Method for preparing single-layer graphene film on SiO2 substrate directly

A single-layer graphite, direct technology, applied in the field of preparing two-dimensional nanomaterial single-layer graphene sheets directly on SiO2 substrates, can solve the problem of losing the properties of single-layer graphene layers, graphene sheets with many chemical impurities, and sheet Strong interaction with the substrate and other issues, to achieve the effect of low pressure, low cost and tight combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

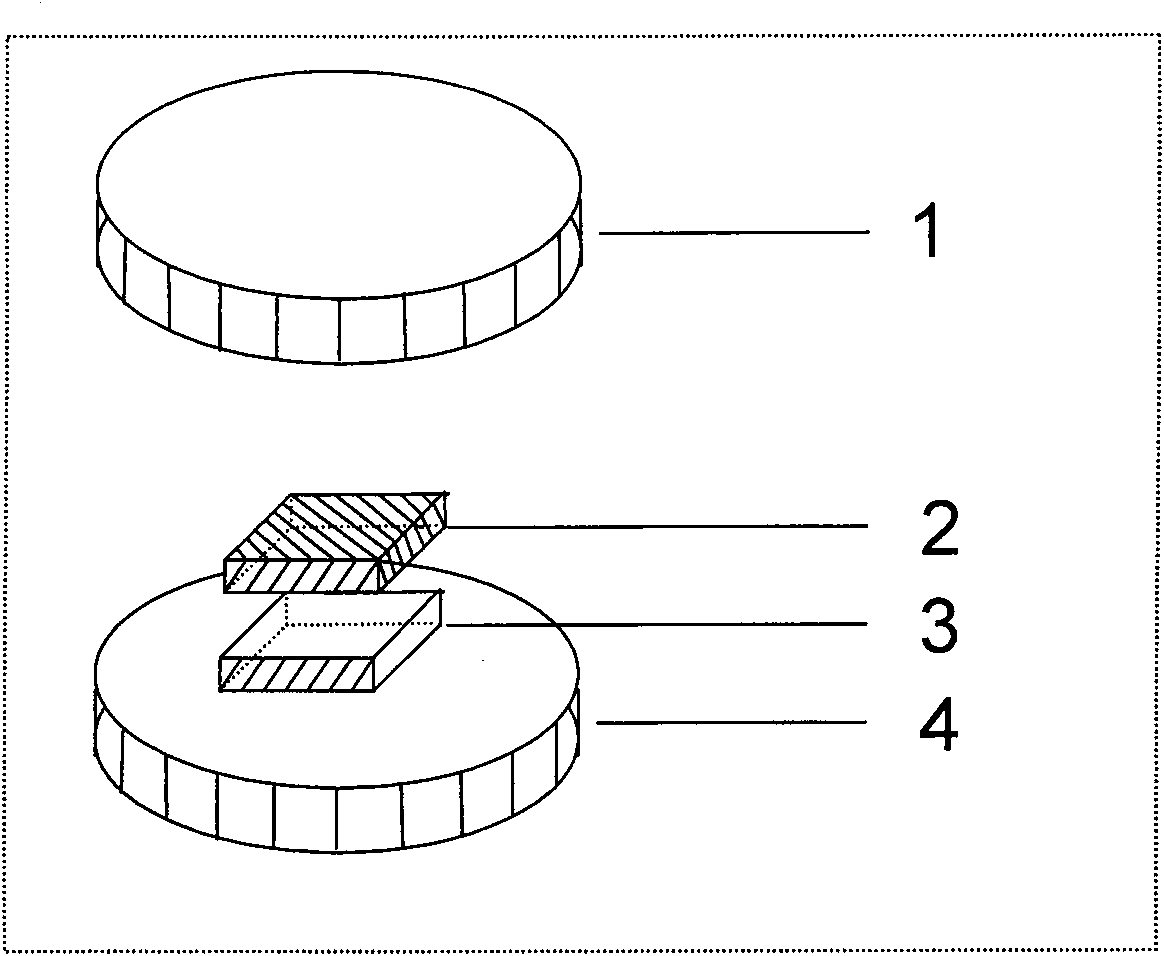

[0032] refer to figure 1 , to describe in detail the process flow of the method for preparing single-layer graphene by mechanical pressure of the present invention.

[0033] The preparation process of this embodiment is as follows:

[0034] 1). Prepare two flat, (111) crystal-oriented silicon wafers with a size of 10cm×10cm of 300nm thick silicon dioxide layer evaporated, one as the substrate, and the second as the backing plate in step 2); use Ultrasonic cleaning with acetone twice, the first time for 10 minutes, the second time for 5 minutes to make the surface clean; then ultrasonic cleaning with ethanol for 5 minutes to remove acetone molecules; ultrasonic cleaning with deionized water for 5 minutes to remove ethanol molecules; finally High-intensity cleaning with oxygen plasma for 5 minutes to remove molecules adsorbed on the surface;

[0035] 2). Take a block of grade A highly oriented pyrolytic graphite (HOPG) with a size of 10cmX10cmX2cm, use a sharp blade to cleava...

Embodiment 2

[0046] 1. Prepare a flat, 90nm-thick silicon dioxide layer evaporated, 10cmX10cm size (111) crystal-oriented silicon wafer as the substrate; clean it twice with acetone ultrasonically, the first time is 10 minutes, and the second time is 5 minutes , to make the surface clean; then ultrasonic cleaning with ethanol for 5 minutes to remove acetone molecules; ultrasonic cleaning with deionized water for 5 minutes to remove ethanol molecules; finally, high-intensity oxygen plasma cleaning for 5 minutes to remove surface-adsorbed molecules;

[0047] In order to further clean the substrate, it is also possible to perform a chemical solution immersion rinse before ultrasonic cleaning, that is, the cleaning process in the conventional semiconductor manufacturing process, such as soaking with acetone or isopropanol organic cleaning solution for 3-5 minutes, and then using ethanol Solution flushing;

[0048] 2. Take a block of grade A highly oriented pyrolytic graphite (HOPG) with a size...

Embodiment 3

[0057] Press the preparation method of embodiment 1, just change the pressure size into 15kg, change the time of keeping pressure into 5 minutes. The resulting graphene is similar. A mica sheet is selected as a backing plate, and it is cleaned and used by the cleaning process in the conventional semiconductor manufacturing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com