Patents

Literature

35 results about "Ejection velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An ejection seat is test-fired at NASA to analyze the seat's ability to perform a zero-altitude, zero-velocity ejection. Ejecting from an airplane is a violent sequence of events that places the human body under an extreme amount of force.

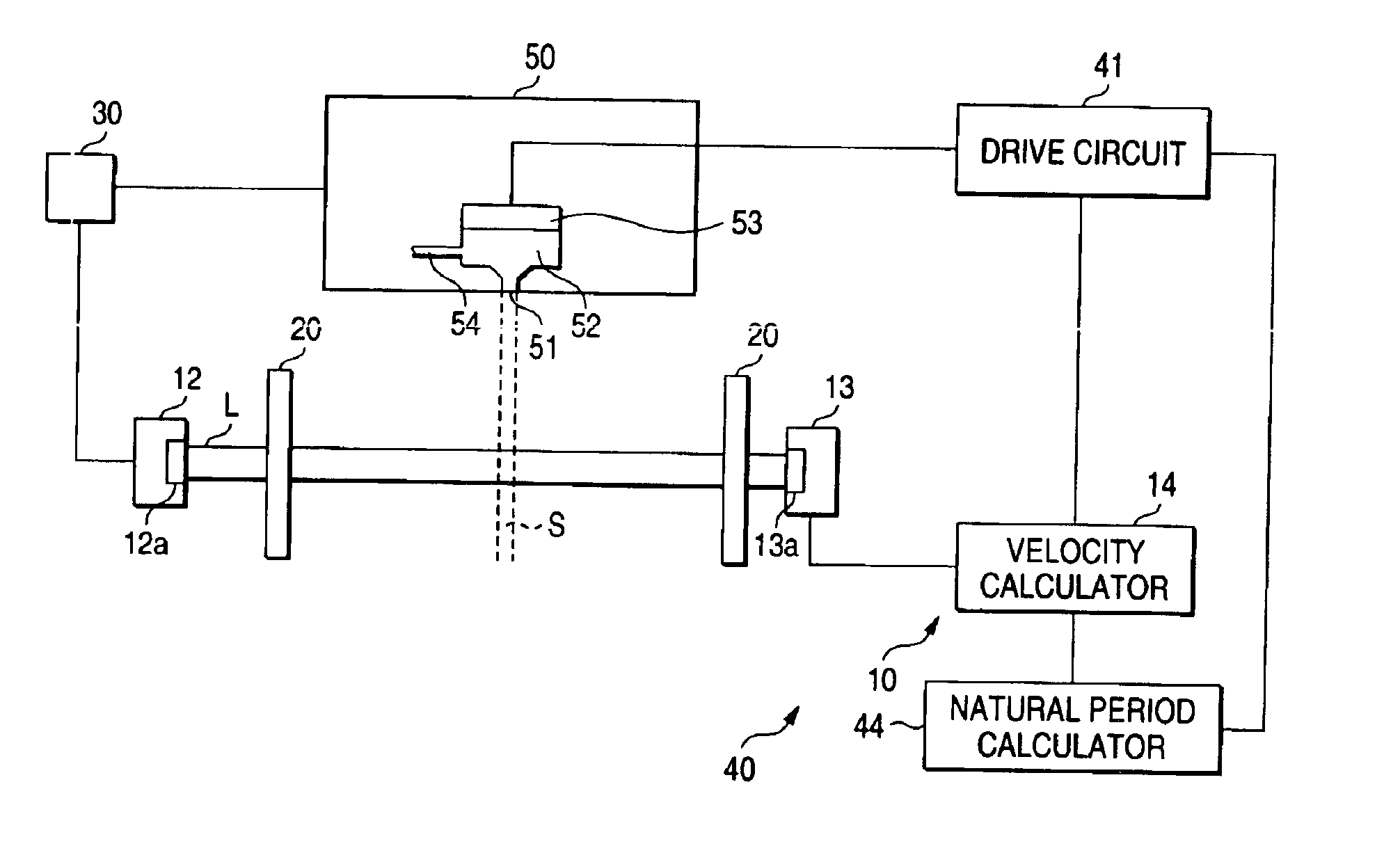

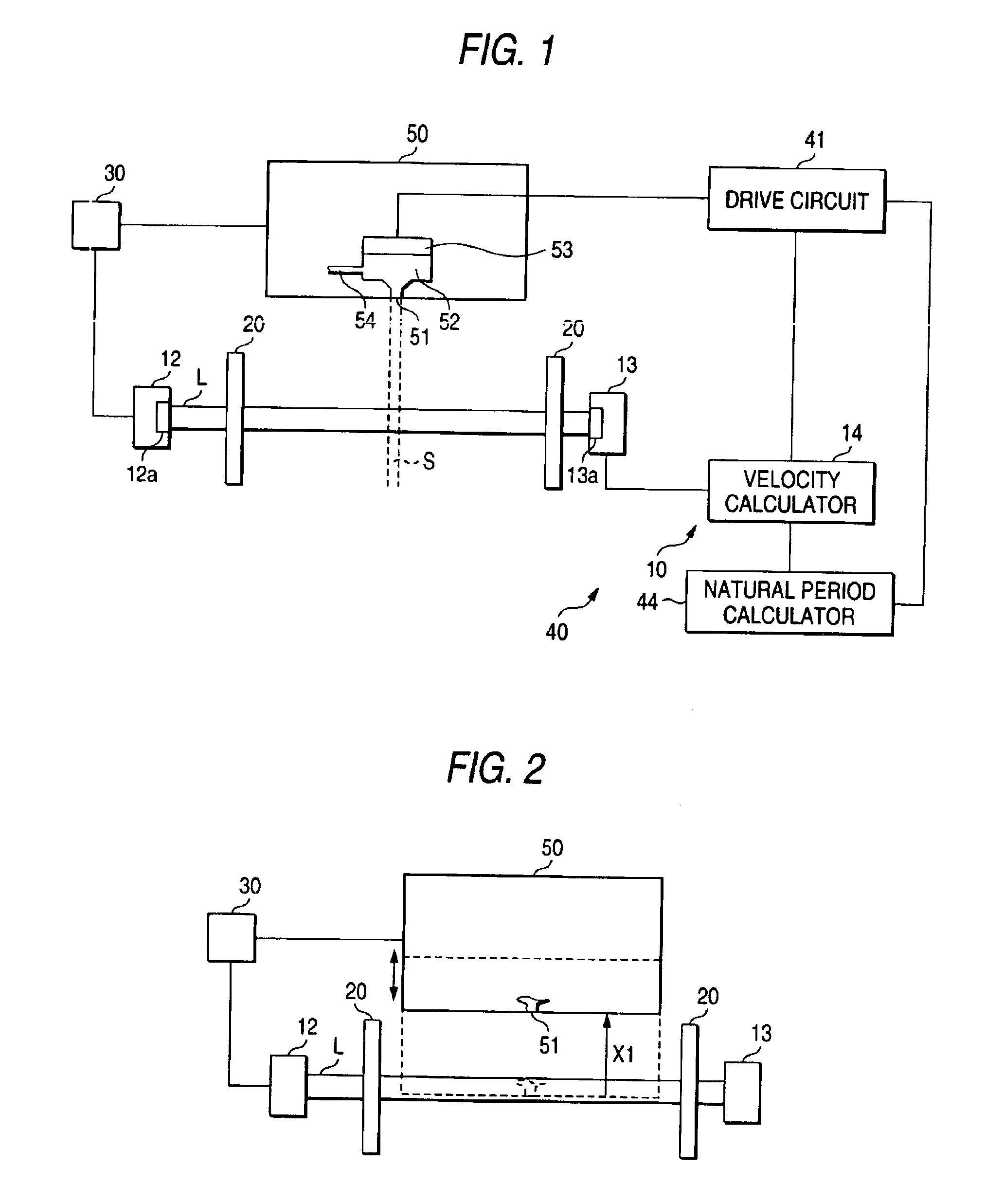

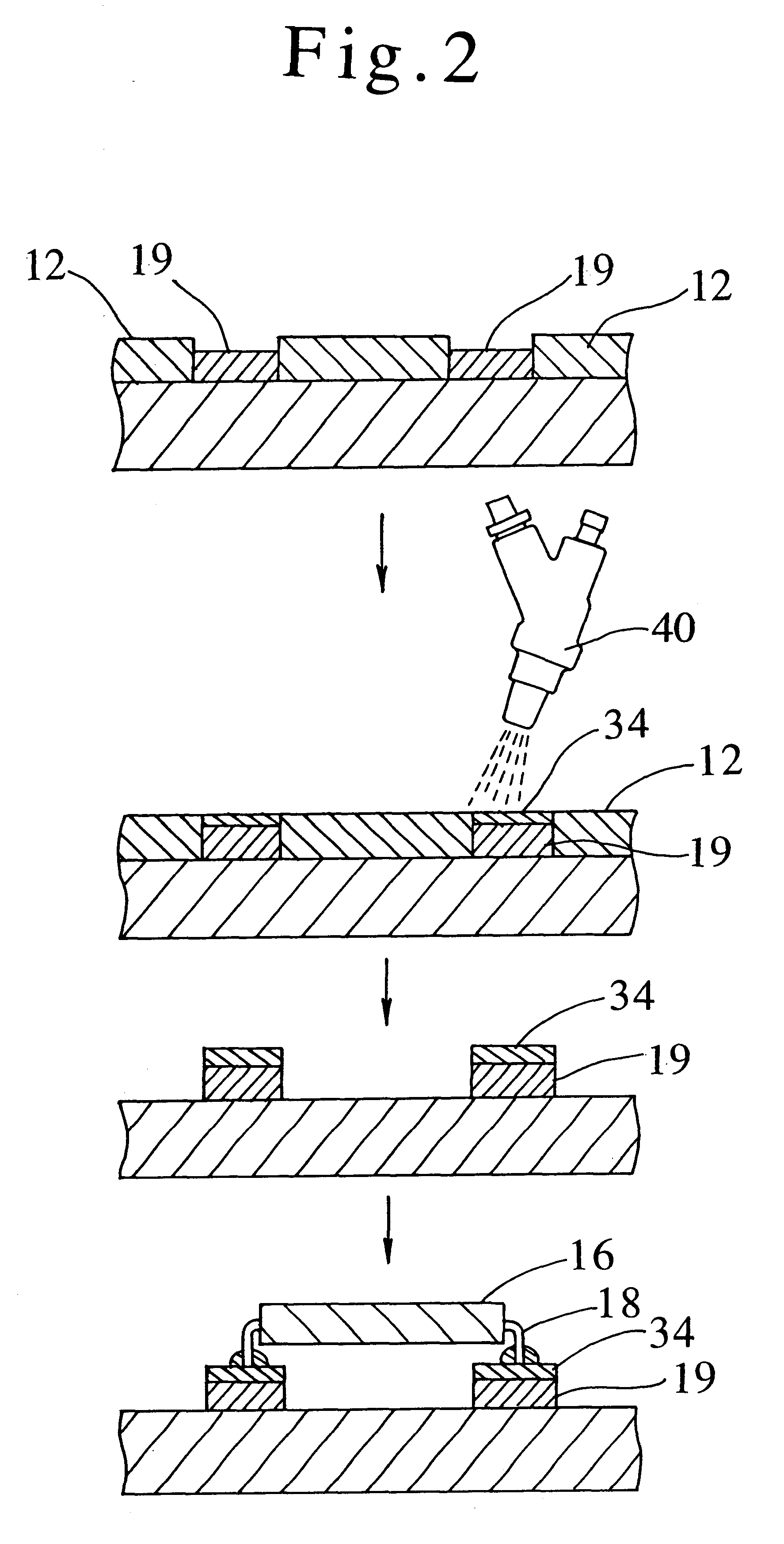

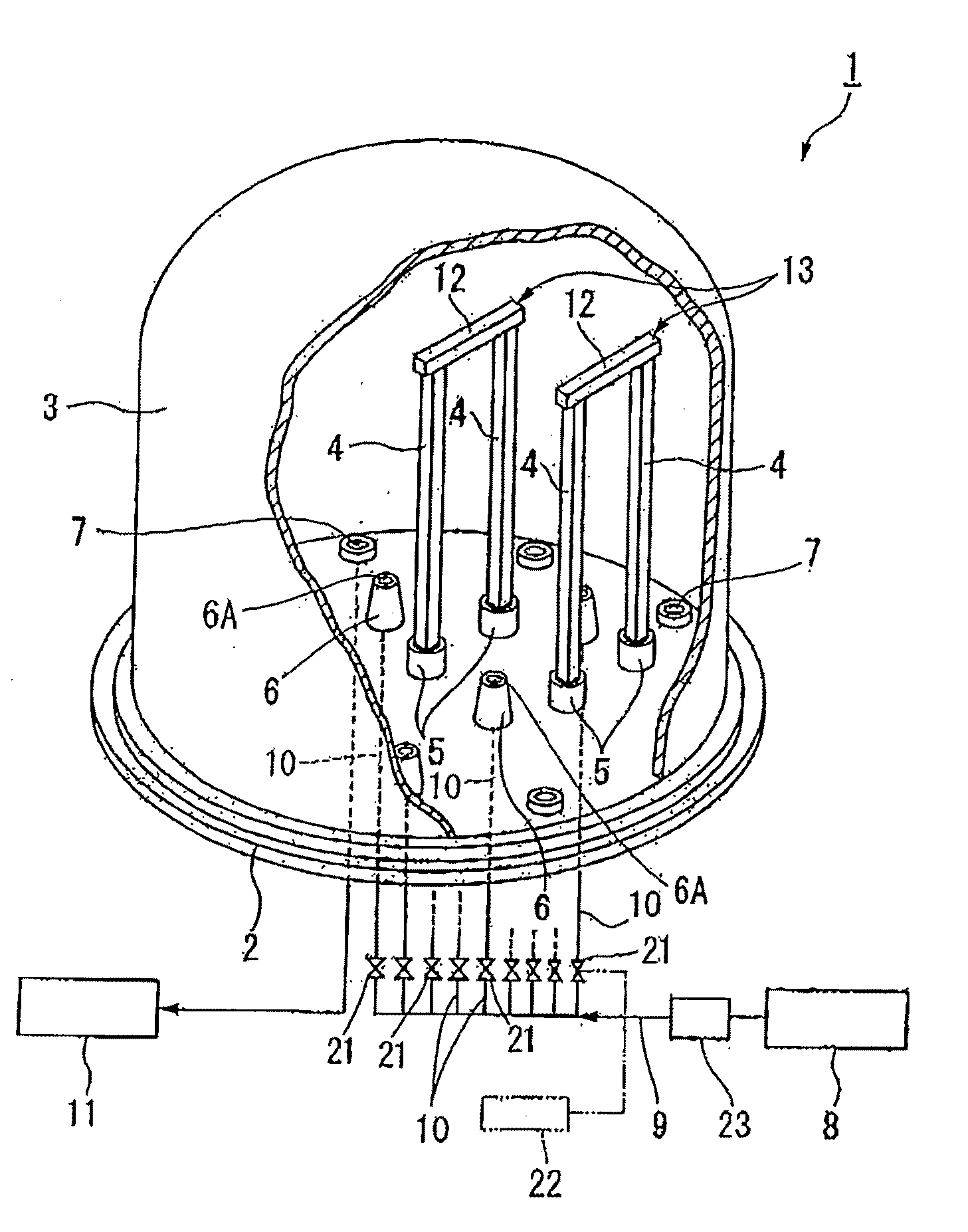

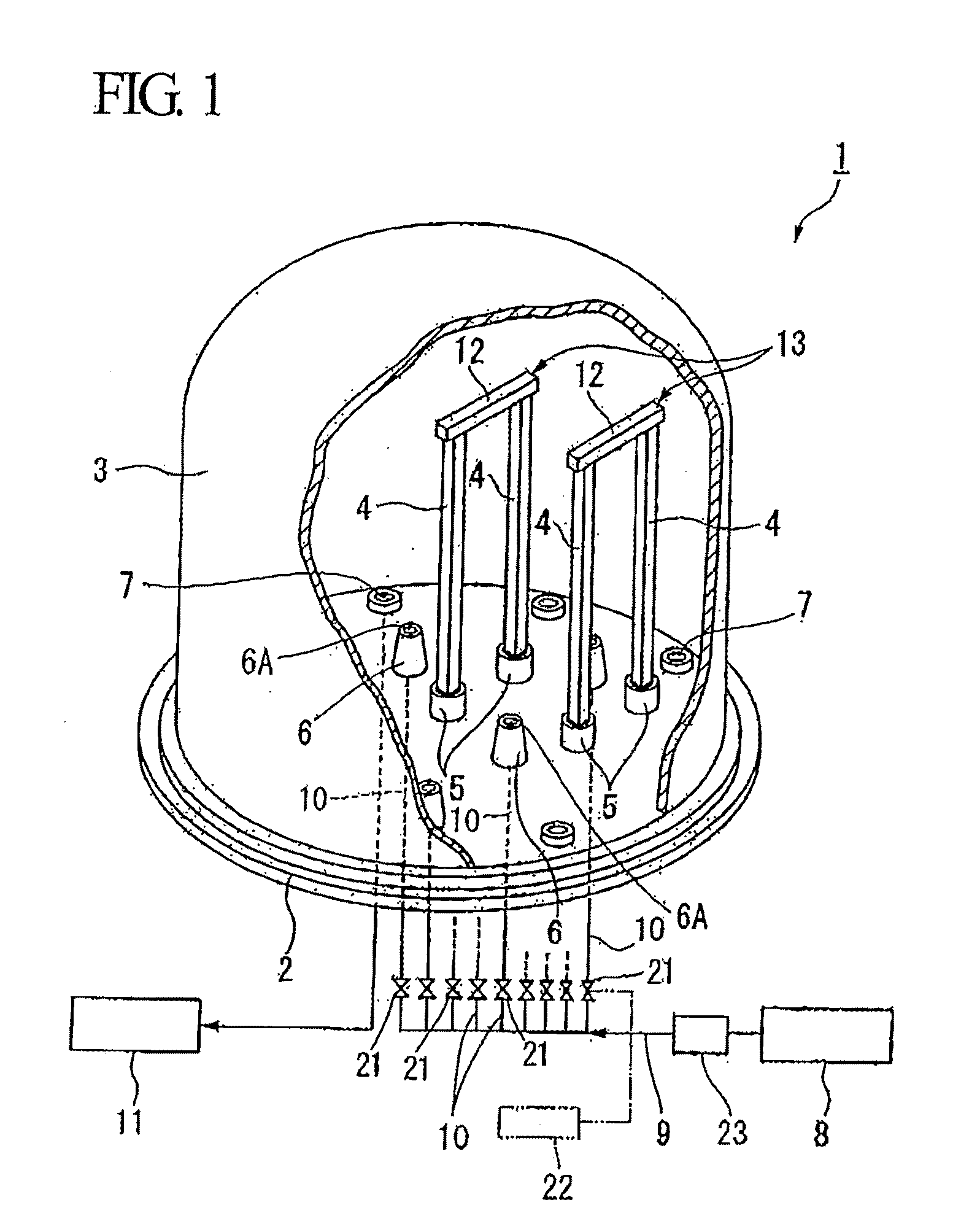

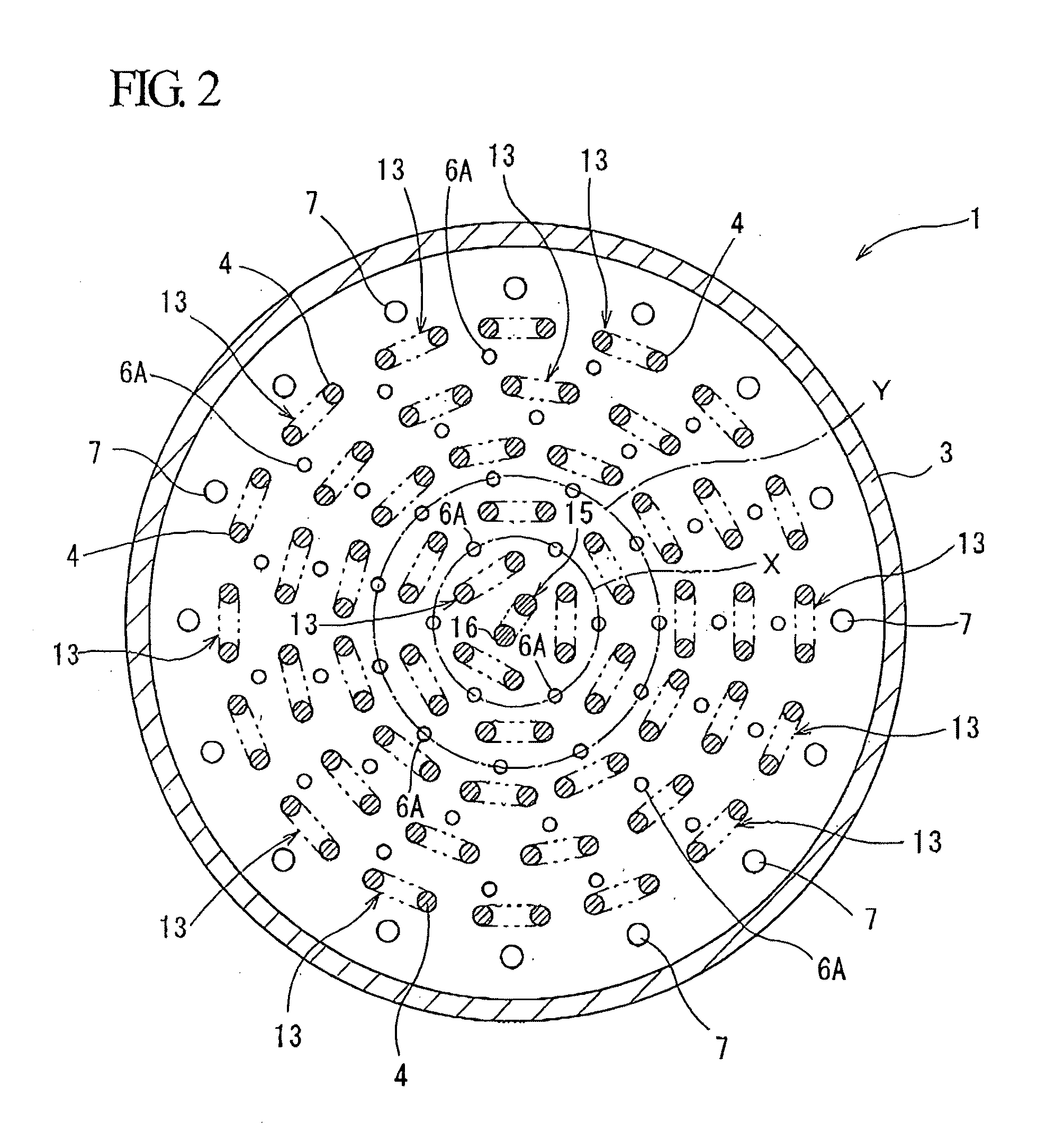

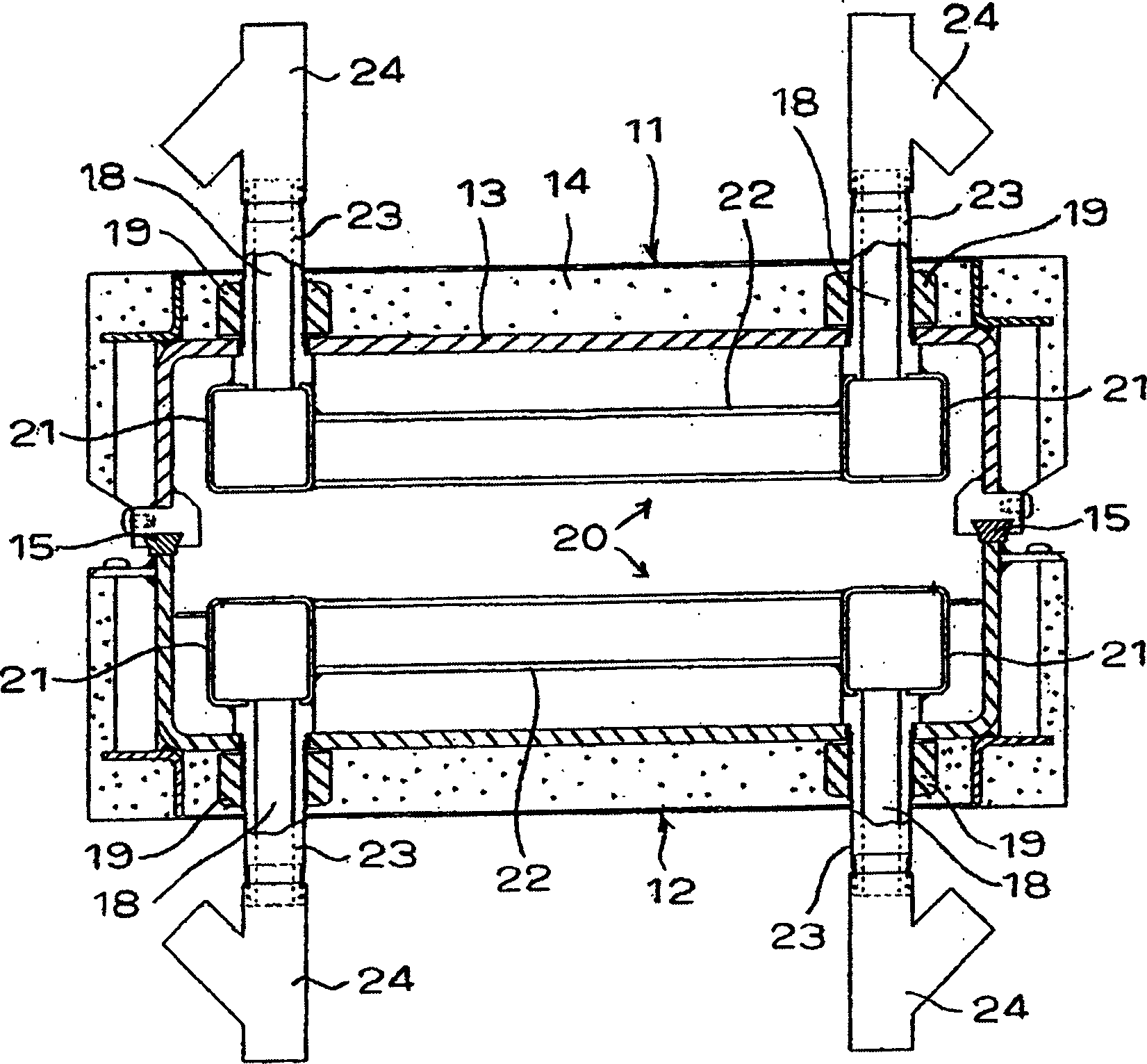

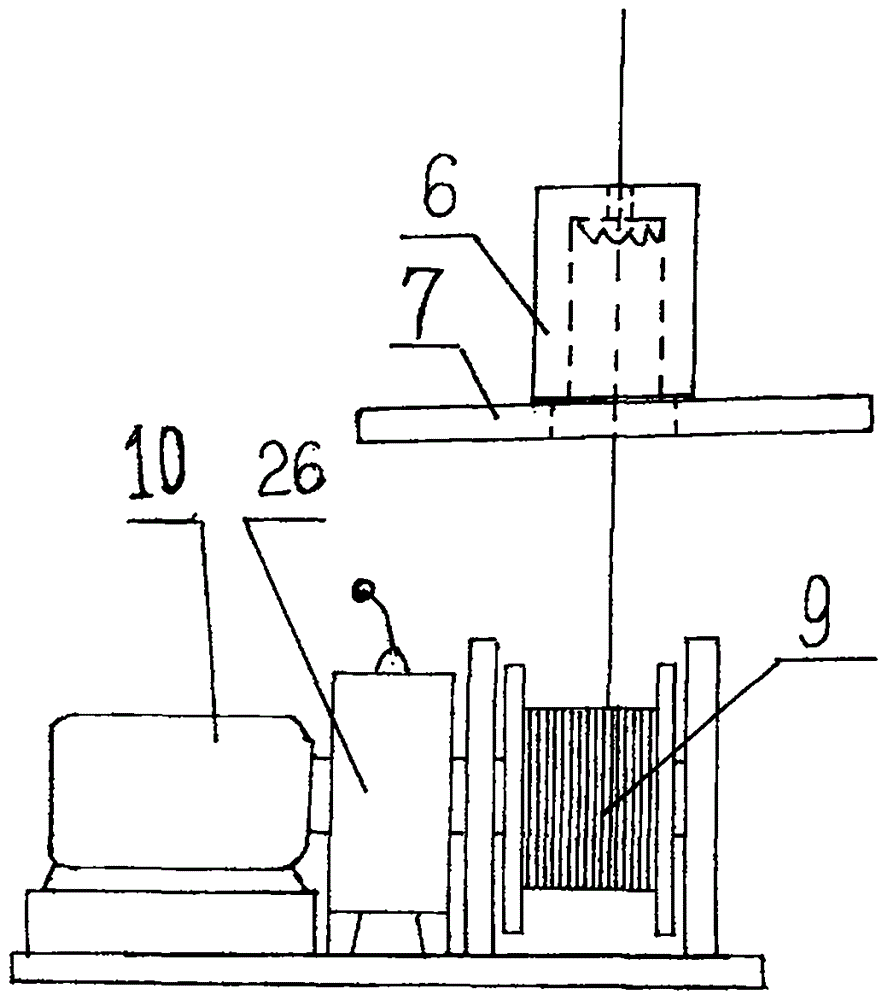

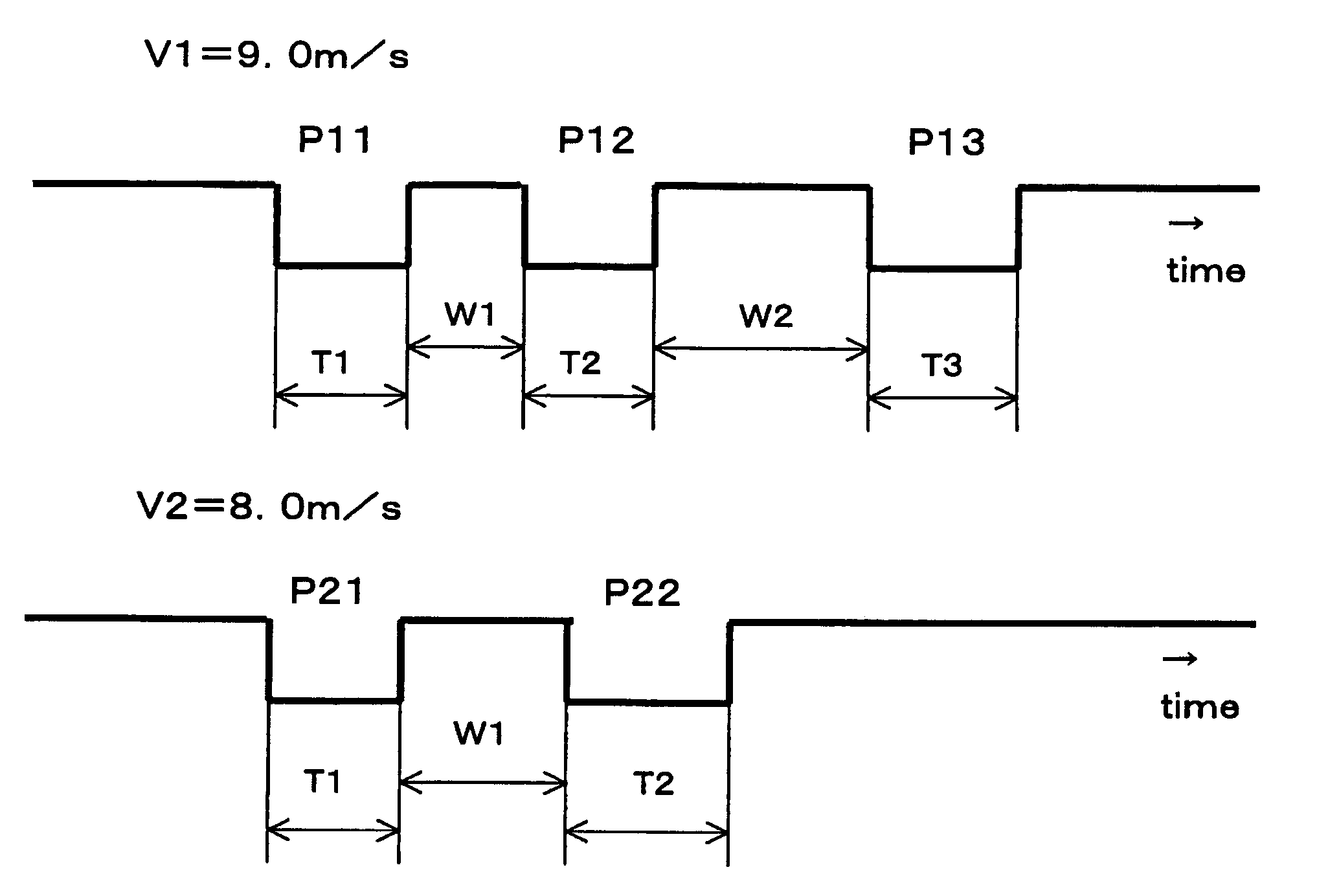

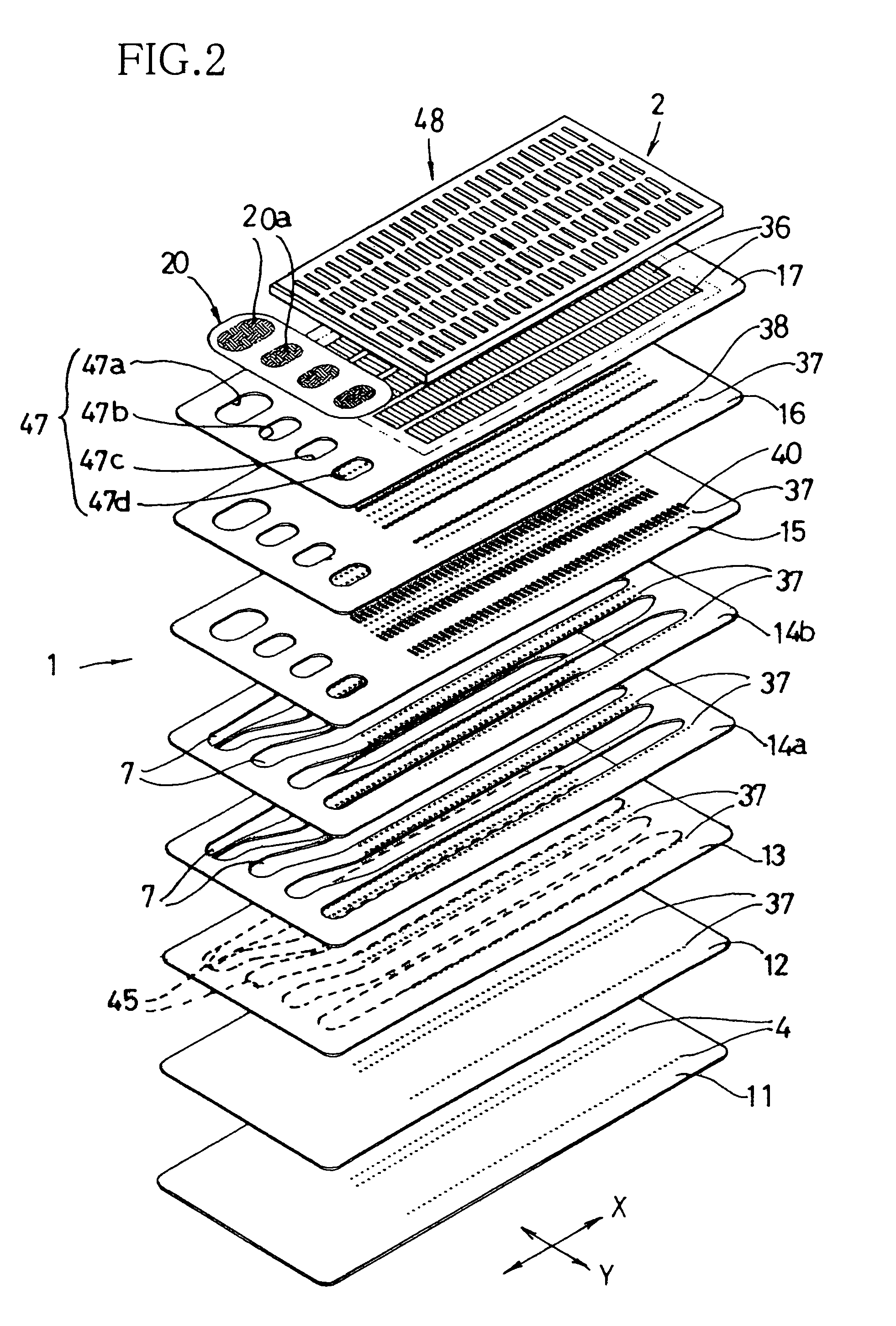

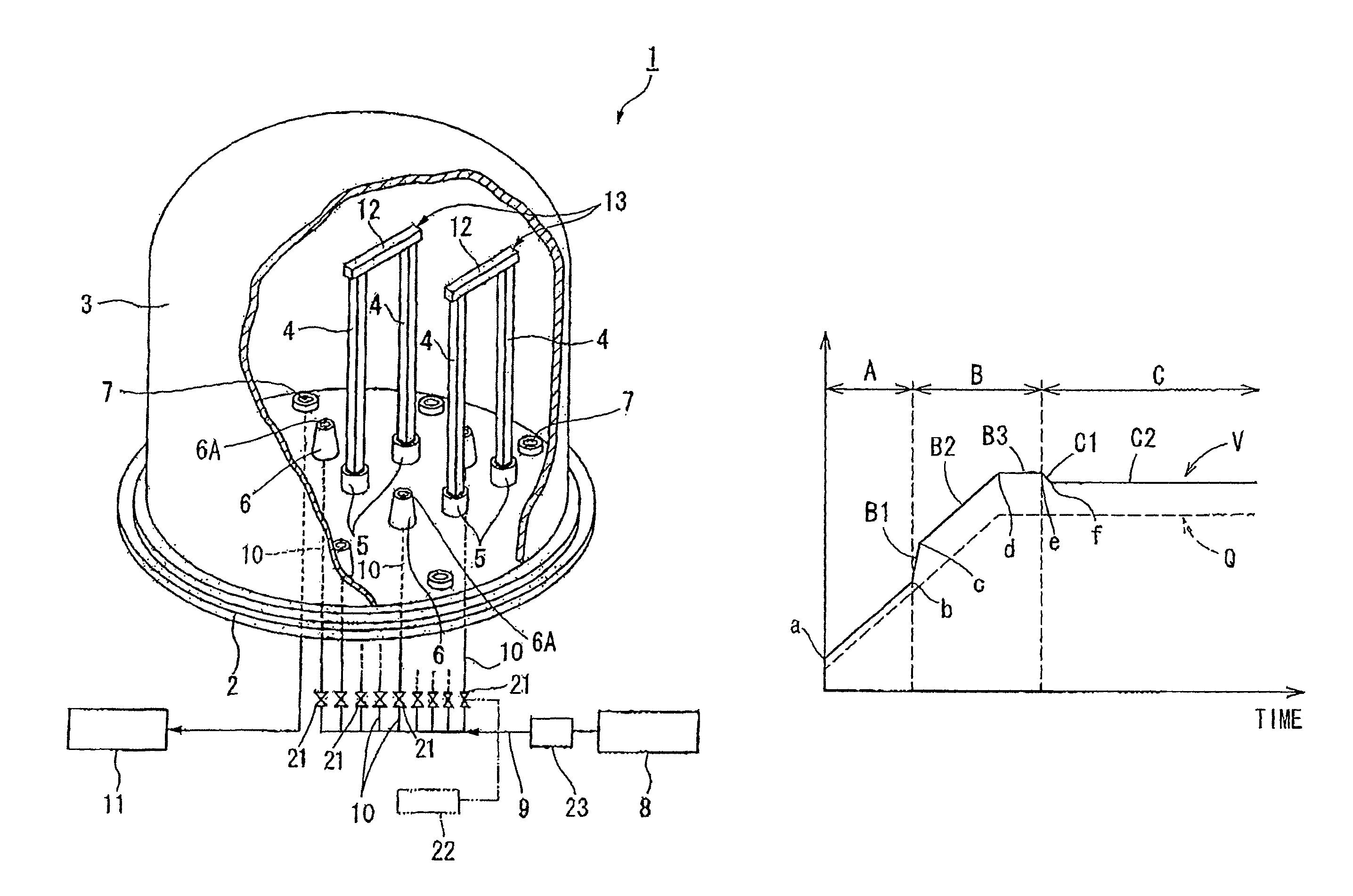

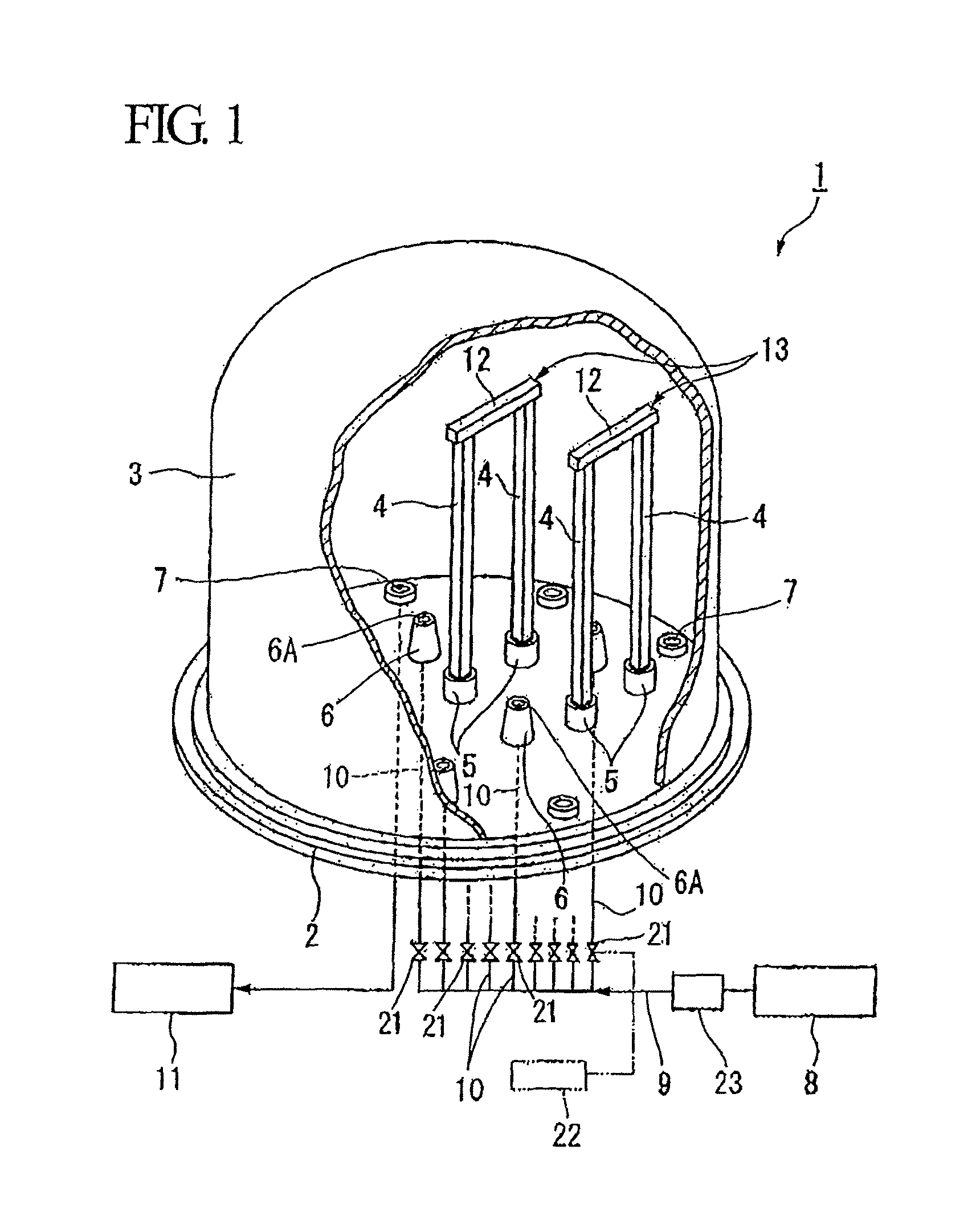

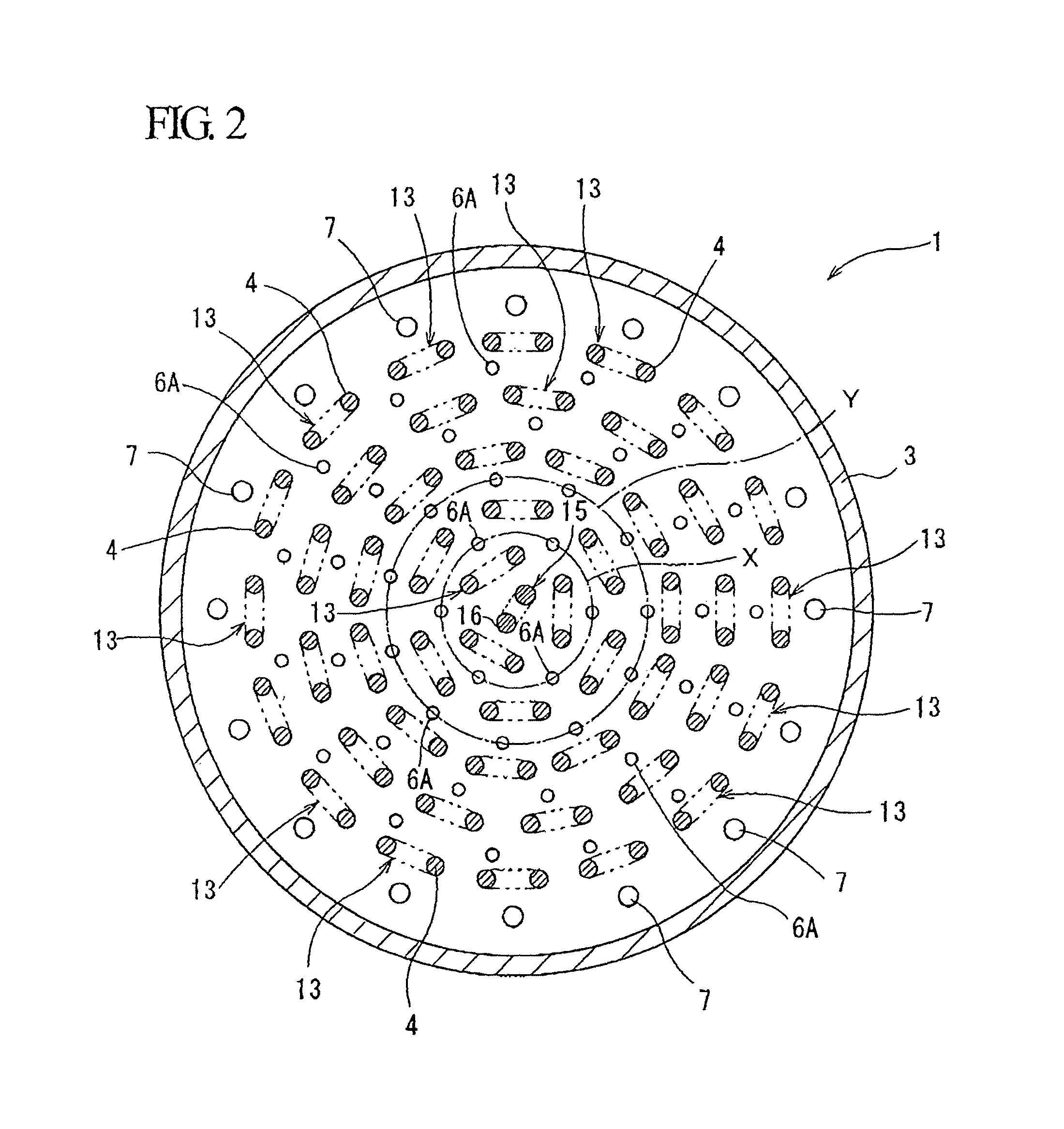

Apparatus and method for measuring natural period of liquid

InactiveUS6858860B2Improve accuracySolve the lack of durabilityInvestigating moving fluids/granular solidsScattering properties measurementsLight beamEngineering

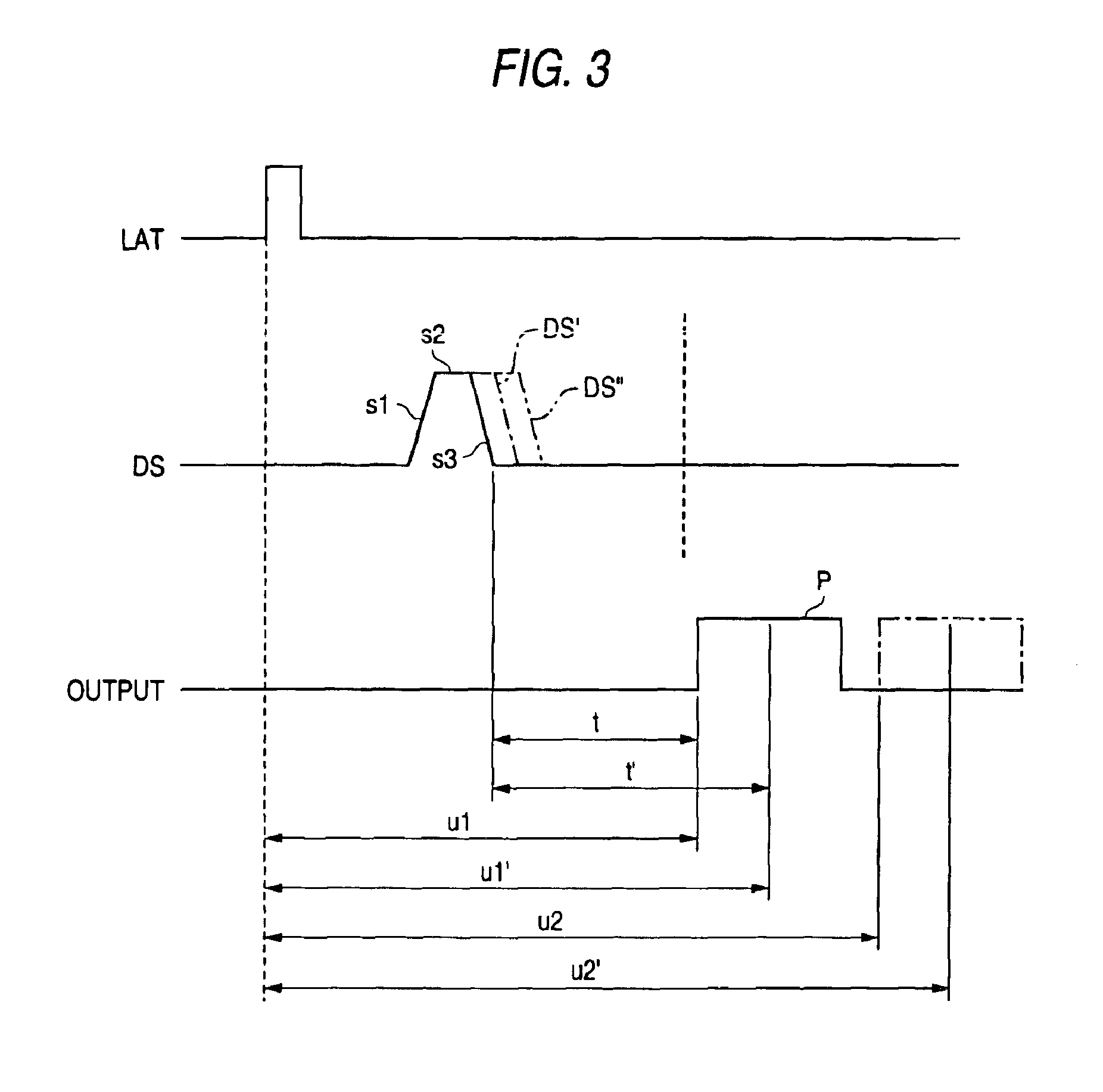

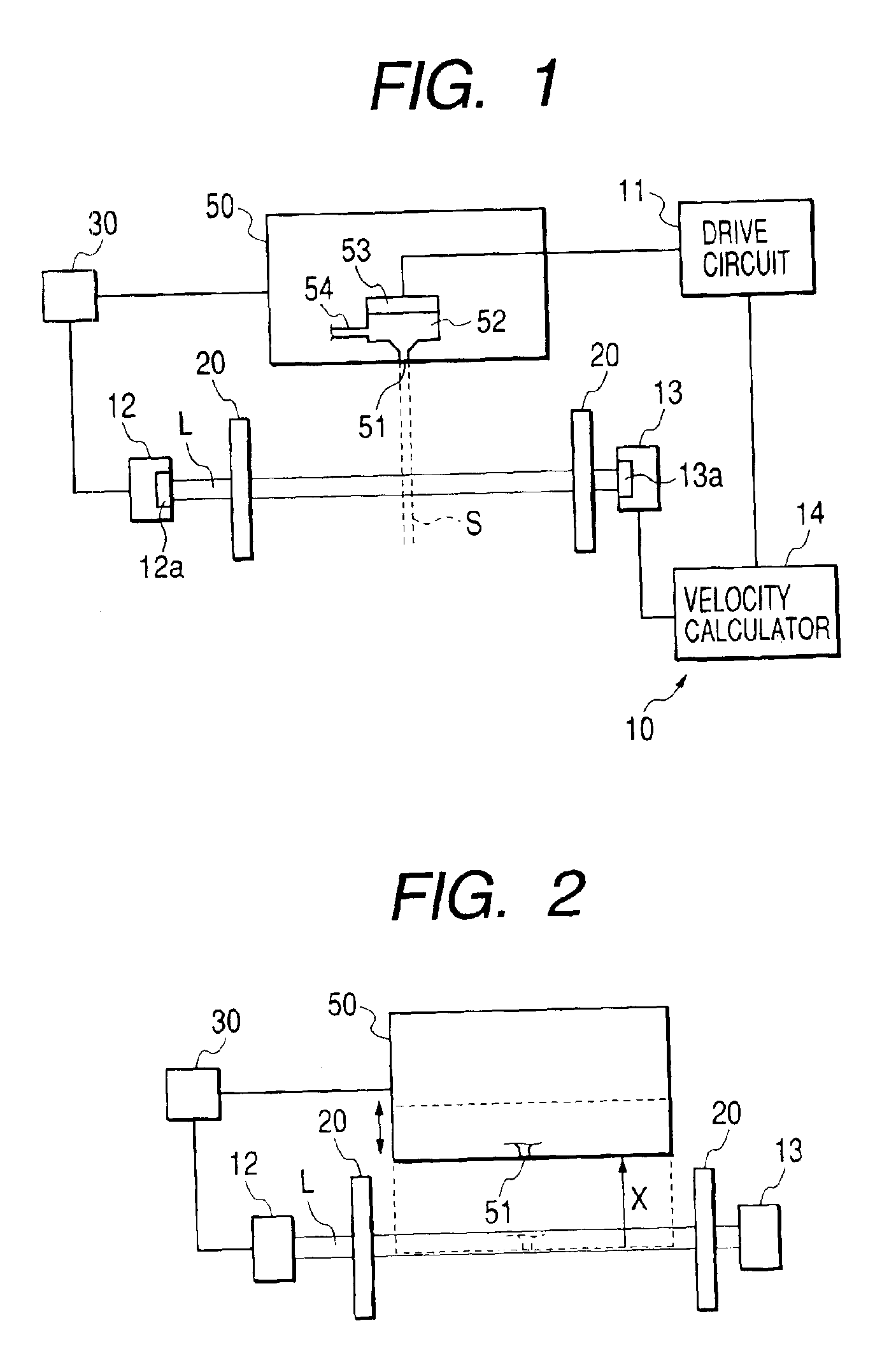

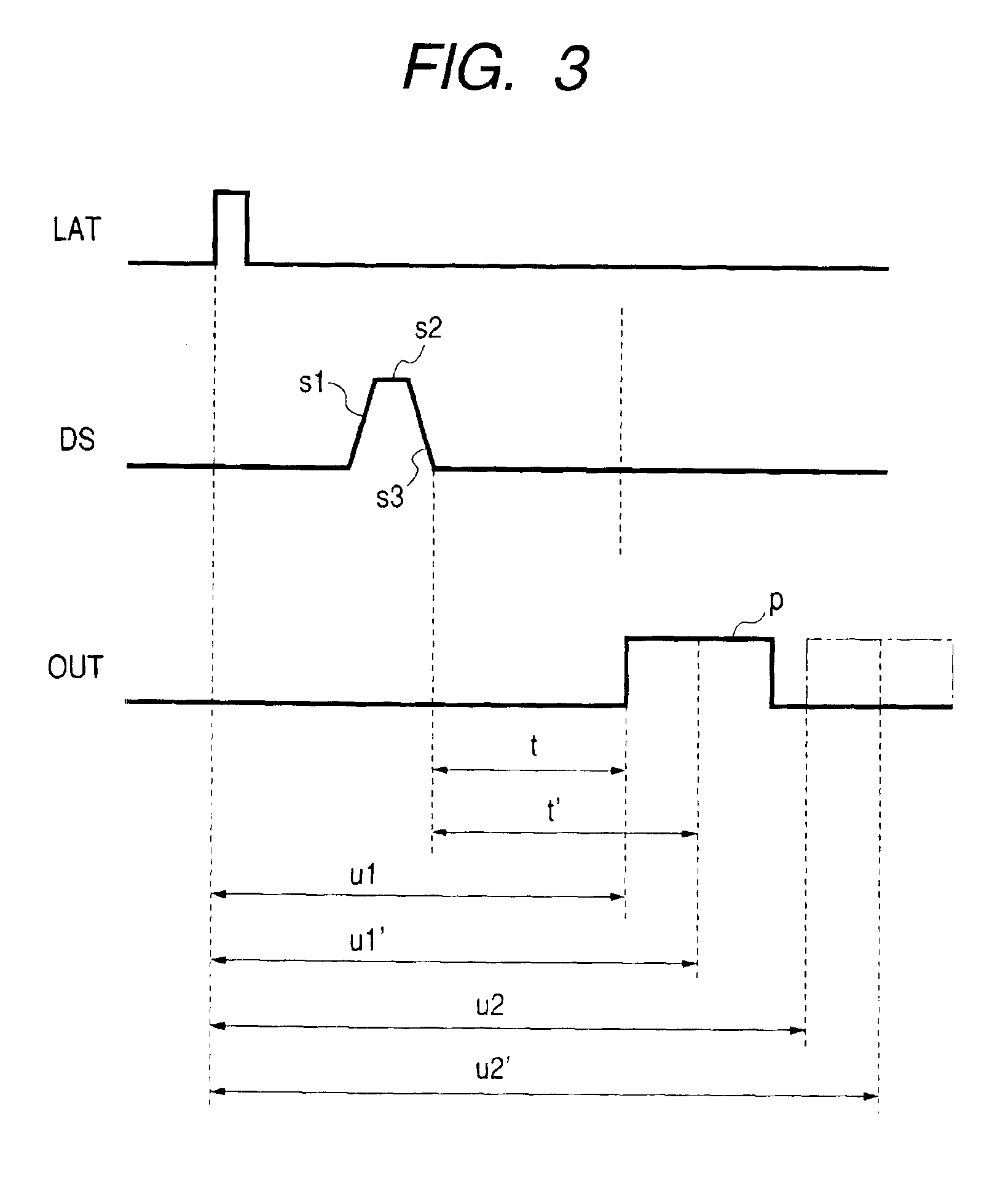

In an apparatus for measuring a natural period of liquid in a pressure chamber formed in a head device which is provided with a nozzle orifice communicated with the pressure chamber and an actuator which varies pressure of the liquid contained in the pressure chamber, a driver generates a plurality of drive signals, each of which drives the actuator to eject a liquid droplet from the nozzle orifice under a condition different from the conditions established by the other drive signals. A light emitter emits a light beam so as to intersect a space through which the liquid droplet passes. A light receiver receives the light beam which has been passed through the space. A first calculator calculates an ejection velocity of the liquid droplet based on a timing at which the actuator is driven and a change in a photo-receiving state of the light receiver, with regard to every drive signal. A second calculator calculates a natural period of the liquid based on a change in the ejection velocity which is obtained from the plural drive signals.

Owner:SEIKO EPSON CORP

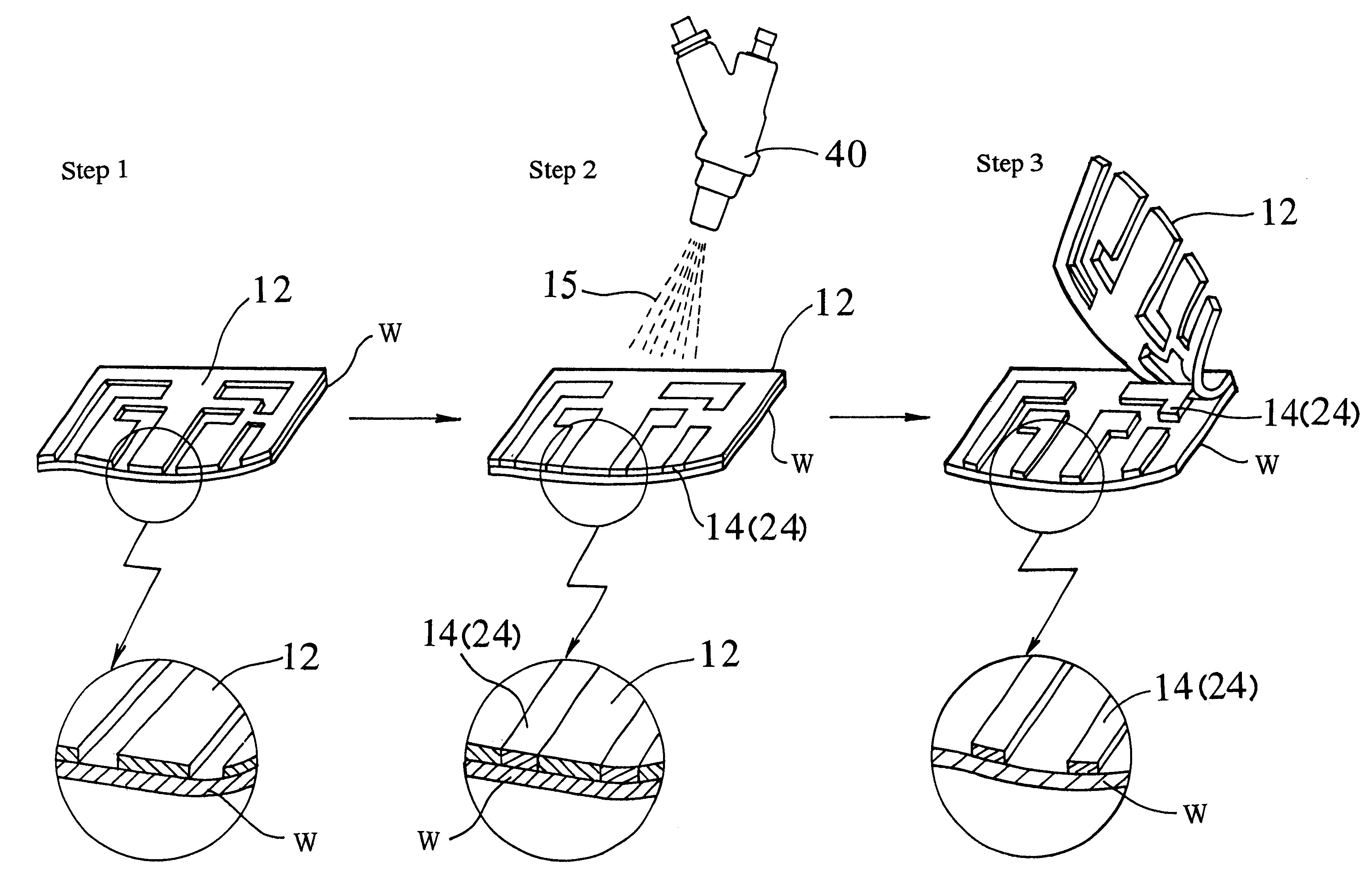

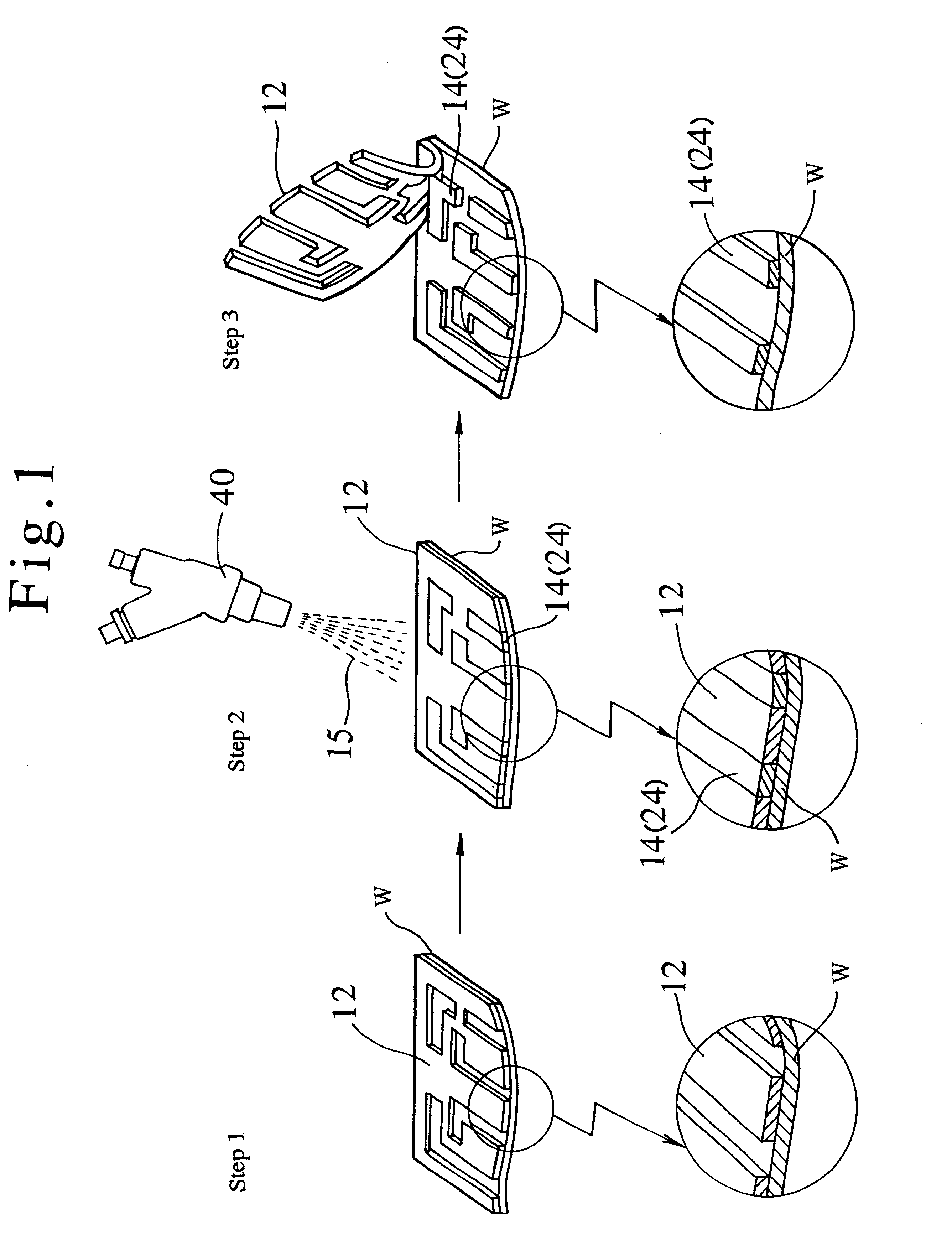

Method for forming a metallic coat by impacting metallic particles on a workpiece

InactiveUS6291012B1Prevent nitridingHigh densityPretreated surfacesSolid state diffusion coatingAbrasive blastingUltimate tensile strength

Method for forming metallic coat where, the surface of workpiece is partly covered with a masking material having a predetermined pattern, and metallic powders are ejected to the surface at the ejection velocity of 80 m / sec or higher or at the ejection pressure of 0.3 Mpa or higher by utilizing an ejection apparatus such as blast work apparatus, in order to easily attain the metallic coat having high adhesion strength without washing process, nor heat process by a relatively simple facility.

Owner:FUJI KIHAN CO LTD

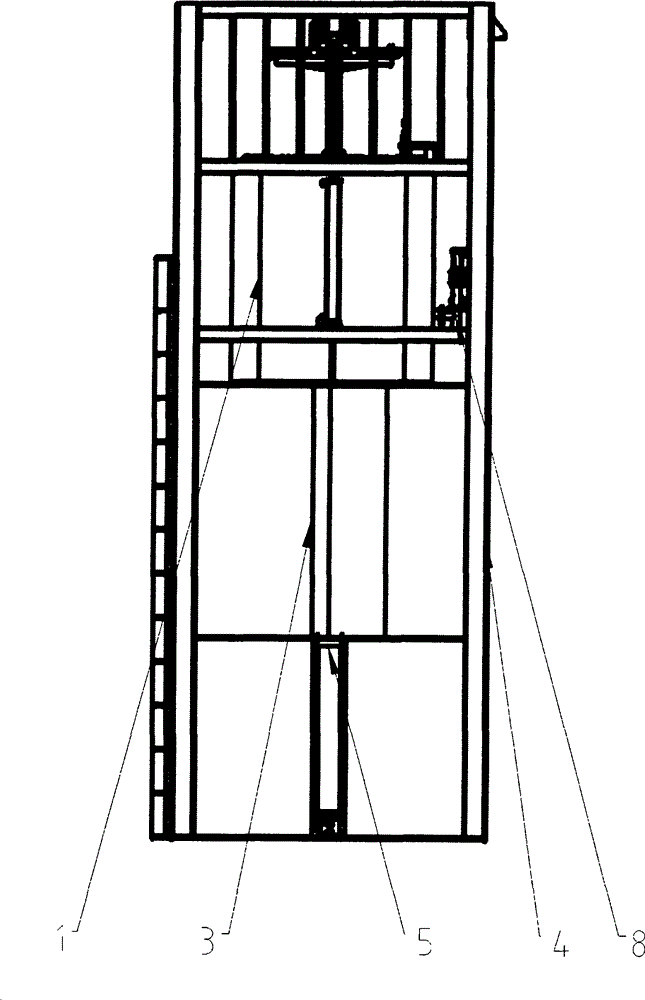

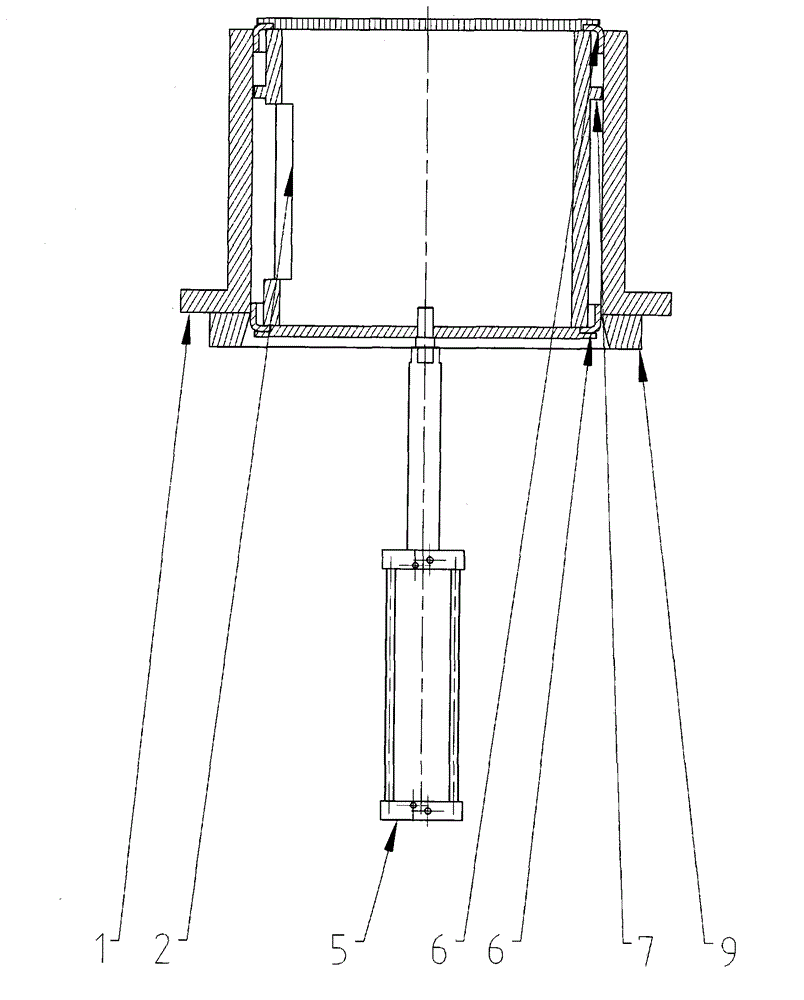

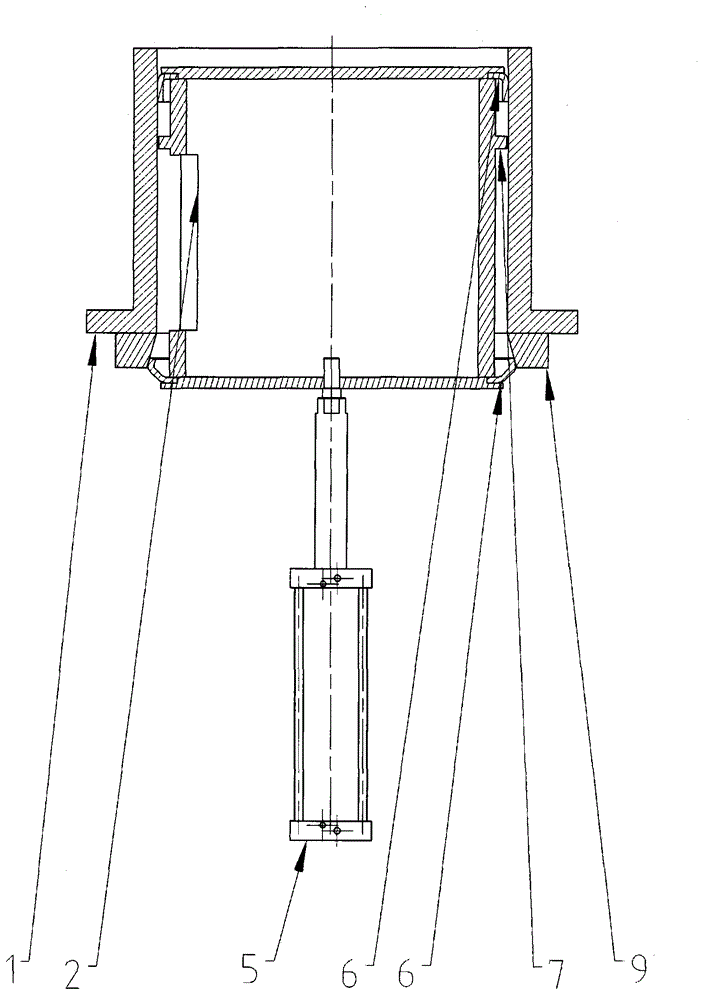

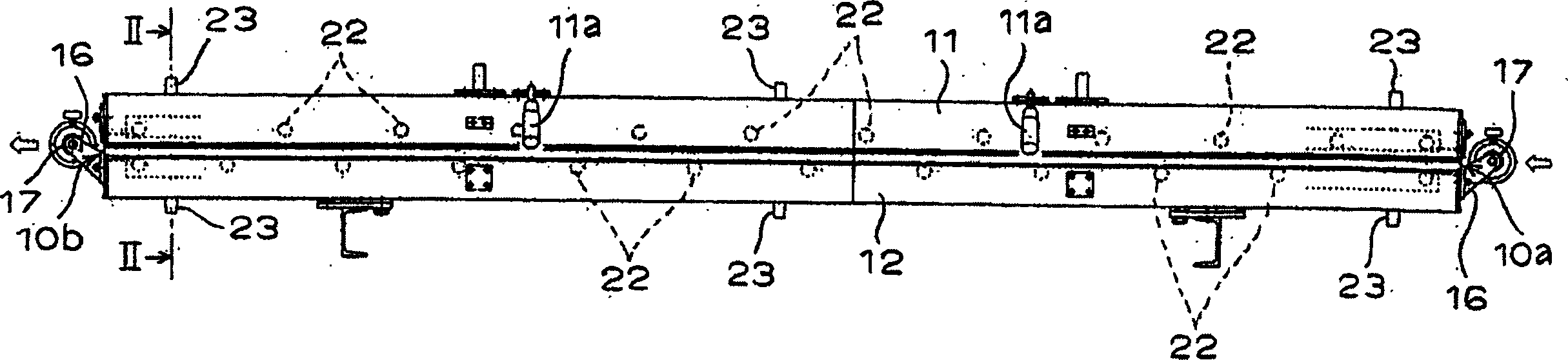

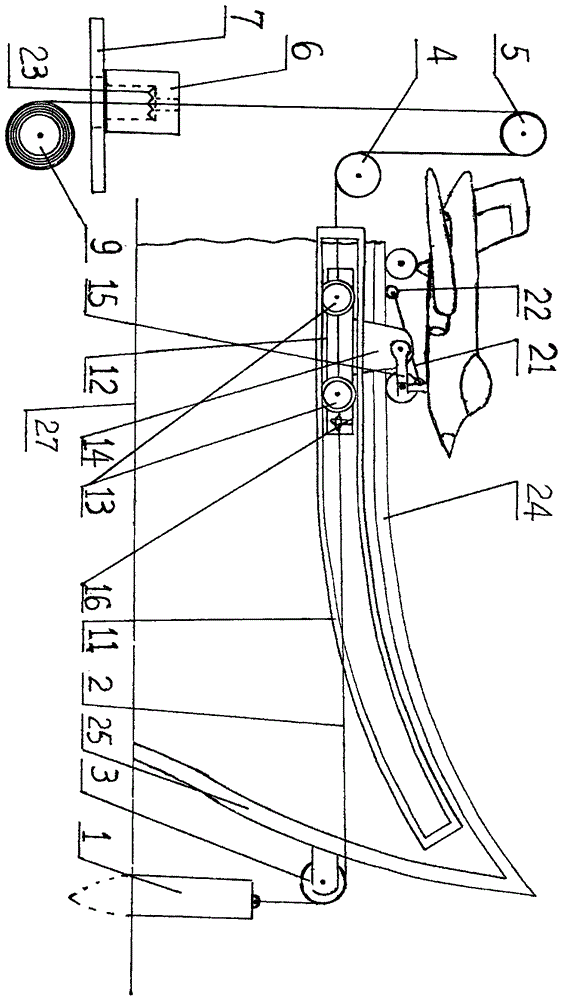

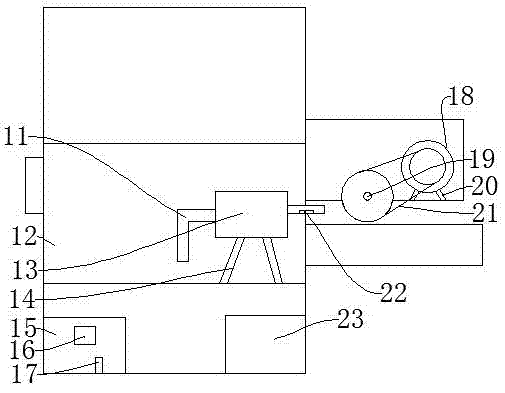

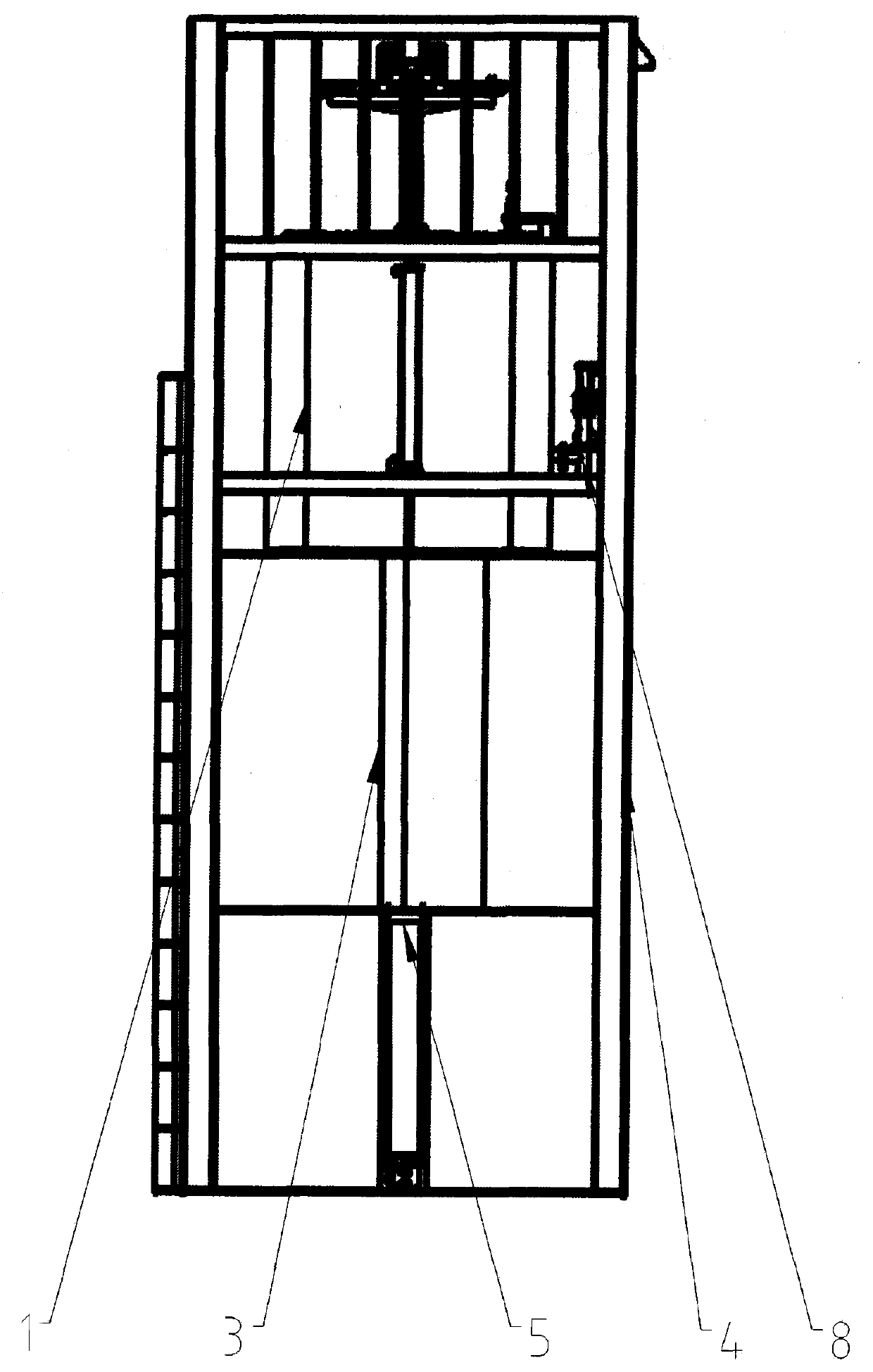

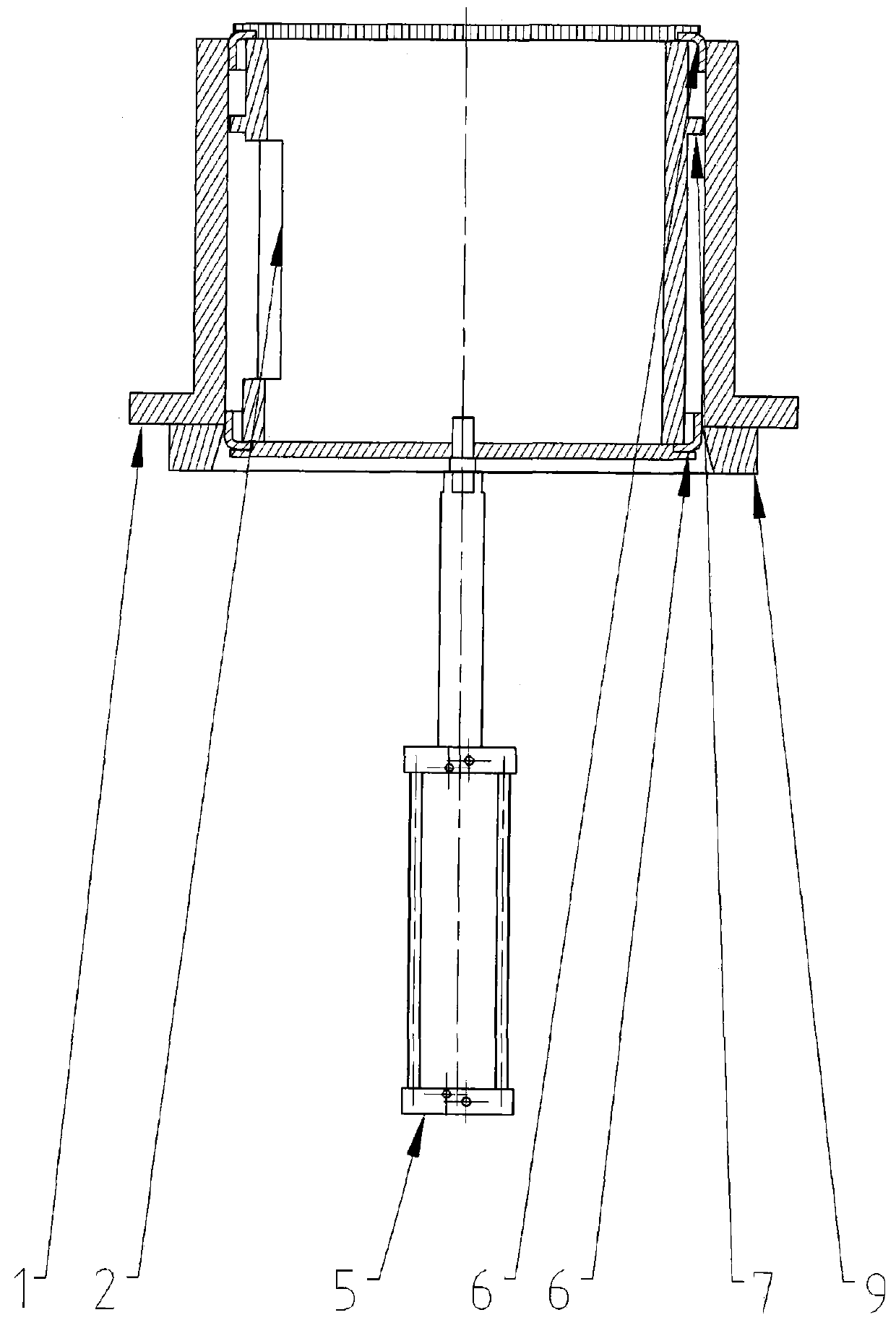

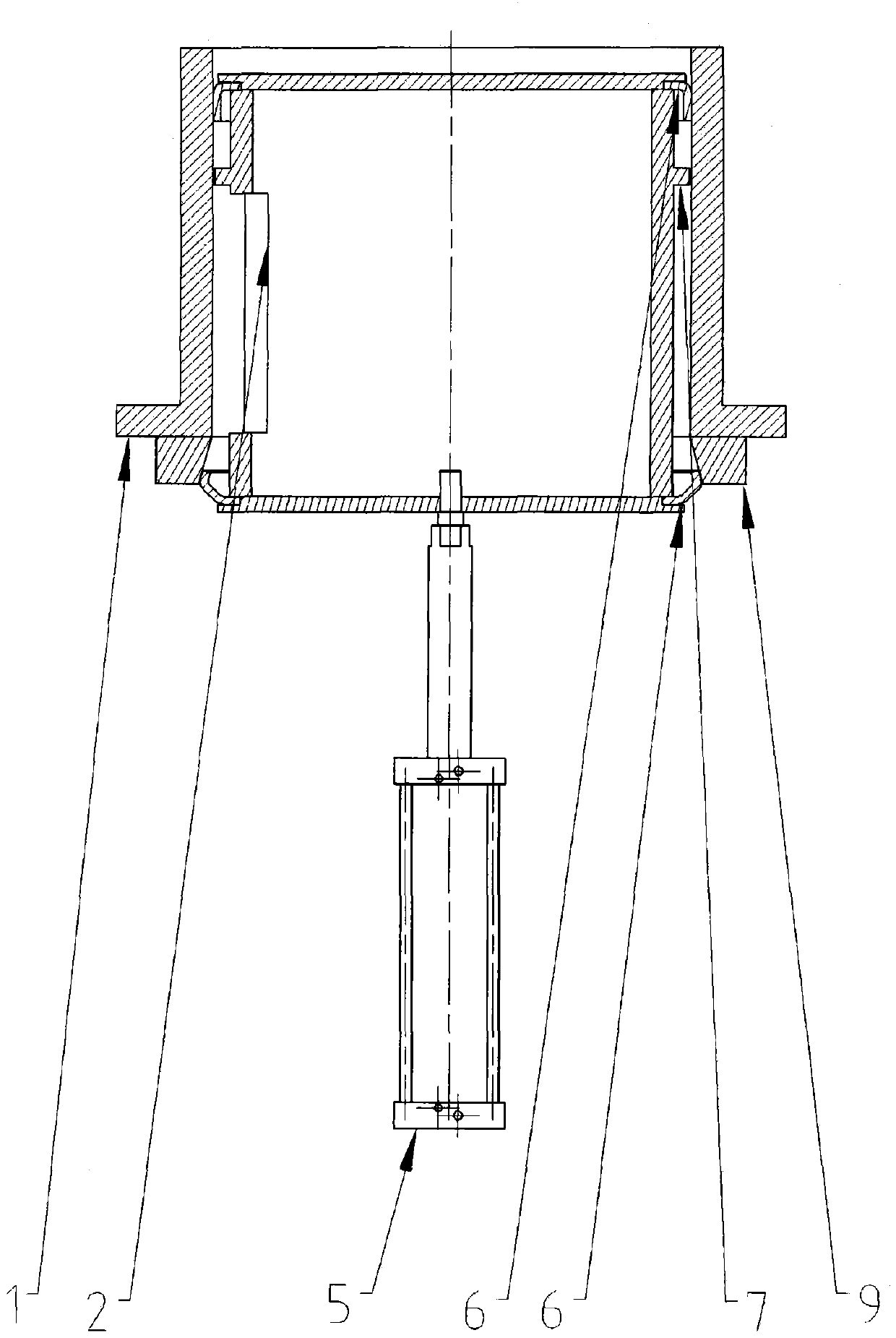

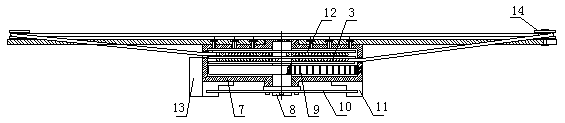

Instantaneous ejection type steam explosion machine

ActiveCN105642188AAchieving suddennessGuarantee the same effect of steam explosionPressurized chemical processProcess scaleTime extension

The invention relates to production equipment for steam explosion treatment of micropore structure substances, and the equipment is key treatment equipment of biomass utilization, biochemical engineering, fermentation brewing, solid waste treatment and other industries. The invention provides an instantaneous ejection type steam explosion machine utilizing the steam ejection principle to complete the steam explosion process. Opening of an explosion channel of the steam explosion machine utilizes the steam ejection pressure generated by section difference, thus overcoming the problem of prolonged deflation time along with treatment volume increase in traditional hot blow process. With the increase of the cylinder volume, the section difference also increases accordingly, so that the cylinder ejection velocity can maintain consistent, thus laying the foundation for process scale-up.

Owner:中集竹链科技有限公司

Method for manufacturing polycrystalline silicon

ActiveUS20090136666A1Uniform surface topographyEfficient growth processVacuum evaporation coatingSputtering coatingRough surfacePolycrystalline silicon

A method for manufacturing polycrystalline silicon with high quality by effectively preventing undesired shape such as giving an rough surface to silicon rods or an irregularity in diameter of the silicon rods. The method for manufacturing polycrystalline silicon includes: an initial stabilizing step of deposition wherein a velocity of ejecting the raw material gas from the gas ejection ports is gradually increased; the shaping step wherein first the ejection velocity is increased at a rate higher than that in the stabilizing step and then the ejection velocity is gradually increased at a rate lower than the previous increasing rate; and a growing step wherein, after the shaping step, the ejection velocity is made slower than that at the end of the shaping step until the end of the deposition.

Owner:HIGH-PURITY SILICON CORP

Instrument and method for measuring ejection velocity of liquid

InactiveUS6897466B2Accurate measurementShort timeInvestigating moving fluids/granular solidsScattering properties measurementsLight beamActuator

In an apparatus for measuring an ejection velocity of a liquid droplet ejected from a nozzle orifice of a head device which is provided with a pressure chamber communicated with the nozzle orifice and an actuator which varies pressure of liquid contained in the pressure chamber, a driver generates a drive signal to drive the actuator to eject a liquid droplet from the nozzle orifice. A photo emitter emits a light beam so as to intersect a space through which the liquid droplet passes. A photo receiver receives the light beam which has been passed through the space. A calculator calculates an ejection velocity of the liquid droplet based on a timing at which the actuator is driven and a change in a photo-receiving state of the photo receiver.

Owner:SEIKO EPSON CORP

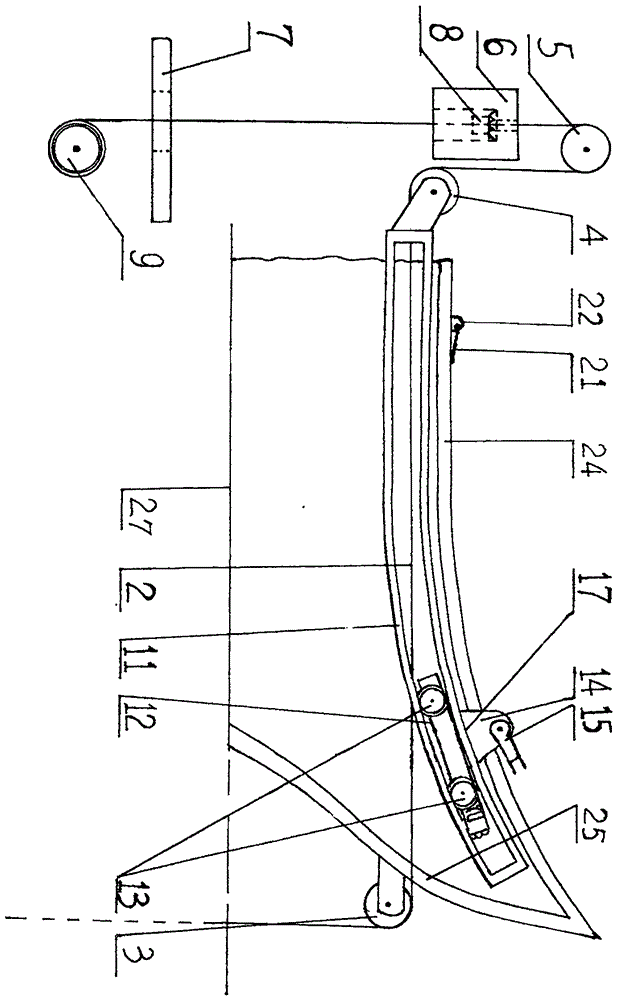

Wet & heat stretching method and apparatus for acrylonitrile fibre

The present invention provides a wet heat stretching method and a wet heat stretching device for acrylonitrile fiber bundles, which can improve productivity and can stably obtain high-quality acrylonitrile fiber bundles as raw materials for high-bulk products. In the present invention, in the wet heat stretching process of continuously stretching the acrylic fiber after the relaxation heat treatment in a humid heat atmosphere, the stretched 1kg acrylic fiber bundle is sprayed at a speed of 10 to 30m / s. Spray 50-200g of steam. At this time, the distance between the ejection port and the ejection surface of the acrylic fiber bundle was 8 to 22 mm, and the injection steam was ejected from a plurality of atmospheric pressure steam ejection ports (22a) with a diameter of 1.0 to 3.0 mm. Regardless of the thickness, even if the drawing treatment speed is high, moist heat can be applied uniformly to the entire fiber bundle, and high-quality acrylic fibers having a desired high steam shrinkage rate can be obtained.

Owner:MITSUBISHI CHEM CORP

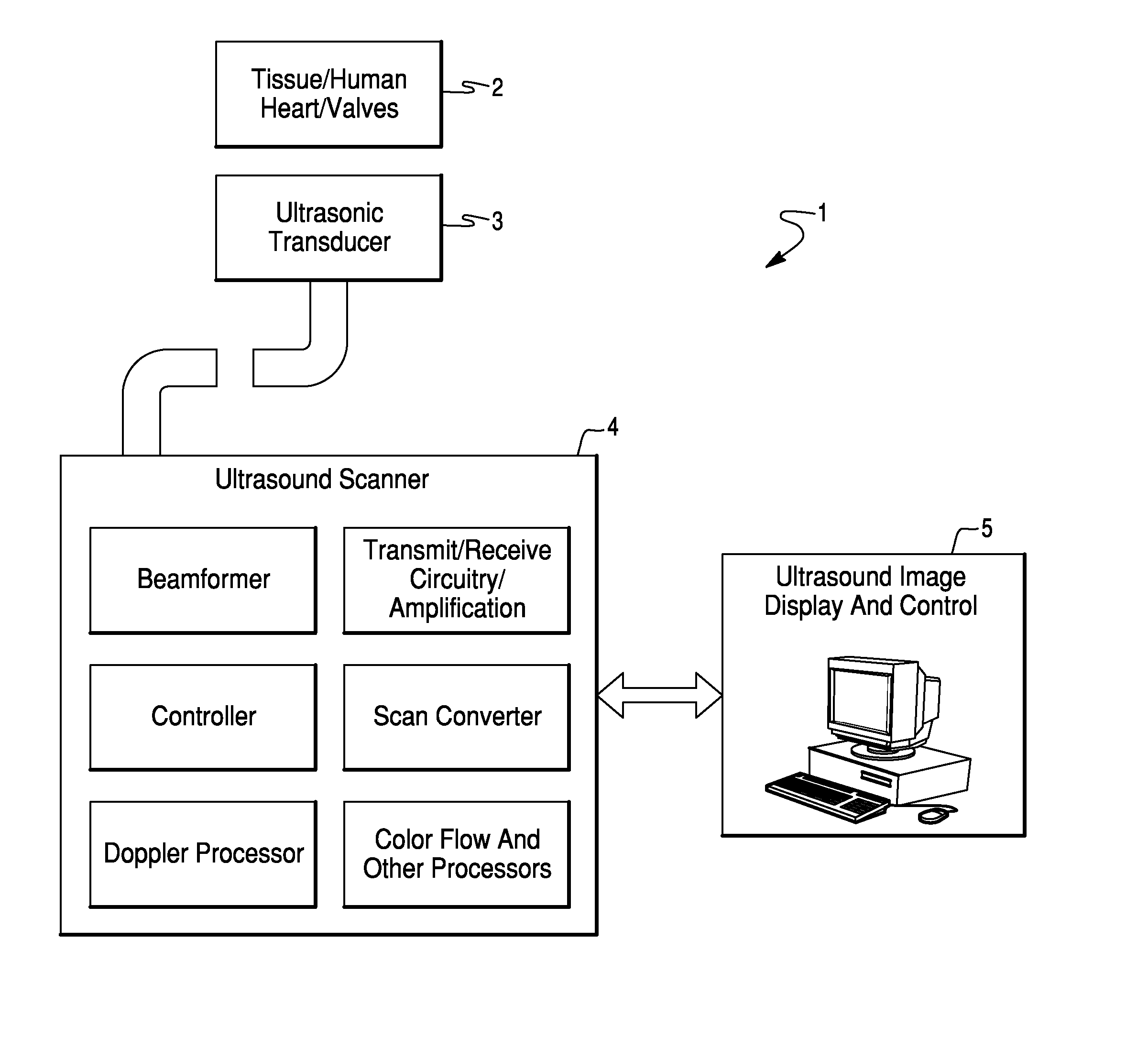

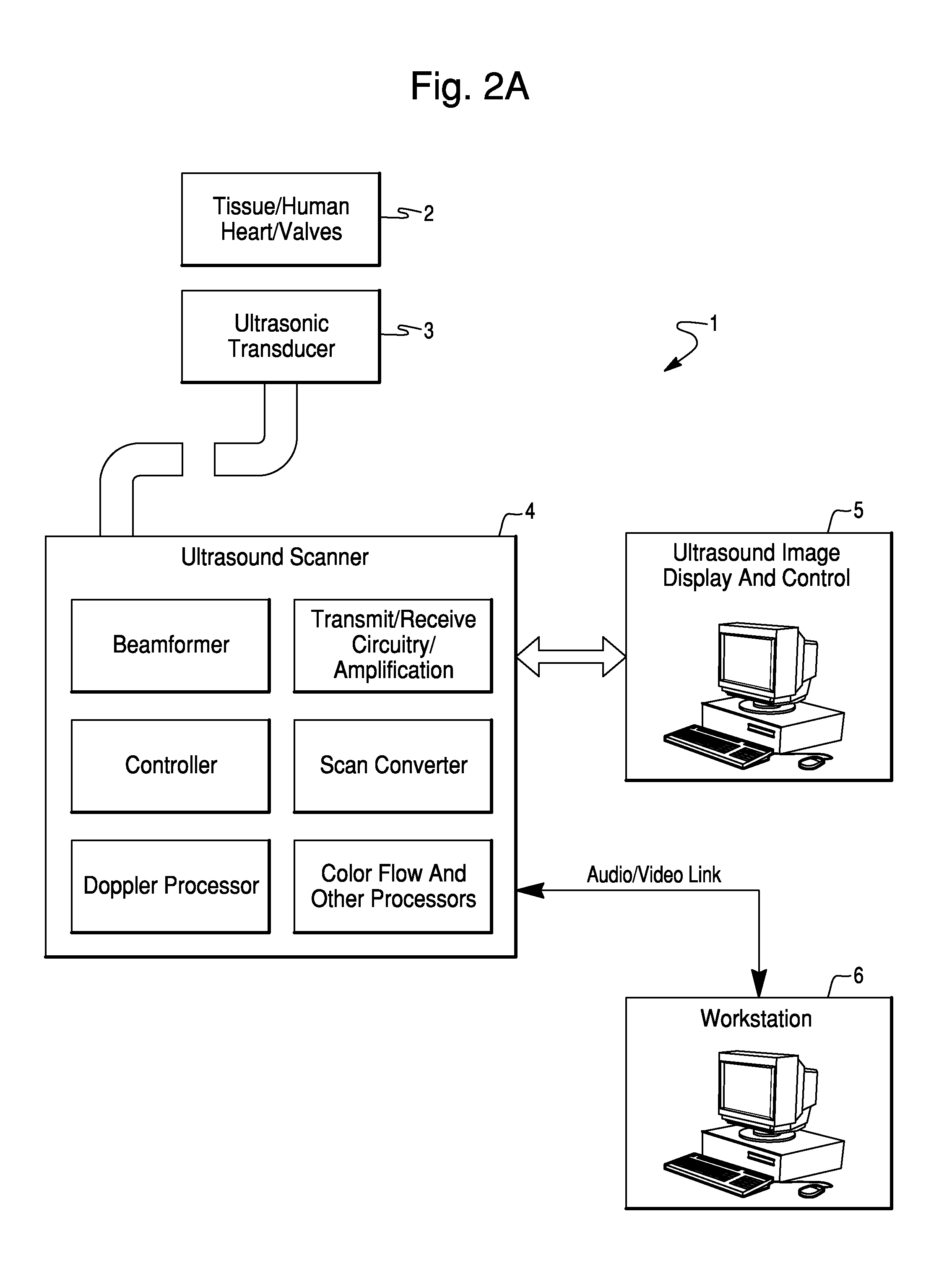

Method and System For Estimating Cardiac Ejection Volume Using Ultrasound Spectral Doppler Image Data

InactiveUS20070083118A1Improve bindingBlood flow measurement devicesInfrasonic diagnosticsGraphicsCardiac cycle

A method and system for estimating the volume of blood ejected from a cardiac ventricle or atrium uses spectral Doppler ultrasound while imaging a portion of the heart. The method computes the mean ejection velocity Vavg(t) at time t from the spectral Doppler data. The process may further utilize a discrete graphical technique to compute a measure of cardiac output. Further, the measure of cardiac output can yield an approximation to the mean-ejection-velocity integral, which is the area under the curve Vavg(t) for all moments t within a cardiac cycle.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

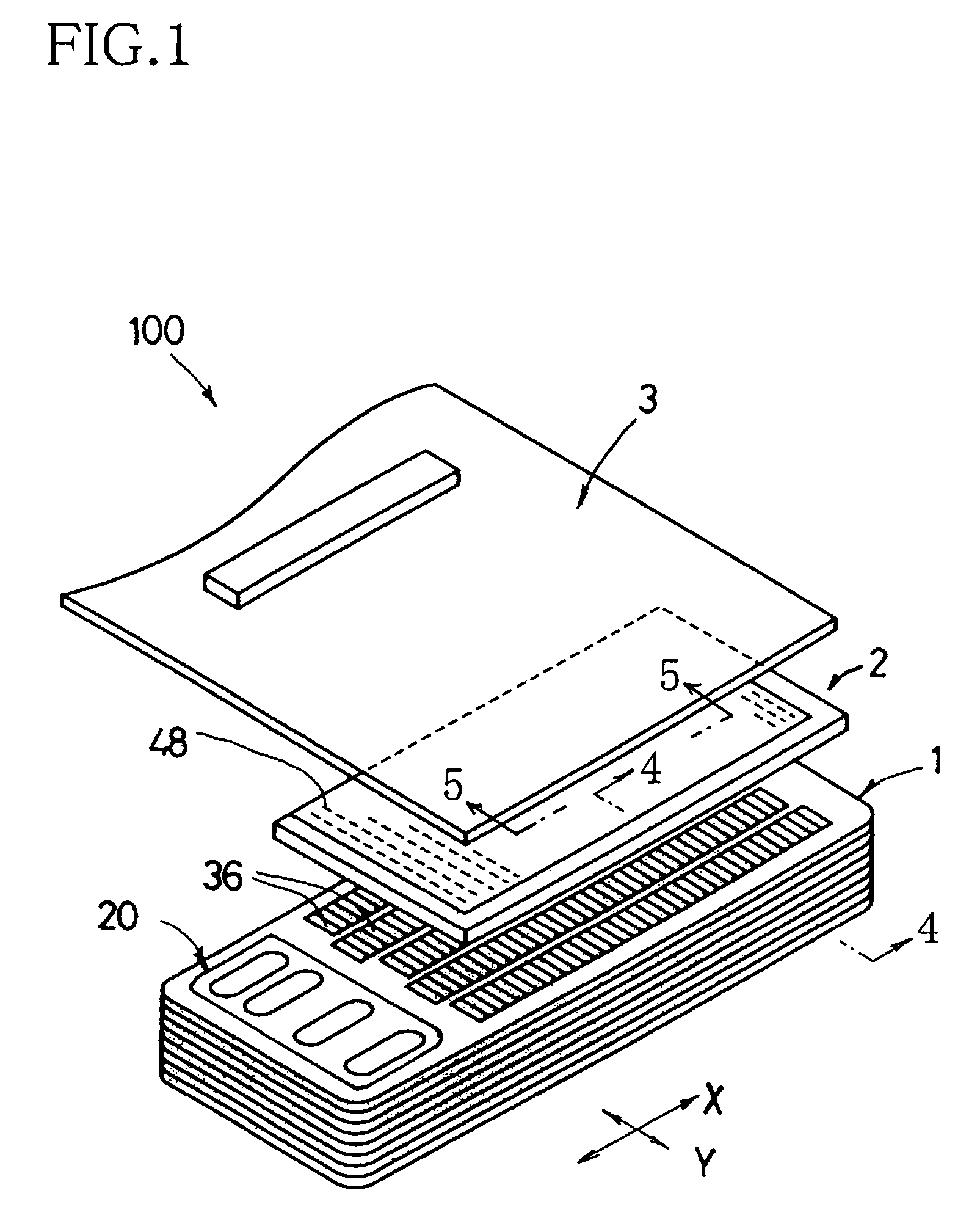

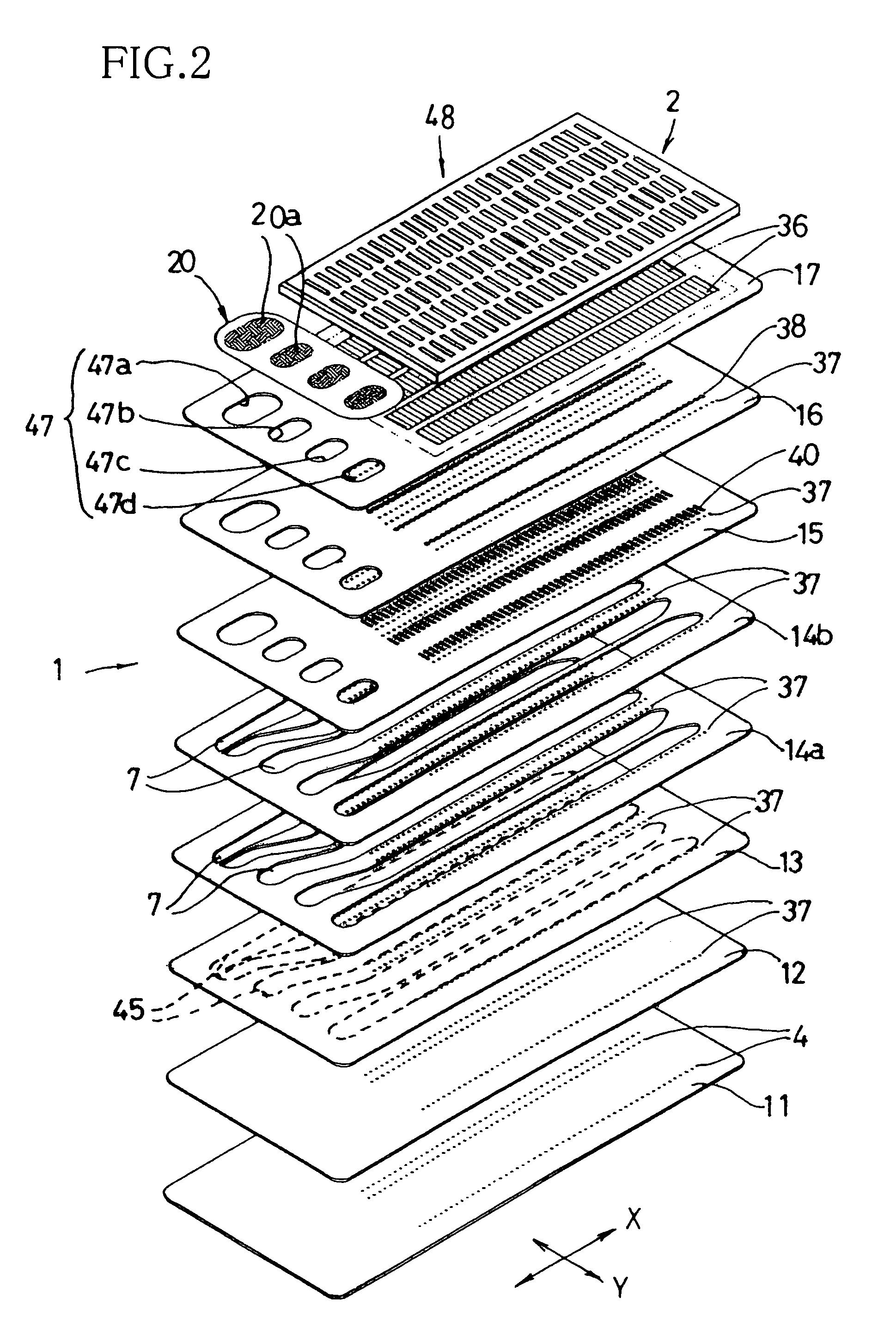

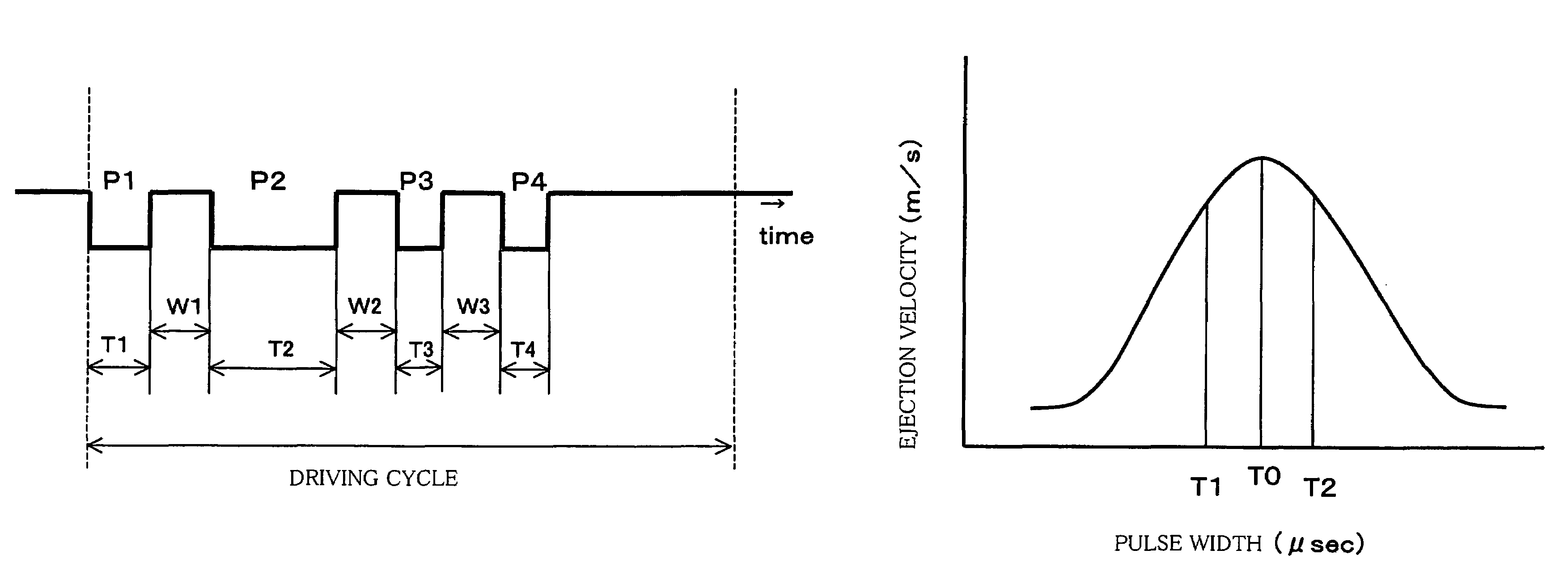

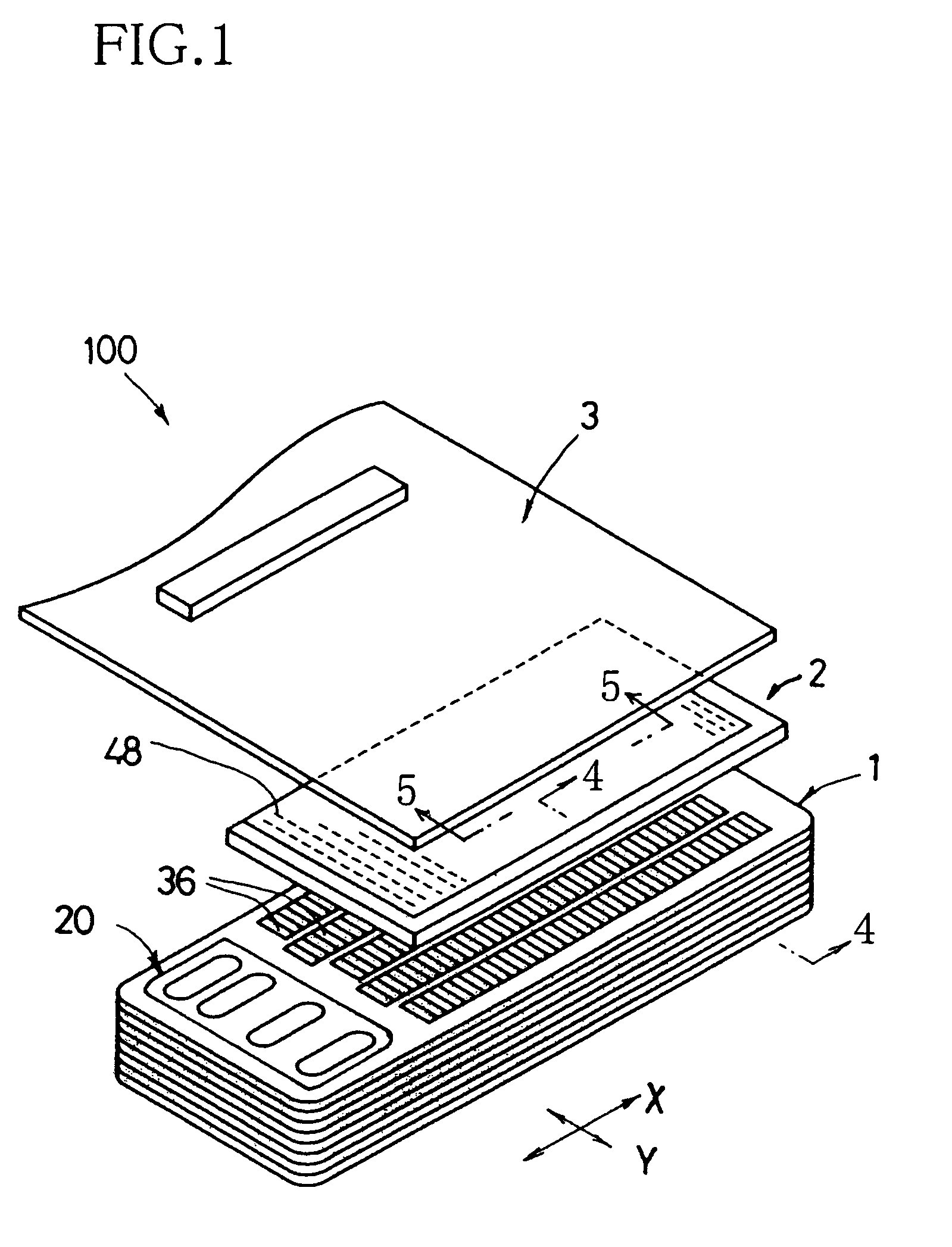

Device and method for ejecting ink droplet

An ink droplet ejection device including: (a) actuators each operable to apply an ejection pressure to an ink stored in a corresponding pressure chamber, for causing an ink ejection through a corresponding nozzle, whereby an image formed as a result of the ink ejection is produced on a medium; and (b) a controller operable to supply a control signal to each actuator, and incorporating a drive pulse train into the control signal for causing ejection of at least two cooperative ink droplets that cooperate to form one dot of the image. The drive pulse train includes at least two drive pulses. One of the at least two drive pulses has a first pulse width smaller than a maximizing value that maximizes an ejection velocity and a volume of each ink droplet to be ejected. Another one of the at least two drive pulses has a second pulse width larger than the maximizing value. Also disclosed a method of producing the image on the medium by using the ink droplet ejection device.

Owner:BROTHER KOGYO KK

Method for printing an ink jet marking on a surface

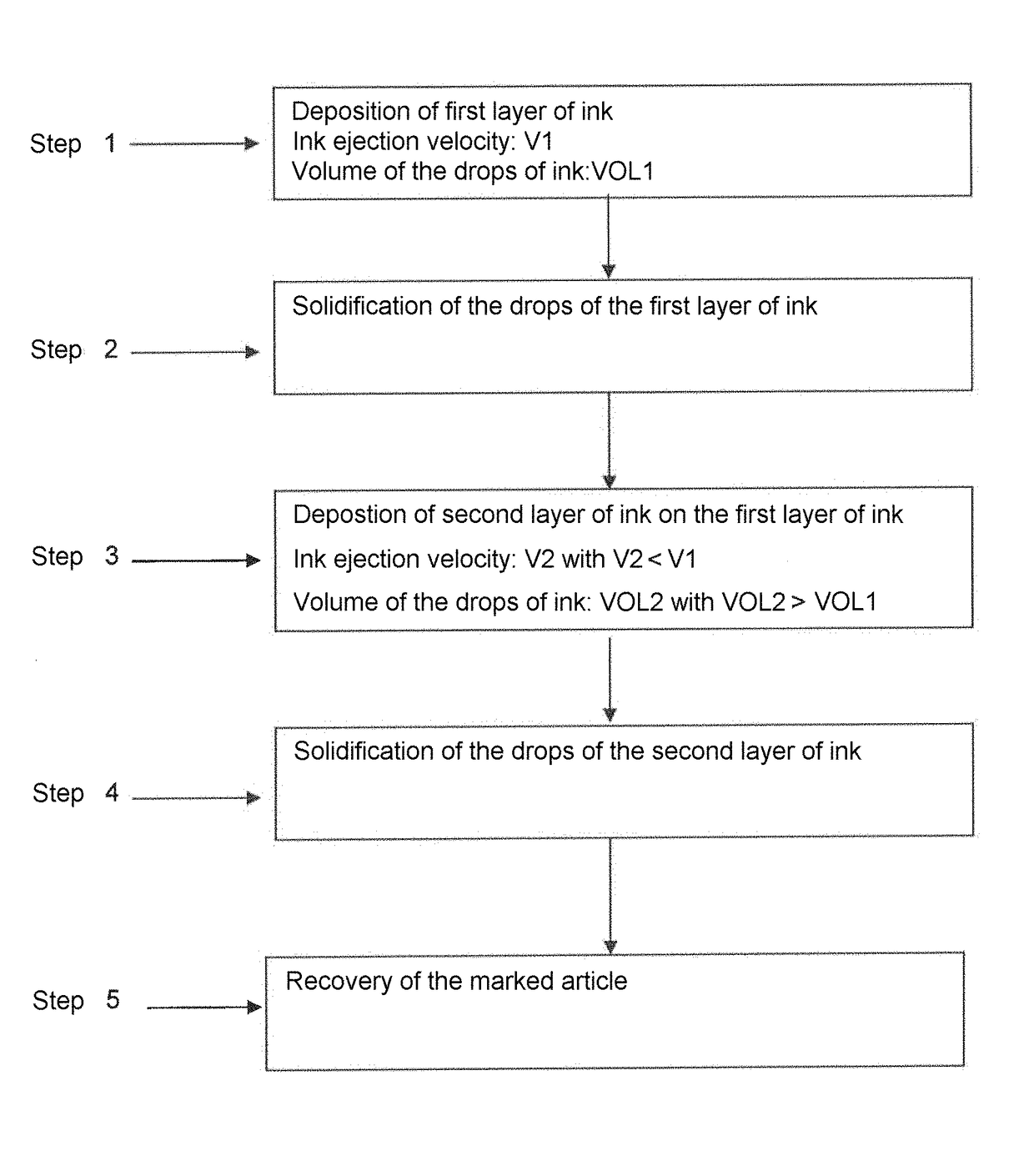

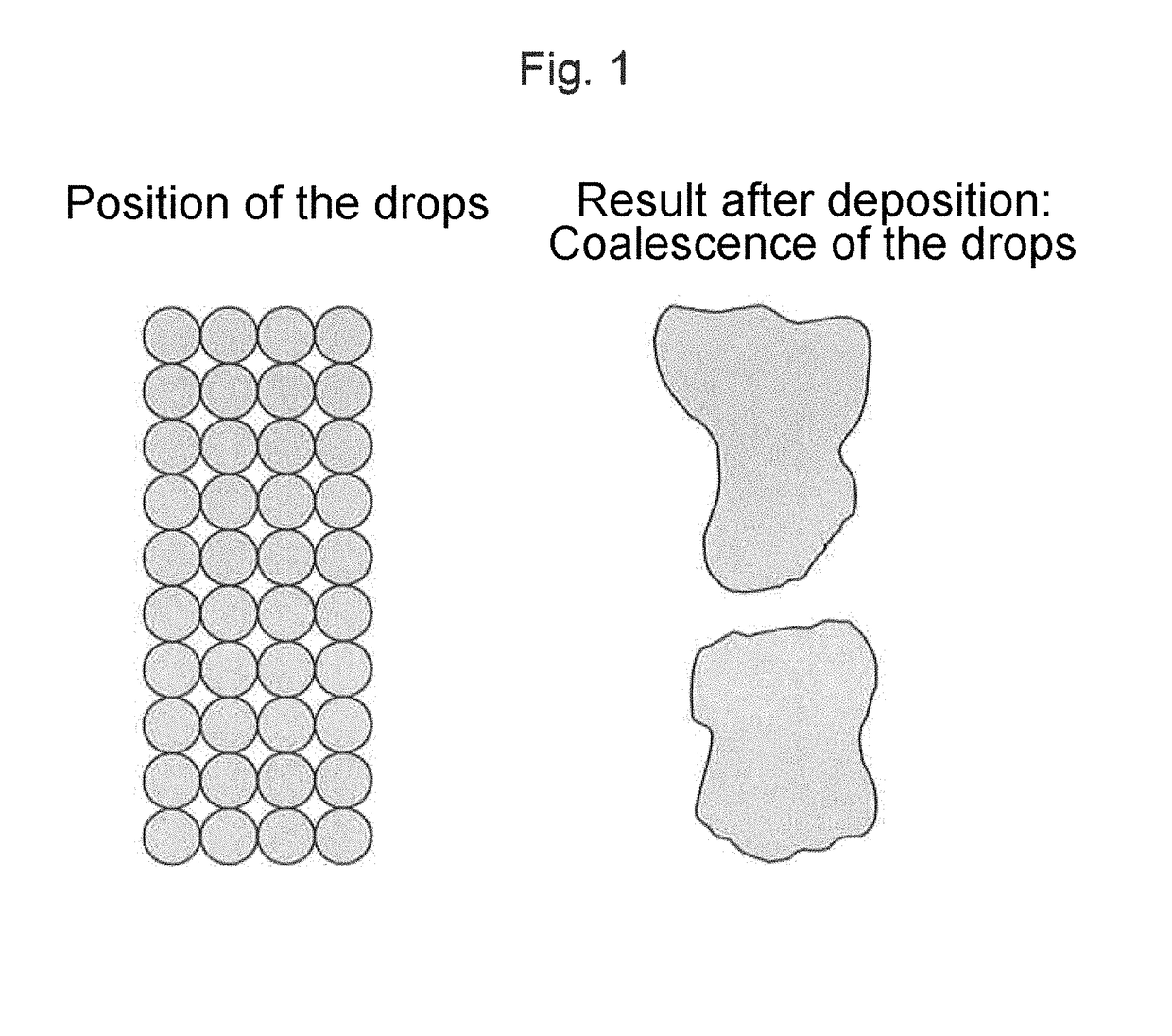

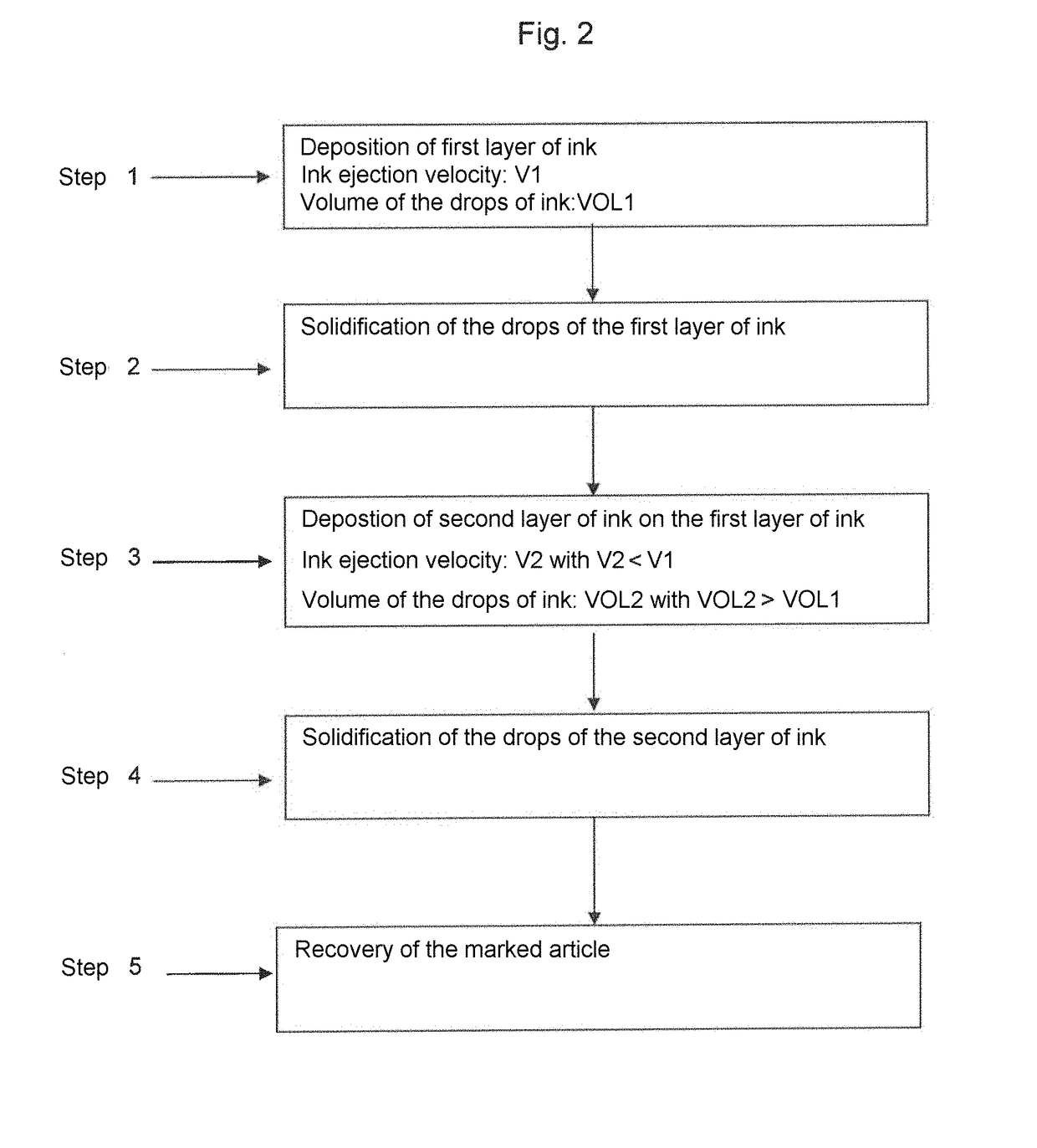

ActiveUS9709819B2Increase elasticityImprove visibilitySpectales/gogglesDuplicating/marking methodsNon wettingEngineering

A method for printing an ink jet marking on a non-wetting surface for liquid ink, includes forming at least a first drop of solidified ink on the surface, by ejecting, by means of a printhead, a first drop of liquid ink at a first given ejection velocity and with a first given volume, and depositing, on at least one portion of said first drop of solidified ink, at least a second drop of ink having a second volume VOL2, by ejecting, by means of a printhead, a second drop of liquid ink at an ejection velocity.

Owner:ESSILOR INT CIE GEN DOPTIQUE

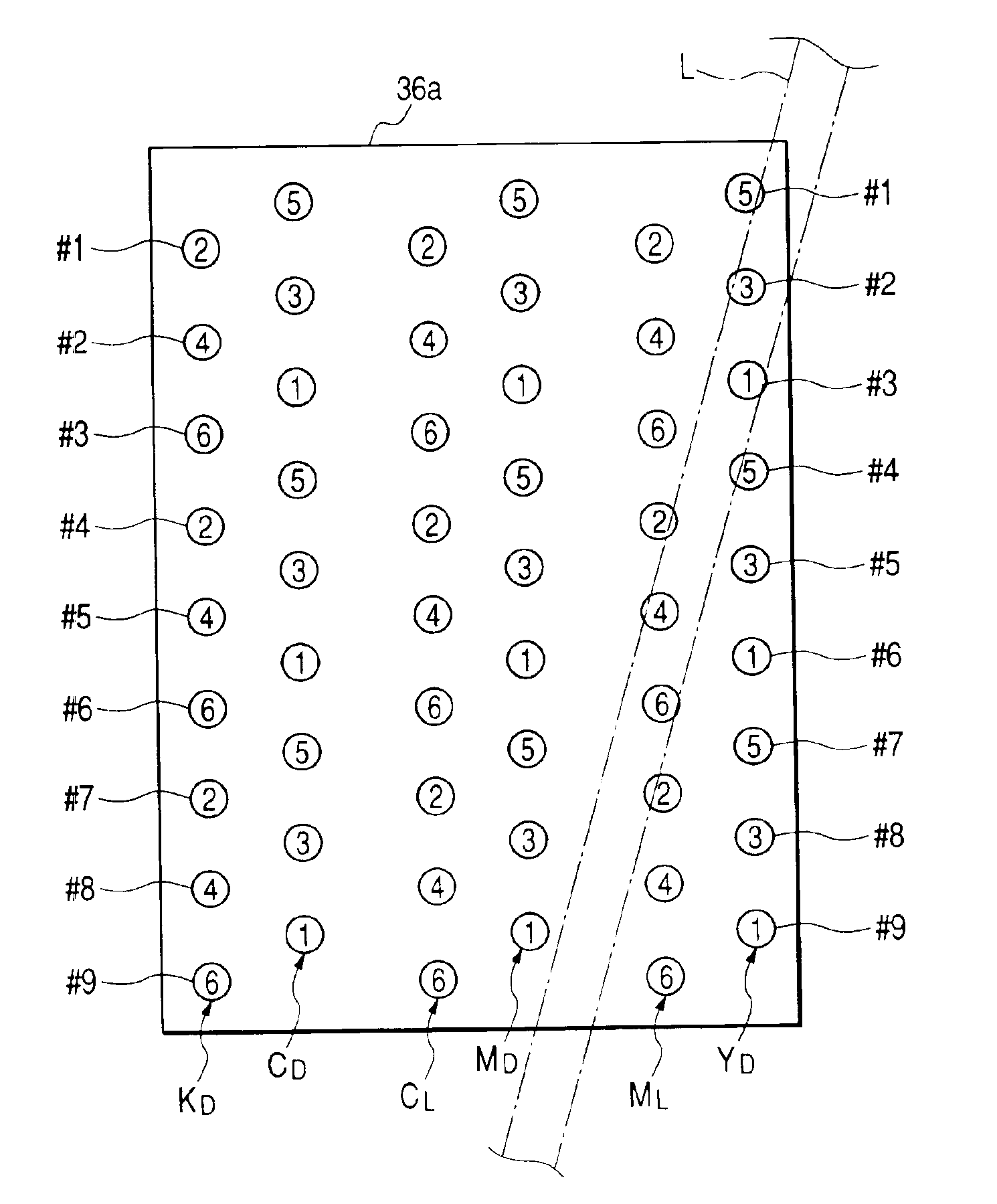

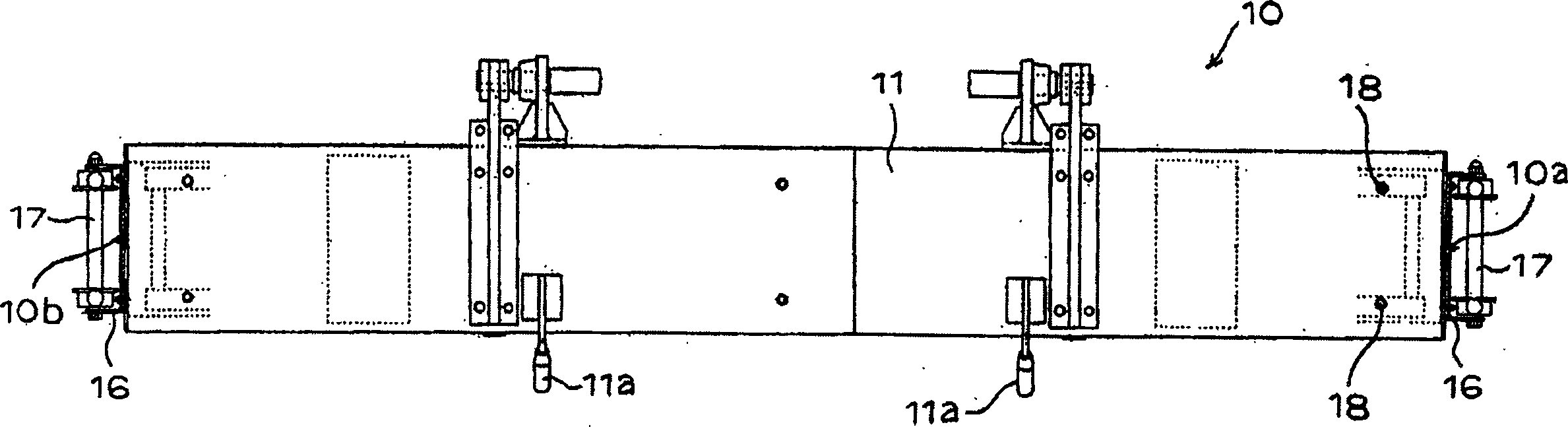

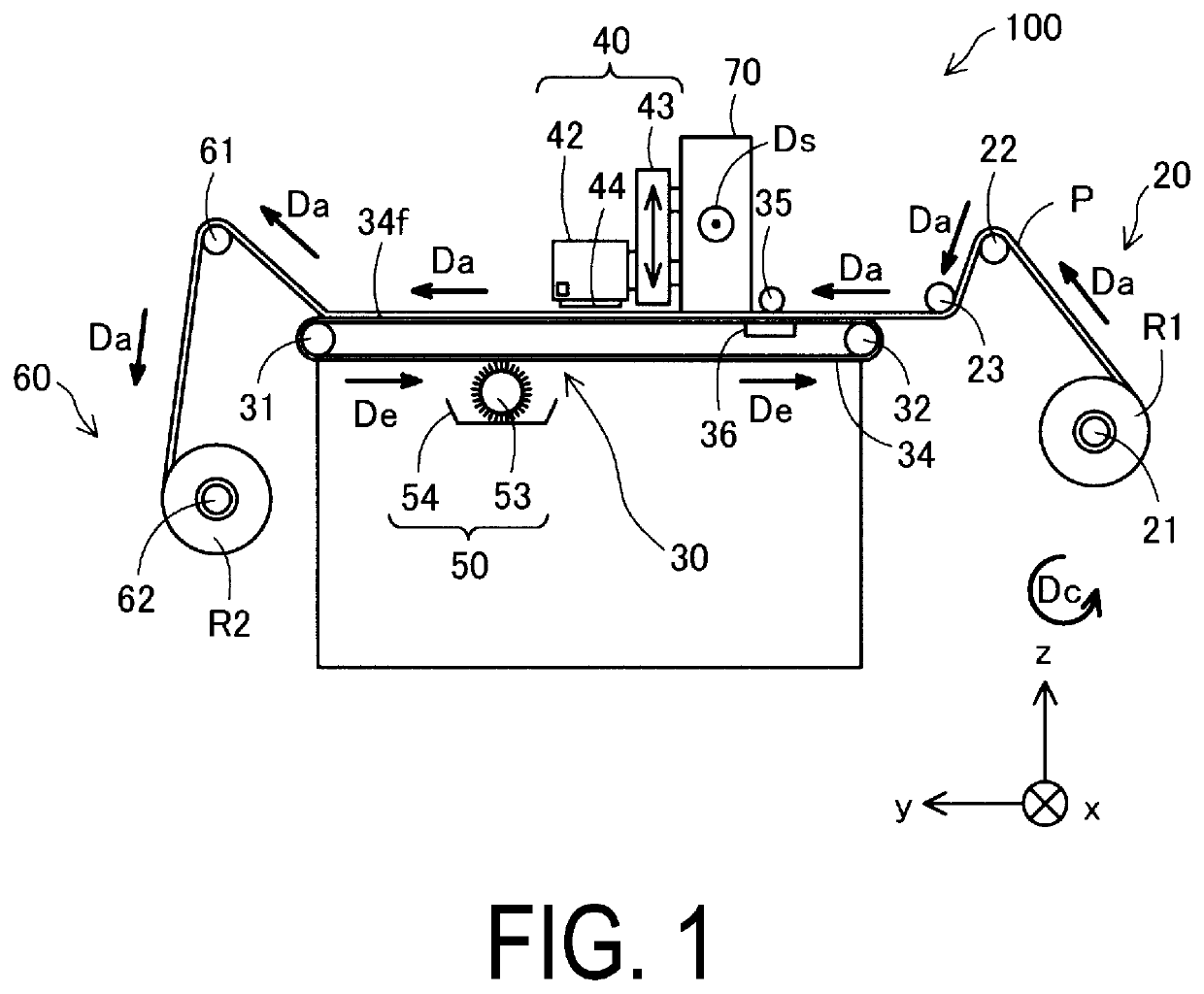

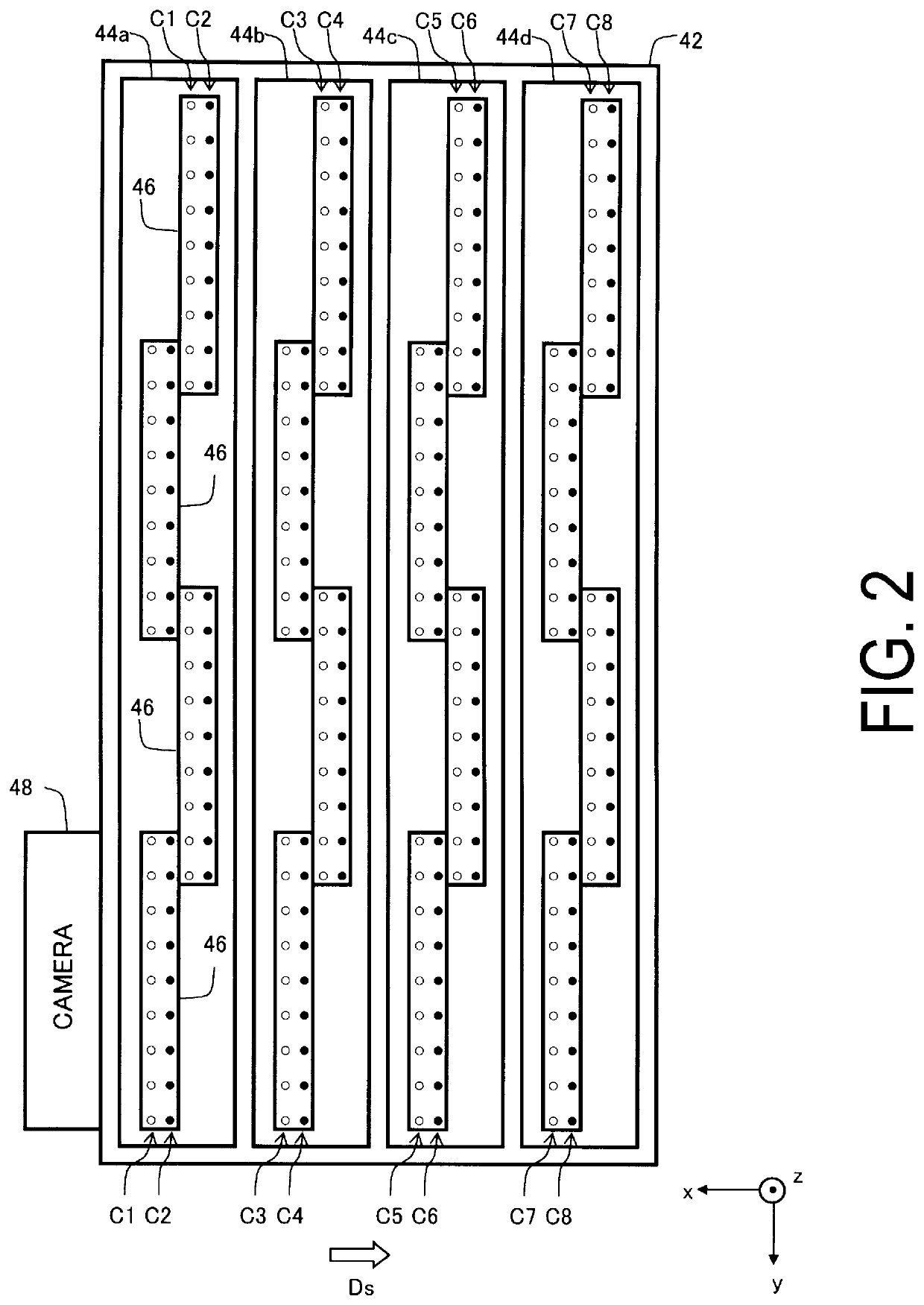

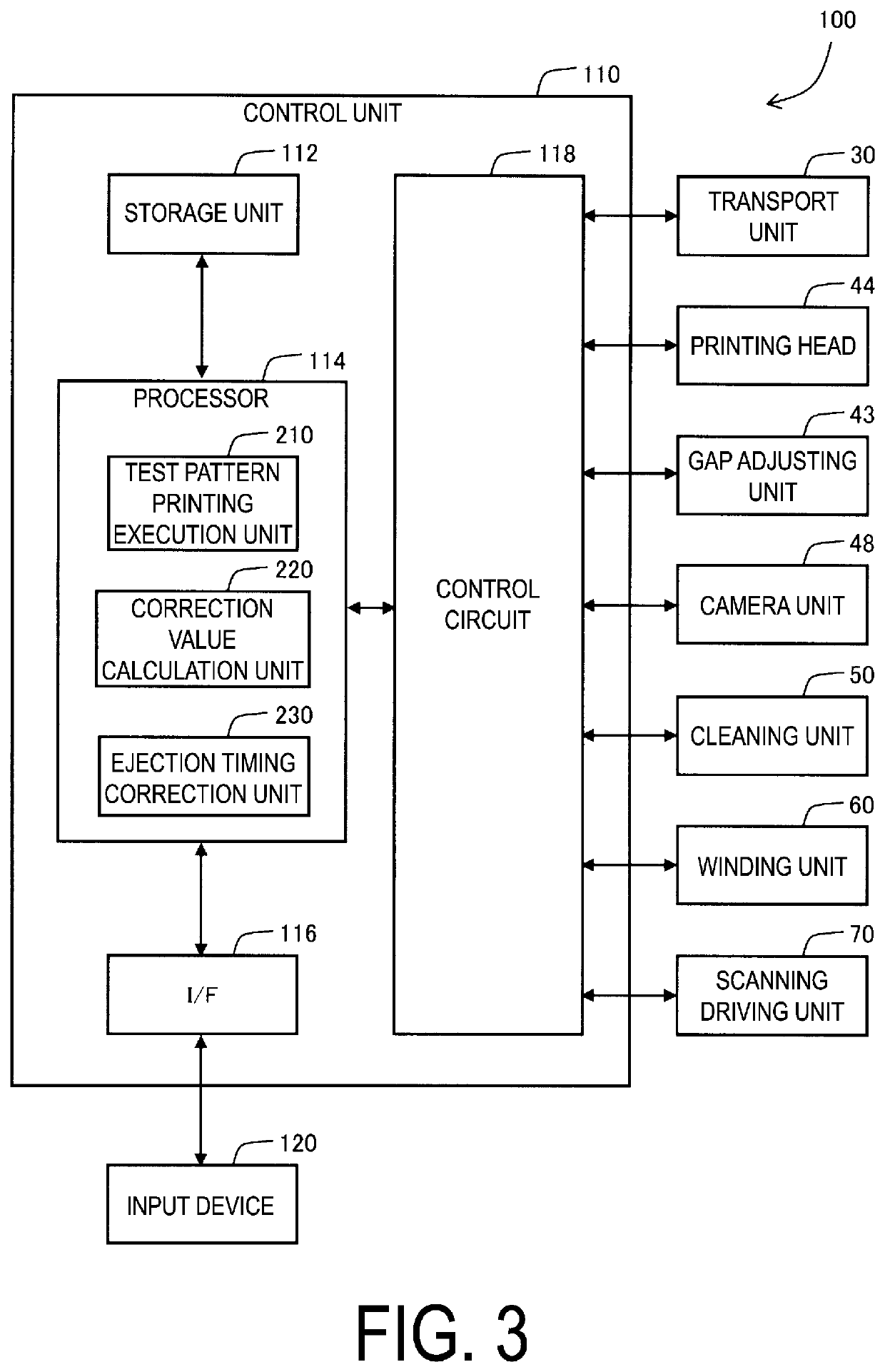

Liquid ejecting device and a method for correcting landing position deviation of liquid

A liquid ejecting device includes a supporting unit supporting a medium, an ejecting unit ejecting liquid onto the medium, a scanning driving unit moving the ejecting unit, and a control unit controlling the ejecting unit and the scanning driving unit. The control unit is configured to be capable of performing, a first processing for forming a test pattern, and acquiring an ejection velocity parameter associated with an ejection velocity of the liquid detected from the test pattern, a second processing for calculating the ejection velocity of the liquid from the ejection velocity parameter, calculating a first correction component that depends on the calculated ejection velocity, and setting a correction value including the first correction component, and a third processing for correcting ejection timing of the liquid using the correction value, when the liquid is ejected from the ejecting unit onto the medium as the ejecting unit is moved.

Owner:SEIKO EPSON CORP

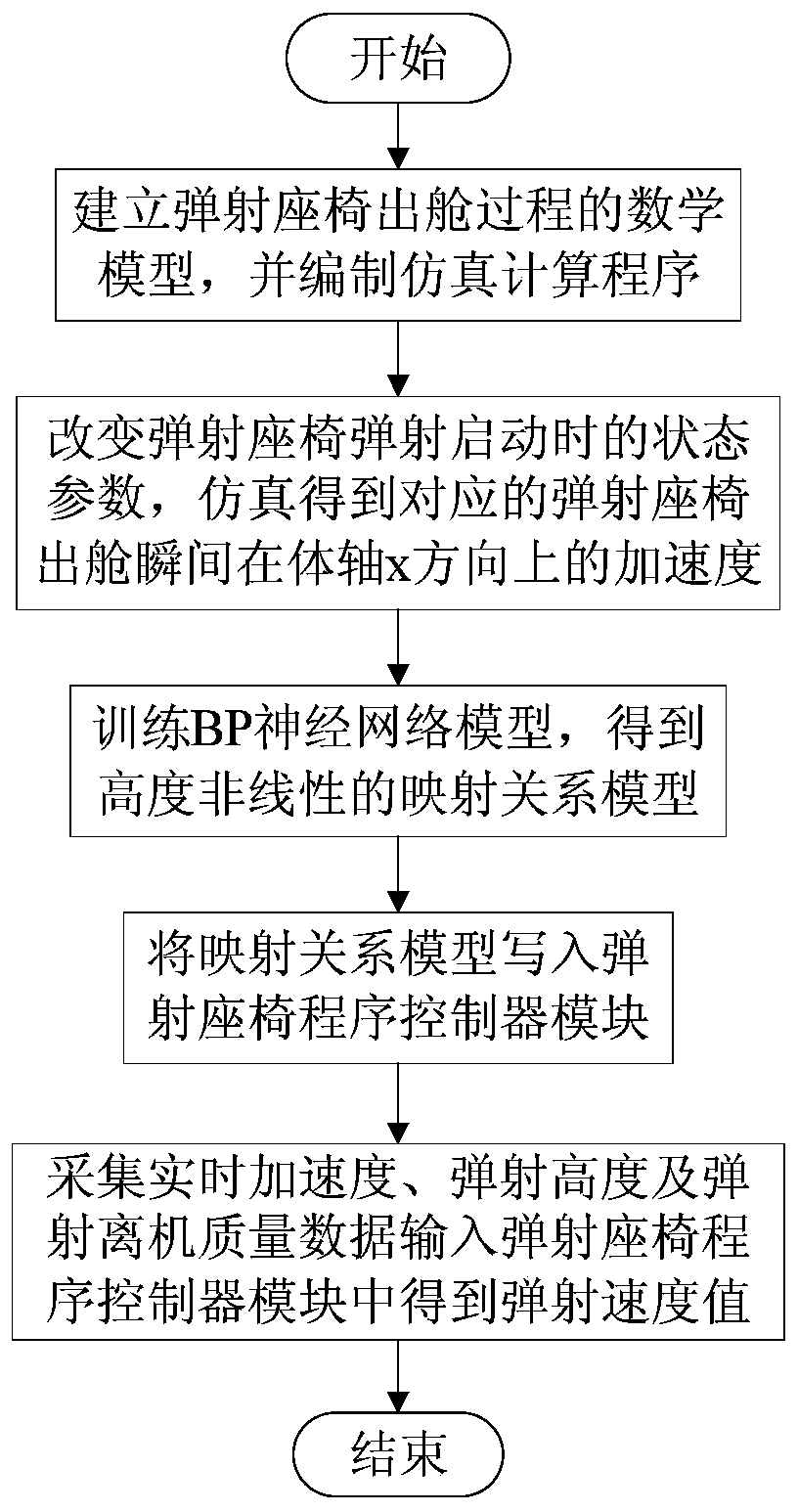

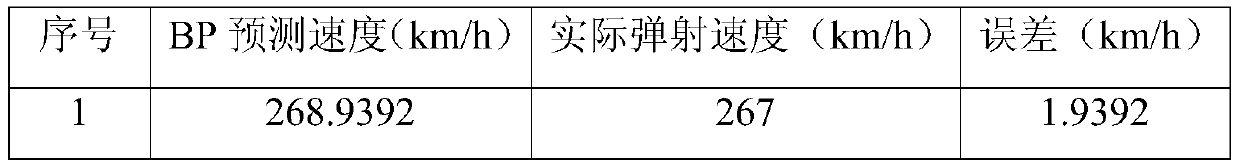

New ejection delivery speed measurement method for ejection seat

InactiveCN110803301ANot afraid of blockageEliminate the possibility of inaccurate measurementsAircraft ejection meansAircraft components testingAviationBody axis

The invention discloses a new ejection delivery speed measurement method for an ejection seat, and belongs to the technical field of aviation ejection life-saving. According to movement characteristics of the ejection seat, based on a computer simulation method, a mapping relation model of body axis x-direction acceleration value and ejection velocity of the ejection seat based on a BP neural network is established in advance; a body axis x-direction acceleration sensor is mounted in an appropriate position of the ejection seat, and the body axis x-direction acceleration value of the ejectionseat at that moment of delivery is measured; and the corresponding ejection delivery speed is calculated on the basis of the acceleration value according to the mapping relation model which is established in advance. According to the method, the probability of inaccurate measurement caused by blockage of an airspeed head and influence of an external flow field is avoided, slight errors are produced, and engineering application requirements are met.

Owner:SHENYANG AEROSPACE UNIVERSITY

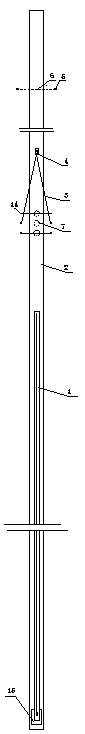

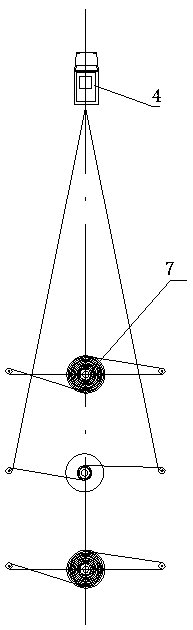

Gravity acceleration catapult of aircraft carrier shipboard aircraft

InactiveCN105667821AEnsure direct collisionReduce energy consumptionLaunching/towing gearJet aeroplaneFree falling

The invention relates to a gravitational acceleration ejection of an aircraft carrier-based aircraft. According to the law of free fall motion, mg=ejection thrust, ν=g·t=ejection velocity ν, and a streamlined counterweight iron with huge mass is used to pull the wire rope and the ejection. The two fixed pulleys, front and rear, change the traction force of the wire rope that falls into the sea water freely into the ejection take-off thrust in the horizontal direction, which is referred to as the gravitational acceleration ejection. The gravitational acceleration ejection starts from zero, and there is no impact damage to the carrier-based aircraft at the beginning of the ejection, so it can also eject small unmanned reconnaissance aircraft, bombers, aerial tankers, anti-submarine aircraft, and early warning aircraft. It solves the problem that the carrier-based aircraft with a large amount of bombs and various take-off speeds cannot take off due to the short rolling distance of the aircraft carrier. Gravitational acceleration ejection, low energy consumption, simple structure, safe, reliable, fast and practical.

Owner:王善良 +1

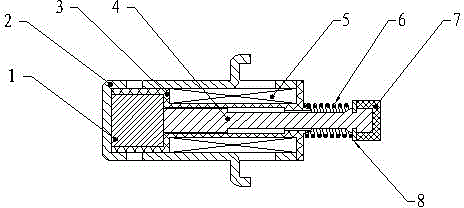

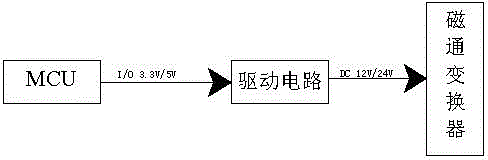

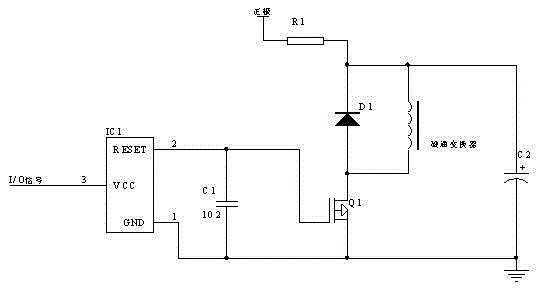

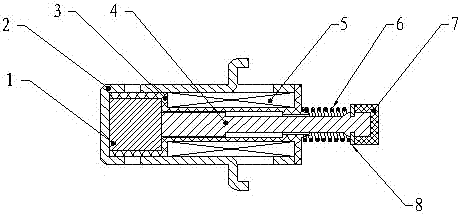

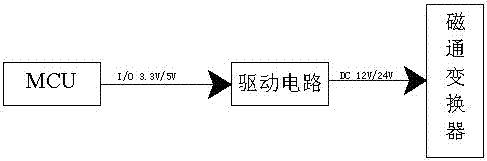

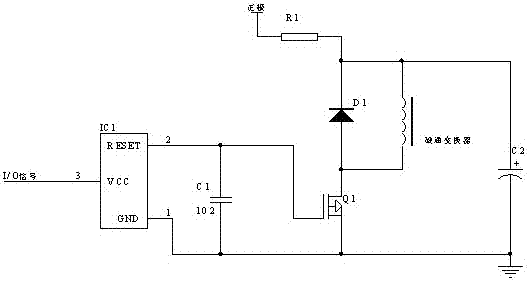

Magnetic flux convertor optimum design method based on genetic algorithm and ANSYS simulation

ActiveCN104392036AAction performance indicators improvedReduce volumeSpecial data processing applicationsElectrical resistance and conductanceCapacitance

The invention relates to the optimum design field of magnetic flux convertors, in particular to a magnetic flux convertor optimum design method based on a genetic algorithm and ANSYS simulation. The magnetic flux convertor optimum design method based on the genetic algorithm and the ANSYS simulation includes: selecting resistance, capacitance and drive voltage in a drive circuit of the magnetic flux convertor as main optimum parameters, and using the genetic algorithm in combination with the ANSYS simulation to perform optimum design of the drive circuit. The number of indexes for measuring motion performance of the magnetic flux convertor is two, and the two indexes are respectively final ejection velocity v of an ejector rod and execution time t of a whole tripping motion. The magnetic flux convertor optimum design method based on the genetic algorithm and the ANSYS simulation considers an actual tripping dynamic process of the magnetic flux convertor on the premise of optimizing design. The magnetic flux convertor optimum design method based on the genetic algorithm and the ANSYS simulation facilitates the optimum design of the magnetic flux convertor, and thereby raises the motion performance indexes of the magnetic flux convertor.

Owner:TONGJI UNIV

Ink droplet ejection device

An ink droplet ejection device including: (a) actuators each operable to apply an ejection pressure to an ink stored in a corresponding pressure chamber, for causing an ink ejection through a corresponding nozzle, whereby an image formed as a result of the ink ejection is produced on a medium; and (b) a controller supplying a control signal to each actuator, and including (b-1) a portion operable to incorporate a composite-dot forming pulse train into the control signal, for causing successive ejection of a plurality of ink droplets that cooperate to form a composite dot of the image, and (c) a portion operable to incorporate a non-composite-dot forming pulse train into the control signal, for causing an ejection of a single ink droplet that forms a non-composite dot of the image. The composite-dot forming pulse train and non-composite-dot forming pulse train have respective waveforms configured such that an ejection velocity of the single ink droplet forming the non-composite dot is lower than an ejection velocity of said plurality of ink droplets cooperating to form the composite dot.

Owner:BROTHER KOGYO KK

Device and method for ejecting ink droplet

An ink droplet ejection device including: (a) actuators each operable to apply an ejection pressure to an ink stored in a corresponding pressure chamber, for causing an ink ejection through a corresponding nozzle, whereby an image formed as a result of the ink ejection is produced on a medium; and (b) a controller operable to supply a control signal to each actuator, and incorporating a drive pulse train into the control signal for causing ejection of at least two cooperative ink droplets that cooperate to form one dot of the image. The drive pulse train includes at least two drive pulses. One of the at least two drive pulses has a first pulse width smaller than a maximizing value that maximizes an ejection velocity and a volume of each ink droplet to be ejected. Another one of the at least two drive pulses has a second pulse width larger than the maximizing value. Also disclosed a method of producing the image on the medium by using the ink droplet ejection device.

Owner:BROTHER KOGYO KK

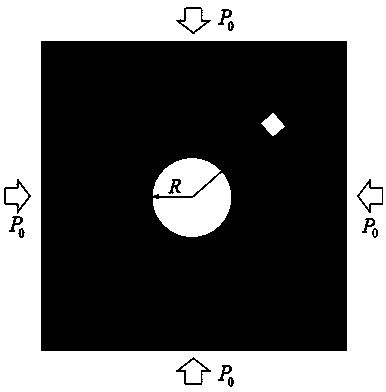

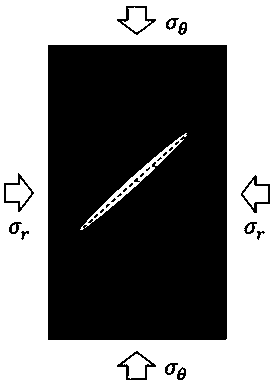

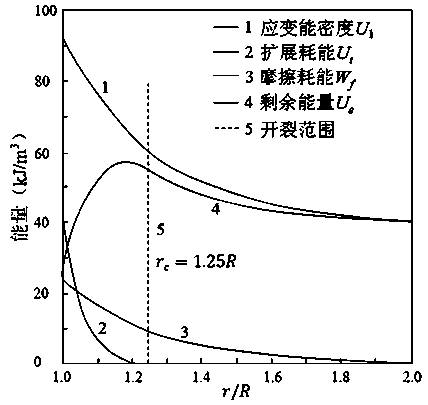

A Method for Predicting the Ejection Velocity of Rock Burst Fragments Based on Releasable Elastic Strain Energy

ActiveCN106326636BObjectively reflect agglomerationEasy to operateSpecial data processing applicationsInformaticsStrain energyEnergy consumption

The invention discloses a rock burst fragment ejection speed predicting method based on releasable elastic strain energy. The method comprises the following steps: step 1, calculating elastic strain energy U1 of surrounding rock after excavating; step 2, calculating surrounding rock wing crack expansion energy consumption Ut and friction energy consumption Wf on a main crack surface; step 3, deducting energy consumption value Ud in a surrounding rock cracking process in surrounding rock strain energy density U1 to obtain releasable elastic strain energy Ue of the cracked surrounding rock, and calculating residual elastic energy Qe in a cracked area of the cracked surrounding rock under induction of excavating and unloading if assuming that tunnel excavating footage as Le; and step 4, converting the residual elastic energy Qe of the rock into rock fragment ejection kinetic energy E to obtain average ejection speed v of the rock burst fragments. Through the rock burst fragment ejection speed predicting method based on releasable elastic strain energy, the problem that the accuracy and the reliability of the existing stress model predicting method are difficult to grasp can be solved; the predicting accuracy of the rock burse fragment ejection speed in the excavating process of deeply buried tunnels is improved.

Owner:CHINA THREE GORGES UNIV

Method for manufacturing polycrystalline silicon

ActiveUS8043660B2Uniform surface topographyEfficient growth processVacuum evaporation coatingSputtering coatingRough surfacePolycrystalline silicon

A method for manufacturing polycrystalline silicon with high quality by effectively preventing undesired shape such as giving an rough surface to silicon rods or an irregularity in diameter of the silicon rods. The method for manufacturing polycrystalline silicon includes: an initial stabilizing step of deposition wherein a velocity of ejecting the raw material gas from the gas ejection ports is gradually increased; the shaping step wherein first the ejection velocity is increased at a rate higher than that in the stabilizing step and then the ejection velocity is gradually increased at a rate lower than the previous increasing rate; and a growing step wherein, after the shaping step, the ejection velocity is made slower than that at the end of the shaping step until the end of the deposition.

Owner:HIGH-PURITY SILICON CORP

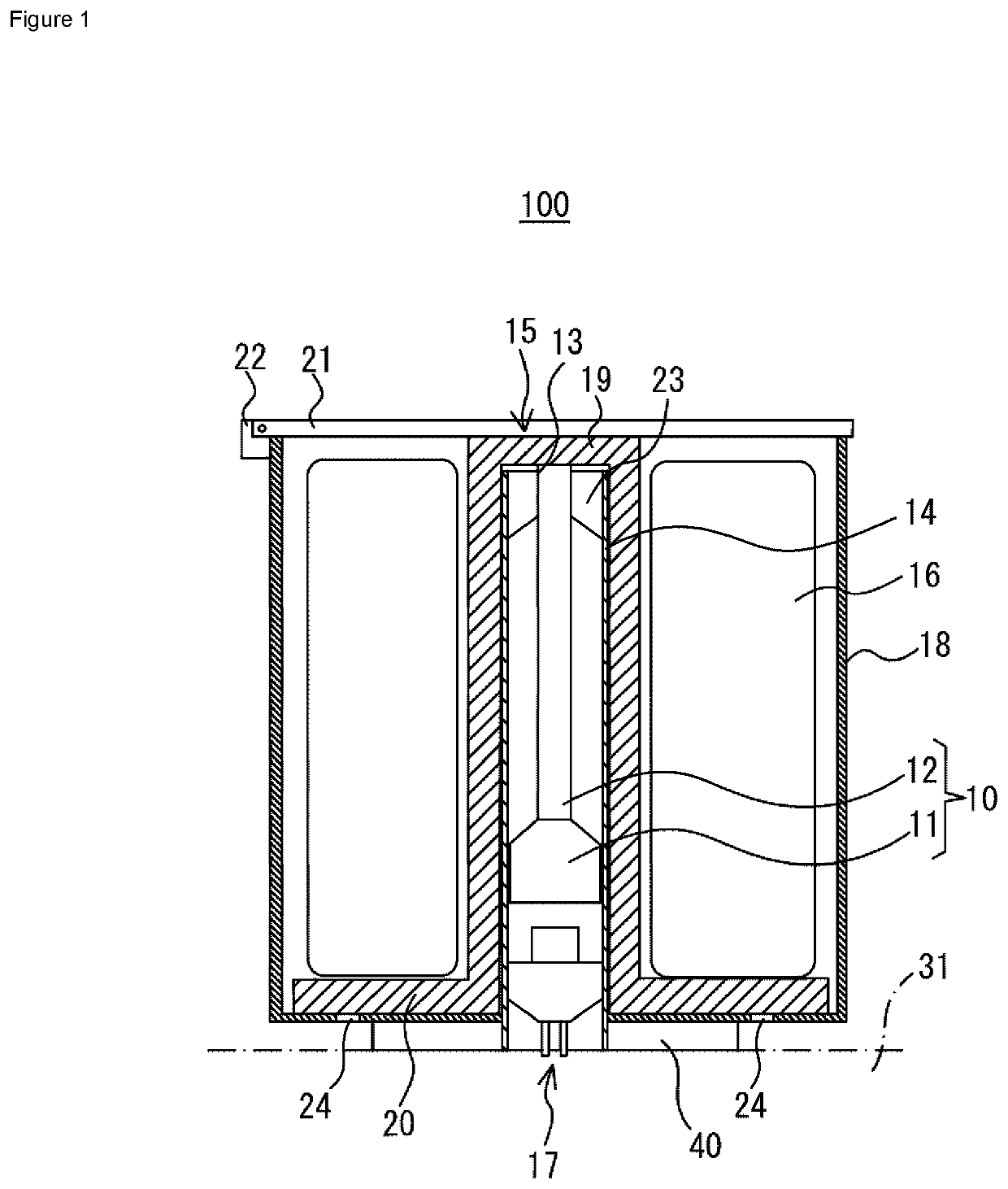

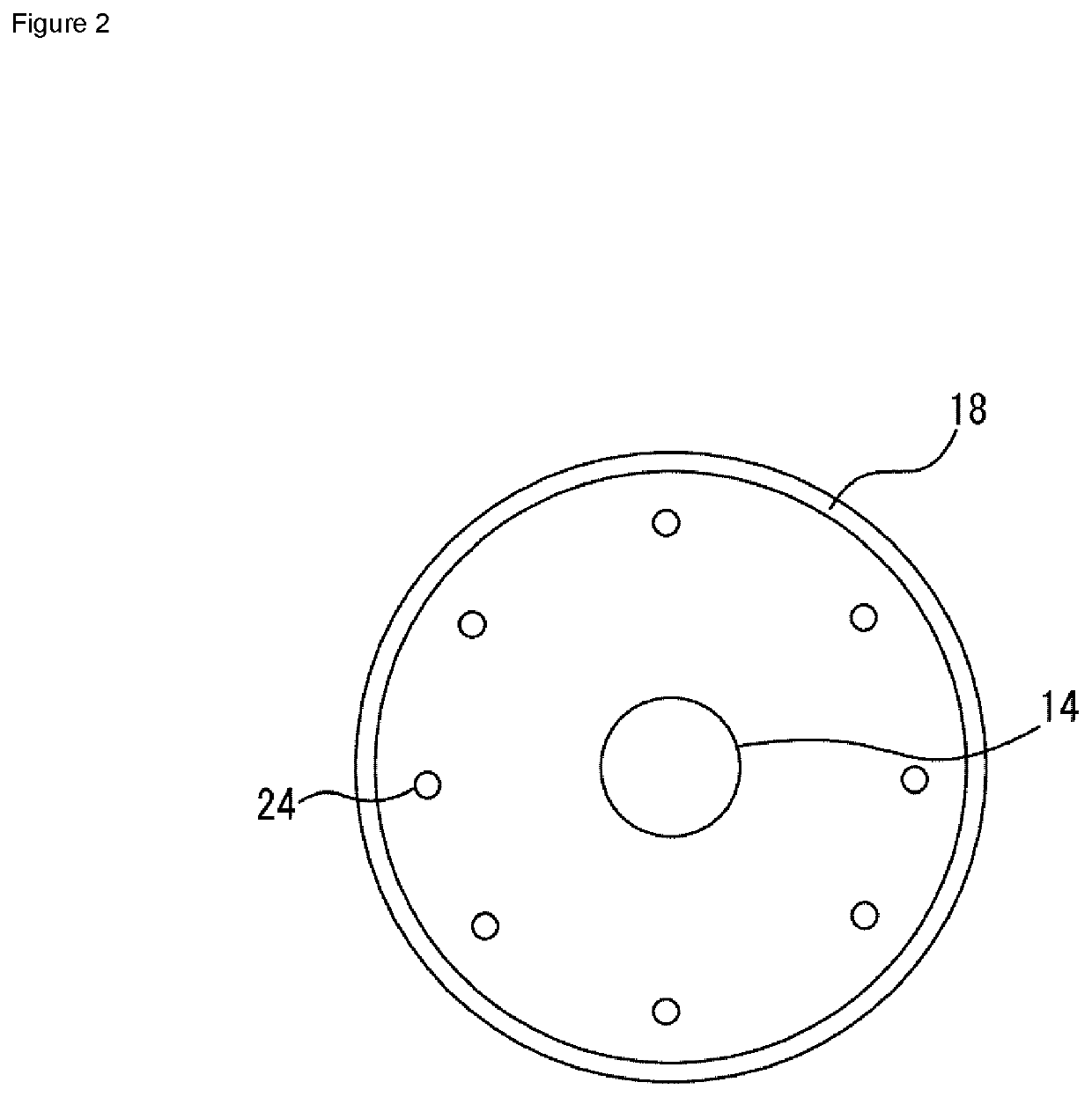

Ejection device and flying body provided with ejection device

PendingUS20210206497A1Reduce weightReduce ejection speedUnmanned aerial vehiclesParachutesGas generatorPiston

Provided are an ejection device with reduced weight without reducing an ejection speed of an ejected object and a flying object including the ejection device. An ejection device 100 includes a piston member 10, a cylinder 14 which accommodates the piston member 10 and is provided with a hole portion 13 for allowing the piston member 10 to project outward during operation, a push-up member 15 pushed up in one direction by the piston member 10, an ejected object 16 pushed up while being supported by the push-up member 15, and a gas generator 17 which moves the piston member 10 in the cylinder 14, and in the ejection device 100, the push-up member 15 has a support portion 20 disposed on a distal end side of the piston member 10 with a tip of the piston member 10 in a moving direction of the piston member 10 set as a reference.

Owner:NIPPON KAYAKU CO LTD

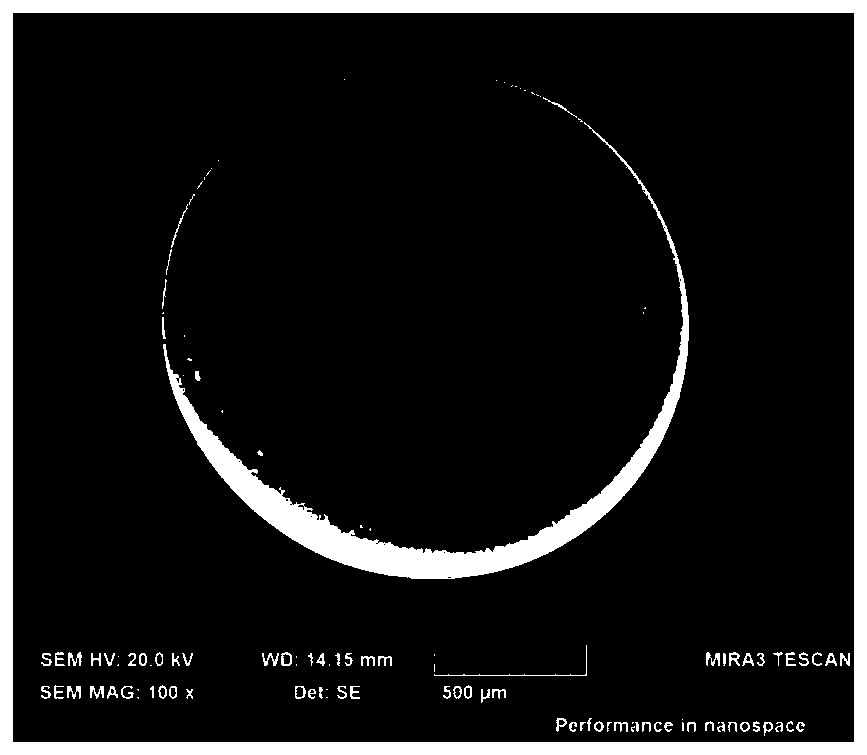

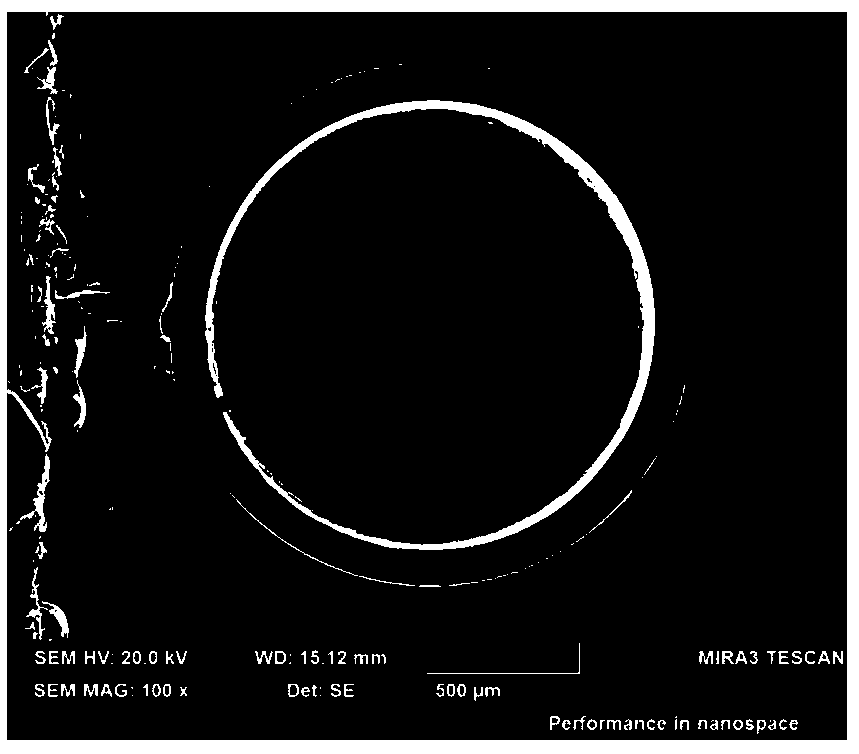

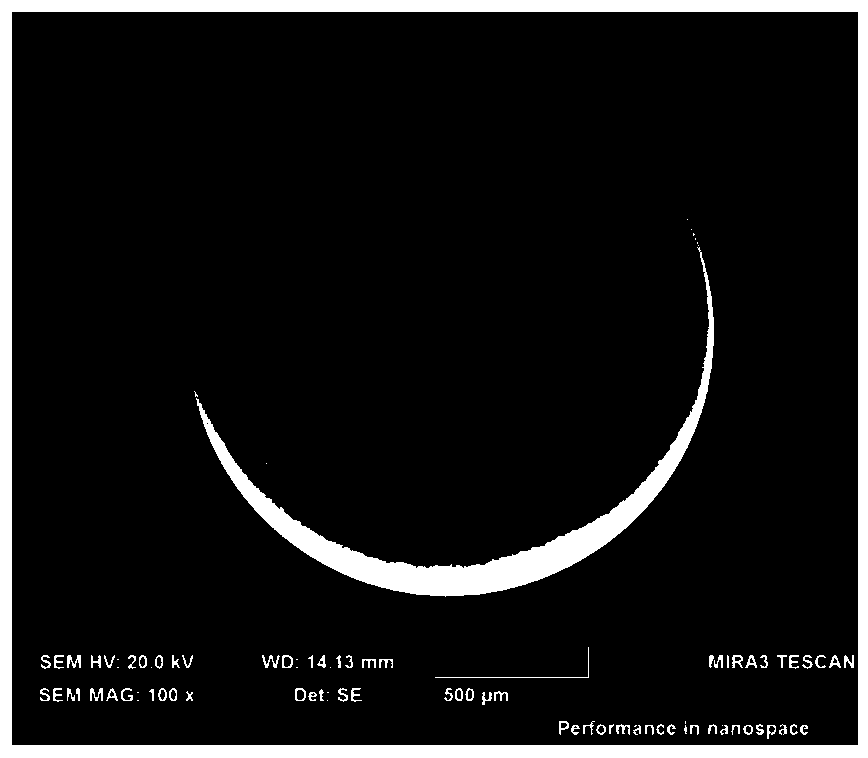

Preparation method for millimeter-grade polyacrylonitrile hollow microsphere

ActiveCN110523353AAccelerate evaporationAchieve evaporationMicroballoon preparationMicrocapsule preparationMicrosphereEvaporation

The invention discloses a preparation method for a millimeter-grade polyacrylonitrile hollow microsphere. The method includes the following steps: firstly selecting high viscosity silicone oil as a first oil phase O1 and a second oil phase O2, and a polyacrylonitrile dissolved solution as a water phase W; forming a uniform and stable O1 / W dual-composition liquid drop by controlling the ejection velocities of a first injector and a second injector, and dropping the liquid drop in a collection bottle containing the second oil phase O2; standing the collection bottle subsequently, and realizing microsphere solidification by rotary evaporation; subsequently soaking the solidified microsphere in low viscosity silicone oil; then replacing the low viscosity silicone oil inside the microsphere through Soxhlet extraction; and finally removing an extraction solvent inside the microsphere through drying to obtain the millimeter-grade polyacrylonitrile hollow microsphere. The hollow microsphere prepared by the preparation method of the invention has a diameter of 1.5-2mm and a wall thickness of 60-130 [mu]m. In addition, the spherical degree, the concentric degree, the wall thickness uniformity, and other properties of the hollow microsphere are better.

Owner:NAT UNIV OF DEFENSE TECH

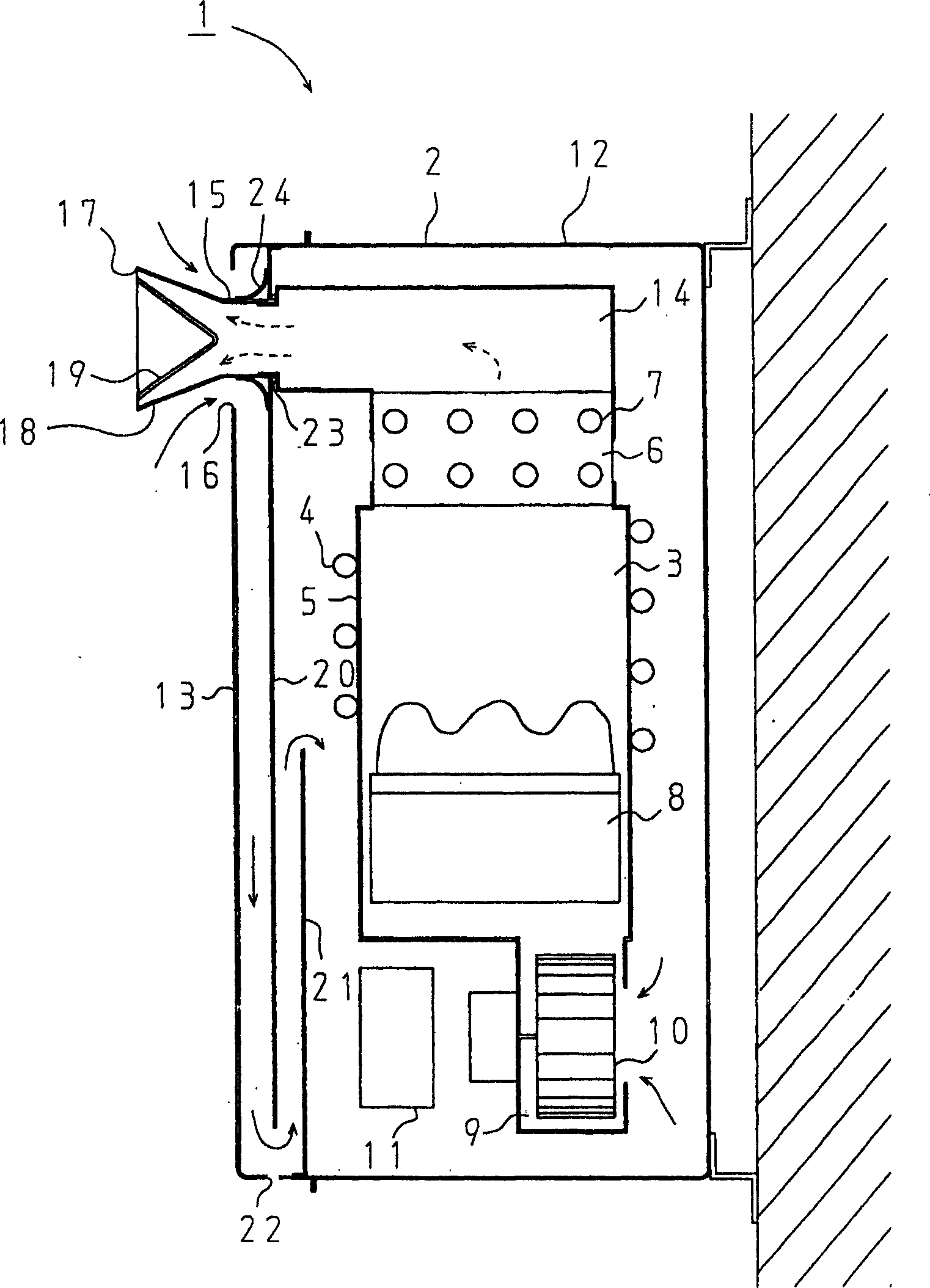

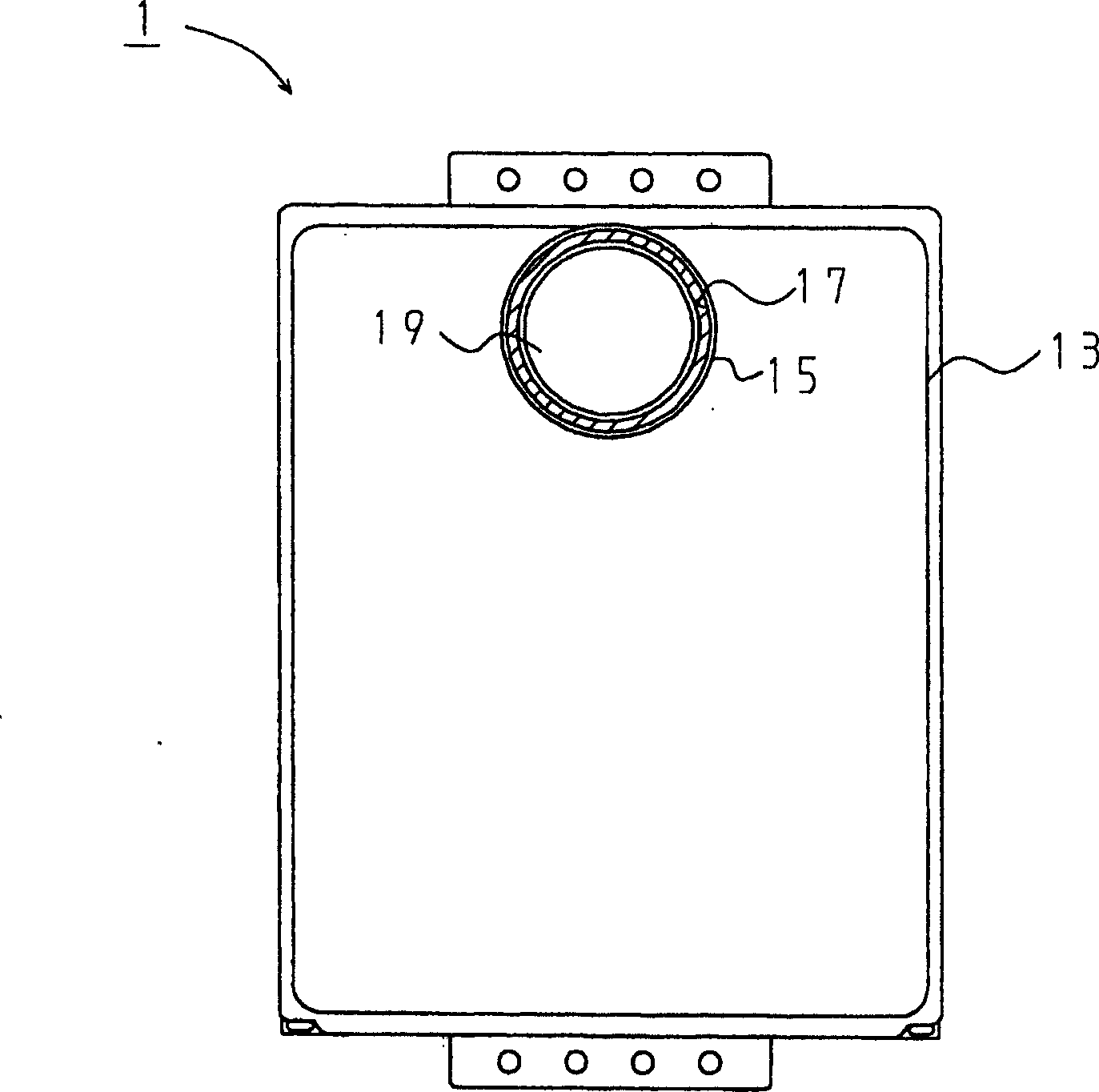

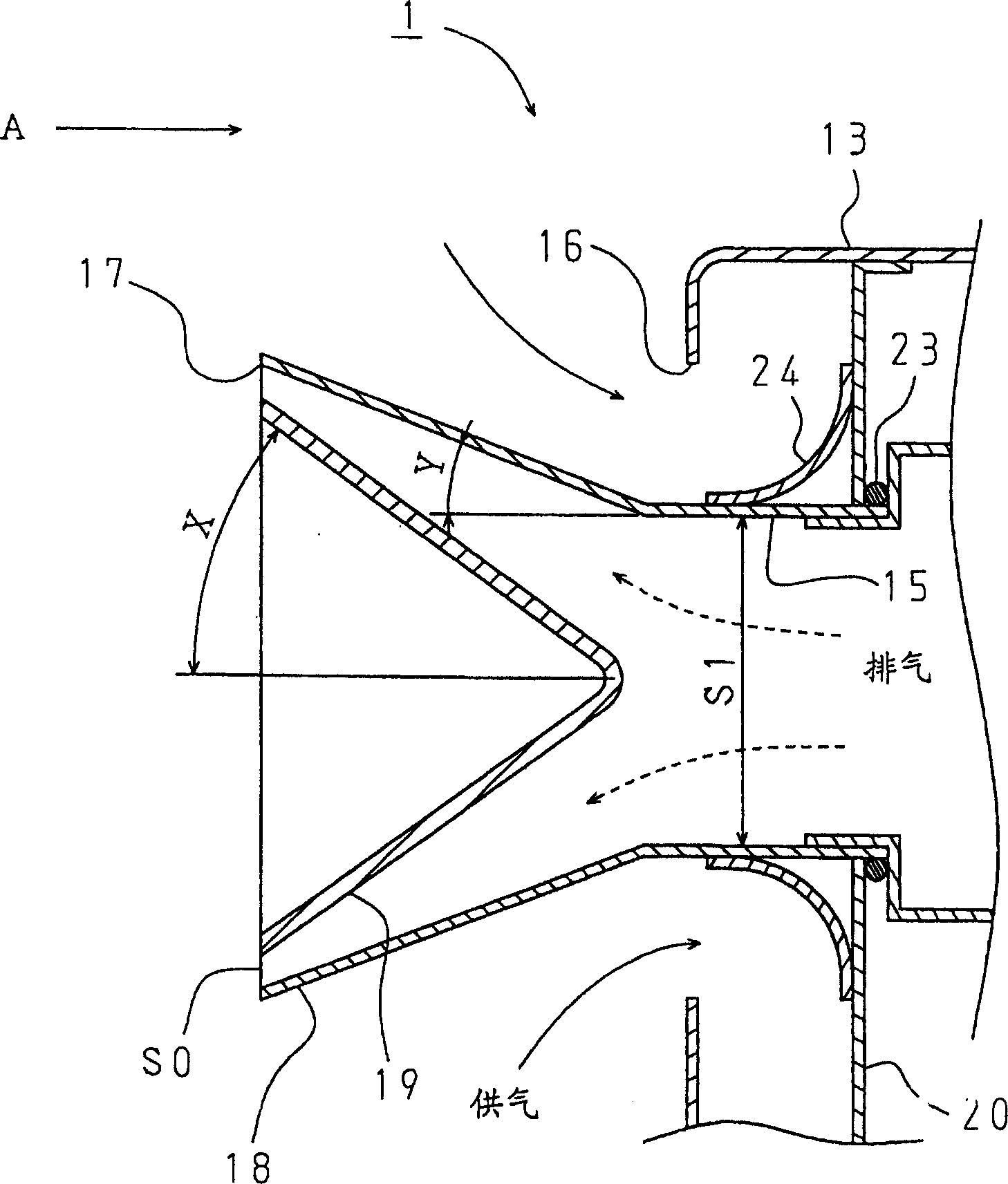

Outside external burner

InactiveCN1696571ASpeed up the flowIncrease flow rateFluid heatersNon-combustible gases/liquids supplyCombustionEngineering

An object of the present invention is to prevent the exhaust gas from being mixed into the air supply side when there is a headwind. According to the water heater (1) of this embodiment, by setting the conical backwind preventing plate (19) in the exhaust passage, the area S0 of the exhaust port is smaller than the area S1 of the exhaust passage in the exhaust tube (115), so that the exhaust The flow velocity (extrusion velocity) of the gas is increased, and the exhaust gas discharge can be spread far away. As a result, it is possible to prevent the exhaust gas from being mixed into the air supply port (16) at the time of headwind, and it is possible to maintain good combustion performance. Moreover, since the air outlet (17) has a backwind preventing plate (19), it can prevent wind from directly blowing into the air outlet (17). Therefore, even in a strong wind, exhaust can be smoothly performed, and good combustion performance can be maintained.

Owner:PALOMA KOGYO KK

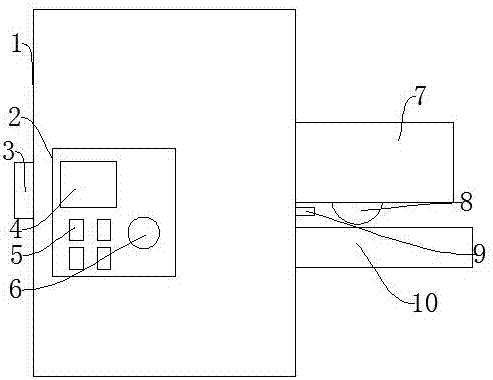

Adjustable type forming device for rubber conveying belts

InactiveCN106965363AKnow the ejection speed in real timeControl production speedBeltsDomestic articlesVisibilityEngineering

The invention discloses an adjustable rubber conveyor belt molding device, which includes a machine body, a control panel, a workbench and a distribution box. A feed pipe is arranged on the side of the machine body, the control panel is arranged on the surface of the machine body, and the A display screen is arranged on the control panel, a control button is arranged on the side of the display screen, a power switch is arranged on the side of the control button, the workbench is arranged on the other side of the body, and a The nozzle is provided with a flow detector inside the nozzle. The beneficial effect is that the rubber conveyor belt molding device can know the ejection speed of the raw material in real time through the flow detector, and then control the ejection speed and the pressing speed of the raw material to the recommended value through the pump controller and the governor, which is convenient for adjustment and can Accurate control of production speed.

Owner:山东盛润胶带有限公司

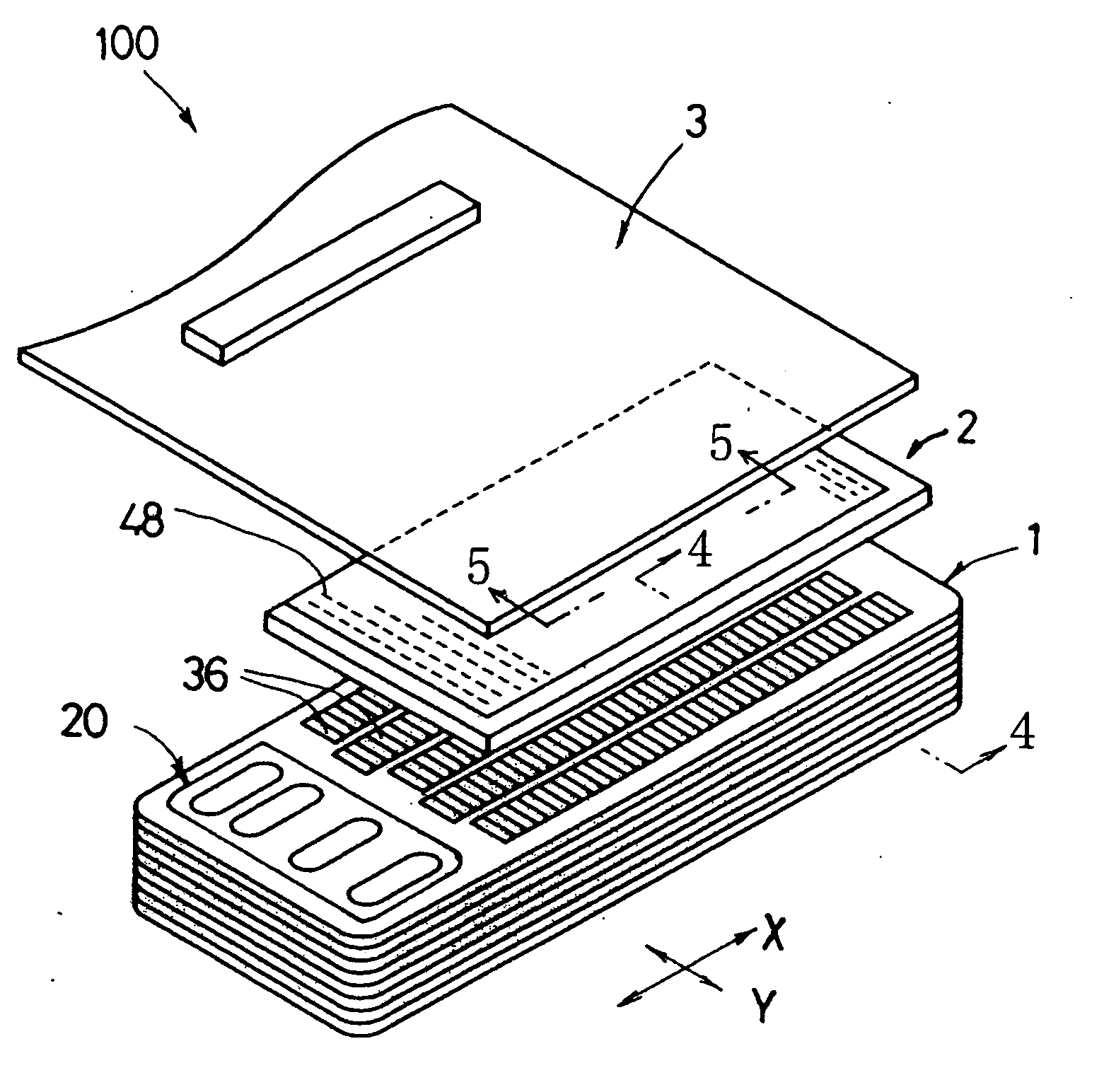

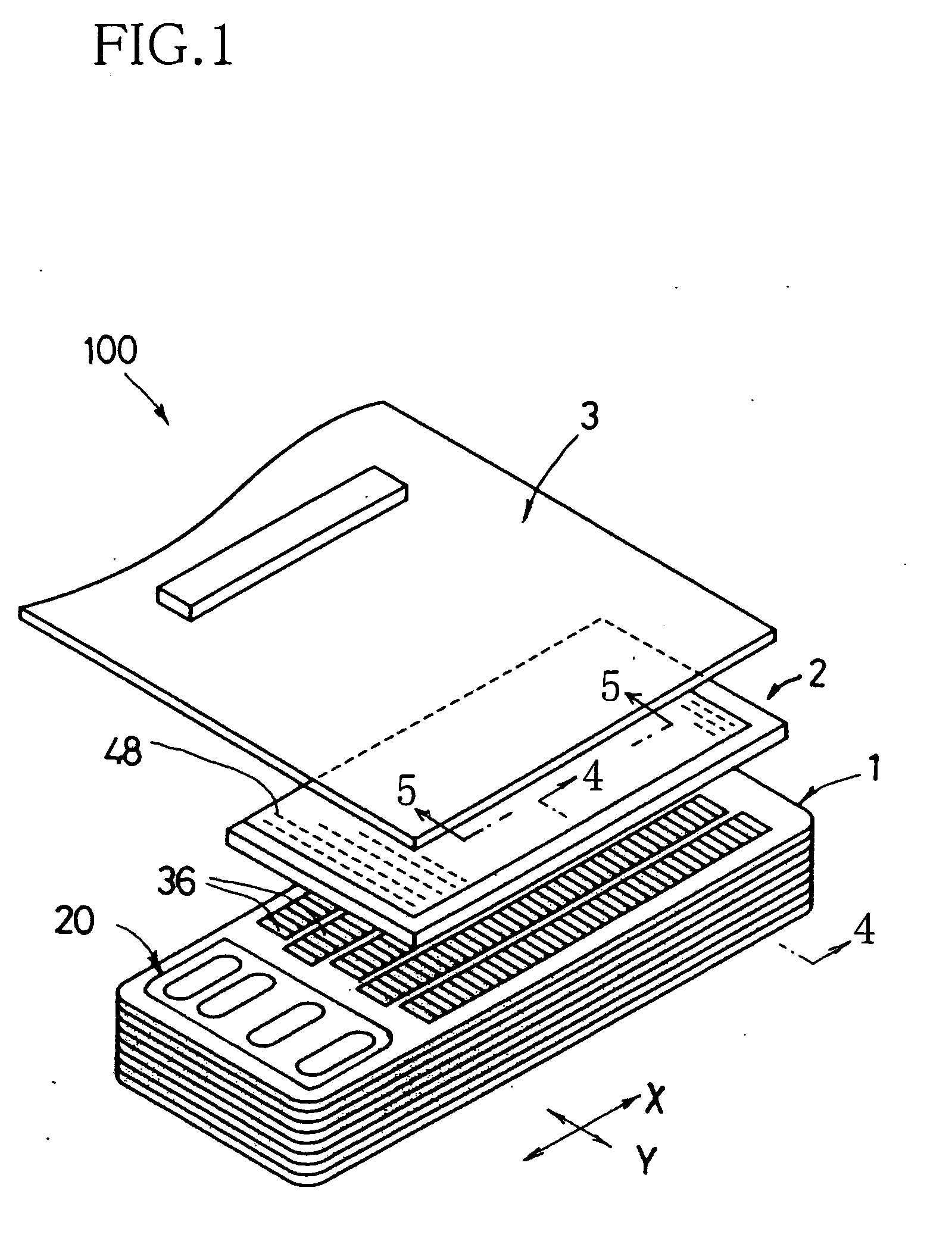

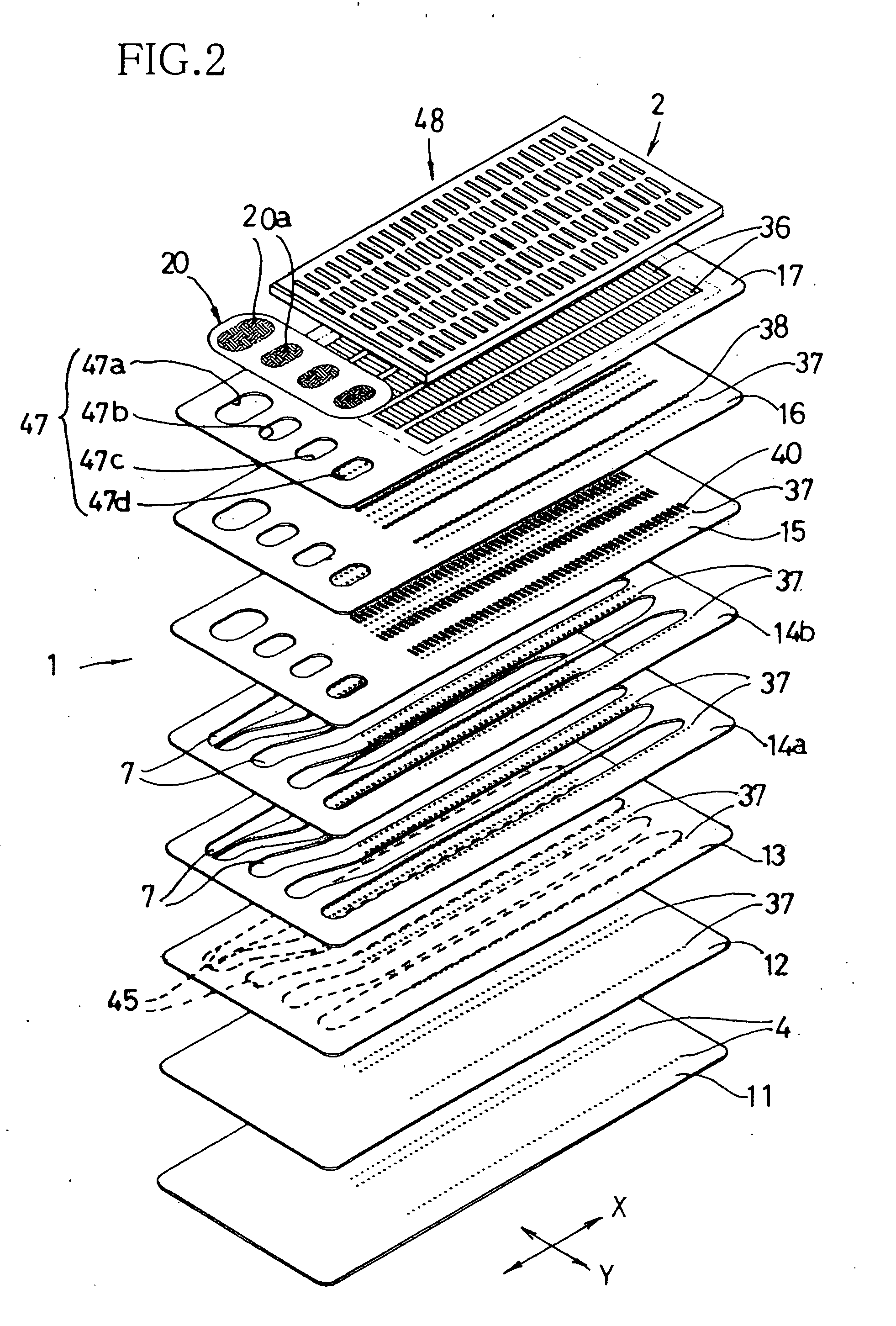

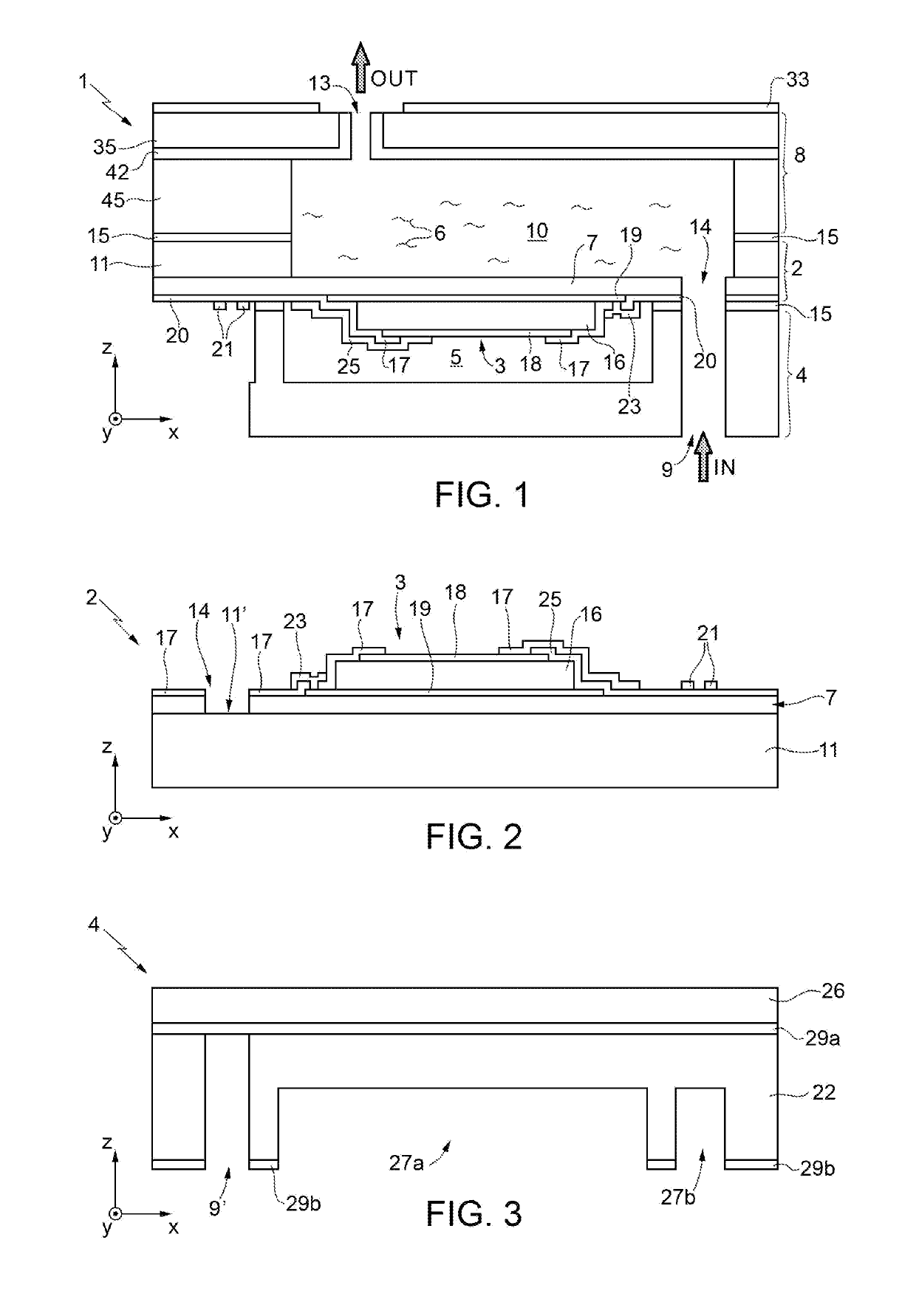

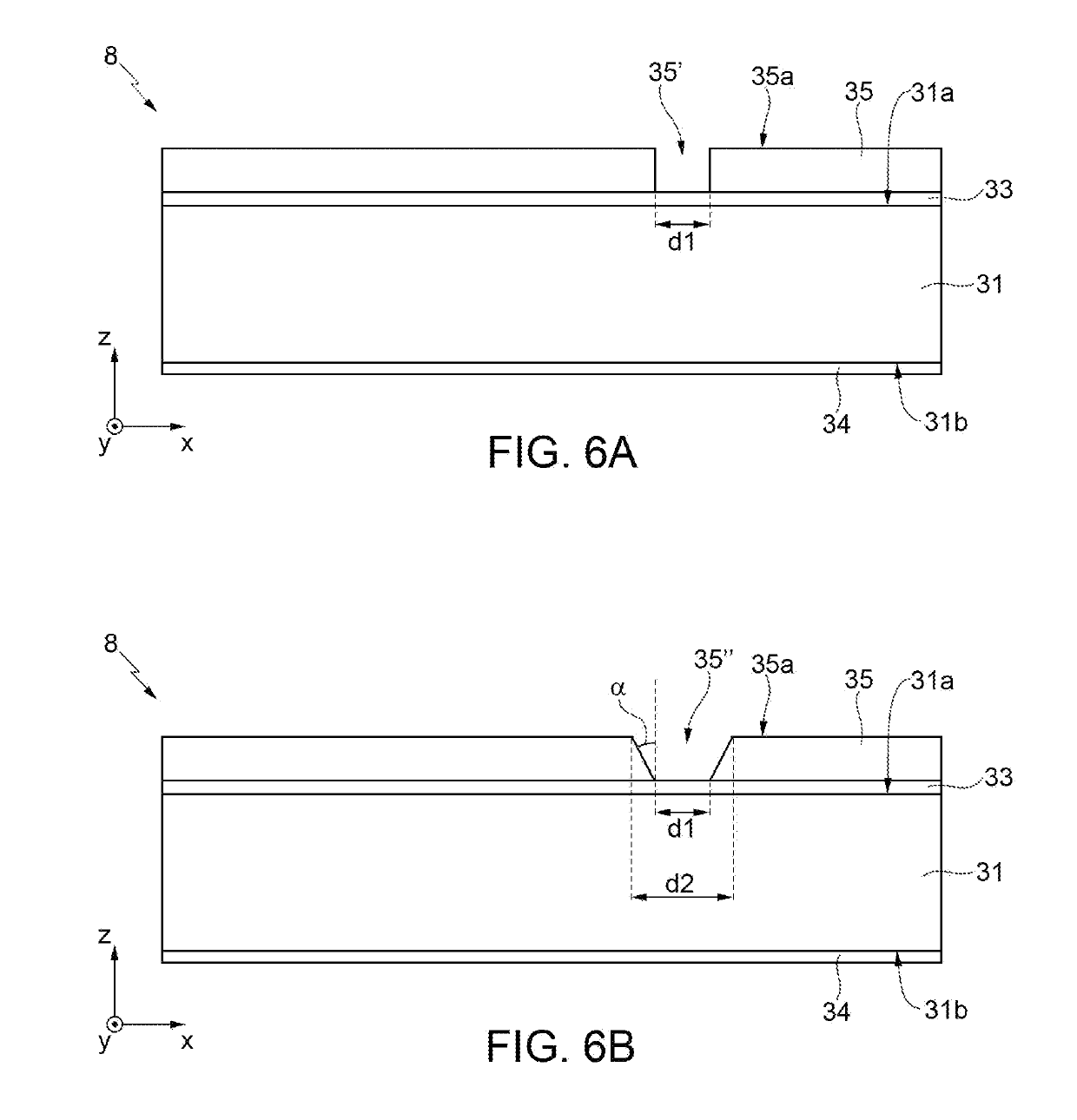

Method for manufacturing a fluid-ejection device with improved resonance frequency and fluid-ejection velocity, and fluid-ejection device

A method for manufacturing a device for ejecting a fluid, comprising the steps of: forming, in a first semiconductor wafer that houses a nozzle of the ejection device, a first structural layer; removing selective portions of the first structural layer to form a first portion of a chamber for containing the fluid; removing, in a second semiconductor wafer that houses an actuator of the ejection device, selective portions of a second structural layer to form a second portion of the chamber; and coupling together the first and second semiconductor wafers so that the first portion directly faces the second portion, thus forming the chamber. The first portion defines a part of volume of the chamber that is larger than a respective part of volume of the chamber defined by the second portion.

Owner:STMICROELECTRONICS SRL

Instantaneous ejection steam explosion machine

ActiveCN105642188BAchieving suddennessGuarantee the same effect of steam explosionPressurized chemical processProcess scaleTime extension

The invention relates to production equipment for steam explosion treatment of micropore structure substances, and the equipment is key treatment equipment of biomass utilization, biochemical engineering, fermentation brewing, solid waste treatment and other industries. The invention provides an instantaneous ejection type steam explosion machine utilizing the steam ejection principle to complete the steam explosion process. Opening of an explosion channel of the steam explosion machine utilizes the steam ejection pressure generated by section difference, thus overcoming the problem of prolonged deflation time along with treatment volume increase in traditional hot blow process. With the increase of the cylinder volume, the section difference also increases accordingly, so that the cylinder ejection velocity can maintain consistent, thus laying the foundation for process scale-up.

Owner:中集竹链科技有限公司

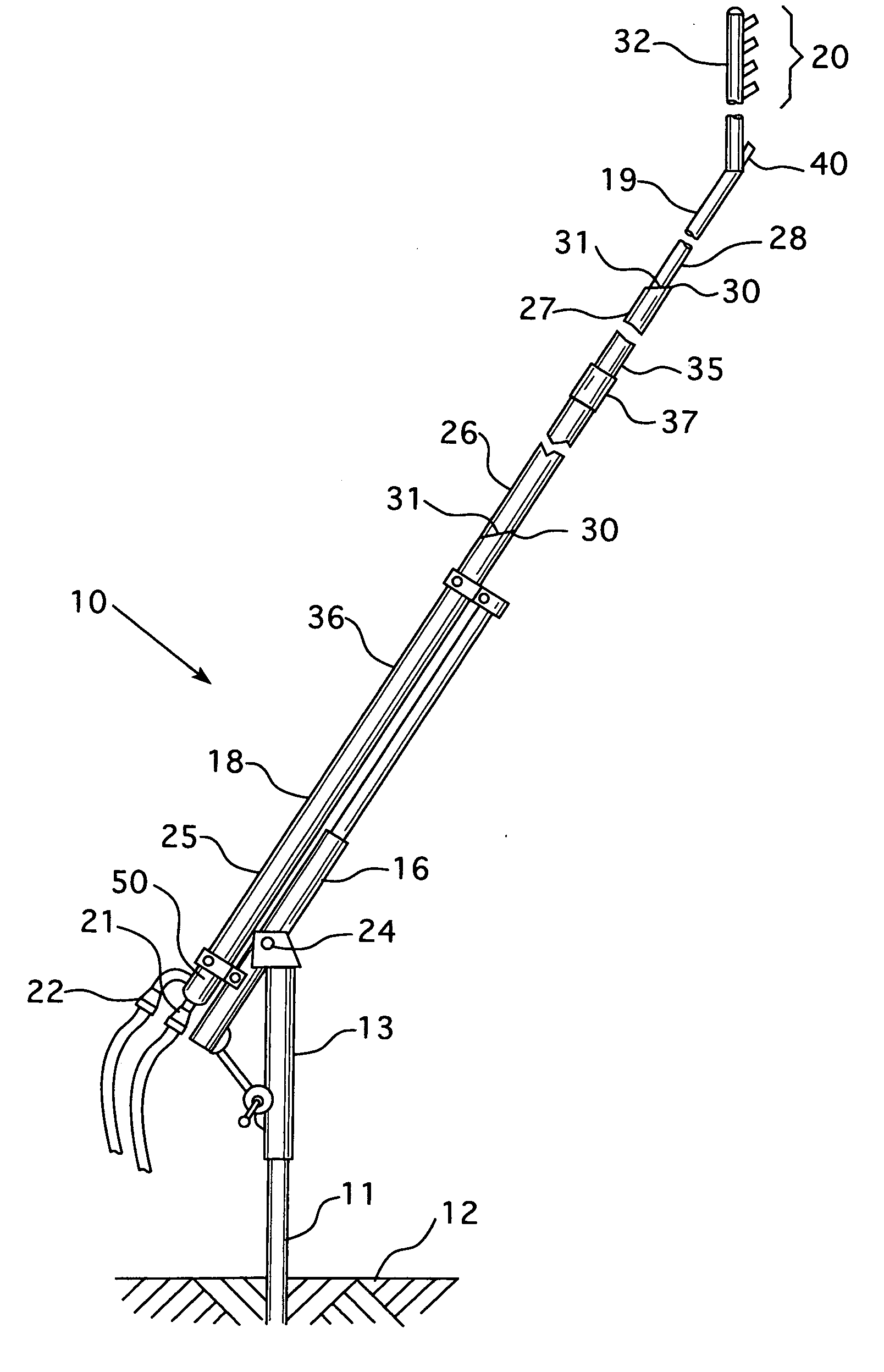

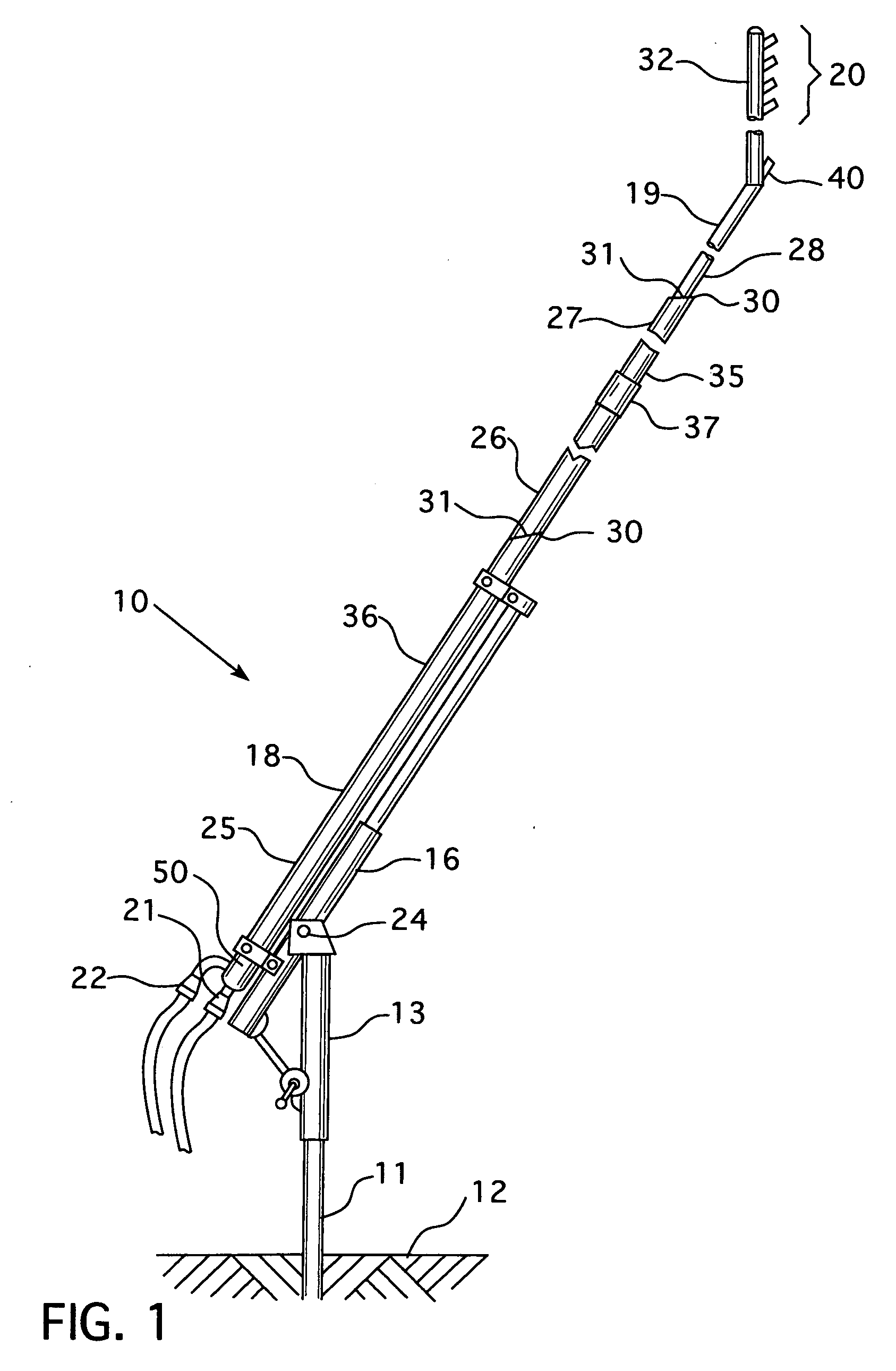

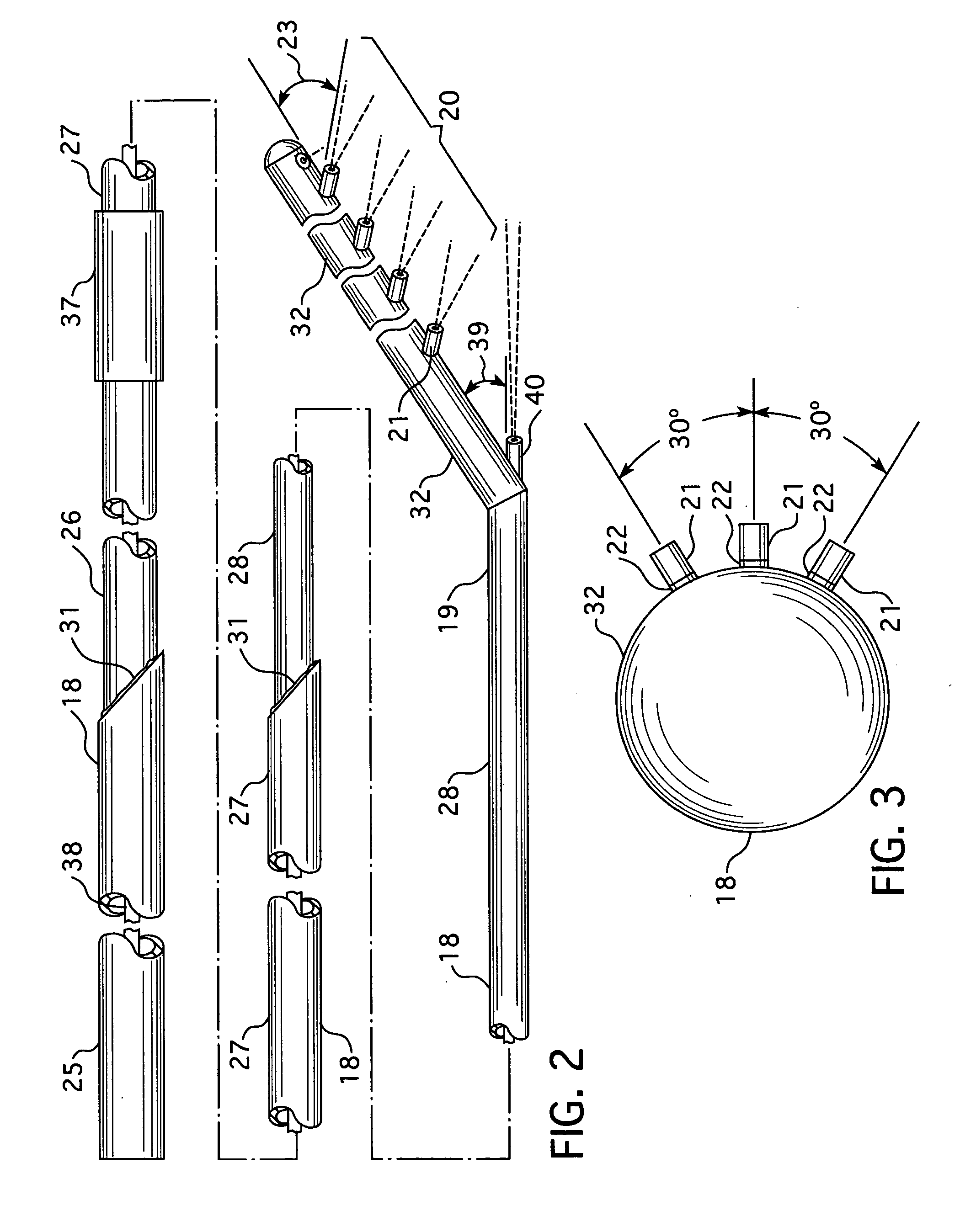

Snow making tower and method of making snow

InactiveUS20130056546A1Cheap to shipRecreational ice productionLighting and heating apparatusAtmospheric airWater flow

A snow making tower pipe comprised of multiple aluminum pipe segments of different diameters dimensioned whereby the segments are telescopically fitted and welded end to end with the segment of larger diameter at the lower end, and the end to end weld fittings are angled relative to the longitudinal axis of the tower pipe at an angle of less than 90 degrees to provide a maximum strength weld connection. The snow making tower ejects air and water under pressure through snow making nozzles to form an atomized plume of water in adjacent ambient atmosphere under sub-freezing conditions. Water is ejected under pressure from a projection nozzle in the form of a spray stream at a velocity greater than the ejection velocity of the plume and this water stream is directed to engage the plume and thereby project the plume outwardly farther than possible without the assistance of the spray stream.

Owner:DUPRE HERMAN K

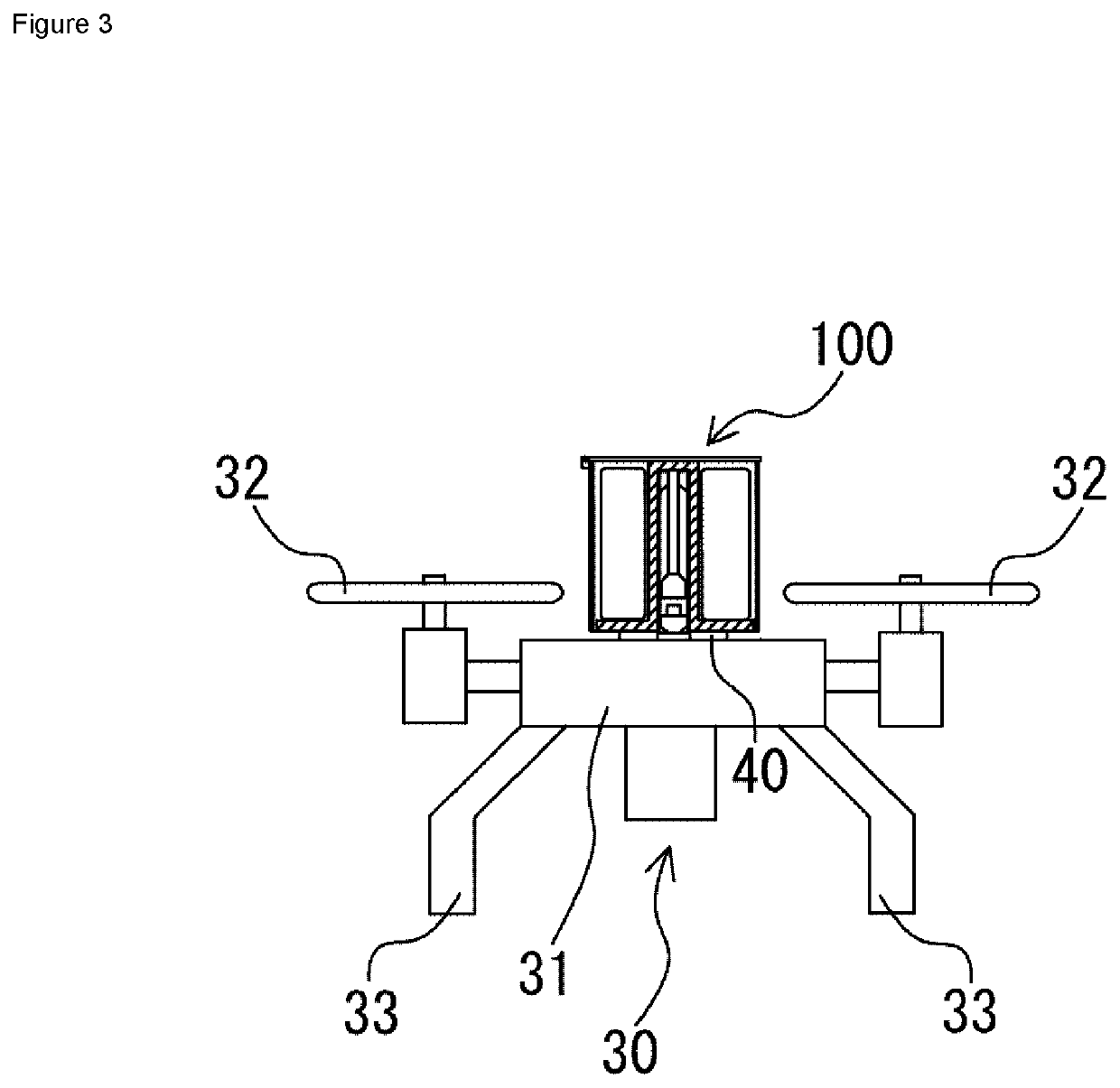

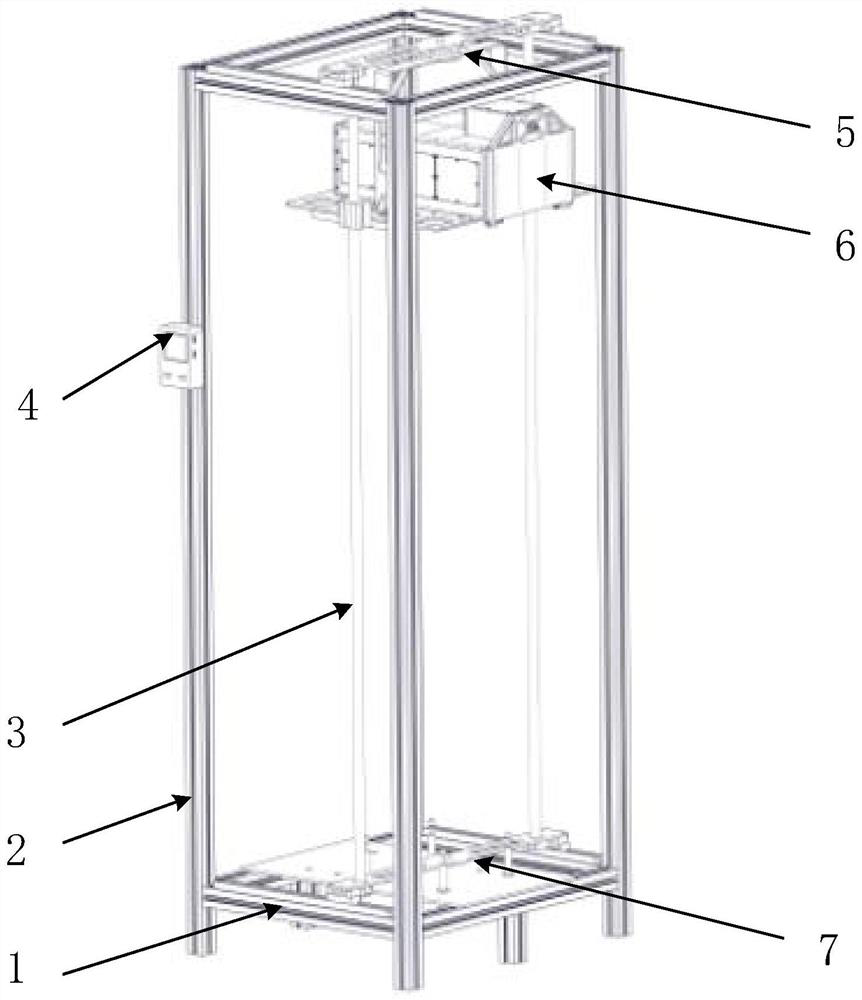

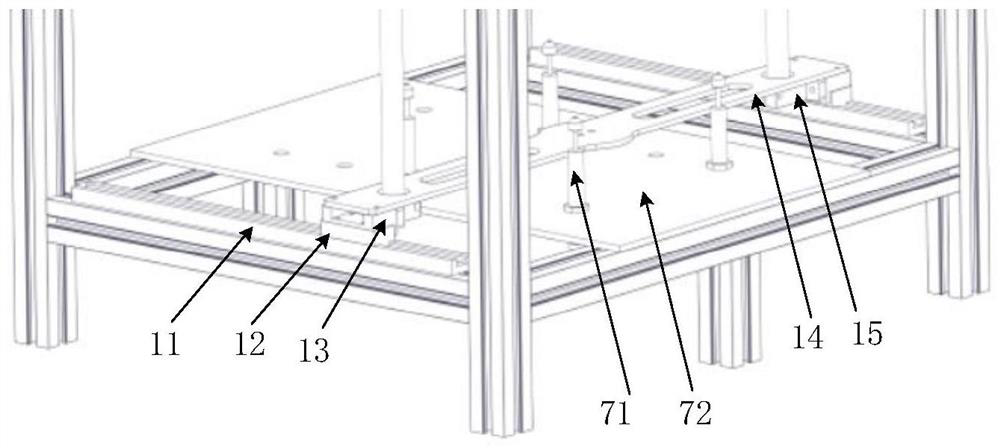

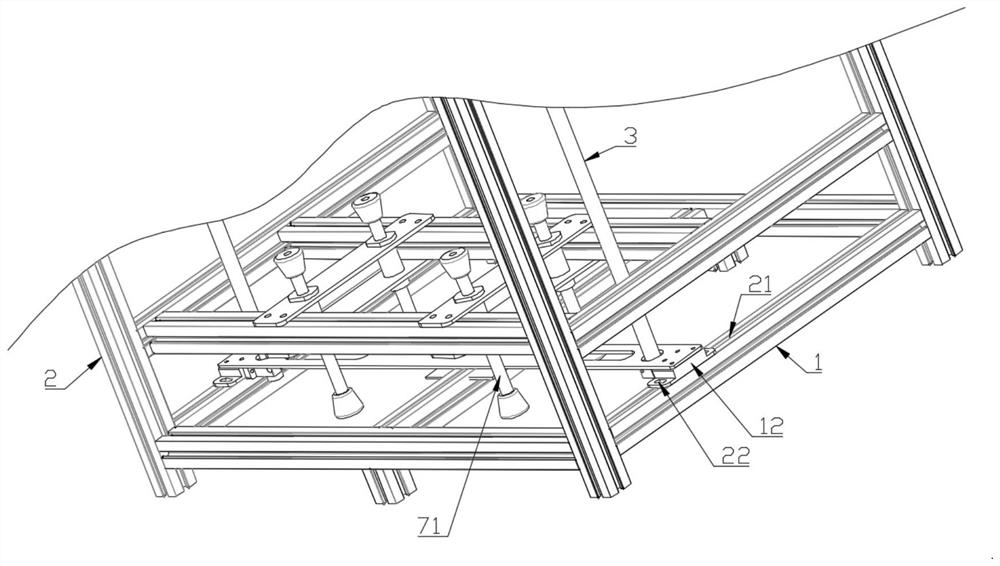

Test device for simulating weightlessness ejection of cubesat

PendingCN113607391AReduce impactImplement constraints in the separation directionMachine part testingFree fallingStructural engineering

The invention provides a test device for simulating the weightless ejection of a cubesat. With the device provided by the invention adopted, human influence can be avoided, a good initial state of a free falling body can be ensured, the synchronization of falling starting time of a catapult and the power-up time of the catapult can be ensured, or the time difference between the falling starting time and power-up starting time can be strictly controlled according to the power-up unfolding time of the catapult; meanwhile, when the catapult is unfolded and pops out of the cubesat, a Pod is restrained in a separation direction, so that it can be ensured that the ejection speed of the cubesat and a real in-orbit separation speed can be the same. The test device comprises a catapult, a vertical frame and a sliding rod installed in the frame, the catapult can be used for containing the cubesat and catapulting the cubesat, the catapult is installed on the sliding rod in a sliding mode through a sliding sleeve and is guided through the sliding rod; The test device further comprises an iron block installed at the top of the catapult, a suction cup magnet assembly capable of being attracted to the iron block is installed at the top of the frame, and the catapult is suspended at the top of the frame through attraction of the suction cup magnet assembly and the iron block.

Owner:陕西智星空间科技有限公司

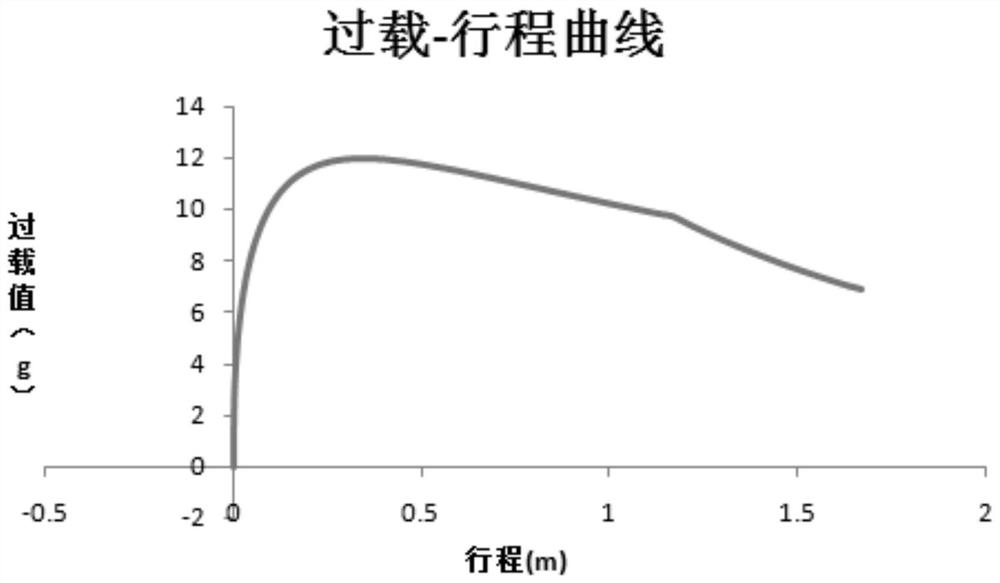

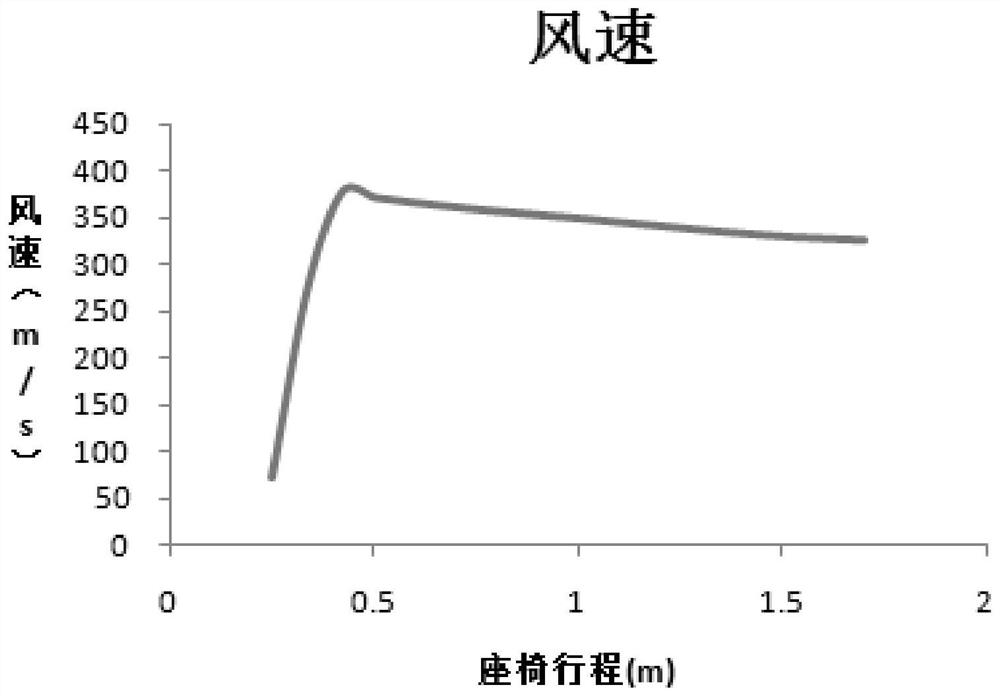

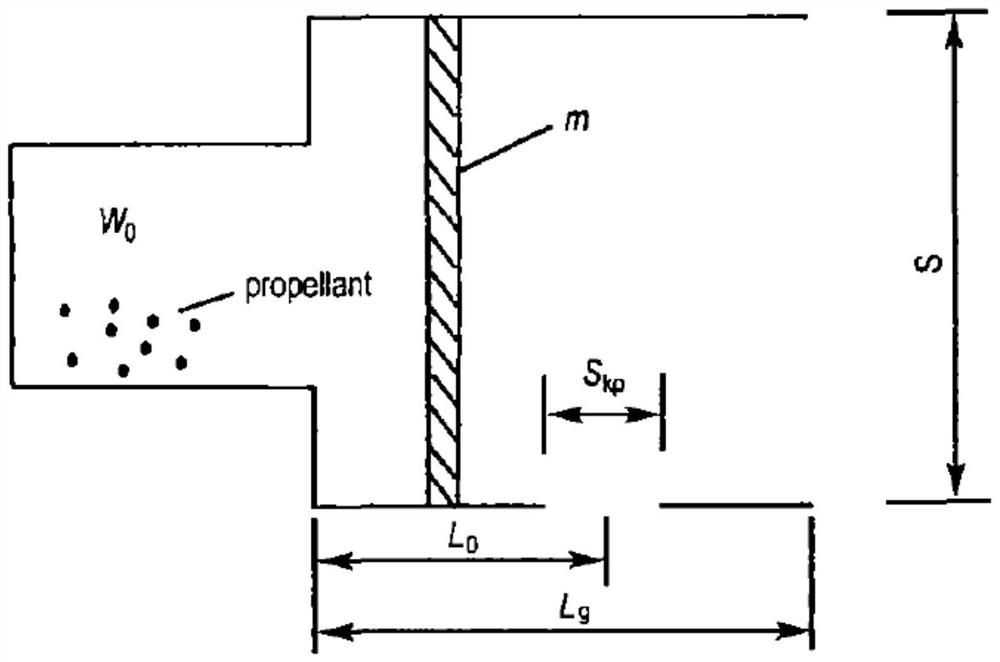

Method for calculating neck load in pilot ejection process through ground simulation

PendingCN113779900AReduce in quantityImprove the development effectDesign optimisation/simulationSustainable transportationClassical mechanicsControl theory

The invention discloses a method for calculating neck load in a pilot ejection process through ground simulation. The method comprises the following steps: measuring a pure aerodynamic lift value of a head wearing system under a corresponding ejection speed condition; performing inner ballistic performance calculation according to the inner ballistic physical model of the ejection power system to obtain an overload-stroke curve of the pilot seat in an ejection cabin-out stage; obtaining a speed-stroke curve of a head seat in a flow field in the ejection cabin-out stage under the corresponding ejection speed condition through simulation, and finding out the seat stroke under the condition that the airflow speed is maximum according to the speed-stroke curve; finding a seat overload value when the seat travel is s according to the overload-travel curve; adding the actually measured weight of the head wearing system to the head weight of the corresponding pilot to obtain the weight of the head system; and obtaining the maximum value of the neck load in the ejection process. The number of ejection tests with high cost is effectively reduced, the development effect is improved, and the test cost is reduced.

Owner:AEROSPACE LIFE SUPPORT IND LTD

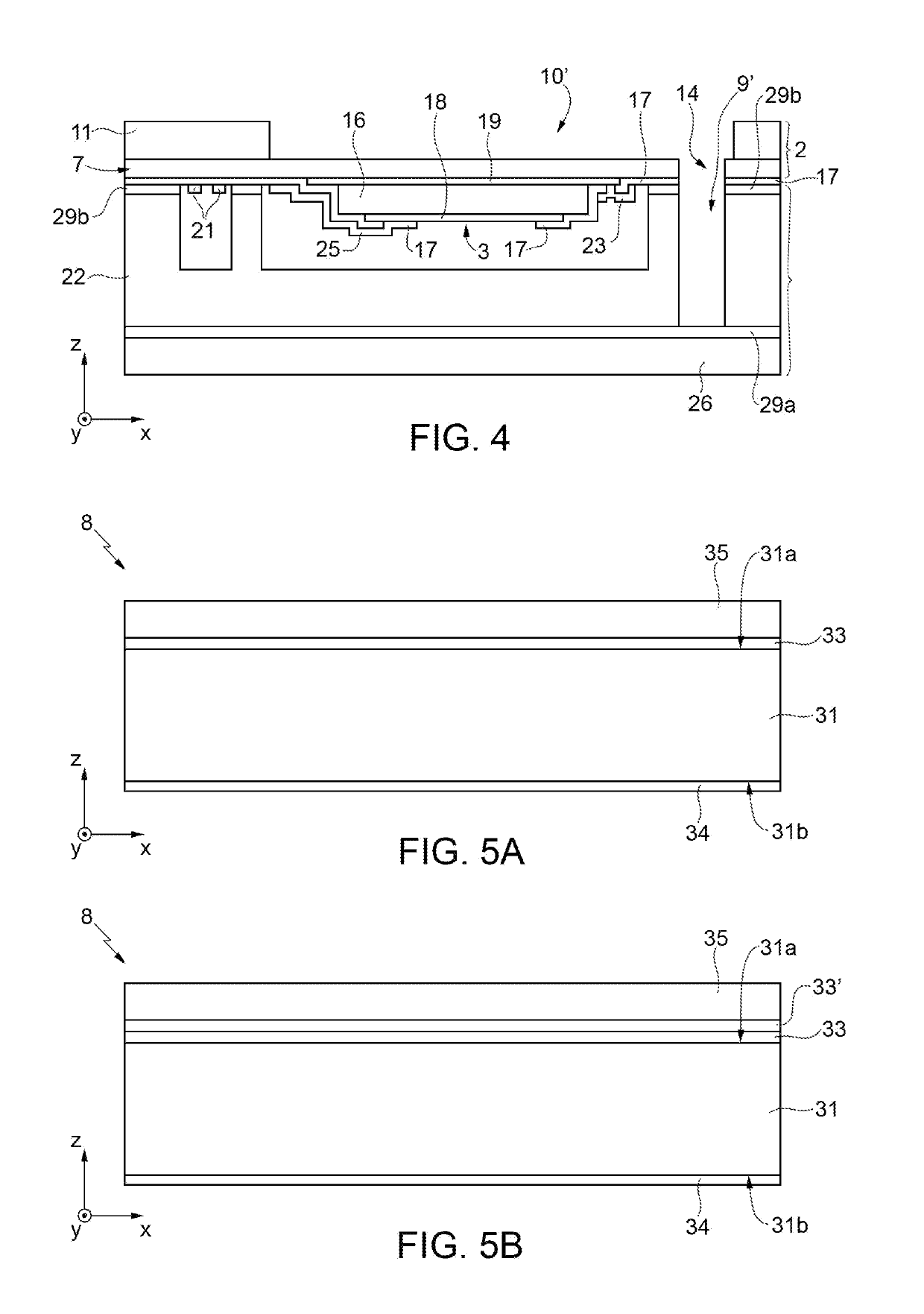

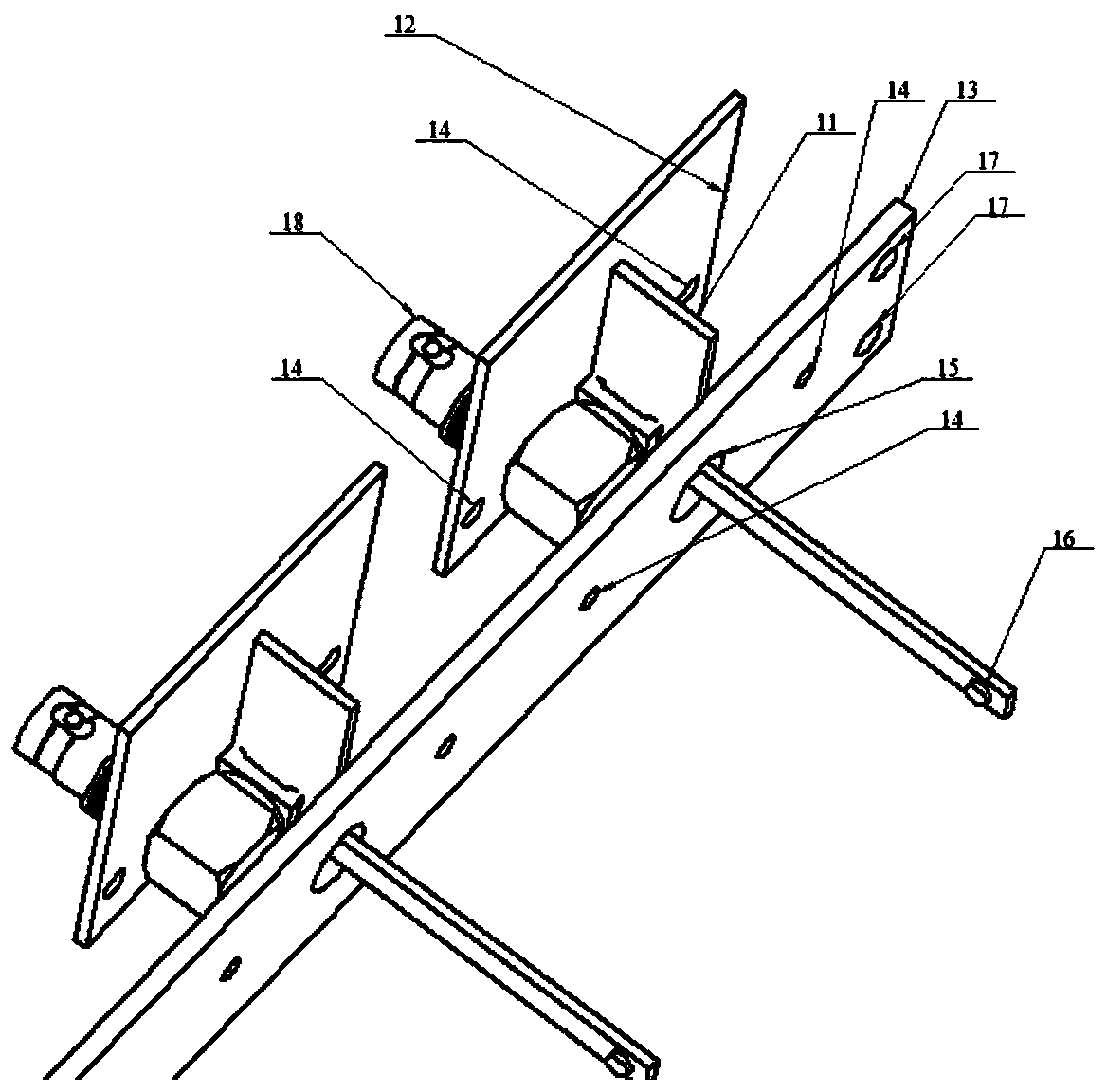

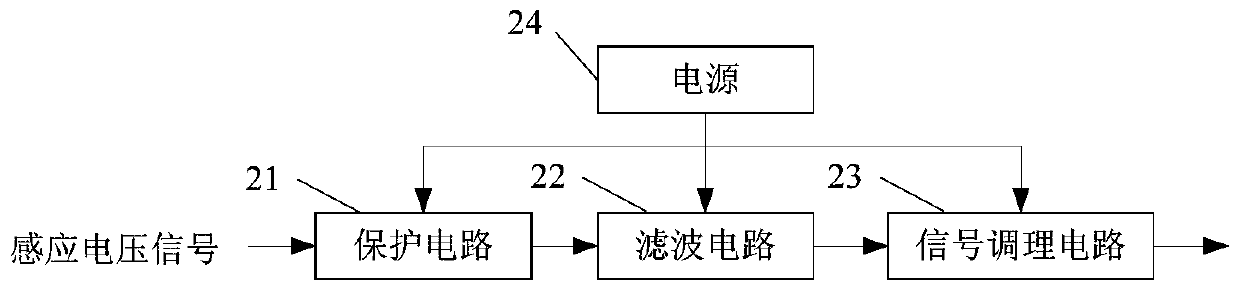

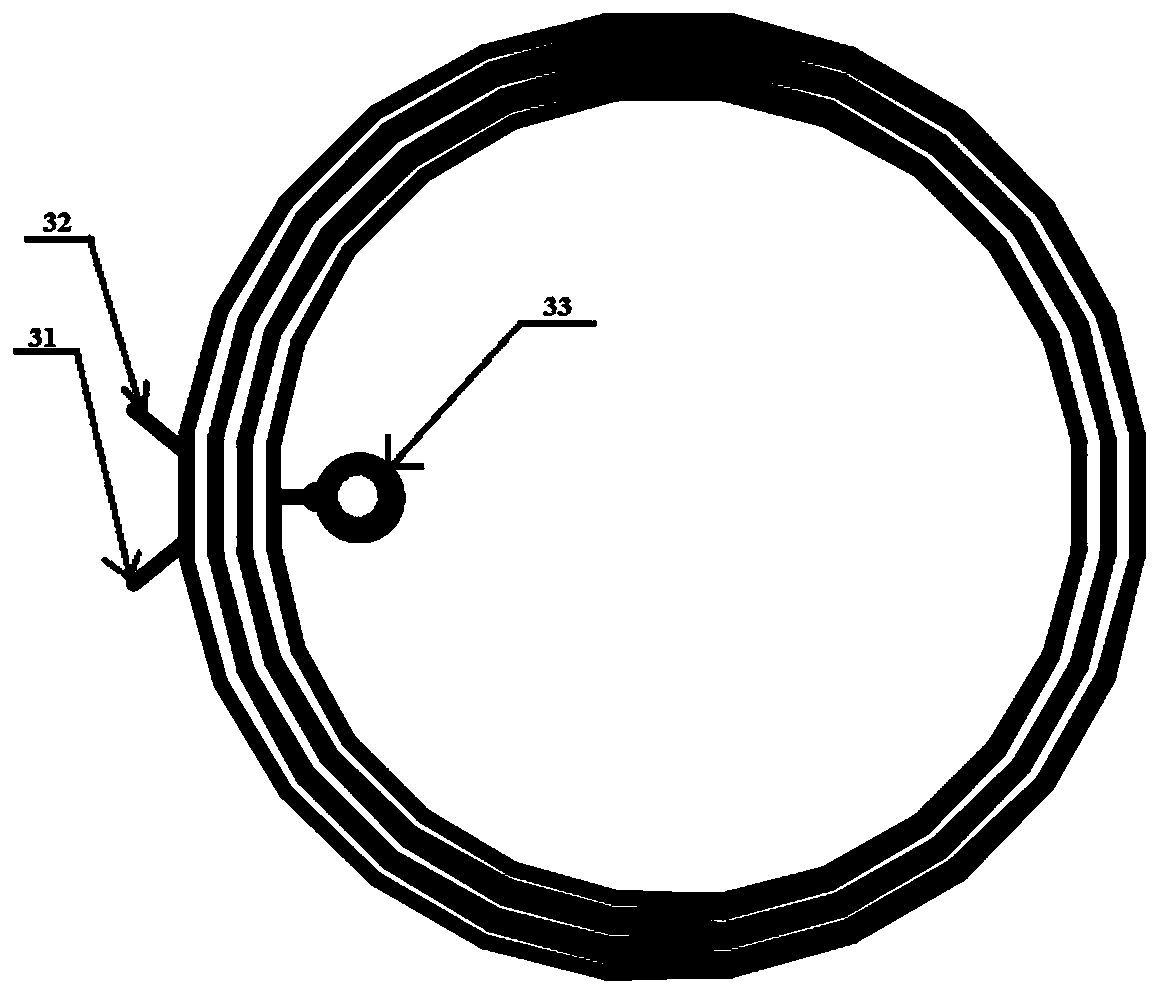

A magnetic probe array device, an electromagnetic thrust velocity measurement device and method

ActiveCN107192844BImprove consistencyHigh measurement accuracyDevices using time traversedMeasurement deviceMeasurement precision

The invention discloses a magnetic probe array device and an electromagnetic ejection velocity measurement device and method. The magnetic probe array device comprises a plurality of magnetic probes, bottom plates fixedly connected with the magnetic probes respectively, and a skeleton fixation strip. The bottom plates and the skeleton fixation strip are provided with probe positioning holes for connecting the bottom plates and the skeleton fixation strip through screws; the skeleton fixation strip is provided with probe location holes corresponding to the magnetic probes respectively; after the bottom plates are connected with the skeleton fixation strip, induction coils of the magnetic probes pass through the probe location holes correspondingly; and the skeleton fixation strip has fixation strip positioning holes for enabling the skeleton fixation strip to be fixedly arranged to an electromagnetic ejection device through screws. The magnetic probe array device solves the problem of low measurement precision due to unstable external installation of the magnetic probes on the electromagnetic ejection device, and thus measurement precision is improved; and during repeated disassembly and assembly, positions and angles of the magnetic probes can be identical to those in the last time when the magnetic probes are reinstalled, and thus consistency of velocity measurement is improved.

Owner:YANSHAN UNIV

An Optimal Design Method of Flux Transformer Based on Genetic Algorithm and Ansys Simulation

ActiveCN104392036BAction performance indicators improvedReduce volumeSpecial data processing applicationsElectrical resistance and conductanceCapacitance

The invention relates to the optimum design field of magnetic flux convertors, in particular to a magnetic flux convertor optimum design method based on a genetic algorithm and ANSYS simulation. The magnetic flux convertor optimum design method based on the genetic algorithm and the ANSYS simulation includes: selecting resistance, capacitance and drive voltage in a drive circuit of the magnetic flux convertor as main optimum parameters, and using the genetic algorithm in combination with the ANSYS simulation to perform optimum design of the drive circuit. The number of indexes for measuring motion performance of the magnetic flux convertor is two, and the two indexes are respectively final ejection velocity v of an ejector rod and execution time t of a whole tripping motion. The magnetic flux convertor optimum design method based on the genetic algorithm and the ANSYS simulation considers an actual tripping dynamic process of the magnetic flux convertor on the premise of optimizing design. The magnetic flux convertor optimum design method based on the genetic algorithm and the ANSYS simulation facilitates the optimum design of the magnetic flux convertor, and thereby raises the motion performance indexes of the magnetic flux convertor.

Owner:TONGJI UNIV

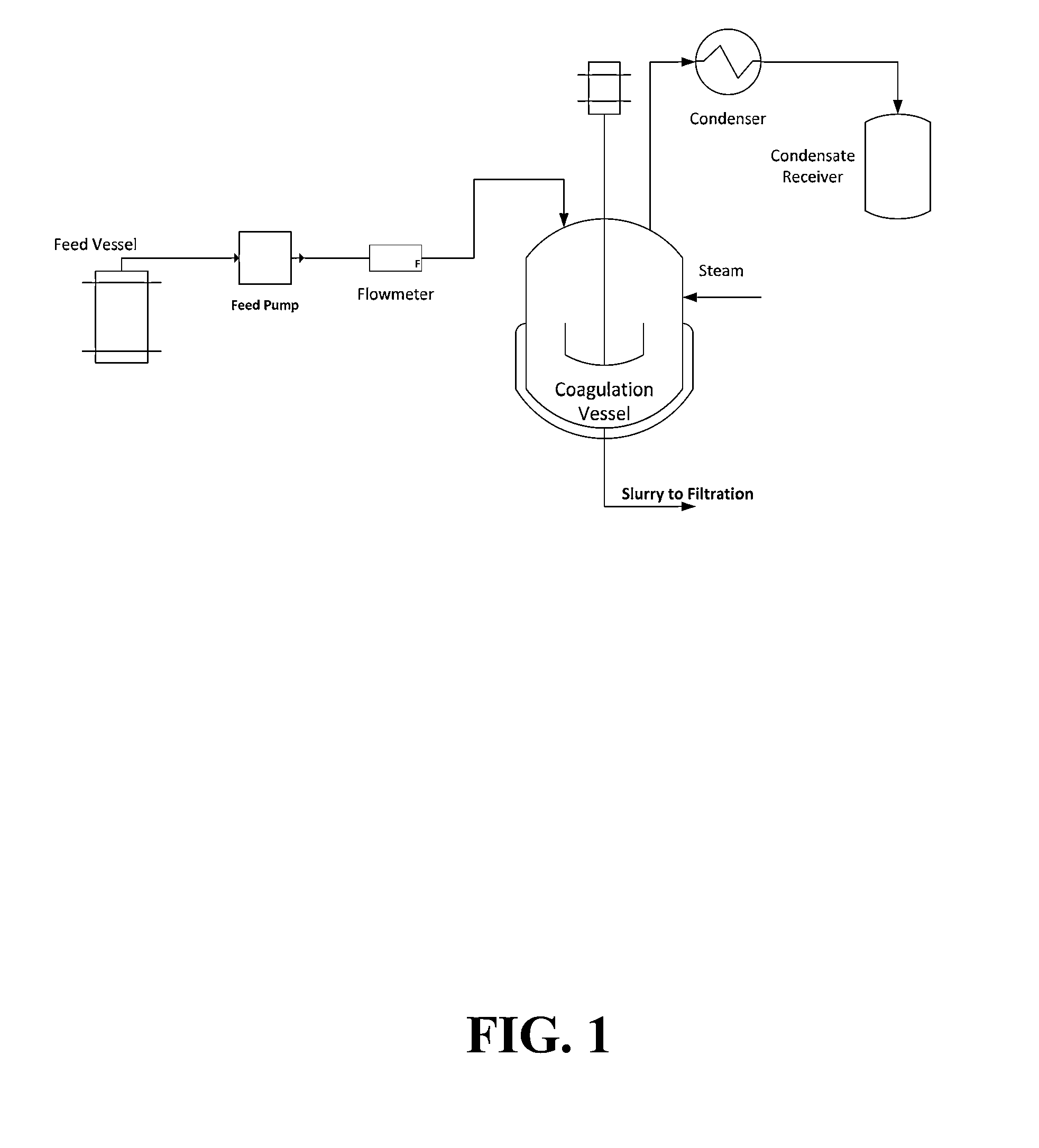

Process for coagulating sulfonated block copolymers

ActiveUS20150099815A1Easy to implementFacilitate subsequent processingIon-exchanger regenerationAnion exchangersOrganic solventFiltration

Sulfonated block copolymers (SBCs) are coagulated from SBC solutions in one or more organic solvents, including reaction mixtures obtained in the sulfonation process, by a process in which the SBC solution is ejected into or onto water provided that no steam is added to the SBC solution prior to ejection and provided that the ejection velocity as well as the water temperature and convection are controlled and balanced. The coagulation process is easy to implement and avoids or at least diminishes problems due to foaming and the formation of micro dispersions of the SBC which cannot be separated successfully or easily by conventional filtration or centrifuging.

Owner:KRATON POLYMERS US LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com