Shielding device with vacuum cavity body

A vacuum chamber and magnetic fluid technology, applied in vacuum evaporation plating, ion implantation plating, metal material coating process, etc., can solve the problems of high production cost and complex structure, and achieve high efficiency, simple structure, and economical efficiency. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

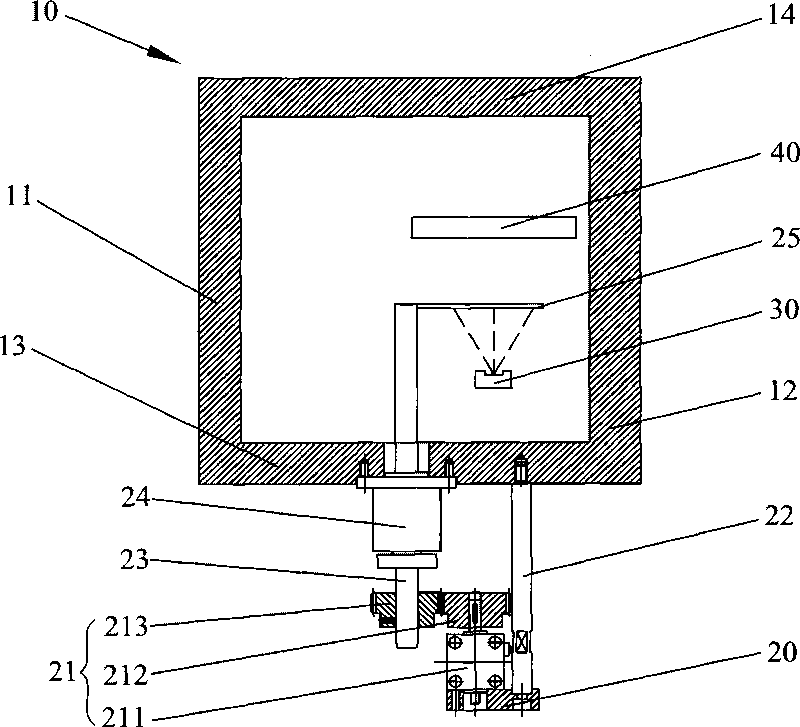

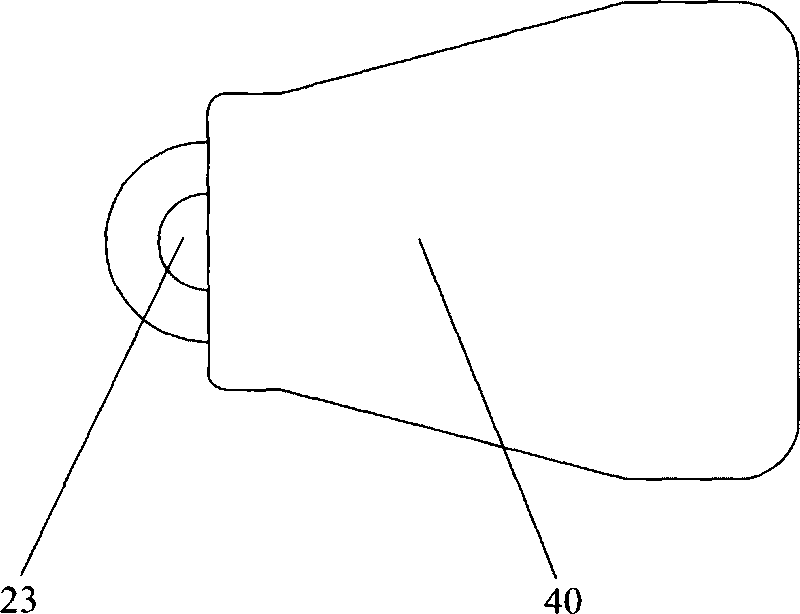

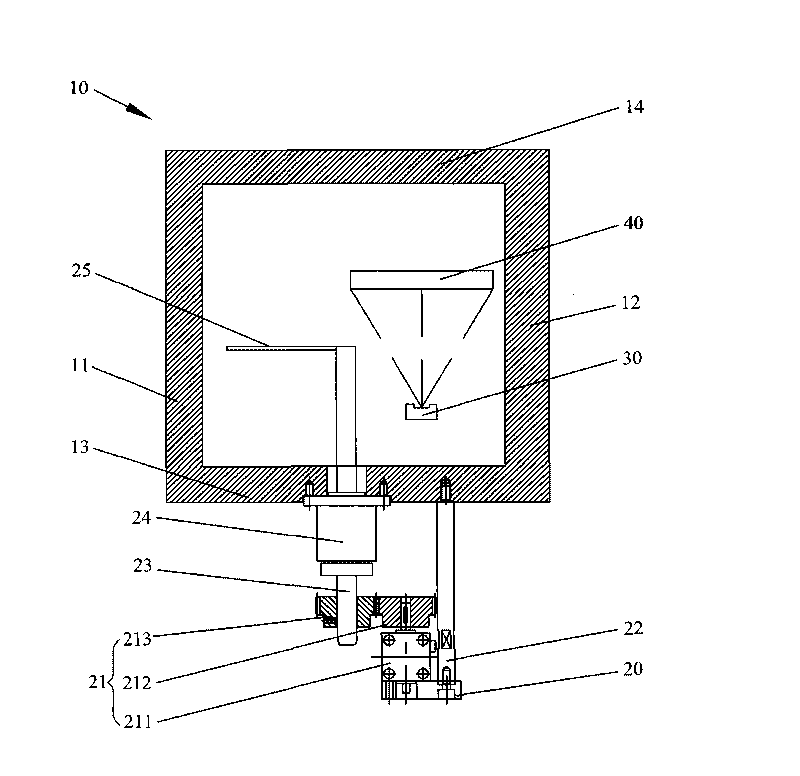

[0013] In order to describe in detail the technical content and structural features of the vacuum chamber shielding device of the present invention, further description will be given below with reference to the embodiments and the accompanying drawings.

[0014] see figure 1 and figure 2 . exist figure 1 and figure 2 , the vacuum chamber 10 is surrounded by a left side wall 11 , a right side wall 12 , a bottom wall 13 and a top wall 14 to form a hollow sealing structure. The processing plate 40 is disposed in the vacuum chamber 10 and above the evaporation source 30 . The vacuum chamber shielding device of the present invention is suitable for shielding the evaporation source 30 and the processing plate 40 in the vacuum chamber 10 for providing vacuum coating, and includes a support base 20, a driving mechanism 21, a fixed rod 22, a rotating shaft 23, a magnetic Fluid 24 and baffle 25. The fixing rod 22 is fixed on one end of the support base 20 to strengthen the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com