Production method of high-strength, high-conductivity and heat-resistant copper alloy

A production method and technology of heat-resistant copper, applied in the field of copper alloy processing, can solve the problems of inability to produce copper-chromium alloy products, limitations of casting weight and length, difficult control of alloy composition, etc., so as to improve mechanical properties and softening resistance, reduce The effect of energy consumption and burning loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention provides a production method of a high-strength, high-conductivity and heat-resistant copper alloy, comprising the following steps:

[0035] (1) The raw material composition of high-strength and high-conductivity heat-resistant copper alloy is as follows: Cr 0.5wt%, Mg 0.18wt%, Si: 0.05wt%, Zr: 0.07wt%, and the balance is Cu. The raw materials are added to the induction melting furnace, and the covering agent Using a mixture of cryolite, industrial soda ash, fluorite and charcoal, the mass ratio is 10%: 20%: 15%: 55%, heated to 1300°C under nitrogen protection for smelting, mechanical stirring, and then slag removal to obtain a uniform composition Stable copper alloy melt;

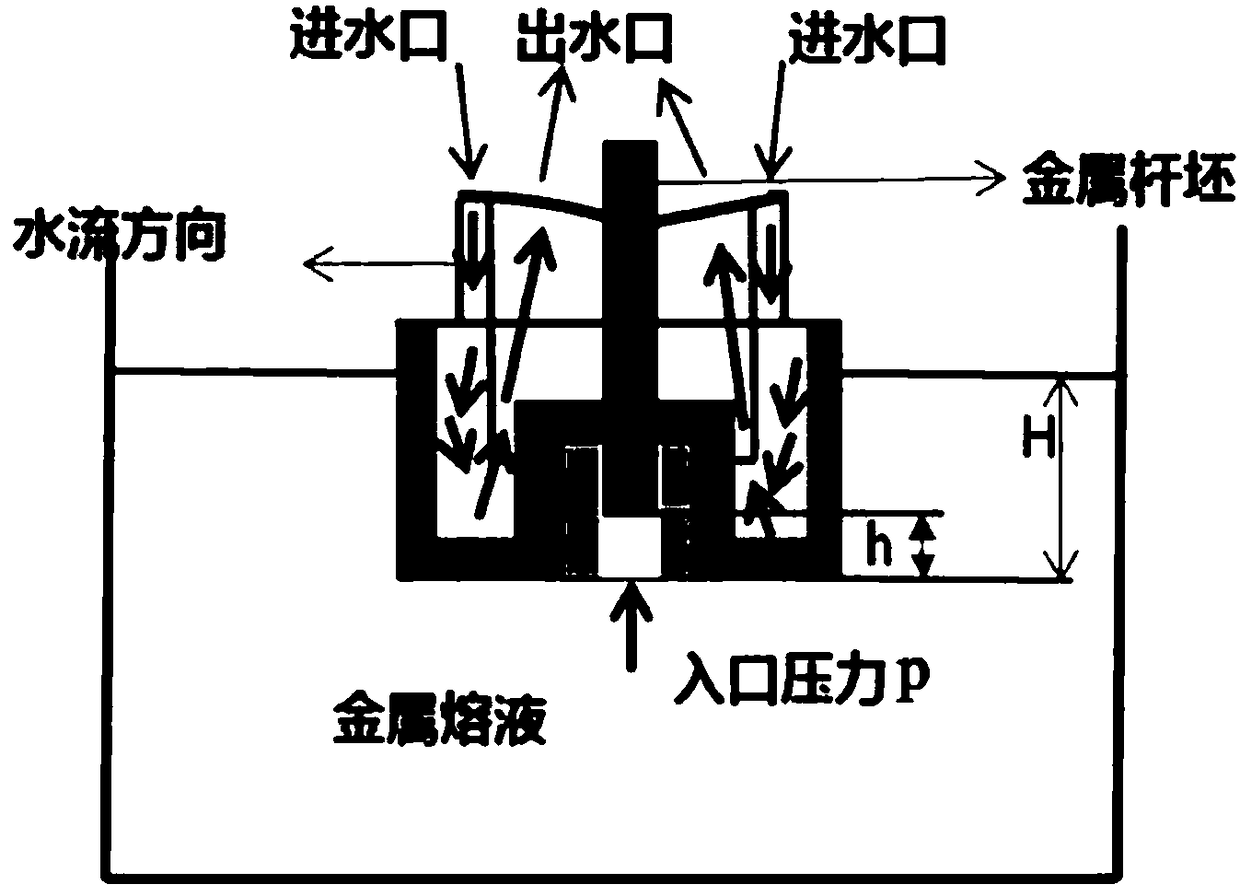

[0036] (2) Transfer the copper alloy melt into the upward-drawing continuous casting furnace, use charcoal as the covering agent, the thickness of the charcoal is 150mm, control the pressure of the upper-drawing furnace liquid level protective gas nitrogen to 0.6 atmospheres, and the cas...

Embodiment 2

[0040] The invention provides a production method of a high-strength, high-conductivity and heat-resistant copper alloy, comprising the following steps:

[0041] (1) The raw materials of high-strength and high-conductivity heat-resistant copper alloy are as follows: Cr 0.45wt%, Mg 0.2wt%, Zr: 0.03wt%, and the balance is Cu. The raw materials are added to the induction melting furnace, and the covering agent is cryolite and industrial soda ash , a mixture of fluorite and charcoal, with a mass ratio of 10%: 20%: 15%: 55%, heated to 1350°C under nitrogen protection for smelting, mechanical stirring, and then slag removal to obtain a copper alloy melt with uniform and stable composition;

[0042] (2) Transfer the copper alloy melt into the upward-drawing continuous casting furnace, use charcoal as the covering agent, the thickness of the charcoal is 200mm, control the pressure of the upper-drawing furnace liquid level protective gas nitrogen to 0.5 atmospheres, and the casting temp...

Embodiment 3

[0046] The invention provides a production method of a high-strength, high-conductivity and heat-resistant copper alloy, comprising the following steps:

[0047] (1) The raw materials of high-strength and high-conductivity heat-resistant copper alloy are as follows: Cr 0.46wt%, Mg 0.13wt%, Zr: 0.10wt%, Ce 0.05wt%, and the balance is Cu. The raw materials are added to the induction melting furnace, and the covering agent is A mixture of cryolite, industrial soda ash, fluorite and charcoal, the mass ratio is 10%: 20%: 15%: 55%, heated to 1320°C under nitrogen protection for smelting, mechanical stirring, and then slag removal to obtain a uniform and stable composition Copper alloy melt;

[0048] (2) Transfer the copper alloy melt into the upward-drawing continuous casting furnace, use charcoal as the covering agent, the thickness of the charcoal is 200mm, control the pressure of the upper-drawing furnace liquid level protective gas nitrogen to 0.5 atmospheres, and the casting te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com