Patents

Literature

418results about How to "Avoid roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

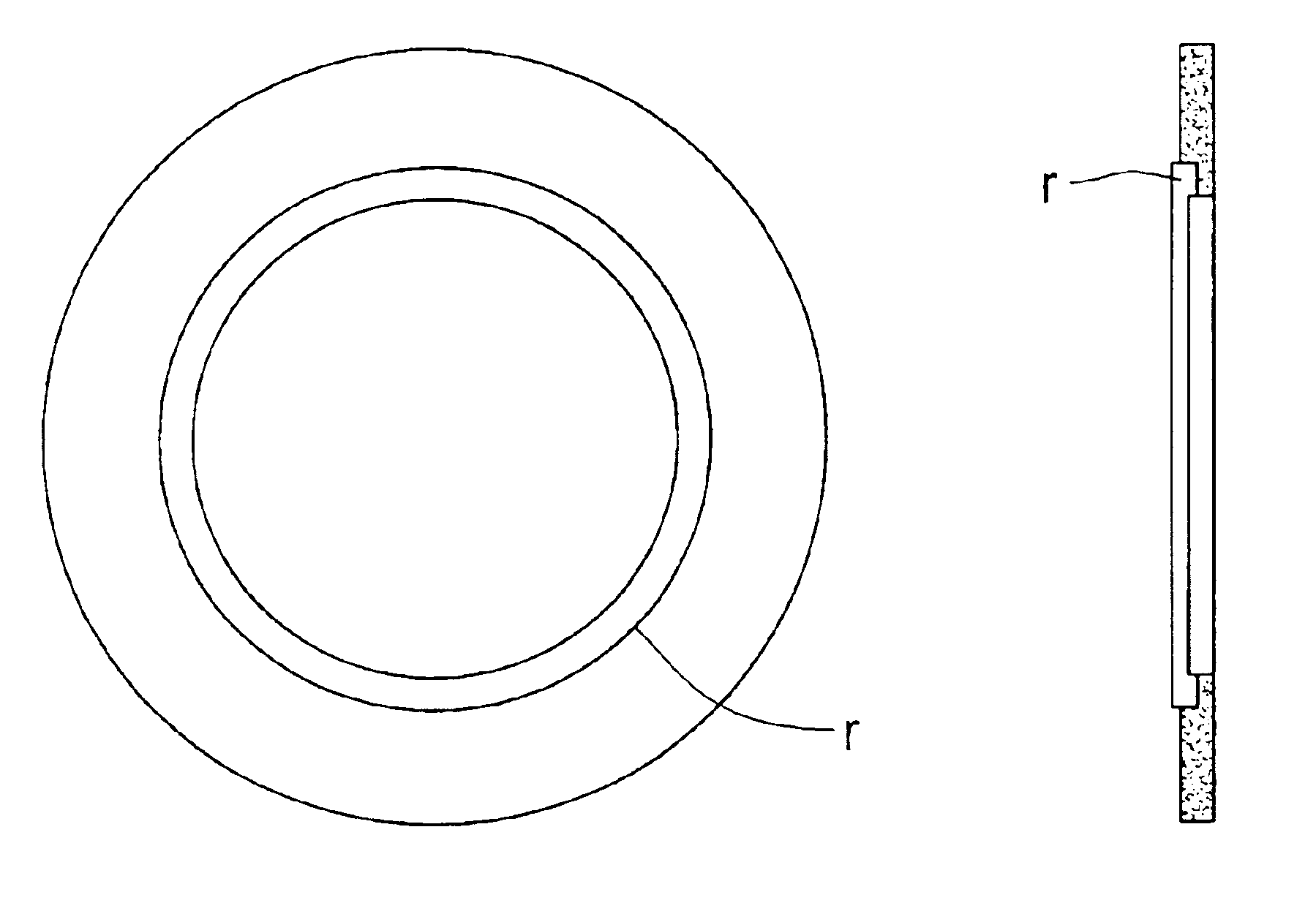

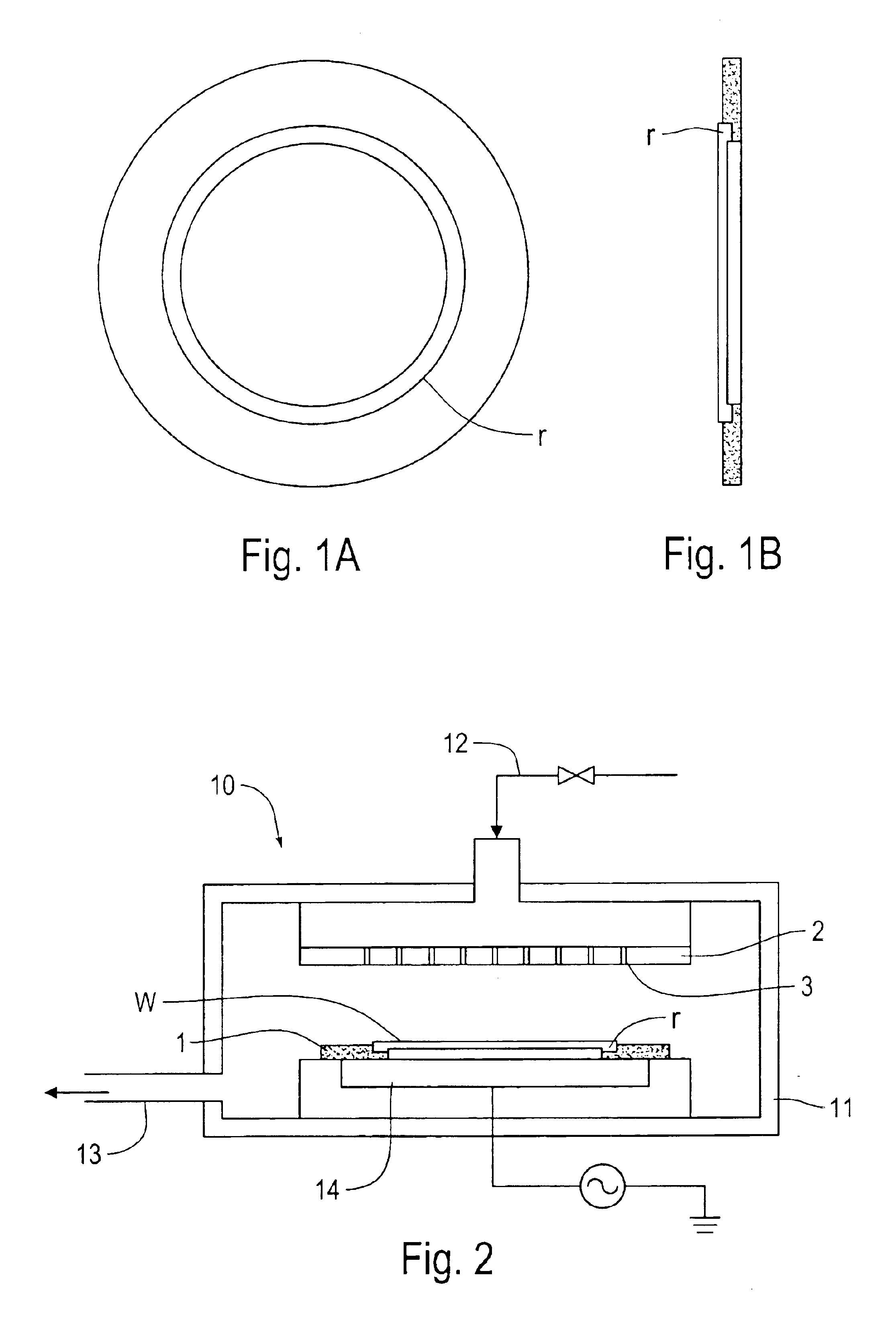

Silicon focus ring and method for producing the same

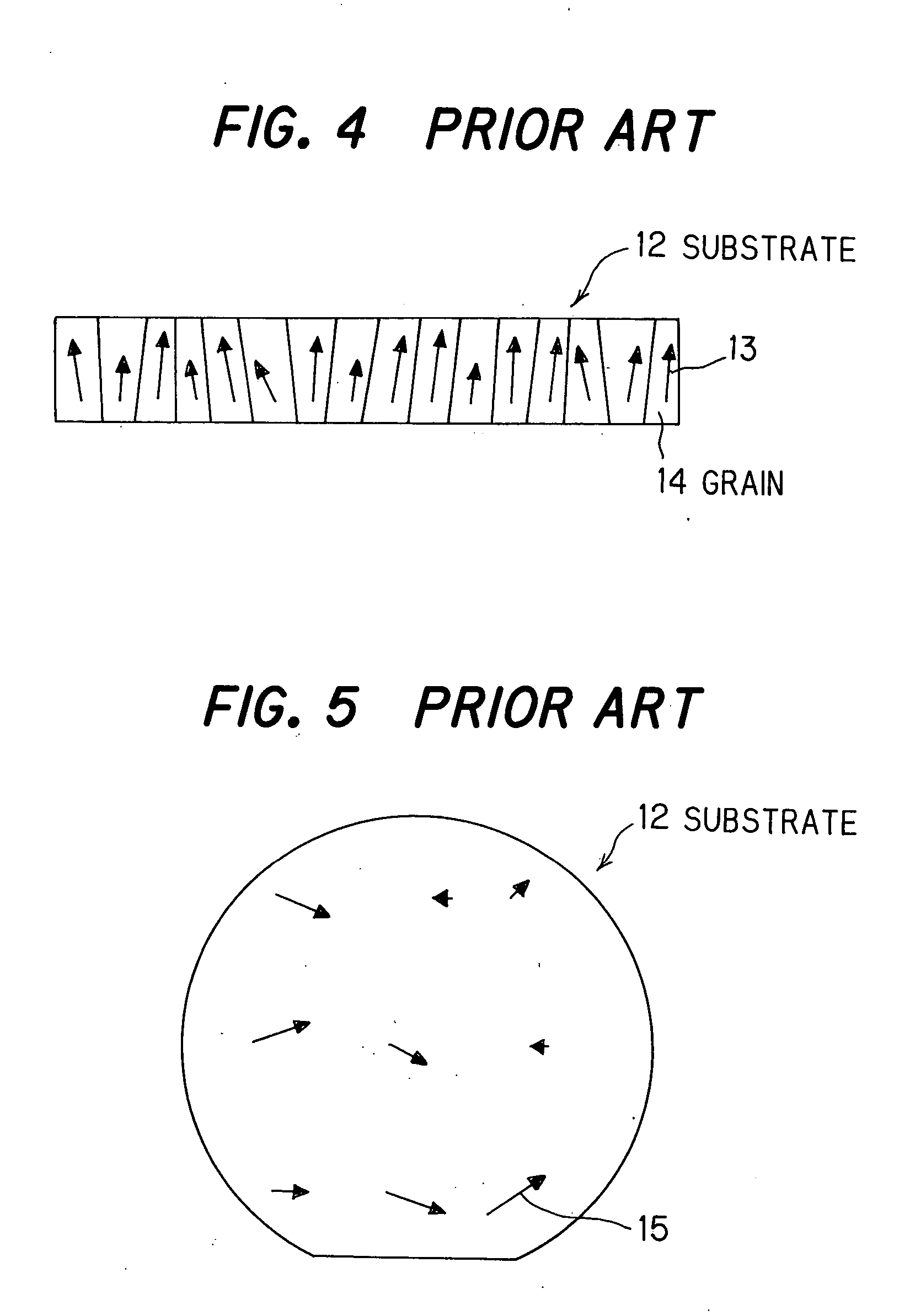

InactiveUS6815352B1Reduce Particle GenerationAvoid roughnessPolycrystalline material growthElectric discharge tubesCzochralski methodSingle crystal

There is disclosed a silicon focus ring consisting of silicon single crystal used as a silicon focus ring in a plasma apparatus, wherein concentration of interstitial oxygen contained in the silicon focus ring is not less than 5x10<17 >atoms / cm<3 >and not more than 1.5x10<18 >atoms / cm<3>, and a producing method for a silicon focus ring used for a plasma apparatus, wherein a single crystal silicon wherein concentration of interstitial oxygen contained in the silicon focus ring is not less than 5x10<17 >atoms / cm<3 >and not more than 1.5x10<18 >atoms / cm<3 >is grown by a Czochralski method, the single crystal silicon is processed in a circle, and a silicon focus ring is produced. There can be provided a silicon focus ring, which can prevent disadvantage due to impurities such as heavy metal.

Owner:SHIN ETSU CHEM IND CO LTD

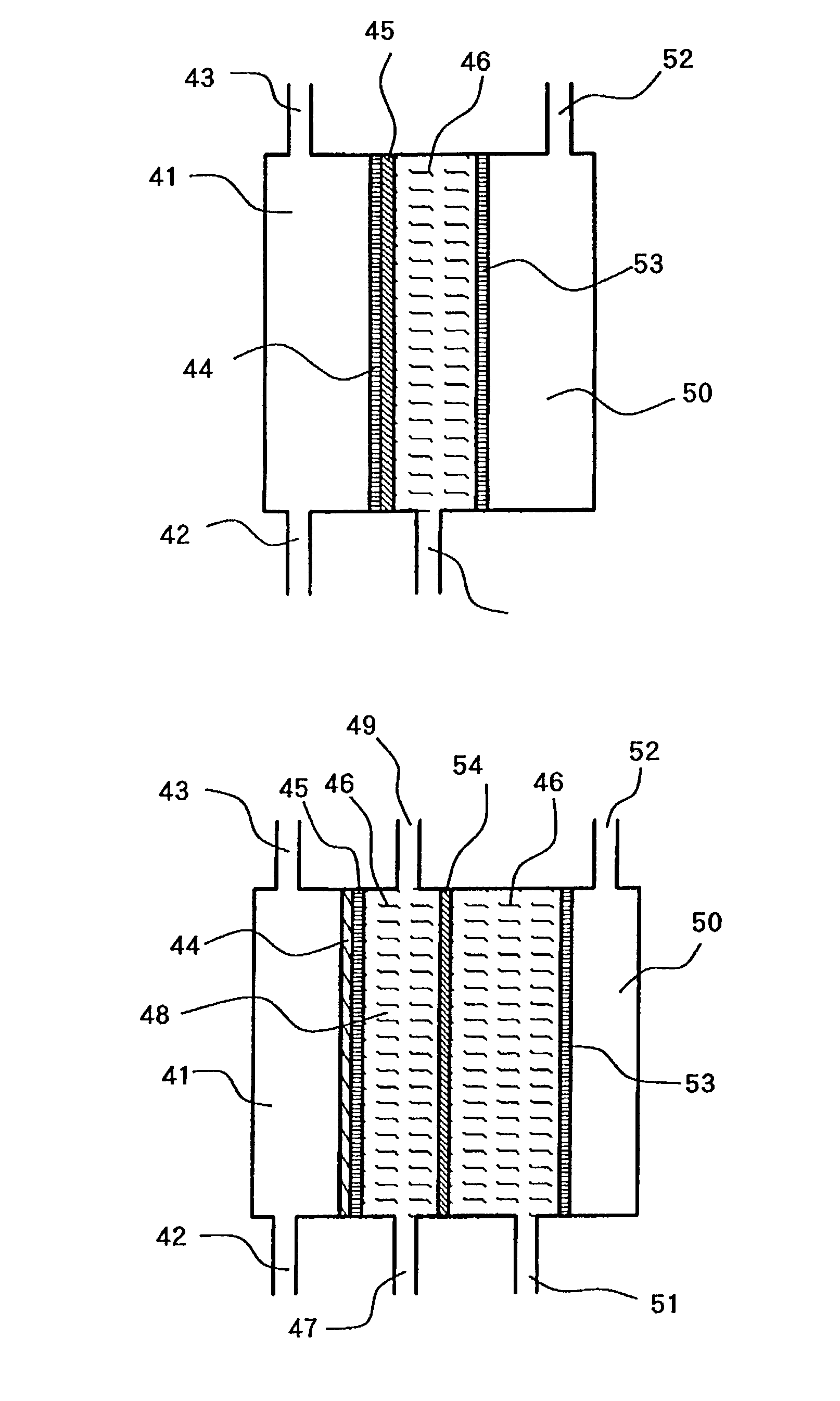

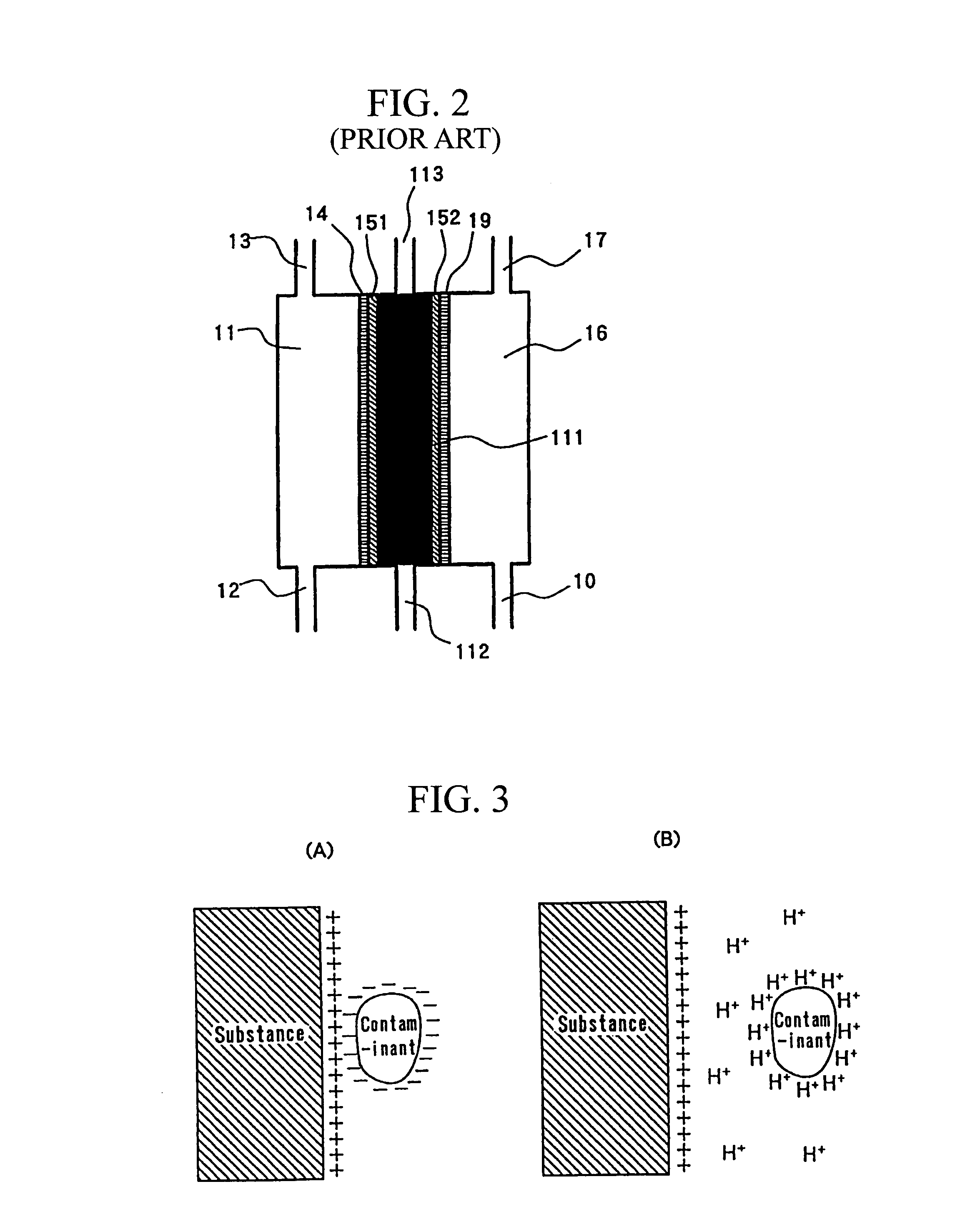

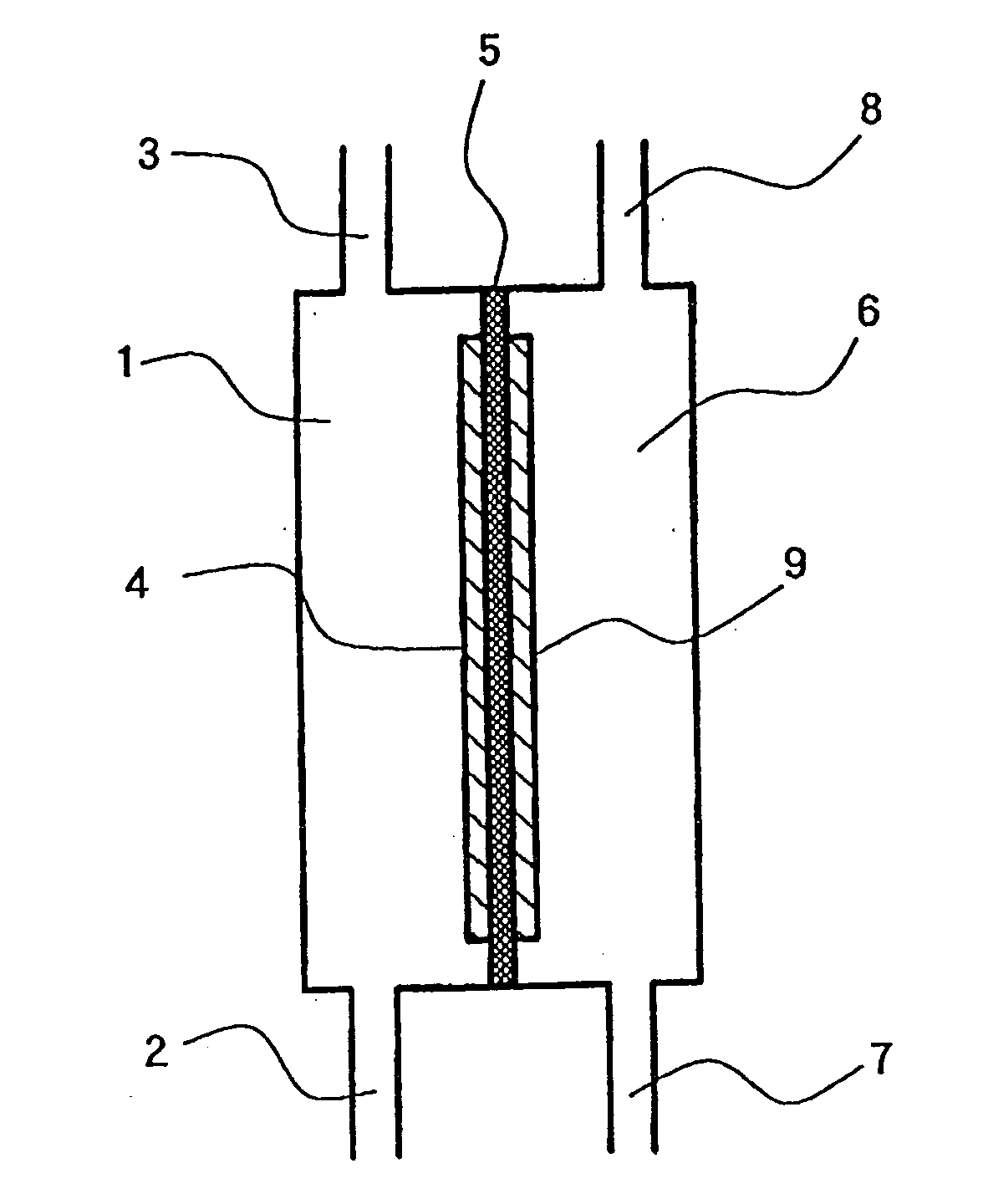

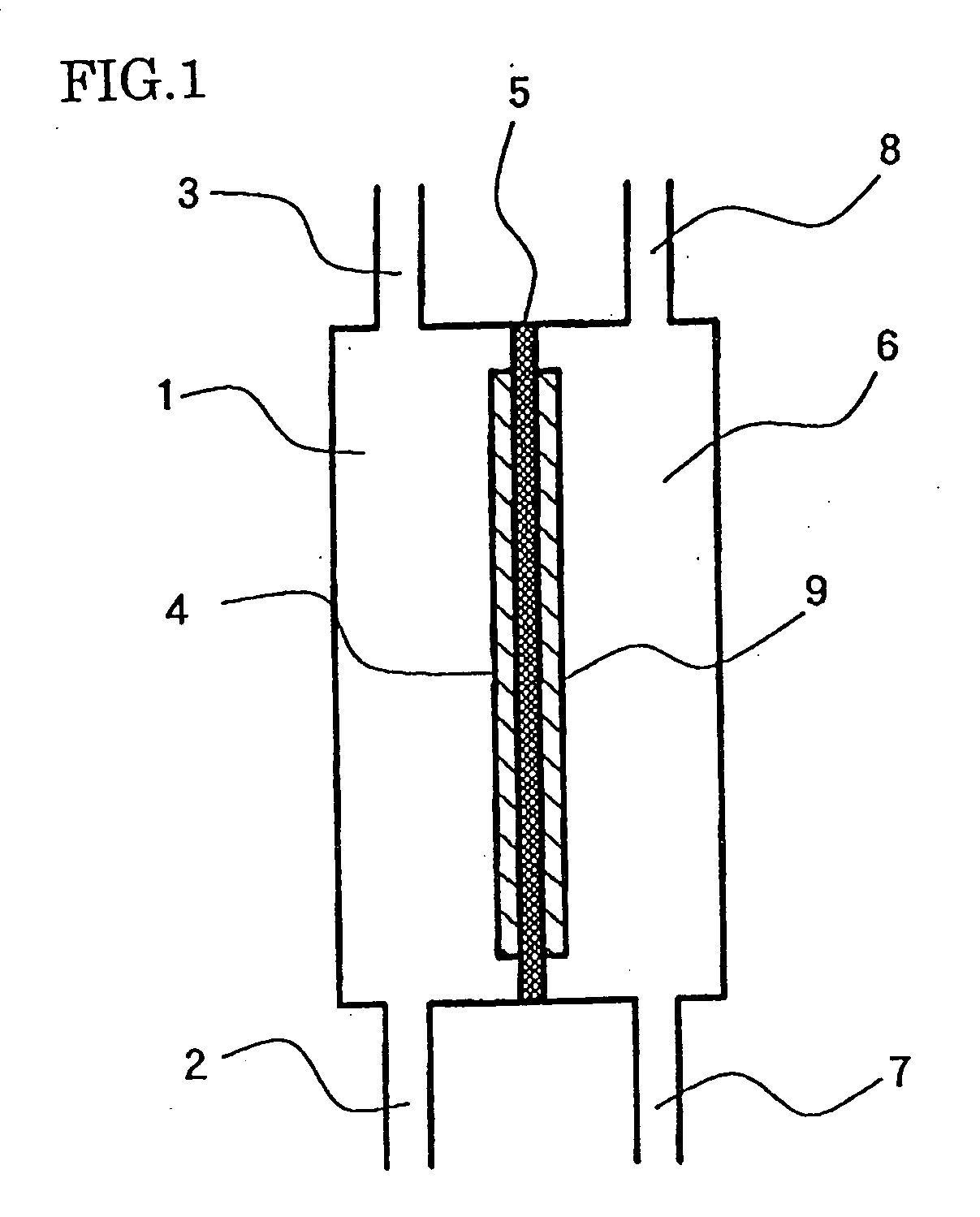

Electrolytic cell for producing charged anode water suitable for surface cleaning or treatment, and method for producing the same and use of the same

InactiveUS7090753B2Reduce the binding forceEasy to cleanCellsWater treatment parameter controlSurface cleaningElectrical battery

The present invention provides an electrolytic cell, which can efficiently produce, charged water having an excellent performance of improving surface cleaning or treatment of an object, e.g., semiconductor, glass, or resin and of cleaning and sterilizing medical device.The electrolytic cell of the present invention is for producing charged anode water suitable for surface cleaning or treatment, including the cathode chamber 41 and anode chamber 50, fluorinated cation-exchange membrane 46 provided to separated these chambers from each other, cathode 44 closely attaché to the cation-exchange membrane 45 on the side facing the cathode chamber 41, and middle chamber 48 filled with the cation-exchange resin 46, provided on the other side of The cation-exchange membrane 46, the cation-exchange resin 46 being arranged in such a way to come into contact with the fluorinated cation-exchange membrane 45, wherein the feed water is passed into the middle chamber 48 and passed thorough The anode chamber 50 to be recovered as the charged anode water.

Owner:SONOMA PHARMA INC

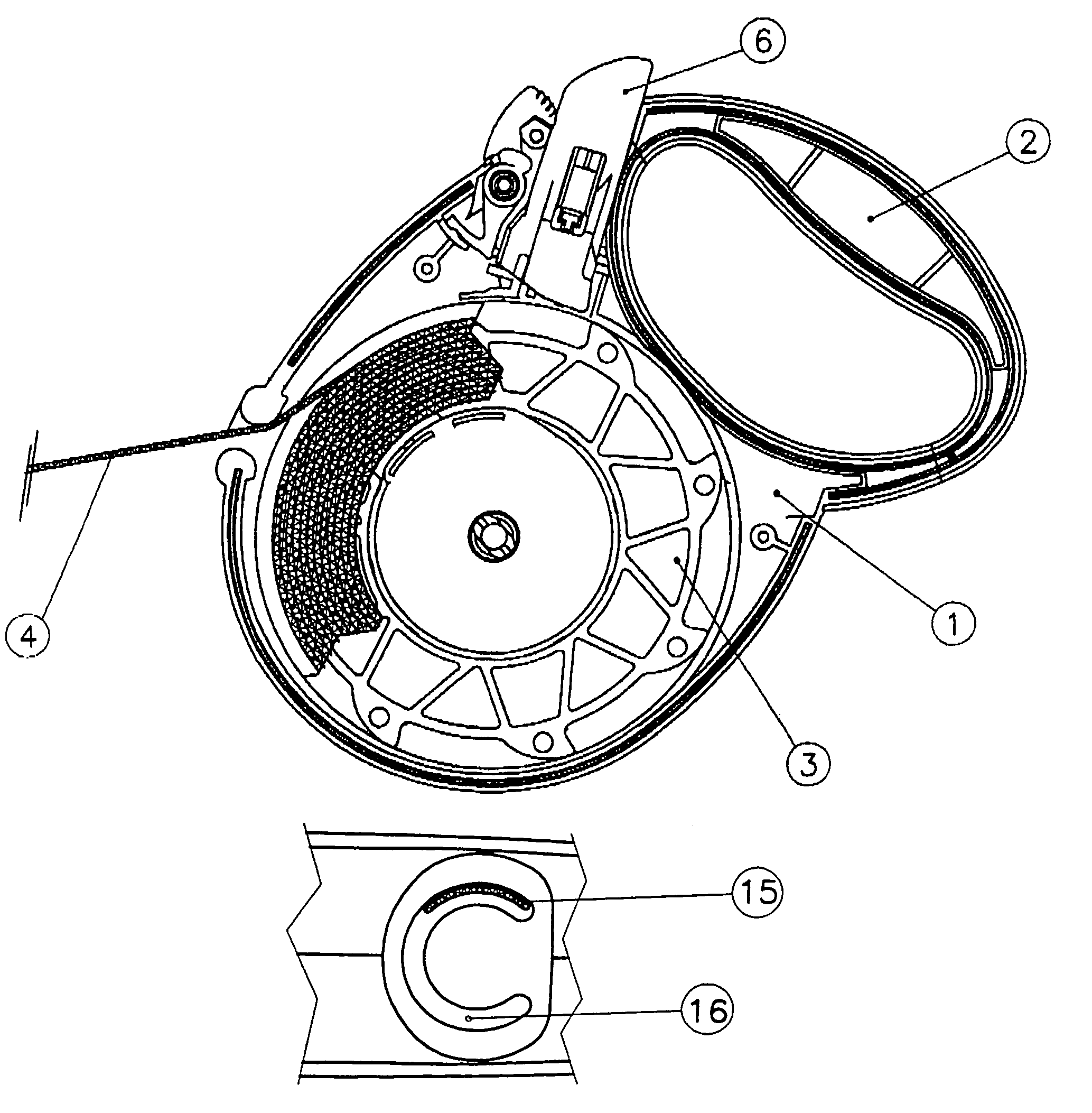

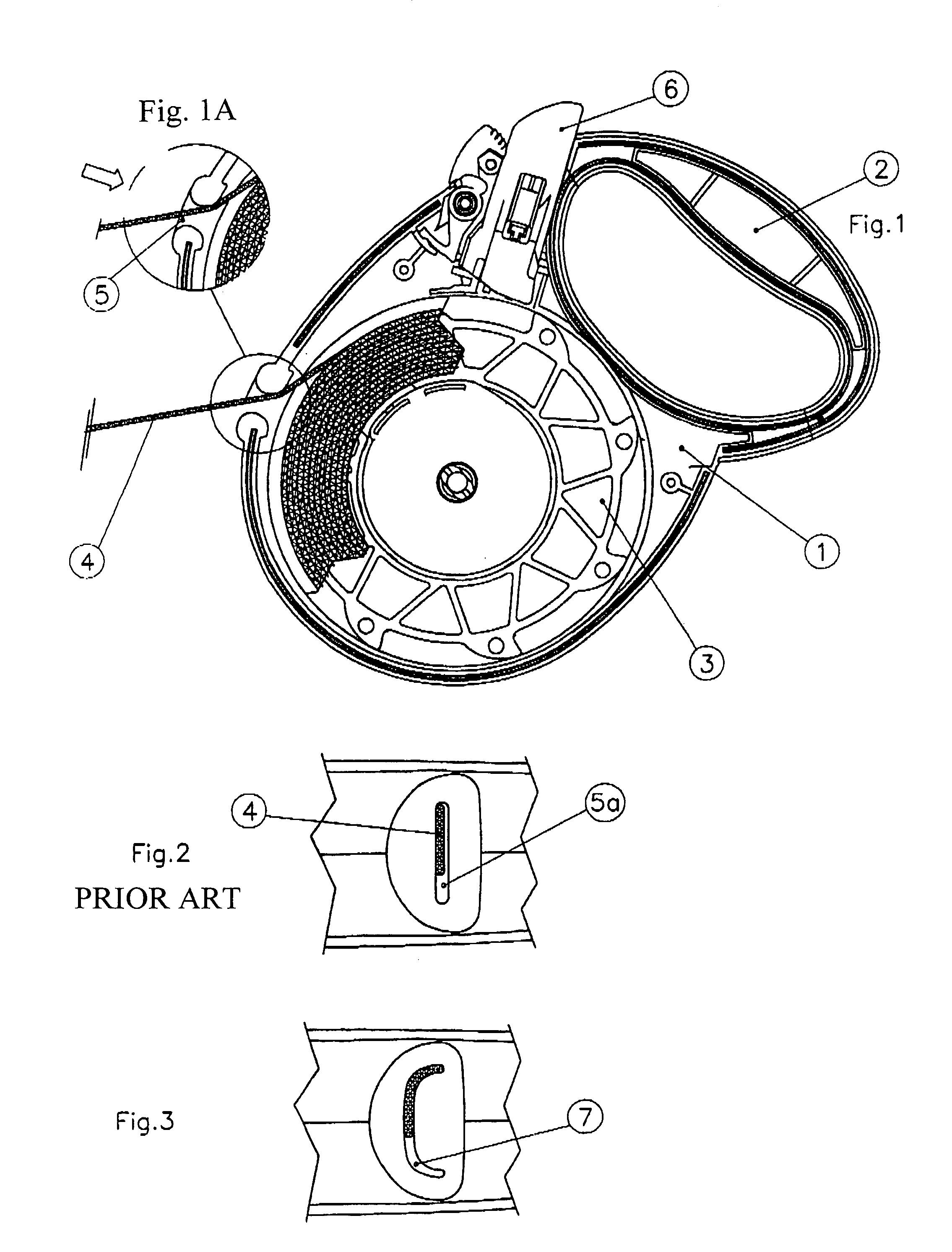

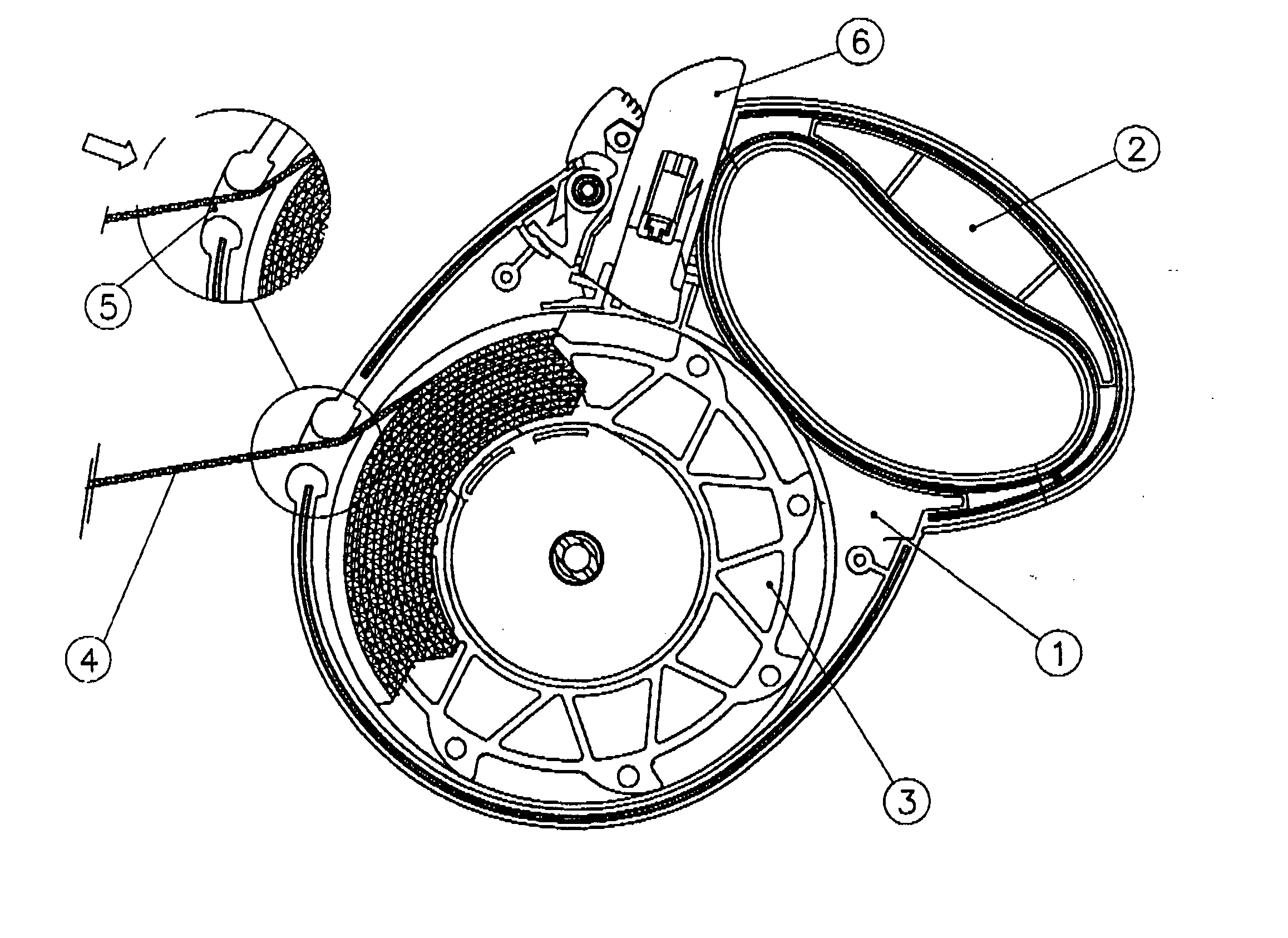

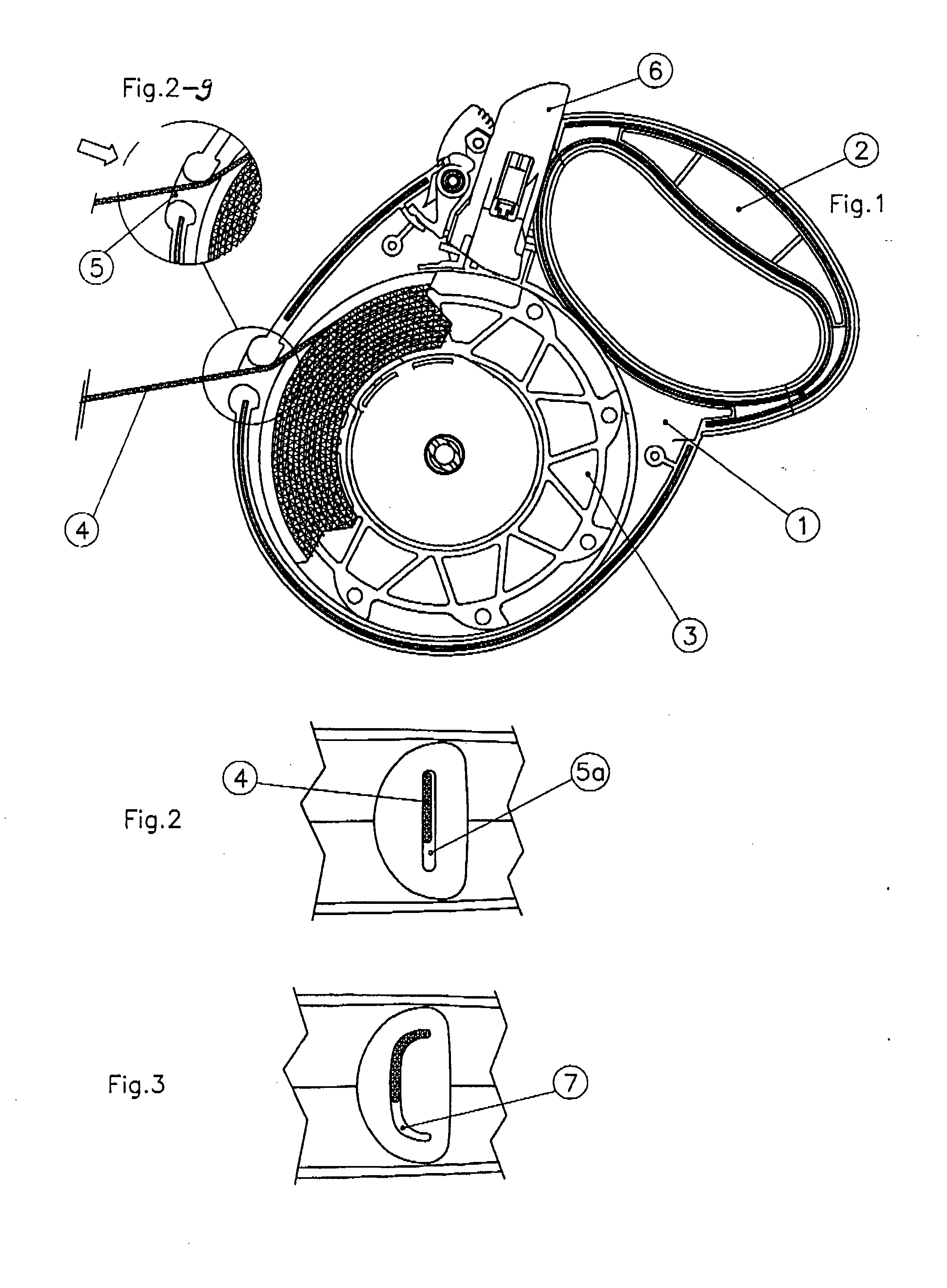

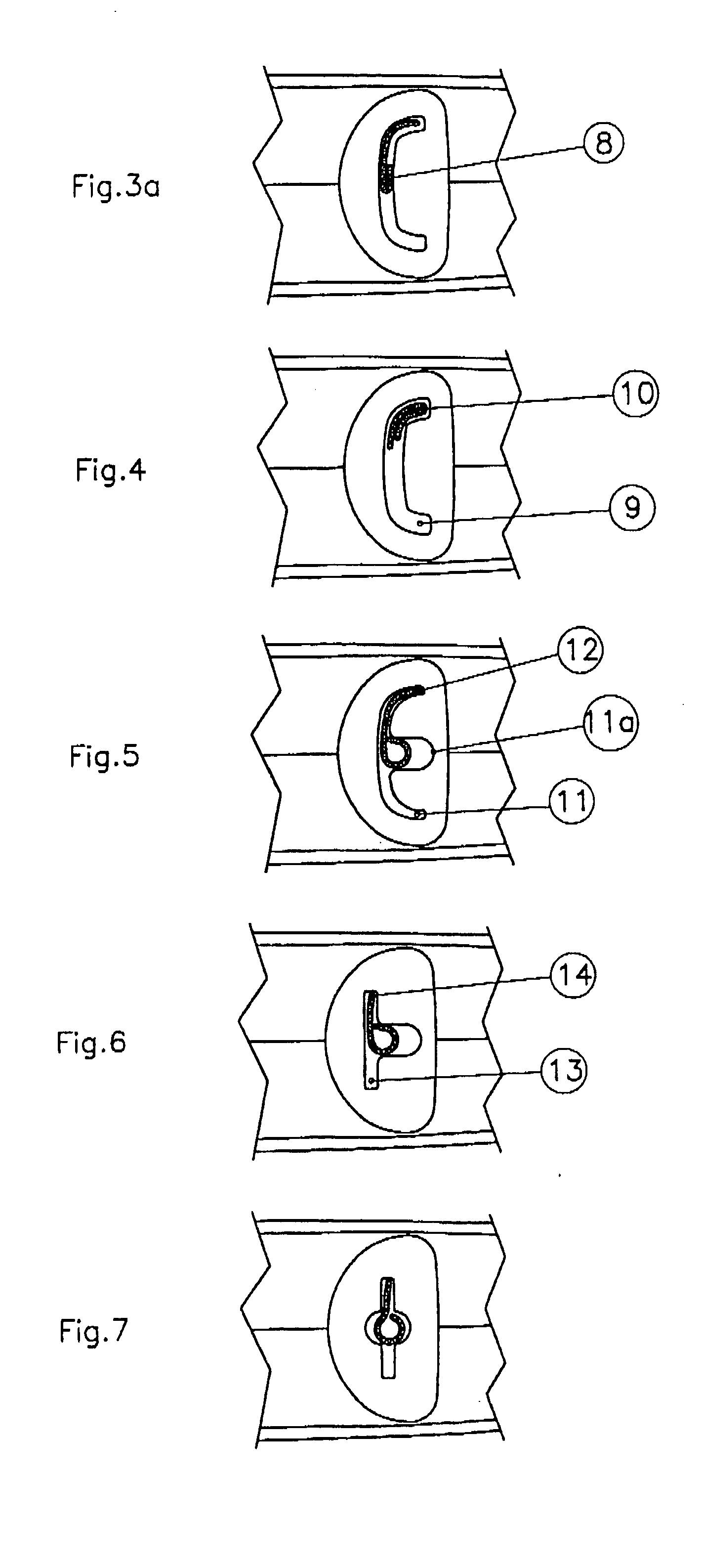

Leash assembly for a retractable leash to walk animals

ActiveUS7168393B2Roughening of the edges of the strap is avoidedAvoid roughnessProjector film strip handlingCamera film strip handlingEngineeringMechanical engineering

Owner:FLEXI BOGDAHN TECHN

Skin preparation for external use characterized by containing sugar derivative of alpha, alpha-trehalose

ActiveUS20070003502A1Prevent and improve rough skinPrevent and improve and suntanAntibacterial agentsCosmetic preparationsScattering effectSugar derivatives

The present invention has an object to provide an external dermatological formulation having satisfactory blood flow-promoting effect, antiinflammatory effect, antibacterial effect, moisturizing effect, whitening effect, UV-absorbing effect, UV-scattering effect, antioxidant effect, hair growing effect, hair nourishing effect, emusifying effect, astringent effect, wrinkle-reducing effect, cell-activating effect and / or transdermal absorption-promoting effect with a satisfactory safety and skin feeling; The object is solved by providing an external dermatological formulation comprising a saccharide derivative of α,α-trehalose and one or more members selected from substances having any one of blood flow-promoting effect, antiinflammatory effect, antibacterial effect, moisturizing effect, whitening effect, UV-absorbing effect, UV-scattering effect, antioxidant effect, hair growing efect, hair nourishing effect, emulsifying effect, astringent effect, wrinkle-reducing effect, cell-activating effect and transdermal absorption-promoting effect.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

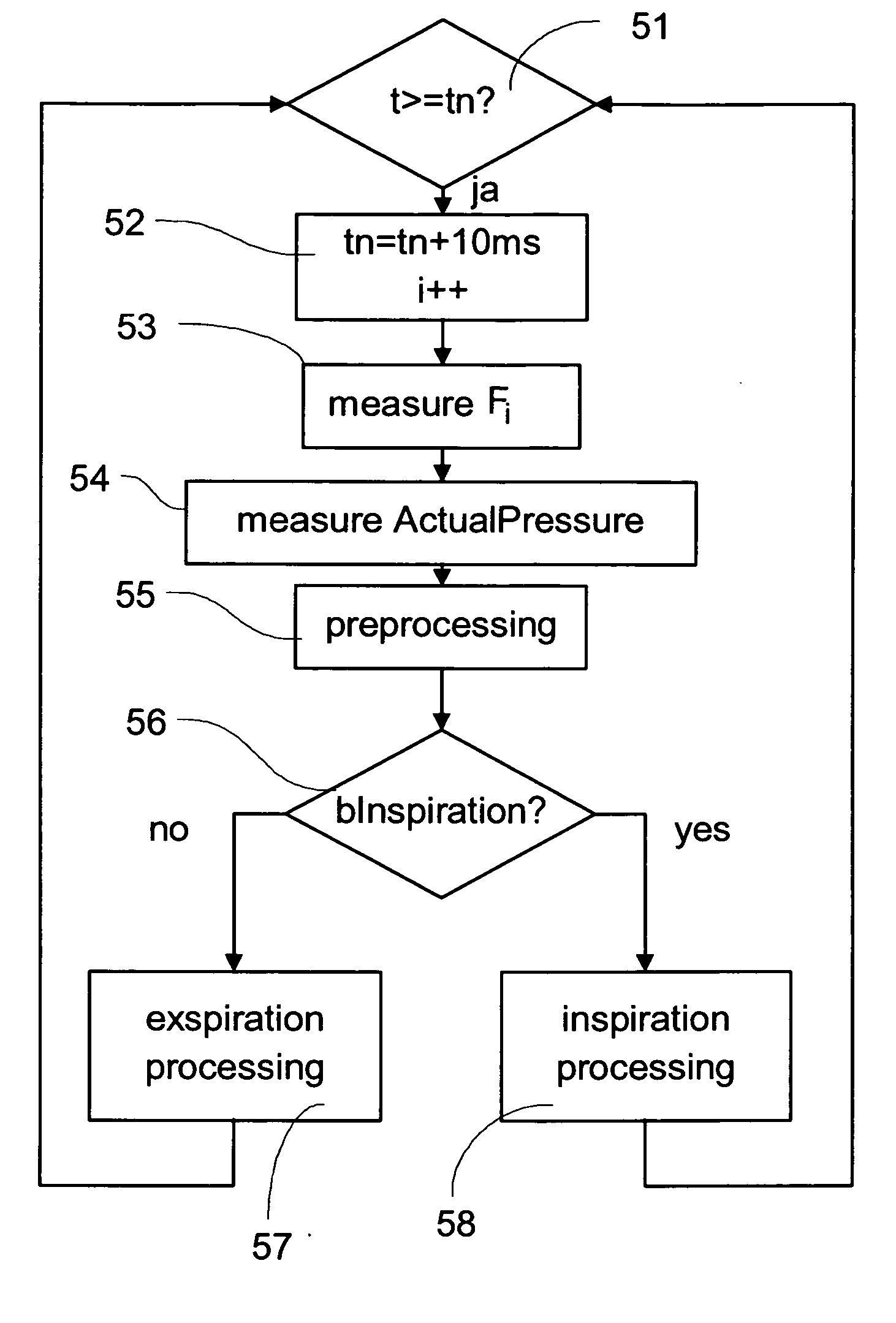

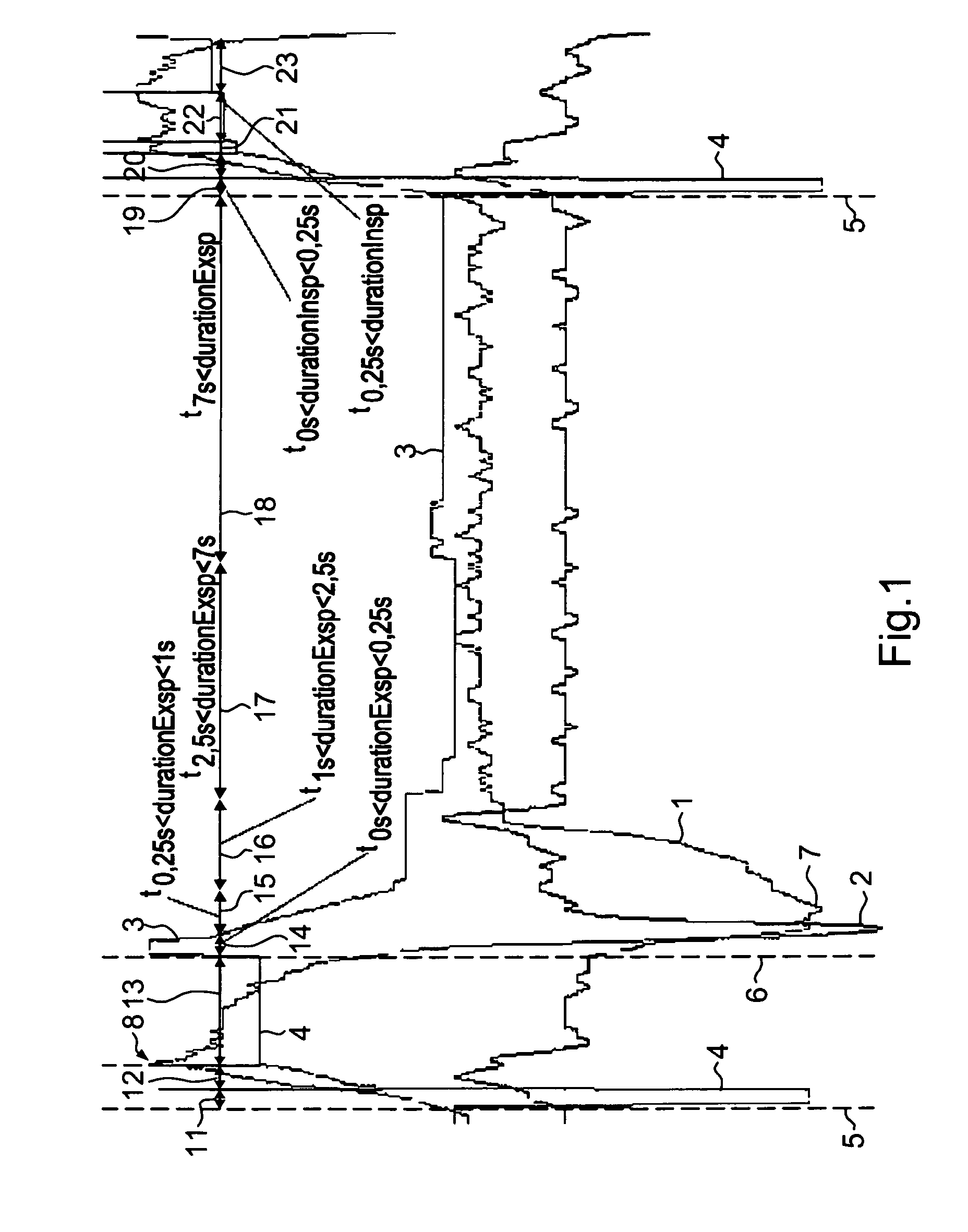

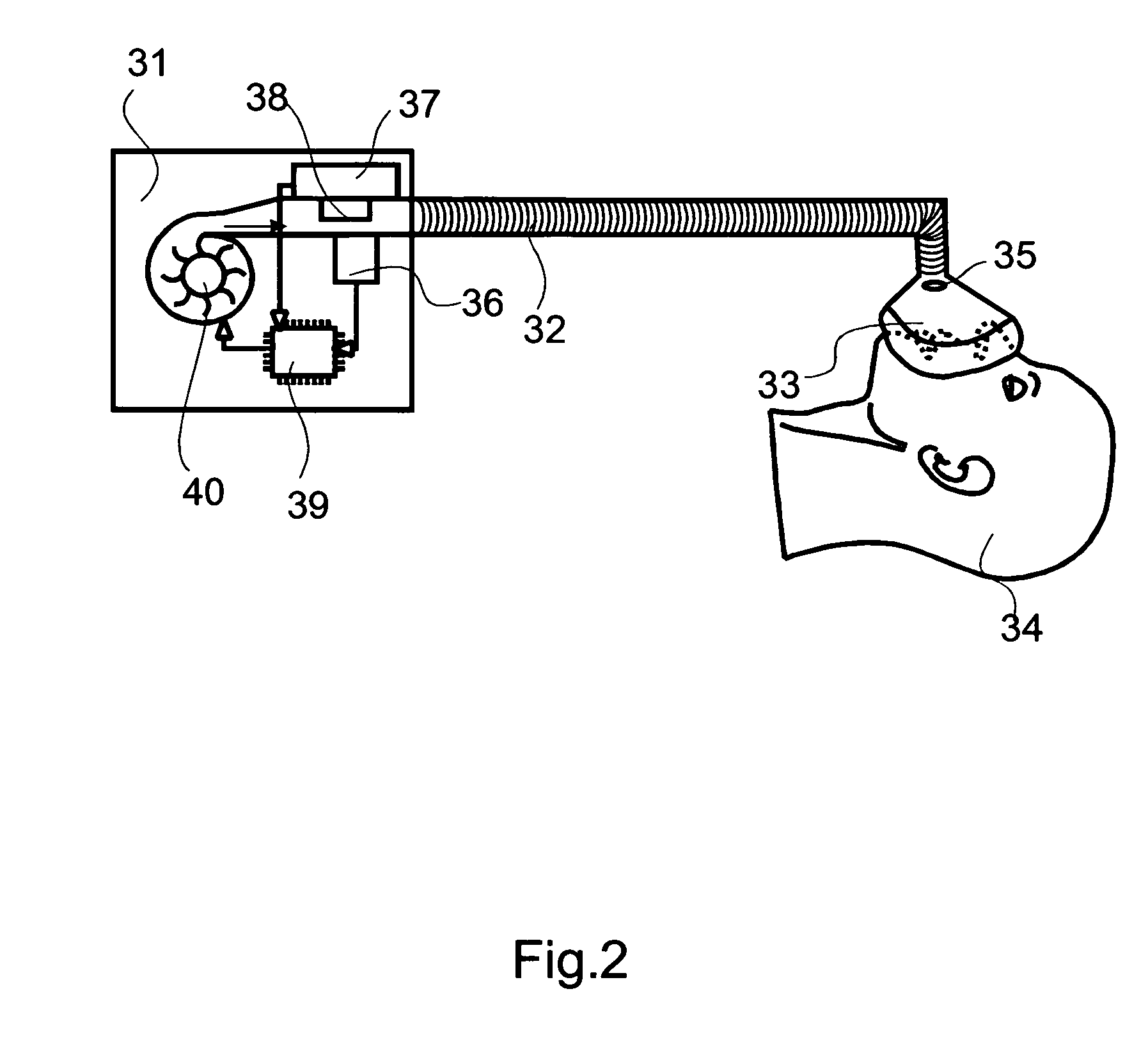

Method for controlling a bi-level apparatus, and bi-level apparatus

ActiveUS20070089745A1Improve reliabilityAvoid roughnessRespiratorsOperating means/releasing devices for valvesEngineeringAirflow

This invention relates to a method for controlling a bi-level apparatus. The method includes repeatedly measuring an airflow, choosing an expiration threshold value and choosing an inspiration threshold value. Switching to an inspiration mode takes place if the airflow is greater than the expiration threshold value in a comparison with the expiration threshold value. A switching back to the expiration mode takes place if the airflow is smaller than the inspiration threshold value in a comparison with the inspiration threshold value. Moreover, the invention relates to a bi-level apparatus for performing the method.

Owner:VYAIRE MEDICAL GMBH

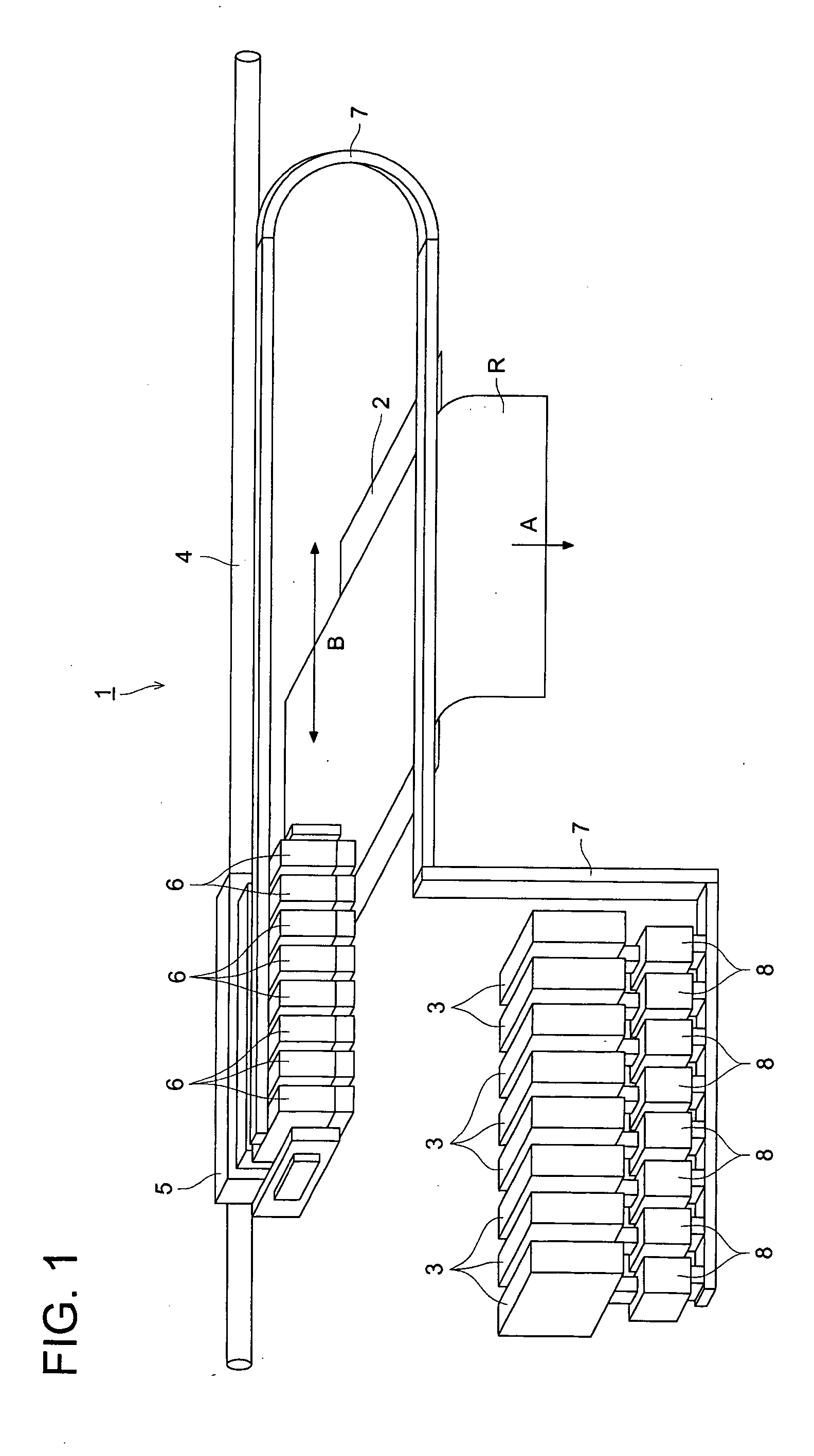

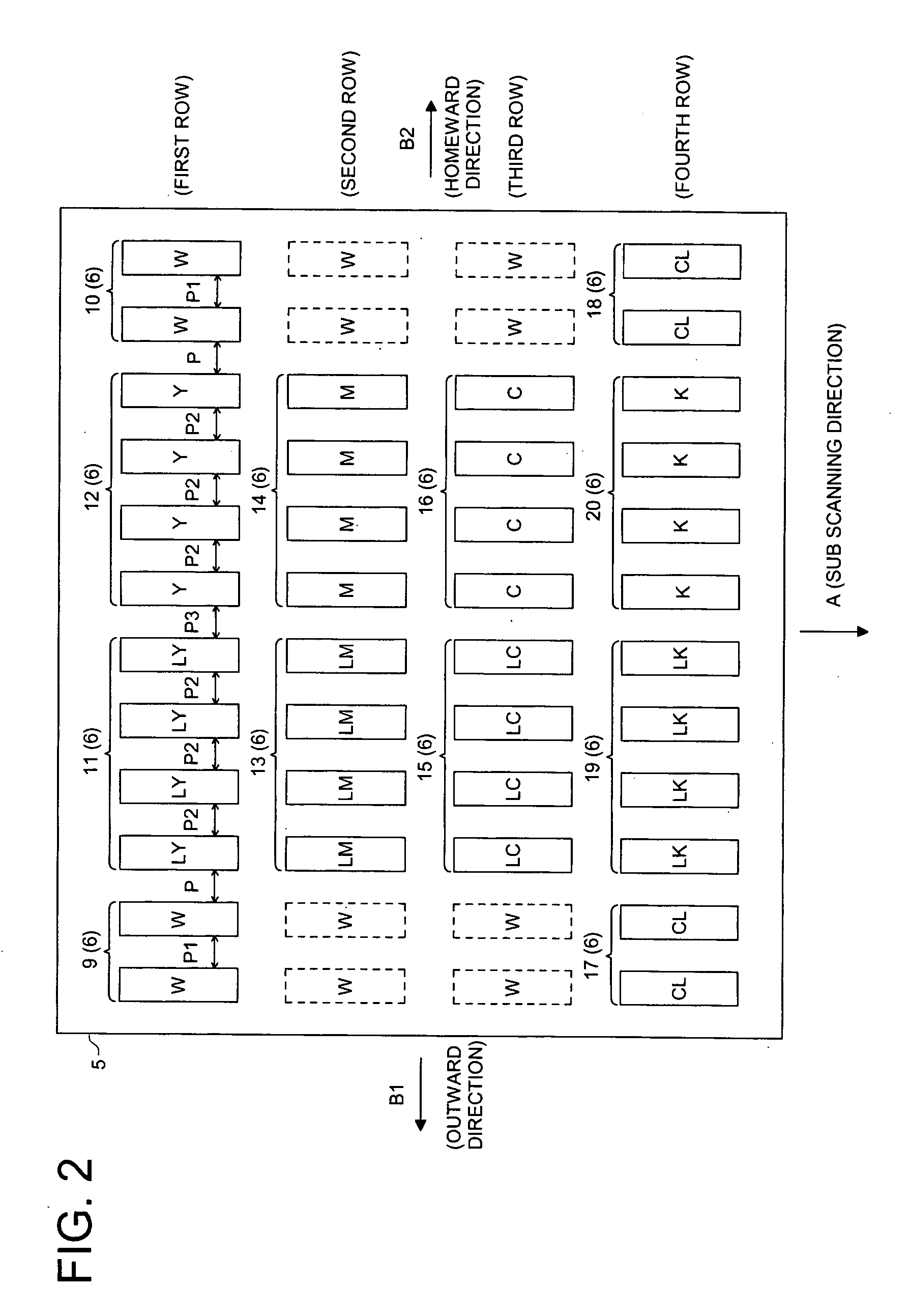

Inkjet recording apparatus

ActiveUS20050179725A1MiniaturizeReduce manufacturing costOther printing apparatusEngineeringRecording media

An ink jet recording apparatus includes a conveying device for conveying a recording medium to a recording area where ink is jetted, and a plurality of recording heads for jetting ink onto the recording medium, wherein the plurality of recording heads includes a background-color ink recording head for jetting a background-color ink, process-color ink recording heads for jetting process-color inks in respective process colors, and a transparent ink recording head for jetting a transparent ink, and wherein the background-color ink recording head is disposed on a most upstream side in a conveying direction of the recording medium, and the transparent ink recording head is disposed on a most downstream side in the conveying direction of the recording medium.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

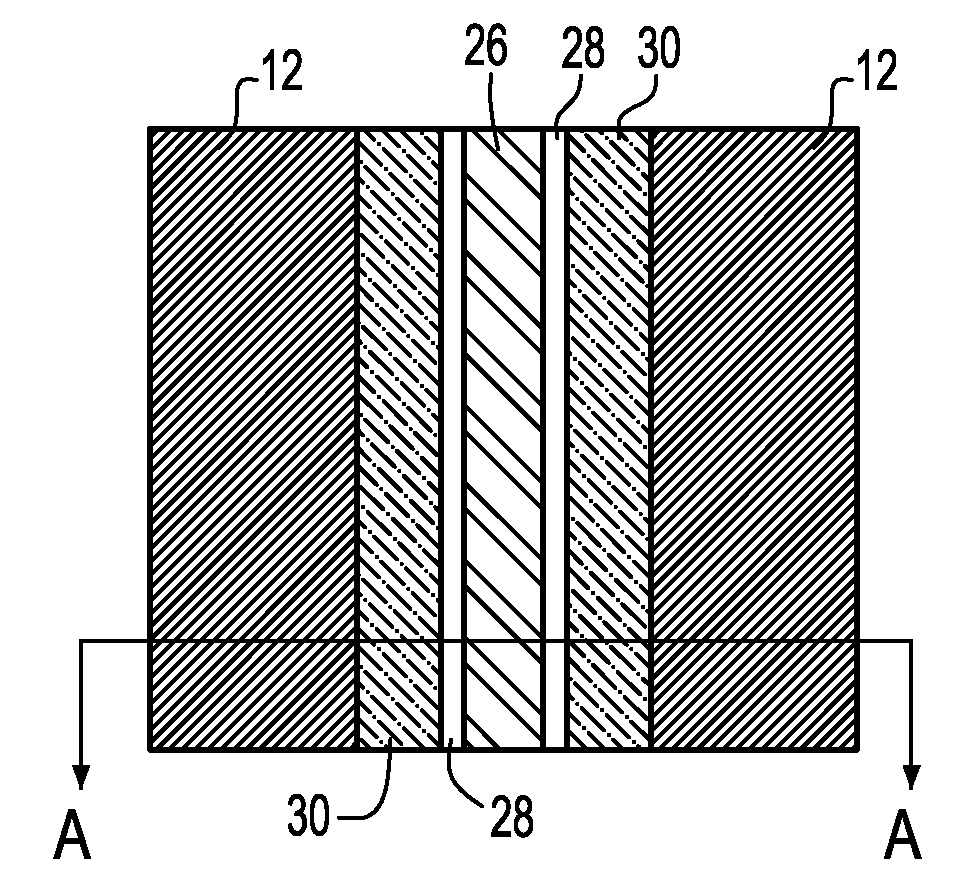

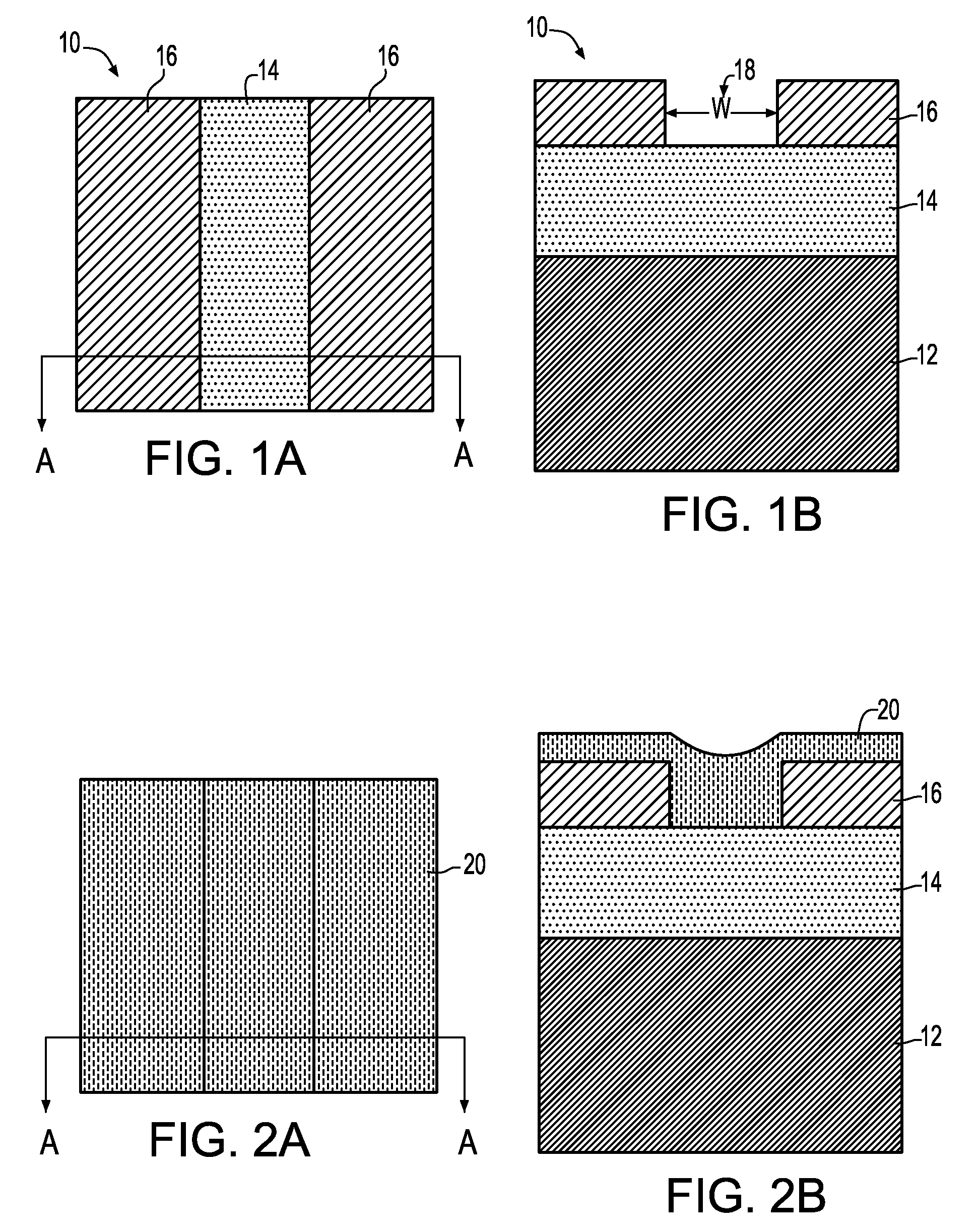

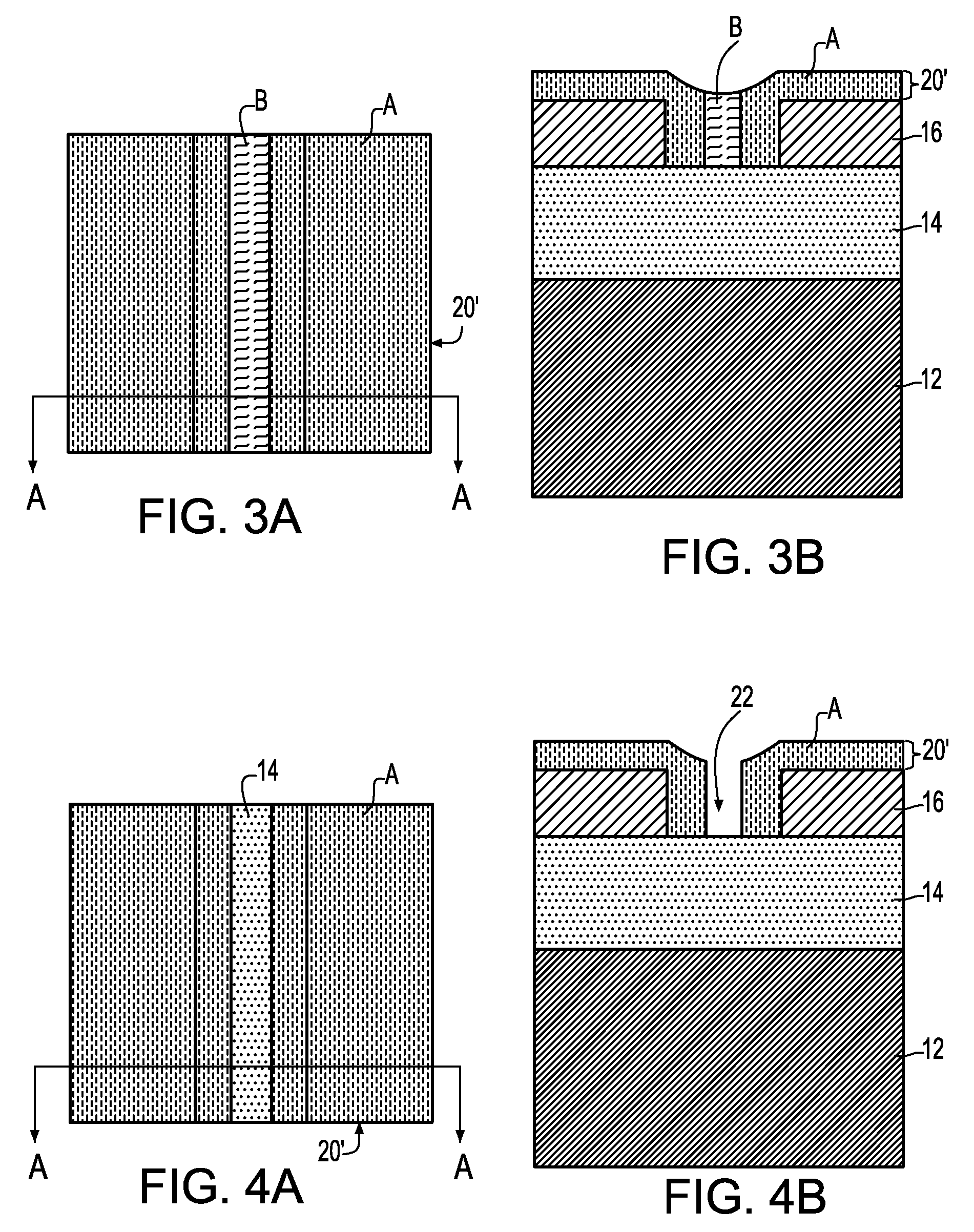

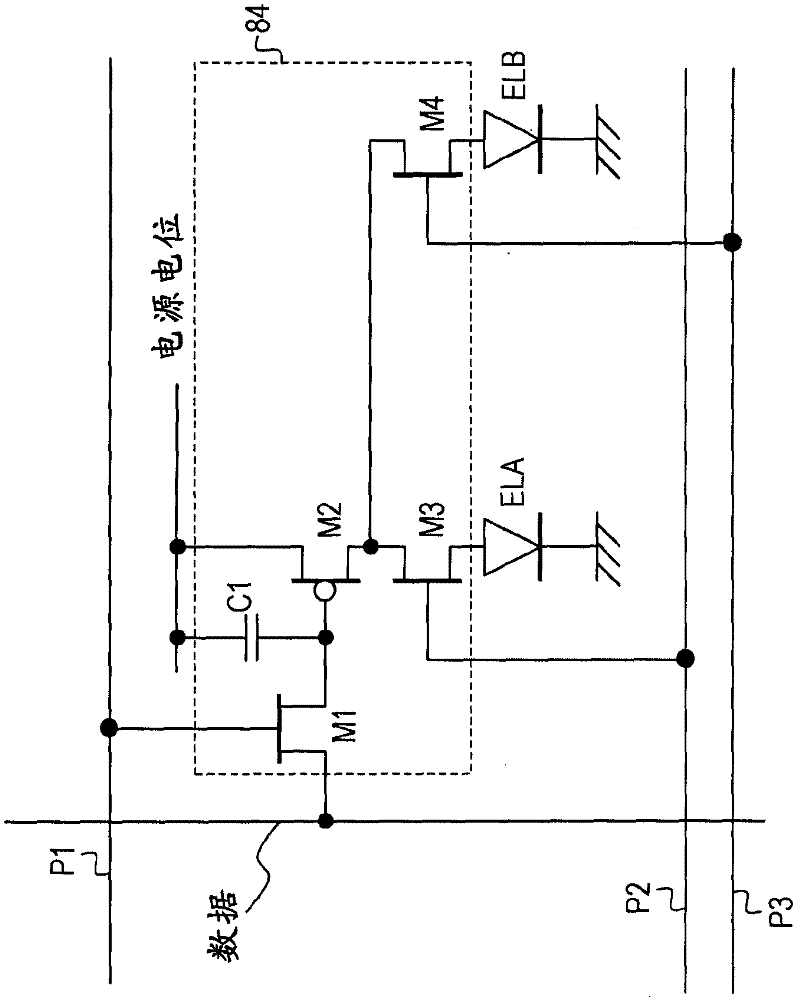

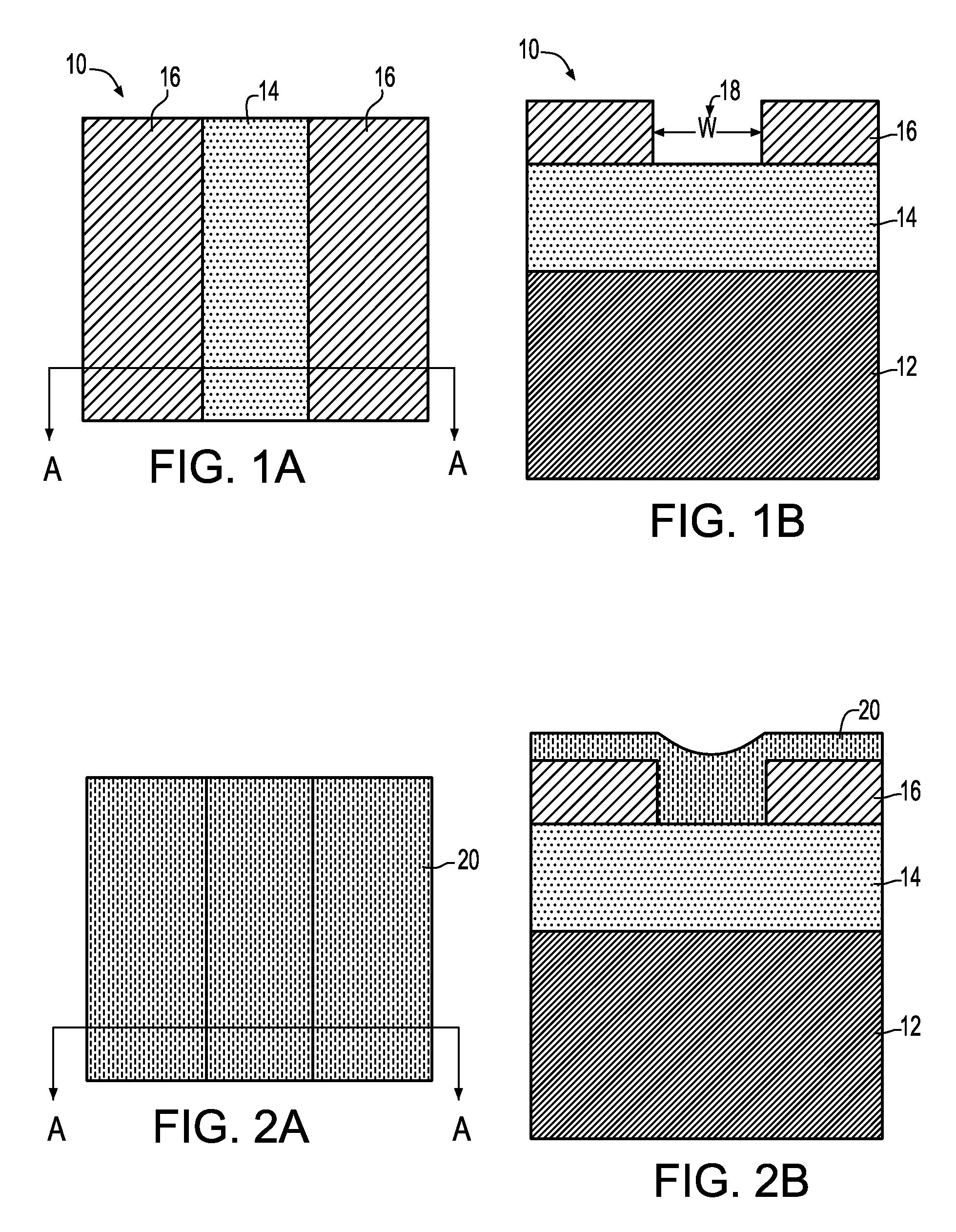

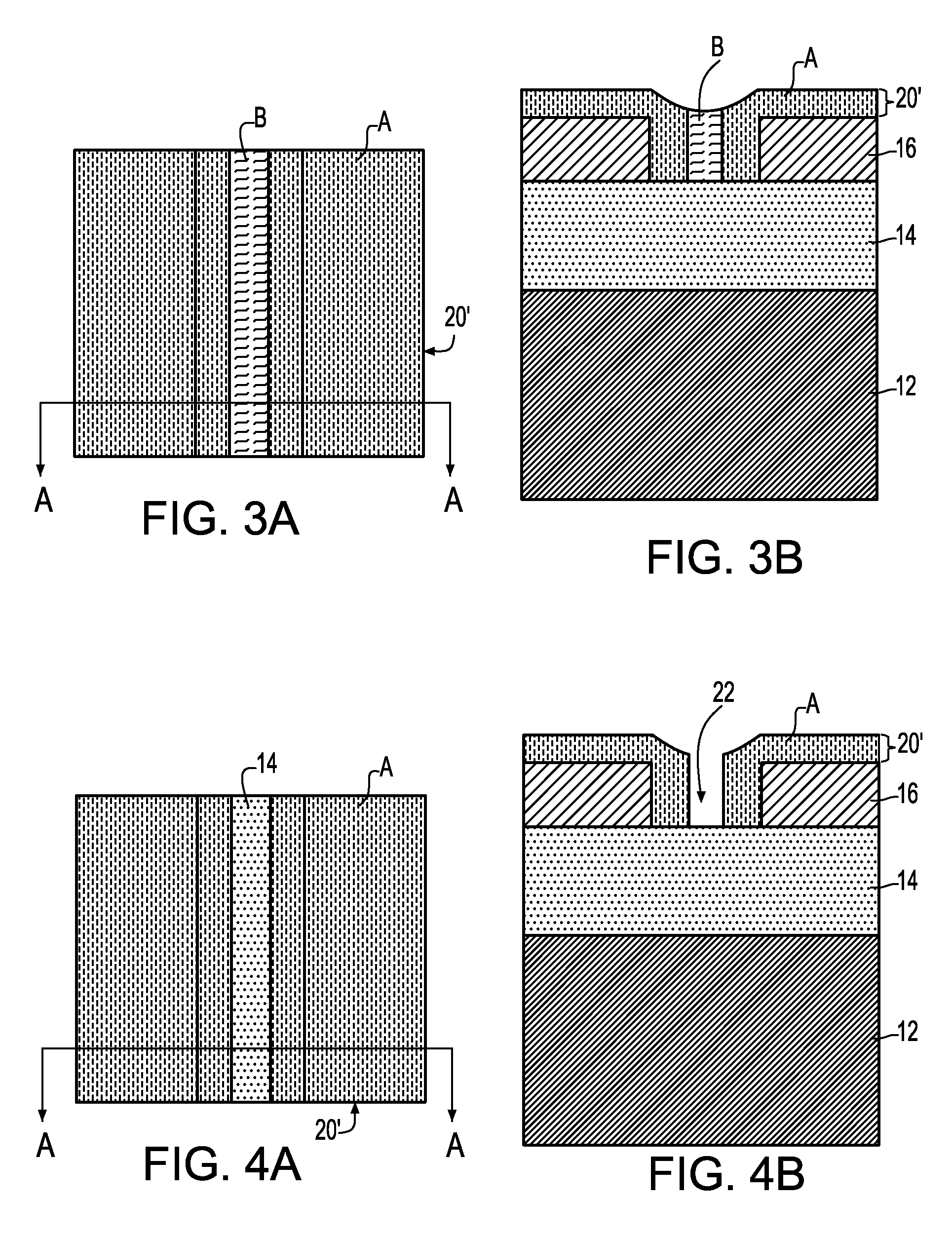

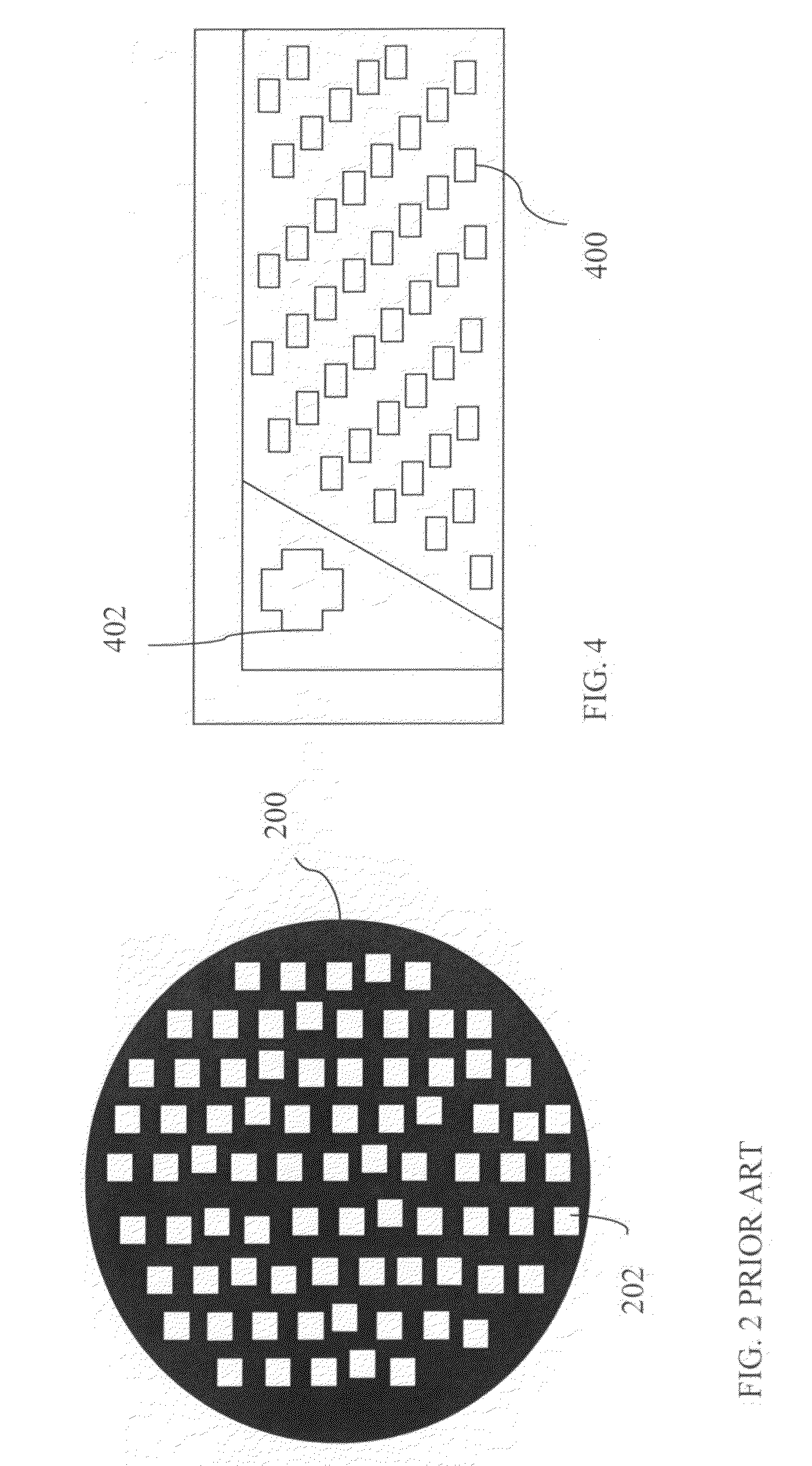

Sub-lithographic gate length transistor using self-assembling polymers

ActiveUS20080099845A1Reduced process windowReduced product performance degradationMaterial nanotechnologySolid-state devicesSemiconductor structureEngineering

A semiconductor structure including at least one transistor located on a surface of a semiconductor substrate, wherein the at least one transistor has a sub-lithographic channel length, is provided. Also provided is a method to form such a semiconductor structure using self-assembling block copolymer that can be placed at a specific location using a pre-fabricated hard mask pattern.

Owner:ELPIS TECH INC

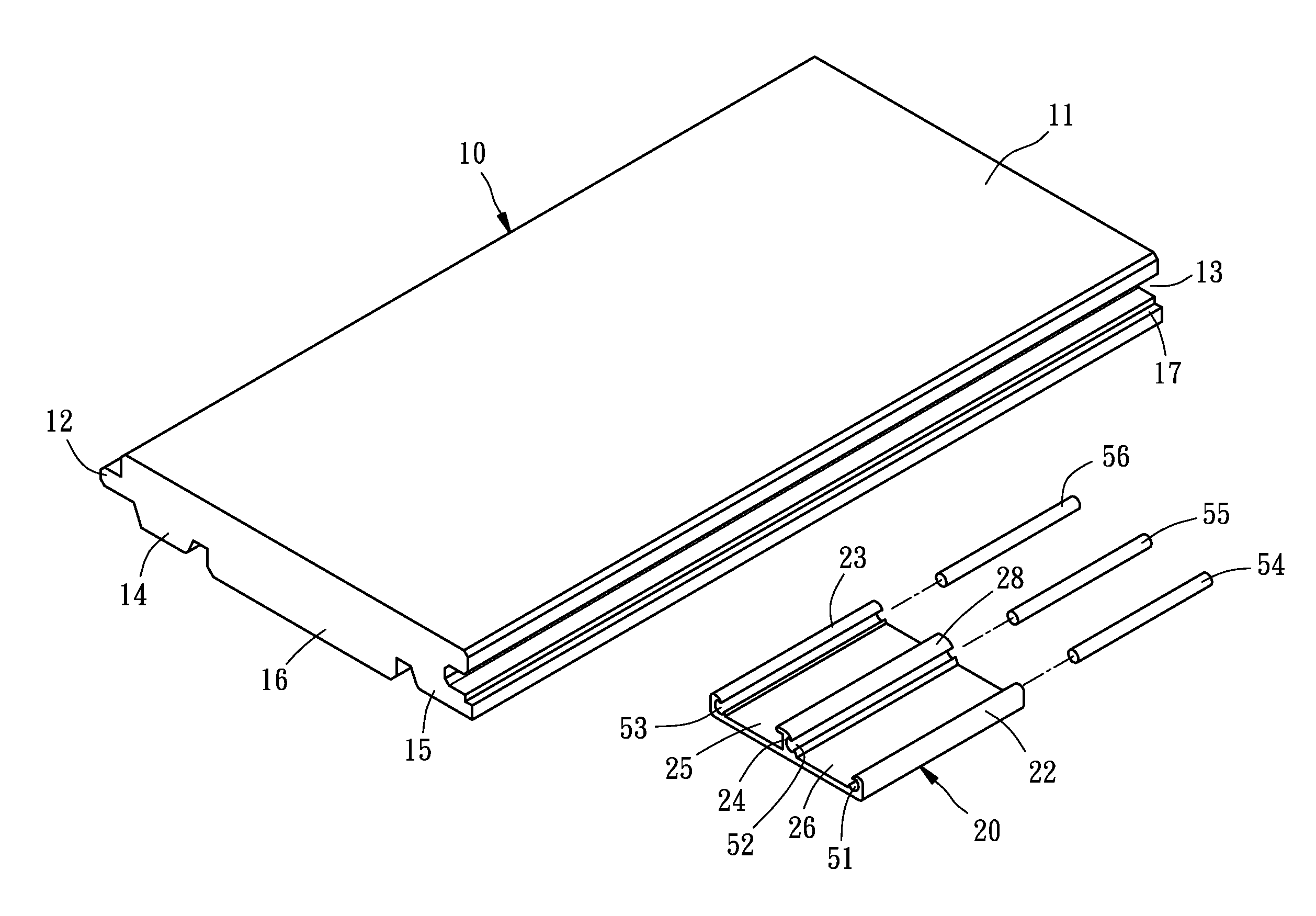

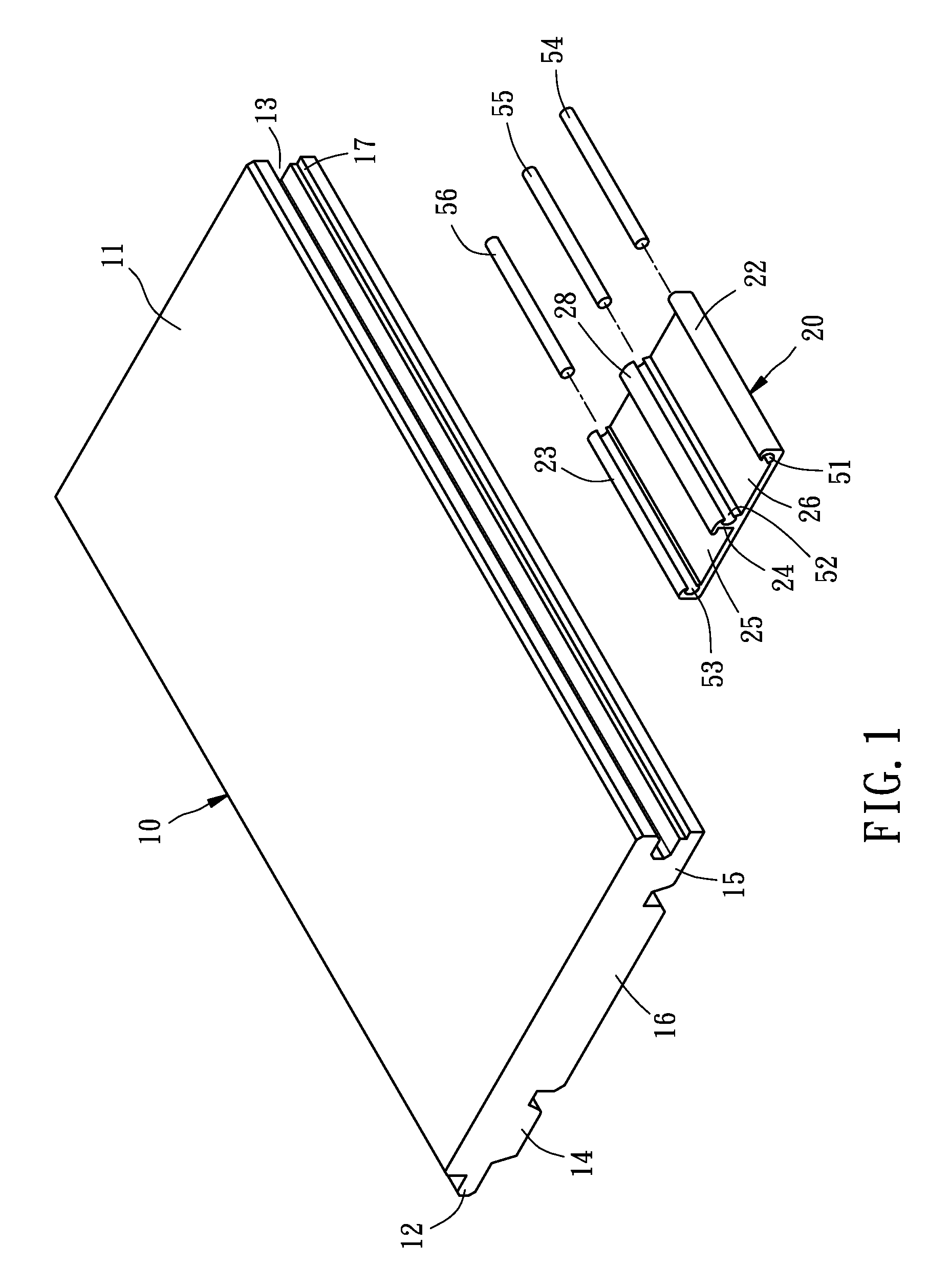

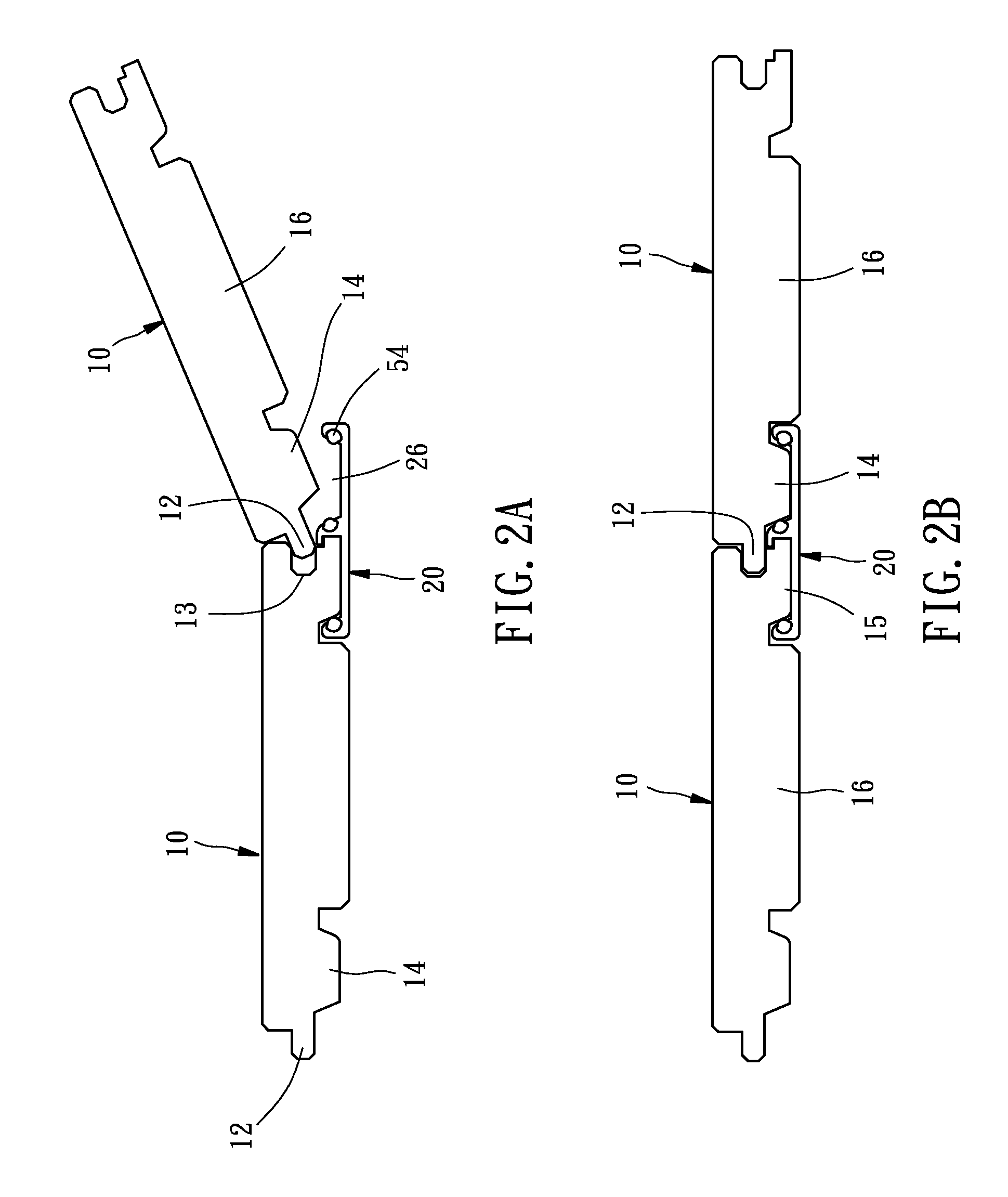

Modular floor

ActiveUS8276343B2Avoid subsidence resulted from defective combinationAvoid roughnessConstruction materialWallsEngineeringMechanical engineering

A modular floor is composed of a plurality of floor panels and combination members. Each of the floor panels includes a rectangular main body, a ridge formed at one side of the main body, an outer socket formed at an opposite side of the main body relative to the ridge, a first lateral bottom portion formed below the ridge, and a second lateral bottom portion formed below the outer socket. Each of the combination members includes a base, a front retainer protruding upward from one side of a top side of the base, a rear retainer protruding upward from an opposite side of the top side of the main body relative to the front retainer, and a partition protruding upward from a midsection of the top side of the base.

Owner:EASIKLIP FLOORS INC

Whitening and freckle-removing cream

InactiveCN107714539AImprove beauty effectBalance oil secretionCosmetic preparationsToilet preparationsEthylhexyl palmitateGlycyrrhiza glabra Root

The invention discloses whitening and freckle-removing cream which comprises water, hydrogenated polydecene, butanediol, glycerol, ethylhexyl palmitate, isopropyl palmitate, ceteareth-25, ceteareth-6,C12-15 alcohol-benzene formic ester, cetostearyl alcohol, polydimethylsiloxane, magnesium ascorbyl phosphate, simmondsia chinensis seed oil, preservatives, tocopheryl acetate, arbutin, xanthan gum, bisabolol, allantoin, essence, EDTA (ethylene diamine tetraacetic acid) disodium, glycyrrhiza glabra root extracts, sodium hyaluronate and citric acid. Whitening active components such as the glycyrrhiza glabra root extracts, the magnesium ascorbyl phosphate and the arbutin are added in a formula, the whitening and freckle-removing cream can penetrate into skin bottoms, melanogenesis is continuously inhibited, melanin decomposition is accelerated, skins are thoroughly whitened from inside to outside, and rapid whitening and freckle-removing effects are achieved. The magnesium ascorbyl phosphateand vitamin E achieve synergistic effects, and the whitening and freckle-removing effects are better.

Owner:广州君研生物科技有限公司

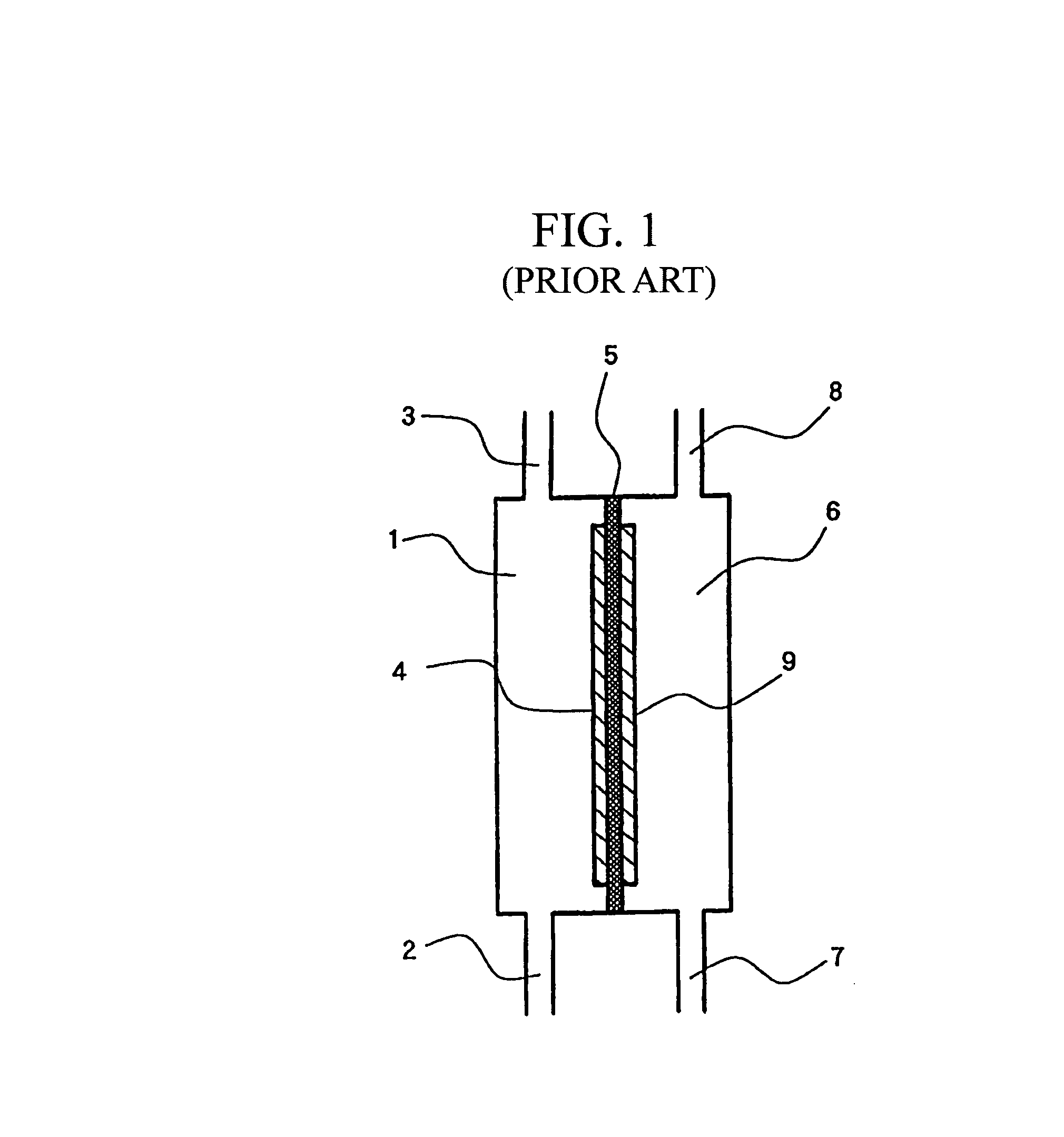

Electrolytic cell for producing charger anode water suitable for surface cleaning or treatment, and method for producing the same and use of the same

InactiveUS20060272954A1Reduce the binding forceEasy to cleanCellsWater treatment parameter controlSurface cleaningElectrical battery

The present invention provides an electrolytic cell, which can efficiently produce charged water having an excellent performance of improving surface cleaning or treatment of an object, e.g., semiconductor, glass, or resin and of cleaning and sterilizing medical device. The electrolytic cell of the present invention is for producing charged anode water suitable for surface cleaning or treatment, including the cathode chamber 41 and anode chamber 50, fluorinated cation-exchange membrane 46 provided to separate these chambers from each other, cathode 44 closely attach to the cation-exchange membrane 45 on the side facing the cathode chamber 41, and middle chamber 48 filled with the cation-exchange resin 46, provided on the other side of the cation-exchange membrane 46, the cation-exchange resin 46 being arranged in such a way to come into contact with the fluorinated cation-exchange membrane 45, wherein the feed water is passed into the middle chamber 48 and passed thorough the anode chamber 50 to be recovered as the charged anode water.

Owner:SONOMA PHARMA INC

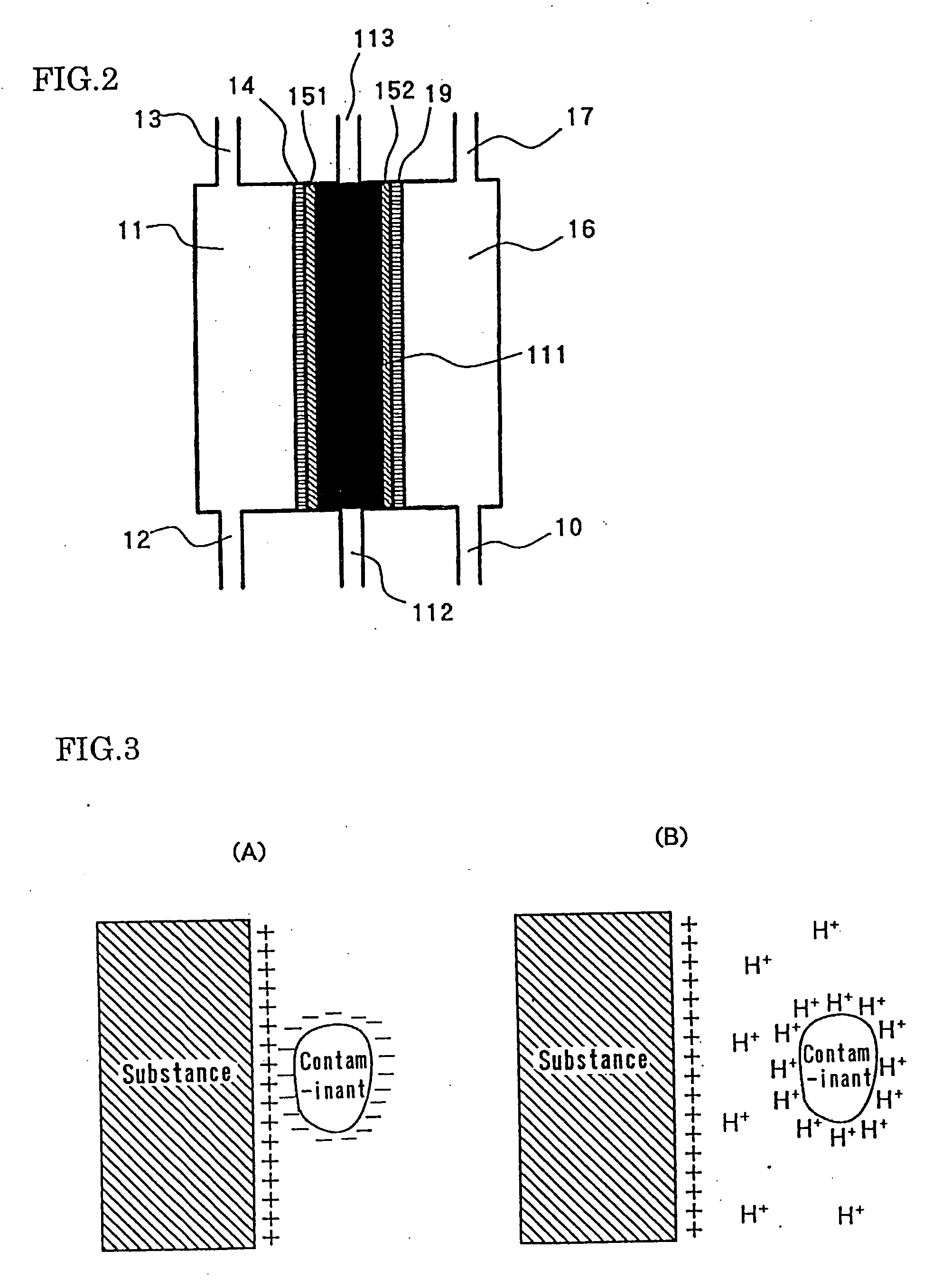

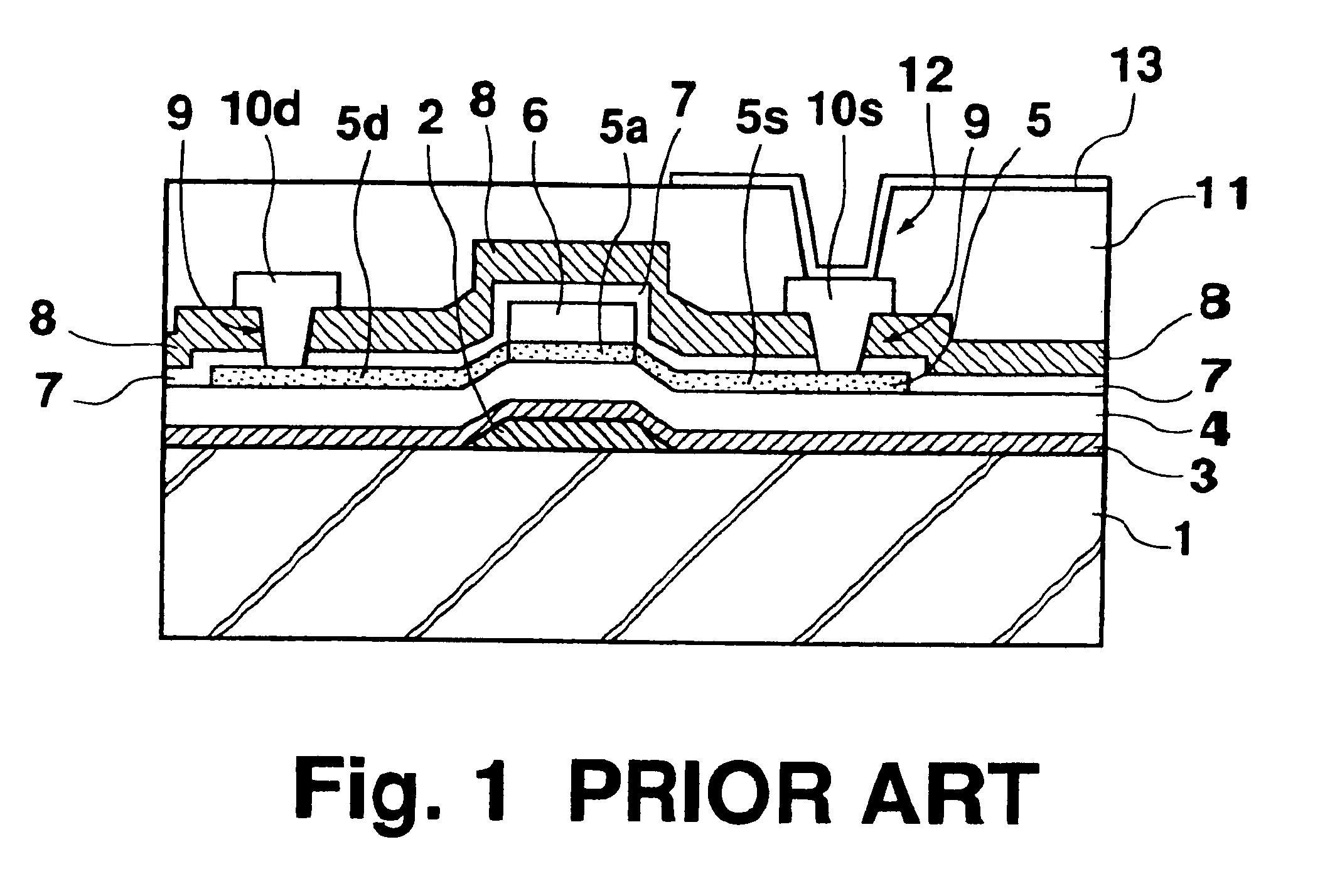

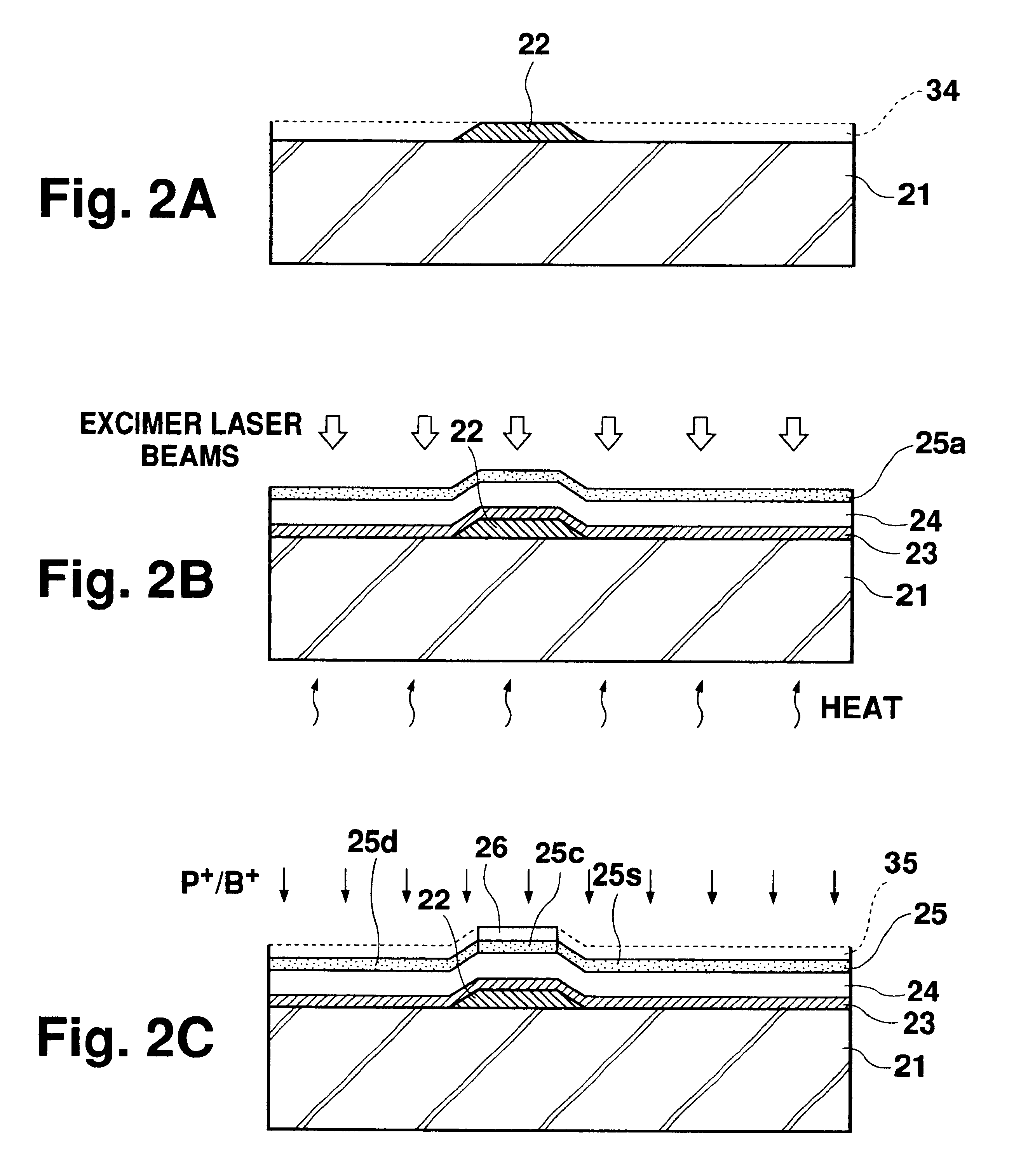

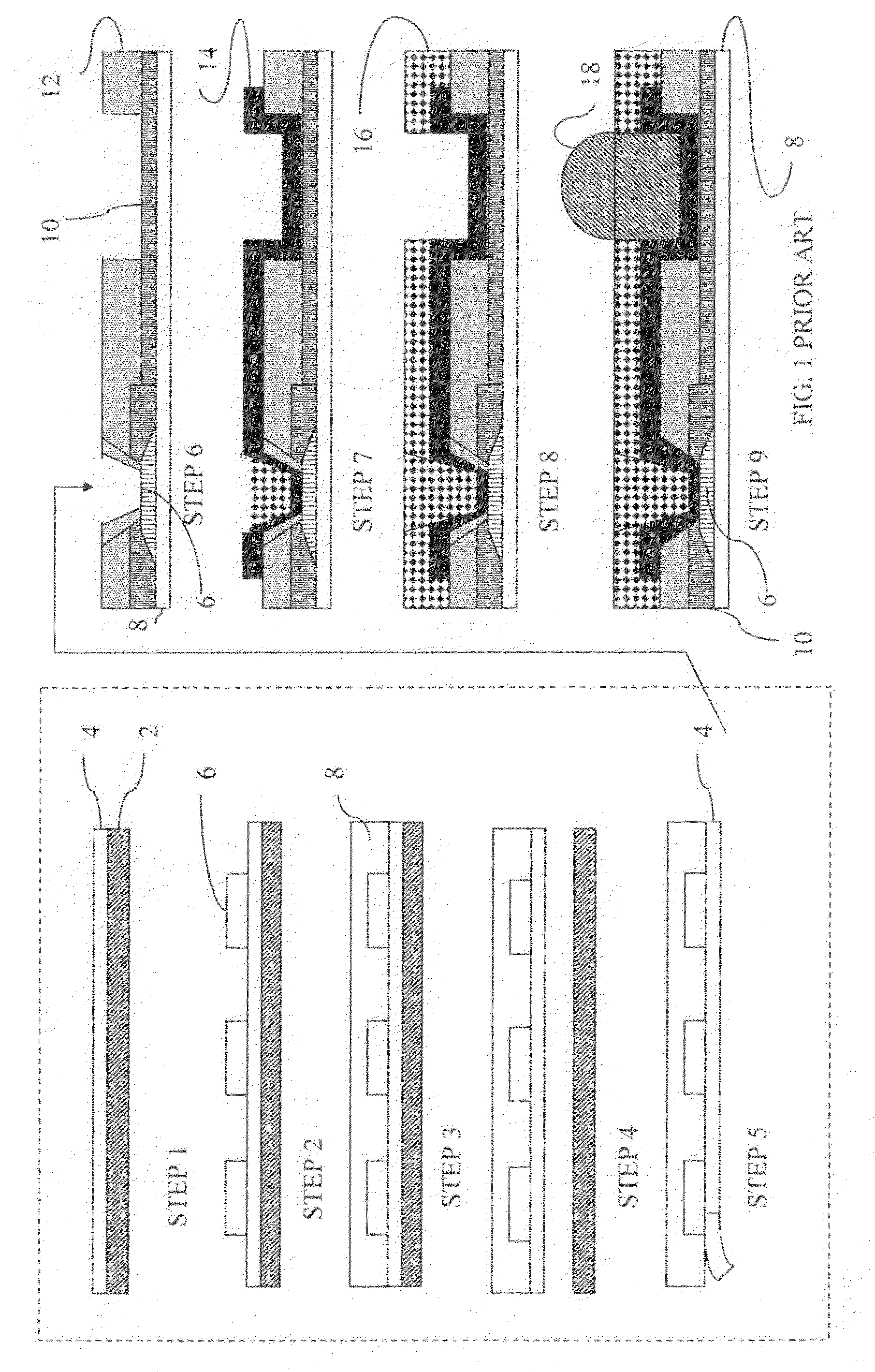

Method of manufacturing a thin film transistor

InactiveUS6335232B1Reduce hydrogen concentrationDiminished hydrogenTransistorSolid-state devicesRough surfaceHydrogen

On a transparent substrate where a gate electrode is formed, an amorphous silicon film is deposited by plasma CVD with a gate insulating film interposed therebetween. The silicon film is heated in a nitrogen atmosphere at 430±20° C. for an hour or longer to discharge hydrogen remaining in the film when it is formed. The silicon film is then melted by laser irradiation to crystallize, to thereby form a polycrystalline silicon film serving as an active region. Thus, when amorphous silicon is crystallized to form a polycrystalline silicon film, it is made possible to prevent creation of a rough film surface and penetration of impurity ions in the atmosphere into the polycrystalline silicon.

Owner:SANYO ELECTRIC CO LTD

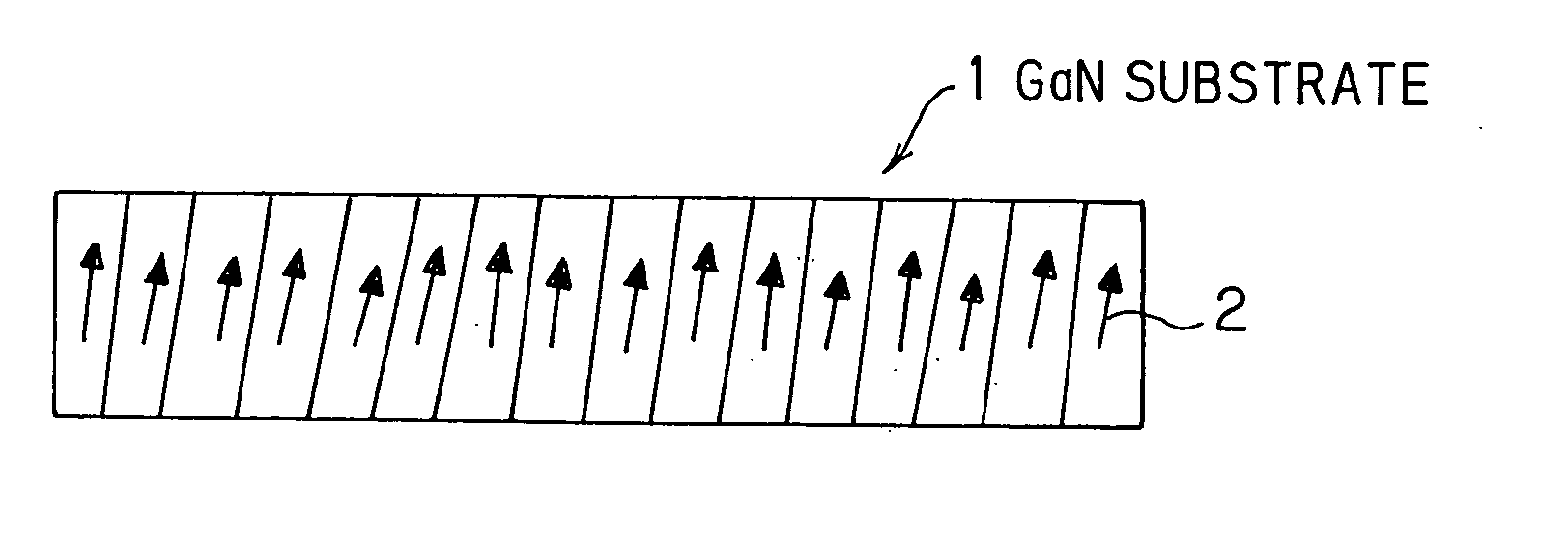

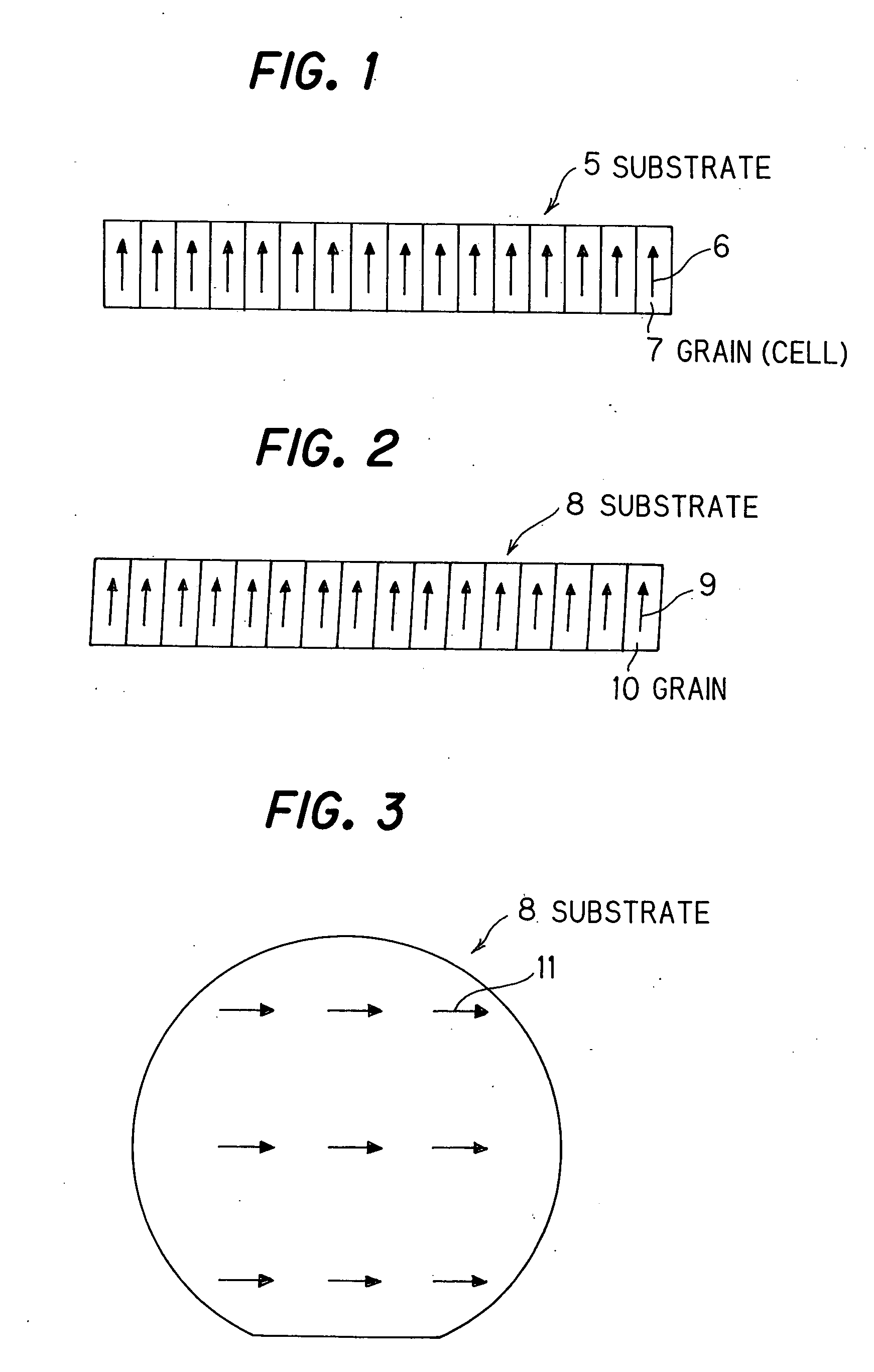

III-V group nitride system semiconductor substrate

ActiveUS20050093003A1Speed up the processImprove production yieldPolycrystalline material growthSolid-state devicesIn planeRefractive index

A III-V group nitride system semiconductor substrate has III-V group nitride system single crystal grown on a hetero-substrate. The III-V group nitride system semiconductor substrate has a flat surface and satisfies the relationship of θ>α, where θ [deg] is given as an average in angles of the substrate surface to low index surfaces closest to the substrate surface measured at a plurality of arbitrary points in plane of the substrate, and a variation range of the measured angles to θ is represented by ±α [deg].

Owner:SUMITOMO CHEM CO LTD

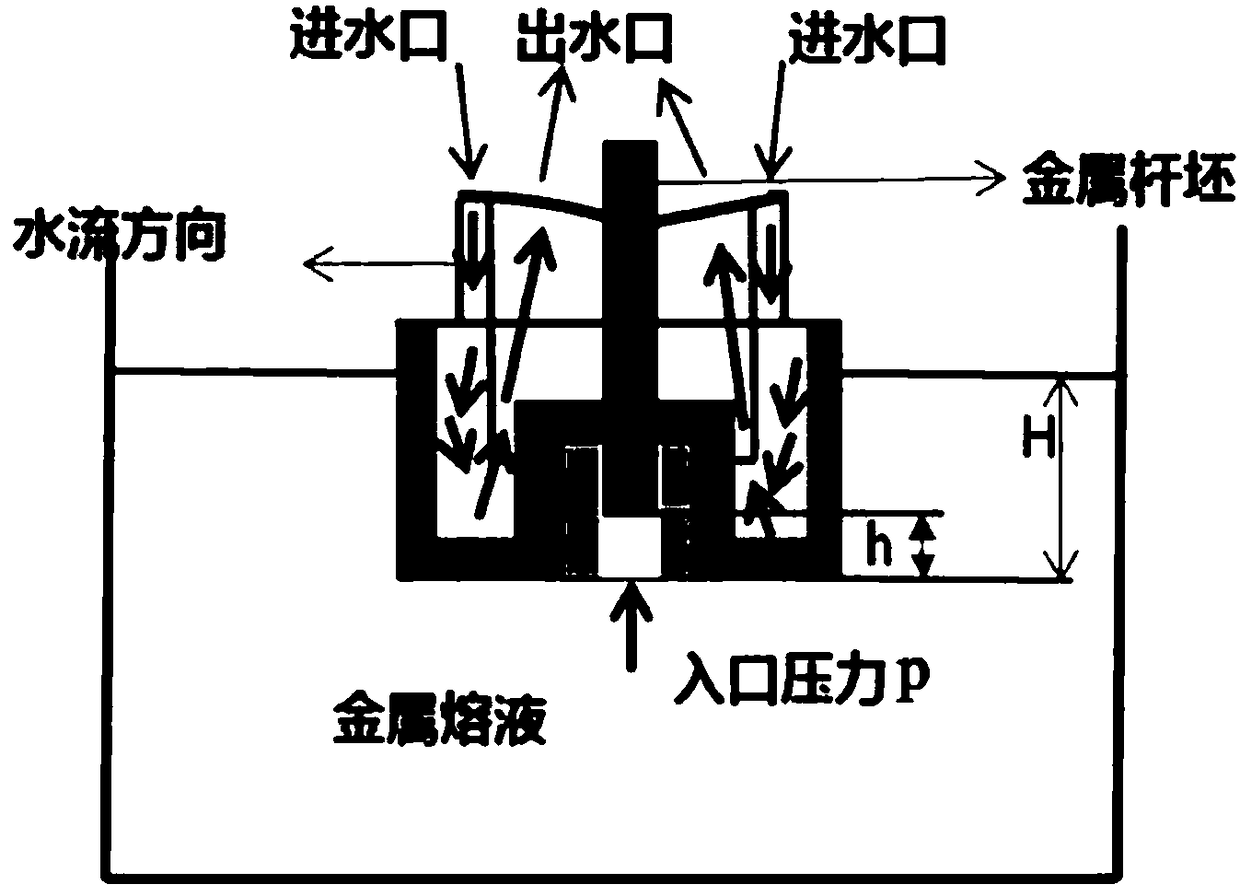

Production method of high-strength, high-conductivity and heat-resistant copper alloy

ActiveCN108526422AGuaranteed lubrication effectImprove thermal conductivityCarbon compositesShielding gas

The invention discloses a production method of a high-strength, high-conductivity and heat-resistant copper alloy, and belongs to the technical field of copper alloy machining. Accoding to the production method of high-strength, high-conductivity and heat-resistant copper alloy, the inner liner of a crystallizer adopted in the upper-induced continuous casting process is a carbon-carbon composite material so as to ensure the lubrication, high heat conduction and high temperature resistance properties; the temperature of the upper-induced continuous casting is 1180-1230 DEG C, the casting temperature is low so that the problem that molten liquid in the crystallizer is difficult to solidify and the crystallizer inner liner is worn during casting can be effectively avoided; the pressure of protective gas nitrogen in the liquid surface of an upper-induced furnace is controlled to be 0.2-0.7 atmosphere, so that the phenomenon of solid-liquid interface separation in the crystallizer is avoided, and a copper-chromium alloy product with larger weight and length is produced; according to the production method of the high-strength, high-conductivity and heat-resistant copper alloy, the cheapelement (Mg) is used for replacing the rare noble metal, and the mechanical property and the softening resistance property of the copper-chromium alloy are improved; and the production method is a non-vacuum and short-process preparation technology, the cost is low, and the production method is suitable for large-scale industrial production and has important economic and social significances.

Owner:CENT SOUTH UNIV

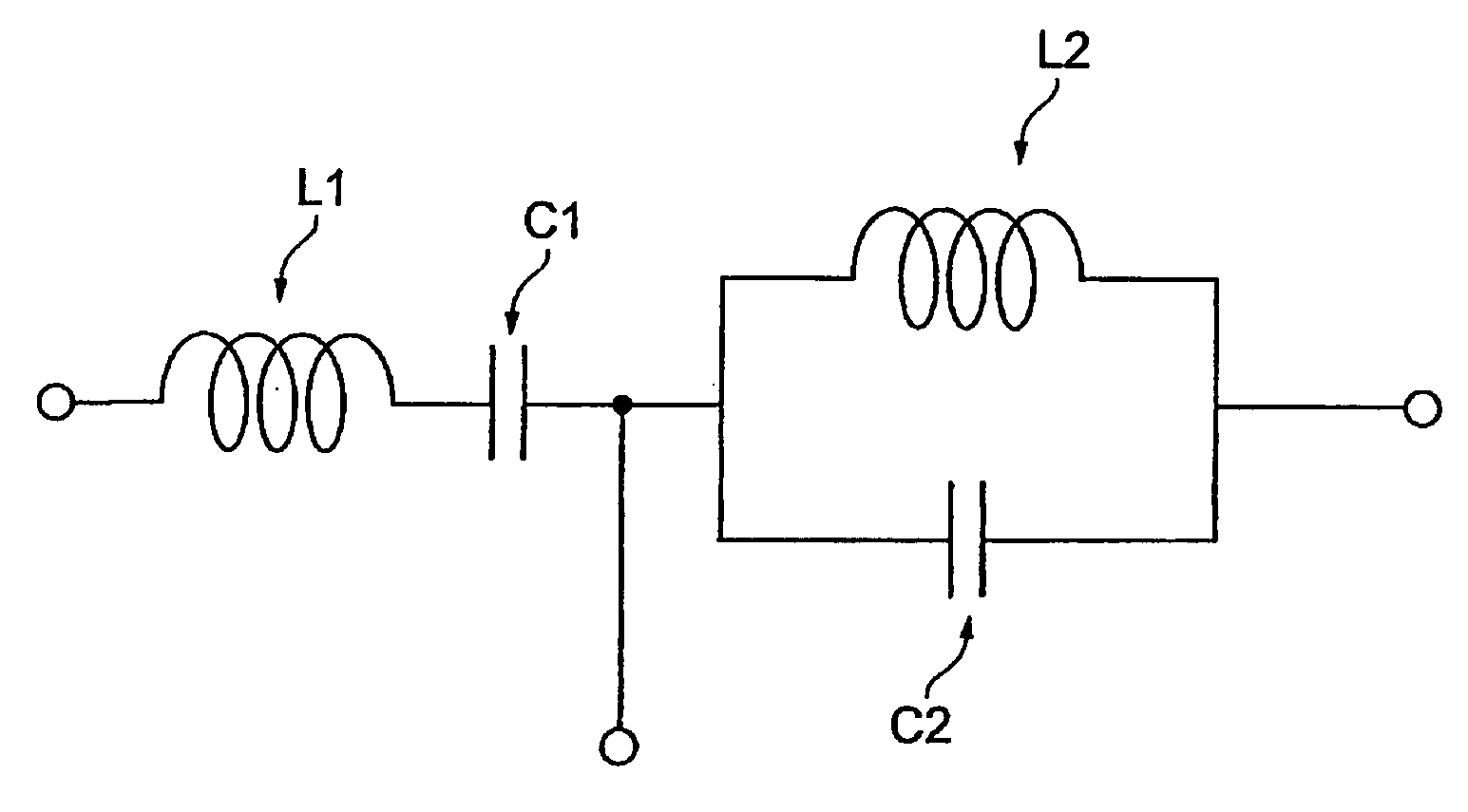

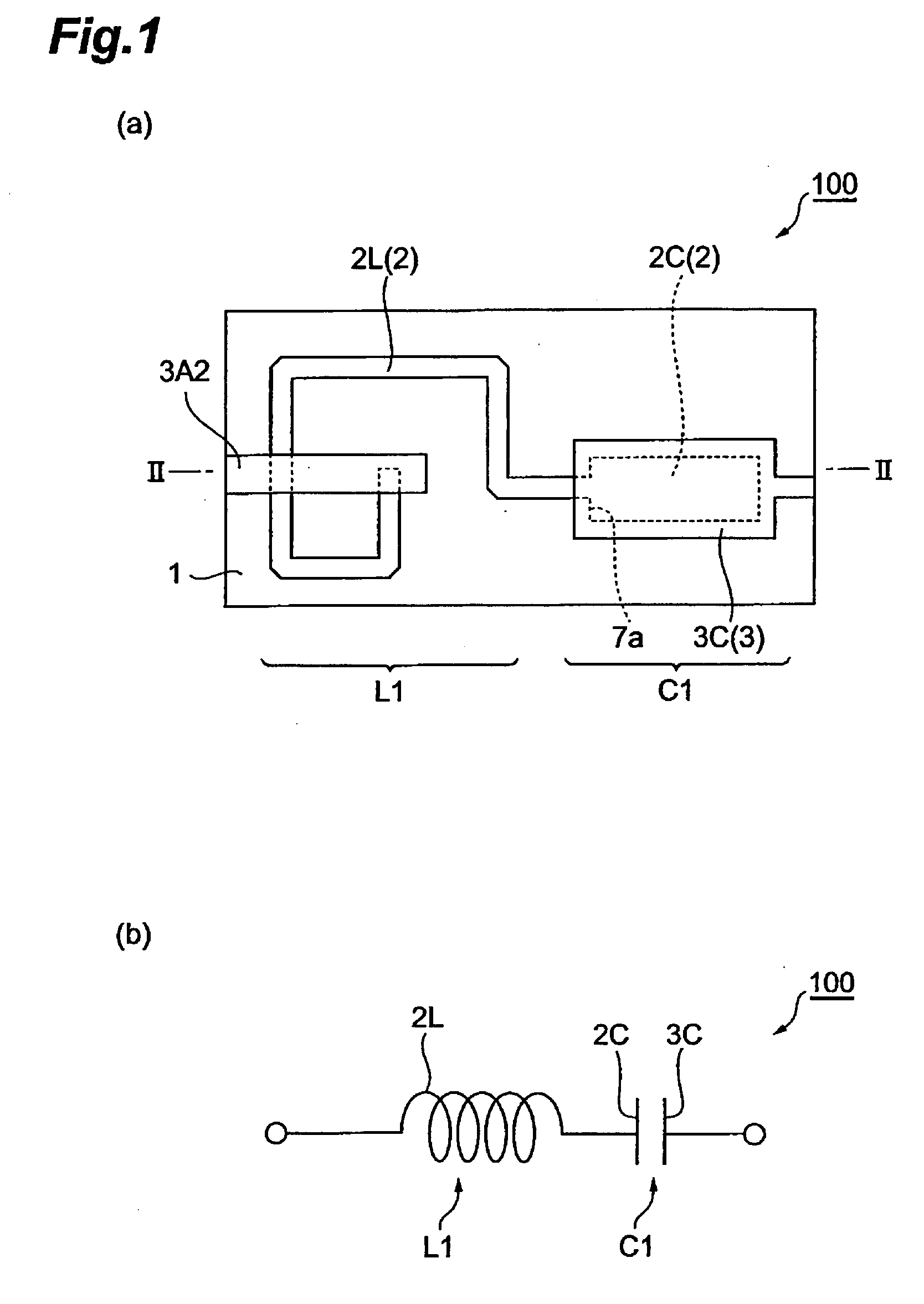

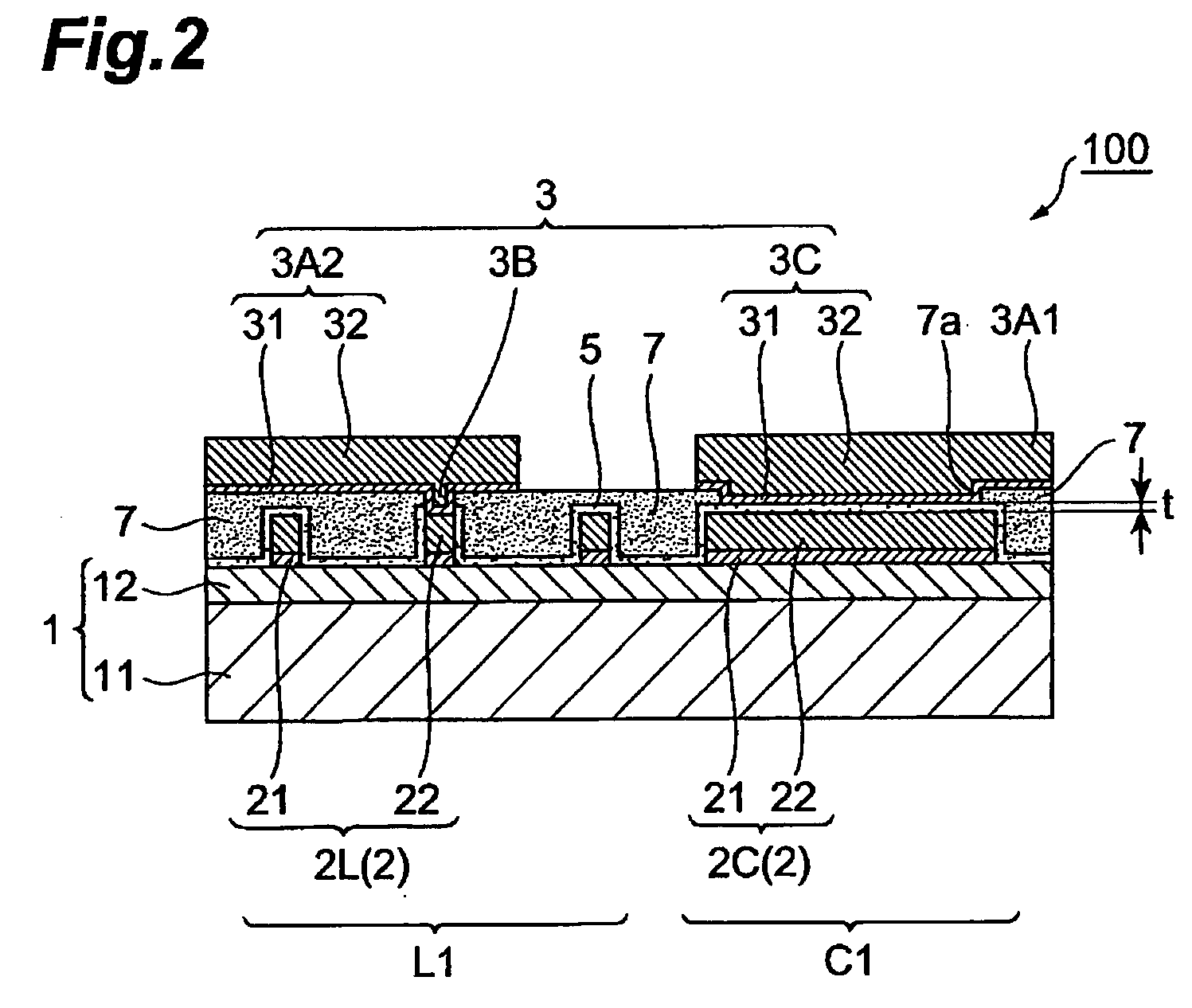

Electronic component and method for manufacturing same

ActiveUS20080023219A1Improve efficiencyLow costMultiple-port networksSolid-state devicesDielectricElectrical conductor

An electronic component having: a substrate, a lower conductor layer provided on the substrate; an inorganic dielectric film that covers the lower conductor layer; and an upper conductor layer having an upper electrode portion provided on the inorganic dielectric film. The lower conductor layer has a lower electrode portion that together with the upper electrode portion and the inorganic dielectric film constitutes a capacitor, and a coil portion that constitutes an inductor. The entire inorganic dielectric film is formed integrally, and the lower conductor layer is in contact only with the substrate, inorganic dielectric film, and upper conductor layer.

Owner:TDK CORPARATION

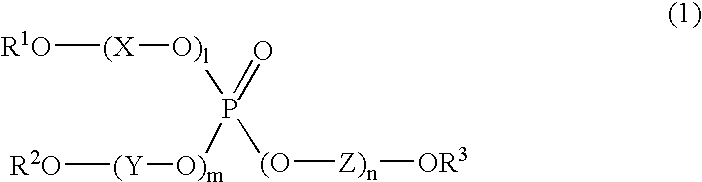

Cosmetic composition comprising a phosphoric triester and a skin activating component

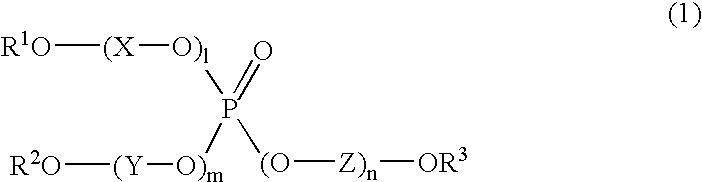

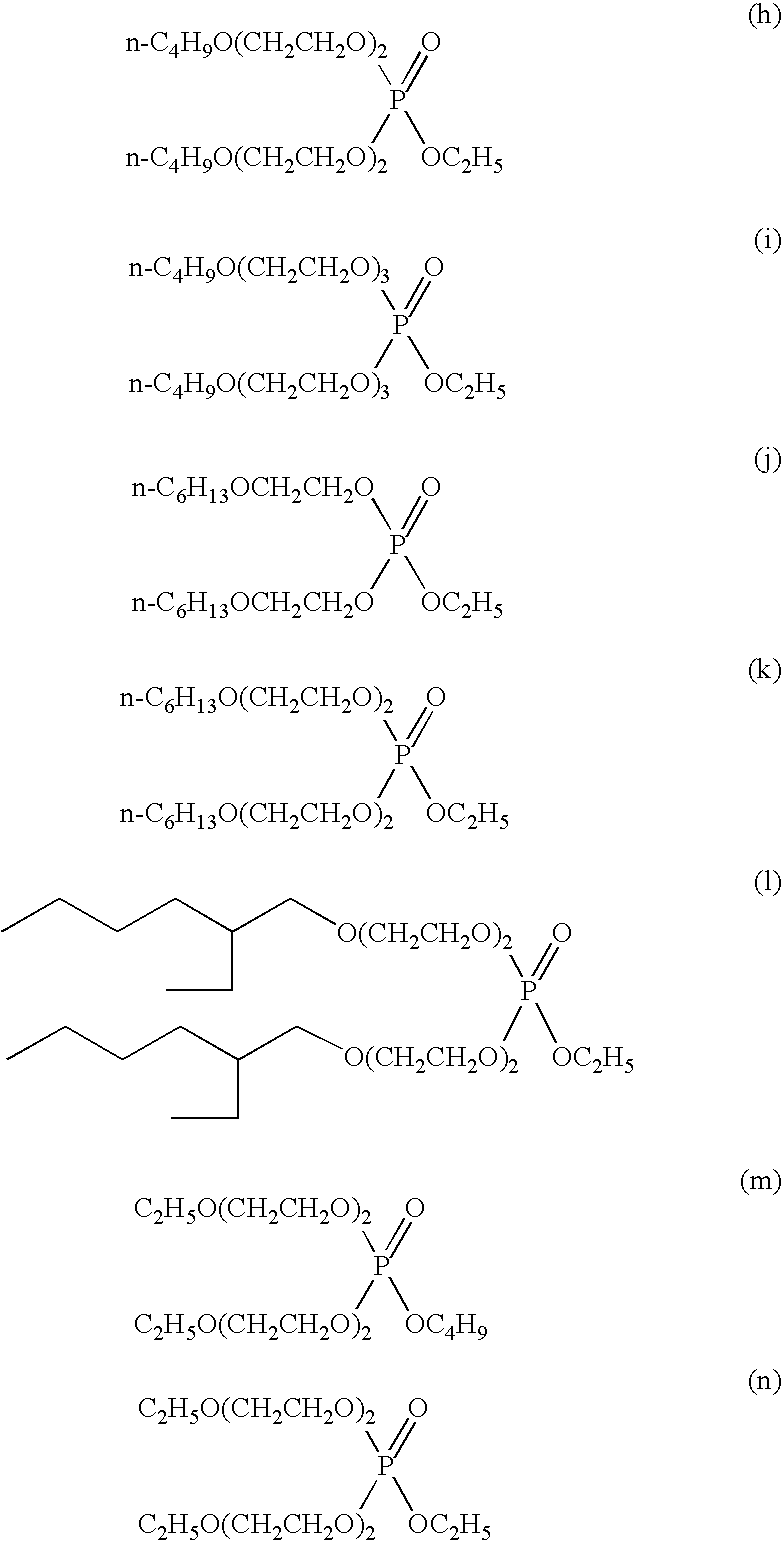

InactiveUS6932975B2Improve permeabilityGood effectCosmetic preparationsHair removalPhotochemistryCarbon atom

A cosmetic comprising (A) a phosphoric triester represented by the general formula (1): wherein R1 and R2 are independently an alkyl group having 1 to 8 carbon atoms, R3 is an alkyl group having 1 to 4 carbon atoms, X, Y and Z are independently an alkylene group having 2 or 3 carbon atoms, l and m are independently a number of 1 to 10, and n is a number of 0 to 10, and (B) a skin activating component.

Owner:KAO CORP

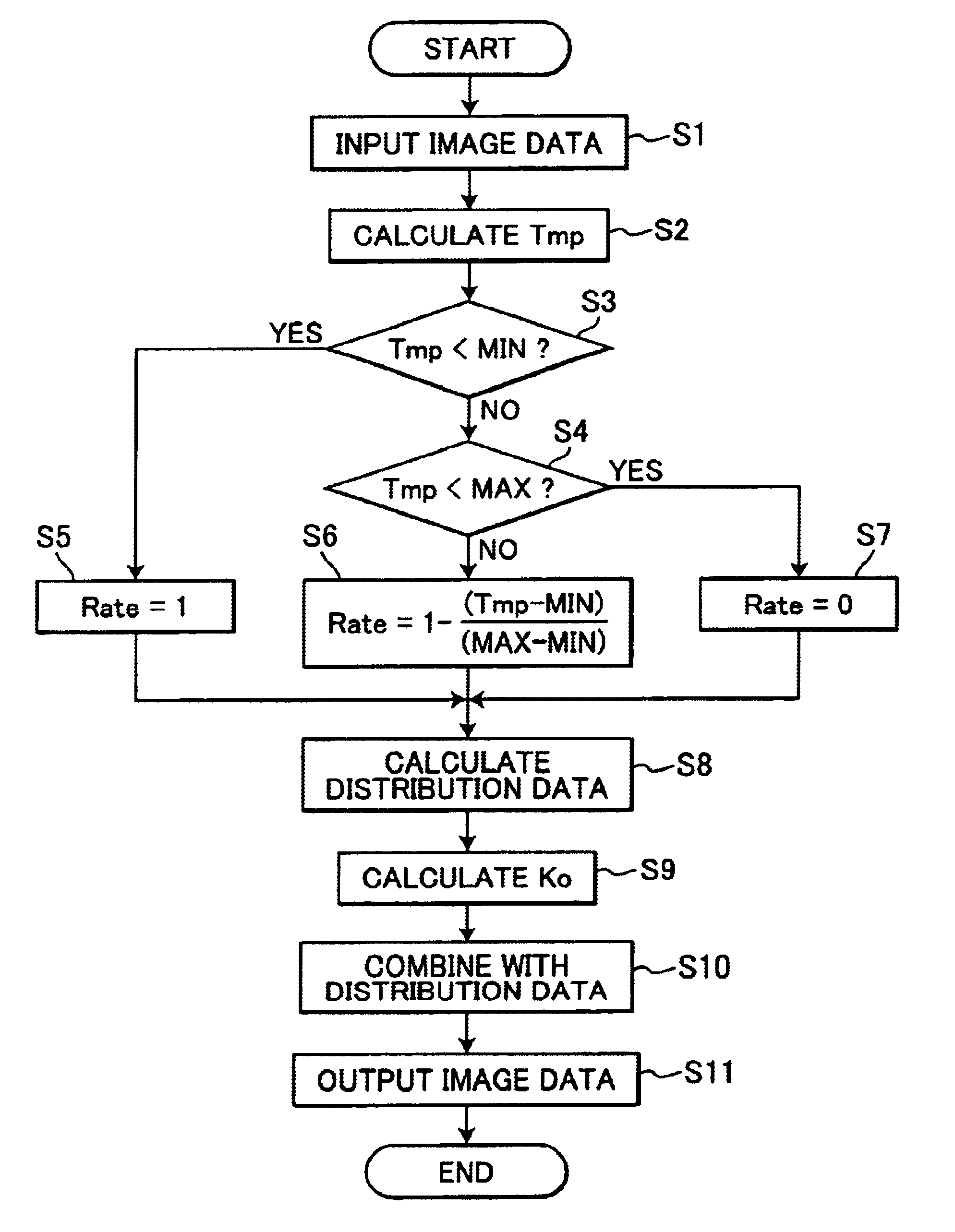

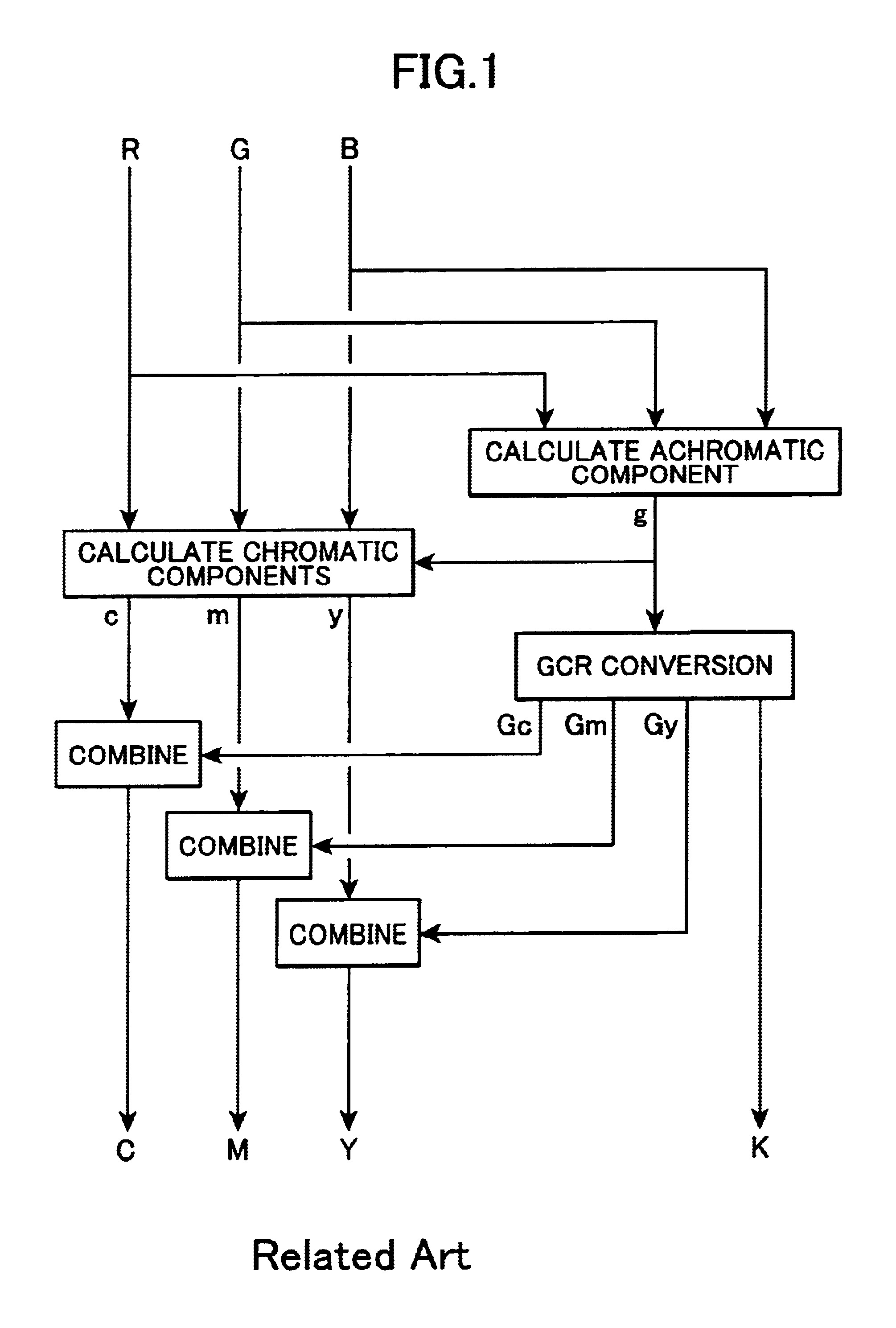

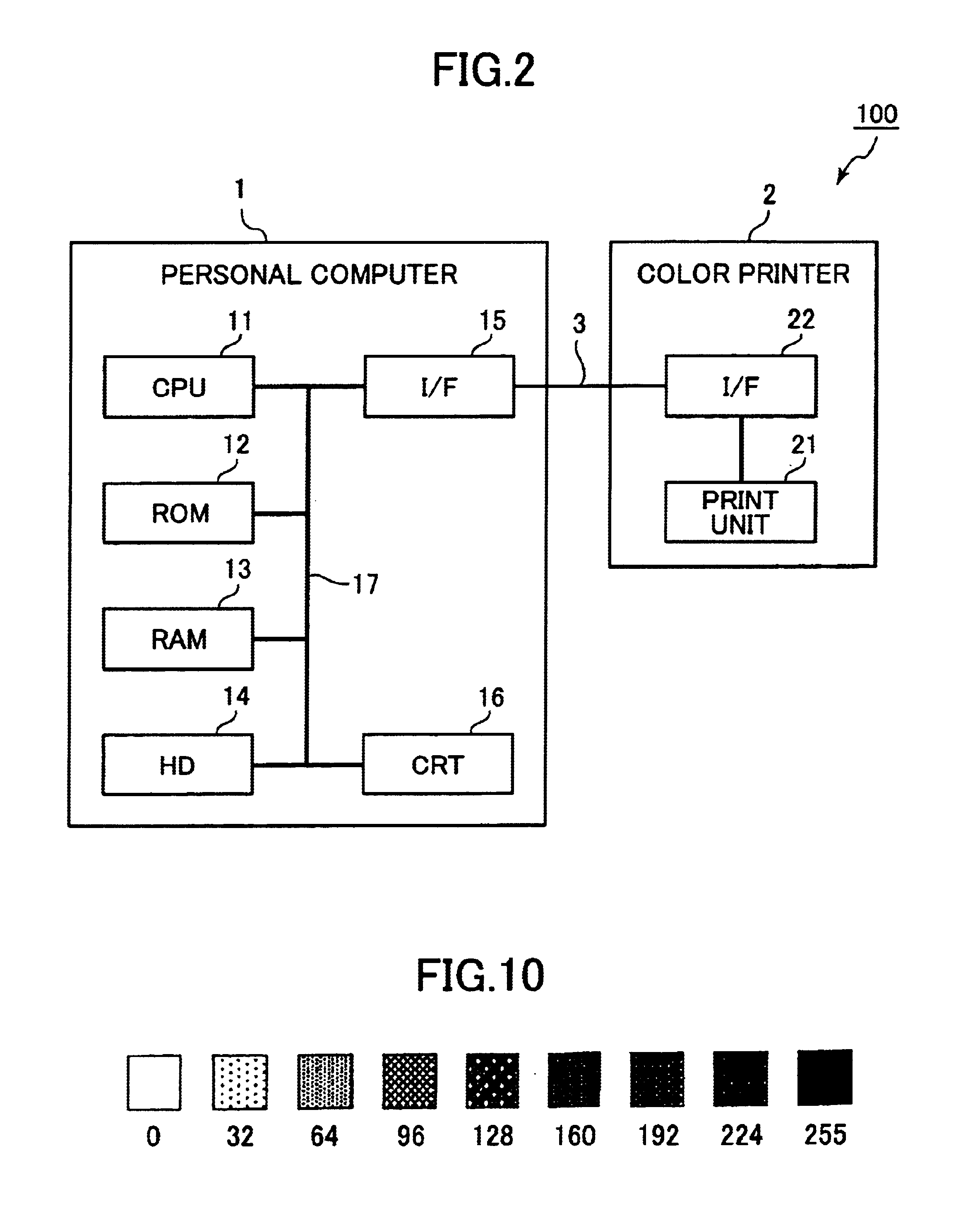

Image data conversion method

InactiveUS6917445B2Avoid roughnessSuppress lightDigitally marking record carriersVisual presentation using printersPattern recognitionData conversion

Owner:BROTHER KOGYO KK

Facial cleansers

InactiveUS20040151684A1Satisfactory elasticitySatisfactory glossCosmetic preparationsToilet preparationsLipid formationCleansers skin

The object of the present invention is to provide a face wash which effectively removes pore stains and aged horny layers of the skin and gives whitening effect but has lesser stimulant feel. The present invention solves the object by providing a face wash comprising a protein-degrading enzyme, lipid-degrading enzyme, trehalose, D-glucose, and ascorbic acid and / or a derivative thereof as effective ingredients.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

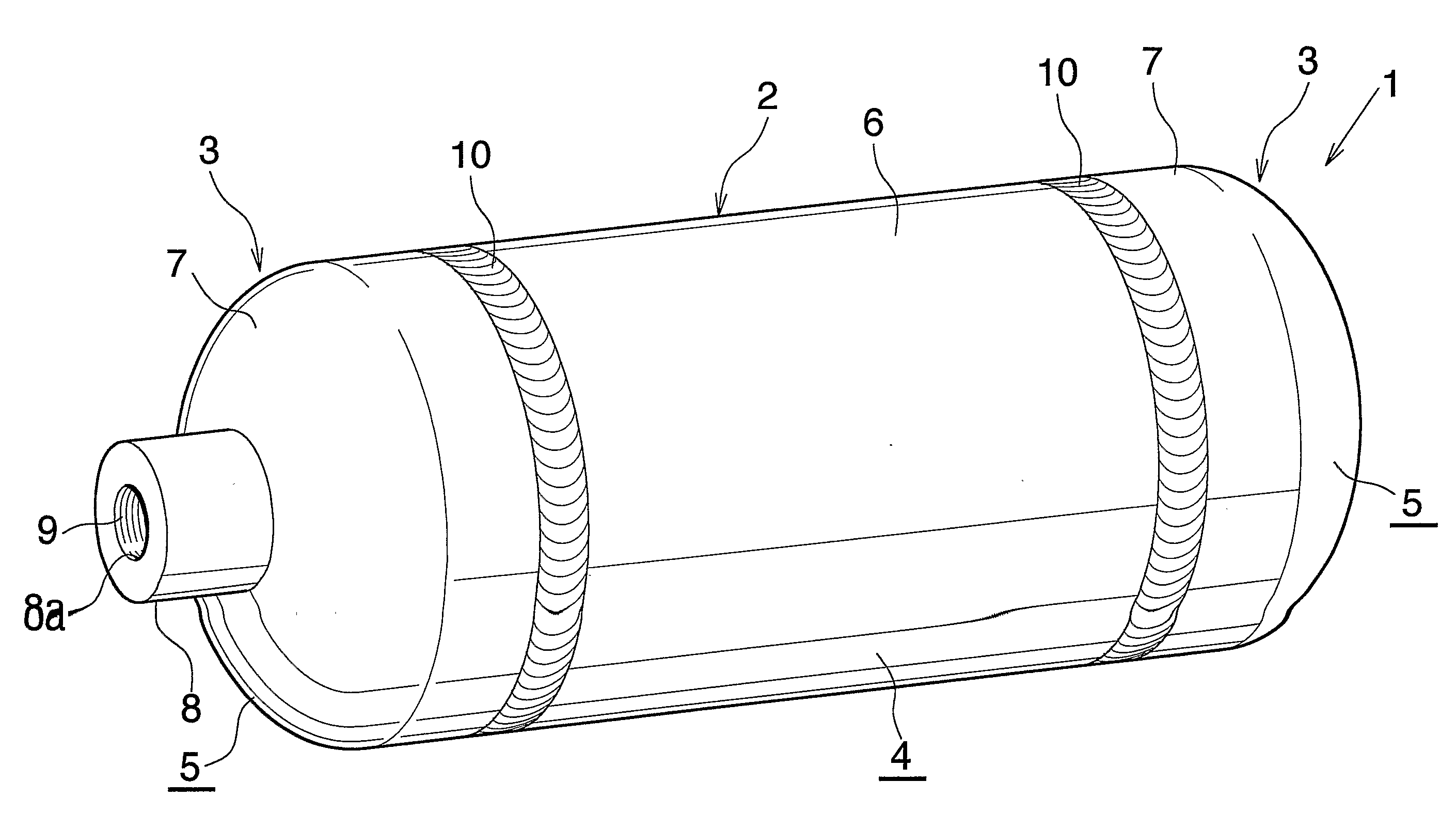

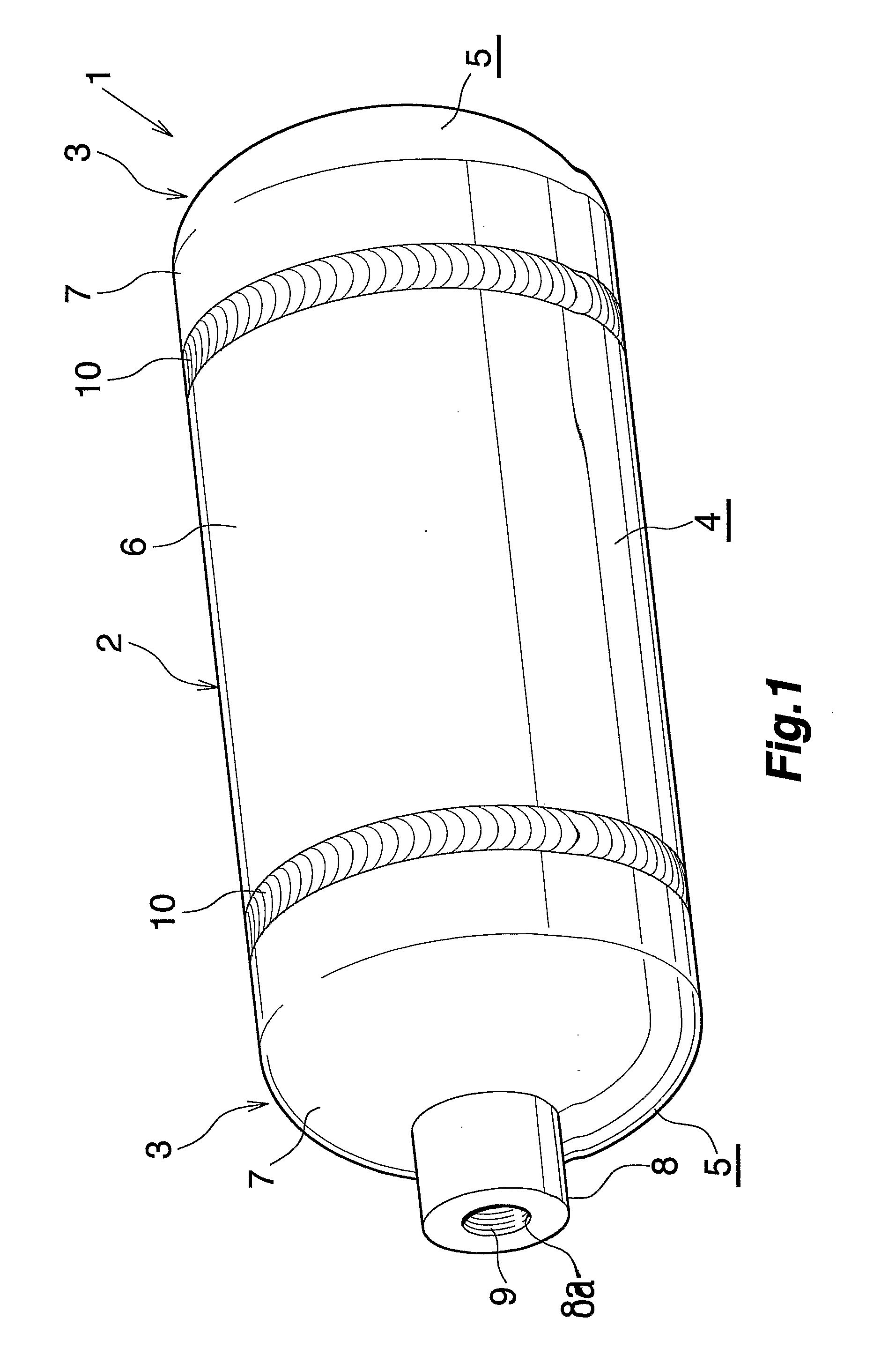

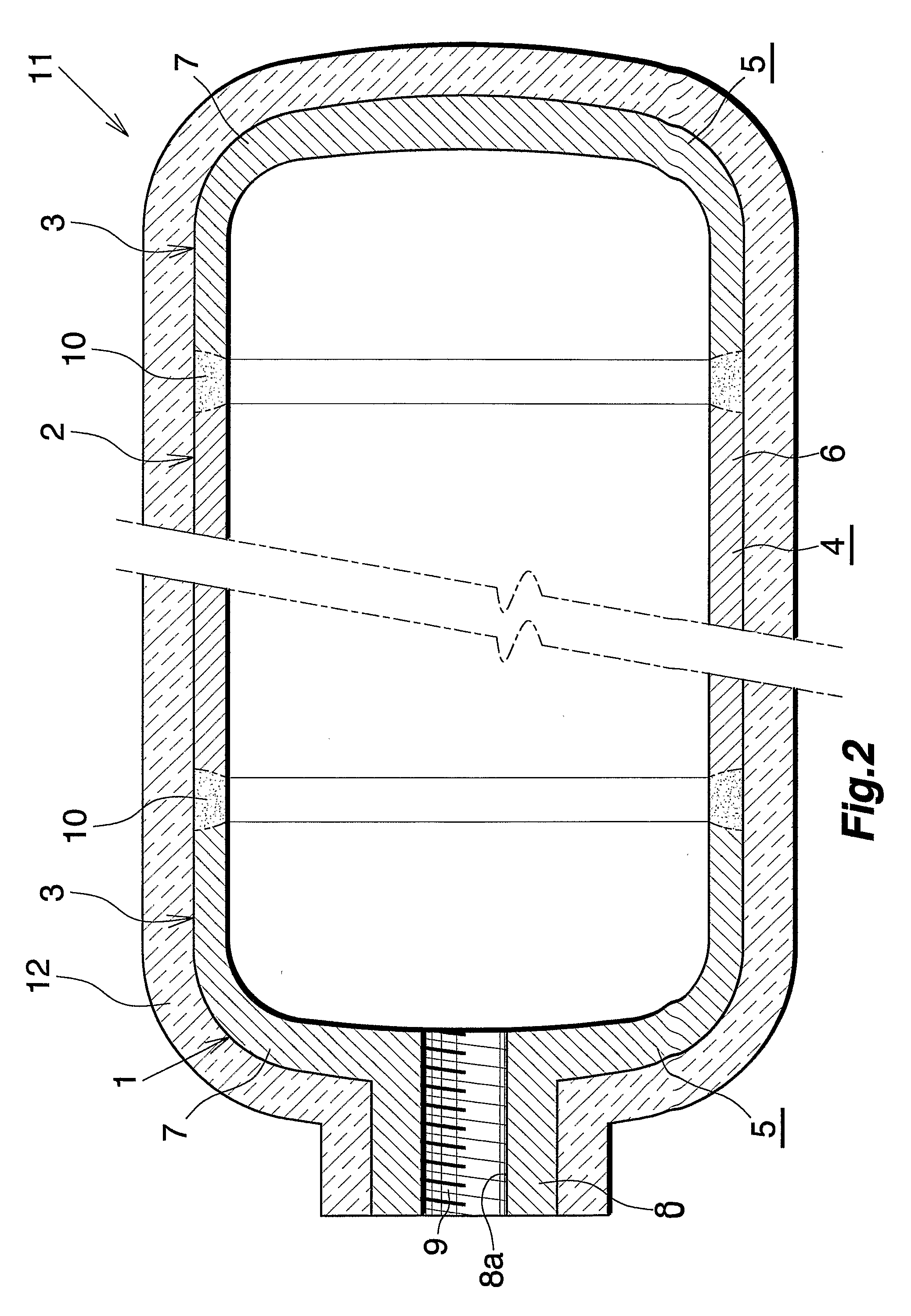

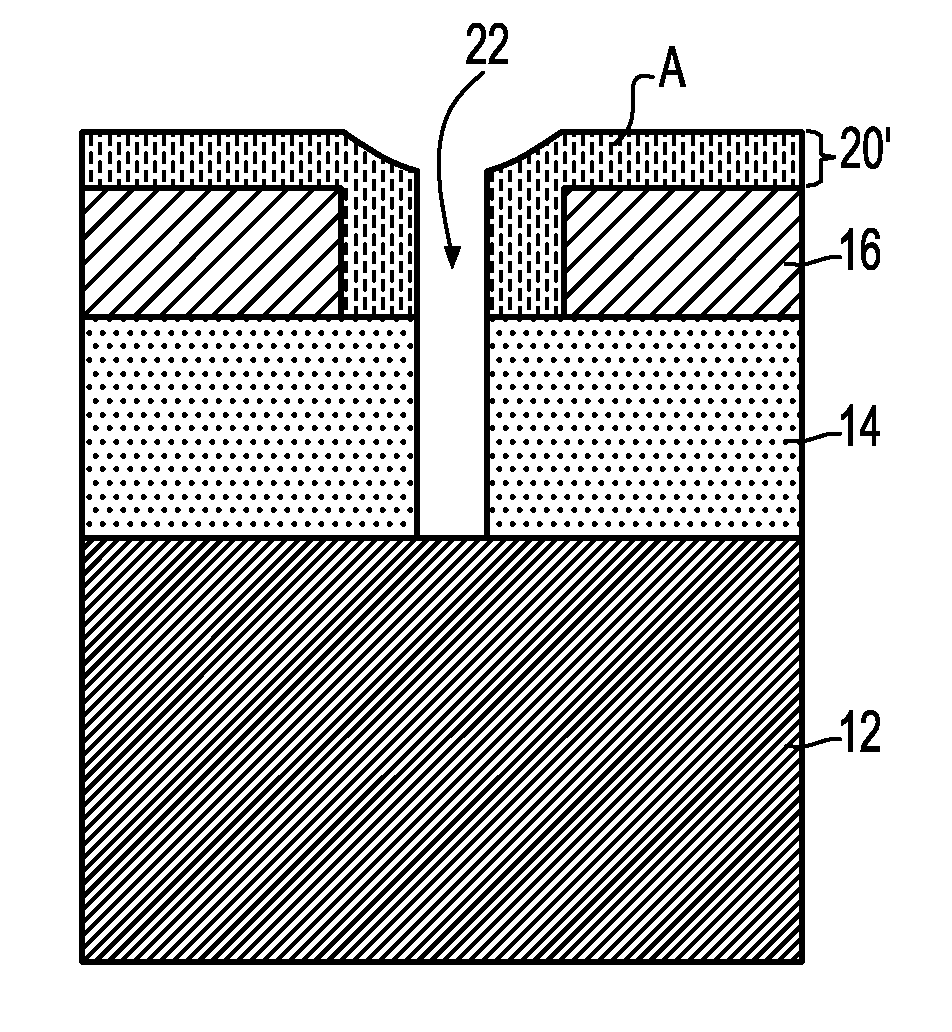

Process for Fabricating Pressure Vessel Liner

InactiveUS20080274383A1Avoid deformationCost of apparatus can be reducedGas handling applicationsFuel cellsProduction rateEngineering

A process prevents a reduction in the strength of the joint between the liner components, and assures high productivity without impairment. The peripheral walls (6, 7) of the liner component (4) and each of the second liner components (5) are brought into contact with each other, a probe (22) of friction agitation joining tool (20) is placed into the two liner components across the contact portions thereof, and the probe (22) in rotation is thereafter moved relative to the two liner components (4, 5). Assuming that the number of revolutions of the probe (22) is R rpm and that the speed of joining of the two liner components (4, 5) is V mm / min, R / V is in the range of 2≦R / V≦12.

Owner:SHOWA DENKO KK

Leash assembly for a retractable leash to walk animals

ActiveUS20050011472A1Avoids undesired momentEasy to placeProjector film strip handlingFilament handlingEngineeringMechanical engineering

A leash assembly having a strap or leash that can be winded off or winded up for walking animals. The assembly has a handle and a housing attached thereto in which the strap is arranged on a turnable roller device for being wound up or wound off. The assembly also includes a brake key that can stop and prevent rotation of the roller device to restrict a part of the strap extending externally of the housing to a desired length. In addition, the assembly includes an exit opening through which the strap extends externally of the housing. Preferably, the exit opening is formed as a slit, and the slit has a central region along its longitudinal extension that has an enlarged opening portion extending laterally from at least one side of the slit.

Owner:FLEXI BOGDAHN TECHN

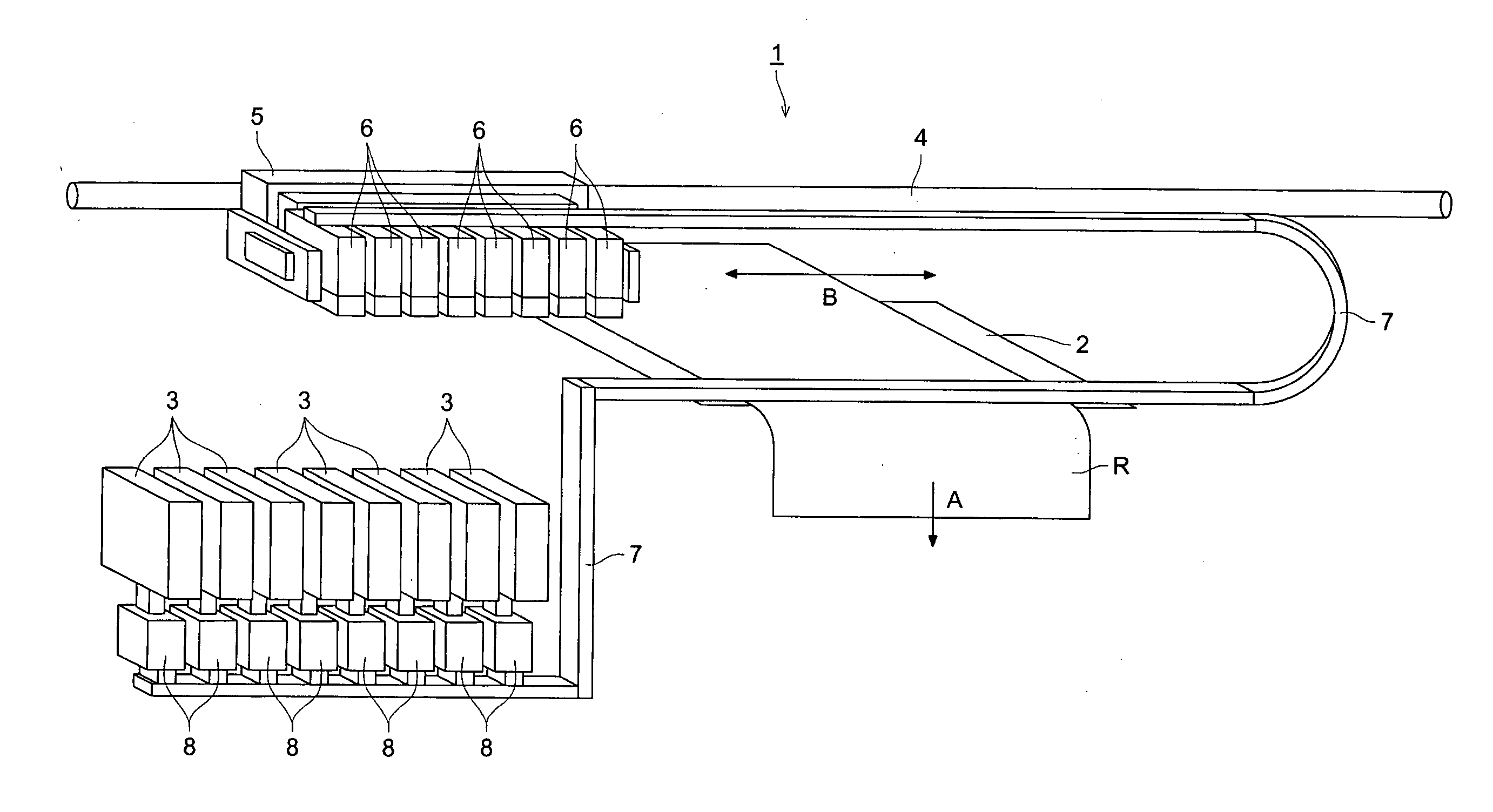

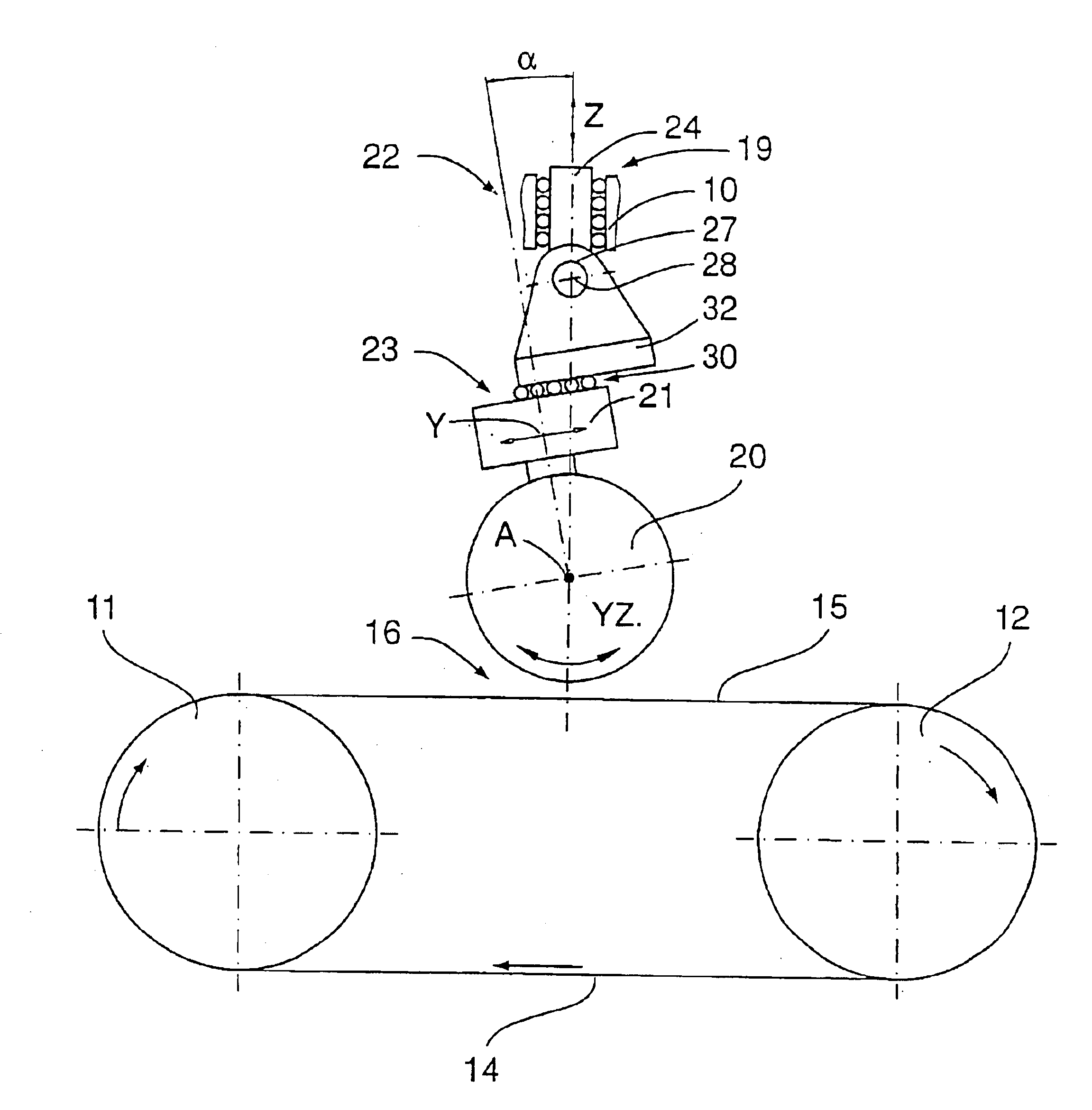

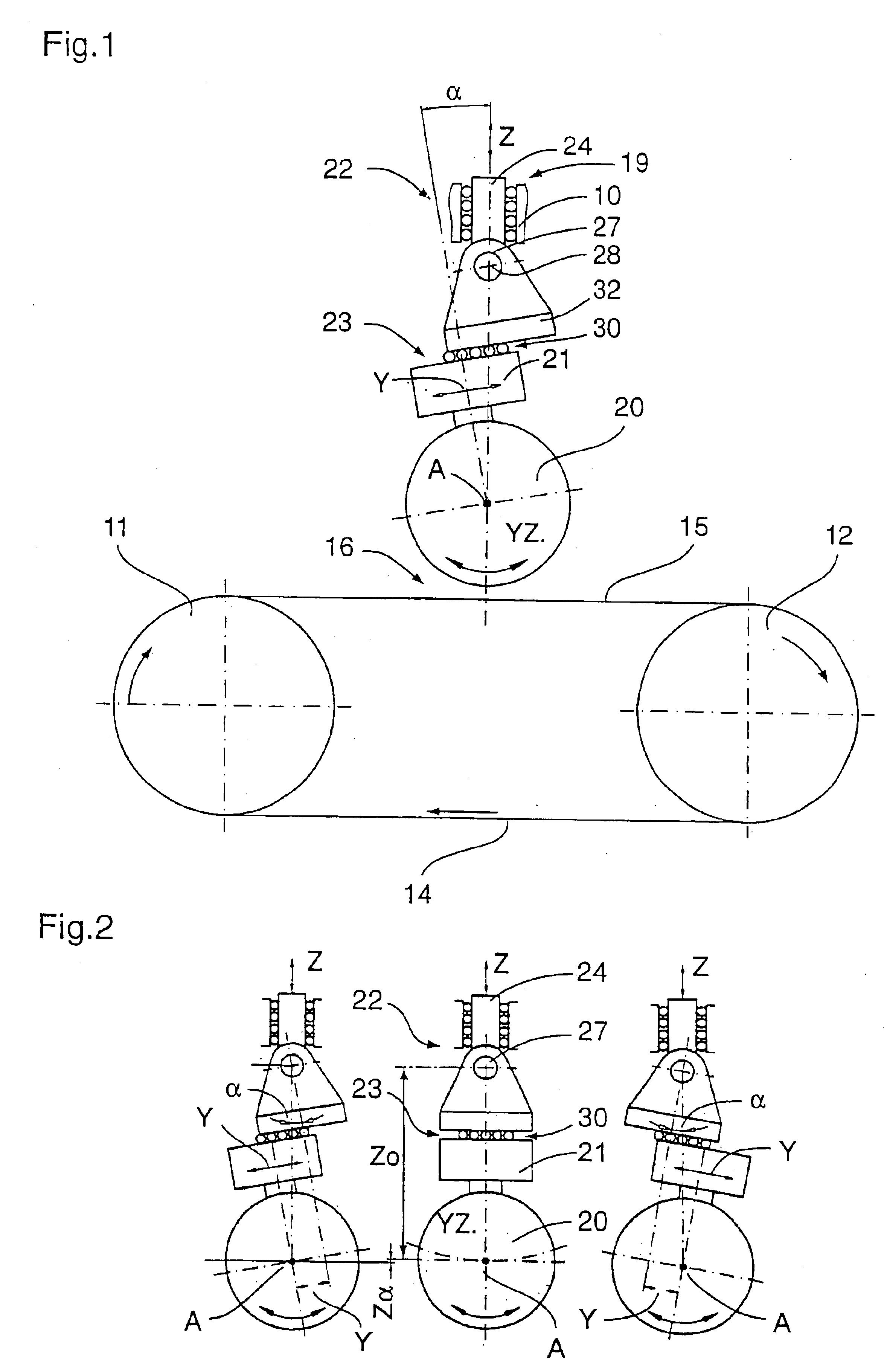

Wire saw with means for producing a relative reciprocating motion between the workpiece to be sawn and the wire

InactiveUS6886550B2High precisionAvoid roughnessMetal sawing devicesWorking accessoriesRotational axisWire rod

A sawing device includes a wire assembly (15) supported on wire-guiding rolls (11, 12) and pressed against a workpiece to be sawn (20) fixed on a support table (21). An oscillating device (23) produces a relative reciprocating movement between the workpiece and the wire assembly (15) around an oscillation axis (A) whereof the spatial position can be adjusted and programmed so that the oscillation axis (A) is at a programmable and adjustable distance from an effective axis of rotation (28) of the oscillating device (23).

Owner:APPLIED MATERIALS SWITZERLAND

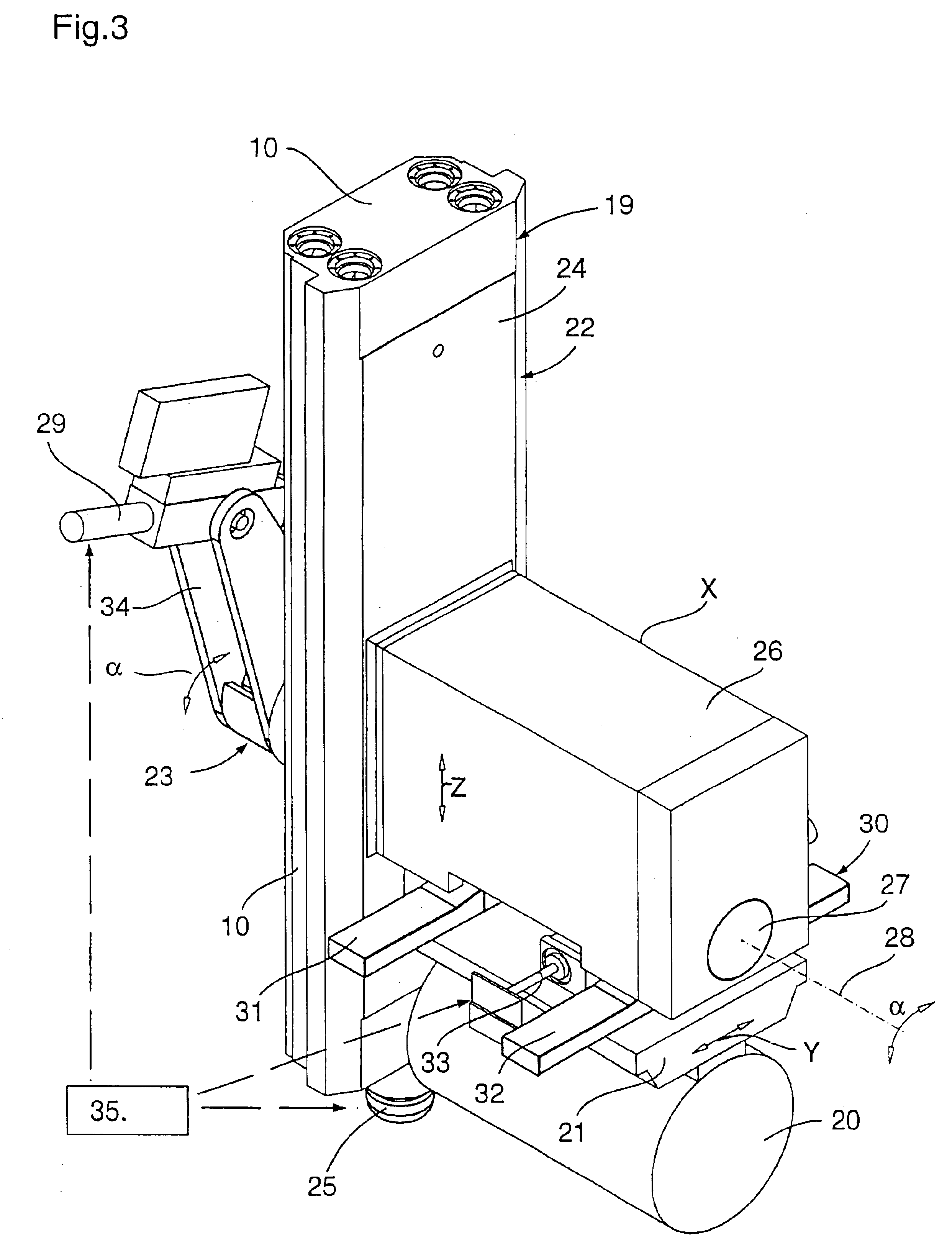

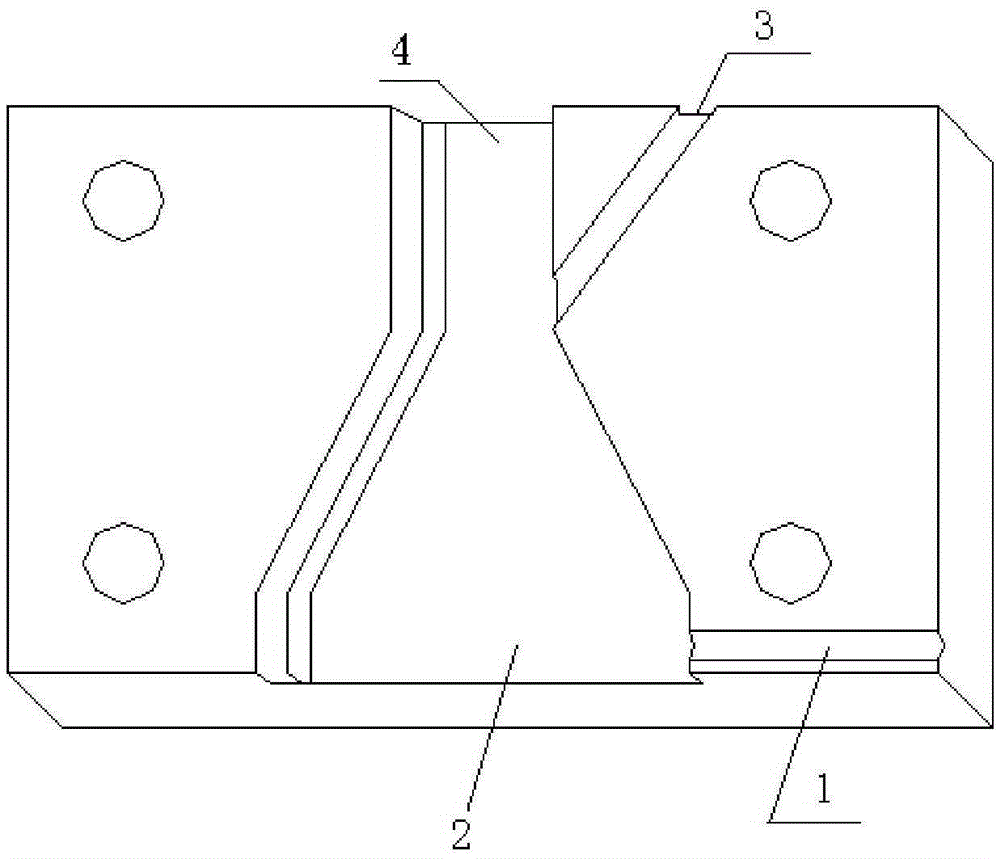

Tail-cover-free embedding process of electric connector and testing method

ActiveCN105261913AImprove reliabilityAchieve lightweightContact member assembly/disassemblyResistance/reactance/impedenceRough surfaceElectricity

The invention discloses a tail-cover-free embedding process of an electric connector and a testing method. According to a mould designed in the invention, glue injection is carried out from the bottom of the mould, and exhaust holes arranged at two sides of a wire hole are used for exhaust. Bubble-free embedding of the electric connector is realized, so that the requirement of insulativity of the electric connector is satisfied, and the quality of embedding is improved. The material of the mould is polytetrafluoroethylene, thereby reducing production cost of the mould. During embedding, demoulding is directly performed without coating of a releasing agent, so that a rough surface, due to uneven coating of the releasing agent, of an embedded body is prevented. According to the tail-cover-free embedding process adopted in the invention, the problem above is overcome; weight reduction is realized; tedious processing of the tail cover in the prior art is eliminated; and the reliability of a cable network is improved.

Owner:BEIJING SATELLITE MFG FACTORY

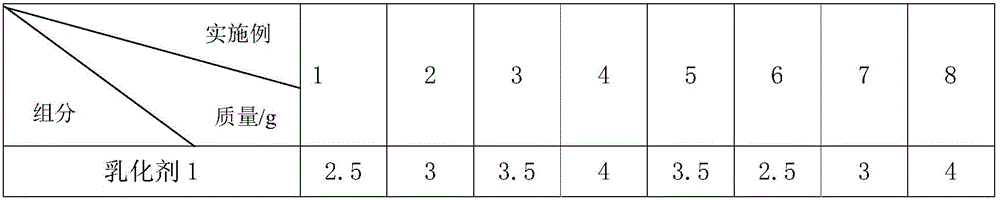

Whitening cream and preparing method thereof

InactiveCN106309272AInhibitory activityCatalytic action to inhibit hydrolysisCosmetic preparationsToilet preparationsMethoxylaricinolic acidGlycyrrhiza glabra Root

The invention discloses a whitening cream and a preparing method thereof, which aims to provide a stable whitening cream with high safety, good skin whitening effect; the technical scheme is: the whitening cream is made from, by weight percentage, 0.5-0.3% of tranexamic acid, 0.5-3.5% of nicotinamide,4- 0.2-1.5% of potassium methoxysalicylate, 0.005-0.04% of glycyrrhiza glabra root extract, 0.5-2% of leucojum extract , 0.1-1.5% of saxifraga stolonifera extract, 3-6% of emulsifier, 2-5% of co-emulsifier, 10.1-23.2% of grease, 0.05-0.1% of antioxidant, 0.05-0.1% of disodium EDTA, 0.2-0.5% of allantoin, 4-10% of polyhydric alcohols, 2.25-8.55% of humectant, 0.2-0.5% of aqueous thickener, 0.5-1% of thickened stabilizer, 0.5-3% of anti-allergic conditioner, 0.8-1% of preservative, 0.5-1.2% of pigment and the margin is water; the invention belongs to the field of cosmetics technology.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

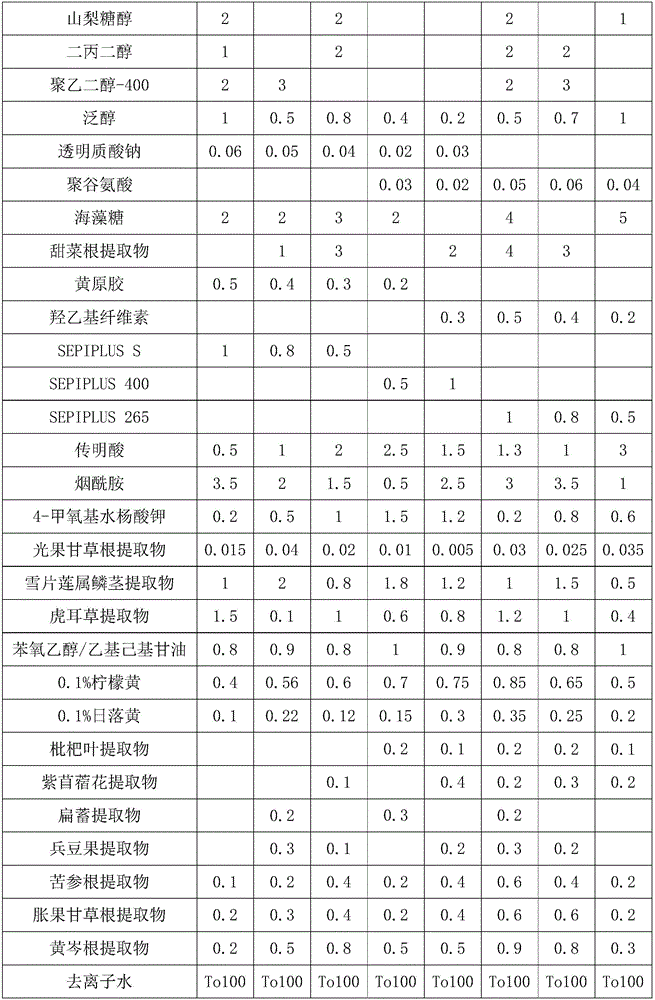

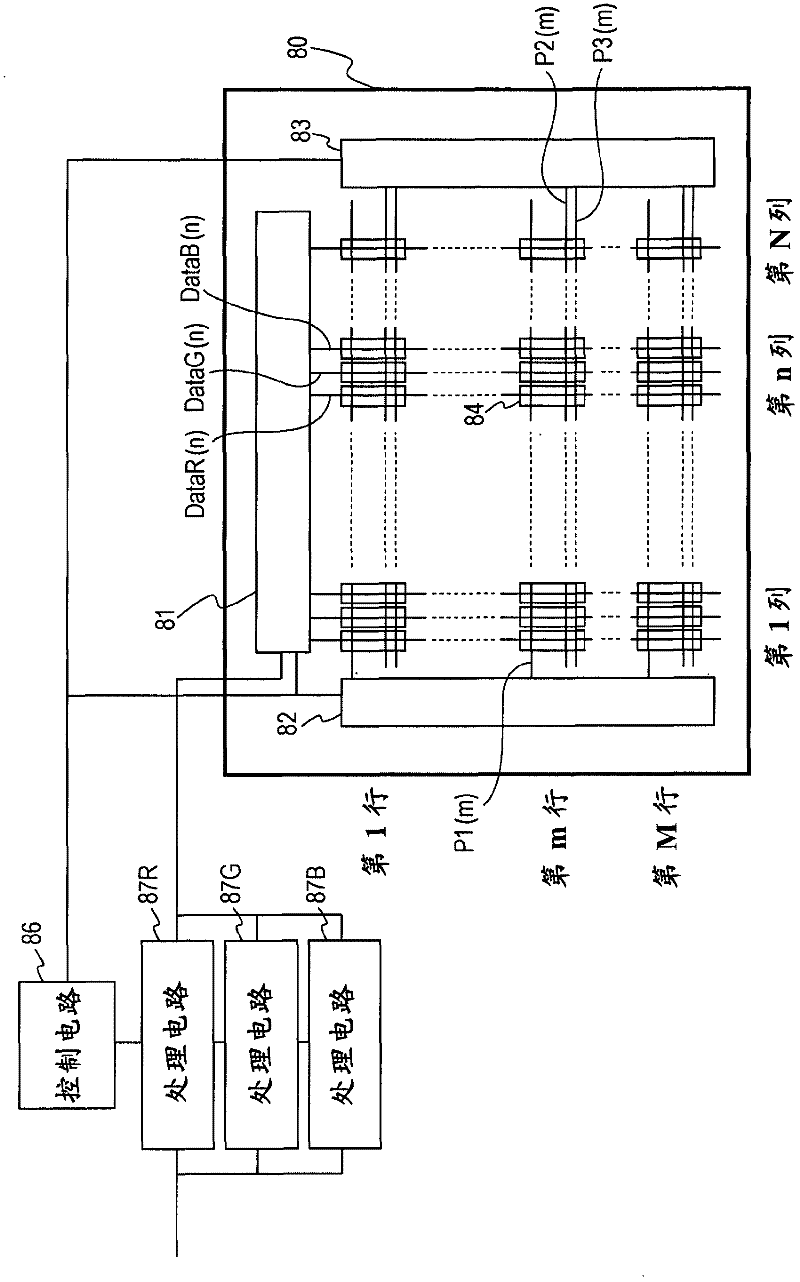

Display apparatus

InactiveCN102479485AAvoid roughnessImprove display qualityStatic indicating devicesEngineeringConsecutive frame

Owner:CANON KK

Sub-lithographic gate length transistor using self-assembling polymers

ActiveUS7384852B2Reduce degradationReduce processMaterial nanotechnologySolid-state devicesSemiconductor structureEngineering

A semiconductor structure including at least one transistor located on a surface of a semiconductor substrate, wherein the at least one transistor has a sub-lithographic channel length, is provided. Also provided is a method to form such a semiconductor structure using self-assembling block copolymer that can be placed at a specific location using a pre-fabricated hard mask pattern.

Owner:ELPIS TECH INC

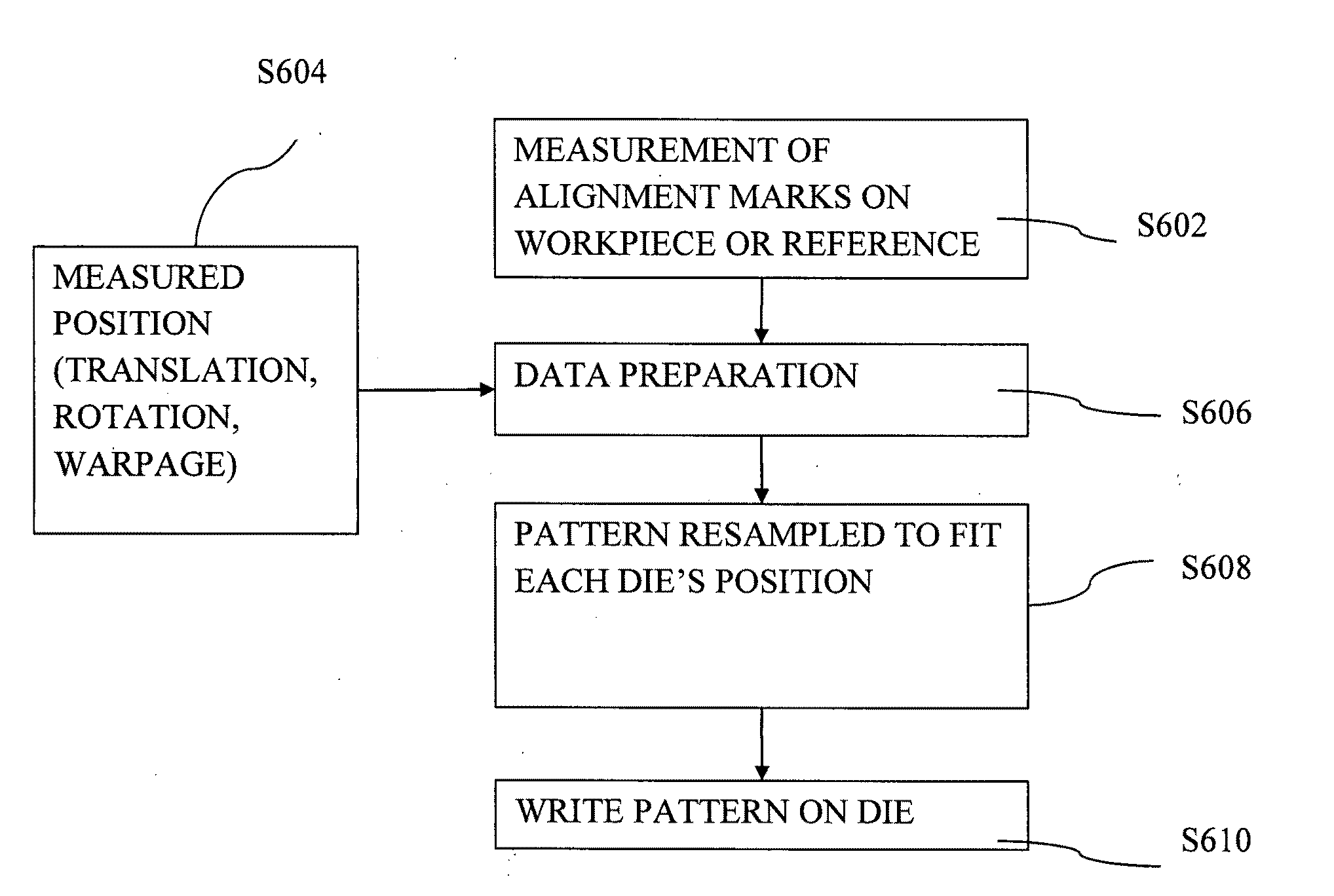

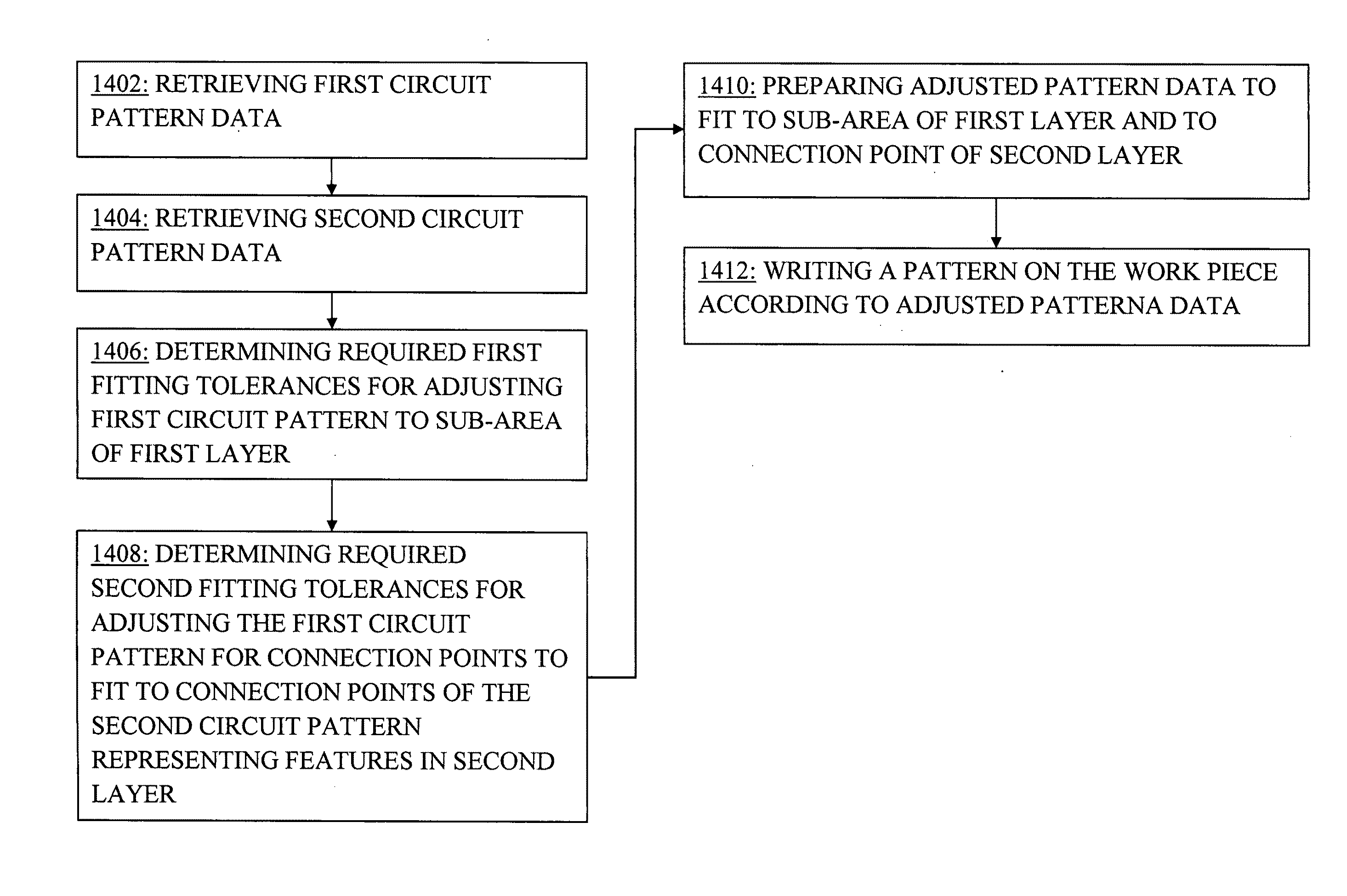

Method and apparatus for performing pattern reconnection after individual or multipart alignment

ActiveUS20110257777A1Avoid connectionAvoid roughnessPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringSystem in package

Owner:MICRONIC LASER SYST AB

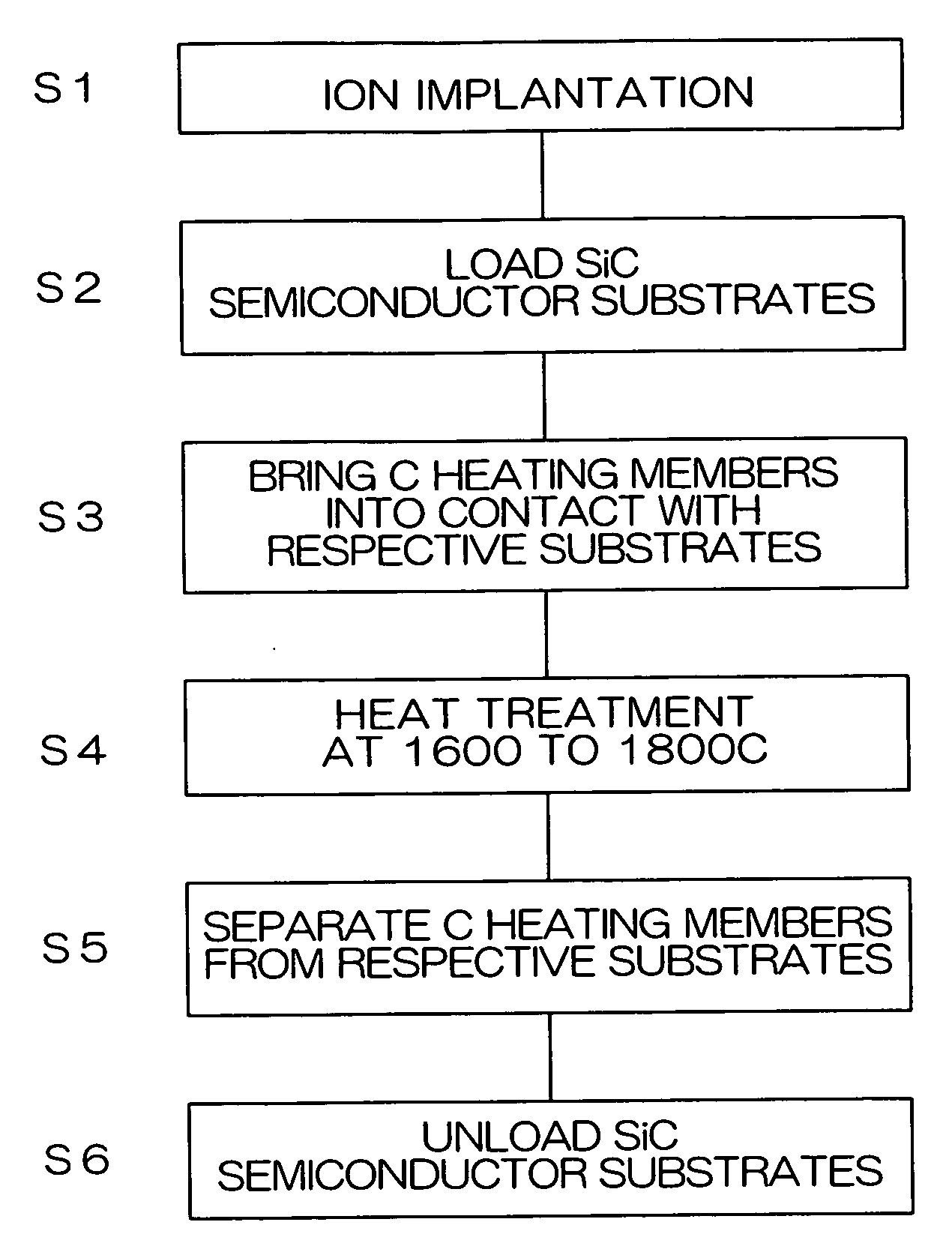

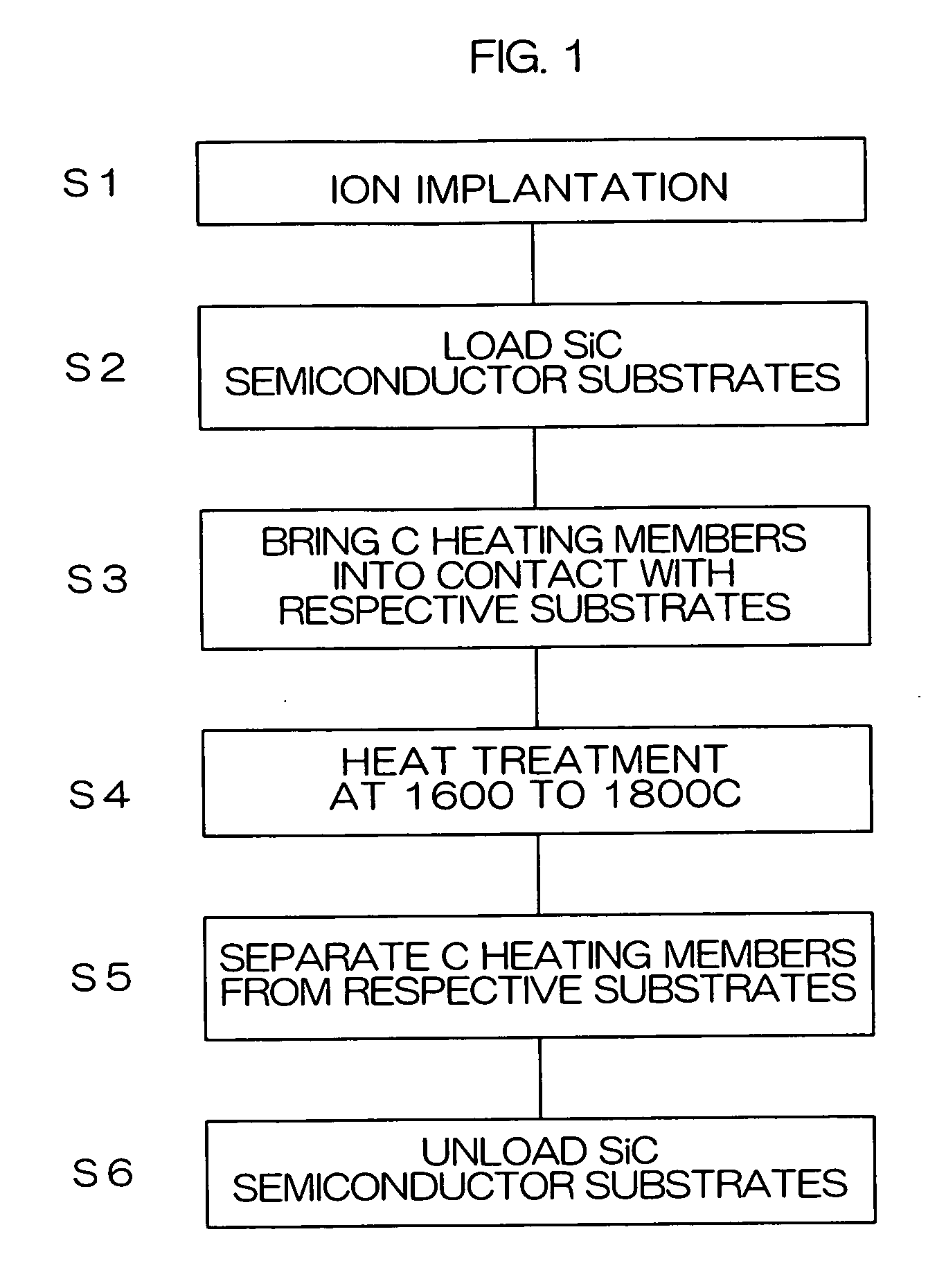

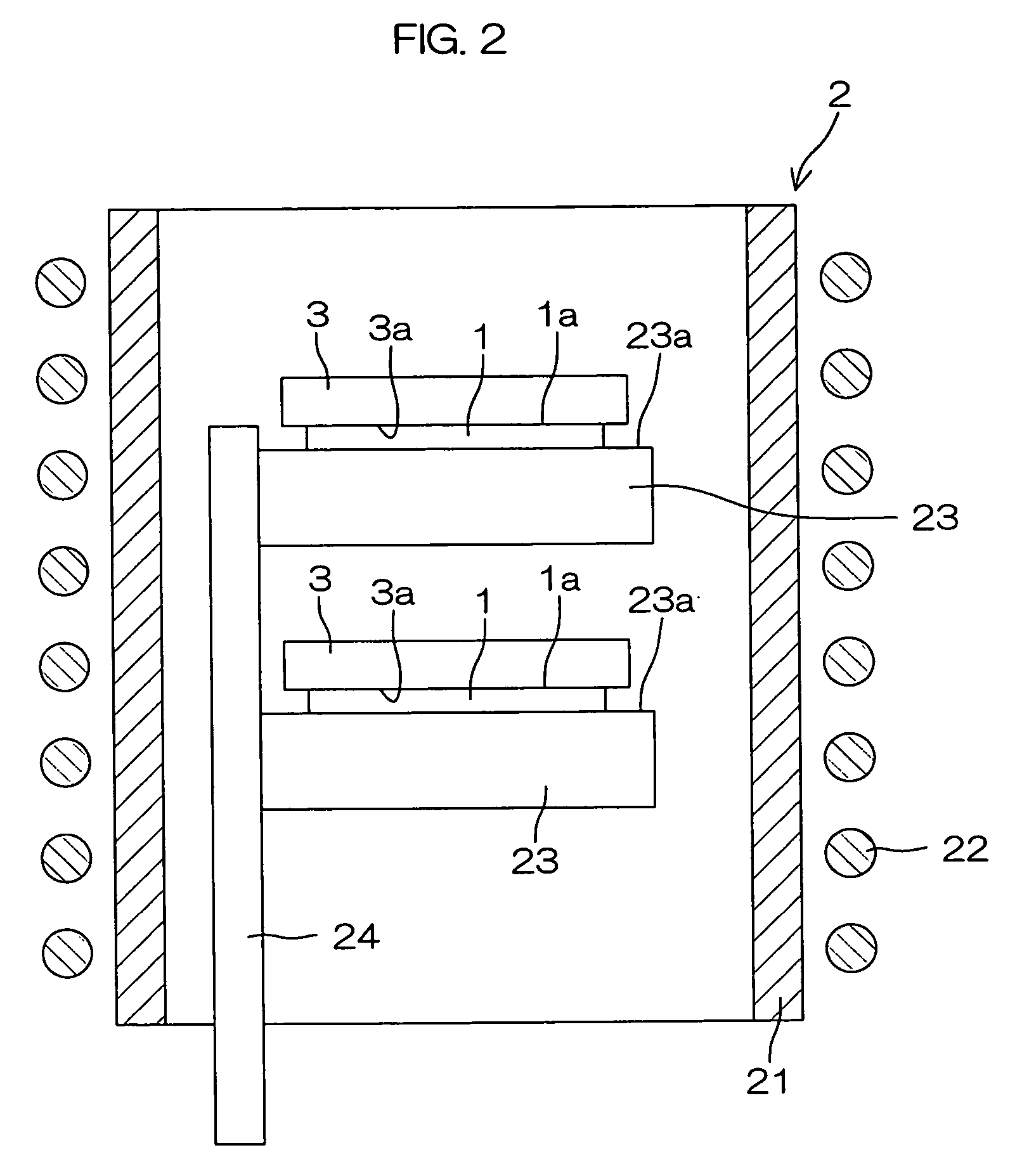

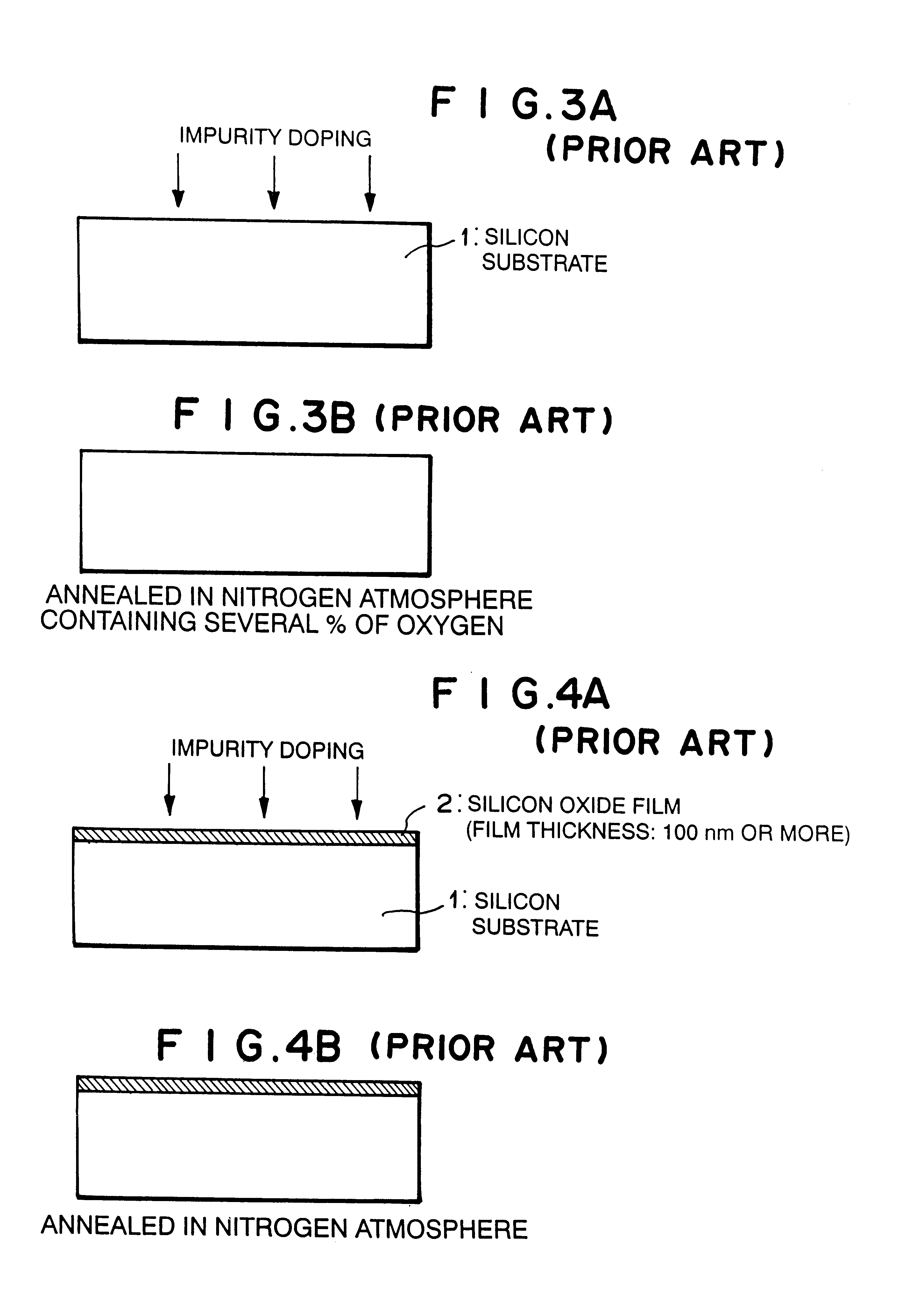

Production method for semiconductor device

ActiveUS20070167026A1High purityAvoid impuritiesSemiconductor/solid-state device manufacturingSemiconductor devicesSusceptorMetallurgy

In a production process for a semiconductor device employing an SiC semiconductor substrate (1), the SiC semiconductor substrate (1) is mounted on a susceptor (23), and a C heating member (3) of carbon is placed on a surface of the SiC semiconductor substrate (1). An annealing process is performed to form an impurity region in the surface of the SiC semiconductor substrate (1) by causing the susceptor (23) and the C heating member (3) to generate heat at high temperatures.

Owner:ROHM CO LTD

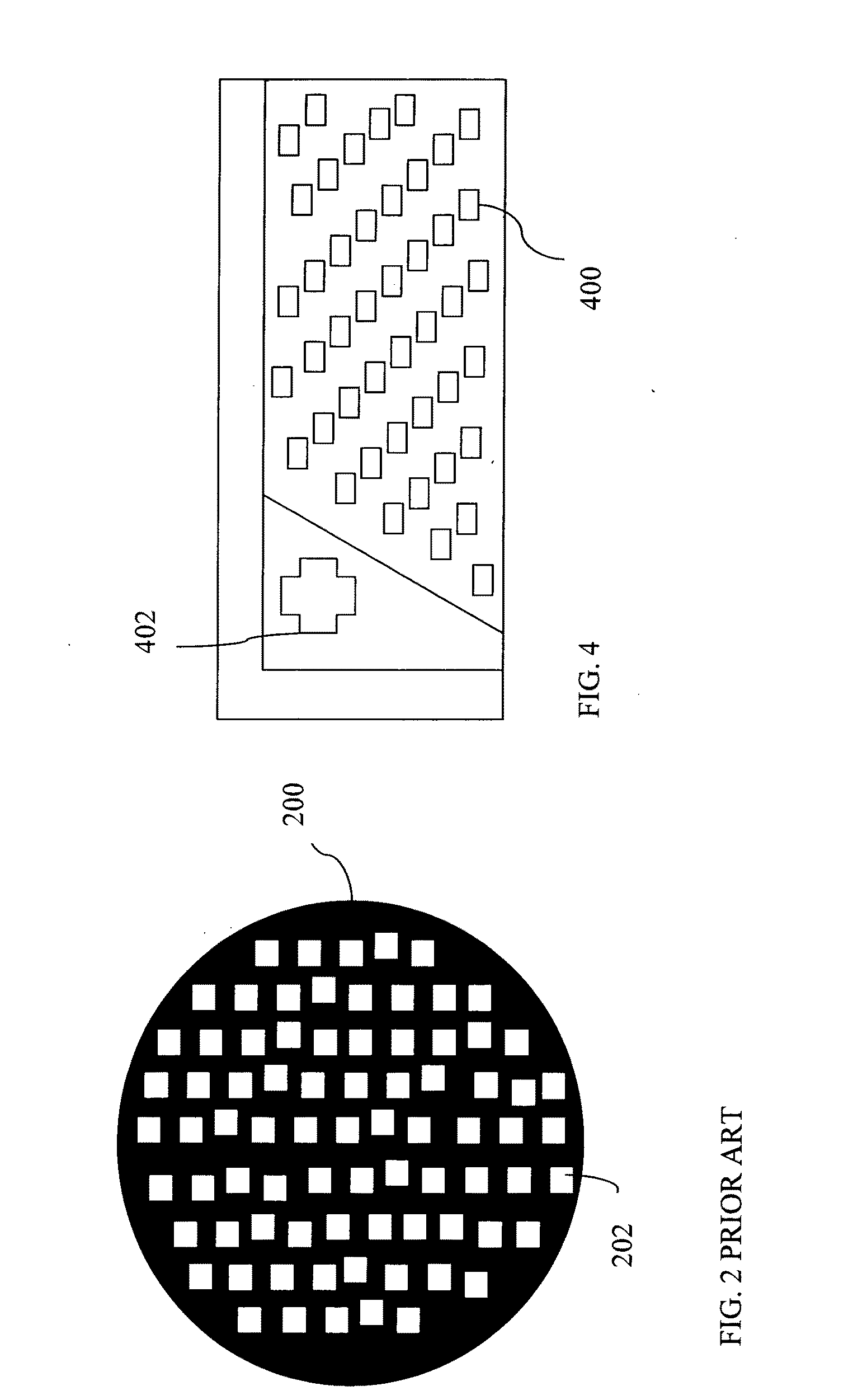

Method and apparatus for performing pattern alignment to plurality of dies

ActiveUS20110213484A1Placement accuracy requirementAvoid connectionPhotomechanical apparatusPrinted circuit manufactureElectrical and Electronics engineeringHemt circuits

A method for patterning a workpiece in a direct write machine in the manufacturing of a multilayer stack, wherein a first circuit pattern comprising patterns for connection points is transformed according to determined fitting tolerances to fit to connection points of a second circuit pattern and to circuit pattern(s) of specific features such as random placed dies, or group of dies, on or in the workpiece. The second layer may be a previously formed layer or a layer to be formed on the same workpiece or on a different workpiece for the stack. Pattern data associated with selected die is transformed into adjusted circuit pattern data using the transformation defined by the transformed positions such that the circuit pattern is fitted to the selected die(s).

Owner:MICRONIC LASER SYST AB

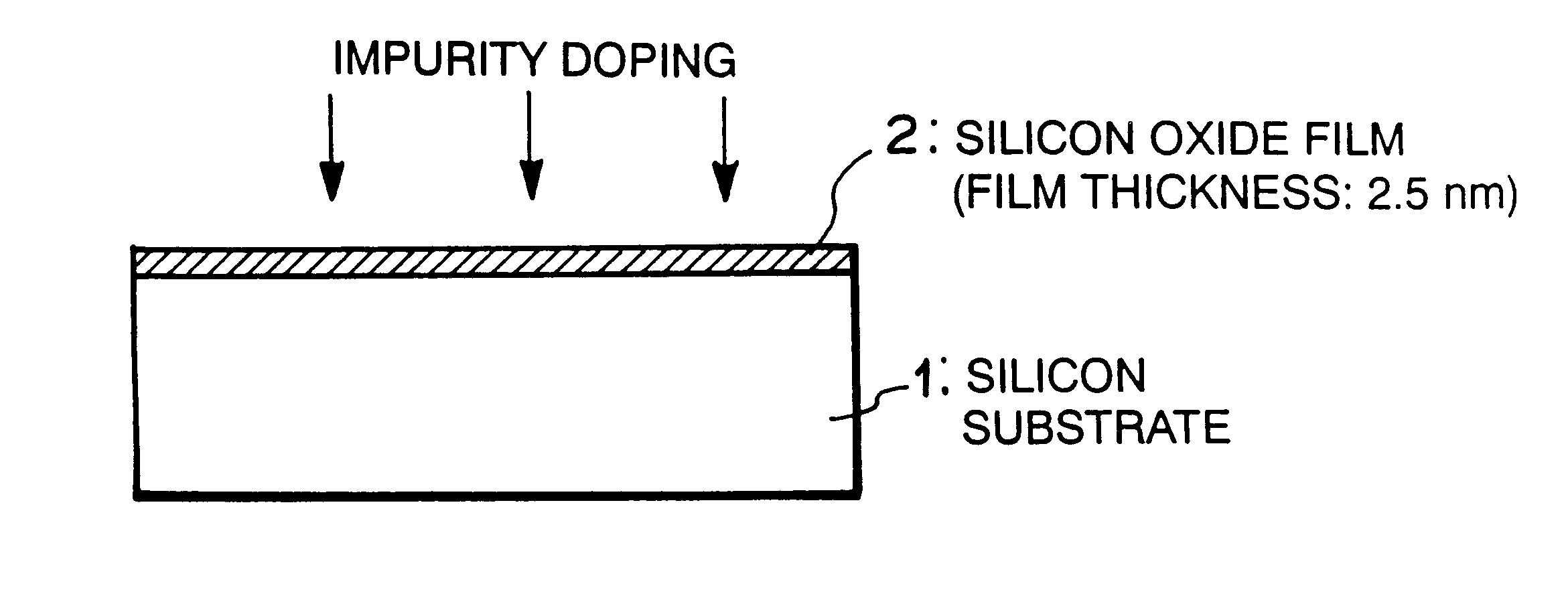

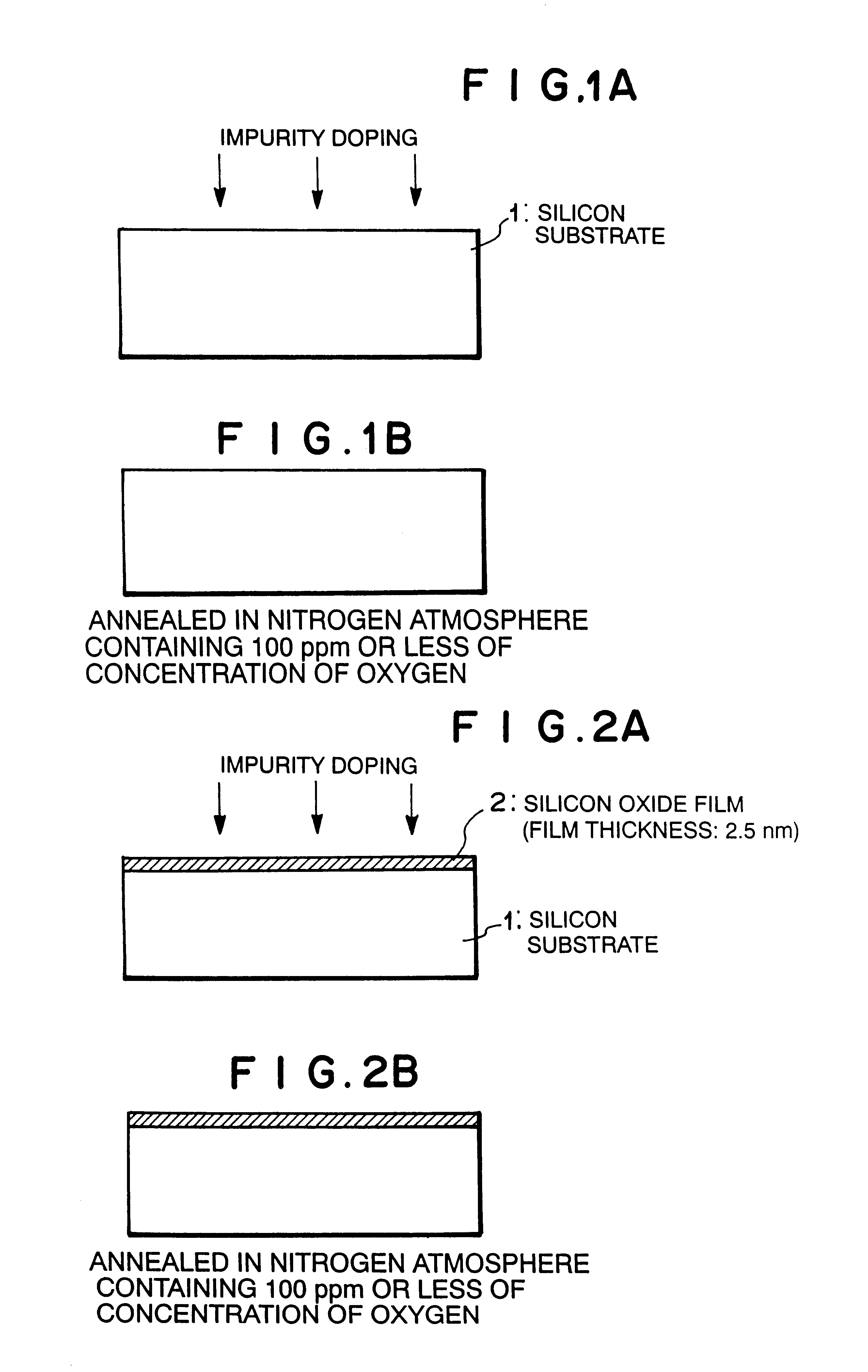

Method of manufacturing semiconductor device having shallow junction

InactiveUS6218270B1Avoid formingAvoid concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesImpurity diffusionImpurity doping

A method of manufacturing a semiconductor device having a silicon substrate containing an impurity diffusion layer is disclosed, that comprises the steps of doping impurities to the silicon substrate through a silicon oxide film with a thickness of 2.5 nm or less at an accelerating voltage of 3 keV or less, the silicon oxide film being formed on the silicon substrate and annealing the silicon substrate with the oxide film left.

Owner:RENESAS ELECTRONICS CORP

Method for preparing Bi high temperature superconducting line or strip material

ActiveCN103440932ASimple preparation processReasonable designCable/conductor manufactureHigh-temperature superconductivityManganese

The invention discloses a method for preparing a Bi high temperature superconducting line or strip material. The method comprises the following steps: firstly, preparing a primary composite body; secondly, drawing the primary composite body, and then annealing the drawn primary composite body so as to obtain a line material; thirdly, bundling a plurality of line materials, and then packing into a silver-base alloy pipe so as to prepare a secondary composite body; fourthly, drawing the secondary composite body, and then annealing the drawn secondary composite body so as to obtain a Bi line material; and fifthly, putting the Bi line material into an atmosphere furnace for heat treatment so as to obtain the Bi high temperature superconducting line material; or rolling the Bi line material into a Bi strip material, and then putting into the atmosphere furnace for heat treatment so as to obtain the Bi high temperature superconducting strip material. According to the method, the manufacturing dislocation quantity of silver and silver-manganese alloy is effectively controlled by adopting an unconventional annealing process, so that the phenomenon that a silver super interface is severely rough caused by an excessively soft silver sheath is effectively avoided, and the current-carrying performance of the Bi line or strip material is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

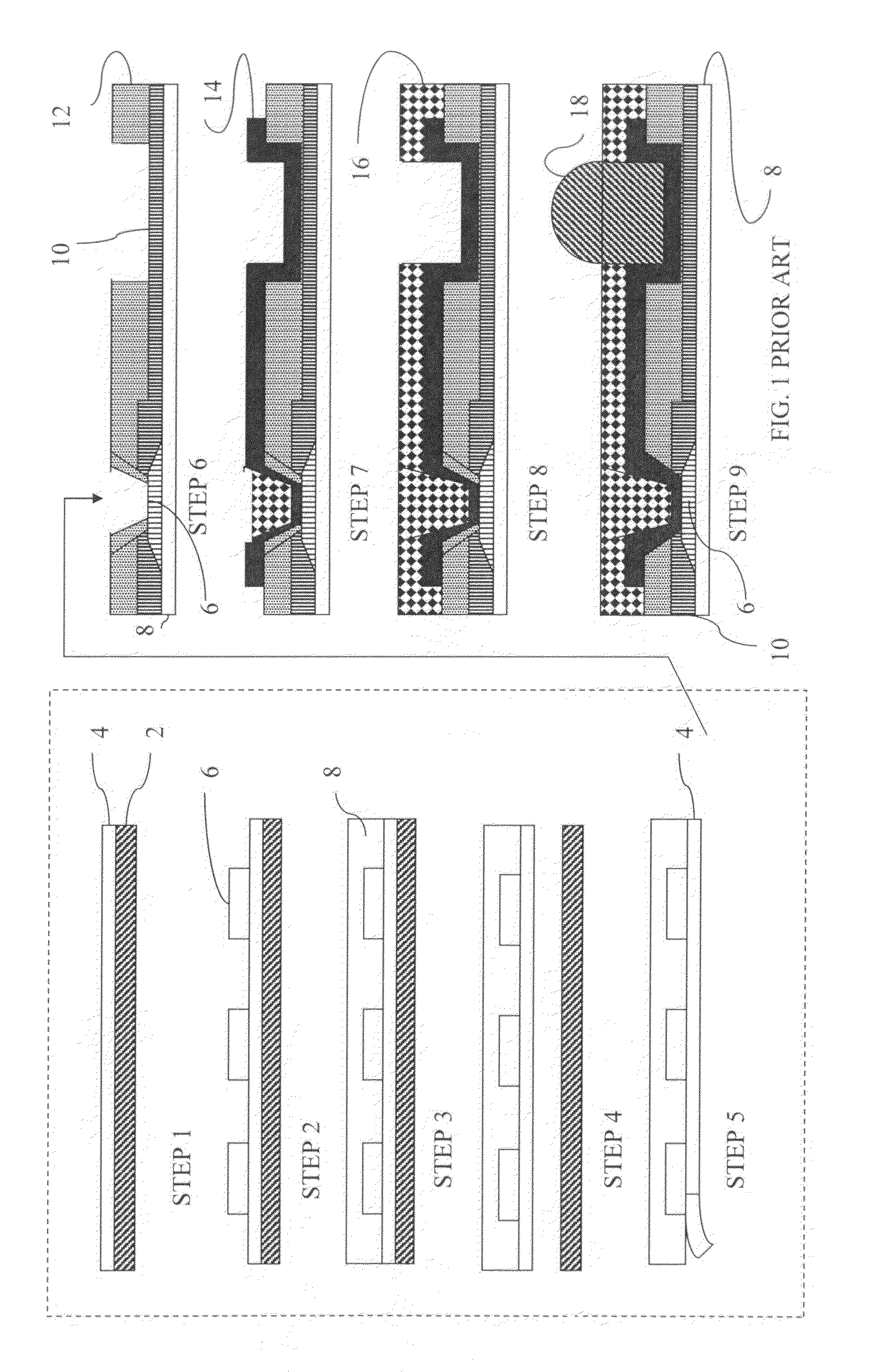

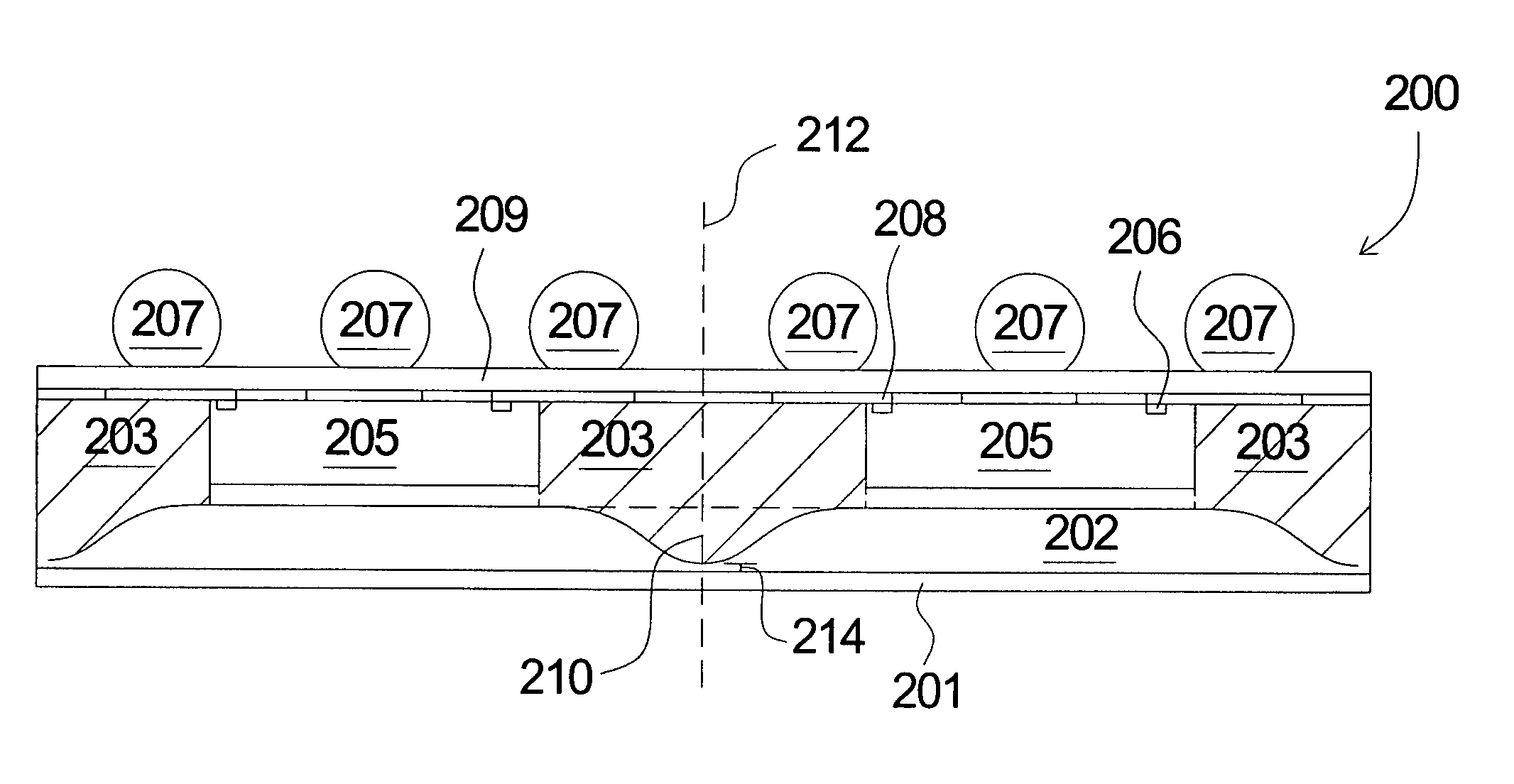

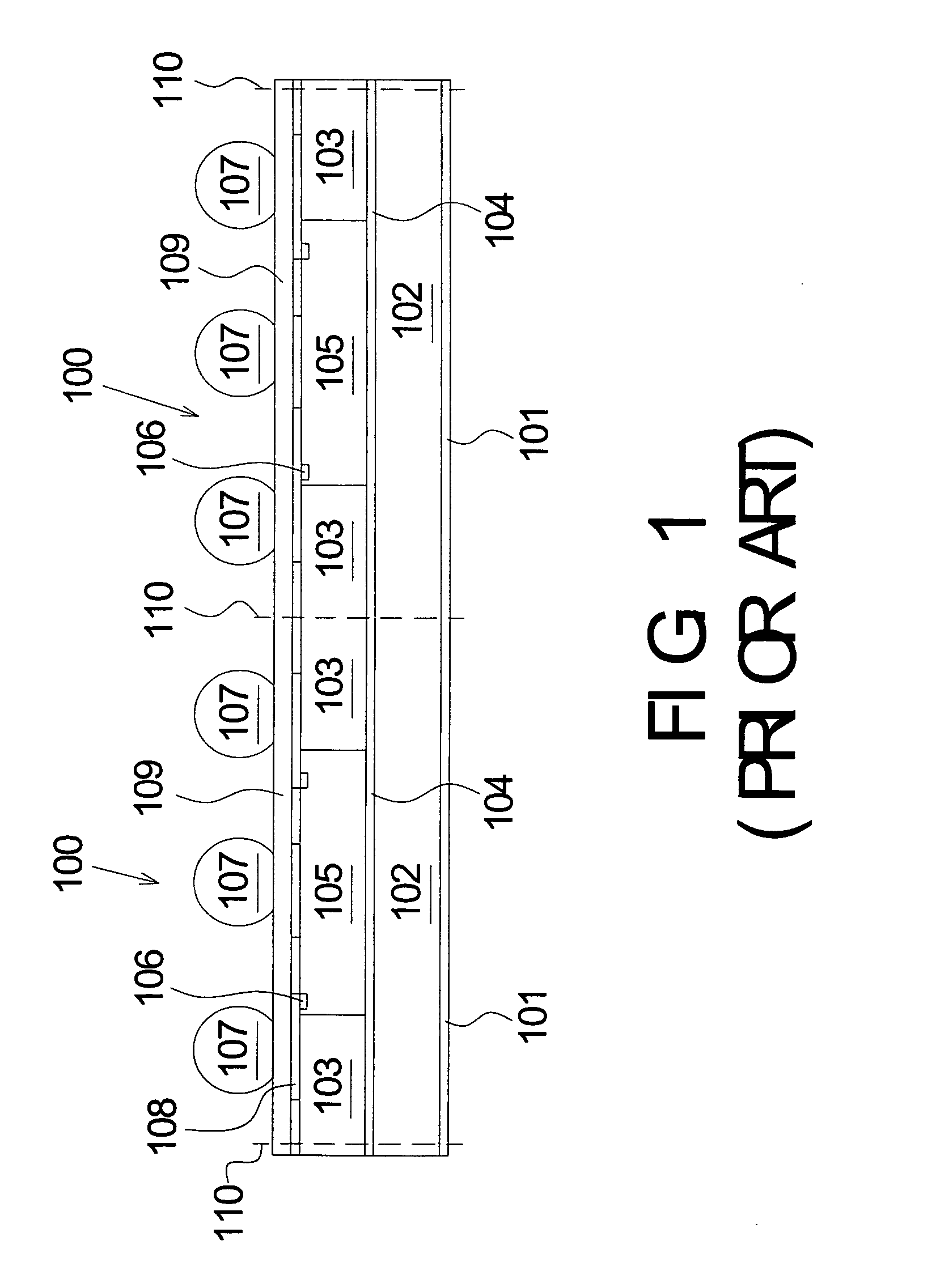

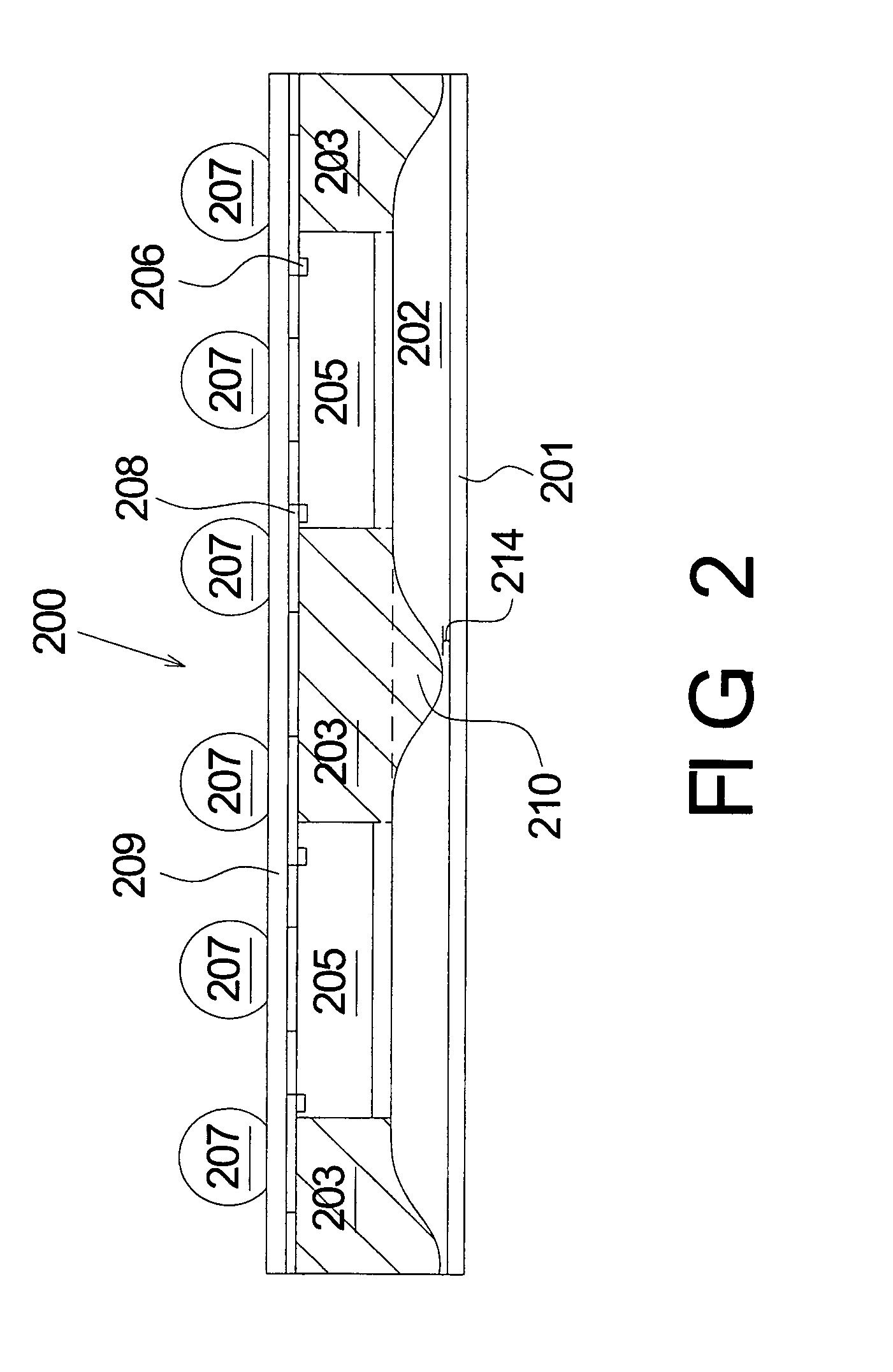

Semiconductor package structure and method for separating package of wafer level package

InactiveUS20070128835A1Avoid roughnessLow costSemiconductor/solid-state device detailsSolid-state devicesDevice materialWafer dicing

The present invention provides a separating process of a semiconductor device package of wafer level package. The method comprises a step of etching a substrate to form recesses. Then a buffer layer is formed on the first surface of the substrate, wherein the buffer layer is filled with the corresponding recesses to form infillings on adjacent the semiconductor device package. Dicing the wafer into individual package along substantial center of said infillings, the step may avoid the roughness on the edge of each die and also decrease the cost of the separating process.

Owner:ADVANCED CHIP ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com