Preparation of preserved beancurd

A fermented bean curd and process technology, applied in food preparation, application, food science and other directions, can solve the problems of affecting the protein decomposition rate in soybeans, affecting the yield, taste, and prolonging the fermentation time, so as to shorten the fermentation time, soften the taste, and enrich the protein. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

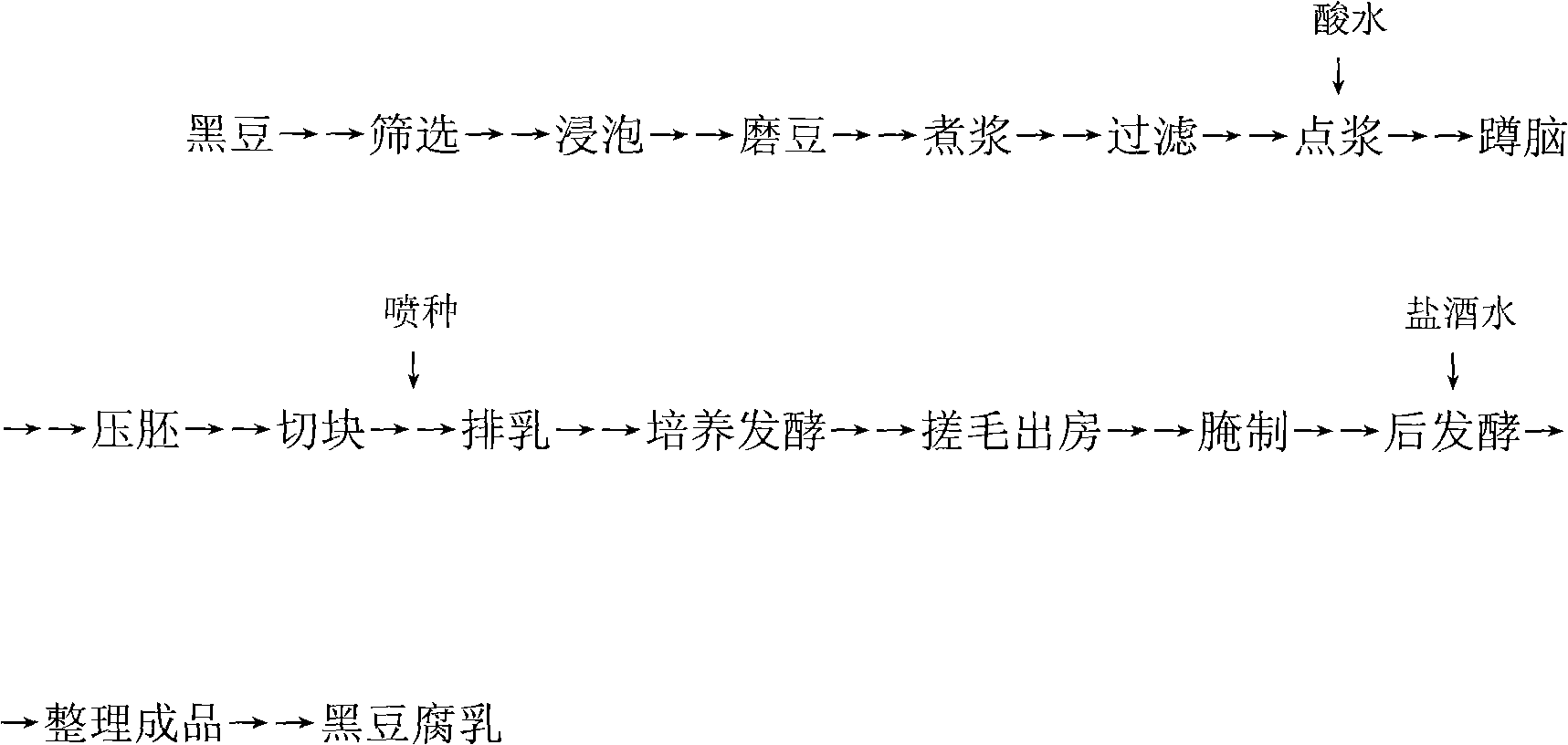

[0027] The preparation method of a kind of fermented bean curd according to the present invention adopts black soybeans as the main raw material of beans, and makes fermented bean curd according to the conventional process including soaking, refining, boiling, filtering, ordering, pressing, dicing, pre-processing Fermentation, pickling, post-fermentation and other processes, the specific operation steps are as follows:

[0028] 1. Screening: The black beans that have passed the inspection are screened by an electric vibrating screen.

[0029] 2. Soaking: Put the black beans into the pool for soaking. Water: dried beans = 3.5:1. Soak at room temperature for 6-12 hours.

[0030] 3. Grinding beans: add water to the soaked black beans for machine grinding, and the fineness is 8-10um.

[0031] 4. Boiling: Boil the ground black soybean paste, heat to 95-100°C, and keep warm for 5 minutes.

[0032] 5. Filtration: filter the boiled pulp. After 100 mesh nylon silk cloth. The bean...

Embodiment 1

[0051] A fermented bean curd product with black beans as the main raw material is formed according to the preparation method of the present invention, and it includes the following components (weight percentage):

[0052] Black bean curd block 62.2%

[0053] Water 22.6%

[0054] Refined salt 7.5%

[0055] Liquor 4.6%

[0056] Sesame Oil 1.5%

[0057] Black Sesame 0.7%

[0058] Capsicum 0.7%

[0059] Spices (star anise / cumin / pepper) 0.2%

Embodiment 2

[0061] A fermented bean curd product with black soybeans as the main raw material is black fermented bean curd with black truffle mushroom juice made according to the preparation method of the present invention, which includes the following components (weight percentage):

[0062] Black bean curd block 62%

[0063] Water 24.4%

[0064] Refined salt 7.5%

[0065] Liquor 4.6%

[0066] Shiitake Mushroom 1.1%

[0067] Black Truffle 0.4%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com