Patents

Literature

92results about How to "Avoid untidy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rooting induction method of test-tube plantlet of cunninghamia lanceolata

ActiveCN103229723AHair root unificationFast rootingPlant tissue cultureHorticulture methodsSocial benefitsEconomic benefits

The invention discloses a rooting induction method of a test-tube plantlet of cunninghamia lanceolata. The rooting induction method comprises the steps of: cutting a 1-2cm multiplication subculture plantlet, inoculating in a pre-rooting culture medium for culturing, wherein the pre-rooting culture medium uses 1 / 2MS-MS as a base culture medium, and also comprises 0.02-0.08mg / L of NAA (Naphthalene Acetic Acid), 2.5 percent of cane sugar and 0.7 percent of agar; carrying out rooting culture after pre-rooting and culturing for 15-25 days, wherein a rooting culture medium uses improved 1 / 2 MS as a basic culture medium, and also comprises 0.10-0.25mg / L, 0.05-0.08mg / L of IAA (Indole-3-Acetic Acid), 2.5 percent of cane sugar and 0.7 percent of agar; and placing in a proper environment for culturing to obtain a rooted test-tube plantlet. After the cunninghamia lanceolata is rooted and cultured by adopting the rooting induction method, the rooting rate, the root system quantity and the root system germination uniformity of the test-tube plantlet of the cunninghamia lanceolata can be increased, more excellent rooted test-tube plantlets are provided for production and application, and good economic benefit and social benefit are obtained.

Owner:GUANGXI FORESTRY RES INST

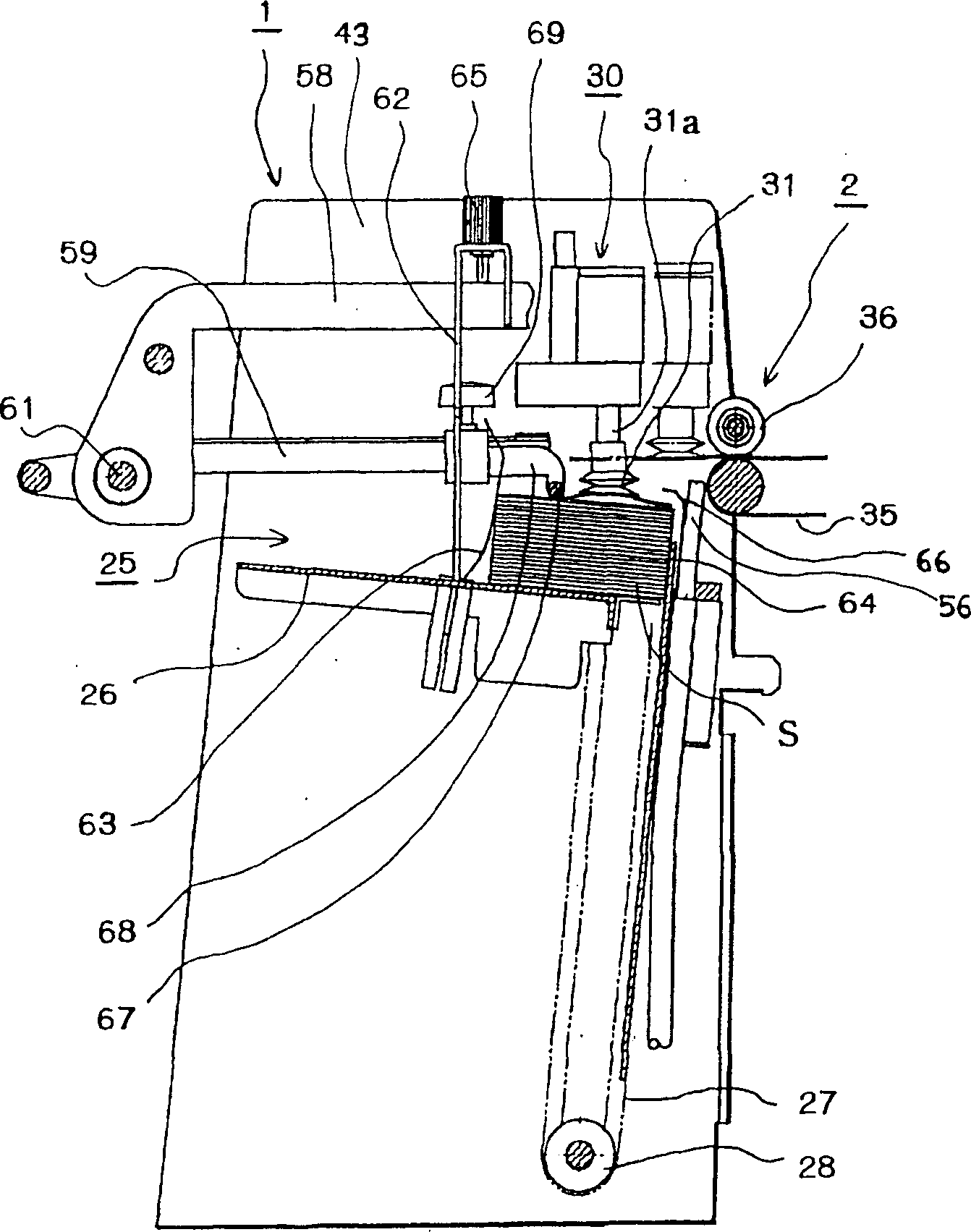

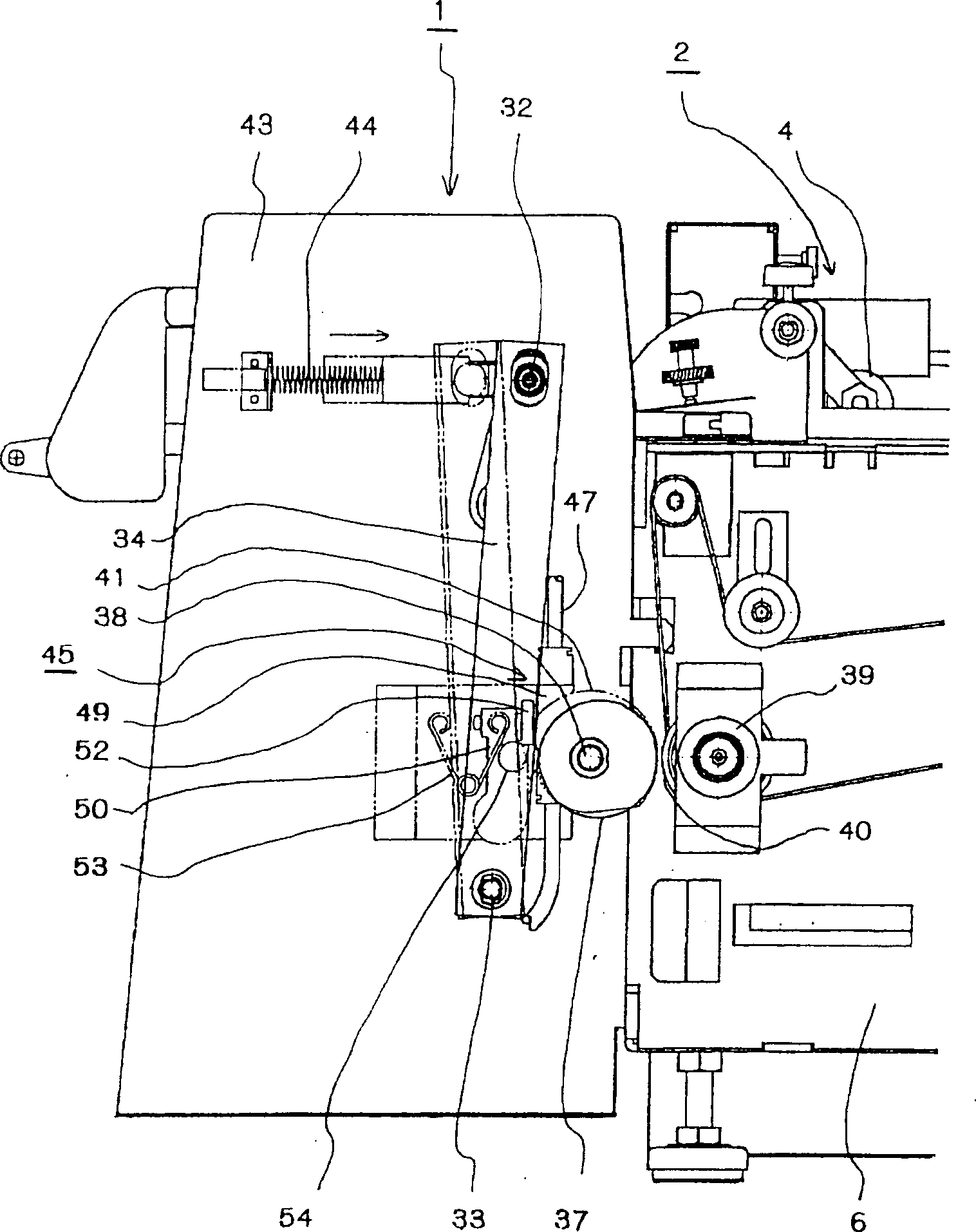

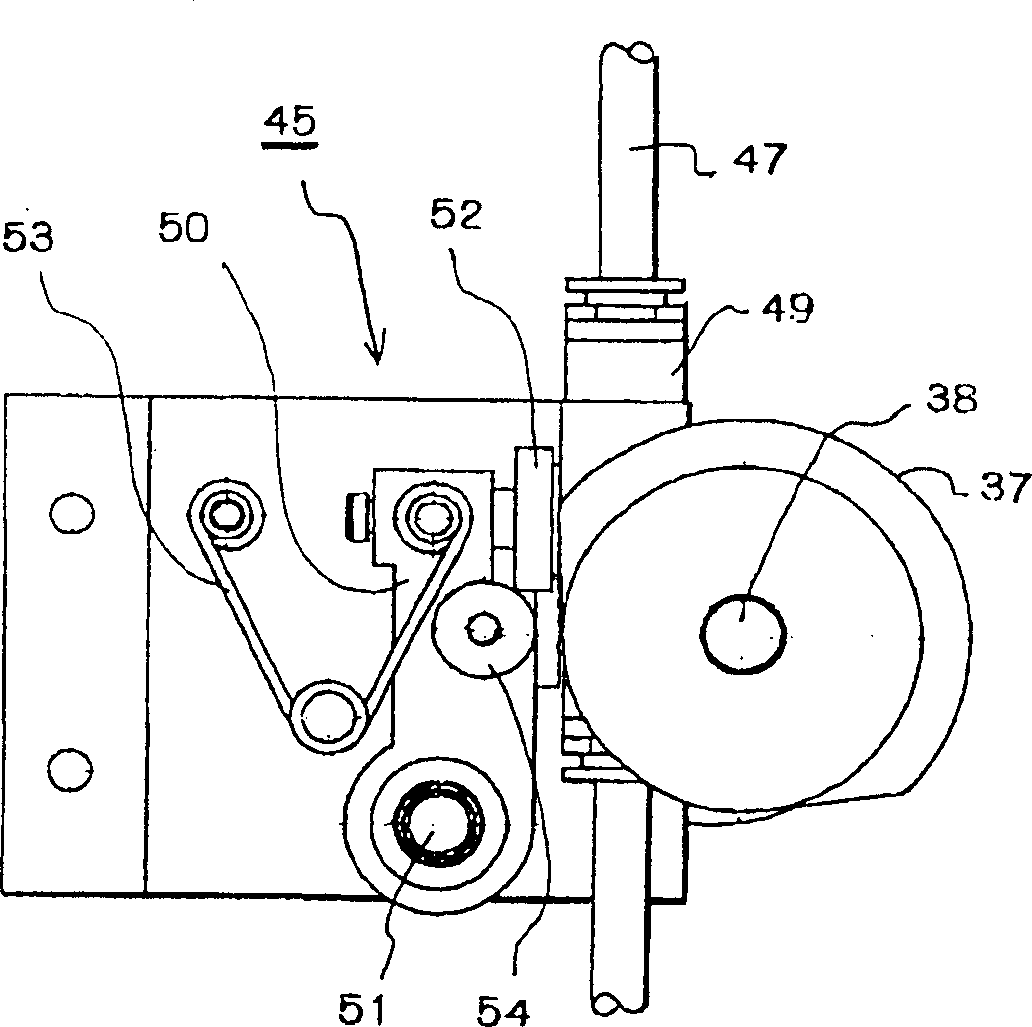

Sheet separating supplier and offset printer

InactiveCN1530219ASimple device structureLow installation costPrinting press partsArticle separationTransfer mechanismEngineering

A simplified sheet separating and supplying device with low cost and easy maintenance is disclosed, which features that its adsorptive moving mechanism and air attraction mechanism are driven by a single drive-transfer mechanism, and the air attraction valve is controlled by the reciprocating movement of adsorptive unit.

Owner:SHINANO KENSHI

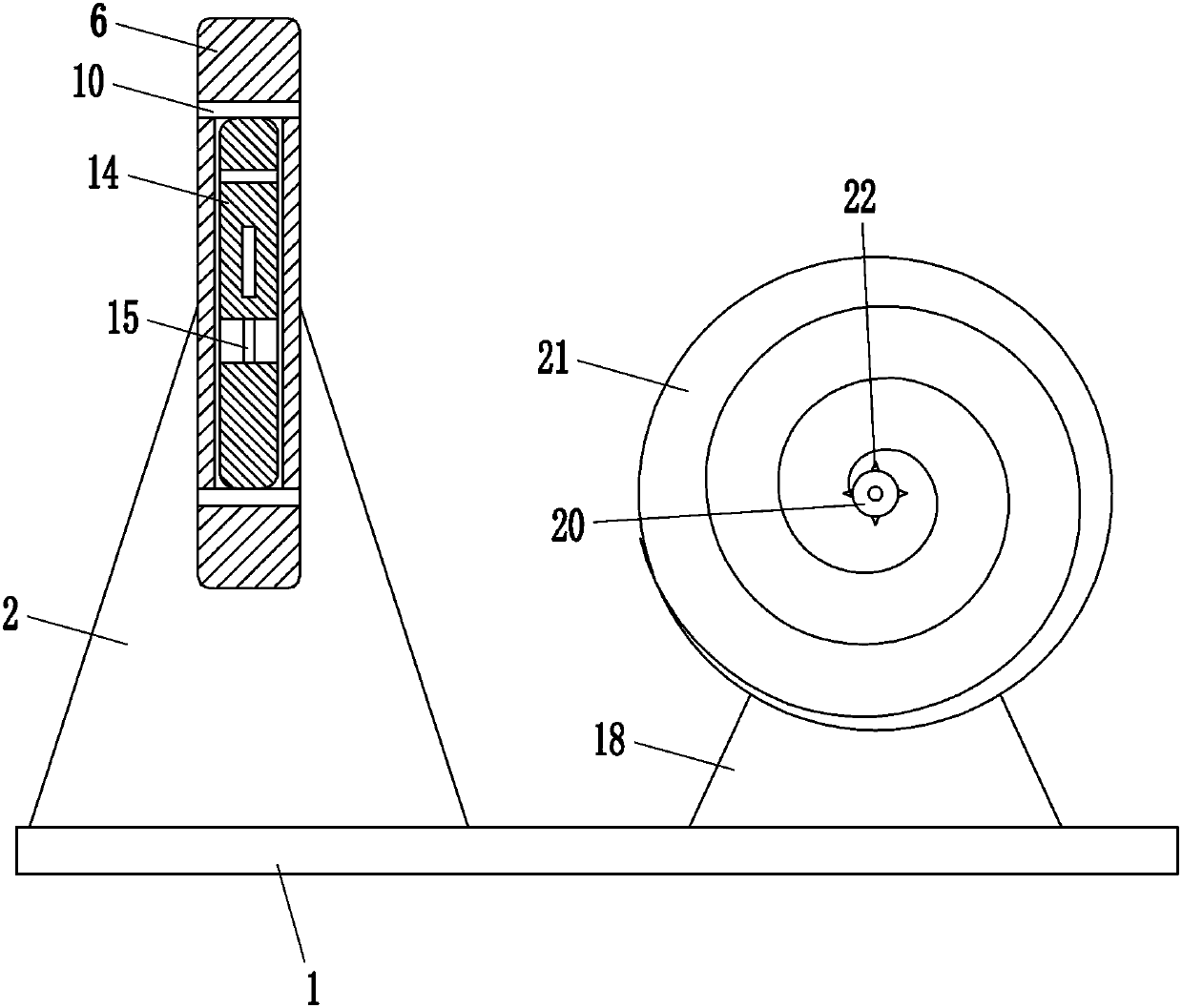

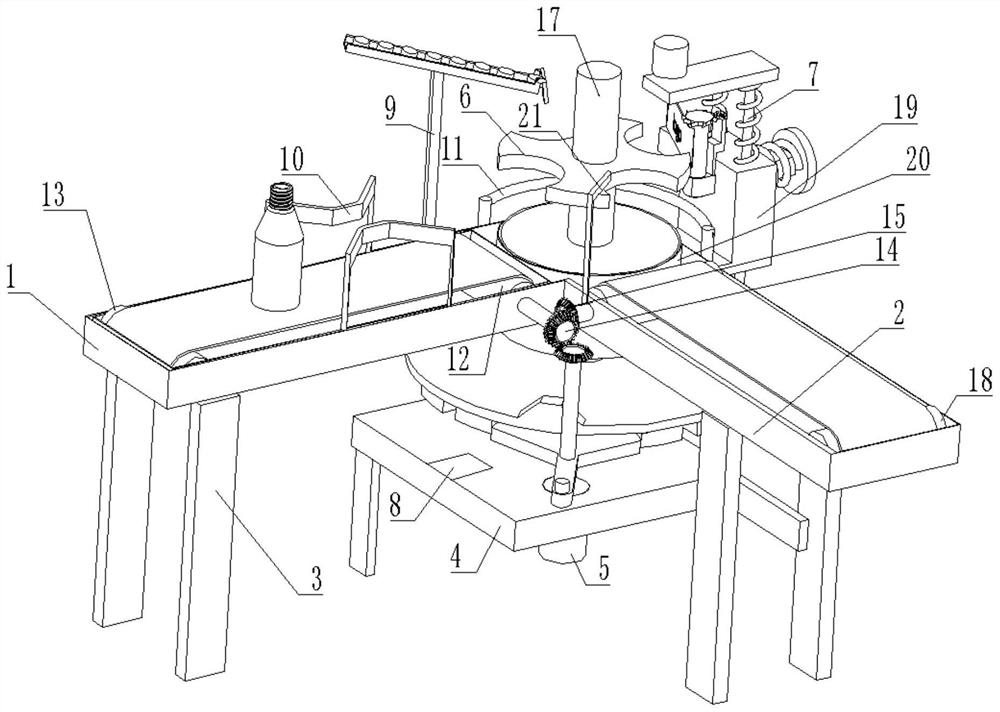

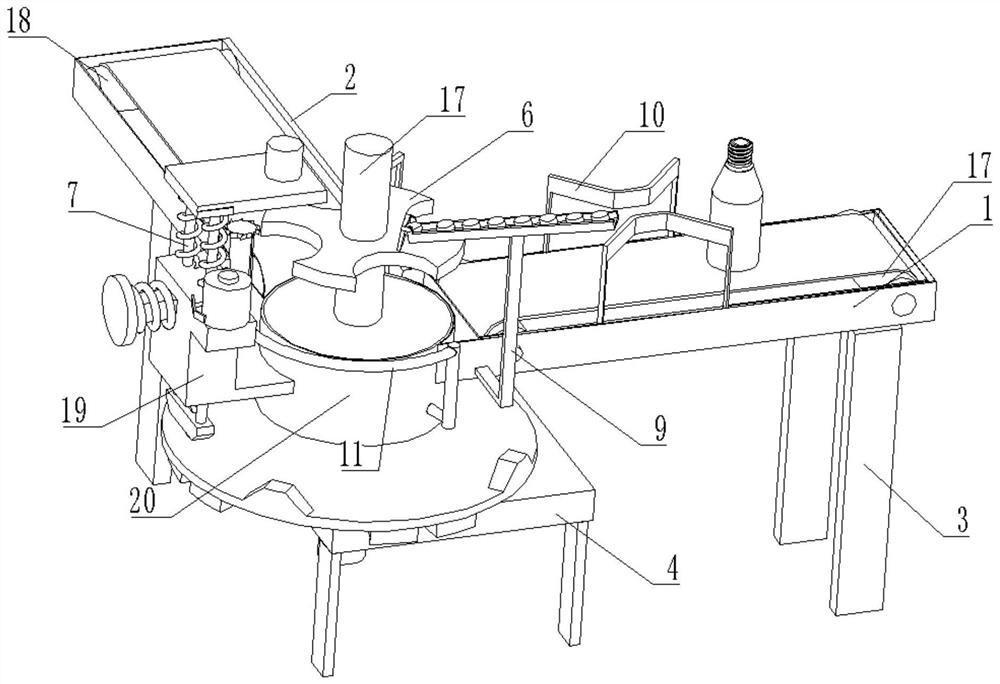

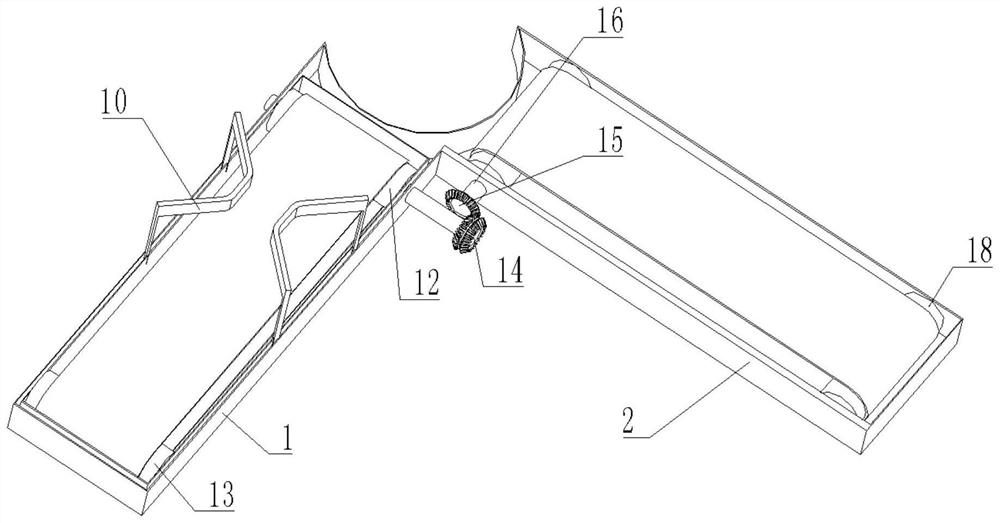

Plaster bandage folding machine

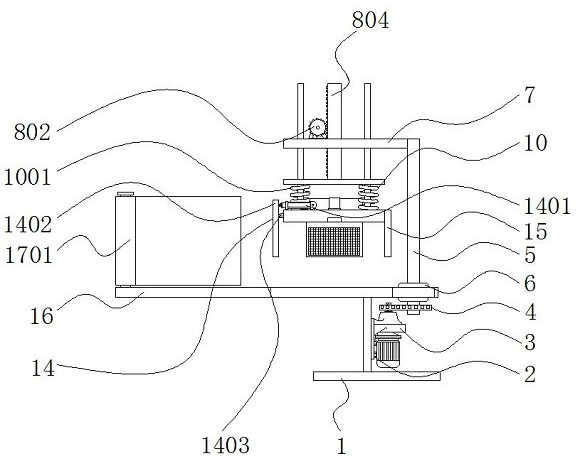

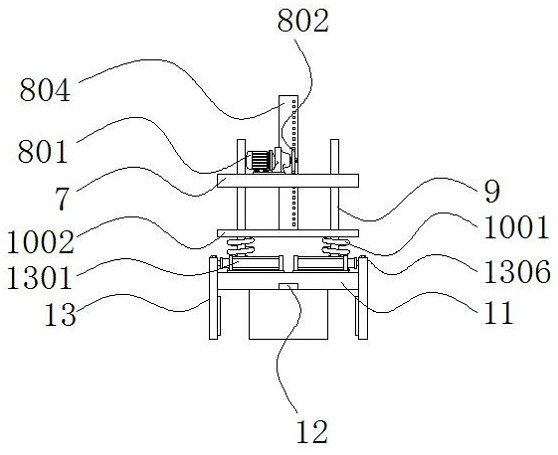

The invention relates to a folding machine, in particular to a plaster bandage folding machine. The invention aims at providing the plaster bandage folding machine which can save time and improve thefolding efficiency. According to the technical implementation scheme, the plaster bandage folding machine is characterized by comprising a bottom plate, a supporting plate, a first bearing pedestal, arotating shaft, a rocker rod, a rotating plate, a connecting block, an annular push plate, an elastic rope, a push block, sliding rails, a sliding block, a pressing plate, an elastic sheet and the like, wherein the supporting plate for supporting is fixedly connected with the front left side of the top of the bottom plate; the first bearing pedestal is bolted to the top of the supporting plate; the T-shaped rotating shaft is installed in the first bearing pedestal; the L-shaped rocker rod is fixedly connected with the left end of the rotating shaft; and the rotating plate is connected with the right end of the rotating shaft. According to the invention, the rotating plate can be driven to rotate clockwise by rotating the rocker rod clockwise so as to fold a plaster bandage, and medical workers do not need to cut the plaster bandage and then fold the plaster bandage manually, so that the time is saved and the folding efficiency is improved.

Owner:THE PEOPLES HOSPITAL SHAANXI PROV

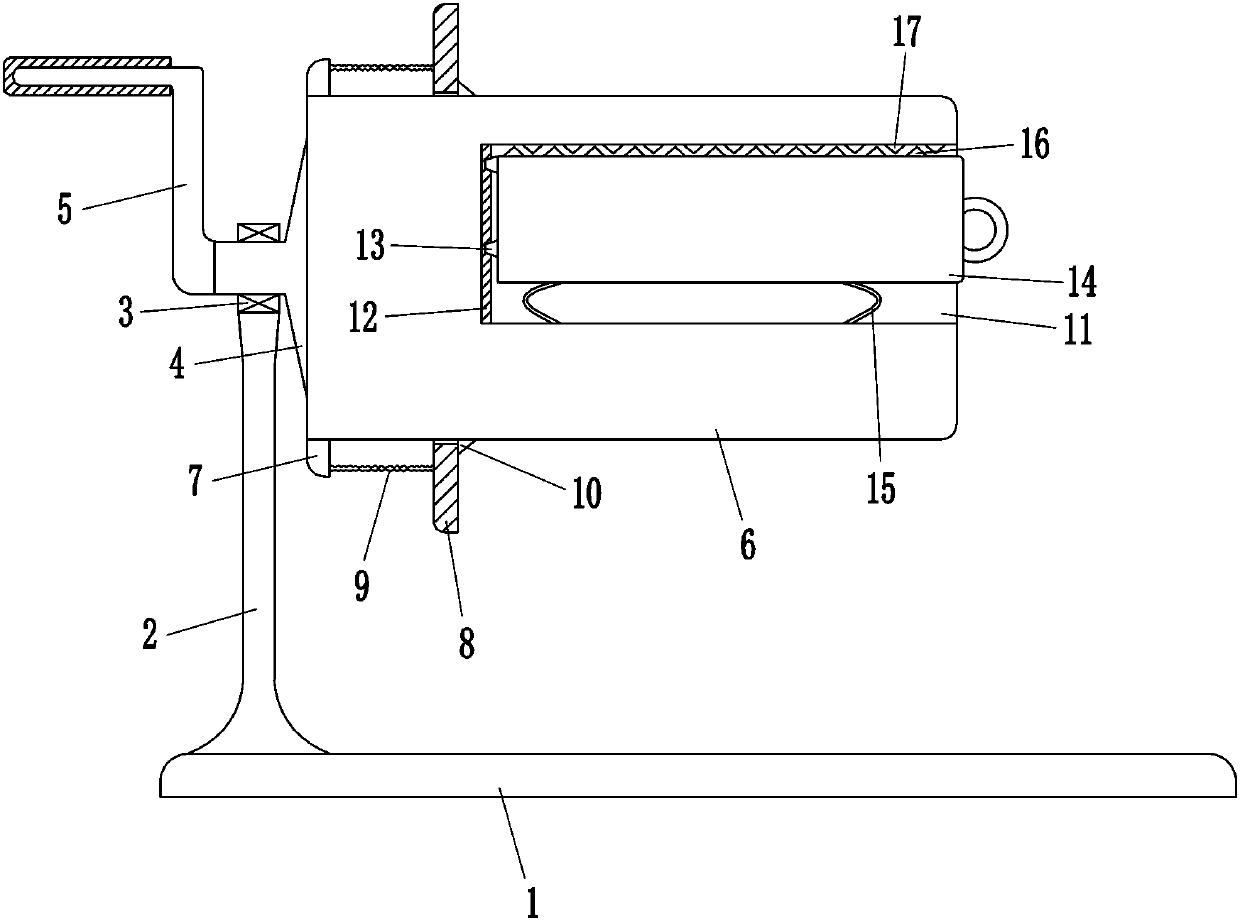

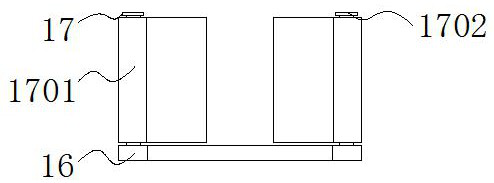

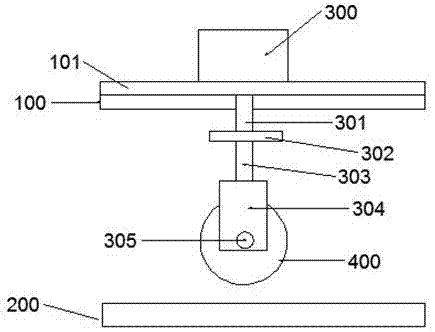

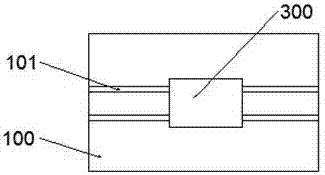

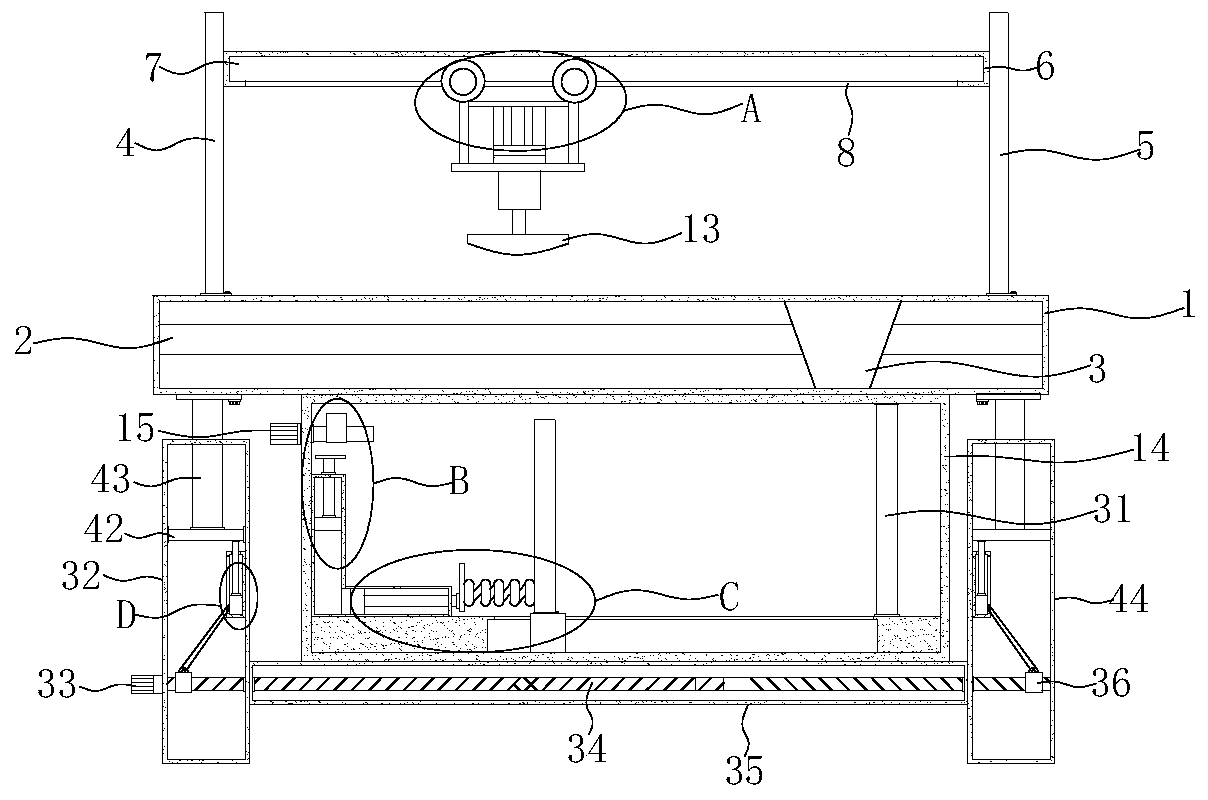

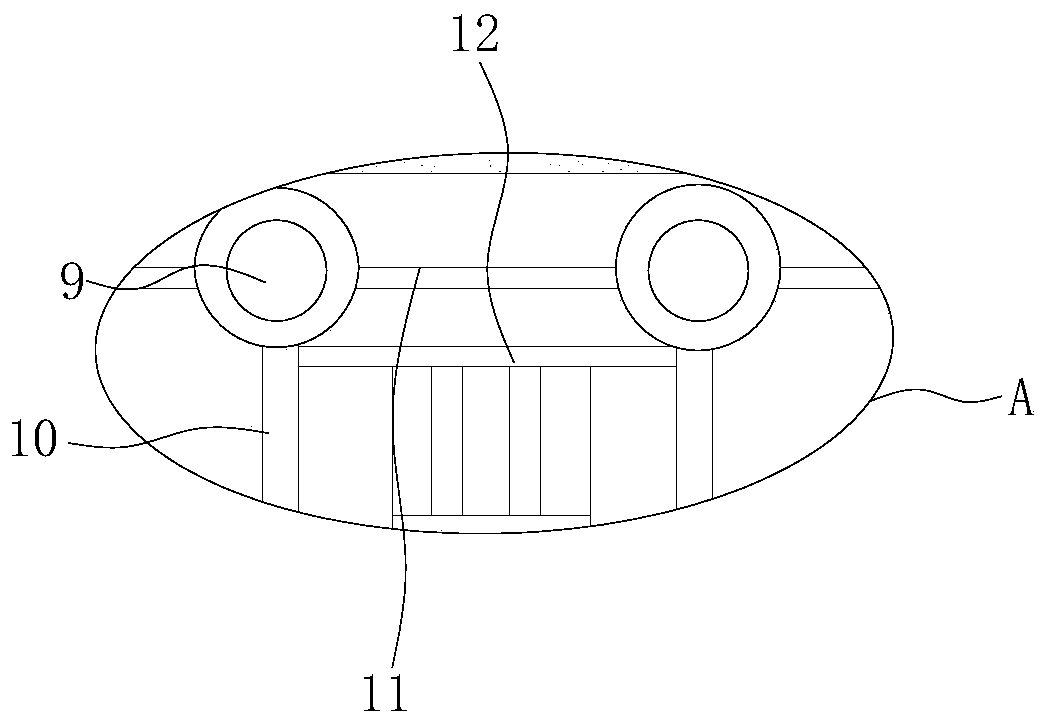

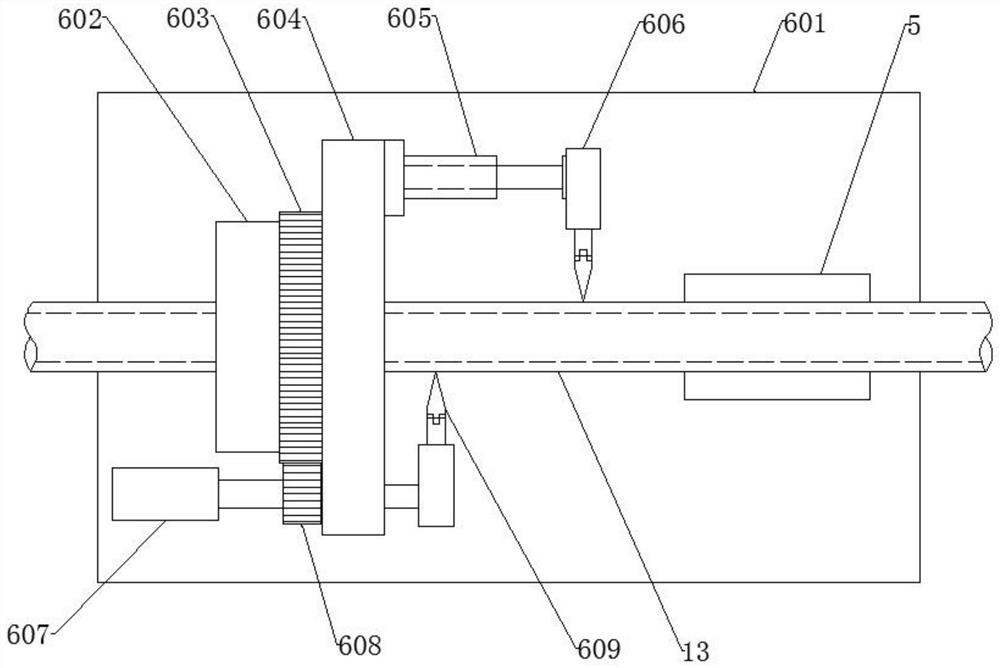

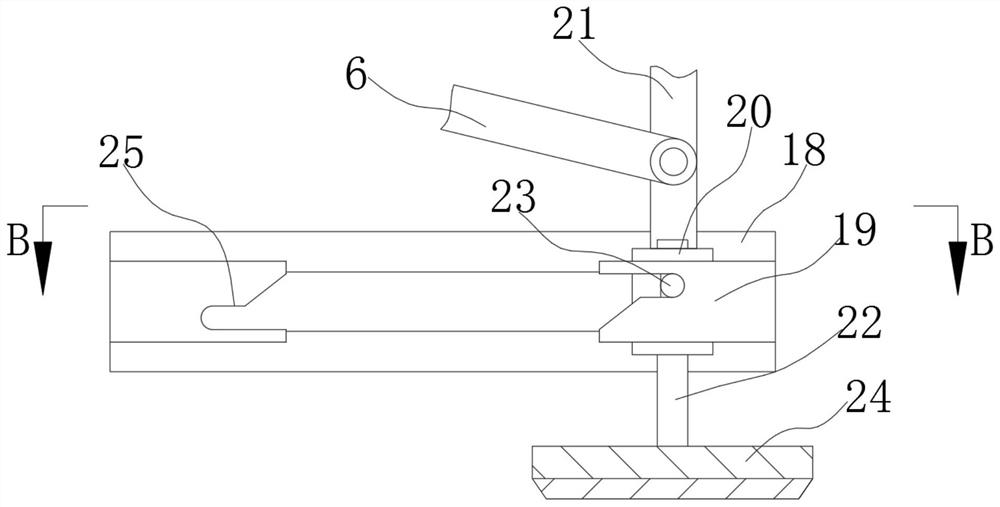

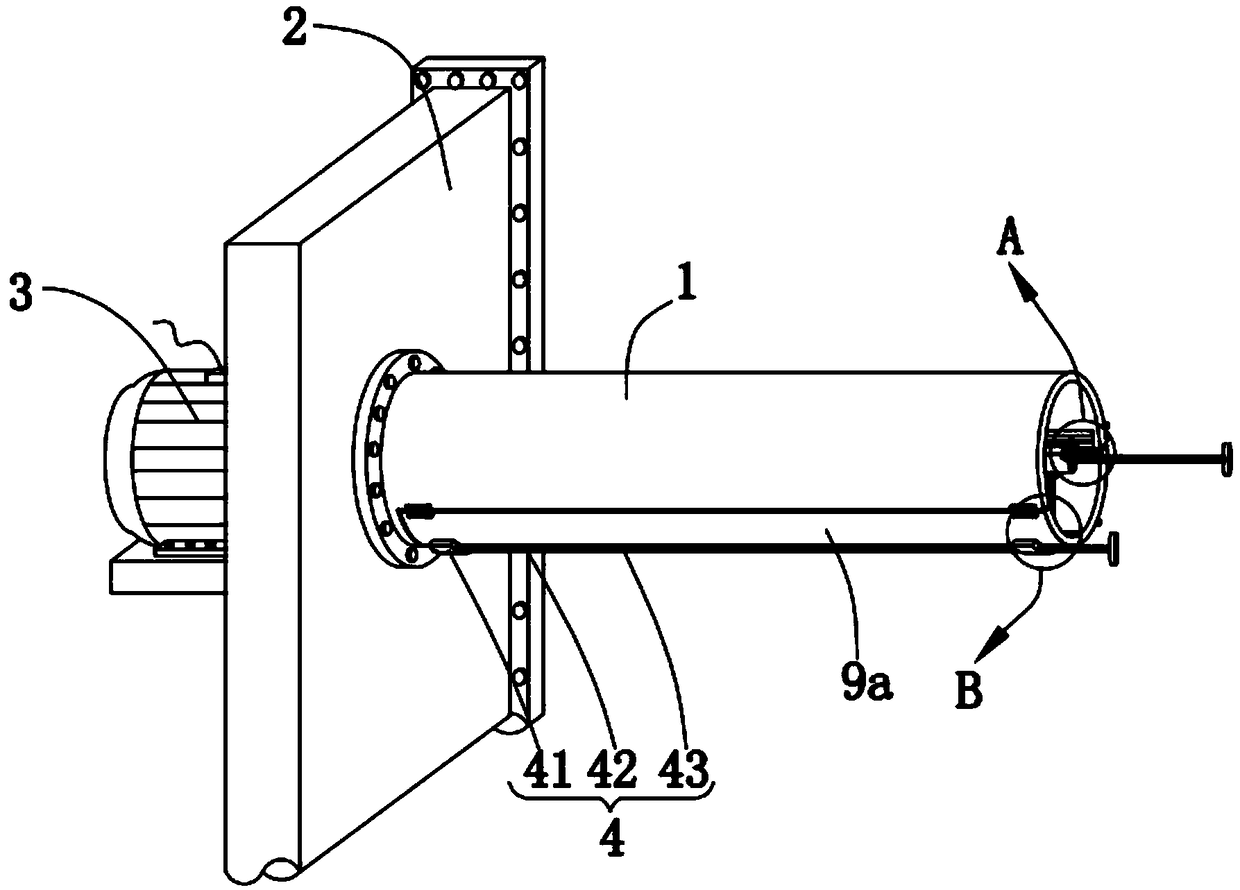

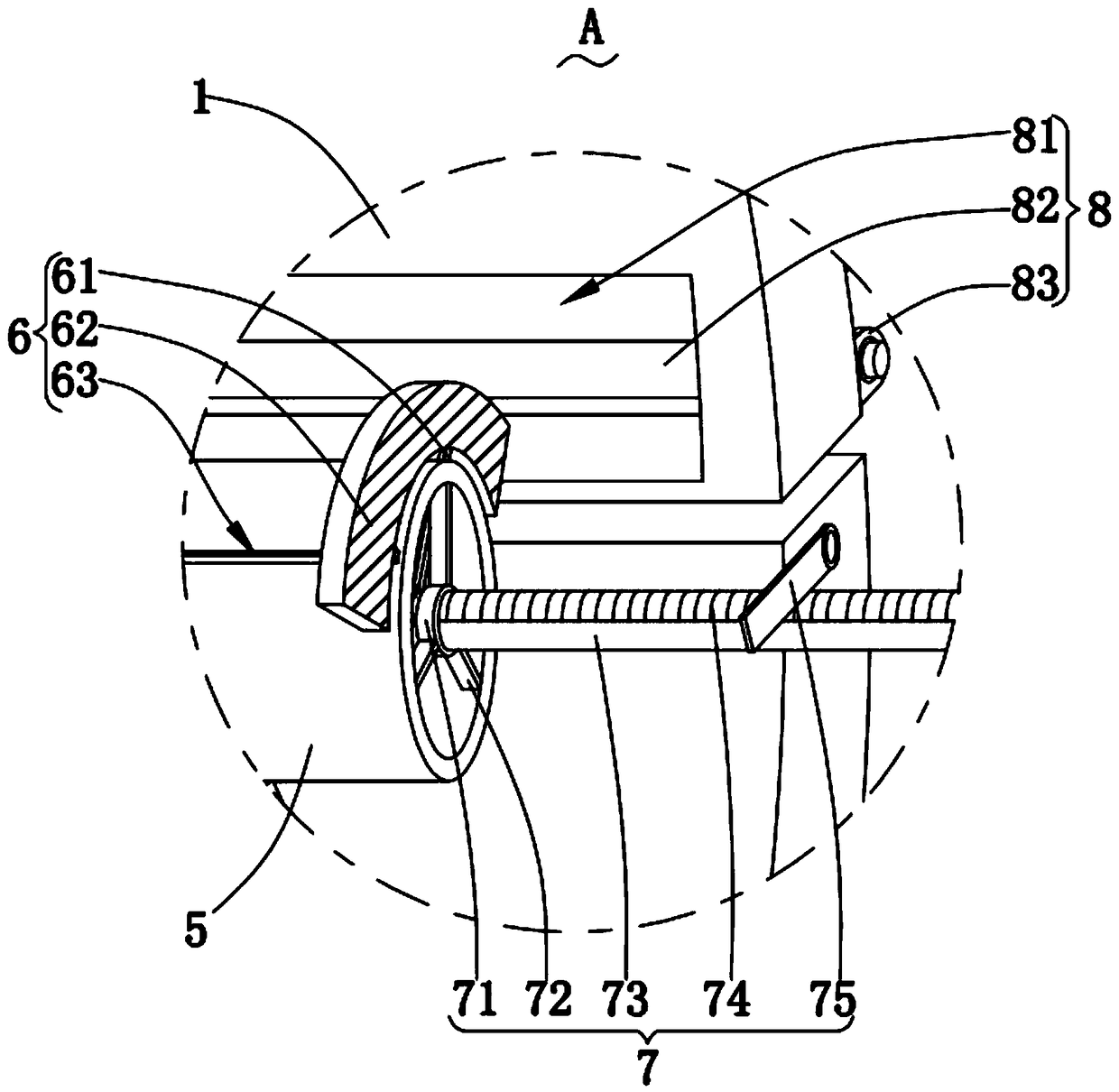

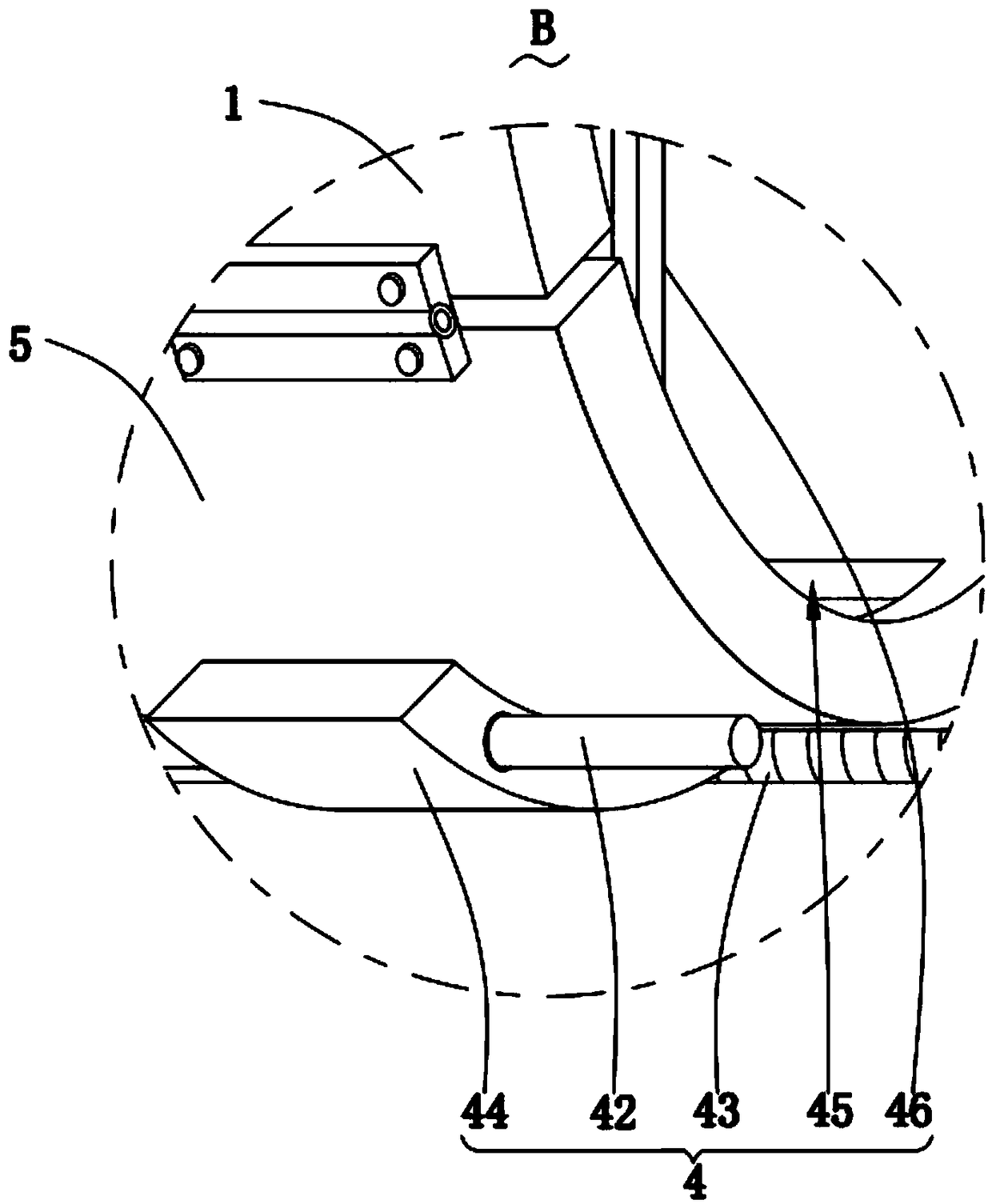

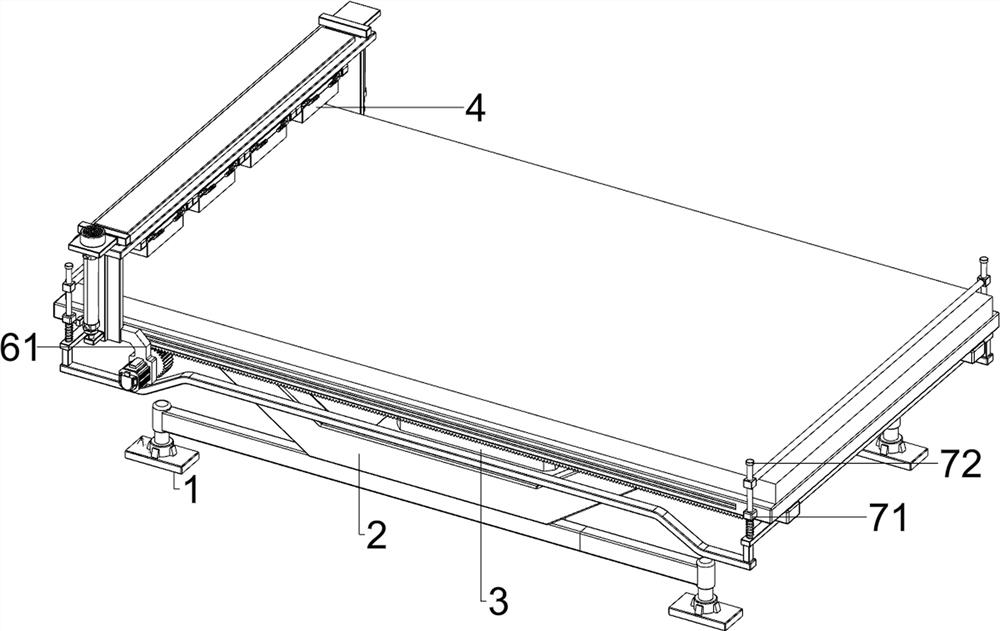

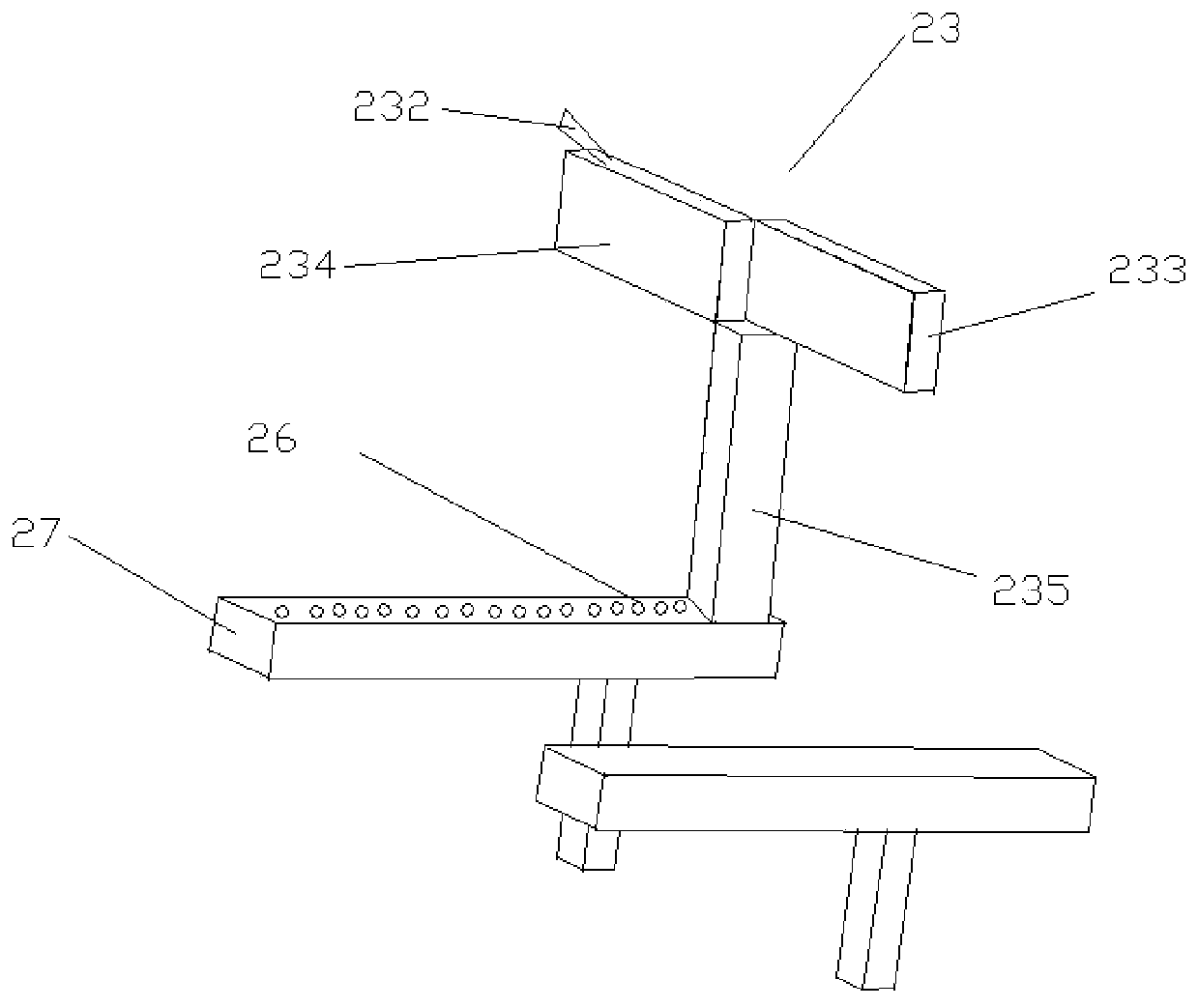

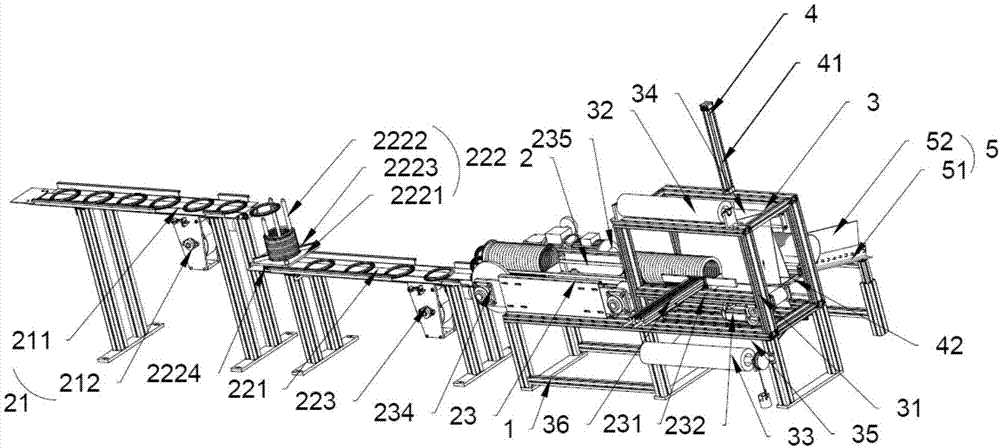

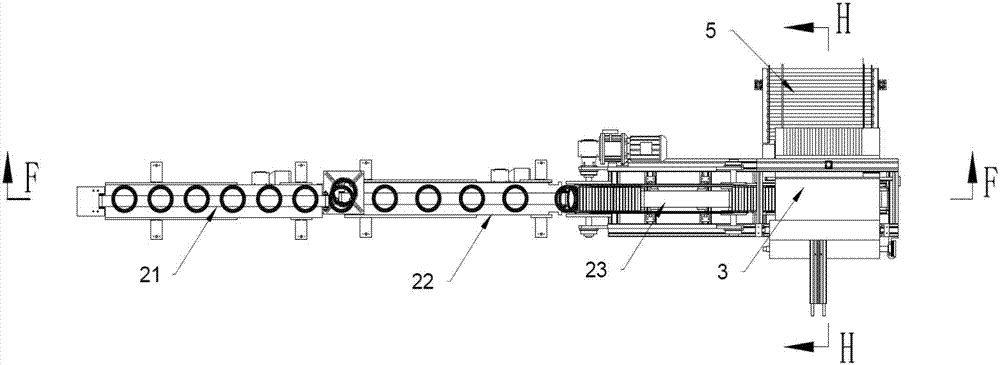

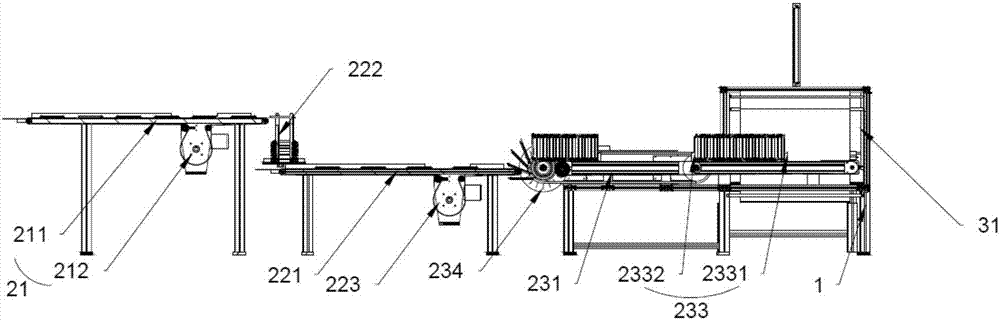

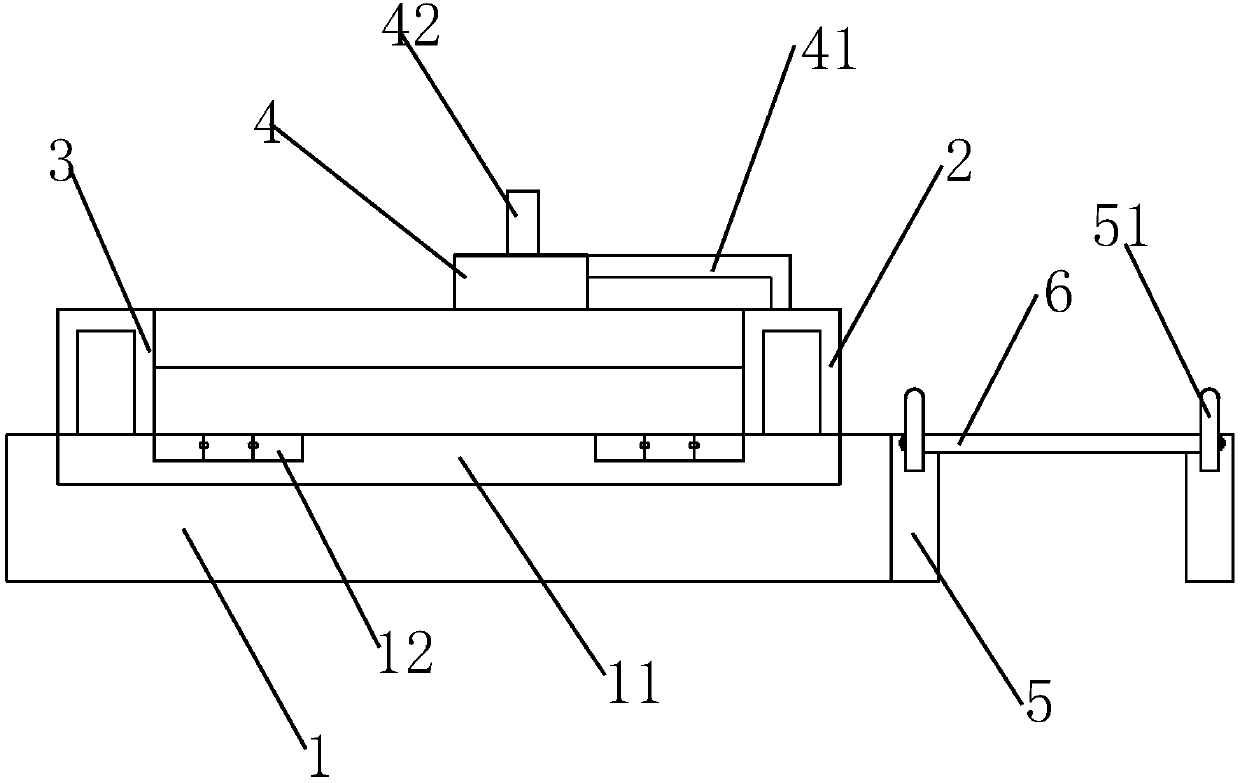

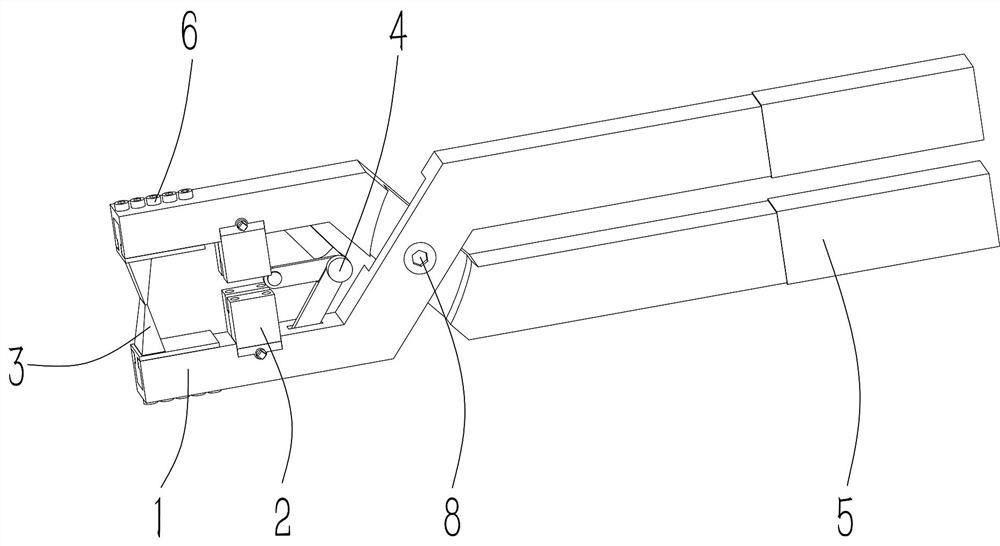

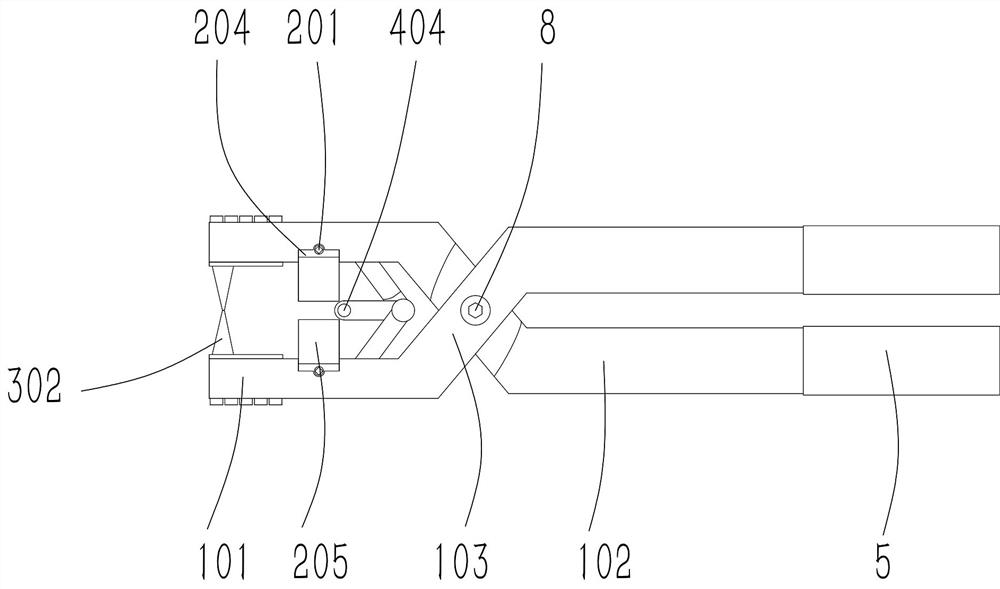

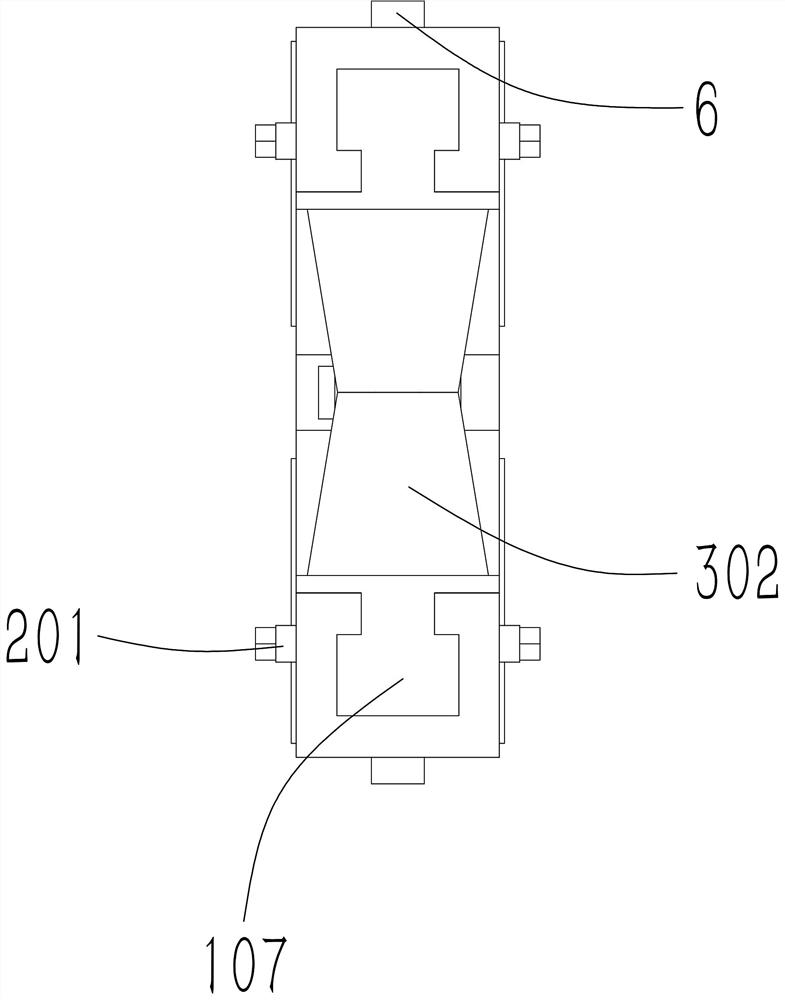

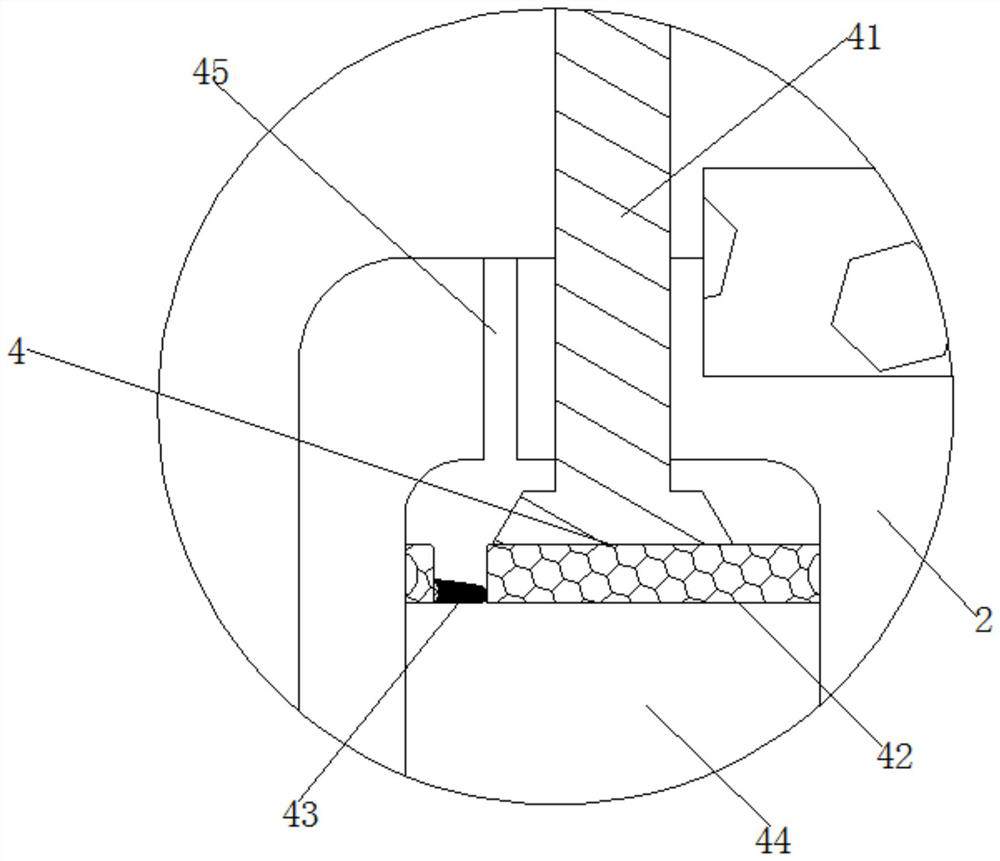

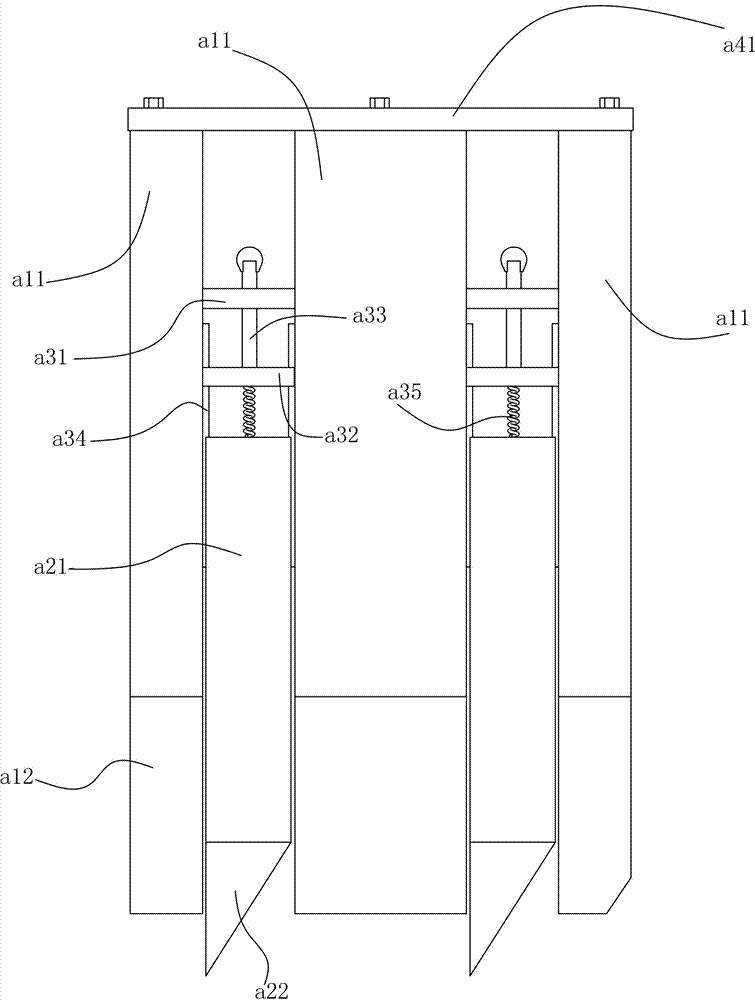

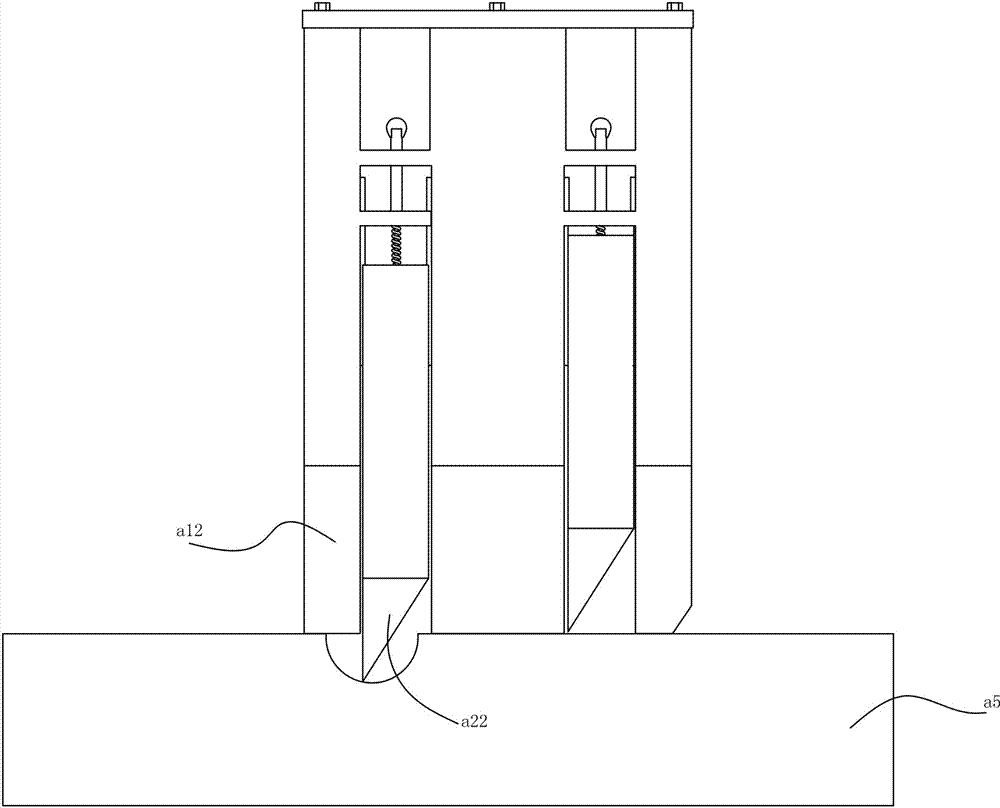

Rolled cloth feeding and cutting device

ActiveCN107761351AReduce labor intensityAvoid untidySevering textilesWebs handlingEngineeringMechanical engineering

The invention discloses a rolled cloth feeding and cutting device. The device includes a rack, a cloth feeding device and a cloth cutting device are arranged on the rack, the cloth feeding device includes a driving roller, an extrusion belt is arranged on the driving roller and tensioned on two extrusion rollers on a floating bracket, the floating bracket is sleeved with a fixing bracket, two placing rollers are arranged below the driving roller, a right-angular trapezoid platform is arranged at the left ends of the placing rollers, and a middle roller is arranged on the right-angular trapezoid platform; the cloth cutting device includes two guiding columns, the upper ends of the two guiding columns are fixedly connected with each other through a connecting plate, an air cylinder is fixedto the connecting plate and connected with a blade rod, a blade is fixed to the blade rod, and a rectangular groove is formed in the bevel of a folding plate and exactly faces the blade edge of the blade. According to the rolled cloth feeding and cutting device, by utilizing the right-angular trapezoid platform, cloth can be rolled onto the two placing rollers, and by utilizing the cloth feeding device to feed the cloth to the cloth cutting device, the blade of the cloth cutting device can uniformly cut off the cloth, and therefore irregular edges caused by manual cutting are avoided.

Owner:苏州炽诚织造有限公司

Efficient cutting device for rubber synchronous belt corner cutting

The invention discloses an efficient cutting device for rubber synchronous belt corner cutting. The efficient cutting device for rubber synchronous belt corner cutting comprises a cutting table; corner crushing through holes are formed in the two side table surfaces of the cutting table; a fine material collecting box is placed on the bottom end ground of a fine material charging hopper; a crude material collecting box is correspondingly placed on the ground rightly below the right side of a right side followup rotating wheel; guide sliding channels are respectively formed in the left side wall and the right side wall of a box body of a lifting buffer box; and a compression buffer spring sleeves a rod body of a support frame rod between the top side wall of an inner cavity of the lifting buffer box and the upper surface of a plate body of a movable slide plate. Cut leftovers can be smoothly classified and collected, so that the problem of untidy table surface caused by accumulation ofthe leftovers on the worktable is prevented, and meanwhile, the problem of unsuccessful cutting caused by deviation of a belt body is prevented; the rubber synchronous belt cutting effect is improved;and the cutting efficiency is guaranteed.

Owner:贵溪静星信息技术服务有限公司

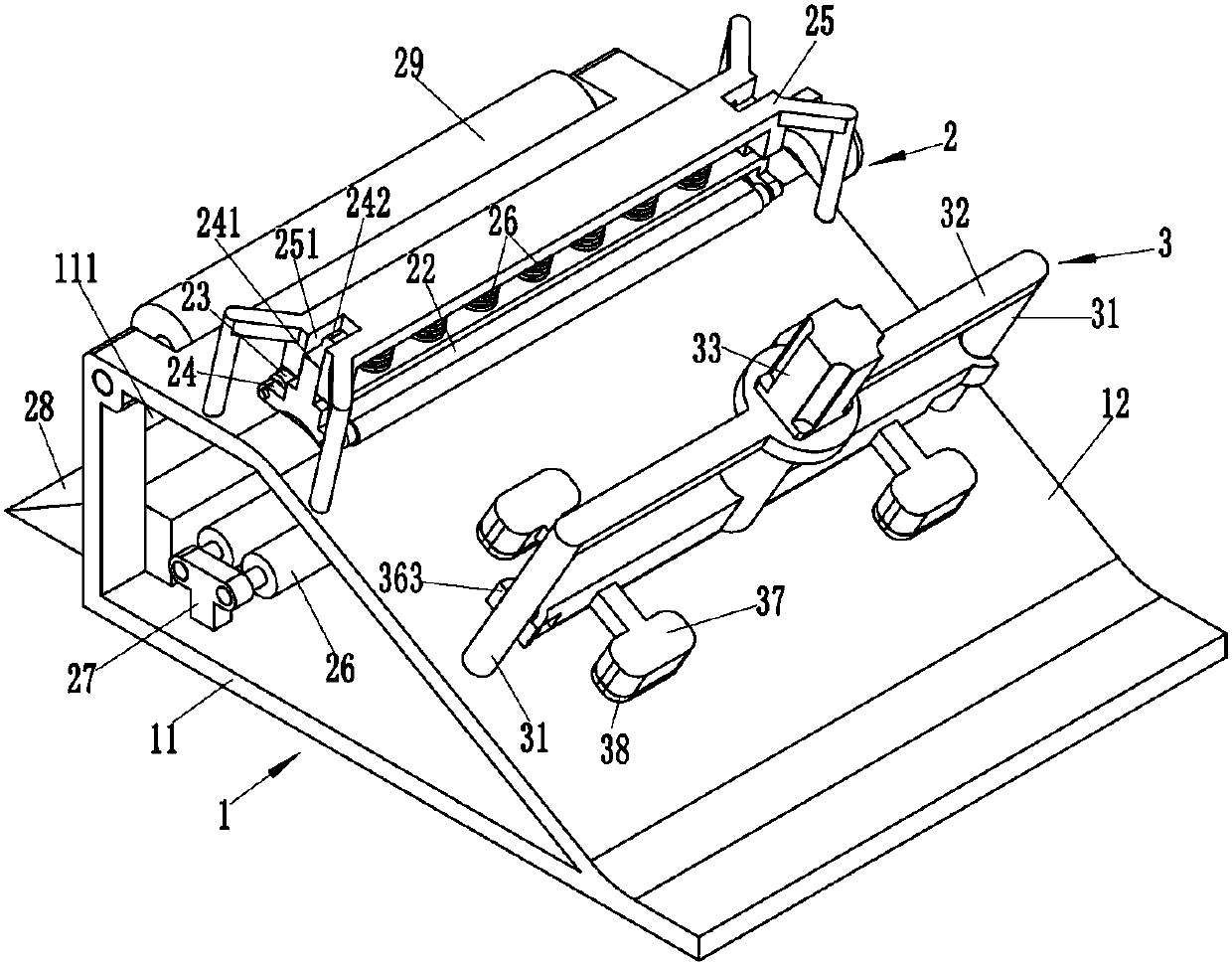

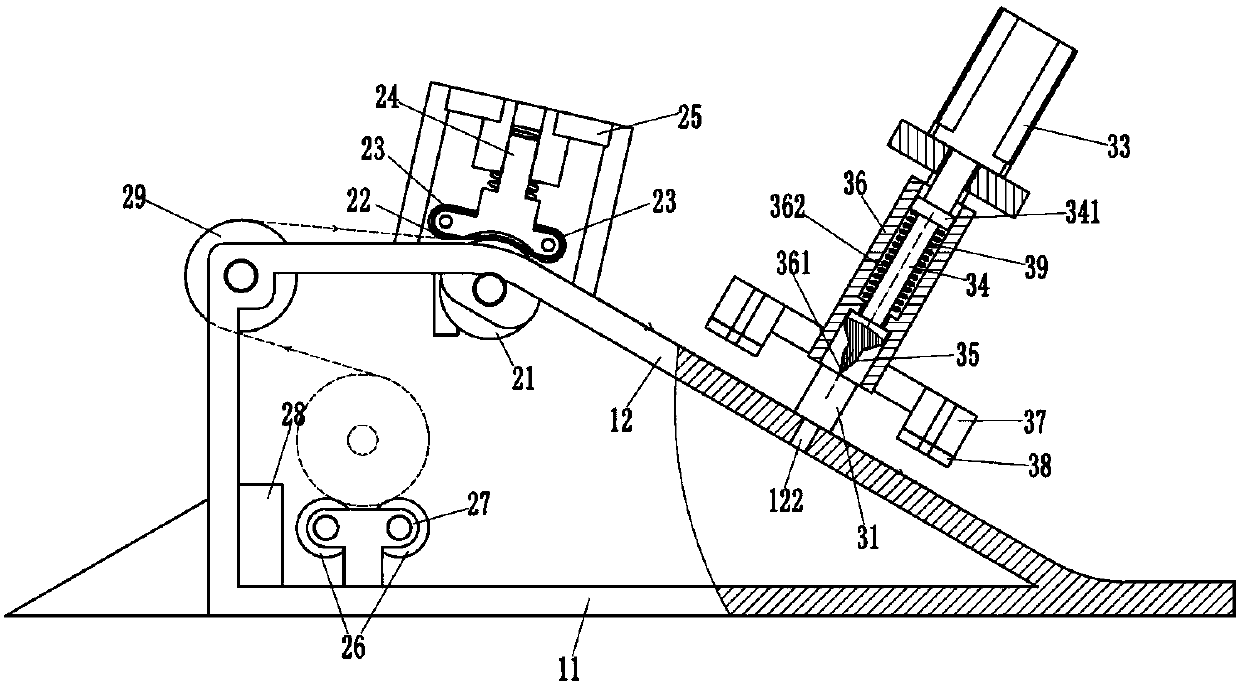

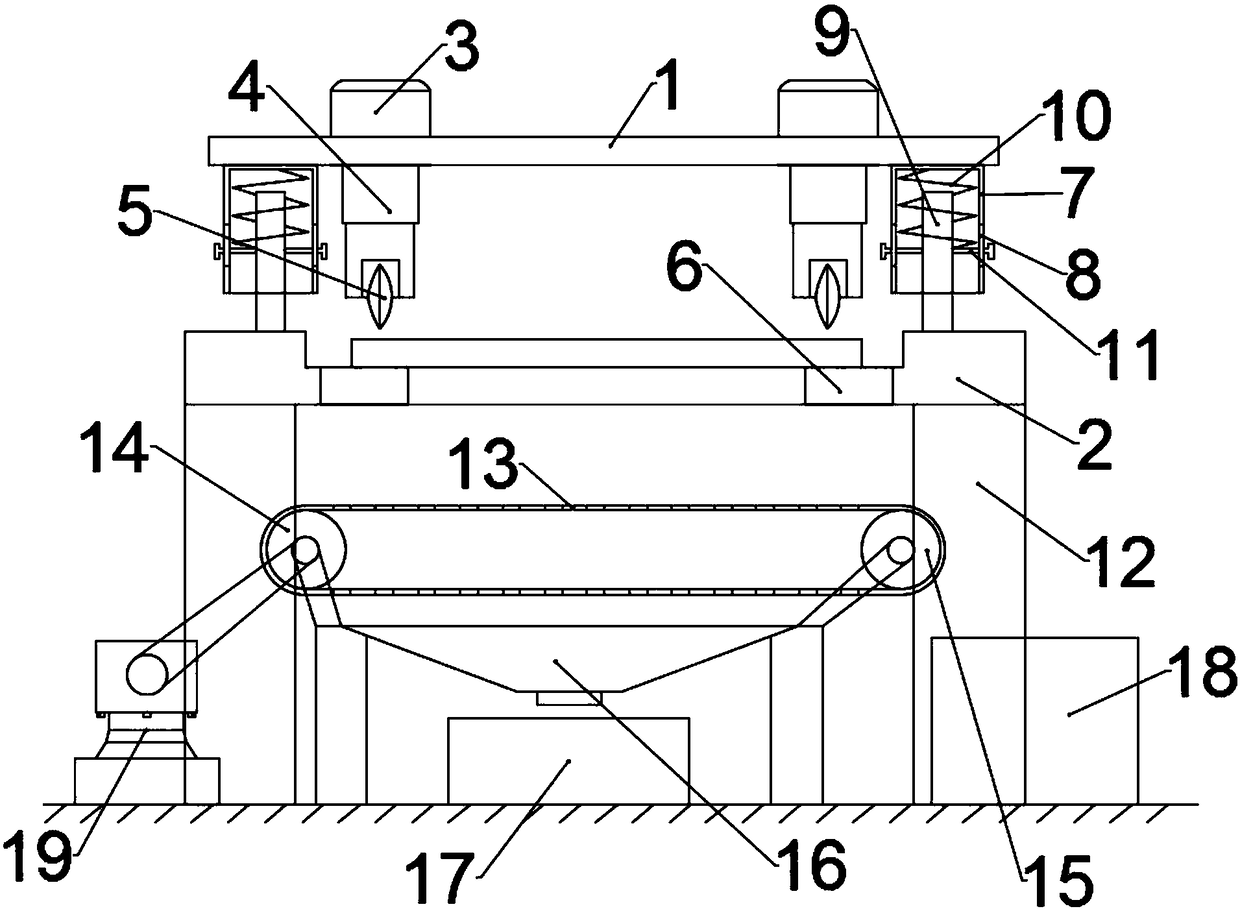

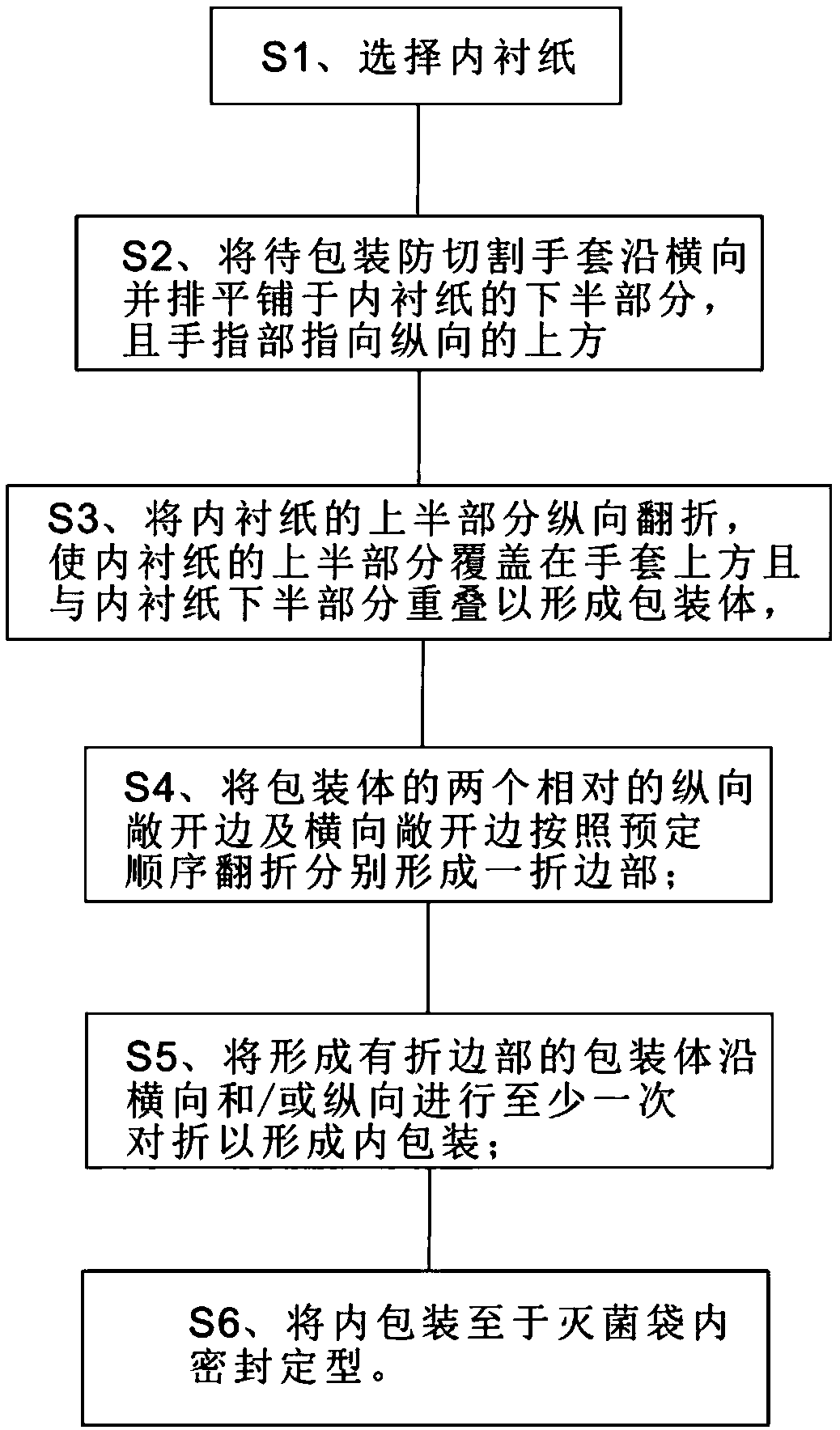

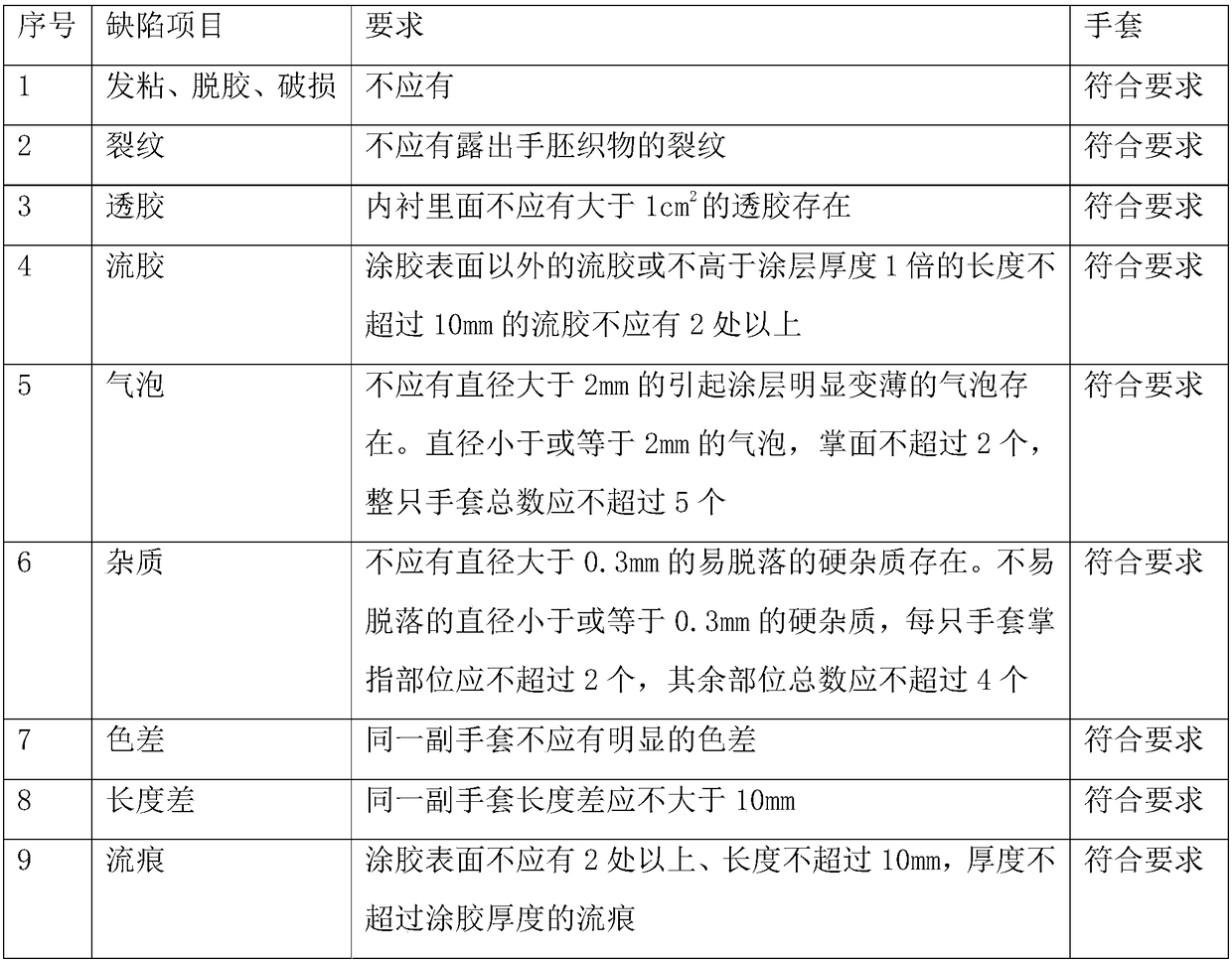

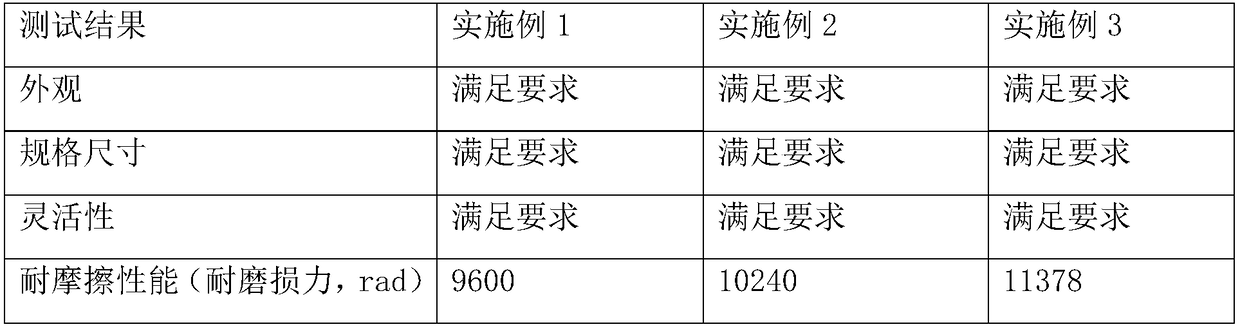

Anti-cutting glove and packaging method thereof

InactiveCN108978013AImprove cut resistanceWon't failWeft knittingWrapper folding/bending apparatusYarnPolyvinyl chloride

The invention discloses an anti-cutting glove and a packaging method thereof and belongs to the technical field of work gloves. The anti-cutting glove is made by knitting yarns which are one or any ofpolyethylene / aramid fiber, polyethylene / aramid fiber / steel wire, PVC-coated (polyvinyl chloride-coated glass fiber spandex yarn, and steel wire; the yarns are knitted into a glove core by an automatic glove knitter; the outside of the glove core is provided with a polymer coating by dipping; the polymer coating is one or a combination of butyronitrile rubber latex, polyurethane and rubber. The anti-cutting glove has excellent cutting protection which is far higher than provisions of national standard of China and European Union standards, has good flame retardance and excellent thermal protection, is light in weight and flexible to wear, and is good in wear resistance, low in production cost and high in batch production efficiency.

Owner:花春丽

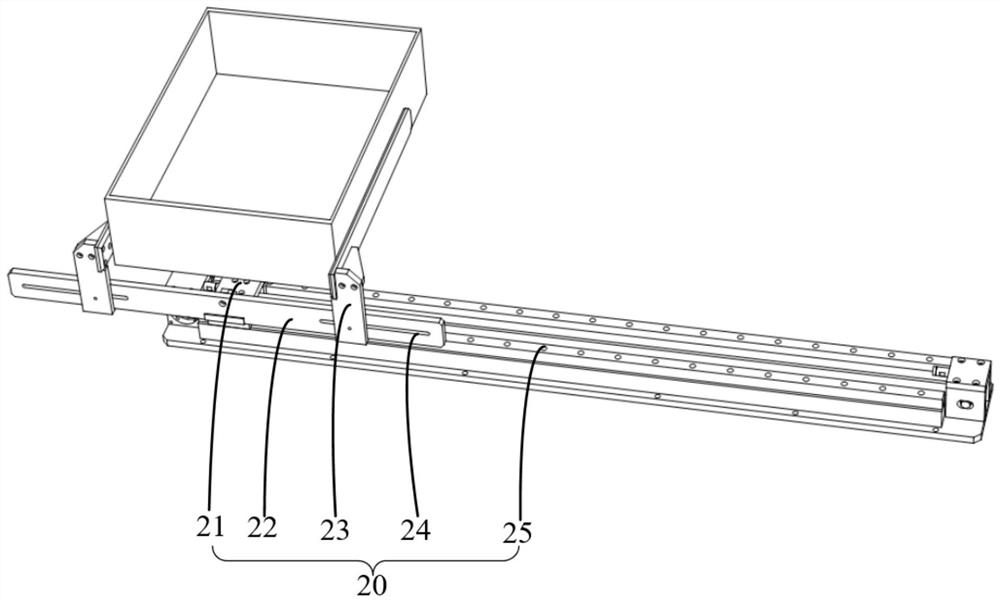

Pressing device used for automatic packing machine

InactiveCN111942642AAccurate positioningAvoid untidyBundling machine detailsElectric machineryEngineering

The invention relates to a pressing device used for an automatic packing machine. The pressing device comprises an installation base and a pressing mechanism. A screw is arranged on one side of the installation base. A chain is connected to the upper portion of a first motor. A wheel shaft is arranged outside a rotating shaft. The pressing mechanism is located above a fixed top plate. A buffer mechanism is arranged outside positioning guide rods. The lower portion of the buffer mechanism is connected with a pressing plate. A pressure sensor is embedded in the pressing plate. The pressing device has the beneficial effects that according to the pressing device used for the automatic packing machine, pressed objects are positioned through an anti-deviation positioning structure so that the pressed objects can accurately move to the position below the device. By means of four baffles, the situation that the pressed objects bear pressure, slide towards the periphery and then scatter is prevented. The pressed objects can be clamped and transported to the other position to be machined through clamping limiting mechanisms. The pressed objects are arranged through an arrangement mechanism,pressing of the device is facilitated, and by means of the buffer mechanism, the situation that due to the fact that pressure is excessively large, the objects are damaged is prevented.

Owner:重庆信易源智能科技有限公司

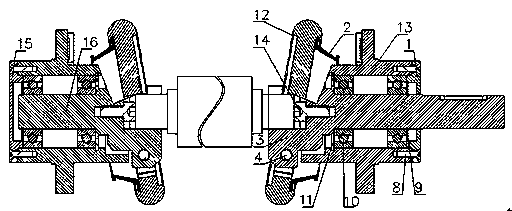

Safety chuck device allowing wound and unwound roll materials to be conveniently stored, clamped and taken out

InactiveCN108545518AStrong resistance to deformationAvoid product quality degradationWebs handlingConductor CoilQuenching

The invention discloses a safety chuck device allowing wound and unwound roll materials to be conveniently stored, clamped and taken out. The safety chuck device comprises a drive end chuck and a supporting end safety chuck, and a mandrel or an expansion shaft is clamped between groove blocks at the shaft ends of the drive end chuck and the supporting end safety chuck. The safety chuck device hasthe advantages that the structure is compact, the design is reasonable, a threaded hole is formed in a clamping opening, and the length deviation of the gas expansion shaft or the mandrel can be compensated by adjusting the depth of a screw; the safety chuck device has high bearing capacity and is made of high-quality steel, and the bearing weight is greatly improved due to the special structure;the service life is long, maintenance is easy, the clamping opening is subjected to high-frequency quenching treatment, all parts can be exchanged for use, and thus maintenance is convenient; and theusage precision is high, the parts are chromeplated, blackened and quenched to achieve abrasion resistance, the parts are high in precision, high in deformation resistance and small in circular runout, irregular winding and overhigh pendulum amplitude of unwound rolls are effectively avoided, and thus the product quality can be prevented from dropping.

Owner:安徽哲乐机电有限公司

Silicon chip cutting device

InactiveCN107283657AAvoid damageAvoid offsetWorking accessoriesFine working devicesPulp and paper industryEngineering

A silicon wafer cutting device, including an upper bracket, a fixed table, a cylinder, and a cutting knife; the upper bracket is arranged above the fixed table, and two slide rails are arranged on the upper bracket, and the two slide rails are connected to each other. Parallel, the cylinder is horizontally arranged between the two slide rails, the telescopic end of the cylinder is vertically arranged below the upper bracket, and the end of the telescopic end close to the fixed table is horizontally provided with a push plate, The bottom of the push plate is longitudinally provided with a connecting rod, and the bottom of the connecting rod is fixed with a cutting knife fixing frame, and the cutting knife is arranged in the cutting knife fixing frame; a positioning cutting groove is horizontally arranged on the fixing platform. The beneficial effects of the present invention are as follows: (1) the cutting device can cut a single silicon chip at one time, avoiding back and forth cutting, resulting in damage to the silicon chip and irregularity of the edge of the silicon chip; (2) the fixed table is equipped with The positioning of the cutting groove avoids the deviation of the silicon wafer during cutting and reduces the waste of cost.

Owner:安徽中柜智能科技有限公司

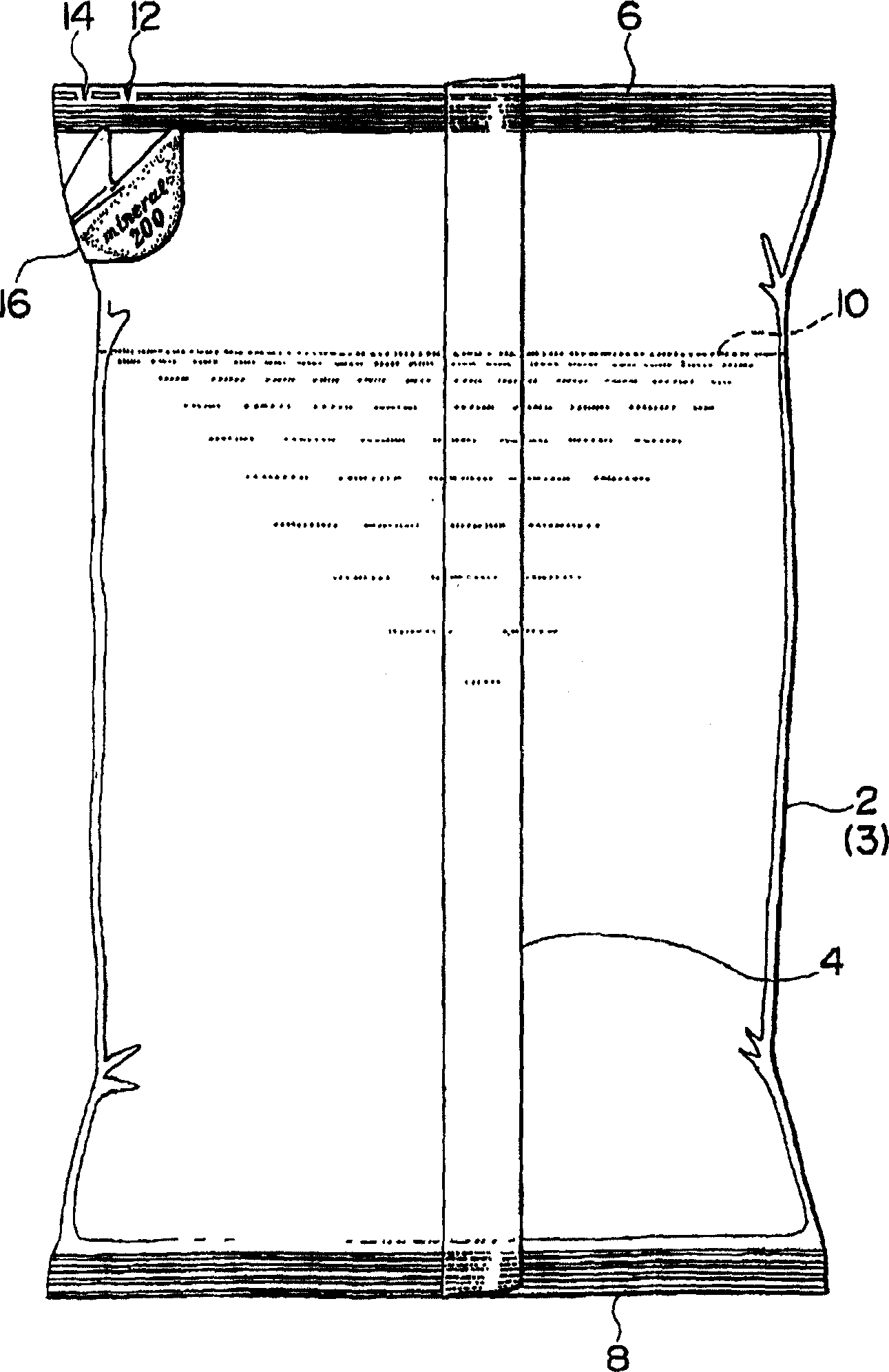

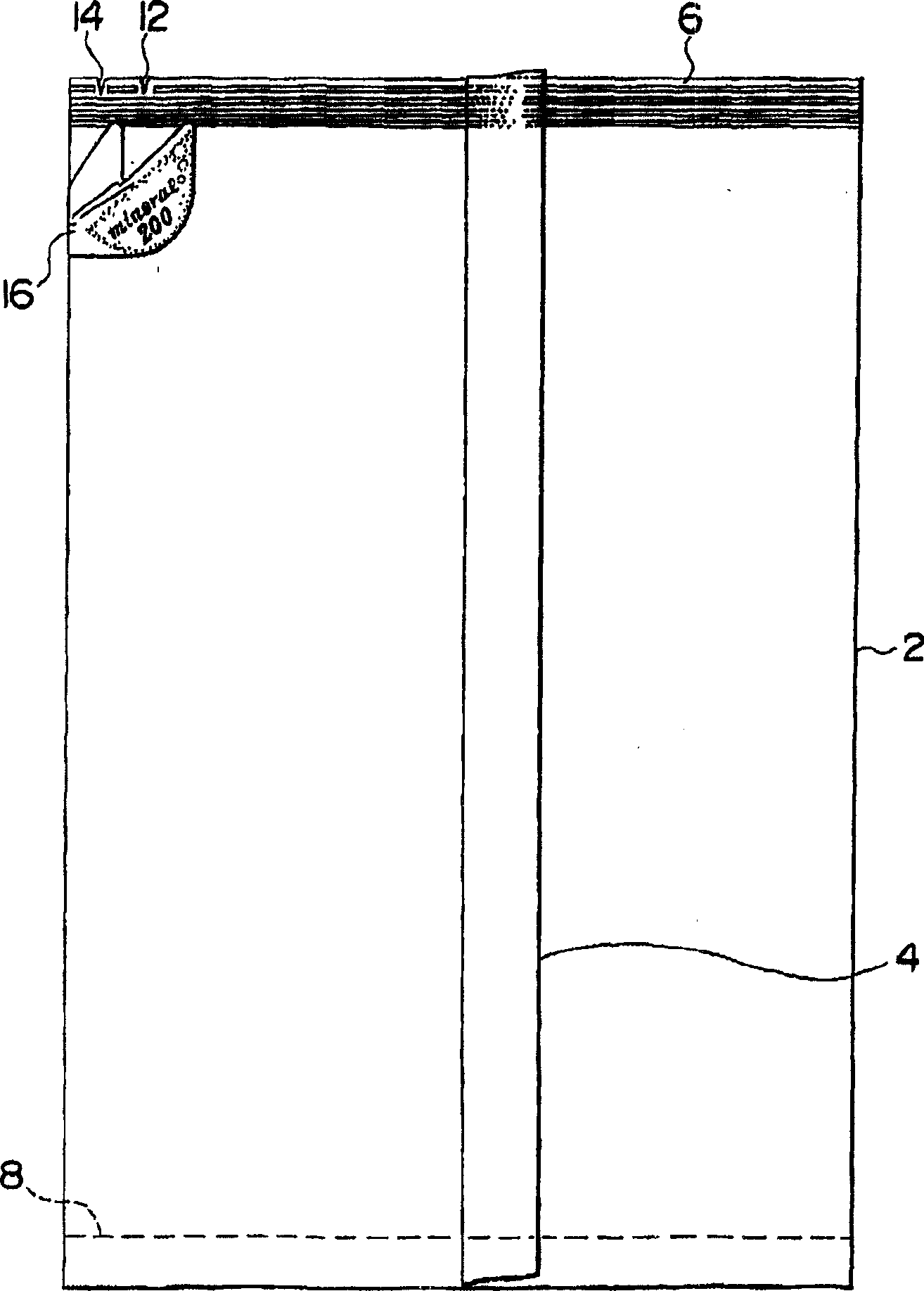

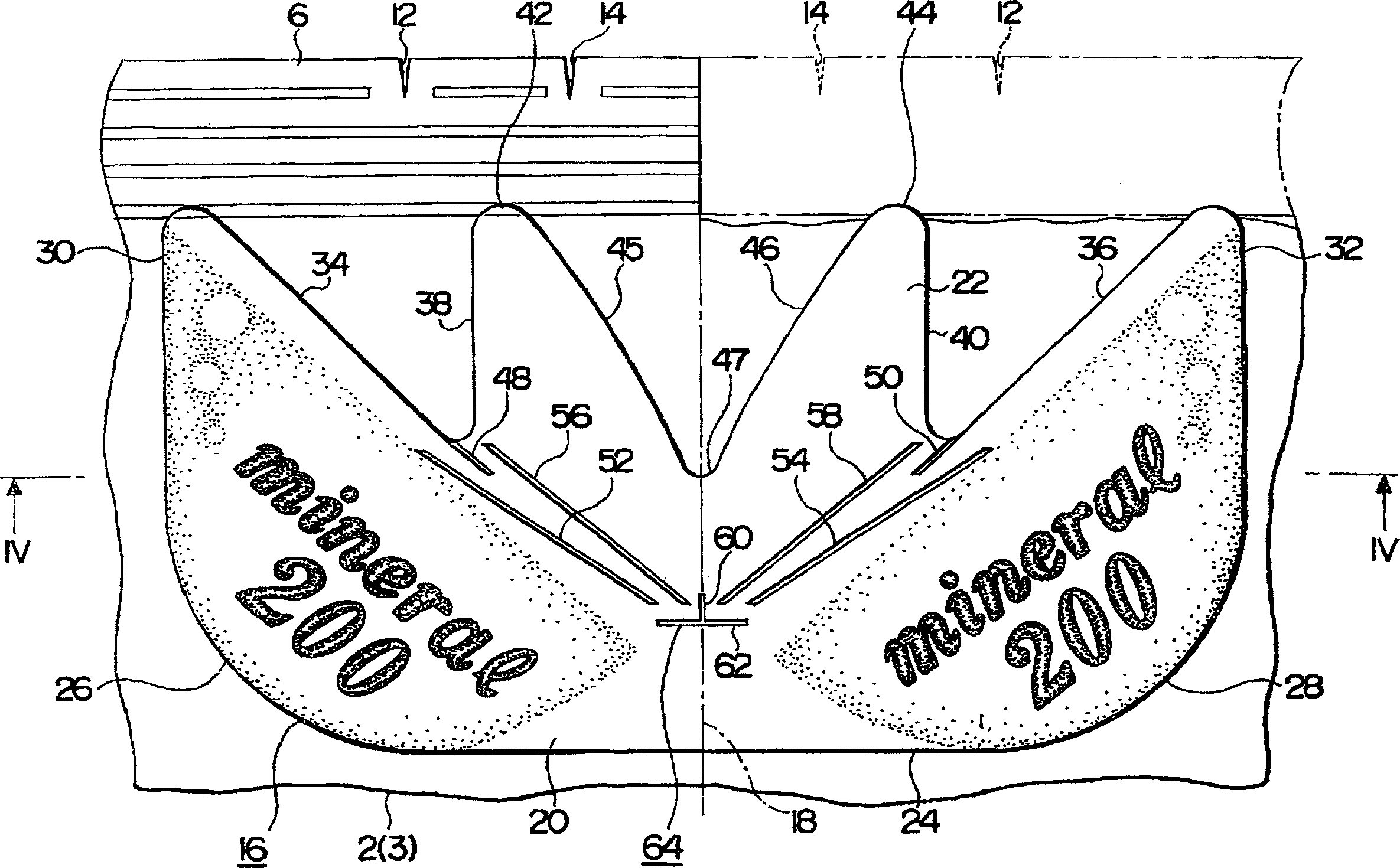

Flexible container, method of forming the container, unsealing guide of flexible container, method of filling liquid into container, and liquid

Owner:KURITA WATER INDUSTRIES LTD

Waste material cutting-processing recycling device for garment production

InactiveCN110771980AImprove convenienceImprove accuracyClothes making applicancesWaste materialWorkbench

The invention discloses a waste material cutting-processing recycling device for garment production, and relates to the technical field of garment production. The waste material cutting-processing recycling device for garment production comprises a work table, a feeding pipe is arranged on the work table, a first bracket is fixedly mounted on the top of the work table, a second bracket is fixedlymounted on the top of the work table, the first bracket and the second bracket are arranged adjacently, a first sliding base is fixedly mounted on the outer wall of one side of the first bracket, oneside, far away from the first bracket, of the first sliding base is fixedly connected with the second bracket, a first sliding chute is formed in the first sliding base, sliding wheels are movably mounted in the first siding chute, two groups of sliding wheels are available, a first opening is formed in the bottom of the first sliding base, the sliding wheels longitudinally pass through the firstopening and are fixedly provided with connecting rods, and two groups of connecting rods are available. The device is convenient to operate, the use stability of the device is improved to a certain extent, and thus the use performance of the device can be improved.

Owner:湖州橘柚茜服饰有限公司

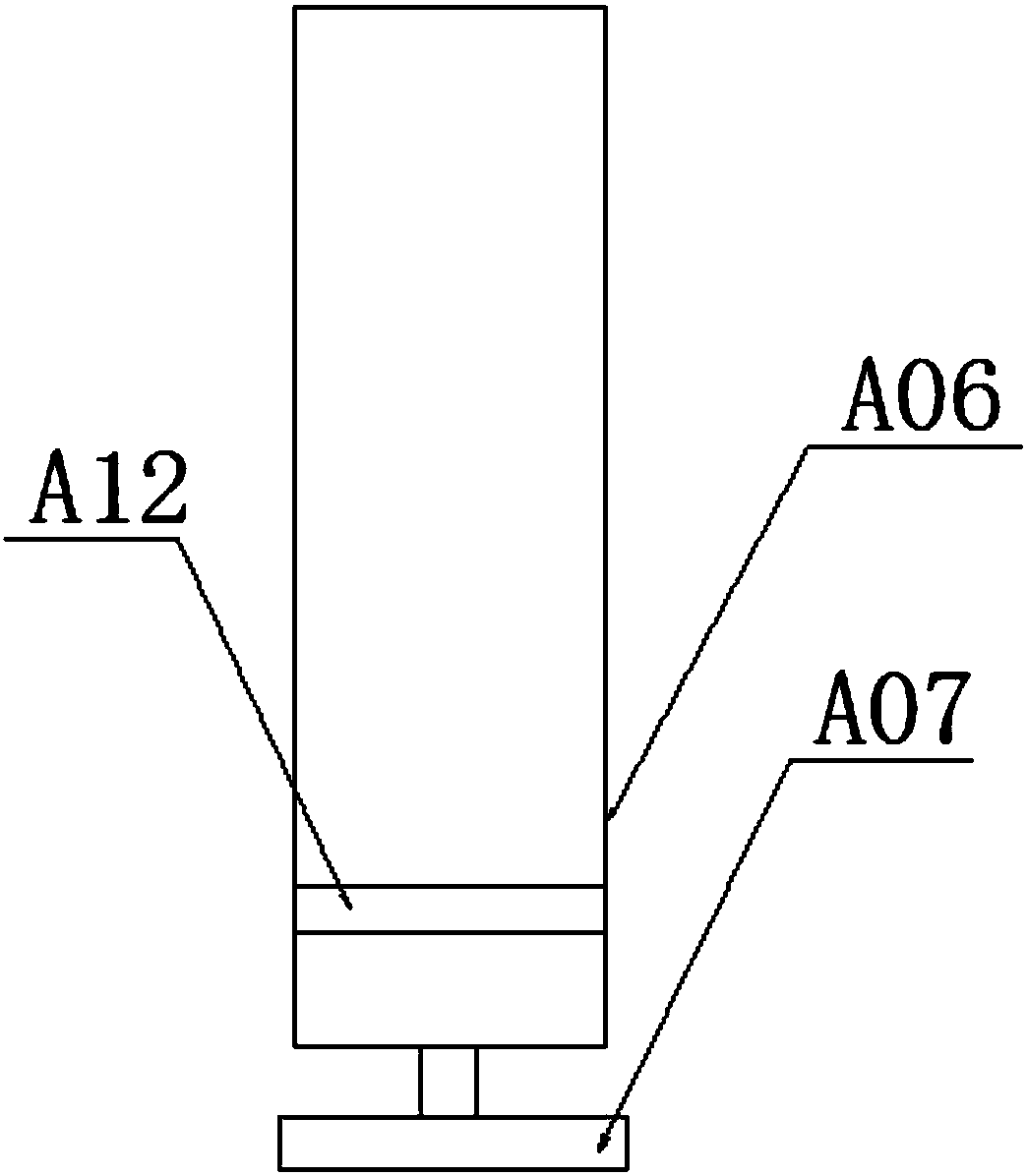

Plastic film blowing system with reheating function

InactiveCN111497058AImprove energy utilizationImprove drying efficiencyFlat articlesActivated carbonElectric machine

The invention discloses a plastic film blowing system with a reheating function. The plastic film blowing system involves a raw material drying device and a film blowing device, wherein plastic raw material dried by the raw material drying device is manually fed into a storage hopper of the film blowing device; the raw material drying device comprises a drying housing, wherein the bottom wall of the drying housing is fixedly connected with a reheating cylinder, a stirring motor is fixedly connected to the upper end of the reheating cylinder, and an output shaft of the stirring motor is fixedlyconnected with a stirring block through a folding rod; an electric material falling door is formed in the bottom wall of the drying housing, an electric heater is fixedly connected in the reheating cylinder, the upper end of the electric heater is in communication with an outlet of a suction fan through an air inlet pipe of the heater, an inlet of the suction fan is in communication with an outlet of an activated carbon box, multiple layers of honeycomb activated carbon layers are arranged in the activated carbon box, an inlet air pipe of the activated carbon box is provided with an opening located at the surface of the reheating cylinder, and an outlet pipe of the electric heater is in communication with a plurality of branched spray pipes; and a material falling housing is arranged below the drying housing, a gate plate door is arranged at the bottom of the material falling housing, and a material collecting barrel with an opening in the upper end is placed below the gate plate door.

Owner:明柏森

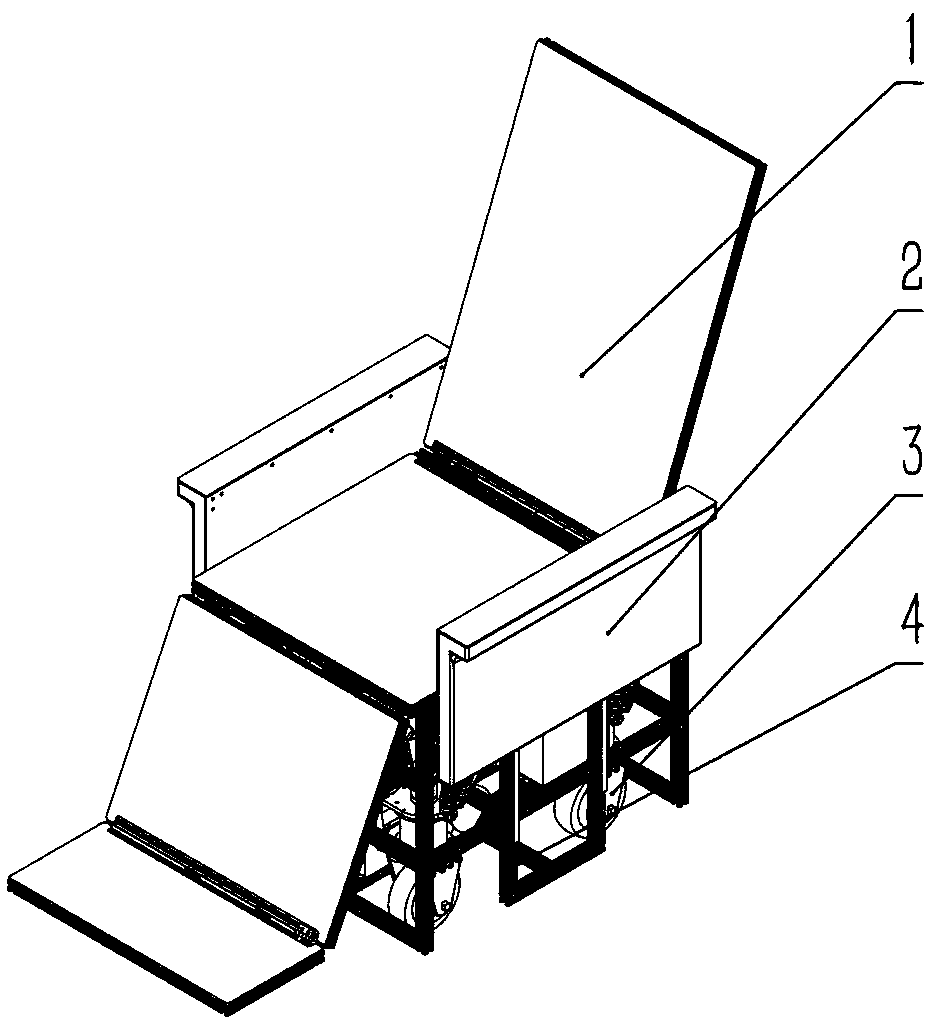

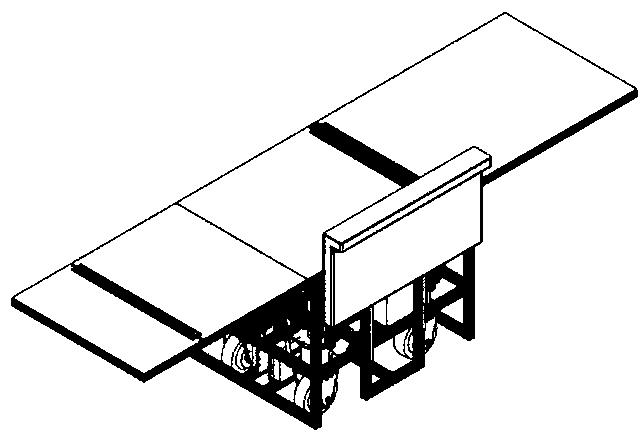

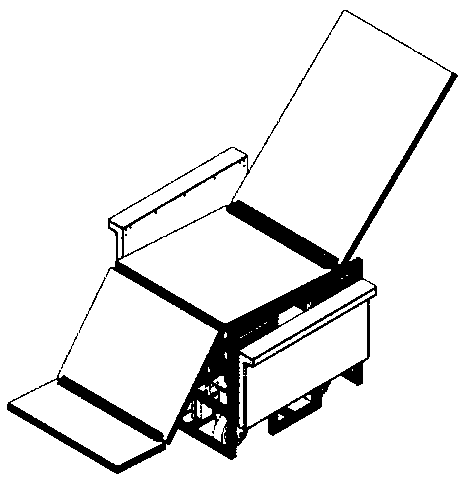

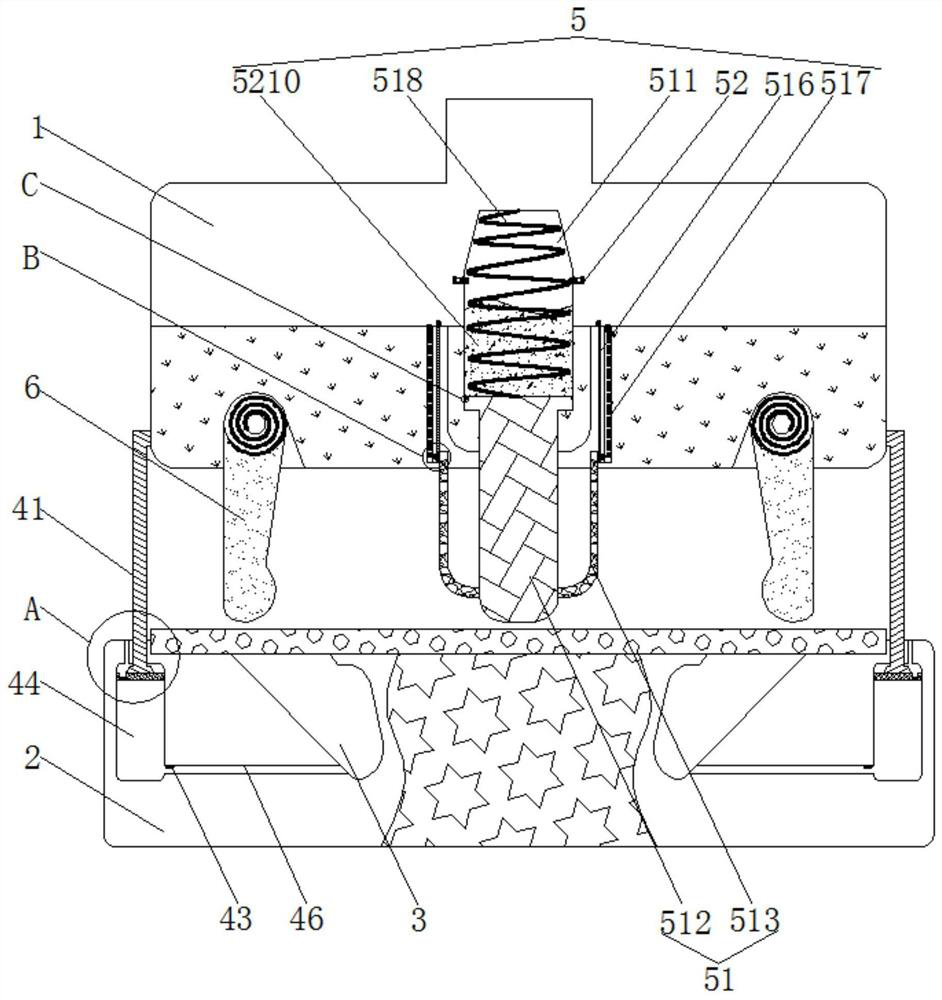

An omni-directional mobile intelligent wheelchair bed

ActiveCN109199724AOvercome start-stop slippageImprove driving stabilityWheelchairs/patient conveyanceDrive wheelWheelchair

The invention relates to an omni-directional mobile intelligent wheelchair bed, which is based on four-wheel omni-directional independent driving-steering platform, including seat frame, two side rails, four sets of independent suspension steering-drive wheel set and chassis. The seat frame consists of five parts: back, buttocks, legs, feet and side rails. Each part is driven by an electric motor,and the reciprocating motion of the push rod motor makes the bed shape automatically converted. The lateral push-rod motor mounted on the chassis and the side armrest constitute three links, which can only move in the vertical degree of freedom through the overconstraint of two sets of linear rails. The independent suspension steering-drive wheel set is composed of a suspension mechanism, a steering mechanism and a driving mechanism. The suspension mechanism plays a shock-absorbing effect through a four-bar linkage deformation compression shock absorber. The steering mechanism applies a driving force to the hub motor for changing the direction of travel. The drive mechanism controls the hub motor to provide forward driving force through the hub motor driver.

Owner:BEIJING UNIV OF TECH

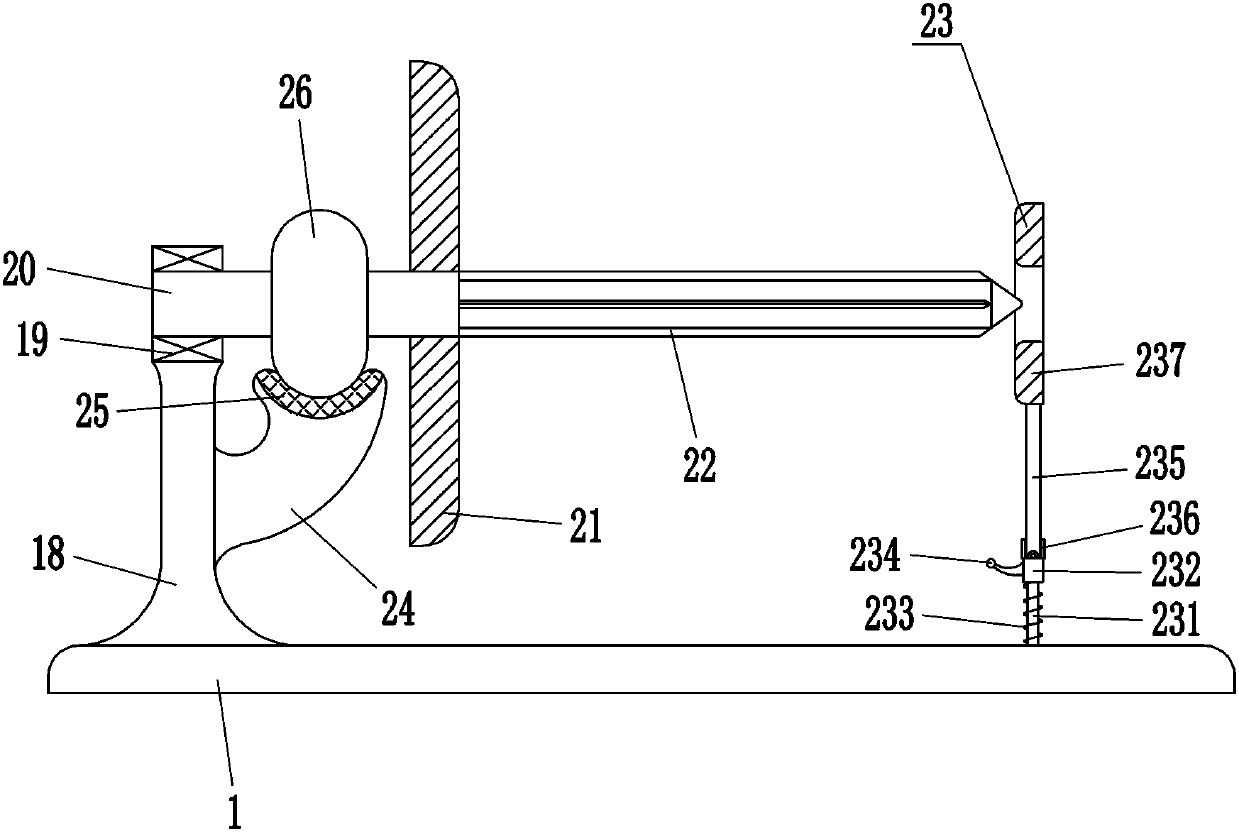

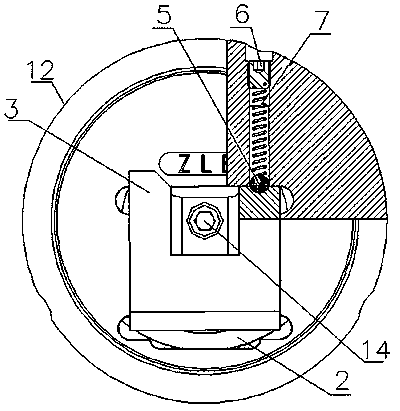

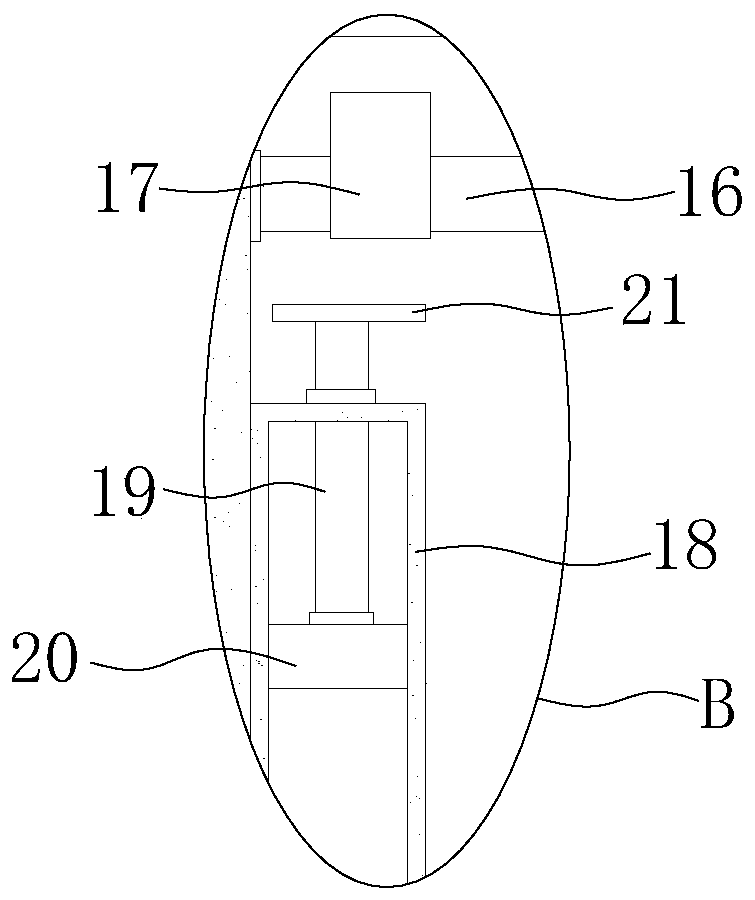

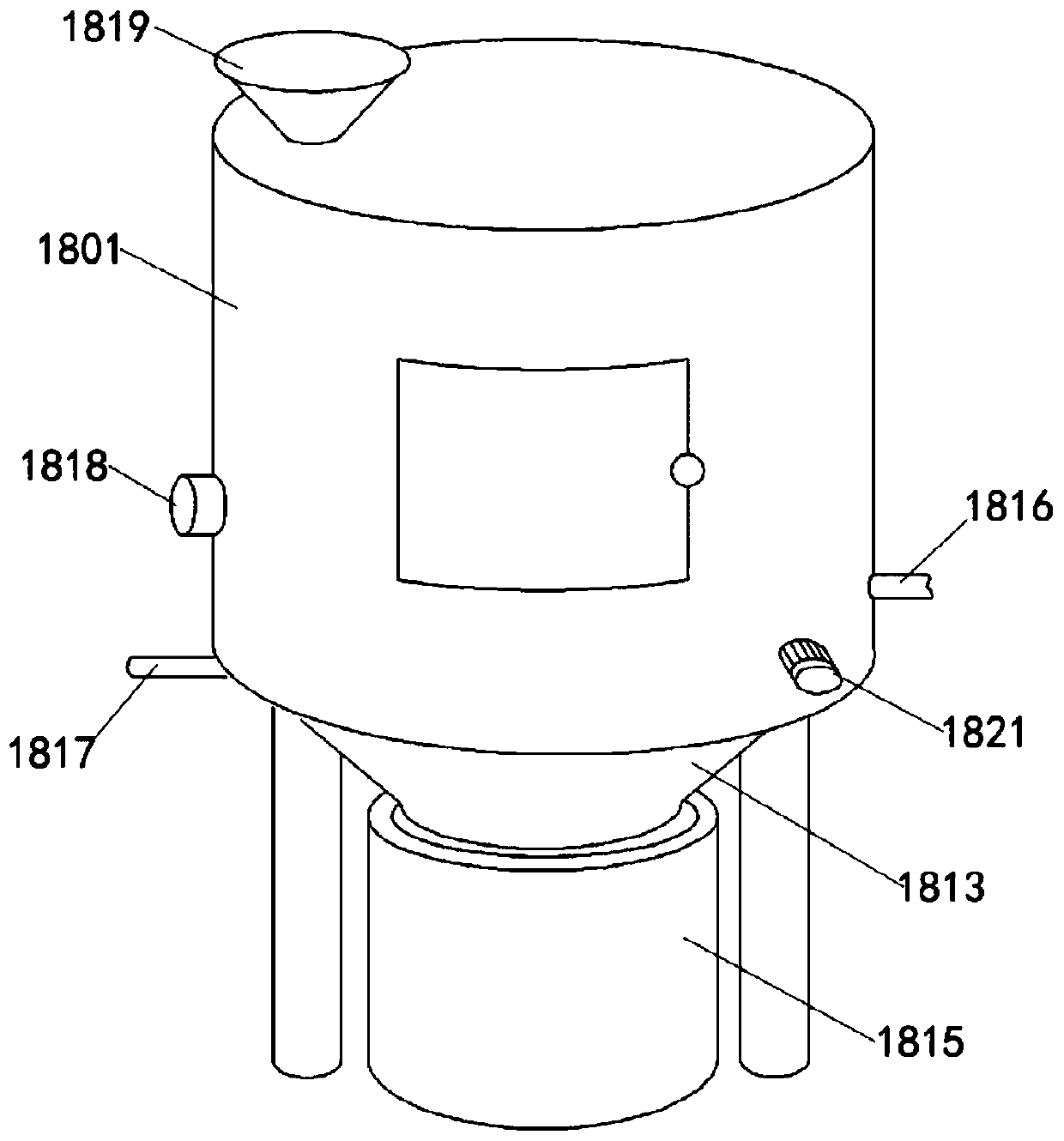

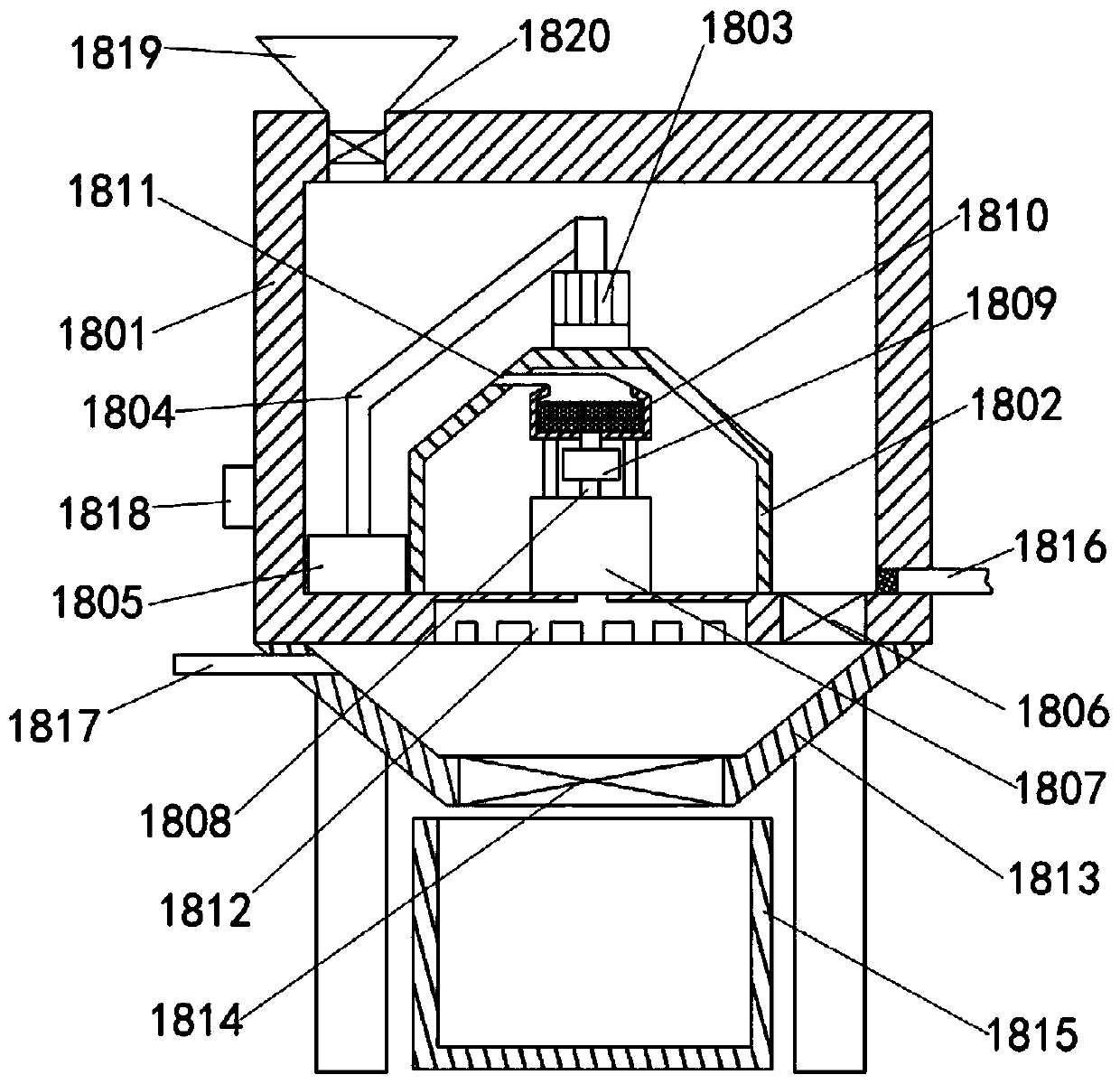

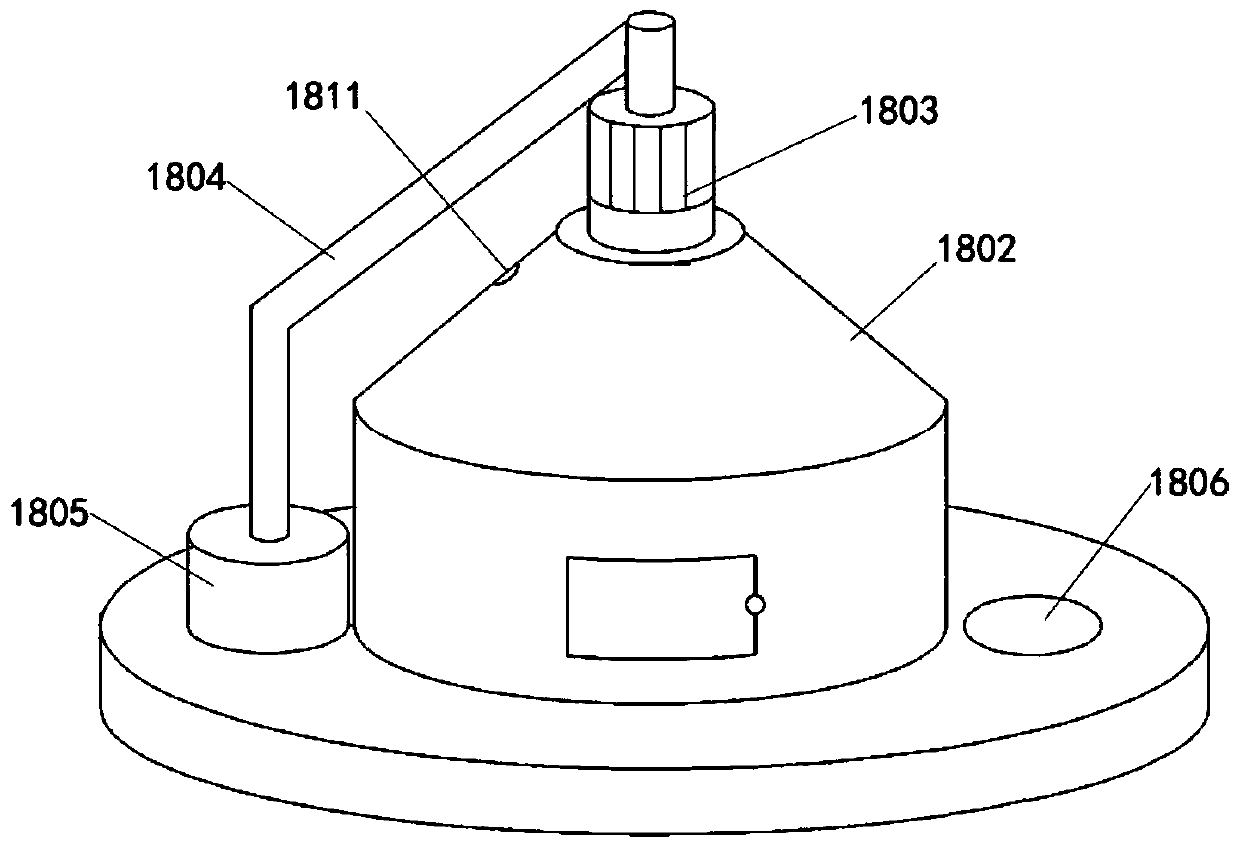

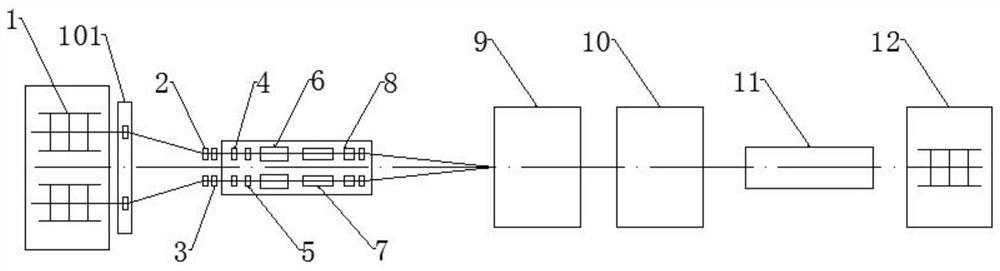

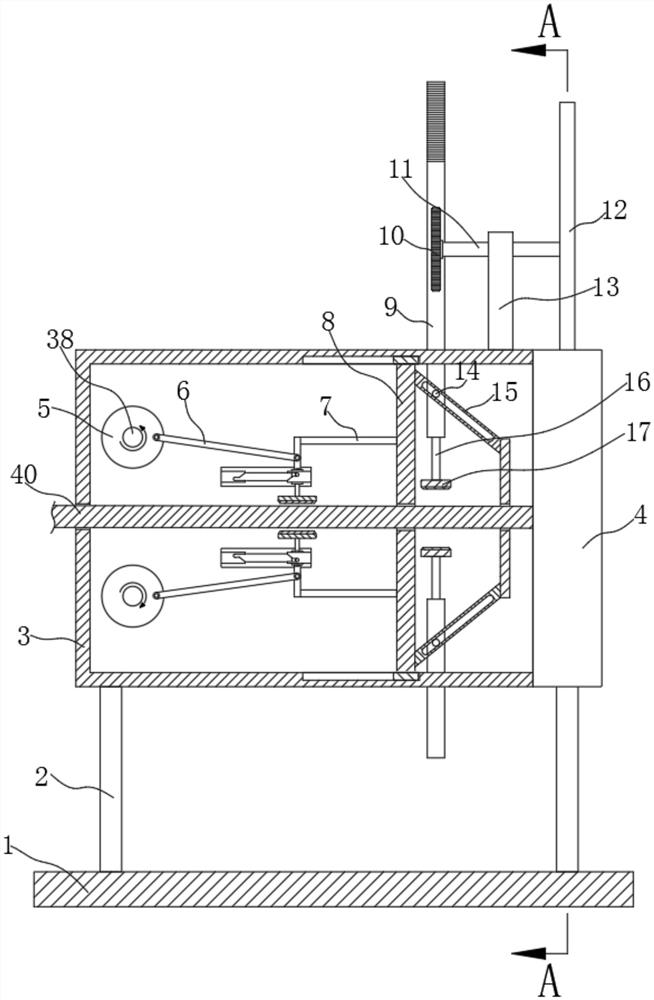

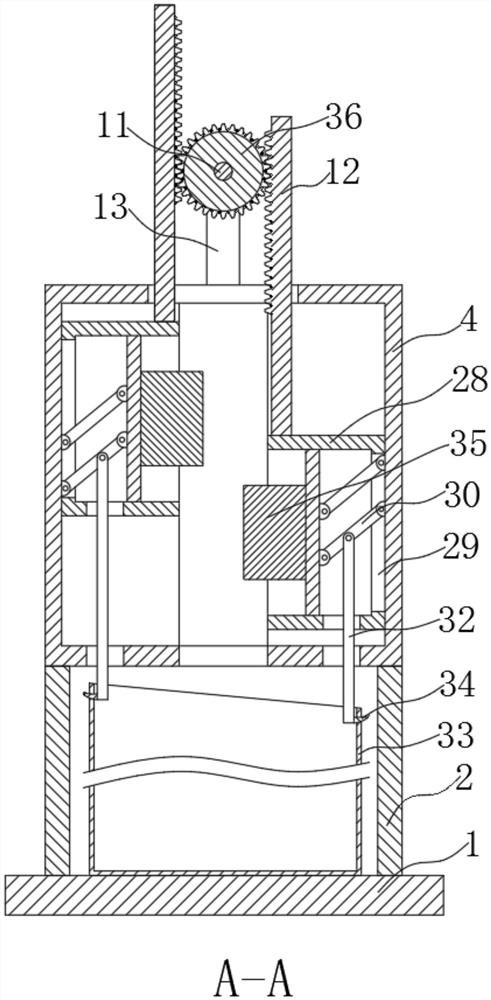

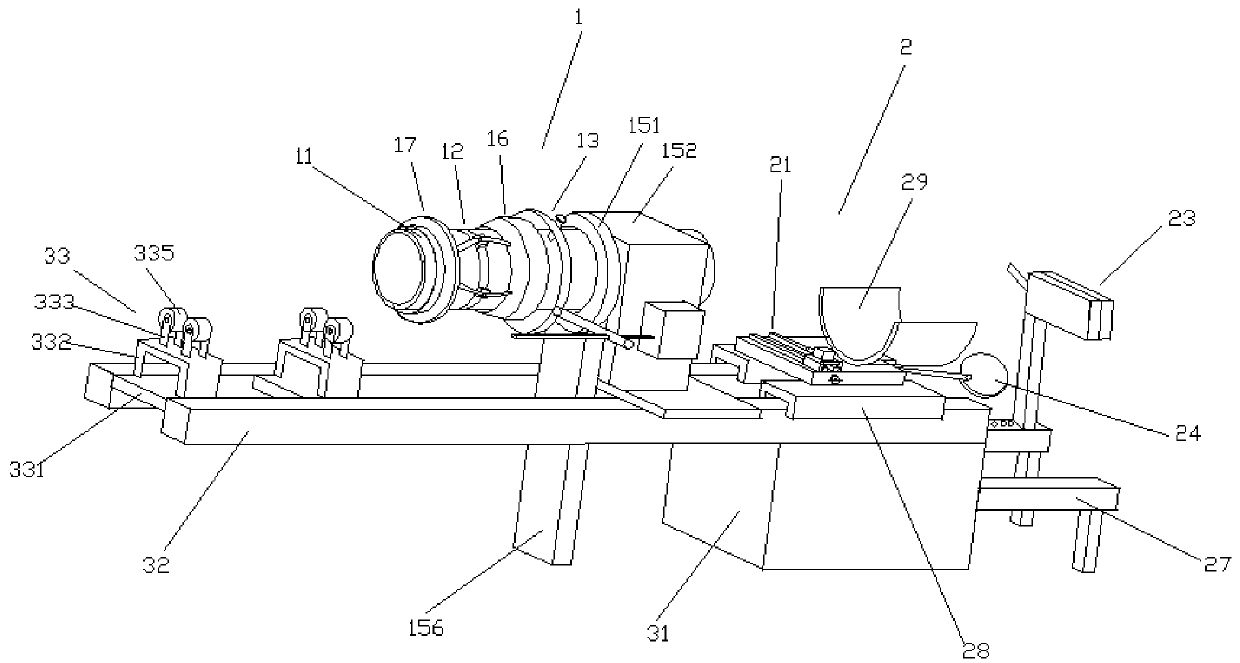

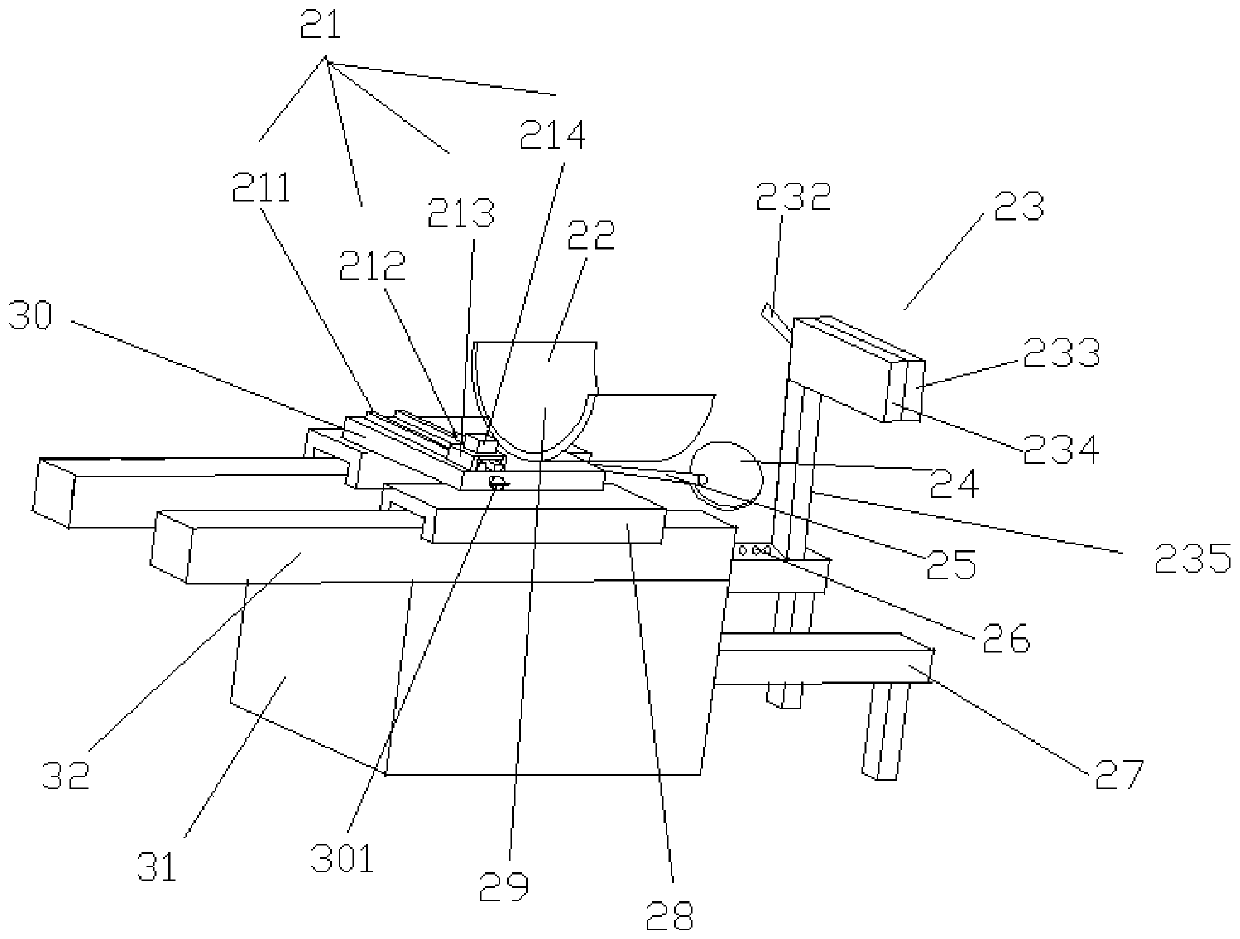

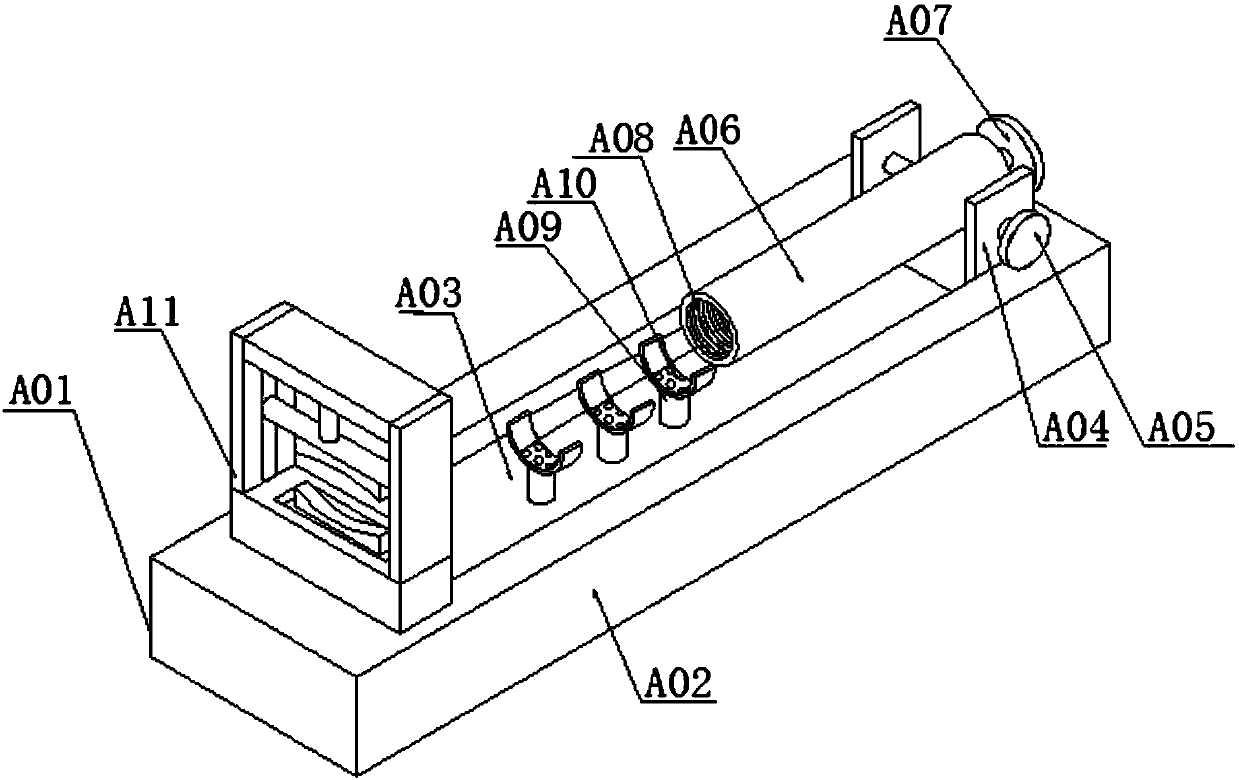

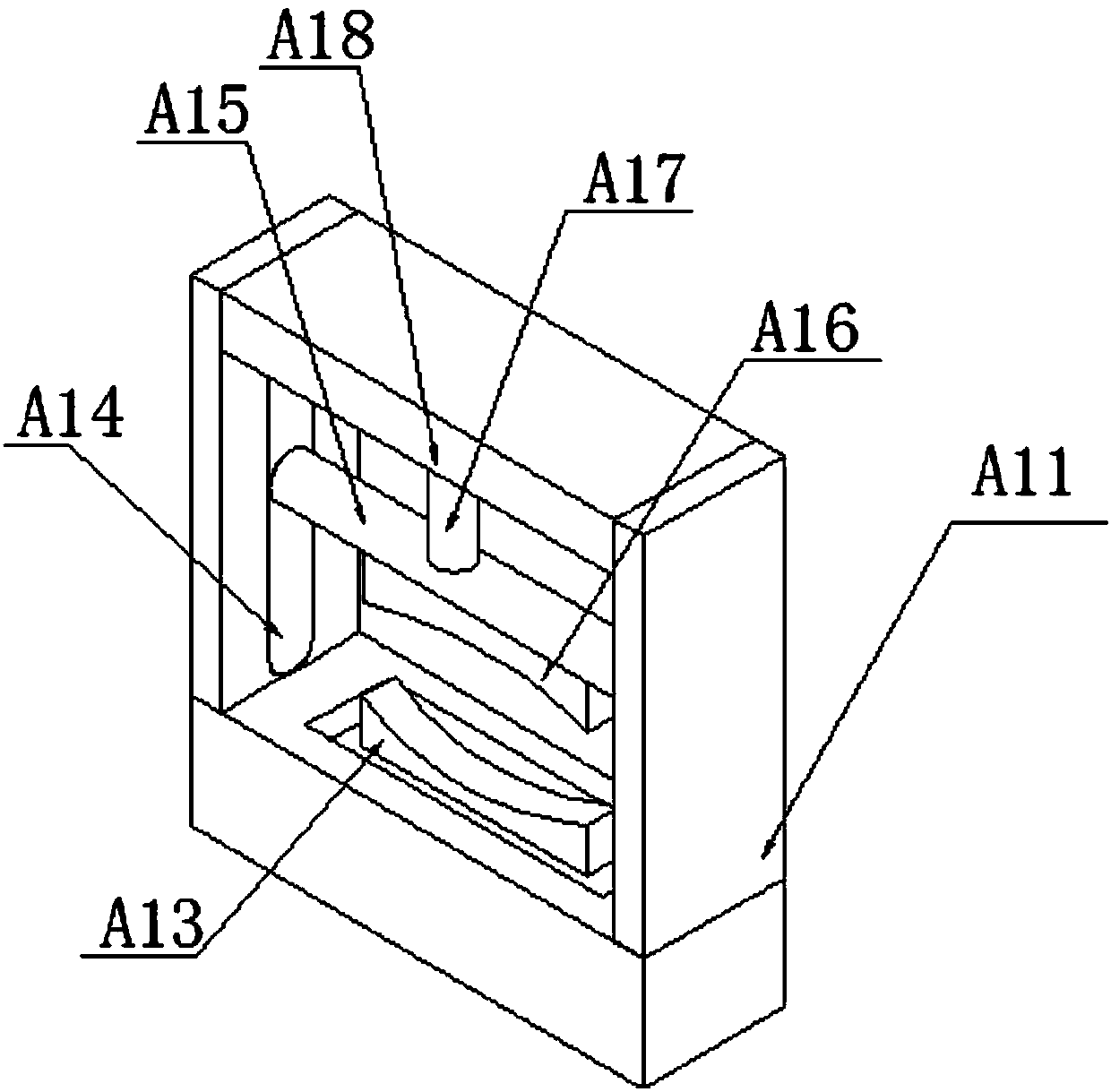

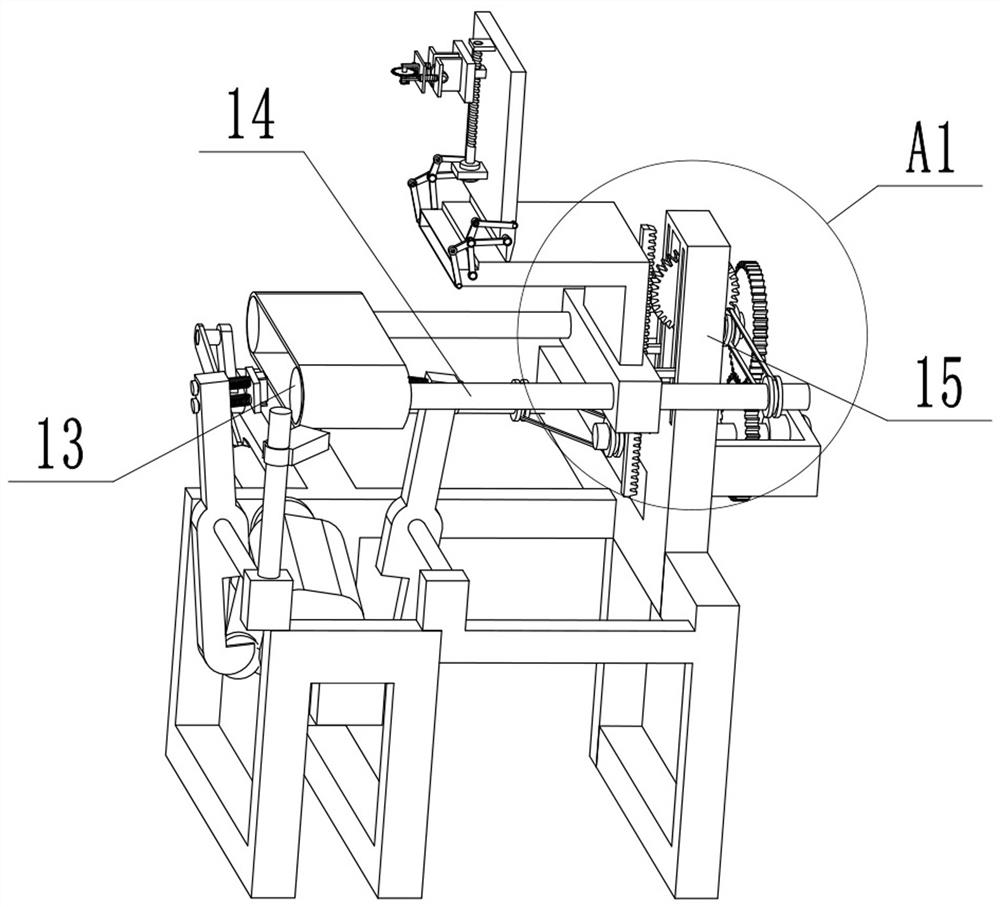

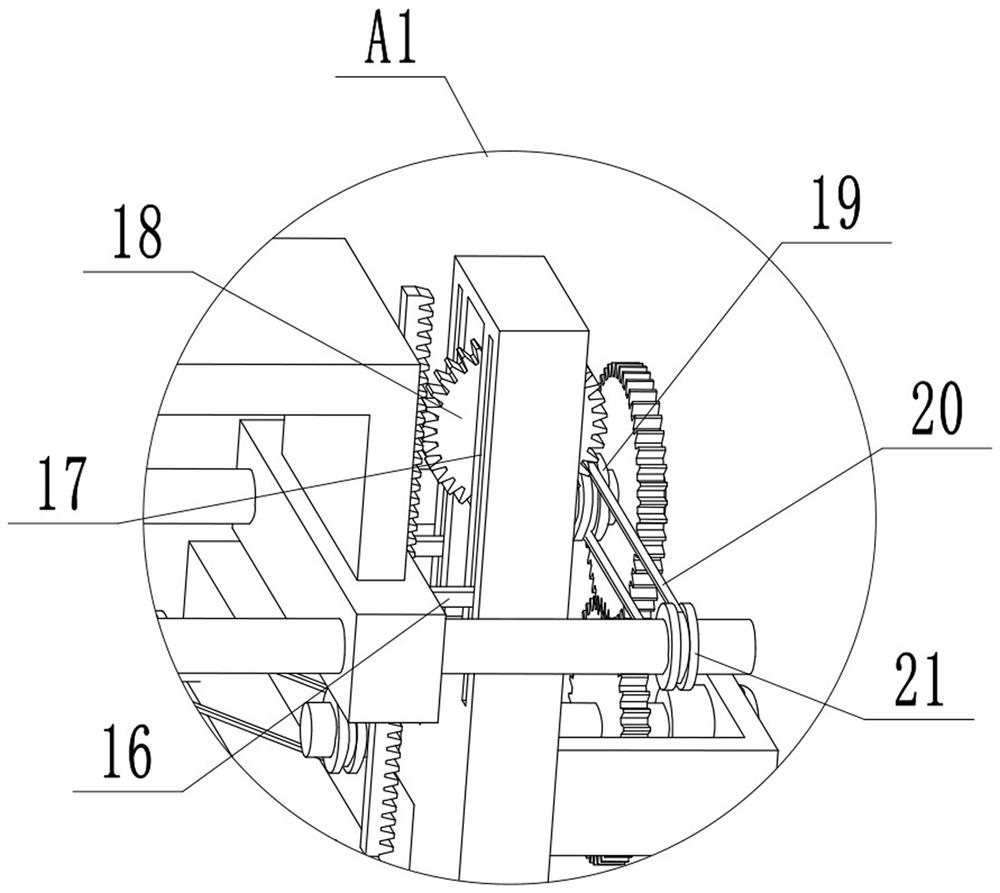

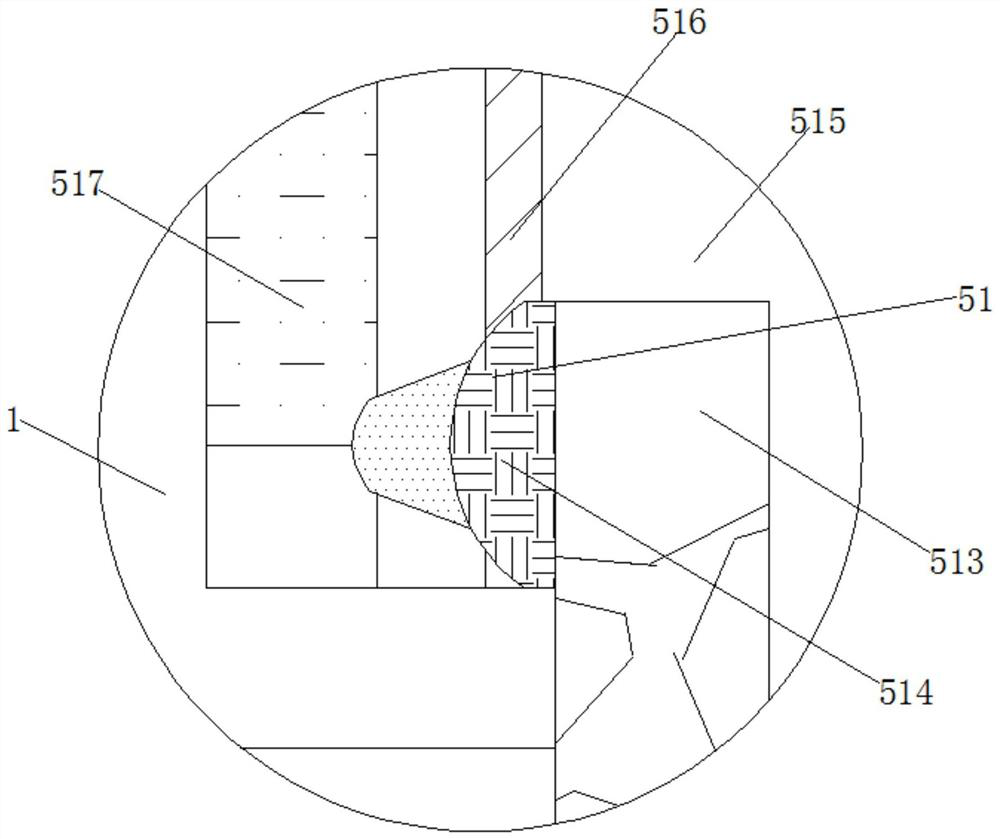

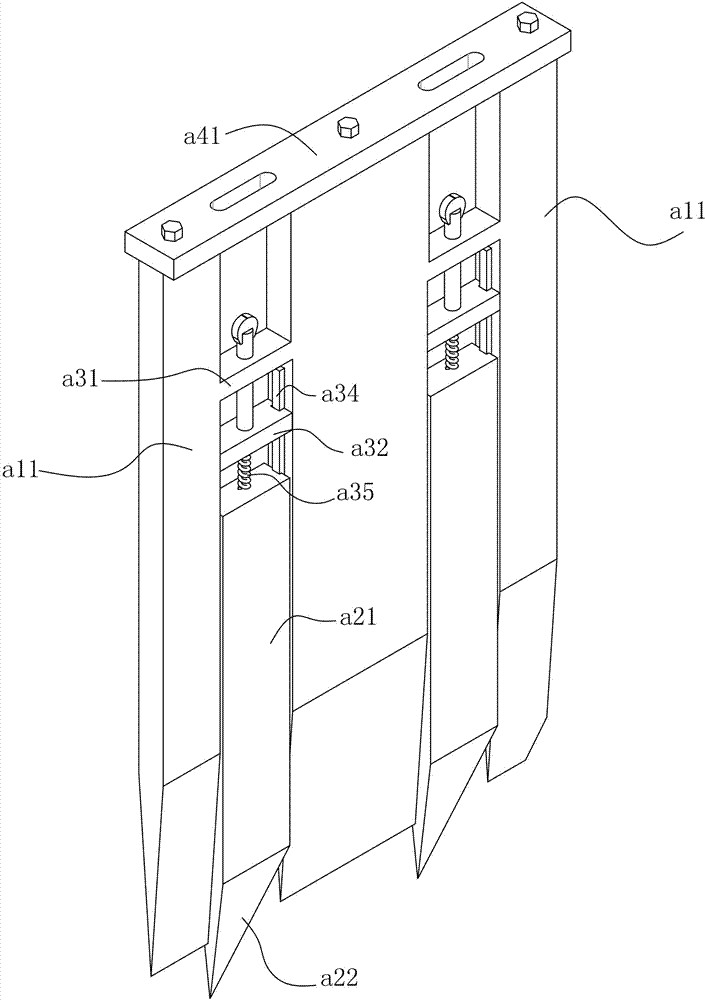

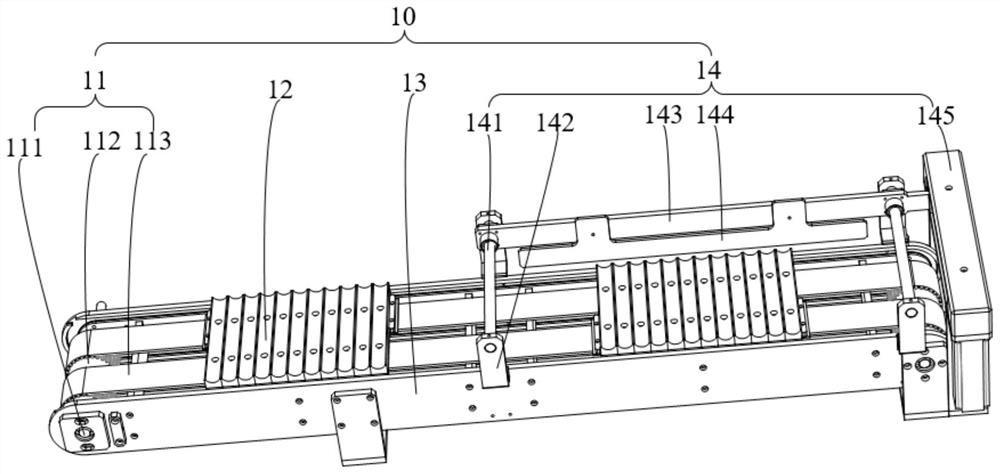

Pre-branch cable production and processing system

PendingCN112927865AAvoid untidyEffective clampingCable/conductor manufactureInjection molding machineElectric cables

The invention discloses a pre-branch cable production and processing system in the field of pre-branch cable production. The system comprises a pay-off machine, a wire stripping machine, a wire connecting machine, an injection molding machine, a traction machine and a take-up machine which are sequentially arranged, wherein the pay-off machine comprises two pay-off mechanisms arranged side by side, the wire stripping machine comprises two groups of wire stripping assemblies arranged side by side, each group of wire stripping assembly comprises a meter counter, a front guide wheel, a ring cutter, a longitudinal cutter, a cutter and a rear guide wheel which are arranged in sequence. According to the invention, the problems of great influence of human factors and high labor intensity in the existing production process of the pre-branch cable can be solved.

Owner:重庆鸽牌电线电缆有限公司

Shearing and packaging integrated equipment for plastic products

InactiveCN112720614AAchieve the effect of automatic feedingFully automatedPackagingMetal working apparatusPipe fittingStructural engineering

The invention discloses shearing and packaging integrated equipment for plastic products. The shearing and packaging integrated equipment for the plastic products comprises a base, supporting legs are fixedly arranged on the tops of the two sides of the base, a supporting shell and a shearing shell are fixedly arranged on the tops of the supporting legs, the supporting shell and the shearing shell are fixedly connected, a feeding mechanism is arranged in a cavity in one side, away from the shearing shell, of the supporting shell, a fixing mechanism is arranged in a cavity in the side, close to the shearing shell, of the supporting shell, and a shearing mechanism is arranged in the shearing shell. According to the shearing and packaging integrated equipment for the plastic products, through cooperation and linkage between structures, the effect of automatically feeding plastic pipe fittings is achieved along with continuous left-right movement of a sliding block, automation of plastic pipe fitting machining is further achieved, clamping and fixing are carried out on the plastic pipe fittings in the process of stopping feeding of the plastic pipe fittings, then shearing machining is carried out on the plastic pipe fittings, the sheared plastic pipe fittings can fall into packaging bags below to be collected and packaged, and therefore the shearing and packaging integrated effect is achieved.

Owner:徐陆林

Cold-stamping printing system

The invention relates to the field of cold-stamping printing, in particular to a cold-stamping printing system. The cold-stamping printing system comprises a protective shell, a fixed plate, a motor,a first regulating mechanism, a winding column, a second regulating mechanism, a control mechanism, a feeding mechanism, a fixed nut and a bottom shell, wherein the side wall of the fixed plate is fixedly connected with the protective shell of an arc-shaped structure; the bottom of the protective shell is hinged with the bottom shell with a side surface of a semi-circular structure; the winding column which is rotatably connected with one end of the motor for winding waste foil is arranged between the protective shell and the bottom shell; the second regulating mechanism is connected on the surface of the winding column in a sliding mode; the bottom of the bottom shell is connected with the first regulating mechanism which is symmetrical with the second regulating mechanism in the slidingmode; and a distance between two limiting plates is regulated by a slide pushing rod and a rotary lead screw, so that waste foils of different dimensions are limited, and therefore, the waste foils are prevented from being disorderly and uneven during winding.

Owner:武汉宇恩防伪技术有限公司

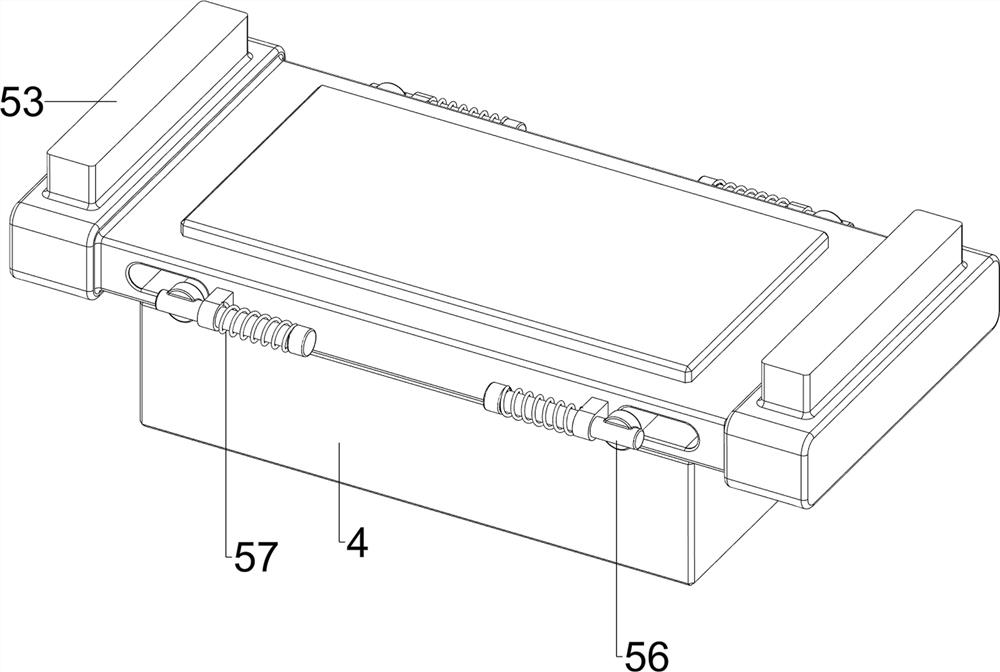

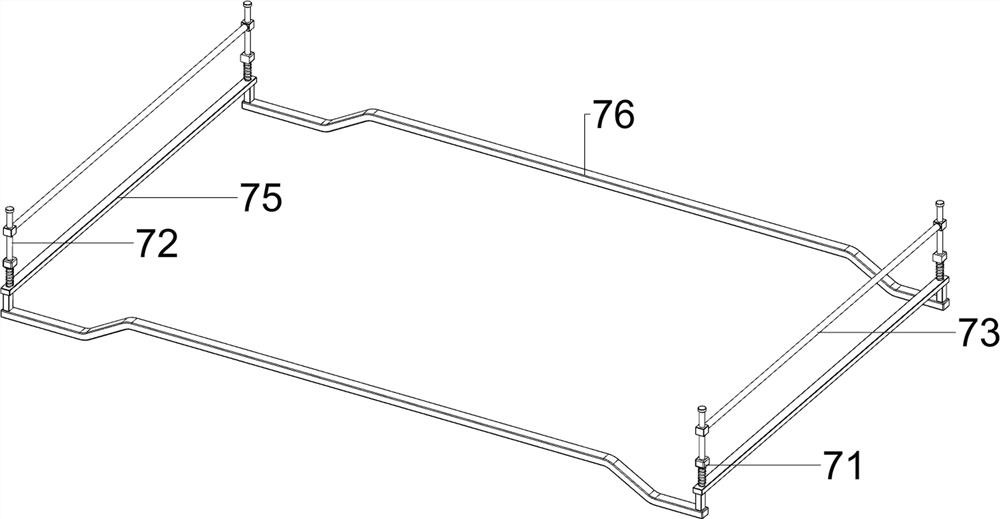

Customized sponge packing material contour forming equipment

ActiveCN113500662AImprove work efficiencyAvoid equipment damageMetal working apparatusEngineeringWorkbench

The invention relates to forming equipment, in particular to customized sponge packing material contour forming equipment. According to the technical aims, the customized sponge packing material contour forming equipment is high in working efficiency and capable of utilizing sponge to the maximum extent. The customized sponge packing material contour forming equipment comprises bases, a workbench, a cutting mechanism, a contour mold and a translation mechanism, and the bases are symmetrically installed on the two sides of the bottom of the workbench; the cutting mechanism is mounted on one side of the workbench; the contour mold is mounted on the cutting mechanism; and the translation mechanism is mounted on one side of the workbench. The contour mold can be heated through a heating plate, then the contour mold can be driven to move up and down by taking an electric push rod as a driving force, and the contour mold can be driven to move rightwards intermittently by taking a first servo motor as a driving force, so that the contour mold can cut the contour of sponge intermittently, time and labor are saved, and the working efficiency is high.

Owner:深圳市伟林海棉包装制品有限公司

Processing device capable of packaging foods conveniently

ActiveCN112919384AImprove packaging efficiencyImplement automatic installationCapsThreaded caps applicationElectric machineryEngineering

The invention relates to the technical field of food packaging, and discloses a processing device capable of packaging foods conveniently. The processing device comprises a left rack, a right rack is welded on the surface of the left rack, supports are welded to the bottoms of the left rack and the right rack, a round box is fixedly connected in the left rack, a rotating shaft is rotatably connected in the round box, a driving mechanism is arranged on the surface of the rotating shaft, a packaging mechanism is arranged in a fixed frame, a transmission motor is fixedly installed in a fixed plate, and a discharging device is arranged on the surface of the left rack. According to the processing device capable of packaging foods conveniently, through driving of a motor, simultaneous operation of a conveying belt and an output belt is controlled, four grooves are formed in a classification plate, and therefore in the rotating process, four bottle materials can enter the processing device at a time, continuous operation is carried out, and therefore rapid and efficient operation of packaging is achieved, and the overall packaging efficiency is improved.

Owner:保定振宏食品股份有限公司

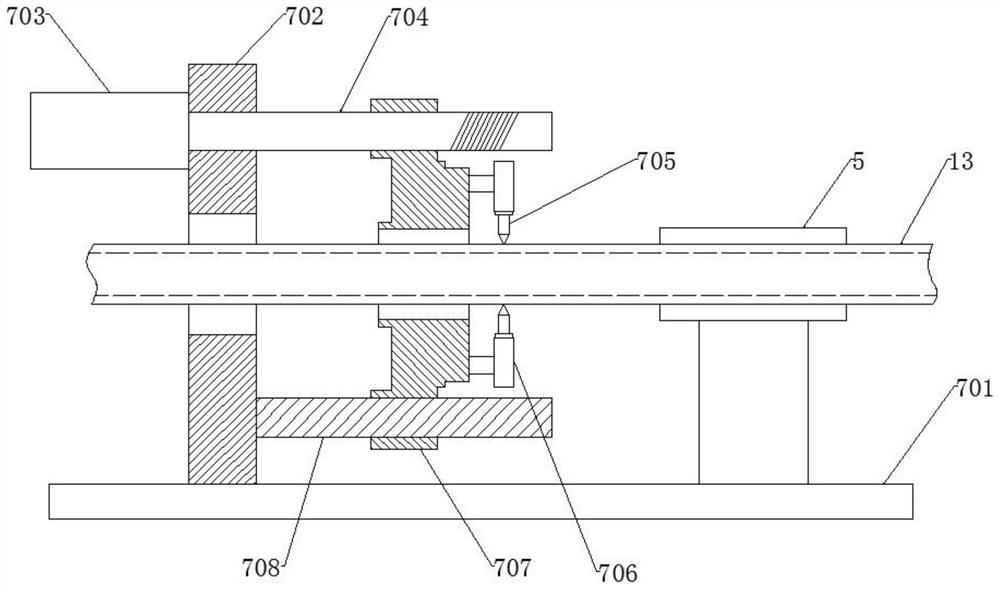

Circular pipe clamping and cutting device

PendingCN111055312AAchieve clampingPracticalMetal working apparatusClassical mechanicsStructural engineering

The invention provides a circular pipe clamping and cutting device which comprises guide beams. At least one guide support assembly is fixed at the front ends of the guide beams, the guide support assembly is located between the two guide beams, a clamping mechanism is fixed at the top of the middle end of the guide beam, a cutting mechanism is fixed at the tops of the rear ends of the guide beams, a base is fixed at the bottoms of the rear ends of the guide beams, a supporting cross beam is fixed on the side wall of the base, and a positioning assembly is connected to the top of the supporting cross beam. The circular pipe clamping and cutting device not only can adjust the cutting length as required, but also can adjust the cutting position as required, can clamp the end part of a circular pipe through a sliding assembly, the clamping assembly and a moving assembly which are matched with each other, and is high in practicability and wide in application range.

Owner:天津鑫凯建业科技有限公司

Metal steel pipe numerical control cutting device

InactiveCN108015337AReasonable designSimple structureTube shearing machinesNumerical controlCivil engineering

The invention provides a metal steel pipe numerical control cutting device, and relates to the technical field of human body numerical control cutting. A base is arranged at the bottom of a device body, a work groove is formed in the top of the base, a clamping plate is arranged at one end of the work groove, an adjusting bolt is arranged on one side of the clamping plate, the cutting device is fixedly connected with the base, a steel pipe conveying cylinder is rotatably connected with the clamping plate through an adjusting bolt, an outer connection power source is electrically connected witha servo motor, a rotating disc is rotatably connected with the steel pipe conveying cylinder through a thread groove, a sliding rod is in sliding connection with a sliding groove, the servo motor isin threaded connection with a piston rod. According to the metal steel pipe numerical control cutting device, the steel pipe conveying cylinder is arranged, the steel pipe can be fixed, meanwhile, a steel pipe supporting frame and a magnet are arranged, and therefore when the steel pipe is transported, the steel pipe is fixed, and the problems that in the cutting process, the steel pipe deviates,and the cutting face is not in order are solved. The device is reasonable in design, simple in structure, safe, reliable, and easy to maintain and has the good use and popularization value.

Owner:傅清萍

Can lid packaging machine

InactiveCN107572063AAvoid untidyAvoid dropping the coverWrappers shrinkageWrapping material feeding apparatusScratchingPackaging machine

The invention discloses a can lid packaging machine. The can lid packaging machine comprises a rack, a conveying device, a packaging device and a hot cut-off device. The packaging device comprises a vertical frame, an upper shrink film fixing mechanism fixed to the vertical frame, a lower shrink film tensioning mechanism arranged below the vertical frame, an upper shrink film laid on the upper shrink film fixing mechanism, a lower shrink film laid on the lower shrink film tensioning mechanism and a pushing air cylinder. The vertical frame is fixed to the rack. One end of the upper shrink filmand one end of the lower shrink film are bonded to form a complete shrink film. The pushing air cylinder pushes a can lid on the conveying device to the shrink film to be tightly wrapped. The hot cut-off device is arranged in the pushing direction of the pushing air cylinder and is used for cutting off the redundant shrink film on the packaging can lid. By means of the packaging device, automaticpackaging of the can lid is achieved, the working efficiency is improved, the problems of irregular packaging, lid dropping, scratching and the like are solved, materials are greatly saved, and the labor cost is saved.

Owner:WANTONG TANK MACHINE IND

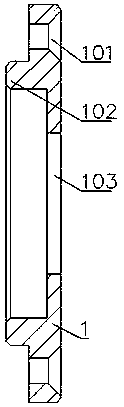

Clamping feeding device of band sawing machine

The invention provides a clamping feeding device of a band sawing machine. The clamping feeding device of the band sawing machine is reasonable in design and compact in structure, and is safe, reliable and convenient to use by the adoption of clamping and conveying with an oil hydraulic cylinder. Due to the fact that a positioning pressing device is arranged on a crossbeam, after a band saw bladeis inserted into a channel, the back of the band saw blade is attracted to magnet strips, the band saw blade can be attracted through the magnet strips, the band saw blade is prevented from sliding down in the process of upward stepping, thus, the compaction degree of a saw band can be adjusted, the sawing toughness of the saw band is guaranteed, the problem that the saw band generates an irregular phenomenon and massive vibration during sawing is avoided, and meanwhile the problem that the saw band produces screams during sawing is avoided. The height of the upper end of a roller is adjustedthrough lifting with two lifting oil cylinders, the front end of a workpiece material is automatically adjusted to the same plane of a clamping workbench during automatic feeding of the band sawing machine, smooth feeding is guaranteed, and the clamping feeding device of the band sawing machine has the advantages of simple structure, good effect and the like.

Owner:宁波中宸汽车部件有限公司

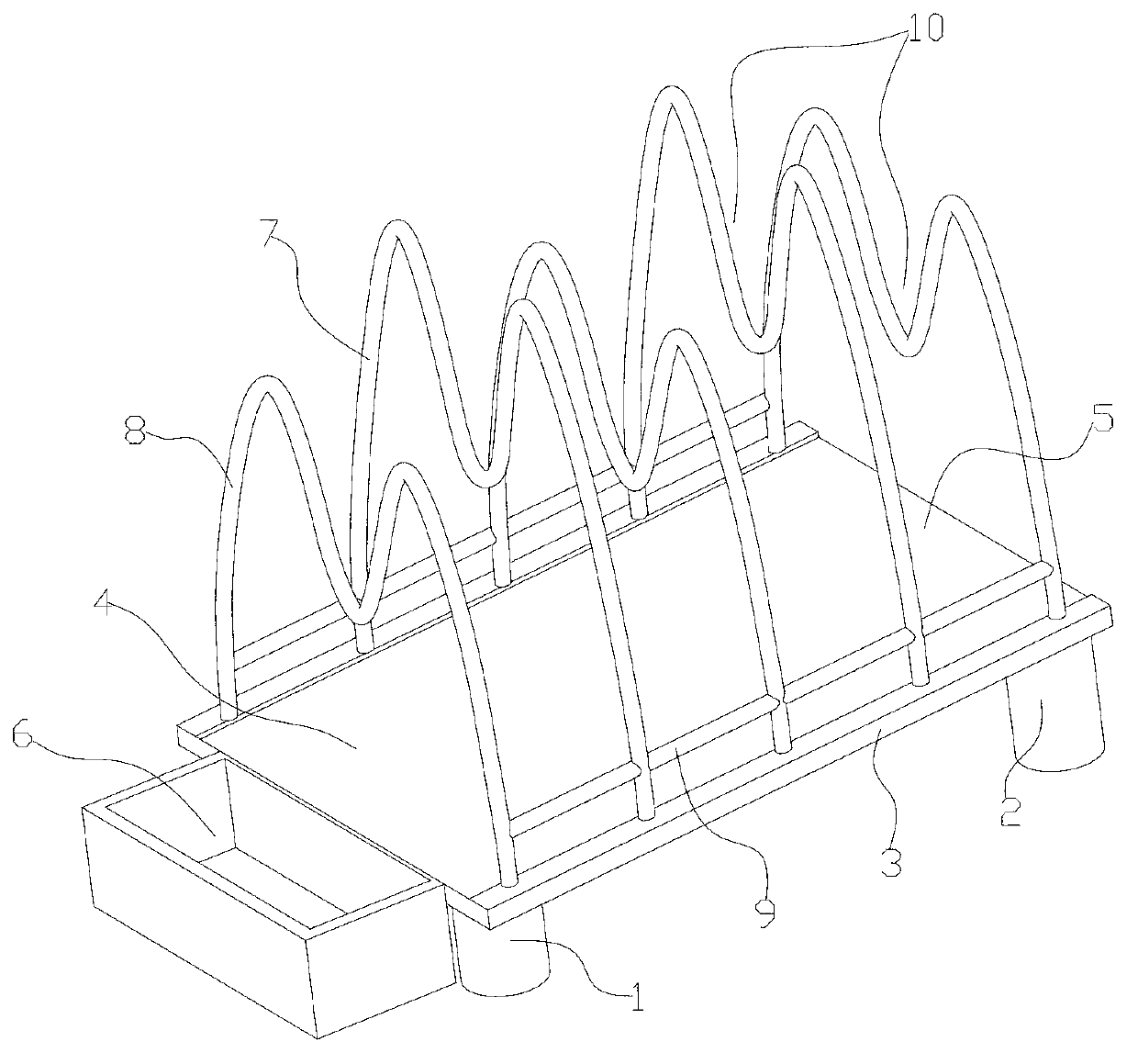

Pot cover frame for kitchen

The invention discloses a pot cover frame for a kitchen. The pot cover frame comprises a front base and a rear base; the front base is lower than the rear base in height; a substrate is arranged at the top ends of the front base and the rear base; the substrate is entirely inclined; two sides of the substrate are respectively a low-position side and a high-position side; a water collection groove is formed in the low-position side of the substrate; and high and low stand frames are arranged above the substrate in a staggered way. When the post cover frame provided by the invention is in use, a pot cover is placed between the high and the low stand frames; a lifting button on the pot cover is clamped in notches in the middles of the high and low stand frames, so as to ensure that the pot cover is stable, is prevented from sliding down, and can prevent a person from being burnt; and the water collection groove is arranged at the low-position side of the inclined substrate, so that water dropping along the surface of the pot cover drops into the water collection groove to be collected. Therefore, the environment disorder caused by that the water drops everywhere can be avoided. The pot cover frame is sanitary and safe.

Owner:王琰

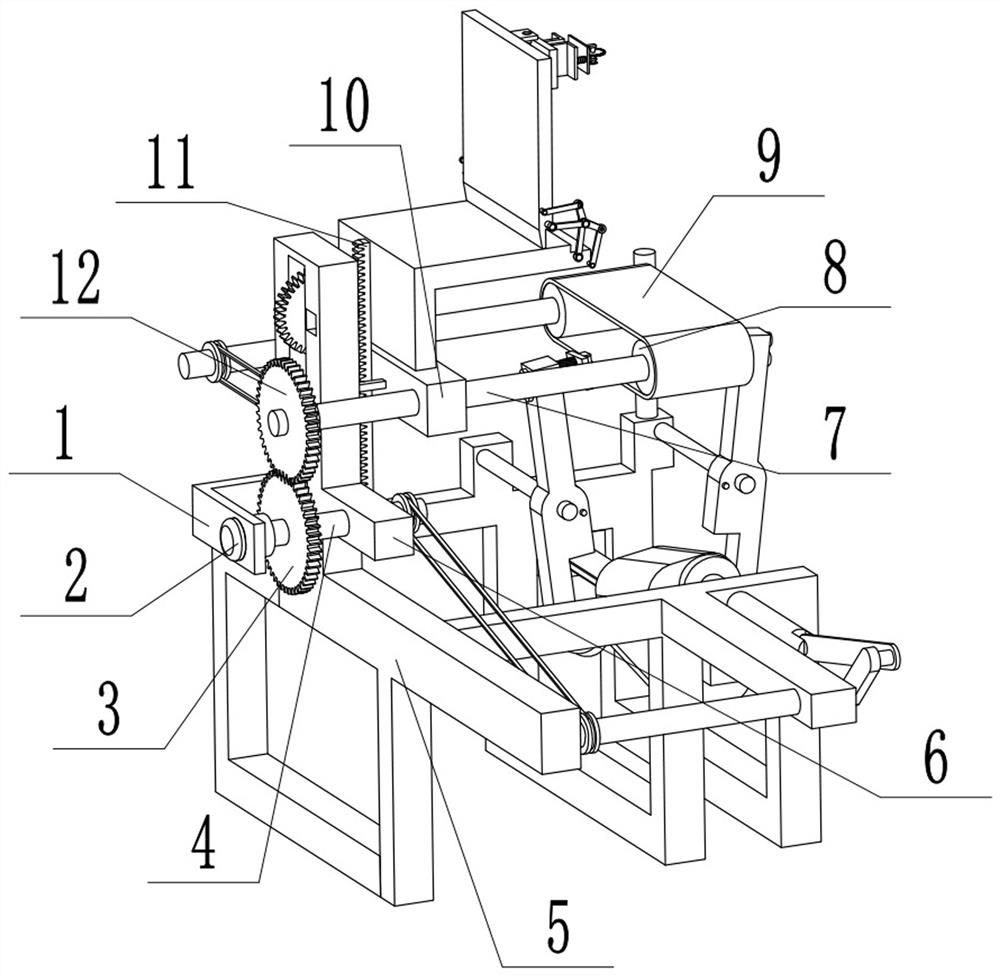

Automatic cutting device for production of triangular belt of oil pumping unit

The invention discloses an automatic cutting device for pumping unit triangular belt production, and mainly relates to the technical field of triangular belt production, the automatic cutting device comprises a placing mechanism and a positioning mechanism, the placing mechanism is slidably mounted on a fixing frame, a power assembly is arranged on the fixing frame, and the placing mechanism is used for sleeving a cut triangular belt and is driven by the power assembly; a plate turning mechanism is installed on the placing mechanism, the plate turning mechanism can reserve enough space for sleeving the triangular belt, a cutting mechanism is installed on the plate turning mechanism in a sliding mode, the cutting mechanism comprises a cam assembly and a cutting knife, and the cam assembly enables the cutting knife to intermittently cut the triangular belt; the positioning assembly can drive the closing claw assembly to do opening and closing movement through the moving assembly to position the triangular belt, and the transferring assembly is used for driving the moving assembly to change the opening and closing angle of the closing claw assembly so as to adapt to the triangular belts with different widths. According to the triangular belt cutting device, unqualified cutting caused by deviation of the position of the triangular belt can be prevented when the triangular belt is cut.

Owner:胜利油田长龙橡塑有限责任公司

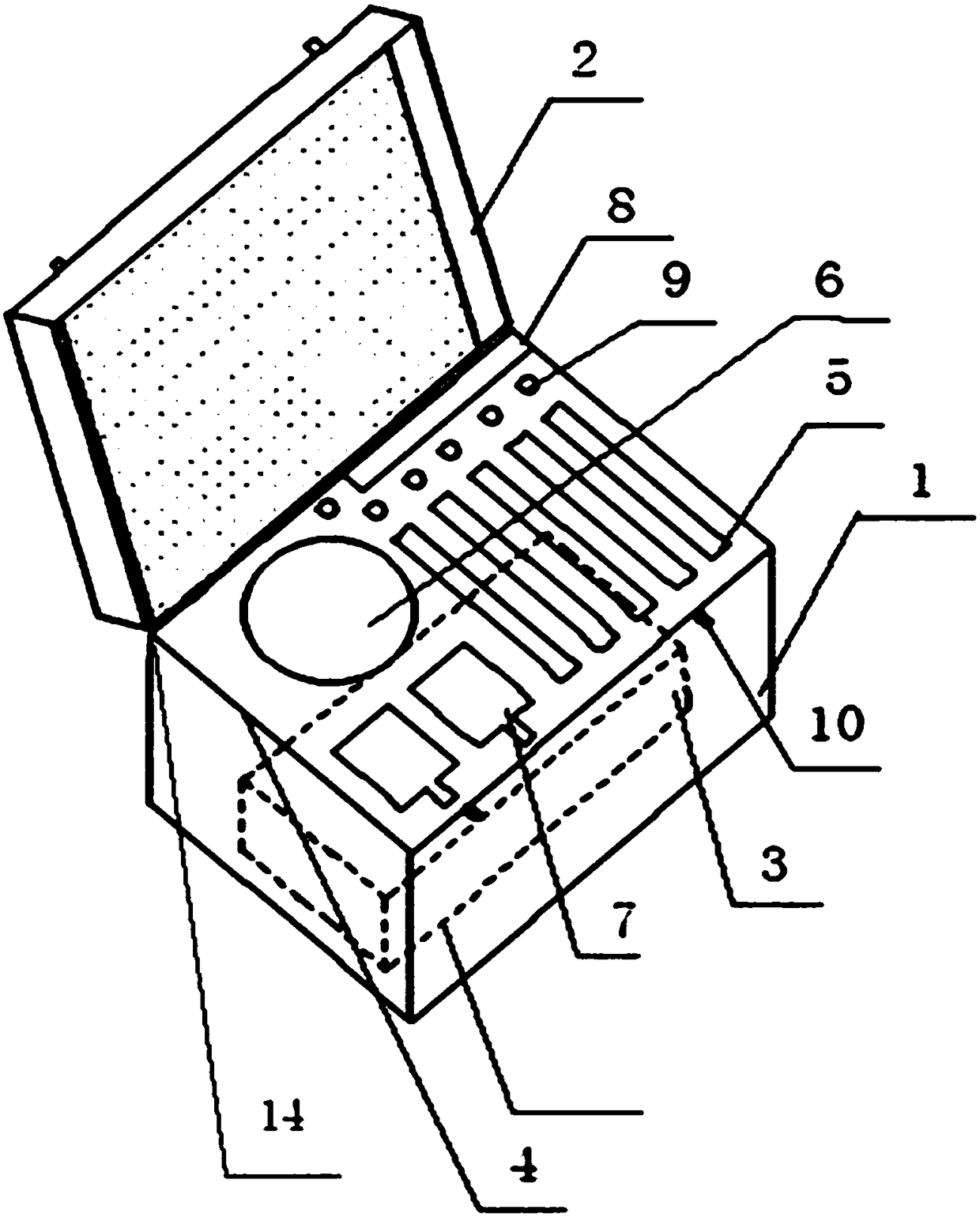

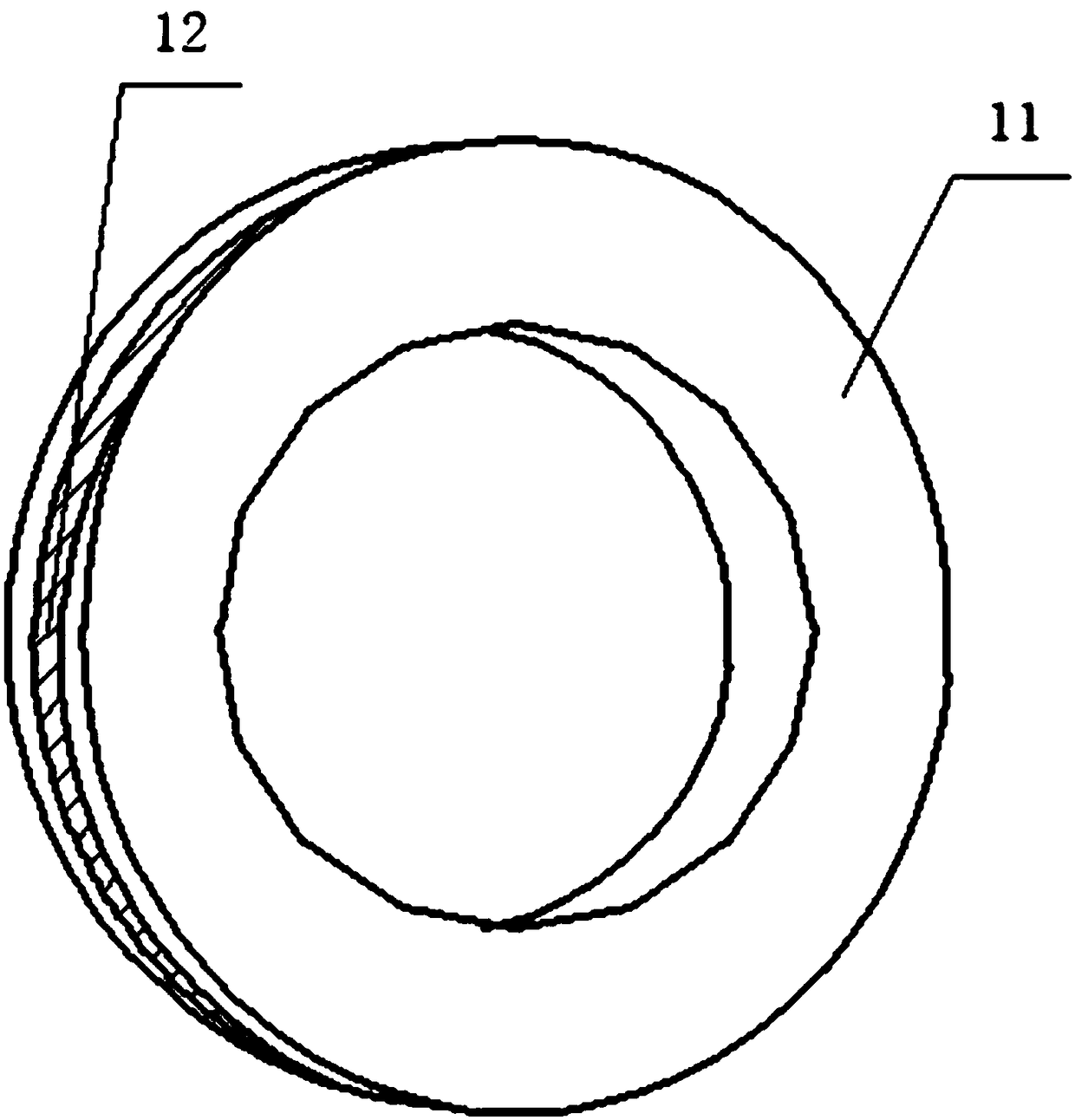

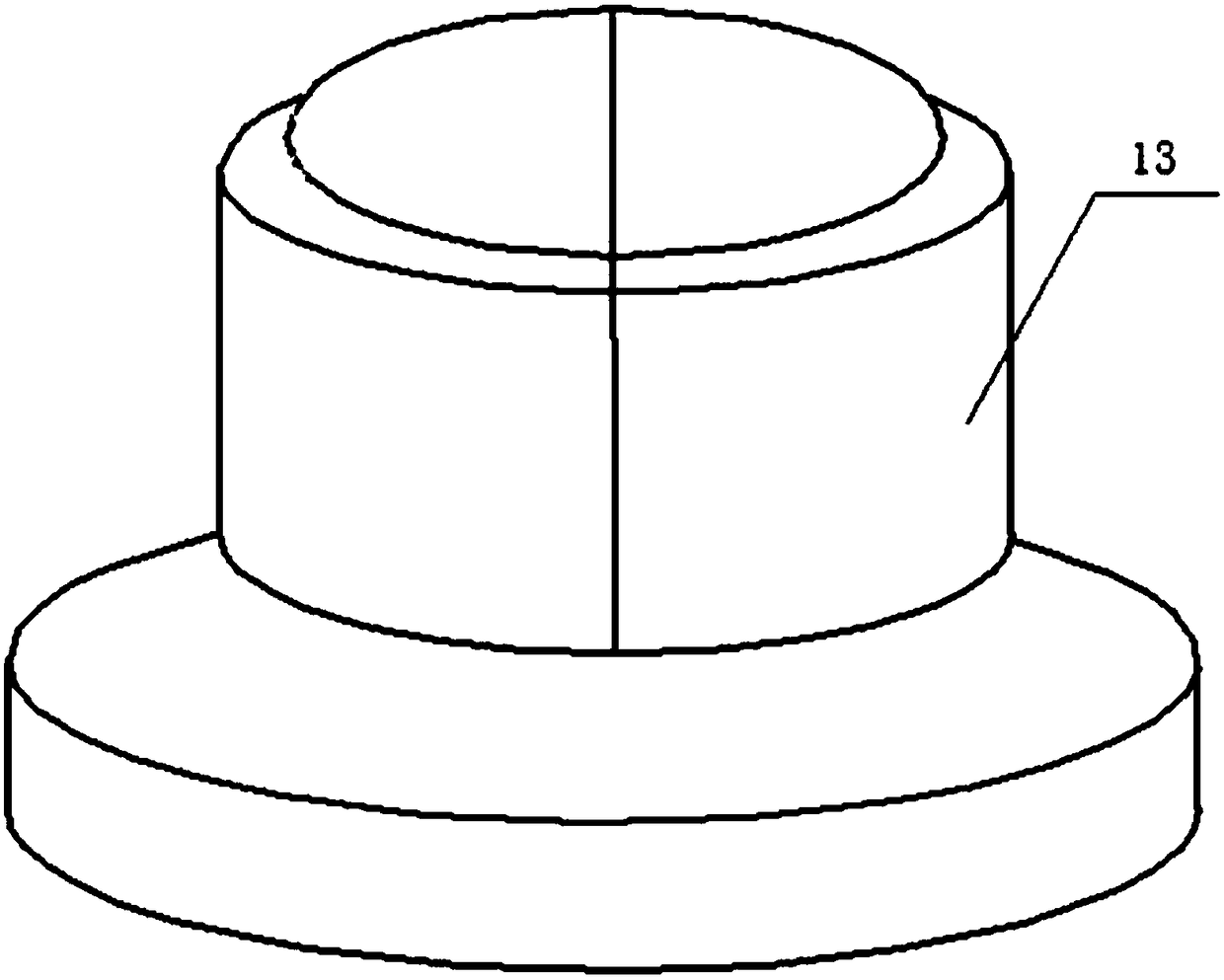

Field intrusion prevention early warning and protection system

InactiveCN108109301AEasy to messAvoid untidyAnti-collision systemsTraffic signalsEngineeringProtection system

The invention provides a field intrusion prevention early warning and protection system. The system comprises a tool box, a warning ring, an alarm flashing lamp and an alarm intercom. The tool mesa ofthe warning ring, the alarm flashing lamp and the alarm intercom is accommodated in the tool box. According to the technical scheme, the system is easy to manufacture, easy to implement and economical in capital and guarantees sufficient electric quantity of the equipment in case of field operation and enhances the working efficiency.

Owner:CHENGDU ZHENGGUANG ELECTRONICS TECH CO LTD

Aluminum alloy formwork opposite-pulling piece dismantling tool

ActiveCN113027128AGood consistencyImprove versatilityForm treatmentStructural engineeringManufacturing engineering

The invention provides an aluminum alloy formwork opposite-pulling piece dismantling tool. The aluminum alloy formwork opposite-pulling piece dismantling tool comprises two opposite clamping rods which are oppositely hinged, each opposite clamping rod comprises a clamping head, one end of each clamping head is provided with an opposite-cutting unit, one side of each opposite-cutting unit is provided with a fixing unit and a pulling and holding unit, and the pulling and holding units are used for pulling and fixing opposite-pulling pieces. The problem that fractures generated when the opposite-pulling pieces are dismantled are irregular is solved, the problem that the opposite-pulling pieces are broken on the outer side of a wall due to the fact that the opposite-pulling piece ends of the opposite-pulling pieces are bent outwards towards a vertical face during dismantling is solved, and the problem that a user hurts the hand in the using process is solved; the structure is ingenious, using performance is high, reliability is high, and the cutting efficiency of the opposite-pulling pieces is greatly improved; and meanwhile, the construction safety and the working standardization are greatly improved.

Owner:CCCC SECOND HARBOR ENG

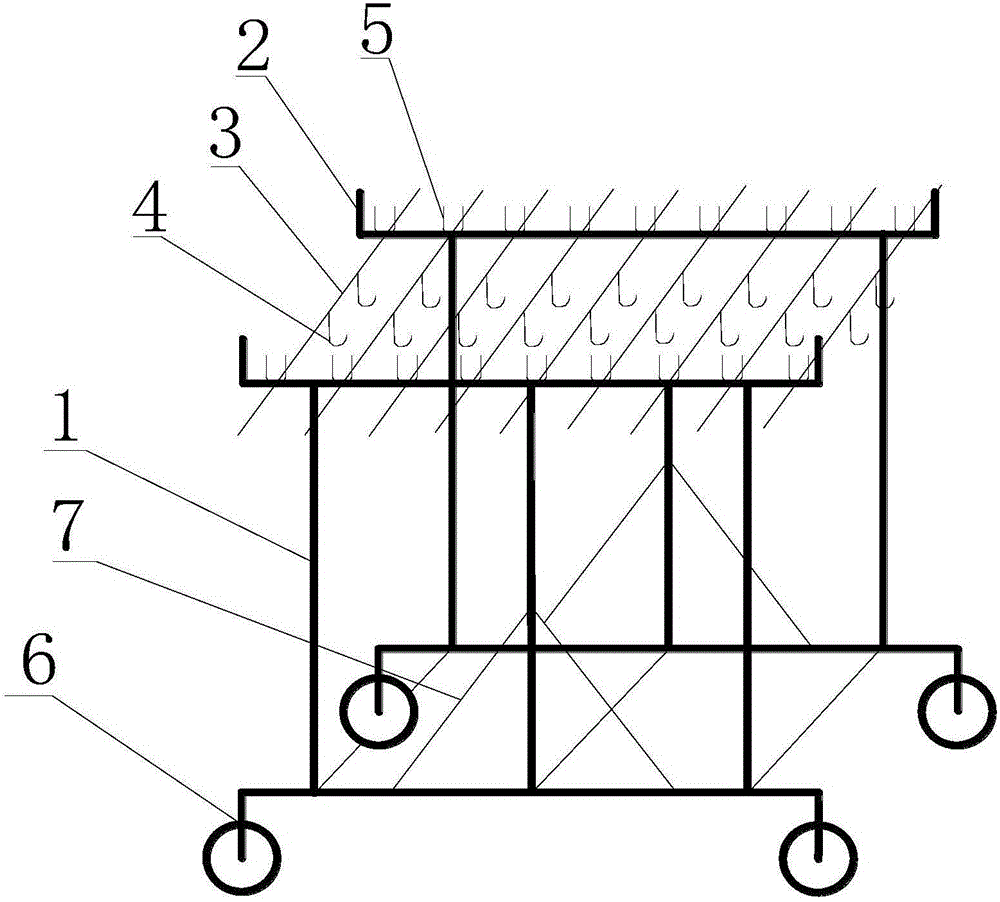

Plastic film display support

InactiveCN105818123AAvoid wrinklesAvoid untidyWork tools storageOther workshop equipmentPlastic filmEngineering

The invention discloses a plastic film display support comprising a support body and film hanging cross rods, wherein universal rollers are arranged on four corners of the bottom of the support body; two ends of poles at the upper part of the support body are vertically provided with limiting stop levers which are shaped like [-shaped supports with upward openings; the limiting stop levers are provided with a plurality of U-shaped clamps; the parallel film hanging cross rods are displayed in a plurality of groups of U-shaped clamping slots; and the film hanging cross rods are vertically provided with pothooks. The plastic film display support is low in cost, simple in structure, convenient and practical as well as capable of meeting the production requirement; the aim that a plastic film is hung after the former process is ended is effectively achieved, so that drapes and irregularity caused by stacking of the film are avoided; in addition, the rollers are arranged at the bottom of the plastic film display support, so that the film can be easily moved.

Owner:TONGCHENG ZHONGHUI PLASTIC IND CO LTD

Intelligent pressure detection device for metal product stamping

InactiveCN113399524AAvoid damageInduction in timeShaping safety devicesCleaning using gasesEngineeringMechanical engineering

The invention relates to the technical field of metal product stamping, and discloses an intelligent pressure detection device for metal product stamping. The intelligent pressure detection device comprises an upper die and a lower die, wherein two symmetrical extrusion grooves are formed in the surface of the lower die, a quality guaranteeing mechanism for assisting complete forming of a metal plate is arranged inside the lower die, and a pressure detection mechanism for monitoring the force when the upper die and the lower die are extruded is arranged outside the upper die. According to the intelligent pressure detection device, the circumstance that the extrusion force of the upper die on the lower die is too large is detected through an excessive pressure sensing assembly, so that the situation that the upper die and the lower die can be timely sensed when the stamping force is too large can be guaranteed; and the upper die is limited through a conductive limiting assembly, so that when the stamping force is too large, the upper die and the lower die cannot get close to each other, the damage of the upper die, the lower die and a stamping device caused by the fact that the stamping force between the upper die and the lower die is too large is avoided, and the intelligent pressure detection device is more suitable for actual stamping operation.

Owner:张宇

Cutting tool bit for light guide plates

The invention discloses a cutting tool bit for light guide plates. The cutting tool bit comprises three main tool bits; a wedge-shaped main blade is arranged at the bottom of each main tool bit; a connecting rod is arranged between every two adjacent main tool bits; and ribs are arranged on the opposite side surfaces of every two adjacent main tool bits. The cutting tool bit further comprises sliding blocks arranged between every two adjacent main tool bits; and first guide grooves matched with the ribs are formed in two sides of the sliding blocks. The cutting tool bit further comprises screws; the bottoms of the screws are connected with the tops of the sliding blocks; the screws penetrate through the connecting rods; and the tops of the screws are in threaded connection with adjusting nuts. With two groups of tool bits, one group is retractable, cutting seams in the surfaces of the light guide plates can be effectively cut in place, and the conditions that the edges of the light guide plates are coarse and irregular when the light guide plates are split due to positions which are not cut can be avoided.

Owner:东莞质研工业设计服务有限公司

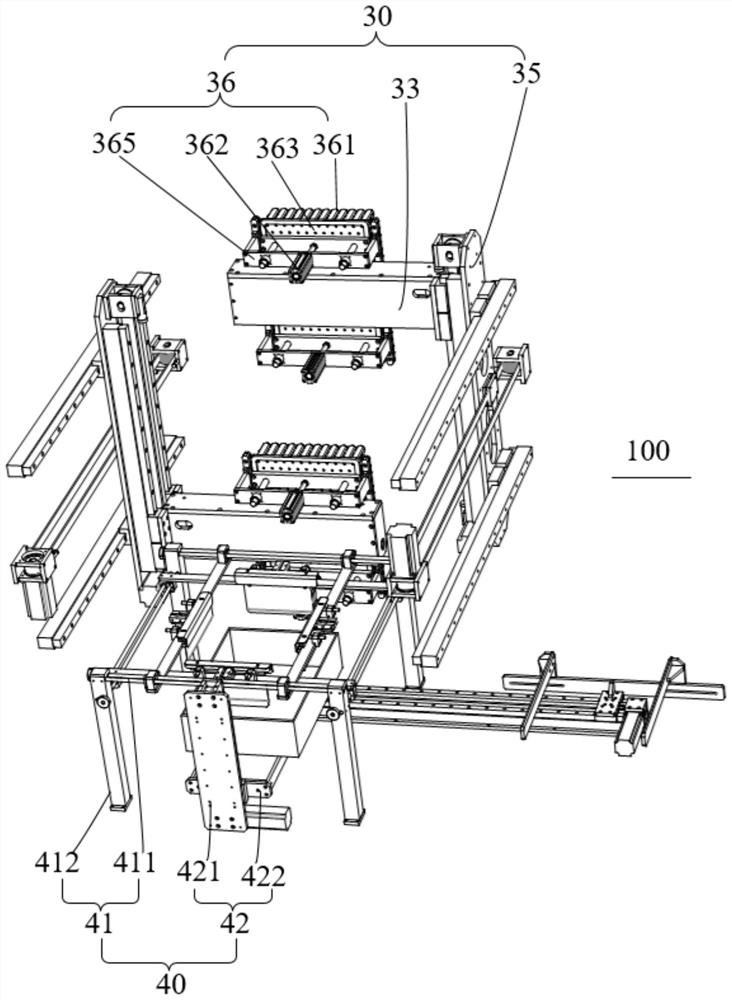

Hose boxing equipment and automatic hose boxing machine capable of preventing disorder

The invention discloses hose boxing equipment and an automatic hose boxing machine capable of preventing disorder. The hose boxing equipment comprises a hose conveying assembly, a plurality of transfer assemblies, a carton translation assembly and a carton lifting assembly. According to the technical scheme, all hoses are placed into a carton together, the situation that the hoses are placed in the carton in batches to cause hose placement disorder and irregularity is avoided, the manual arrangement process is omitted, the boxing efficiency is improved, manual participation is avoided in the hose transferring and boxing process, and the risk that the hoses are polluted by hair and microorganisms is avoided; and under transportation of the hose conveying assembly and the plurality of transfer assemblies, the hoses can be conveyed to the plurality of transfer assemblies alternately all the time, normal conveying of the hoses is guaranteed, retention is avoided, continuous boxing is guaranteed through alternate operation of the plurality transfer assemblies, and then the hose conveying and boxing working efficiency is effectively improved.

Owner:SHENZHEN BEAUTYSTAR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com