Centrifugal film evaporator

A thin film evaporator and evaporator technology, applied in evaporation, separation methods, chemical instruments and methods, etc., can solve the problems of long residence time, scraper power consumption, material changes, etc., to improve evaporation efficiency and effect, evaporation time The effect of shortening and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

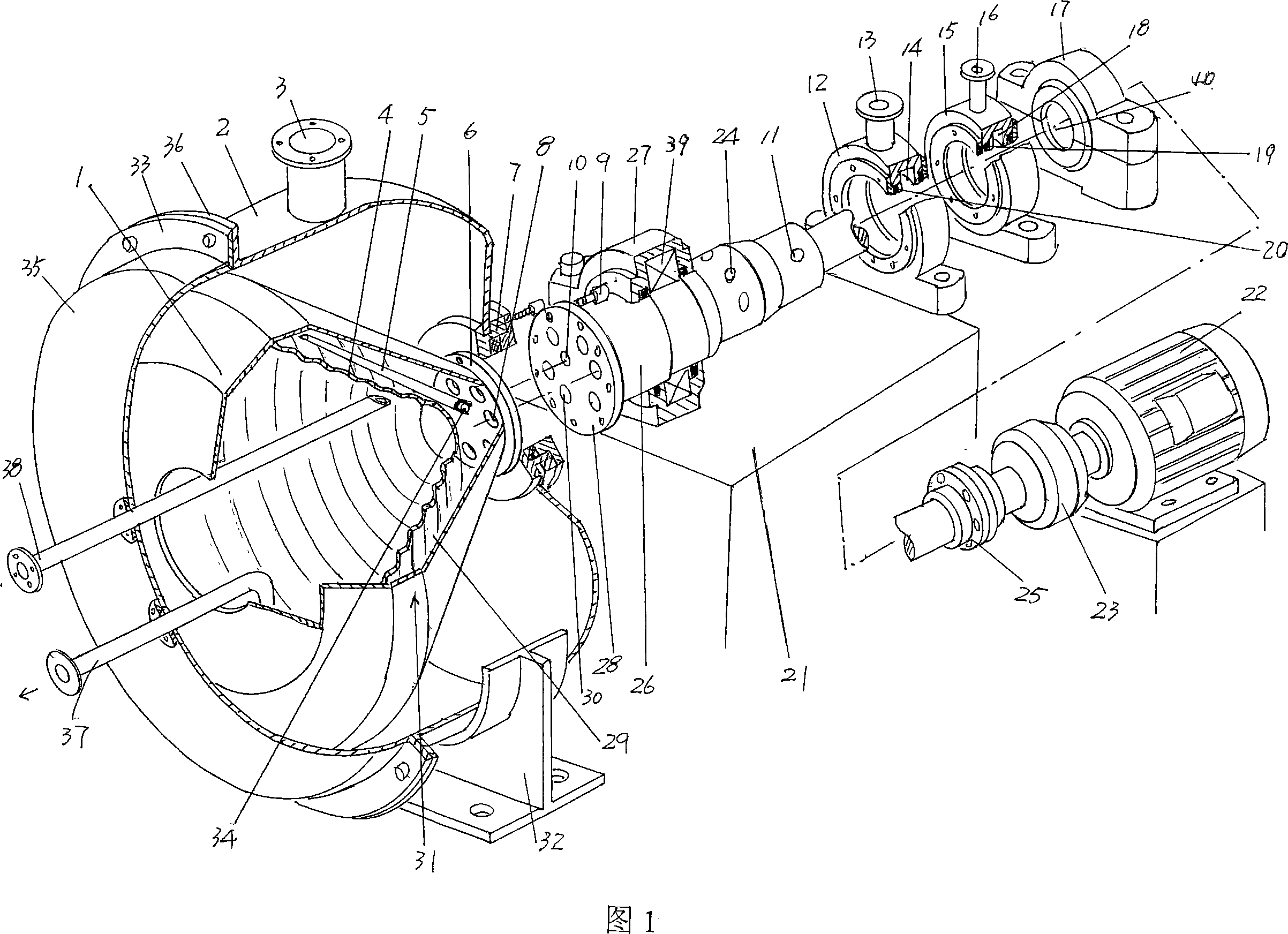

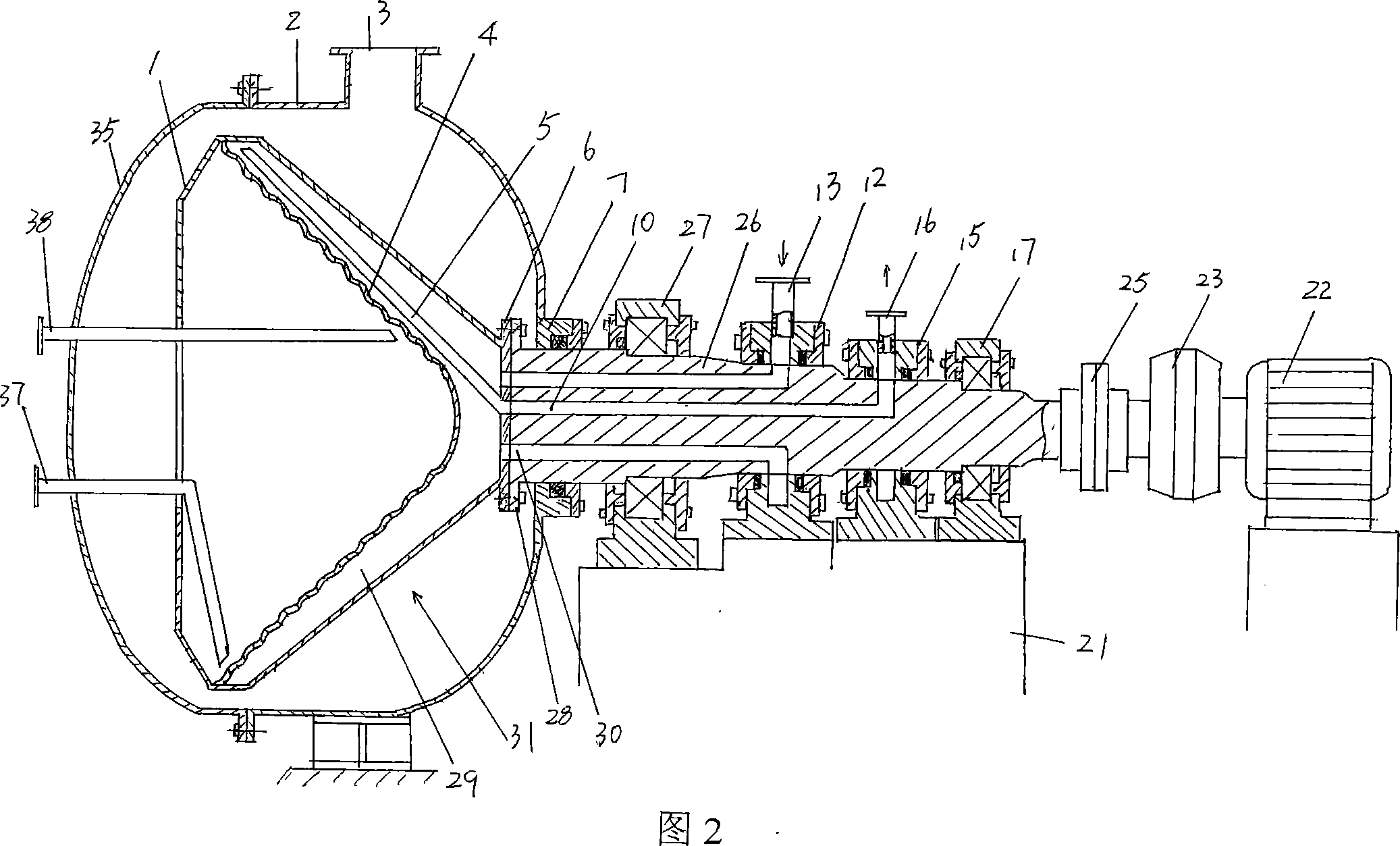

[0018] In order to enable the examiners of the patent office, especially the public, to further understand the structural features and beneficial effects of the present invention, the specific embodiments of the present invention are described in detail below with reference to the accompanying drawings and examples. However, the applicant declares that any change in form or modification in text based on the concept of the present invention shall be regarded as the scope of the technical solution disclosed in the present invention.

[0019] Please refer to FIG. 1 and FIG. 2. The motor 22 recommended by the present invention is a motor whose speed can be adjusted. When the centrifugal thin film evaporator of the present invention is installed and used, it should be horizontal. Therefore, the main shaft 26 It is connected with the power output shaft of the motor in a horizontal state, and is specifically connected through a coupling 25, and a hydraulic coupling 23 is also arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com