Patents

Literature

457 results about "Transparent adhesive tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

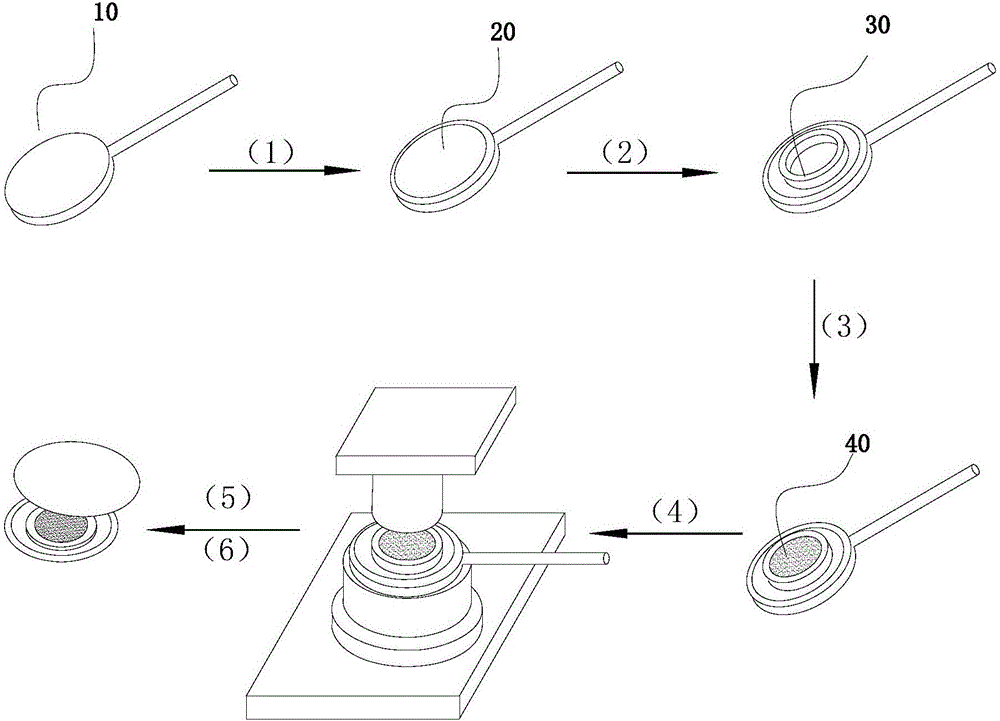

Substrate-free LED filament and manufacturing method thereof, and substrate-free LED filament lamp

ActiveCN105140381AIncrease powerIncrease luminous fluxPoint-like light sourceElectric circuit arrangementsEngineeringLED filament

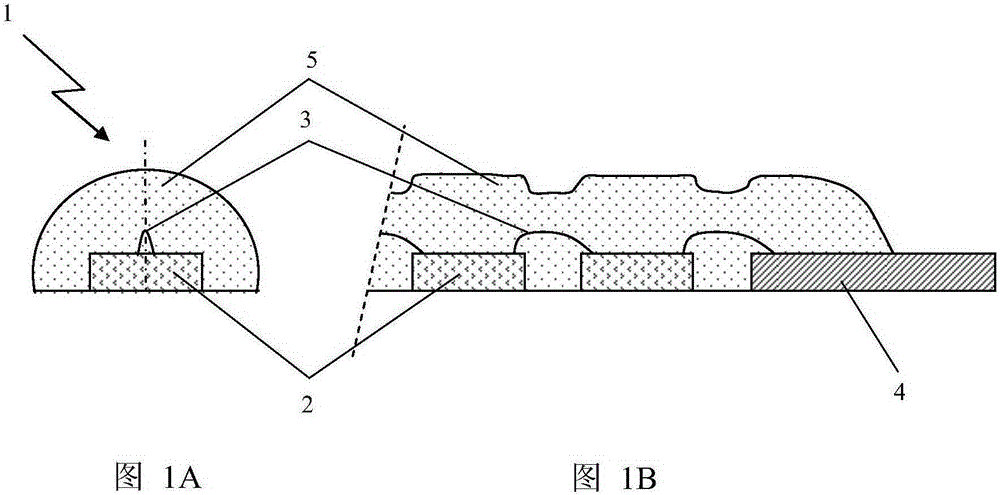

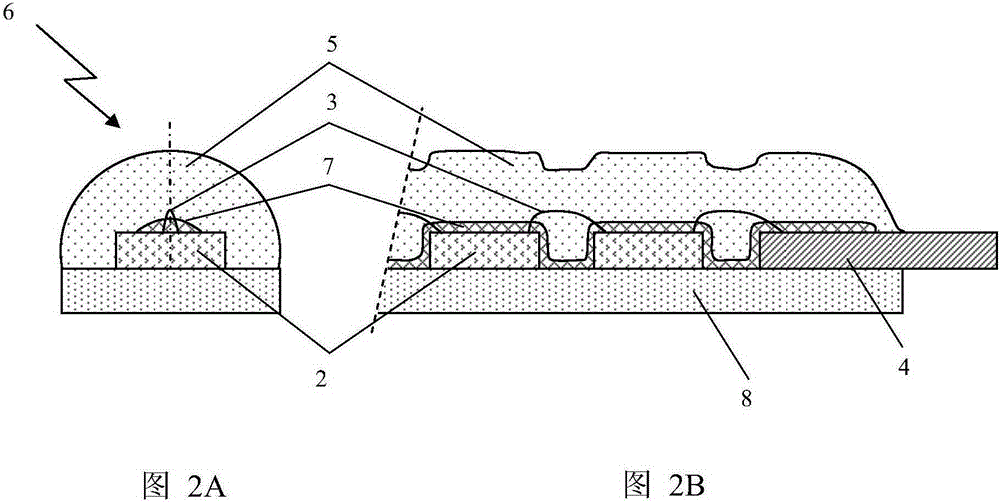

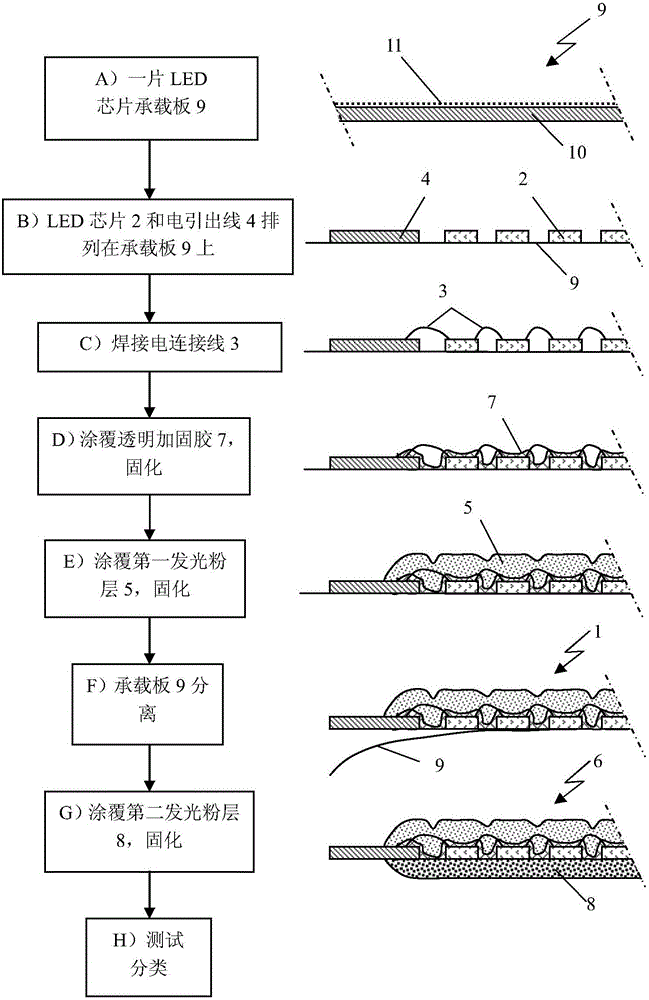

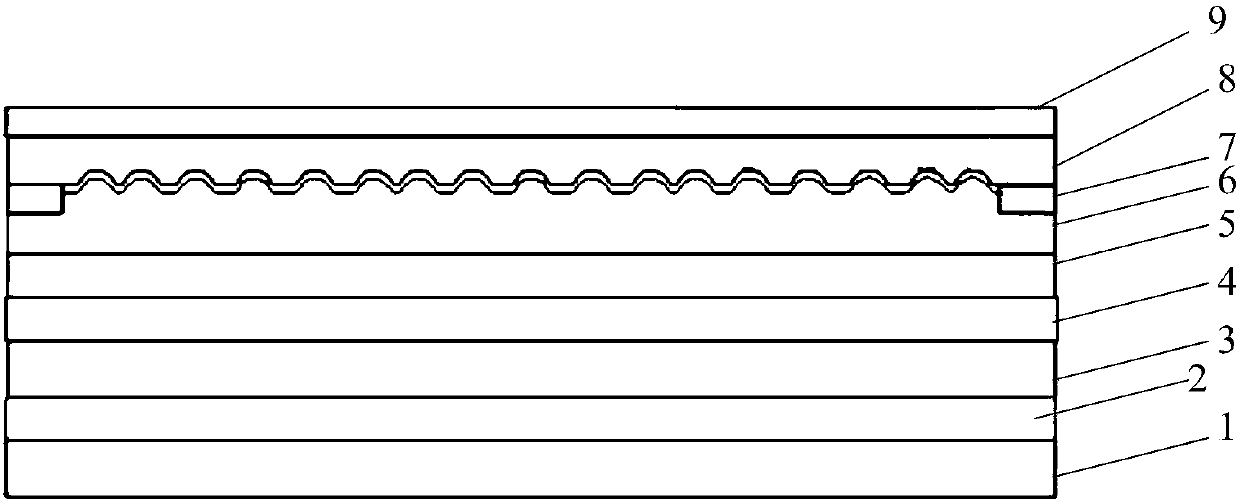

The invention provides a substrate-free LED filament and a manufacturing method thereof, and a substrate-free LED filament lamp. The filament comprises at least a string of LED chips with same or different illuminant colors, electric lead-out wires, and electric connecting wires arranged between the chips and between the chips and the electric lead-out wires, welding terminals of the chips, the electric connecting wires, and the electric lead-out wires are coated by first luminescent powder layers to form an initial substrate-free LED filament, the other side of the initial substrate-free LED filament is coated by a second luminescent powder layer to form the substrate-free LED filament, and the substrate-free LED filament can be adhered on the external surface of a transparent high-heat-conductivity tube via transparent adhesive tapes or luminescent powder glue to form a cylindrical substrate-free LED filament light source used for manufacturing a high-power LED filament lamp. The substrate-free LED filament lamp comprises at least a bulb shell sealed in a vacuum manner and inflated with heat radiation protection gas, at least one substrate-free LED filament light source is arranged in each bulb shell, and the substrate-free LED filament light source comprises the initial substrate-free LED filament, the substrate-free LED filament or the cylindrical substrate-free LED filament light source; an LED drive, a drive shell, and an electric connector etc. and used for illumination.

Owner:ZHEJIANG LEDISON OPTOELECTRONICS

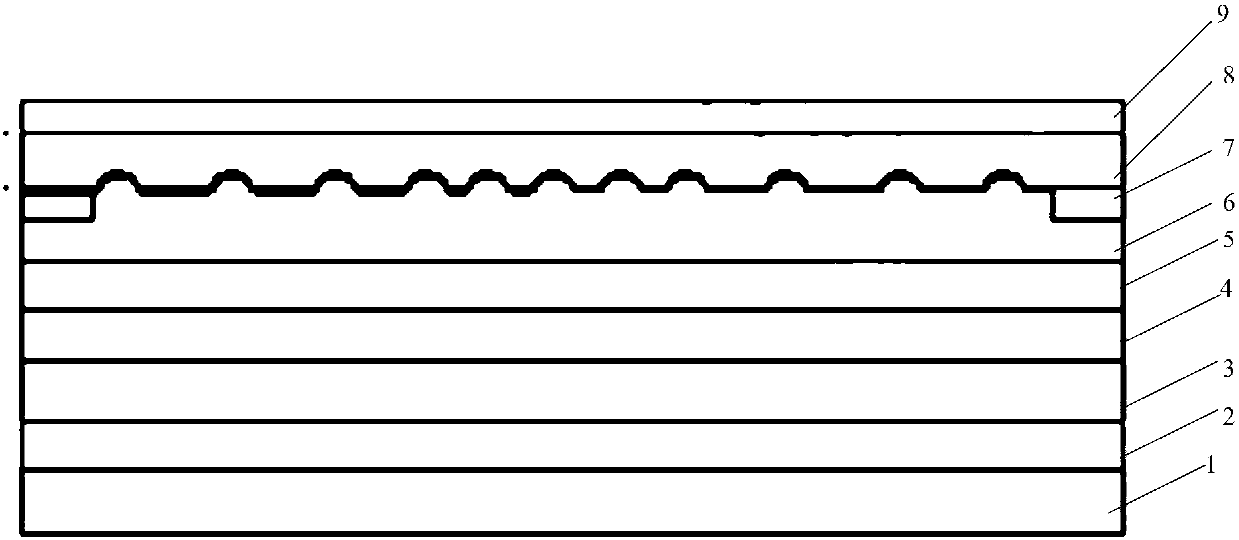

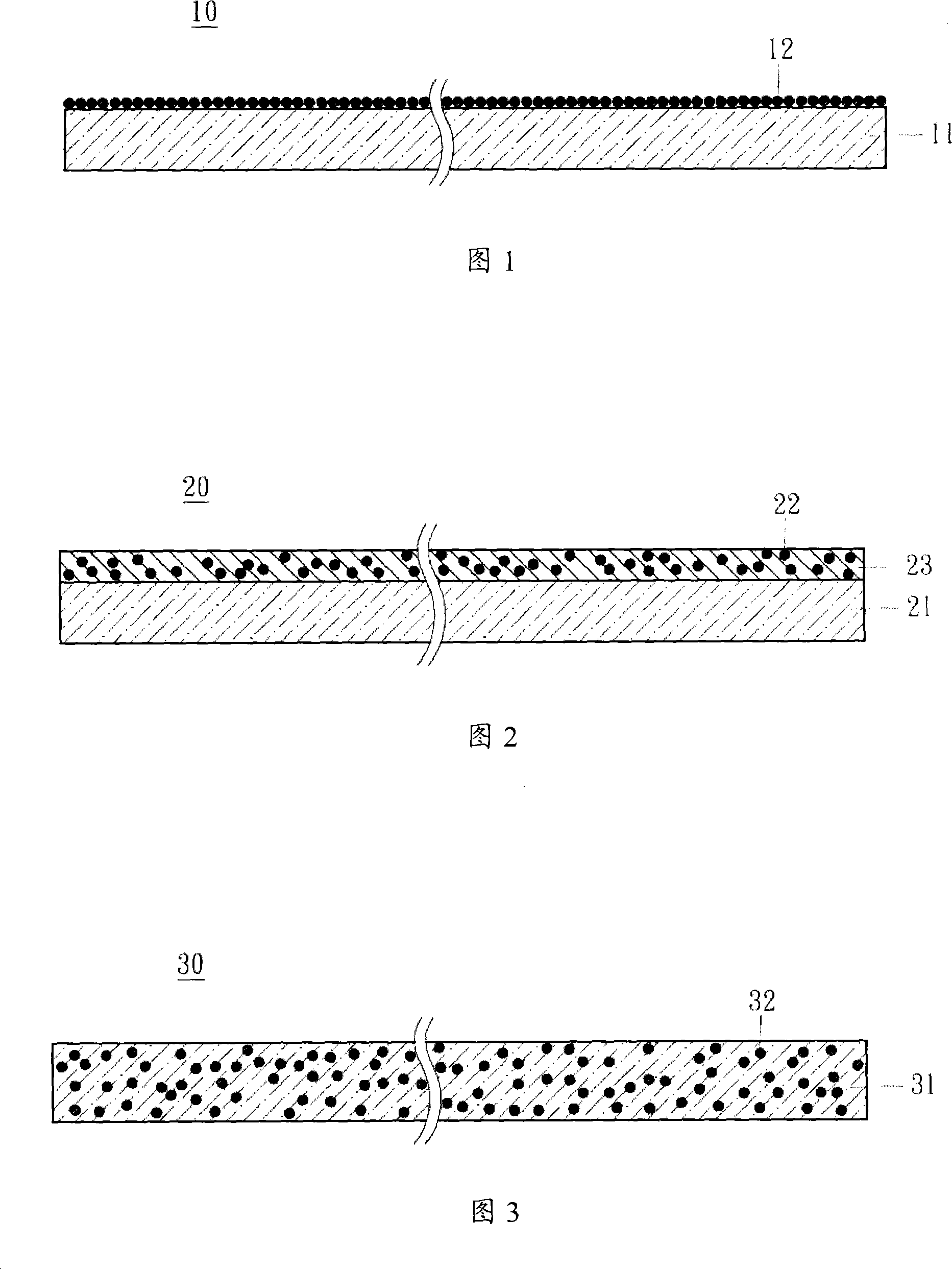

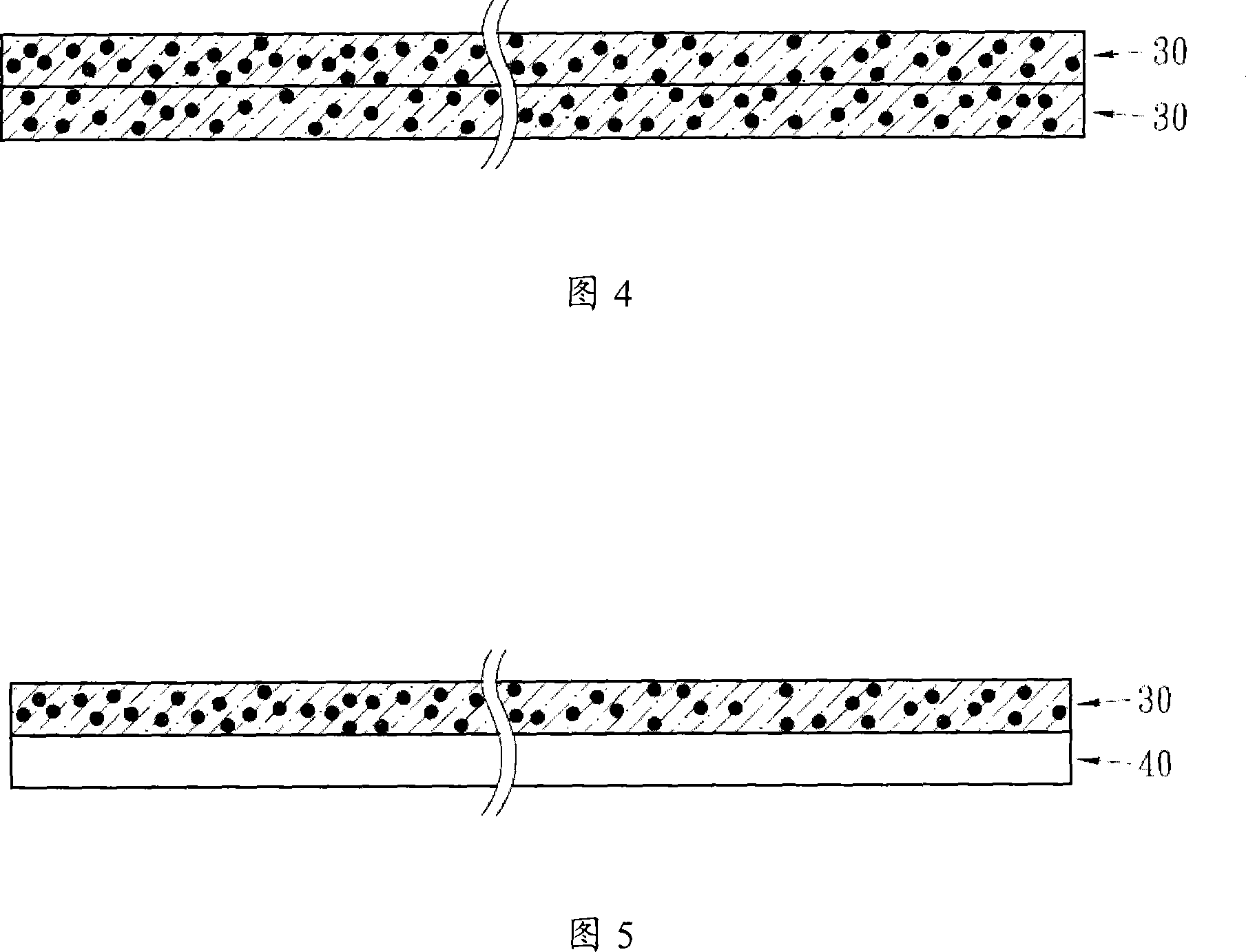

Flexible display device and manufacturing method thereof

ActiveCN107799574AReduce internal stressSolve crackingSemiconductor/solid-state device detailsSolid-state devicesEngineeringFlexible display

The invention discloses a flexible display device and a manufacturing method thereof, and belongs to the filed of display technology. The flexible display device comprises a flexible display module and a flexible covering layer, wherein the flexible display module is covered with the flexible covering layer; the flexible covering layer and the flexible display module are adhered together through an optical transparent adhesive tape; and the surface, in contact with the optical transparent adhesive tape, of the flexible covering layer is rugged. Through the technical scheme, the bending resistance of the flexible display device can be improved.

Owner:BOE TECH GRP CO LTD

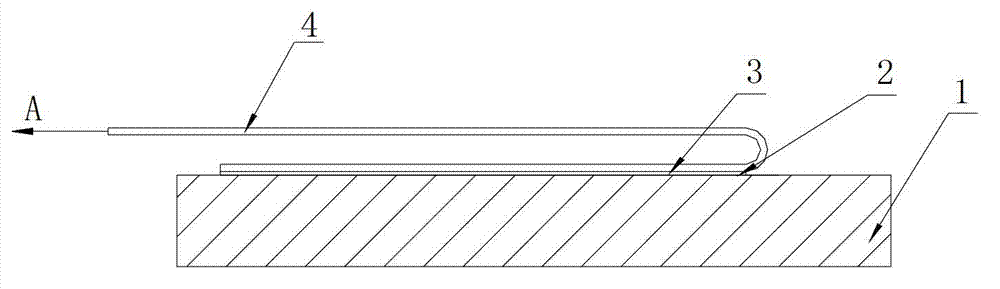

Method for measuring adhesive force of lithium ion battery pole piece coating

ActiveCN102788746AEasy to measureGood repeatabilityUsing mechanical meansMaterial analysisElectrical batteryPole piece

The invention discloses a method for measuring the adhesive force of a lithium ion battery pole piece coating, comprising the following steps: taking a test base plate, bonding a layer of a transparent adhesive tape on the surface of the test base plate, bonding a layer of a double faced adhesive tape on the adhesive-free surface of the transparent adhesive tape, bonding the other adhesive surface of the double faced adhesive tape onto the coating of a pole piece to be tested by pressing, and reserving an unbonded part at one end in the length direction of the pole piece; clamping the reserved unbonded part by a stretch chuck of a stretch testing machine, bending the pole piece in the length direction of the pole piece and stretching, after peeling the coating of the pole piece to be tested, reading the adhesive force value of the pole piece coating. According to the invention, without changing the technological conditions and process flow of the battery manufacturing technique, the adhesive force value of the pole piece coating can be conveniently measured with small error and good repeatability, and the invention provides the design and manufacturing process of batteries with a reliable basis.

Owner:中创新航科技(江苏)有限公司

Process for preparing coated fabric with glaring and charming visual effect

InactiveCN101608404AVisual Effects SavingsSave raw materialsLiquid/gas/vapor open-width material treatmentSynthetic resin layered productsEngineeringPre treatment

The invention provides a process for preparing a coated fabric with a glaring and charming visual effect, belonging to the technical field of coated fabric preparation process. The process is characterized by comprising the following steps: a, coating the fabric which is subjected to pre-treatment, dyeing or dyed printing and presetting, wherein, the coating process is divided into two parts: (1) first coat: the first coat adopts PA transparent adhesive tape for dry coating; (2) top coat: the top coat adopts PA adhesive mixed with fantasy pearlescent powder or colorful pearlescent powder for dry coating; and b, after finishing: the after finishing comprises the following steps: preparing a stiff and water resistance finishing solution for the fabric, and padding the coated fabric on a setting machine with a groove. The fabric prepared by the process not only can emit pearly luster, and has glaring and charming visual effect, but also has the functions of stiffness and water resistance, is particularly suitable for manufacturing umbrella fabrics, curtains, bath curtains and other products, and has wide application range. Furthermore, the preparation process saves raw materials and energy consumption.

Owner:RIXIN TEXTILE

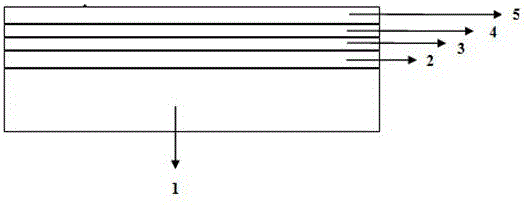

SiC SUBSTRATE SEPARATING METHOD

ActiveUS20170136572A1Efficient introductionHigh refractive indexEdge grinding machinesSolid-state devicesEngineeringLaser beams

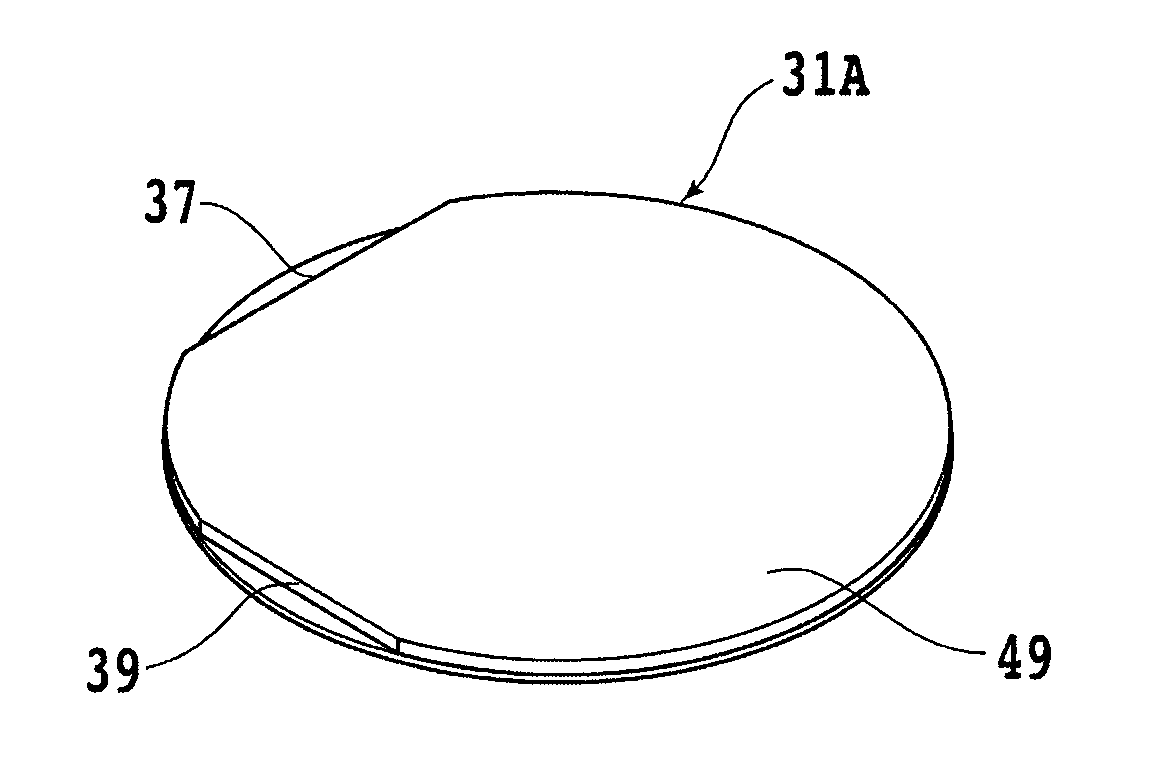

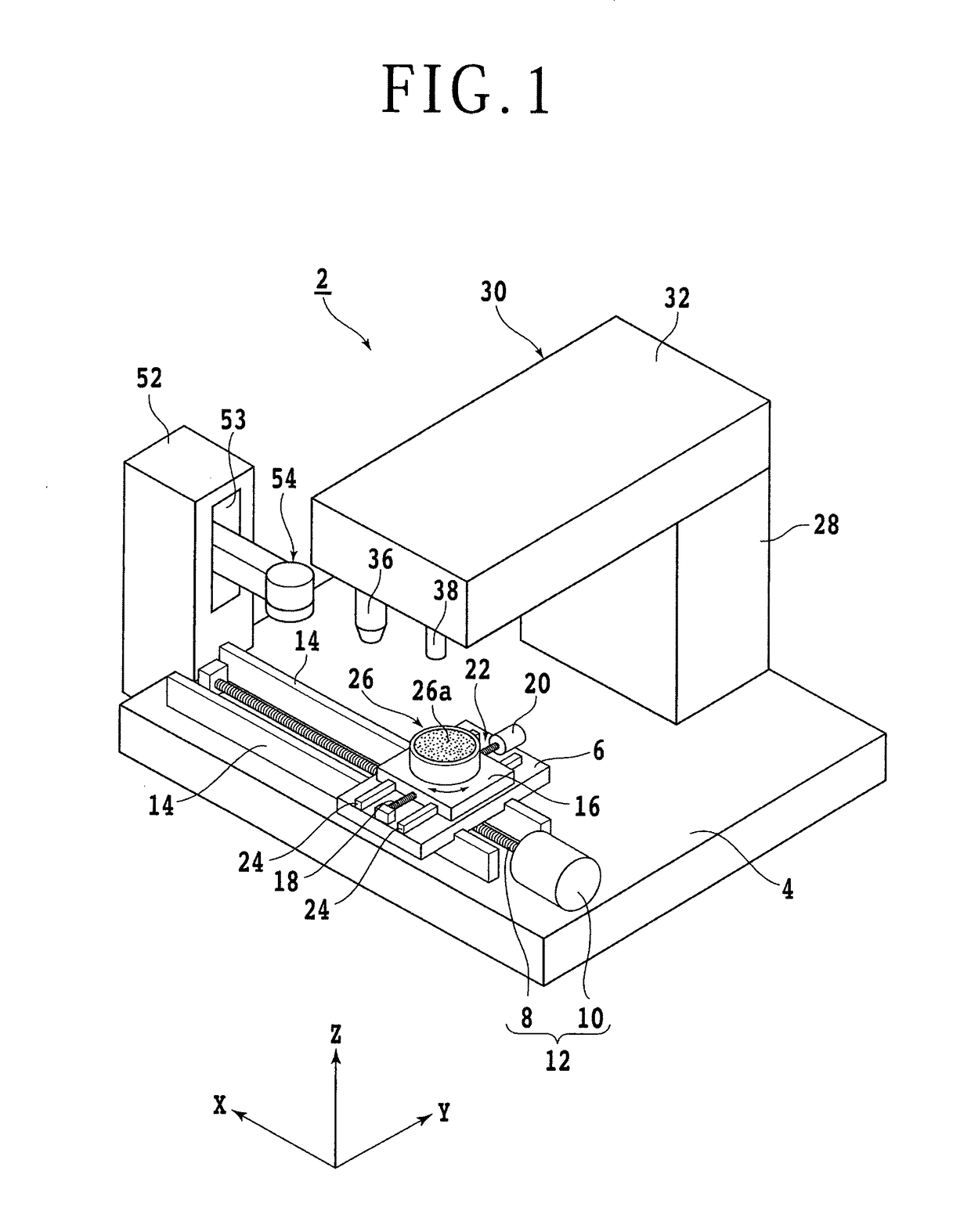

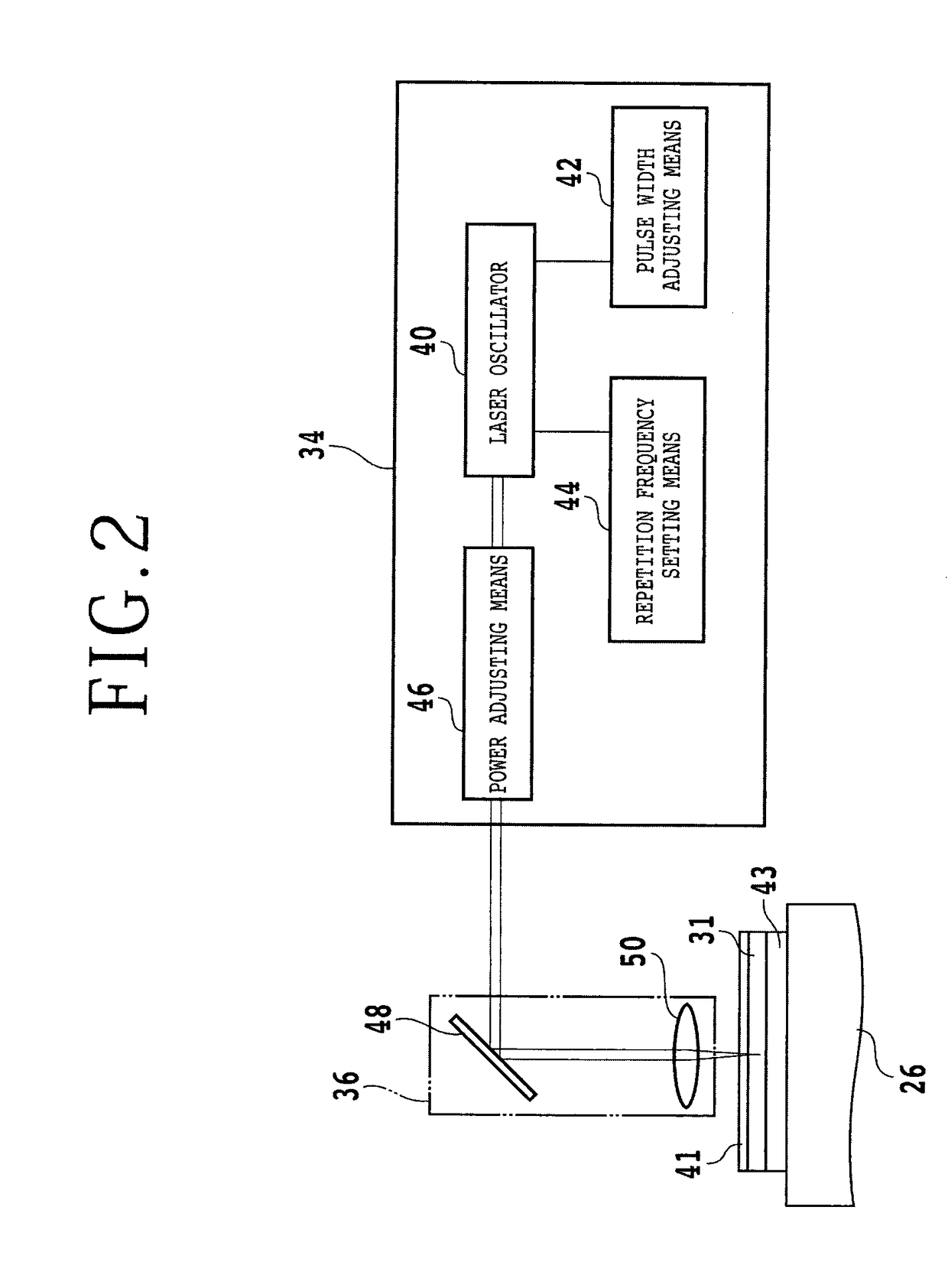

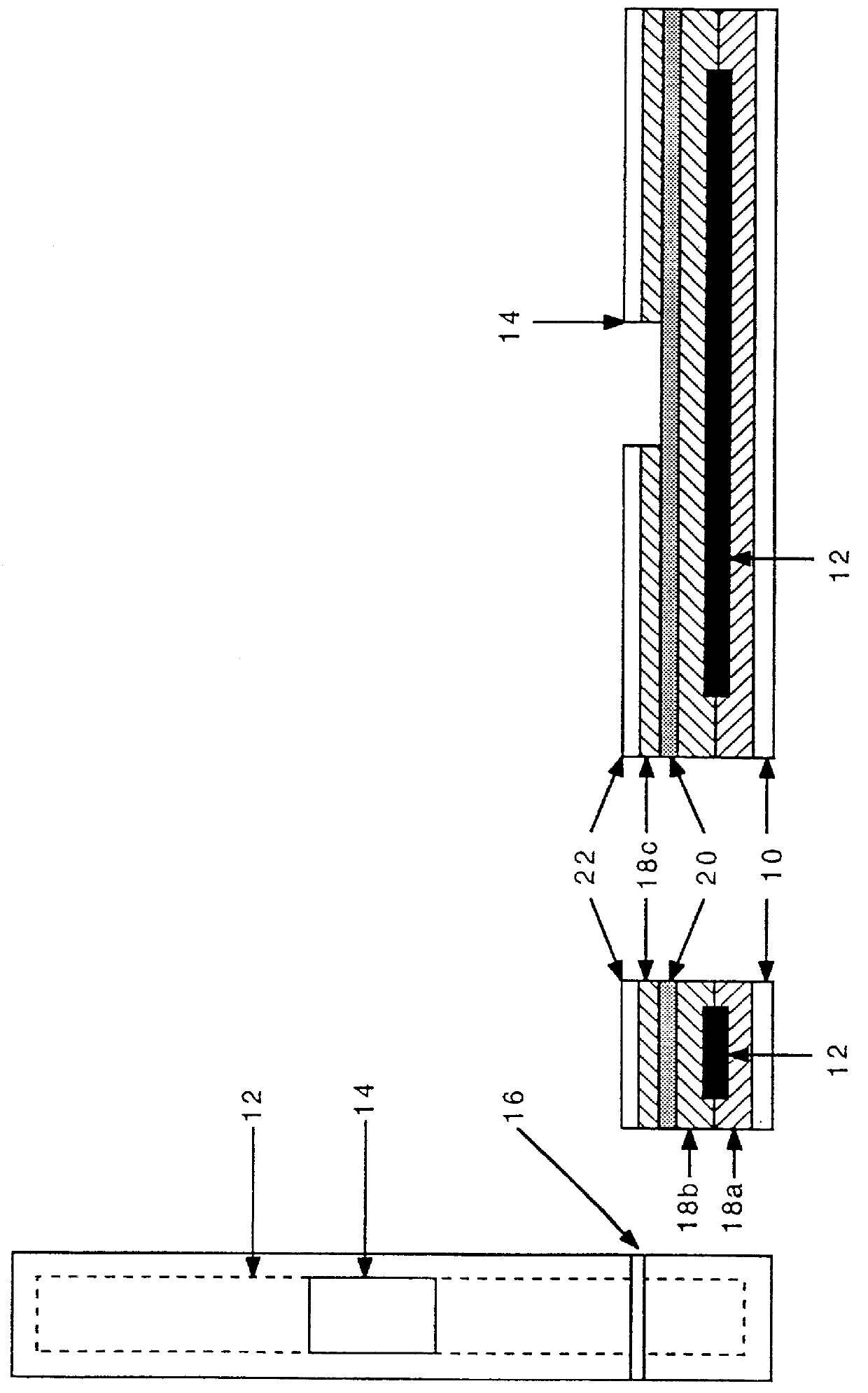

Disclosed herein is an SiC substrate separating method for separating an SiC substrate into at least two parts in a planar manner. The SiC substrate separating method includes an adhesive tape attaching step of attaching a transparent adhesive tape to a first surface of the SiC substrate, a support member attaching step of attaching a support member to a second, opposite surface of the SiC substrate, and a separation start point forming step of setting the focal point of a laser beam at a predetermined depth from the adhesive tape and next applying the laser beam to the adhesive tape while relatively moving the focal point and the SiC substrate to thereby form a modified layer parallel to the first surface of the SiC substrate and cracks propagating from the modified layer, thus forming a separation start point.

Owner:DISCO CORP

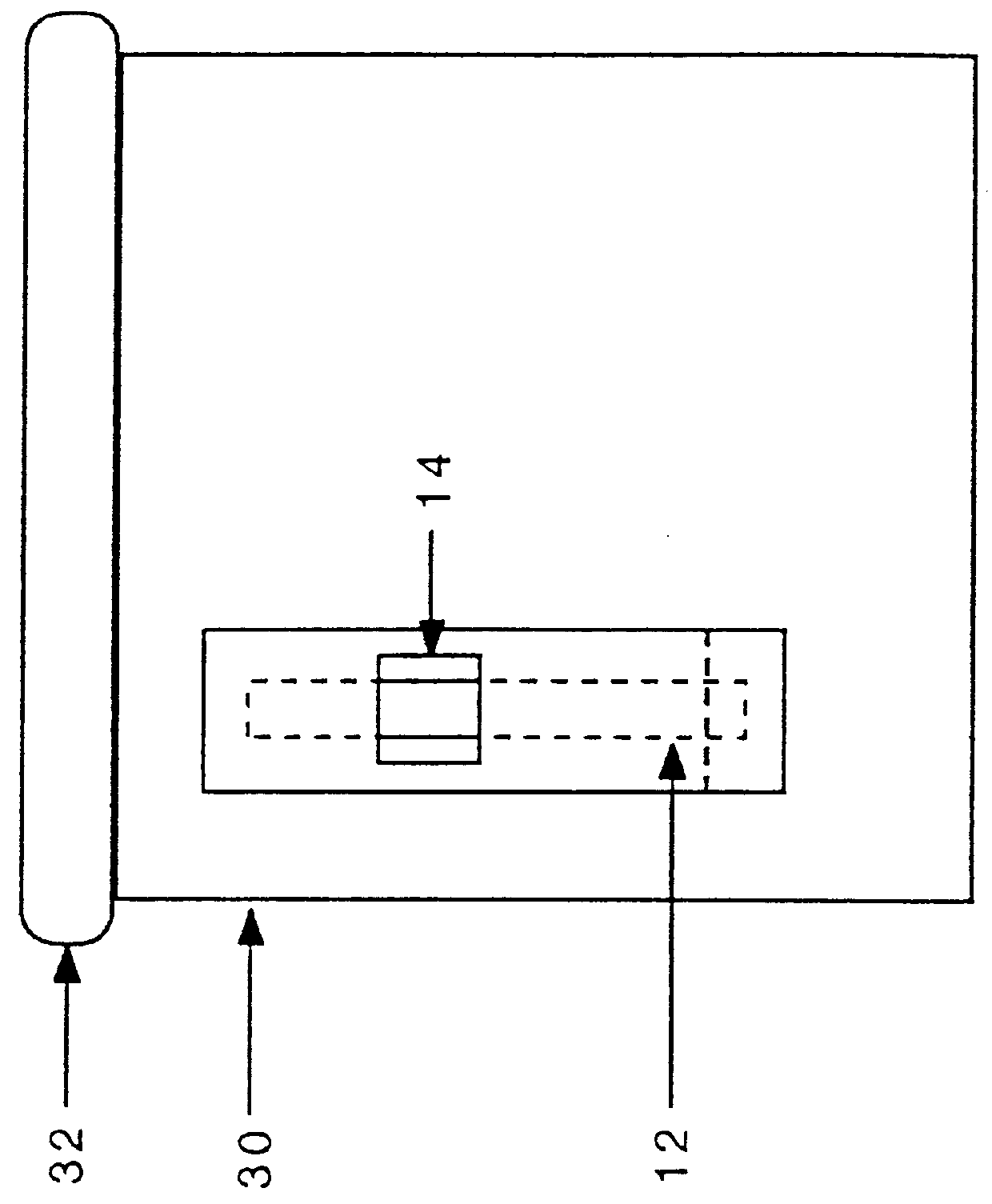

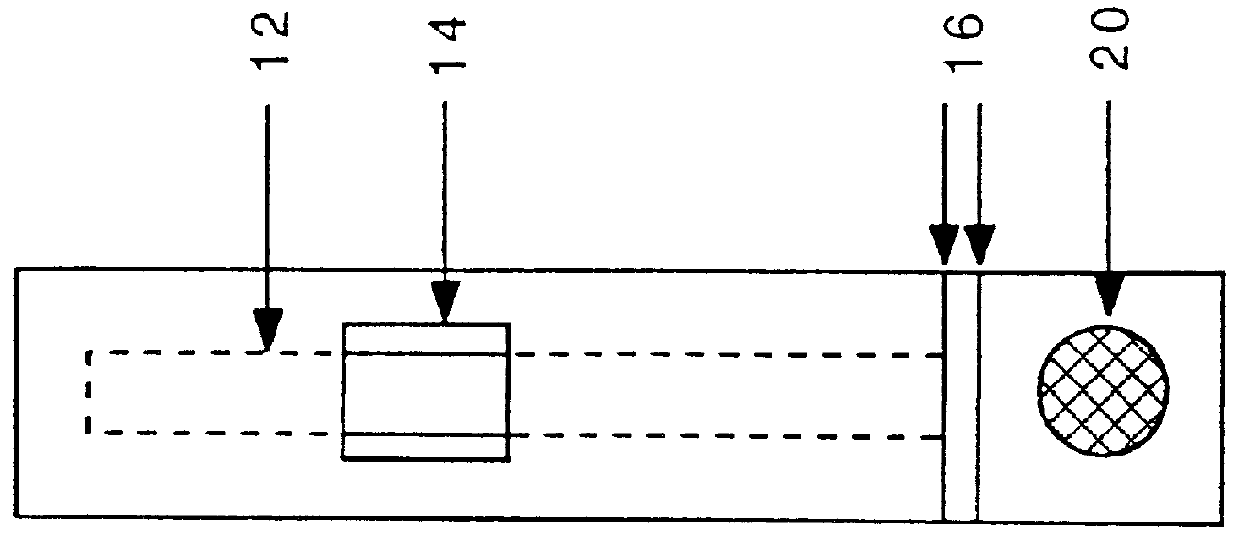

Integrated packaging holder device for immunochromatographic assays in flow-through or dipstick formats

InactiveUS6087185ABioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteUrine cotinine level

The prevent invention relates to an integrated package-holder assay devices for detecting the presence of analyte in a sample. The device serves the dual roles of supporting and protecting an immunochromatographic assay. The device is compatible with any immunochromatographic assay format. The assay can be performed in a single apparatus for use in a laboratory or a field setting. In a specific example, the assay device is a nylon membrane formatted for an immunochromatographic assay for cotinine sealed between transparent adhesive tape and a stiff plastic strip. White tape placed over the plastic strip defined a window for observing the assay results.

Owner:SEREX

Anti-dandruff shampoo of common camellia seed

ActiveCN101129310AGood effectCosmetic preparationsToilet preparationsAmmonium dodecyl sulfateIrritation

The invention relates to an antidandruff shampoo of camellia seed, which comprises the following steps: adding fatty alcohol polyoxyethylated ether sodium sulfate and laurel ammonia sulfate into emulsifying tank with demonized water to stir to be homogeneity; adding TAB-2 and carbon 16 / carbon 18 fatty alcohol to stir to be homogeneity; adding the demonized water dissolving guar gum into the emulsifying tank to sir and stew and cool after homogeneity; adding into the emulsifying tank to stir to be homogeneity respectively after moistening polyquaternary ammonium salt-10 to be transparent adhesive tape state through the demonized water and dissolving tea saponin through the demonized water then adding fatty acid alkanolamide and coco oil amide propel botanies into the emulsifying tank to sir to be homogeneity and cooling; adding pearl plasma and GMT into the emulsifying tank to be homogeneity and cooling to add kai-spine and perfume compounds to stir to be homogeneity; adjusting consistency and stewing and short immersing naturally to produce the shampoo. The invention has effects of sterilizing, relieving itching, antidandruff and hair care, which has no irritation to skin and makes hair crow black with brightness and high resilience.

Owner:广东新大地生物科技股份有限公司

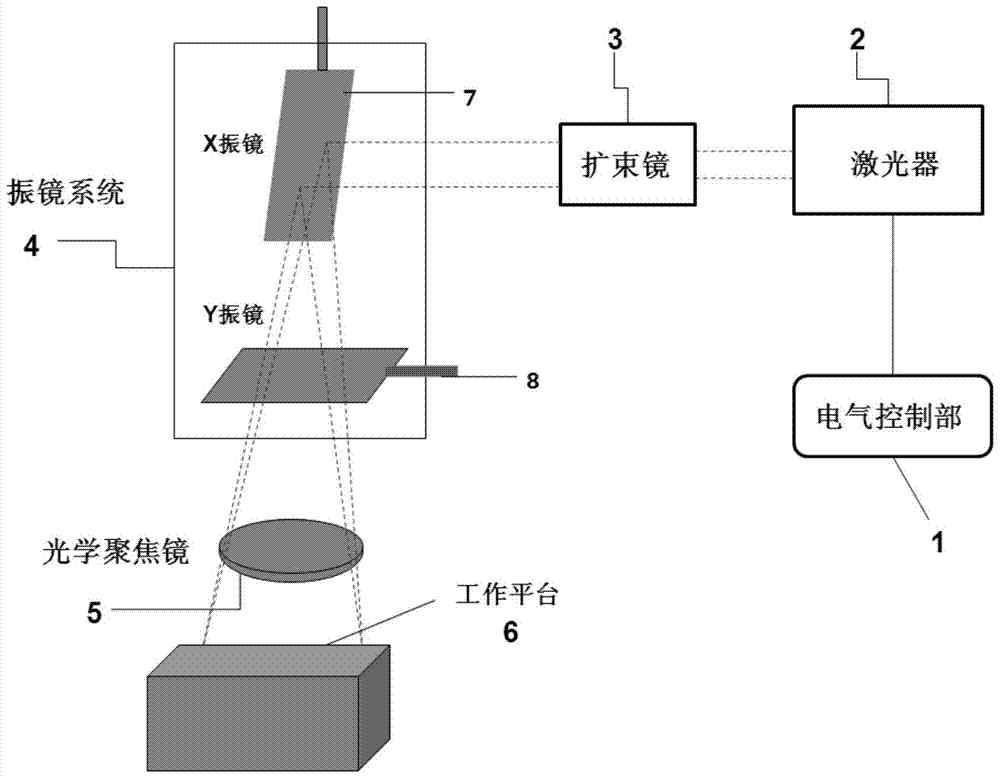

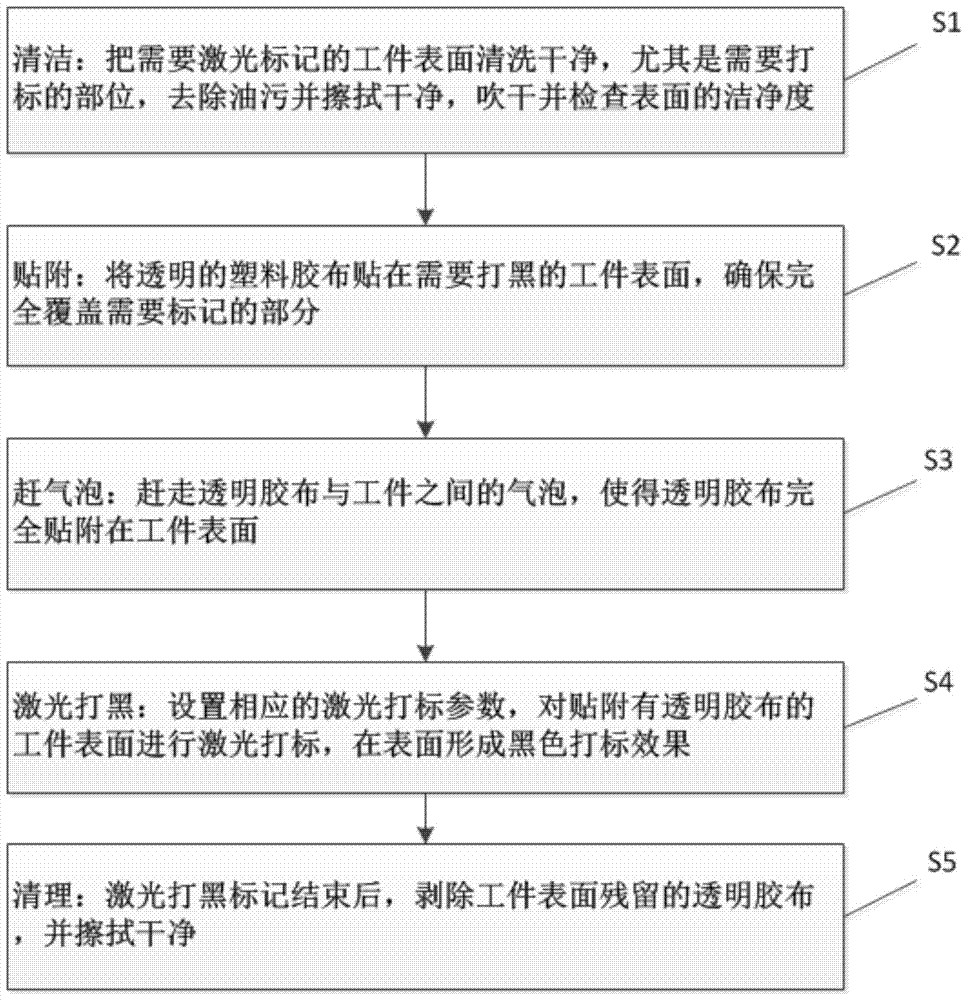

Laser marking machine and marking method thereof

ActiveCN106994560AImprove the quality of marking productsNo pollution in the processWelding/soldering/cutting articlesLaser beam welding apparatusBeam expanderGalvanometer

The embodiment of the invention relates to a laser marking machine and a marking method thereof. The laser marking machine comprises an electrical control part, a laser device, a beam expander, a galvanometer system, an optical focusing lens and a working platform. The electrical control part provides energy power for the laser device and controls the laser device to transmit lasers. The lasers transmitted by the laser device are amplified through beam expansion to shoot into the galvanometer system, the amplified lasers shoot onto the optic focusing lens after being deflected through the galvanometer system, and the lasers irradiate the surface of a workpiece put on the working platform for marking after being focused by the optic focusing lens. According to the laser marking machine and the marking method thereof, anodic oxidation treatment does not need to be carried out on an aluminum alloy material, the lasers penetrate a transparent adhesive tape film, a laser beam acts on the surface of an aluminum alloy, permanent marking is achieved, cost is low, and pollution is avoided.

Owner:HANS LASER TECH IND GRP CO LTD

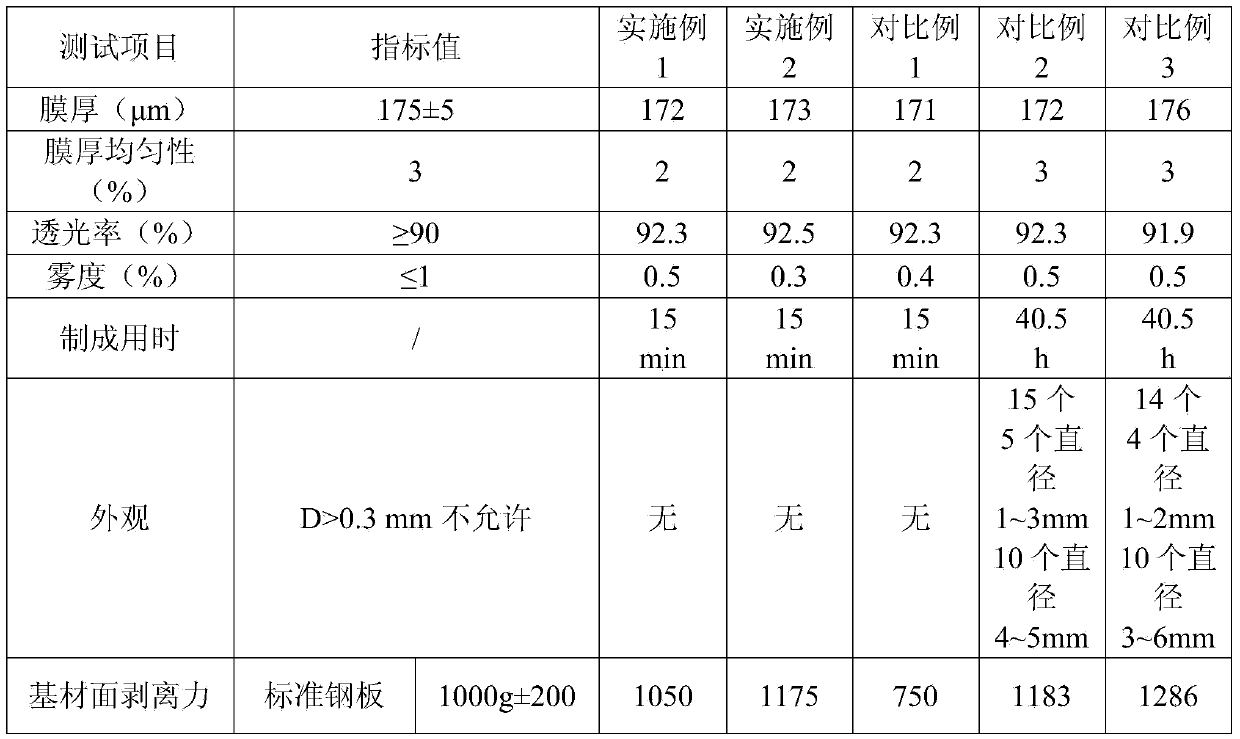

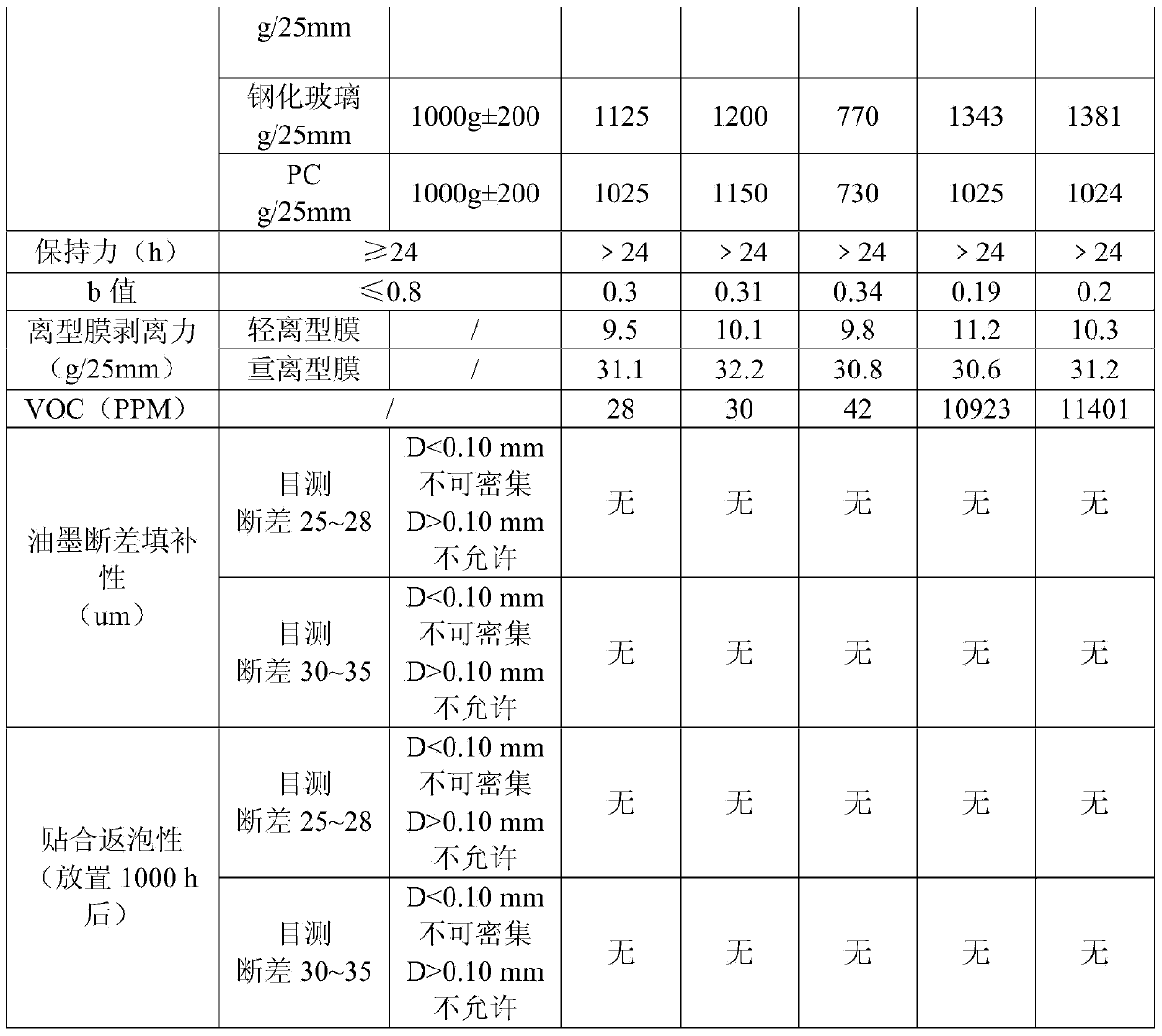

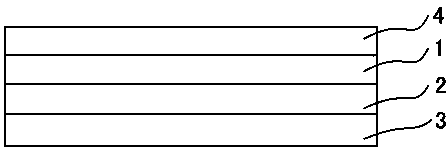

Solvent-free UV (ultraviolet) curing glue for optical transparent adhesive tape and preparation method and application thereof

ActiveCN103725245ALow VOCGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceSolvent free

The invention belongs to the technical field of UV (ultraviolet) curing glue, and discloses solvent-free UV curing glue for an optical transparent adhesive tape and a preparation method and application thereof. The glue comprises the following components in parts by mass: 20-60 parts of aliphatic polyurethane acrylate, 5-15 parts of hyperbranched polyester acrylate, 10-25 parts of acrylate monomer, 1-10 parts of thiol, 1-10 parts of tackifying resin, 0.1-1 part of leveling agent, 0.5-2 parts of antifoaming agent and 0.5-2 parts of photoinitiator. In the invention, the colloid crosslinking density and colloid strength are improved by preferentially adopting aliphatic polyurethane acrylate with low functionality degree and adding hyperbranched polyester acrylate; the acrylate monomer adjusts the viscosity and enhances the colloid strength; the caking property is improved by adding the thiol containing an ether structure; the prepared non-solvent UV curing glue for an optical transparent adhesive tape has high toughness, high light transmittance, low haze, high colloid strength, high viscosity, high thickness and low VOC (volatile organic compound) content.

Owner:广州慧谷功能材料有限公司

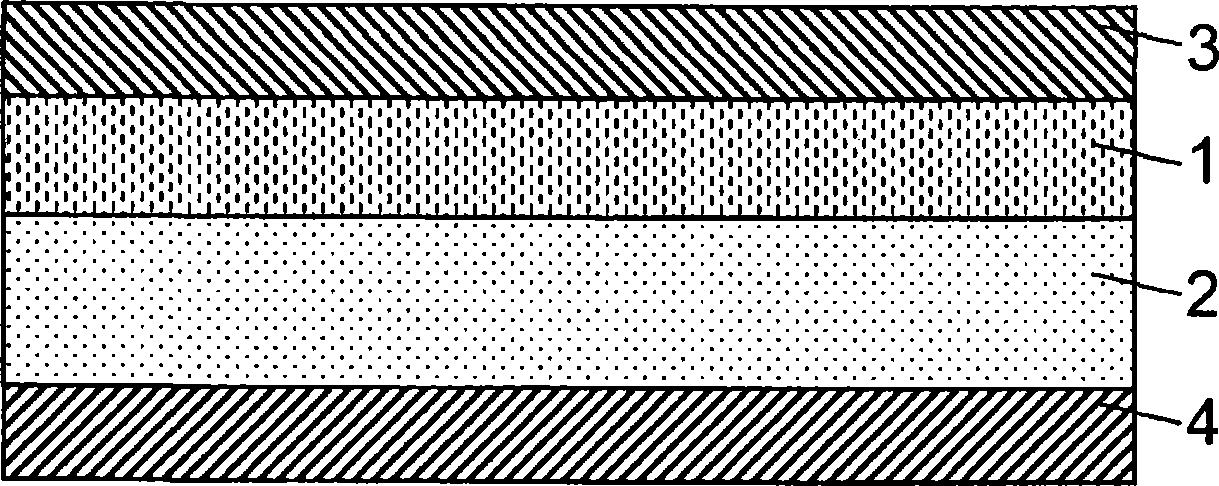

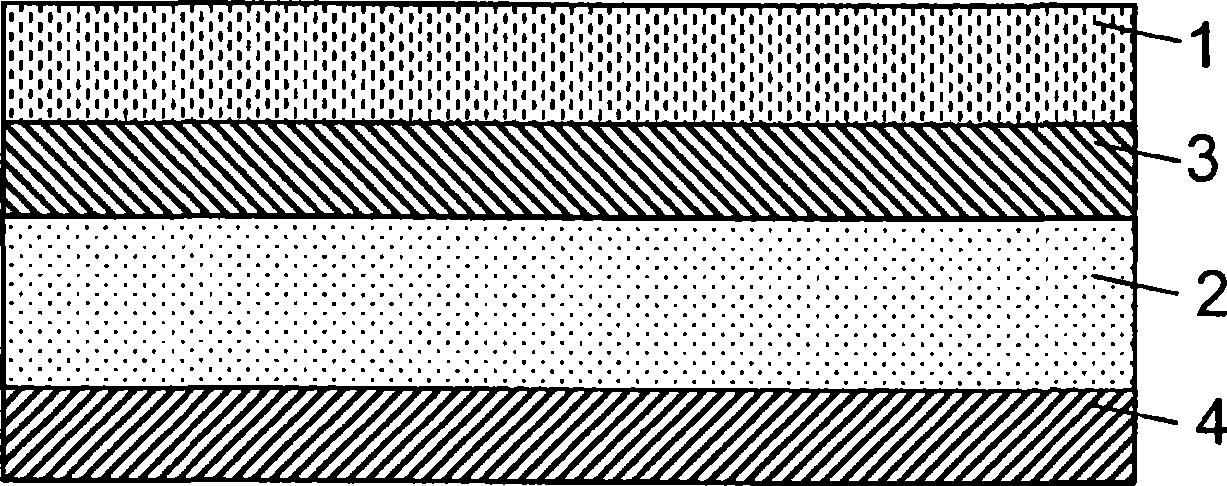

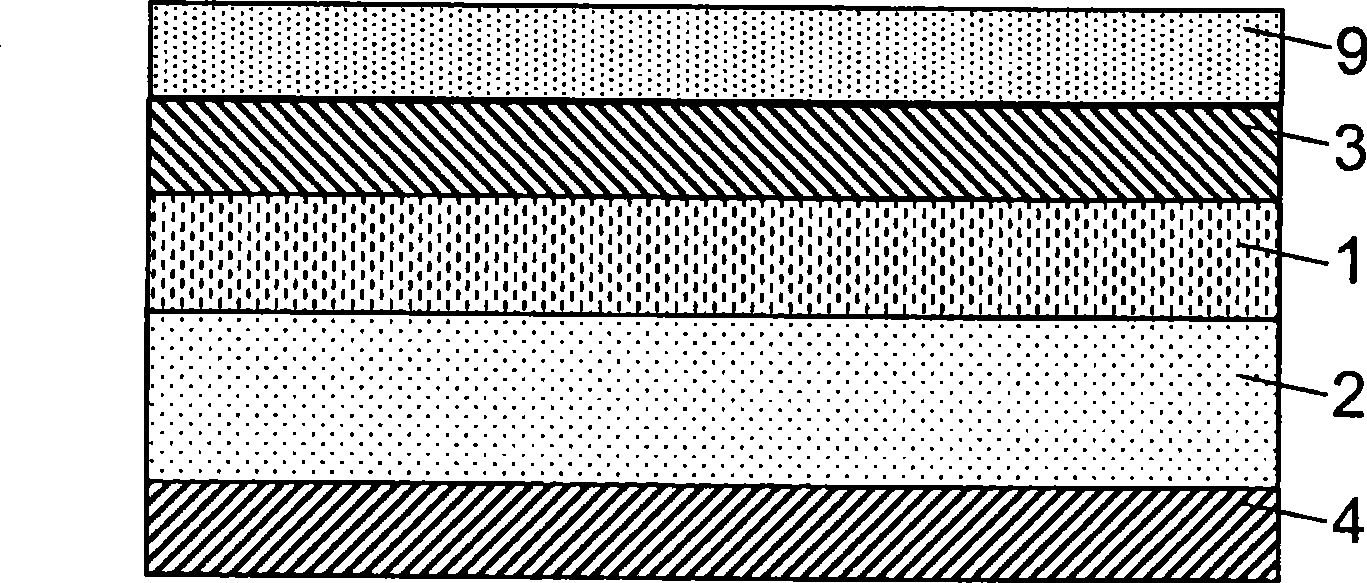

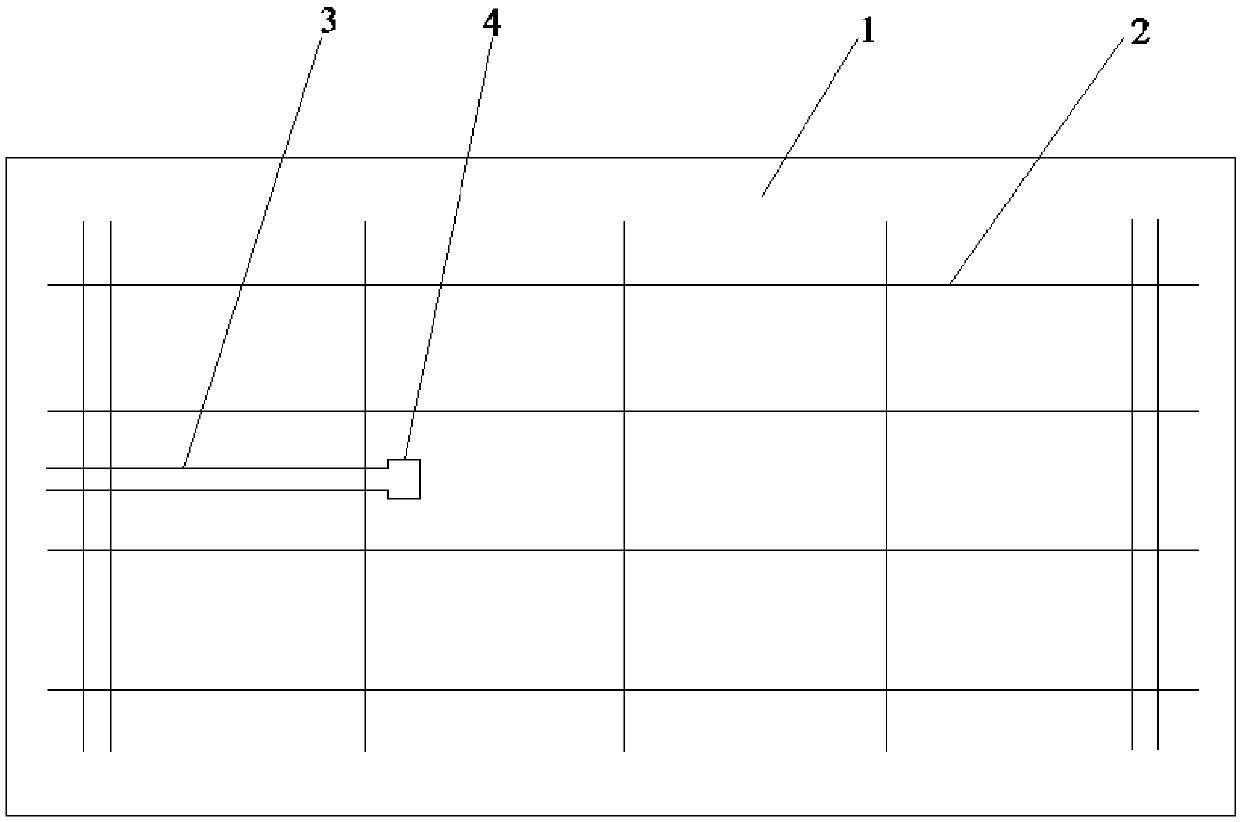

Graphene thin film touch sensor and manufacturing method thereof

InactiveCN103941918AGood electrical contactEasy to operateInput/output processes for data processingMetallic electrodeLaser processing

The invention discloses a graphene thin film touch sensor. The graphene thin film touch sensor mainly comprises a substrate, a metal lead electrode and a graphene thin film, and further comprises optical transparent adhesive tape. The metal lead electrode is arranged on the surface of the substrate, the graphene thin film directly covers the metal lead electrode, and the optical transparent adhesive tape is attached to the surface of the graphene thin film. A manufacturing method of the graphene thin film touch sensor comprises the steps that firstly, the metal lead electrode and an alignment target are arranged on the substrate; secondly, the graphene thin film is transferred to the substrate on which the metal lead electrode is arranged; thirdly, patterning is carried out on the surface of the graphene thin film based on the laser machining technology; fourthly, the optical transparent adhesive tape is attached to the surface of the patterning graphene thin film, and therefore the graphene thin film touch sensor is formed. According to the product and method, the sensor lead electrode is buried below the patterning graphene conducting thin film, good electric property contact is achieved, and the requirement for the adhesive force of graphene and the metal electrode is met in the process of manufacturing the touch sensor.

Owner:WUXI GRAPHENE FILM

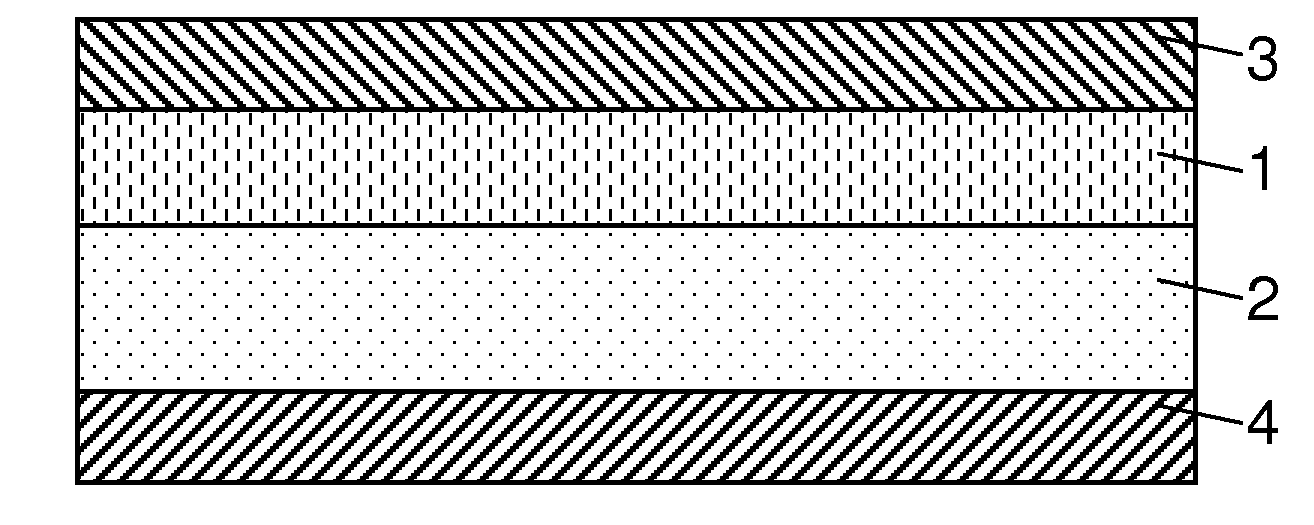

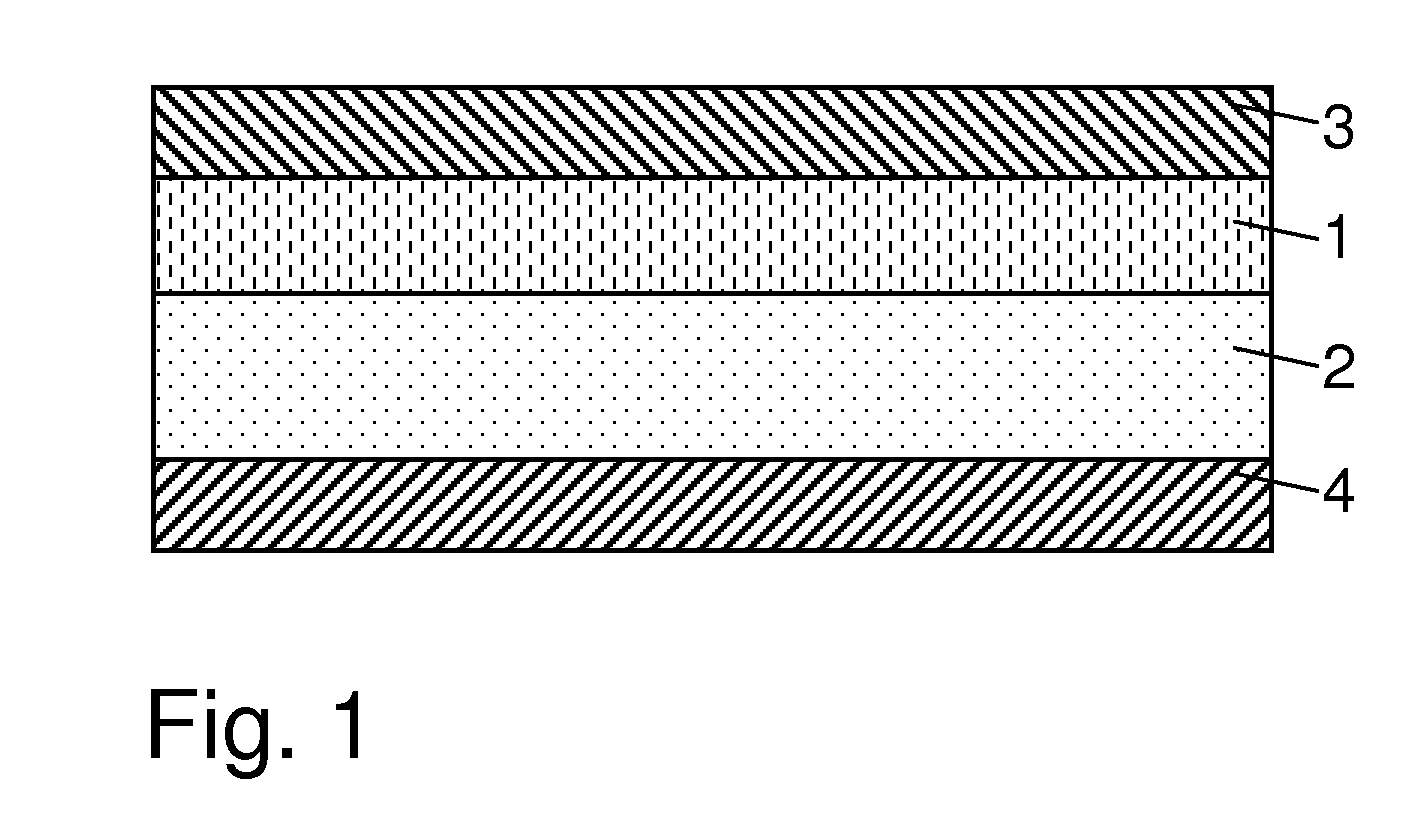

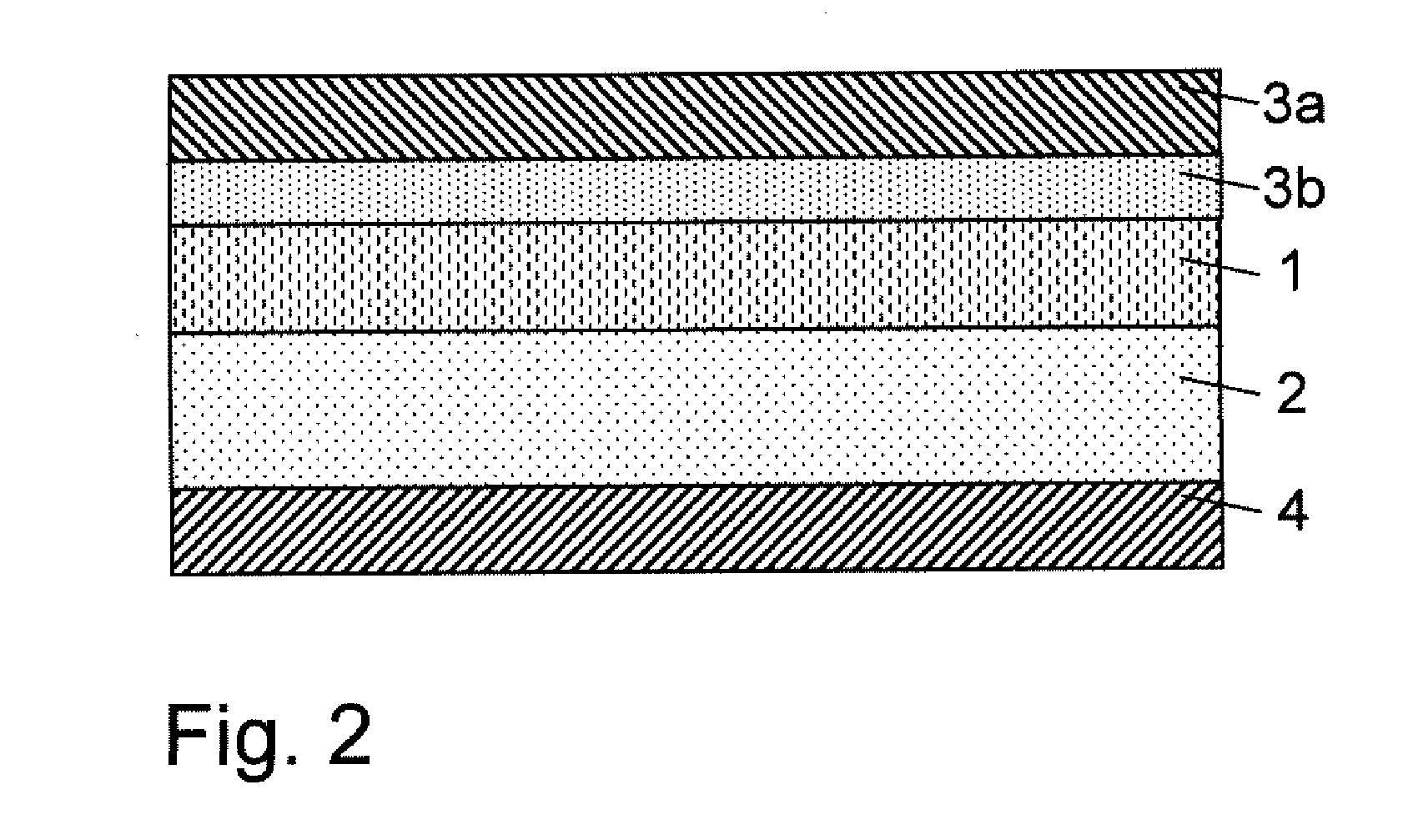

Transparent adhesive tape

InactiveUS20090081452A1Intuitive displayDrawback can be obviatedLamination ancillary operationsFilm/foil adhesivesBiomedical engineeringBrittleness

A unilaterally bondable, transparent, substantially two-dimensional element (2D element) is presented which has a support and an adhesive, and which is used as a shatterproofing device for brittle 2D bodies. The surface of the support is protected from damage by means of a temporary covering means. The temporary covering means is designed such that it is residue-lessly detachably joined to the support and hence ensures optimal transparency of the 2D element following detachment of the temporary covering means.

Owner:TESA SE

Anti-fog optical resin lens and its preparation method

ActiveCN106405691AImprove transmittanceReduce reflectivityOptical elementsMegasonic cleaningAnti-fog

The invention discloses an anti-fog optical resin lens and its preparation method. The lens comprises the following elements arranged in sequence: a resin lens substrate, a stiffened film layer, a penetration increasing and reflection reducing film layer, a connecting adhesive layer and an anti-fog film layer. The method further discloses a preparation method for the anti-fog optical resin lens, and the method comprises the following steps: conducting ultrasonic cleaning to the resin lens substrate; using an immersing and coating manner to plate for the stiffened film layer; under the vacuumed condition, plating on the stiffened layer the penetration increasing and reflection reducing film layer; and finally, coating the connecting adhesive layer onto the penetration increasing and reflection reducing film layer; and adhering the anti-fog film layer. The anti-fog film layer is prepared from a high-molecular hydrophilic film. According to the anti-fog optical resin lens of the invention, the optical transparent adhesive tape is used to have a penetration increasing and reflection reducing film layer and a high-molecular hydrophilic film adhered together, which means that without undermining the original functions of the resin lens, the penetration rate of the resin lens is increased while the reflection rate is reduced and that the lens has an anti-fog function.

Owner:JIANGSU CONANT OPTICS +1

Heat-proof polychloroethylene transparent adhesive tape

InactiveCN101157829AEasy to makeReduce processing costsFilm/foil adhesivesScreening effectThermal insulation

A transparent polyvinyl chloride coated fabric for heat insulation is made by the processing method of non-coating. The coated fabric has the function of shading infrared and ultraviolet. The preparation method is that polyvinyl chloride colophony containing special formula, plasticizer, inorganic thermal insulation particles and other mixtures of adding addition agent are used directly in the traditional process of making the polyvinyl chloride coated fabric, as a result, the transparent polyvinyl chloride coated fabric for thermal insulation not only has the existing physical properties of polyvinyl chloride, but also transparency, little fog, and excellent screening effect against infrared and ultraviolet.

Owner:NANYA PLASTICS CORP

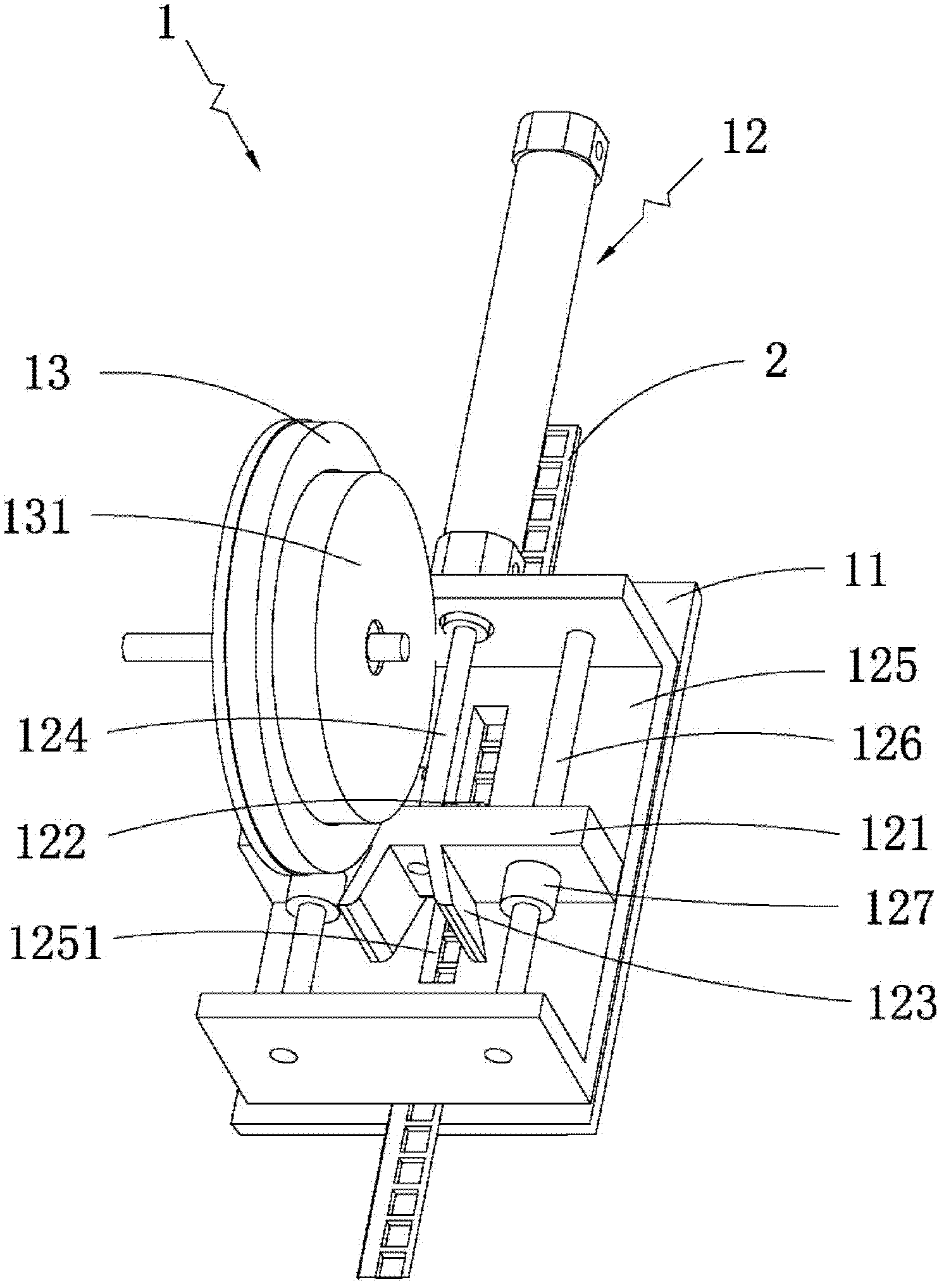

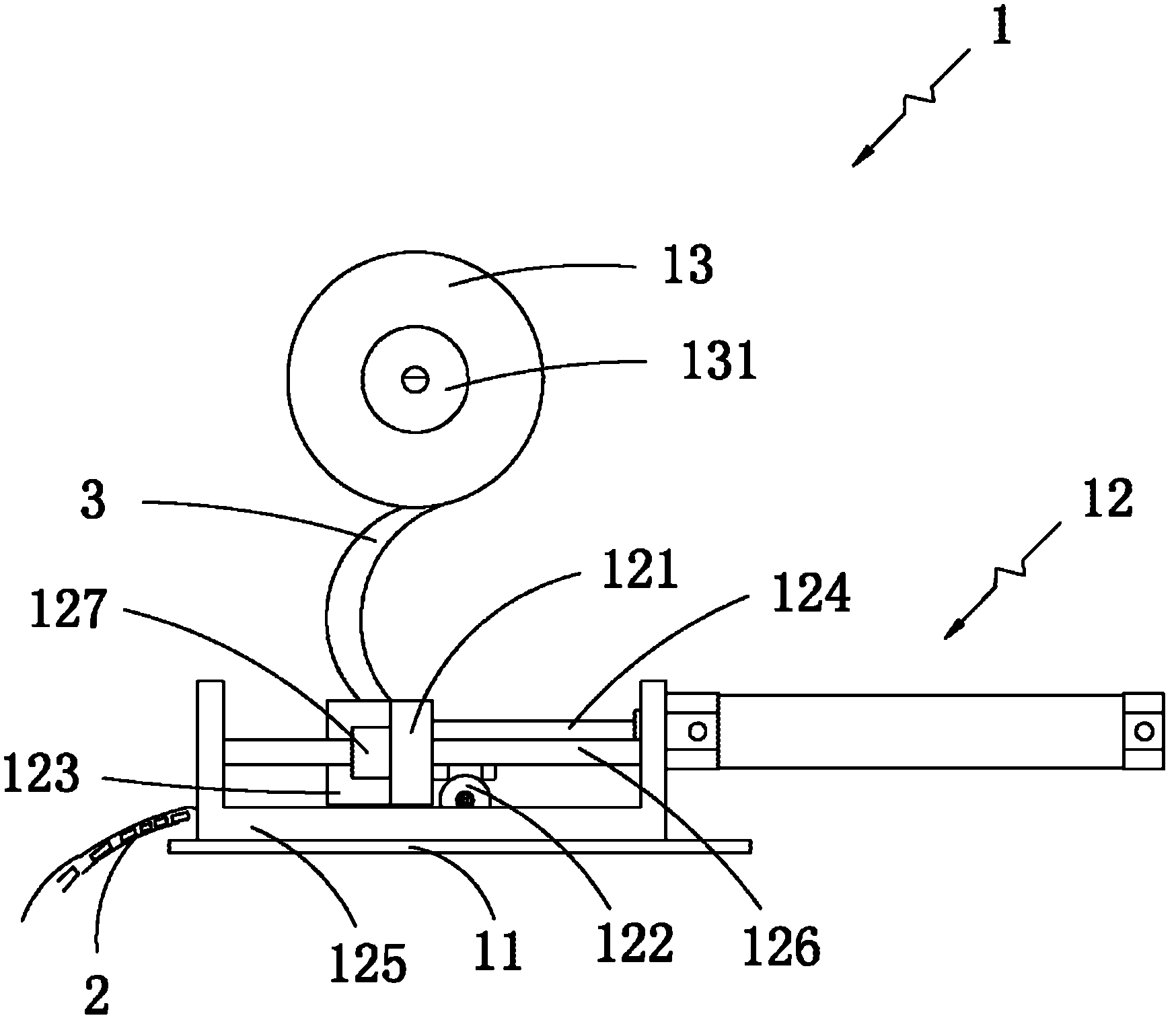

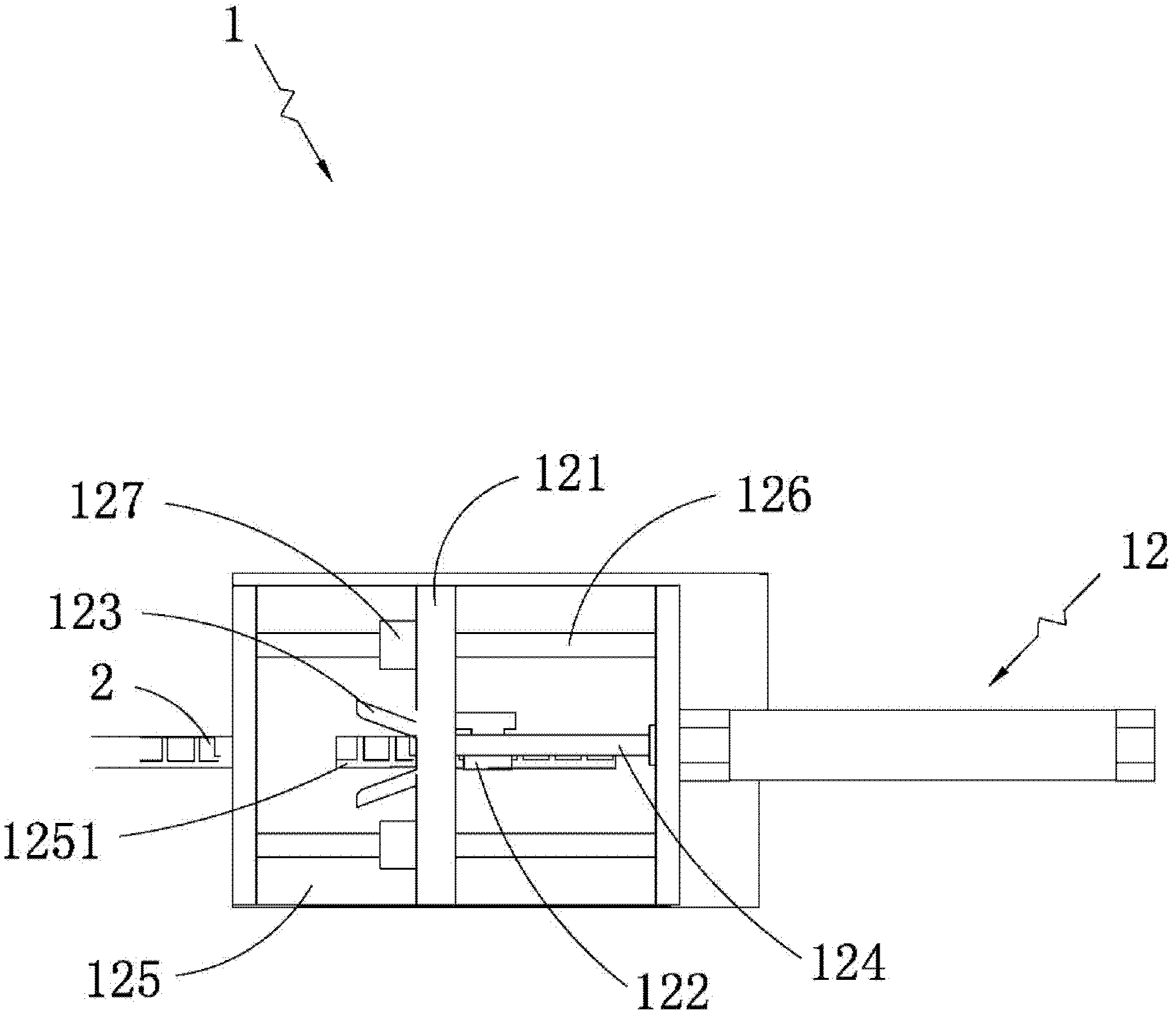

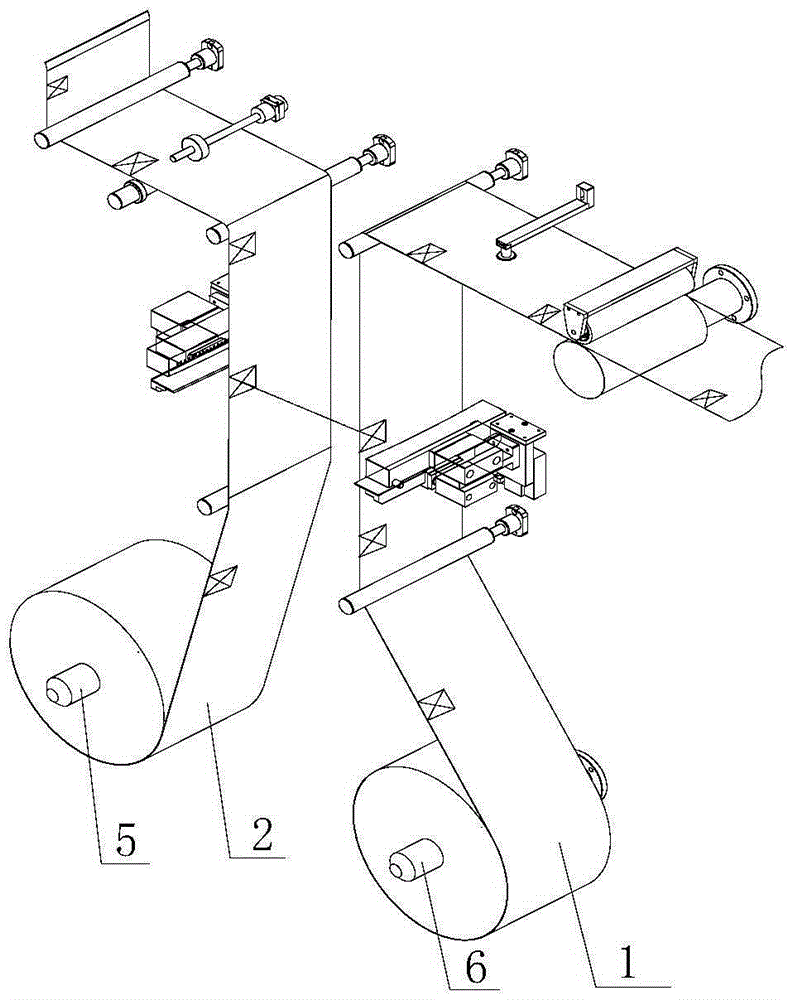

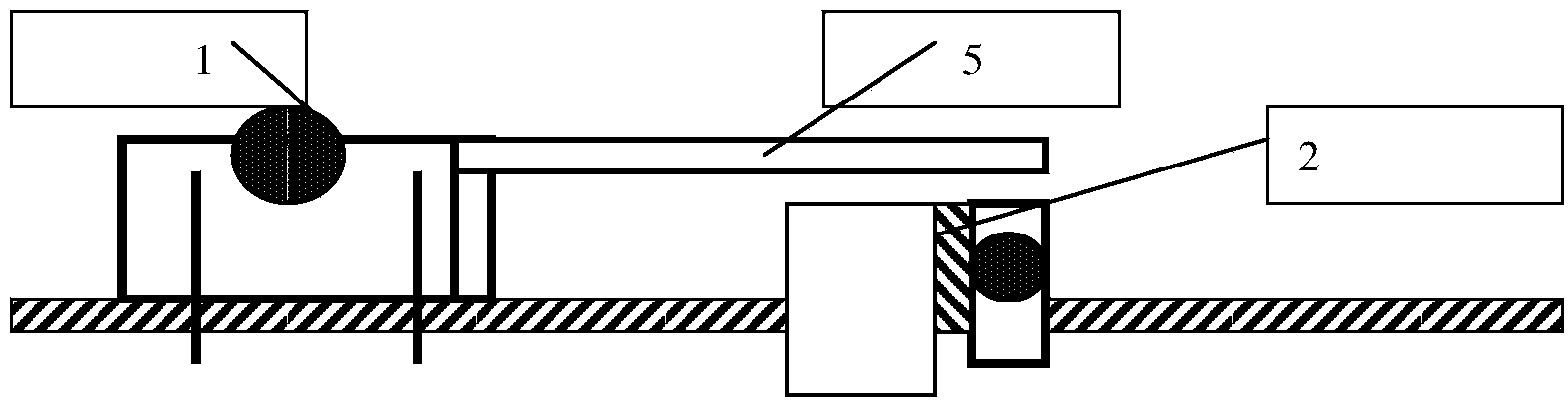

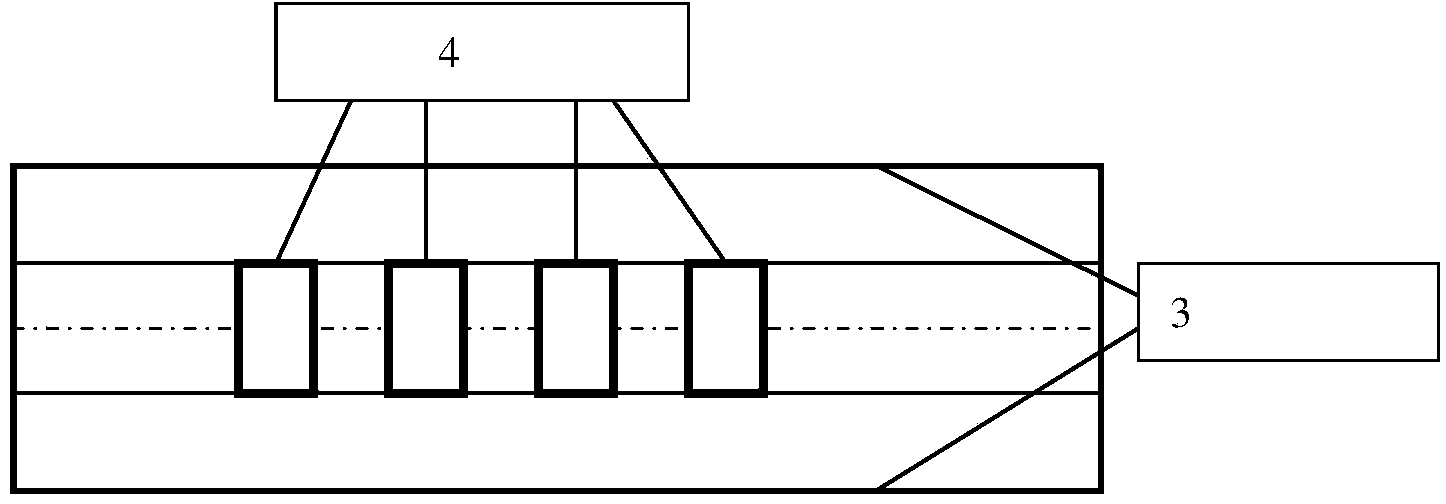

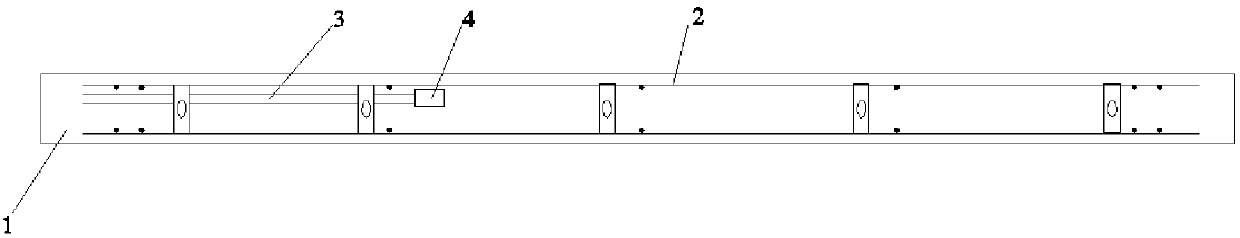

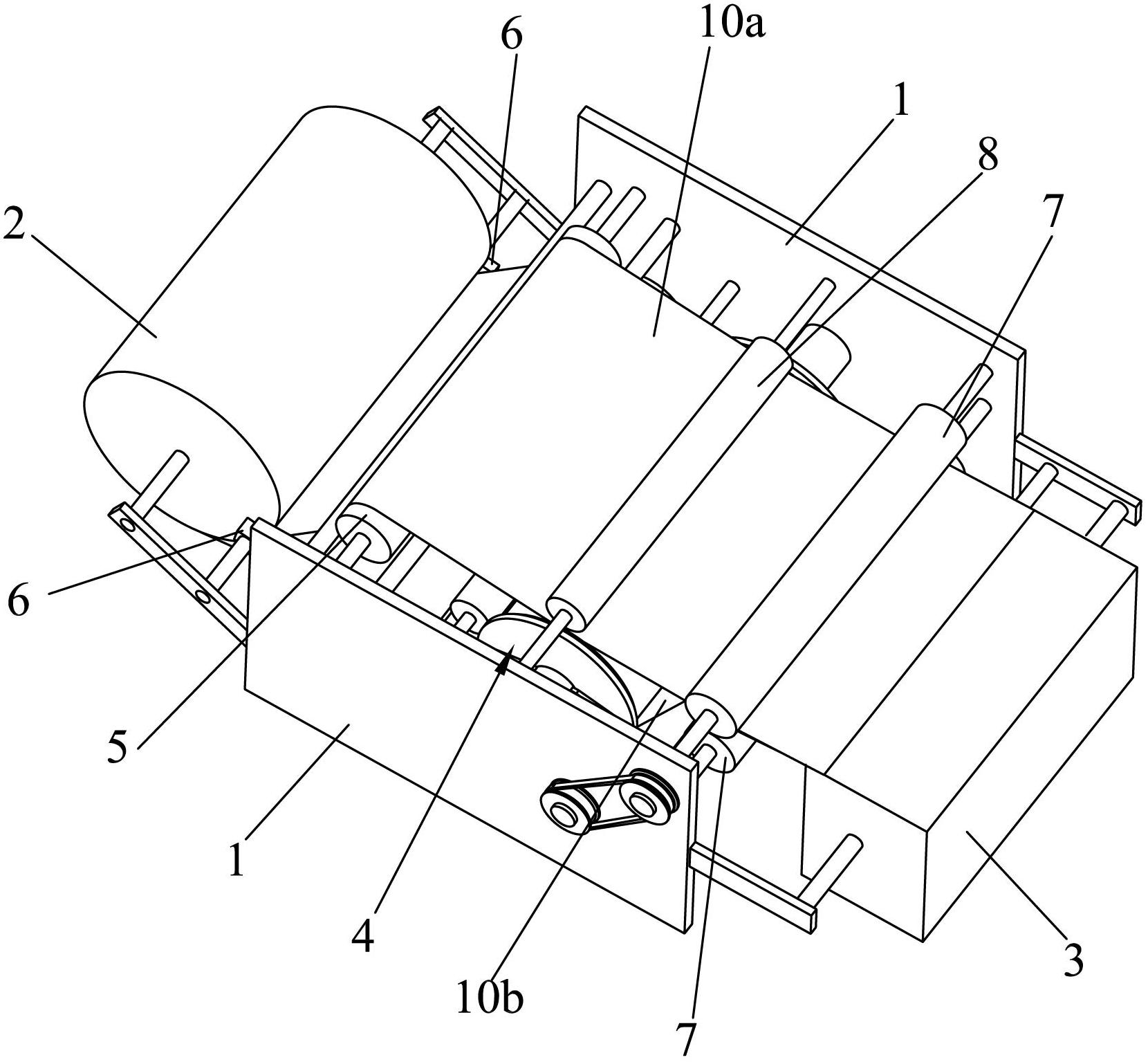

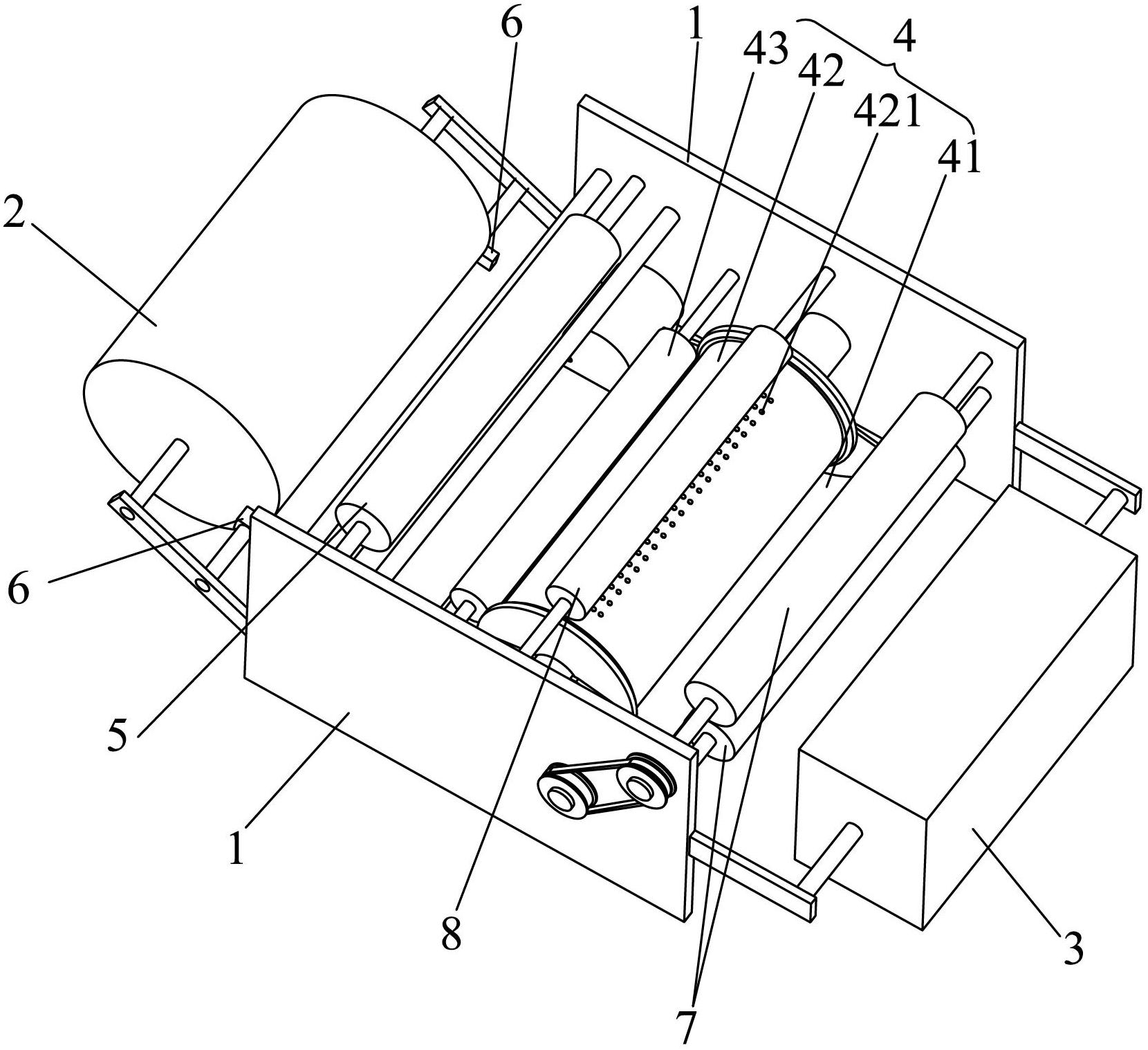

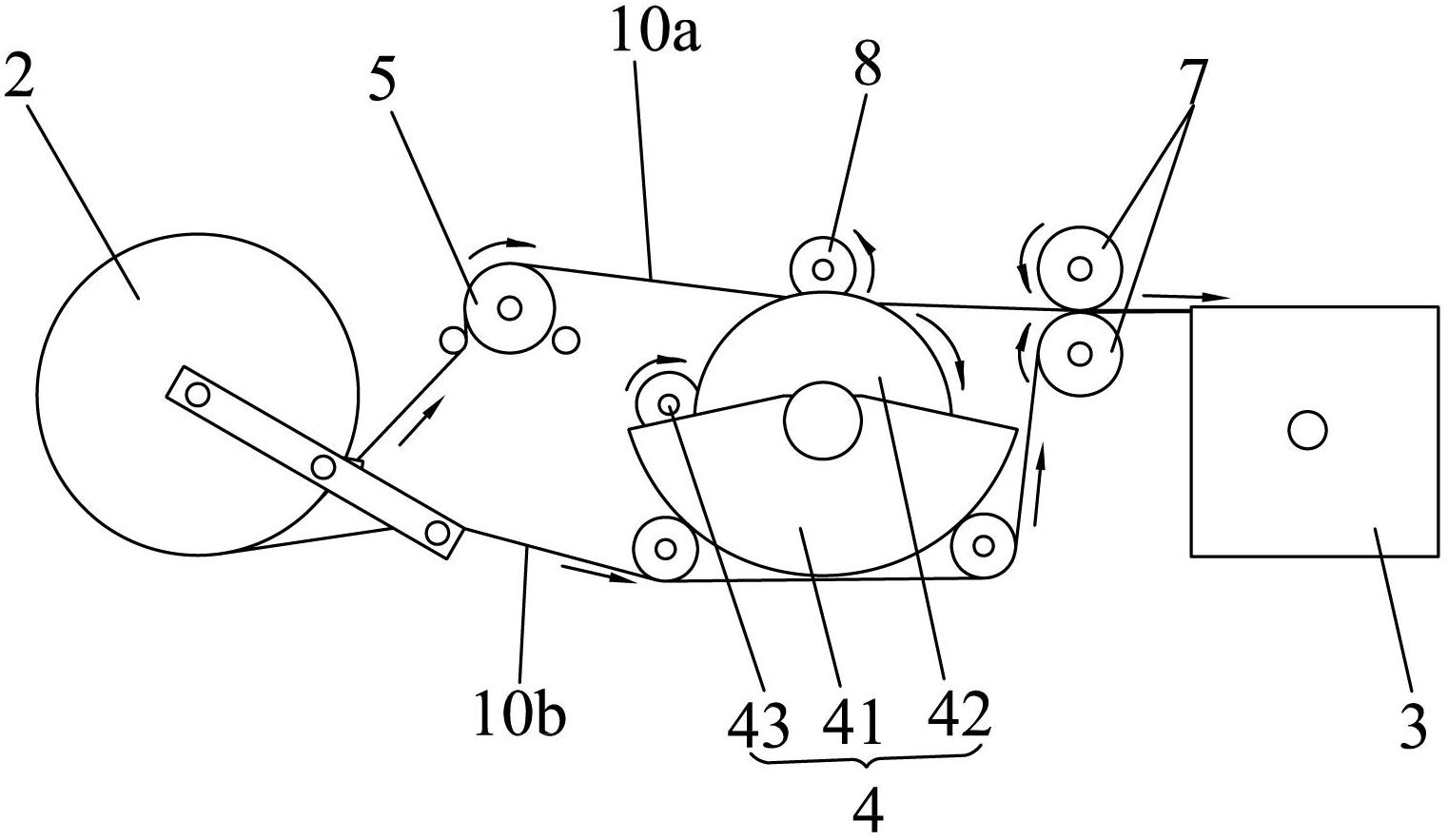

Automatic adhering device of transparent adhesive tape

ActiveCN102305228ASmooth transmissionAutomatic paste evenlyFastening meansMechanical engineeringAir bubble

The invention provides an automatic adhering device of a transparent adhesive tape. The automatic adhering device adheres to an object to be adhered by utilizing the transparent adhesive tape and comprises a driving mechanism. The driving mechanism is arranged on a base plate, the base plate is provided with a guiding slot through which the object to be adhered passes, the driving mechanism drives a sliding block to carry out sliding displacement on the base plate, a rolling wheel is arranged on one side of the sliding block and can roll on the object to be adhered, and a locating structure is arranged on the other side of the sliding block and is used for locating the transparent adhesive tape. The transparent adhesive tape is suspended above the rolling wheel, the head of the transparent adhesive tape is firstly adhered on the object to be adhered, and the driving mechanism drives the rolling wheel to roll and drives the transparent adhesive tape to roll and automatically press the object to be adhered, thus the adhesion is ensured to be more uniform, firmer and better quality, and no bubbles or adhesion misalignment generates in the adhering process; the transparent adhesive tape is located by utilizing the locating structure so as to ensure that the transparent adhesive tape can stably convey without interruption; in addition, the automatic adhering device further has the advantages of simple structure and low cost, and the labor and the time are saved due to manual adhesion replaced by the automatic adhesion.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

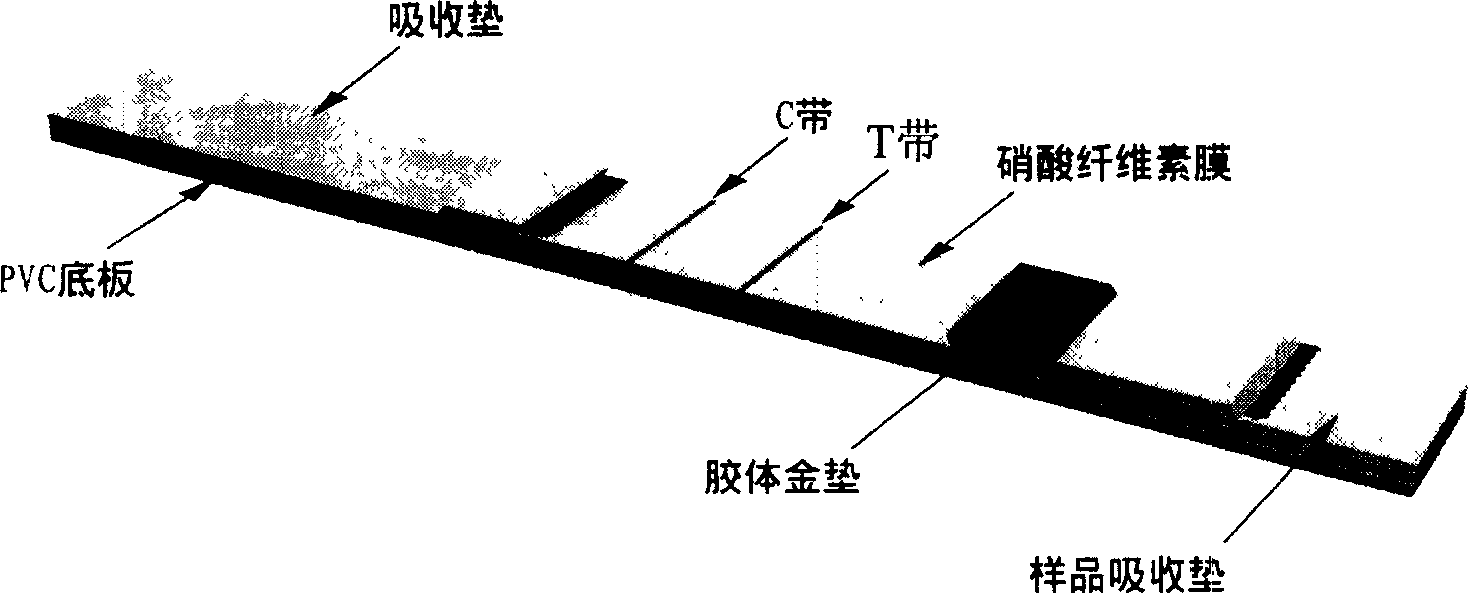

Insecticidal crystallin BT-Cry1Ab/1Ac rapid detection test bar

The invention is a pesticidal crystal protein BT-Cry1Ab / 1Ac fast-detecting testing strip. It uses an one-stage translational immune affinity chromatography and a monoclonal antibody and colloidal gold labeling technique, to fast detect protein BT-Cry1Ab / 1Ac in the sample. It provides a direct evidence for justifying if the sample to be detected contains transgenation plant sample (trans-Bt-Cry protein gene). The detecting result can provide a basis for quality evaluation of plant seeds, applied in the departments such as frontier defence, custom plant inspection, food safety detection to make spot and fast check on doubtful sample. The testing strip includes: high protein affinity fibrin film acts on the reacting carrier of the system and display the reacting result, the sample pad absorbs the sample to be detected and provides the proper reflecting condition for the reacting system, the colloidal gold pad is a solid-phase carrier of colloidal gold labeled antibody, the water absorbing pad absorbs the sample after detected, the plastic basal plate act as the supporting plate of the reacting system, the double- and single- surface adhesive tapes at different standards fix each reacting film and water-absorbing material on the supporting plate, the transparent adhesive tape fixes the sample protective pad and the colloidal gold pad, and the color marked adhesive tape acts as the characteristic mark of the detecting strip.

Owner:CHONGQING JINBIAO BIOTECH

Construction method of prestress carbon fiber cloth reinforced reinforced-concrete square pillar

The invention discloses a construction method of a prestress carbon fiber cloth reinforced reinforced-concrete square pillar. The method comprises the steps that a modularized reactive powder concrete (RPC) cushion block (an angle radian block, a common rectangular block and an anchor side rectangular block) is prefabricated, the surface of the cushion block is coated with an epoxy adhesive layer evenly so as to be smooth, and the pre-stress friction loss of carbon fiber-reinforced plastic (CFRP) cloth is reduced; the cloth is bonded to the surface of the reinforced reinforced-concrete (RC) square pillar so that arc angles can be formed; a self-locking anchor is embedded in a groove formed by the RPC cushion block and the surface of the reinforced RC square pillar, and the anchor is sealed with RPC after tension prestress is exerted; a transparent tape is bonded to the surface of the carbon fiber cloth before wrapping is carried out so that burrs at the edges are avoided; and after the carbon fiber cloth is tensioned, the surface of the carbon fiber cloth is coated with an epoxy adhesive layer, so that the overall bearing capacity is improved. According to the method, construction steps are clear, simple and practical, noise and a large amount of dust generated in the arc angle grinding process are avoided, the reinforced RC square pillar is prevented from being damaged by grinding, and rapid reinforcement of the RC square pillar through prestress FRP is achieved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Machining process for batched machining in multi-surface polishing of sapphire single-crystal cuboid window

The invention discloses a machining process for batched machining in multi-surface polishing of a sapphire single-crystal cuboid window, which adopts double-surface grinding and polishing equipment for grinding and polishing on window workpieces. The machining process comprises the following steps of: putting a sapphire hexahedral window in a wandering-star wheel clamp by using the workpieces, firstly grinding big surfaces, using a clamp made of epoxy resin material , adopting W40 boron carbide for coarse grinding and adopting W7 boron carbide for fine grinding; then carrying out grouped bonding on workpieces according to the specifications, and carrying out coarse grounding and fine grinding on the four end surfaces of the bonded workpieces; after grinding, using silicon dioxide solution (the particle diameter is 80-100nm and the pH value is 10-11) to polish the bonded end surfaces; after polishing, carrying out splitting on the workpieces, protecting the four end surfaces of polished single workpiece by using transparent adhesive tapes, and then polishing the big surfaces of the window workpieces. The machining process disclosed by the invention has the advantages that batched machining is carried out on multi-surface polishing of the similar hexahedral window, the production efficiency is high, the consistency of products is good, the quality is excellent, and all process links and quality parameters can be controlled; and the roughness of the polished surfaces of the workpieces is less than 0.3nm, the degree of parallelism is less than 10 seconds and the optimal finish can reach 40-20.

Owner:大连淡宁实业发展有限公司

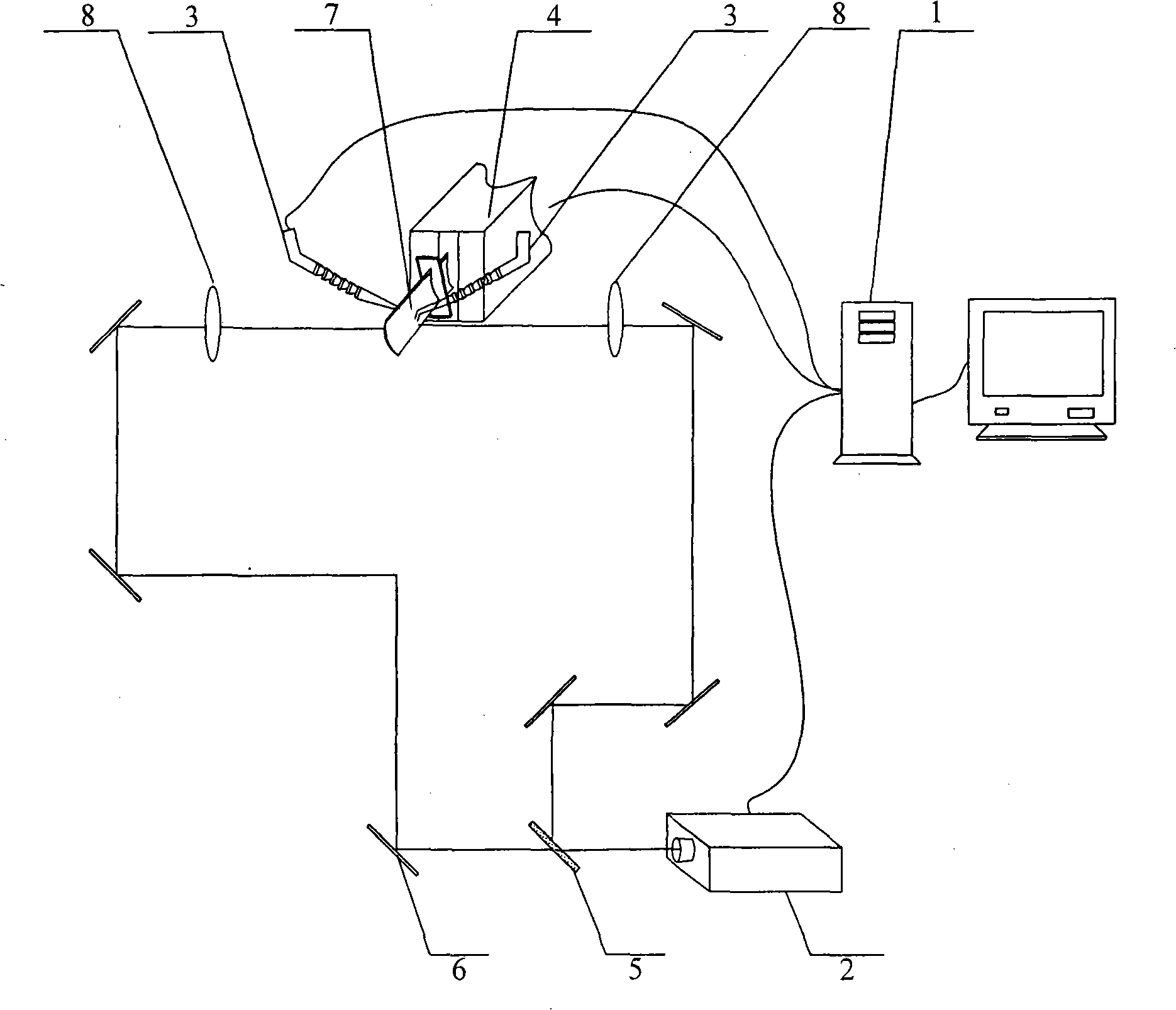

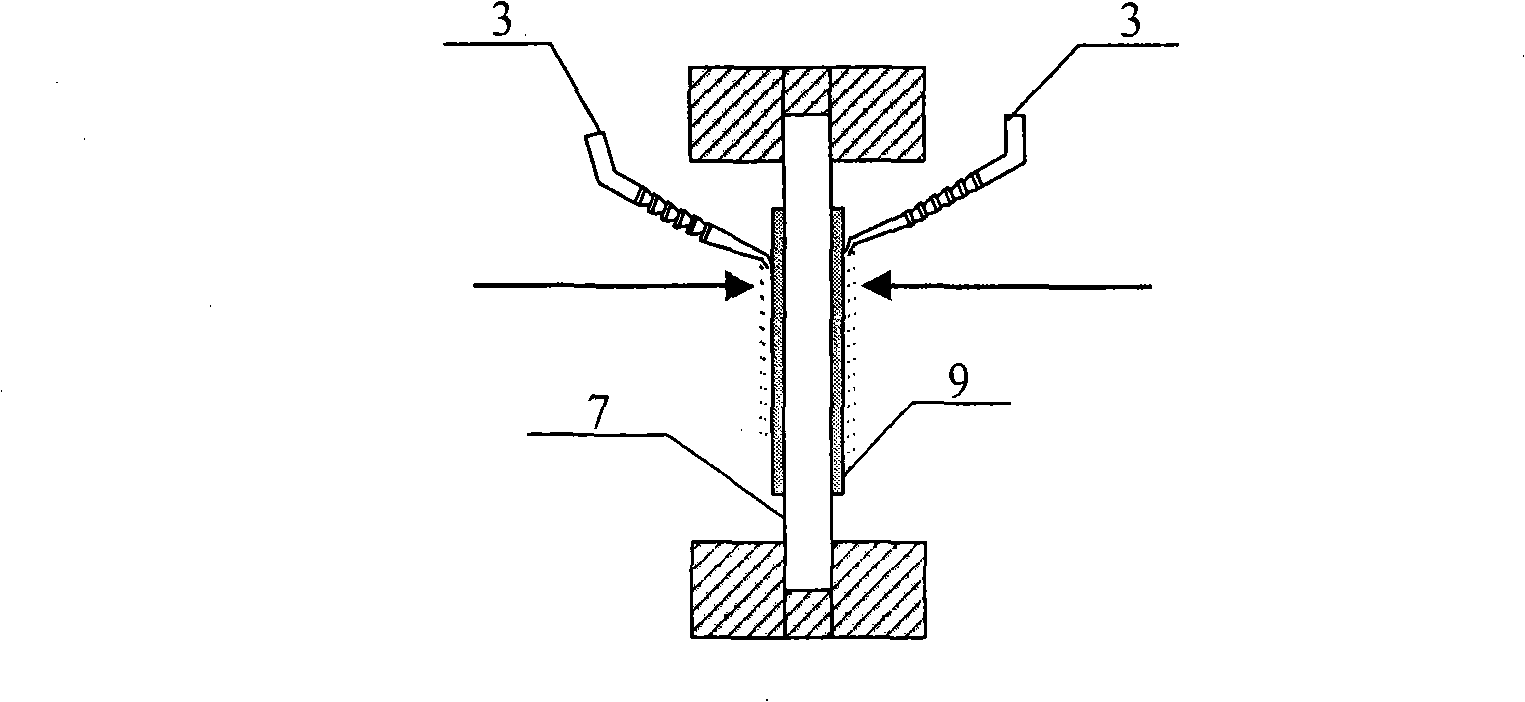

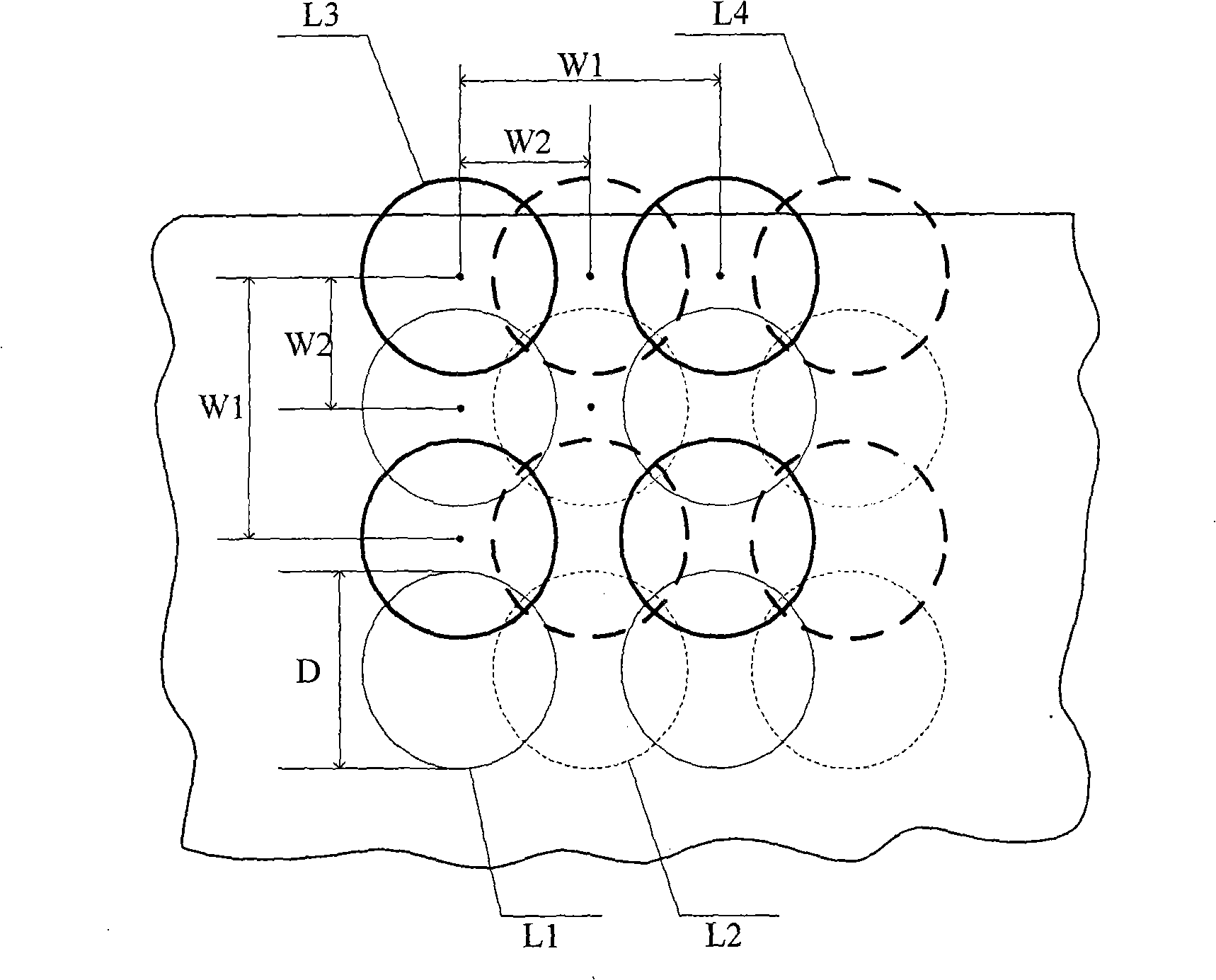

Superimposing method of circular light spot laser shock strengthening tracks

InactiveCN101537534AAvoid damageAchieve shock effectLaser beam welding apparatusLight spotSuperimposition

The invention discloses a superimposing method of circular light spot laser shock strengthening tracks, a double-sided impact laser strengthening system is used, an absorption protective layer of a shock piece is made of a non-transparent adhesive tape with colloid on one side or a metallic film, and water is adopted as a restraint layer of the shock piece; the superimposing rate of a shock light spot diameter is determined to be x%, the light spot diameter is D, and four shocks are performed; and the centers of adjacent light spots in each shock are at intervals of 2D(1-X%), the null points of two adjacent shocks are at intervals of D*(1-X%), and whether films need pasting again in each shock is determined according to the characteristics of the used protective layer material. The method avoids damage to the shock piece surface due to film fracture, and achieves the shock effect of light spot superimposition.

Owner:西安天瑞达光电技术股份有限公司

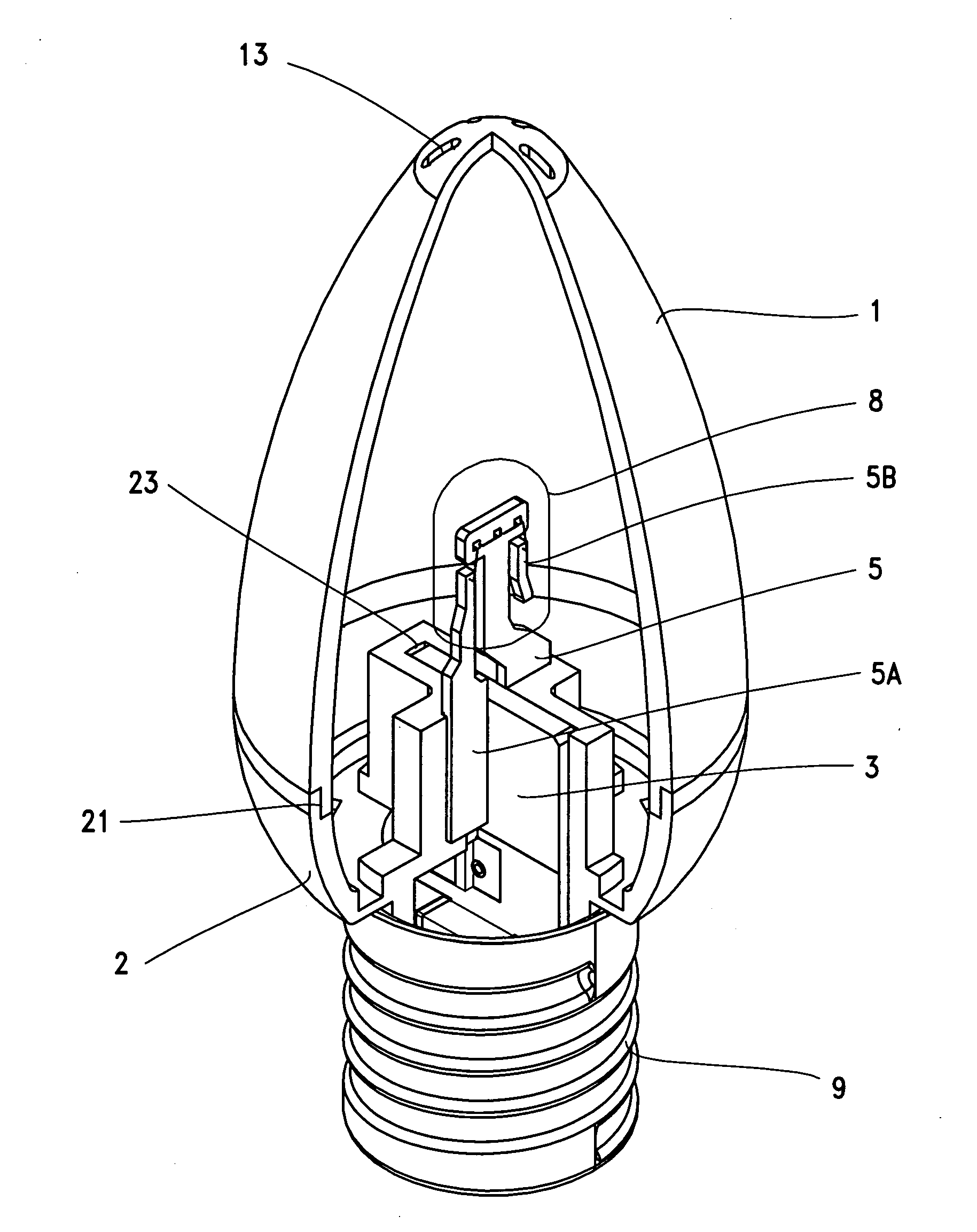

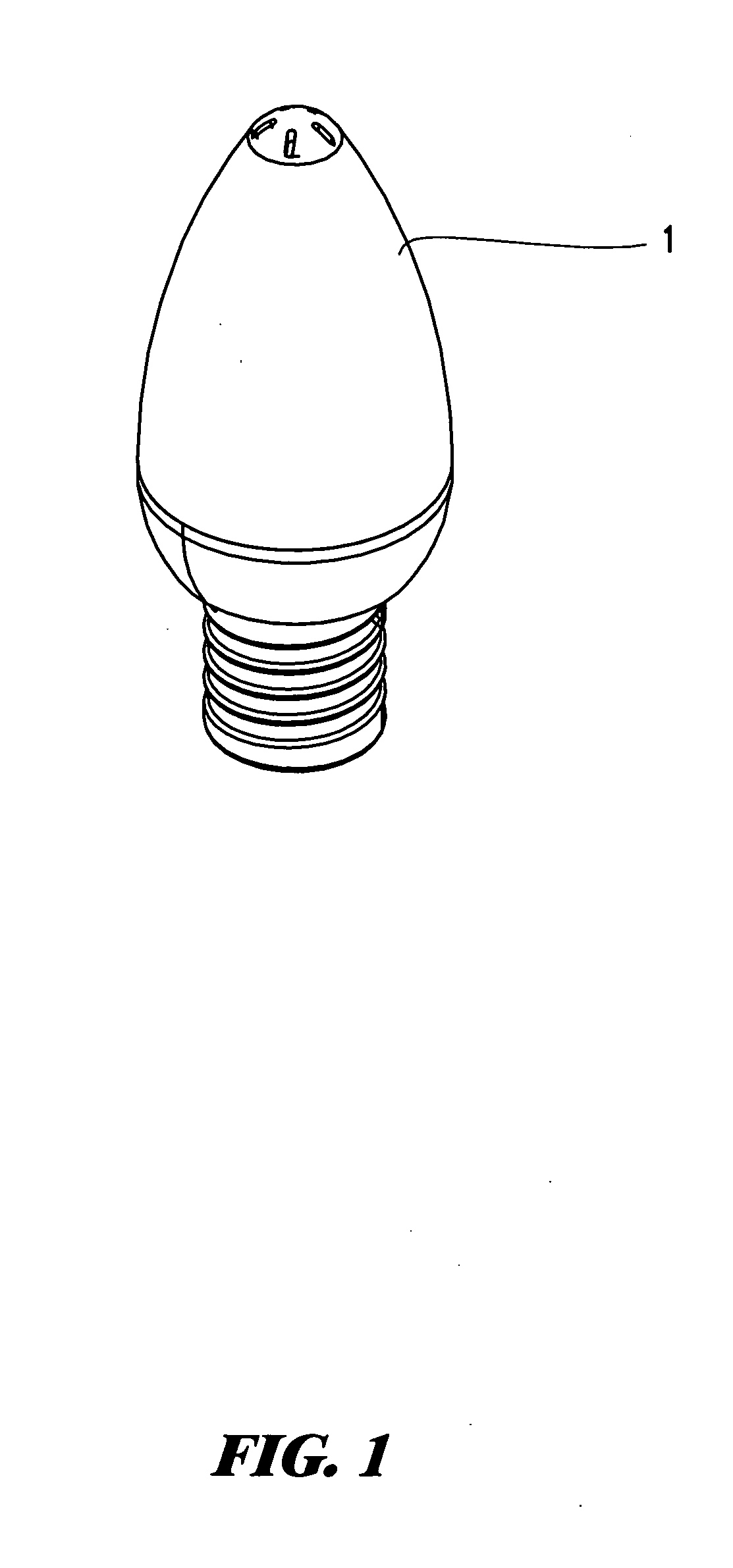

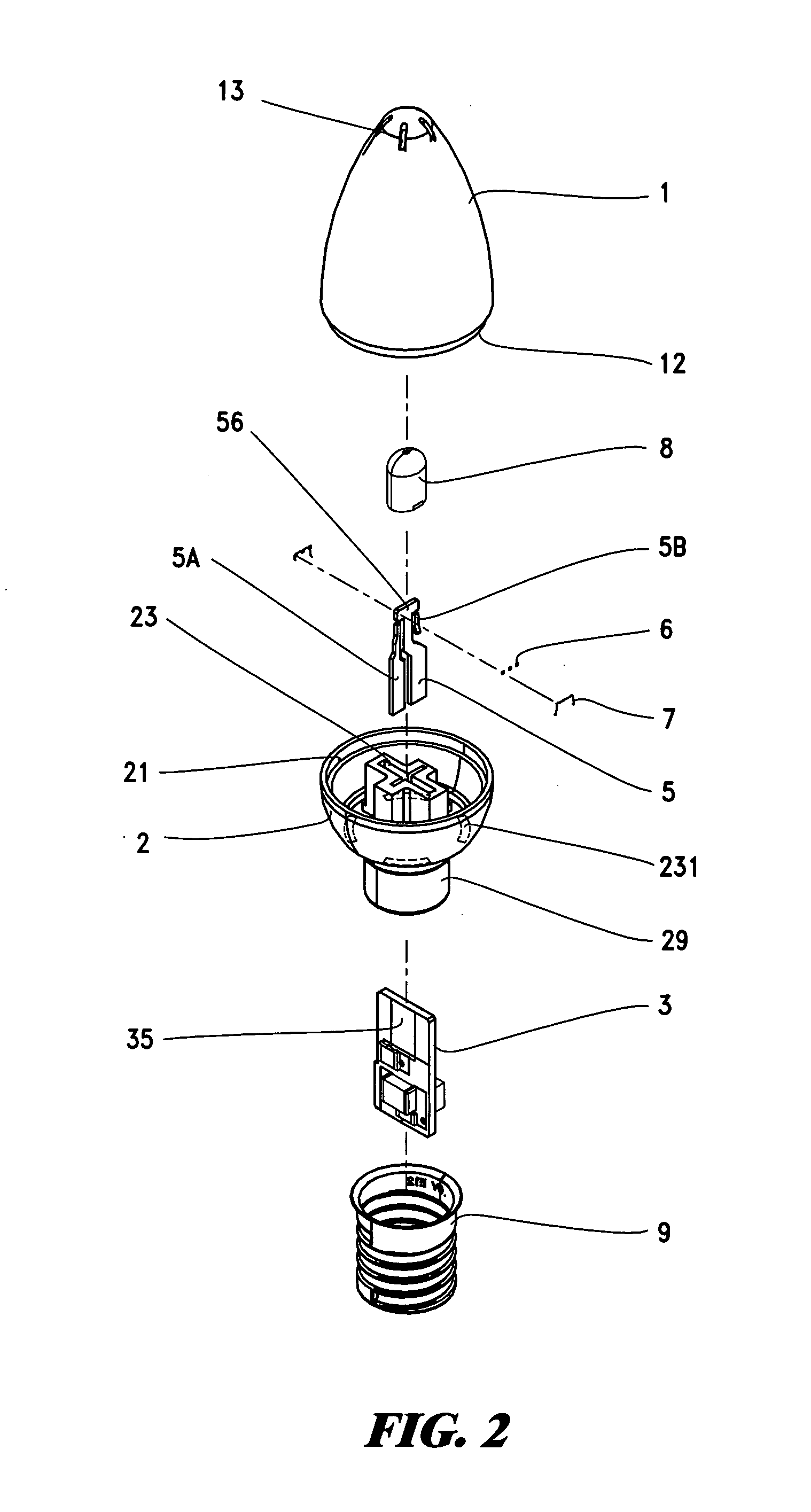

LED bracket weld-free plug-in lamp

InactiveUS20110141748A1Prevent quality of chipExtended service lifeNon-electric lightingPoint-like light sourceEngineeringCopper

The present invention relates to a LED bracket weld-free plug-in lamp, comprising the lamp cover, lamp seat, circuit board, two conducting brackets, chips, conducting wires, transparent adhesive tapes and copper heads, wherein a cross ring groove is provided at the center of the lamp seat for embedding and fastening of the circuit board so that the two conducting brackets are pressed in and inserted and the positive and negative plates on the two sides of the circuit board press tightly into one to stabilize the conducting effect, prevent the quality of chips from being undermined due to traditional direct solder fusion and significantly extend the service life of the LED chips.

Owner:LEE HAN MING

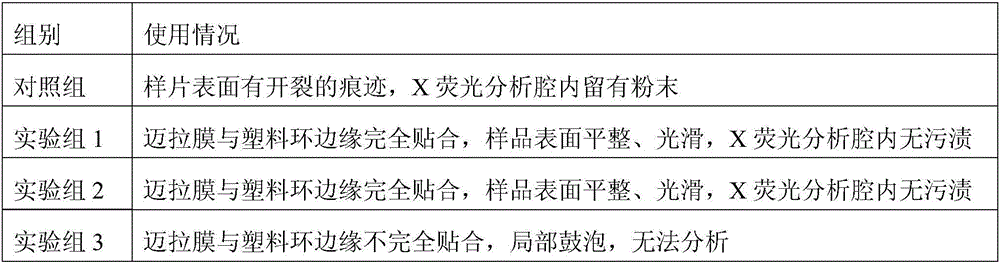

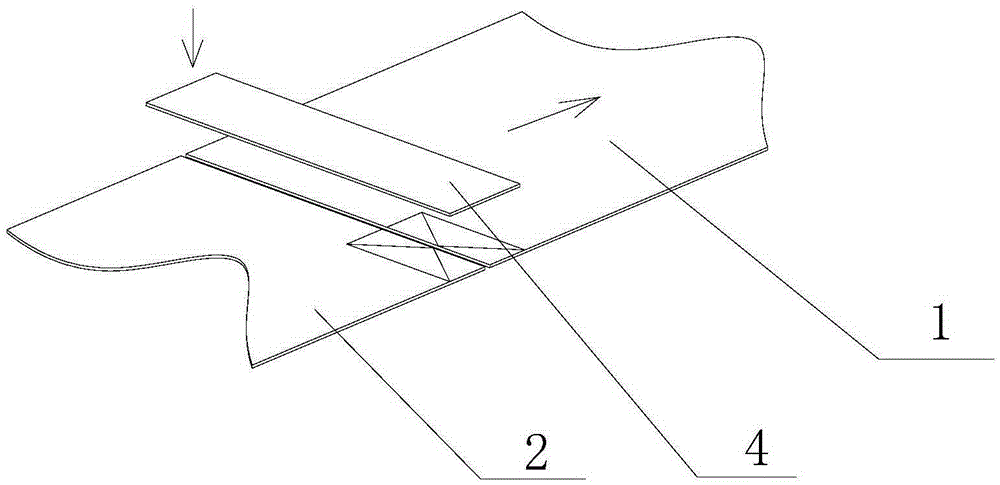

Powder sampling method for X-fluorescence analysis

ActiveCN106501047AQuality improvementEasy to useMaterial analysis using wave/particle radiationPreparing sample for investigationFluorescenceX-ray

The invention relates to the technical field of chemical analysis, and in particular to a powder sampling method for X-fluorescence analysis. The powder sampling method comprises the following steps: (1) covering a working tray with an XRF Mayra film, placing a plastic ring on the XRF Mayra film, and enabling the working tray to hold the plastic ring completely; (2) adding a powder sample into the plastic ring, flattening, and compacting to enable powder to be parallel to the opening of the plastic ring so as to obtain a product to be manufactured; and (3) pressing the product to be manufactured on a sample pressing machine, molding, removing the working tray, and tightly sealing one side directly contacting air, of a sample piece, by using a transparent adhesive tape, thereby obtaining a finished product. The powder sampling method provided by the invention is simple, convenient and rapid to operate, the prepared sample piece is good in quality and use effect, surface flatness and smoothness can be stilled maintained under X-ray radiation and an environment approximate to vacuum environments, and cracking can be avoided in the actual analysis process, so that an analysis cavity can be prevented from being polluted, light splitting crystal can be prevented from corrosion in analysis, and the sample analysis accuracy and the X-fluorescence use security can be greatly improved.

Owner:TONGLING NON FERROUS METAL GROUP CORP

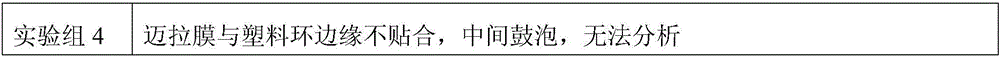

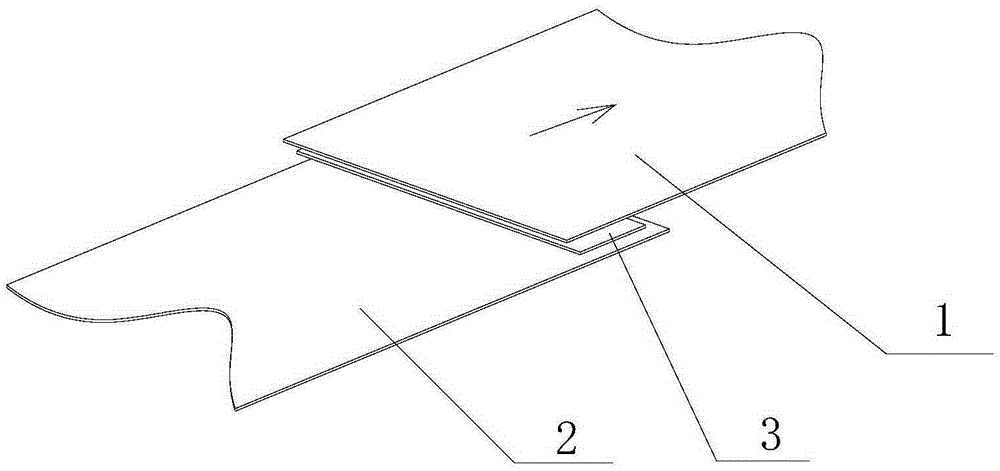

Positioning splicing method and device for sheets with patterns

ActiveCN105417242AThe principle is simpleGood stitchingArticle deliveryWebs handlingPulp and paper industryRejection rate

The invention discloses a positioning splicing method and device for sheets with patterns. The method comprises the following steps: firstly, positioning a standby material and a used material to enable the patterns of the standby material and the used material to be aligned, then, cutting off the standby material and the used material respectively to form aligned cutting openings, and connecting the materials at the cutting openings through sticking a transparent adhesive tape. The device comprises an unreeling mechanism, a lower clamping mechanism, an upper clamping mechanism, a shearing fixing mechanism, a waste separation mechanism, a left pattern positioning standard-board and a right pattern positioning standard-board, wherein the upper clamping mechanism, the shearing fixing mechanism and the lower clamping mechanism are sequentially distributed between the unreeling mechanism and the waste separation mechanism; the left pattern positioning standard-boar and the right pattern positioning standard-boar are respectively arranged on the left side and the right side of the waste separation mechanism. The process method disclosed by the invention is simple in principle, good in splicing effect, particularly suitable for the positioning splicing process of the sheets with the patterns, low in rejection rate, and suitable for high-speed high-yield production of products, better meets market demands and the device can realize seamless positioning non-waste splicing of the sheets with the patterns.

Owner:GUANGZHOU XINGSHI EQUIPS

Fluorescent glass and preparation method and application thereof

The invention provides fluorescent glass and a preparation method and application thereof. Fluorescent powder is spherical non-aggregated fluorescent powder, so that higher optical performance is achieved, high-speed stirring is performed by only using a stirrer in the preparation process of the fluorescent glass, the stirring mixing time is short, the efficiency is high, treatment such as sieving, planar grinding, polishing and the like is not required, a processing technic is easier, the cost is lower, and the obtained fluorescent glass has higher light transmittance and high airtightness; and when the obtained fluorescent glass is applied to encapsulation of an LED (Light-Emitting Diode) chip, glass micro powder with higher airtightness, light transmittance and anti-ageing performance than silica gel or a transparent adhesive tape is coated on the chip, and the fluorescent glass is arranged on a glass micro powder layer on the chip with a dispensing method, so that the encapsulating operation is easier and more convenient, the airtightness and light transmittance is more excellent, and the radiating performance is high. The fluorescent glass is particularly suitable for encapsulating ultraviolet LEDs.

Owner:厦门市华海光电科技有限公司

Sampling method for non-damage fixed position observation of plant stomata in field experiment

InactiveCN101556215ANo damageWithdrawing sample devicesMaterial analysis by optical meansDiseasePlant Stomata

The invention discloses a sampling method for non-damage fixed position observation of plant stomata in a field experiment, which comprises the following steps of: according to experimental design, selecting functional leaves, avoiding overripe leaves, over tender leaves, leaves damaged by diseases and insects and malformed leaves, and cleaning object leaves; evenly coating a thin layer of nail polish at a position to be observed, and natural drying or blowing to be nearly dry by using a washing ear ball; flatly and tightly pasting a transparent adhesive tape on a clean glass slide, using a dissecting needle or a clean blade for slowly guiding to prevent air bubbles, and tightly pasting the adhesive tape with the width being at least 2mm around the nail polish on the glass slide; and numbering, clean packaging, and taking back to the laboratory for microscopic observation and measurement. The method has the advantages of being capable of bulk sampling in field living leaves, having no damage to the leaves, fixed position recording stomatal conditions, observing daily change of the stomata of the leaves under different processing conditions, and the like, and can be used for the research and practice in the fields such as bioecology, plant physiology, plant germplasm resource, plant thremmatology, cultivation science, etc.

Owner:NORTHWEST A & F UNIV

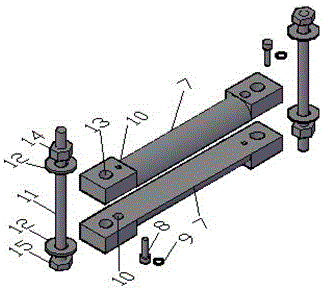

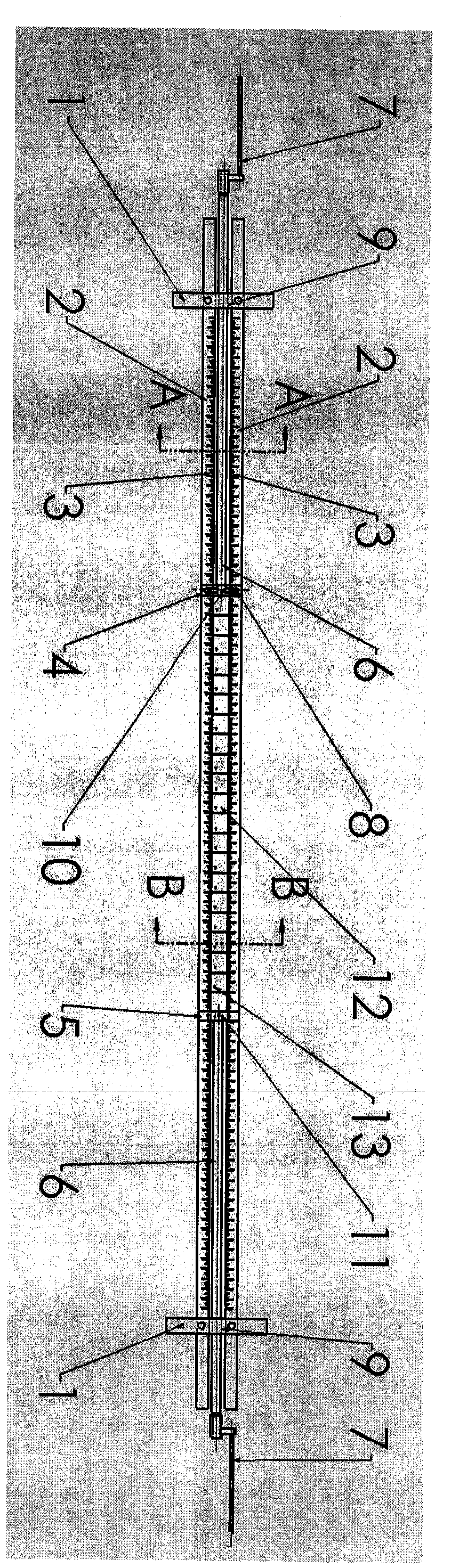

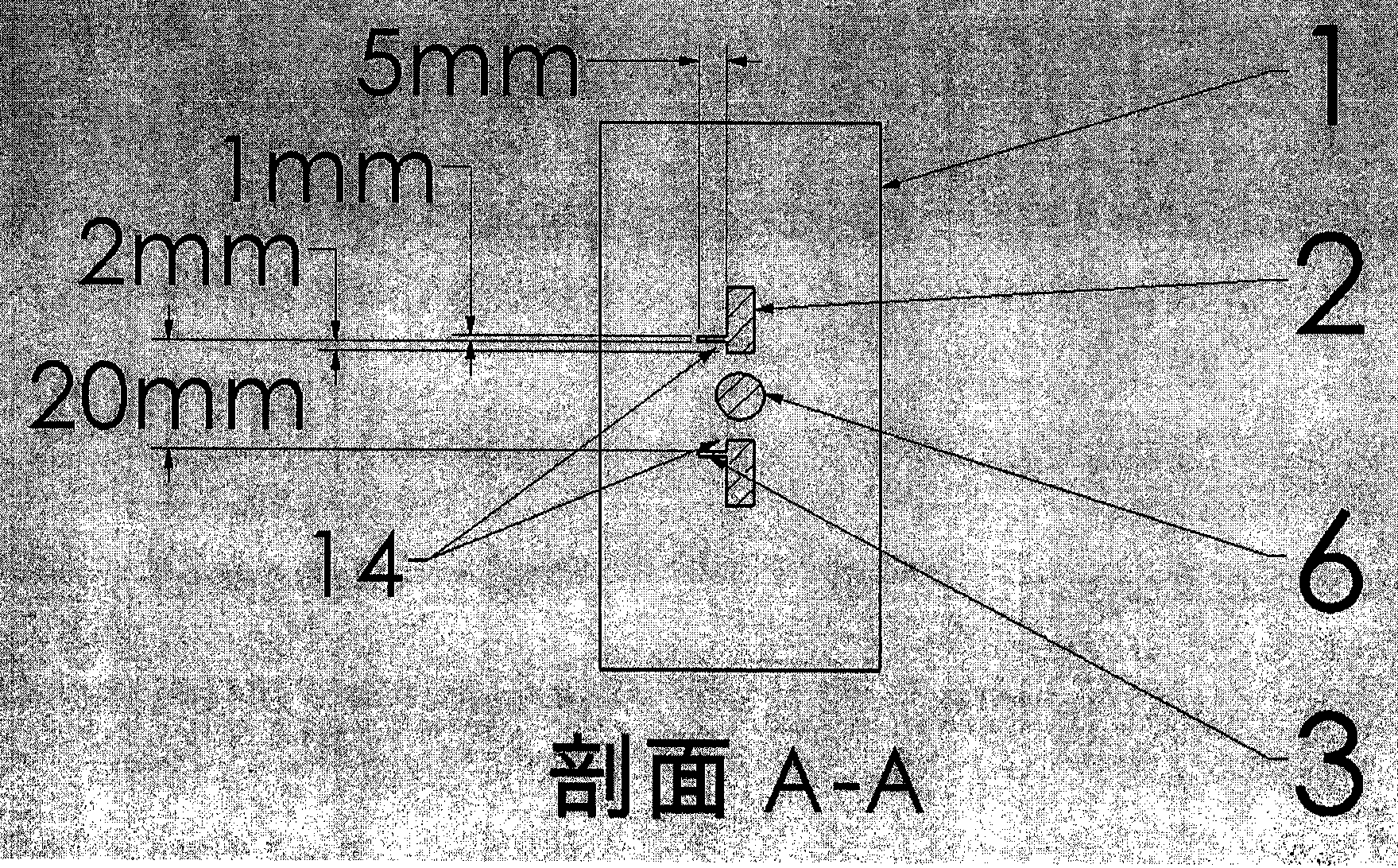

Method and auxiliary device for pasting strain gages on circular bar and strain gage placing template

ActiveCN103673974ARealize one-time pastingAvoid pollutionMeasurement devicesAdhesive beltEngineering

The invention relates to a method and auxiliary device for pasting strain gages on a circular bar and a strain gage placing template. The method includes the steps that firstly, a plurality of strain gages are fixed to transparent adhesive tape at intervals in a parallel mode; then, the transparent adhesive tape is straightened and flat placed on a sample abutting block provided with a sample groove, the first strain gage to be pasted is controlled to be aligned with the sample groove and is coated with a binding agent, the sample abutting block is made to abut upon the sample afterwards, the other strain gages are coated with binding agents after the first strain gage is firmly pasted, the sample abutting block is made to slightly descend by pulling the other end of the adhesive tape, the sample is rotated so that the cylindrical surface of the sample can be wrapped by the adhesive tape, and then the strain gages can be pasted. By adopting the strain gage pasting auxiliary device and the strain gage placing template to paste the strain gages on the circular bar, pasting flatness is improved, the interval parallelism and uniformity of the strain gages are guaranteed, and the multiple strain gages can be pasted at one time.

Owner:西北稀有金属材料研究院宁夏有限公司

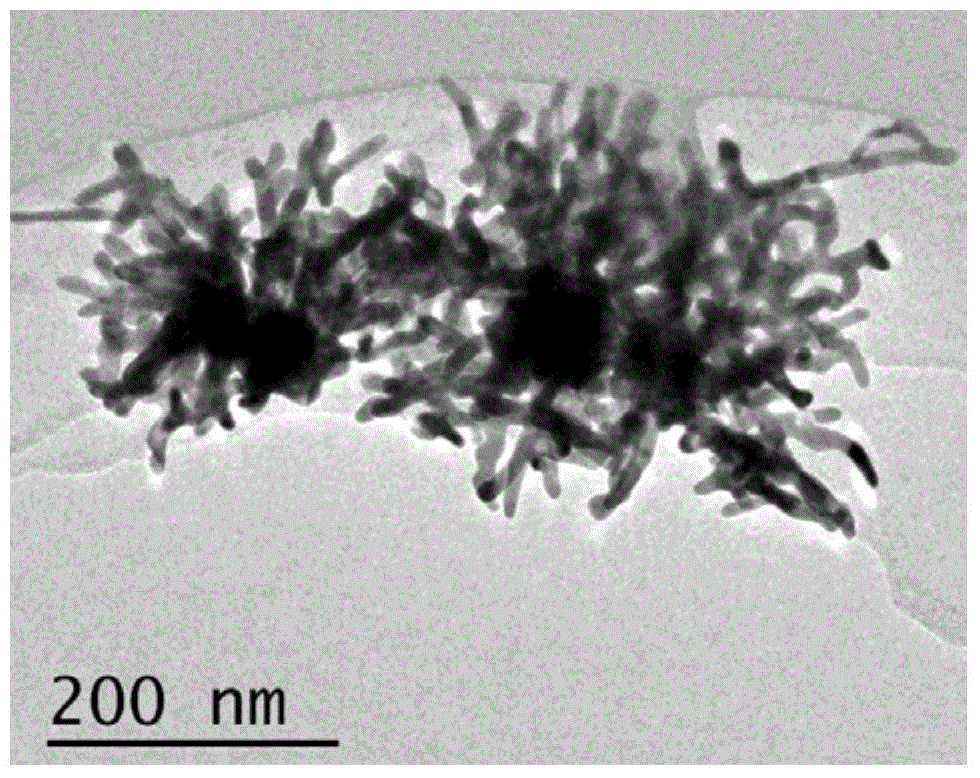

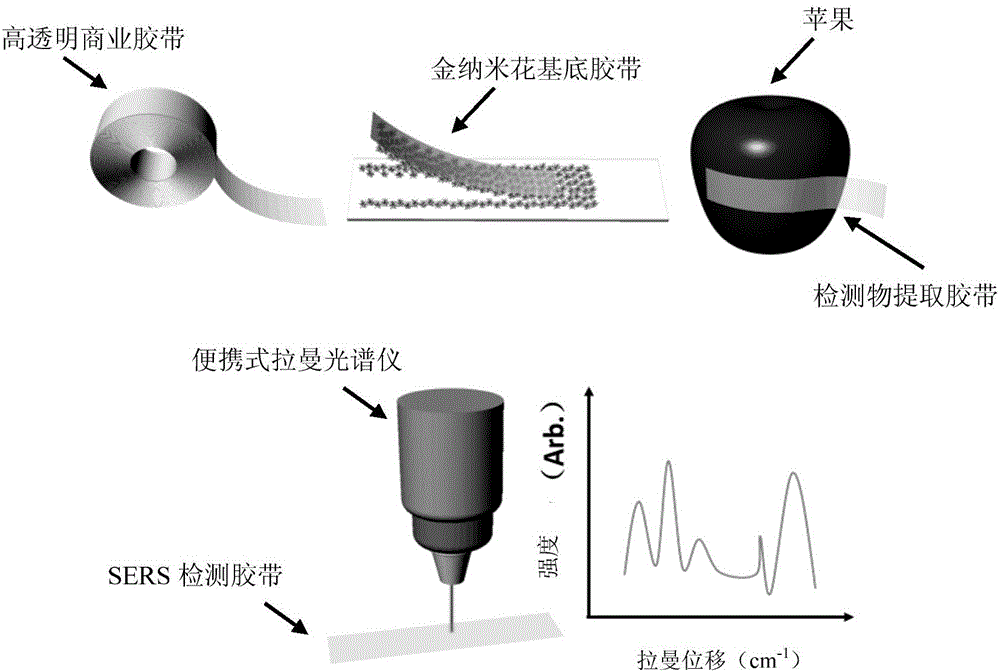

Surface reinforced Raman scattering detection adhesive tape and preparation method and application thereof

ActiveCN106153594ASimple structureEasy to manufactureFilm/foil adhesivesRaman scatteringRaman scatteringChemistry

The invention discloses surface reinforced Raman scattering detection adhesive tape. The surface reinforced Raman scattering detection adhesive tape comprises a gold nano substrate adhesive tape and detection object extraction adhesive tape. The gold nano substrate adhesive tape comprises first adhesive tape, and gold nano particles with Raman activity are attached to a selected area of the gold nano substrate adhesive tape. The detection object extraction adhesive tape comprises second adhesive tape, and is provided with a selected area to which to-be-detected matter is attached. The selected area of the first adhesive tape and the selected area of the second adhesive tape can be attached, bonded and fixed to each other. Commercialized transparent adhesive tape is adopted as the first adhesive tape or the second adhesive tape. The invention further discloses a preparation method and application of the surface reinforced Raman scattering detection adhesive tape. The surface reinforced Raman scattering detection adhesive tape is simple in structure, easy to prepare, low in cost, easy and fast to operate during use and precise in detection result.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Transparent adhesive tape

A construction is presented for a unilaterally bondable, high-transparency, substantially two-dimensional element (2D element) having a support and an adhesive, which is used as a shatterproofing device for brittle 2D bodies.

Owner:TESA SE

Sand aerated concrete panel with pre-embedded cable box and cable pipe and preparation method thereof

ActiveCN107859232AGuaranteed structural performanceImprove integrityConstruction materialCeramic shaping apparatusSocial benefitsPolystyrene

The invention discloses a sand aerated concrete panel with a pre-embedded cable box and cable pipe and a preparation method thereof. The sand aerated concrete panel comprises a sand aerated concrete panel body, a steel bar mesh cage, a cable box and a cable pipe. The steel bar mesh cage comprises a plurality of longitudinal main steel bars, a plurality of lateral auxiliary steel bars, and multipleconnection iron parts. The cable box and the cable pipe are fixed on the steel bar mesh cage, wherein the inside of the cable box and the end portion of the cable pipe are sealed by transparent adhesive tape after being jammed with polystyrene boards, and the steel bar mesh cage and the cable box and the cable pipe are poured in the sand aerated concrete panel body. Compared with a grooving modeadopting cutting machines or drilling machines used in the present construction site, the sand aerated concrete panel with the pre-embedded cable box and cable pipe solves the problems that in the prior art, processes are tedious, cost is high, and dust and noise pollute the environment; the potential quality hazard of the structure of panels and walls caused by on-the-spot slotting is avoided, labor force is reduced greatly, labor intensity and labor cost are reduced, and economic benefits and social benefits are prominent.

Owner:SHAANXI NITYA NEW MATERIALS TECH CO LTD

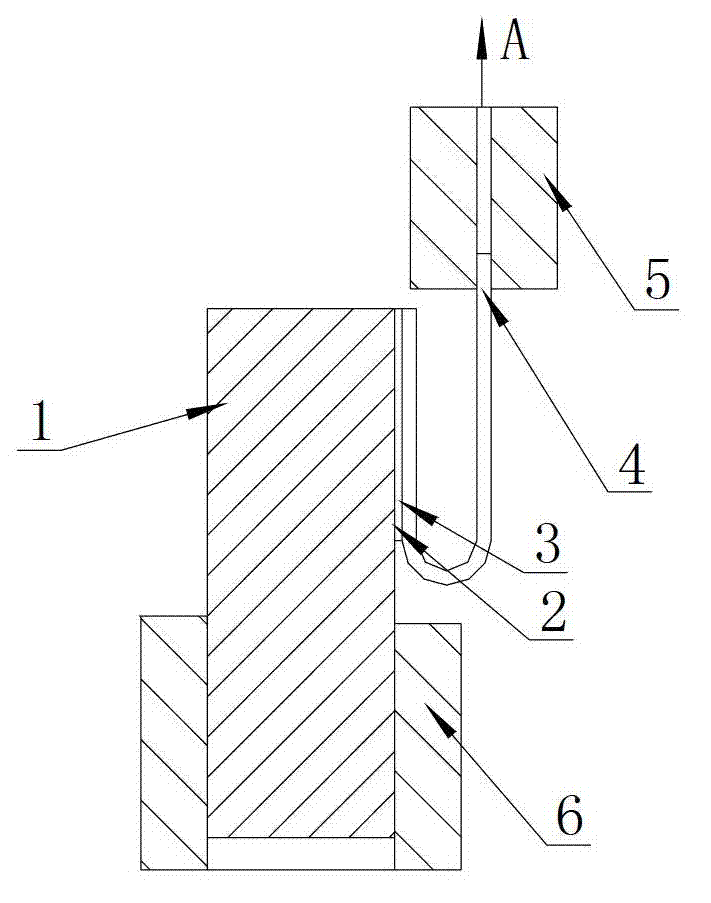

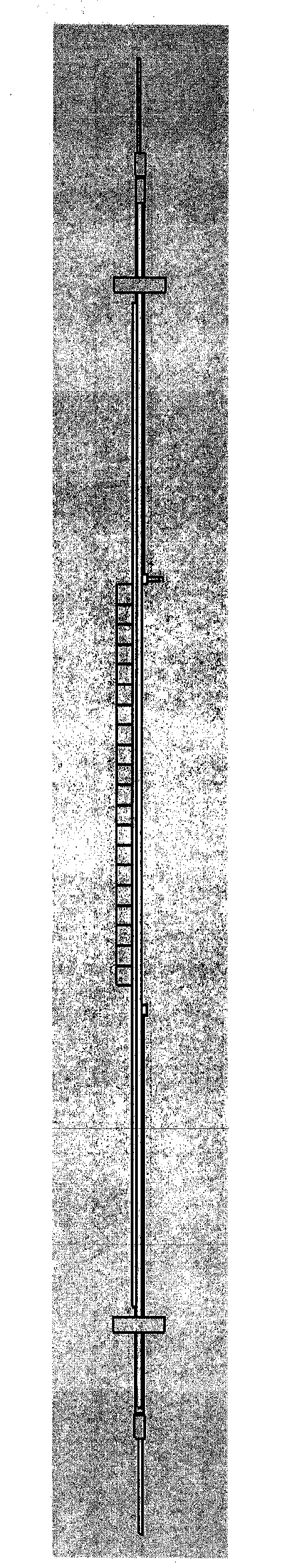

Simple ocean sediment sample separating device for paleomagnetism research

InactiveCN104236975ALocation pinpointingWon't fall offPreparing sample for investigationPaleomagnetismOcean sea

A simple ocean sediment sample separating device for paleomagnetism research comprises support end plates (1), steel plates (2) with scales, blades, sliders (4 and 5), screw rods (6) and shaking handles (7), wherein the blades are mounted on the steel plates (2), a transparent adhesive tape support (8) is mounted on the slider (4), a thread counterbore is formed in the middle of the slider (4) and matched with one screw rod (6), a thread counterbore (11) is formed in the middle of the slider (5) and matched with the other screw rod (6), threaded through holes are formed in the middle of the support end plates (1) and matched with the screw rods (6), the shaking handles (7) are connected with the screw rods (6) through inside hexagonal bolts, any number of sample boxes (12) with openings on one surface can be clamped between two sliders, all that is required is to make the opening surfaces of the sample boxes to face downward and press the sample boxes into ocean sediments by uniform force for one time during sampling, and the sampling can be completed.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Fully automatic hot fix rhinestone layout machine and hot fix rhinestone layout method

InactiveCN102687919ARealize fully automatic operationSave labor resourcesGarmentsPattern printingPaper tapeEngineering

The invention discloses a fully automatic hot fix rhinestone layout machine in the technical field of garment processing equipment. The fully automatic hot fix rhinestone layout machine comprises a machine frame, wherein an uncoiling device and a material collecting device are arranged on the machine frame, at least one group of layout assemblies is sequentially arranged between the uncoiling device and the material collecting device, each layout assembly comprises a hopper and a roller, the hopper is arranged on the machine frame, the roller is rotatablely arranged on the machine frame, in addition, the bottom of the roller extends into the hopper, magnetic rhinestone absorption holes are arranged on the circumferential surface of the roller, the roller rotates and absorbs magnetic hot fix rhinestones in the hopper into the magnetic rhinestone absorbing holes in a magnetic absorption method, a hot fix tape of the uncoiling device is peeled off, a transparent adhesive tape is covered on the top surface of the roller, the hot fix rhinestones are pasted and connected onto the adhesive surfaces of the transparent adhesive tape along with the rotation of the rolling tube and the movement of the transparent adhesive tape, one kind of layout of the hot fix rhinestones is completed in such a way, the transparent adhesive tape is continuously moved to a next group of layout assemblies for carrying out the other kind of layout of the hot fix rhinestones, finally, the transparent adhesive tape glued and connected with the hot fix rhinestones is pasted with white bottom paper for completing the hot fix rhinestone layout work, the fully automatic operation is adopted in the whole process, and the production efficiency is high.

Owner:王华

Pre-stressing carbon fiber cloth reinforcement reinforced concrete column construction method

ActiveCN105888277AReduce frictionIncrease the effective prestressBuilding repairsReinforced concrete columnFiber

The invention discloses a pre-stressing carbon fiber cloth reinforcement reinforced concrete column construction method. The method comprises the steps: performing chamfering, surface polishing and hole filling treatments on a to-be-reinforced concrete column, and coating the surface of a pre-designed to-be-reinforced part with epoxy, thereby achieving a function of reducing surface friction force between carbon fiber cloth and concrete after the epoxy is solidified, and effectively transferring a pre-stressing force; meanwhile, in order to prevent the edge of the carbon fiber cloth from running before covering, adhering a transparent adhesive tape on the surface of the carbon fiber cloth; clamping the carbon fiber cloth by utilizing self-locking type anchorage clamping pieces, winding the carbon fiber cloth around the covered concrete column, and screwing a screw rod by utilizing a spanner to apply a pre-stressing force; after the pre-stressing force is up to a preset size, and re-coating the surface of the carbon fiber cloth with a layer of epoxy, thereby preventing individual fibers of the carbon fiber cloth from generating breaking and running situations, and ensuring the integral stress. The pre-stressing carbon fiber cloth reinforcement reinforced concrete column construction method has the advantages that the concept is novel, construction steps are clear, simple and practical, and a high-strength function of the carbon fiber cloth is fully exerted, so that the reinforcement effect is integrally improved, and the method is convenient to popularize and apply.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com