Patents

Literature

142results about How to "Smooth to the touch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hair dye composition

InactiveUS20040103488A1Good effectSmooth to the touchCosmetic preparationsHair cosmeticsHair dyesAmmonia

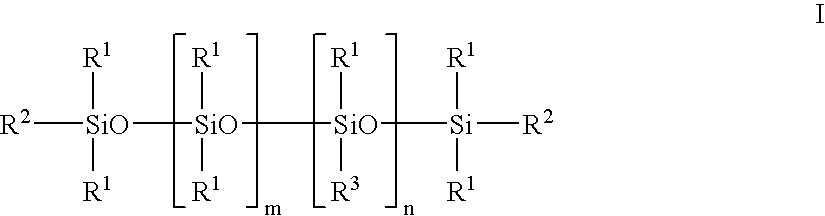

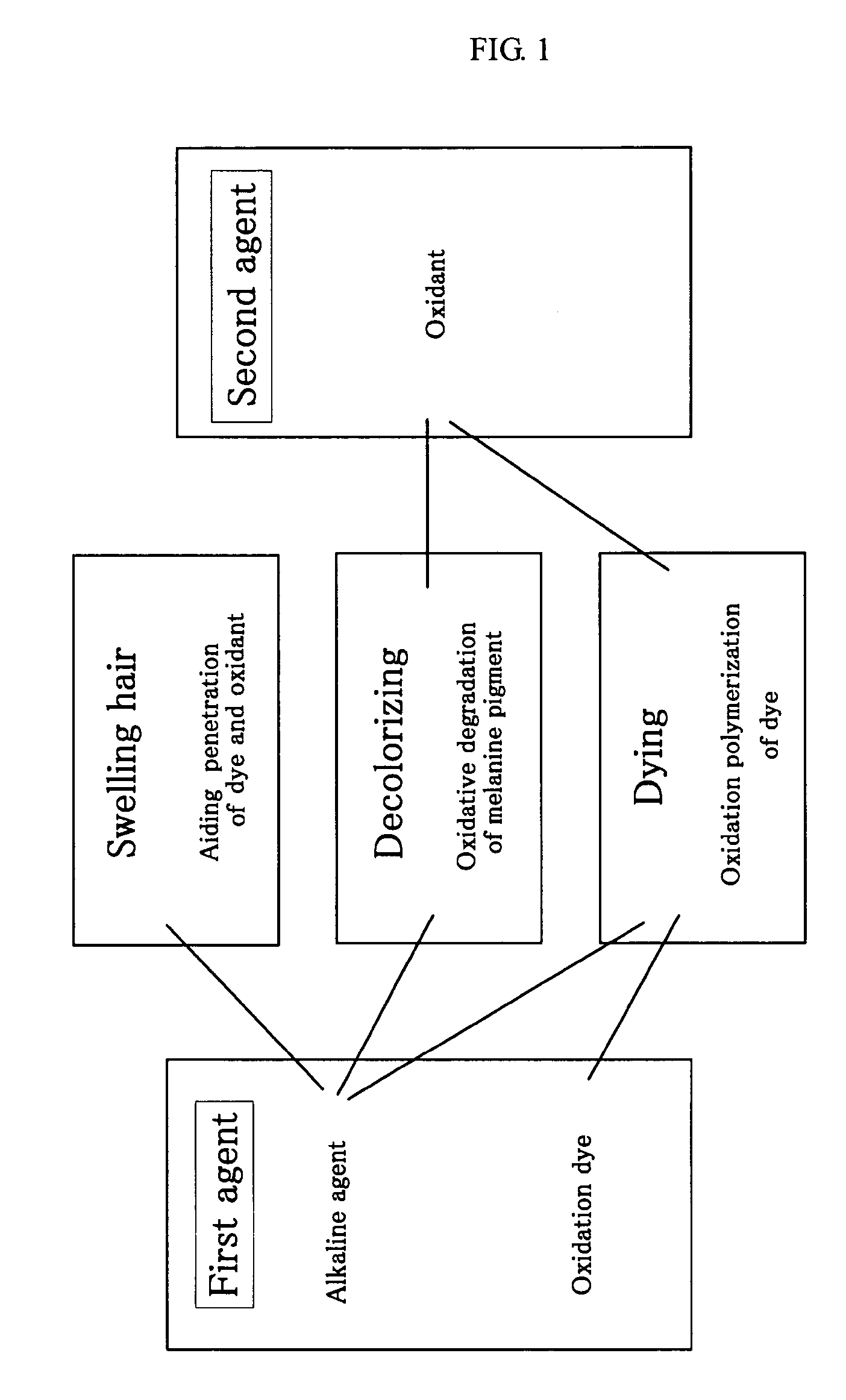

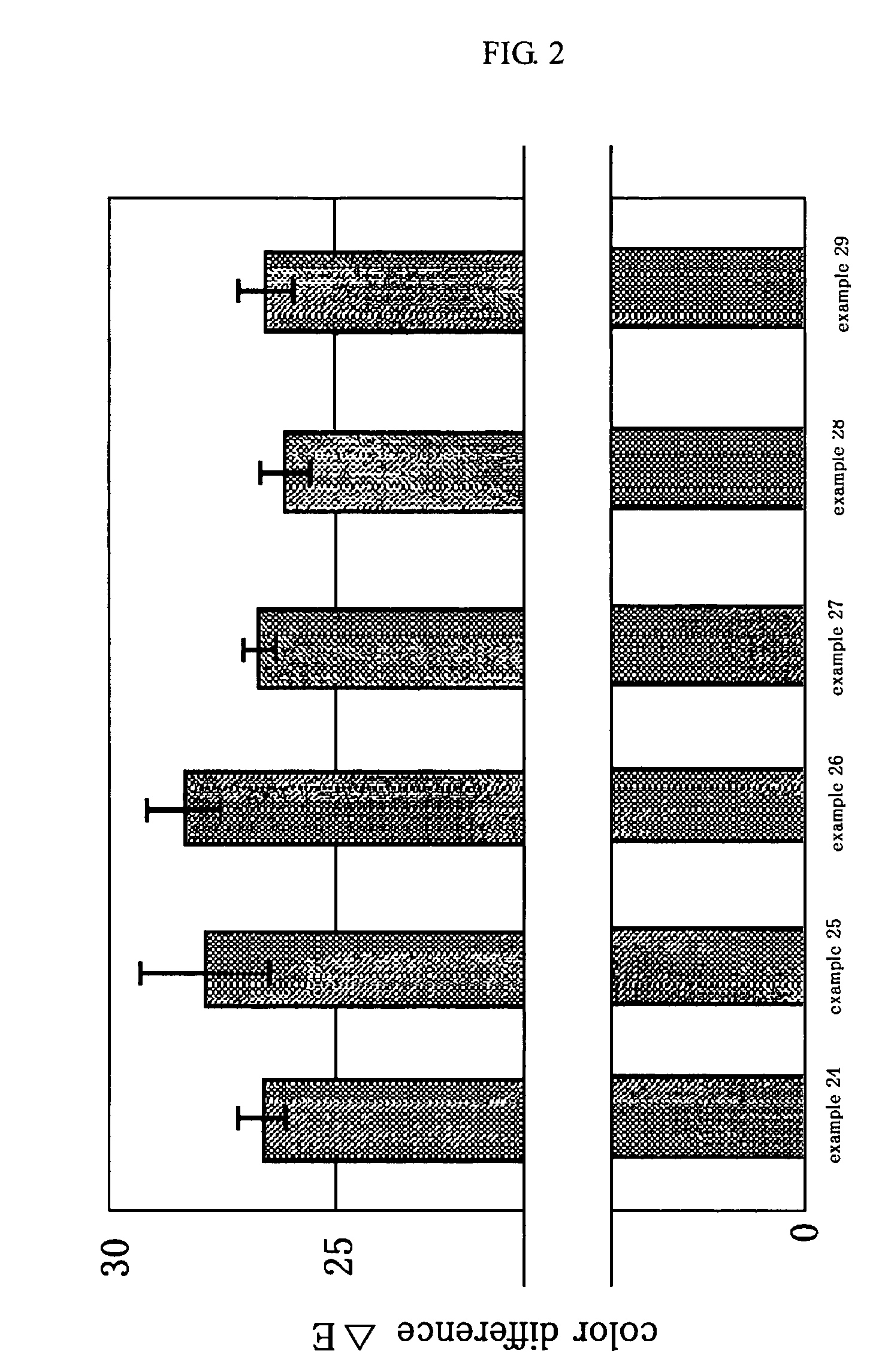

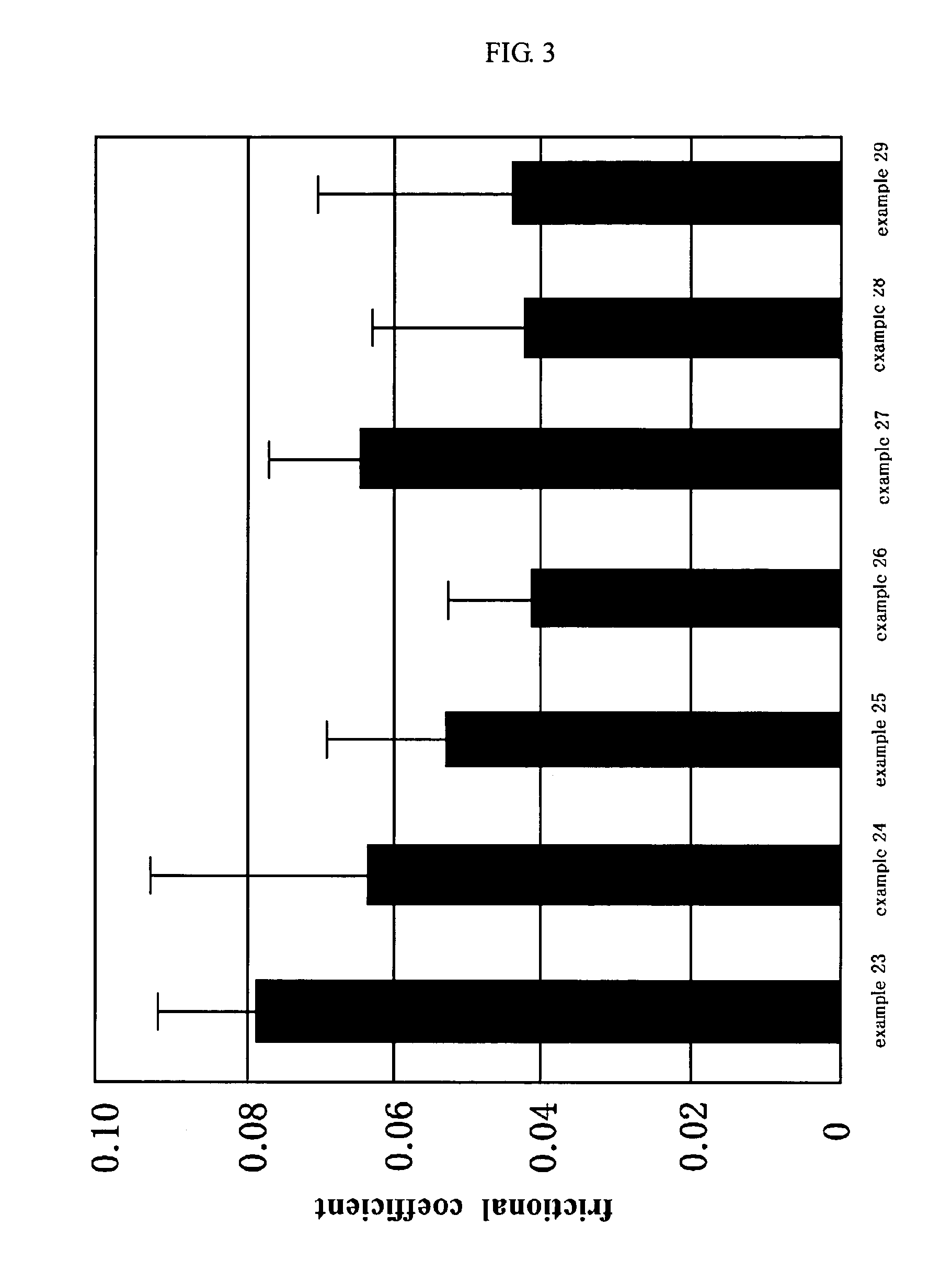

An objective of the invention is to provide a hair dye composition having sufficient decolorizing performance and dying performance without exhibiting any irritative odor, and also having an ability of imparting the hairs with an excellent smoothness. The aspect of the invention is a hair dye composition comprising: a first agent containing an alkanolamine and an oxidation dye; and, a second agent containing an oxidant, wherein a higher alcohol and a quaternary ammonium salt cationic surfactant are contained in the first agent and / or the second agent; wherein the molar ratio of the higher alcohol to the quaternary ammonium salt cationic surfactant is in the range of 3 to 15. In the composition described above, it is preferable that substantially no ammonia is contained.

Owner:SHISEIDO CO LTD

Method for realizing the intelligent tour-inspection of power tower based on miniature multi-rotor unmanned helicopter

InactiveCN102510011AGood securityEnsure safetyActuated automaticallySwitchgearDecision-makingTransmission line

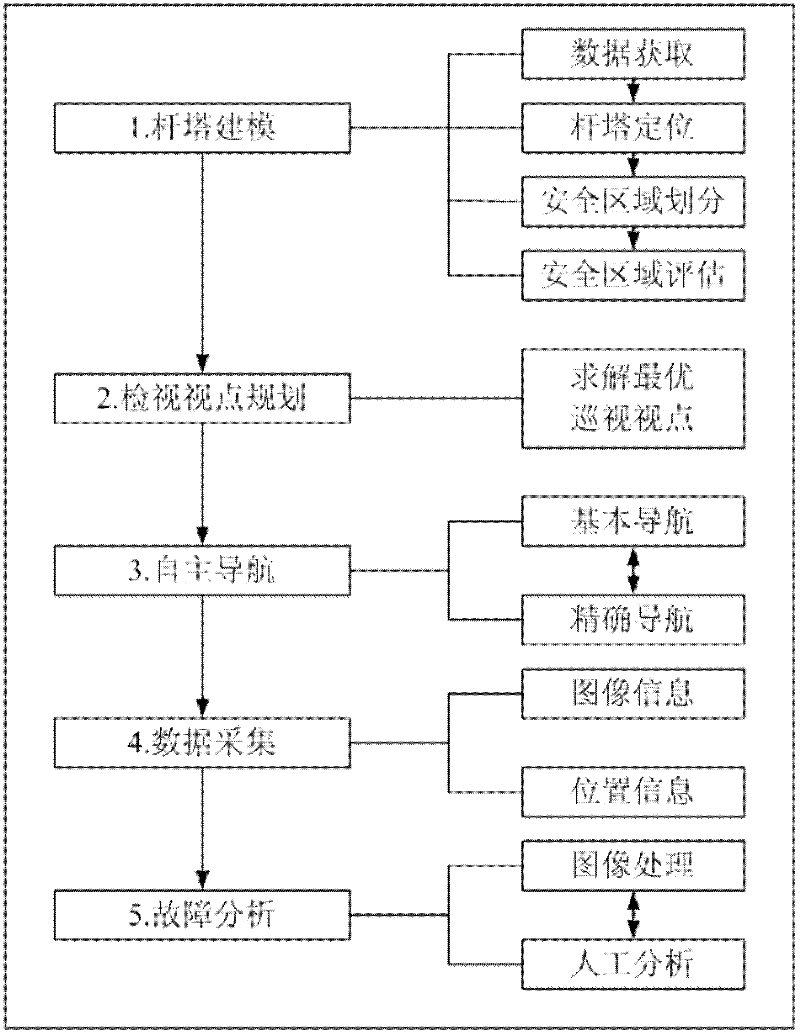

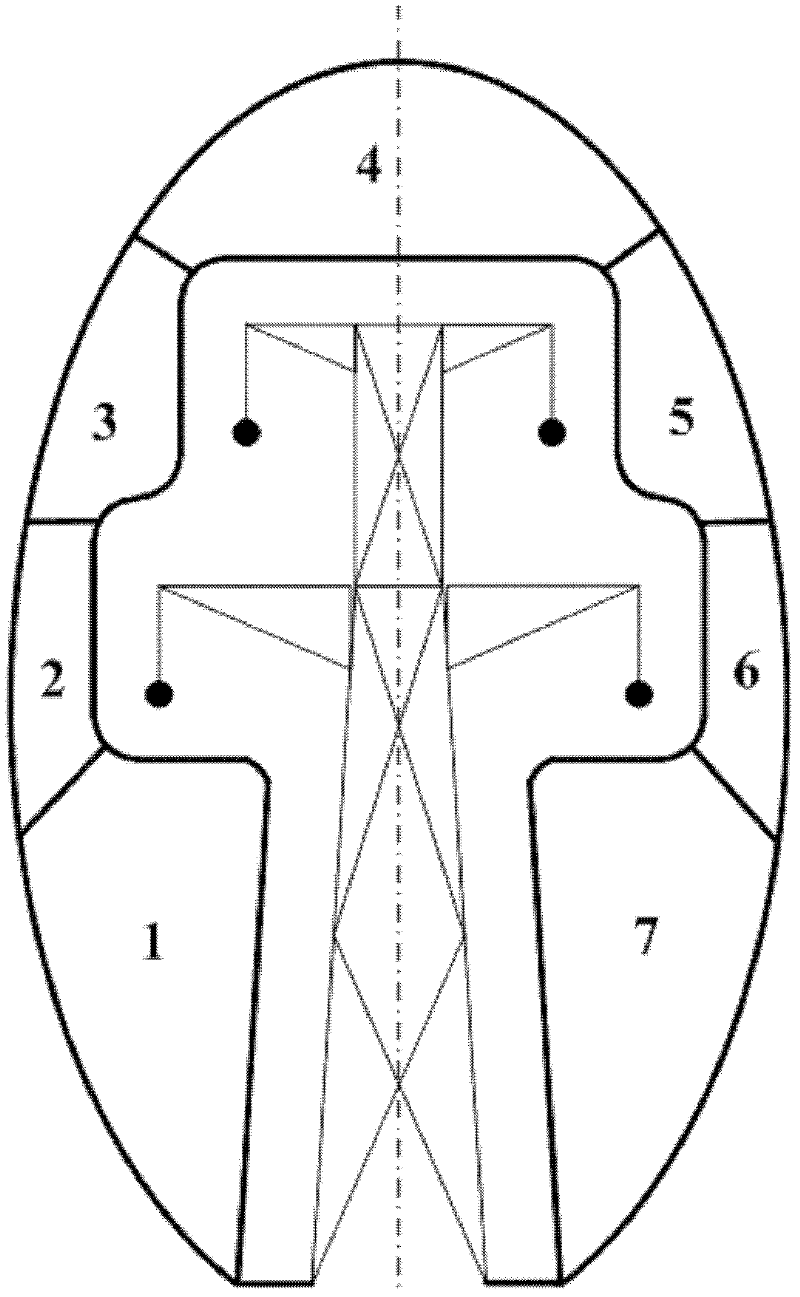

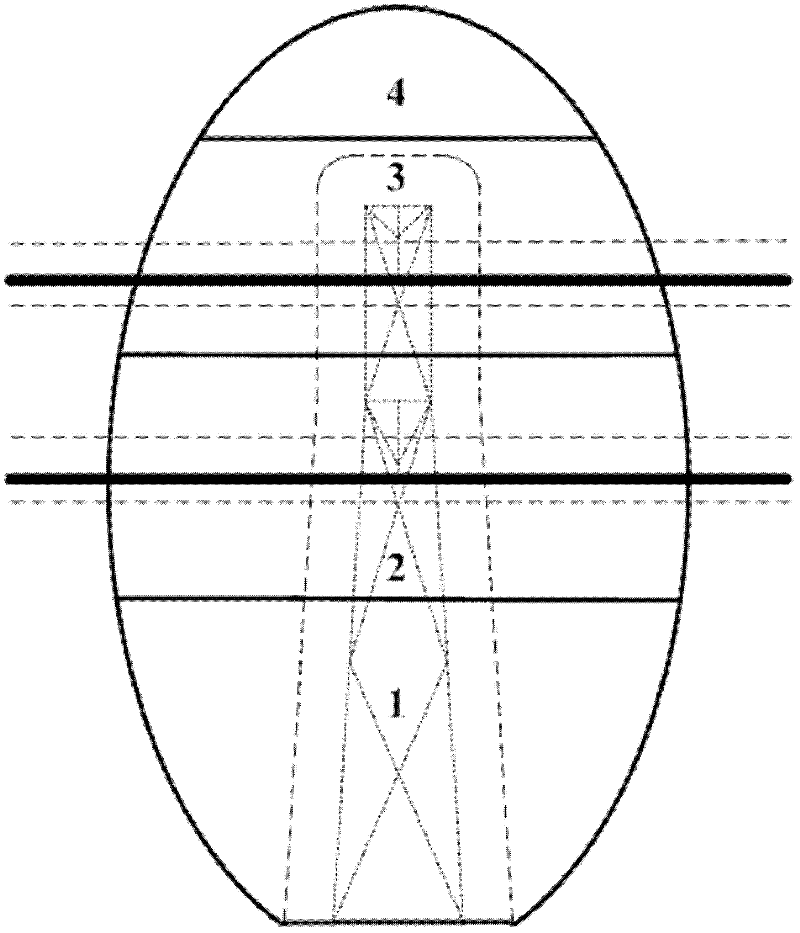

The invention discloses a method for realizing the intelligent tour-inspection of a power tower based on a miniature multi-rotor unmanned helicopter, and belongs to the technical field of tour-inspection of transmission lines. The method comprises the following steps of: tower modeling, inspection viewpoint planning, autonomous navigation, data acquisition and failure analysis, wherein the tower modeling step comprises a data acquisition process, a tower positioning process, a security zone division process and a security zone evaluation process; the inspection viewpoint planning step refers to a process of solving an optimal observation viewpoint according to related constraint conditions; the autonomous navigation step comprises a basic navigation sub-step and an accurate navigation sub-step; the data acquisition step refers to a process of transmitting related data back to a ground station by using the miniature multi-rotor unmanned helicopter; and the failure analysis step refers to a process of performing analysis, judgment and diagnosis according to the data transmitted back to the ground station by tour-inspection and decision making personnel. The method has the advantages of high safety, detection accuracy, tour-inspection efficiency and flexibility, low cost and high operability.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

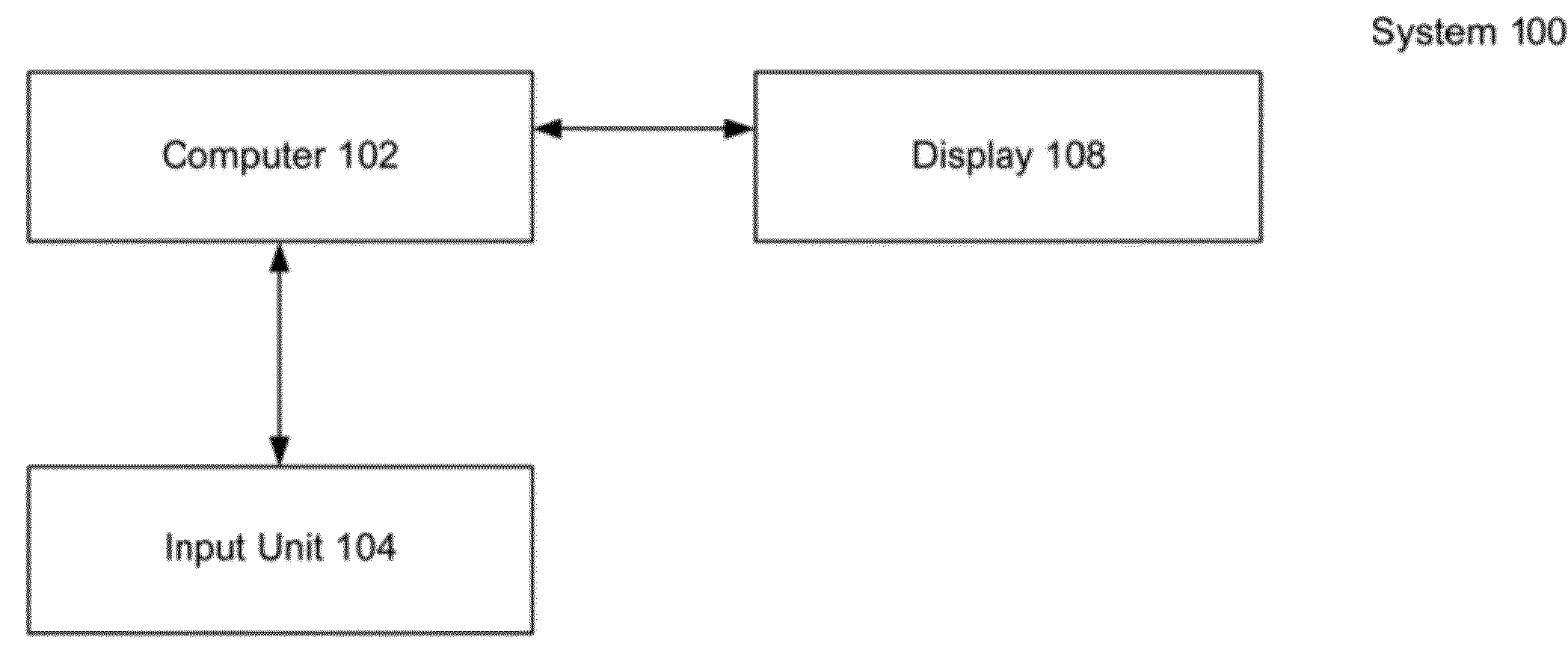

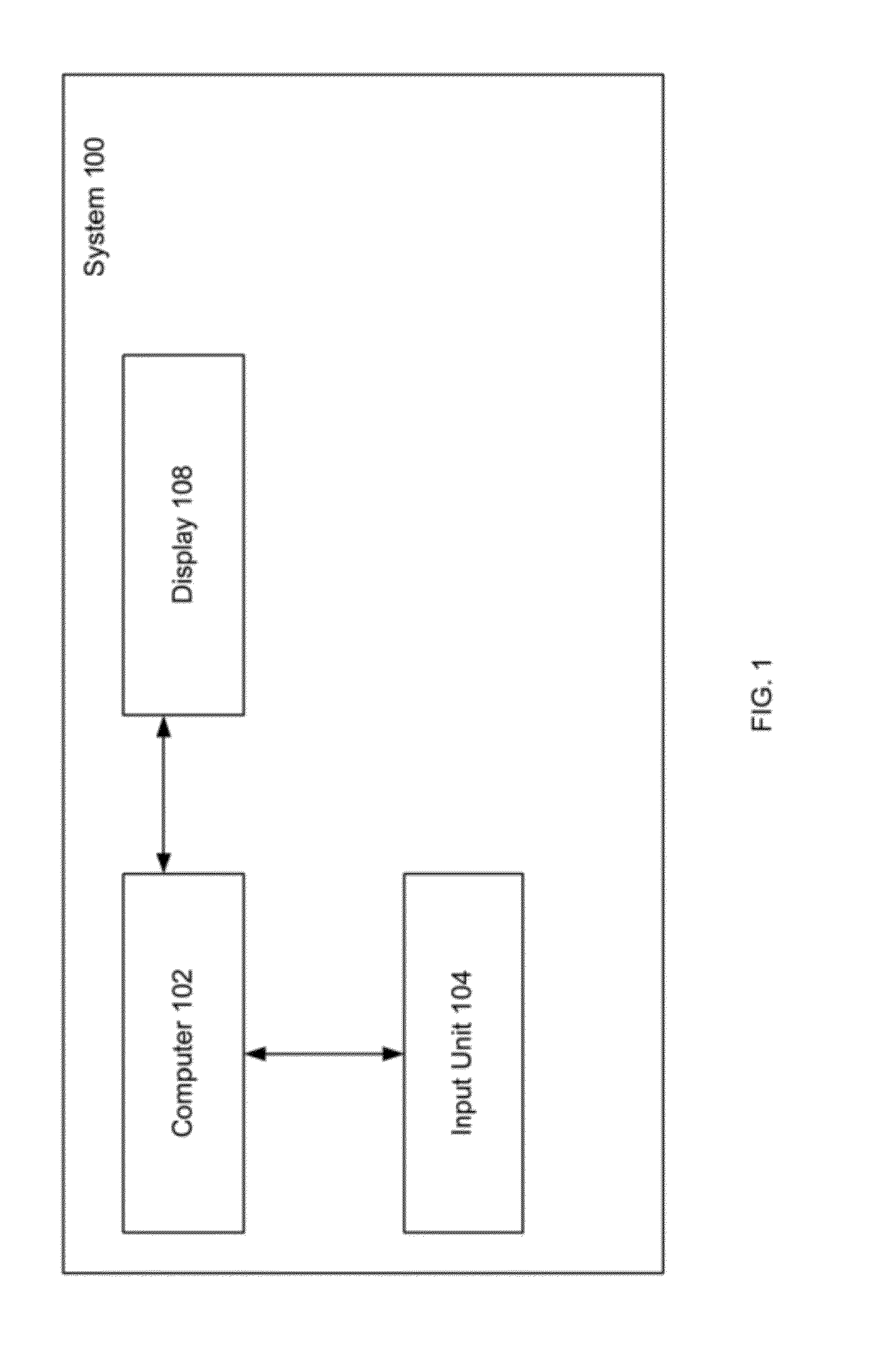

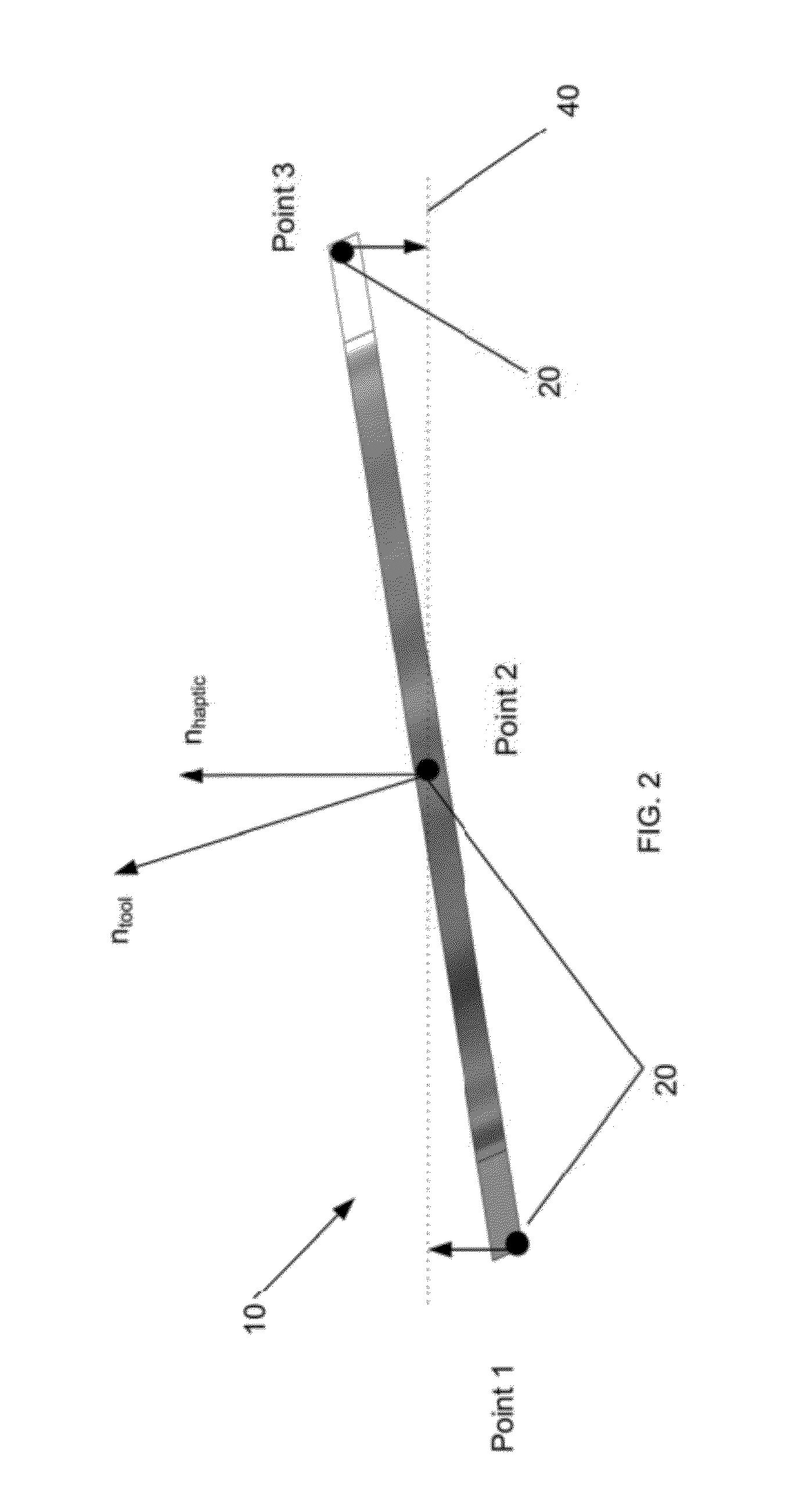

System and method for providing substantially stable haptics

ActiveUS20120176306A1Smooth to the touchInput/output for user-computer interactionDiagnosticsGeometric primitiveHaptic interaction

A system for providing substantially stable haptics includes at least one computer configured to identify a first subset and a second subset of haptic interaction geometric primitives for a virtual tool. The computer is configured to determine based on the first subset, haptic forces in a first subspace. The computer is also configured to determine based on the second subset, haptic forces in a second subspace different from the first subspace.

Owner:MAKO SURGICAL CORP

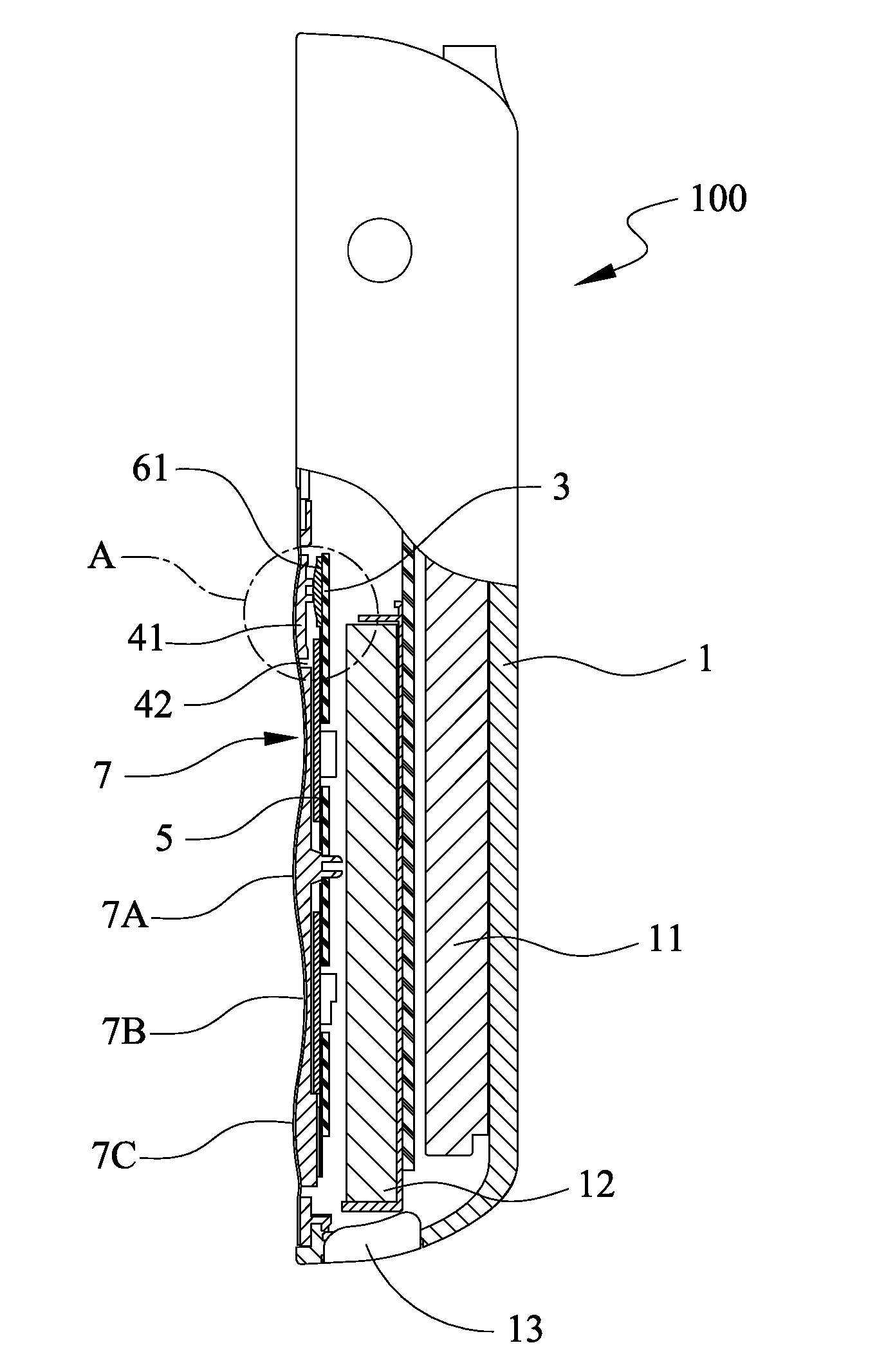

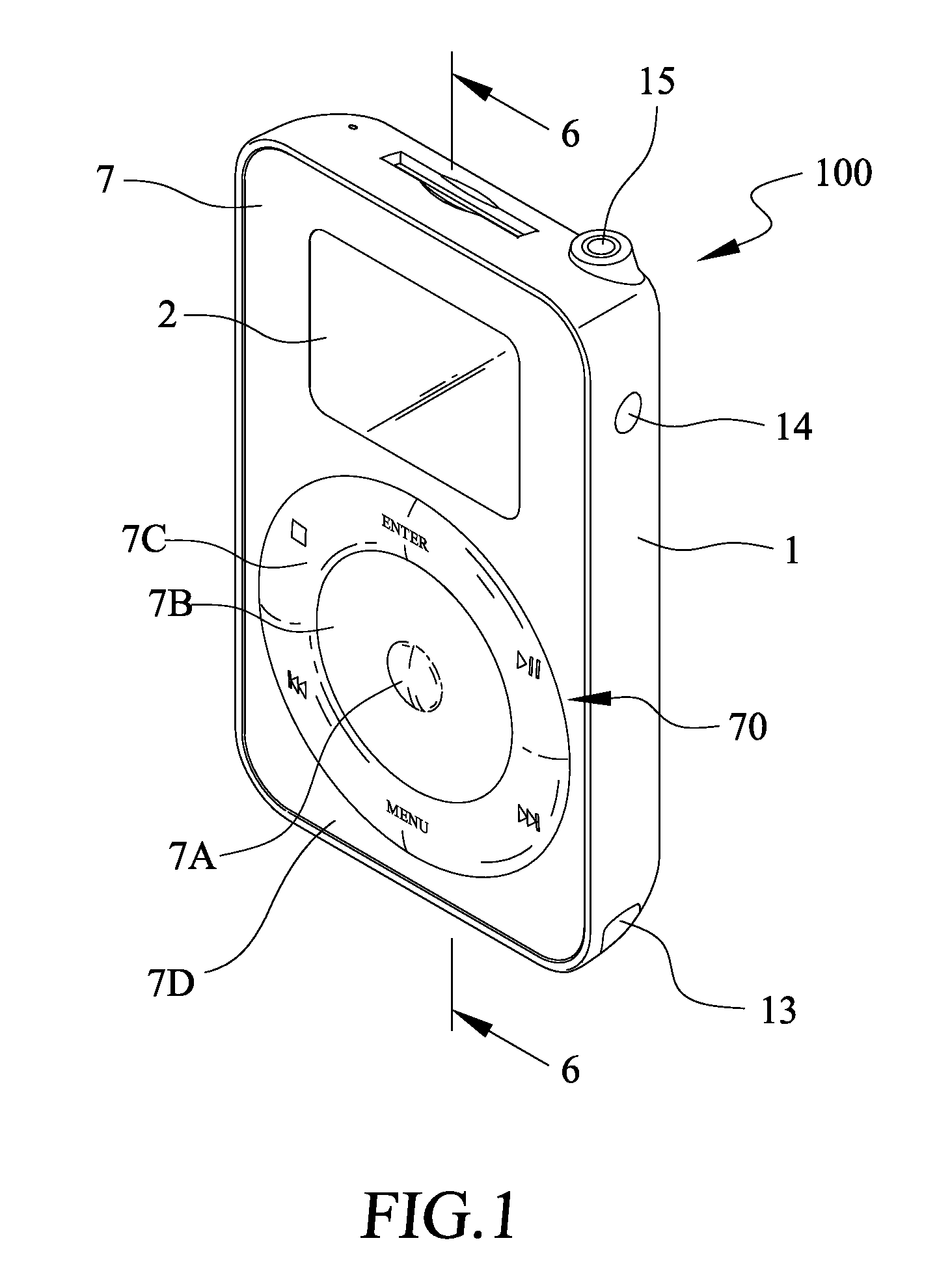

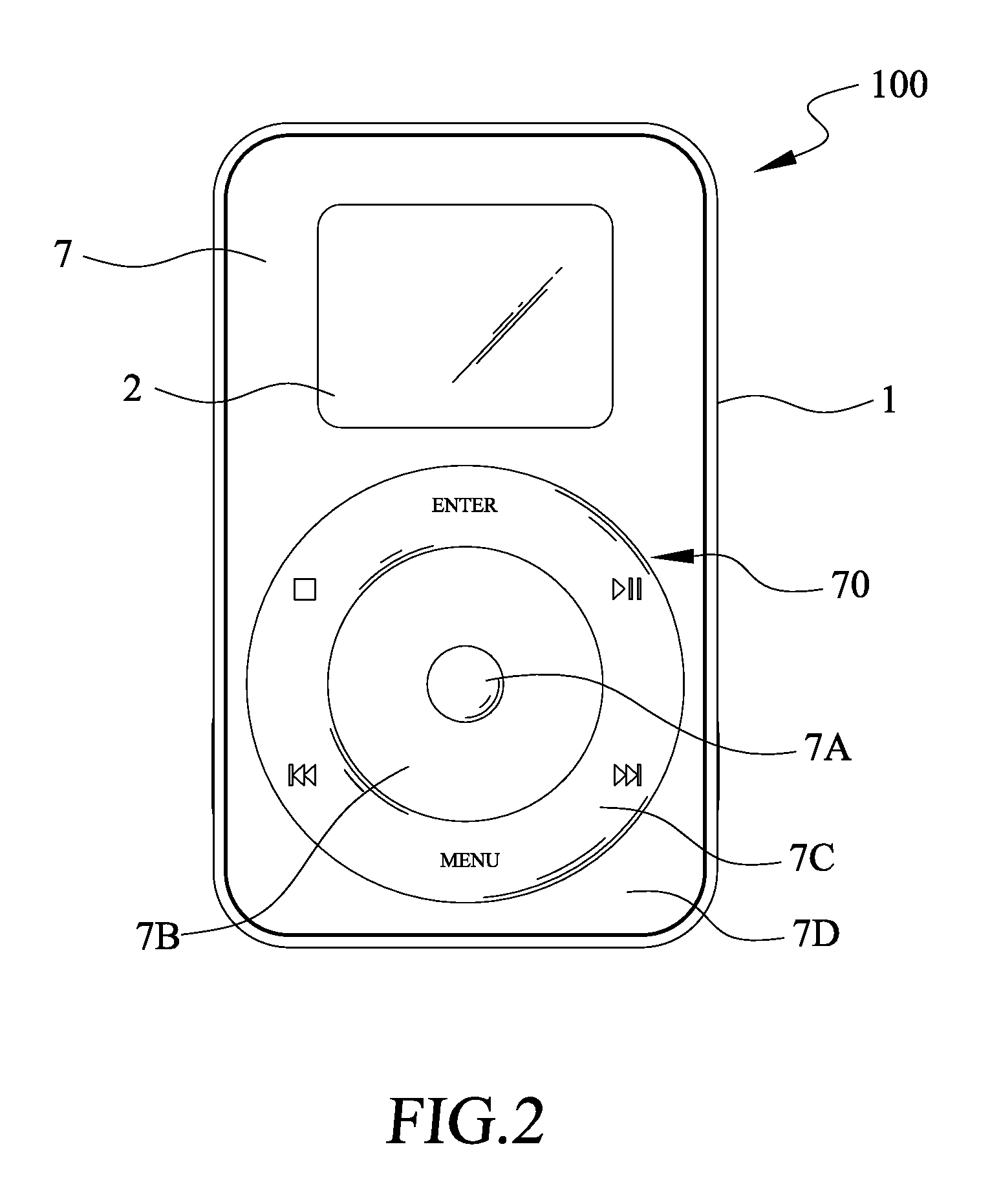

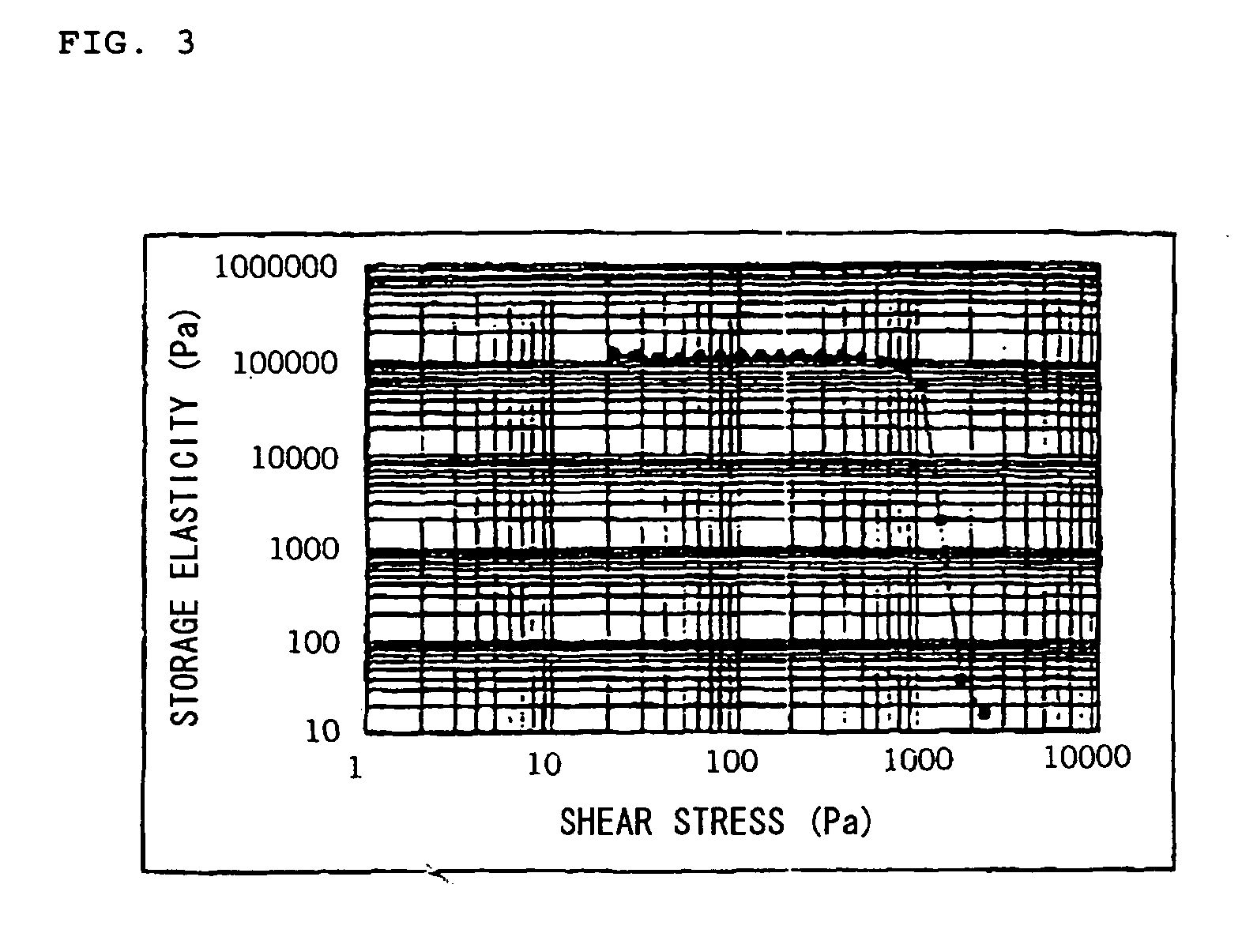

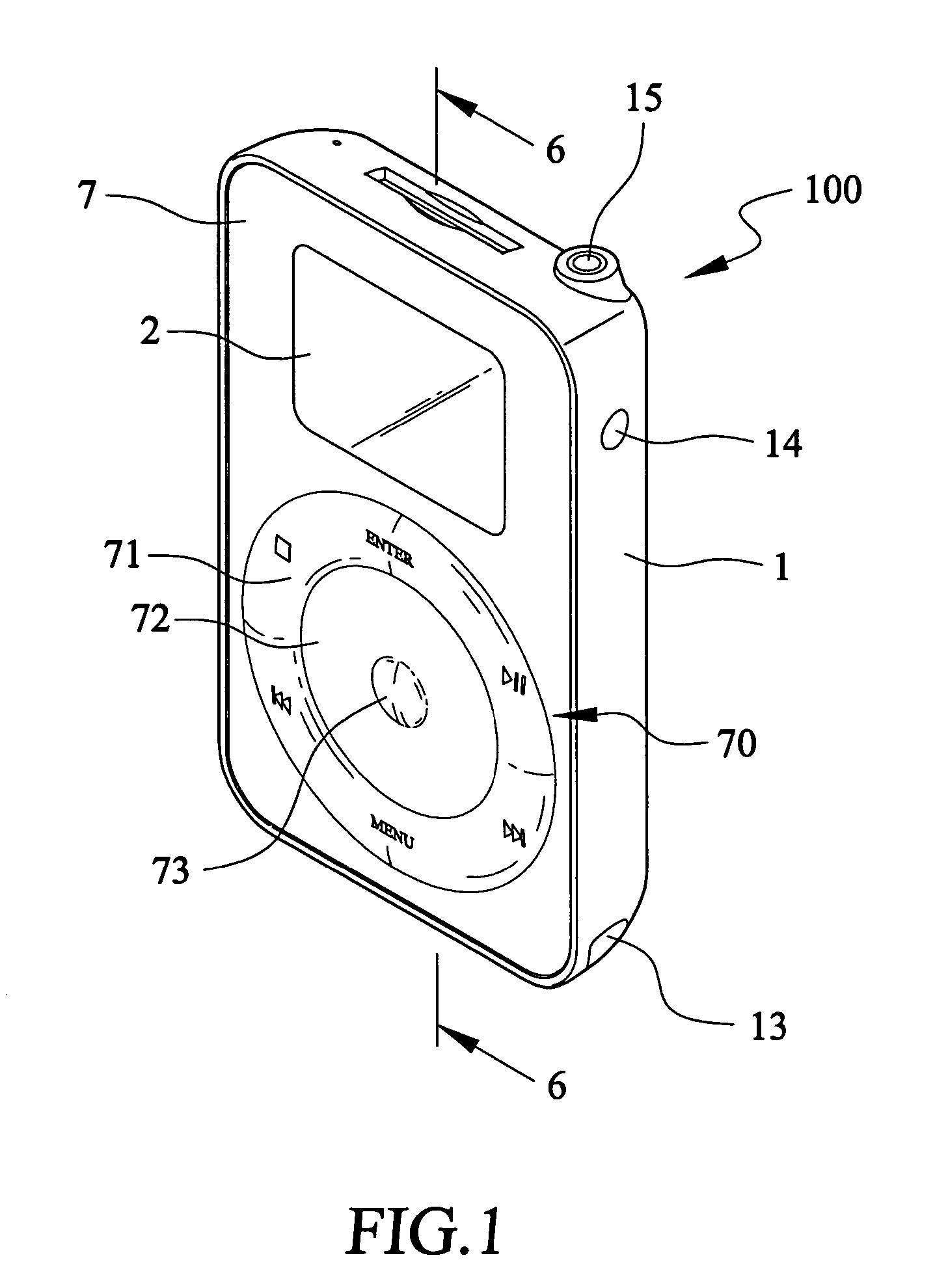

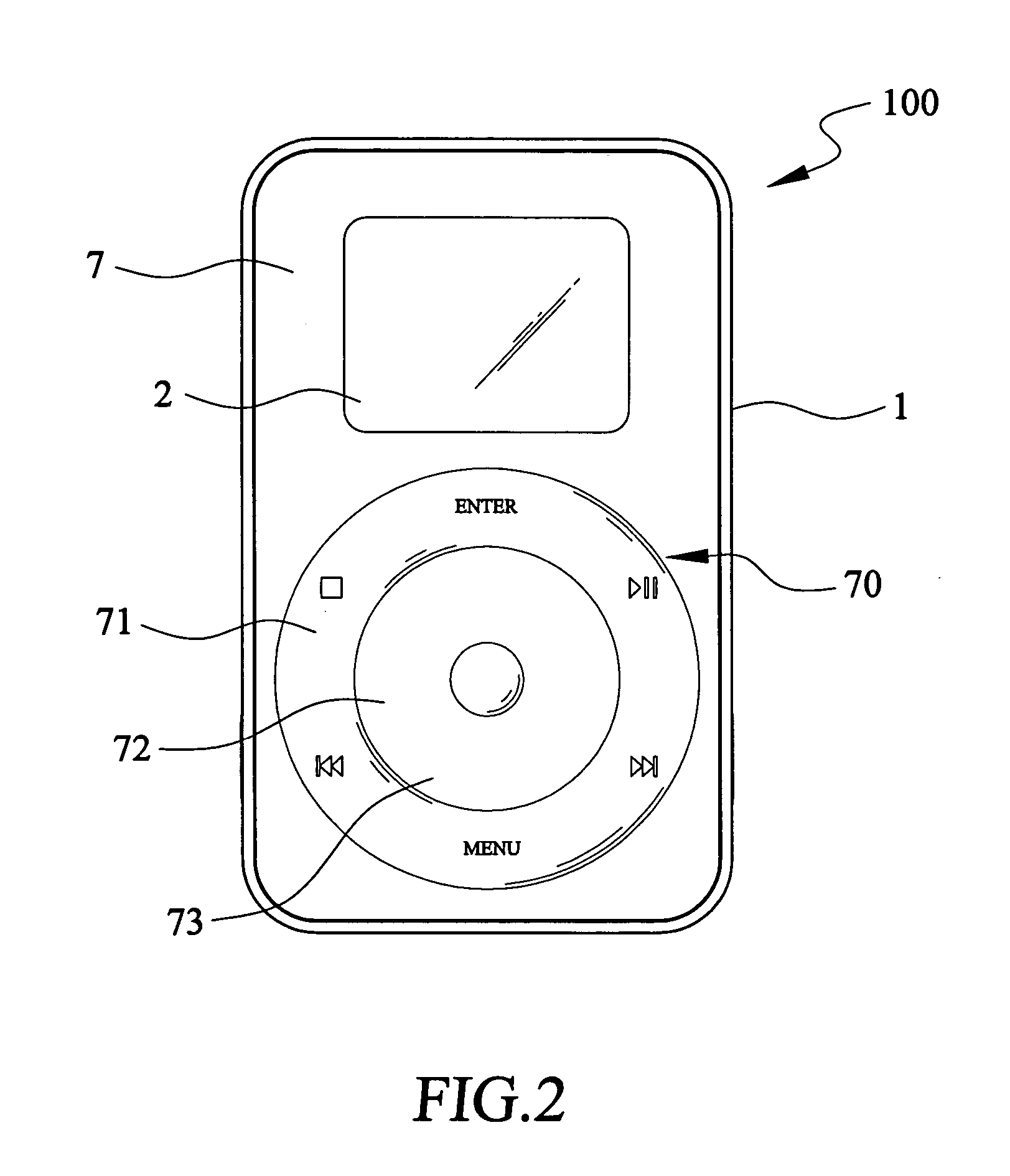

Digital audio/video playing device

InactiveUS8212779B2Smooth to the touchImprove isolationInput/output for user-computer interactionDigital data processing detailsEngineeringMechanical engineering

A digital audio / video playing device includes a touch control board, a plurality of switch units disposed outside a perimeter of the touch control board, and a support plate disposed on the touch control board and switch units. The support plate includes a central portion, an intermediary portion ringing the central portion, and an outer portion ringing the intermediary portion. The central portion and the outer portion are thicker than the intermediary portion such that the intermediary portion is recessed relative to the central portion and the outer portion. The intermediary portion is disposed directly facing the touch control board. A plurality of depressible tabs are formed in the outer portion, each depressible tab corresponding to and directly facing a corresponding one of the switch units. A surface film is arranged over and covering the support plate such that a raised-recessed-raised configuration is formed.

Owner:GETAC TECH CORP

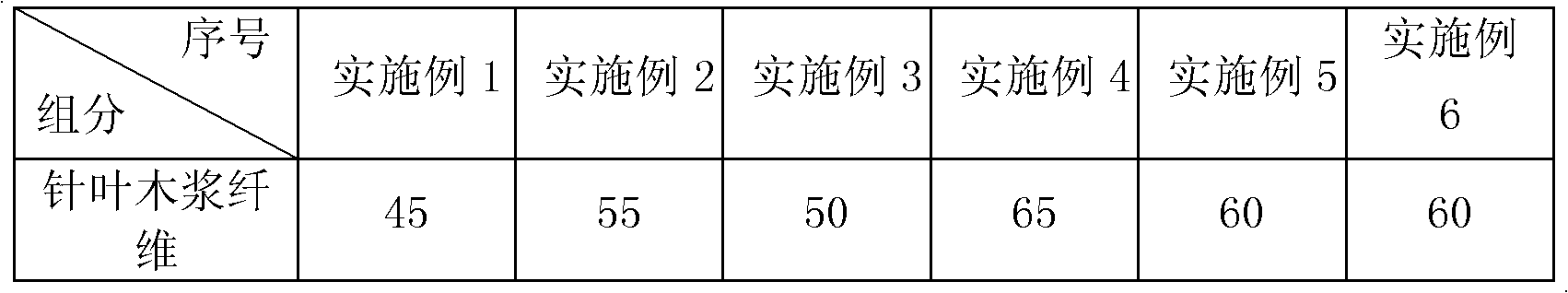

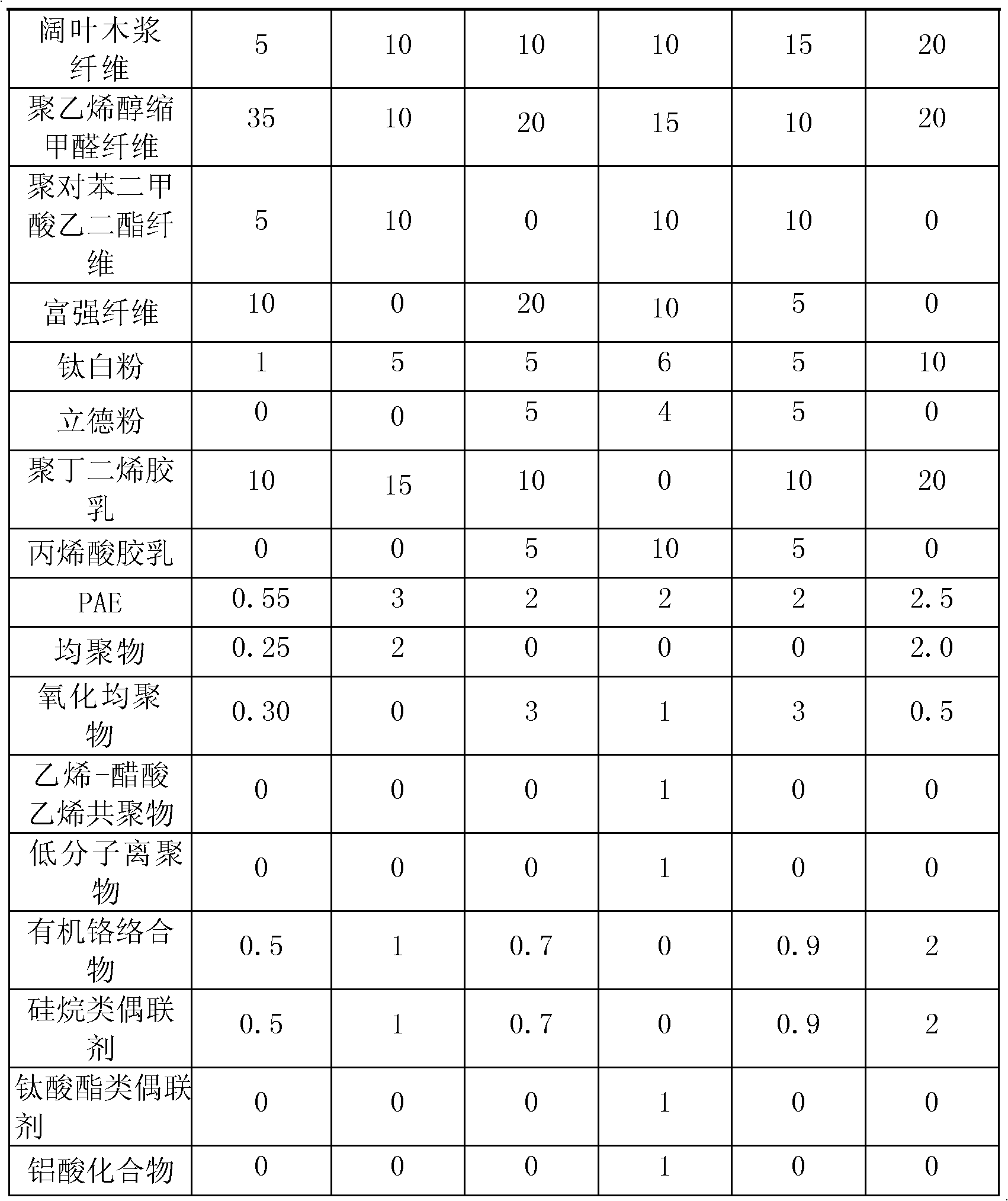

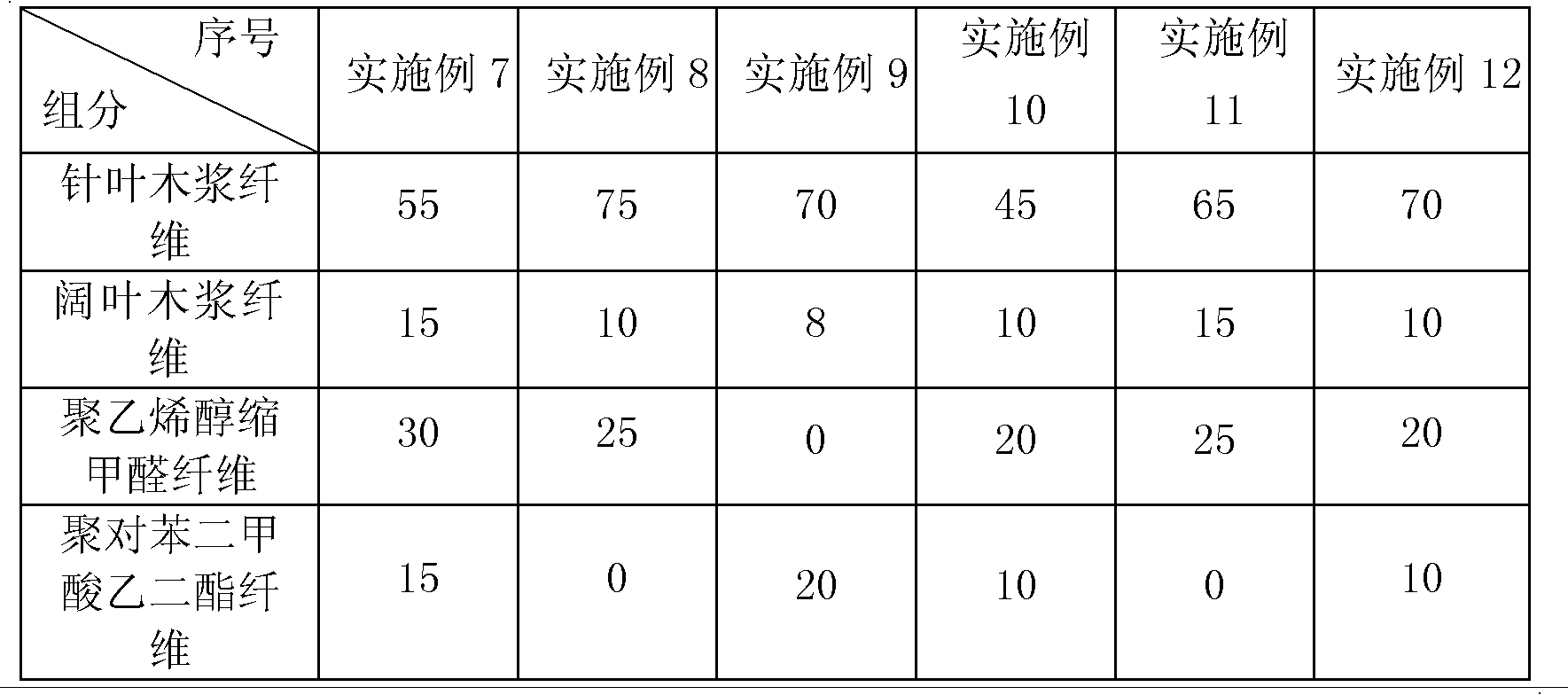

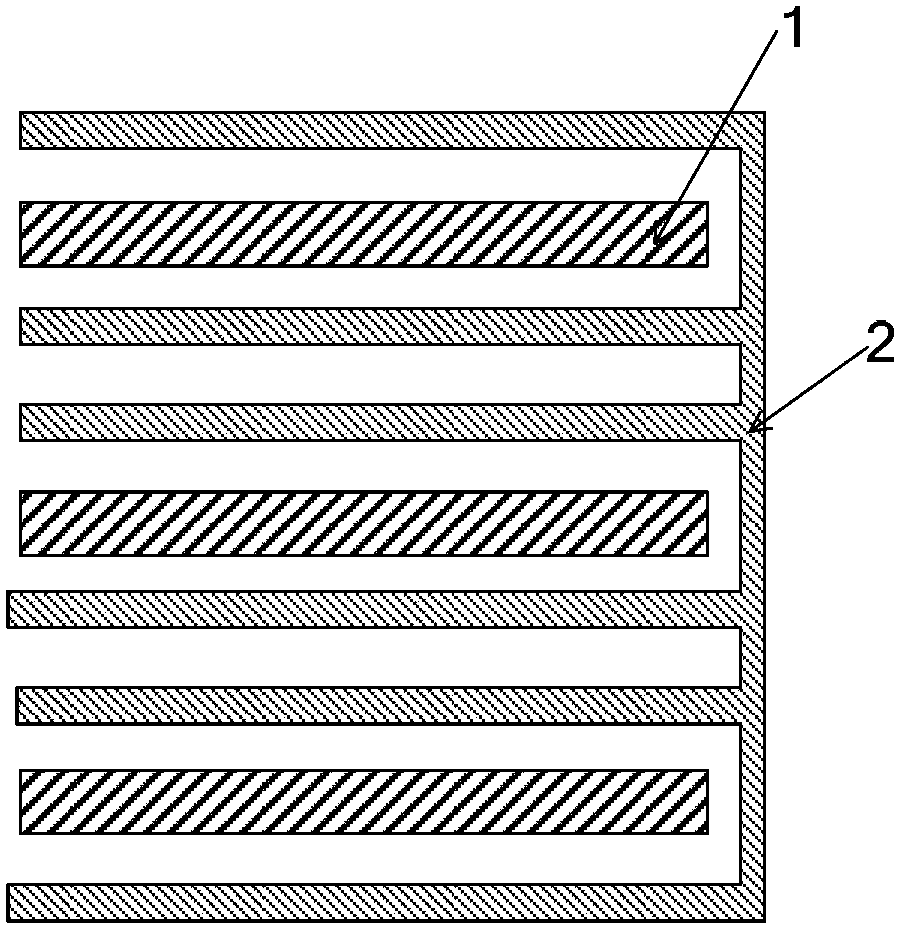

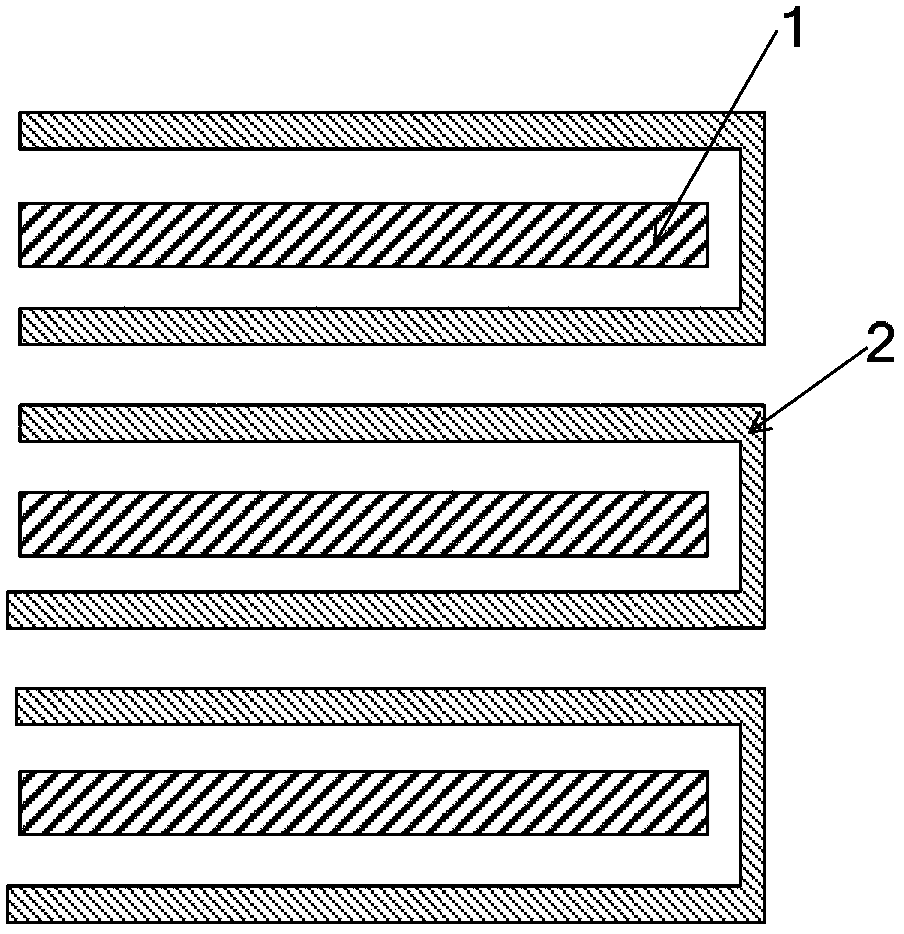

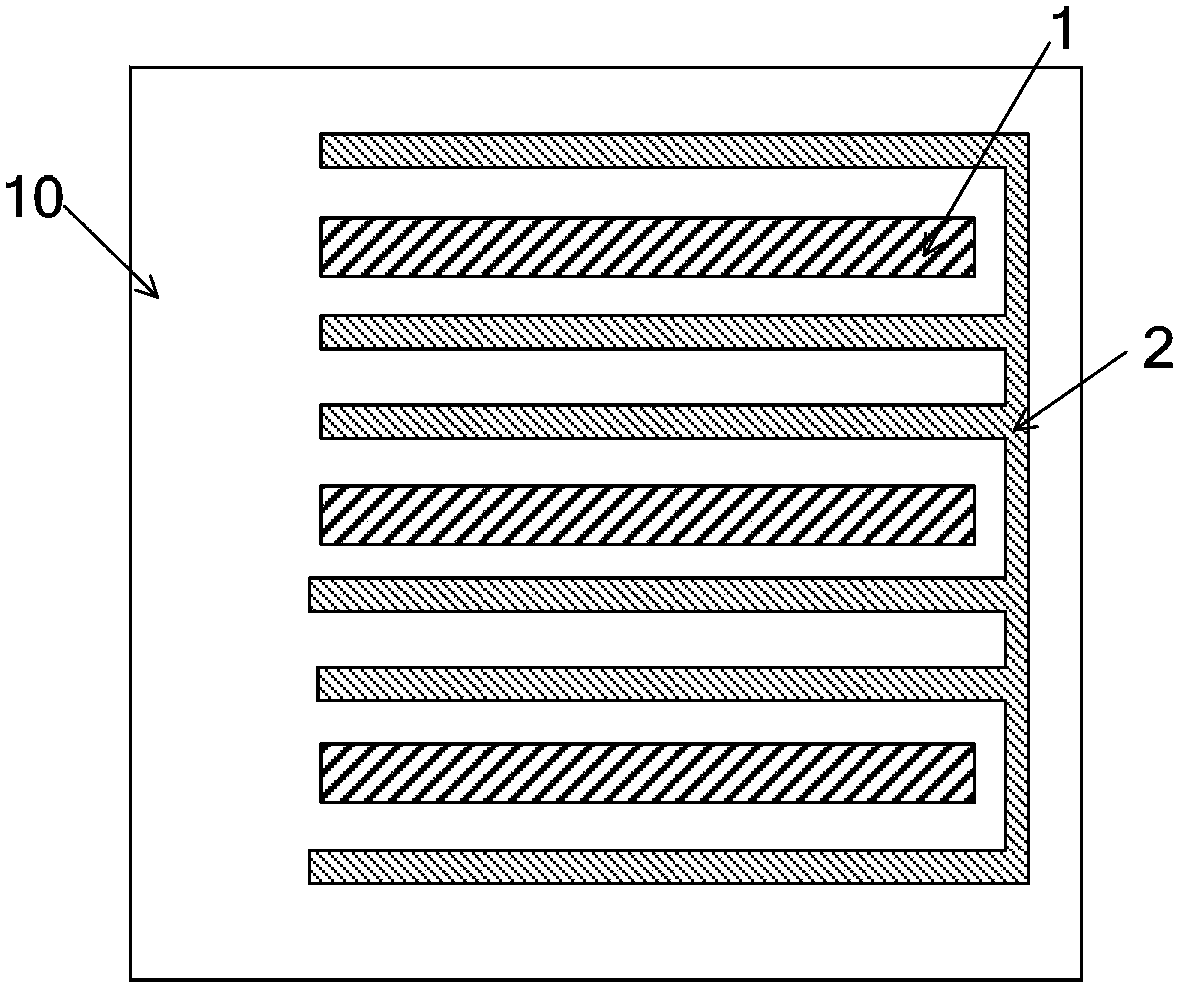

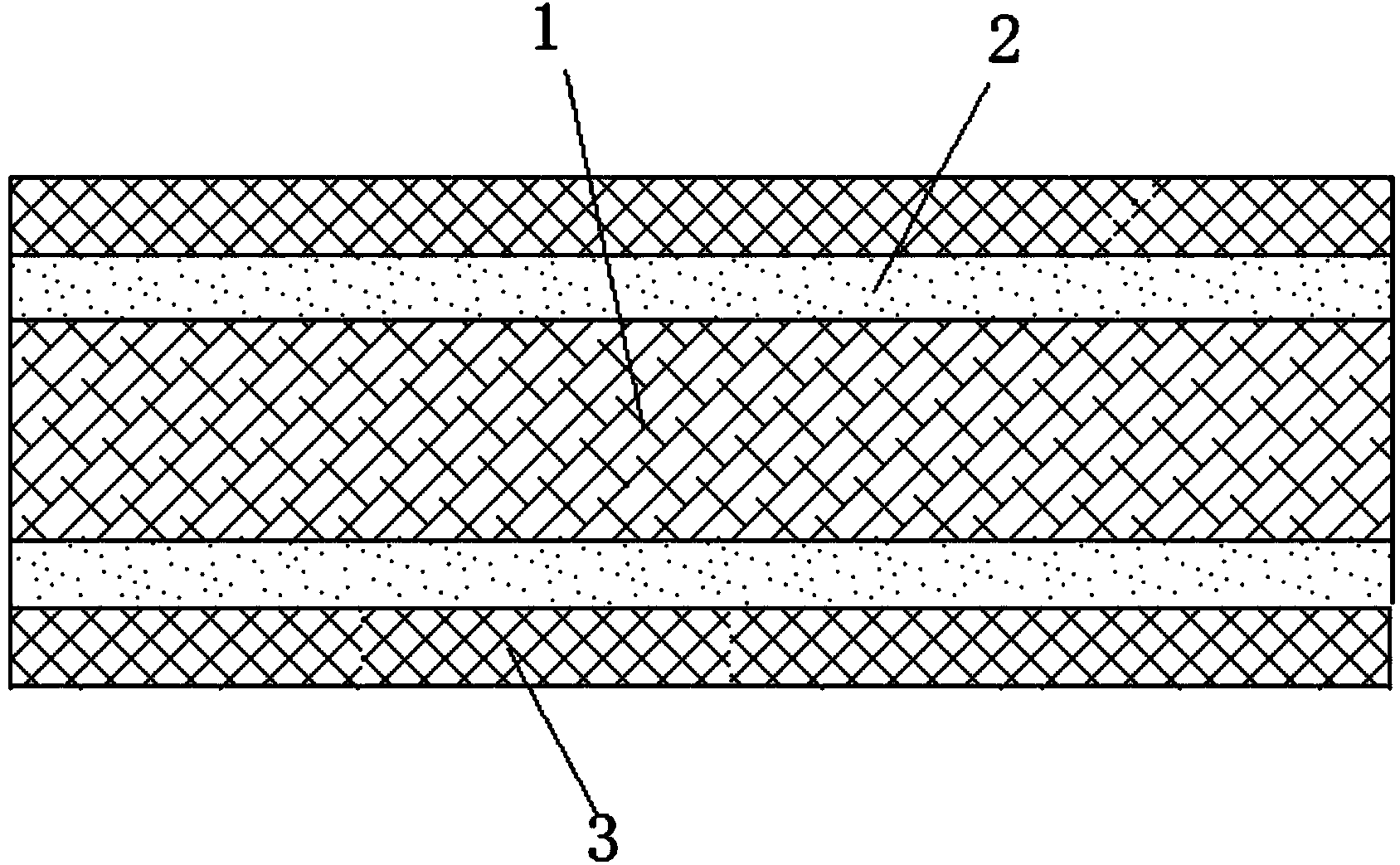

Environment-friendly high-printability non-woven wallpaper base and preparation method thereof

ActiveCN102619127ASoft touchSmooth to the touchSpecial paperPaper coatingEnvironmental resistanceFiber

The invention relates to an environment-friendly high-printability non-woven wallpaper base and a preparation method thereof, belongs to the field of processing of non-woven fabric and mainly relates to the environment-friendly high-printability non-woven wallpaper base and the preparation method thereof. The environment-friendly high-printability non-woven wallpaper base comprises the following components in percentage by weight: 50-80 parts of wood pulp fiber, 20-50 parts of chemical fiber, 1-19 parts of inorganic filler, 10-20 parts of latex, 1.1-5 parts of chemical additives and 1-4 parts of surface treating agent, wherein the wood pulp fiber is of a mixture formed by mixing softwood pulp fiber and hardwood pulp fiber according to the weight ratio of 3-9: 1. The environment-friendly high-printability non-woven wallpaper base disclosed by the invention has the advantages of uniform ink absorption, strong color spreading capability, lower flexibility, higher softness, good printability, economy and environment-friendly property.

Owner:ZIBO OU MU SPECIAL PAPER

Touch module and manufacturing method thereof

InactiveCN104049814AAdapt to the requirements of transformation productionDoes not affect working statusInput/output processes for data processingInsulation layerOptoelectronics

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Hair dye composition

An objective of the invention is to provide a hair dye composition having sufficient decolorizing performance and dying performance without exhibiting any irritative odor, and also having an ability of imparting the hairs with an excellent smoothness.The aspect of the invention is a hair dye composition comprising:a first agent containing an alkanolamine and an oxidation dye; and,a second agent containing an oxidant,wherein a higher alcohol and a quaternary ammonium salt cationic surfactant are contained in the first agent and / or the second agent;wherein the molar ratio of the higher alcohol to the quaternary ammonium salt cationic surfactant is in the range of 3 to 15.In the composition described above, it is preferable that substantially no ammonia is contained.

Owner:SHISEIDO CO LTD

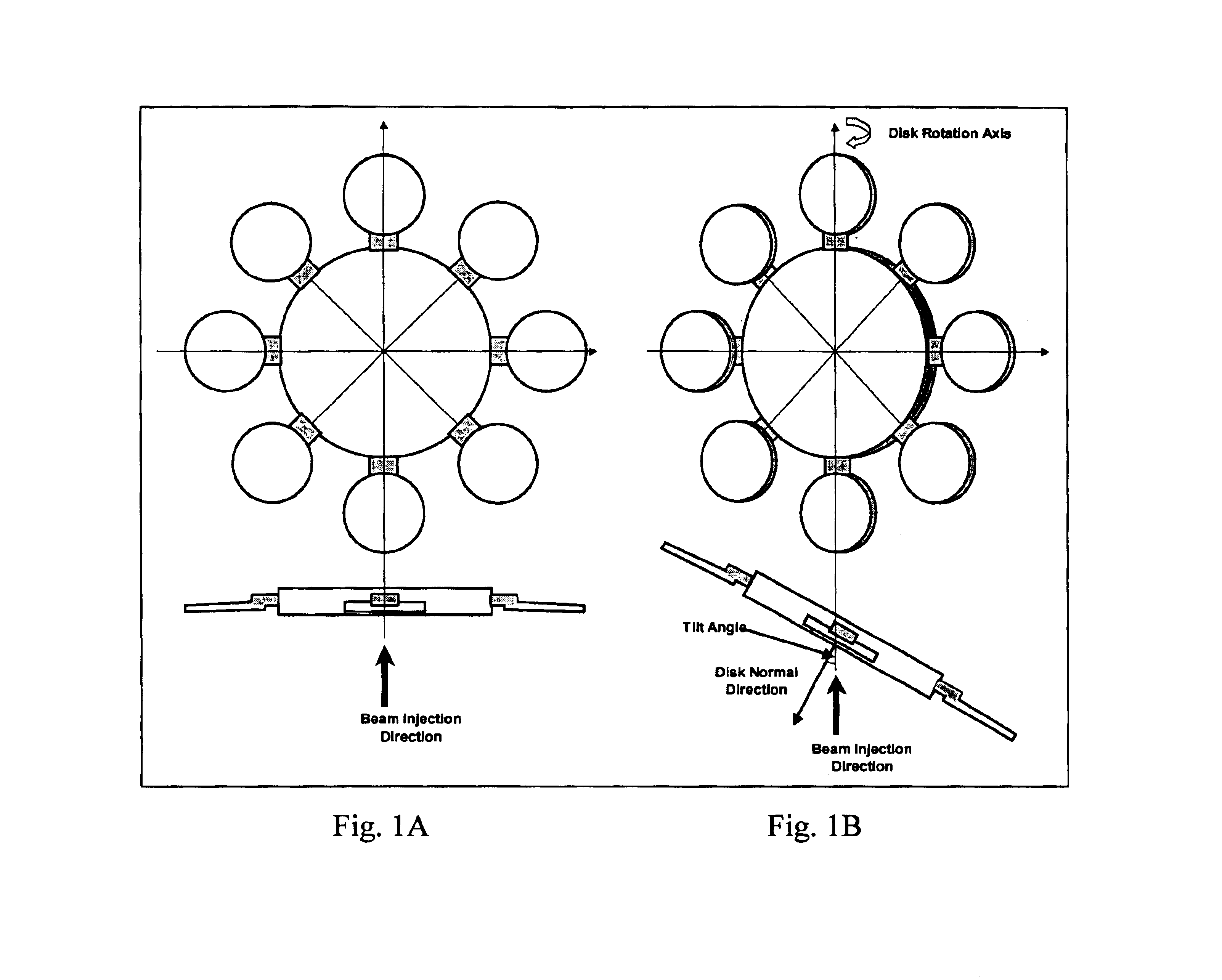

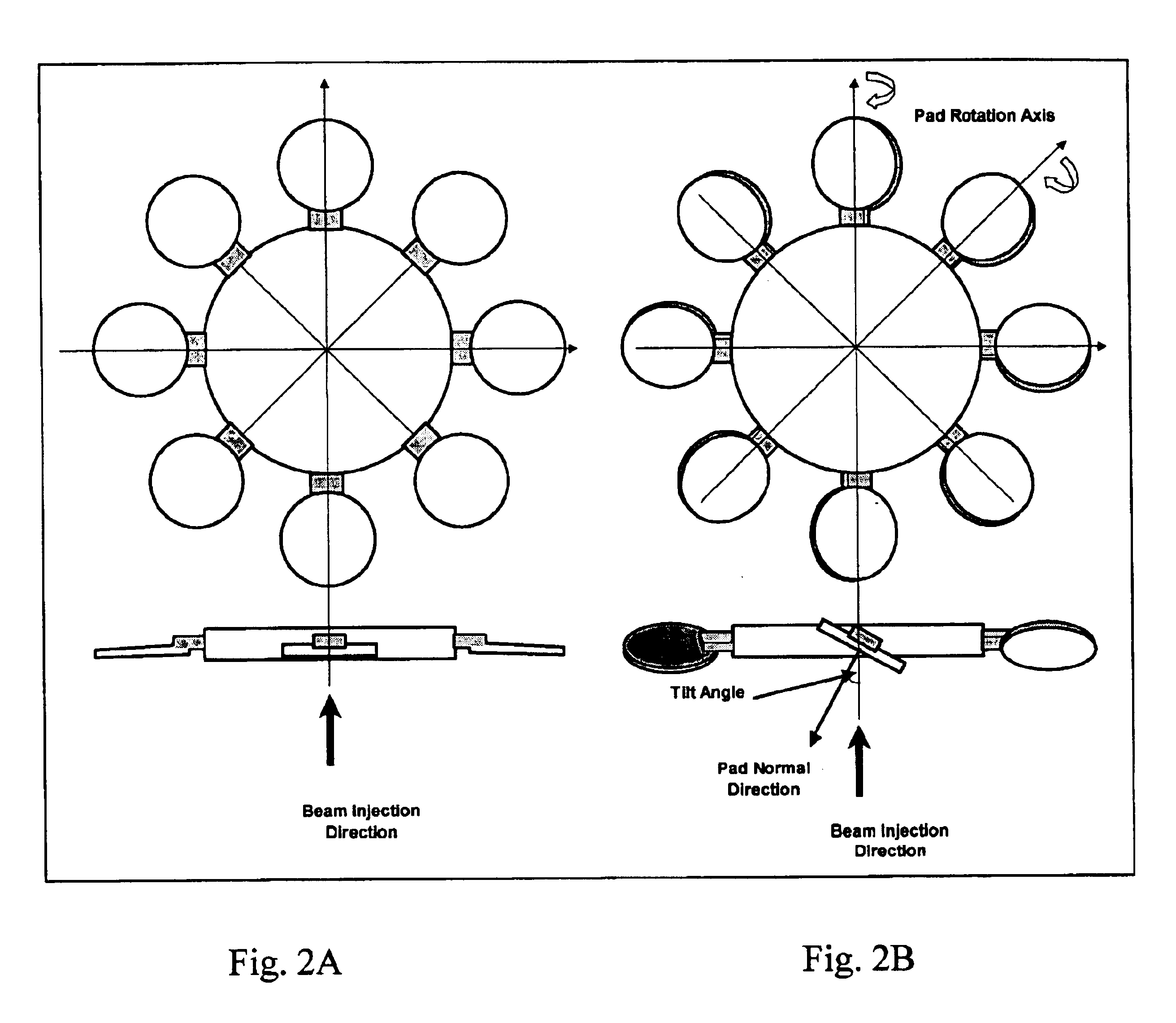

Apparatus and method for reducing implant angle variations across a large wafer for a batch disk

InactiveUS6806479B1Minimize pad rotation errorMinimal tilt/twist angle variationElectric discharge tubesIrradiation devicesFriction torqueLocking mechanism

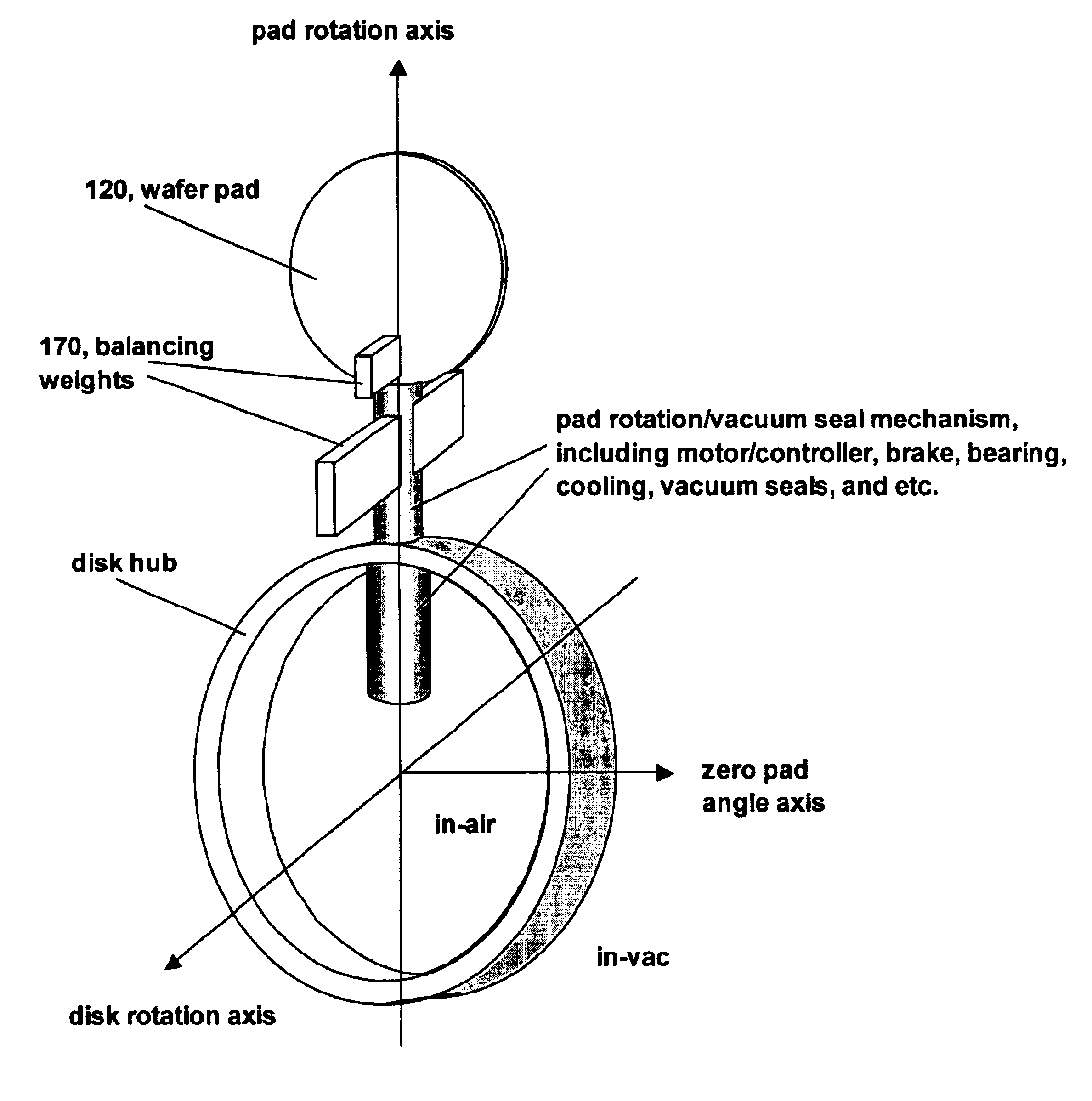

A method to rotate individual pad of a batch disk to an implant angle and lock them in place, with the pad surface having conical or near conical surface to minimize the implant angle variation across a wafer on the pad for both tilt angle and twist angle, at large tilt angle implant. The implanter includes a disk with multiple attached pads that can hold substrates securely when the hub is at rest or rotates. The disk rotates around its spin axis, which moves laterally at a programmed speed profile so that all substrates on the hub can get evenly touched by the fixed ion beam. The pad rotation axis is at an angle with the disk spin axis, and the angle is preferable 90 degrees. The nominal of the pad surface is at an angle, i.e., a tilt angle, relative to the incident ion beam. A rotation mechanism is applied to each individual pad to rotate the pad to the desired tilt angle. A locking mechanism is applied to each individual pad assembly to lock the pad at the desired tilt angle with minimum angle variation under high centrifugal force during fast disk spin. The locking mechanism includes: a) add brake to the rotation mechanism in the pad assembly so that the pad cannot rotate due to mechanical friction force or lock-key. B) use motor to hold the pad assembly. The sum of the friction torque and the motor holding torque should be larger than the centrifugal torque. A torque balancing mechanism is applied to pad mechanical design to minimize the total pad rotation torque under centrifugal force during fast disk spin by adding mass to counter balance the original wafer pad mass.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

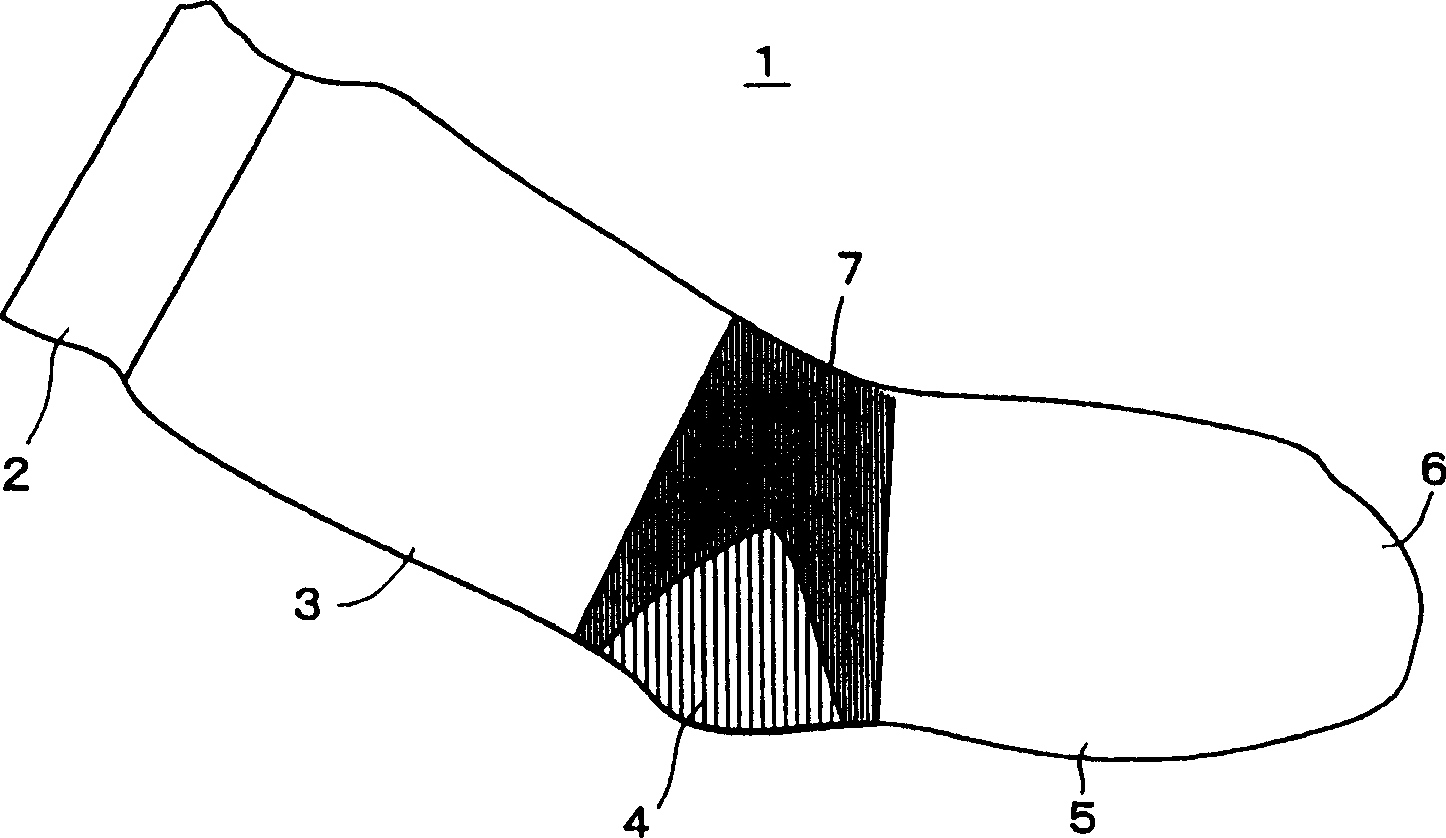

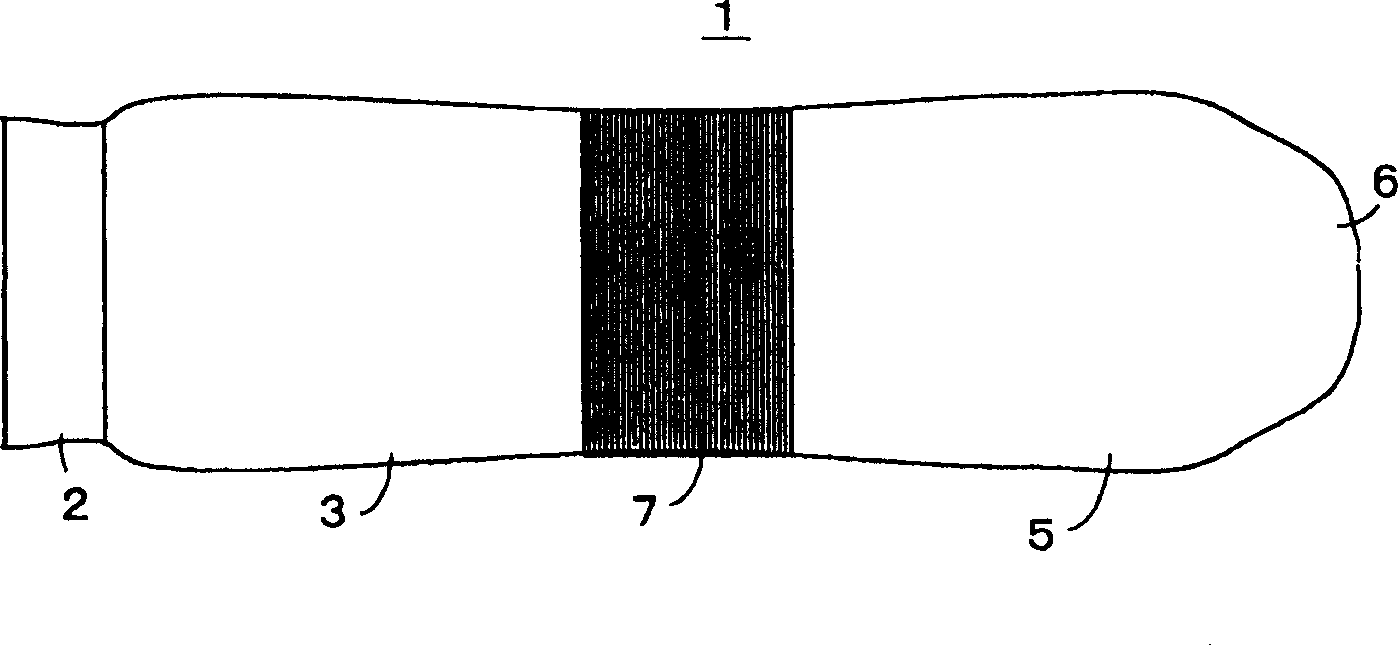

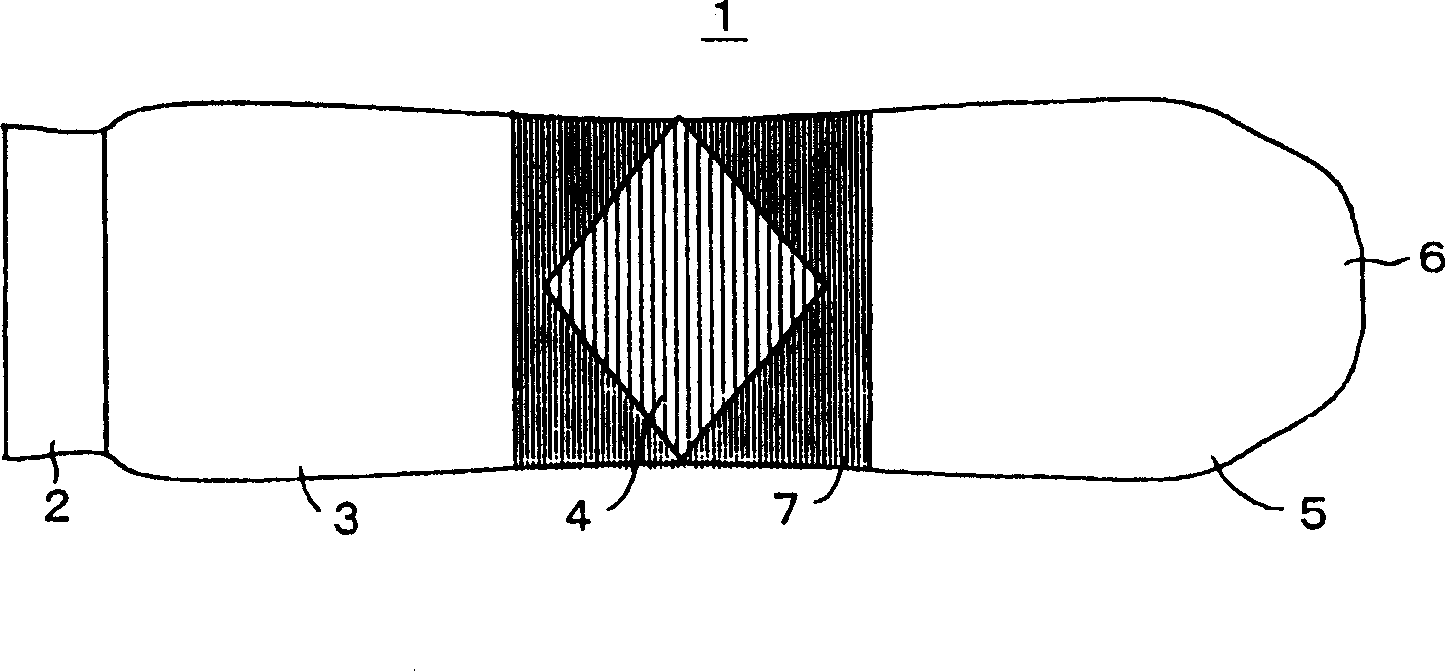

Knitting method of solid knitting fabric and knitting fabric

InactiveCN1834323AGood lookingReduce appearance differencesPanty-hoseHosieryEngineeringMechanical engineering

The invention relates to a weave method of solid knit-weaving fabric and relative knit-weaving fabric. Wherein, using flat coil to weave the leg (3), foot (5), and the heel (4); for around part (7), weaving with contracting along the longitudinal direction of coil but not contracting along the arrange direction of coil; the around part (7) is contracted along the longitudinal direction relative to the heel part (4); if using the around part (7) as reference, the heel (4) is convex on the longitudinal direction of coil; the around part (7) is between the leg (3) and the foot (5) to be bended; the around part (7) and the heel (4) can be woven via continuous coil arrangement, without turning over the coil or releasing pin / receiving pin. Since the around part of convex part is contracted, the solid knit-weaving fabric can be beautiful.

Owner:SHIMA SEIKI MFG LTD

Deeply permeating absorbed skin care composition capable of promoting metabolism and delaying senescence

ActiveCN104042502APromote metabolism and respirationFlexibleCosmetic preparationsToilet preparationsAcetyl hexapeptide-3Medicine

Owner:广州中芙生物科技有限公司

Hair cleansing compositions

InactiveUS6914038B2Smooth to the touchGood flexibilityInorganic/elemental detergent compounding agentsCosmetic preparationsOrganic acidAdditive ingredient

A hair cleansing composition comprises the following ingredients (A) to (D):(A) an anionic surfactant having a sulfate group,(B) a cationic guar gum,(C) an organic acid selected from a hydroxycarboxylic acid, a dicarboxylic acid or an aromatic carboxylic acid, and(D) a salt;and has a pH of from 1 to 4 when diluted 20-fold by weight with water.The hair cleansing composition has good foamability and high-lubricity foam quality upon washing and smooth touch upon rinsing, and is excellent in the luster and softness of hair after drying and also superb in stability.

Owner:KAO CORP

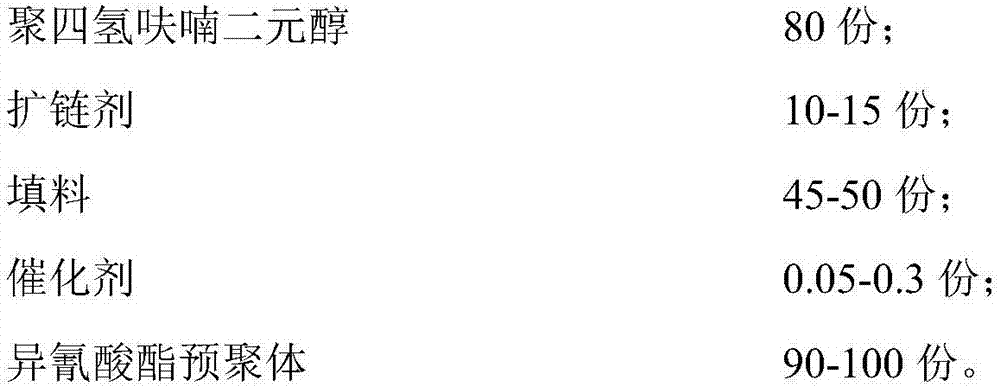

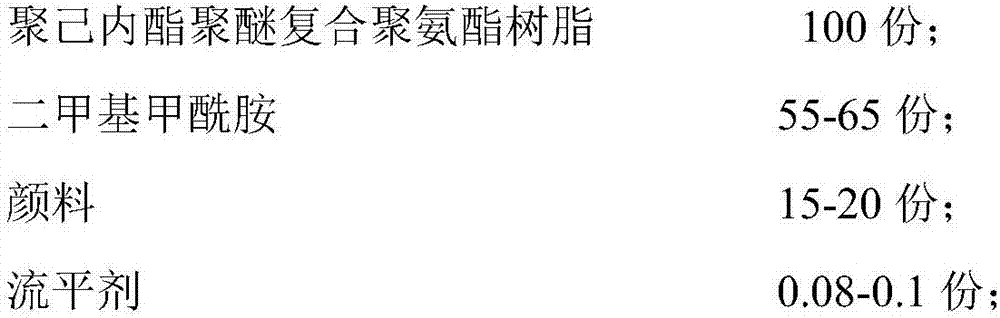

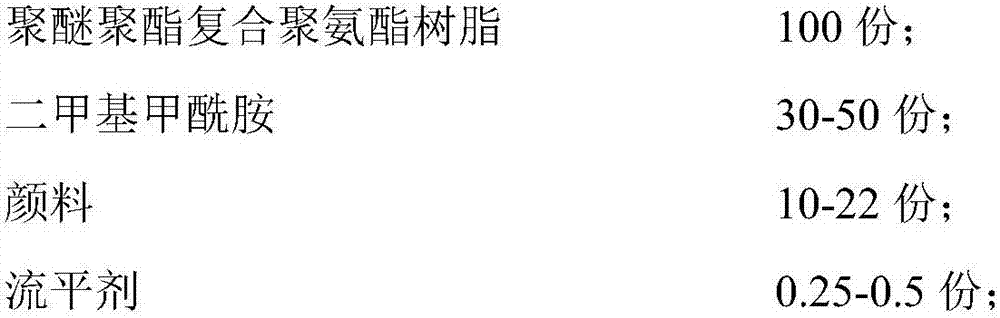

Solvent-less high-light finish ultrafine fiber polyurethane synthetic leather and preparation method thereof

The invention discloses solvent-less ultrafine fiber high-light finish polyurethane synthetic leather. The solvent-less ultrafine fiber high-light finish polyurethane synthetic leather is composed of a surface polyurethane layer, a middle polyurethane layer, a polyether type solvent-less polyurethane layer and ultrafine fiber polyurethane synthetic leather sequentially from top to bottom. The solvent-less ultrafine fiber high-light finish polyurethane synthetic leather is prepared by the following steps: coating a high-light mirror mask with surface layer polyurethane slurry, coating middle layer polyurethane slurry after baking, coating polyether type solvent-less polyurethane slurry after baking, laminating with constant-breadth ultrafine fiber polyurethane synthetic leather after pre-reaction, conducting aging, rolling together and aging again, and stripping the high-light mirror mask to obtain the finished product. The solvent-less ultrafine fiber high-light finish polyurethane synthetic leather prepared by the invention has the following superior properties: high gloss, high flatness, no crease, smooth tactility, cuts comparable to genuine leather, hydrolysis resistance, wear resistance, normal-temperature deflection resistance, freezing resistance, high efficiency, environmental protection and the like, and can be widely applied to high grade shoes, bags, suitcases and decorative materials.

Owner:ANHUI ANLI MATERIAL TECH

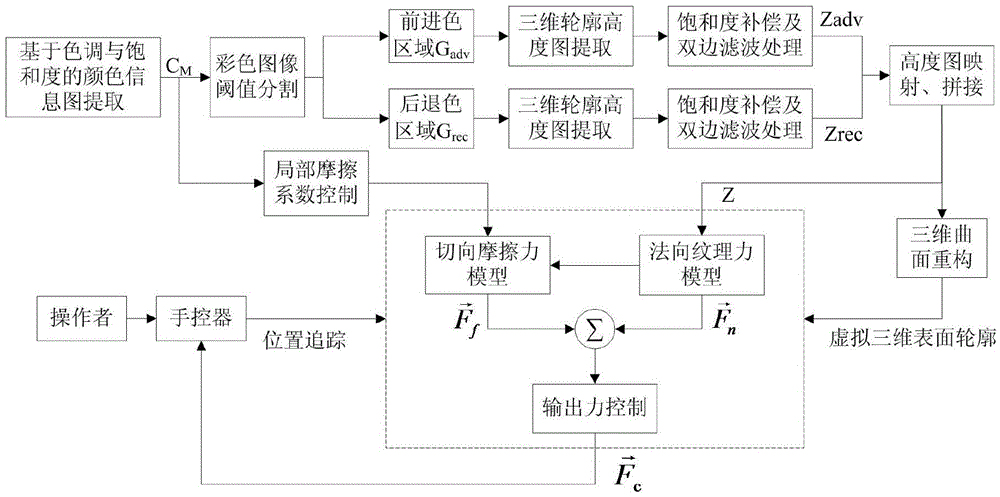

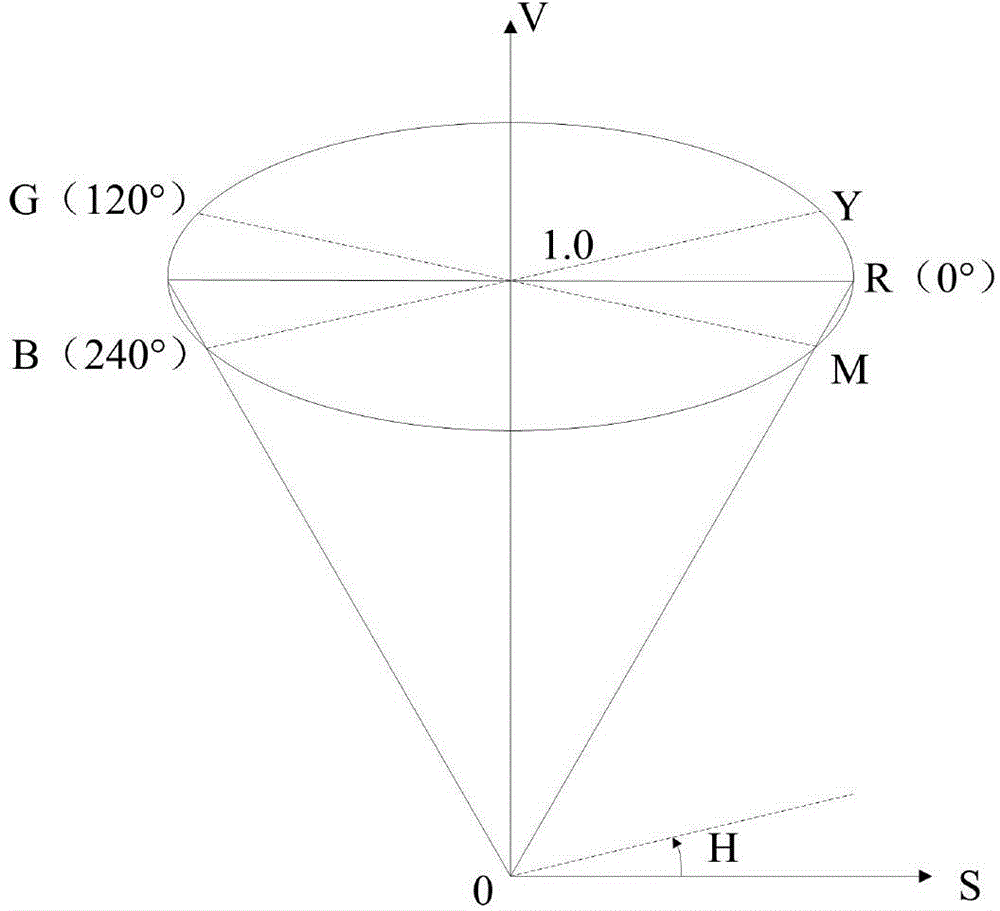

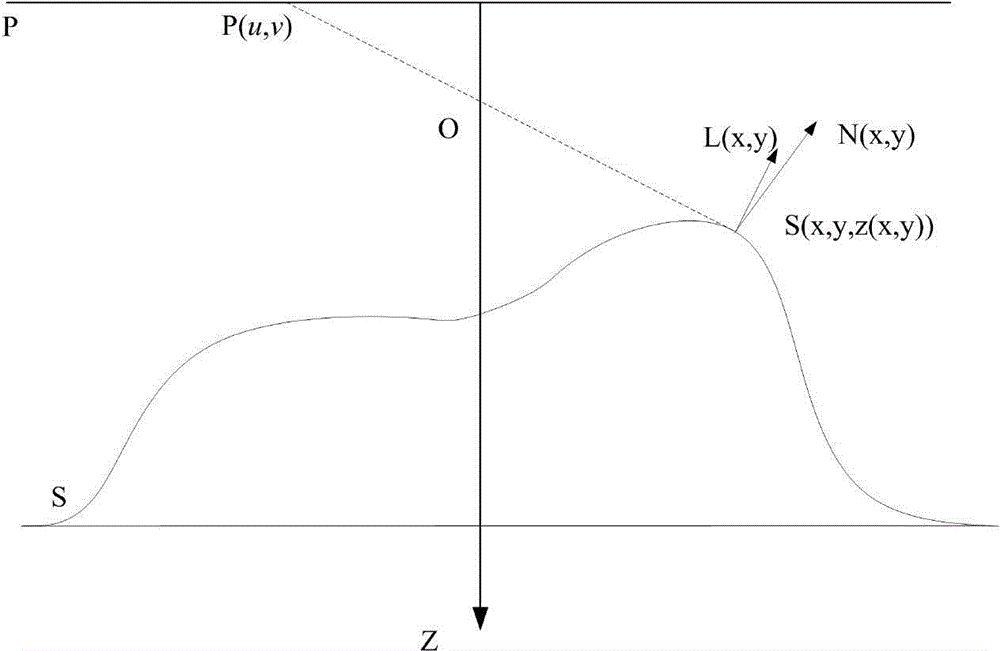

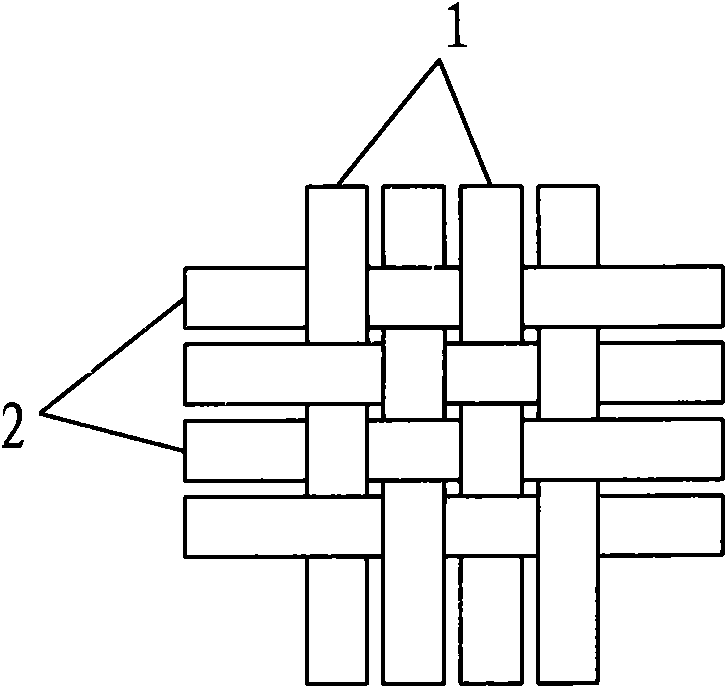

Color image texture force tactile reproduction method based on color transform space

ActiveCN104157002AFull reproduction of color characteristicsImprove realism3D-image renderingColor imageHue

The invention discloses a color image texture force tactile reproduction method based on a color transform space. The method comprises the following steps: a color information graph is acquired according to hue information and saturation information of a color image, and threshold segmentation is carried out on the color image based on the color information graph; three-dimensional profile recovery is carried out on the segmented regions by the method of shape from shading, a recovery result is compensated and adjusted with the use of the saturation component of the color image, and then a bilateral filtering algorithm is adopted to carry out de-noising; the obtained three-dimensional profile height maps of the two regions are mapped to different height layers of a virtual three-dimensional surface, and are spliced to obtain the three-dimensional profile height map of the color image; a virtual surface is drawn, and a force feedback model is constructed; and the obtained resultant force is calculated and fed back to an operator by a hand controller. According to the method, the shading distribution characteristic of the surface profile of an object formed under light and the intrinsic color distribution characteristic of the appearance image of the object are combined, surface texture feature information extraction, three-dimensional profile recovery and texture perceptivity feedback are carried out on the color image, the texture features of the color image can be fully reproduced, and the sense of reality of force tactile reproduction is improved.

Owner:SOUTHEAST UNIV

Antimicrobial anti-aging refrigerator door sealing strip and preparation method thereof

InactiveCN105111624ASmooth to the touchIncrease elasticityDomestic cooling apparatusLighting and heating apparatusRefrigerator carEpoxy

The invention provides an antimicrobial anti-aging refrigerator door sealing strip and a preparation method thereof. The antimicrobial anti-aging refrigerator door sealing strip comprises a rubber sleeve and magnetic powder, wherein the rubber sleeve comprises raw materials with percentage by weight: polyvinyl chloride 30-65%, ethylene-vinyl acetate copolymer 3-10%, chlorinated polyethylene 7-15%, tributyl citrate 20-30%, natural antibacterial agent 3.5-12% and epoxy alopecuroides seed oil 1.5-3%. The rubber sleeve is made through many process methods, the magnetic powder is added in the rubber sleeve, the positions of four corners are welded through fusing or bonded to make into the antimicrobial anti-aging refrigerator door sealing strip, and the antimicrobial anti-aging refrigerator door sealing strip is smooth in sense of touch and high in rebound resilience. The antimicrobial anti-aging refrigerator door sealing strip has the effects of wide antimicrobial spectrum, high efficiency, persistence and safety, also can improve mechanical strength, cold resistant and ageing resistance ability, has the effects of aroma enhancement and far infrared radiation, plays the roles of purifying the environment, eliminates peculiar smell and self cleaning and mildew proofing, and is beneficial for human bodies to obtain more health interests. The antimicrobial anti-aging refrigerator door sealing strip does not deform, excellent in sealing effect, energy-saving and environmentally friendly and long in service life.

Owner:陆思烨

Compound silk-cloth fabric

The invention provides a compound silk-cloth fabric, which is interwoven by warp yarns and weft yarns and adopts a plain weave structure. The warp yarn is a 50D / 25F fully stretched cotton composite filament of which the glossiness is semi-dull, the warp yarn is fiber splitting typed, and each warp yarn totally comprises 400 fine fibers after the fiber splitting. The weft yarn is a 75D / 144F fully stretched terylene filament of which the glossiness is full dull. The warp wise density of the fabric is the combination of different fibers, so that the surface of the cloth is touched slippery and smooth, and the surface of the fabric also shows a reminiscent style, and can embody a feeling of modern people to seek leisure, health and sports. The fabric has wide application range, and in particular, the fabric is suitably used for producing jackets, dust coats and sportswear to show unique styles of the products; and when a user wears the clothes produced by the fabric, the clothes can make the user more modern and beautiful, and can also add fashionable charm to the user.

Owner:XIANGXING INDAL TEXTILE FINISHING SUZHOU

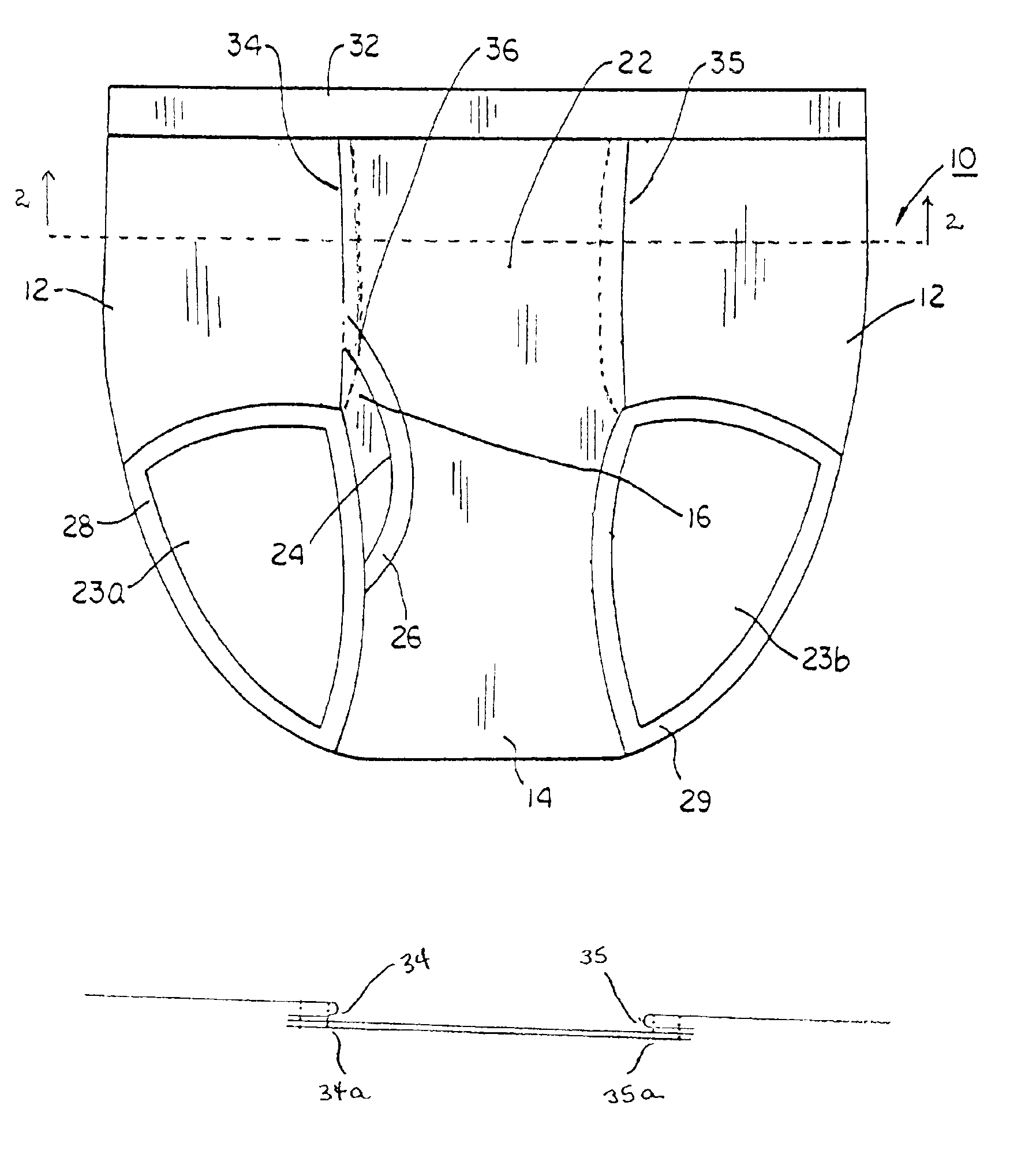

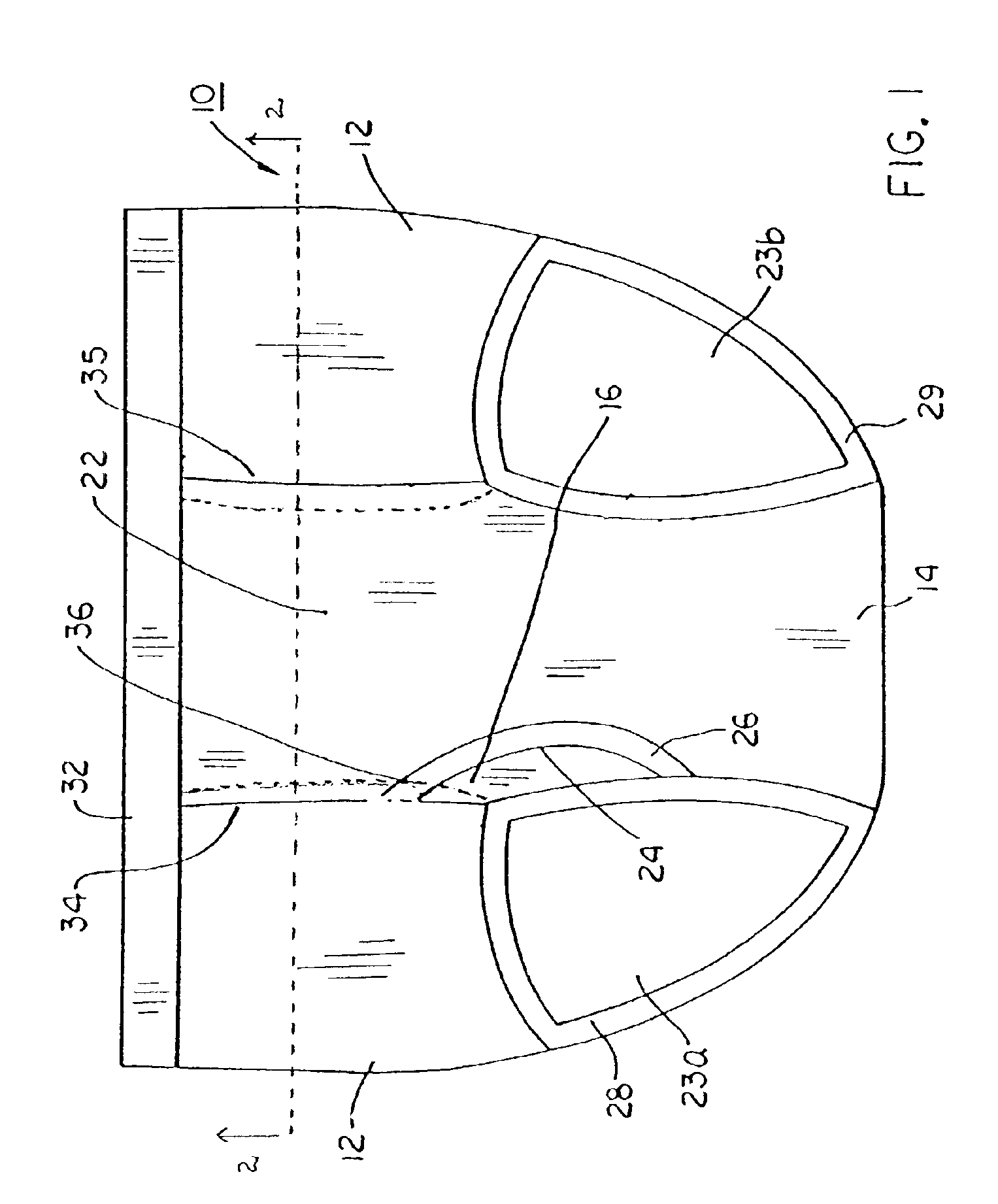

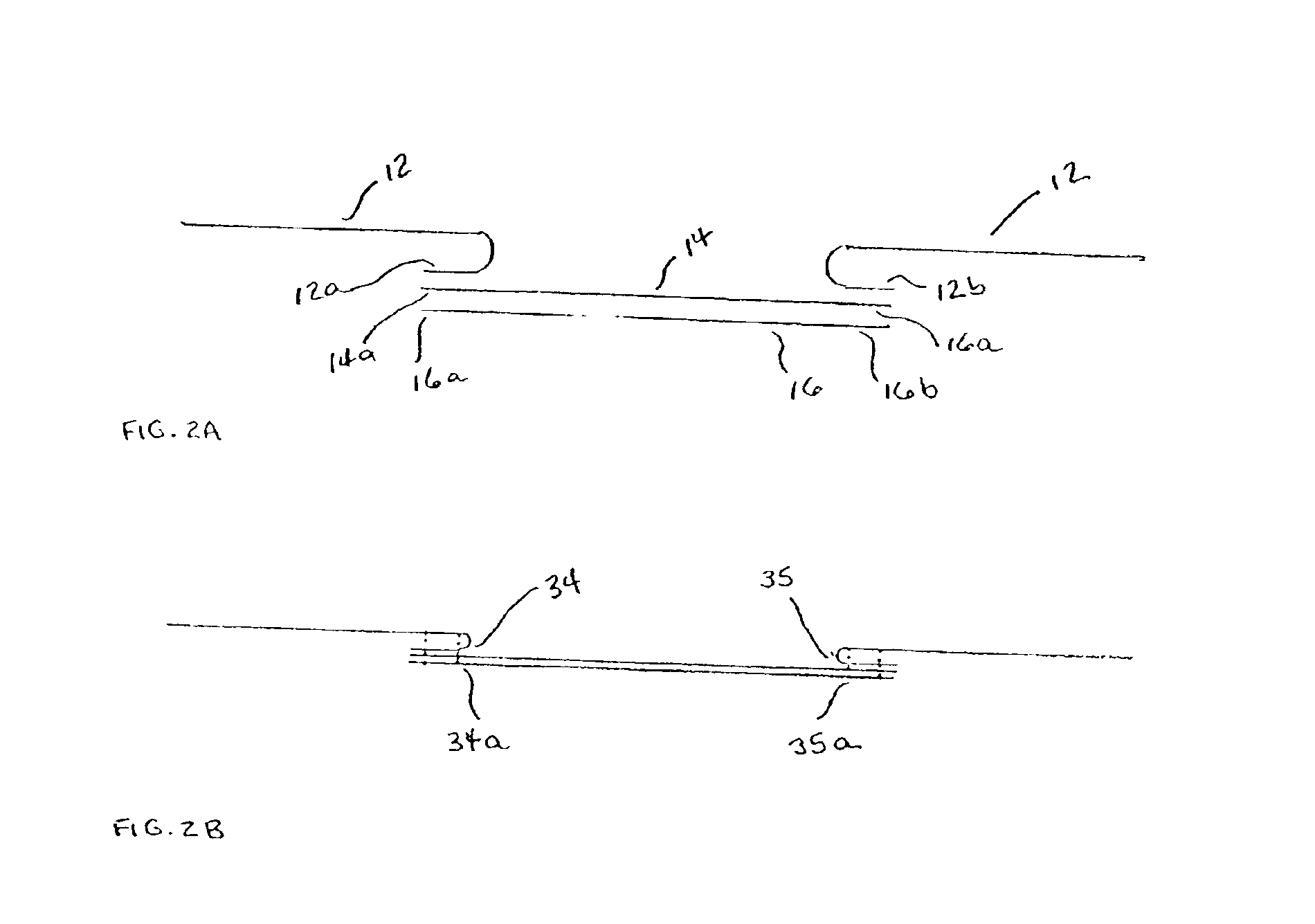

Underwear with trimless seam

InactiveUS6898805B1Smooth to the touchMore inexpensivelyUndergarmentsArchitectural engineeringBuilding construction

Owner:HBI BRANDED APPAREL ENTERPRISES

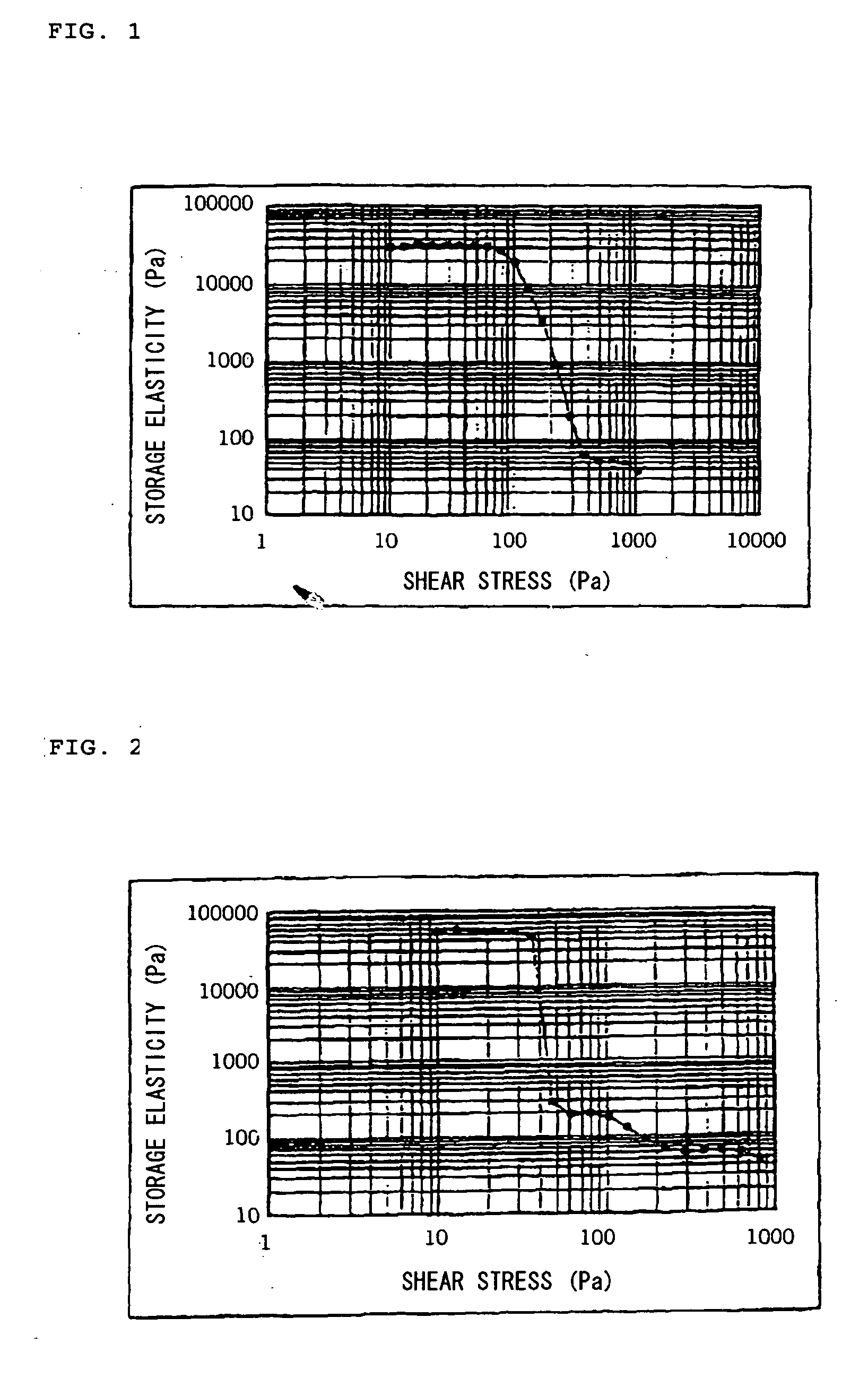

Skin cosmetic

InactiveUS20060034788A1Imparting transparencyConditioning the skin textureCosmetic preparationsBody powdersParallel plateWrinkle

There is provided a cosmetic, particularly a skin cosmetic, excellent in imparting transparency (transparent feeling) to the skin, conditioning the skin texture and making wrinkles and hair follicles imperceptible when applied. The cosmetic comprises a powder of porous spherical silica having an average particle size (based on volume) from 3.0 to 20 μm, a maximum particle size of 50 μm or smaller, and a pore volume from 1.5 to 3.0 cm3 / g, wherein the powder is characterized in that the minimum value of dlog (storage elasticity) / dlog (shear stress) is −10 or more, when 40 g of squalane is added to 15 cm3 of apparent volume of said powder of porous spherical silica, the resulting paste is charged in thickness of 2 mm between parallel plates of 2.5 cm diameter, one of the plates is subjected to an angular vibration to another in a frequency of 2 Hz, dynamic viscoelasticity is measured by increasing an average shear stress between the plates from 10 Pa to 10 kPa and correlation between log (shear stress) versus log (storage elasticity) is measured.

Owner:MIYOSHI KASEI +2

Digital audio/video playing device

InactiveUS20060123977A1Guaranteed uptimeExtended service lifeElectrophonic musical instrumentsDigital data processing detailsCantileverDigital audio

A digital audio / video playing device includes a support plate forming a plurality of depressible tabs. Each tab is formed by forming an elongate slit surrounding the tab with a small connection with the support plate to form a cantilever, elastically deflectable tab. A plurality of switch units and a touch control board are arranged between a base plate of the playing device and the support plate. A surface film is attached to the support plate and has a continuous raised-recessed configuration, including a smoothly-raised external ring section and a touch-control internal ring section to allow a user to depress the depressible tabs of the support plate and to operate the touch control board via the surface film.

Owner:MITAC TECH CORP

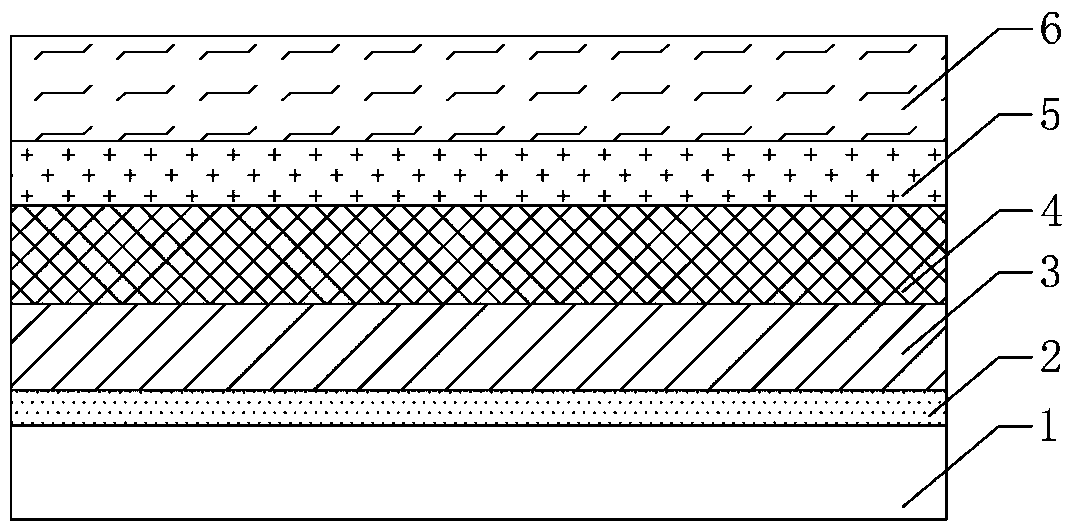

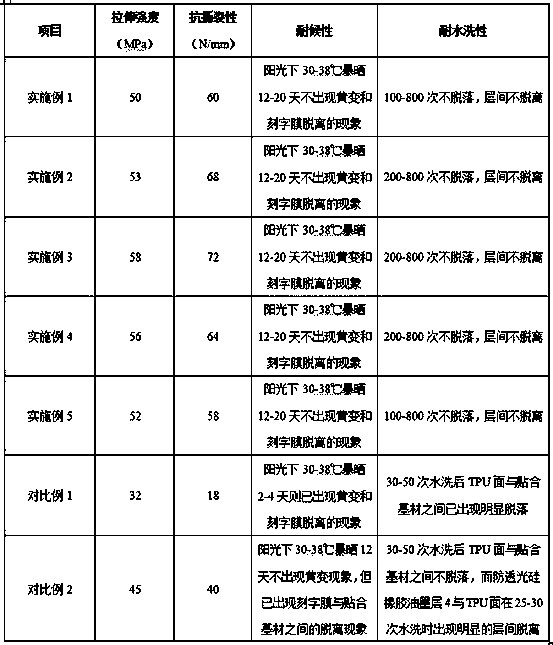

High elasticity silicone rubber heat transfer film and preparation method thereof

ActiveCN108690515AImprove water resistanceImprove processing efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceSurface layer

The invention relates to the technical field of heat transfer films, and specifically relates to a high elasticity silicone rubber heat transfer film and a preparation method thereof. The high elasticity silicone rubber heat transfer film comprises following components from bottom to top: a bearing base material, a release layer, a silicone rubber surface layer, an interface bonding agent layer, and a TPU hot melt adhesive membrane; wherein the interface bonding agent layer is prepared an interface bonding agent, which comprises two resin components. The provided heat transfer film has the advantages of silicone rubber and TPU, such as excellent elasticity, high tearing resistant strength, weatherability, yellowing resistance, washing resistance, and the like. Layering is difficult to happen. Even if the heat transfer film is exposed under the sun, color change or fading is difficult to happen. The water washing fading rate is not more than 0.5%. When the color transfer film is washedwith materials with other colors, other materials will not be dyed easily. The stability is high. The heat transfer film can be easily adhered on multiple materials, the bonding strength is strong, the heat transfer film is not easy to peel off, the stability is good, the hand feeling is fine, the appearance is good, and the service life is long.

Owner:卢汉军

Anti-bacterial cutting-chopping-resistant plastic cutting board and preparation method thereof

The invention provides an anti-bacterial cutting-chopping-resistant plastic cutting board and a preparation method thereof. According to a formula, the plastic cutting board comprises the following raw materials in percentage by weight: 70-90% of a polymer, 5-17% of a natural anti-bacterial agent, 3-8% of a cutting-chopping-resistant agent and 2-5% of a coupling agent, wherein the natural anti-bacterial agent is prepared from 75-90% by weight of loess powder, 3-9% by weight of a honeysuckle leaf extractive, 2-6% by weight of a ficus carica leaf extractive and 5-10% by weight of an emblic leaf extractive; the cutting-chopping-resistant agent is prepared from 30-60% by weight of erucicamide, 15-30% by weight of acer truncatum seed oil and 25-40% by weight of dimethyl polysiloxane. Accordingly, the plastic cutting board is prepared by multi-approach processing means, and has not only anti-bacterial, broad-spectrum, efficient, lasting and safe effects, but also a far infra-red radiation effect and the functions of self-cleaning and environmental purification when being high in aging resistance and abrasion resistance and low in possibility of cutting marks, so that the using safety and the dietetic hygiene are improved.

Owner:陆思烨

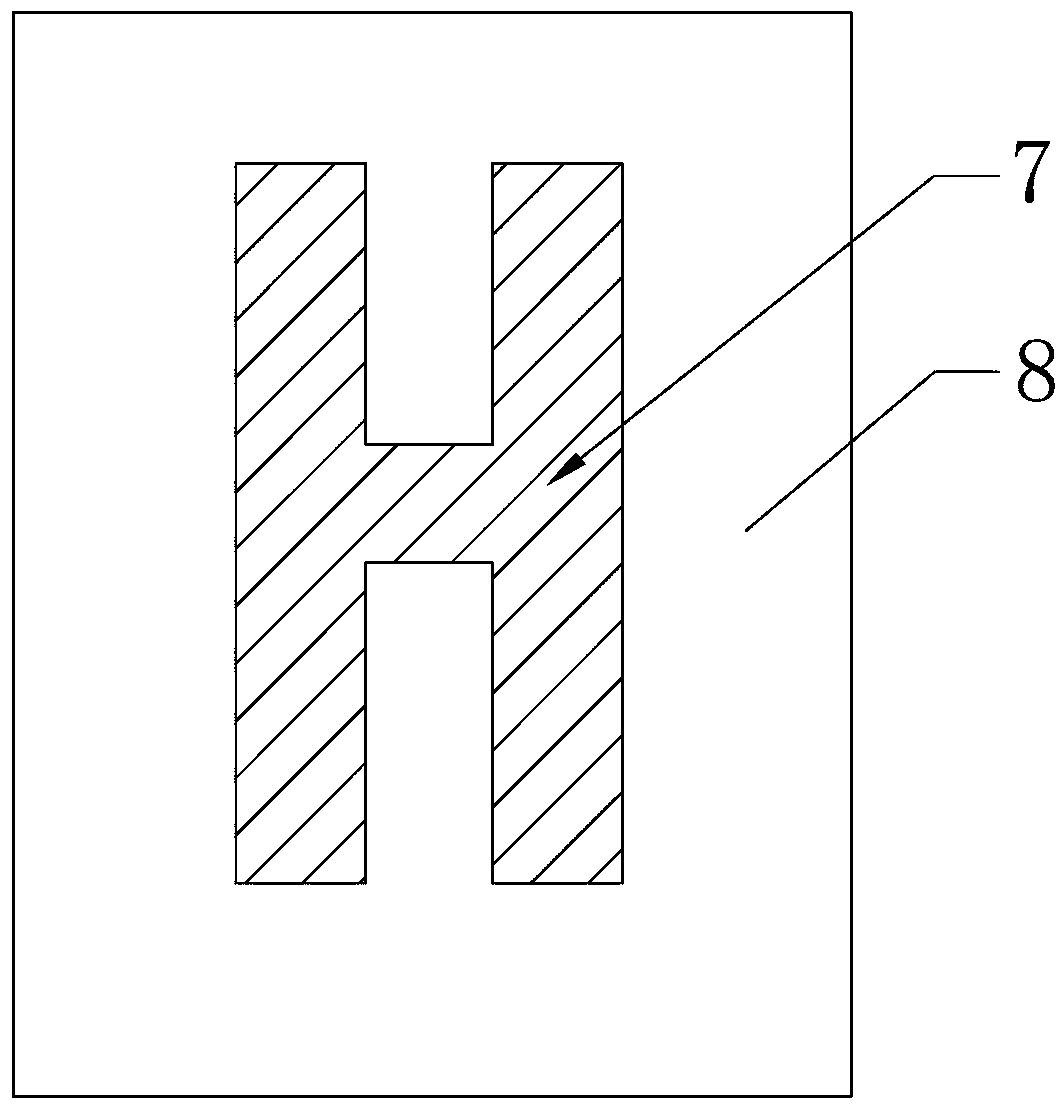

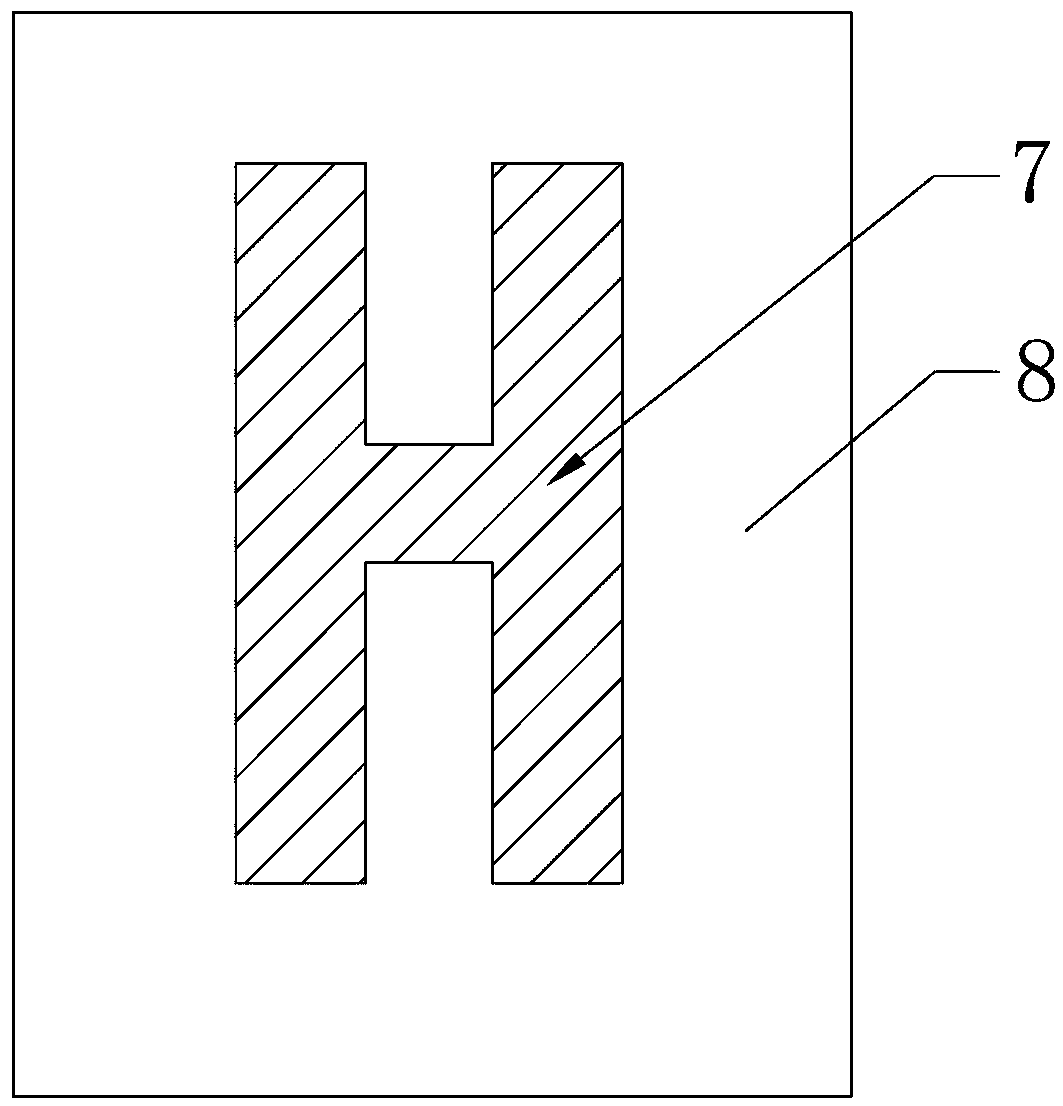

High-elasticity silicone rubber lettering film and preparation method and application method thereof

ActiveCN108610997AIncrease elasticityAvoid deformationPolyureas/polyurethane adhesivesInksRubber materialPolymer science

The invention relates to the technical field of thermal transfer printing lettering film, and in particular, relates to a high-elasticity silicone rubber lettering film and a preparation method and anapplication method thereof. The high-elasticity silicone rubber lettering film comprises a load-bearing substrate, a release layer, a surface layer silicone rubber ink layer, an anti-photopermeable silicone rubber ink layer, an adhesive interfacial agent layer and a TPU hot melt adhesive film which are connected from bottom to top successively; the adhesive interfacial agent layer is prepared from an adhesive interfacial agent, and the adhesive interfacial agent is an adhesive interfacial agent containing dual-resin components. The silicone rubber lettering film has the advantages of both thesilicone rubber material and the TPU material, has good elasticity, tearing strength, weatherability, yellowing resistance, water washing resistance and other comprehensive properties, has layers noteasy to separate, is not easy to discolor or fade by sunlight exposure, and has the water-washing fading rate not less than 0.5%, is not easy to dye when being mixed and washed with materials with other colors, and is high in stability, easy to bond with a variety of materials, high in bonding strength, not easy to peel off, good in stability, delicate in hand feeling, good in aesthetic degree, and long in service life.

Owner:卢汉军

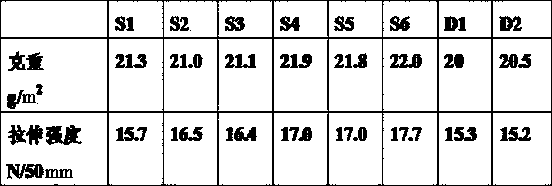

Preparation method of light and thin all-cotton non-woven fabric, non-woven fabric and application

ActiveCN108660606ASmooth to the touchGood hygroscopicityNon-woven fabricsVegetal fibresNonwoven fabricIonic liquid

The invention discloses a preparation method of light and thin all-cotton non-woven fabric. The preparation method includes the following steps that S1, cotton fibers are arranged, blowing, combing and lapping are carried out, and cotton fiber nets are obtained; S2, the cotton fiber nets obtained in S1 are subjected to primary spunlace, and spunlace non-woven fabric with the gram weight of 20-28 g / m<2> is prepared; S3, the non-woven fabric obtained after primary spunlace is guided into a lye tank for mercerization, and after mangling is completed, the non-woven fabric is guided out for scouring, bleaching and washing; S4, the mercerized non-woven fabric carrying water is soaked in a normal-temperature cellulose ionic liquid solution, and after mangling is completed, the non-woven fabric issubjected to secondary spunlace and drying; S5, the non-woven fabric is subjected to washing and secondary drying, and the finished light and thin all-cotton non-woven fabric is obtained. The all-cotton non-woven fabric is adopted as the raw material, and through mercerization, then by means of binding points formed after regenerated cellulose is left in the cotton nets of the non-woven fabric, the obtained all-cotton non-woven fabric is light, thin, rich in gloss and smooth in touch, and has the good hygroscopicity and tensile property. The invention further discloses the light and thin all-cotton non-woven fabric and application thereof.

Owner:阳光卫生医疗科技江阴有限公司

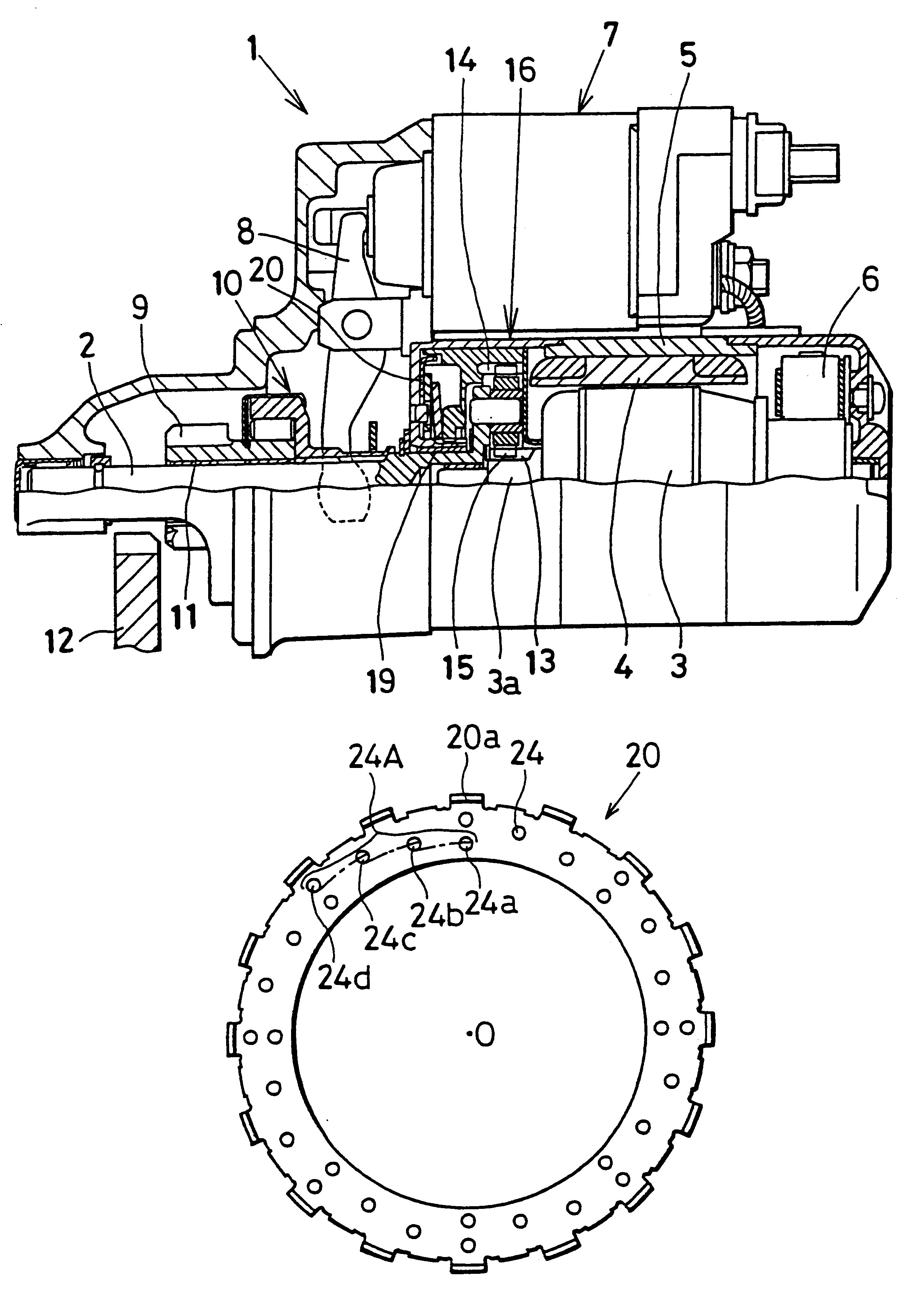

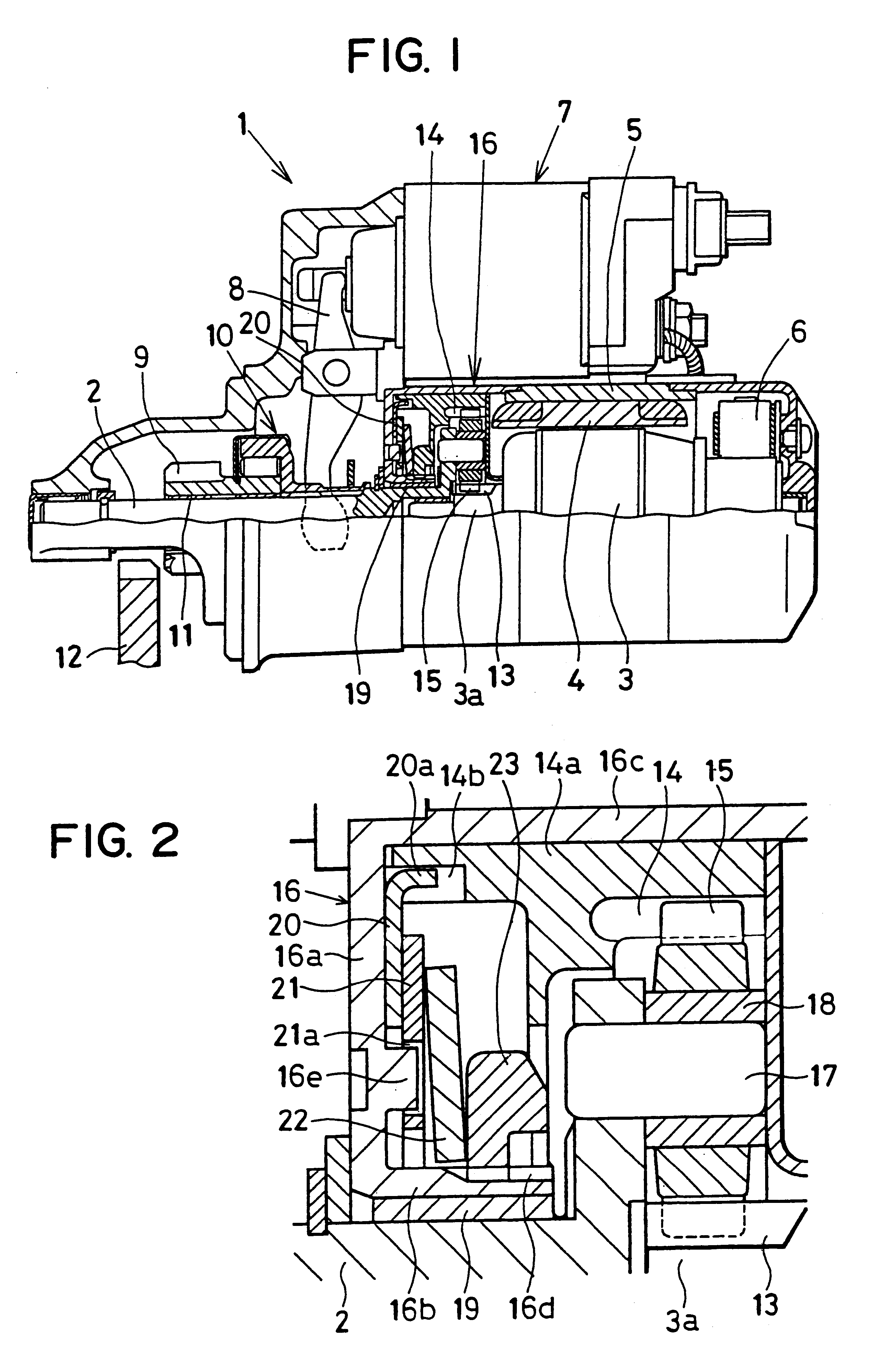

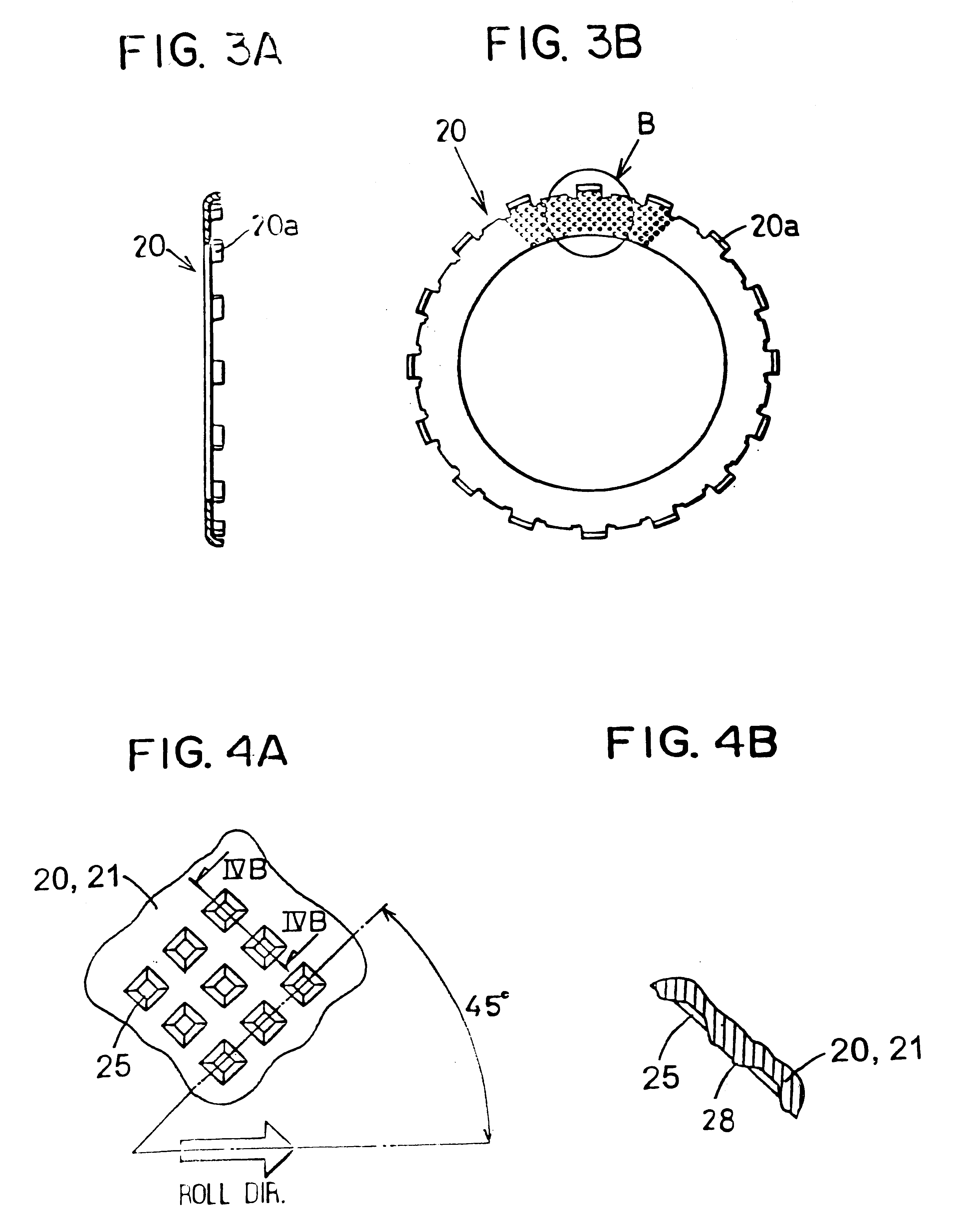

Shock absorber

InactiveUS6887160B2Difference in heightSmooth to the touchPower operated startersSlip couplingEngineeringShock absorber

A shock absorber for a starter is presented. The shock absorber includes a rotary disk, a stationary disk and a disk spring. The rotary disk is pressed by the disk spring against a stationary disk to generate frictional force when the rotary disk is rotated by an excessive shock thereby absorbing the shock. The rotary disk has a plurality of press-formed rectangular dimples at a surface opposite the stationary disk, and each side of each the rectangular dimple inclines to a direction of rolling of the raw material of the rotary disk.

Owner:DENSO CORP

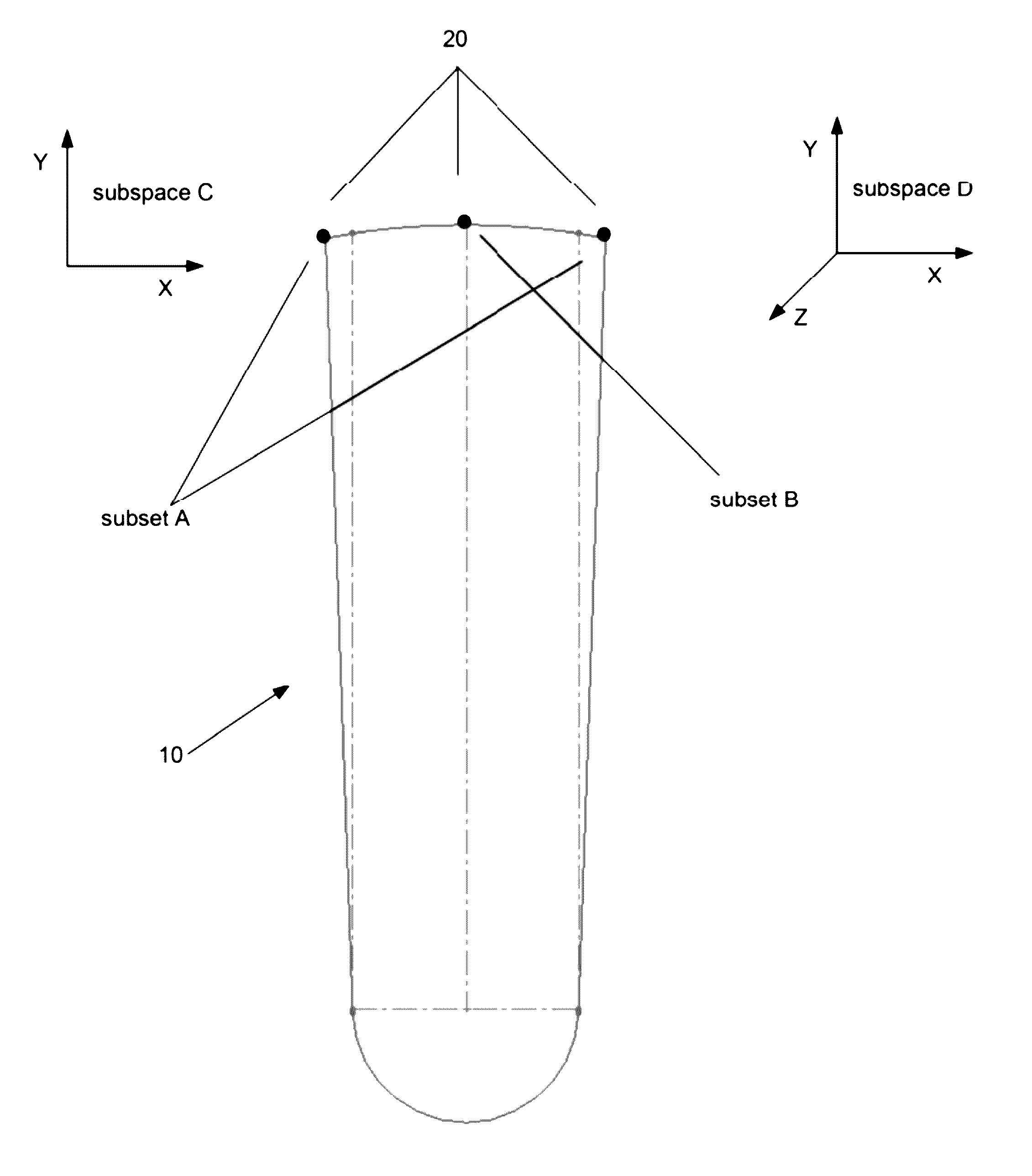

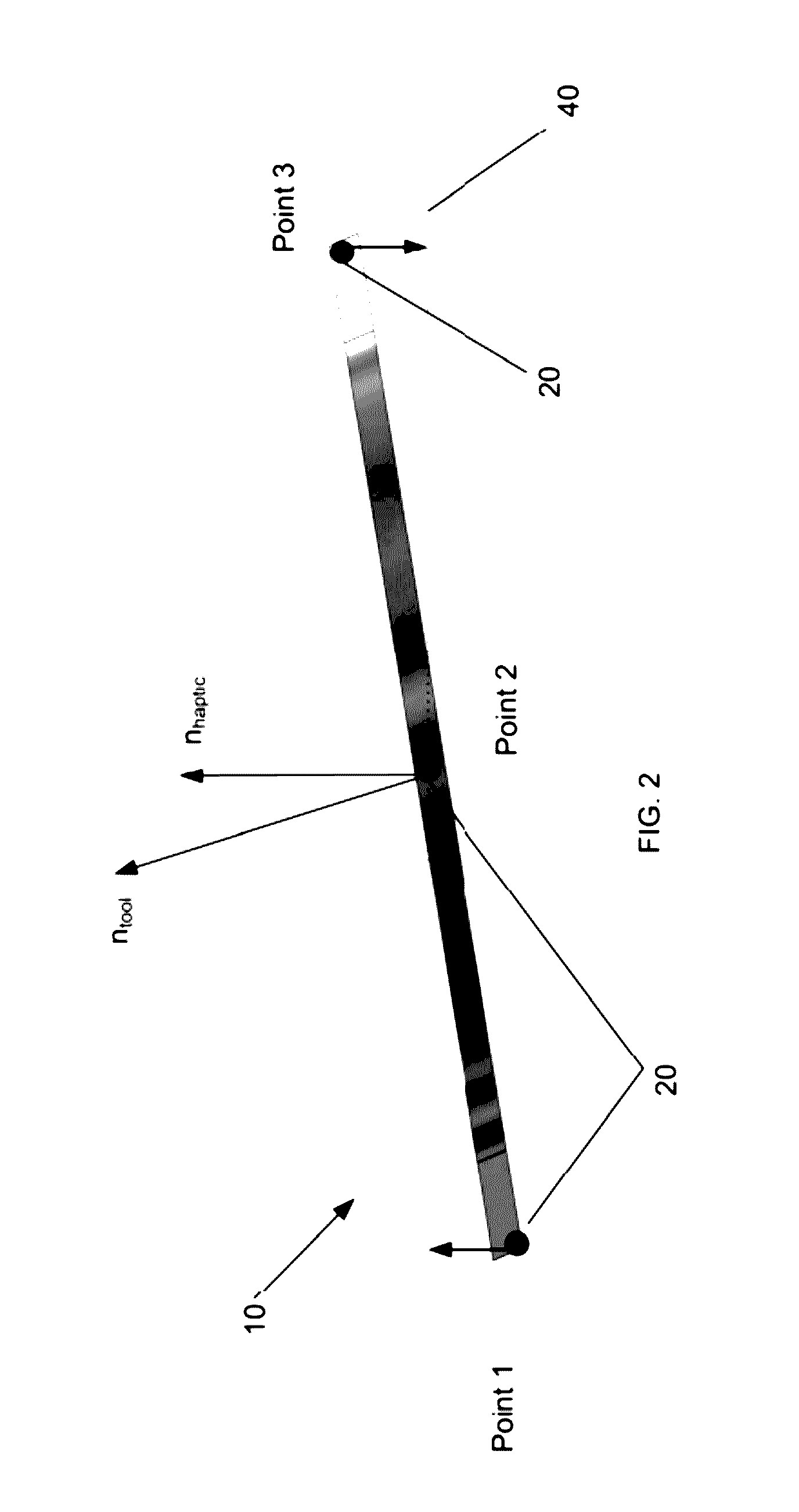

System and method for providing substantially stable haptics

ActiveUS9588583B2Smooth to the touchInput/output for user-computer interactionSurgical navigation systemsGeometric primitiveHaptic interaction

A system for providing substantially stable haptics includes at least one computer configured to identify a first subset and a second subset of haptic interaction geometric primitives for a virtual tool. The computer is configured to determine based on the first subset, haptic forces in a first subspace. The computer is also configured to determine based on the second subset, haptic forces in a second subspace different from the first subspace.

Owner:MAKO SURGICAL CORP

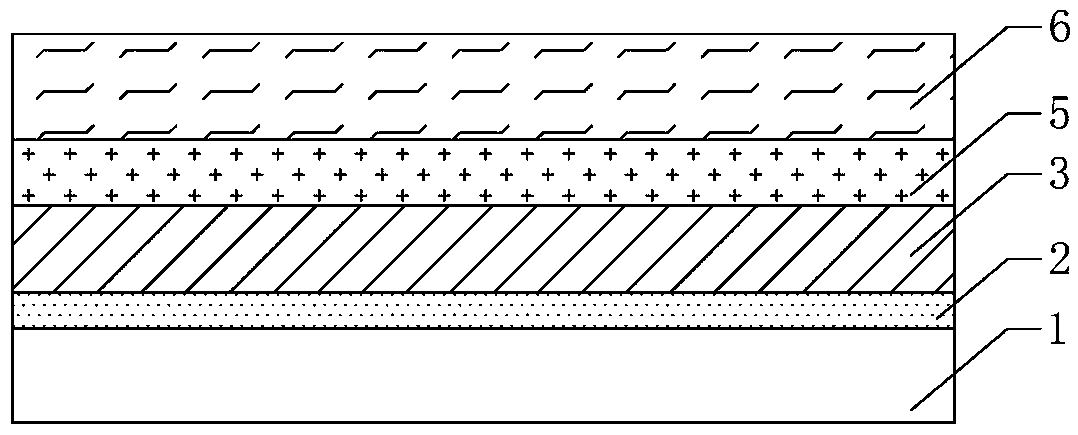

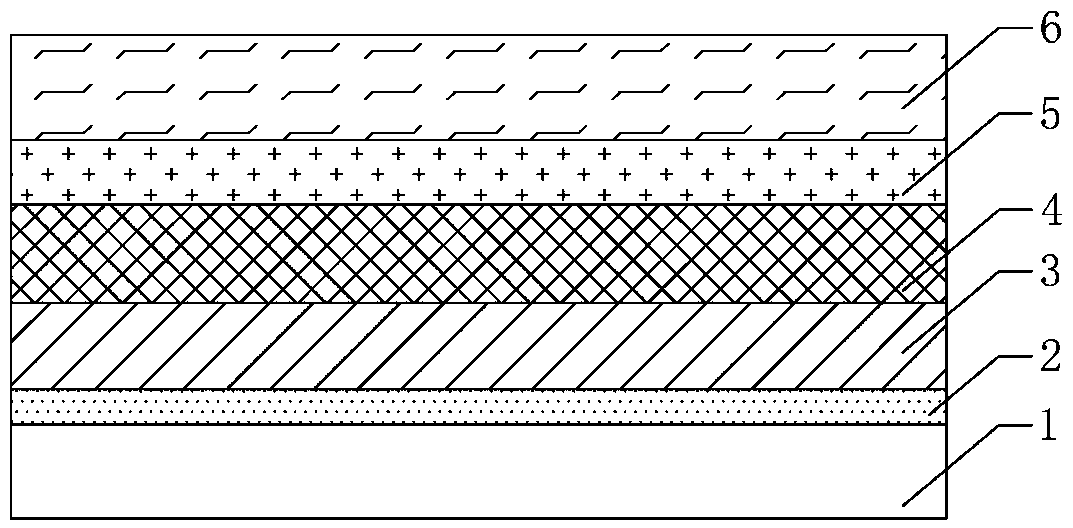

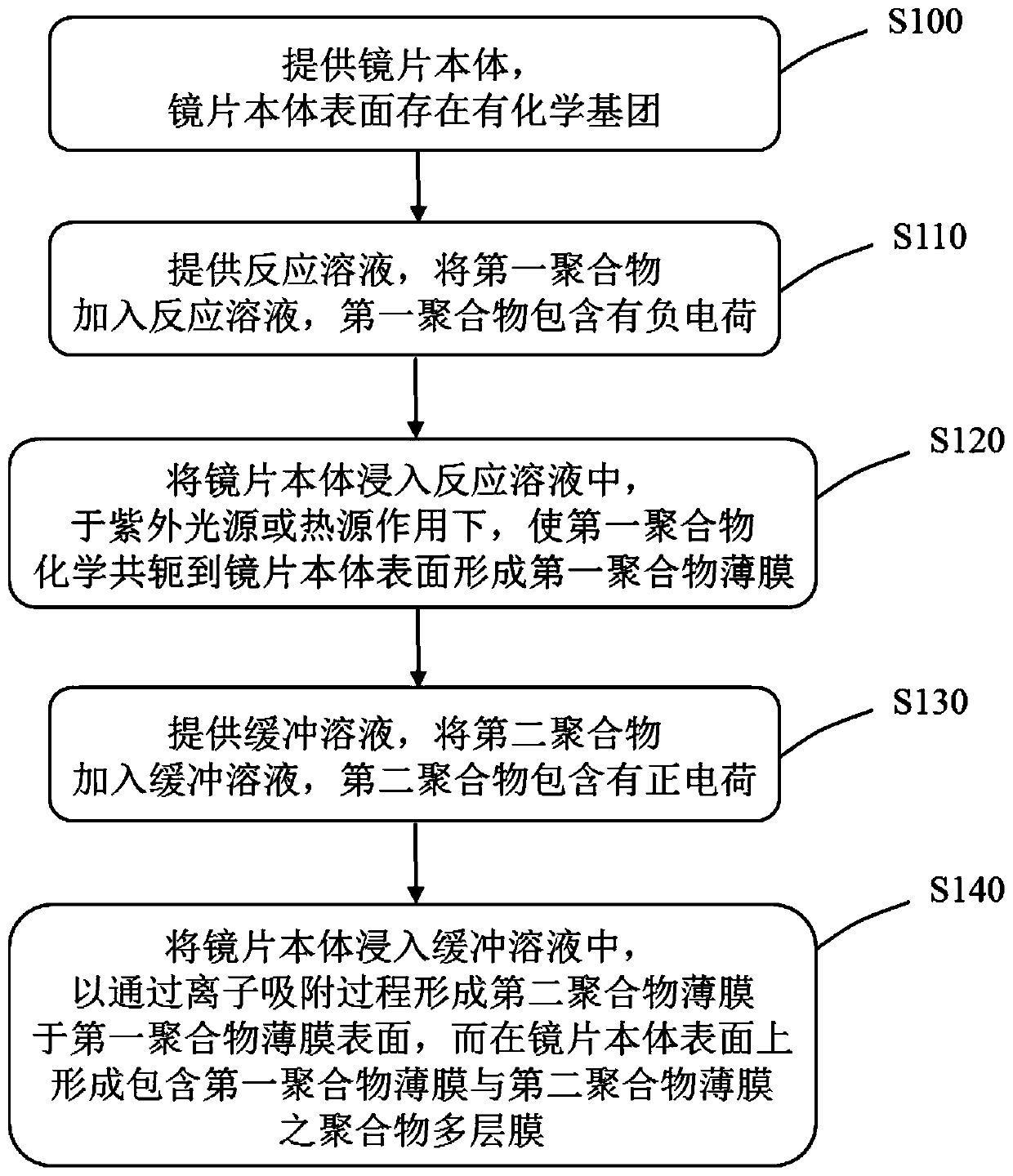

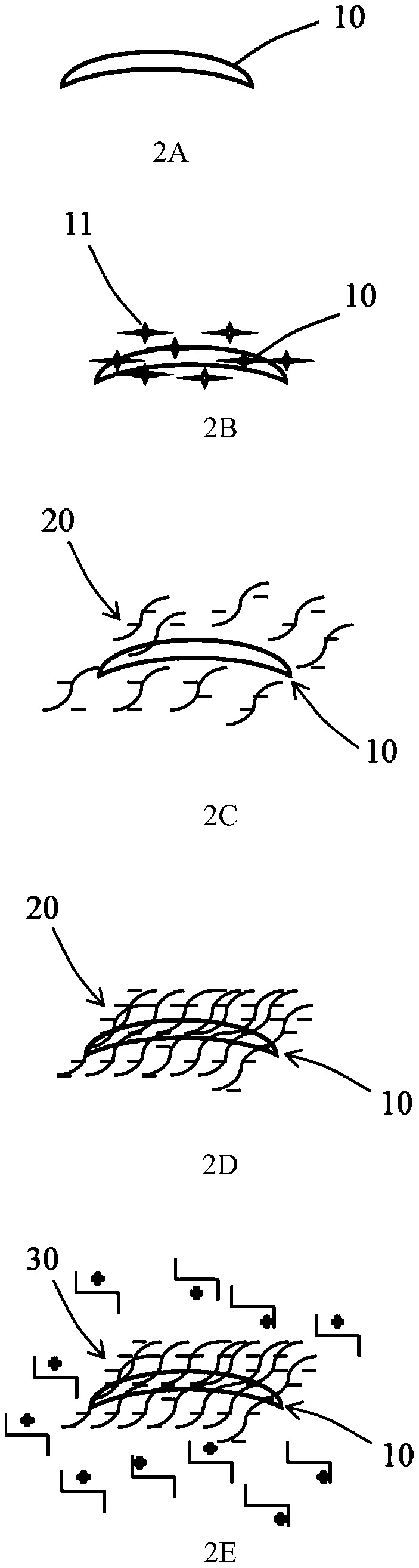

Method for preparing contact lens having polymer multilayer film

InactiveCN110082931ABeneficial technical effectSmooth to the touchOptical partsPOLYMER SUBSTANCEPolymer science

A method for preparing a contact lens having a polymer multilayer film is provided. The method includes chemically conjugating a polymer film to a surface of a lens body, and then producing another polymer film by utilizing ion adsorption between a negative charge and a positive charge of the polymer substance to form a polymer multilayer film comprising the two polymer films bonded well on the surface of the lens body. When the contact lens is worn, the polymer multilayer film provides a smoother touch to the surface of the eye, and a higher water content can be achieved, which improves the comfort of wearing.

Owner:UNICON OPTICAL

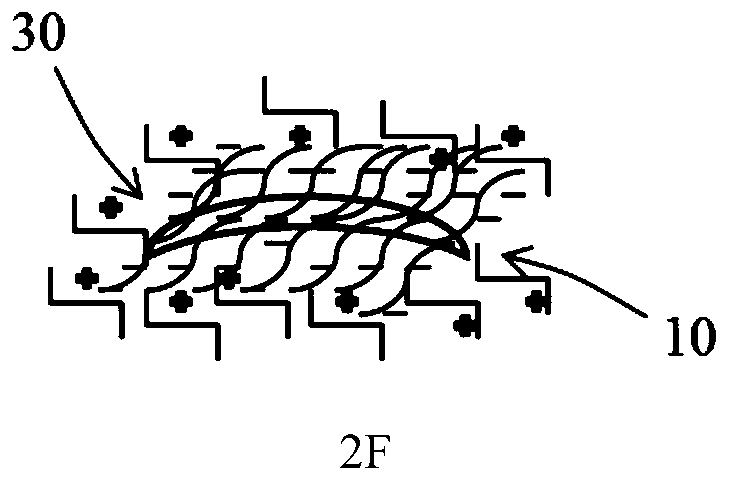

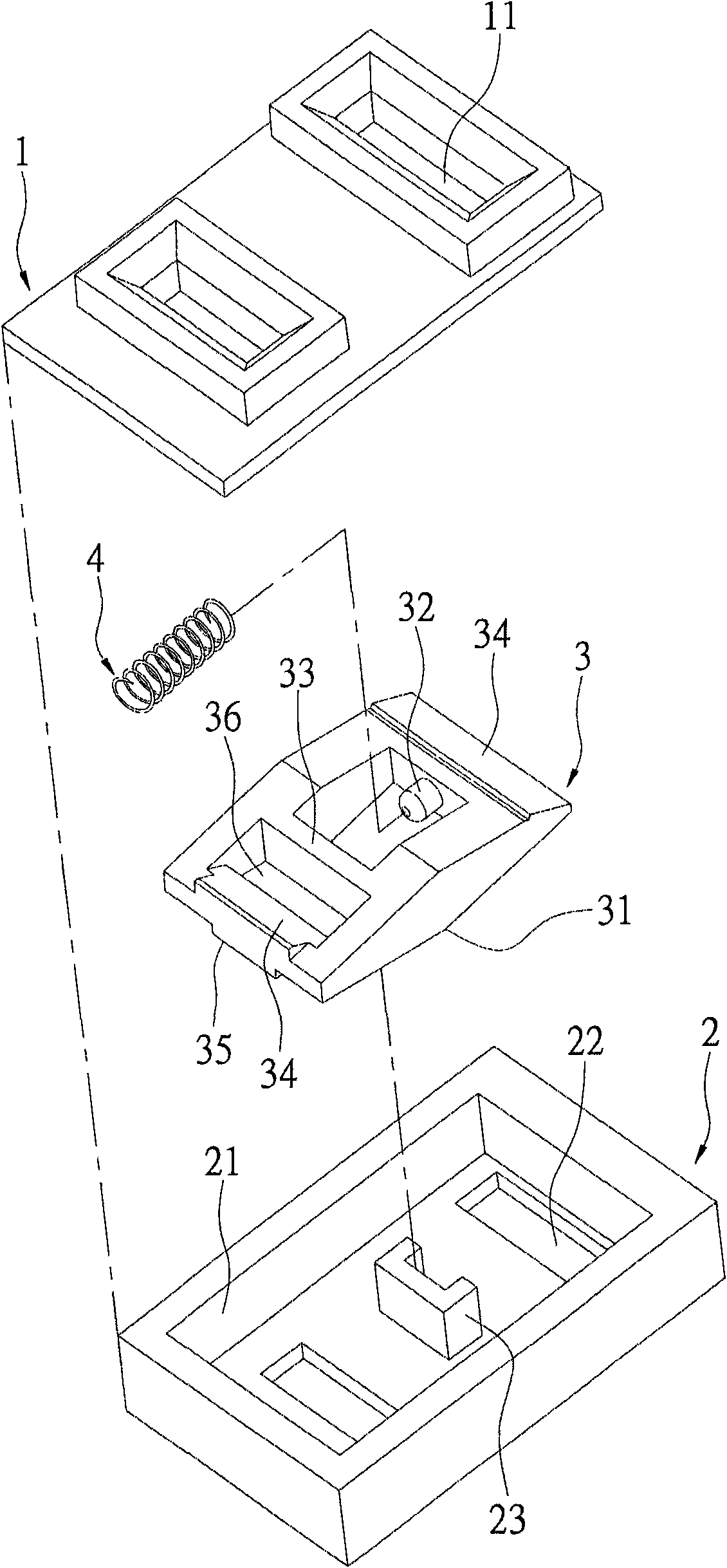

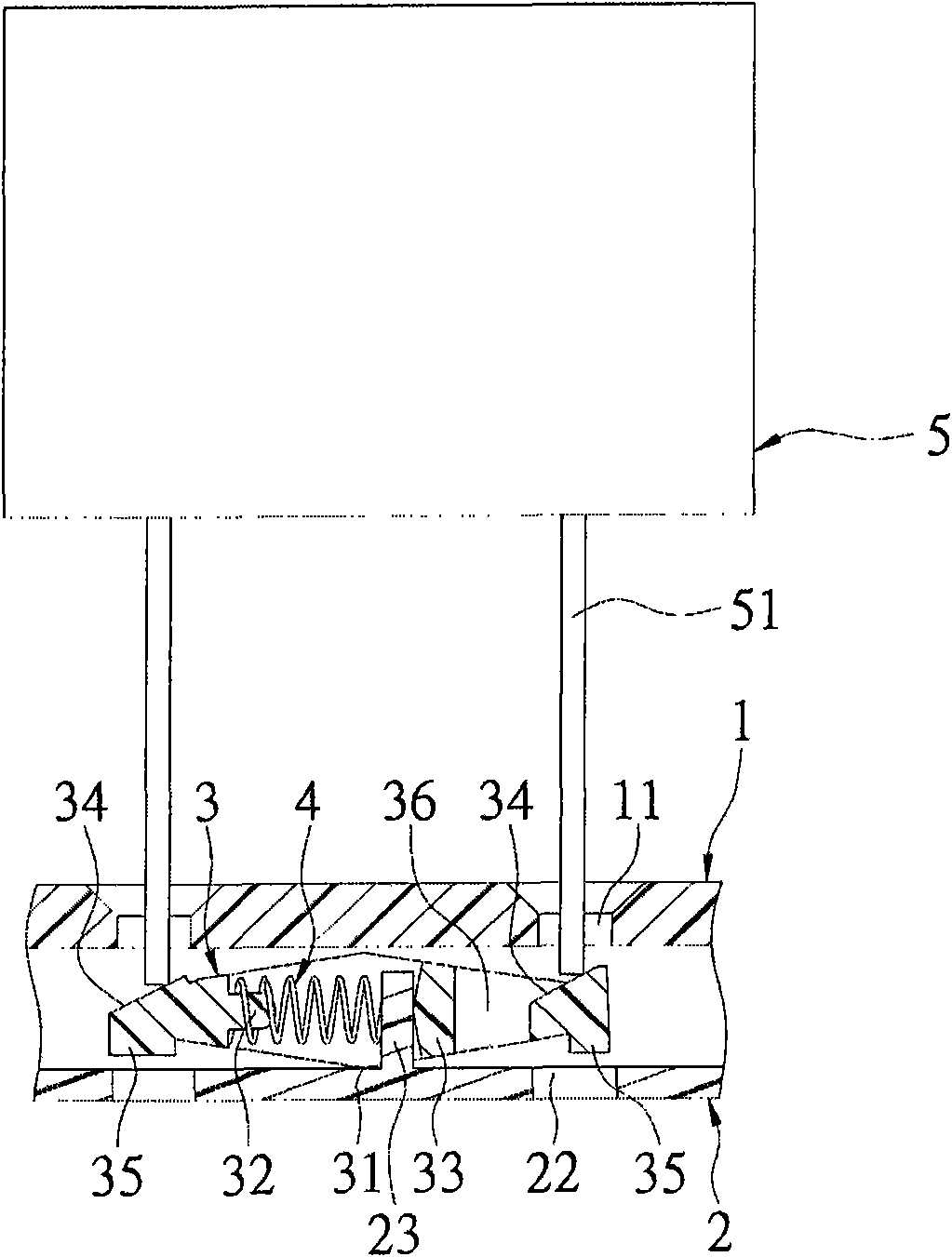

Safety device for socket

The invention provides a safety device for a socket, which comprises an upper cover, a lower cover, a cover board body and an elastic element. The upper cover is provided with two first jacks; the lower cover is arranged below the upper cover, provided with two second jacks corresponding to the first jacks and combined with the upper cover; the cover board body is arranged between the upper and lower covers in such a way that the cover board body can move towards the left and right sides, and the cover board body is provided with a pivot part, two oblique surfaces corresponding to the first jacks and two braking parts corresponding to the second jacks, wherein the cover board body is supported on the lower cover at the pivot part; and the elastic element supports against the cover board body so that the cover board body is shielded between the two first jacks and the two second jacks in a normal state. Therefore, a safety device for the socket is designed to prevent foreign materialsfrom being inserted into the socket so as to avoid danger of an electric shock.

Owner:POWERTECH INDAL

Health-care glossy ganoderma jelly and preparation method thereof

The invention discloses health-care glossy ganoderma jelly and belongs to the technical field of jelly. Every 100 g of the jelly is prepared from raw materials in parts by weight as follows: 0.13-0.18 g of xanthan gum, 1.2-1.8 g of carrageenan, 0.35-0.4 g of potassium chloride, 15-20 g of white granulated sugar, 0.05-0.15 g of citric acid and 77-82 mL of a glossy ganoderma liquid. The invention further provides a preparation method of the health-care glossy ganoderma jelly. The method is simple and easy to operate, and the prepared health-care glossy ganoderma jelly tastes good and is novel, green, natural, nutritional, healthy, health-care, fashionable and casual food which is suitable for people of all ages and is a combination of Chinese and Western elements.

Owner:HEBEI UNIV OF ENG

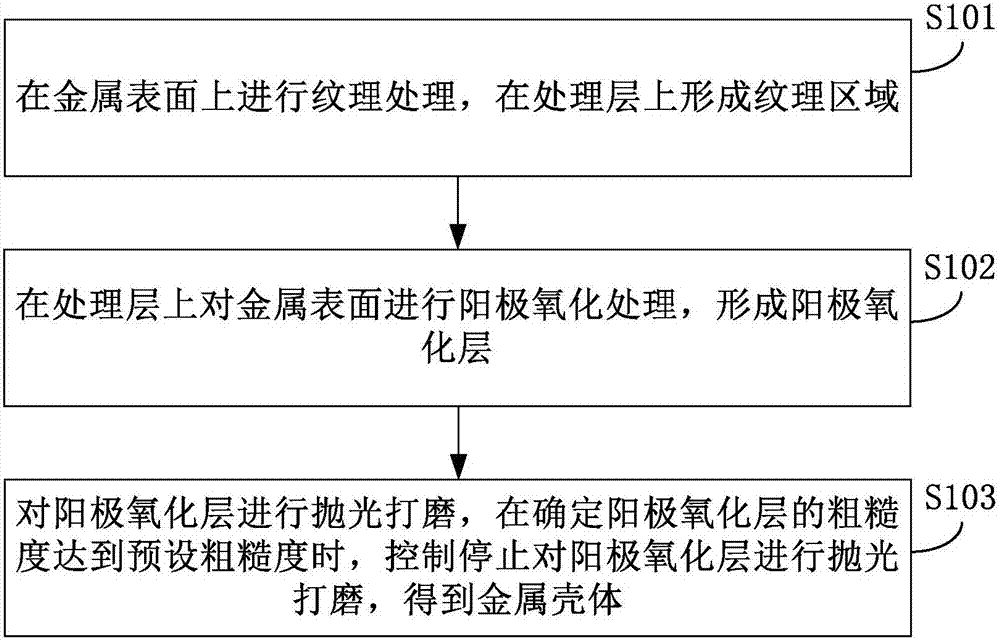

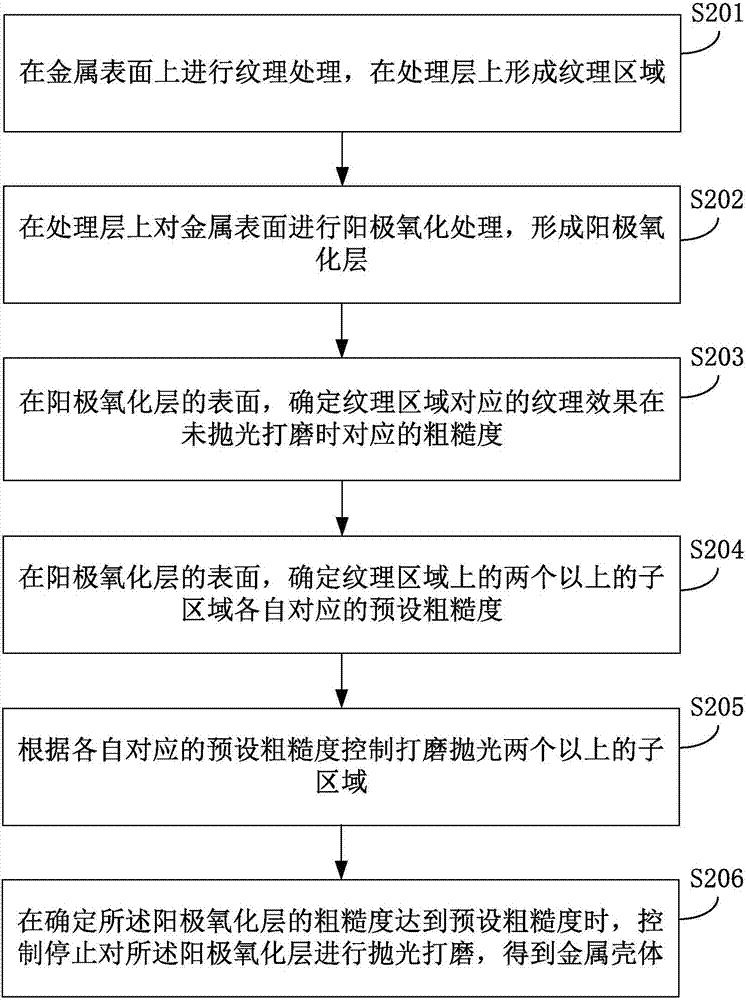

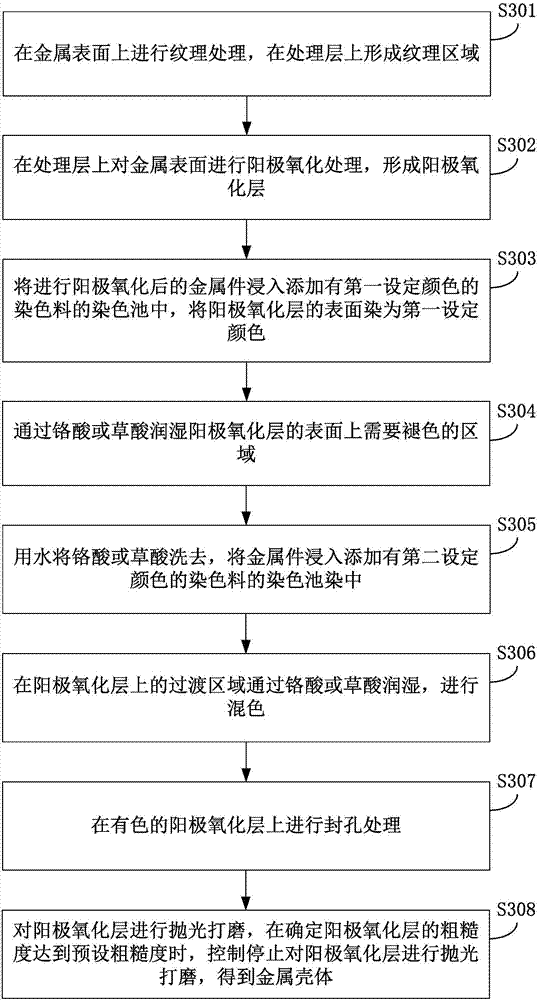

Method for manufacturing metal shell, metal shell and terminal equipment

ActiveCN107338462AImprove the effectSmooth to the touchAnodisationDecorative surface effectsAnodic oxidationMetal

The invention discloses a method for manufacturing a metal shell, the metal shell and terminal equipment. The method comprises the steps that texture processing is conducted on the surface of metal, and a texture region is formed on a processing layer; anodic oxidation processing is conducted on the surface of metal on the processing layer, and an anodic oxidation layer is formed; and polishing and grinding are conducted on the anodic oxidation layer, and when it is determined the roughness of the anodic oxidation layer reaches the preset roughness, polishing and grinding of the anodic oxidation layer are controlled to be stopped, and the metal shell is obtained. By the adoption of the technical scheme, the finished metal shell is made to visually have the rough textured effect and have the smooth touch, and the visual and tactile effects of the metal surface are improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Wear-resistant and easily-stain-removing luggage fabric and processing method thereof

ActiveCN104044322AEasy to print and dyeRemove surface glossLamination ancillary operationsSynthetic resin layered productsPrepolymerChemistry

The invention relates to a wear-resistant and easily-stain-removing luggage fabric and a processing method thereof. The wear-resistant and easily-stain-removing luggage fabric is characterized by comprising base cloth made of polyester air texturing yarns or an interlaced yarn fabric, wherein the upper surface and the lower surface of the base cloth are both coated with a thin low-polymerization-degree low-modulus polyurethane adhesive layer; the surface layers of the low-modulus polyurethane adhesive layer are respectively coated with a thin-layer high-modulus polyurethane layer; 0.5%-10% of cellulose prepolymer components for extinction, resisting blocking and aging are added in high-modulus polyurethane adhesive in a mixing manner; the upper surface and the lower surface of the base cloth are coated twice; the low-modulus polyurethane adhesive layer is coated with primer for the first time so as to be used as a blocking layer; the high-modulus polyurethane adhesive layer is coated with surface adhesive for the second time so as to be used for enhancing the waterproofness and the wear resistance. The wear-resistant and easily-stain-removing luggage fabric and the processing method thereof, which are provided by the invention, are widely adopted for processing products of various luggage, tool bags, protective covers, tents and the like.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

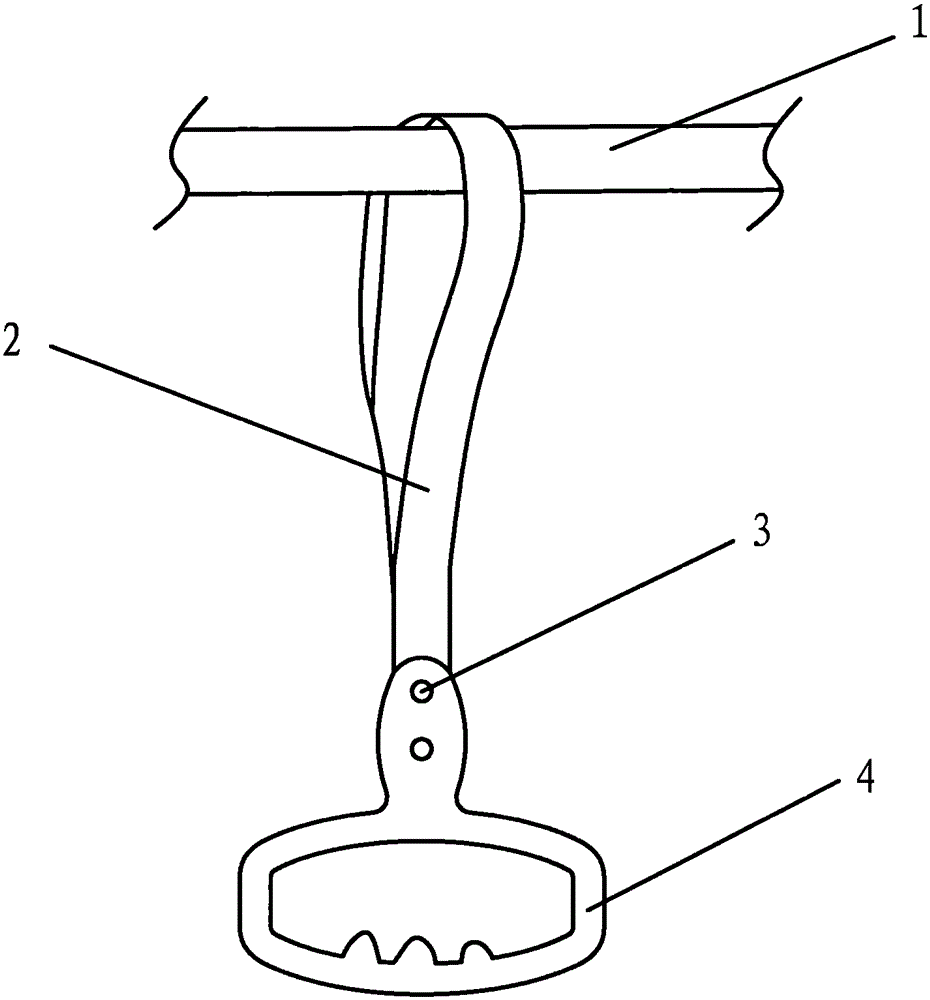

Bus and subway handle with antibacterial and healthcare function and preparation method thereof

The invention provides a bus and subway handle with an antibacterial and healthcare function and a preparation method thereof, wherein the handle of the bus and the subway is fastened with a hammock through a bolt, then surrounds a cross-bar in the bus and the subway, and the handle in the bus and the subway is prepared from the following components in percentage by weight: 45 to 75 percent of makrolon, 20 to 30 percent of acrylonitrile-butadiene-styrene / polycarbonate, 3 to 20 percent of natural antibacterial agent, 1.2 to 3.5 percent of lettuce seed oil, and 0.8 to 1.5 percent of coupling agent. The raw materials are prepared into the handle of the bus and the subway by multiple ways of processing methods, so that microorganisms such as various harmful bacteria, fungus and germs which adhere to the handle of the bus and the subway can be killed, and the handle can automatically emit far infrared and slowly release out a health protection component, so the human immune capability is improved, the effects of self-cleaning and anti-fouling, odor eliminating, and environment purifying are realized, and the health of passengers is guaranteed. Meanwhile, excellent oxidation resistance and better mechanical strength are shown, and the service life is greatly prolonged.

Owner:陆思烨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com