Transparent adhesive tape

A technology of transparent components and components, applied in adhesives, shielding, film/sheet adhesives, etc., can solve problems such as decreased transmittance, low light intensity, and reduced intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

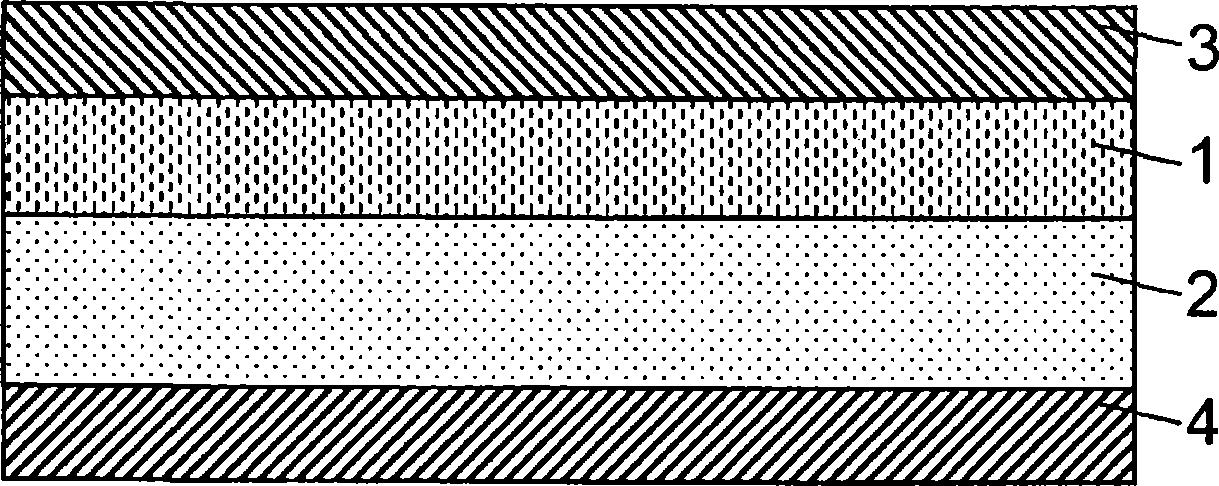

[0253] figure 1 The first structural embodiment of the 2D element shown has a carrier 1 as a second functional layer in the form of a polymer film; the adhesive coating 2 is an acrylate pressure-sensitive adhesive; the first functional layer is An adaptation layer in the form of an anti-reflection coating 3; and a temporary carrier 4 which is a siliconized anti-adhesive film. The carrier film 1 is uniformly covered over the entire area of one side thereof by the pressure-sensitive adhesive 2 . The other side of the carrier film 1 is provided with an antireflection coating 3 . The antireflection coating 3 is therefore arranged here between the carrier 1 and the surrounding medium. In order to prevent contamination and to prevent undesired adhesion to the release film, the entire area of the adhesive 2 is covered with a temporary carrier 4 .

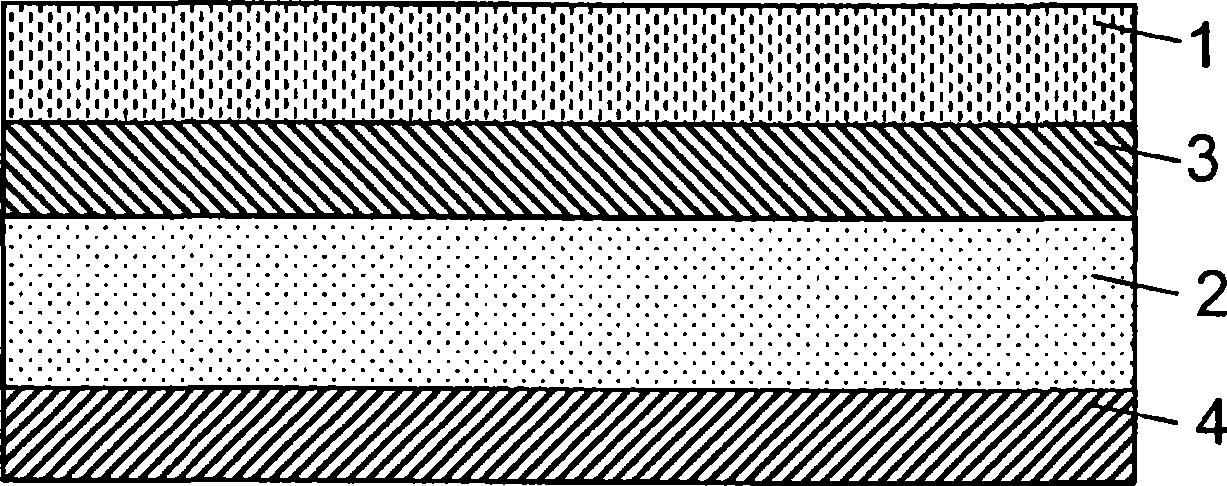

[0254] figure 2 The second structural embodiment of the 2D element shown has and figure 1 The structural embodiments shown have...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com