Patents

Literature

68results about How to "Strong extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

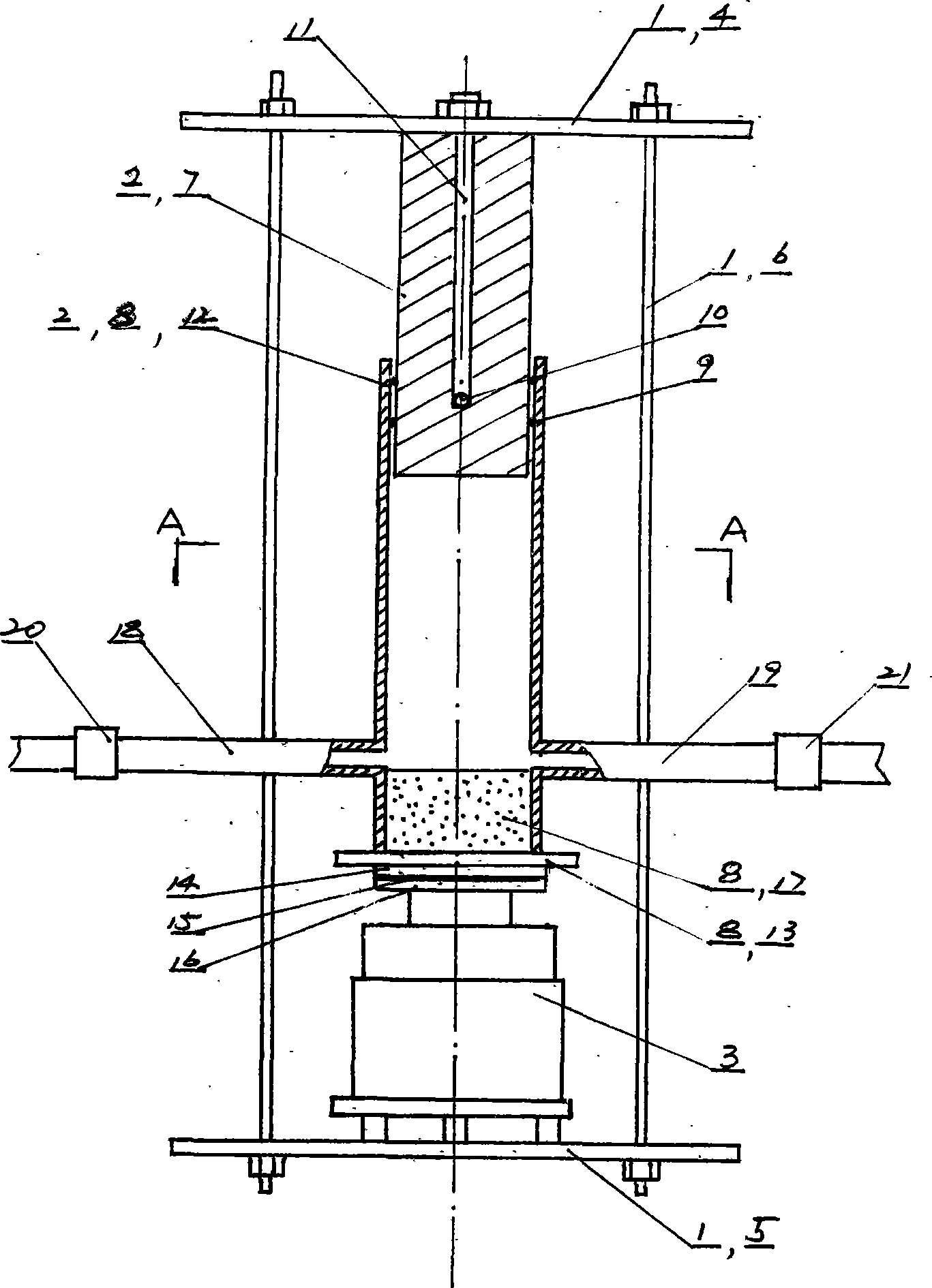

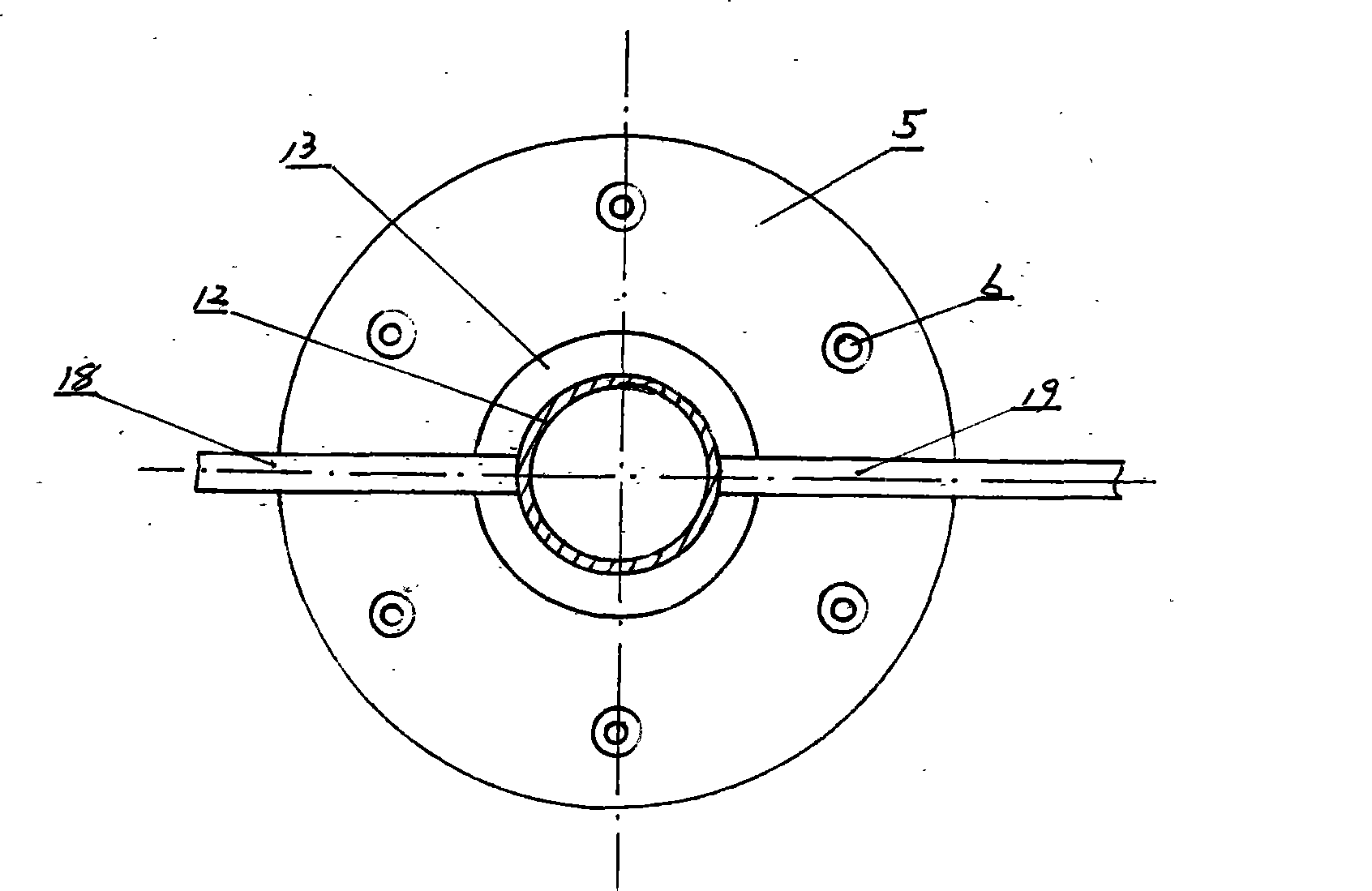

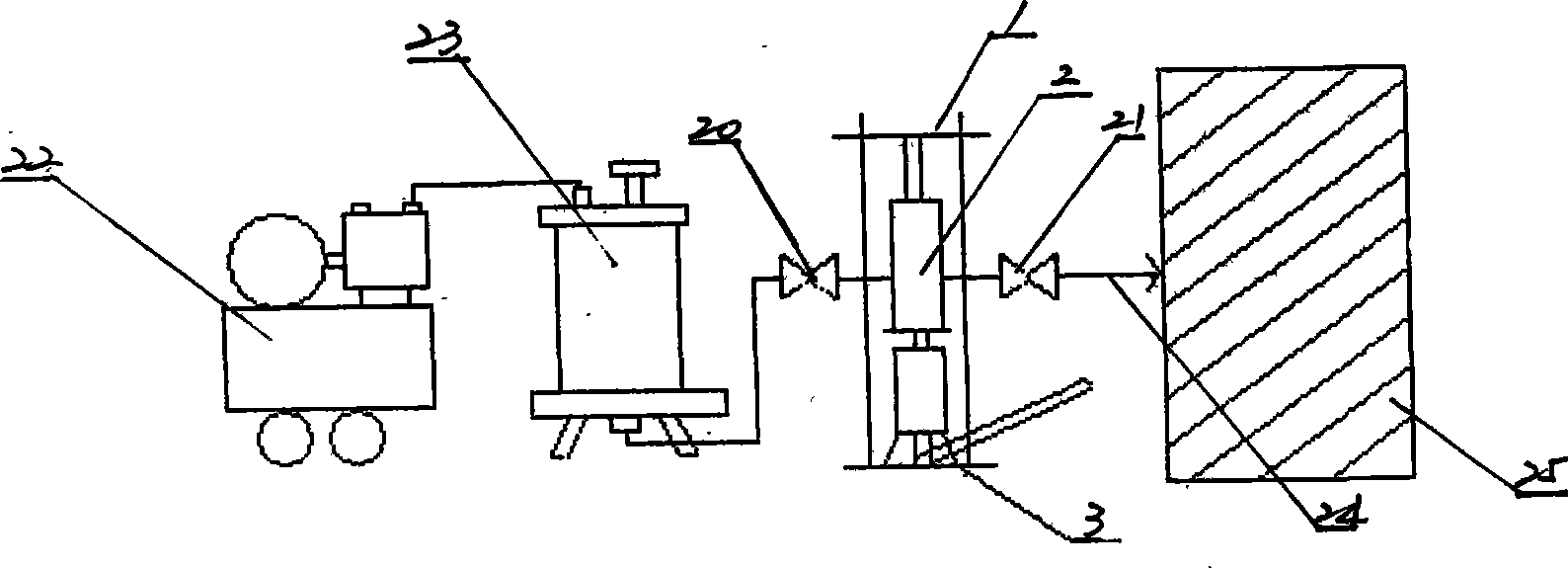

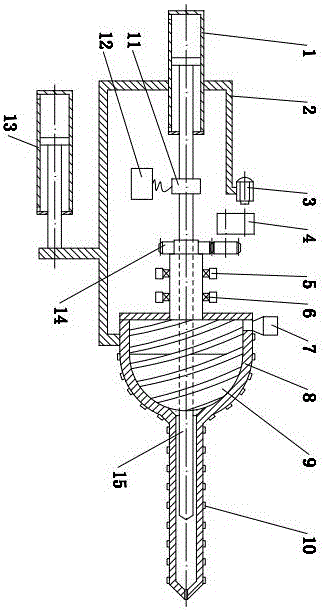

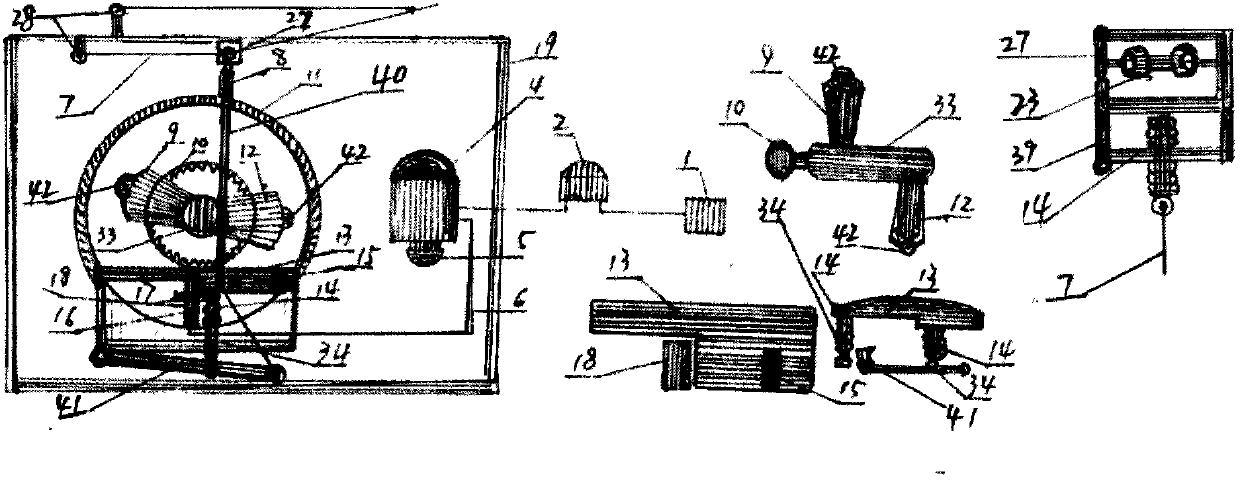

Inorganic material pressurization grouter used for mending concrete hole and seam

InactiveCN101429818AGuaranteed lubrication effectGood restorativeBuilding repairsCircular discRubber ring

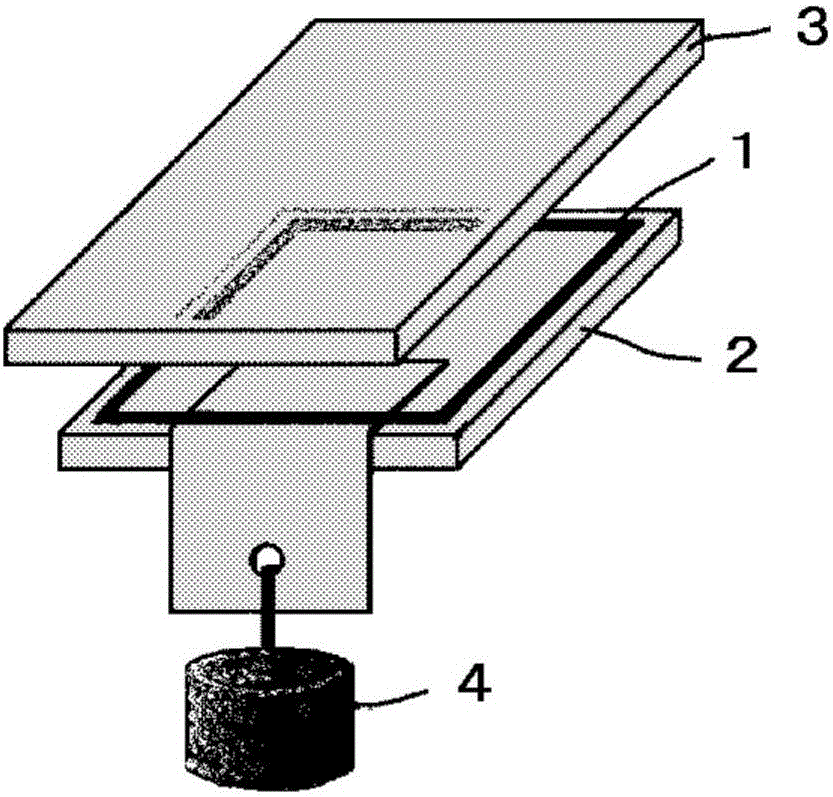

The invention discloses an inorganic material pressure grouting machine for repairing holes and seams of concrete, which relates to a pressure grouting machine. The pressure grouting machine can generate powerful extrusion force, and can extrude slurry of an inorganic material into the holes and the seams of the concrete to guarantee the full repair of defects of the concrete. The pressure grouting machine comprises a support, a plunger cylinder and a jack, wherein the support comprises an upper round disk, a lower round disk and a plurality of bolts which are fixedly connected between the upper round disk and the lower round disk; the plunger cylinder comprises a plunger and a cylinder body, the upper end of the plunger is fixed under the upper round disk, the lower end of the plunger is inserted into the cylinder body, and the plunger and the cylinder body are glidingly connected by two sealing rubber rings; the plunger between the two sealing rubber rings is provided with a lubricating oil outlet; the cylinder body comprises a cylinder barrel, a cylinder bottom cover, and a rubber block; the cylinder bottom cover is arranged on the top end of the jack; the cylinder bottom cover in the cylinder barrel is provided with the rubber block; and the lower part of the cylinder barrel is provided with a slurry inlet pipe and a slurry outlet pipe. The pressure grouting machine is used for repairing the holes and the seams of the concrete by using inorganic slurry to overcome the defects caused by adopting organic material fillers.

Owner:王镇生 +1

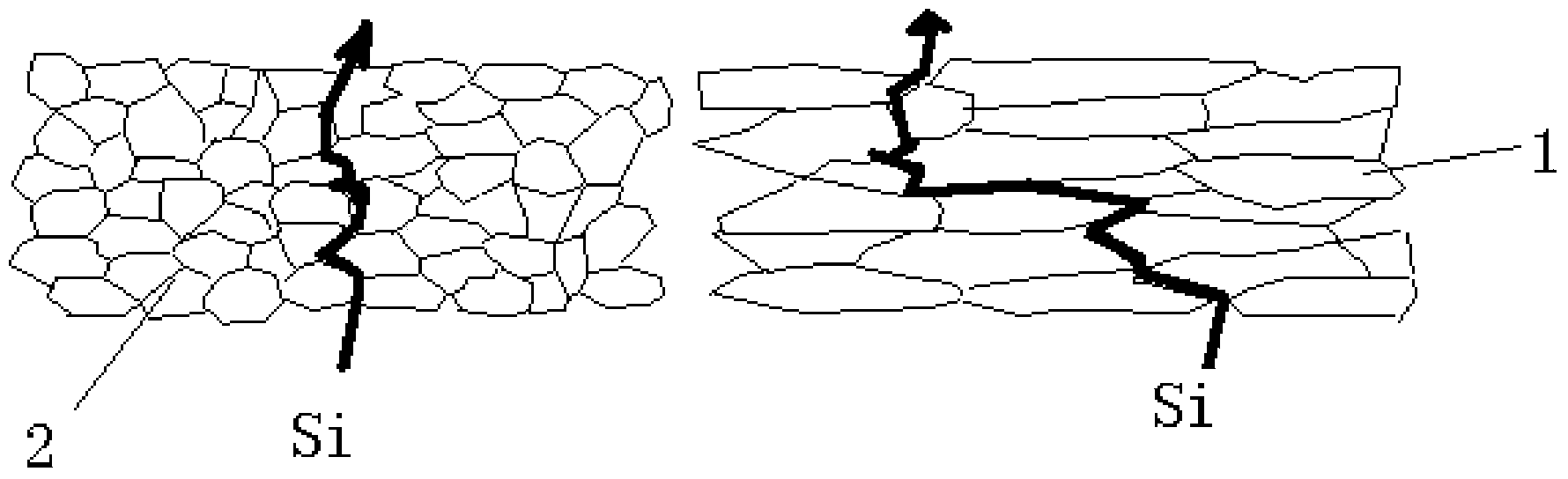

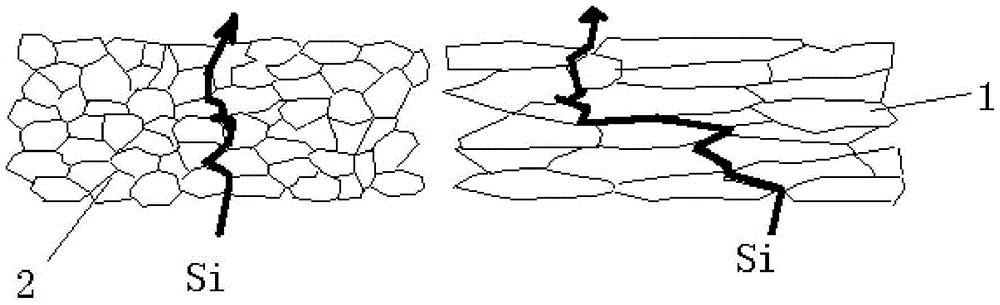

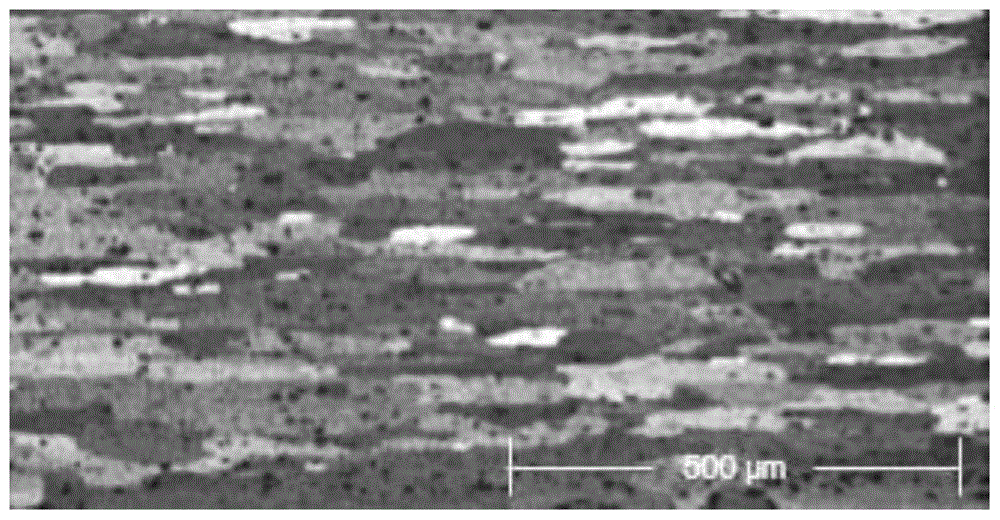

Aluminum alloy, micro channel aluminum flat tube, preparation method of micro channel aluminum flat tube, heat exchanger and electric appliance

ActiveCN104109781ALow degree of alloyingImprove the extrusion effectTubular elementsRare-earth elementPlate heat exchanger

The invention discloses an aluminum alloy, a micro channel aluminum flat tube, a preparation method of the micro channel aluminum flat tube, a heat exchanger and an electric appliance provided with the heat exchanger. The aluminum alloy includes an Al element and inevitable elements, wherein the inevitable elements include an Fe element and an Si element; with the total weight of the aluminum alloy as 100%, the weight percentages of the Fe element and the Si element are 0<Fe<=0.2% and 0<Si<=0.15%; the aluminum alloy also includes the following elements by the weight percentage: 0.1%<=Mn<=0.5%, 0.15%<=Cu<=0.45%, and at least two of Zr, B, Cr and RE, wherein the total content of at least two of Zr, B, Cr and RE is 0.05%-0.5%, and RE is a rare earth element. The aluminum alloy has the advantages of low alloying degree, good extrusion performance and high corrosion resistance; and the micro channel aluminum flat tube prepared by the aluminum alloy has excellent corrosion resistance under a condition without any additional coating layer. The heat exchanger comprising the micro channel aluminum flat tube and the electric appliance have strong corrosion resistance and long service life.

Owner:MIDEA GRP CO LTD

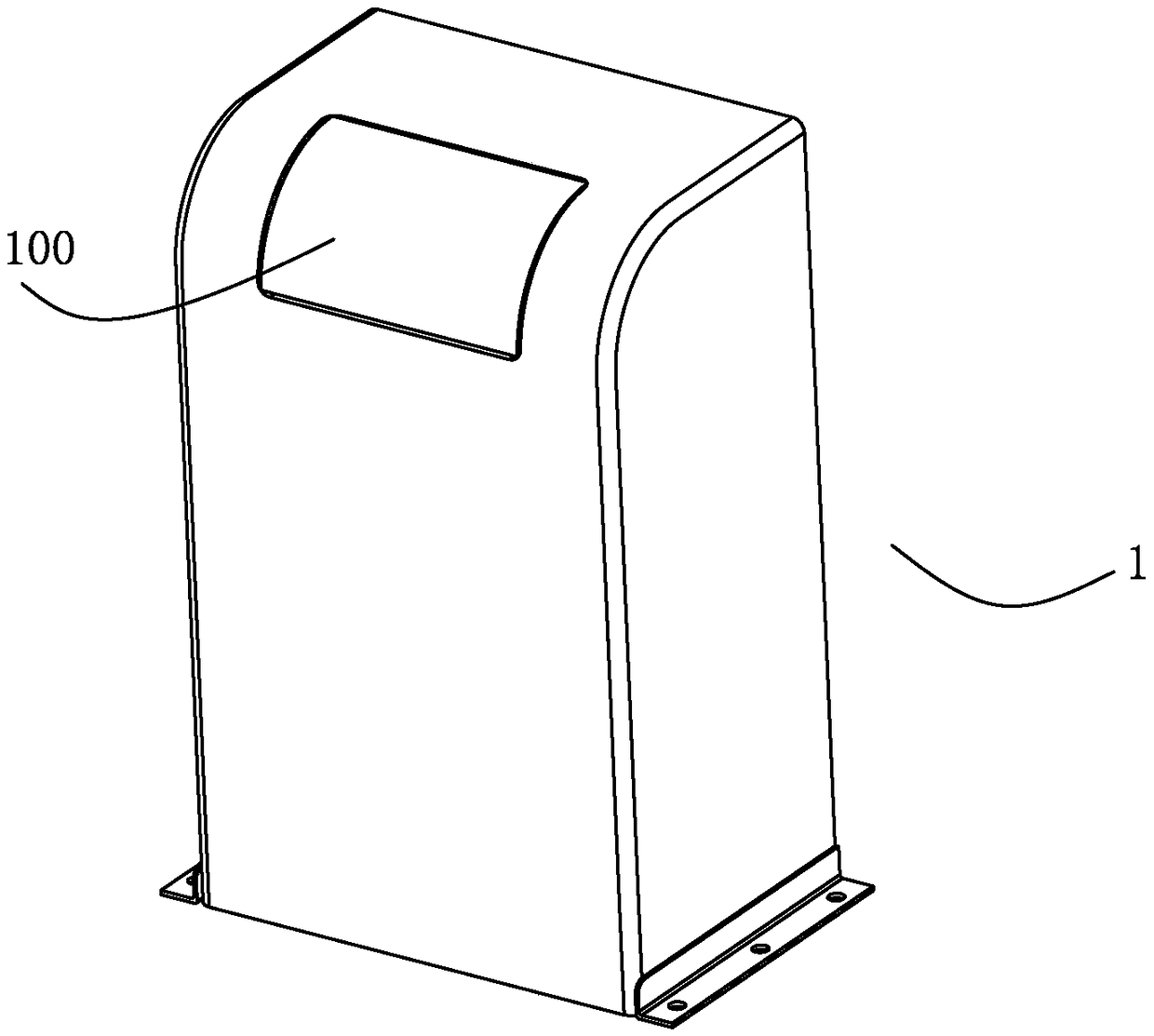

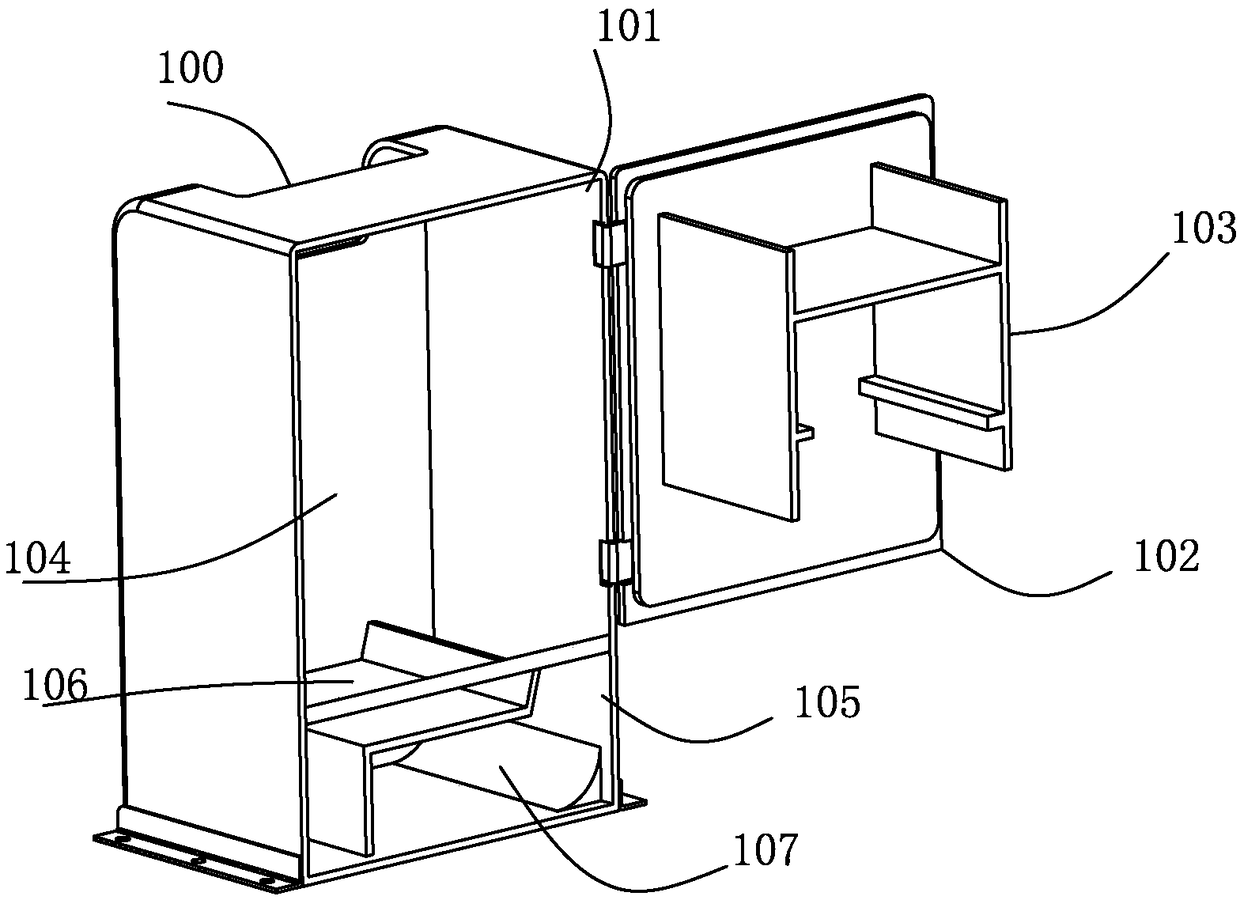

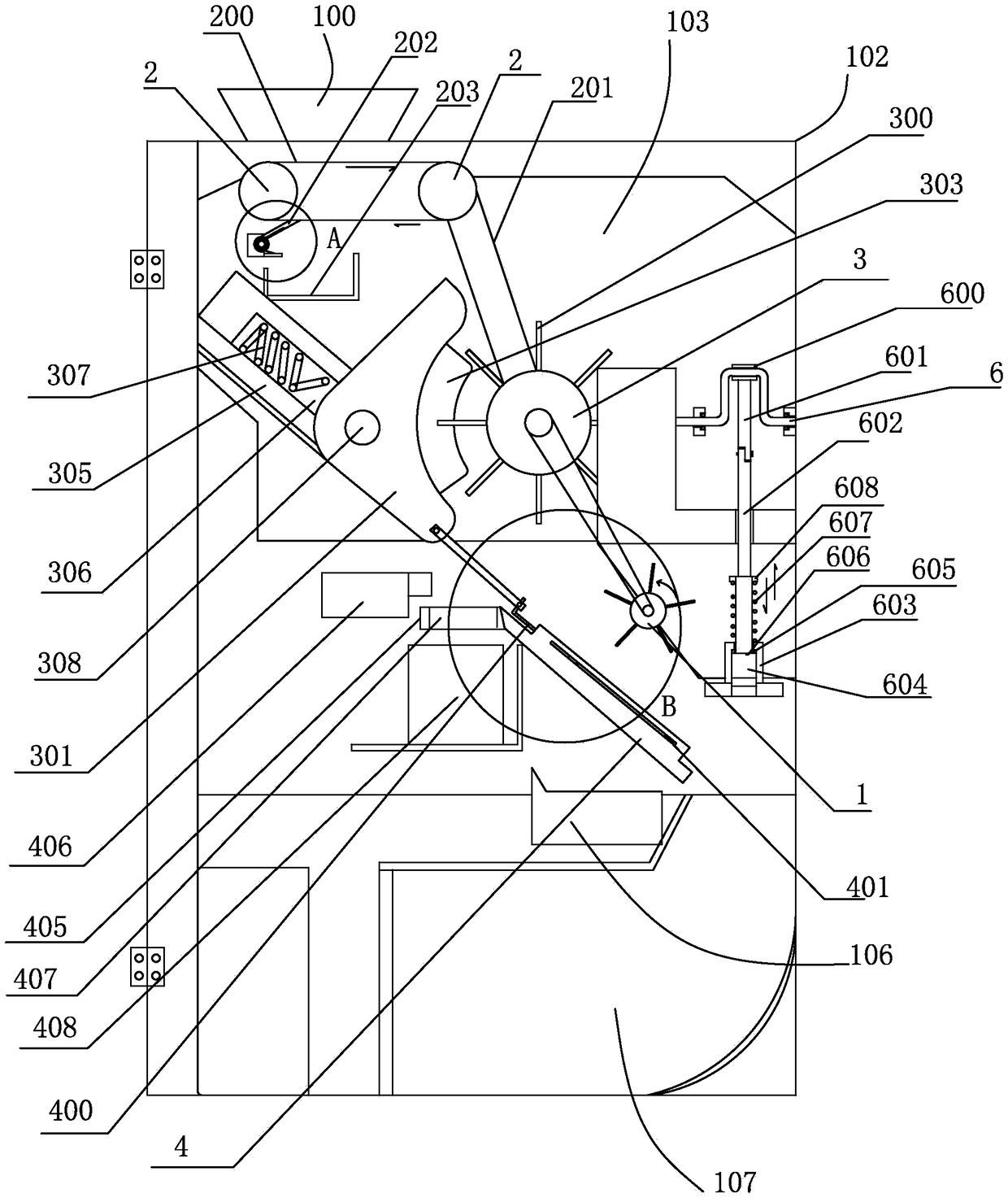

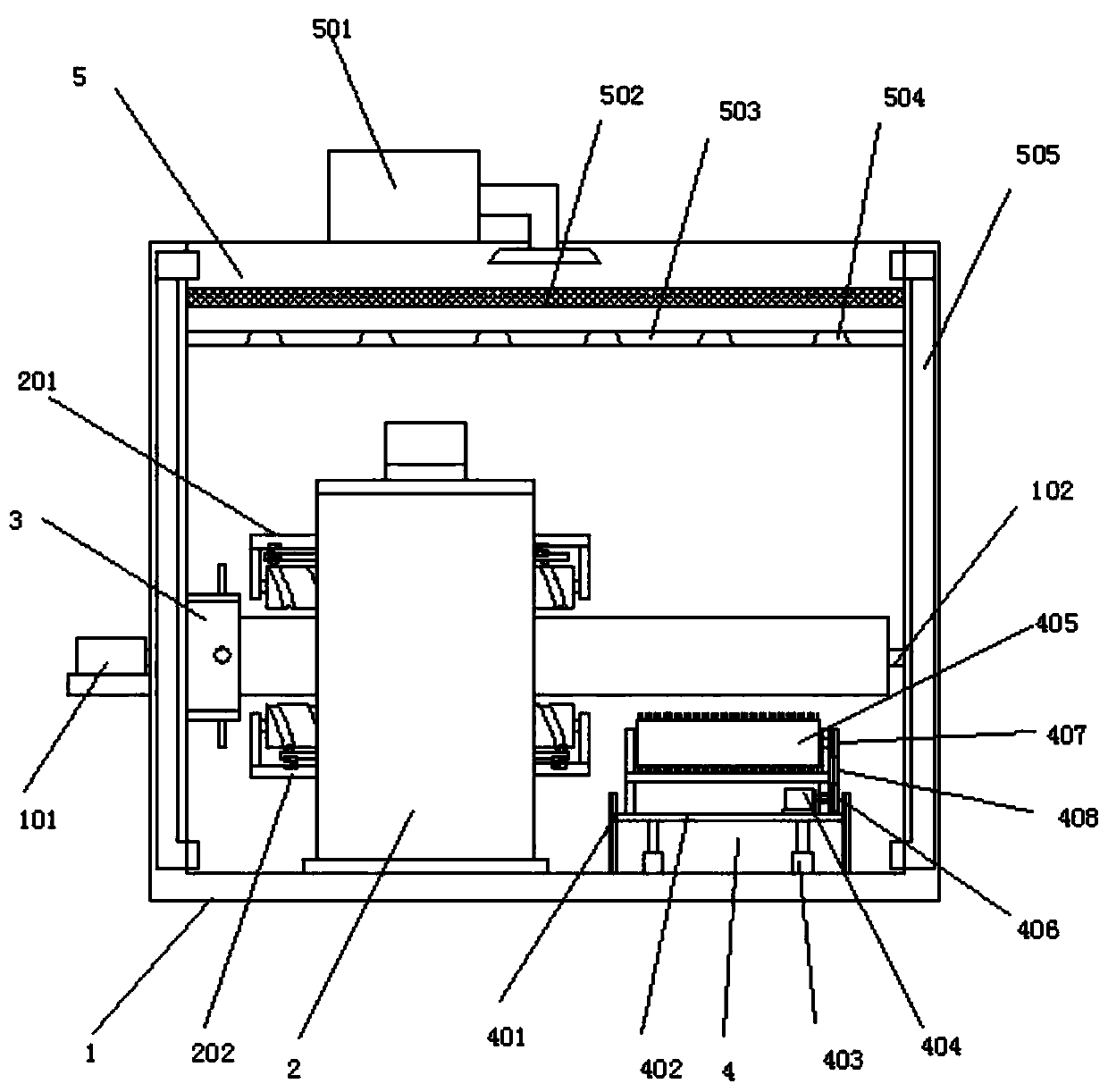

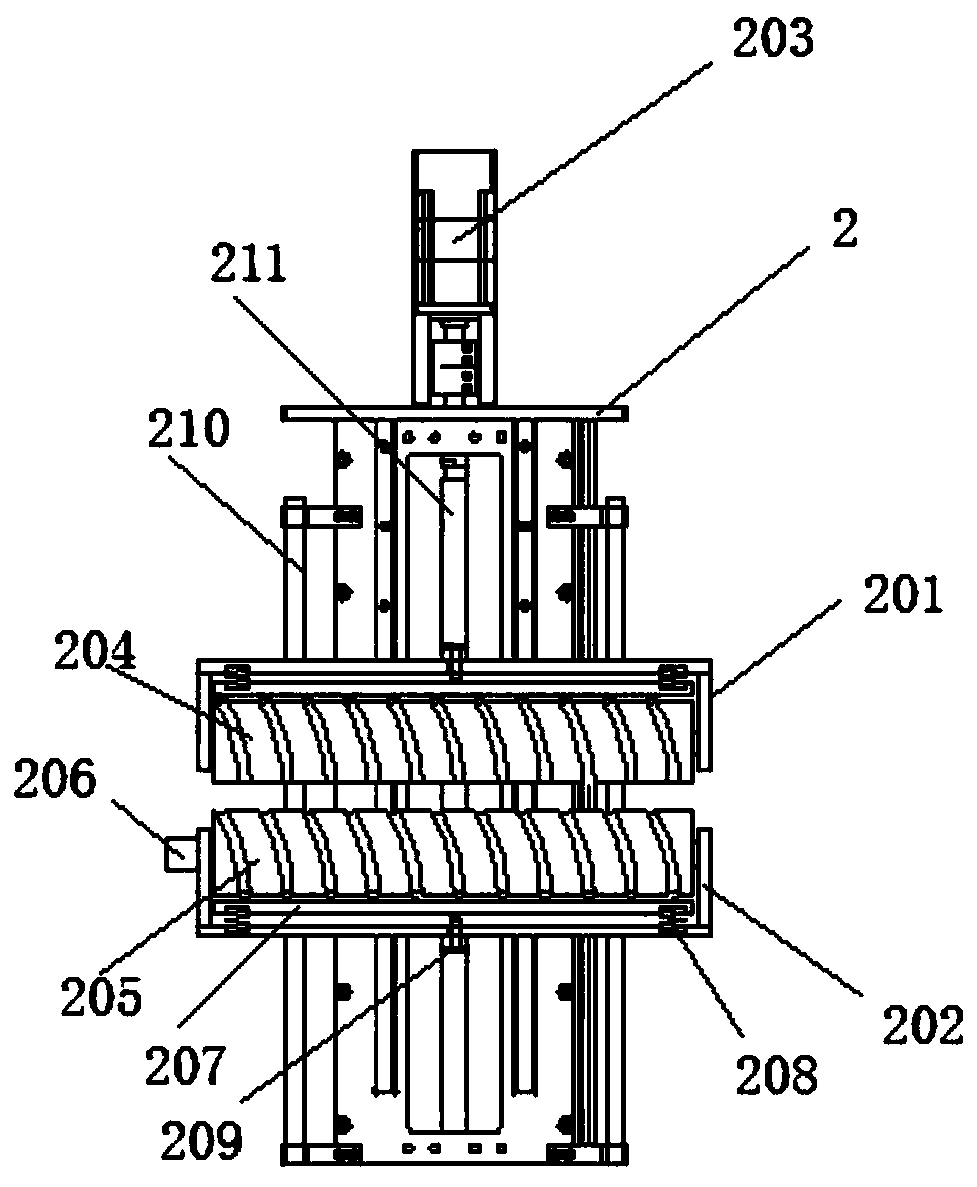

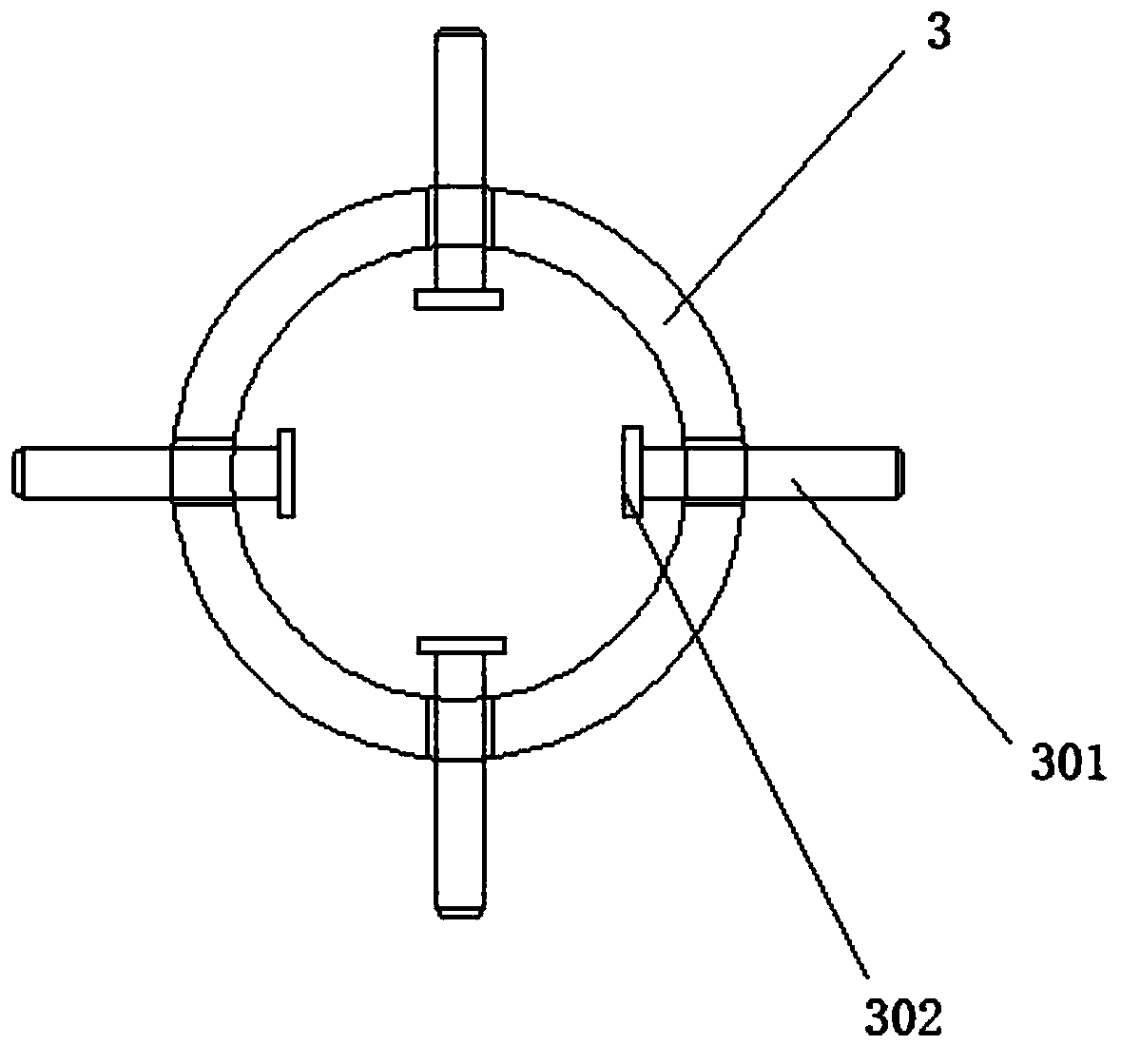

Environment-friendly garbage can

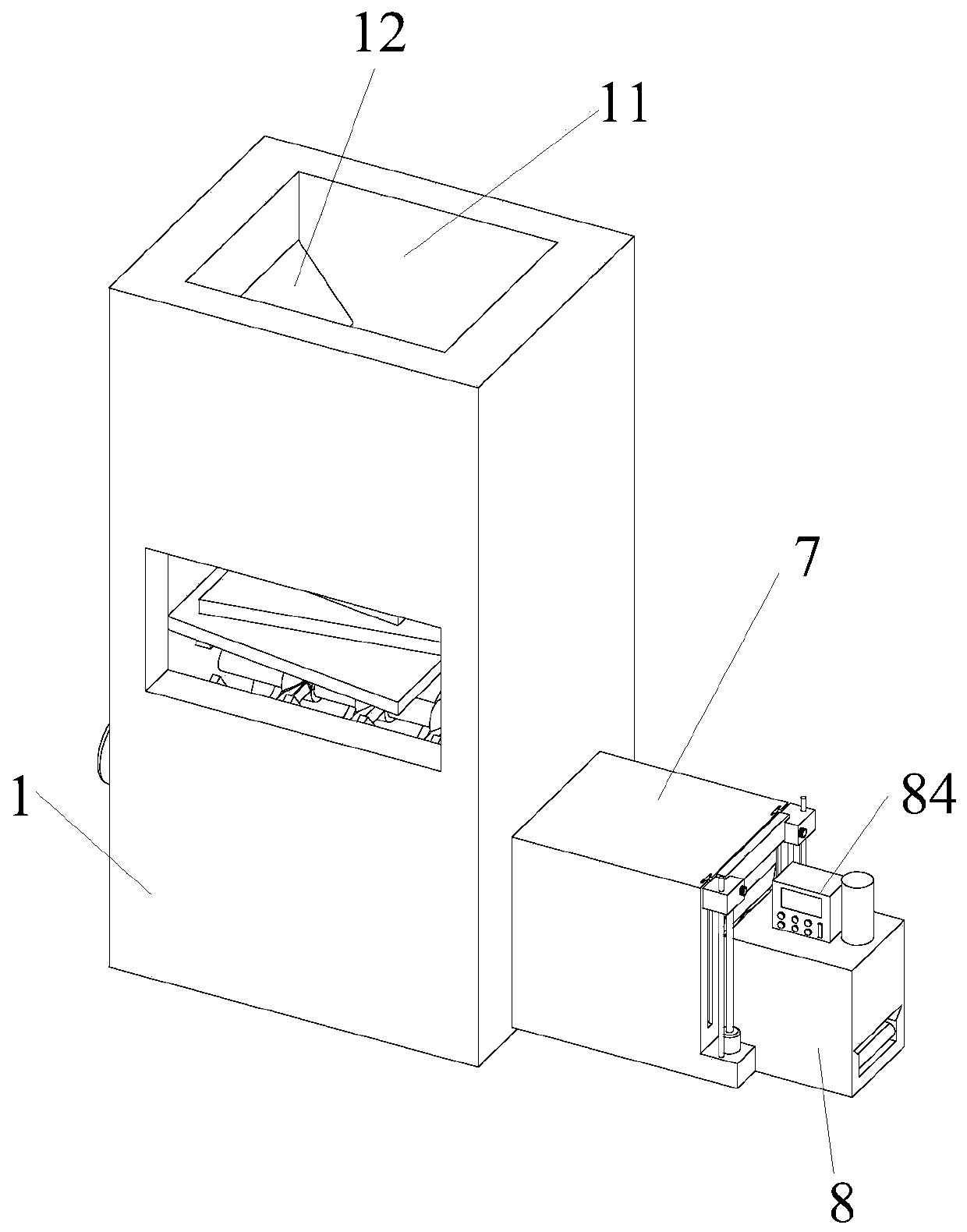

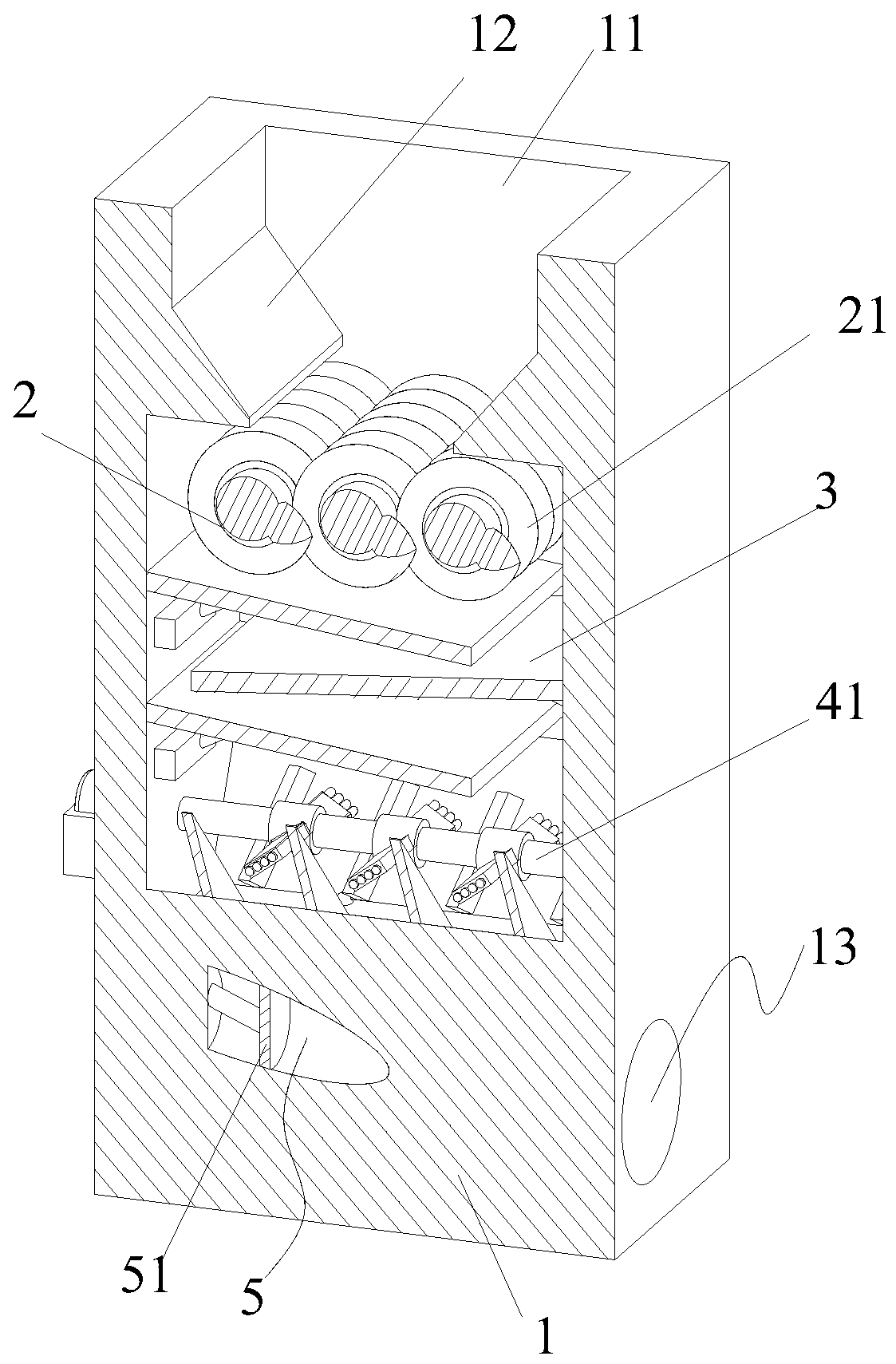

InactiveCN108773613ASmall footprintAvoid safety hazardsRefuse receptaclesWaste collectionDrive motor

The invention discloses an environment-friendly garbage can. The environment-friendly garbage can comprises a garbage can body; an inner cavity, a garbage feeding opening and a garbage discharging opening are formed in the garbage can body, and a garbage conveying device, a crushing mechanism, a screening mechanism, a compressing mechanism, a driving motor and at least two garbage collecting siloscommunicating with the garbage discharging opening are arranged in the inner cavity of the garbage can body; the garbage conveying device is arranged below the garbage feeding opening, the crushing mechanism is arranged below the output end of the garbage conveying device; the screening mechanism is arranged below the crushing mechanism, and a plurality of leaking holes are formed in the screening mechanism to sort the garbage into two types; and the compressing mechanism is used for compressing the lightweight garbage falling from the lower end of the screening mechanism. The environment-friendly garbage can is compact and simple in structure, the burden of the follow-up garbage disposal can be reduced, the garbage can be compressed, the garbage occupying space is saved, the amount of the garbage storage is improved, and the garbage sorting collection and cleaning are facilitated.

Owner:叶于诚

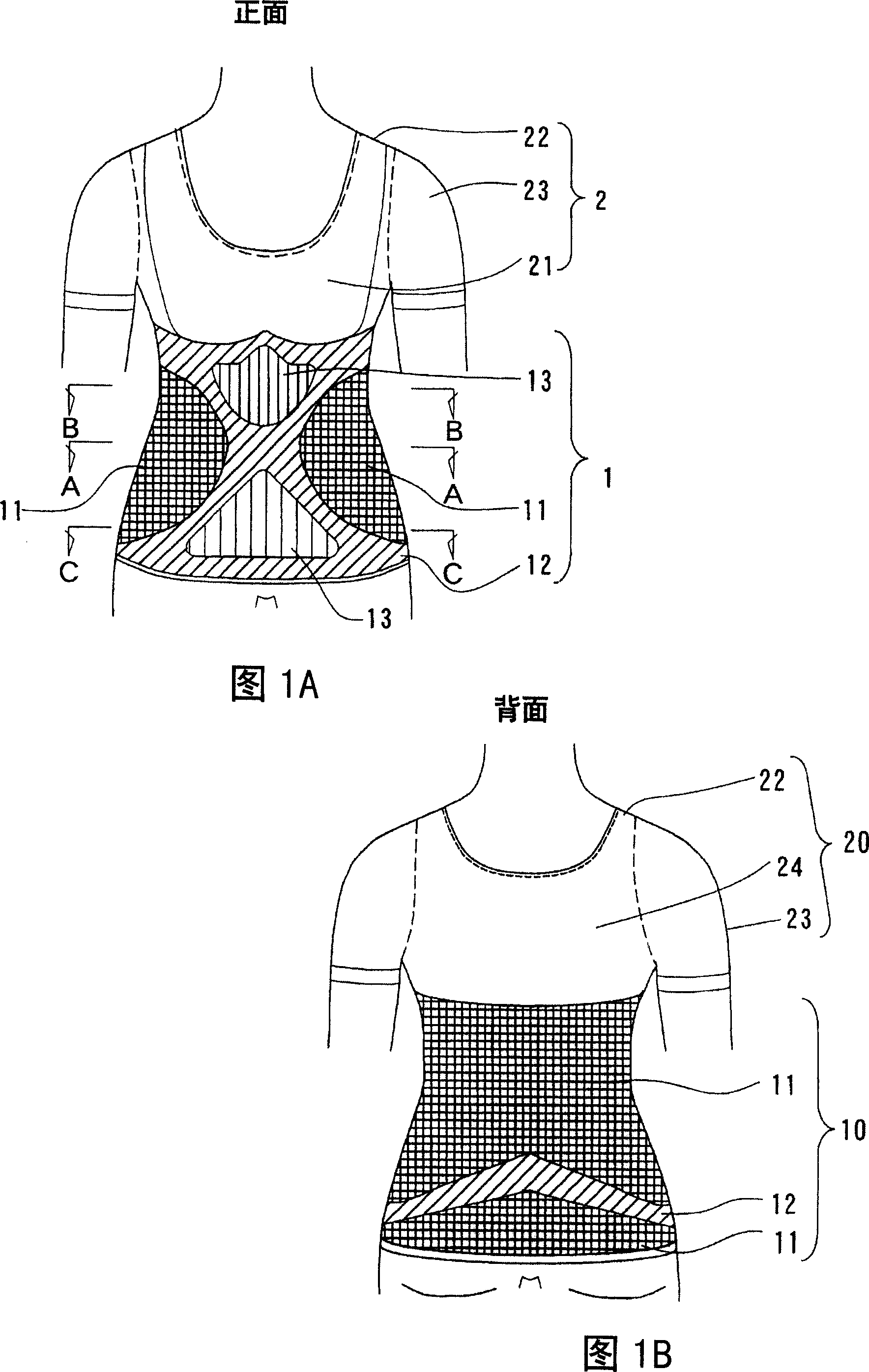

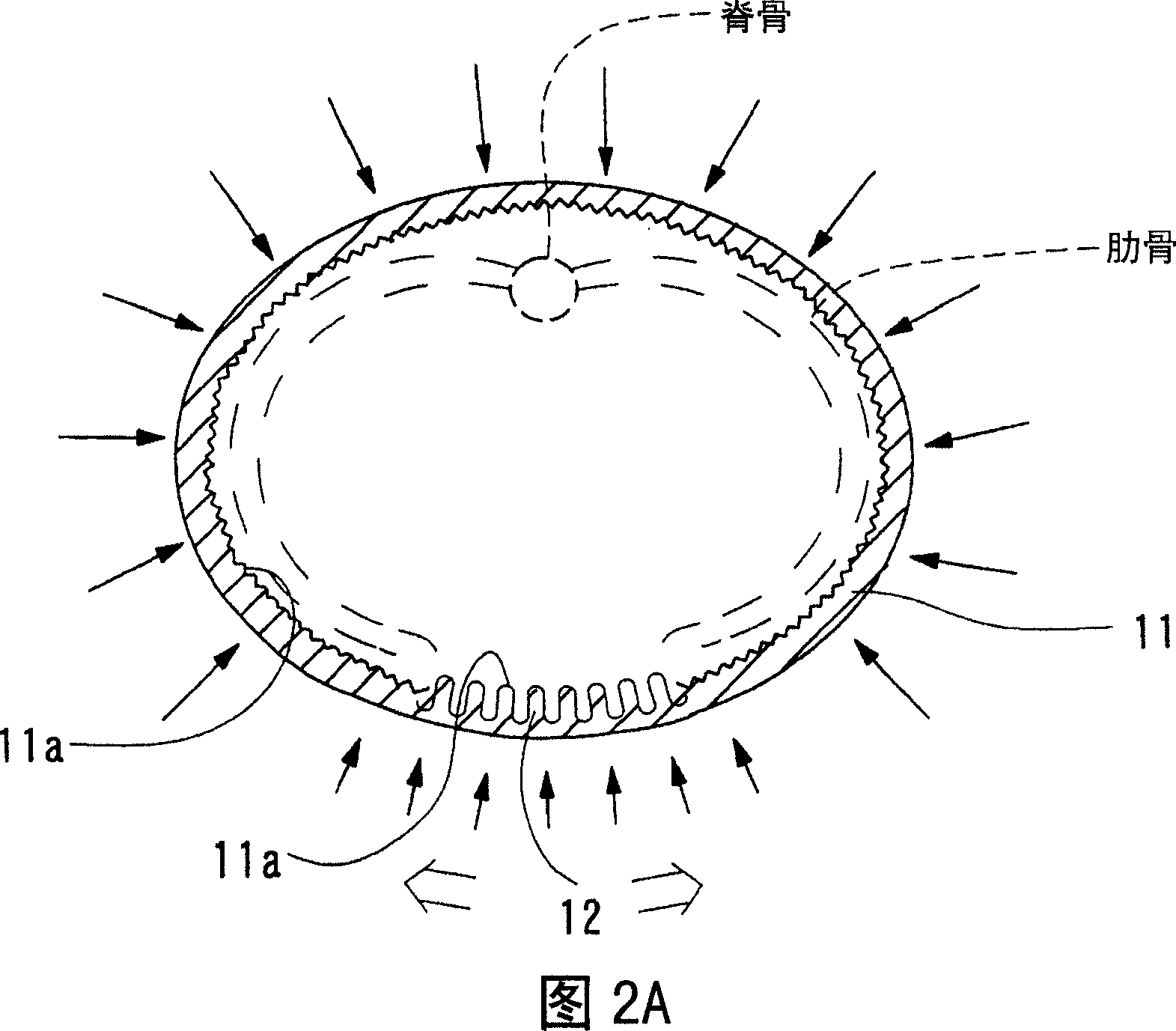

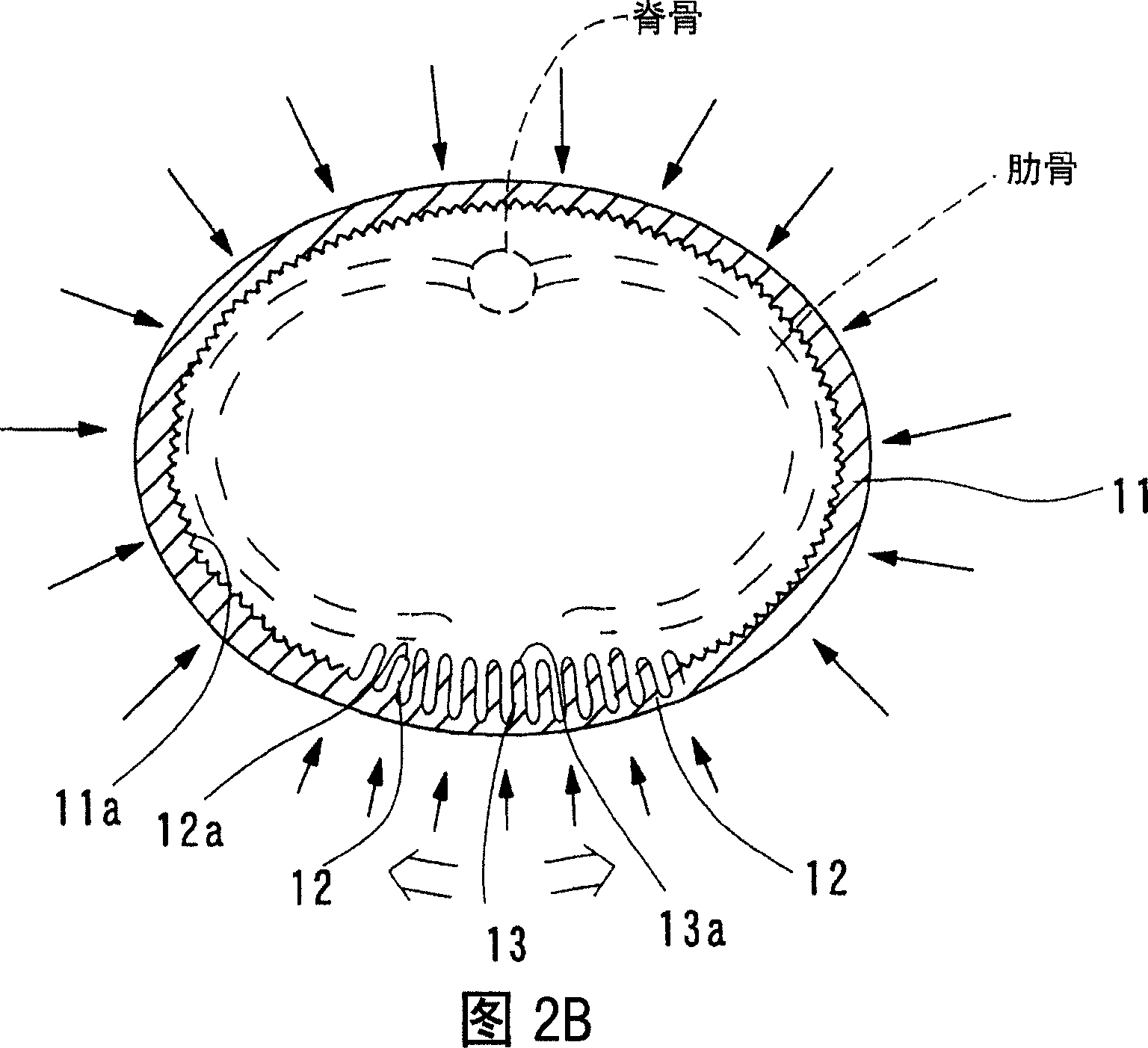

Clothes

InactiveCN1973713AEnhanced Body ShapingImprove extruded aestheticsGarmentsBiological bodyEngineering

The invention provides a dress which does not disturb the organism function of wearing people and reinforces body type dressing and enhances aesthetic feeling of wearing shape. A high-pressure weave tissue forms a high-pressure weave region which extends from the back side of body to the center of the front side to form a taper shape region, and a mid-pressure weave region consisting of a mid-pressure weave tissue is formed adjacent to the high-pressure weave region, and a low-pressure weave region consisting of low-pressure weave tissue is formed near the taper high-pressure region in the mid-pressure weave region. So the back side framework of the people wearing the dress can be supported with strong force in manner of being squeezed by the high-pressure weave tissue, and the people's abdomen is squeezed softly and firmly under the effect of the taper high-pressure weave tissue continuously from back side to front side and the adjacent mid-pressure weave tissue and the low-pressure weave tissue, therefore, the biological function such as visceral function and like will not be disturbed, and the dress can reinforces body type modifying and enhance the squeezed aesthetic feeling.

Owner:IIDAKUTSUSHITA +1

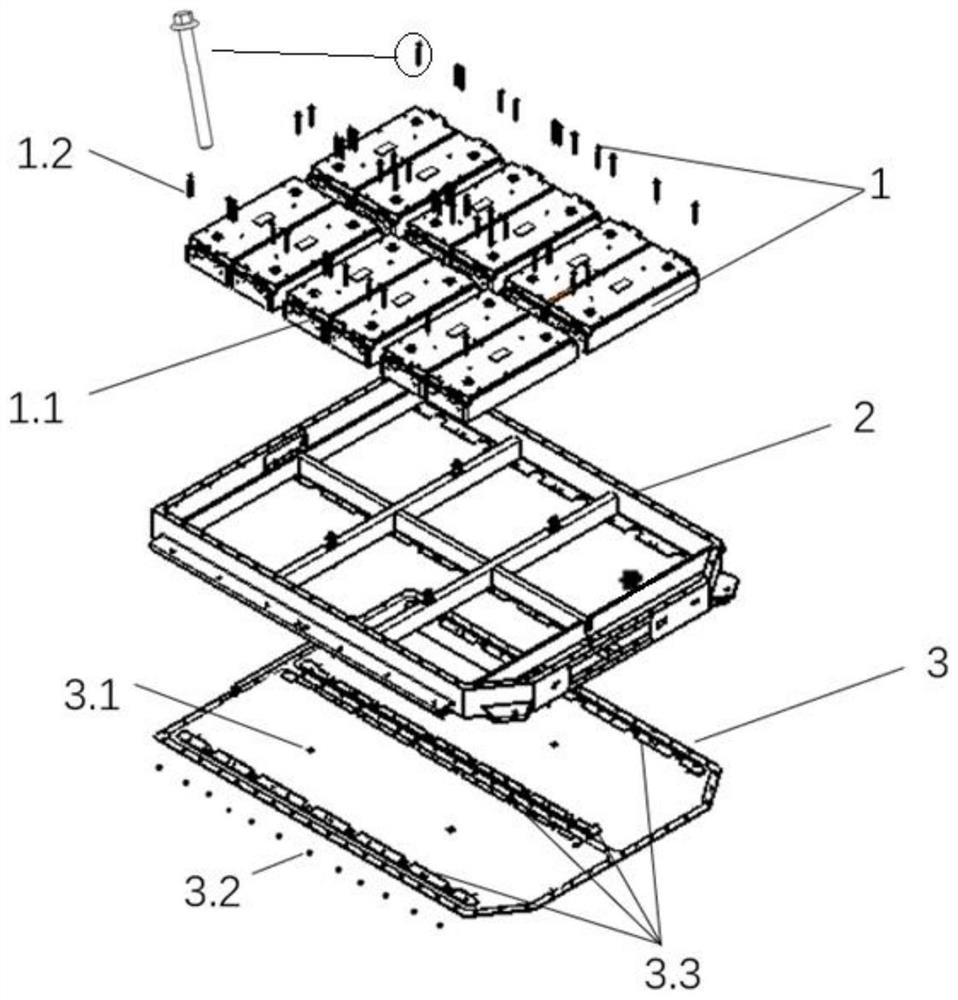

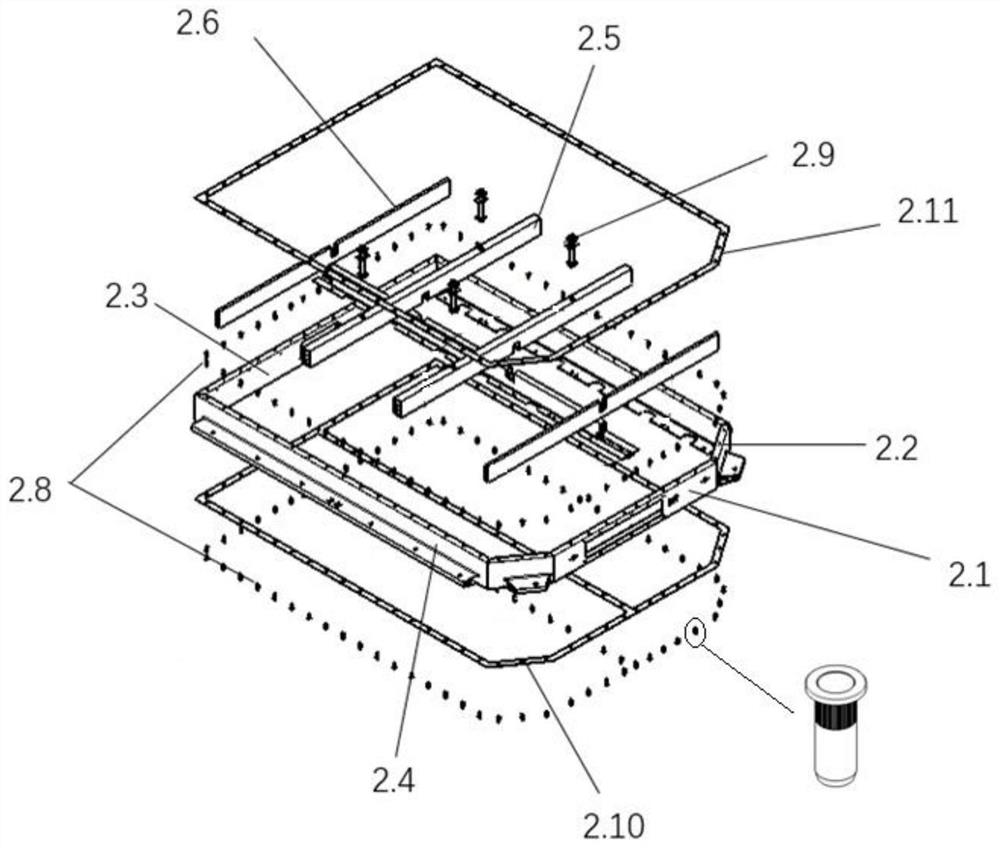

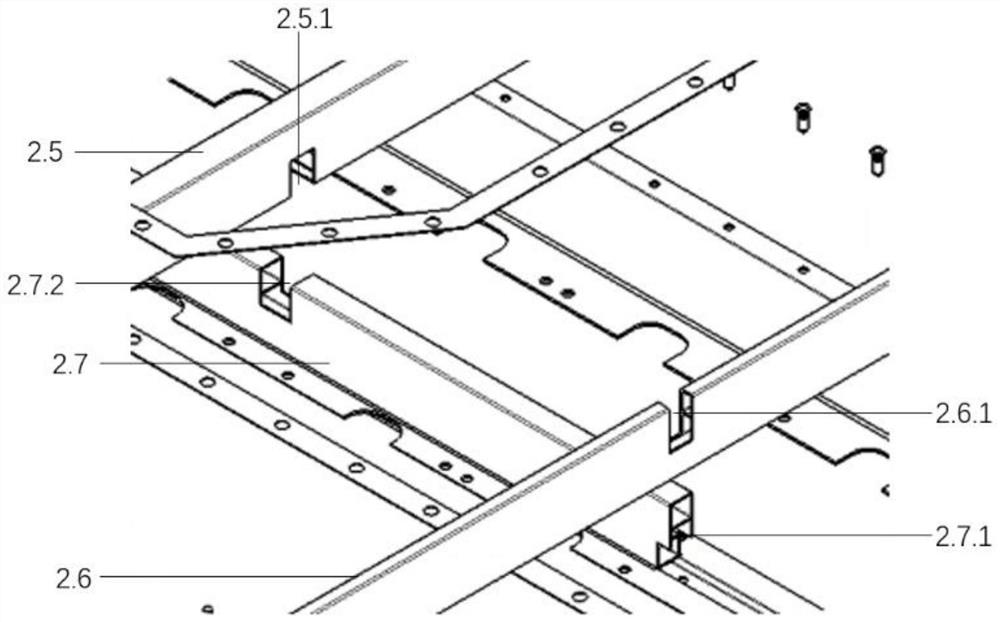

Lower box body of power battery

InactiveCN112117410AStrong impact resistanceStrong extrusionCell component detailsPropulsion by batteries/cellsPower batteryLap joint

The invention discloses a lower box body of a power battery. The lower box body comprises a power battery module assembly, a frame beam assembly and a steel lower bottom plate, wherein the main body of the frame beam assembly is an extruded aluminum profile; the frame beam assembly comprises a front edge beam, a rear edge beam, left and right edge beams, corner edge beams, cross beams and longitudinal beams; u-shaped openings are formed in the lap joint positions of the cross beams on the front side and the rear side and the longitudinal beams, and steps are arranged on the lap joint positionsof the longitudinal beams and the cross beams on the front side and the rear side; an n-shaped opening is formed in the position, in lap joint with the longitudinal beam, of the middle cross beam, and a u-shaped opening is formed in the position, in lap joint with the middle cross beam, of the longitudinal beam; rivet nuts are evenly distributed on the upper side and the lower side of the edge beam along the line, sealing foam is attached to the upper box body on the upper side of the frame beam assembly, sealing foam is attached to the lower bottom plate on the lower side of the frame beam assembly, and the frame beam assembly is fixed to the upper box body through upper box body fastening bolts and the rivet nuts and fixed to the lower bottom plate through lower bottom plate fastening bolts and the rivet nuts. The composite material is light in weight, low in cost and high in impact resistance and extrusion resistance.

Owner:DONGFENG MOTOR CORP HUBEI

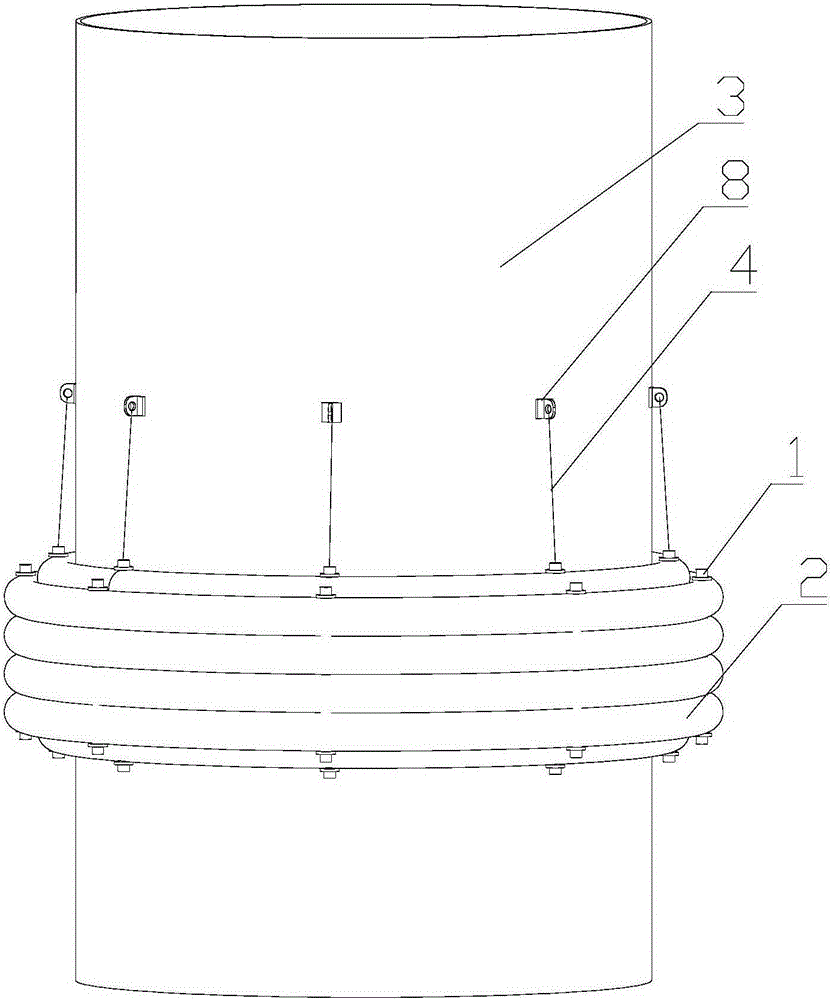

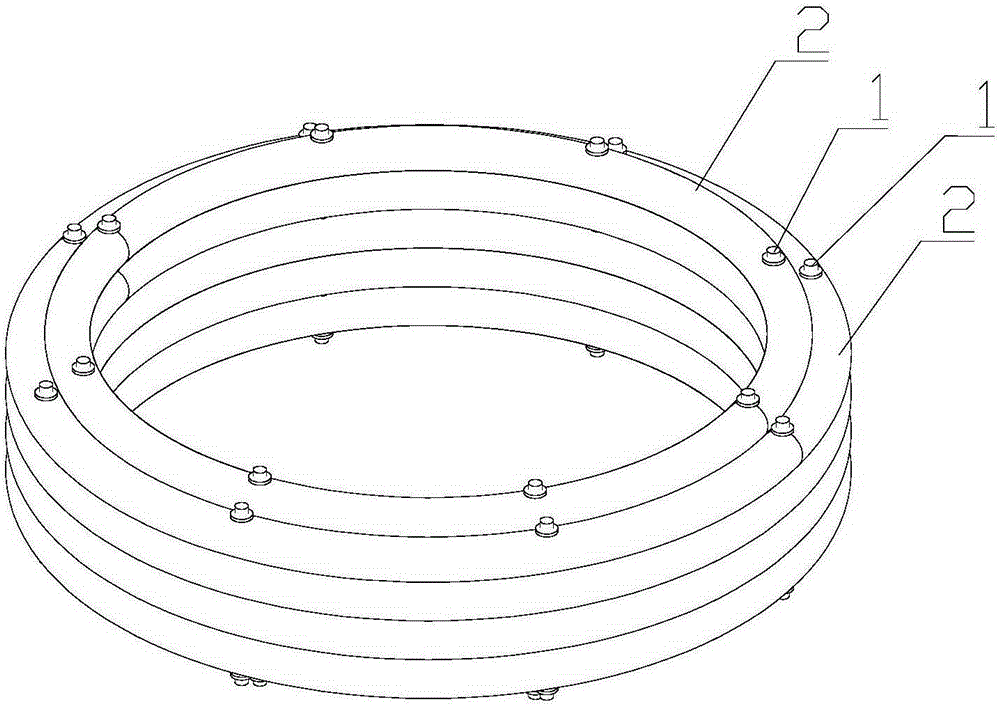

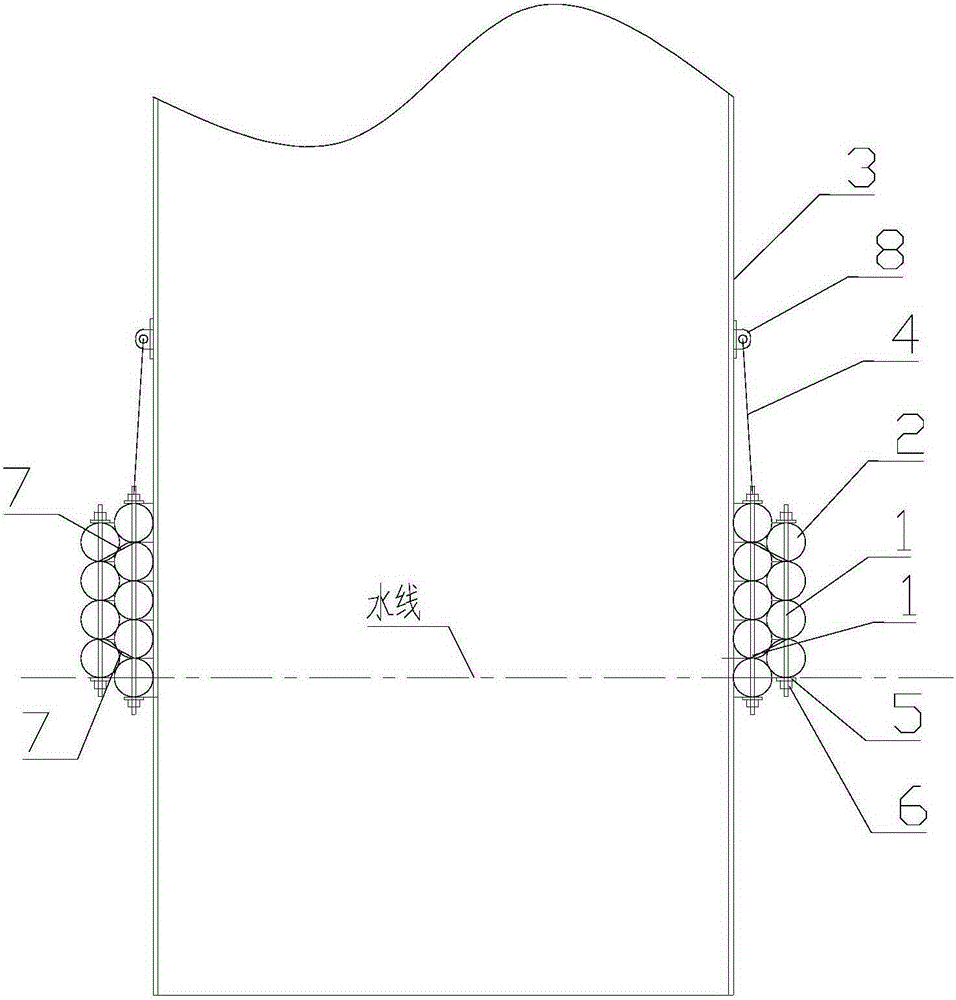

Collision and ice preventing device of sea fan

ActiveCN105297681AEasy to transportReduce weightClimate change adaptationShipping equipmentSea iceEngineering

The invention relates to a collision and ice preventing device of a sea fan. The device comprises collision preventing cylinder structures with two or more layers, wherein the collision preventing cylinder structure consists of more than two collision preventing rings; the collision preventing rings are vertically laminated; multiple serial connecting rods are vertically inserted in the peripheral direction of the collision preventing cylinder structure; the serial connecting rods penetrate through the collision preventing rings one by one to serially connect the collision preventing rings; the collision preventing rings are spliced by collision preventing rubber pipes passing through the serial connecting rods; the spliced ports of the collision preventing rings are staggered from one another; clamping parts are arranged at the two ends of the serial connecting rods exposed on the collision preventing cylinder structure; the adjacent collision preventing cylinder structures are mutually connected through connecting pieces; and the collision preventing cylinder structures coat a fan foundation, and are lifted with the fan foundation through lifting cables. The collision and ice preventing device has the advantages of easy installation and low manufacturing cost. The structure can effectively buffer the impact of operation and maintenance ships to the fan foundation and the squeezing effect of ice layers in the winter sea icing season on the fan foundation, and can effectively weaken the scouring effect of seawater on the fan foundation.

Owner:NEW UNITED GROUP

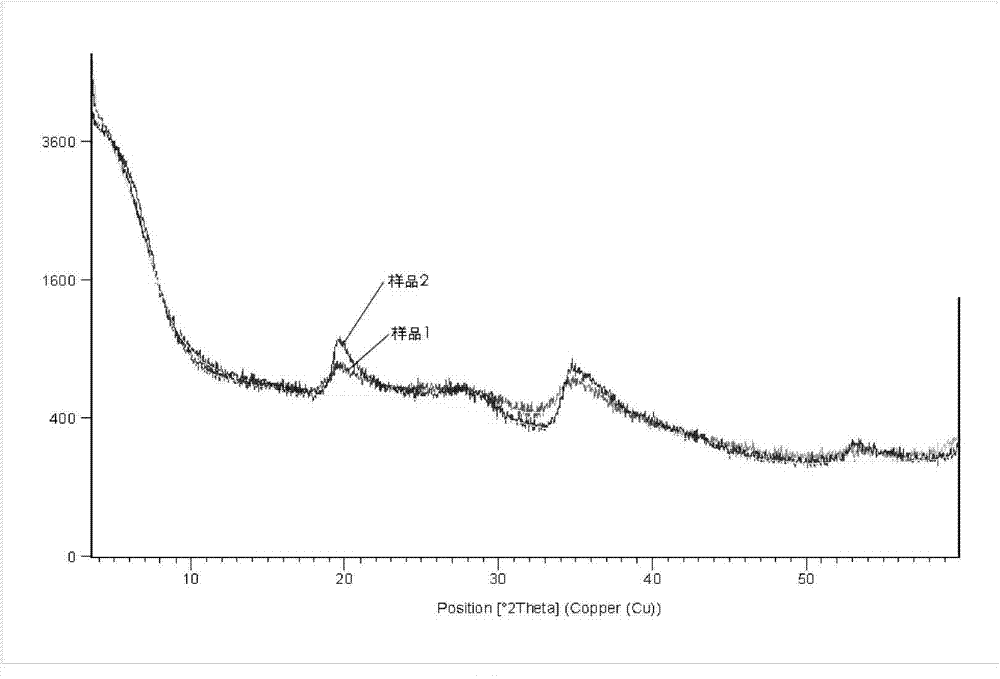

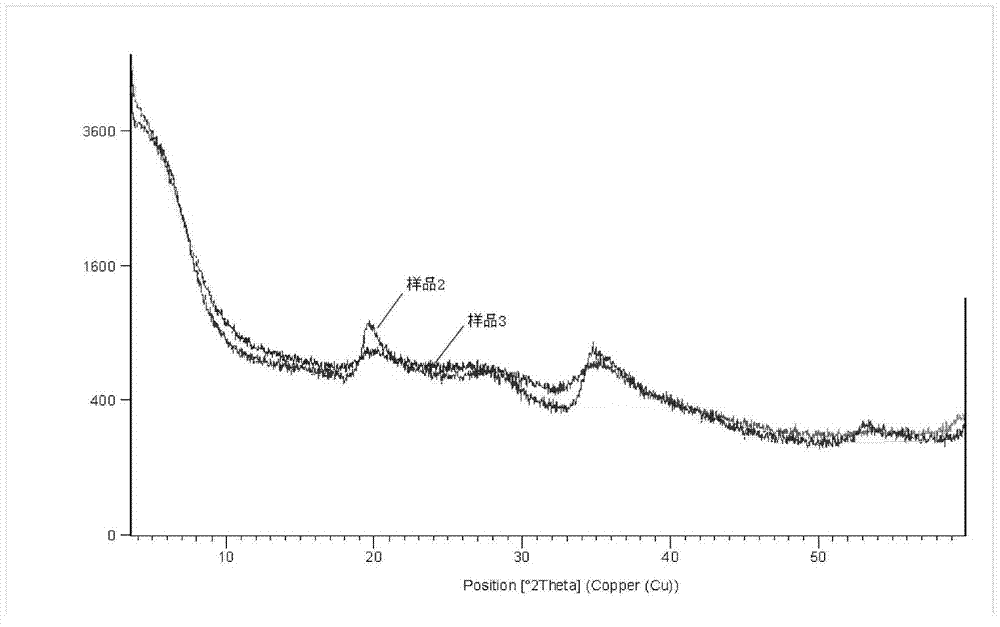

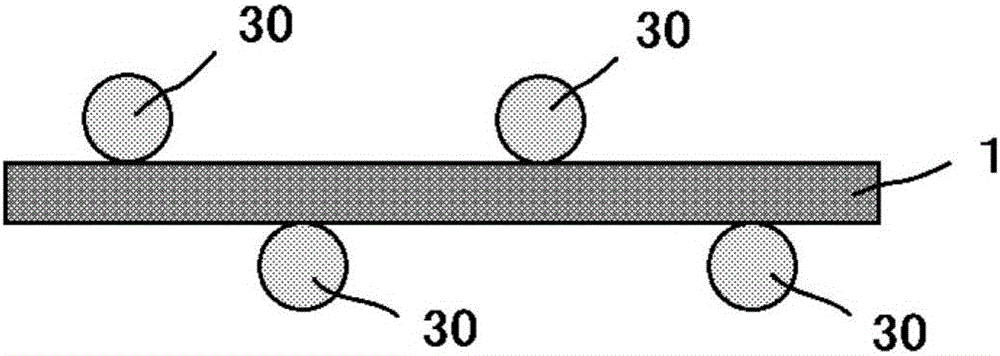

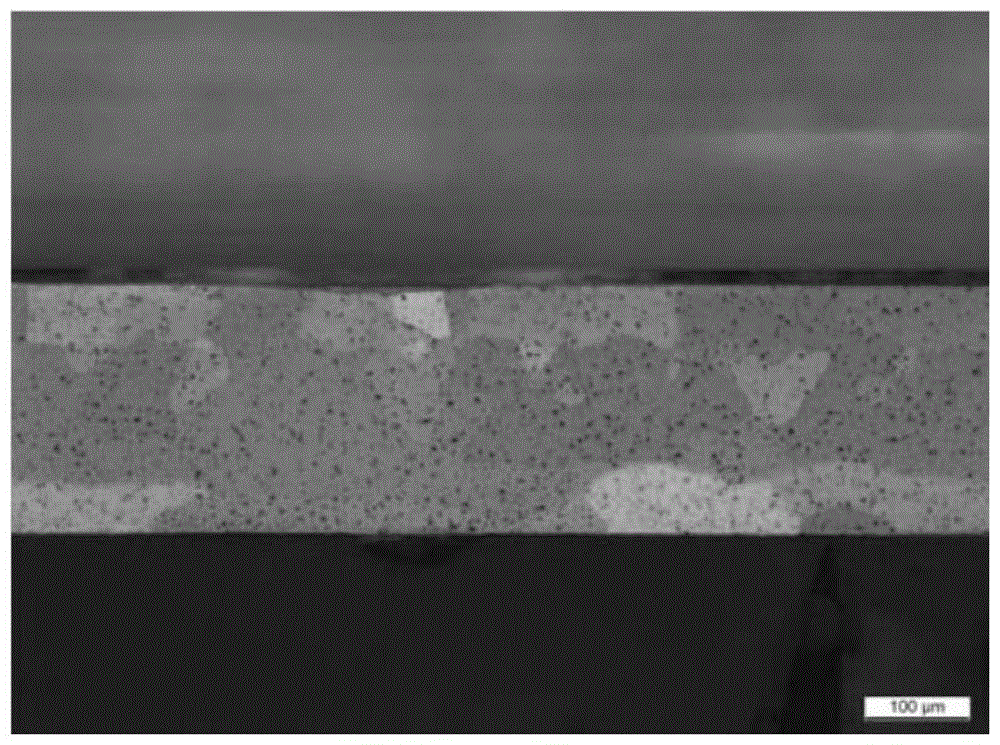

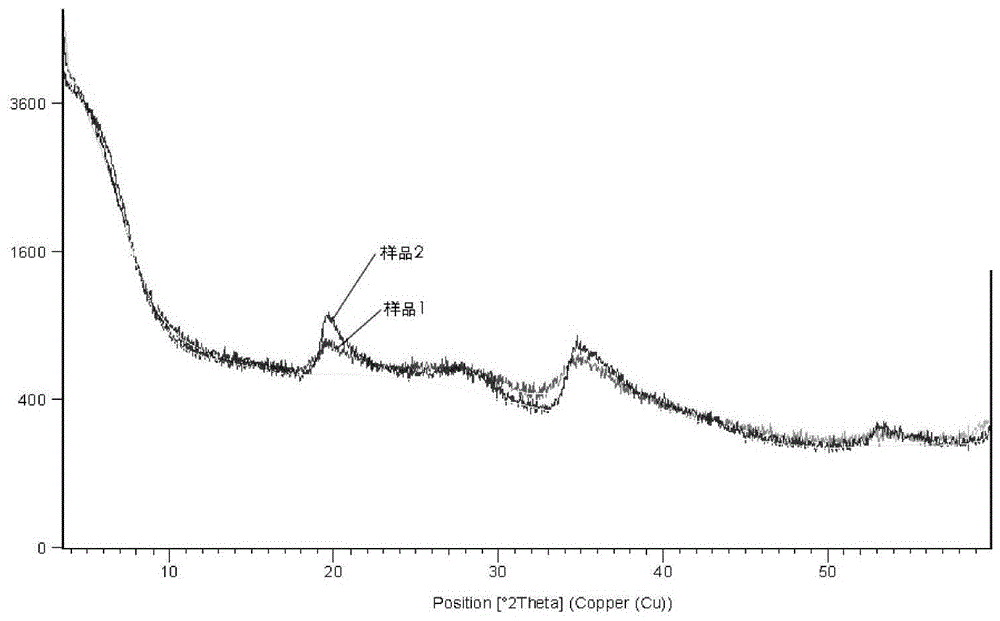

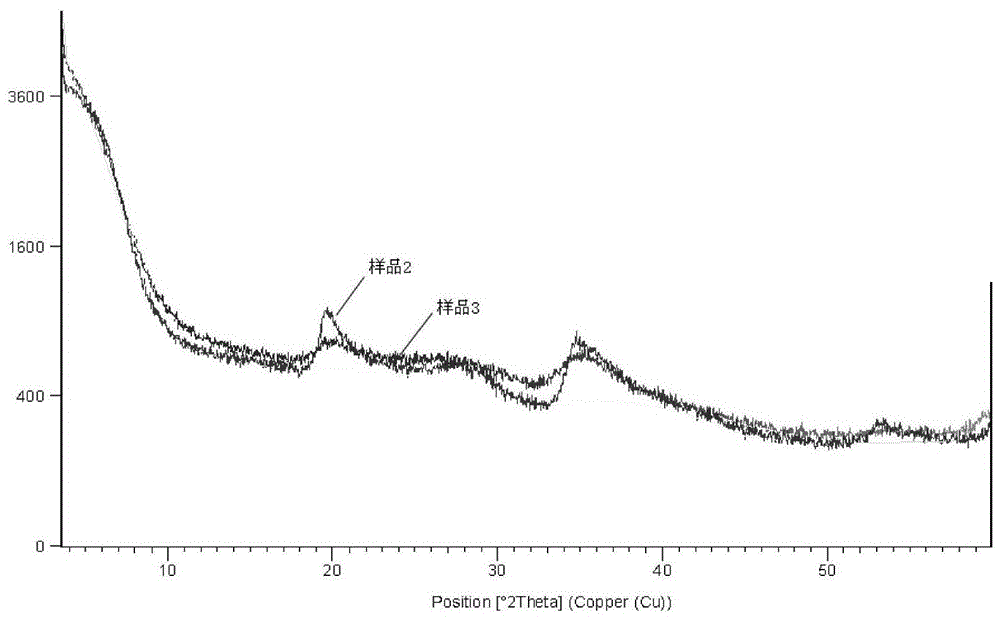

Method for mechanochemically synthesizing magnesium lithium silicate

ActiveCN104760966AGuaranteed uniformitySmall particle sizeSilicon compoundsSlurryTemperature resistance

The invention discloses a method for mechanochemically synthesizing magnesium lithium silicate, which comprises the following steps: 1) synthesizing a magnesium lithium silicate precursor, and controlling the temperature of the precursor at 30-99 DEG C; and 2) feeding the precursor into a wet-process superfine treatment device, grinding at 90-99 DEG C for 5-90 minutes, and drying the obtained slurry to obtain the target product magnesium lithium silicate. The diameter of the grinding medium spheres used by the wet-process superfine treatment device is 0.1-5mm, and the linear speed of the grinding medium spheres is 8-20 m / s. The magnesium lithium silicate is synthesized by using high temperature and high pressure instantaneously generated by the grinding medium, so the requirements for high temperature resistance and high pressure resistance of the device are low. The superfine treatment device in peculiar structure can perform continuous production, and can solve the problem in batch production in the traditional hydrothermal reaction kettle. Compared with the traditional hydrothermal synthesis, the method disclosed by the invention has the advantages of lower cost and higher safety, and can easily implement industrialization.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

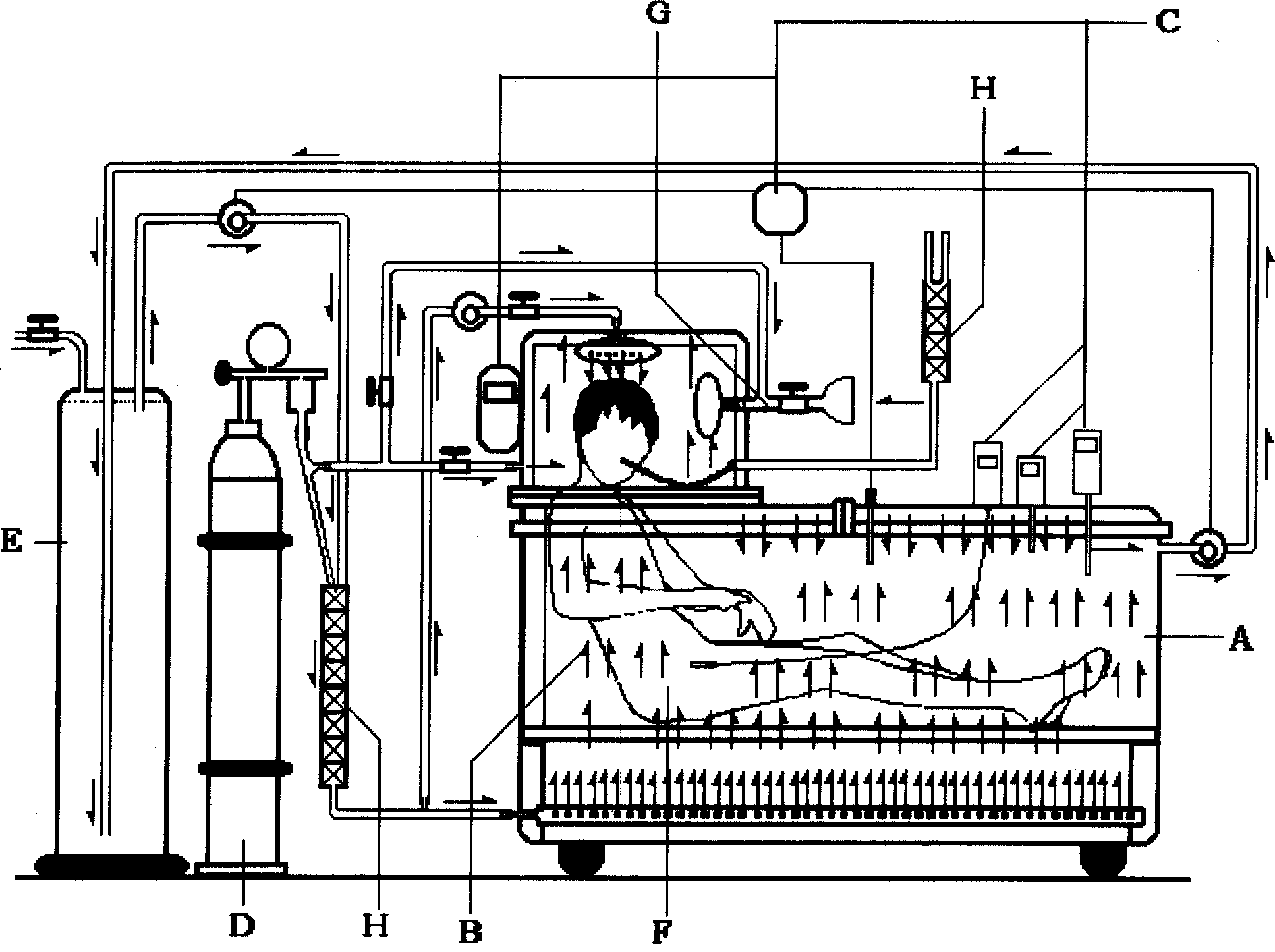

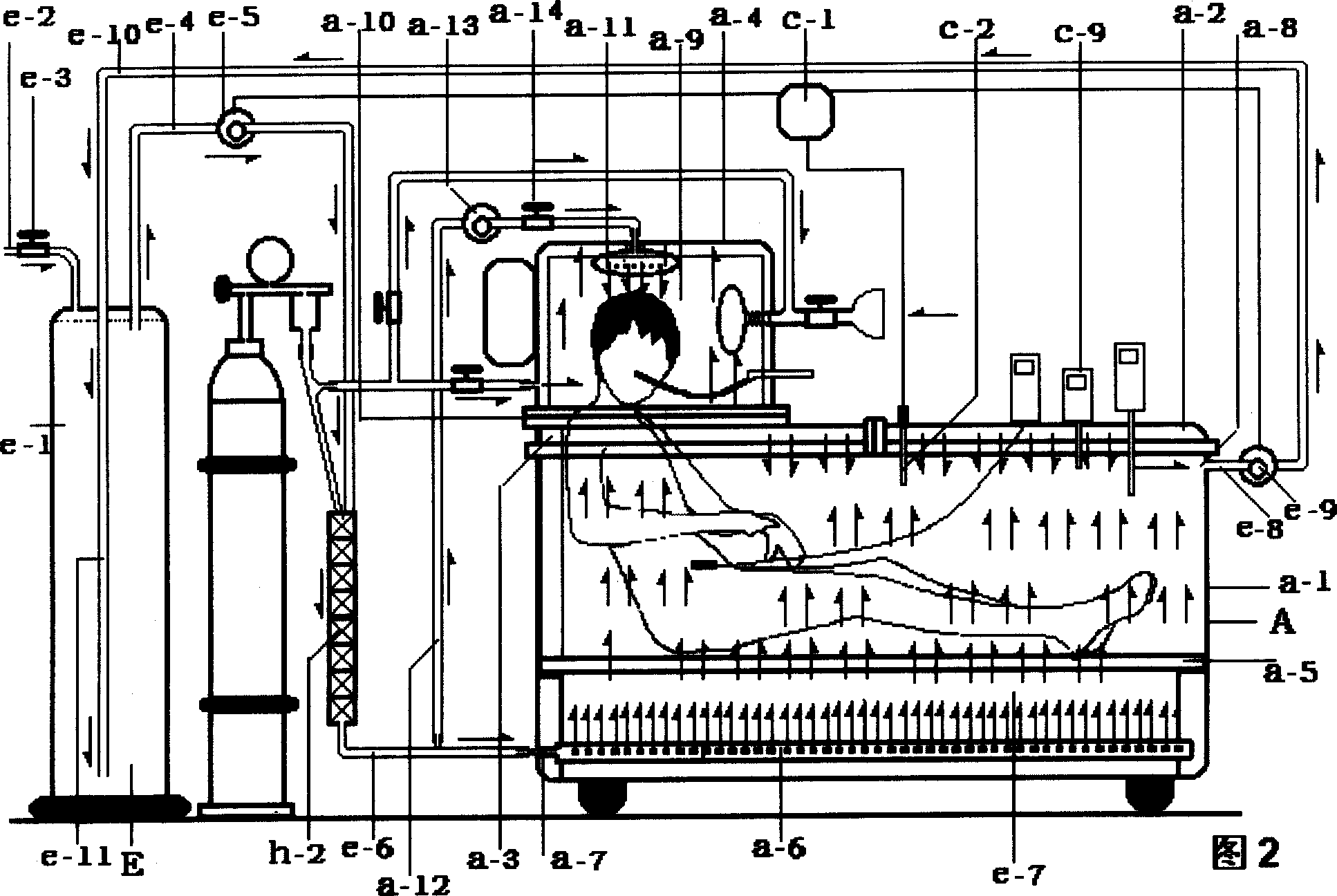

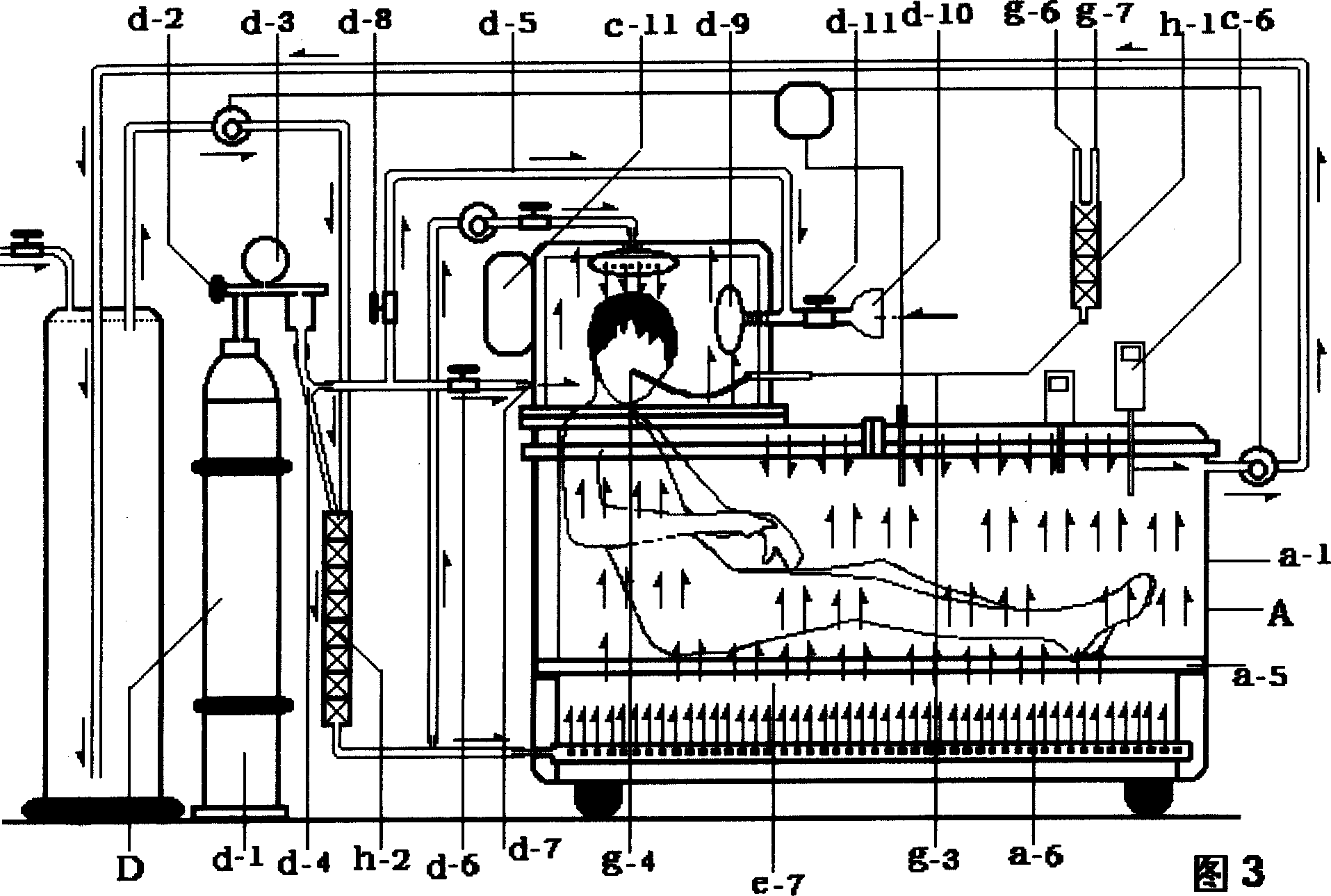

Ultra dissolving oxygen high pressure high temperature hot water facility for prevention and treatment of cancer

The oxygen-dissolving high pressure and high temperature hot water cancer preventing and treating apparatus includes treating bed unit, hot water supplying unit, oxygen supplying unit, nano mixer, high temperature oxygen dissolving water, monitor and outer breathing and beverage replenishing unit. The present invention performs physiotherapeutic prevention and treatment and may be named as 'energy-ecologic balance treatment method'. The present invention is one cheap and green cancer preventing and treating method.

Owner:陈绍勇

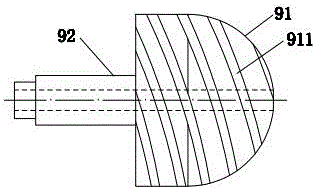

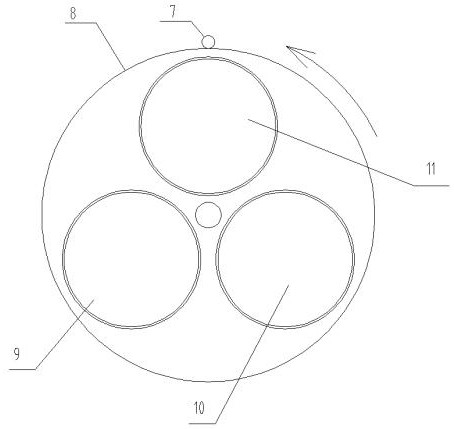

Injection molding device with spherical rotor

The invention relates to an injection molding device with a spherical rotor.The injection molding device comprises an injection oil cylinder, an injection seat frame, a motor, a transmission mechanism, a stand, an angular-contact bearing, a hopper, a machine barrel, an electric heater, a movable oil cylinder, a gear and a plunger.The injection molding device is characterized by further comprising the plasticizing rotor which comprises a hemispherical rotor body and a cylinder connected with the hemispherical rotor body into a whole, and a continuous outer threaded groove is formed in the hemispherical rotor body; the machine barrel comprises a hemispherical plasticizing cavity and an injection barrel, the hemispherical rotor body is located in the hemispherical plasticizing cavity and can rotate, the hopper is installed in the plasticizing cavity, the left end of the outer threaded groove is communicated with the hopper, and the right end of the outer threaded groove is communicated with the injection barrel; the plunger is located on the hemispherical rotor body and in a central hole of the cylinder and the injection barrel and can axially move, a vibrating device is installed between the plunger and a push rod of the injection oil cylinder, and the plunger is in clearance fit with the injection barrel.The injection molding device has the advantages of being high in plasticizing, smashing and squeezing capability, good in molded product quality and the like.

Owner:泗县微腾知识产权运营有限公司

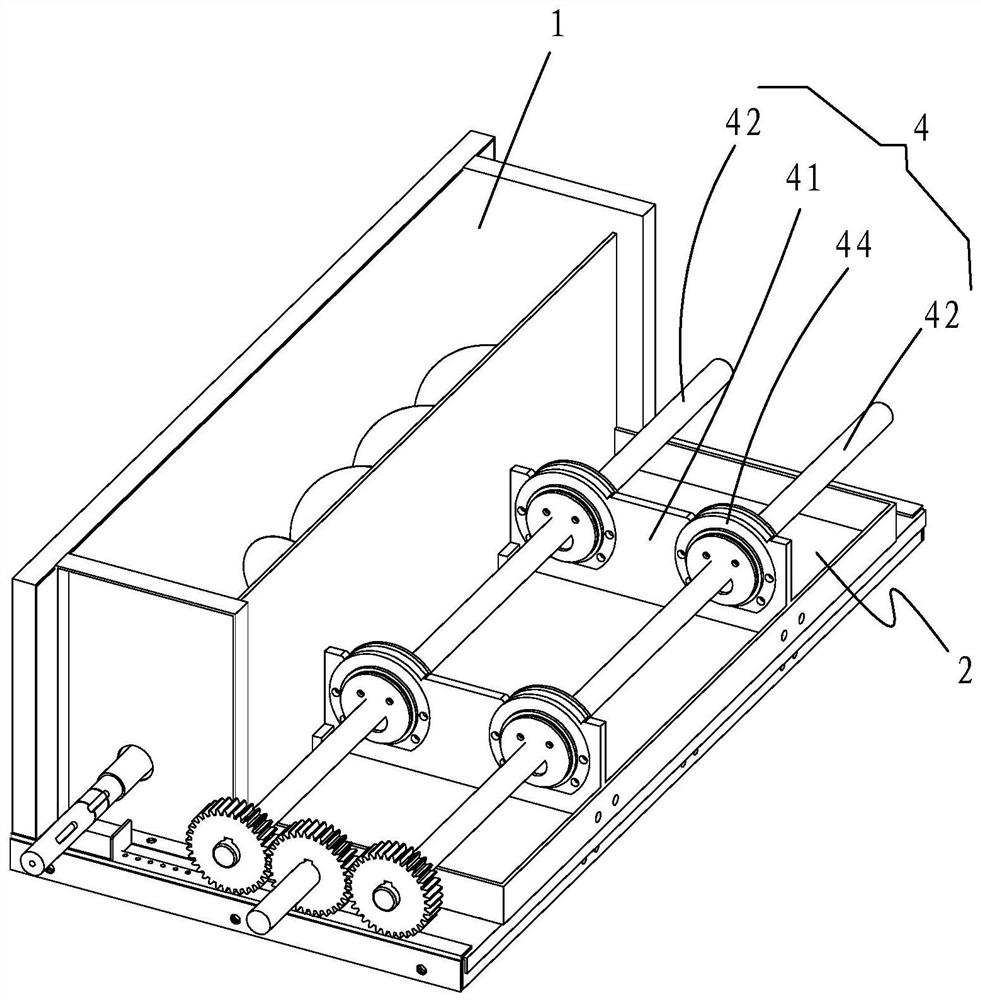

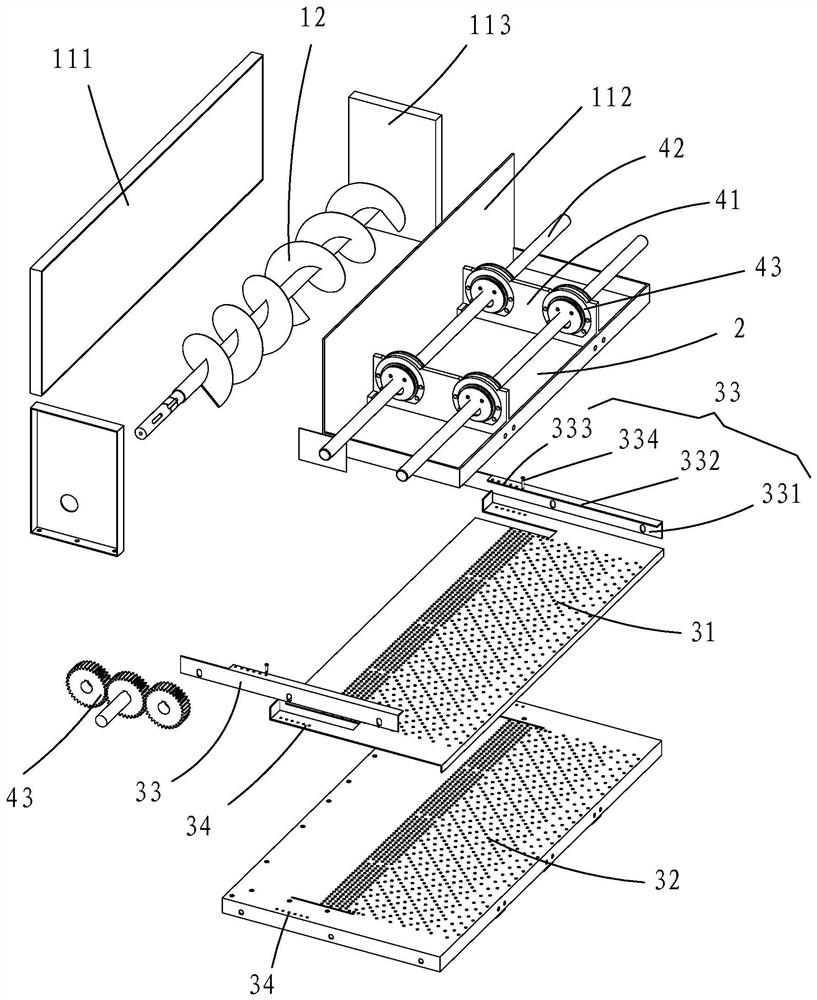

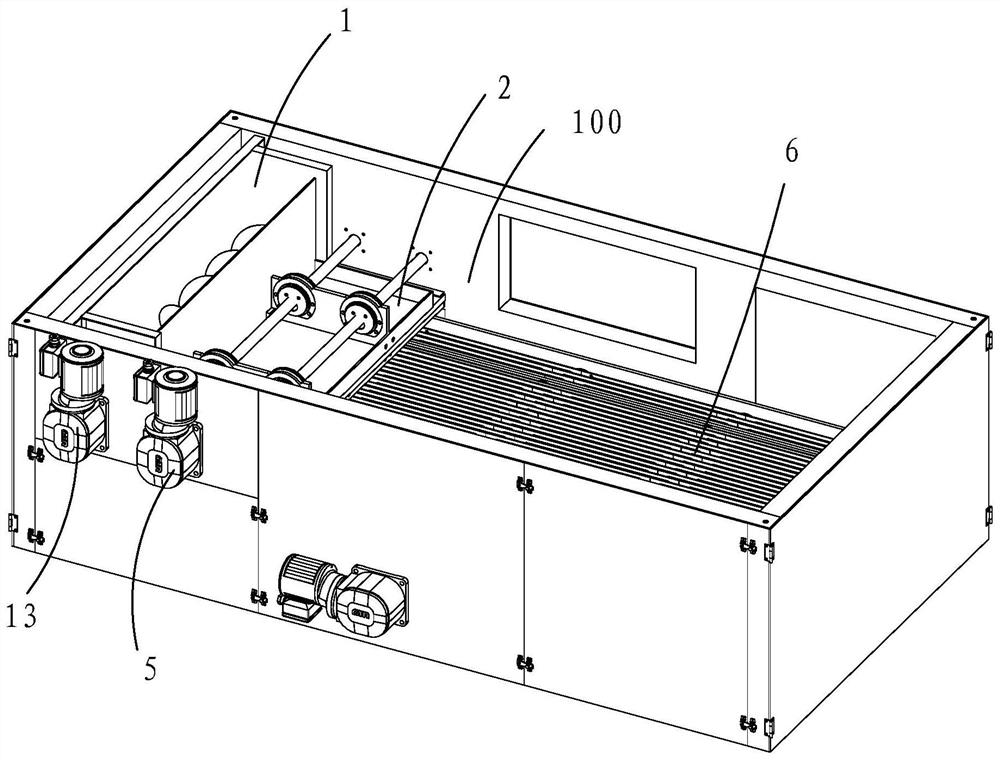

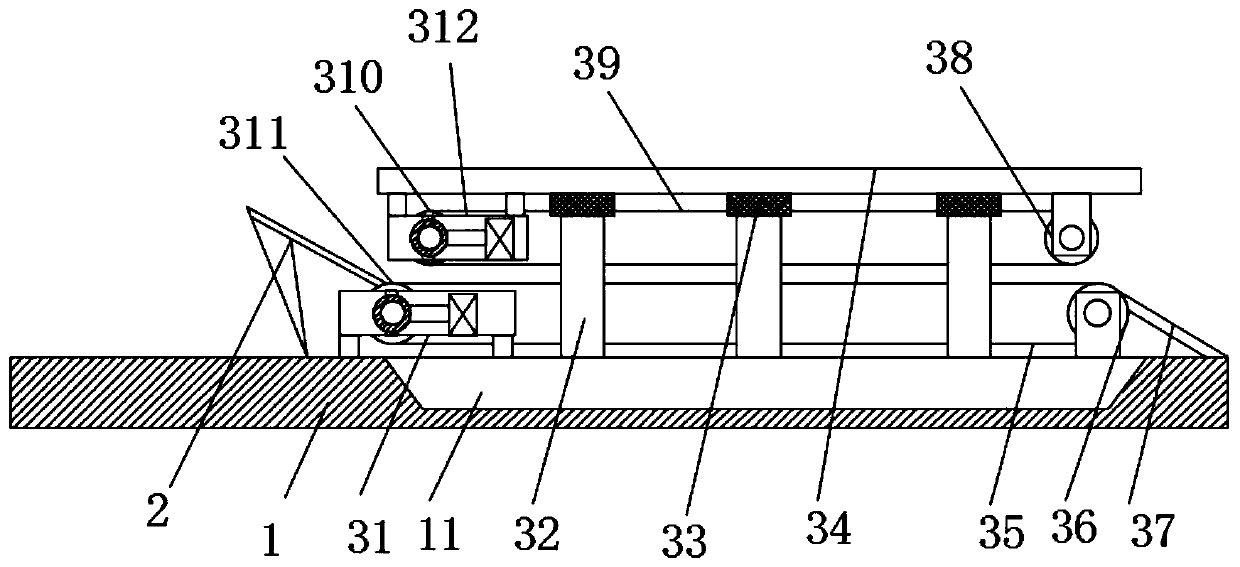

Reciprocating rolling material forming device

A reciprocating rolling material forming device comprises a feeding mechanism, a rolling plate and a bearing plate, wherein the rolling plate and the bearing plate are arranged in parallel, the bearing plate is located below the rolling plate, and a plurality of holes are formed in the bearing plate; the feeding mechanism is located at the same ends of the rolling plate and the bearing plate, andmaterials enter the gap between the rolling plate and the bearing plate from the feeding mechanism; at least one of the rolling plate and the bearing plate is connected with a driving mechanism, and the driving mechanism is connected with a first power source; and the first power source drives the driving mechanism to drive at least one of the rolling plate and the bearing plate to do reciprocating synchronous circular motion, so that the materials on the bearing plate are rolled and poked, and the materials are extruded and formed from the holes of the bearing plate located below. According to the device, the materials are periodically and intermittently rolled, so that the formed materials are short, accumulation is avoided, and the evaporation area can be enlarged.

Owner:AMCON FUJIAN ENVIRONMENT PROTECTION EQUIP CO LTD

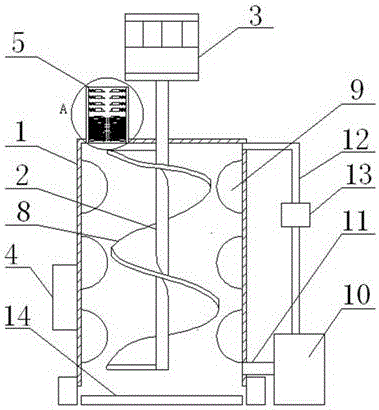

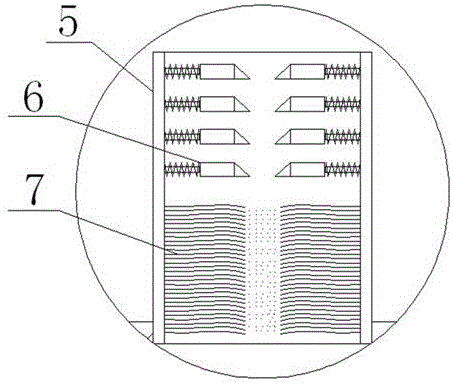

High efficiency coptis chinensis drying machine with mud removing effect

InactiveCN105935380AEasy to dropGood for shaving rootsDrying gas arrangementsDrying solid materialsBristleHelical blade

The invention discloses a high efficiency coptis chinensis drying machine with mud removing effect. The drying machine comprises a vertical drying cylinder supported on the ground by a spring, a blade welded rotating shaft disposed in the drying cylinder, and a vibrator arranged on the outer wall of the drying cylinder. The extension end of the rotating shaft is in transmission connection with a deceleration motor disposed above the drying cylinder, the top of the drying cylinder is communicated with a mud removing cylinder, the mud removing cylinder is internally provided with a plurality of razors and a plurality of bristles, the razors are located above the bristles, the drying cylinder is externally provided with an air heater, and the bottom of the drying cylinder is a discharge port. The blades welded on the rotating shaft are helical blades. The inner wall of the drying cylinder is provided with a plurality of hemispherical bumps. The air heater is connected to an air inlet pipe and an air outlet pipe, the air inlet pipe is communicated with the lower part of the drying cylinder, the air outlet pipe is communicated with the upper part of the drying cylinder, and a dryer is arranged between the air outlet pipe and the air heater. And a conveyor belt is arranged below the discharge port. The high efficiency coptis chinensis drying machine provided by the invention has the advantages of simple structure, high efficiency, good drying effect, and effective removal of sediment.

Owner:成都市斯贝佳科技有限公司

Adhesive tape

ActiveCN106414638AImprove impact resistanceImprove antistatic performanceFilm/foil adhesivesAdhesive beltShearing deformation

A pressure-sensitive adhesive tape which comprises a substrate and a pressure-sensitive adhesive layer disposed on one or both surfaces thereof, characterized in that the substrate comprises 30 mass% or more ethylene / vinyl acetate copolymer and has a tensile modulus, as determined in accordance with JIS K7161 2014, of 30 N / mm2 or greater. The pressure-sensitive adhesive tape is excellent in terms of various properties including impact resistance, resistance to static electricity, high-temperature shear deformation, and resistance to pressing.

Owner:TERAOKA SEISAKUSHO

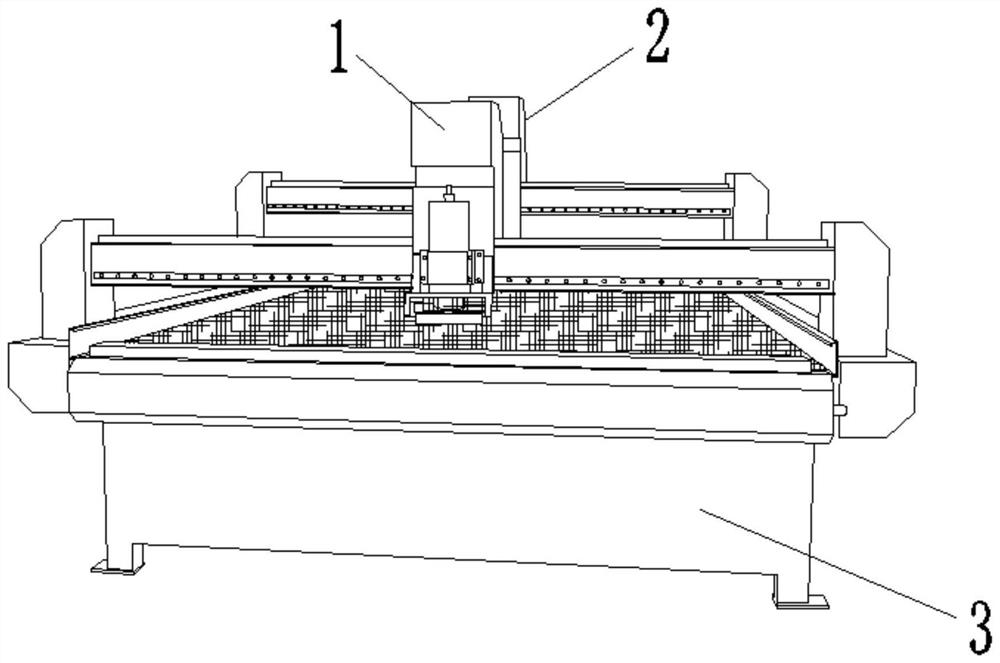

Processing method for reducing surface roughness of target

PendingCN111889768AStrong extrusionControl Surface FinishMilling cuttersVacuum evaporation coatingSurface finishSurface roughness

The invention provides a processing method for reducing the surface roughness of a target. The processing method comprises: adopting different milling process parameters to perform rough processing, semi-finish processing and finish processing on the surface of the target in sequence; in the rough processing flow, reducing the surface roughness Ra of the target to be 1.0 microns or less by controlling the milling process parameters; in the semi-finish processing flow, further reducing the surface roughness of the rough-processed target to 0.6 microns or less by controlling the milling processparameters; and in the finish processing flow, further reducing the surface roughness of the semi-finish-processed target to 0.2 microns or less by controlling the milling process parameters. By optimizing the milling process parameters, the surface smoothness of the machined target can be effectively controlled, the surface roughness of the target is reduced, and the normal use of the target in the sputtering process is guaranteed.

Owner:合肥江丰电子材料有限公司

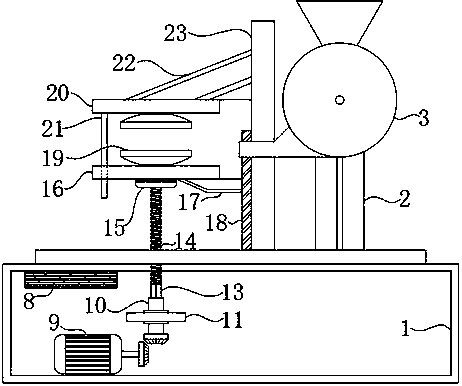

Granulating device for producing flame-retardant plastic-wood composite material

The invention discloses a granulating device for producing a flame-retardant plastic-wood composite material, and relates to the technical field of material processing equipment. The granulating device comprises a shell, wherein a feeding hopper is arranged at the upper end of the shell, a mounting cavity is formed in the lower end of the shell, and an material extruding cylinder is connected in the mounting cavity; and the material extruding cylinder comprises a cylinder head, a cylinder body and an material extruding head which are connected in sequence, a heat preservation installation base is arranged outside the material extruding cylinder, and the heat preservation installation base is fixedly connected with a conveying mechanism. According to the granulating device, a material mixing bin, a material conveying channel, the material extruding cylinder, a material cutting mechanism and the conveying mechanism are arranged, the material is fully heated and mixed through the material mixing bin, and the material is continuously supplied to the material extruding cylinder through a material pushing piston of the conveying channel for cutting and granulation, the material cutting mechanism is used for cutting, and finally, flue gas and heat are removed through the material conveying mechanism, and the flue gas and the heat are conveyed out, so that the granulation operation is completed, the structure is simple, the problems that the quality of an existing granulating device is low and the corresponding process is environment-friendly are solved, and the granulating device is suitable for popularization.

Owner:南京聚锋新材料有限公司 +1

Water-resisting bi-component artificial turf backing coating

InactiveCN108130020AGood compatibilityImprove mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveArtificial turf

The invention discloses a water-resisting bi-component artificial turf backing coating and belongs to the technical field of adhesives. A preparation method comprises the following steps: mixing (N-amidino)dodecyl acrylamide with a polyethylene glycol derivative according to the mass ratio ranging from 2:1 to 4:1, adding p-dichlorobenzene the mass of which is 0.2 to 0.4 time that of the polyethylene glycol derivative and ferrocene the mass of which is 0.12 to 0.18 time that of the polyethylene glycol derivative; carrying out thermostatic mixing reaction, filtering and drying to obtain a modified additive; putting latex, tackifying resin, filler, pigment, acetum and water into a material mixer for stirring and mixing to obtain a component A; putting organosilane, the modified additive and isocyanate into a beaker for stirring and mixing to obtain a component B; separately packaging the component A and the component B, thus forming the water-resisting bi-component artificial turf backingcoating. The water-resisting bi-component artificial turf backing coating provided by the invention has excellent mechanical properties and water resistance for a system.

Owner:董晓

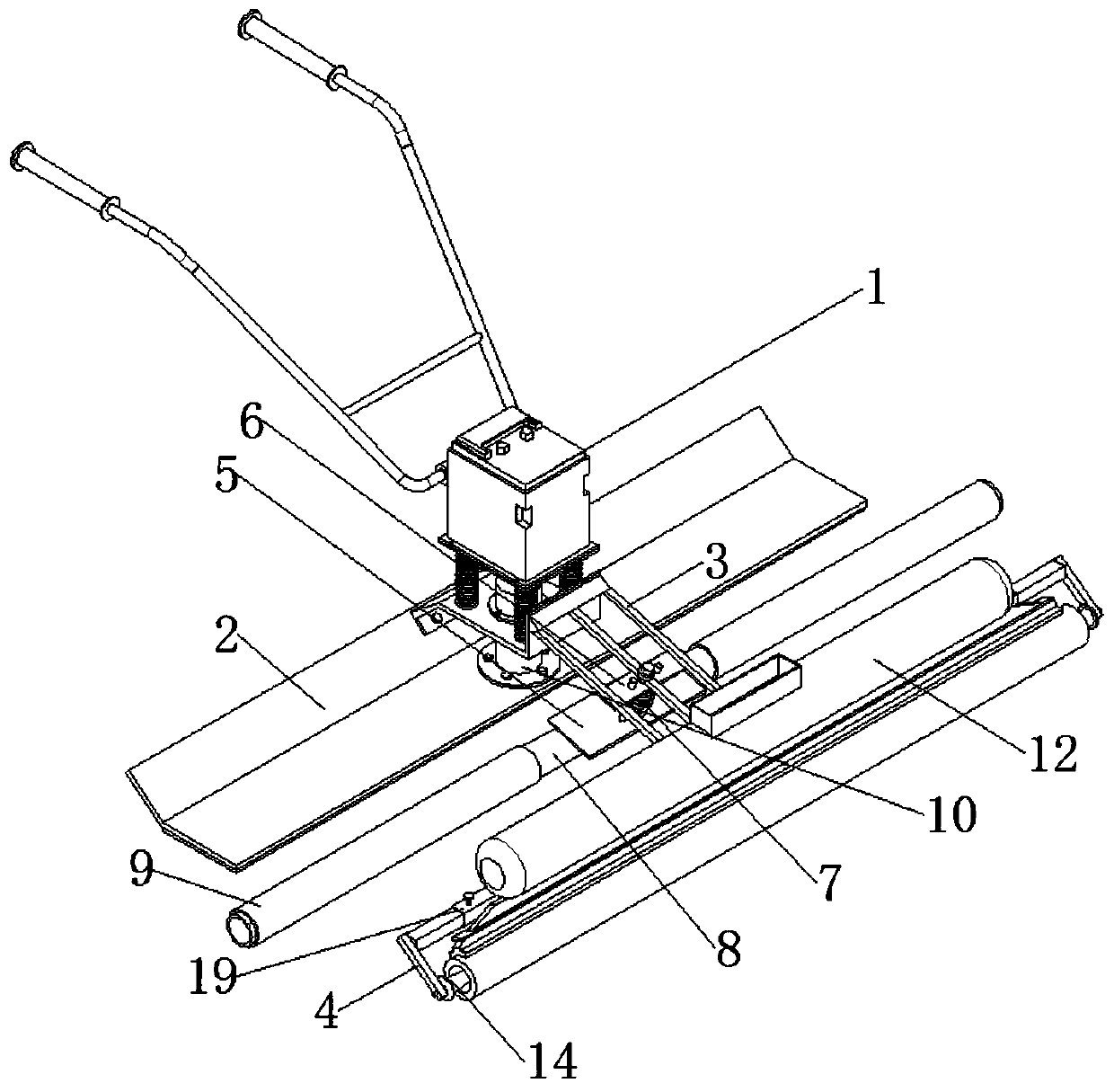

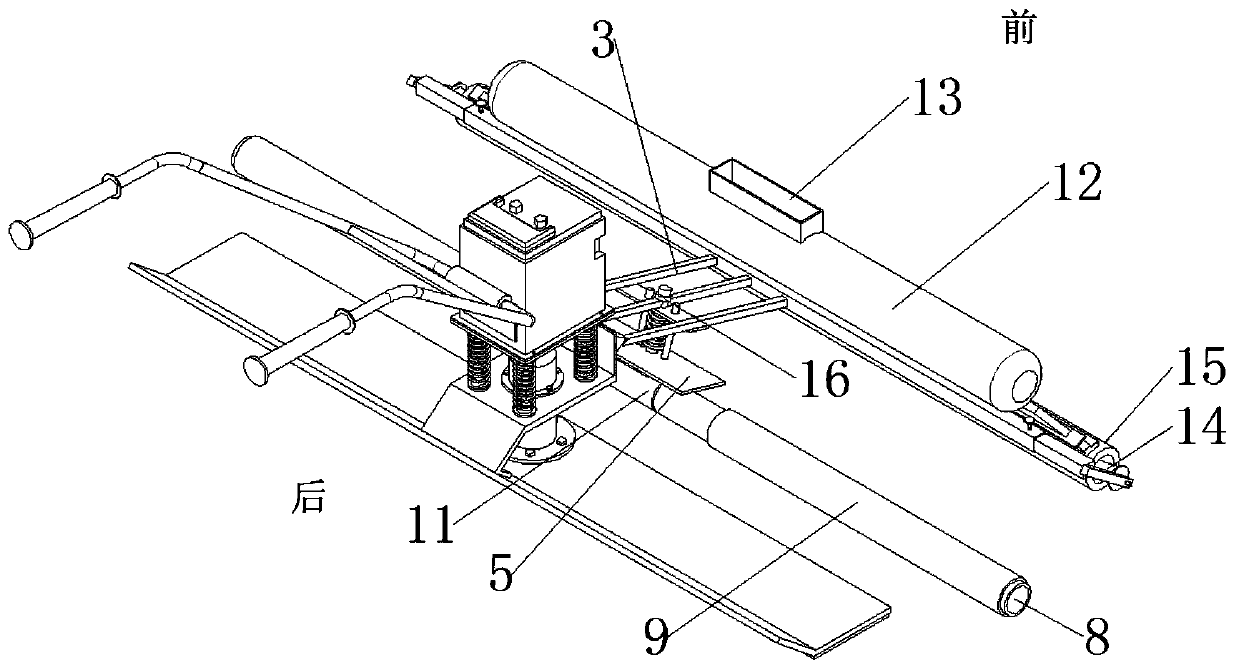

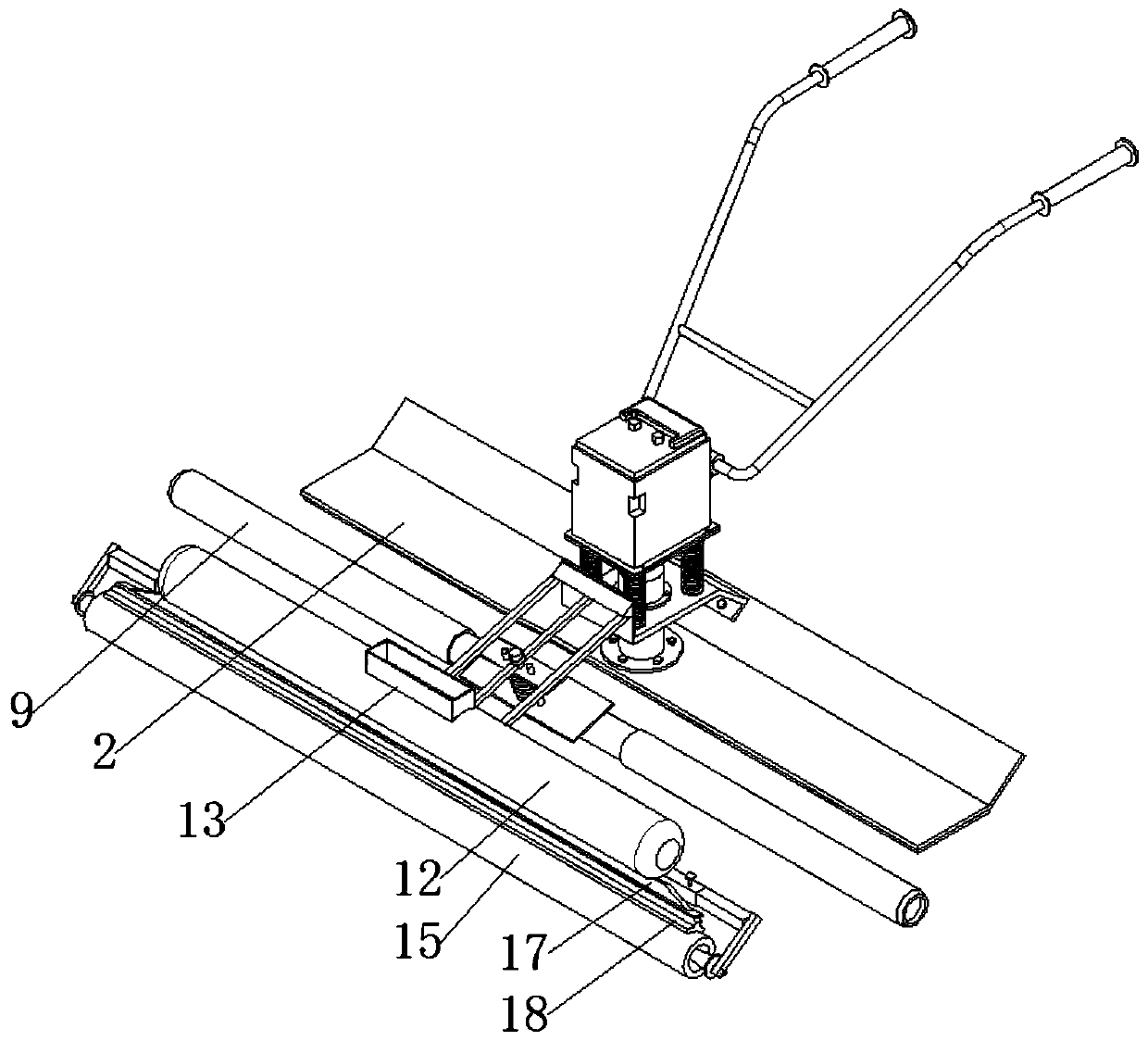

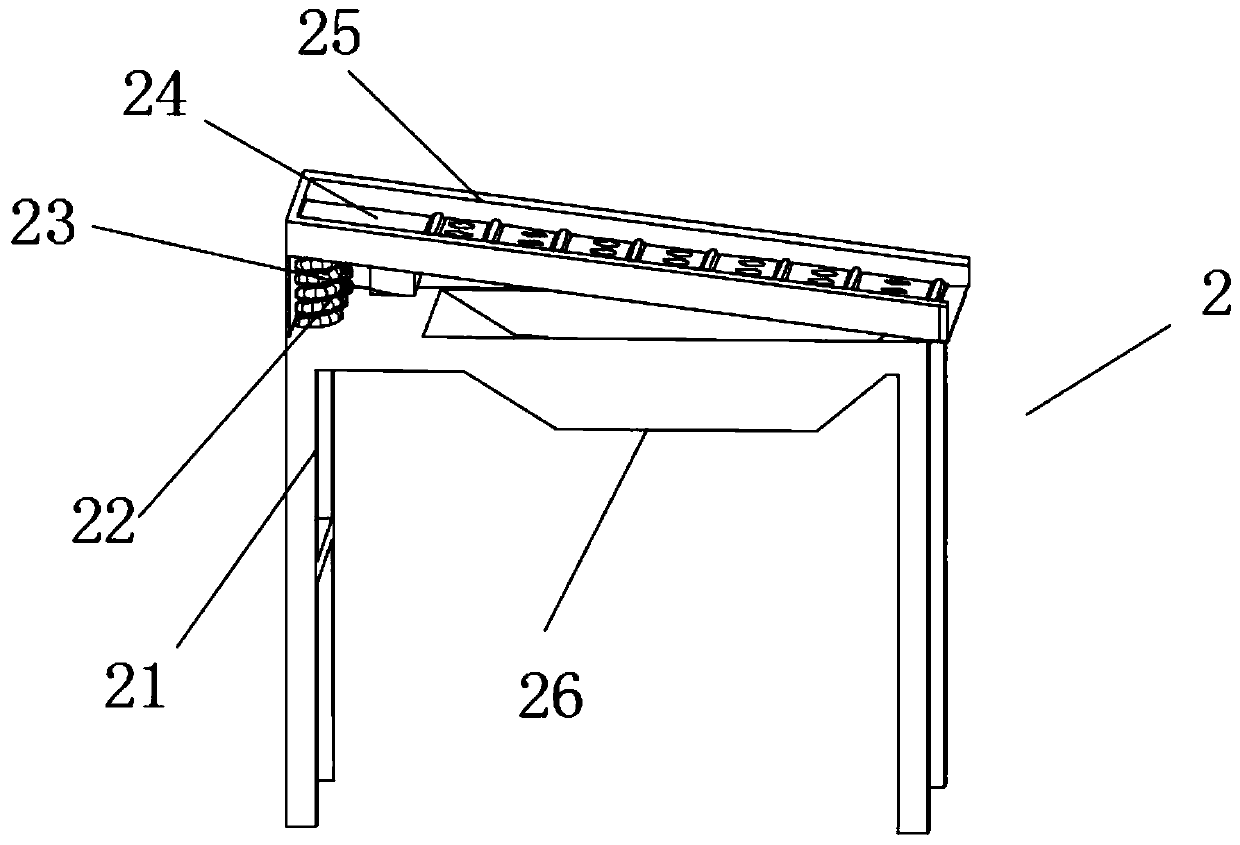

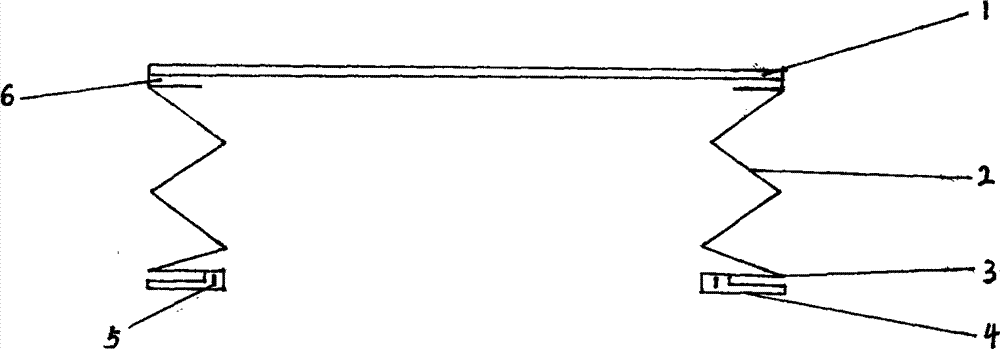

Film covering equipment before final coagulation after primary coagulation

ActiveCN110607915APrevent twisting and deformationStrong extrusionBuilding material handlingRoad surfaceHigh frequency vibration

The invention provides film covering equipment before final coagulation after primary coagulation, and belongs to the technical field of the structure of the film covering equipment for civil engineering. The film covering equipment solves the problems that cracks are generated on the road surface which is dried for a long time, wetting covering can not be met, and the phenomenon that the road surface does not crack due to rapid drying can not be ensured. The film covering equipment before final coagulation after primary coagulation comprises a high-frequency vibration base, wherein the high-frequency vibration base is composed of a top power supply and a bottom high-frequency vibrator, a thin plate-shaped film pressing plate is mounted on the bottom surface of the high-frequency vibrator,the middle position of the film pressing plate is fixedly connected with a bottom mounting plate of the high-frequency vibration base through bolts, the front side of the equipment is provided with aset of water supply mechanism, the water supply mechanism utilizes foam seats obliquely arranged at the front lower portion of the bottom side of a front side barrel cavity so that the injected clearwater can be synchronously coated to the backward conveyed film in an infiltration mode, and backward action is performed following the film on the film roller one by one.

Owner:枣庄市国兴工程材料有限公司

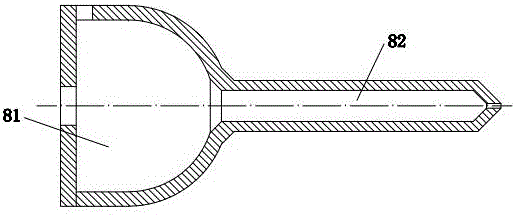

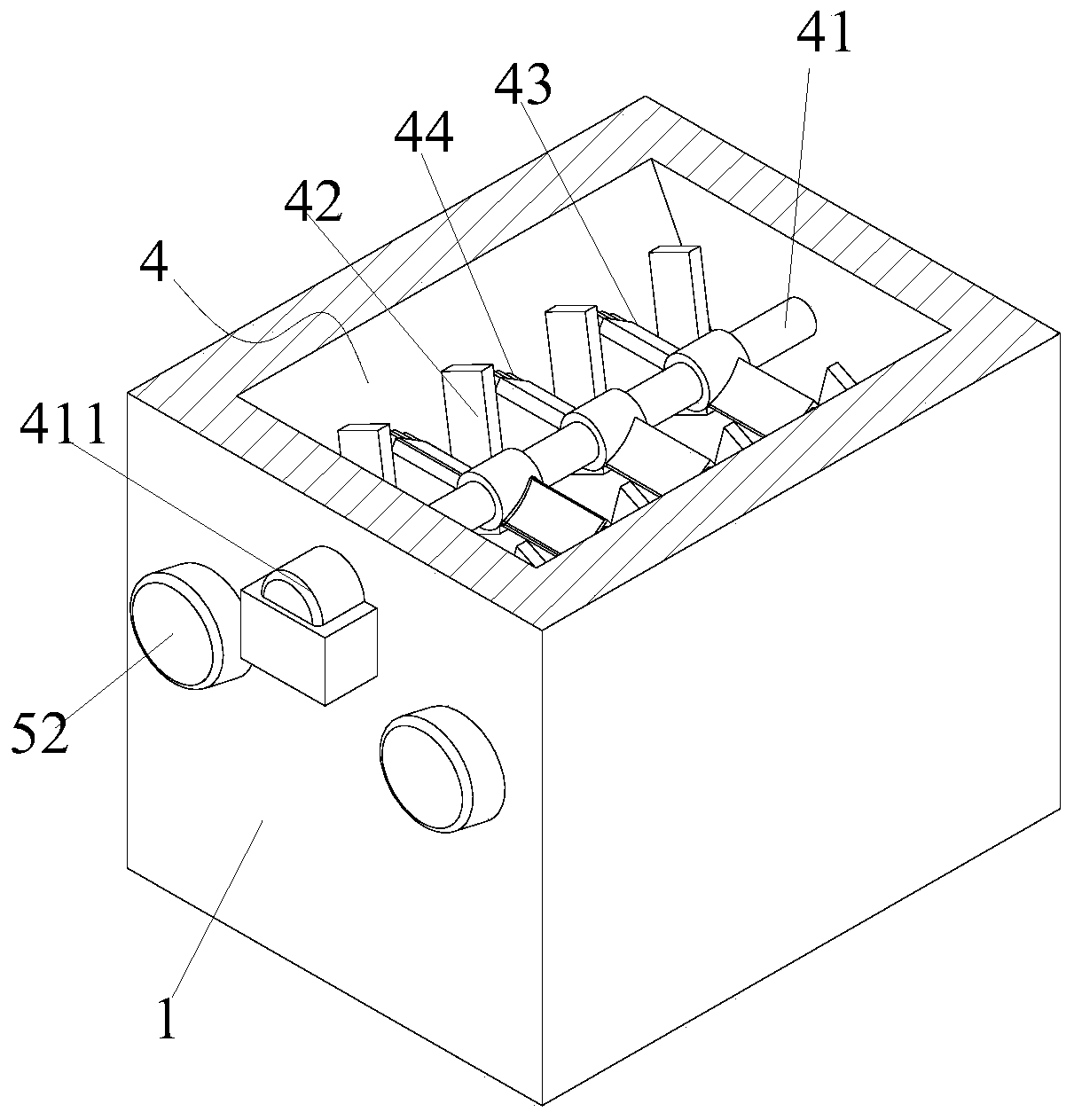

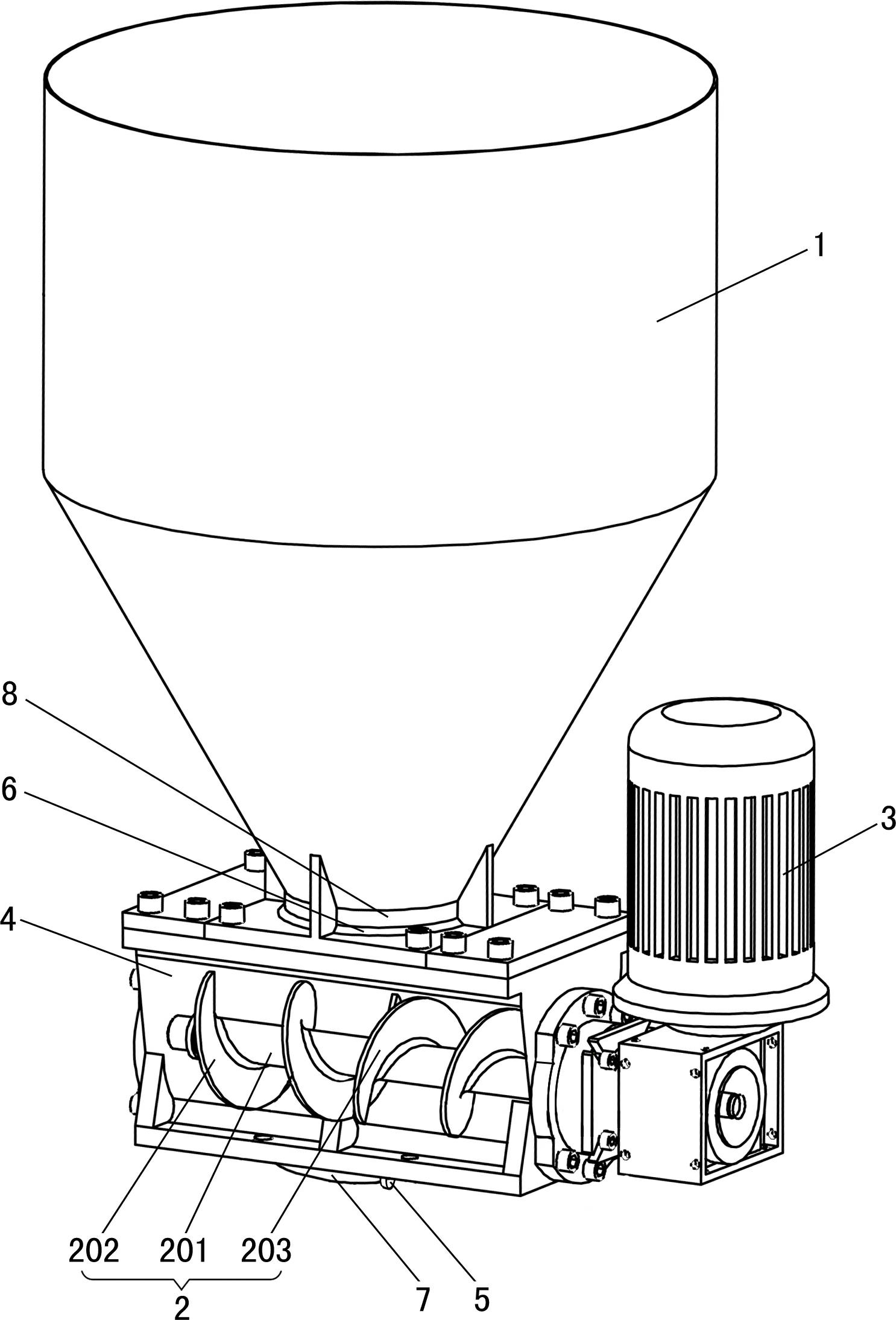

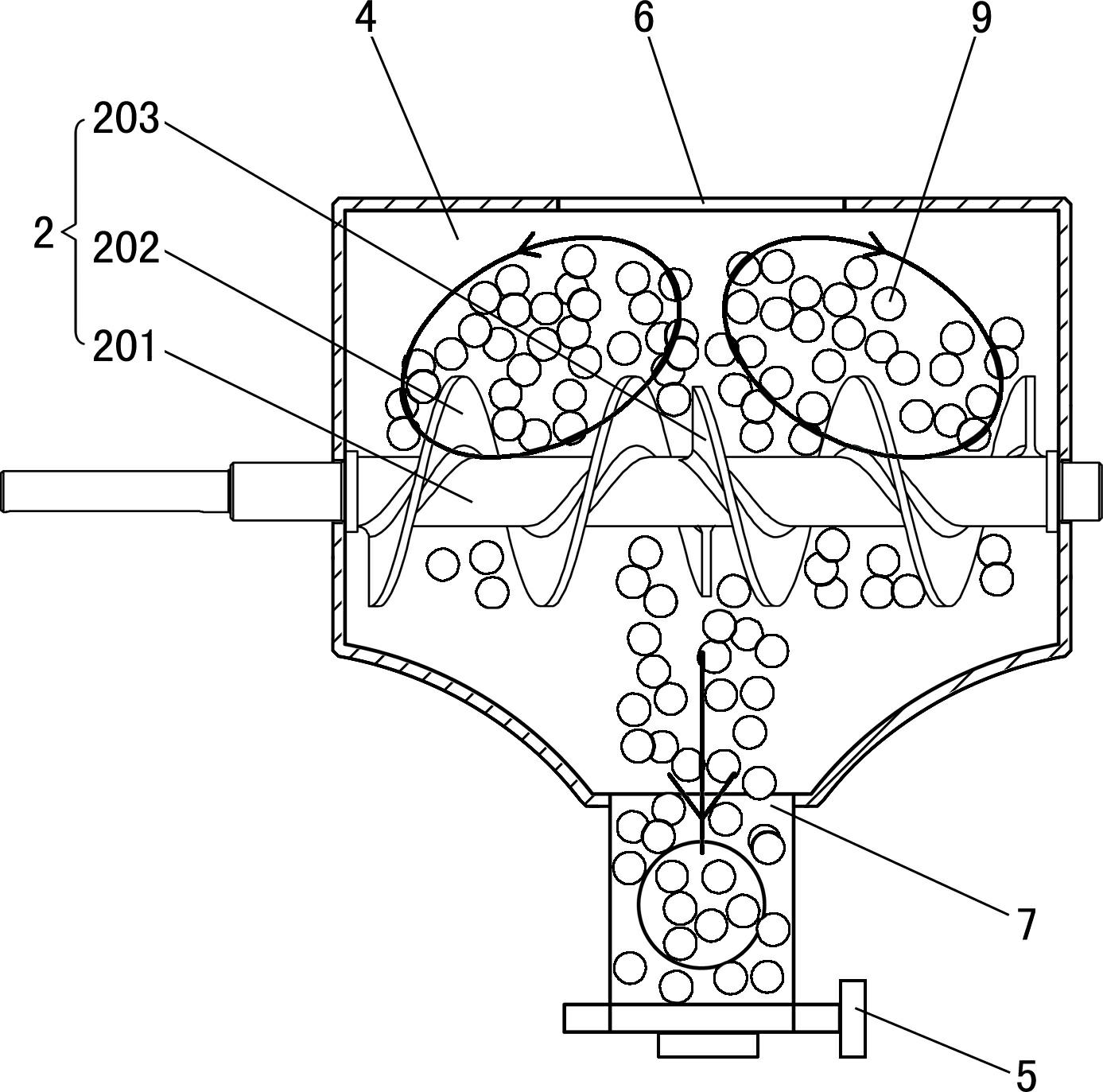

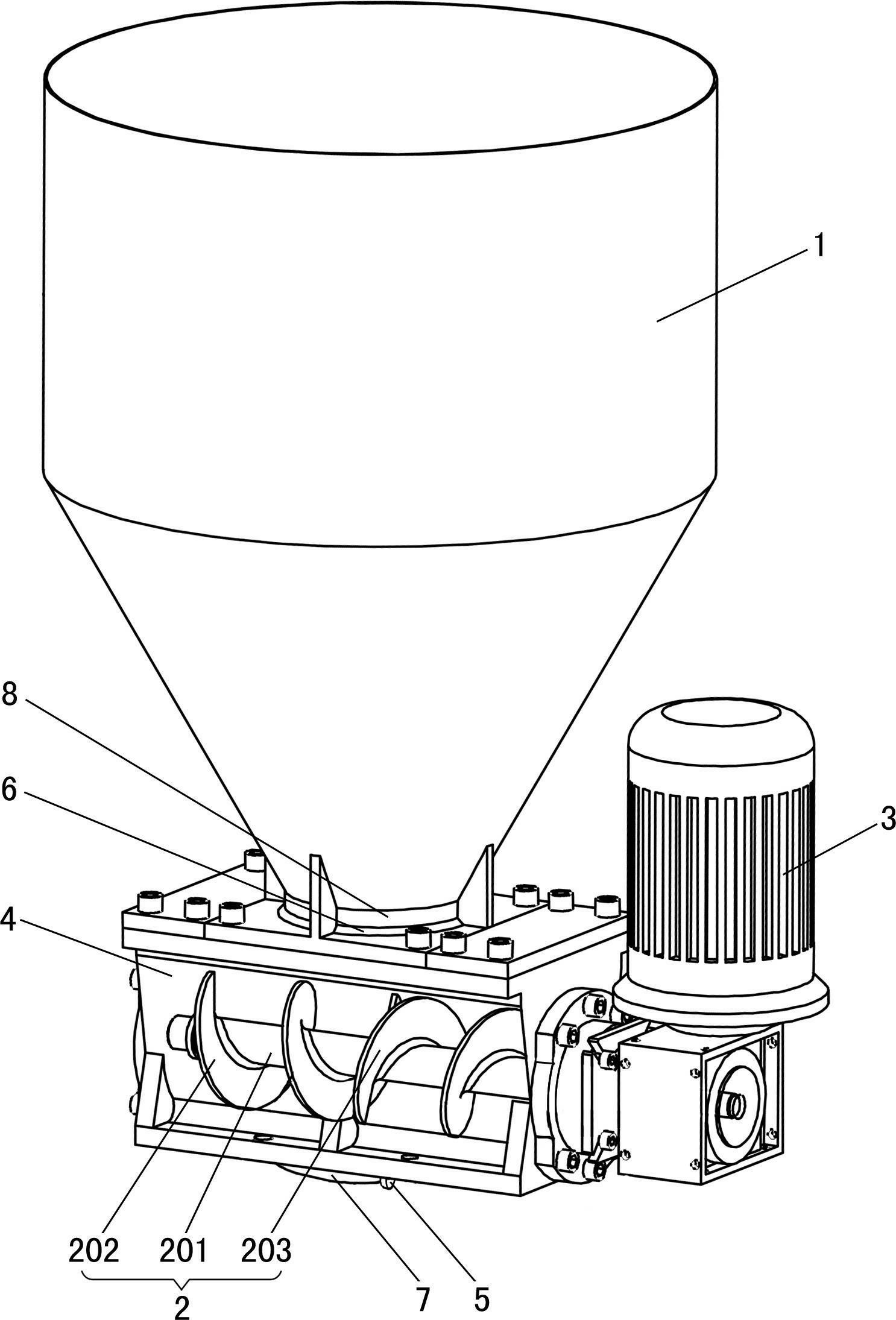

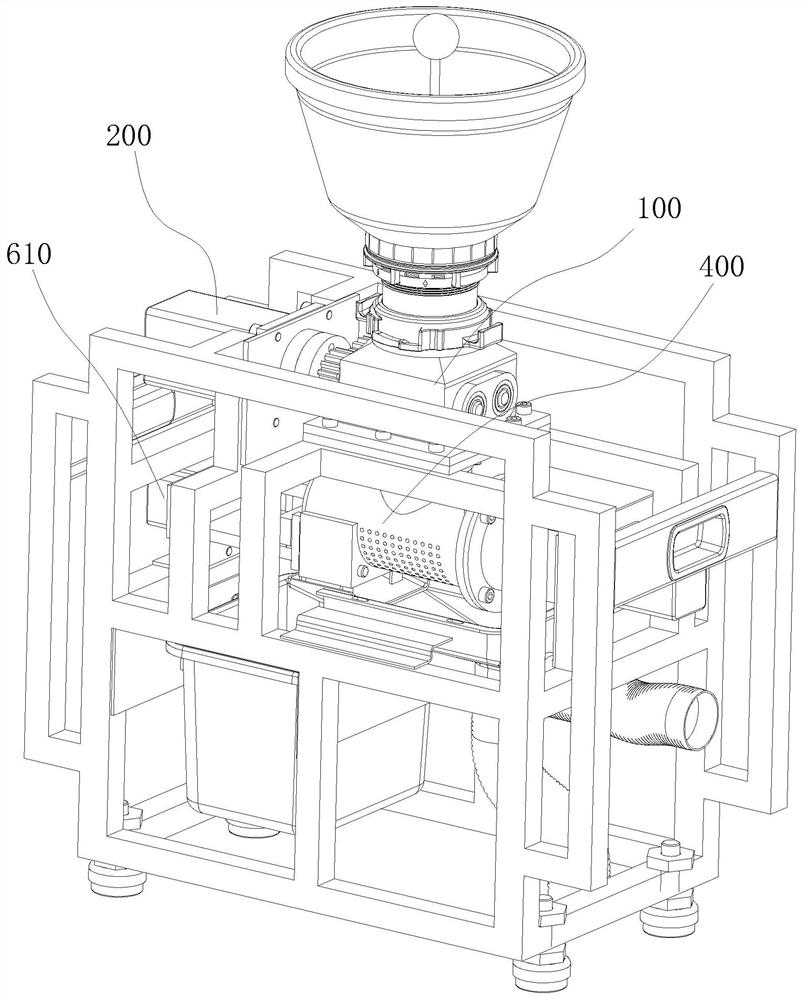

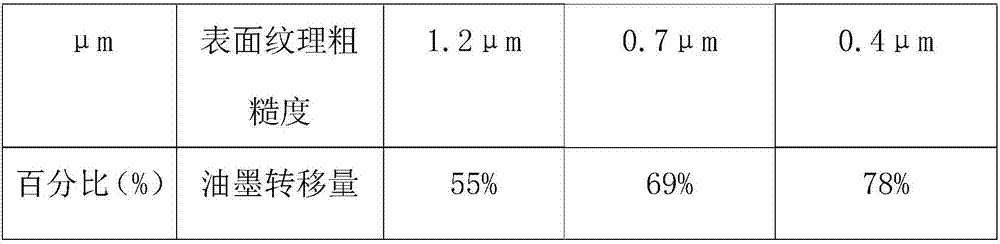

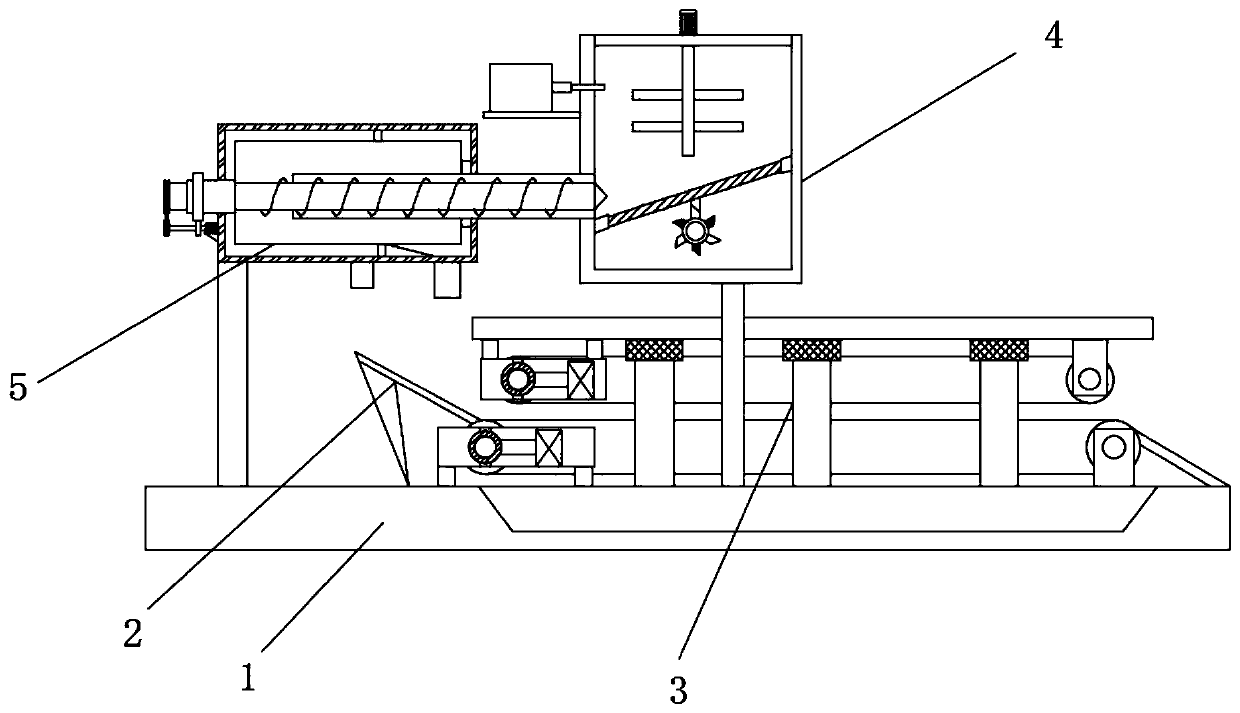

Forced feeding device with mixing function

The invention relates to a forced feeding device with a mixing function. The device is provided with a material mixing bin, and a feeding screw is provided with a positive thread section and a reverse thread section; when a driving device drives the screw to rotate, both the positive thread section and the reverse thread section push a material to be fed to the middle, one part of material is discharged from a discharge hole, and the other part of material is upwards arched and gradually raised; and when the arched material reaches a certain height, the material is dispersed to two ends, and mixing of the material is finished. Mixing and conveying of the material are realized on the same device; the device is quite compact in structure, occupies a small space, and saves land resources; and without a middle conveying step, the material is not layered, so that the quality of a processed product is improved.

Owner:SHANTOU DACHENG ENVIRONMENTAL PROTECTION PRECISION MACHINE TECH CO LTD

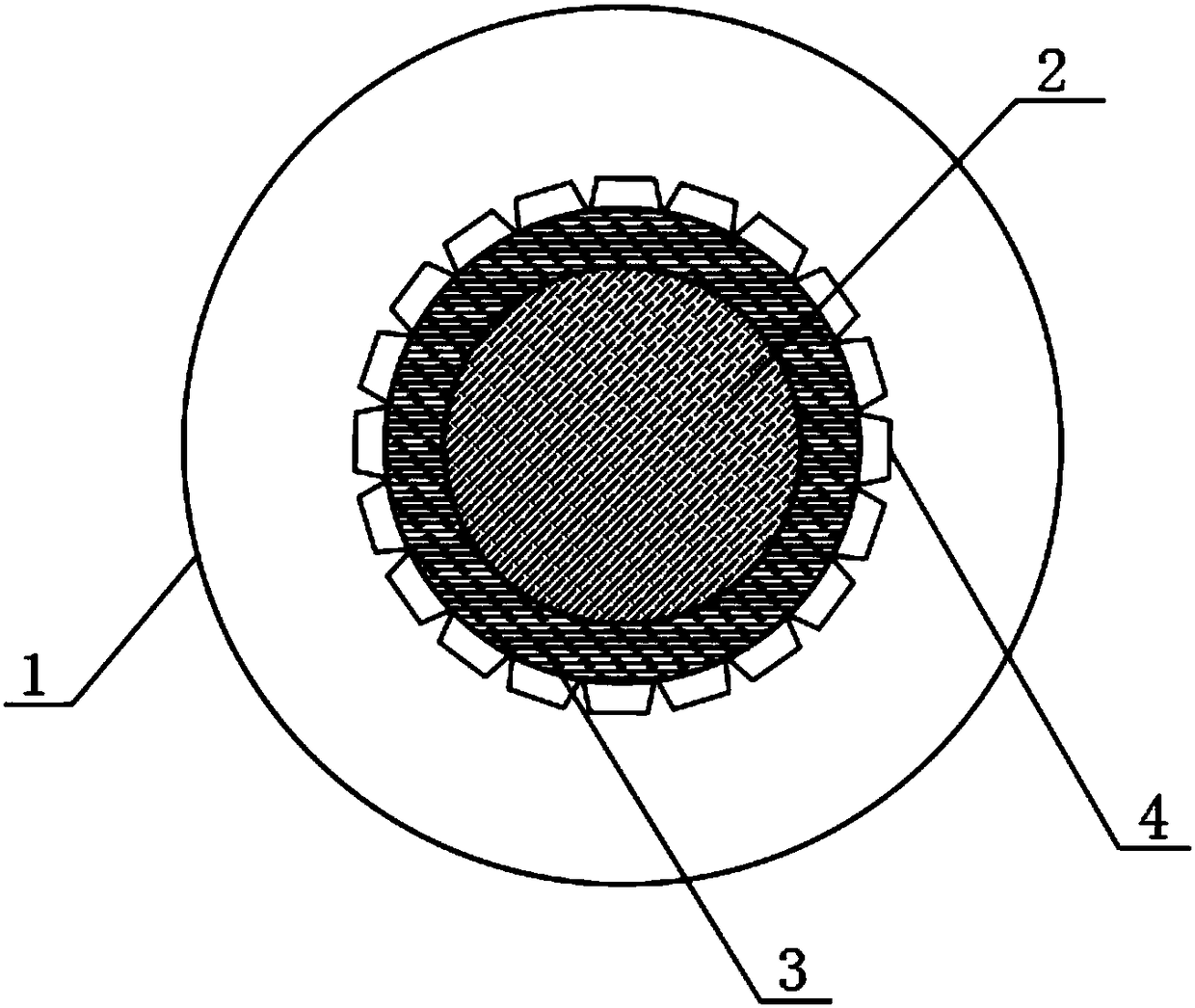

Electroplating anode phosphorus copper ball and preparation method thereof

The invention discloses an electroplating anode phosphorus copper ball and a preparation method thereof. The electroplating anode phosphorus copper ball comprises a ball body; a hollow groove is formed in the ball body; reinforcing rings are encircled around the outer side of the hollow groove; and projection blocks are encircled around the outer sides of the reinforcing rings. Hydrogen peroxide is added in a reaction kettle, and can oxidize copper powder to improve the phenomenon of looseness, unevenness and no luster of a cathode deposition layer caused by uniform deposition of Cu+ on a loose crystal and to improve the service life and the beauty of the phosphorus copper ball; through continuous stirring of melts, uniform distribution of phosphorus elements is guaranteed, so that the purposes of compact crystallizing particles and compact structure are achieved, and formation of monovalent copper ions is effectively inhibited; and phosphorus is proper in content and uniform in distribution, anode mud is less, and an anode bag is generally cleaned generally more than half a year, so that the electroplating production efficiency is improved, and such auxiliary raw materials as theanode bags are saved.

Owner:江西江南新材料科技股份有限公司

Plastic pipeline and preparation method thereof

InactiveCN111393735APrevent deviationImprove winding qualityLinear low-density polyethyleneLow-density polyethylene

The invention discloses a plastic pipeline, which includes the following raw materials: HDPE high density polyethylene, LLDPE linear low density polyethylene, nano zirconium dioxide, nano silicon carbide, nano calcium carbonate, nano bamboo charcoal powder, a silane coupling agent, an anti-aging agent, a defoaming agent, an antistatic agent, an antibacterial agent and titanium dioxide loaded withthe antibacterial agent. Nano zirconium dioxide, nano silicon carbide, nano calcium carbonate and nano bamboo charcoal powder are used as mixed auxiliary materials for preparing the pipeline; the nanoparticles have a large specific surface area, and have a good cross-linking effect with HDPE and LLDPE, the strength of the polymer material can be improved, the thermal stability, wear resistance andcorrosion resistance of the material can be enhanced, a significant acceleration effect is achieved on the plastic pipeline, and the tensile strength of the plastic pipeline can be effectively improved.

Owner:ANHUI HUAQI PIPE

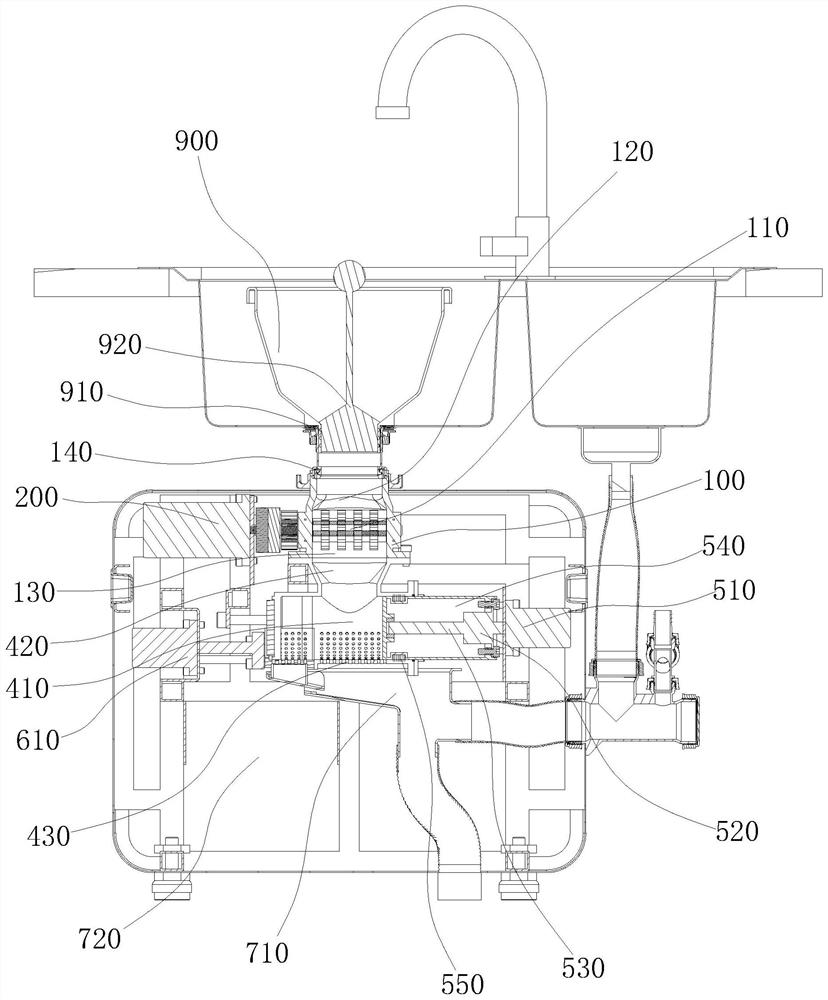

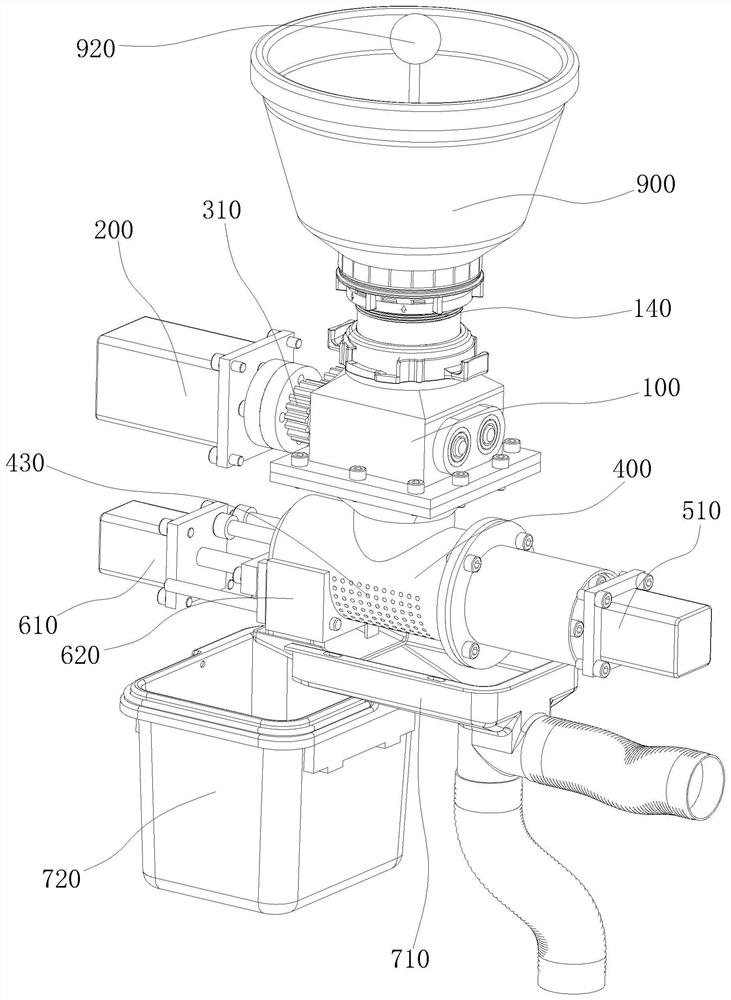

Kitchen garbage disposer

PendingCN113006218AThe overall structure is ingeniousImprove crushing efficiencyDomestic plumbingRefuse DisposalsMechanical engineering

The invention provides a kitchen waste disposer, and belongs to the technical field of kitchen waste crushing and dewatering equipment. The kitchen waste disposer is characterized in that a crushing seat is provided with a crushing cavity, a first feed port and a first discharge port; a crushing assembly comprises a first driving block and a serrated knife block, the serrated knife block is arranged in the crushing cavity, and the first driving block is in linkage connection with the serrated knife block; a dewatering seat is provided with a dewatering cavity, a second feeding hole and a dewatering hole, and the second feeding hole and the dewatering hole both communicate with the dewatering cavity; a dewatering assembly comprises a second driving block and a sliding block, the sliding block is movably arranged in the dewatering cavity, and the second driving block is connected with the sliding block; a water receiving disc is arranged below a dewatering seat, and the dewatering hole faces the water receiving disc; and a collecting box is arranged below the dewatering seat. The kitchen waste disposer has the beneficial effects that the overall structure is ingenious, kitchen garbage can be crushed and dehydrated, then water and residues are discharged respectively, and therefore the purposes of harmlessness and resource circulation of the garbage are achieved.

Owner:NINGBO NEW GUANLIAN MOTOR ELECTRONICS

Train and automobile multiple-brake-device system

InactiveCN103287405AIncrease contact frictionImproved braking stabilityBraking action transmissionFoot actuated initiationsStatic frictionAutomobile Accident

The invention discloses a train and automobile multiple-brake-device system which is a brake drum device system and automobile machinery pedal pressure brake by pressing the switch to brake, remote control brake and induction brake in a train and automobile. The structural features of the system are as follows: a current main switch is arranged in the middle of a steering wheel or in areas in a driver's reach; a remote control device and an anti-theft coded lock are also mounted; a foot pressure assisting notch board at the lower end is connected with a power supply battery, an electronic inductive head and a motor brake drum at the lower end of a vehicle body in series or in parallel; and a double-shear-type brake clamp bites the complete equipment of a brake disc. According to the invention, small force defeats large force, high technology is combined with mechanics of machinery, the mechanical resistance between static friction and dynamical friction is adopted for speed reduction brake, and the brake can be loosened quickly at will and are not locked. Traffic accidents are terrible and unpreventable, and can kill people at one second. In daily life, 80% exquisite work is completed through collaboration of hands and the head, and the sensitivity of hands and the head for responding to danger is far higher than that of feet and the head.

Owner:佘运强

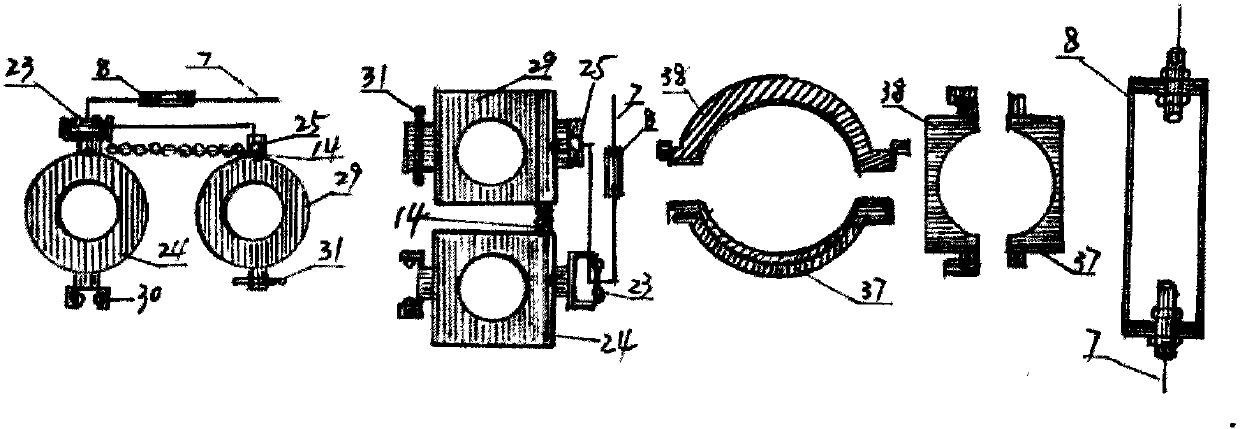

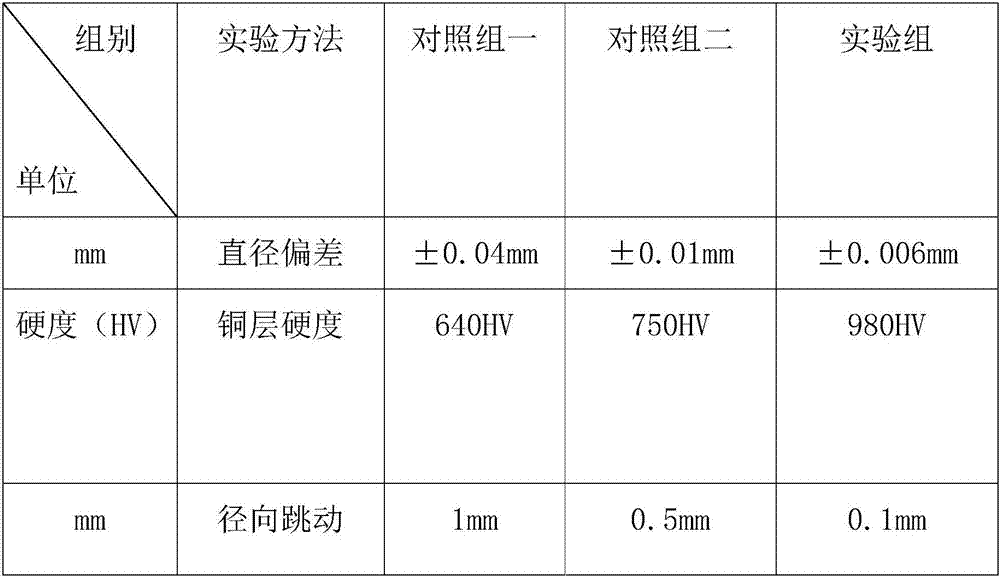

Preparation technique of embossing plate roller

The invention discloses a preparation technique of an embossing plate roller. The preparation technique comprises the steps that a roller body material is selected and subjected to welding pre-machining treatment, then the roller body material is subjected to annealing treatment, turning and drilling and laser engraving, copper plating and polishing are conducted, and finally, the embossing plate roller is packaged and stored. The embossing plate roller obtained through the preparation technique has the advantages of being clear in line, rich in gradation and good in hardness, can bear high extrusion force during use, and is not prone to breakage or abrasion.

Owner:LONGYOU YUNCHENG PRESS GRAIN PLATE MAKING

Concentrator capable of cleaning sludge automatically

PendingCN110240384AEasy dischargeEasy to transportSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesHigh concentrationFlocculation

The invention discloses a concentrator capable of cleaning sludge automatically. The concentrator comprises a base, a conveying mechanism, an extrusion mechanism, a flocculation mechanism and a concentration mechanism, wherein the extrusion mechanism is fixedly mounted at the top of the base; the extrusion mechanism comprises a first adjusting component, a second adjusting roller and a second adjusting component; a first transmission roller is moveably mounted at one end of the top of the base through a support column; a discharge plate is arranged on one side of the first transmission roller; and the first adjusting component is fixedly mounted at the other end of the top of the base. Due to adoption of the extrusion mechanism, floc can be extruded conveniently and moisture in the floc can be discharged; in addition, due to adoption of the adjusting components, a caterpillar band and filtering cloth are kept at a tightened state constantly, the dehydration effect of the concentrator can be improved, and a high concentration degree is achieved; and due to adoption of a high-pressure nozzle, the interior of the equipment can be conveniently cleaned.

Owner:ANHUI ZHONG NENG MACHINERY MFG

Aluminum alloy, microchannel aluminum flat tube and preparation method thereof, heat exchanger, electrical appliance

ActiveCN104109781BLow degree of alloyingImprove the extrusion effectTubular elementsRare-earth elementSi element

The invention discloses an aluminum alloy, a microchannel aluminum flat tube and a preparation method thereof, a heat exchanger and an electrical appliance provided with the heat exchanger. The aluminum alloy includes Al element and inevitable elements, and the inevitable elements include Fe element and Si element. Based on the total weight of the aluminum alloy as 100%, the weight percentage of Fe and Si elements is 0<Fe≤0.2% , 0<Si≤0.15%; the aluminum alloy also includes the following elements by weight percentage: 0.1%≤Mn≤0.5%, 0.15%≤Cu≤0.45%, the total amount of at least two of Zr, B, Cr, RE The content is 0.05% to 0.5%; RE is rare earth element. The aluminum alloy has low alloying degree, good extrusion performance and high corrosion resistance, and the microchannel aluminum flat tube prepared with the aluminum alloy has excellent corrosion resistance without any additional coating. Heat exchangers and electrical appliances containing the micro-channel aluminum flat tubes have strong corrosion resistance and long service life.

Owner:MIDEA GRP CO LTD

A kind of mechanochemical method for synthesizing lithium magnesium silicate

ActiveCN104760966BGuaranteed uniformitySmall particle sizeSilicon compoundsSlurryTemperature resistance

The invention discloses a method for mechanochemically synthesizing magnesium lithium silicate, which comprises the following steps: 1) synthesizing a magnesium lithium silicate precursor, and controlling the temperature of the precursor at 30-99 DEG C; and 2) feeding the precursor into a wet-process superfine treatment device, grinding at 90-99 DEG C for 5-90 minutes, and drying the obtained slurry to obtain the target product magnesium lithium silicate. The diameter of the grinding medium spheres used by the wet-process superfine treatment device is 0.1-5mm, and the linear speed of the grinding medium spheres is 8-20 m / s. The magnesium lithium silicate is synthesized by using high temperature and high pressure instantaneously generated by the grinding medium, so the requirements for high temperature resistance and high pressure resistance of the device are low. The superfine treatment device in peculiar structure can perform continuous production, and can solve the problem in batch production in the traditional hydrothermal reaction kettle. Compared with the traditional hydrothermal synthesis, the method disclosed by the invention has the advantages of lower cost and higher safety, and can easily implement industrialization.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

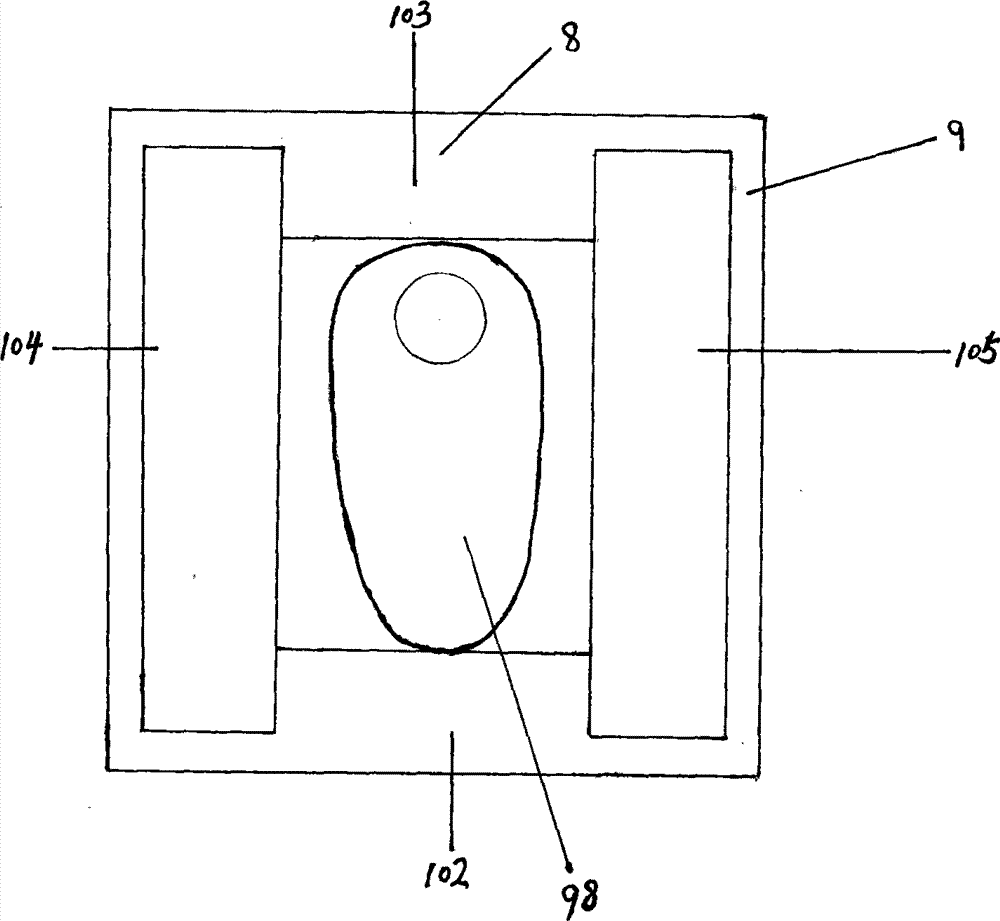

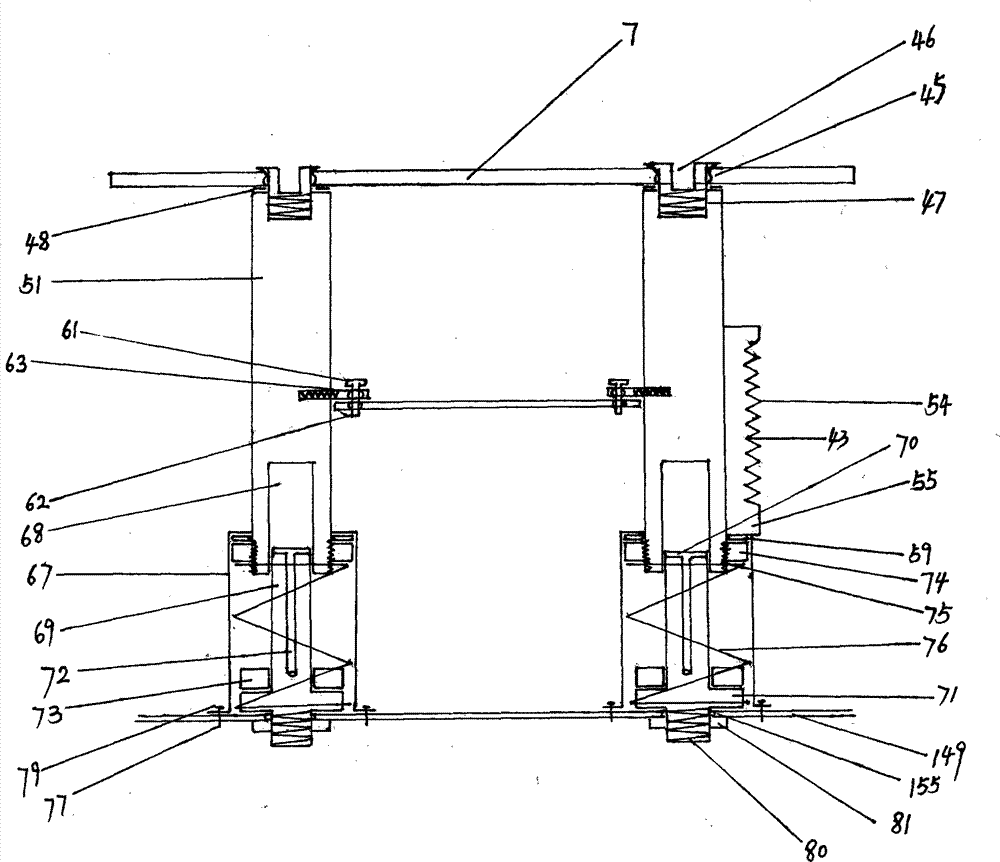

A mechanical seal packing automatic compression device

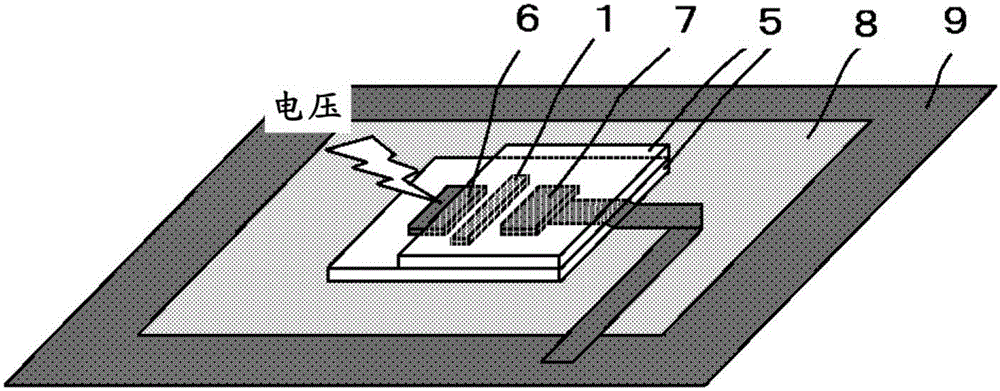

ActiveCN106965480BImprove gripImprove sealingEngine sealsMetal-working hand toolsCouplingEngineering

The invention discloses an automatic compacting device for mechanical-sealed packing. The automatic compacting device for the mechanical-sealed packing comprises a control box, an automatic packing device, a rotary extrusion device, extrusion dies and a main support column, wherein the automatic packing device and the main support column are arranged at the upper end of the control box. The automatic packing device comprises a shell, a packing device support frame is fixedly arranged at the bottom of the shell, a rotary shaft is arranged on the middle portion of the shell, and outer side of the rotary shaft in the shell is fixedly connected with material distributing pieces, the rotary shaft is connected with a rotor shaft of a packing motor through a coupling, the packing motor is electrically connected with a controller; and a charging opening is formed at the top of the shell, and a discharging opening is formed in the side of the shell. The automatic compacting device is simple in structure, capable of fixing the position accurately, providing greater pressure, improving the quality of the sealed products and conveying the packing accurately, and worthy of popularization and use.

Owner:重庆欣卓矿山机械有限公司

Automatic deodorizing economic squatting pan with environmental protection and energy conservation functions

InactiveCN103938700AImprove waterproof performanceImprove antifreezeWater closetsWater savingAgricultural science

The invention belongs to squatting closestools in toilets, and relates to a novel substitute product of the squatting closestools. A squatting pan is characterized in that the squatting pan is of a stainless steel rubber body structure and attractive in appearance, an odor-free silica gel seal gasket is designed at the bottom end, provided with a plurality of suckers and connected with a ground seal, and the suckers absorb and grab the ground for fixing to install and fix the whole squatting pan. The squatting pan can be installed by any adult, the placing position can be changed freely, the squatting pan is never blocked, installation and operation are simplest, and a water-sealed joint and a latex seal ball are arranged on a drain outlet of the squatting pan, so that order is removed, and water is saved. An upper opening of the squatting pan is automatically opened and closed through a multiple automatic functional connecting, poking and sliding plate, and the sliding plate has a multi-stem magnetic seal function for effectively sealing and deodorizing the odor; square inflator pumps are arranged on the left side and the right side of the squatting pan, and the flushing intensity is improved through inflation and pressurization, so that the squatting pan is flushed more clean. Water is saved to the maximum, and a three-section pressure rod and a gear rod are connected to achieve the integral automatic function. The squatting pan is safe, sanitary, environmentally friendly, economic, easy and convenient to use and widely applied to large-scale, medium-scale and small-scale toilets of houses, army hotels, airplanes, trains, ships and other industries, saves energy, drains contamination and removes the odor.

Owner:王向前

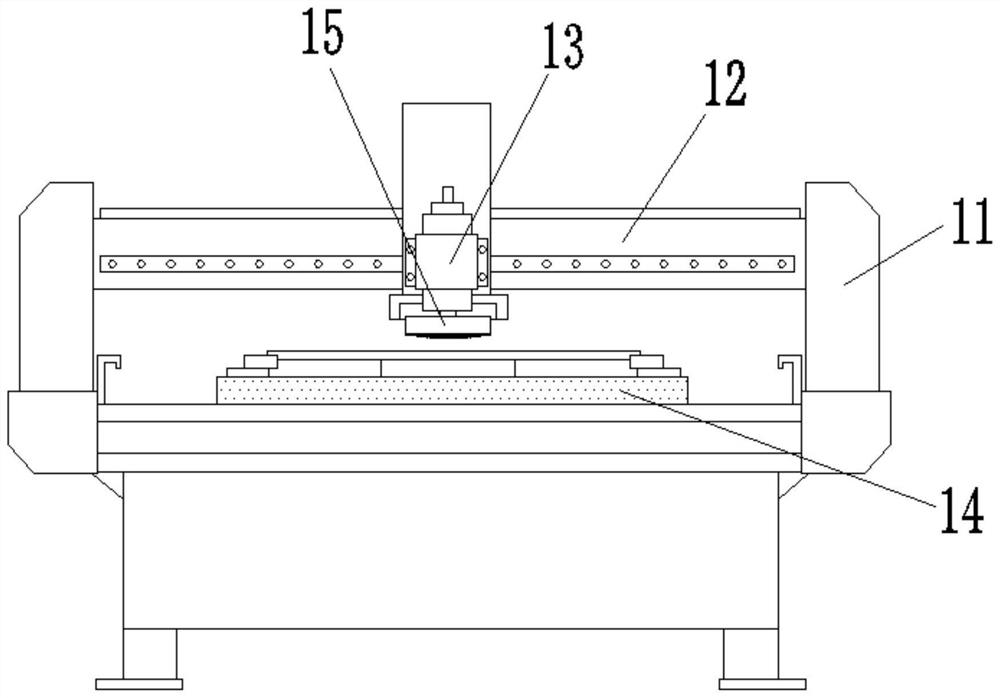

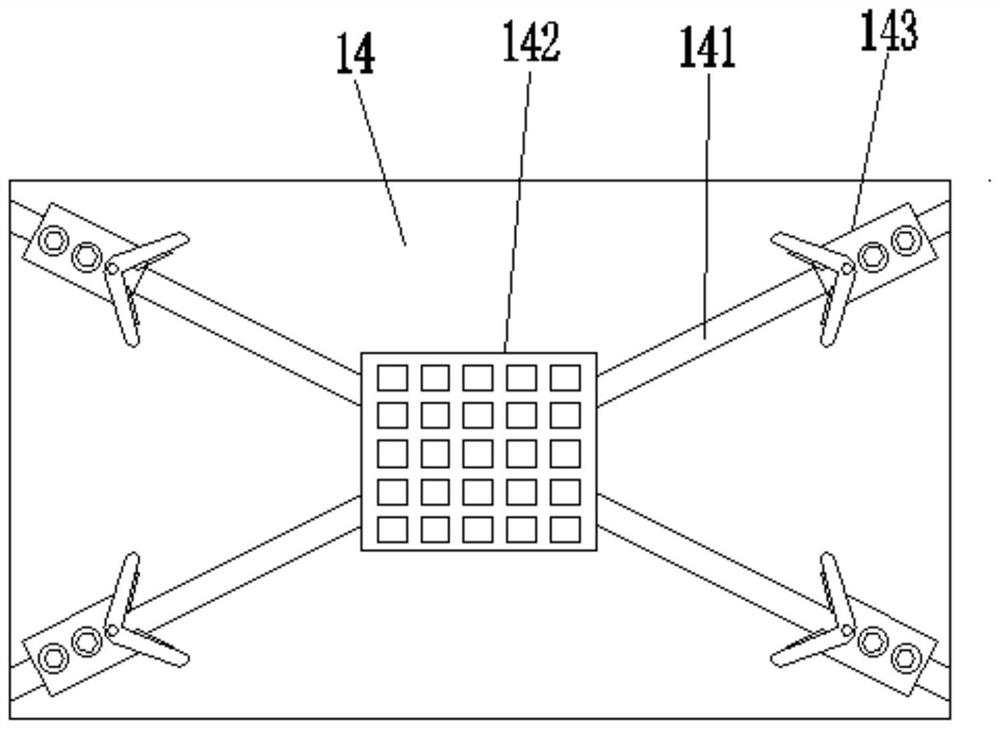

Full-automatic street lamp plate cutting and grinding device

InactiveCN113305664AExtended service lifeStrong extrusionGrinding carriagesOther manufacturing equipments/toolsGrinding wheelCooling fluid

The invention discloses a full-automatic street lamp plate cutting and grinding device which comprises a grinding mechanism, a cutting mechanism and a supporting base. The grinding mechanism is installed at the top of the supporting base, and the cutting mechanism is arranged on the back face of the grinding mechanism. The grinding mechanism comprises supporting frames, a supporting cross rod, a main shaft, a workbench and a grinding wheel, the supporting cross rod is arranged above the supporting base, and the supporting frames are installed on the left side and the right side of the supporting cross rod. According to the full-automatic street lamp plate cutting and grinding device, by the arrangement of a cooling mechanism, a fixing seat drives a bag to move upwards through pressing of a grinding plate, arc-shaped pressing plates contract inwards to press a pressing plate downwards, then the generated extrusion force is larger through upward moving of the bag, cooling liquid in the bag is extruded into a cooling groove from a leakage groove through the generated extrusion force by air in the bag, and then the grinding plate is cooled. The service life of the grinding wheel is prolonged, and the cost is saved.

Owner:吴远鸳

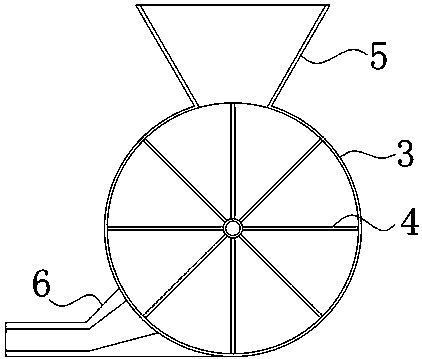

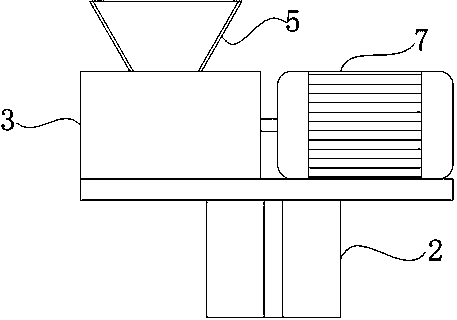

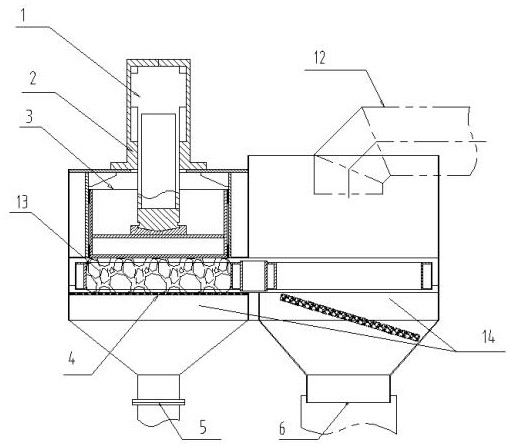

High-pressure extrusion dehydrator for garbage treatment

The invention belongs to the field of garbage treatment, and relates to kitchen garbage and restaurant garbage treatment, in particular to a high-pressure extrusion dehydration and dry-wet separationmachine for kitchen garbage and restaurant garbage and in more particular to a high-pressure extrusion dehydrator for garbage treatment. The high-pressure extrusion dehydrator is characterized in thatthe high-pressure extrusion dehydrator comprises a dehydrator main body, a main pressing oil cylinder, a pressing head, a filter hole plate, a wet material outlet, a dry material outlet, a rotating motor, a material rotating disc, a first material bin, a second material bin, a third material bin, a feeding station, an extrusion station and a discharging station; and the main pressing oil cylinderis arranged on the dehydrator main body, the pressing head for compressing the kitchen garbage and the restaurant garbage is arranged at the bottom of the main pressing oil cylinder, the filter holeplate for filtering wet materials in the kitchen garbage and the restaurant garbage is arranged at the bottom of the dehydrator main body, the wet material outlet is formed below the filter hole plate, the material rotating disc is arranged between the dehydrator main body and the filter hole plate, and the dry material outlet is formed below the material rotating disc.

Owner:CHONGQING ENDURANCE & SHINMAYWA IND +2

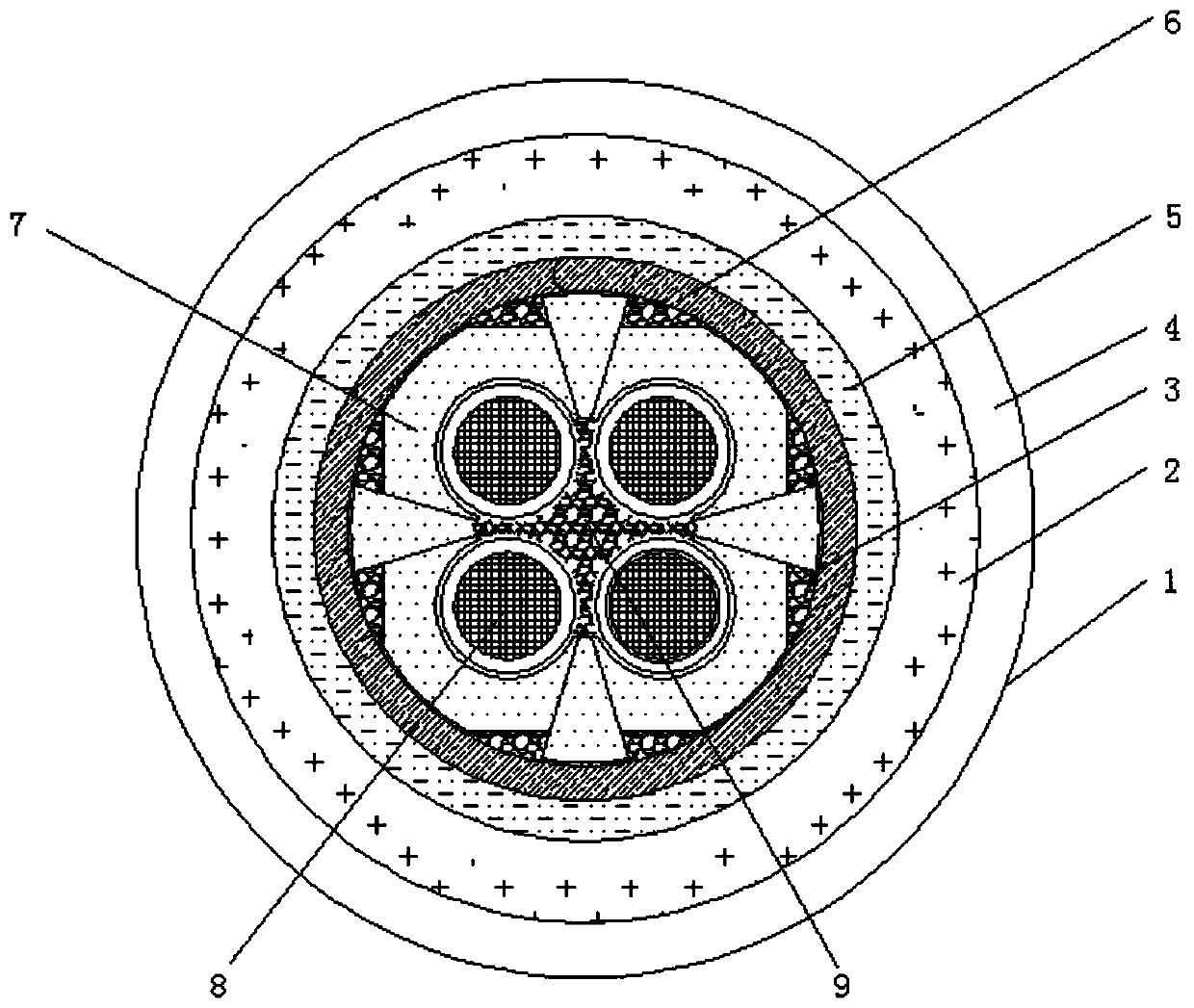

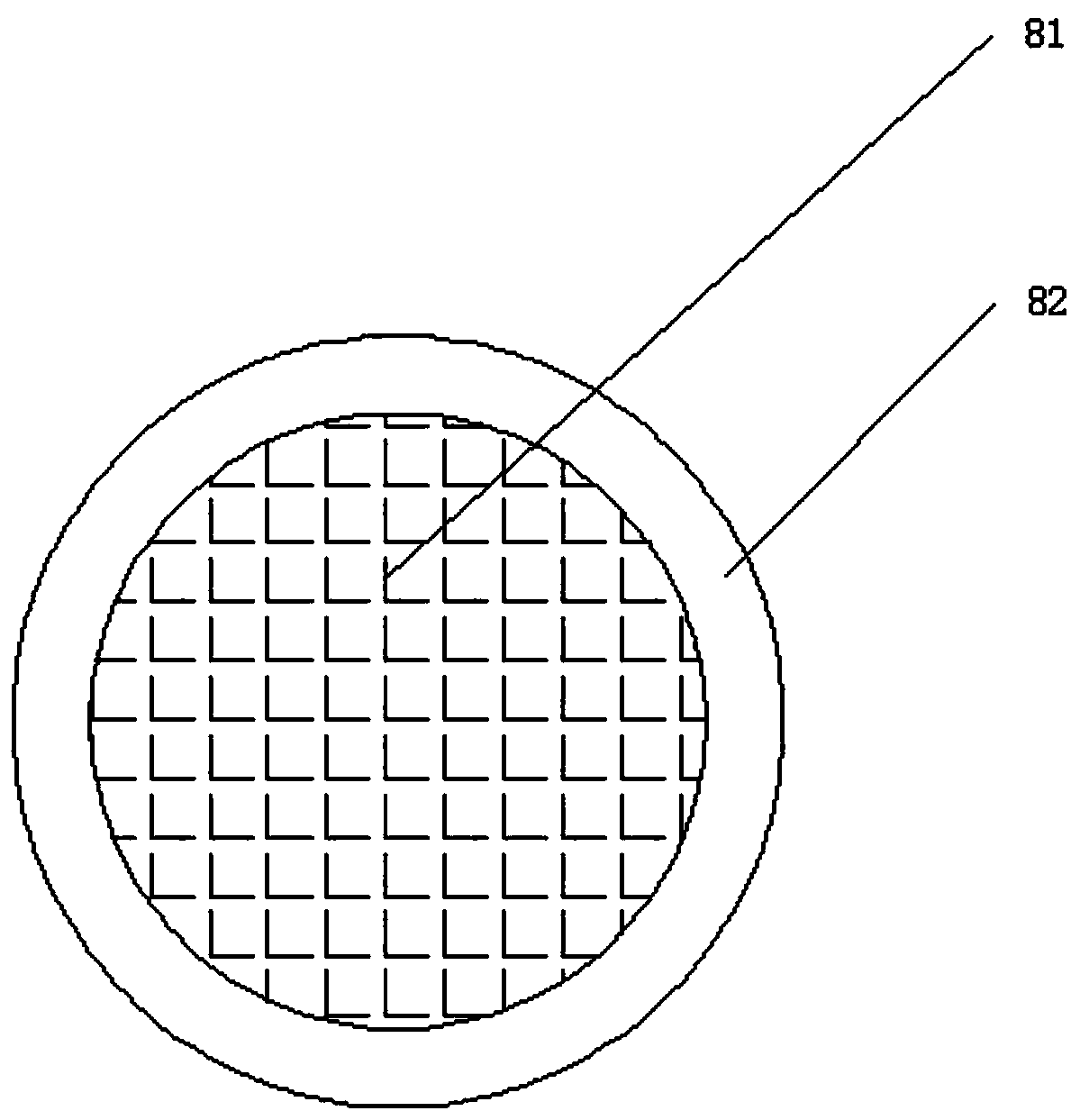

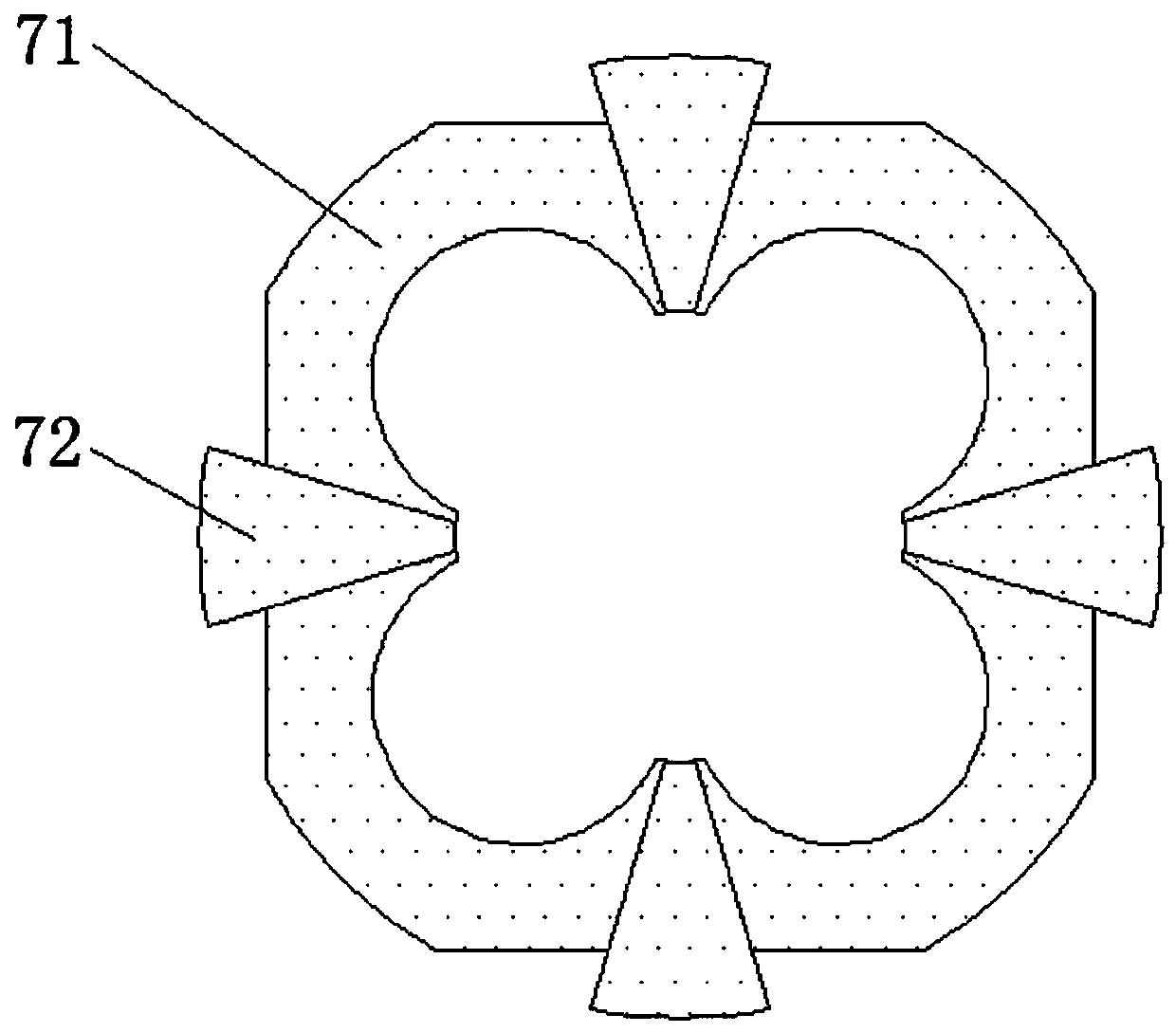

Anti-ultraviolet, anti-corrosion, anti-water, loadable and anti-extrusion magnetic measuring cable for ship

ActiveCN110517823AAvoid harmImprove the load-bearing capacity, that is, the tensile strengthRubber insulatorsInsulated cablesUltravioletEngineering

The invention discloses an anti-ultraviolet, anti-corrosion, anti-water, loadable and anti-extrusion magnetic measuring cable for a ship. The cable comprises a cable body. A bracket is arranged at themiddle position of the cable body. The bracket comprises four protective strips and four sliding strips. The four protective strips and the four sliding strips are arranged at intervals. The whole bracket can be disassembled and assembled so that the wire core can be clamped on the inner side of the bracket and use is convenient. When the cable is extruded somewhere and the extruding force acts on the sliding strips, the sliding strips move inwardly. When the sliding strips move inwardly, the protective strips and the sliding strips on the sides move to the two sides and the force is decomposed onto a plurality of load layers. When the extruding force acts on the protective strips, the protective strips move inwardly. When the protective strips move inwardly, the sliding strips and the protective strips on the two sides move to the two sides and the force is decomposed onto a plurality of load layers to prevent extruding damage to the wire core so as to have excellent load force.

Owner:ANHUI LINGYU CABLE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com