Gravity installed anchor

a technology of installed anchors and anchors, which is applied in the direction of anchors, waterborne vessels, vessel construction, etc., can solve the problems of large reduction of the holding capacity of the top attachment, limited mooring line attachment points to such anchor designs, and significant penetration into the soil for adequate holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Those having skill in the relevant art will recognize various changes which may be made to the embodiments disclosed herein, without departing from the nature and spirit of the invention. For illustrative purposes, some of the presently preferred embodiments of the invention will now be described, with reference to the drawings.

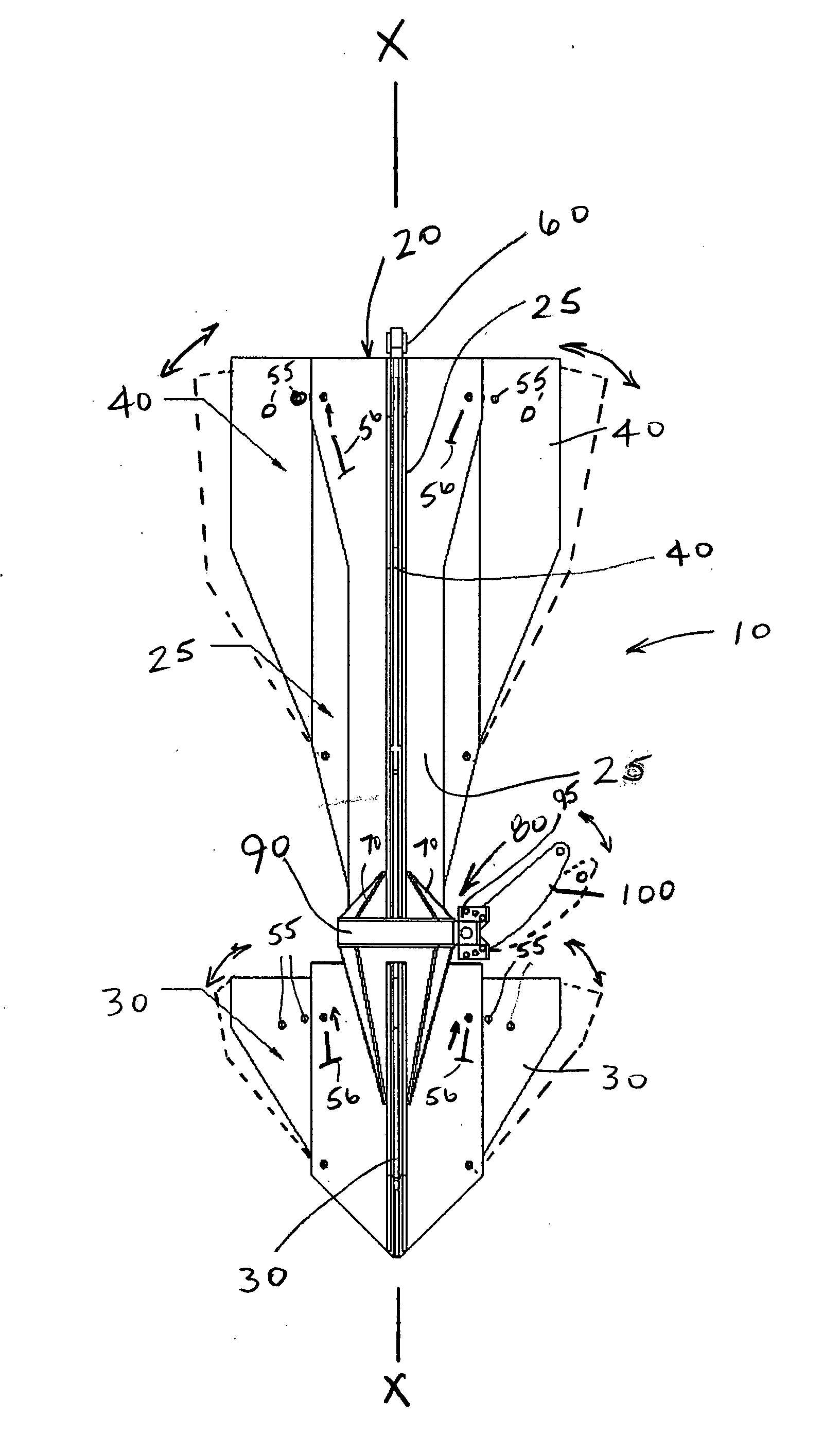

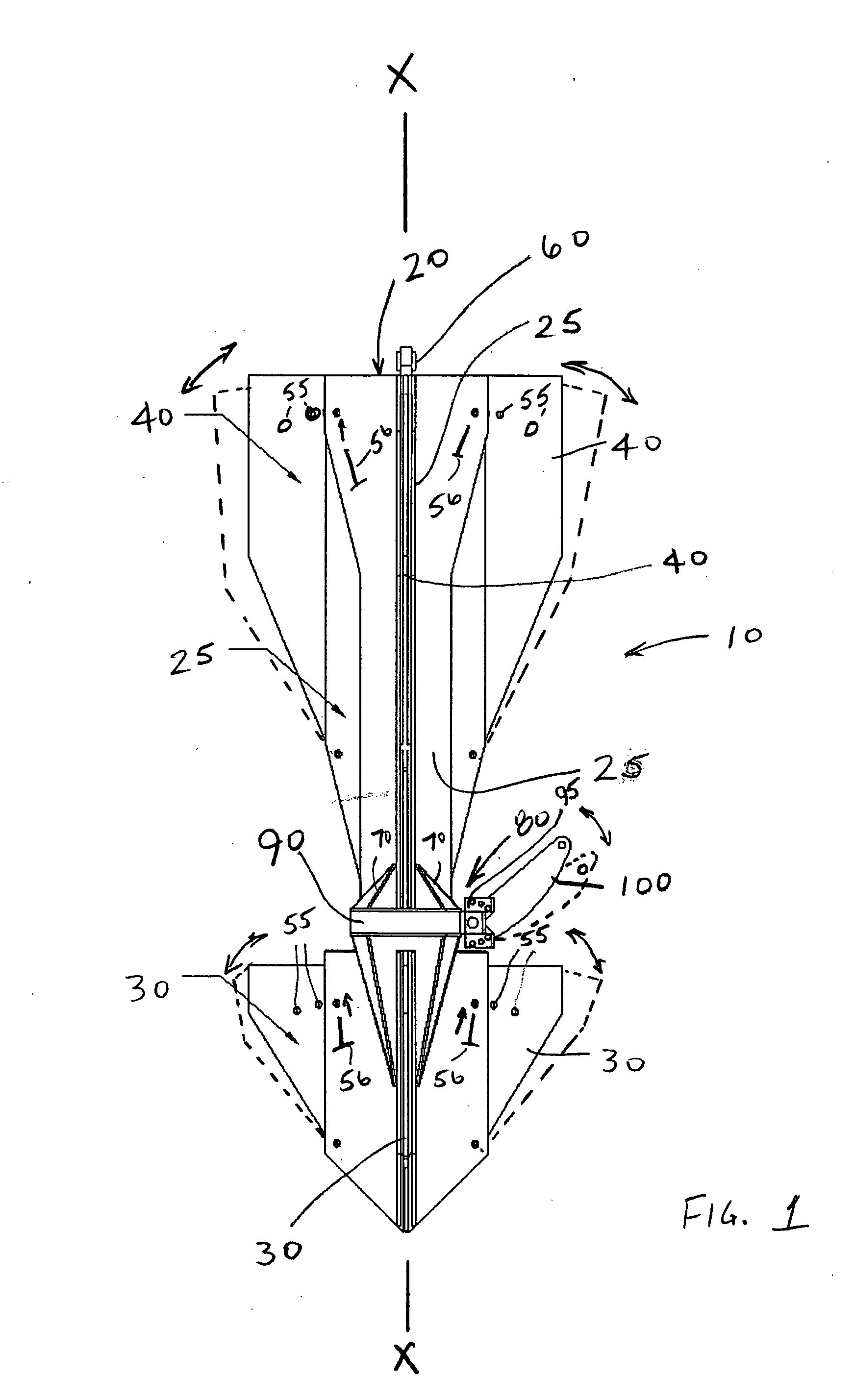

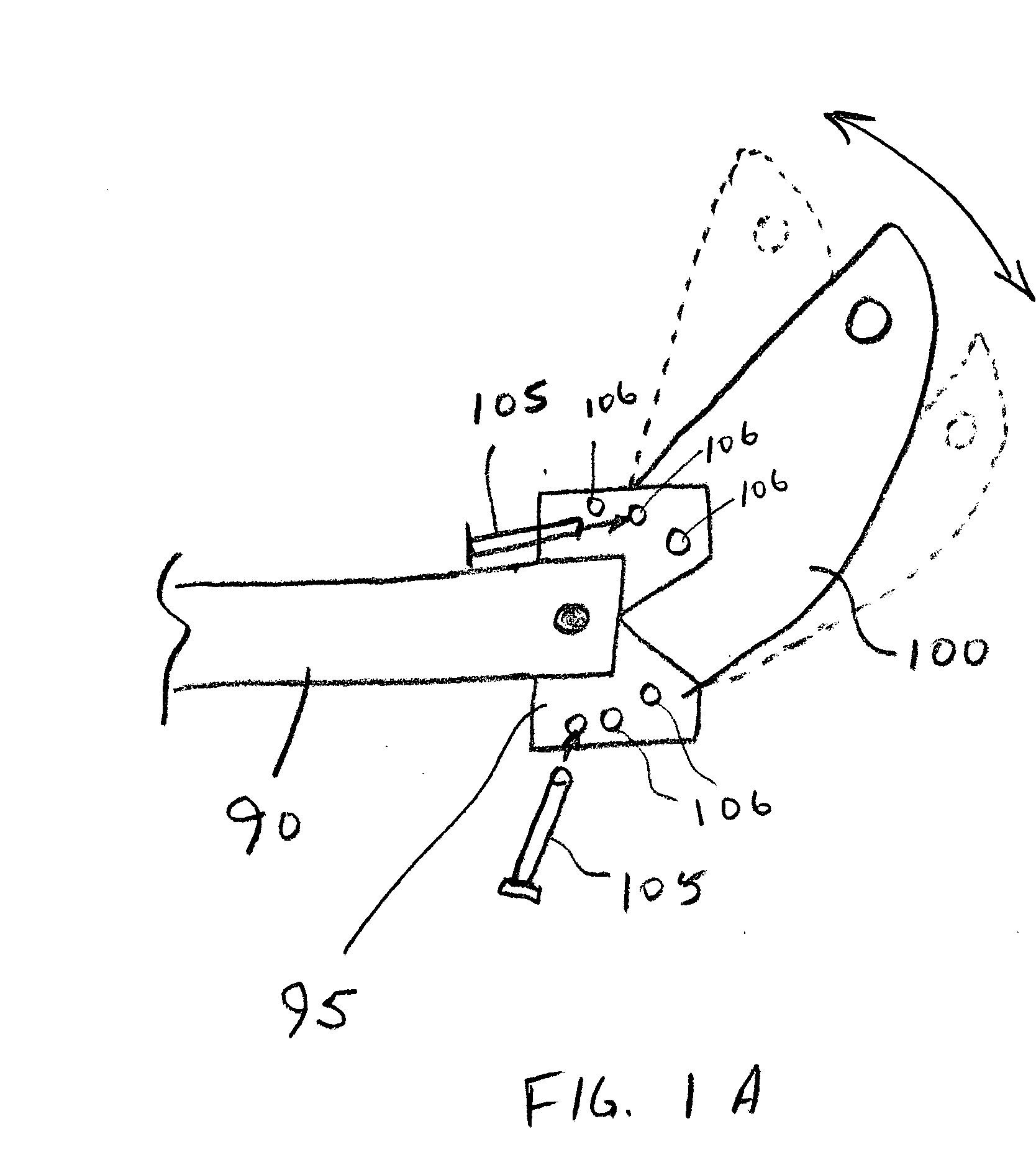

[0017]FIGS. 1-3 show the key structural elements of the anchor. Anchor 10 comprises an elongated central body 20 having a longitudinal axis X and comprising a plurality of radially outwardly extending channel members 25, as especially seen in FIGS. 2 and 3. While the particular embodiment shown comprises three channel members, each spaced 120 degrees apart from one another around the entire circumference, it is understood that two, four, or more channel members could be used. In comparison to the generally circular in cross section main shafts of certain prior art anchors, in certain applications the multiple channel member central body is a more capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com