Patents

Literature

661results about How to "Save labor resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modifiable reputation evaluation system and method based on block chain, and electronic payment system

ActiveCN107967557AAvoid injusticeGuaranteed transaction privacyFinanceDigital data protectionRing signatureE-commerce

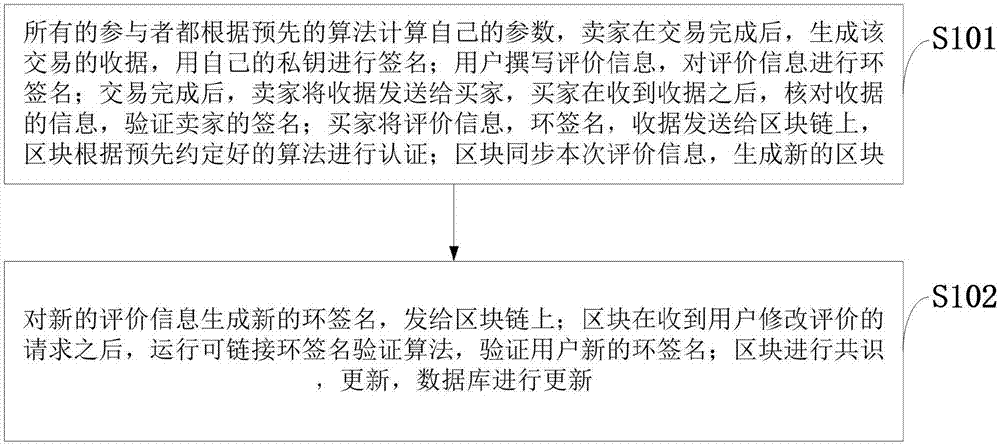

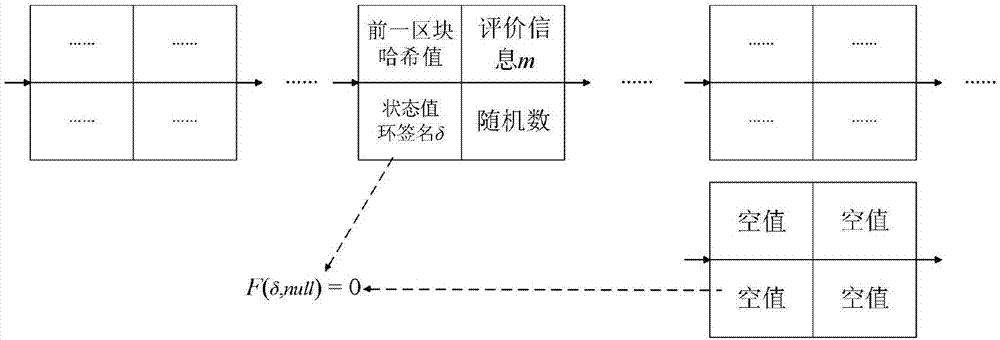

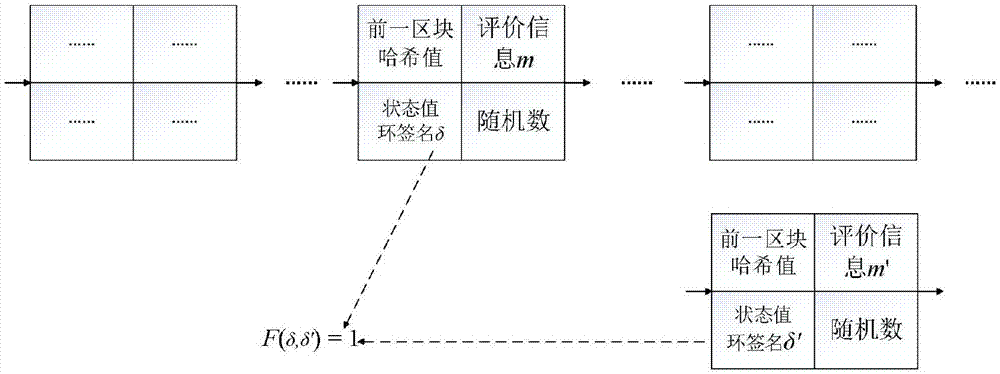

The invention belongs to the e-commerce technology field and discloses a modifiable reputation evaluation system and method based on a block chain, and an electronic payment system. A receipt from a seller is received by a user, the signature of the seller in the receipt is verified, and the evaluation information is generated; after verification is completed, a ring signature of the evaluation information is generated by the user, and the ring signature is sent to the block chain; the receipt and the ring signature of the user are verified by the block chain; a database is updated after the block is generated; a new signature is acquired by the user through a signature algorithm, and the new signature is sent to the block chain; validity of the signature is verified by the block chain, and whether the two signatures are completed by the same user is determined; a pointer corresponding to the block of a previous message is modified after verification completion, the previous message ismarked as invalid, and the previously-revoked information is replaced by the block of the message. The method is advantaged in that on the condition that user anonymity and transaction non-tamperability are guaranteed, integrity and openness of the evaluation information are guaranteed, and reliability of the evaluation information is guaranteed.

Owner:XIDIAN UNIV

Detecting device and method

InactiveCN103257465AImprove accuracyWide spectral response rangeImage enhancementImage analysisImaging processingLiquid-crystal display

The invention relates to the technical field of detection, and discloses detecting device and method. The detecting device comprises an image acquiring module and an image processing module, wherein the image acquiring module acquires image information of a liquid crystal display panel to be detected, and the image processing module is in signal connection with the image acquiring module. The image processing module compares received image information with a defect database and judges defect level of the liquid crystal display panel to be detected. During use of the detecting device, the image acquiring module can acquire image information of any position of the liquid crystal display panel to be detected, the image processing module compares received the image information acquired by the image acquiring module with the defect database and judges the defect level of the liquid crystal display panel to be detected. Accordingly, by the detecting device, defect identification rate and detection efficiency of the liquid crystal display panel are improved.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

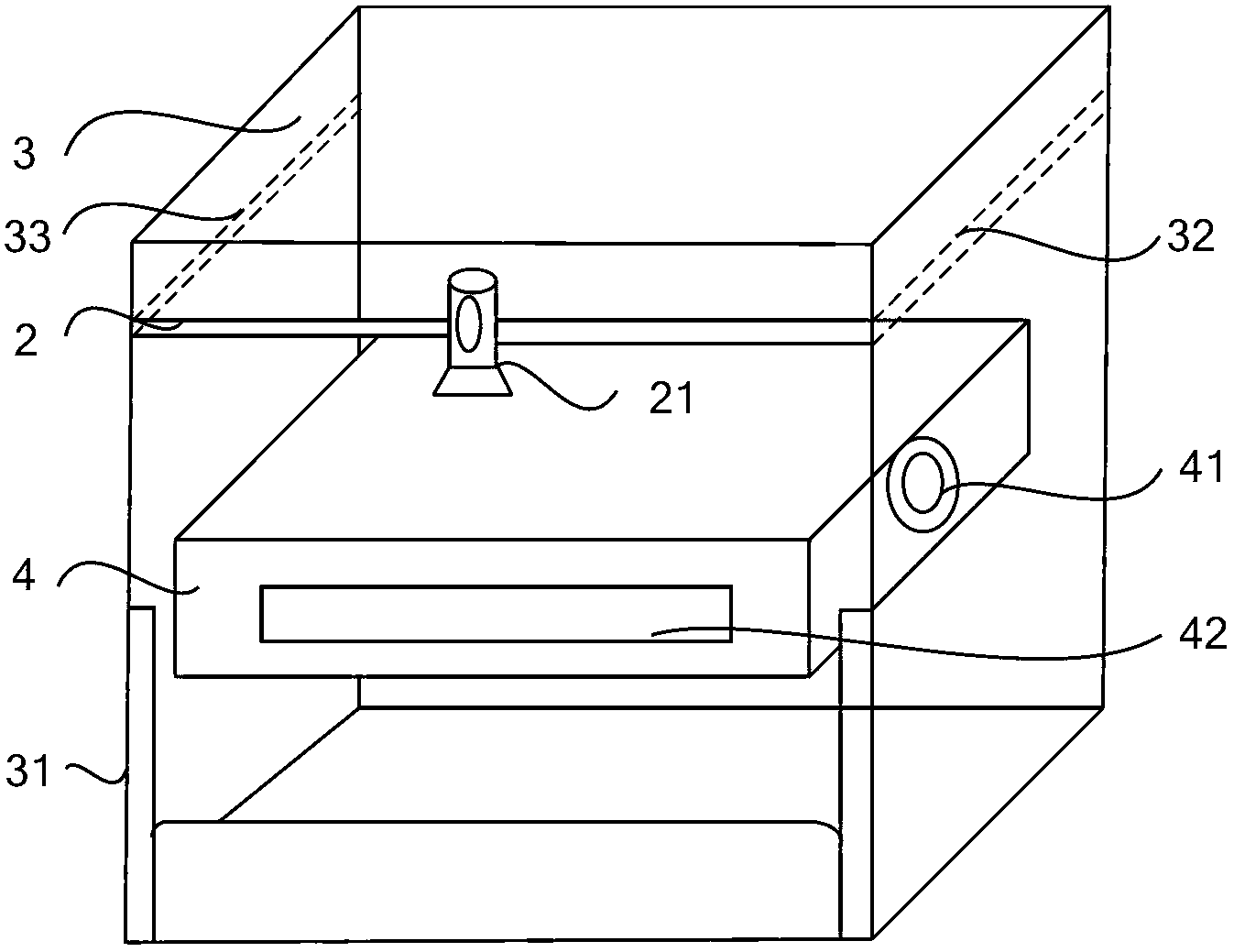

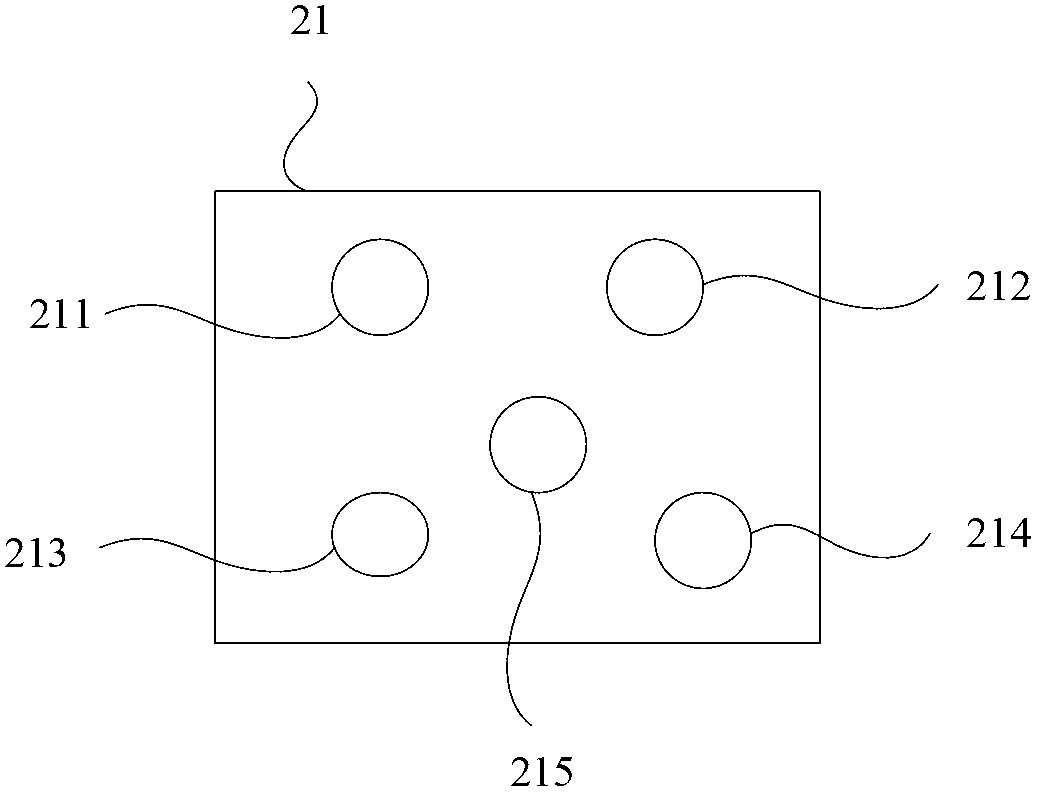

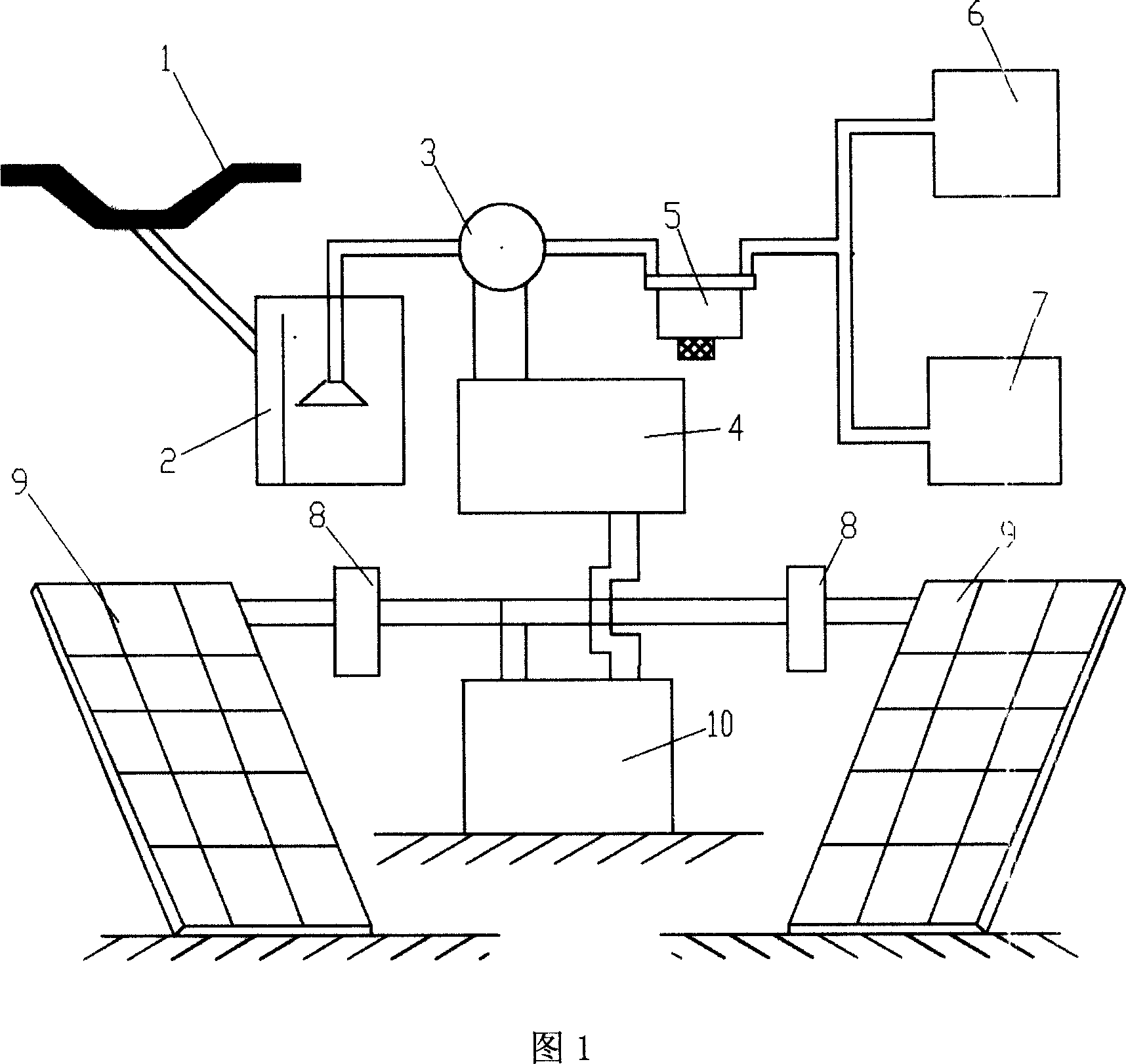

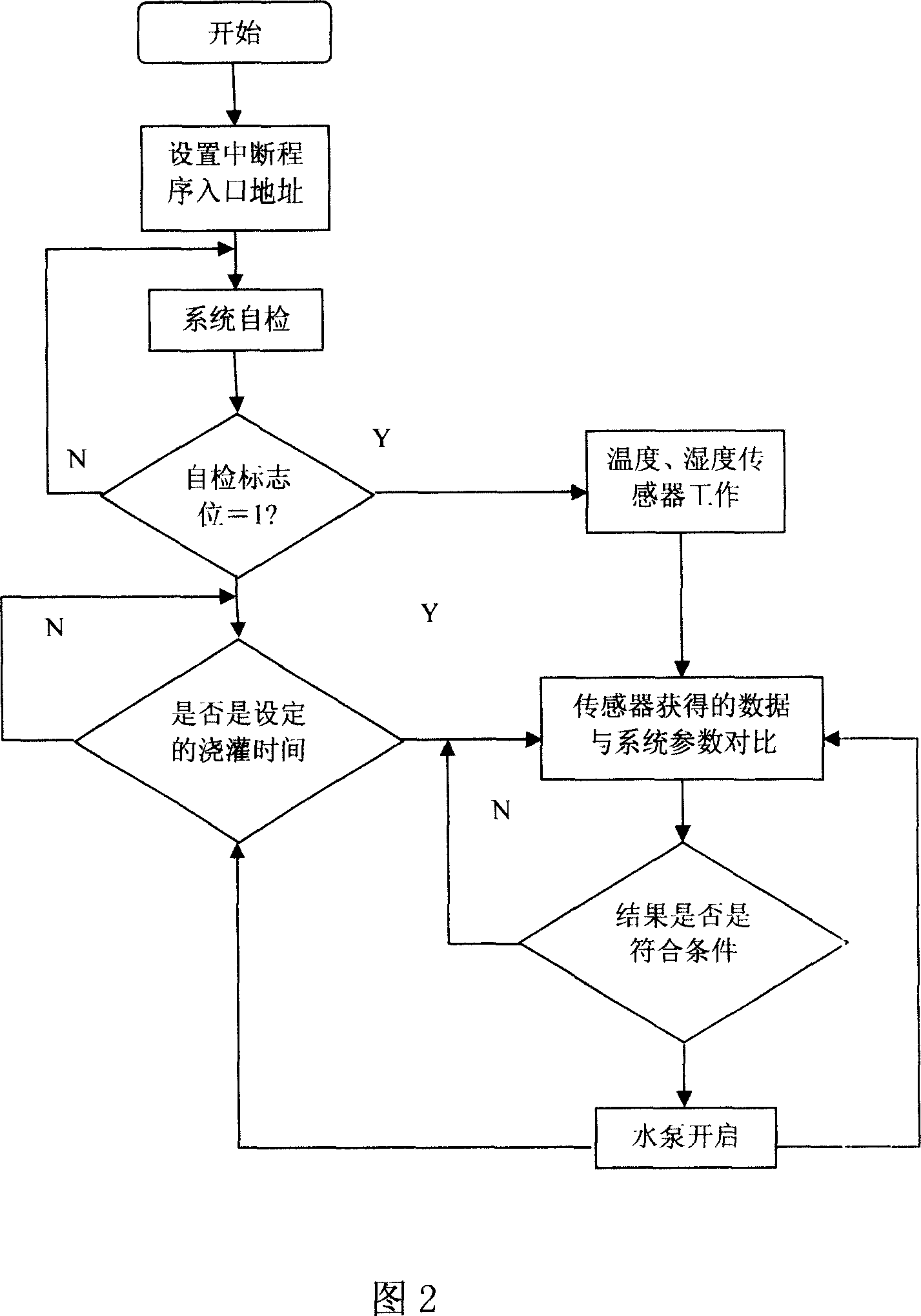

Solar automatic irrigation system for afforestation

InactiveCN1994056AProtection lifePrevent reverse chargingBatteries circuit arrangementsClimate change adaptationMicrocontrollerAutomatic control

The invention relates to a solar-energy green automatic irrigating system, which comprises solar energy battery plate, water pump, irrigating and micro irrigating system, rain collector, water feeder, fertilizer, water container, accumulator, charge controller, and automatic control system formed by single chip and sensor; the solar energy battery plate is connected to the accumulator via charge controller, to charge accumulator and control the over-charge or over-discharge of accumulator; the accumulator via automatic controller is connected to the water pump; the water inlet of water pump is connected to the water container, while water outlet is connected to the irrigating and micro irrigating system; the rain collector, water feeder, fertilizer are connected to the water container. The inventive system can save water.

Owner:DONGHUA UNIV

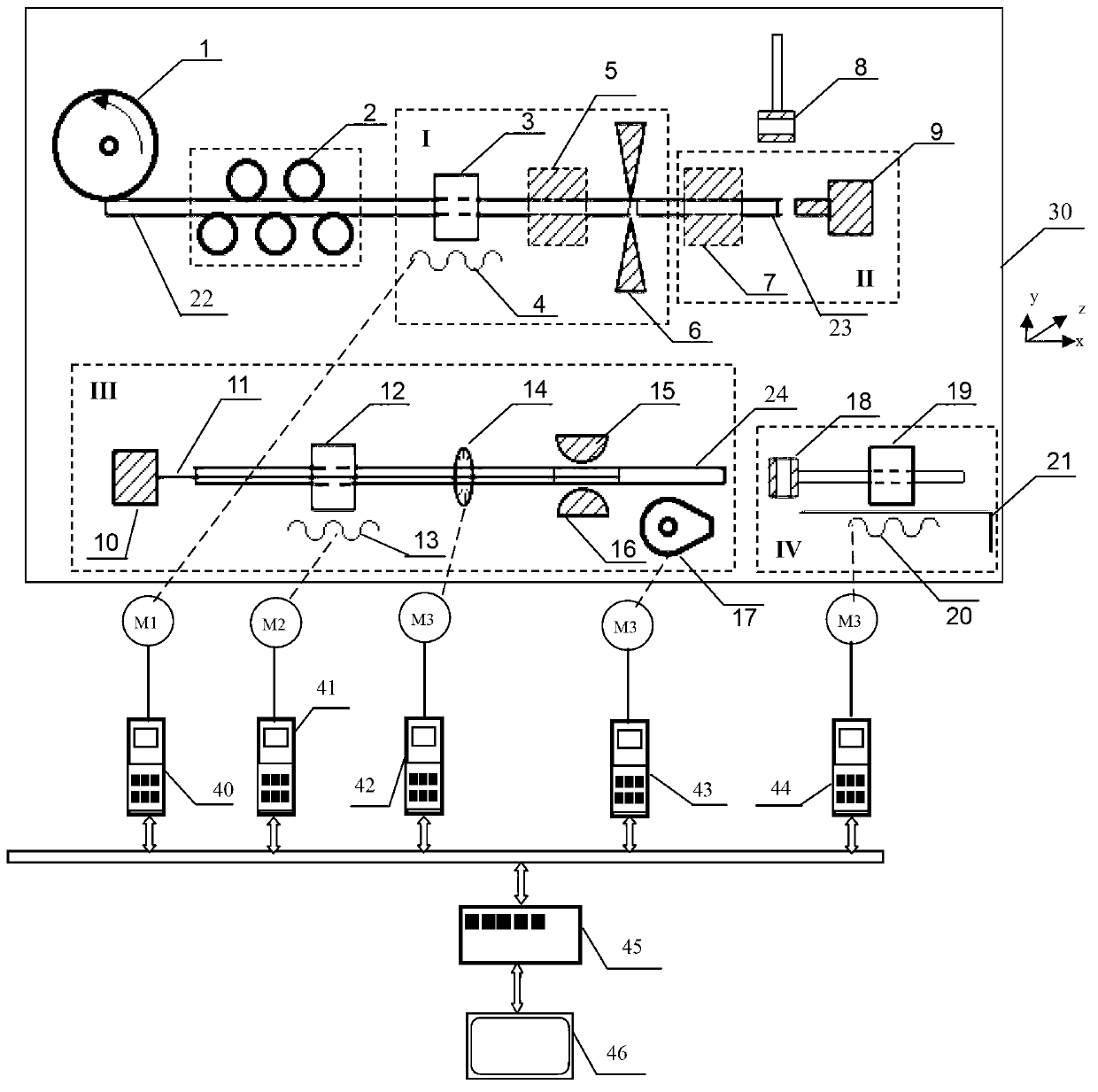

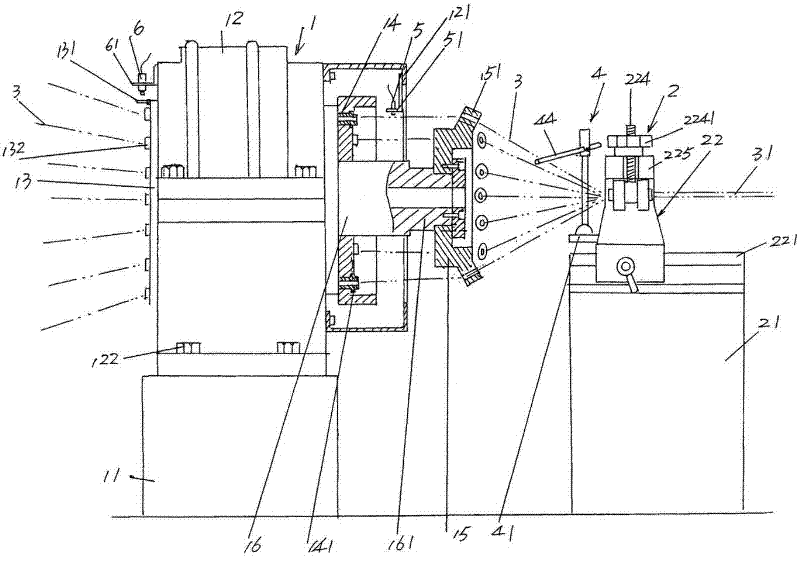

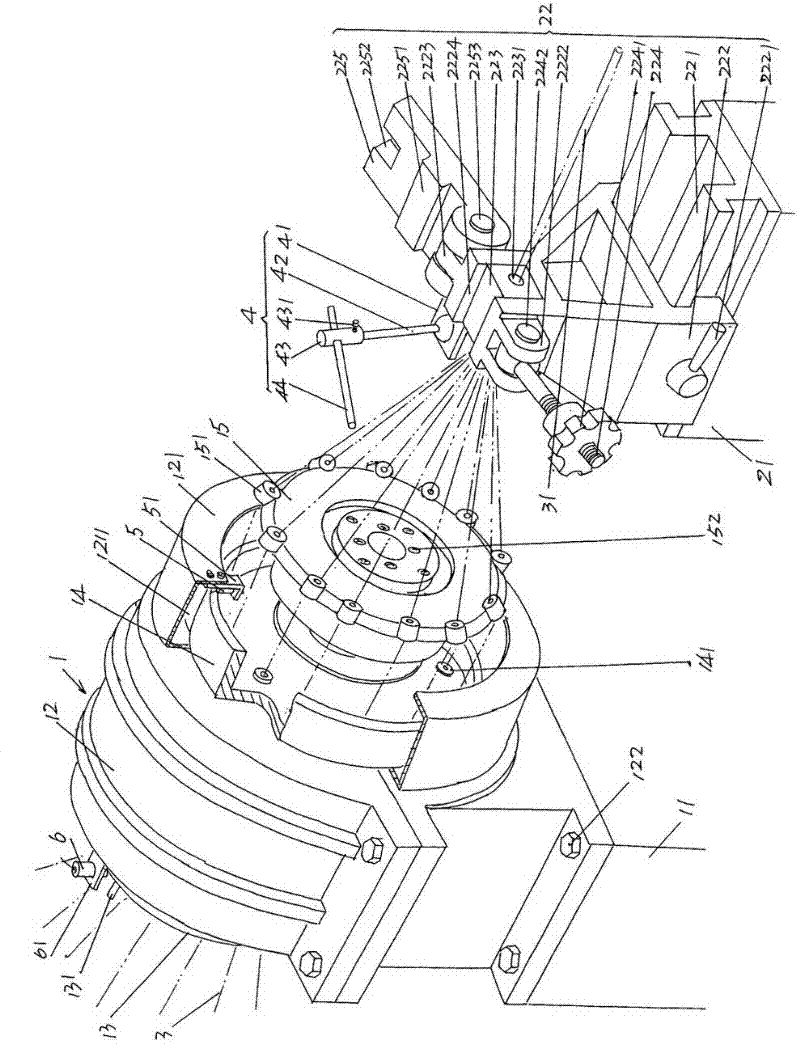

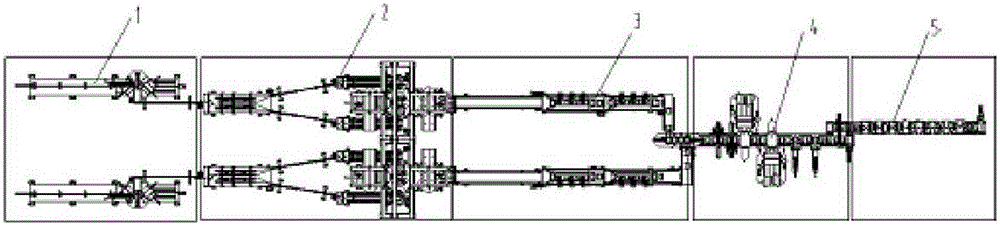

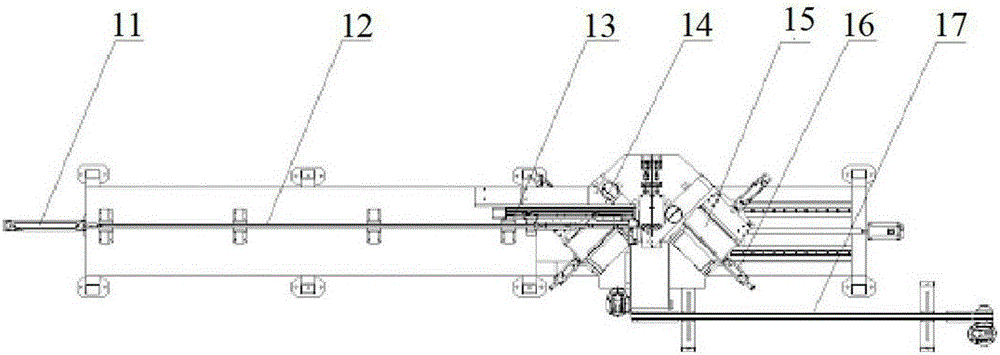

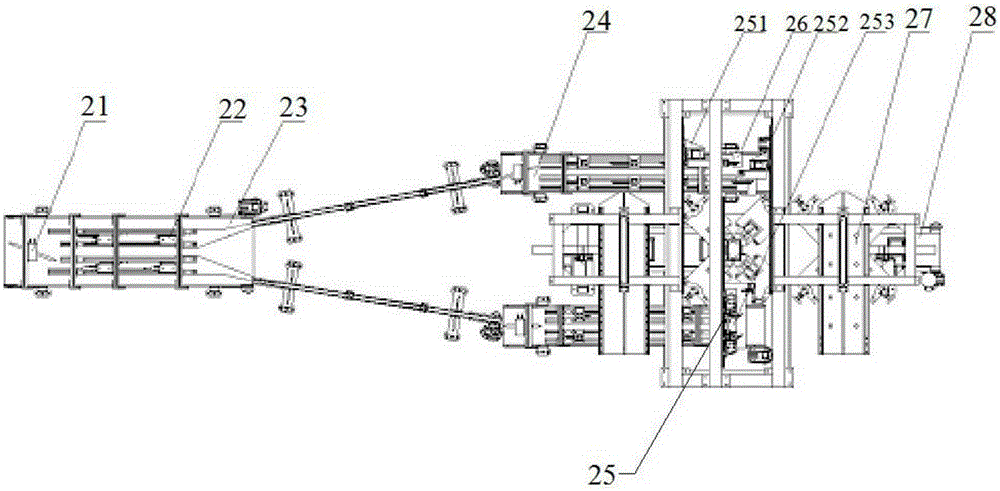

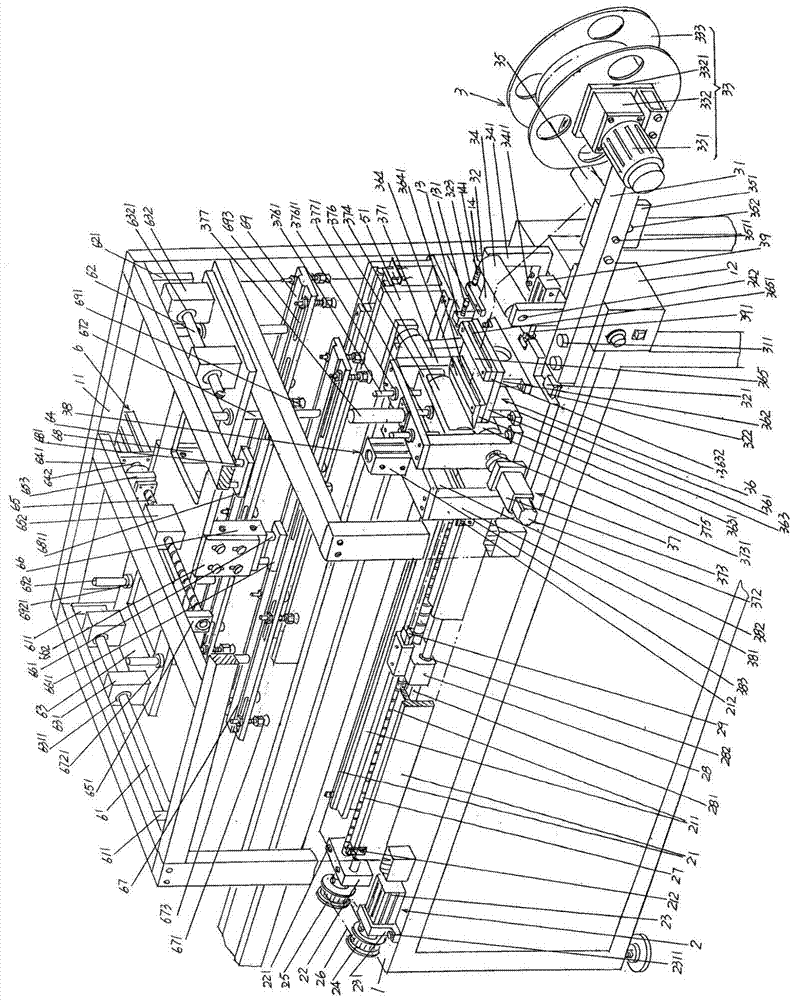

Method for optimization of pipe integrated numerical control machining process

InactiveCN103341521AImprove production efficiencyImprove processing qualityMetal-working feeding devicesStripping-off devicesNumerical controlMotor drive

The invention provides a method for optimization of a pipe integrated numerical control machining process. The method comprises the following steps of rough shape cutting, pipe end molding, bend pipe molding, and split charging and discharging. A controller transmits control signals to servo drivers ((40)-(44)). The servo drivers drive motors (M1-M5) on processing devices and the motors drive the corresponding processing devices to work so that high-precision processing is finished. The method can automatically realize integrated numerical control machining or any combined machining such as pipe rough shape cutting and feeding, chipless rough shape cutting, spinning pipe end molding, bend pipe and manipulator automatic-feeding, three-dimensional bend pipe and manipulator automatic-discharging according to drawing information only by manual introduction of a pipe to a material picking opening of a machine tool, can avoid complex processing adopting multiple machine tools and multiple processing steps, can realize continuous automatic production, can improve production benefits and processing quality of pipe production, and can be used for bending molding processing of pipes used in the industries of air conditioners, water heaters, refrigerators or automobiles.

Owner:WUHAN UNIV OF TECH

Ladle bottom castable and preparation method thereof

The invention relates to a ladle bottom castable and a preparation method thereof. The technical scheme is as follows: 60-70wt% of titanium-iron slag particles are taken as aggregate, and 25-35wt% of titanium-iron slag fine powder, 1-4wt% of zirconia micro powder and 2-5wt% of titanium oxide micro powder are taken as substrate materials; according to the content of the aggregate and the substrate materials, the substrate materials are uniformly mixed firstly, and then the uniformly mixed substrate materials are added to the aggregate to be uniformly mixed; silica sol accounting for 3-7wt% of the sum of the substrate materials and the aggregate is added, and the mixture is uniformly stirred, subjected to vibratory compaction, cured for 6-12 h under the condition of room temperature and finally subjected to heat preservation for 12-24 h under the condition of 90-110 DEG C to prepare the ladle bottom castable. The ladle bottom castable and the preparation method have the characteristics of low cost and simple process, and the prepared ladle bottom castable has good high-temperature volume stability and good corrosion resistance to slag.

Owner:WUHAN UNIV OF SCI & TECH +1

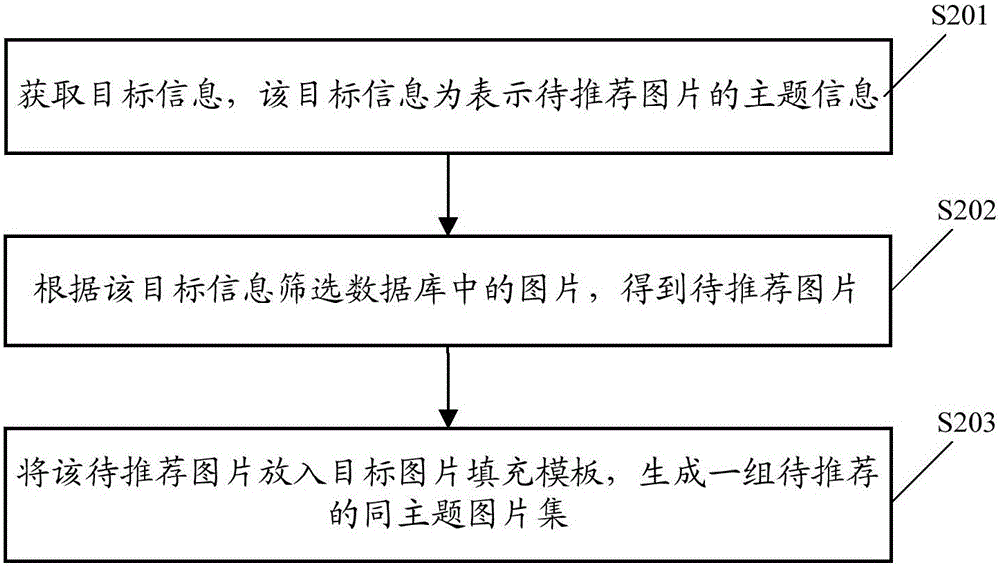

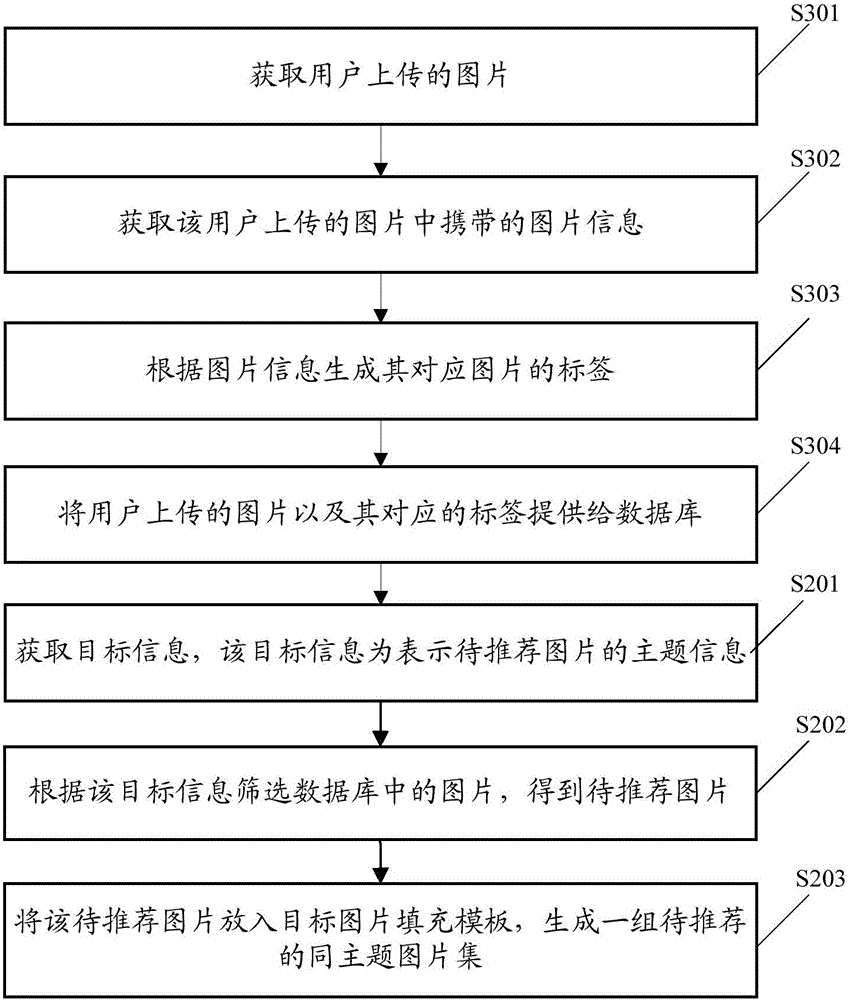

Picture processing method, device and equipment

InactiveCN105975612AImprove screening efficiencyAvoid manual screeningSpecial data processing applicationsComputer graphics (images)Algorithm

The embodiment of the invention discloses a picture processing method, device and equipment. The method comprises the steps of obtaining target information, screening pictures in a database according to the target information to obtain the picture to be recommended and putting the obtained picture to be recommended into a target picture filling template to generate a same-theme picture collection to be recommended, wherein the target information is theme information of a picture to be recommended. According to the technical scheme, by means of the picture processing method, device and equipment, the step of artificially screening pictures can be avoided, the step of artificially generating the same-theme picture collection to be recommended can also be avoided, the efficiency of screening the pictures is improved, and meanwhile a certain amount of human resources can be reduced.

Owner:KINGSOFT

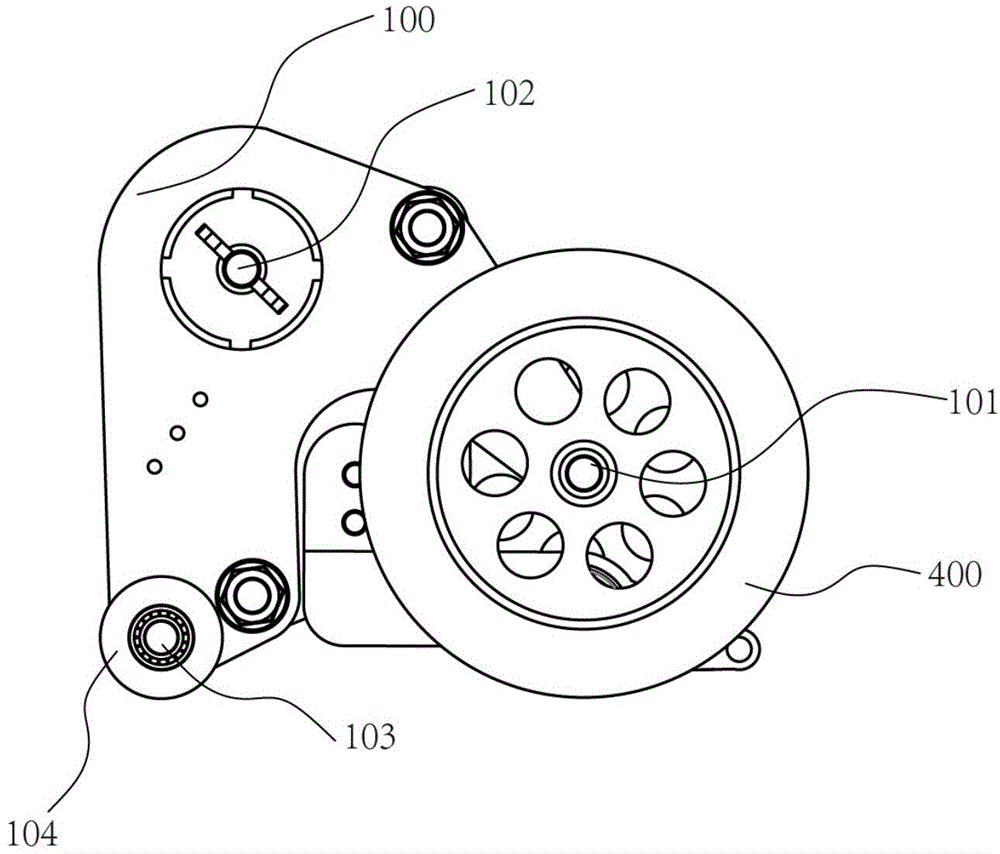

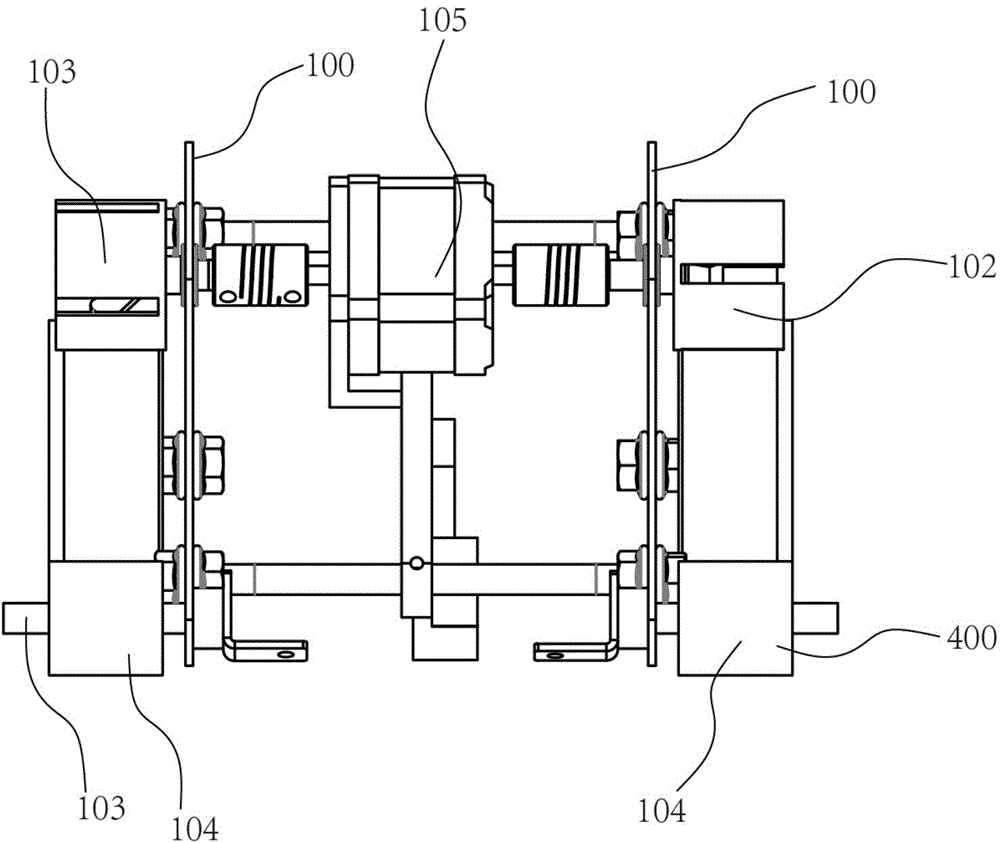

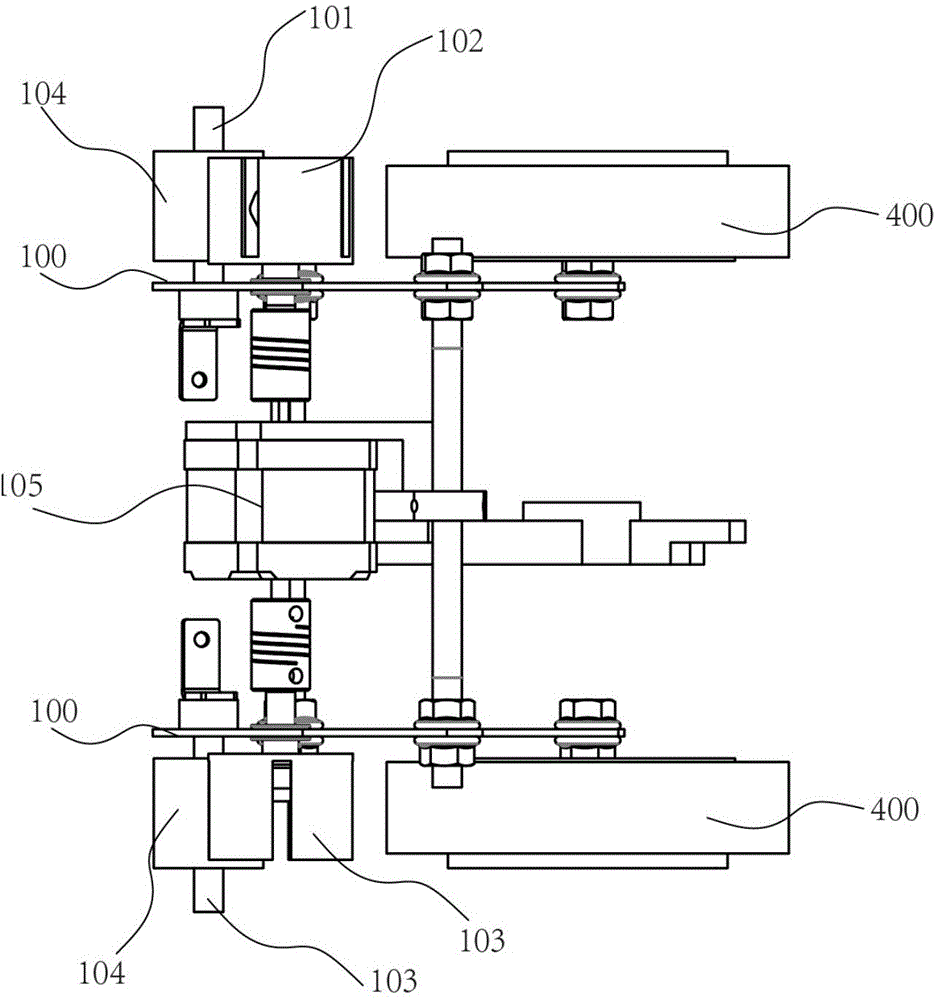

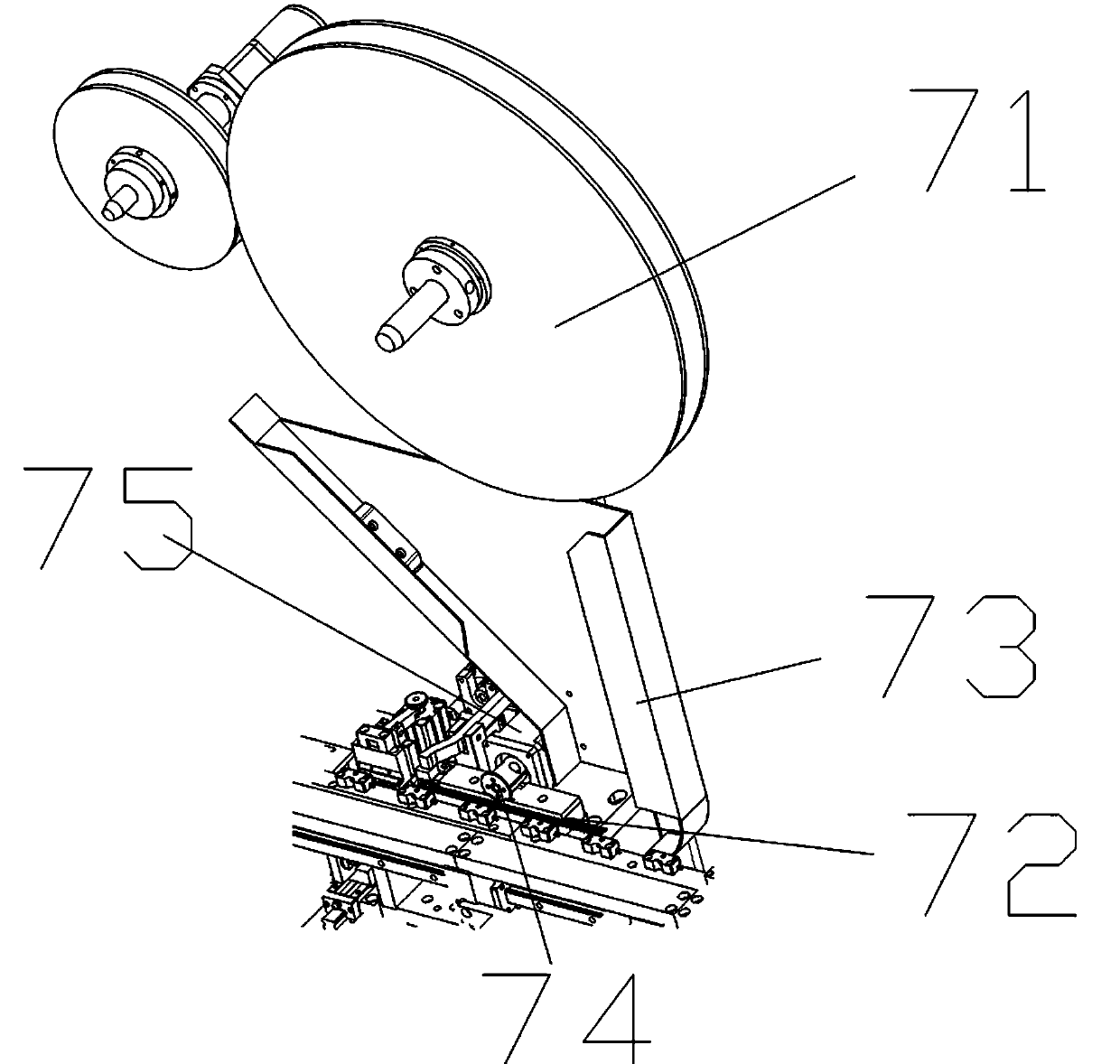

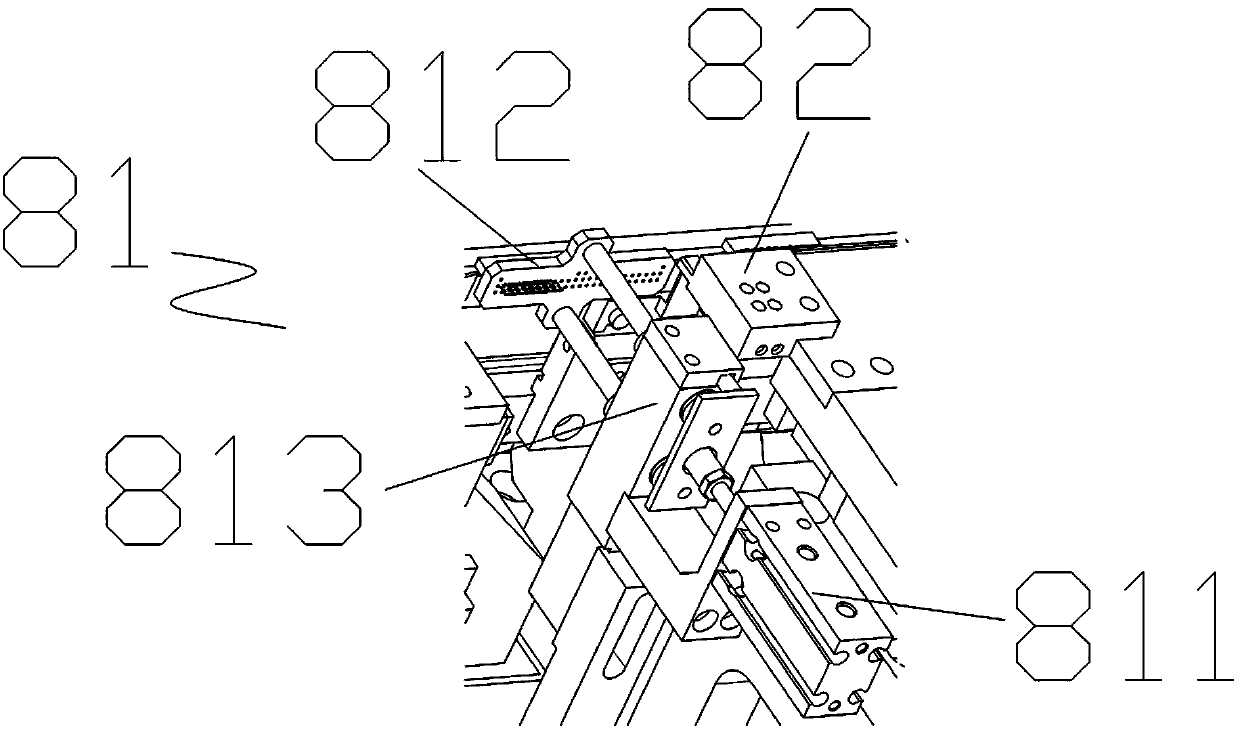

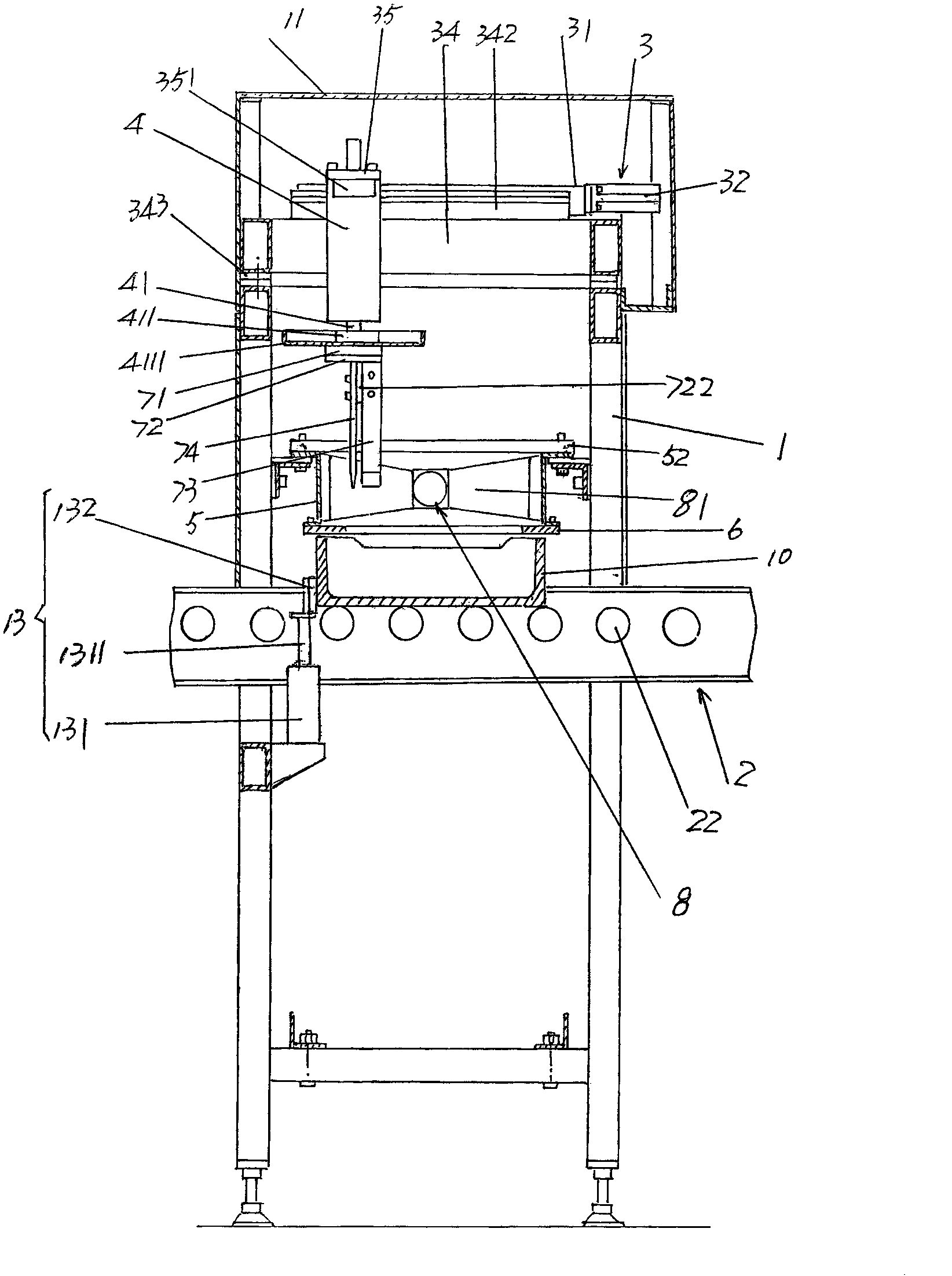

Automatic sticking device and sticking method thereof

ActiveCN104621821AFree laborSave labor resourcesClothes making applicancesEngineeringMechanical engineering

The invention discloses an automatic sticking device and a sticking method thereof. The automatic sticking device comprises a control device, a grabbing component and a conveying component, the grabbing component is provided with an adhering portion, a retaining plate and an adhesion driving element driving the adhering portion to move, the retaining plate is provided with a through hole, the adhering portion is located over the retaining plate and faces the through hole of the retaining plate, the conveying component is provided with a conveying driving component driving the grabbing component to move, and the control device is electrically connected to the adhesion driving element and the conveying driving component. The automatic sticking device realizes automatic sticking and cutting piece separation, labor is freed, and labor resources and time are saved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

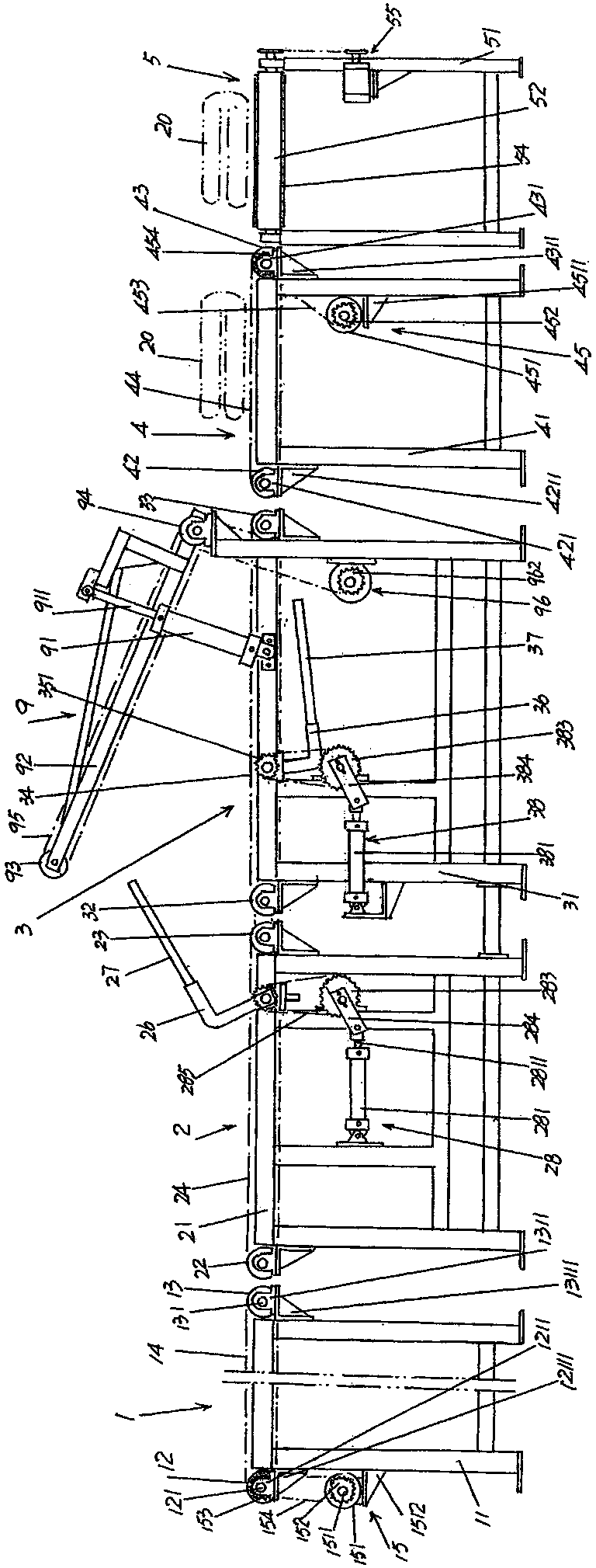

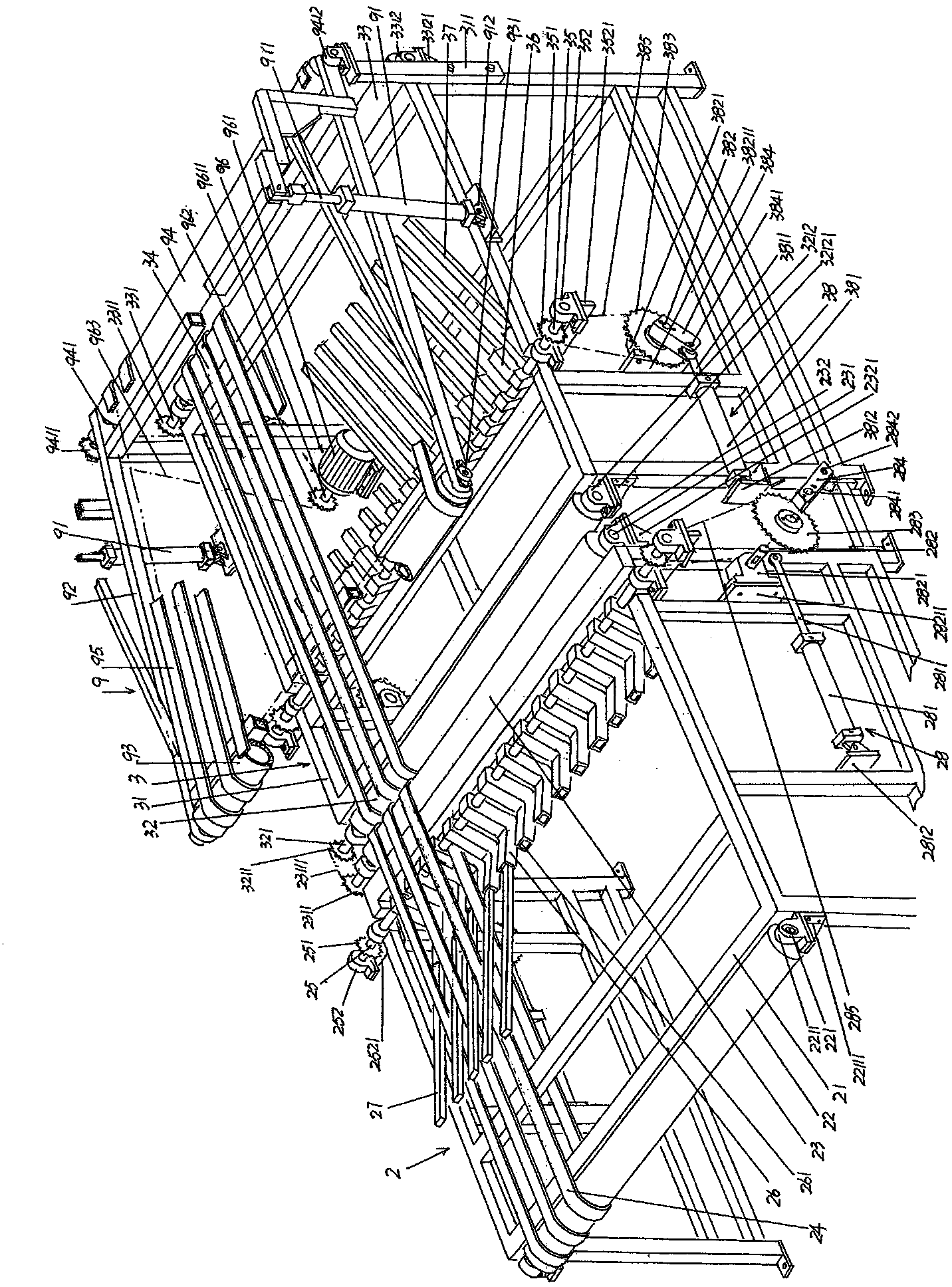

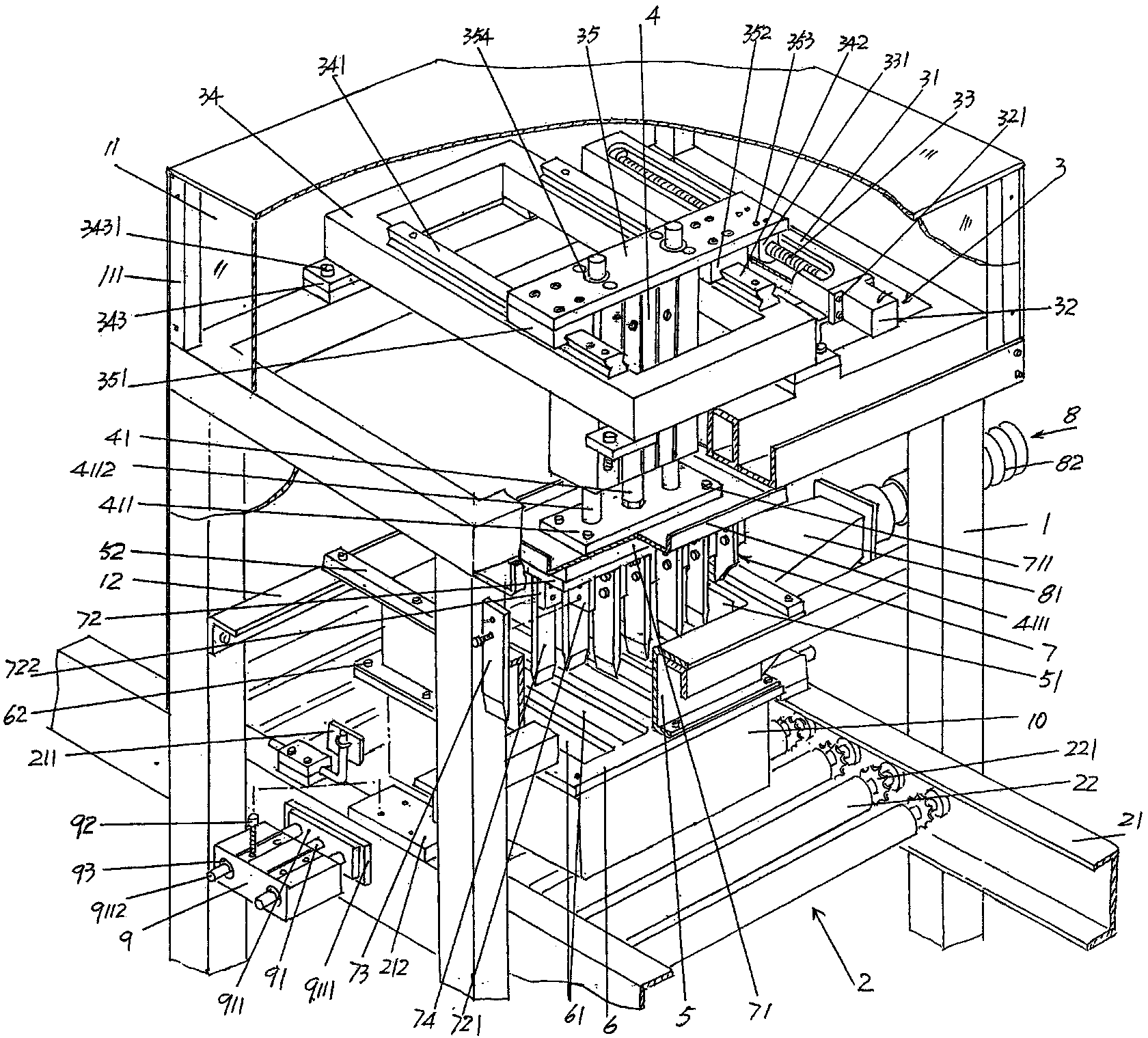

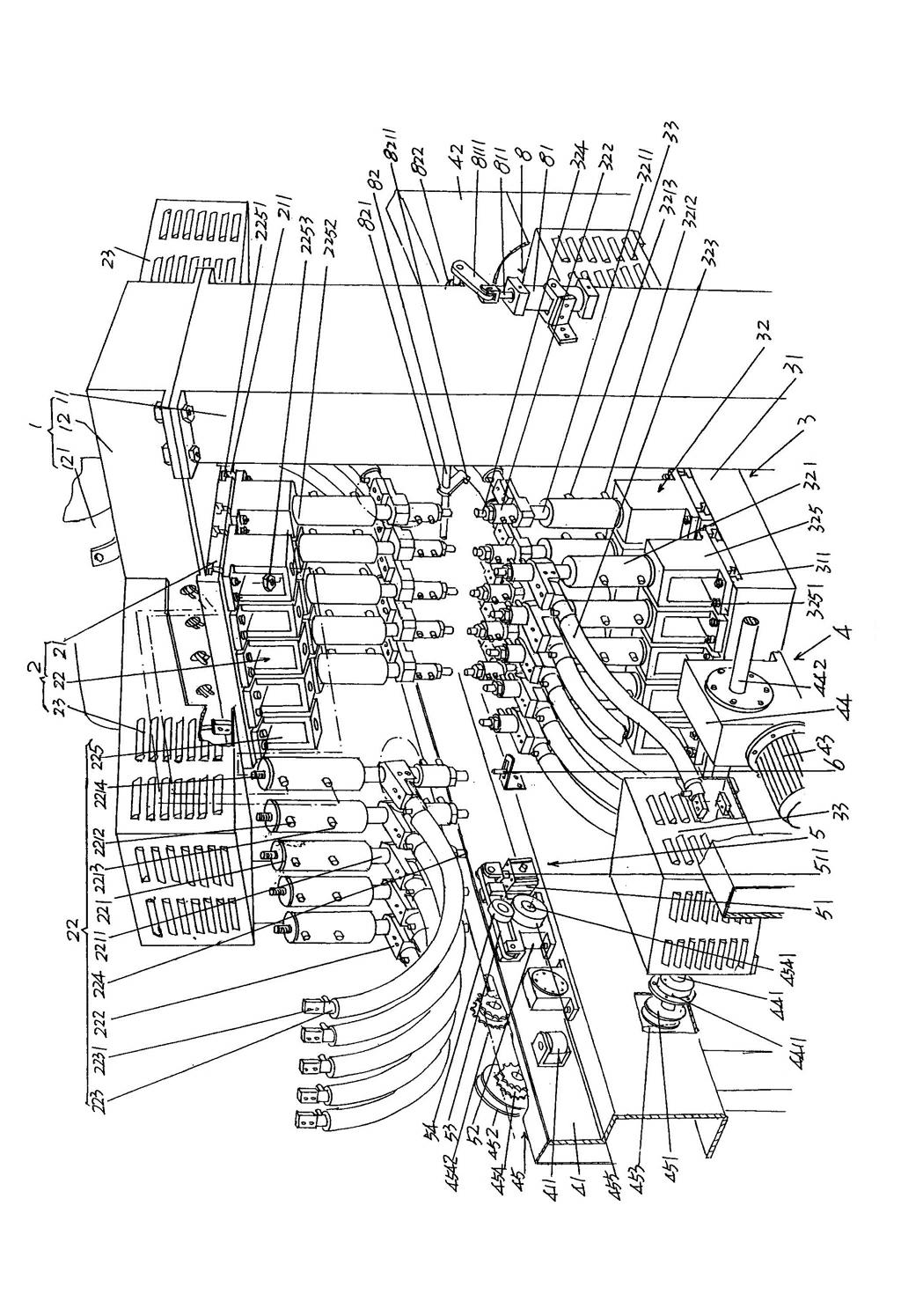

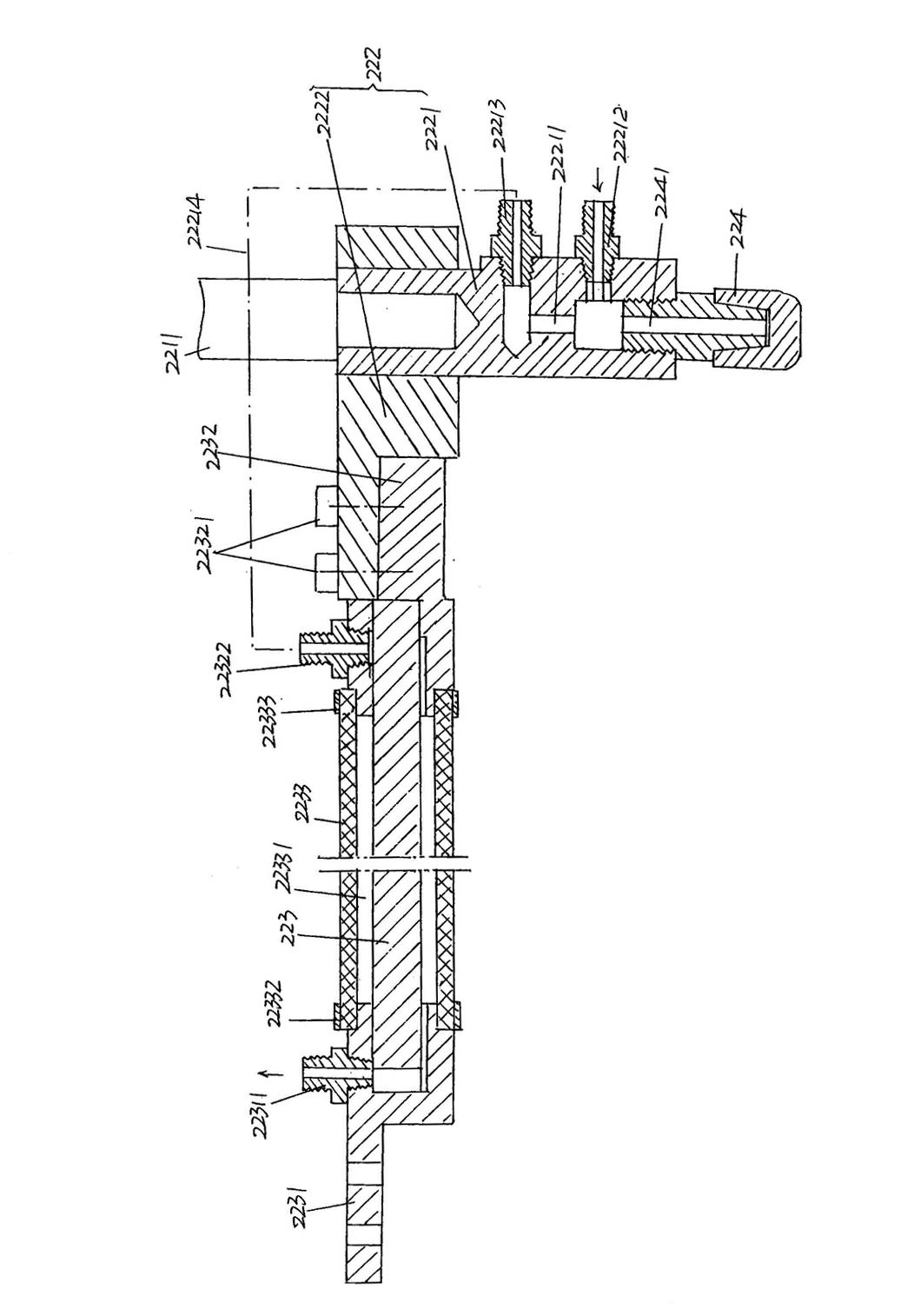

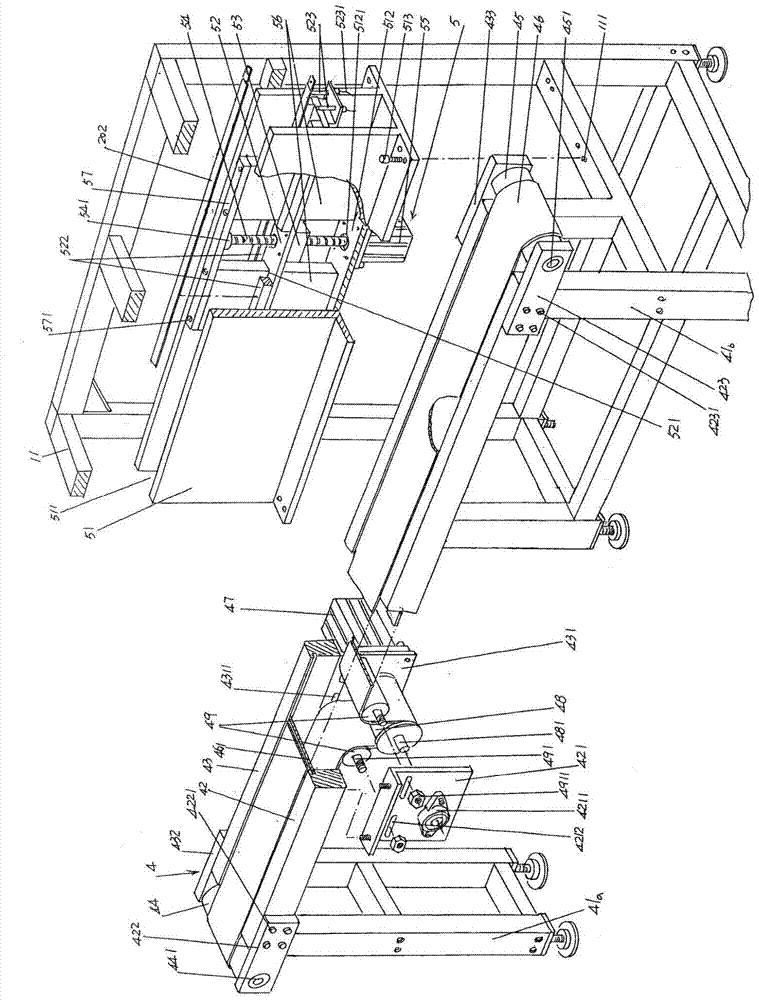

Quilt folding machine

ActiveCN104108497ARealize automatic foldingReduce human inputFolding thin materialsPackagingEngineeringAssembly line

The invention relates to a quilt folding machine, and belongs to the technical field of packaging machines. The quilt folding machine comprises a quilt tiling guiding-in mechanism, a front longitudinal quilt folding mechanism, a back longitudinal quilt folding mechanism, a folded quilt transferring mechanism, a folded quilt conveying mechanism, a transverse quilt folding mechanism and a folded quilt output mechanism; wherein the back longitudinal quilt folding mechanism is located between the quilt tiling guiding-in mechanism and the front longitudinal quilt folding mechanism, the folded quilt transferring mechanism corresponds to the front longitudinal quilt folding mechanism, the folded quilt conveying mechanism corresponds to the folded quilt transferring mechanism, the transverse quilt folding mechanism corresponds to the folded quilt conveying mechanism, the folded quilt output mechanism is located between the transverse quilt folding mechanism and a bagging mechanism and used for conveying a folded quilt folded and shaped by the transverse quilt folding mechanism to the bagging mechanism, and the folded quilt coming from the folded quilt output mechanism is guided into a packaging bag through the bagging mechanism. The quilt folding machine has the advantages that manual folding is not needed so that manual input can be remarkably reduced, and labor resources can be saved; as the quilt can be automatically folded so that the folding efficiency can be high and can adapt to the production efficiency of a quilt manufacturing assembly line; as mechanical automatic folding is achieved, the stable folding effect is achieved to guarantee the packaging quality.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

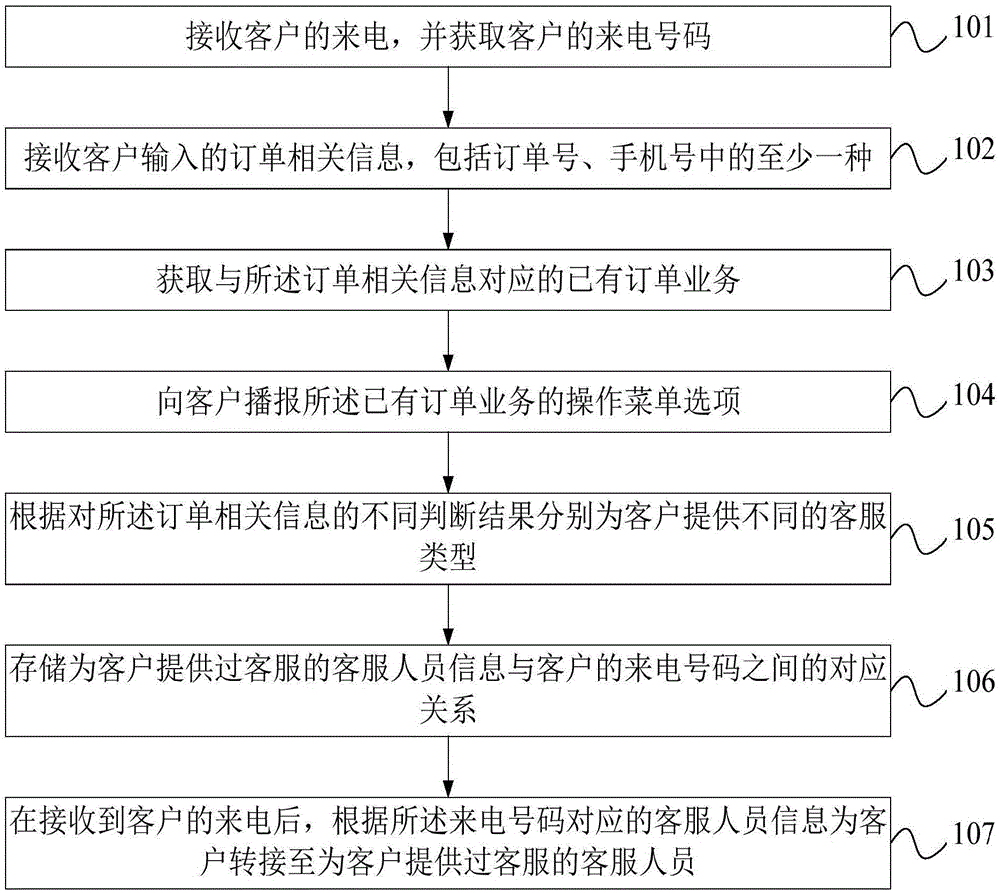

Incoming call processing method of IVR system

ActiveCN105530387AShorten the timeReduce work intensitySpecial service for subscribersOther databases queryingBroadcastingComputer science

The invention discloses an incoming call processing method of an IVR system. The incoming call processing method comprises the following steps: receiving an incoming call of a customer, and obtaining an incoming call number of the customer; S2, receiving related order information input by the customer; S3, obtaining existing order business corresponding to the related order information; and S4, broadcasting operation menu options to the customer. The incoming call processing method disclosed by the invention can be used for quickly positioning and obtaining the existing order business of the customer through the related order information input by the user, thereby saving a large amount of resources and times, and the incoming call processing method disclosed by the invention can be used for quickly judging the identity of the customer after obtaining the incoming call number of the customer and intelligently selecting to serve the customer by customer service personnel according to the existing order business and the former incoming call information when the customer repeatedly calls, thereby saving the communication time and cost.

Owner:SHANGHAI CTRIP COMMERCE CO LTD

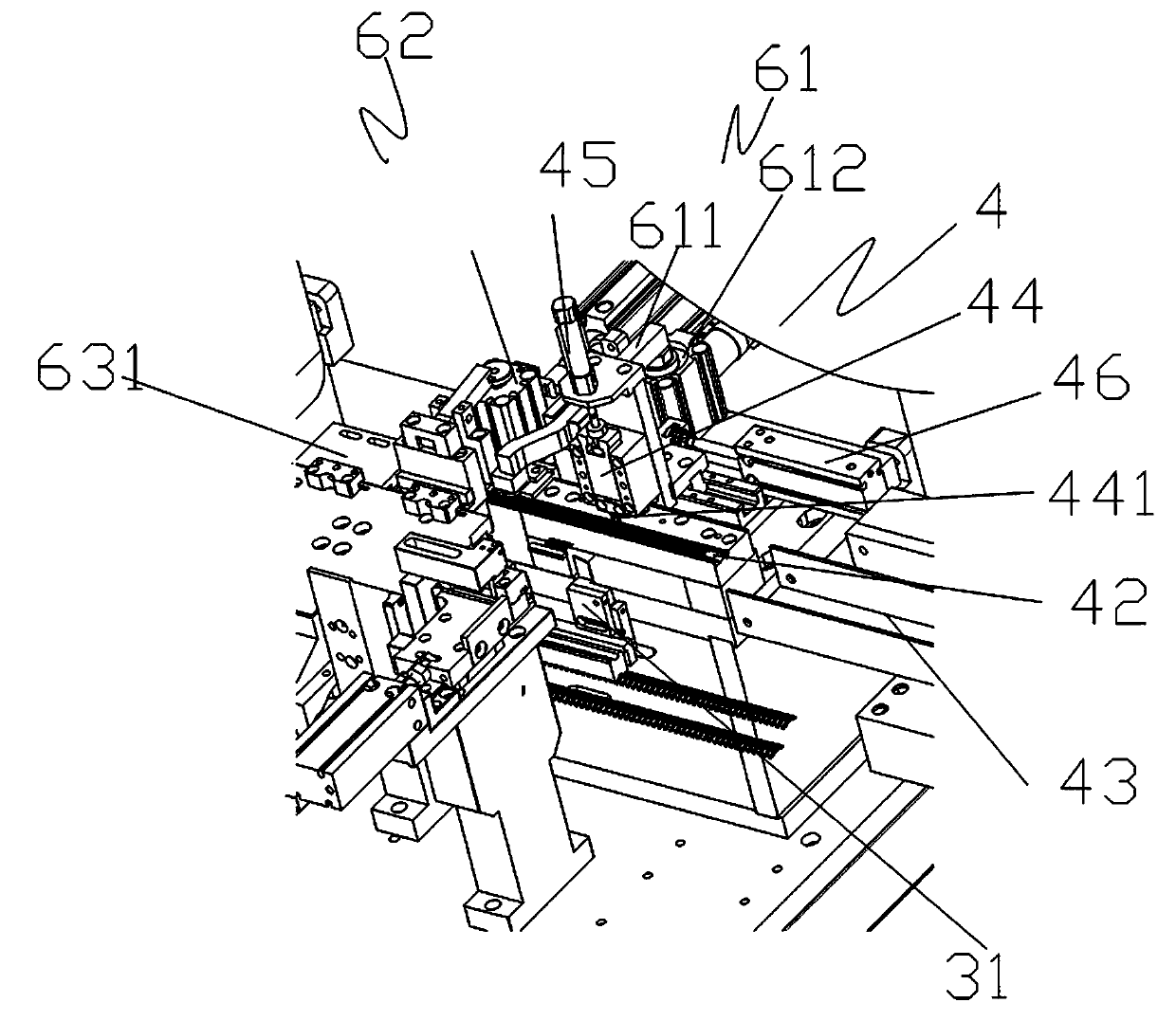

Connector terminal installation assembling machine

ActiveCN104393469ANot enough quantityReduce defective rateContact member assembly/disassemblyEngineeringProduction quality

A connector terminal installation assembling machine comprises a machine frame, a vibrating disc and a rail; a groove is formed in the rail; a transmission mechanism is fixedly installed below the rail of a bearing platform; a first feeding mechanism, a first linkage transmission device, a second feeding mechanism, a second linkage transmission device, a third feeding mechanism, a third linkage transmission device and a press fit mechanism are sequentially installed on the bearing platform along the rail direction. The connector terminal installation assembling machine has the advantages of improving the terminal feeding efficiency due to mechanical control automation, effectively avoiding a connector casing from being deformed or cracked caused by terminal insertion when the terminal is inserted into the connector, improving the production efficiency and the production quality, avoiding generation of a large amount of rejects and avoiding resource wasting; directly discharging the produced rejects, enabling finished products to automatically enter a package box after being qualifiedly detected, changing original manual package, achieving automatic production and package from feeding to the finished products, improving the improved efficiency by 20 times higher than the manual efficiency and saving labor resources.

Owner:AMPHENOL AORORA TECH (HUIZHOU) CO LTD

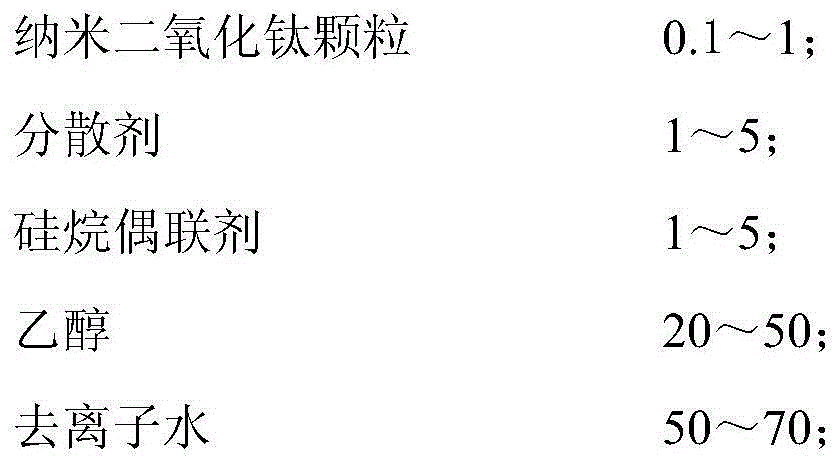

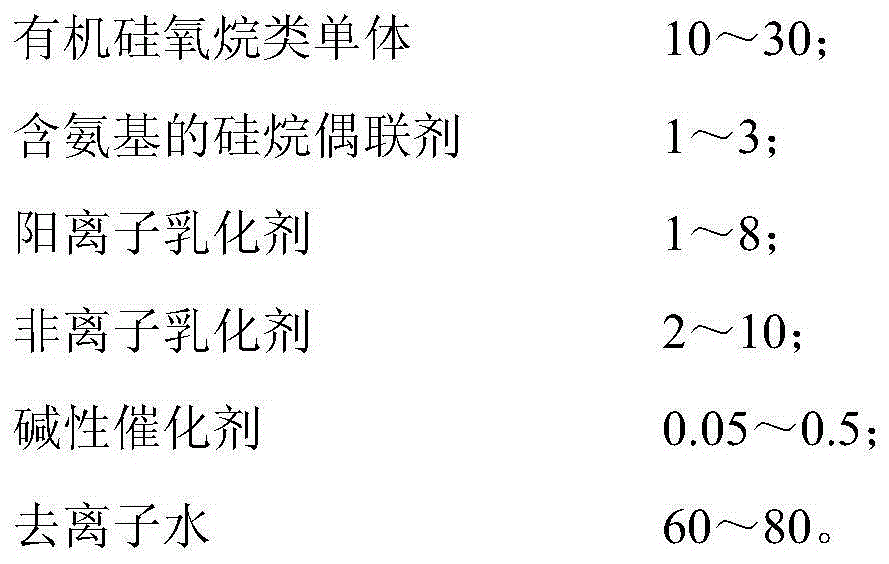

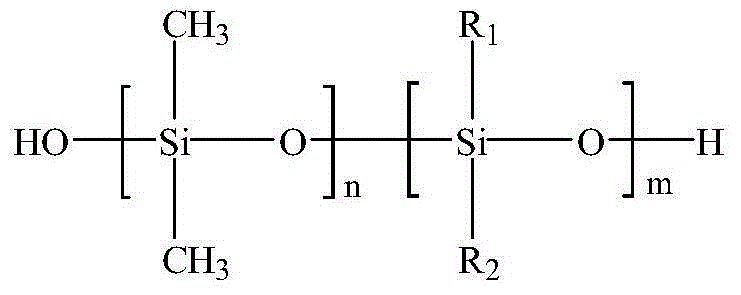

Color-deepening finishing agent for dyed polyester textiles

The invention relates to a color-deepening finishing agent for dyed polyester textiles. Nano-titanium dioxide particles serving as solids and an amino modified polyorganosiloxane microemulsion serving as a film-forming material are compounded to form the color-deepening finishing agent for the polyester textiles. Due to the small grain size effect and the large specific surface area of the nanoparticles, the contact of the nanoparticles with fibers is increased and a relatively high adsorption rate can be formed; due to the flexibility and the film-forming property of the organic silicon junction fragment of the film-forming material covering the nanoparticles, the color-deepening finishing agent is capable of forming an uneven thin film capable of generating scattering reflection on the surface of the treated fabric, and consequently, the absorptive amount of the fabric to the incident light can be greatly increased, the reflected light can be reduced and the effect of enhancing the color depth of the fabric can be achieved. The dyed polyester textiles treated by use of the color-deepening finishing agent are deepened in color under the circumstance that the inherent characteristics of the dyed fiber products are not damaged; besides, the treated dyed polyester textiles have good color fastness and also have antibacterial property.

Owner:科凯精细化工(上海)有限公司

Colored textile hyperchromic washing agent

InactiveCN101514304AColor enhancementAchieve the effect of frequent washing and constant newnessNon-ionic surface-active compoundsAnionic surface-active compoundsBleachPyrophosphate

The invention discloses a colored textile hyperchromic washing agent, which contains a washing agent, a deep dyeing promoter, a penetrating agent, a dispersing agent, a color fixing agent, a levelling agent, a dyeing auxiliary, a brightening agent, a bleaching agent and a bluing agent, wherein the penetrating agent is aliphatic alcohol or oxirane; the color fixing agent is dicyanodiamide formaldehyde or organosilicon; the dyeing auxiliary is sodium sulfide; the bleaching agent is sodium hydrosulfite or sodium pyrophosphate; and the deep dyeing promoter is chitosan or acetic acid. The product of the present invention has no contamination, the washed clothes is clear and colorful after washing, discarding and replacement of the clothes after washing is avoided, thereby saving a large amount of weaving resource, energy, labor resource and life fund for purchasing new clothes.

Owner:吉林省亨泰服装洗染科学技术研究所

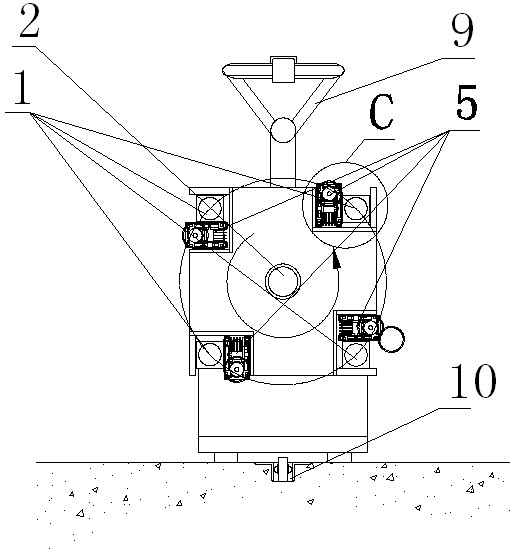

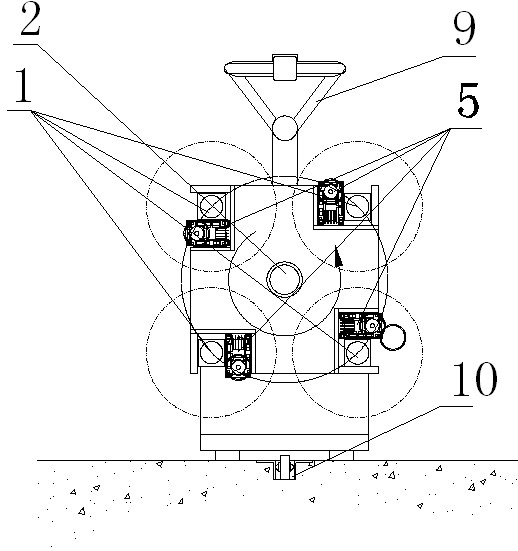

Crushing machine for electronic powder material

ActiveCN103521314BReduce work intensityMeet the use requirementsDirt cleaningGrain treatmentsEngineeringUltimate tensile strength

The invention relates to a crushing machine for an electronic powder material, belonging to the technical field of supporting facilities of an electronic kiln. The crushing machine for the electronic powder material comprises a machine frame, wherein the machine frame follows a saggar conveying mechanism of an automatic production flow line of an electronic kiln; a crushing action cylinder horizontal displacement mechanism is arranged on the top of the machine frame; a crushing action cylinder is connected with the crushing action cylinder horizontal displacement mechanism; a saggar mouth edge part enclosing pallet is fixed on the machine frame; a crushing blade scraping plate is fixed at the bottom of the saggar mouth edge part enclosing pallet; a crushing mechanism is connected with a crushing action cylinder column and corresponds to the crushing blade scraping plate; a dust leading-out mechanism is connected with the saggar mouth edge part enclosing pallet; a pair of saggar clamping action cylinders are arranged on the saggar conveying mechanism in a face-to-face state and correspond to the positions below the two corresponding sides of the crushing blade scraping plate. According to the crushing machine for the electronic powder material, the operation intensity is alleviated, scalding phenomenon is avoided, the efficiency is high, labor resources are saved, a clean environment is guaranteed, and the using requirement of the automatic production flow line of the electronic kiln can be met.

Owner:SUZHOU HUIKE EQUIP CO LTD

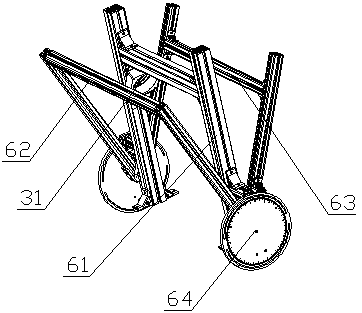

Stranding device

InactiveCN102394152AQuality assuranceReduce labor intensityCable/conductor manufactureTextile cablesEngineeringWinch

A stranding device belongs to the technical field of wire and cable processing equipment, and comprises a stranding cage mechanism and a die guiding mechanism, wherein the stranding cage mechanism comprises a stranding cage base, a stranding cage, left and right wire guiding plates, a winch and a winch shaft; the stranding cage is fixed on the stranding cage base; a stranding cage shaft is supported on the stranding cage; the left wire guiding plate is arranged at the left end of the winch shaft and corresponds to the left side of the stranding cage; the right wire guiding plate is arranged at the right end of the winch shaft and corresponds to the right side of the stranding cage; the shaft head of the winch shaft extends out of the stranding cage; the winch is fixed on the shaft head; and the die guiding mechanism corresponds to the right side of the stranding cage mechanism, and comprises a wire guiding die holder and a wire guiding die which is arranged on the wire guiding die holder and corresponds to the winch. The stranding device is characterized by also comprising an automatic wire break alarm mechanism which is arranged on the wire guiding die, and corresponds to the side part of the winch, facing to one side of the wire guiding die. The stranding device has the advantages of being beneficial to guaranteeing the quality of a cable core and being conductive to reducing the labor intensity of workers and saving human resources.

Owner:CHANGSHU CABLE WORKS

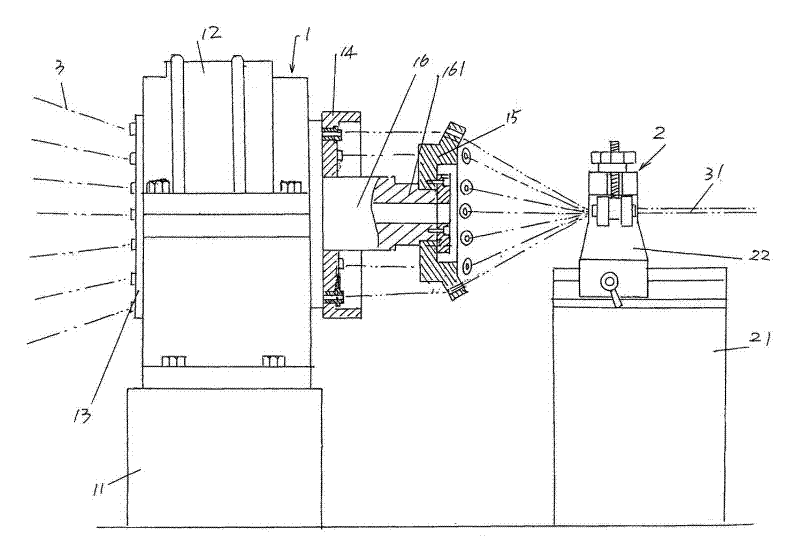

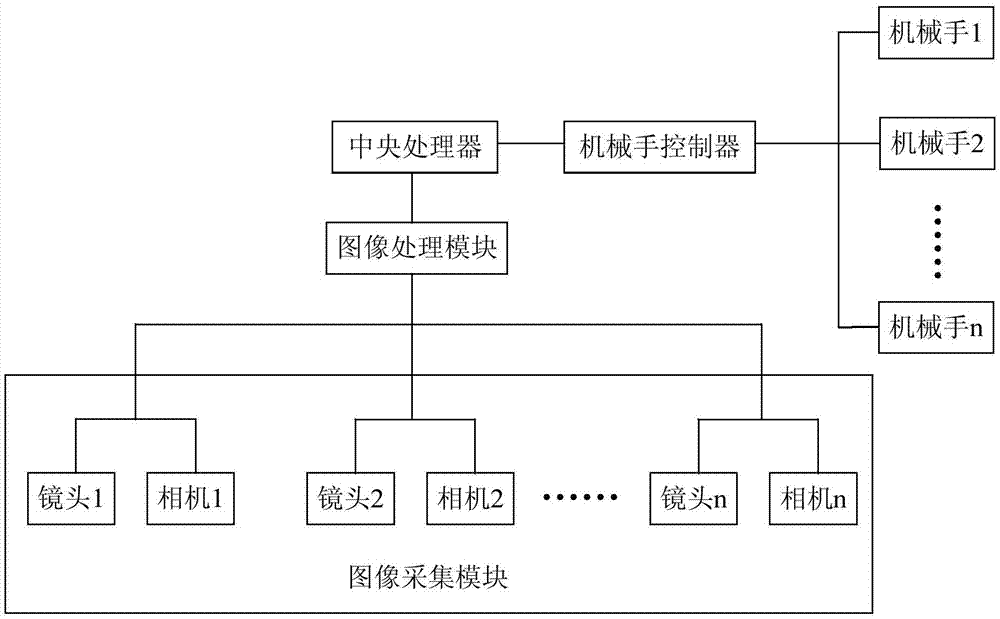

Automatic screw machine based on visual identification and screw installation method thereof

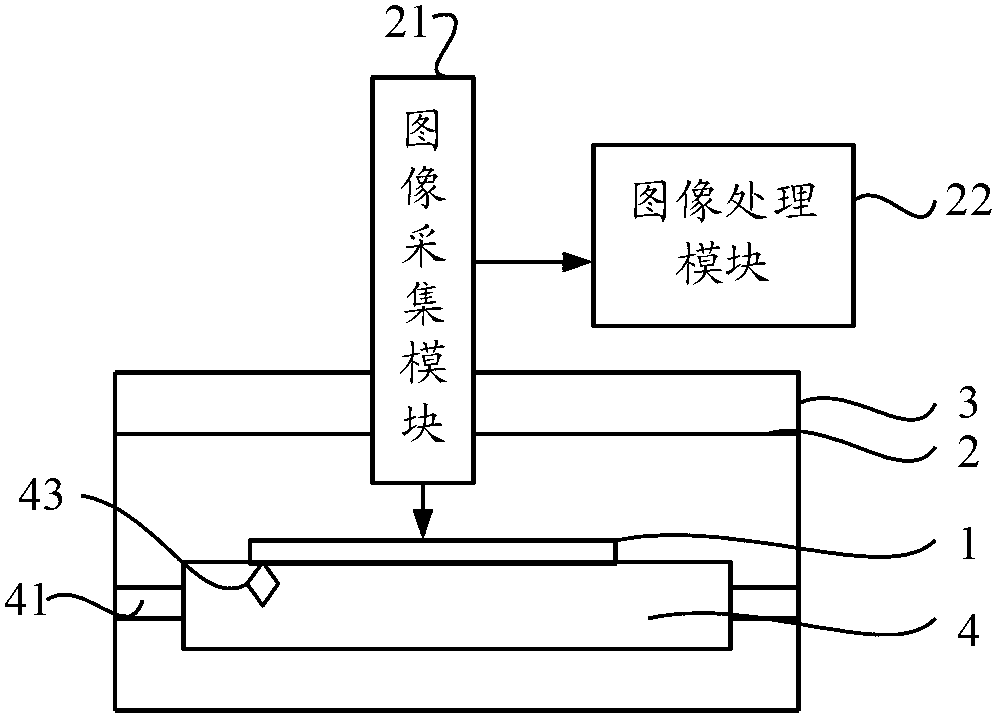

The invention discloses an automatic screw machine based on visual identification. The machine is characterized in that a manipulator, a visual identification system and a control system are included, the control system comprises a central processing unit and a manipulator controller connected with the central processing unit, and the visual identification system comprises an image collecting module and an image processing module connected with the image collecting module and the central processing unit. The automatic screw machine is simple in structure and low in cost, accurate image information of a hole where a screw is installed can be obtained through the image collecting module, the image processing module processes the image information, collected by the image collecting module, of the screw installation hole and then sends the image information to the central processing unit, the central processing unit controls the manipulator to install the screw on the screw installation hole accurately through the manipulator controller, and accordingly machining precision and the service life of a product can be guaranteed. Labor sources are saved, production efficiency is improved, intelligent factories are obtained, and the automatic screw machine is suitable for being used and popularized.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Bulk collecting and intensive placing spinning cake device for semiautomatic joint spinning machine

ActiveCN102424307AImprove coordinationRealize the function of unloadingFilament handlingUltimate tensile strengthMechanical engineering

The invention relates to a bulk collecting and intensive placing spinning cake device for a semiautomatic joint spinning machine. At present, equipment special for carrying and intensively placing spinning cakes scattered on every spinning machine. The bulk collecting and intensive placing spinning cake device comprises a forklift body, and is characterized by further comprising a driving piece, a spinning cake storage rod transposition device, a spinning cake storage rod lateral sway device, a plurality of spinning cake storage rods, spinning cake push heads and spinning cake storage rod reversing devices, wherein the spinning cake storage rod transposition device is provided with a filament taking working position; the spinning cake storage rod lateral sway device is arranged at the front end of the forklift body; the spinning cake storage rod transposition device is arranged on the spinning cake storage rod lateral sway device; on the spinning cake storage rod transposition device,every spinning cake storage rod is arranged on the spinning cake storage rod transposition device through a spinning cake storage rod reversing device; the spinning cake storage rods have horizontal structures; each spinning cake push head is arranged on a spinning cake storage rod respectively; and the driving piece is connected with the spinning cake push heads. The bulk collecting and intensive placing spinning cake device has a reasonable structural design, the labor frequency of workers can be lowered effectively, the labor intensity is lowered, and the labor resource is saved.

Owner:CHINA UNITED ENG

Refractory casting material for ladle splash guard and preparation method of refractory casting material

The invention relates to a refractory casting material for a ladle splash guard and a preparation method of the refractory casting material. According to the technical scheme, the refractory casting material is prepared by taking 61-71wt% of ferrochrome slag as aggregate, 11-16wt% of fine ferrochrome slag powder, 13-18wt% of fine powder of Cr7-C3, 1-4wt% of zirconia micro powder and 2-5 wt% of crystalline flake graphite micro powder as matrix materials, firstly, uniformly mixing the matrices, adding the uniformly mixed matrix materials into the aggregate, and mixing, thereby obtaining a mixed material; subsequently, adding silica sol which accounts for 3-7wt% of the mixed material, stirring, molding, and maintaining for 12-24 hours at the room temperature; finally, keeping the temperature for 12-24 hours at 90-110 DEG C, thereby preparing the refractory casting material for the ladle splash guard. The preparation method has the characteristics of low cost and simple process, and the refractory casting material for the ladle splash guard is high in density, good in volume stability and high in anti-molten iron / slag corrosion.

Owner:河南胜诚耐火材料有限公司

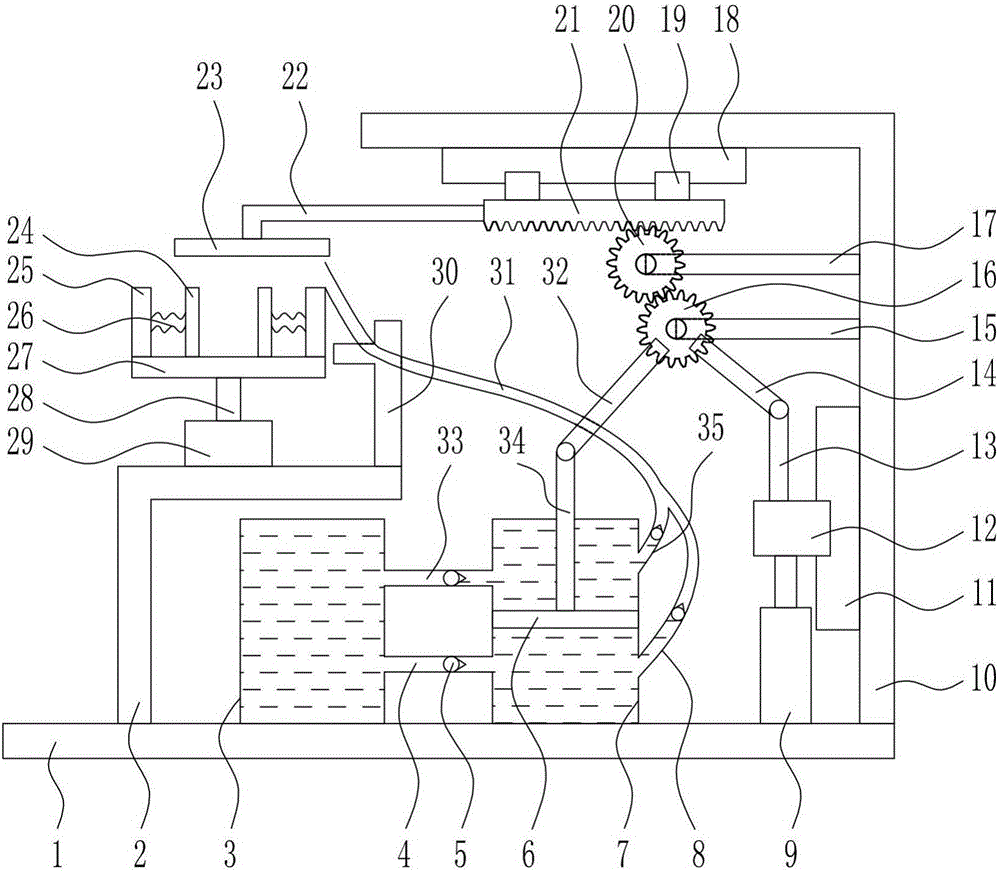

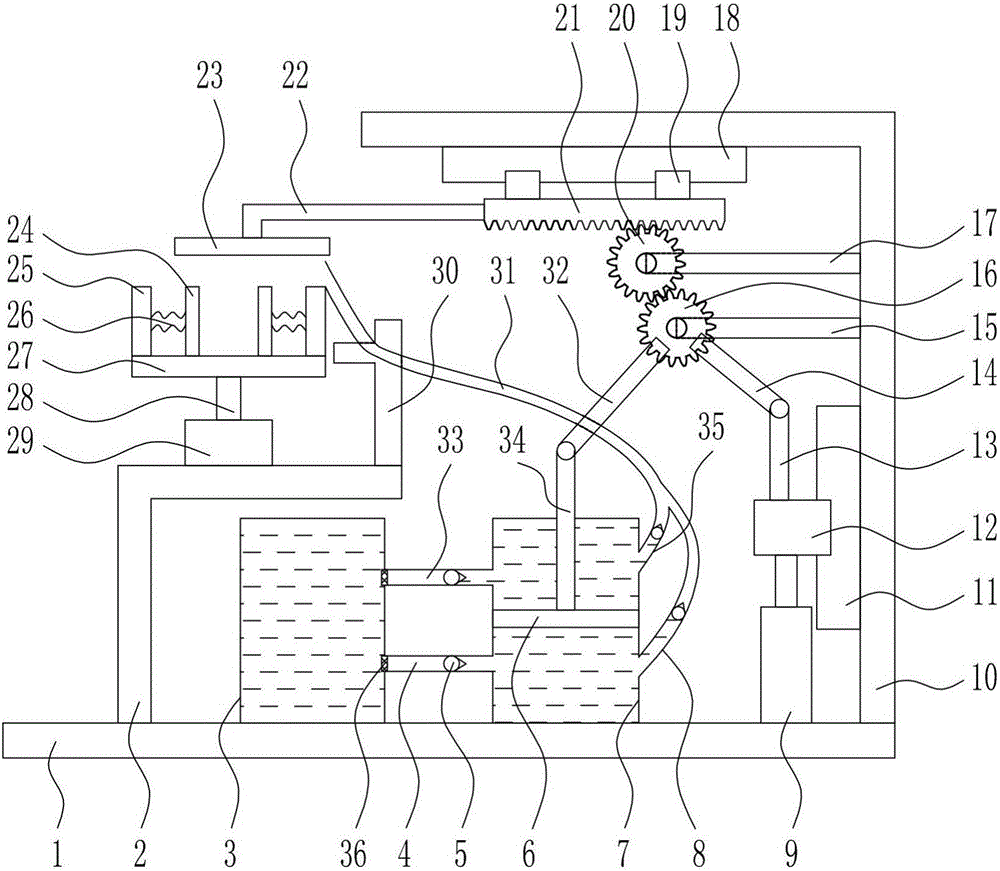

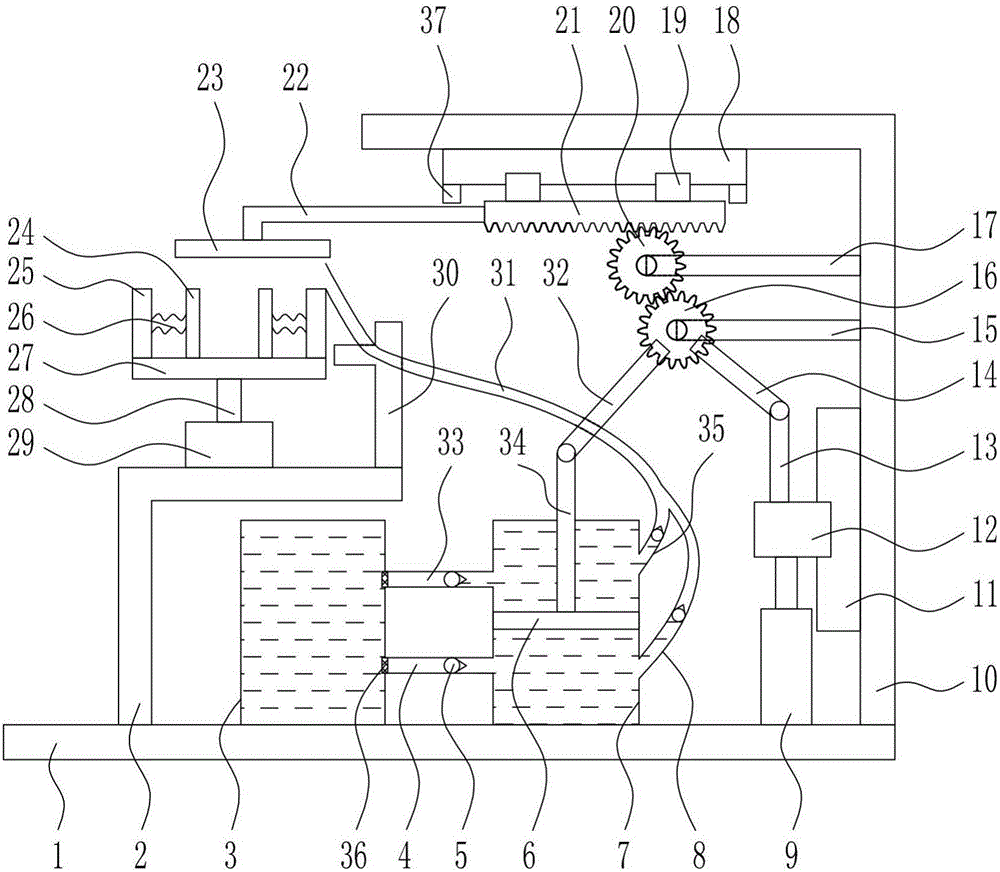

Efficient hardware product grinding device

InactiveCN106181720AGrinding speed is fastImprove grinding effectGrinding carriagesGrinding drivesEngineeringAtmospheric pressure

The invention relates to a grinding device, in particular to an efficient hardware product grinding device. The invention aims to provide the efficient hardware product grinding device which is uniform in grinding and high in grinding efficiency and can save labor resources. In order to solve technical problems, the efficient hardware product grinding device comprises a bottom plate, a left rack, a water tank, a first pipe, a one-way valve, a piston, a cylinder body, a third pipe, an electric push rod, a right rack, a first sliding track, a first sliding block, a connecting rod, a first joint lever, a first strut, a first gear, a second strut, a second sliding track, a second sliding block, a second gear, a gear rack and the like; and the left rack, the water tank, the cylinder body, the electric push rod and the right rack are successively arranged on the top of the bottom plate from left to right. The motor and the electric push rod work simultaneously, and respectively drive a hardware product to rotate and a grinding stone to move in the left-right direction, so that the grinding speed is increased, and the acting force of air pressure is utilized.

Owner:周栋

Method for rapidly producing donkey-hide gelatin

The invention provides a method for rapidly producing donkey-hide gelatin. According to the method, a fresh donkey hide is processed and an airing step is reduced, so that a hide immersing time is shortened by 2-3 days; and the risk of going bad in a donkey hide storage process is avoided. According to the method, a production process is optimized; the quality of a product is improved, the production period is shortened and the manpower and the water source are saved.

Owner:SHAN DONG DONG E E JIAO

Glass defect detection device

PendingCN107607549ASolve the Single Defect Detection ProblemMeet defect detection requirementsMaterial analysis by optical meansError reportingEngineering

The invention belongs to the field of product defect detection, and particularly relates to a glass defect detection device. The device comprises a main rack body, a transfer unit, an illumination unit, an imaging unit, an image acquisition unit, a data processing unit, a control unit and a rotation adjusting mechanism, wherein the rotation adjusting mechanism is arranged on the main rack body; the illumination unit and the image acquisition unit are arranged on the rotation adjusting mechanism, and the rotation adjusting mechanism adjusts the mutual position relationship between the illumination unit and the image acquisition unit, so that the image acquisition unit can perform bright and dark field conversion according to detection requirements. Various lighting schemes as well as imaging lenses and linear array cameras at different angles are integrated in one detection position, so that various defect detection requirements can be met, detection efficiency is improved, and the device is applicable to pipeline working places. The device is low in error reporting rate, high in detection precision and capable of working stably for a long time, a large quantity of labor resources are saved, and therefore, the device has broad application prospect.

Owner:SHENZHEN JINGCHUANG TECH CO LTD

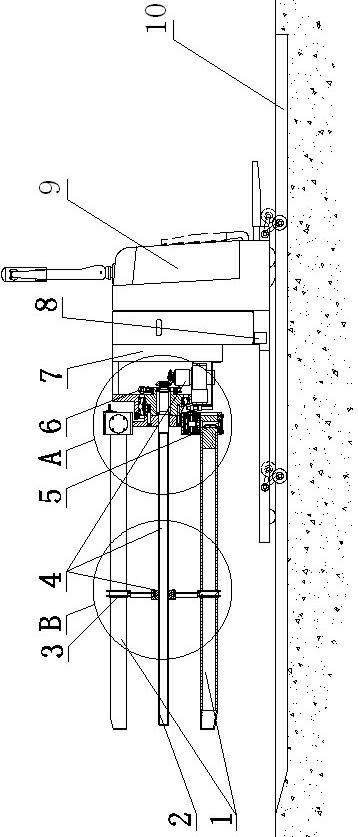

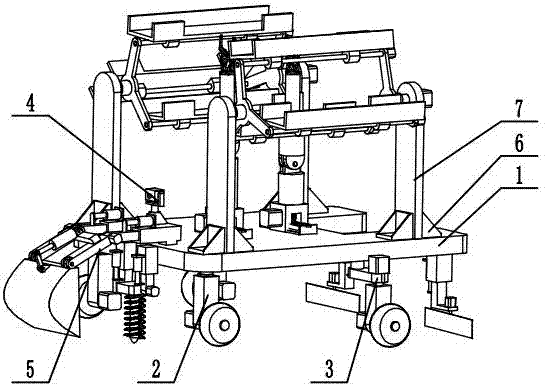

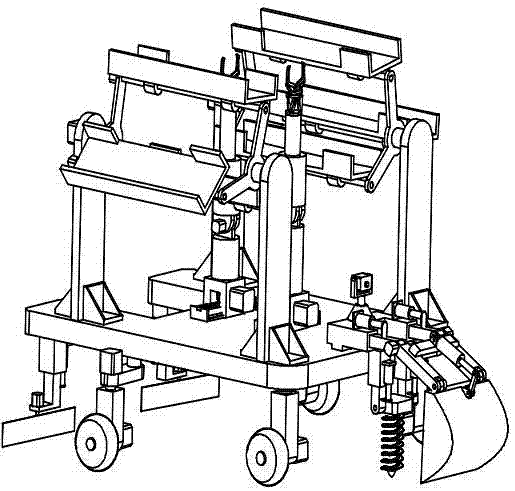

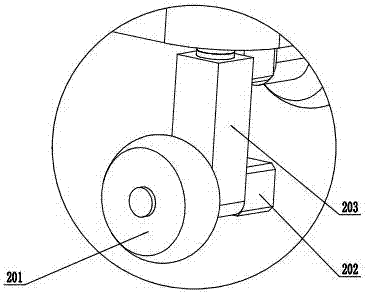

Ornamental tree and shrub transplanting robot

ActiveCN106856751ASave labor resourcesImprove work efficiencyTransplantingVehicle frameOrnamental tree

The invention discloses an ornamental tree and shrub transplanting robot which comprises a platform, two front-drive structures, two rear-drive structure, a camera set, a digging device, eight connection corner parts, four fixed frames, two motor bases, six tree storage baskets, four rotary disks, six first servo motors, two second servo motors, six rotating shafts, a first fixed rod, a third servo motor, a first electric cylinder, a second fixed rod and the like. The ornamental tree and shrub transplanting robot is characterized in that the two front-drive structures are arranged at the front end of the platform, the upper ends of front car frames of the two front-drive structures are fixedly connected with the platform, seventh servo motors are arranged on the inner sides of the lower ends of the front car frames, and shafts of the seventh servo motors are connected with front wheels through the rotating shafts. The ornamental tree and shrub transplanting robot disclosed by the invention can achieve autonomous digging and burying work through the digging structure at the front end and a scraper blade at the rear end, reduces manual resources and achieves transplanting work of a plurality of trees and shrubs through a structure of the tree storage baskets; thus, the work efficiency is improved.

Owner:深圳市林建园林工程有限公司

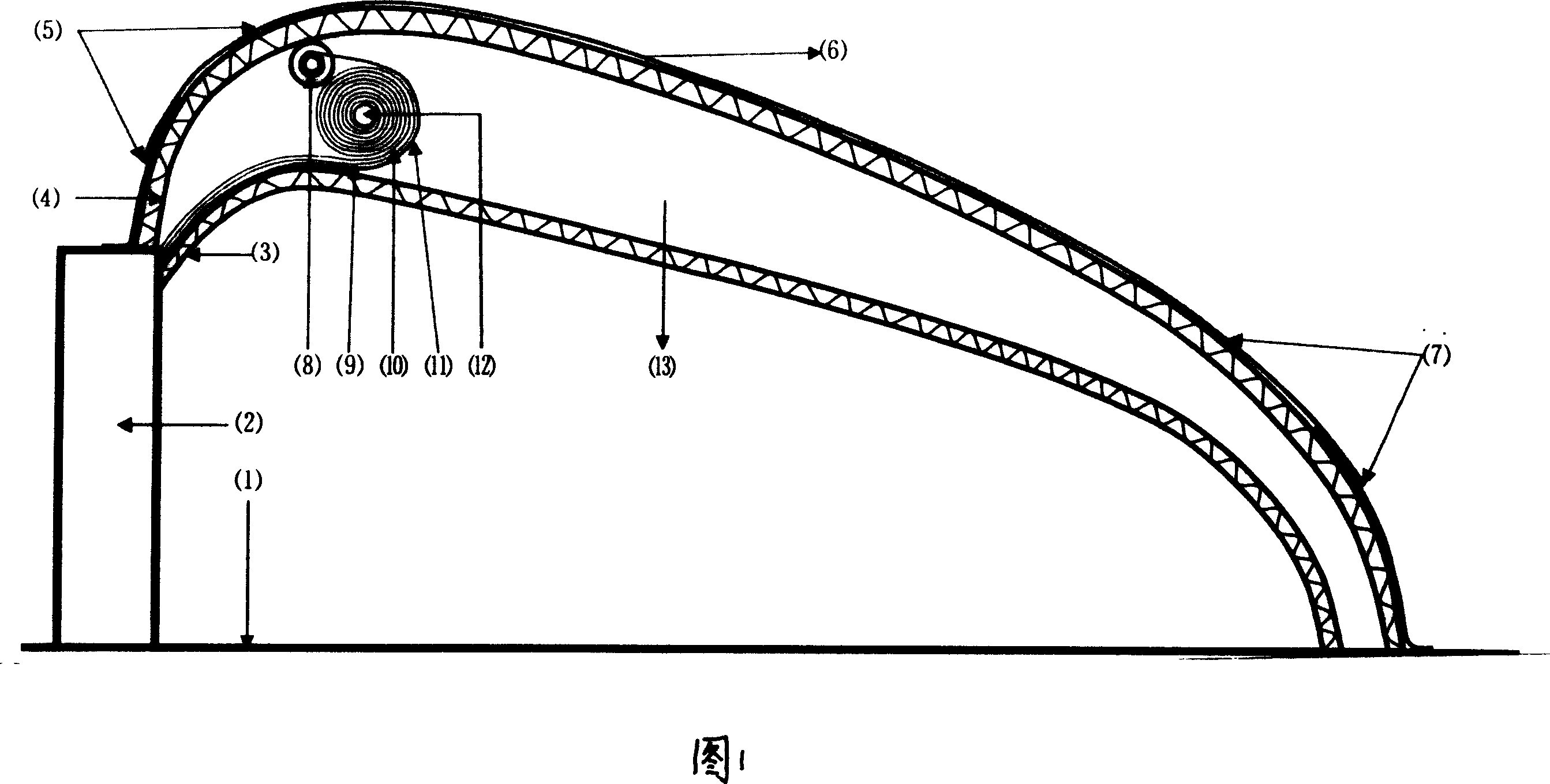

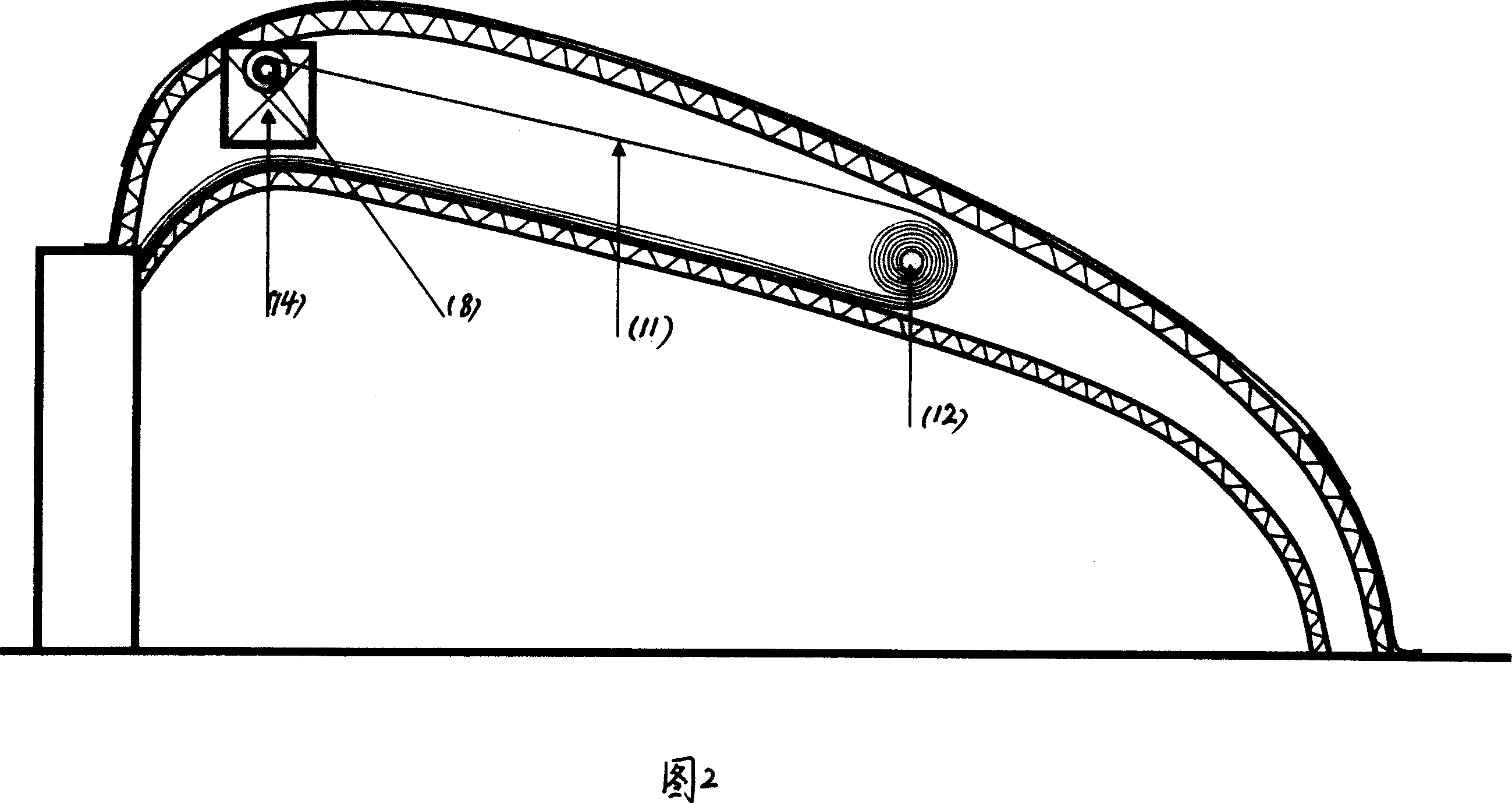

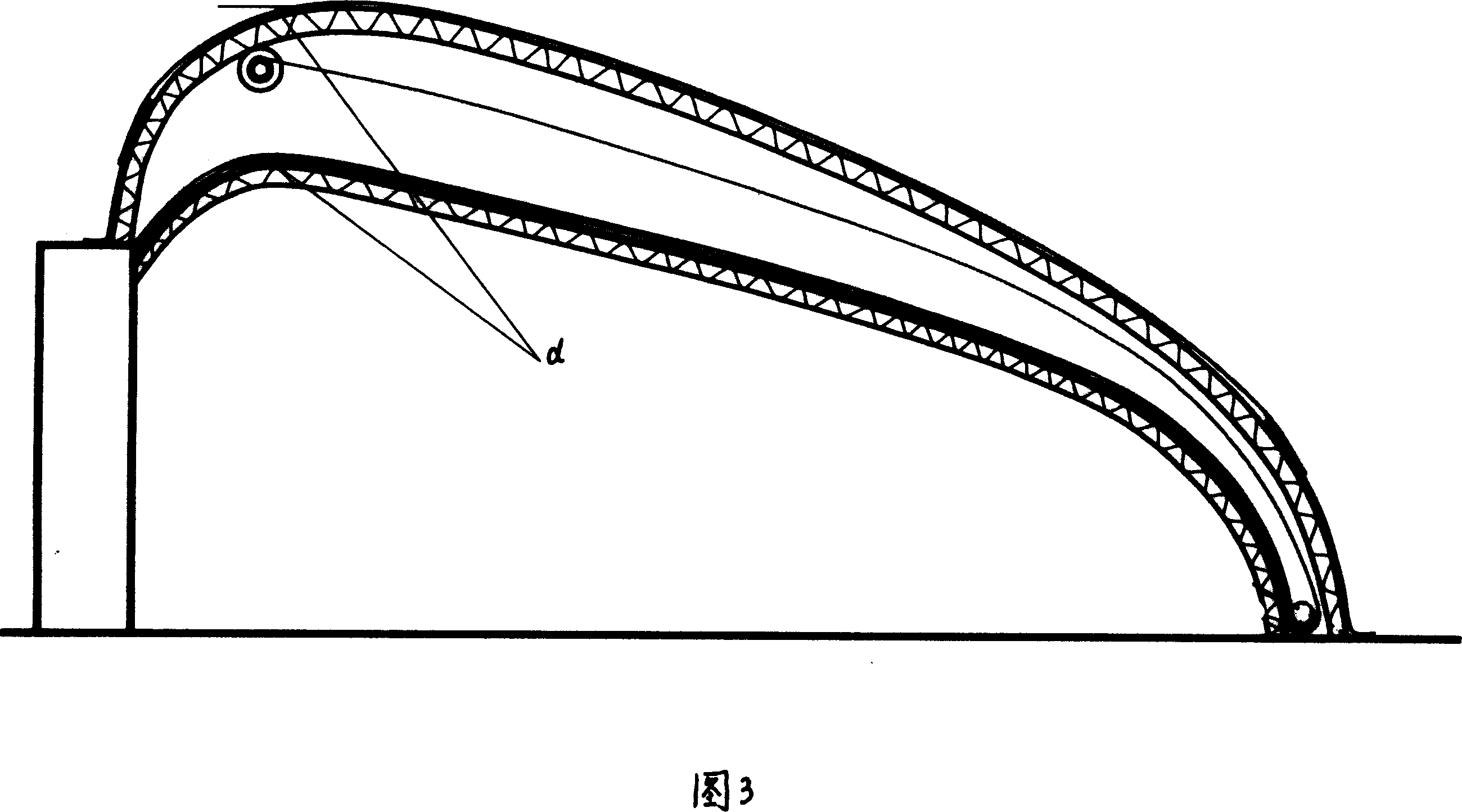

High-efficiency energy-saving type internal insulation day-light greenhouse

InactiveCN101151959AImprove wind and snow resistanceImprove insulation effectClimate change adaptationSaving energy measuresGreenhouseDaylight

An inner heat preservation sunlight greenhouse with high efficient energy saving type consists of an inner and an outer layers of frameworks, the surfaces of which are respectively provided with an inner waterproof heat preservation layer and an outer euphotic heat preservation layer. A grass curtain (or a heat preservation quilt) and a rolling curtain are arranged between the inner and the outer frameworks, meanwhile a heat-insulating layer is formed between the inner and the outer frameworks. The outer framework is provided with a front wind gap and a back wind gap. The invention has the advantages of: 1. largely improving anti wind and snow abilities of the sunlight greenhouse; 2. sound heat preservation performance; 3.needing disassembly in each season, which saves labor resources, as well as prolongs service life of the grass curtain(or the heat preservation quilt), 3. shading for vegetables planted in the greenhouse due to the assembly of the grass curtain in the framework of the greenhouse. The invention also has the advantages that: 4. the lowest temperature in the room can be increased 3-5 DEG C than that of the common energy saving greenhouse; 5. the invention exempts workers from sweeping the snow on the top, which lowers labor strength, as well as reduces operational risk.

Owner:天津市渔桥蔬菜研究所

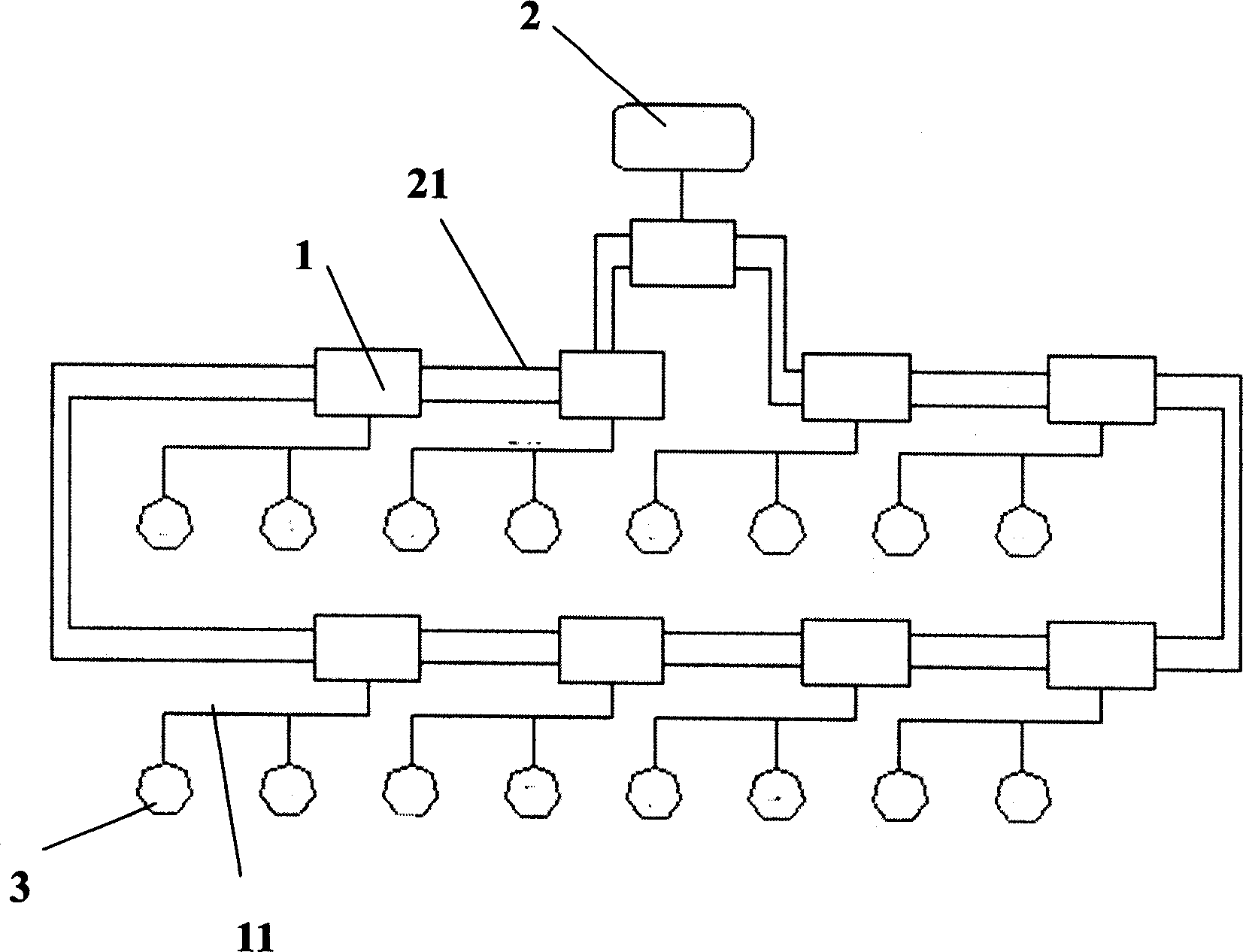

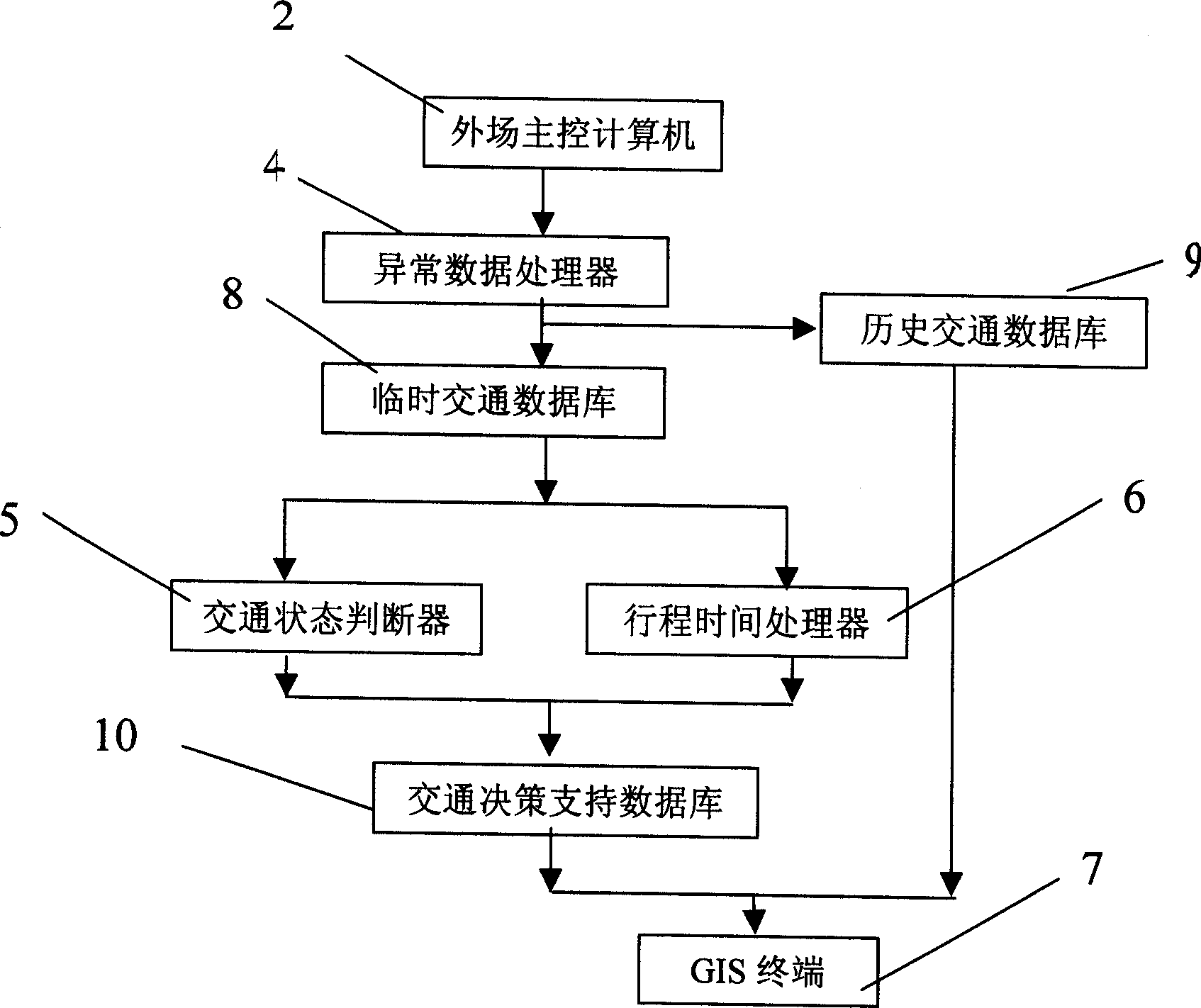

Taffic information processing system for urban through street

InactiveCN1725208AEasy to handleRealize intelligenceRoad vehicles traffic controlSpecial data processing applicationsInformation processingProcess systems

This invention relates to a traffic information process system used in city high-speed roads composed of an outer field system and an internal field system, among which, the outer field includes optical-end devices and a master control computer the internal system is made up of an information process system, optical-end devices are connected with an outer field signal collection device and connected to form a ring net in a ring topological structure, the master control computer is connected with the optical-end devices and connected to the information process unit to finish signal analysis and strategy control.

Owner:上海市市政工程管理处 +1

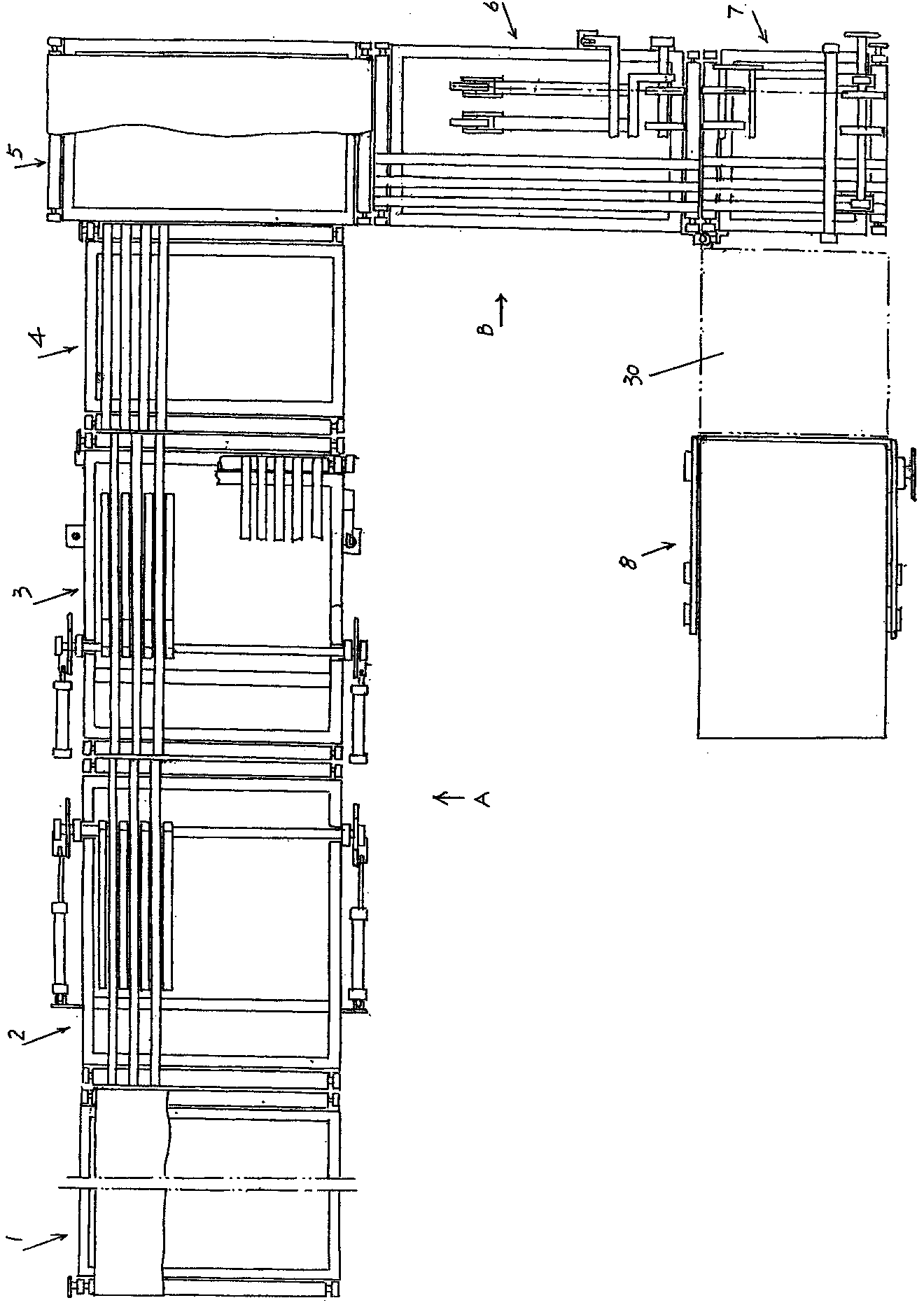

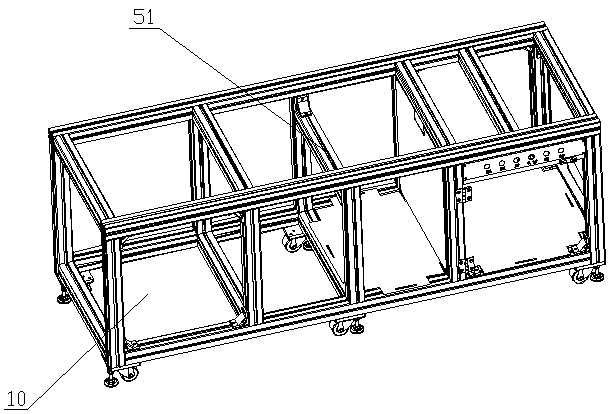

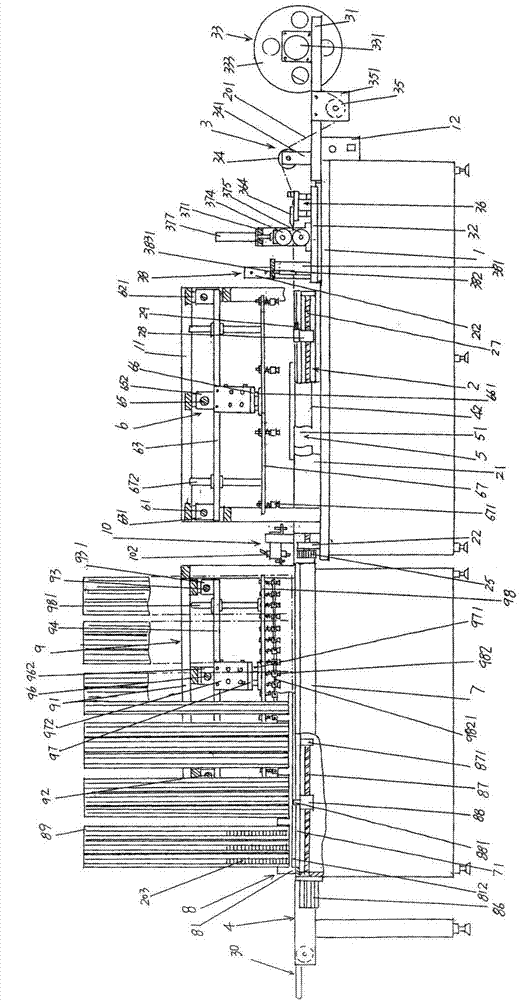

Automatic production line for photo frames

ActiveCN105146977AFully automatedSave labor resourcesPicture framesDomestic mirrorsProduction lineManufacturing engineering

The invention relates to an automatic production line, and particularly to an automatic production line for photo frames. The automatic production line for photo frames includes corner cutters, frame assembling machines, cleaning machines, a card sender and a back nail machine. The corner cutters, the frame assembling machines, the cleaning machines, the card sender and the back nail machine are connected in order to form a production line capable of cutting corner, assembling frames, cleaning, sending cards and hitting back nails. Two corner cutters, two frame assembling machine and two cleaning machines are symmetrically disposed, material is conveyed and corners are cut, and the processed material is conveyed to the frame assembling machines. All the production processes from corner cutting to back nail hitting of photo frames can be automatically implemented, only three steps need workers, and only material supplement is needed. Most labor force resource can be saved, five devices in the automatic production line are novel devices or optimal modified devices, the production efficiency of photo frames reaches up to two seconds per photo frame, the whole efficiency is greatly raised.

Owner:青岛科捷机器人有限公司

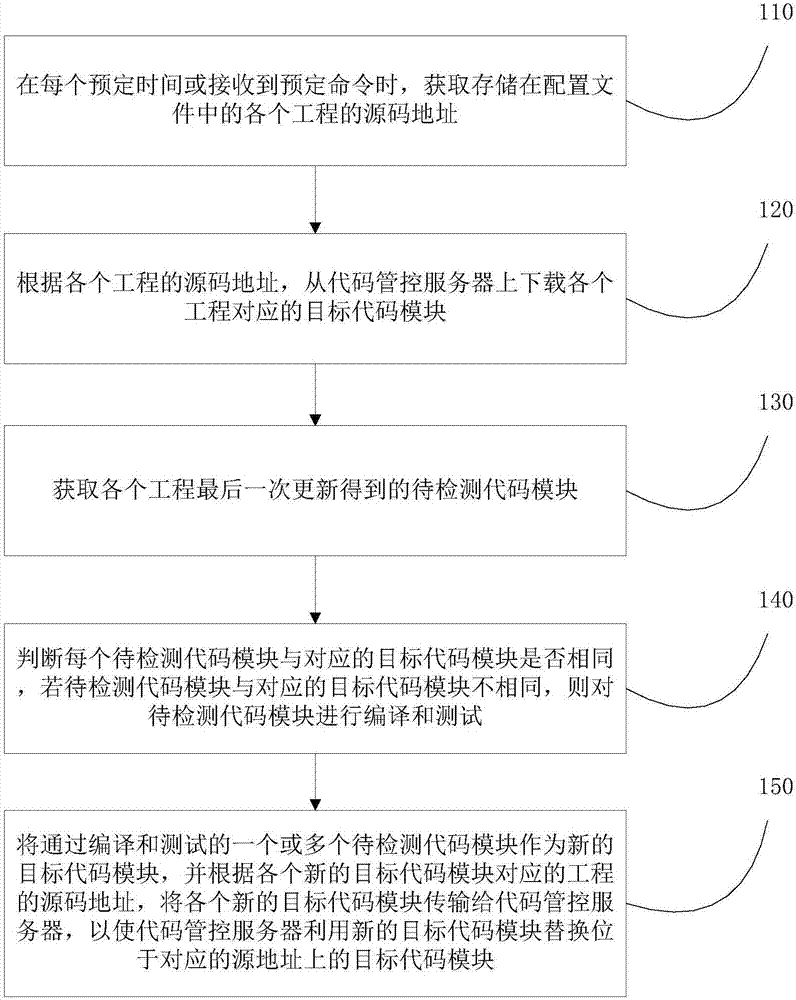

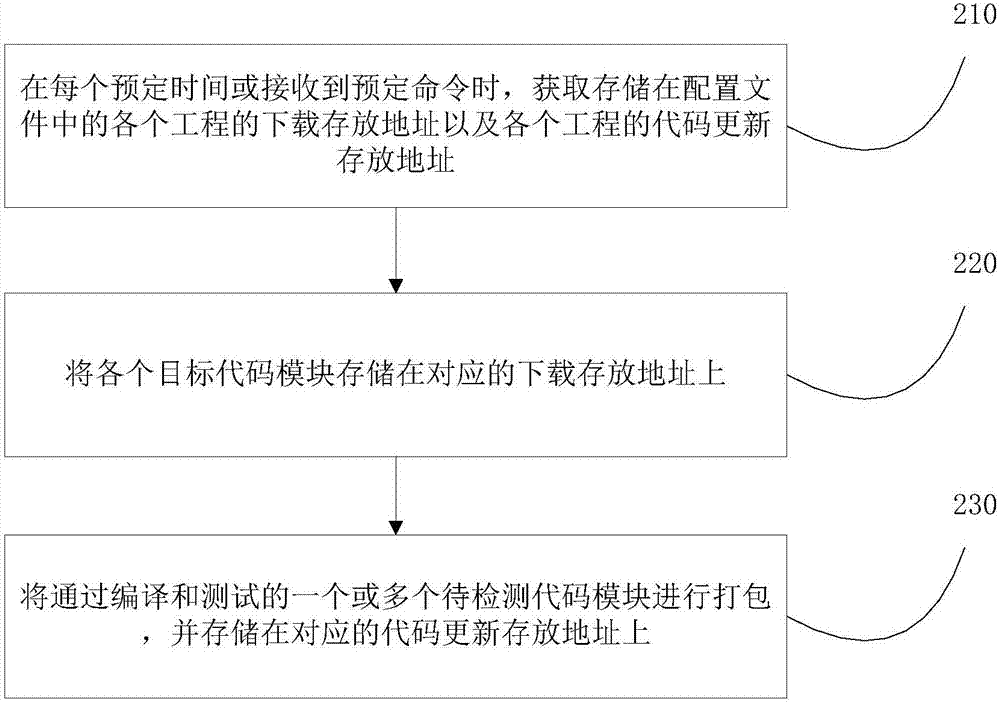

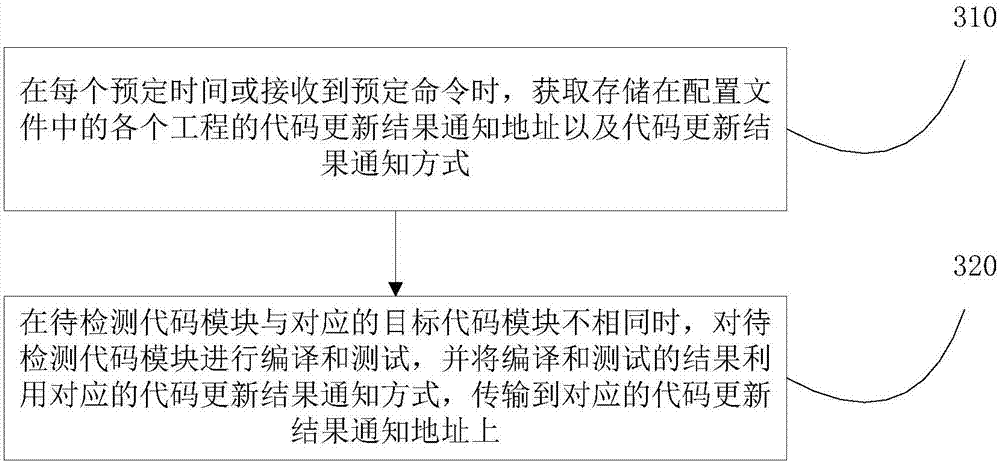

Method, device and system for automatically generating/updating software engineering project

InactiveCN107885521AImprove development efficiencyImprove update efficiencySoftware testing/debuggingSoftware deploymentCode moduleObject code

The embodiments of the invention provide a method, device and system for automatically generating / updating a software engineering project. The method, device and system, at a predetermined time or when receiving a predetermined command, downloads the target code module corresponding to each project according to source code addresses in a configuration file, and compares the target code module withthe corresponding to-be-detected code module; if the target code module and the corresponding to-be-detected code module are different, the to-be-detected code module is compiled and detected, and the to-be-detected code module which is compiled and detected is returned to a code control server as a new target code module to replace the original target code module. The method, device and system solve the problem that a project corresponding to the current code module cannot be generated or updated due to the error of the referenced module, improve the development or update efficiency of the code module corresponding to the project, and therefore improve the efficiency of the development or updating of the software engineering project. At the same time, the method, device and system can automatically generate or update the project with code change, thereby further improving the efficiency of generating or updating the project.

Owner:LUSTER TERABAND PHOTONICS TECHNOLOGY CO LTD

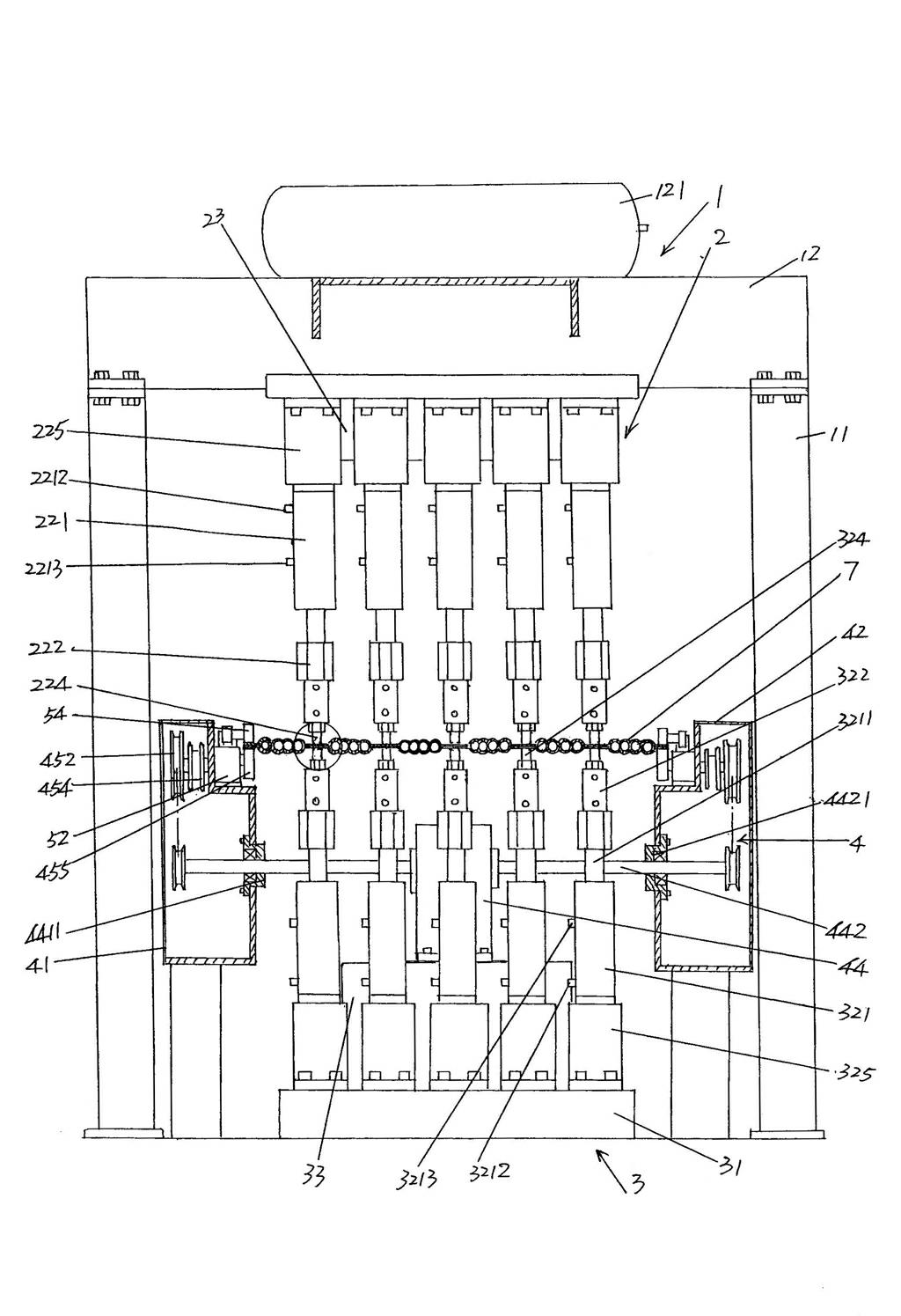

Cooling fin point welding machine of transformer finned radiator

InactiveCN102528261AImprove Spot Welding EfficiencyGuaranteed RegularityResistance welding apparatusEngineeringHeat spreader

The invention relates to a cooling fin point welding machine of a transformer finned radiator, and belongs to the technical field of welding machines. The cooling fin point welding machine comprises a rack, upper and lower point welding mechanisms, and a cooling fin convey mechanism, wherein the rack is composed of a pair of upright posts and a beam, and an air tank is arranged on the beam; the upper point welding mechanism comprises a first base and at least two groups of upper point welding devices and upper electric welders, and the lower point welding mechanism comprises a second base, lower point welding devices and lower electric welders the quantity of which are equal to that of the upper point welding devices; the lower point welding devices are electrically connected with the lower electric welders, and also are connected with a gas path of the air tank; and the second base is arranged on the bottom corresponding to the space between the pair of upright posts, and is corresponding to the first base. The cooling fin point welding machine provided by the invention has the advantages of being capable of remarkably improving point welding efficiency on cooling fins on the premise of not increasing the quantity of single point welding machines, being capable of saving equipment investment, reducing occupancy space of a production field and saving labor resources, and particularly being capable of insuring finishing effects of bonding points and guaranteeing the welding quality of the cooling fins.

Owner:CHANGSHU YOUBANG RADIATOR

Electric furnace cover castable with aluminum-chromium slag being main material and preparation method thereof

The invention relates to electric furnace cover castable with aluminum-chromium slag being a main material and a preparation method thereof. According to the technical scheme, 10-15 wt% of fused zirconia alumina particles and 50-55 wt% of aluminum-chromium slag particles serve as aggregate, and 13-18 wt% of aluminum-chromium slag fine powder, 5-8 wt% of Cr7C3 fine powder, 10-15 wt% of rho-Al2O3 micro powder nad 1-4 wt% of yttrium oxide micro powder serve as a substrate material; according to the content of the aggregate and the content of the substrate material, the substrate material is first mixed uniformly and then added into the aggregate, and the mixture is mixed uniformly; then, alumina soil which accounts for 15-20 wt% of the sum of the substrate material and the aggregate is added, the mixture is stirred uniformly, subjected to vibration molding, maintained for 6-12 h at room temperature and kept warm for 12-24 h at the temperature of 90-110 DEG C, and finally the electric furnace cover castable with the aluminum-chromium slag being the main material is prepared. The method has the advantages of being low in cost and simple in technology; the prepared electric furnace cover castable is low in specific gravity, high in strength, excellent in thermal shock resistance and volume stability.

Owner:锦州集信高温材料有限公司

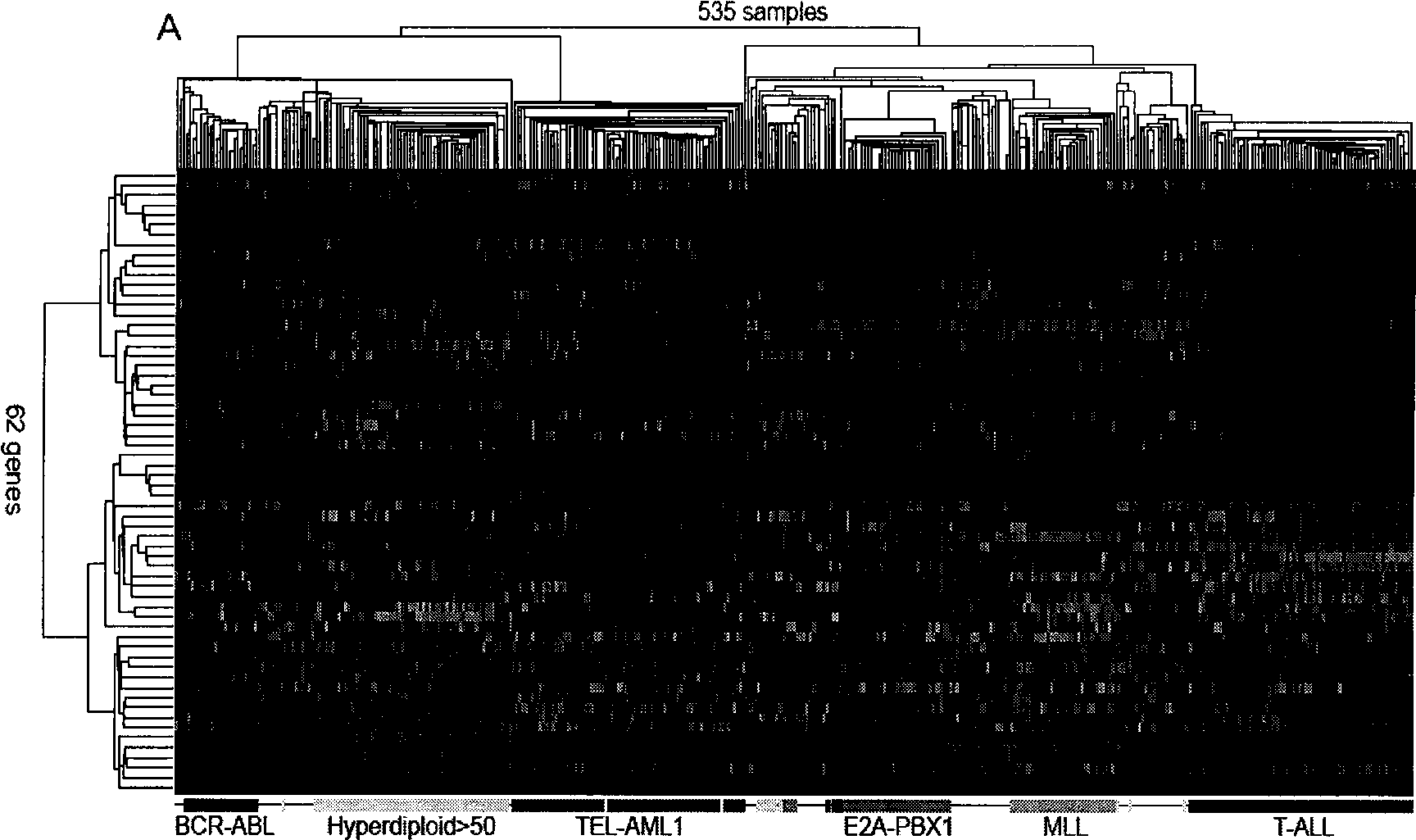

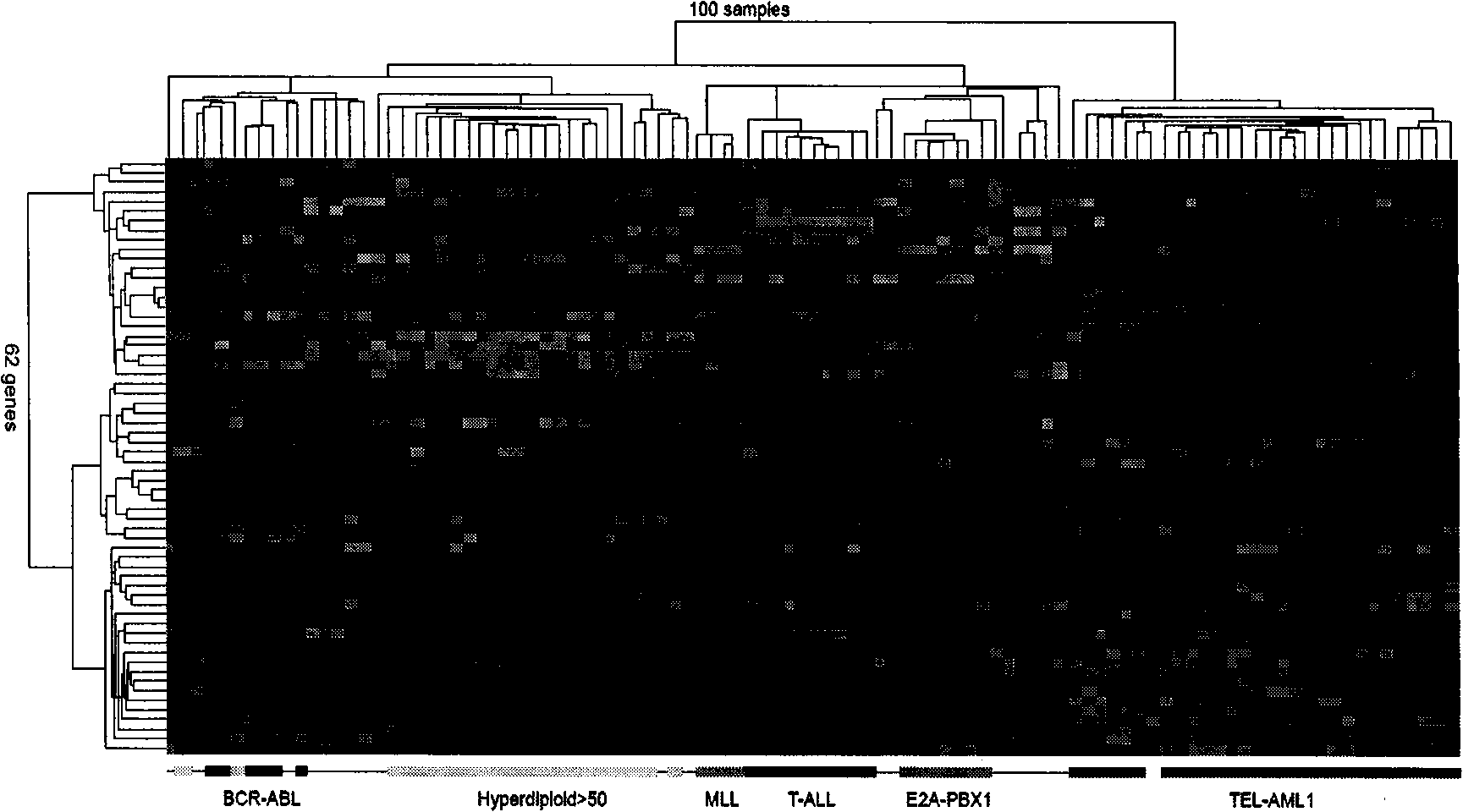

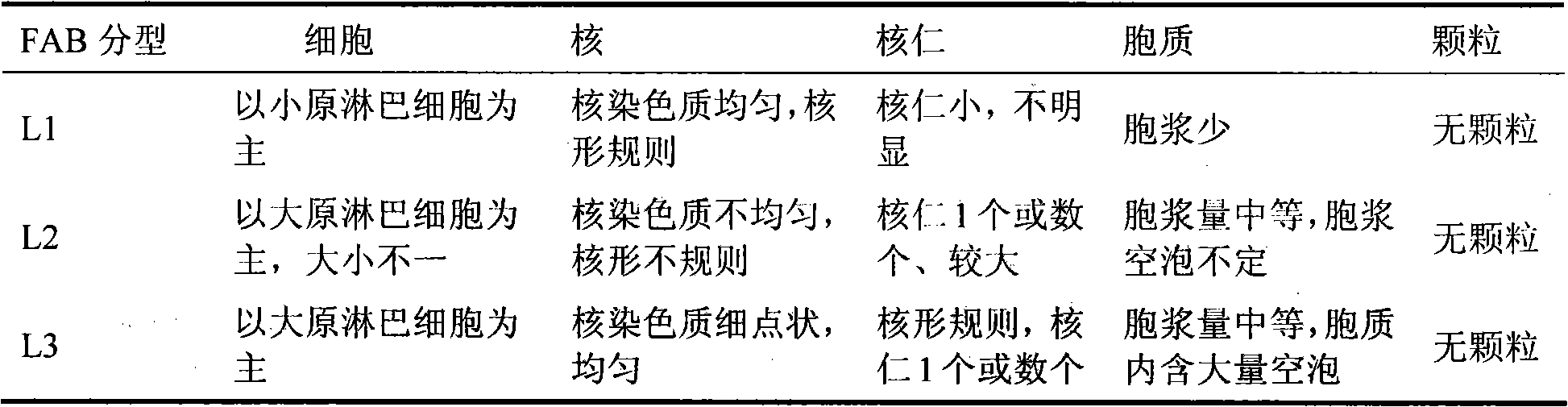

Children acute lymphoblastic leukaemia genotyping diagnosis chip

InactiveCN101525667AReduce complicationsHigh cure rateNucleotide librariesMicrobiological testing/measurementLife qualityA-DNA

The invention discloses a children acute lymphoblastic leukaemia genotyping diagnosis chip. The children acute lymphoblastic leukaemia genotyping diagnosis chip is a DNA chip which is fixed with 62 DNA fragment arrays on the surface of a carrier. .The nucleotide sequences of the 62 DNA fragment arrays are respectively the sequence 1 to the sequence 62 of the sequence list. The invention further discloses a children acute lymphoblastic leukaemia genotyping method. The genetic chip of the invention can provide precise typing so as to help correctly choose a chemo-treatment plan of appropriate strength, thereby reducing complicating disease and improving curative ratio and life quality. The genetic chip of the invention can be used to carry out genotyping on childhood ALL. Therefore, the genetic chip not only saves diagnosis cost, but also has significance in protecting labour resource and promoting family and society harmony.

Owner:BEIJING CHILDRENS HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV +1

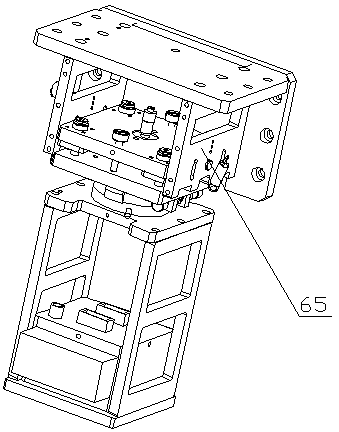

Automatic assembly device of heater PTC heating core

ActiveCN103878584AMeet the requirements of industrial scale-up productionReduce work intensityAssembly machinesTransfer mechanismAutomation

The invention discloses an automatic assembly device of a heater PTC heating core and belongs to the technical field of automation machines. The automatic assembly device comprises an insulating film strip conveying working table and a PTC element conveying working table. An insulating film strip traction mechanism is arranged on the insulating film strip conveying working table. An insulating film strip conveying mechanism is arranged on the insulating film strip conveying working table. A conveying belt mechanism is arranged on a floor, and an electrode slice feeding mechanism is arranged on the rear side of a working table rack. A film strip and electrode slice transferring mechanism is arranged on the working table rack. A PTC element feeding mechanism is arranged on the PTC element conveying working table. A PTC element transferring mechanism is arranged on the rear side of the conveying belt mechanism. An adhesive spraying mechanism is arranged on the conveying belt mechanism. Labor input is reduced, and assembly efficiency is improved; operation intensity is relieved; quality is guaranteed; the insulating film strip, electrode slices and the surface electrode layers of a PTC element can not be stained or damaged; mutual reliable combination between the PTC element and the electrode slices can be guaranteed.

Owner:浙江西塘实业有限公司

Hami melon peeling machine

InactiveCN106858649AIncrease incomeReduce labor intensityVegetable peelingMelon (food)Pneumatic cylinder

A kind of cantaloupe peeling machine discloses a kind of cantaloupe peeling machine which can complete the rotary peeling of cantaloupe. Cylinder, upper and front grip, knife rod, knife body, cantaloupe, lower grip, jaw pulley, where the knife body is installed on the knife bar, the knife bar is connected with the lifting platform through a hinge, and moves up and down with the lifting platform, guiding The rod is used to limit the lifting table to move up and down. The upper and lower jaws play the role of clamping the melon. The cylinder provides a certain amount of force to clamp the melon. The lower jaw is installed on the same shaft as the pulley to play The function of driving the rotation of the cantaloupe can complete the peeling operation of the cantaloupe; the cantaloupe peeling machine has the characteristics of reducing the labor intensity of workers, high operating efficiency, simple structure, and convenient use and maintenance.

Owner:韩会义

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com