Precise detection method for strip surface defects based on histogram decomposition

A detection method and histogram technology, which is applied in image analysis, image enhancement, image data processing, etc., to achieve the effects of fast detection speed, high detection rate and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

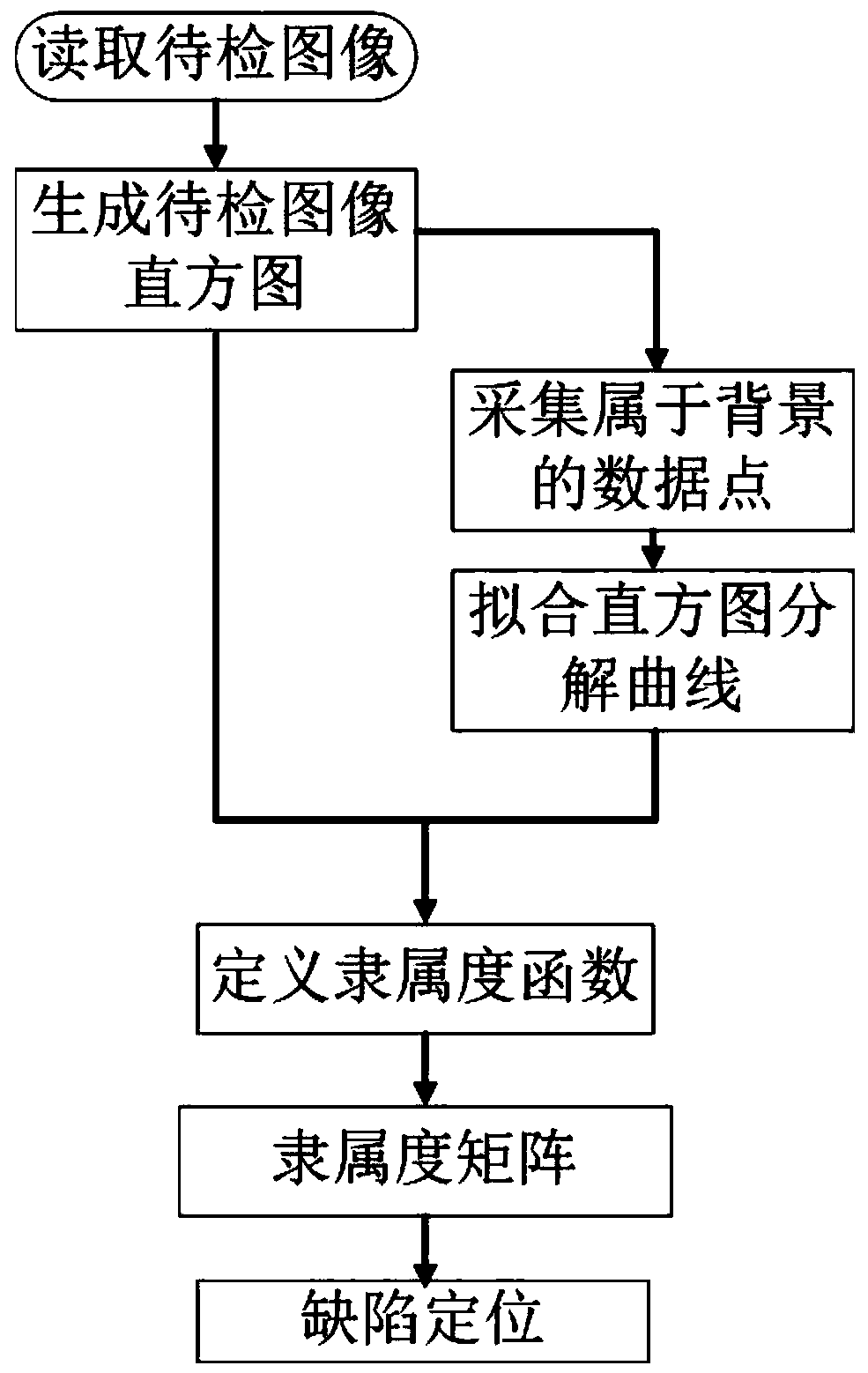

[0080] The steps of the accurate detection method for strip surface defects based on histogram decomposition in this embodiment are:

[0081] Step 1, read the image:

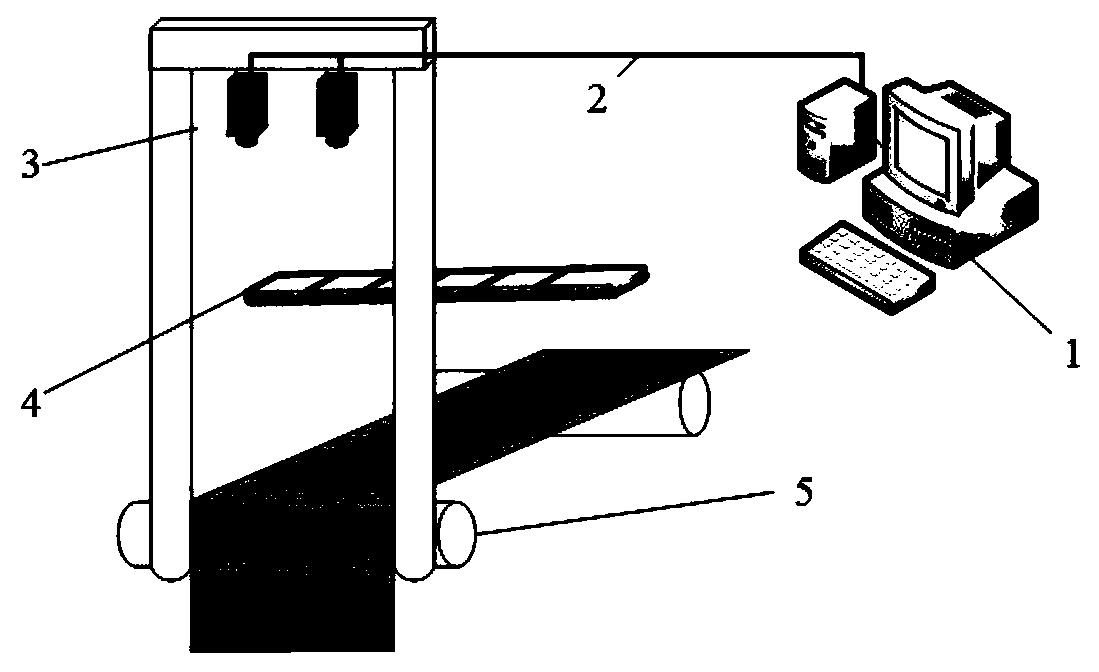

[0082] use as figure 2 The detection device shown online acquires the grayscale image I to be detected,

[0083] 1-1: Before defect detection, use a strip stroboscopic light source to provide a light source for the strip surface, and obtain the grayscale image I to be detected through a line array camera and store it in the memory of the computer;

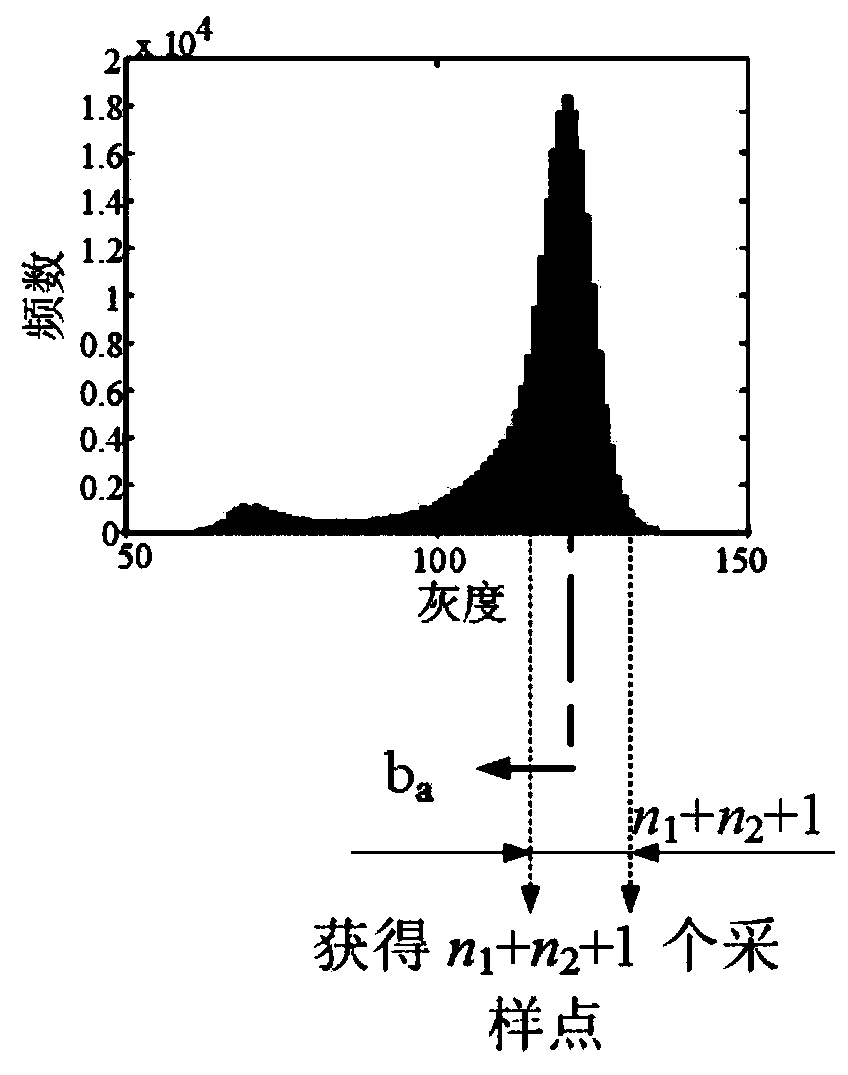

[0084] 1-2: Read the grayscale image I to be detected from the memory of the computer, generate a histogram of the grayscale image to be detected, and obtain each grayscale g i The corresponding frequency f(g i ), where i∈[1,L] and i∈Z,L is the total number of gray levels contained in the gray image to be detected.

[0085] Step 2, collect and determine the sampling points belonging to the background from the histogram of the grayscale image to be detected:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com