Patents

Literature

40 results about "Natural cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

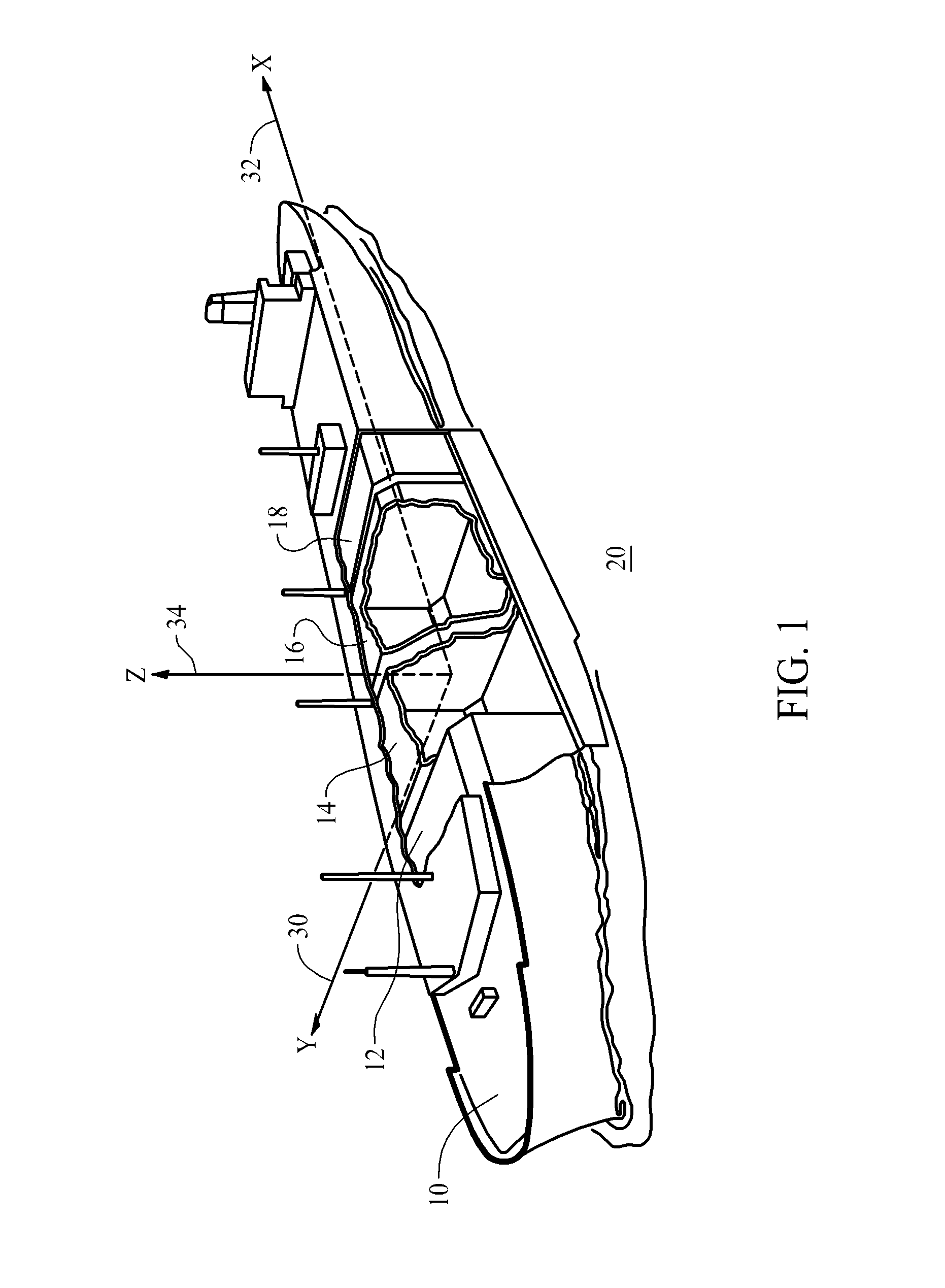

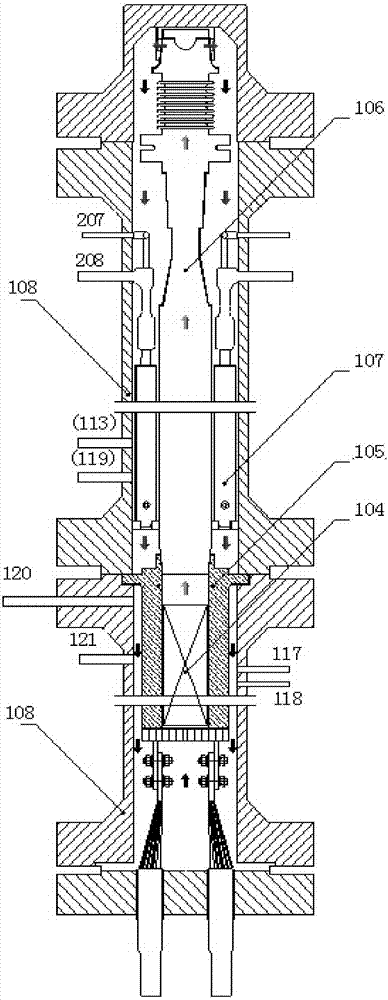

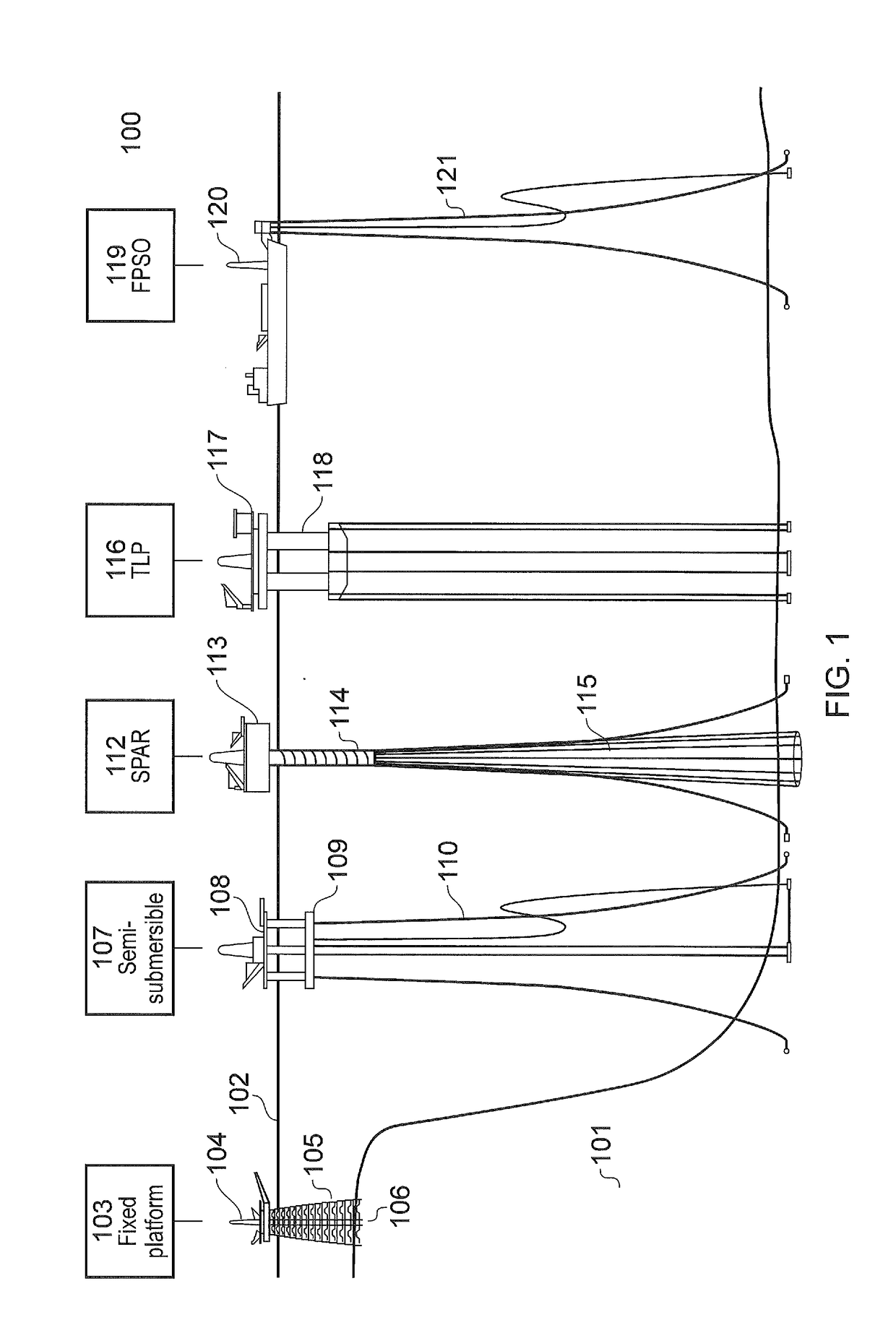

Offshore floating production, storage, and off-loading vessel for use in ice-covered and clear water applications

InactiveUS20090126616A1Reduces dynamic amplificationReduce resonanceProtective foundationMovement controllersResonanceBuoy

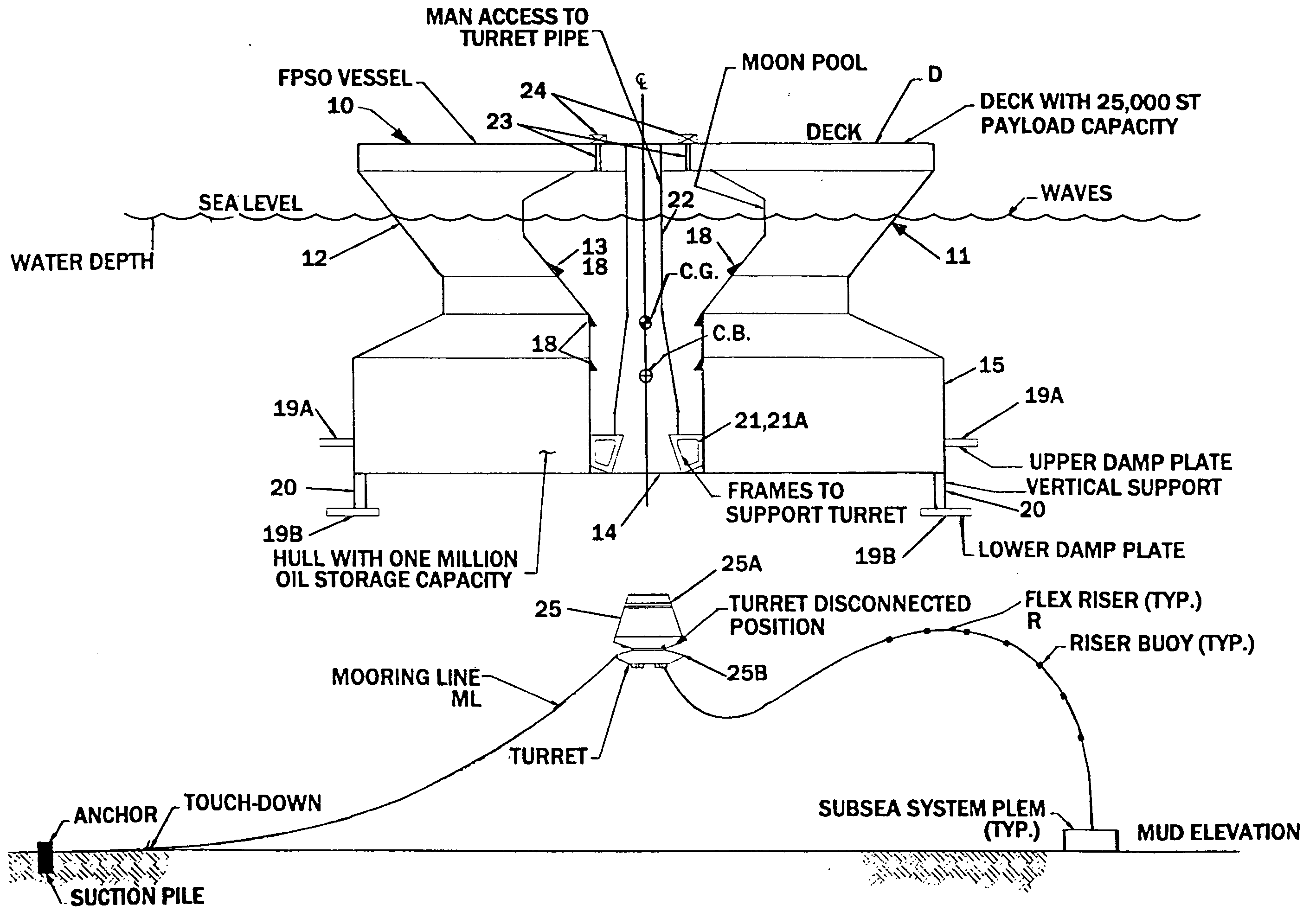

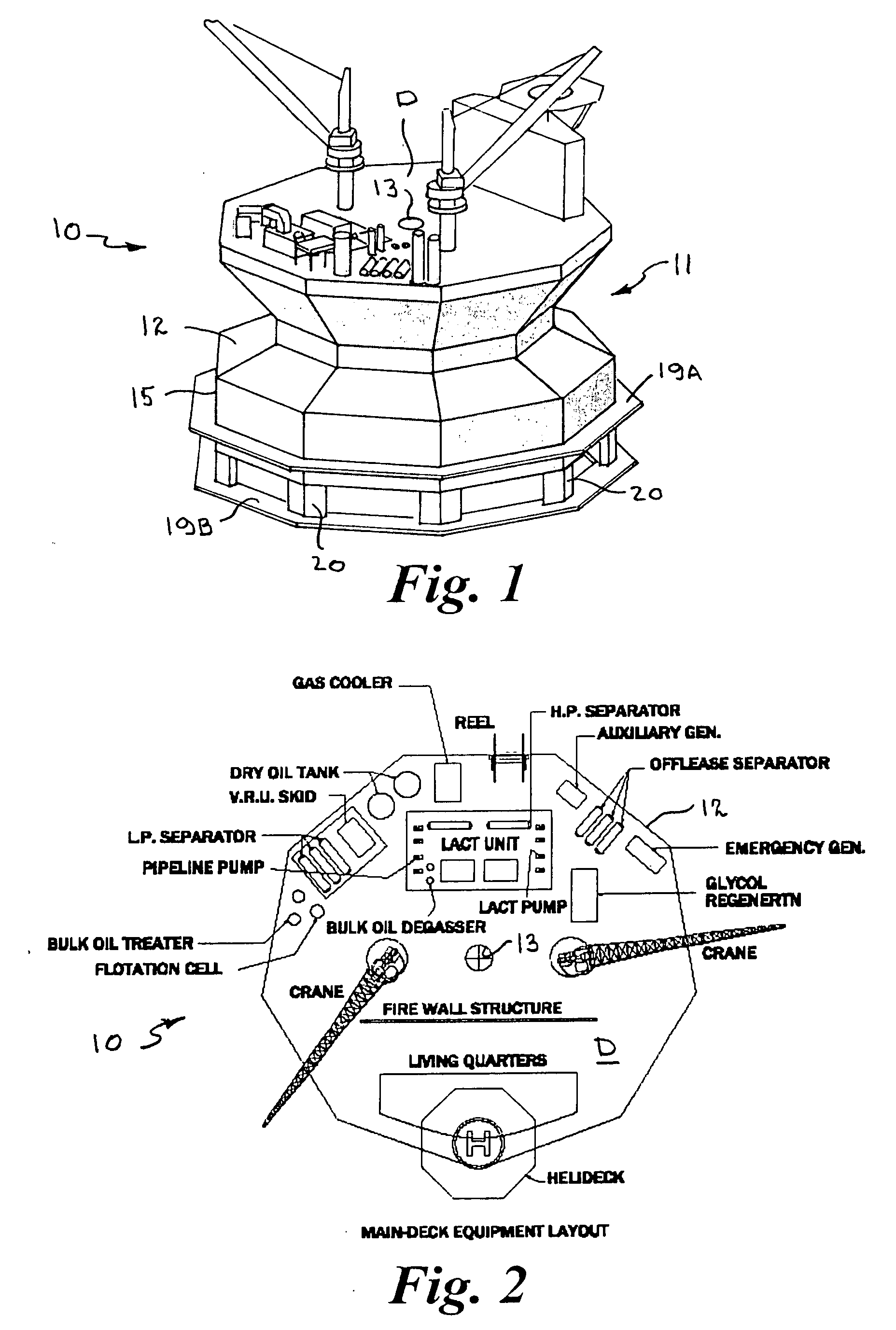

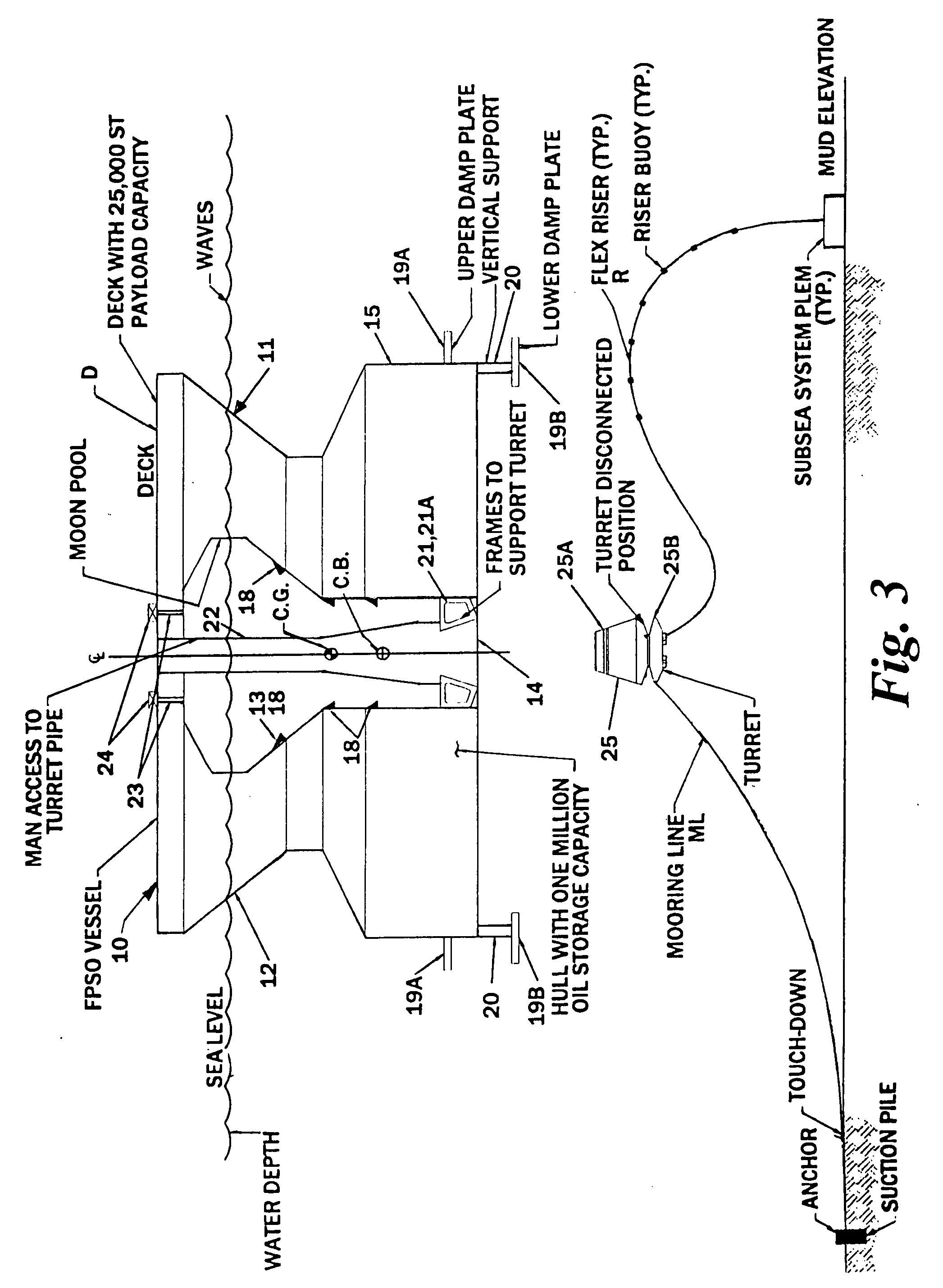

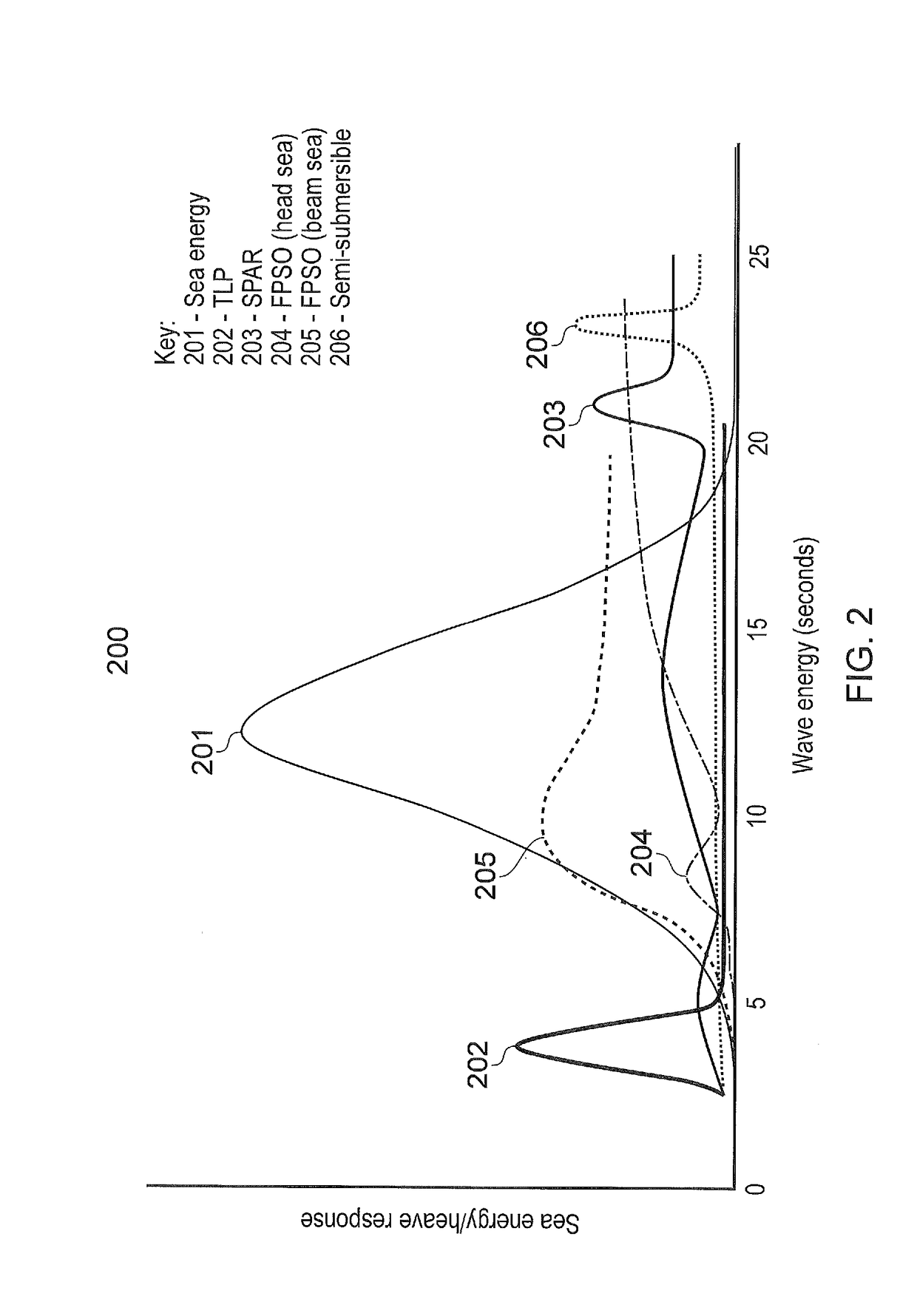

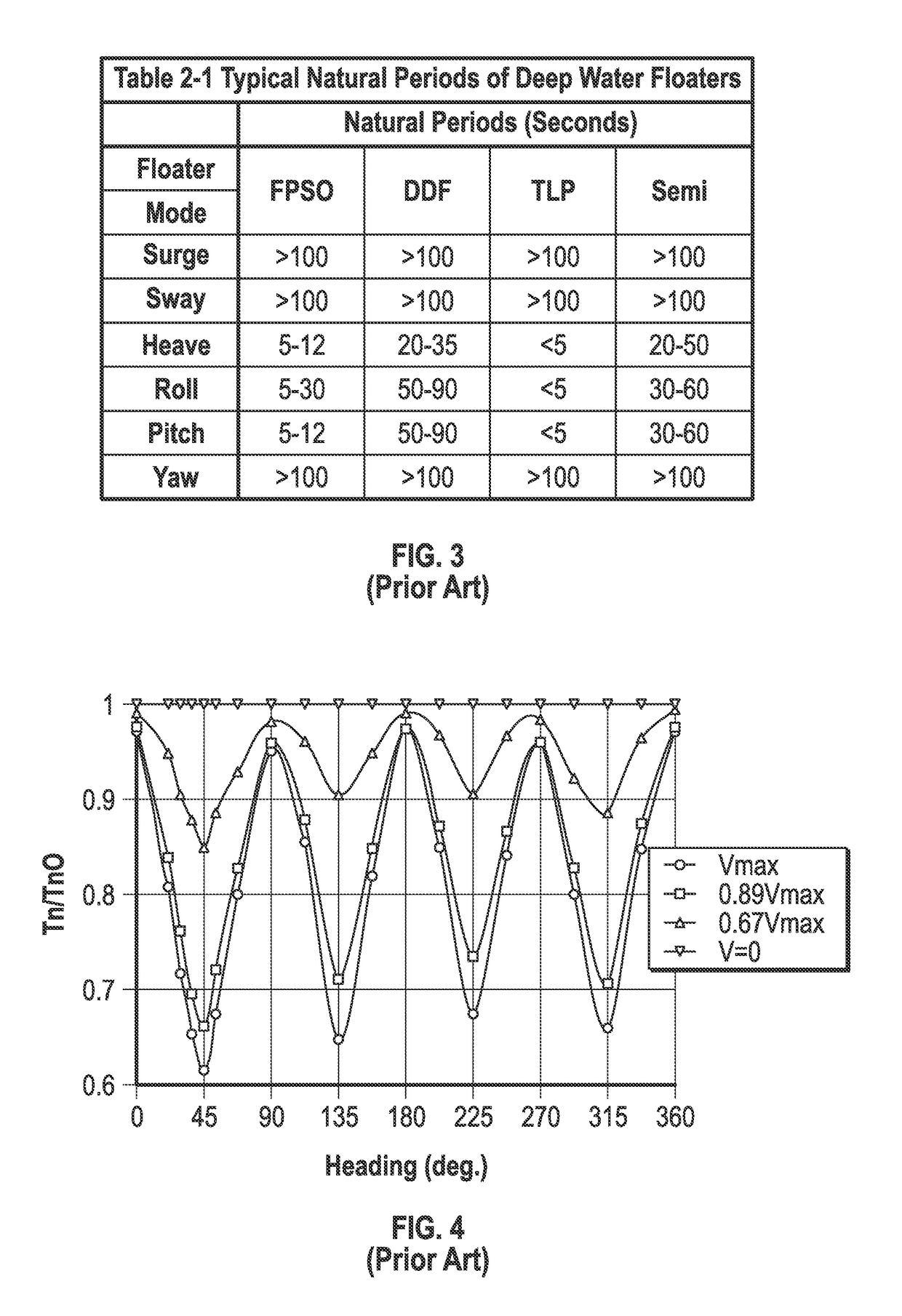

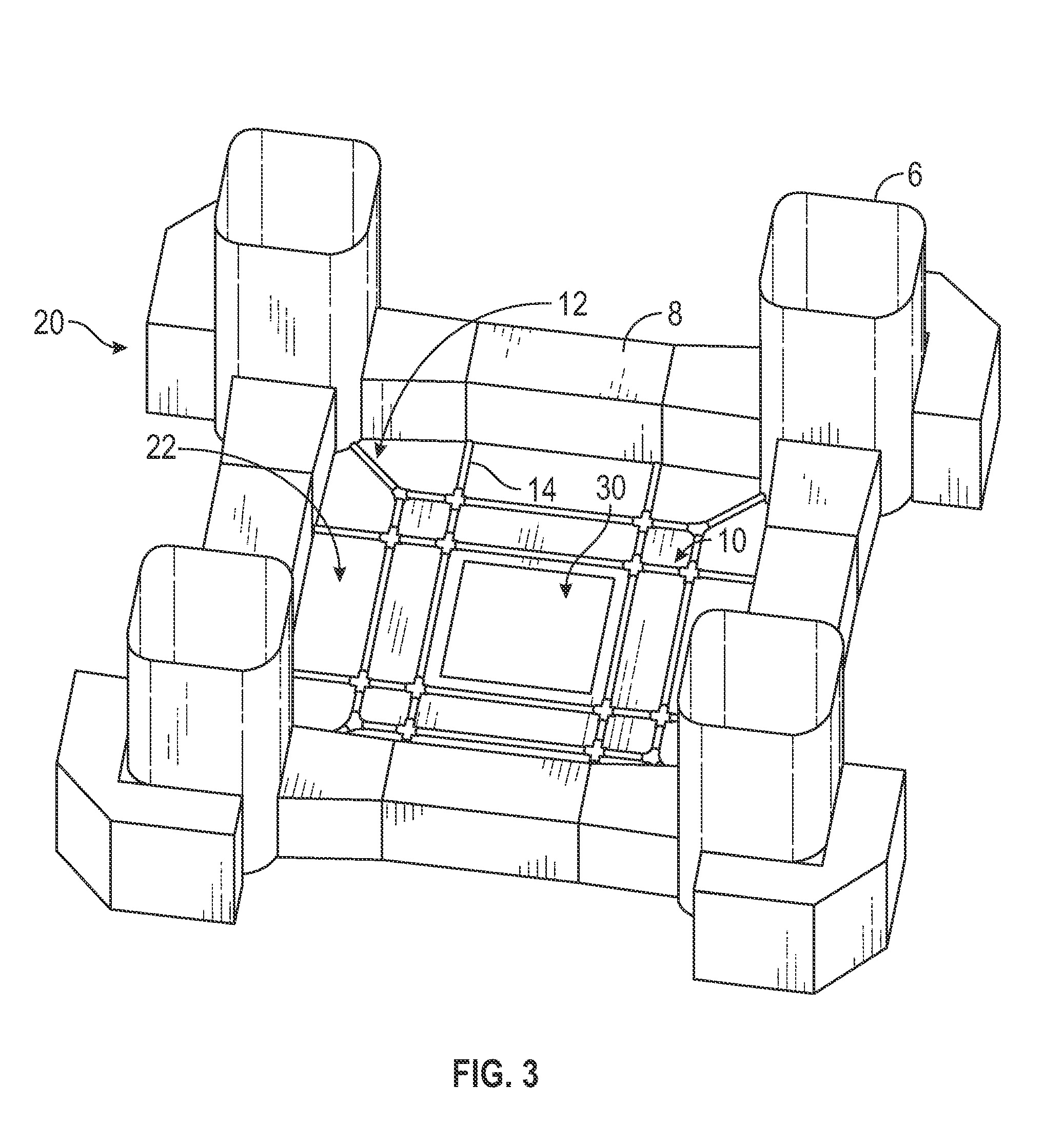

An offshore floating production, storage, and off-loading vessel has a monolithic non ship-shaped hull of polygonal configuration surrounding a central double tapered conical moon pool and contains water ballast and oil storage compartments. The exterior side walls of the hull have flat surfaces and sharp corners to cut ice sheets, resist and break ice, and move ice pressure ridges away from the structure. An adjustable water ballast system induces heave, roll, pitch and surge motions of the vessel to dynamically position and maneuver the vessel to accomplish ice cutting, breaking and moving operations. The moon pool shape and other devices on the vessel provide added virtual mass capable of increasing the natural period of the roll and heave modes, reducing dynamic amplification and resonance due to waves and vessel motion, and facilitate maneuvering the vessel. The vessel may be moored by a disconnectable turret buoy received in a support frame at the bottom of the moon pool and to which flexible well risers and mooring lines are connected.

Owner:SRINIVASAN NAGAN

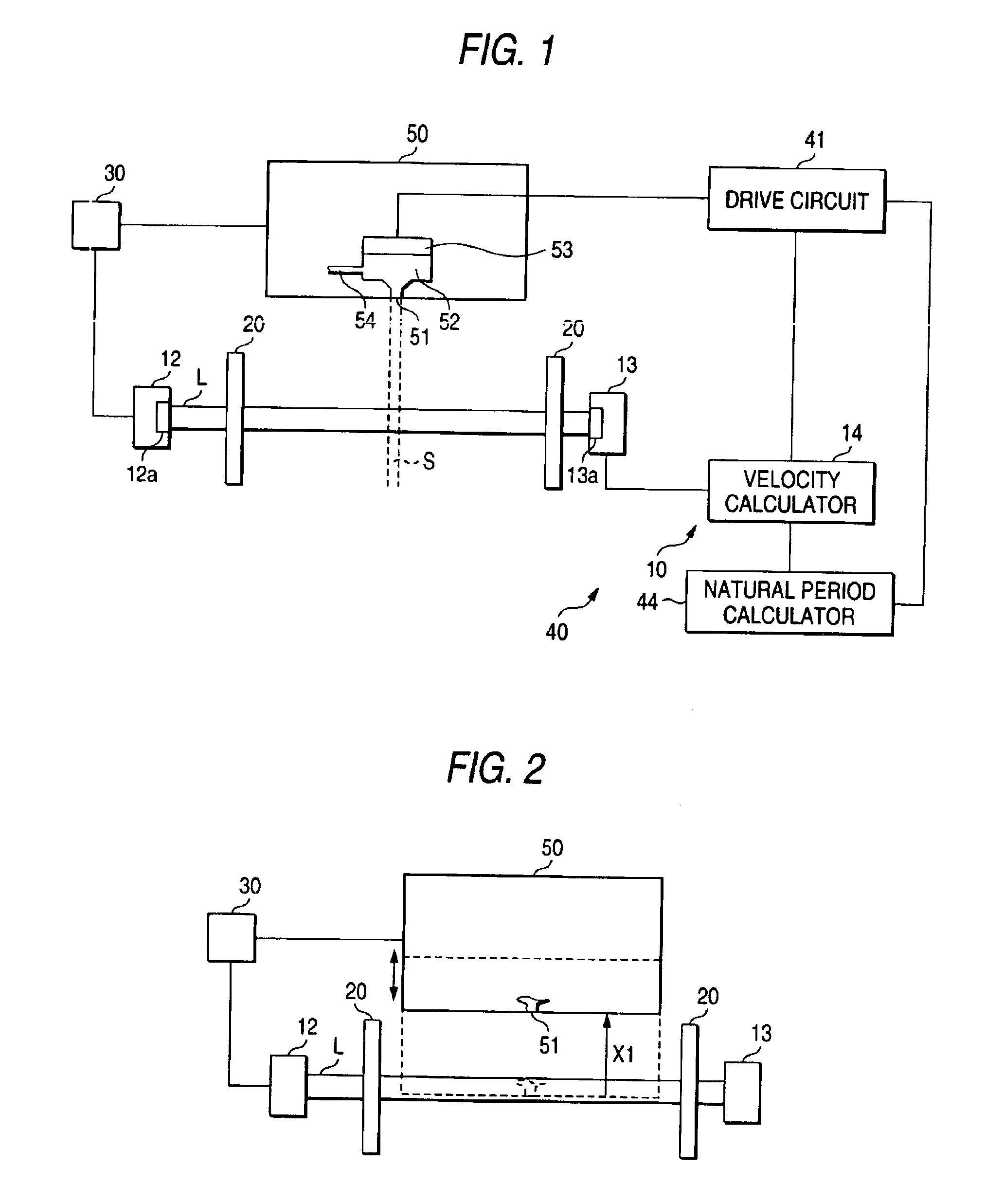

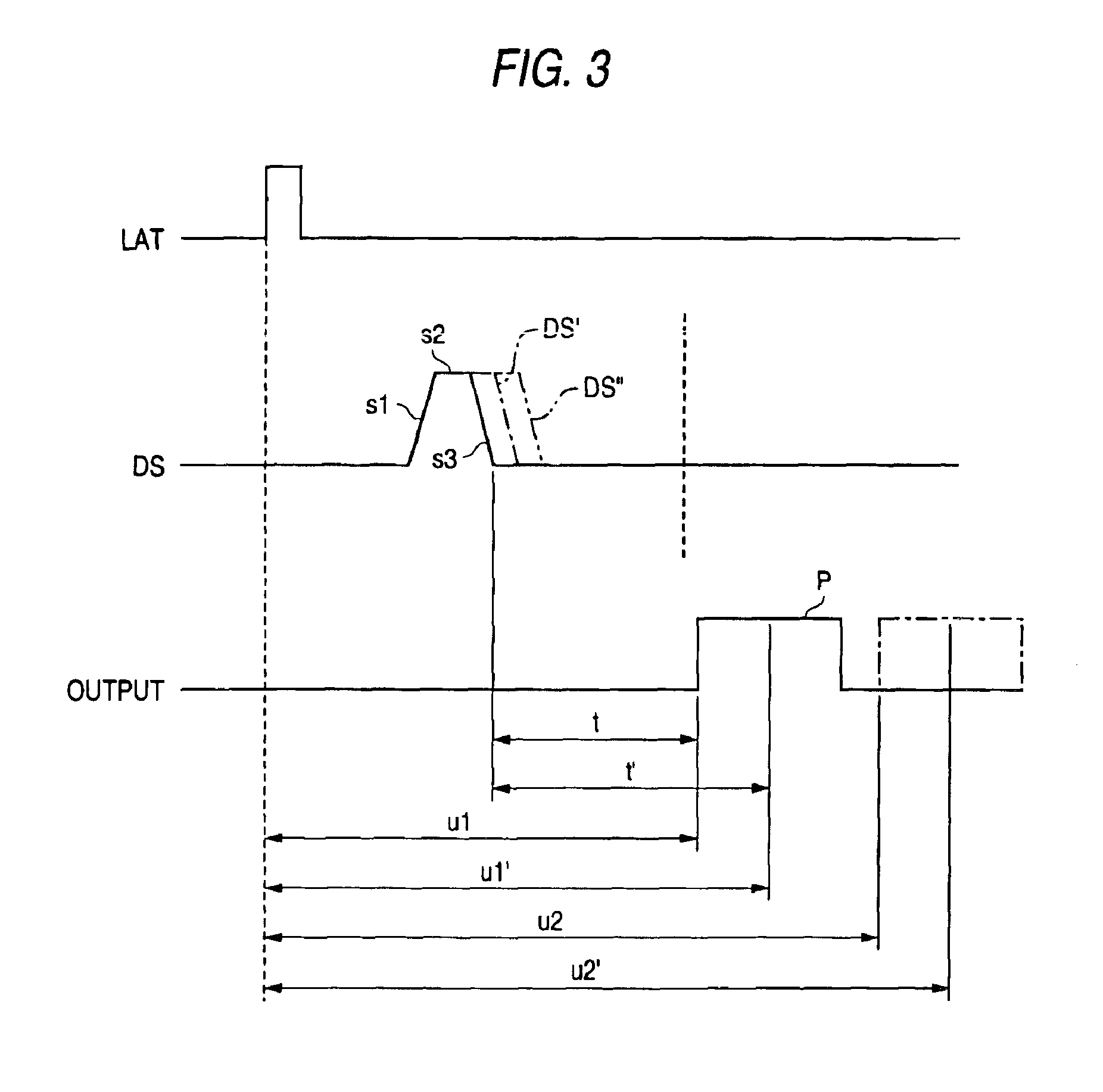

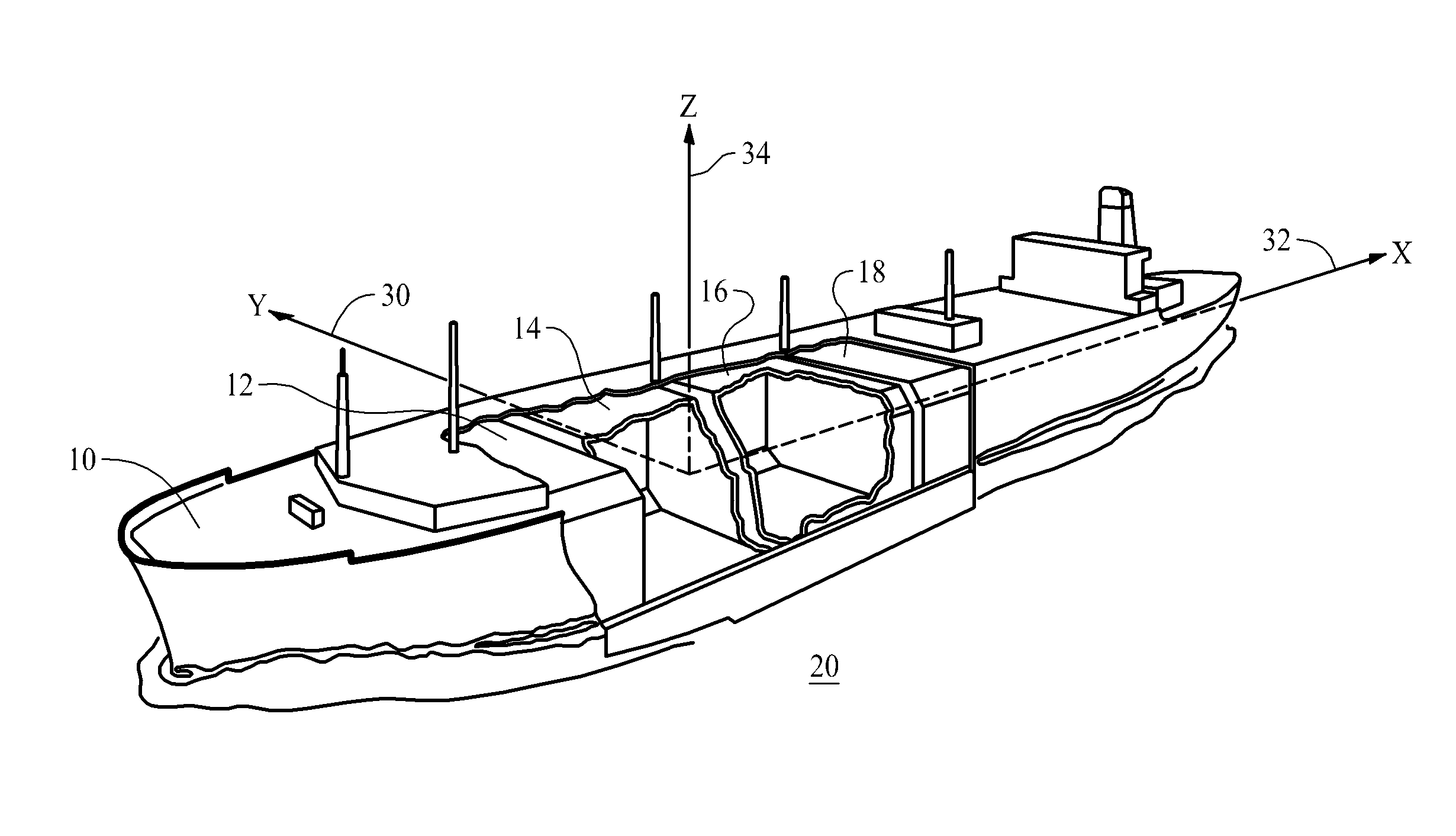

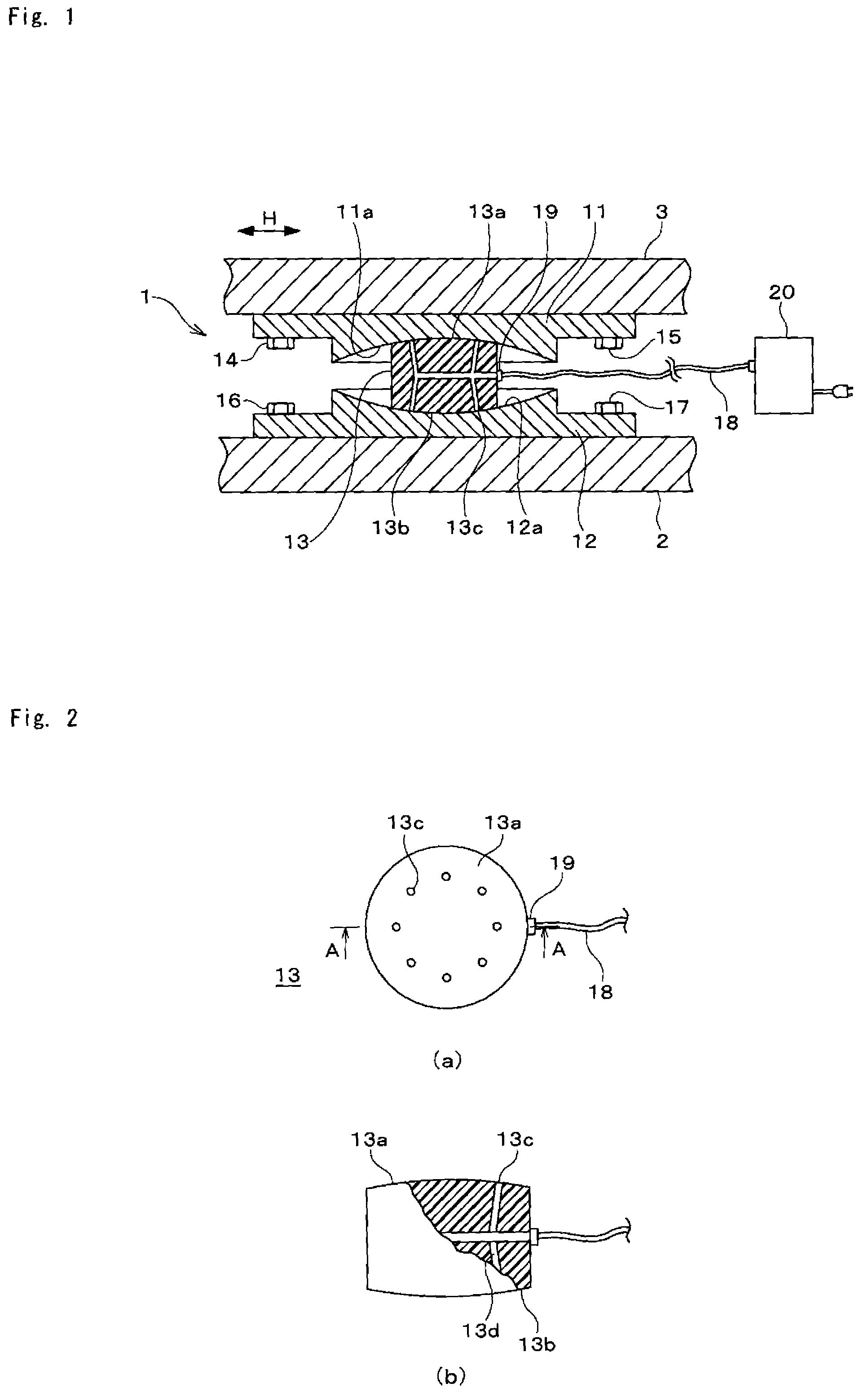

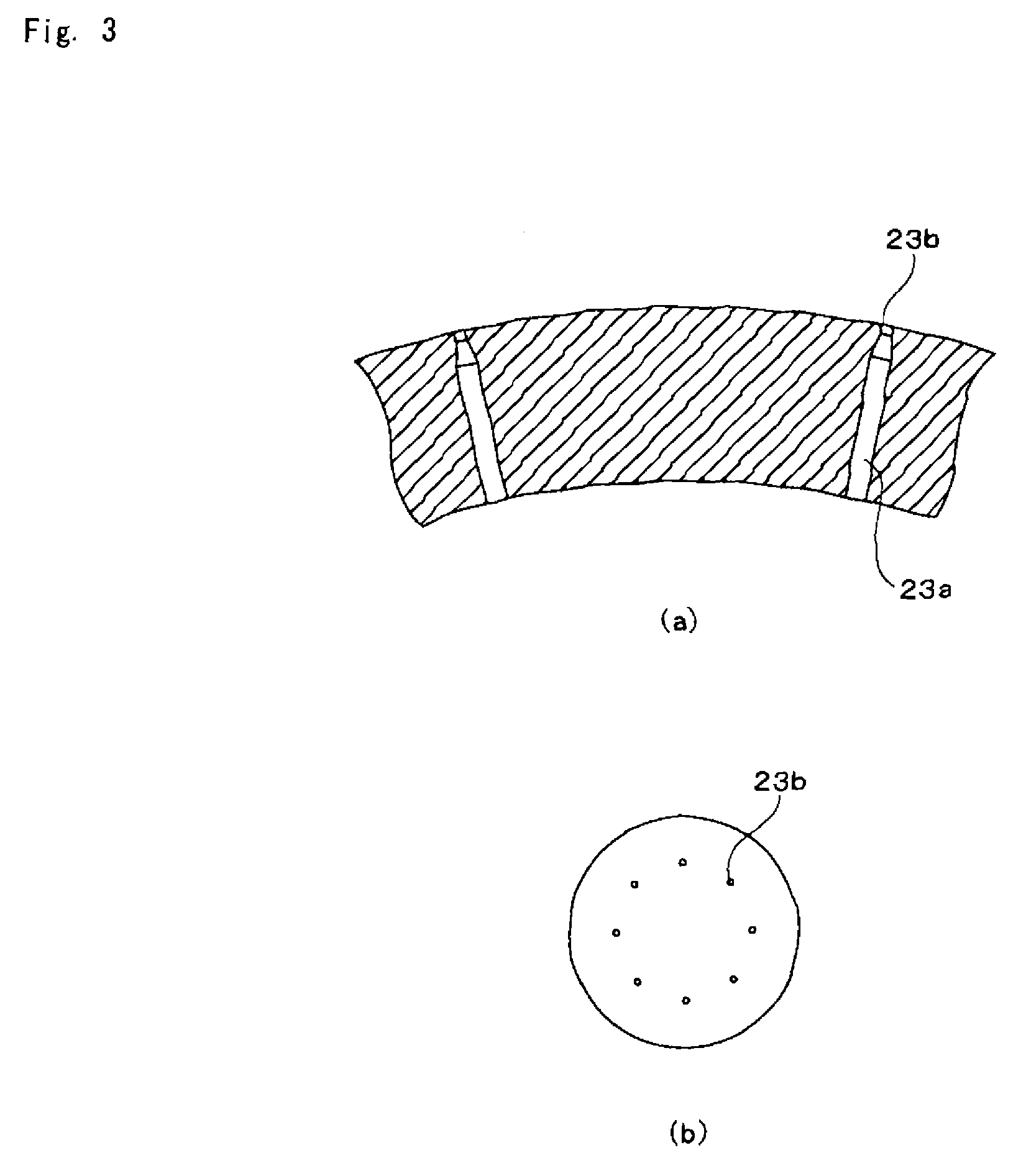

Apparatus and method for measuring natural period of liquid

InactiveUS6858860B2Improve accuracySolve the lack of durabilityInvestigating moving fluids/granular solidsScattering properties measurementsLight beamEngineering

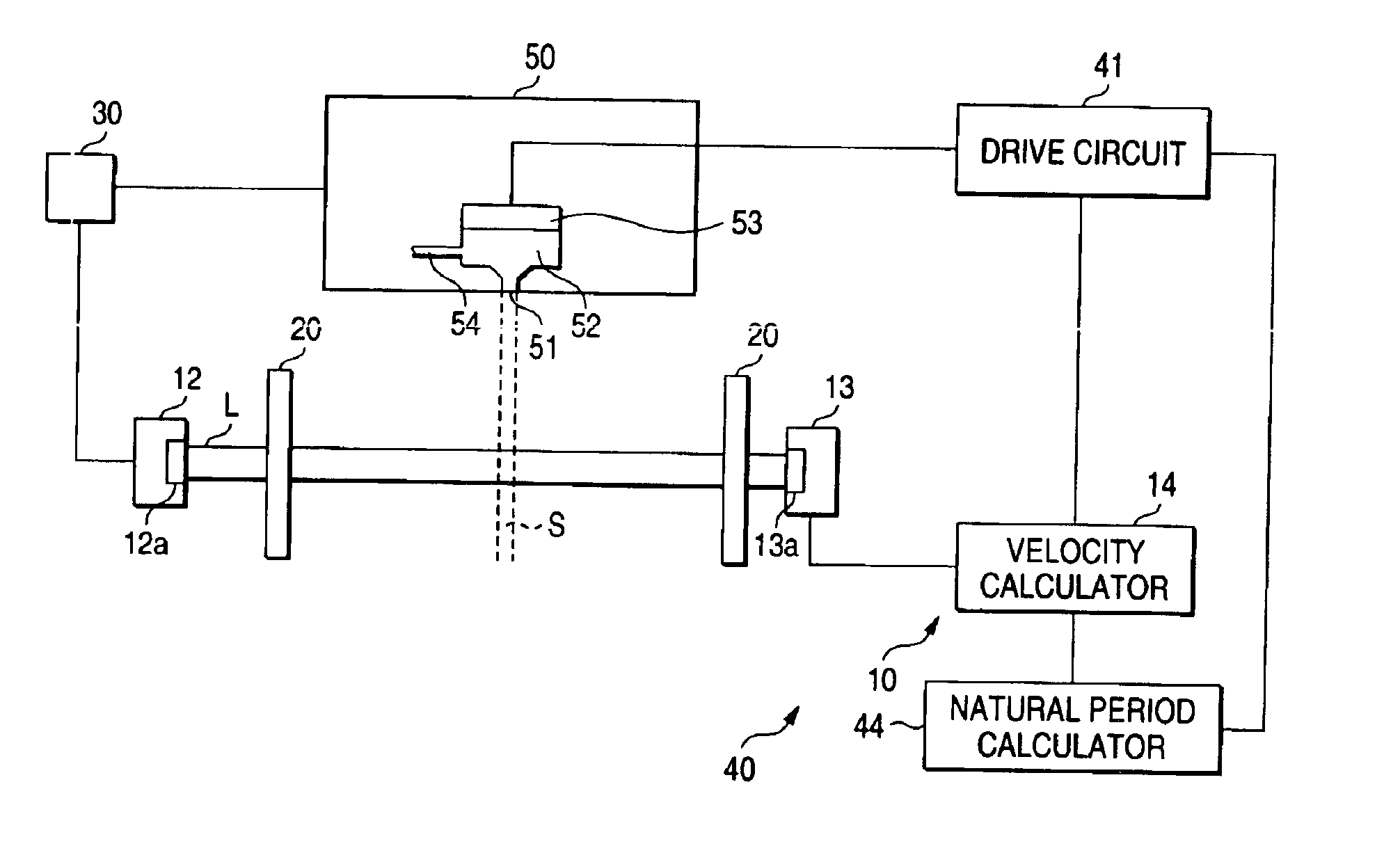

In an apparatus for measuring a natural period of liquid in a pressure chamber formed in a head device which is provided with a nozzle orifice communicated with the pressure chamber and an actuator which varies pressure of the liquid contained in the pressure chamber, a driver generates a plurality of drive signals, each of which drives the actuator to eject a liquid droplet from the nozzle orifice under a condition different from the conditions established by the other drive signals. A light emitter emits a light beam so as to intersect a space through which the liquid droplet passes. A light receiver receives the light beam which has been passed through the space. A first calculator calculates an ejection velocity of the liquid droplet based on a timing at which the actuator is driven and a change in a photo-receiving state of the light receiver, with regard to every drive signal. A second calculator calculates a natural period of the liquid based on a change in the ejection velocity which is obtained from the plural drive signals.

Owner:SEIKO EPSON CORP

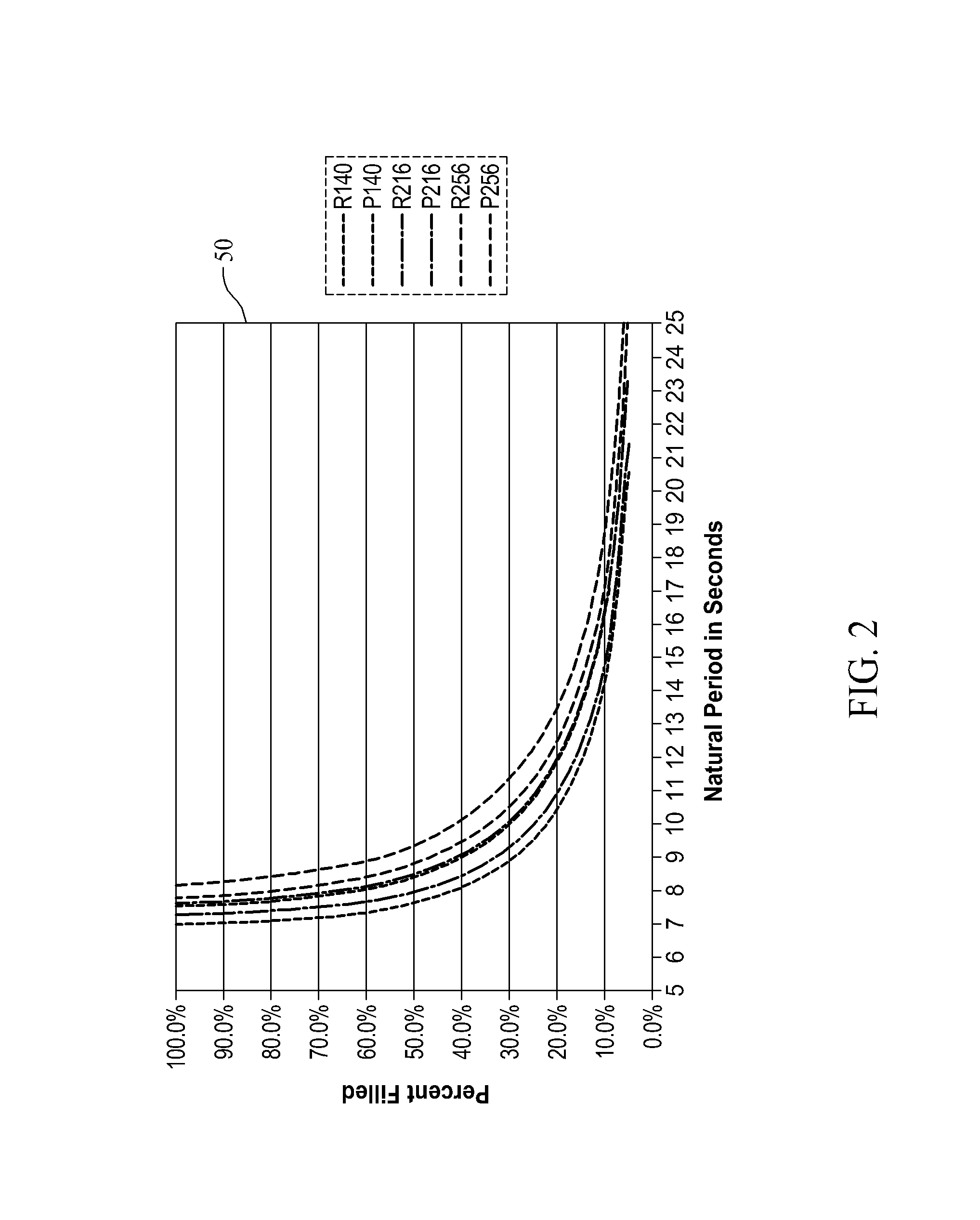

Methods and systems for providing sloshing alerts and advisories

A method is described for providing an alert when the motion of a ship indicates a potential of sloshing damage from liquid cargo being transported by the ship. The method includes calculating, with a processing device, a natural period for the tanks holding the liquid cargo based on the configuration and fill levels of the tanks, receiving, at the processing device, data describing the actual or predicted motion of the ship with respect to three orthogonal axes, determining, with the processing device, a proximity of the natural period of the tanks to a period defined by the actual or predicted motion of the ship, and providing an alert to a user if the proximity in periods is within a threshold value.

Owner:THE BOEING CO

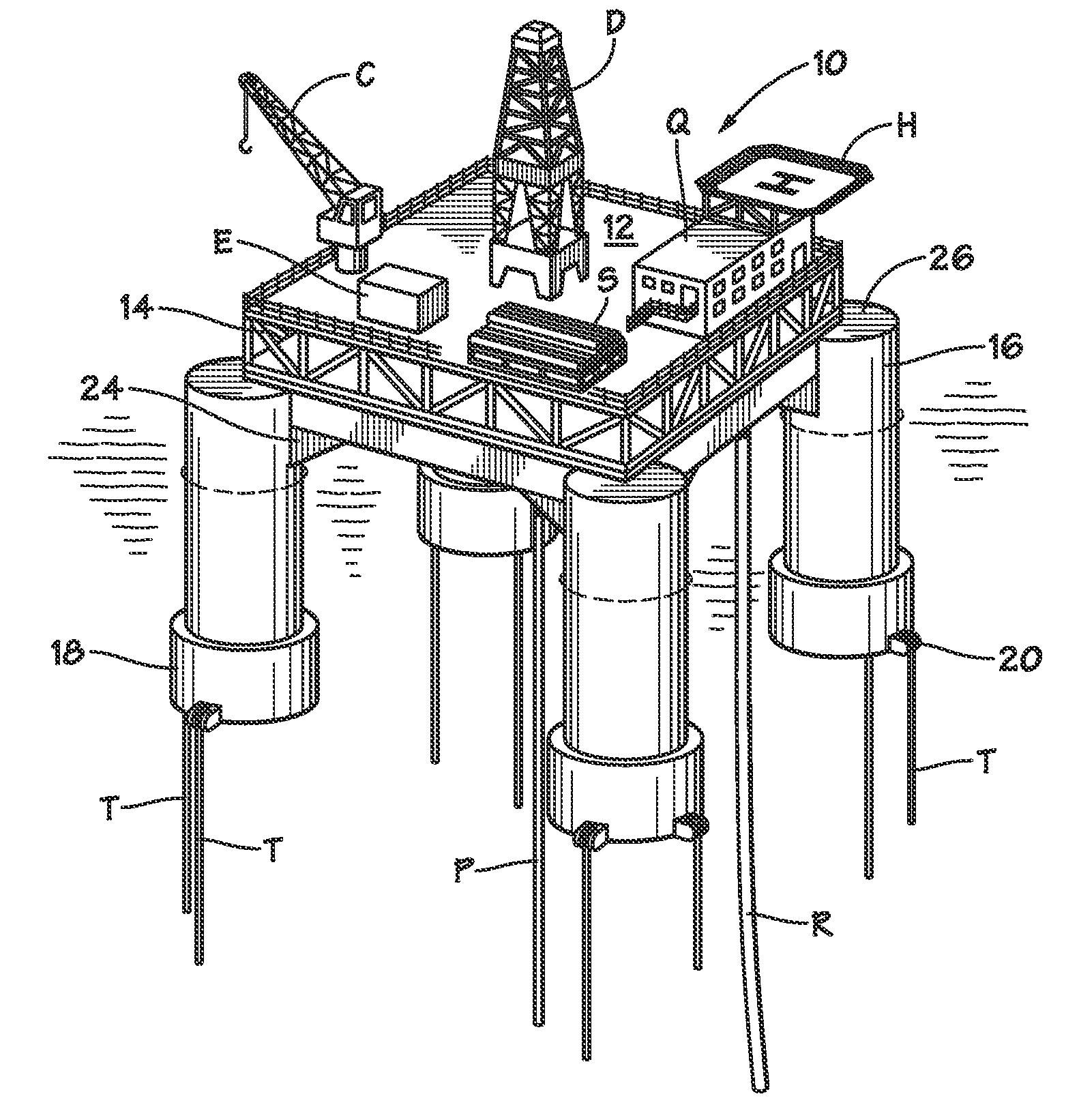

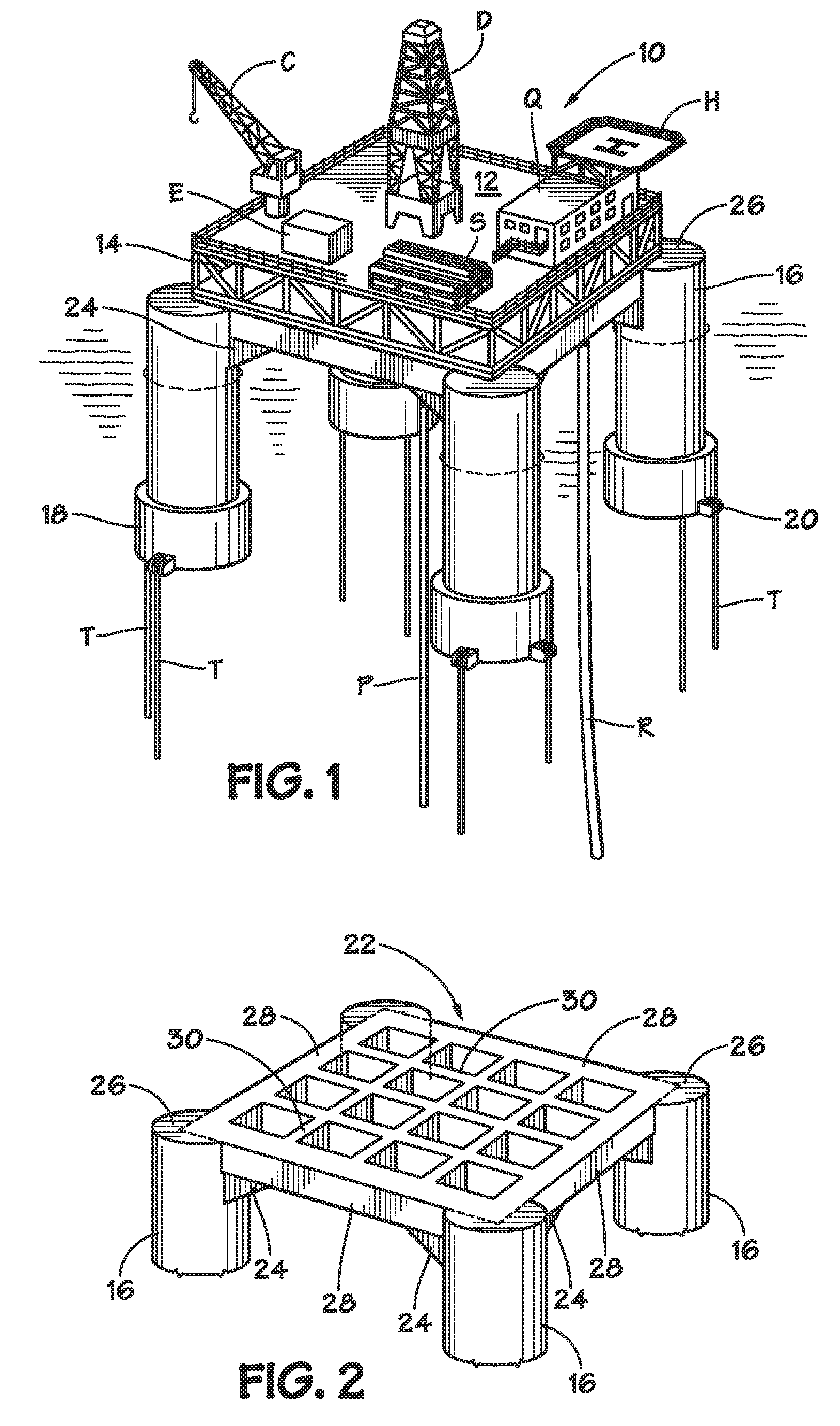

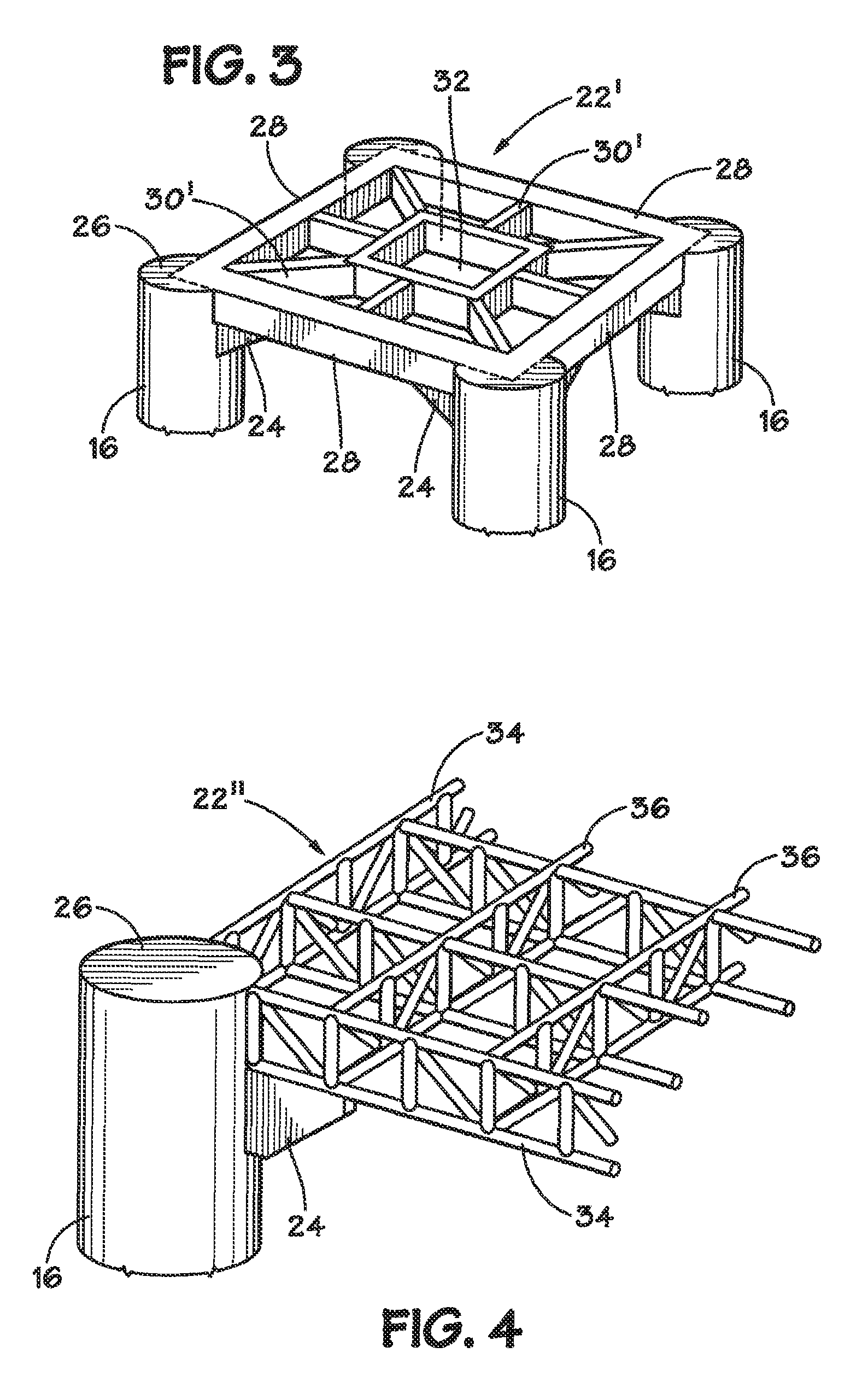

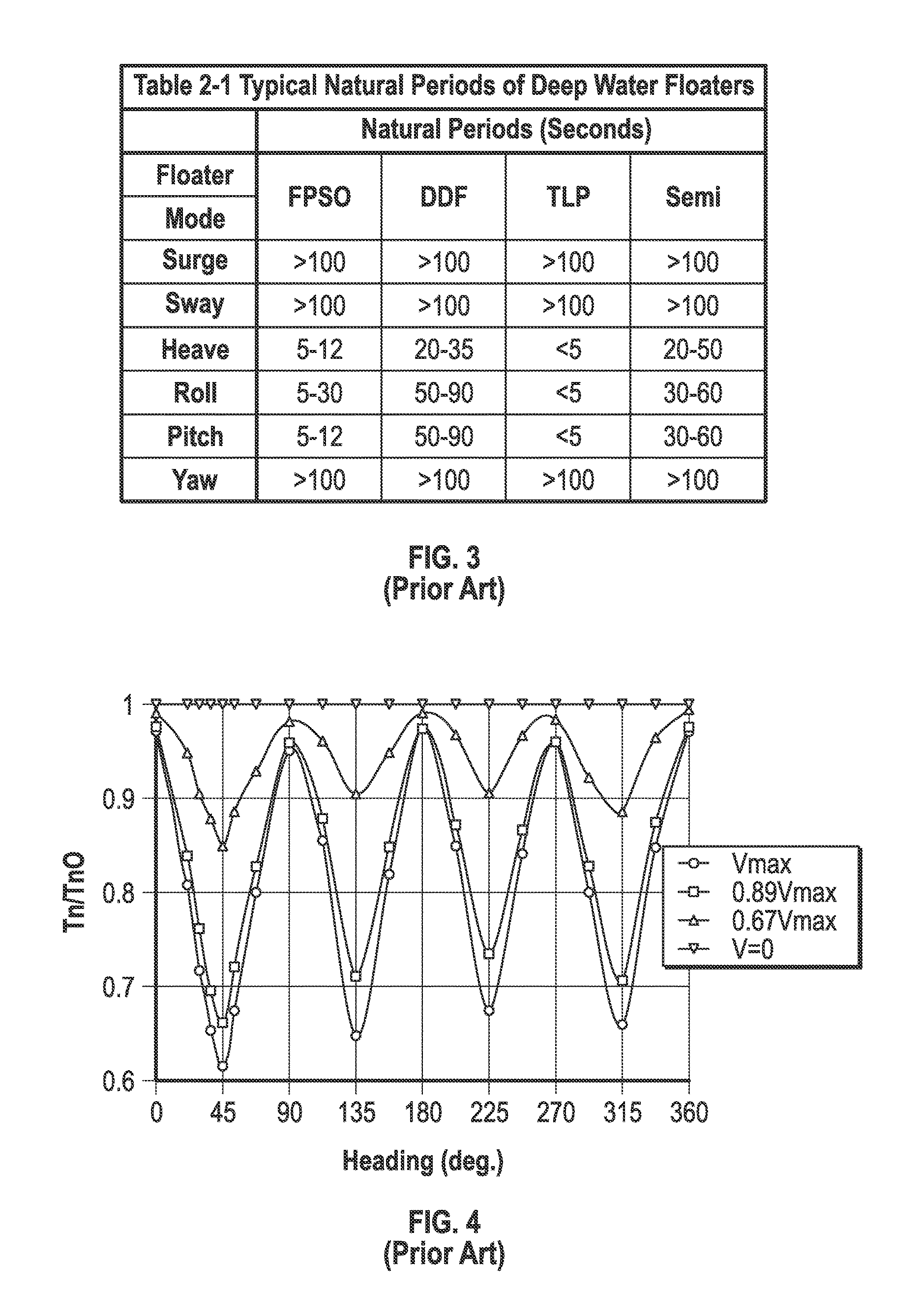

Pontoonless tension leg platform

InactiveUS7854570B2Buoyancy of the columns is increasedIncrease the cross-sectional areaFloating buildingsHydrodynamic/hydrostatic featuresVertical tubeOcean bottom

A pontoonless tension leg platform (TLP) has a plurality of buoyant columns connected by an above-water deck support structure. The design eliminates the need for subsea pontoons extending between the surface-piercing columns. In certain embodiments, the buoyancy of the columns is increased by the addition of subsea sections of increased diameter (and / or cross-sectional area) to provide the buoyancy furnished by the pontoons of the TLPs of the prior art. A pontoonless TLP has a smaller subsea projected area in both the horizontal and vertical planes than a conventional multi-column TLP of equivalent load-bearing capacity having pontoons between the columns. This reduction in surface area produces a corresponding reduction in the platform's response to ocean currents and wave action and consequently allows the use of smaller and / or less costly mooring systems. Moreover, the smaller vertical projected area results in a shorter natural period which enables a pontoonless TLP according to the invention to be used in water depths where conventional TLPs cannot be used due to their longer natural periods. The absence of pontoons in a multi-column TLP also has the added benefit of providing an unobstructed path for risers to connect with the deck of the platform.

Owner:SEAHORSE EQUIP

Method for automatically producing high-temperature nuclear energy for long term under any power

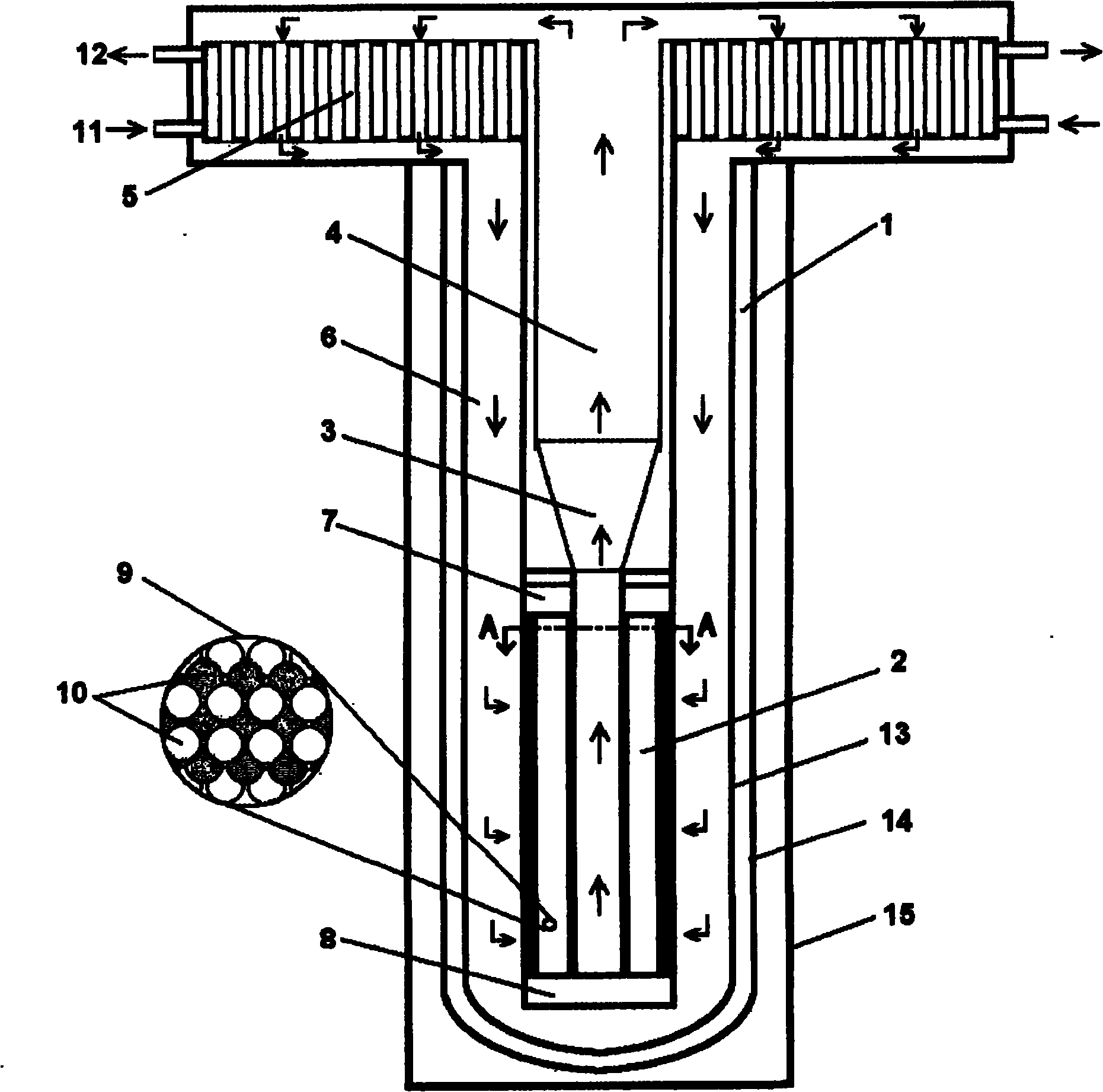

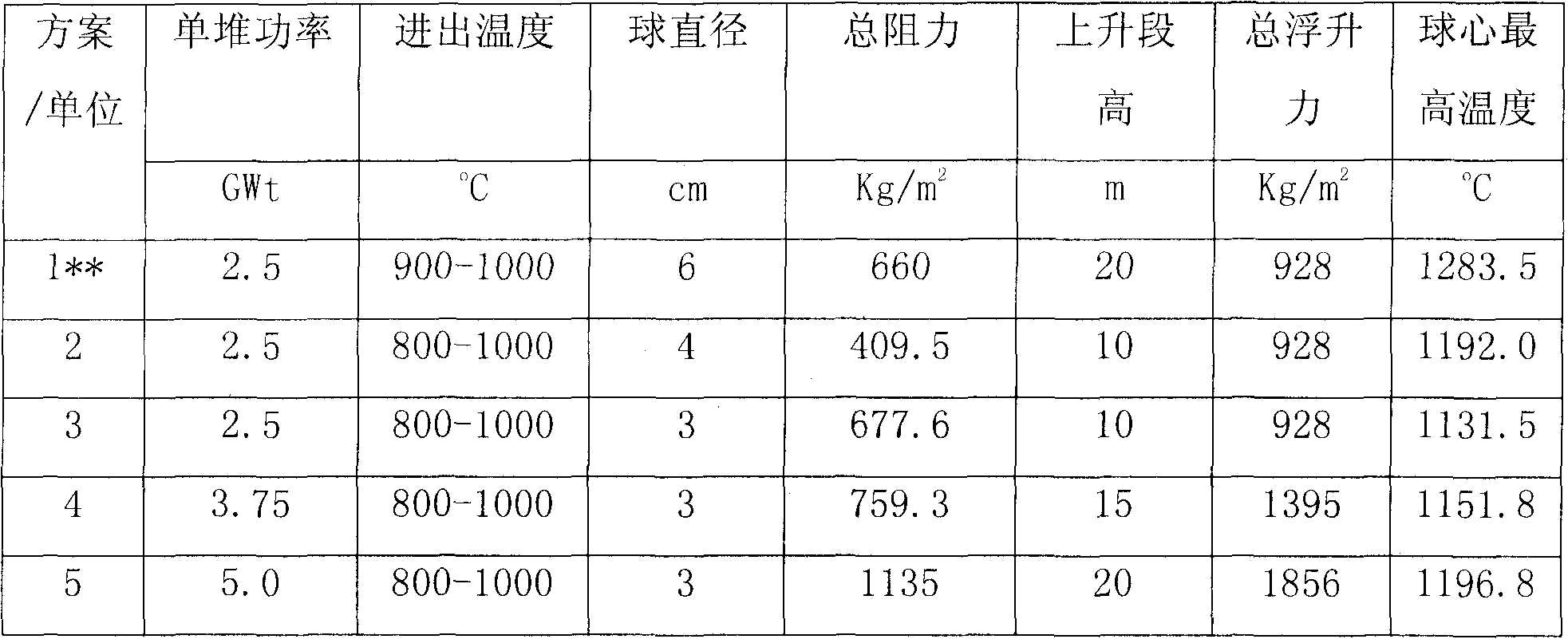

InactiveCN101814325AHigh power outputRealize automatic operationNuclear energy generationHeterogenous reactorsNatural cycleHeat energy

The invention discloses a method for automatically producing high-temperature nuclear energy for long term under any power. The method comprises the following steps of: in a high-boiling point heating medium deep-tank type reactor which runs under the normal pressure, generating a natural cycle with a temperature difference of a high-boiling point heating medium between an ascending flow passage and a descending flow passage in the high-boiling point heating medium deep-tank type reactor; making the high-boiling point heating medium transversely flow by an ultra-low-resistance annular pebble bed reactor in the high-boiling point heating medium deep-tank type reactor with the natural cycle; making the high-boiling point heating medium pass through an ultra-low-resistance open heat exchanger in the high-boiling point heating medium deep-tank reactor with the natural cycle; totally transferring fission produced by the reactor to a secondary high-boiling point heating medium; not arranging a plurality of control-compensation rod bundles in the high-boiling point heating medium deep-tank type reactor; under the function of a negative temperature coefficient of the reactor per se and along with demands on external loads, ending a life cycle of the reactor from the starting to running of the reactor; and when the reactor is automatically run for long, making the secondary high-boiling point heating medium enter an energy-utilization factory through a group of overpressure double-protection valves so as to directly utilize high-temperature heat energy or generate electricity.

Owner:吕应中

First House II

InactiveUS20080034681A1Increase flexibilityBuilding roofsMachines/enginesAir cycle machineDifferential pressure

First House II is a self regulating, solar powered, air cycle machine. Thermo radiation and photovoltaic conversion interact proportionally to moderate [climatic] extremes. It incorporates the natural cycles for water, waste, garbage, household dirt and for air purification.The interior cantilever post and beam skeleton, with innovative joinery, is sheathed in rigid non-biodegradable skin to form a permanent, low maintenance structure.The interior and exterior geometry for radiant energy absorption also utilizes skin openings, temperature and pressure differentials to control air quality and flow. [Openings for doors], windows and holes are precision cut from the skin and [then] reinstalled to prevent unintentional convection, conduction or radiant energy loss.Pre-manufactured interchangeable parts permit phased construction or expansion with no onsite waste or refuse. Structural materials are multifunctional and provide capabilities for energy independence with no need for municipal services over its unlimited service life.

Owner:MCDONALD PAUL FRANCIS

Method for simulating natural circulation flow characteristics of nuclear reactor fluid

InactiveCN107527664ASimulation is accurateSolving the simulation puzzle of natural cyclesNuclear energy generationNuclear monitoringReactor systemNuclear reactor

The invention discloses a method for simulating the natural circulation flow characteristics of nuclear reactor fluid, aiming at solving the problems that a simple way of reducing the power scale and reducing the system size is adopted, so that fluid flow and heat transfer characteristics in a reactor core and a steam generator are greatly different from the actual characteristics, and the natural cycle characteristics can not be the accurately simulated. The method comprises the steps of acquiring a simulation ratio of the main parameters of an experimental device and a prototype reactor system according to the criteria number of simulating single-phase natural circulation and on the basis of a limiting condition of the criteria number of the experimental device being the same as that of the prototype reactor system; setting the experimental device according to the simulation ratio so as to obtain the natural circulation characteristics which are the same as the natural circulation characteristics of the prototype reactor system. The method can be used for accurately simulating the natural circulation capability of the reactor core in real time after the accident of a nuclear reactor happens as well as the variation rule of the parameters which are closely related with the safety of the reactor based on a small-scale experimental size proportion.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

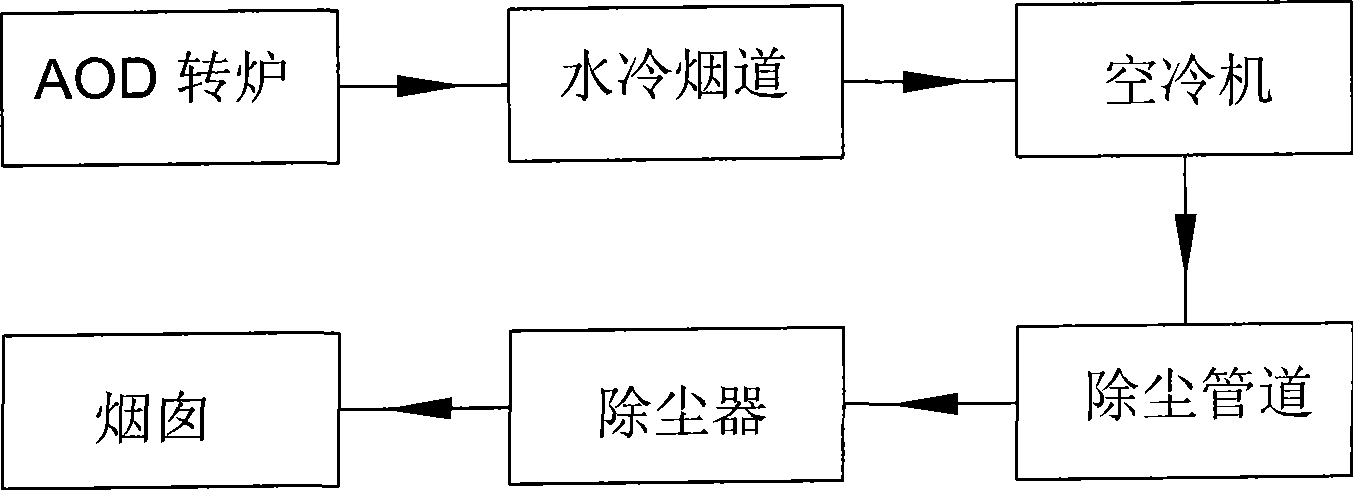

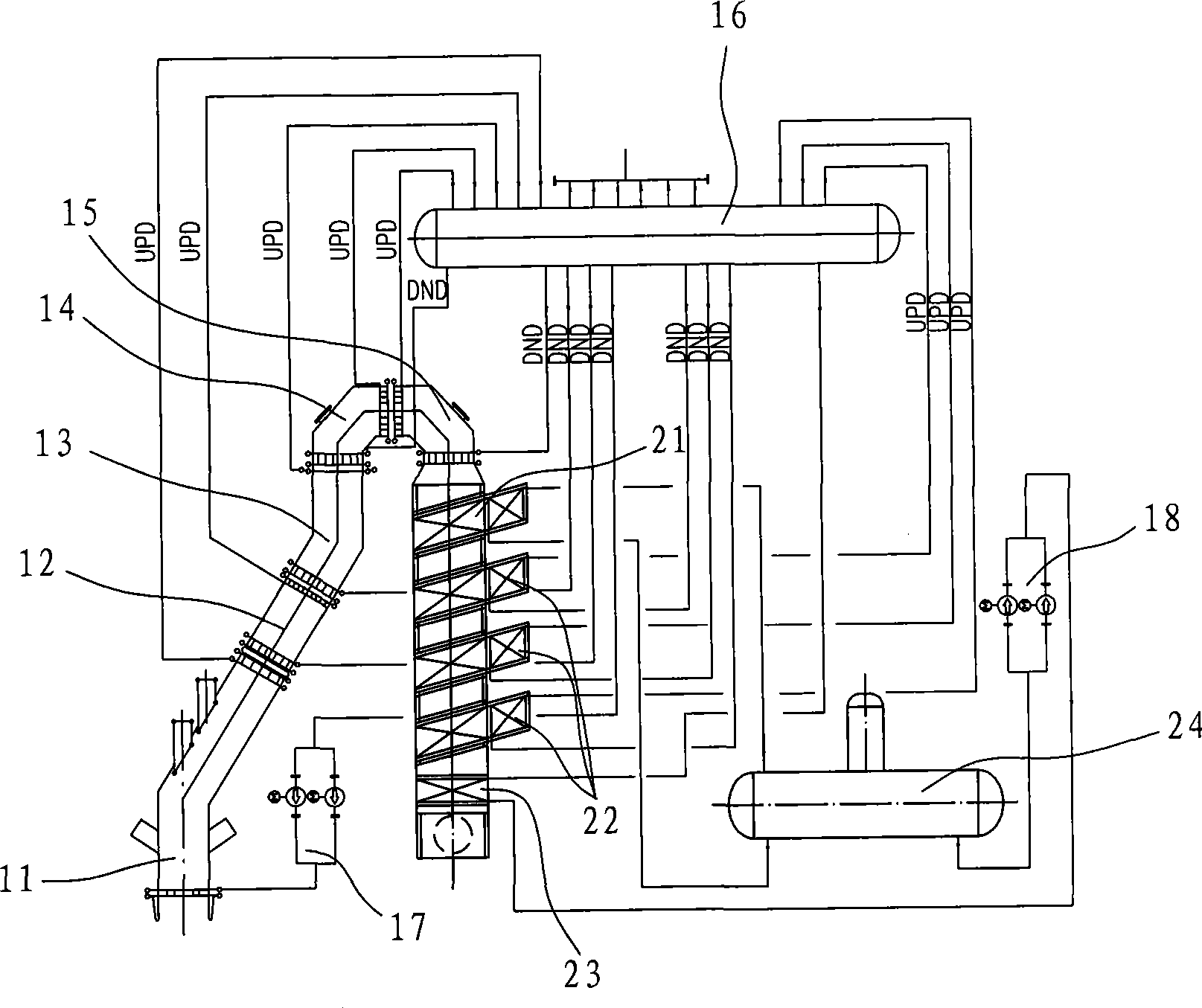

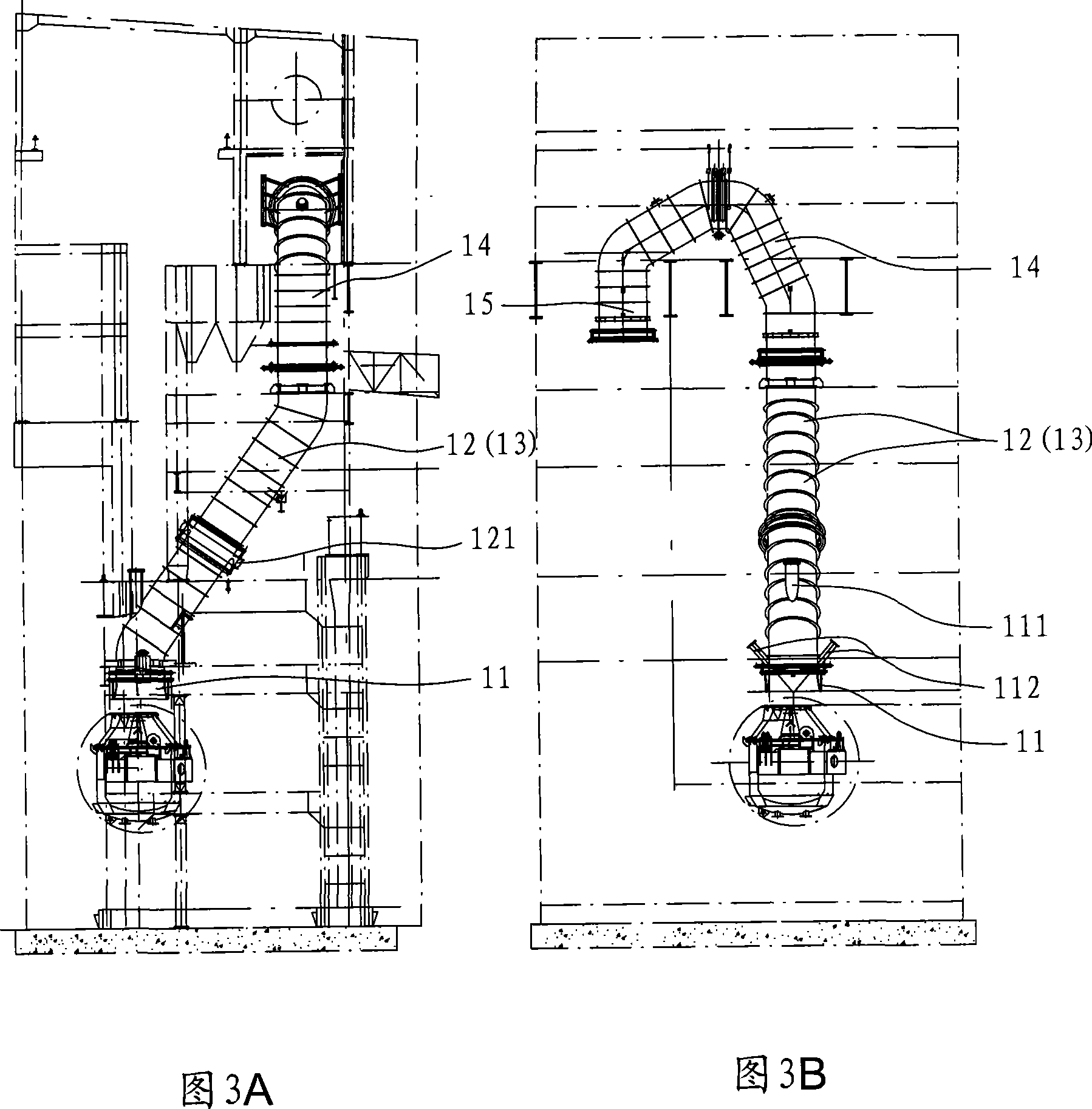

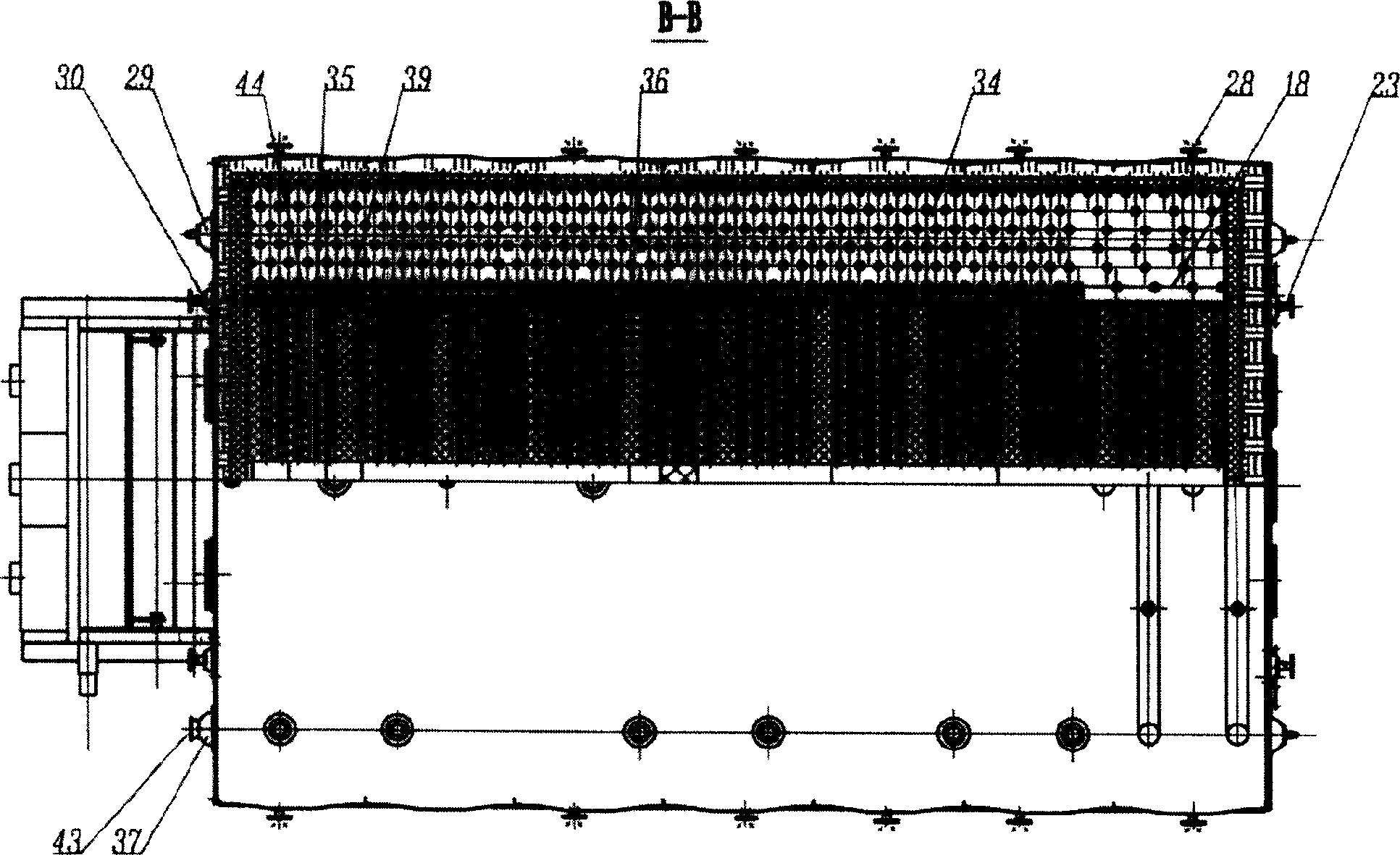

AOD converter flue gas waste heat recovery apparatus

ActiveCN101476015AReduce the temperatureAvoid pipe burstsManufacturing convertersEvaporationDeaerator

The invention provides an AOD convertor flue gas waste heat recovery apparatus comprising a high-temperature flue gas evaporation cooling part and a low-temperature flue gas waste heat recovery part. The high-temperature flue gas evaporation cooling part comprises a fire hole fixed segment smoke canal, a middle I segment smoke canal, a middle II segment smoke canal, a middle III segment smoke canal, an end segment smoke canal and a steam dome which are communicated one by one, and the middle I segment smoke canal, the middle II segment smoke canal, the middle III segment smoke canal, the end segment smoke canal, the steam dome and the ascending pipe and the corresponding descending pipe which are communicated with the upper side thereof together form a natural cycle system; the low-temperature flue gas waste heat recovery part comprises a pre-heater, a heat exchanger, a coal economizer, a deaerator and a water supply pump, wherein, the pre-heater and the deaerator form a natural loop through the connected ascending pipe and descending pipe for heating and deoxidizing the water in the deaerator and saving the steam consumption, the deoxidized water is then pumped by the water supply pump to the steam dome through the coal economizer, therefore, smoke temperature can be reduced sufficiently and heat can be recovered, in addition, because no recirculating pump is added to the heat exchanger singly, the electrical energy is saved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

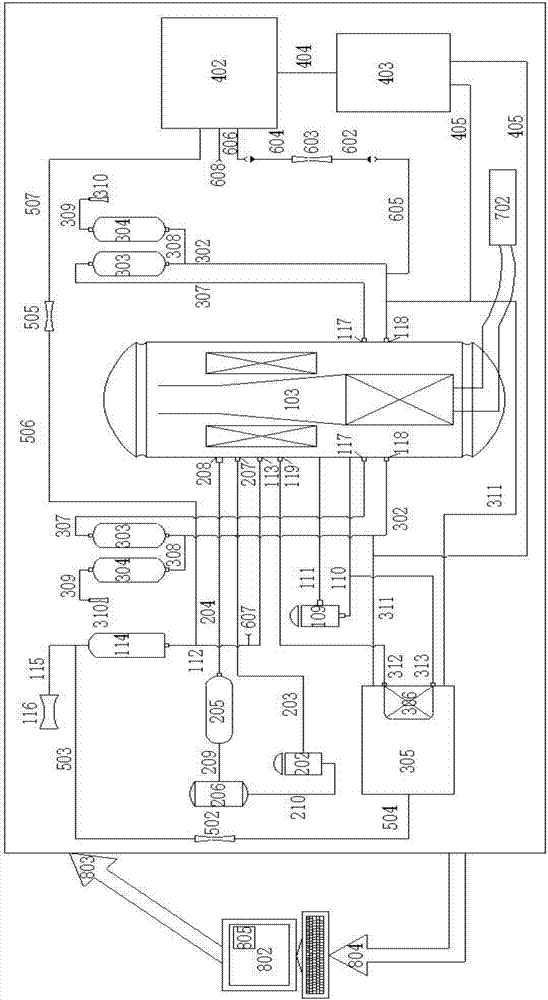

Overall thermal hydraulics performance simulator for engineered safety system of reactor

ActiveCN107093474AHigh design parametersRealize automatic trigger controlNuclear energy generationNuclear monitoringLow voltageSystem pressure

The invention discloses an overall thermal hydraulics performance simulator for an engineered safety system of a reactor. The simulator comprises a coolant experiment system for a simulation experiment of coolants, a vapor condensation system, a passive safety injection and waste heat removal experiment system, a recycling experiment system, a pressure relief experiment system, a coolant loss accident experiment system, a power supply system and a thermal parameter acquisition control system. According to the simulator disclosed by the invention, whole-process continuous experimental study is realized from totally seven phases such as a high-power normal operating state, total-pressure burst blow, high-pressure injection, system pressure relief, medium pressure safety injection, low-pressure injection and establishment of low-voltage long-term natural cycle. The continuous experimental study from the high-power normal operating state to establishment of a passive waste heat removal system in the station blackout phase reaching the period within 72 hours after the accident is realized. The simulator has the advantages of high design parameter and wide parameter range, and comprehensively covers the passive engineered safety system of the conventional novel reactor, the adjustability and controllability of the device are excellent, and the adjustability and controllability of a simulated accident sequence are excellent.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

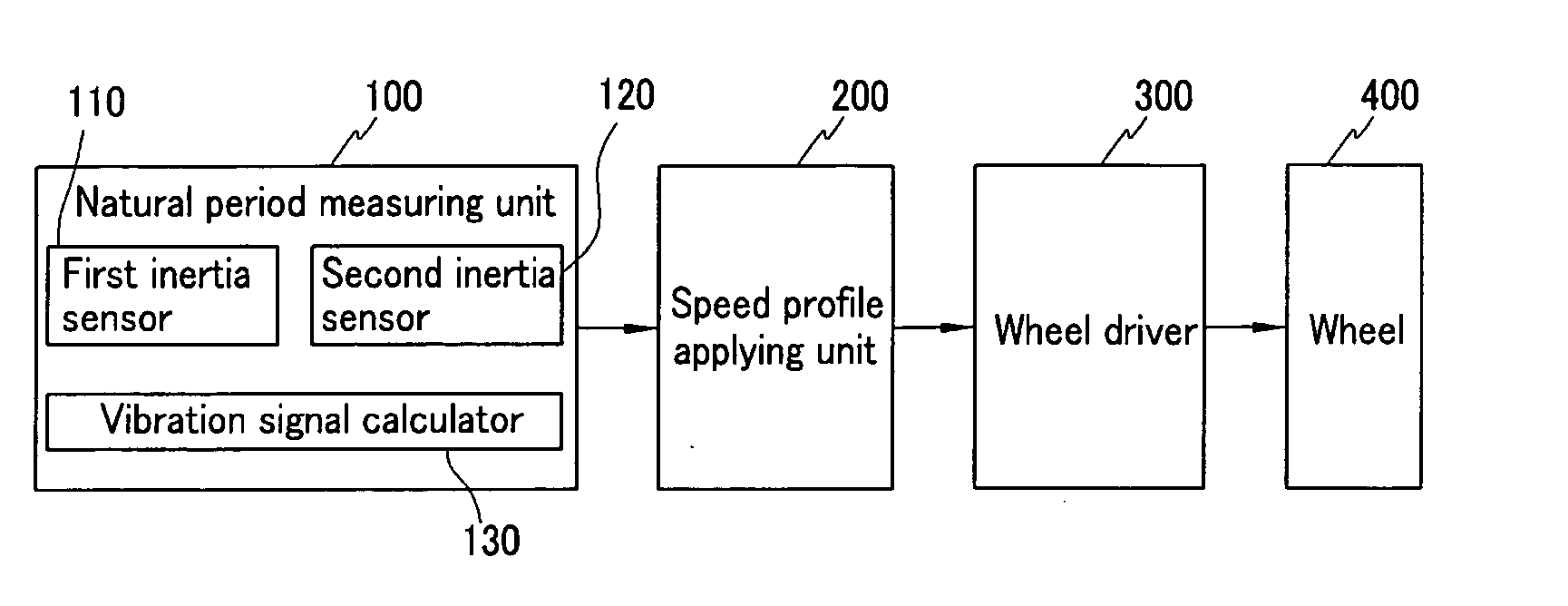

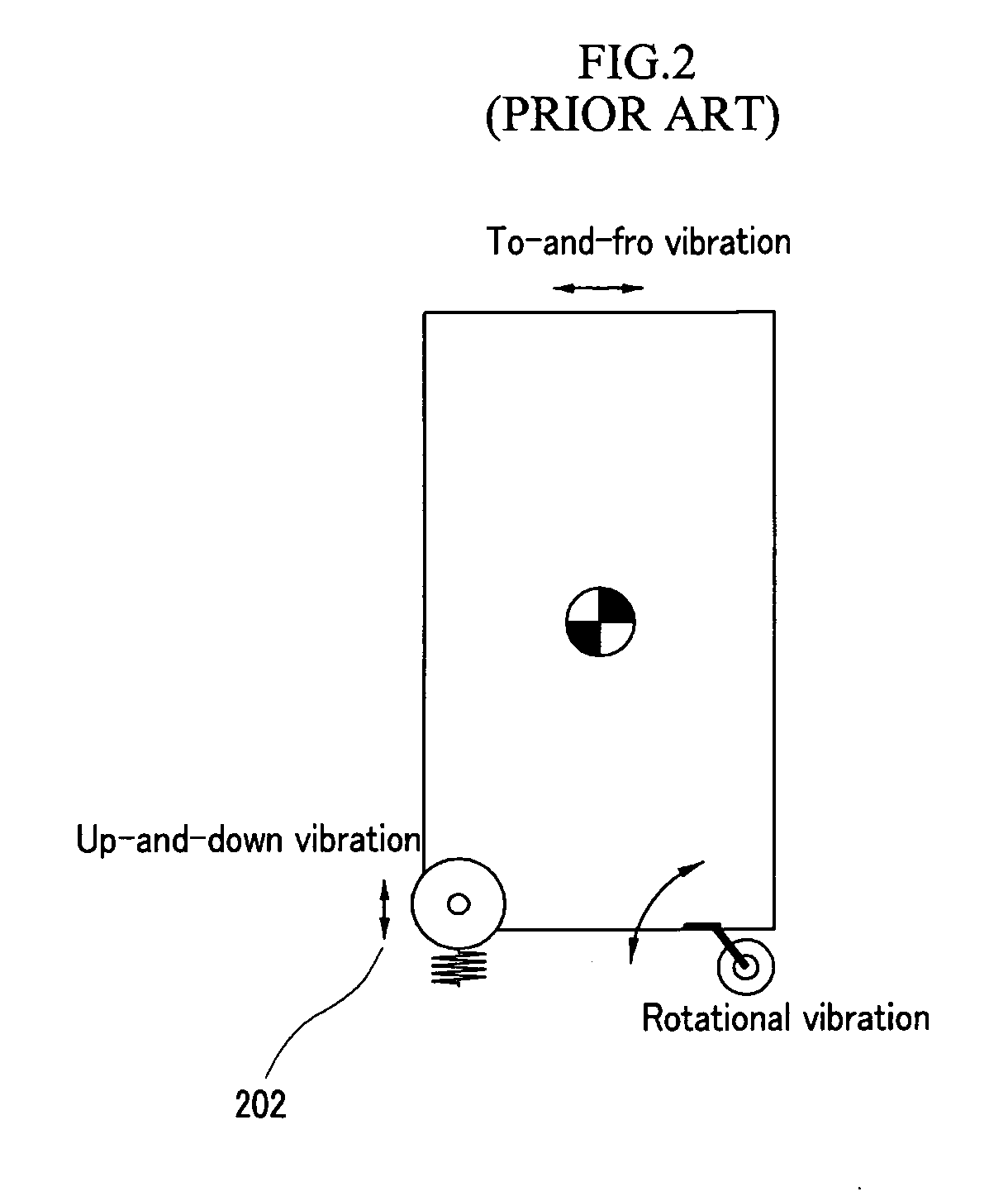

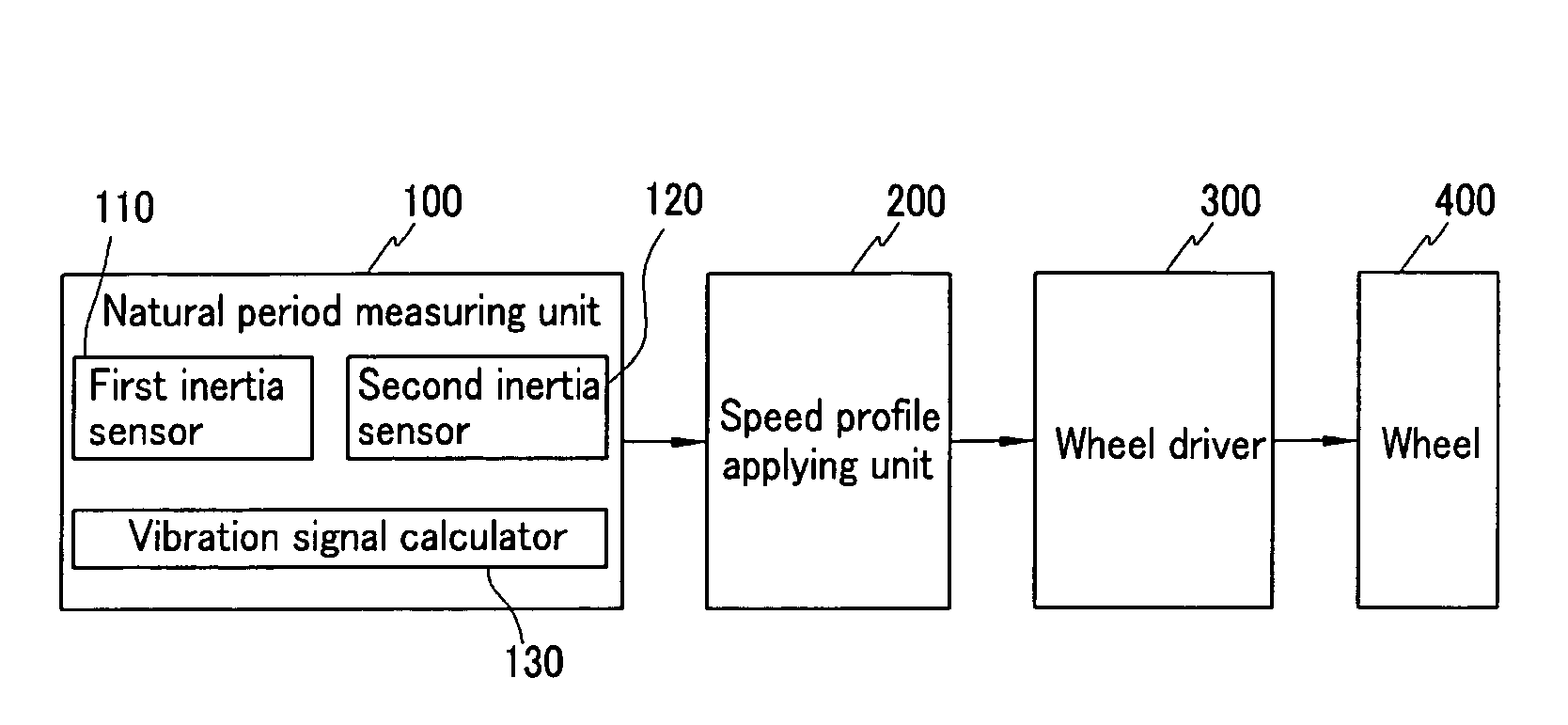

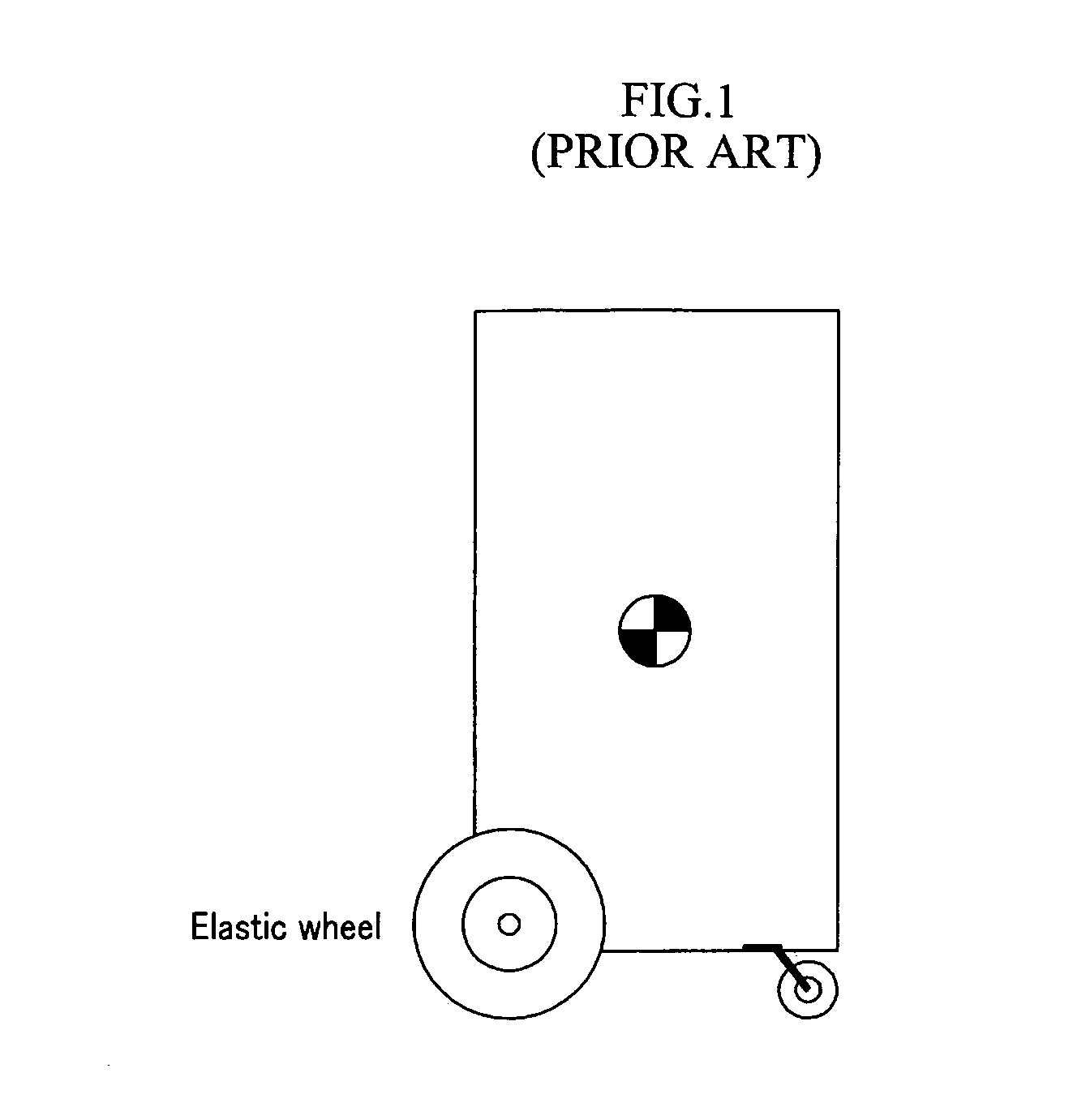

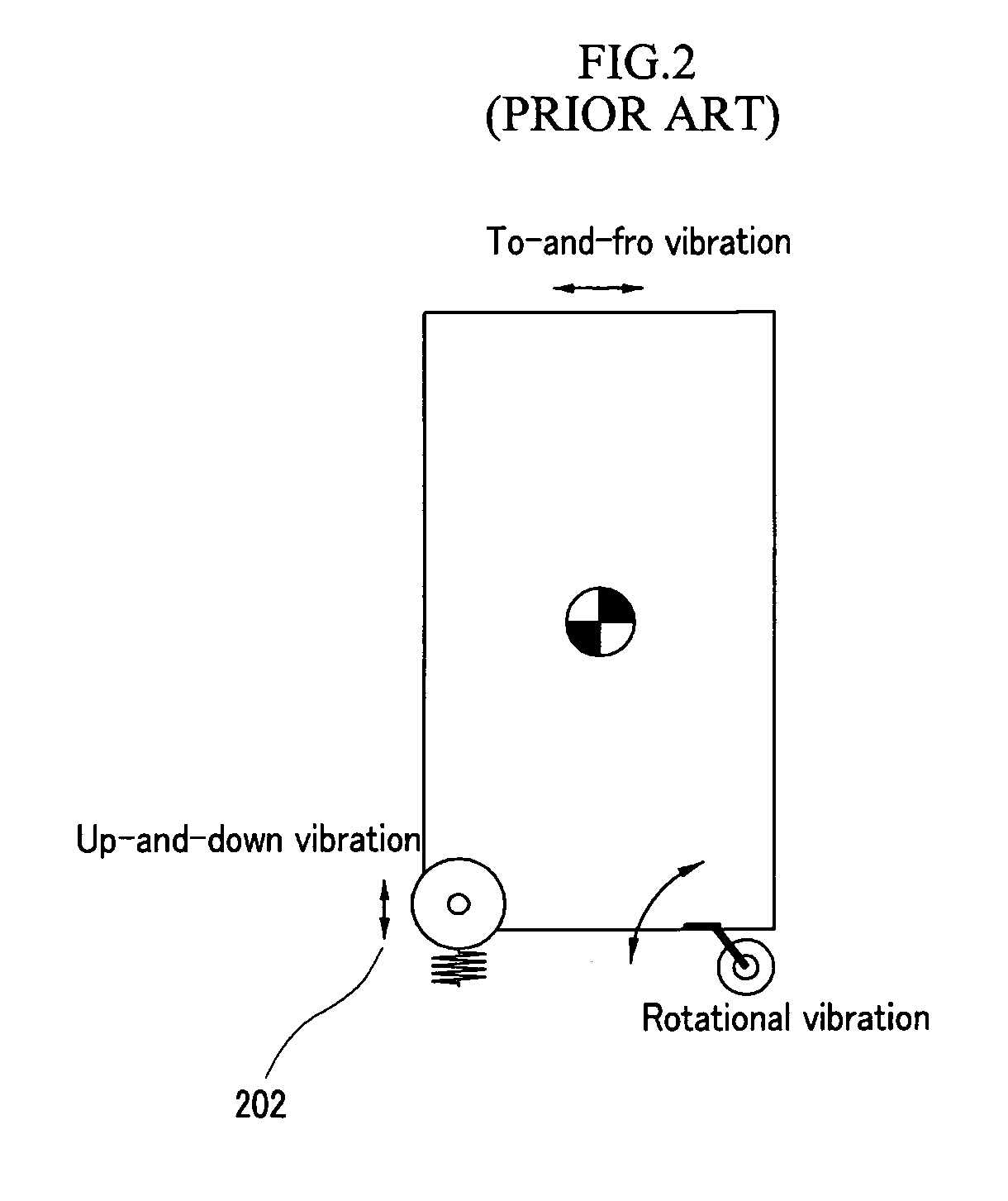

Mobile system and driving method thereof

The present invention relates to a mobile system and a moving method of the mobile system. According to the present invention, a natural period is measured from a vibration component signal generated by a force due to acceleration / deceleration of wheels, and the mobile system moves by applying an acceleration profile containing an acceleration period or a deceleration period based on the natural period. Therefore, the acceleration profile based on the natural period is applied such that vibration that is visible to a user is not generated during acceleration and deceleration of the mobile system. As a result, quality of the mobile system is improved.

Owner:ELECTRONICS & TELECOMM RES INST

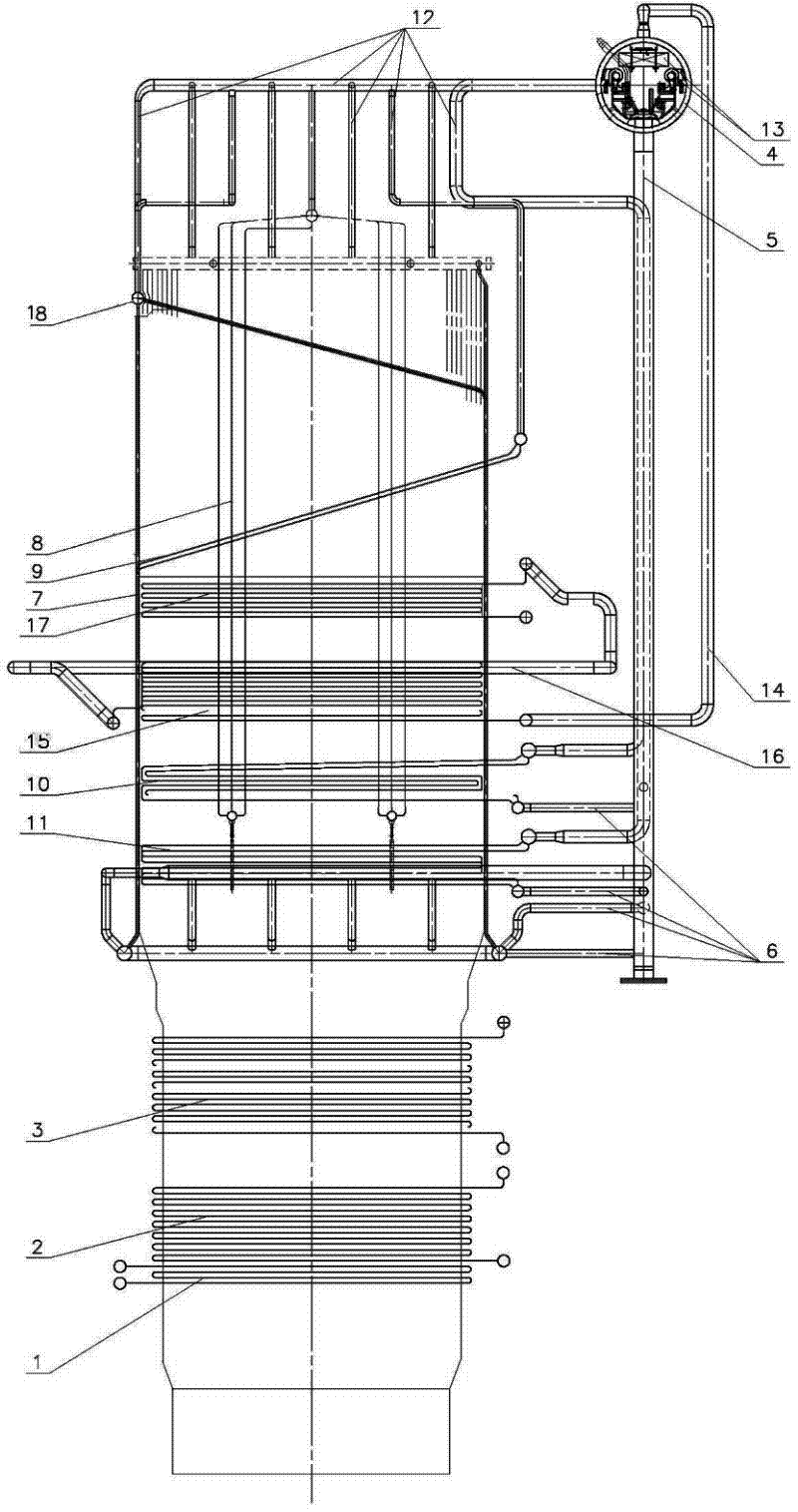

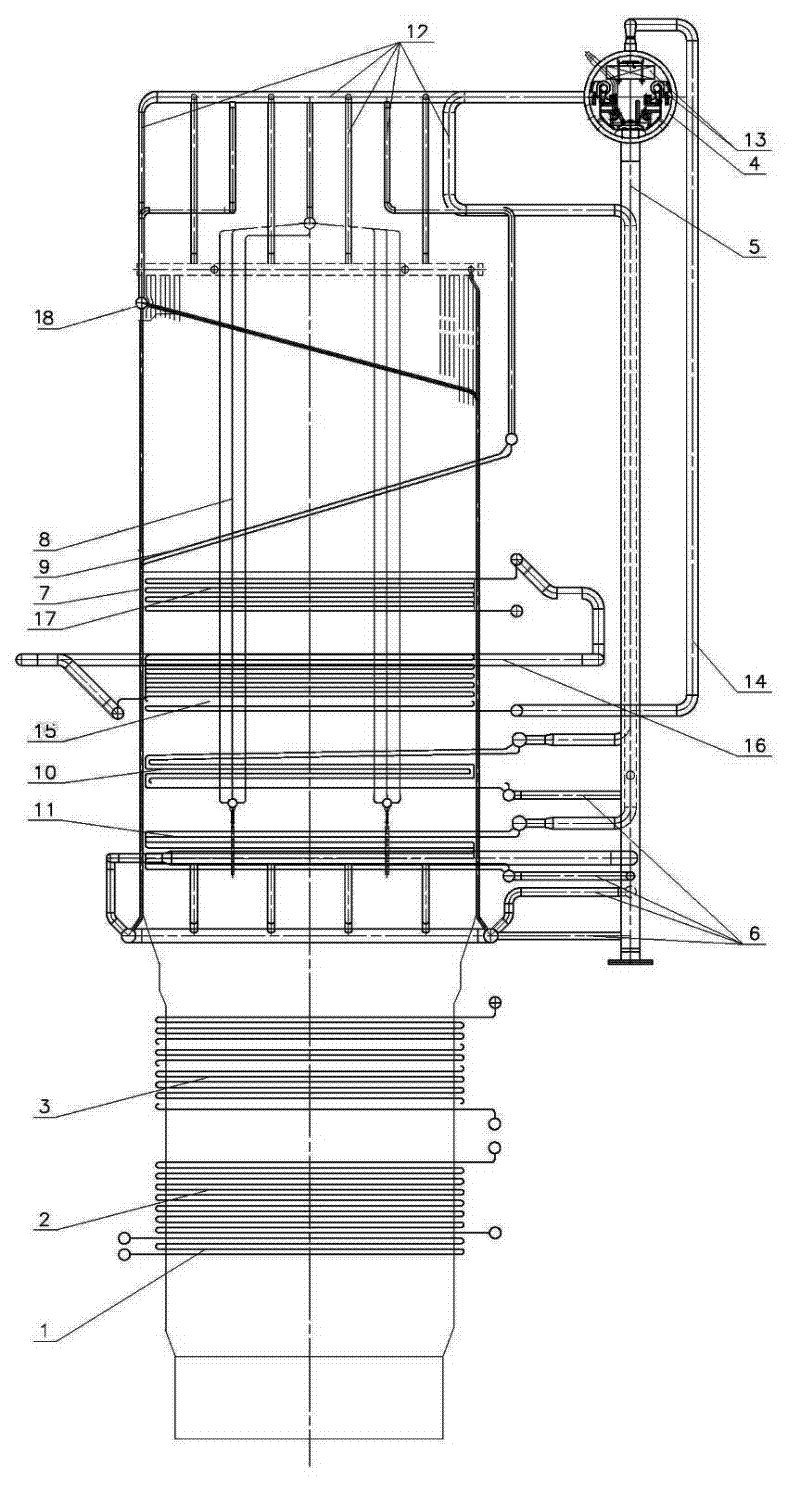

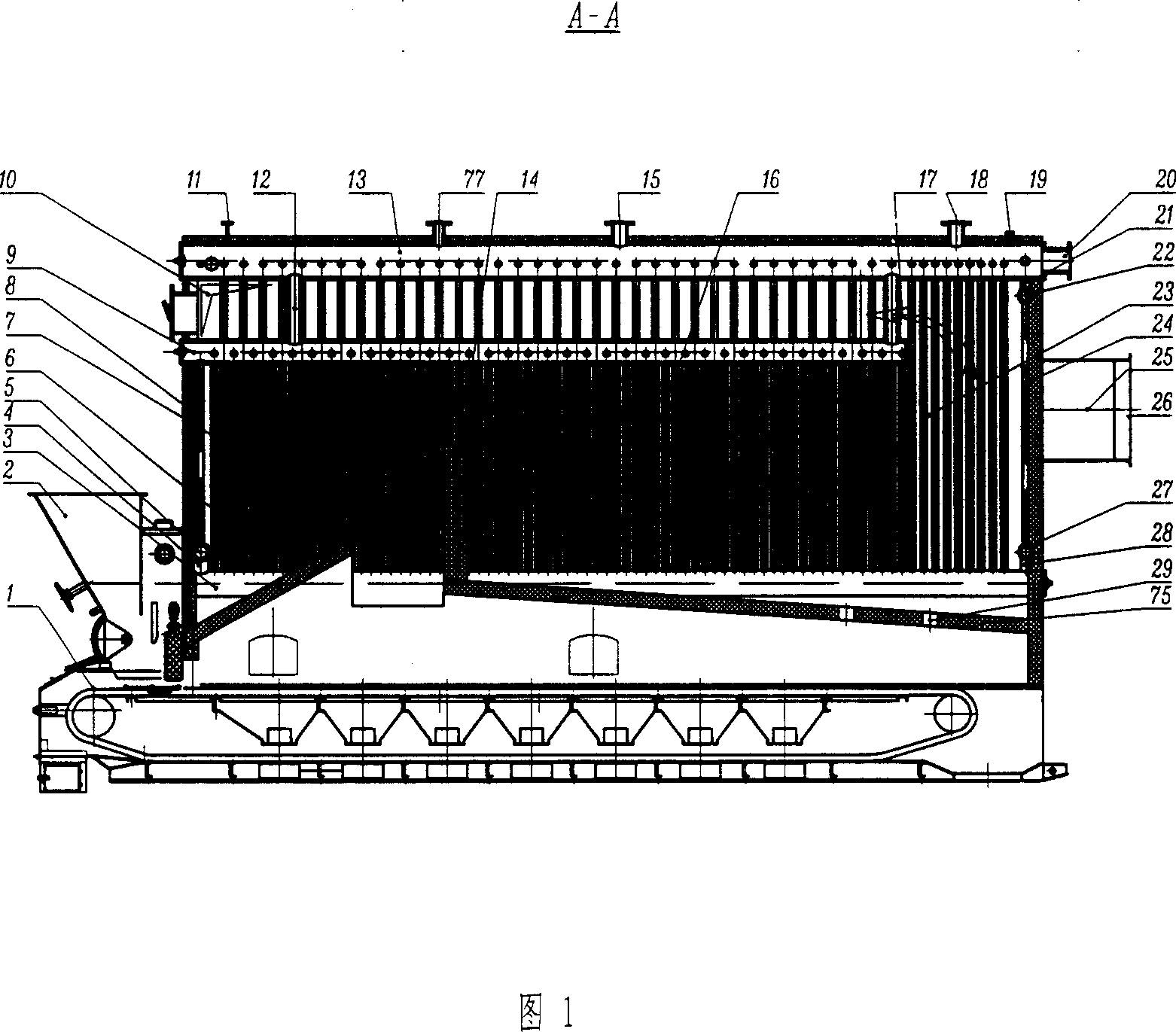

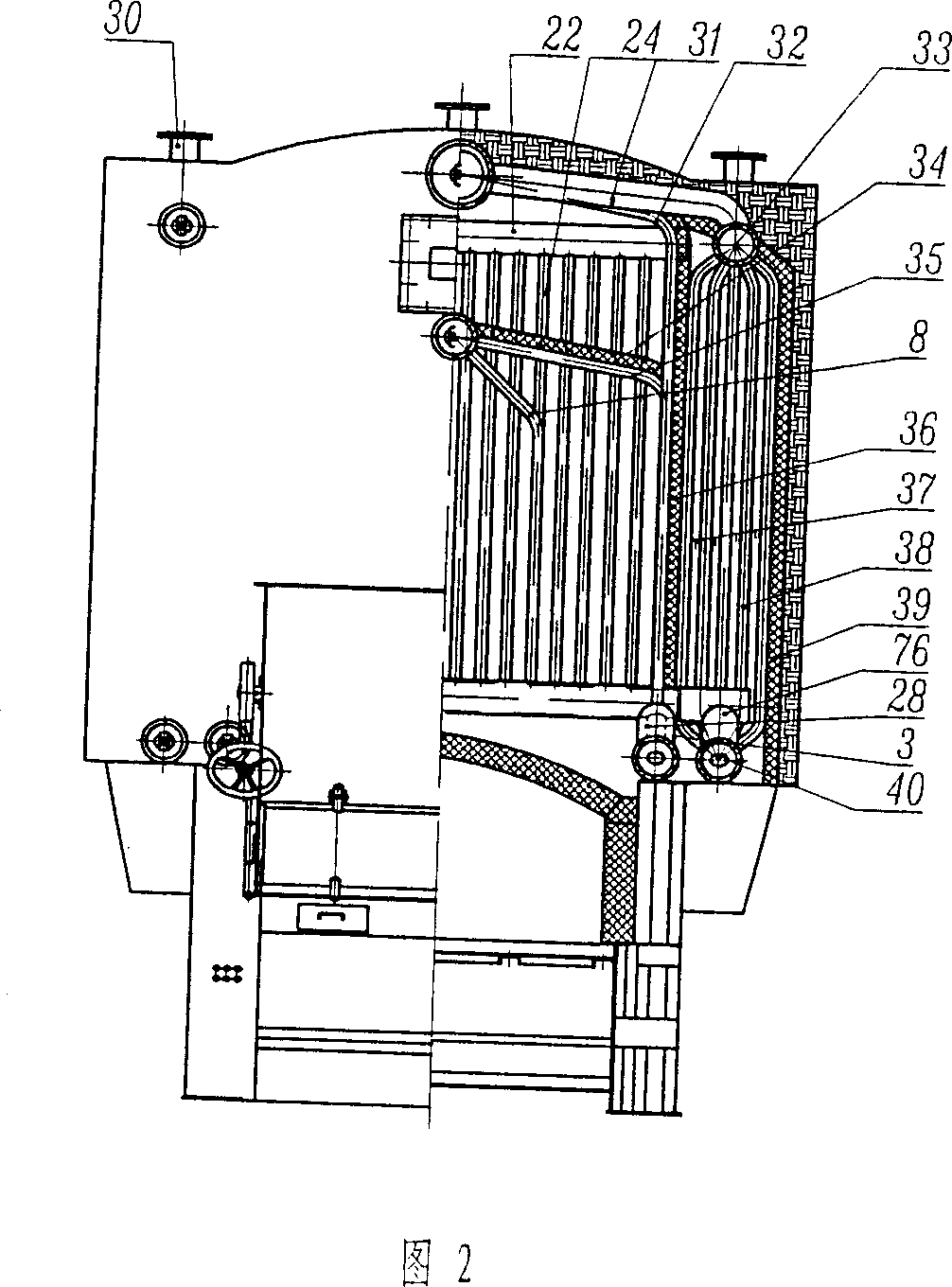

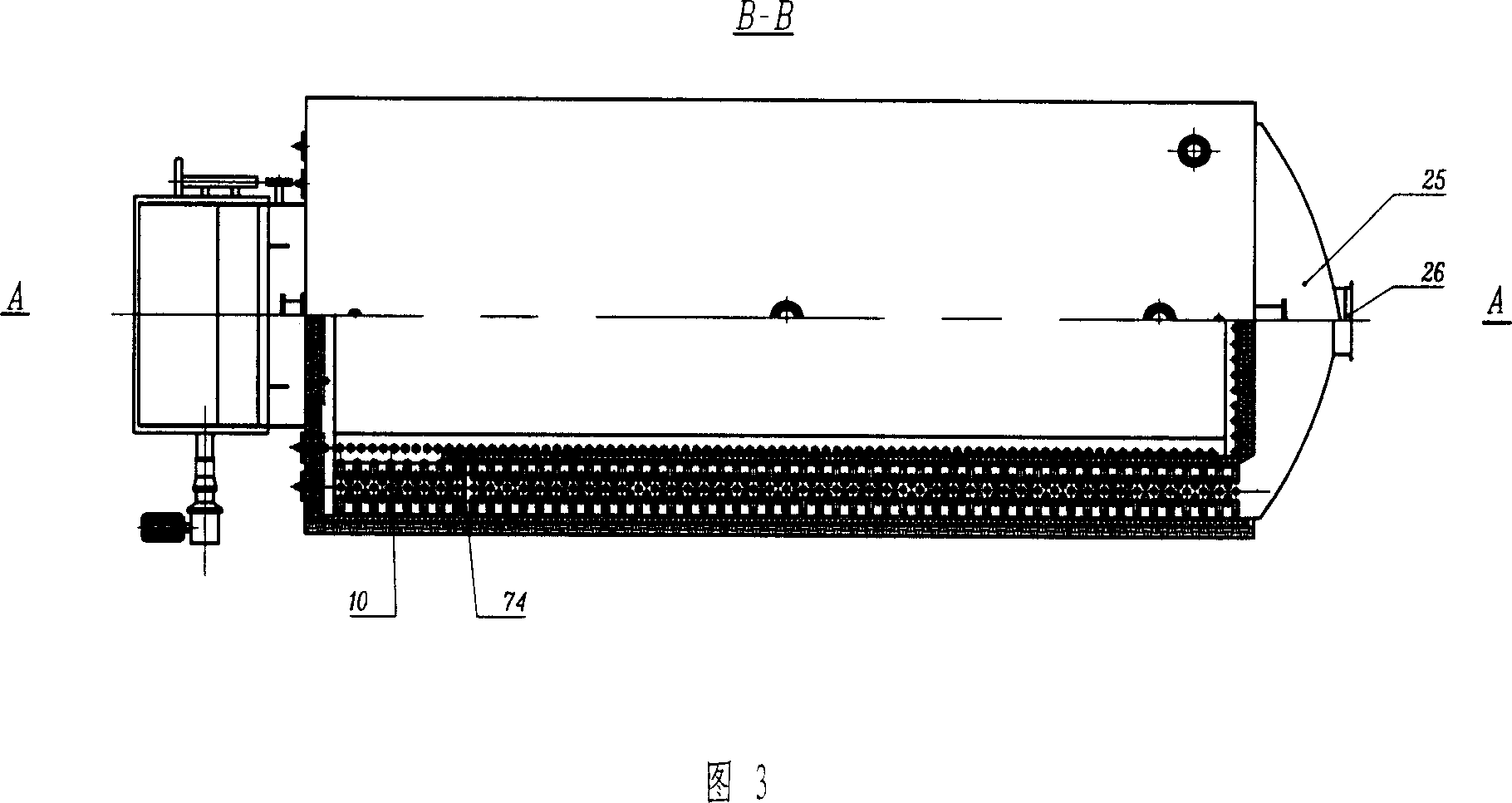

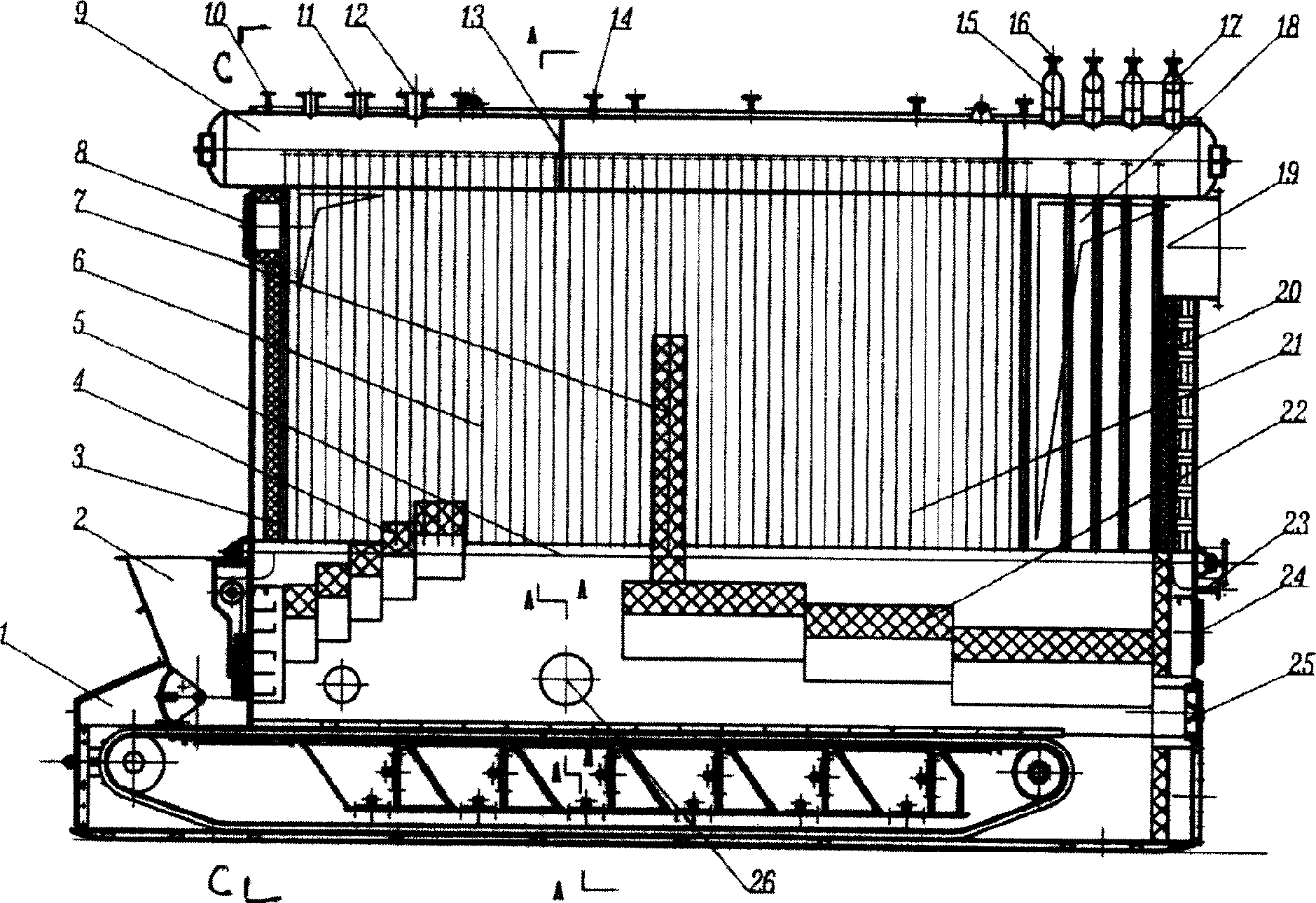

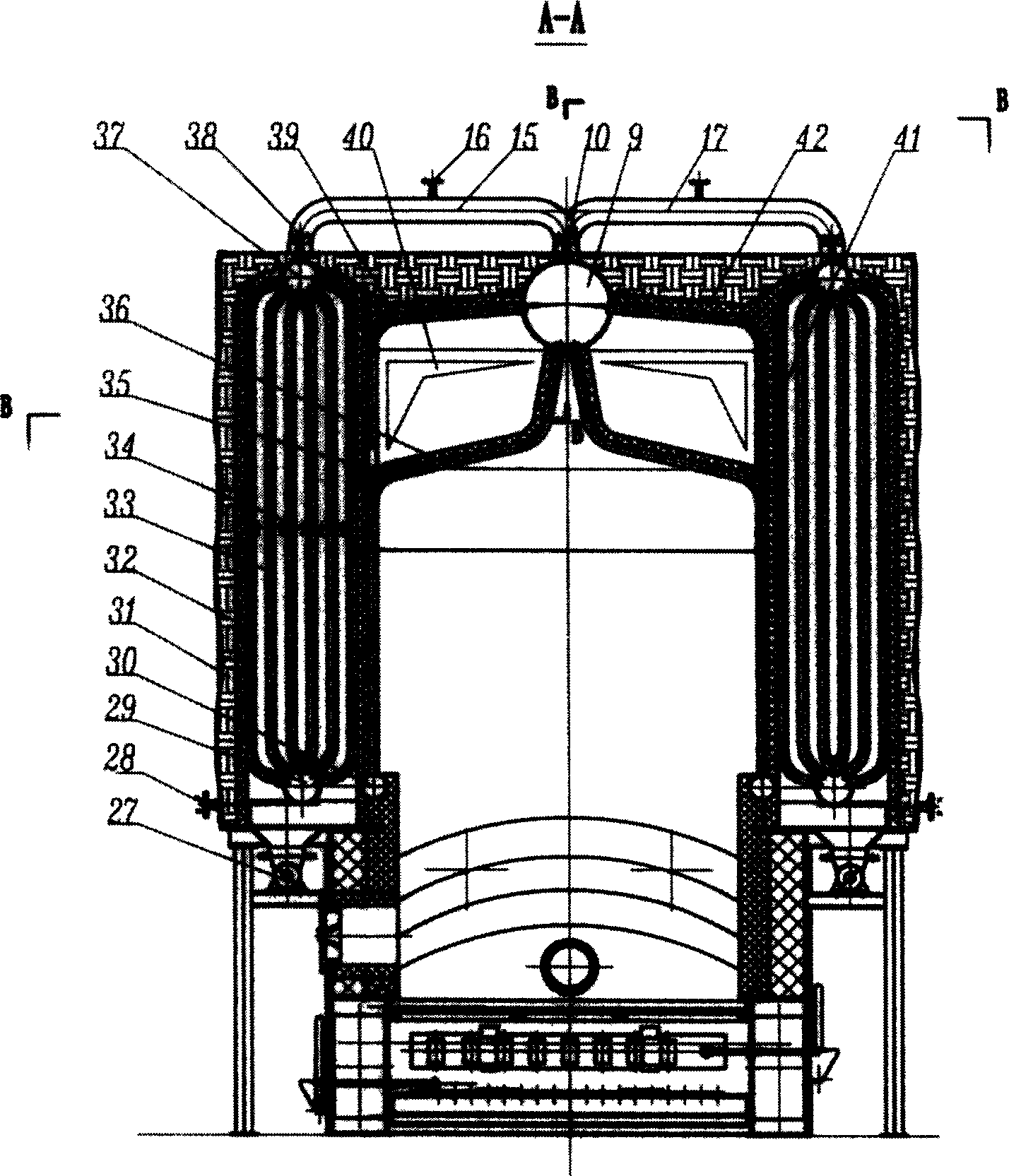

Tamping coke high-pressure high-temperature CDQ (coke dry quenching) waste heat boiler

InactiveCN102374515AAvoid wear and tearSolve Vibration ProblemsSteam superheatersSteam boilersNatural cycleDeaerator

The invention relates to a tamping coke high-pressure high-temperature CDQ (coke dry quenching) waste heat boiler which utilizes high-temperature waste heat of circulation inert gas to generate high-pressure high-temperature steam in CDQ for a tamping coke oven. The waste heat boiler is composed of a hot-water heating section, a vaporization system and a superheating system, wherein the hot-water heating section is mainly composed of an auxiliary economizer, a low-temperature economizer, and a high-temperature economizer which are all in a spiral extended surface tube structures; the auxiliary economizer is arranged on the tail of the boiler, and the auxiliary economizer is connected with a thermal deaerator used for deoxidizing water which is not deoxidized after the effluent of the economizer; the thermal deaerator is respectively connected with the low-temperature economizer, and the high-temperature economizer and finally connected with a boiler barrel of a vaporization system through a connecting pipe sequentially; a natural cycle system is adopted for the waste heat boiler provided by the invention, and a forced circulation pump is not arranged, the potential fault point is reduced, and the power consumption is saved; and the superheating system comprises a low temperature superheater, an attemperator, and a high-temperature superheater, the high-temperature superheater is arranged in a downstream manner, the heat of the stable high-temperature superheater is transferred uniformly, thereby avoiding overtemperature booster of a superheater tube.

Owner:HANGZHOU HANGGUO INDUSTRIAL BOILER CO LTD

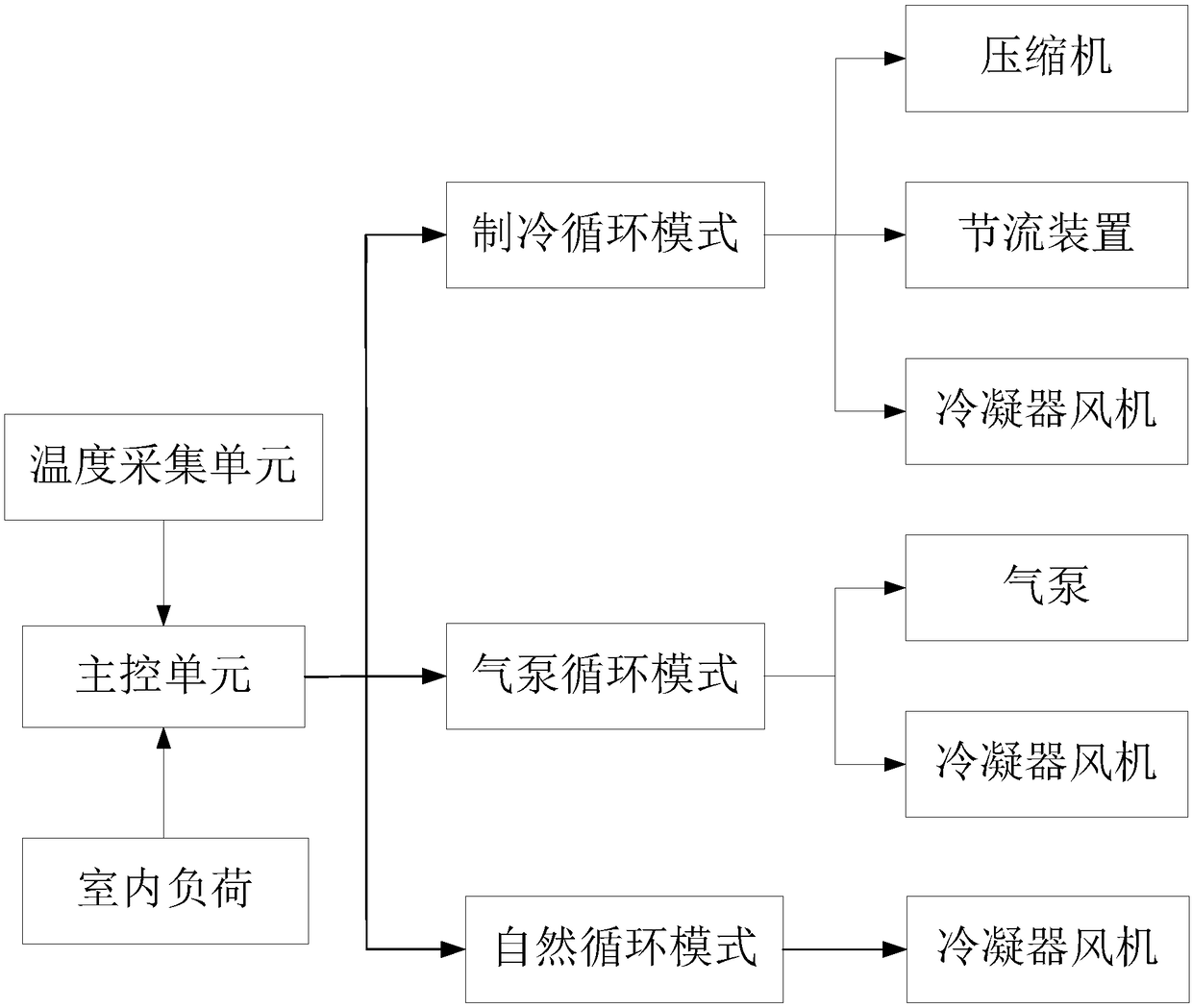

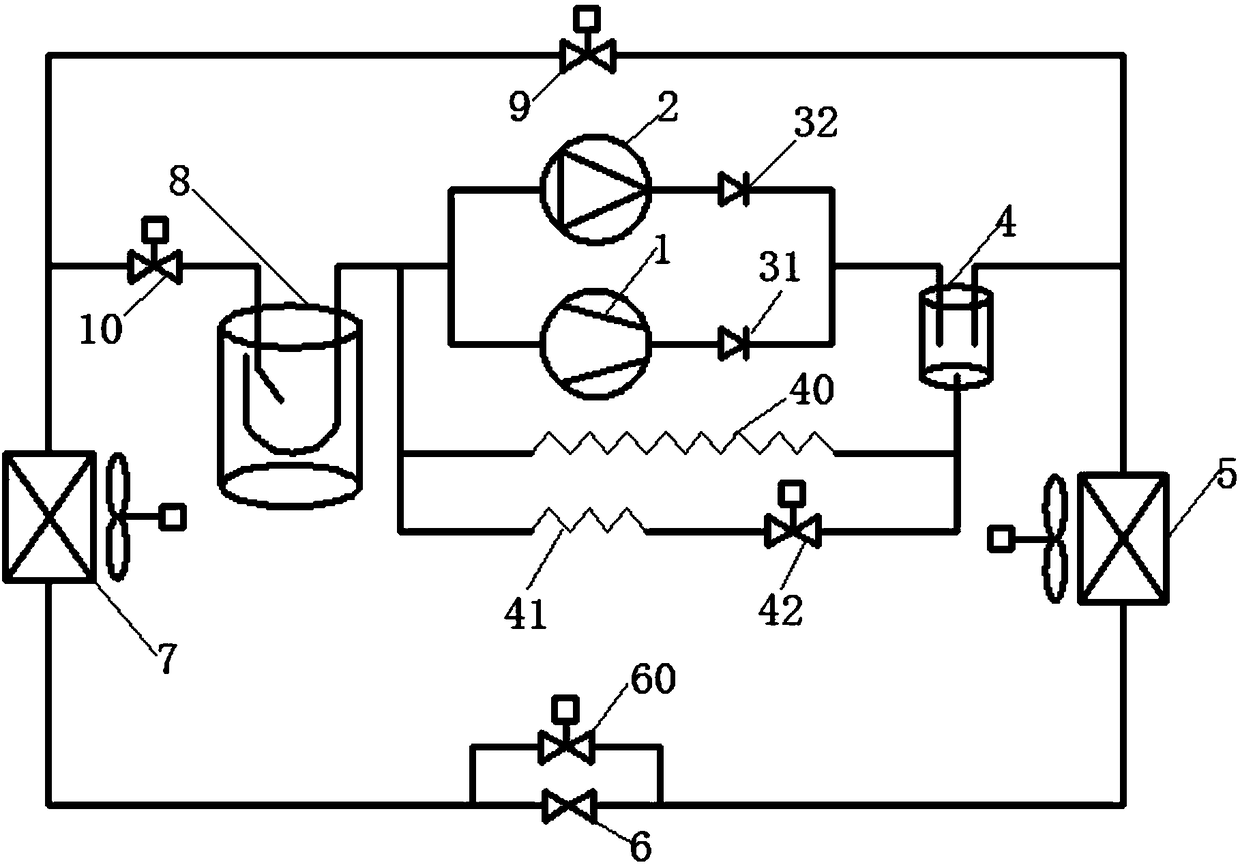

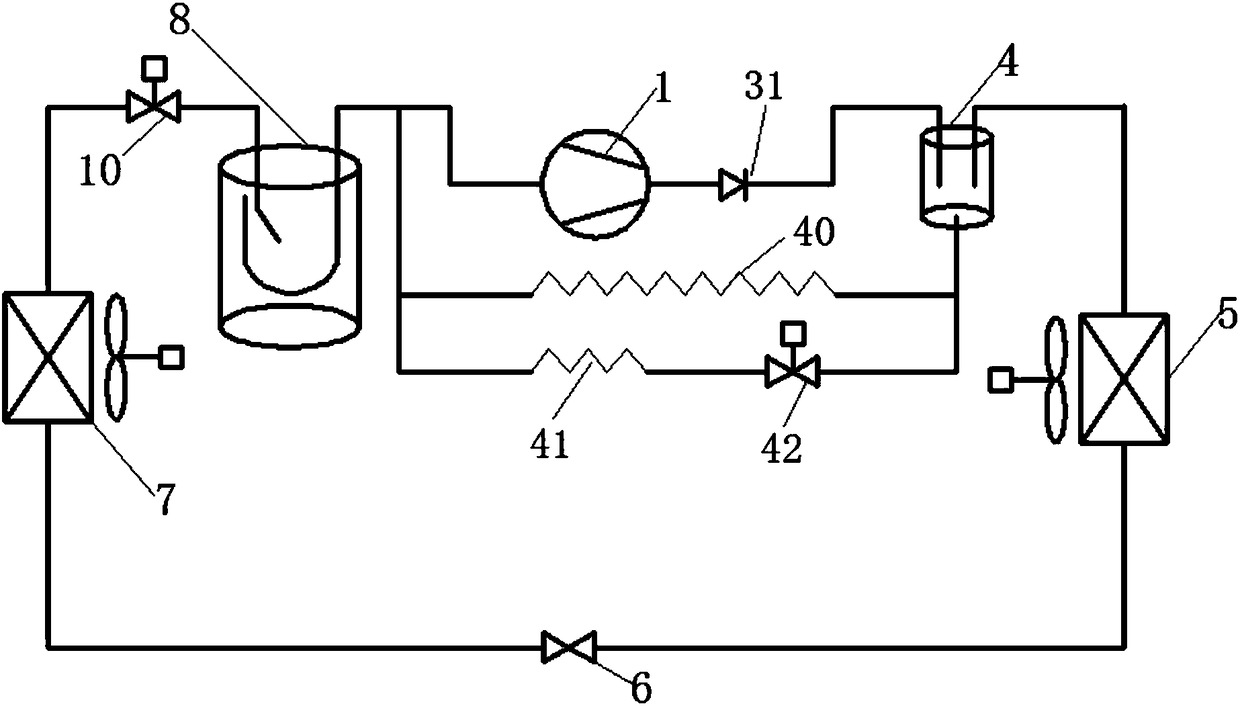

Control method of multimode machine room air conditioning system

InactiveCN108278738ALower unit costGuaranteed uptimeMechanical apparatusSpace heating and ventilation safety systemsAir pumpEngineering

The invention discloses a control method of a multimode machine room air conditioning system. Outdoor temperatures fall into three different functional zones, and a cold source system is correspondingly switched to run in a refrigeration cycle mode, a gas pump cycle mode and a natural cycle mode according to the functional zone into which the outdoor temperature falls. According to the control method, the running states of a compressor, an air pump, a throttling device and a condenser can be adjusted according to the outdoor temperature and an indoor load, an outdoor natural cold source is employed in a low-temperature season by replacing a compression refrigerating cycle with the gas pump cycle mode and the natural cycle mode, the unit cost of an existing compound-type air conditioning system is lowered, the system structure is simplified, and the maintenance difficulty is lowered; in addition, running energy consumption is lowered substantially by effectively employing outdoor natural cold sources at day and night, in transition seasons and in winter, and the control method has the excellent effects of energy conservation and emission reduction.

Owner:CLIMAVENETA CHATUNION REFRIGERATION EQUIP SHANGHAI

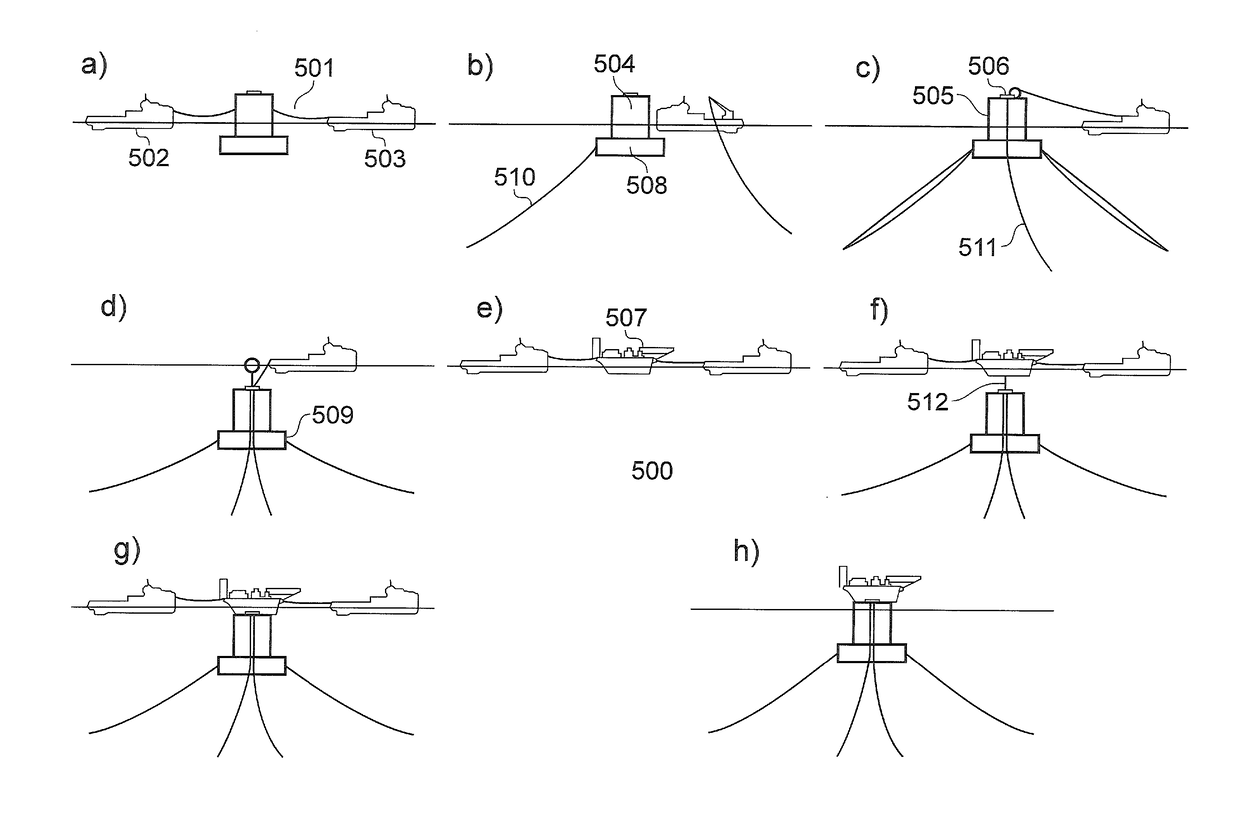

Floating production unit and method of installing a floating production unit

ActiveUS20180141625A1Small amount of equipmentEquipment structureDrilling rodsVessel partsHydrocotyle bowlesioidesMarine engineering

The present disclosure relates to an unmanned floating production unit (300) and method of installing a floating production unit comprising a deck structure (301) for mounting equipment for processing hydrocarbons, and a hull structure (302) formed from a first section (303) and a second section (306), wherein the second section (306) is wider than the first section (303). The floating production unit (300) according to the present disclosure can provide a compact unit, which has dimensions which can lead to a heave natural period outside an area of significant wave energy, and as a result, it has substantially reduced and improved hydrodynamic responses. The floating production unit is configured to be small and lightweight, and can be fabricated, launched and towed to the installation site in two parts, without the requirement for heavy lifting or construction machinery, thus lowering manufacturing costs. In addition, the two parts of the floating production unit can be joined together at the installation site using a buoyancy and ballasting based technique. The floating production unit is designed to be unmanned during routine production operations, thus ensuring operating costs are low.

Owner:CRONDALL ENERGY CONSULTANTS LTD

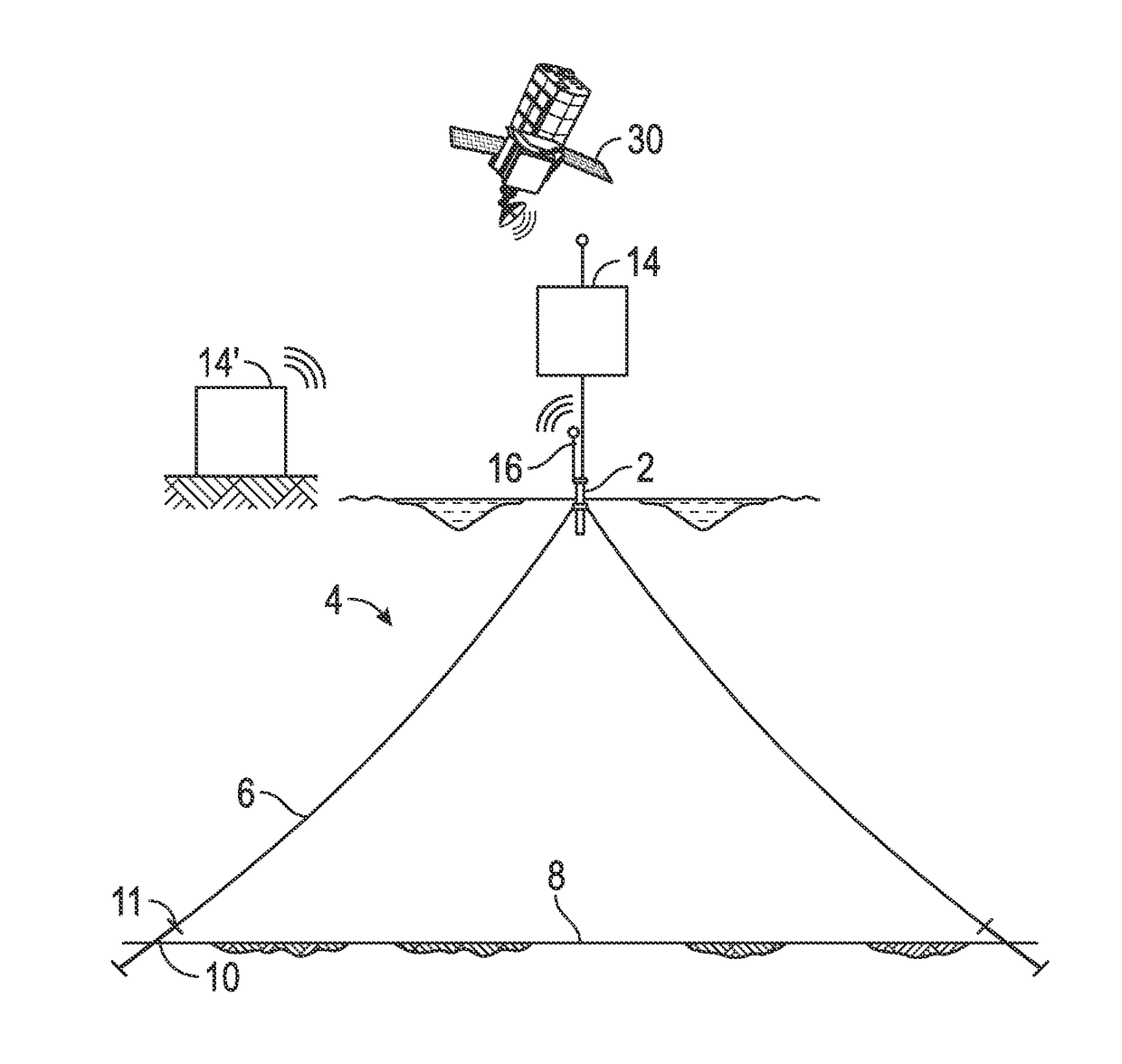

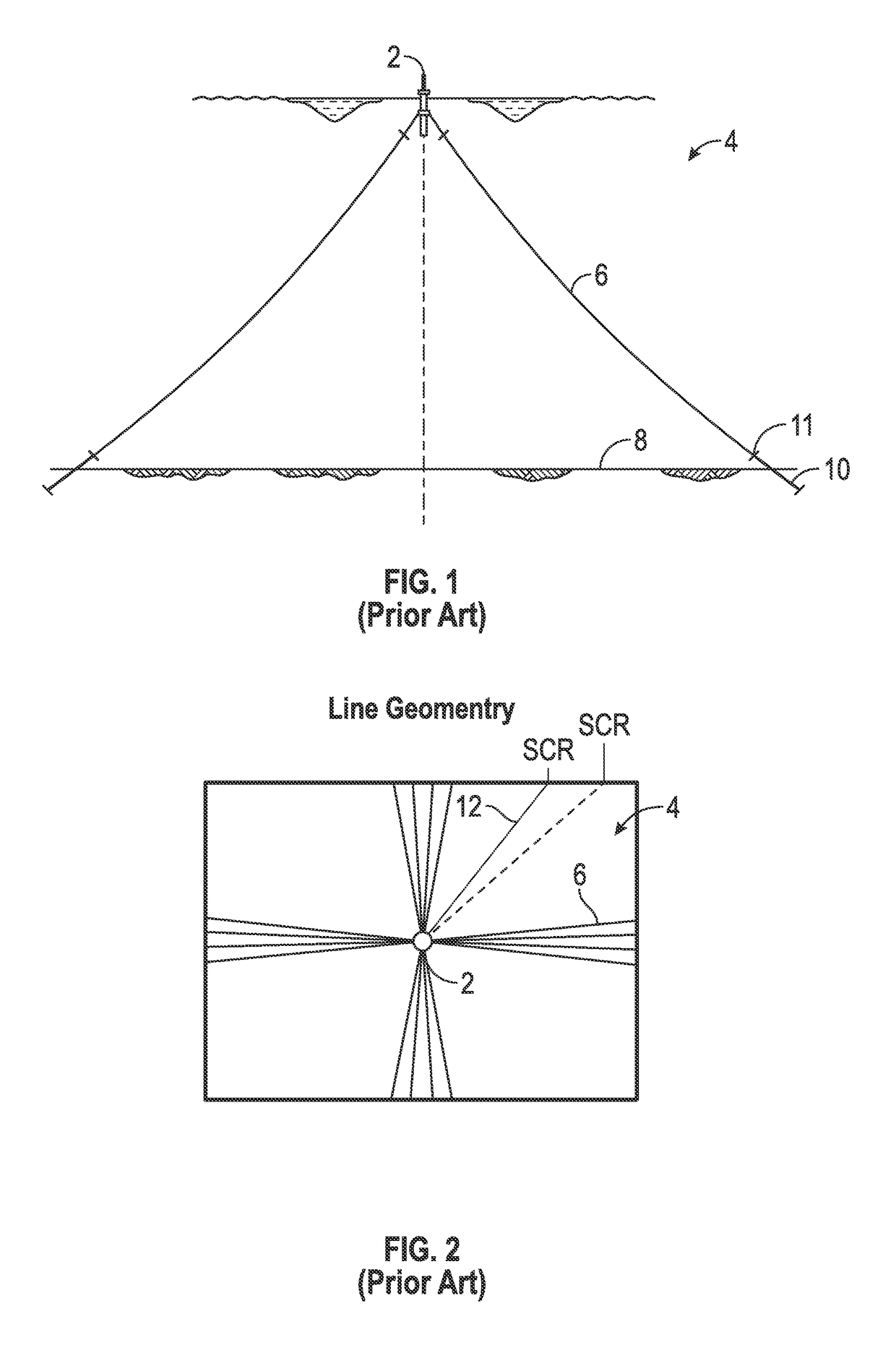

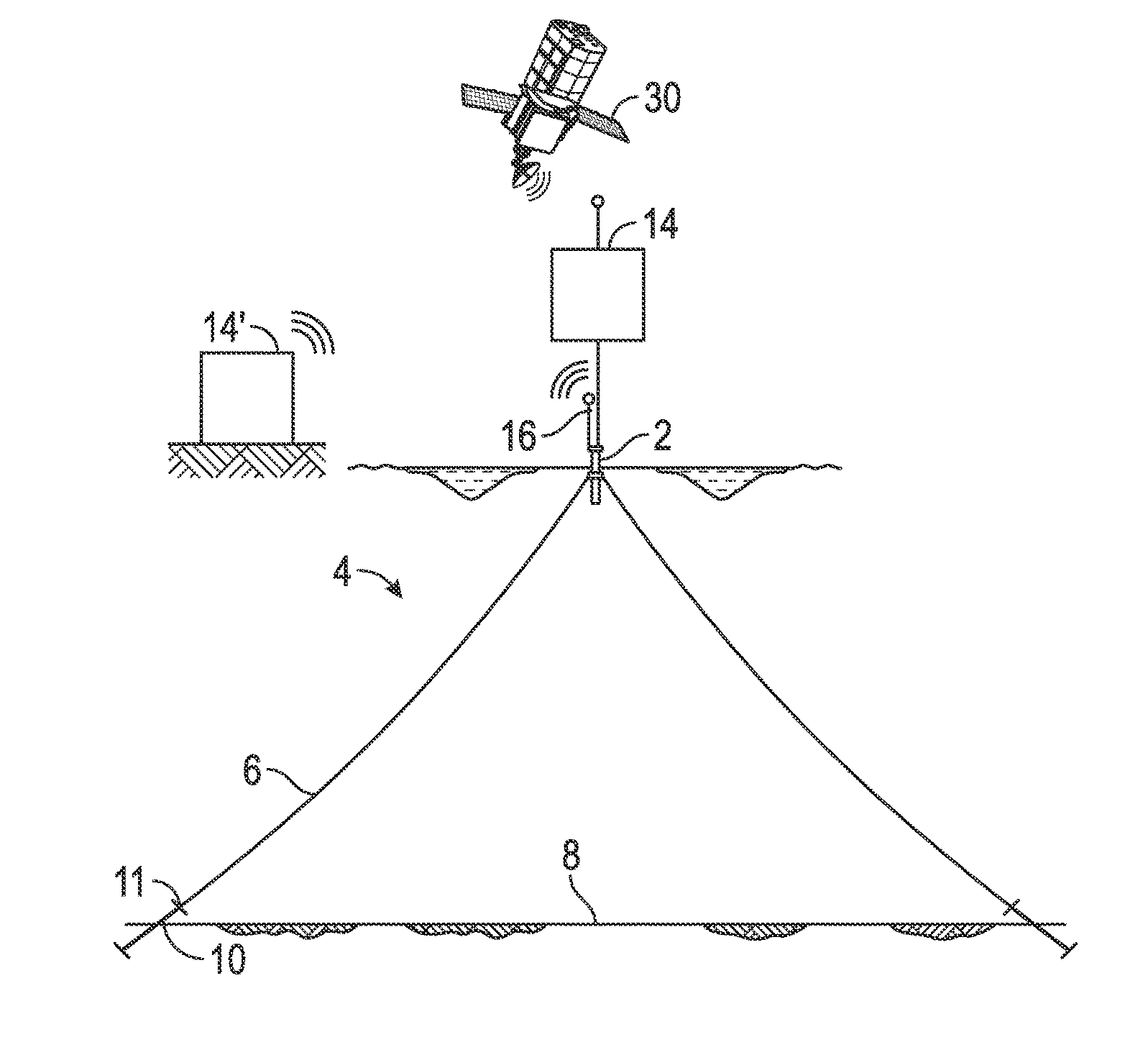

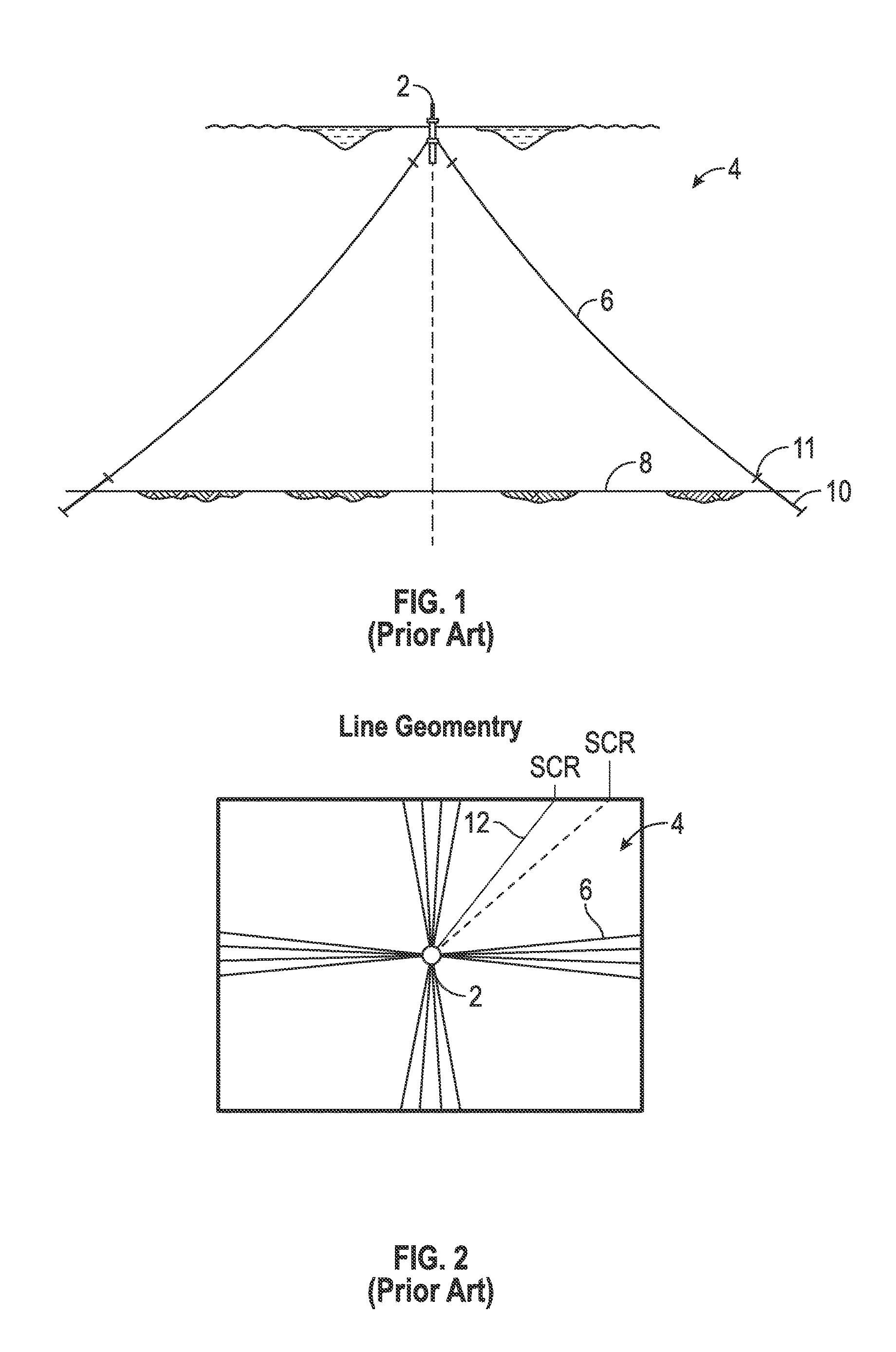

Monitoring system and method for vessel mooring

ActiveUS9671231B2Navigational calculation instrumentsSatellite radio beaconingMooring systemMonitoring system

The present disclosure provides a system and method of monitoring a mooring system for a floating vessel using the time of the natural period independent of environmental conditions. The natural period can be calculated and / or established experientially over time by measuring movement of the vessel to establish the natural period at given geographical positions of a secure and intact mooring system. The natural period can be monitored based on the time to complete a natural period. A change in a mooring line stiffness, whether by a failure, stretching, a degradation of the mooring line integrity, or a significant displacement of the anchoring point, will be translated into a different natural period with a different time. By monitoring the natural period for a given geographical position (and corresponding heading) to be compared to the theoretical values (and / or previous recorded values) it is then possible to assess that at least a portion of the mooring system has failed or that a significant damage has occurred.

Owner:TECH FRANCE SA

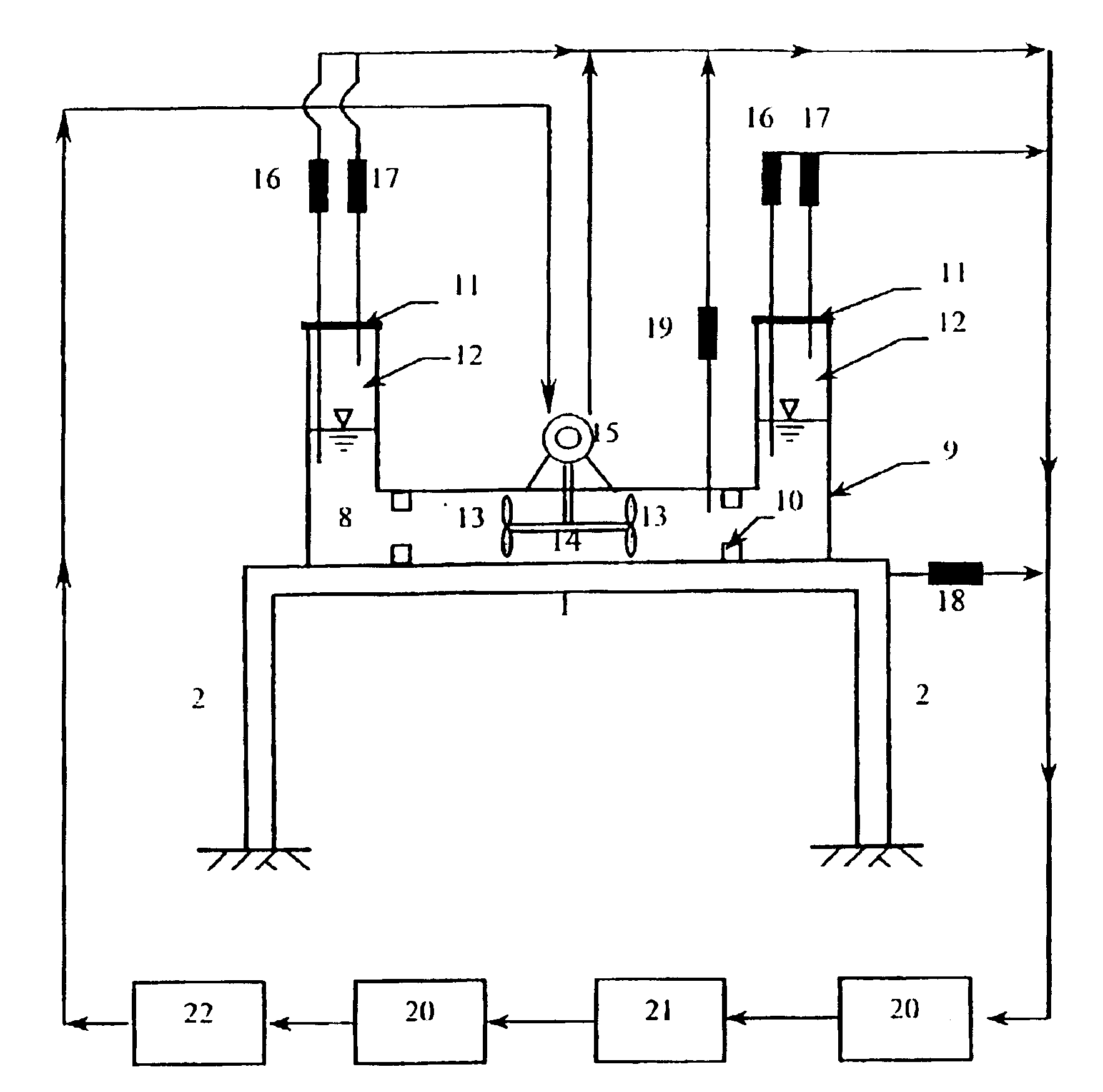

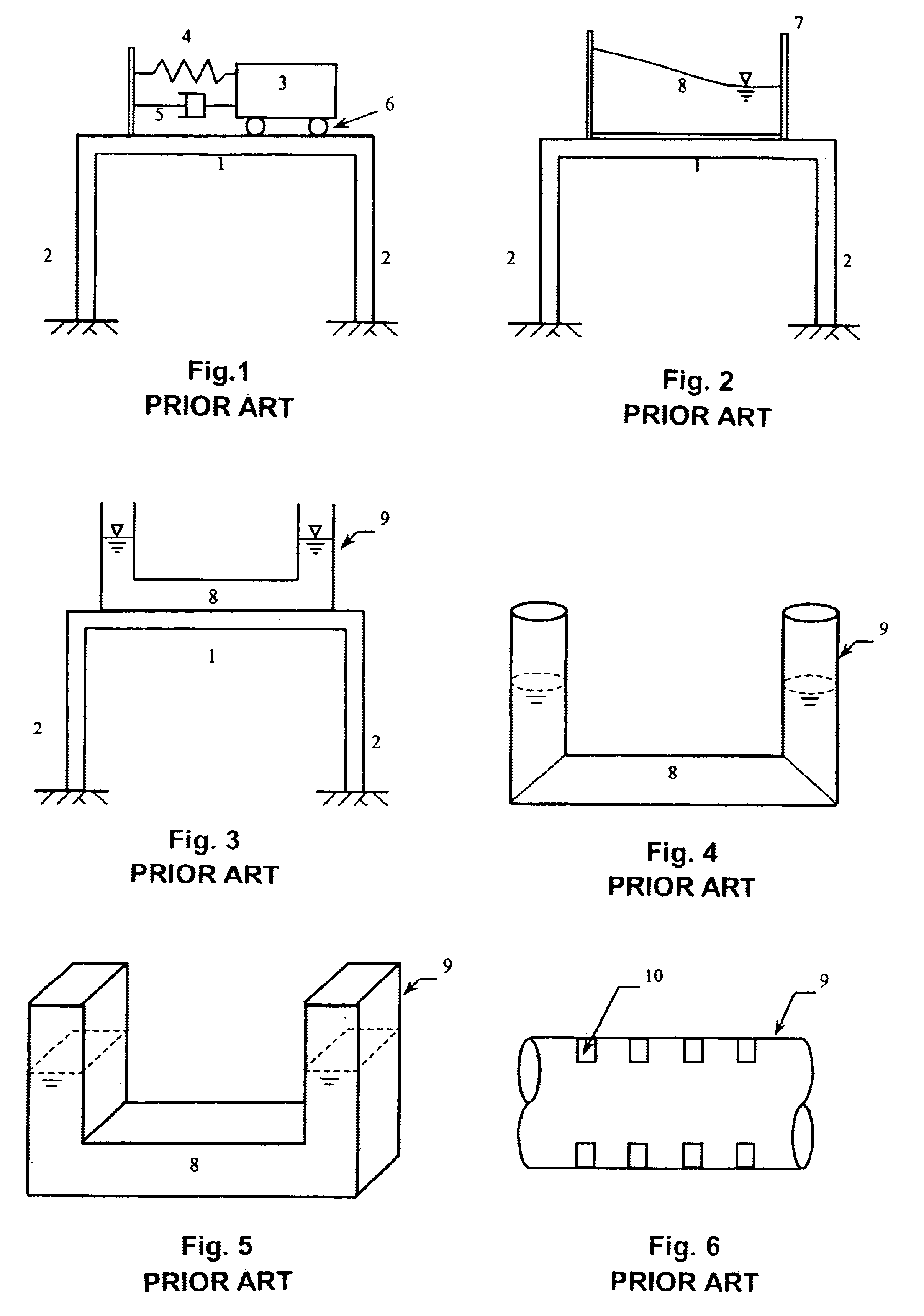

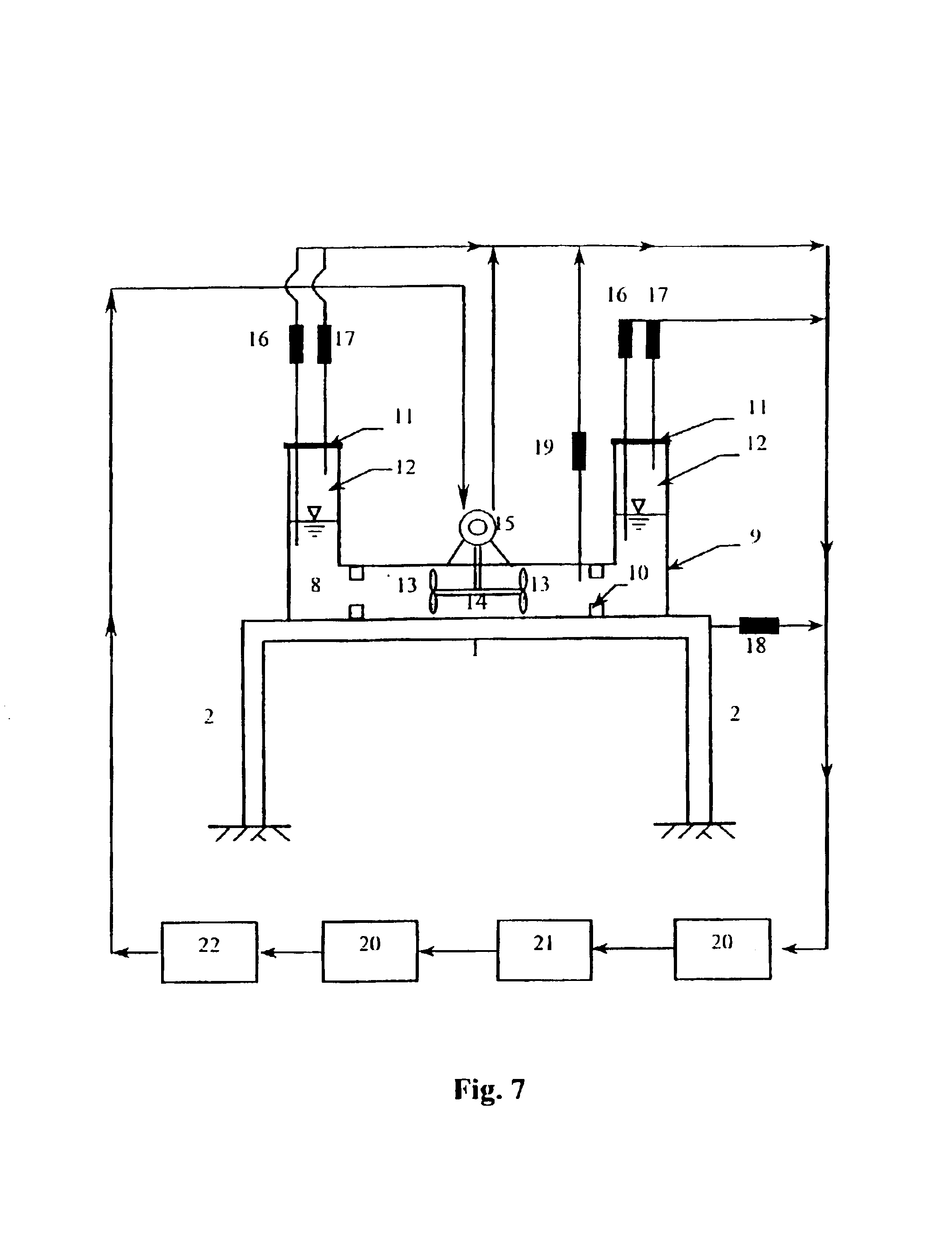

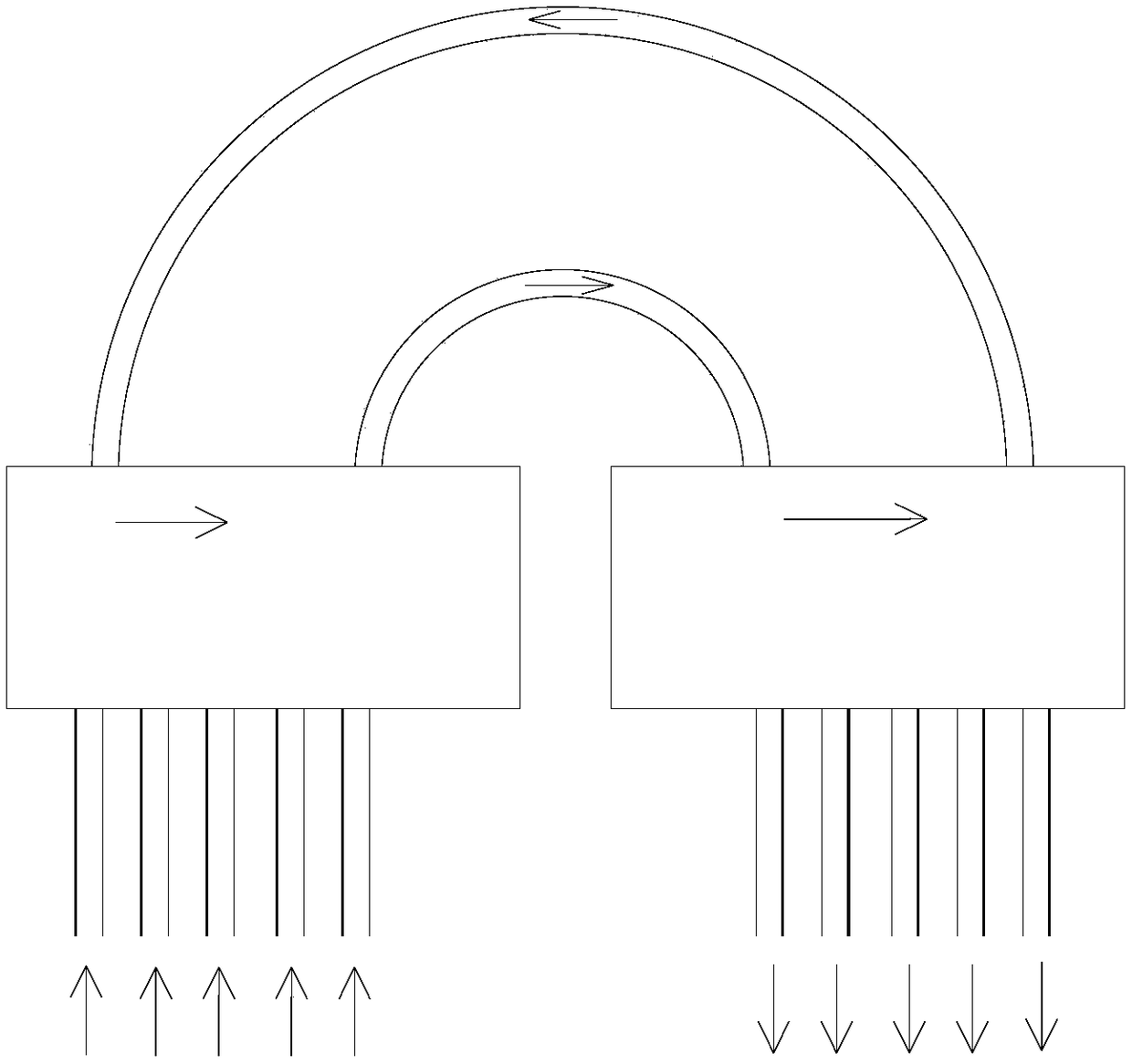

Propeller-controlled active tuned-liquid-column damper

InactiveUS6857231B2Control suppressReduce vibrationStands/trestlesProtective buildings/sheltersVibration controlAir volume

A propeller controlled active tuned-liquid-column damper (TLCD), which can control and suppress the vibration thereof, such as building, tower, bridge, vehicle, ship, offshore platform, facilities, and instrument, etc. This invention is composed of a passive TLCD, one or more propellers, a gear-shaft unit, a servo-motor, and a computer-control system. One or more propellers are installed in a line along the gear-shaft unit inside the horizontal section of the U-shape vessel, the propellers are driven by a servo-motor controlled by the computer-control system which start the servo-motor to drive the propellers immediately. Both fluid (or water) acceleration and the propellers' thrust can yield the resistance force to increase the vibration-control ability significantly. The natural period of an open TLCD can be adjusted by only changing the wetted length, whereas a closed TLCD can be adjusted by changing the wetted length, air pressure and air volume in the air chamber.

Owner:CHEN YUNG HSIANG

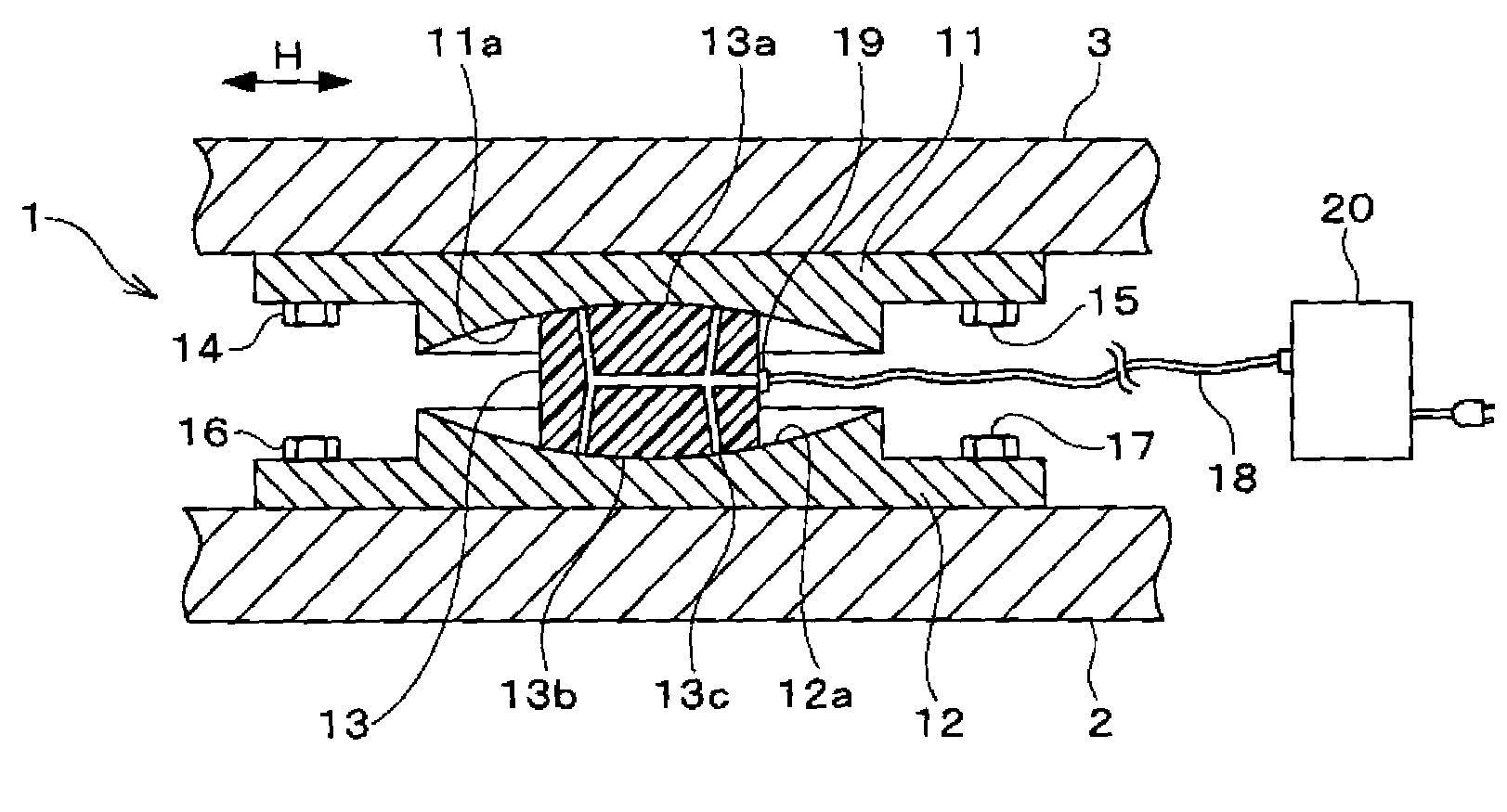

Seismic isolation device and seismic isolation structure

InactiveUS8833745B2Use air pressureExcellent vibration energy absorbing capacityMachine framesLiquid springsNatural cycleEngineering

The present invention is intended to provide a seismic isolation device which, regardless of a load to be supported, is capable of reducing acceleration through lengthening a natural period of an upper structure, with excellent vibration energy absorbing capacity by obtaining a properly preferable frictional force as well as a returning characteristic, and others.

Owner:TOKYO DENKI UNIVERSITY

Non-closed high-temperature hot water boiler

InactiveCN1975279ANatural cycle impactRealization of natural circulationWater heatersEngineeringHearth

A unclosed high-temperature hot water boilers, constructed that the upper and lower central box are connected with the tube and box of water wall and the fore and after wall tube and box, the convection bank is connected with the side-upper and lower box, constitute a natural cycle waterway and convection and radiation heating surface via connectivity, masonry boiler walls and smoke walls to form the hearth box and the three-pass smoke canal. This invention fundamentally change the positive circulation routine of the conventional pipe-rack boiler, totally eliminate the complex exhaust gas and pollution discharge process, contaminant separation difficulties of the box and power outages safeguard, the high temperature hot water can be obtained using static pressure in the invention, the boiler is absolute secure without burst pipe. The invention facilitates the design of the economic velocity and layout of heating area, no need to manufacture boiler tube, substitute with large, medium and small tubes, can significantly increase the thermal efficiency and manufacturing efficiency, reduce original emission concentration, and reduce power and steel consumption. It is energy-efficient with low energy consumption, low emission, environment protection, safe-type boiler.

Owner:王森

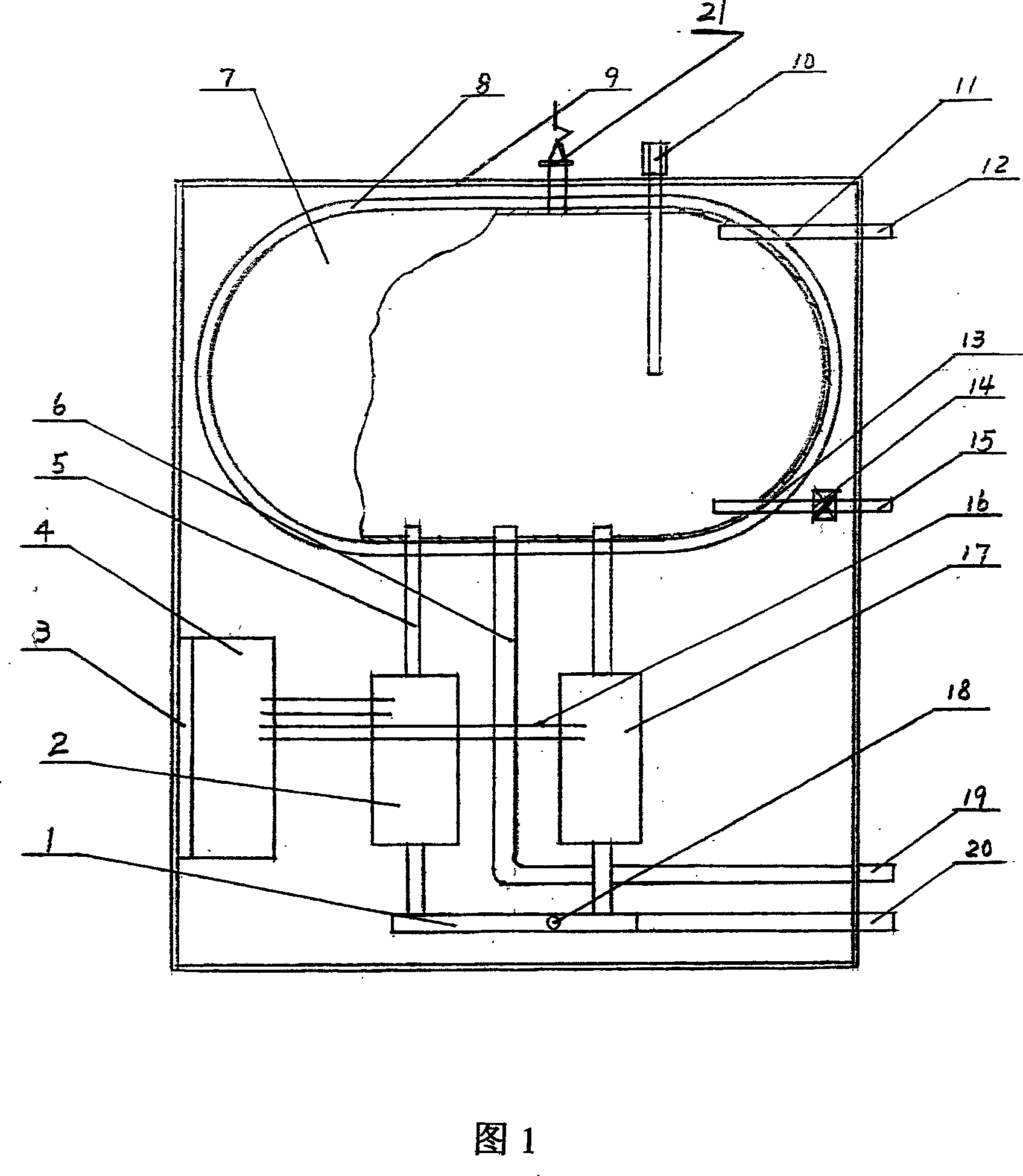

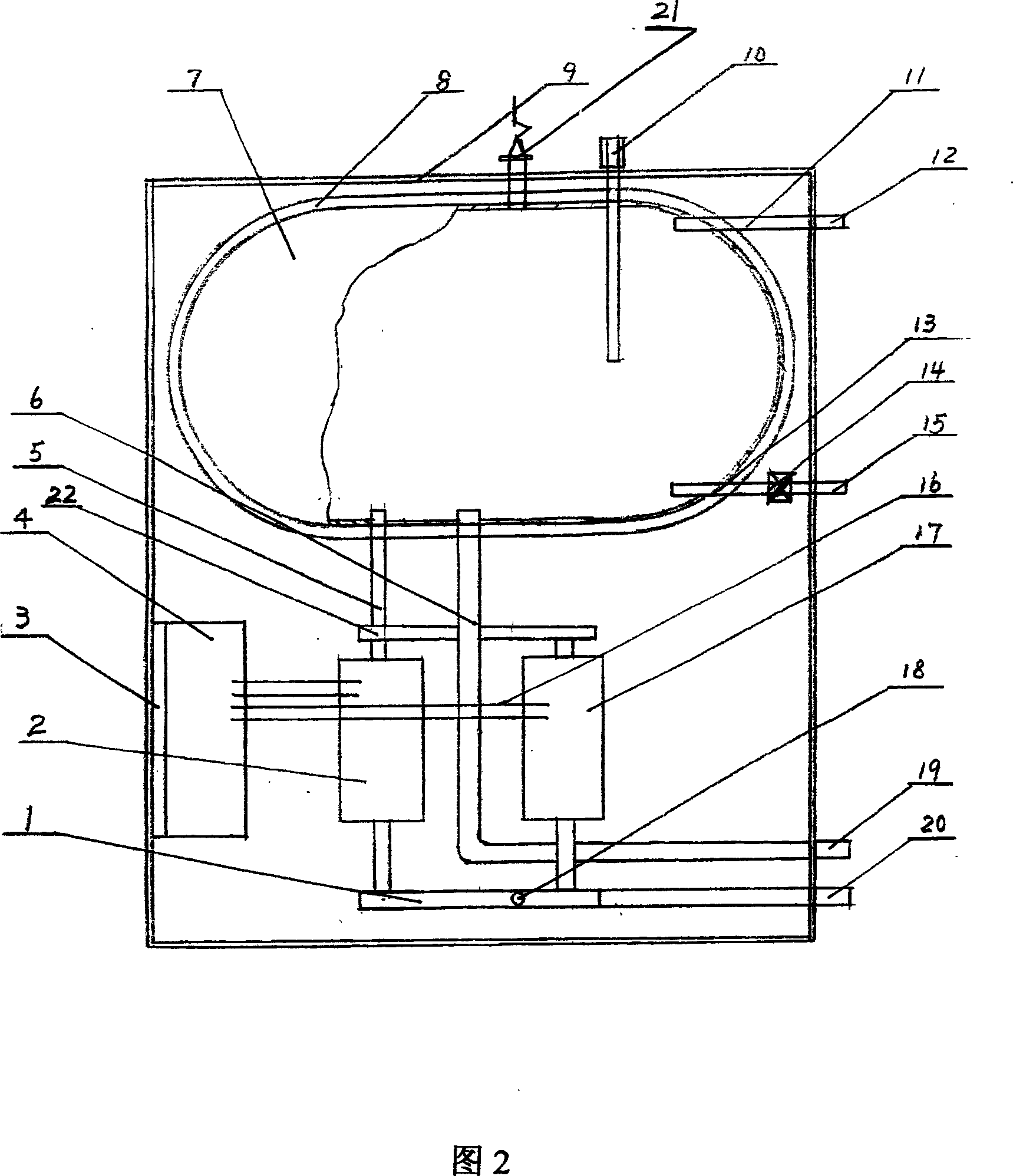

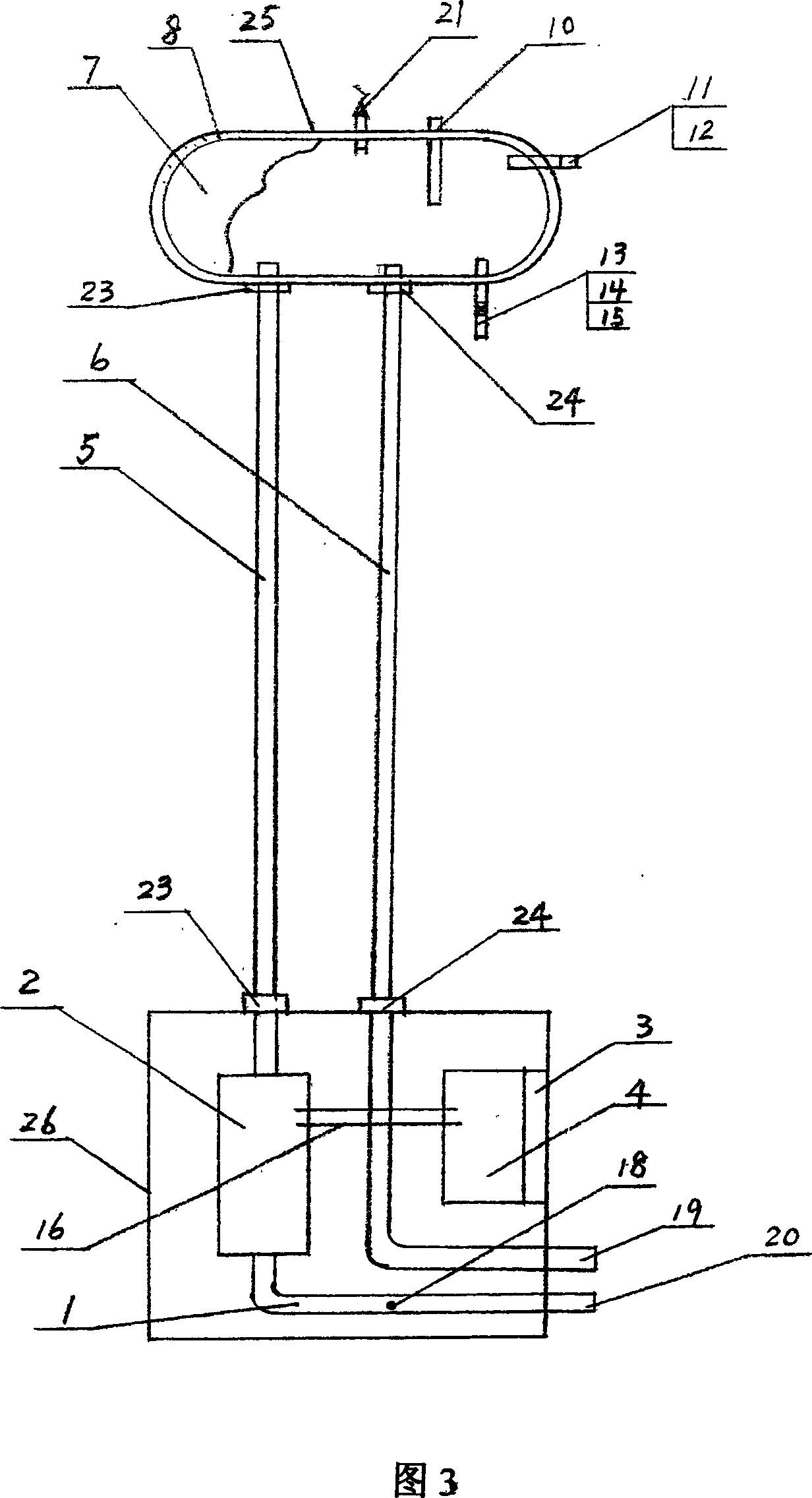

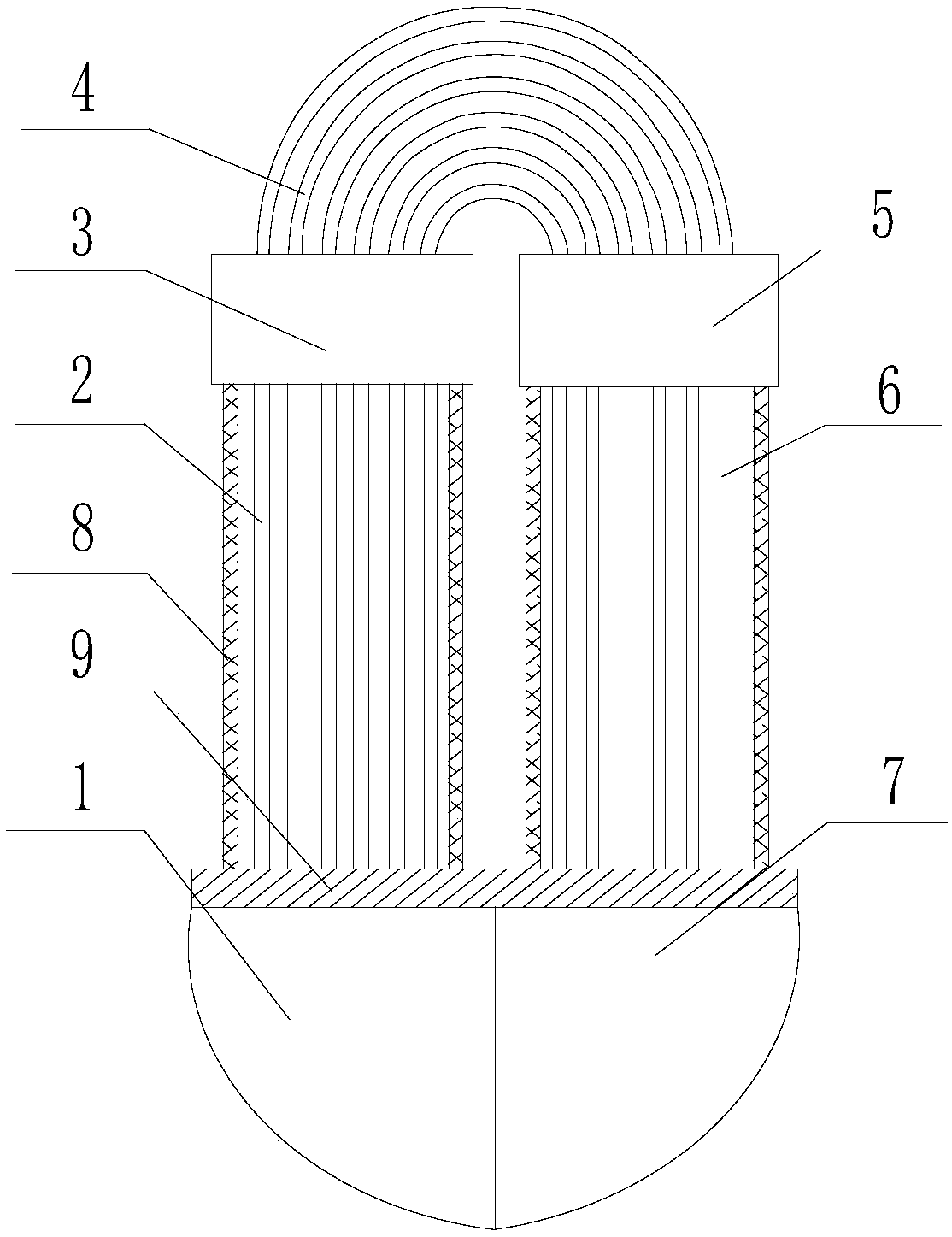

Induction heating type electrically-heated boiler for naturally circulated hot water heating system

The invention discloses an induction heating electric boiler of the natural cycle hot water heating system, which includes induction heating tube, water store implement, AC power device. The induction heating tube includes: induction coils, the water-pipe which is made of the non-permeable material, heat pipe which is made of magnetic materials. The store quantity of the water pipe in the induction heating tube is small as the heat water ascending tube, after the induction heating tube heat, the water of the water pipe flows out from one end and through the ascending tube into the water store implement, under the water temperature density difference function, the water of the water store implement through the drop tube and the heat distribution implement of the heating system inflows from the another end of the water pipe to form the natural cycle. In the natural cycle hot water heating system, it eliminates the circulating pump, the intenerate water processor, heat exchanger, saves energy manufacturing and use energy. The induction heating tube is detached of the water and electricity, so has a long service life, maintenance-free.

Owner:郝明君

Monitoring System and Method for Vessel Mooring

ActiveUS20170023366A1Navigational calculation instrumentsSatellite radio beaconingMooring systemMonitoring system

The present disclosure provides a system and method of monitoring a mooring system for a floating vessel using the time of the natural period independent of environmental conditions. The natural period can be calculated and / or established experientially over time by measuring movement of the vessel to establish the natural period at given geographical positions of a secure and intact mooring system. The natural period can be monitored based on the time to complete a natural period. A change in a mooring line stiffness, whether by a failure, stretching, a degradation of the mooring line integrity, or a significant displacement of the anchoring point, will be translated into a different natural period with a different time. By monitoring the natural period for a given geographical position (and corresponding heading) to be compared to the theoretical values (and / or previous recorded values) it is then possible to assess that at least a portion of the mooring system has failed or that a significant damage has occurred.

Owner:TECH FRANCE SA

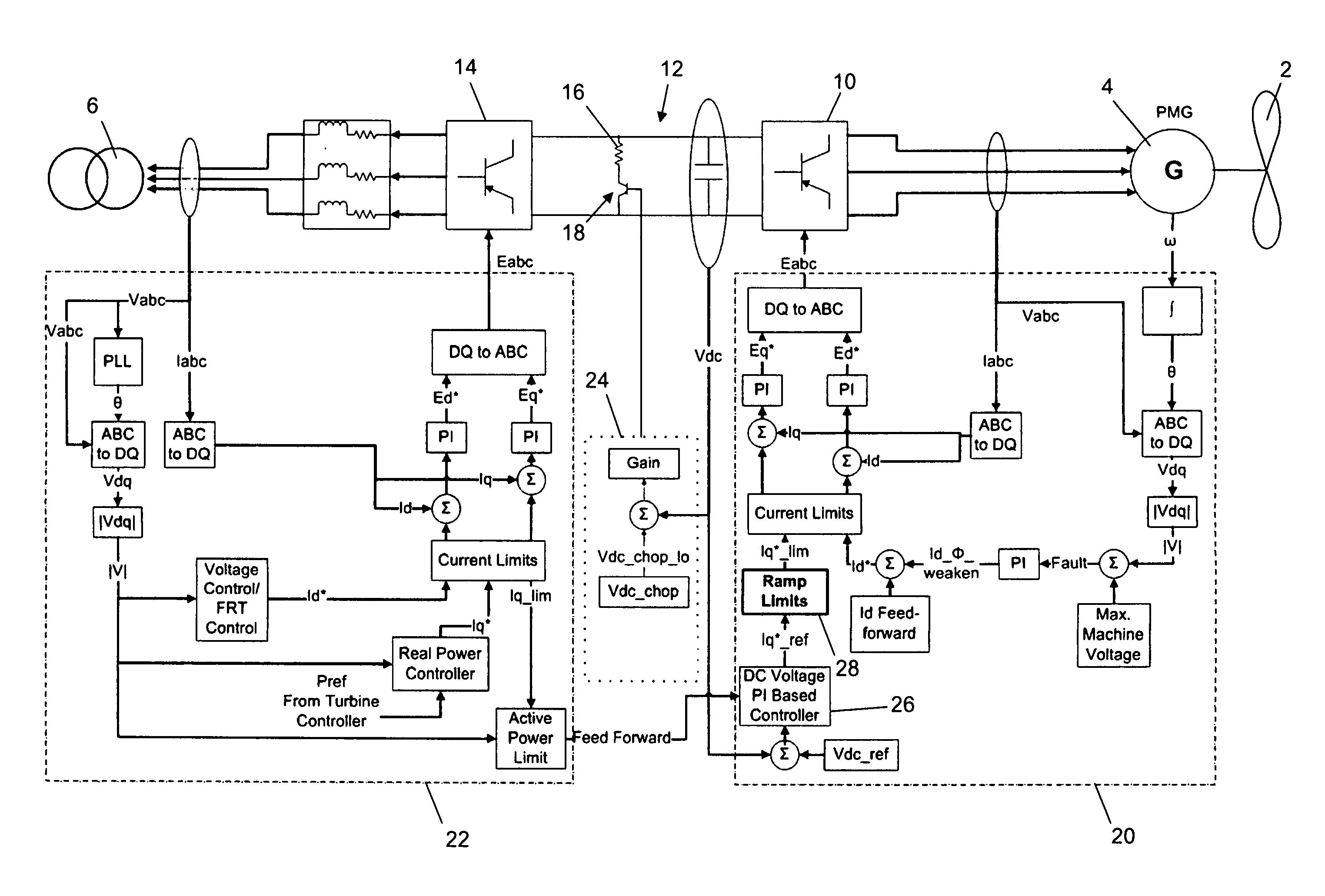

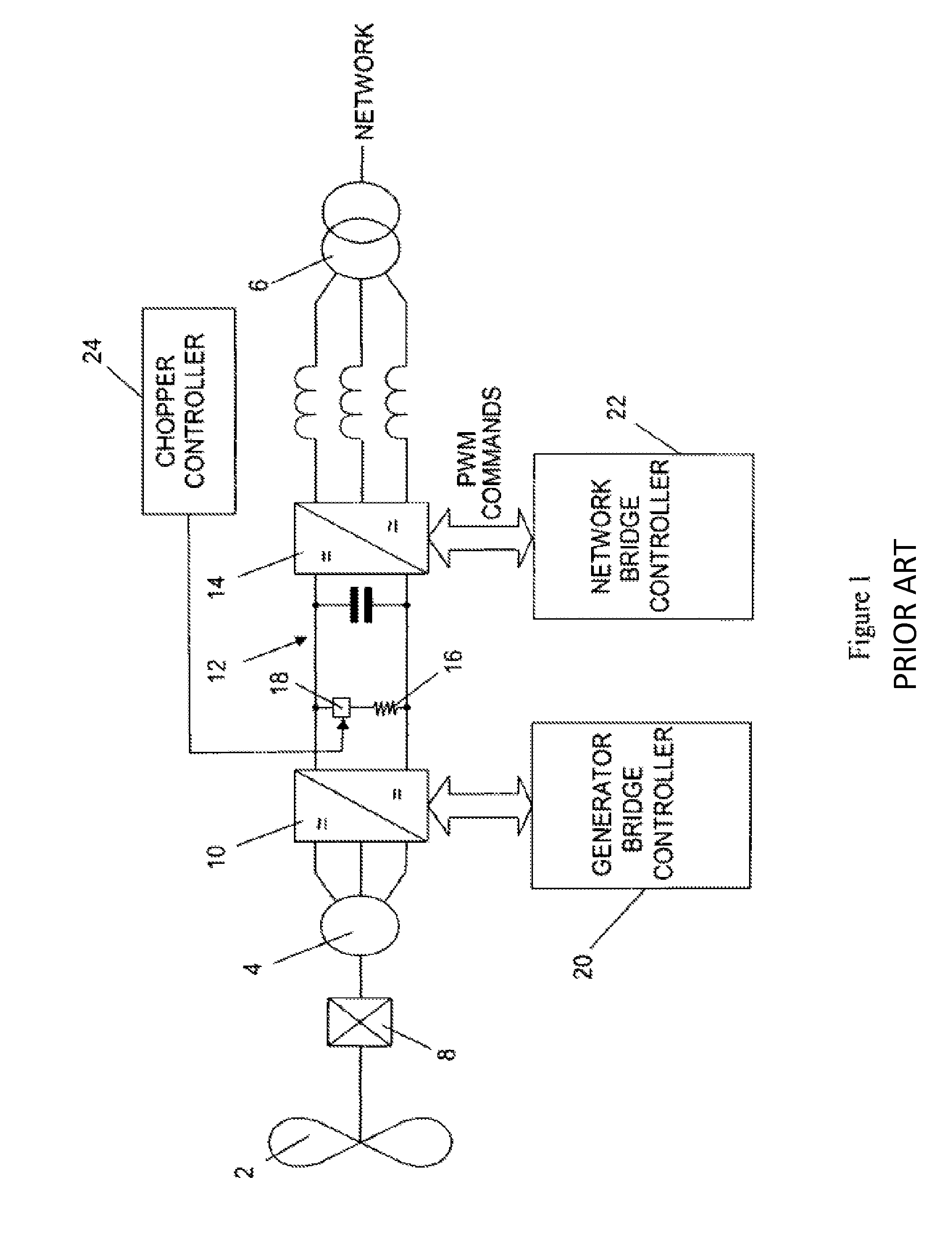

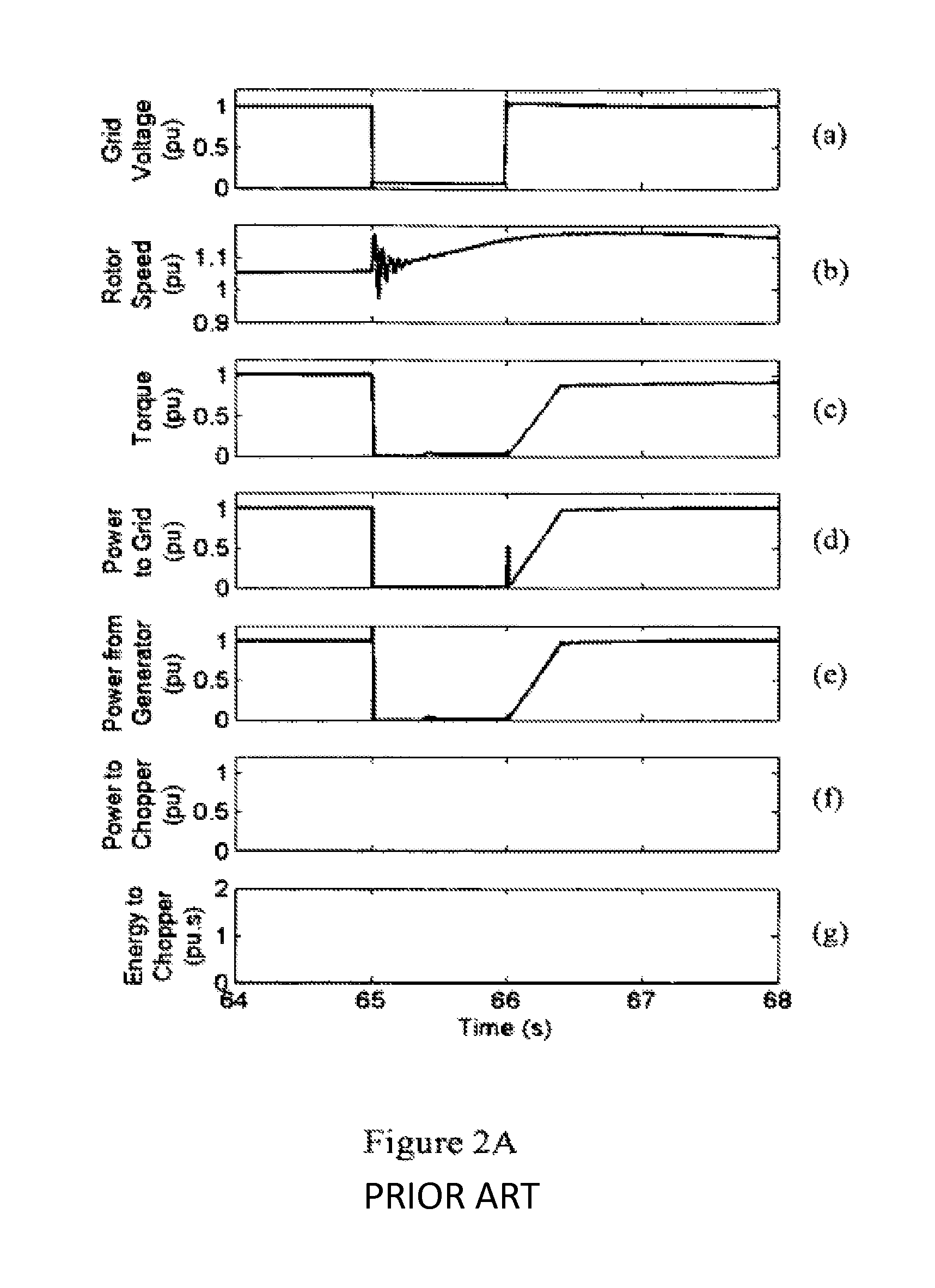

Generator torque control methods

ActiveUS8981584B2Few windingsMinimise peak generator speedWind motor controlGeneration protection through controlGrid faultPower grid

A wind turbine typically includes a generator and a rotating mechanical system having a natural period. The present invention relates to a method of controlling generator torque that minimizes oscillations in the speed of the generator rotor. In the event of a grid fault or transient, or a fault in the power converter, the generator torque is decreased at a substantially constant rate with respect to time. The rate at which the generator torque is decreases is proportional to the nominal rated torque of the generator and inversely proportional to an integer multiple of the natural period of the rotating mechanical system.

Owner:GE ENERGY POWER CONVERSION TECH

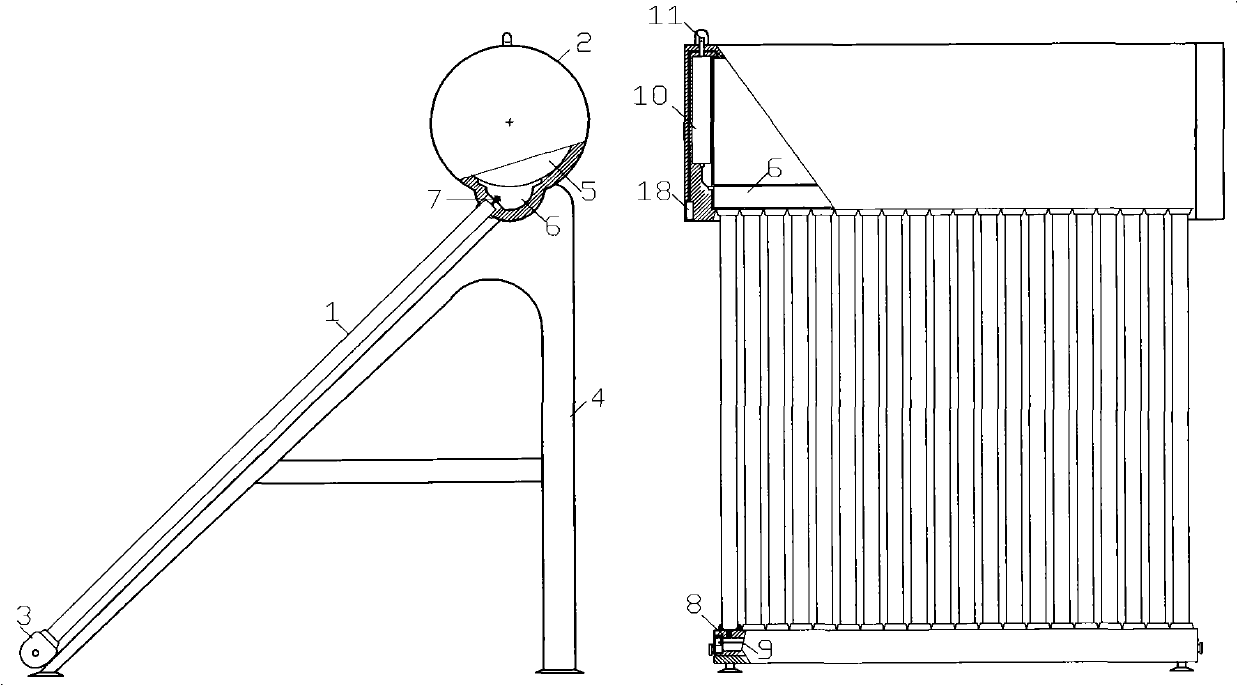

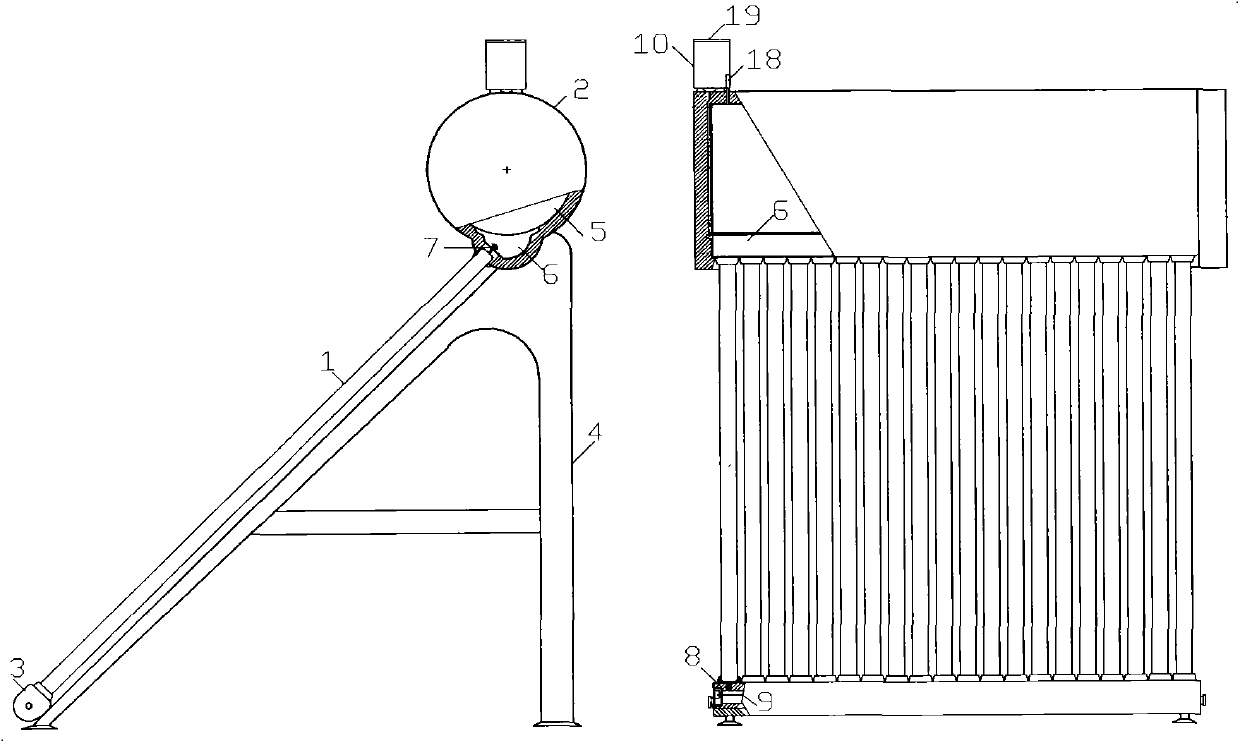

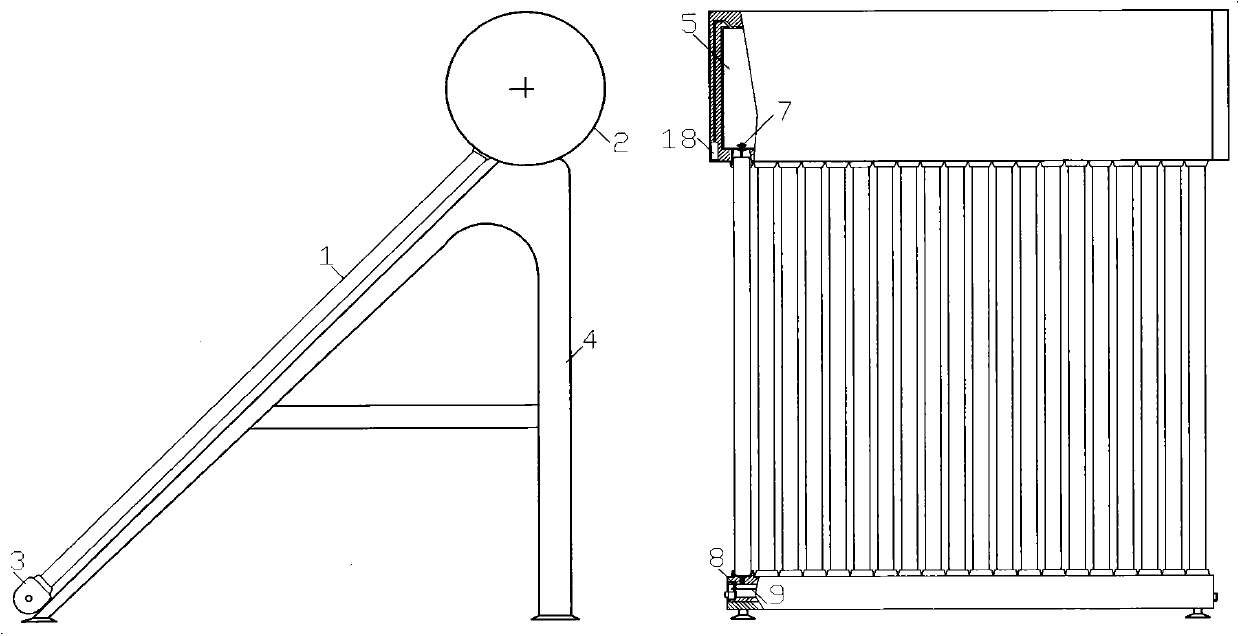

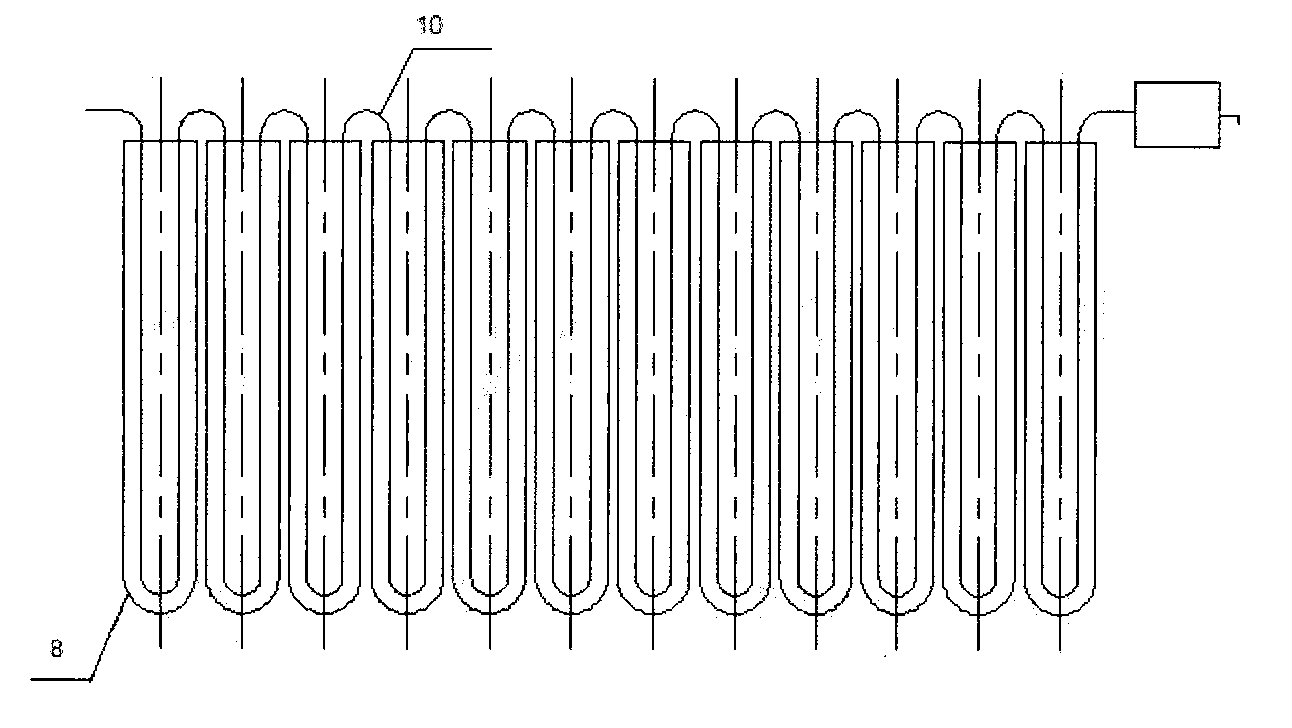

Compact liquid-tube vacuum tube water heater compatible with phase change heat storage function

InactiveCN103968572ASmall footprintShort cycle pathSolar heating energySolar heat devicesTemperature controlEngineering

A compact liquid-tube vacuum tube water heater compatible with a phase change heat storage function is available in four types, namely phase change heat storage, non-phase-change heat storage, single natural cycle heat storage, and double natural cycle heat storage. The compact liquid-tube vacuum tube water heater comprises liquid-tube vacuum tubes (1), an insulation water tank (2), a multifunctional header (3), a support (4) and the like. The upper end of a heat transfer liquid tube (16) in each liquid-tube vacuum tube (1) is communicated with a heat transfer liquid tube connector (7) of the insulation water tank (2) through a seal ring; the lower end of every heat transfer liquid tube (16) is communicated with a flow passage of a header tube (8) in the multifunctional header (3) through a seal ring. An electric heating tube (9) is mounted in the flow passage of the header tube (8) of the multifunctional header (3). A temperature control fan (18) is mounted on the insulation water tank (2). The liquid-tube vacuum tubes (1) include liquid-tube vacuum collector tubes and liquid-tube phase change heat storage vacuum collector tubes; the two types of tubes are universal, compatible and exchangeable and can be mixed for use. The compact liquid-tube vacuum tube water heater has the functions of freezing prevention, adjustable water temperature of the lower end of the water tank, controllable temperature of the upper end of the water tank and the like.

Owner:秦三根

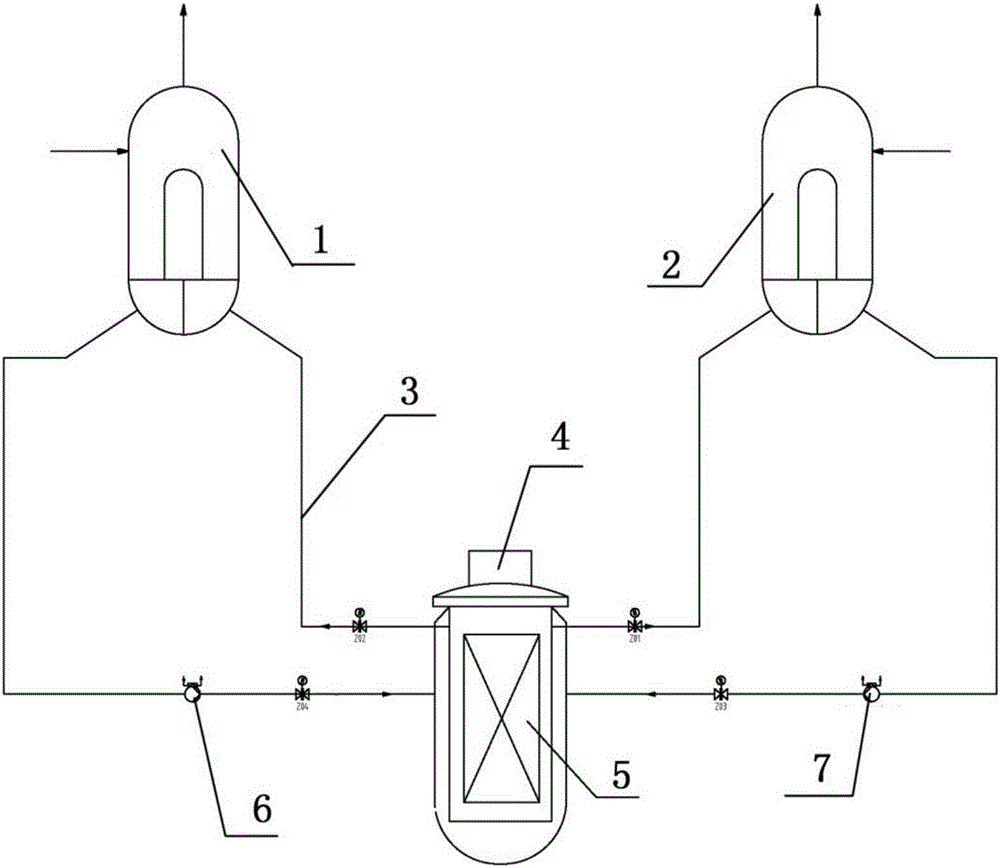

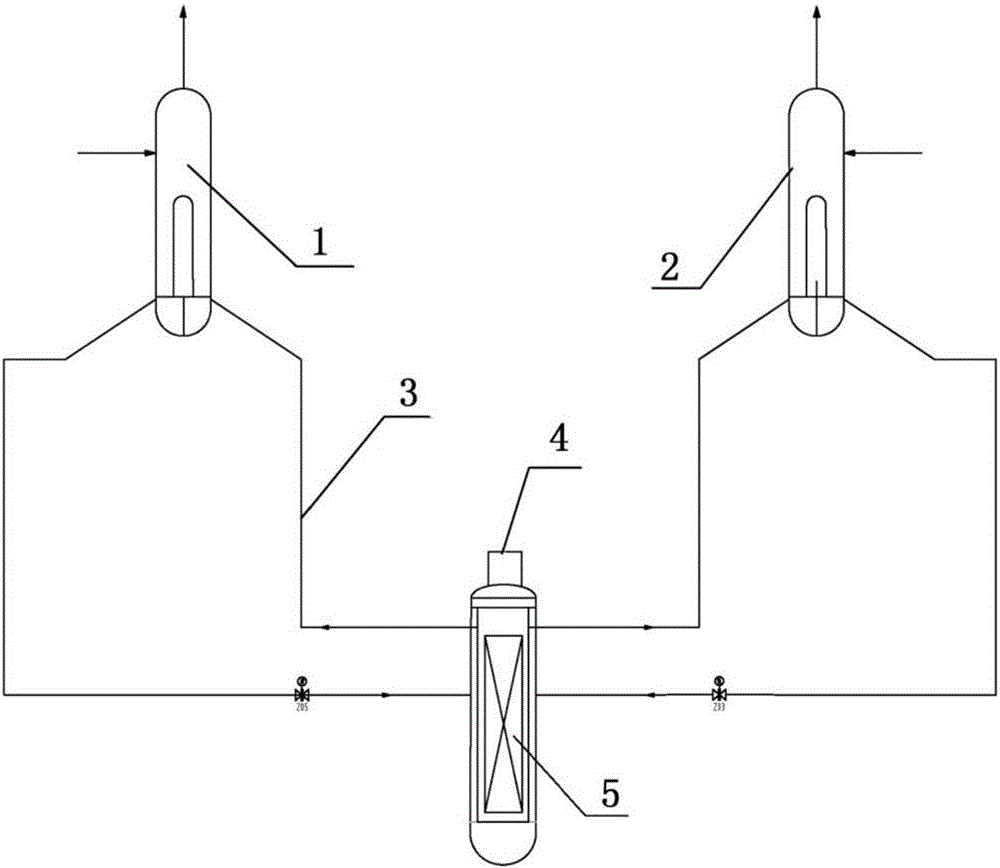

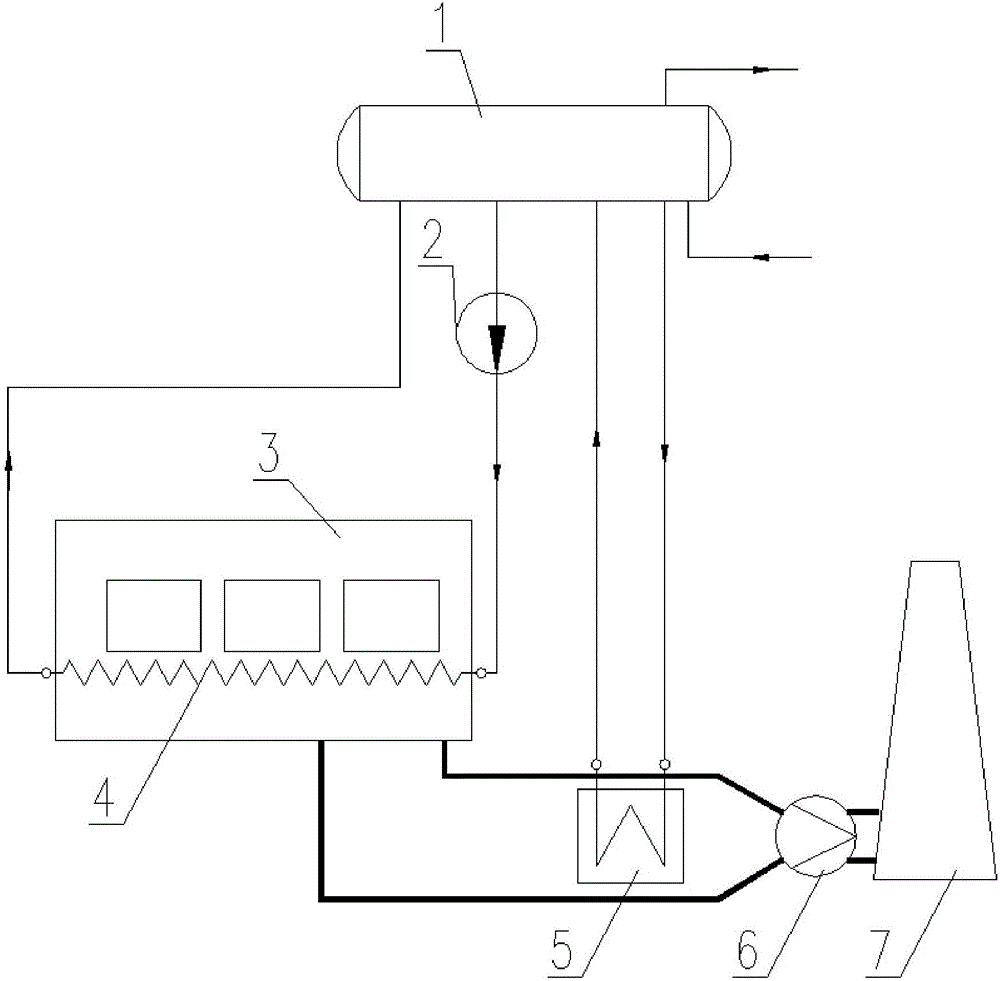

Heating furnace waste heat combined cycle recovery system

InactiveCN106091713AReduce in quantityReduce operating energy consumptionIncreasing energy efficiencySteam generation using hot heat carriersProcess engineeringNatural cycle

The invention discloses a heating furnace waste heat combined cycle recovery system, and provides a heating furnace waste heat combined cycle recovery system combined with a recovery gasifying and cooling mechanism and tail smoke heat. The system is mainly aimed at solving the problems that many heating furnace waste heat independent recovery devices exist and expenditures are high. The system comprises a gasifying and cooling mechanism arranged in a hearth of a heating furnace, a smoke heat exchange mechanism arranged in a tail flue of the heating furnace and a vapor-water separator, wherein the vapor-water separator comprises a vapor-water container, a natural cycle inlet, a natural cycle outlet, a forced cycle inlet, a forced cycle outlet, a water inlet and a saturated vapor outlet, wherein the natural cycle inlet, the natural cycle outlet, the forced cycle inlet, the forced cycle outlet and the water inlet are formed in the lower portion of the vapor-water container, and the saturated vapor outlet is formed in the upper portion of the vapor-water container. The natural cycle outlet is communicated with the water inlet of the smoke heat exchange mechanism. The natural cycle inlet is communicated with the water outlet of the smoke heat exchange mechanism. The forced cycle outlet is communicated with the inlet of the gasifying and cooling mechanism. The forced cycle inlet is communicated with the outlet of the gasifying and cooling mechanism. The number of devices is small, and running power consumption is low.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

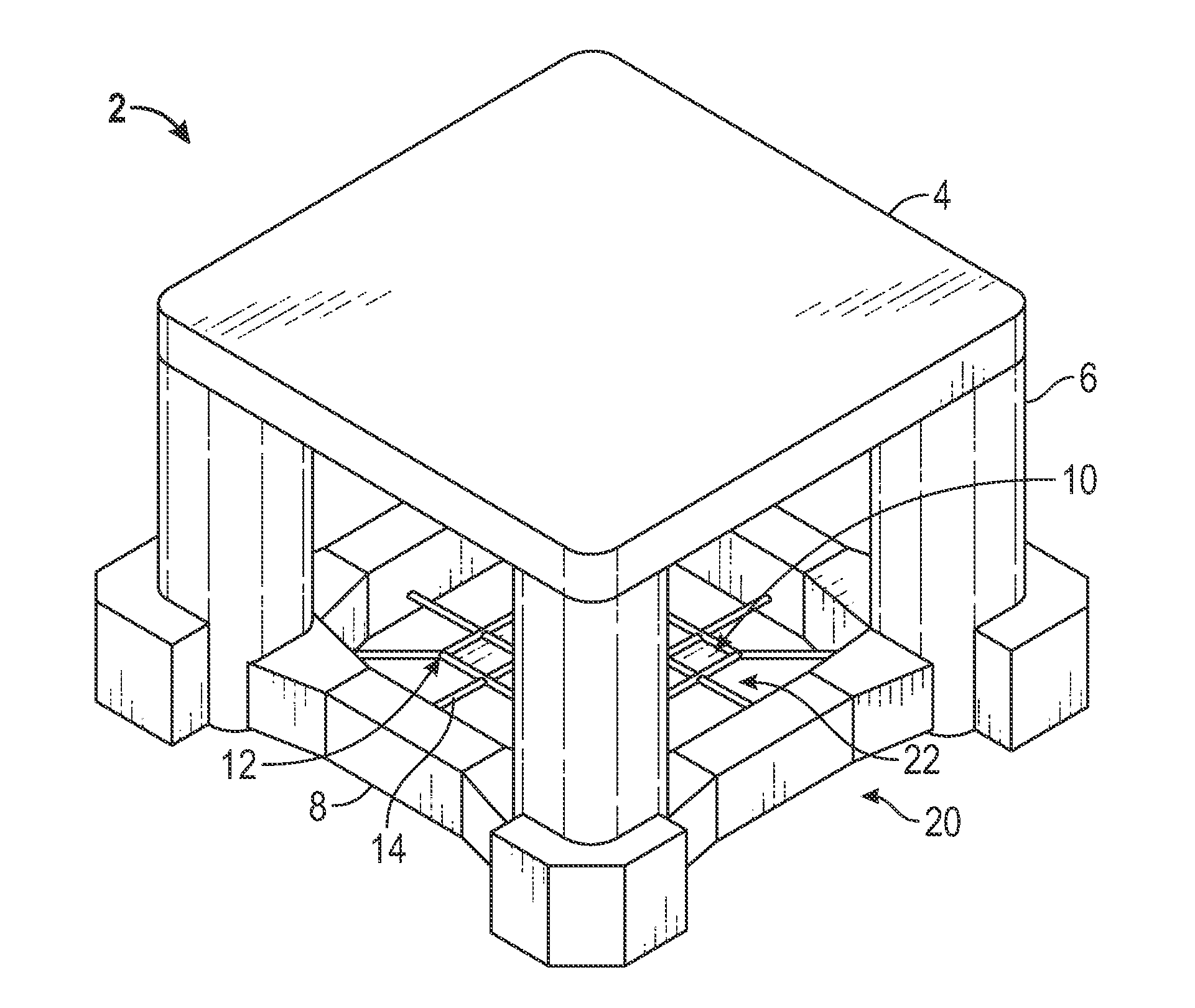

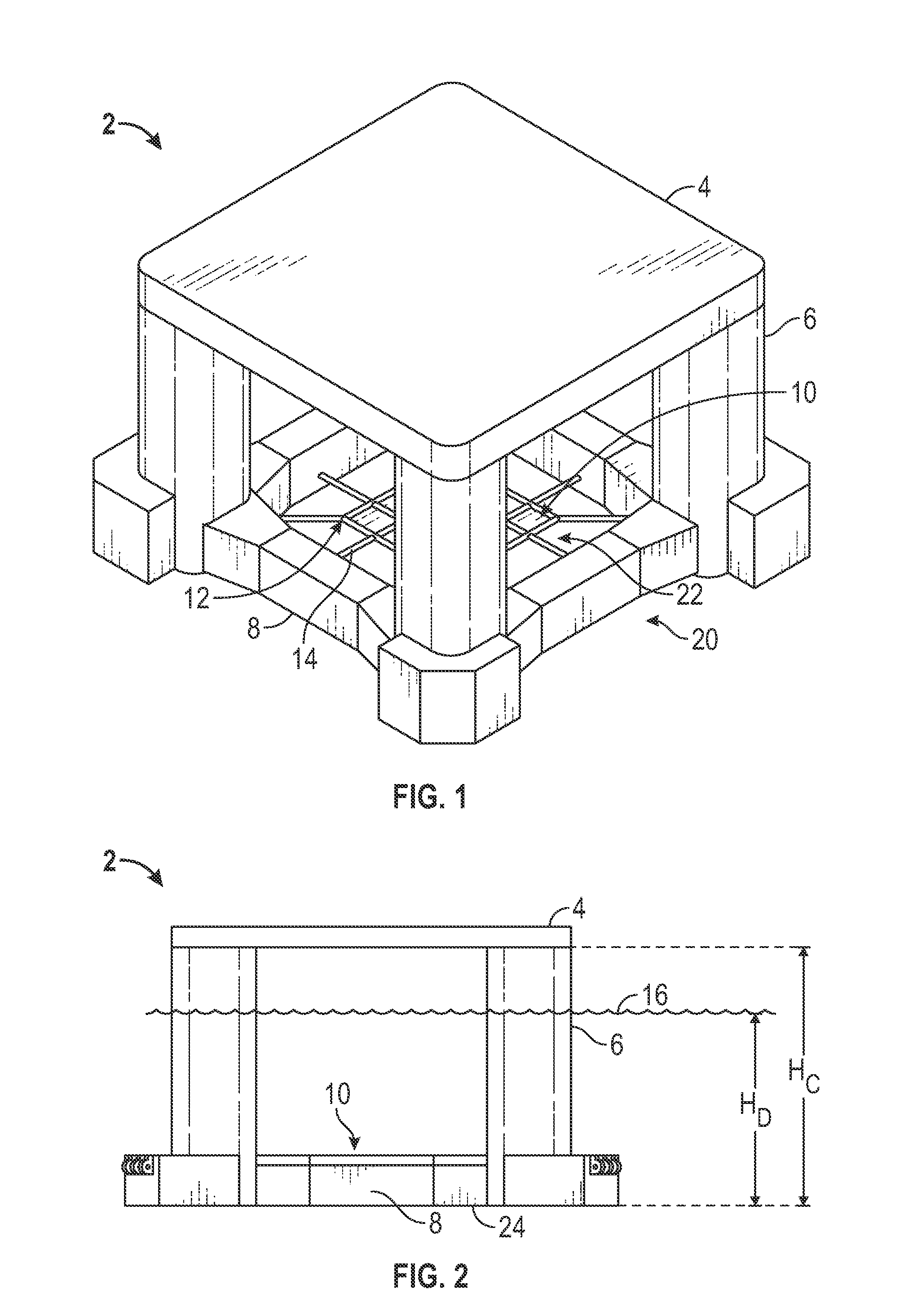

Floating offshore platform and centralized open keel plate

ActiveUS20140000502A1Improve stabilityReduce vertical movementVessel movement reduction by foilsMovement controllersKeelNatural cycle

The disclosure reduces vertical movement of a floating offshore platform by including a centralized open keel plate coupled to the hull that allows water below and above the keel plate. As the floating platform moves vertically, the keel plate separates the water and causes drag on the platform. The water moving vertically with the plate also increases the dynamic mass. The drag results in less vertical movement of the offshore platform without the need to extend legs of the platform to gain an equivalent reduction in vertical movement. The added dynamic mass increases the natural period of the vertical motion away from the wave excitation period to minimize the wave driven motion. The keel plate generally is above or at the same level of the keel, and therefore would not reduce the clearance between the seabed and the keel of the hull at the quayside.

Owner:TECH FRANCE SA

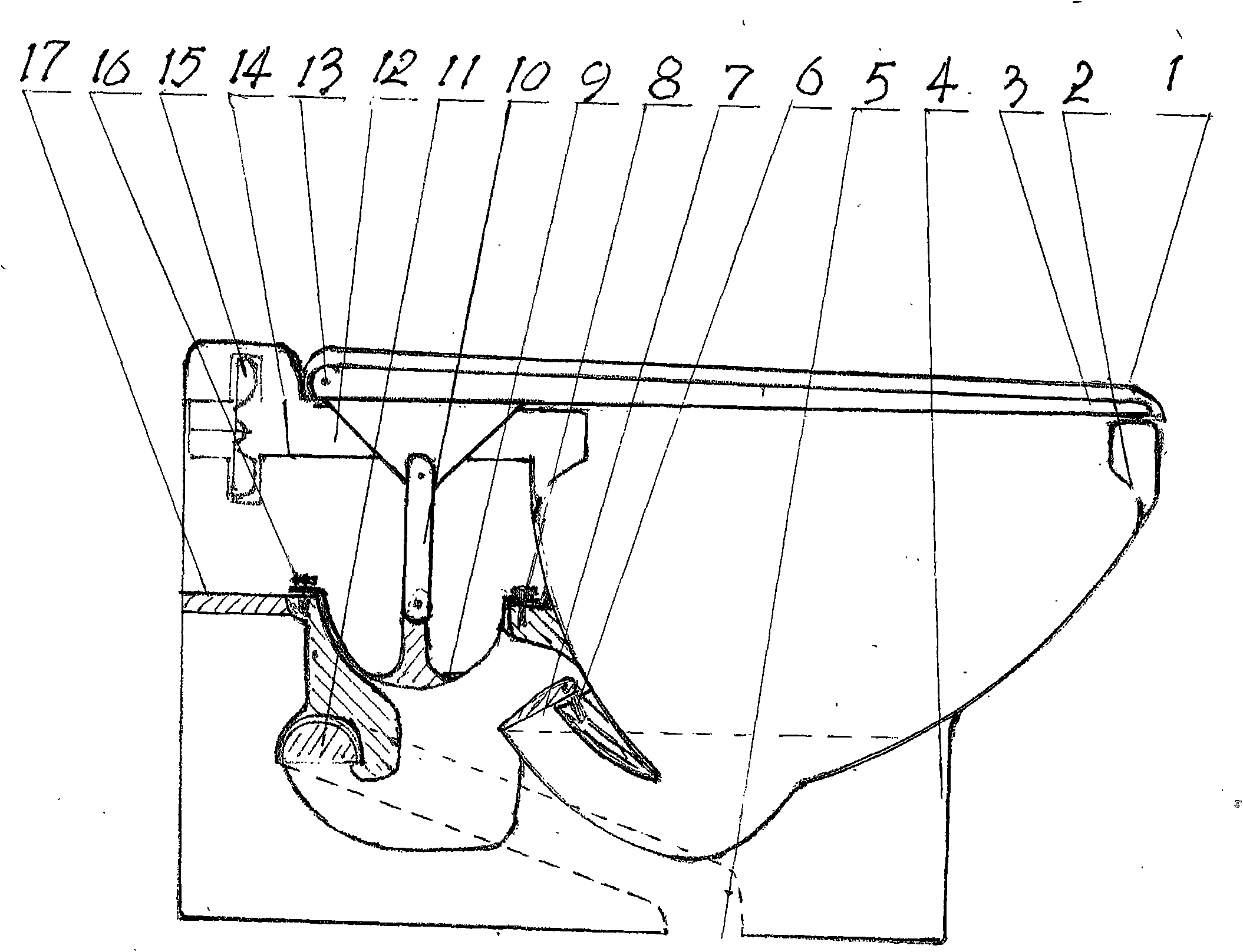

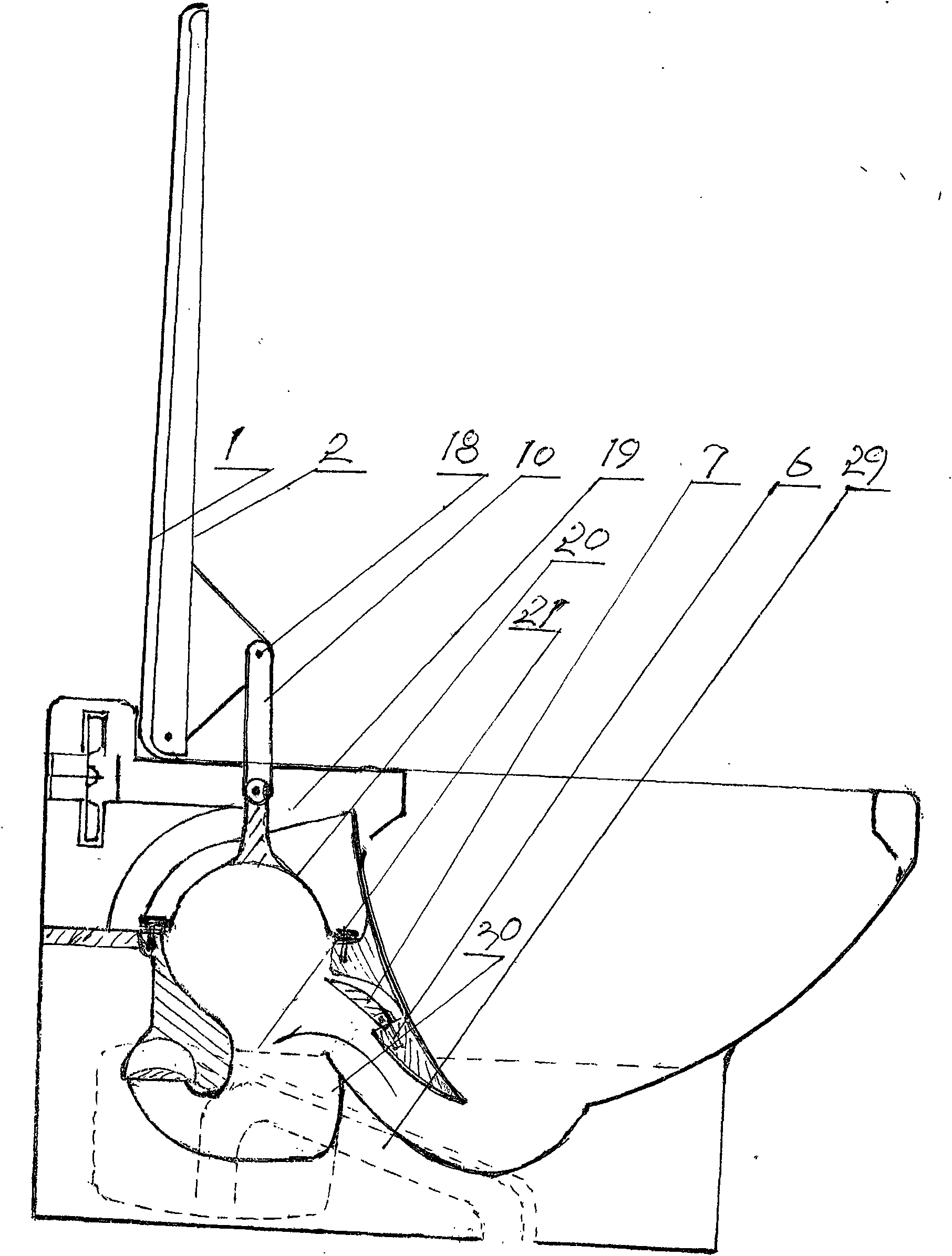

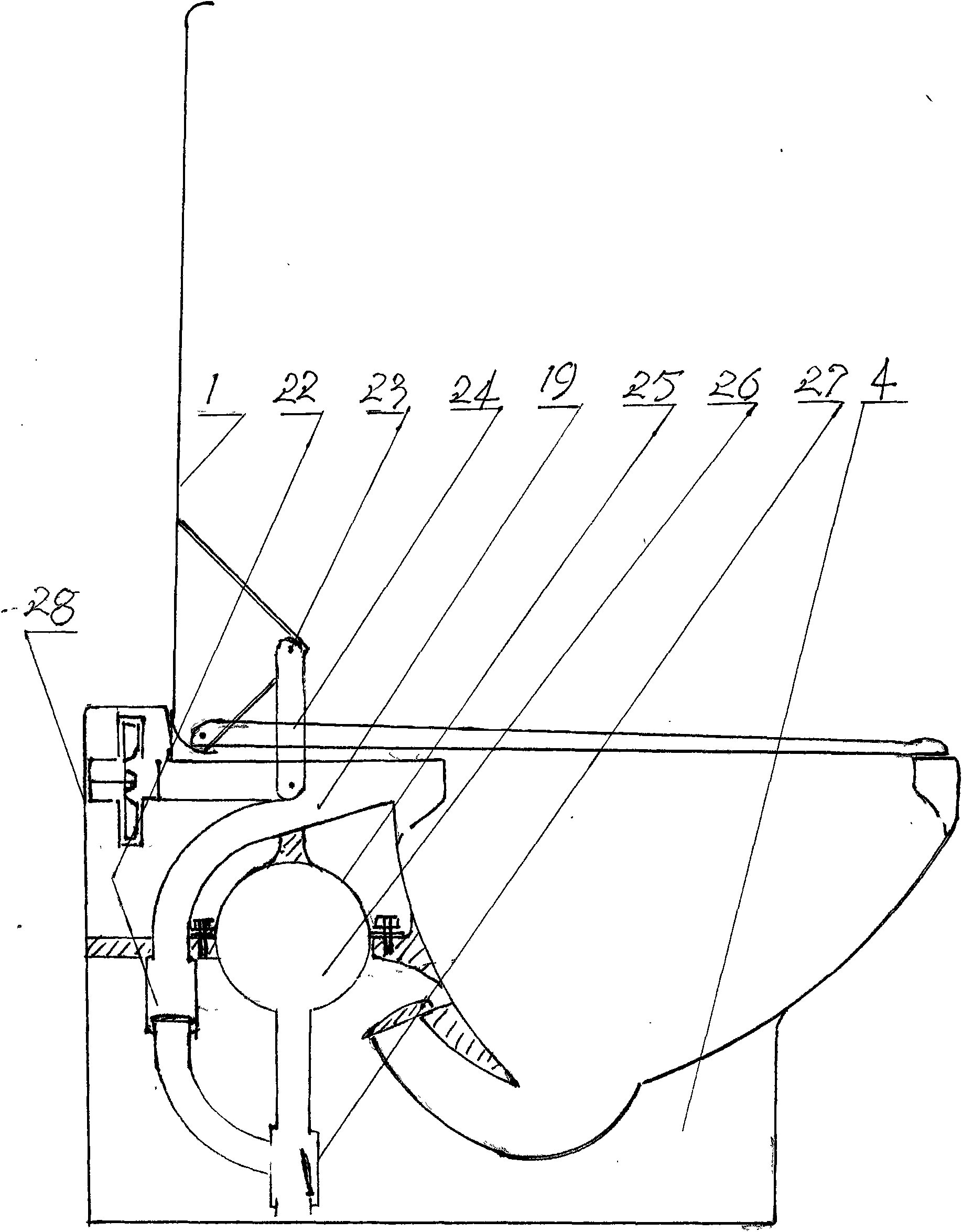

Odorless efficient energy-saving and emission-reducing closestool

The invention relates to an odorless efficient energy-saving and emission-reducing closestool field and is concentrated on the subjects of energy conservation and emission reduction, services for agriculture, rural area and farmers, income-increasing and reduce expenditure-reducing and attentions to the peoples livelihood; and the invention particularly performs further technical research and development to the natural flow by using the concentrated excrement residue-liquid ratio and creates a new path for the technological innovation of the flush toilet. Therefore, the water consumption of the invention is extremely small, excrements can be collected and used as raw material for producing methane, and then methane is transferred intensively or directly to outskirts for supporting agriculture, restoring ecosystems and beautifying the environment. The traditional flush toilet uses large water to push excrements so that excrements can not be collected, thus polluting rivers, lakes and seas, degrading the environment and resulting in a vicious circle. Compared with the traditional flush toilet, the product of the invention is used to change excrements into renewable energy, recombine resource, change the harmful substance to the treasure, ensure human to be grateful to the land, recover ecological balance and build the idea of returning natural cycle life again.

Owner:FUZHOU BAITE ENERGY SAVING TECH +1

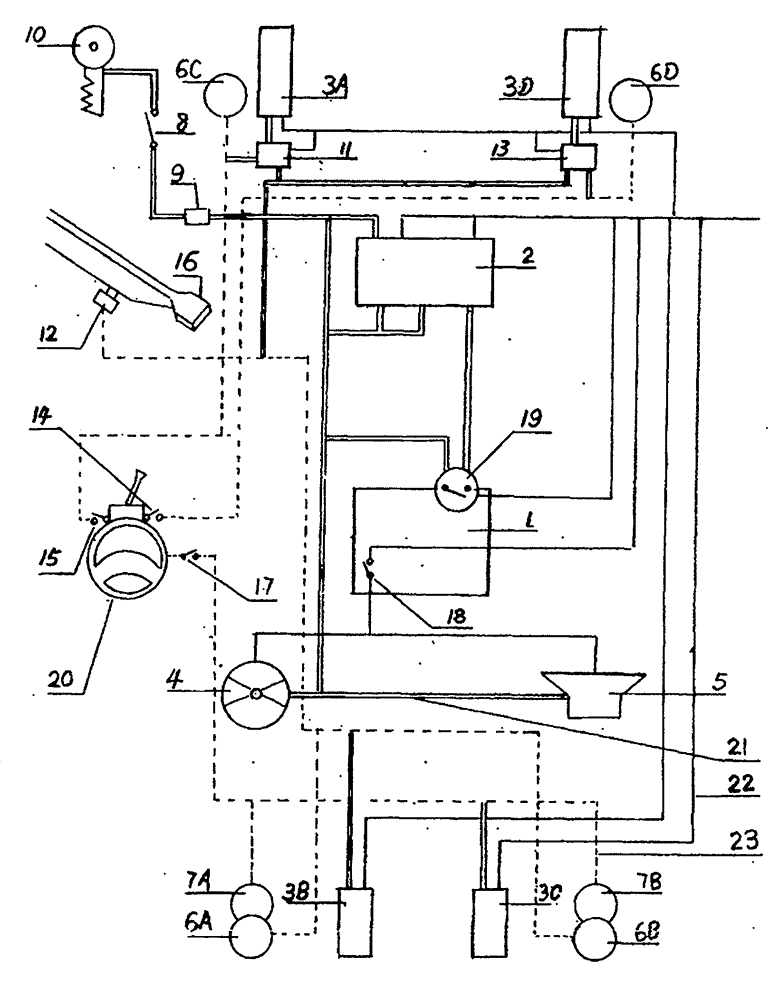

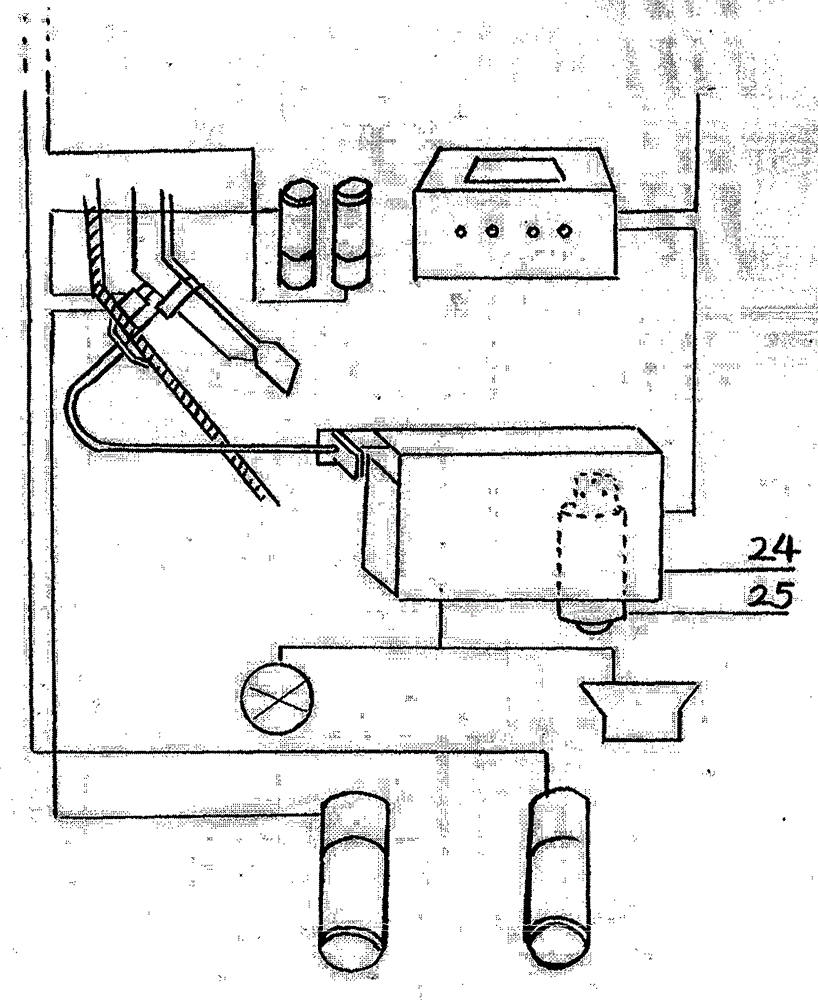

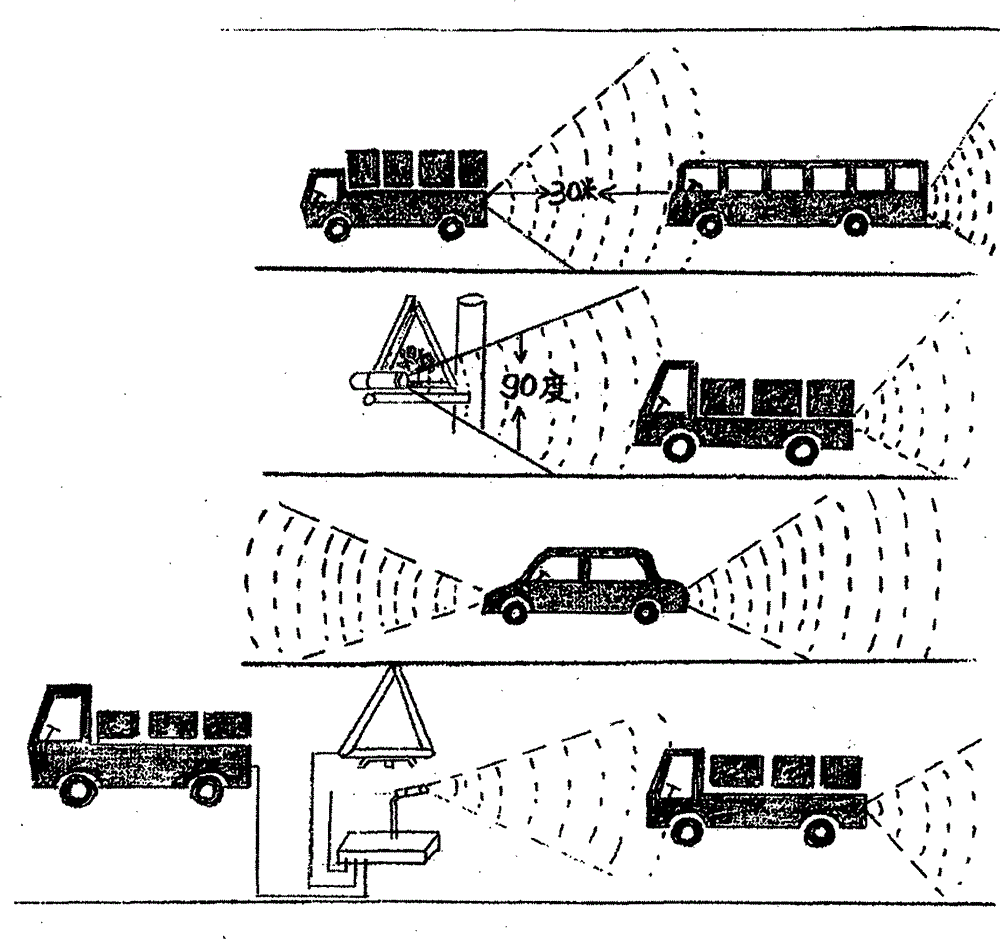

Automobile automatic braking natural circulation system

InactiveCN103171534BSimple structureDo not destroy the systemAutomatic initiationsOptical signallingElectric power systemAutomatic braking

The invention relates to an automobile automatic braking natural cycle system. The automobile automatic braking natural cycle system comprises a host machine, a signal system vice machine, an annunciator, a photoacoustic warning system, an automatic braking system switch, an automatic braking system insurance, a photoacoustic system automatic switch, and an automatic return switch. A pedal plate drives the automatic switch to enable the annunciator to work automatically. After receiving signals and identifying the signals, the vice machine provides the host machine with power, the host machine automatically drives the photoacoustic warning system and the host machine return switch, and the host machine drives a brake pedal plate to enter a next circle. According to the automobile automatic braking natural cycle system, infrared rays are used for controlling electric power, the electric power controls a special motor to drive the host machine, and steel wires and the pedal plate are pulled to achieve braking. The automobile automatic braking natural cycle system is simple in structure, capable of not destroying an original system and operating procedures, convenient to use, reliable in performance and capable of being used in various motor vehicles.

Owner:康德彪 +2

Mobile system and driving method thereof

The present invention relates to a mobile system and a moving method of the mobile system. According to the present invention, a natural period is measured from a vibration component signal generated by a force due to acceleration / deceleration of wheels, and the mobile system moves by applying an acceleration profile containing an acceleration period or a deceleration period based on the natural period. Therefore, the acceleration profile based on the natural period is applied such that vibration that is visible to a user is not generated during acceleration and deceleration of the mobile system. As a result, quality of the mobile system is improved.

Owner:ELECTRONICS & TELECOMM RES INST

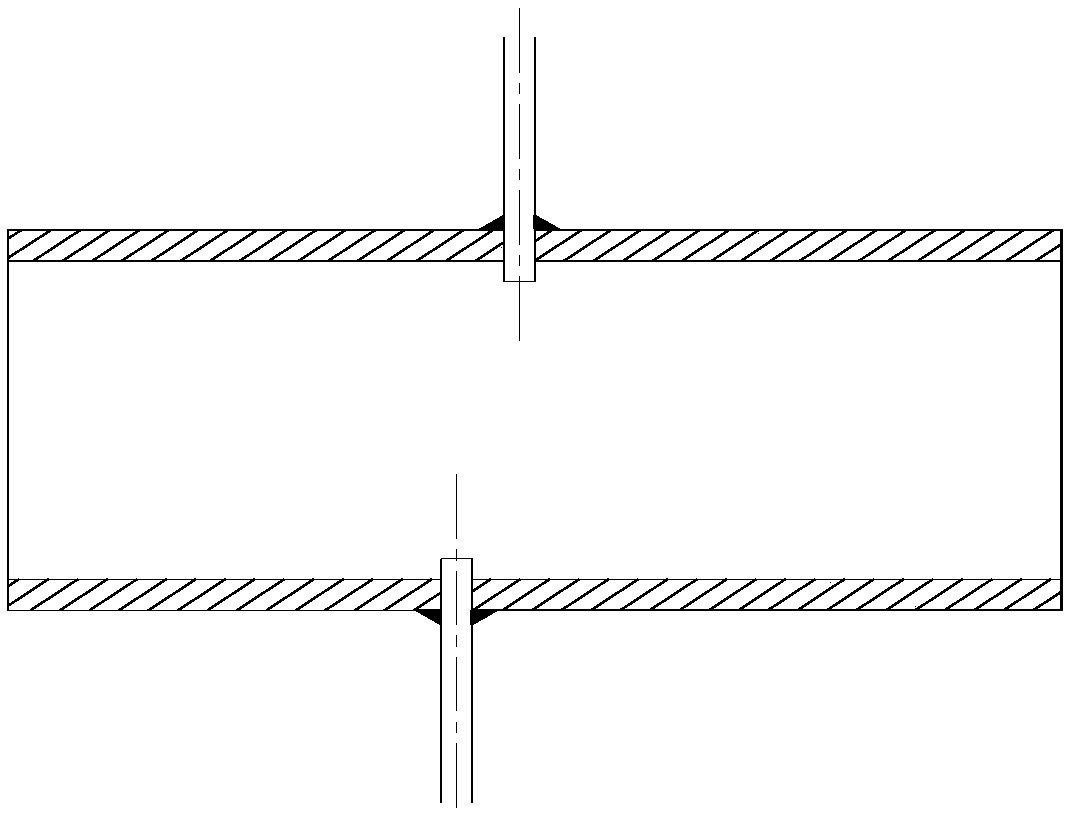

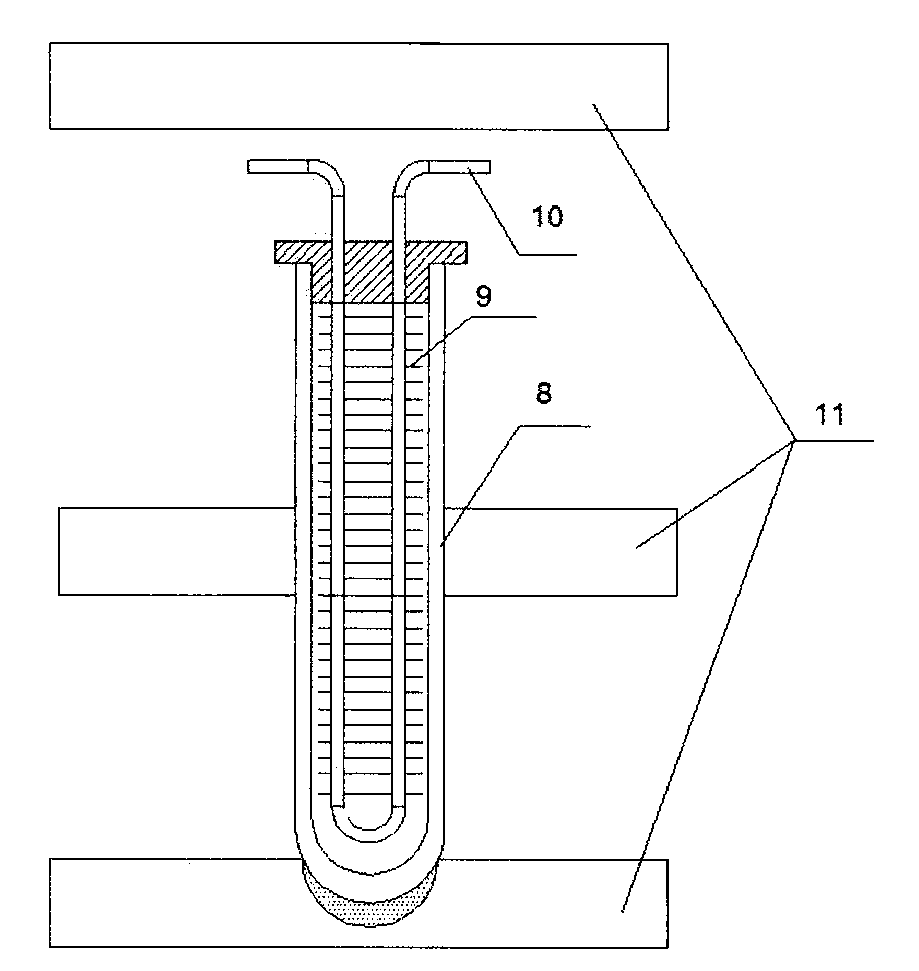

Steam generator primary-side structure capable of alleviating backflow of U-shaped pipes

ActiveCN108447569AEasy to useEliminate local backflowNuclear energy generationContainmentStraight tubeEngineering

The invention discloses a steam generator primary-side structure capable of alleviating backflow of U-shaped pipes. The steam generator primary-side structure comprises several parallel-connection U-shaped pipes, the parallel-connection U-shaped pipes comprise an inlet straight-tube segment, a bending segment and an outlet straight-tube segment, an inlet end and an outlet end of the bending segment are respectively connected with the outlet end of the inlet straight-tube segment and the outlet end of the outlet straight-tube segment, the outlet end of the inlet straight-tube segment is connected with the inlet end of the bending segment through an inlet middle header, and the inlet end of the outlet straight tube segment and the outlet end of the bending segment through an outlet middle header. Through the communication effect of the inlet middle header and the outlet middle header, the local backflow phenomenon of the straight-tube segment of the U-shaped pipes can be effectively eliminated, and the backflow of the bending segment of the U-shaped pipes can be alleviated, problems of increased flow resistance and small natural cycle driving force due to backflow can be solved, andthe usage performance of the steam generator under natural cycle condition can be obviously increased.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

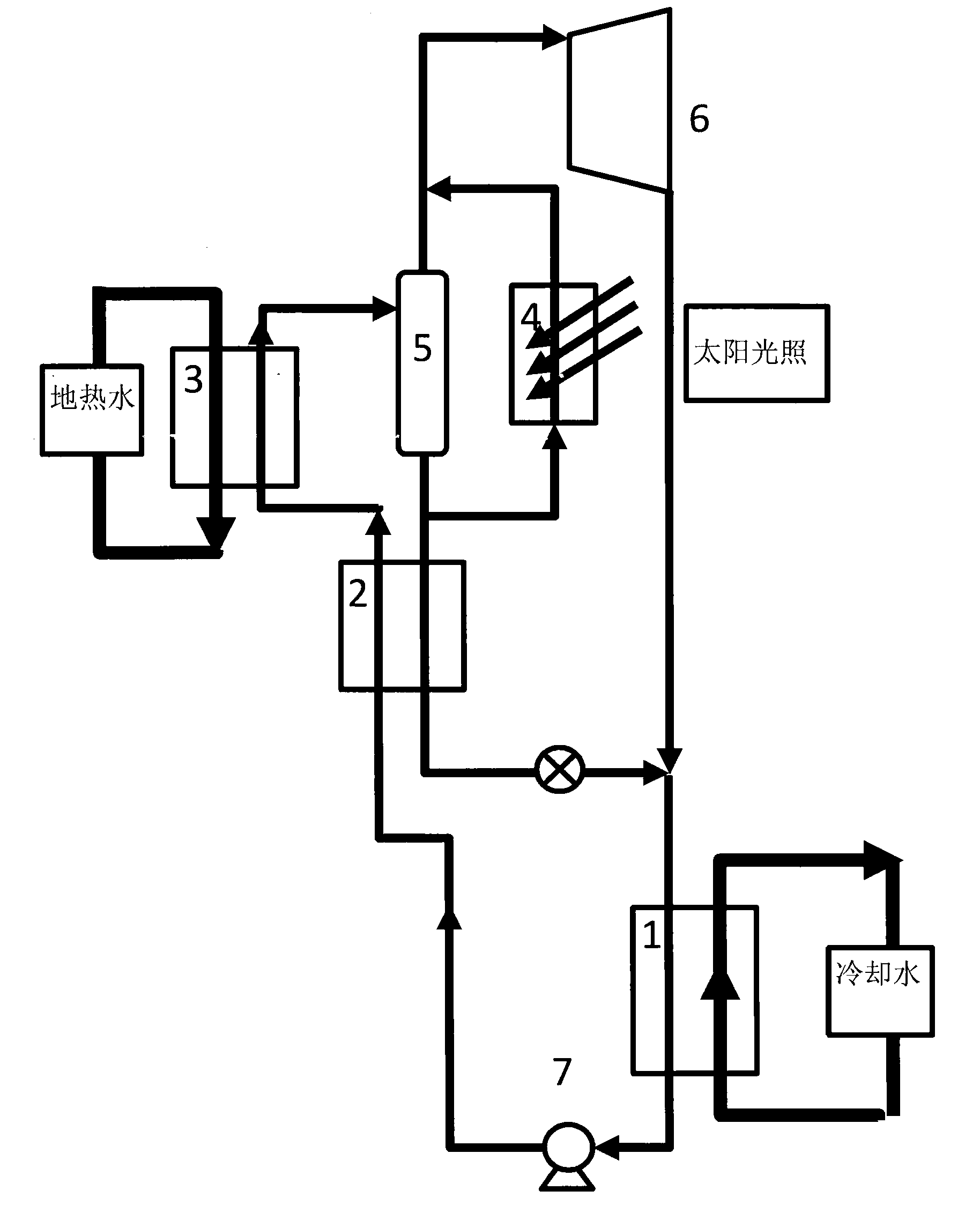

Geothermal power generation system by adopting photo-thermal twice evaporating

InactiveCN103306918AImprove protectionEfficient power generationFrom solar energyGeothermal energy generationEngineeringNatural cycle

The invention relates to a geothermal power generation system by adopting photo-thermal twice evaporating, which is characterized by comprising an evaporator, a heat regenerator, a fractional distillation and condensation unit, a solar energy ammonia heat collector, a separator, a turbonator and an ammonia supplying pump. The invention provides the geothermal power generation system by adopting the photo-thermal twice evaporating, and belongs to the field of thermoelectric conversion devices for converting geothermal energy and solar energy. Compared with the traditional geothermal power generation technology, Kalina cycle technology is adopted; a middle-low-temperature heat source is utilized; the circulating efficiency is 20 to 50 % larger than the conventional Rankine cycle in the middle-low-temperature range, which is considerable on the energy utilization; the running reliability and the power generation efficiency are improved; and the solar energy ammonia heat collector is adopted to form natural cycle with the separator to collect solar energy to enable the ammonia water to evaporate twice to produce ammonia vapour, thereby realizing efficient switch of the photo-thermal power generation on the basis of geothermal power generation. The technology is mature; the economy is feasible; and the photo-thermal conversion efficiency reaches up to more than 95% which cannot be transcended by other solar energy heat collectors.

Owner:SHANGHAI SHENGHE NEW ENERGY RESOURCES SCI & TECH

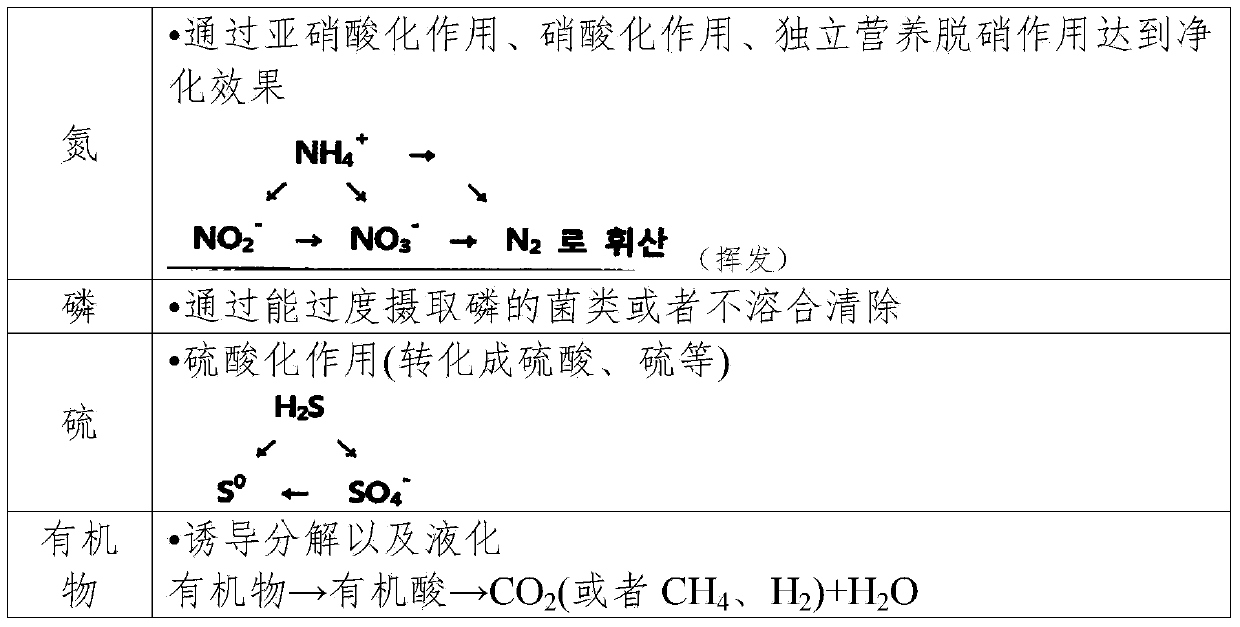

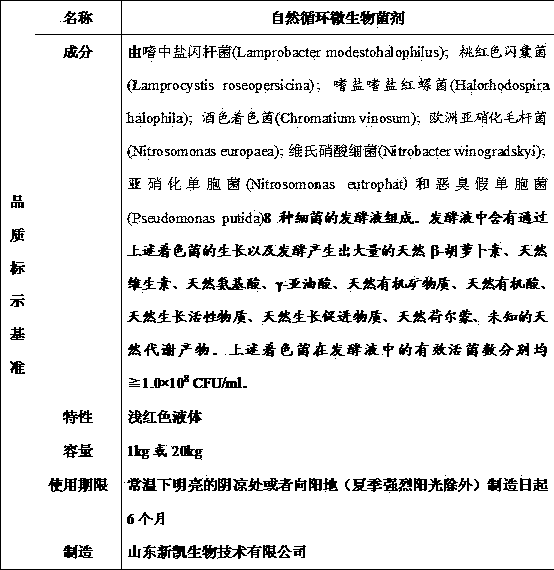

Natural cycle microbial agent for purifying water and preparation method thereof

The invention discloses a natural cycle microbial agent for purifying water and a preparation method thereof. The natural cycle microbial agent is prepared from eight bacteria of allochromatium (allochromatium), lamprocystis (lamprocystis), halorhodospira (halorhodospira), chromatium (chromatium), nitrosomonas (nitrosomonas), nitrobacter (nitrobacter), nitrosomonas (nitrosomonas) and pseudomonas (pseudomonas). The effective viable counts of the eight bacteria in a fermentation liquor respectively are greater than or equal to 1.0*10<8>CFU / ml. The microbial agent disclosed by the invention has good cleanup effects on kinds of sewages and wastewaters.

Owner:侯希波

Energy-saving low-discharge heating boiler

InactiveCN1670443ALarge furnace volumeImprove pressure resistanceWater heatersElectricityEngineering

This invention provides low energy consumption, low discharge heat supply boiler; it relates to a civil boiler that is hot water heating field. It includes up center header tank (boiler barrel), down header tank, water screen tube bundle, three return pipe rack, lateral up and down header tank (boiler barrel) and convection bank of tubes. Water screen tube bundle is connected to up center header tank and down header tank. Furnace radiation heating surface, three return flues and convection heating surface is consisted by consisted by front, back and lateral walls and furnace ceiling and three return ceiling. Two return flues or convection heating surface is consisted by convection bank of tubes connecting to up and down header tanks. Full compulsive cycle or half compulsive half natural cycle water route is consisted by setting separator, communicating tube equipment and down cast. Its technique is advanced, structure is compact, low steel consumption, low electricity consumption and low discharging and other composite benefit is very great by three space enlargement and natural economic flow speed in furnace. Its technique feature can be widely used in civil boiler.

Owner:王森

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com