Reciprocating rolling material forming device

A reciprocating, material technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of poor feeding, accumulation, difficult to make bar shape and size adjustment, etc., to increase the evaporation surface area, increase Large evaporation area, good effect of making strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

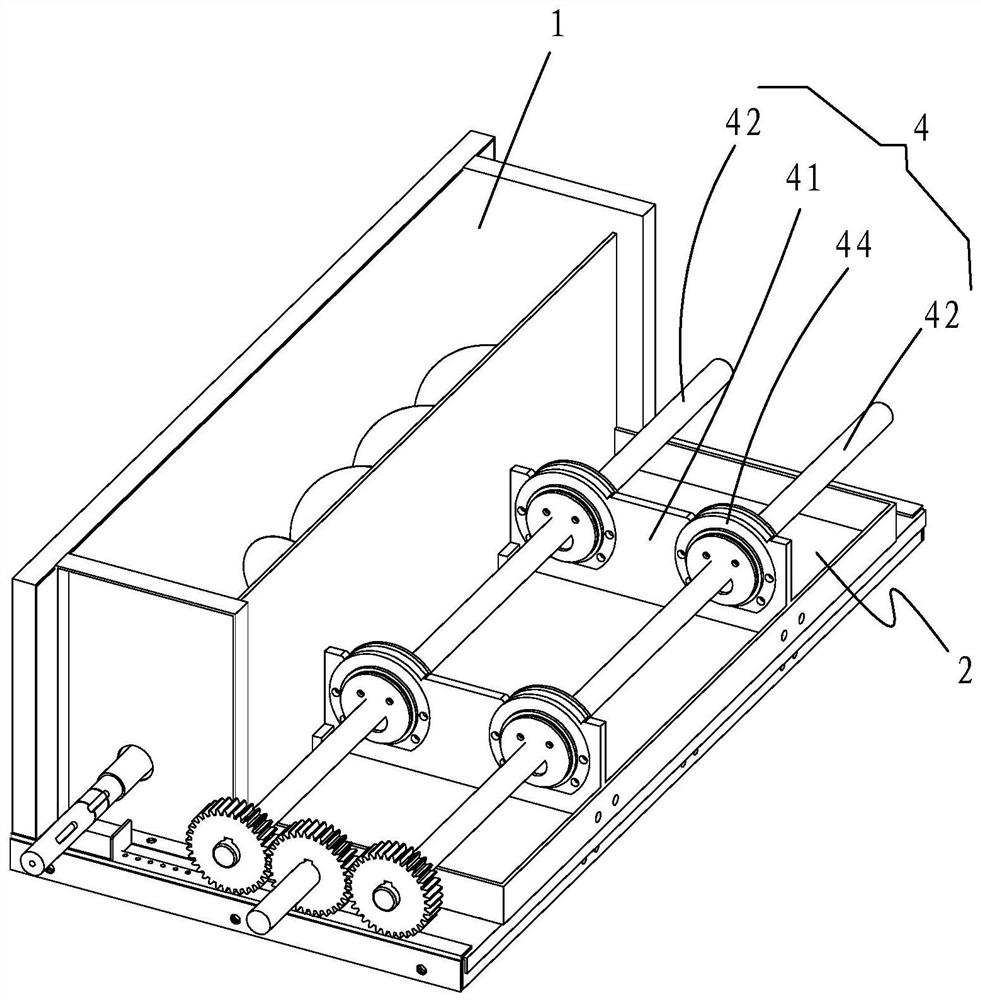

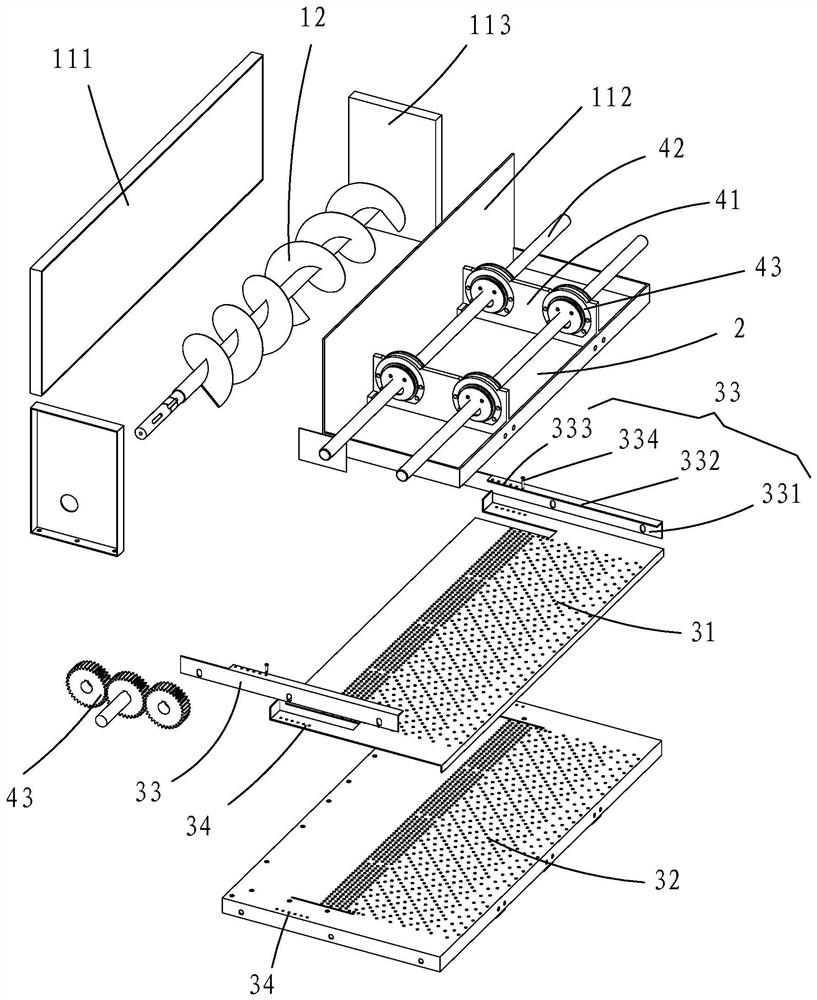

[0032] like figure 1 and figure 2 As shown, a reciprocating rolling material forming device includes: a feeding mechanism 1, a rolling plate 2, and two stacked and fixedly connected pressure bearing plates 31, 32.

[0033] The two pressure bearing plates 31 and 32 are provided with a plurality of circular or elongated holes; the upper pressure bearing plate 31 is a movable pressure bearing plate, and the lower pressure bearing plate 32 is an immovable pressure bearing plate; The pressure bearing plate 32 located below is fixed on the frame 100 on both sides (in practice, the frame 100 can be the two side walls of the drying equipment), and its two sides are respectively fixedly connected with an L-shaped firmware guide rail 33, L-shaped One side 331 of the firmware guide rail part 33 and the side of the pressure bearing plate 32 are fixed on the frame 100 on both sides, and the other side 332 is parallel to the pressure bearing plate 32, and the gap between the two forms a g...

no. 2 example

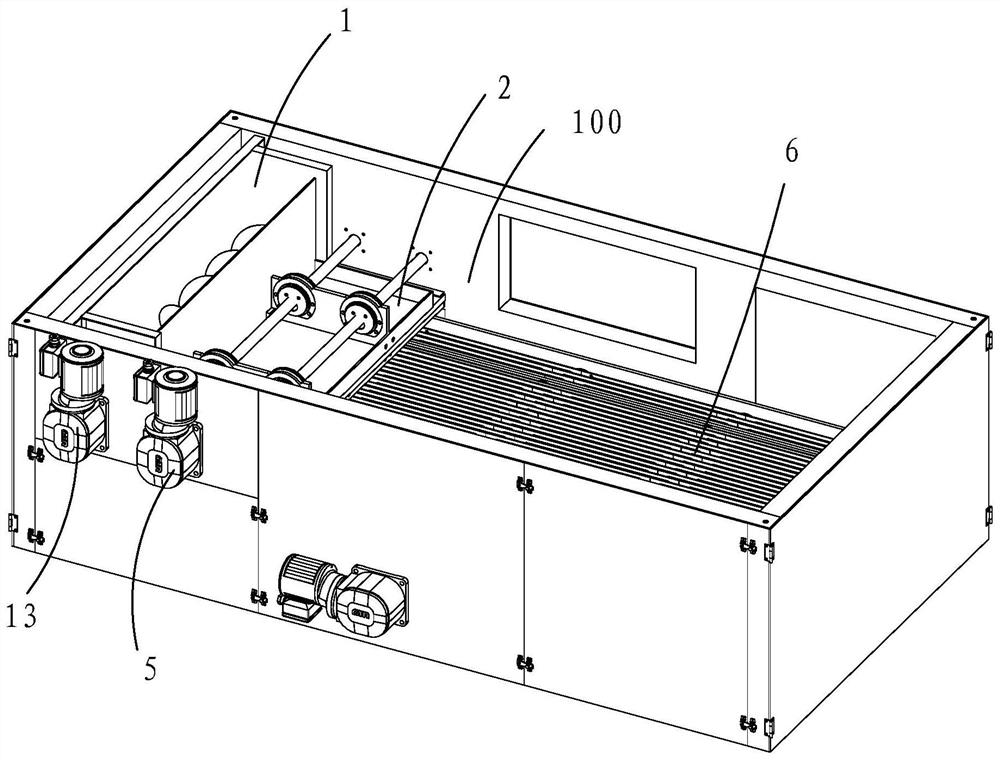

[0042] see Figure 3 to Figure 7 As shown, in the second embodiment, a quick-transfer drying platform 6 is set under the pressure-bearing plate 32 in the first embodiment, so that the formed material is transferred quickly. For the specific structure of the fast-transfer drying platform 6 , please refer to the stacked push-type material delivery platform in a peristaltic push-type drying equipment disclosed in Chinese invention patent 2019107487193.6.

[0043] Working process: The material enters from the upper part of the feeding bin 11 of the feeding mechanism 1, and through the rotation of the two-way screw shaft 12, the material is evenly transported to the entire feeding bin 11, and the material can be fed into the rolling plate 2 and In the gap formed by the pressure bearing plates 31, 32. Since the baffle plate 112 connected to the rolling plate 2 performs reciprocating synchronous circular motion, material accumulation or bridging can be avoided. At the same time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com