Inorganic material pressurization grouter used for mending concrete hole and seam

An inorganic material and concrete technology, applied in building maintenance, construction, building construction, etc., can solve the problems of poor concrete affinity, unsatisfactory results, easy aging of fillers, etc., to ensure complete repair and overcome low strength , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

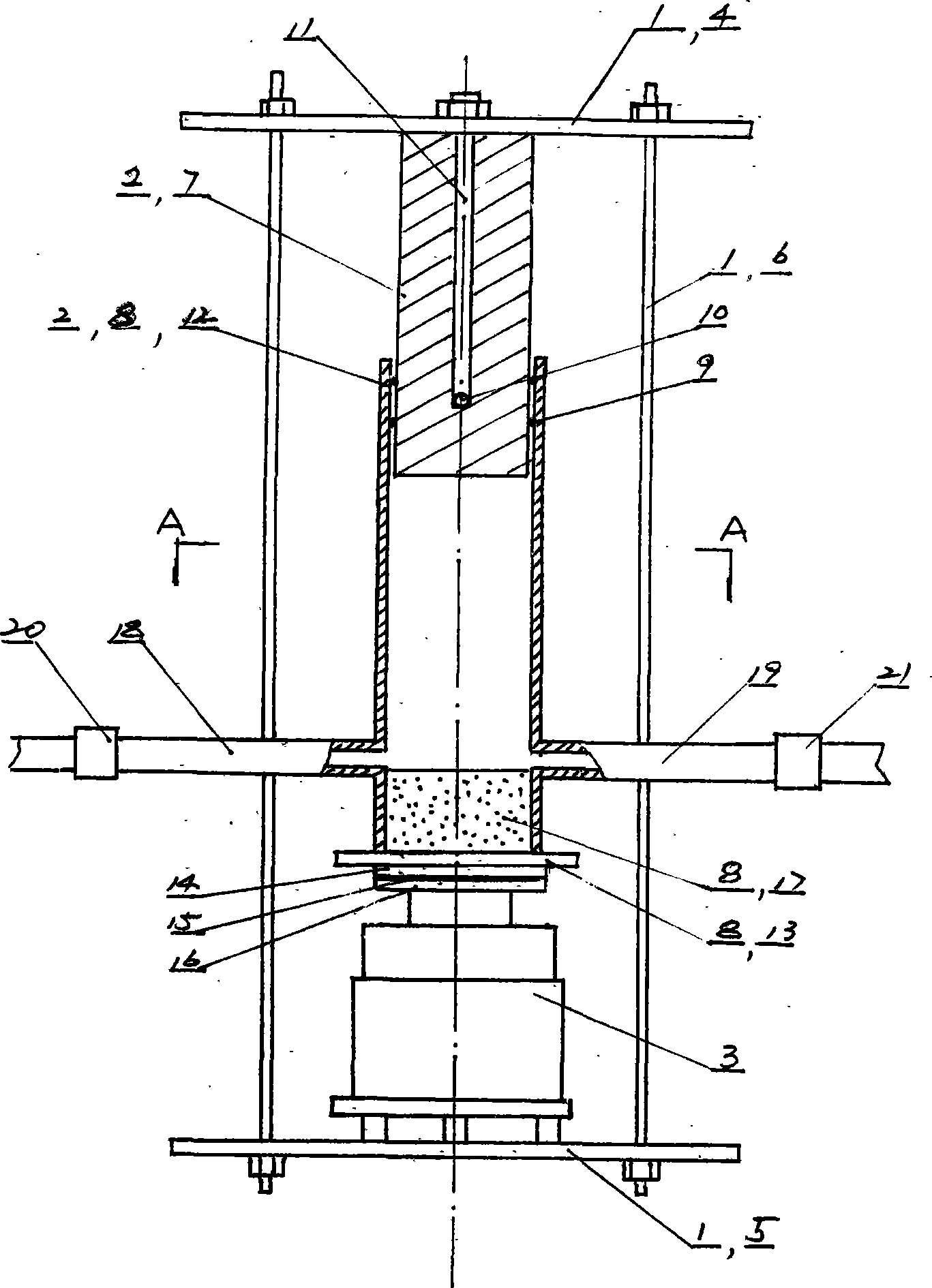

[0024] Refer to attached figure 2

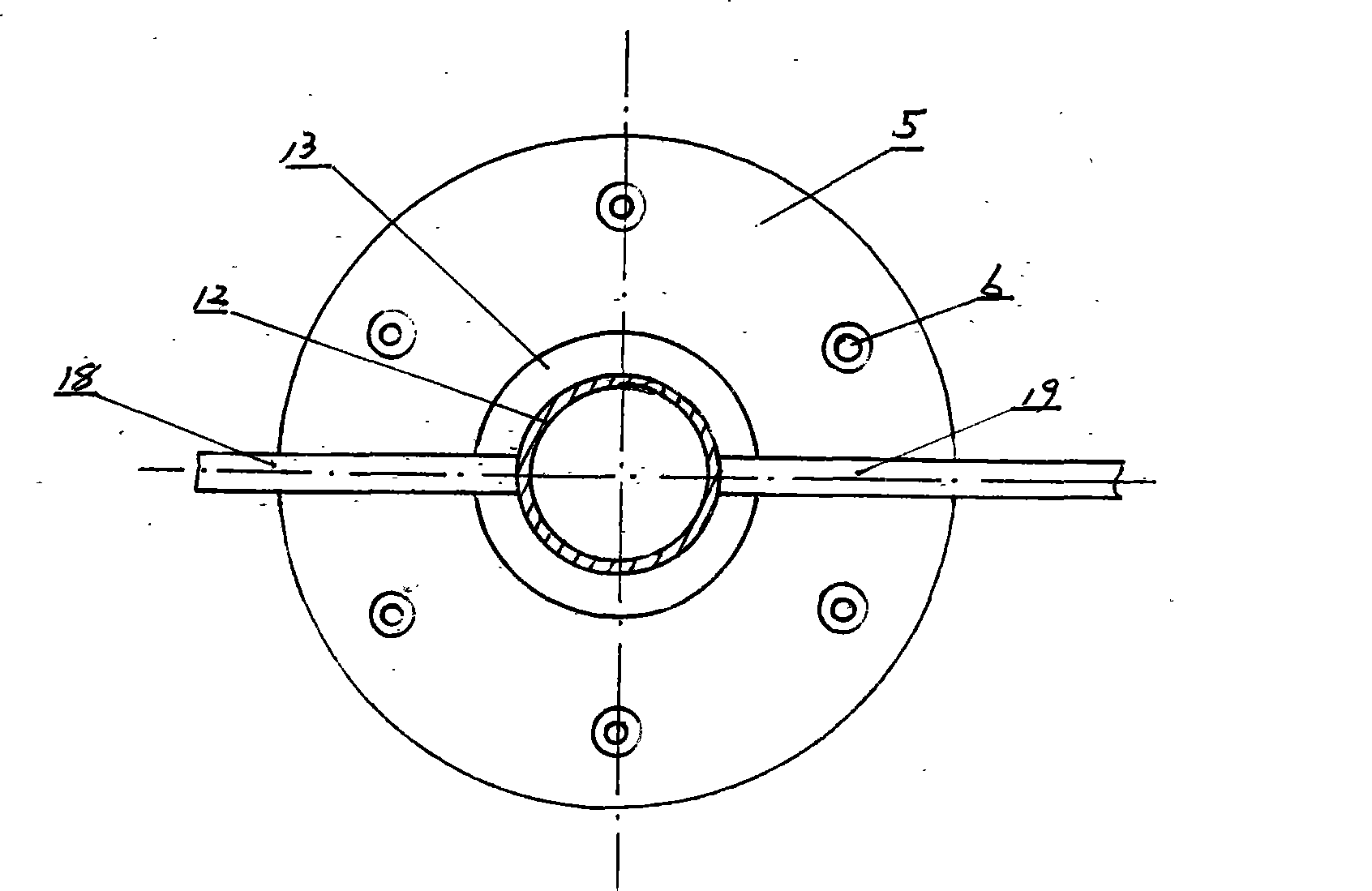

[0025] Connect the upper disc 4 and the lower disc 5 with 6 bolts 6 to form a bracket 1; the inner diameter of the plunger cylinder 2 is 92 mm, and the plunger cylinder 2 includes a plunger 7 and a cylinder body 8, and the upper end of the plunger 7 is connected to the The upper disc 4 is fixedly connected, the lower end of the plunger 7 is inserted into the cylinder body 8, and the plunger 7 and the cylinder body 8 are connected by sliding with two sealing rubber rings 9; on the plunger 7 between the two sealing rubber rings 9 There is a lubricating oil outlet 10, and the center of the plunger 7 is provided with a lubricating oil channel 11 communicating with the lubricating oil outlet 10; the cylinder body 8 includes a cylinder barrel 12, a cylinder bottom cover 13, and a rubber block 17; the cylinder bottom cover 13 is connected with a blind plate 14 , the rubber pad 15, the flange 16 is fixedly connected with the top of the jack 3; the...

Embodiment 2

[0031] When the cylinder bottom cover 13 is not fixedly connected with the top of the jack 3, the top of the jack 3 can be separated from the cylinder bottom cover 13.

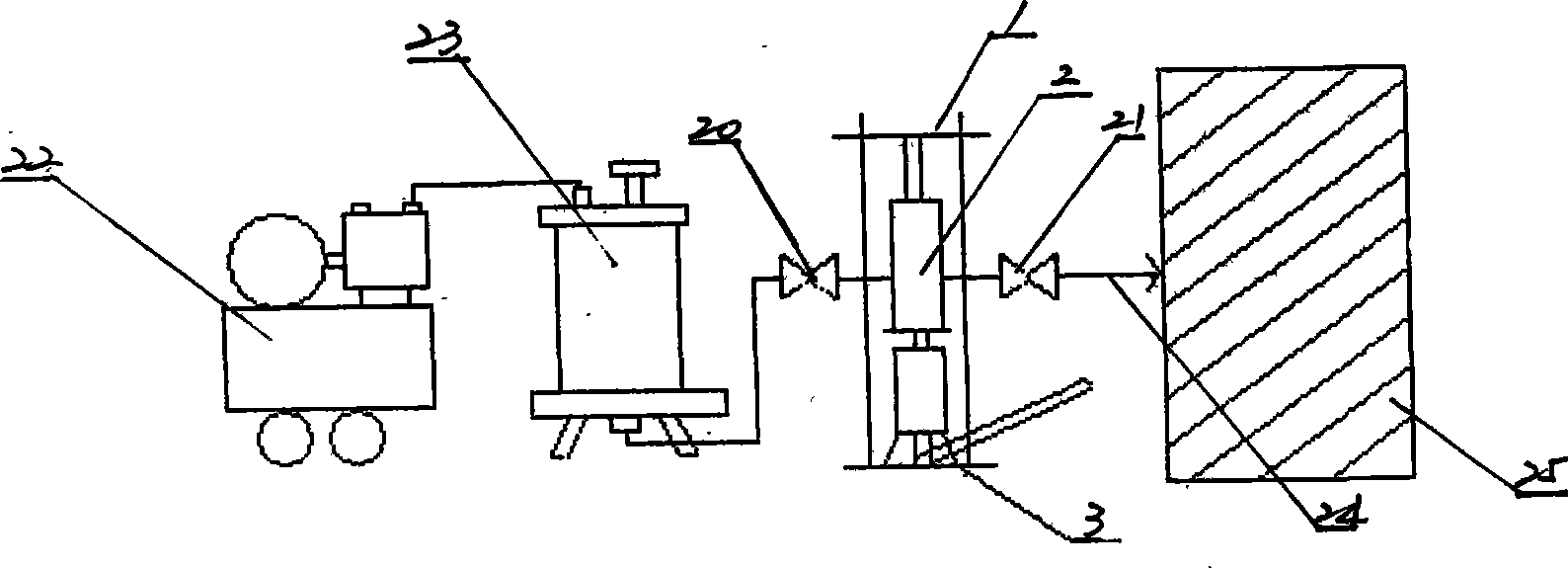

[0032] In the initial state, the plunger 7 in the plunger cylinder 2 is at the lowest position in the cylinder body 8, and the top of the jack 3 is separated from the cylinder bottom cover 13. When the inner volume of the cylinder barrel 12 reaches the maximum space and is filled with nanometer waterproof cement slurry During feeding, due to the downward movement of the cylinder body 8, the top of the cylinder bottom cover 13 and the jack 3 gradually approaches and joins.

[0033] Along with the starting and rising of the jack 3, the nanometer waterproof cement slurry in the cylinder 12 is injected into the hole and the seam of the concrete member 25 to be repaired by the slurry outlet pipe 19 and the spray pipe 24.

[0034] After the nano-waterproof cement slurry in the cylinder 12 is extruded, the plunger 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com