Glass defect detection device

A detection device and glass defect technology, which is applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of waste of manpower, high product error reporting rate, low detection accuracy, etc., and achieve long-term stable work and improve detection. Efficiency, the effect of saving labor resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description is used to disclose the present invention so that those skilled in the art can implement the present invention. The preferred embodiments in the following description are only examples, and those skilled in the art can think of other obvious variations. The basic principles of the present invention defined in the following description can be applied to other embodiments, modifications, improvements, equivalents, and other technical solutions that do not depart from the spirit and scope of the present invention.

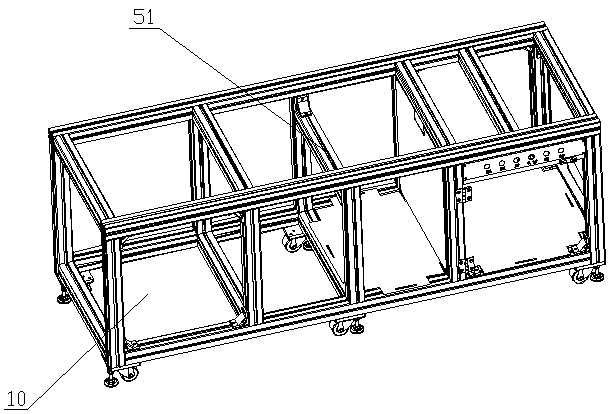

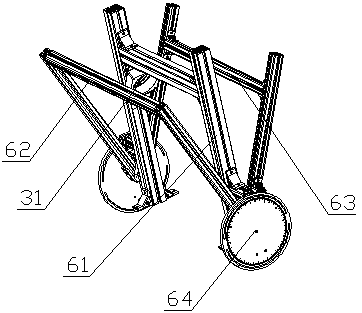

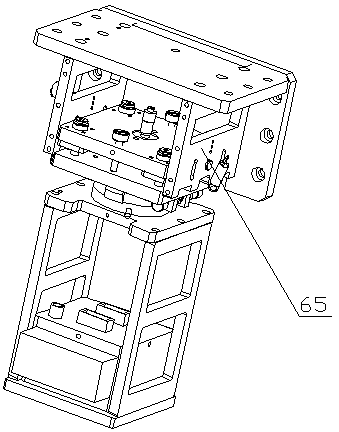

[0032] Figure 1-Figure 6 It shows a schematic structural diagram of an embodiment of the glass defect detection device of the present invention, and is also a schematic diagram of a preferred embodiment. Such as figure 1 , figure 2 As shown, the glass defect detection device in this embodiment includes a frame body 10, a transmission unit 20, an illumination unit 30, an imaging unit 40, an image acquisition unit 50, a rotation adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com