System and technology for utilizing low-temperature smoke to enhance concentration of brine wastewater

A technology for saline wastewater and low-temperature flue gas, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of reducing the treatment efficiency of saline wastewater, poor heat and mass transfer efficiency, etc. problems, to achieve the effect of promoting energy saving, reducing waste water treatment cost, and improving evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

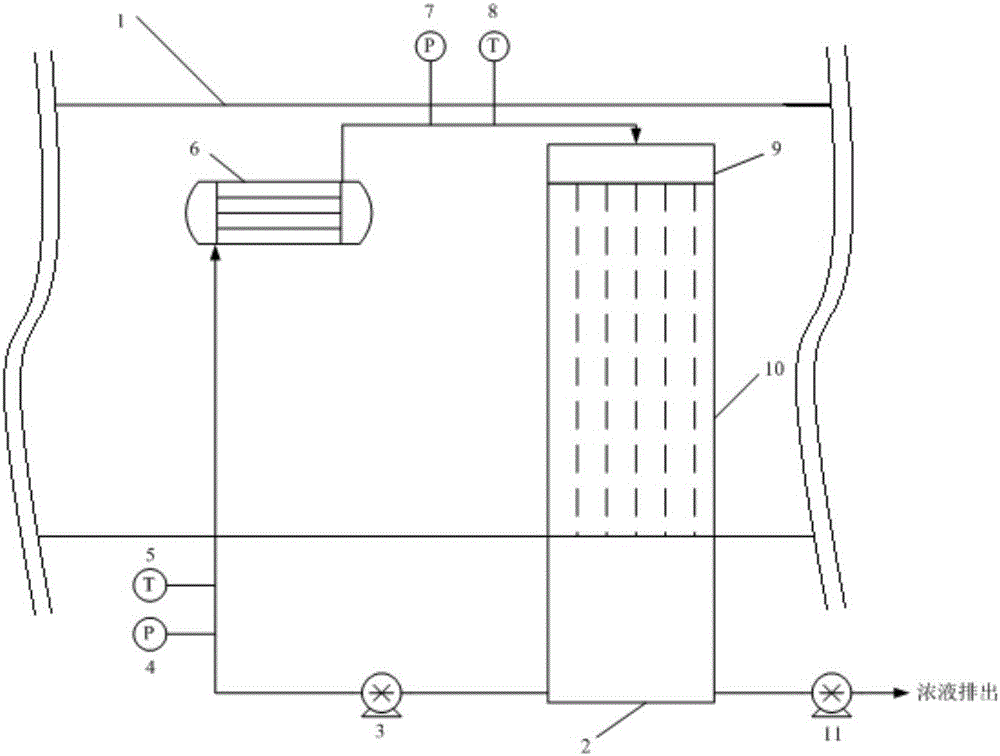

[0044] like figure 1 As shown, a system for using low-temperature flue gas to strengthen the concentration of saline wastewater includes a flue 1, a first water pump 3, a wastewater pressurized preheater 6, a water distribution device 9, a falling film flash evaporator 10, a sump 2 and The second water pump 11, the water distribution device 9 is installed on the upper end of the falling film flash evaporator 10, the sump 2 is installed on the bottom of the falling film flash evaporator 10, and the water distribution device 9 and the falling film flash evaporator 10 are all arranged in the flue 1, The falling film flash evaporator 10 is arranged parallel to the flow direction of the low-temperature flue gas. The saline waste water passes through the first water pump 3, the waste water pressurized preheater 6, the water distribution device 9, and the falling film flash evaporator 10 to the sump 2 in sequence, and the low-temperature flue gas in the flue 1 is used as the waste wa...

Embodiment 2

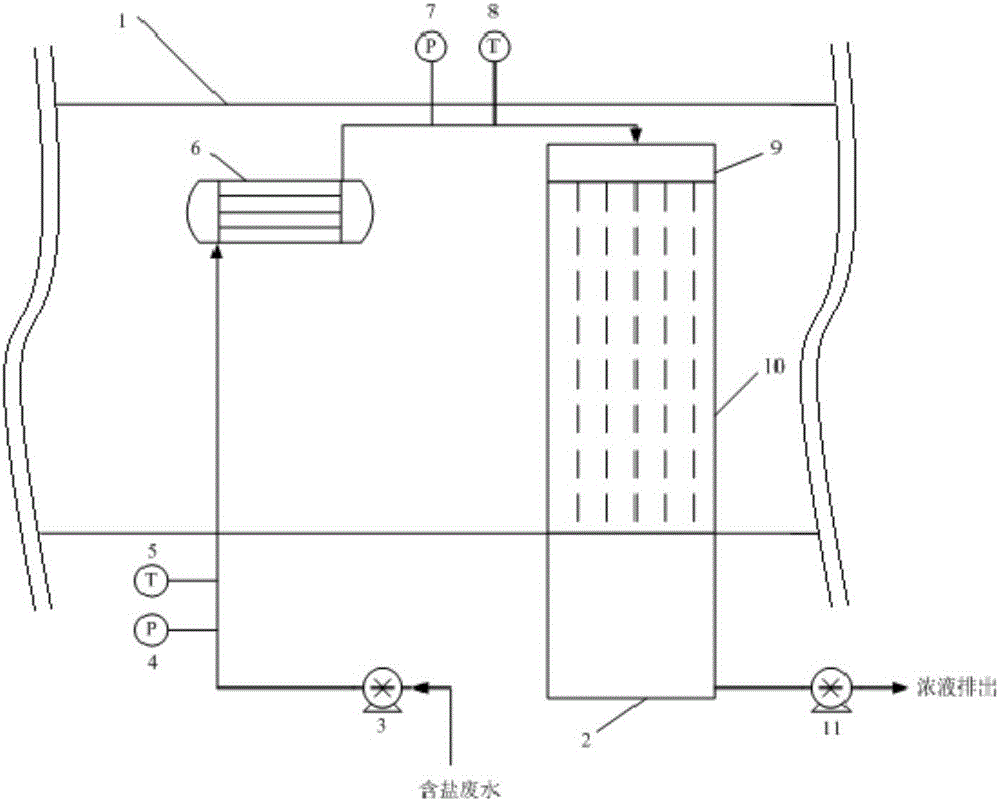

[0048] like figure 2 As shown, it is the same as in Example 1, except that when the concentration ratio is low, the concentrated saline wastewater in the sump 2 is no longer circulated, and is directly output by the concentrated liquid discharge pump 11, and the rest is the same as in Example 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com