Patents

Literature

431results about How to "Improve folding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soluble T cell receptor

InactiveUS20020142389A1High affinityStrong specificityBacteriaPeptide/protein ingredientsHeterologousExtracellular Structure

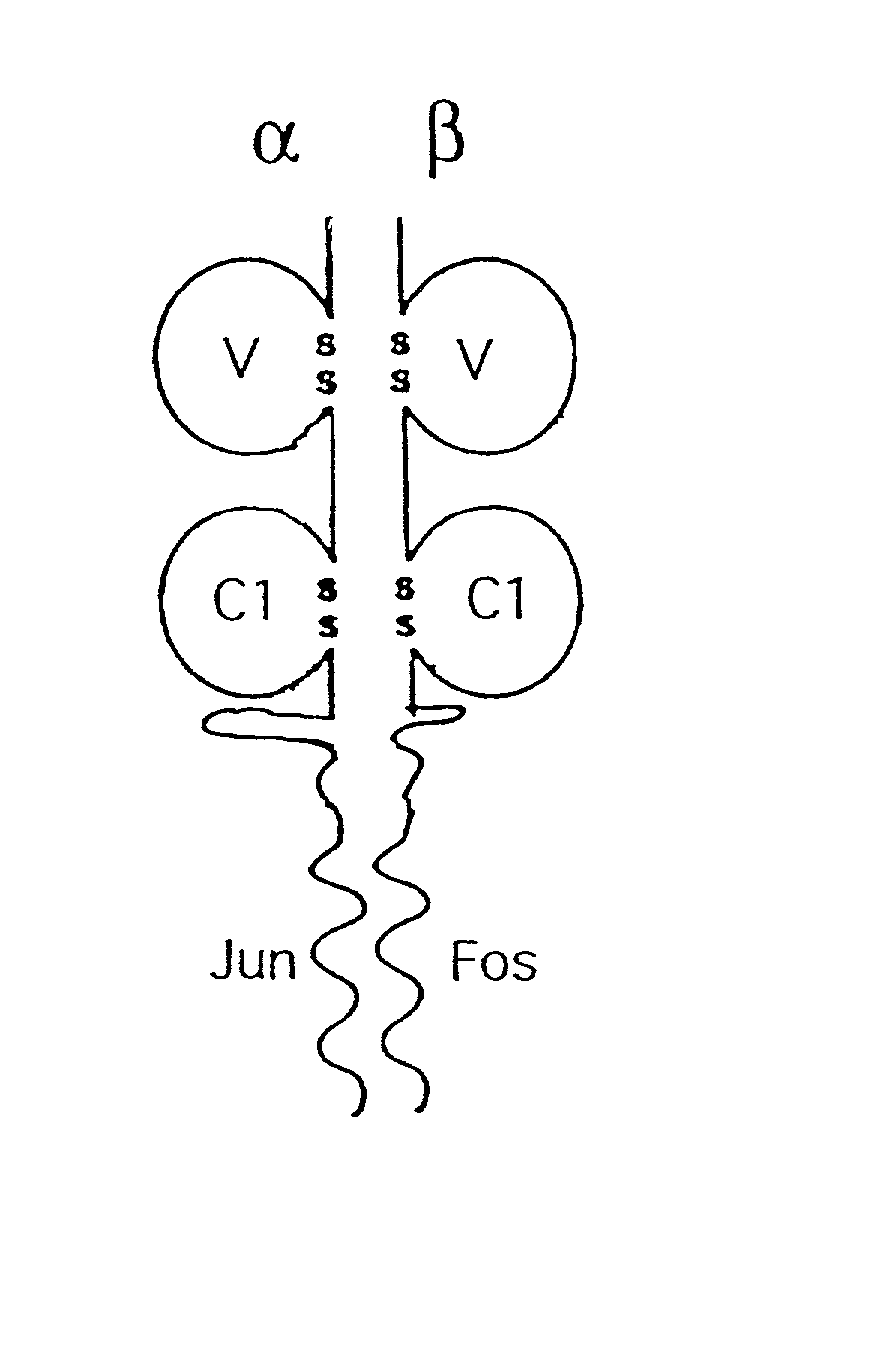

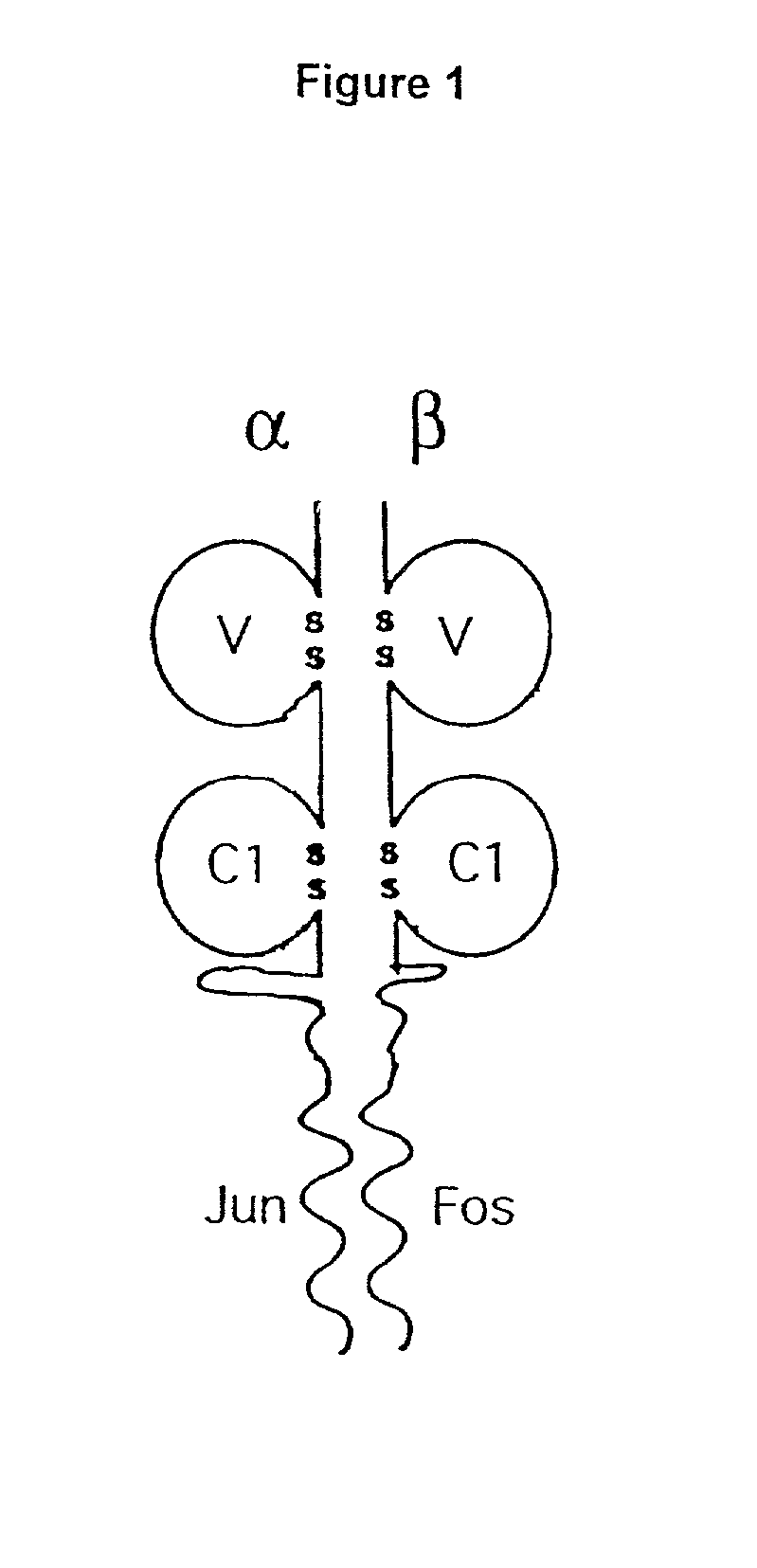

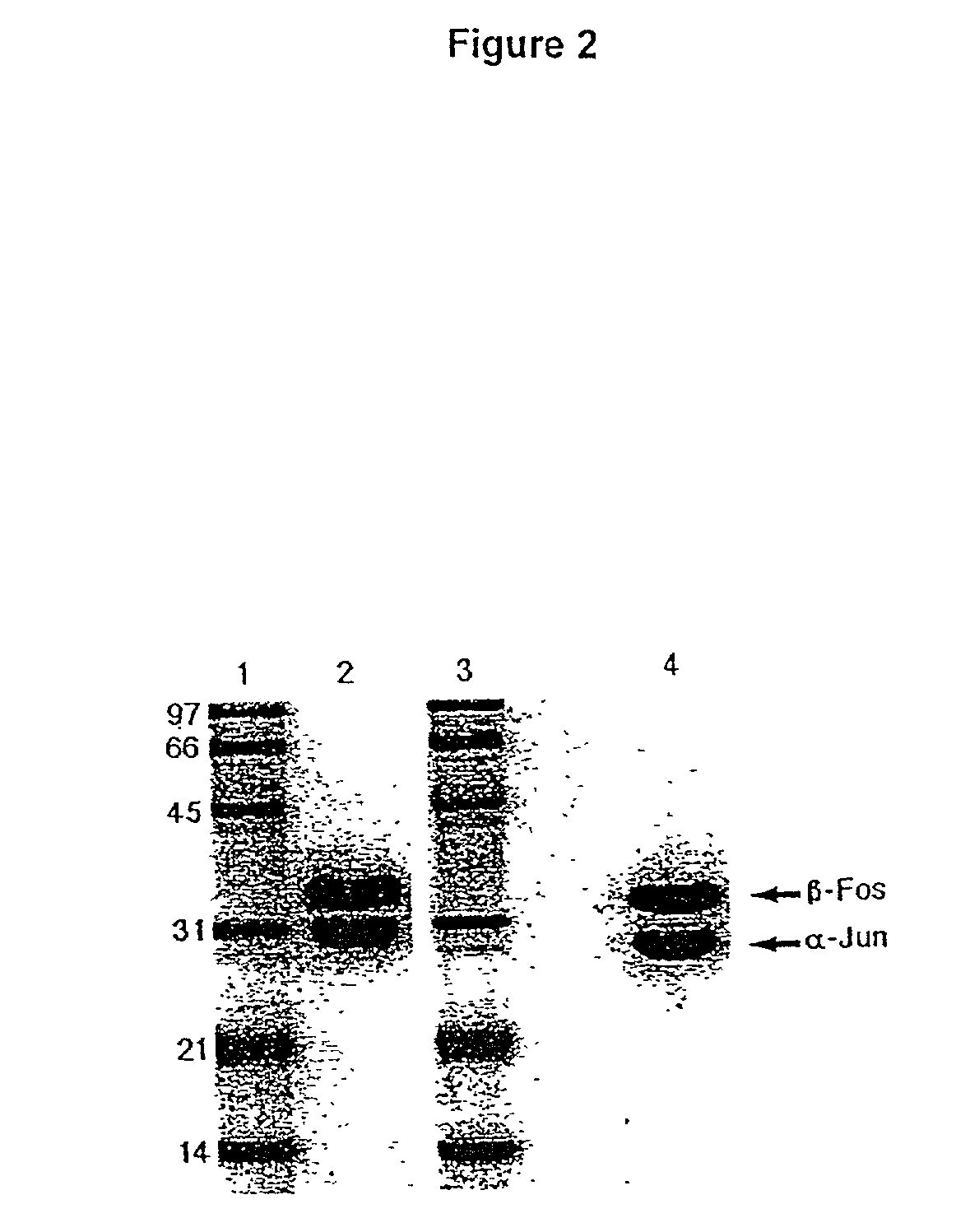

The present invention relates to a recombinant soluble T cell receptor. The T cell receptor (TCR) is refolded and comprises a recombinant TCR alpha or gamma chain extracellular domain having a first heterologous C-terminal dimerisation peptide; and a recombinant TCR beta or delta chain extracellular domain having a second C-terminal dimerisation peptide which is specifically heterodimerised with the first dimerisation peptide to form a heterodimerisation domain, which may be a coiled coil domain. The invention also provides nucleic acid sequences encoding the recombinant TCR and a method for producing the recombinant TCR. The TCR may be labelled with a detectable label so as to enable the detection of specific MHC-peptide complexes. Alternatively, it can be linked to a therapeutic agent such as a cytotoxic agent or an immunostimulating agent so as to deliver such an agent to the site of a specific MHC-peptide complex.

Owner:JAKOBSEN BENT KARSTEN +4

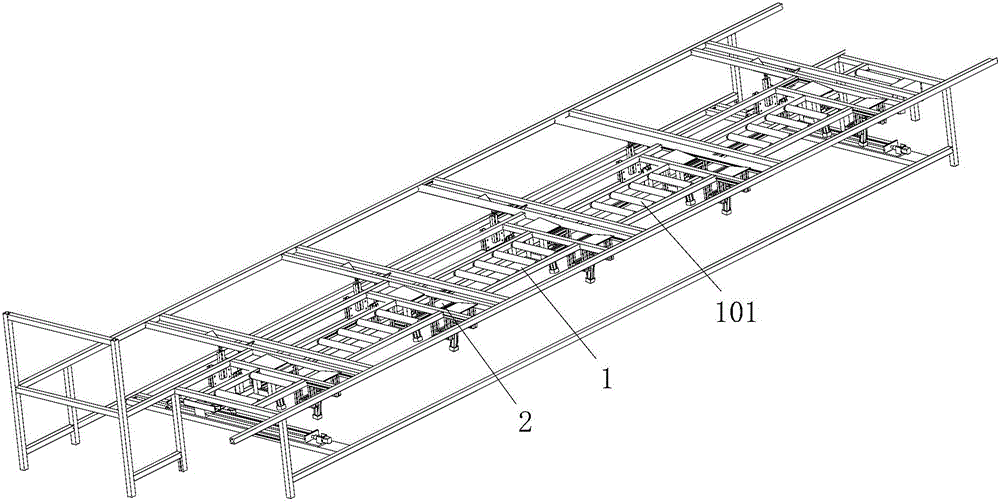

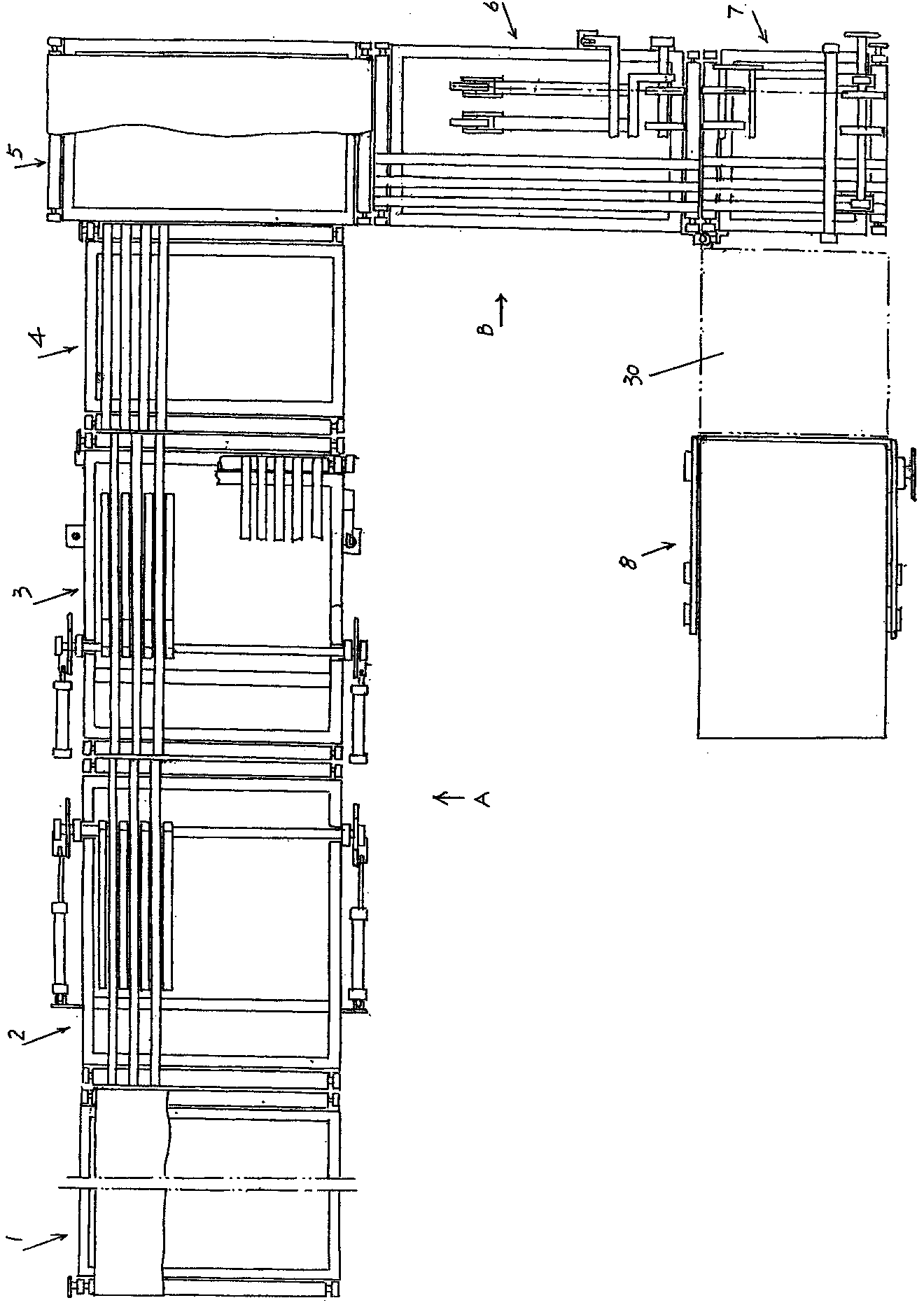

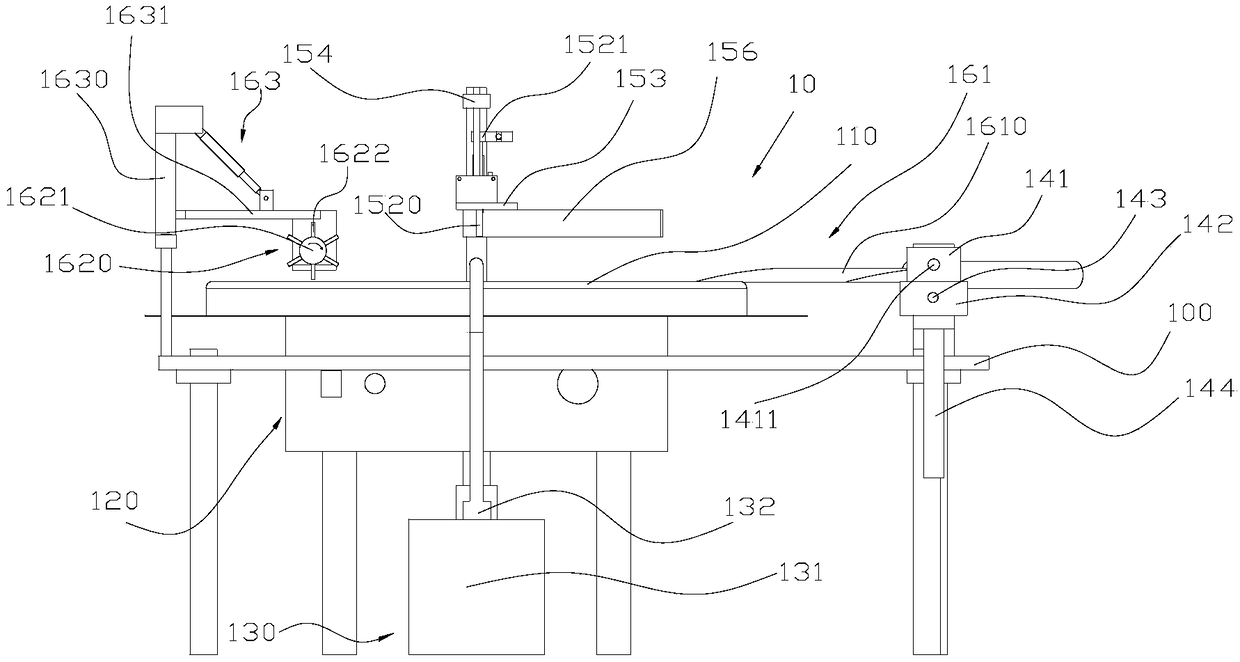

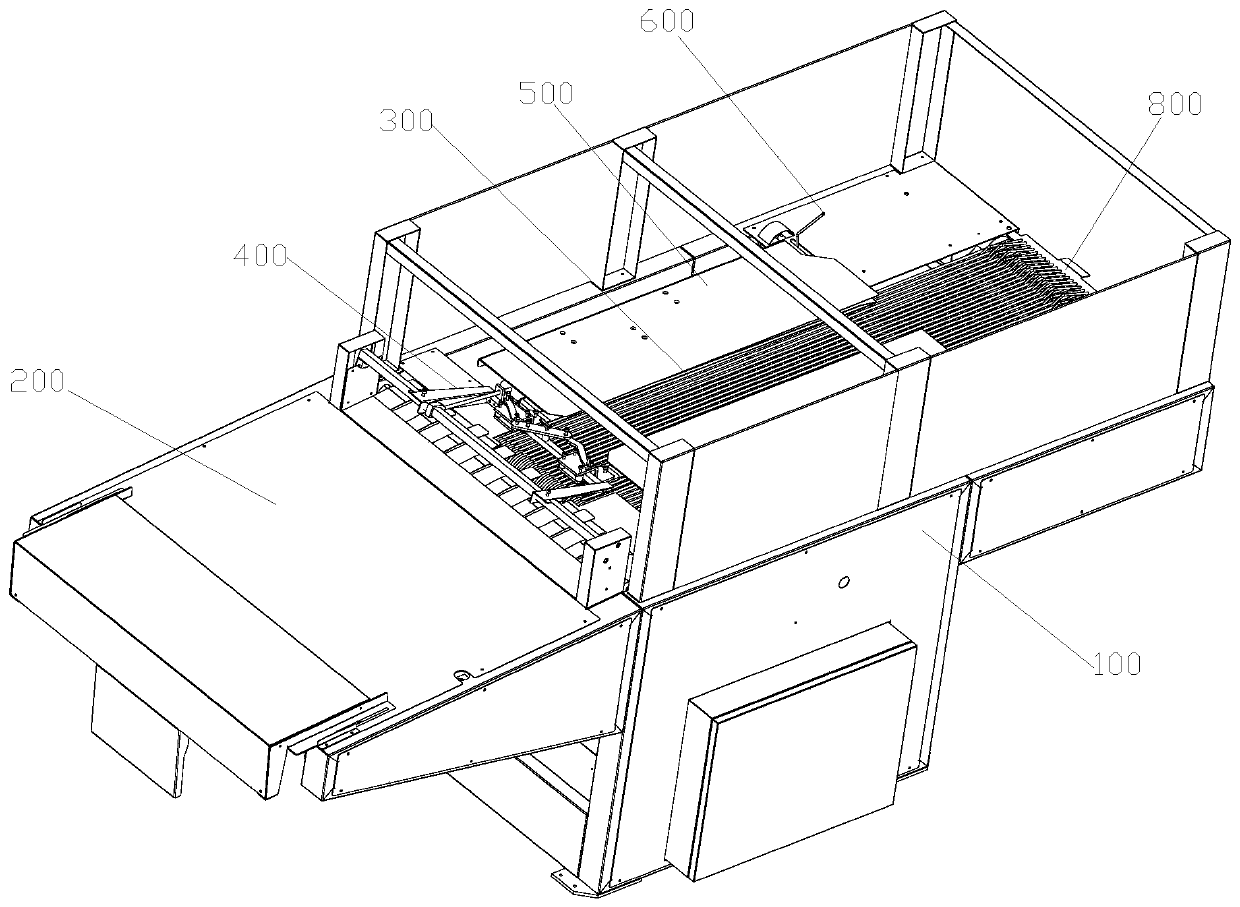

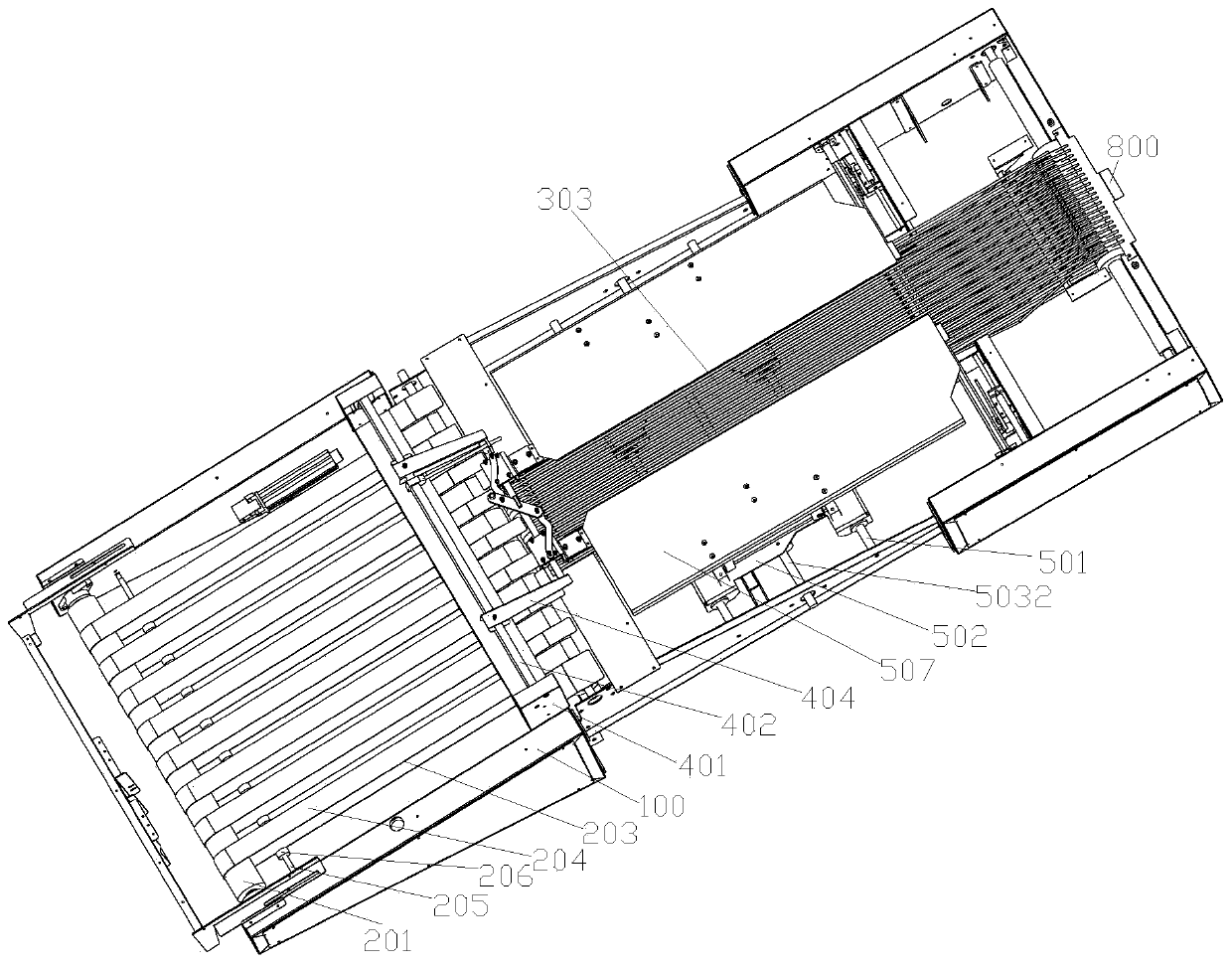

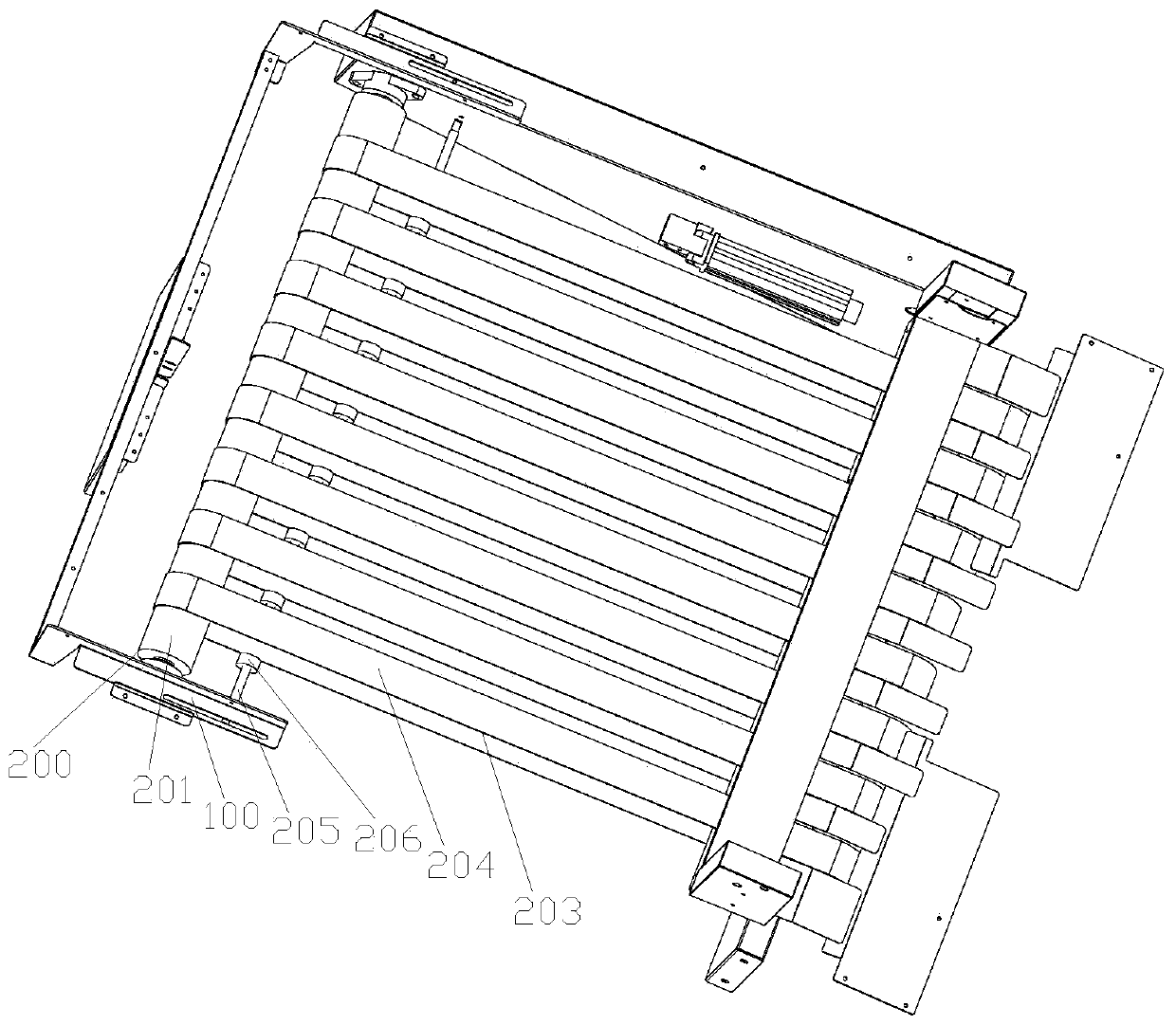

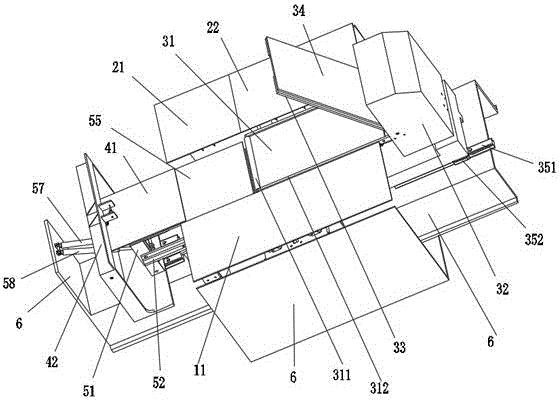

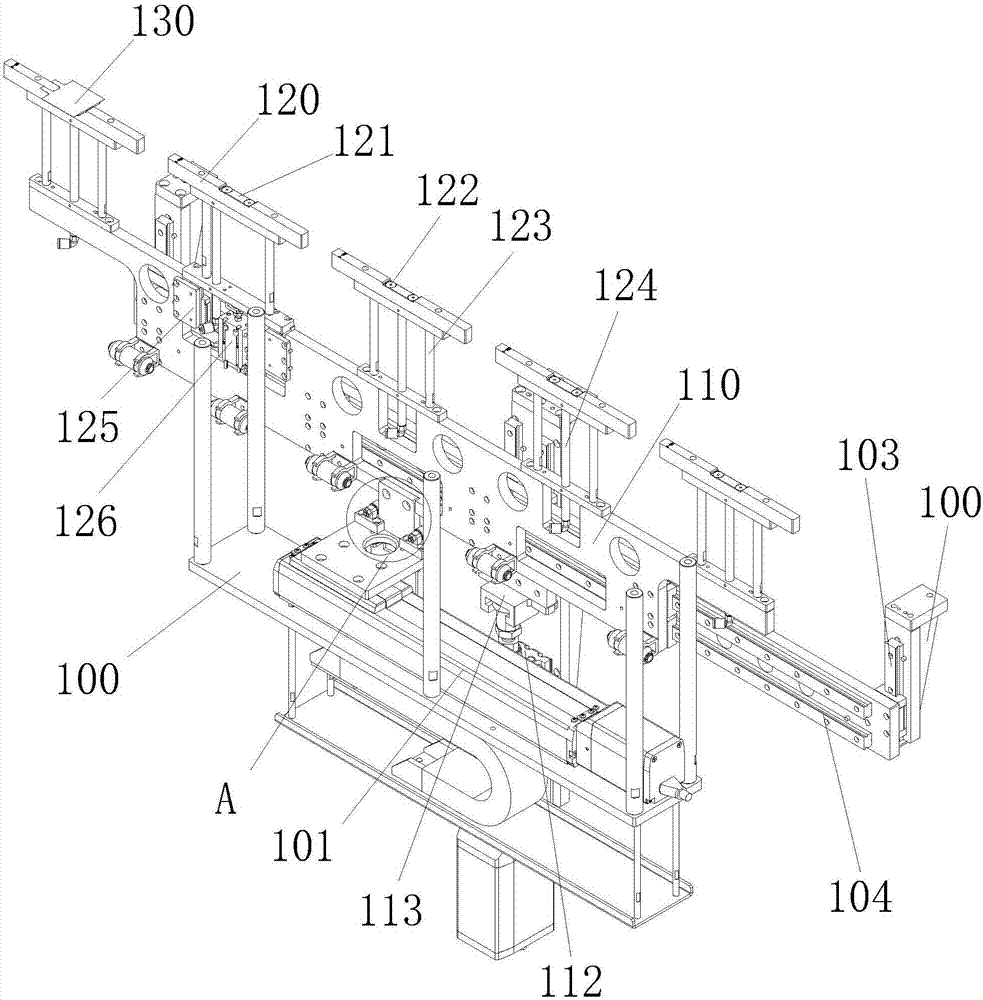

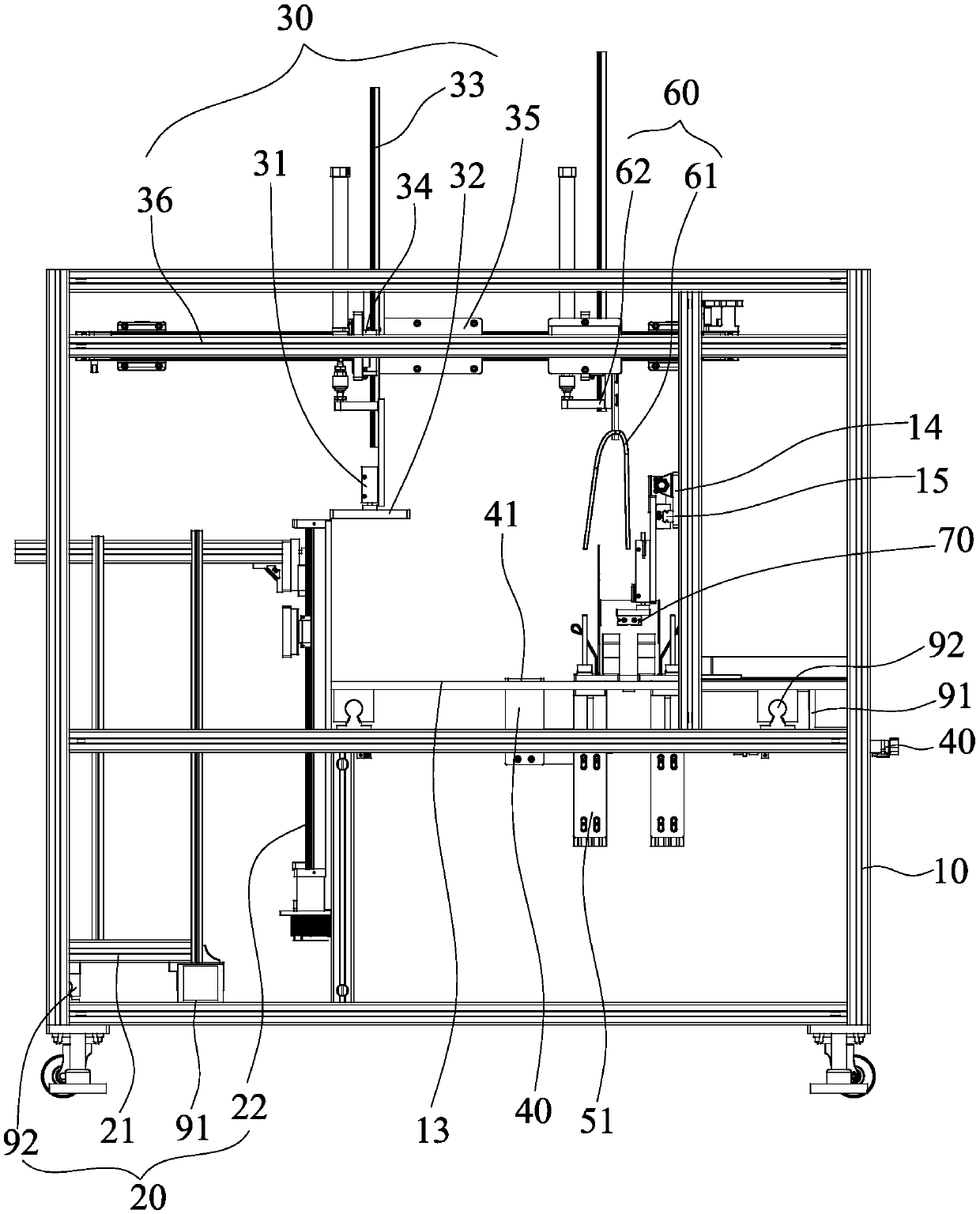

Automatic package machine for corrugated cartons with different lengths

InactiveCN105730772AHigh conveying precisionModerate delivery speedWrapper twisting/gatheringCartonEngineering

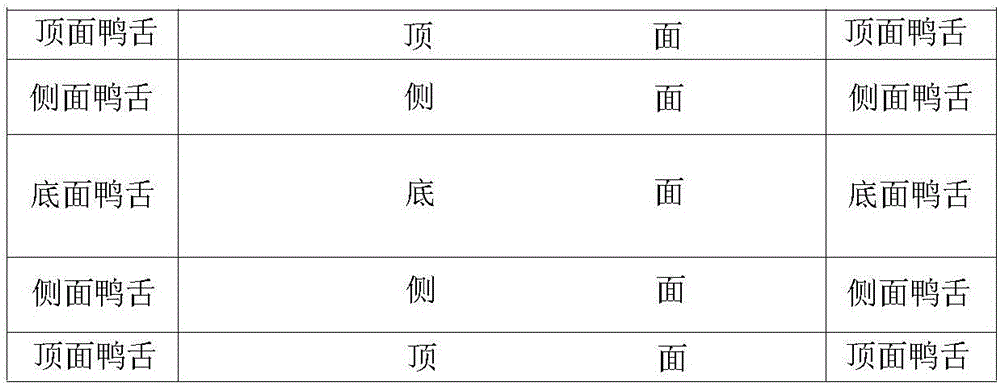

The invention discloses an automatic package machine for corrugated cartons with different lengths. The automatic package machine comprises a rack. An initial material position containing area, a wrapping forming area and a carton sealing area are sequentially arranged on the rack in the carton conveying direction. A material conveying device is arranged below the initial material position containing area. A carton containing area is arranged in the wrapping forming area. A top face folding mechanism, a front end folding system and a tail end folding system are arranged in the carton containing area. A side face folding mechanism is arranged below the carton containing area. Each of the front end folding mechanism and the tail end folding mechanism comprises a side face duck tongue folding mechanism, a top face duck tongue folding mechanism and a bottom face duck tongue folding mechanism. A plurality of powerless transmission rollers are arranged in the carton sealing area in the length direction of the carton sealing area. A two-end carton sealing mechanism, a length direction carton sealing system and a width direction carton sealing system are arranged in the carton sealing area in the carton conveying direction. By means of the automatic package machine, packaging of carton type products of different specifications and different sizes can be achieved, and the application range is wide.

Owner:SHANDONG UNIV OF SCI & TECH

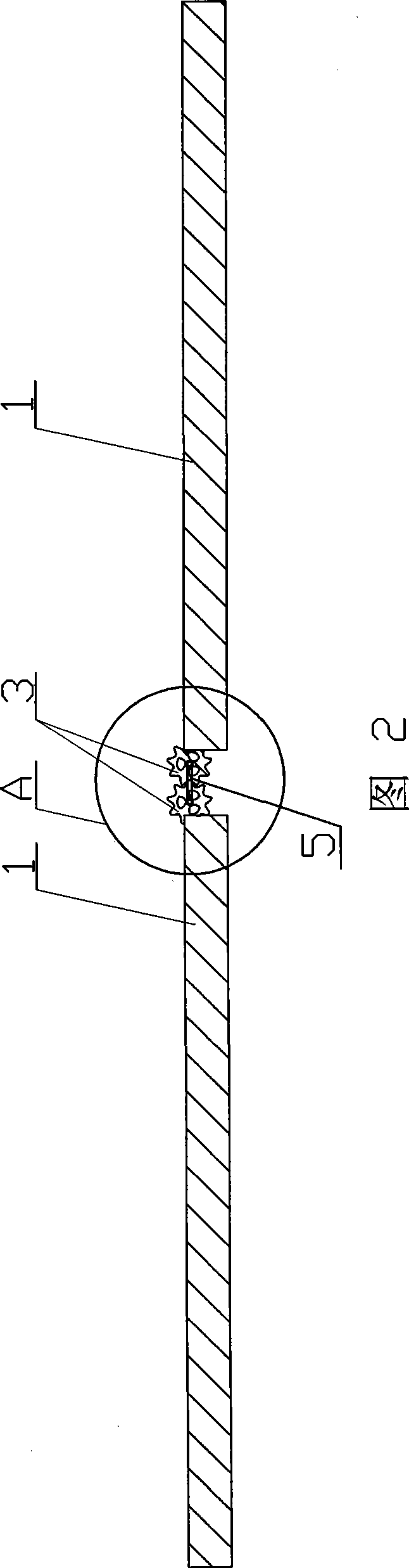

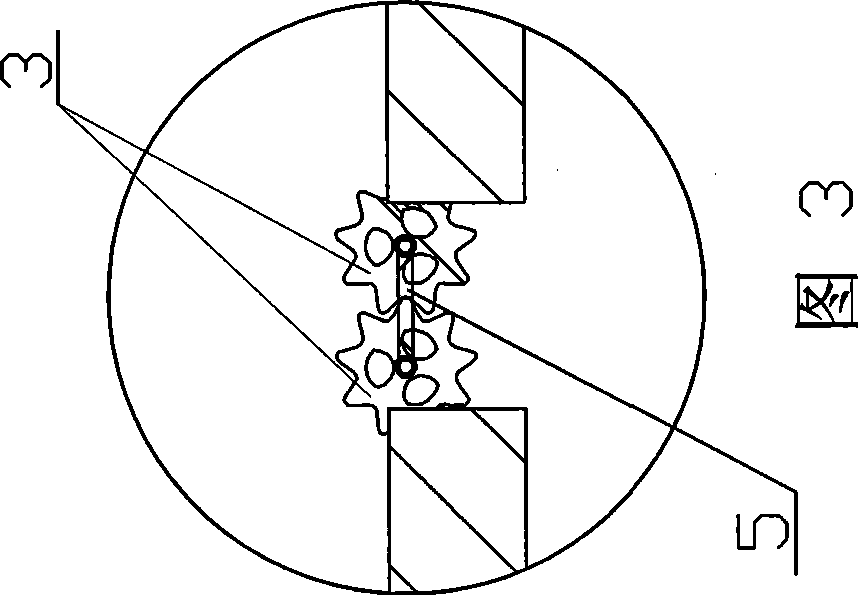

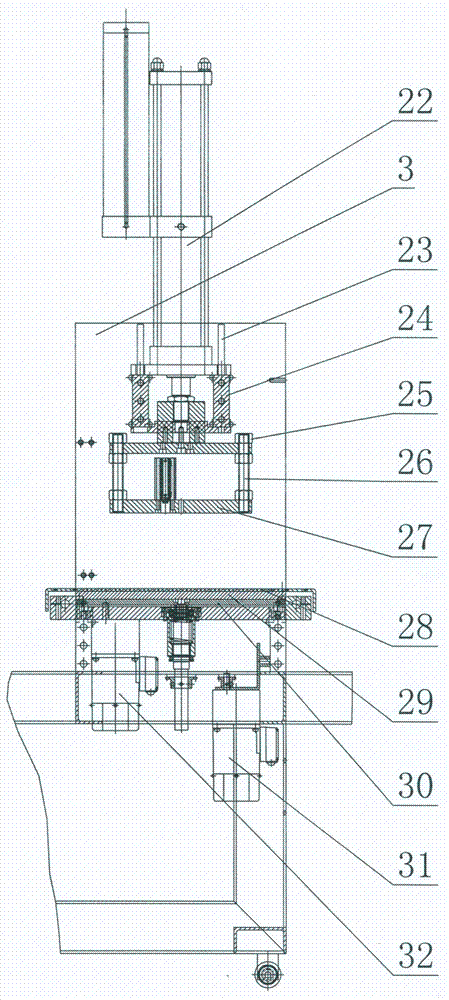

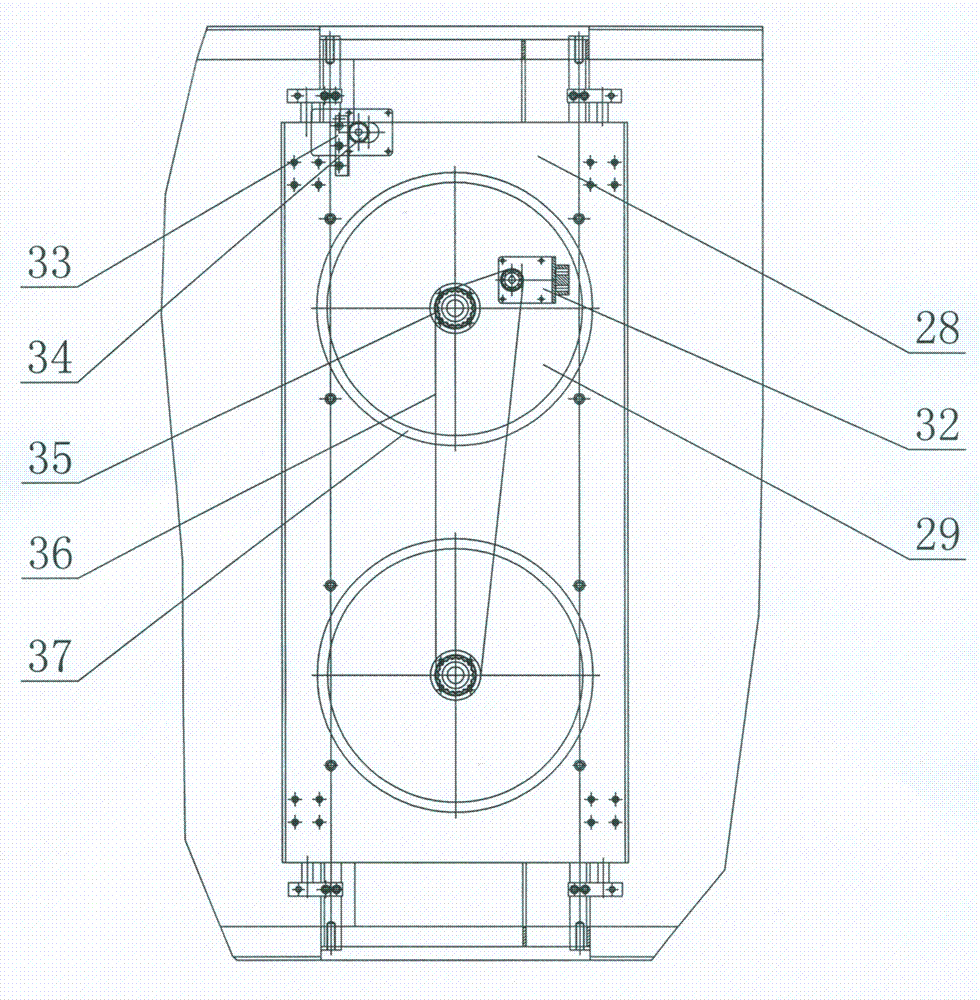

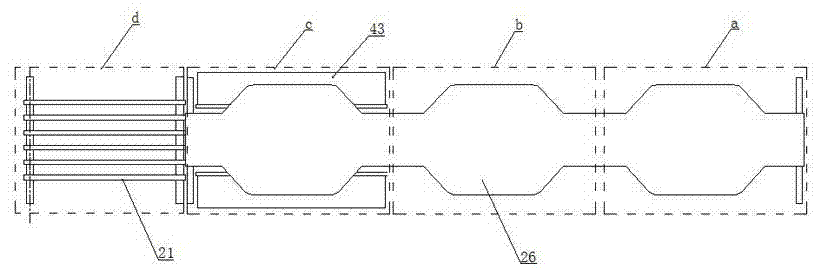

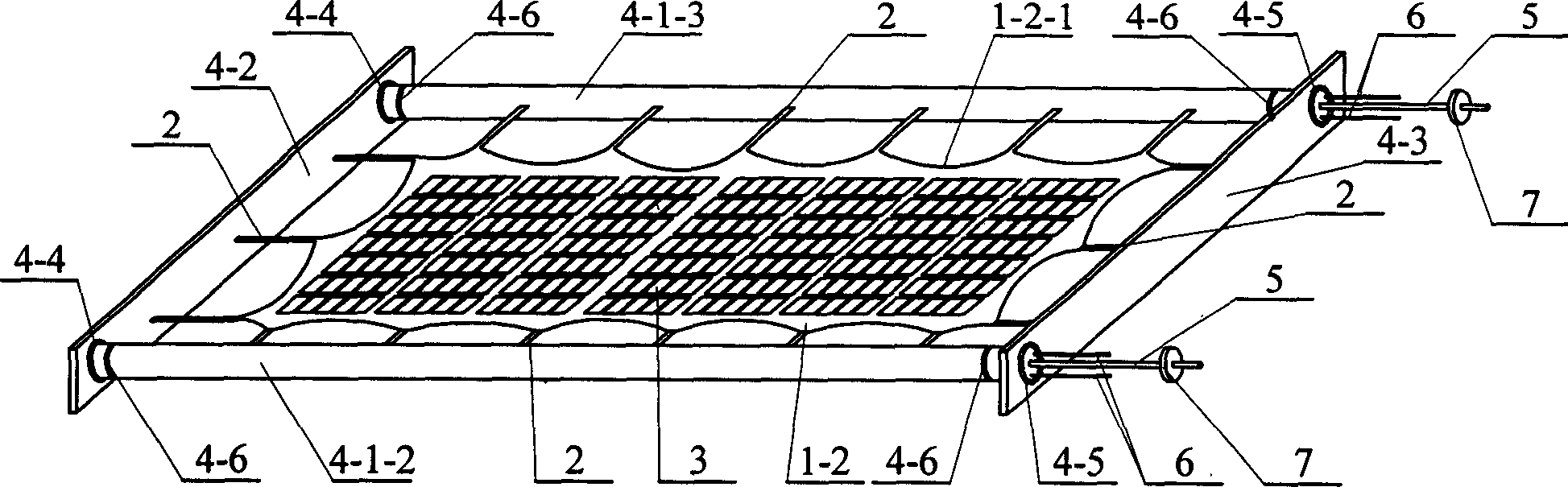

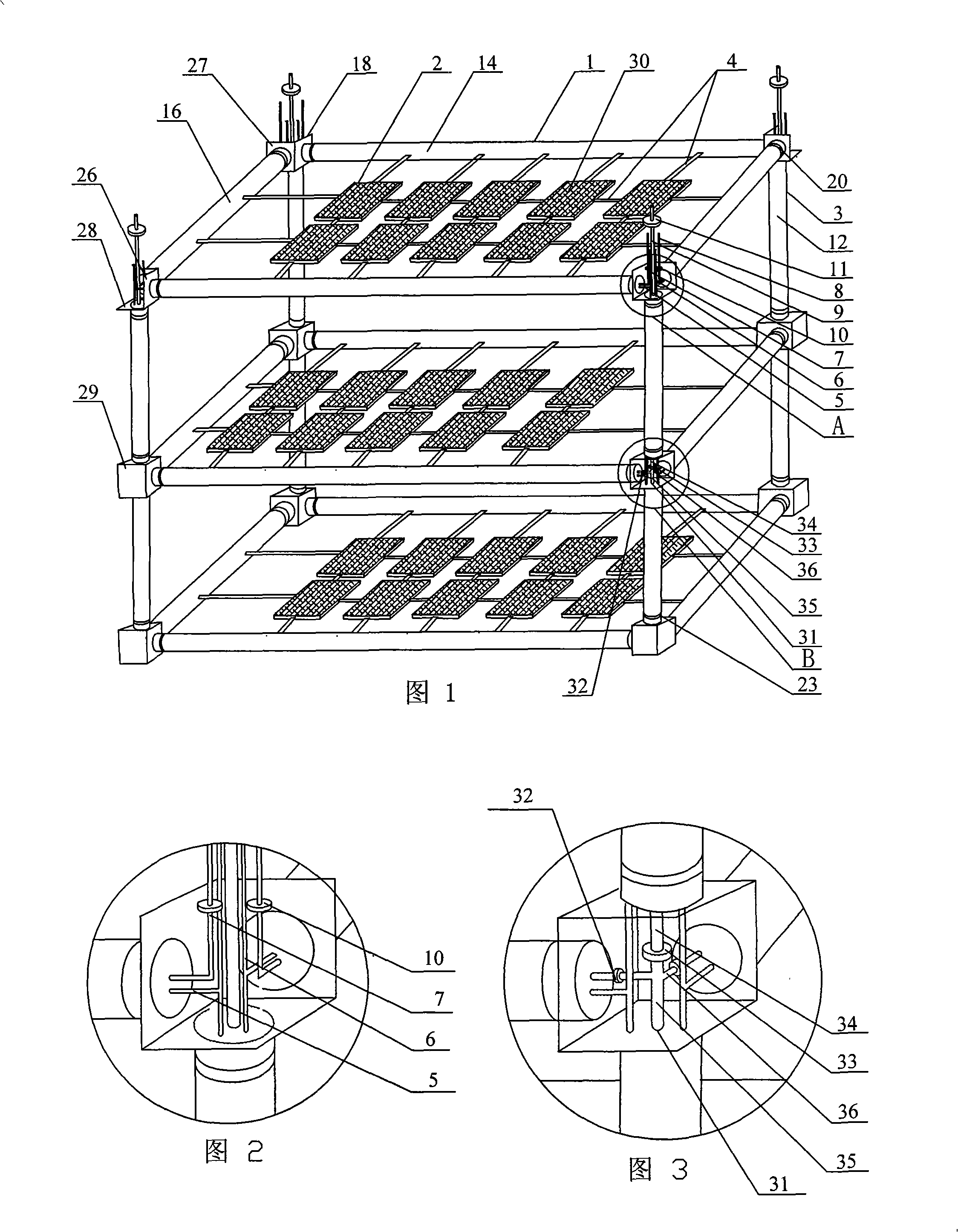

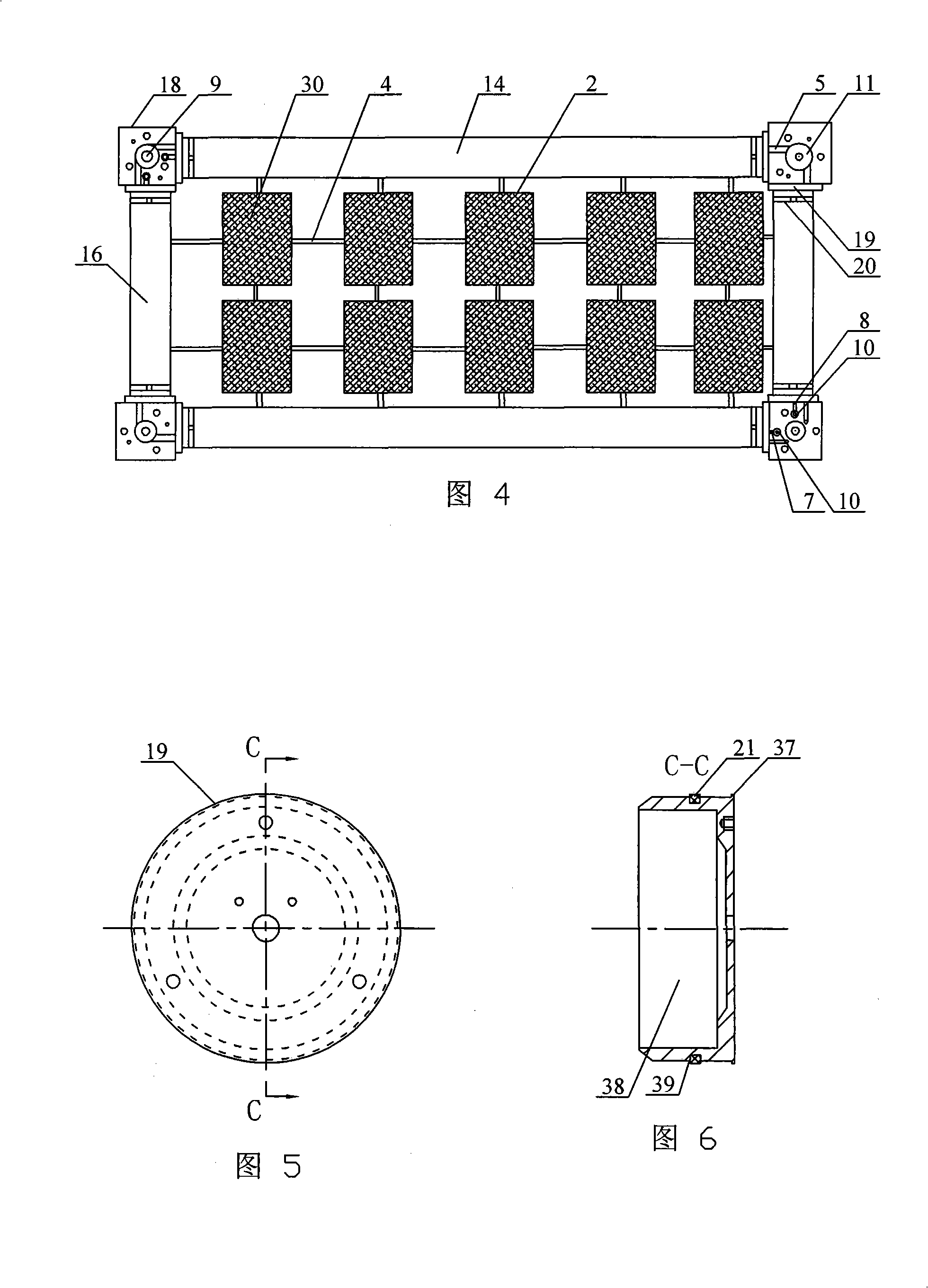

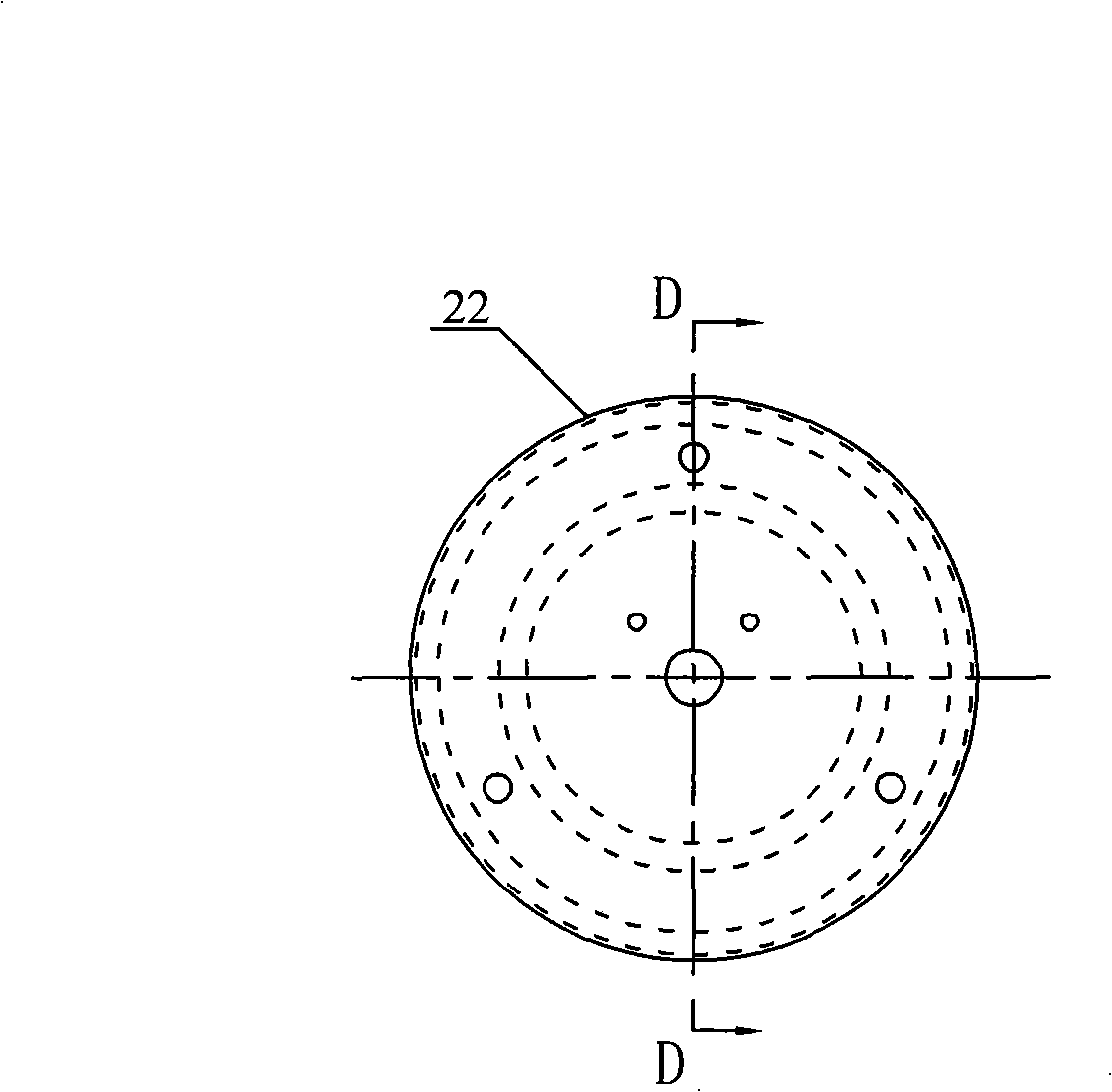

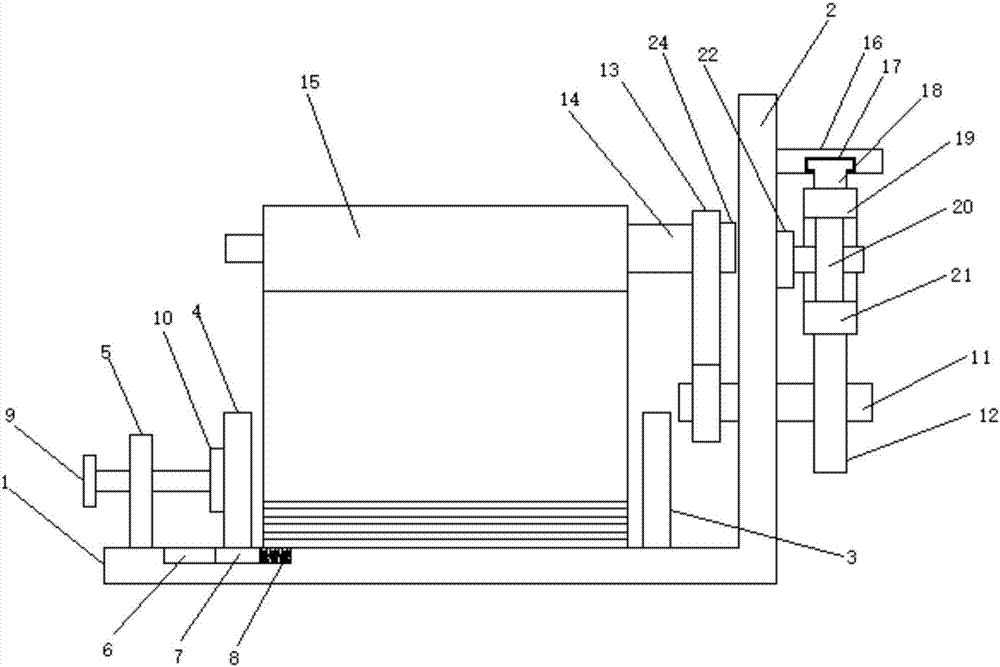

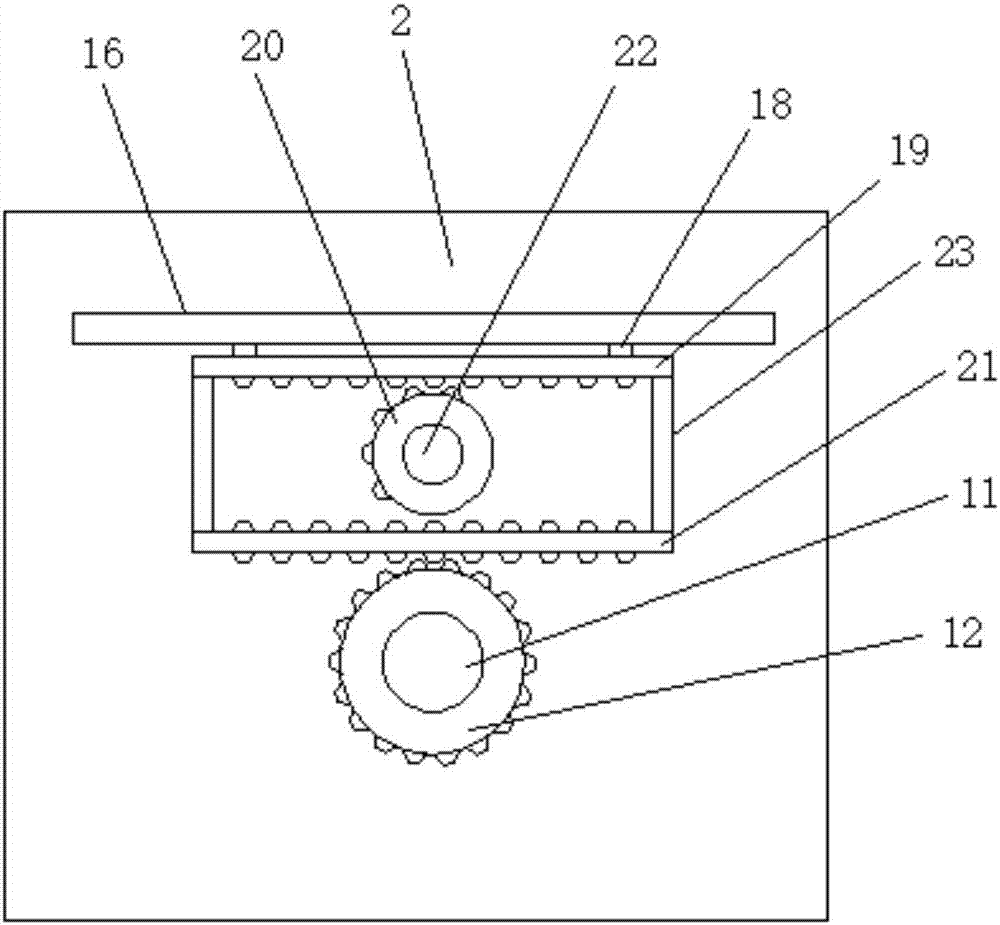

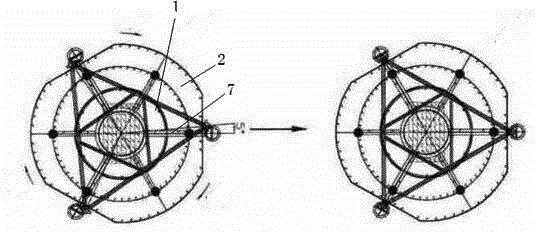

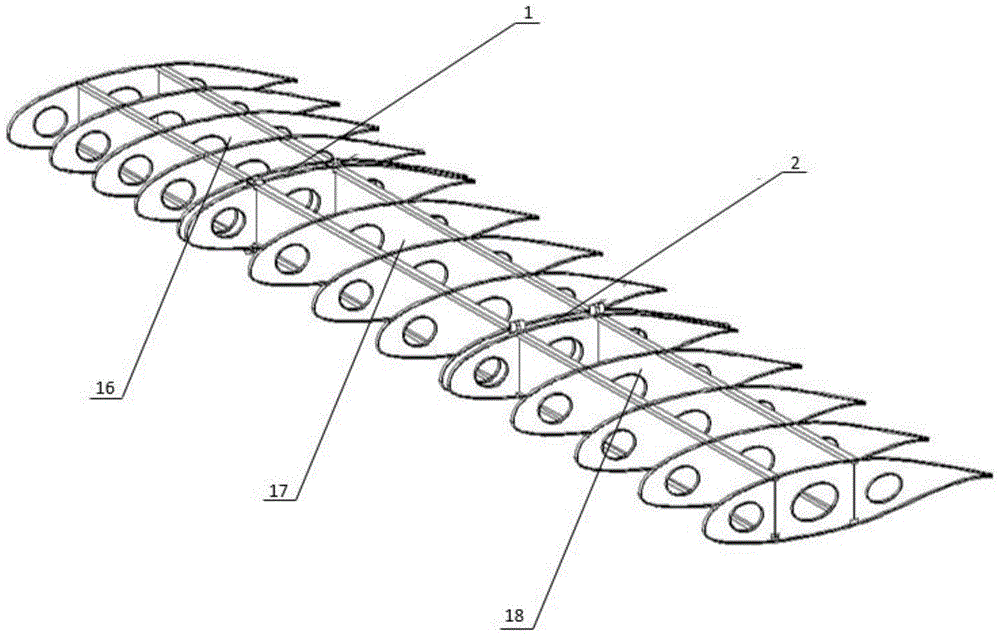

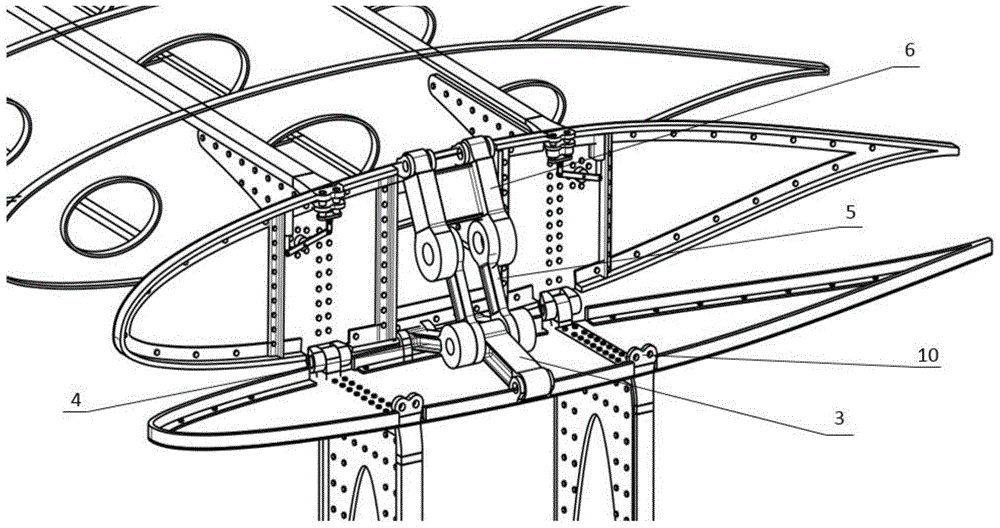

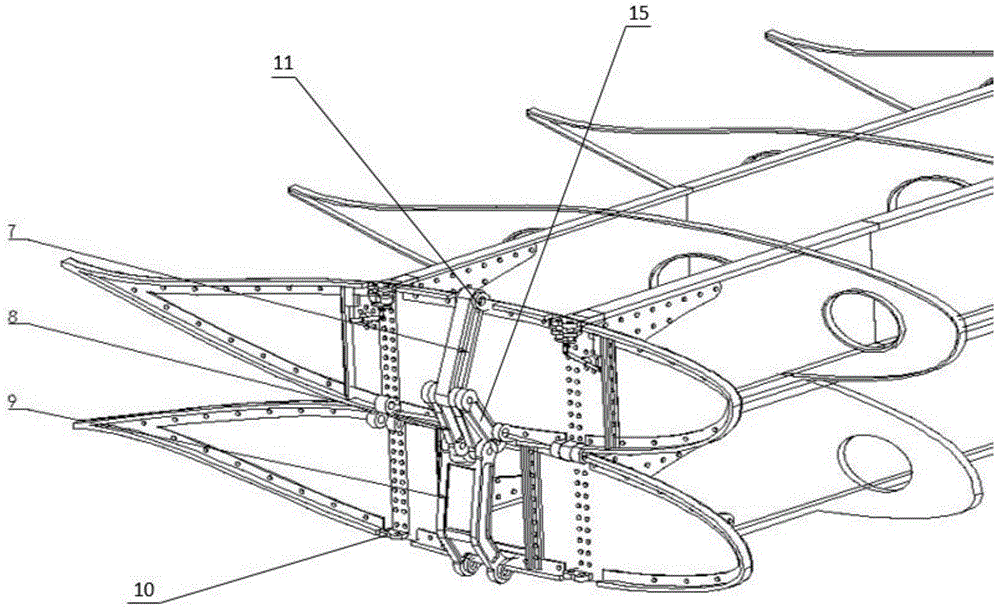

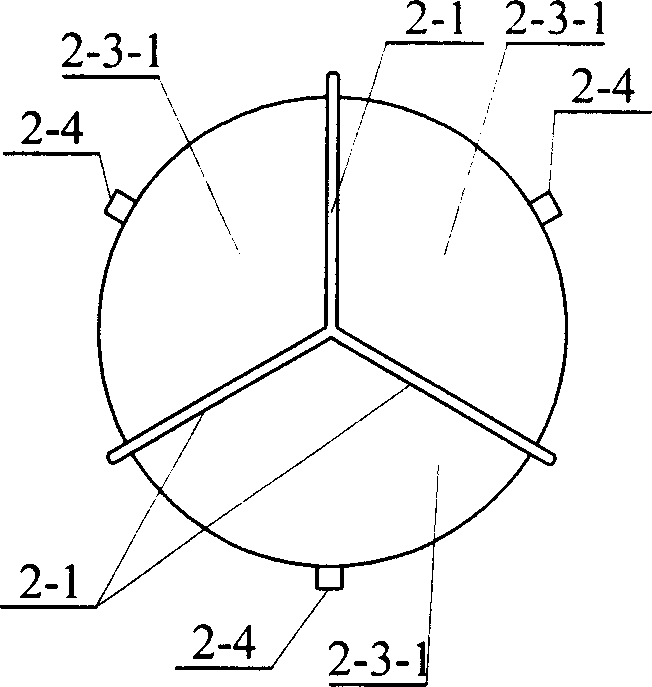

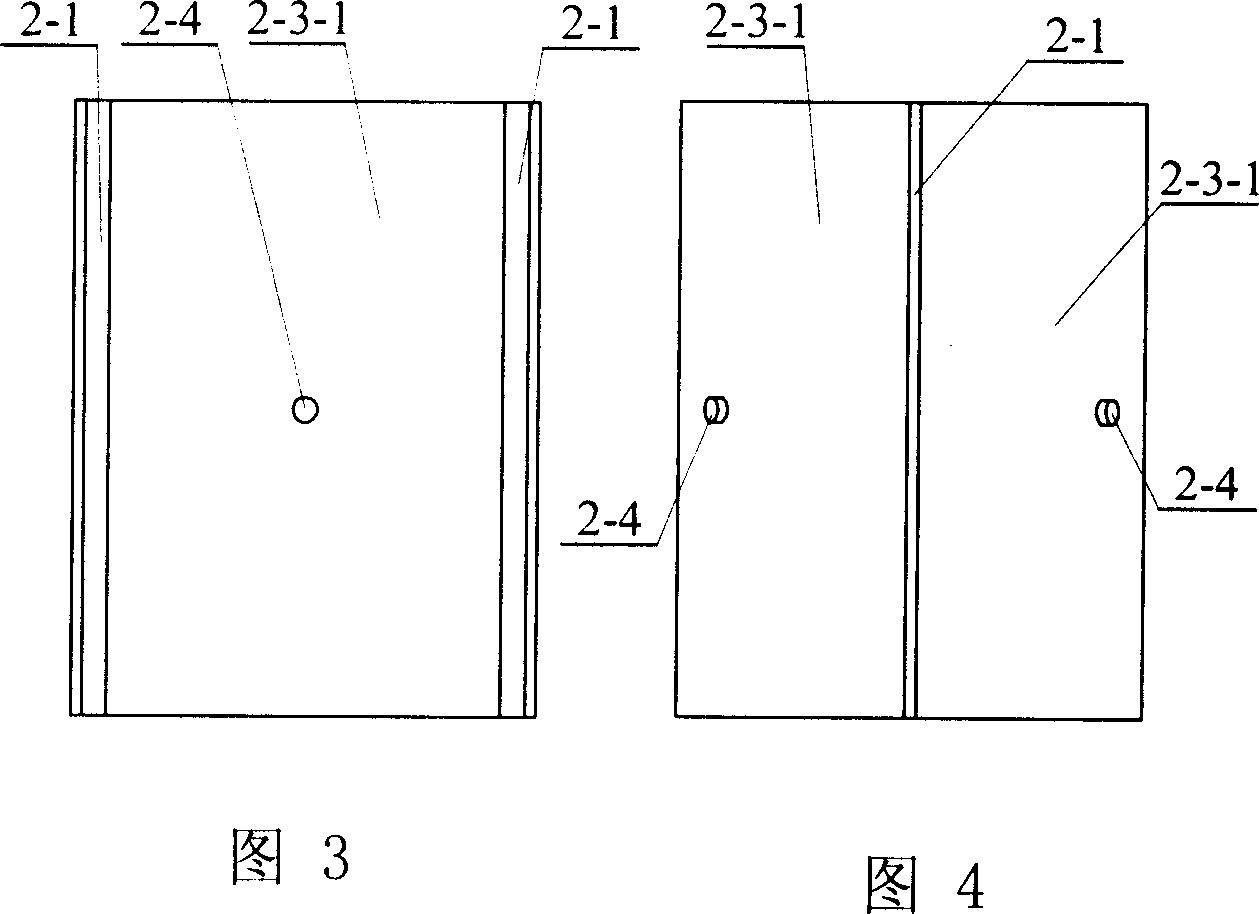

Synchronous expansion mechanism for foldable inflating expansion solar cell paddles

InactiveCN101383568ASmall sizeSmall amount of influenceCosmonautic power supply systemsPhotovoltaicsEngineeringSolar cell

The invention discloses a synchronous deployment mechanism for a folding inflating expansion type solar panel substrate, and the synchronous deployment mechanism relates to a solar panel substrate deployment mechanism. Aimed at solving the problems of the prior solar panel substrate deployment mechanism that the reliability is bad, the volume is large, the weight is heavy, the cost is high, and the synchronous deployment performance is low, an inflation driving pipe and an inflation guiding pipe are arranged above and below the solar panel substrate, a pair of mutually meshed gears is respectively arranged at the upper end and the lower end, both of which are positioned between the two adjacent solar panel substrates, the two ends of a connecting rod are sleeved on the gear shafts of each pair of gears, each pair of gears is connected with the adjacent solar panel substrate, a connecting ring pillar sleeved on the inflation driving pipe is fixedly connected with the inflation driving pipe, a connecting ring pillar sleeved on the inflation guiding pipe is glidingly matched with the inflation guiding pipe, connecting shafts are arranged in the connecting ring pillars, the external end faces of the connecting shafts are fixedly connected with the solar panel substrates, and a gas source is communicated with the inflation driving pipe and the inflation guiding pipe. The invention has the advantages of simple structure, light weight, high folding efficiency, good reliability and synchronous deployment.

Owner:HARBIN INST OF TECH

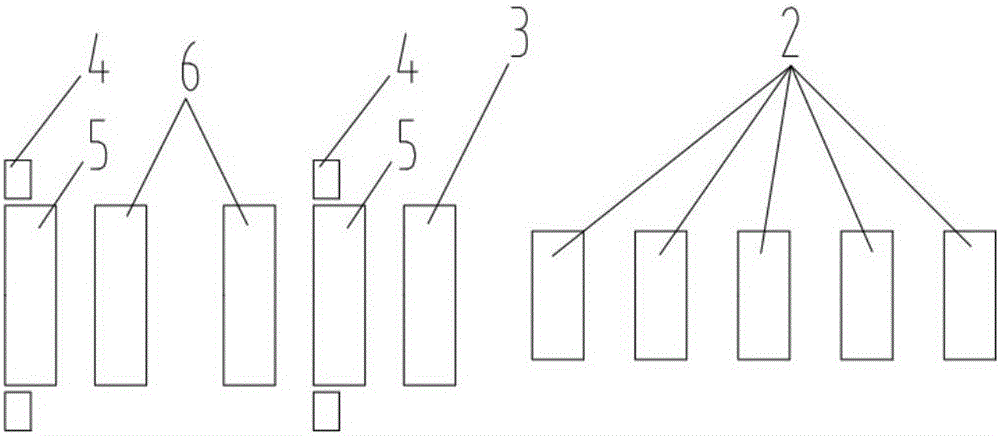

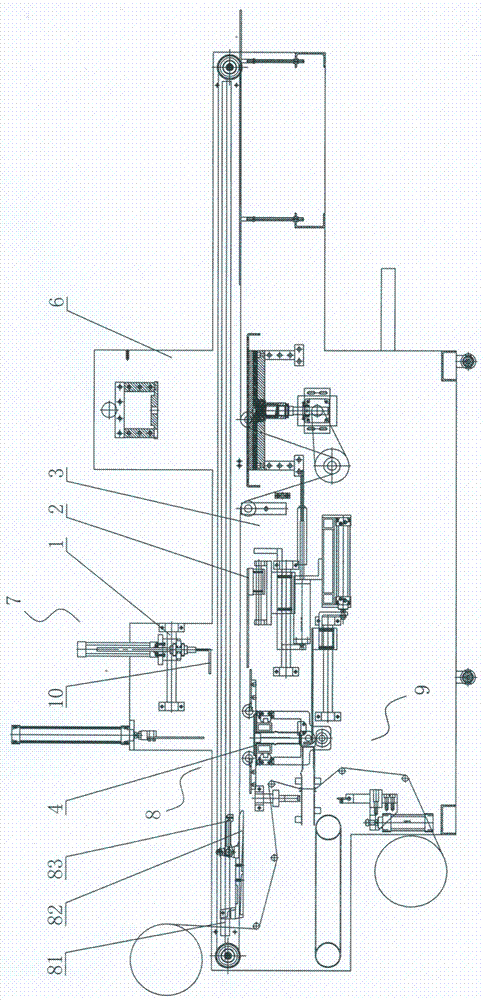

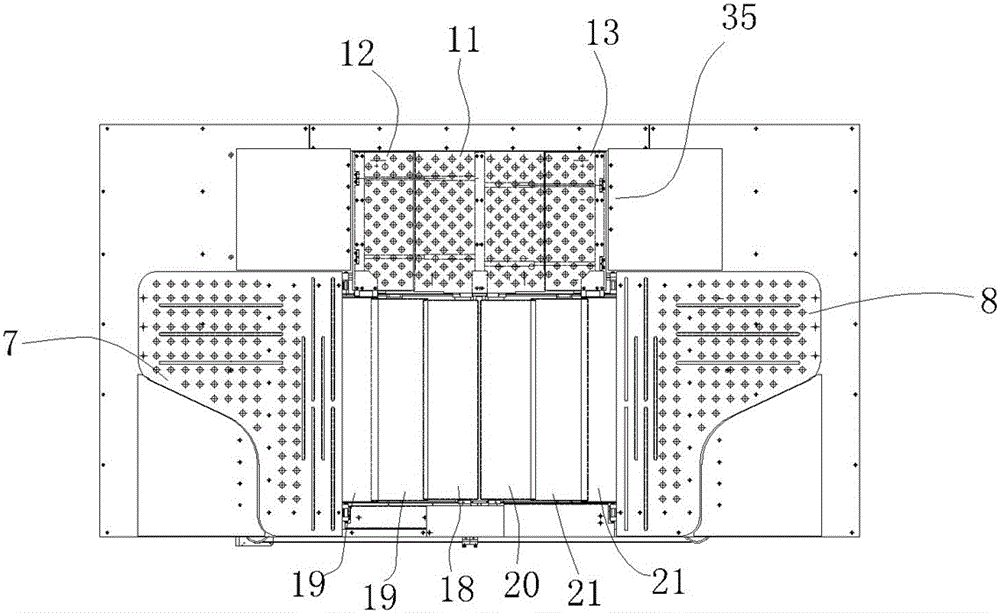

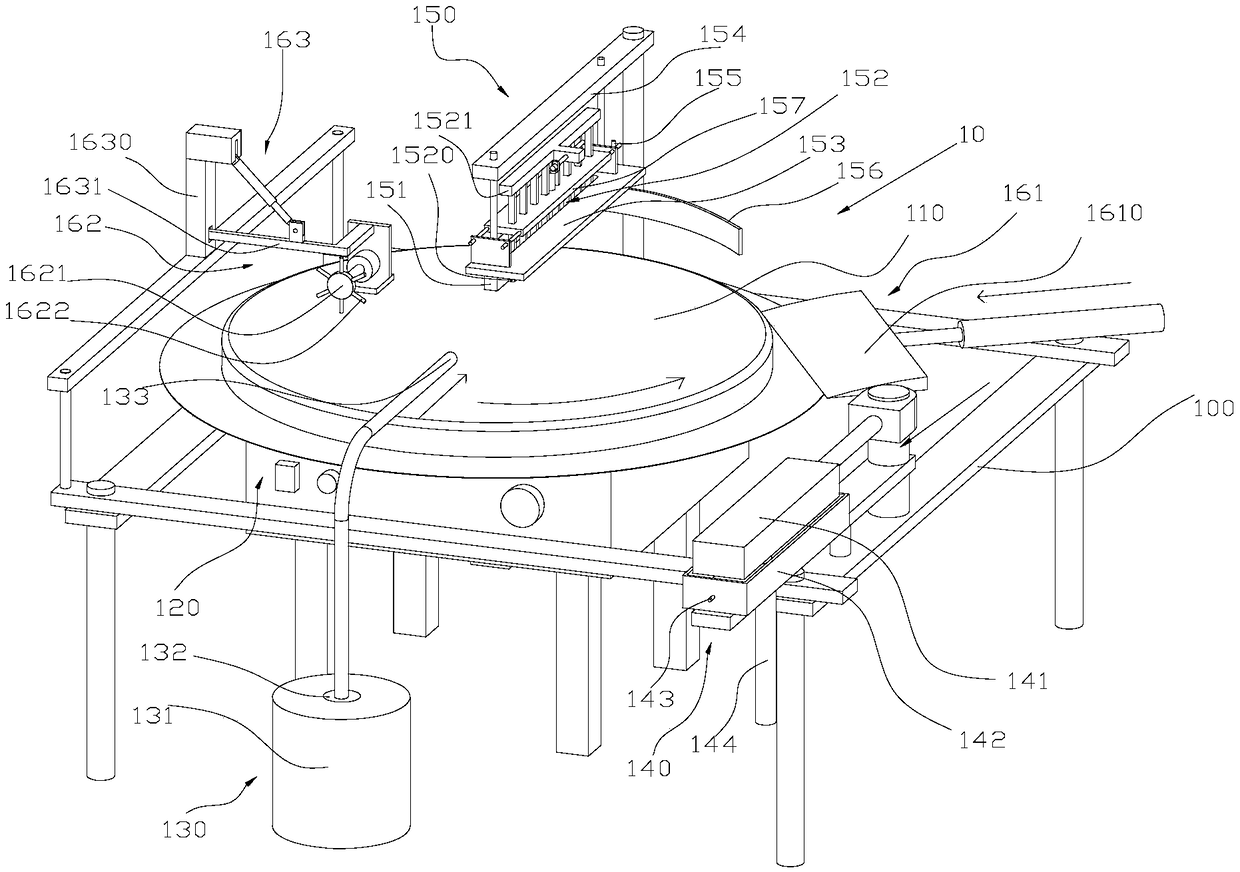

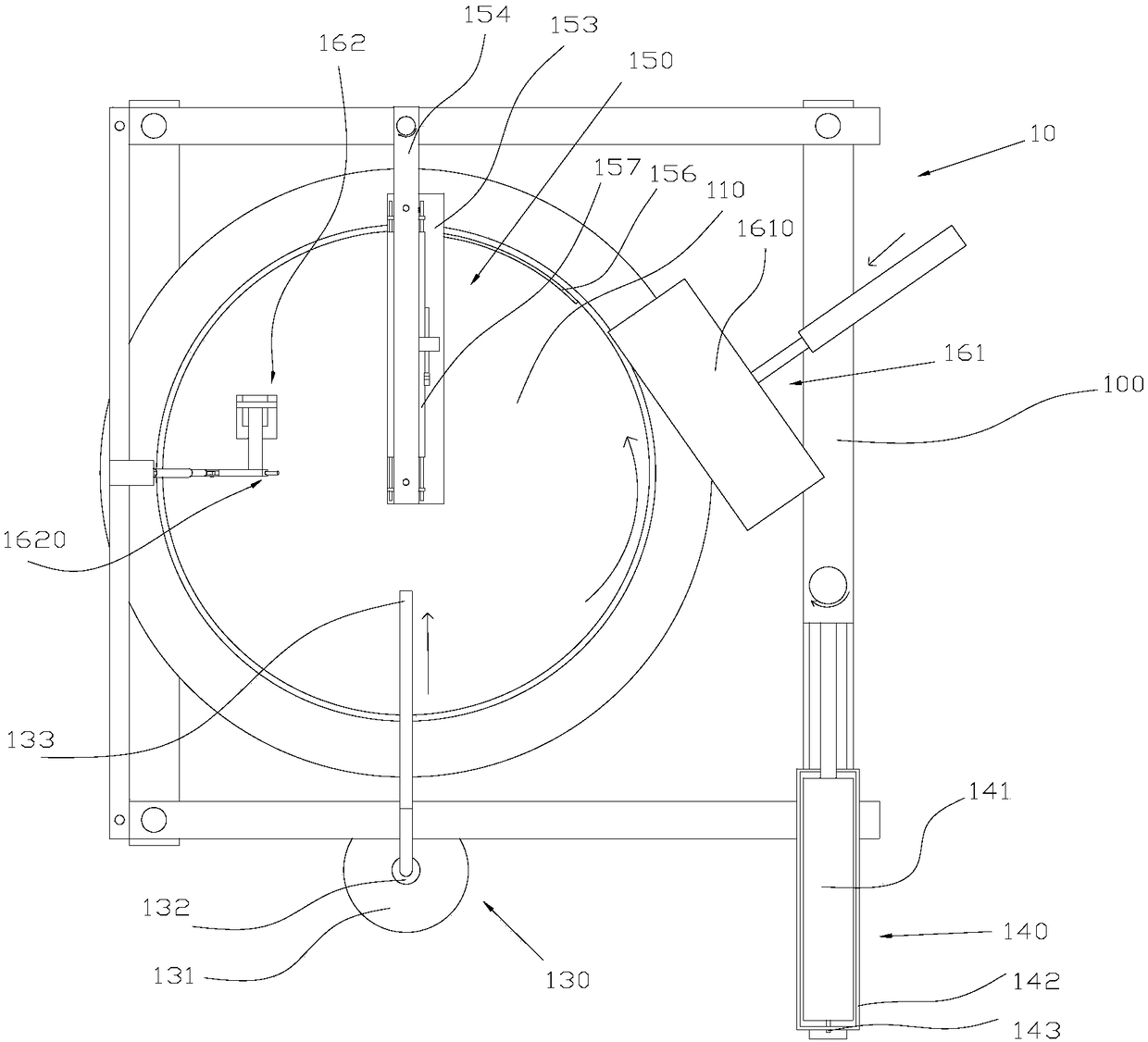

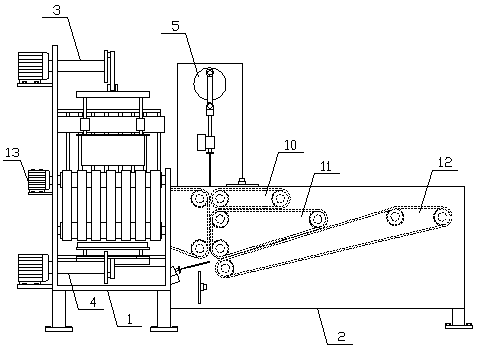

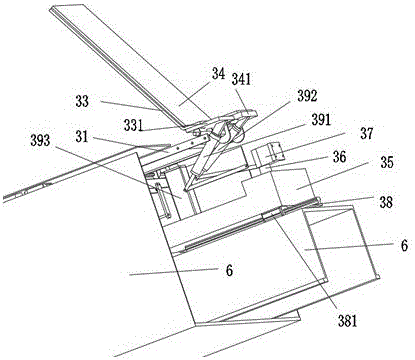

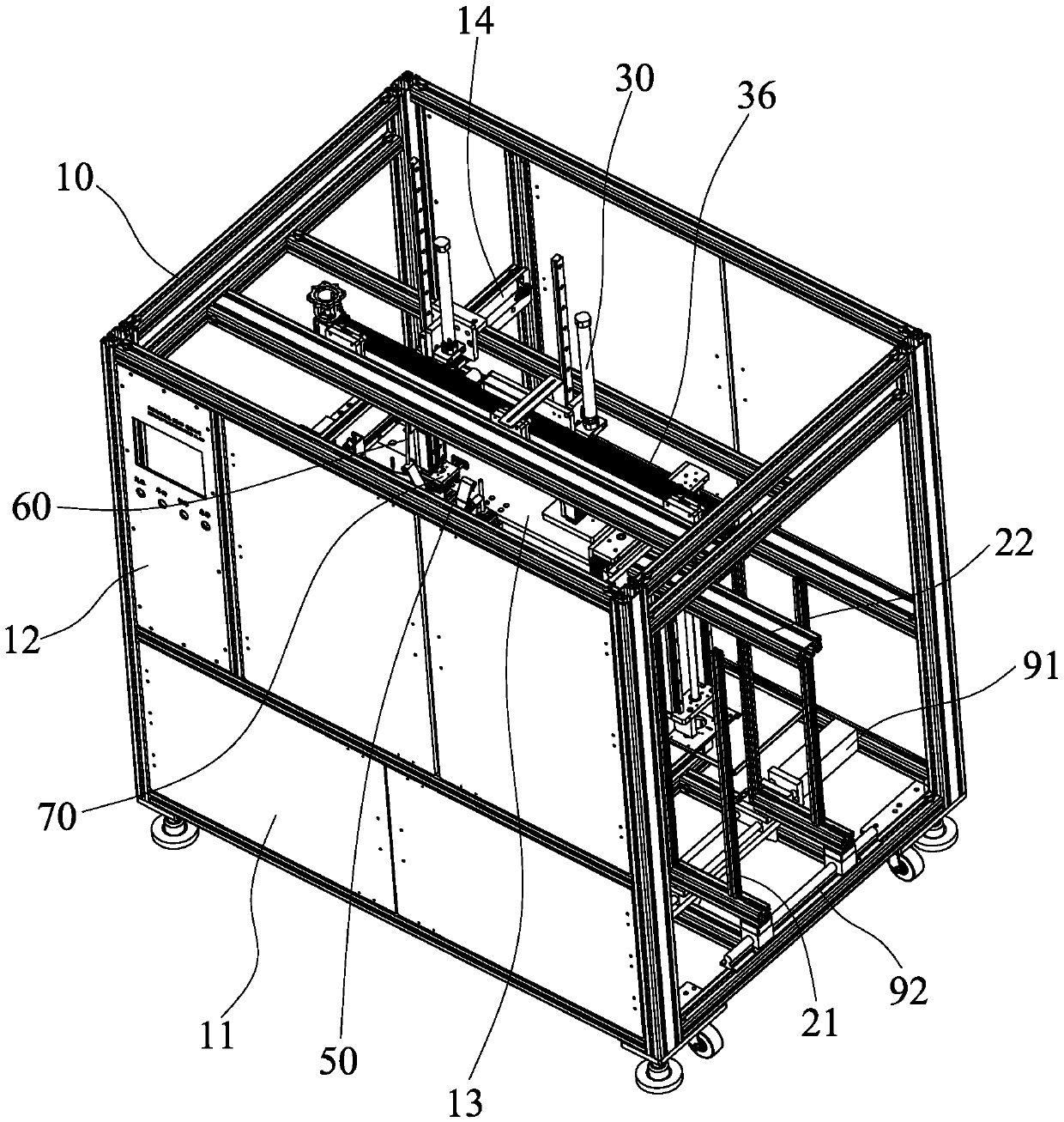

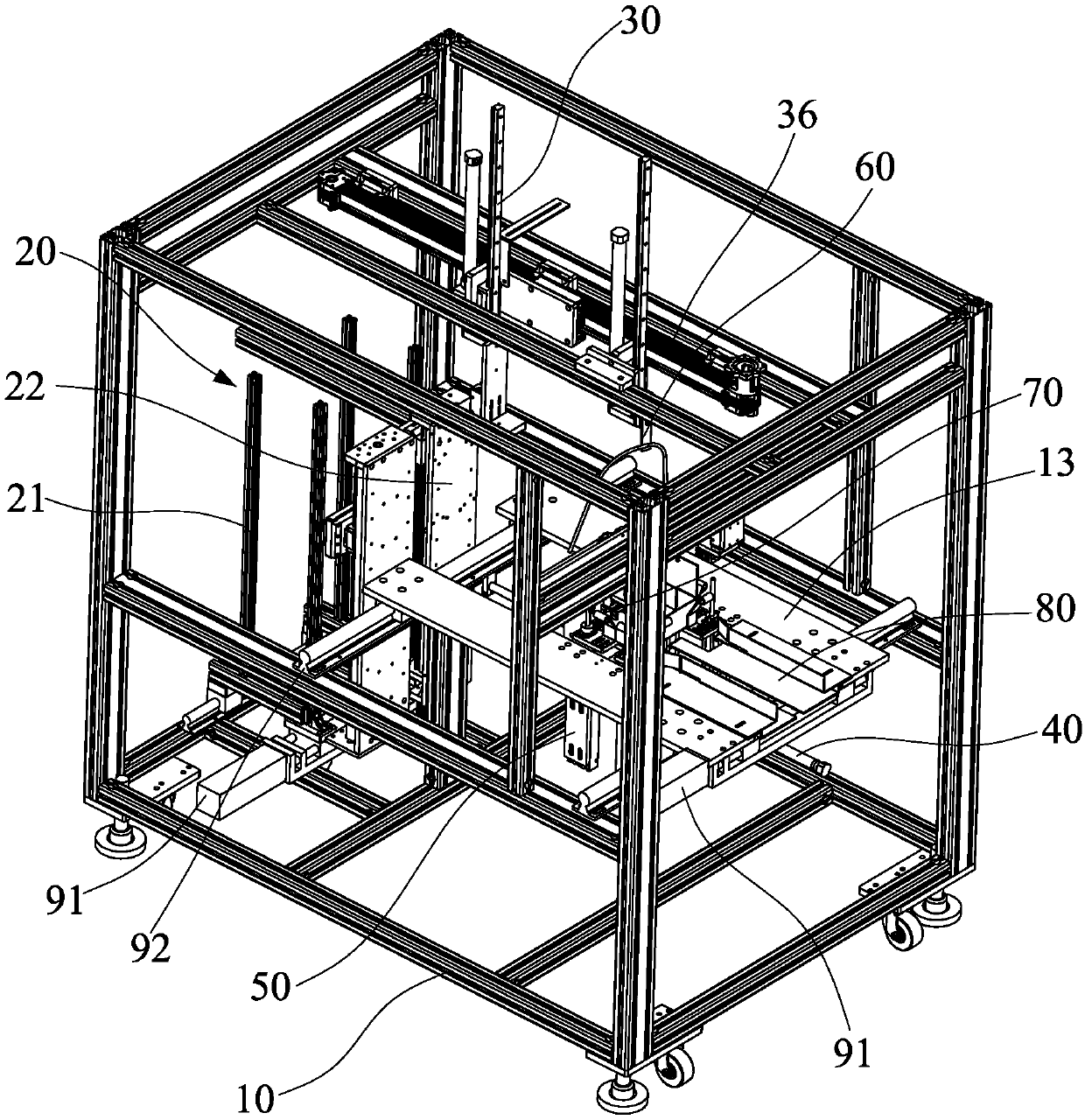

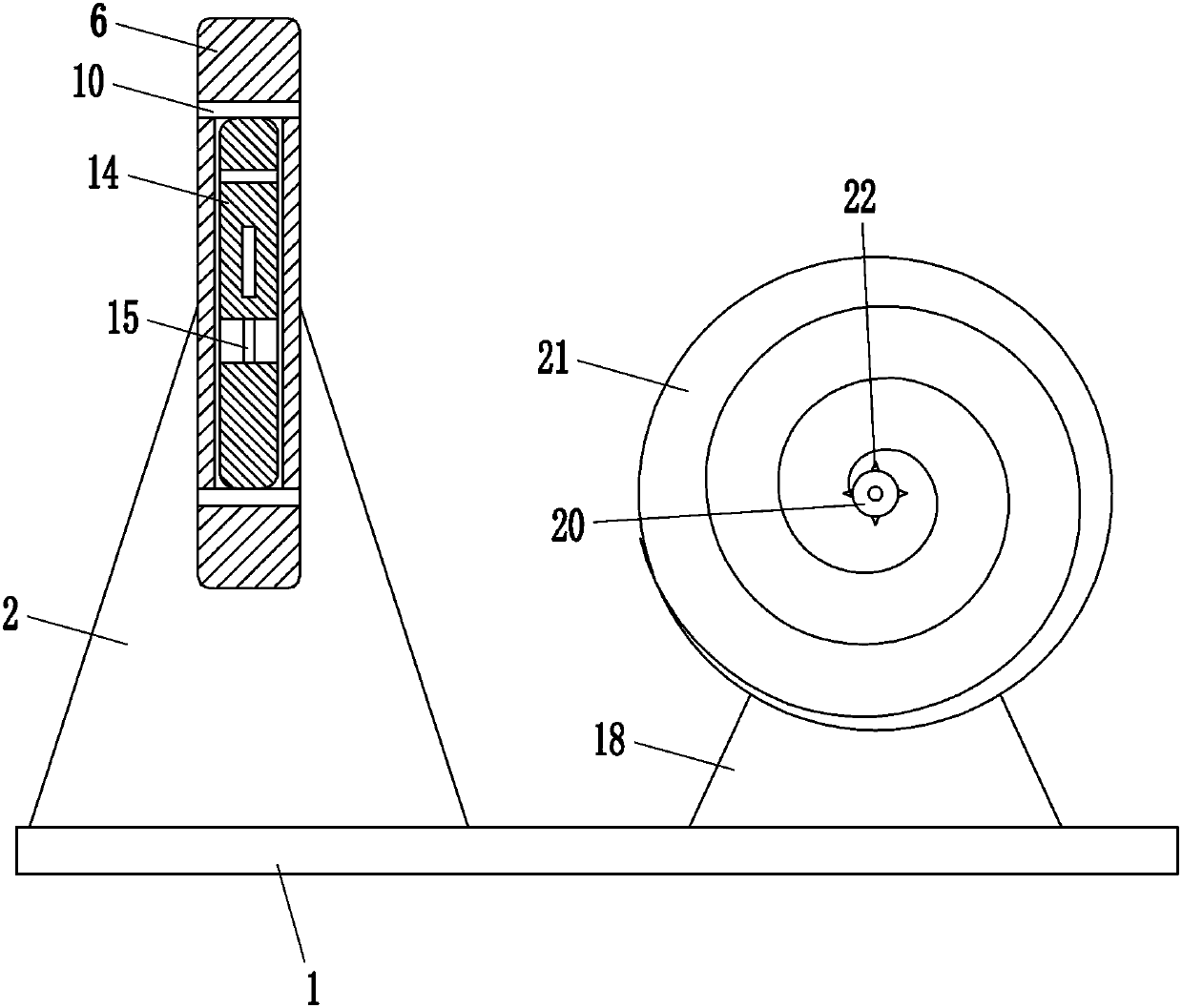

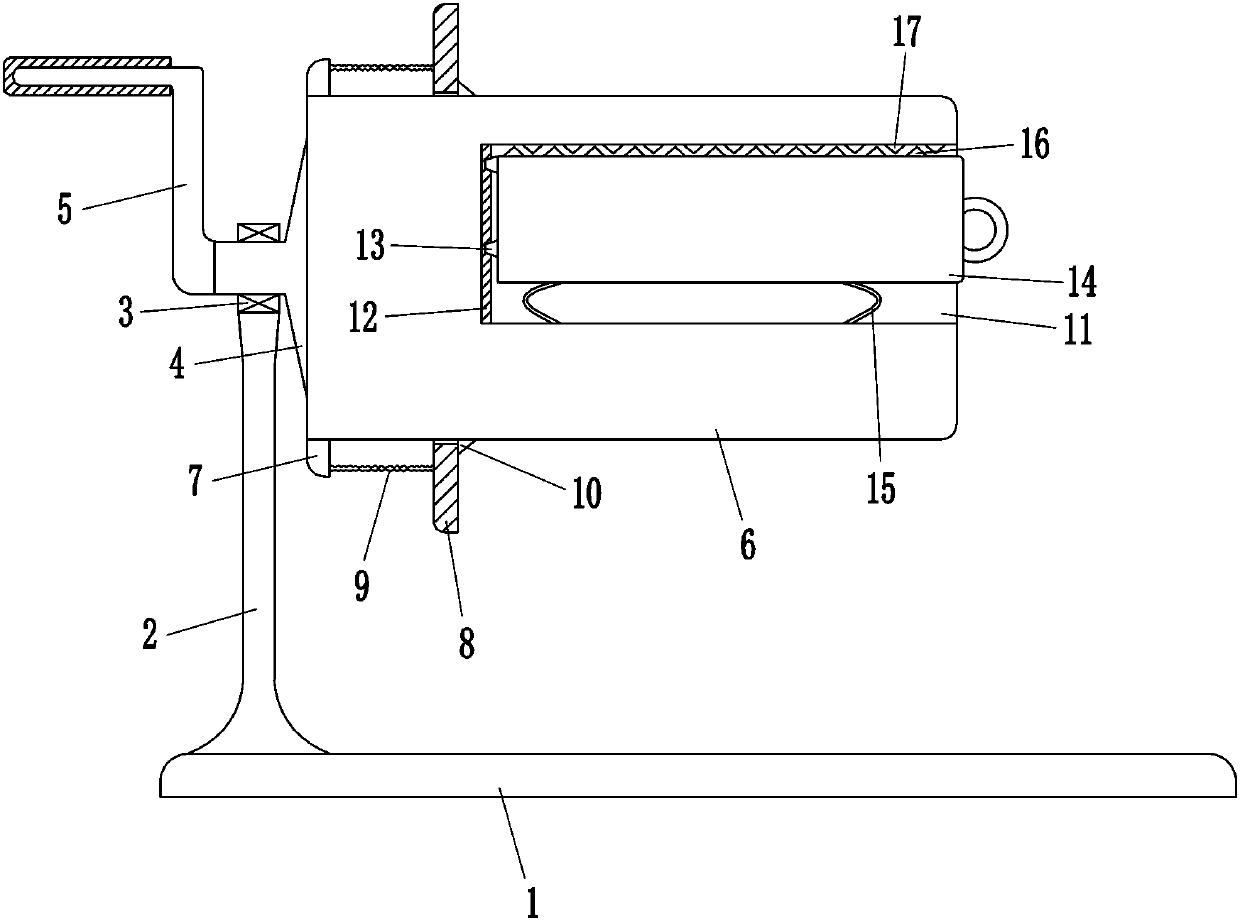

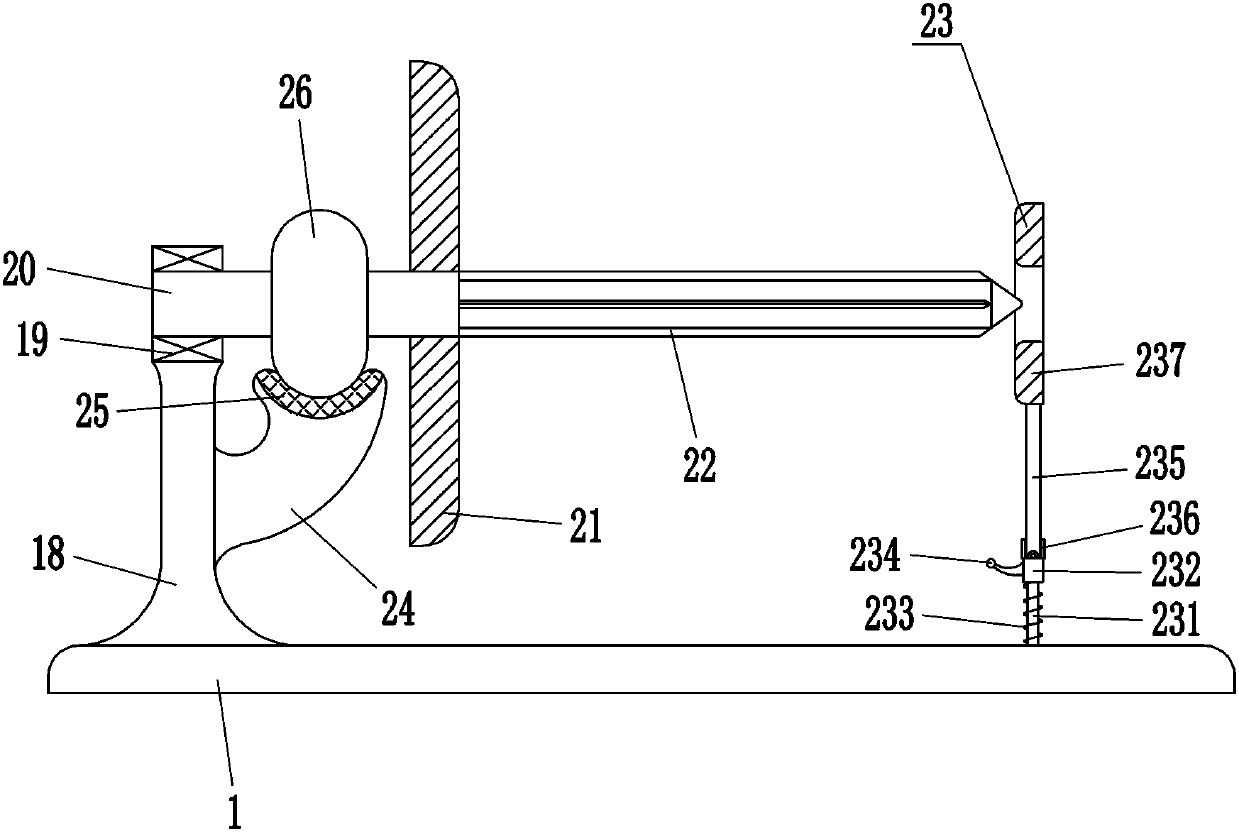

Folding and bundling integrated machine for packaging bag

ActiveCN106864886AImprove folding efficiencyTied up firmlyPaper article packagingBinding material applicationEngineeringMachining

The invention discloses a folding and bundling integrated machine for a packaging bag. The folding and bundling integrated machine comprises a machine frame, a bag body folding mechanism and a bundling mechanism, and is characterized in that the bag body folding mechanism comprises a supporting plate, a center positioning device, a front folding device for folding the bottom of a bag body backwards, and a rear folding device for folding a bag opening part of the bag body forwards. The front folding device and the rear folding device are arranged in front of and behind the supporting plate correspondingly. The center positioning device comprises positioning pressing plates, lifting parts driving the positioning pressing plates to rise and fall, and adjustment parts used for adjusting the transverse positions of the positioning pressing plates. The positioning pressing plates include the left pressing plate and the right pressing plate. The left pressing plate and the right pressing plate are arranged over the supporting plate and arranged on the two sides of the supporting plate correspondingly. Under the folding working condition, the bag body is arranged on the supporting plate, a front pressing plate and a rear pressing plate. According to the folding and bundling integrated machine, folding of the bag body is achieved in a center positioning and frontward-backward folding manner, the structure is simple, the machining cost is low, and the bag body folding efficiency is high.

Owner:浙江晨宇科技股份有限公司

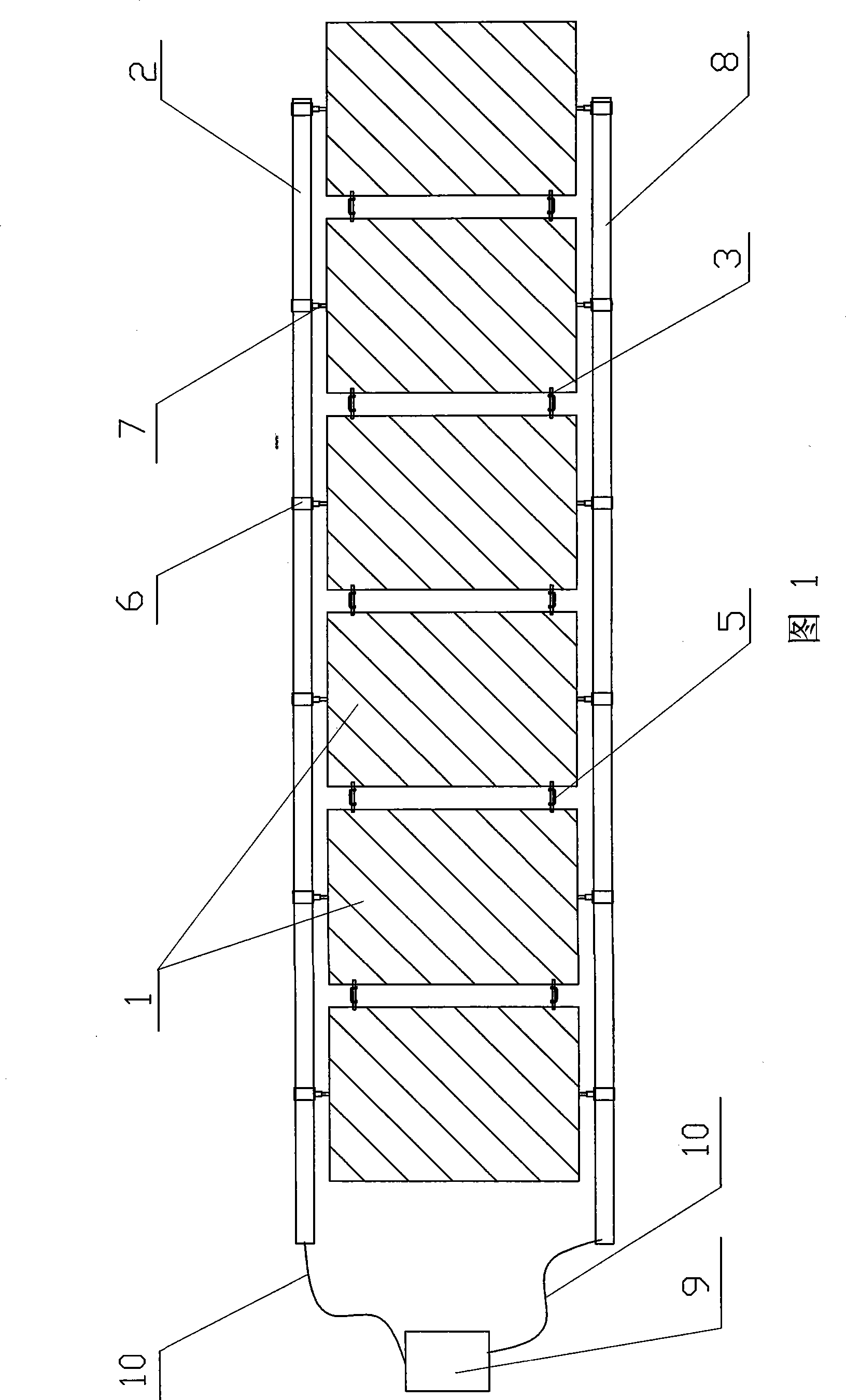

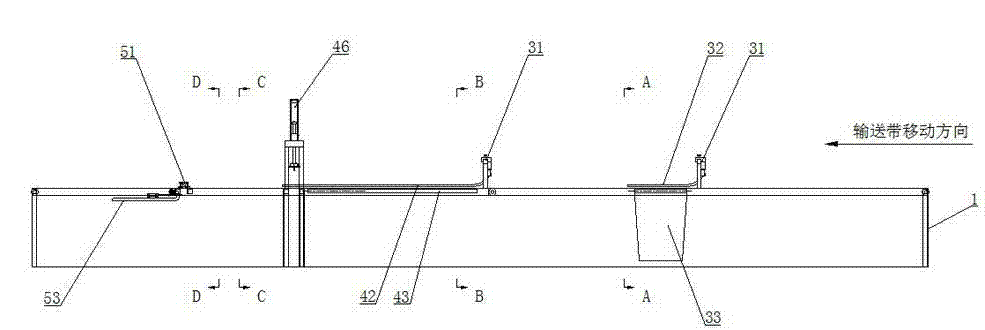

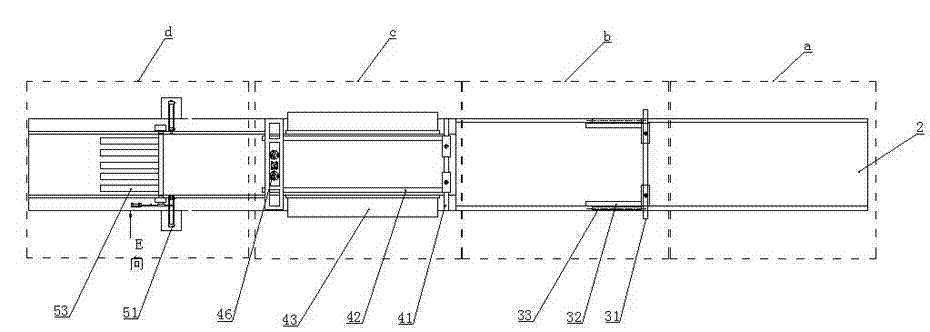

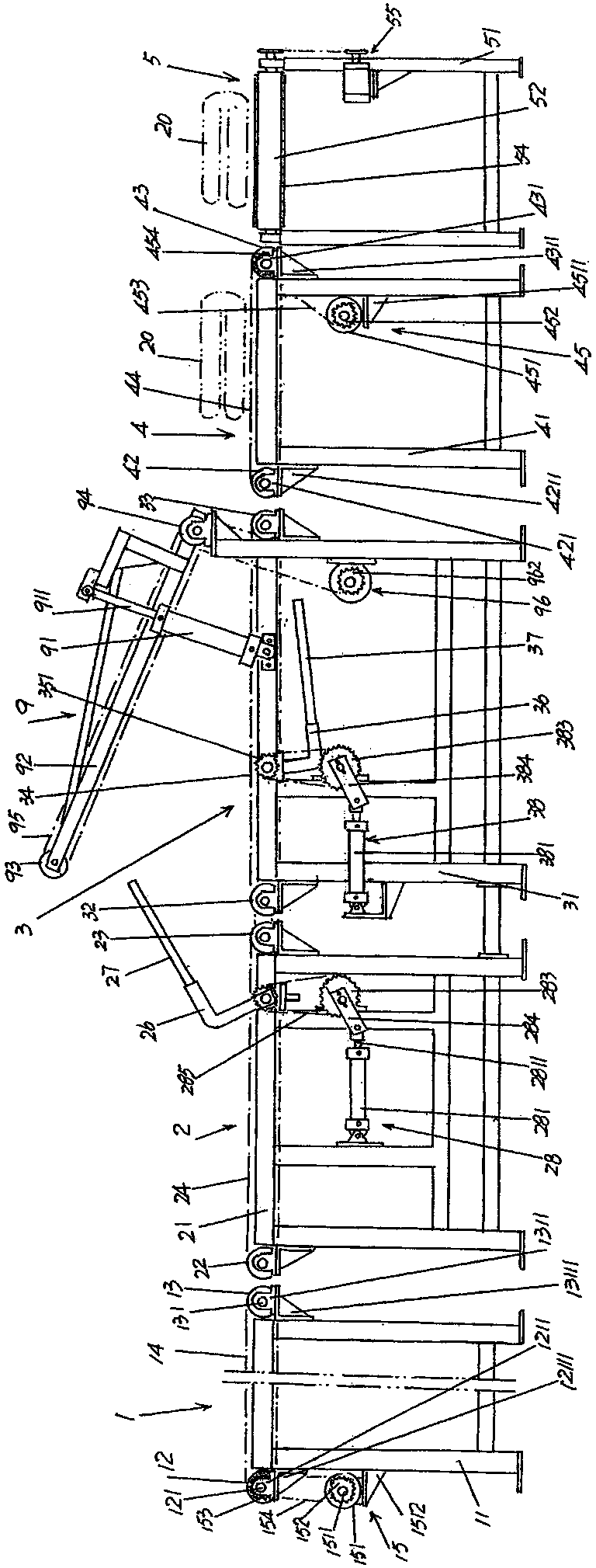

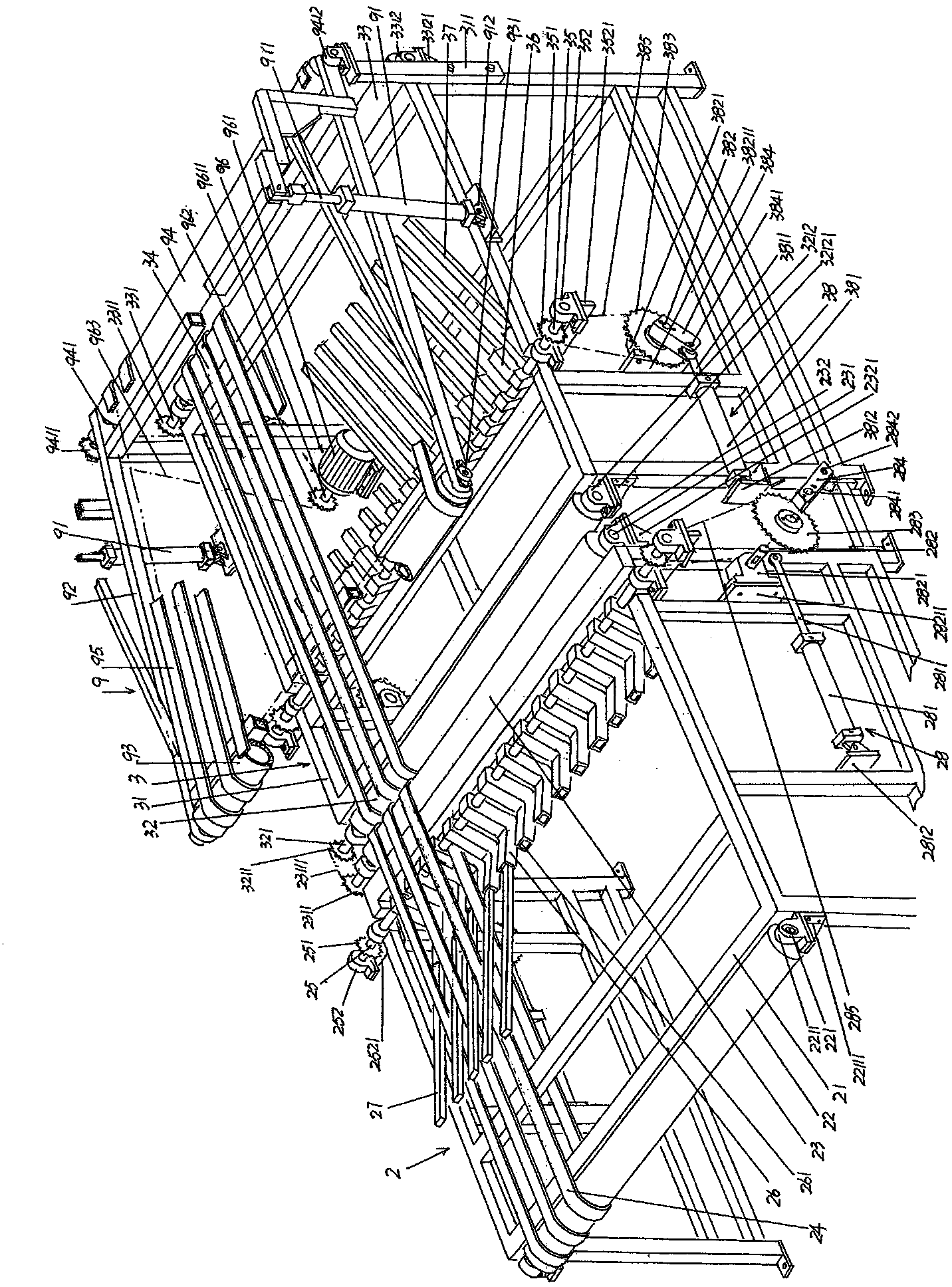

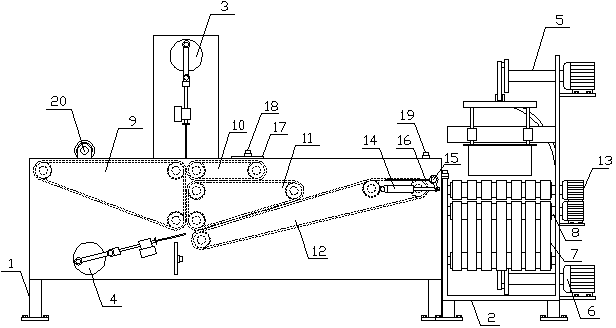

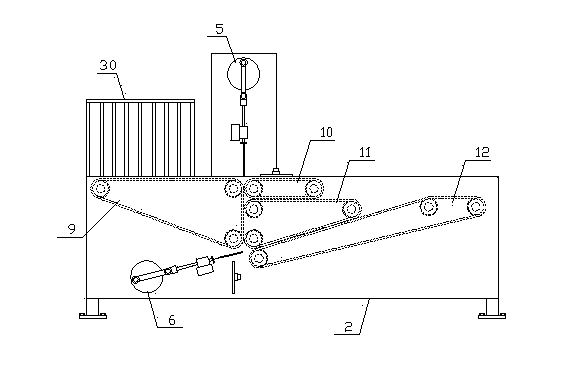

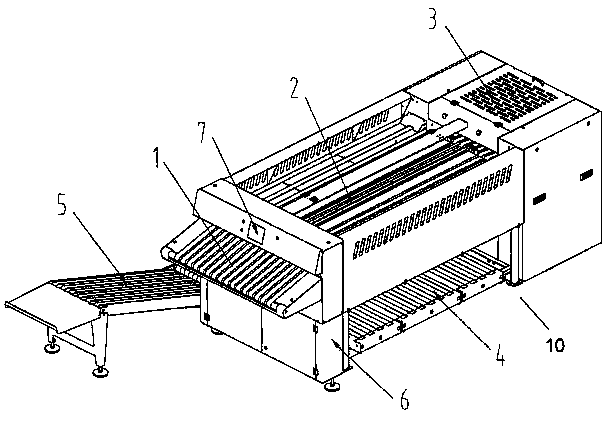

Automatic costume folding machine

ActiveCN102887249AReduce labor intensityImprove folding efficiencyPackagingAutomationProduction line

The invention relates to an automatic costume folding machine. The innovation points are as follows: the automatic costume folding machine comprises a stander and conveyer belts, wherein a preparation station, a first folding station, a second folding station and a third folding station are respectively arranged in an extending direction of the stander; the preparation station, the first folding station, the second folding station and the third folding station of the stander are provided with the conveyer belts with the same moving direction and the same speed; and a first folding mechanism, a second folding mechanism and a third folding mechanism are respectively arranged on the first folding station, the second folding station and the third folding station. An operator only needs to flatly pave a costume on the preparation station; the costume is driven by the conveyer belts to pass through the first folding station, the second folding station and the third folding station and is automatically folded by the corresponding folding mechanisms at the stations; the manual folding of the operator is not needed, so that the labor intensity of the operator is low, the folding efficiency is high, and labor is saved; the sizes of the folded costumes are consistent; the appearance effect is good; the automatic costume folding machine is beneficial to production lines; and the degree of automation of costume preparation is improved.

Owner:邱德强

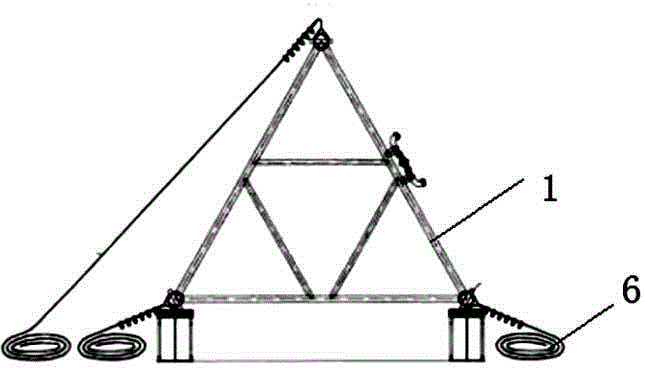

Plane framework supporting structure capable of steel charge expansion

InactiveCN1770550AMeet structural rigidity requirementsImprove folding efficiencyPhotovoltaic supportsAntenna supports/mountingsBaseboardEngineering

This invention relates to rigidity and charging extension plane frame supportive structure, which solves the current solar sailboard and plane antenna plane frame supportive structure mechanic extension and complex existence structure and bad reliability and low efficiency of folding. The frame rack is loaded with frame rack longitude baseboard, wherein, the baseboard and frame rack is connected through band; the baseboard upper end has sticking layer; the wire left end is fixed on frame rack supportive tube and is connected to supportive tube with electricity layer; the charging channel left end is fixed inside supportive tube with control valve.

Owner:HARBIN INST OF TECH

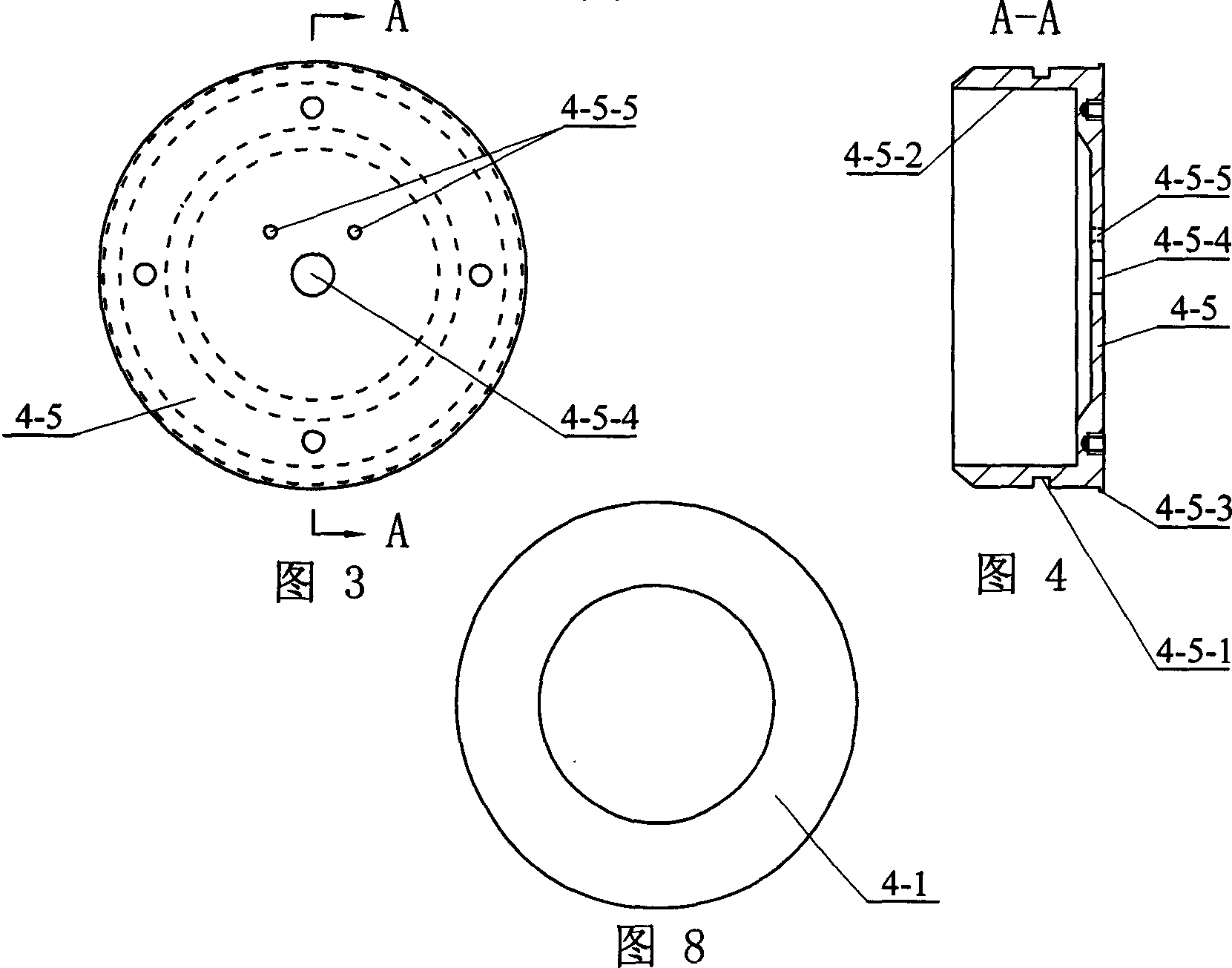

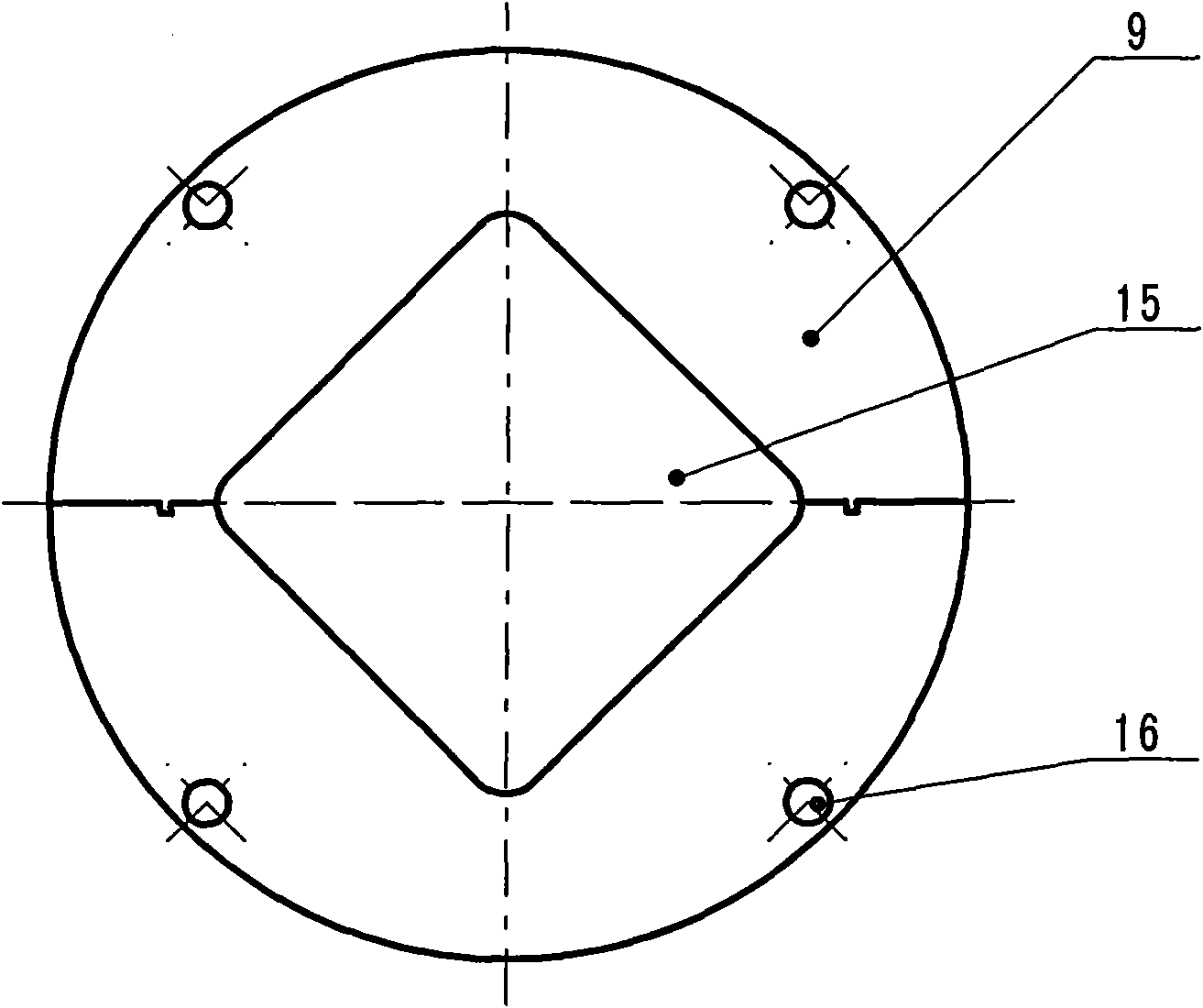

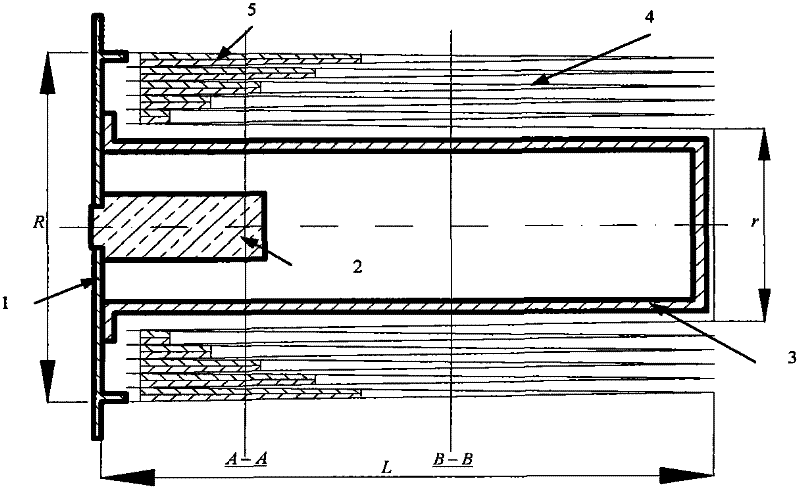

Prestressed spun concrete square piles and mould thereof

ActiveCN101560769AConsistent tensile stressUniform thicknessCeramic shaping apparatusBulkheads/pilesHoopingPrestressed concrete

The invention relates to a prestressed spun concrete square pile, comprising a square pile and a square metal end plate, wherein, the square pile consists of a reinforcing cage and the concrete. The reinforcing cage consists of a main reinforcement and a spiral hooping which is welded on the main reinforcement. The four arms of angle of the square pile and square metal end plate are all of circular arcs with the same radius of 10 to 40mm. The mould consists of an upper mould, a lower mould, a locking device and a hanging tight bolt. After the snap-fit of the upper mould and the lower mould, the inner chamber of the mould is square, wherein, the four interior arms of angle of the square are of circular arcs with the same radius. A locating pin is positioned at the joint part of upper mould and the lower mould; the hanging tight bolt is a coarse thread bolt, with the thread pitch of 2 to 4mm. The prestressed spun concrete square piles have the characteristics that the tensile stress of the main reinforcement is consistent after moulding and tension-releasing of the pile body, the concrete protective layer enfolded on the main reinforcement is uniform, the strength of the pile body is high; the hanging tight bolt on the mould of the prestressed spun concrete square pile has the advantages of high efficiency in folding and packing, long life and low cost.

Owner:凌德祥

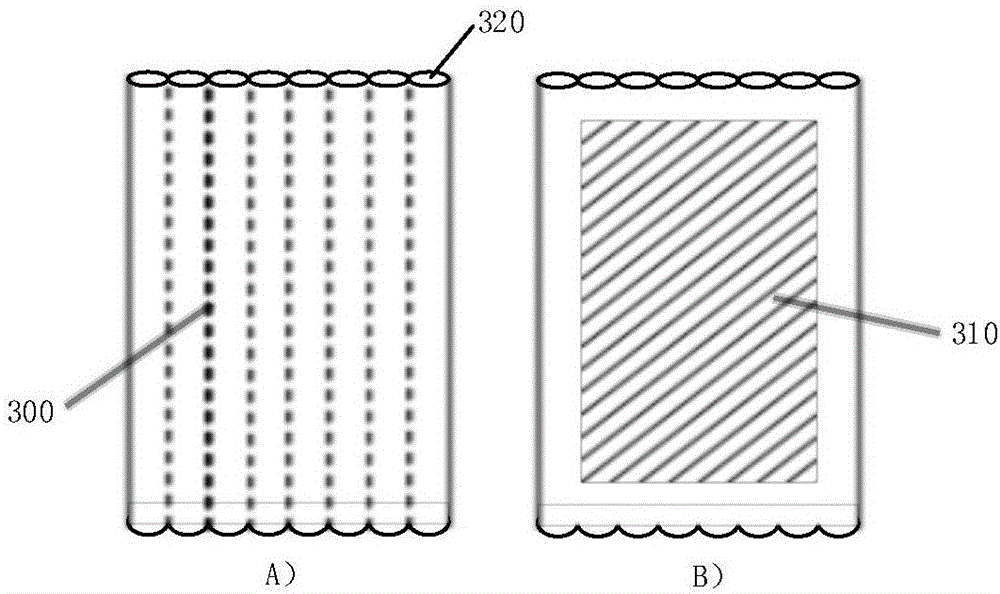

Multi-layer cavity type inflating expansion protection mechanism

InactiveCN101367440AImprove the protective effectStable inflation processProtection against meteoritesProtection mechanismEngineering

A multi-layer cavity-type aeration for expansion protection mechanism relates to an aeration for expansion protection mechanism, which aims at solving the problems that a monolayer protection screen can not effectively avoid the damage caused by the collision from the space chippy fraction, and a mechanism-typed expansion protection mechanism has low folding efficiency, low expansion reliability and a small volume after expansion. Parts of the periphery of the adjacent two protection screens cling together to form a cavity-type aeration for expansion protection screen to be rigidified, which is connected with an aeration supporting frame to be rigidified; a main inflation pipe is arranged in the cavity-type aeration for expansion protection screen to be rigidified and communicated with an air-discharging pipe; the lower end of the aeration supporting frame to be rigidified is provided with an aeration supporting pipe to be rigidified, which is communicated with the inflation pipe of a supporting pipe; two ends of an aeration bent pipe are communicated with an aeration pipe to be rigidified and the aeration supporting pipe to be rigidified. The invention can avoid the damage caused by the collision from the space chippy fraction, and has the advantages of high folding efficiency, high expansion reliability and a large volume after expansion.

Owner:HARBIN INST OF TECH

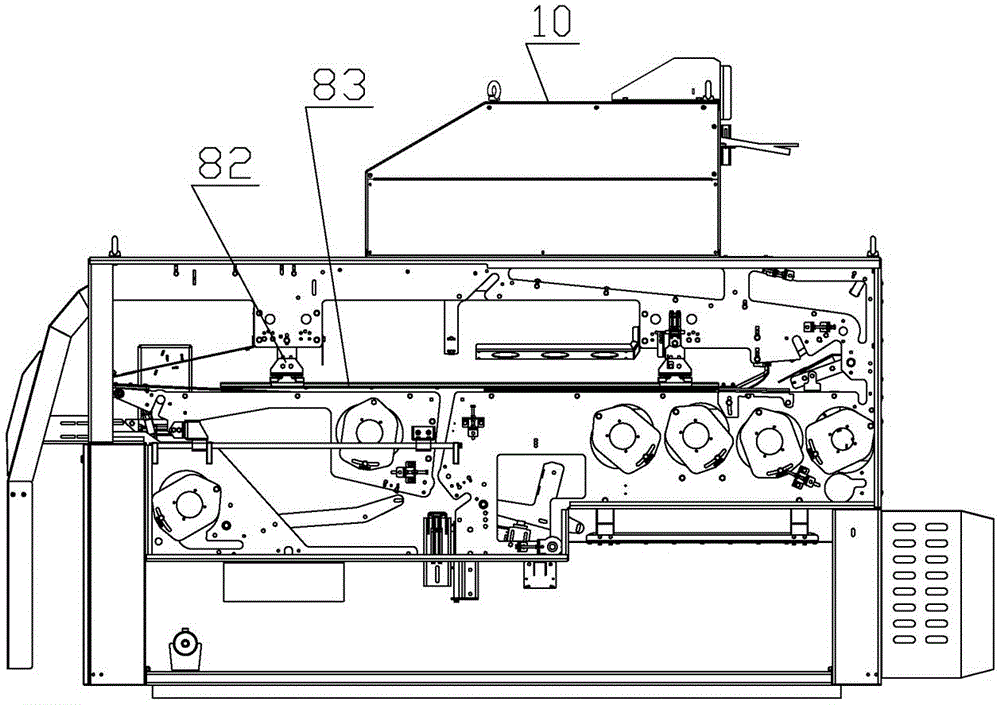

Quilt folding machine

ActiveCN104108497ARealize automatic foldingReduce human inputFolding thin materialsPackagingEngineeringAssembly line

The invention relates to a quilt folding machine, and belongs to the technical field of packaging machines. The quilt folding machine comprises a quilt tiling guiding-in mechanism, a front longitudinal quilt folding mechanism, a back longitudinal quilt folding mechanism, a folded quilt transferring mechanism, a folded quilt conveying mechanism, a transverse quilt folding mechanism and a folded quilt output mechanism; wherein the back longitudinal quilt folding mechanism is located between the quilt tiling guiding-in mechanism and the front longitudinal quilt folding mechanism, the folded quilt transferring mechanism corresponds to the front longitudinal quilt folding mechanism, the folded quilt conveying mechanism corresponds to the folded quilt transferring mechanism, the transverse quilt folding mechanism corresponds to the folded quilt conveying mechanism, the folded quilt output mechanism is located between the transverse quilt folding mechanism and a bagging mechanism and used for conveying a folded quilt folded and shaped by the transverse quilt folding mechanism to the bagging mechanism, and the folded quilt coming from the folded quilt output mechanism is guided into a packaging bag through the bagging mechanism. The quilt folding machine has the advantages that manual folding is not needed so that manual input can be remarkably reduced, and labor resources can be saved; as the quilt can be automatically folded so that the folding efficiency can be high and can adapt to the production efficiency of a quilt manufacturing assembly line; as mechanical automatic folding is achieved, the stable folding effect is achieved to guarantee the packaging quality.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

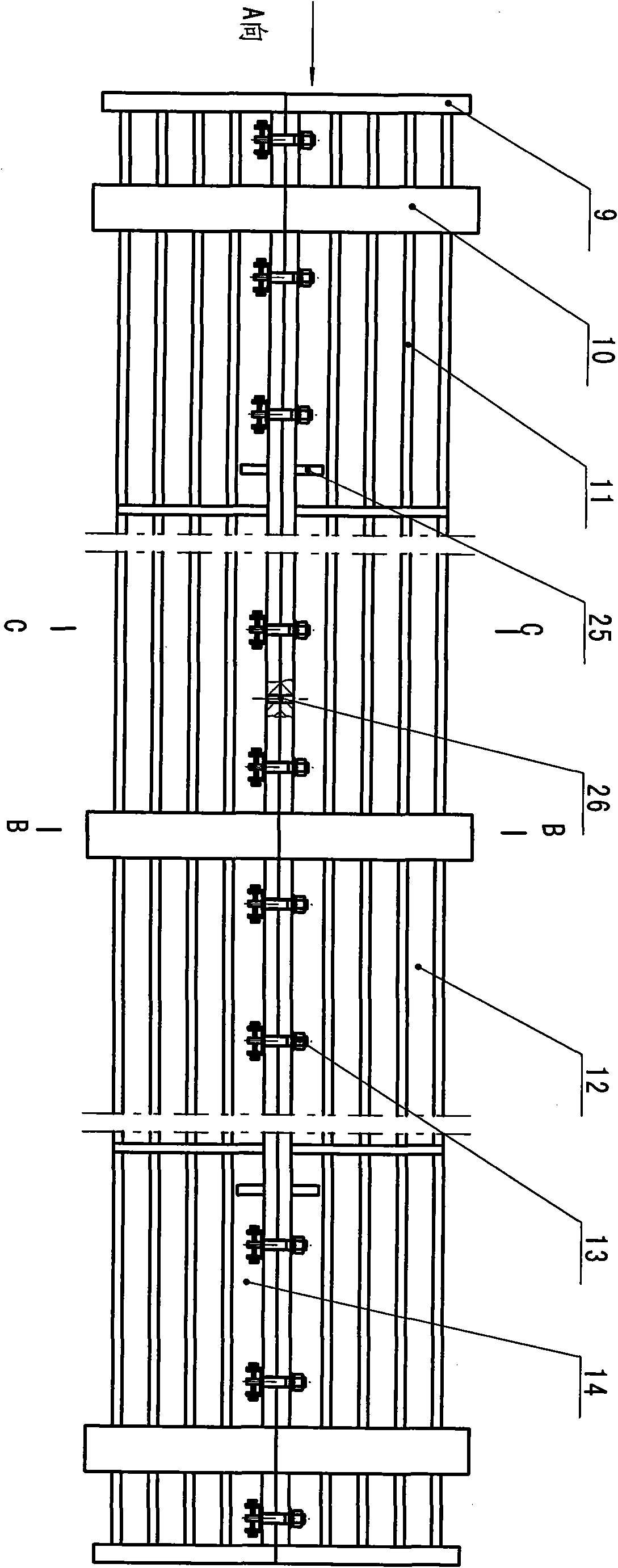

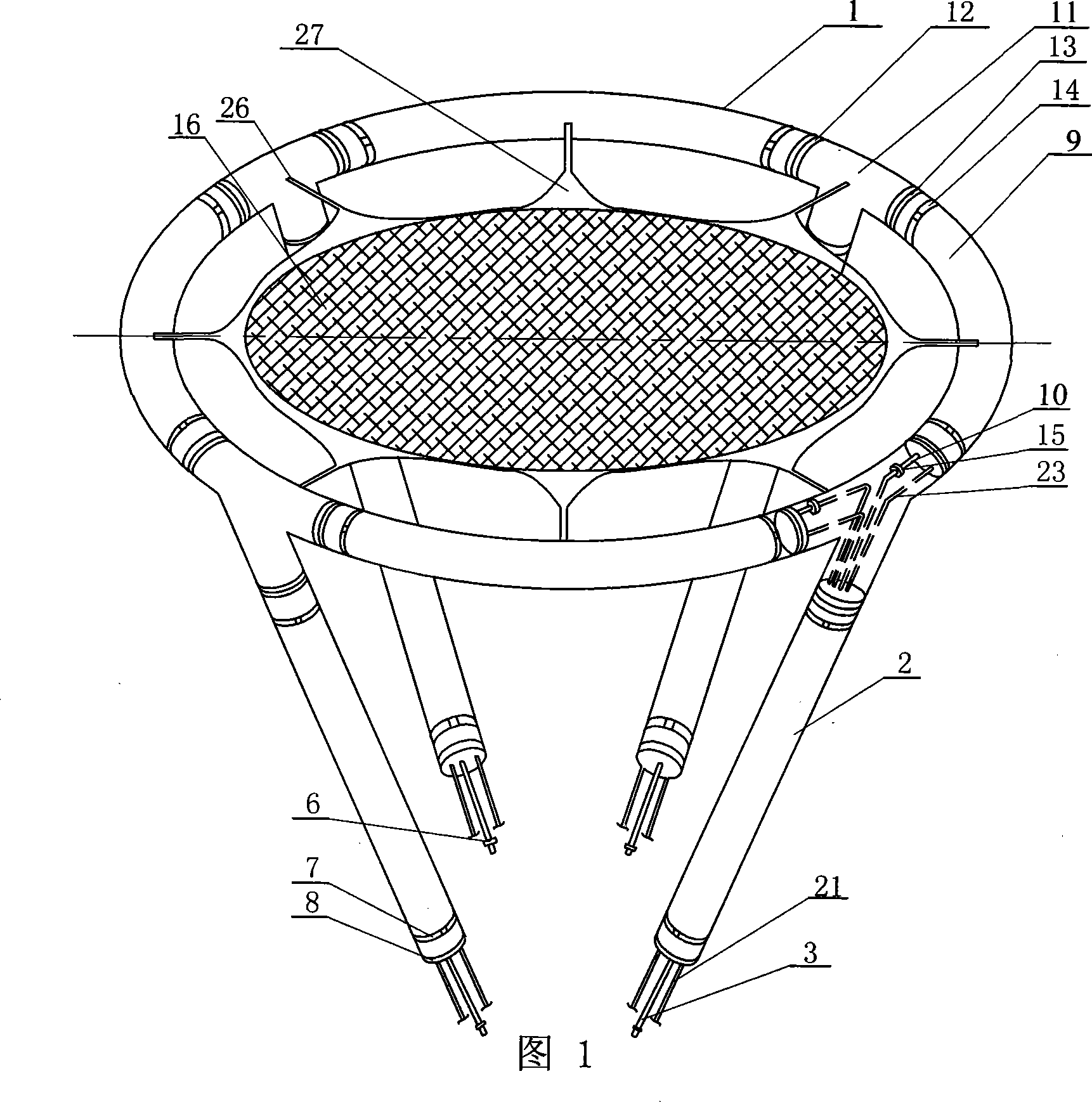

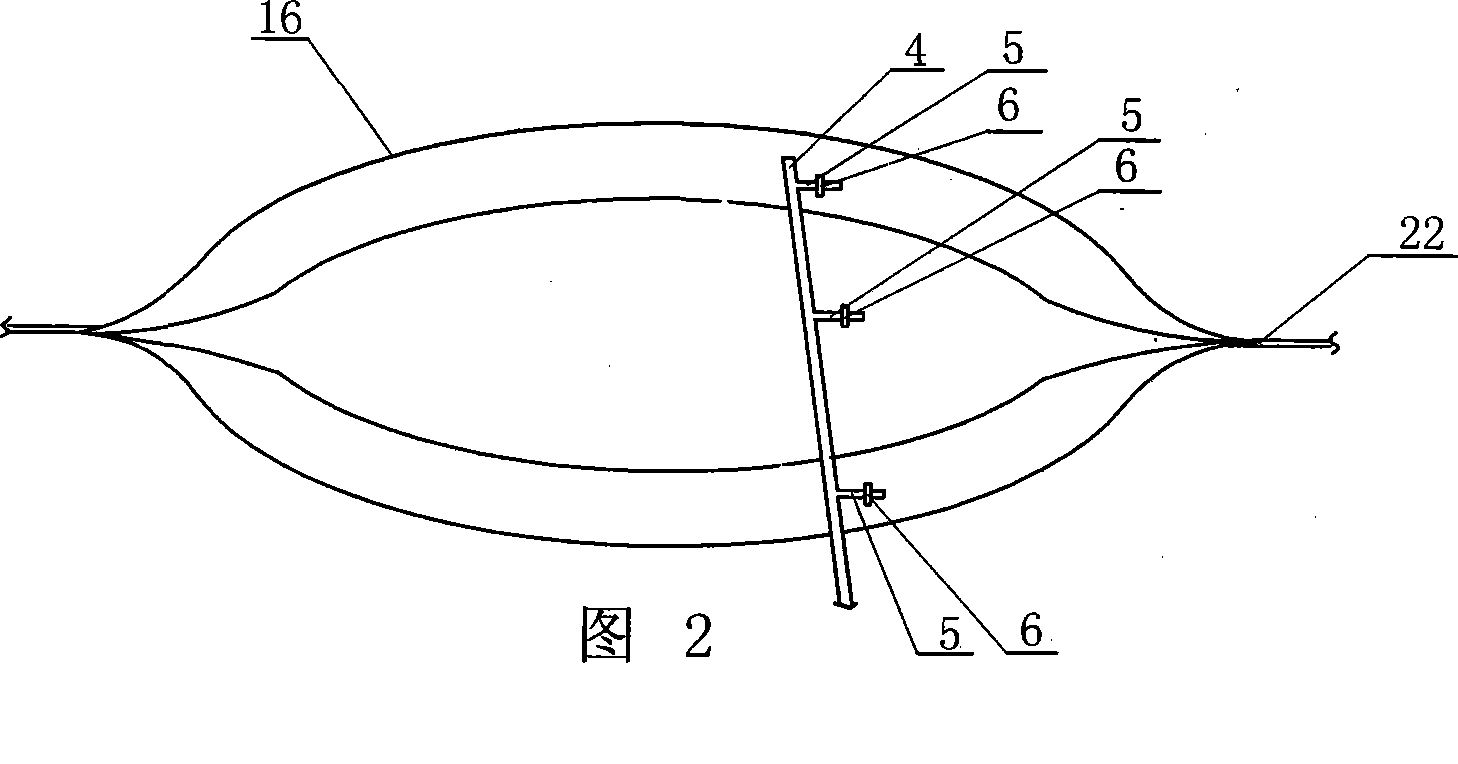

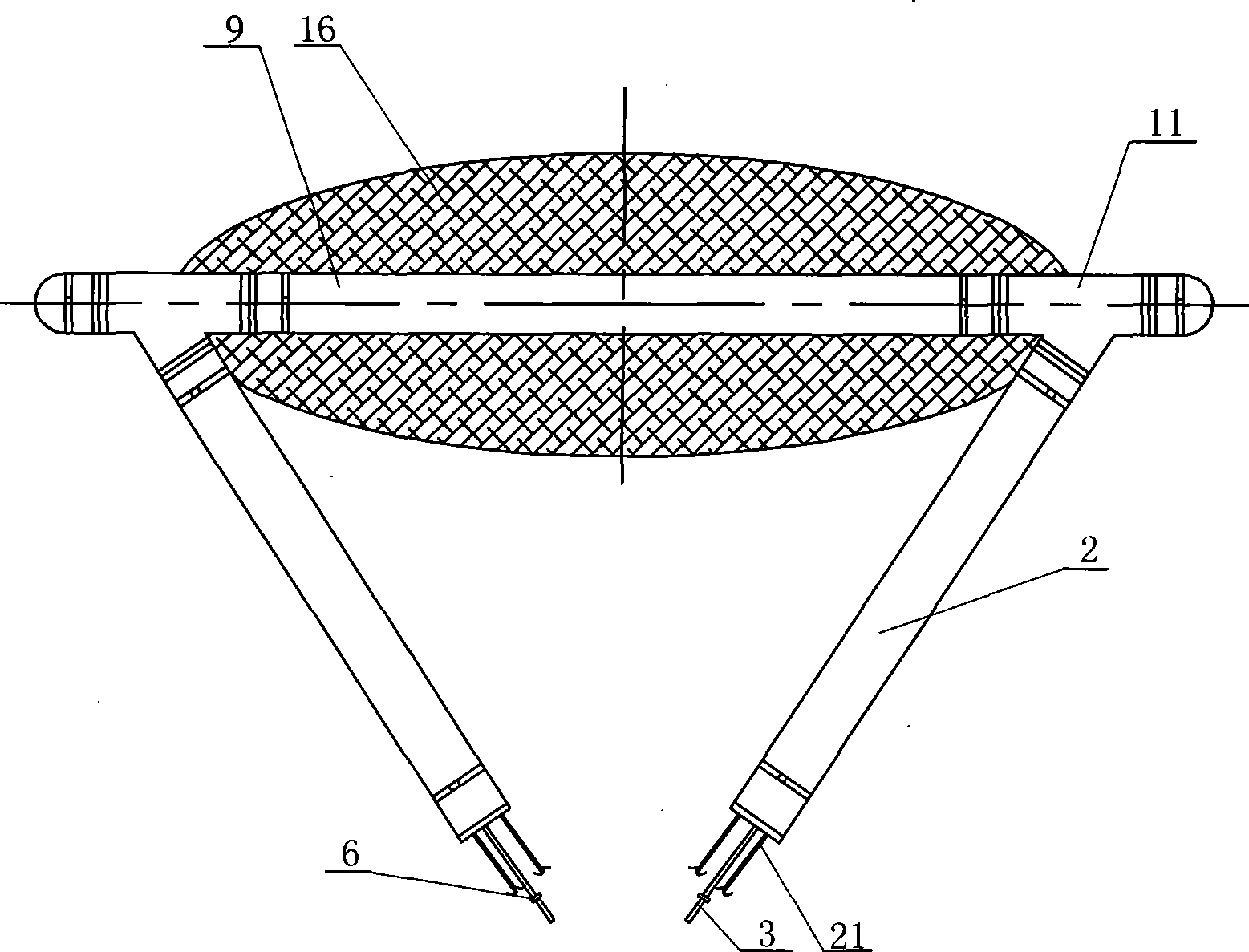

Space fragment and micrometeoroid impact resistant protection mechanism capable of inflating and expanding on rails

InactiveCN101342947AStable inflation processControllable inflation and deployment processProtection against meteoritesVertical tubeProtection mechanism

A defense mechanism which can be charged and unfolded on track and is capable of resisting the impact from space debris and micrometeoroid relates to a defense mechanism for resisting the impact from space debris and micrometeoroid, aiming at solving the problems of high cost and big difficulty in large size defense screens assembled in space for one or more launches and the problems of low folding efficiency, low reliability and small size after being unfolded on mechanically unfolded defense screens. Two adjacent layers of plane frames which can be hardened and can be unfolded by charging are connected through a support upright pipe assembly which can be unfolded by charging, and defense screens are arranged in the plane frames which can be hardened and can be unfolded by charging and are connected with the plane frames which can be hardened and can be unfolded by charging; horizontal leads and air inlet pipes are arranged inside the plane frames which can be hardened and can be unfolded by charging; vertical parallel leads and charging pipes are arranged inside the support upright pipe assembly which can be unfolded by charging; the horizontal leads are connected with the vertical parallel leads; the first charging pipe and the second charging pipe are communicated with short and long support pipes which can be hardened and can be unfolded by charging; the vertical charging pipes are communicated with the support upright pipes which can be hardened and can be unfolded by charging. The defense mechanism is good in defending effect, high in reliability, light in weight, high in folding efficiency and low in cost.

Owner:HARBIN INST OF TECH

Box folding mechanism

The invention relates to a box folding mechanism. The box folding mechanism comprises a rack, wherein a square folding platform is fixed on the rack, two groups of folding plates are separately hinged to two opposite sides of the folding platform, and ear folding plates are separately hinged to the rack at two opposite sides of one group of folding plates; a folding plate jacking mechanism and an ear folding plate jacking mechanism are separately arranged on the rack below the folding platform, the folding plates are movably connected with the folding plate jacking mechanism separately through links, and the ear folding plates are movably connected with the ear folding plate jacking mechanism separately through links, two pressing mechanisms are further arranged on the rack above the folding platform, one pressing mechanism is used for pressing ear folding parts of carton boards, and the other pressing mechanism is used for pressing carton boards parts, which do not need folding, located on the folding platform. According to the box folding mechanism, all corners of each cut planar carton board can be automatically folded as required according to box folding requirements. The folding efficiency is high, the folding quality is high, and the space occupied by the box folding mechanism is small.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

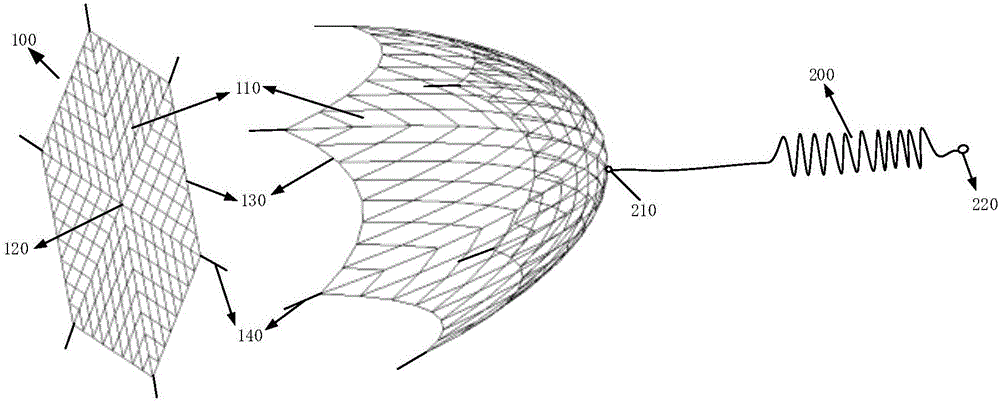

Storing and packaging method for hexagonal rope net

ActiveCN105667841AAvoid center of mass shiftAchieving symmetrical pull-outToolsEngineeringConductor Coil

The invention provides a storing and packaging method for a hexagonal rope net. The method is used for storing and packaging the hexagonal rope net used for space capturing and comprises the following steps that firstly, a rope net central knot is pulled upwards to pull the rope net to be in the shape of a net beam, and sideline ropes are folded in a W-shaped mode to be stored in a plurality of sideline rope bags correspondingly; secondly, a coiled mooring rope bag is inserted into innermost net bag separation cloth, and a mooring rope platform connecting ring is located below the separation cloth and penetrates through a net hold bottom hole; and thirdly, the sideline rope bags are pulled upwards to pull the rope net to be in the shape of a beam, the central knot of the rope net and a rope net connecting ring of a mooring rope are connected, the rope net is stored in a net bag from the rope net central knot to outside step by step, and the sideline rope bags are adhered to the multiple side surfaces of a net hold correspondingly to complete the rope net storing process. According to the storing and packaging method, on the basis of a manual storing mode, the mooring rope, rope net meshes and sidelines are effectively isolated, the orderliness of the rope net drawing-out and folding process is ensured, and the problem that winding, crossing, knotting and the like are prone to occurring in the work process is solved.

Owner:NAT UNIV OF DEFENSE TECH

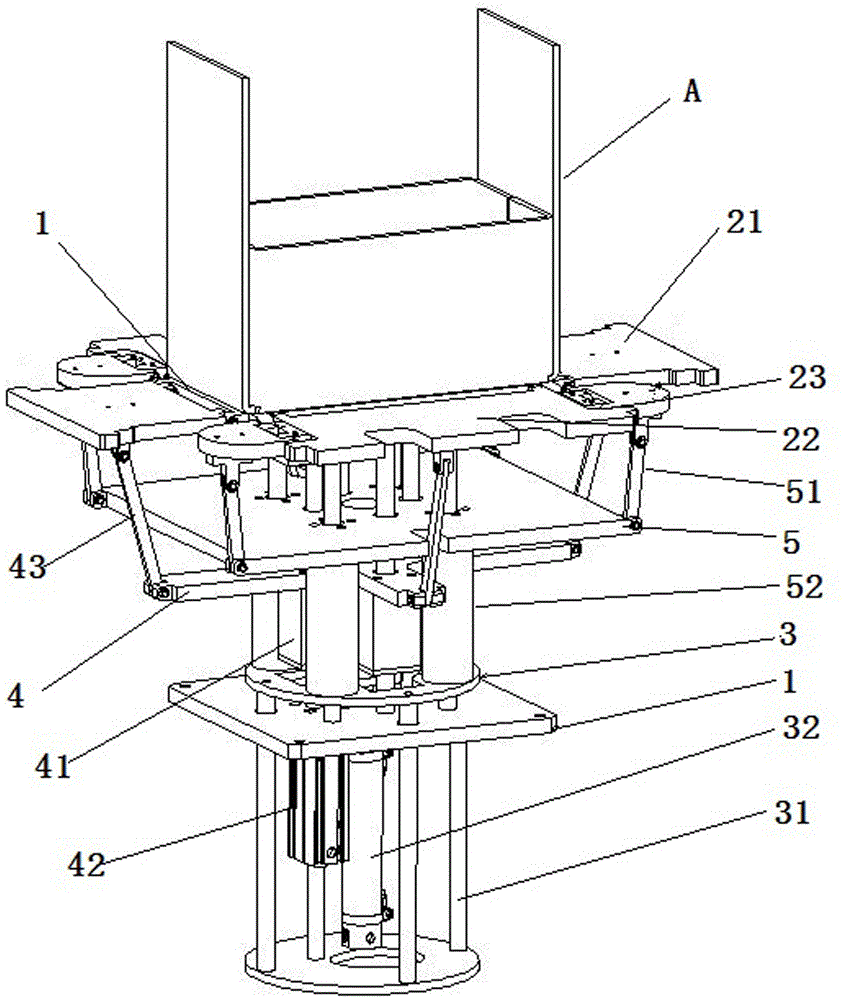

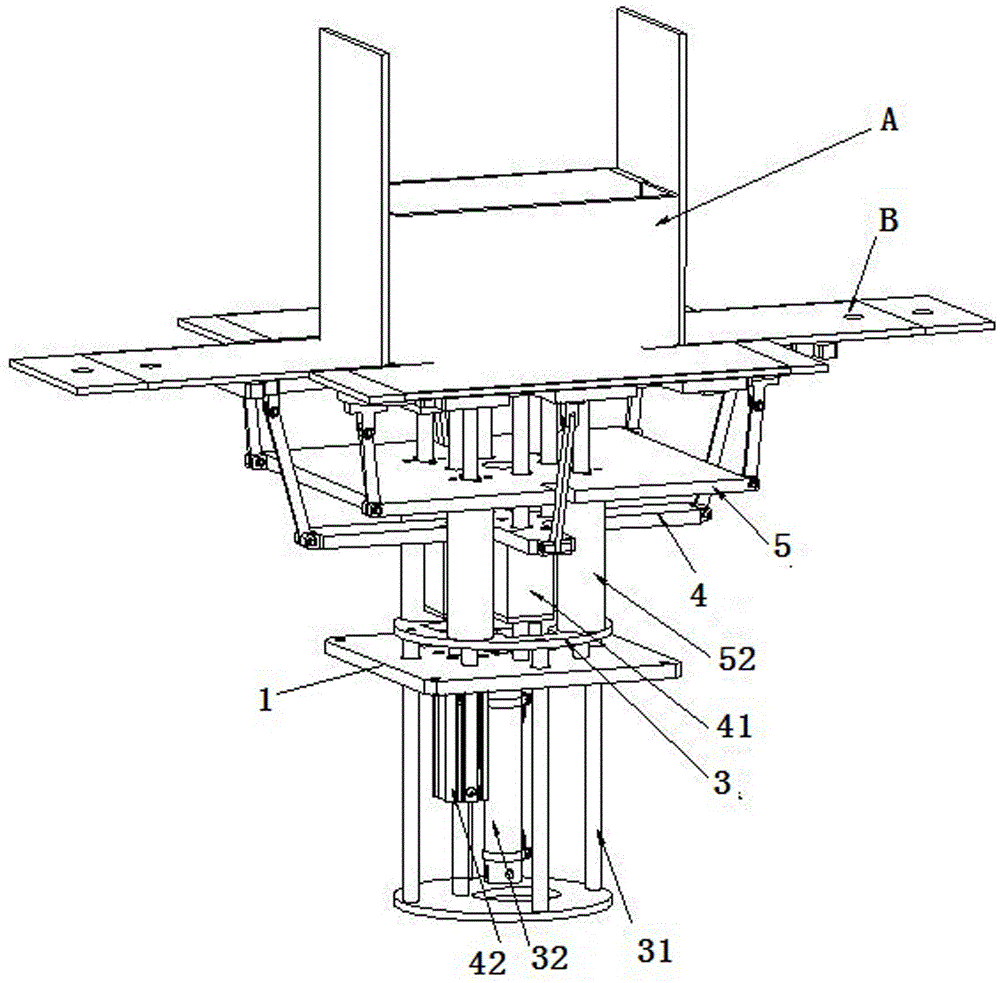

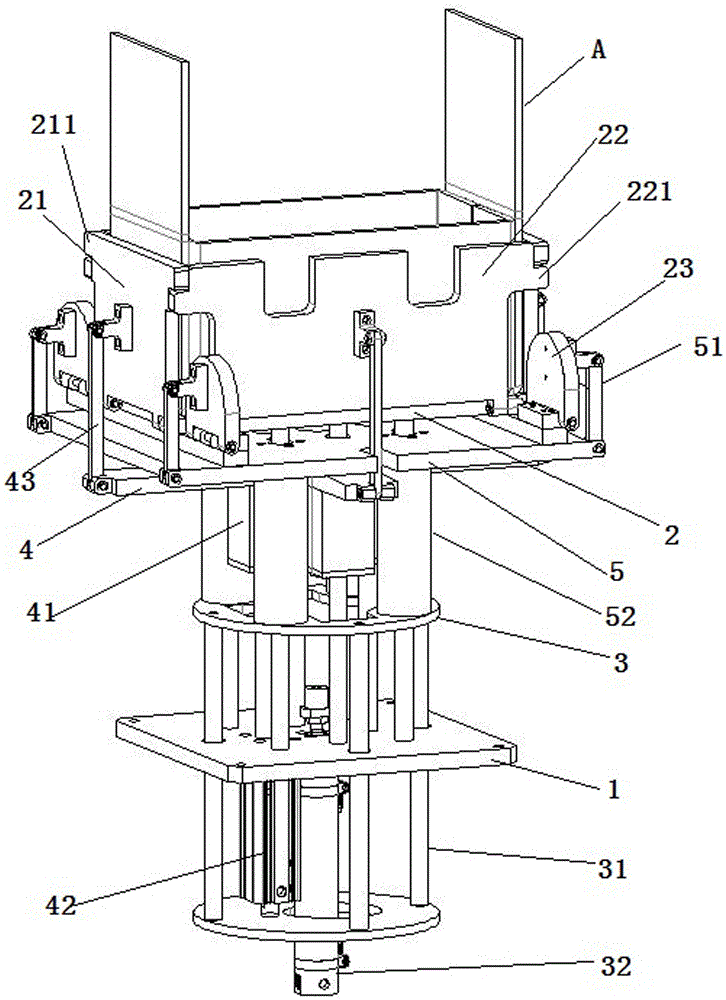

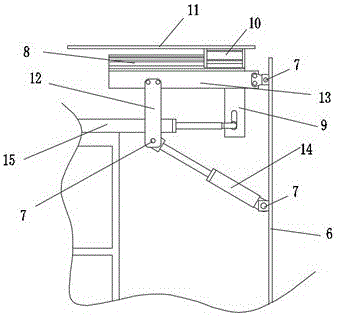

Clothes folding rack assembly for ironer

ActiveCN105019216AImplement custom stackingImprove folding efficiencyFolding thin materialsTextiles and paperStructural engineeringMechanical engineering

The invention provides a clothes folding rack assembly for an ironer. The clothes folding rack assembly comprises a bottom rack which is provided with a front supporting beam and a rear supporting beam. The front supporting beam is provided with a left sliding rack in a sliding mode, and the rear supporting beam is provided with a right sliding rack in a sliding mode, wherein the right sliding rack is located on the right of the left sliding rack. The left sliding rack is in transverse pivot joint with a left sleeve folding turnover plate stretching across the left sliding rack. The right sliding rack is in transverse pivot joint with a right sleeve folding turnover plate stretching across the right sliding rack. A large body turnover plate is arranged between the left sleeve folding turnover plate and the right sleeve folding turnover plate. A clothes falling drawing plate is arranged between the front supporting beam and the rear supporting beam and comprises a left drawing plate and a right drawing plate. The left drawing plate and the right drawing plate can be folded or unfolded respectively. The clothes folding rack assembly can fold and stack clothes automatically, and is high in clothes folding efficiency.

Owner:NINGBO ZHITENG KNITTING SCI & TECH

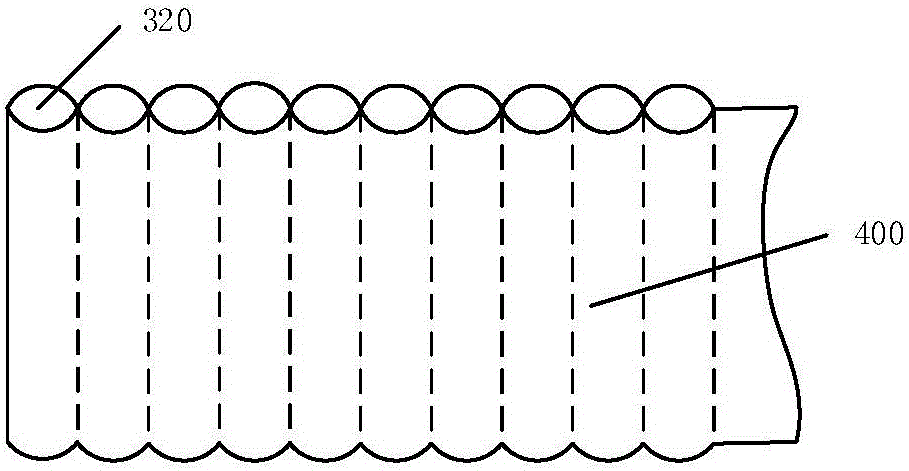

Rapidly-controlled aeration releasing mechanism

ActiveCN102243038AEfficient foldingThe overall structure is light in weightSelf-propelled projectilesEngineeringControllability

The invention relates to a rapidly-controlled aeration releasing mechanism which mainly comprises an end cap, a gas generator, a guide cylinder, a thin film tube and a thread gluing and the like, wherein the gas generated by the gas generator ensures the folded thin film tube to be unfolded. The rapidly-controlled aeration releasing mechanism provided by the invention has the characteristics of light weight, small volume, rapid unfolding process and controllability, thereby providing an effective method for realizing the requirement of rapid releasing structures in the aerospace field and relative fields.

Owner:HARBIN INST OF TECH

Food folding equipment

ActiveCN108925596AImprove efficiencyImprove folding efficiencyConveyorsBaked articles handlingAssembly lineEngineering

The invention discloses food folding equipment. The food folding equipment comprises a cake transporting unit for transporting cakes and a cake folding unit for folding the cakes. Through adoption ofthe food folding equipment provided by the invention, the automation degree of the processing of the cakes is increased, the product quality is improved, and the processing and making cost of the products is reduced; and the food folding equipment is particularly suitable for assembly lines and large-scale production, and has favorable application prospect.

Owner:泾县集知佳工业设计有限公司

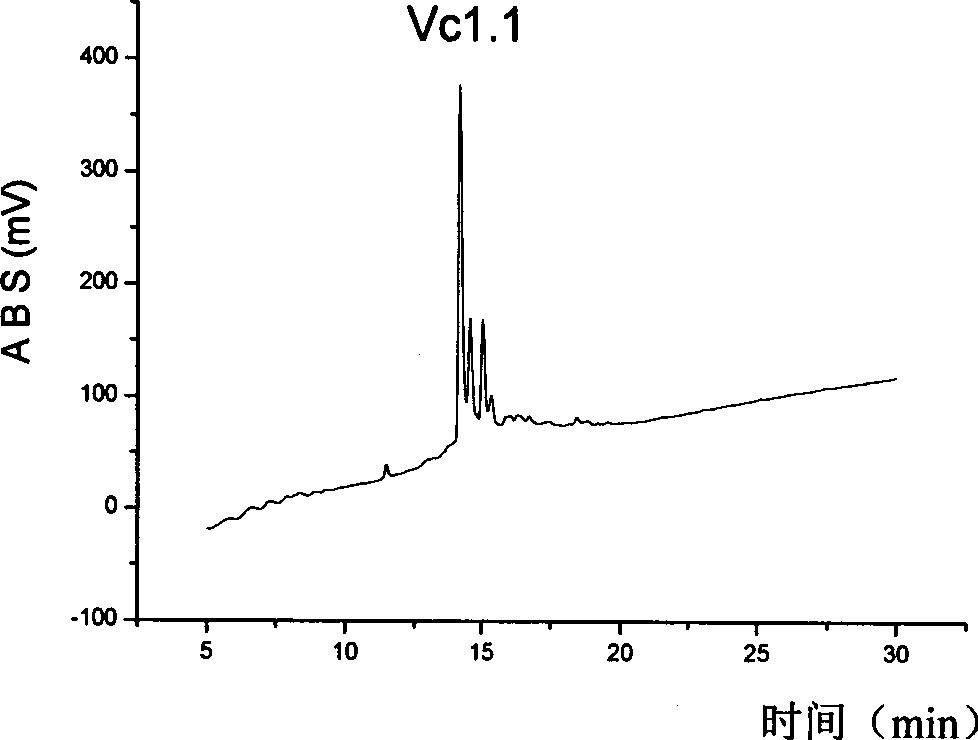

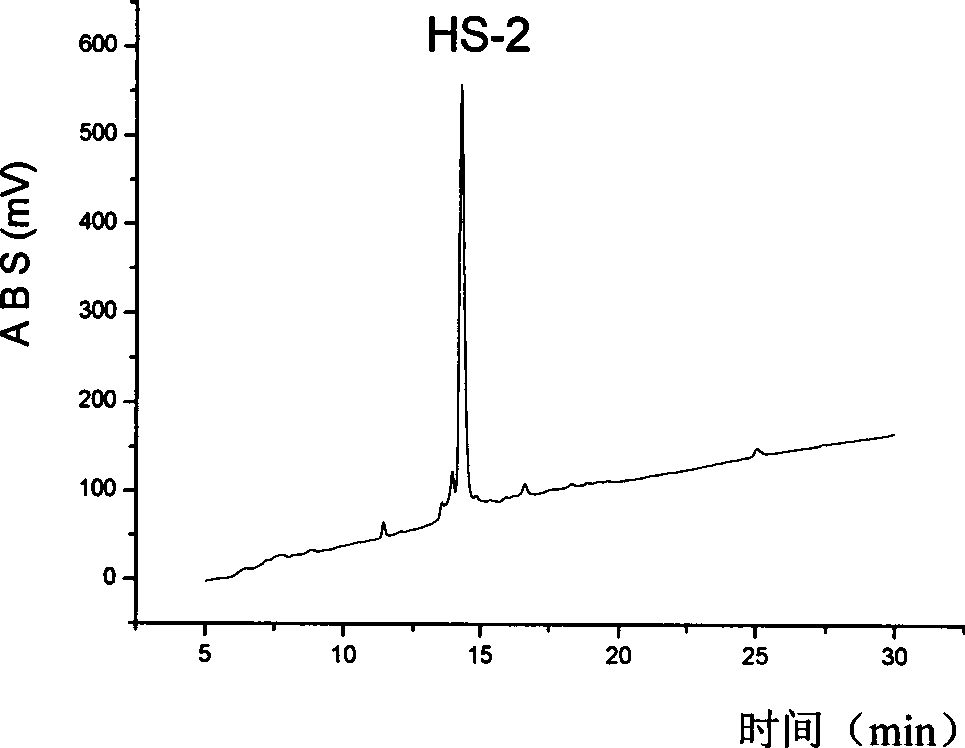

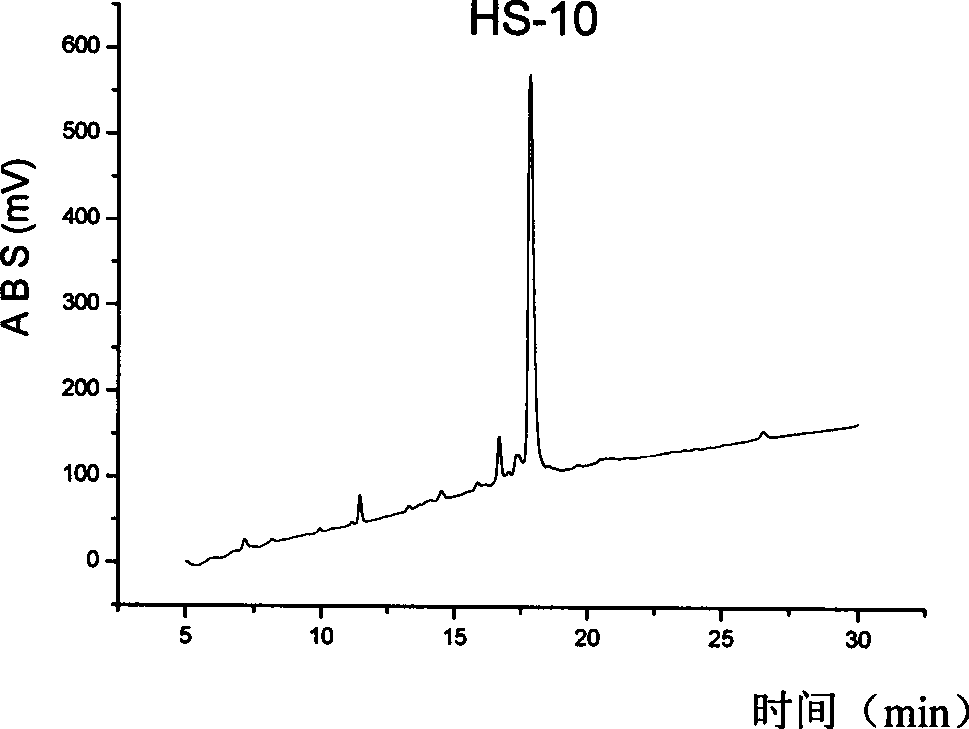

Alpha type conotoxin peptide derivates and use thereof

InactiveCN101381403AStrong analgesic activityHigh analgesic activityNervous disorderPeptide/protein ingredientsConusDrug metabolism

The invention discloses an alpha conus polypeptide derivative, amino acid residues of which are shown in sequence 1 in a sequence table. To effectively resist the degradation digestion of partial protease in a human body, and improve the bioavailability and the drug metabolism performance, an N end of the alpha conus polypeptide derivative can be connected with a benzoyl group. The alpha conus polypeptide derivative can also be subjected to cyclization, fattening or PEG modification to strengthen the treatment effect of the alpha conus polypeptide derivative. A big mouse experiment shows that the alpha conus polypeptide derivative shows strong analgesic activity in a neuropathic pain model of a big mouse, and the analgesic activity is remarkably higher than that of control peptide Vc1.1 and shows dose-dependent relation.

Owner:INST OF BIOENG ACAD OF MILITARY MEDICAL SCI OF THE CHINESE

Full-automatic clothes folding machine

InactiveCN110589136AAchieve horizontal foldAchieving Vertical FoldingConveyorsFolding thin materialsEngineeringAutomation

The invention relates to the technical field of clothes packaging, and specifically discloses a full-automatic clothes folding machine. The full-automatic clothes folding machine comprises a machine frame, wherein a first conveying mechanism, a second conveying mechanism, a cloth pressing mechanism, a cloth folding mechanism, a positioning mechanism, a cloth turning mechanism and an output sectionare arranged on the machine frame, the cloth pressing mechanism is positioned above the second conveying mechanism, the position of the cloth folding mechanism on the machine frame corresponds to theposition of the cloth pressing mechanism, the positioning mechanism is located on the machine frame at the position where the clothes are away from the cloth folding mechanism, the cloth turning mechanism is at the position where the machine frame corresponds to the positioning mechanism, and the output section is located at the position where the machine frame is located at the output end of thesecond conveying mechanism. The full-automatic clothes folding machine has the characteristics of no deviation of a conveying strip, good conveying effect, convenient adjustment of the folding width,better adjustment precision, better folding flatness, better folding consistency, better appearance, higher degree of automation, higher production efficiency, low labor intensity and ability of adapting to large-yield demand.

Owner:浙江雅力士自动化设备科技有限公司

Object storage bag folding device

InactiveCN104029871AEfficient foldingTo achieve the purpose of foldingFolding thin materialsPackagingObject storageMachining

The invention discloses an object storage bag folding device, and belongs to the field of packaging devices. The object storage bag folding device comprises a frame and a folding mechanism. The folding mechanism is arranged on supports. The supports include the main support and the auxiliary support, wherein the main support and the auxiliary support are perpendicular to each other, a first folding mechanism and a second folding mechanism are sequentially arranged on the main support in the conveying direction of object storage bags, one end of the main support is provided with a bag turning mechanism, a third folding mechanism and a fourth folding mechanism are sequentially arranged on the auxiliary support in the conveying direction of the object storage bags, one end of the auxiliary support is provided with a bag blocking guardrail, the main support and the auxiliary support are respectively provided with four transmission mechanisms, and a soft rubber layer is arranged on the surface of a conveyor belt. The object storage bag folding device is simple in structure, capable of rapidly, efficiently and accurately folding the object storage bags and convenient to operate, lowers labor intensity of workers, improves object storage bag machining efficiency and meets the requirements for production.

Owner:TONGXIANG KAIRUI PACKAGING MATERIAL

Swing-type protecting film folding device

ActiveCN107381201ANeatly foldedImprove folding efficiencyFolding thin materialsTectorial membraneTransverse axis

Owner:山东菏益科技有限公司

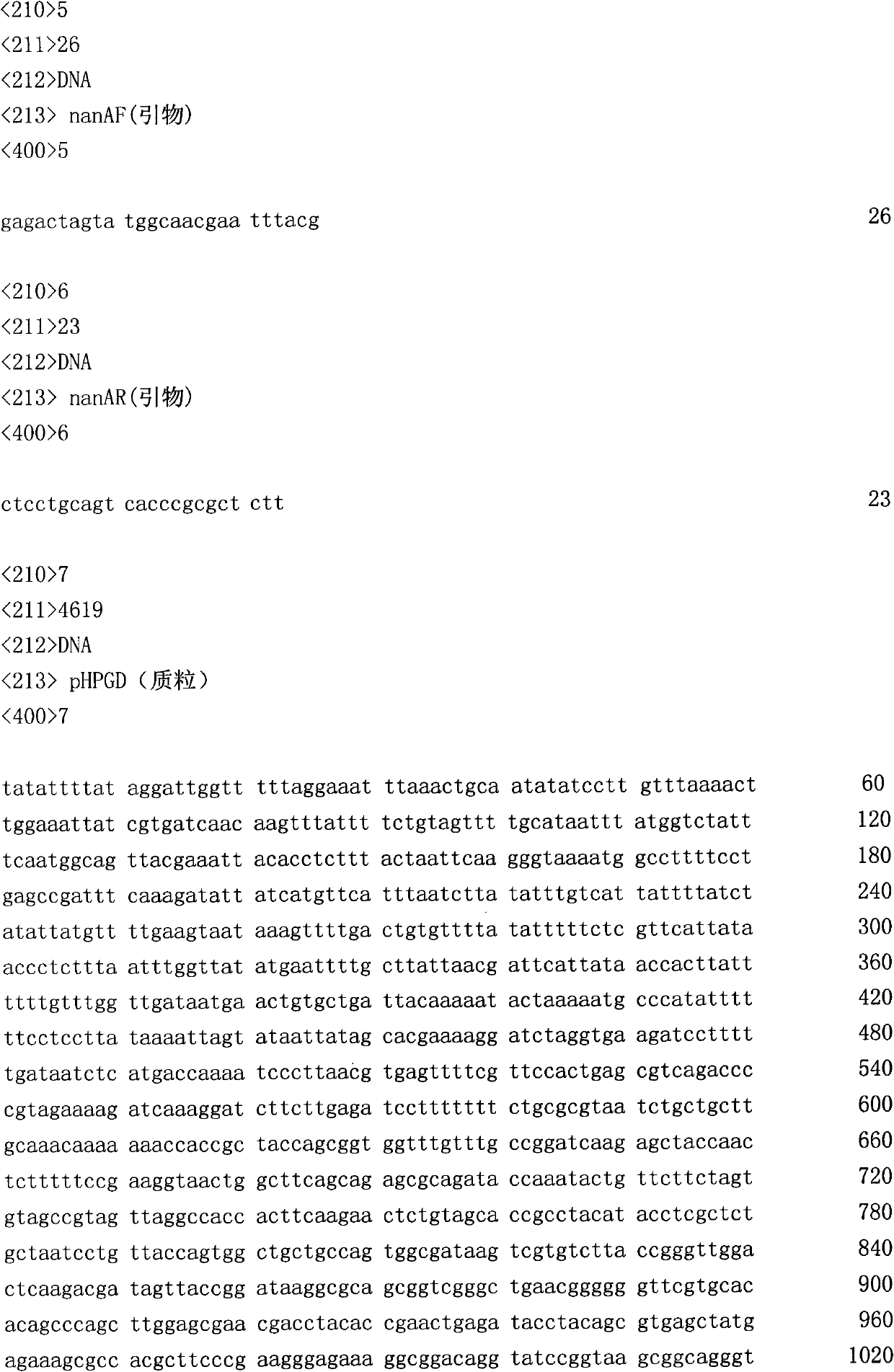

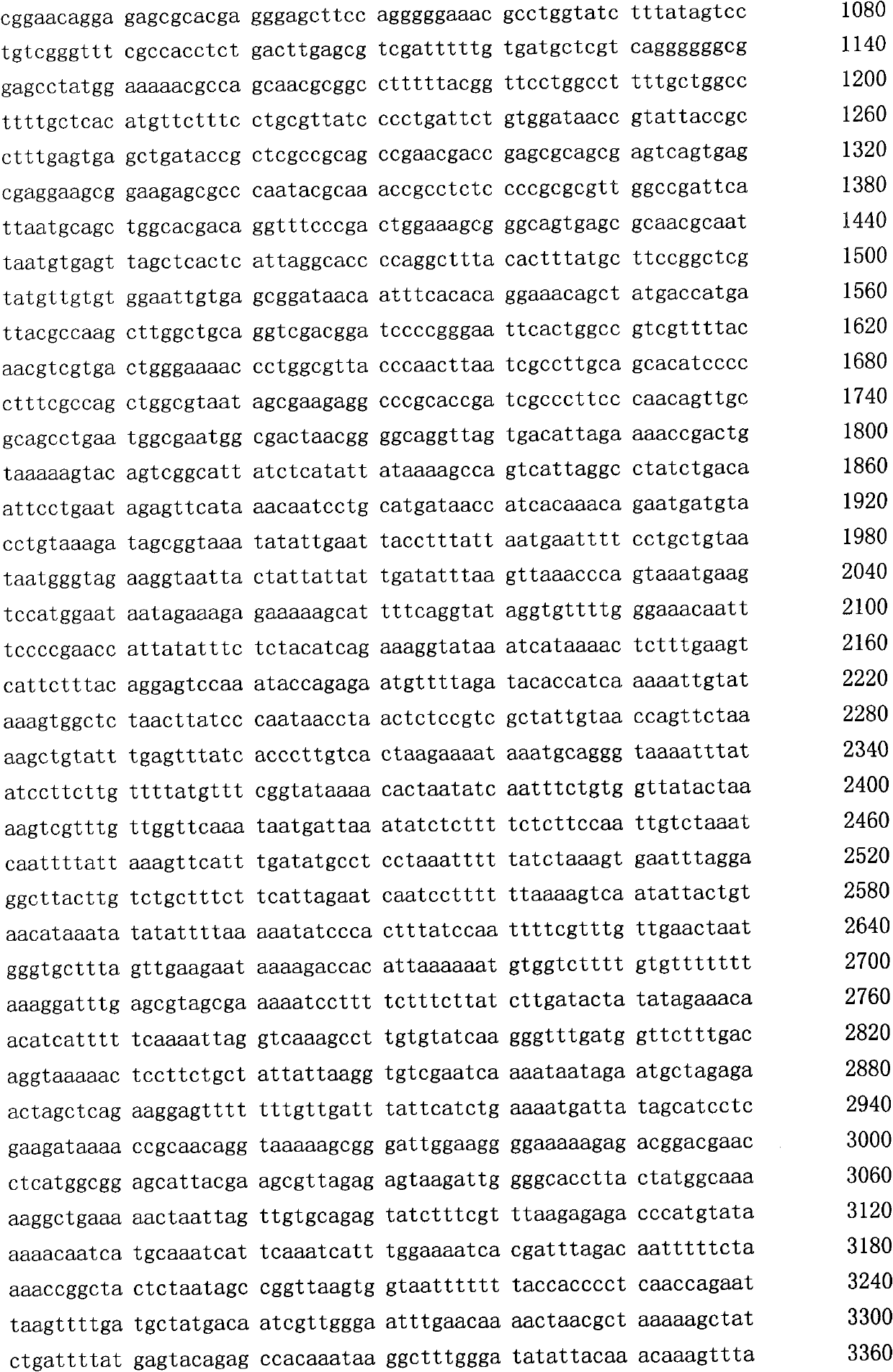

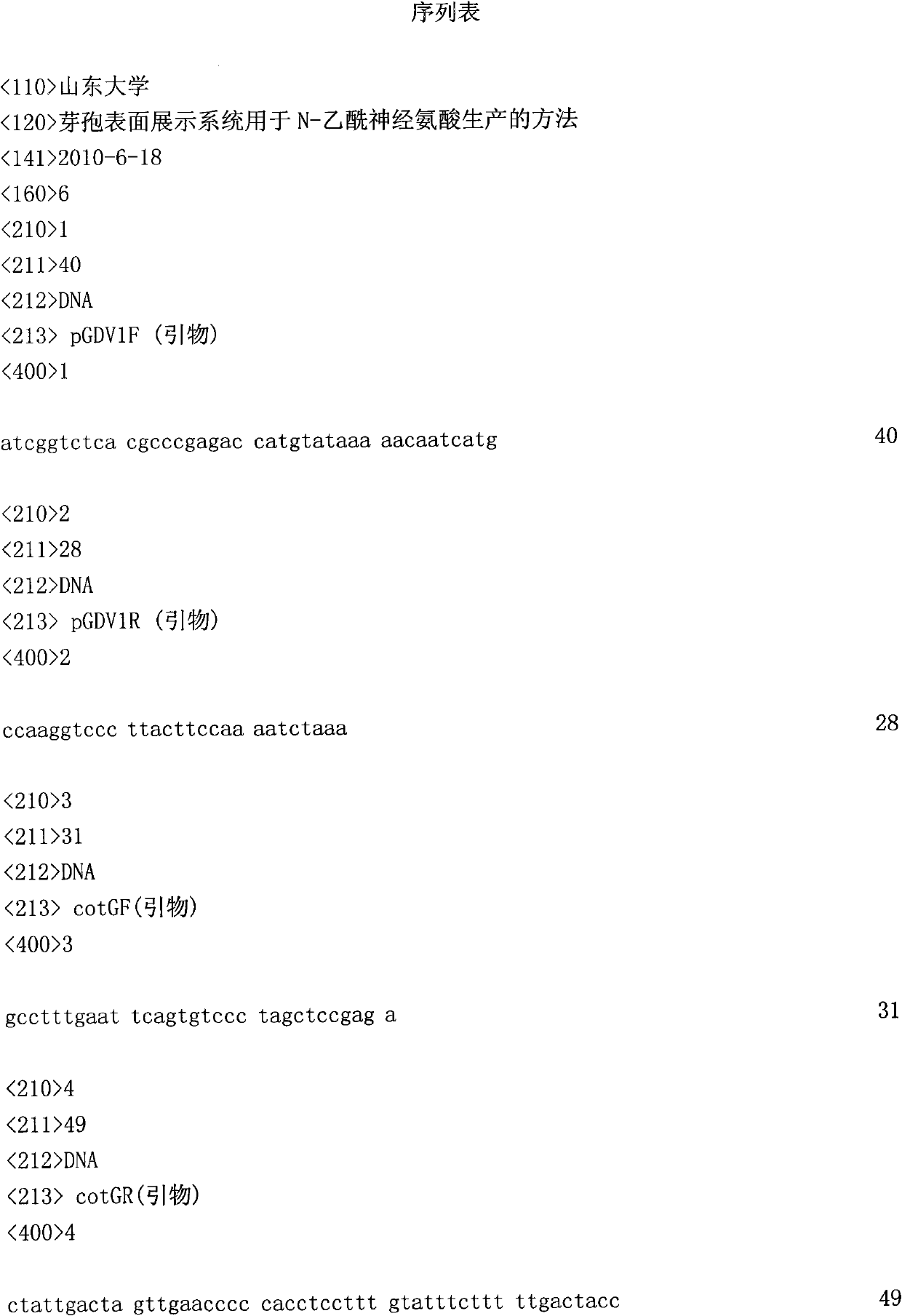

Method for producing N-acetylneuraminic acid by spore surface display system

InactiveCN101906449ASafe, simple and efficient preparationImprove efficiencyBacteriaMicroorganism based processesSurface displayN-acetylneuraminic acid aldolase

The invention discloses a method for producing N-acetylneuraminic acid by a spore surface display system. The method comprises the following step of: after recombining with a spore coating protein gene and an N-acetylneuraminic acid aldolase gene by utilizing a high-copy shuttle vector, constructing a surface display expression carrier; and converting the surface display expression carrier into bacillus subtilis to obtain a recombined strain, wherein a spore of the recombined strain can catalyze the synthesis of the N-acetylneuraminic acid. Compared with other methods in the field, the invention can finish the expression, purification and immobilization of enzyme at one step and has concise and efficient operating process. In addition, by utilizing the characteristics of stable spore, easy separation and stress resistance of the bacillus subtilis, the following separating process is simplified, the stability of N-acetylneuraminic acid aldolase is improved, and the safety of the whole catalyzing process is improved.

Owner:SHANDONG UNIV

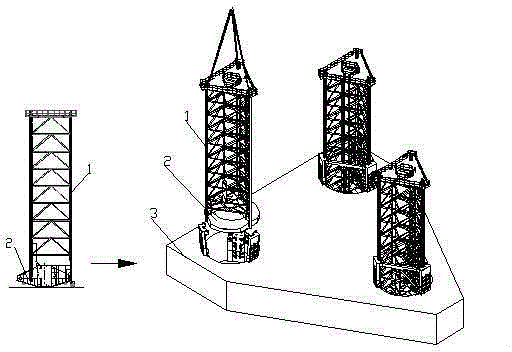

300-foot self-elevating drilling platform spud leg and shoe segmented carrying method

ActiveCN104929097AImprove the construction environmentExcellent space conditionsArtificial islandsUnderwater structuresIndustrial engineeringBuilding construction

The invention relates to a 300-foot self-elevating drilling platform spud leg and shoe segmented carrying method. The method comprises the steps that firstly, a first section of a spud leg and a shoe are combined, and then a trunk section of the first section of the spud leg is integrally hoisted to be positioned; and the combining method of the first section of the spud leg and the shoe comprises the steps of arrangement of a shoe jig frame, reversed installation of a mooring rope at the first section of the spud leg, hoisting of the first section of the spud leg, fixing of the mooring rope, adjusting and welding of the relative positions of the first section of the spud leg and the shoe section, and installation of a reinforcing rib plate and a bulk tube. The 300-foot self-elevating drilling platform spud leg and shoe segmented carrying method has the advantages that combination is conducted before hoisting; combination of a spud leg and a shoe in a narrow space of the trunk section in the prior art is changed into combination on a maritime work platform; the construction environment is improved; a superior spatial condition is provided for welding; the welding quality and working efficiency are improved.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

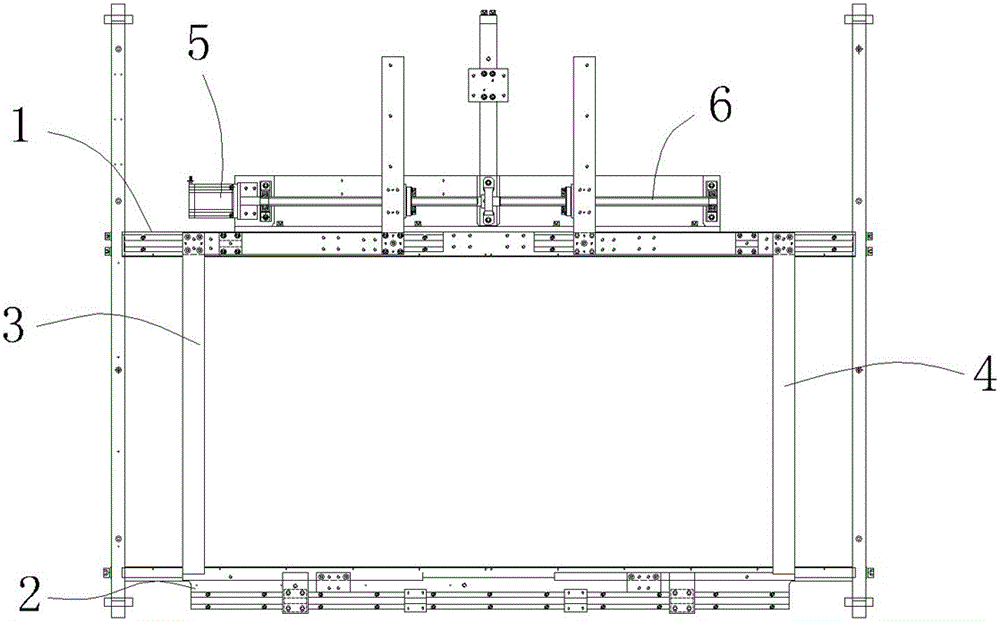

Automatic shirt folding device

InactiveCN106283586AAccurate placementFolds accurately and flatFolding thin materialsTextiles and paperProgrammable logic controllerAutomation

The invention discloses an automatic shirt folding device which comprises a rack, a folding part I, a folding part II, a folding part III, a folding part IV, a head support part and a PLC (Programmable Logic Controller), wherein the folding part I comprises a folding plate I, a folding plate bracket I, a folding guide rail support I, a guide rail and a sliding block capable of sliding on the guide rail; the folding part II comprises a front folding plate II, a rear folding plate II, two folding plate brackets II, a front guide rail support, a rear guide rail support, two guide rails and sliding blocks; the folding part III comprises a folding plate III, a folding part guide rail III, a tail box, a clamping plate, a tail press plate, a cylinder support, a sliding column and a tail box sliding block; the folding part IV comprises a folding plate IV and a folding plate bracket IV; the head support part comprises a head bracket, two L-shaped steel beams, a support plate bracket, a head press plate bracket, a head press plate and a support plate. To-be-folded clothes are placed on the support plate, the folding plates, the clamping plate and the tail press plate are driven to move by virtue of a cylinder so as to fold the clothes. The automatic shirt folding device is accurate and flat in folding, high in folding efficiency, high in speed, high in automation degree and low fabric blockage possibility.

Owner:HUBEI UNIV OF TECH

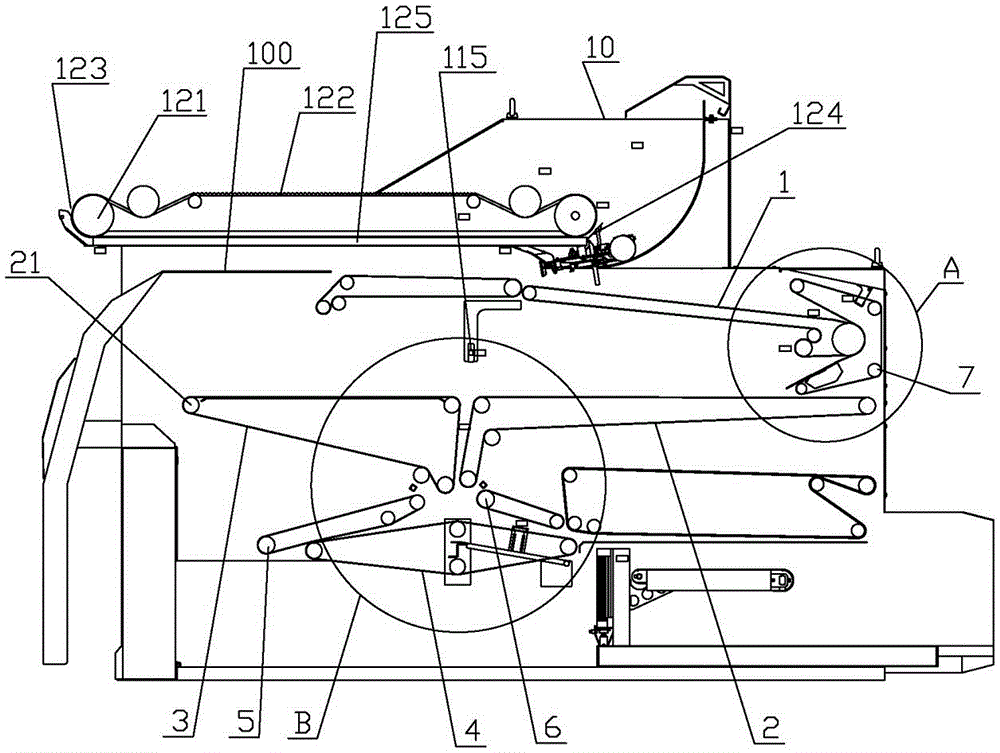

Towel folding machine for laundry center

InactiveCN103466374AImprove efficiencyReduce labor intensityFolding thin materialsEngineeringLaundry

The invention relates to a towel folding machine for a laundry center. According to the towel folding machine, a feeding device is arranged on a front box body; the rear end of the feeding device is connected with one end of a transverse folding device, so as to convey linen at the front end backwards; a front box body is connected with the lower end of the transverse folding device so as to support the transverse folding device; the front end of the transverse folding device is connected with the feeding device; the rear end of the transverse folding device is connected with a longitudinal folding device so as to transversely fold the linen conveyed by the feeding device two times and convey into the longitudinal folding device backwards; the front end of the longitudinal folding device is connected with the transverse folding device so as to longitudinally fold the linen two times; a discharge device is arranged below the transverse folding device and is connected with the longitudinal folding device so as to convey the fed and folded linen to a corresponding stacking device; the stacking device is positioned on one side of the discharge device. Due to adoption of the towel folding machine, the automatic folding and stacking of washed and dried towels in the laundry center are achieved, the folding efficiency and the folding effect are improved, the working intensity is alleviated, and the towels are clean and sanitary in the folding process.

Owner:SHANGHAI SAILSTAR MACHINERY GRP

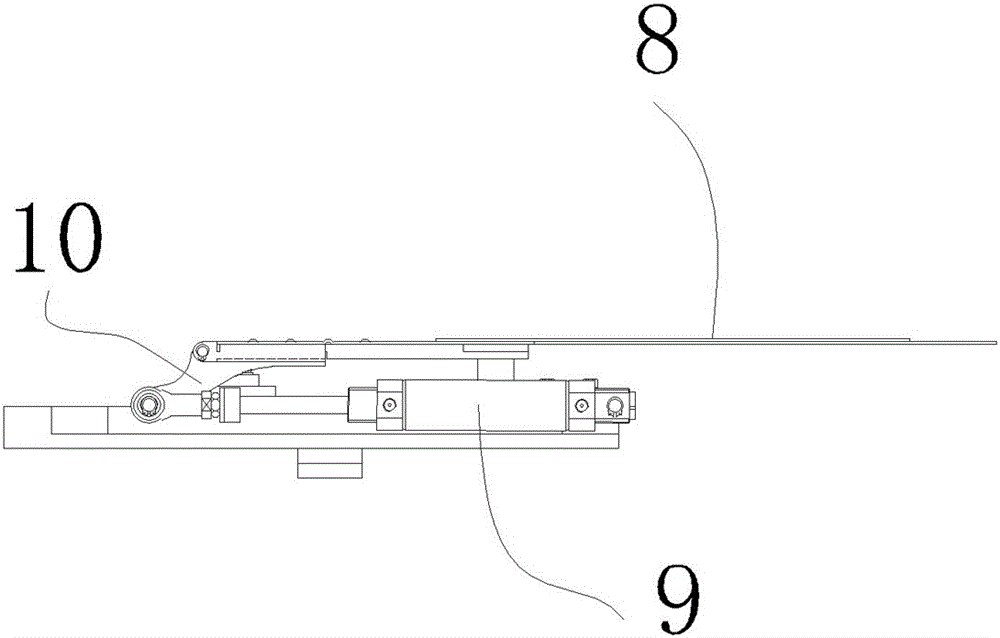

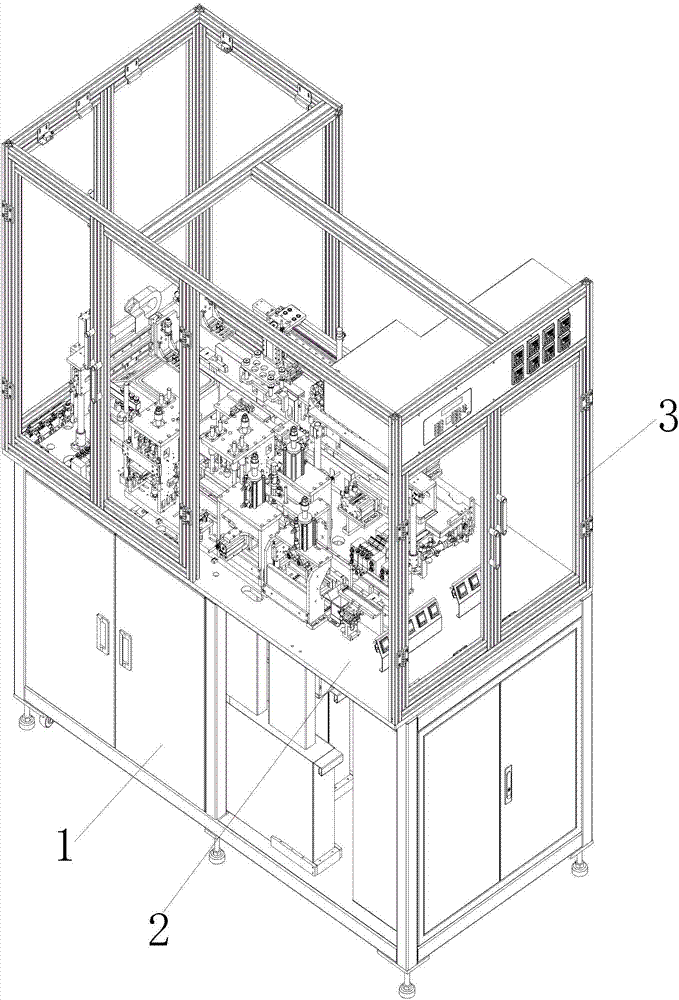

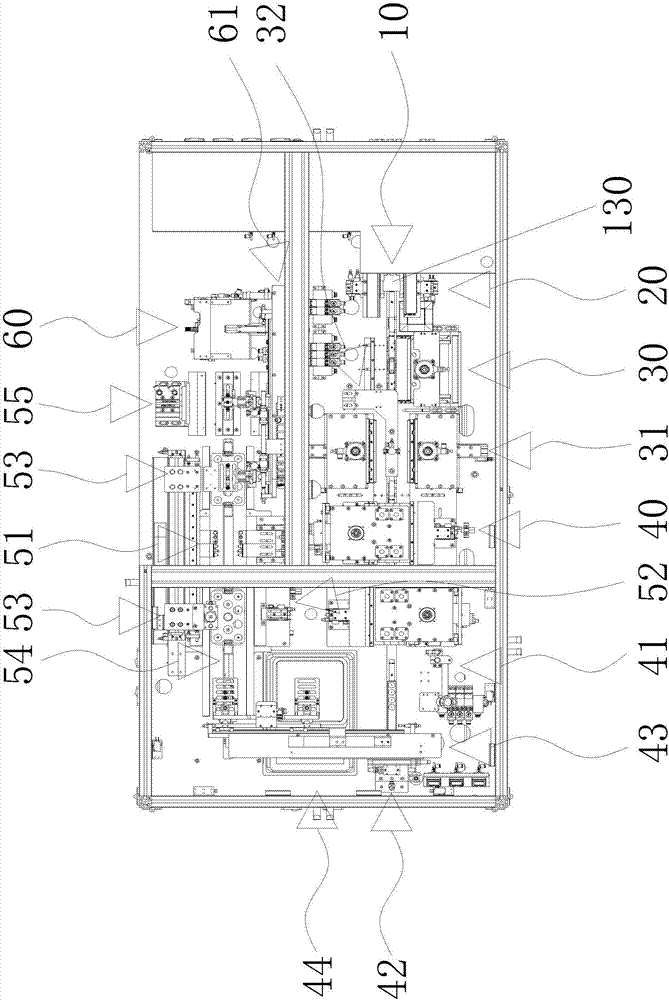

Flanging machine

PendingCN107984733AStrong adsorptionFast deliveryFinal product manufactureElectrolyte accumulators manufactureEngineeringFlanging

The invention discloses a flanging machine. The flanging machine comprises a rack and a base arranged on the rack, wherein a trimming carrying and conveying mechanism, an alignment mechanism, a trimming mechanism and a flanging mechanism are arranged on the base; the trimming carrying and conveying mechanism is used for conveying a battery; the alignment mechanism is positioned on the two sides ofthe trimming carrying and conveying mechanism and is used for seeking the central line of the battery; the trimming mechanism is used for cutting a redundant laminating film; the flanging mechanism is used for bending the residual laminating film; an overturning mechanism used for overturning the battery is arranged in the position, following the flanging mechanism, on the base; a roll folding and carrying mechanism used for carrying the battery, a prepressing locating mechanism which is positioned on the two sides of the roll folding and carrying mechanism and is used for prepressing the laminating film and locating the battery, and a roll folding mechanism used for folding the laminating film through rolling are arranged in the position, following the overturning mechanism, on the base;and a hot pressing shaping mechanism used for leveling the laminating film is arranged in the position, following the roll folding mechanism, on the base. According to the flanging mechanism, trimming, flanging, code scanning, weighing, shaping and overturning can be automatically carried out on the battery, the automation degree is high, product specifications are uniform, the battery is not damaged, manpower is greatly saved, and quality is improved.

Owner:SUZHOU SUNMICRO AUTOMATION TECH CO LTD

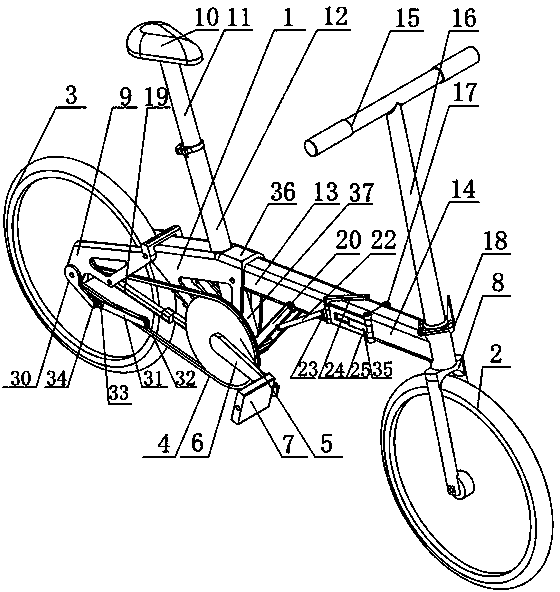

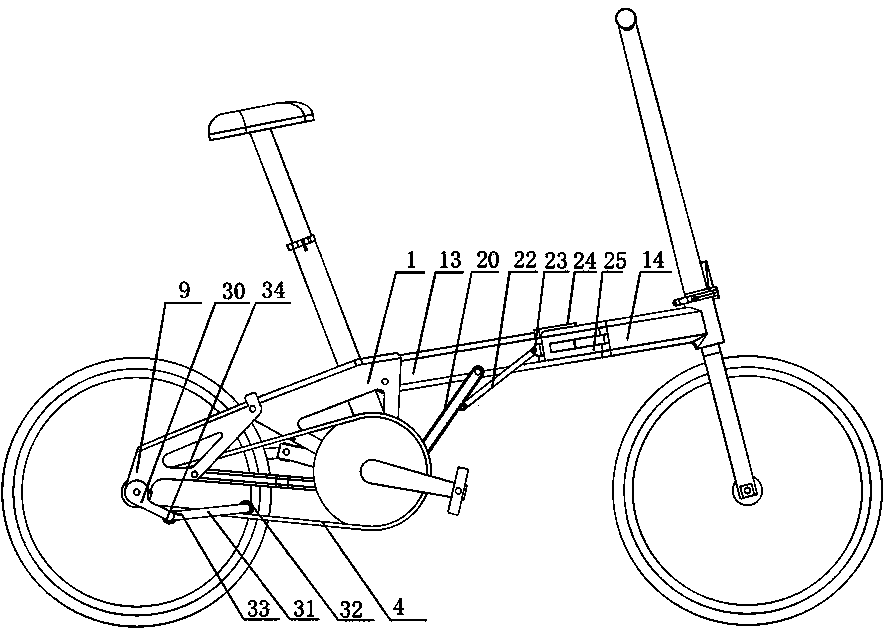

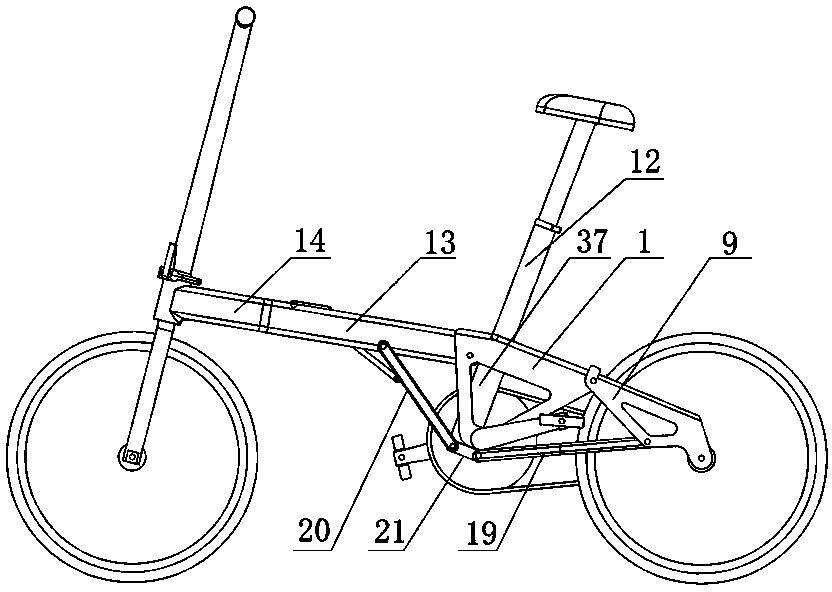

Foldable bicycle

The invention relates to the technical field of bicycles, in particular to a foldable bicycle. The foldable bicycle comprises a main beam, a connecting beam and a front beam, wherein a folding device which is used for simultaneously driving the front beam to fold when the main beam and the connecting beam are folded is arranged between the connecting beam and the front beam; pedals are in foldable connection with a chain wheel crank; the foldable bicycle is also provided with a folding device for folding a chain. The foldable bicycle has the advantages of compact structure, good stability, short folding time, convenience in folding and small occupied area after being folded, and the chain does not fall when the foldable bicycle is folded.

Owner:陈文朗

Novel folding wing and driving and deadlocking mechanism

ActiveCN105000169AImprove folding efficiencyPossibility of fully verifying engineering applicationsWing adjustmentsEngineeringActuator

The invention discloses a novel folding wing. The novel folding wing is overall divided into an inner segment, a middle segment and an outer segment. Folding positions comprise a 90-degree position and a 180-degree position. A folding manner is simple, easy to implement and high in efficiency. A hinge four-rod mechanism is selected as a body of a driving mechanism, and meanwhile a hydraulic actuator cylinder is selected as a power source. On the aspect of materials, high-strength alloy hardened and tempered steel is selected as materials of shaft pins, and strength titanium alloy materials are selected as materials of connecting rod structures and lug sheets. Rotating and locking structures are arranged on upper flanges and lower flanges of an upper beam and a rear beam, and it is guaranteed that unlocking and locking are reliably achieved. In the design process of the novel folding wing, the size is determined by meeting certain strength requirements.

Owner:BEIHANG UNIV

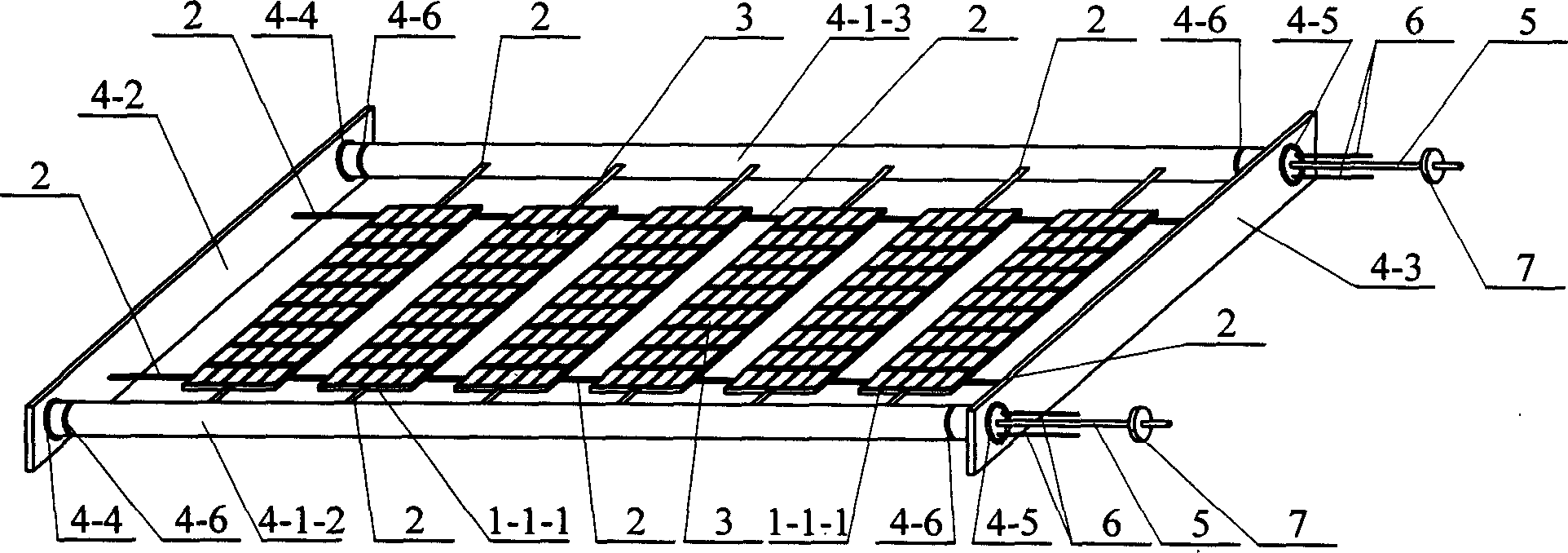

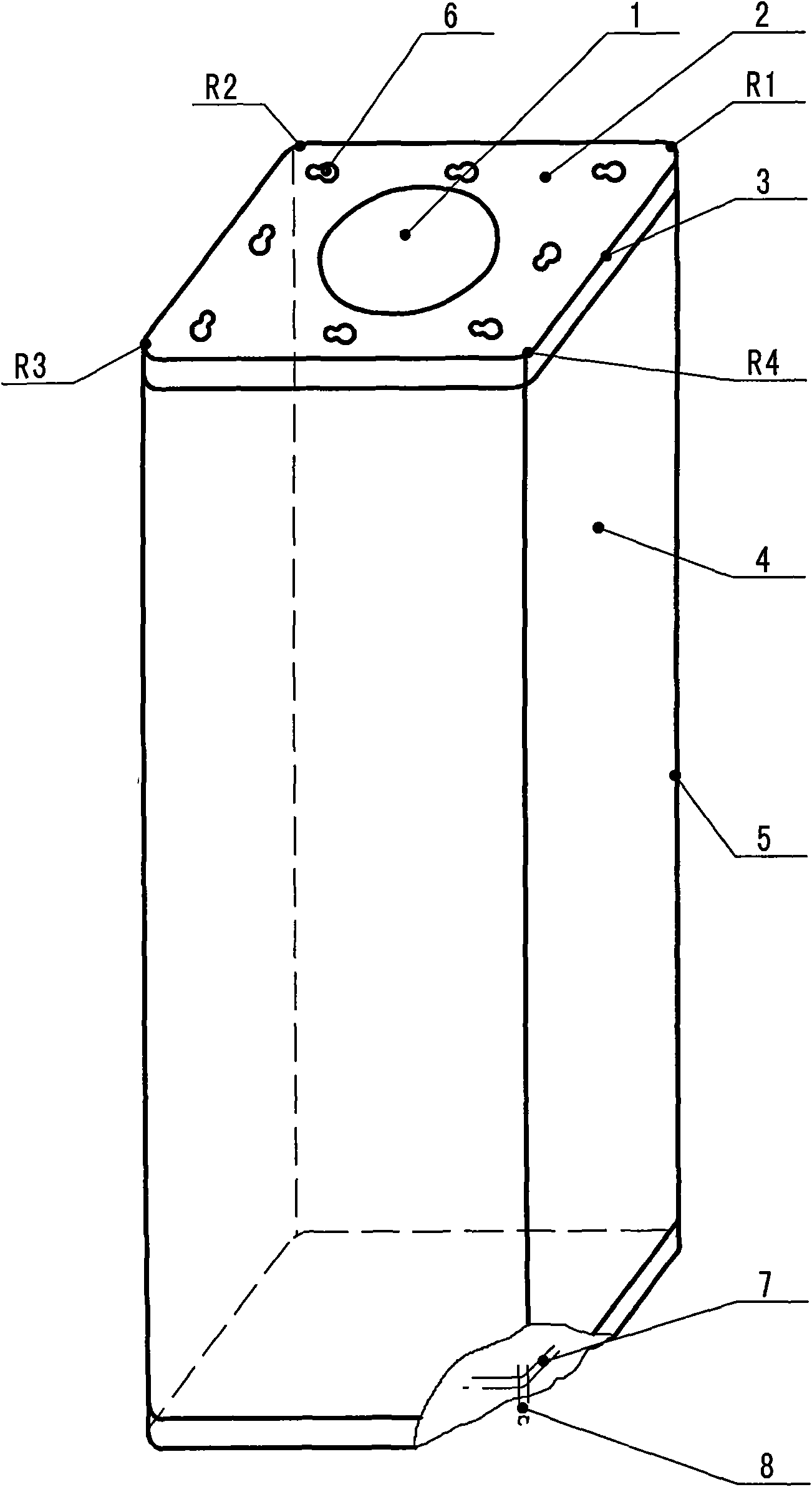

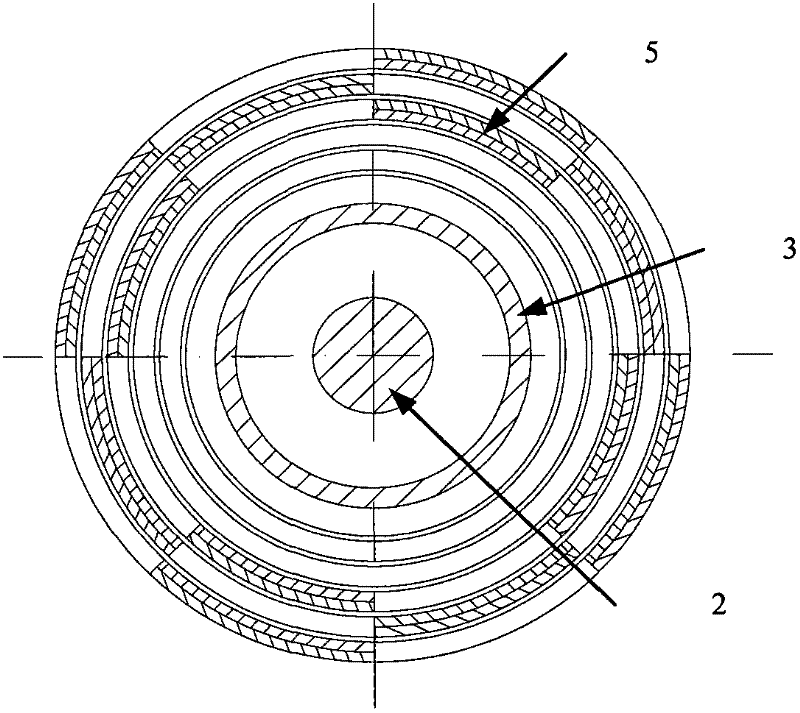

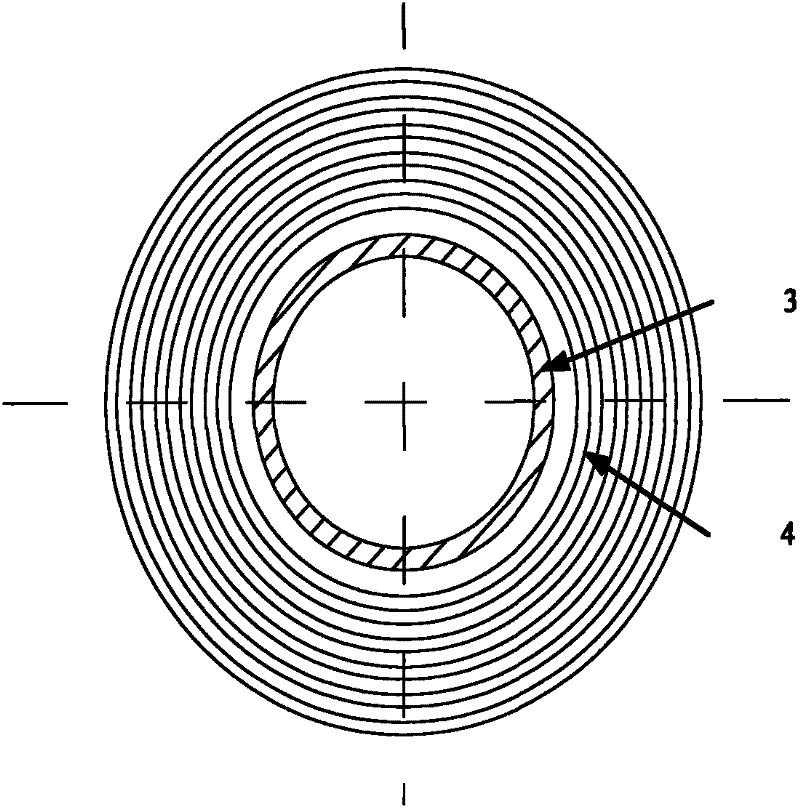

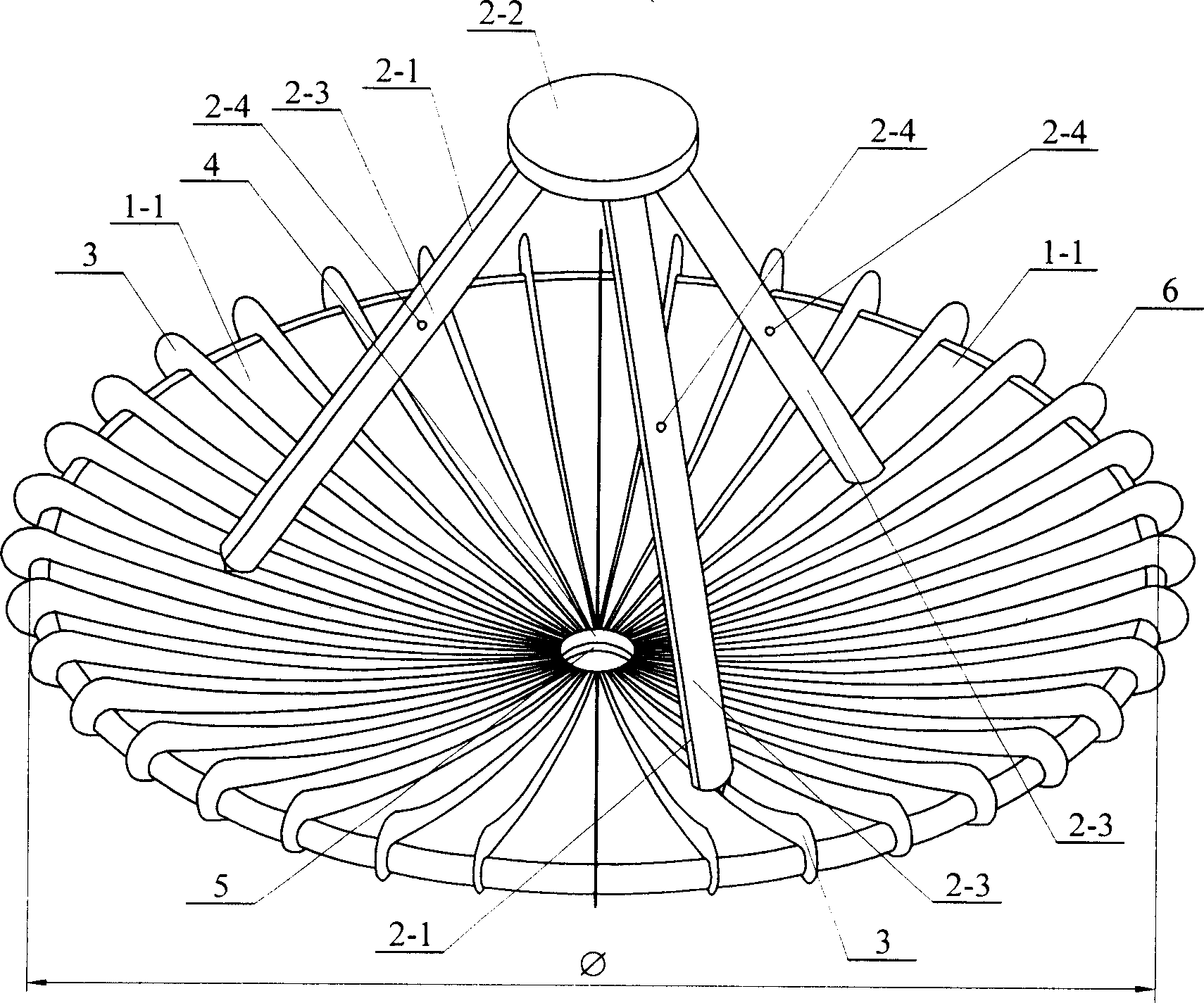

Ribbed plate support and inflation deployment type heavy caliber paraboloidal antenna

The big diameter parabolic antenna with floor supporting and charging expansion relates to satellite communication antenna to send and receive electromagnetic wave. Wherein, the reflecting object comprises a group of unit charging chamber 1-1 with floor 3 fixed between two chambers; the floor 3 fixes to separation plate 2-1 of holding frame assembly with back end connected to center link frame 4 and top end adhered reflector layer 6; the back end of unit charging chamber fixes to charging device 5; the reflection object has caliber Phi of 5-25m and composes inner layer of aluminum foil material and side layers of plastic thin membrane. This invention decreases weight, volume and cost, and fits to ideal satellite communication antenna.

Owner:HARBIN INST OF TECH

Automatic box folding method of automatic box folding machine

ActiveCN109677005ATo offer comfortSolve the problem of automatic folding boxPaper-makingBox making operationsPaperboardEngineering

The invention discloses an automatic box folding method of an automatic box folding machine. The automatic box folding machine comprises a rack, a shifting mechanism, an edge folding mechanism, a longedge guide mechanism and clamping lug mechanisms, wherein workbenches which are arranged at intervals are arranged on the rack; the shifting mechanism with a suction plate is arranged at the lower part of the rack between the two workbenches; the edge folding mechanism is arranged between the two workbenches and comprises four lifting air cylinders which are symmetrically arranged; a metal platewith two clamping plates is fixed to the top surface of each lifting air cylinder; the long edge guide mechanism is arranged above the edge folding mechanism and is provided with an inverted V-shapedguide rod; the clamping lug mechanisms are symmetrically arranged at the two sides above the edge folding mechanism; and the automatic box folding operation of paperboards is completed through the coordination of all the mechanisms. The automatic box folding method can improve the box folding efficiency, saves cost, is convenient for providing folded boxes faster and better for subsequent packaging and reduces the steps of folding the boxes.

Owner:HONGHAI ELECTRONICS TECH ZHANGZHOU

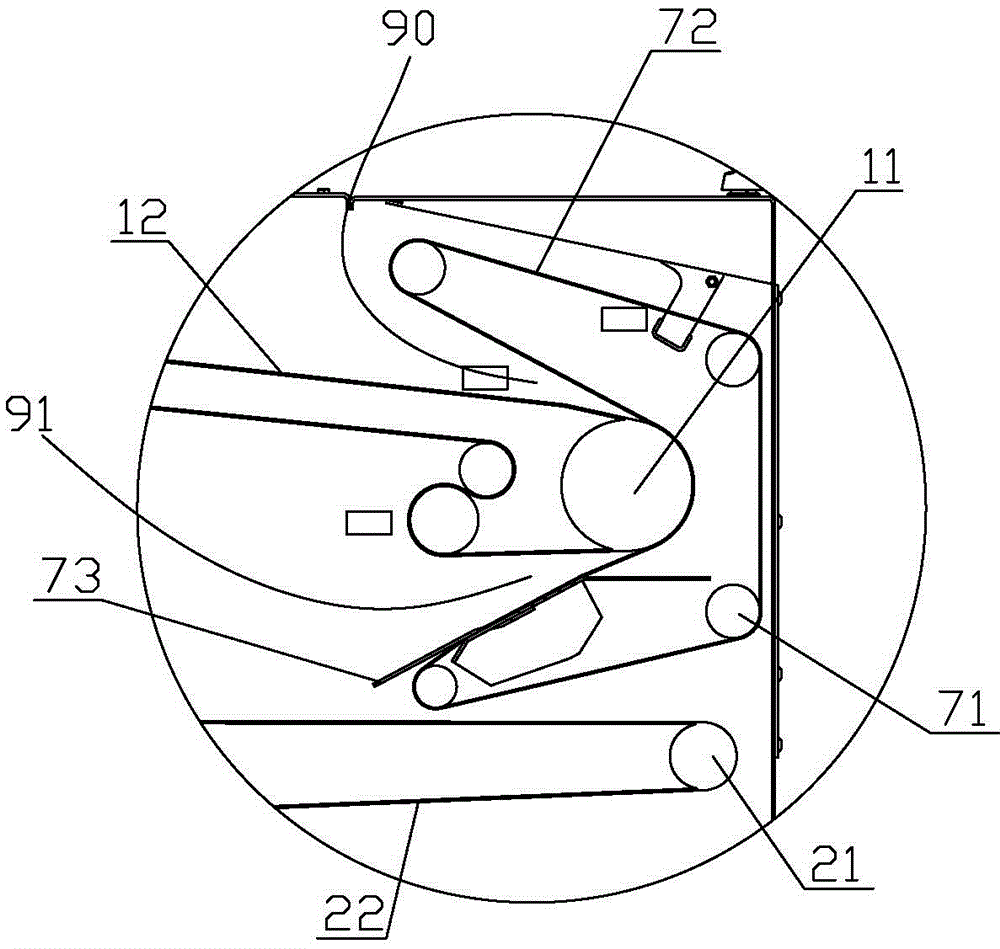

Work clothes folding device in work clothes folding machine

ActiveCN105544173AWrinkle freeImprove folding efficiencyFolding thin materialsTextiles and paperEngineeringMechanical engineering

The invention discloses a work clothes folding device in a work clothes folding machine. A sleeve folding device capable of folding sleeves to the back of work clothes in a crossing mode is arranged at the feeding position of a machine frame body. A first conveying device is arranged on the rear side of the sleeve folding device and can receive the work clothes output out of the sleeve folding device. A multi-folding conveying device is arranged below the first conveying device and can fold the working clothes at least one time. A transferring device used for conveying the work clothes output out of the first conveying device to the multi-folding conveying device is arranged on the rear side of the first conveying device. The work clothes folding device can fold the work clothes automatically, the folded work clothes are flat without wrinkles, large-batch and automatic folding can be achieved, the folding efficiency of the work clothes folding machine is greatly improved, human input is small, and cost is greatly reduced.

Owner:JIANGSU SEA LION MASCH GRP CO LTD

Plaster bandage folding machine

The invention relates to a folding machine, in particular to a plaster bandage folding machine. The invention aims at providing the plaster bandage folding machine which can save time and improve thefolding efficiency. According to the technical implementation scheme, the plaster bandage folding machine is characterized by comprising a bottom plate, a supporting plate, a first bearing pedestal, arotating shaft, a rocker rod, a rotating plate, a connecting block, an annular push plate, an elastic rope, a push block, sliding rails, a sliding block, a pressing plate, an elastic sheet and the like, wherein the supporting plate for supporting is fixedly connected with the front left side of the top of the bottom plate; the first bearing pedestal is bolted to the top of the supporting plate; the T-shaped rotating shaft is installed in the first bearing pedestal; the L-shaped rocker rod is fixedly connected with the left end of the rotating shaft; and the rotating plate is connected with the right end of the rotating shaft. According to the invention, the rotating plate can be driven to rotate clockwise by rotating the rocker rod clockwise so as to fold a plaster bandage, and medical workers do not need to cut the plaster bandage and then fold the plaster bandage manually, so that the time is saved and the folding efficiency is improved.

Owner:THE PEOPLES HOSPITAL SHAANXI PROV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com