Solvent-less high-light finish ultrafine fiber polyurethane synthetic leather and preparation method thereof

A solvent-free polyurethane and ultra-fine fiber technology, applied in textiles and papermaking, can solve the problems of DMF residue, coarse wrinkles, poor flatness, etc., and achieve excellent hydrolysis resistance, smooth touch, and high wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

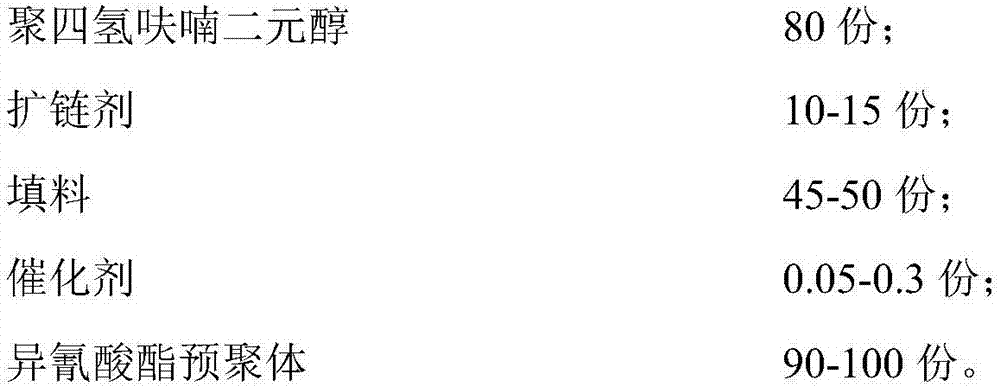

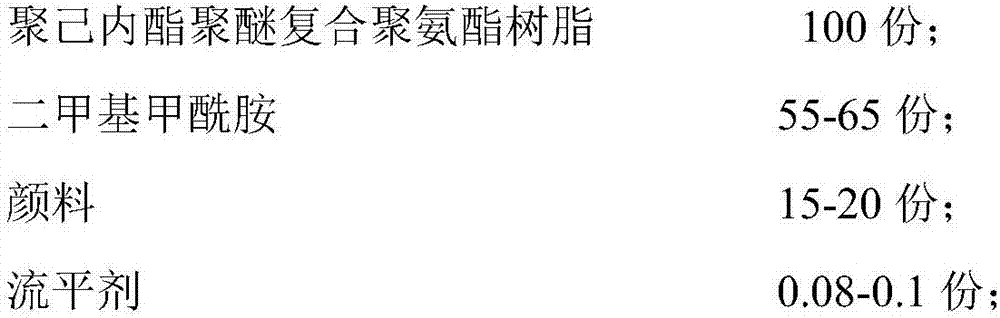

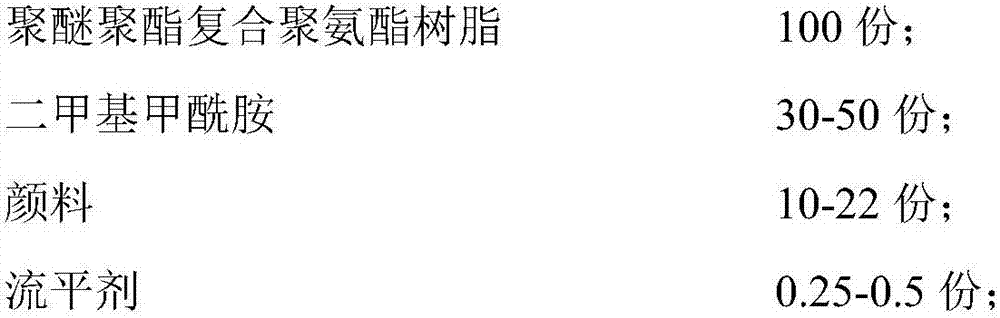

Method used

Image

Examples

Embodiment 1

[0046] Evenly coat a layer of surface layer polyurethane slurry with a thickness of 13 silk on the high-gloss mirror film, and dry at 120°C to form a surface layer polyurethane layer; evenly coat a layer of thickness of 30 silk middle layer polyurethane slurry on the surface layer polyurethane layer The material is dried at 140°C to form a middle polyurethane layer; a layer of polyether-type solvent-free polyurethane slurry with a thickness of 40 filaments is uniformly coated on the middle polyurethane layer, and the polyether-type solvent-free polyurethane is formed after pre-reaction at 90°C for 3 minutes. Layer: 0.7mm microfiber polyurethane synthetic leather is fixed at 140°C, after cooling, it is laminated with polyether-type solvent-free polyurethane layer, cured in an oven at 140°C for 10 minutes, rolled together, and then cured in a 70°C curing room for 24 hours; The mirror film is peeled off to obtain a finished product of solvent-free high-gloss varnish microfiber pol...

Embodiment 2

[0055]Evenly coat a layer of surface polyurethane slurry with a thickness of 15 silk on the high-gloss mirror film, and dry at 125°C to form a surface polyurethane layer; evenly coat a layer of 25 silk middle layer polyurethane slurry on the surface polyurethane layer The material is dried at 120°C to form the middle polyurethane layer; a layer of polyether-type solvent-free polyurethane slurry with a thickness of 45 filaments is evenly coated on the middle polyurethane layer, and the polyether-type solvent-free polyurethane slurry formed after pre-reaction at 100°C for 2.5 minutes Polyurethane layer: 0.9mm microfiber polyurethane synthetic leather is fixed at 150°C, after cooling, it is laminated with polyether solvent-free polyurethane layer, cured in an oven at 150°C for 8 minutes, rolled together, and then cured in a 70°C curing room for 24 hours; The high-gloss mirror film is peeled off to obtain a finished product of solvent-free high-gloss paint surface microfiber polyur...

Embodiment 3

[0064] Evenly coat a layer of surface layer polyurethane slurry with a thickness of 16 silk on the high-gloss mirror film, and dry at 130°C to form a surface layer polyurethane layer; evenly coat a layer of thickness of 30 silk middle layer polyurethane slurry on the surface layer polyurethane layer The material is dried at 140°C to form the middle polyurethane layer; a layer of polyether-type solvent-free polyurethane slurry with a thickness of 50 filaments is evenly coated on the middle polyurethane layer, and the polyether-type solvent-free polyurethane is formed after pre-reaction at 110°C for 2 minutes. layer; 1.2mm microfiber polyurethane synthetic leather is fixed at 160°C, after cooling, it is laminated with polyether type solvent-free polyurethane layer, and cured in an oven at 150°C for 10 minutes. The mirror film is peeled off to obtain a finished product of solvent-free high-gloss varnish microfiber polyurethane synthetic leather.

[0065] Microfiber polyurethane s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com