Method for constructing metal organic frame film on graphite base

A metal-organic framework, graphite-based technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of difficulty in guarantee, complicated operation, difficult preparation, etc., and achieves low cost, uniform film formation, and acceptable crystal form. tuning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 0.72mg of 4,4’-tetracosyl-2,2’-bipyridine in 20mL of organic solvent-phenyloctane, ultrasonically vibrate for 5 minutes, and prepare a concentration of 1×10 -4 Mixed solution of M;

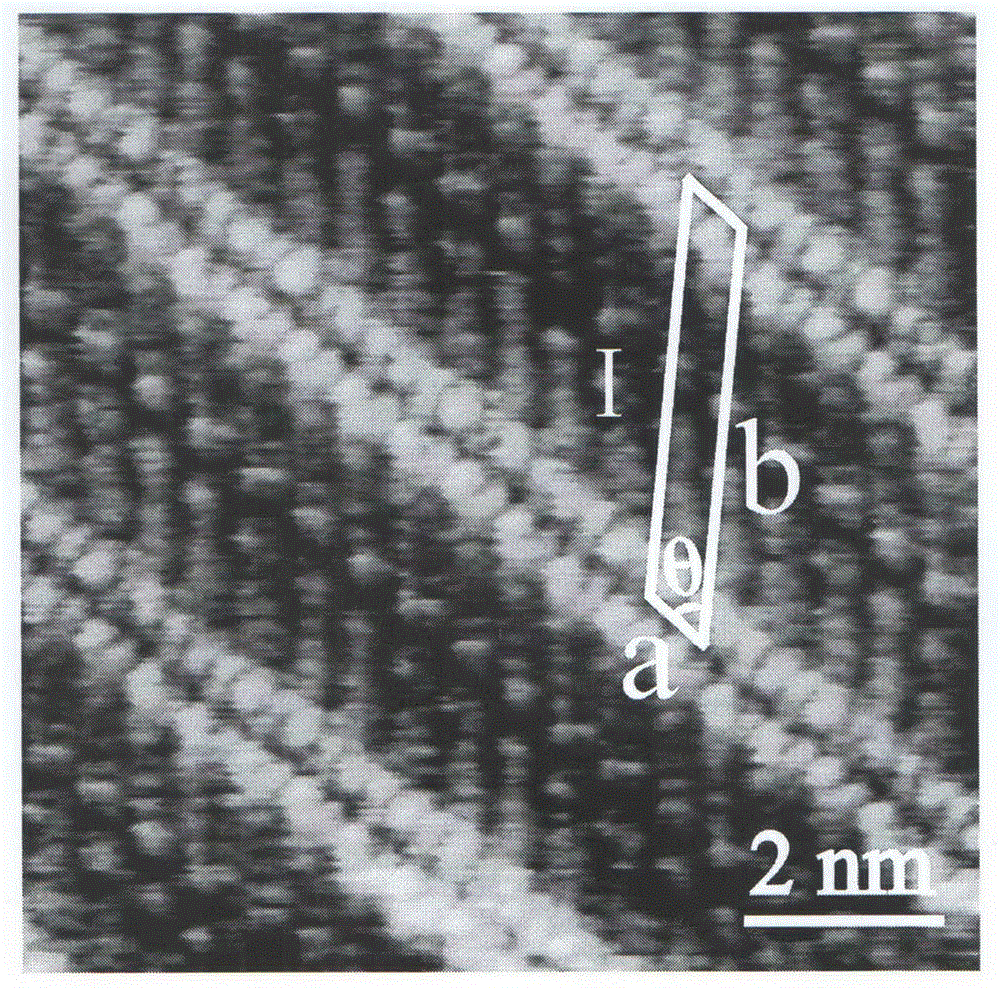

[0023] Take highly oriented pyrolysis graphite with a size of 5 mm × 5 mm, peel off the surface layer with scotch tape, drop 0.8 μL of the obtained mixed solution on the graphite substrate, and let it stand at room temperature for 5 minutes at 25 ° C until the self-assembly process is fully completed. A 4,4'-tetradecyl-2,2'-bipyridyl thin film with a single crystal structure I was obtained on a graphite substrate ( figure 1 ).

Embodiment 2

[0025] a. Dissolve 0.72mg of 4,4’-tetracosyl-2,2’-bipyridine in 20mL organic solvent-phenyloctane, oscillate ultrasonically for 5 minutes, and prepare a concentration of 1×10 -4 Mixed solution of M;

[0026] b. Dissolve 0.44mg of zinc acetate in 20mL of organic solvent ethanol, ultrasonically vibrate for 5 minutes, and prepare a concentration of 1×10 -4 M's zinc acetate ethanol solution;

[0027] c. Then take 10mL of zinc acetate ethanol solution and add it into 10mL of phenyloctane to prepare a concentration of 5×10 -5 M's zinc acetate solution;

[0028] d. Take highly oriented pyrolysis graphite with a size of 5mm×5mm, peel off the surface layer with scotch tape, drop 0.8 μL of the 4,4'-tetradecyl-2,2'-bipyridine solution in step a on the graphite 4,4'-tetradecyl-2,2'- bipyridyl film;

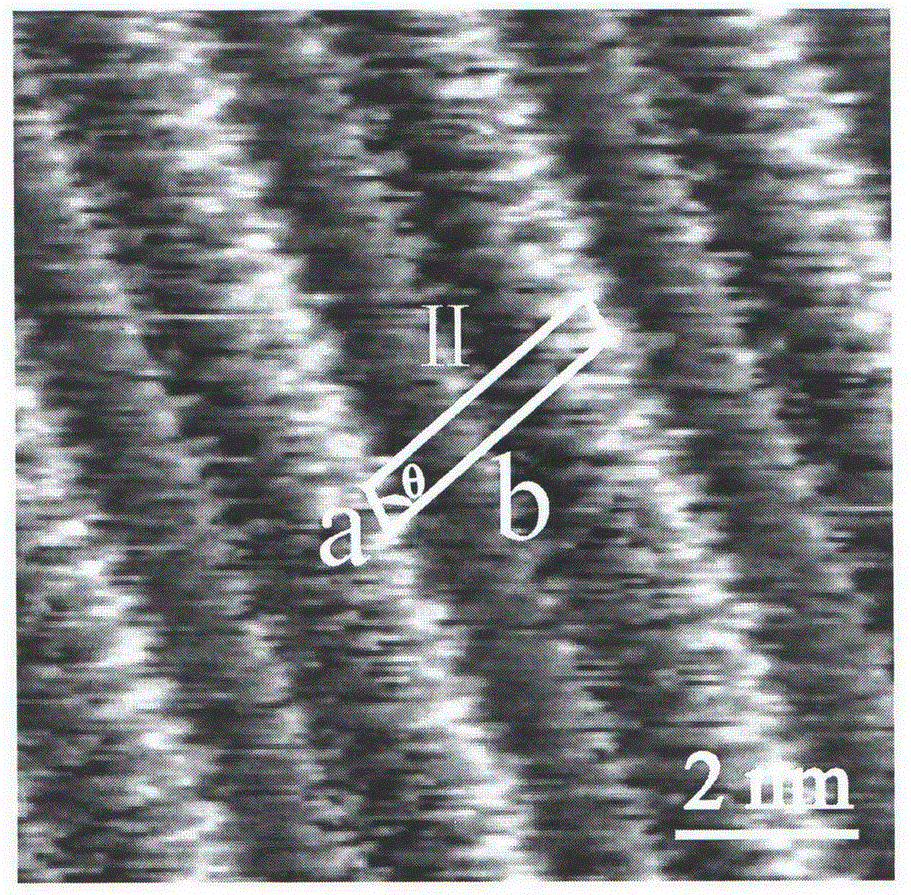

[0029] e. Add 0.8 μL of the zinc acetate solution prepared in step c dropwise on the 4,4'-tetradecyl-2,2'-bipyridine film in situ to obtain a single crystal structure on the graphite sub...

Embodiment 3

[0031] a. Dissolve 0.72mg of 4,4’-tetracosyl-2,2’-bipyridine in 20mL organic solvent-phenyloctane, oscillate ultrasonically for 5 minutes, and prepare a concentration of 1×10 -4 Mixed solution of M;

[0032] b. Dissolve 0.44mg of copper acetate in 20mL of organic solvent ethanol, ultrasonically vibrate for 5 minutes, and prepare a concentration of 1×10 -4 Mixed solution of M,

[0033] c. Take 10mL of copper acetate ethanol solution and add it to 10mL of phenyloctane to make a concentration of 5×10 -5 Copper acetate solution of M;

[0034] d. Take highly oriented pyrolysis graphite with a size of 5mm×5mm, peel off the surface layer with scotch tape, drop 0.8 μL of the 4,4'-tetradecyl-2,2'-bipyridine solution in step a on the graphite After the self-assembly process is fully completed, the 4,4'-tetradecyl-2,2'- bipyridyl film;

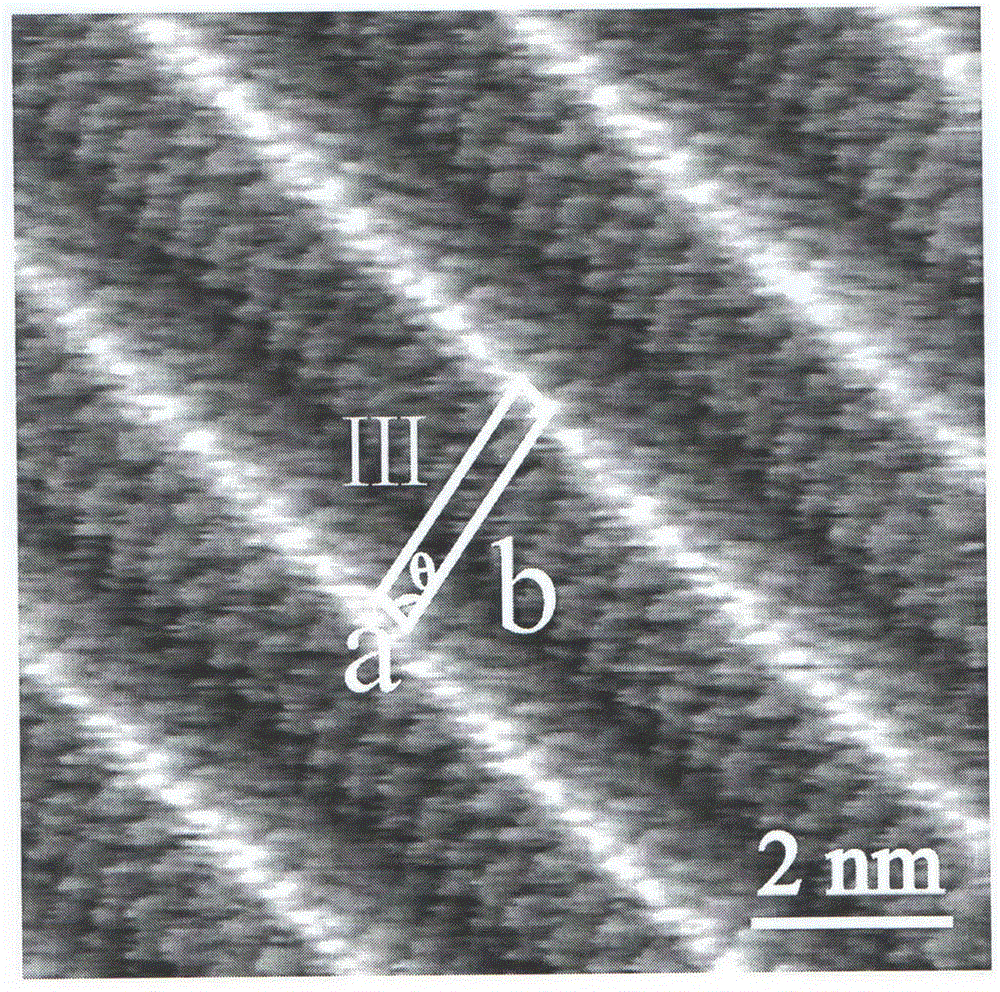

[0035] e. Drop 0.8 μL of the prepared copper acetate solution in step c on the 4,4'-tetradecyl-2,2'-bipyridine film in situ to obtain a single crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com