Patents

Literature

53 results about "Highly oriented pyrolytic graphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

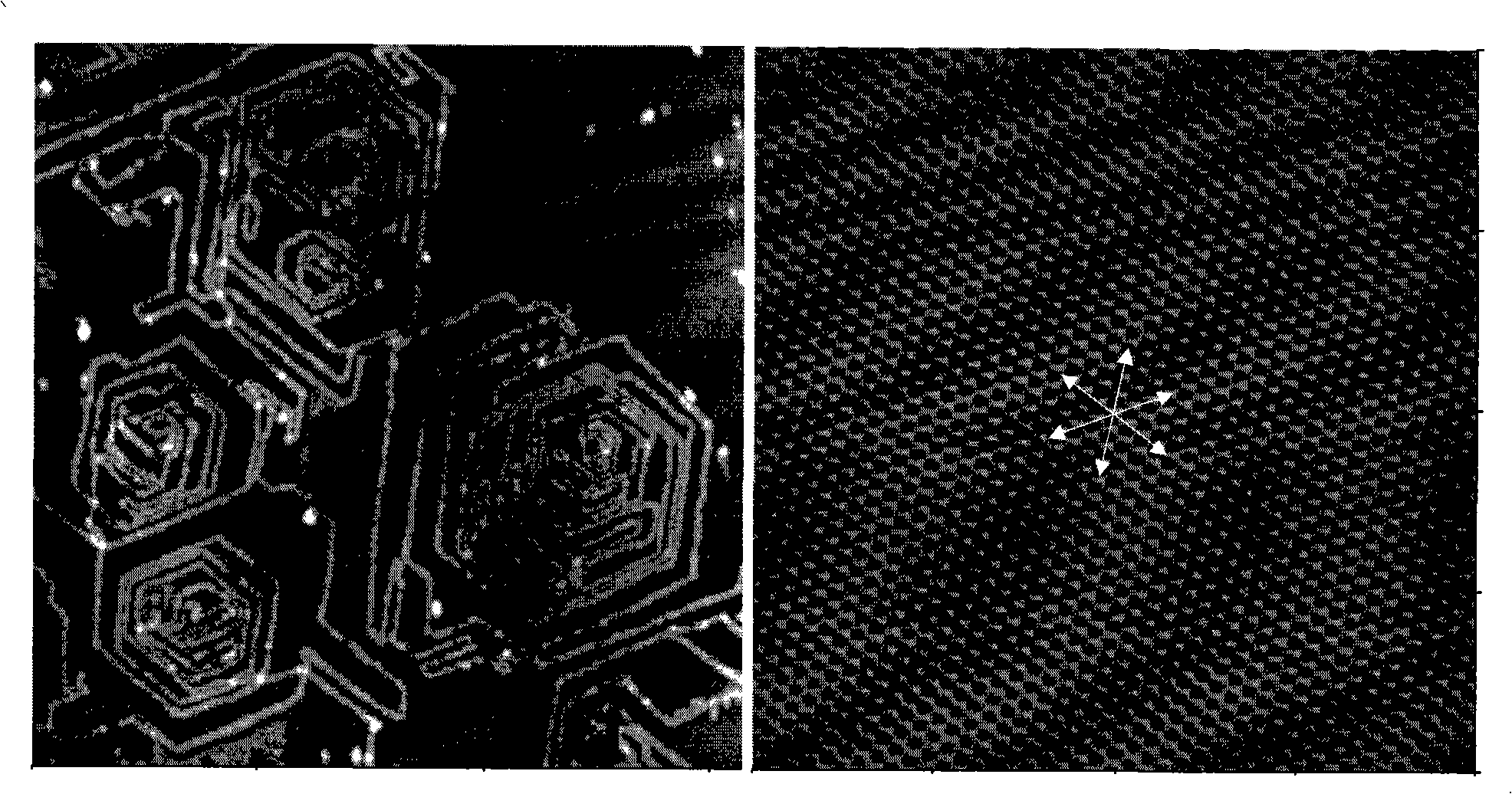

Highly oriented pyrolytic graphite (HOPG) is a highly pure and ordered form of synthetic graphite. It is characterised by a low mosaic spread angle, meaning that the individual graphite crystallites are well aligned with each other. The best HOPG samples have mosaic spreads of less than 1 degree.

Method of making graphene sheets and applicatios thereor

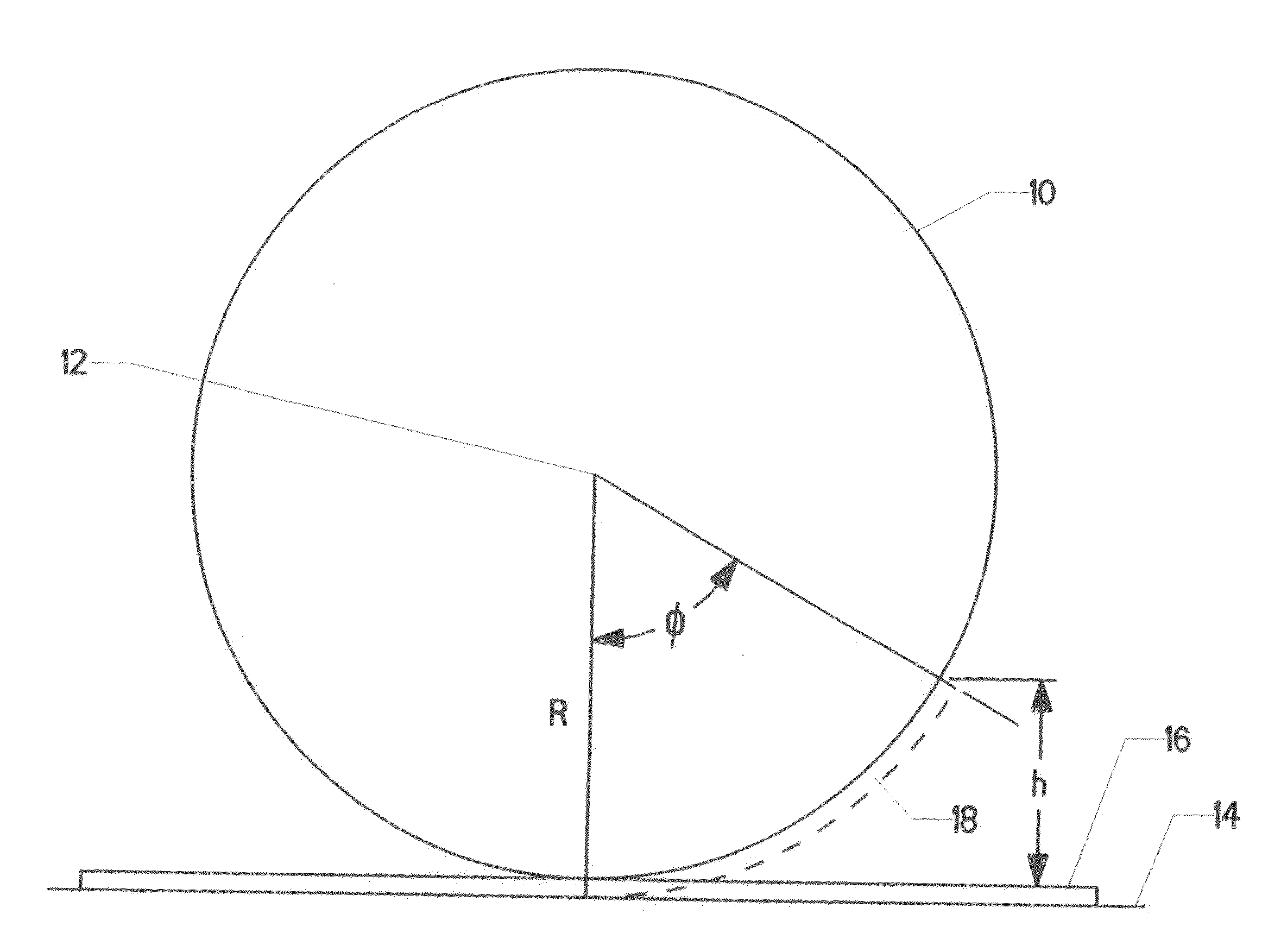

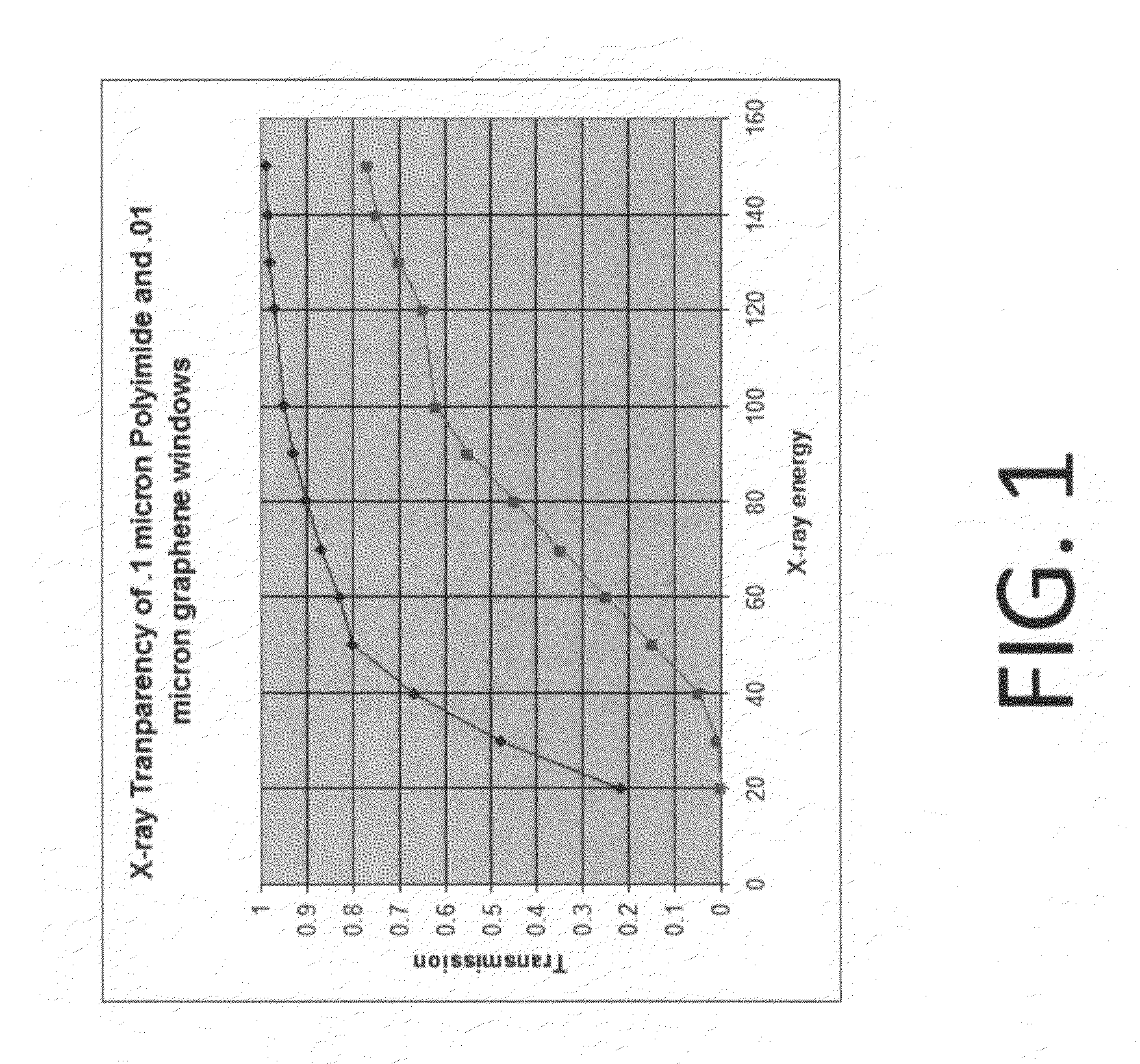

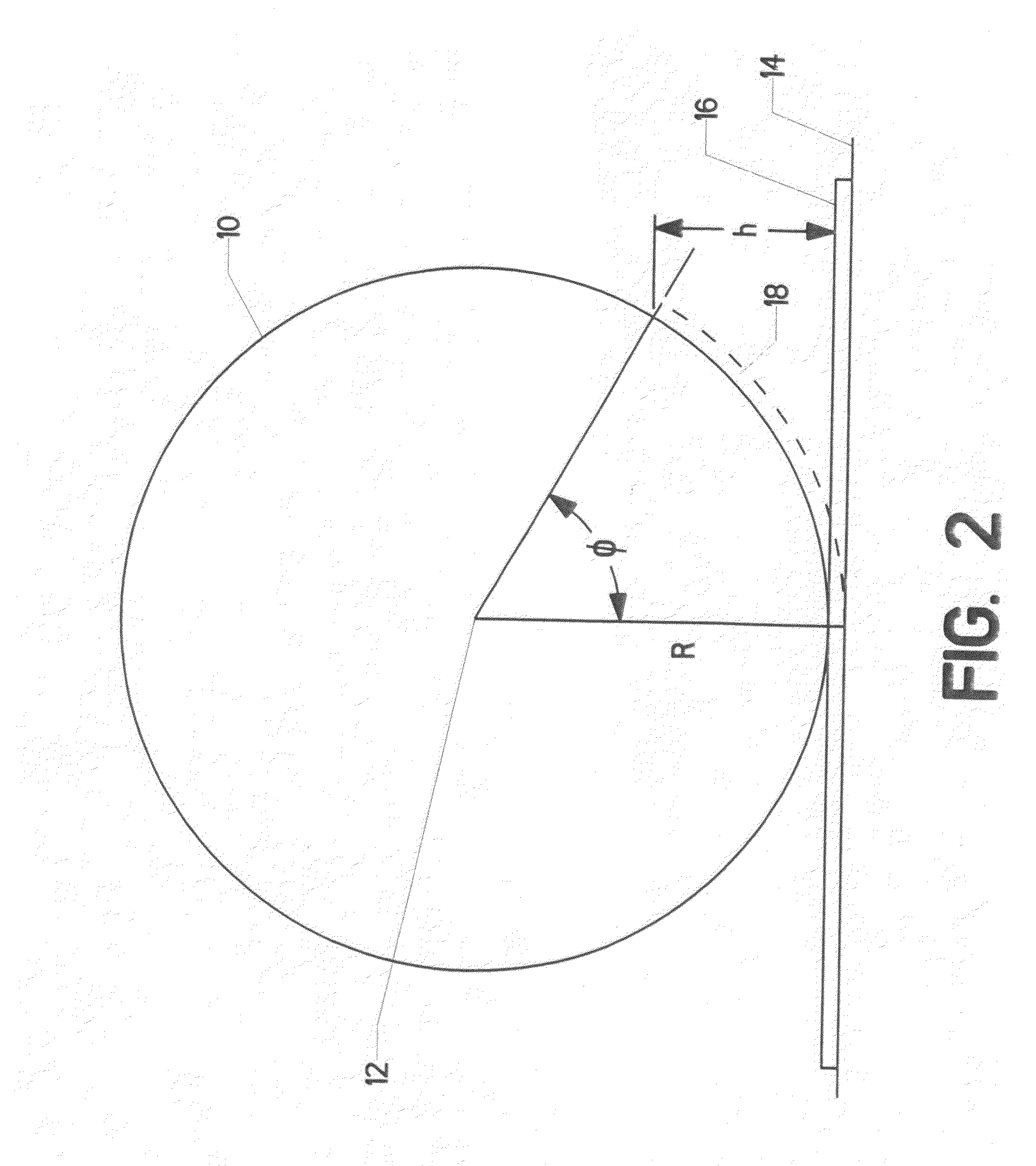

InactiveUS20100126660A1Material nanotechnologyLamination ancillary operationsHighly oriented pyrolytic graphiteX-ray

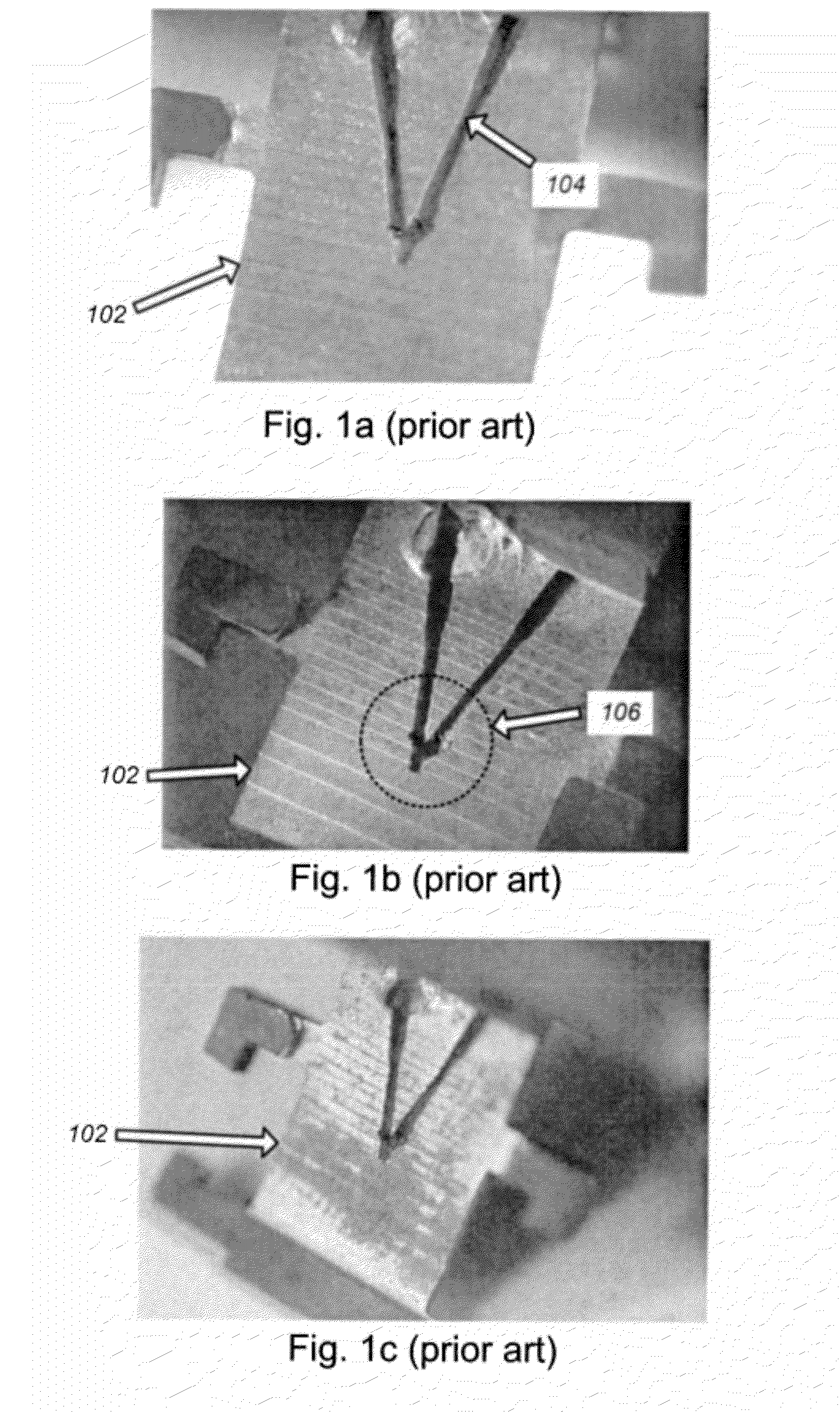

A method of making graphene sheets having a desired thickness. The method starts with Highly Oriented Pyrolytic Graphite (“HOPG”). A plurality of graphene layers are pulled off of the HOPG and attached to a substrate. An adhesive device is then used to pull a selected number of graphene layers off of the HOPG sample attached to the substrate. The number of layers selected determines the thickness of the graphene sheet produced. The graphene sheet has many applications. It is particularly suitable as an X-ray window.

Owner:OHARA DAVID

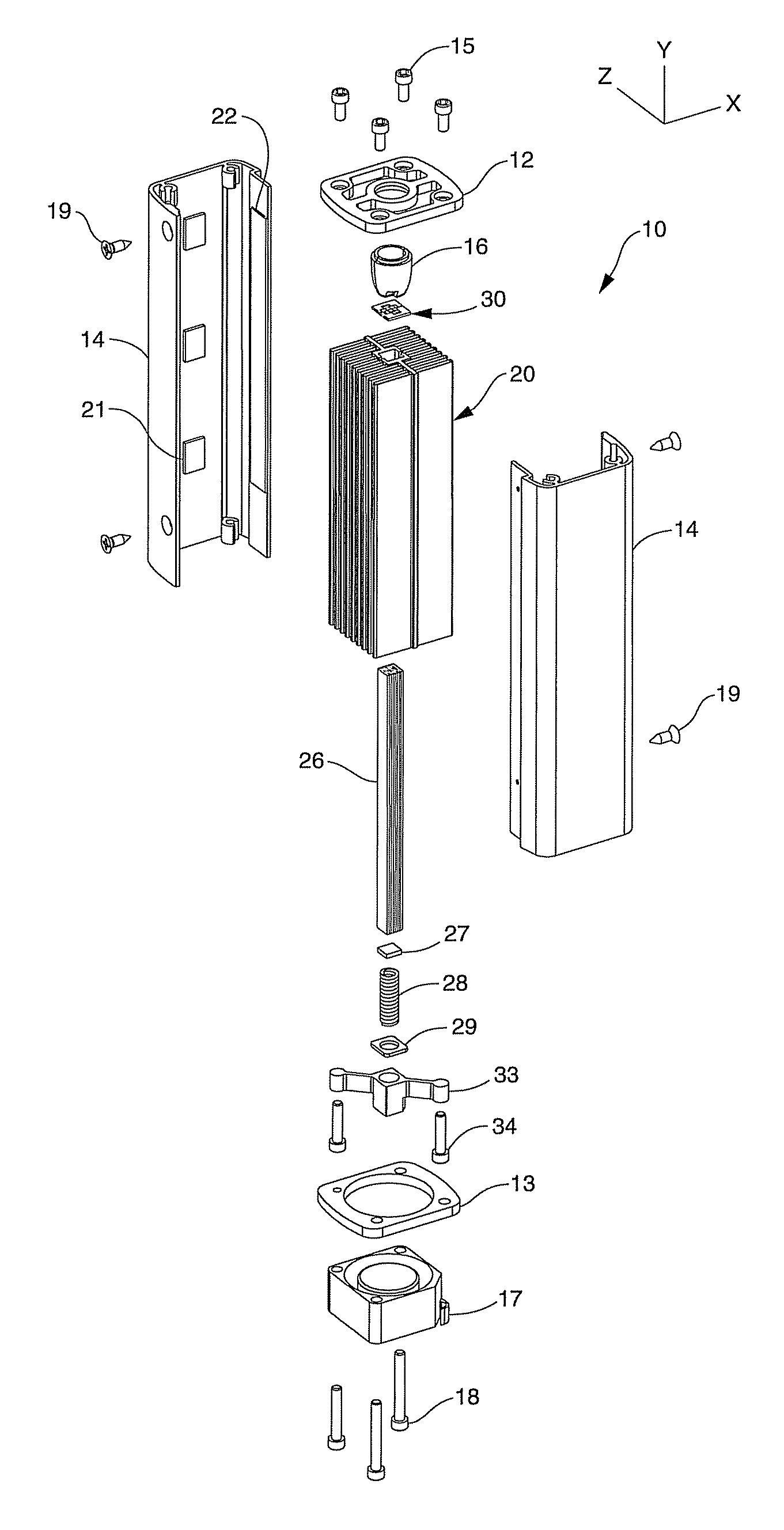

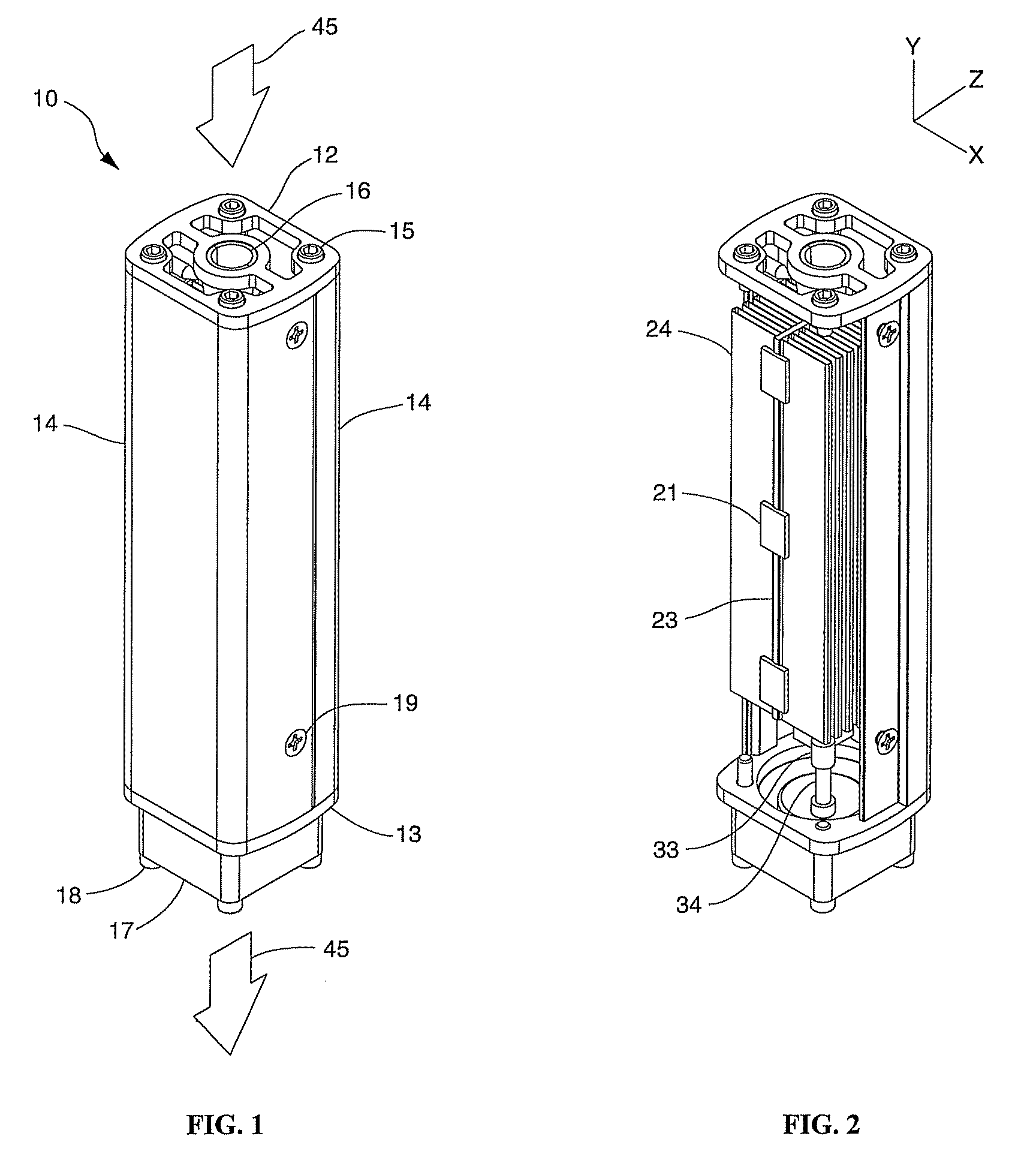

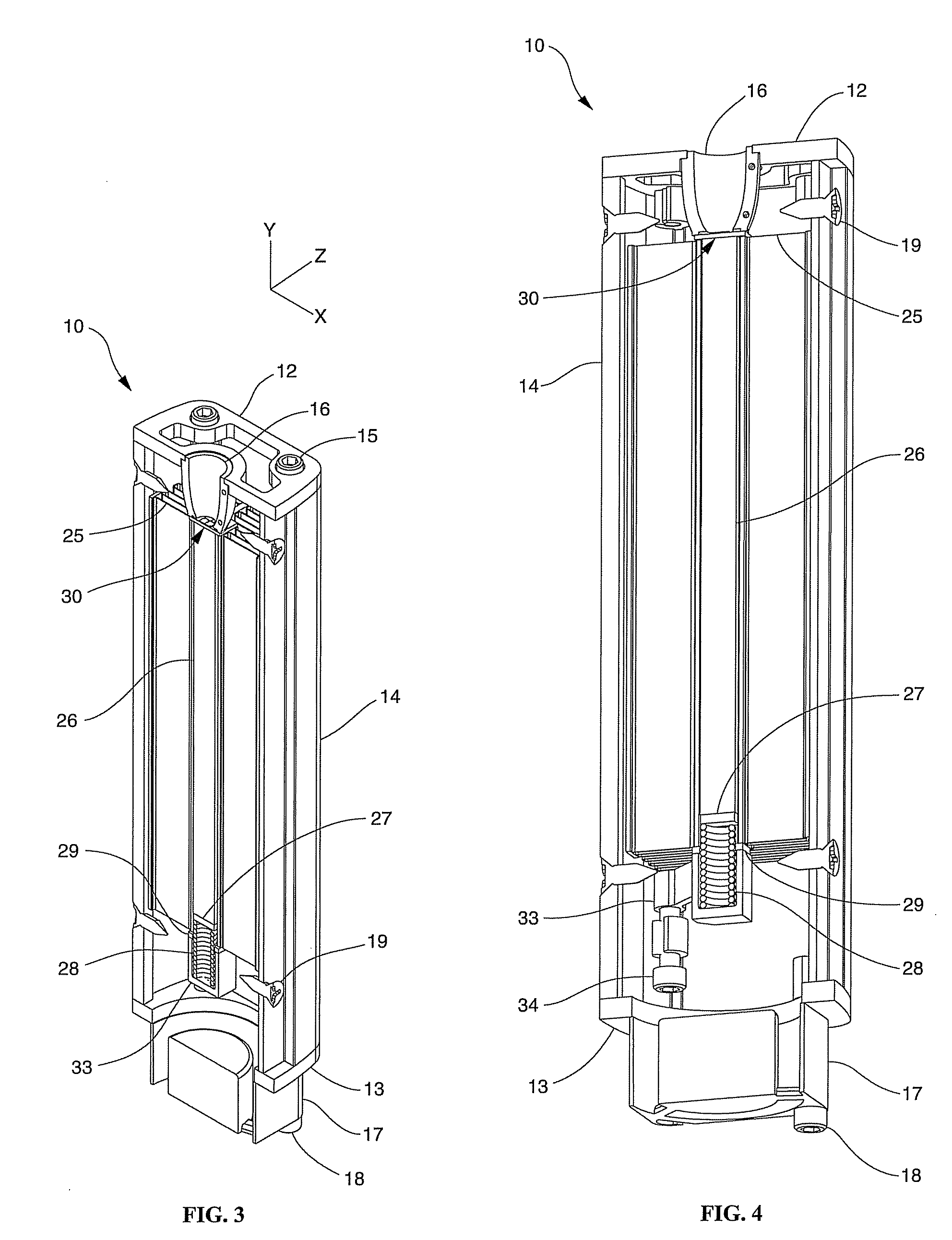

Solid state lighting apparatus utilizing axial thermal dissipation

InactiveUS7740380B2Improve cooling effectHeat dissipationPoint-like light sourceLighting support devicesLight equipmentHighly oriented pyrolytic graphite

A solid state lighting apparatus characterized by its compact, predominately axial form factor, utilizes an axial thermal transfer member constructed of Highly Oriented Pyrolytic Graphite (HOPG) to aid in the dissipation of waste heat generated during its operation. The lighting apparatus is chiefly comprised of a Light Emitting Diode (LED) die array and circuit structure assembly affixed to one end of the axial thermal transfer member and further includes a transversely mounted heat sink structure, running the length of, and being affixed to, opposite sides of the axial member. The axial member serves to distribute waste heat down its length, and simultaneously, into a transverse plane where the waste heat is dissipated into the transversely mounted heat sink structure. A fan may be utilized to evacuate the waste heat out of the lighting apparatus and into the ambient environment.

Owner:THRAILKILL JOHN E

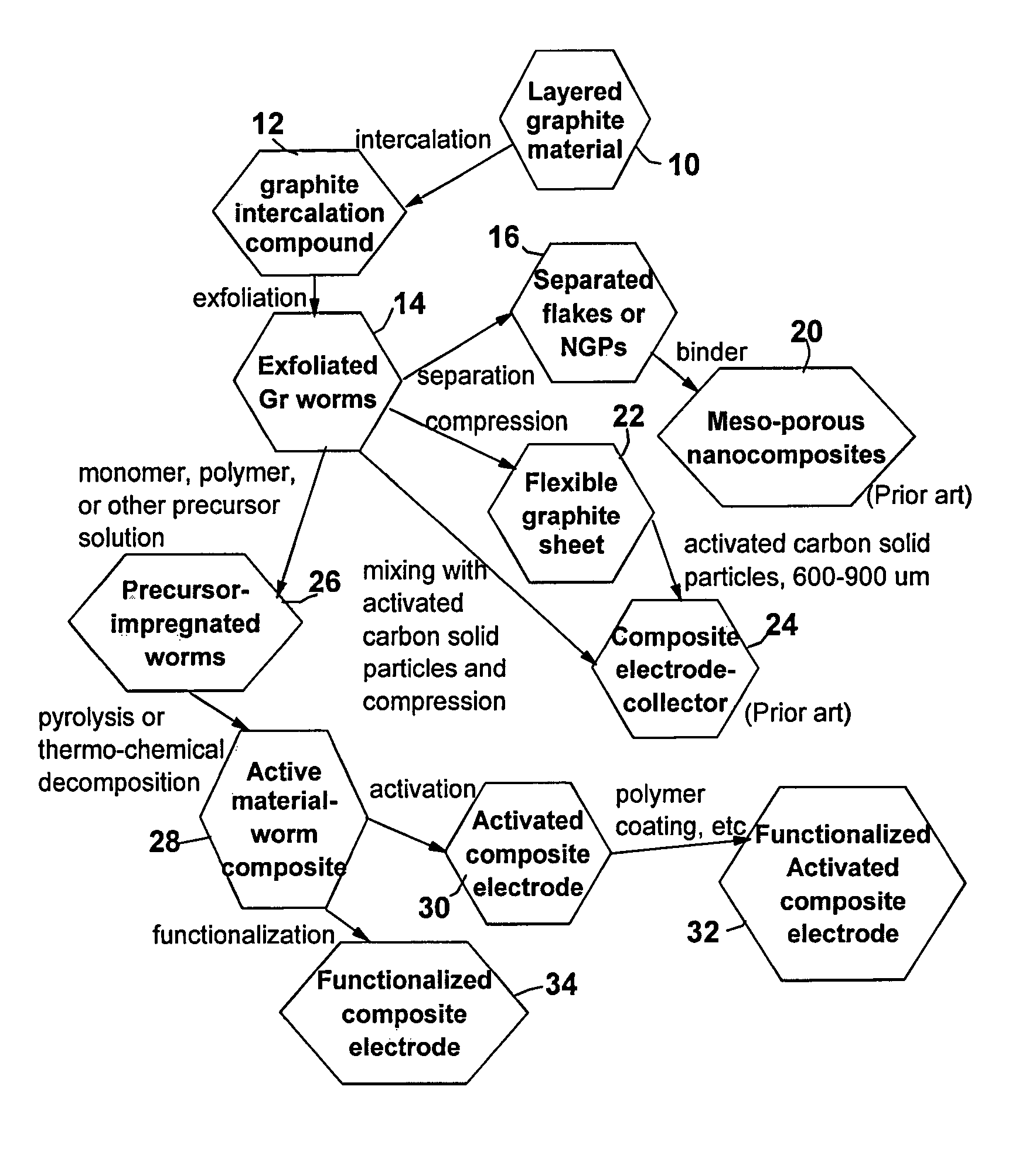

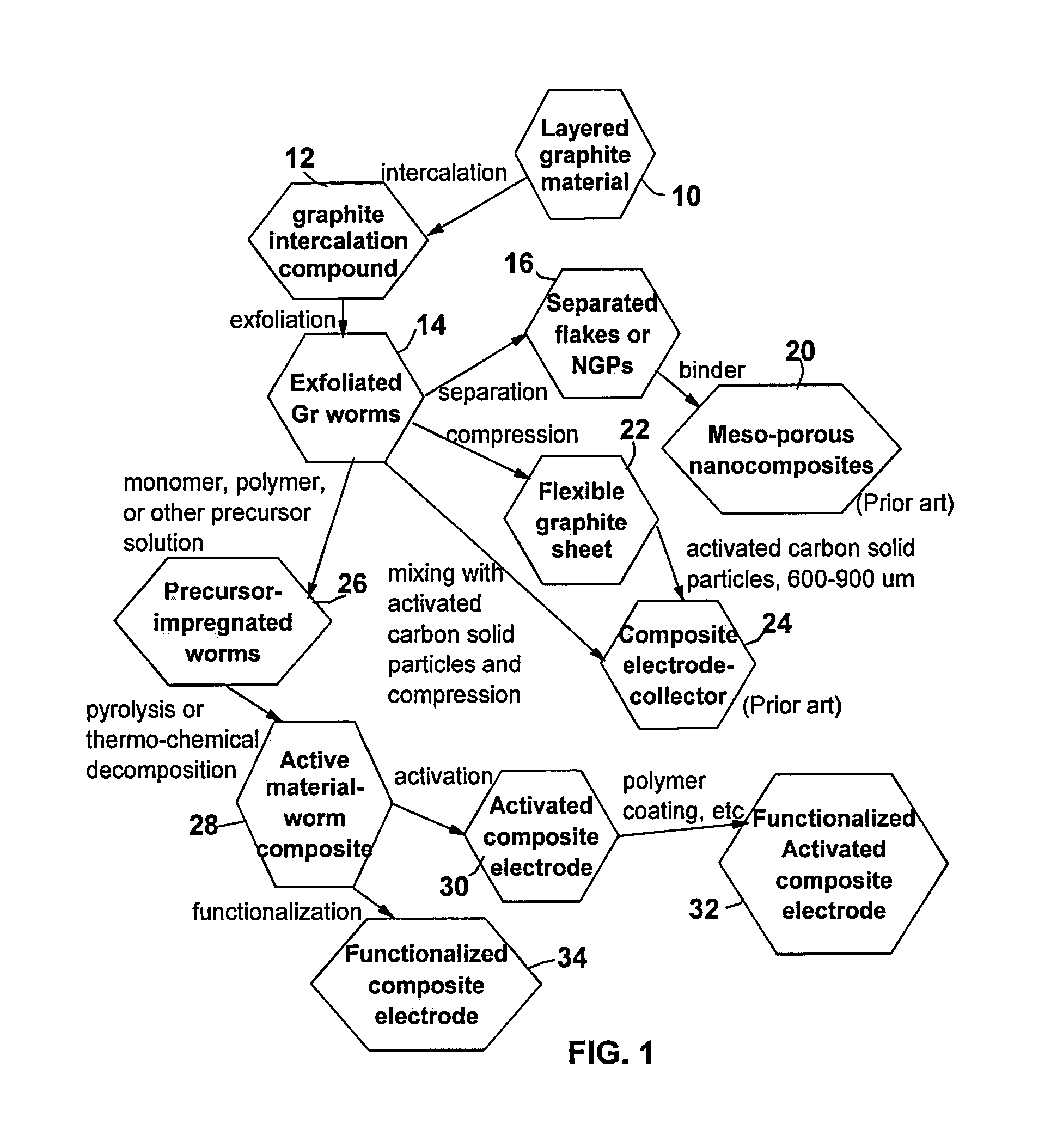

Method of producing graphite-carbon composite electrodes for supercapacitors

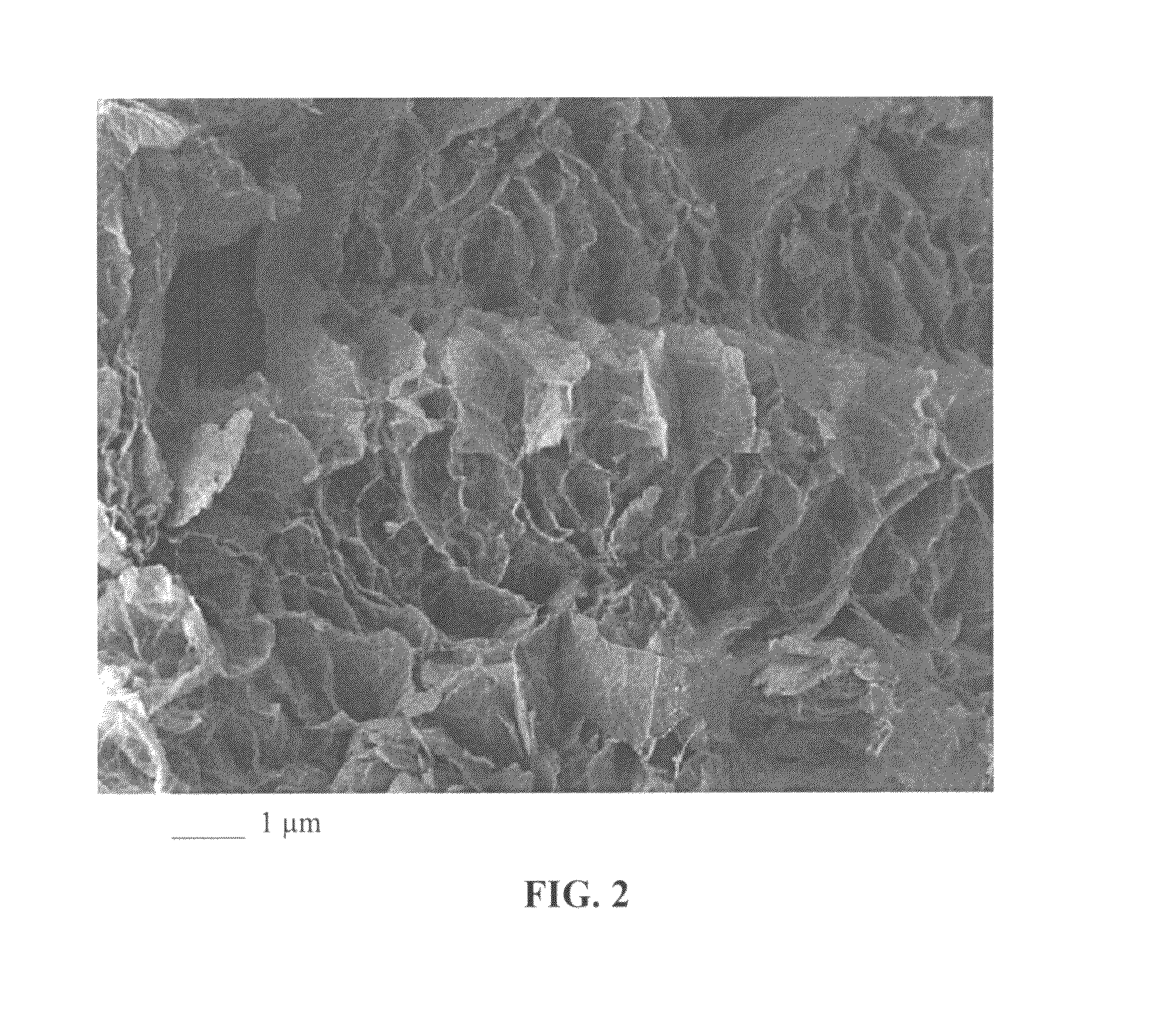

A method of producing a composite electrode having a specific surface area of at least 100 m2 / gm for use in an electrochemical capacitor. The method comprises (a) providing exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores; and (b) incorporating an electrochemically active material into at least a pore of the graphite network to form the composite electrode. The exfoliated graphite flakes are preferably obtained from the intercalation and exfoliation of a laminar graphite material selected from natural graphite, spheroidal graphite, synthetic graphite, highly oriented pyrolytic graphite, meso-carbon micro-bead, carbon / graphite fiber, carbon / graphite whisker, carbon / graphite nano-fiber, carbon nano-tube, or a combination thereof. A supercapacitor featuring such a composite electrode exhibits an exceptionally high capacitance value and low equivalent series resistance.

Owner:NANOTEK INSTR GRP LLC

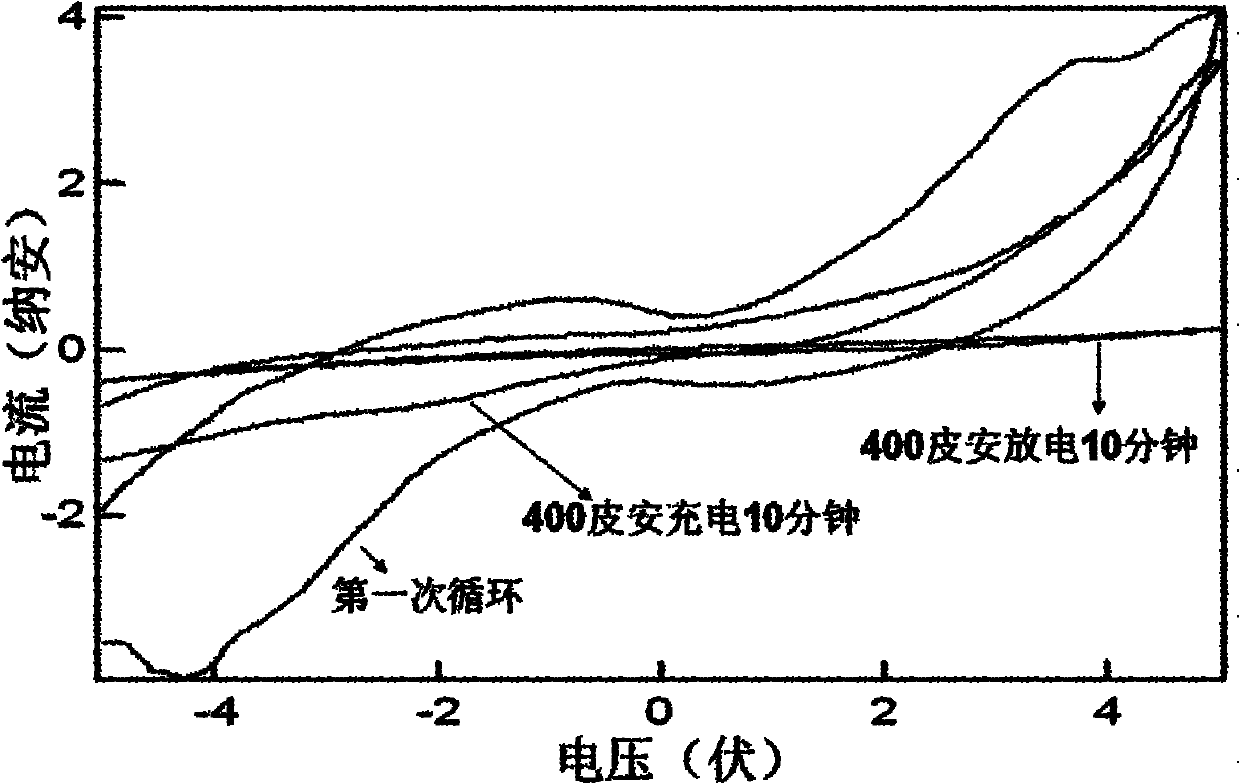

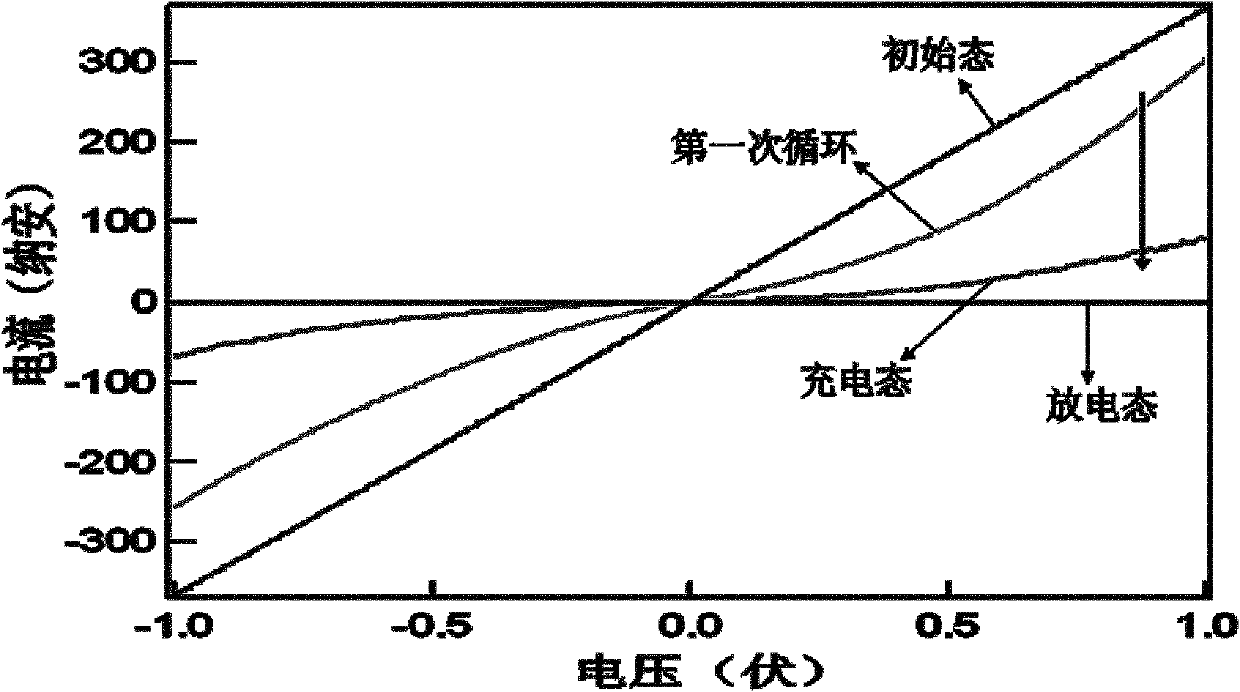

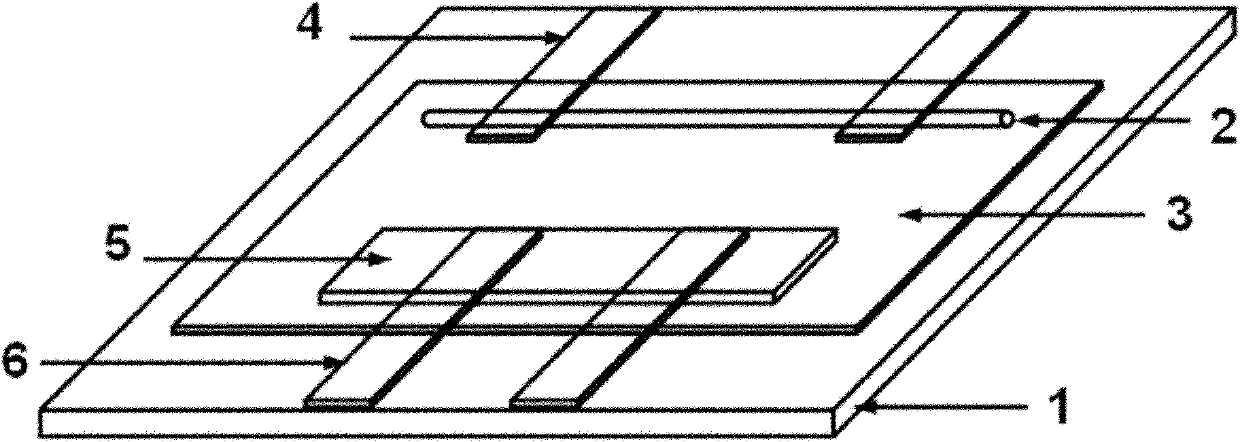

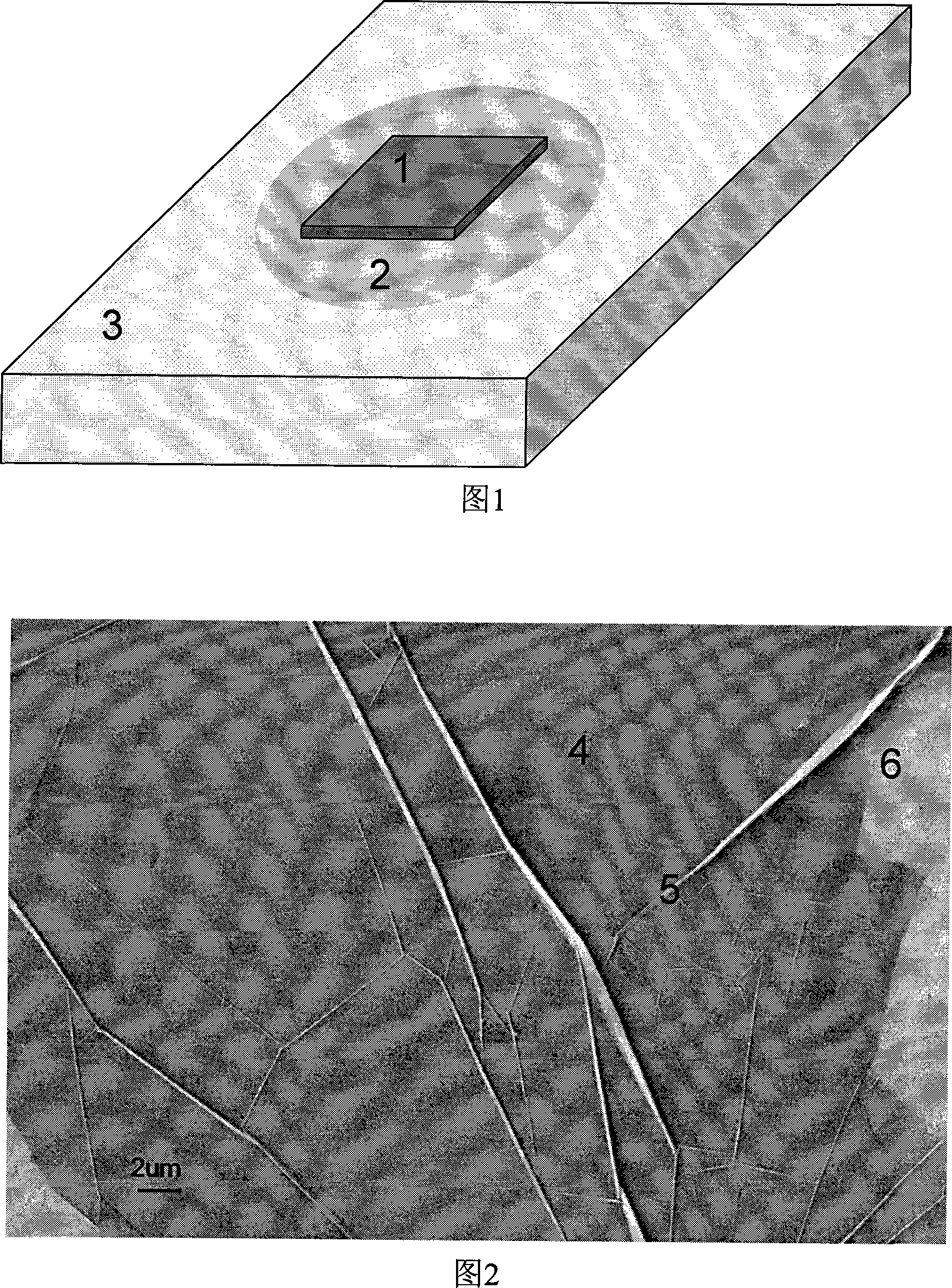

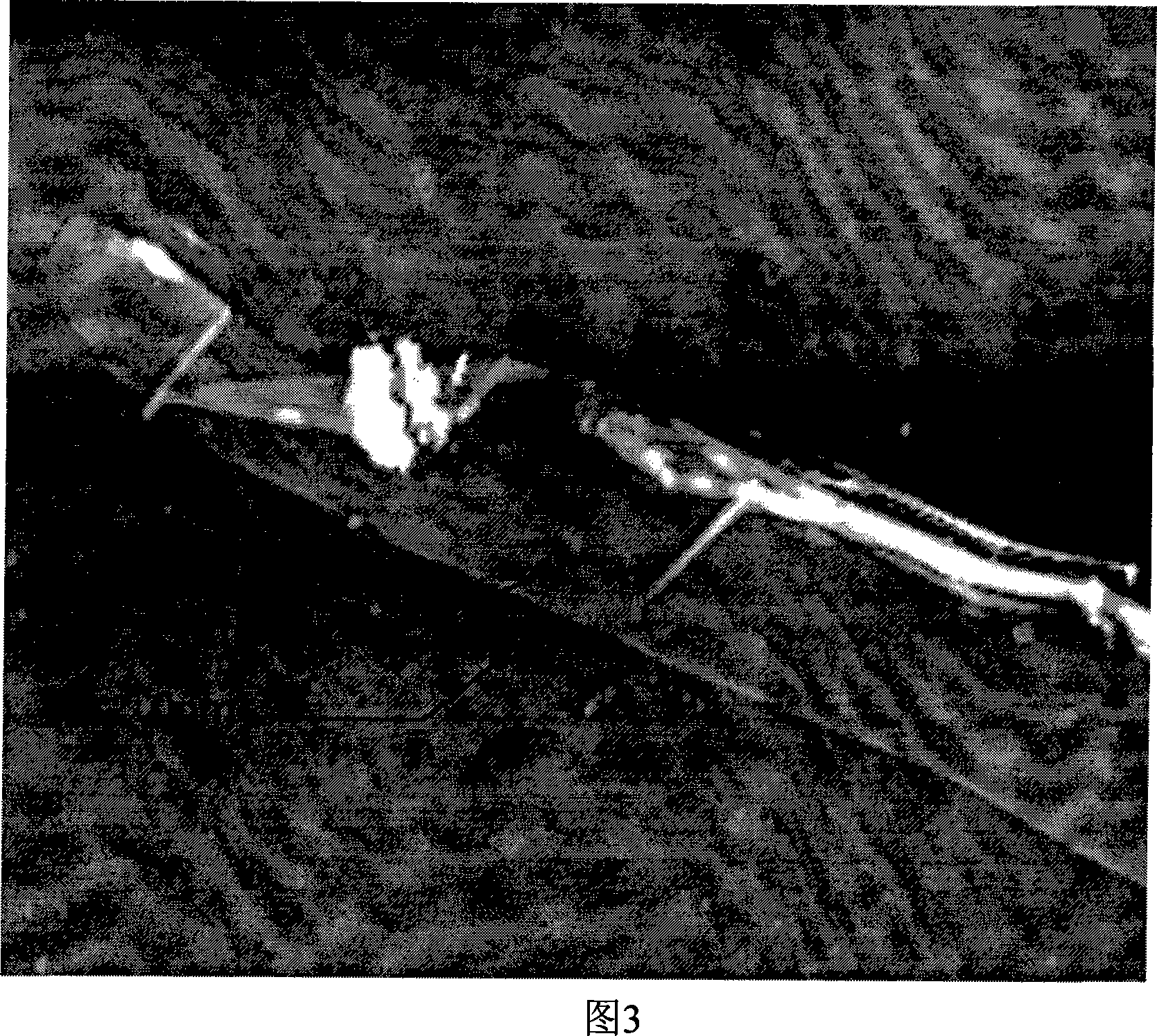

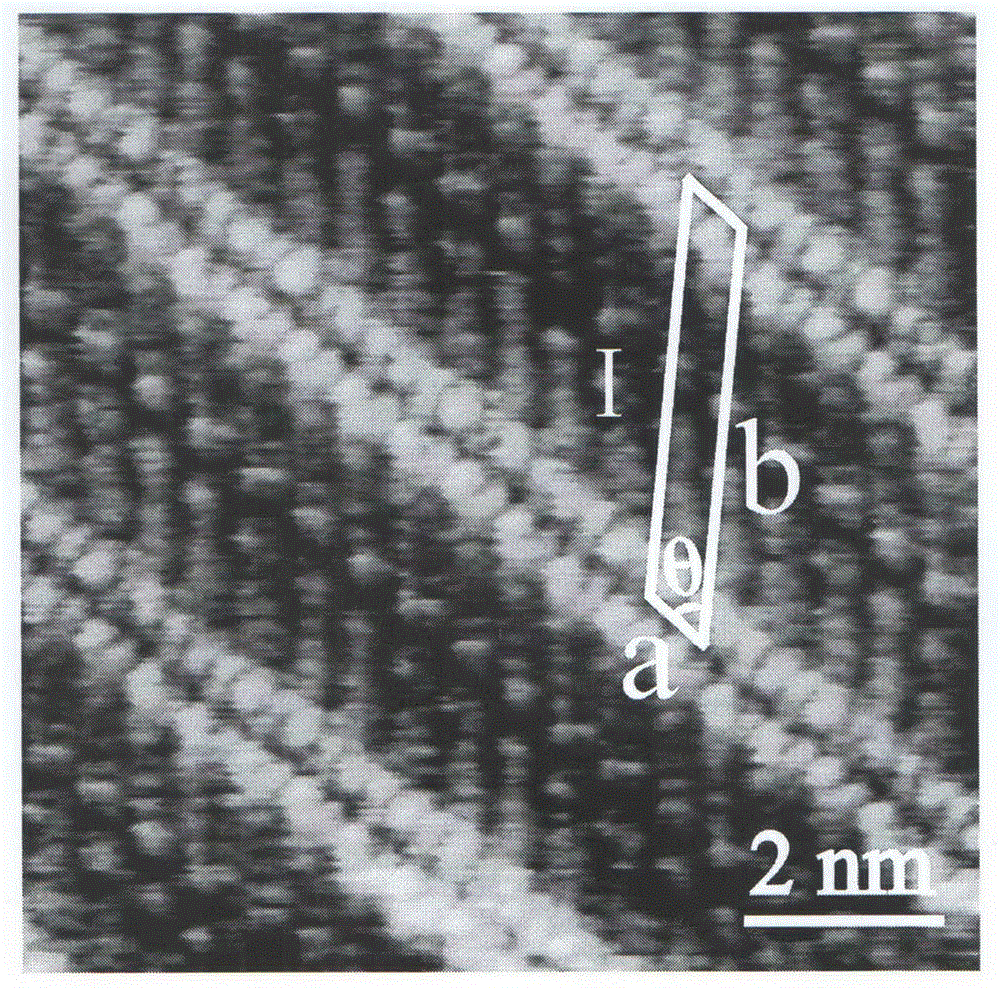

Single nanowire electrochemical device and assembly and in-situ characterization method thereof

ActiveCN101924202APerformance degradationReduce capacityCell electrodesSecondary cells servicing/maintenanceVanadium oxideMetal electrodes

The invention relates to a single nanowire electrochemical device and an assembly and in-situ characterization method thereof. The method comprises the following steps of: dispersing nanowire anodes of vanadium oxide nanowires, and the like, nano film cathodes of HOPG (Highly Oriented Pyrolytic Graphite), and the like or nanowire cathodes of silicon nanowires, and the like and nano film anodes of LiCoO2, and the like on a substrate; respectively making metal electrodes at both ends of the nanowires and the nano films as current collectors by adopting technologies, such as PECVD (Plasma-Enhanced Chemical Vapor Deposition), and the like; then, depositing silicon nitride or spinning a photoresist on the metal current collectors as protection layers of the current collectors by adopting the PECVD technology, and the like; and finally, dispensing a polymer electrolyte on the surface of the substrate to finish the assembly of the single nanowire electrochemical device. In the invention, charging and discharging tests are carried out on the electrochemical device, then in-situ electrical transport performance tests, micro-domain Raman spectrum analysis, and the like are carried out on the single nanowire electrodes in different charging and discharging states, the direct relation among the electrical transport, the structure and the electrochemical performance of the nanowire electrode material is established, a platform is provided for battery diagnosis, and the like and a support power supply can be provided for the nano device.

Owner:武汉楚理佳纳新能源科技有限公司

Method for macroscopic super-lubricity of friction surface grown graphene

ActiveCN107032330AAchieve lubricationAchieve macroscopic super slipperyGrapheneEngine lubricationLubricationMaterials science

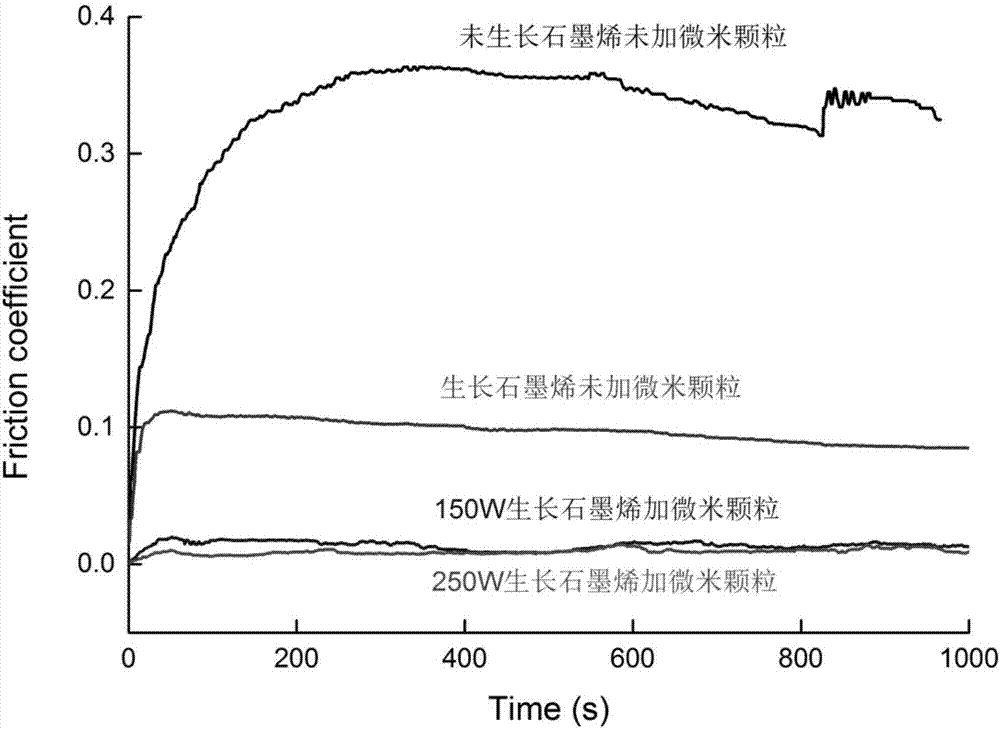

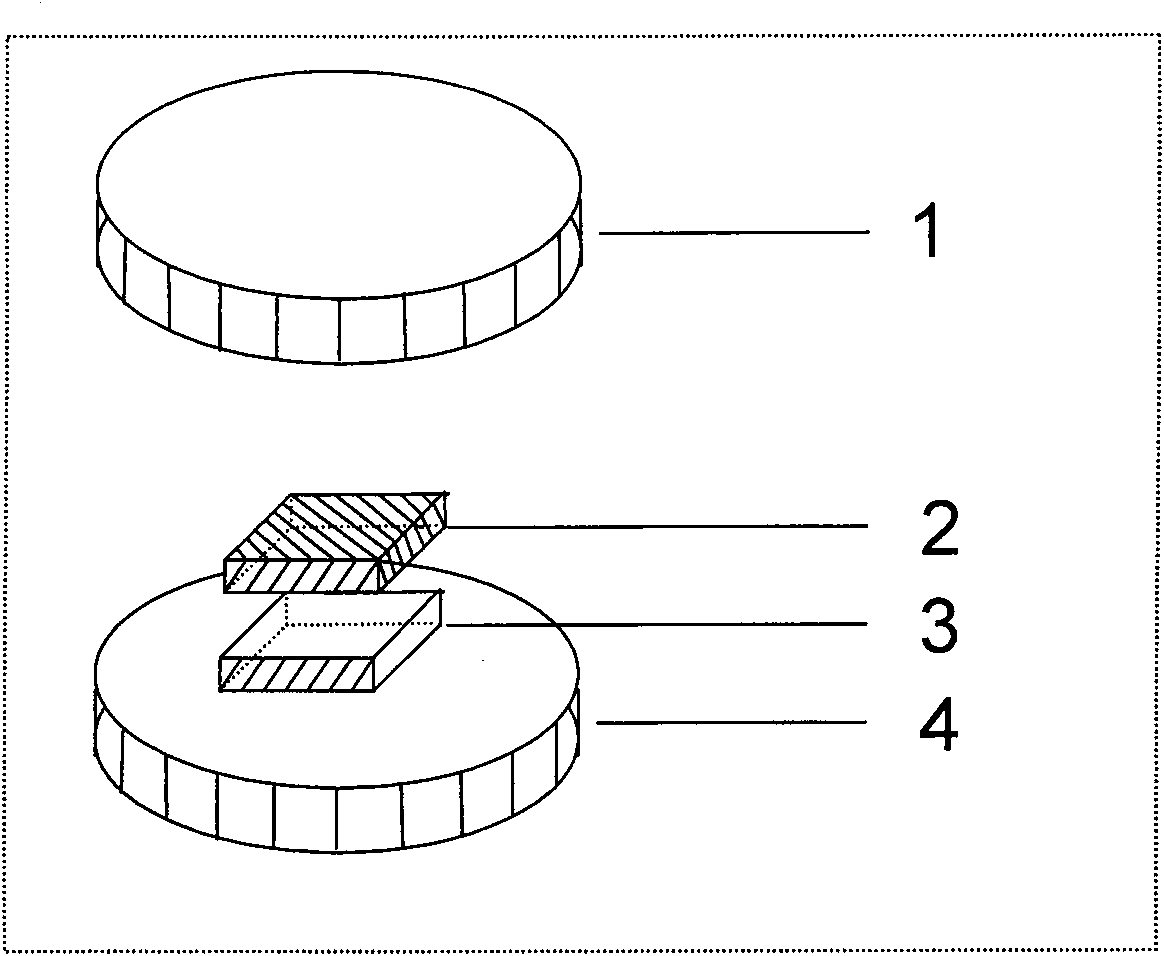

The invention provides a method for macroscopic super-lubricity of friction surface grown graphene and belongs to the technical field of macroscopic lubrication. A friction pair pairing surface is provided with highly oriented pyrolytic graphite, molybdenum disulfide, tungsten disulfide or quartz where graphene grows, copper or nickel. The particle size of lubricating particles is 0.5-100 [mu]m, and the lubricating particles have a single particle size or a combination of different particle sizes. A cleaned friction pair or the lubricating particles are placed in a plasma enhanced chemical vapor deposition tube furnace, hydrogen is led in, the temperature rises to 600-1000 DEG C in 40-60 min, methane is led in to serve as a growth precursor, and growth time is 20-60 min. The lubricating particles are evenly distributed between the upper surface and the lower surface of the friction pair, an applied load is 1 mN to 1 N, a friction distance is 0.5-2 mm, and swing frequency is 0.1-2 Hz. Under room temperature conditions, through testing for 800-1000 s, the friction coefficient is stabilized at 0.003-0.008. The method for surface macroscopic super-lubricity is implemented.

Owner:DALIAN UNIV OF TECH

Method for preparing single-layer graphene film on SiO2 substrate directly

InactiveCN101768012ASimple stepsEasy to implementHighly oriented pyrolytic graphiteSingle layer graphene

The invention relates to a method for preparing two-dimensional nanomaterial single-layer graphene film on SiO2 substrate directly, comprising (1) preparing substrate and conducting purification treatment; (2) processing block-shaped highly-oriented pyrolytic graphite or natural flake-shaped graphite; (3) preparing the single-layer graphene film sample through mechanical compression method: adjusting pressure within 10kg-20kg, keeping pressure within 5-10min, then releasing the pressure, removing the block-shaped graphite, and taking out the silicon substrate to obtain the single-layer graphene film sample. The method for preparing the single-layer graphene film uses fewer devices, has low cost and high successful rate, and is easy to implement. The raw material is directly contacted with the substrate, accordingly, the pollution to the sample caused by the introduction of other auxiliary media can be avoided. The obtained graphene sample is of a complete sheet shape due to effect of pressure, without folds.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

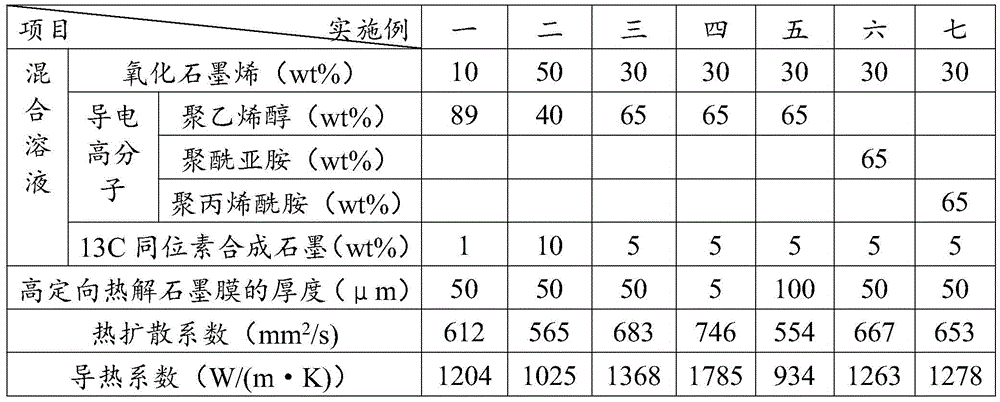

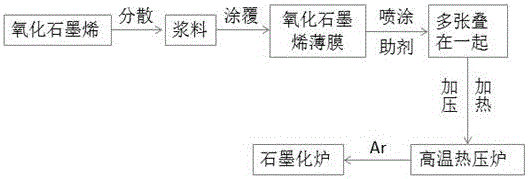

Graphene oxide based method for preparing highly oriented pyrolytic graphite film

InactiveCN105541328AImprove thermal conductivityImprove conductivityHighly oriented pyrolytic graphiteConductive polymer

The present invention discloses a graphene oxide based method for preparing highly oriented pyrolytic graphite film. The method comprises the steps of: 1) adding a graphene oxide powder to water, and conducting ultrasonic dispersion to obtain an aqueous solution of graphene oxide; 2) adding conductive polymer and high purity graphite in the aqueous solution of graphene oxide, mixing thoroughly to obtain a mixed solution of graphene oxide; 3) uniformly coating the mixed solution of graphene oxide on a substrate, pre-drying, curing, uniformly rolling, and drying to obtain a graphene film; and 4) placing the graphene film in a graphite furnace, graphitizing under protection of inert gas, and naturally cooling to obtain the highly oriented pyrolytic graphite film. Compared with a conventional preparation method of highly oriented pyrolytic graphite film by using an organic polymer film with high degree of orientation, the method of the invention omits the carbonization process, and has simple process and low production cost; and the obtained highly oriented pyrolytic graphite film has controllable shape and thickness and good heat conduction function.

Owner:WUXI HUICHENG GRAPHITE ALKENE TECH APPL CO LTD

Method for preparing graphene blocks and graphene blocks prepared by same

ActiveCN105692601AShort preparation cycleSimple processHighly oriented pyrolytic graphiteHigh pressure

The invention provides a method for preparing graphene blocks. According to the method provided by the invention, a plurality of graphene oxide films are heated at high pressure under the action of a binding aid to form graphene blocks. According to the method for preparing the graphene blocks, graphene oxide is used as a raw material to prepare highly-oriented graphene heat-conduction blocks, and each of the highly-oriented graphene heat-conduction blocks can be made to be larger in size to reach a volume over 400*400*400mm, instead of highly-oriented pyrolytic graphite. The method provided by the invention is simple in process, short in preparation cycle, low in cost and more widely applied.

Owner:CHANGZHOU FUXI TECH CO LTD

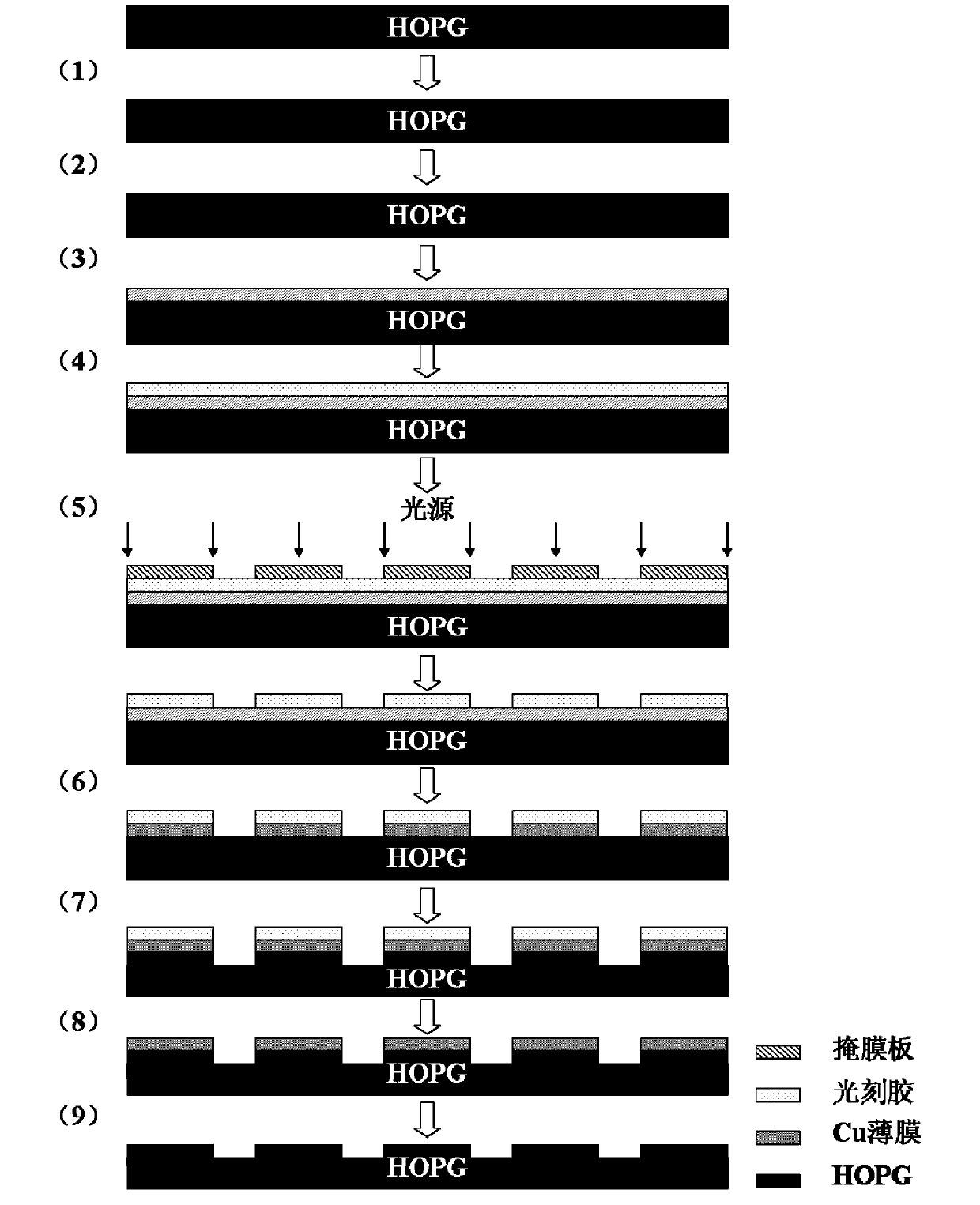

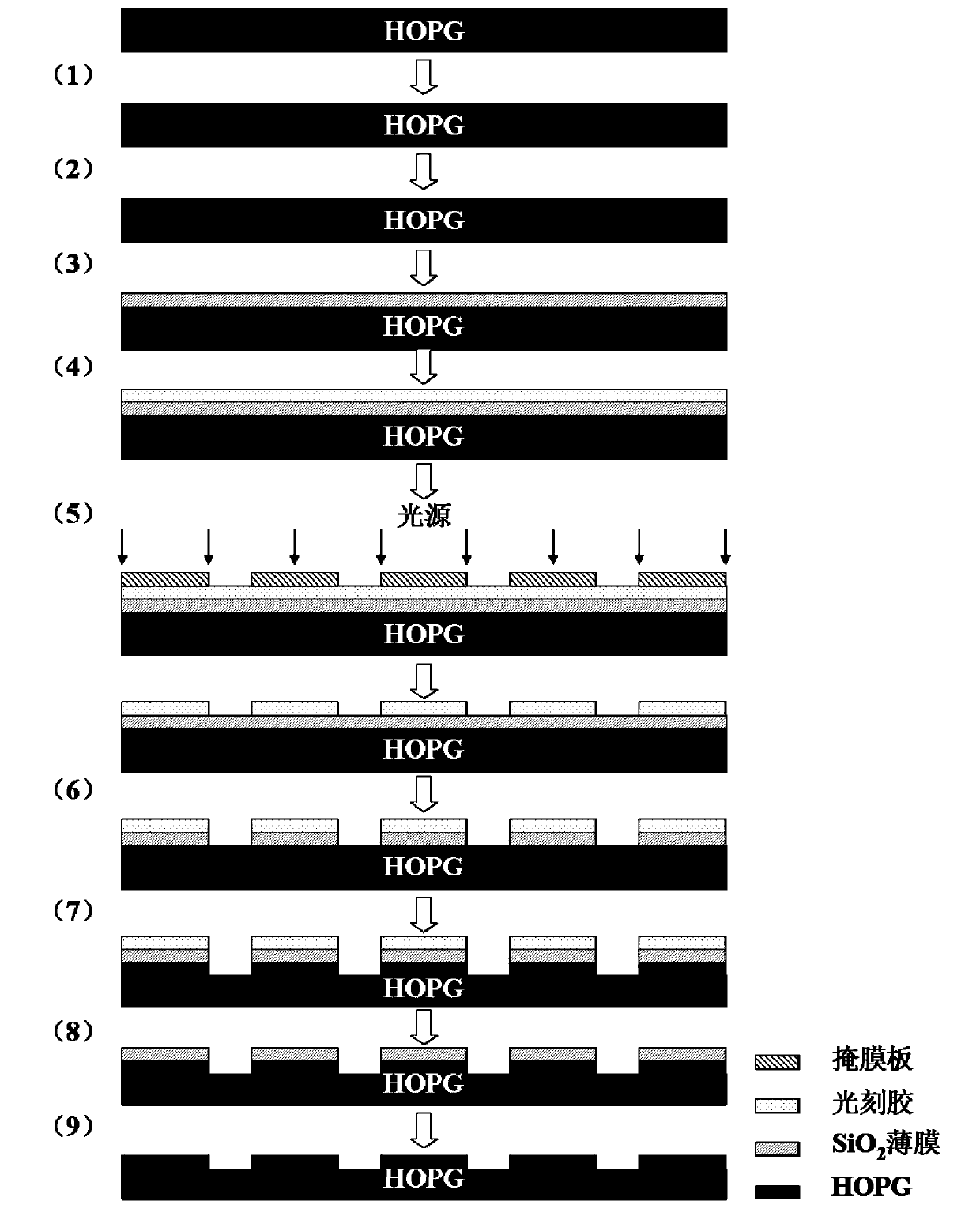

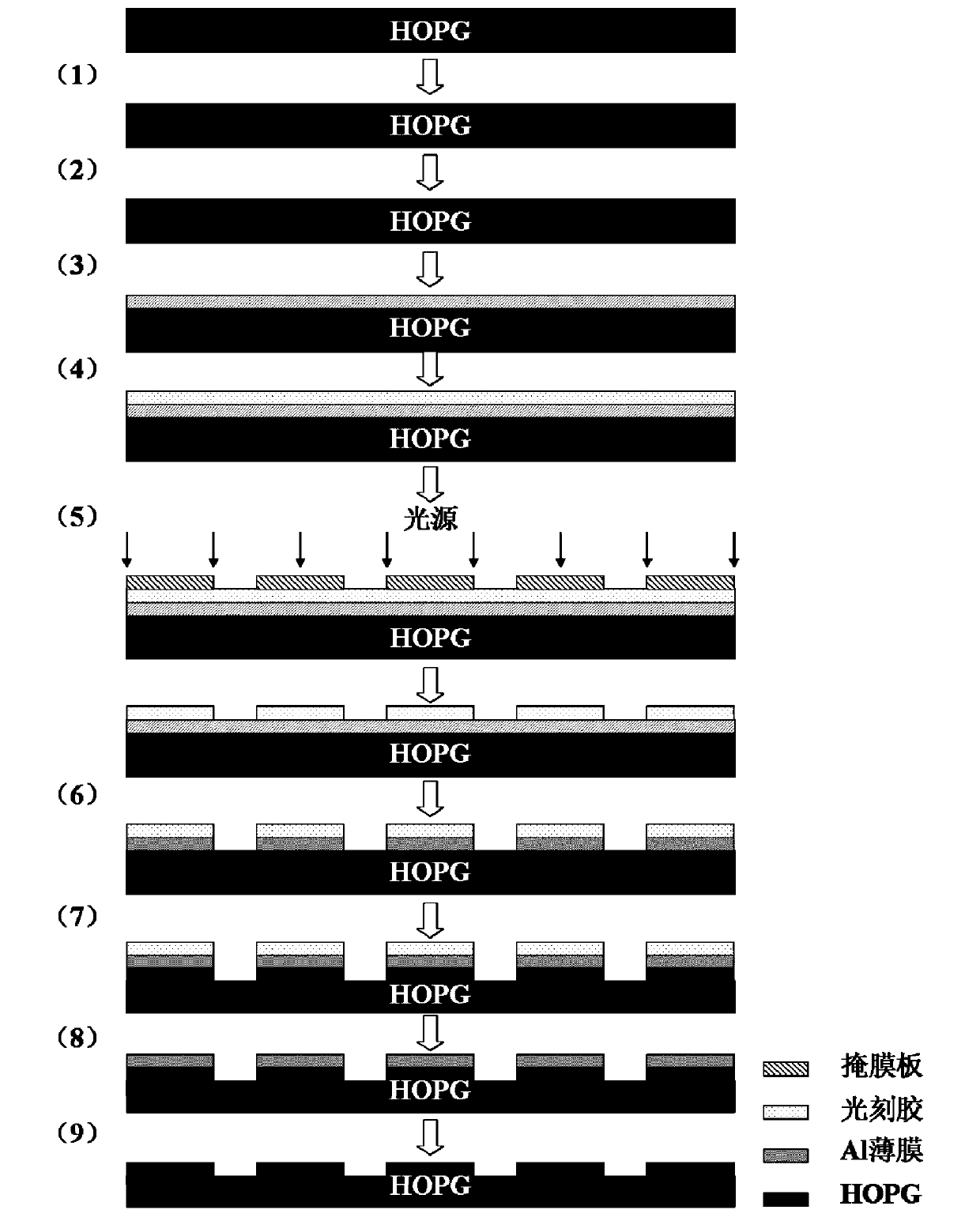

Method for processing microstructure on highly oriented pyrolytic graphite by using photolithography technique

InactiveCN103121659AMature production lineGood value for moneyDecorative surface effectsChemical vapor deposition coatingProduction lineHighly oriented pyrolytic graphite

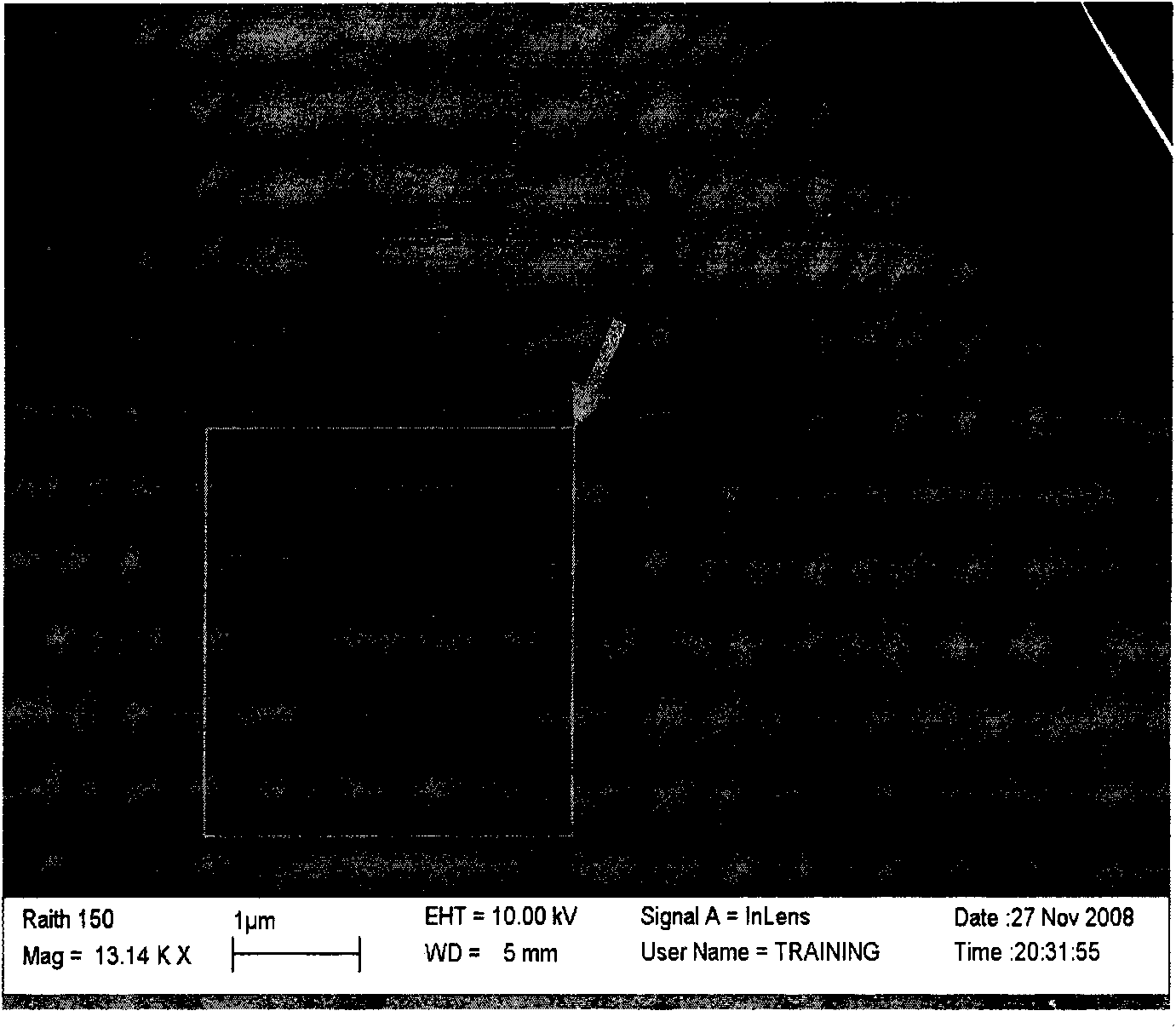

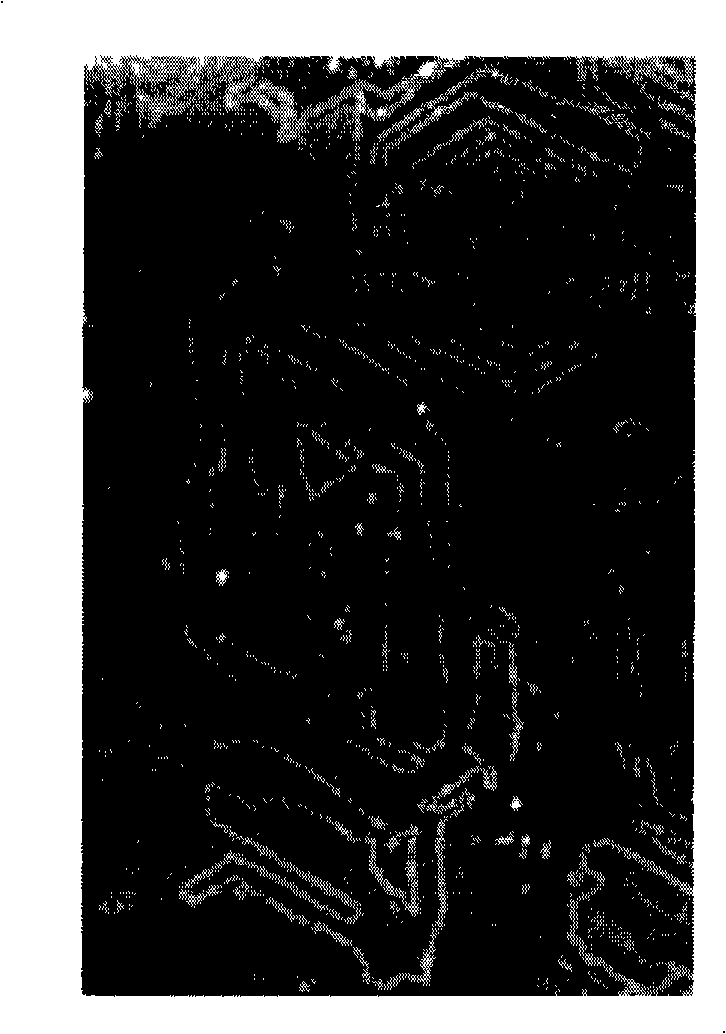

The invention discloses a method for processing a microstructure on highly oriented pyrolytic graphite by using a photolithography technique. The method comprises the following steps: 1, leveling the surface, namely grinding a highly oriented pyrolytic graphite (HOPG) surface by using a grinding machine, and polishing the surface; 2, cleaning the surface; 3, manufacturing a mask of the HOPG; 4, spinning a photoresist to serve as a mask of a SiO2 film or a metal film; 5, photoetching; 6, patterning the HOPG mask; 7, etching the HOPG; 8, removing the photoresist; and 9, removing the HOPG film. The method has the effective effects that the HOPG is directly processed by means of the common photoetching method for micro-electronics and micro-electromechanical systems (MEMS), and the method is mature in process production line, high in cost performance and suitable for directly processing patterns with the characteristic scale of more than 500nm on the HOPG.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

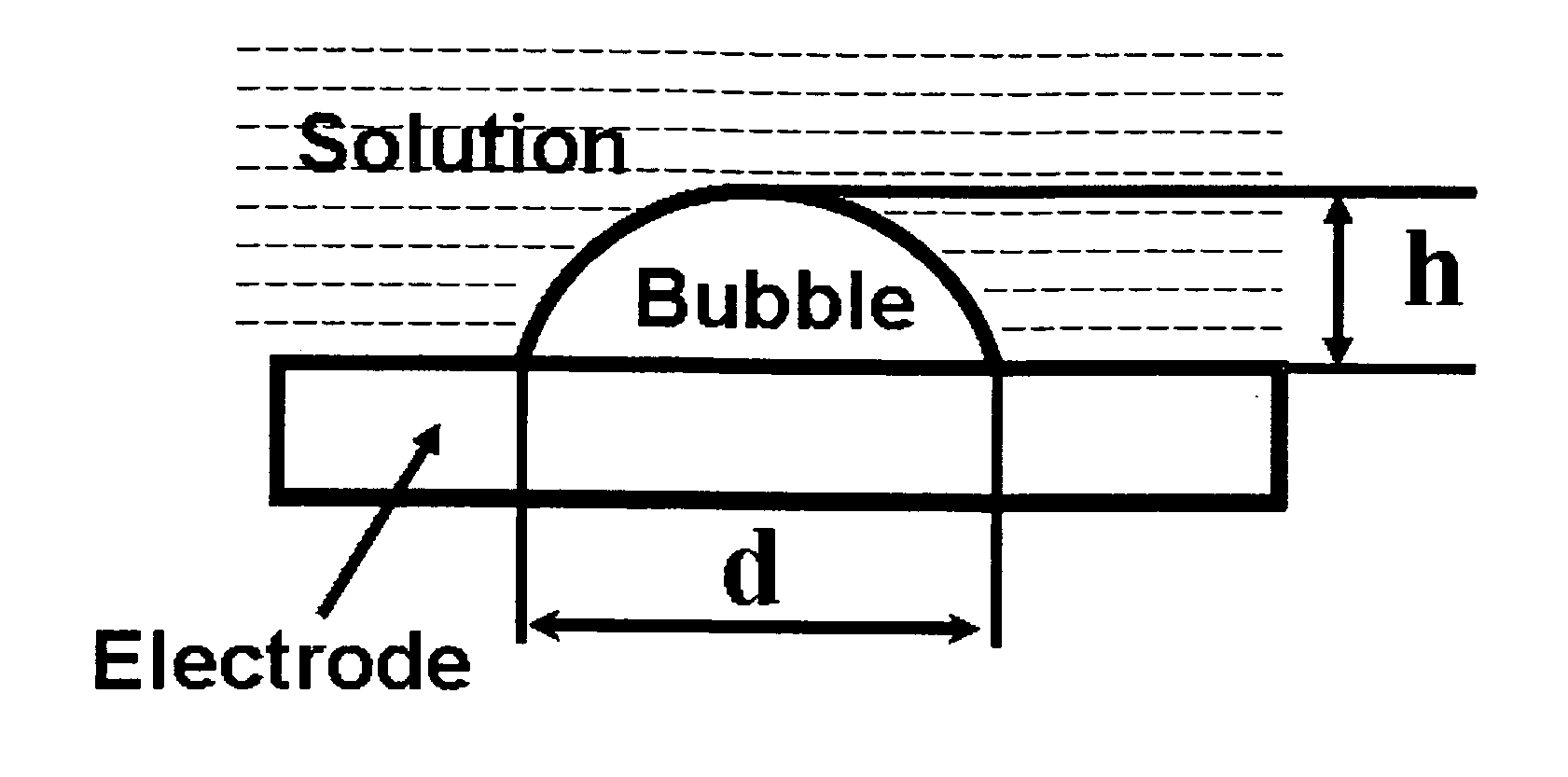

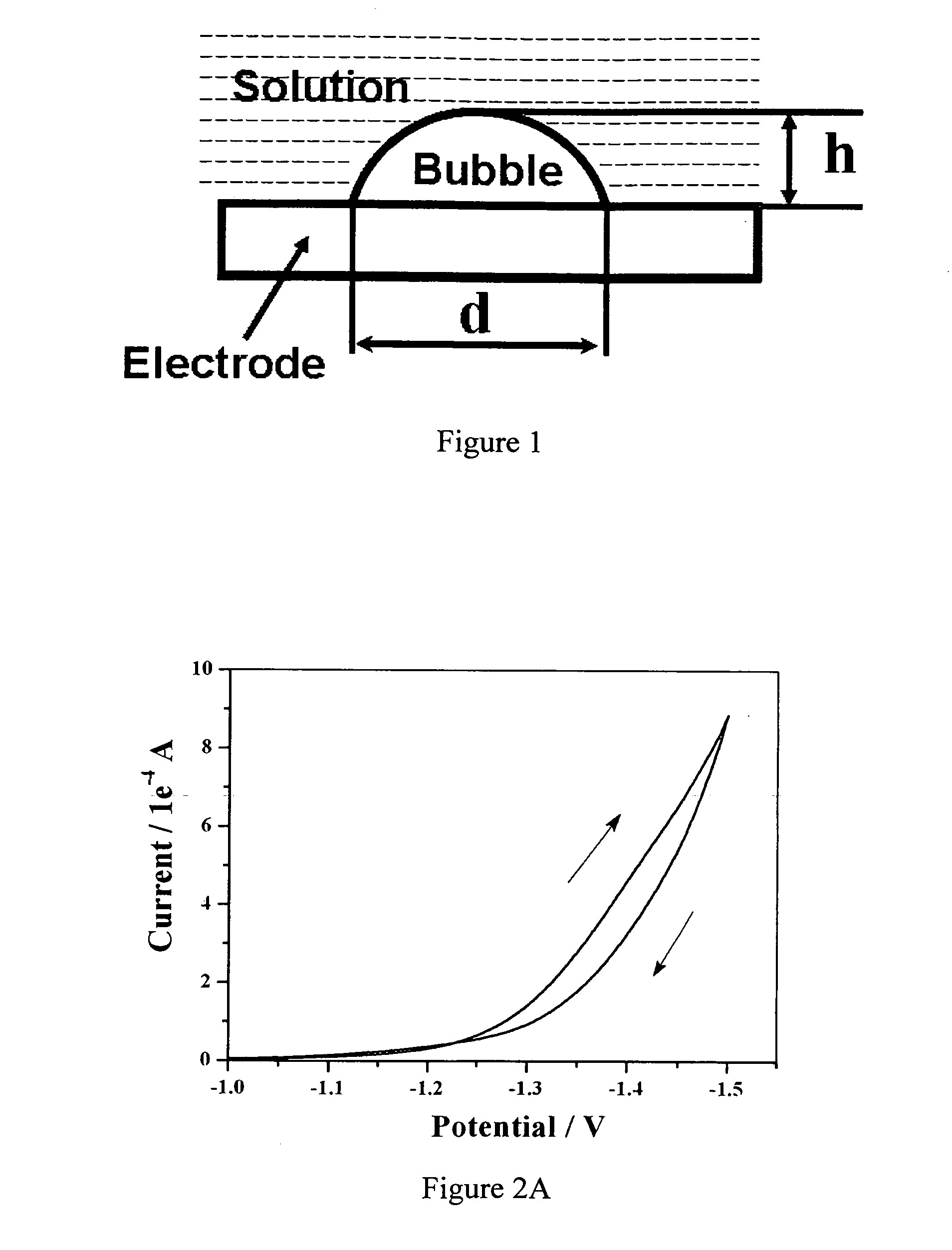

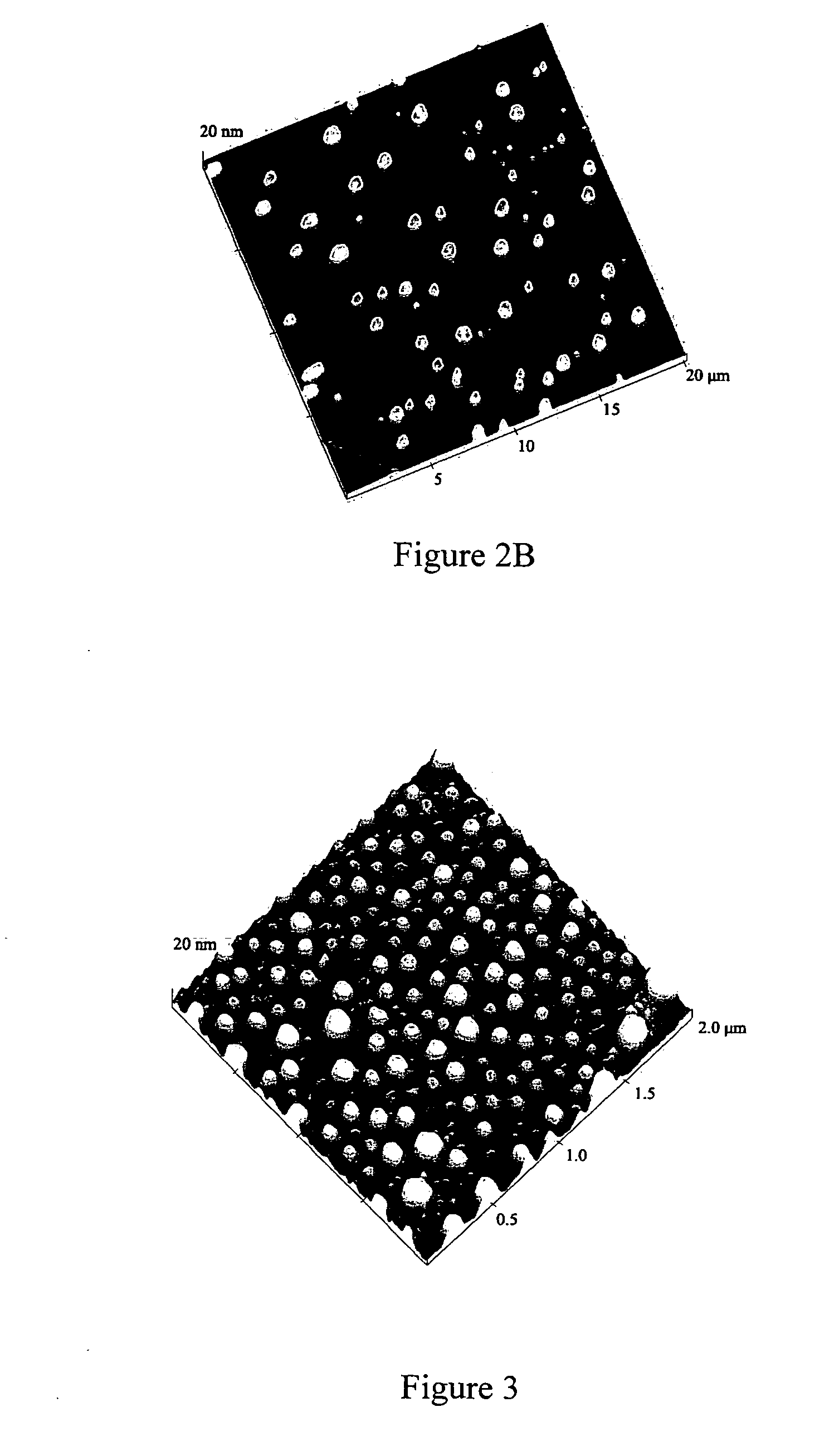

Method for Gas Storage

InactiveUS20080317664A1Good repeatabilityNot bring contaminationMaterial nanotechnologyReversible hydrogen uptakeInorganic saltsHighly oriented pyrolytic graphite

This invention released a method for gas storage, characterized that gas is stored in the form of nanometer scale bubbles or gas layers on the solid-liquid surfaces. Said gas is hydrogen, the surface of the solid is planar solid surface, irregular solid surface, or porous material surface, especially highly oriented pyrolytic graphite (HOPG) surface, and the liquid is water, inorganic acid, inorganic salt, inorganic alkali, organic solution or colloid solution. The gas to be stored is produced by electrochemical method, inorganic reaction, organic reaction, biologic reaction or physical method.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Method for preparing ultra-thin two-dimension graphite sheet

InactiveCN101143708AFully contactedEasy to makeNanostructure manufactureHighly oriented pyrolytic graphiteWork in process

The invention belongs to the nanometer art and novel material area, which specifically relates to a preparation method of an ultra thin two dimensional graphite piece. The preparation process is that: (1) a substrate is prepared and purified; (2) a thin water film is prepared on the substrate; (3) a massive highly oriented pyrolytic graphite is processed and a clean cleavage surface is contacted with the water film; (4) the graphite is frozen in a minor 5DGE C-30DGE C environment until the water film is solidified and stuck to the graphite; (5) the massive graphite is taken down, the large and thick graphite piece is removed through the adhesion function of an adhesive tape and a semi-finished product is obtained; (6) the semi-finished product is baked in a 50 DGE C -200 DGE C environment so as to remove the water molecules on the graphite piece surface and the water molecules between the graphite piece and the substrate, and a finished product is obtained; (7) a screening process is according to the application requirements. The invention selects water as the adhesive material to stick the graphite, the force of the Vander Waal between the water film and the graphite is very strong after the water is frozen into ice, a few under layers of graphite are taken down by adhesion from the massive graphite without leaving impurity contamination, which makes the product very clean. As the freezing point of water is at the normal temperature and the water is an easy volatile solvent, the whole preparation process is simple and the operation is convenient.

Owner:UNIV OF SCI & TECH OF CHINA

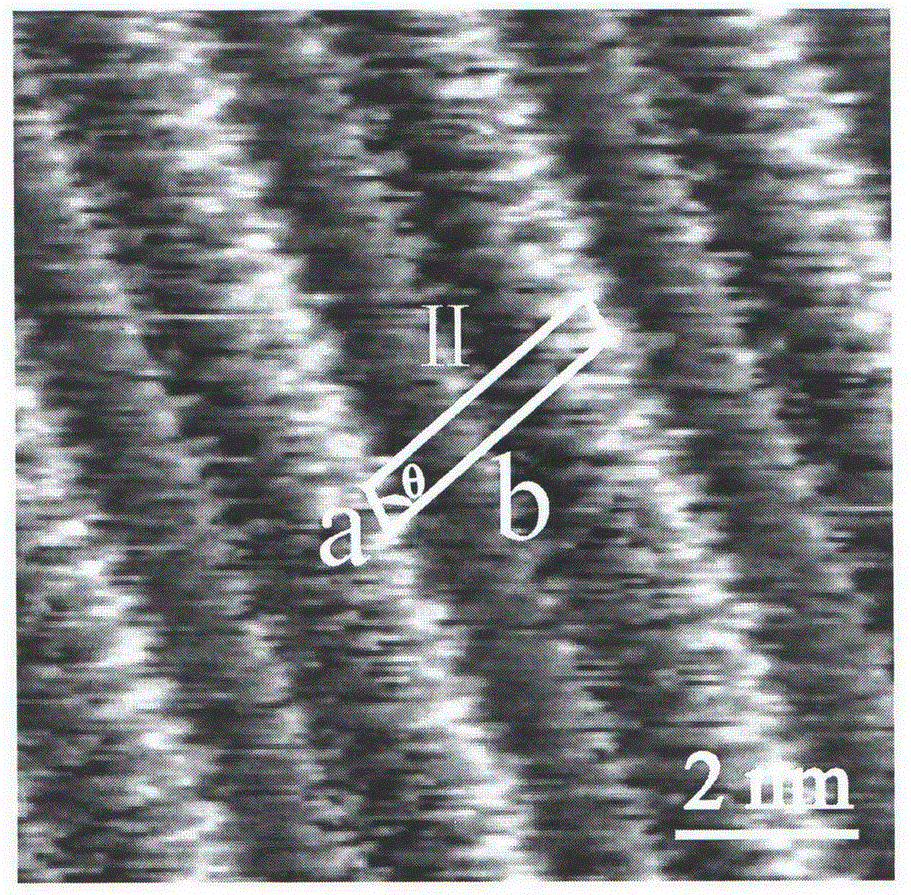

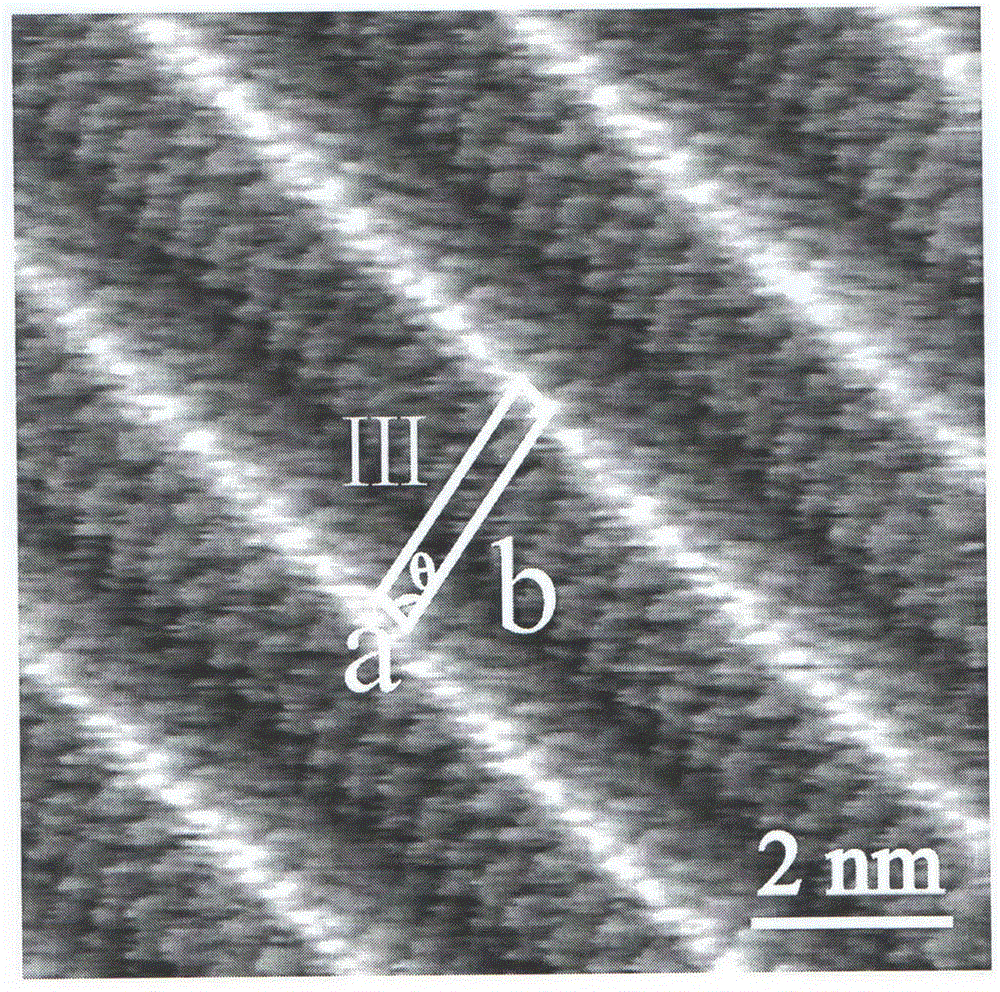

Method for constructing metal organic frame film on graphite base

InactiveCN105826170ASimple manufacturing methodImprove efficiencySemiconductor/solid-state device manufacturingMetal-organic frameworkGraphite substrate

The invention relates to a method for constructing a metal organic frame film on a graphite substrate. According to the method, 4,4'-tetracosyl-2,2'-bipyridine is adopted to form a self-assembly film of a crystal structure I on a graphite base through a molecule self-assembly method; and with a zinc acetate solution and a copper acetate solution adopted, a metal organic frame film of a crystal structure II or a metal organic frame film of a crystal structure III can be obtained through adopting an in-situ dropwise adding method. The concentration of the 4,4'-tetracosyl-2,2'-bipyridine solution is low; the highly-oriented pyrolytic graphite is formed by stacking graphene layers, and the surface of the highly-oriented pyrolytic graphite is flat; a transparent adhesive tape can be pressed on the surface layer of the highly-oriented pyrolytic graphite, and then the surface layer can be peeled off, so that a clean graphite surface can be obtained, and therefore, the film can be cleaned easily and can be repeatedly used; temperature condition is mild; and the crystal structure of the metal organic frame film can be adjusted according to demands. The graphite based metal organic frame film prepared by using the method has the advantages of uniform film formation, few defects and simple operation, and can be applied to fields such as photoelectric molecular sensors.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

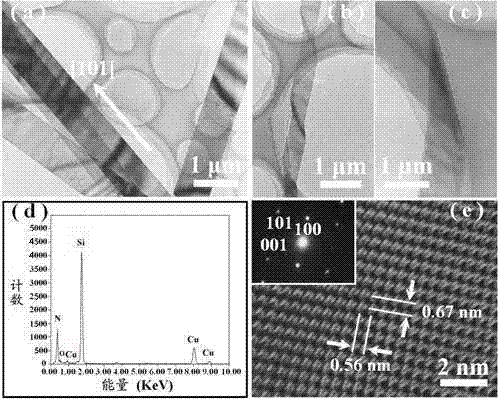

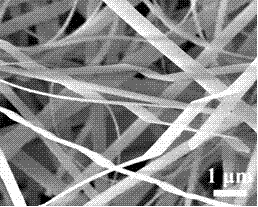

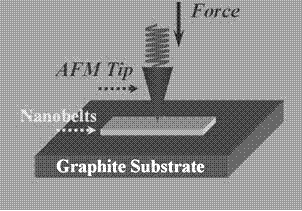

Silicon nitride nanobelt high-sensitivity pressure sensor

ActiveCN104776945AHigh sensitivityImprove structural stabilityNitrogen compoundsForce measurement using piezo-resistive materialsPtru catalystEngineering

The invention discloses a method for manufacturing a Si3N4 nanobelt high-sensitivity pressure sensor. The method comprises the following specific steps: (1) putting raw materials, that is, two organic precursors polysilazane and aluminum isopropoxide into a ball-milling tank for planet ball milling in a weight ratio of 95:5; performing low-temperature cross-linking curing on the organic precursors which are uniformly mixed and reacted in the presence of N2 protecting atmosphere so as to obtain non-crystal solid; introducing 3wt% of Al metal powder as a catalyst, and performing high-energy ball-milling crushing; performing high-temperature pyrolysis on the powder obtained through high-energy ball-milling crushing by keeping the temperature of 1550 DEG C for 2 hours in the presence of the N2 protecting atmosphere, thereby preparing a Si3N4 single-crystal nanobelt; (2) performing ultrasonic dispersion on the Si3N4 single-crystal nanobelt in ethanol, and subsequently dropping and spraying onto highly oriented pyrolytic graphite. The Si3N4 nanobelt high-sensitivity pressure sensor can be constructed in an atomic force microscope conductive mode, and by exerting different pressures by using probes, electric signals can be detected under different pressures. Compared with reported operation, the Si3N4 nanobelt high-sensitivity pressure sensor manufactured by using the method can achieve feedback and detection of nN-order force, and is relatively high in sensitivity.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

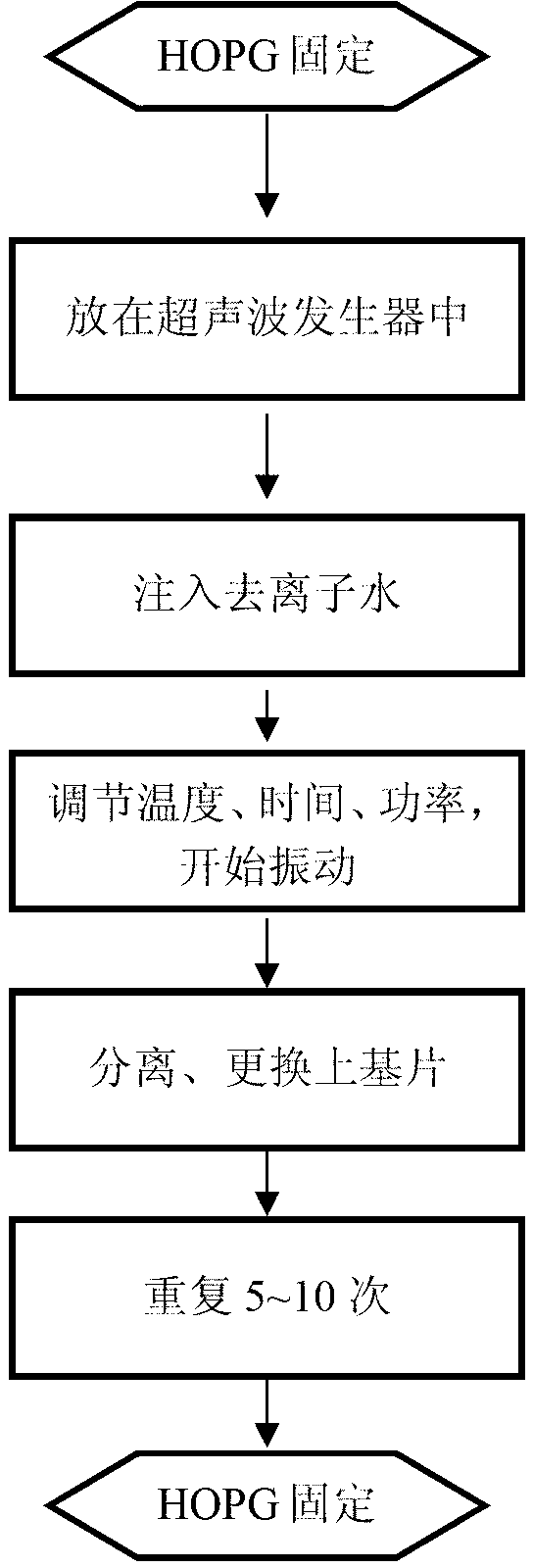

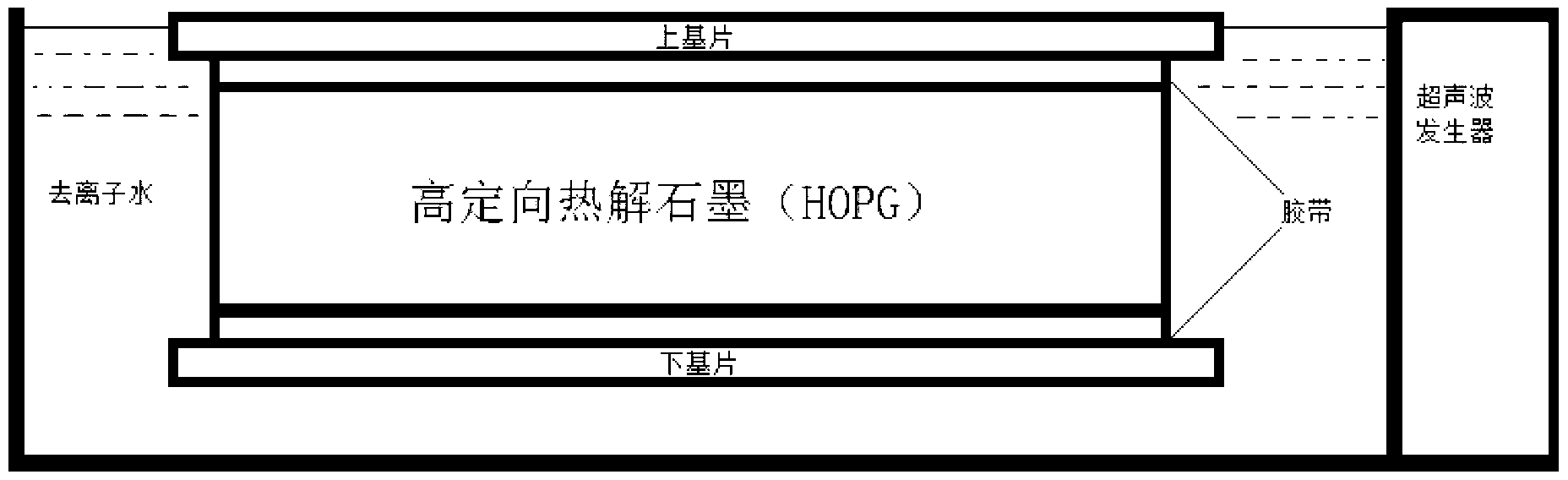

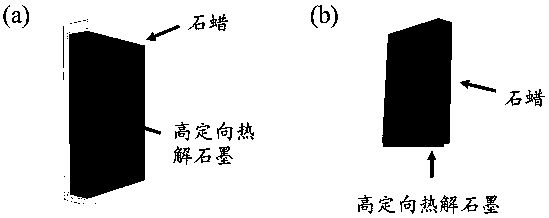

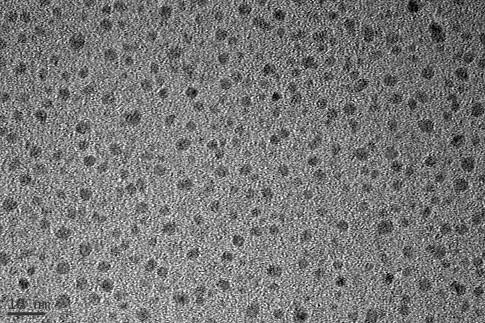

Method for stripping graphene with ultrasonic assist

InactiveCN103065939AImprove efficiencyImprove uniformitySemiconductor/solid-state device manufacturingUltrasonic assistedHighly oriented pyrolytic graphite

The invention belongs to the technical field of semiconductor material manufacture, and provides a method for stripping graphene with ultrasonic assist. The method for stripping the graphene with the ultrasonic assist comprises fixing highly oriented pyrolytic graphite (HOPG) between an upper substrate and a lower substrate through double sticky tapes, putting the fixed HOPG in an ultrasonic generator, soaking the HOPG in deionized water, and adjusting ultrasonic power to be in a range form 0.1J to 2*105J, time to be in a range form 1min to 50min and temperature to be in a range from 10DEG C to 40DEG C; starting the ultrasonic generator, and carrying lateral oscillation; separating the HOPG from the upper substrate, and fixing the HOPG below an upper substrate; repeating the above processes for 5-10 times until the graphene is obtained; and removing residue adhesive tape components on the surface of the graphene by using analytically pure acetone. The The method for stripping the graphene with the ultrasonic assist uses ultrasonic wave to destroy bonds between graphitic layers so as to strip the graphene, is good in homogeneity and high in efficiency, avoids influence of adhesive tape residue of a manual stripping method, and has good value of popularization and application.

Owner:西安海辰兴新材料科技有限公司

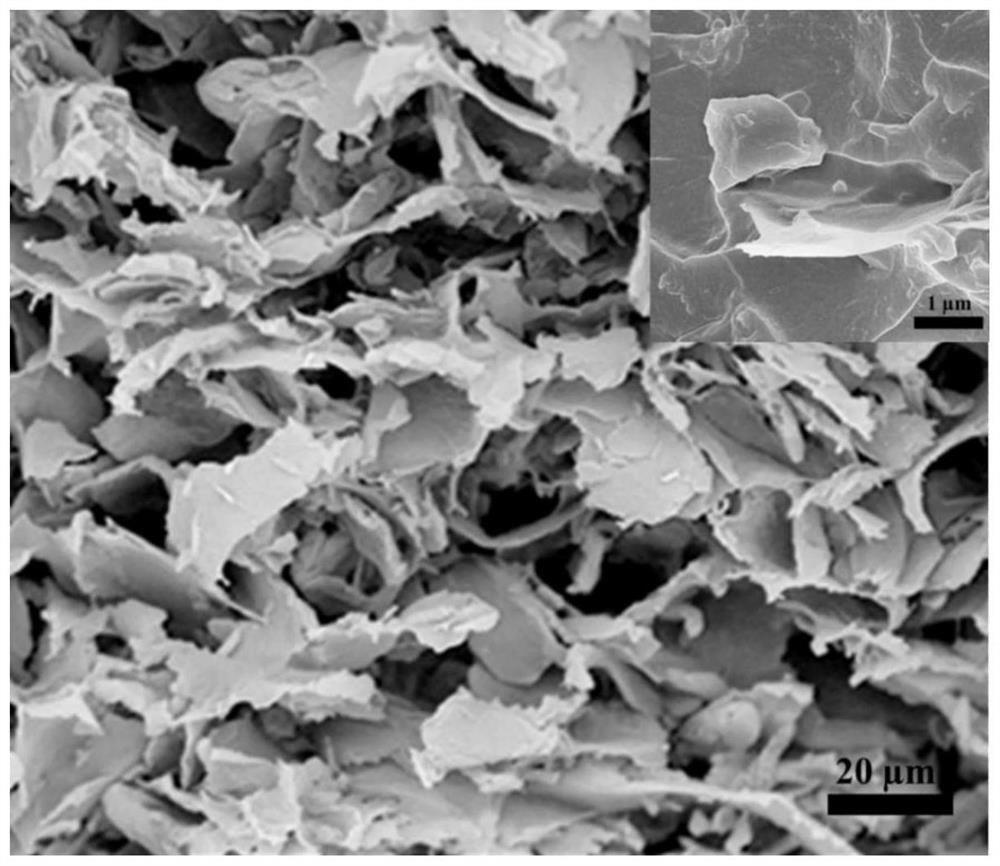

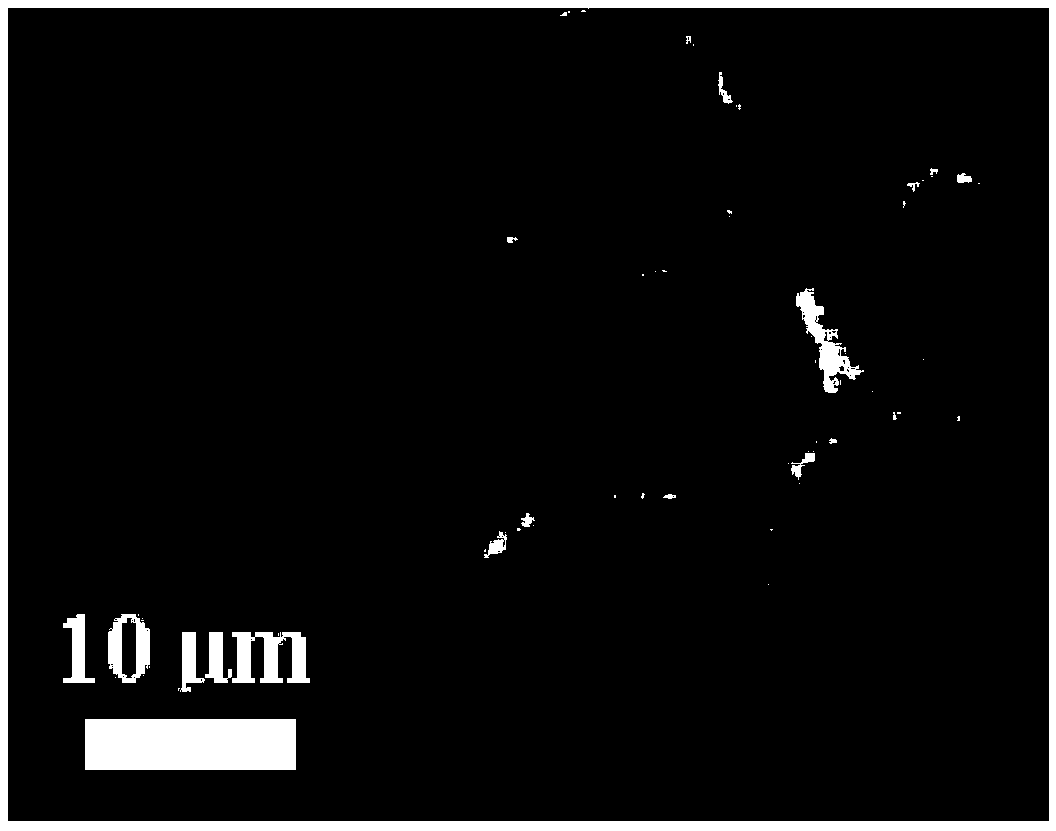

Method for preparing high-quality graphene quantum dot or large-lamella graphene oxide

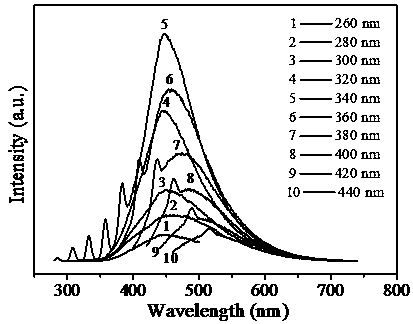

ActiveCN109485032AImprove stripping efficiencyHigh yieldSingle layer grapheneLuminescent compositionsElectrochemical responseSolubility

The invention provides a method for preparing a high-quality graphene quantum dot or large-lamella graphene oxide. The high-quality graphene quantum dot or large-lamella graphene oxide can be respectively prepared from highly-oriented pyrolytic graphite or pyrolytic graphite with a relatively high orientation degree, graphite foil and the like serving as raw materials by using a controllable selective crystal surface electrochemical stripping method. A single crystal surface is selected to be exposed into an electrolyte to be subjected to an electrochemical stripping reaction by utilizing a difference of electrochemical reaction energy of different crystal surfaces of graphite, and thus, large-lamella graphene oxide is obtained in an acidic or neutral electrolyte; and a blue fluorescent graphene quantum dot which is high in yield, capable of realizing further separation without aftertreatment, good in water solubility, uniform in size, unique in chemical component and narrow in spectrum and has a half-peak breadth is prepared in an alkaline electrolyte.

Owner:HENAN UNIVERSITY

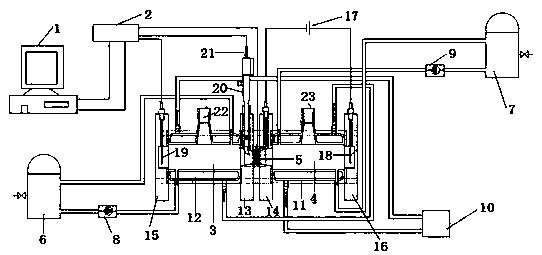

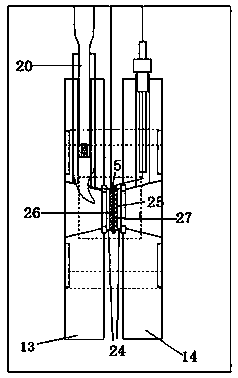

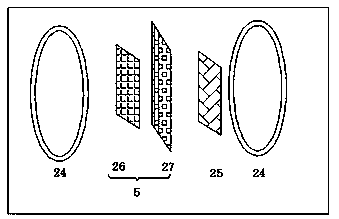

Unsaturated organic matter circulating hydrogenation and energy storage device

ActiveCN108654535AHigh yieldInhibition of hydrogen evolution side reactionEnergy based chemical/physical/physico-chemical processesWater bathsFiber

The invention discloses an unsaturated organic matter circulating hydrogenation and energy storage device, and belongs to the field of electro-catalysis materials and chemical equipment. The device comprises an anode reaction chamber, solid polymer electrolyte membrane electrodes (SPEME), a cathode reaction chamber, a material circulating and constant-temperature water-bath circulating loop, a direct-current steady-voltage source, an electrochemical workstation, a computer, highly oriented pyrolytic graphite electrodes (HOPGE), graphite fiber cloth electrodes (GFCE), a lead and a gas collecting system. The investment on the device is lower than the investment on high-pressure hydrogen storage and liquefaction hydrogen storage, the hydrogen storage density of the device is higher than thatof metal hydride, the hydrogenation current efficiency and the yield of target products are greatly improved, the economy of hydrogenation and energy storage is high, the safety is high under the conditions of normal pressure and normal temperature, environmental pollution is small, and the unsaturated organic matter circulating hydrogenation and energy storage device is simple to operate, convenient to maintain and long in service life.

Owner:KUNMING UNIV OF SCI & TECH

Vacuum electron device electrodes and components manufactured from highly oriented pyrolytic graphite (HOPG)

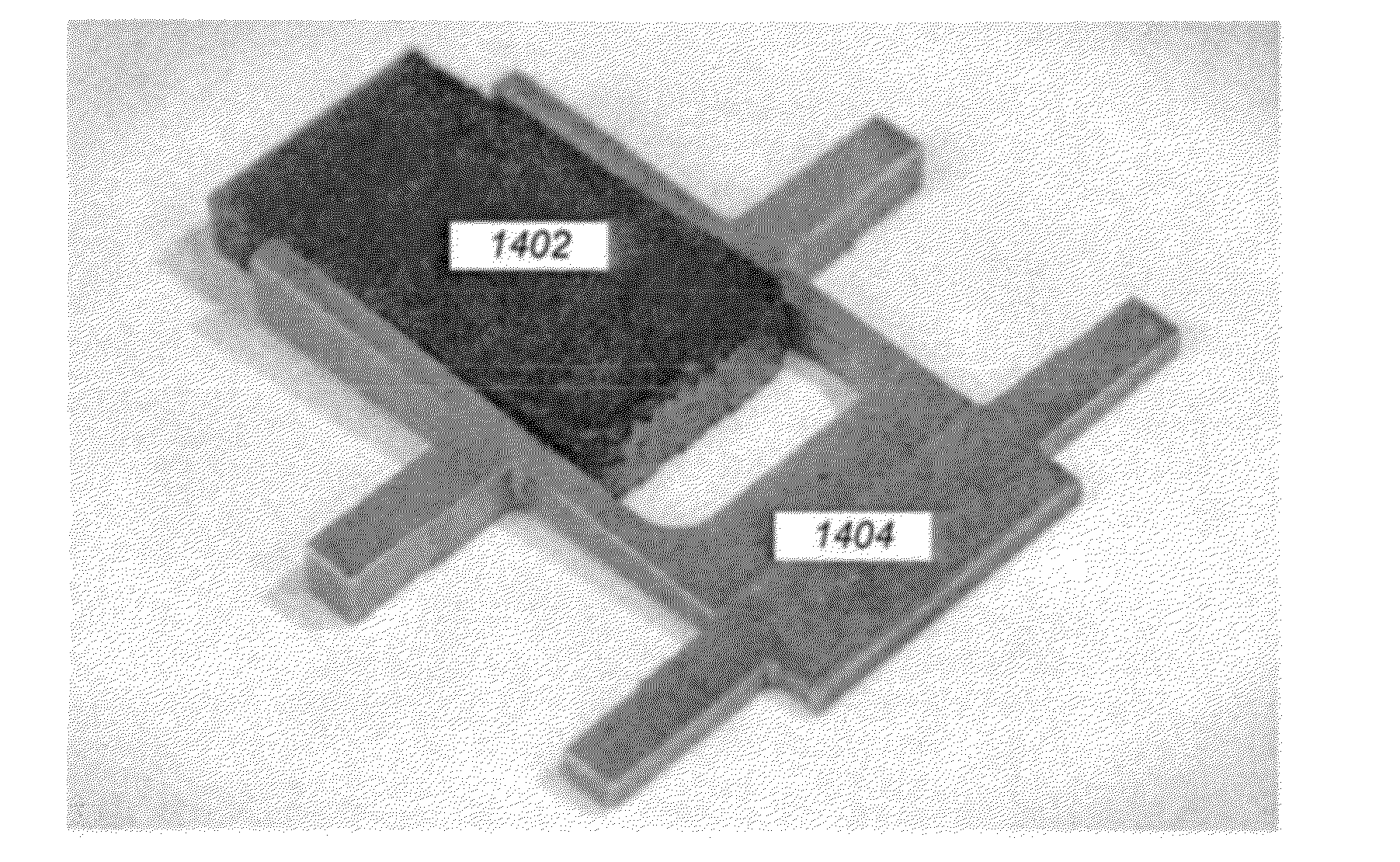

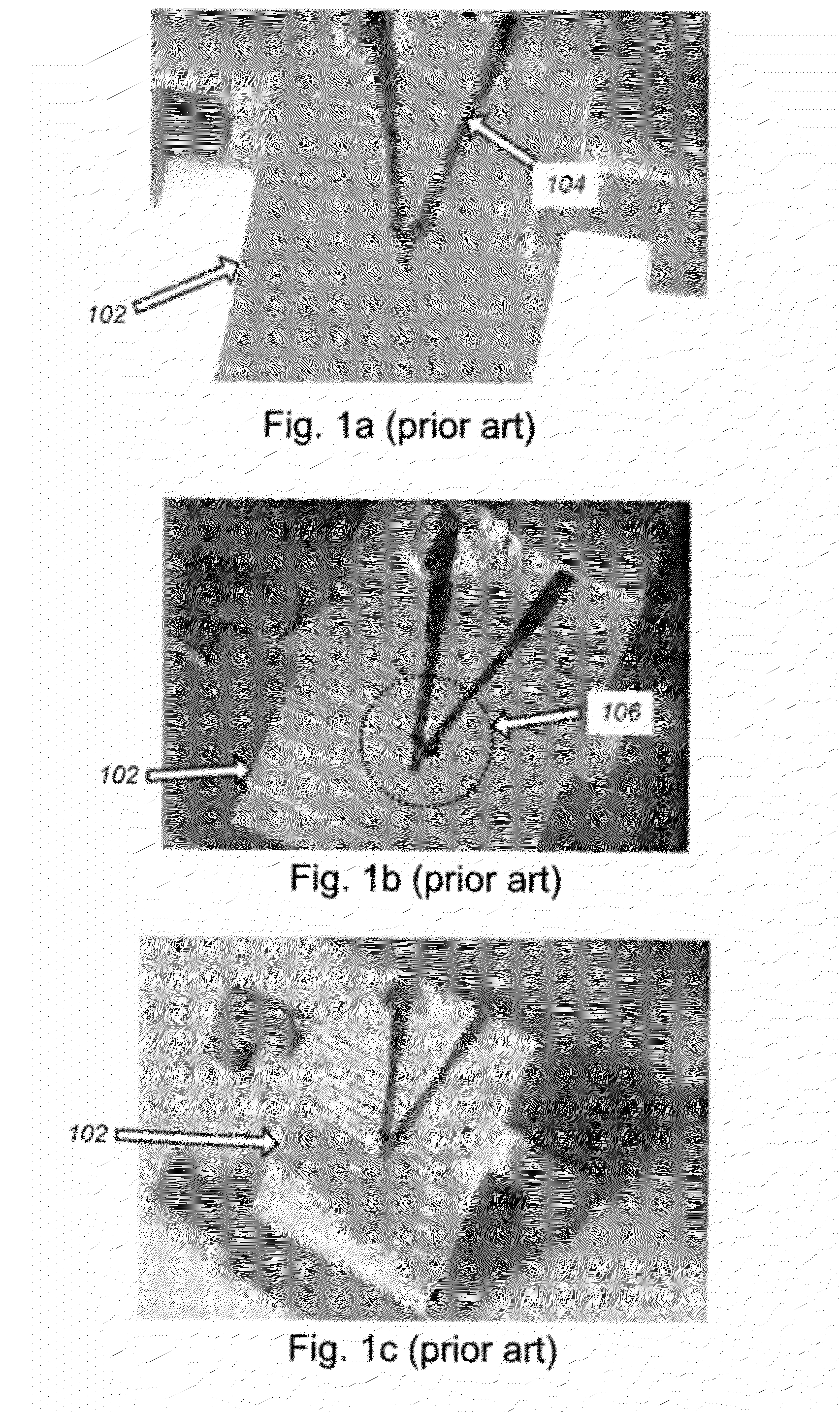

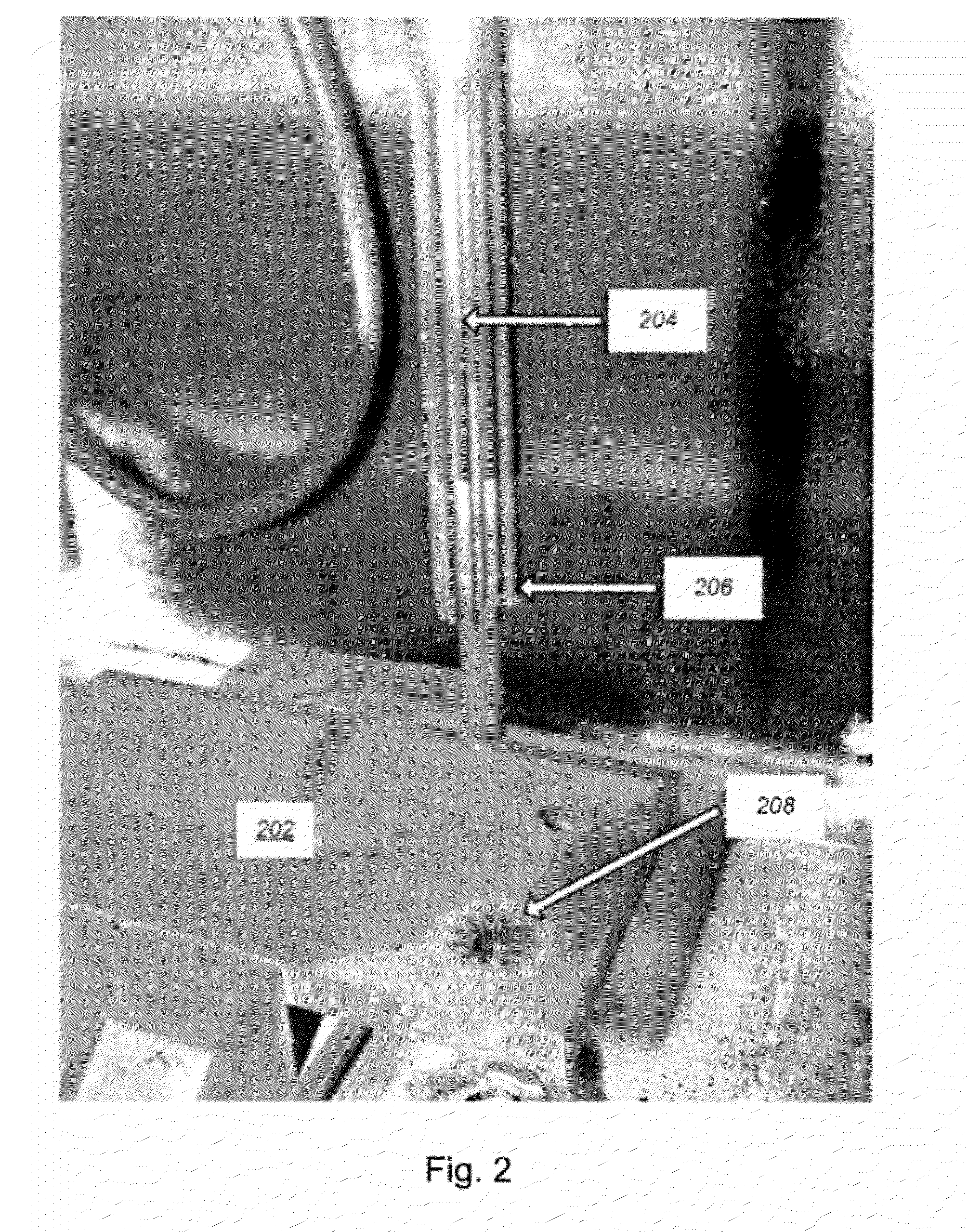

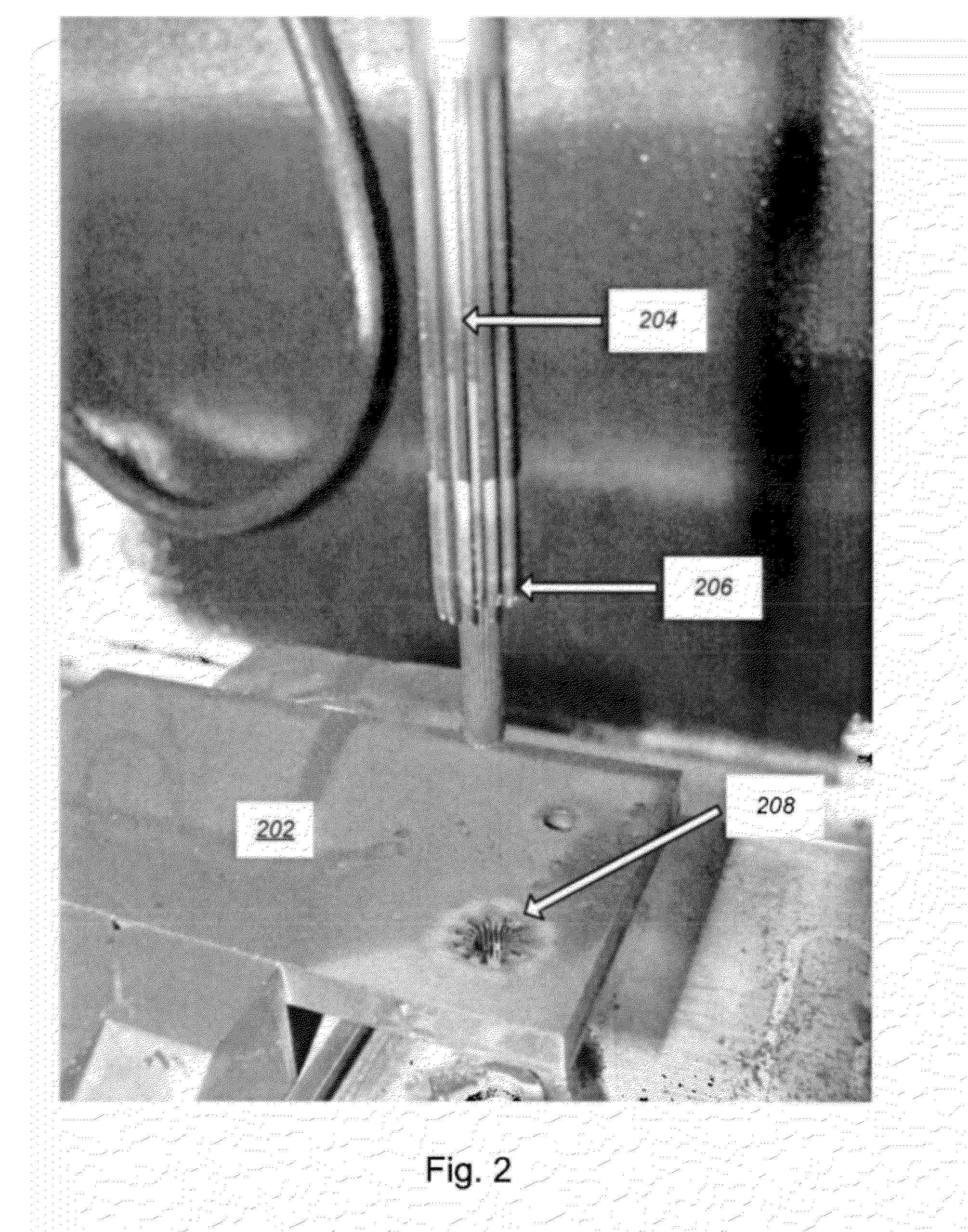

ActiveUS20120313505A1Keep the pressureEliminate voidsMagnetronsLamp incadescent bodiesHighly oriented pyrolytic graphiteErosion rate

Components for use in vacuum electron devices are fabricated from highly oriented pyrolytic graphite (HOPG) and exhibit excellent thermal conductivity, low sputtering rates, and low ion erosion rates as compared to conventional components made from copper or molybdenum. HOPG can be reliably brazed by carefully controlling tolerances, calculating braze joint material volume, and applying appropriate compression during furnace operations. The resulting components exhibit superior thermal performance and enhanced resistance to ion erosion and pitting.

Owner:L3 TECH INC

Preparation of special modified graphene automobile finish polishing and grinding material as well as application thereof

The invention discloses a preparation of a special modified graphene automobile finish polishing and grinding material as well as an application thereof. According to the invention, a solvent stripping method is employed, graphite flake stripped from highly oriented pyrolytic graphite (HOPG) is subjected to oxidation treatment to obtain graphene oxide, then graphene oxide and thionyl chloride are subjected to a reaction to obtain the graphene with the surface containing acyl chloride group, the graphene and 1,3-propane diamine, melamine, and a dihydric alcohol compound are subjected to a nucleophilic substitution reaction to obtain graphene with the surface containing hydroxy group, and the hydroxy content is 0.01-0.03%. The obtained modified graphene has good water solubility and is in favor of stable dispersion of graphene, the characteristic of the modified graphene is used for enabling the graphene to be conveniently mixed with the other grinding agent preparation materials, and uniform dispersion is carried out, and the obtained modified graphene is used for preparing the automobile finish polishing and grinding material. In addition, the preparation method has the advantages of easy satisfaction of operation condition, and easy acquisition of the raw materials, cost is effectively reduced, economic benefit is increased, and the method has good application prospect.

Owner:广州市新稀冶金化工有限公司

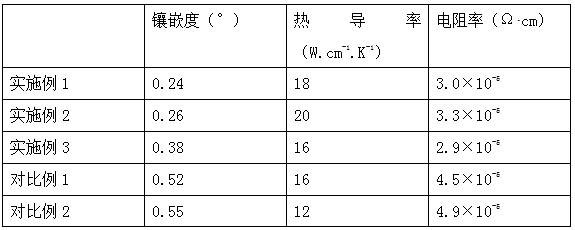

Preparation method of highly oriented pyrolytic graphite

ActiveCN112813496AQuality improvementGood orientationPolycrystalline material growthSingle crystal growth detailsHighly oriented pyrolytic graphiteGraphite substrate

The invention belongs to the field of preparation of novel carbon materials, and particularly relates to a preparation method of highly oriented pyrolytic graphite. The method is realized by the following steps: firstly, soaking a graphite substrate in a pretreatment solution, taking out the graphite substrate, airing the graphite substrate, and then introducing methane and nitrogen by adopting a chemical deposition method to obtain a pyrolytic graphite plate; cooling the pyrolytic graphite plate to 700-750 DEG C, putting the pyrolytic graphite plate into a magnetic field, and taking out the pyrolytic graphite plate when the temperature is reduced to 100 DEG C; and taking out the pyrolytic graphite plate subjected to magnetic field treatment, putting the pyrolytic graphite plate into a high-pressure and high-temperature furnace, introducing inert gas, and carrying out heat treatment. According to the method, the graphite base material is pretreated, then the pyrolytic graphite is prepared through the chemical vapor deposition method; in the subsequent heat treatment process, the pyrolytic graphite easily forms the high-orientation pyrolytic graphite with the higher orientation degree, and the heat treatment time is relatively short, so that the high-orientation pyrolytic graphite with the higher quality is obtained with the lower cost; in addition, the graphite base material is subjected to magnetic field treatment in advance, so that the orientation degree of pyrolytic graphite is improved.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

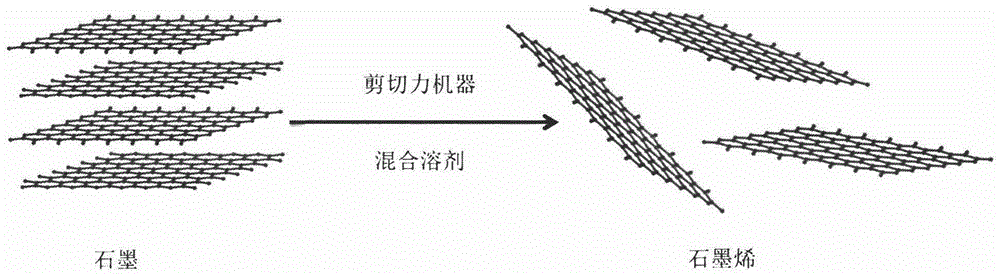

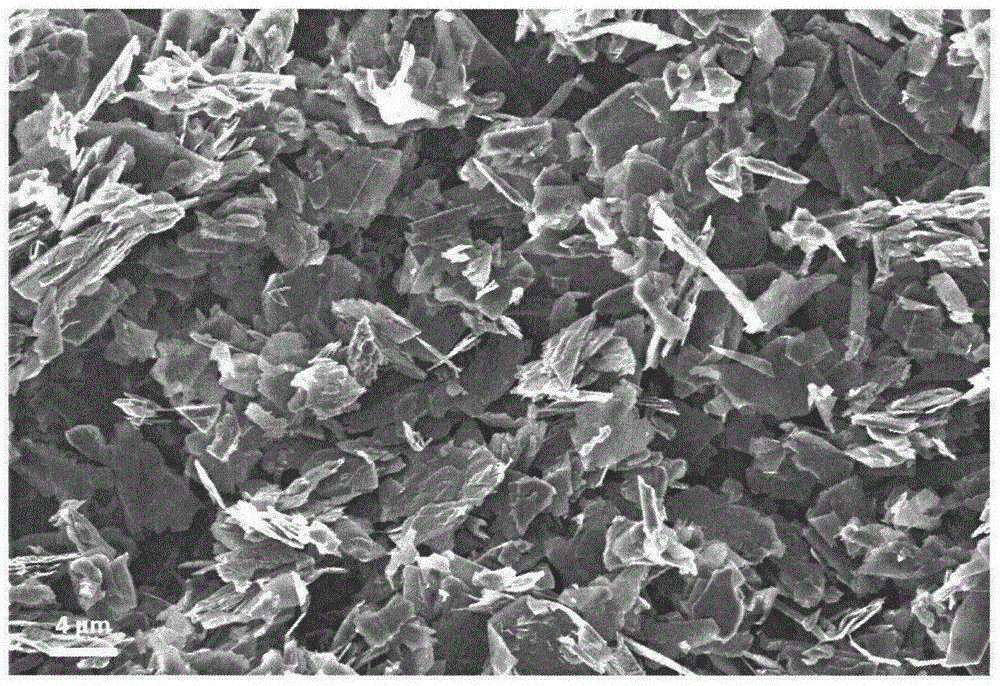

Method for peeling off graphite to obtain graphene based on shear force machine

The invention relates to the technical field of nanometer preparation, in particular to a method for peeling off graphite to obtain graphene based on a shear force machine. The method comprises the specific steps that 5-1*10<9> mg of one or more of massive crystalline graphite, crystalline flake graphite, cryptocrystalline graphite, expanded graphite and highly oriented pyrolytic graphite are weighed, 50-5*10<6> mL of water and a mixing solvent with 10 or smaller carbon atom alcohol are added, the uniformly-mixed solution is placed into the shear force machine for performing peeling for 0.3-120 h, standing is performed, the centrifuging speed is 100-10000 rpm / min, and post-treatment is performed, so that graphene is obtained. The preparation method is mild in condition, the reaction is green, adopted raw materials and solvents are simple, no liquid waste pollution exists, large-scale preparation can be performed, and the method has the application prospect for producing graphene.

Owner:苏州烯墨纳米科技有限公司

Method for preparing high-quality graphite monocrystal

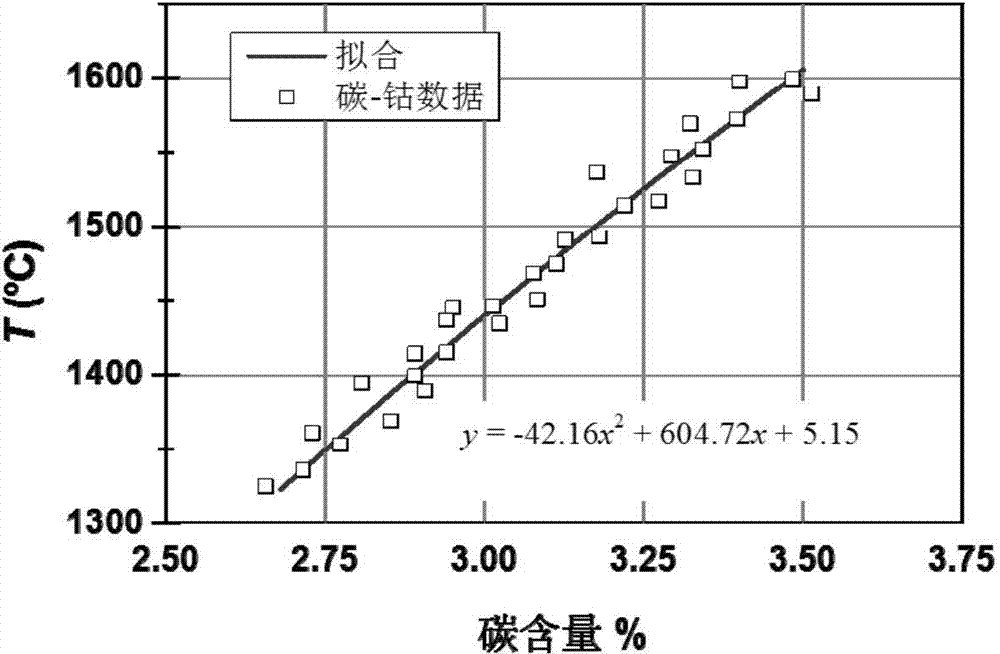

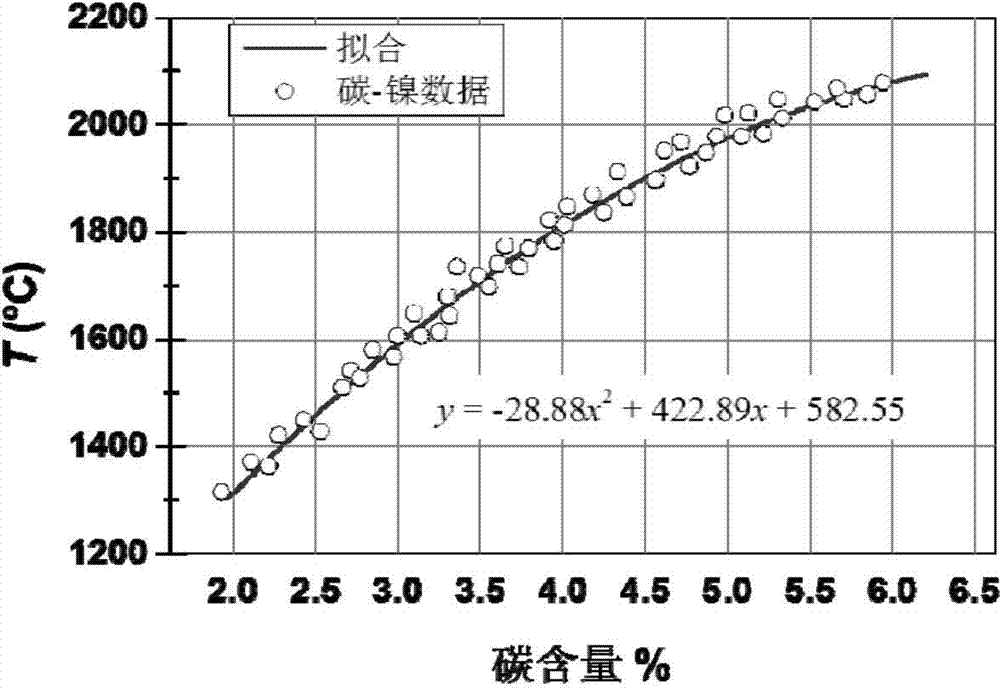

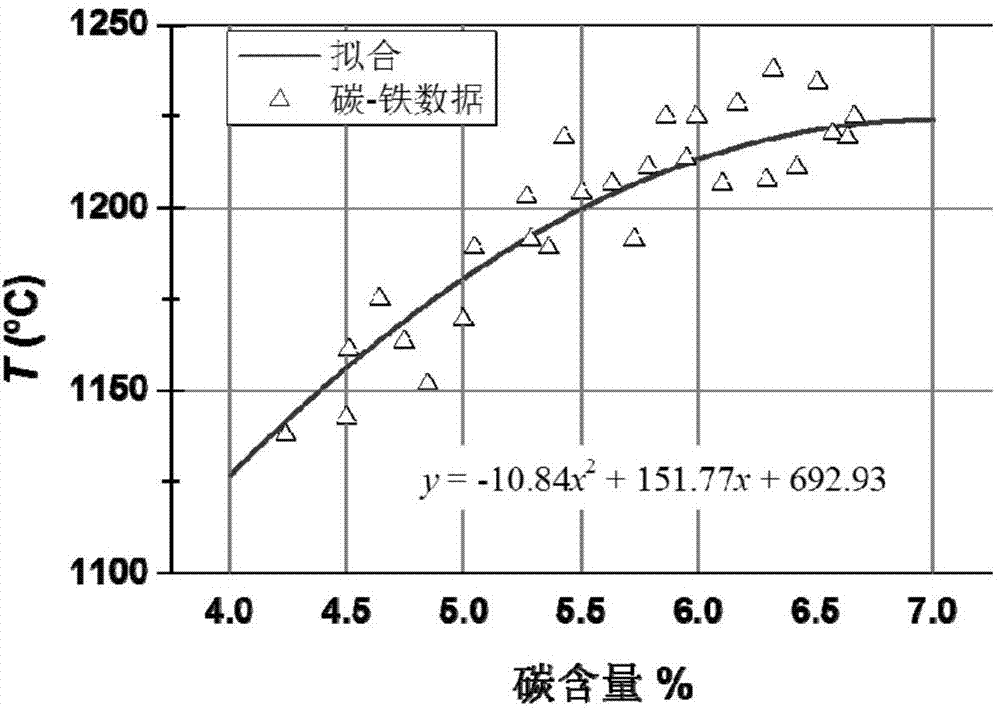

InactiveCN104775147AQuality improvementReduce the temperaturePolycrystalline material growthEutectoid materials demixingHighly oriented pyrolytic graphiteHeat conducting

The invention discloses a method for preparing a high-quality graphite monocrystal. The method adopts a comelting-crystallization process and comprises the following steps: uniformly mixing a transition metal or transition metal compound with a carbon raw material, heating to form a comelt, cooling to obtain a metal / graphite two-phase separation body, and carrying out mechanical separation to obtain the high-performance heat-conducting graphite. The high-quality graphite monocrystal prepared by the method has high crystallinity; and the grain size can reach Lc(002)=100nm, and the interplanar distance is d(002)=0.335nm, which are respectively higher than the index of the highly-oriented pyrolytic graphite.

Owner:南京奥依菲光电科技有限公司

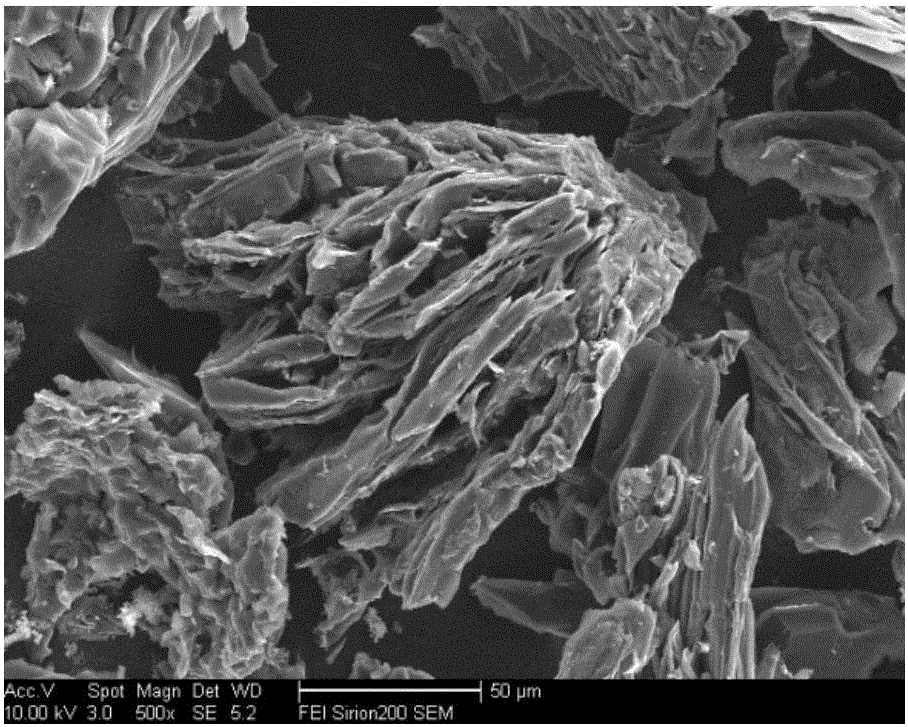

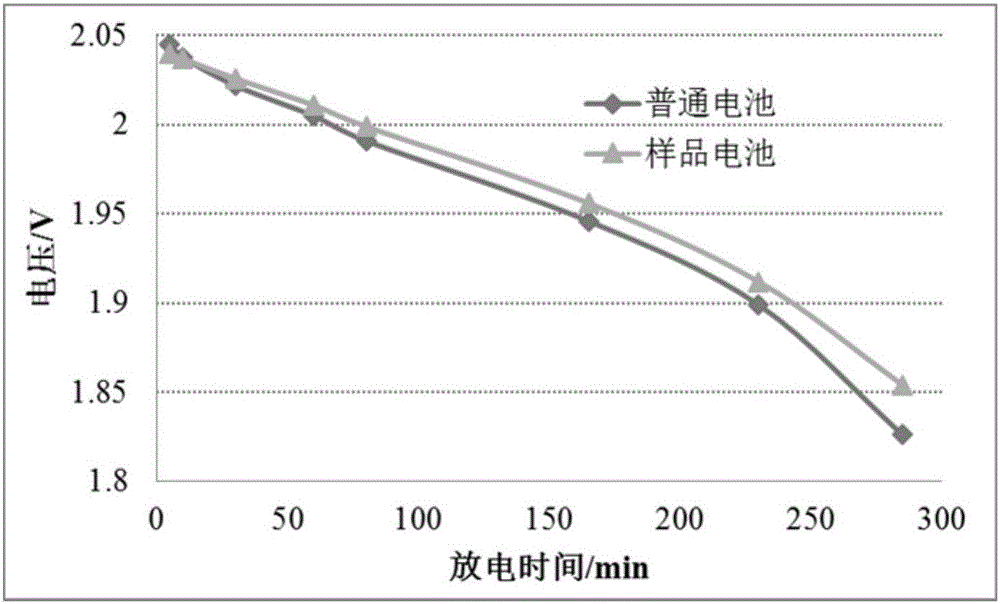

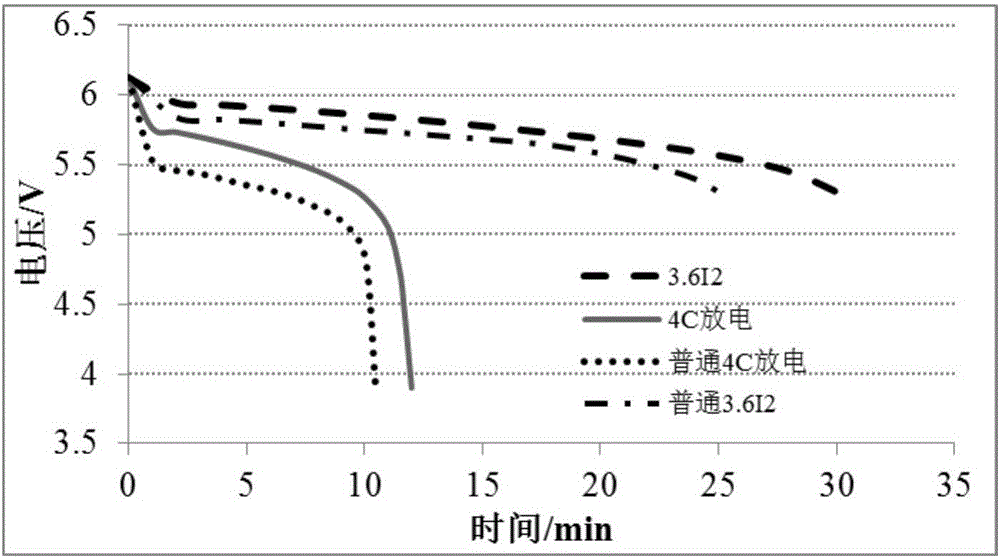

Lead-carbon battery negative electrode and preparation method thereof

The invention belongs to the technical field of lead storage batteries, and particularly relates to a lead-carbon battery negative electrode and a preparation method thereof. The lead-carbon battery negative electrode comprises the raw materials including, by weight, 0.2-2% of flocculent carbon materials, 0.1-0.3% of humic acid, 0.05-0.1% of conductive graphite, 0.01-0.05% of indium oxide, 0.1-0.5% of barium sulfate, 0.5-1.5% of a binding agent, 0.5-2.5% of thionyl chloride and the balance lead powder. According to the flocculent carbon materials, highly oriented pyrolytic graphite is used as the positive pole, a lead plate is used as an auxiliary electrode, electrolysis is performed in an electrolyte, the current density ranges from 10 mA / cm<2> to 20 mA / cm<2>, then dispersion is performed, the dispersion speed ranges from 2000 r / min to 3000 r / min, and the time is 2-5 h. The hydrogen evolution potential of a negative plate can be improved, the large-current charging and discharging performance is excellent, the preparation method of the lead-carbon battery negative electrode and the paste mixing technology are simple, and the consistency is good.

Owner:ZIBO TORCH ENERGY

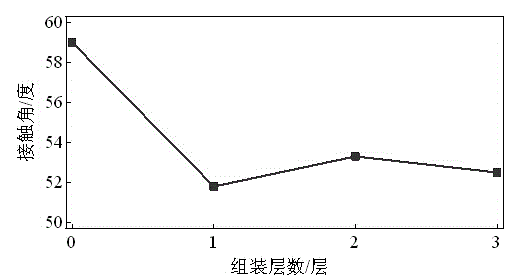

Composite film with high electrochemical performance and preparation method of composite film

ActiveCN104576072AImprove electrochemical performanceImprove stabilityLight-sensitive devicesCapacitor detailsComposite filmElectrochemistry

The invention discloses a composite film with high electrochemical performance and a preparation method of the composite film, and belongs to the field of composite material preparation. The composite film is formed by alternately self-assembling amphipathic ruthenium complex molecular films and symmetrical ruthenium complex molecular films, a highly oriented pyrolytic graphite(Highly Oriented Pyrolytic Graphite, HOPG) is used as a base, wherein an amphipathic ruthenium complex is [Ru(Py2G1MeBip)(XPOH)](PF6)2, and a symmetrical ruthenium complex is [Ru(XPOH)2](PF6)2. The composite film obtained by the preparation method disclosed by the invention is uniformly and sufficiently modified on the electric conduction base, so that the composite film has favorable mechanical stability and chemical stability. The composite film unifies the respective advantages of two kinds of materials, so that compared with a single self-assembly film, the electrochemical performance and the stability of the composite film are obviously improved. The composite film can be operated by using a simple container under a room temperature without special conditions or complex costly instruments. Compared with other layered assembly techniques, the composite film disclosed by the invention is simple and convenient to operate, is short in assembly time, is high in bond strength with the base, and has better popularization and application values.

Owner:KUNMING UNIV OF SCI & TECH

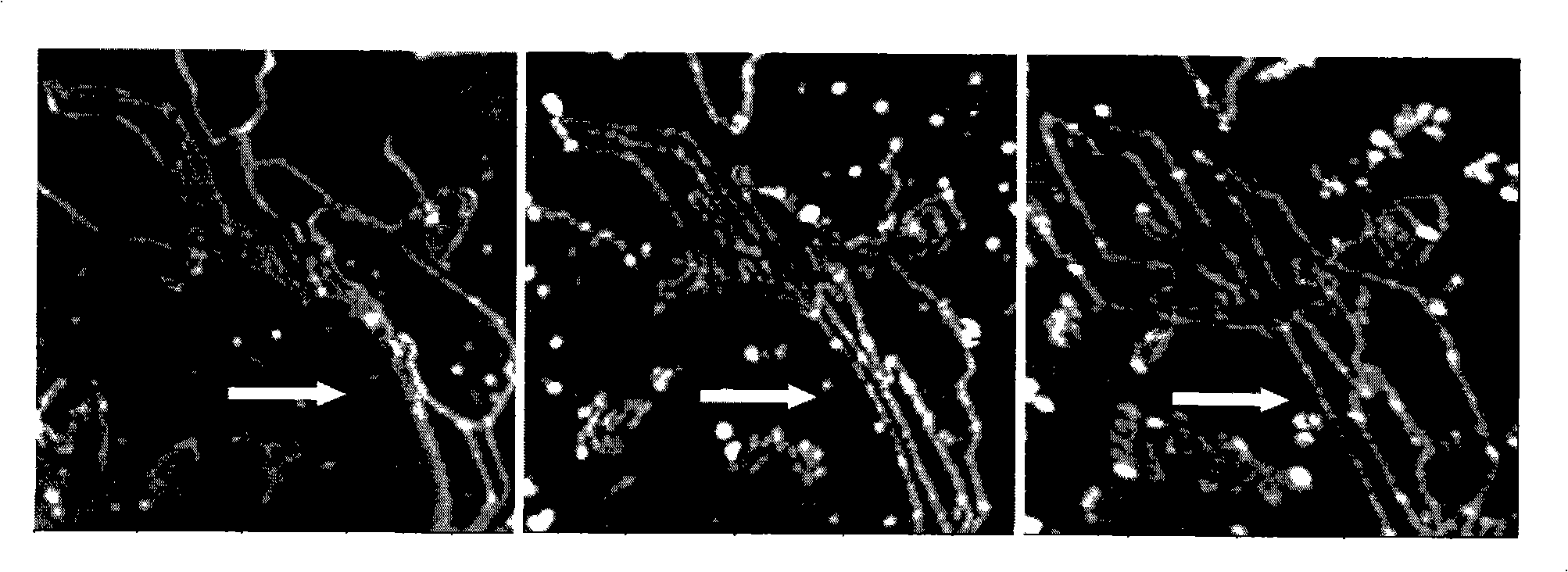

Construction method of micro/nano graph of DNA molecule

InactiveCN101323851AEfficient constructionSimplified means of operationFermentationGenetic engineeringHighly oriented pyrolytic graphiteNanodevice

The invention discloses a construction method of the micron / nano pattern of DNA molecules, which comprises the steps of: dispersing and adsorbing the DNA molecules on a highly-oriented pyrolytic graphite substrate, adopting liquid disturbance to regularly assign the DNA molecules into a nano or micron pattern. The method of the invention can construct the complicated micron / nano pattern of the DNA molecules efficiently, has simple operational approaches and low cost. The constructed nano pattern of the DNA molecules can provide a good template for designing controllable reaction on the basis of the nano devices and the nano level of the DNA molecules.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

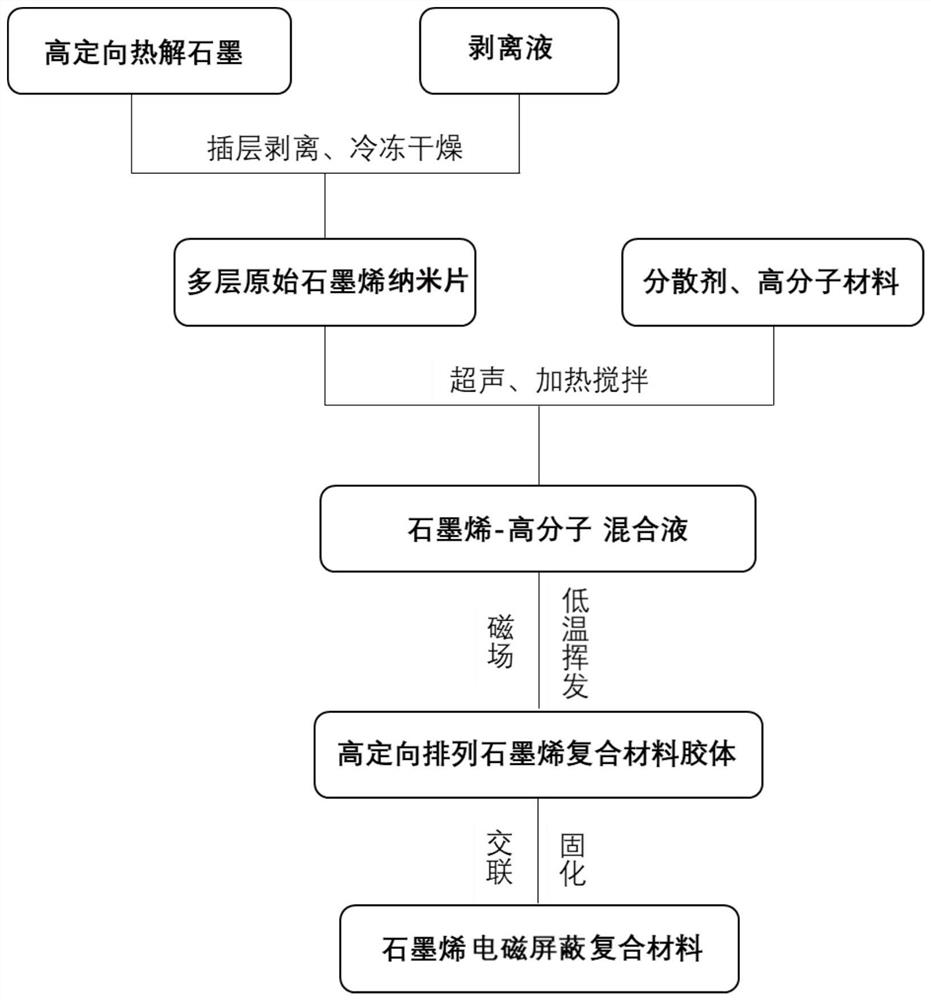

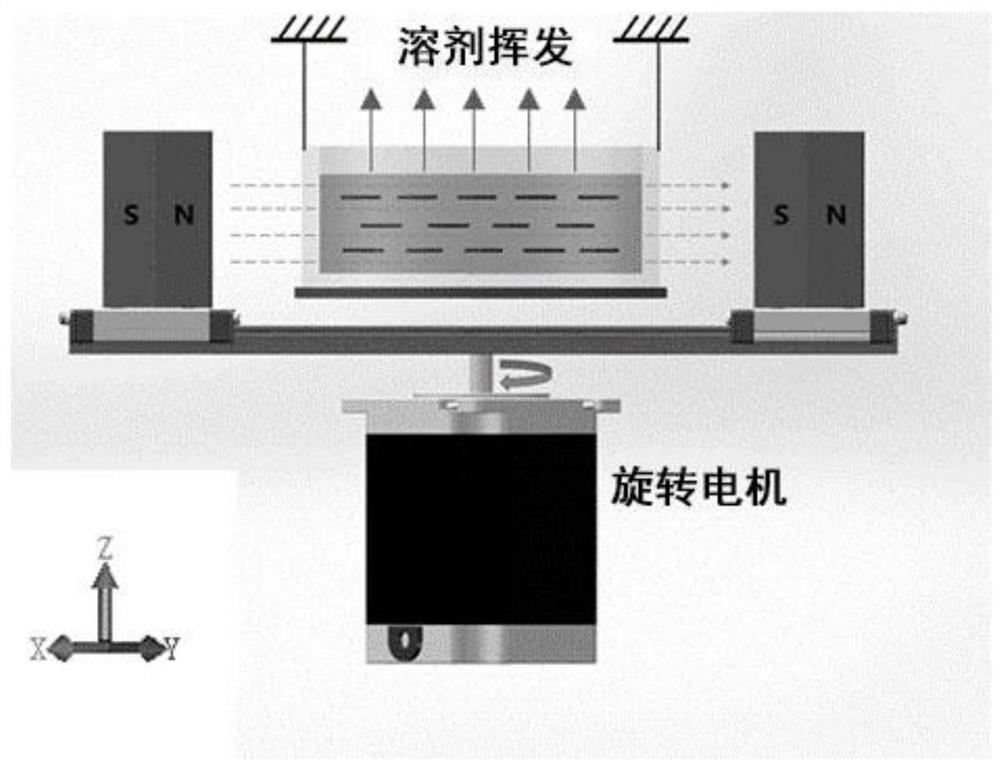

Graphene electromagnetic shielding composite material and preparation method thereof

ActiveCN114426691AExcellent intrinsic diamagnetismImprove performanceMagnetic/electric field screeningHighly oriented pyrolytic graphiteGraphene

The invention relates to a preparation method of a graphene electromagnetic shielding composite material. The preparation method comprises the following steps: stripping highly oriented pyrolytic graphite by adopting a physical or chemical method to prepare graphene nanosheets; the preparation method comprises the following steps: dispersing graphene nanosheets and a polymer matrix material in a polar organic dispersant to form a graphene-polymer mixed solution; and finally, realizing directional arrangement of the graphene nanosheets in the solution through an external magnetic field, and curing the graphene nanosheets to obtain the anisotropic graphene electromagnetic shielding composite material with high directional arrangement. The nanosheets in the graphene electromagnetic shielding composite material can be directionally arranged, and the graphene nanosheets without functional groups are adopted, so that the problem of poor performance of the graphene electromagnetic shielding material is solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

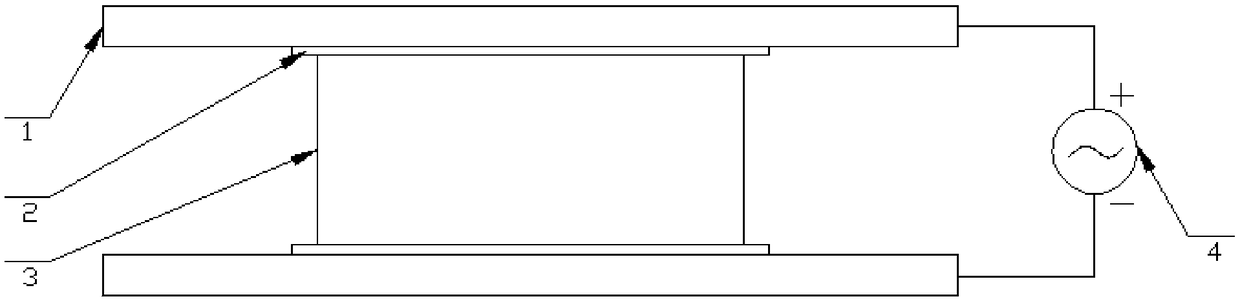

Method for preparing phospholipid vesicle by utilizing highly oriented pyrolytic graphite

InactiveCN109107507AImprove uniformityReduce pollutionEnergy based chemical/physical/physico-chemical processesHighly oriented pyrolytic graphiteGraphite electrode

The invention relates to a method for preparing phospholipid vesicle by utilizing highly oriented pyrolytic graphite, and relates to a preparation method of phospholipid vesicle, which aims at solvingthe problem that the phospholipid vesicle prepared in an electric forming method is poor in homogeneity. The preparation method comprises the following steps: preparing a phospholipid solution, uniformly smearing the phospholipid solution onto the surface of a plane highly oriented pyrolytic graphite electrode, drying to obtain the plane highly oriented pyrolytic graphite electrode loaded with aphospholipid dry membrane, placing two pieces of the plane highly oriented pyrolytic graphite electrodes loaded with the phospholipid dry membrane in parallel, arranging the phospholipi dry membrane in opposite directions, arranging a cylinder body between the plane highly oriented pyrolytic graphite electrodes loaded with the phospholipid dry membrane to obtain a reaction cell, injecting a reaction medium solution, respectively connecting the graphite electrodes with a signal generator, applying an electric field, thus preparing the phospholipid vesicle. The phospholipid vesicle prepared by the method has controllability and homogeneity, and is low in cost, simple in operation, high in forming speed, mild in reaction conditions, and small in environmental pollution. The method is suitablefor preparing the phospholipid vesicle.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

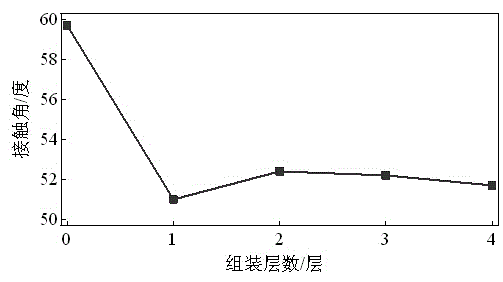

Ruthenium complex monomolecular film and method for preparing ruthenium complex monomolecular film on HOPG

ActiveCN104576071AAchieve self-assemblyImprove bindingLight-sensitive devicesHighly oriented pyrolytic graphiteRuthenium

The invention relates to a ruthenium complex monomolecular film and a method for preparing the ruthenium complex monomolecular film on HOPG (highly oriented pyrolytic graphite), and belongs to the technical field of molecule self-assembling chemistry. Pyrenyls in a ruthenium complex in a ruthenium complex monomolecular film and the HOPG with a Pi-electronic environment act with each other through Pi-Pi, and the two pyrenyls of the ruthenium complex are fixed on an HOPG interface; the general formula of the ruthenium complex is [Ru(Py4G2MeBip2)](PF6)2. The method comprises the steps of preparing a ruthenium complex solution, then performing surface treatment on the HOPG, and finally self-assembling the ruthenium complex on an HOPG substrate by a spinning method or an immersion method to prepare the ruthenium complex monomolecular film. The ruthenium complex monomolecular film is prepared by two methods, so that the prepared ruthenium complex monomolecular film has the advantages that the mechanical and chemical stability is high, and the thickness of the molecular film can be controlled and the like.

Owner:KUNMING UNIV OF SCI & TECH

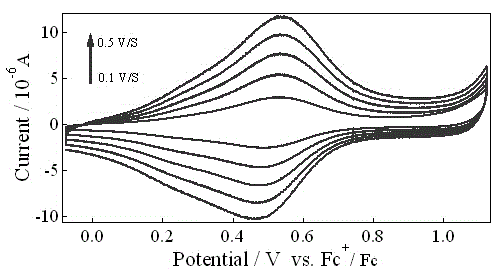

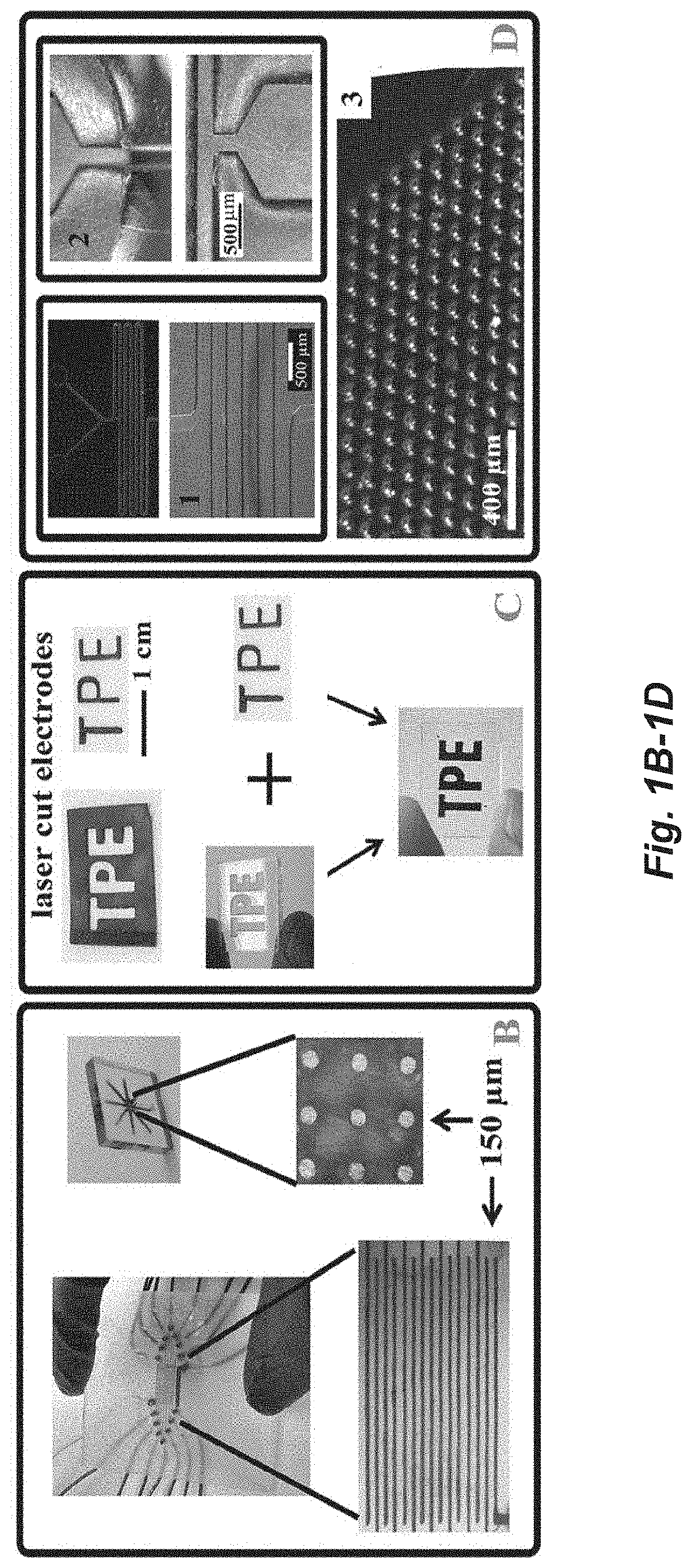

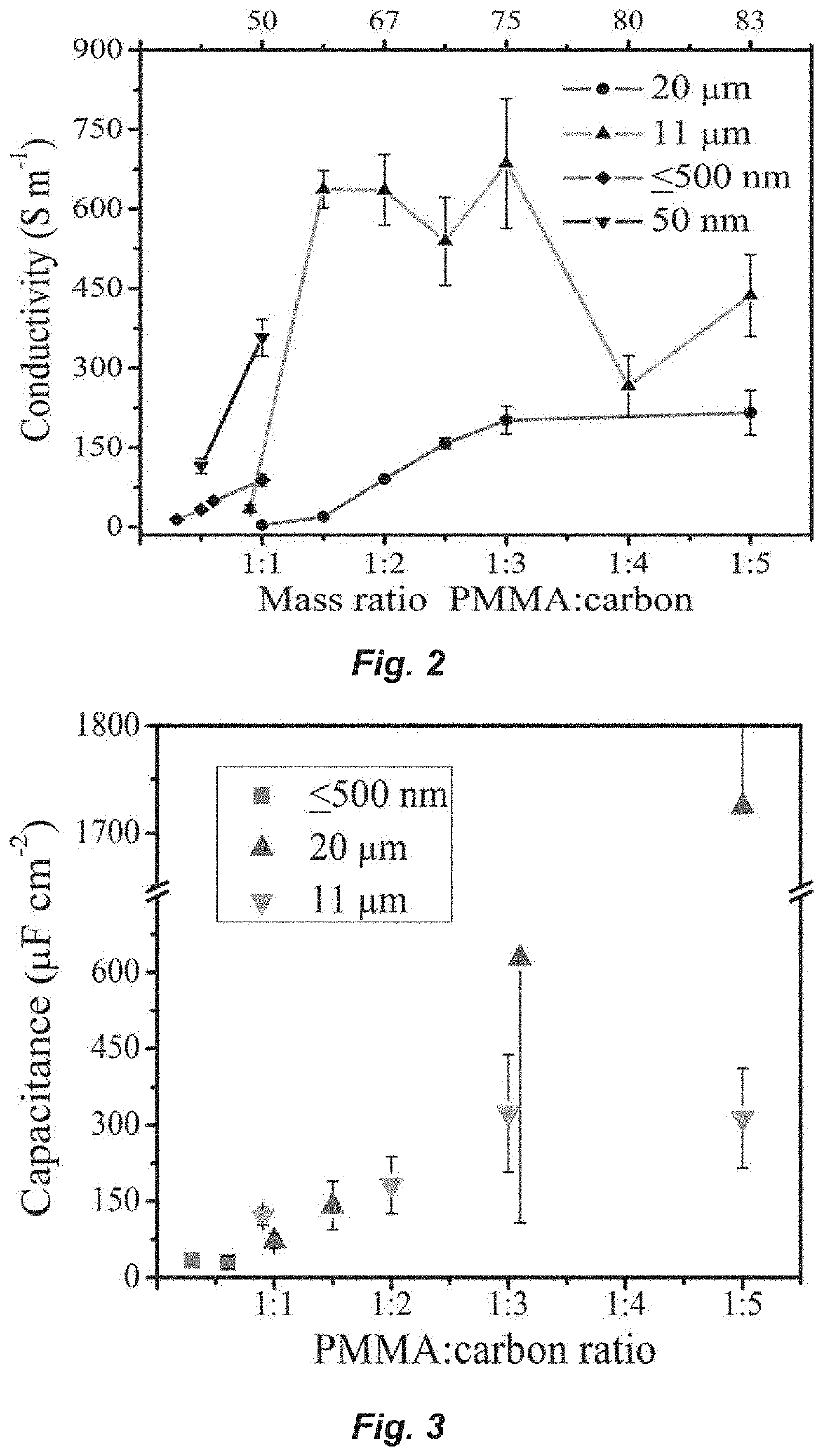

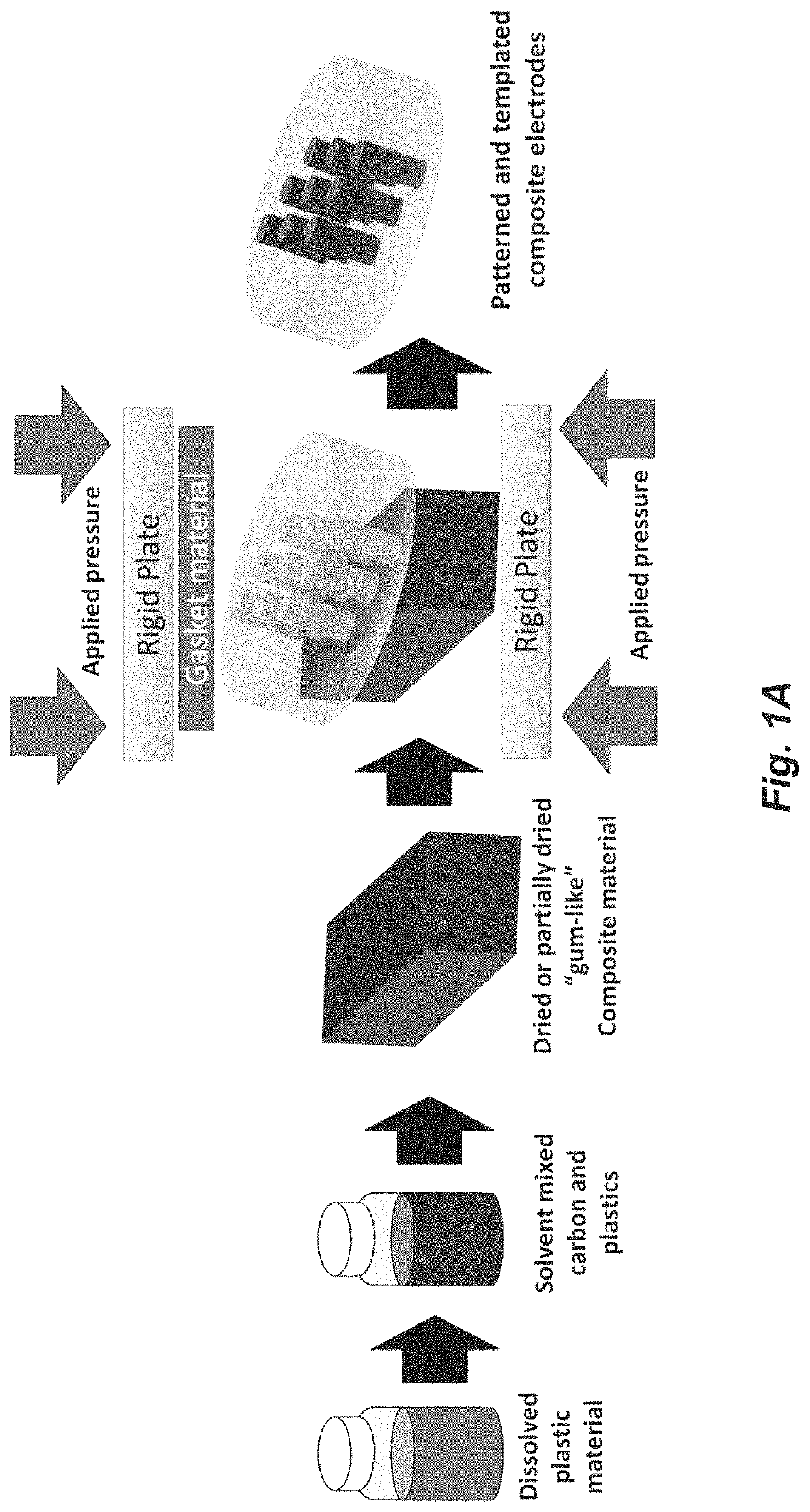

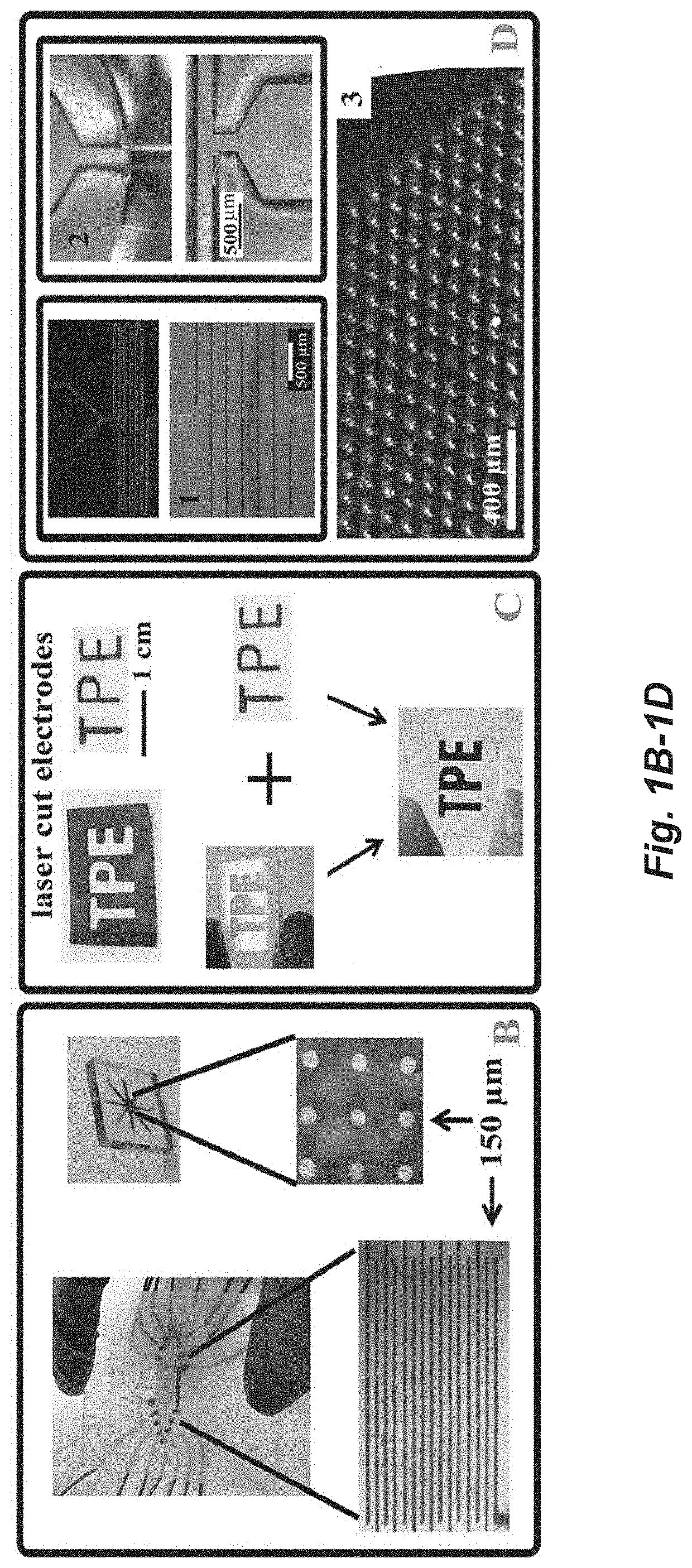

Thermoplastic carbon composite electrodes

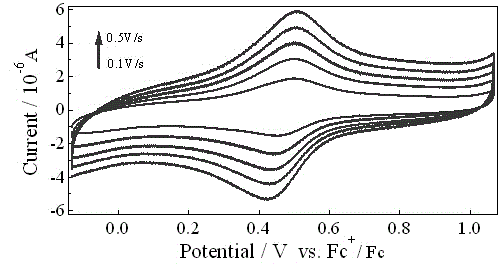

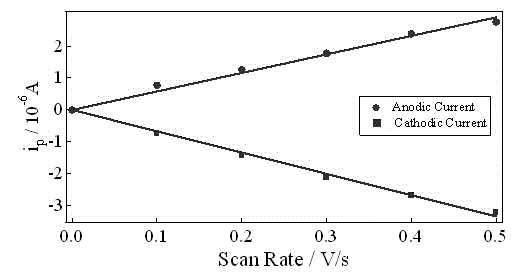

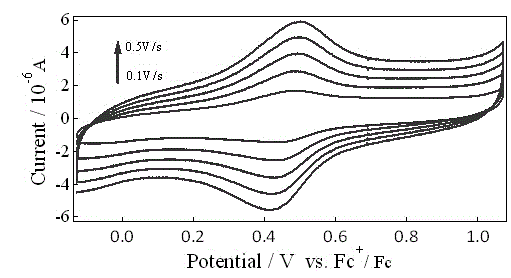

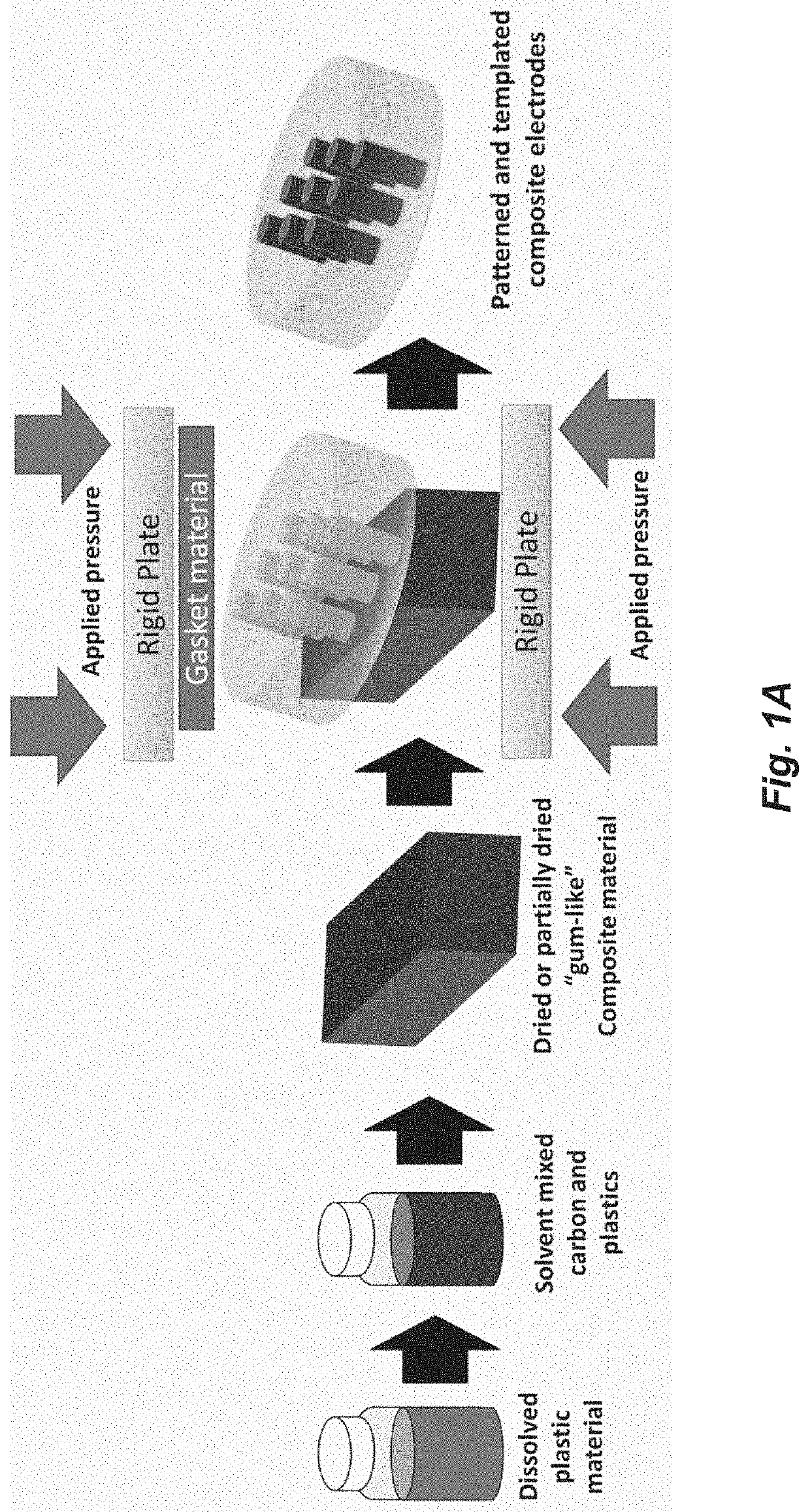

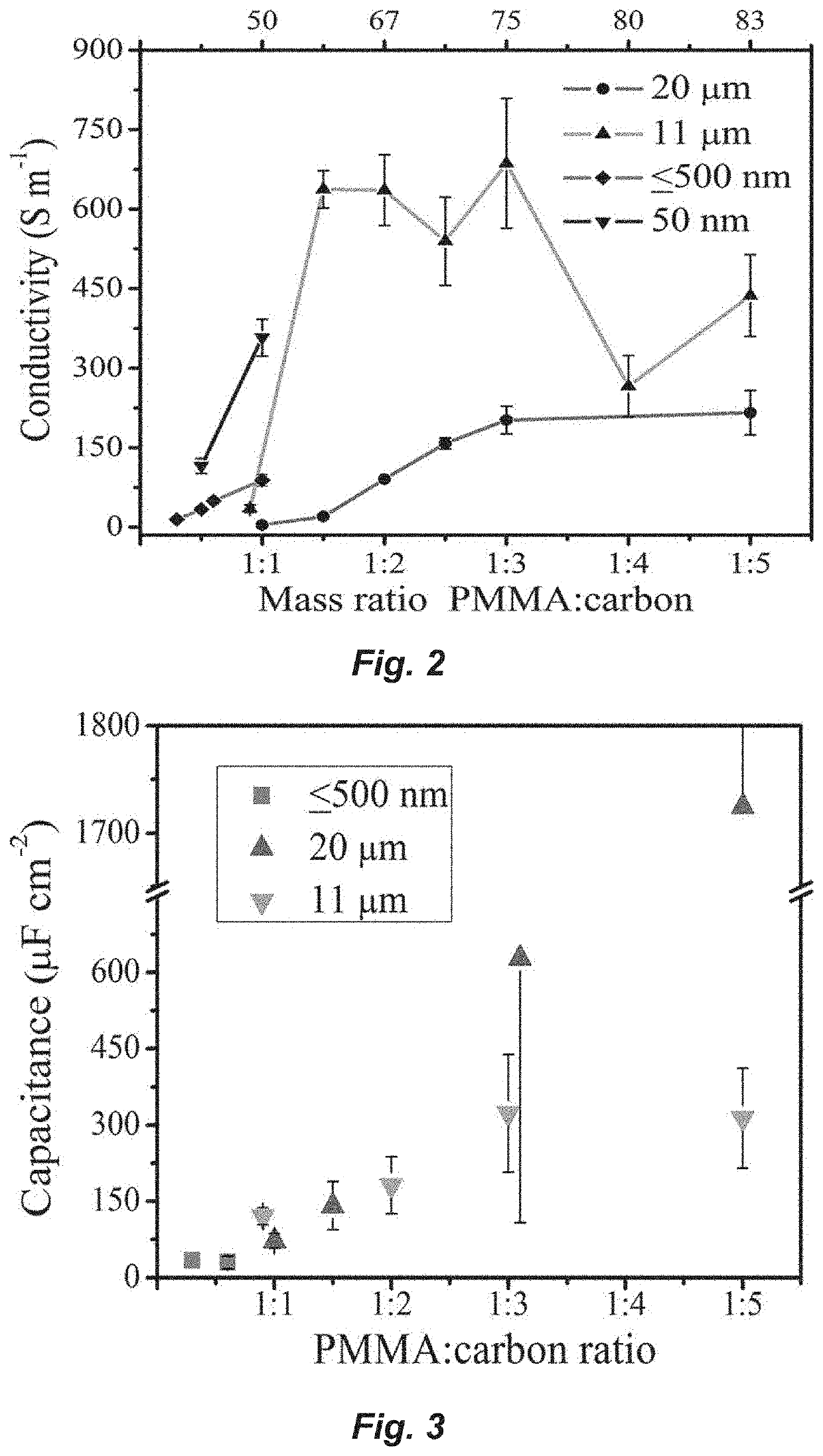

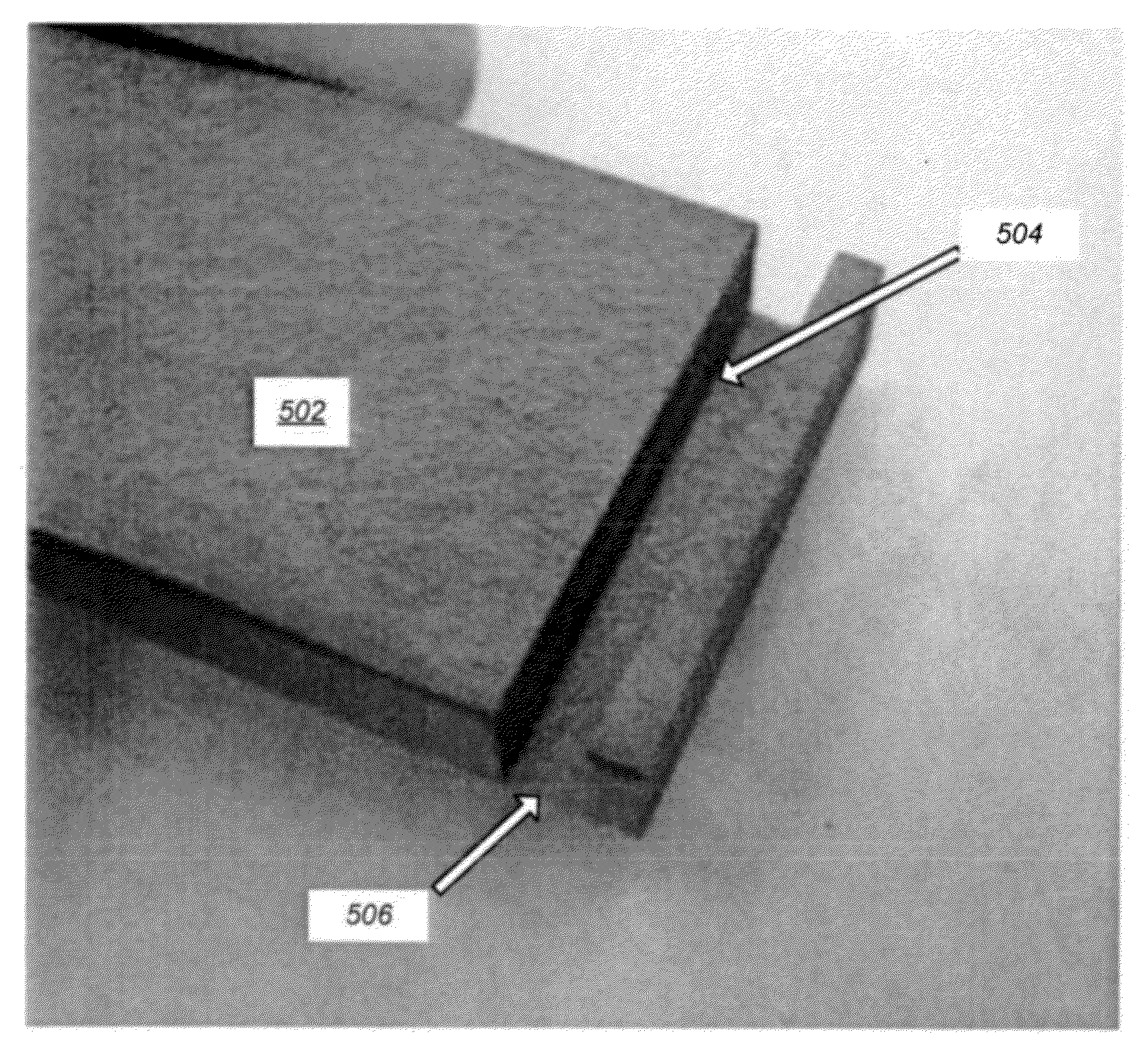

ActiveUS20190362867A1Simple processEasy to customizeMaterial nanotechnologyHybrid capacitor electrodesCarbon compositesPeak current

A new solvent-based method is presented for making low-cost composite graphite electrodes containing a thermoplastic binder. The electrodes, termed thermoplastic electrodes (TPEs), are easy to fabricate and pattern, give excellent electrochemical performance, and have high conductivity (1500 S m−1). The thermoplastic binder enables the electrodes to be hot embossed, molded, templated, and / or cut with a CO2 laser into a variety of intricate patterns. These electrodes show a marked improvement in peak current, peak separation, and resistance to charge transfer over traditional carbon electrodes. The impact of electrode composition, surface treatment (sanding, polishing, plasma treatment), and graphite source were found to impact fabrication, patterning, conductivity, and electrochemical performance. Under optimized conditions, electrodes generated responses similar to more expensive and difficult to fabricate graphene and highly oriented pyrolytic graphite electrodes. These TPE electrodes provide an approach for fabricating high-performance carbon electrodes with applications ranging from sensing to batteries.

Owner:COLORADO STATE UNIVERSITY

Thermoplastic carbon composite electrodes

A new solvent-based method is presented for making low-cost composite graphite electrodes containing a thermoplastic binder. The electrodes, termed thermoplastic electrodes (TPEs), are easy to fabricate and pattern, give excellent electrochemical performance, and have high conductivity (1500 S m−1). The thermoplastic binder enables the electrodes to be hot embossed, molded, templated, and / or cut with a CO2 laser into a variety of intricate patterns. These electrodes show a marked improvement in peak current, peak separation, and resistance to charge transfer over traditional carbon electrodes. The impact of electrode composition, surface treatment (sanding, polishing, plasma treatment), and graphite source were found to impact fabrication, patterning, conductivity, and electrochemical performance. Under optimized conditions, electrodes generated responses similar to more expensive and difficult to fabricate graphene and highly oriented pyrolytic graphite electrodes. These TPE electrodes provide an approach for fabricating high-performance carbon electrodes with applications ranging from sensing to batteries.

Owner:COLORADO STATE UNIVERSITY

Vacuum electron device electrodes and components manufactured from highly oriented pyrolytic graphite (HOPG)

ActiveUS8610343B2Eliminate voidsKeep the pressureMagnetronsLamp incadescent bodiesHighly oriented pyrolytic graphiteErosion rate

Components for use in vacuum electron devices are fabricated from highly oriented pyrolytic graphite (HOPG) and exhibit excellent thermal conductivity, low sputtering rates, and low ion erosion rates as compared to conventional components made from copper or molybdenum. HOPG can be reliably brazed by carefully controlling tolerances, calculating braze joint material volume, and applying appropriate compression during furnace operations. The resulting components exhibit superior thermal performance and enhanced resistance to ion erosion and pitting.

Owner:L3 TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com