Superimposing method of circular light spot laser shock strengthening tracks

A technology of laser shock strengthening and light spot, which is applied in the field of laser shock strengthening treatment and superposition of circular spot laser shock strengthening track, which can solve the problem of superposition of circular spot laser shock strengthening track that has not been found.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

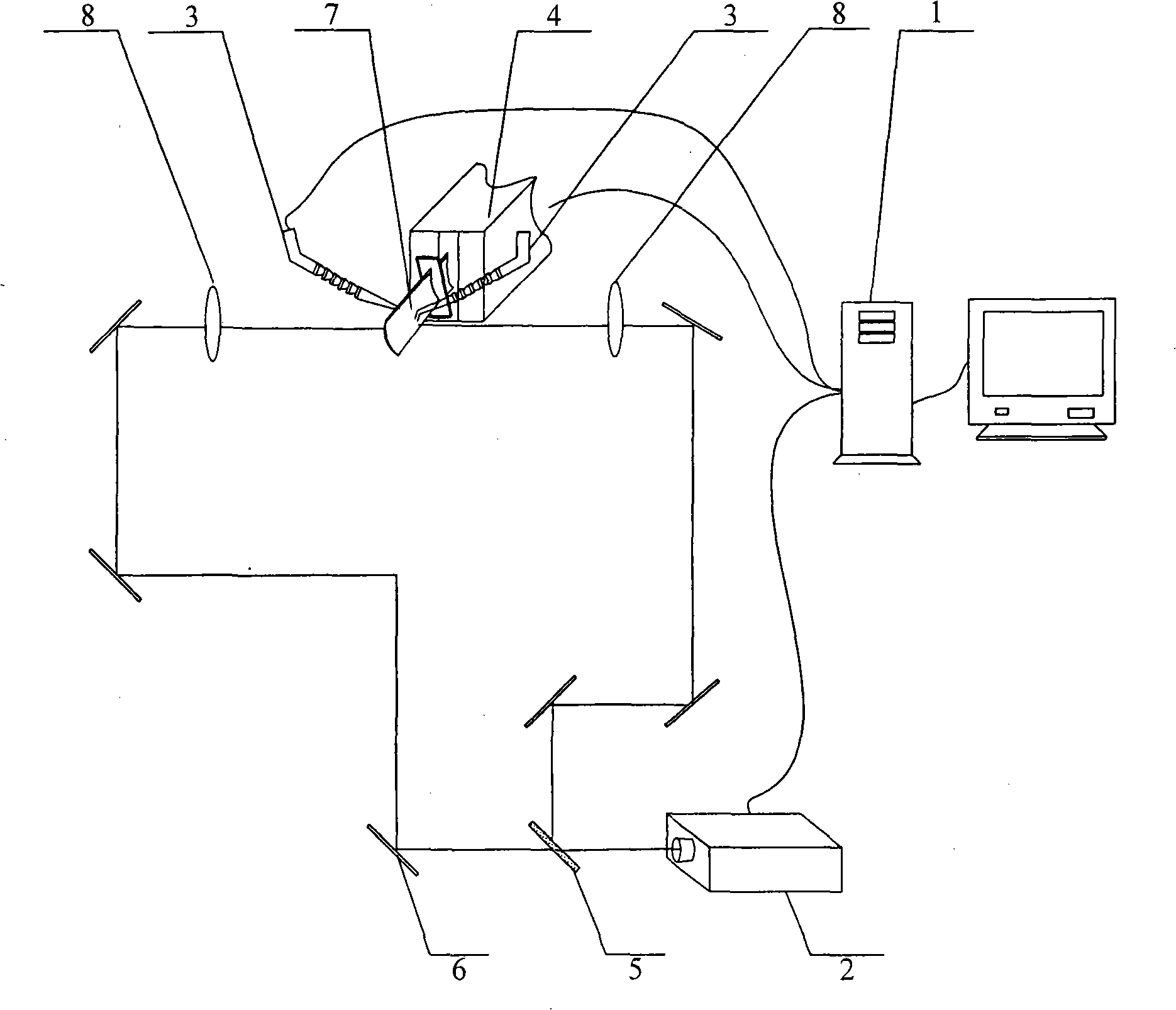

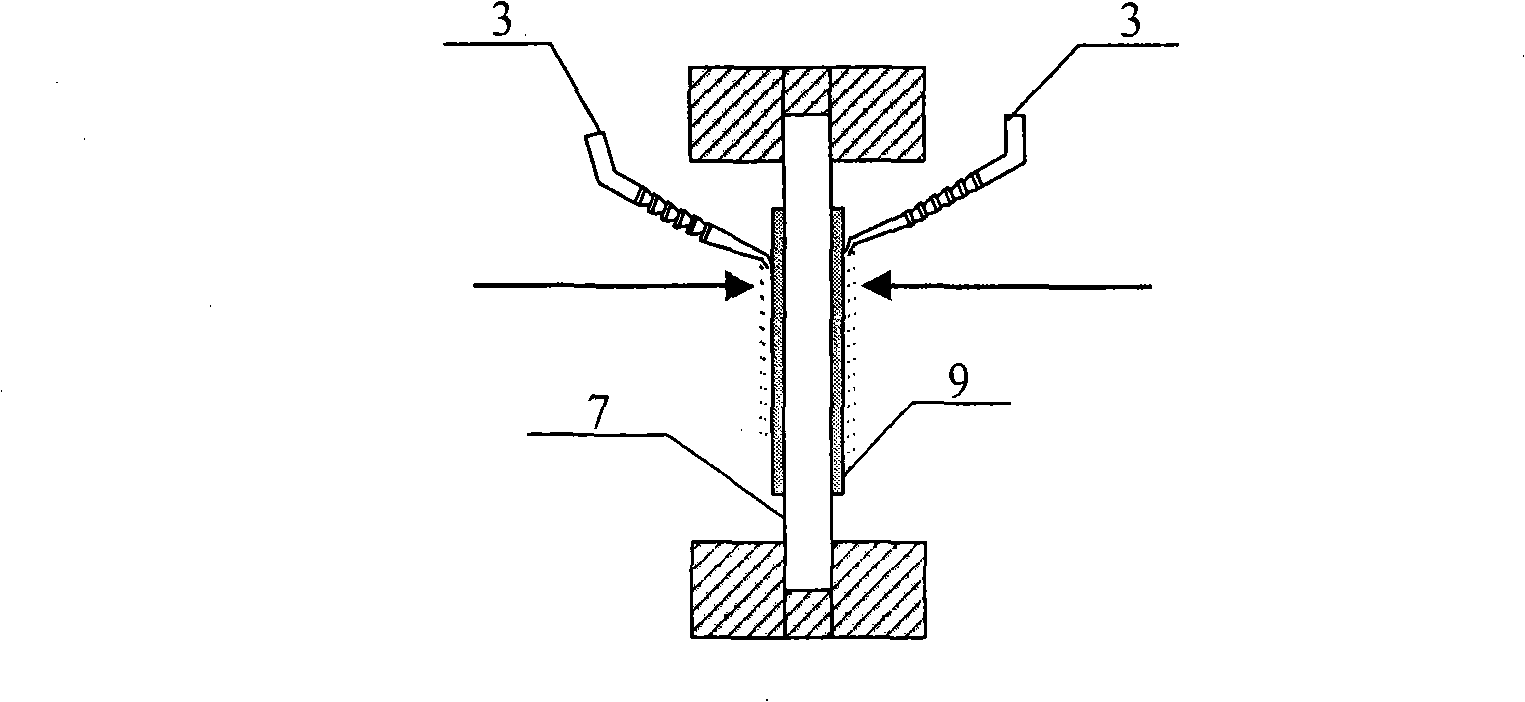

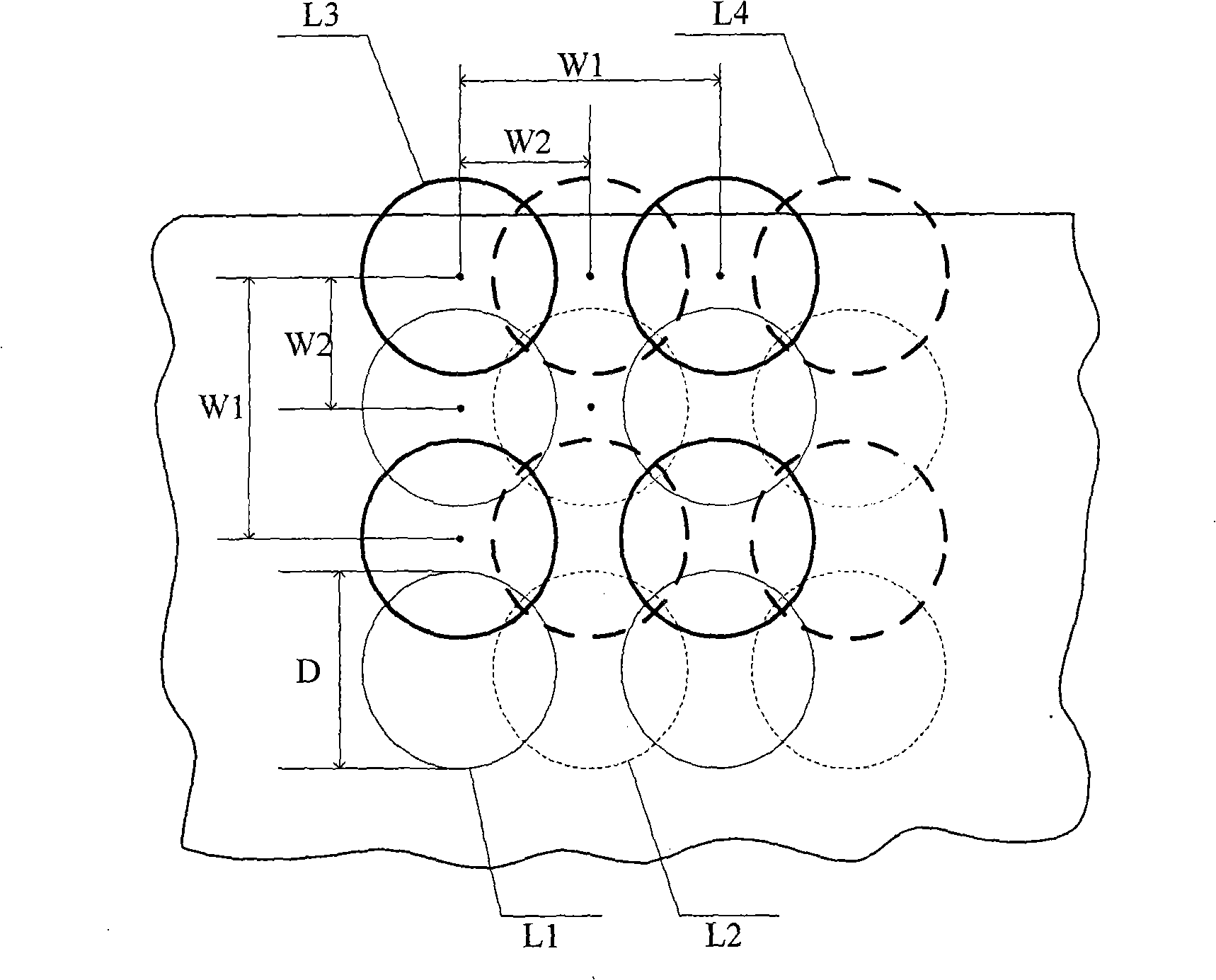

[0027] The used laser shock strengthening device of the present invention is prior art: as figure 1 The shown laser shock strengthening device emits laser light from a high-power pulse laser 2, and divides the laser light into two identical laser beams by a 45° semi-transparent and semi-reflective beam splitter 5, and through a series of adjustments of 45° total reflection mirrors 6, the The focusing mirror 8 focuses the two laser beams with the same optical path respectively, and adjusts the position of the focusing mirror 8 so that the focused spot size and pulse width of the two laser beams irradiated on the front and back sides of the impact piece 7 are the same, and the light spots on the surface of the impact piece use Front focus spot. The controllable water nozzle 3 sprays water to form a uniform water curtain on the surface of the impact membe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bond strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com