Patents

Literature

770results about How to "Decompose fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing silicon thin film heterojunction solar cell

InactiveCN1588649AAvoid damageReduce hydrogen contentFinal product manufacturePhotovoltaic energy generationHeterojunctionSilicon thin film

A prepn. method of silicon thin film heterojunction solar cell includes following steps: cleaning substrate, semiconductor cleaning technology is used to do primary cleaing to substrate surface, then do ultrasonic cleaning in deionized water several times; nitrogen blow drying; prepare nitrinsic amorphous silicon layer by heater chemical vapour phase depositing technology, tungsten filament temp. is measured by pyrometer, temp of heater and sample are determined separately by two electric thermo-couples, temp. is controlled by electric temp. controller; to react and grow thin film on substrate surface; to redeposit a transmitting layer on intrinsic amorphous silicon thin film; front and back electrodes forming, sputtering technology is used to form front and back electrodes; finally to proceed vacuum heat annealing process. The thin film produced by the invention has illumination stability, the photoconduction gain can reach to 10 to the power 6 on Am1.5 100mW / cm2 standard illumination.

Owner:SHANGHAI JIAO TONG UNIV

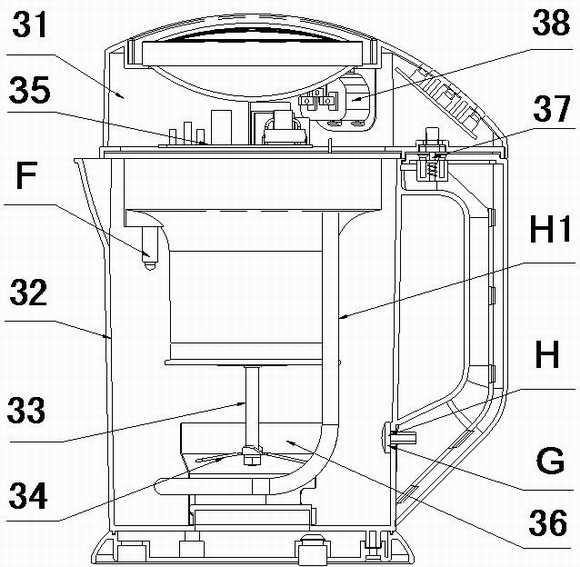

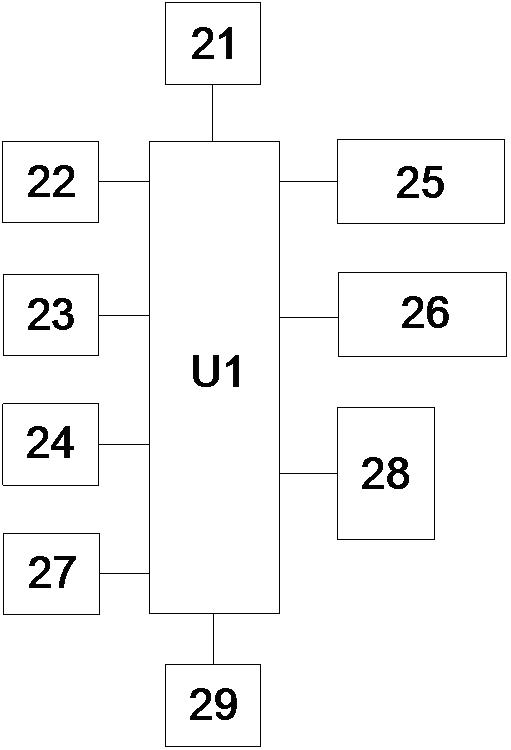

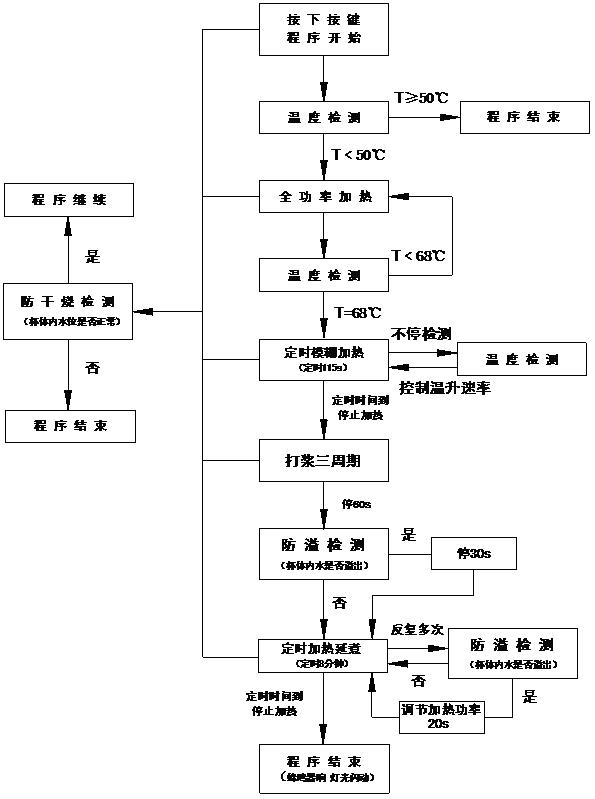

Electric-heating full-automatic soybean milk machine with fuzzy control

ActiveCN102160575AGreat tasteSimple circuit structureBeverage vesselsMilk substitutesRise rateElectric heating

The invention discloses an electric-heating full-automatic soybean milk machine with fuzzy control, comprising a nose, a cup body, a motor, a motor transmission shaft, a rotary blade, a heating element, a temperature-measuring sensing head, an anti-overflow sensing head, an anti-dry-burning sensing head and a control circuit board, wherein because of the adoption of the control circuit board, a preparation method of soybean milk, is programmed and systemized, intelligent control on the processing process of the soybean milk is realized by a single chip microcomputer, especially the functions of automatically adjusting the heating power according to the temperature and controlling the temperature rising rate can be introduced during a plurality of time intervals in the processing process of the soybean milk.

Owner:KINGCLEAN ELECTRIC

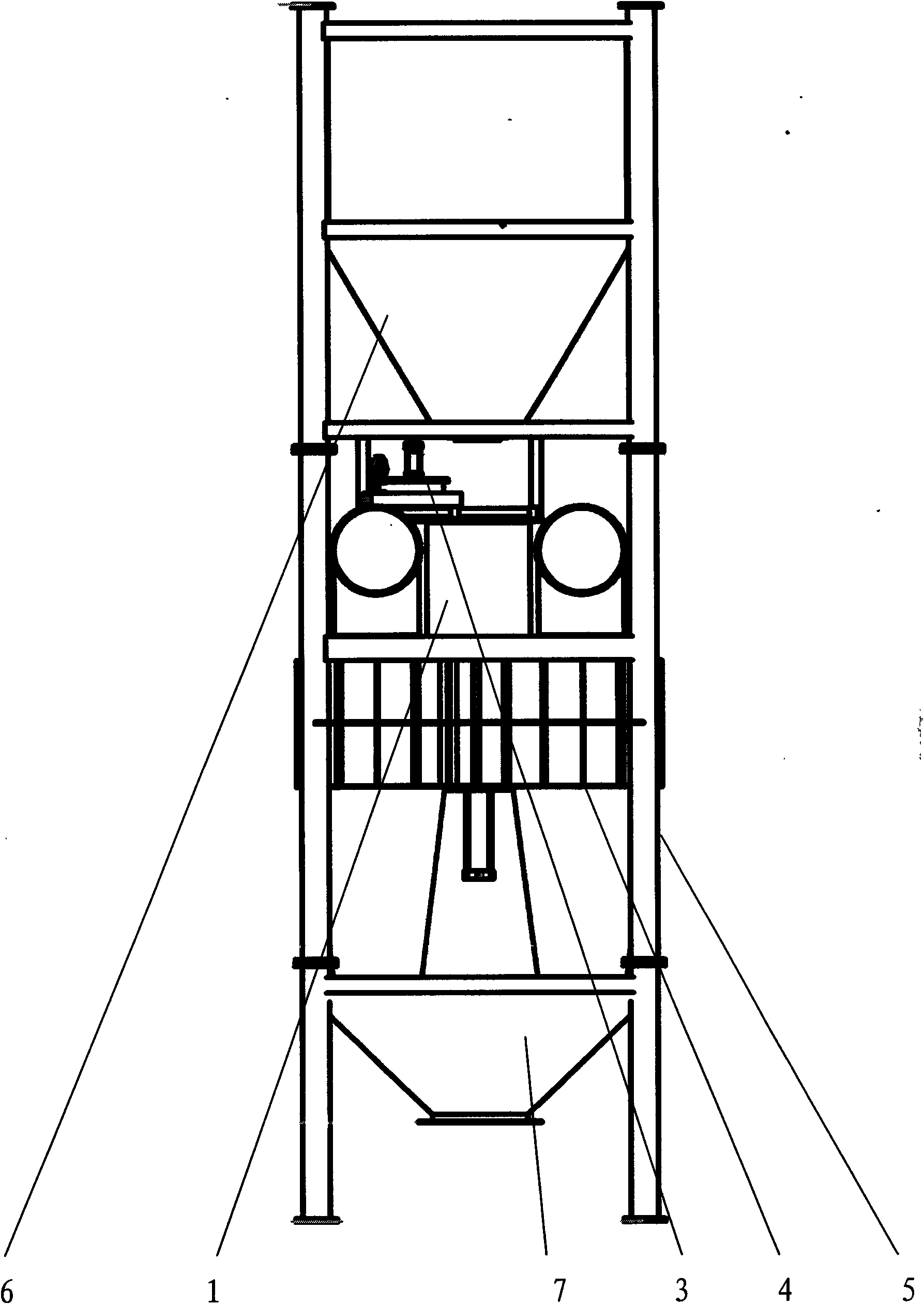

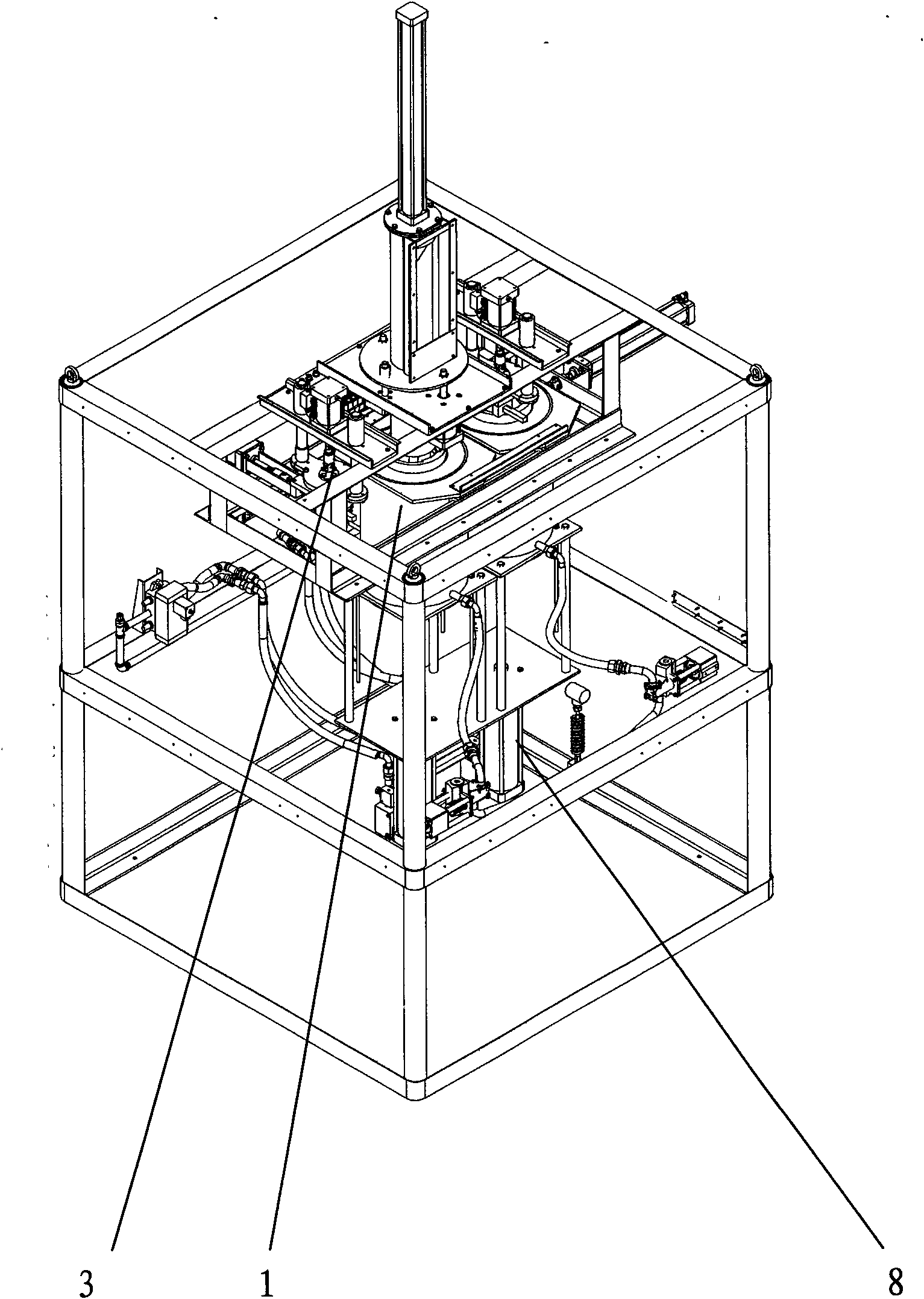

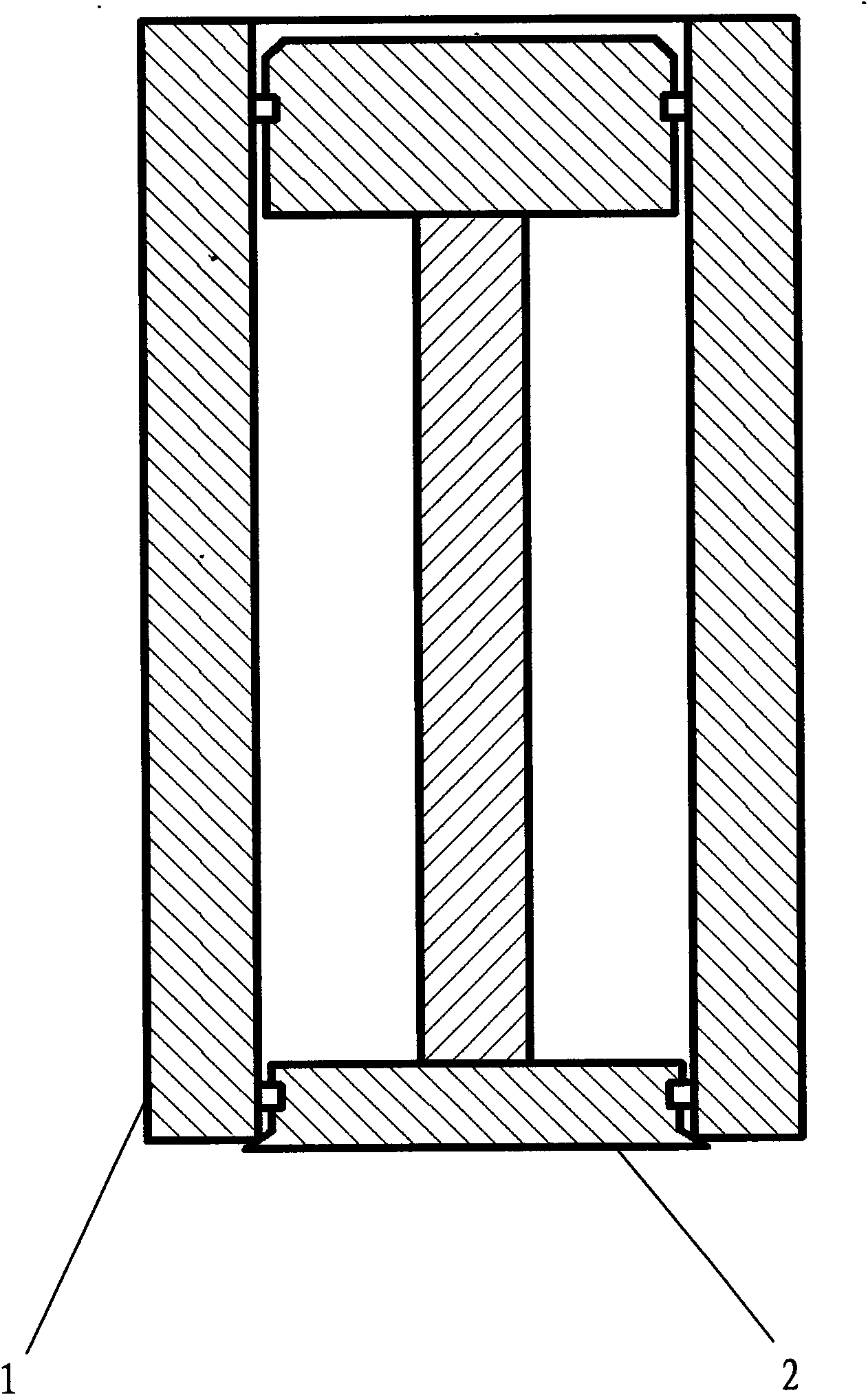

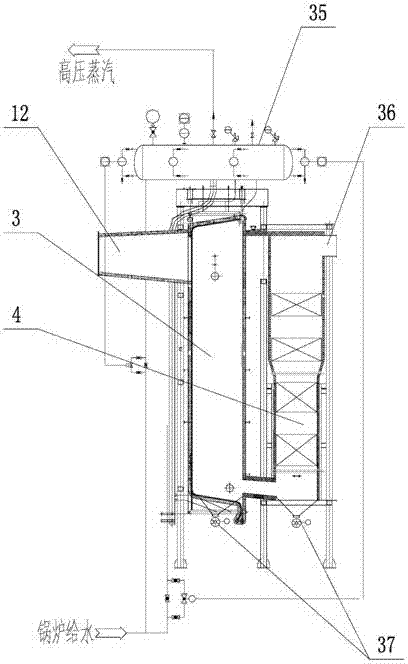

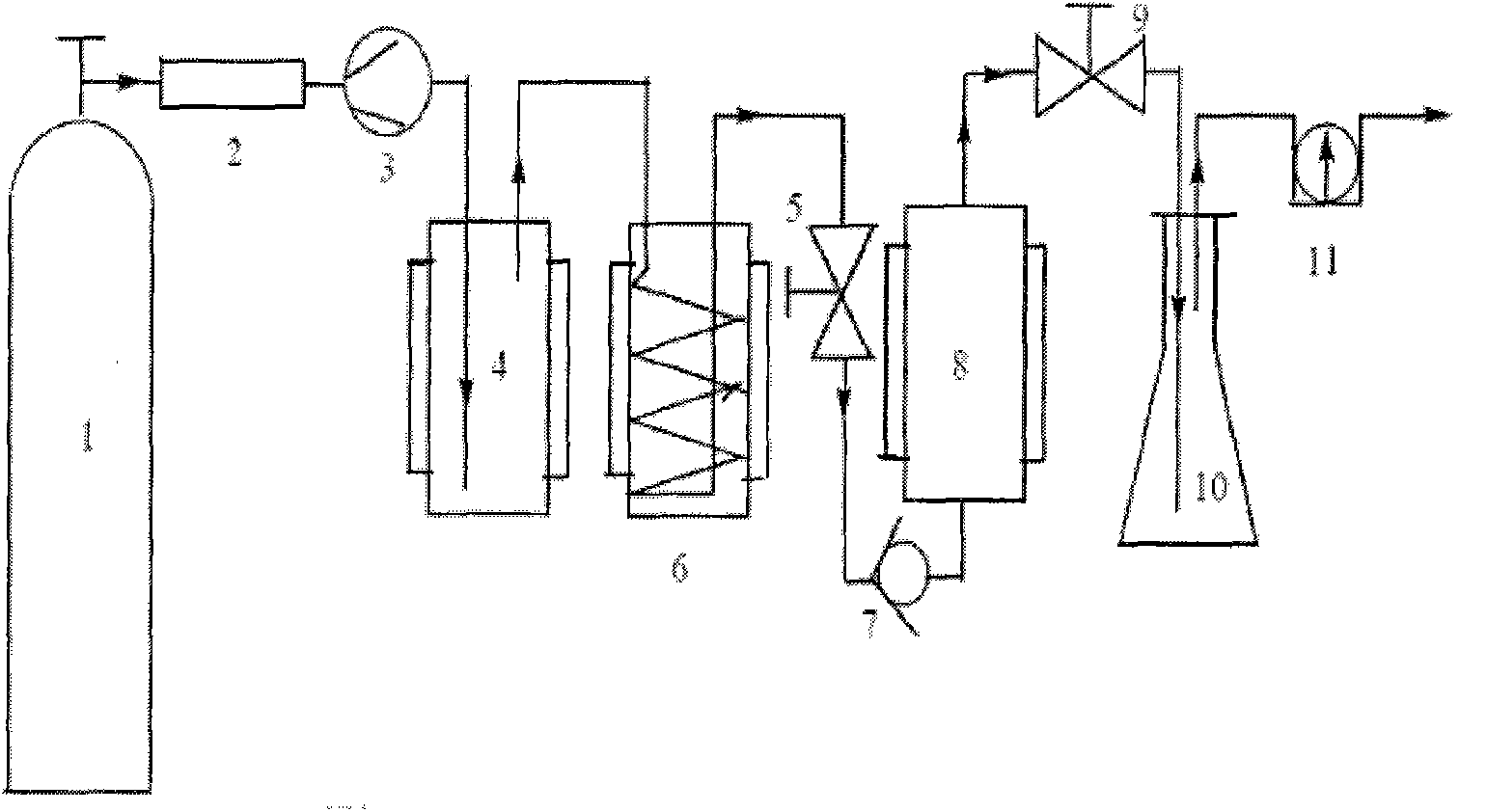

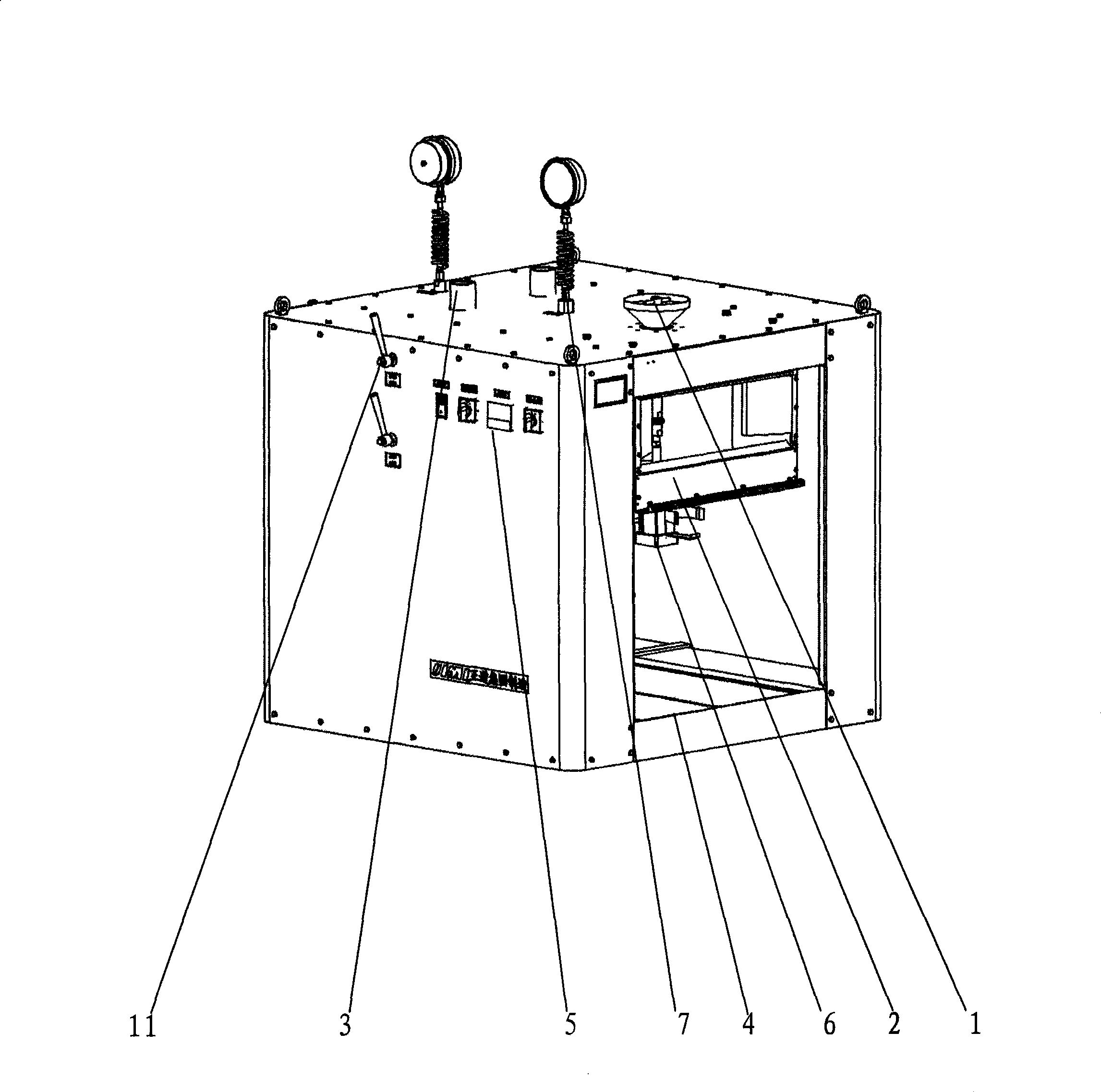

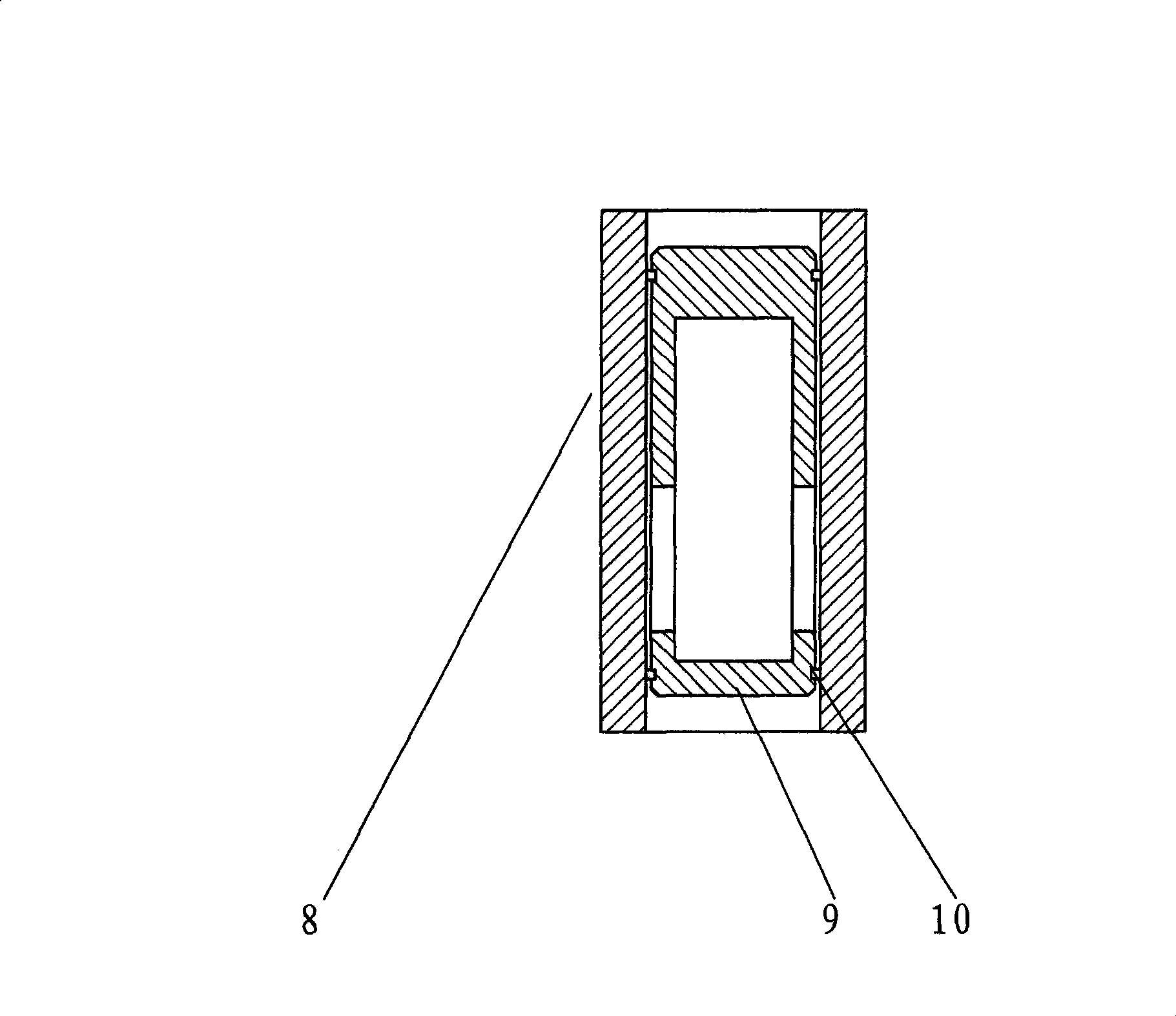

Numerically controlled continuous steam explosion machine

InactiveCN102600763AAchieving suddennessGuarantee the same effect of steam explosionPressurized chemical processFixed ratioEngineering

The invention relates to a production device for steam explosion pretreatment of biomass, in particular to a pretreatment device for the industry of biomass utilization, and provides a numerically controlled continuous steam explosion machine, which can complete supersonic steam explosion in milliseconds (0.00875s) based on the principle of a sliding cover. Since the cross-sectional area of the steam explosion machine for gas discharging, i.e. the cross-sectional area of the sliding cover, is equal to the cross-sectional area of a high-pressure cylinder, the cross-sectional area of the steam explosion machine for gas discharging and the steam explosion treatment volume form a fixed ratio, the problem that the gas discharging time is prolonged along with increase in the treatment volume in the traditional hot blowing process can be solved, and the power and density of steam explosion can be increased by three orders of magnitude. Moreover, the 'rawness and maturity' of materials which are subjected to batch treatment can be kept identical, and a foundation is laid for the consistency of industrial biochemical treatment. Meanwhile, the machine has the function of feeding and discharging materials automatically and the continuous steam explosion production can be realized.

Owner:于政道

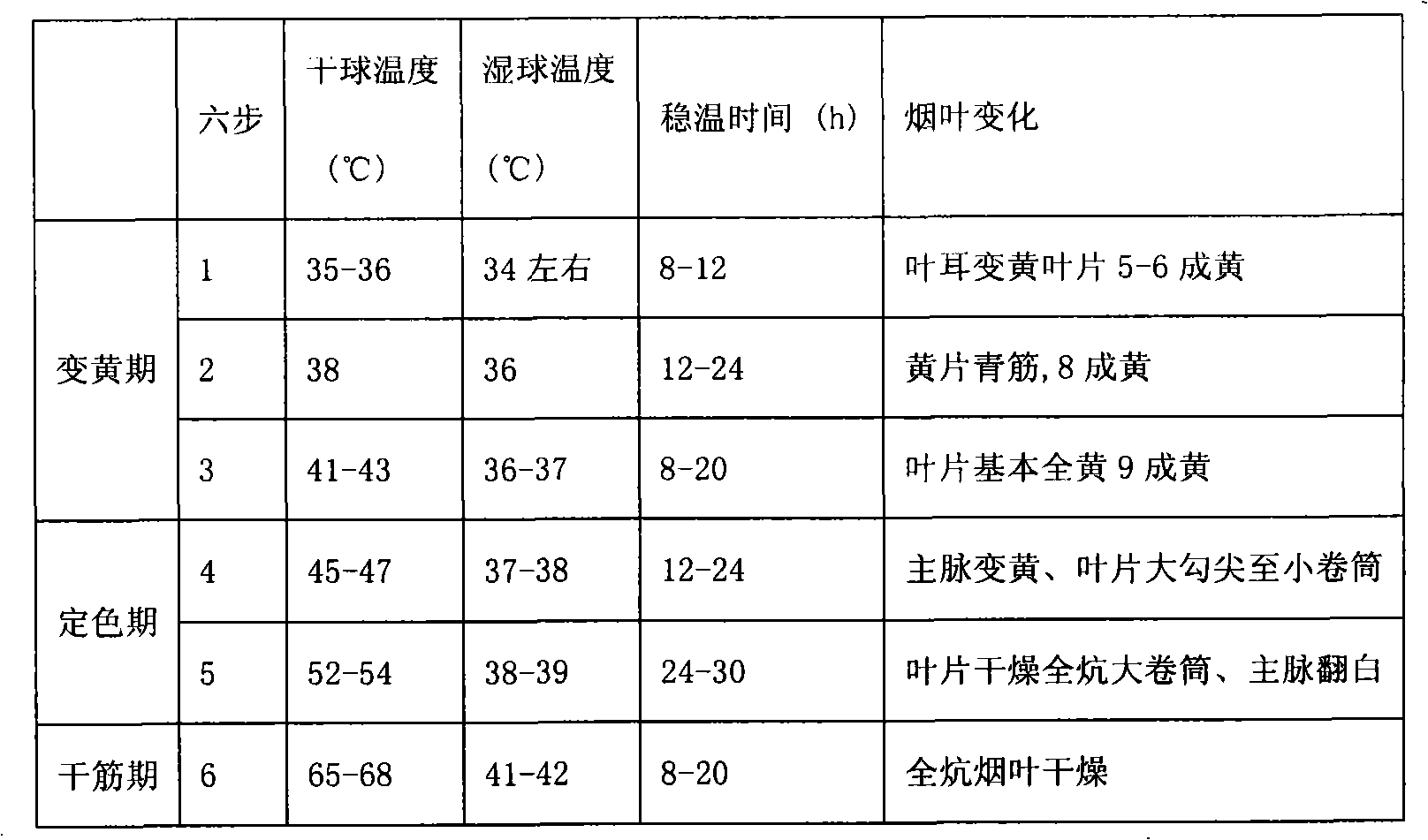

Three-section six-step tobacco baking method

Owner:TOBACCO SCI RES INST CHONGQING CITY COMPANY OF CHINA NAT TOBACCO

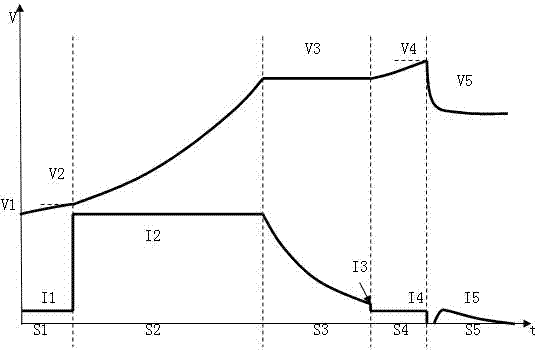

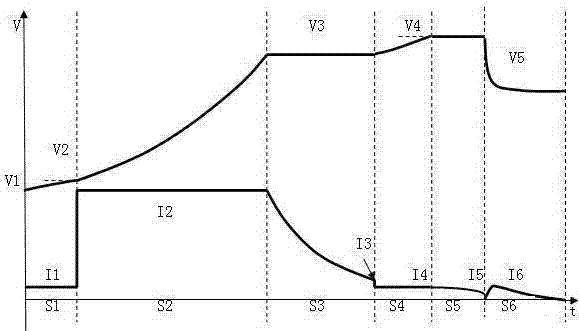

Charge method of lead-acid storage battery

InactiveCN103762391AExtended service lifeShorten charging timeSecondary cells charging/dischargingThird phaseCharge voltage

The invention discloses a charge method of a lead-acid storage battery. Different charge voltage and current are controlled in six phases, wherein in the first phase of pre-charge, the battery is activated with low current; in the second phase of constant current, the battery is charged with high current; in the third phase of constant voltage, the voltage is maintained while the current is limited; in the fourth phase of trickle charge, low-current trickle charge is realized; the fifth phase realizes secondary constant-voltage charge; in the sixth phase of float charge, float charge with low current is realized. According to the method, a phase of secondary constant-voltage charge is added based on the existing five-stage comprehensive charge method, and the lead sulfide of the cathode of the lead-acid storage battery can be sufficiently decomposed in the phase, thus the lead-acid storage battery can be fully charged and is not damaged by the sulfation thereof due to insufficient charge; meanwhile, overcharge is avoided for sure, the service life of the battery is prolonged, and the charge time is shortened.

Owner:JIANGSU JIAYU NEW POWER TECH

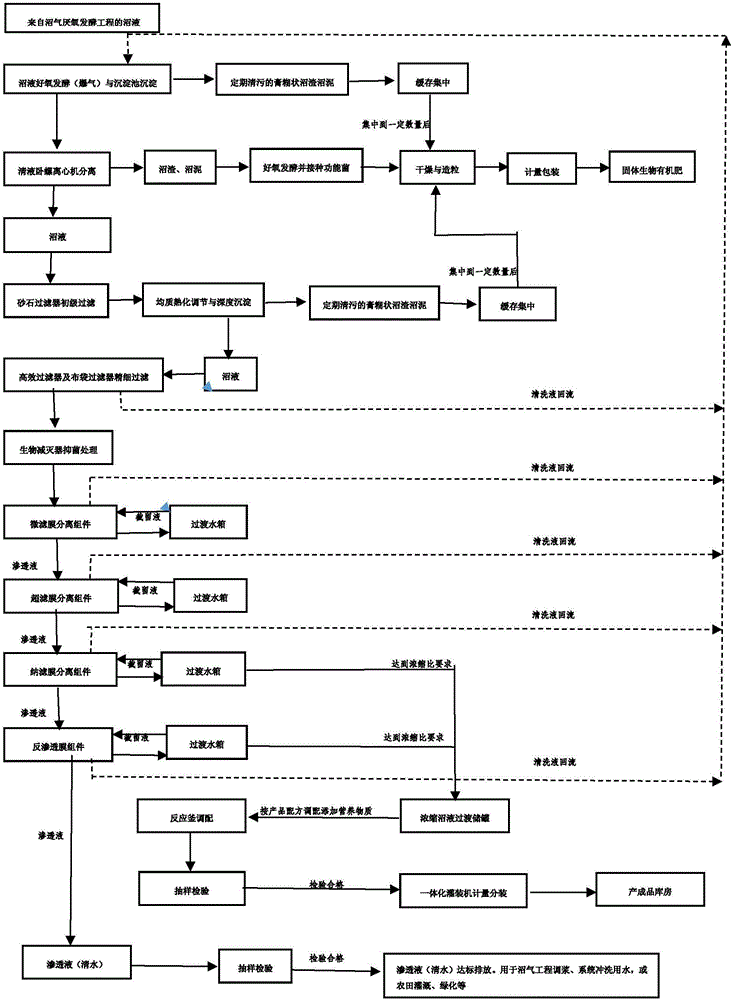

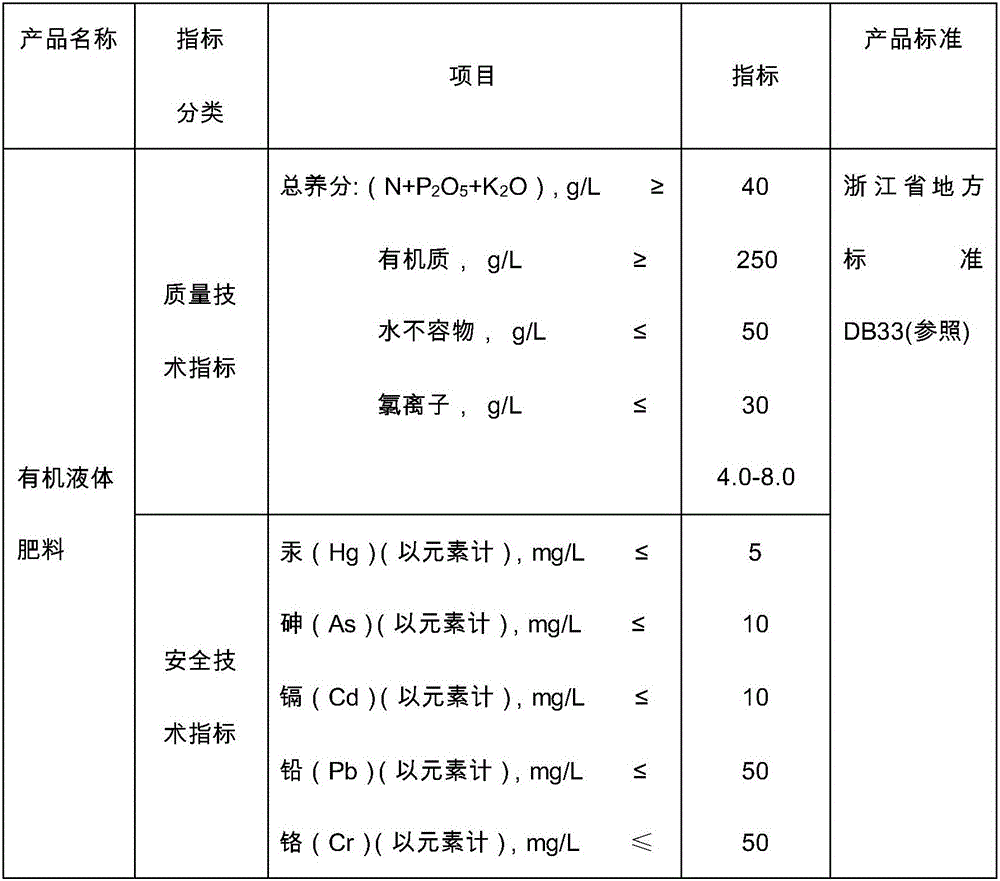

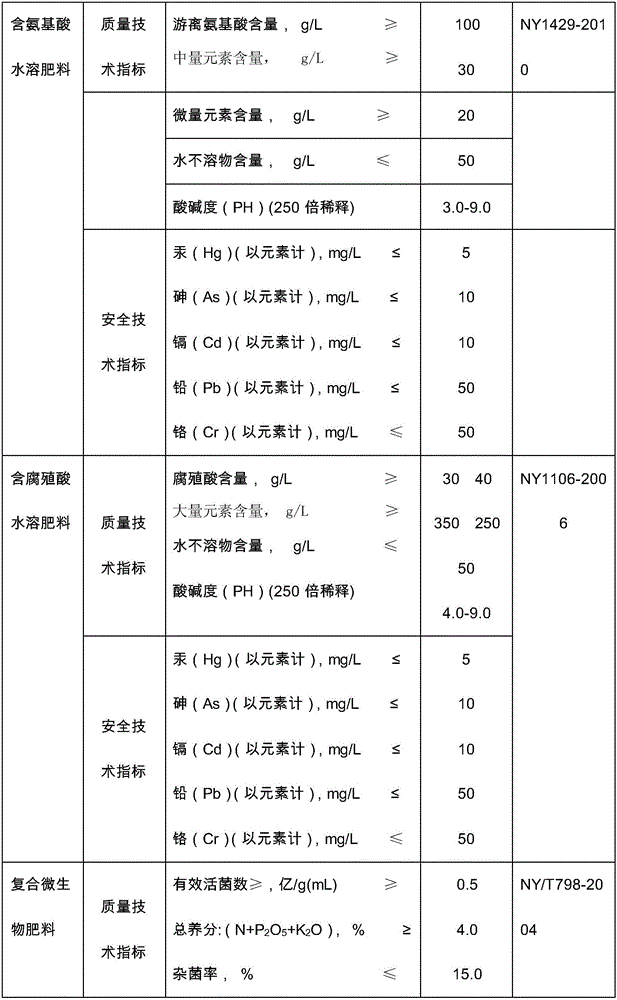

Production process for producing organic fertilizer through concentrating biogas slurry by using multistage membrane separation technology

InactiveCN106336253AFully removedReduce pollutionBio-organic fraction processingClimate change adaptationUltrafiltrationSeparation technology

The invention discloses a production process for producing an organic fertilizer through concentrating biogas slurry by using a multistage membrane separation technology; the production process comprises the following steps: a, pretreatment: carrying out pretreatment of biogas slurry after anaerobic fermentation through precipitation, aerobic fermentation, solid-liquid separation, primary filtration, homogeneous curing adjustment, deep precipitation, fine filtration and biological bacteria inhibition; b, multistage membrane separation before concentration: carrying out microfiltration membrane separation and ultrafiltration membrane separation of the biogas slurry after fine filtration and biological bacteria inhibition; c, multistage membrane concentration: carrying out multistage membrane concentration of the biogas slurry penetrated fluid obtained by ultrafiltration membrane separation through nanofiltration membrane concentration, reverse osmosis membrane concentration and concentration membrane protection; d, blending: adding large, medium and trace elements and other nutritional ingredients and functional components into the intercepted concentrate obtained by nanofiltration and reverse osmosis membrane separation, blending to obtain a liquid organic fertilizer, and sub-packaging; and e, product packaging. The production process has the advantages of flexible structure, advanced equipment and scientific process layout, can meet resource comprehensive utilization development of biogas slurry of all large and medium sized biogas projects.

Owner:NINGXIA SHUNBAO MODERN AGRI CO LTD

Lithium supplementing slurry for lithium ion energy storage device, and preparation method and application of lithium supplementing slurry

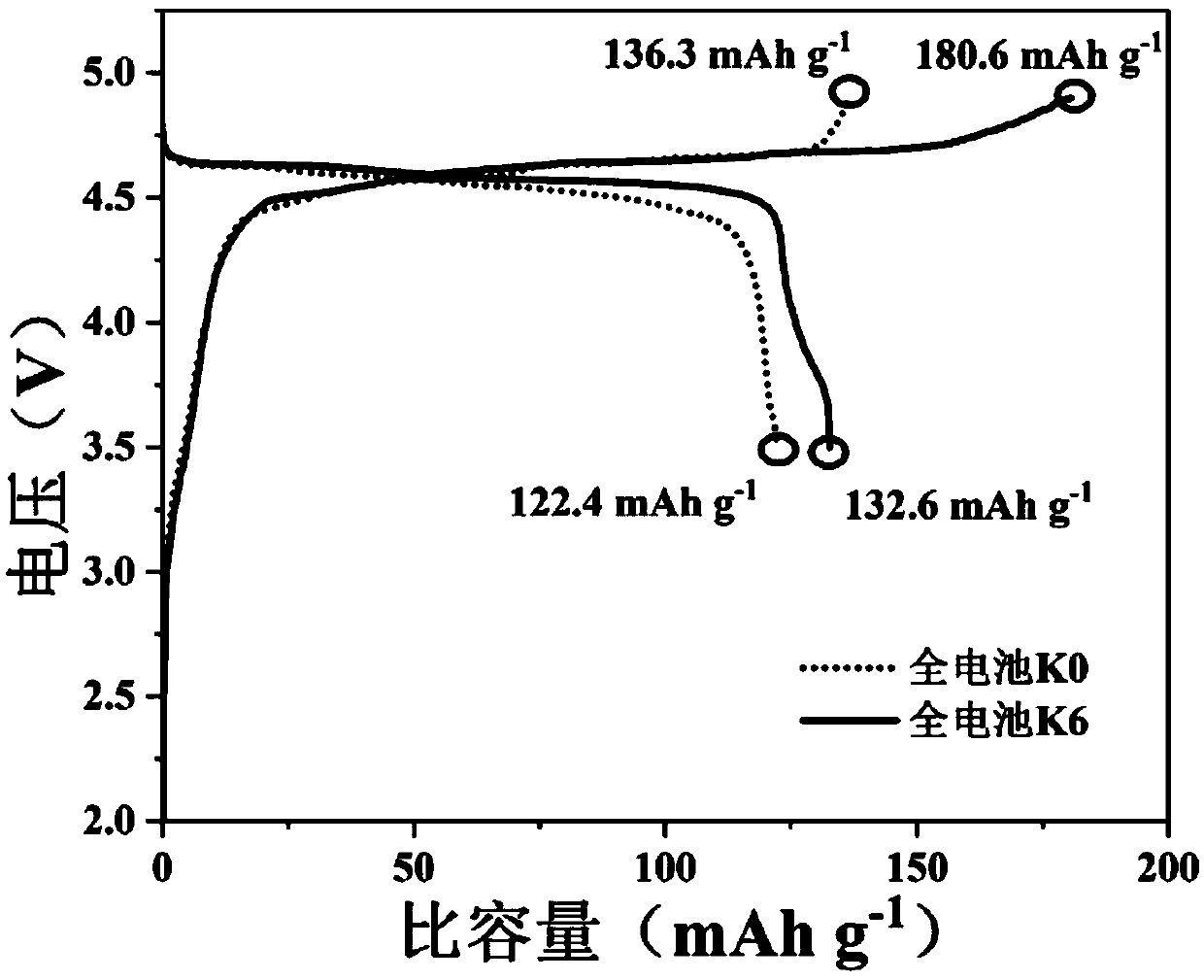

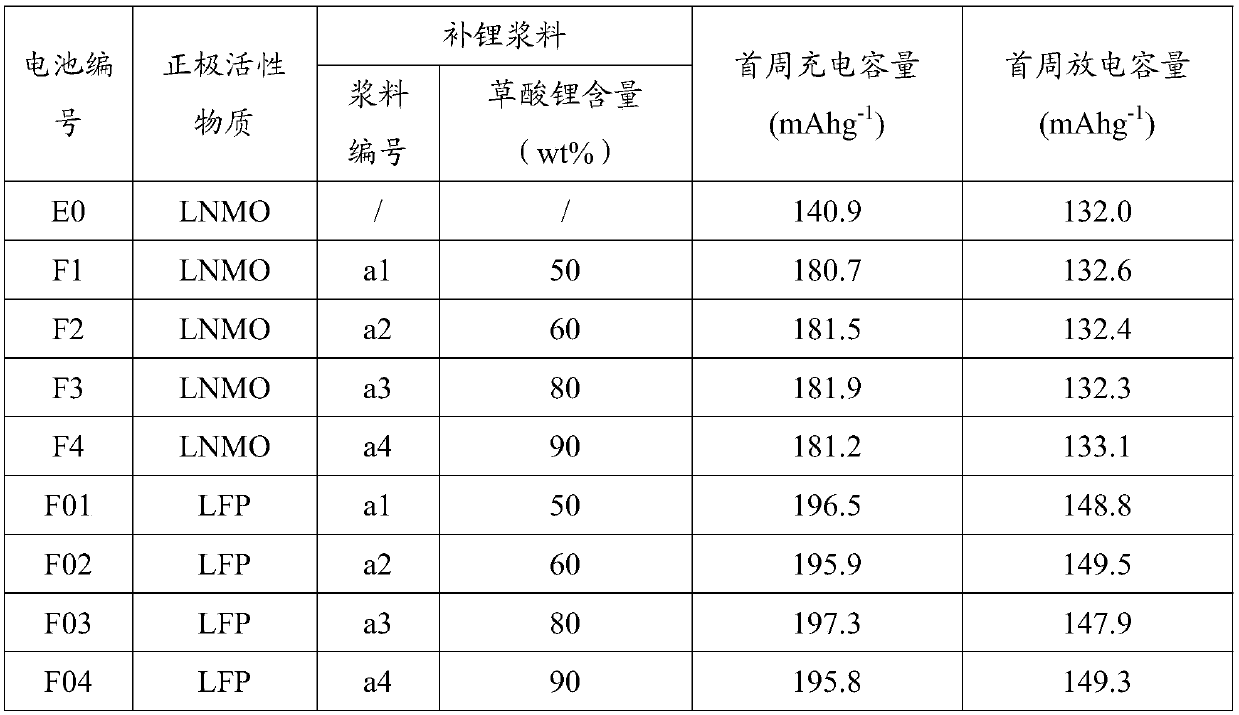

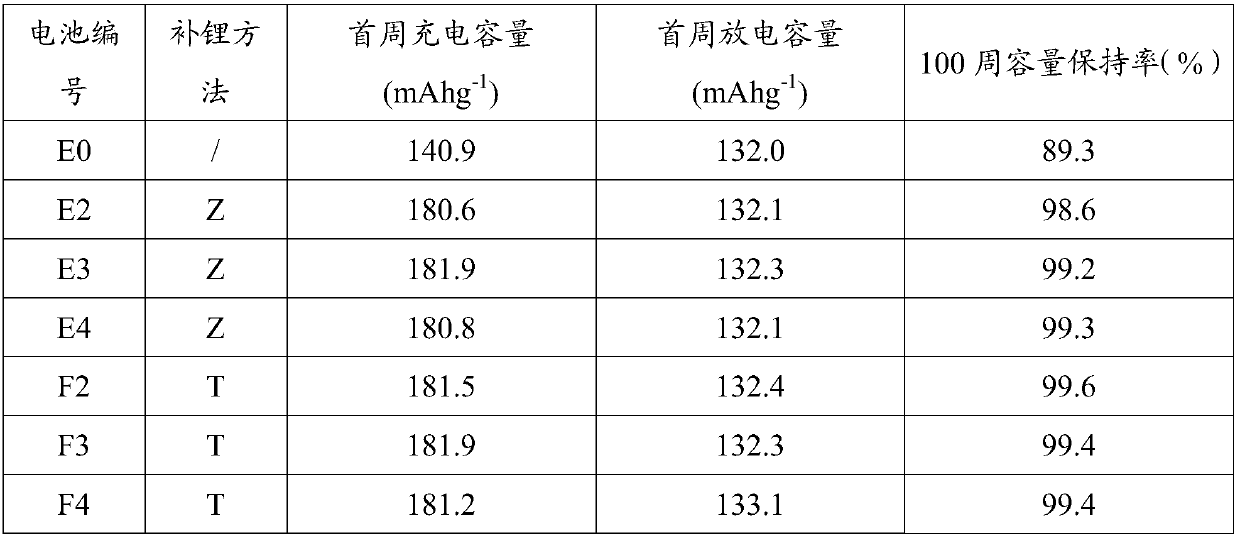

PendingCN110838573AMake up for irreversible capacity lossImprove charge and discharge efficiencyNon-aqueous electrolyte accumulator electrodesSecondary cells servicing/maintenanceElectrolytic agentCapacity loss

The invention provides lithium supplementing slurry for a lithium ion energy storage device, and a preparation method and application of the lithium supplementing slurry. The lithium supplementing slurry comprises lithium oxalate serving as a lithium supplementing active substance, a transition metal compound serving as a catalyst and a solvent. The invention also provides a method for preparing the lithium supplementing slurry for the lithium ion energy storage device. The method comprises the following steps: adding lithium oxalate, a transition metal compound, an optional conductive additive and an optional binder into a solvent, and carrying out mixing to obtain the lithium supplementing slurry. The prepared slurry is used for a positive electrode of the lithium ion energy storage device, so redundant active lithium is effectively released in the first-week charging and discharging process, the irreversible capacity loss of a battery is made up, and meanwhile, the coulombic efficiency and the cycling stability of a positive electrode material are effectively improved. The lithium supplementing slurry is simple to operate, low in cost, high in safety and good in compatibility with electrolyte, and can be directly used for large-scale production.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

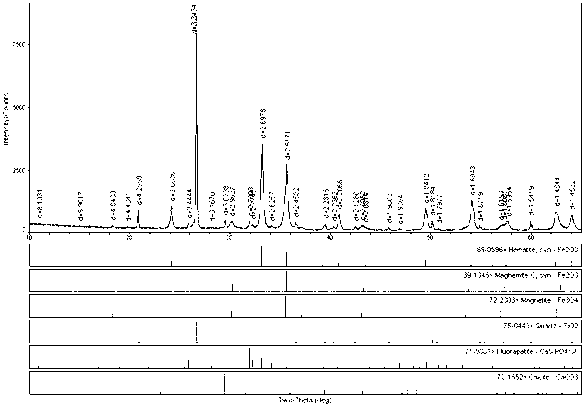

Separation process for refractory iron ores

InactiveCN102974456ADecompose fullyUniform qualityMagnetic separationOre concentrateSeparation process

The invention provides a separation process for refractory iron ores. The separation process comprises the following steps of: magnetizing and baking dry powdered raw ores with the particle size being less than 1mm at flash speed under a high-temperature reduction atmosphere condition at the temperature of 520 to 560 DEG C to obtain baked materials with available ores being Fe3O4, separating the baked materials to obtain concentrate. By the process, a baking process is executed under a stable and controllable condition by controlling the particle size of the raw ores, reducing the baking temperature and selecting proper baking time; the raw ores (such as ferrous carbonate) are fully decomposed, and reducing reaction is stable; furthermore, overburning is avoided, and a phenomenon that a part of magnetite is reduced into Fourier bodies is avoided; the quality of a baked product is uniform; loss of available ores is low; the reaction energy consumption is low; the reaction condition is mild; a process is stable and easy to control and the separation process can be used for separation of the refractory iron ores, such as poor (magnetic) iron cores, siderite, limonite and oolitic hematite; gamma-Fe2O3 fine ores with high grade which is generally not lower than 60 percent) can be obtained; and the full iron recycling rate is not lower than 75 percent.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

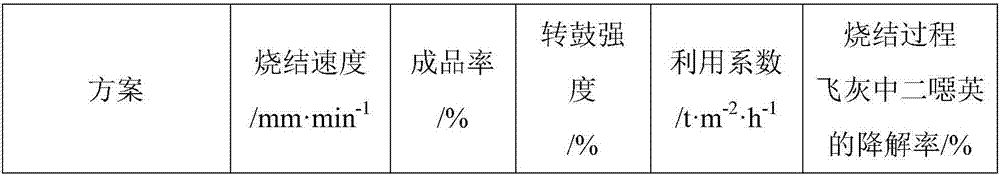

Dioxin control method for iron ore sintering garbage fly ash coprocessing process

ActiveCN107159678ARealize normal sinteringEffectively fixedTransportation and packagingSolid waste disposalSludgeLitter

The invention discloses a dioxin control method for the iron ore sintering garbage fly ash coprocessing process. According to the method, garbage fly ash, lime milk, flammable solid fuel and sludge are subject to mixed granulation and drying, and small balls containing garbage fly ash are obtained; iron core sintering raw materials are granulated and then are mixed with the small balls of the garbage fly ash, and after distribution, ignition and sintering are carried out. According to the method, on the premise that the iron ore sintering is not affected, efficient decomposing of dioxin contained in the fly ash can be achieved, dioxin secondarily formed in the garbage fly ash sintering process is prevented, according to the method, the decomposing rate of the garbage fly ash dioxin reaches 90% or above, meanwhile, effective solidifying of the garbage fly ash can be ensured, and in the sintering process, the aim of cleaning the garbage fly ash is achieved.

Owner:CENT SOUTH UNIV +1

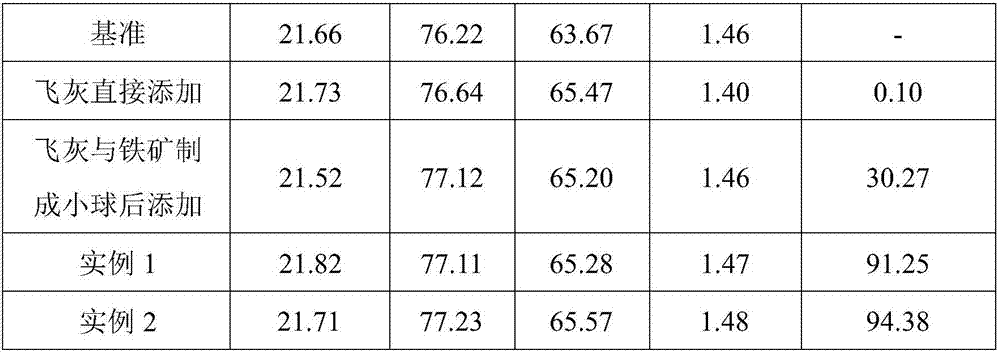

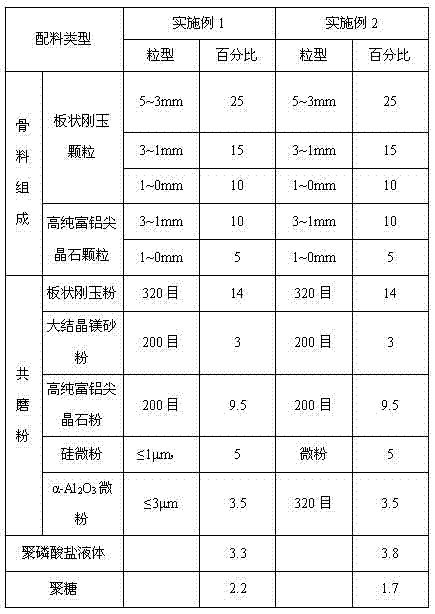

Mechanically-pressed carbon-free corundum spinel ladle brick as well as preparation method thereof

The invention discloses a mechanically-pressed carbon-free corundum spinel ladle brick. The mechanically-pressed carbon-free corundum spinel ladle brick comprises the following components in percentage by weight: 30%-50% of plate-shaped corundum particles, 10%-20% of high-purity aluminum-rich spinel particles, 10%-20% of plate-shaped corundum fine powder, 1%-9% of large crystallized magnesia fine powder, 5%-15% of high-purity aluminum-rich spinel fine powder, 1%-10% of high-purity silicon micro powder, 2%-10% of imported multimodal alpha-Al2O3 micro powder, 1%-4% of metal silicon and a bonding agent which is composed of 1%-5% of polyphosphate and 1%-3% of polysaccharide. The mechanically-pressed carbon-free corundum spinel ladle brick disclosed by the invention adopts an organic-inorganic compound combining system, is wet-milled and mixed under high pressure, formed under high pressure, high in density, good in thermal stability under high temperature, and resistant to molten steel and slag, and does not pollute the molten steel; moreover, production efficiency can be greatly improved, and therefore, the mechanically-pressed carbon-free corundum spinel ladle brick can be extensively applied to various ladles, especially refined low-carbon steel and ultralow-carbon ladles.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

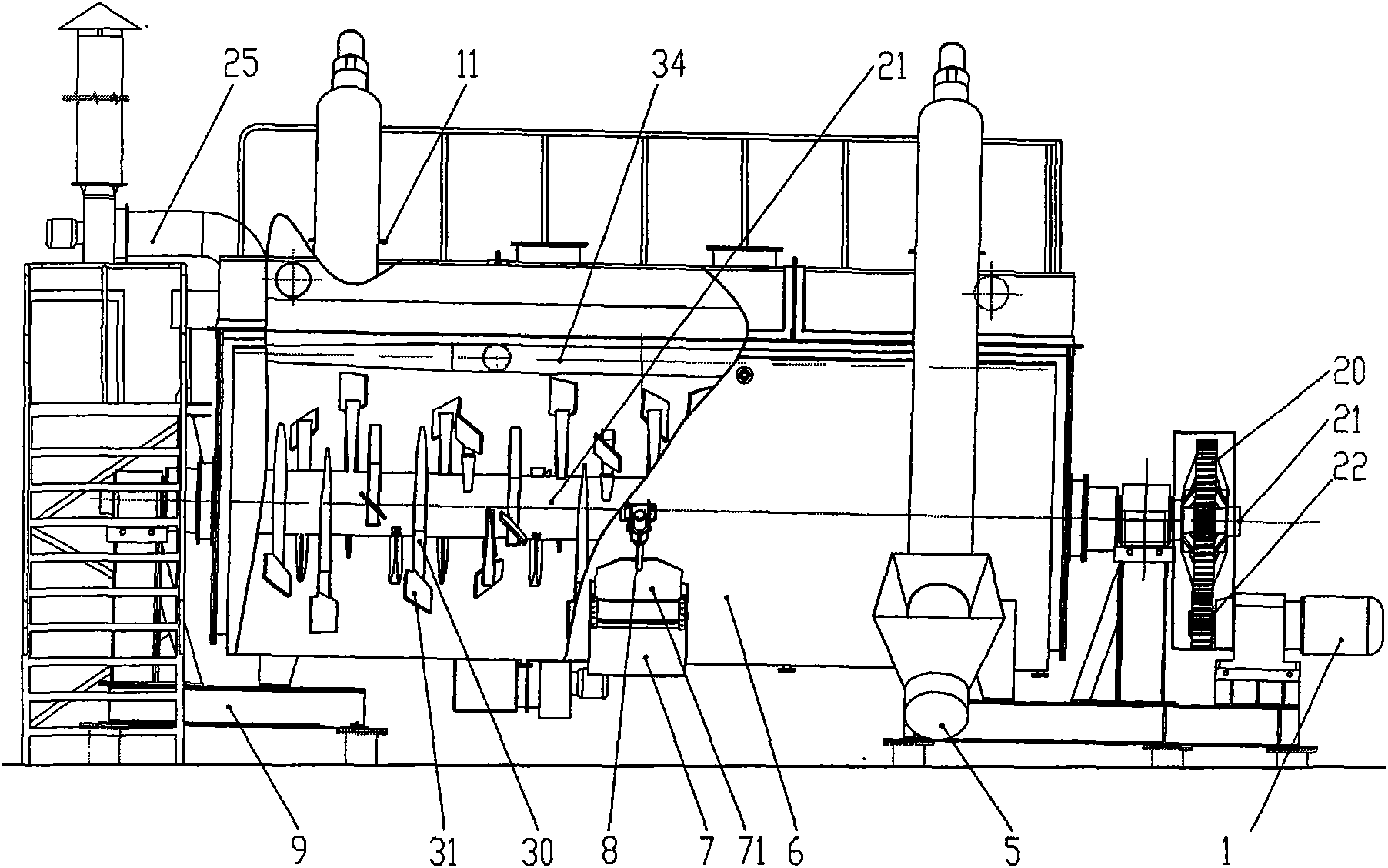

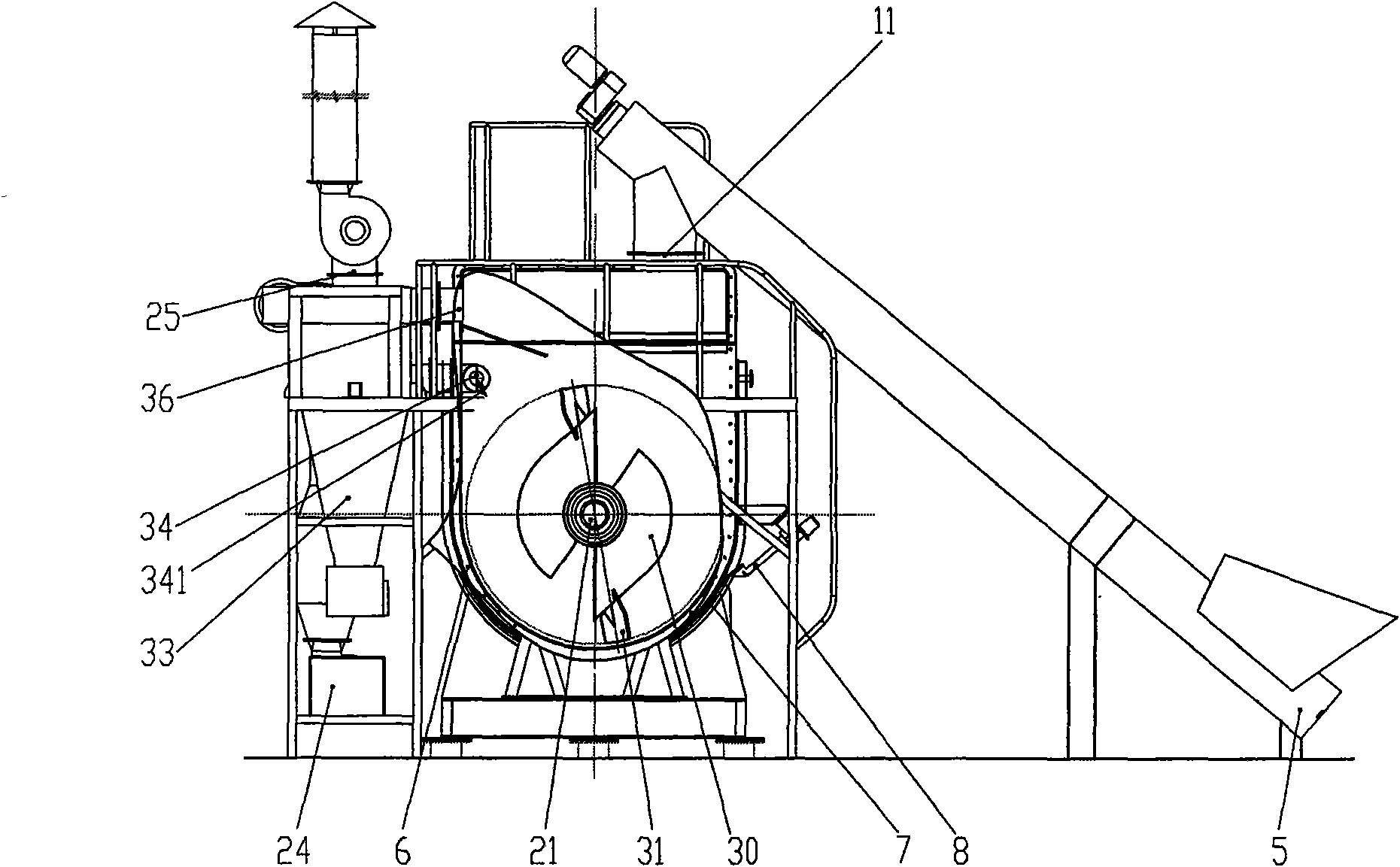

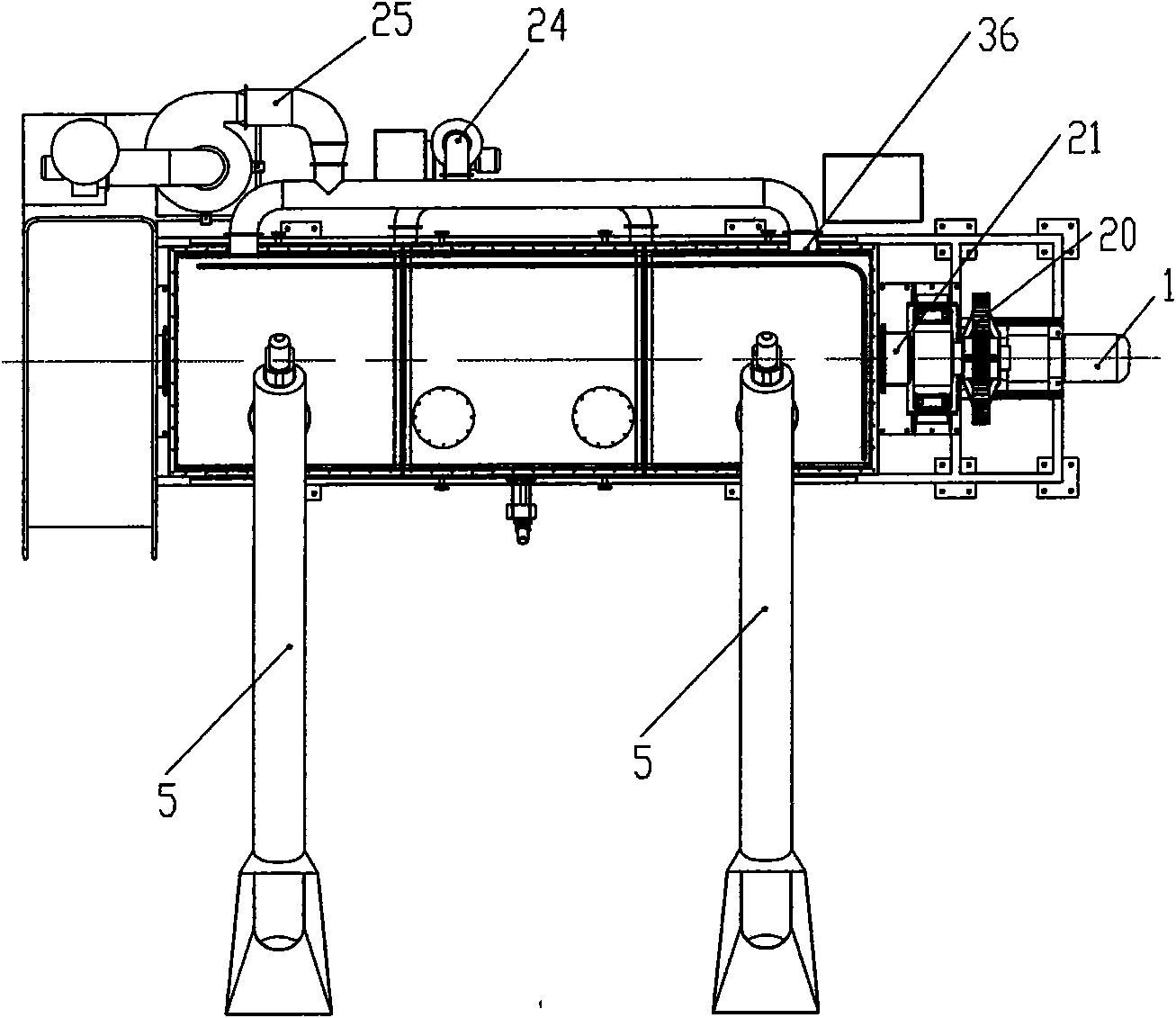

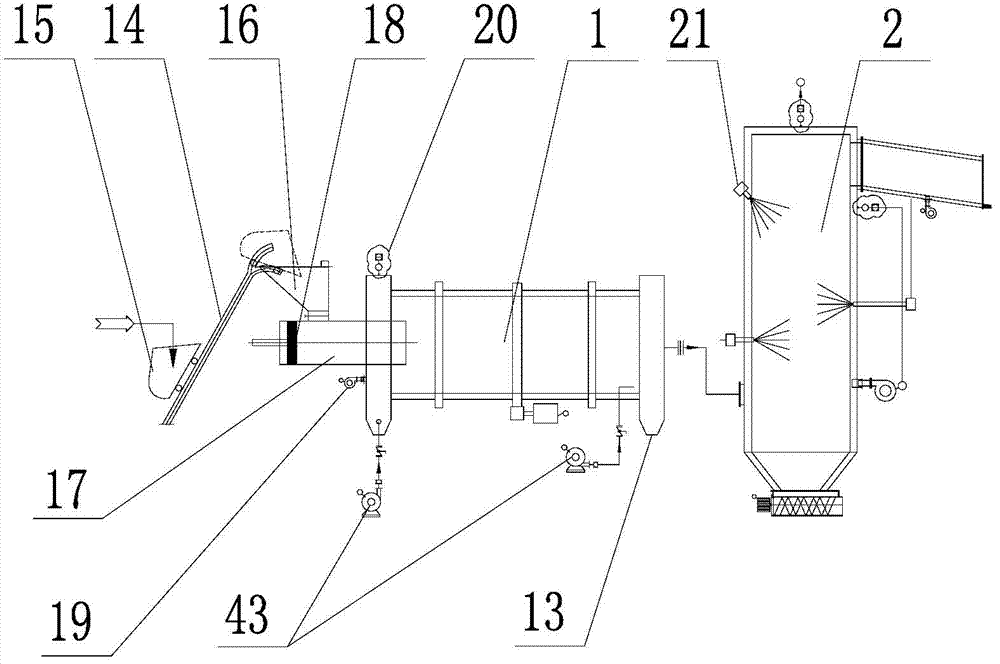

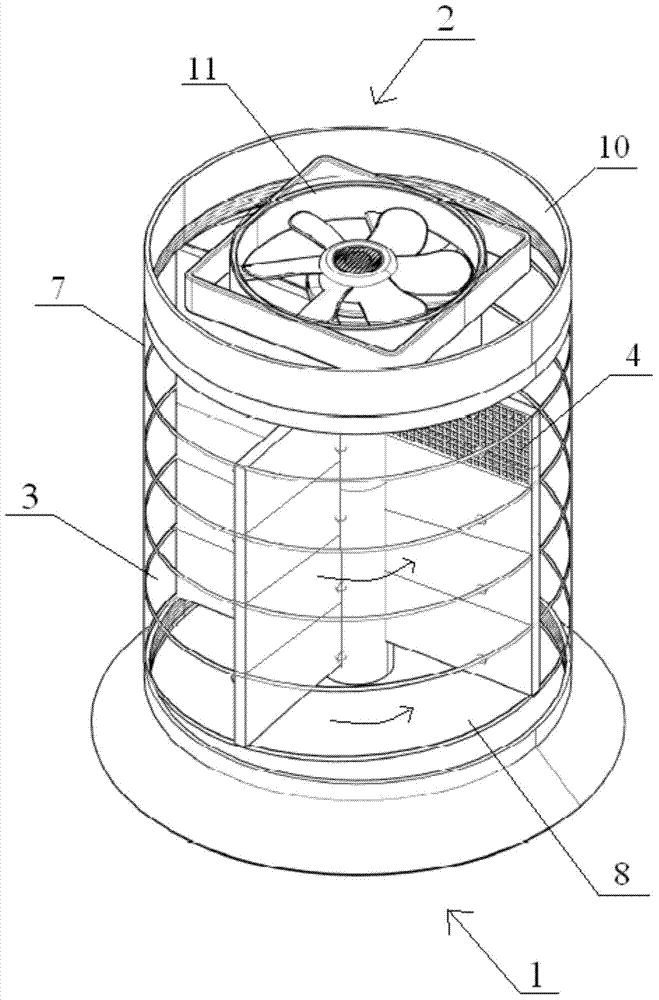

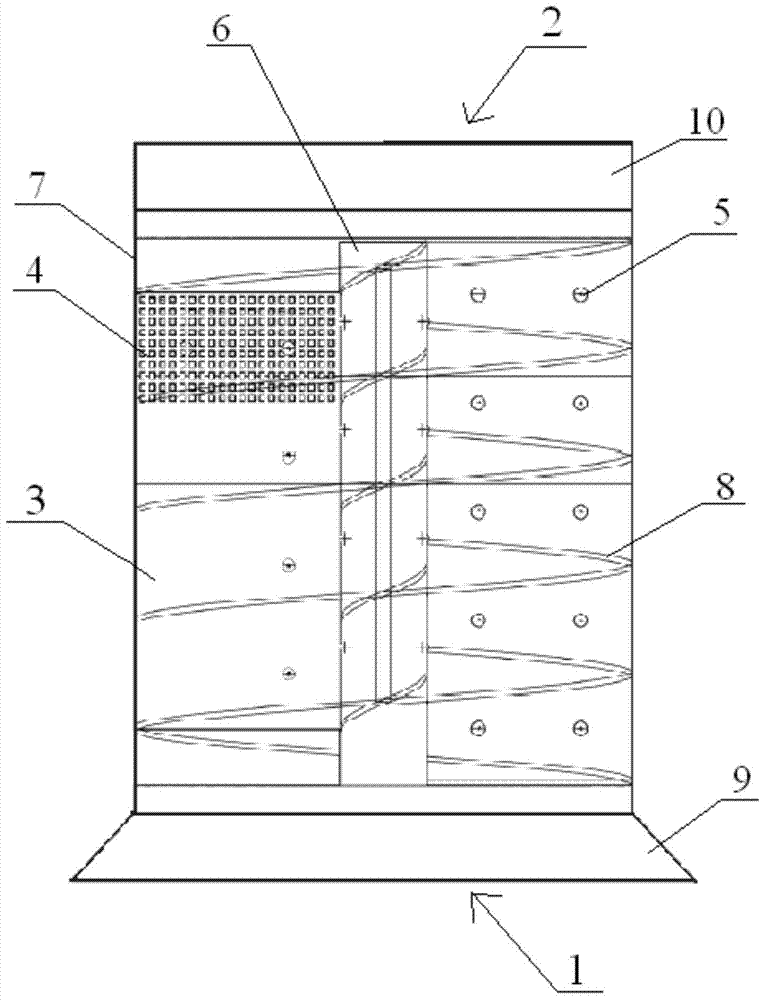

Organic waste biochemical processor

ActiveCN101632997ADecompose fullyIncrease the heat exchange areaBio-organic fraction processingSolid waste disposalOxygenPollution

The invention relates to an organic waste biochemical processor comprising a fermenting and drying chamber with a U-shaped cross section, wherein the upper end of the fermenting and drying chamber is provided with a feeding hole, and the lower end of the fermenting and drying chamber is provided with a discharging hole which is sealed by a discharging hole baffle plate; a hollow mixing shaft passes through both sides of the fermenting and drying chamber, the left end and the right end of the mixing shaft are respectively connected with a steam input pipe and a condensed water outlet pipe, the right end of the mixing shaft is connected with a reducing motor by a driving device, a hollow mixing blade is arranged on the mixing shaft, a cavity of the mixing blade is communicated with a cavity of the mixing shaft, the inner upper part of the fermenting and drying chamber is provided with an air distributing pipe, an air inlet of the air distributing pipe is communicated to an air outlet of a heat exchanger outside the fermenting and drying chamber, an air outlet of the air distributing pipe is positioned into the fermenting and drying chamber, and the upper part of the fermenting and drying chamber is provided with a humidity discharging hole which is communicated to an inlet of a dust collector of a waste gas processing device by a humidity discharging duct. The organic waste biochemical processor has low pollution and can sufficiently ferment and dry the organic waste by oxygen.

Owner:BEIJING GOLDENWAY BIO TECH

Composite material prepreg for restoring ultraviolet light curing structure and preparation method thereof

InactiveCN104312192AImprove light curing efficiencyMeet curing requirementsGlass fiberUltraviolet lights

The invention provides a composite material prepreg for quickly ultraviolet light curing a resin base structure reinforced by glass fibers with certain thickness and a preparation method thereof. In the method, a common free radical curing resin as a matrix, a proper photoinitiator, a thermal initiator and other assistants are preferably selected to form a light-thermal composite initiation system, a glass fiber textile is used as a reinforcement material, and the composite material prepreg with a certain thickness is prepared by a proper compound process. The prepreg can be cured by irradiating ultraviolet light on a single surface for 10 minutes, and the light curing thickness at one time can be higher than 15 mm. By adopting the invention, the existing technical problem that the ultraviolet light cannot be used for curing composite material structural members with large thicknesses (10-15 mm and larger) at one time is solved, the composite material prepreg is cured more conveniently and efficiently. The light-cured resin and the composite material thereof express huge application prospect and market potential in some special fields, for example, trenchless repair of municipal drainage pipelines.

Owner:WUHAN UNIV OF TECH

Microbial compound liquid fertilizer and method for preparing the same

InactiveCN1422828ADecompose fullyImprove soil fertilityOrganic fertilisersMicroorganismPesticide residue

The invention discloses a microbial composite liquid fertilizer anjd the preparing mehtod, adopting urea, potash or potassium sulfate, phosphoric acid, zinc sulfate, epson salt, allantoid element, active bacterium liquid, amino acid and so on to make it by the techniques such as neutralization, standing by, filtering, mixing and pH value adjustment. It is a new ecotypic leaf-surface fertilizer, able to be used to dip seeds, touch roots and spray leaf-back surface and used as soiless-culture nutritious liquid.

Owner:黎保文

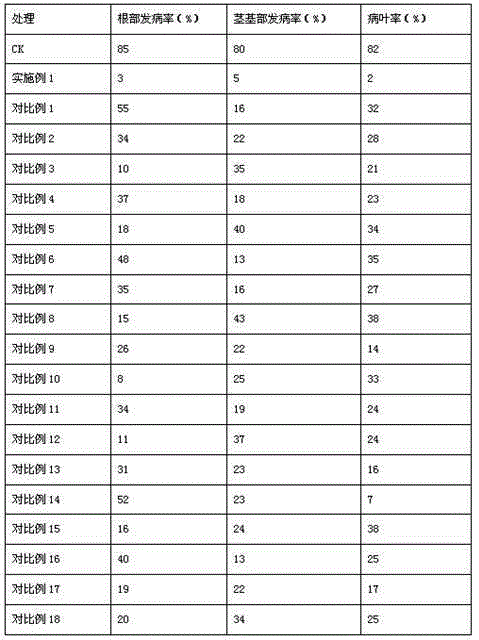

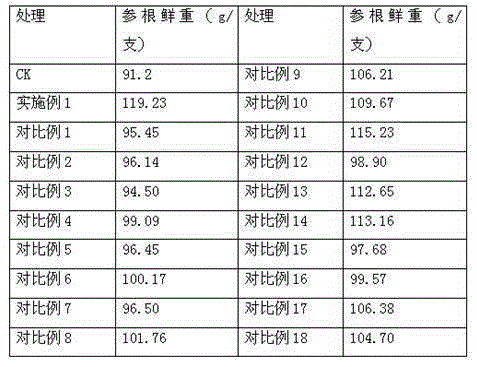

Anti-disease composite microbial fertilizer specially-used for American ginseng and preparation method thereof

InactiveCN105237110AMeet the nutritional requirements for growthPromote growthFertilizer mixturesPotassiumRoot rot

The invention belongs to the technical field of fertilizers and particularly relates to an anti-disease composite microbial fertilizer specially-used for American ginseng and also relates to the preparation method of the microbial fertilizer. The microbial fertilizer includes furfural residue, cassava residue, decayed cow dung, lignite humic acid, plant ash, tea residue, clay, mineralized yellow-brown potassium humate and a composite probiotic agent. The microbial fertilizer is balanced in nutrients and is abundant in microelements and can effectively increase productivity and improve fertility level of soil. The added composite probiotic agent can significantly inhibit the main diseases of the American ginseng, such as cylindrocarpon destructans diseases, root rot, damping off, black spot and the like. By means of the composite microbial fertilizer, the yield of the American ginseng is increased by 30-35% effectively and diseases rate is reduced by more than 90%. The fertilizer, when being used for long time, can effectively improve soil. The fertilizer is long-acting in fertilizer efficiency, achieves the effects in the whole growing period of American ginseng, and also has the effect of improving the quality of the American ginseng.

Owner:QINGDAO SHENLAN FERTILIZER IND

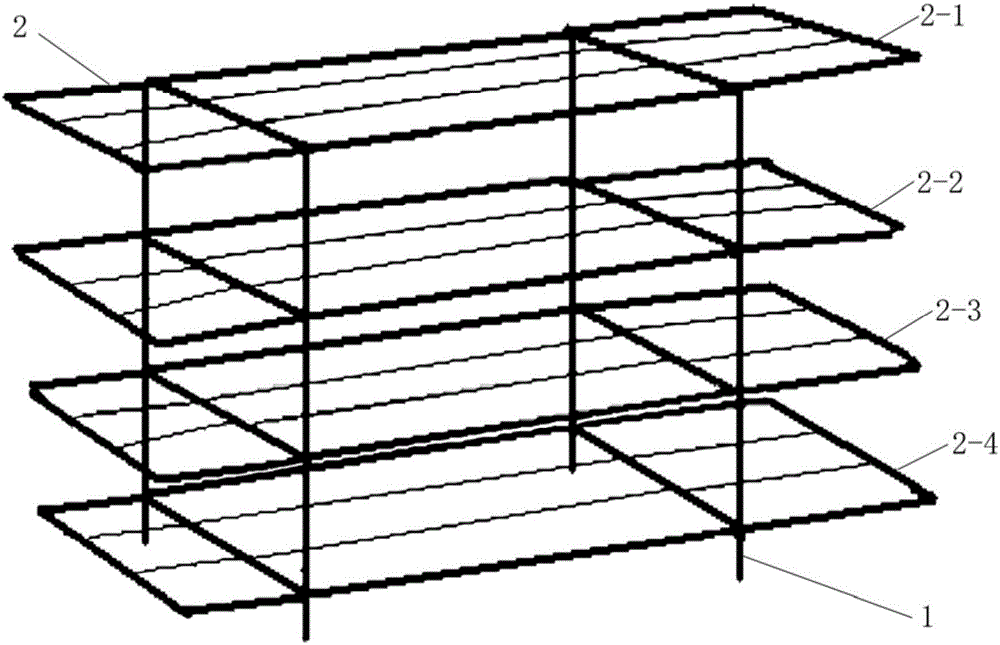

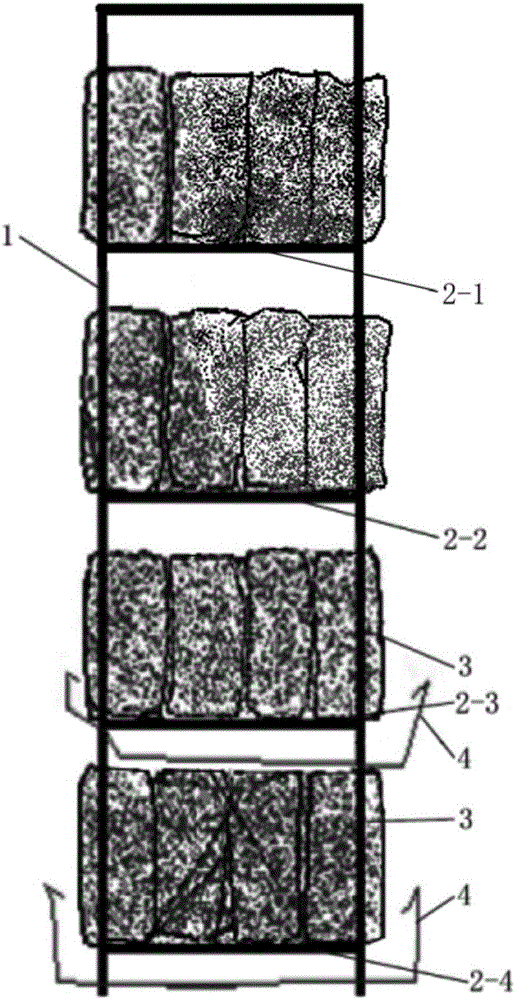

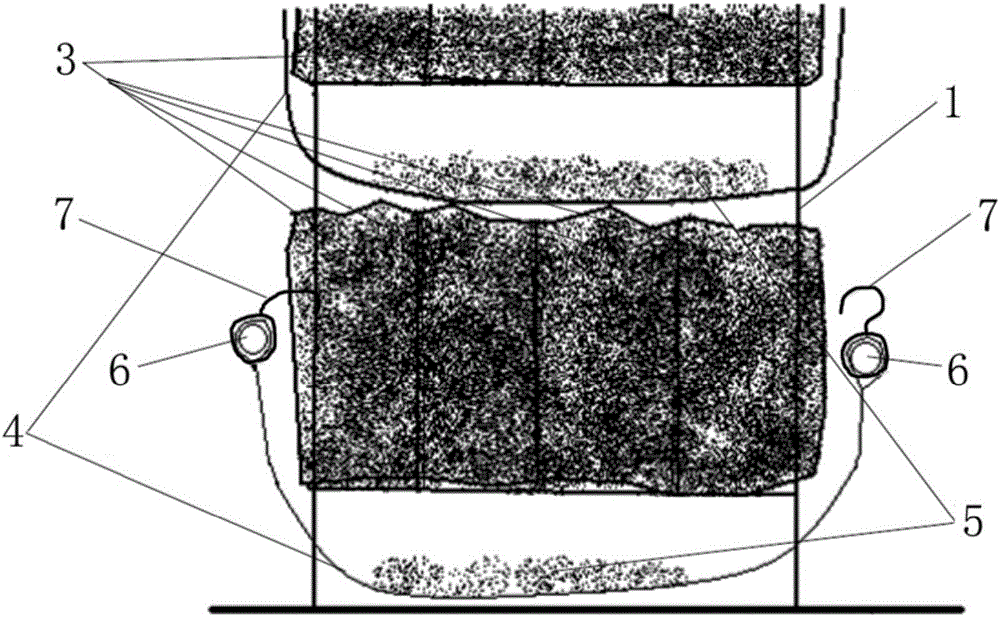

Culture medium for breeding earthworms and stereoscopic earthworm breeding method and device

ActiveCN106577556ASuitable for growthSuitable for breedingFood processingAnimal feeding stuffFiberFeces

The invention relates to a culture medium for breeding earthworms and a stereoscopic earthworm breeding method and device and belongs to the technical field of earthworm breeding. The culture medium is prepared through the following method that firstly, a base material and EM bacterium liquid are mixed, humidity is adjusted to 80%-90% to obtain a mixed material, and the base material is mainly composed of livestock feces, coarse fiber materials and sludge; secondly, the mixed material is subjected to closed anaerobic fermentation for 22-26 h, and after temperature is lowered to 28-32 DEG C, the EM bacterium liquid is added to continue the closed anaerobic fermentation for 22-26 h, and a fermented material is obtained; and thirdly, net bags are filled with the fermented material, and after compacting, the culture medium is obtained after piling and thorough decomposing are performed for 1-3 days. The culture medium achieves that pollution is treated through cultivation and achieves effective recycling of organic solid waste, nutrient substances in the base material are reserved to the maximum extent, and the culture medium is suitable for growing and breeding of the earthworms; and a three-dimensional stereoscopic space is provided for activity and breeding of the earthworms, adult earthworms are not needed to be separated manually, and intensified stereoscopic breeding of the earthworms in a greenhouse or in an indoor environment can be achieved easily.

Owner:海南晟延农业投资有限公司

Production technology for producing nutrient seasoning powder by enzymatic method with comprehensive utilization of avian skeleton

The invention relates to the technical field of condiment production with biological enzyme method, especially relating to a production technology for producing nutrient seasoning powder by enzymatic method with comprehensive utilization of avian skeleton. The production technology includes the following steps: (a) preparing raw materials; (b) performing cooking process; (c) performing a first step of enzymolysis reaction; (d) performing a second step of enzymolysis reaction; (e) performing Maillard reaction; (f) performing homogenizing treatment; and (g) performing powder spraying treatment: subjecting the mixture after homogenizing treatment to powder spraying treatment in a spray tower, sieving to remove the residues with a sieve mesh, and uniformly stirring to obtain the nutrient seasoning powder. The invention uses new biological enzyme to perform enzymolysis and extraction to the nutrients in the avian skeleton completely, so that the prepared condiment has rich nutrition, rich aroma, good quality, pure natural taste, and high product yield.

Owner:广东味霸味业科技有限公司

Ultra-wearable rubber formulation for sports shoes sole

The invention discloses a superwear-resisting rubber formulation of sport sole, and is characterized in that the formulation according to parts by weight comprises 80 parts of polybutadiene rubber, 20 parts of natural gum STR-5L, 1 part of uniform tackiness resin, 45-48 parts of white carbon black, 3.5 parts of softening oil, 3-3.2 parts of coupler, 5.2-5.8 parts of activator, 1 part of zinc stearate, 1 part of antifog agent, 1.9-2.1 parts of sulphur, and 1.65-1.95 part of accelerating agent, an ideal raw material functional combination can be obtained after applying the rubber formulation for sports shoes, which makes the sport shoe rubber sole having superwear resistance which is superior to ordinary rubber sole, and has a plurality of excellent properties such as wet-skid resistance, impact resistance and the like.

Owner:ANTA CHINA

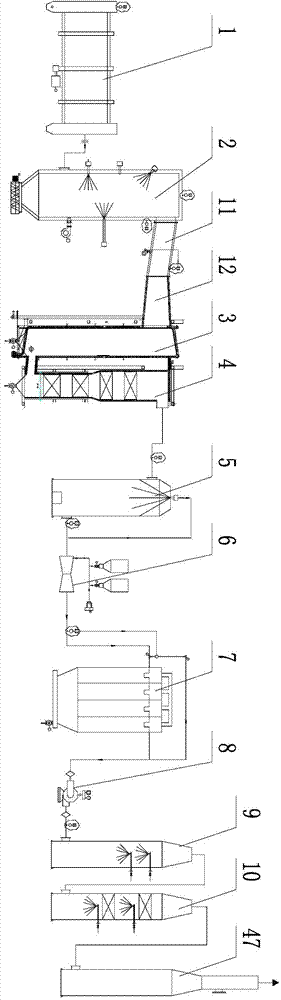

Industrial hazardous waste incineration system

ActiveCN104501178AEliminate acid gasBurn fullyIncinerator apparatusCombustion chamberCooling chamber

The invention discloses an industrial hazardous waste incineration system comprising a rotary kiln, a waste liquor furnace, a membrane wall-type drop-tube furnace, a membrane wall-type waste heat boiler, a half-dry quench tower, a dry reactor, a bag-type dust collector, a draught fan, a spray tower, an absorption tower, a natural gas pipeline, a low-pressure steam pipeline, a compressed air pipeline and a chimney. A secondary combustion chamber and a pre-cooling chamber are arranged between the waste liquor furnace and the membrane wall-type drop-tube furnace. The industrial hazardous waste incineration system is simple in structure, convenient to operate, low in cost, long in service life, effective in sufficiently burning the hazardous waste, low in hazard, high in working efficiency, capable of simultaneously treating solid and liquid independently, strong in university and lower in cost.

Owner:江苏百茂源环保科技有限公司

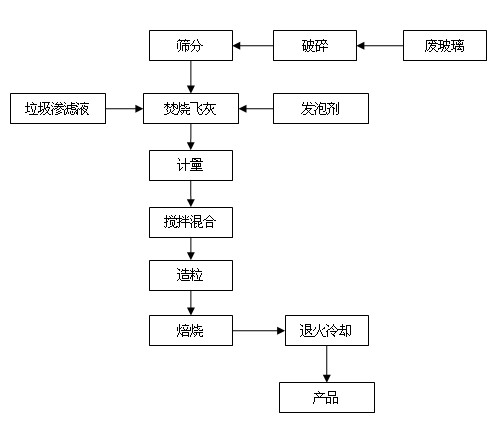

Method for preparing ceramsite by using waste incineration fly ash and waste glass

InactiveCN102643109ACause secondary pollutionEfficient curingSolid waste disposalCeramicwareFoaming agentHardness

The invention relates to a method for preparing ceramsite by using waste incineration fly ash and waste glass. The method includes the steps that waste glass is broken and ball ground to 200 meshes, and then waste incineration fly ash, rubbish leachate and a foaming agent are added according to certain proportion; and the mixture is stirred evenly, granulated and placed in a furnace to go through a pre-heating stage, a temperature rising stage and a heat preservation anneal stage to obtain the glass ceramsite. The glass ceramsite prepared through the preparation method is good in structural strength, low in water absorbing rate, large in hardness, good in chemical stability and wide in an application range. Simultaneously, dioxin pollutant in raw materials can be decomposed and damaged, heavy metal is cured in firing products, a toxic leaching standard of our country is met, and a purpose of disposing the rubbish leachate and the waste incineration fly ash is achieved simultaneously. The glass ceramsite produced through the method meets requirements of building aggregate, and the method not only turns waste into wealth, but also protects environment.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

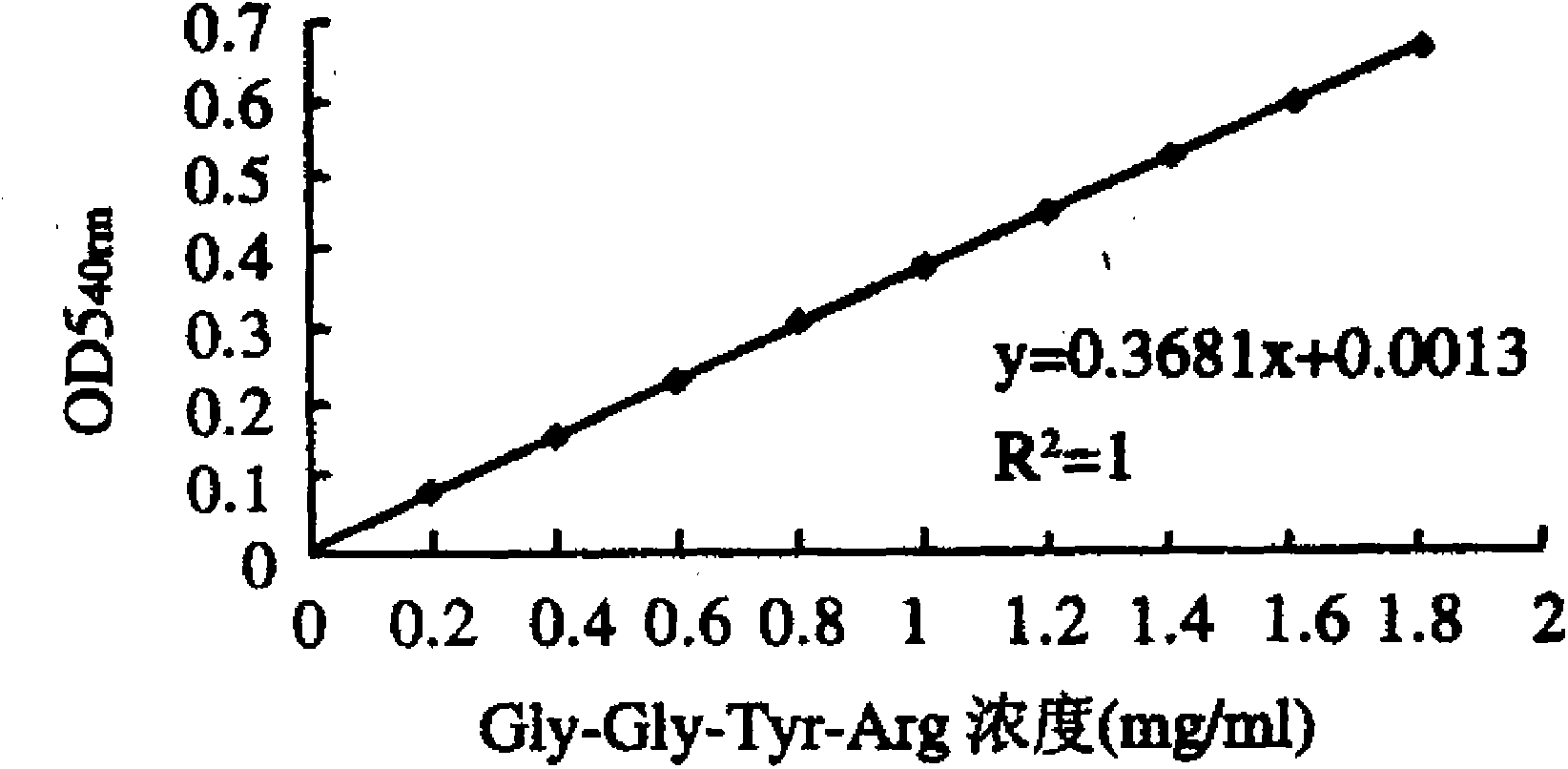

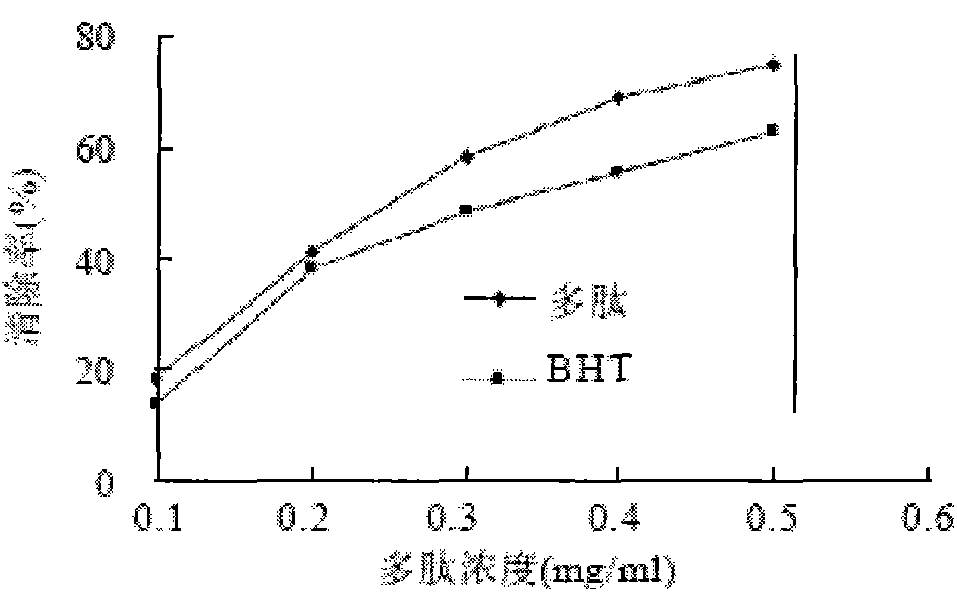

Method for preparing queen bee embryo peptide by enzyme hydrolysis method

ActiveCN103725742AFlavor Enhancement and ImprovementFlavor protease=1:1) to enhance and improve hydrolysisCompound screeningApoptosis detectionWater bathsEnzymatic hydrolysis

The invention relates to a method for preparing queen bee embryo peptide by an enzyme hydrolysis method. The method comprises the steps of carrying out sample pretreatment, degreasing queen bee larva powder, preparing queen bee larva powder sample solution, treating the queen bee larva powder sample solution by ultrasonic waves, carrying out enzymatic hydrolysis reaction on the queen bee larva powder sample solution, heating enzymatic hydrolysate in a boiling water bath for 20min to realize enzyme deactivation, cooing to room temperature, adjusting pH value of the enzymatic hydrolysate to 7.0, centrifuging to take out supernate, and drying the supernate to obtain the hydrolyzed queen bee embryo powder. The prepared queen bee embryo polypeptide can be used for preparing health products for improving the function of human body, and more important, the bioactive polypeptides beneficial to human body can be screened out from the hydrolyzed queen bee embryo polypeptide.

Owner:山东欣悦肽生物技术有限公司

Sintered light-weight environment-friendly brick produced from electroplating sludge and manufacture method thereof

The invention relates to a sintered light-weight environment-friendly brick produced from electroplating sludge and a manufacture method thereof. The sintered light-weight environment-friendly brick is characterized by being prepared by adopting electroplating sludge, base waste sludge, furnace slag, refuse ash, calcium oxide, calcium sulfate, sodium carbonate, boric acid, ferrous sulfate, magnesium sulfate, Li macromolecular heavy metal trapping agent and water are adopted as raw materials; and the manufacture method comprises the following steps of: mixing and stirring the raw materials in a biaxial mixer to be in a moisture state; extruding into rectangular bars by a vacuum sludge extruder; cutting and forming by a blank cutter; manufacturing light-weight environment-friendly brick blanks of electroplating sludge under the pressure of 20-30 MPa; and conveying the formed and naturally dried light-weight environment-friendly brick blanks into a tunnel kiln to roast and manufacture light-weight environment-friendly brick products. Air laying bricks and pavement bricks in different specifications can also be manufactured by the raw materials of the invention, and the product has the advantages and the effects of light weight, great strength, zero pollution, low cost and good benefits.

Owner:清远绿由环保科技有限公司

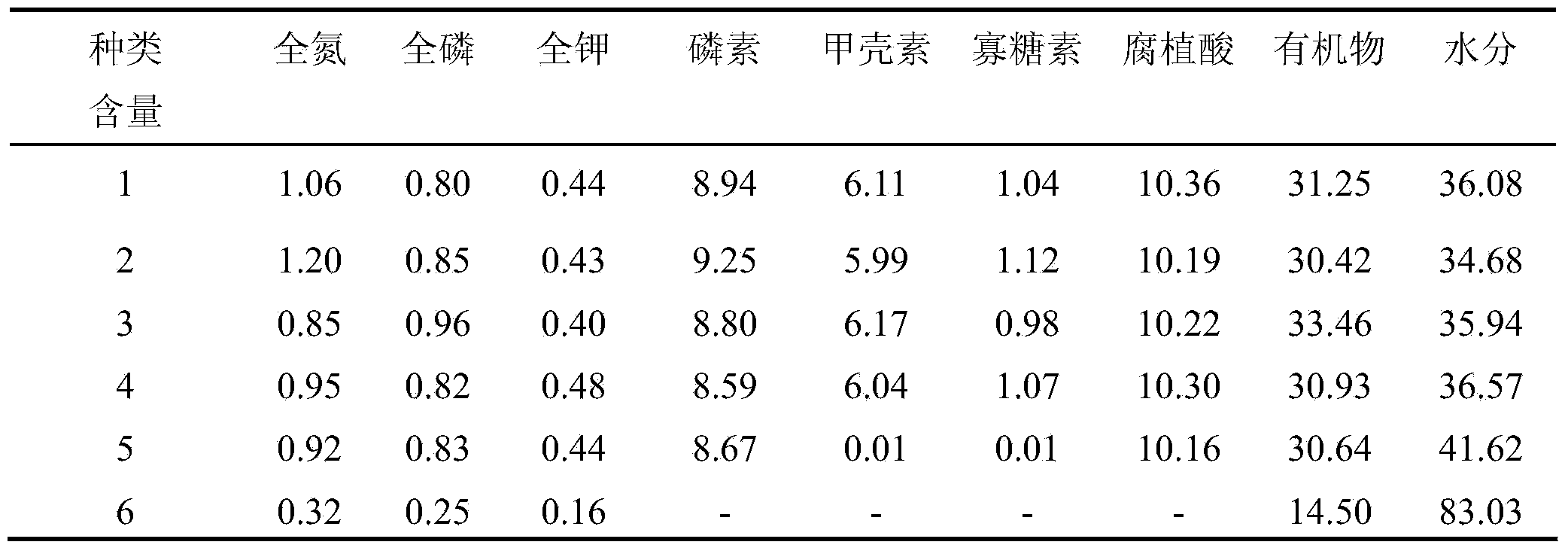

Preparation method of organic fertilizer rich in chitin

ActiveCN103864474AReduce environmental pollutionImprove the agricultural ecological environmentClimate change adaptationExcrement fertilisersNutrientDecomposition

The invention relates to a preparation method of an organic fertilizer rich in chitin, particularly relates to a method for preparing a fertilizer from wastes or residues, more particularly relates to a method for preparing a fertilizer rich in chitin through the combination of microbiological decomposition and an earthworm digestive system, and aims to provide a preparation method for an organic fertilizer with high chitin content, wherein the preparation method is free of specially extracting chitin, low in production cost and little in environment pollution. The preparation method of the organic fertilizer rich in chitin comprises the following steps of crushing shells of insects or crustaceans; composting to ferment a base material; feeding earthworms and collecting vermicompost; collecting vermicompost fertilizer rich in chitin. The preparation method provided by the invention is safe, simple and convenient in operation, low in production cost and little in environment pollution; the organic fertilizer prepared by the invention is high in chitin content, capable of effectively improving a soil structure and improving the qualities of agricultural products, and free of environment pollution in an applying process; in addition, nutrients in the organic fertilizer are easily absorbed by plants. The preparation method is used for the technical field of fertilizer production.

Owner:BEIJING WOKEFENG TECH DEV

Preparation method of high-yield high-activity alkynol-coated vinyl platinum complex

ActiveCN105255192AHigh yieldHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsSodium bicarbonatePlatinum complex

The invention discloses a preparation method of a high-yield high-activity alkynol-coated vinyl platinum complex. The preparation method is characterized by comprising the following steps that 1, 100 parts by weight of 1,3-divinyltetramethyldisiloxane is taken to be poured into a reaction kettle; 2, 1-8 parts by weight of chloroplatinic acid is dissolved with solvent to obtain a chloroplatinic acid solution, the chloroplatinic acid solution is poured into the reaction kettle to be stirred, the temperature is increased to 50-60 DEG C, and the reaction time is set for 0.5-2 h; 3, 5-30 parts by weight of sodium bicarbonate is added into the reaction kettle, then the temperature is increased to 60-80 DEG C, and stirring is continuously performed to enable a reaction to be performed for 1-3; 4, 1-10 parts by weight of alkynol is dissolved with 10-100 parts by weight of solvent to obtain an alkynol solution, the alkynol solution is dropwise added into the reaction kettle, and dropwise adding is completed in 0.5-2 h; 5, filtering is performed to obtain filtrate and sodium bicarbonate residues; 6, reduced-pressure solvent removing is performed on the filtrate at 60 DEG C to obtain liquid; 7, vinyl silicone oil is added into the liquid to obtain the high-yield high-activity alkynol-coated vinyl platinum complex. The preparation method is simple and easy to achieve, and the yield of the prepared product can be more than 98 percent.

Owner:ANHUI ZHENGJIE HIGH TECH MATERIALS CO LTD BY SHARE

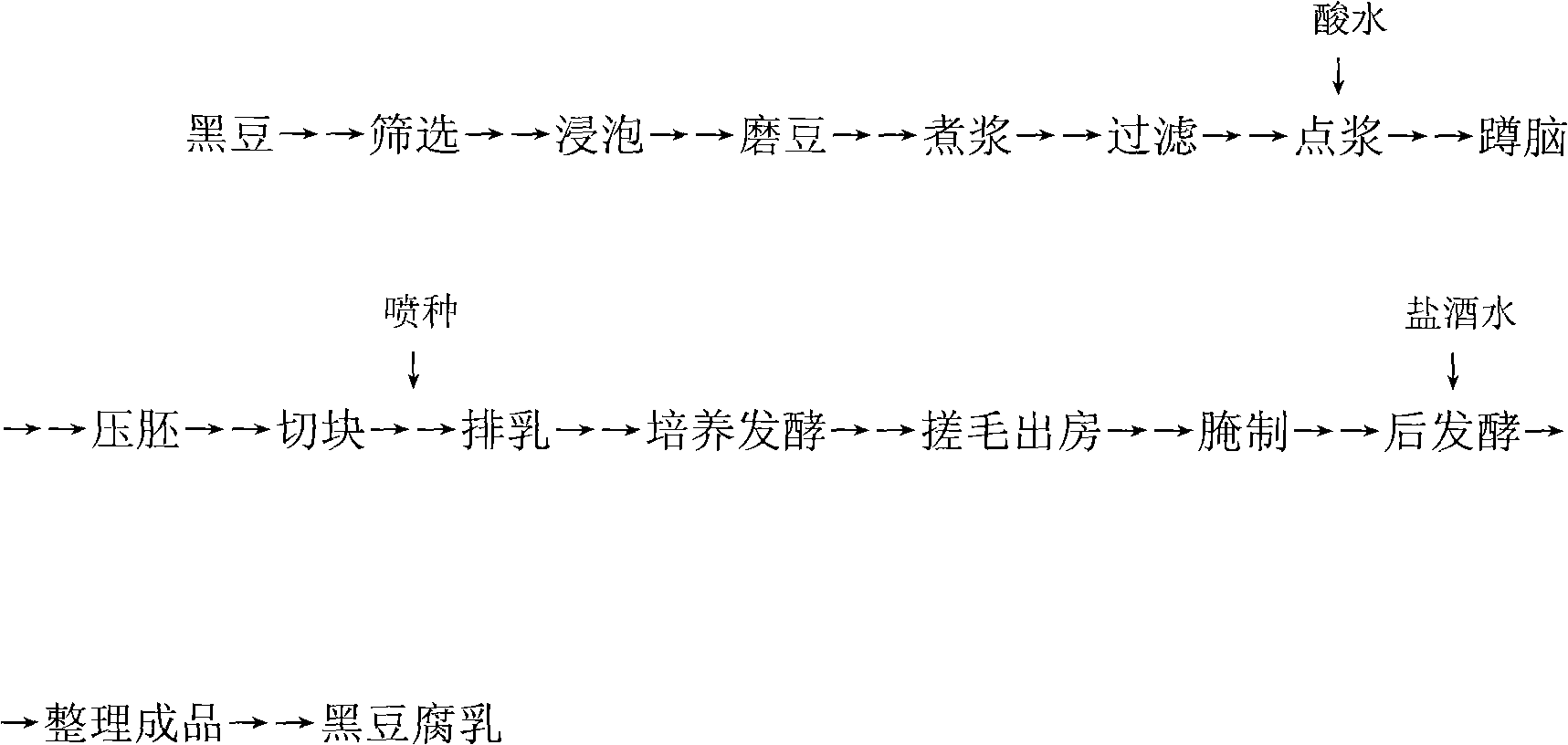

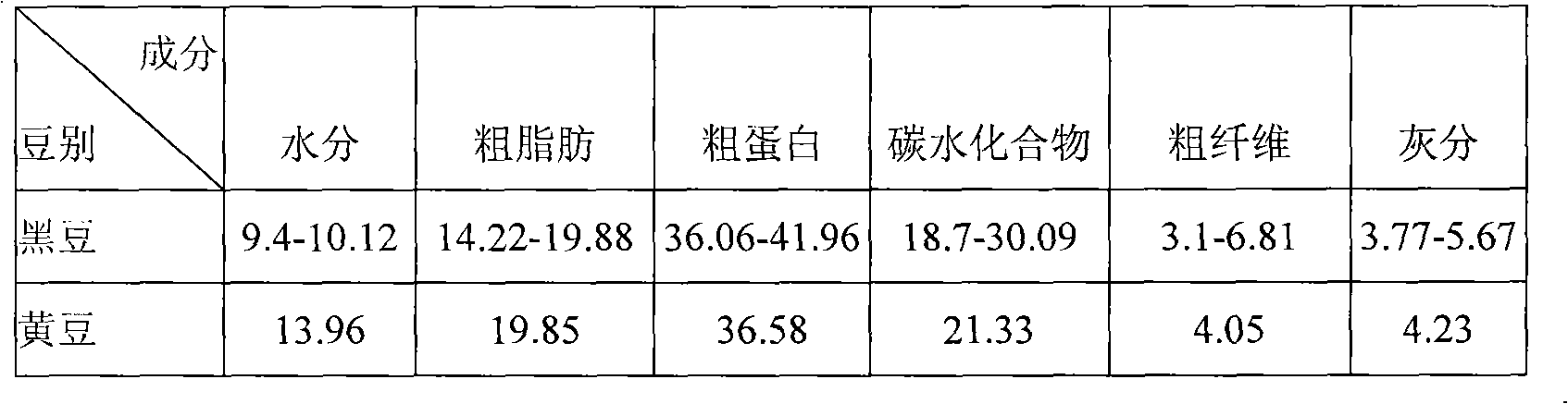

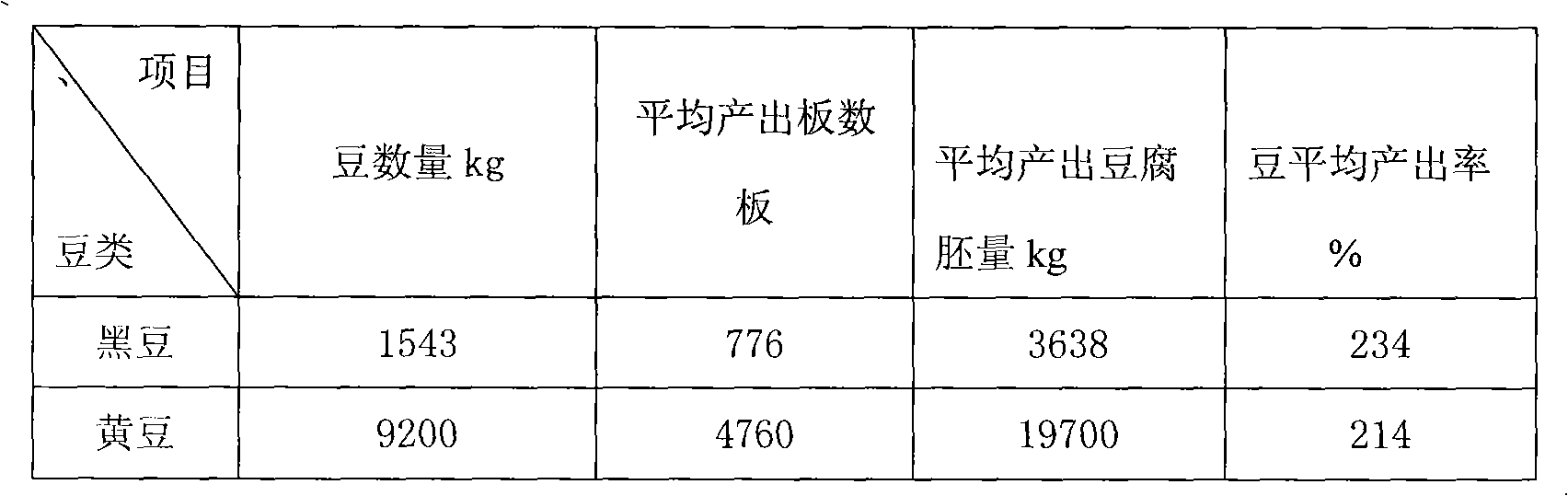

Preparation of preserved beancurd

The invention relates a method for producing preserved beancurd, which is characterized in that black beans are used as main raw materials and the product is produced by using a preserved beancurd process, compared with a common process, the coagulant used for shaping beancurd in the slurry curdling process according to the invention is 1% acid water; in the primary cultivation and fermentation process, the low-temperature bacterium cultivation process is used, the room temperature is controlled at 20-24 DEG C all around the year, the cultivation time is 36-40 hours; in the secondary fermentation process of the post production process, the concentration of the recombined salt wine is lower than the common concentration, so the content of the protein and aminoacid in the produced black preserved beancurd is higher, and the product has salt-fragrant, fresh sweet and soft glutinous mouth feelings.

Owner:开平广合腐乳有限公司

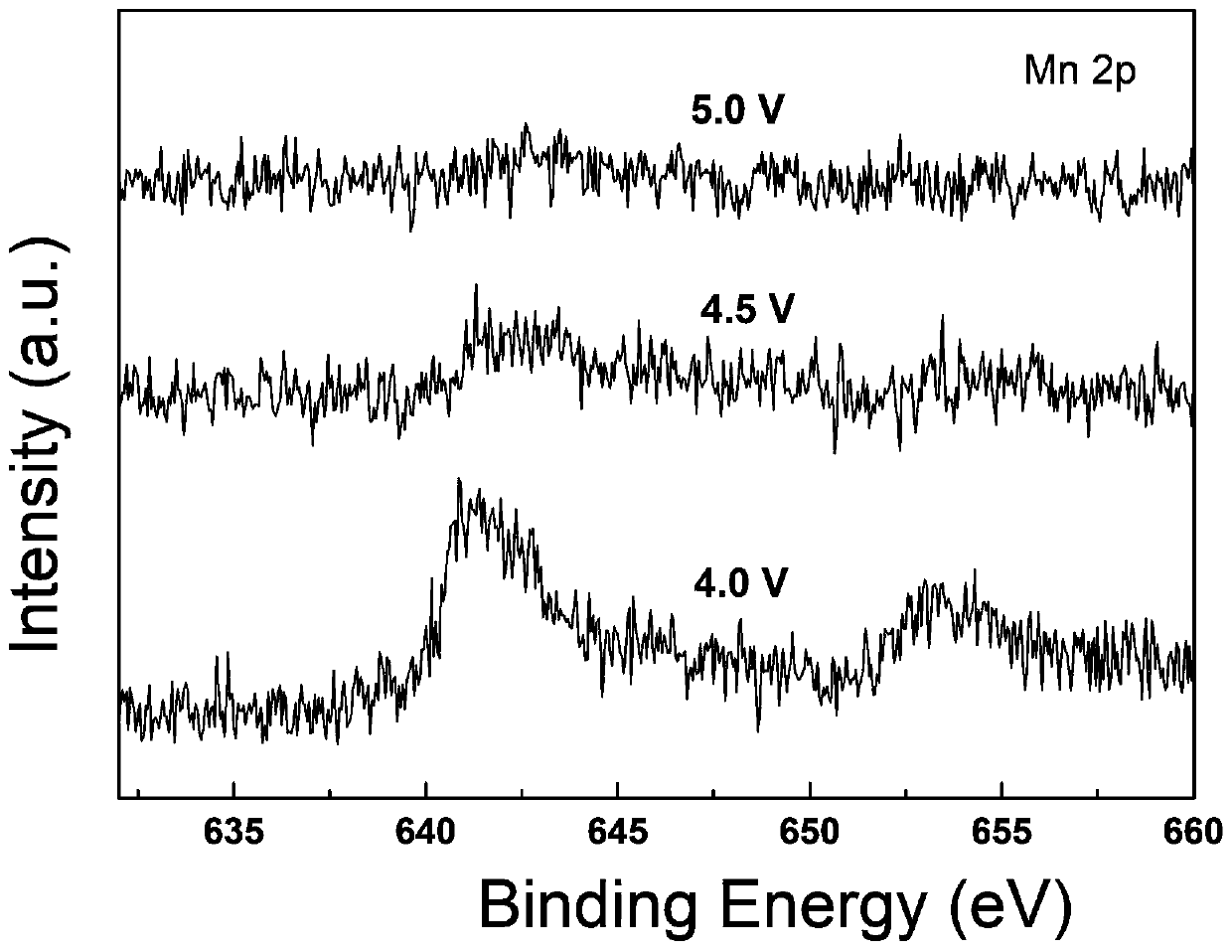

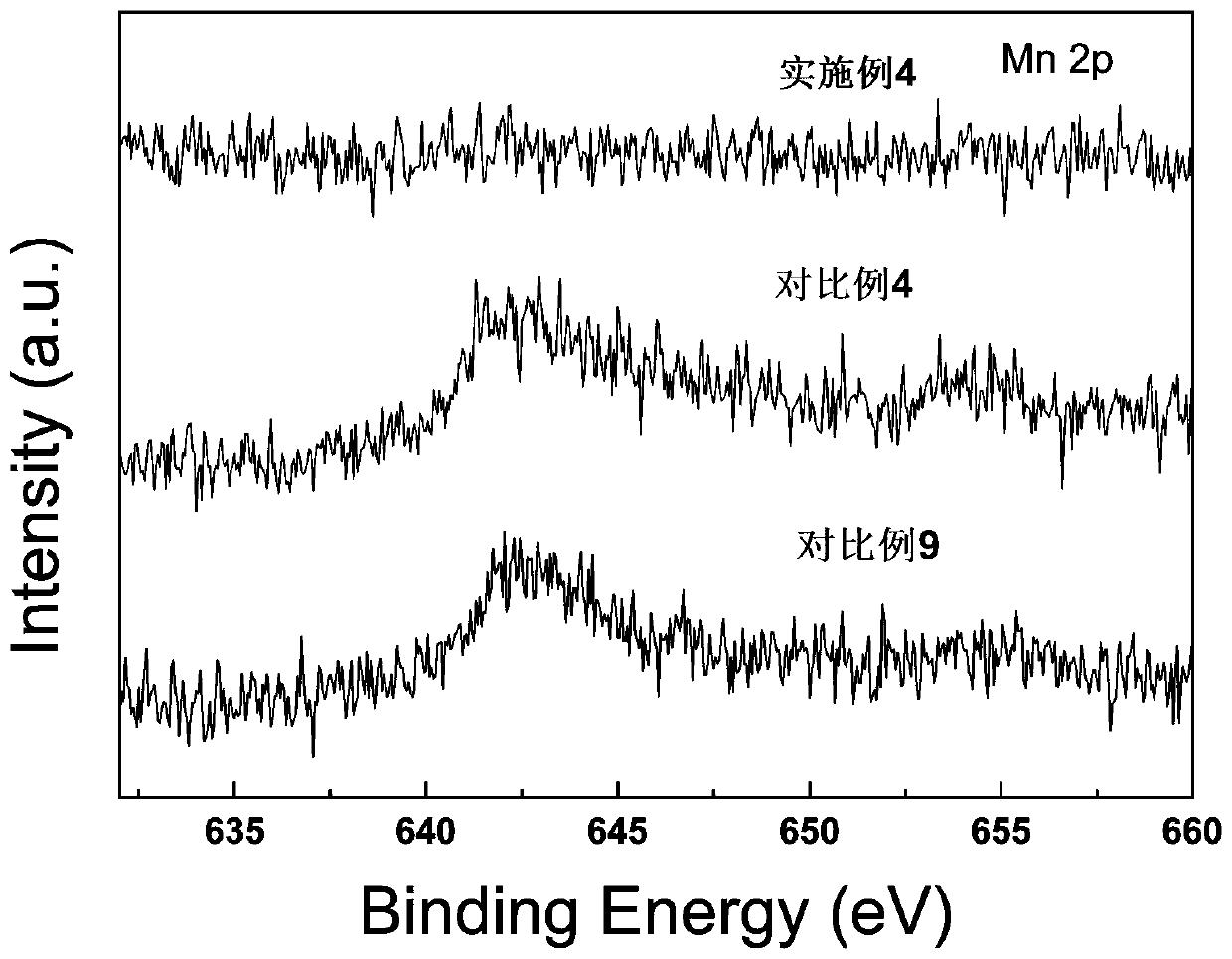

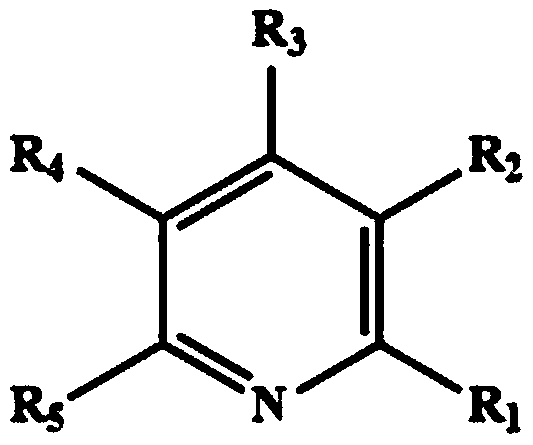

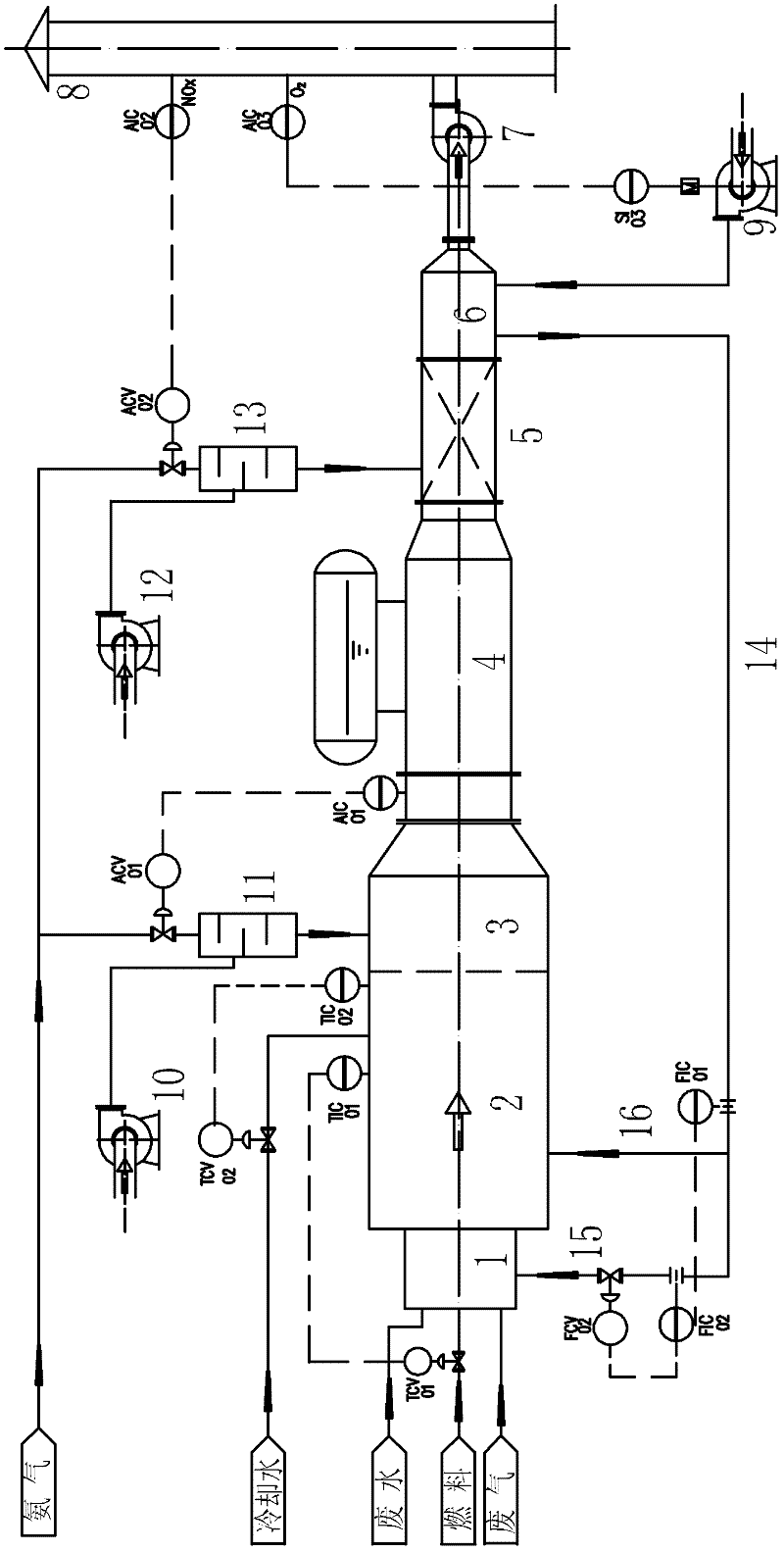

High-voltage lithium ion battery electrolyte additive, electrolyte, battery and formation method thereof

InactiveCN111244543AImprove efficiencyImprove cycle performanceSecondary cells charging/dischargingOrganic electrolytesElectrolytic agentElectrochemistry

The invention discloses a high-voltage lithium ion battery electrolyte additive, an electrolyte, a battery and a formation method thereof. The high-voltage lithium ion battery electrolyte additive provided by the invention is a pyridyl compound, formation is carried out at high temperature and high voltage, the pyridine compound additive is relatively sufficiently decomposed, a stable interface film containing Li<x>NO<y> is formed on the surfaces of the positive electrode and the negative electrode, and side reactions on the electrolyte and a positive electrode interface are inhibited under high voltage; and meanwhile, dissolution of transition metal ions and damage of the transition metal ions to a negative electrode interface film are inhibited, the efficiency and the cycle performance of the battery are improved, especially the electrochemical performance of the battery at high temperature is improved, and the invention has the advantages of small addition amount, low cost, simple synthesis and the like, is easy to implement and is beneficial to wide popularization and application.

Owner:SONGSHAN LAKE MATERIALS LAB

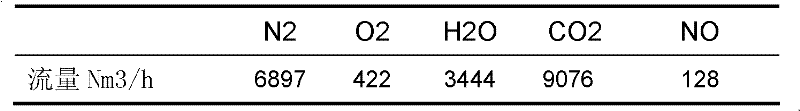

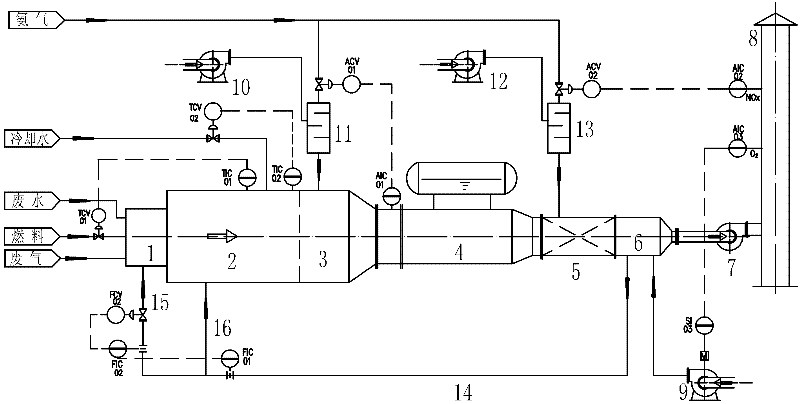

Incineration treatment device for nitrogen-containing organic wastes and incineration treatment process

ActiveCN102644922AEvenly distributedReduce the temperatureIncinerator apparatusChemical industryFlue gas

The invention discloses an incineration treatment process for nitrogen-containing organic wastes, which includes: a, sending wastes into an incinerator to incinerate at a high temperature and maintaining the incineration temperature by injecting after-burning fuel; b, injecting combustion-supporting air which is divided into primary air and secondary air according to a certain proportion into a fire chamber for supporting combustion; c, injecting reducing agents to the tail of a hot oxidation furnace and reducing part of NOx in flue gas by the SNCR (selective non-catalytic reduction) method; d, leading high-temperature flue gas from the hot oxidation furnace into a waste heat boiler to recover part of heat; e, leading the flue gas from the waste heat boiler into an SCR(selective catalytic reduction) treater to reduce content of NOx in flue gas further; and f, further recovering afterheat of flue gas by the aid of an air preheater arranged at the downstream of the SCR treater and then discharging flue gas through a chimney. The incineration treatment process is simple and low in cost for incineration of organic wastes, denitration efficiency can be guaranteed by a two-stage denitration process, emission standards can be met, afterheat of flue gas can be recovered, and accordingly the incineration treatment process can be applied to the similar organic waste treatment projections in the chemical industry.

Owner:天津辰创环境工程科技有限责任公司

Photocatalytic type air purification device and method

The invention discloses a photocatalytic type air purification device which comprises a spiral channel with an air inlet and an air outlet, wherein a plurality of catalytic units are arranged in the spiral channel; the catalytic unit comprises a catalyst carrier with a pore structure and a g-C3N4 optical catalyst attached to the catalyst carrier; the periphery of the catalyst carrier is hermetically connected with the inner wall of the spiral channel; the side wall of the spiral channel is made of light transmission materials; a visible light source irradiating the g-C3N4 optical catalyst is arranged in the spiral channel. The invention further provides a photocatalytic type air purification method. According to the photocatalytic type air purification device, the spiral channel structure is adopted for guiding air stream, so that the utilization rate of a space in the device is greatly increased, the path and the time for passing through the catalyst by air are prolonged, the area of contact between the air and the catalyst when the air passes through the catalyst is enlarged, the photocatalytic efficiency is improved, and the overall size of the device is reduced; the device is suitable for being used in various occasions.

Owner:ZHEJIANG UNIV

Steam explosion technique testing desk

InactiveCN101361588ADecompose fullyIncrease energy densityPressurized chemical processFood shapingFiberThermodynamics

The invention relates to a test device for determining parameters of steam explosion technology, belonging to physics test equipment. In the current technology mode, which realizes steam explosion through fast valve opening, long pressure release time reduces the energy density, so the material decomposition degree is low, little facilitating later enzymatic hydrolysis. The technological test bench based on the principle of cylinder explosion piston provided by the invention can finish the steam explosion within milliseconds, improving the energy density and fully decomposing the material. The technical principle of the test bench is also reflected in the design of industrial steam explosion devices, which accurately simulates the production environment for future industrialization of steam explosion and, thereby, accurately determining parameters of the steam explosion technology and providing fiber pretreatment materials for metaphase experiments of biochemical treatment such as enzymatic hydrolysis and the like. Experiments of the invention are relatively independent, creating conditions for contrast tests and final parameter determination.

Owner:于政道

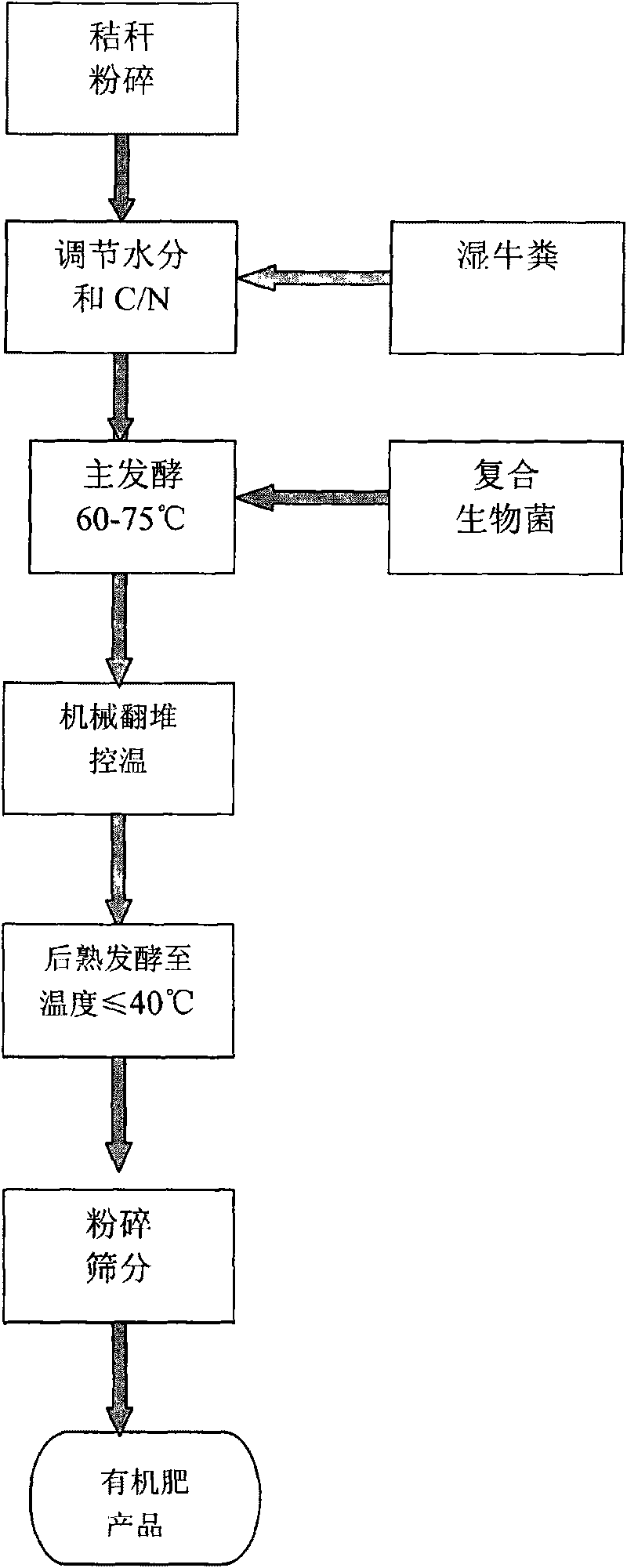

Treatment method for rice/wheat straw waste

ActiveCN101759466ADecompose fullyHigh Quality Organic FertilizerBio-organic fraction processingOrganic fertiliser preparationContinuous fermentationMicroorganism

The invention relates to a microbiological treatment method for rice / wheat straw waste, belonging to the technical field of resources and environment. On the basis of the study on the composition and properties of the rice / wheat straw waste, the invention provides the method for the rice / wheat straw waste to be stacked in a centralized manner and to be transplanted with a compound microbe for fermentation so as to carry out pollution-free treatment. Under the function of the compound microbe which is composed of bacillus subtilis, clostridium and rhizopus, continuous fermentation and temperature rising are carried out on the rice / wheat straw waste; at the same time as harmful pathogens are killed, the rice / wheat straw waste is decayed after being completely decomposed, so as to obtain excellent organic fertilizer. The treatment method is simple in processing, and the waste is recycled. Therefore, the treatment method in the invention is an ideal one that accords with the national conditions, needs low cost and can effectively treat the rice / wheat straw waste in cities and suburbs.

Owner:上海合庆火龙果科技开发有限公司

Visible-light-curing vinyl ester resin composite prepreg, and preparation method and application method thereof

The invention particularly provides a visible-light-quick-curing vinyl ester resin composite prepreg, and a preparation method and application method thereof, belonging to the field of repair of a fiber-reinforced resin-base structure with certain thickness. A special vinyl ester resin is used as a matrix; the proper visible light initiator, thermal initiator and other aids are selected to constitute the light-thermal composite initiation system; magnesium oxide is used as a thickener; different types of fabrics are selected as fiber-reinforcing materials according to performance requirements; and a proper composite technique is utilized to prepare the composite prepreg with certain thickness. The visible-light-curing prepreg material can be cured within 5 minutes under the single-side irradiation of visible light, and the once-time photocuring thickness can reach 10mm or above, thereby basically solving the problems of poor operability, poor safety and insufficient film thickness under ultraviolet light. The visible-light-curing prepreg can be subjected to mass application in the field of structure repair.

Owner:四川远鸣科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com