Patents

Literature

588 results about "Antireflection coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

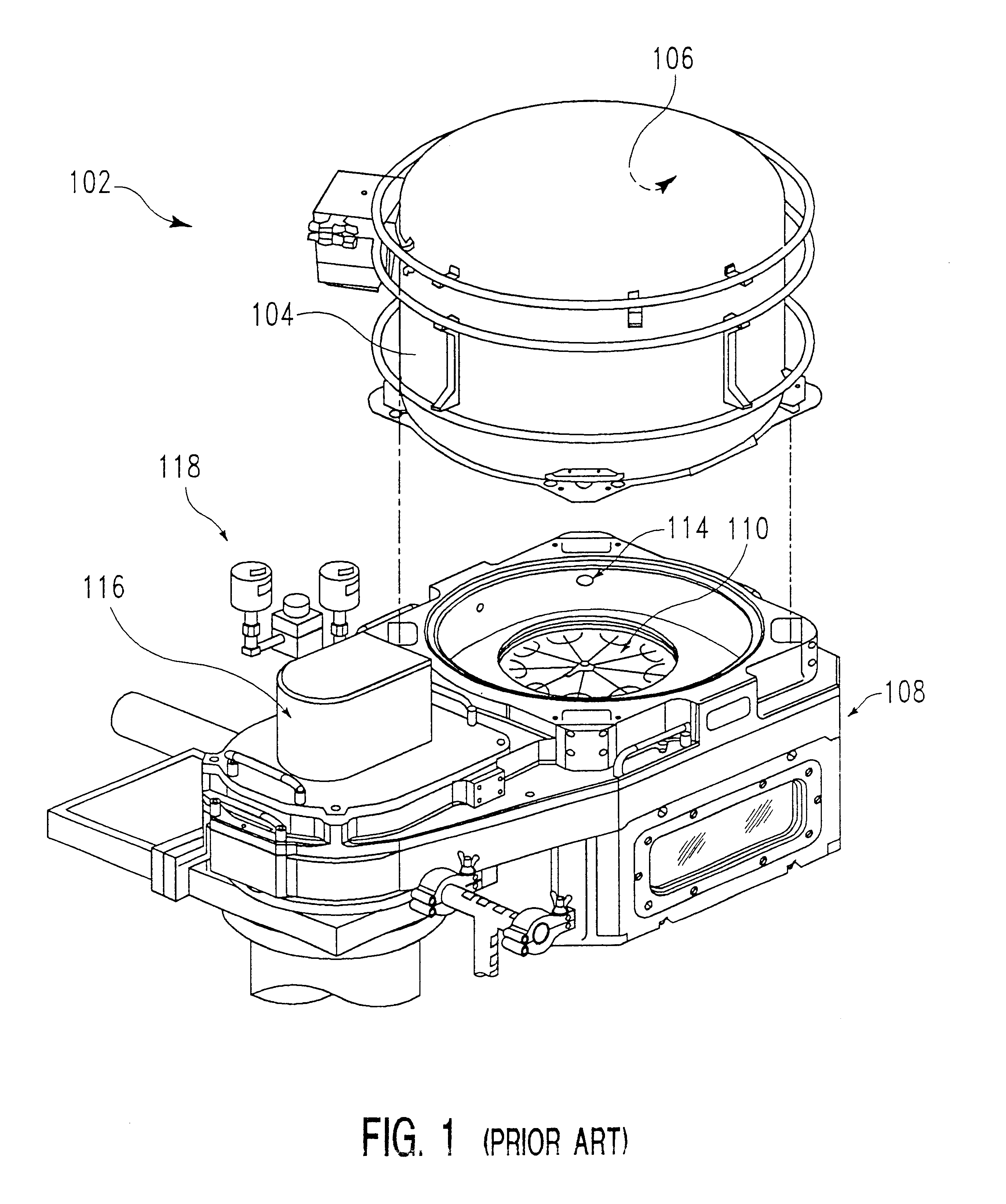

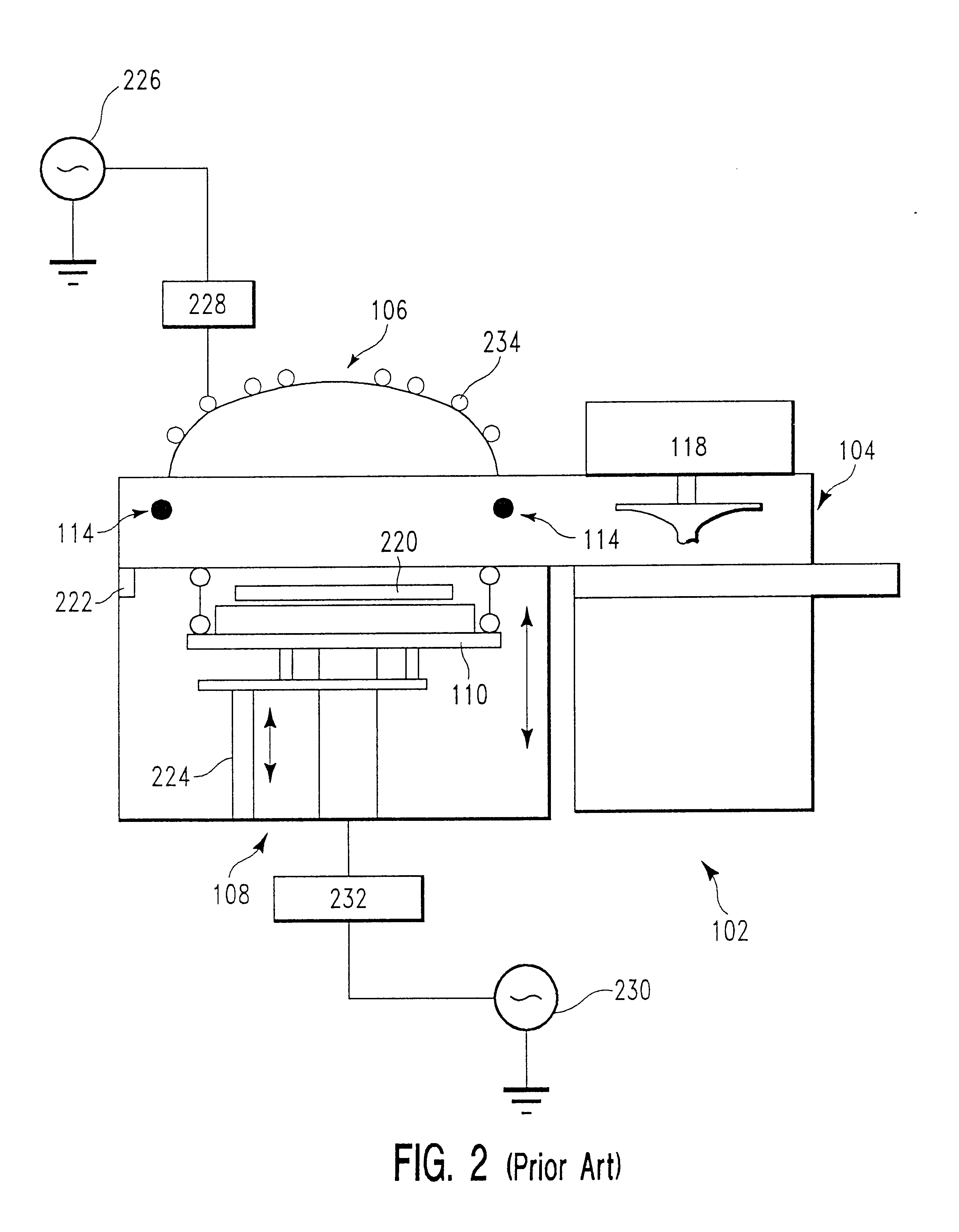

Method for etching silicon oxynitride and inorganic antireflection coatings

InactiveUS6013582ADecorative surface effectsSemiconductor/solid-state device manufacturingMetallurgyOxygen

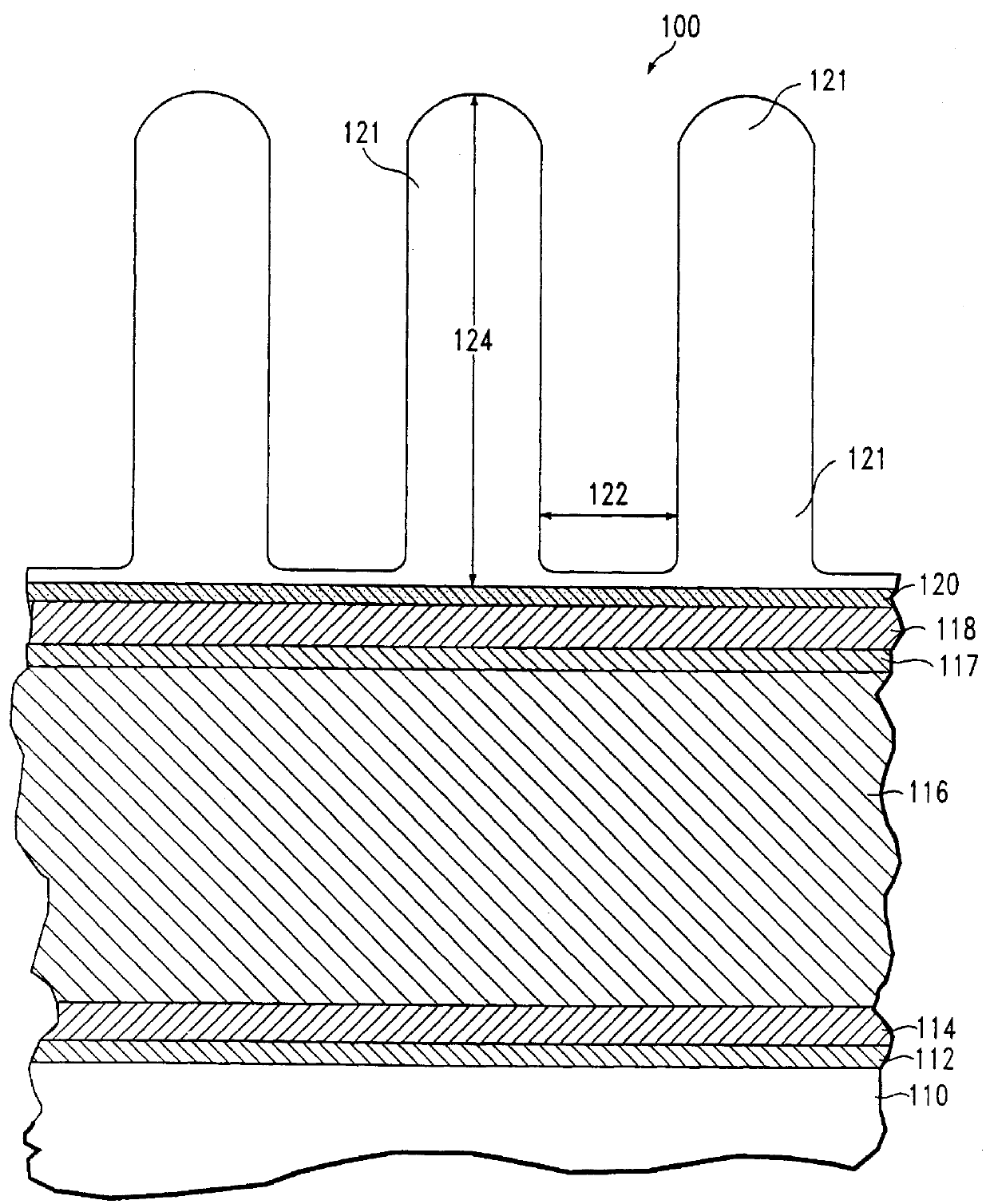

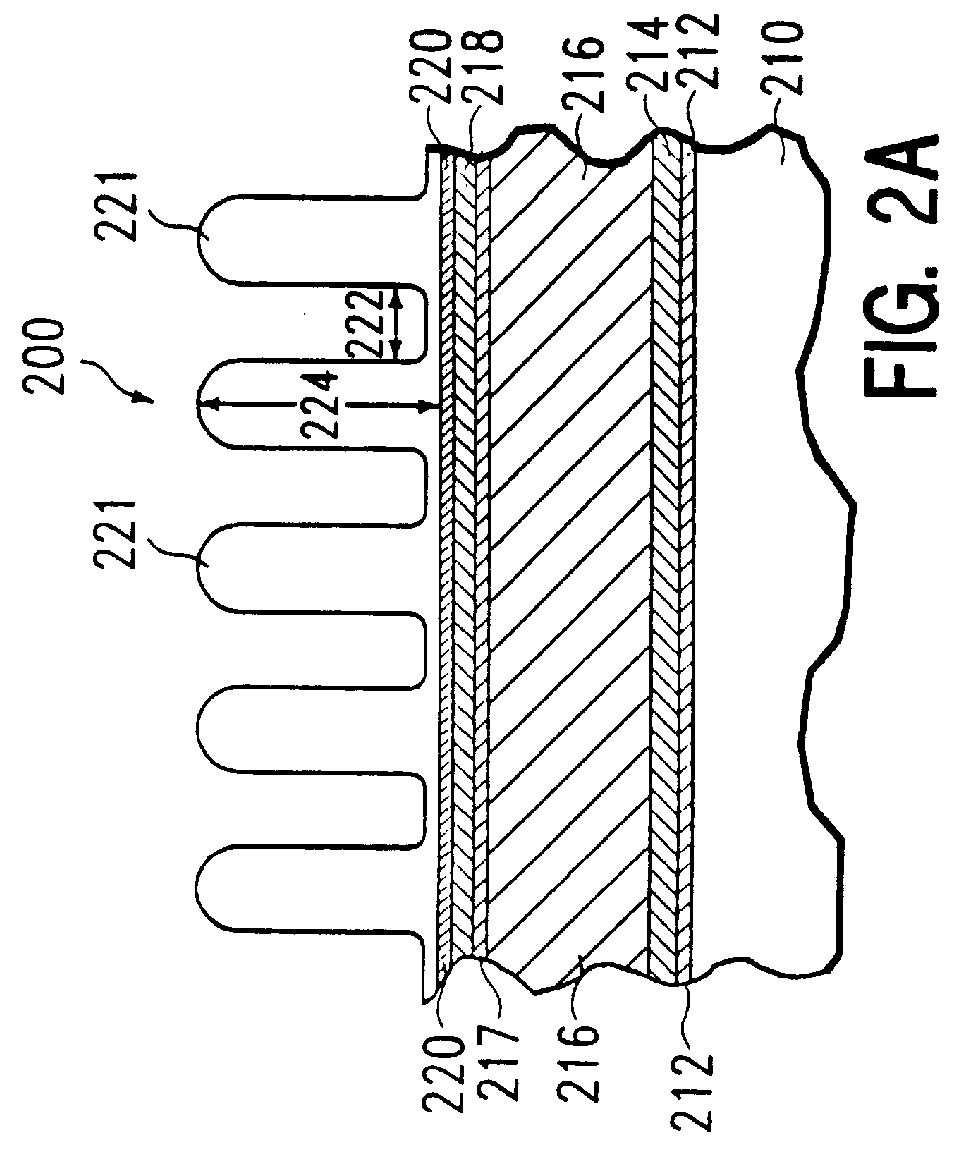

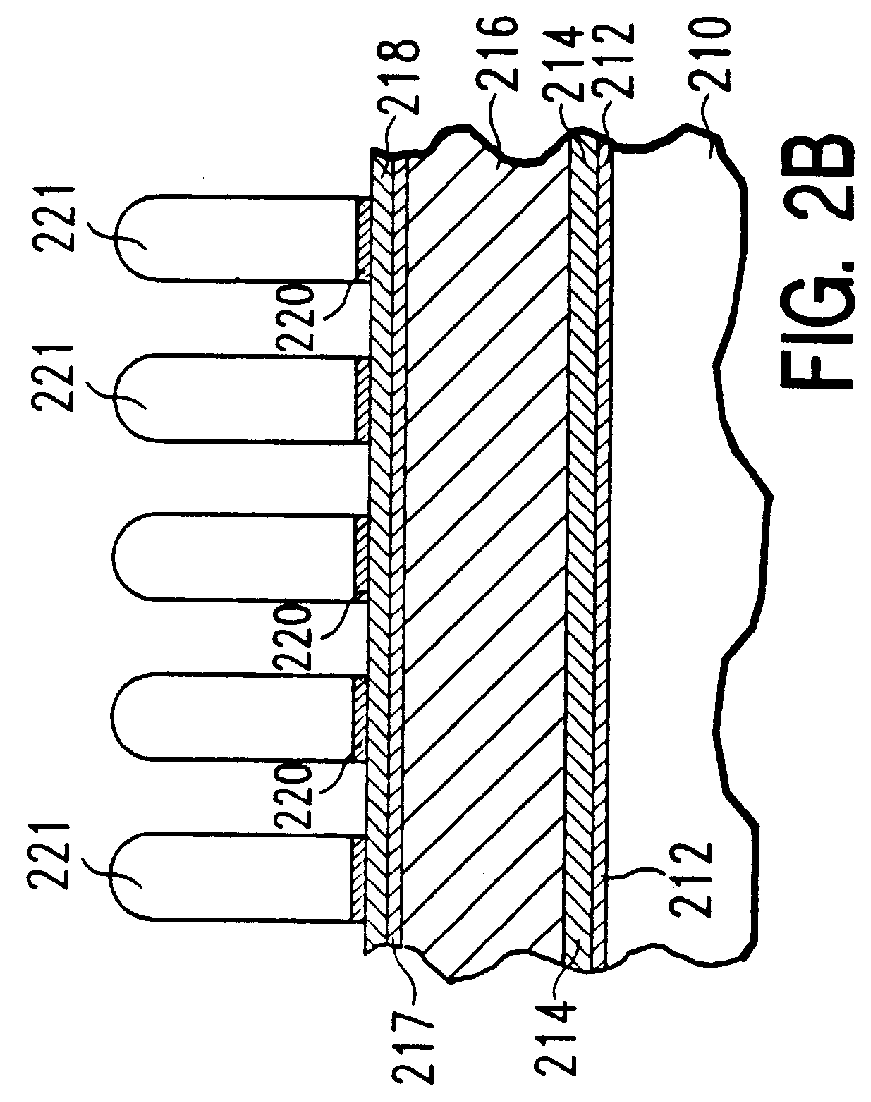

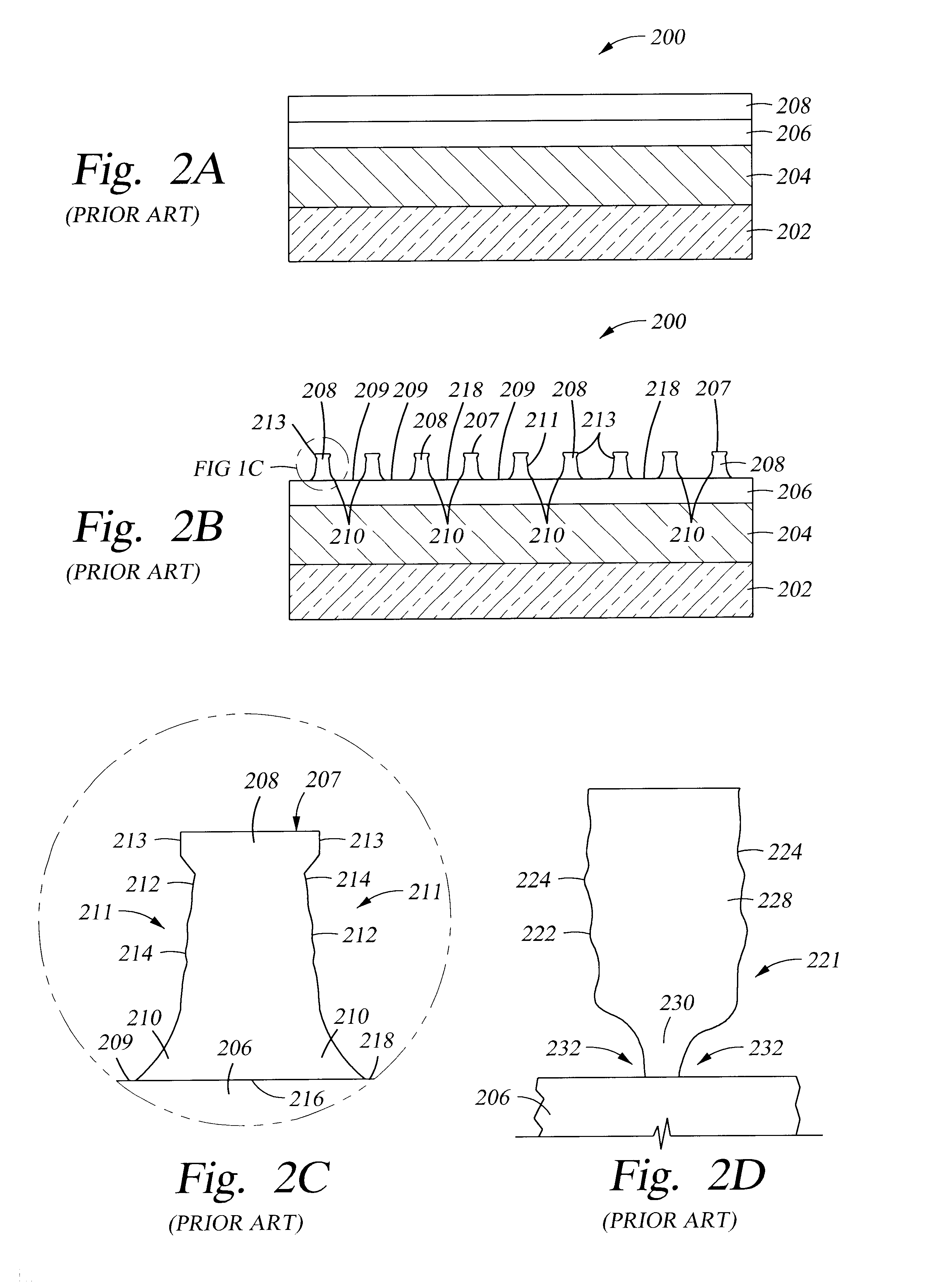

The present disclosure pertains to a method for plasma etching a semiconductor patterning stack. The patterning stack includes at least one layer comprising either a dielectric-comprising antireflective material or an oxygen-comprising material. In many instances the dielectric-comprising antireflective material will be an oxygen-comprising material, but it need not be limited to such materials. In one preferred embodiment of the method, the chemistry enables the plasma etching of both a layer of the dielectric-comprising antireflective material or oxygen-comprising material and an adjacent or underlying layer of material. In another preferred embodiment of the method, the layer of dielectric-comprising antireflective material or oxygen-comprising material is etched using one chemistry, while the adjacent or underlying layer is etched using another chemistry, but in the same process chamber. Of particular interest is silicon oxynitride, an oxygen-comprising material which functions as an antireflective material. A preferred embodiment of the method provides for the use of a source of carbon and an appropriate halogen-comprising plasma, to achieve selective etch of one oxygen-containing material compared with another material which contains a more limited amount of oxygen.

Owner:APPLIED MATERIALS INC

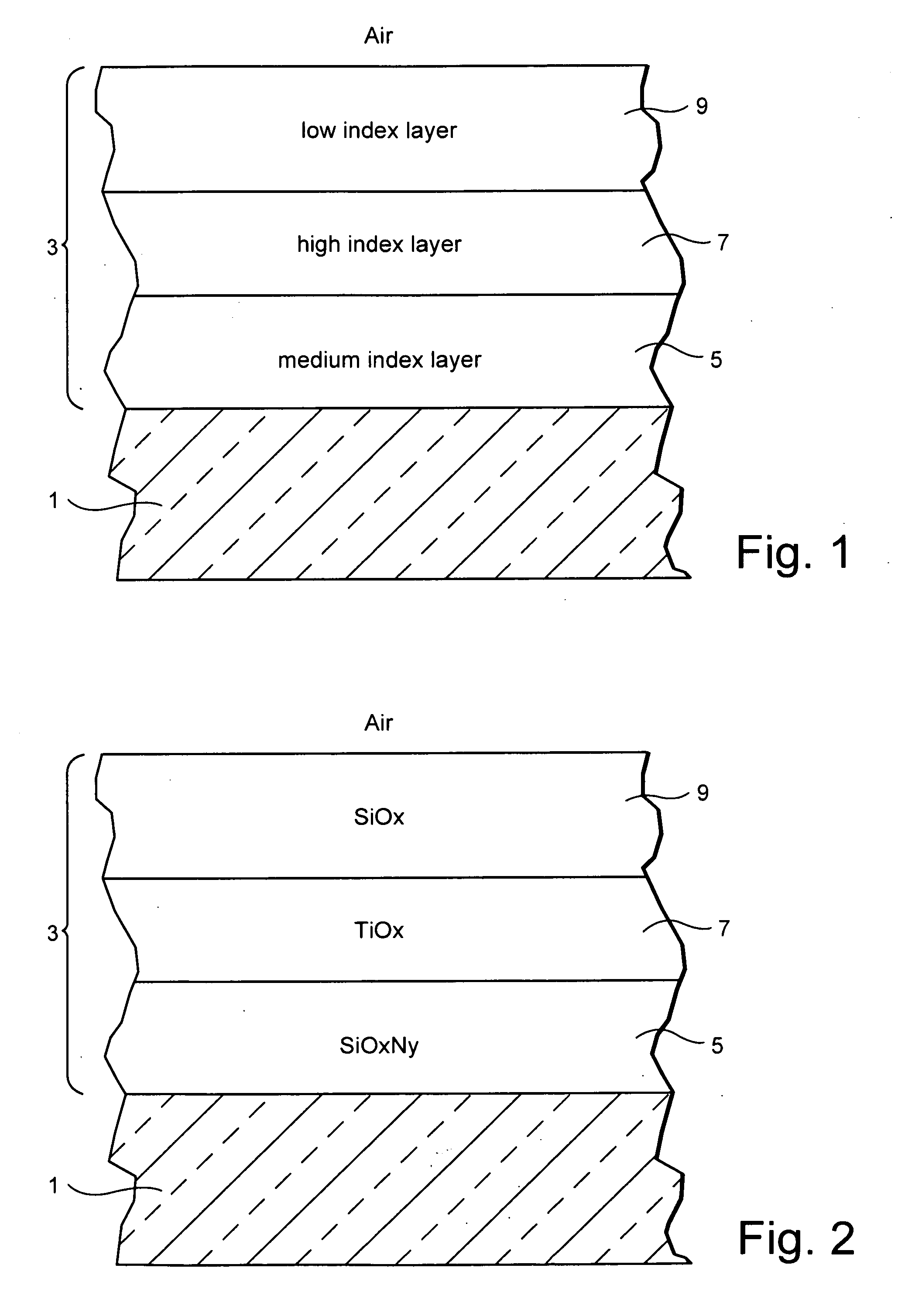

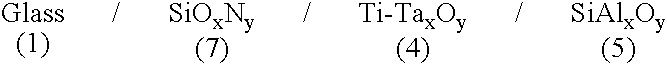

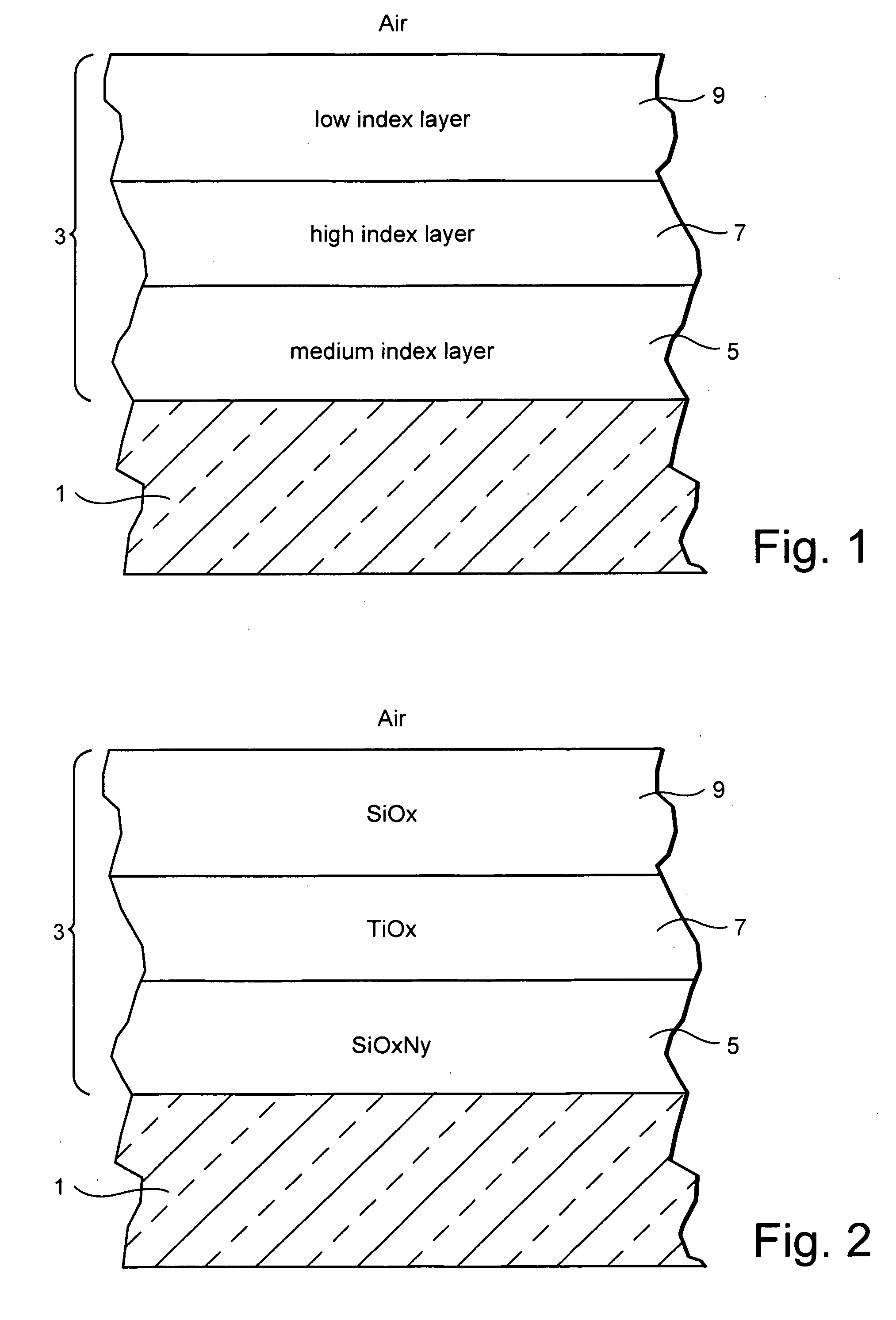

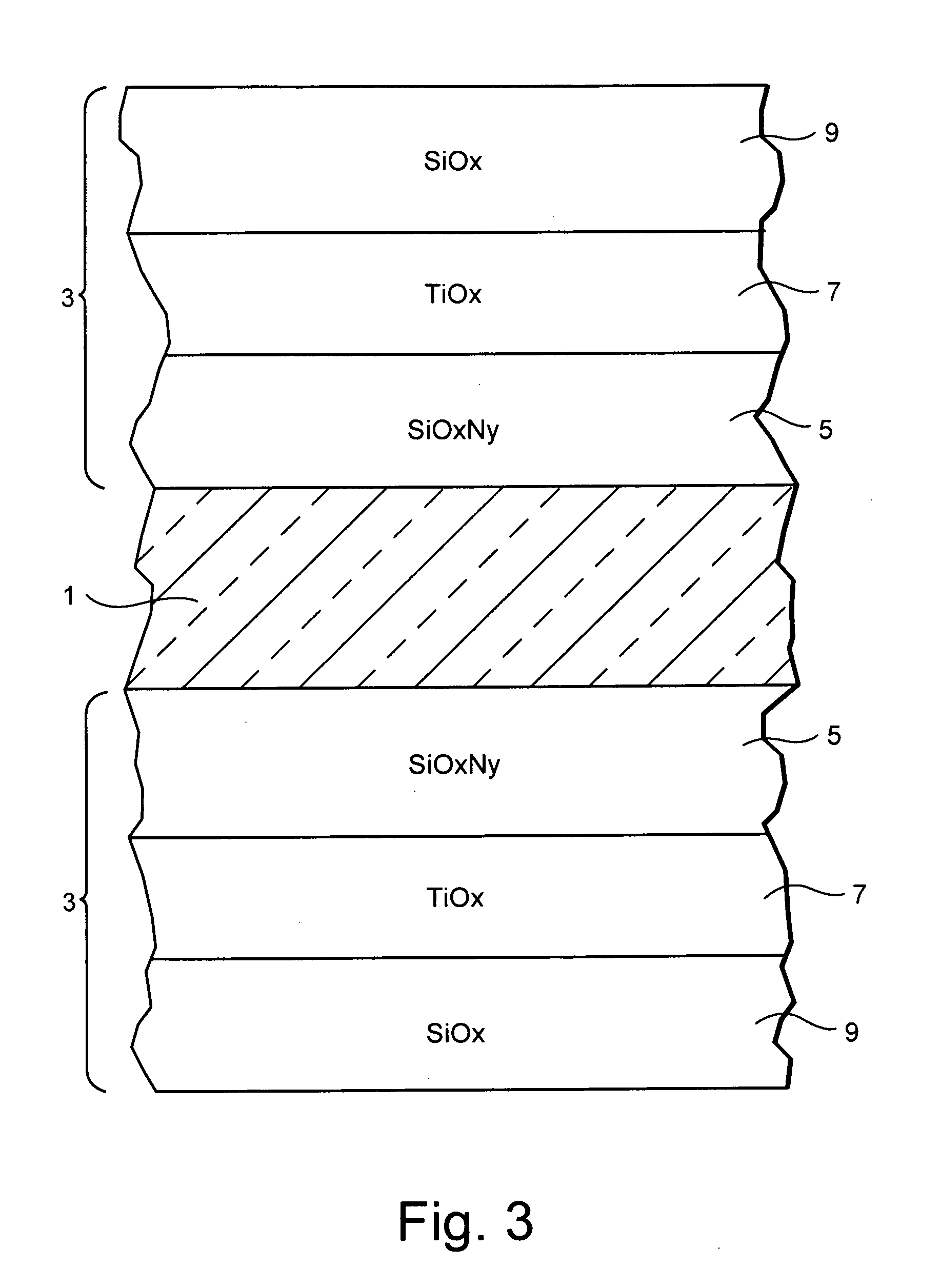

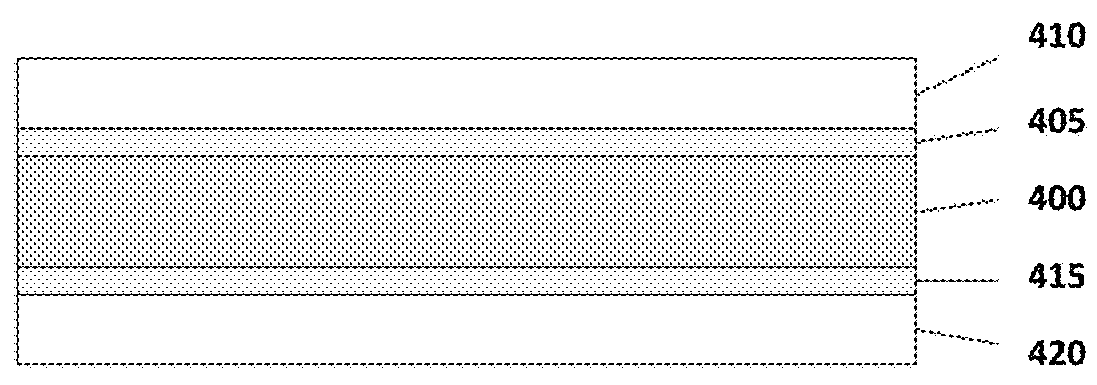

Temperable three layer antireflective coating, coated article including temperable three layer antireflective coating, and/or method of making the same

ActiveUS20110157703A1Electrostatic spraying apparatusSpecial surfacesOptical propertyRefractive index

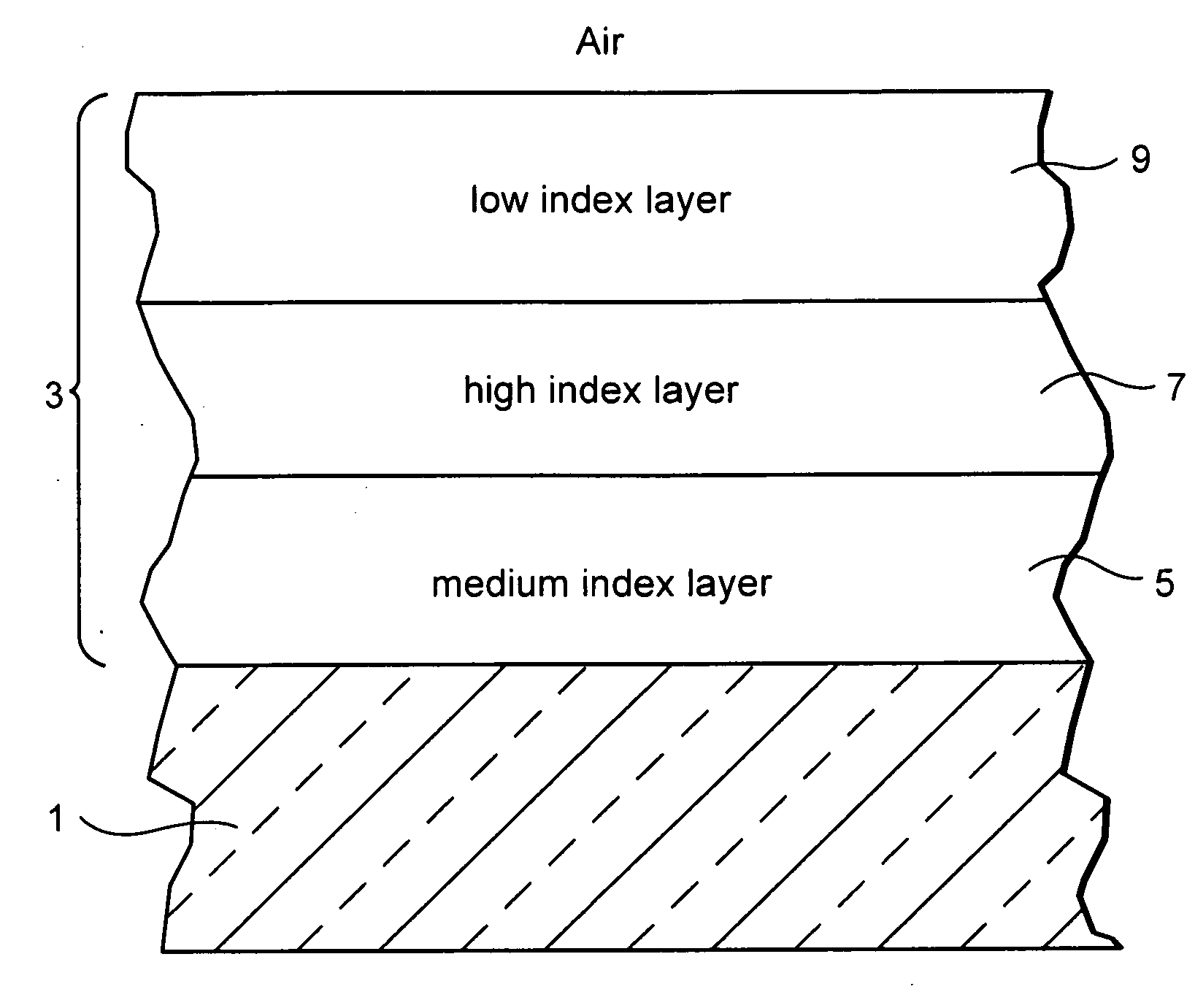

A coated article includes a temperable antireflection (AR) coating that utilizes medium and low index (index of refraction “n”) layers having compressive residual stress in the AR coating. In certain example embodiments, the coating may include the following layers from the glass substrate outwardly: silicon oxynitride (SiOxNy) medium index layer / high index layer / low index layer. In certain example embodiments, depending on the chemical and optical properties of the high index layer and the substrate, the medium and low index layers of the AR coating are selected to cause a net compressive residual stress and thus optimize the overall performance of the antireflection coating when the coated article is tempered and / or heat-treated.

Owner:GUARDIAN GLASS LLC

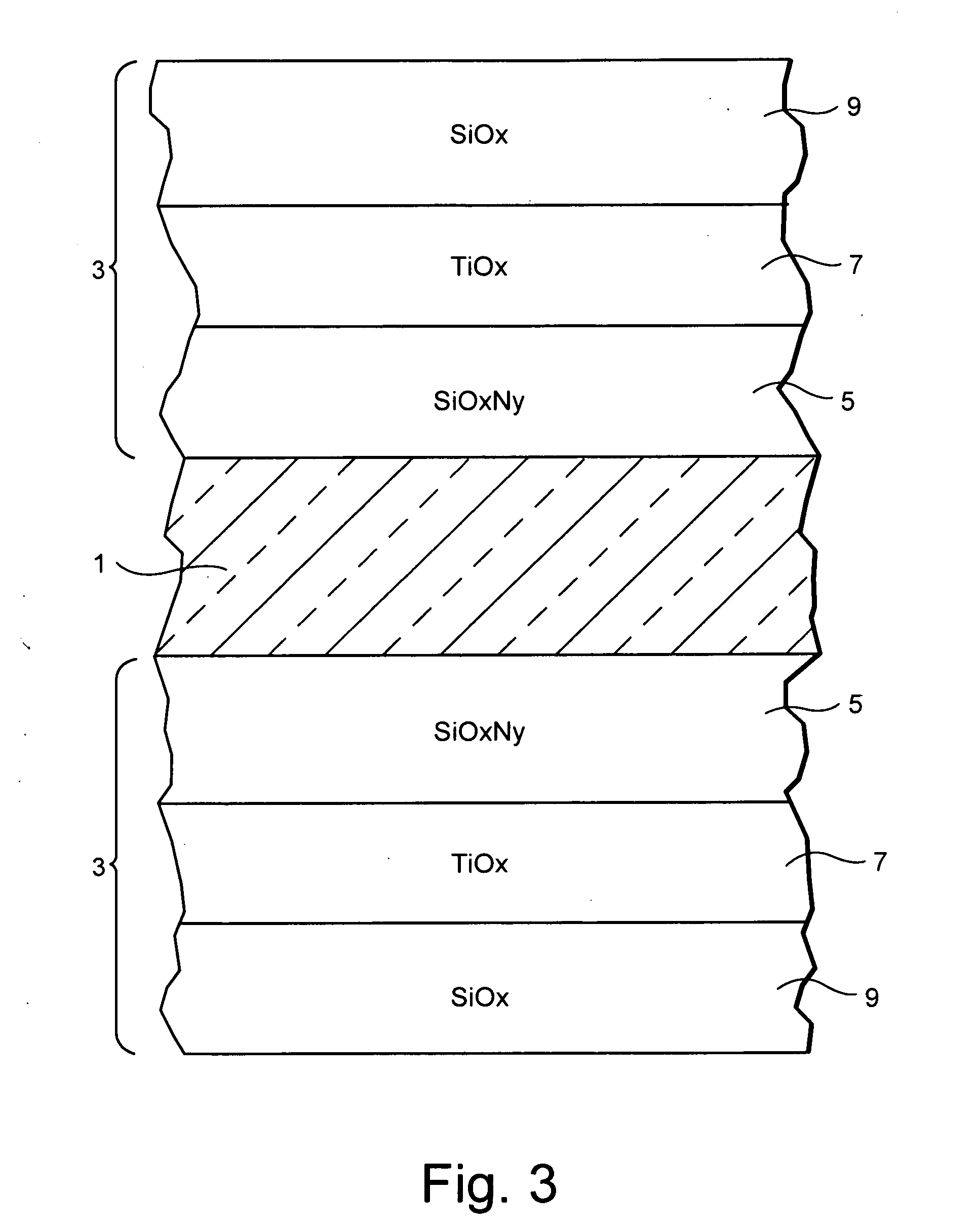

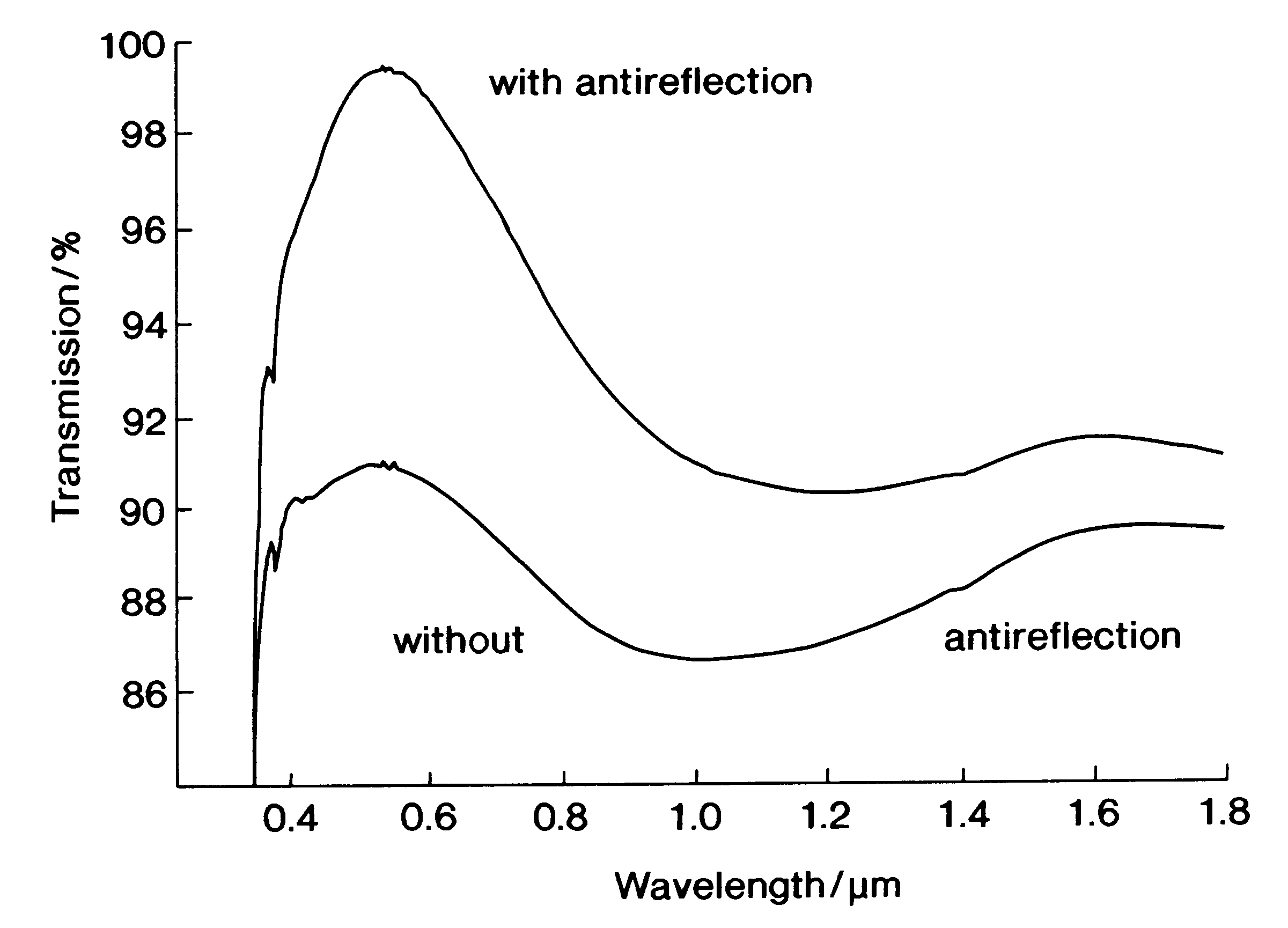

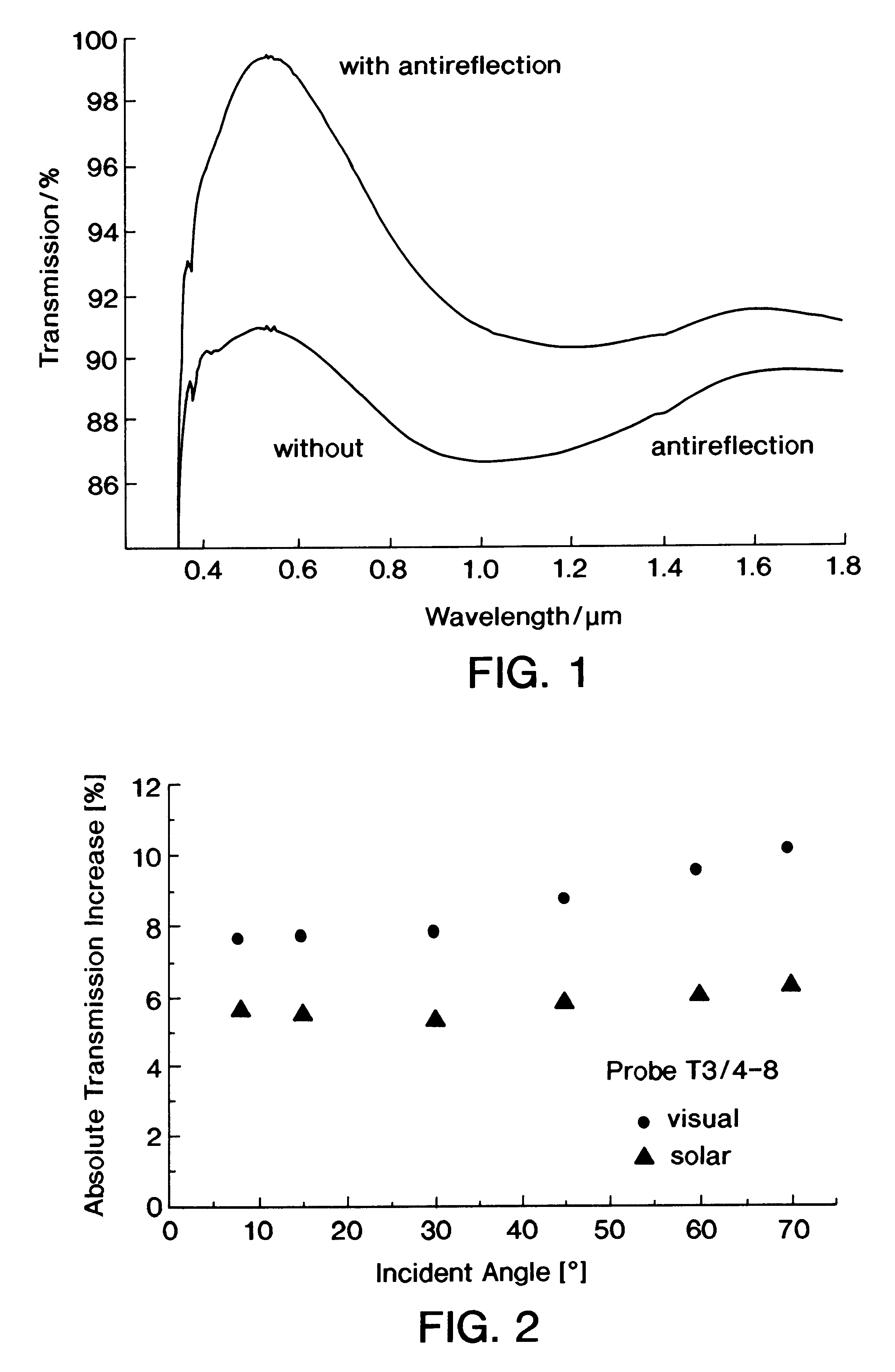

Transparent substrate with an antireflection, low-emissivity or solar-protection coating

A transparent substrate and methods of making a transparent substrate having, on at least one of its faces, an antireflection coating made of a multilayer stack of alternating thin layers of high and low refractive indices. Preferably, the thin layers are based on a dielectric material. At least one of the thin high-index layers comprises titanium oxide which is modified so as to reduce its refractive index to a value of at most 2.40, preferably to a value of at most 2.35.

Owner:SEKURIT SAINT GOBAIN DEUT

Method of making an anti-reflection coating

InactiveUS6177131B1Reducing and eliminating reflectionReduce and even reflectionSolar heat devicesPretreated surfacesSilanesRefractive index

A method of and a solution for making a highly porous optical antireflection coating of a selectively designed index of refraction, by applying a colloidal dispersion derived from hydrolytically condensing, in the presence of water and a catalyst, one or more silicon compounds of the general formula RaSiX4-a, or precondensates derived therefrom, to a substrate. In the formula, R is an organic group having from 1 to 10 carbon atoms which may be interrupted by oxygen atoms and / or sulfur atoms and / or amino groups, X is hydrogen, halogen, hydroxy, alkoxy, acyloxy, alkylcarbonyl, alkoxycarbonyl or NR'2, R' being hydrogen, alkyl or aryl and a being 0, 1 or 2. The solution also contains colloidally dispersed organic polymers at a molar ratio, relative to the silane, between 0.1 mmol / mol silane and 100 mmol / mol silane, the median molecular mass of the polymer being between 200 and 500,000. Sol-vents, preferably alcohol, may also be present in the solution. After being applied to an optical substrate, the solution is dried and organic components are removed from it to leave a porous coating of predetermined index of refraction.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

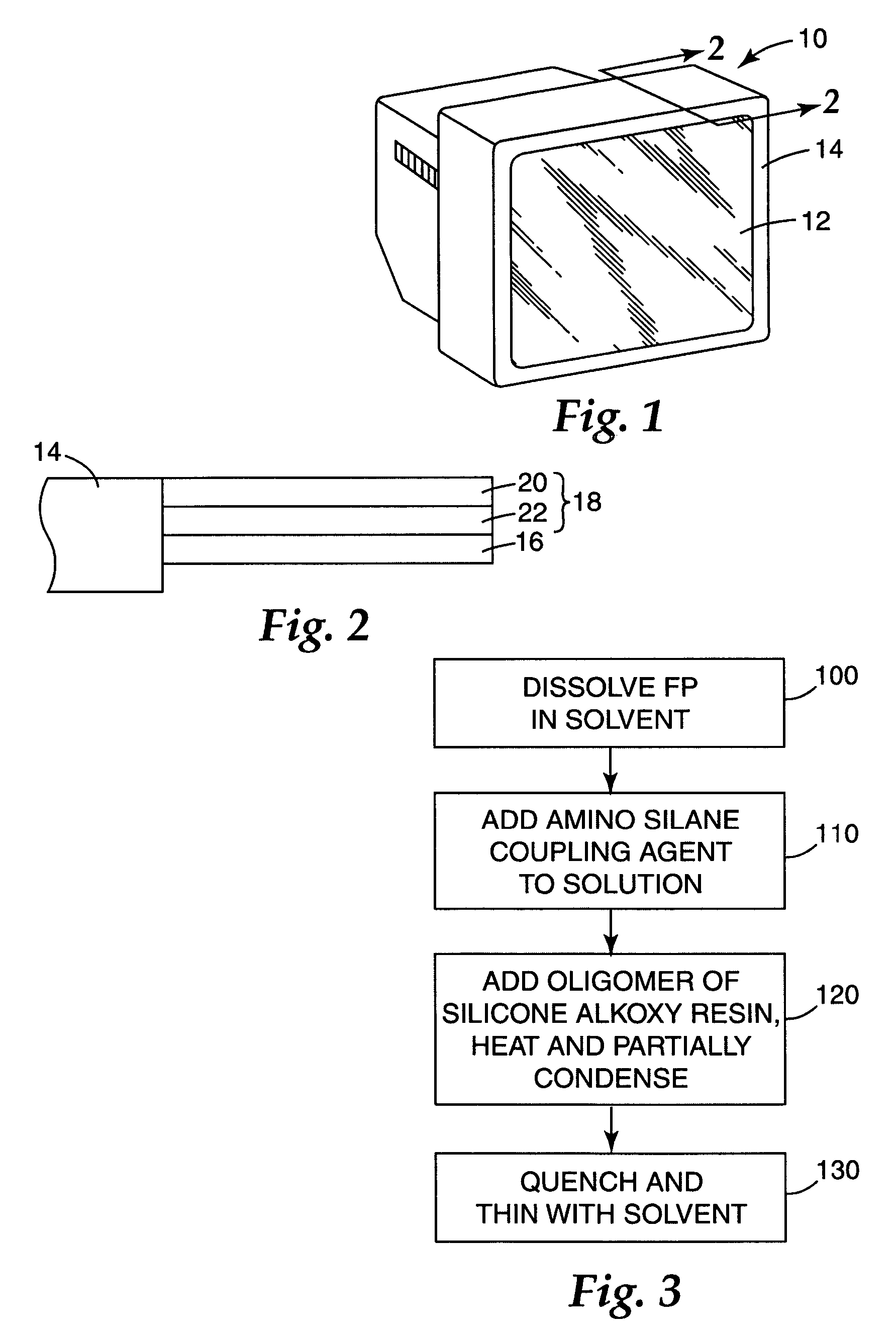

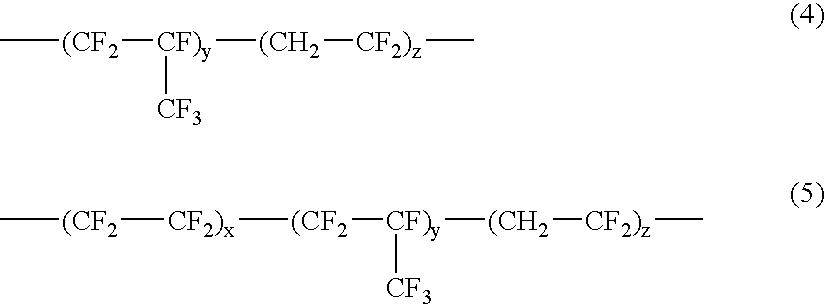

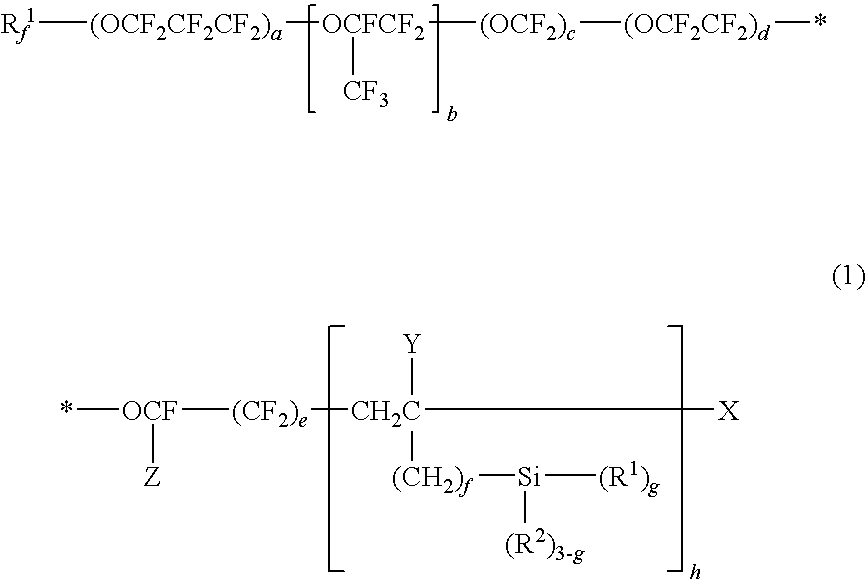

Low refractive index coating composition for use in antireflection polymer film coatings and manufacturing method

InactiveUS7374812B2Easy to manufactureImprove wettabilitySynthetic resin layered productsThin material handlingPolymer scienceSilanes

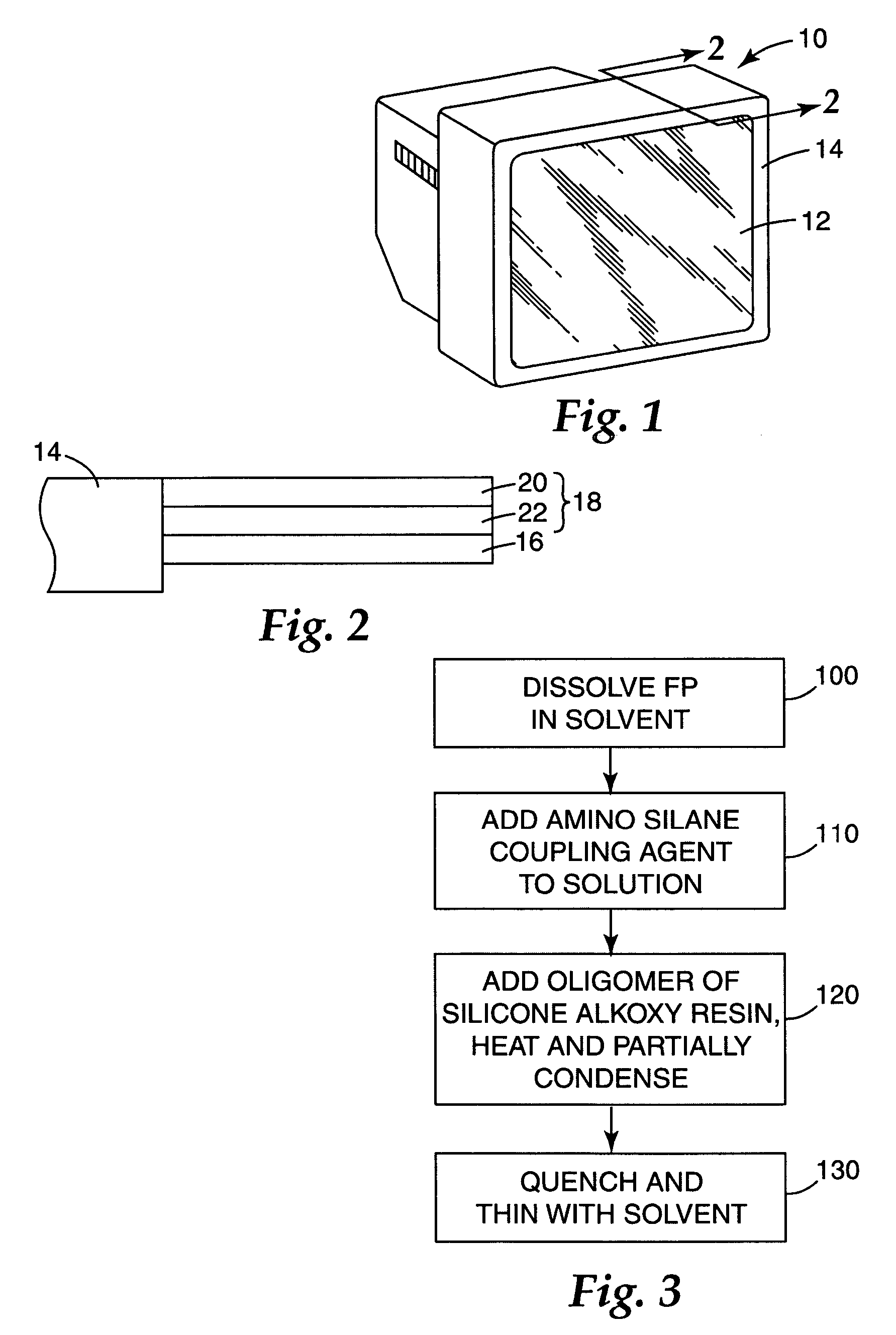

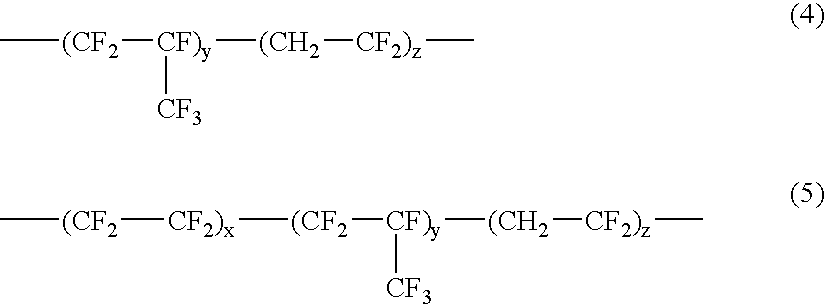

A silicone-modified fluoropolymer is formed by first dissolving a fluoropolymer in an organic solvent, the fluoropolymer having at least one monomer of vinylidene fluoride coupled to a hexafluoropropylene monomer unit, and subsequently reacting the mixture with an amino silane coupling agent to form an aminosilane-modified fluoropolymer. The aminosilane fluoropolymer is subsequently heated and partially condensed with an oligomer of a silane compound including alkoxy silane. The resultant composition is suitable for use as a low refractive index layer in an antireflection coating on an optical substrate.

Owner:3M INNOVATIVE PROPERTIES CO

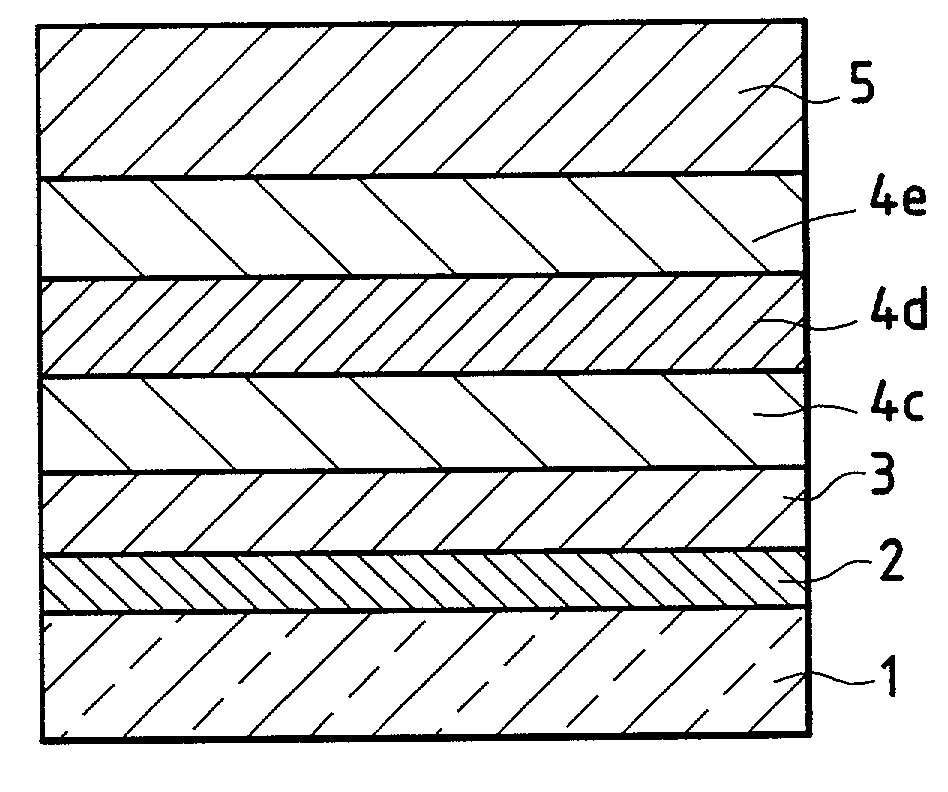

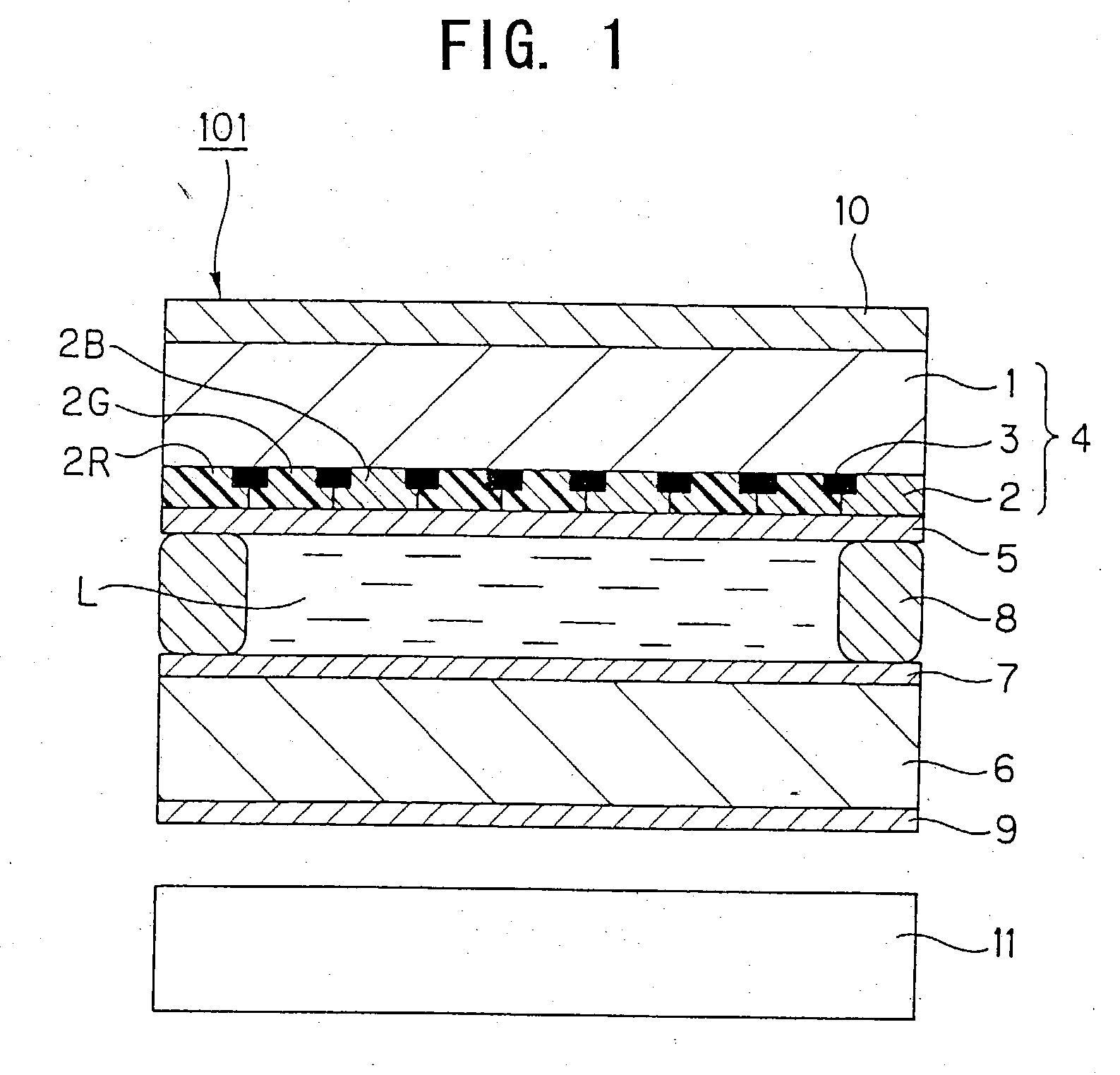

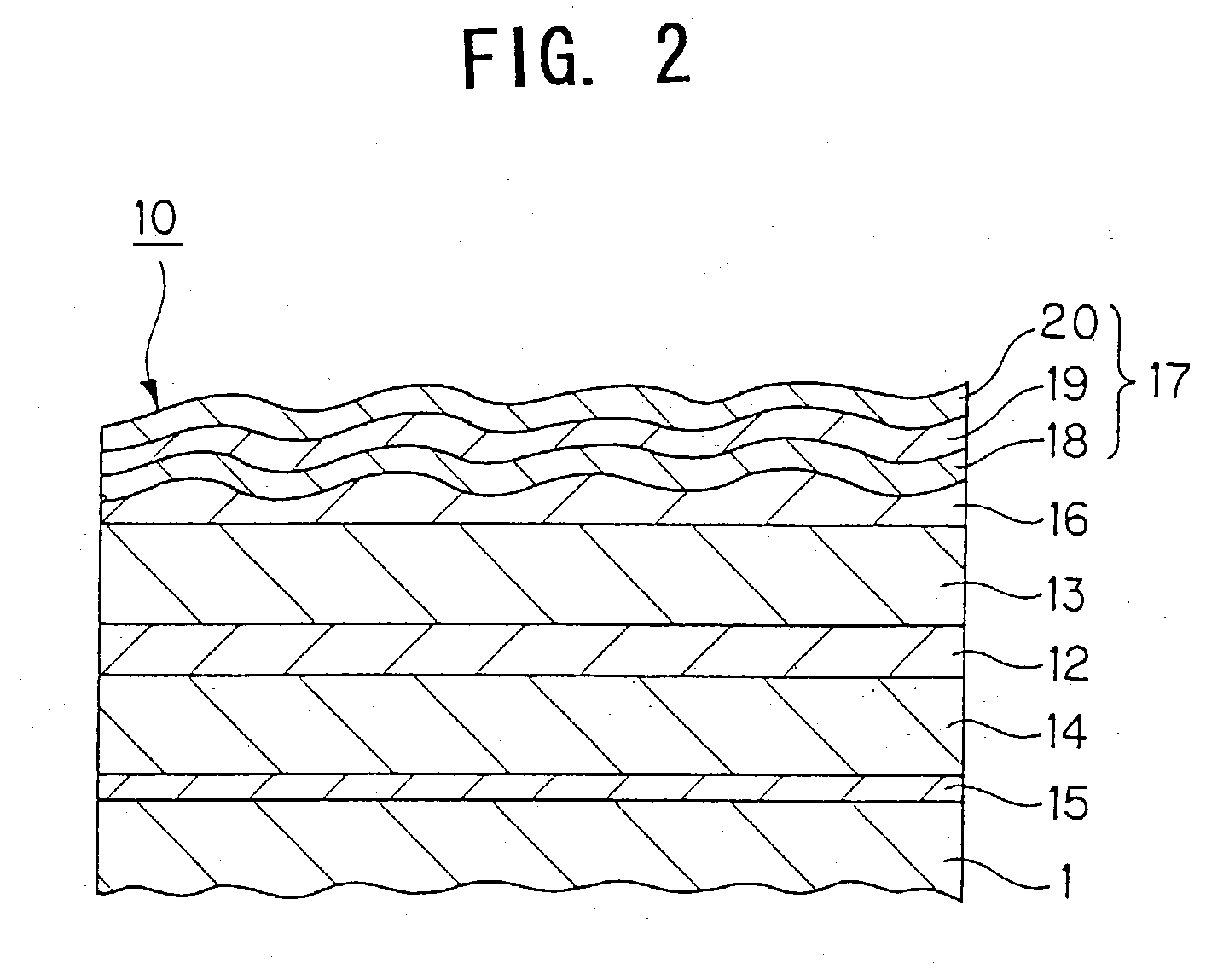

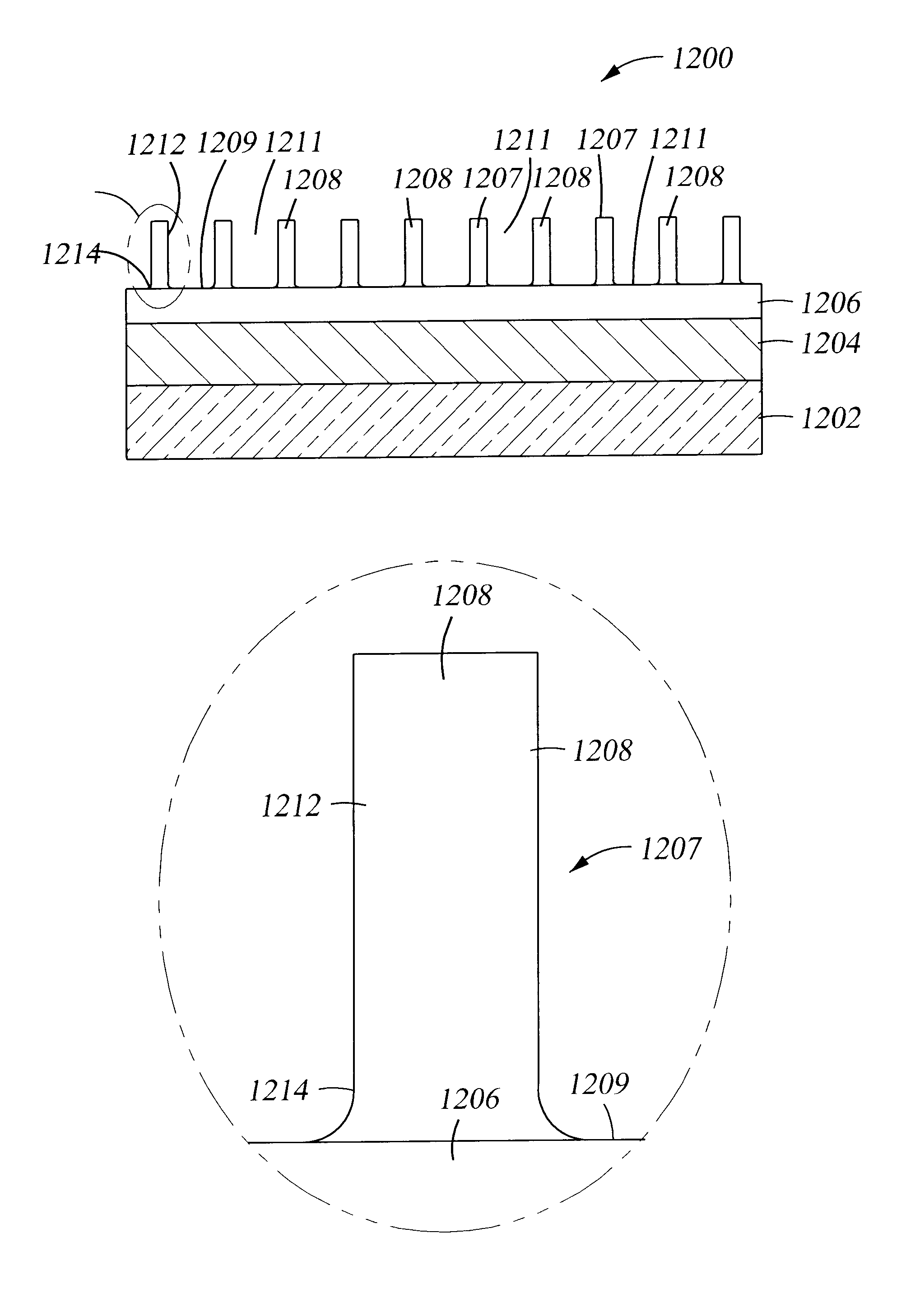

Coating composition, coating film thereof, antireflection coating, antireflection film, image display, and intermediate product

InactiveUS20030096102A1Good dispersibilityGood dispersionSynthetic resin layered productsCellulosic plastic layered productsMetallurgyRefractive index

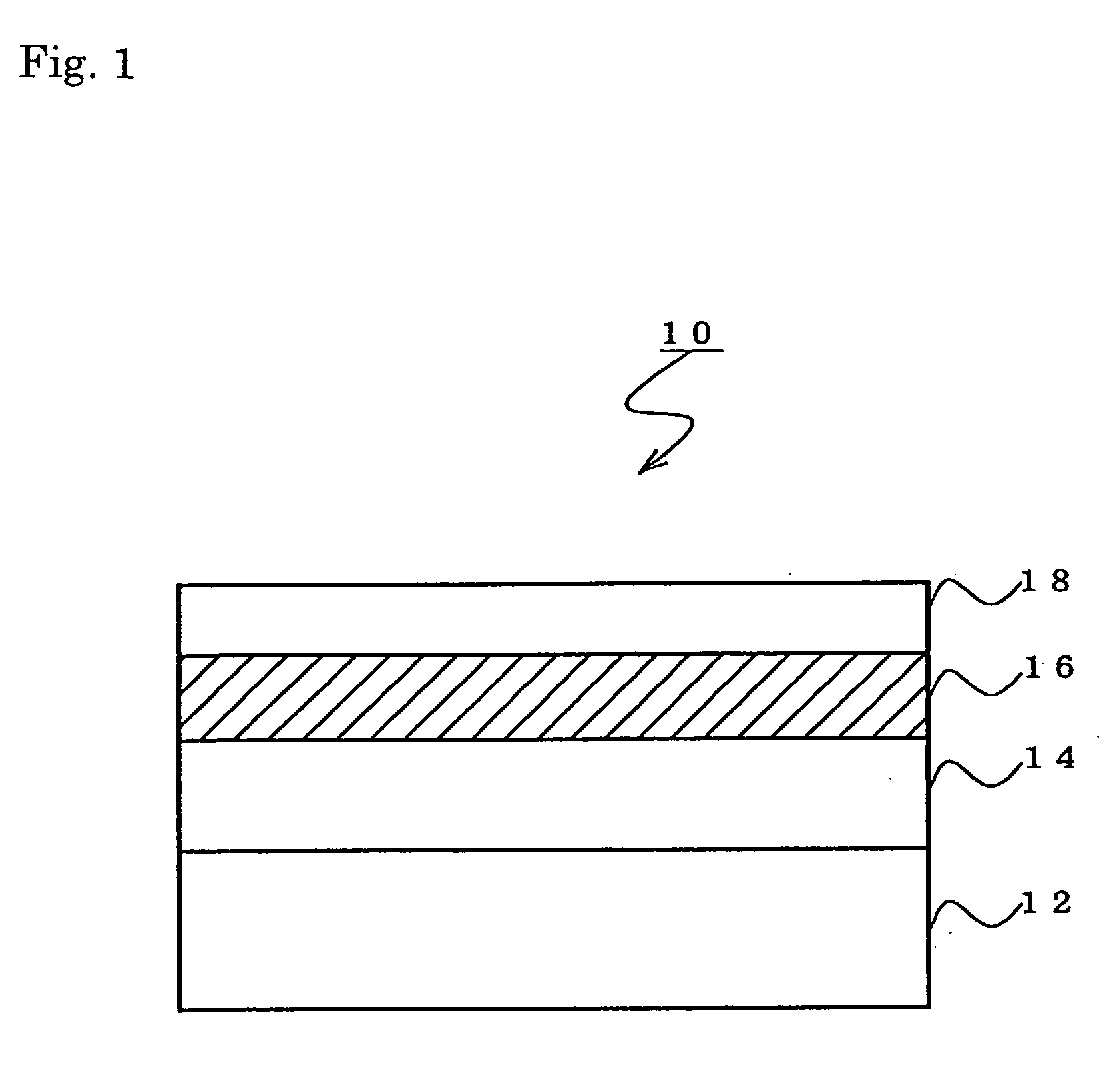

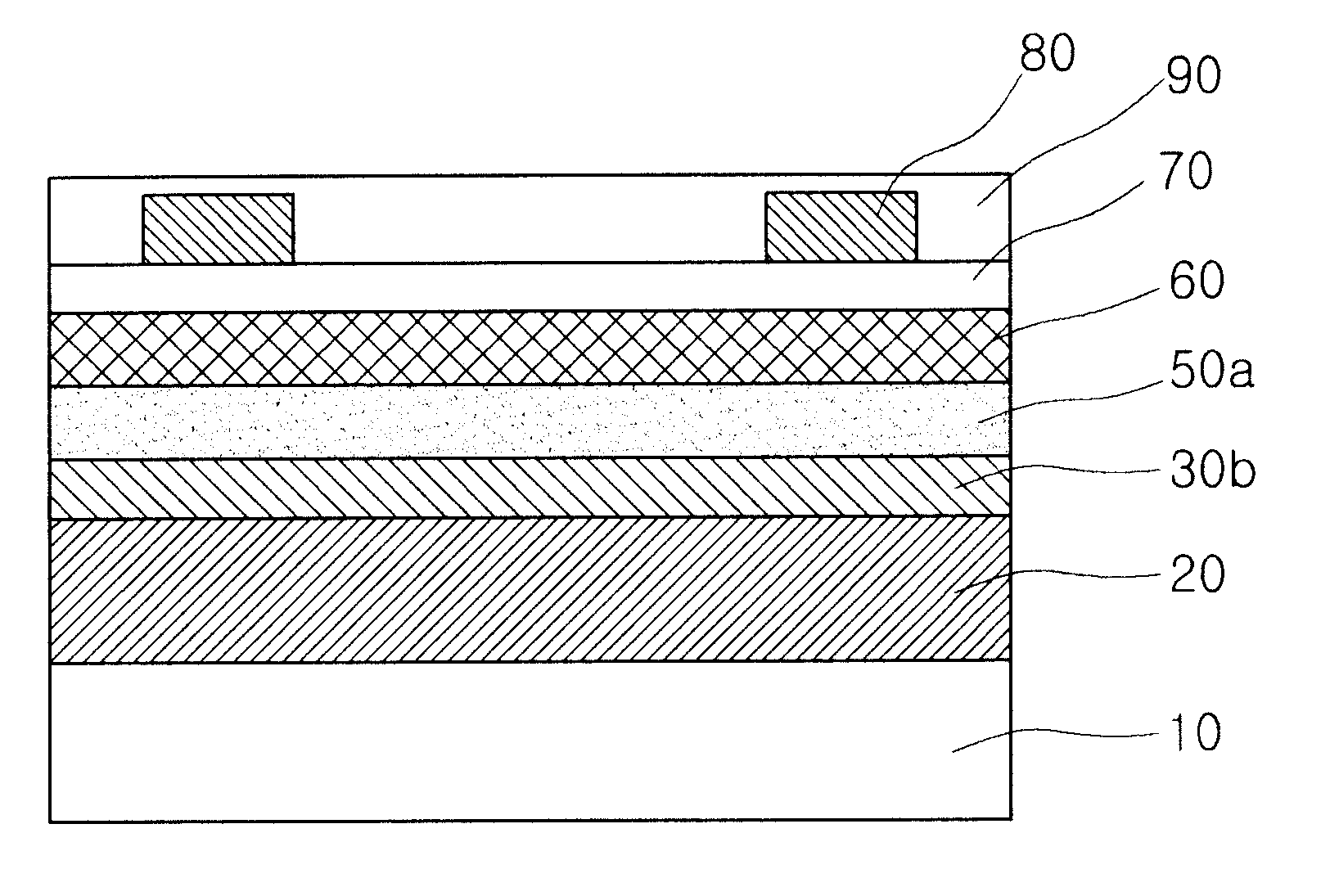

A coating material capable of forming a high-quality thin film having a regulated refractive index; a coating film formed from the coating material; an antireflection coating comprising the coating film; an antireflection film to which the antireflection coating is applied; and an image display. The coating composition comprises (1) rutile-form titanium oxide having primary particle diameter of 0.01 to 0.1 mum and coated with an inorganic compound for reducing or eliminating the photocatalytic activity and with an organic compound having an anionic polar group and / or an organometallic compound, (2) a binder ingredient curable with an ionizing radiation, (3) a dispersant having an anionic polar group, and (4) an organic solvent. The coating film formed from the coating composition is suitable for forming a light-transmitting layer constituting or contained in a single- or multi-layer antireflection coating (17), in particular, a medium-refractive-index layer (18), high-refractive-index layer (19), or hard coat layer (16) having a high refractive index.

Owner:DAI NIPPON PRINTING CO LTD

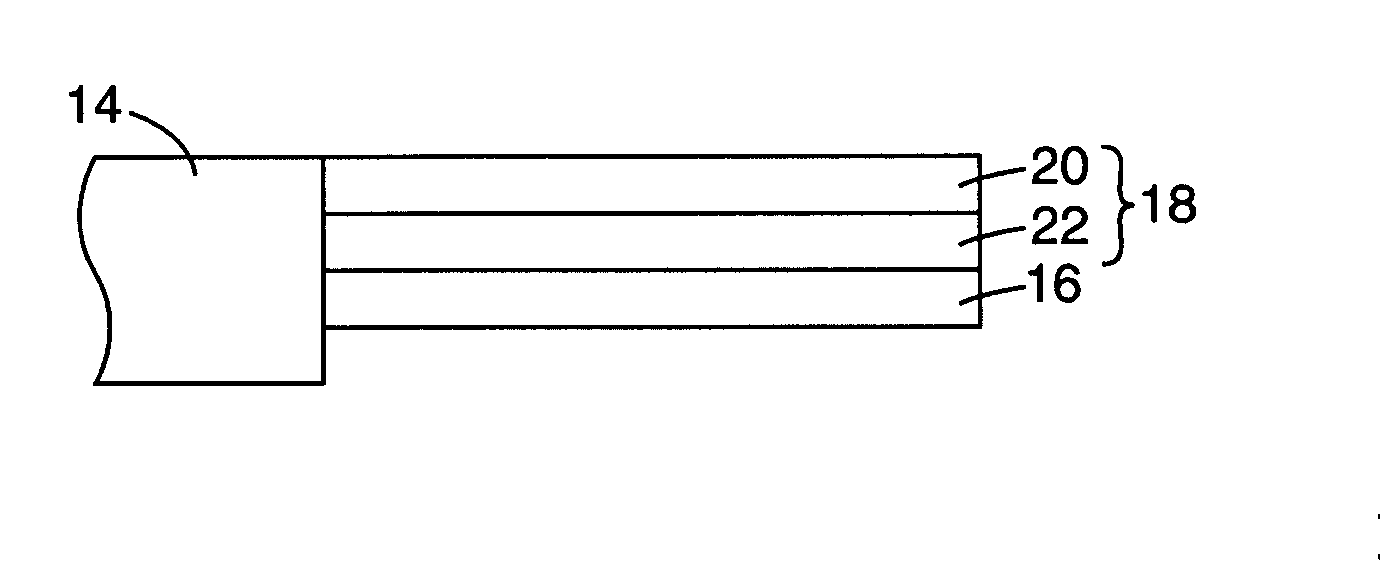

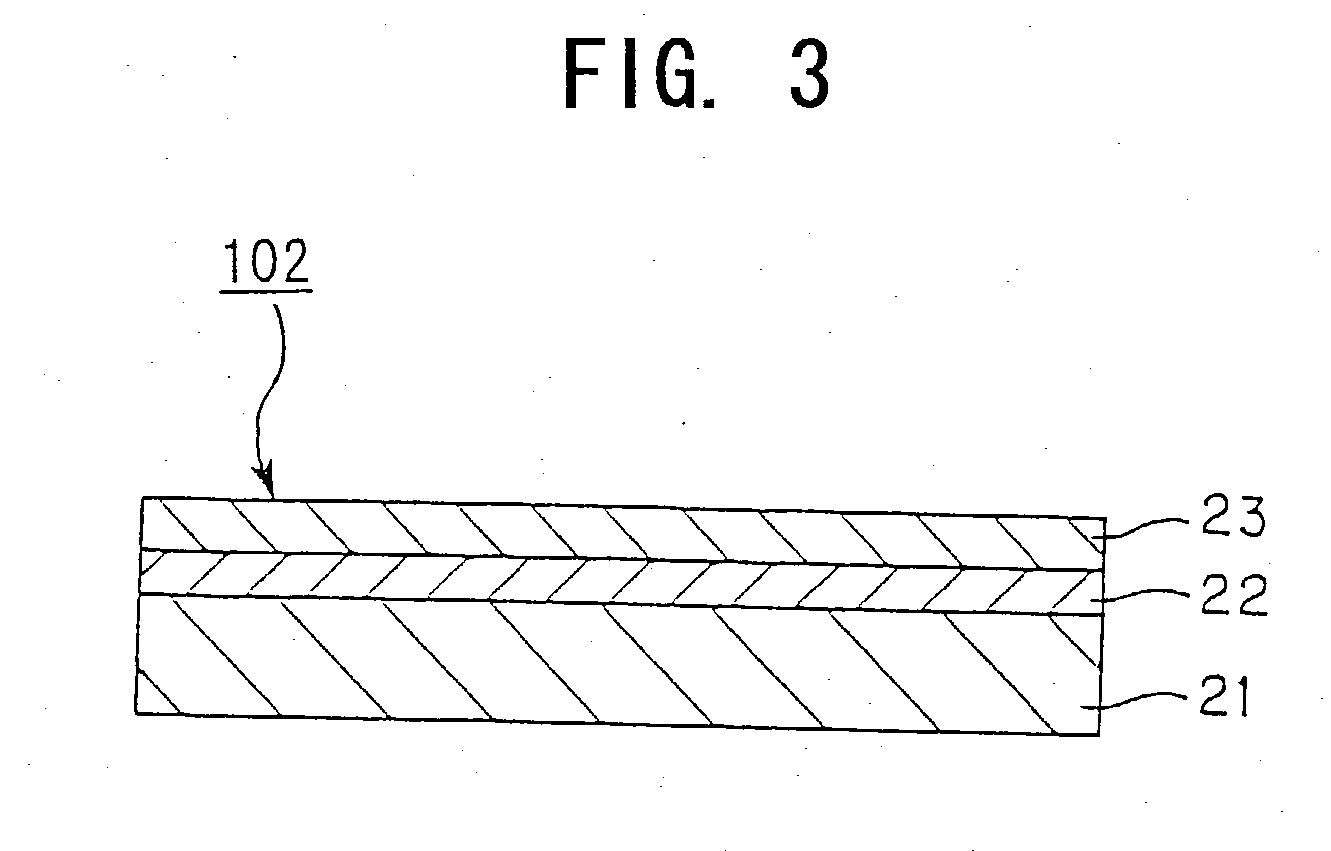

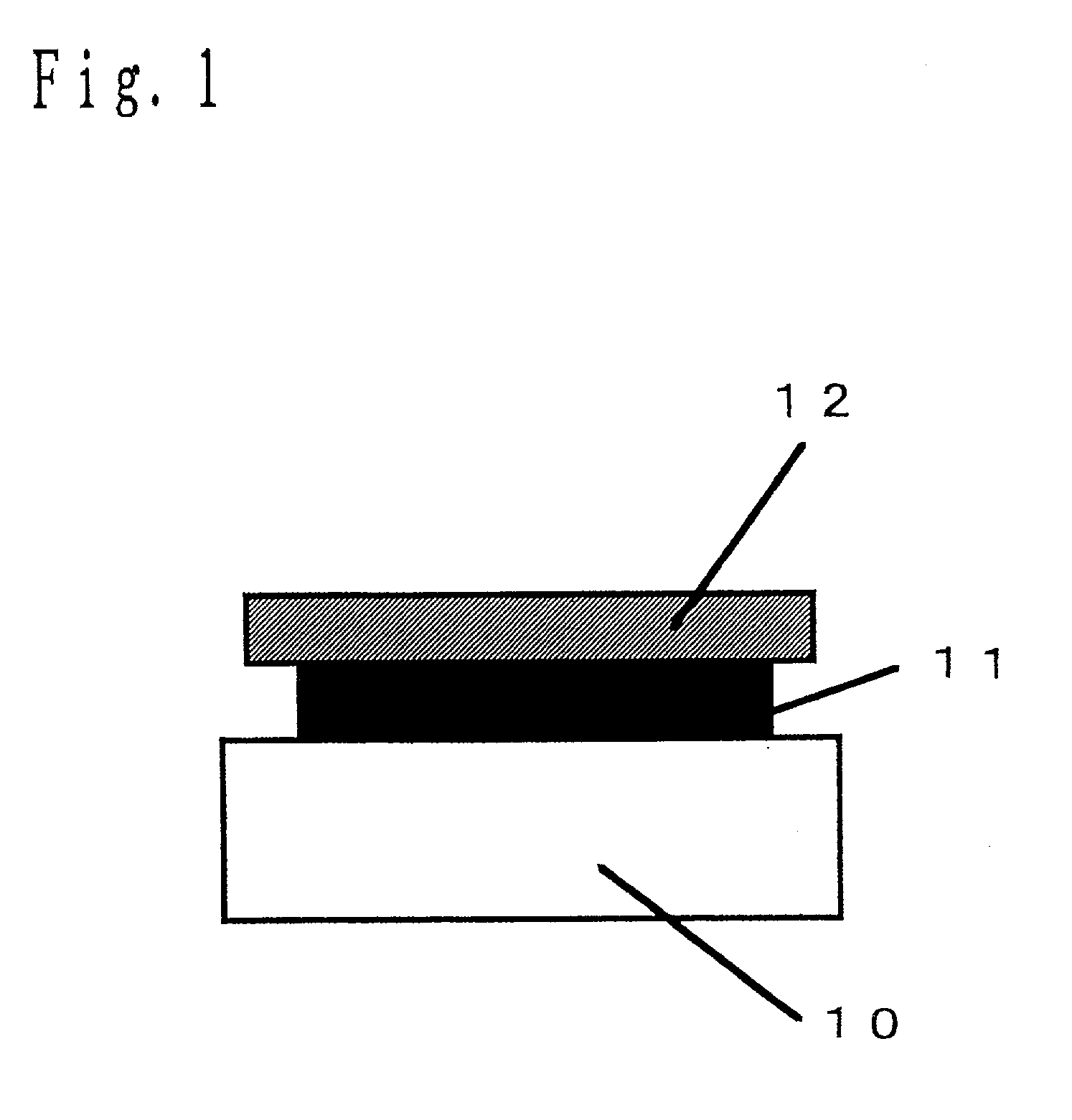

Transparent member, timepiece, and method of manufacturing a transparent member

InactiveUS20100027383A1High hardnessLayered productsVacuum evaporation coatingRefractive indexSilicon oxide

A transparent member has a transparent substrate, and an antireflection coating that has a high index of refraction layer made of silicon nitride and a low index of refraction layer made of silicon oxide alternately laminated on at least a part of a surface of the substrate. The content of silicon nitride in the region to a depth of 150 nm from the outside surface of the antireflection coating is 30-50 vol %.

Owner:SEIKO EPSON CORP

Inorganic-Organic Hybrid Nanocomposite Antiglare and Antireflection Coatings

InactiveUS20090004462A1Simple processImprove anti-reflection effectSynthetic resin layered productsGlass/slag layered productsTransmittanceEngineering

Embodiments of this disclosure relate to compositions, and a method of making UV or heat curable anti-reflection and anti-glare hard coatings. Such coatings may be useful, for example, for simultaneously improving transmission and preventing undesired visible reflection on various monitor or display panels and optical lenses. For the panels with plastic covers, the coating will also improve the surface mechanical properties such as abrasion and scratch resistance.

Owner:OPTIMAX TECHNOLOGY CORPORATION

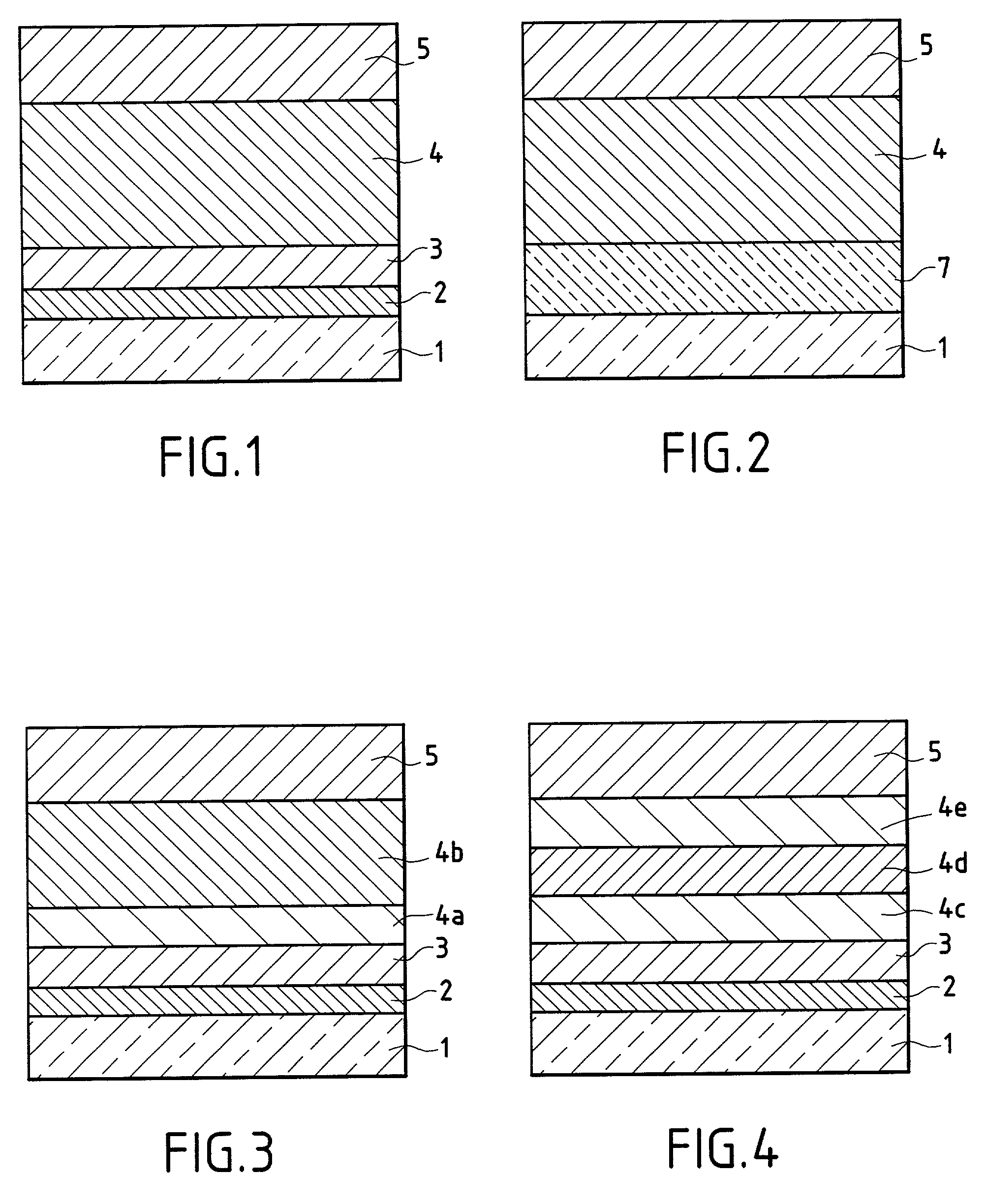

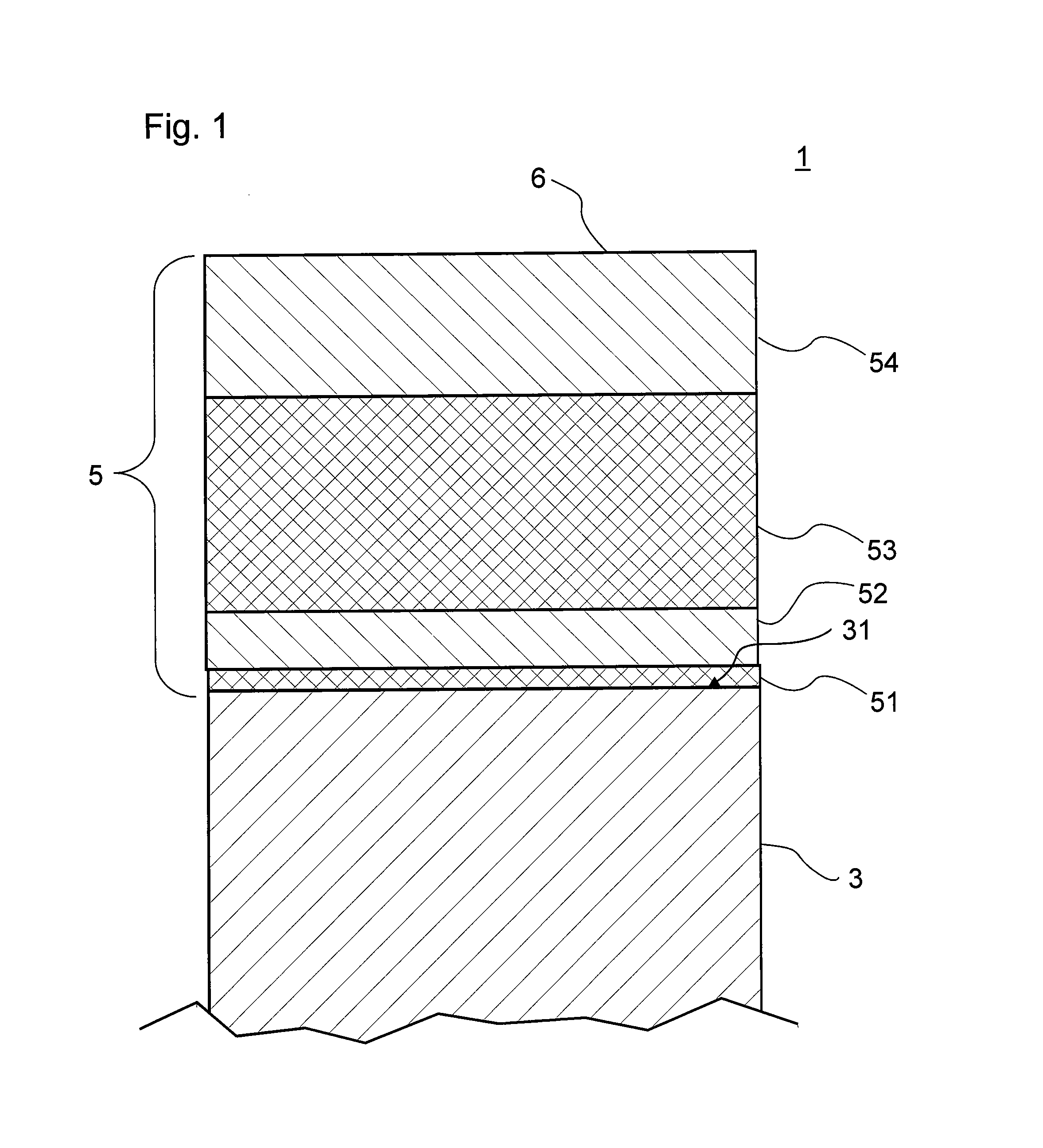

Substrate with antireflection coating and method for producing same

ActiveUS20120212826A1Decrease of antireflection effectHigh refractive indexElectric discharge tubesVacuum evaporation coatingRefractive indexSilicon oxide

A substrate is provided with an abrasion resistance antireflection coating. The coated substrate includes a multilayer antireflection coating on at least one side. The coating has layers with different refractive indices, wherein higher refractive index layers alternate with lower refractive index layers. The layers having a lower refractive index are formed of silicon oxide with a proportion of aluminum, with a ratio of the amounts of aluminum to silicon is greater than 0.05, preferably greater than 0.08, but with the amount of silicon predominant relative to the amount of aluminum. The layers having a higher refractive index include a silicide, an oxide, or a nitride.

Owner:SCHOTT AG

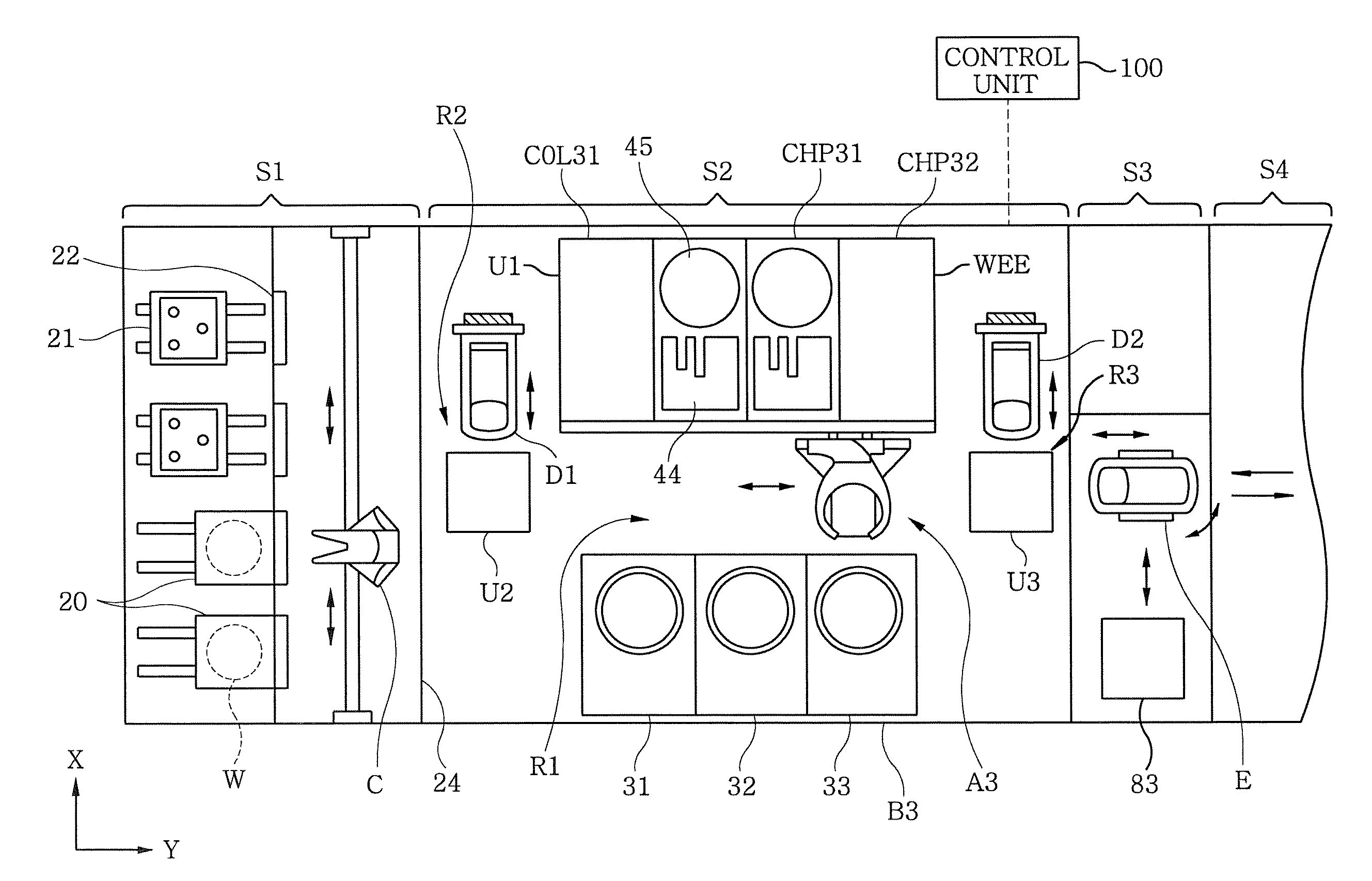

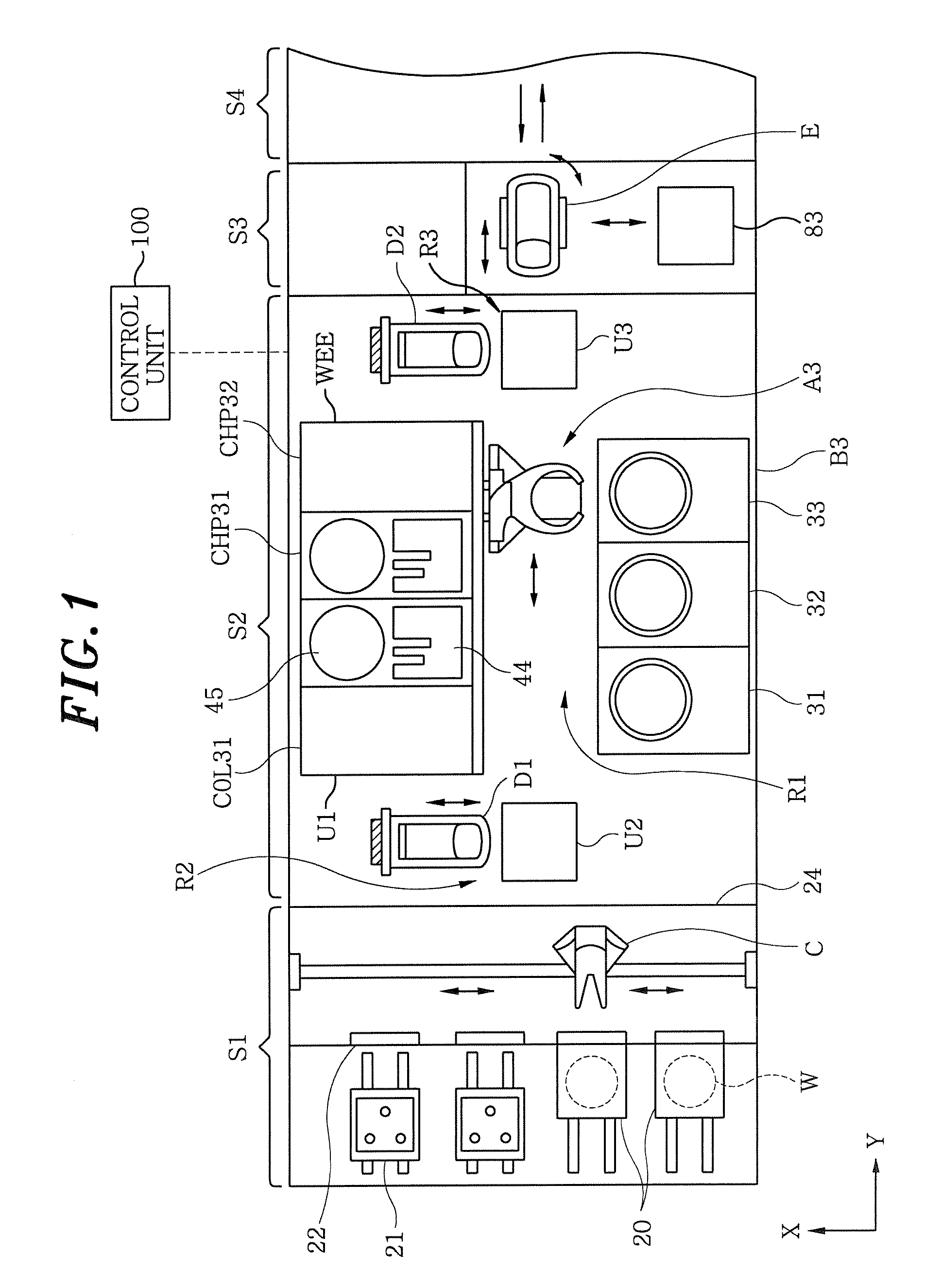

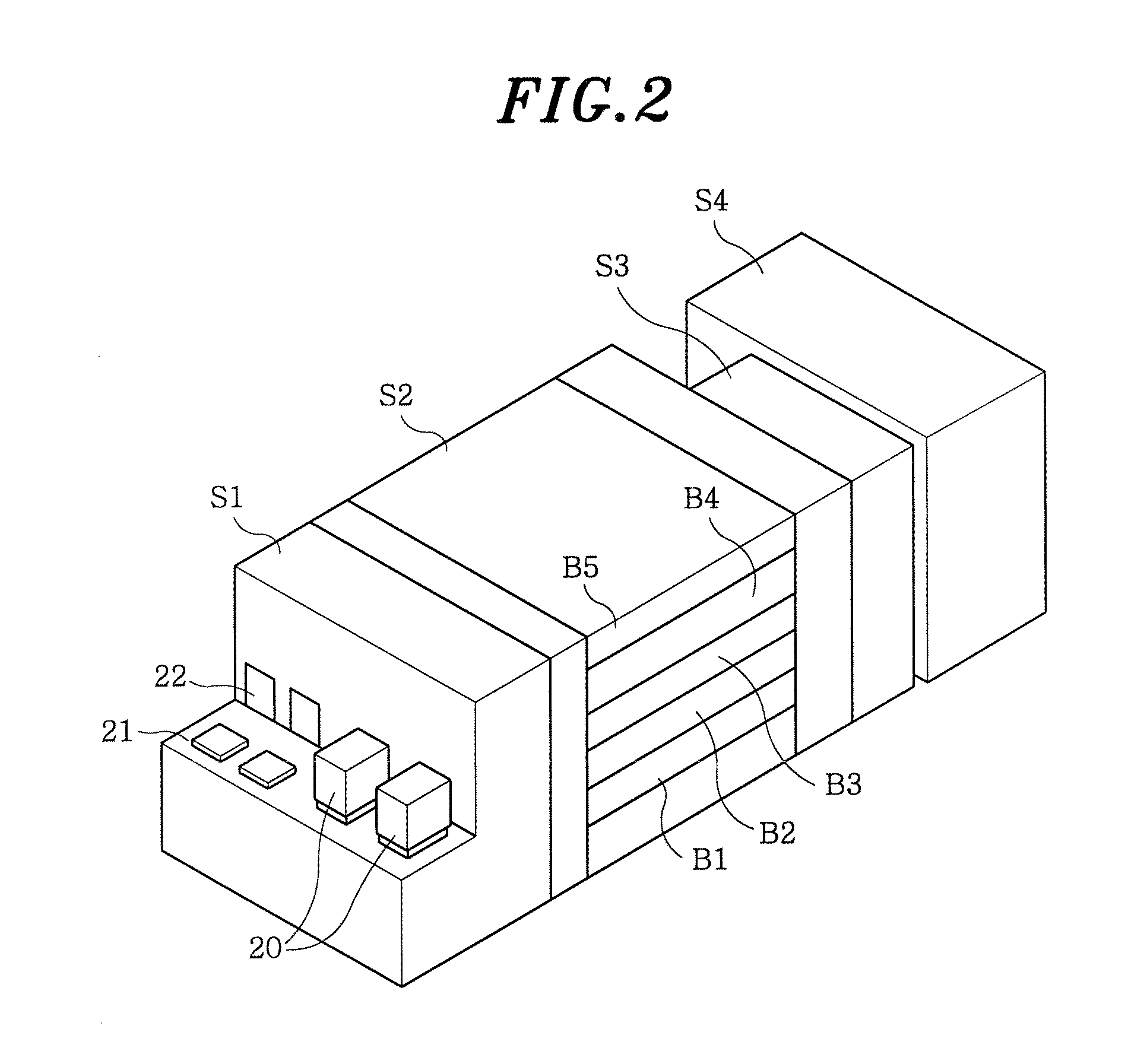

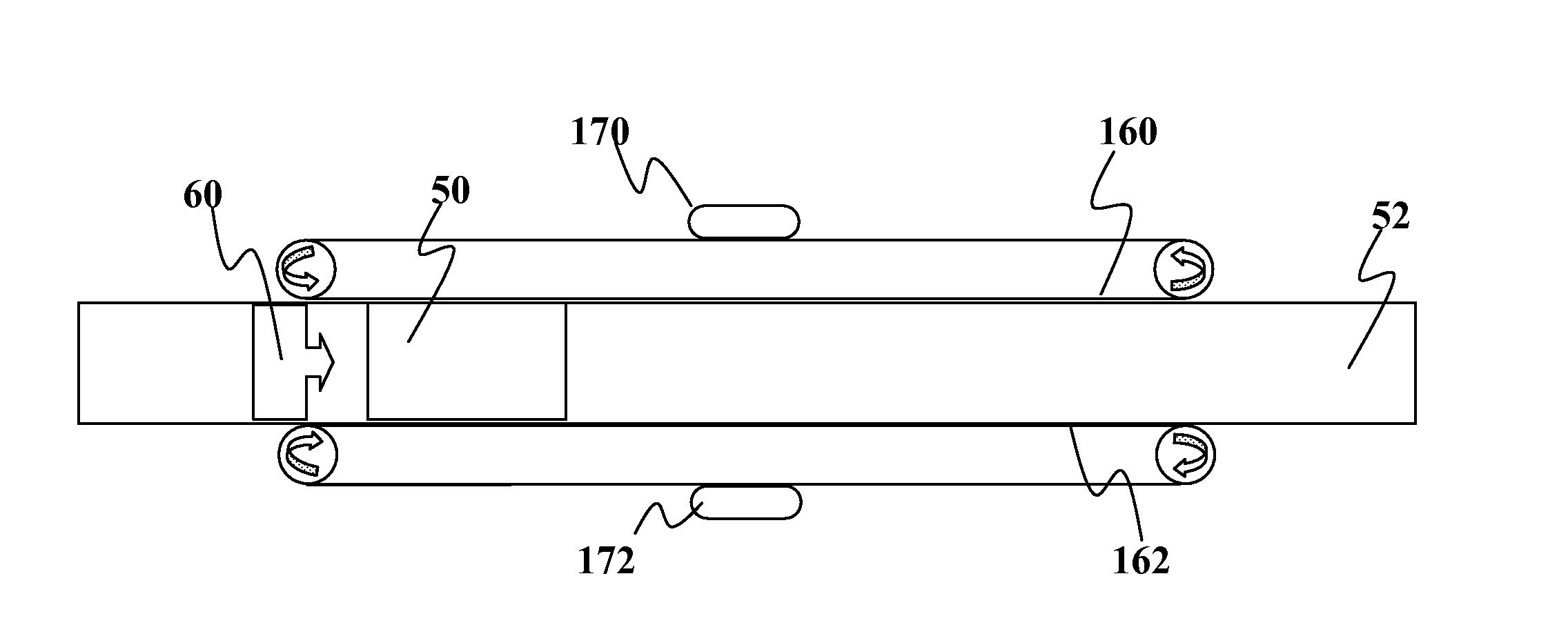

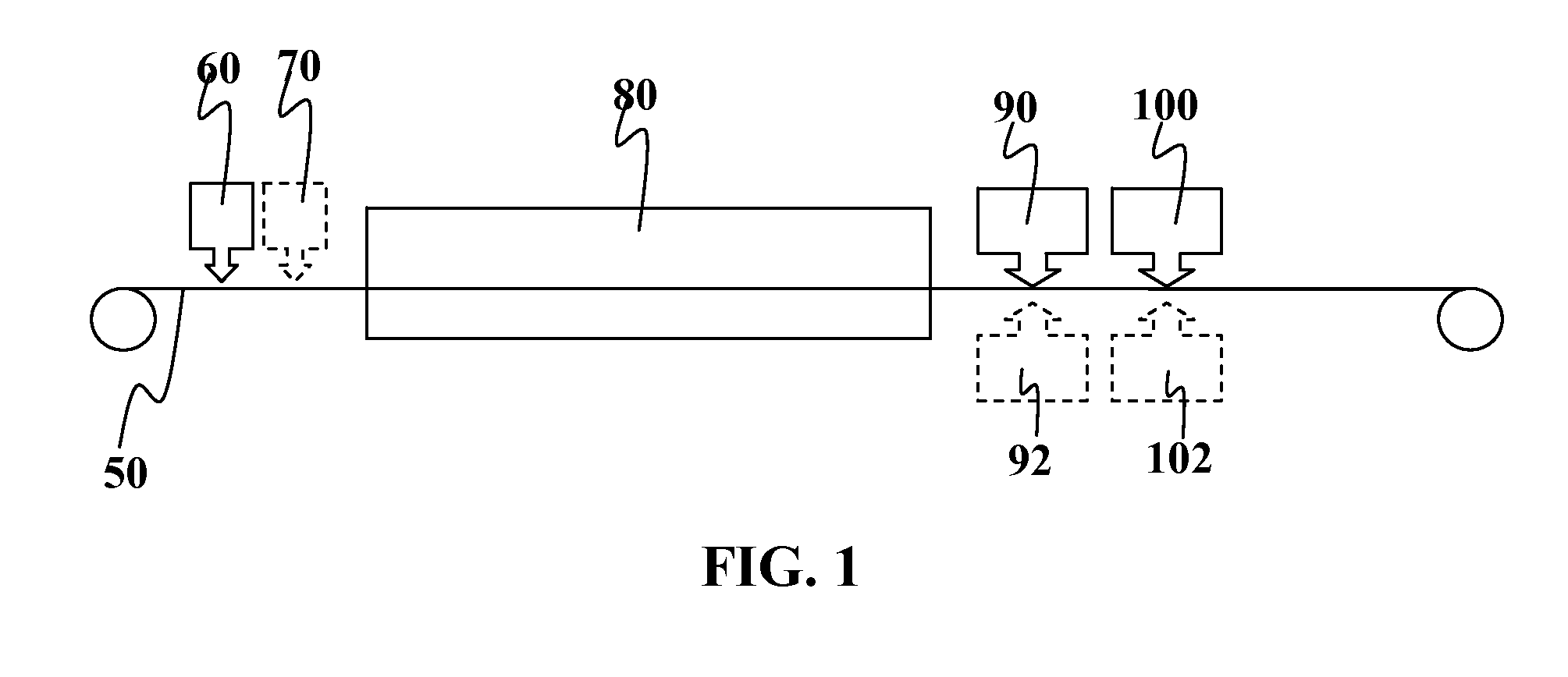

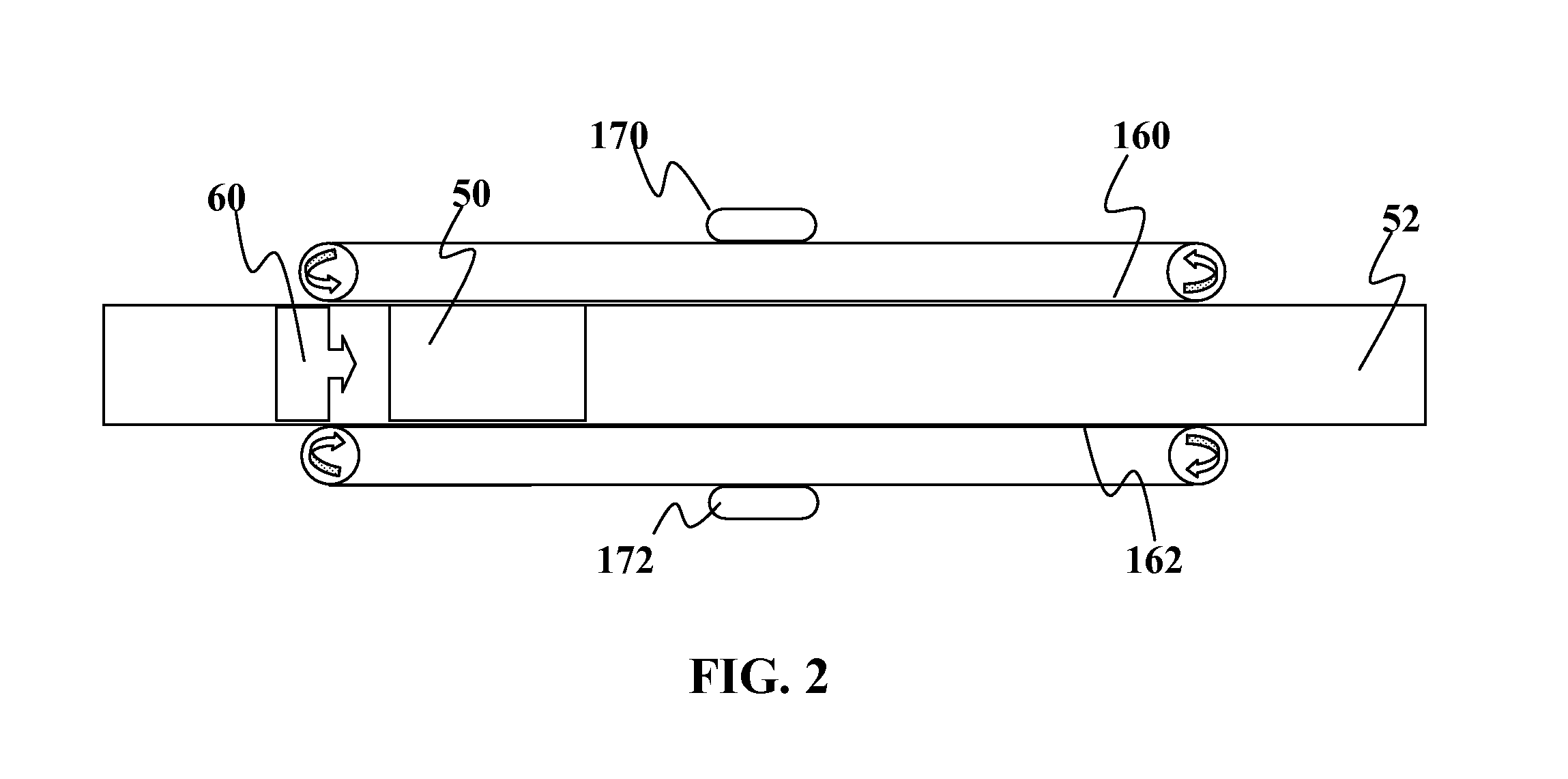

Coating/developing device and method

ActiveUS20060201423A1Save spaceEasy to useLiquid processingPhotomechanical apparatusResistCompound (substance)

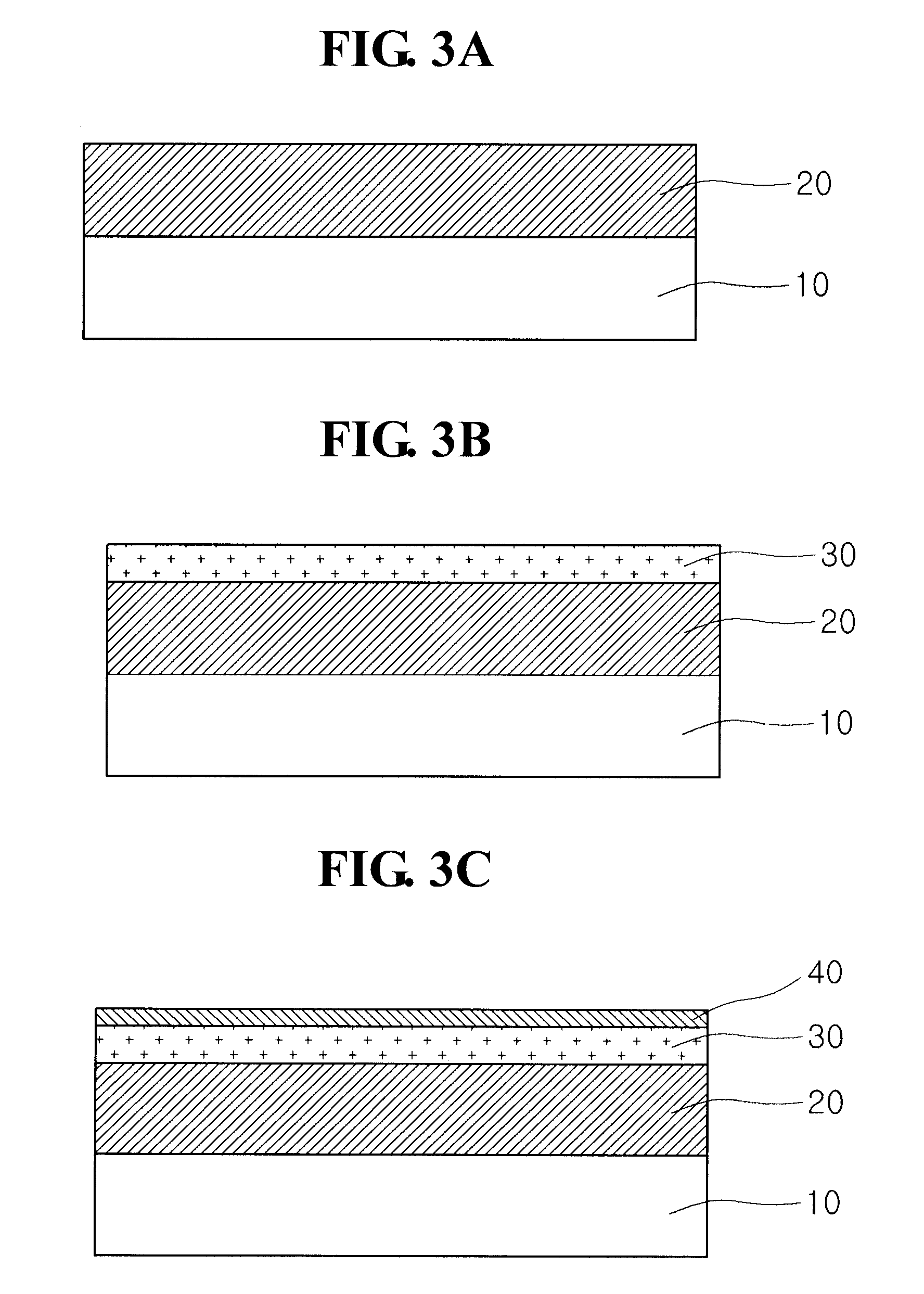

A coating / developing device includes a processing block having a plurality of coating unit blocks stacked and a developing unit block stacked on the coating unit blocks. Each of the unit blocks is provided with a liquid processing unit for coating a liquid chemical on a substrate, a heating unit for heating the substrate, a cooling unit for cooling the substrate and a transfer unit for transferring the substrate between the units. The liquid processing unit is provided with a coating unit for coating a resist liquid on the substrate, a first bottom antireflection coating (BARC) forming unit for coating a liquid chemical for a BARC on the substrate before the resist liquid is coated thereon, and a second BARC forming unit for coating a liquid chemical for the BARC on the substrate after the resist liquid is coated thereon.

Owner:TOKYO ELECTRON LTD

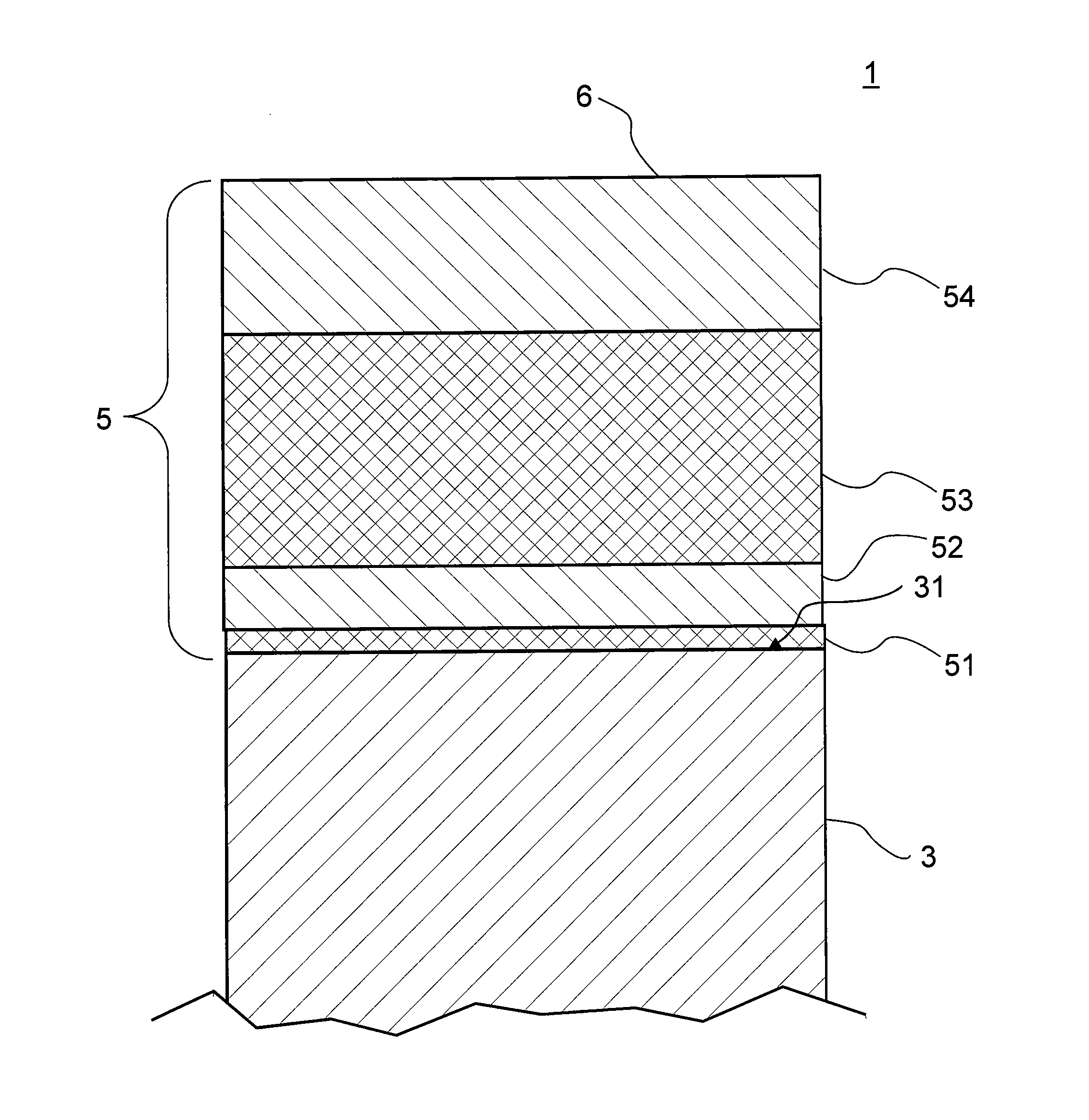

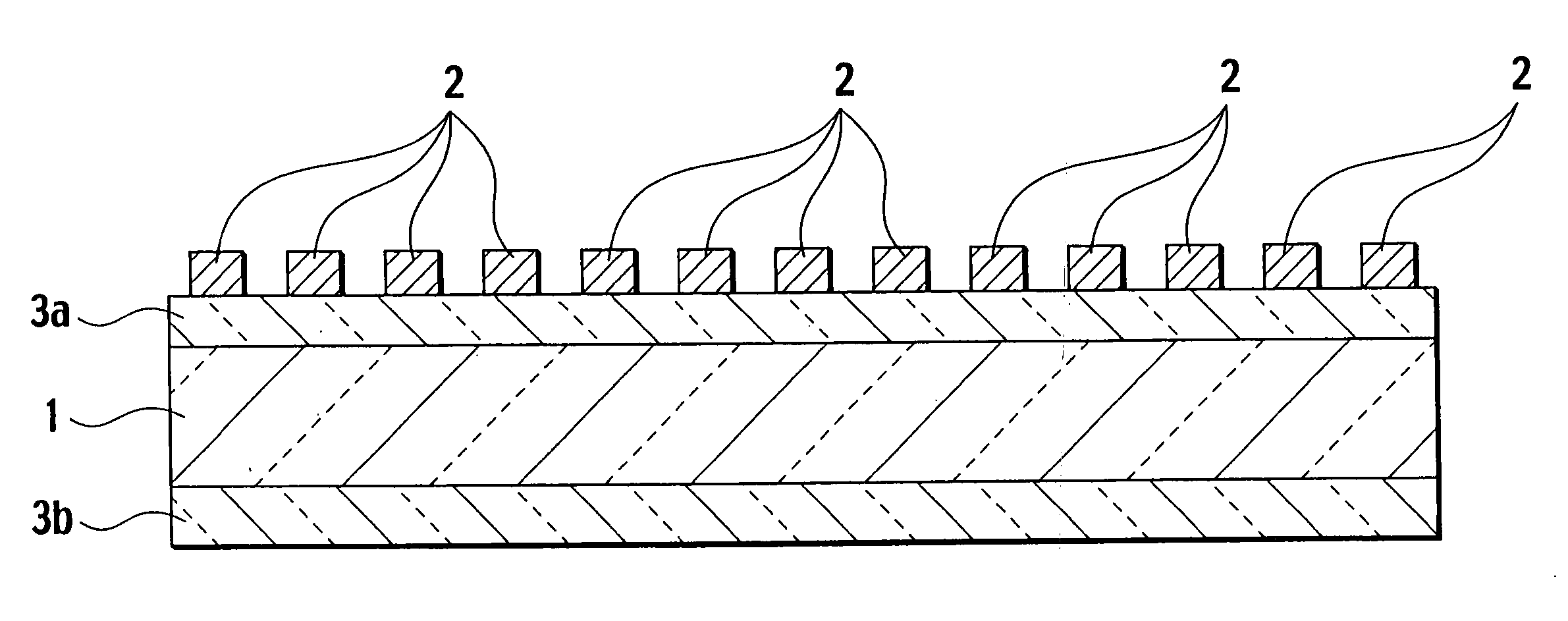

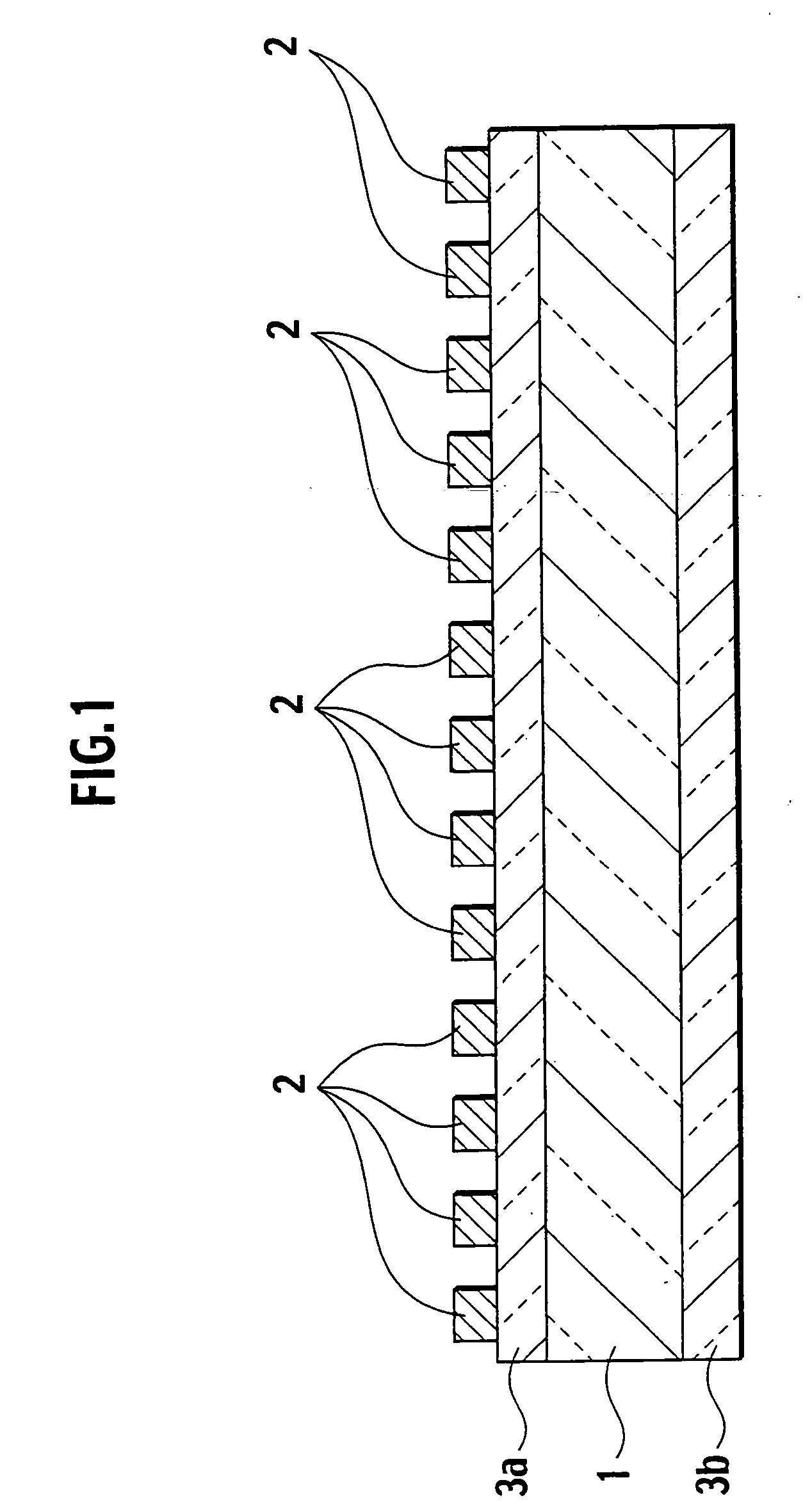

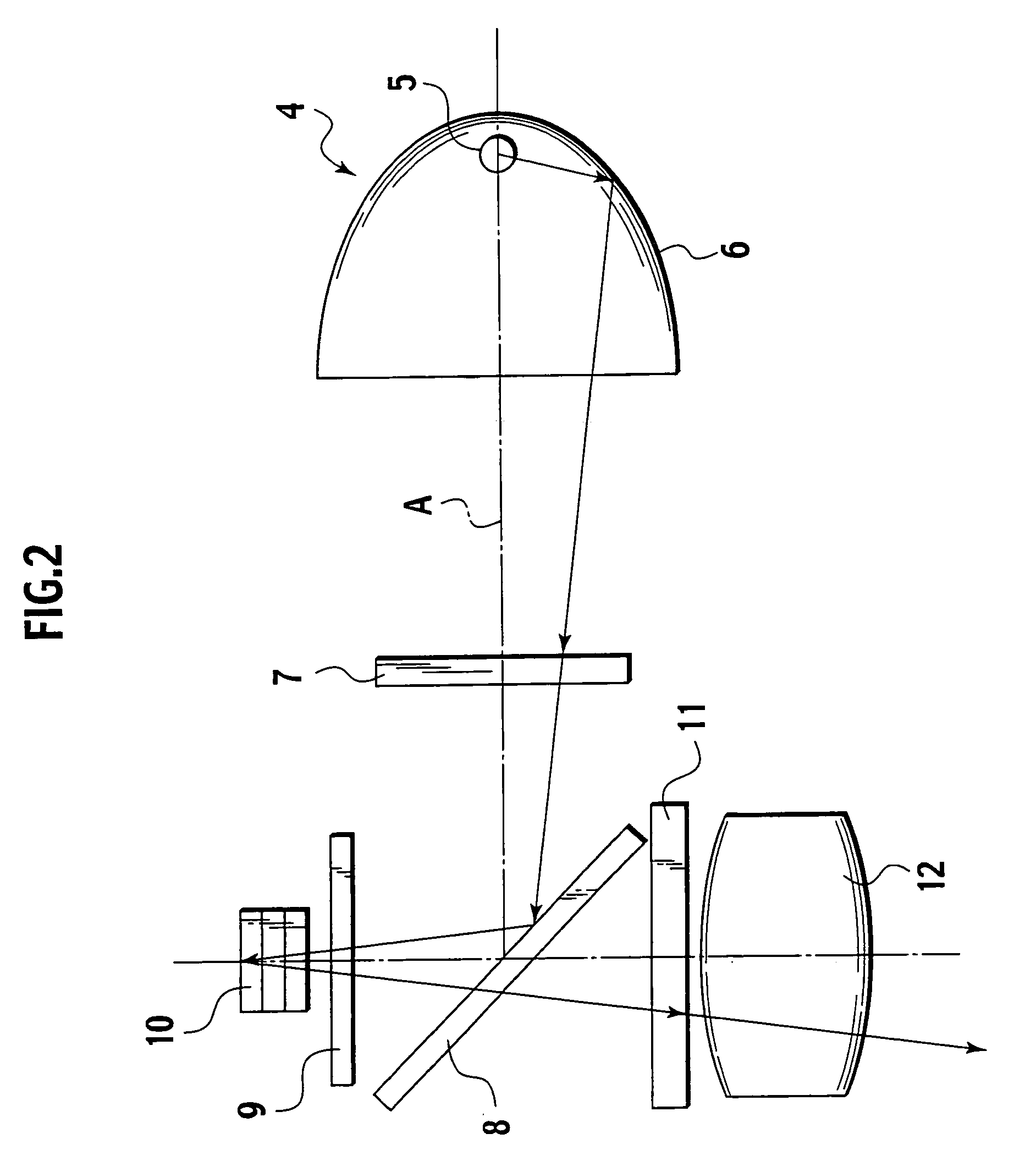

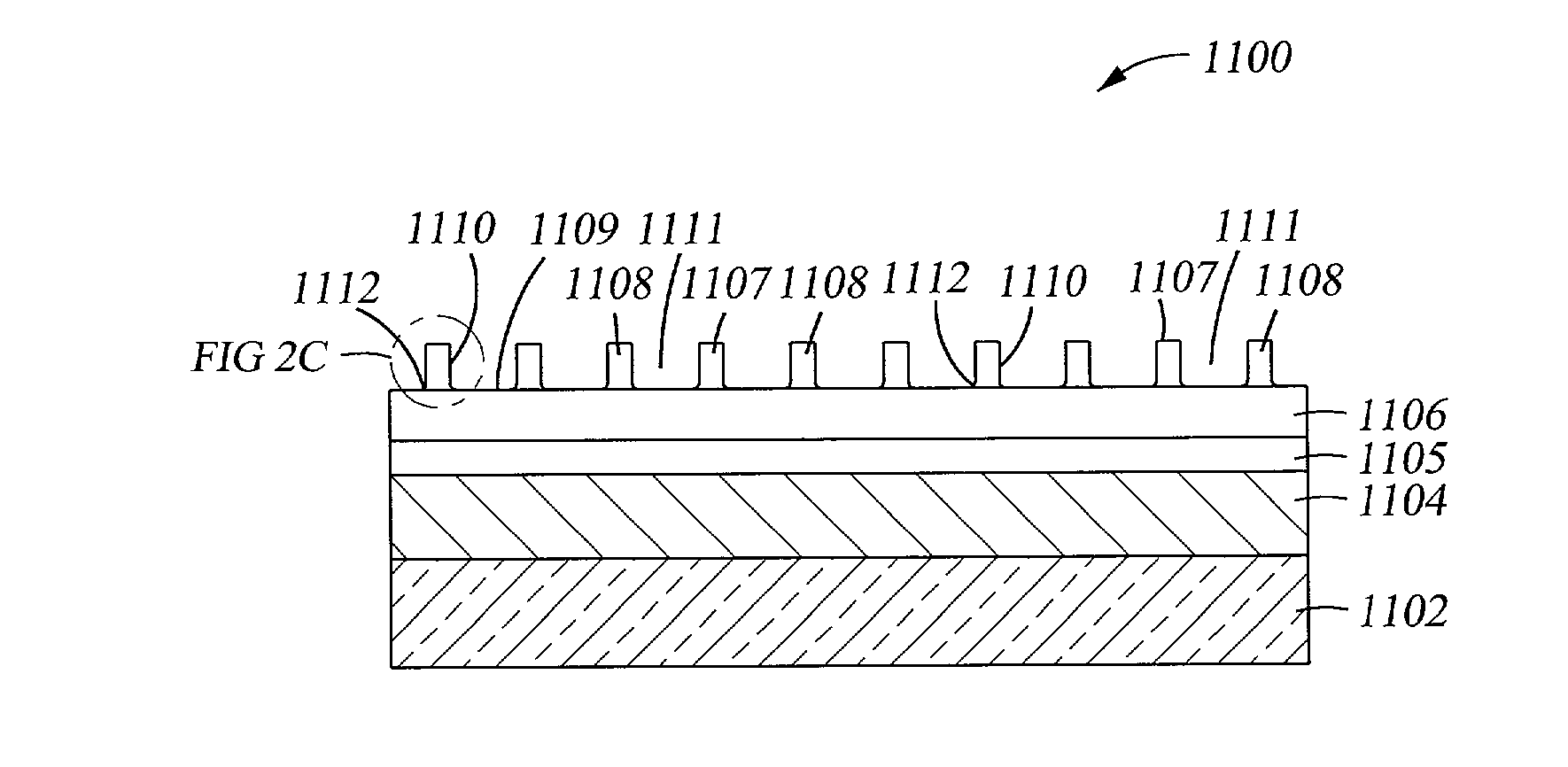

Wire grid polarizer

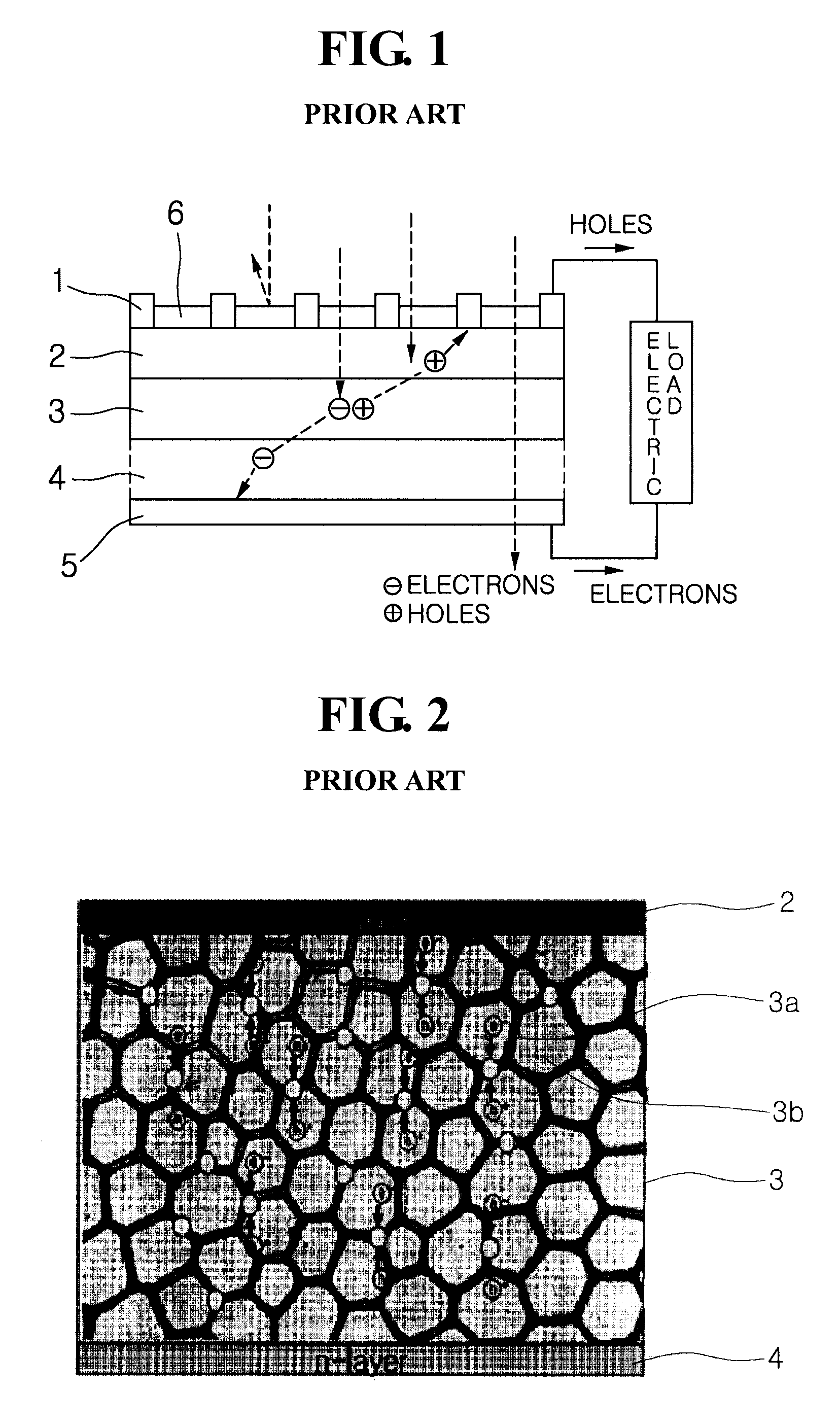

InactiveUS20050190445A1Reduce power consumptionEasy to usePolarising elementsNon-linear opticsWire gridDisplay device

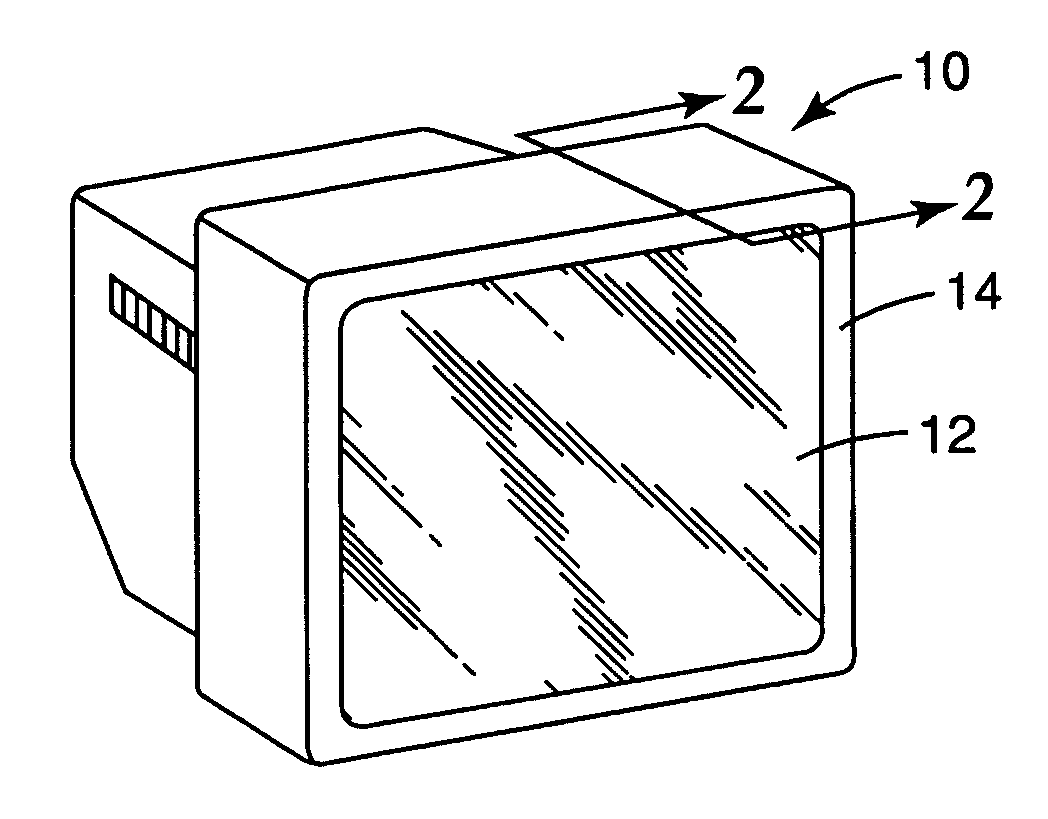

To provide a wire grid polarizer used in an image display apparatus, in which even when the image display apparatus is of a small compact structure and provides high output of power from the light source, shape transformation of the glass substrate occurring due to generation of heat caused by light absorption in the wire grid is prevented and in which by efficient usage of light rays from the light source, high-quality images can be displayed by the image display device and power consumption is low. A wire grid 2 formed of metal in a fine comb shape is formed on a glass substrate 1 and antireflection coatings 3a and 3b are disposed respectively on the front surface part and the rear surface part of the wire grid 2 of the glass substrate 1.

Owner:VICTOR CO OF JAPAN LTD

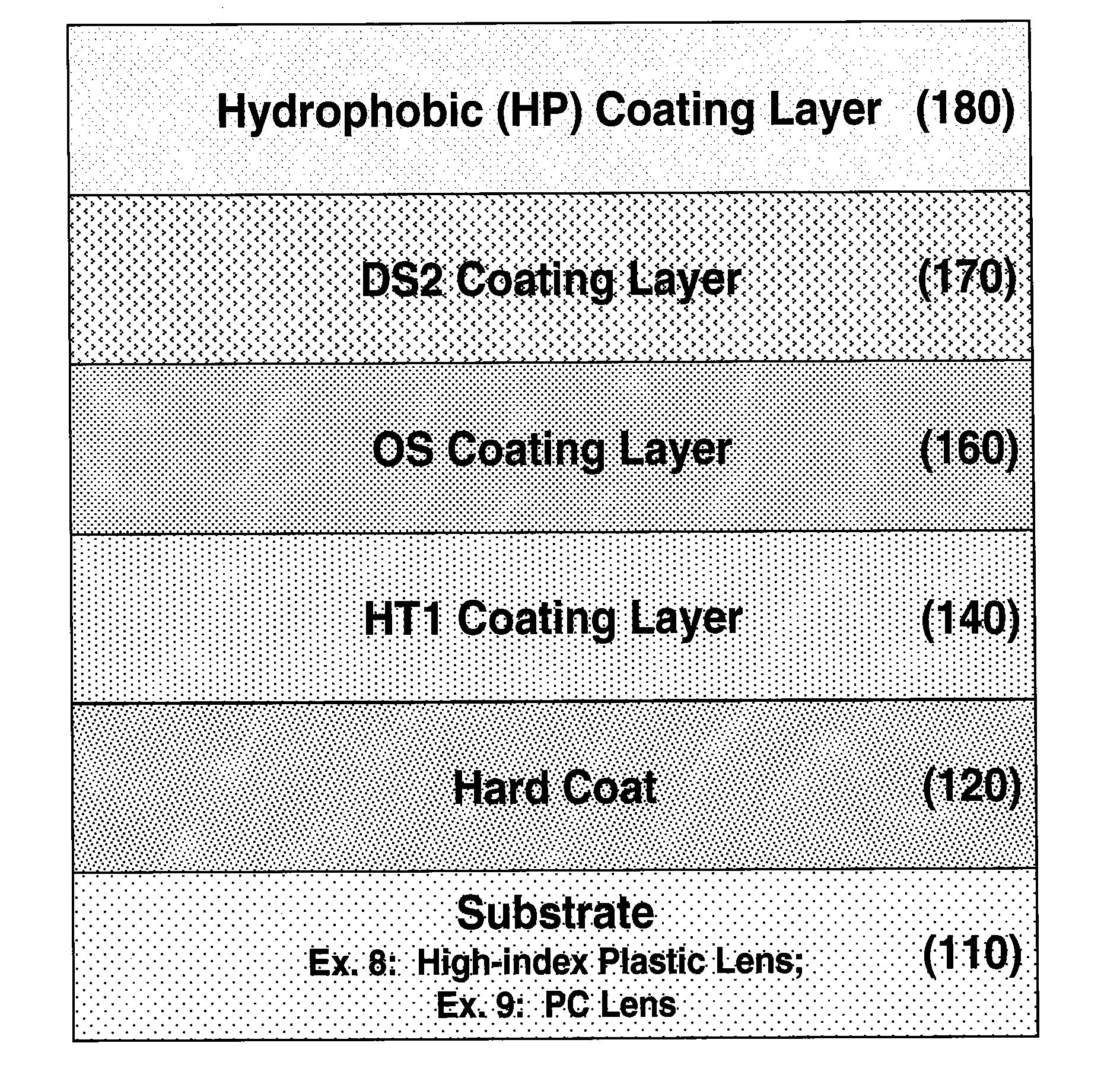

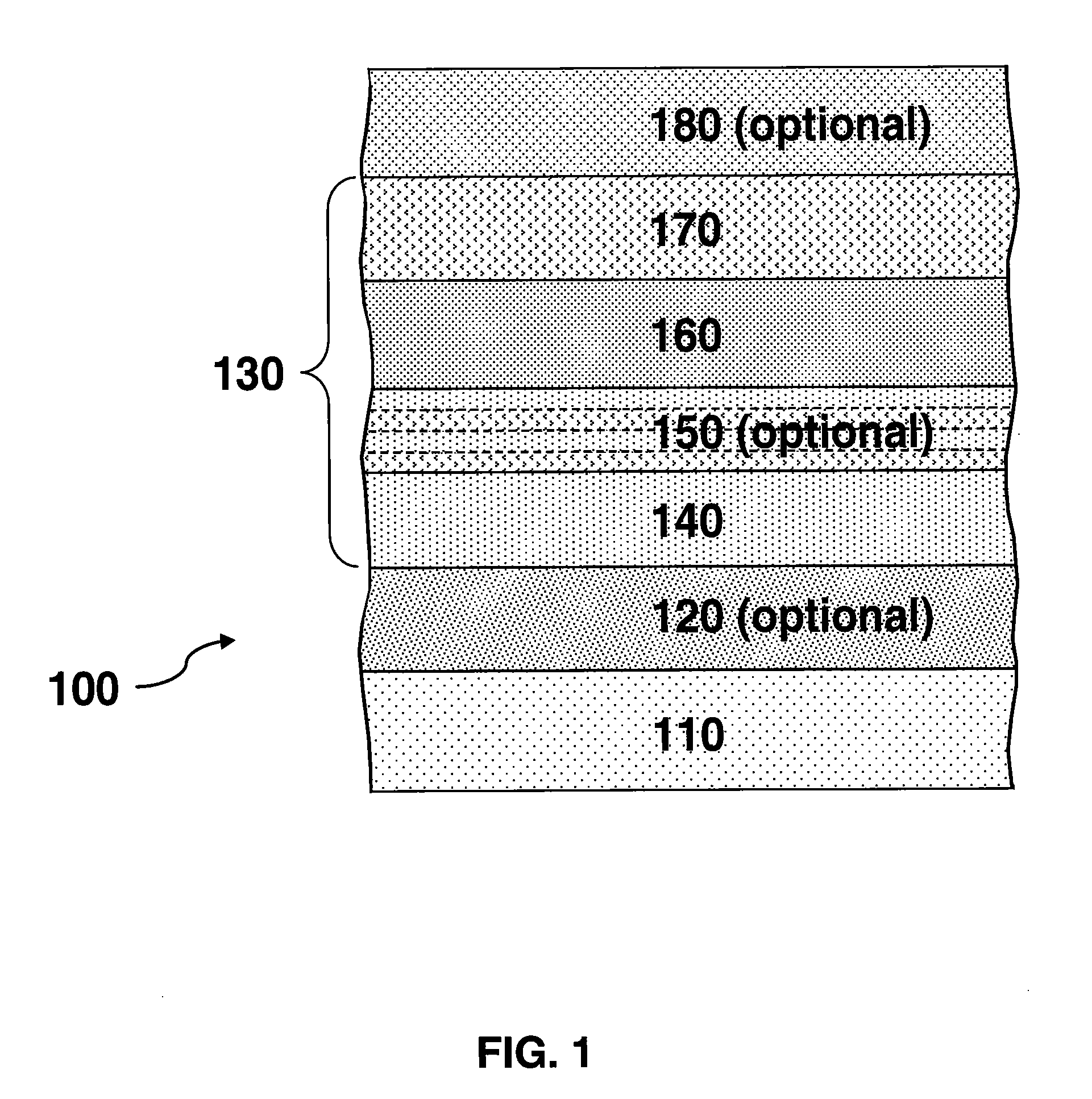

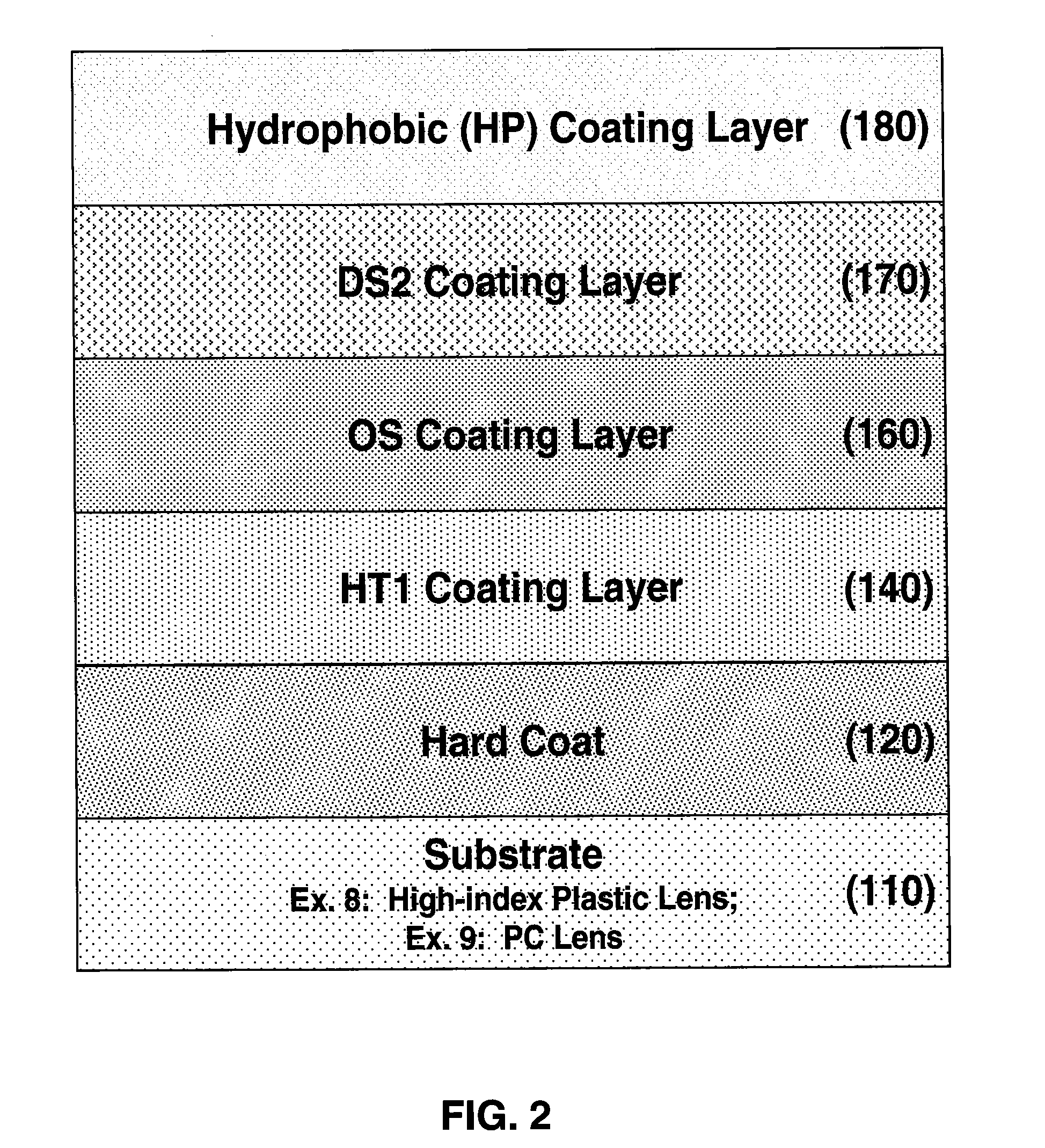

Durable Anti-reflection coatings

InactiveUS20120019915A1Reduce light reflectivityIncreased durabilityLayered productsCoatingsRefractive indexSilica coating

An article comprising a substrate and an anti-reflection coating, and methods for depositing the coating, are disclosed. The coating comprises (a) a first coating layer having a high refractive index deposited on the substrate; (b) an epoxide-silica coating layer deposited onto the high refractive index coating layer, comprising an inorganic silica component and an organic organo-silicate component, and (c) a silica coating layer consisting essentially of silica, deposited directly onto the epoxide-silica coating layer. The anti-reflection coating optionally comprises a stack of coating layers, between the first high refractive index coating layer and the epoxide-silica coating layer, having alternating a low refractive index and a high refractive index. Individual coating layer compositions, refractive indexes, and thicknesses are carefully controlled such that reflectance is minimized through destructive interference in the visible light wavelength range of 400 to 700 nm. The resulting deposited coating provides excellent mechanical, chemical, and environmental durability.

Owner:YAZAKI CORP

Anti-reflective coating

InactiveUS20110019277A1High light transmittanceAvoid problemsCoatingsSpecial surfacesPorosityAnti-reflective coating

Methods and devices are provided for improved anti-reflective coatings. Non-vacuum deposition of transparent conductive electrodes in a roll-to-roll manufacturing environment is disclosed. In one embodiment of the present invention, a device is provided comprising a multi-layer anti-reflective coating formed over a substantially transparent substrate; wherein the multi-layer anti-reflective coating comprises of a plurality of nanostructured layers, wherein each of the layers has a tuned porosity and at least some of the nanostructured layers have different porosities to create a different index of refraction for those layers. In some embodiments, the absorber layer for use with this anti-reflective layer is a group IB-IIIA-VIA absorber layer.

Owner:SAGER BRIAN M +1

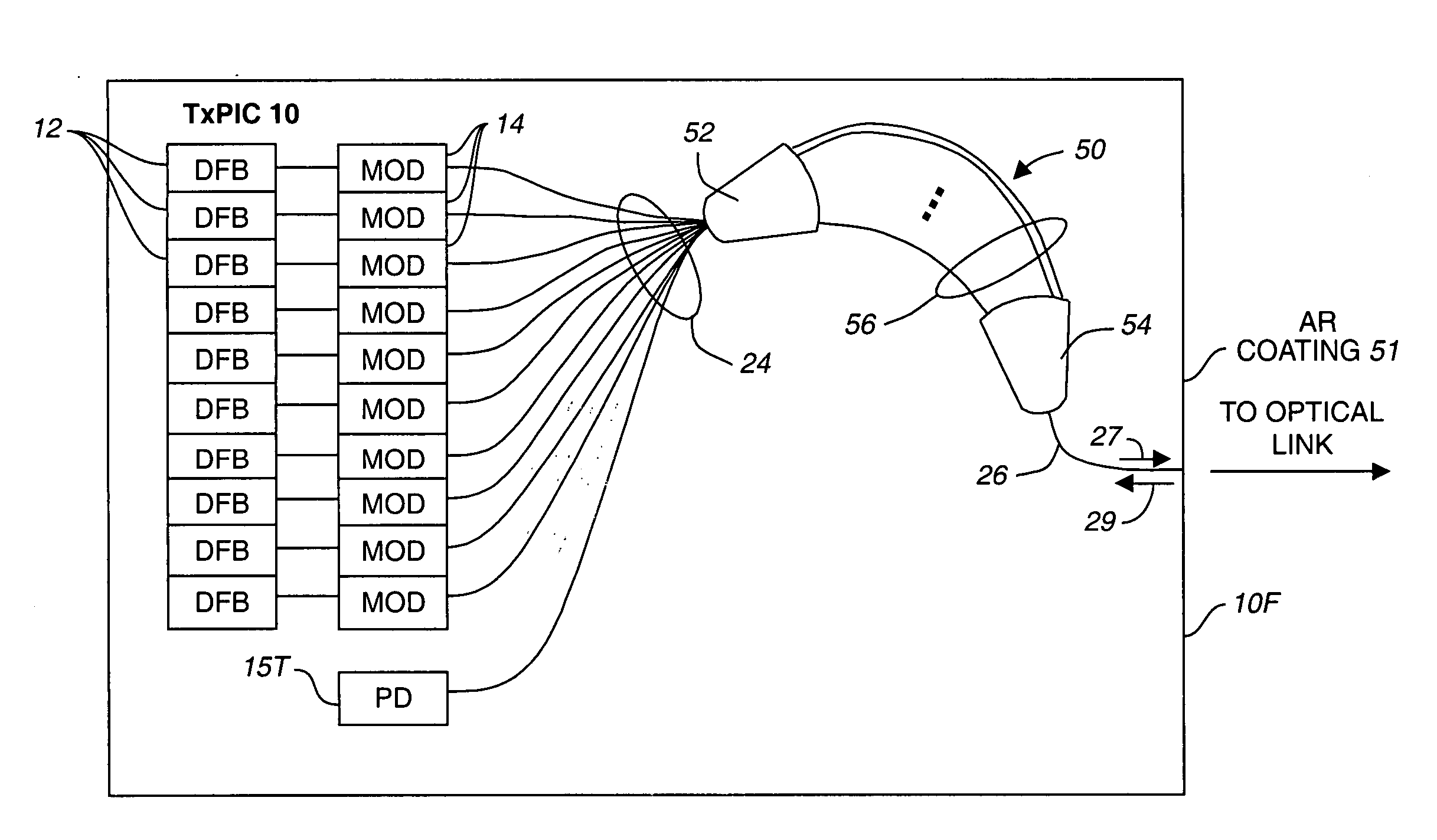

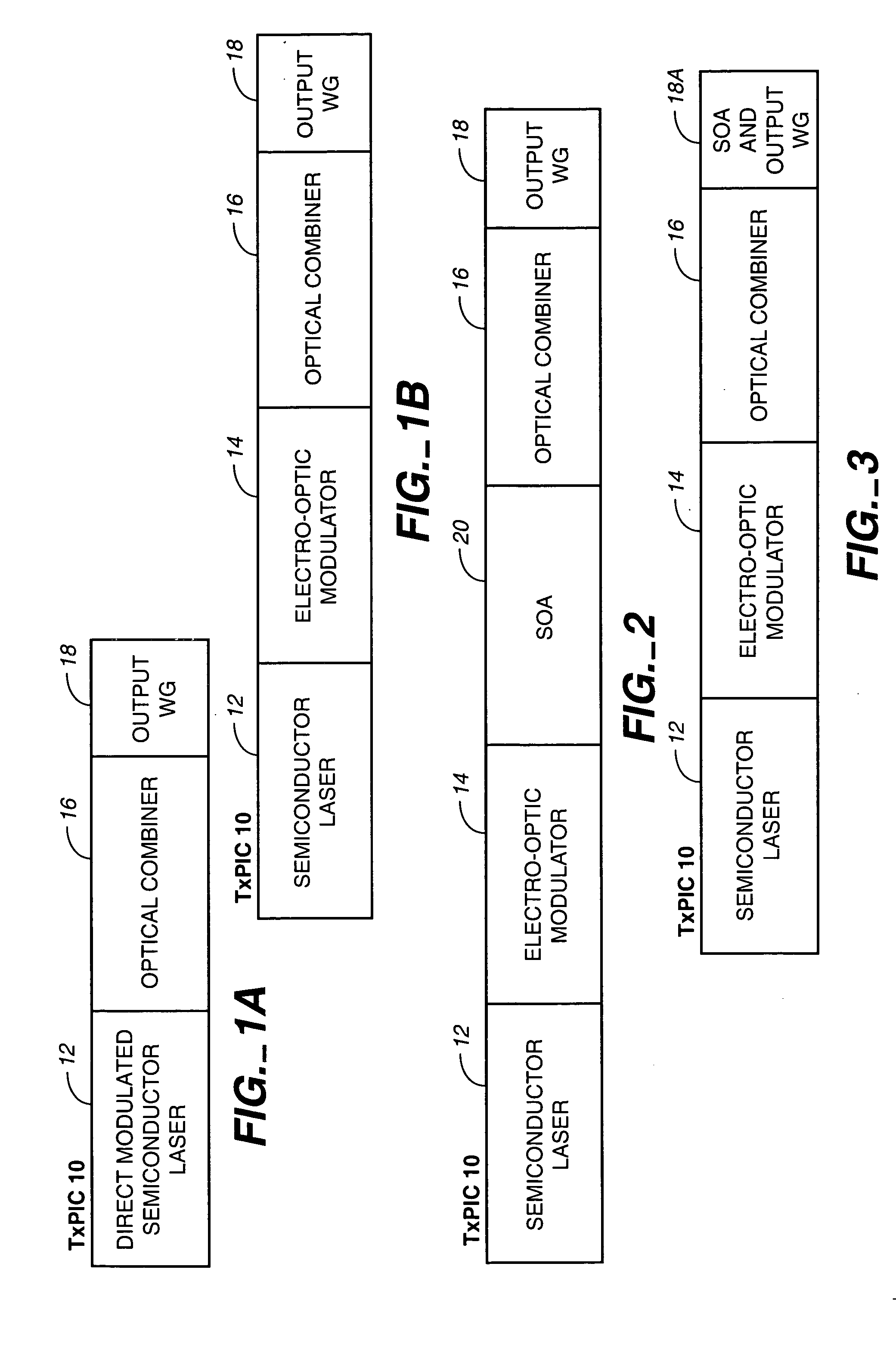

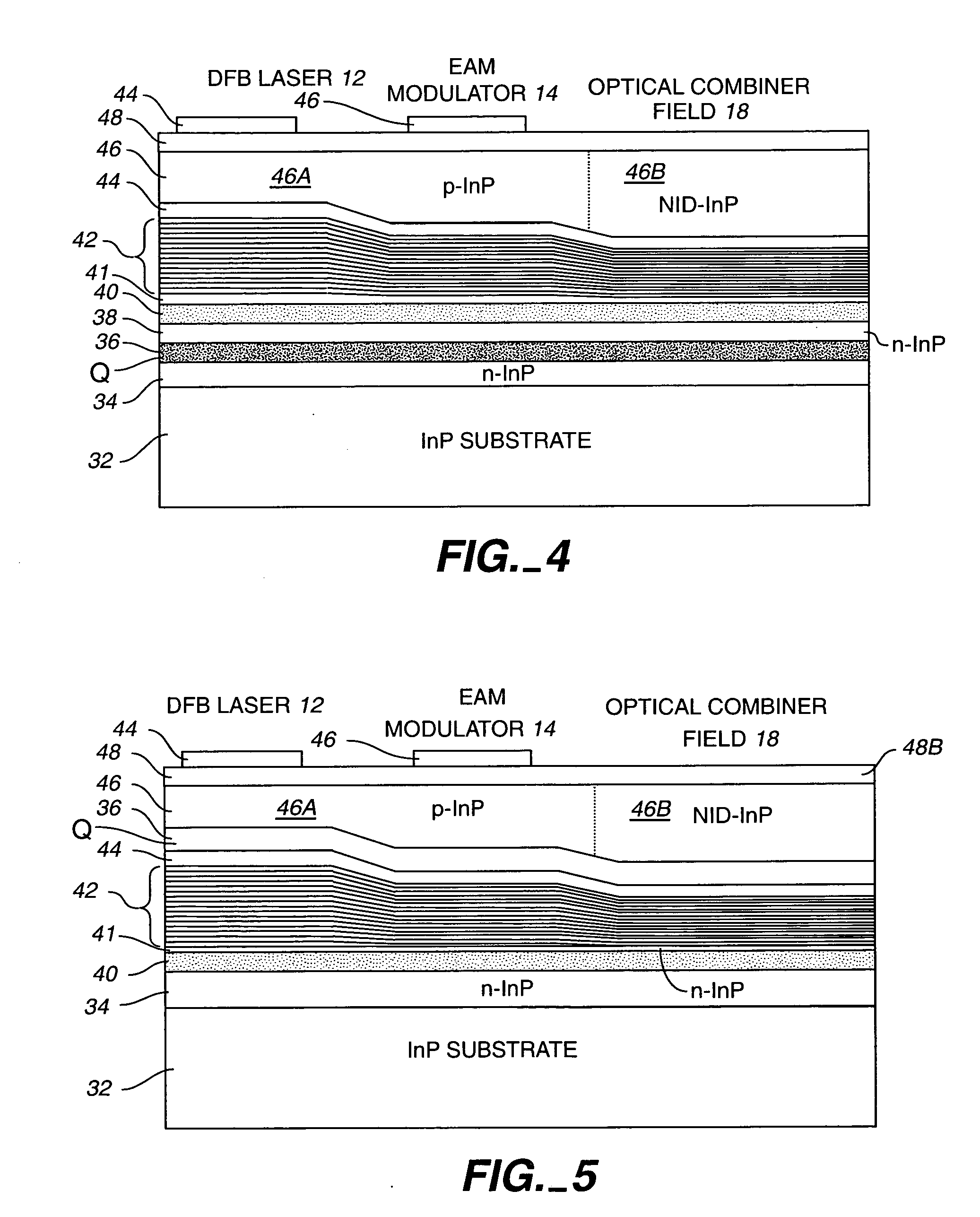

Method and apparatus for providing an antireflection coating on the output facet of a photonic integrated circuit (PIC) chip

An on-chip photodiode is provided in a photonic integrated circuit (PIC) on a semiconductor chip to monitor or check for antireflection qualities of an AR coating applied to the front facet of the semiconductor chip.

Owner:INFINERA CORP

Fluoropolymer containing ethylenically unsaturated groups, and curable resin compositions and antireflection coatings, made by using the same

ActiveUS20050038187A1Antiscratching propertyIncreased durabilityPretreated surfacesPolyurea/polyurethane coatingsAnti-reflective coatingFluoropolymer

An ethylenically unsaturated group-containing fluoropolymer, which is obtained by reacting a compound containing one isocyanate group and at least one ethylenically unsaturated group, and a hydroxyl group-containing fluoropolymer at an isocyanate group / hydroxyl group molar ratio of 1.1 to 1.9. According to the present invention, an ethylenically unsaturated group-containing fluoropolymer having superior antiscratching property, coating property and durability, as well as a curable resin composition and an antireflection film using the same can be provided.

Owner:JSR CORPORATIOON

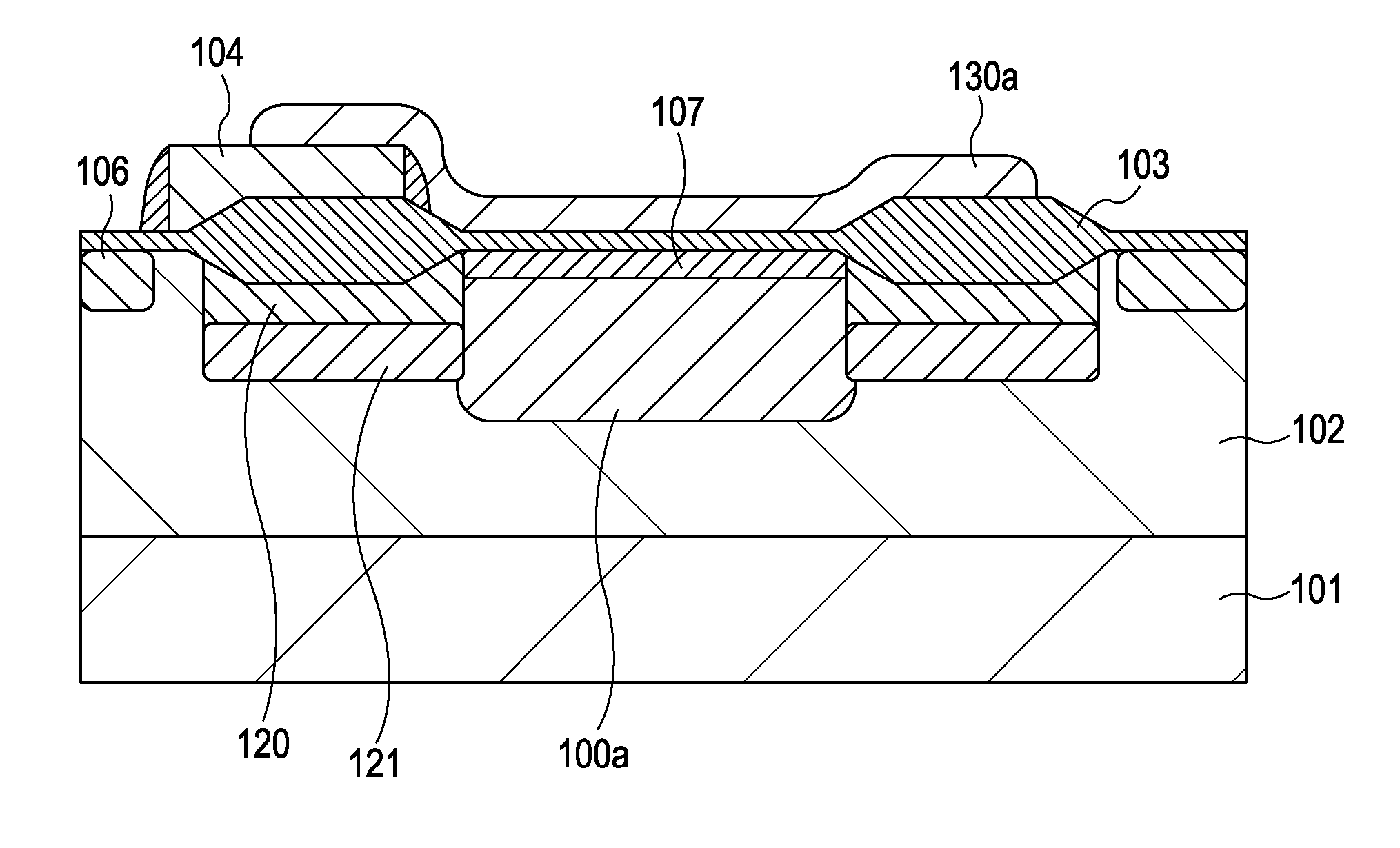

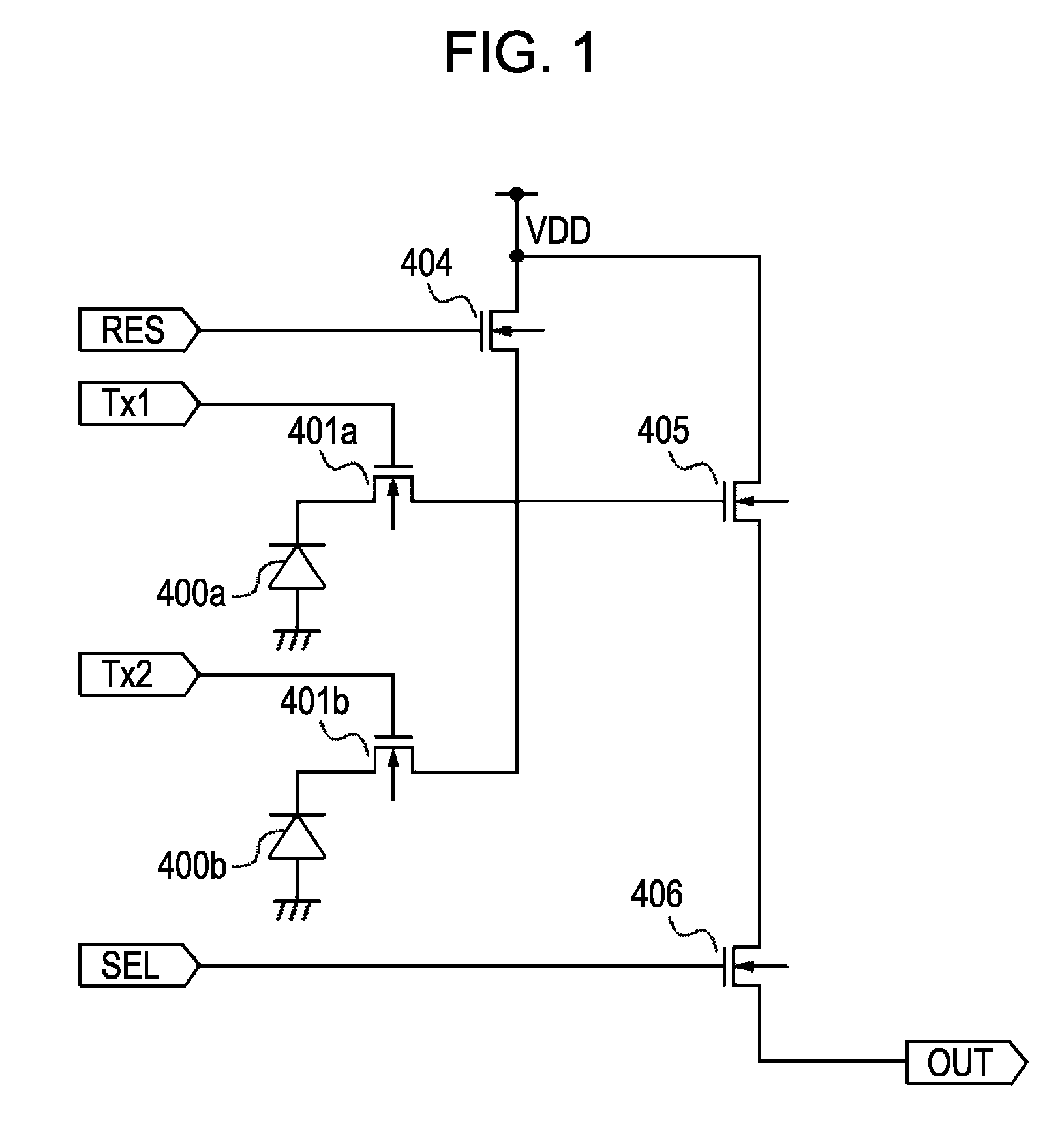

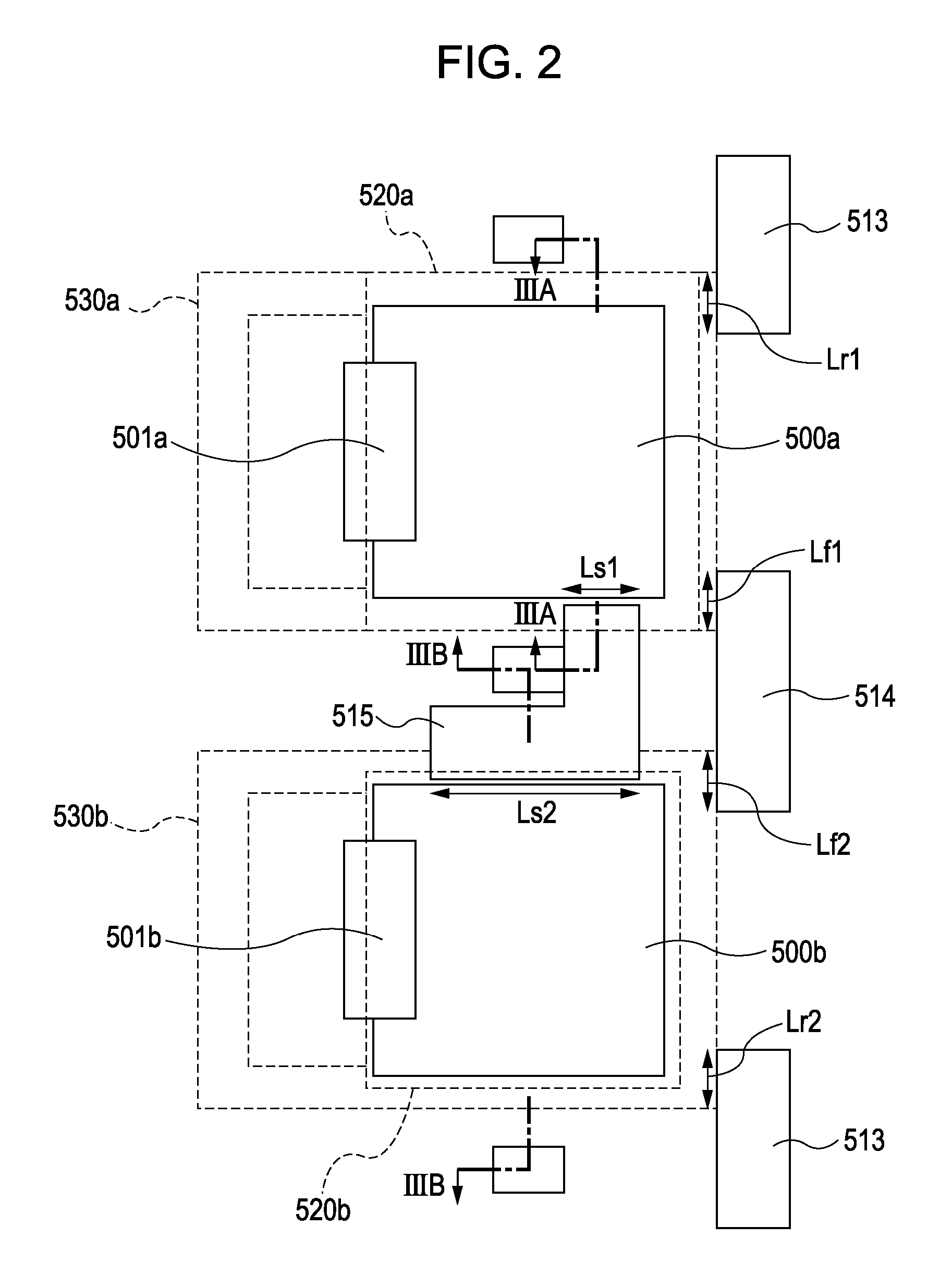

Solid-state image pickup apparatus

InactiveUS20090237543A1Reduce the differenceTelevision system detailsColor signal processing circuitsAnti-reflective coatingPhotoelectric conversion

A solid-state image pickup apparatus includes a first antireflection coating film formed on a light-receiving surface of a first photoelectric conversion element and a second antireflection coating film formed on a light-receiving surface of a second photoelectric conversion element. A total length of first photoelectric conversion element facing portions of gate lines adjacent to the first photoelectric conversion element is shorter than a total length of second photoelectric conversion element facing portions of gate lines adjacent to the second photoelectric conversion element. An area of the first antireflection coating film is larger than that of the second antireflection coating film.

Owner:CANON KK

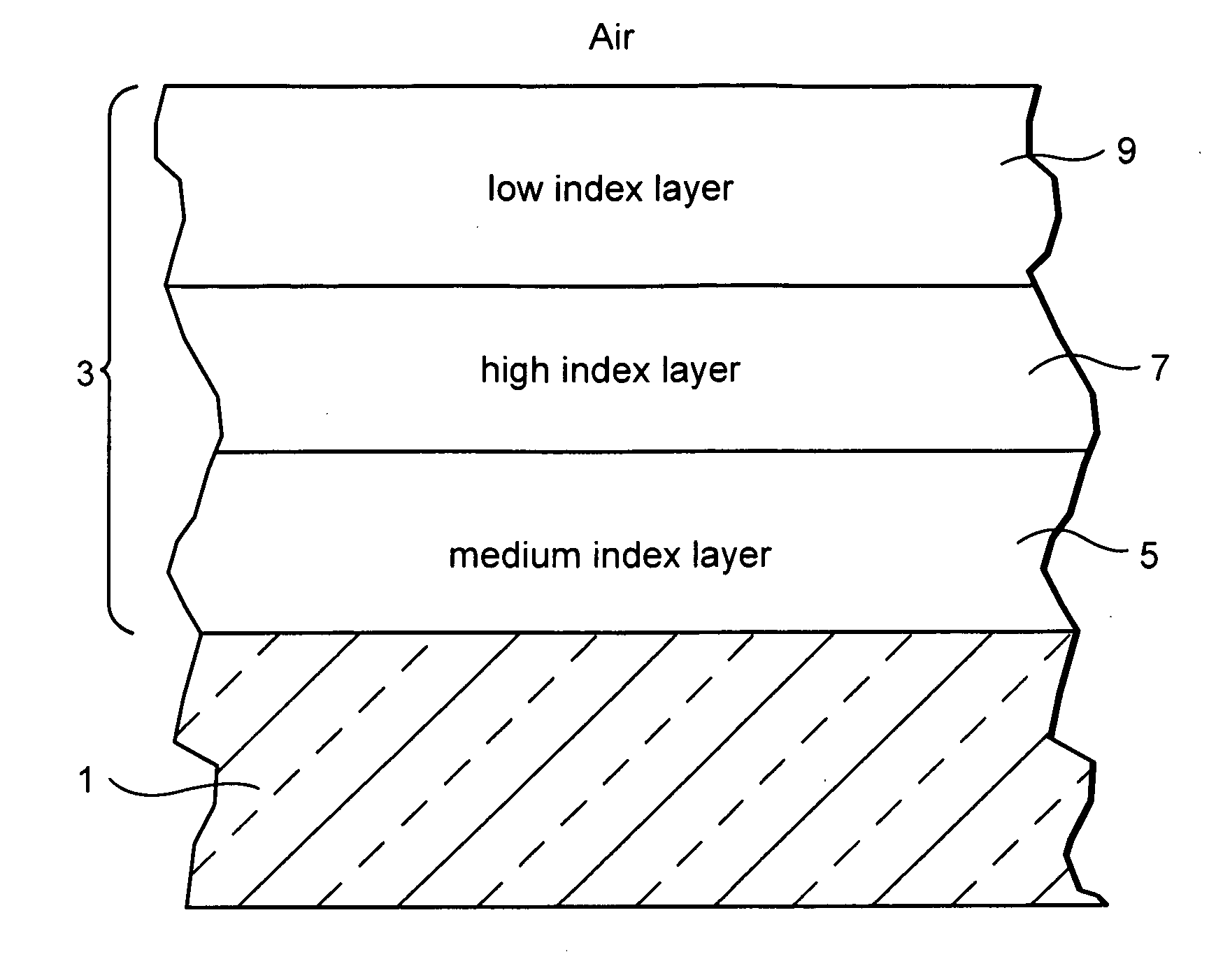

Temperable three layer antirefrlective coating, coated article including temperable three layer antirefrlective coating, and/or method of making the same

ActiveUS20120057236A1Reduced visible light reflectionGood refractive indexCoatingsOptical elementsOptical propertyRefractive index

A coated article includes a temperable antireflection (AR) coating that utilizes medium and low index (index of refraction “n”) layers having compressive residual stress in the AR coating. In certain example embodiments, the coating may include the following layers from the glass substrate outwardly: silicon oxynitride (SiOxNy) medium index layer / high index layer / low index layer. In certain example embodiments, depending on the chemical and optical properties of the high index layer and the substrate, the medium and low index layers of the AR coating are selected to cause a net compressive residual stress and thus optimize the overall performance of the antireflection coating when the coated article is tempered and / or heat-treated.

Owner:GUARDIAN GLASS LLC

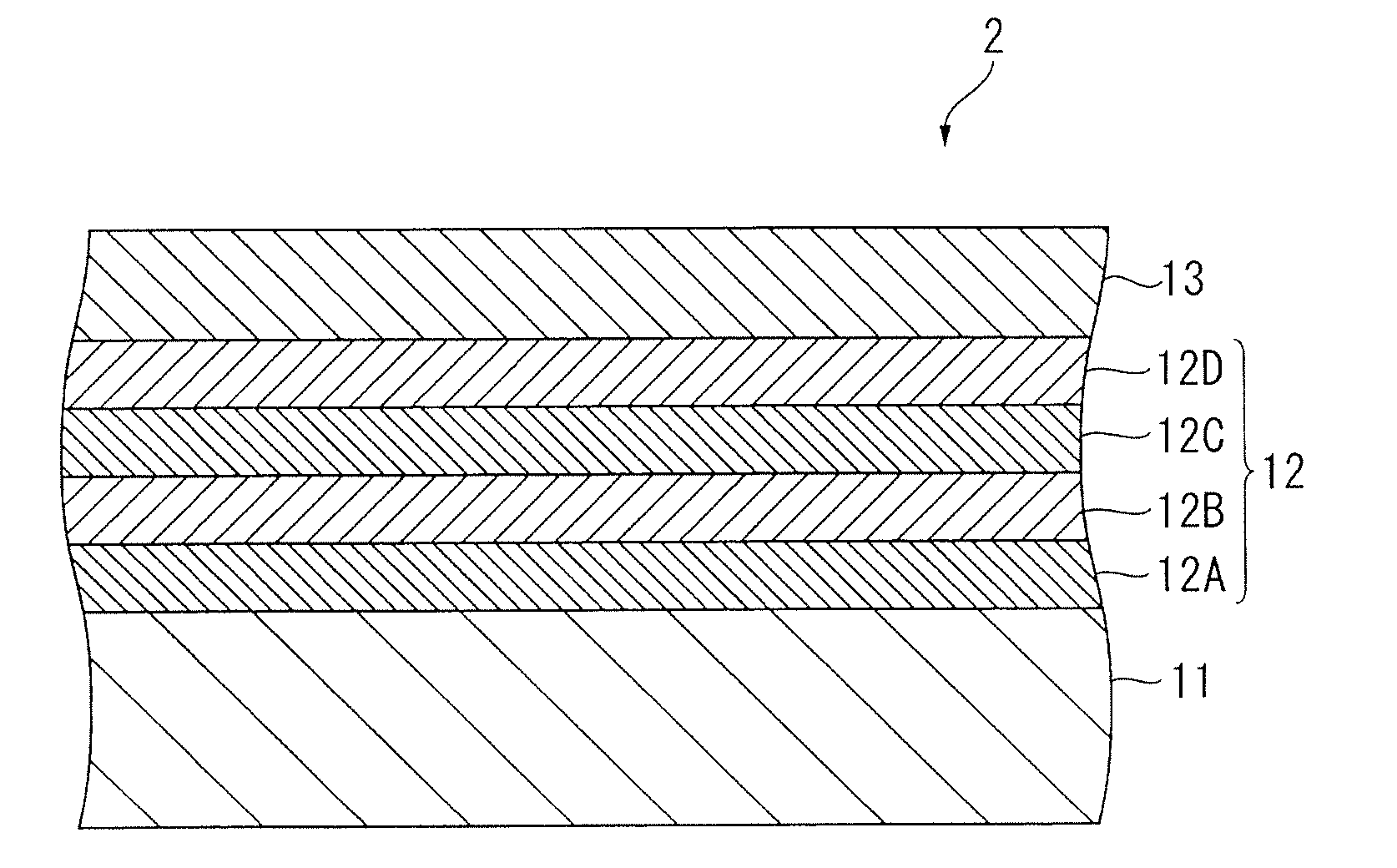

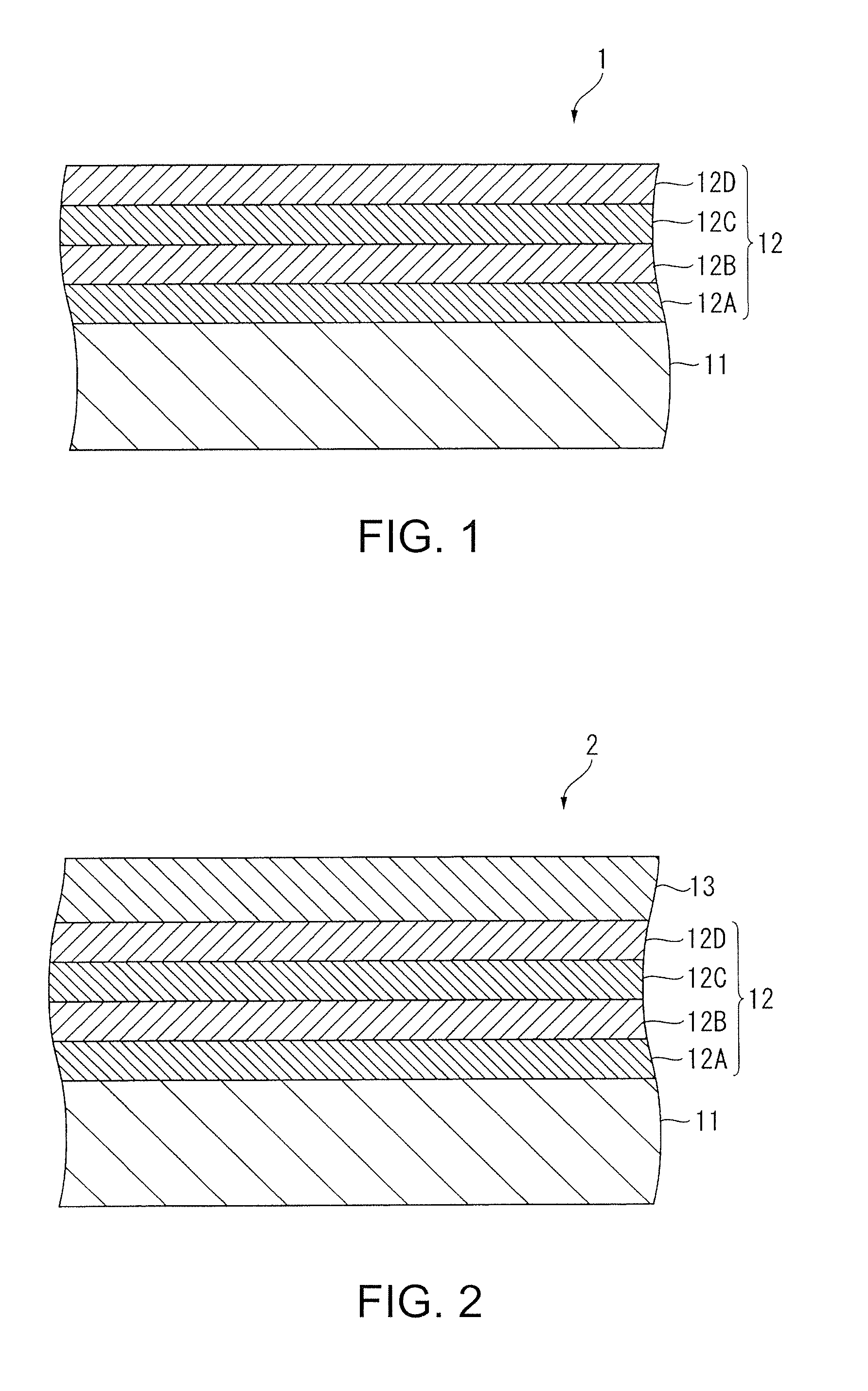

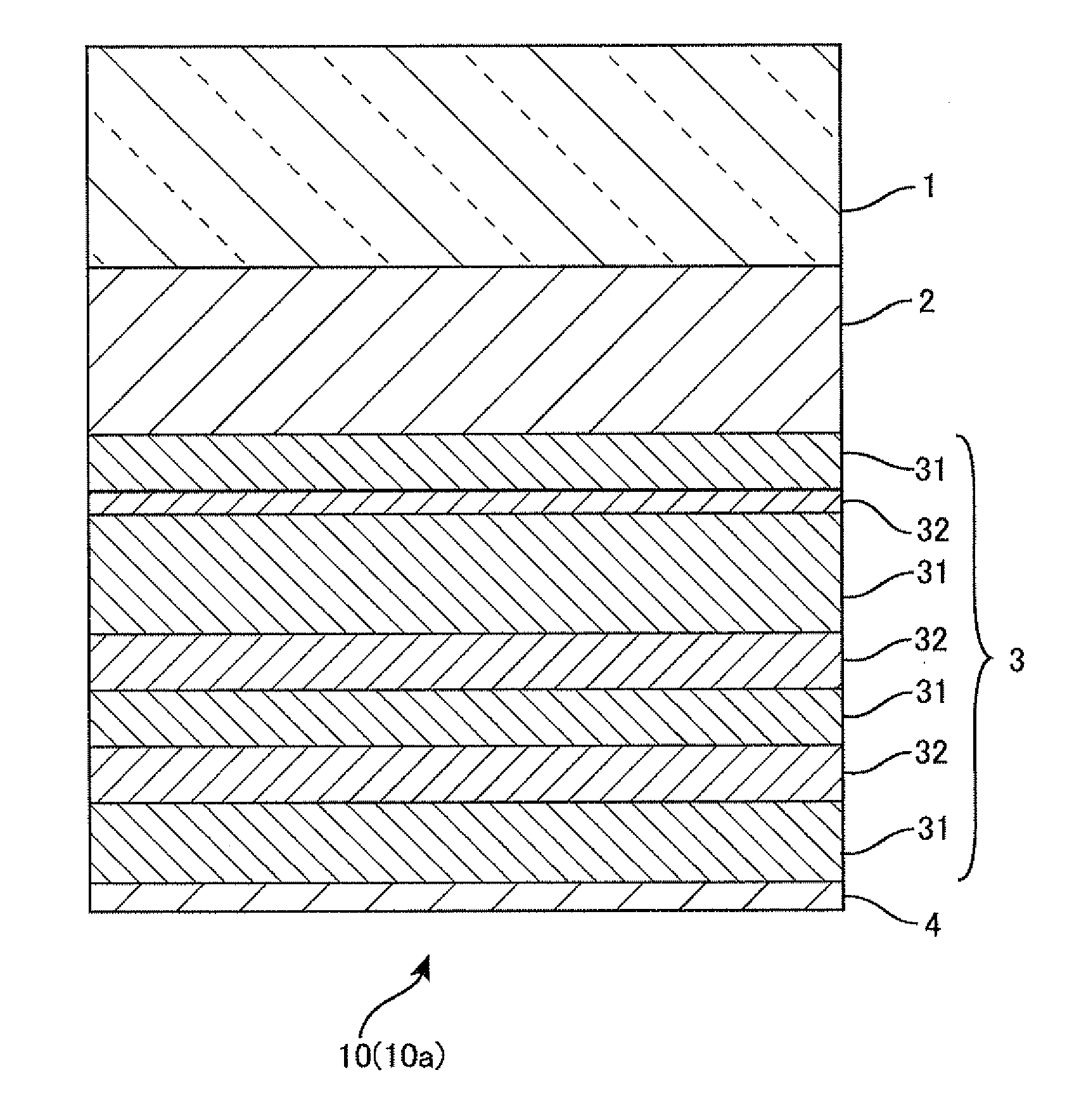

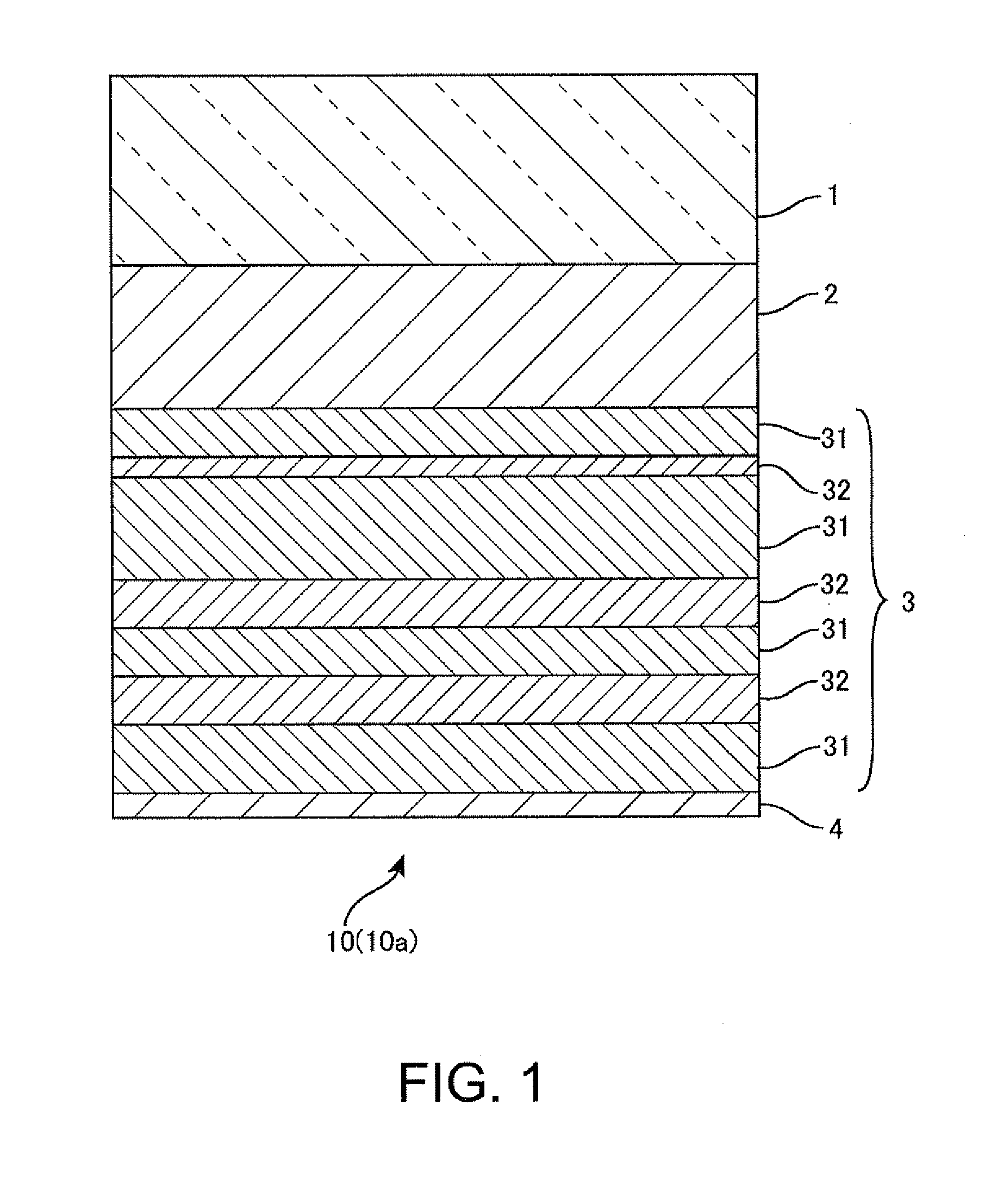

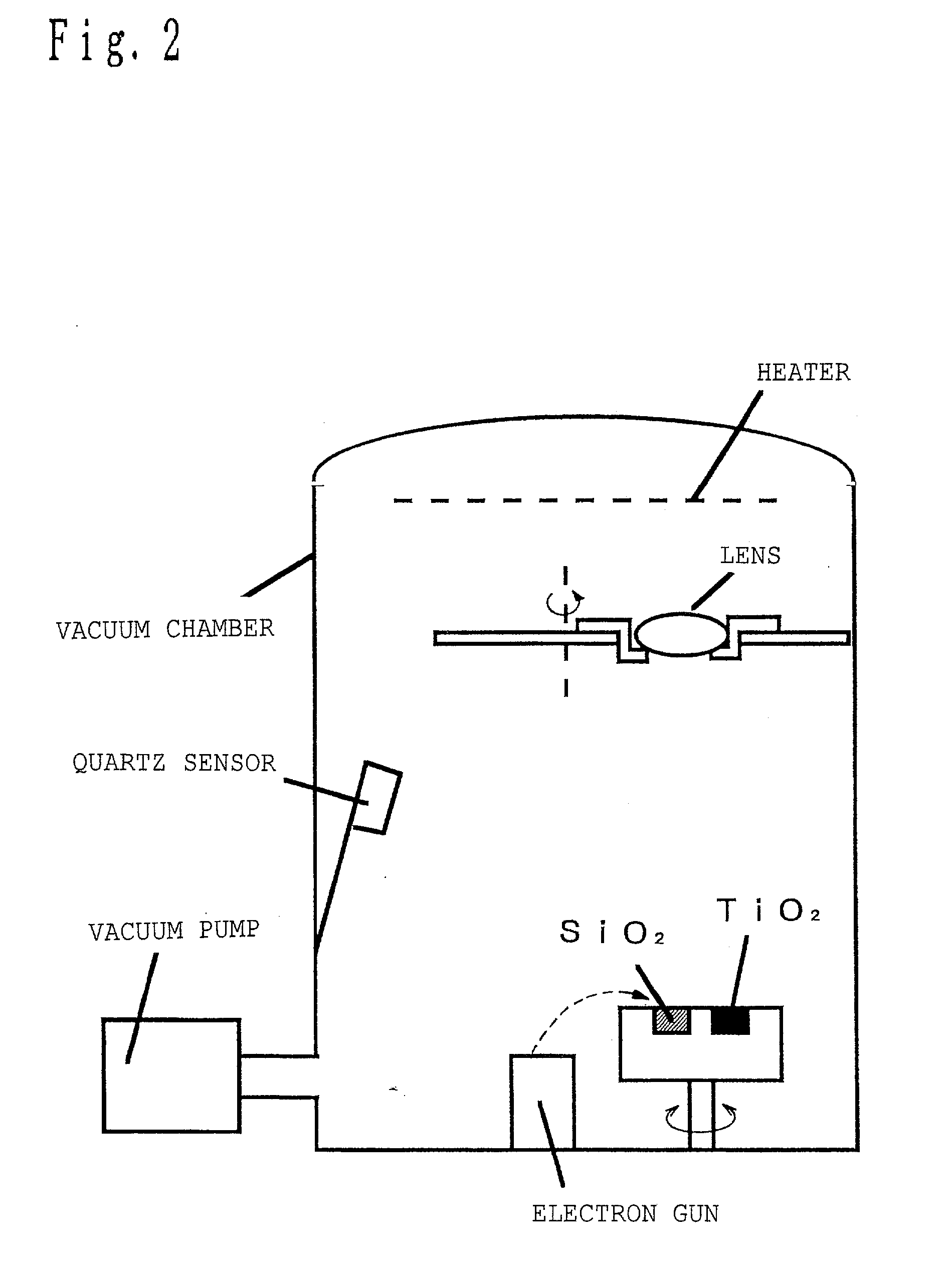

Optical Article and Method for Producing Optical Article

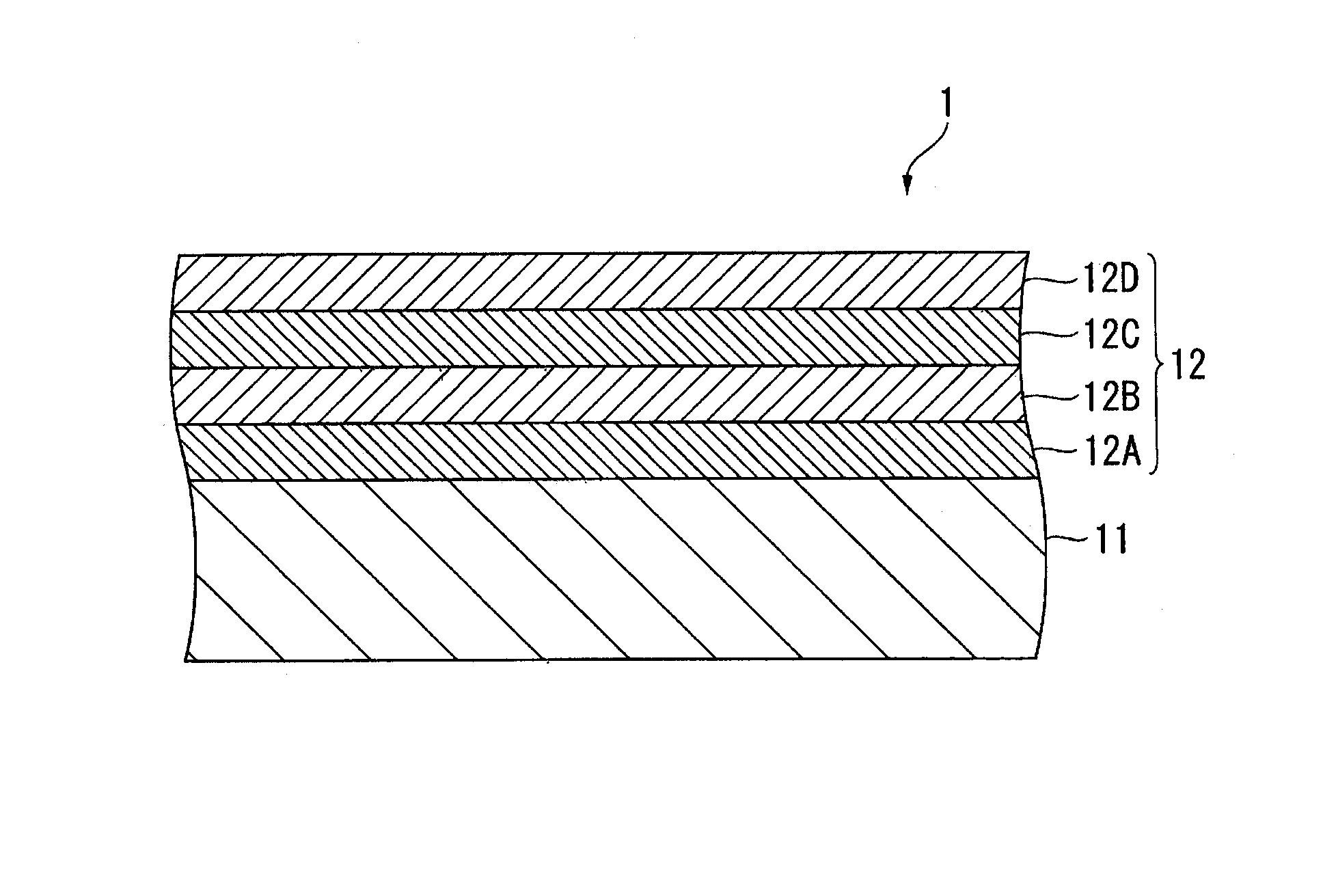

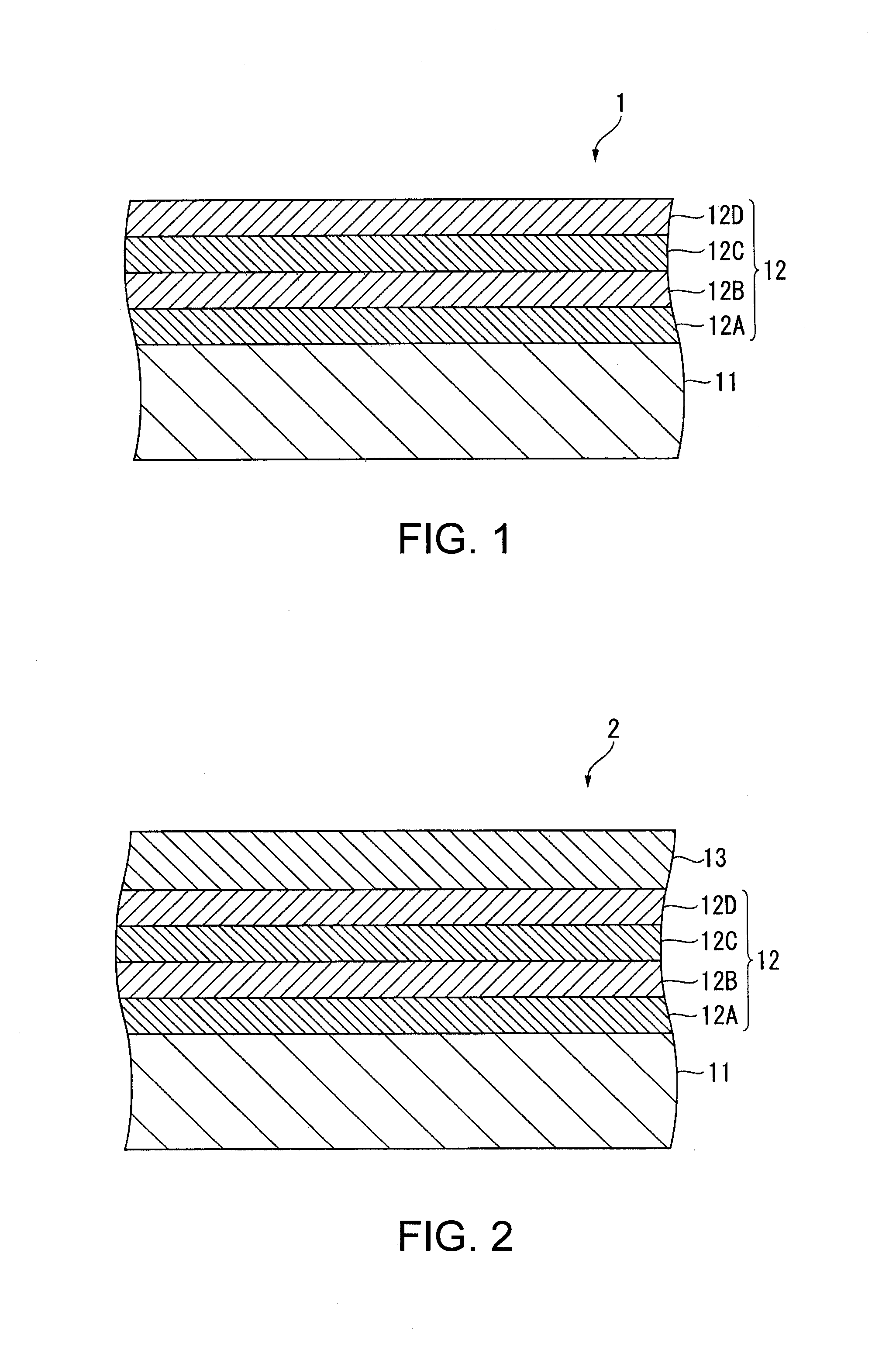

InactiveUS20120154916A1High level of performanceHigh levelSpecial surfacesCoatingsAnti-reflective coatingRefractive index

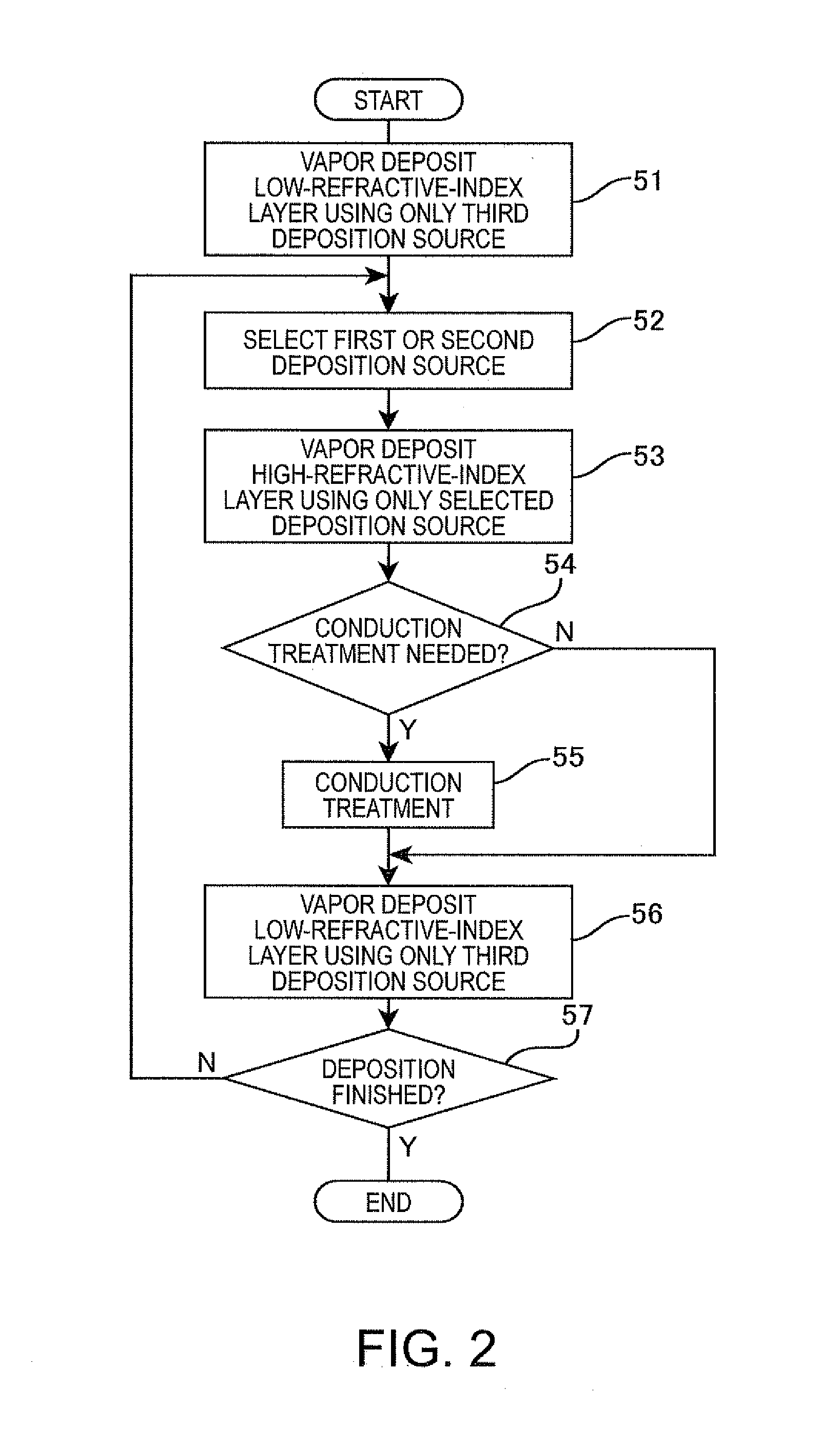

An optical article includes an antireflection coating that is configured from alternately laminated n+1 low-refractive-index layers and n high-refractive-index layers (where n is an integer of 2 or more) . At least one of the n high-refractive-index layers is a first-type layer formed by vapor deposition using only a first deposition source that includes zirconium oxide as the main component. The remaining layers) in the n high-refractive-index layers is a second-type layer (s) formed by vapor deposition using only a second deposition source that includes titanium oxide as the main component. The n+1 low-refractive-index layers are third-type layers formed by vapor deposition using only a third deposition source that includes silicon oxide as the main component. The proportion of the total thickness of the second-type layer (s) in the total thickness of the n high-refractive-index layers is from 15% to 90%.

Owner:HOYA LENS MFG PHILIPPINES

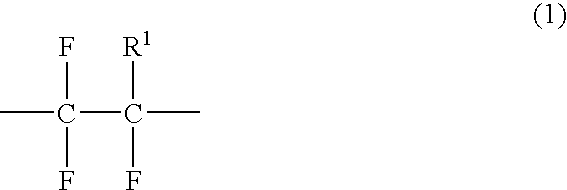

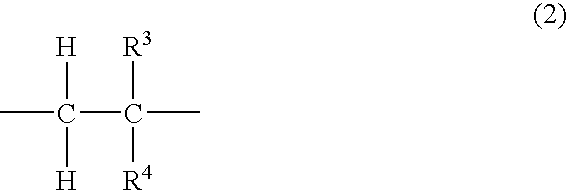

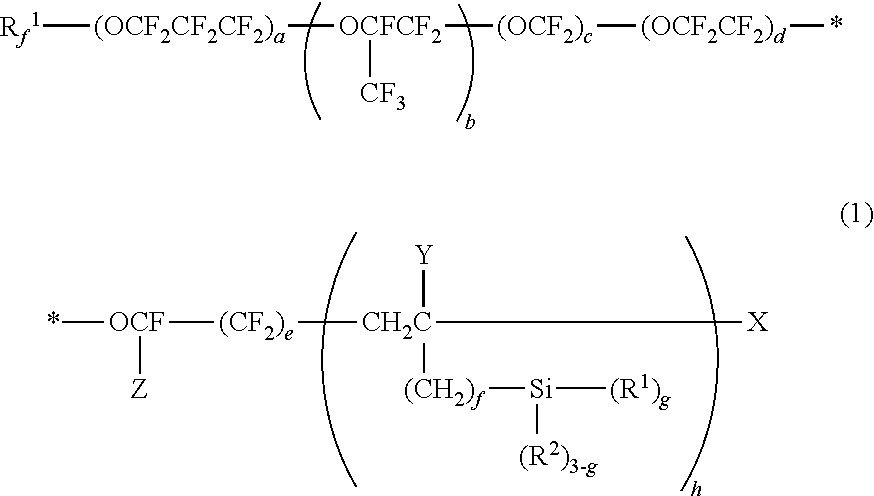

Low refractive index coating composition for use in antireflection polymer film coatings and manufacturing method

InactiveUS20060147724A1Easy to manufactureImprove wettabilitySynthetic resin layered productsThin material handlingPolymer scienceHexafluoropropylene

A silicone-modified fluoropolymer is formed by first dissolving a fluoropolymer in an organic solvent, the fluoropolymer having at least one monomer of vinylidene fluoride coupled to a hexafluoropropylene monomer unit, and subsequently reacting the mixture with an amino silane coupling agent to form an aminosilane-modified fluoropolymer. The aminosilane fluoropolymer is subsequently heated and partially condensed with an oligomer of a silane compound including alkoxy silane. The resultant composition is suitable for use as a low refractive index layer in an antireflection coating on an optical substrate.

Owner:3M INNOVATIVE PROPERTIES CO

Transparent member, timepiece, and method of manufacturing a transparent member

InactiveUS20130260115A1High hardnessLayered productsVacuum evaporation coatingRefractive indexSilicon oxide

A transparent member has a transparent substrate, and an antireflection coating that has a high index of refraction layer made of silicon nitride and a low index of refraction layer made of silicon oxide alternately laminated on at least a part of a surface of the substrate. The content of silicon nitride in the region to a depth of 150 nm from the outside surface of the antireflection coating is 30-50 vol %.

Owner:SEIKO EPSON CORP

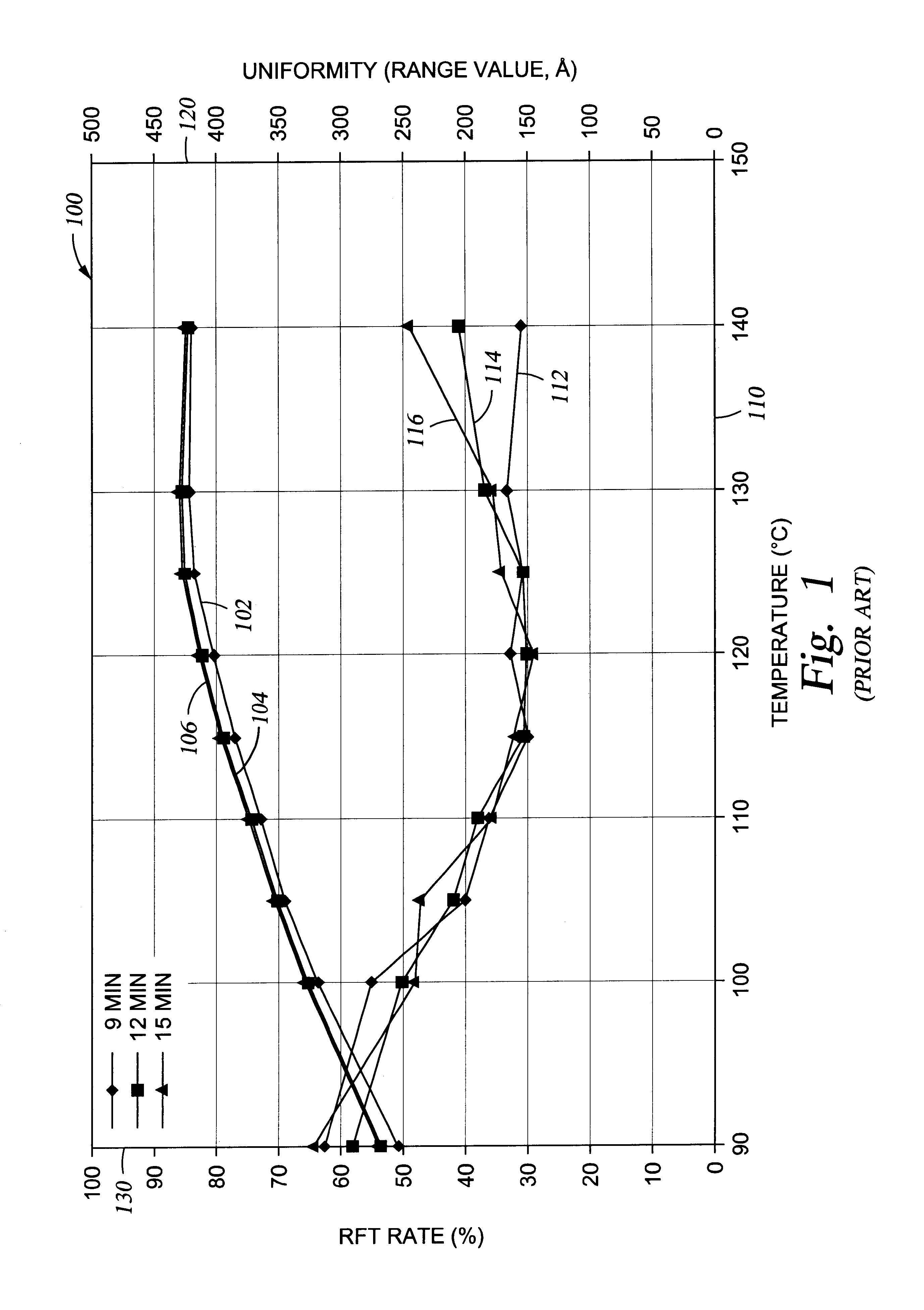

Method of preparing optically imaged high performance photomasks

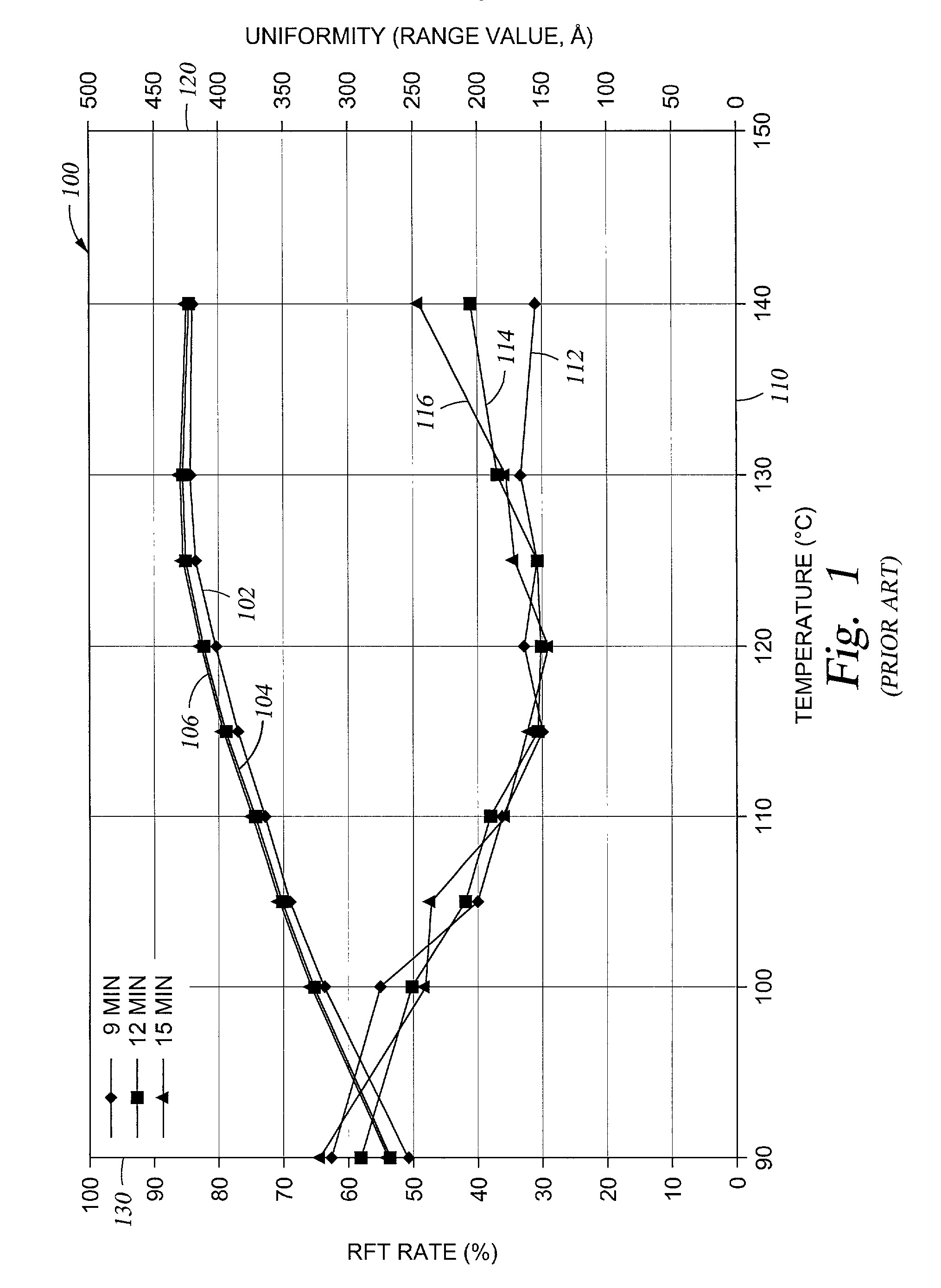

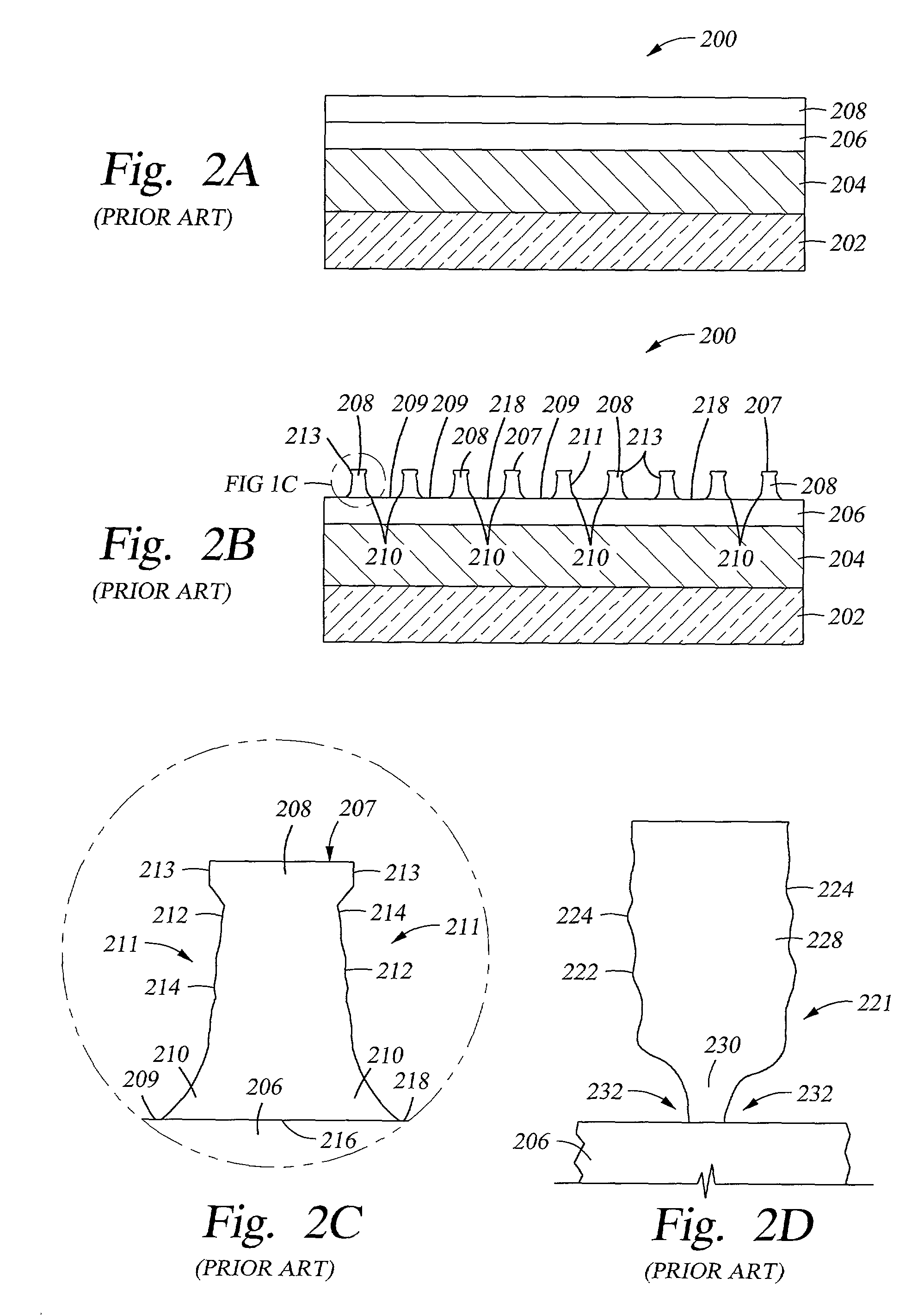

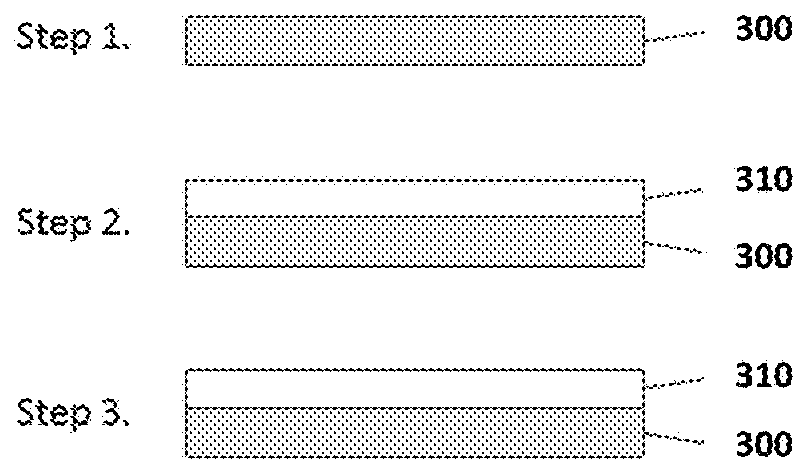

InactiveUS20030027083A1Uniform critical dimensionLong stable periodRadiation applicationsSemiconductor/solid-state device manufacturingContinuous waveLength wave

One principal embodiment of the disclosure pertains to a method of optically fabricating a photomask using a direct write continuous wave laser, comprising a series of steps including: applying an organic antireflection coating over a surface of a photomask which includes a chrome-containing layer; applying a chemically-amplified DUV photoresist over the organic antireflection coating; post apply baking the DUV photoresist over a specific temperature range; exposing a surface of the DUV photoresist to the direct write continuous wave laser; and, post exposure baking the imaged DUV photoresist over a specific temperature range. The direct write continuous wave laser preferably operates at a wavelength of 244 nm or 257 nm. In an alternative embodiment, the organic antireflection coating may be applied over an inorganic antireflection coating which overlies the chrome containing layer.

Owner:APPLIED MATERIALS INC

Attenuating filter for ultraviolet light

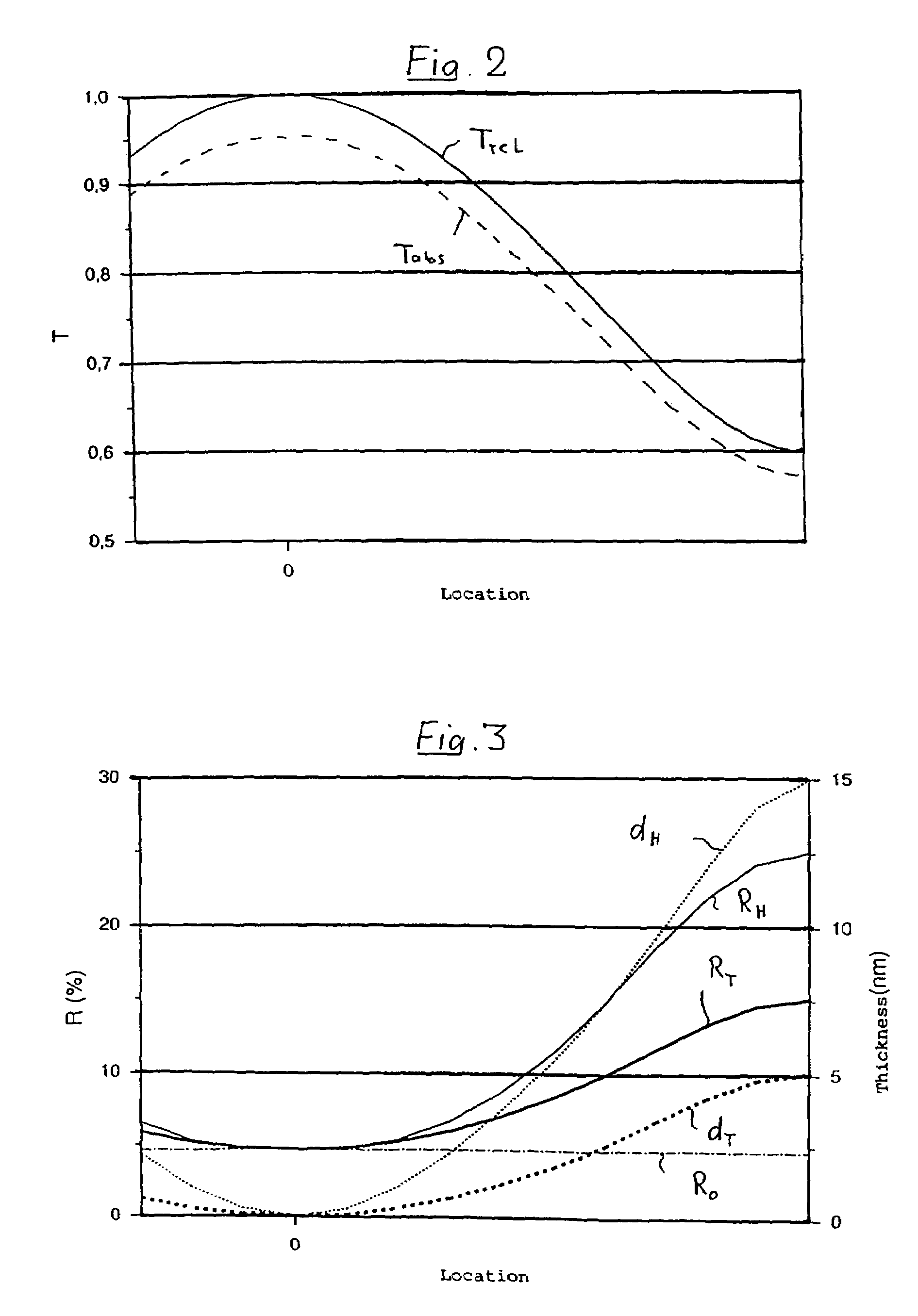

InactiveUS7196842B2Simple and inexpensive to fabricateVariation of the transmittance of the filter coatingMirrorsOptical filtersSpectral transmittanceUltraviolet lights

Owner:CARL ZEISS SMT GMBH

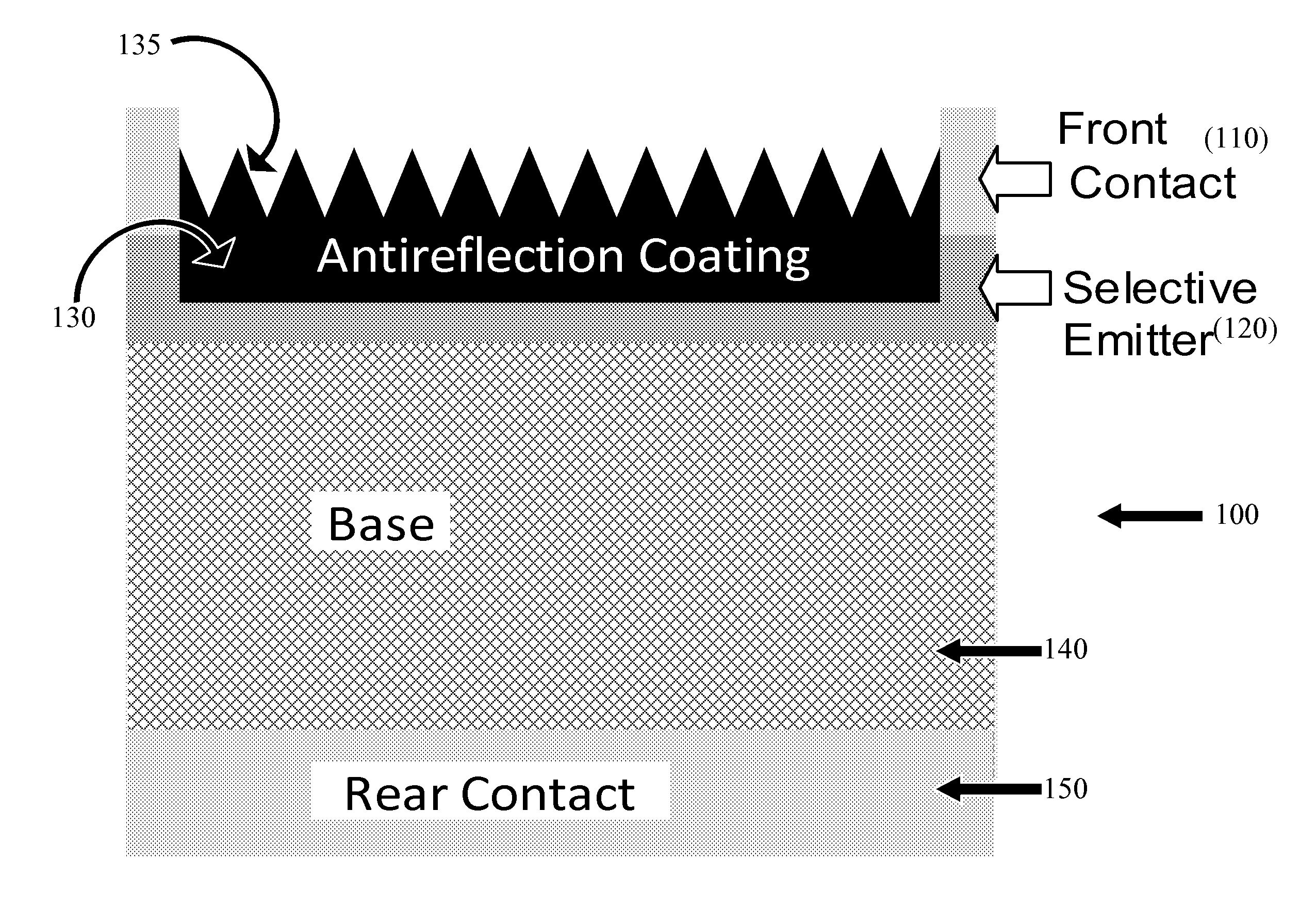

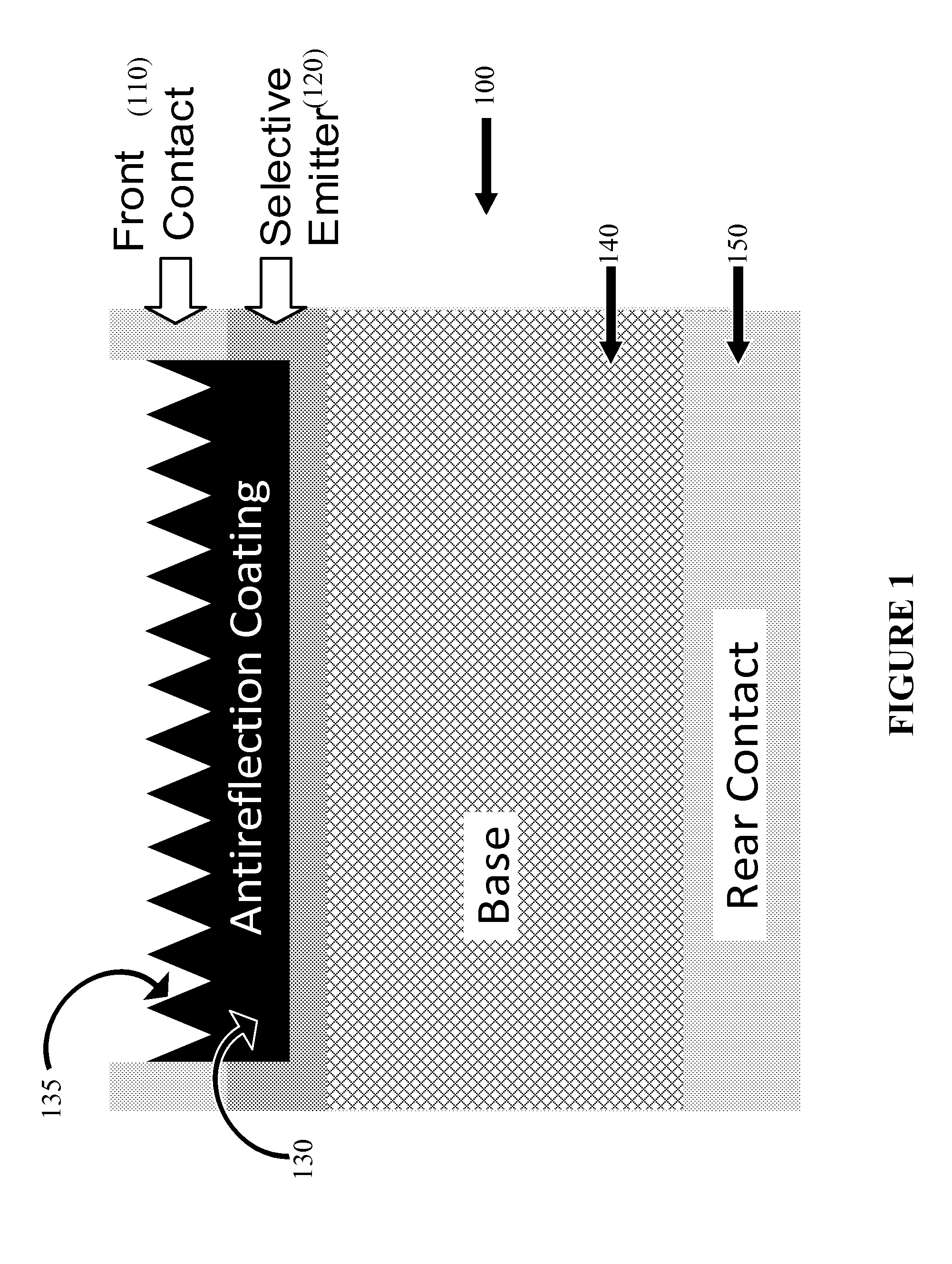

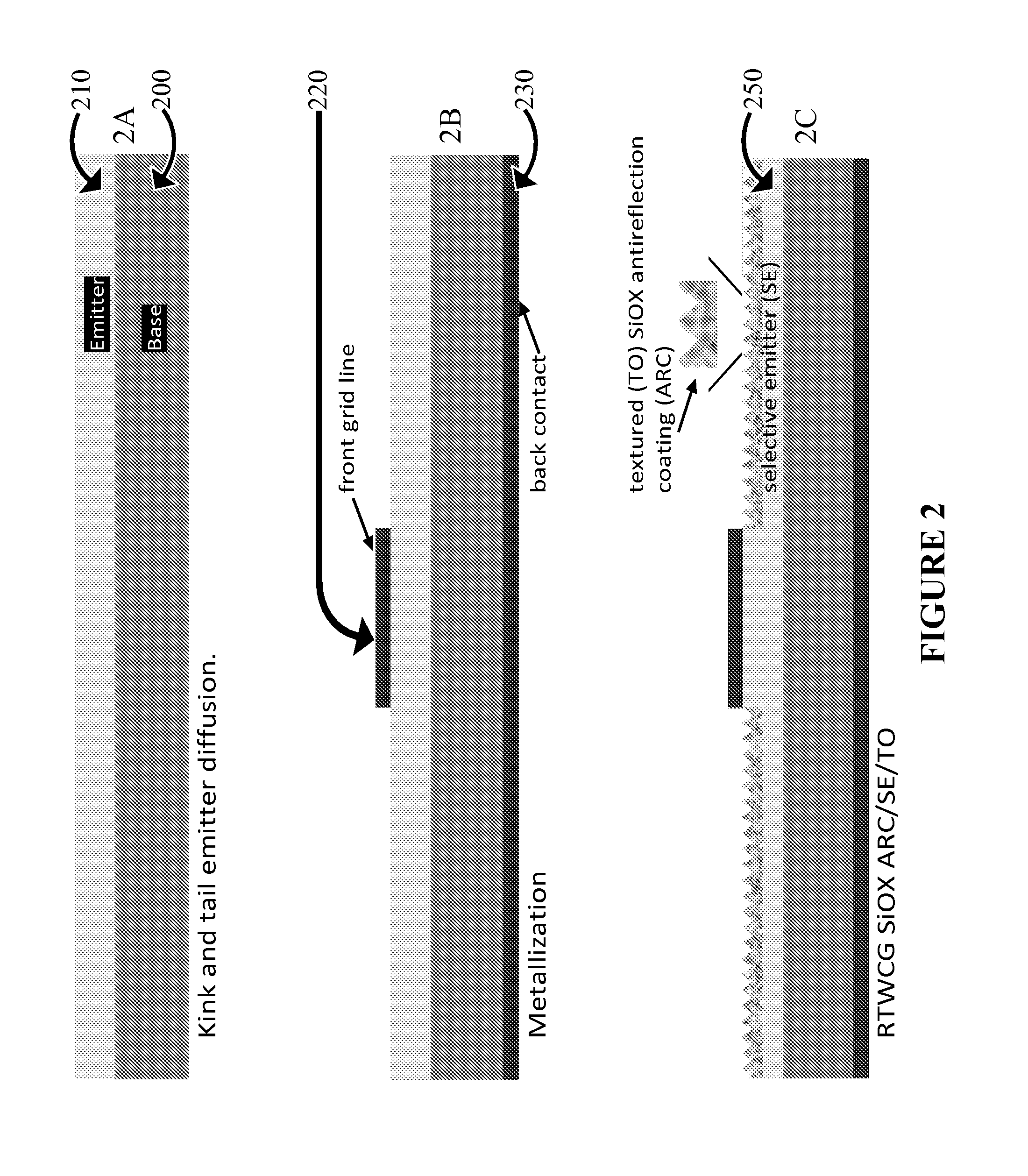

Methods, process and fabrication technology for high-efficiency low-cost crystalline silicon solar cells

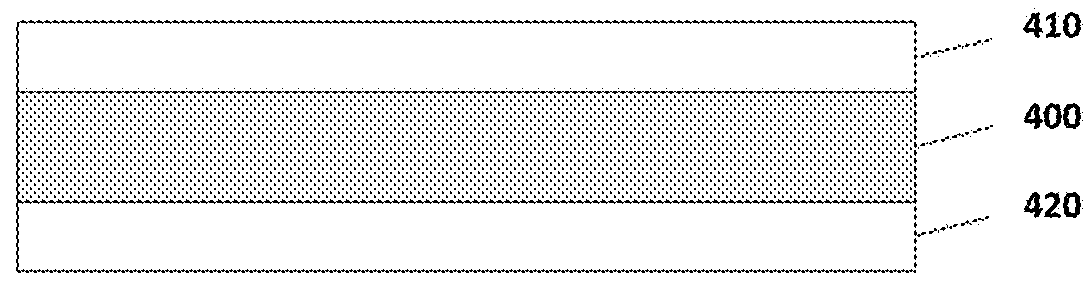

ActiveUS20140061531A1Improve efficiencyLow costFinal product manufacturePhotovoltaic energy generationManufacturing technologySingle crystal

Disclosed is a method, process, solar cell design, and fabrication technology for high-efficiency, low-cost, crystalline silicon (Si) solar cells including but not restricted to solar grade single crystal Si (c-Si), multi-crystalline Si (mc-Si), poly-Si, and micro-Si solar cells and solar modules. The RTWCG solar cell fabrication technology creates a RTWCG SiOx thin film antireflection coating (ARC) with a graded index of refraction and a selective emitter (SE). The resulting top surface of the SiOx oxide can be textured (TO) concomitant with the growth process or through an additional mild wet chemical step.

Owner:SPECIAL MATERIALS RES & TECH

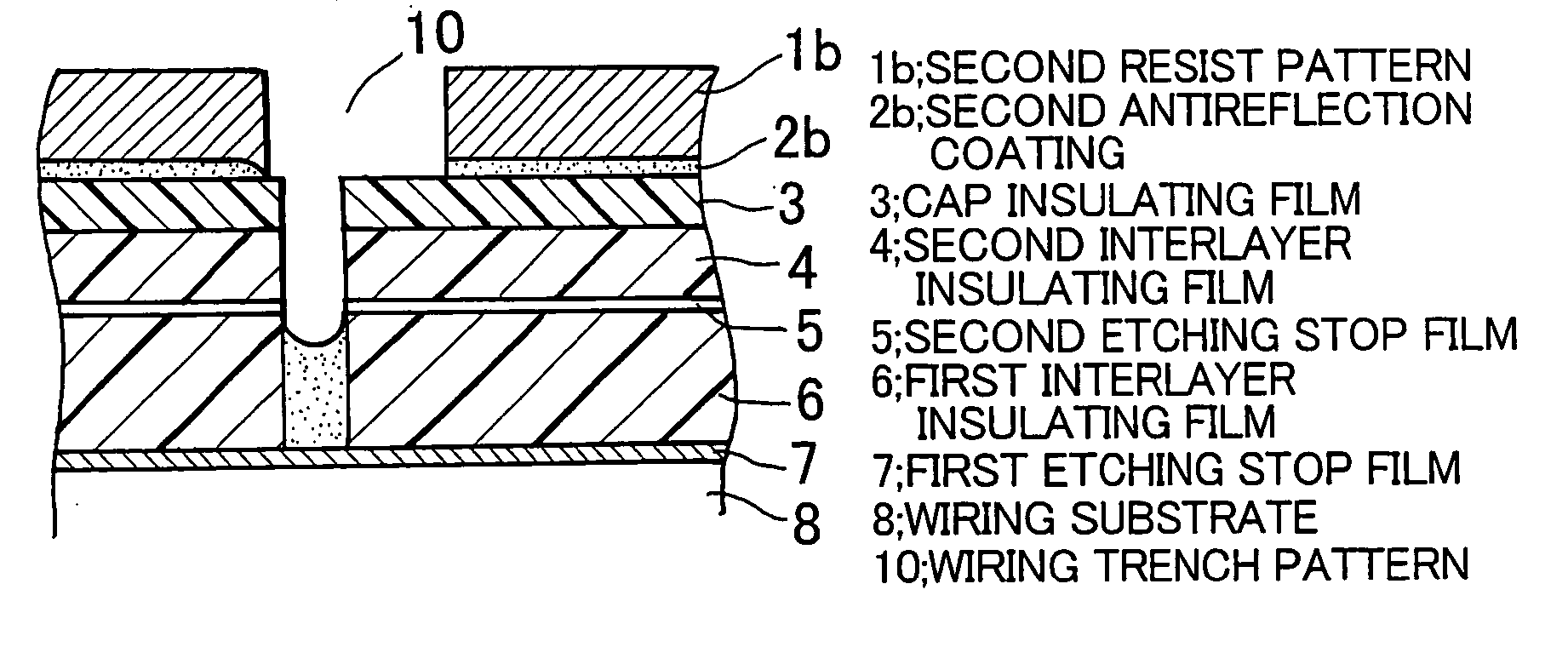

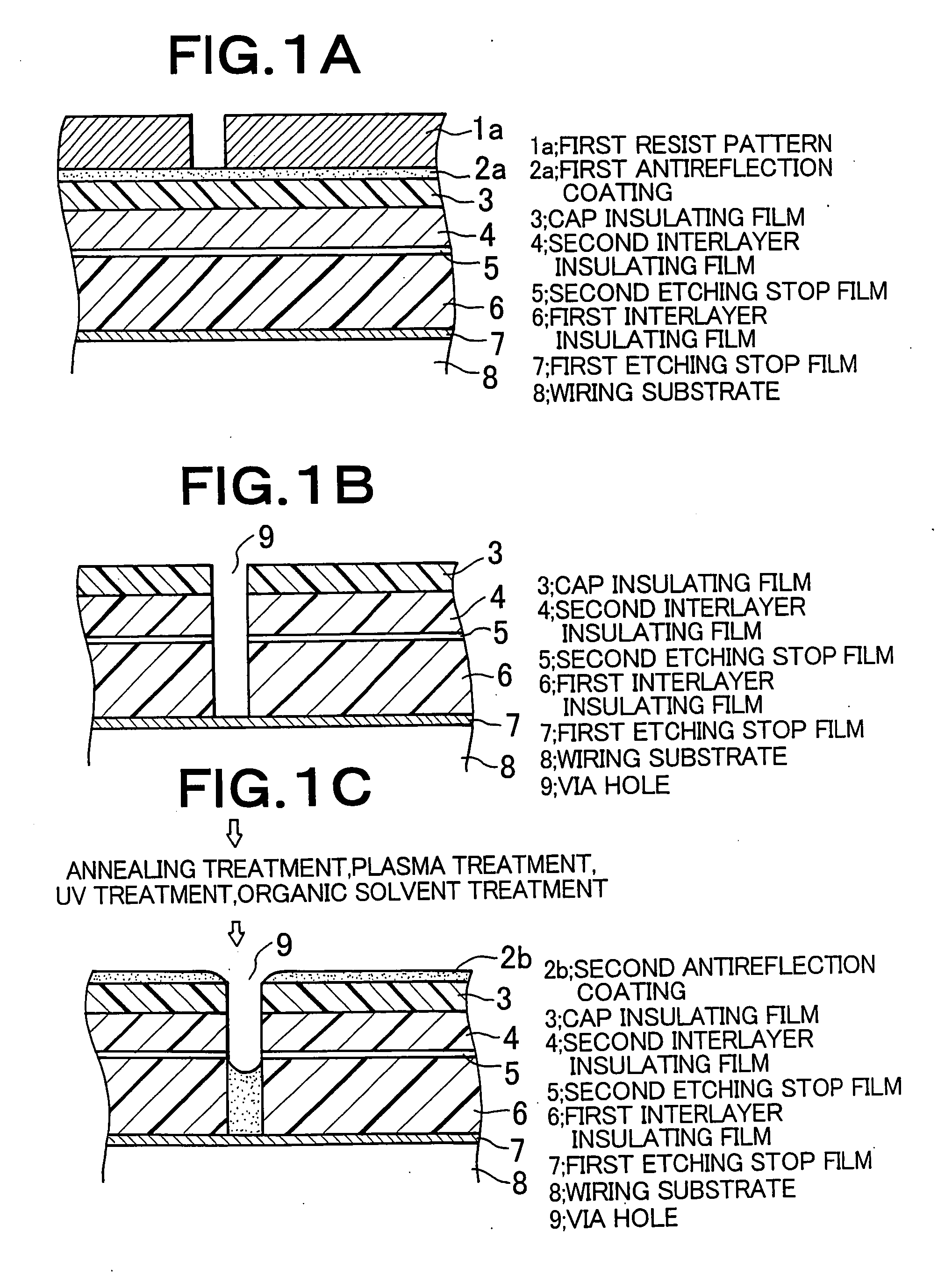

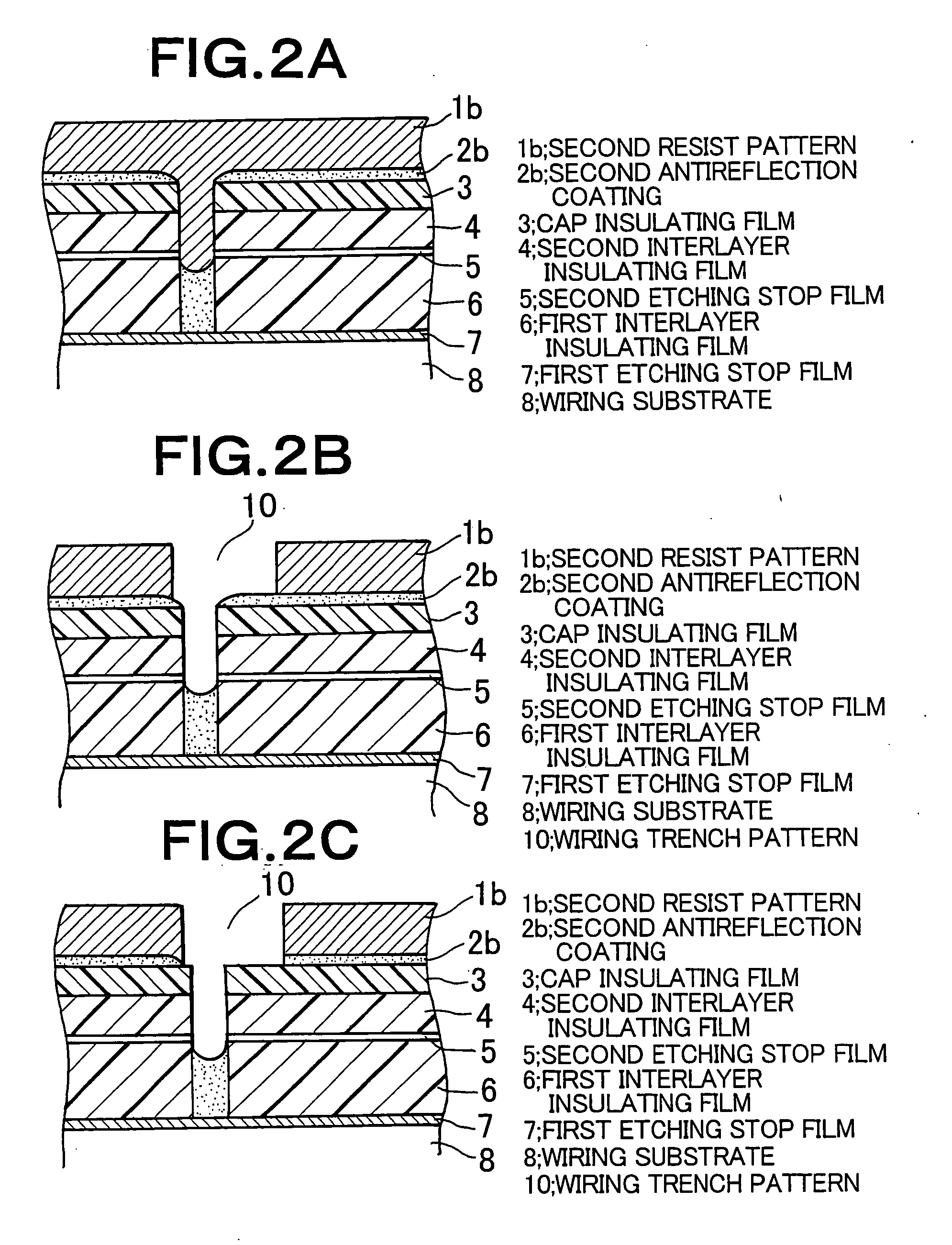

Semiconductor device and method of manufacturing the same

InactiveUS20050124168A1Inhibition effectPrevent materialSemiconductor/solid-state device manufacturingPhotosensitive material processingResistDevice material

A method of manufacturing a semiconductor device having a damascene structure contains a process of forming a first interlayer insulating film (6) and a second interlayer insulating film (4) formed of a low dielectric-constant film on a substrate, forming via holes (9) by using a first resist pattern (1a) formed on the second interlayer insulating film, conducting an organic peeling treatment using organic peeling liquid containing amine components and then forming a second resist pattern (1b) on the second interlayer insulating film. After the wet treatment, before a second antireflection coating (2b) is coated so as to be located below the second resist pattern is coated, at least one of an annealing treatment, a plasma treatment, a UV treatment and an organic solvent treatment is carried out to remove amine components which inhibit the catalysis reaction of acid occurring in the resist at the light exposure, thereby preventing degradation of the resolution of the second resist pattern (1b).

Owner:RENESAS ELECTRONICS CORP

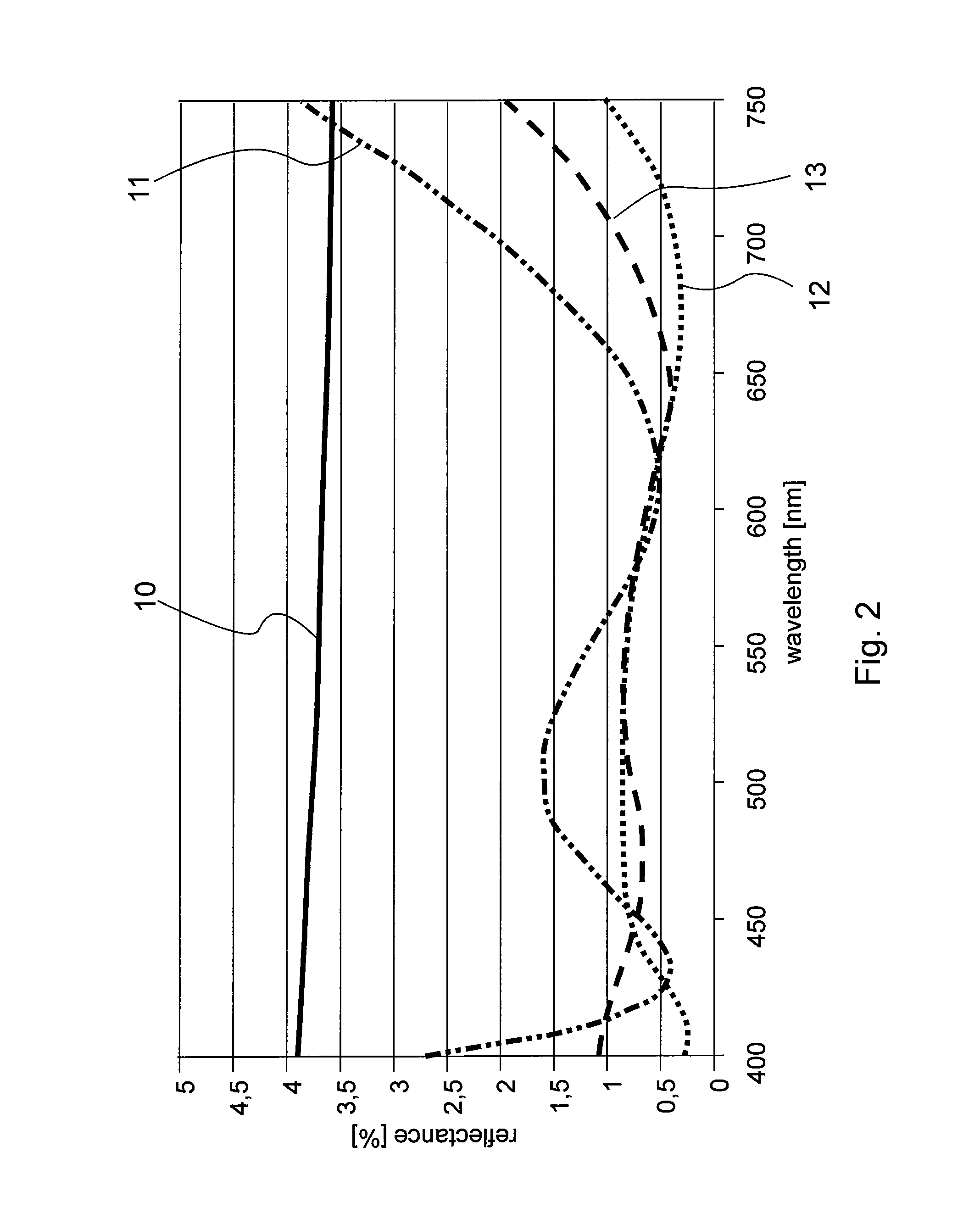

Antireflection coating and optical element using the same

An antireflection coating has at least a first layer constituted by a coating with refractivity of n1 and optical thickness of d1 which is provided on a substantially transparent substrate with refractivity of n0, and a second layer constituted by a SiO2 coating with optical thickness of d2 which is provided on the first layer, wherein the n0, n1, d1 and d2 satisfy the following conditions: 1.42<=n0<=1.53, 1.95<=n1<=2.35, 0.40lambd<=d1<=0.44lambd, and 0.40lambd<=d2<=0.44lambd, wherein the central wavelength of light to be prevented from being reflected is lambd.

Owner:PANASONIC CORP

Method of preparing optically imaged high performance photomasks

InactiveUS6703169B2Radiation applicationsSemiconductor/solid-state device manufacturingContinuous waveWavelength

Owner:APPLIED MATERIALS INC

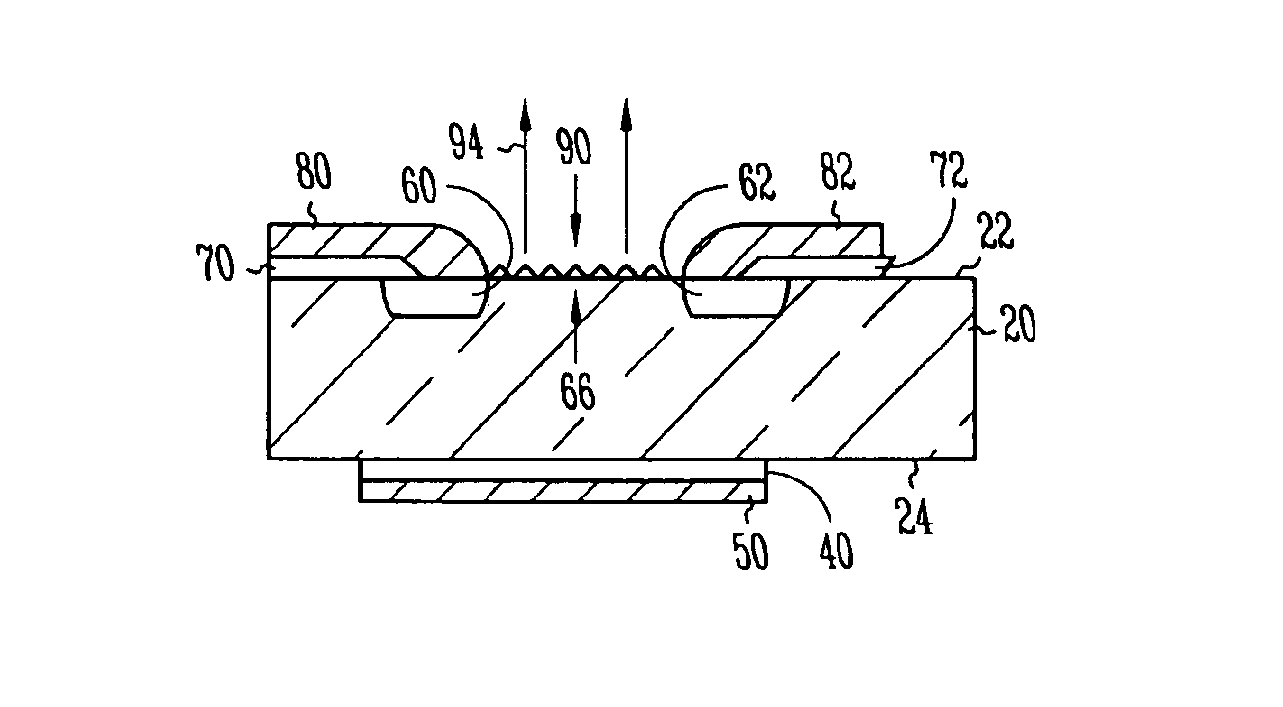

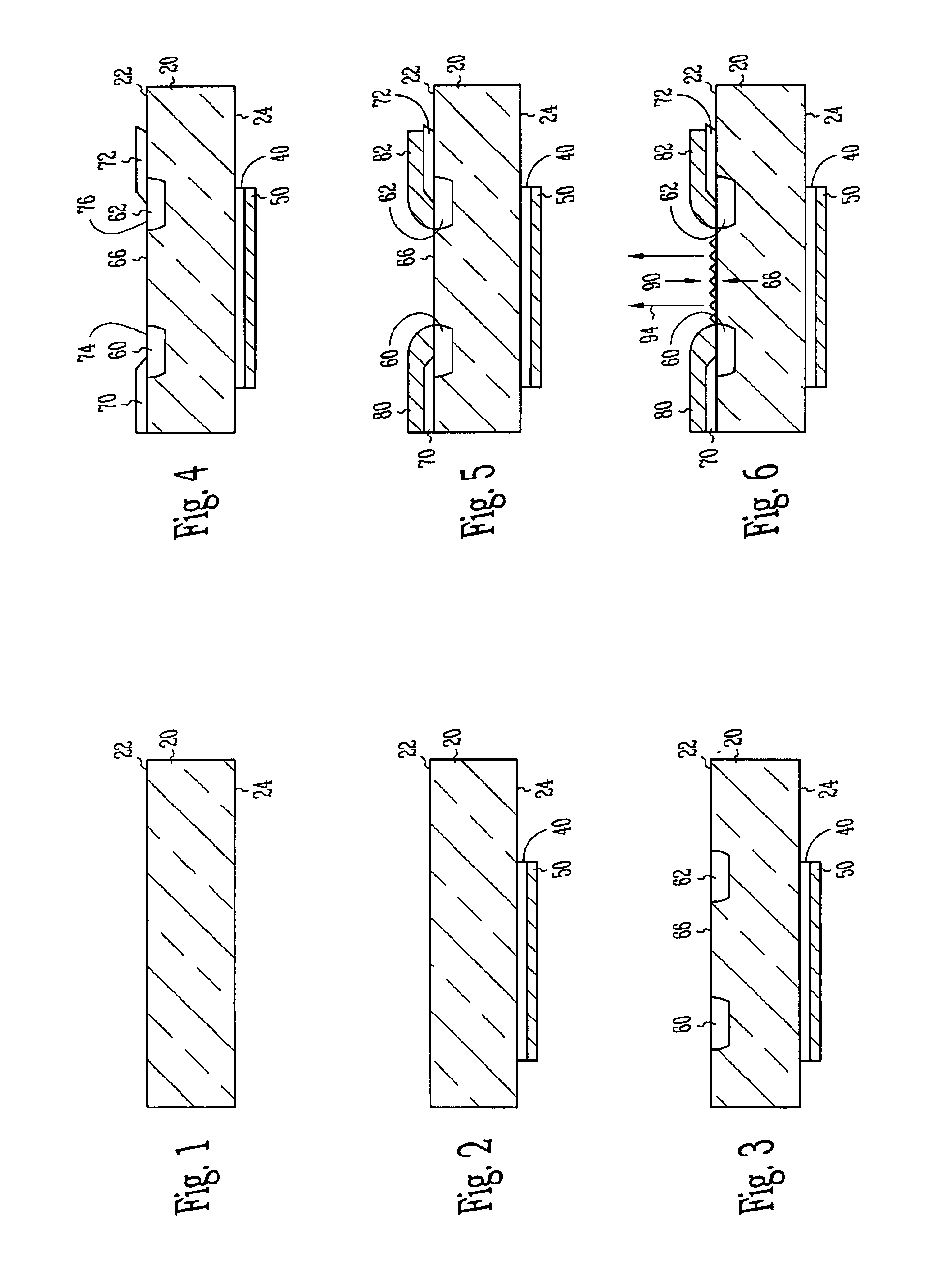

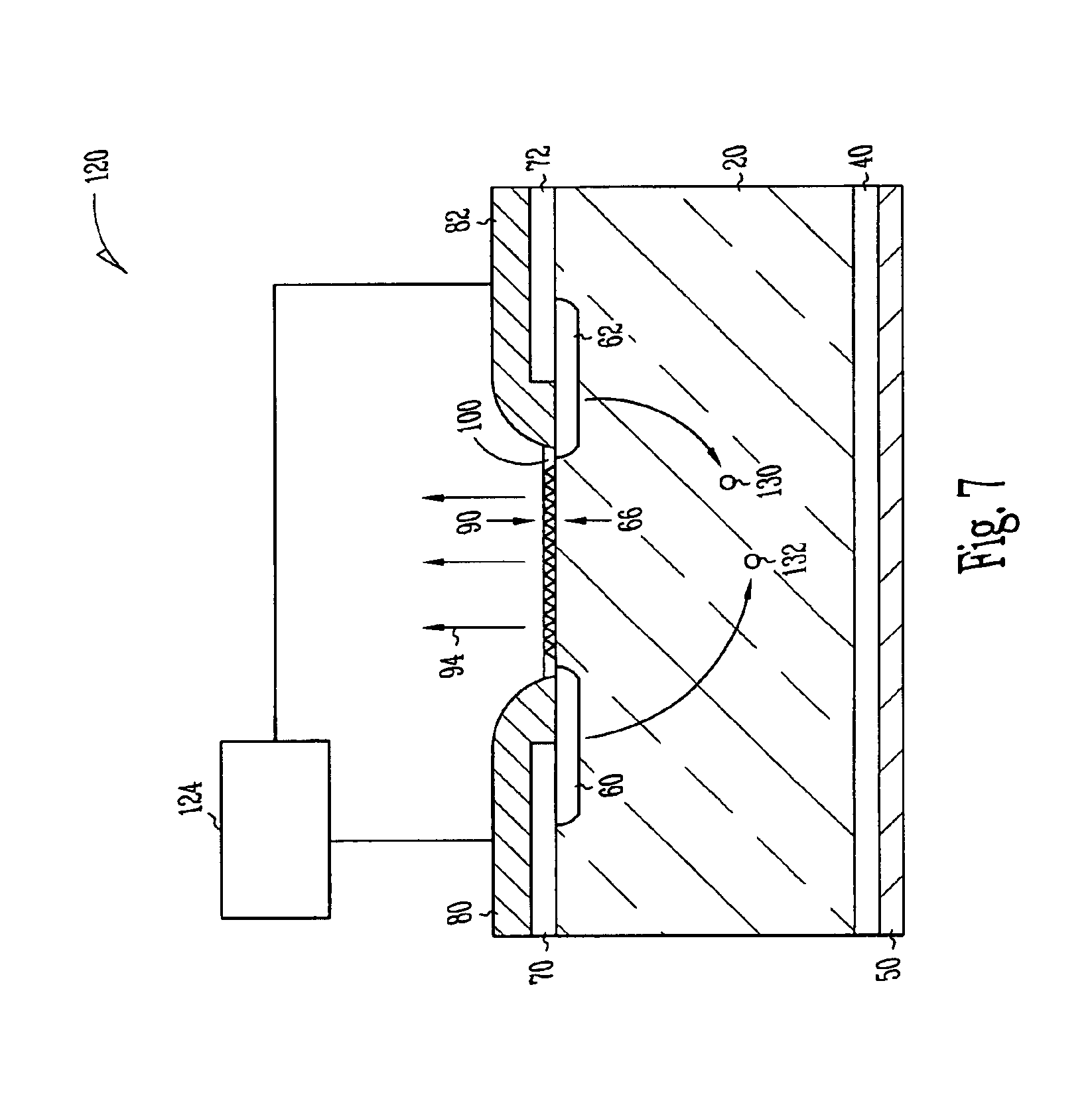

Silicon and silicon/germanium light-emitting device, methods and systems

A light-emitting device and optical communication system based on the light-emitting device is disclosed. The light-emitting device is formed in a float-zone substrate. The light-emitting device includes on the substrate lower surface a reflective layer and on the upper surface spaced apart doped regions. The portion of the upper surface between the doped regions is textured and optionally covered with an antireflection coating to enhance light emission. The light-emitting device can operate as a laser or as a light-emitting diode, depending on the reflectivities of the antireflection coating and the reflective layer.

Owner:INTEL CORP

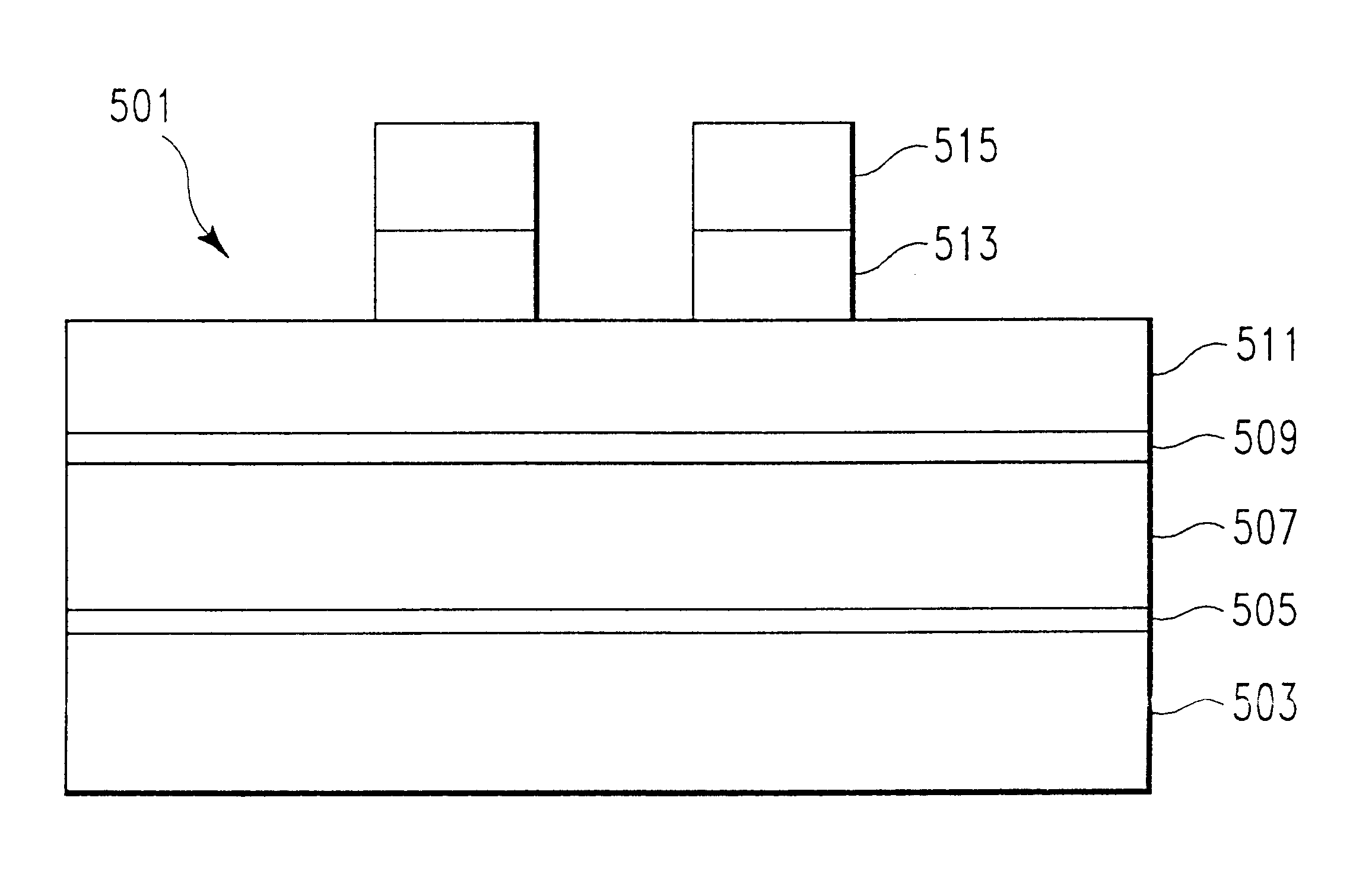

Method for in situ removal of a dielectric antireflective coating during a gate etch process

InactiveUS6613682B1Semiconductor/solid-state device manufacturingSemiconductor devicesMetal silicideNitrogen

The present invention provides a method for the simultaneous removal of an oxygen and / or nitrogen-containing dielectric antireflective coating ("DARC") during plasma etching of an underlying layer in a film stack. According to the method of the invention, the film stack is etched using a plasma containing reactive fluorine species. The concentration of reactive fluorine species within the plasma is controlled based on one or more of the following factors: the oxygen content of the antireflective coating, the nitrogen content of the antireflective coating, the thickness of the antireflection coating layer, and the thickness of the underlying film stack layer. The disclosure of the invention provides preferred combinations of plasma source gases which provide for the simultaneous removal of an oxygen and / or nitrogen-containing DARC layer during etching of an underlying etch stack layer, where the underlying stack layer comprises a metal silicide, polysilicon, or a metal. Also provided herein is a formula for determining the total amount of DARC removed using a given etch process recipe, based on the etch selectivity of the particular process recipe

Owner:APPLIED MATERIALS INC

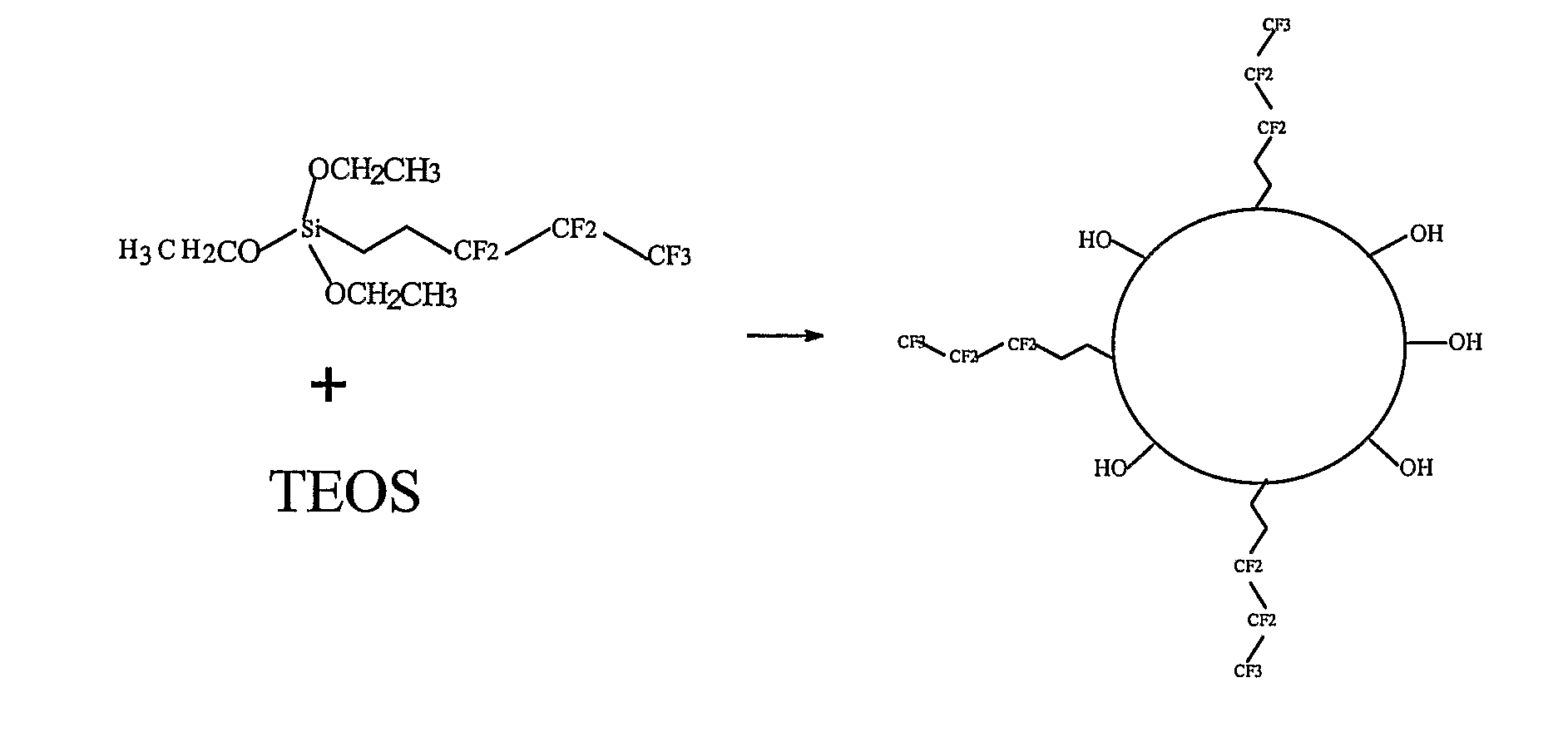

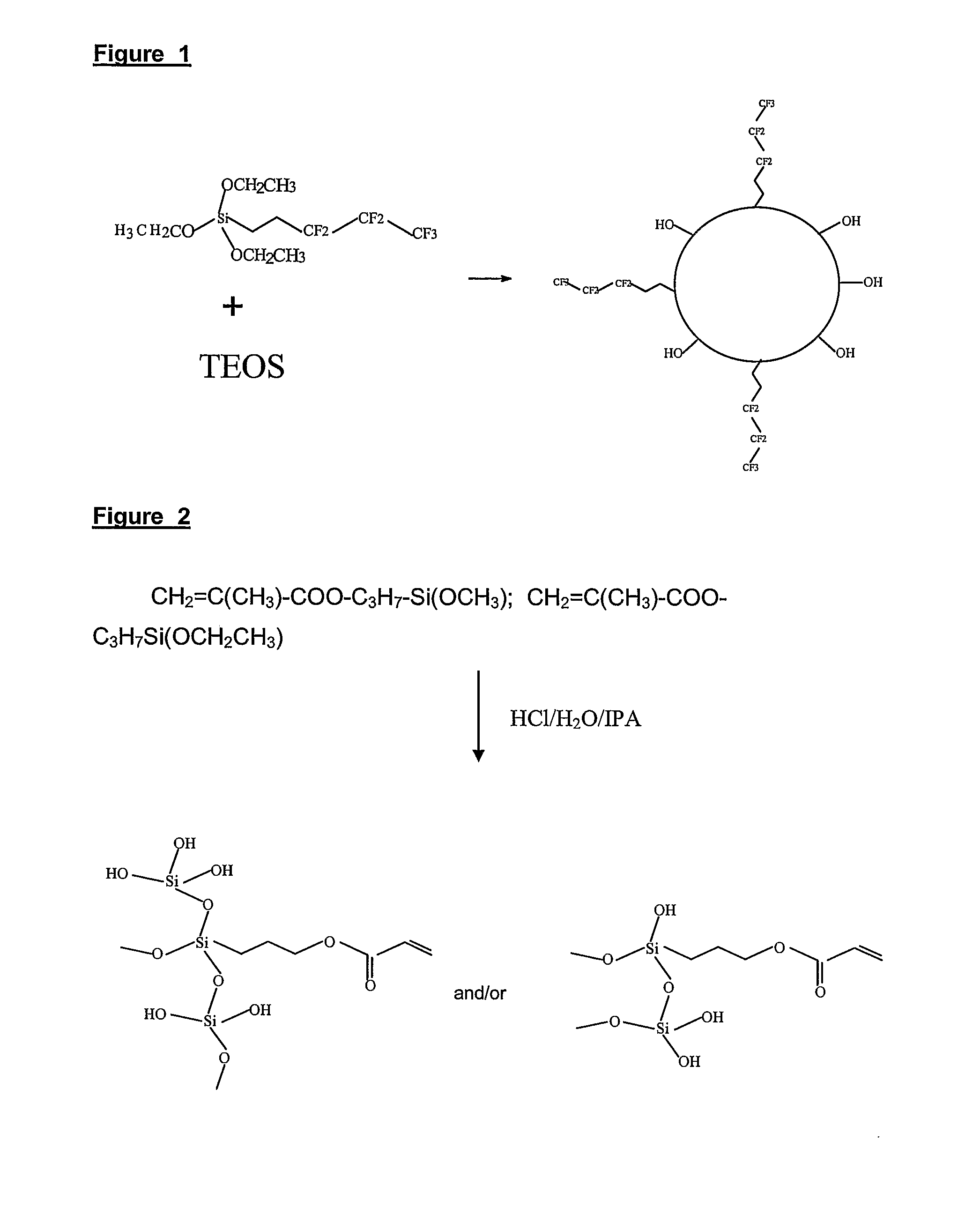

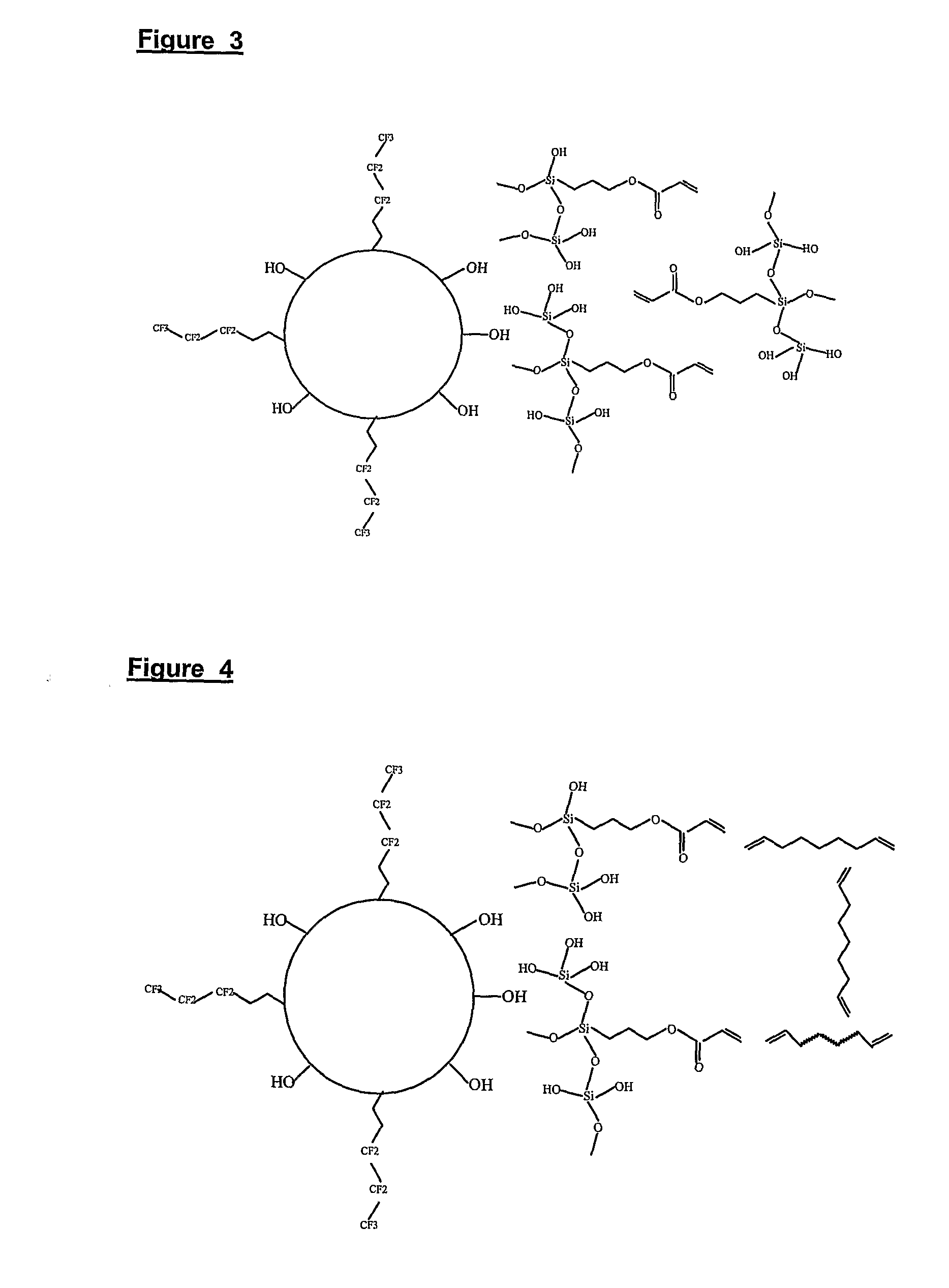

Novel carbosiloxane polymer compositions, methods of producing the same and the use thereof

ActiveUS20180277691A1Improve propertiesImprove functionalityFinal product manufactureSolid-state devicesOrganic groupOxygen

A method of producing a photovoltaic cell having a cover, comprising the steps of: providing a photovoltaic cell which comprises a crystalline silicon substrate; providing a transparent substrate; forming an antireflective coating on said transparent substrate to provide a coated transparent substrate; and covering the photovoltaic cell with said coated transparent substrate. The antireflective coating is a hybrid organic-inorganic material having an inorganic portion comprising silicon, oxygen and carbon, and further comprising an organic portion with organic groups connected to the inorganic portion. Methods of producing solar panels, coated glass substrates as well as antireflection coatings are disclosed as well as novel compositions of hybrid organic-inorganic materials.

Owner:OPTITUNE

Polycrystalline silicon solar cell having high efficiency and method for fabricating the same

ActiveUS20090178711A1Improve efficiencyHigh solar efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationAmorphous siliconOptoelectronics

Disclosed herein is a polycrystalline silicon solar cell, including: a back electrode formed on a transparent insulating substrate; an N-type polycrystalline silicon layer in which amorphous silicon is crystallized through MIC process, and in which electrons are accumulated; a light-absorbing layer which is formed by vertically crystallizing an intrinsic amorphous silicon layer using the polycrystalline silicon layer as a seed for crystallization through MIVC process, in which pairs of electrons and holes are generated in response to incident light, and which has a vertical column grain structure in which grains are arranged in the direction in which electrons and holes move; a P-type polycrystalline silicon layer which has the vertical column grain structure, and in which holes are accumulated; a transparent electrode layer; front electrodes; and an antireflection coating film, and is a method of fabricating the same.

Owner:SEOUL NAT UNIV R&DB FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com