Compound silk-cloth fabric

A technology of fabric and silk cloth, which is applied in the field of textiles, can solve the problems of hard hand feeling and limit the application of polyester fiber fabrics, etc., and achieve the effect of soft hand feeling, adding fashion charm, and delicate skin velvet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

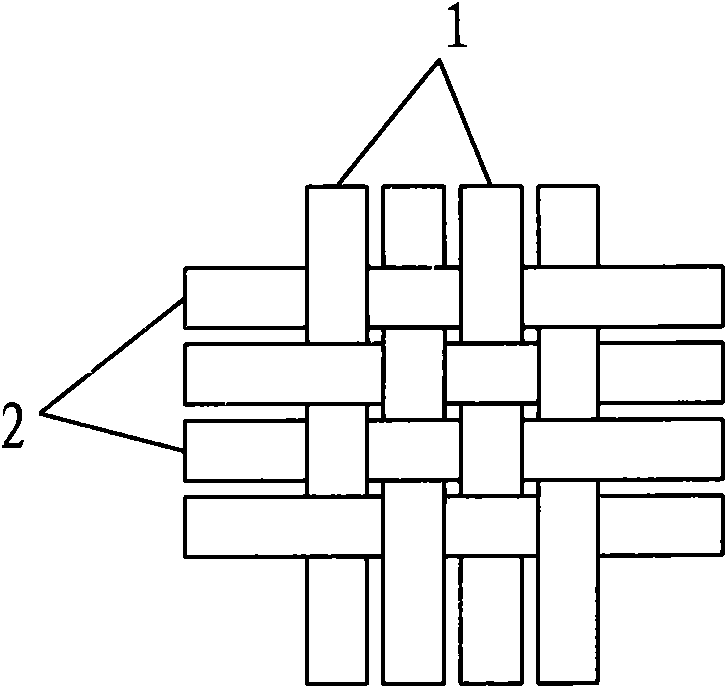

[0018] as attached figure 1 The shown composite silk cloth fabric is formed by interweaving warp yarns 1 and weft yarns 2, and the warp yarns 1 and weft yarns 2 are of a plain weave structure above and below.

[0019] Warp 1 is 50D / 25F full-stretched polyester-nylon composite filament with semi-matte gloss. Warp 1 is open fiber type, and each warp 1 has a total of 400 fine fibers after opening.

[0020] The weft yarn 2 is 75D / 144F fully drawn polyester filament, and the gloss is fully matt.

[0021] D (denier, Denier number) in 75D / 144F in the above technical scheme refers to the thickness unit of a finished yarn, which is expressed by the weight grams that can be weighed out of the finished yarn at a length of 9000 meters, also called denier. . The larger the D, the thicker the yarn. For example, 75D is thicker than 50D. F (filament, number of filaments), 75D / 144F means that a finished yarn consists of 144 spun yarns, and the total weight of a 9000-meter-long finished yar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com