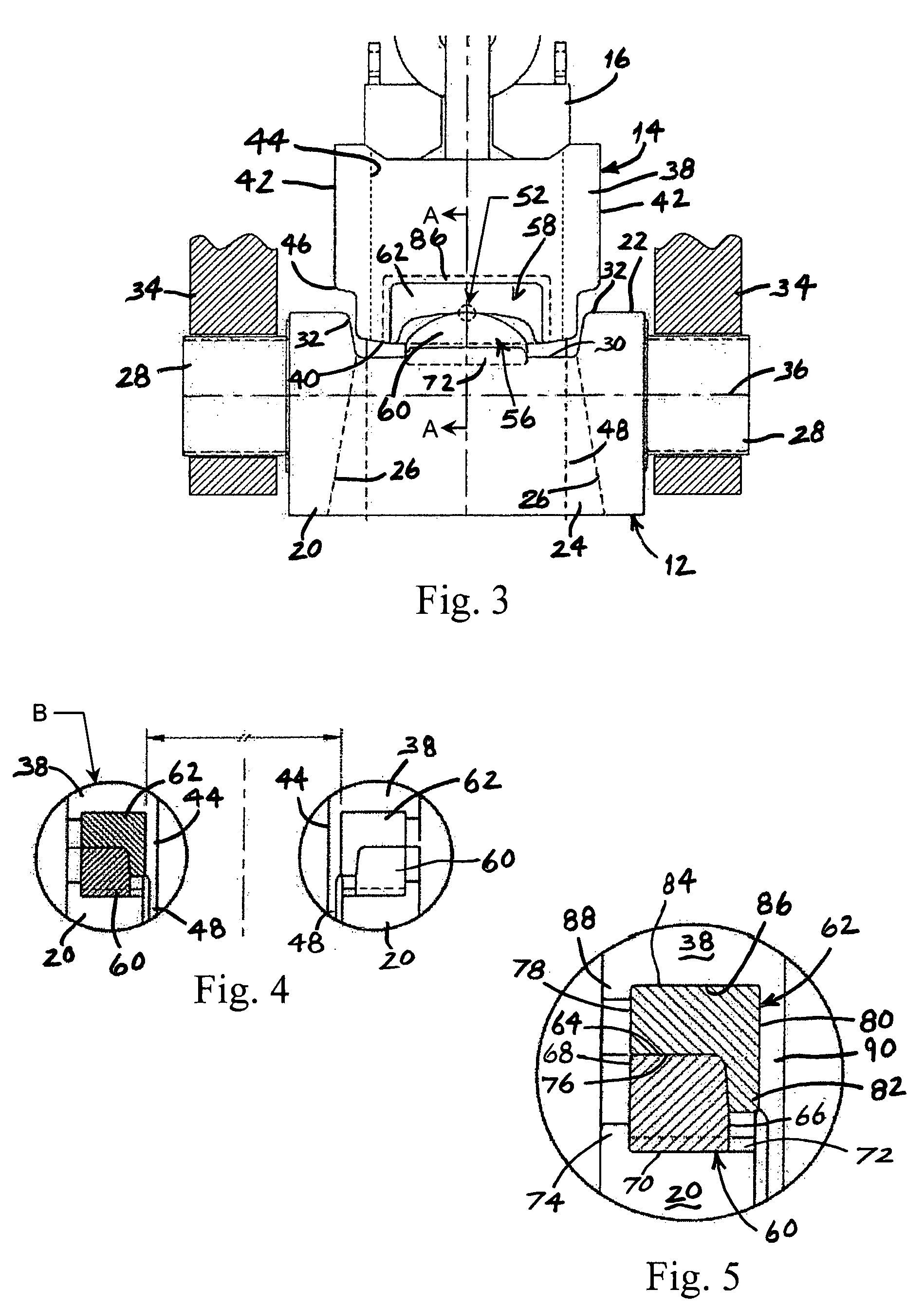

Method and apparatus for suction anchor and mooring deployment and connection

A method and apparatus for deployment of mooring systems for buoyant marine structure such as mobile offshore drilling units (MODU's) and for connecting the same to the mooring lines thereof. An anchor handling vessel carries one or more anchors each having a deployment connection and a mooring connection and individually moves each anchor over its stern roller and deploys it to the sea bottom for installation. A handling line is disconnected by ROV from the deployment connection and is moved from the deployment connection to the mooring connection so as to become the main mooring line. Syntactic buoys are then mounted on the main mooring line for elevating it above the sea bottom for recovery. When MODU stationing is desired the anchor handling vessel then recovers the surface buoy and connects to the rig mooring line using a short section of mooring chain. A J-chaser stopper device is then installed in the mooring string and is connected to the mooring line of the MODU by a short section of chain. The J-chaser lowers the mooring string, completing the mooring connection between the anchor and the MODU. A plurality of mooring strings, typically eight, are deployed in this manner to properly station the MODU. Disconnection of the MODU is accomplished essentially by the reverse of the above deployment procedure.

Owner:DELMAR SYST

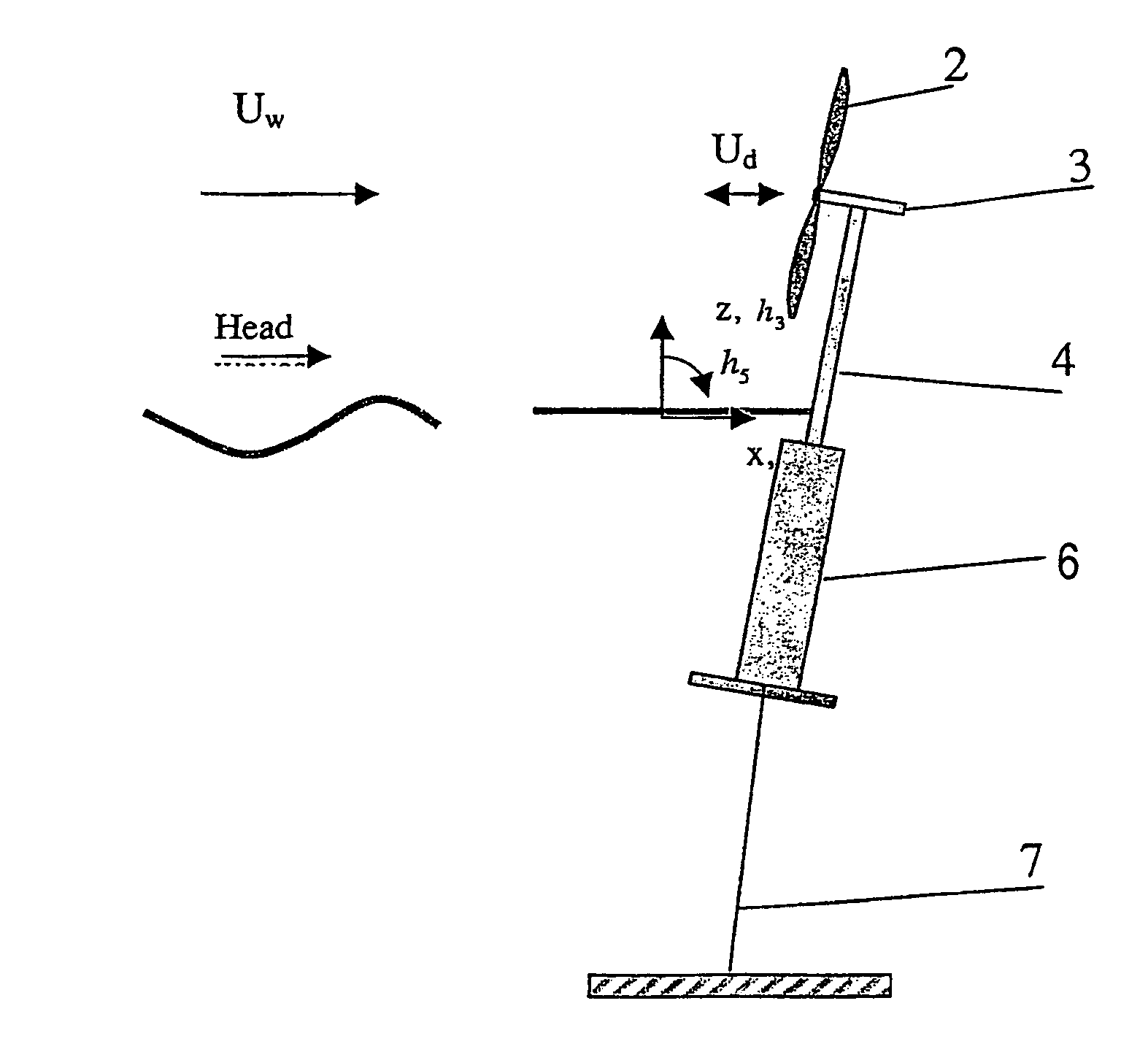

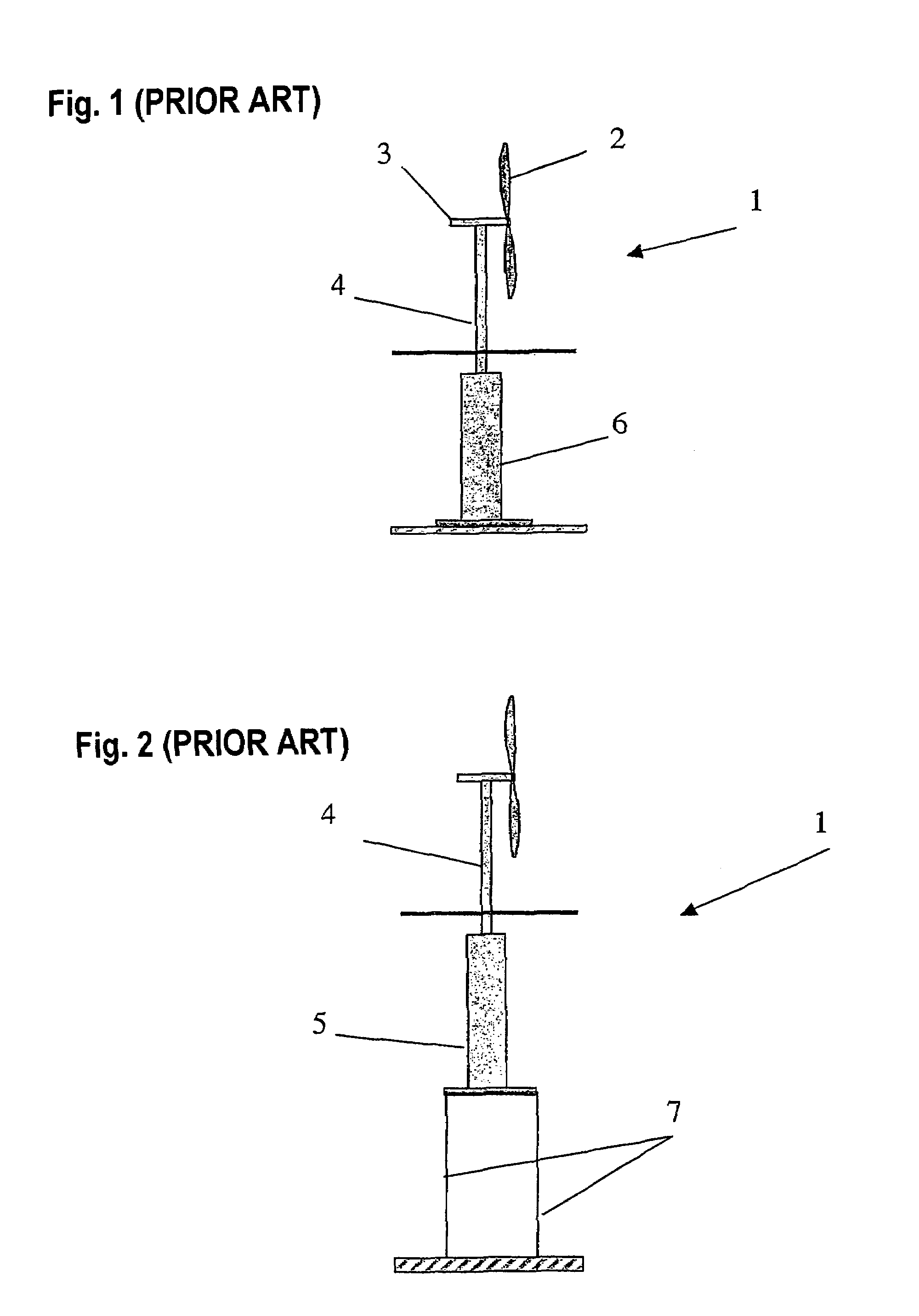

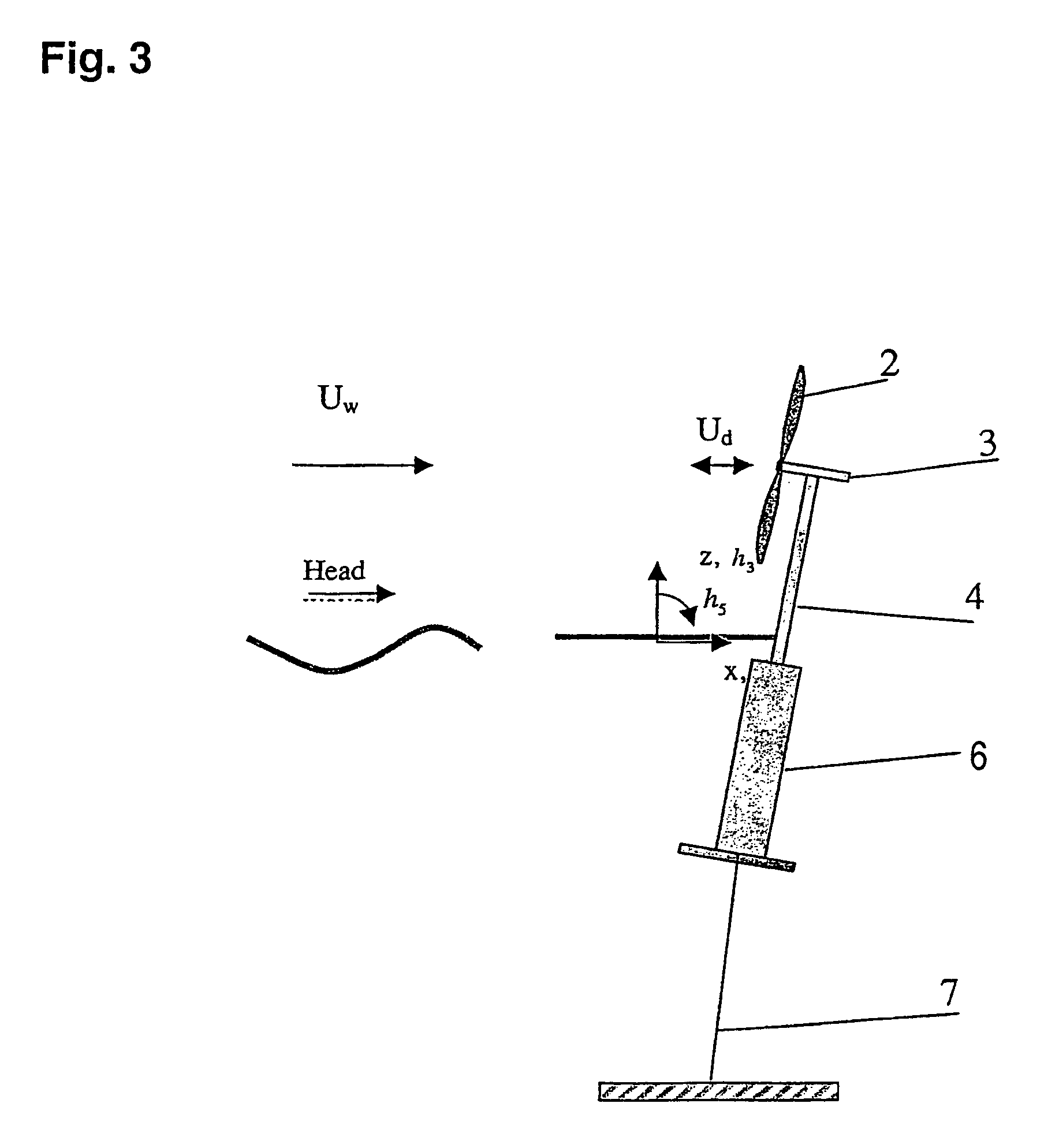

Wind turbine for use offshore

ActiveUS7456515B2Reduce relative motionReduce loadArtificial islandsWind energy with water energyVertical planeResonance

A procedure and a device in connection with the use of a wind turbine offshore, including a wind turbine (2) connected via a shaft to a generator (3), which is rotationally mounted on a tower (4), and a foundation underneath in the form of a float (6) on which the tower (4) is mounted. The float is anchored so that it can move freely in the vertical plane via an anchor or a mooring in the form of mooring lines, hinges or tethers (7). As a consequence of the effect of the waves on the float, the motion of the wind turbine will act as a damping mechanism on the motion and thus extract energy from the waves. The wind turbine's resonance period can be adjusted by adjusting the platform's center of gravity and / or the tension in the anchor with which the wind turbine is attached to the sea bed.

Owner:HYWIND AS

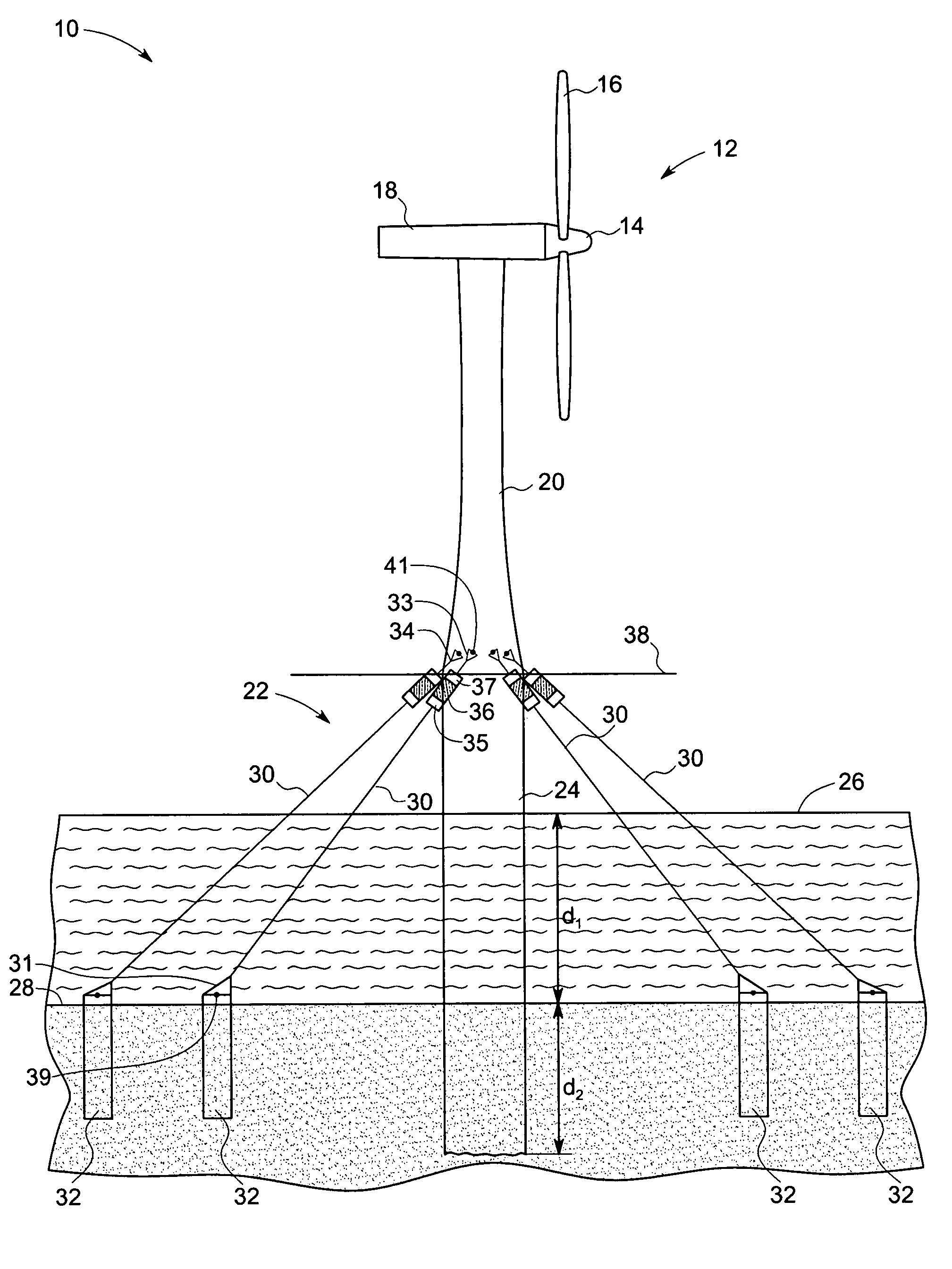

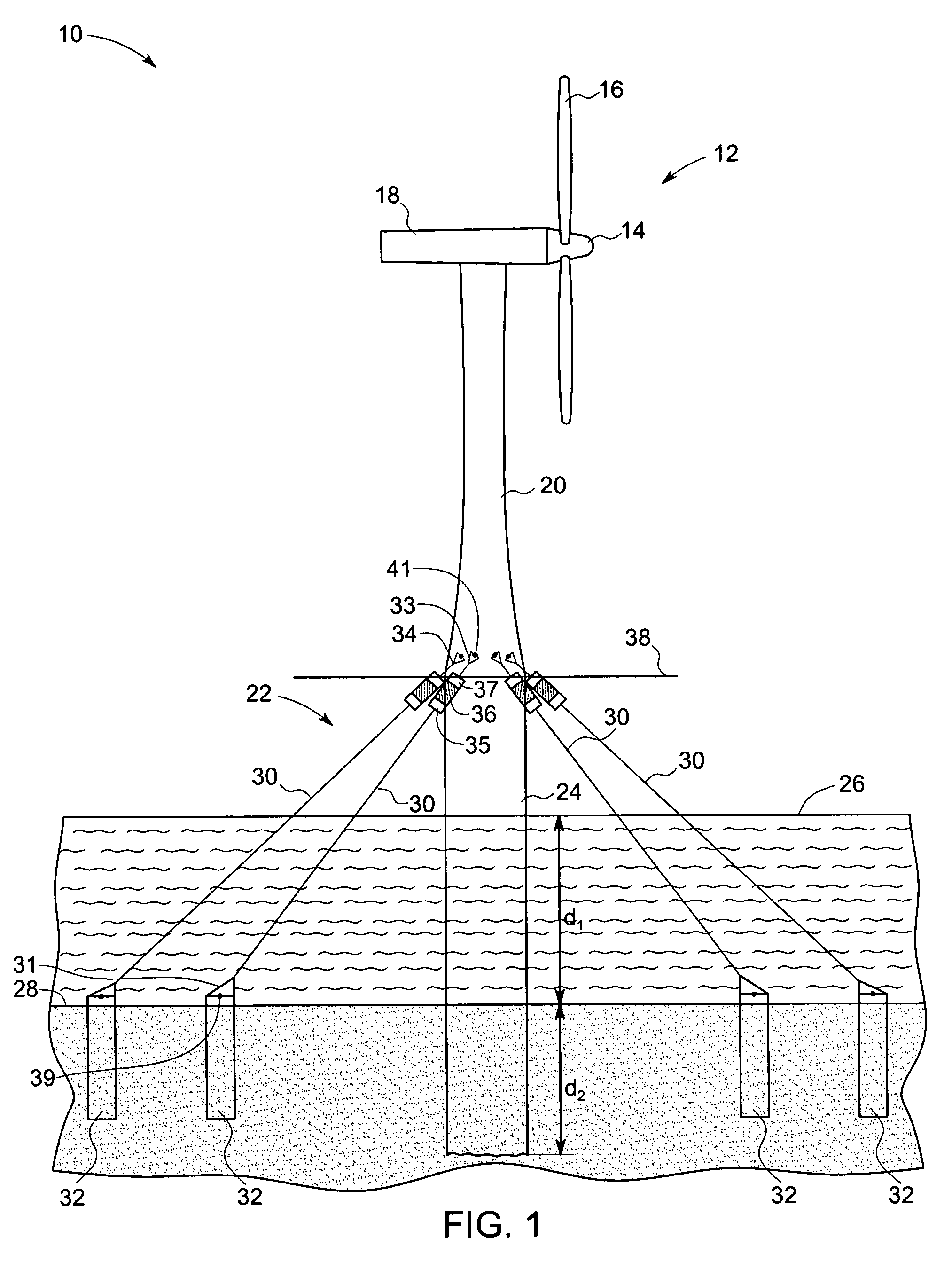

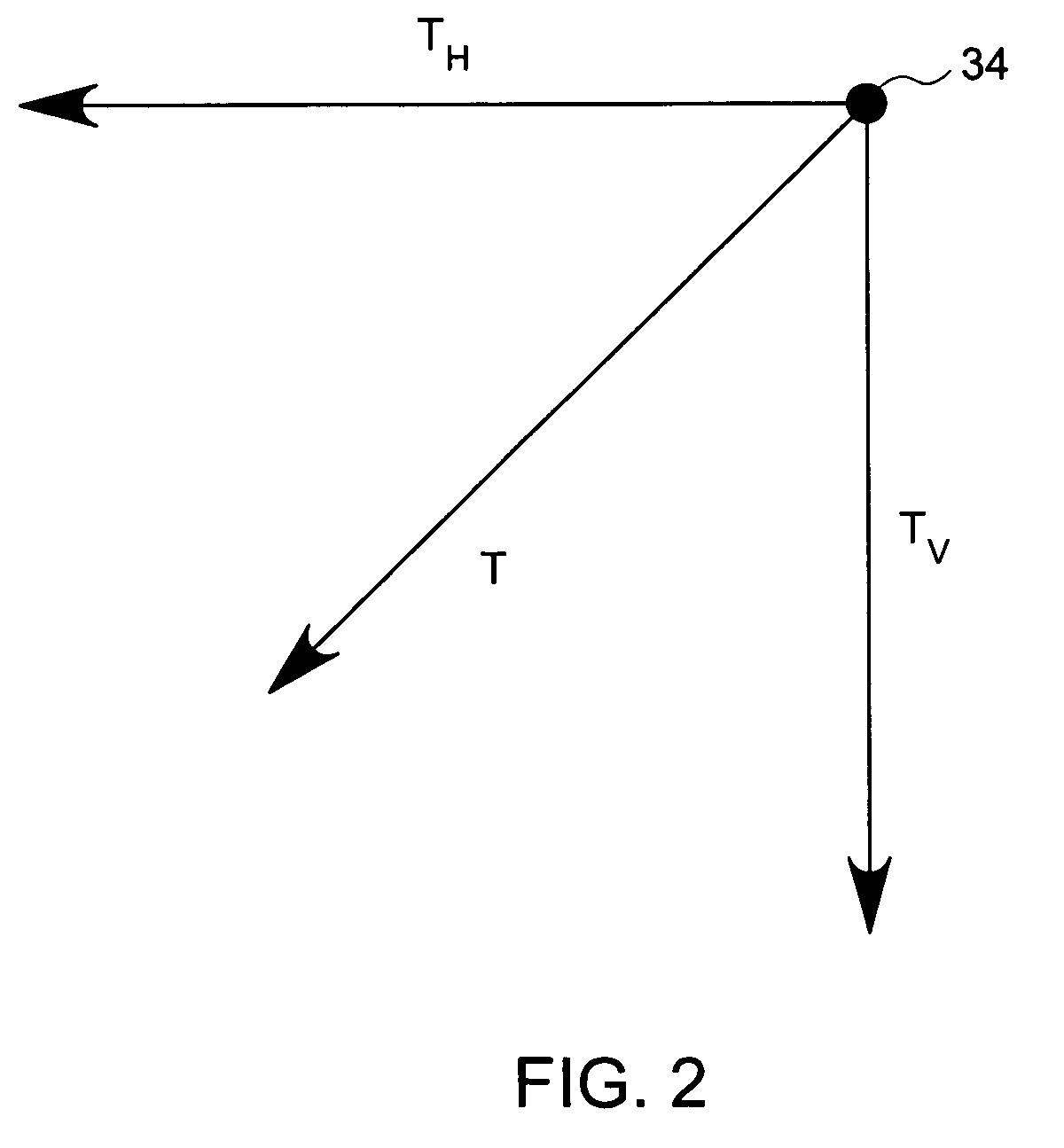

System and method for installing a wind turbine at an offshore location

A wind turbine system includes a wind turbine generator having a rotor and a nacelle mounted atop wind tower. The wind tower is mounted on a central caisson. The wind turbine system further includes a plurality of tensioned mooring lines flexibly secured to the central caisson. The mooring lines are further secured to a plurality of anchors fixed on to a sea bed. The anchors are adapted to support lateral loads on the wind turbine system.

Owner:GENERAL ELECTRIC CO

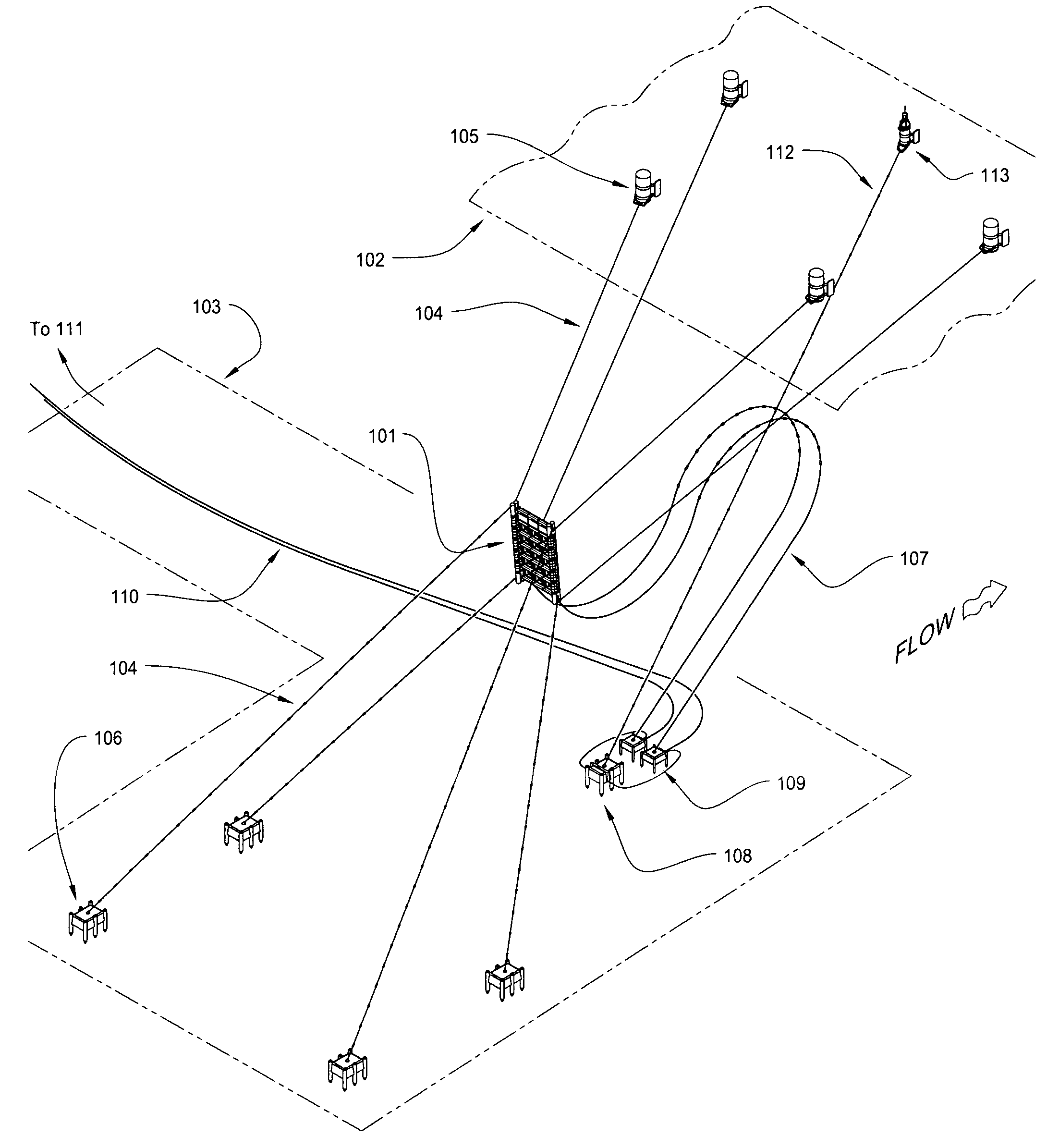

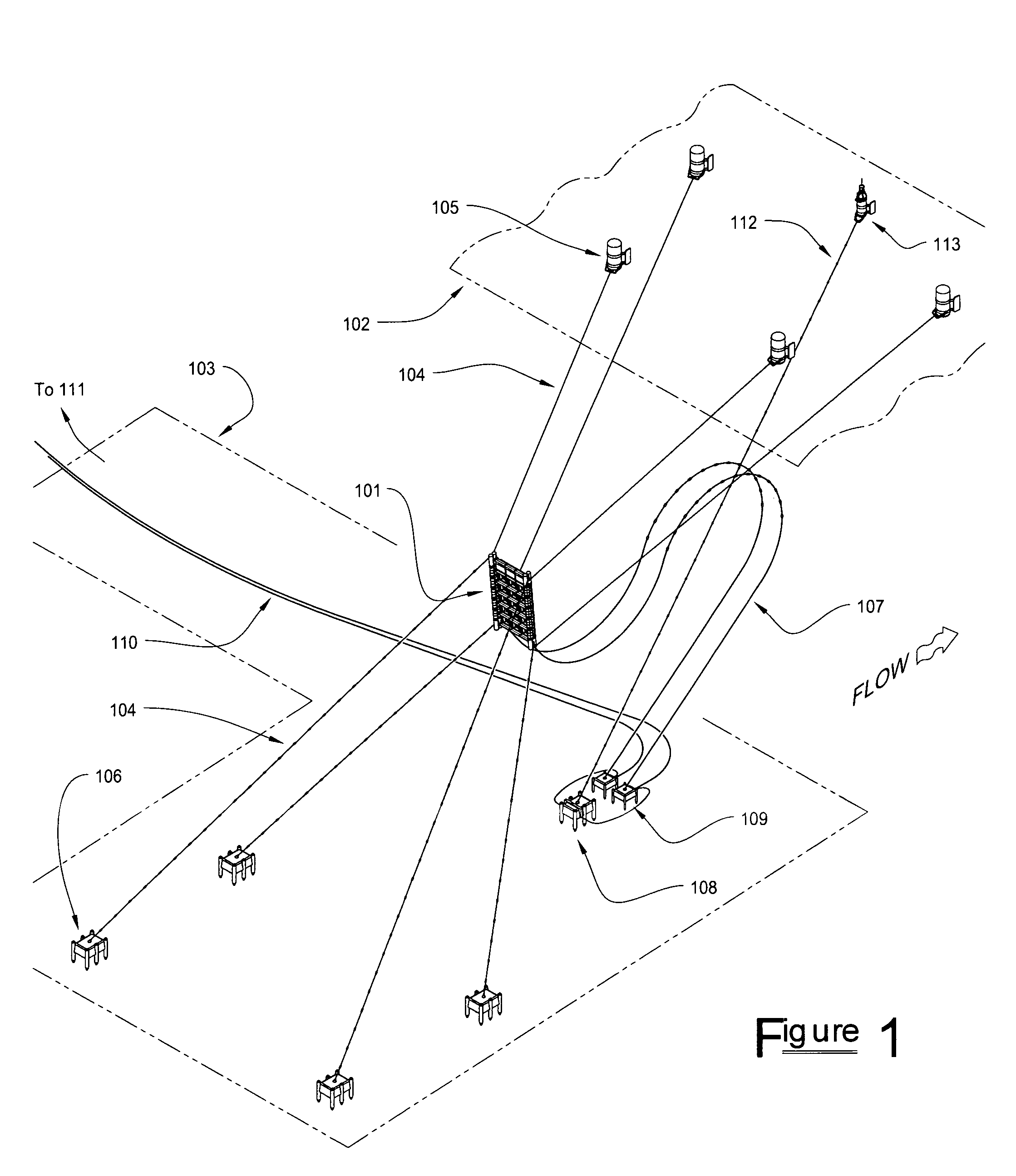

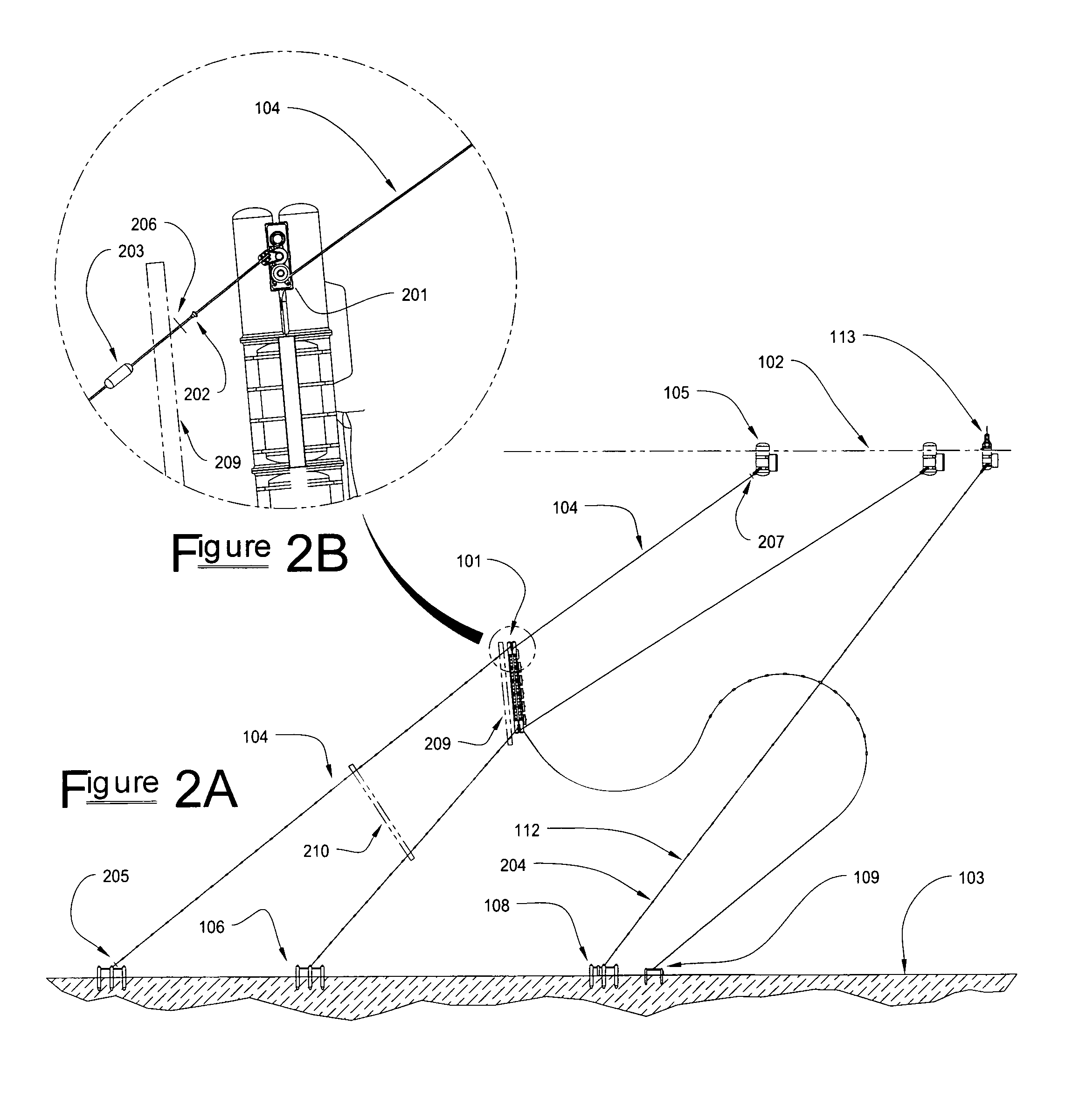

Floating spar for supporting production risers

A subsea production system is provided for producing a number of subsea wells which may be arranged in groups. Each of the groups of subsea wellheads is connected to deliver production flow to a subsea manifold and each subsea manifold is connected to deliver production flow to a production riser. A plurality of production risers each being connected to receive production flow from one of said subsea manifolds extend from the subsea manifolds for groups of wells. A deep draft floating spar is located generally above the subsea wellheads with mooring lines and has a production platform located above the sea surface and has buoyancy and ballast chambers to control floatation. The spar structure defines a riser bore receiving the production risers extending from the subsea wellheads to the production platform. The spar is also capable of being shifted laterally by its mooring lines for positioning above a selected well to thus permit well intervention activities as needed. The subsea wells are each provided with wellheads having a removable cap to permit ROV actuated cap removal and replacement as needed to permit well intervention.

Owner:FMC TECH INC

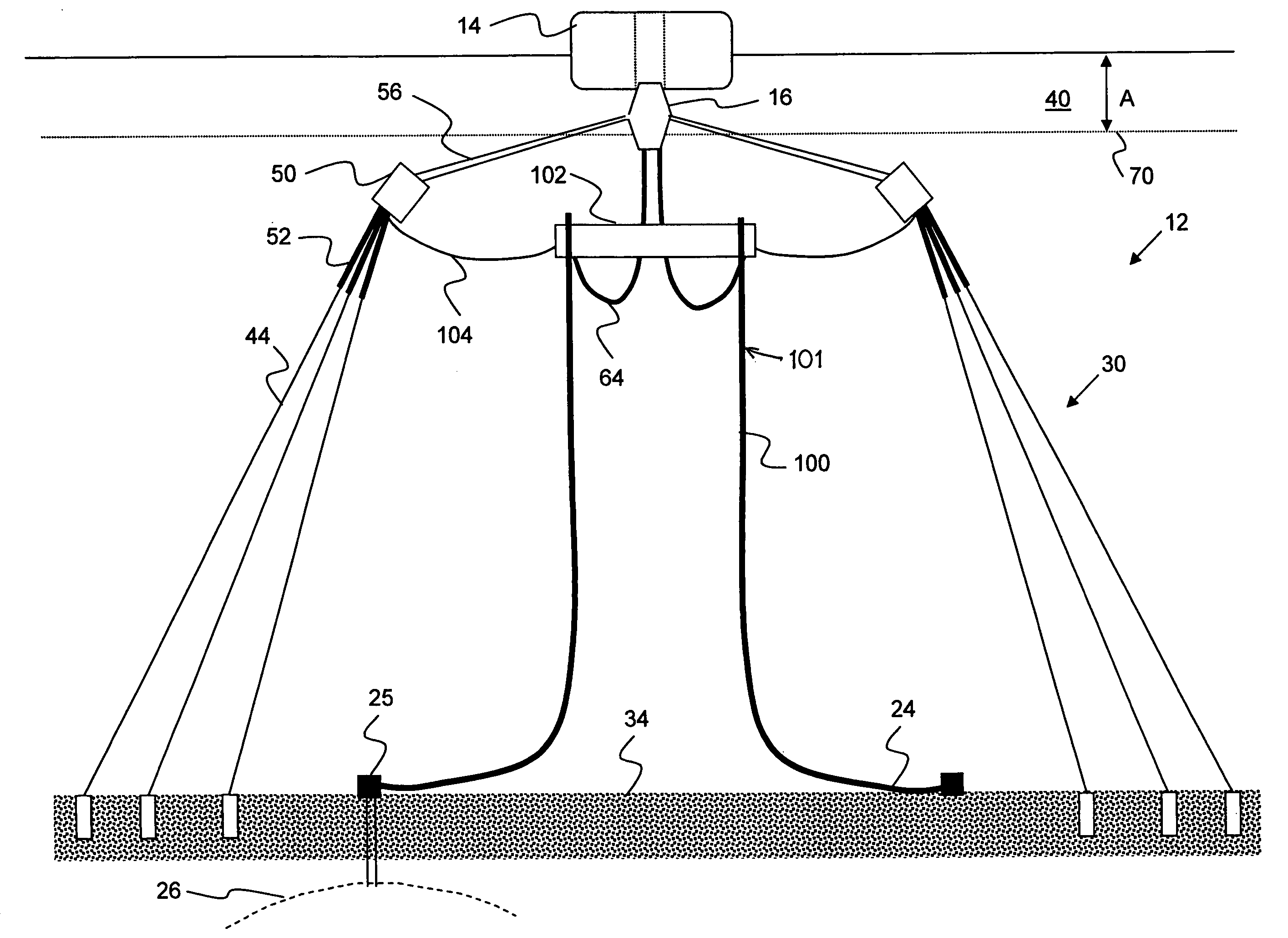

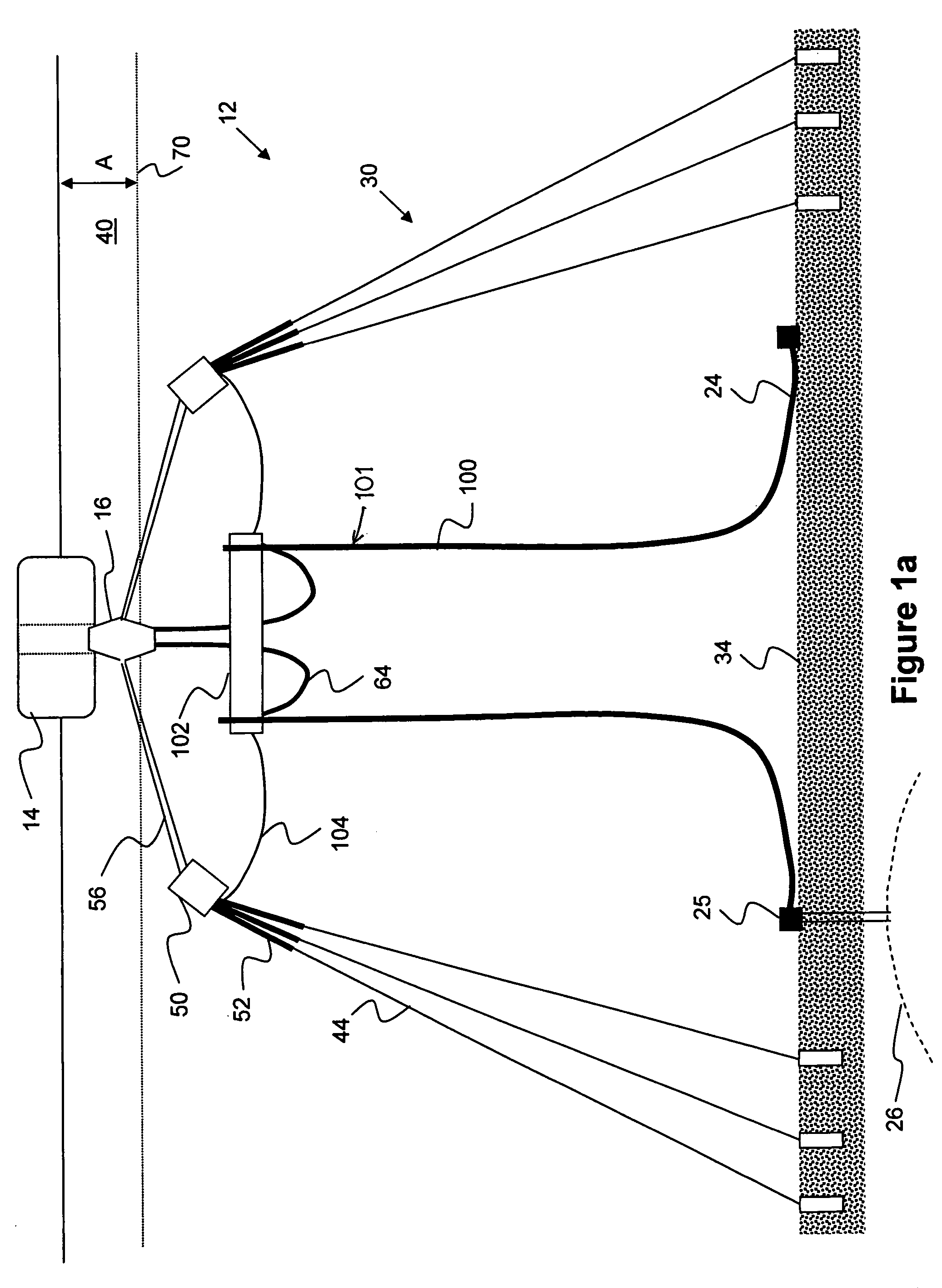

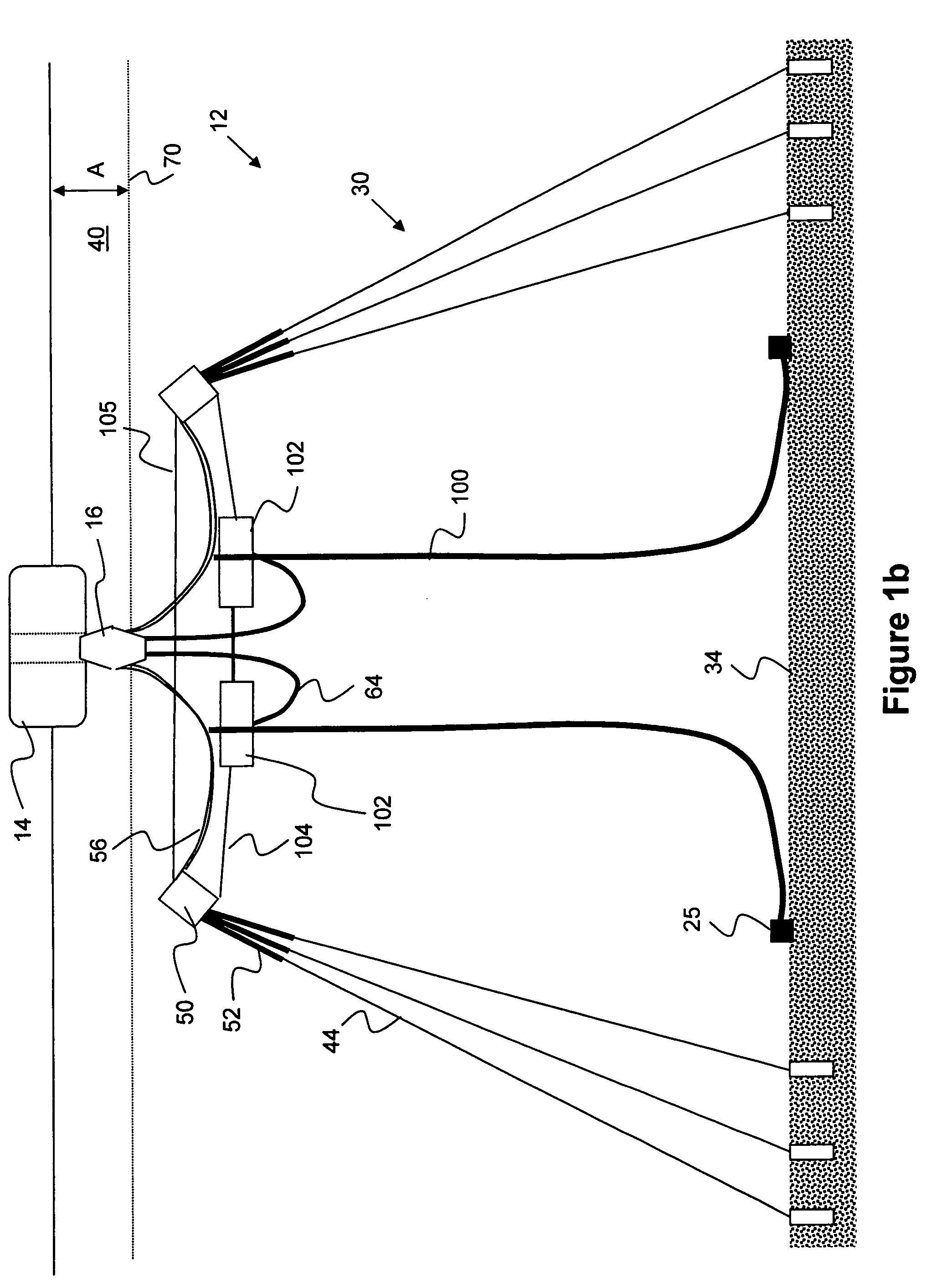

Disconnectable riser-mooring system

A system is described for use at offshore locations of large depth, for mooring a production vessel or floating unit (14) at a location over a hydrocarbon reservoir (26) and for connecting risers (101) that can be carrying hydrocarbons up from the sea floor to a production vessel that stores the hydrocarbons, flowlines for water injection, gas lift, gas export, umbilicals and mooring lines that moor the vessel. Both the mooring lines and the risers are disconnectably connected to the vessel though a connection buoy, or connector (16). The invention concerns a system that allows a connector (16) to be used that is of minimum mass and volume, to ease its handling especially during its connection and disconnection to and from a vessel.

Owner:SINGLE BUOY MOORINGS INC

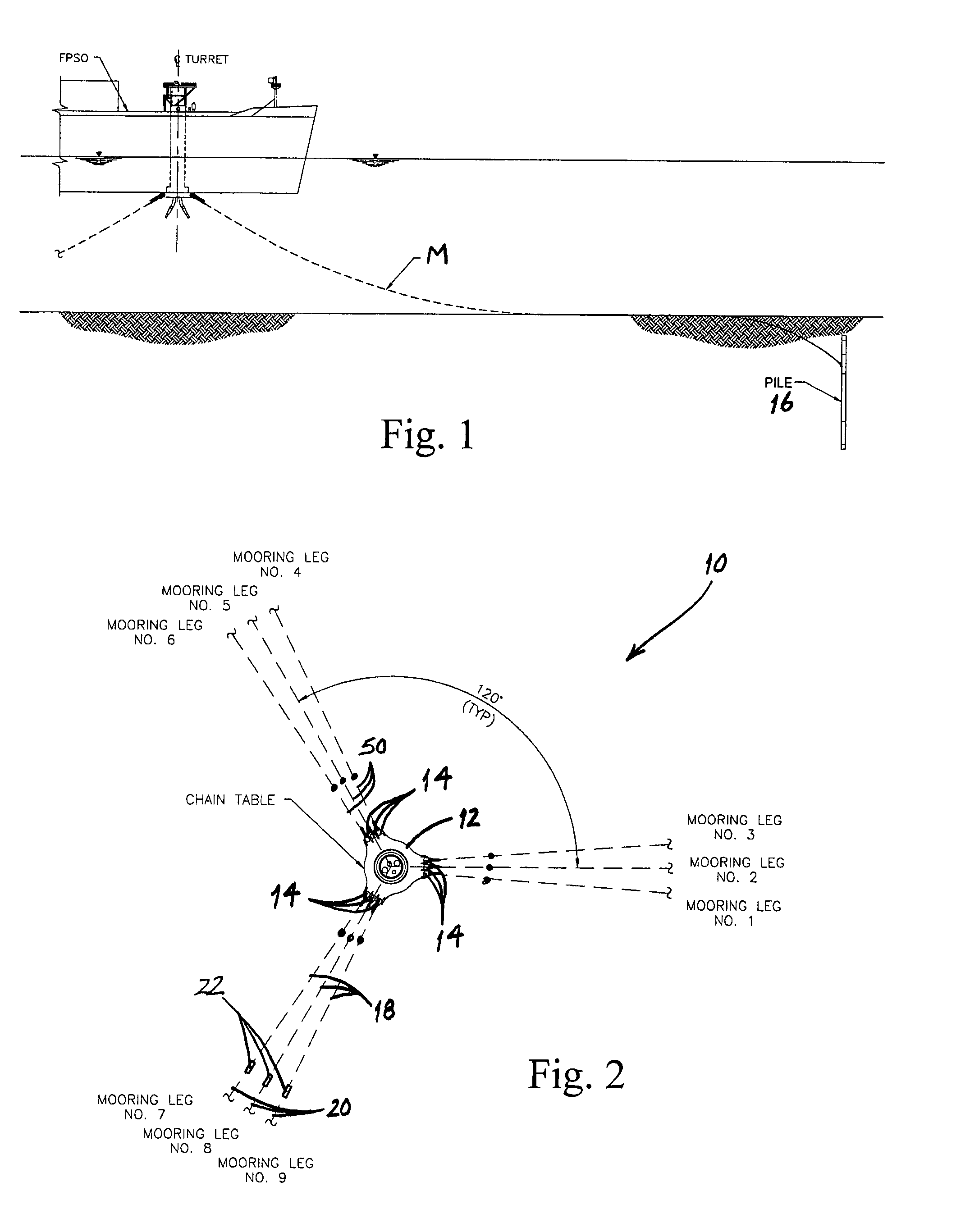

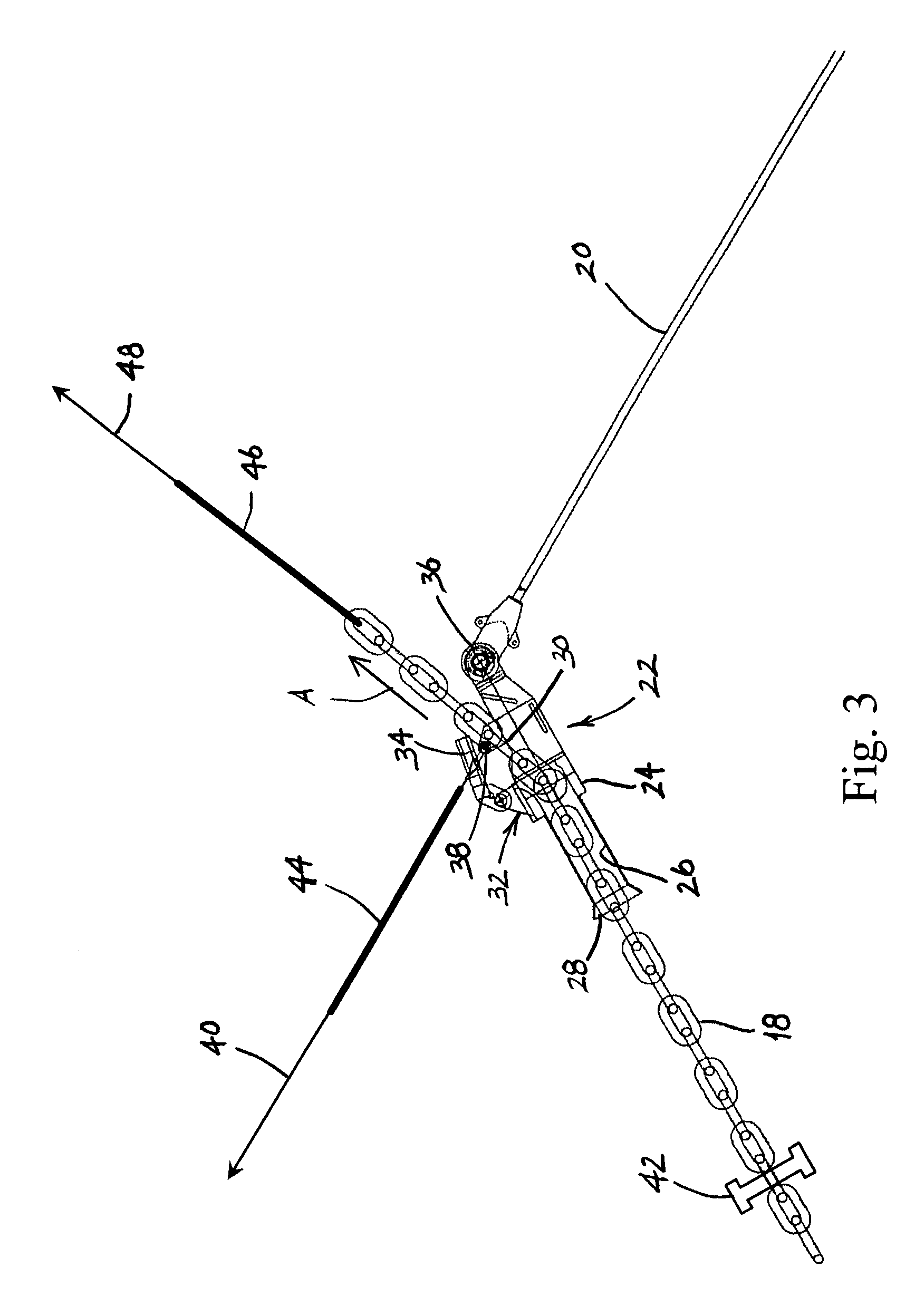

Mooring apparatus and method

ActiveUS7421967B1The process is convenient and fastReduce forceAnchorsMooring equipmentOcean bottomMooring system

A mooring system for securing a floating vessel to the sea floor comprises a plurality of mooring legs, at least one of which includes separate first and second mooring lines. The first mooring line comprises a first end which is connected to the vessel and the second mooring line comprises a first end which is secured to the sea floor. The mooring system also comprises a connection and tensioning device which includes a body, a bore which extends through the body, a chain stopper for adjustably securing the first mooring line to the body, and a connector for connecting a second end of the second mooring line to the body. In use, a second end of the first mooring line is inserted into the bore and the first mooring line is pulled through the bore while the body is subject to an opposing pulling force. Once the first mooring line is pulled through the bore a desired distance, the chain stopper maintains the first mooring line in position relative to the body to thereby secure the vessel to the sea floor.

Owner:SOFEC

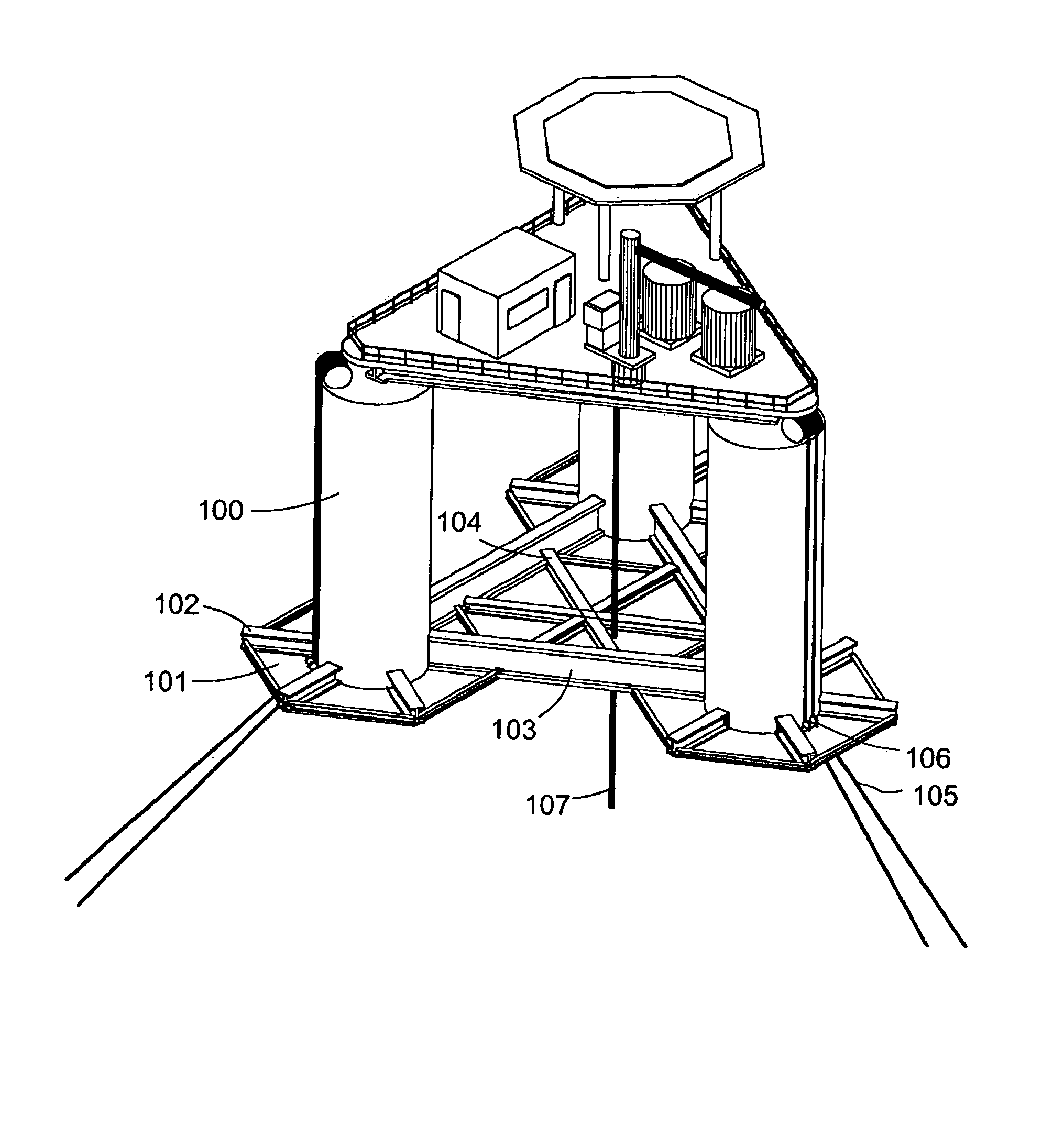

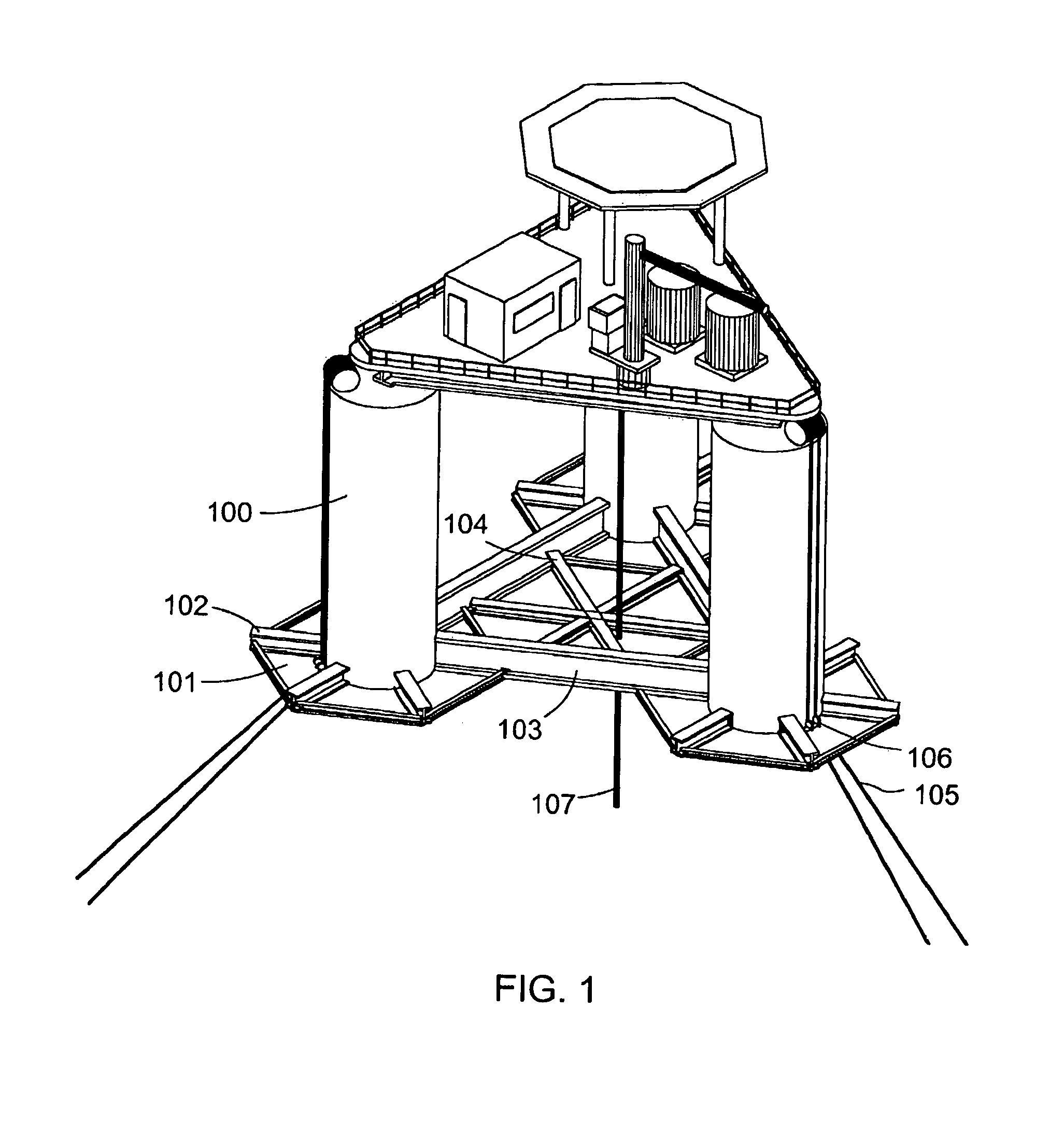

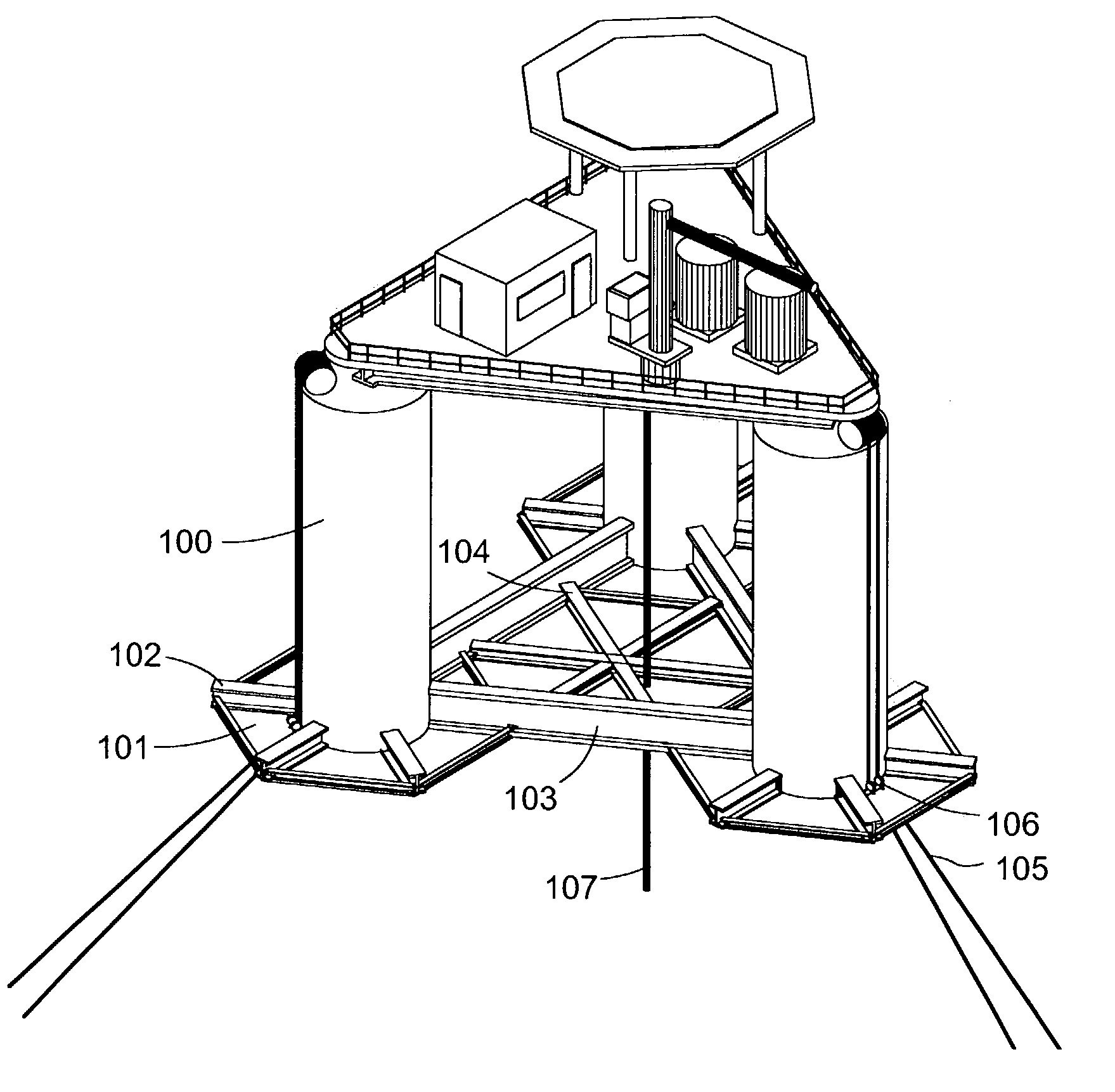

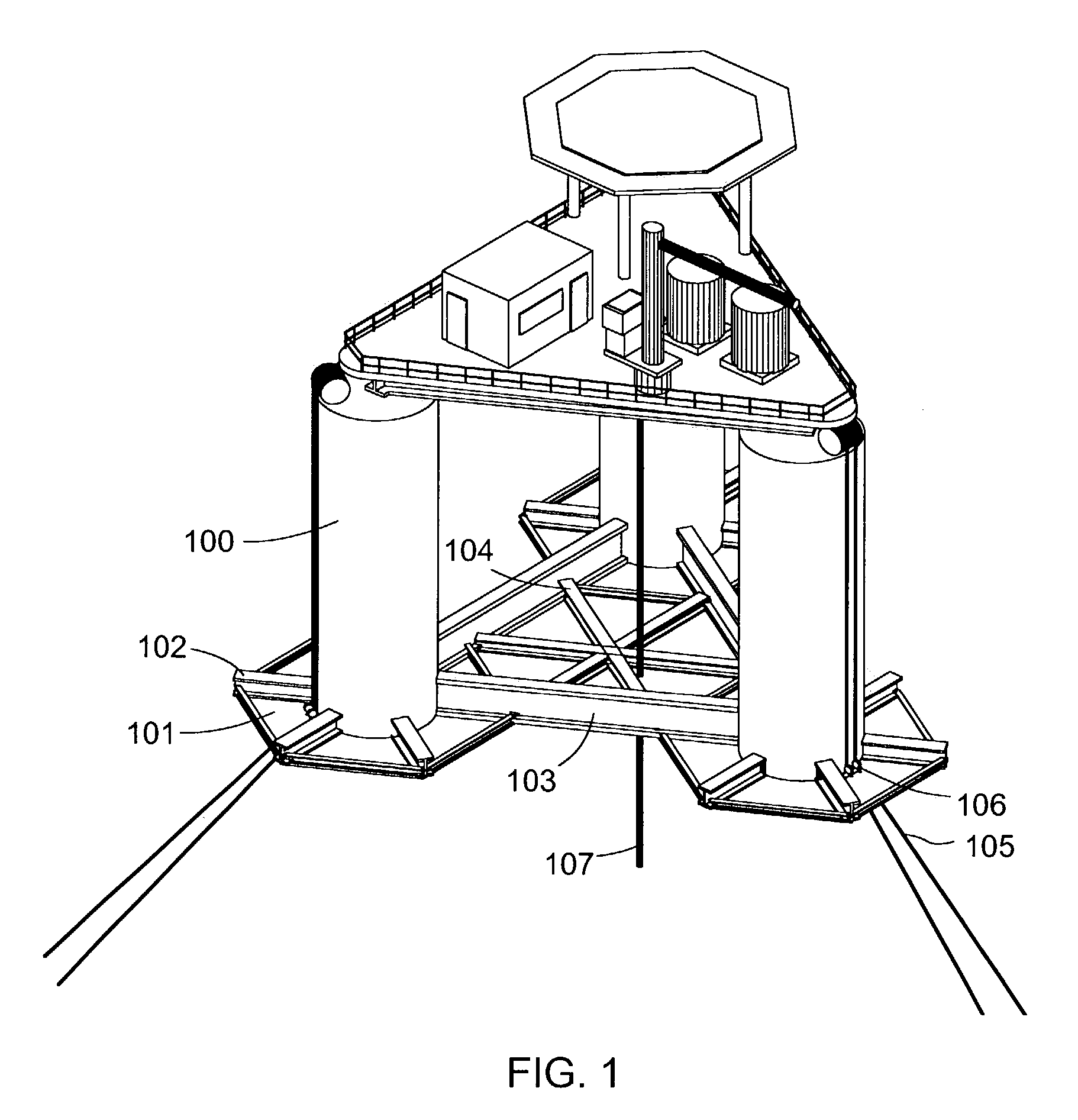

Column-stabilized platform with water-entrapment plate

InactiveUS7281881B1Artificial islandsVessel movement reduction by foilsOcean bottomOffshore oil and gas

An apparatus for use in offshore oil or gas production in which a plurality of vertical stabilizing columns are supported on a submerged horizontal water entrapment plate is provided to support minimum offshore oil and gas production facilities above a subsea wellhead, or subsea processing facilities, or a submarine pipeline, and whose main function is to provide power or chemicals or to perform other operations such as compression, injection, or separation of water, oil and gas. The apparatus is maintained in the desired location by a plurality of mooring lines anchored to the sea-bed. The respective size and shape of the columns and water entrapment plate are designed to provide sufficient buoyancy to carry the weight of all equipment on the minimum floating platform and mooring lines, umbilical and risers attached to it, and to minimize the platform motion during normal operations.

Owner:OCERGY INC

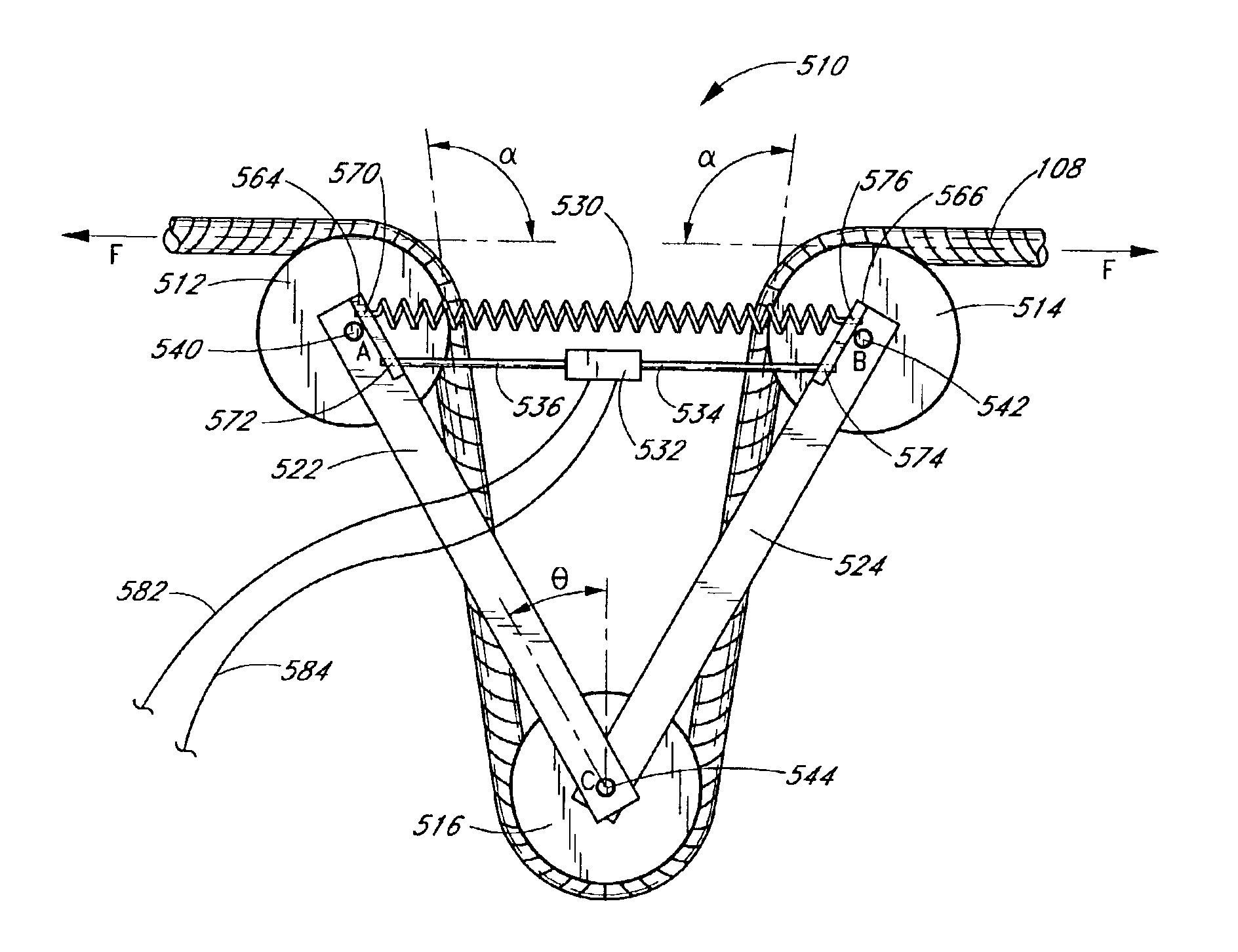

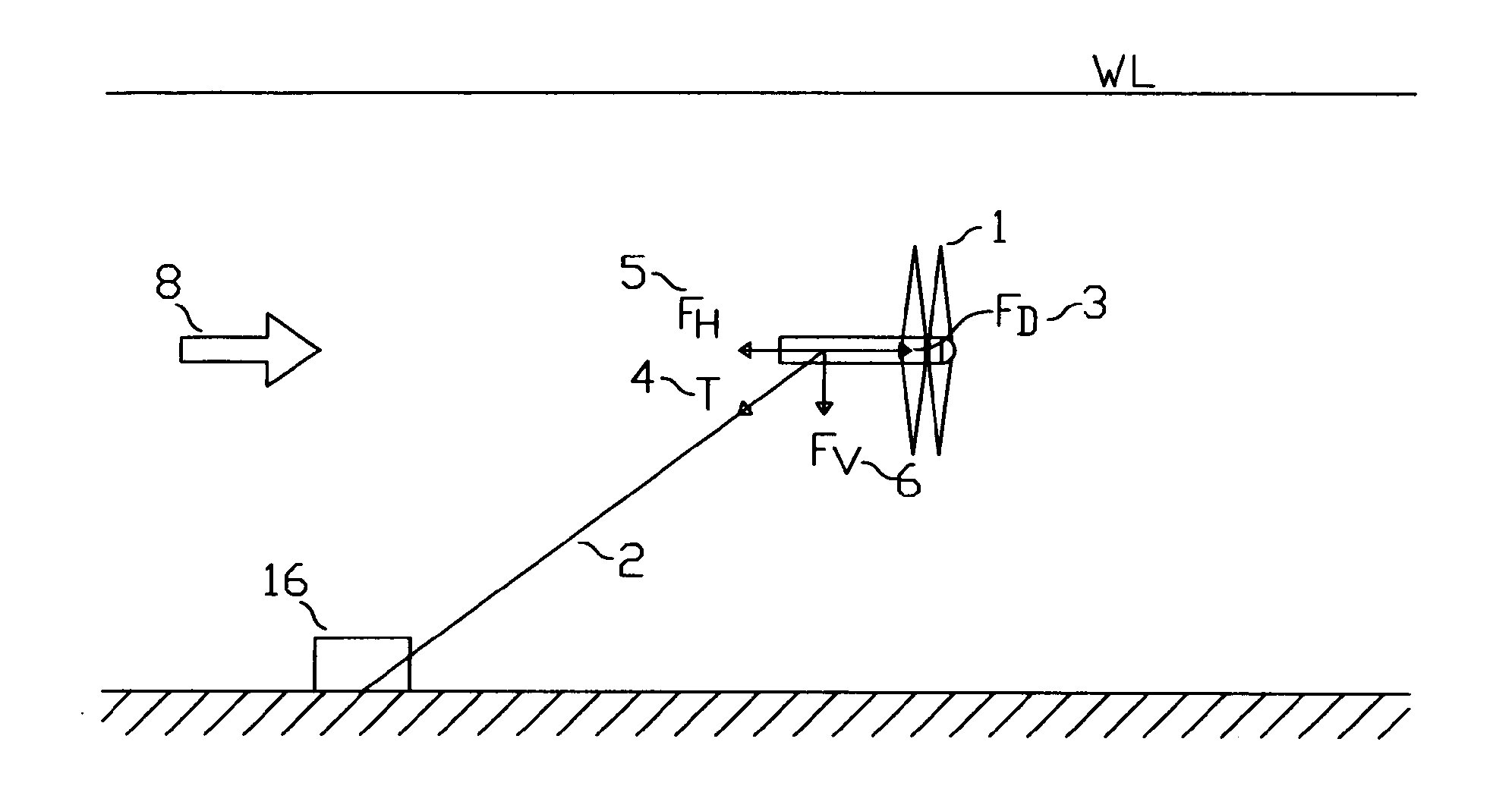

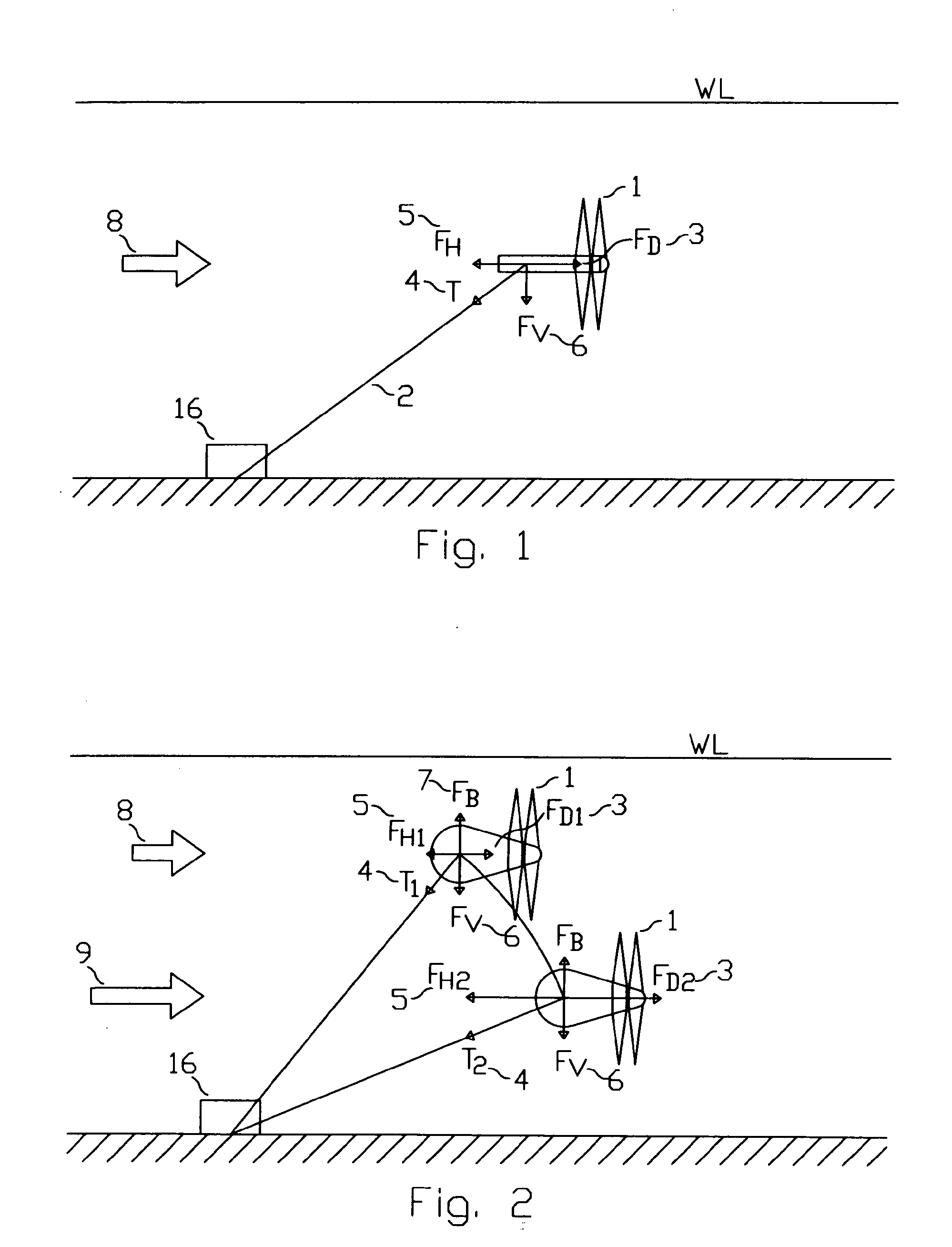

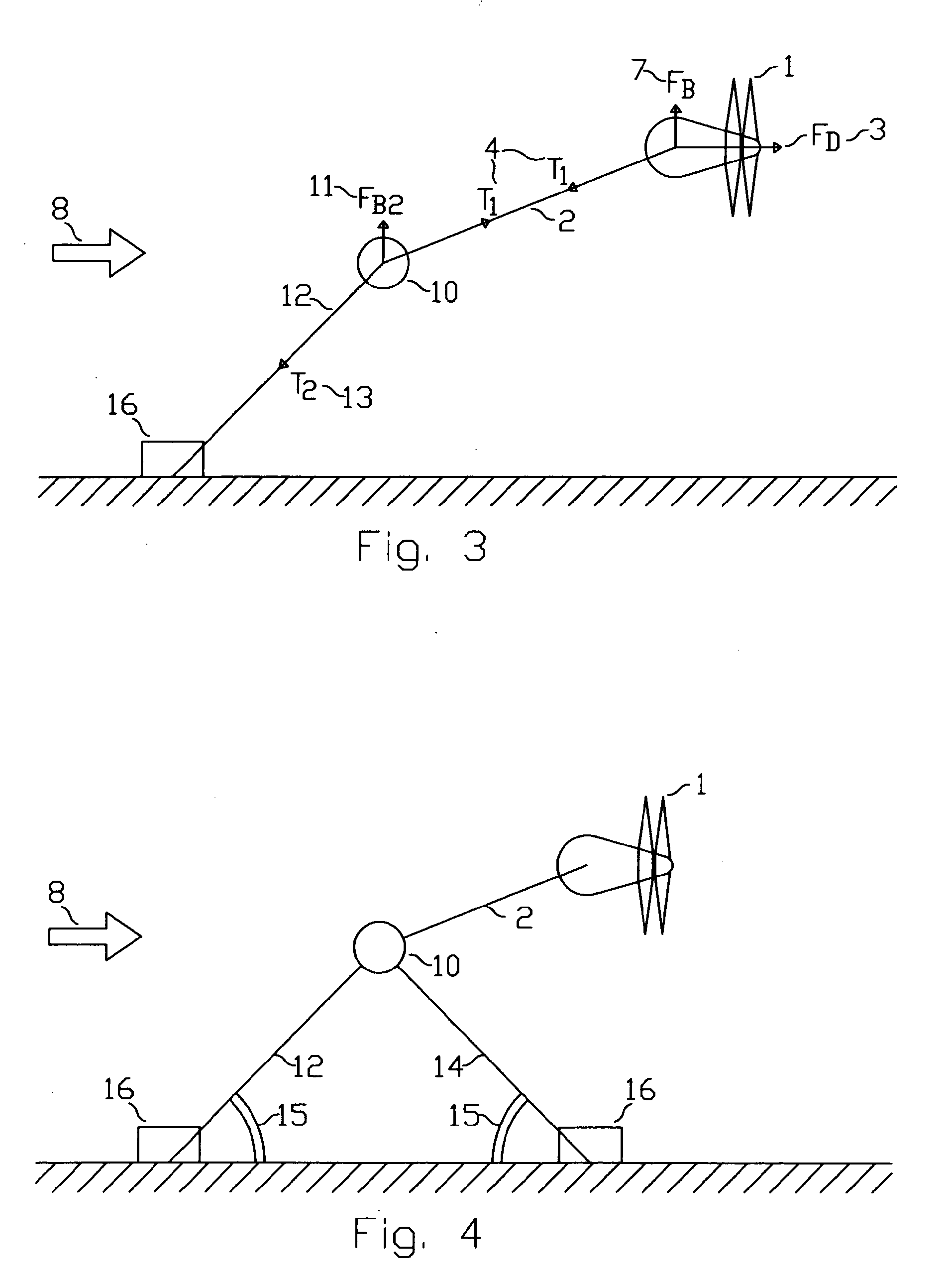

Tension measuring device for mooring line

A device for measuring tension in a line for mooring a ship to a dock or an anchor. The device includes three pulleys secured to rigid frames or springs. Sensors are placed on rigid frames, springs or shafts for securing the pulleys. Portions of the mooring line extending from a center pulley to the other two pulleys are approximately perpendicular to portions of line extending from the two pulleys to a winch or a mooring post or hook. The springs between the pulleys may provide resilience in the mooring line which may obviate a need for a pendent line between the mooring line and the winch. The sensors communicate with a signal-processing unit which transmits amplified sensor signals to a monitor which is accessible to personnel aboard the ship. The monitor may display the tension in the mooring line in text or graphic formats.

Owner:CHEUNG MAXWELL C

Mooring System for Tidal Stream and Ocean Current Turbines

InactiveUS20100230971A1Reduce riskReduce resistanceArtificial islandsMachines/enginesFree rotationMooring system

A tidal stream or ocean current turbine is connected to a submerged buoy that is tethered to the seabed to create a virtual seabed level that is higher than the actual seabed. The buoy is constrained by tensioned tethers or catenary mooring lines such that it is approximately geofixed at a prescribed depth of immersion and orientation. The turbine device is attached to the submerged buoy by a connector strut that allows the device to swivel about the geofixed location. The strut to buoy connection incorporates a bearing system that allows the strut freedom of rotation in the horizontal and vertical planes about the geofixed buoy. The reserve of buoyancy in the submerged buoy acts to resist the vertical component of the mooring force such that the drag force on the turbine device cannot lead the device to submerge excessively or cause the downstream tension tether mooring lines to go slack.

Owner:OCEAN FLOW ENERGY

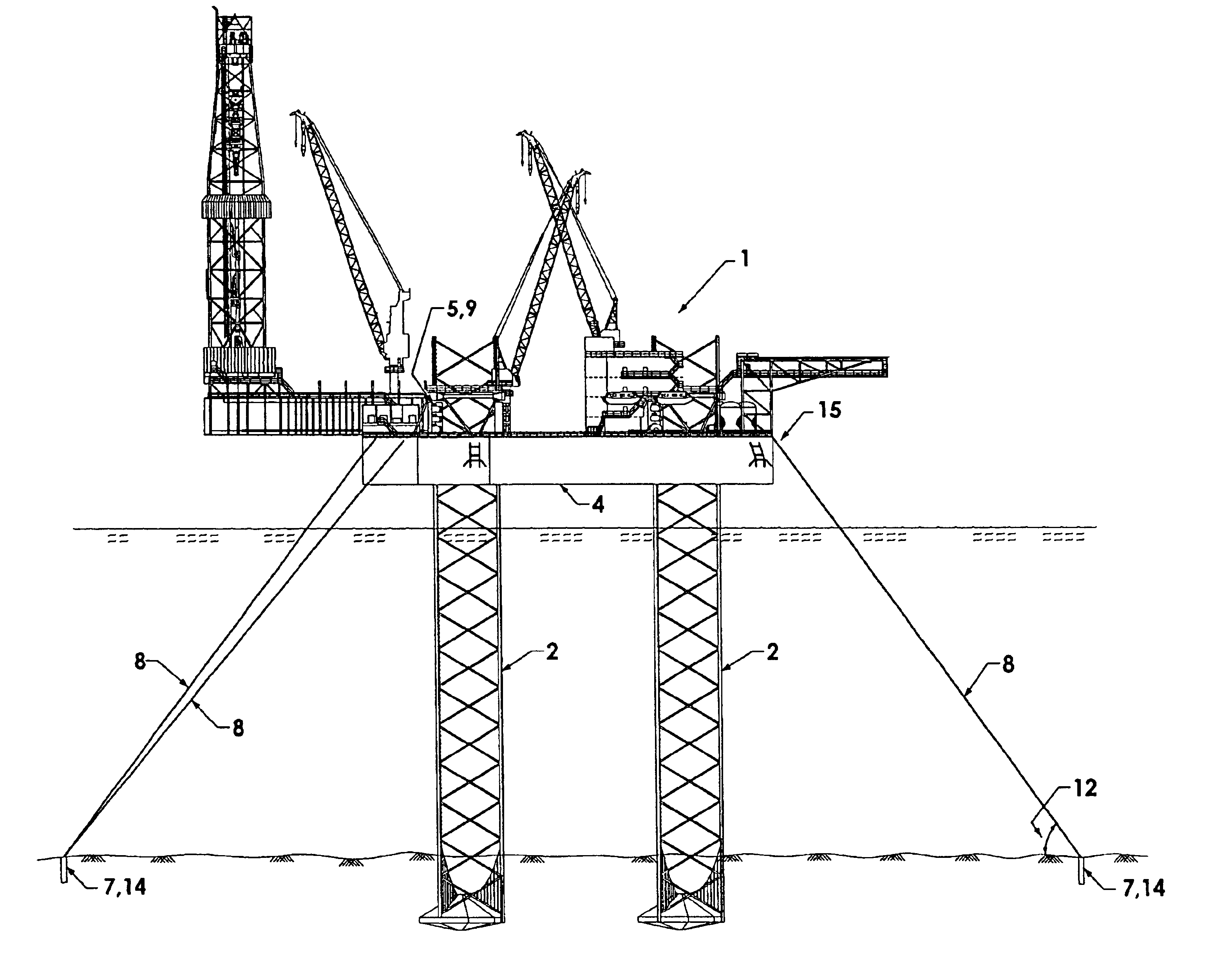

Taut mooring system for jack-up type mobile offshore platforms

InactiveUS6869252B1Reduce natural periodExtended maintenance periodArtificial islandsUnderwater structuresMooring systemMarine engineering

A taut mooring system for use on a mobile offshore jack-up platform while it is in an elevated operating condition. The elevated operating condition is with the hull jacked up a safe distance above the highest anticipated wave crests, on vertically movable legs which extend to the ocean floor. The mooring system consists of: radially spaced mooring line attachment means on the structure of the platform; suction piles that are radially spaced around the platform, consistent with the radial spacing of the mooring line attachment means; and taut mooring lines which radially connect the suction piles to the attachment means. The flexibility of the taut mooring system provides the ability to coact with the platform's free standing storm resistance capabilities, yielding enhanced capabilities that will enable the platform to safely resist storm induced forces that the platform would not normally be capable of withstanding, and to enable the platform to be used with longer legs in deeper water.

Owner:ZENTECH

Minimum floating offshore platform with water entrapment plate and method of installation

An apparatus for use in offshore oil or gas production in which a plurality of vertical stabilizing columns are supported on a submerged horizontal water entrapment plate is provided to support minimum offshore oil and gas production facilities above a subsea wellhead, or subsea processing facilities, or a submarine pipeline, and whose main function is to provide power or chemicals or to perform other operations such as compression, injection, or separation of water, oil and gas. The apparatus is maintained in the desired location by a plurality of mooring lines anchored to the sea-bed. The respective size and shape of the columns and water entrapment plate are designed to provide sufficient buoyancy to carry the weight of all equipment on the minimum floating platform and mooring lines, umbilical and risers attached to it, and to minimize the platform motion during normal operations.

Owner:OCERGY INC

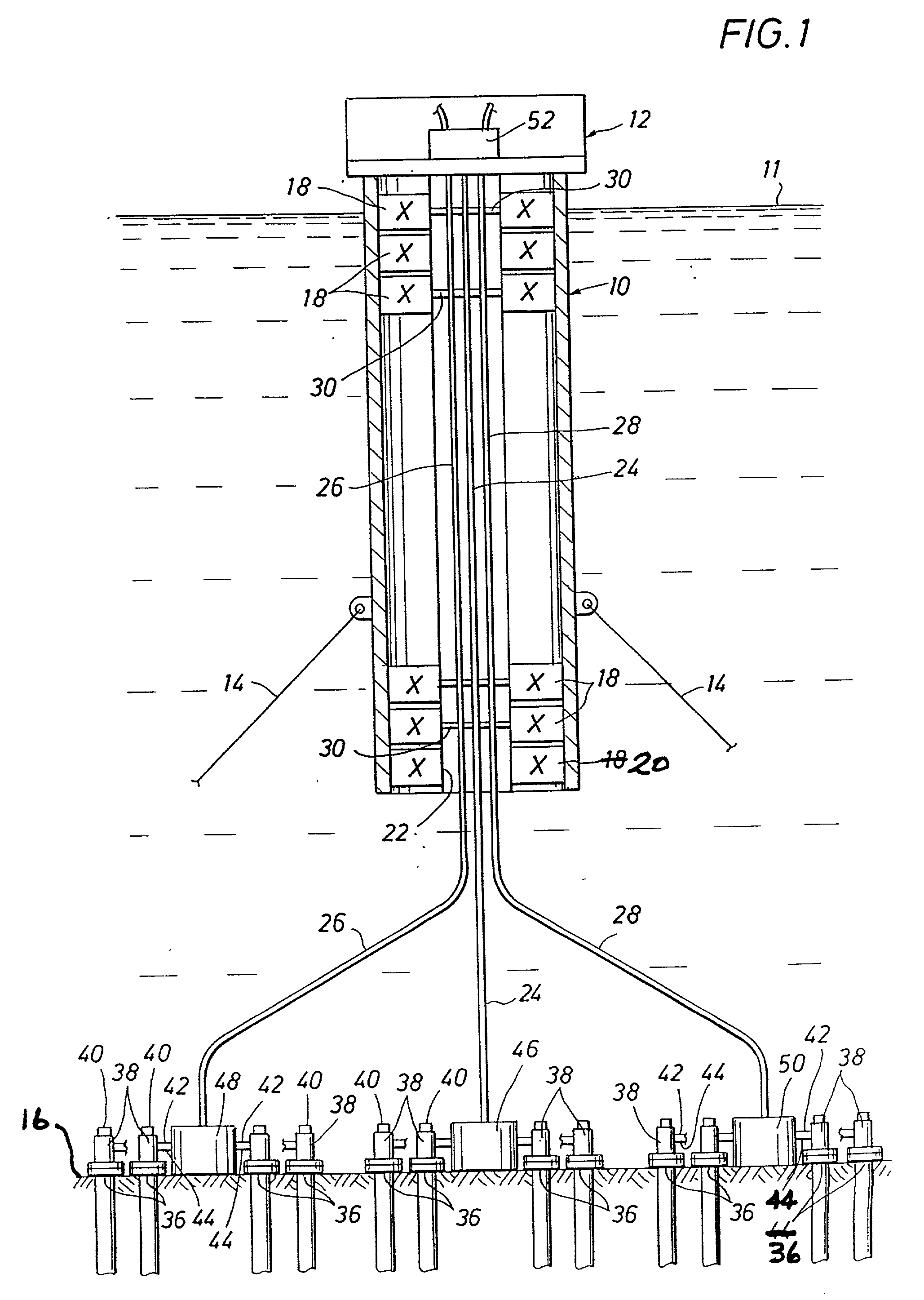

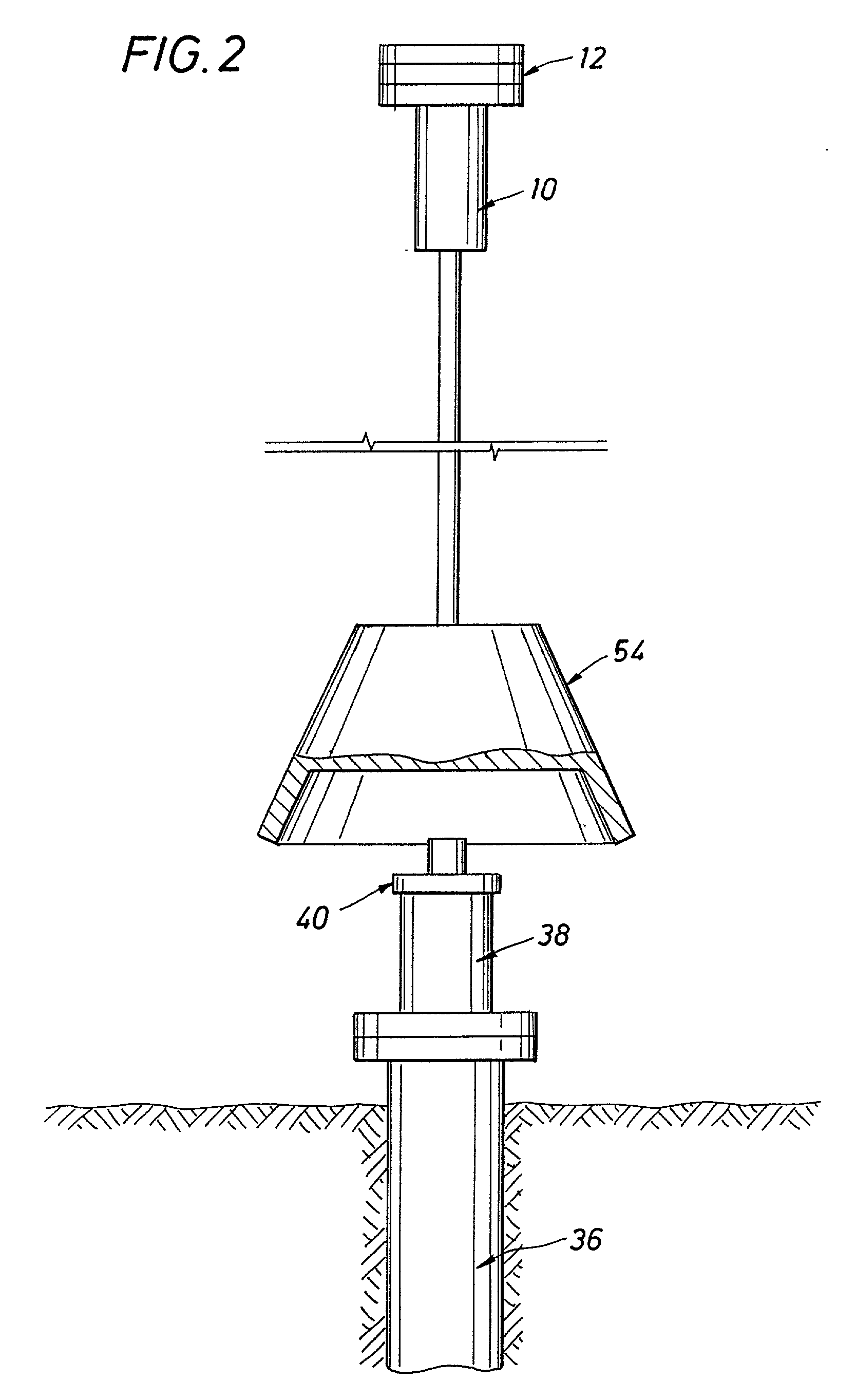

Submersible tethered platform for undersea electrical power generation

InactiveUS7470086B2Eliminate needEasy to separateWater-power plantsMachines/enginesElectric cablesSubmarine

A submersible and remotely-operable platform system for carrying out repeated operations in a submarine position, and producing electrical energy as either a primary or secondary purpose by means of one or more energy-conversion payload devices installed thereon. The platform and payload devices may be periodically brought to the surface and thence, if necessary, to a shore-based facility for maintenance or refit. In deployment, the platform is preferably engaged to its mooring lines and electrical cables while still on the surface. Simultaneous with controlled flooding of certain of its volumes, the platform is guided to an operational depth and attitude by the action of its winch assemblies upon their engaged mooring lines. Subsea currents energize the platform's payload of energy conversion devices, the electrical output being preferably conveyed via one or more surface-attached cables to an off-board facility for further processing, distribution, or consumption.

Owner:JENNINGS CLIFFORD ALLEN +1

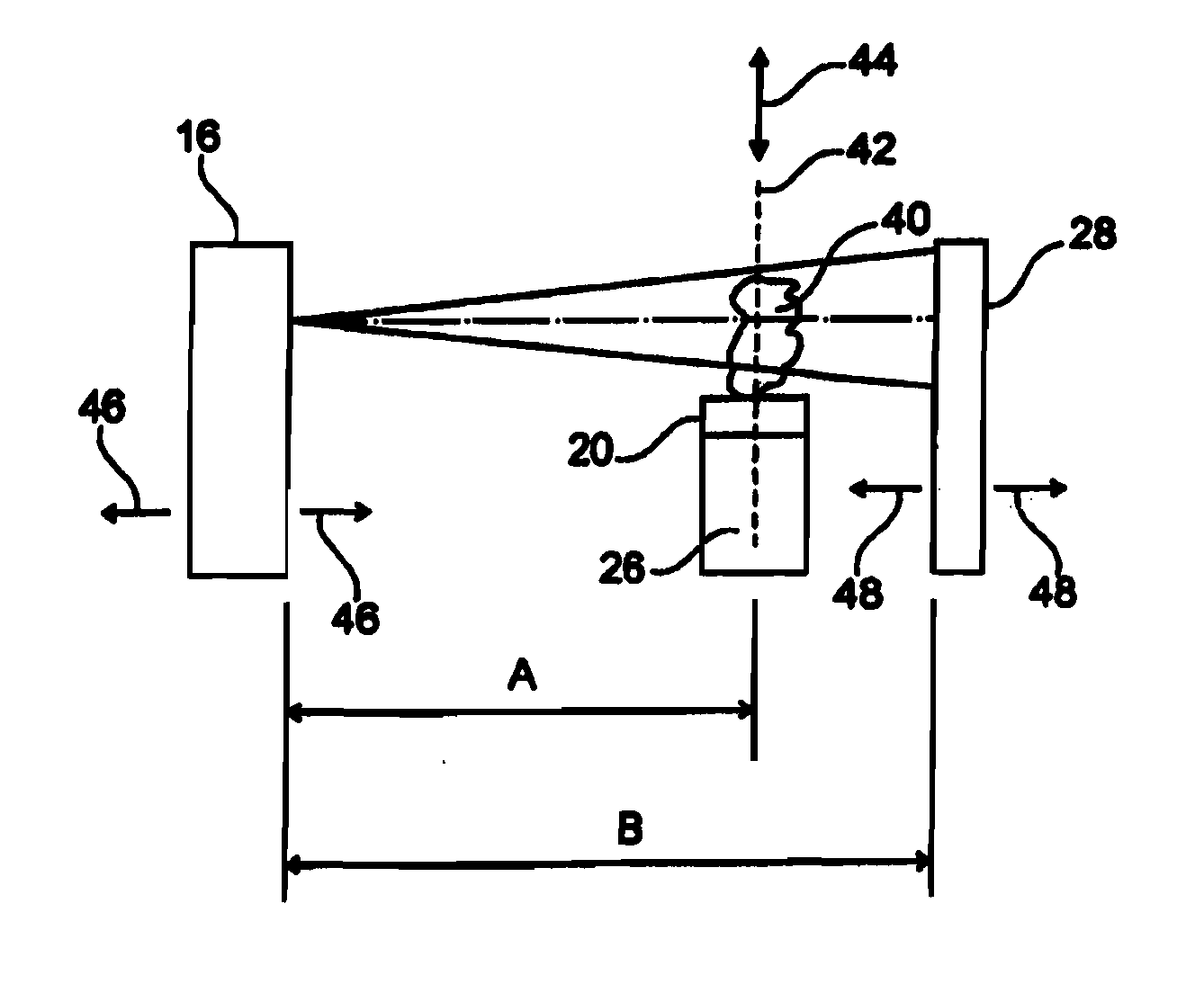

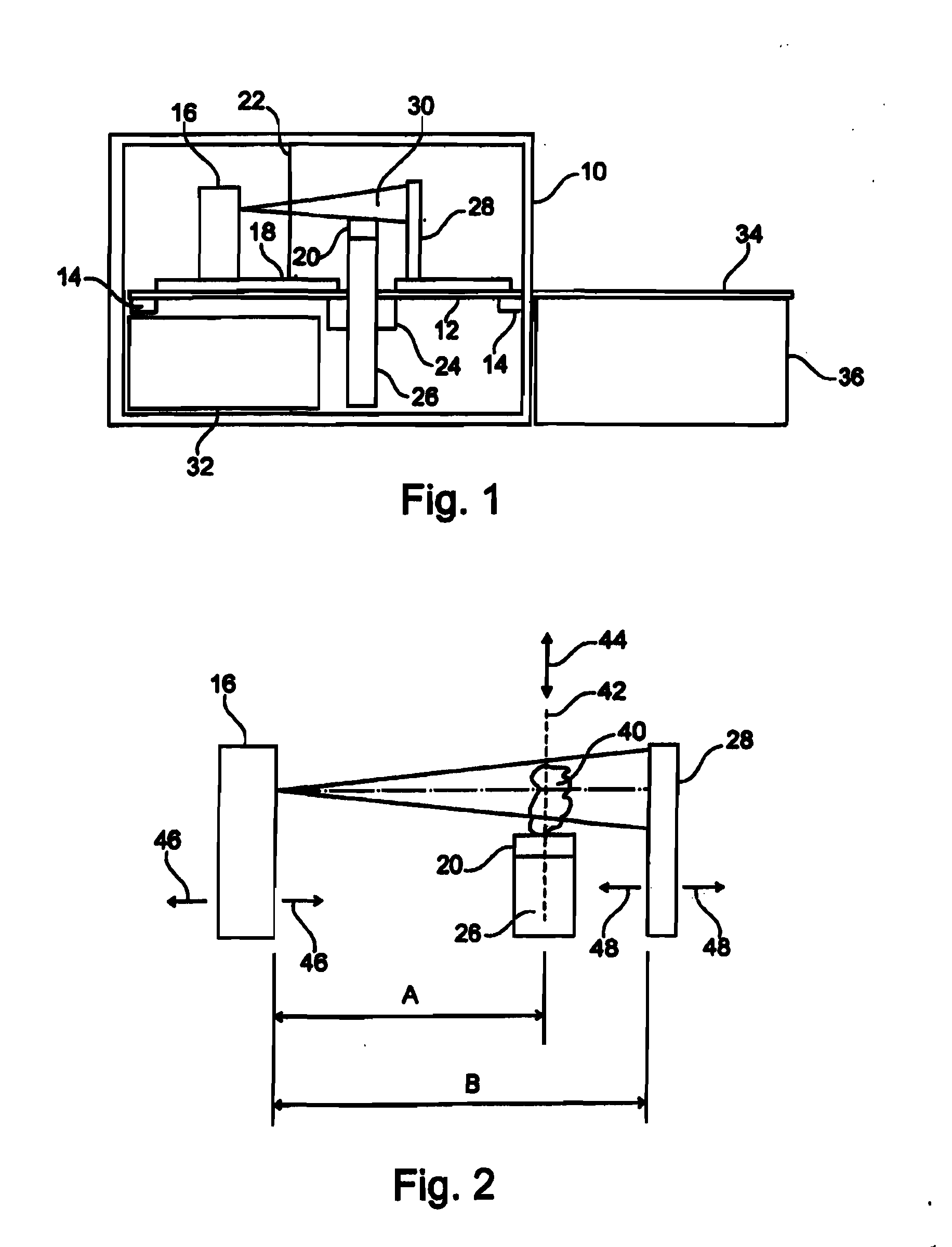

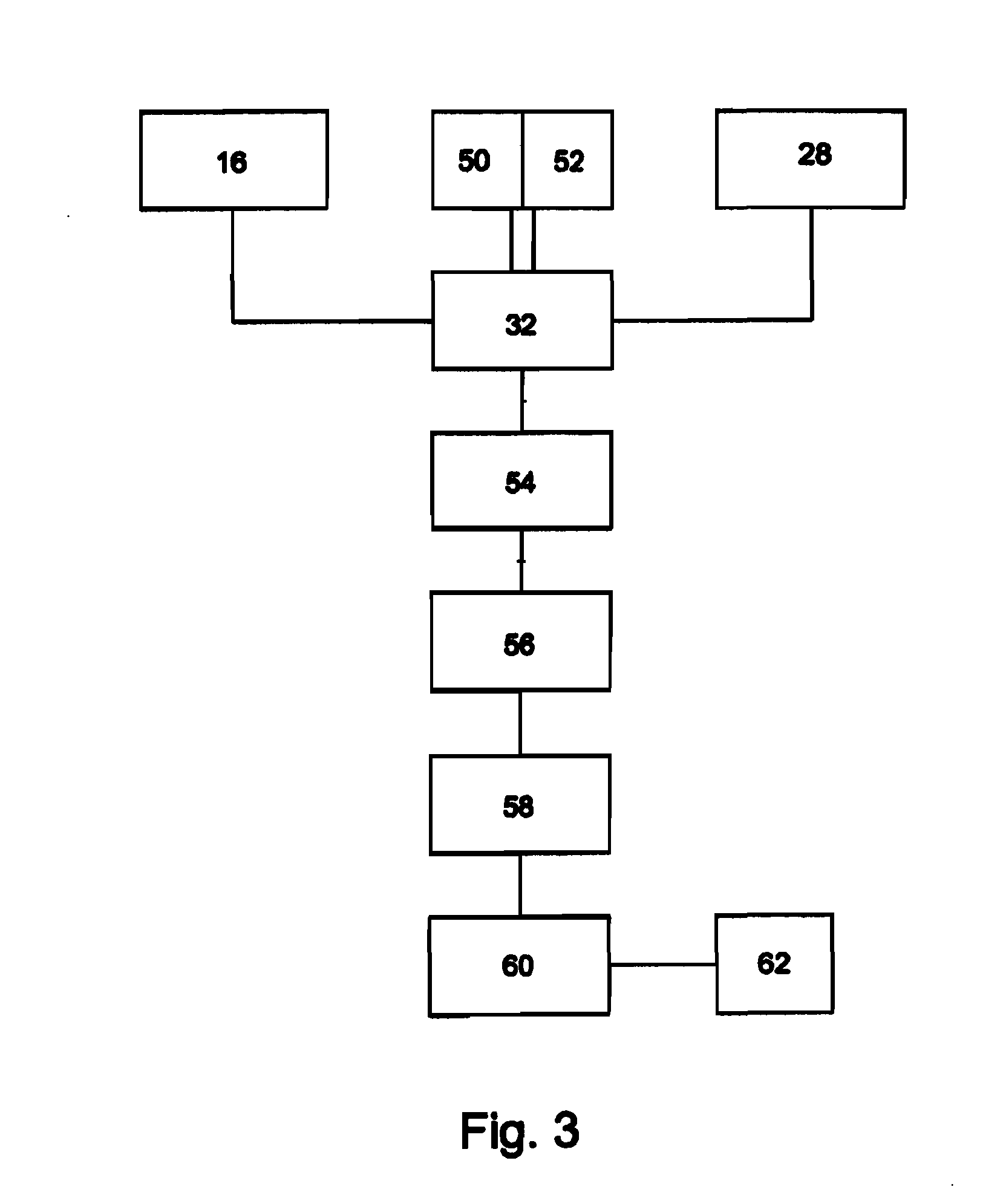

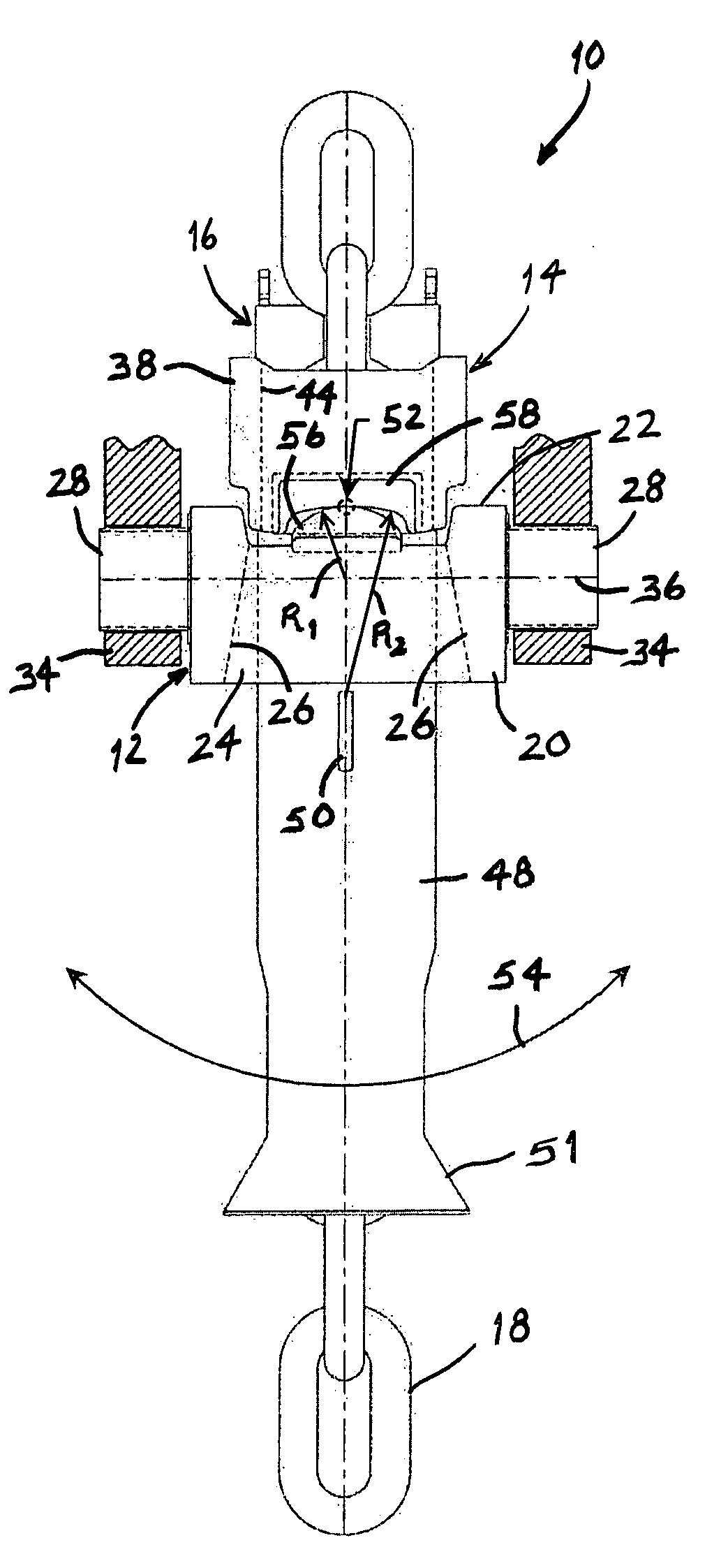

Computer tomographic workpiece measuring device

InactiveUS20120155606A1Reduced dimensionEnhance the imageMaterial analysis using wave/particle radiationWeather/light/corrosion resistanceElectrical devicesBuoy

A marine device has a floating buoy containing electronics, a submerged payload containing electrical devices and electronics, a power source and a mooring line. At least a part of the power source is submerged and electrically connected to at least one of the submerged payload and the floating buoy, and the mooring line extends between the buoy and at least one of the power source submerged part, the submerged payload and a submerged anchor having a mass allowing it to stay under the water surface.

Owner:WENZEL VOLUMETRIK

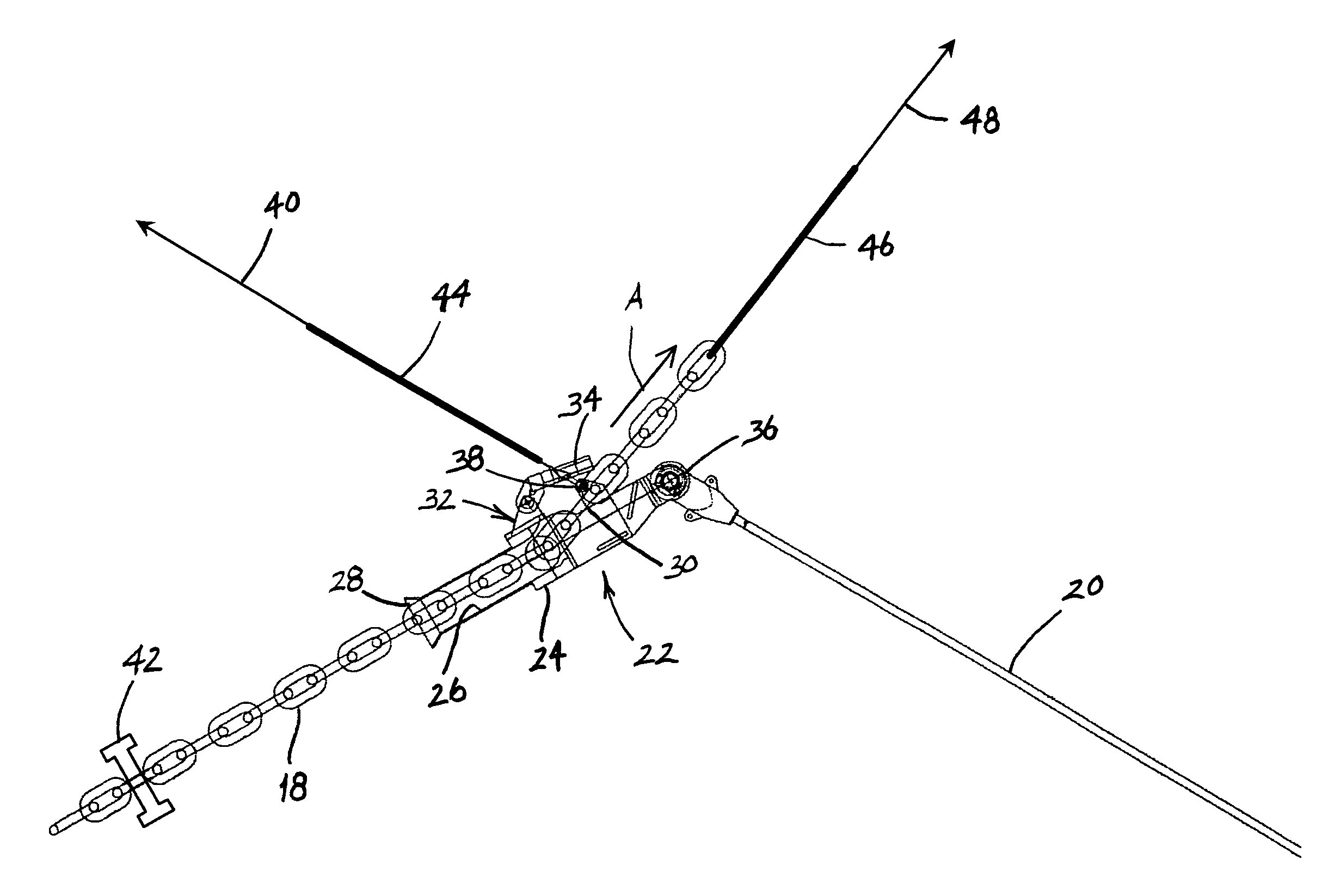

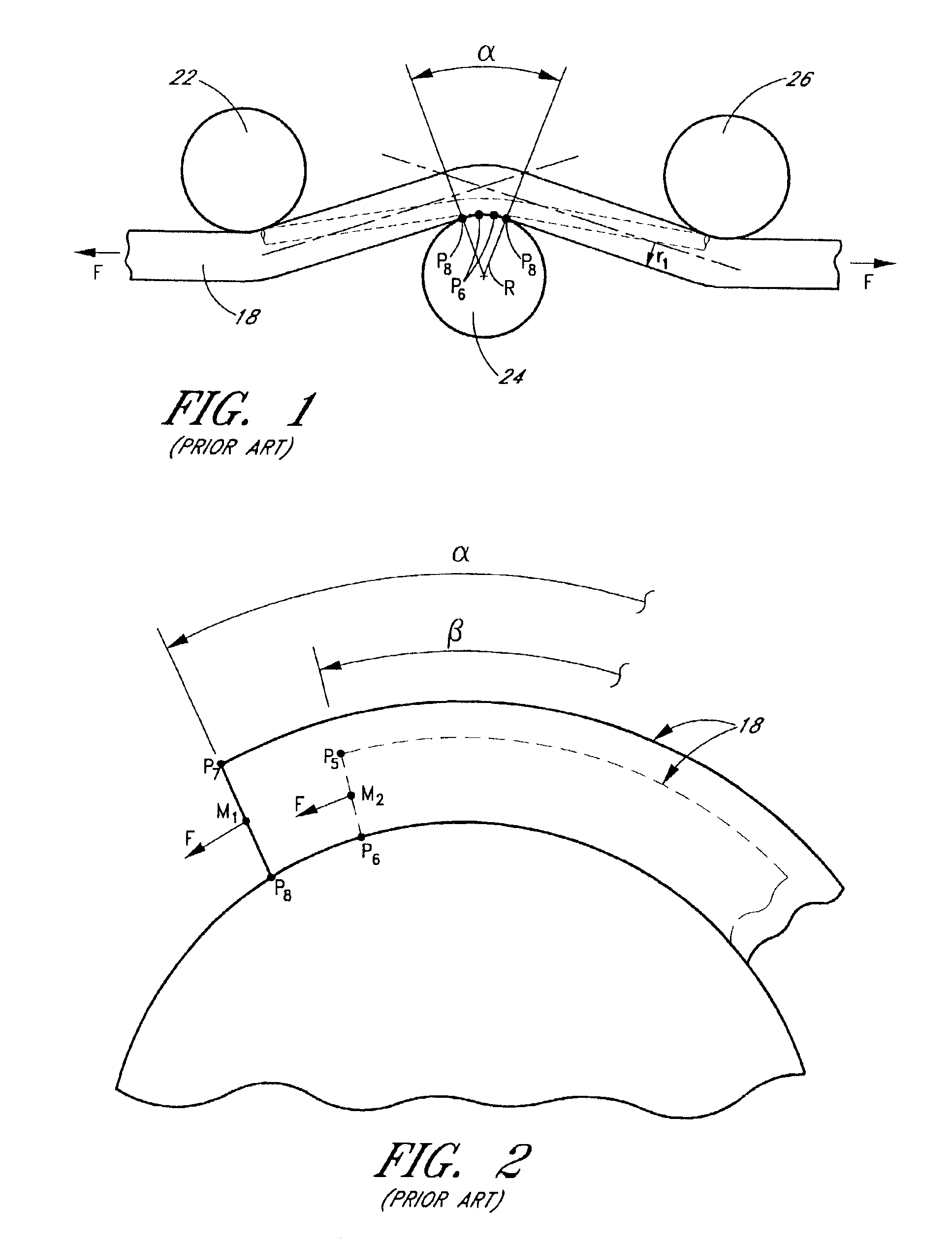

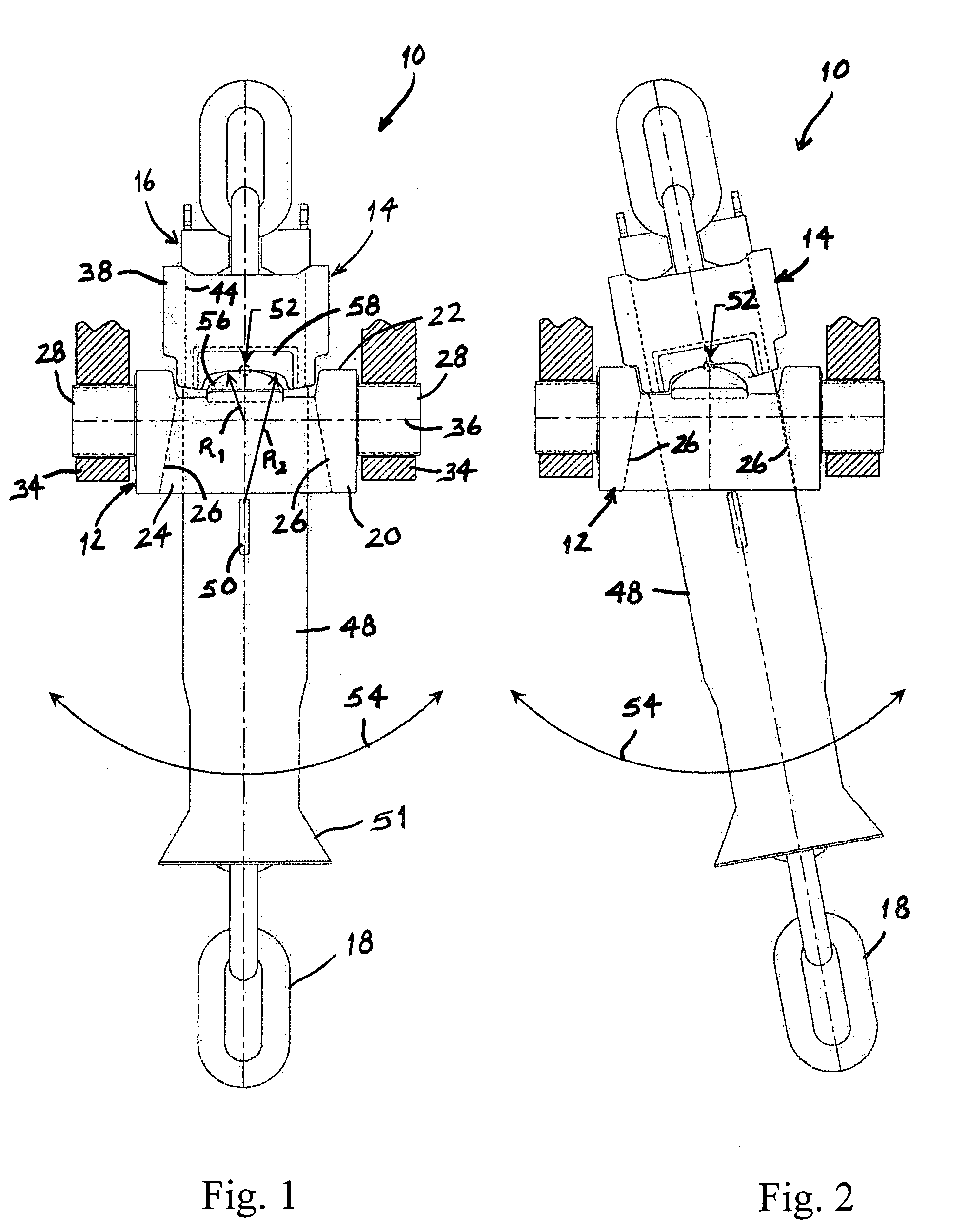

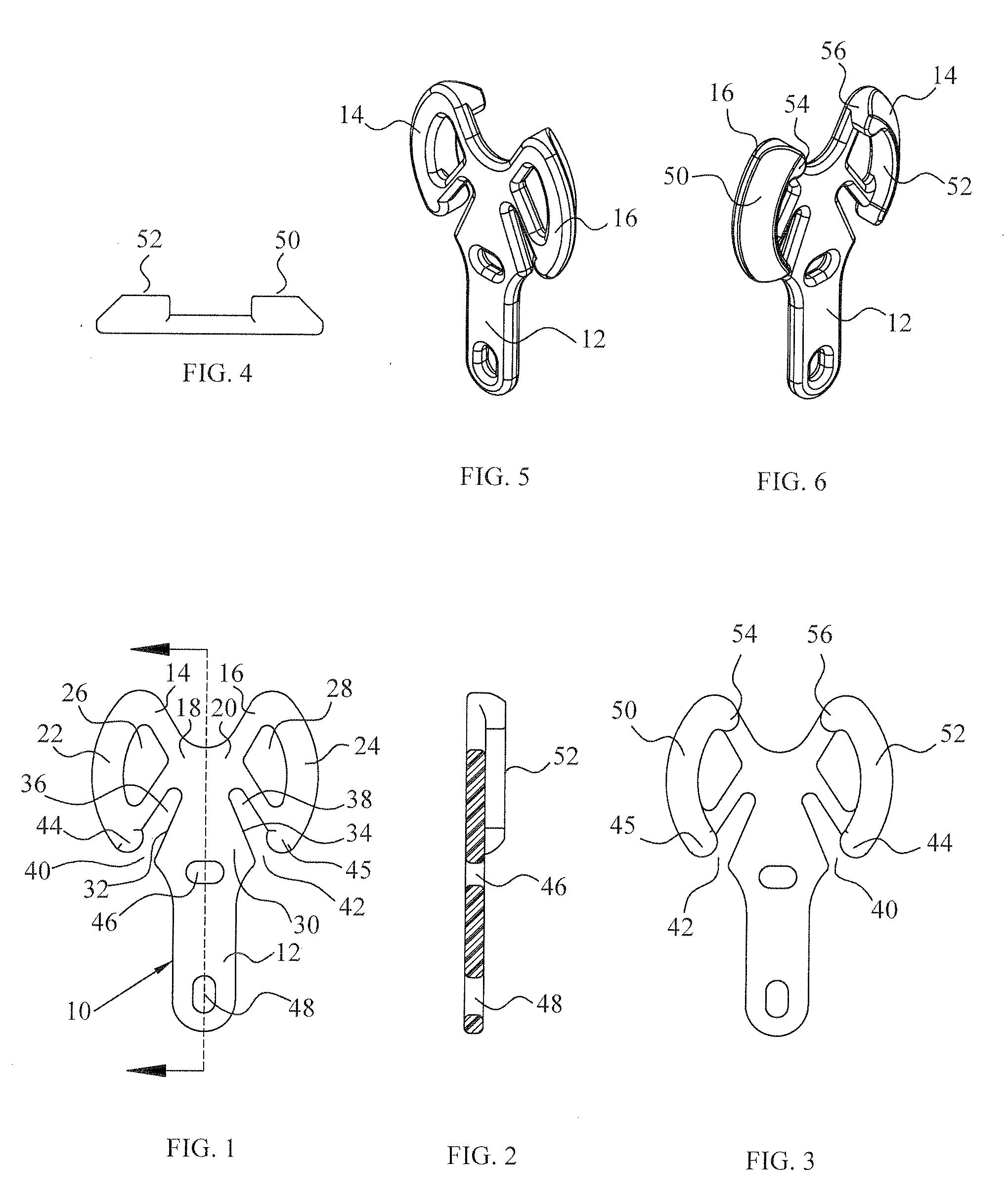

Dual-axis chain support assembly

ActiveUS20060213418A1Reduce and eliminate bending momentAnchorsAnchoring arrangementsConvex sideEngineering

A support assembly for a mooring line of a floating vessel comprises a trunnion block which is pivotally supported on the vessel and a stopper block to which the mooring line is releasably secured. One of the trunnion block and the stopper block comprises a convex surface and the other of the trunnion block and the stopper block comprises a concave surface. In operation, the convex surface engages the concave surface to thereby pivotally support the stopper block on the trunnion block.

Owner:SOFEC

Method and apparatus for suction anchor and mooring deployment and connection

A method and apparatus for deployment of mooring systems for buoyant marine structures such as mobile offshore drilling units (MODU's) and for connecting the same to the mooring lines thereof. An anchor handling vessel carries one or more anchors each having a deployment connection and a mooring connection and individually moves each anchor over its stem roller and deploys it to the sea bottom for installation. A handling line is disconnected by ROV from the deployment connection and is moved from the deployment connection to the mooring connection so as to become the main mooring line. Syntactic buoys are then mounted on the main mooring line for elevating it above the sea bottom for recovery. When MODU stationing is desired the anchor handling vessel then recovers the surface buoy and connects to the rig mooring line using a short section of mooring chain. A J-chaser stopper device is then installed in the mooring string and is connected to the mooring line of the MODU by a short section of chain. The J-chaser lowers the mooring string, completing the mooring connection between the anchor and the MODU. A plurality of mooring strings, typically eight, are deployed in this manner to properly station the MODU. Disconnection of the MODU is accomplished essentially by the reverse of the above deployment procedure.

Owner:BERGERON BILLY J

Mooring hook

An extendible mooring hook has a pair of jaw members spring biased to an open position with a shuttle removably retained on one jaw member. A detent mechanism engages the shuttle member when the jaw members close around a mooring post and pulls the shuttle, and attached mooring line, around the mooring post when the jaw members return to their open position. The pole portion can be extended, and a incorporates a traveler mechanism to compensate for changes in cable length so that cable tension is maintained when the pole is extended.

Owner:MORTON DOUGLAS A

Mooring line for an oceanographic buoy system

A mooring line for an oceanographic buoy system includes four sections. The first section is a protected cable that is connectable to the buoy. The second section is an energy absorbing cable. The third section is a weighted cable. The fourth section is a buoyant cable that is connectable to the anchor. The four sections are connected in series by smooth transitional connections. When the mooring line is deployed, it has an inverse catenary lay.

Owner:CORTLAND IND LLC +1

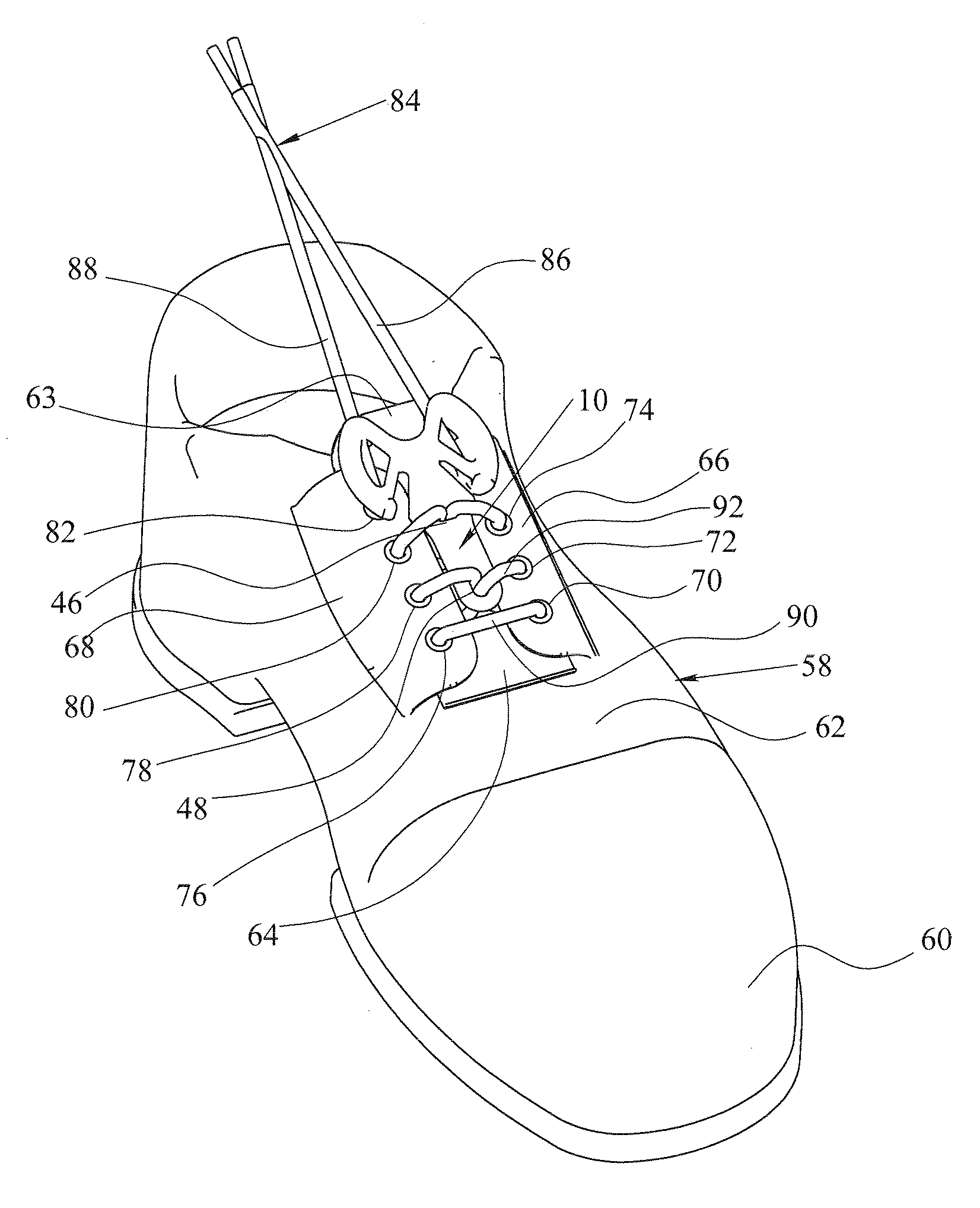

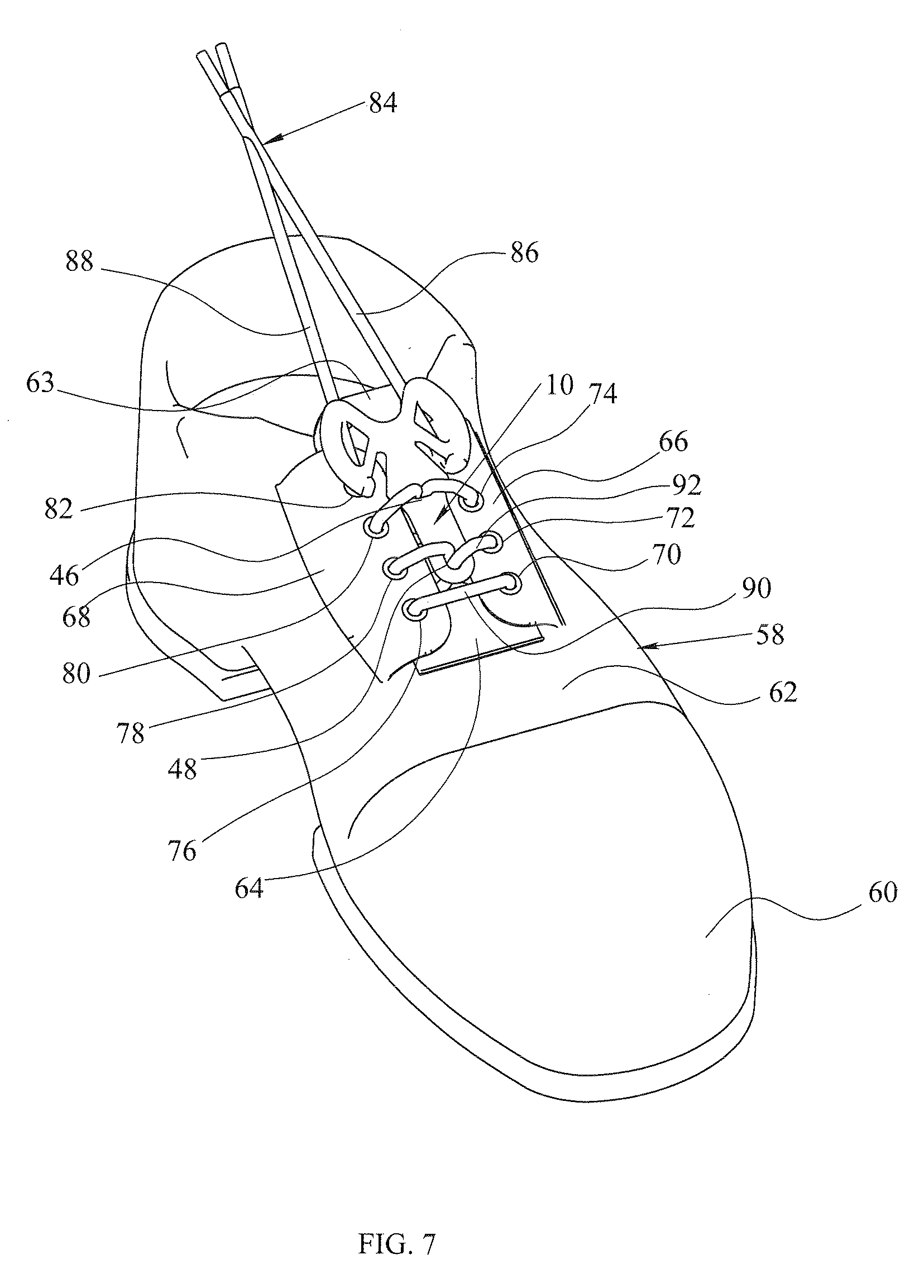

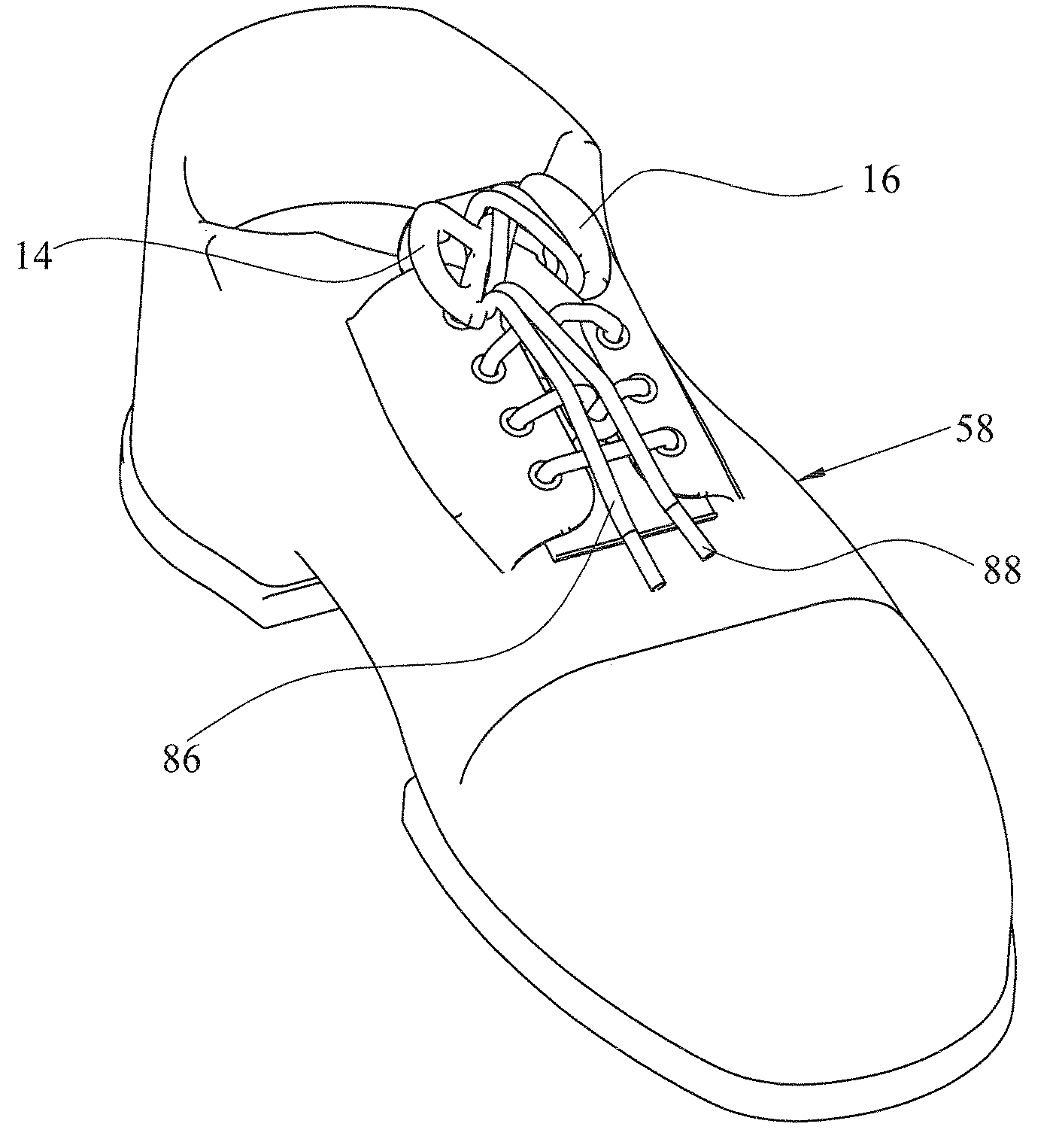

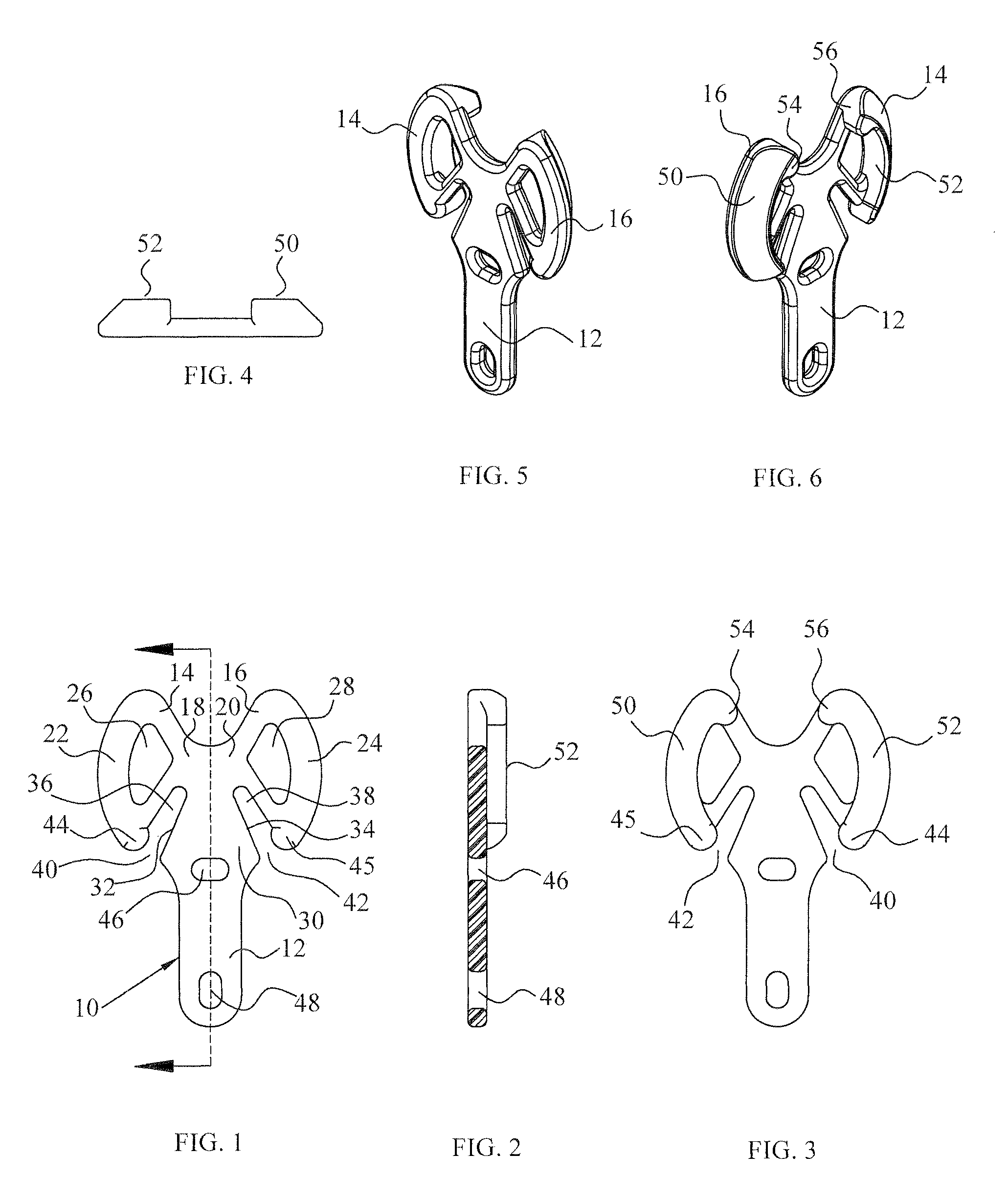

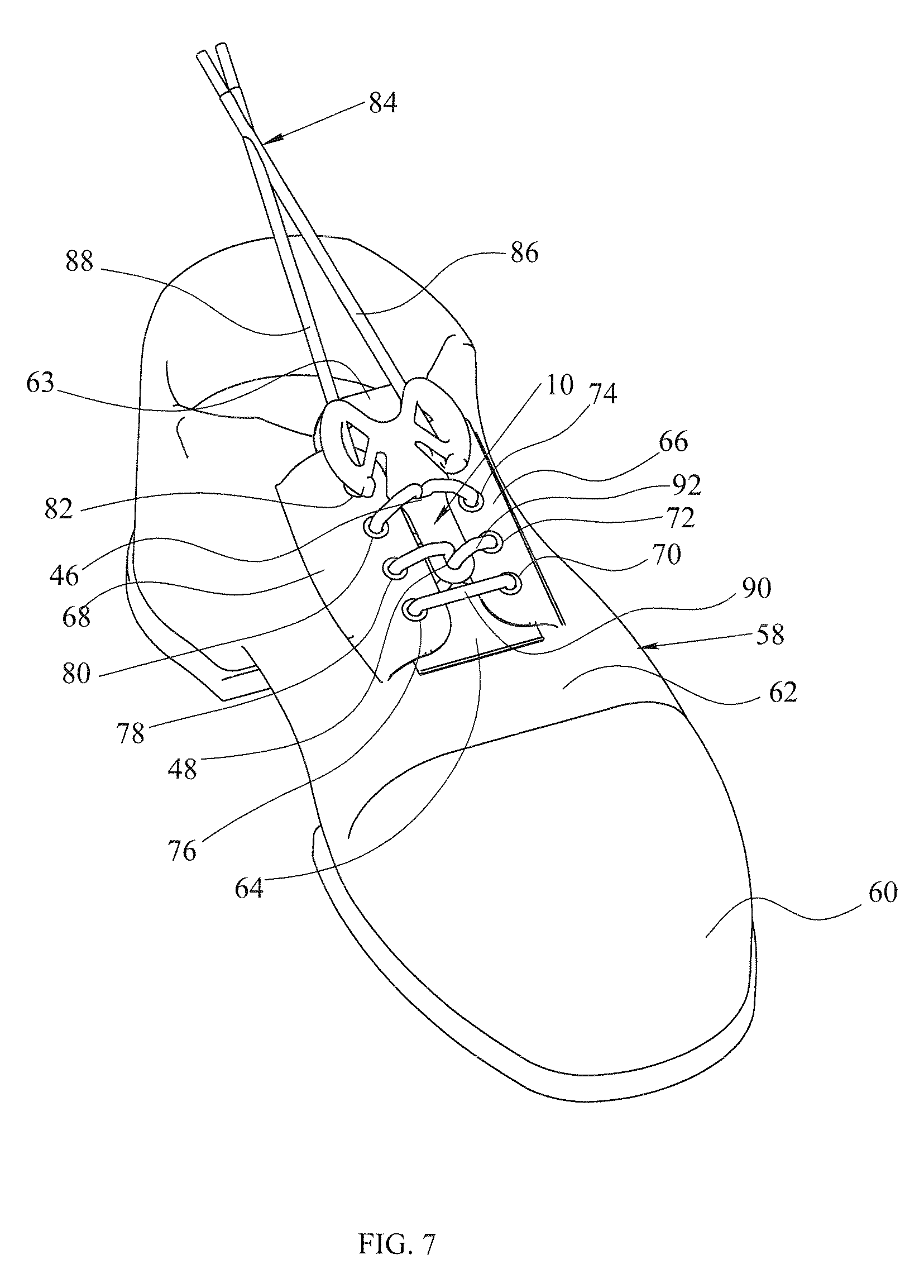

Shoe tying aid and method

InactiveUS20100269373A1The process is simple and effectiveEasy to tieFilament handlingShoe lace fasteningsEngineeringMooring line

A shoe can be tied using only one hand if provided with a tying aid in the form of a generally T-shaped unit comprising a leg having two laterally extending ears. The leg is secured between rows of eyelets on the opposed flaps of the shoe by one or more of the lengths of lace extending across the gap between the flaps. The lengths of shoelace that would otherwise be tied in a bow are instead wrapped around the ears of the tying aid in alternating fashion, preferably twice around each ear, in a manner similar to the manner in which a mooring line is secured to the cleat of a boat.

Owner:THERM OMEGA TECH INC

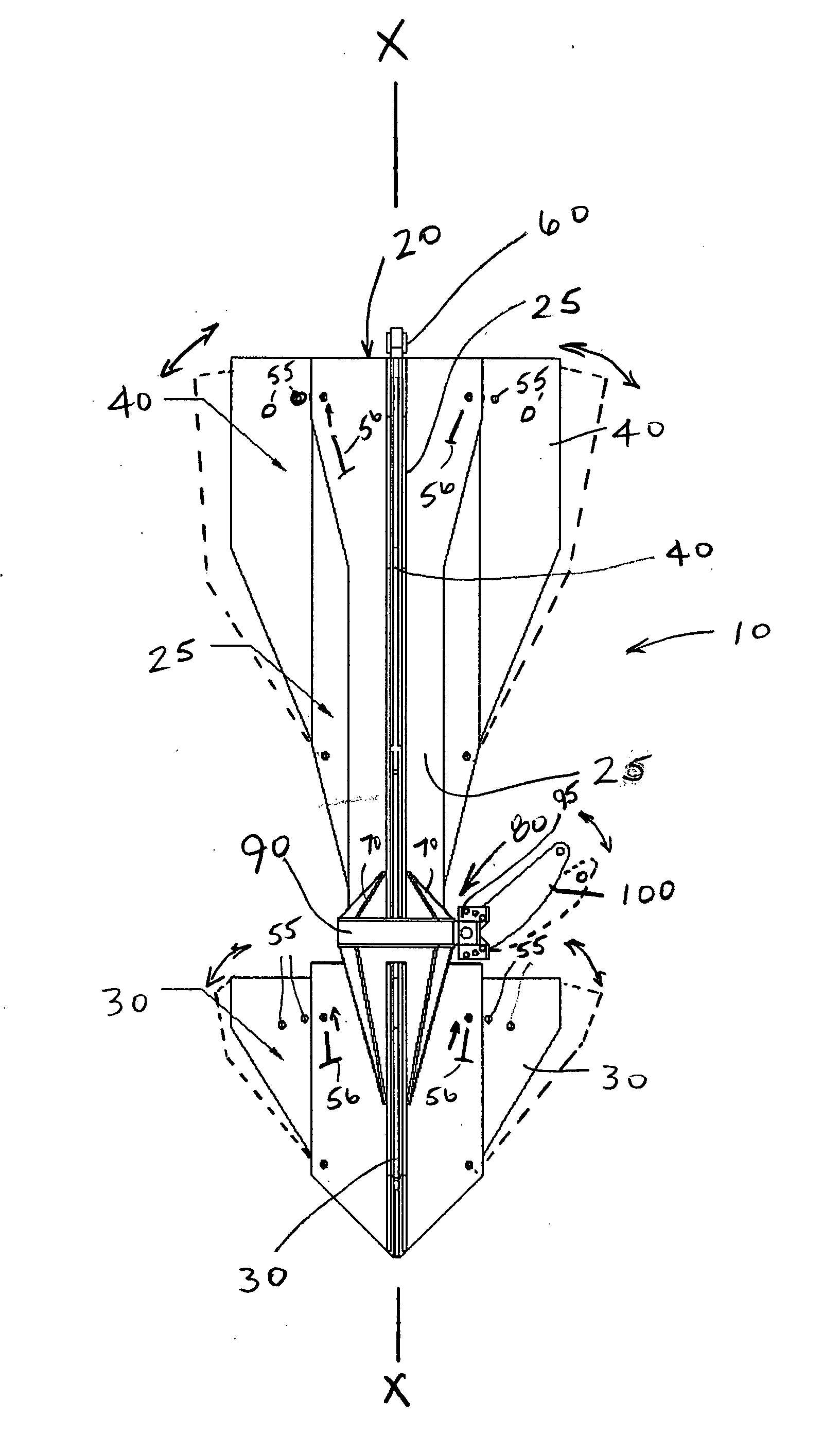

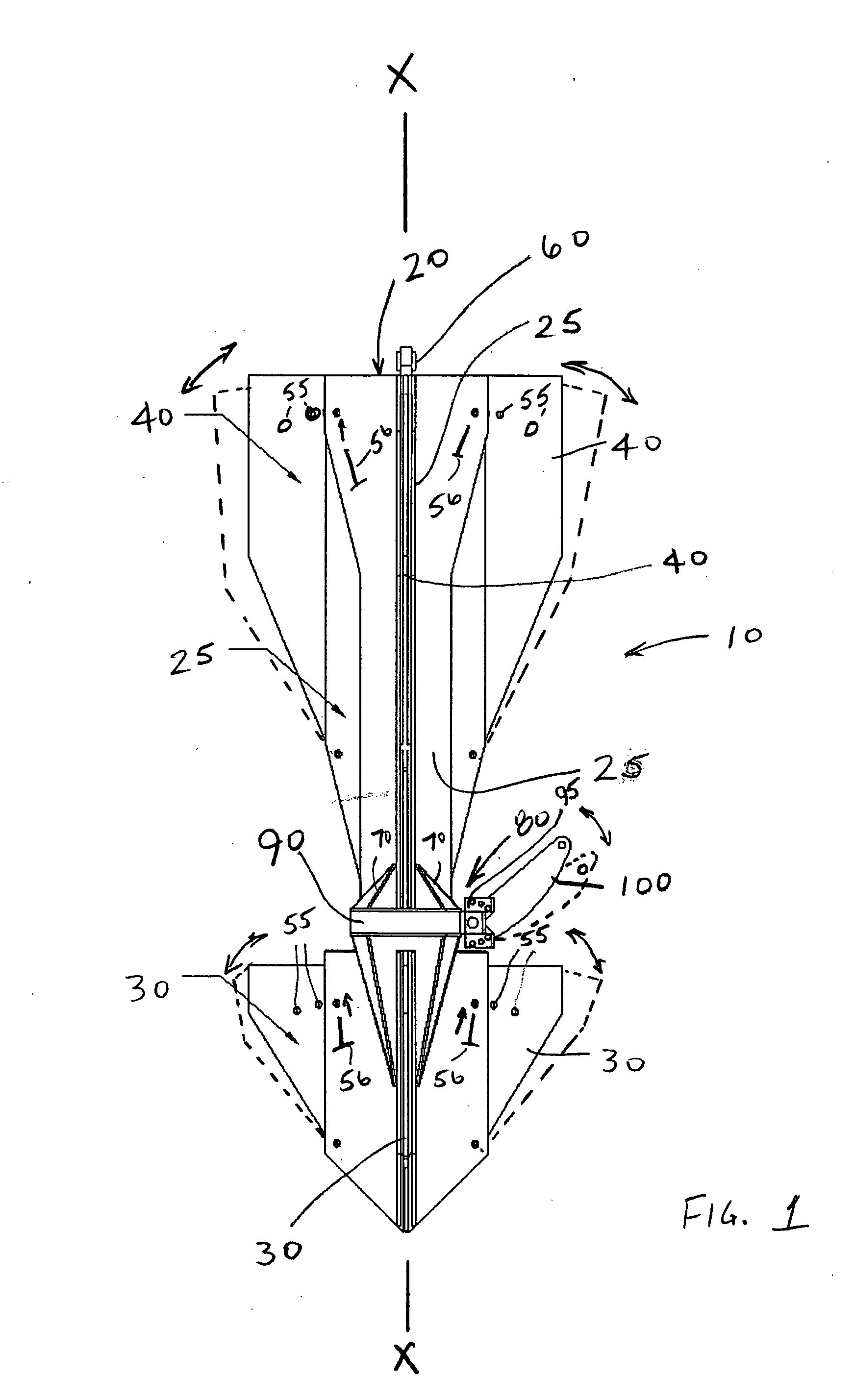

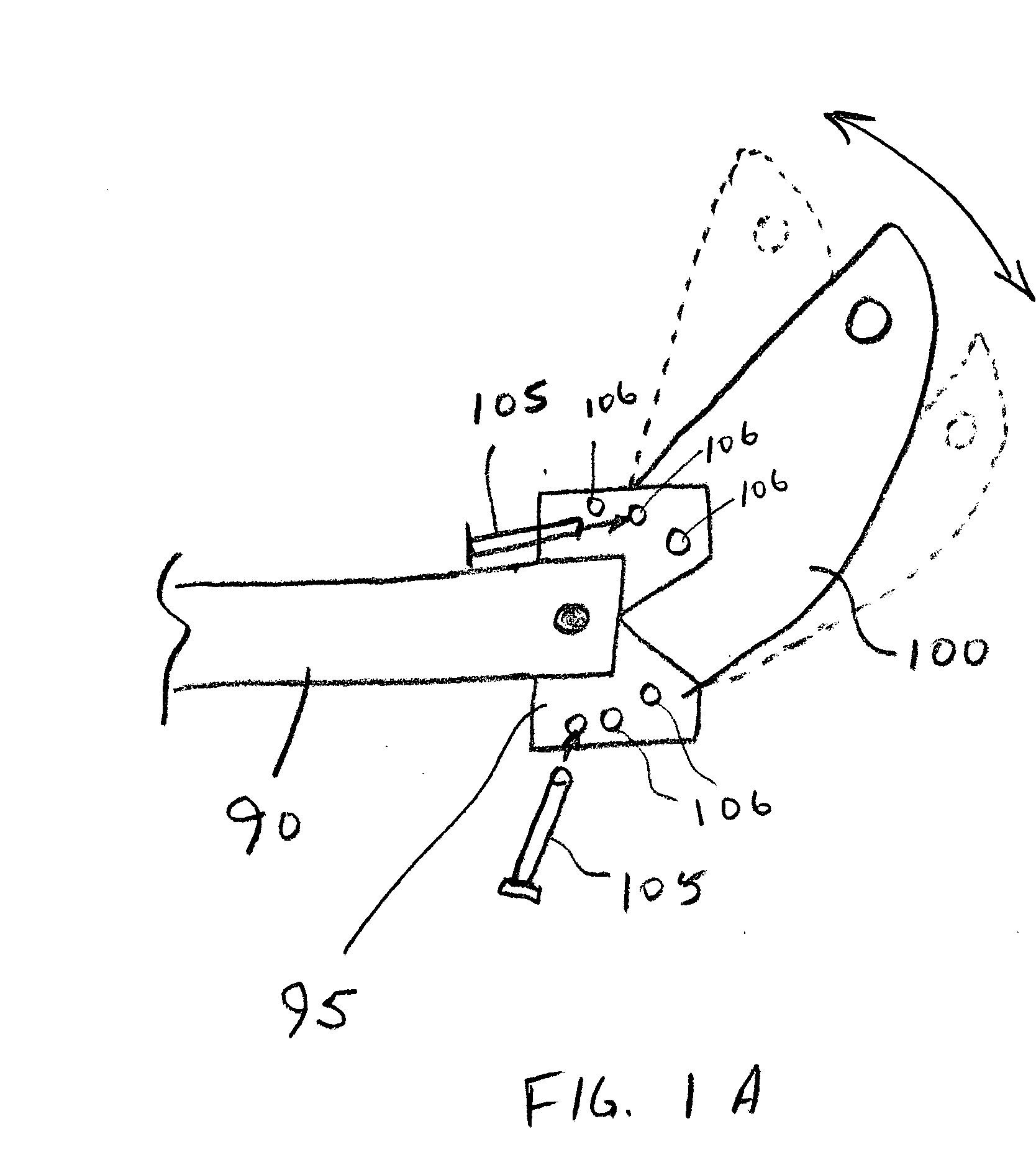

Gravity installed anchor

An anchor for mooring of structures to a water bottom, comprising an elongated central body having a longitudinal axis through its center. The central body comprises a plurality of channel members radiating outward from the center, each with a channel therein. A plurality of nose and tail plates are disposed within the channels, and hingedly connected to the central body, so that the plates can be swung in or out from the central body, and thereafter fixed in place (for example, by pins inserted through mating holes in the channel members and plates). A means for attaching a mooring line to the anchor, for example a load ring encircling the central body and rotatable completely around the circumference of the central body, has an arm hingedly attached thereto. The arm can be rotated to a desired angle with respect to the longitudinal axis of the central body, and fixed at a set angle or within a range of angles to the longitudinal axis.

Owner:DELMAR SYST

Shoe tying aid and method

InactiveUS8056265B2The process is simple and effectiveEasy to tieFilament handlingShoe lace fasteningsEngineeringMooring line

A shoe can be tied using only one hand if provided with a tying aid in the form of a generally T-shaped unit comprising a leg having two laterally extending ears. The leg is secured between rows of eyelets on the opposed flaps of the shoe by one or more of the lengths of lace extending across the gap between the flaps. The lengths of shoelace that would otherwise be tied in a bow are instead wrapped around the ears of the tying aid in alternating fashion, preferably twice around each ear, in a manner similar to the manner in which a mooring line is secured to the cleat of a boat.

Owner:THERM OMEGA TECH INC

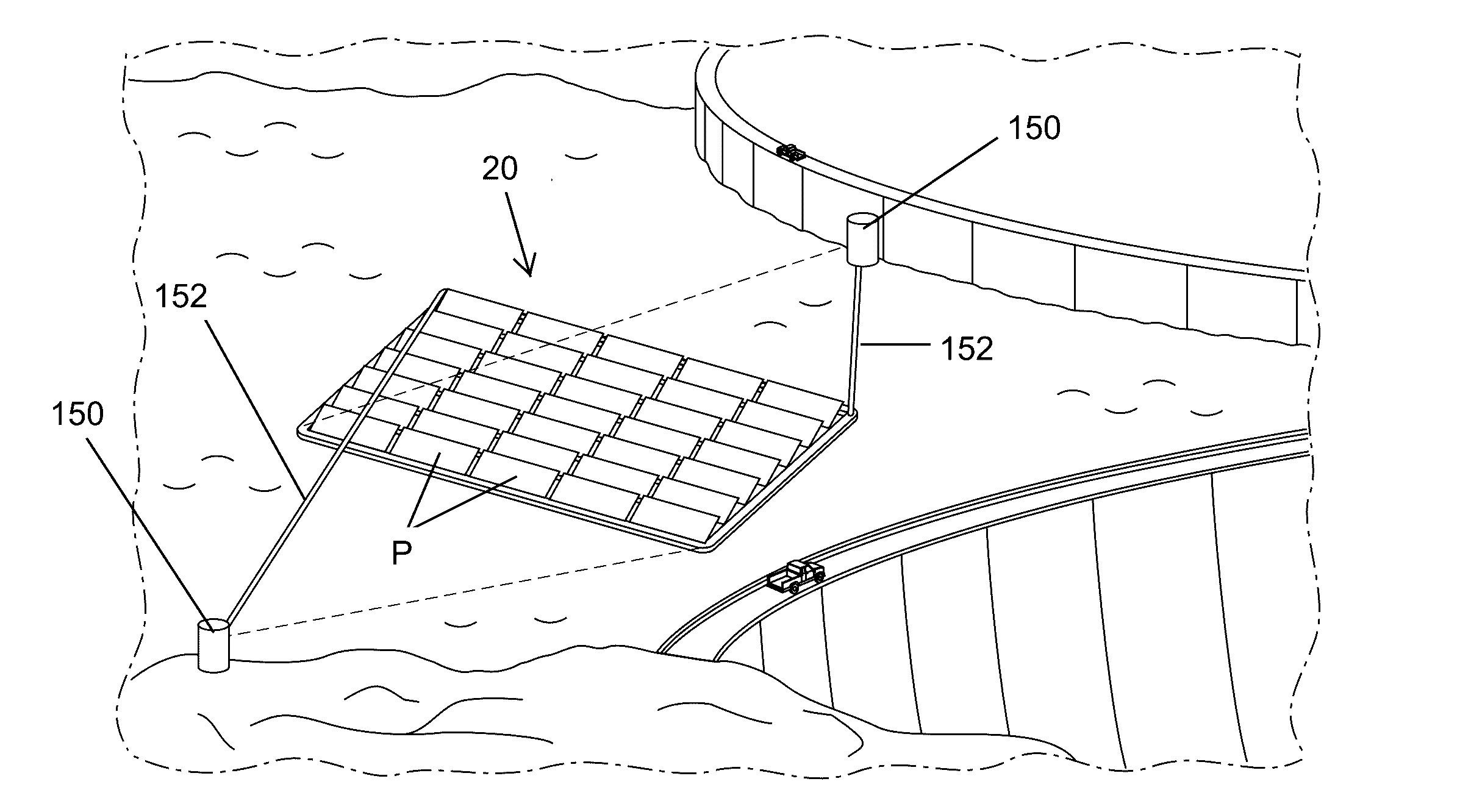

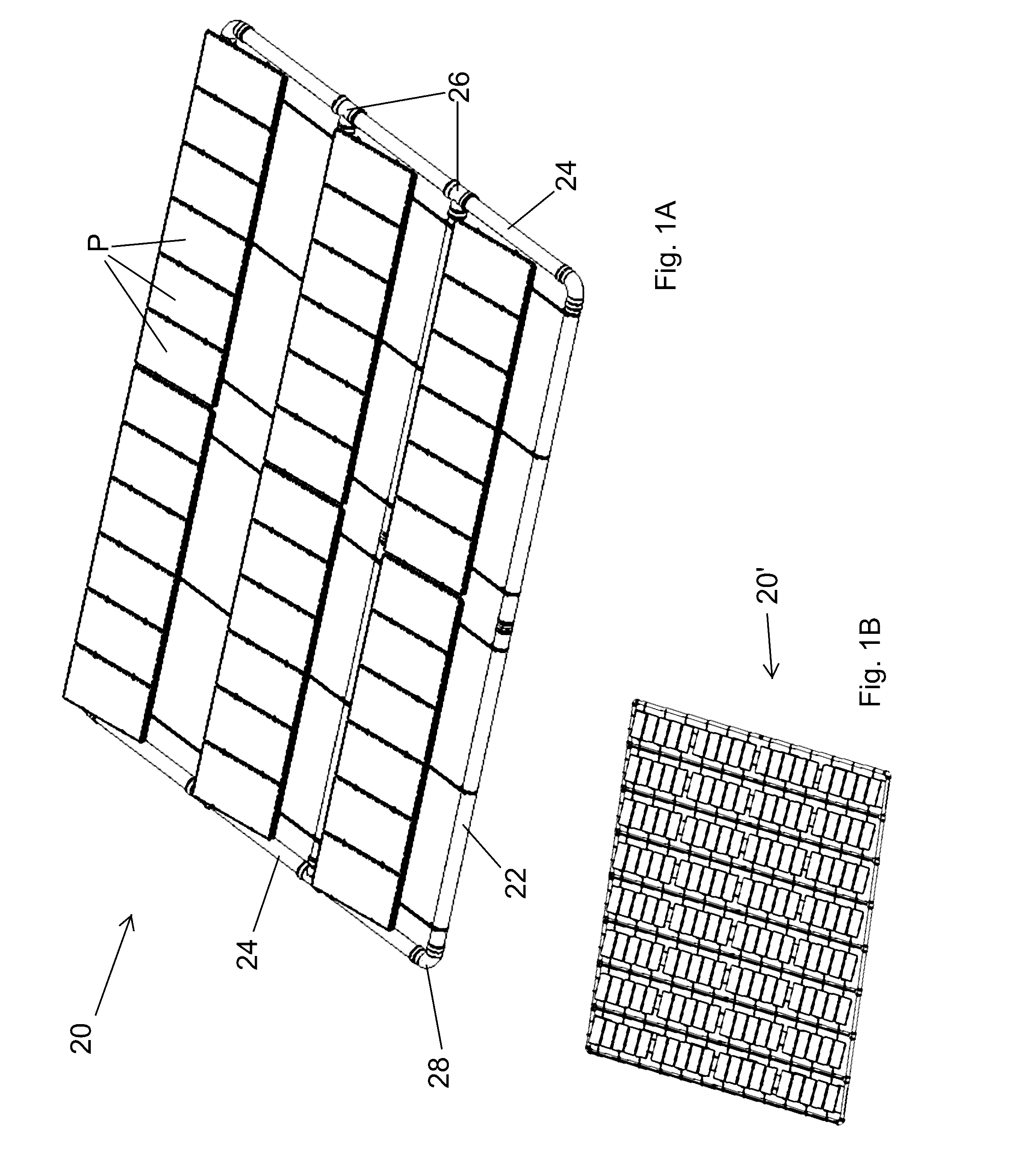

Floating solar panel array with one-axis tracking system

ActiveUS20170040926A1Stable water volumePhotovoltaic supportsSolar heating energyClosed loopWindlass

A floating solar array made of a closed loop of flexible high density polyethylene pipes with elbows, T fittings and couplings. An anti-lift membrane fills with water and mitigates the wind forces. The array can have a stabilizing skirt going downwardly from the border of the array, especially when it is used offshore in the sea. A vertical axis tracking system with windlasses, two anchoring points and four mooring lines allows all the solar panels to face the sun throughout the day. For small lakes or mine tailing, the two anchor points will be onshore, on a concrete foundation. Winches to wind and unwind the mooring lines are located at the anchor point or on the solar array. For larger water areas, or offshore applications in the sea water, the anchor points are under water; using typically a concrete block or a suction pile solution for each anchor.

Owner:4CSOLAR

Method and system for static and dynamic positioning or controlling motion of marine structure

ActiveUS20150246711A1Prolong lifeLow costForce measurementVessel safetyOcean bottomAtmospheric temperature

Disclosed is a system and method for static and dynamic positioning or motion control of a marine structure by using real-time monitoring of at least one of a mooring line, marine environments, 6-dof movement of a marine structure, a tank state, a ship topside, the seabed, or their combinations. The static and dynamic real-time monitoring data of the mooring line is obtained and processed for positioning the marine structure or controlling and managing a motion thereof. Here, 1) a tension of a mooring line is measured by means of real-time monitoring of the mooring line, 2) various marine environment elements such as wind direction, wind speed, air humidity, atmospheric pressure, atmosphere temperature, cloud height, visibility, ocean wave, wave height, sea current speed, sea current direction, rain or the like are measured by means of real-time monitoring of the marine environments, 3) 6-dof movement of the marine structure is measured by means of real-time monitoring of the marine structure, 4) ullage and sloshing data of various tanks in the marine structure are measured by means of real-time monitoring of tank states, 5) damage and life of pipes, facilities or the like located at a ship topside of the marine structure are measured by means of real-time monitoring of the ship topside, 6) damage and life of umbilical cables, pipes, pumps and valves located on the seabed are measured by means of real-time monitoring of the seabed, and suitable static and dynamic positioning or motion control and management may be automatically performed based thereon.

Owner:CYTRONIQ

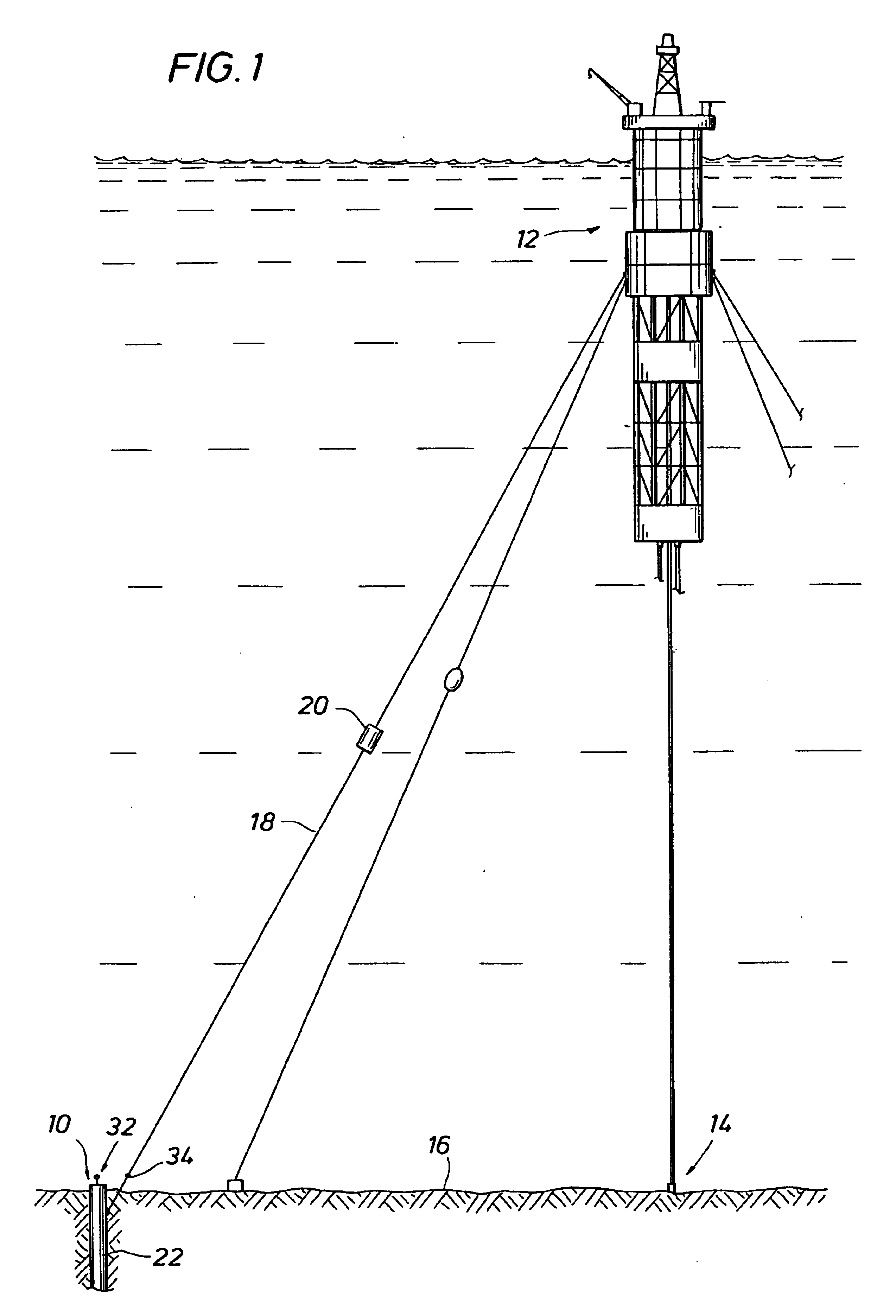

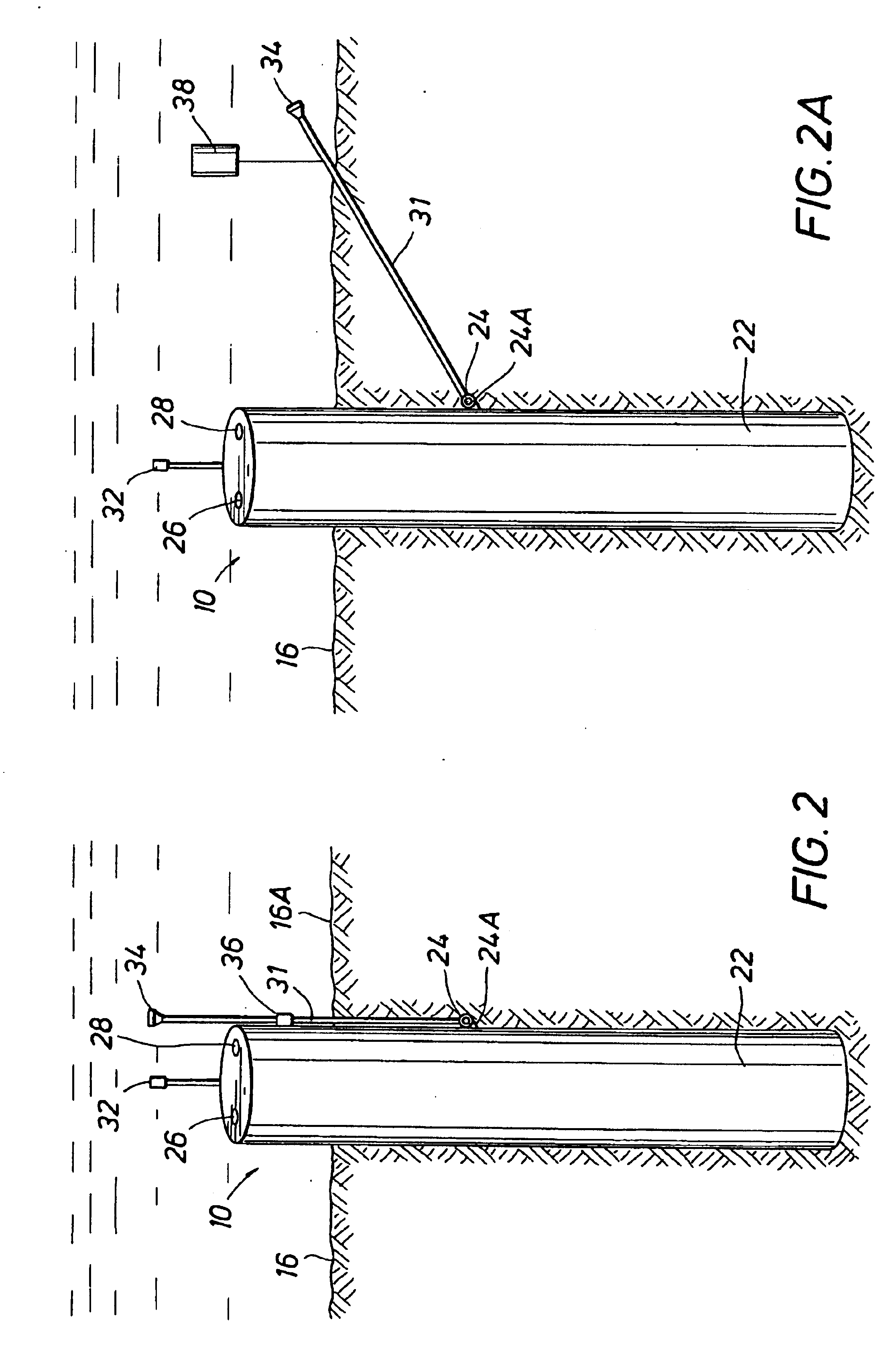

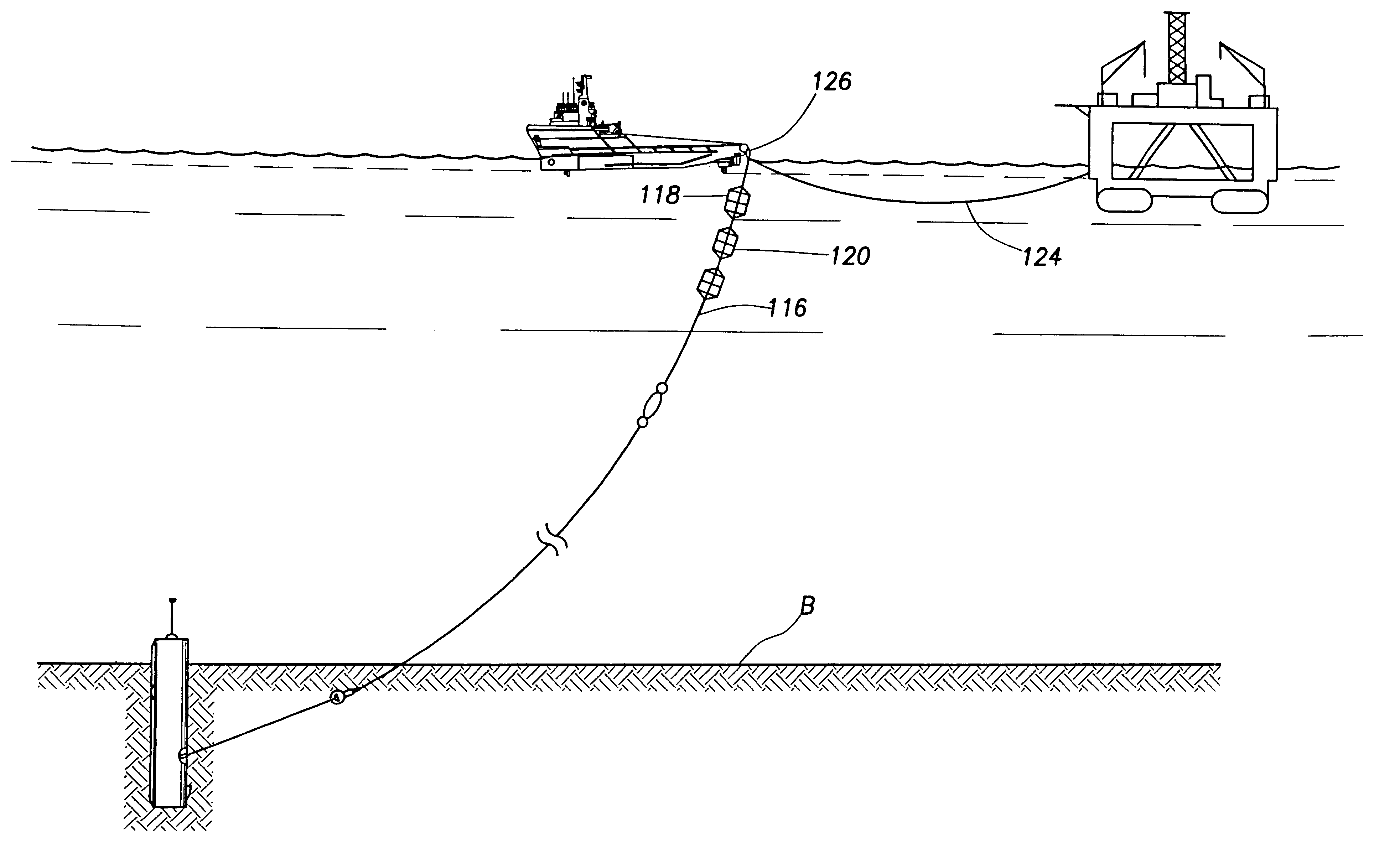

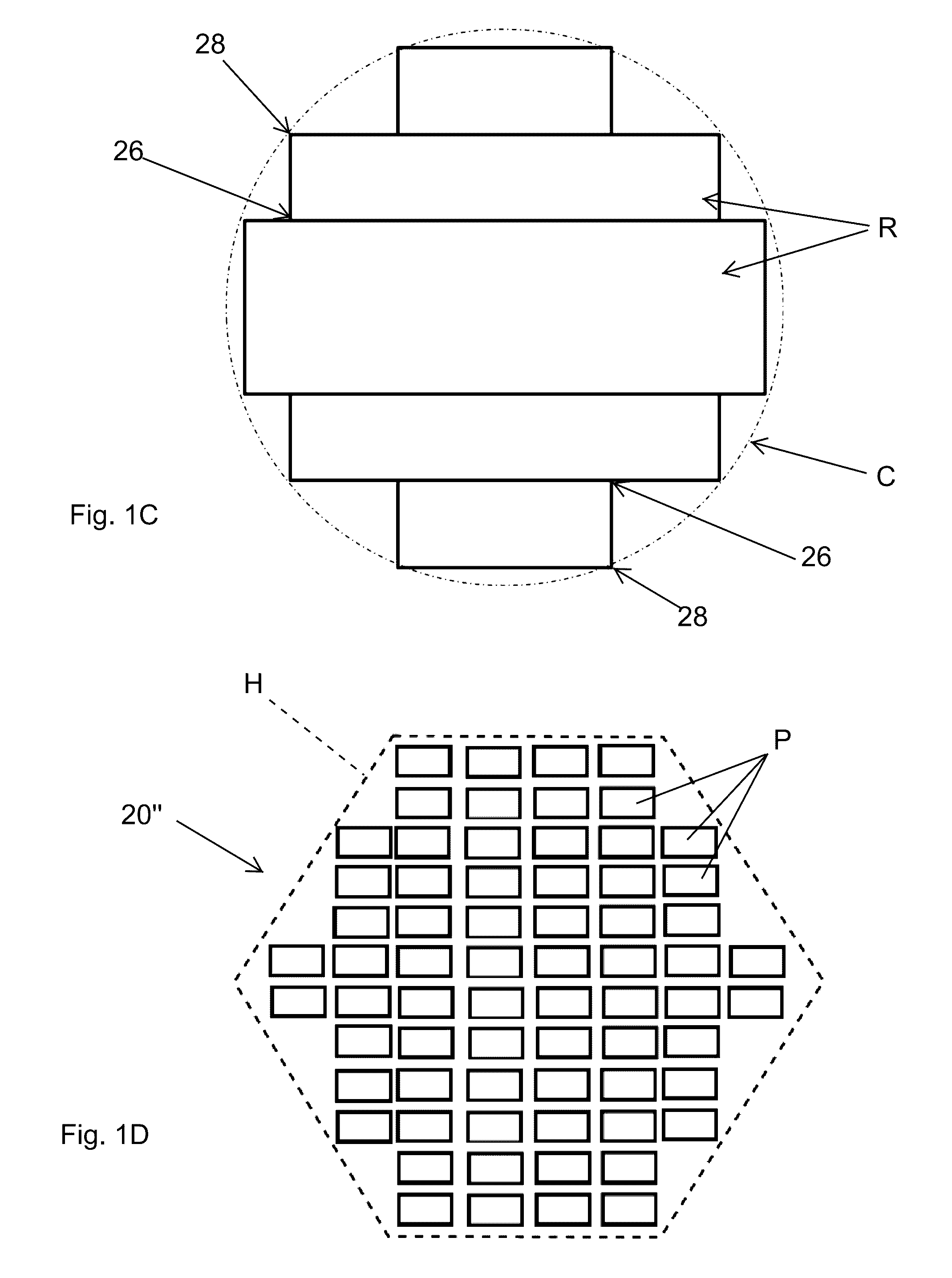

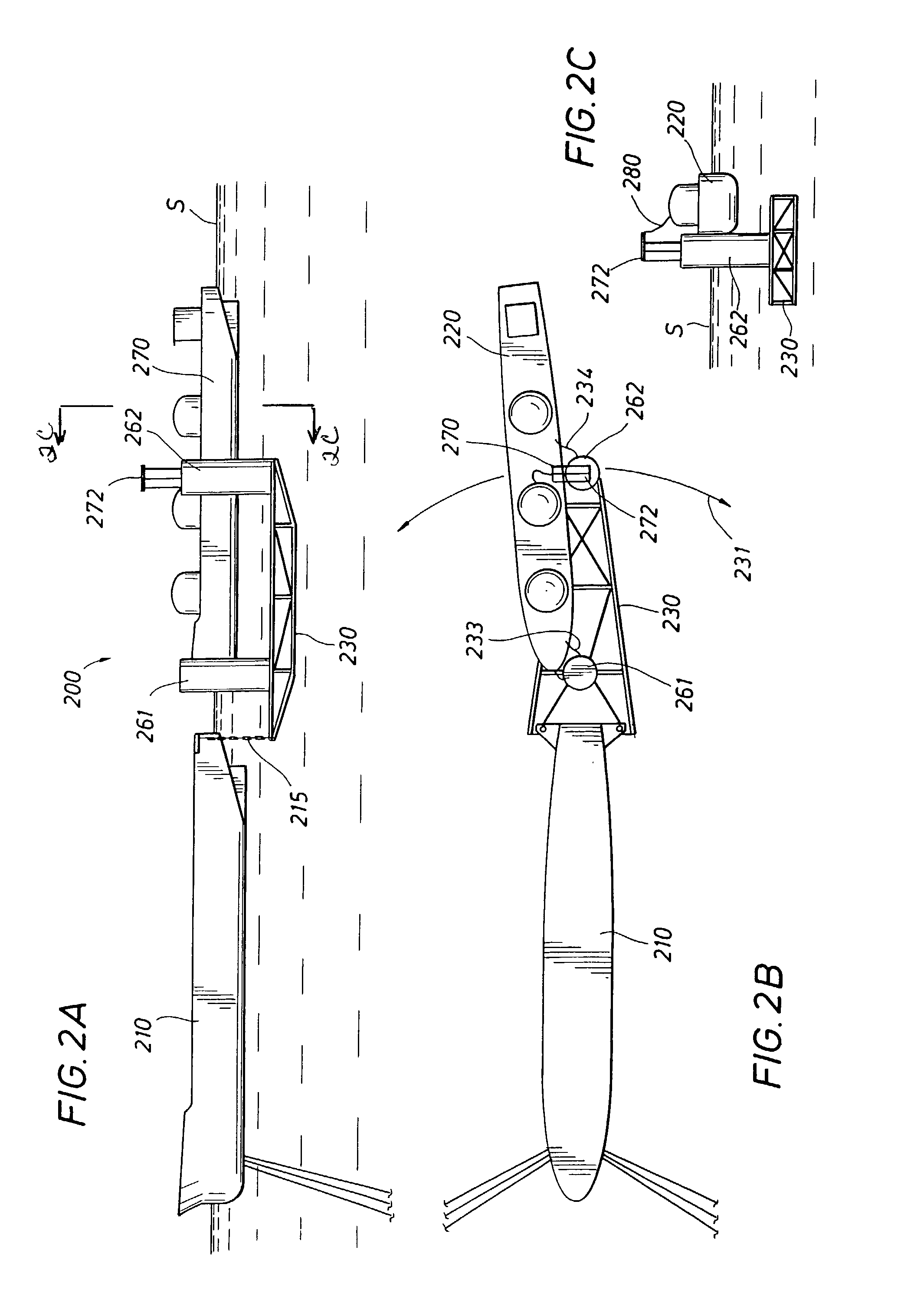

Offloading arrangements for speard moored FPSOs

InactiveUS20030061980A1Avoid contactRapid disconnectionCargo handling apparatusPassenger handling apparatusMooring systemFishery

A mooring arrangement between a floating storage body spread moored in deep water and a shuttle tanker, the arrangement including a single point buoyant member that is adapted for mooring a shuttle tanker in offloading position relative to a floating production, storage and offloading vessel (FPSO) with a link between the floating storage body and the single point buoyant member. One embodiment (100) of the invention employs a submerged yoke (30), having one end (31) rotatably coupled to a FPSO (10) and a second end (32), supported by a buoy. A mooring hawser (28) extends from the buoy to the shuttle tanker and product hoses connect the shuttle tanker with the FPSO and extend along the submerged yoke. In another embodiment, the mooring buoy is stationed by a hold-back mooring system (303-304) and the FPSO or the tanker or both is provided with traction devices (308) to move the tanker into loading position with respect to the FPSO. Other embodiments of the invention establish mooring of a shuttle tanker so that it can weathervane 360 degrees during offloading activity. In another embodiment, the mooring buoy (600) is provided with a dynamic positioning system (614) for controlling shuttle tanker positioning with respect to conditions of the environment or for moving the tanker to a desired position during loading.

Owner:SOFEC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com