Instantaneous ejection type steam explosion machine

A steam explosion machine and catapult-type technology, which is applied in chemical instruments and methods, chemical/physical processes, and methods for chemically changing substances by using atmospheric pressure, can solve problems such as prolonging the deflation time, and achieve improved production capacity, Meet the requirements of process consistency and improve the effect of blasting energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

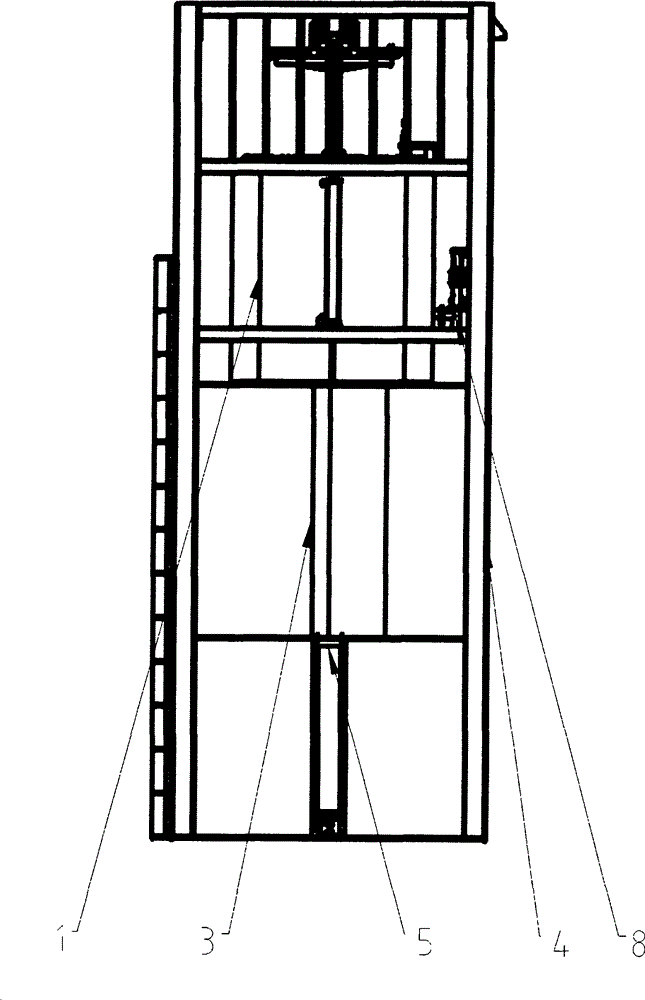

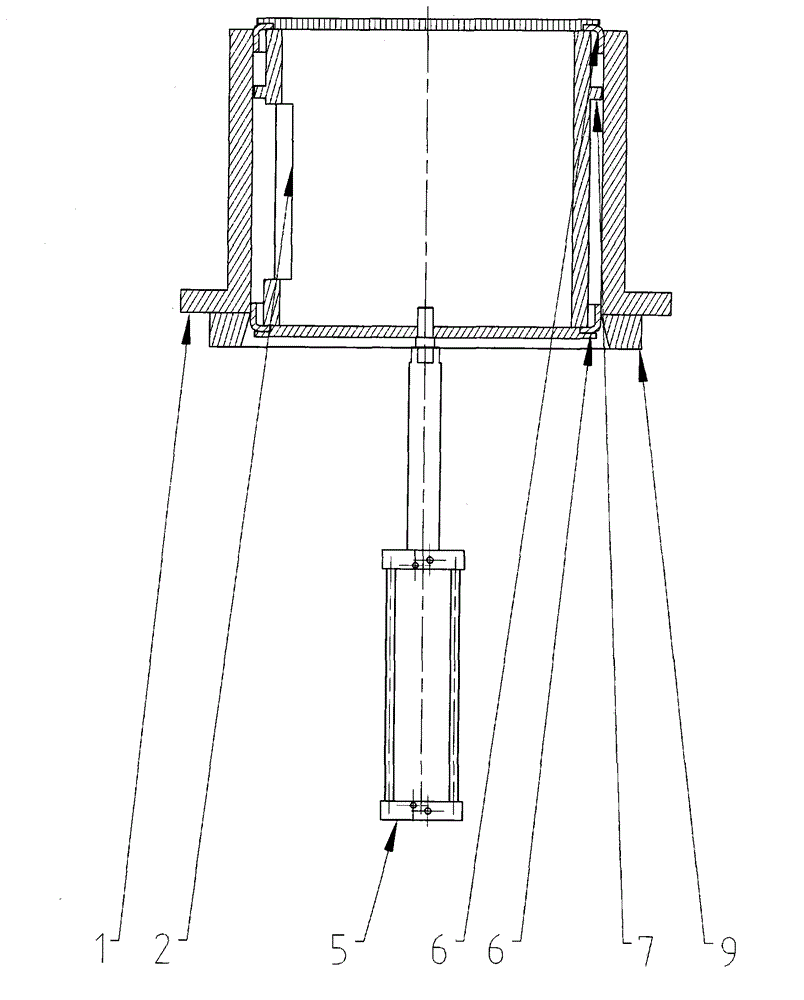

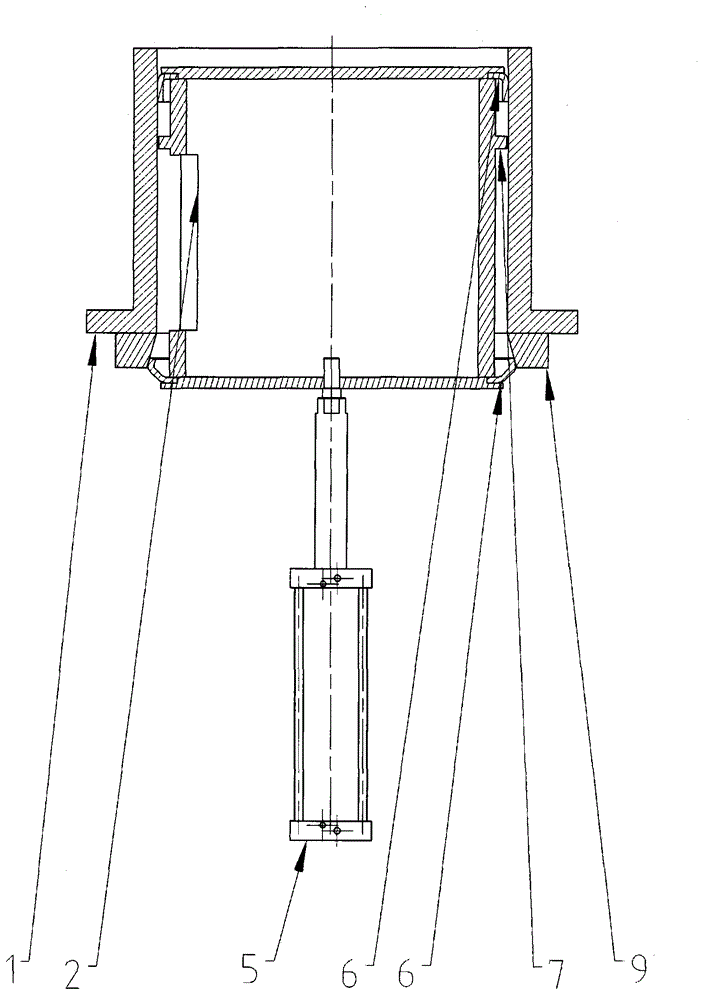

[0020] The QB-1500 instant ejection type steam explosion machine is the specific implementation of the above-mentioned invention. This type of steam explosion machine is equipped with a processing cylinder with a volume of 3,000 liters and a working pressure of 2.5Mpa. It can process 10 tons of straw or 30 tons of grain per hour on average. It is a medium-sized steam explosion machine. It provides industrial steam explosion treatment equipment for the production of biomass utilization, biochemical industry, fermentation and brewing, solid waste treatment and other industries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com