Fully automatic hot fix rhinestone layout machine and hot fix rhinestone layout method

A layout machine, fully automatic technology, applied in clothing, printing, printing technology, etc., can solve the problems of low production efficiency, difficulty in popularization and application, low production efficiency, etc., and achieve high production efficiency and save labor resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

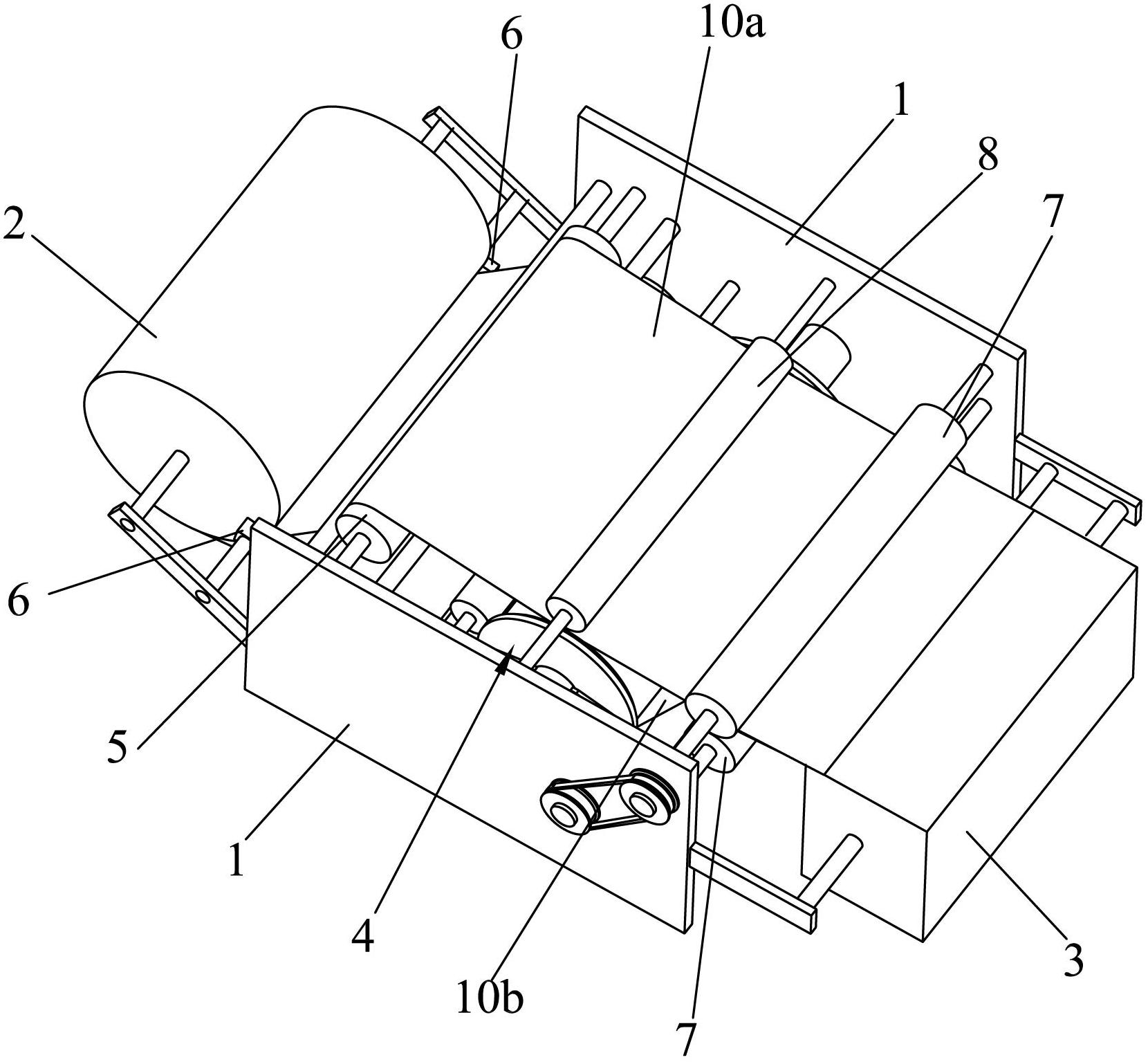

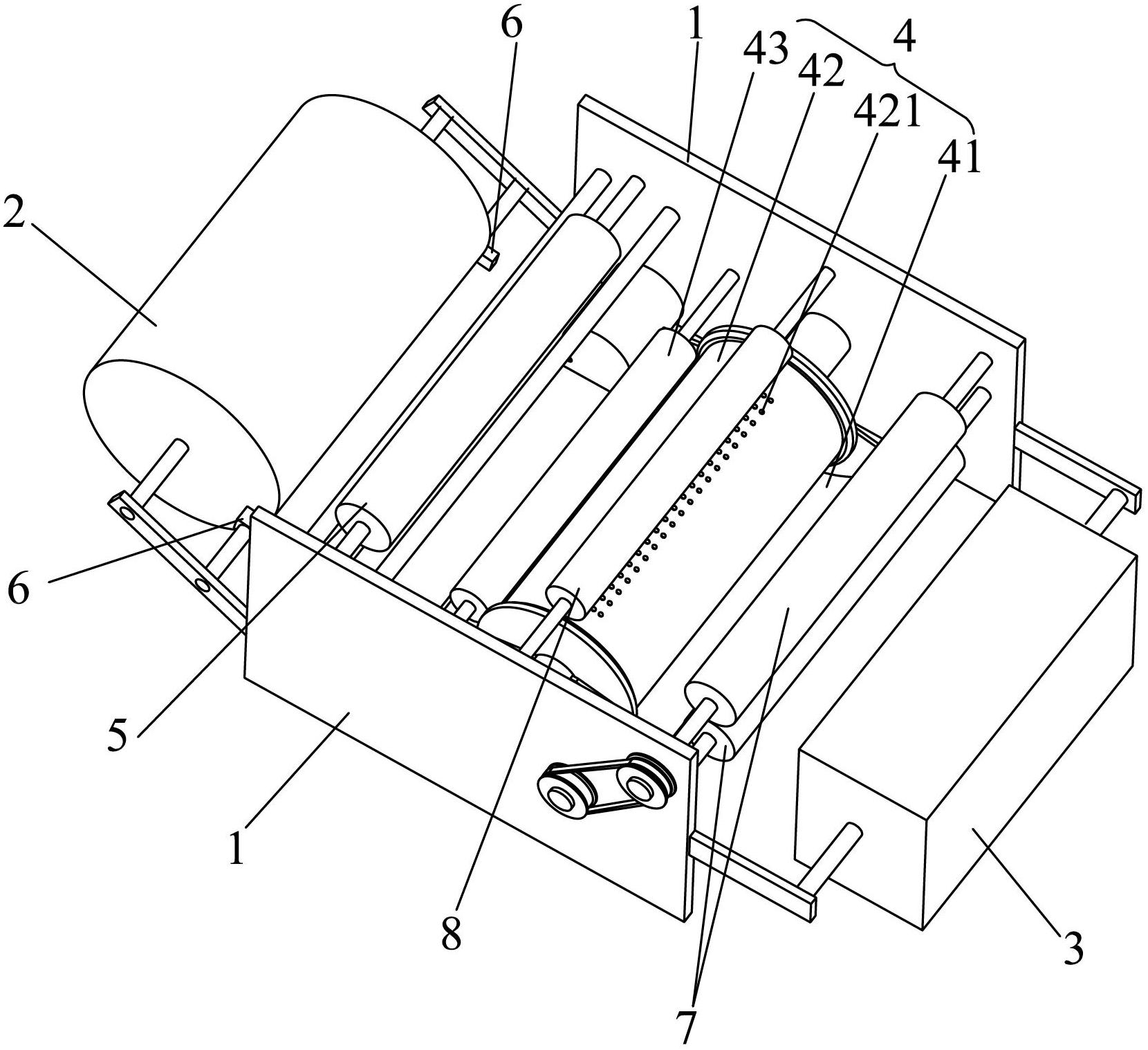

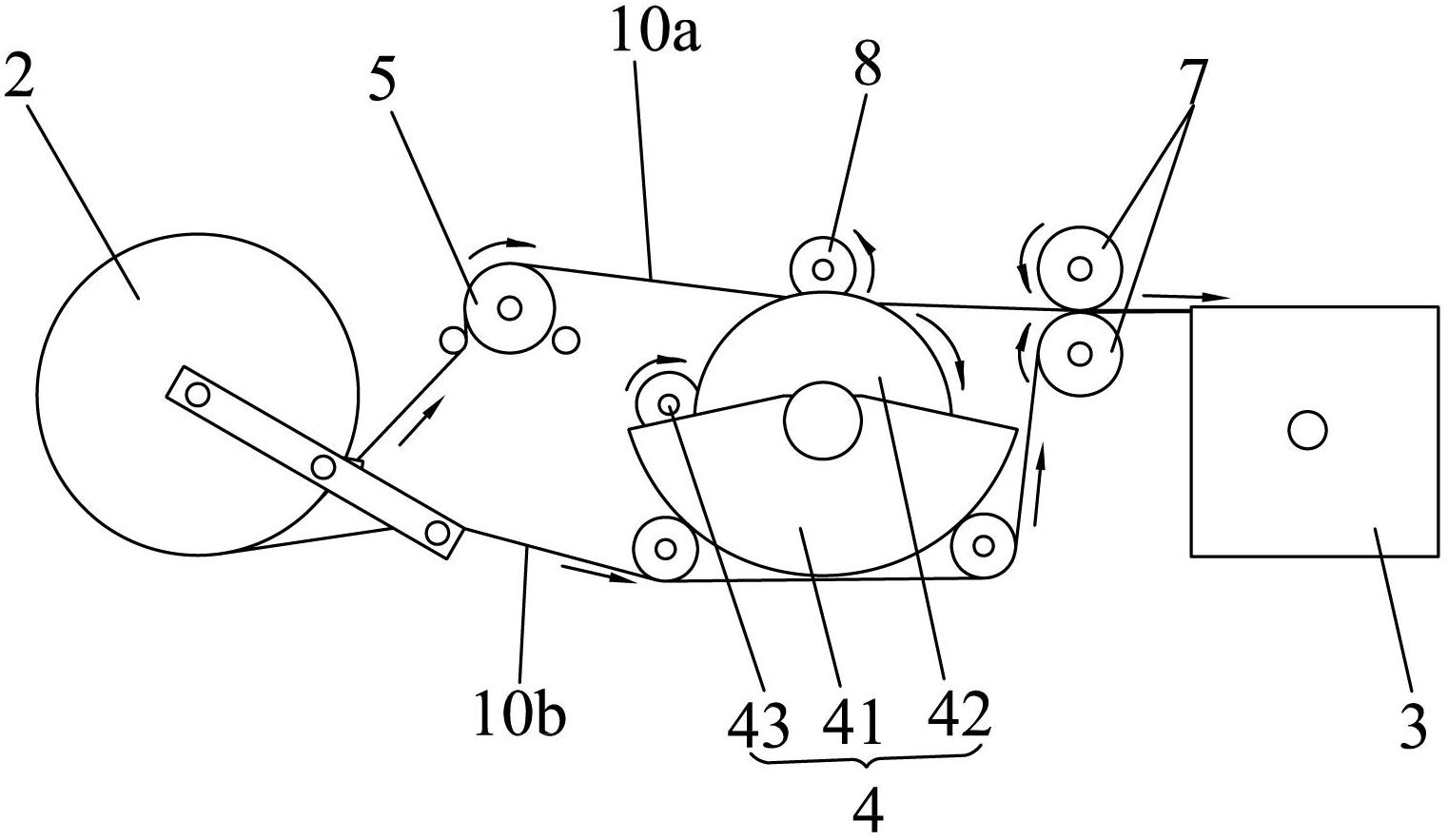

[0025] Please refer to Figure 1~3 As shown, a fully automatic ironing drill layout machine includes a frame 1, and the frame 1 is provided with an unwinding device 2 and a receiving device 3, and the connection between the unwinding device 2 and the receiving device 3 is There is at least one set of layout components 4 in sequence, and the layout components 4 include a hopper 41 and a drum 42 equipped with a magnetic ironing drill. The hopper 41 is arranged on the frame 1, and the drum 42 rotates. It is arranged on the frame 1 and the bottom extends into the hopper 41, and the circumferential surface of the drum 42 is provided with a magnetic suction drill hole 421 for absorbing the magnetic ironing drill; during operation, the drum 42 rotates and is magnetically adsorbed. The magnetic ironing drill in the hopper 41 is adsorbed into the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com