High elasticity silicone rubber heat transfer film and preparation method thereof

A silicone rubber, high-elasticity technology, used in adhesives, temperature recording methods, film/sheet adhesives, etc., can solve the problems of short service life, stiff hand, and reduced aesthetics, and achieve long service life and cool touch. Slippery, fade-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

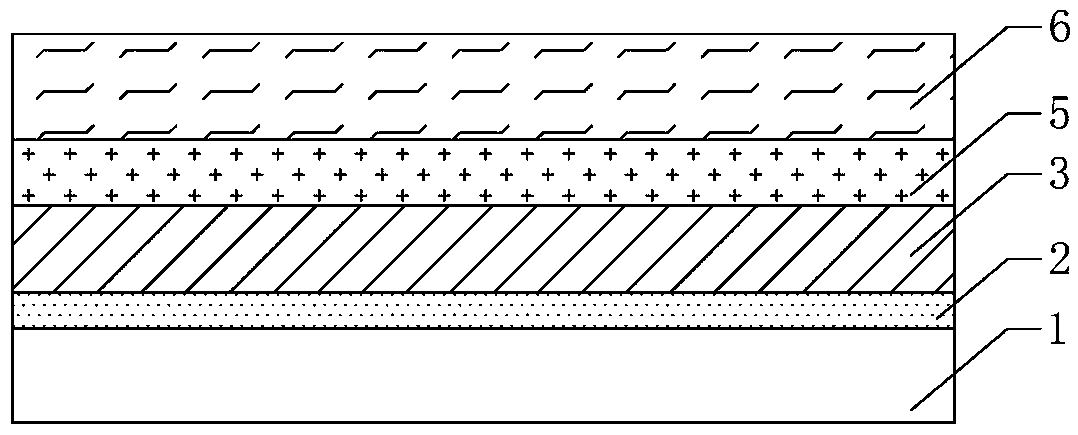

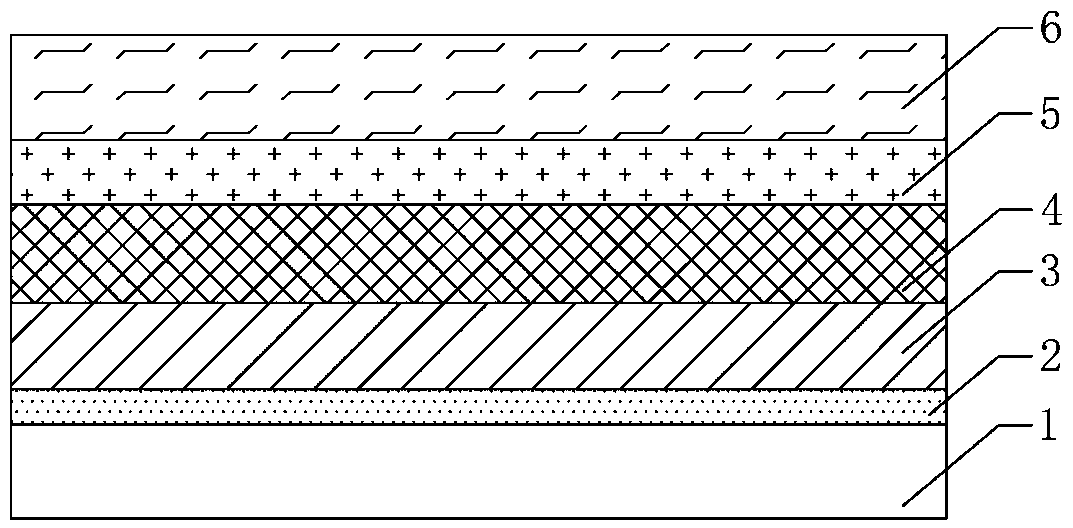

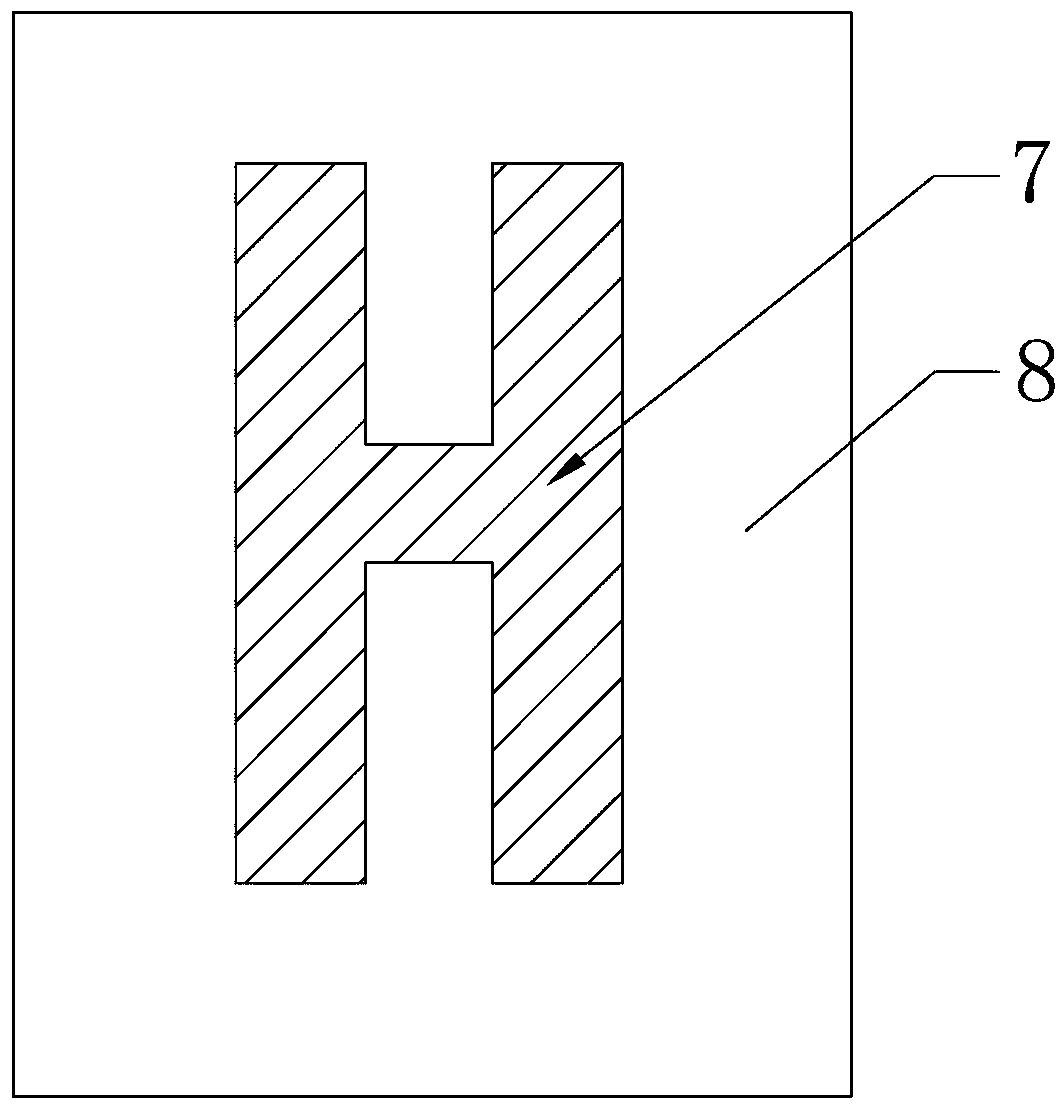

[0091] See figure 1 , 3 , a high-elastic silicone rubber lettering film, said high-elastic silicone rubber lettering film includes a load-bearing substrate 1, a release layer 2, a surface silicon rubber layer 3, an adhesive interface agent layer 5, and a TPU thermal insulation film sequentially connected from bottom to top. Melt adhesive film 6; the adhesive interface agent layer 5 is made of an adhesive interface agent, and the adhesive interface agent is an adhesive interface agent with two resin components.

[0092] The carrying substrate 1 is a polyester frosted film with a thickness of 0.08 mm.

[0093] The thickness of the release layer 2 is 0.8 μm, the thickness of the surface silicone rubber layer 3 is 45 μm, the thickness of the adhesive interface agent layer 5 is 10 μm, and the thickness of the TPU hot melt adhesive film 6 is 80 μm.

[0094] The release layer 2 is obtained by spraying the release liquid on the frosted surface of the polyester frosted film and dryin...

Embodiment 2

[0117] The difference between this embodiment and above-mentioned embodiment 1 is:

[0118] The carrying substrate 1 is a polyester frosted film with a thickness of 0.09mm.

[0119] The thickness of the release layer 2 is 0.9 μm, the thickness of the surface silicone rubber layer 3 is 48 μm, the thickness of the adhesive interface agent layer 5 is 11 μm, and the thickness of the TPU hot melt adhesive film 6 is 90 μm.

[0120] The release layer 2 is obtained by spraying the release liquid on the frosted surface of the polyester frosted film and drying it. The release liquid is composed of water-based fluorine release liquid and water in a weight ratio of 1:48 mixture.

[0121] Described surface layer silicone rubber layer 3 is made by surface layer silicone rubber, and described surface layer silicone rubber comprises the raw material of following weight portion:

[0122] Methyl vinyl silicone rubber 56 parts

[0123] Silicone rubber color masterbatch 38 parts

[0124] Plat...

Embodiment 3

[0143] The difference between this embodiment and above-mentioned embodiment 1 is:

[0144] The carrying substrate 1 is a polyester frosted film with a thickness of 0.10 mm.

[0145] The thickness of the release layer 2 is 1.0 μm, the thickness of the surface silicone rubber layer 3 is 50 μm, the thickness of the adhesive interface agent layer 5 is 12 μm, and the thickness of the TPU hot melt adhesive film 6 is 100 μm.

[0146] The release layer 2 is obtained by spraying the release liquid on the frosted surface of the polyester frosted film and drying it. The release liquid is composed of water-based fluorine release liquid and water in a weight ratio of 1:50 mixture.

[0147] Described surface layer silicone rubber layer 3 is made by surface layer silicone rubber, and described surface layer silicone rubber comprises the raw material of following weight portion:

[0148] Methyl vinyl silicone rubber 58 parts

[0149] Silicone rubber color masterbatch 40 parts

[0150] Pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com