High-temperature composite phase change heat storage material and preparation method thereof

A technology for composite phase change and heat storage materials, applied in the field of high temperature composite phase change heat storage materials and their preparation, can solve the problems of complex process, poor cycle stability, cumbersome process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

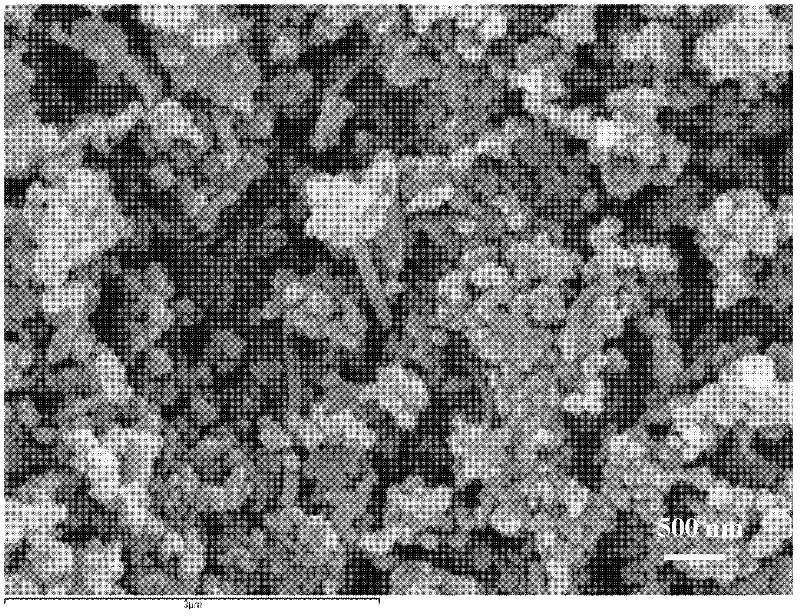

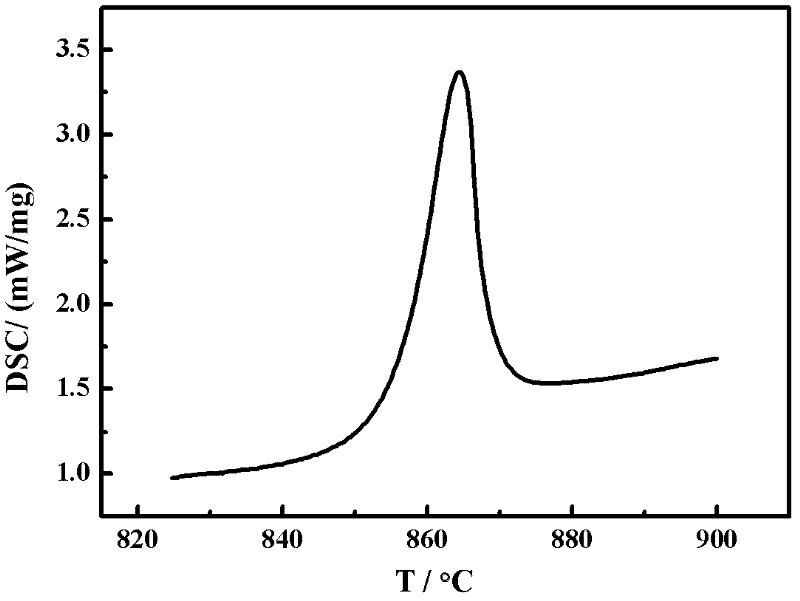

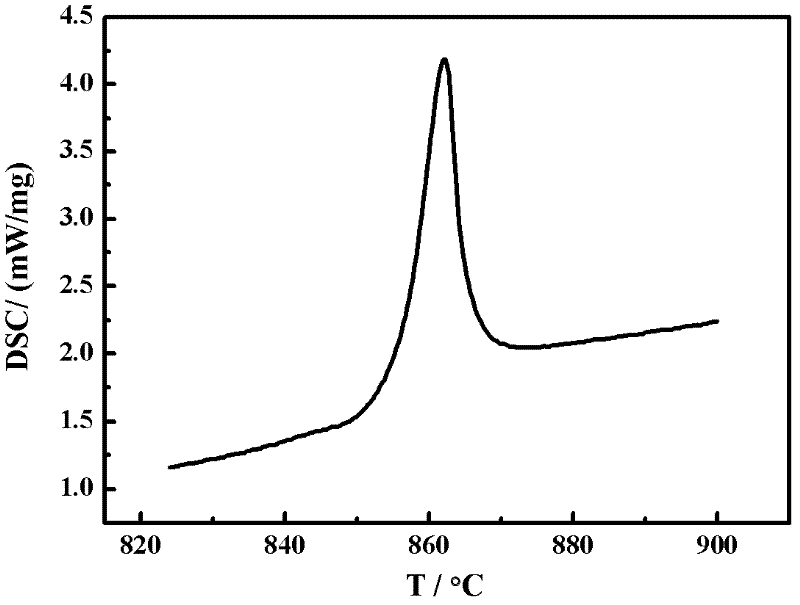

[0056] Pre-heat the carbon nanotubes at 800°C for 20 minutes; mix and grind 6 grams of sodium carbonate and 9 grams of magnesium oxide to prepare 15 grams of inorganic salt / ceramic matrix binary mixture, and then add 1 mg of pretreated carbon nanotubes, mixed and ground for 30 minutes to make a ternary mixture of inorganic salt / ceramic matrix / carbon nanotubes; weigh 3.0 g of the ternary mixture and add it to a steel mold In the process, the molding pressure on the hydraulic press is 10MPa, and the pressure holding time is 10min. After demoulding, take out the pressed sample and put it into a graphite crucible. Under the condition of 30mL / min nitrogen gas, the heating rate is 10℃ / min, and the temperature is raised to 900 ℃, after 1 hour of heat preservation, the temperature was lowered at a cooling rate of 10 ℃ / min, and the temperature was lowered to 50 ℃. The final product is Na 2 CO 3 -MgO-CNTs heat storage material, the yield is above 97%. The results of scanning electro...

Embodiment 2

[0058] Pre-heat the carbon nanotubes at 500°C for 60 minutes; mix and grind 10 grams of sodium carbonate and 10 grams of magnesium oxide to prepare 20 grams of inorganic salt / ceramic matrix binary mixture, and then add 50 mg of pretreated carbon nanotubes, mixed and ground for 40 minutes to make a ternary mixture of inorganic salt / ceramic matrix / carbon nanotubes; weigh 4.5g of the ternary mixture and add it to a steel mold In the process, the molding pressure on the hydraulic press is 15MPa, and the holding time is 6min. After demoulding, take out the pressed sample and put it into a graphite crucible. Under the condition of 20mL / min nitrogen gas, the heating rate is 5℃ / min, and the temperature is raised to 800 ℃, after 2 hours of heat preservation, the temperature was lowered at a cooling rate of 5 ℃ / min, and the temperature was lowered to 50 ℃. The final product is Na 2 CO 3 -MgO-CNTs heat storage material, the yield is above 97%. The results of scanning electron microsc...

Embodiment 3

[0060] The carbon nanotubes were pre-heated at 700°C for 40 minutes; 18 grams of sodium carbonate and 12 grams of magnesium oxide were mixed and ground evenly to prepare 30 grams of inorganic salt / ceramic matrix binary mixture, and then 15 mg of pretreated carbon nanotubes, mixed and ground for 60 minutes to make a ternary mixture of inorganic salt / ceramic matrix / carbon nanotubes; weigh 6.0 g of the ternary mixture and add it to a steel mold In the process, the molding pressure on the hydraulic press is 20MPa, and the holding time is 2min. After demolding, the pressed sample is placed into a graphite crucible, and under the condition of 10mL / min nitrogen gas, the heating rate is 20℃ / min, and the temperature is raised to 750 ℃, after 3 hours of heat preservation, the temperature was lowered at a cooling rate of 20 ℃ / min, and the temperature was lowered to 40 ℃. The final product is Na 2 CO 3 -MgO-CNTs heat storage material, the yield is above 97%. The results of scanning elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com