Fuel injector for dual fuel common rail system

一种燃料喷射器、喷射器的技术,应用在燃料喷射装置、特殊燃料喷射装置、装料系统等方向,能够解决泄漏、燃料交叉泄漏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

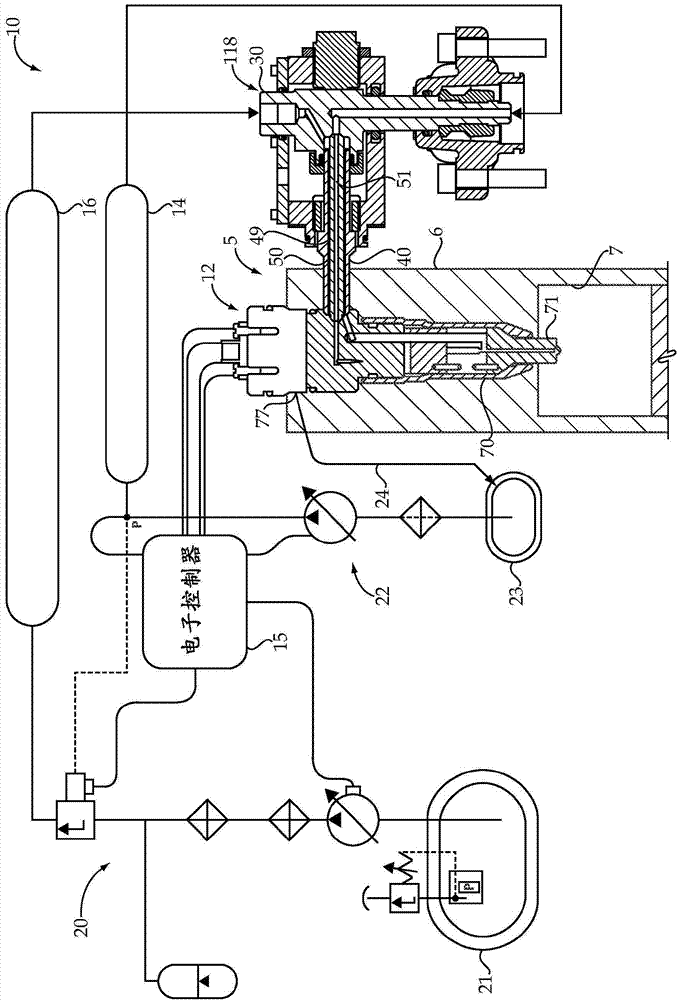

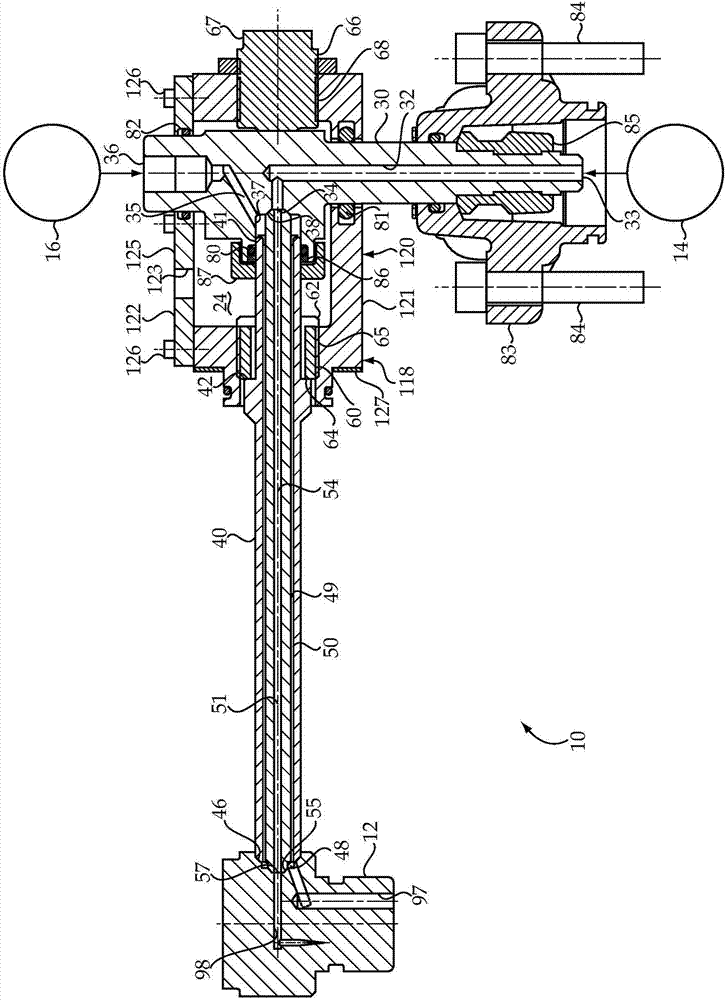

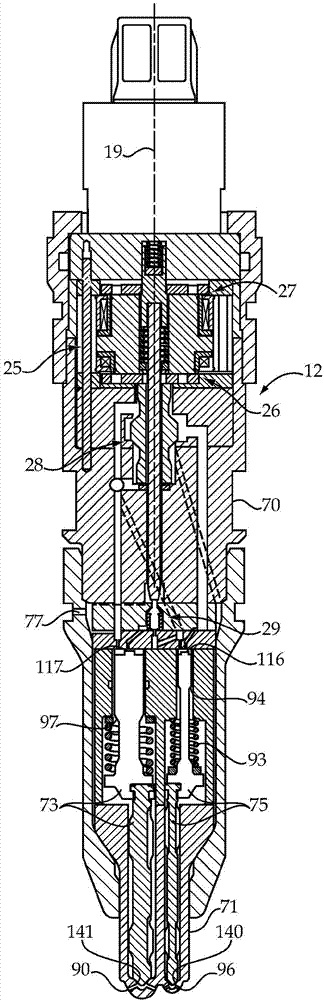

[0014] see figure 1 , the engine 5 according to the present invention uses a dual fuel common rail system 10 . The engine 5 comprises an engine housing 6 defining a plurality of cylinders 7, only one of which is shown in the figure. Dual fuel system 10 includes a plurality of fuel injectors 12 (only one shown) each including an injector body 70 having features configured to inject gaseous and / or liquid fuel directly Spray into the top part 71 in one of the cylinders 7 of the engine. The dual fuel system 10 includes a plurality of concentric outer tubes 40 and inner tubes 50 each extending into the engine housing 6 between a quill 30 and one of the fuel injectors 12 . Each inner tube 50 is compressed between a conical seat on the associated tube shaft 30 and a conical seat on one of the fuel injectors 12 . Thus, each engine cylinder 7 has an associated fuel injector 12 , an outer tube 40 , an inner tube 50 and a tube shaft 30 . Dual fuel system 10 includes a gaseous fuel co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com