Patents

Literature

192results about How to "Realize automatic folding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

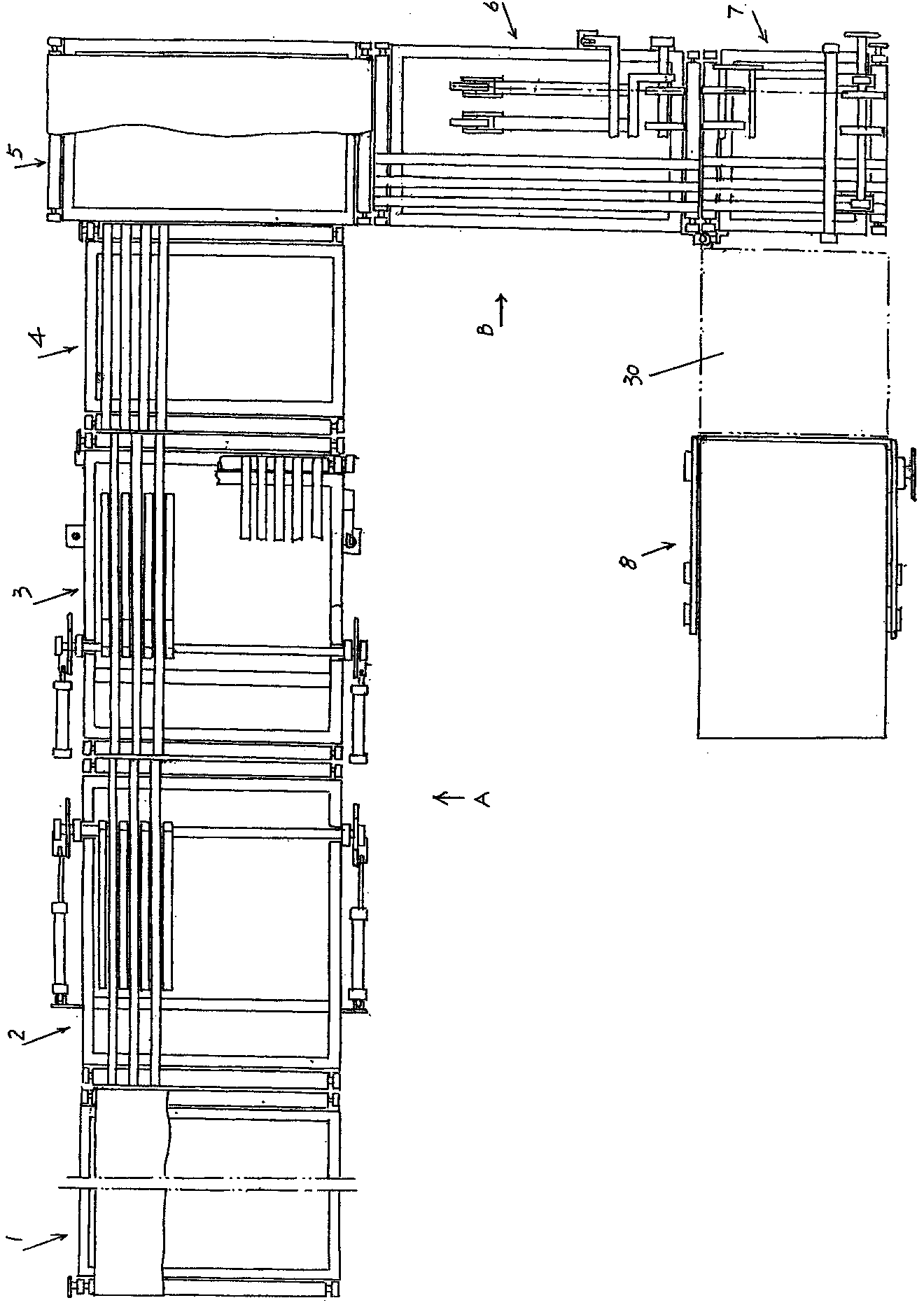

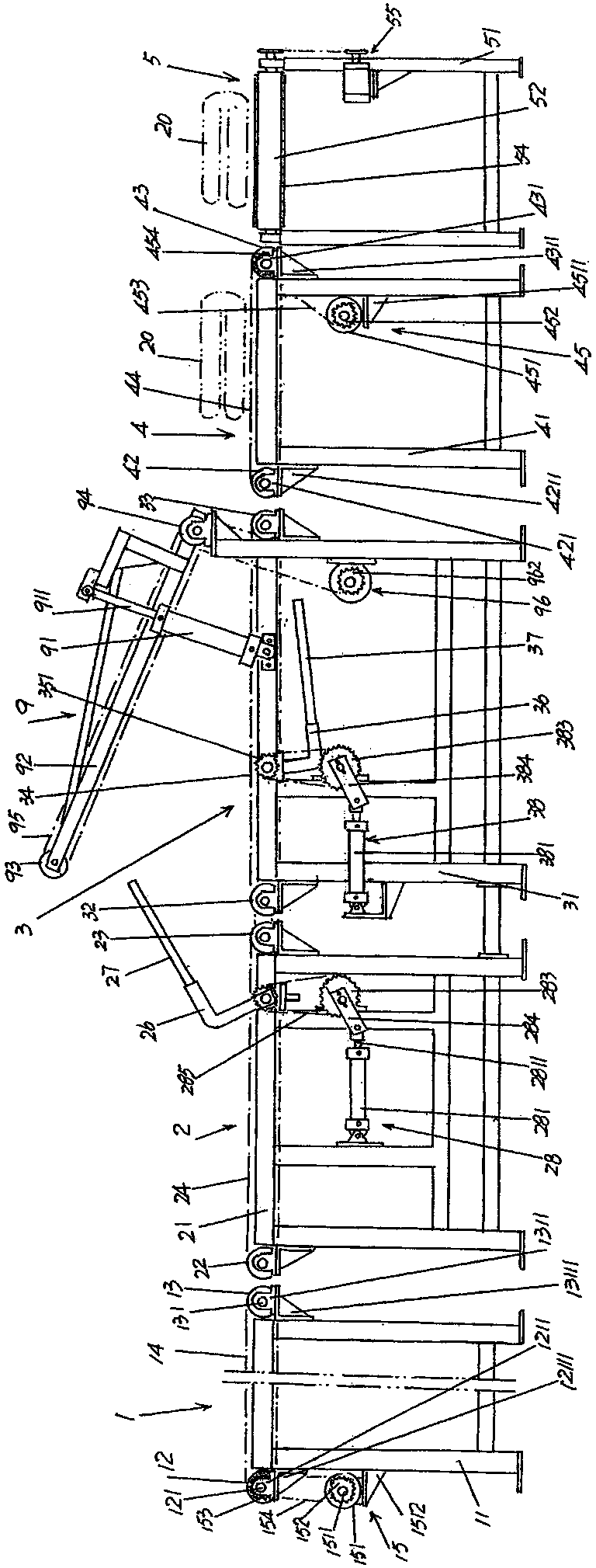

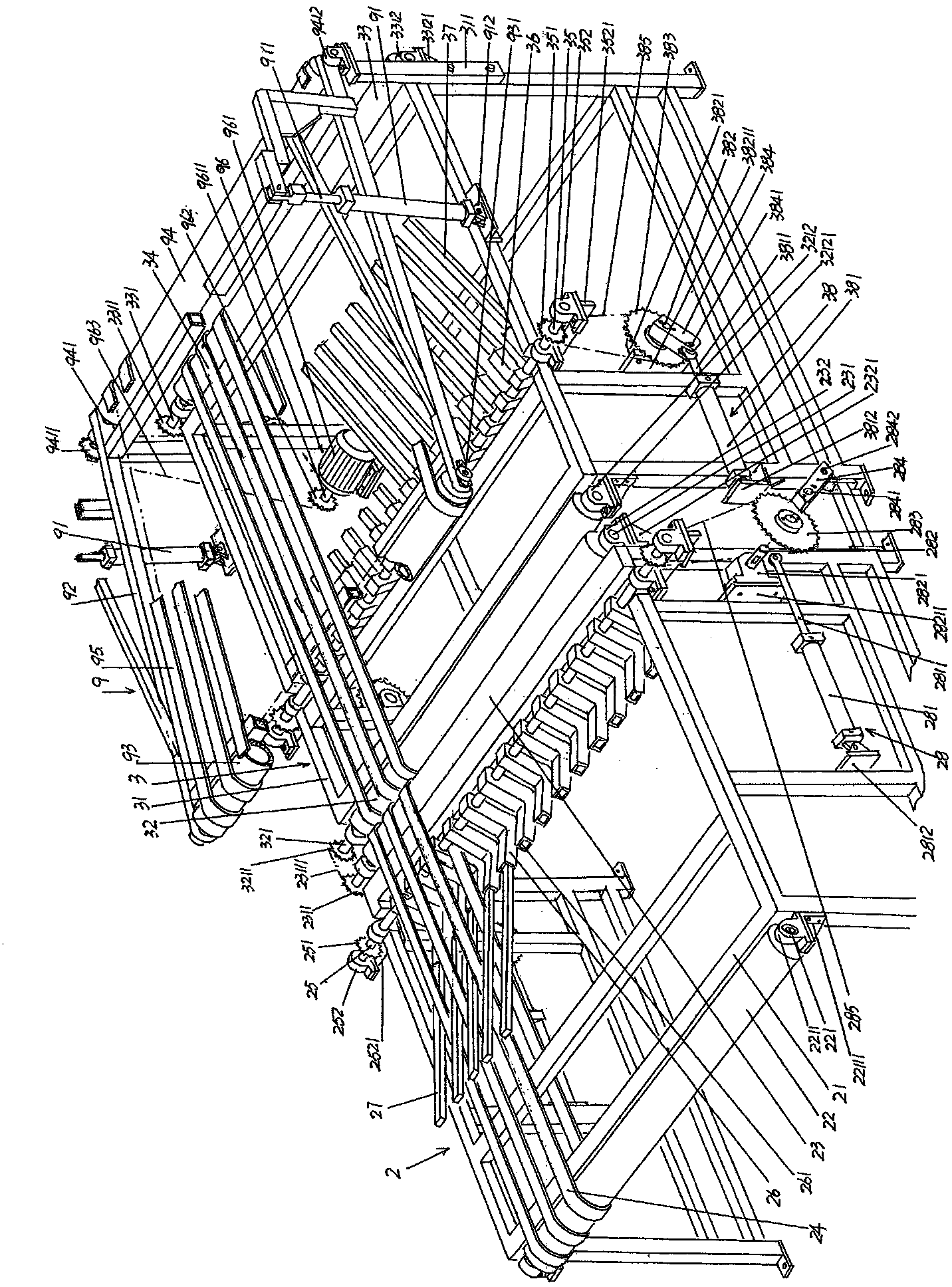

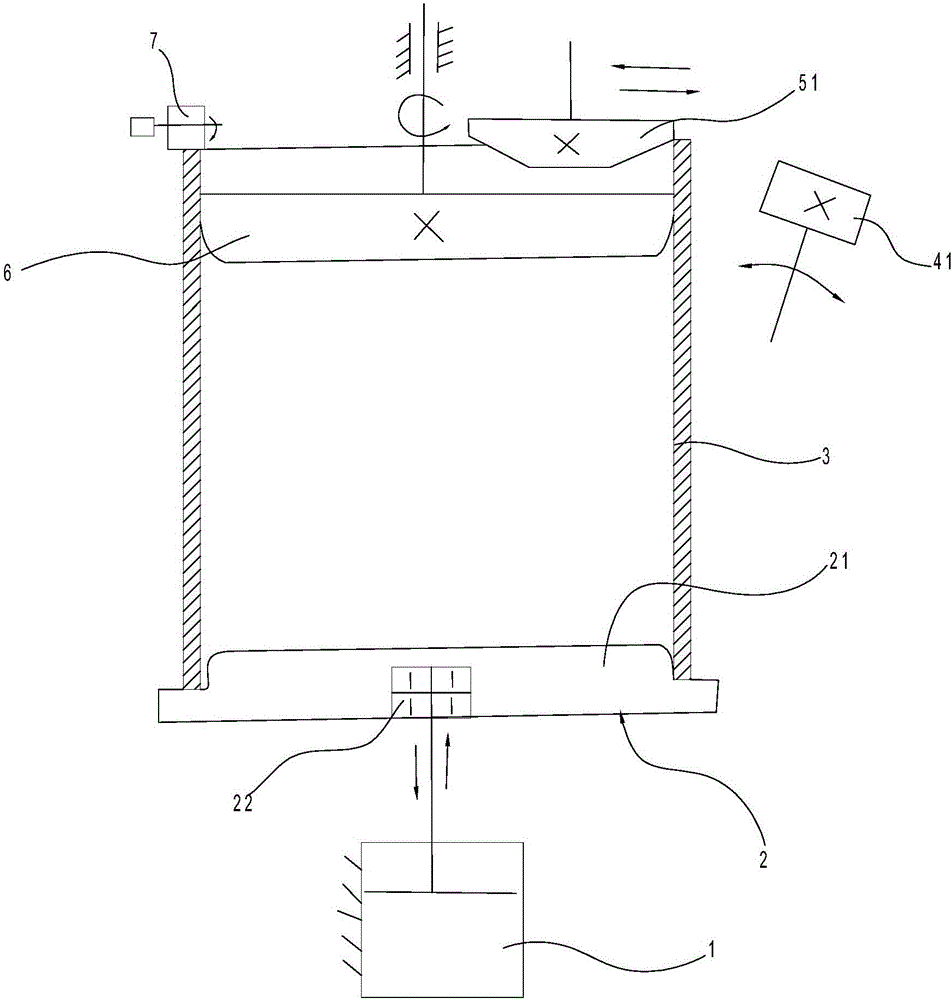

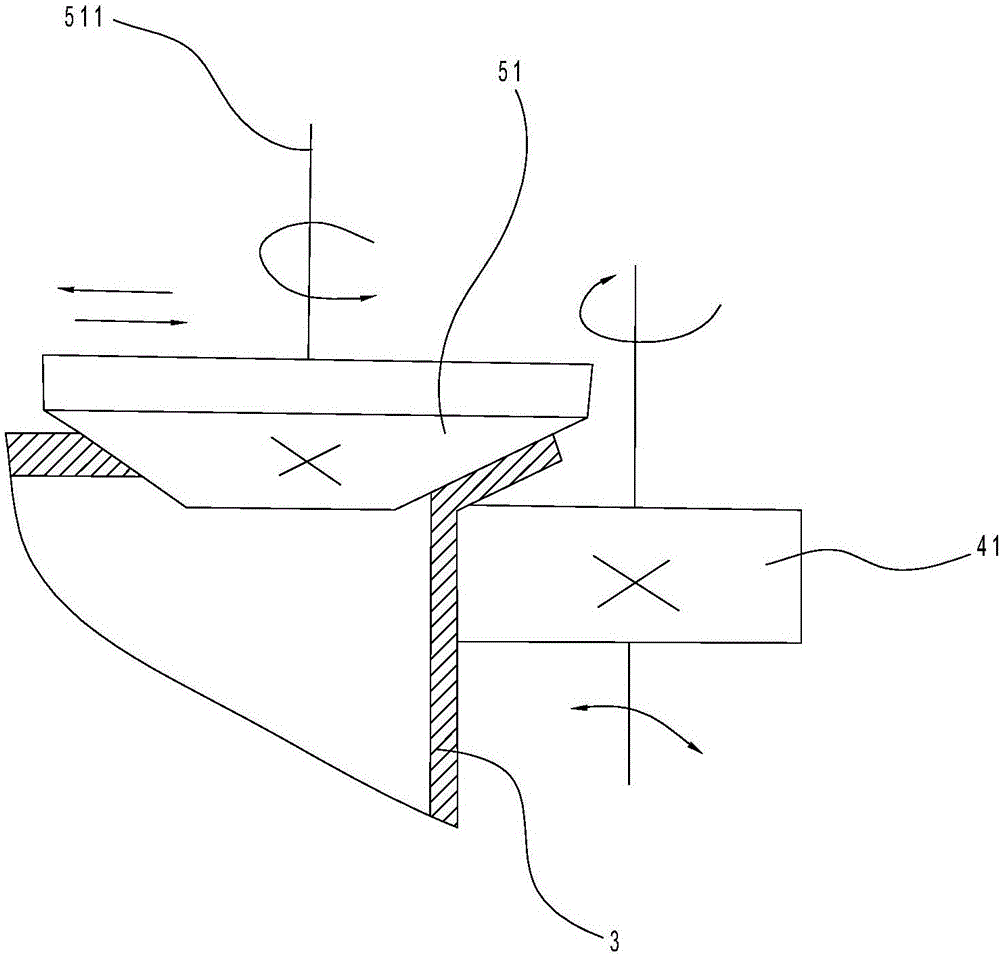

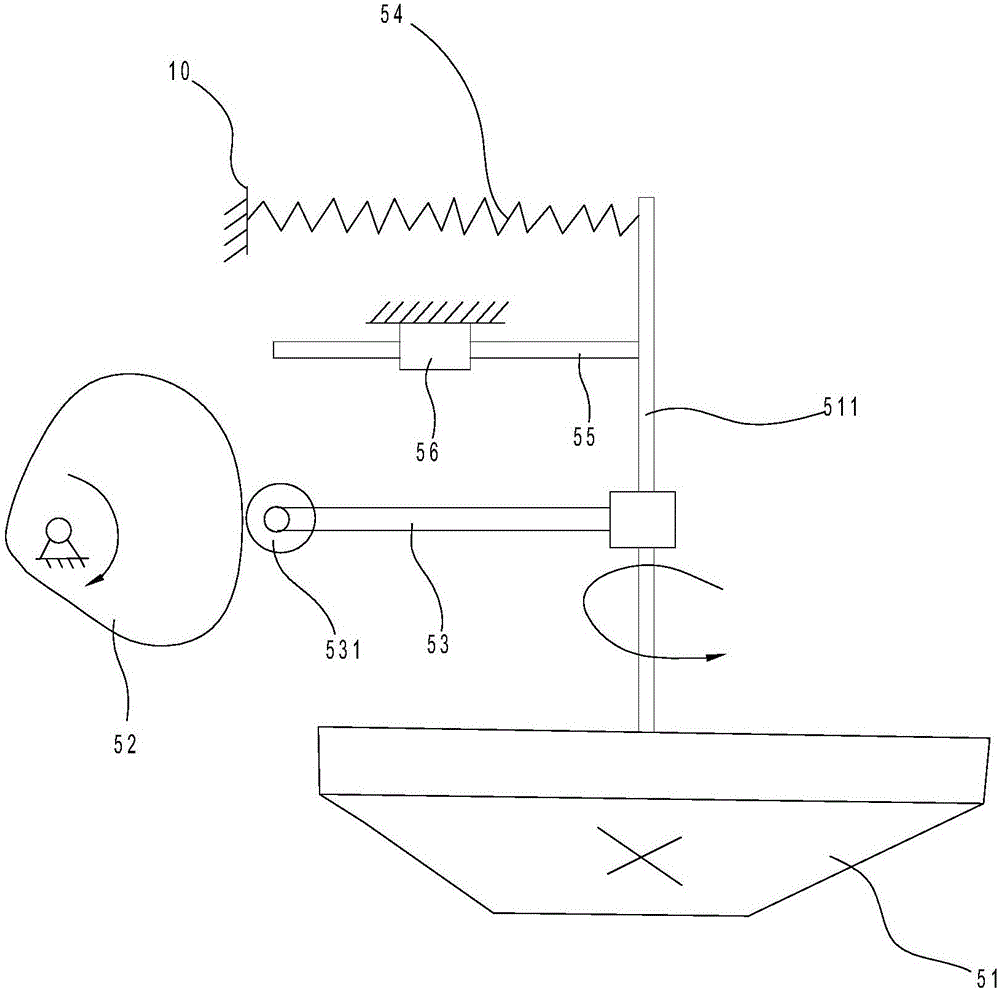

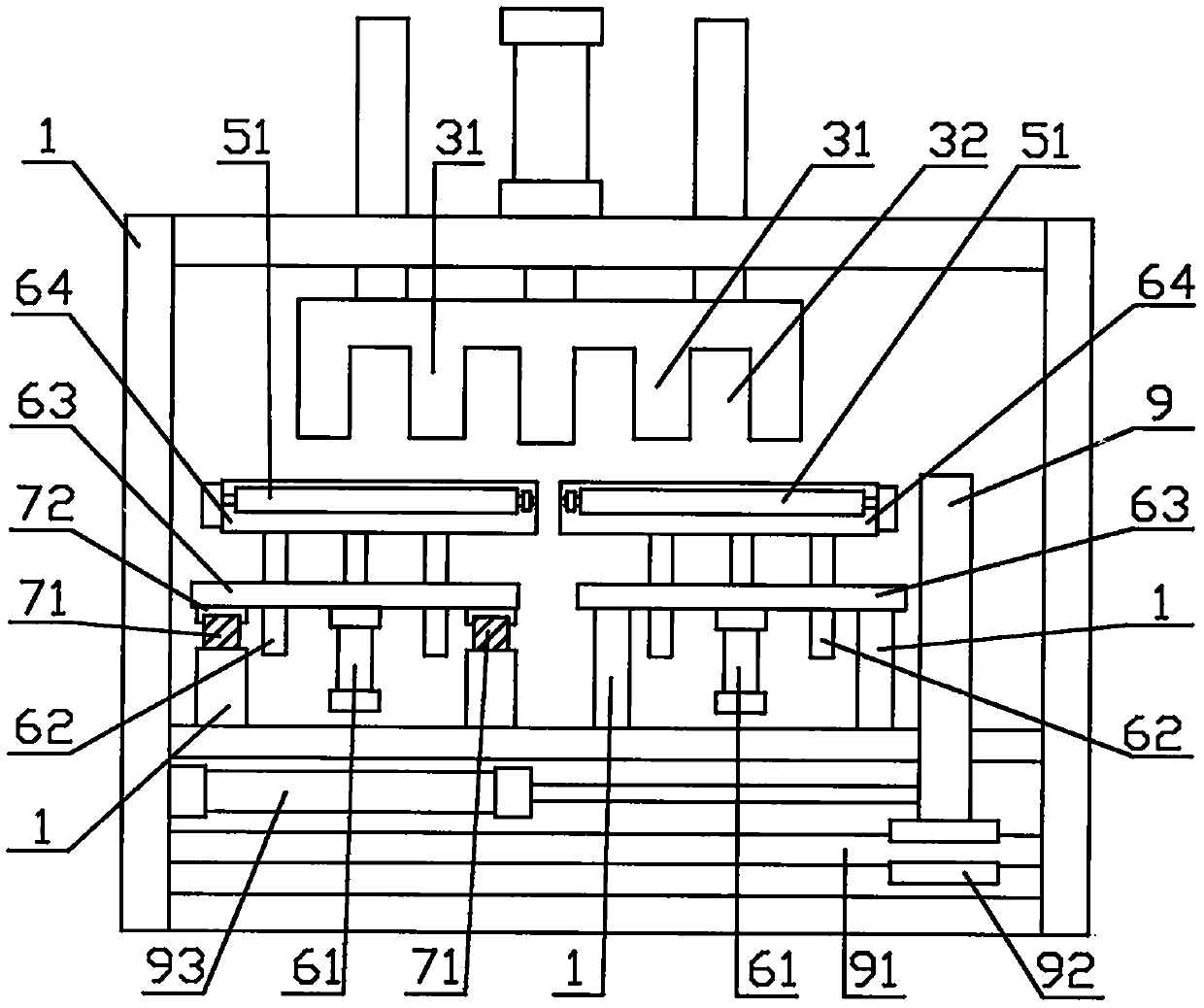

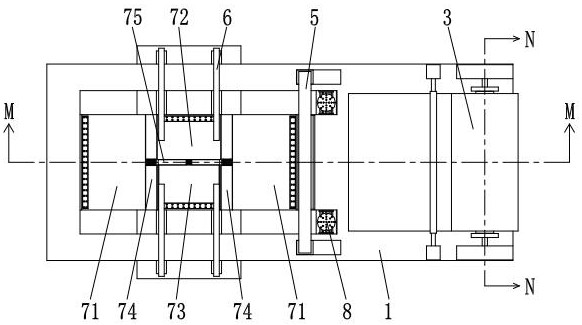

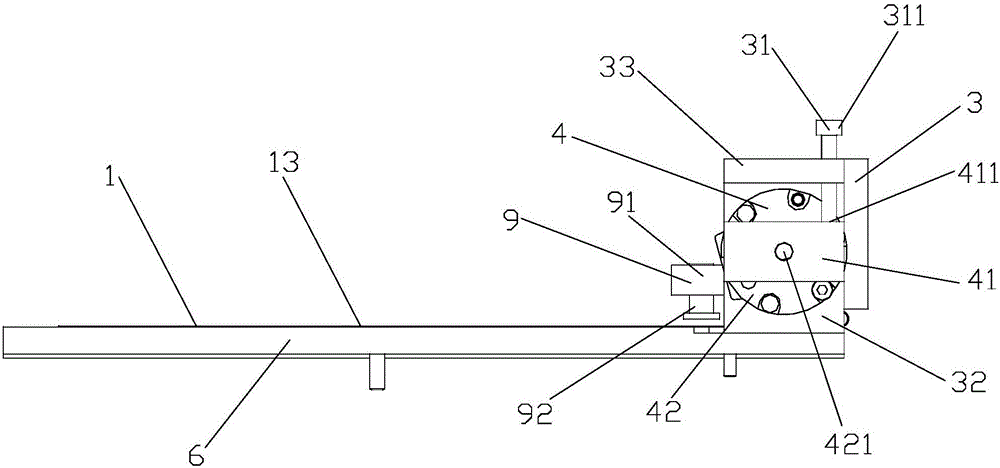

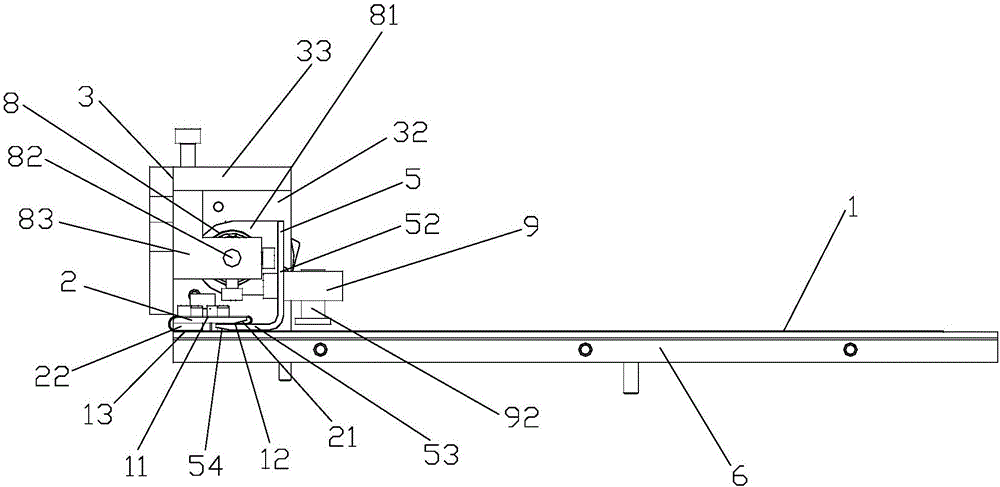

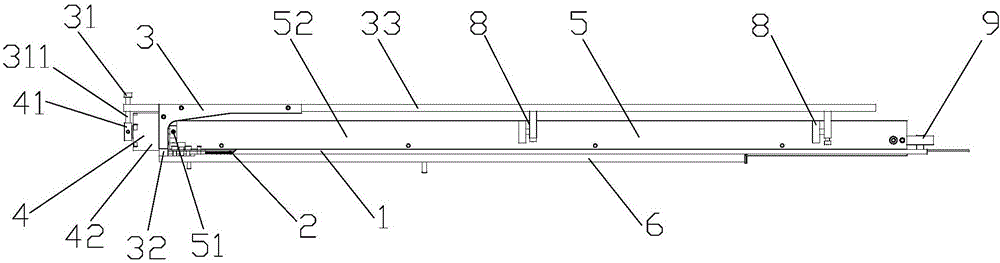

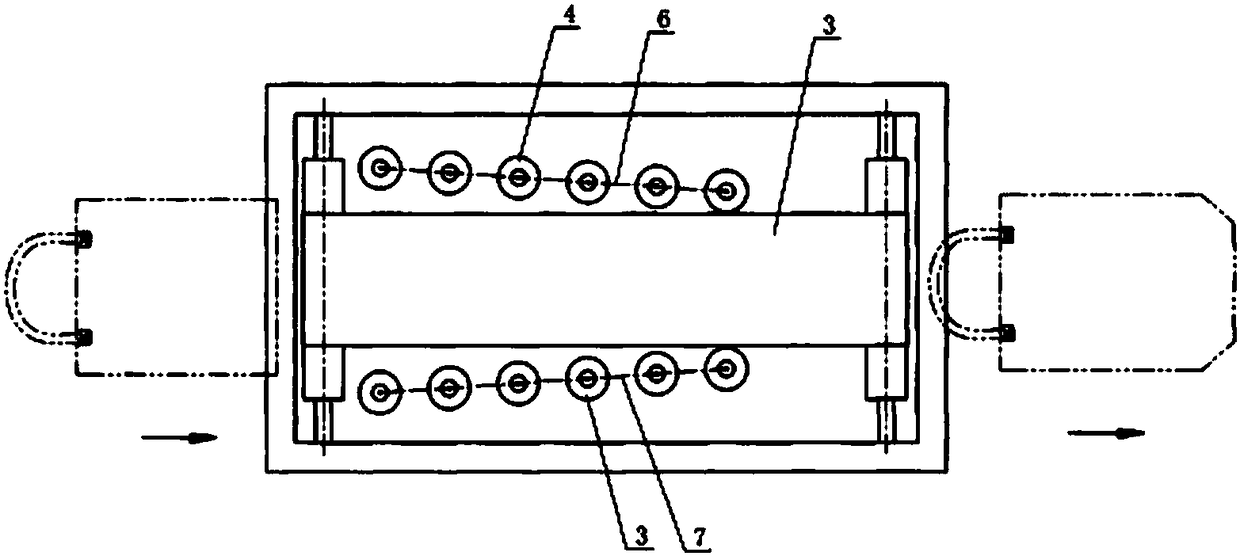

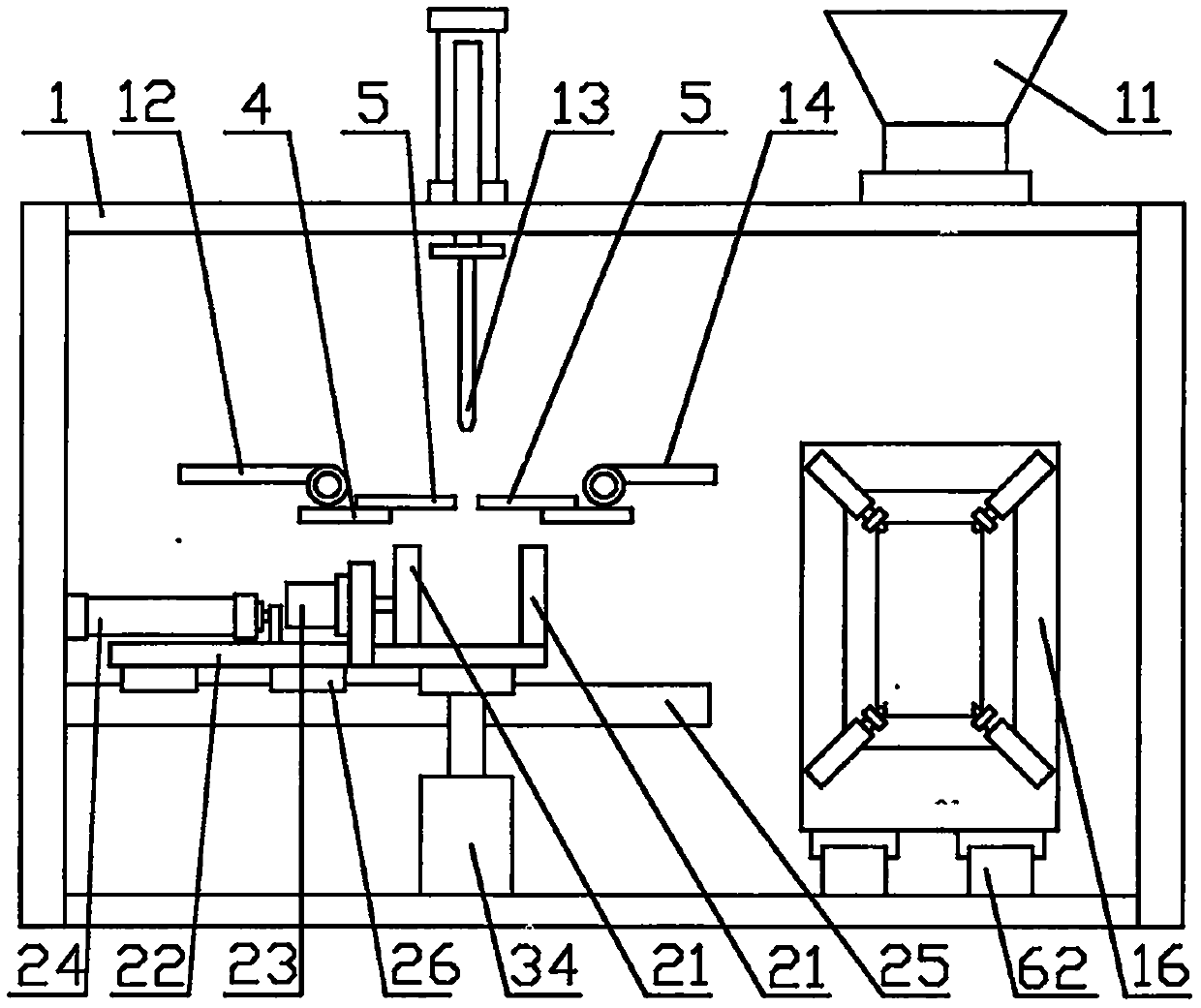

Quilt folding machine

ActiveCN104108497ARealize automatic foldingReduce human inputFolding thin materialsPackagingEngineeringAssembly line

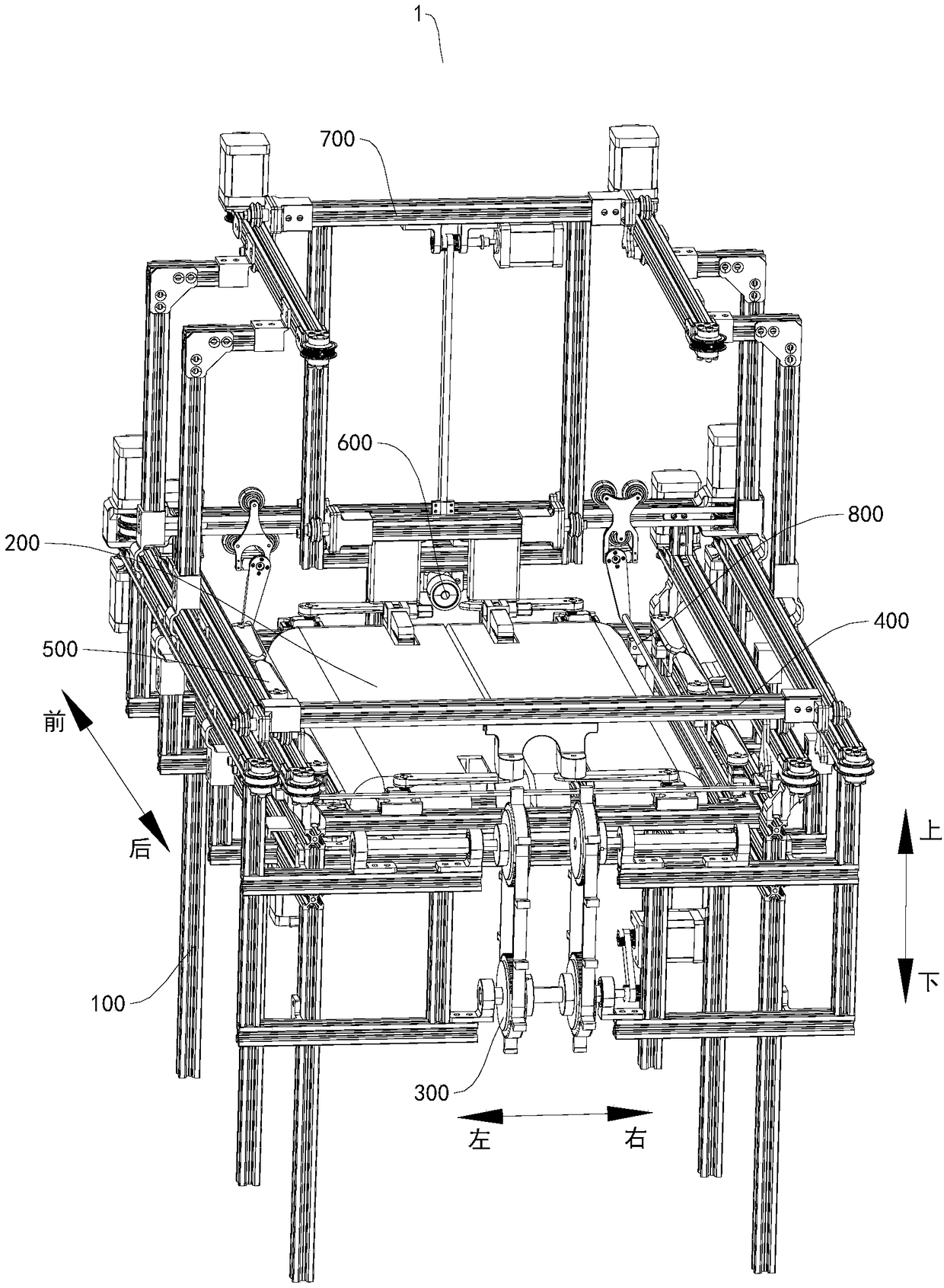

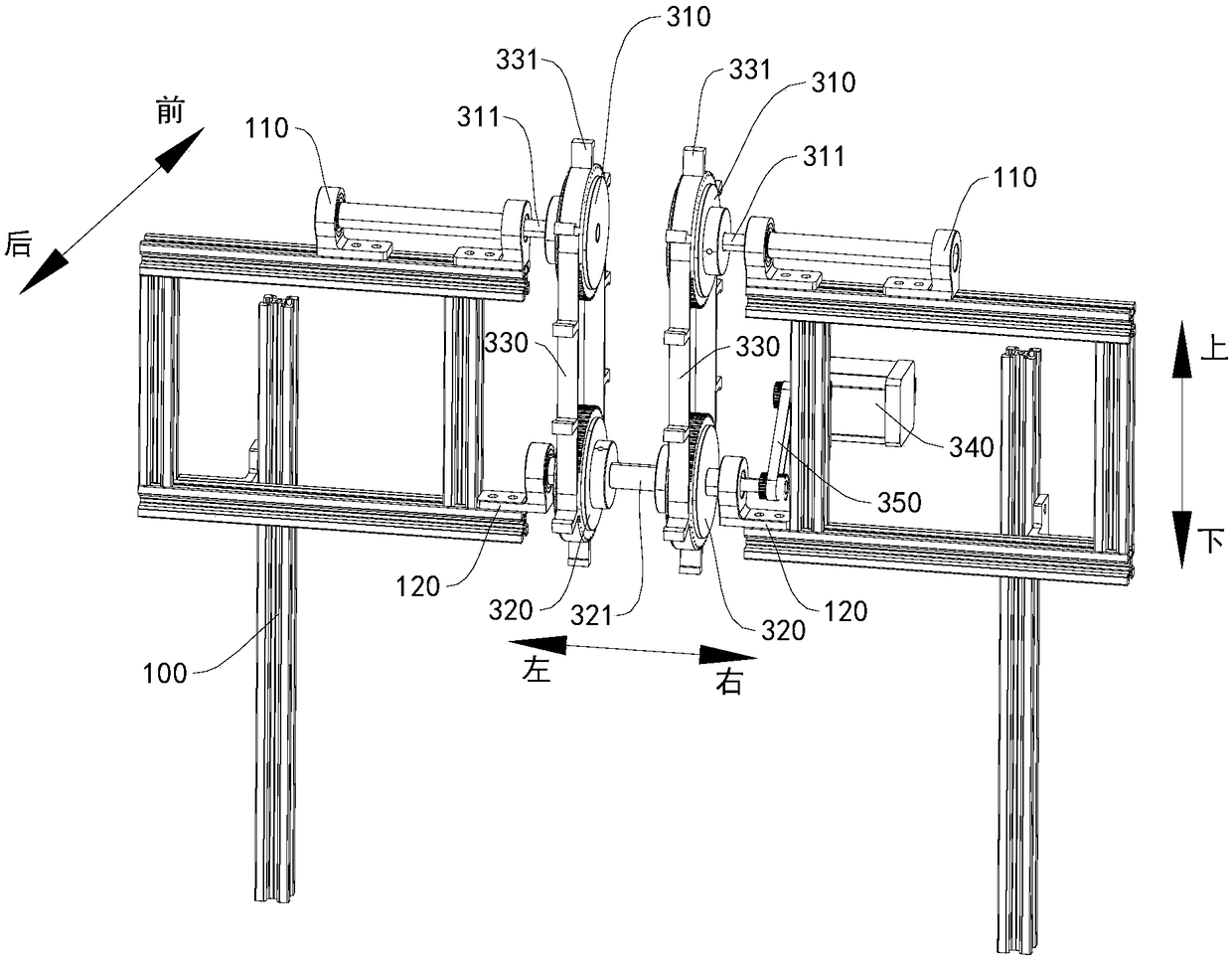

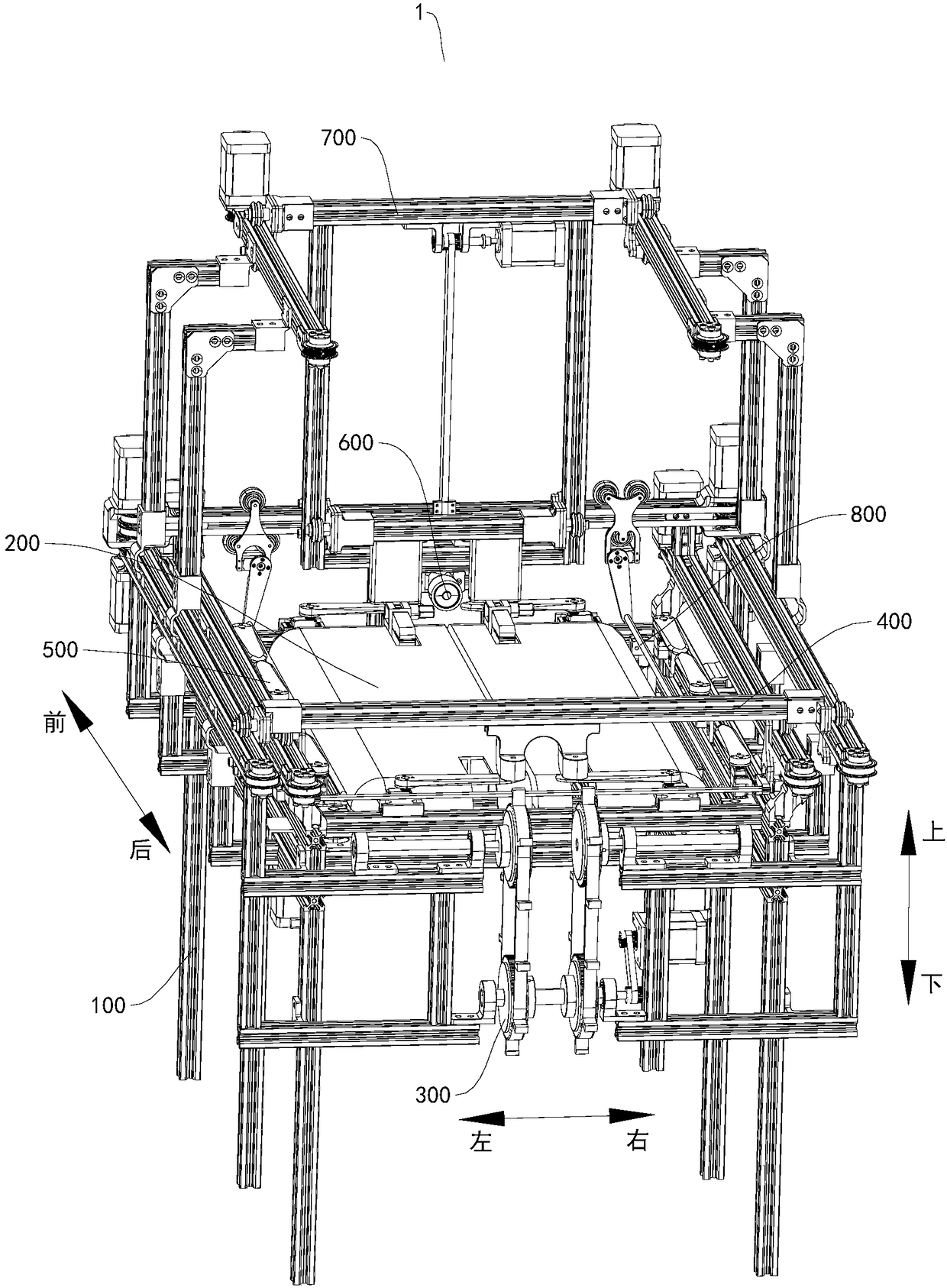

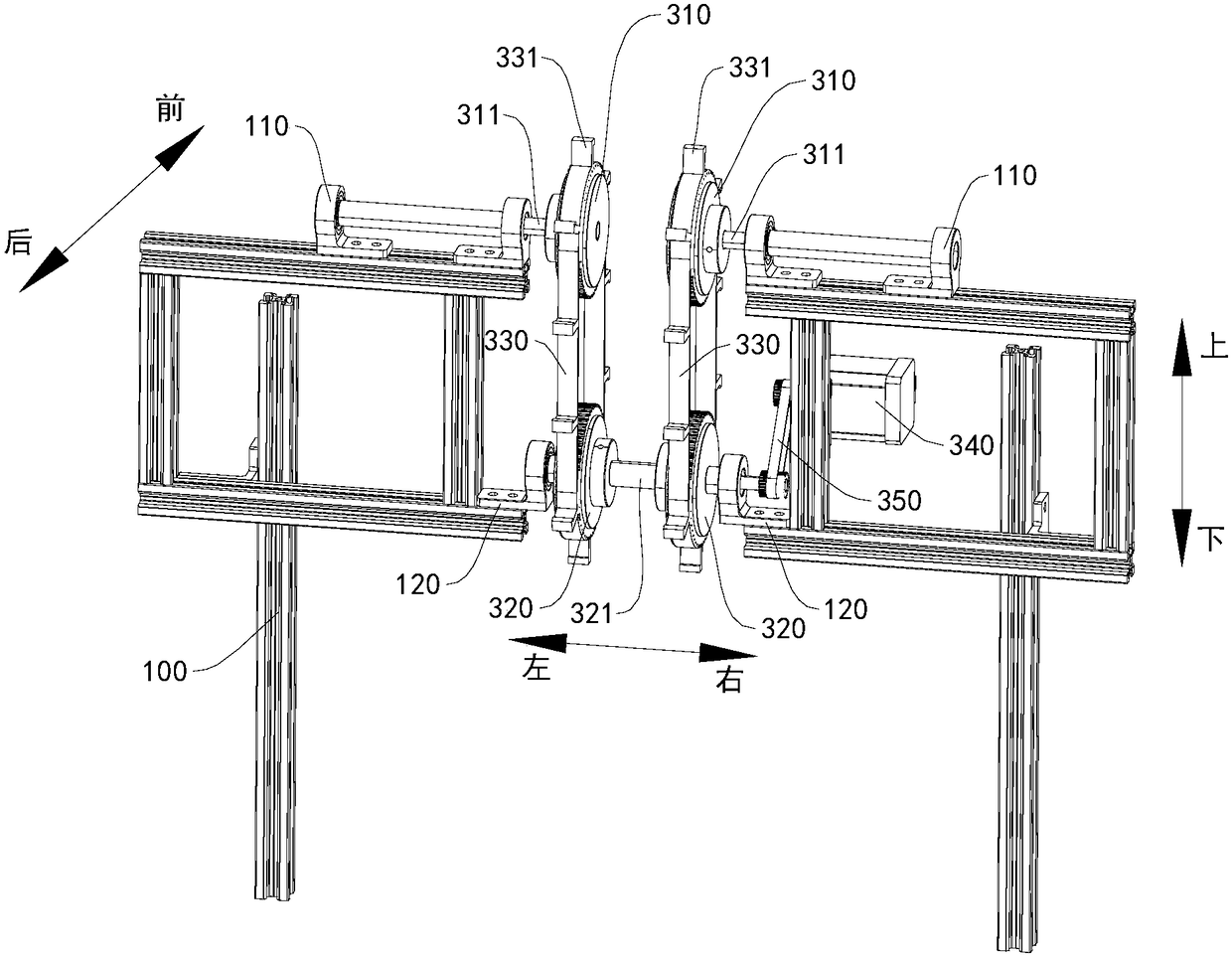

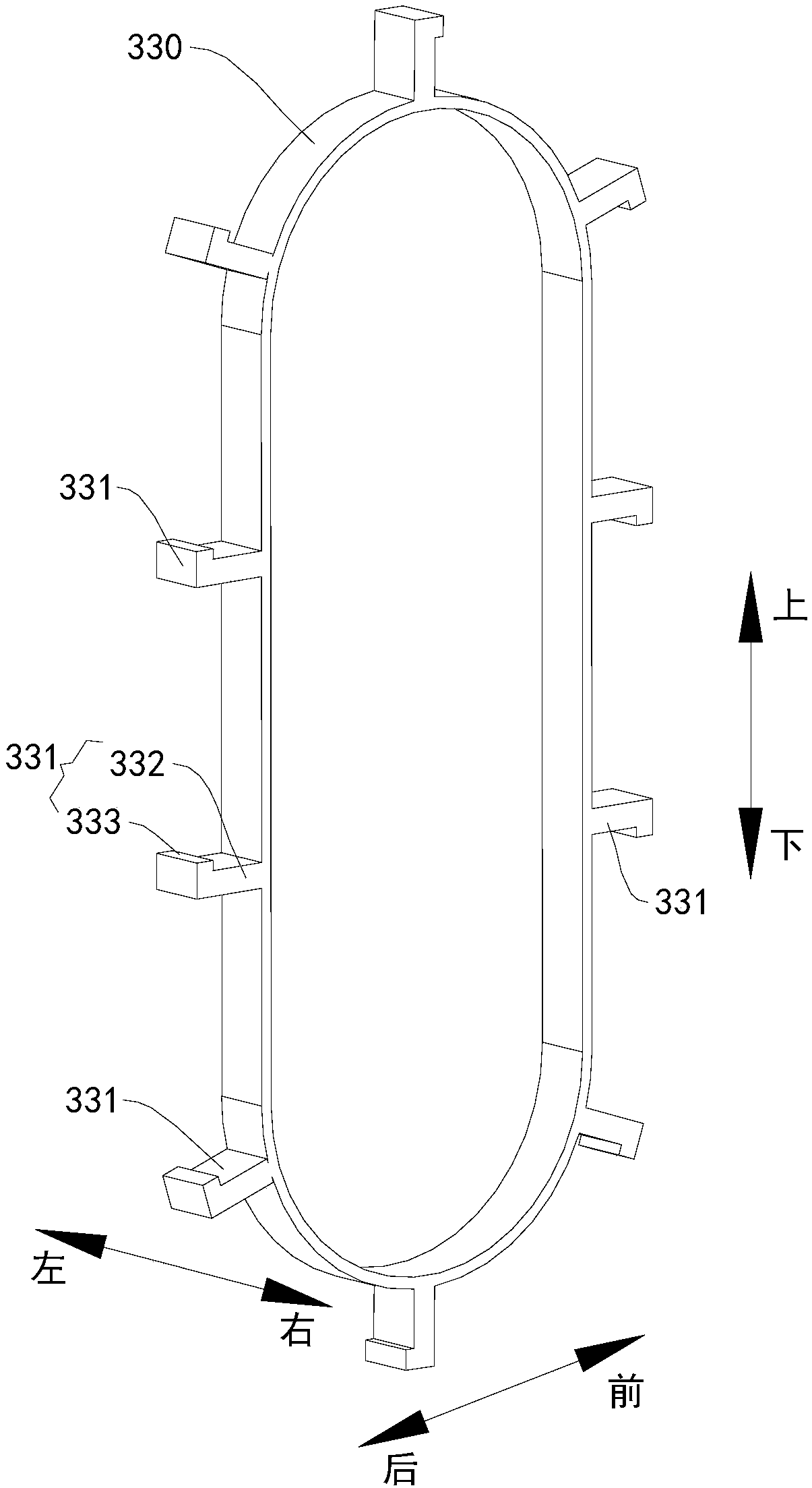

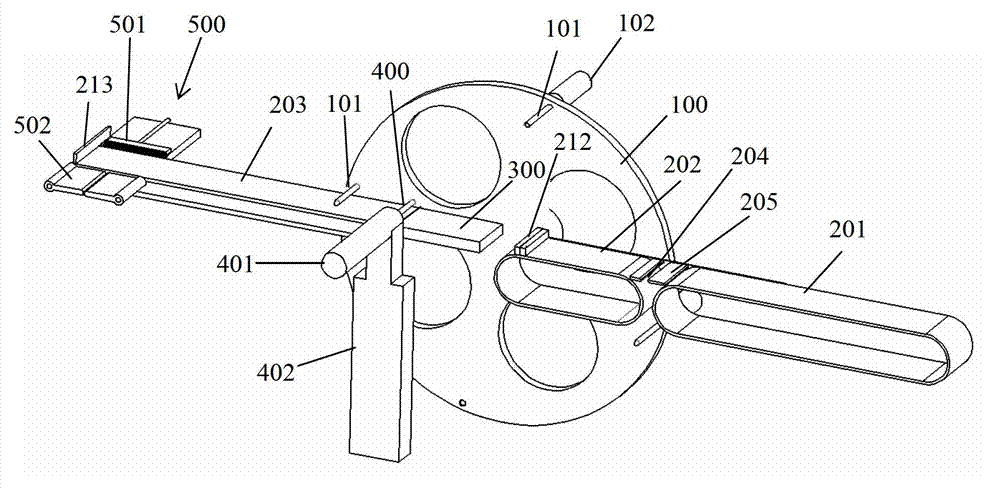

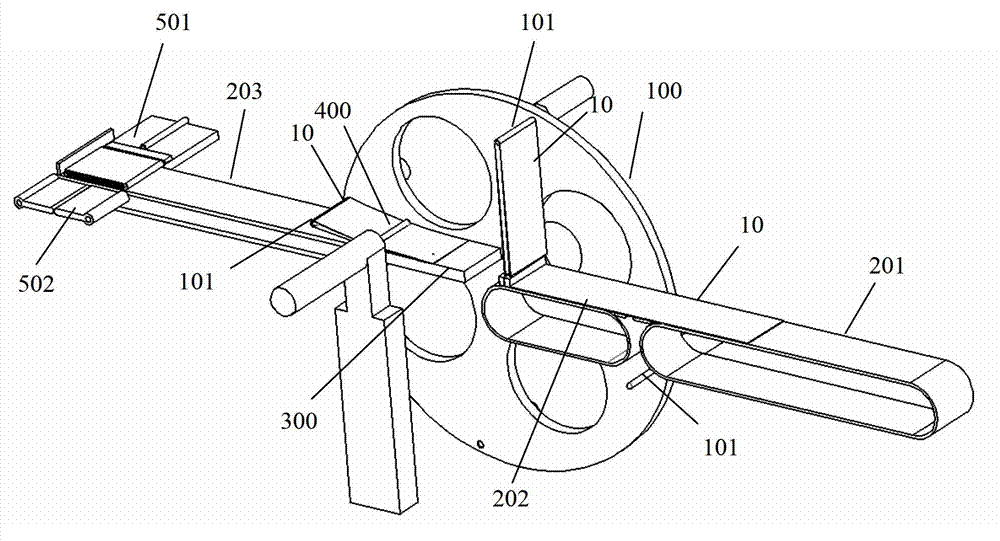

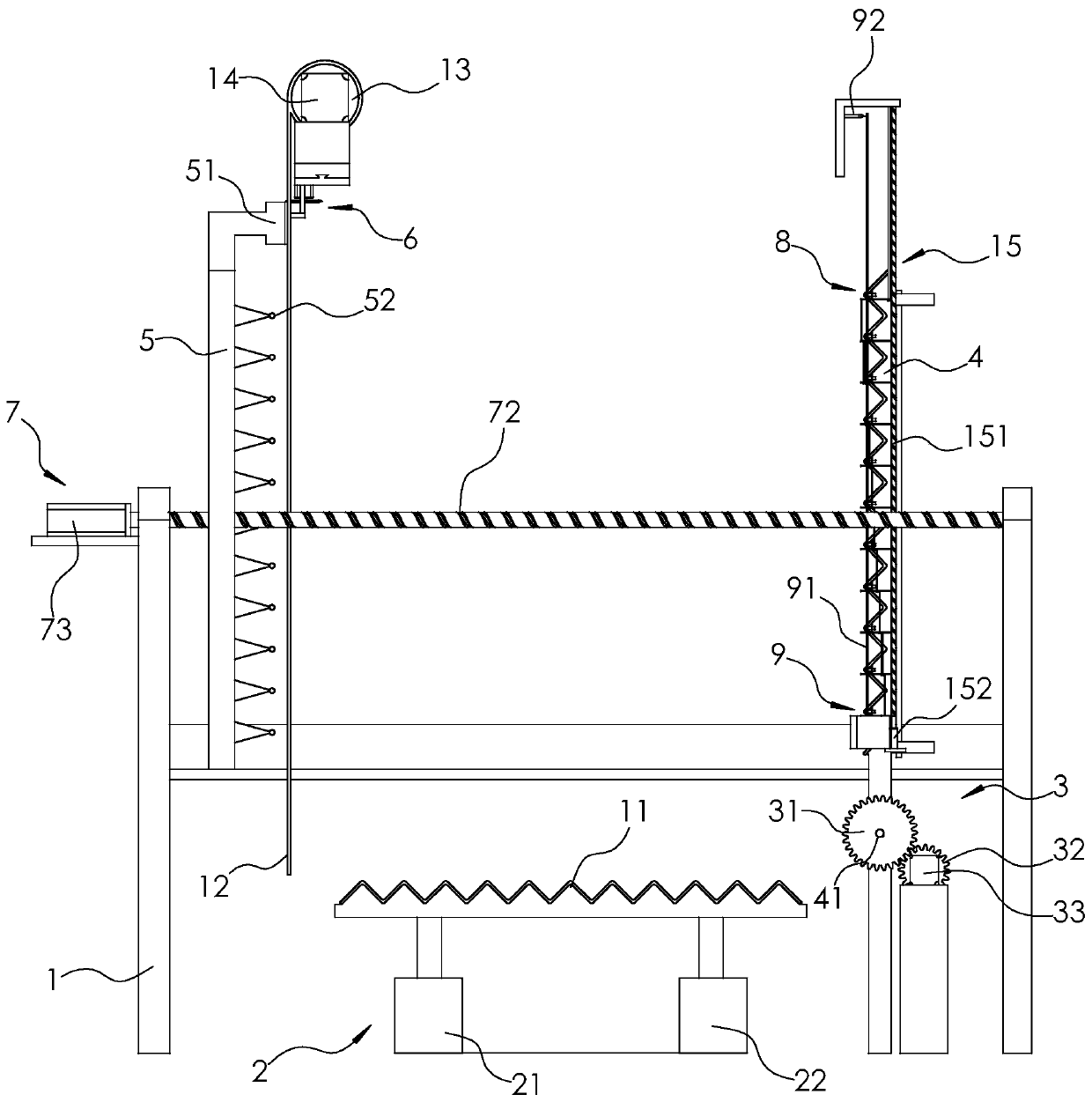

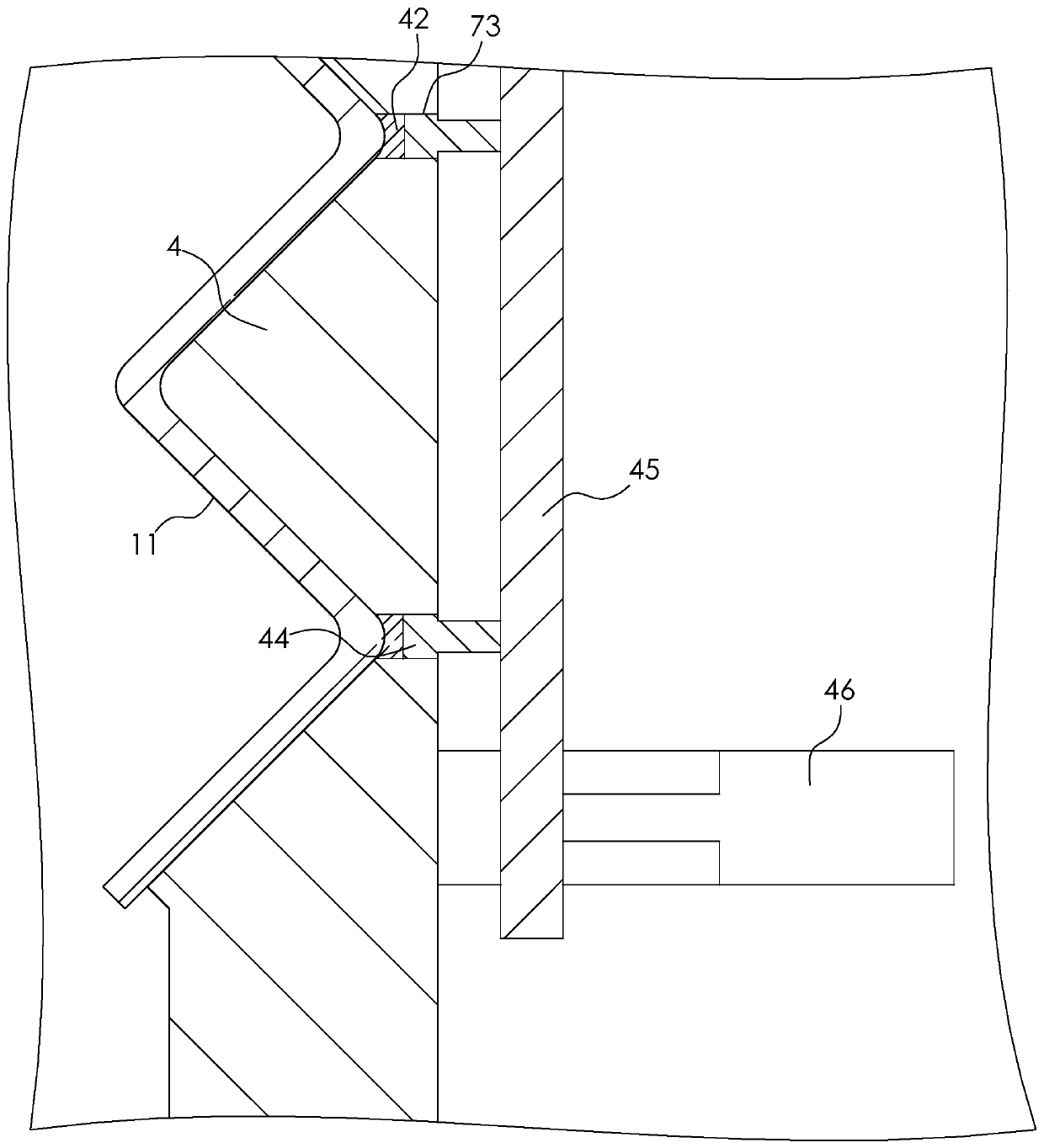

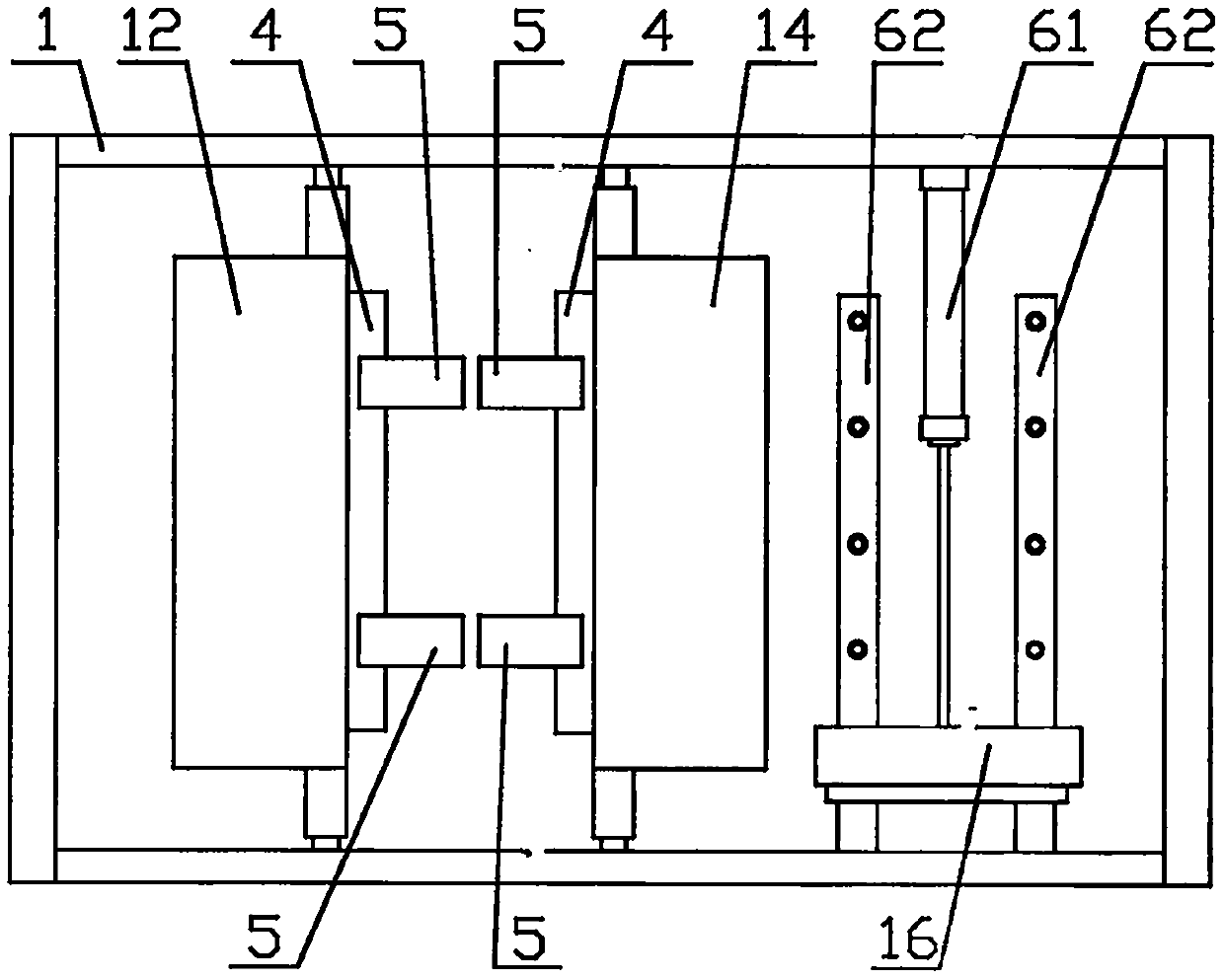

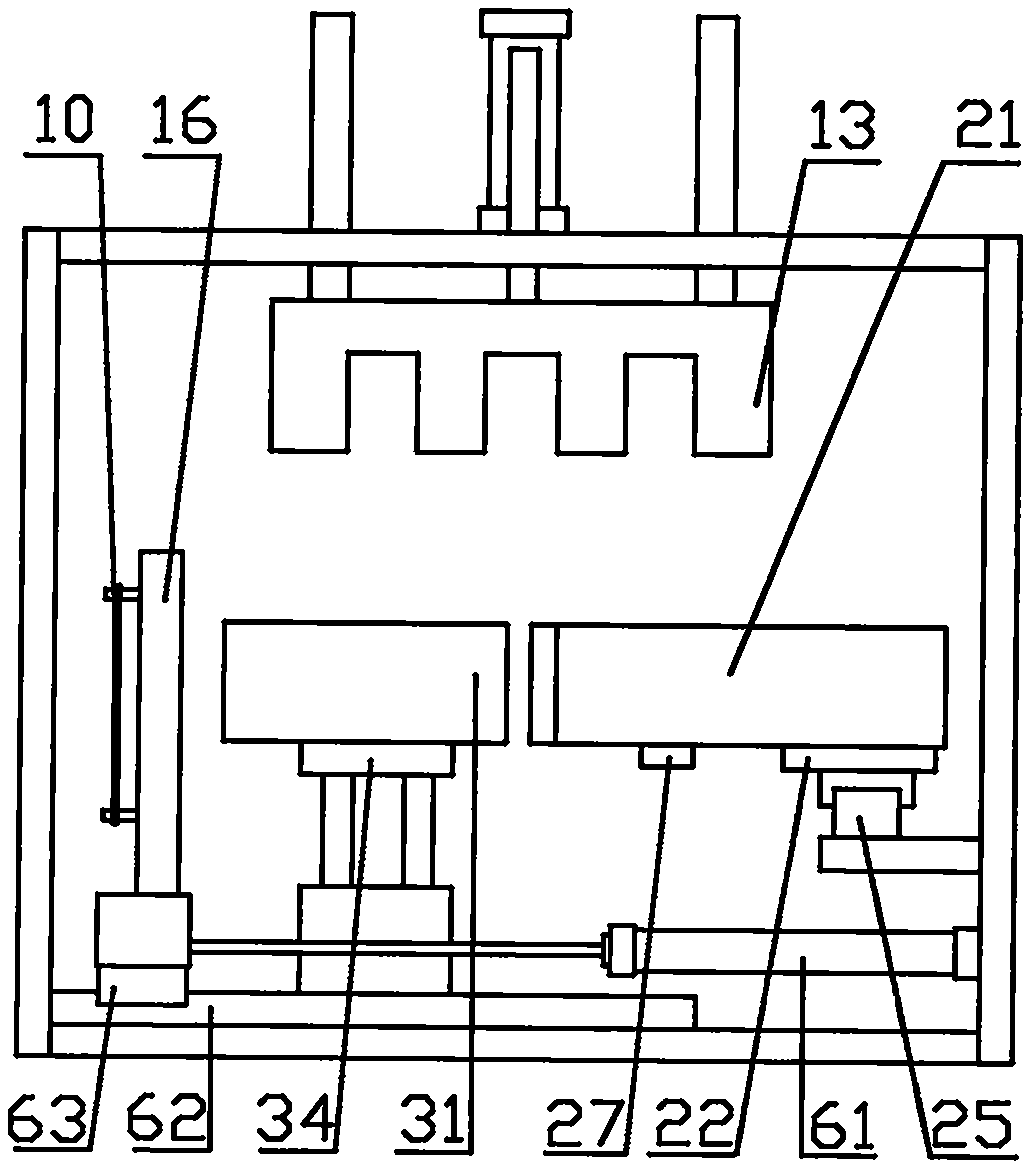

The invention relates to a quilt folding machine, and belongs to the technical field of packaging machines. The quilt folding machine comprises a quilt tiling guiding-in mechanism, a front longitudinal quilt folding mechanism, a back longitudinal quilt folding mechanism, a folded quilt transferring mechanism, a folded quilt conveying mechanism, a transverse quilt folding mechanism and a folded quilt output mechanism; wherein the back longitudinal quilt folding mechanism is located between the quilt tiling guiding-in mechanism and the front longitudinal quilt folding mechanism, the folded quilt transferring mechanism corresponds to the front longitudinal quilt folding mechanism, the folded quilt conveying mechanism corresponds to the folded quilt transferring mechanism, the transverse quilt folding mechanism corresponds to the folded quilt conveying mechanism, the folded quilt output mechanism is located between the transverse quilt folding mechanism and a bagging mechanism and used for conveying a folded quilt folded and shaped by the transverse quilt folding mechanism to the bagging mechanism, and the folded quilt coming from the folded quilt output mechanism is guided into a packaging bag through the bagging mechanism. The quilt folding machine has the advantages that manual folding is not needed so that manual input can be remarkably reduced, and labor resources can be saved; as the quilt can be automatically folded so that the folding efficiency can be high and can adapt to the production efficiency of a quilt manufacturing assembly line; as mechanical automatic folding is achieved, the stable folding effect is achieved to guarantee the packaging quality.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

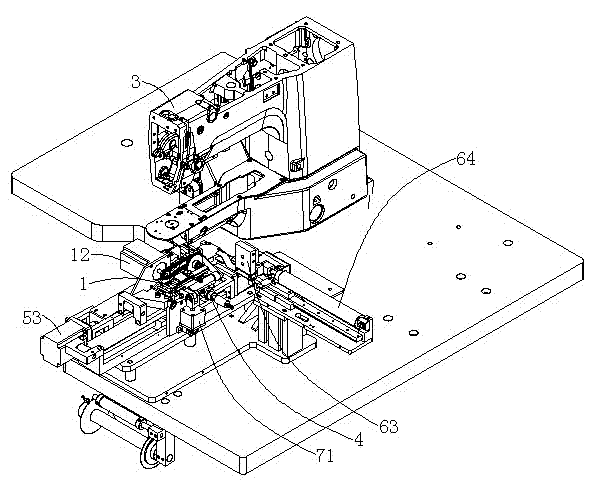

Ribbon loom

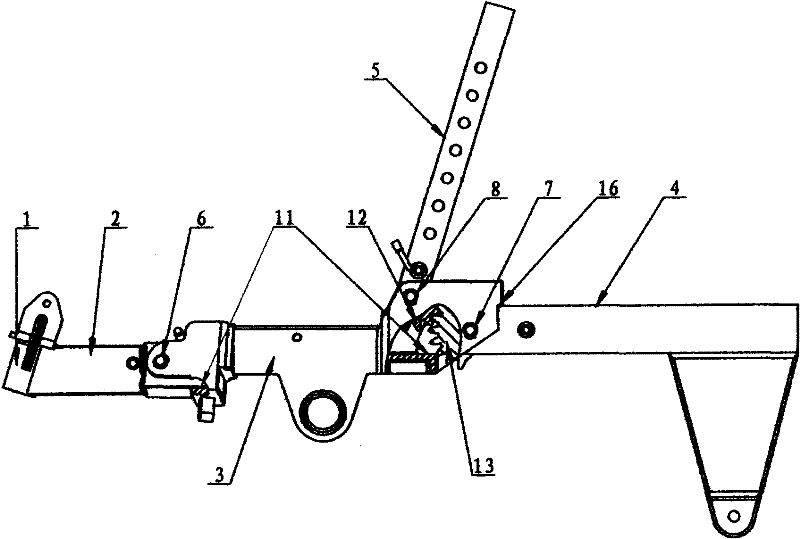

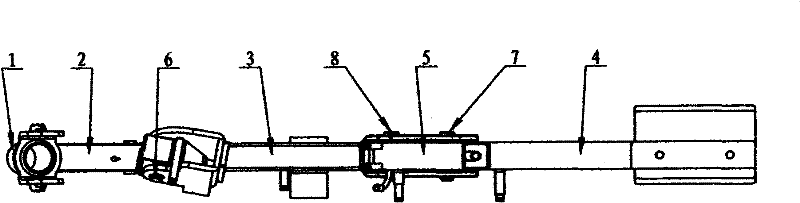

InactiveCN103161038ARealize automatic foldingReduce stepsWorkpiece carriersWork-feeding meansReciprocating motionBand shape

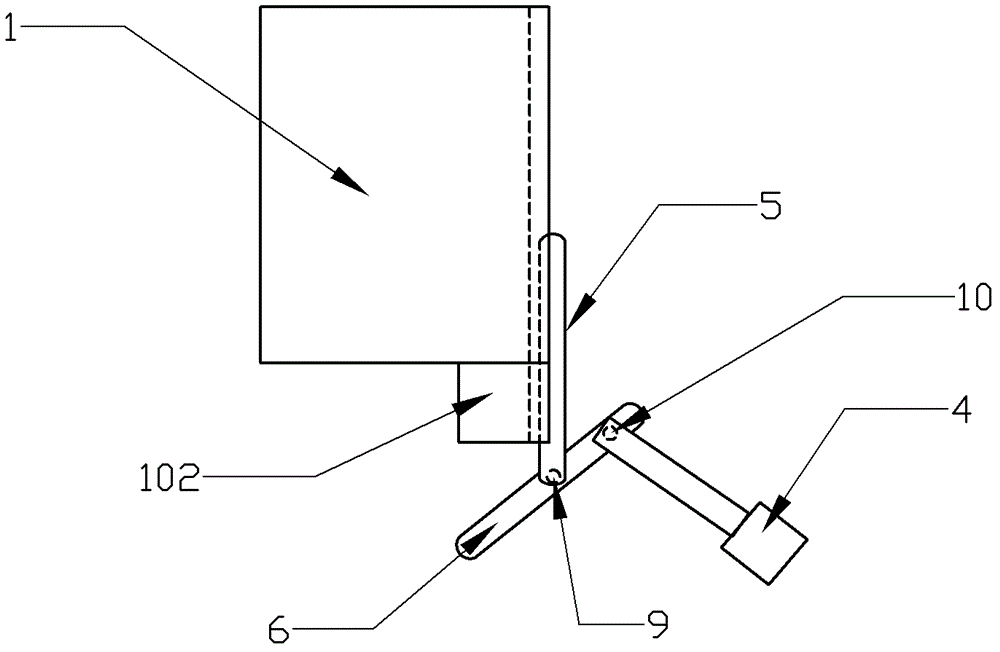

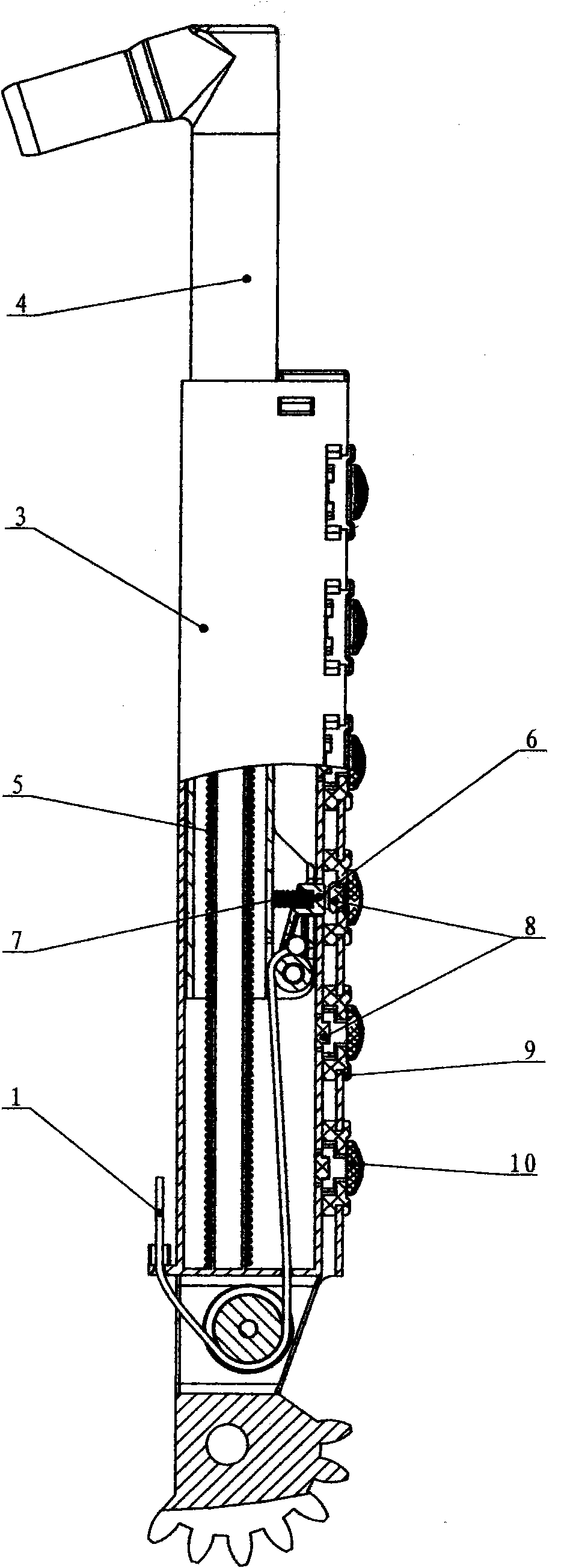

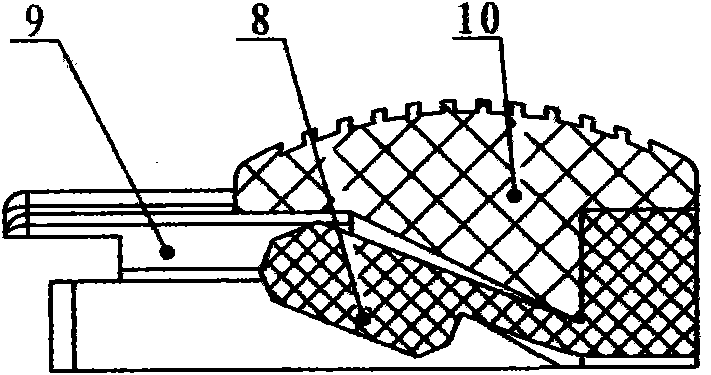

The invention discloses a ribbon loom which comprises a sewing machine head, a feeding guide rail, a material cutting mechanism, a material clamping structure and a feeding structure. The feeding guide rail is used for feeding strip-shaped materials, and the material cutting mechanism is arranged on the end portion of the feeding guide rail and used for cutting off the materials. The material clamping structure can move back and forth along a straight line. The material clamping structure clamps head portions of the strip-shaped materials and moves from an original position to a final position. A material stopping rod which can move up and down is arranged between the original position and the final position. When the material stopping rod abuts against the strip-shaped materials pulled out by the material clamping structure, the material clamping structure returns to the original position from the final position, and the strip-shaped materials are folded around the material stopping rod. The feeding structure is used for fixing folded materials. The feeding structure clamps the folded materials and sends the folded materials to a sewing region of the sewing machine head after the material cutting mechanism cuts off the folded materials.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

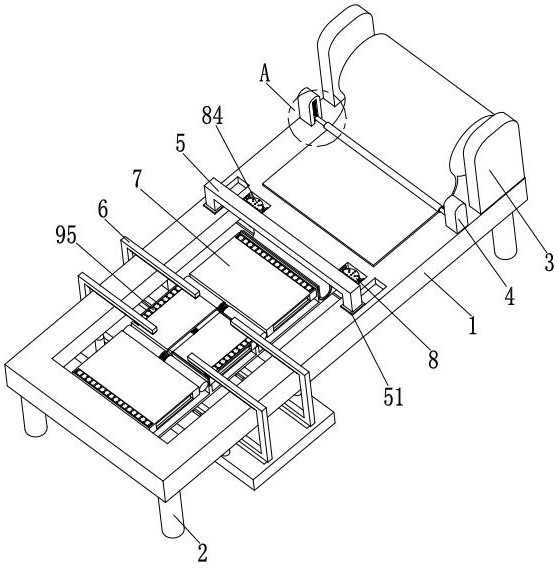

Clothes folding machine

ActiveCN109208298ARealize automatic foldingKeep it clean and consistentFolding thin materialsTextiles and paperEngineering

The invention discloses a clothes folding machine. The clothes folding machine includes a frame, a folding platform mechanism, a clothes conveying mechanism used for conveying hangers hung with the clothes, a clothes dragging mechanism used for laying the clothes on the folding platform mechanism, a clothes positioning mechanism used for compacting the clothes on the folding platform mechanism, ahanger separating mechanism used for separating the clothes on the folding platform mechanism from the hangers, a clothes folding mechanism used for folding the clothes on the folding platform mechanism in cooperation with the clothes positioning mechanism, and a control unit, wherein after folding is completed through the clothes folding mechanism, through overturning of the folding platform mechanism, the clothes is re-folded and drops from the folding platform mechanism. The clothes folding machine is advantaged in that clothes laying, positioning and folding can be carried out, automatic clothes folding is realized instead of manual clothes folding, not only can high efficiency and low labor intensity be realized, but also neatness and consistency of the clothes after folding can be further guaranteed.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Hair sticking and ironing all-in-one machine

InactiveCN108729176ARealize automatic foldingRealize fully automatic sticky hair ironingIroning boardsHousehold cleanersEngineering

The invention discloses a hair sticking and ironing all-in-one machine. The hair sticking and ironing all-in-one machine comprises a machine body, and a lifting and overturning integrated transmissionmechanism which is mounted and fixed on the machine body, wherein the lifting and overturning integrated transmission mechanism is provided with a lifting ironing seat and an apparel fabric overturning mechanism; the machine body is provided with an ironing positioning mechanical arm; the ironing positioning mechanical arm is provided with a hair sticking and ironing seat. According to the hair sticking and ironing all-in-one machine, the hair sticking and ironing seat is positioned through the ironing positioning mechanical arm and clothes can be automatically ironed; two hair sticking barrels are arranged on the hair sticking and ironing seat and can be used for sticking hairs and ironing at the same time; meanwhile, people do not need to hold an ironing machine by hand to carry out ironing for a long time, and the problems of an existing clothes ironing process that the hairs need to be stuck and then the clothes can be ironed so that the ironing speed is relatively low, and scaldsare caused by the fact that the ironing machine is held by hand are solved.

Owner:NANTONG YOUYUAN ART PATTERN DESIGN CO LTD

Clothes folding method of clothes folding machine

ActiveCN109208299ARealize automatic foldingKeep it clean and consistentFolding thin materialsTextiles and paperMechanical engineering

The invention discloses a clothes folding method of a clothes folding machine. The clothes folding machine includes a folding platform mechanism, a clothes conveying mechanism, a clothes dragging mechanism, a clothes positioning mechanism, a hanger separating mechanism and a clothes folding mechanism. The method comprises steps that S1, hangers hung with the clothes are conveyed by the clothes conveying mechanism to the predetermined position; S2, the hangers from the clothes conveying mechanism are received by the clothes dragging mechanism and dragged to the folding platform mechanism; S3, the clothes is positioned through the clothes positioning mechanism; S4, the hangers are separated from the clothes by the hanger separating mechanism in cooperation with the clothes positioning mechanism; and S5, the clothes on the folding platform mechanism is folded by the clothes folding mechanism in cooperation with the clothes positioning mechanism. The method is advantaged in that clothes laying, positioning and folding can be carried out, automatic clothes folding is realized instead of manual clothes folding, not only can high efficiency and low labor intensity be realized, but also neatness and consistency of the clothes after folding can be further guaranteed.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

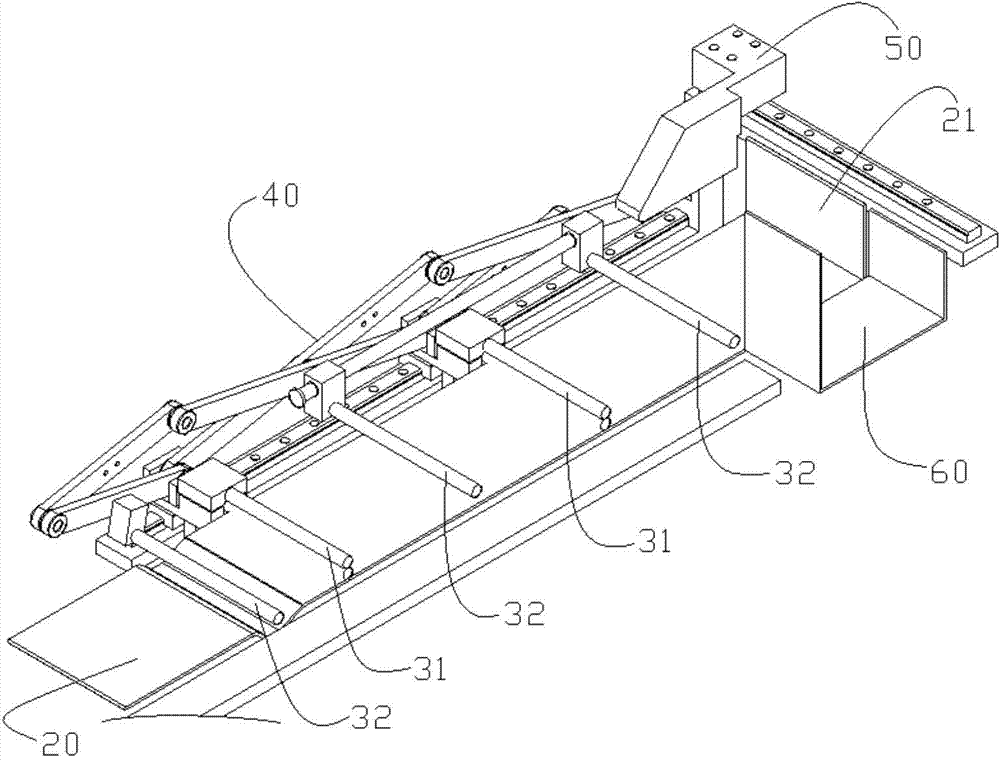

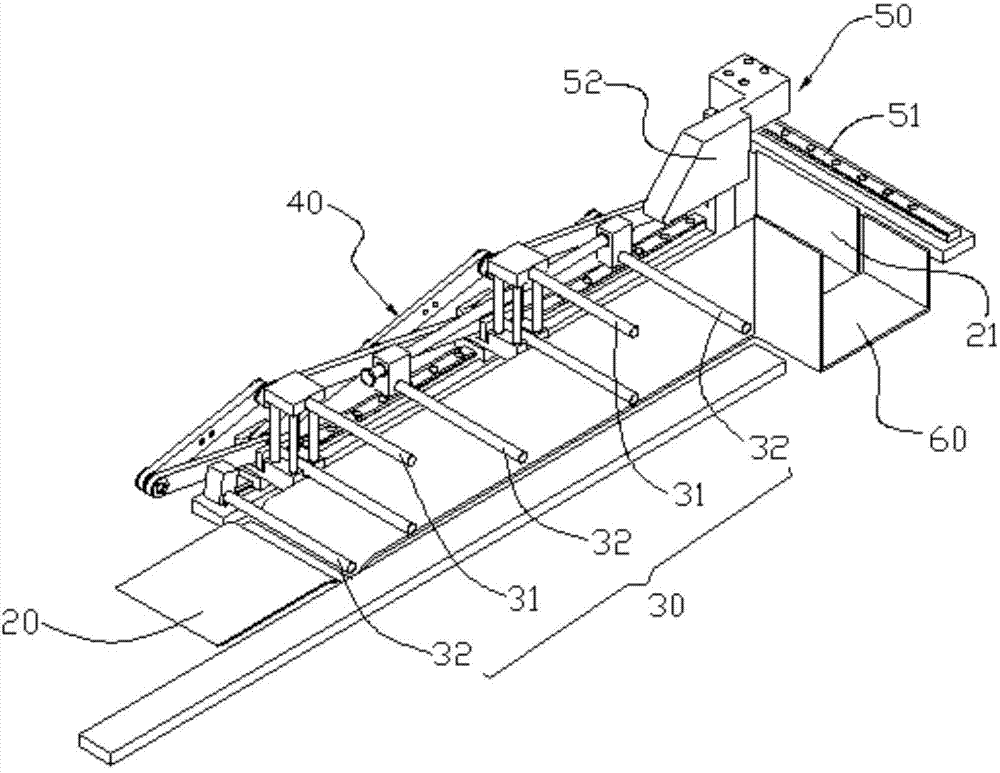

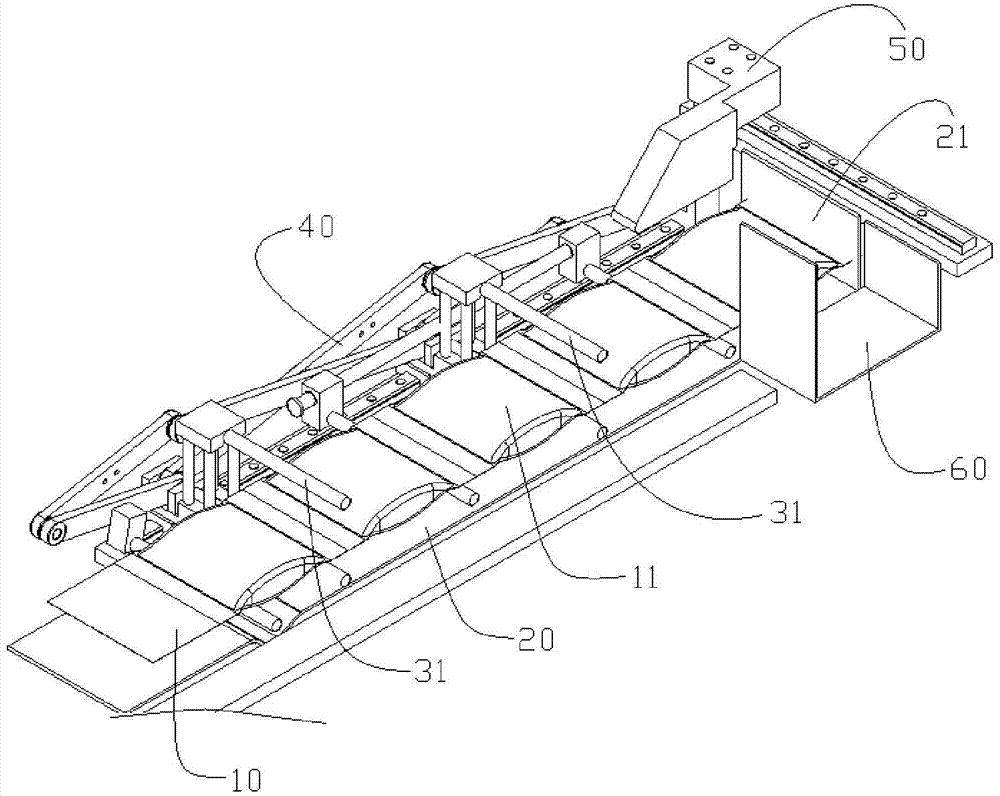

Folding machine for blanket type packaged product

InactiveCN102730251ARealize automatic foldingImprove packaging efficiencyPackagingEngineeringMechanical engineering

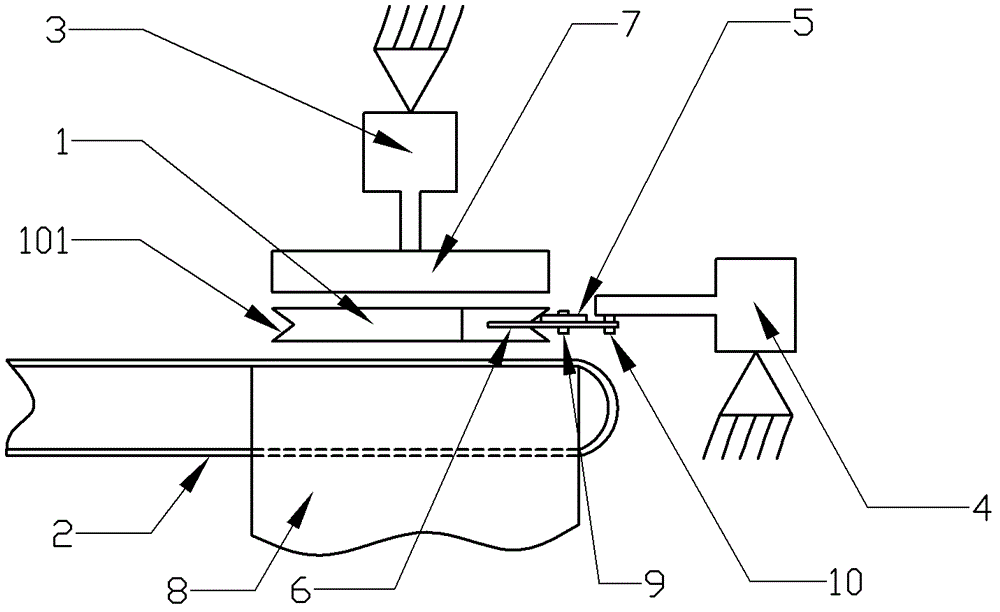

The invention discloses a folding machine for a blanket type packaged product. The folding machine comprises an upright rotary disk, and a first conveying belt, a second conveying belt and a third conveying belt which are positioned one side of the front disk surface of the rotary disk and are arranged in sequence; a telescopic ram perpendicular to the front disk surface is arranged on the rotary disk; a gap through which the telescopic ram passes when the rotary disk rotates is arranged between the first conveying belt and the second conveying belt; the third conveying belt is provided with a folded plate which can be folded upwards at the outer side of an initial end socket; a telescopic pressure rod is arranged above the position of a joint where the initial end socket of the third conveying belt is combined with the folded plate; and a stop end socket of the third conveying belt is provided with a discharging device. By using the folding machine for the blanket type packaged product, which is provided by the invention, the automatically folding of the blanket type packaged product is realized; the folded blanket type packaged product is loaded in a packaging box; and the packaging efficient of such a product is improved.

Owner:SHANGHAI QIANXIANG MASCH EQUIP CO LTD

Automatic folding mechanism for valve bag tongue port

InactiveCN102717530ARealize automatic foldingReduce labor costsBox making operationsPaper-makingEngineeringPackaging machine

Owner:JINAN LIYU MACHINERY TECH

Edge folding mechanism

InactiveCN106694665ARealize automatic foldingRealize hemmingHollow articlesEngineeringMechanical engineering

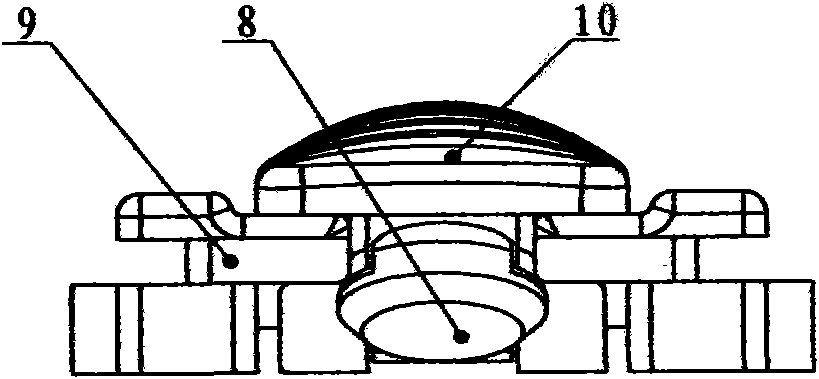

The invention discloses an edge folding mechanism which comprises a base. The edge folding mechanism is characterized in that an air cylinder is fixed to the base, the end of a piston rod of the air cylinder is rotationally provided with a tray through a bearing, the tray is used for containing a barrel needing to be subject to edge folding, a rotary disc is arranged over the tray in a rotational manner, and the diameter of the rotary disc is matched with the internal diameter of the barrel; and a taper inner compression roller moving back and forth in the radial direction of the barrel is arranged on the inner side of the barrel and on the upper side of the rotary disc, and an outer compression roller swinging back and forth is arranged at the position, corresponding to the inner compression roller, of the outer side of the barrel.

Owner:覃小倩

Connected bag folding mechanism

ActiveCN104843249AHigh degree of production automationImprove folding efficiencyPackagingEngineeringProduction automation

The invention discloses a connected bag folding mechanism which comprises a supporting part for carrying connected bags, a transverse rod part and a driving part. The transverse rod part comprises first transverse rods and second transverse rods, wherein the first transverse rods and the second transverse rods are alternately distributed in the length direction of the connected bags. The driving part can drive the transverse rod part to expand or get close in the length direction of the connected bags. Before folding, the first transverse rods and the second transverse rods are in the expanded state and sequentially and alternately located at the upper end and the lower end of a joint of the connected bags. During folding, the driving part drives the first transverse rods and the second transverse rods to get close to the output end of the supporting part at the same time, the first transverse rods get close in the horizontal direction, and the second transverse rods gradually ascend and get close. The connected bag folding mechanism can be used for automatically folding the connected bags and is high in production automation degree and capable of improving the packaging efficiency, lowering the labor intensity of workers and reducing the labor cost.

Owner:广州祥旺食品有限公司

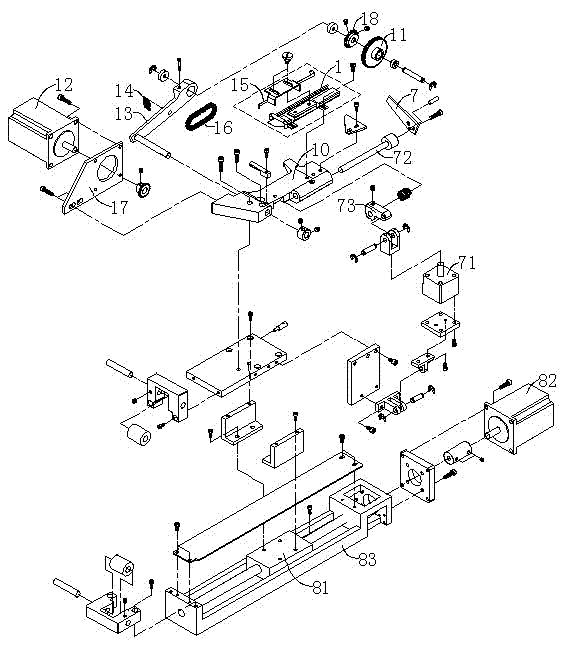

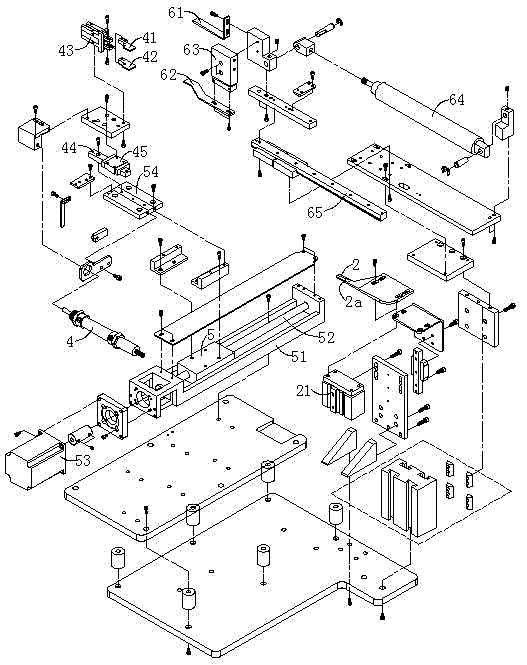

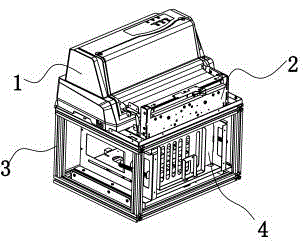

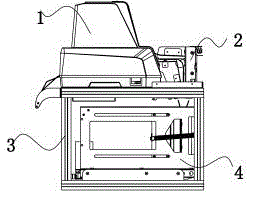

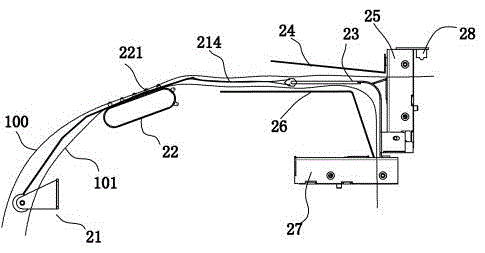

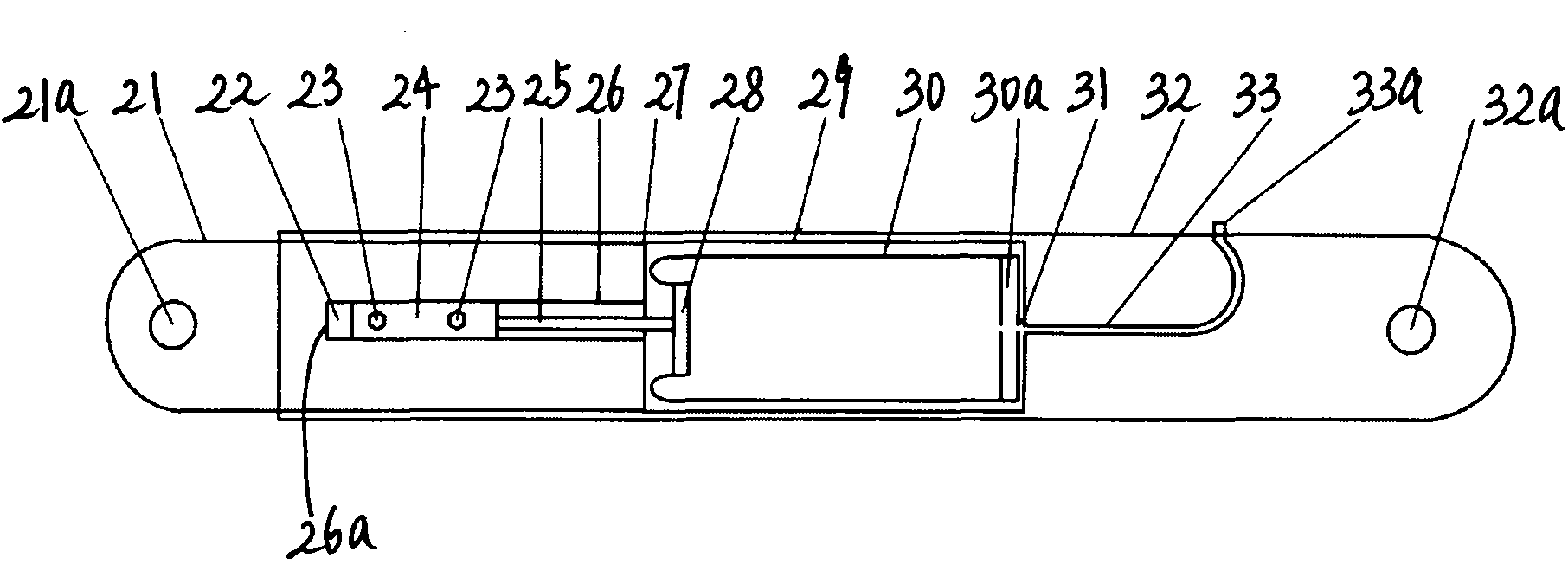

Multi-bill chain type bill separating printer capable of automatically folding retention lists

The invention discloses a multi-bill chain type bill separating printer capable of automatically folding retention lists, comprising a stylus printer, an automatic bill separation mechanism, an installation support and a retention list automatic folding mechanism; the automatic bill separation mechanism comprises a pre-separation device, a paper feeding wheel, a separation plate, a client serial guiding paper board, a client serial cutting knife, a retention serial guiding paper board, a retention serial cutting knife, a sensor and a tension spring; the retention list automatic folding mechanism comprises a bottom plate, a left side plate, a right side plate, a front pushing plate, a pull plate, a back pushing plate, a left buckling plate, a right buckling plate, a motor and a pulling rope; multiple bills printed and outputted by the stylus printer is in match connection with the paper feeding wheel of automatic bill separating mechanism; and the paper feeding port of the retention list automatic folding mechanism is arranged below the retention list bill output channel. The multi-bill chain type bill separating printer has advantages of automatically separating the printed multiple bills and automatically folding the printed bill retention lists.

Owner:FOSHAN MEICHEN TUODA ELECTRONICS CO LTD

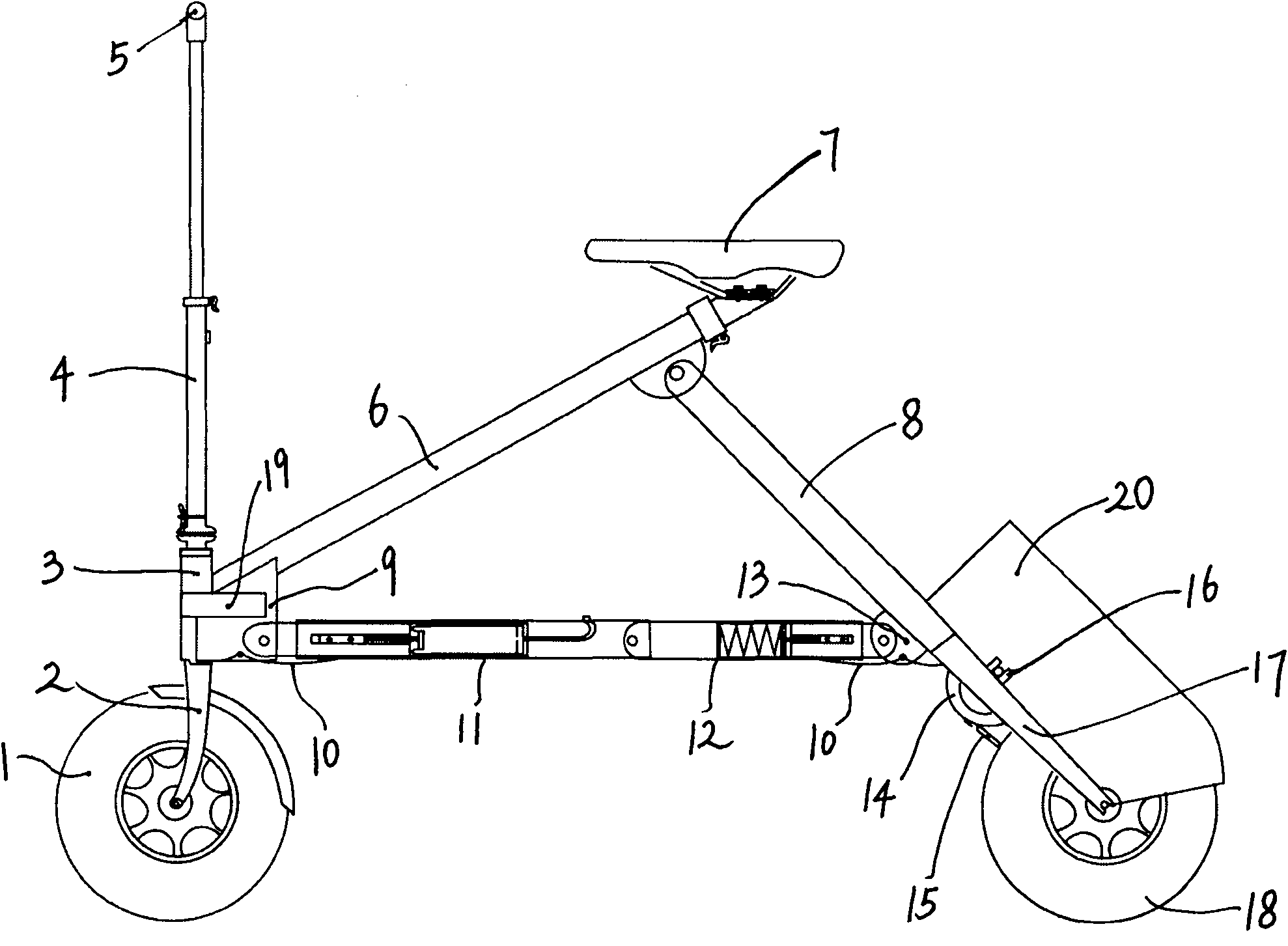

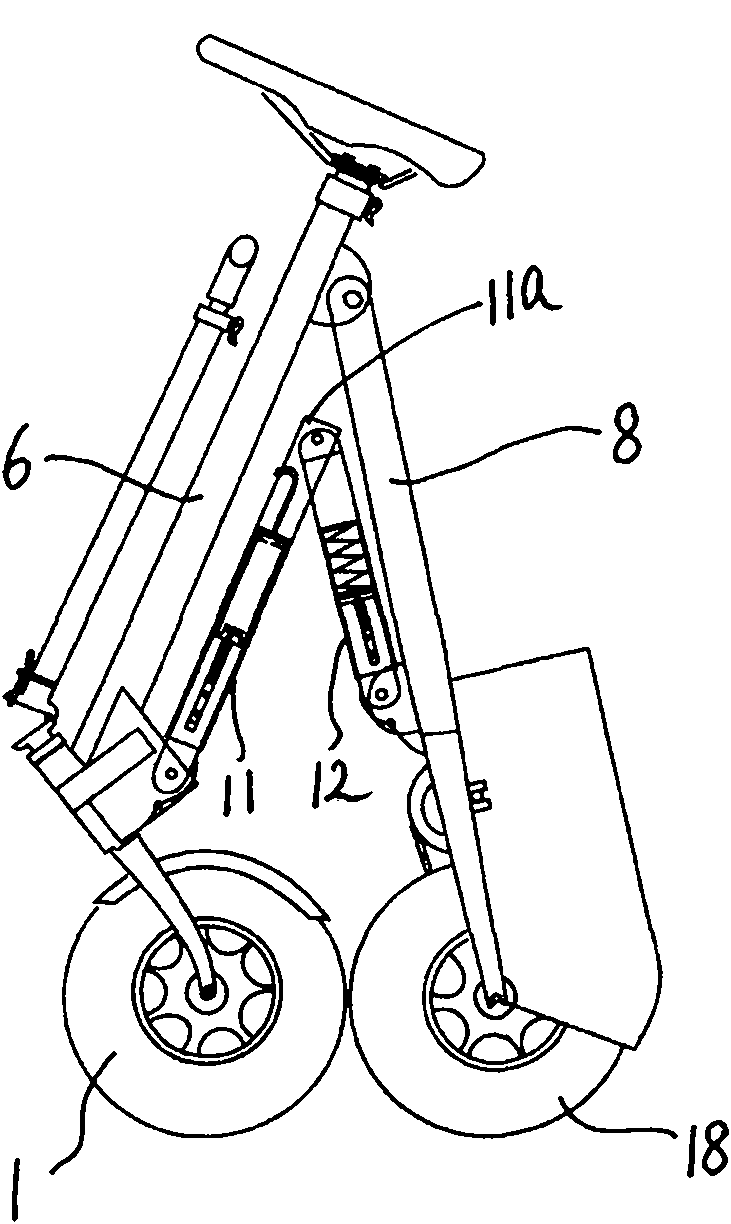

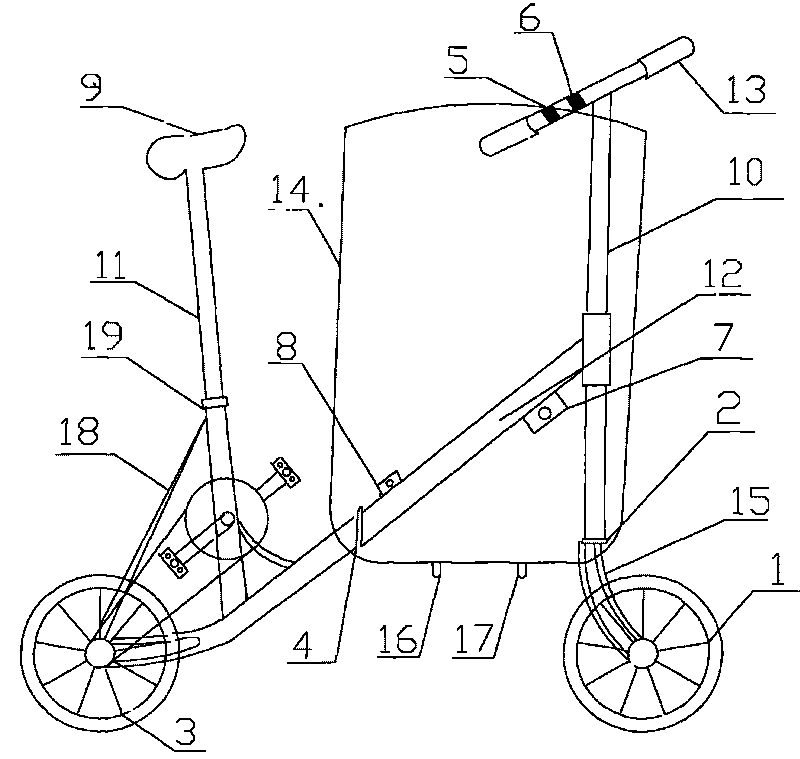

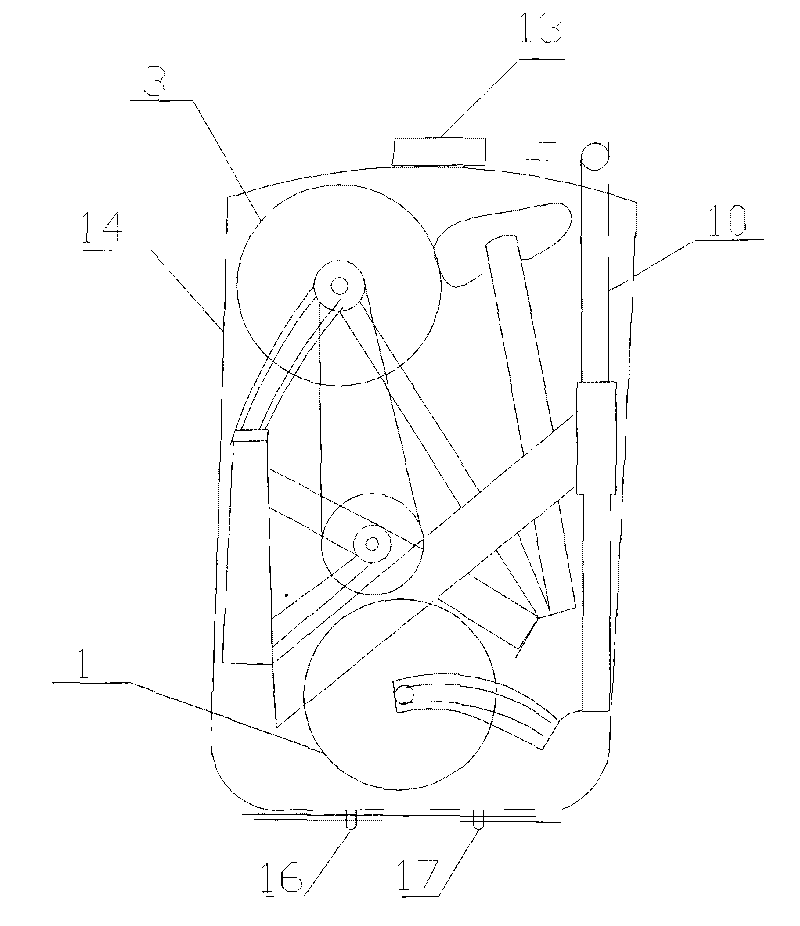

Portable bicycle with small-diameter wheel capable of being vertically folded

InactiveCN101890998ASimplified and stable structureImprove carrying capacityFoldable cyclesVehicle frameEngineering

The invention discloses a portable bicycle with a small-diameter wheel capable of being vertically folded. The portable bicycle comprises a front wheel, a rear wheel, a bicycle frame, a handle frame, a bicycle seat, a front Y-type pipe, a rear Y-type pipe and a power device, wherein the handle frame consists of a handle vertical pipe and a handle transverse pipe; the power device is used for driving the wheels to rotate; the bicycle frame is an upright triangular frame and comprises an inclined frame front pipe, an inclined frame rear pipe and a transverse frame lower pipe which form three angles which are hinged with one another; the front Y-type pipe and the handle frame are connected to the lower part and the upper part of a frame front angle consisting of the frame front pipe and the frame lower pipe respectively; the rear Y-type pipe is connected with a frame rear angle consisting of the frame rear pipe and the frame lower pipe; the bicycle seat is positioned at the top angle of the triangular bicycle frame; the frame lower pipe consists of a front lower pipe and a rear lower pipe which are hinged with each other; and the hinged point of the front lower pipe and the rear lower pipe is positioned in the middle of the frame lower pipe. The bicycle is folded vertically, so the bicycle has the advantages of convenient folding operation, a few folding actions, small volume after being folded and portability.

Owner:张建民

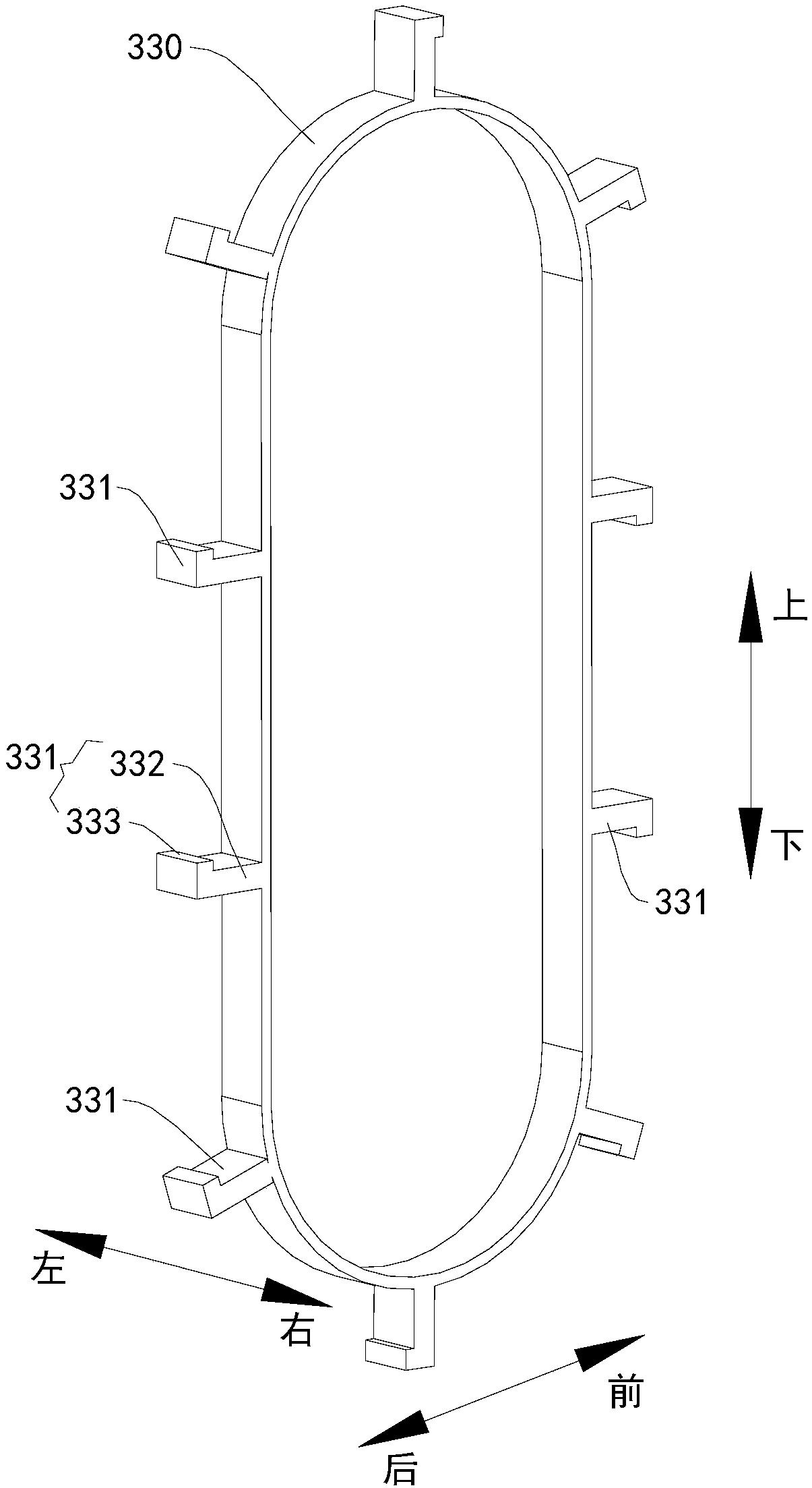

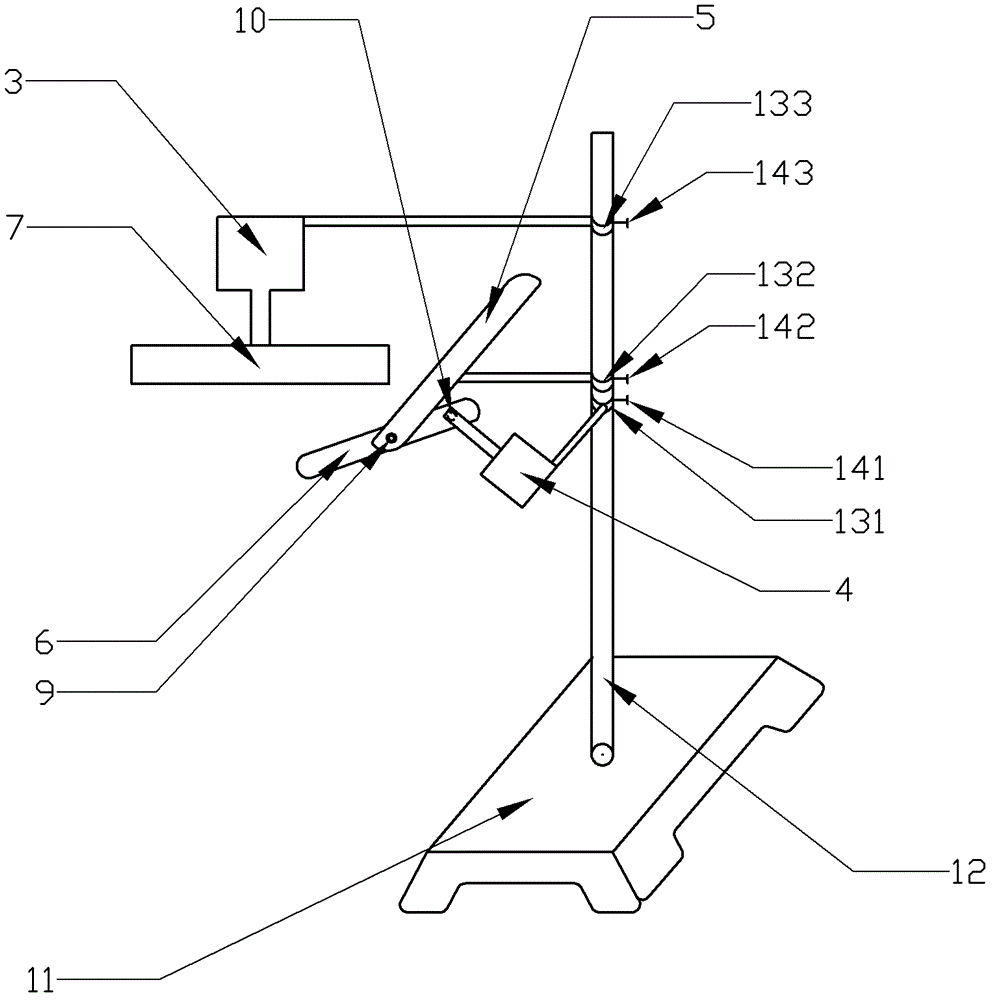

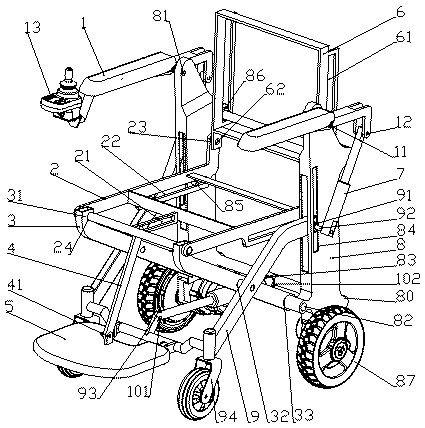

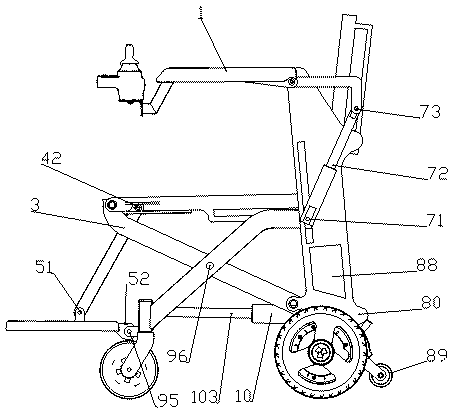

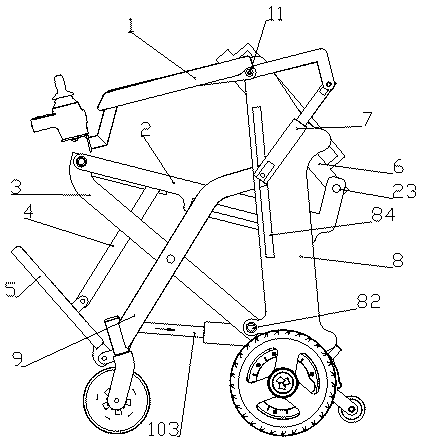

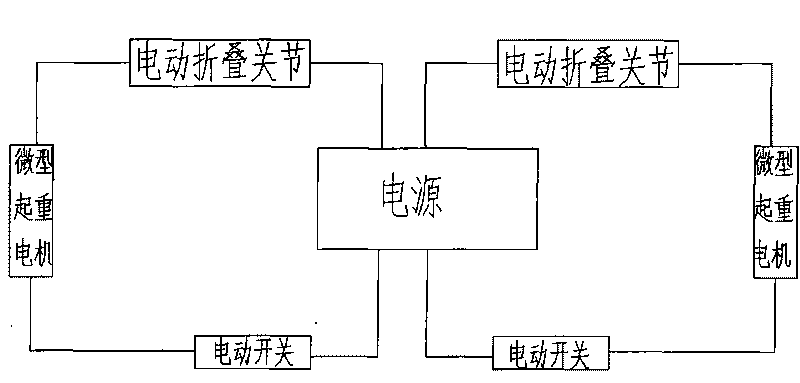

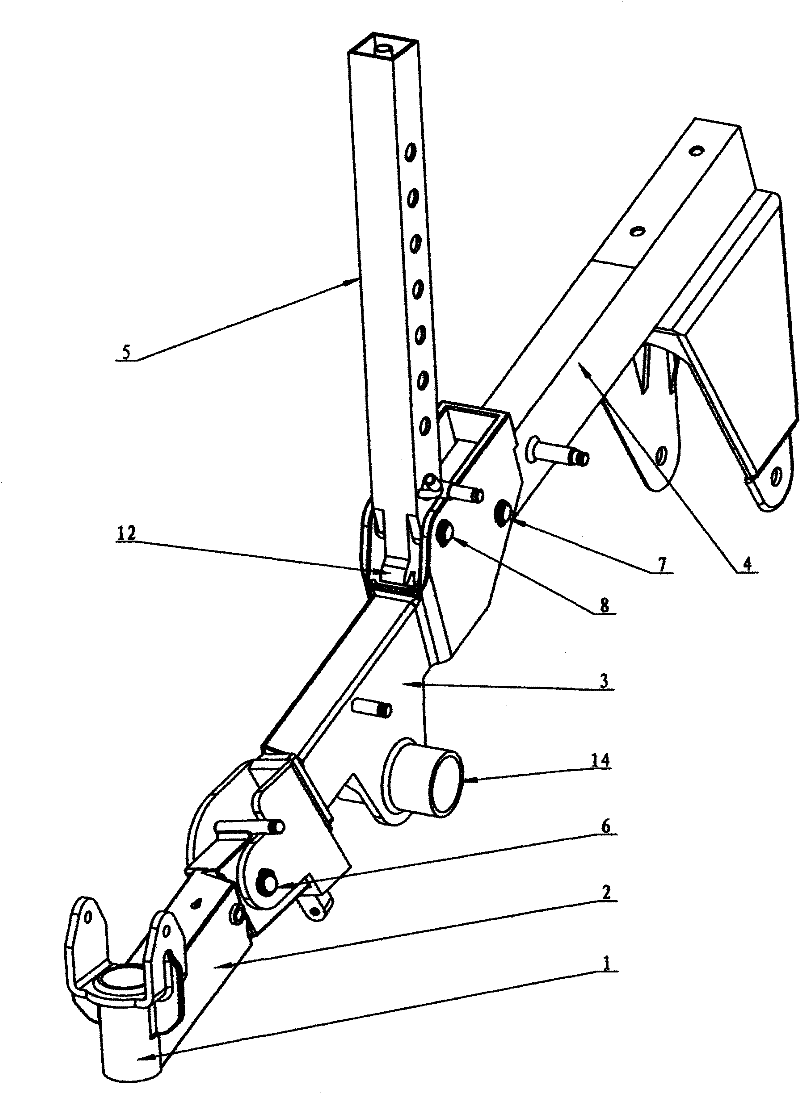

Automatic folding electric wheelchair

ActiveCN105167928ARealize automatic foldingNo manual operationWheelchairs/patient conveyanceWheelchairEngineering

The invention discloses an automatic folding electric wheelchair. The automatic folding electric wheelchair is characterized in that: the integral wheelchair is automatically folded in an electric manner, and an electric pushing rod can be remotely operated to stretch out and draw back; a user does not need to be in contact with the electric wheelchair, and the integral electric wheelchair can be automatically folded; besides, during the folding process, the centre-of-gravity position of the wheelchair moves backwards, and finally, a back tilting prevention wheel stands on the ground, so that the folded wheelchair can automatically stand without being supported by manual work; therefore, the integral electric wheelchair can be automatically folded and automatically stand without the need of manual operation, the folding action is automatic and simple, the labor intensity is small, and the automatic folding electric wheelchair is quite convenient.

Owner:DONGGUAN PRESTIGE SPORTING PROD CO LTD

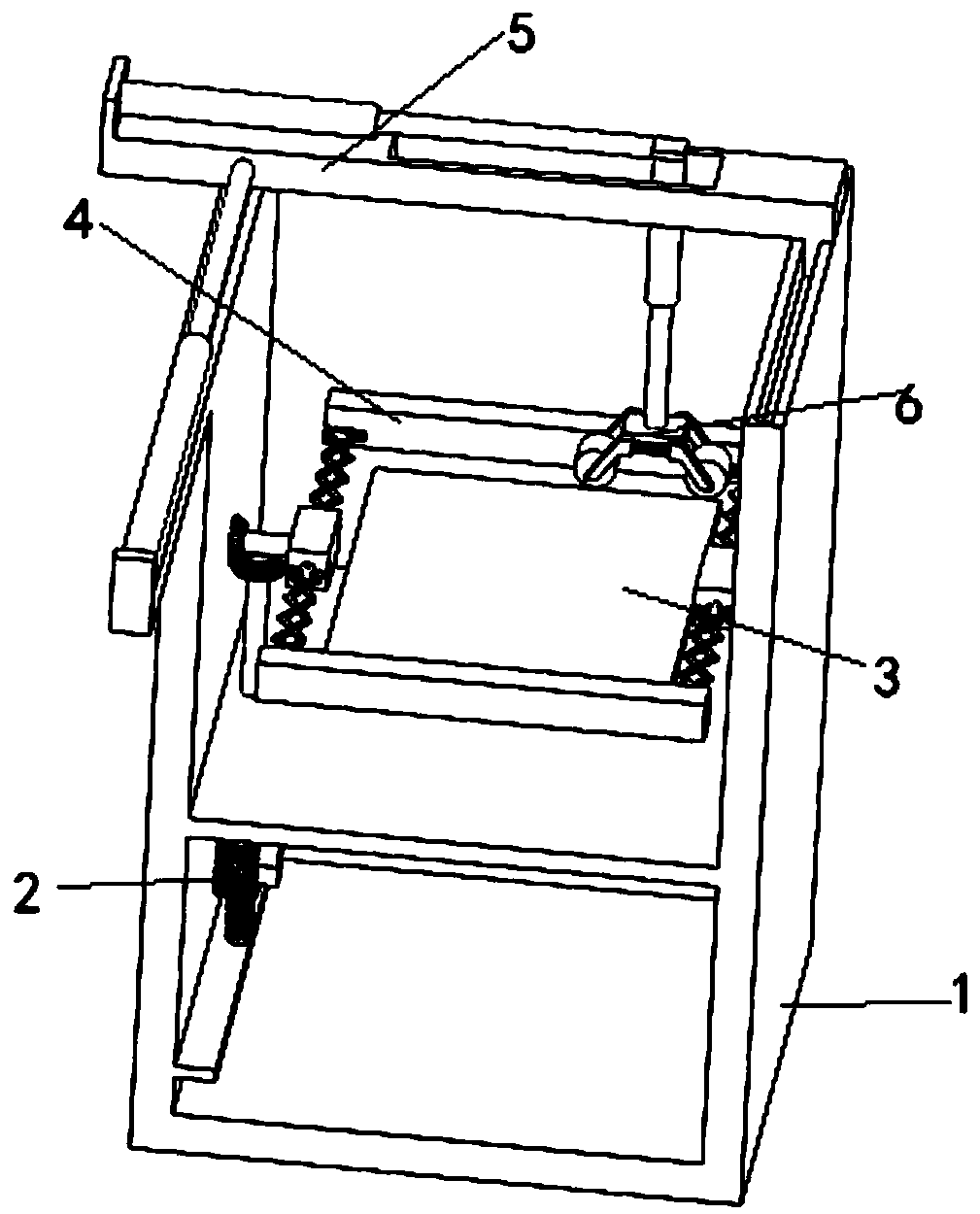

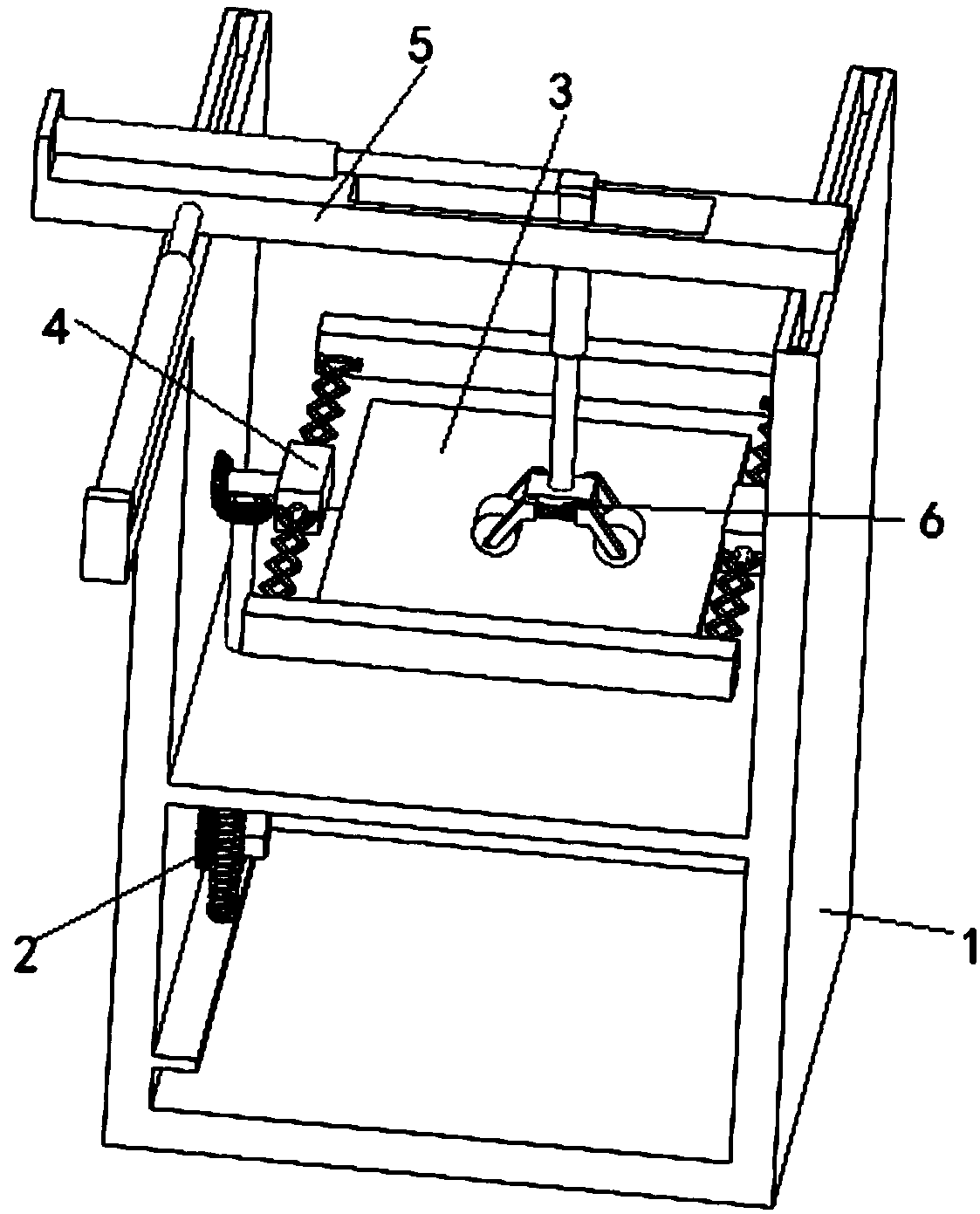

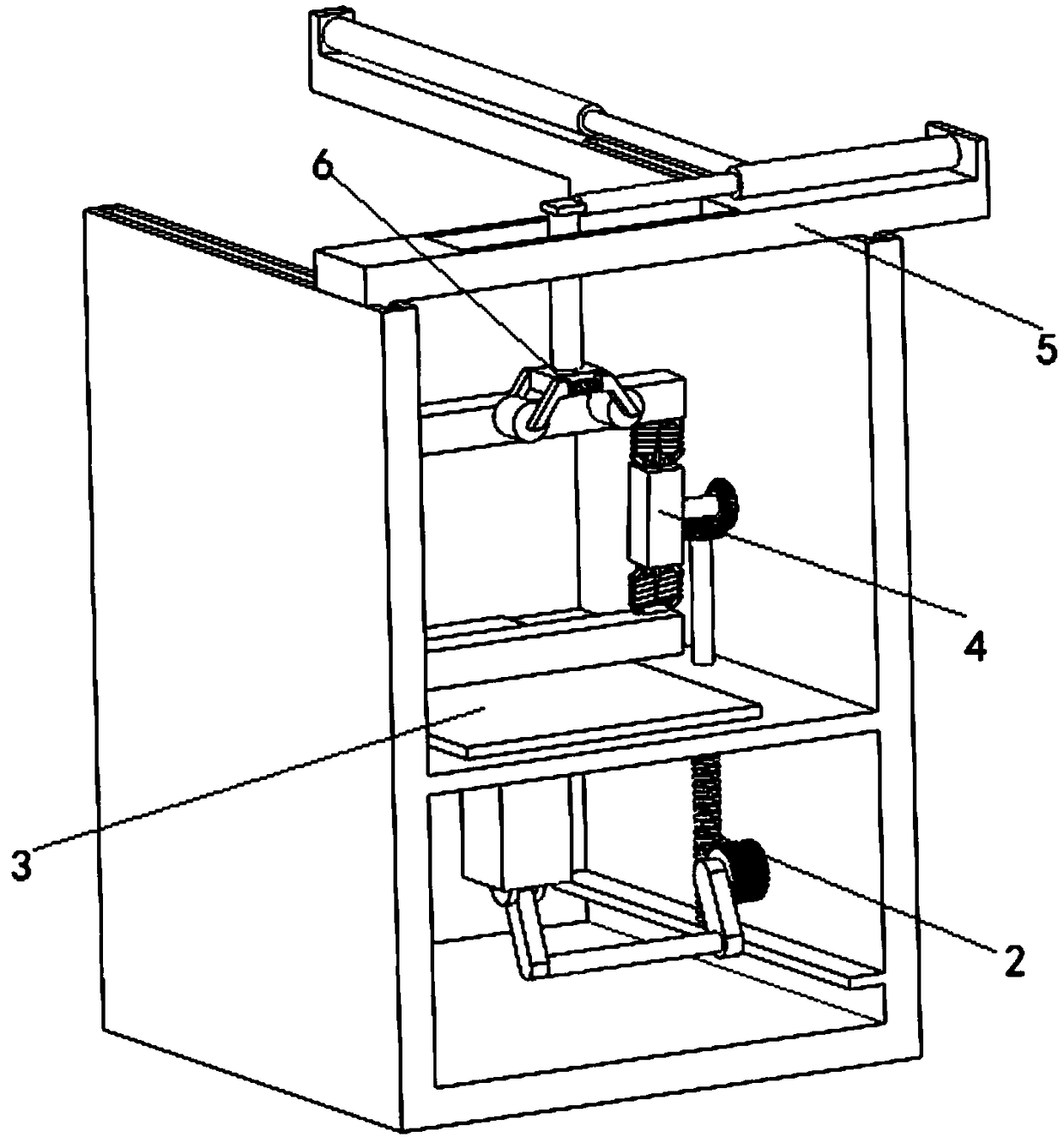

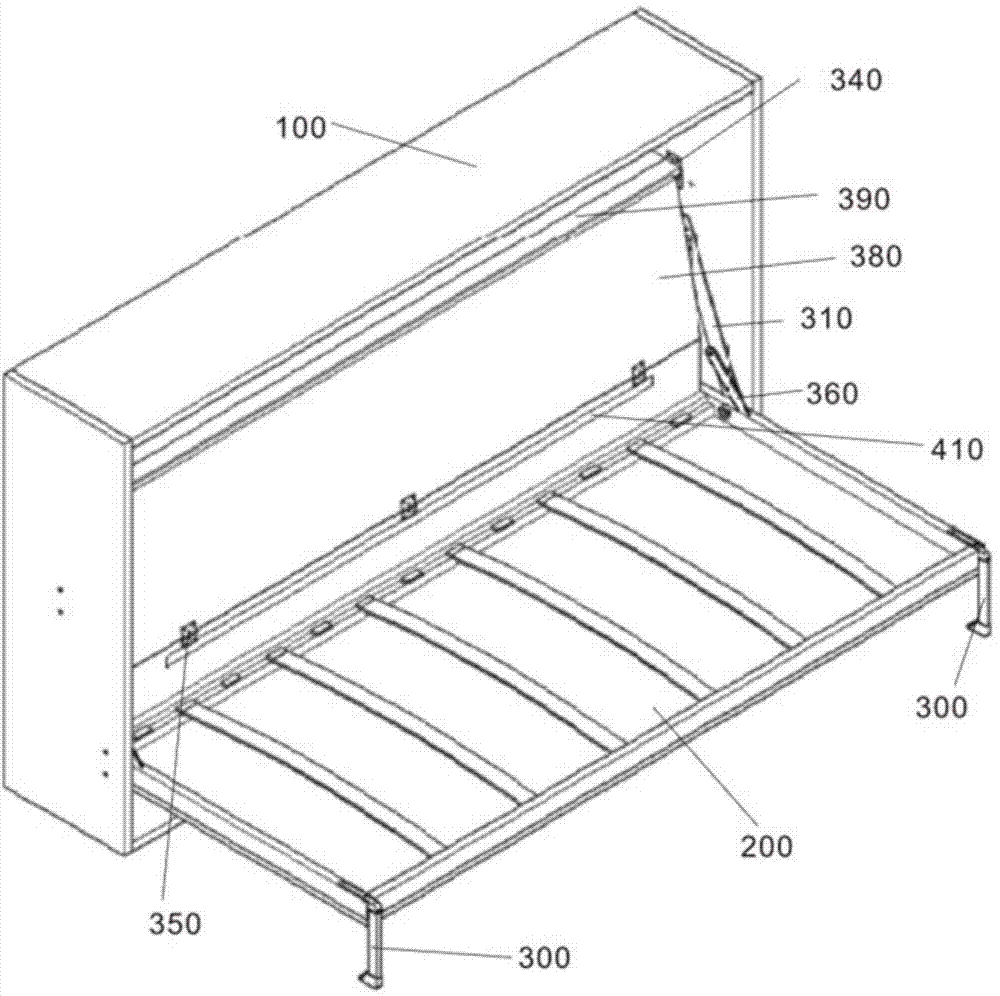

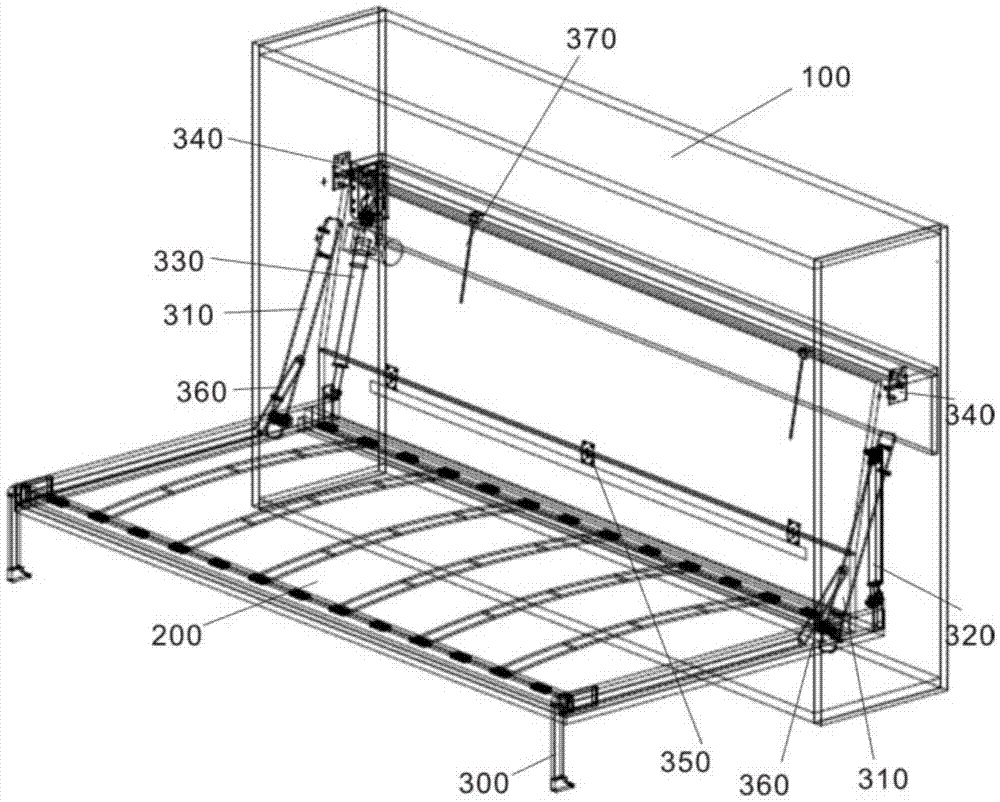

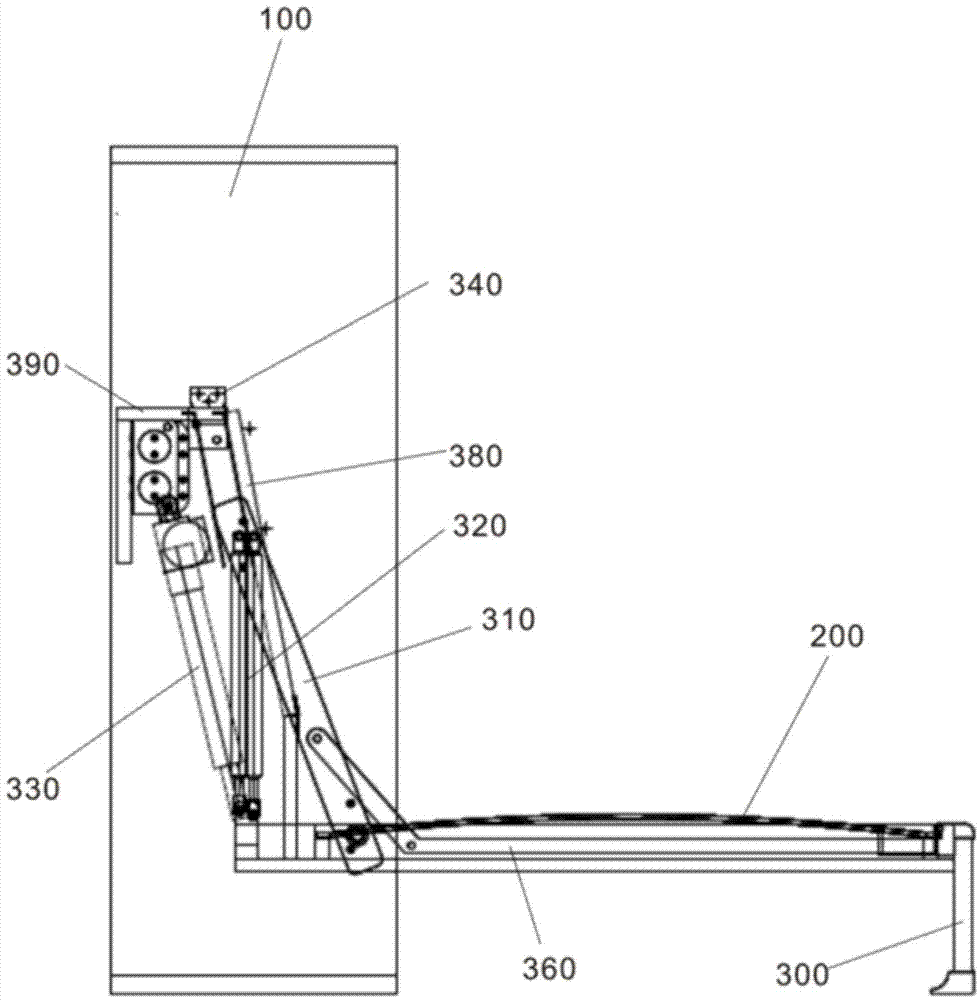

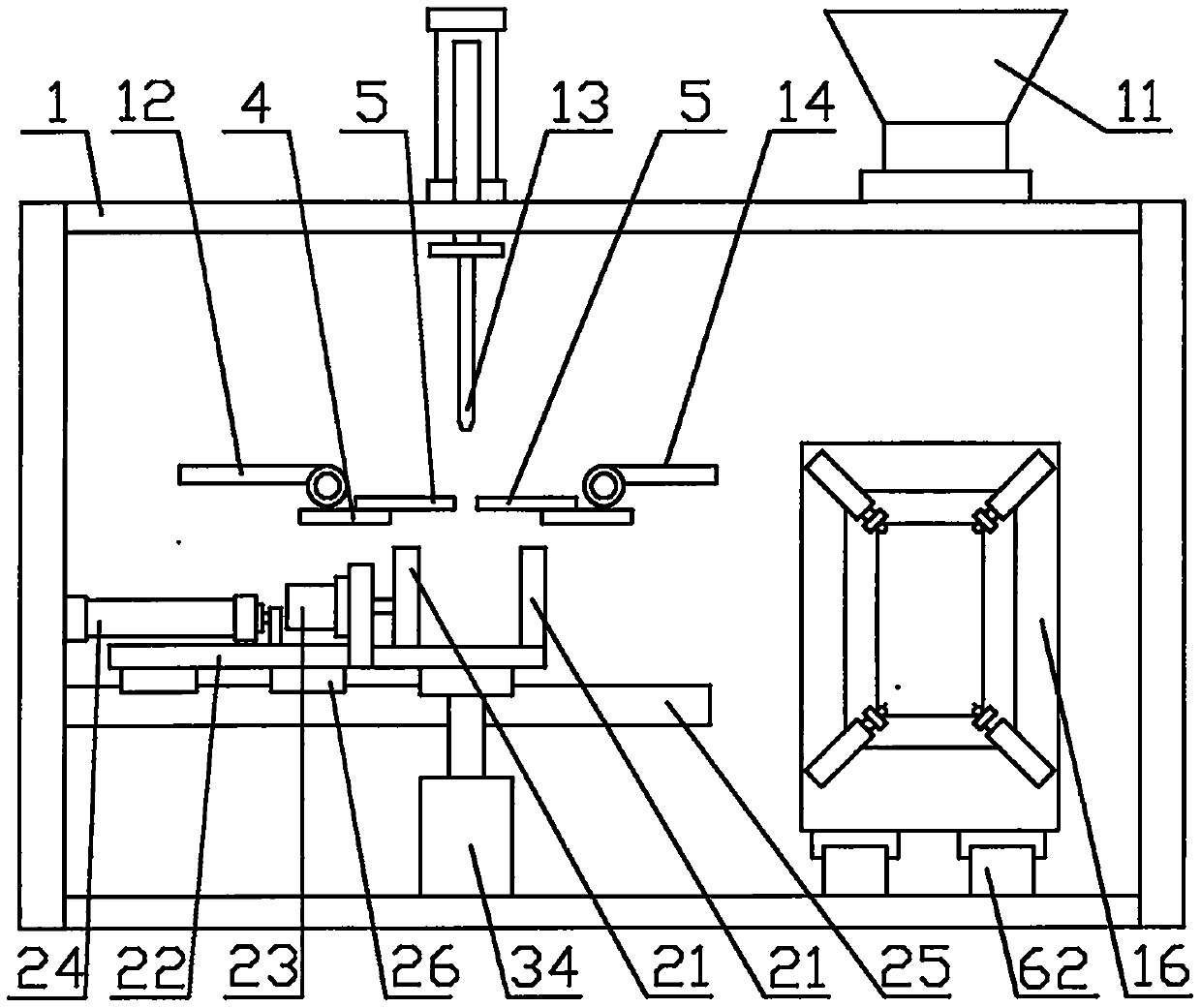

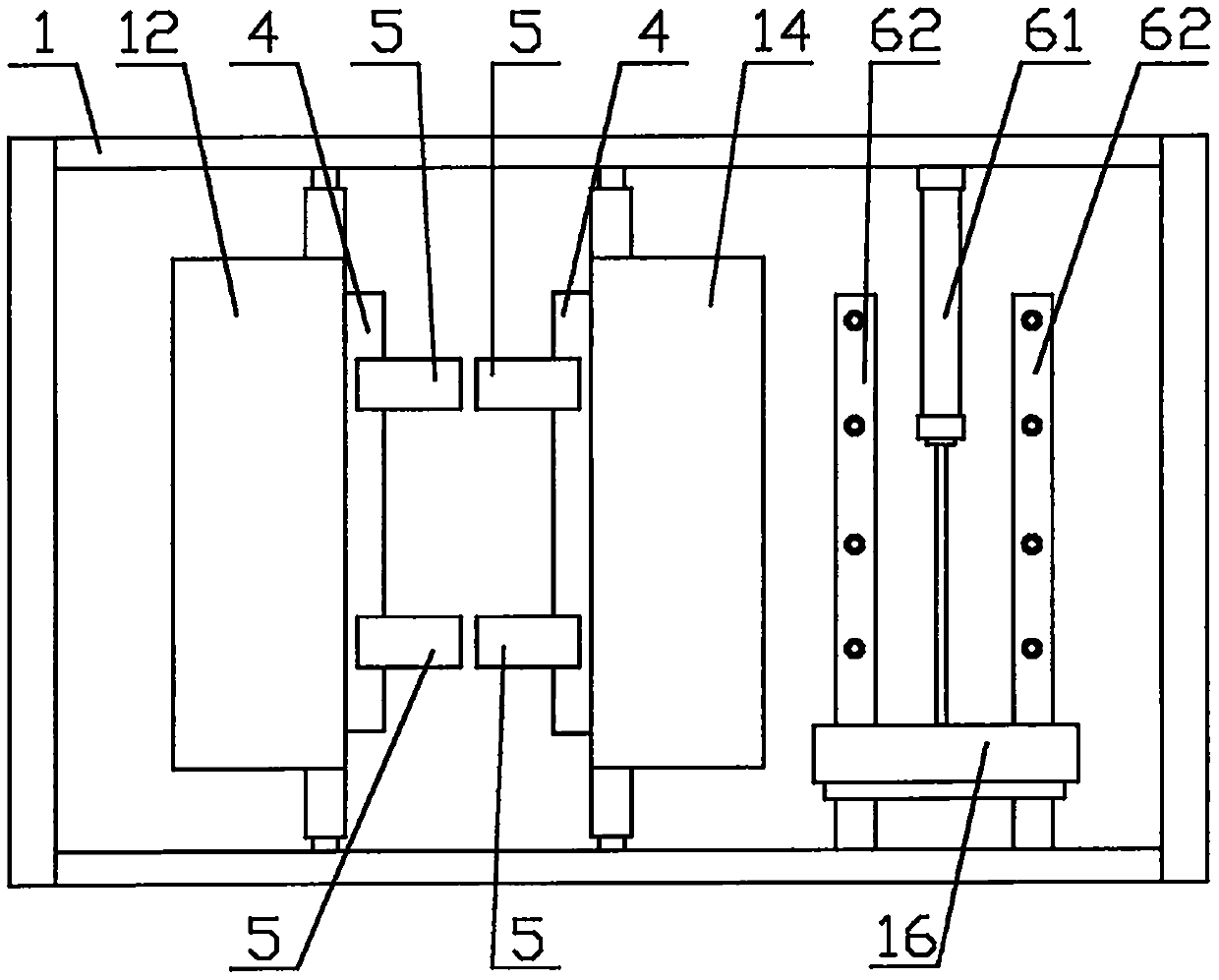

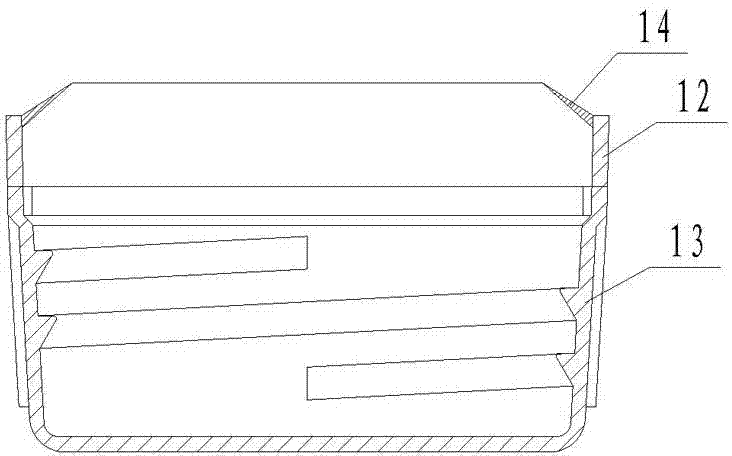

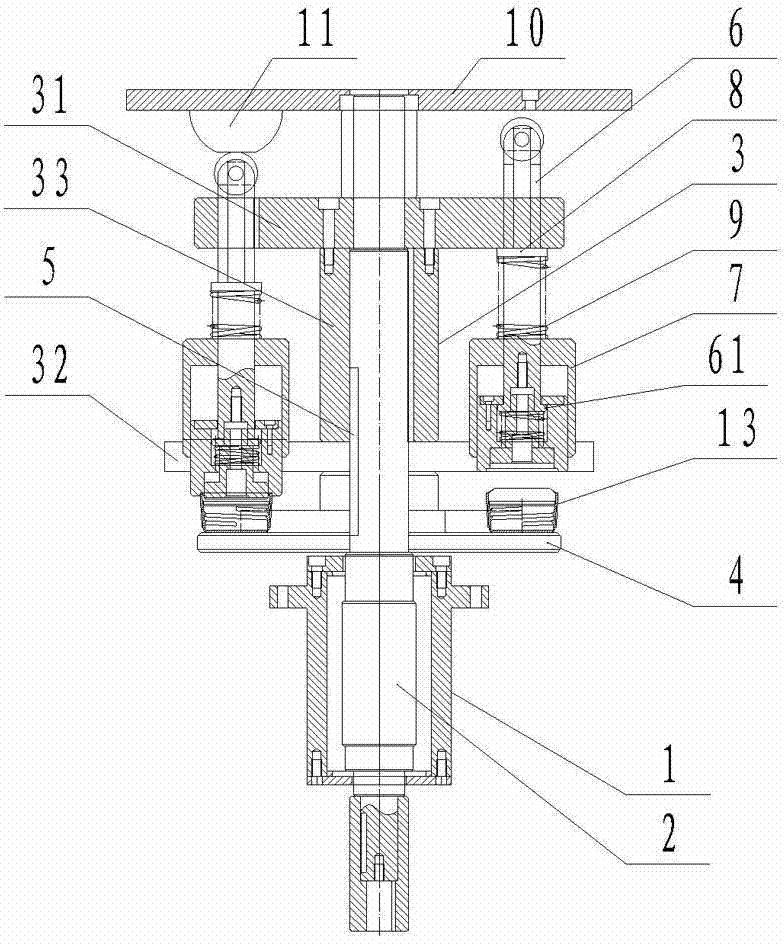

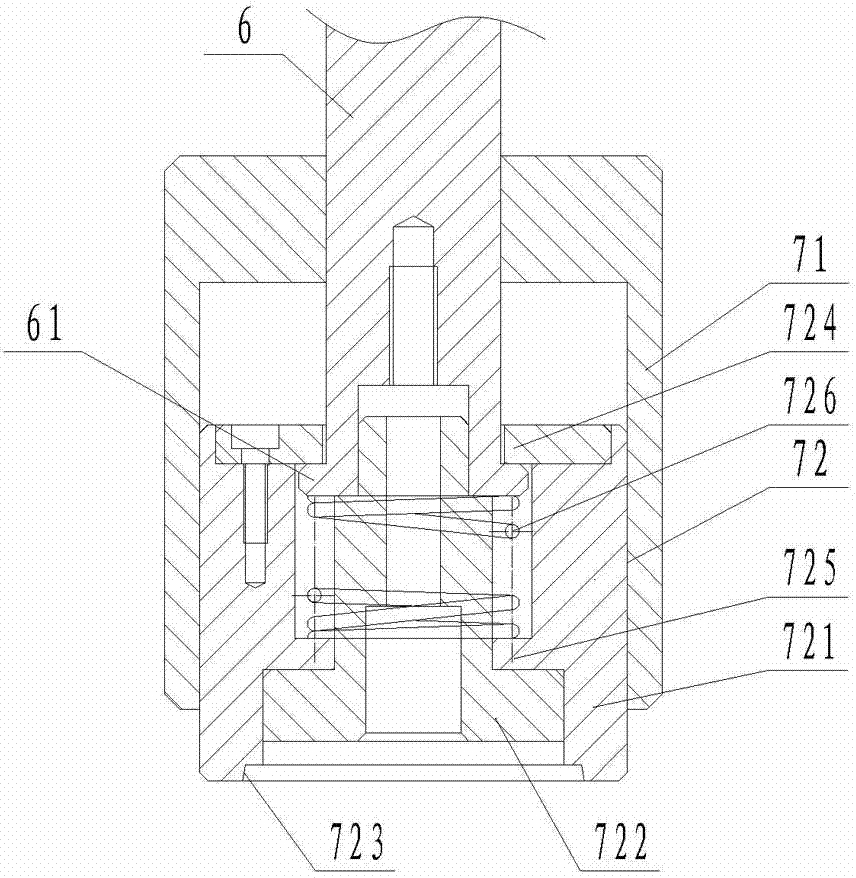

Intelligent and electric invisible bed

The invention relates to the field of a fixture, and in particular relates to an intelligent and electric invisible bed which consists of a bed box and a bed frame, wherein one side of the bed frame is movably articulated in the bed box by a fixed plate; the bed frame is unfolded or put into the bed box in an turnover way; the other side of the bed frame is movably articulated with bed legs; two connecting rods used for driving the bed legs to be folded are arranged between the bed legs and the fixed plate. According to the intelligent and electric invisible bed, the bed legs are folded and put into the bed box under the action of the two connecting rods in the process of storing the bed frame in an overturning way, so that the phenomenon that a person is hurt by the bed legs which protrude outside the bed box can be avoided; the bed legs are driven to be folded completely by the two connecting rods driven by an electric device, and manual operation is not needed, so that the bed legs are automatically folded; therefore, the intelligent and electric invisible bed is more convenient and safer to use and attractive.

Owner:广东左凡智能家居科技有限公司

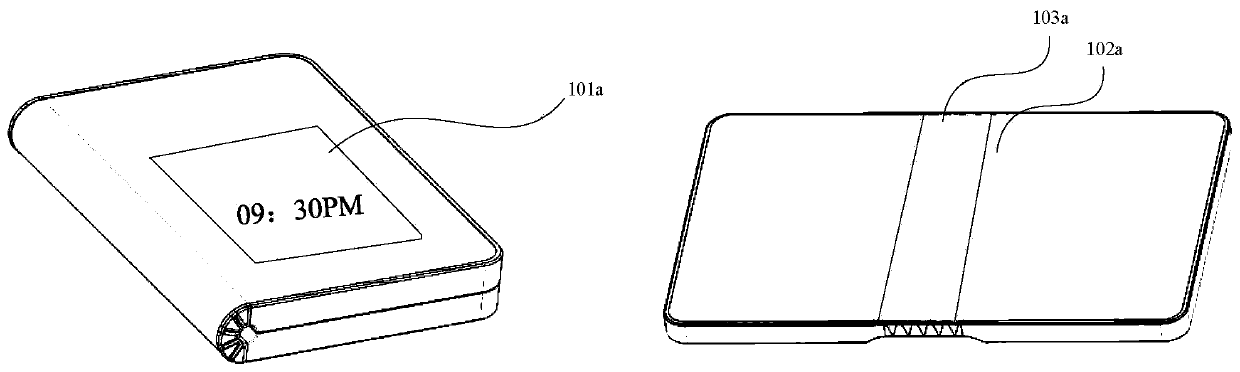

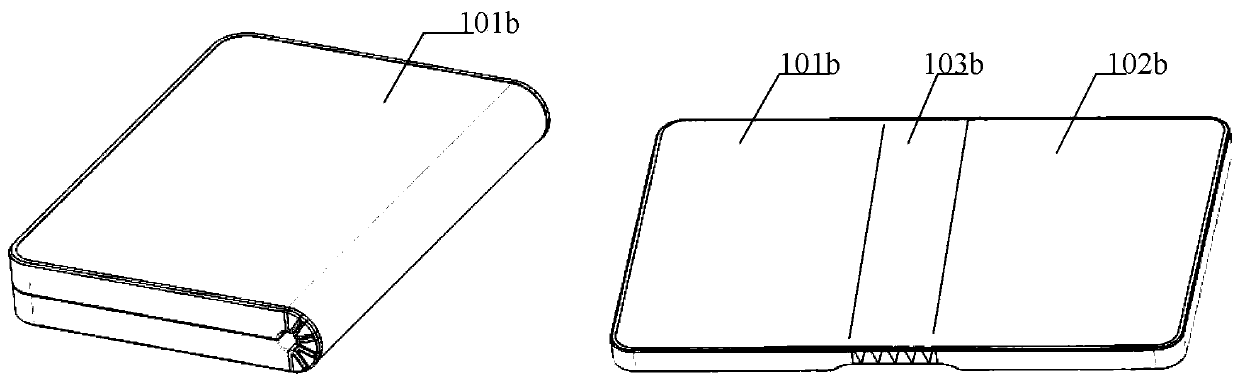

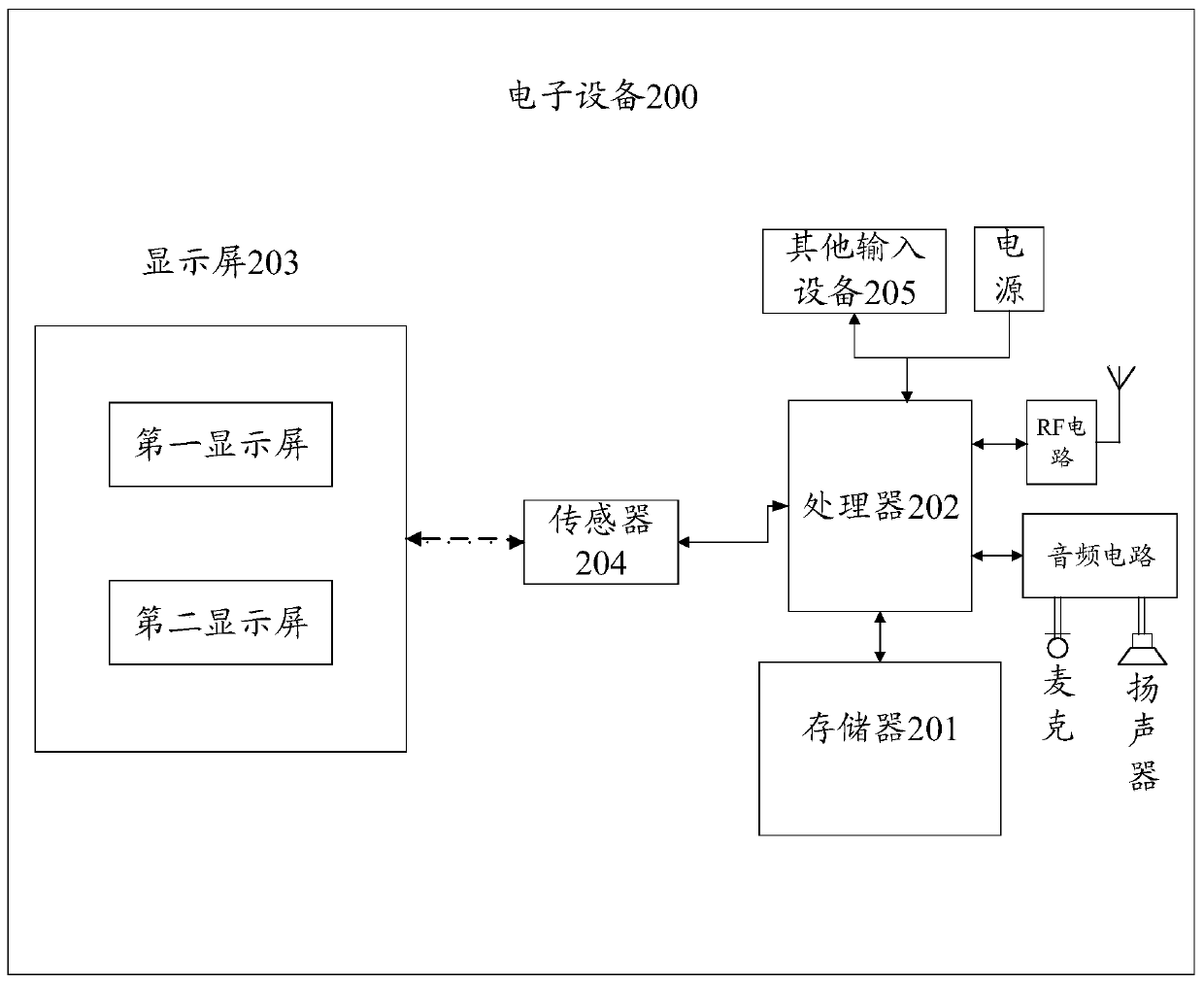

Folding method of foldable touch screen and electronic equipment

ActiveCN110417960AImprove experienceAvoid damageDetails for portable computersTelephone set constructionsTouchscreenComputer science

The invention discloses a folding method of a foldable touch screen and electronic equipment, which are applied to the electronic equipment with the foldable touch screen and are used for fully utilizing the advantage of foldability of the foldable touch screen to realize automatic folding, so that the user experience is richer. The foldable touch screen of the electronic equipment comprises a first screen, a bendable area and a second screen, the first screen is folded with the second screen through the bendable area, and the method comprises the steps of enabling the electronic equipment toreceive a first operation of a user acting on a first application; in response to the first operation, determining a preset included angle corresponding to the first operation; then, obtaining state data collected by the sensor, and when it is judged that the first included angle is different from the preset included angle, controlling the first screen to be folded with the second screen through the bendable area till the second included angle between the first screen and the second screen is equal to the preset included angle due to the fact that the state data comprises the current first included angle between the first screen and the second screen.

Owner:HUAQIN TECH CO LTD

Automatic foldable bicycle

InactiveCN101746459AEasy to carryChange the folding methodFoldable cyclesVehicle frameAgricultural engineering

The invention discloses an automatic foldable bicycle. The bicycle comprises a front wheel, a back wheel, a saddle, a handlebar and a frame, wherein the frame comprises a front wheel bracket, a back wheel bracket and a beam used for connecting the front wheel bracket with the back wheel bracket; the lower section of the back wheel bracket is provided with two pedals; a boxboard is connected with the side part of the front wheel bracket; two motor switches are arranged on the handlebar so as to control the folding of the front wheel and the back wheel; each motor switch is correspondingly connected with a mini-hoisting motor; two mini-hoisting motors are correspondingly connected with a folding joint of the front wheel and a folding joint of the back wheel; the folding joint of the front wheel is connected with a connecting rod which is arranged for controlling the front wheel; the folding joint of the back wheel is rotatably connected with the back section of the beam; and the front wheel and the back wheel are folded for a rotating angle to a preset fixing position by a folder so as to form a box. The bicycle has simple structure, can automatically fold, has small volume after being folded and is convenient to take and store.

Owner:周申传 +1

Plastic bag folding and rubber band binding all-in-one machine

The invention discloses a plastic bag folding and rubber band binding all-in-one machine. The machine comprises a machine frame, a vibration disc device, a rubber band expanding device, a handle folding device, a tail folding device and a plate inserting device, and is characterized in that a bag supporting device, a bag clamping device and a bag conveying movement device are further arranged at the corresponding positions of the inserting plate; the machine further comprises a bundling movement device and a suspension outer bag clamping mechanism, the bag supporting device and the bag clamping device are used for folding a plastic bag from the middle position and clamping and shaping the plastic bag, then the bag clamping device or a bag clamping mechanical arm clamps one side of the plastic bag, and the other side of the plastic bag is inserted into the rubber band expanding device to be bundled. The machine has the advantages that operation from folding to bundling is carried out almost in a clamping plate mechanism of the bag clamping device, so that folding and bundling are integrated without mechanical arm changing, the folding and bundling work is stable and reliable, and the structure is simple and compact.

Owner:王秀来

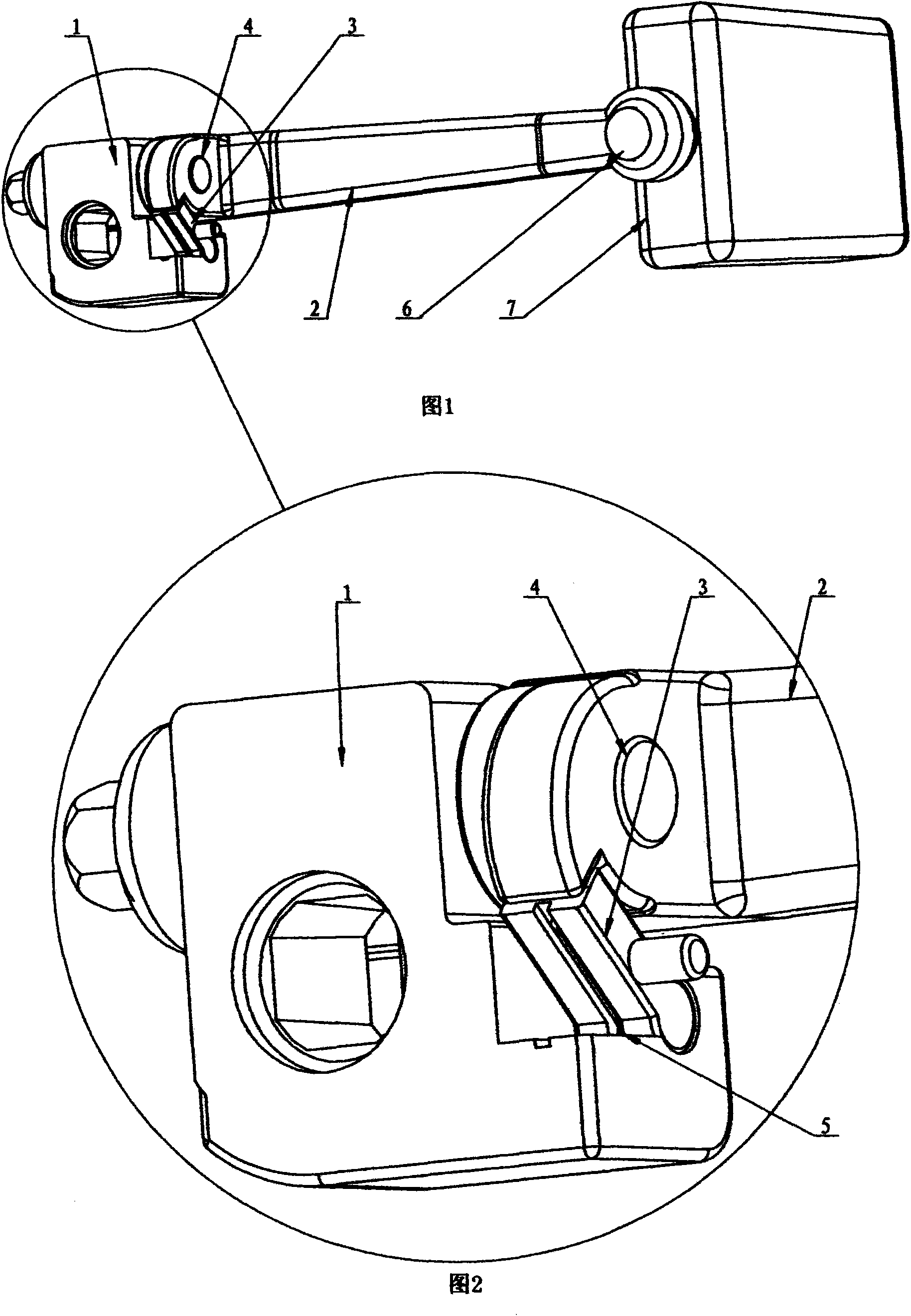

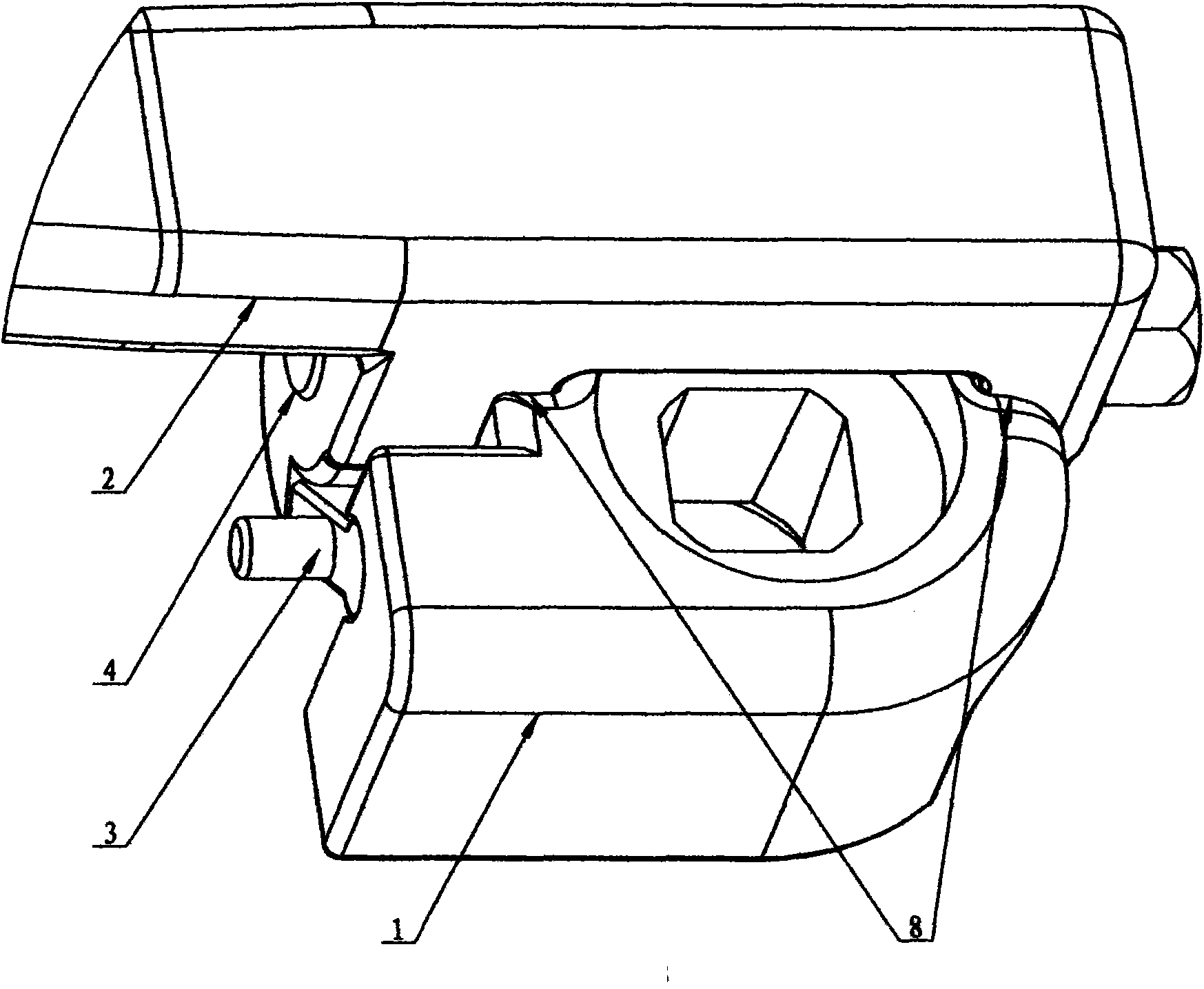

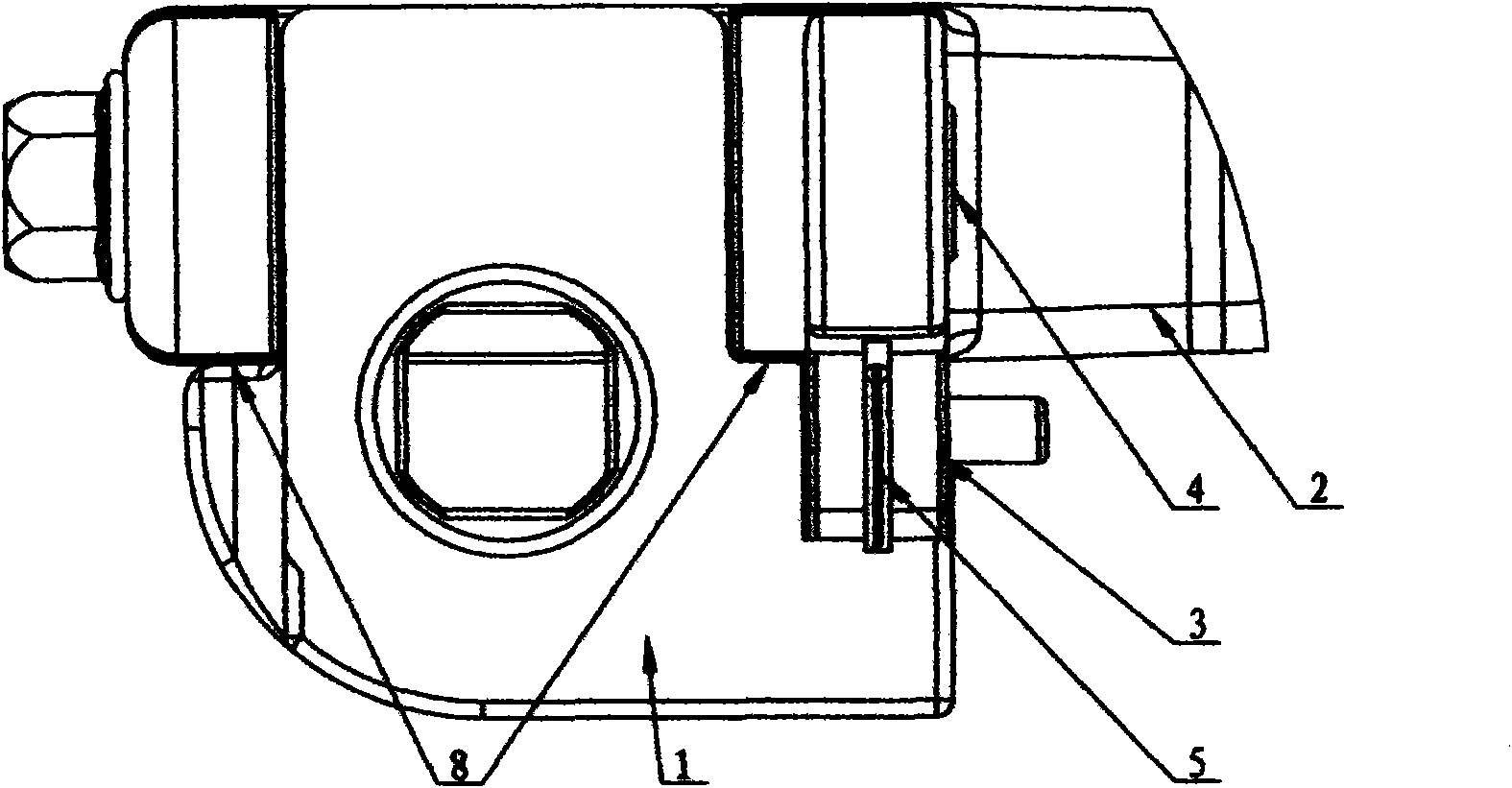

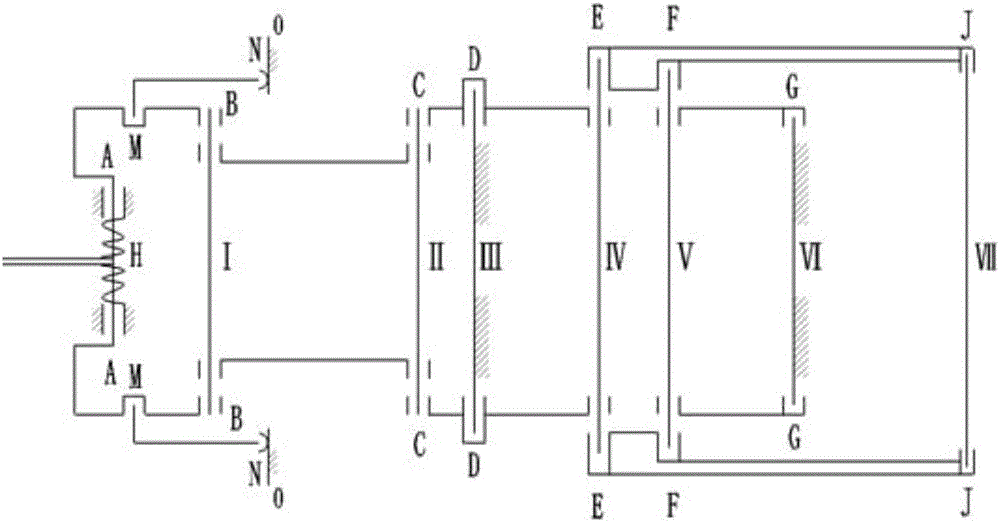

Folded pedal for folded bicycle

The invention discloses a folded pedal for a folded bicycle, and relates to a technology for a structure of a folded pedal for a folded bicycle. The folded pedal mainly comprises a crank base, a crank, a pawl, a pawl returning spring, a series drive cam and a returning spring, wherein the crank is hinged to the crank base; the pawl is hinged to the crank base and is meshed with a corresponding ratchet on the crank; the series drive cam is hinged to the crank base; a cam higher pair is arranged between the series drive cam and the pawl and the crank; the series drive cam sequentially drives the pawl to separate from the crank and drives the crank to be rotationally folded under the action of external force; the external force is from a drive ring sleeved on a center shaft seat; the drive ring is controlled by a folding control mechanism; when the folded pedal is unfolded, the pawl is meshed with the ratchet on the crank, the crank is relatively fixed with the crank base, and the drive ring is separated from the series drive cam; when the pedal is folded, the drive ring pushes the series drive cam outwards to drive the crank to be rotationally folded; and after the external force is cancelled, the returning spring drives the crank to be rotationally unfolded.

Owner:戚善鸣

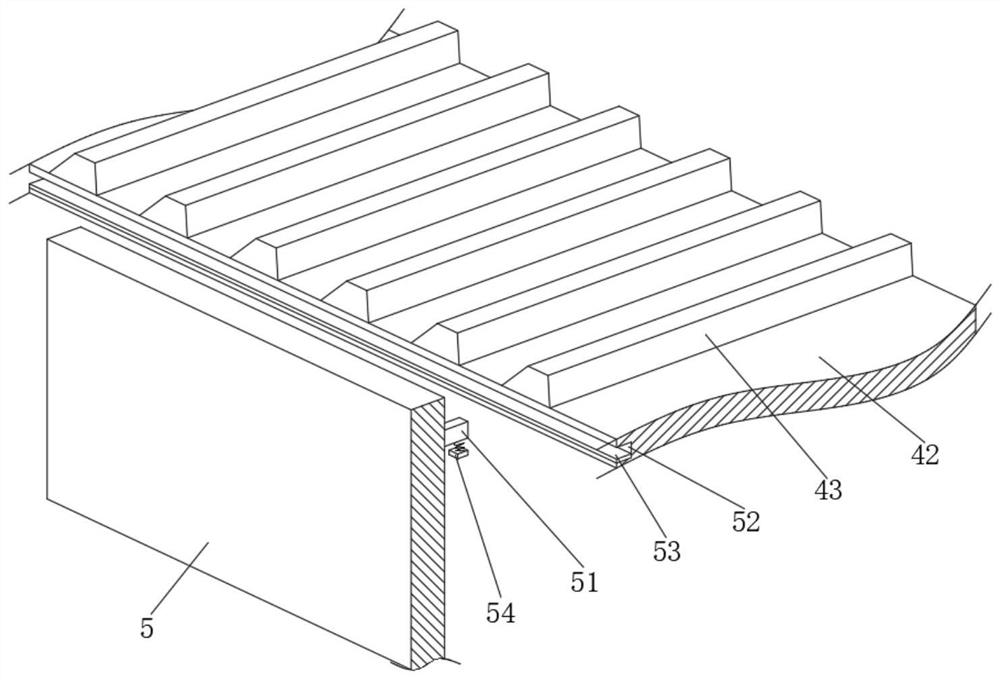

Feeding mechanism for shaping steam box

ActiveCN111485349ARealize automatic fitImprove feeding efficiencyTextile treatment containersSevering textilesPaperboardStructural engineering

The invention discloses a feeding mechanism for shaping steam box. The feeding mechanism comprises a support, a lifting table and a pushing frame; a plurality of thin paperboards are stacked on the lifting table, and a wavy surface is arranged on the upper side of the lifting table; a wavy plate and a rotating assembly are arranged on the support, the wavy plate is rotationally connected to the support through a horizontal shaft, and a plurality of first pasting strips are arranged on the wavy plate; a second pasting strip and a plurality of pressing rods are fixed to the pushing frame, a driving assembly is arranged on the support, and the moving direction of the pushing frame is parallel to the rotating plane of the wave plate; a plurality of clamping units are arranged at the two ends of the horizontal shaft, a penetrating column is fixed to each clamping unit, and the lower end of each penetrating column is fixedly sleeved with a baffle ring; and driving assemblies are arranged atthe two ends of the horizontal shaft. By means of the mechanism, automatic attaching of curtain cloth and a thin paper board, automatic clamping of the curtain cloth and the thin paper board and automatic folding of the curtain cloth and the thin paper board are achieved, and therefore the cloth feeding efficiency is improved; and the feeding efficiency of cloth is improved.

Owner:杭州富阳数马装饰工艺品有限公司

Foldable frame of foldable bicycle

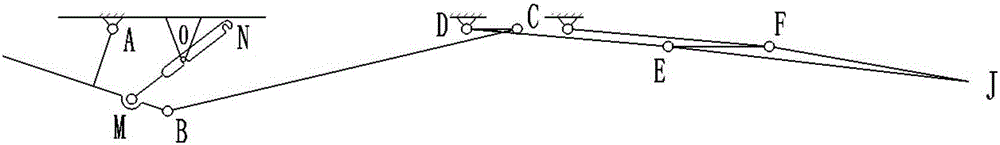

The invention relates to a structural technology for a foldable frame of a foldable bicycle. The foldable frame mainly comprises a front tube, a cross beam, a rear beam, a vertical tube and a rear fork, wherein the front end of the front beam is fixedly connected with the front tube; the front beam, the rear beam and the rear fork are hinged in sequence; in order to overlap a front wheel and a rear wheel alternately to fold the bicycle, the front beam and the rear beam are in oblique-shaft hinge; the vertical tube is hinged on the rear beam; the vertical tube and the rear fork are linked by being engaged mutually by a gear; and an inhaul cable traction arm fixedly connected to the vertical tube drags an inhaul cable of which one end is fixed on the front beam. When the foldable frame is folded, the vertical tube rotates forwards and is overlapped with the rear beam, meanwhile, the rear fork rotates downwards from a horizontal state to a vertical state under the action of the gear, at the same time, the inhaul cable drags the front beam to rotate downwards from the horizontal state to the vertical state; action progresses of the vertical tube and the rear fork when the foldable frame is unfolded are opposite to action progresses of the vertical tube and the rear fork when the foldable frame is folded; and the unfolding of the front beam is driven by a spring when the inhaul cable is released. The foldable frame disclosed by the invention realizes the purpose of automatic folding by using the gear, the inhaul cable and the spring as conditions.

Owner:戚善鸣

Automatic folding device for disposable bed sheet production

ActiveCN113860056ARealize automatic foldingImprove folding efficiencyFolding thin materialsPackagingEngineeringLaser cutting

The invention relates to the technical field of bed sheet production and manufacturing, in particular to an automatic folding device for disposable bed sheet production. The automatic folding device for disposable bed sheet production comprises a bottom plate, a supporting frame, an unwinding unit, a limiting unit, a laser cutting unit, a pressing unit, a folding unit and an adsorption moving unit. The automatic folding device for disposable bed sheet production provided by the invention solves the problems that in the existing bed sheet folding process, due to the fact that a bed sheet is made of a flexible material, the surface of the bed sheet is prone to wrinkling due to the lack of appropriate limiting in the folding process, and the folding effect of the bed sheet is affected; and the bed sheet is made of the flexible material, so that the surface of the bed sheet is usually clamped by a clamp to pull the bed sheet in the process of pulling the bed sheet, the surface of the bed sheet is easily damaged, and the later use effect of the bed sheet is influenced. According to the automatic folding device for disposable bed sheet production provided by the invention, the folding effect of the disposable bed sheet is improved, and the surface of the bed sheet is always kept in a flat state in the folding process of the bed sheet.

Owner:徐州旅悠旅游用品有限公司

Cloth edgefold mechanism and edgefold method

The invention discloses a cloth edgefold mechanism using for flanging cloth. The cloth comprises a cloth edgefold part and a cloth double-flanged part on one side of the cloth edgefold part. The cloth edgefold mechanism comprises an edgefold fixed plate arranged below the cloth edgefold part, an edgefold support is fixed on the opposite location of the edgefold fixed plate, a main actuating device arranged on the edgefold support and an edgefold movable plate connected with the output end of the main actuating device. The main actuating device drives the edgefold movable plate to move in the directions of closing to and being away from the cloth edgefold part. According to the cloth edgefold mechanism, the flanging process of the cloth double-flanged part being folded under the cloth edgefold part is realized. The cloth edgefold mechanism has the advantages of auto flanging which replaces traditional manual flanging and higher flanging efficiency and stability of flanging quality, which saves labor force and reduces processing cost of enterprises.

Owner:JACK SEWING MASCH CO LTD

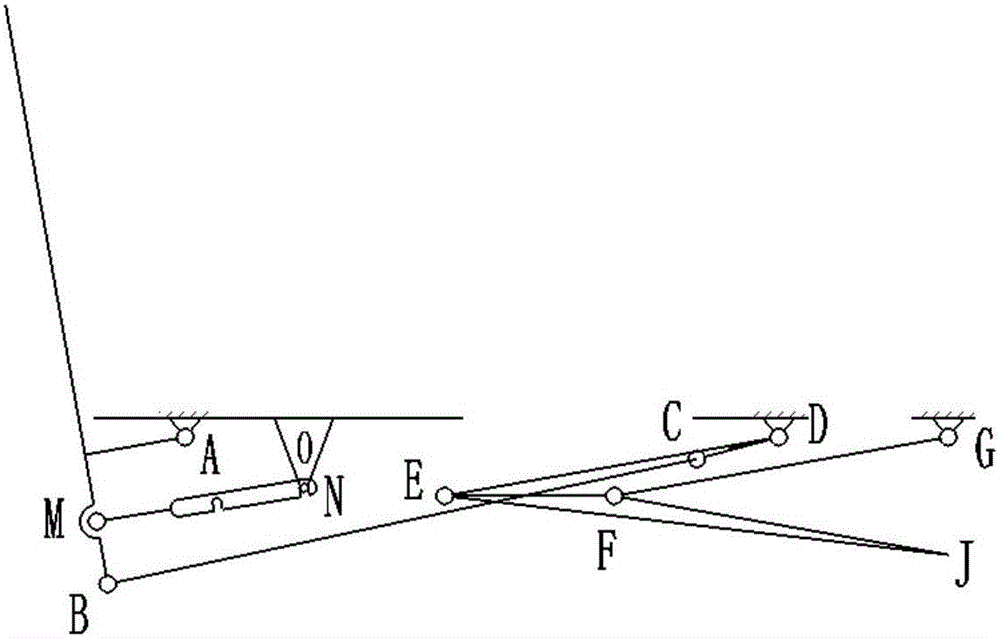

Backrest and foot rest linking mechanism

The invention discloses a backrest and foot rest linking mechanism. At the present, no chairs that integrate a backrest chair and a deck chair and are convenient for letting feet take a rest are provided. A first rocker consists of a chair back supporting rod and a rocking lever which are welded together; the rocking lever is hinged to the bottom of a chair seat through a pin shaft; a resetting torsional spring sleeves the pin shaft; one end of a positioning rod is hinged to the middle part of the chair back supporting rod; two positioning slots are formed in the positioning rod; the bottom end of the chair back supporting rod is hinged to one end of a first connection rod; the other end of the first connection rod is hinged to one end of a second rocker; the other end of the second rocker is hinged to the bottom of the chair seat at a point D; a third rocker is fixedly connected with the second rocker; one end of the third rocker is hinged to the bottom of the chair seat at a point D; the other end of the third rocker is hinged to one end of a second connection rod; the other end of the second connection rod is hinged to one end of a fourth rocker; the other end of the fourth rocker is hinged to the bottom of the chair seat; and the second connection rod is fixedly connected with a triangular block. By the adoption of the backrest and foot rest linking mechanism, the backrest chair can be either used for work in an office or used as a lying chair for taking a rest.

Owner:陈嘉博

Cloth overlock device for cloth processing and overlock method

ActiveCN113699702APrecise edge bandingNo creasesFabric breaking/softeningTextile selvedgesAir pumpEngineering

The invention discloses a cloth overlock device for cloth processing and an overlock method, and relates to the technical field of cloth overlock devices. The cloth overlock device comprises a cloth transfer platform, a sewing machine head is arranged on the top face of the cloth transfer platform, a transfer belt is arranged on the top face of the cloth transfer platform, and an edge folding plate is arranged at the position, close to the transfer belt, of one side of the cloth transfer platform; a conveying belt is arranged between the edge folding plate and the transfer belt, and the sewing machine head is located between the transfer belt and the conveying belt; and a roller is arranged in the middle of the edge folding plate, movable plates are hinged to the two sides, away from each other, of the edge folding plate, each movable plate is composed of a plurality of movable blocks, every two adjacent movable blocks are hinged, an electromagnet and a permanent magnet are fixed between the opposite end faces of every two adjacent movable blocks correspondingly, air holes are formed in the top faces of the edge folding plates, and air pumps are connected into the edge folding plates through pipelines. Through cooperative use of all the devices, cloth packaging can be more convenient, the edge sealing position is more accurate, intervention of workers is not needed in the period, and the cloth edge sealing efficiency can be improved.

Owner:安徽苏博伦服饰有限公司

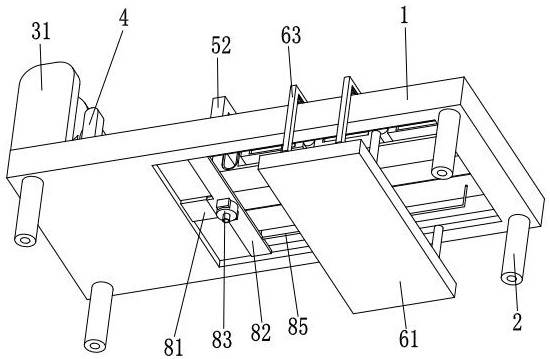

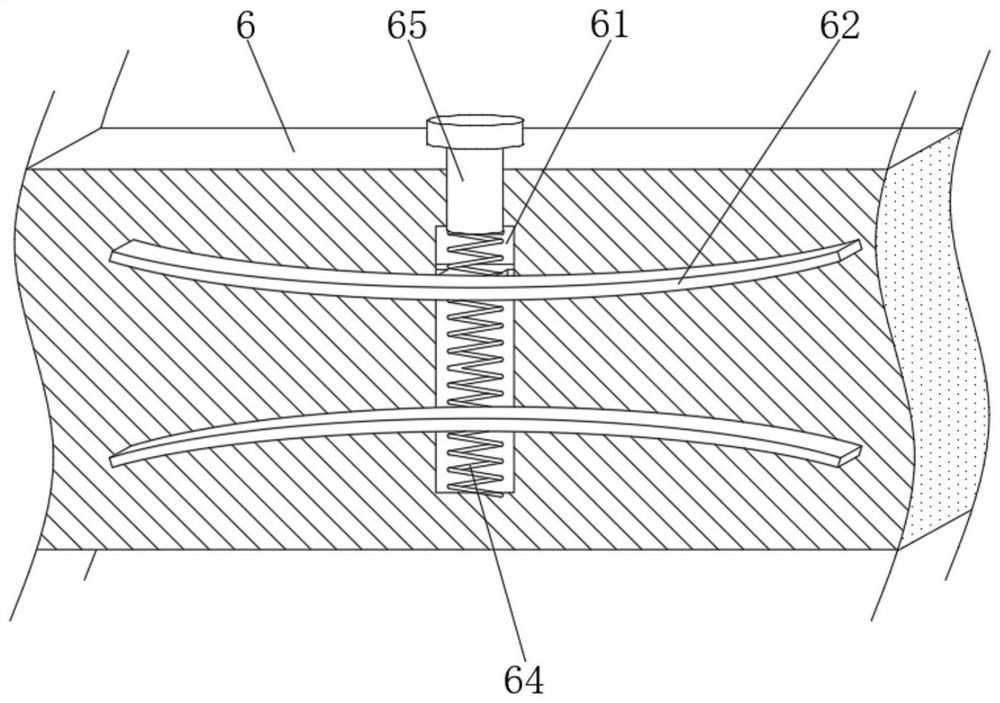

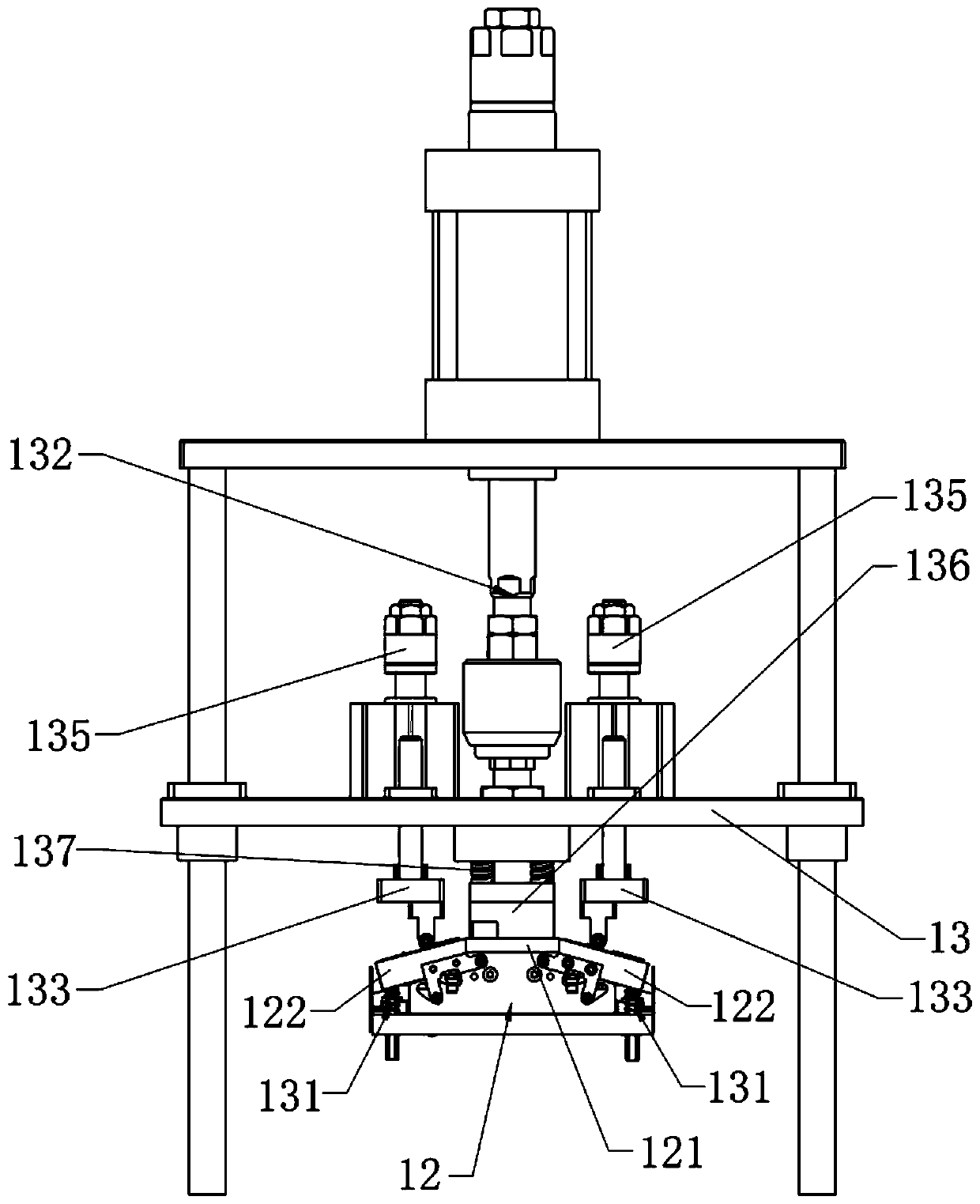

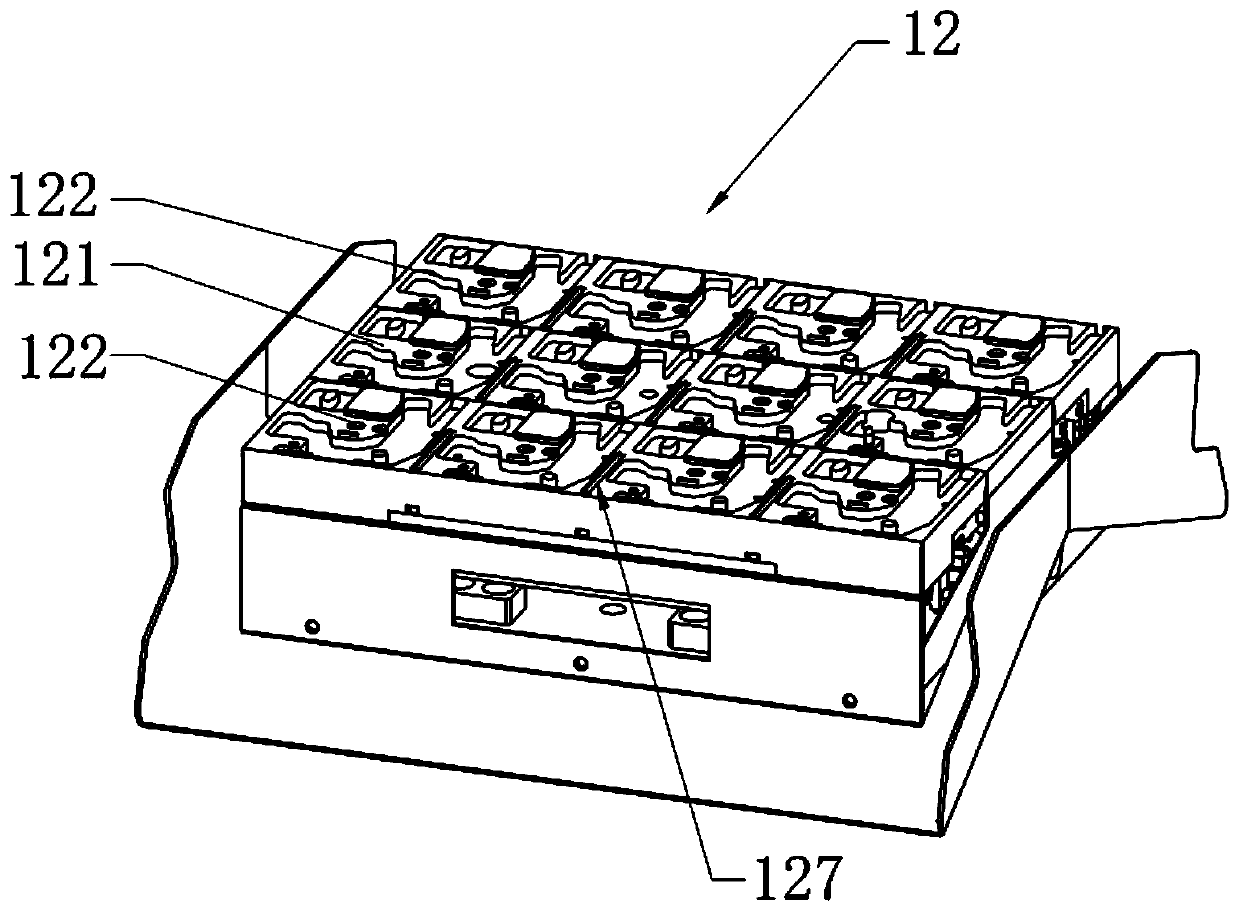

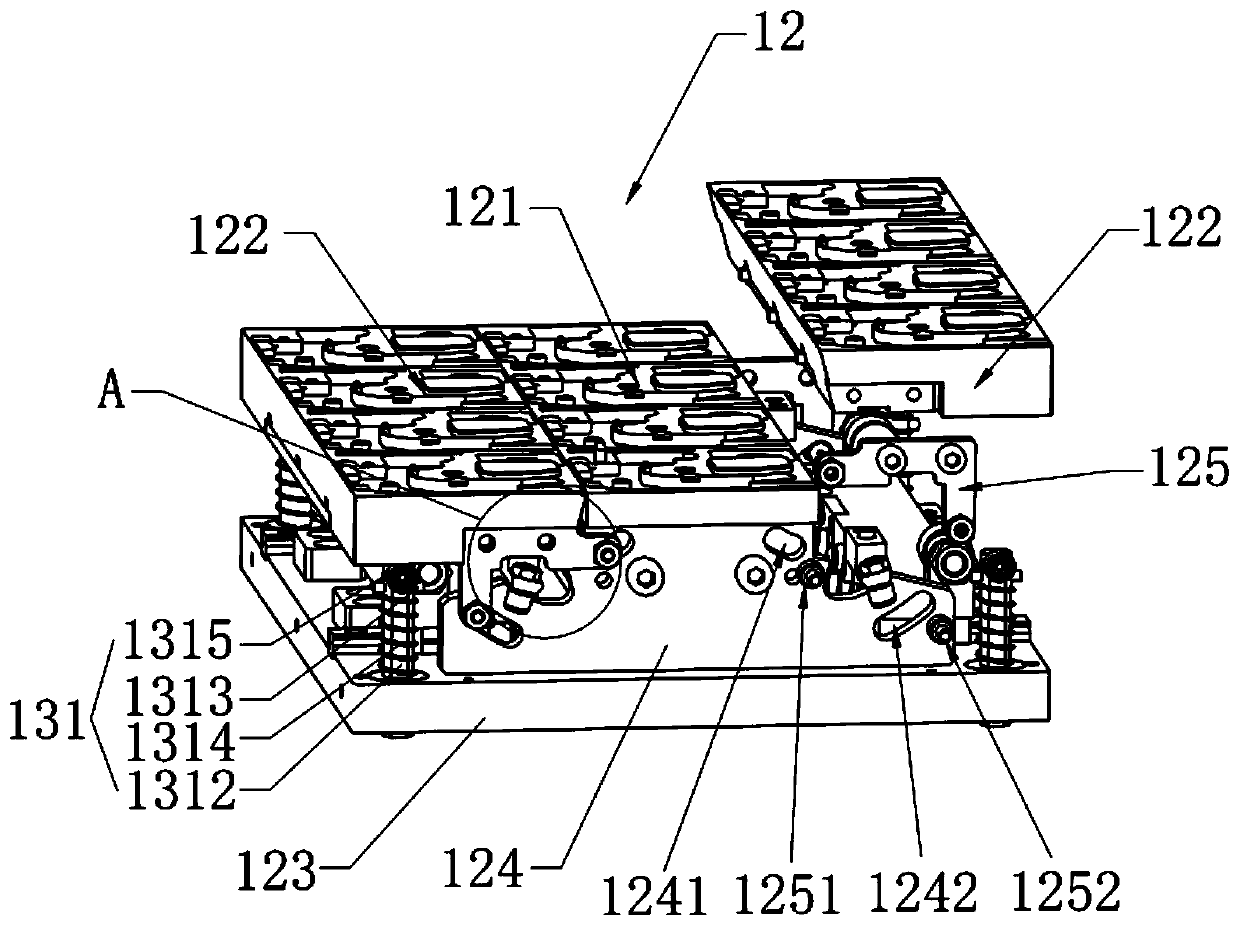

Plate folding mechanism and automatic plate separating machine with same

ActiveCN109760144ARealize automatic foldingImprove efficiencyPrinted circuit manufactureMetal working apparatusAutomationEngineering

The invention relates to the technical field of automation equipment, in particular to a plate folding mechanism and an automatic plate separating machine with the same. The plate folding mechanism comprises a circuit board bearing fixture, a first lifting plate and a first lifting mechanism used for driving the first lifting plate to rise and fall, the first lifting plate is provided with a firstmaterial pressing plate, and two side edge down-pressing blocks and first lifting driving parts used for driving the side edge down-pressing blocks to lift are respectively arranged on the two sidesof the first material pressing plate; and the circuit board bearing fixture comprises a middle bearing plate, rotary bearing plates and bearing plate reset mechanisms used for driving the rotary bearing plate to reset. According to the plate folding mechanism and the automatic plate separating machine with the same, working procedures of edge material removing, plate cutting and plate folding conducted on a circuit board are respectively and automatically completed through an edge material removing mechanism, a plate cutting mechanism and the plate folding mechanism, the manual operation is not needed in the whole process, so that automatic production is achieved, and the production efficiency and the machining quality are improved.

Owner:东莞市九思自动化科技有限公司

Edge folding device for anti-theft ring of cover

Owner:苏州天奇自动化机械制造有限公司

Folding mechanism of non-woven bag

InactiveCN108217291ARealize automatic foldingSimple structureFolding thin materialsEngineeringMechanical engineering

The invention discloses a folding mechanism of a non-woven bag. The folding mechanism of the non-woven bag comprises a folding channel installed in the middle of a machine frame. The folding channel is surrounded by upper and lower conveying flat belts. The upper and lower conveying flat belts have the same linear speed. A conveying direction of the upper and lower conveying flat belts is same asa length direction of the folding channel. The front end of the folding channel is an inlet of the non-woven bag, and the rear end is an outlet of the non-woven bag. The upper wall of the folding channel corresponds to the lower belt surface of the upper conveying flat belt, and the lower wall of the folding channel corresponds to the upper belt surface of the lower conveying flat belt. The lowerbelt surface of the upper conveying flat belt and the upper belt surface of the lower conveying flat belt are installed as a V-shape. A midpoint position of each of the left and right sides of the folding channel is provided with a row of edge-folding wheels. The edge-folding wheels have the same linear speed as the upper and lower conveying flat belts. A center connecting line of a row of the edge-folding wheels at the left side and a center connecting line of a row of the edge-folding wheels at the right side are installed as a V-shape. The folding mechanism is specifically used for automatically folding the non-woven bag, simple in structure, and high in efficiency.

Owner:JIANGSU FEILU HEAVY MACHINERY MFG CO LTD

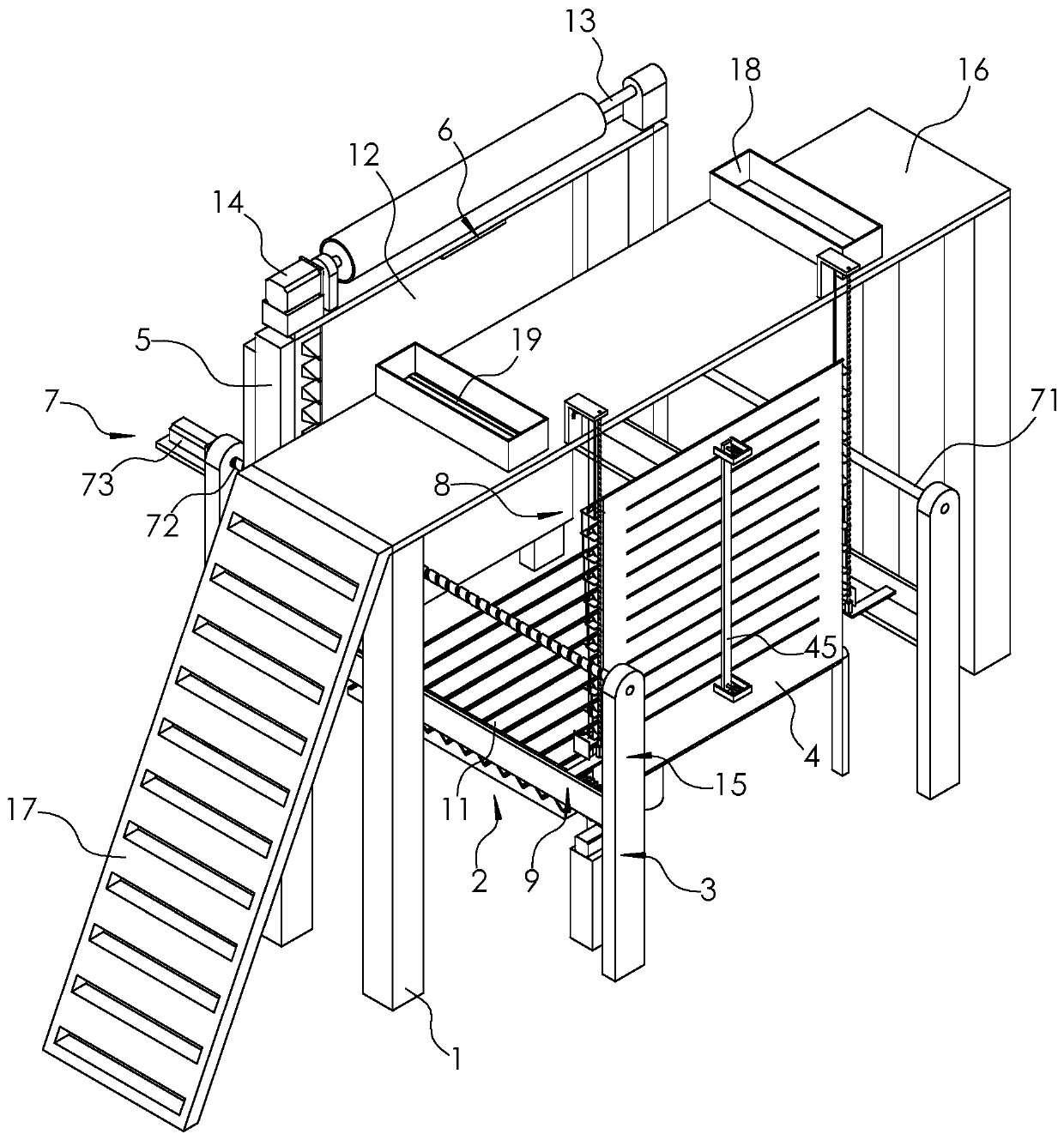

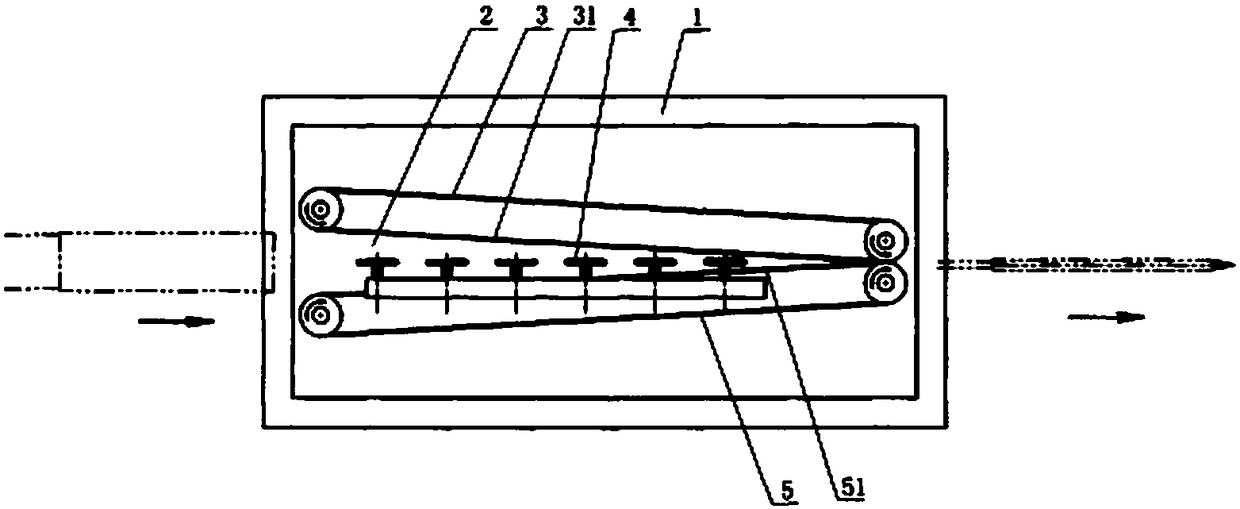

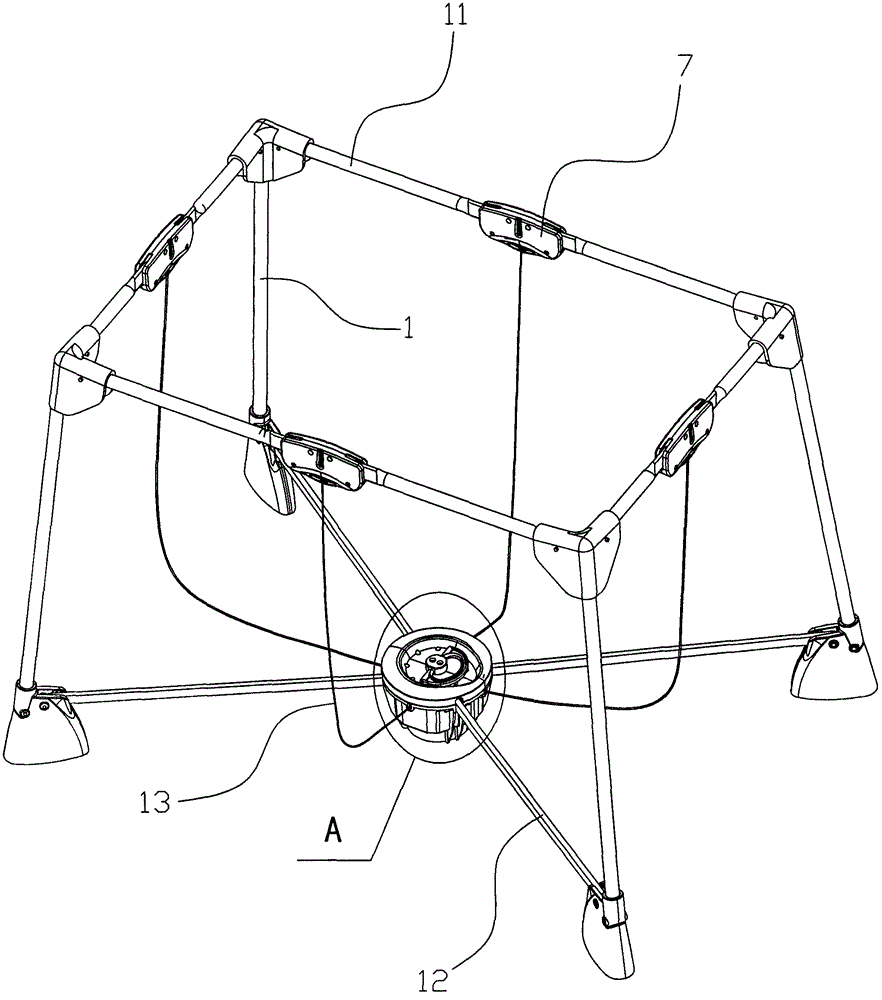

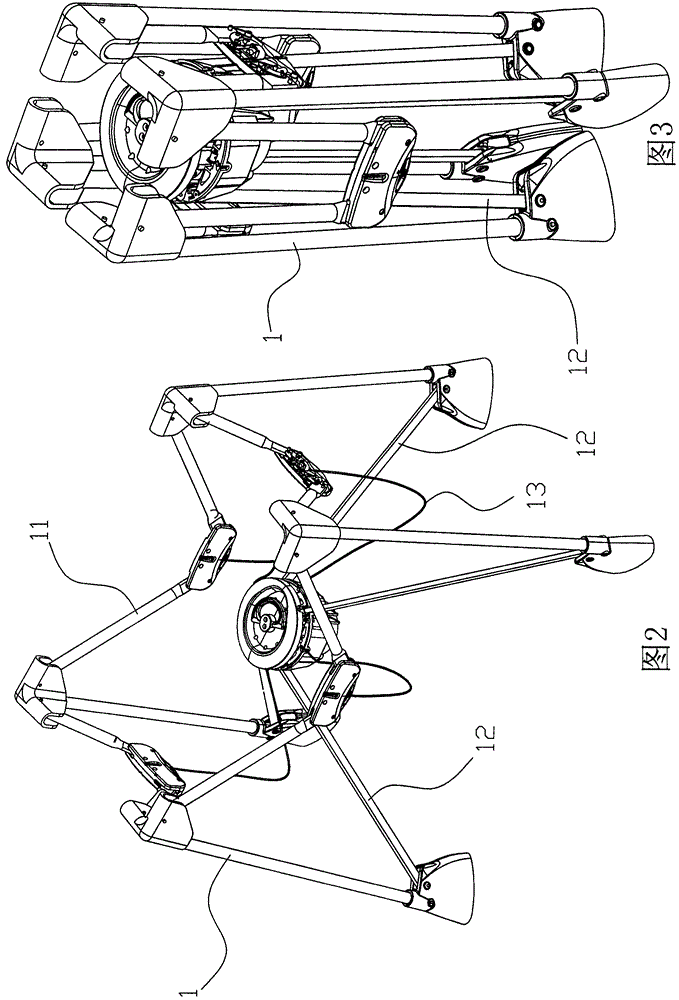

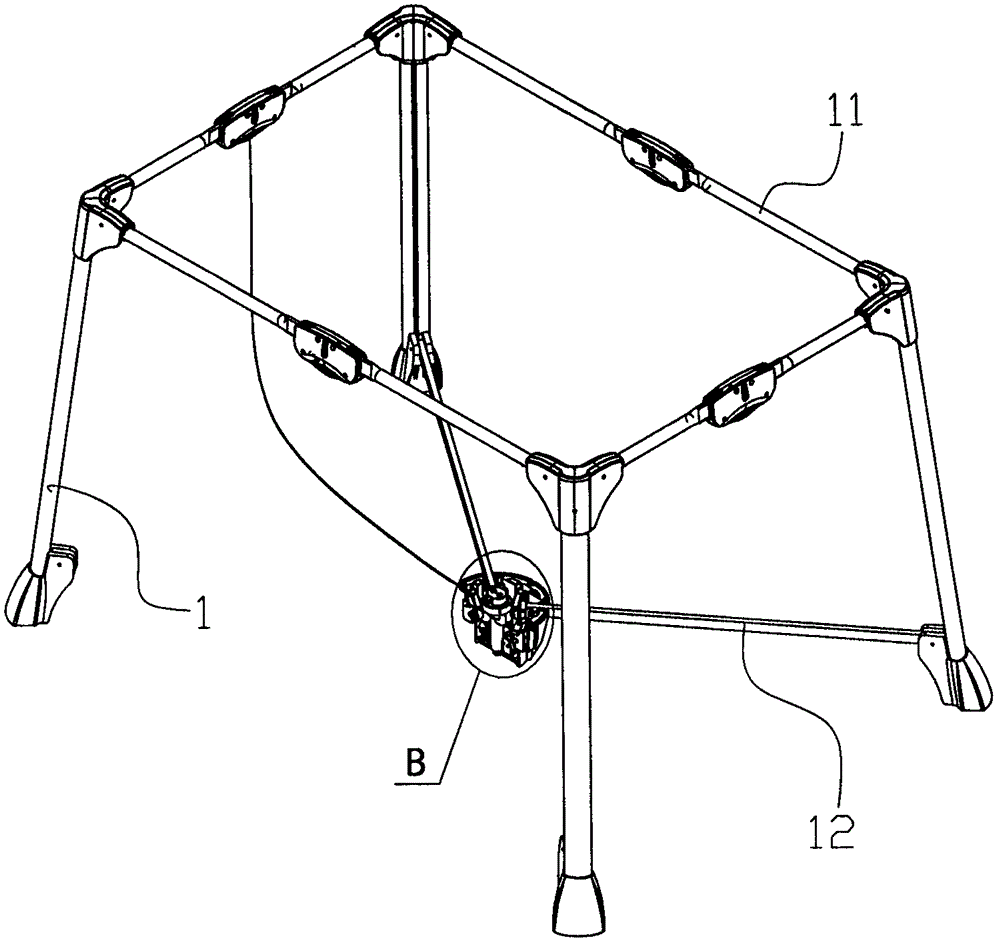

Children game bed

A children game bed comprises four bed legs (1) and a control portion which is disposed at the middle of the bottom of the bed and capable of folding and unfolding a bed body; a support cross bar (11), the middle of which can be folded, is disposed at the top between the adjacent bed legs (1); two ends of each support cross bar (11) are movably connected with the top of the corresponding bed leg (1) respectively; the bottom of the each bed leg (1) is movably connected with one end of a corresponding connecting rod (12); and the other end of each connecting rod (12) is movably connected to a corresponding position of the control portion. The children game bed also comprises four control lines (13); an upper end of each control line (13) is movably connected with a folding mechanism which is foldable and positioned at the middle of the corresponding support cross bar (11) respectively; and a lower end of each control line (13) is respectively connected with a corresponding prompting portion (25) in the control portion. The children game bed has the advantages that the control portion is lifted to drive the folding mechanisms to be synchronously folded, left and right guard bars are folded flexibly and stably, and the four support cross bars can be synchronously folded, thereby achieving the ideal application effect.

Owner:NINGBO HAISHU TIANHUA PROD DESIGN CO LTD

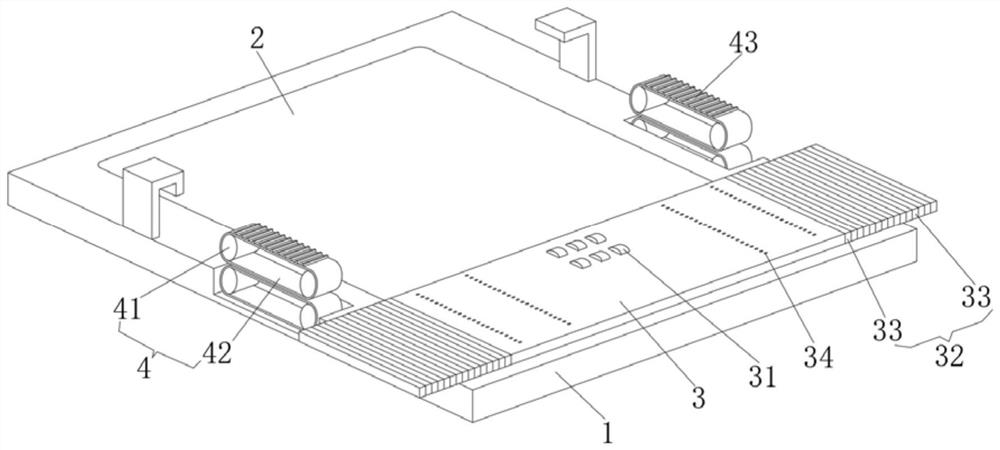

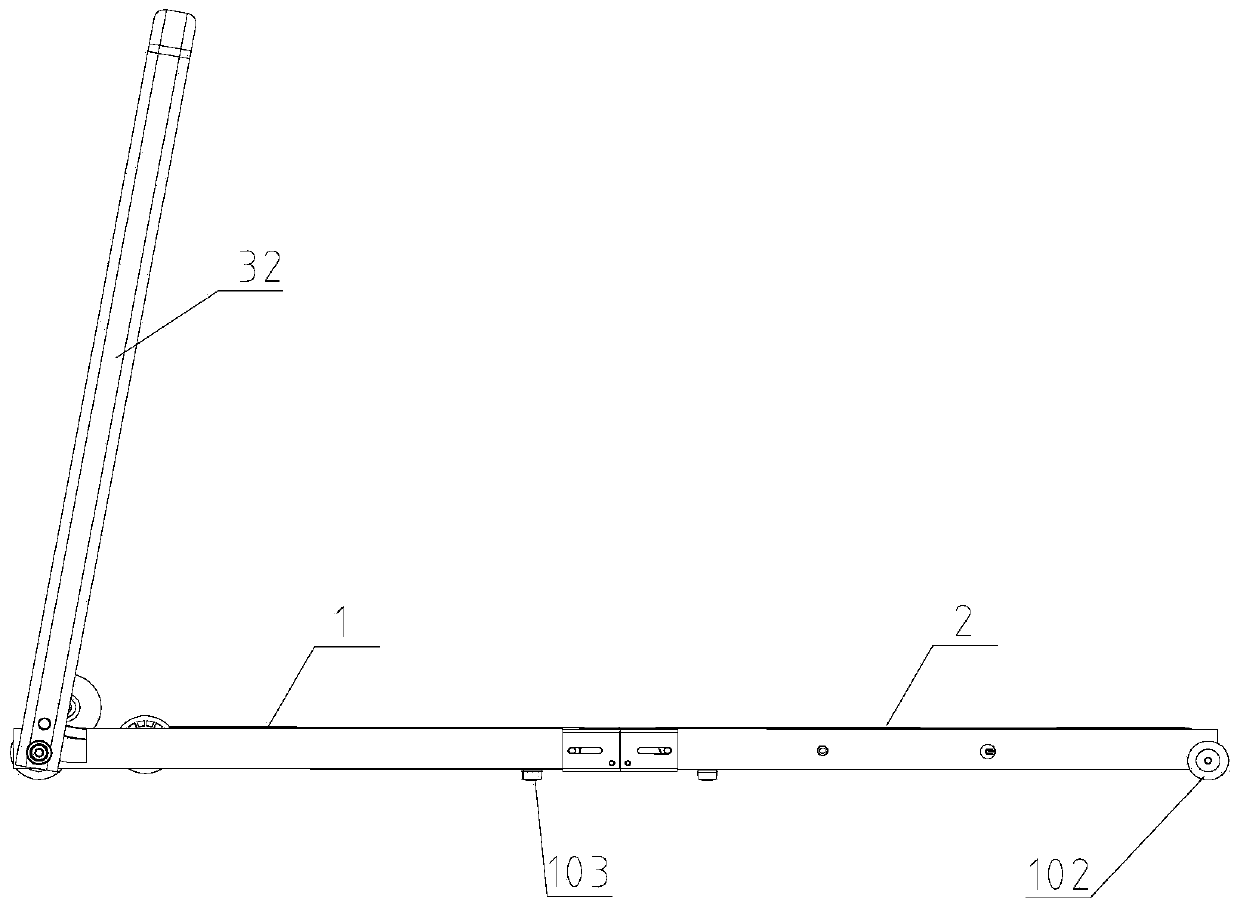

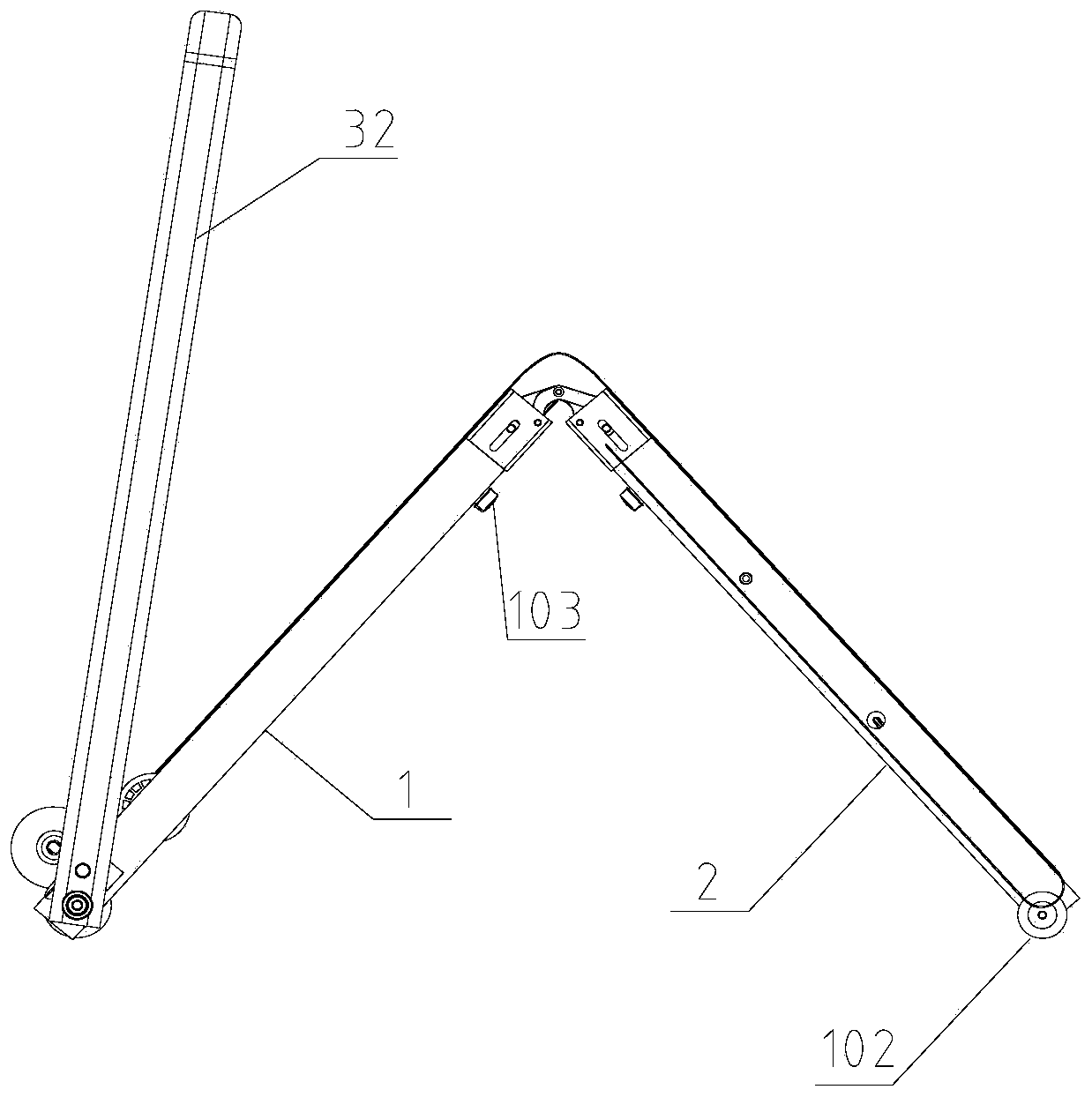

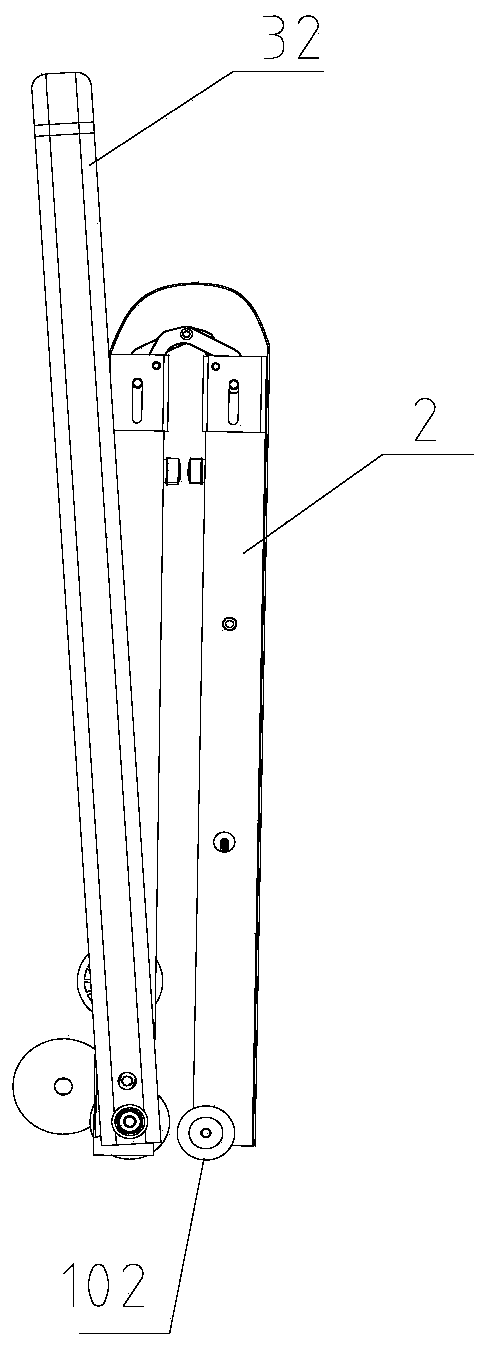

Treadmill

ActiveCN110559606AStand steadyAvoid slackMovement coordination devicesCardiovascular exercising devicesEngineeringHandrail

The invention relates to a treadmill. The treadmill comprises a front running plate assembly, a rear running plate assembly, an annular running belt, a rotary driving mechanism, a running belt adjustment mechanism and handrail posts, wherein the front running plate assembly comprises a front running frame, a front roller and a front running plate; the front roller and the front running plate are installed on the front running frame; the rear running plate assembly comprises a rear running frame, a rear roller and a rear running plate; the rear roller and the rear running plate are installed onthe rear running frame; the rear running plate assembly and the front running plate assembly are connected via a hinge component, and the rear running plate assembly can be driven to rotate towards the lower side of the front running plate assembly along a folding direction to fold the running plate assemblies; the rotary driving mechanism drives the rear running plate assembly to rotate; the running belt adjustment mechanism drives the rear roller to move longitudinally to loosen or tension the annular running belt; the handrail posts are hinged to the front end of the front running plate assembly, and can rotate with respect to the front running plate assembly and keep relative positions. According to the abovementioned technical scheme, the treadmill can be automatically folded and unfolded, to be convenient to store and use.

Owner:BEIJING KINGSMITH TECHNOLOGY CO. LTD.

Automatic folding and rubber band bundling all-in-one machine for plastic bag

InactiveCN109878792AUnified width specificationOmitting componentsPaper article packagingBundling machine detailsRelative motionEngineering

The invention discloses an automatic folding and rubber band bundling all-in-one machine for a plastic bag. The automatic folding and rubber band bundling all-in-one machine for the plastic bag comprises a rack, a vibrating disc device, a rubber band opening device, a lifting handle folding device, a tail folding device and an inserting plate device. The automatic folding and rubber band bundlingall-in-one machine for the plastic bag is characterized in that the automatic folding and rubber band bundling all-in-one machine for the plastic bag further comprises a retreating clamping plate device and a conveying clamping plate device, the retreating clamping plate device and the conveying clamping plate device are used for oppositely folding and clamping one side of the plastic bag, the retreating clamping plate device loosens the plastic bag and retreats after the plastic bag is finalized, then one side of the plastic bag is clamped by the conveying clamping plate device, and the otherside of the plastic bag is inserted into the rubber band opening device to be bundled through relative motion of the inserting device. The automatic folding and rubber band bundling all-in-one machine for the plastic bag has the advantages that the processes from folding to bundling are almost conducted in the conveying clamping plate device and a clamping plate mechanism, integration of foldingand bundling is achieved on the condition that hand changing is not needed, therefore, the folding and bundling work is stable and reliable, and the structure is simple and compact.

Owner:王秀来

A folding method of a foldable bicycle saddle

The invention relates to an automatic folding method of a folding type bicycle saddle seat. The automation means that the folding action is finished under the non-contact state of the hand and the saddle seat or a saddle pipe; the folding means that the saddle seat is shrunk to a set position under the folding state, is restored automatically to a preset height in unfolding and the preset height can be adjusted randomly; the principle is as follows: a pull rope mechanism and a pin expanding and retracting sleeve mechanism are matched to control the folding of the saddle seat; the pin expanding and retracting sleeve mechanism mainly comprises a fixed pipe, an expanding and retracting pipe, an expanding and retracting pipe resetting spring, a pin and a pin resetting spring; the fixed pipe is provided with a plurality of positioning holes; the expanding and retracting pipe is provided with one or a pair of positioning hole(s) corresponding to the positioning holes on the fixed pipe; the saddle seat is fixedly connected on the expanding and retracting pipe; the pin penetrates through the corresponding holes of the expanding and retracting pipe and the fixed pipe to lock the mutual positions; in folding, the locked state of the pin is eliminated by a pull rope, and simultaneously the pull rope pulls the expanding and retracting pipe to the set position; and in unfolding, the pull rope is released and the expanding and retracting pipe resetting spring pushes the saddle seat to a preset height.

Owner:戚善鸣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com