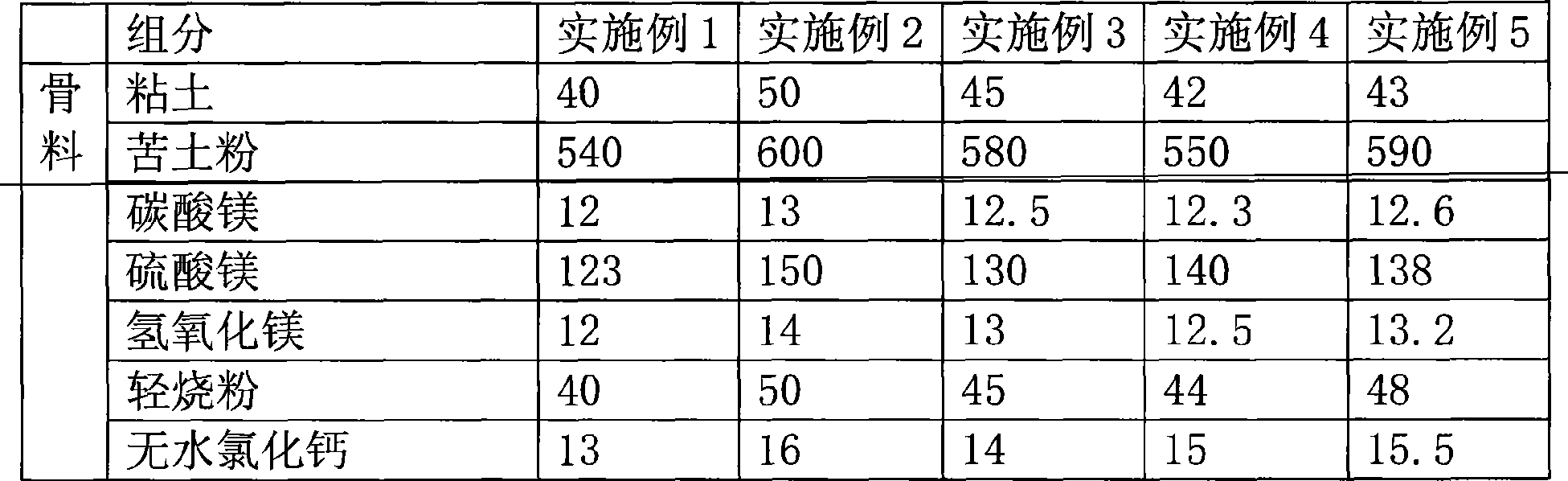

Patents

Literature

562 results about "Silk cloth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

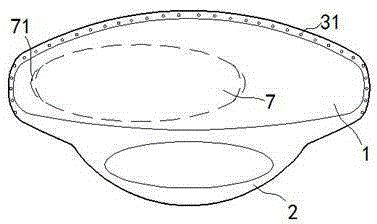

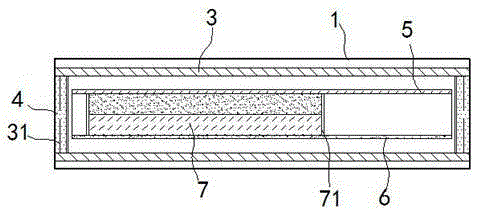

Sanitary napkin

InactiveUS20070055210A1Avoid feeling uncomfortableDisperse fastBaby linensTamponsEngineeringSilk cloth

A sanitary napkin has a top layer, an absorbent layer and a bottom layer with a sensor layer. The absorbent layer has a hollow portion covered with a silk-made cover layer and has multiple holes defined in the cover layer, wherein some silk cloth filled inside the hollow portion. By having the hollow portion with silk cloth, the menstrual blood is drained quickly and absorbed by the absorbent layer to keep the sanitary napkin dry at the top layer and to avoid toxic vapor. Moreover, the holes on the cover layer provide a ventilating efficiency and the silk is cool to be contact so that muggy feeling is efficiently reduced. The sensor at the bottom layer conveniently indicates the changing occasion to the user.

Owner:MAMA HAPPILY DRESS FASCH

Mulberry silk and cuprammonium rayon yarn interwoven fabric and weaving method thereof

InactiveCN101532199ALow costImprove comfortLiquid/gas/vapor removalDyeing processYarnCuprammonium rayon

The invention provides a fabric, in particular to a mulberry silk and cuprammonium rayon yarn interwoven fabric. The fabric is interwoven by the mulberry silk and the cuprammonium rayon yarn, wherein warp is made of the mulberry silk, while weft is made of the cuprammonium rayon. The invention also provides a method for weaving the fabric, which is a method of interweaving the mulberry silk warp and the cuprammonium rayon yarn weft into the fabric, wherein the cuprammonium rayon yarn as the weft is subjected to predrying treatment before use; process steps of the warp and the weft are as follows: the warp adopts reeled silk to be subjected to rolling, primary twisting, doubling, second twisting, skeining, degumming, dyeing, rolling, warping and weaving; and the weft adopts cone winded yarns to be subjected to roll separating, twisting, skeining, dyeing, rolling, quilling, predrying and weaving. The method provides the product interwoven by the mulberry silk and the cuprammonium rayon yarn, and adds new content for colorful silk variety.

Owner:上海丝绸集团股份有限公司

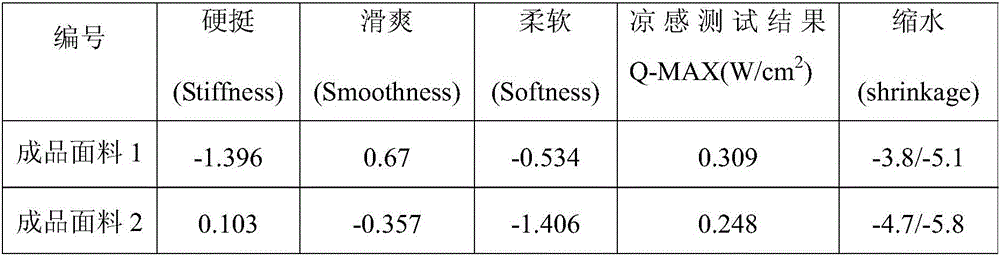

Knitted fabric containing cotton and having silky luster, handfeel and cool feeling and manufacturing method thereof

ActiveCN105734963ACompact structureNo blemishes on the clothWeft knittingBiochemical treatment with enzymes/microorganismsWoolDyeing

The invention provides knitted fabric containing cotton and having silky luster, handfeel and cool feeling and a manufacturing method thereof.The method includes the following steps that yarn is woven into gray fabric with a circular knitting machine, wherein the needle number of the circular knitting machine is 18-40, the yarn count is 20-80 S / 1, length 50 C of the yarn is 90-200 mm, and the gram weight of the gray fabric is 60-240 g / m<2>.The tissue structure of the gray fabric includes tabby, half cardigan, knitted cotton, rib, looped pile and ball wool or jacquard weave; open width alkali mercerizing, boiling-off, enzyme washing, dyeing, drying, soft stabilized finishing and preshrinking are conducted to finally obtain the knitted fabric containing cotton and having silky luster, handfeel and cool feeling.The knitted fabric containing cotton and having silky luster, handfeel and cool feeling has the advantages of being smooth, stiff, good in drapability, resistant to crease and small in shrinking amount and integrates smoothness, stiffness and crease resistance.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

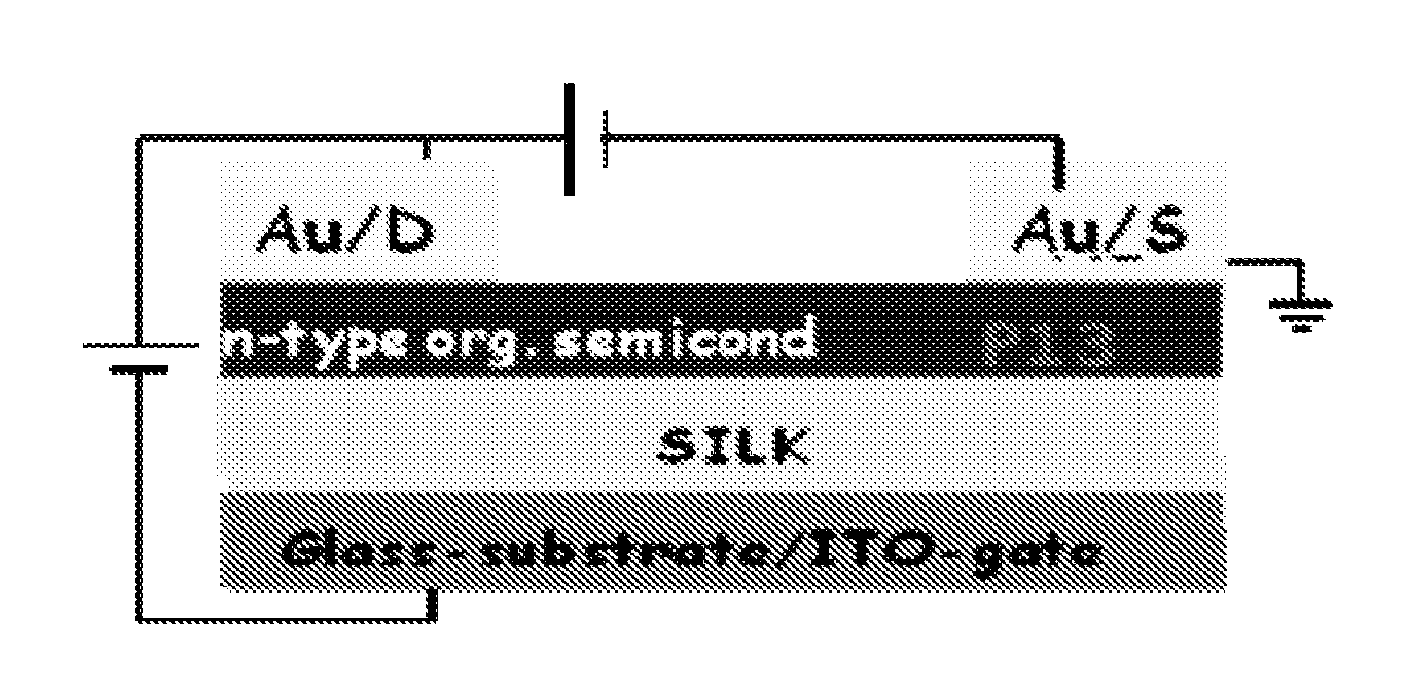

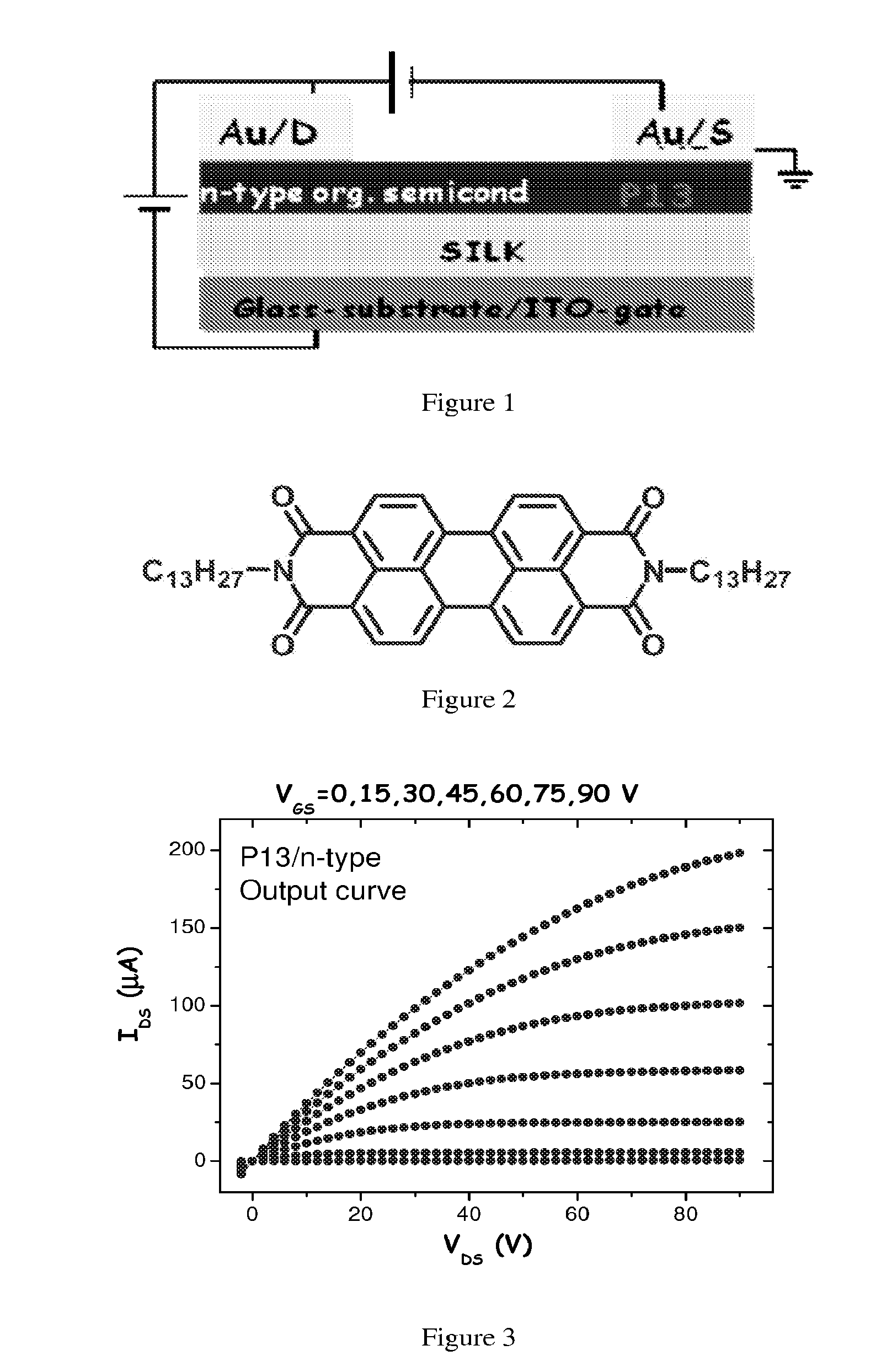

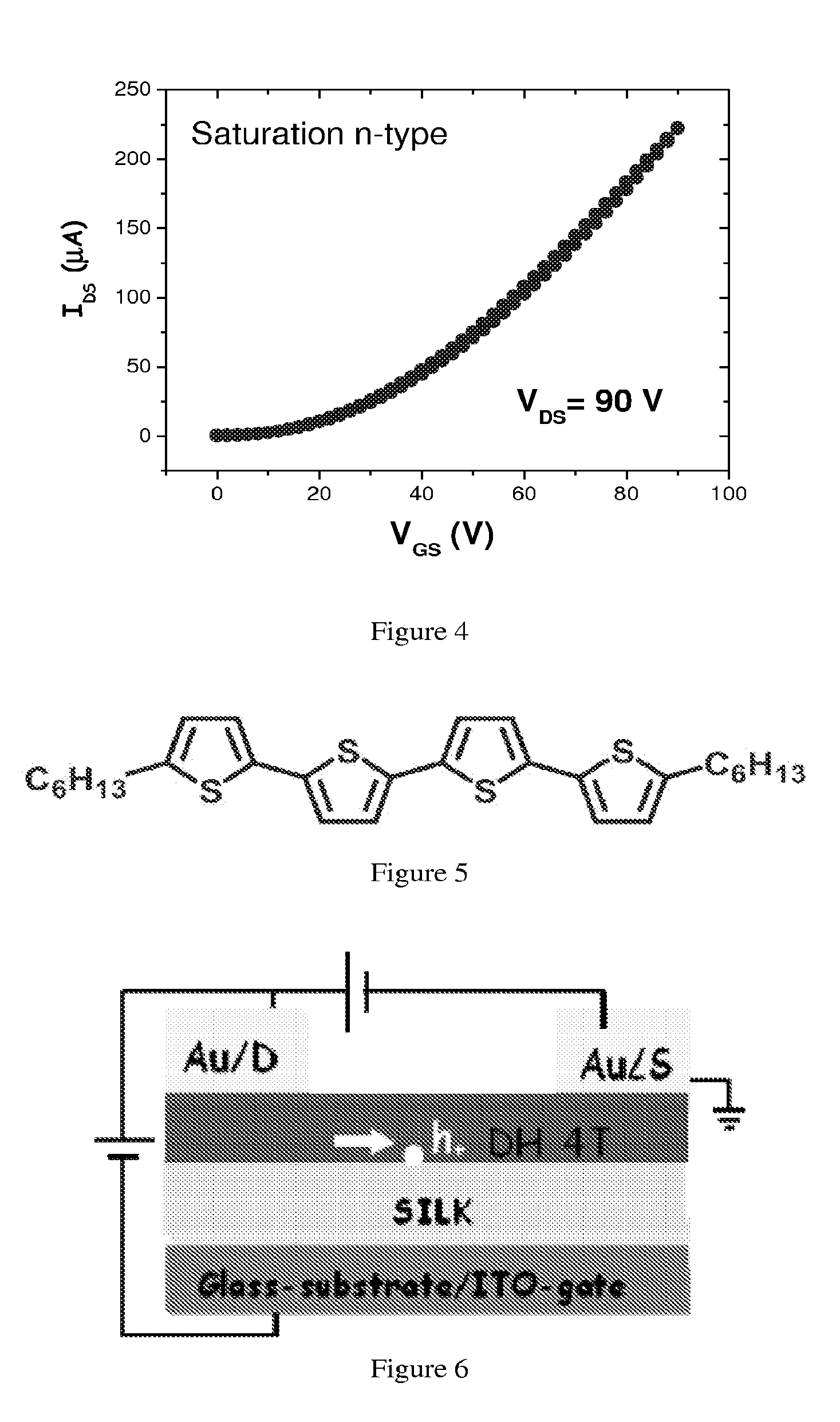

Silk transistor devices

The invention relates to ecosustainable and biocompatible, low cost, ambient friendly electronic and optoelectronic devices, such as transistors and light-emitting transistors, made with silk fibroin or blended with other biopolymers, methods for fabrication and methods of using the silk-based electronics and optoelectronics. The silk-based electronics and optoelectronics can be implanted in vivo and in vitro for biomedical applications, such as for drug discovery or drug screening assays and devices. The silk-based devices may be used in the food industry and embedded in packaging for tracking and sensing, for security purposes or exploited as disposable not harmful for the environment efficient general electronic and optoelectronic devices.

Owner:TUFTS UNIV

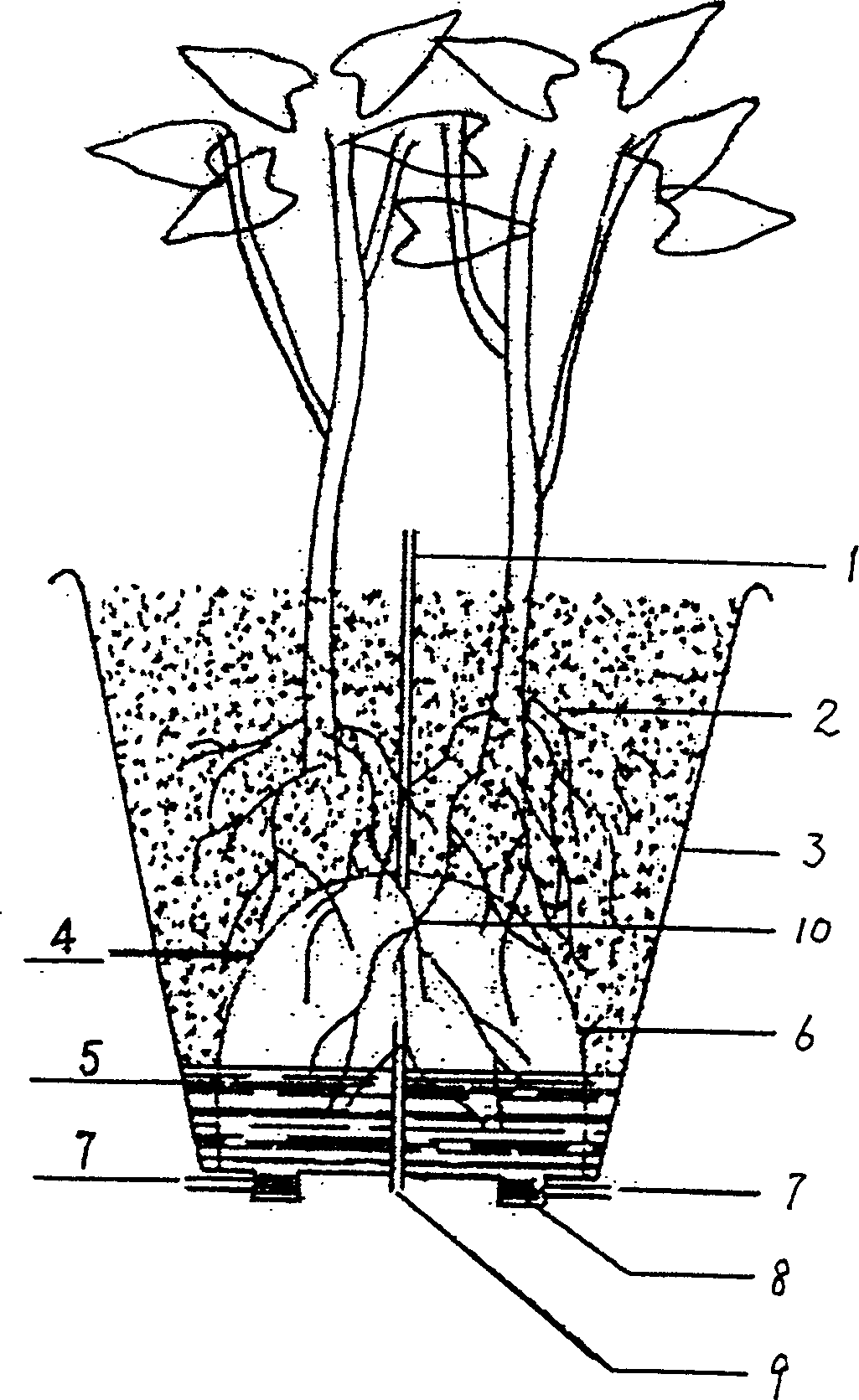

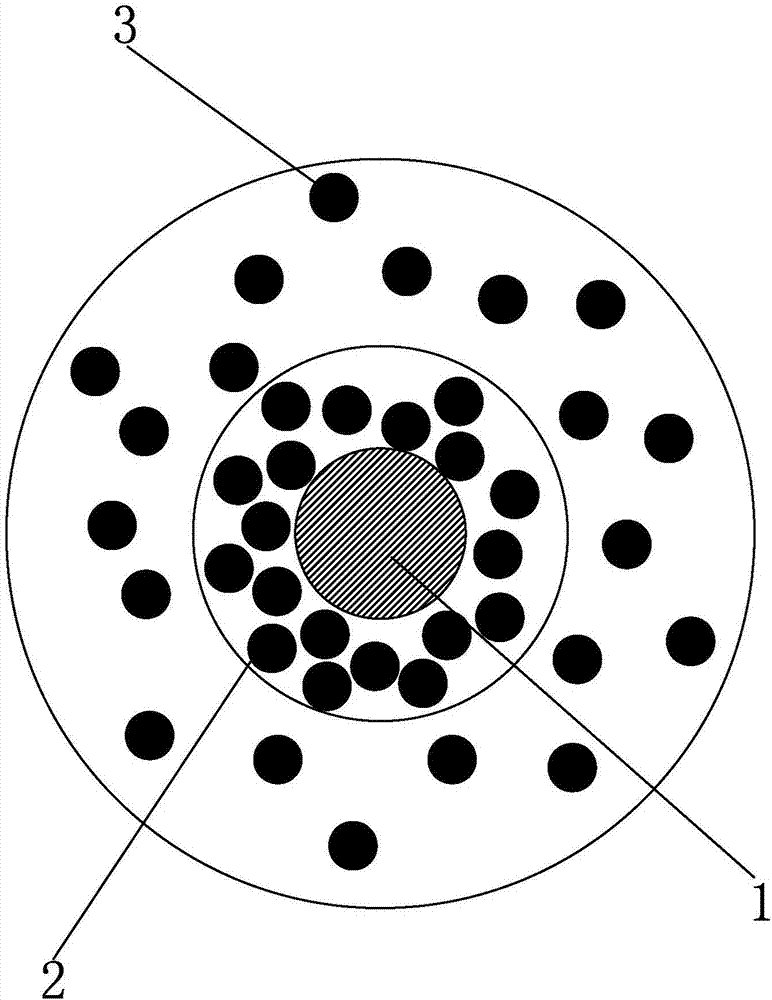

Liquid and air storage type soilless culture apparatus

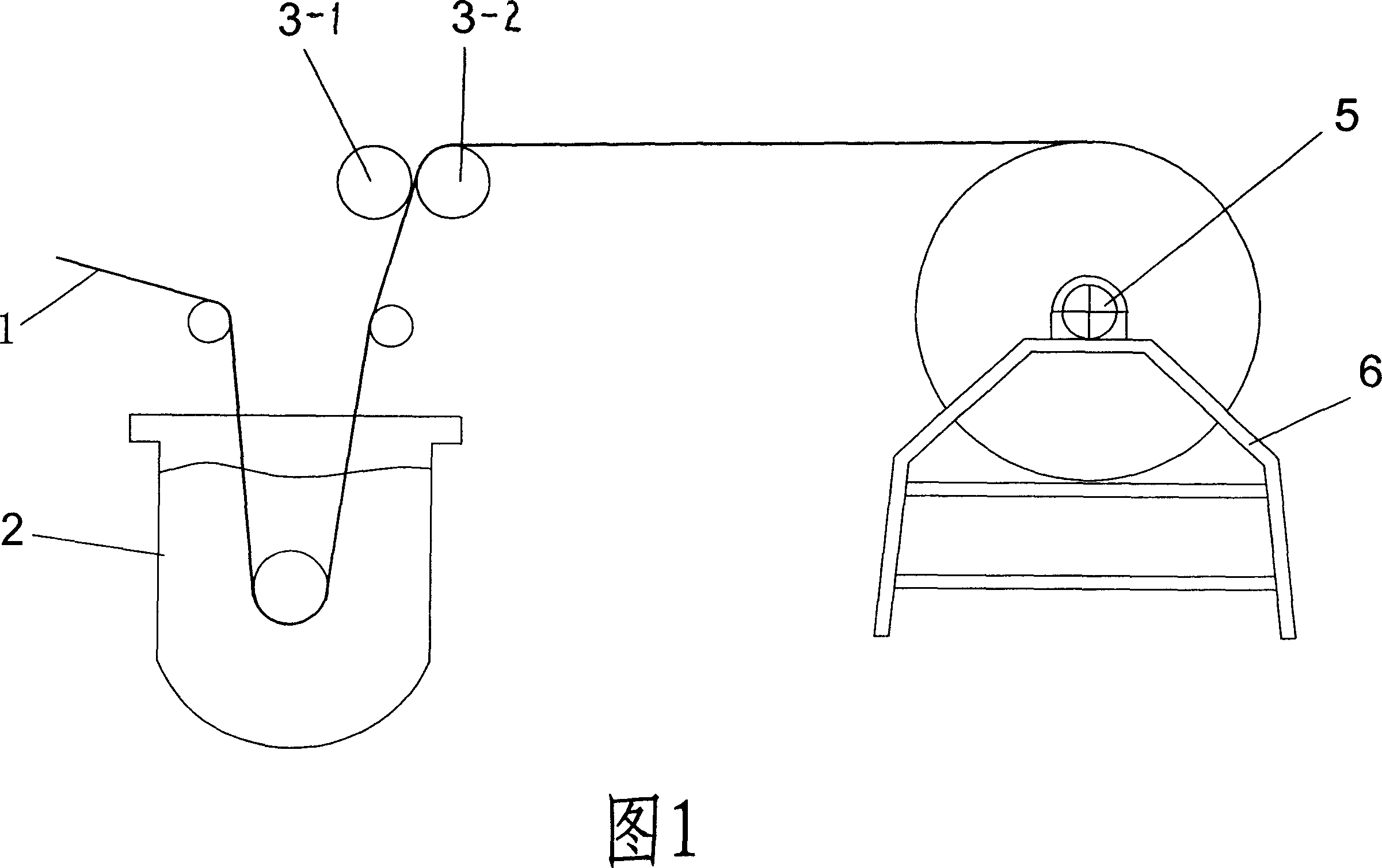

ActiveCN1545848ASimple structureEasy to useAgriculture gas emission reductionCultivating equipmentsEngineeringNutrient solution

A liquid storage and air reserve type soilless cultivation apparatus comprises an outer bucket and a pan-shaped screen aperture grid core arranged on the bottom of the outer bucket, the grid core is provided with nutrient solution and an air layer, the outside of the net core is filled with cultivation base material, the surface of the grid core is covered by a fine-mesh shape or silk-cloth shape substance for supporting the base material, its bottom, lateral surface and upper portion are provided with non-seepage water vent pipe for connecting with the air space in the grid core, the supporting ring on the bottom of the outer bucket is connected with a spigot-and-socket communication pipe.

Owner:太仓戈林农业科技有限公司

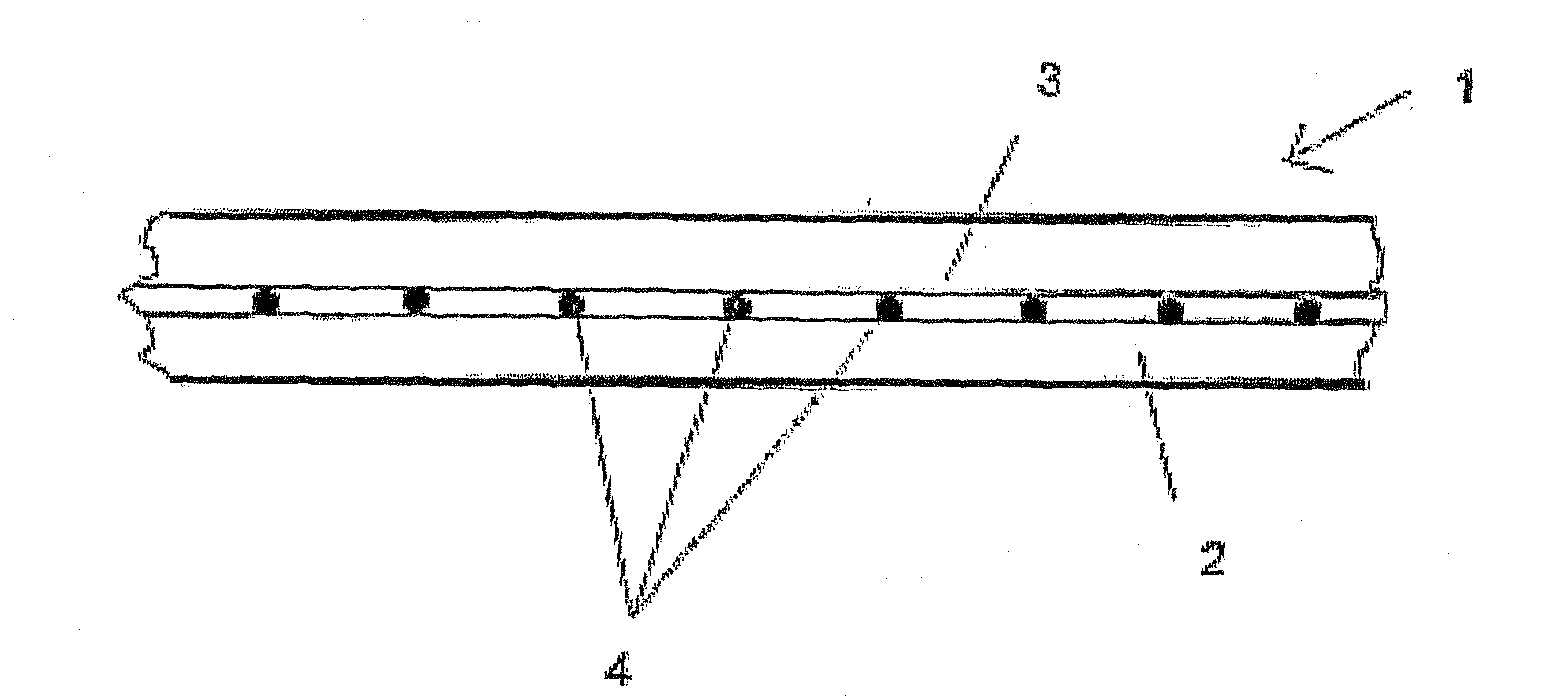

Antifouling paint containing nano oxides

The invention provides an antifouling paint containing nano oxides. The antifouling paint is prepared from the following raw materials based on a weight ratio: 5-20% of nano oxide, 10-30% of cuprous oxide, 20-30% of chlorine-containing polymer, 3-5% of rosin, 1-7% of polymer dispersant, 3-6% of plasticizer, 2-5% of anti-settling agent and 20-40% of solvent. The preparation method comprises the following steps: proportionally adding chlorine-containing polymer powder to the solvent with equivalent mass, and shearing and stirring at a high speed to obtain a transparent chlorine-containing polymer solution; proportionally adding the polymer dispersant to a certain amount of the solvent, and then adding the nano oxides for high-speed dispersion to obtain nano-oxide slurry; proportionally adding the prepared nano-oxide slurry as well as the cuprous oxide, the rosin, the plasticizer, the anti-settling agent and the like to the chlorine-containing polymer solution under the condition of high-speed stirring or grinding and dispersion; and finally filtering the obtained mixed solution with a sieve mesh or silk cloth to obtain the nano-antifouling paint, sampling, weighing and packaging to obtain the finished product after the sample passes a test.

Owner:ZHEJIANG OCEAN UNIV

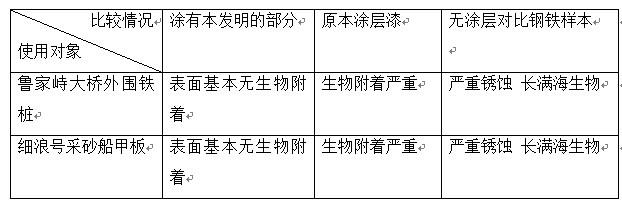

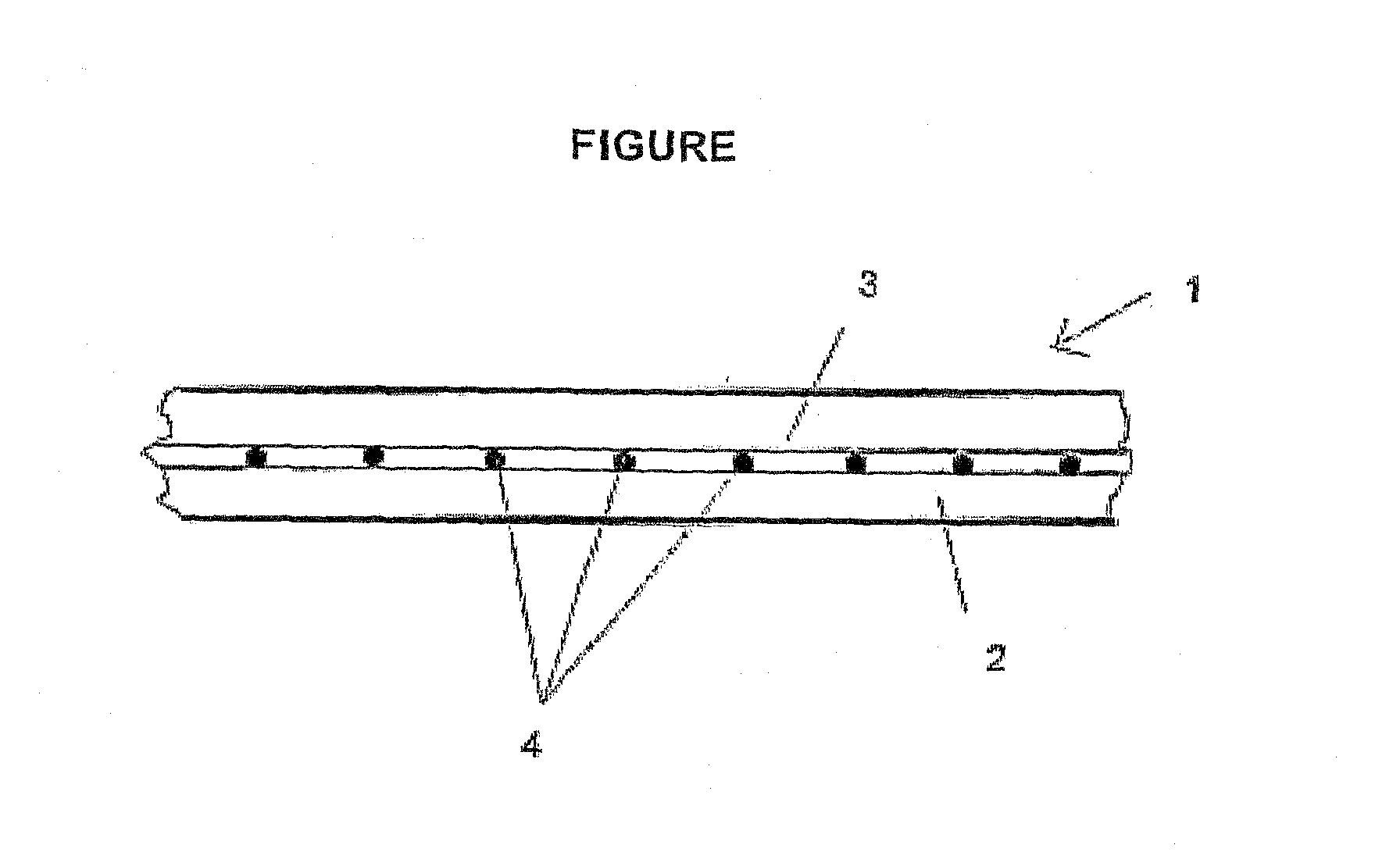

Multi-Ply Technical Composite Which Is Breathable And Moisturising, Releases Active Constituents And Promotes Their Absorption, And Can Be Uses As A Medical Aid Or To Make Clothing Or Structures That Come Into Direct Contact With Healthy Or Diseased Skin

InactiveUS20080195016A1Garment special featuresSynthetic resin layered productsPolyurethane membraneSkin contact

A multi-ply technical composite, usable in particular for making medical aids, garments and medical articles, includes at least two layers (2, 3), the first of which (2), in contact with the skin, is a cotton fabric (elasticised to a greater or lesser extent) or silk, or fabrics to which chitosan, silver or another antibacterial substance or active constituent is added, and the second, outer layer (3) is constituted by a semipermeable membrane, such as polyurethane between 5 and 80 microns thick, with considerable elasticity in order to ensure the user's comfort. Receptors rechargeable with active constituents are inserted into fabric (2) and protected by the polyurethane membrane.

Owner:BOTTINI EMILIO

Wash-free dyeing method for silk

ActiveCN101275365AReduce consumptionEmission reductionHeating/cooling textile fabricsDyeing processWater savingSewage

The invention relates to a textiles dyeing method, especially to a silk facing material dyeing method. The object of the invention is to provide an improved method for silk dyeing. The invention has features of waterless or little water dyeing, reduced cost, reduced sewage water discharging and good products color fastness; the products hand feeling maintains the silk facing material special styles; and the invention is water-saving and energy-saving. The invention adopts the technical scheme: executing according to the following steps in sequence: preparing dye liquor, dyeing, pre baking, decatizing, soft liquid slop padding, drying and finishing.

Owner:杭州喜得宝集团有限公司

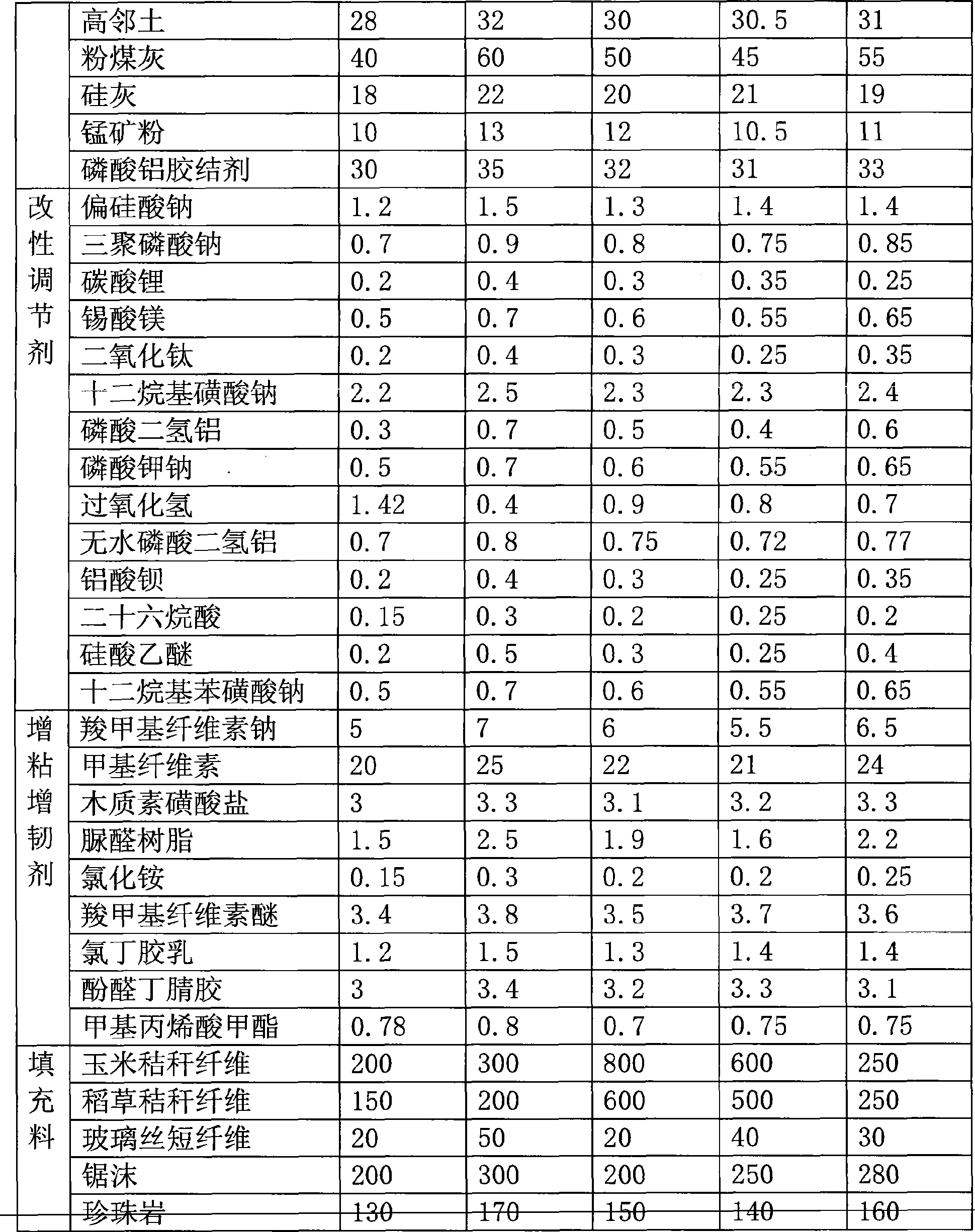

Building board combining magnesium compounds and plant fibre and preparation method thereof

InactiveCN101423371ASave resourcesSave materialSolid waste managementEcological environmentFilling materials

The invention relates to a plate mainly manufactured by vegetable fiber, in particular to a building plate manufactured by mixing a magnesium compound with the vegetable fiber. The invention mainly aims at the defects that large usage of wooden plate damages the ecological environment, and so on and invents a building plate which has low price and environment friendly and easily-obtained materials, and is manufactured by mixing the magnesium compound with the vegetable fiber. The plate mainly comprises aggregate, a modifying agent, a tackifying-toughing agent and filling materials. The manufacturing steps are as follows: mixing, grinding, carbonizing and homogenizing the aggregate, the modifying agent and the tackifying-toughing agent, adding water to the obtained powder and stirring to obtain pasty mixture, adding the filling material to the pasty mixture and stirring, spreading the pasty mixture on glass silk cloth, piling up multi-layers of glass silk cloth, pressing the glass silk cloth by a roller and drying and curing.

Owner:胡家森

Grain boundary corrosion method of high niobium beta titanium alloy

InactiveCN103512791AImprove production efficiencyEasy to operatePreparing sample for investigationNiobiumSilk cloth

The invention discloses a grain boundary corrosion method of a high niobium beta titanium alloy. The grain boundary corrosion method comprises the steps of cutting a metallographic specimen from the high niobium beta titanium alloy, firstly coarse grinding the metallographic specimen, and then fine grinding. The method further comprises the following steps: 1. covering a layer of real silk cloth on a side of a piece of polishing cloth for polishing, adopting the polishing cloth covered with the real silk cloth to carry out mechanical polishing to the fine ground metallographic specimen until the surface of the metallographic specimen is bright and free from scratch; 2. preparing a corrosive agent; 3. placing the mechanically polished metallographic specimen in the corrosive to soak and corrode until the corroded side of the metallographic specimen becomes silver gray; 4. taking out the soaked and corroded metallographic specimen, using water to wash away the residual corrosive agent, and then using ethyl alcohol to rinse the metallographic specimen and drying. The method is simple to operate, easy to control conditions and high in specimen preparing efficiency, can quickly, easily and effectively obtain the clear and complete crystal boundary structure, and solves the problems that the high niobium beta titanium alloy is not easy to polish and does not have a proper corrosion method.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

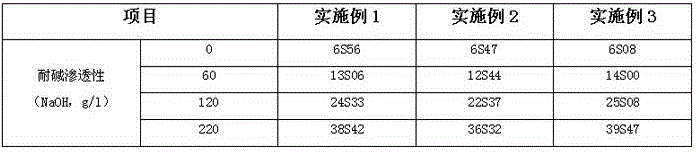

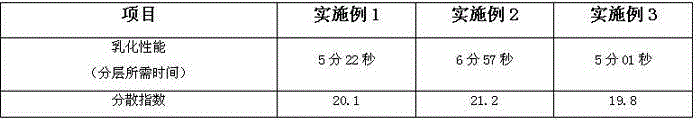

Polyester fiber cospinning textile used dispersion and direct dye alkali bath dyeing method

The invention, belonging to printing and dyeing area for silk cloth, relates to a dyestuff alkali-washing dyeing method for polyester mixed textile dispersedly and directly. Said method is that under the condition of 7<PH<9 alkali, direct and dispersal dye of alkali resistivity are use as dyeing for polyester textile. Under the lower alkali condition, polyester fibre after dyeing can avoid shortcoming of a mass of flaw generated by lixiviation of slurry, oils and other catabolite in acidic bath. It can conquer damnification of dyeing and fibre under the circumstance of high temperature, pressure and alkali. The invention can conserve energy, decrease cost and improve production efficiency.

Owner:FUJIAN CHARME TEXTILE

Microorganism reinforced method of non-strength silk

The invention discloses a strengthless silk cloth microbic reinforcing method, relating to a silk cloth cultural relic protecting method. It is a biochemical method of reinforcing silk cloth by lactobacilli and acetic acid bacilli, and its working principle: using lactobacilli to degrade keratinized substance of silk cloth into sugars and organic acids, using acetic acid bacilli to convert these metabolites into celluloses, thus achieving the purpose of reinforcing strengthless silk cloth. By the sequential processing by lactobacilli mixed liquor, acetic acid bacilli mixed liquor, and frog or fish oil mixed liquor, its strength is greater than 50g / sq m, bending angle is 180 degrees, the gloss is increased by 3-5 degrees, and the percent of water-soluble lost articles is 1%.

Owner:湖北省博物馆

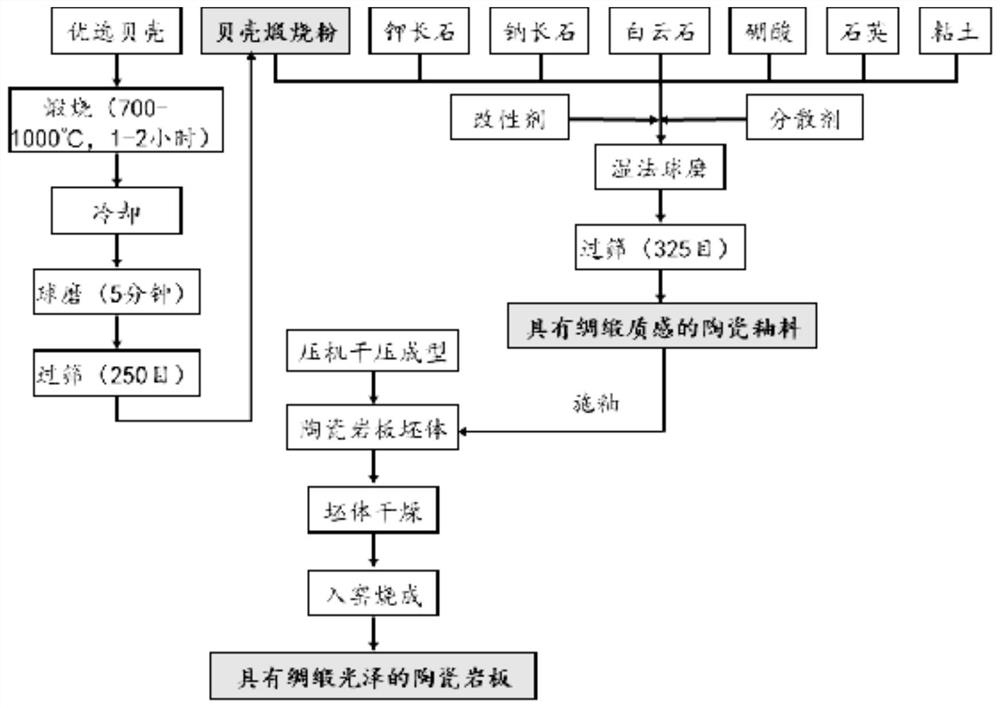

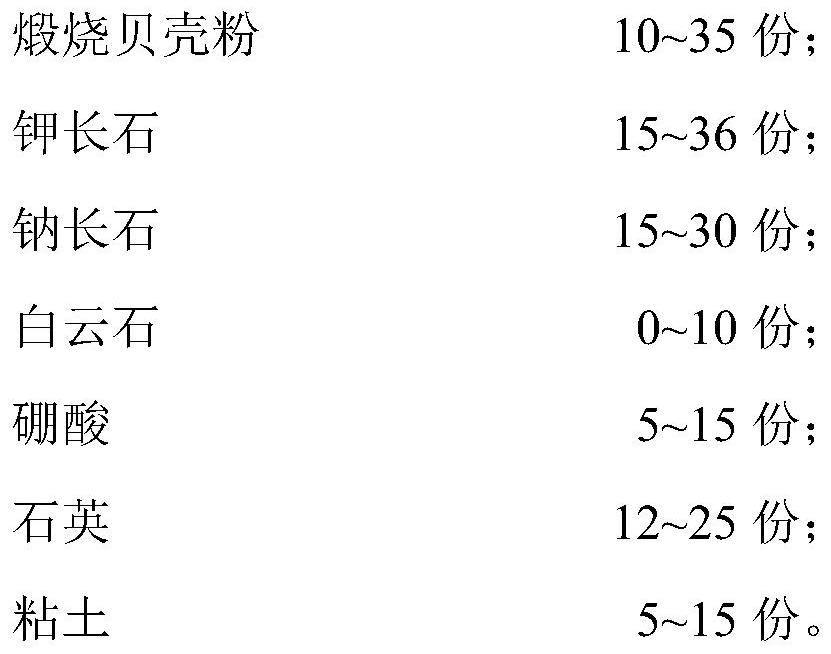

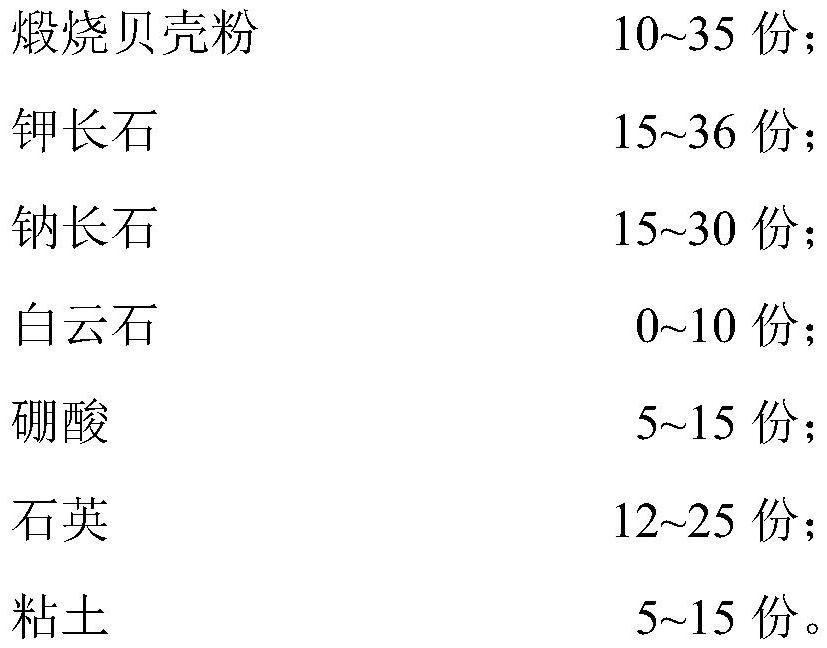

Silk- and satin-texture ceramic glaze, preparation method and ceramic rock plate using silk- and satin-texture ceramic glaze

ActiveCN111943723AExcellent overall performance of the glazeReduce manufacturing costFritPotassium feldspar

The invention discloses a silk- and satin-texture ceramic glaze which comprises the following components in parts by weight: 10-35 parts of calcined shell powder, 15-36 parts of potassium feldspar, 15-30 parts of albite, 0-10 parts of dolomite, 5-15 parts of boric acid, 12-25 parts of quartz and 5-15 parts of clay. According to the ceramic glaze disclosed by the invention, CaO is introduced by taking the calcined shell powder containing a large amount of nepheline crystal forms as a raw material, so that the ceramic glaze has the decorative effects of silk-like luster and texture and the advantage of excellent comprehensive performance of a glaze surface after sintering molding on the premise that a frit glaze raw material with a narrow sintering range is not required to be added; meanwhile, the production cost is low, the firing range is wide, and the glaze is particularly suitable for surface decoration of ceramic rock plates. The invention further discloses a ceramic rock plate withthe silk and satin texture on the surface, and the problems that an existing ceramic rock plate product is poor in surface decoration effect, and an existing ceramic brick with the silk glaze effectis narrow in firing range and high in production cost are solved.

Owner:FOSHAN OCEANO CERAMICS

Dyeing method for copper ammonia fiber and cotton, cotton brocade core-spun yarn interwoven cloth

ActiveCN101082183AIncrease elasticityFeel goodLiquid/gas/vapor open-width material treatmentBiochemical fibre treatmentYarnCuprammonium rayon

The present invention relates to the process of dyeing interwoven fabric of cuperammonium fiber and cotton / cotton-Jinlun covering yarn. The dyeing process includes the following steps: water washing, refining, leaching, cellulose water washing, and dyeing. Thus dyed interwoven fabric has the style similar to silk fabric, good hydroscopic and permeating performance, high elasticity, and other advantages, and is fashionable.

Owner:WUJIANG DEYI FASHIONS CLOTHS

Silk cold rolling and piling method

InactiveCN1928186AIncrease profitImprove flatnessLiquid/gas/vapor textile treatmentLacquerRoom temperature

The invention relates to a method of silk dyeing by uniform dye through a series of process such as dipping and rolling staining solution, wrapping and so on in room-temperature. It is the technical matters which should be solved that provided dyeing methods should be provided with less consumption of steam and water, widely reducing the quantity of dyeing assistant, high utilization ratio for dye and so on. It is the technical scheme that the dyeing methods by cold rolling silk cloth, contains preparing staining solution, delivering staining solution, dipping and rolling staining solution and post process next step. Said silk textile should be refined before delivered into extracting equipment. Reactive color and soft water are applied in said staining solution. Said assistant fluid contains permeate agent, lacquer solvent, fixation accelerator and alkaline agent, the other is soft water. Said silk cloth is real silk fabric and a mixed plus material of silk, cotton, thin silk and so on.

Owner:ZHEJIANG SCI-TECH UNIV

Nano self cleaning silk broadcloth and products

ActiveCN1277019CWith self-cleaning functionIncreased durabilityFibre treatmentChlorideSolid particle

This is a self-clean real silk cloth and its productive method. It features are: To treat the real silk cloth with the organic fluorine regulator it is nano-grade inorganic solid grain, use to soak, to coat or to spray on them, to make their surface have water-distant and oil-distant function. The organic fluorine regulator contains: the organic fluorine resin 10-70g / L, nano-grade inorganic solid grain water 5-30g / L. In the advanced organic fluorine regulator also contain the silicon alkanet, magnesium chloride, or isopropyl alcohol at least one of above compositions.

Owner:韦钧千

High count single yarn double-sided mercerized fabric and processing method thereof

InactiveCN102926114AHigh strengthImprove dye uptakeMercerising of indefinite length fabricsWeft knittingYarnSilk cloth

The invention discloses a high count single yarn double-sided mercerized fabric and a processing method of the high count single yarn double-sided mercerized fabric, and belongs to the field of textile fabric processing. The technical scheme of the high count single yarn double-sided mercerized fabric and the processing method the high count single yarn double-sided mercerized fabric comprises special spinning, yarn processing, double-sized fabric weaving and fabric after-treatment. The special spinning means that a high-strength high-count yarn is manufactured by the adoption of special cotton collocation and the implementation of strong twisting on the special cotton collocation and the yarn processing. The double-sided fabric weaving means that the double-sided fabric is woven by a double-sided machine with high stitch length of 40 stitches or more than 40 stitches. The fabric after-treatment means that a finished production fabric is manufactured by singeing, mercerizing and sizing of the fabric. The high count single yarn double-sided mercerized fabric and the processing method of the high count single yarn double-sided mercerized fabric is characterized in that high-strength high-count yarns manufactured by adopting the special spinning method, and weaving requirement of high stitch distance double-sided machine strength is met. The high count single yarn double-sided mercerized fabric and the processing method of the high count single yarn double-sided mercerized fabric produce high-quality high count single yarn double-sided fabrics, and the fabrics are light and elegant, and comfortable, and have a silky and smooth touch, and the luster of the fabrics is soft and bright, and the fabrics are the best in double-sided fabrics.

Owner:WUXI NATURAL GREEN FIBER TECH

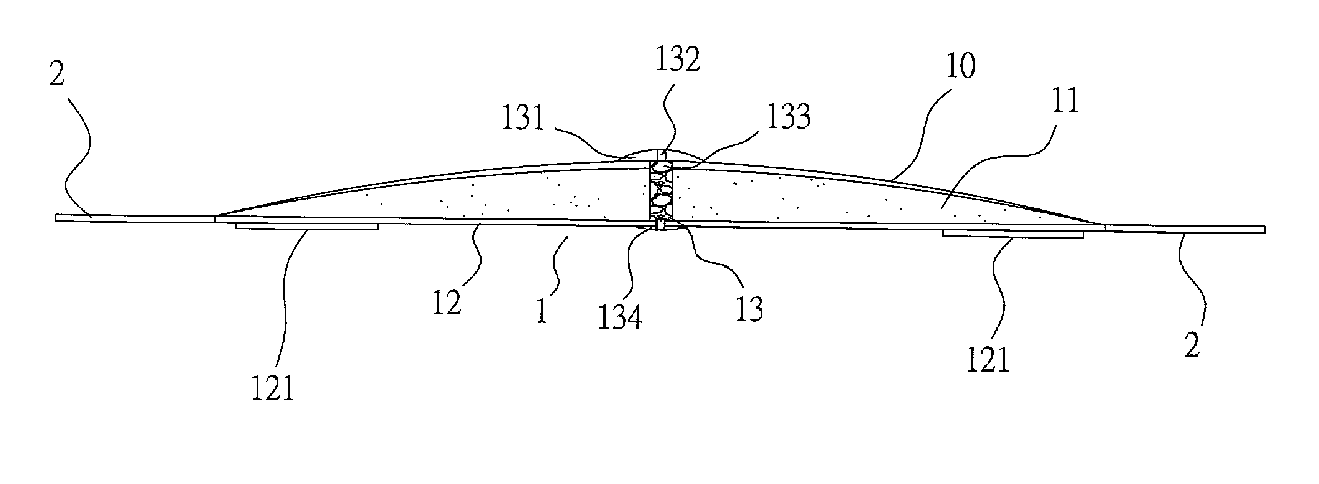

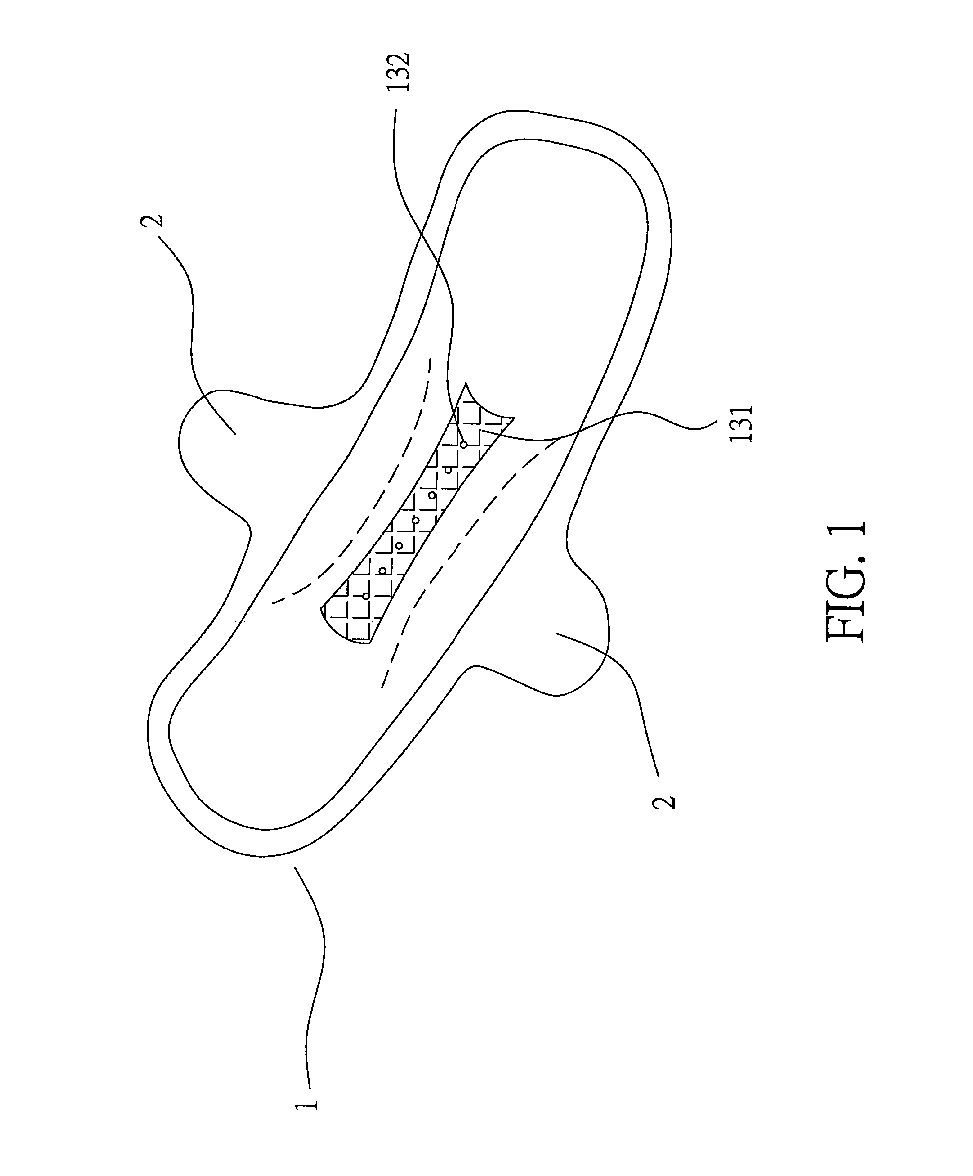

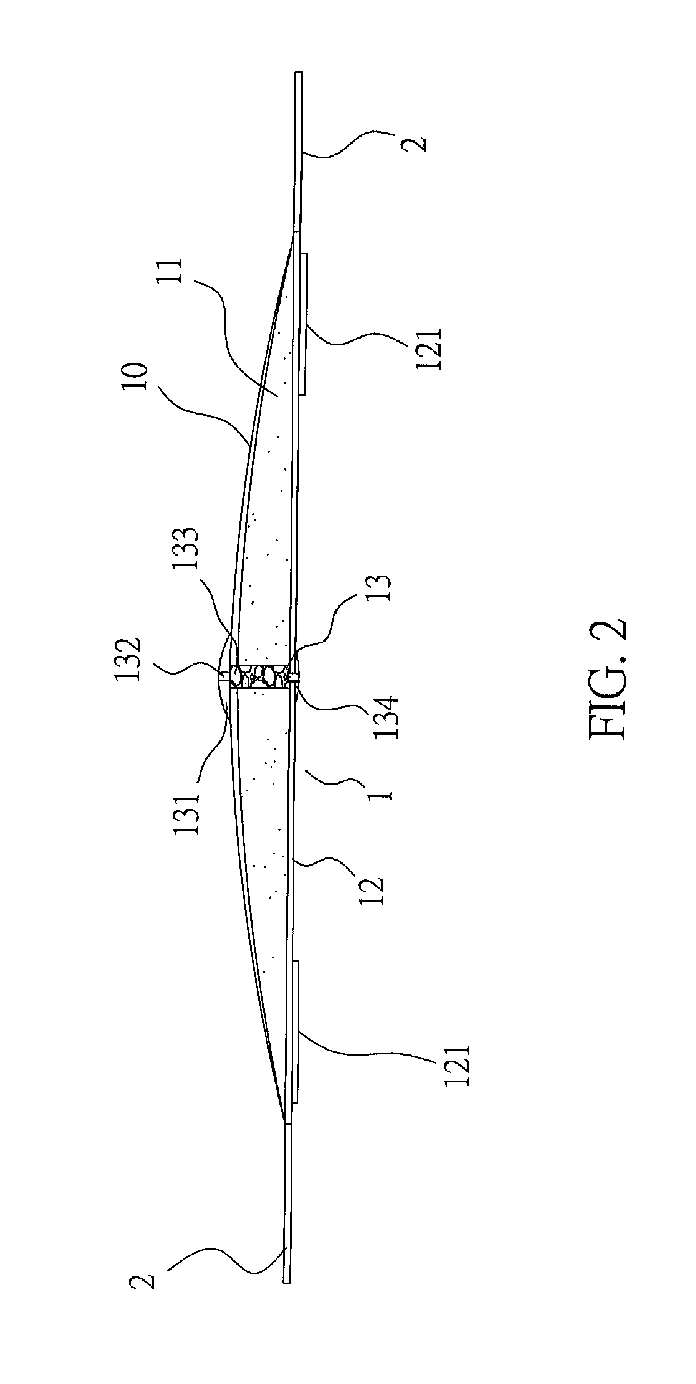

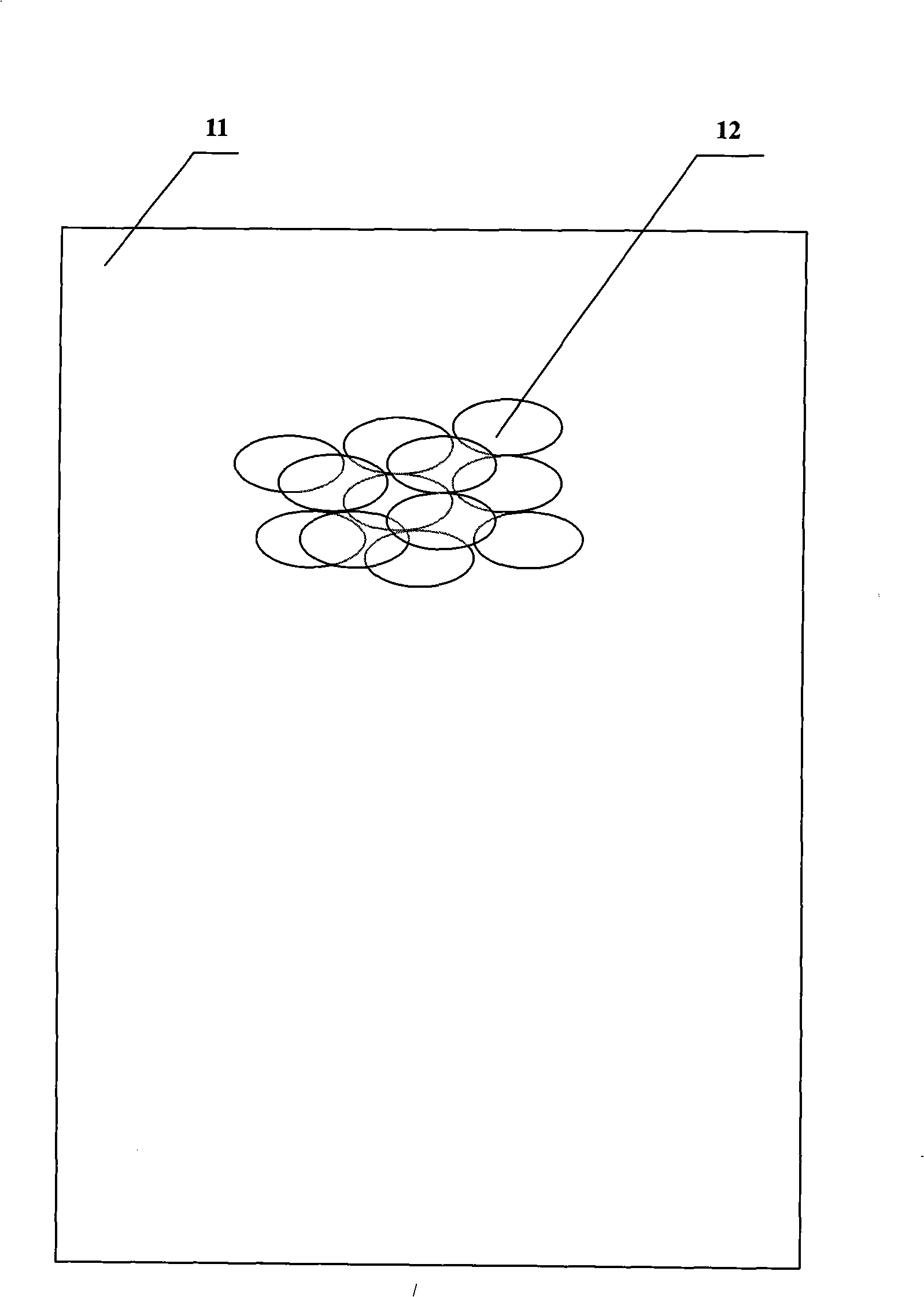

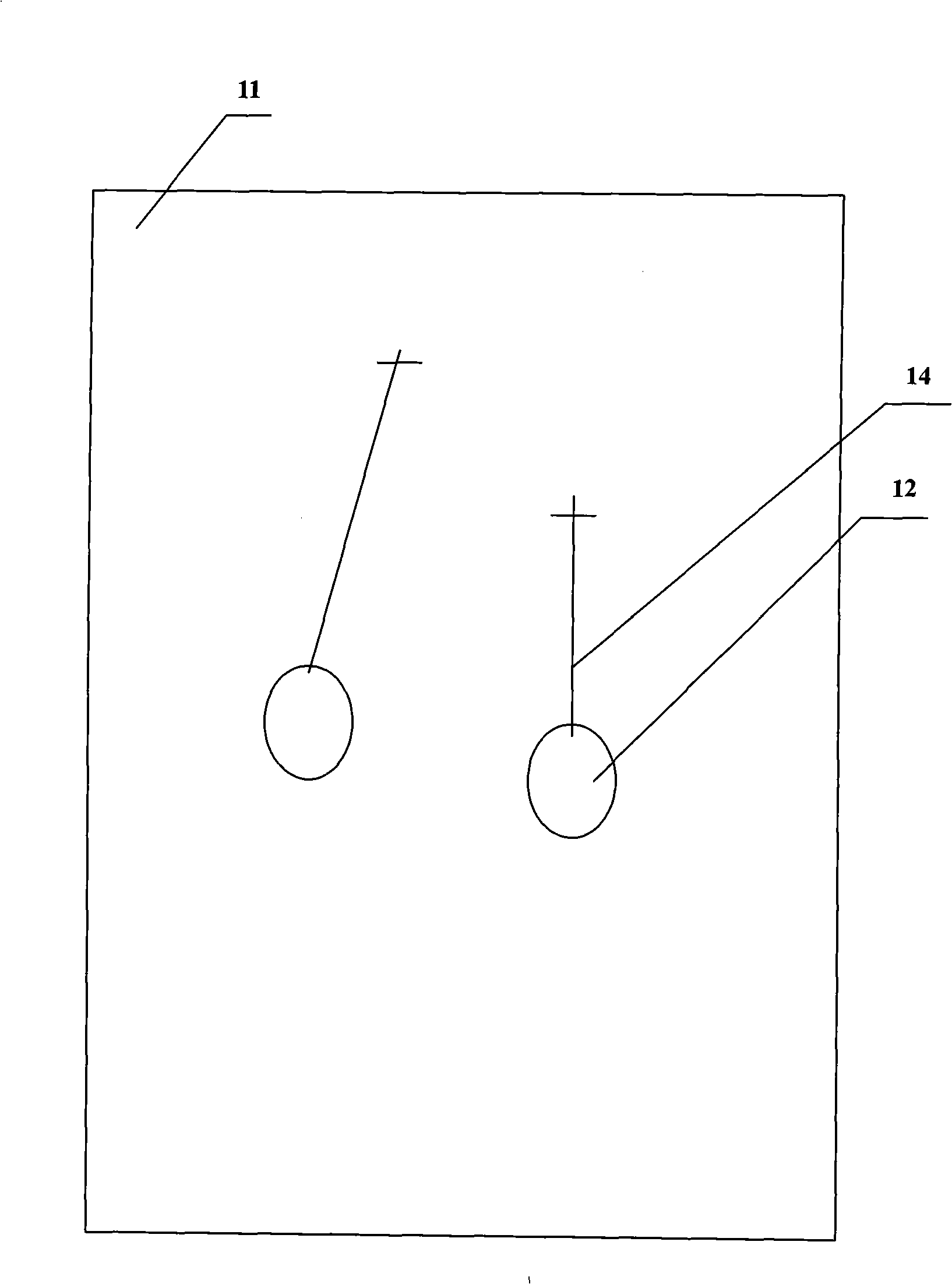

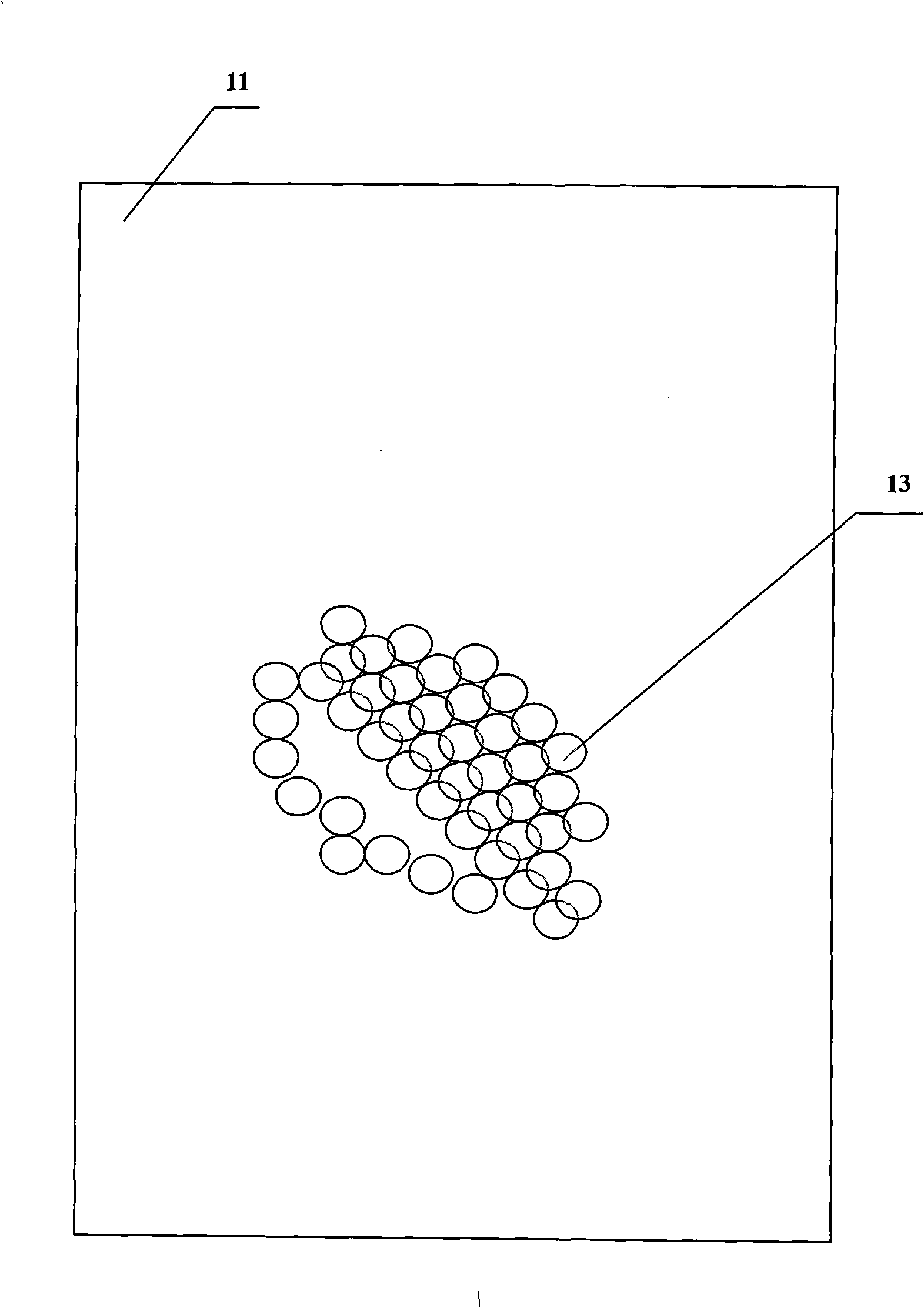

Fabric planted with silkworm cocoon or silkworm cocoon slice

InactiveCN101408005AStrong ornamentalPracticalDecorative surface effectsSpecial ornamental structuresWaddingEngineering

The invention relates to a fabric implanted with silk cocoons or silk cocoon sheets, wherein, at least one layer of underlayer fabric 11 is implanted with the silk cocoons 12 or the silk cocoon sheets 13. The silk cocoons 12 are the natural silk cocoons 12 or the silk cocoons 12 treated with functional processing, and the silk cocoon sheets 13 are formed by that the natural silk cocoons 12 are divided into two pieces or more than two pieces of geometric form platelets. The silk cocoons 12 or the silk cocoon sheets 13 implanted on the underlayer fabric 11 are arranged in the form of a pattern, or loosely and randomly distributed, or tiled, or laminated by a plurality of layers. The silk cocoons 12 treated with functional processing are formed by that the interiors of the silk cocoons 12 are filled with fillers mixed with antibacterial or anthelminthic or fragrant microcapsule finishing agents, or the surfaces of the silk cocoons 12 or the silk cocoon sheets 13 are drawn or sprayed with multicolor superfine snowflake grain shape patterns formed by microcapsule dye liquid droplets internally containing a plurality of colors and auxiliary agents. The fabric of the invention is completely different from the current classical method which obtains raw silks from the silk cocoons by silk reeling so as to weave silk cloth, and directly implant the silk cocoons on the underlayer fabric to lead the fabric to have new and unique visual effect, thus meeting the trends of individuation, fashion-orientation and innovation and variety seeking of the fabrics.

Owner:袁近

Silk based implantable medical devices and methods for determining suitability for use in humans

InactiveUS20130253646A1Increasing the thicknessMaintain strengthMammary implantsWarp knittingTissue repairMedical device

Methods for determining suitability of an implantable silk scaffold for use in human soft tissue repair by implanting a silk scaffold in a quadruped. The silk scaffold is completely or essentially completely bioresorbed by twelve months after implantation, the silk scaffold (to the extent remaining) with ingrown tissue shows at least about a 60% strength increase by 12 months after implantation, and the thickness of the silk scaffold (to the extent remaining) with ingrown tissue increases by more than 100% by 12 months after implantation.

Owner:ALLERGAN INC

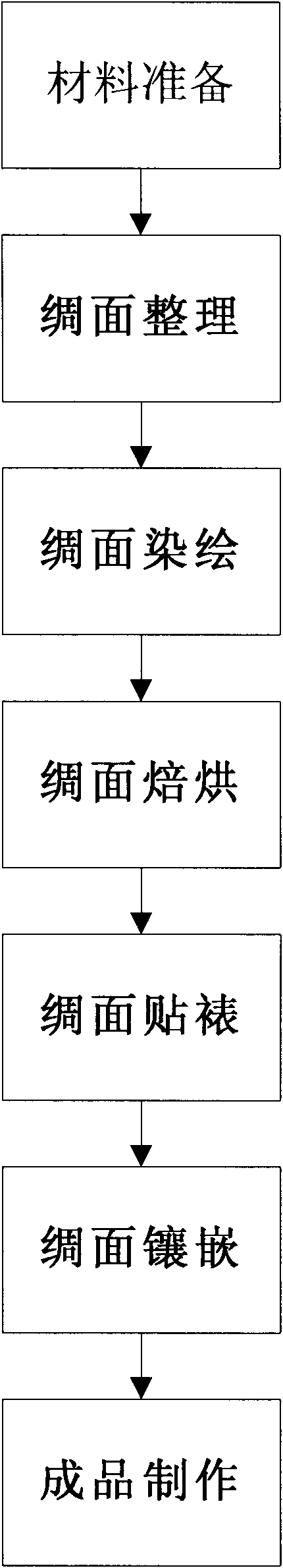

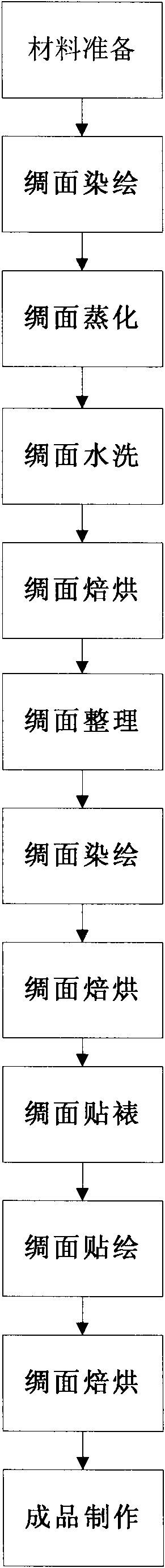

Silk polished lacquer painting and preparation method thereof

InactiveCN102085773AReduce manufacturing costBroad prospects for market development and applicationSpecial artistic techniquesArtistic surface treatmentPolymer scienceLacquer

The invention discloses a silk polished lacquer painting and a preparation method thereof. The silk polished lacquer painting is prepared by the following steps: (1) firstly dyeing, drawing, inlaying, embedding, pasting and etching on a silk surface with polished lacquer painting materials or carrying out digital jet-printing on the silk surface to form an initial product; (2) fixing and drying the initial product on the silk surface and then adjusting a picture; and (3) carrying out lacquering, polishing and refining on the dried initial product to obtain the required silk polished lacquer painting finished product. By preparing the silk polished lacquer painting in the invention, the range of used materials of the polished lacquer painting is expanded, the manufacturing period of the product can be reduced, and the silk polished lacquer preparation and industrialization production in inlaying, embedding, pasting and carving materials are realized.

Owner:SUZHOU UNIV

Static flashing-lamp handbell

ActiveCN105561590AAchieve matching sound and light effectsMatch sound and light effectsMusical toysRoundaboutsEngineeringSilk cloth

The invention relates to a static flashing-lamp handbell. The static flashing-lamp handbell comprises a shell and a handle, wherein induction plates are respectively parallelly mounted on the top and the bottom of the inner surface of the shell, and discharge needles are respectively mounted on the edges of the two induction plates at equal intervals; a glass screen plate and a rubber screen plate are mounted between the two induction plates; the glass screen plate and the rubber screen plate are parallel to the induction plates and have no contact with the induction plates; a friction block is clamped between the glass screen plate and the rubber screen plate, and is made of an insulating material; silk cloth and fur are adhered to the surface, contacting the glass screen plate, of the friction block. The static flashing-lamp handbell is simple in structure and safe to operate, and a harmonious sound-light effect can be generated by matching with the music, so that the atmosphere of a vocal concert can be effectively set off by contrast; meanwhile, the static flashing-lamp handbell is convenient to store and use, and thus the static flashing-lamp handbell has a relatively high promotion value.

Owner:嘉兴磊佳电子科技有限公司

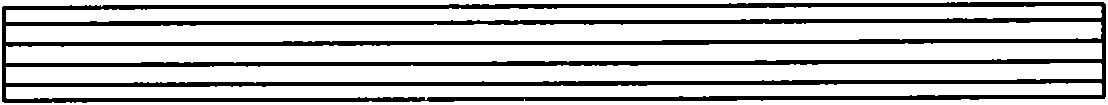

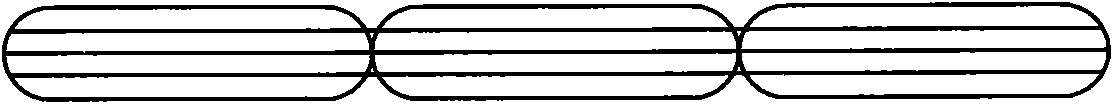

Vortex spinning compound core spun yarn and production method thereof

PendingCN107881615AImprove conductivityLow resistivityContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The invention discloses a vortex spinning compound core spun yarn and a production method thereof. The core spun yarn comprises a yarn body, wherein the yarn body comprises a yarn core and a claddinglayer; the yarn core comprises metal filaments arranged in parallel with one another; the cladding layer is spirally wound and coated on the outer part of the yarn core, and comprises wrapping fibersand parallel twist-free core fibers; the parallel twist-free core fibers are positioned on the inner sides of the wrapping fibers; and the wrapping fibers and the parallel twist-free core fibers are prepared by mixing tencel and superfine denier modals. The vortex spinning compound core spun yarn disclosed by the invention is simple in production process, the manufactured compound core spun yarn has the characteristics of being excellent in conductive effect, low in electrical resistivity, high in tensile strength and difficult to break, and the tencel is capable of improving smoothness and gloss of the yarns, so that the metal filament surface is difficult to wear, and the made fabric has a silk texture. The fine denier modal is capable of increasing the softness and excellent close-fitting service performance of the fabric, and the tencel and the fine denier modal can achieve an excellent insulation effect.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

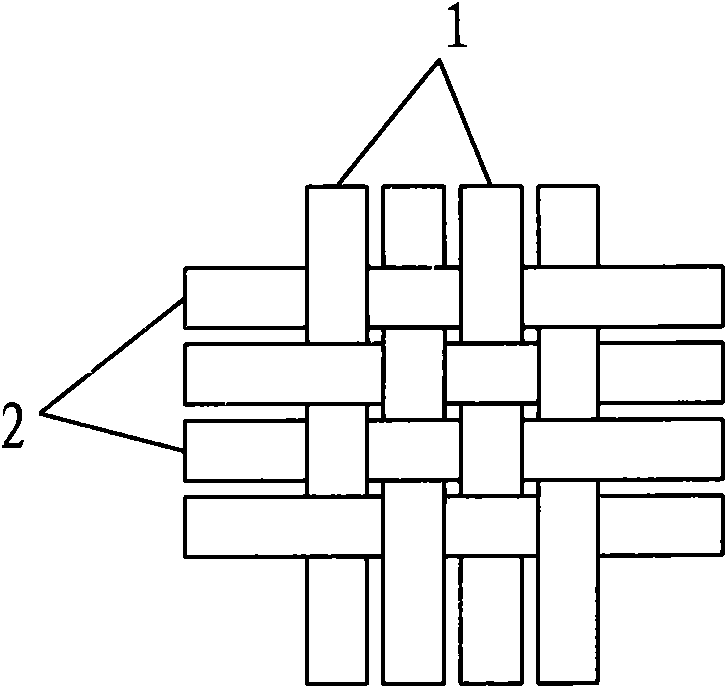

Compound silk-cloth fabric

The invention provides a compound silk-cloth fabric, which is interwoven by warp yarns and weft yarns and adopts a plain weave structure. The warp yarn is a 50D / 25F fully stretched cotton composite filament of which the glossiness is semi-dull, the warp yarn is fiber splitting typed, and each warp yarn totally comprises 400 fine fibers after the fiber splitting. The weft yarn is a 75D / 144F fully stretched terylene filament of which the glossiness is full dull. The warp wise density of the fabric is the combination of different fibers, so that the surface of the cloth is touched slippery and smooth, and the surface of the fabric also shows a reminiscent style, and can embody a feeling of modern people to seek leisure, health and sports. The fabric has wide application range, and in particular, the fabric is suitably used for producing jackets, dust coats and sportswear to show unique styles of the products; and when a user wears the clothes produced by the fabric, the clothes can make the user more modern and beautiful, and can also add fashionable charm to the user.

Owner:XIANGXING INDAL TEXTILE FINISHING SUZHOU

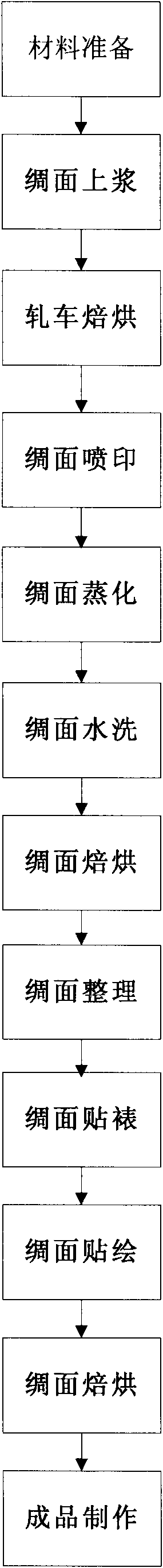

Digital printing non-slurry preprocessing method for silk cloth

InactiveCN103184696AClear outlineHierarchical three-dimensional lifelikeDyeing processParaffin waxConcentration ratio

The invention relates to a digital printing non-slurry preprocessing method for silk cloth. The method comprises a padding step, a drying step, a jet printing step, an ageing step, a washing step and a drying step, wherein padding liquid configured in the padding step comprises 0.2-1 g / l of softener, 0.2-1 g / l of water repellent, 20-40 g / l of sodium chloride and water; the solution concentration ratio of the softener to the water repellent is 1 to 1; the padding liquid is prepared by the steps as follows: adding the water, the softener and the water repellent, uniformly stirring, and adding sodium chloride; the softener belongs to a mixture of a cationic softener or cations and a nonionic softener, and comprises a quaternary ammonium salt softener, fatty acid ester softener and a paraffin wax softener; and the water repellent belongs to a weak cation water repellent and is a perfluoroalkyl polyacrylic copolymer. Due to the adoption of the non-slurry preprocessing process, the printed product is excellent in fineness, the obtained color is rich and gaudy, the color light is stable, and the overall quality is improved.

Owner:浙江华泰丝绸有限公司

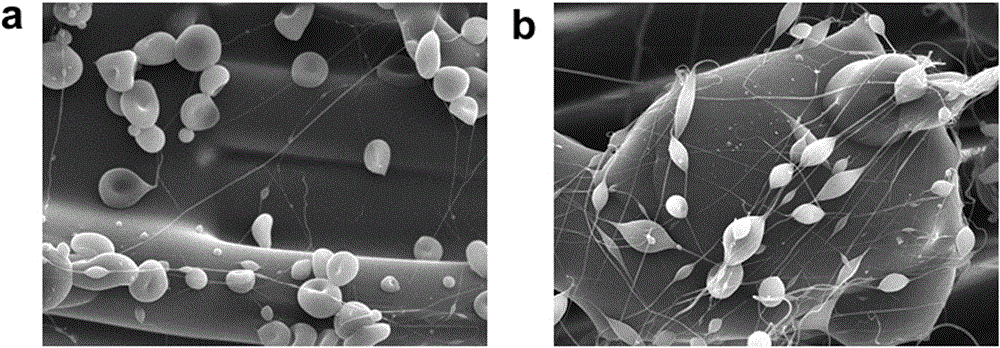

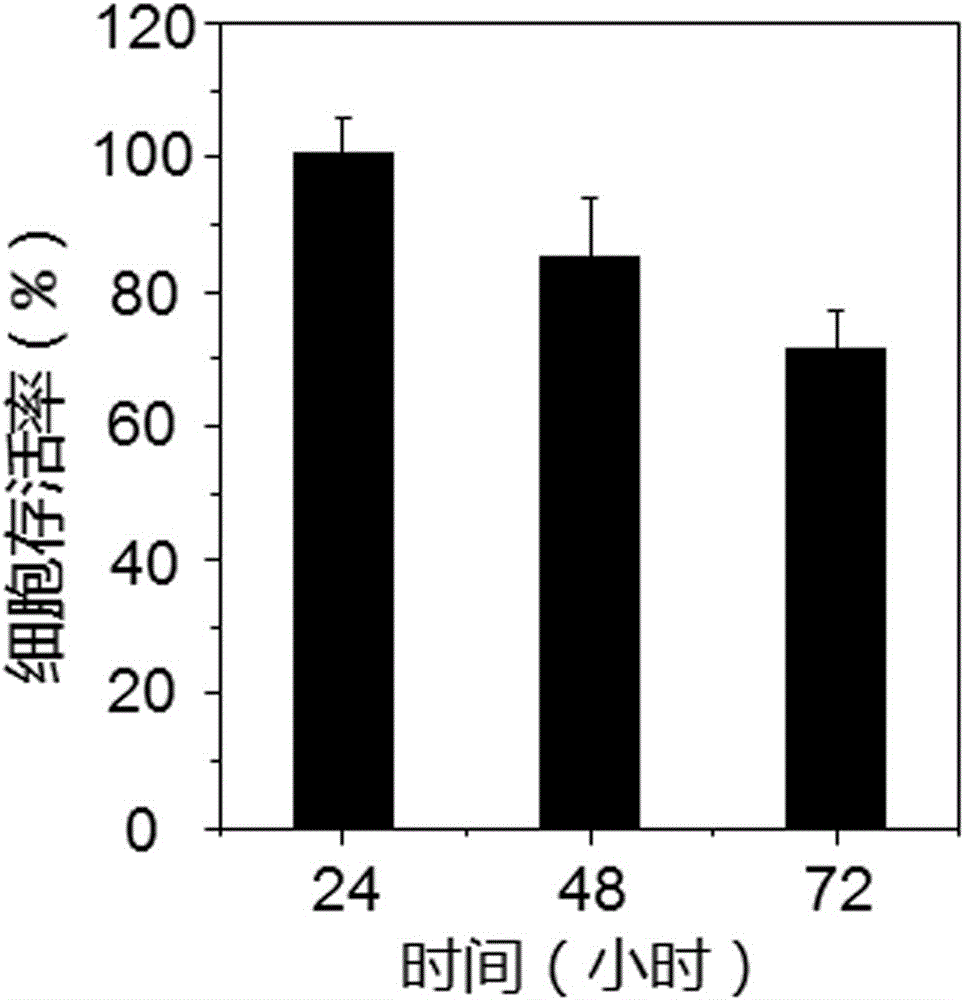

Preparation method of antitumor drug-loaded bead-like nano fibrous membrane

InactiveCN106727447AEasy to prepareMobile and flexibleOrganic active ingredientsPharmaceutical non-active ingredientsSilk clothDrug

The invention discloses a preparation method of an antitumor drug-loaded bead-like nano fibrous membrane. The nano fibrous membrane adopts a biodegradable macromolecular material as a carrier. An antitumor drug and the biodegradable macromolecular material are added into an organic solvent to obtain a spinning stock solution; and then silk cloth is used as a receiver, the spinning stock solution is spun by using a handheld electrostatic spinning instrument, the organic solvent is volatilized, and the antitumor drug-loaded bead-like nano fibrous membrane is prepared. The preparation method has the advantages that the prepared drug-loaded nano fibrous membrane has high antitumor effect, the preparation method is simple, the cost is low and the application prospect is broad.

Owner:SOUTHWEST UNIVERSITY

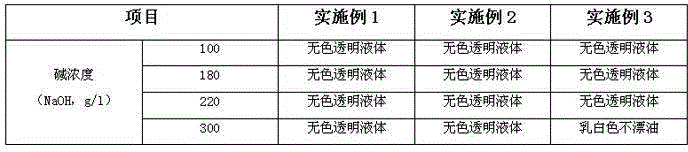

Manufacturing technique of imitation silk bleached cloth

InactiveCN103103713AEmission reductionImprove the grade of fabricFibre typesHeating/cooling textile fabricsPolyesterPolymer science

The invention discloses a manufacturing technique of an imitation silk bleached cloth. The manufacturing technique comprises the steps of pre-forming, alkali peeling, dehydrating, drying, forming and whitening, and calendering; pre-forming a grey cloth under certain tension force, at preset temperature and within set time; adding in sodium hydroxide, an oligomer remover, a scouring agent and a bath softening agent after the pre-forming at a bath ratio of 1:6 to carry out alkali peeling, carrying out water scrubbing at different temperatures, reducing the temperature to normal temperature, adding in an antistatic agent, and taking the resulting cloth out of a cylinder after water scrubbing; after being dehydrated and dried, transferring the resulting cloth to a forming and whitening process; setting whitening temperature and whitening time in a forming machine, wherein a polyester whitening agent, an antistatic agent and a softening agent is used as whitening liquid; and setting calendering temperature, calendering speed, and calendering pressure in a calendering machine for calendering to obtain a finished product. The technique disclosed by the invention has the characteristics of short working procedure, low energy consumption, low pollution, consistent fabric whiteness and the like, and the produced imitation silk cloth is soft and waxy in hand feeling, natural and subdued in luster, draping and elegant in feeling, high in product grade and large in added value.

Owner:谭柏桦

Silk broadcloth grafted cation process

InactiveCN102154827AImprove dye uptakeHigh color fixing rateDyeing processAnimal fibresGraft reactionPre treatment

The invention discloses a silk broadcloth grafted cation process. The method comprises the following steps of: performing grafting reaction on the preprocessed silk broadcloth fabric and a grafting agent at the temperature of 120 DEG C for 30 minutes, wherein the concentration of the grafting agent is 160 percent owf, and the pH value of the grafting agent is 9; and rolling and drying the grafted silk broadcloth fabric, curing at the temperature of between 60 and 70 DEG C for one hour, taking out, washing and drying. The bath ratio of the silk broadcloth fabric to the grafting agent is 1 to 40. The grafting agent is 1,2,3 glycidyl trimethyl ammonium chloride. In the process, the silk is grafted and is subjected to cationic modification, so that the silk dye-uptake and fixation rate of reactive dye can be improved; and the method has the advantages of saving energy, and contributing to clean production and environmental protection, along with simplicity and high efficiency and has wide application prospect.

Owner:JIANGSU HUAJIA SILK

Negative oxygen ion energy chinlon roll and preparing method thereof

InactiveCN110565372AQuick clearEnhance metabolic functionAnimal fibresHigh concentrationHazardous substance

The invention provides a negative oxygen ion energy chinlon roll and a preparing method thereof. The negative oxygen ion energy chinlon roll is prepared from, by weight, 30-50 parts of a taxus chinensis extract liquor, 1-5 parts of rare earth terbium, 1-5 parts of rare earth ytterbium, 30-50 parts of tourmaline, 10-30 parts of titanium dioxide, 15-85 parts of emulsion, 105-135 parts of micromolecule-group water and a proper amount of silk cloth, wherein the hardness of the micromolecule-group water is 180-280, and the pH value is 7.3-8.4. The negative oxygen ion energy chinlon roll can releasehigh-concentration negative oxygen ions, and the high-concentration negative oxygen ions can quickly remove formaldehyde, haze and other hazardous substances which are all positive charges in air andfree radicals in the human body through the electric neutralization effect; meanwhile, the metabolic function of cells of the human body is promoted, ageing is delayed, lymphatic circulation is enhanced, blood circulation of the human body is promoted, and thus the negative oxygen ion energy chinlon roll is beneficial to the body health.

Owner:成都康源量子生物技术研究院

High-alkali-resistance type textile scouring agent and preparation method thereof

InactiveCN104532556AExcellent decontaminationGood hair effectFibre treatmentPolymer scienceActive agent

The invention provides a high-alkali-resistance mild-performance safe and environment-friendly textile scouring agent. The textile scouring agent is prepared from the following components in percentage by weight: 20 to 25% of alcohol alkoxylate, 15 to 25% of alkyl glycoside, 10 to 15% of ethoxy alkyl sodium sulfate, 5% of ethylene glycol monobutyl ether, 2 to 4% of organic solvents, 0.2 to 0.8% of edetic acid, 0.5 to 1.0% of defoaming agents, and 20 to 45% of water. According to the textile scouring agent, the alcohol alkoxylate with high penetration, the alkyl glycoside with a mild performance, and the ethoxy alkyl sodium sulfate which serves as an anionic surfactant are used as active matter raw materials which almost do not irritate the skin and damage cotton, hemp, silk, leather and other high-level fabrics; the formula is basically free of harmful substance residue, high in penetration, high in cleaning capacity, and outstanding in detergency capacity, and the hand feel of a processed fabric is good.

Owner:YANSHI RANHE BIOMATERIAL

High-count, high-mesh and pure-cotton weaving adhesive interlining and production method thereof

ActiveCN104544648ASolve the problem of weft shift and weft skewSolve the problem of easy seepageFibre treatmentGarmentsInterliningEngineering

The invention discloses a high-count, high-mesh and pure-cotton weaving adhesive interlining and production method thereof. The interlining comprises 80s warp and weft yarn counts; when in powder point coating, a 38-mesh engraving roller is utilized for processing the coating; the warp and weft water washing dimension change rate is -0.5 to 0.5%; the free formaldehyde and hydrolysis formaldehyde are not greater than 30mg / kg; the peeling strength of the adhesive interlining is not less than 8N. The production method comprises steps of inverting suturing a gray fabric; singeing; performing cold pad-batch pretreating; performing cold pad-batch dyeing; arranging with resin, performing powder point coating; mechanically pre-retracting; inspecting the quality and packing into boxes. The high-count, high-mesh and pure-cotton weaving adhesive interlining is high in hand feeling, small in free formaldehyde and hydrolysis formaldehyde, small in water washing dimension change rate, and suitable for silk and other high-level thin suit-dresses.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

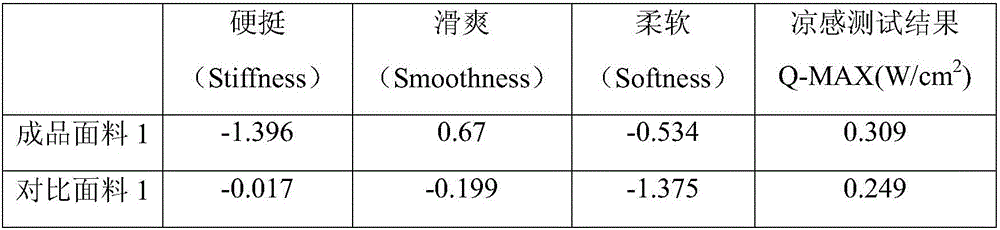

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com