Patents

Literature

51results about How to "Increase the evaporation surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

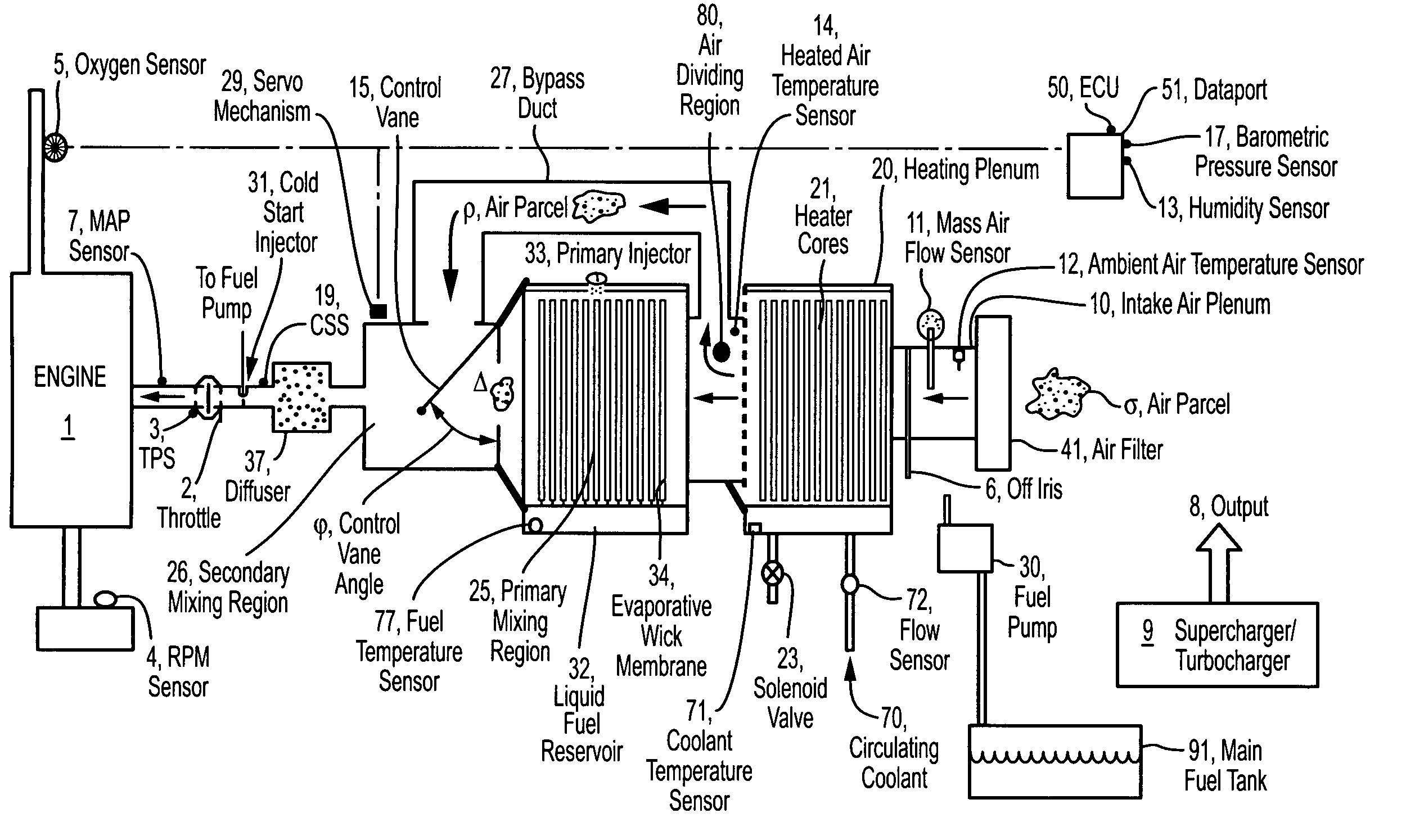

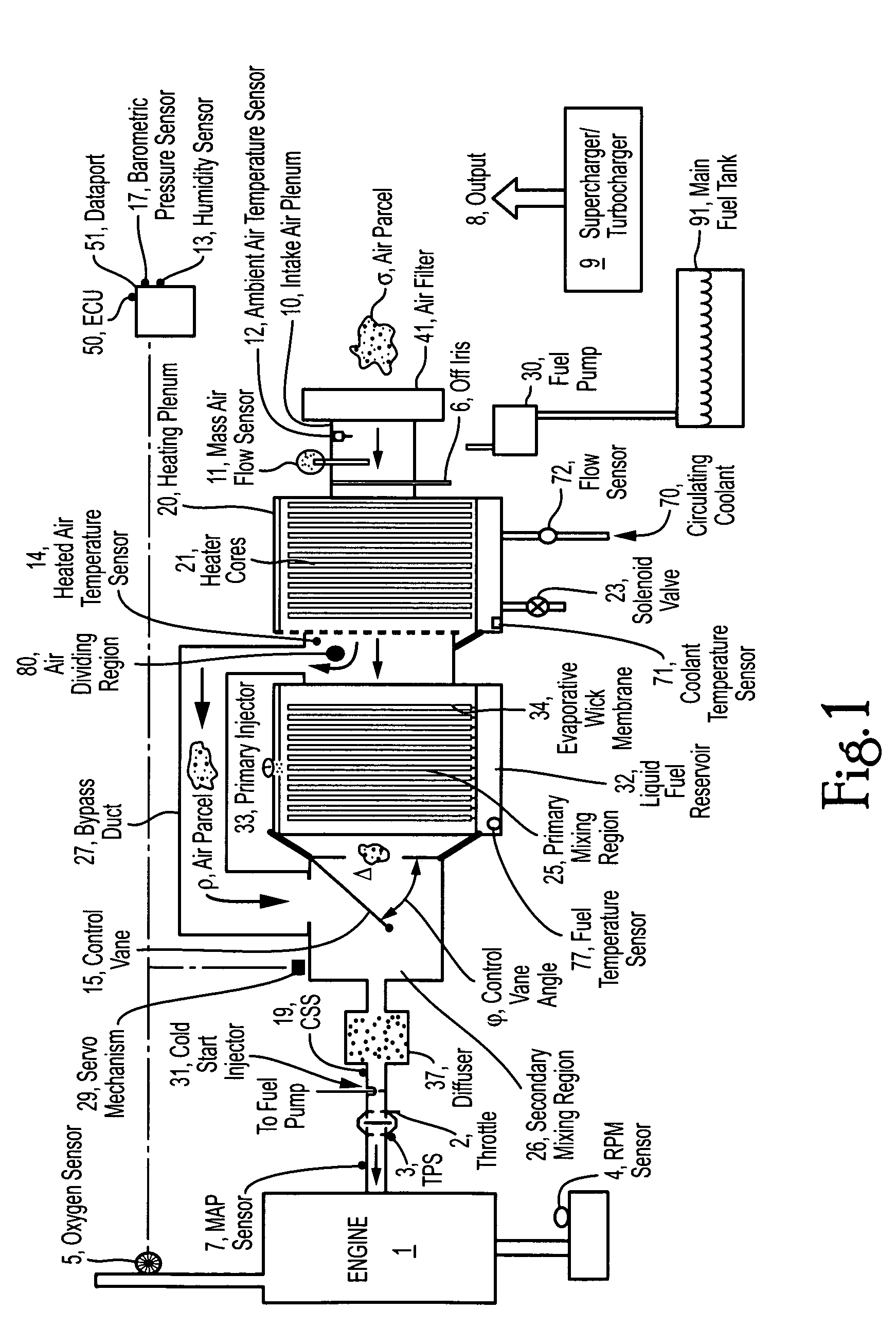

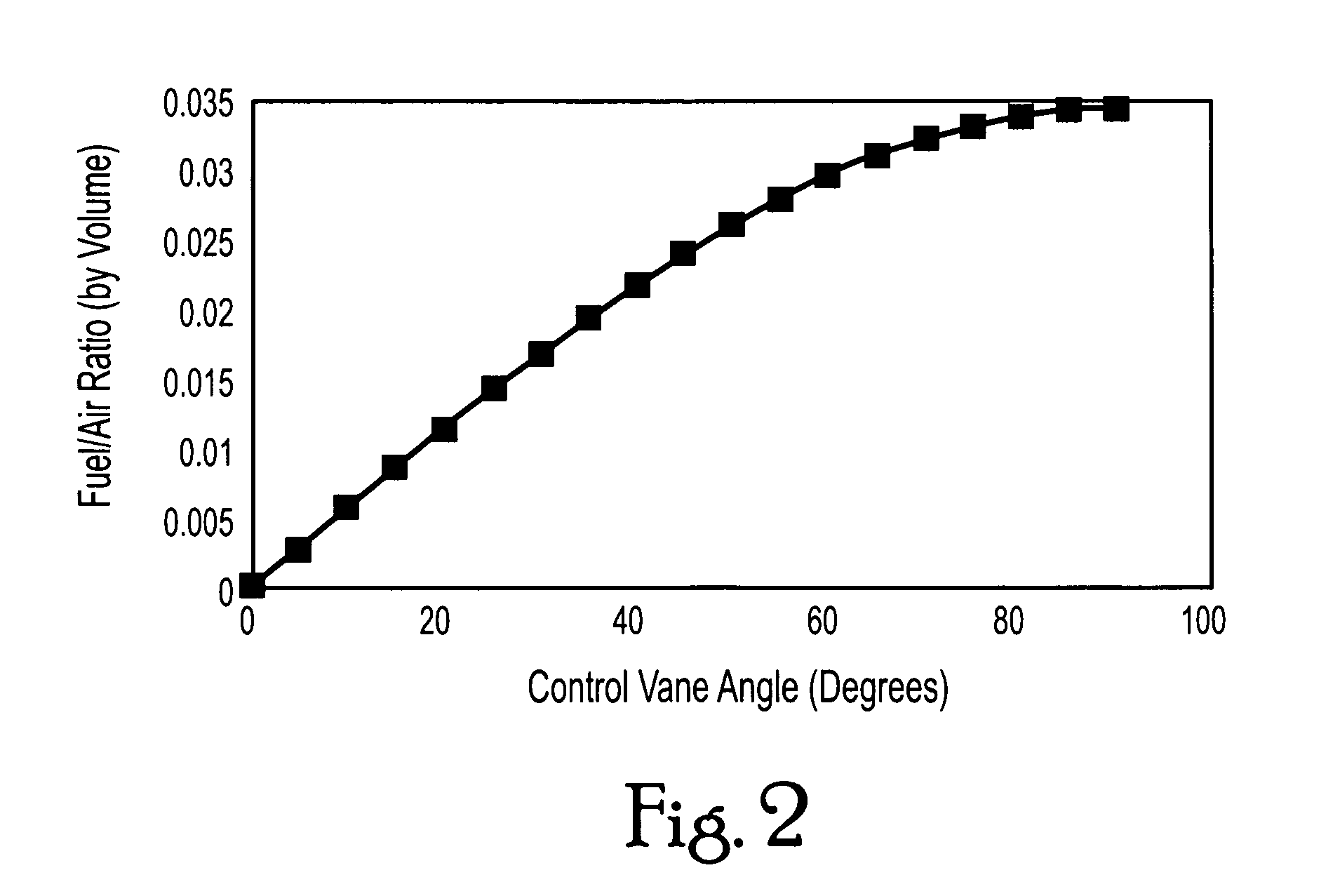

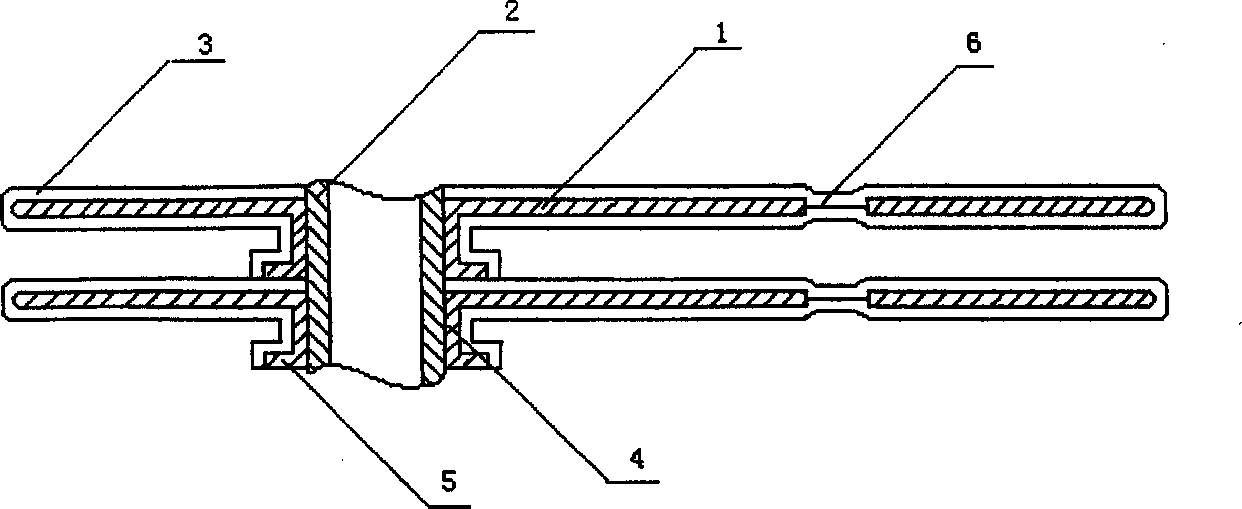

Fuel Delivery System

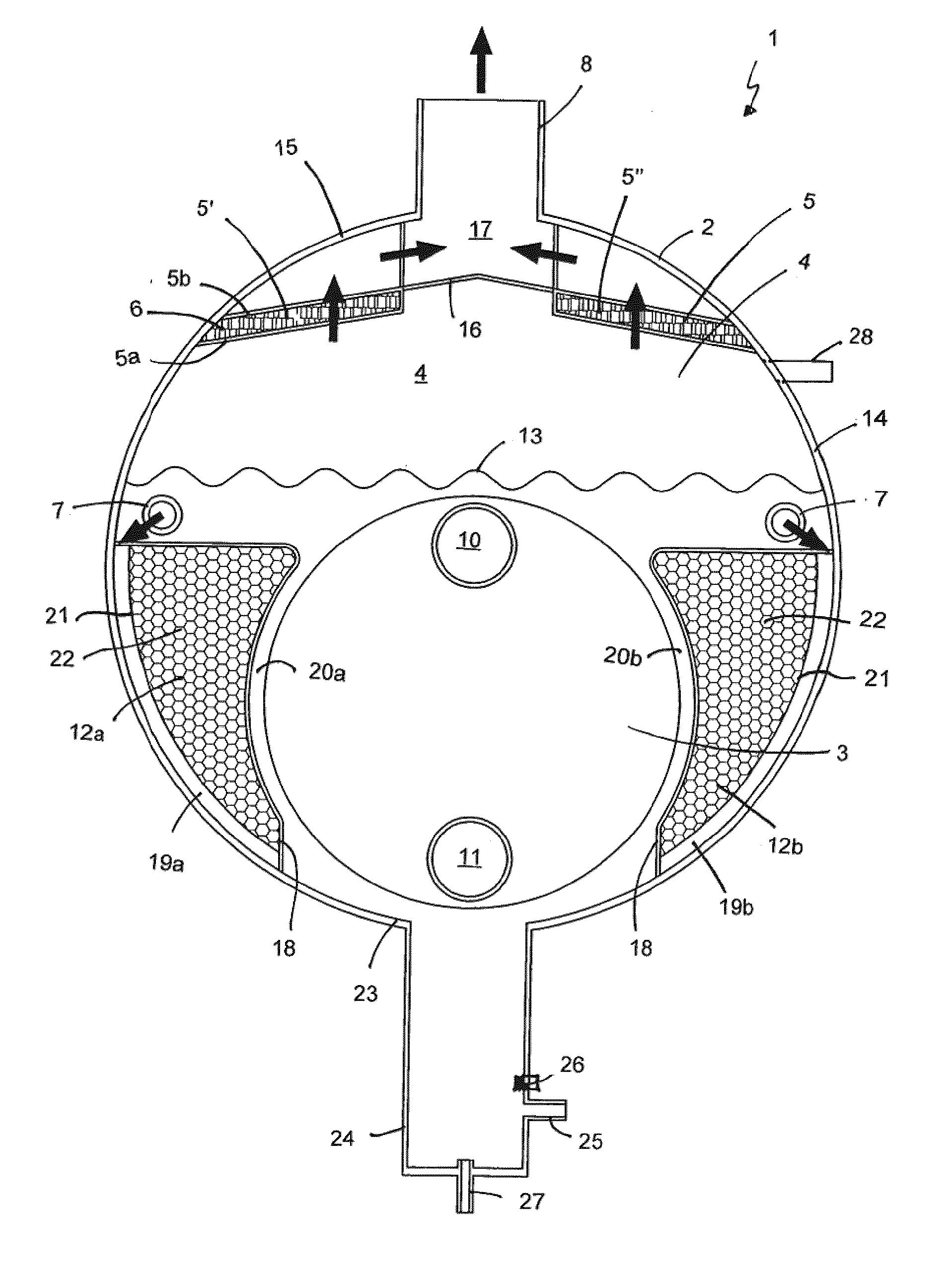

InactiveUS20060249129A1Increase the evaporation surface areaControl of transpirationElectrical controlInternal combustion piston enginesCombustionInternal combustion engine

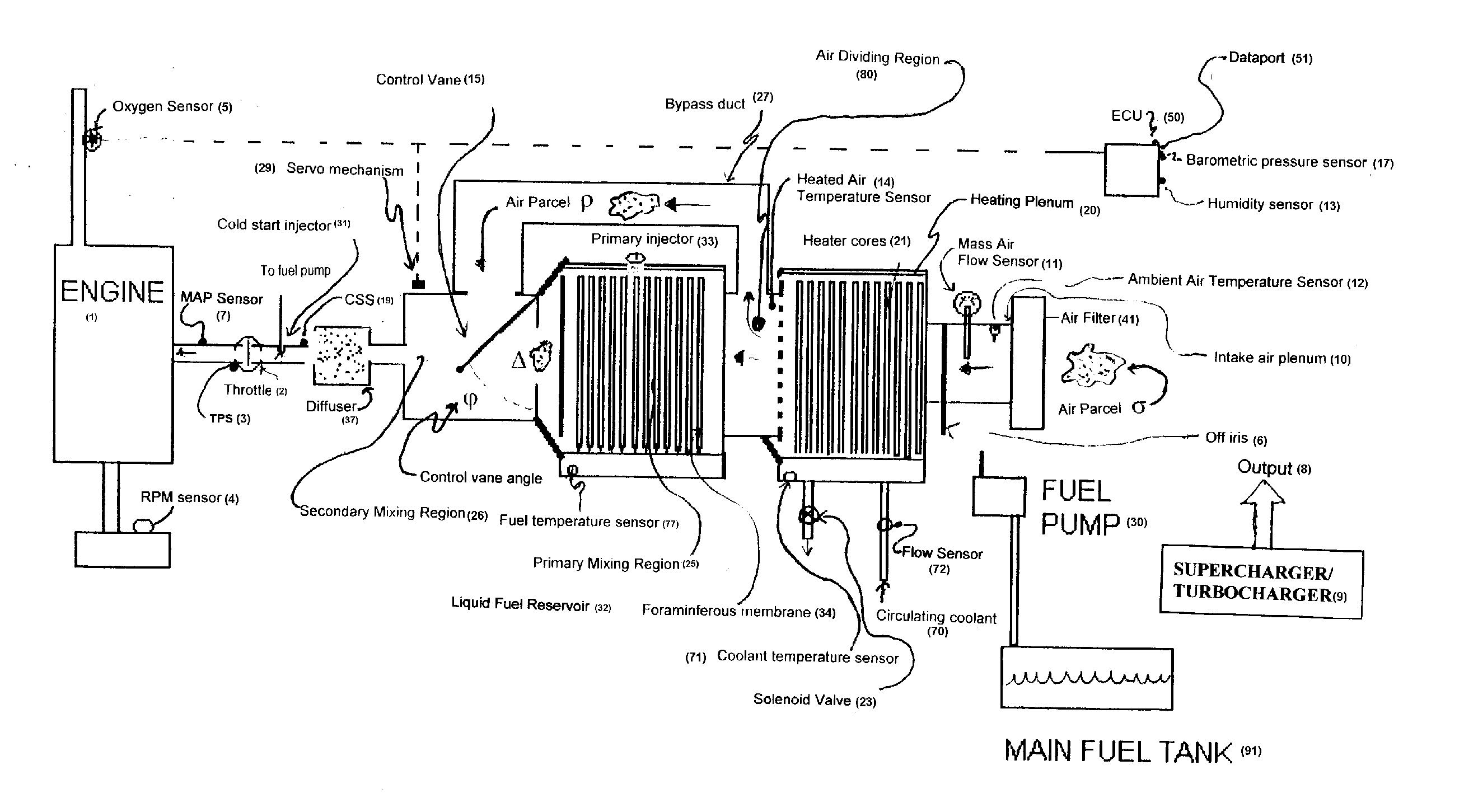

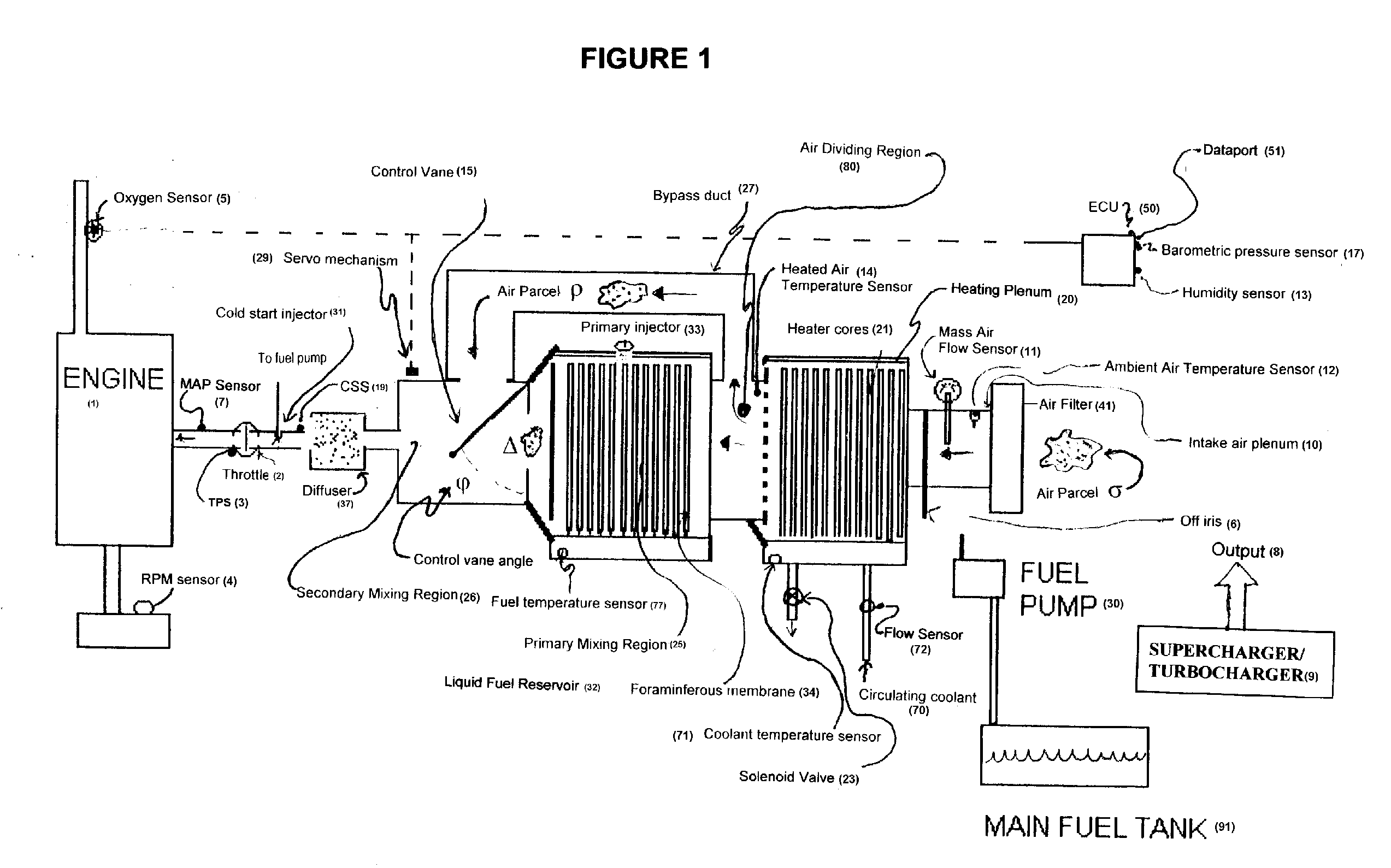

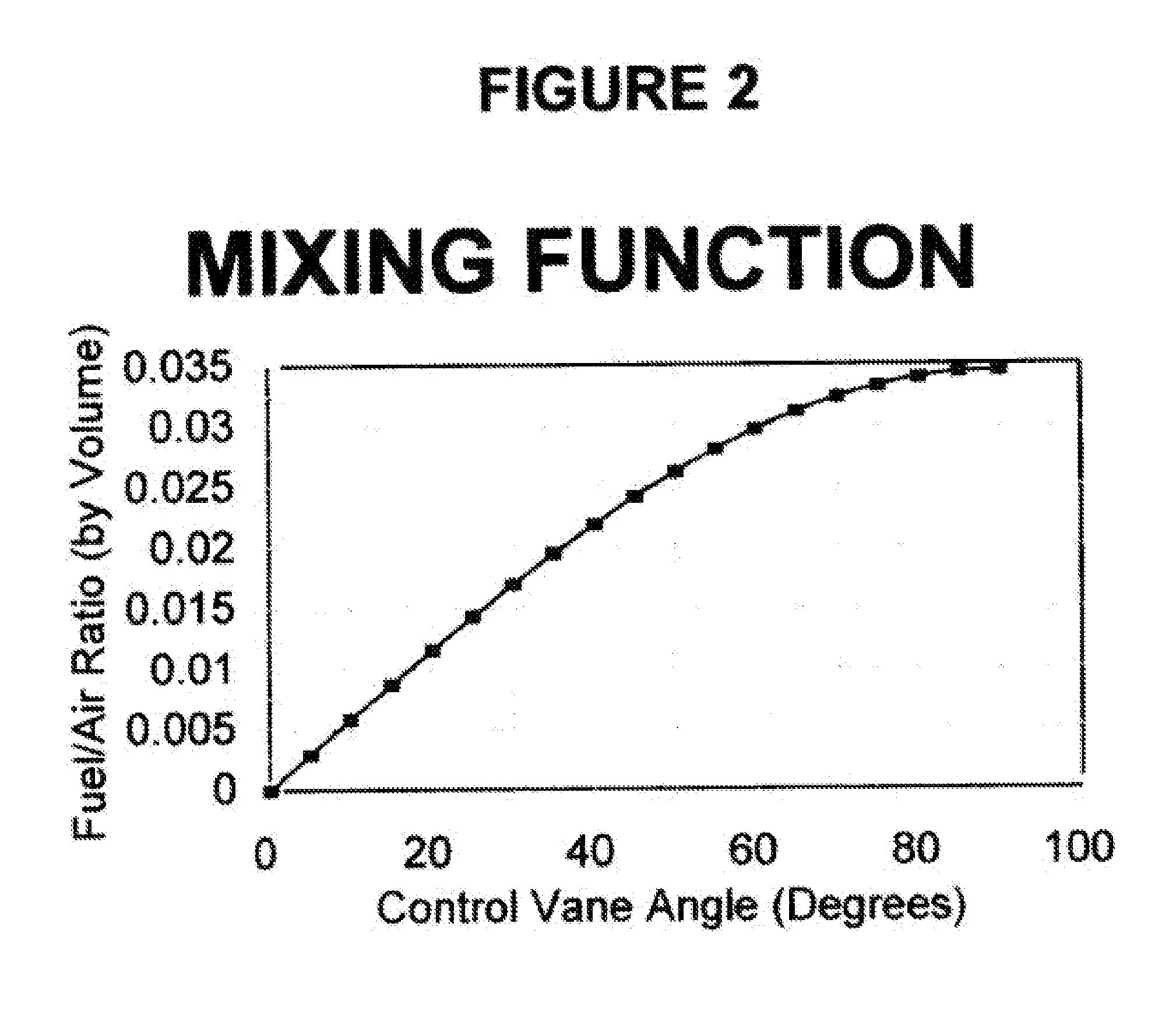

Fuel delivery system for an internal combustion engine comprising a method and apparatus for generating and delivering a homogeneous charge with a variable fuel / air ratio which relies on transpirating fuel membranes in a primary mixing region to which a portion of thermally-regulated air from an air dividing region has come. A single moving control element is used to control the quantity of in-rushing air in the primary mixing region, and therefore the amount of fuel rich air produced in this primary mixing region, and at the same time this single moving control element modulates both the quantity of fuel rich air and the quantity of regular fuel-free combustion air which are brought together in a secondary mixing region where they combine in the desired ratio to form a homogeneous charge with a variable fuel / air ratio. The use of a single moving control element allows extremely economical construction. A further advantage of this method is extremely rapid and accurate control of the fuel / fair ratio of the charge which is generated. The method can be used to safely and reliably generate clean-burning combustible mixtures for internal combustion engines, and to cool supercharged and turbocharged airstreams. Electronic control means are also provided to calculate the correct fuel / air ration under various engine operating and environmental conditions and so that spark plug timing and electromechanical valve timing can be adjusted in concert with adjustments to the fuel / fair ratio so that optimum fuel economy and emissions performance is obtained.

Owner:OZDEMIR PHILLIP NURI

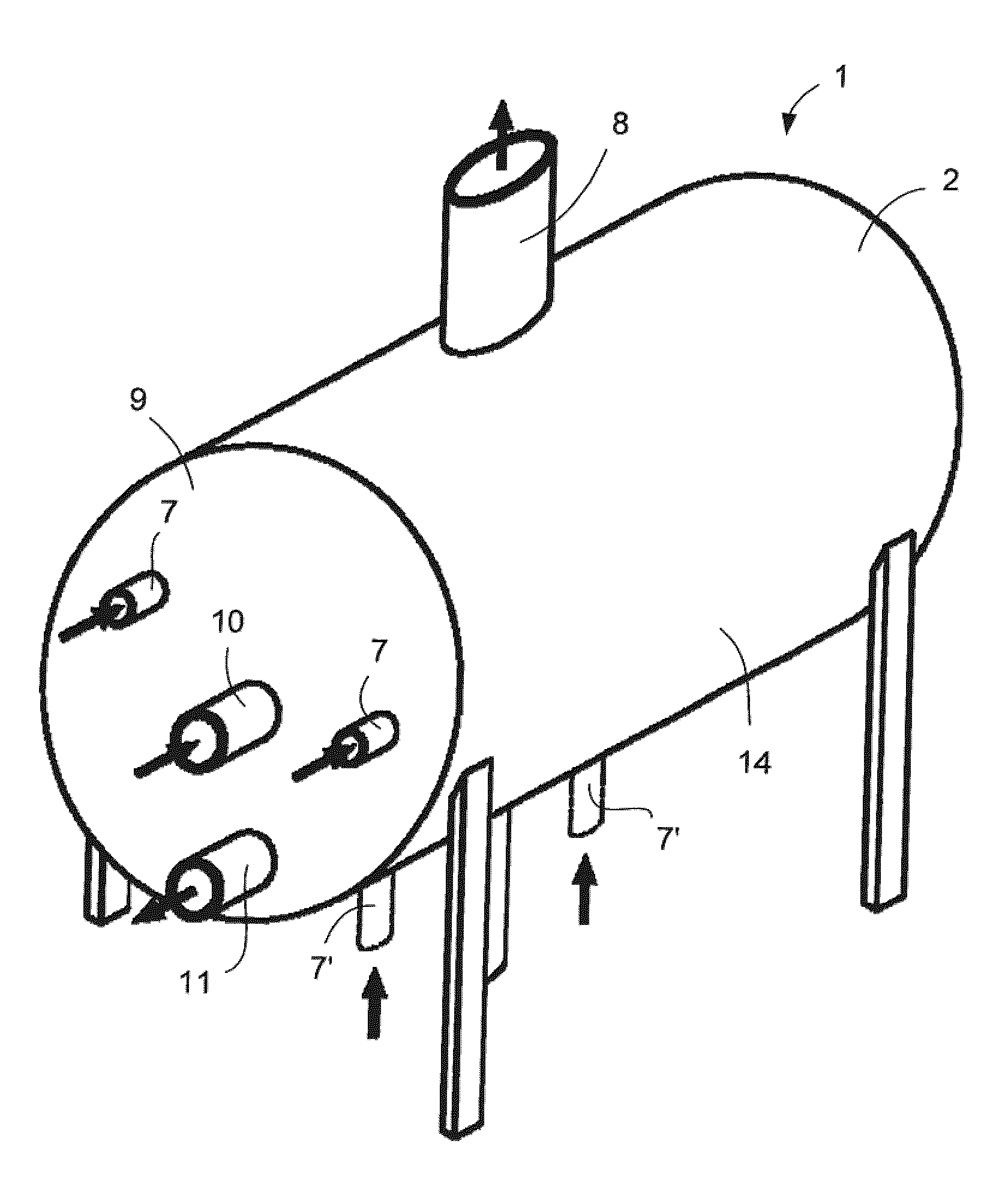

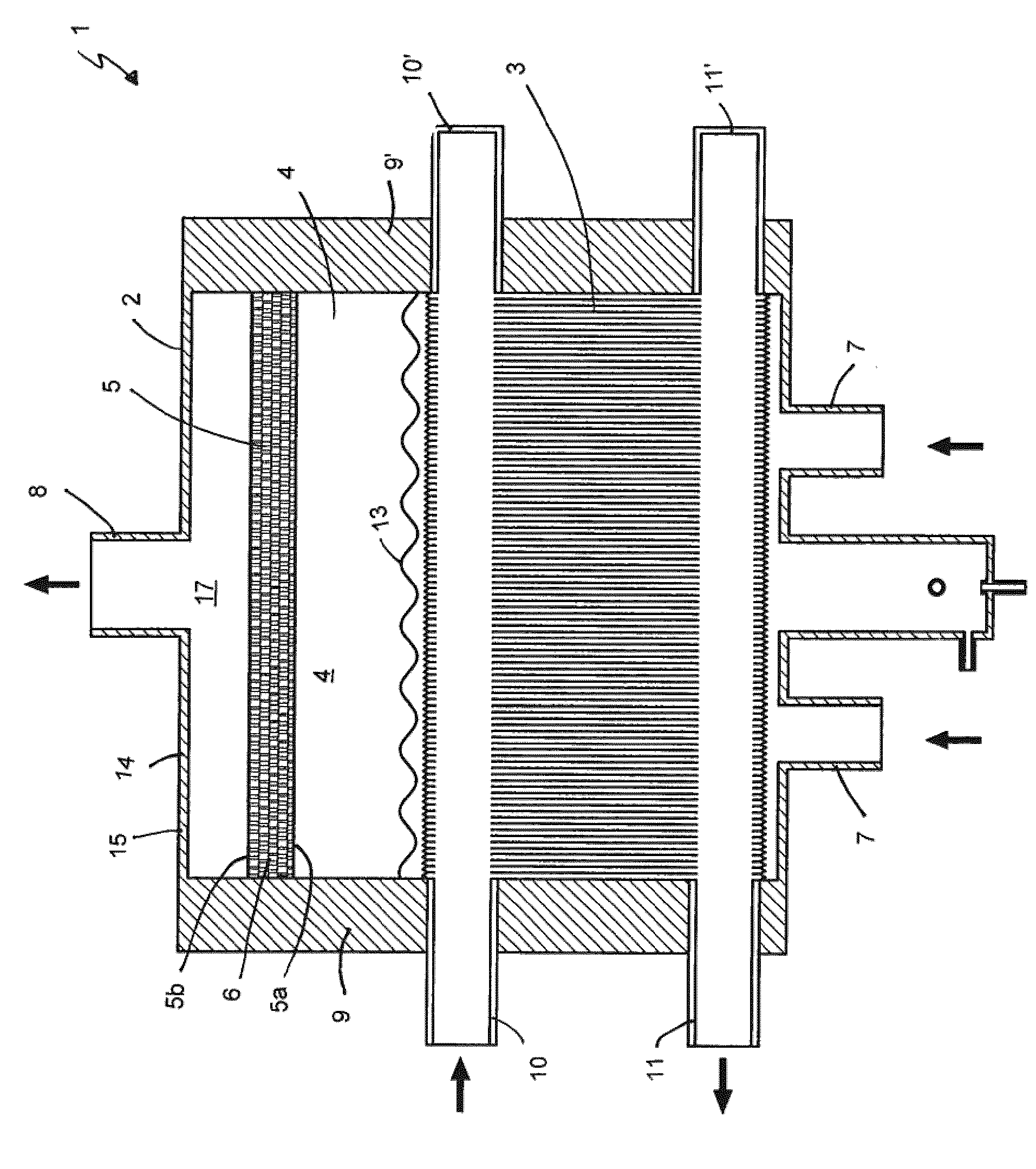

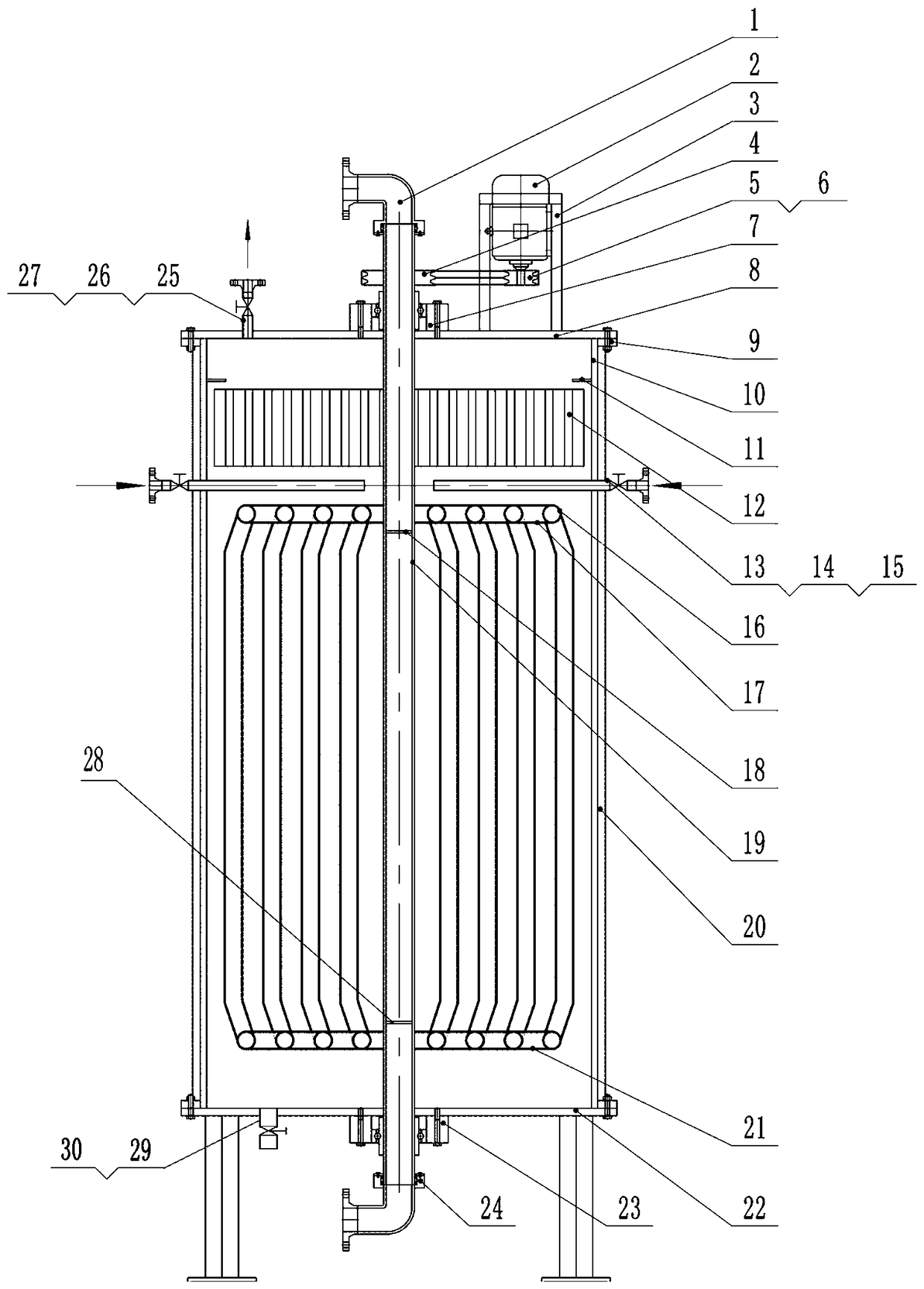

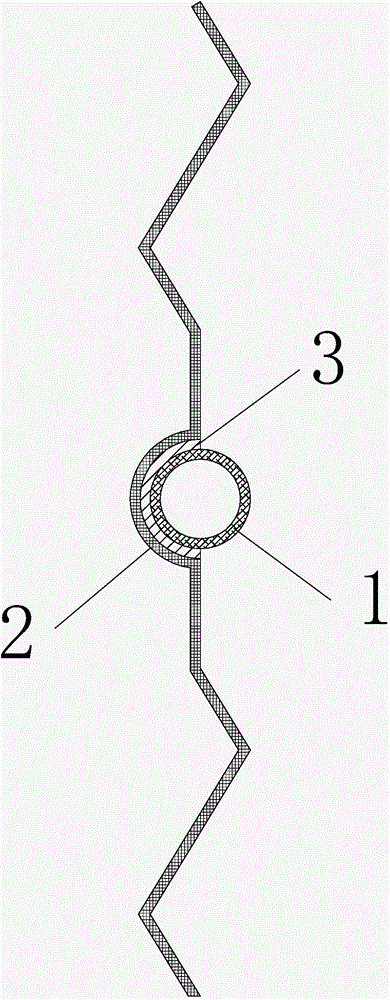

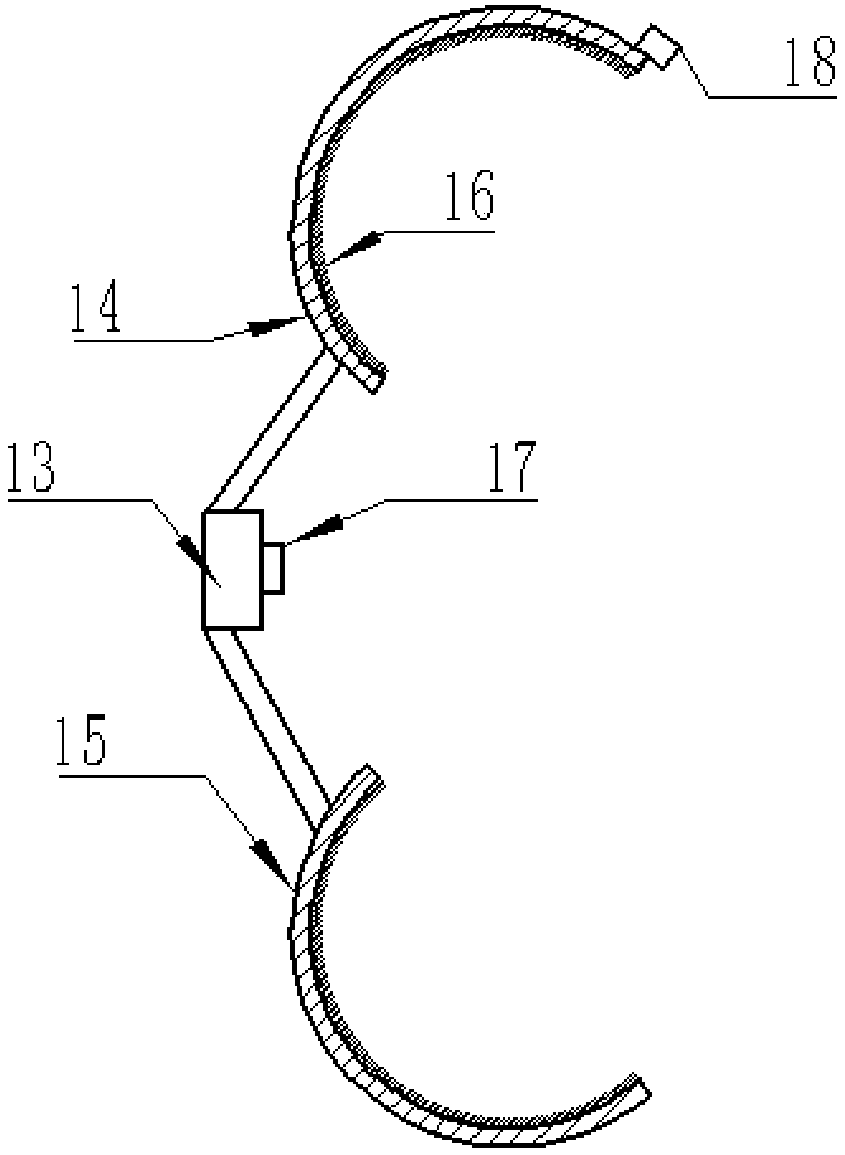

Device for separating droplets

ActiveCN103477164AReduce formationConvenience facilitates separationEvaporators/condensersEvaporationLiquid dropEvaporator

The invention relates to a device (1) for separating droplets, which comprises an outer casing (2), which has a substantially horizontal cylindrical shell (14) and substantially vertical ends (9); an inlet connection (7) for a substance to be vapourised for leading a substance to be vapourised into the outer casing; a plate pack (3) functioning as an evaporator, which is arranged inside the outer casing, in its lower part (23); an inlet connection (10) and an outlet connection (11) for a heating substance for leading a heating substance into the plate pack and out of it; a gravitational droplet separator (4), which is arranged inside the outer casing, above the plate pack; an outlet connection (8) for vapourised substance for leading the vapourised substance out of the outer casing from its upper part (15); and one or more filler units (12a, 12b) arranged between the outer casing (2) and the plate pack (3) for decreasing the liquid volume of the substance to be vapourised inside the outer casing. The invention is suited to be used for example as a flooded evaporator (3) of a refrigerating machinery and a thereto related droplet separator (4, 5).

Owner:VAHTERUS OY

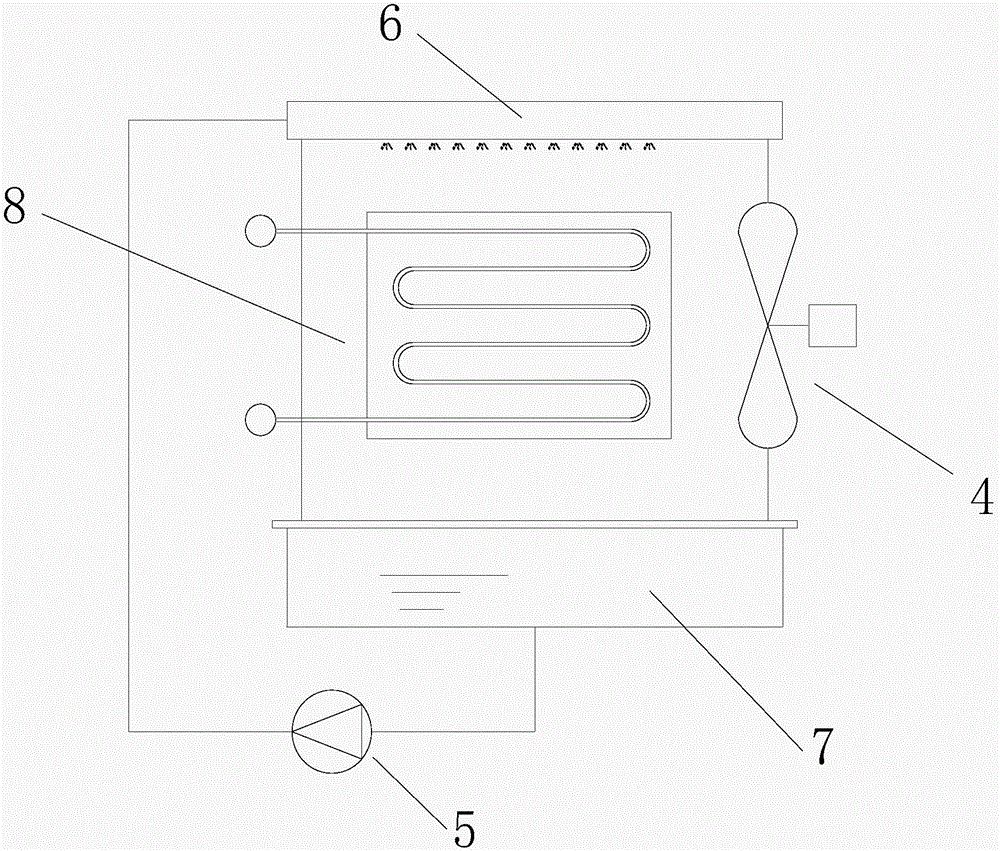

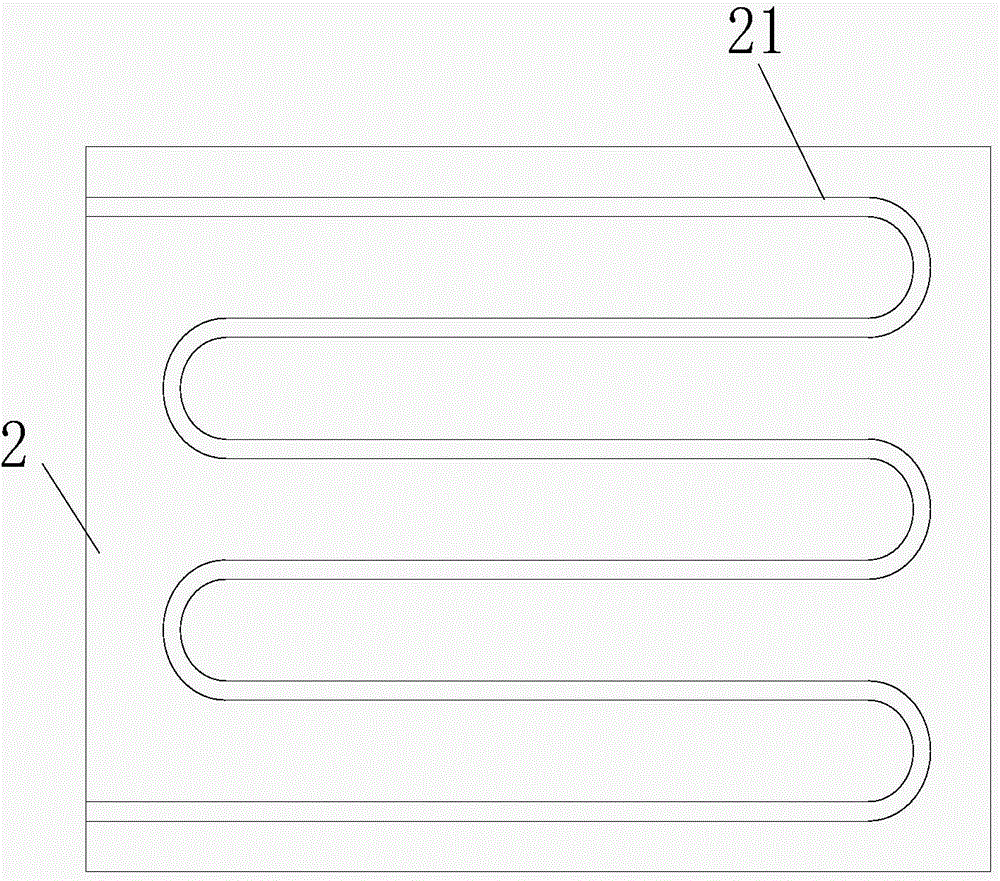

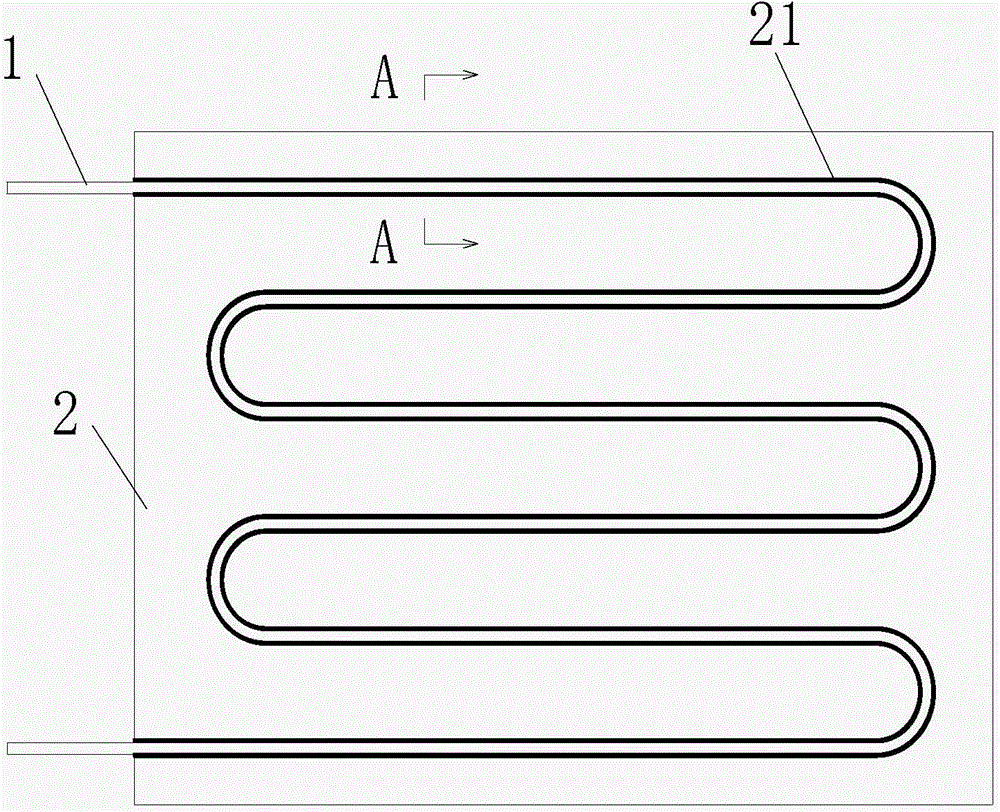

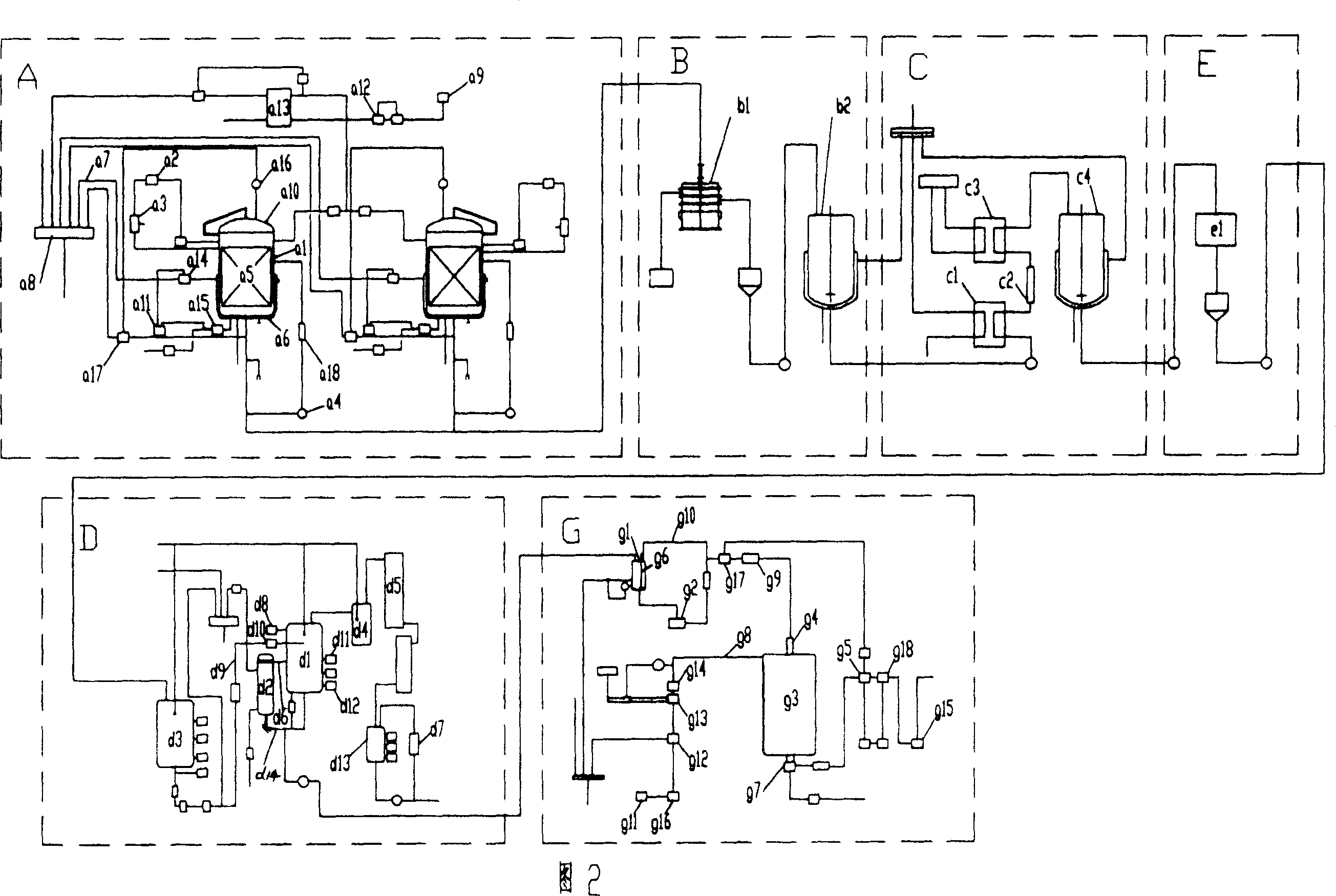

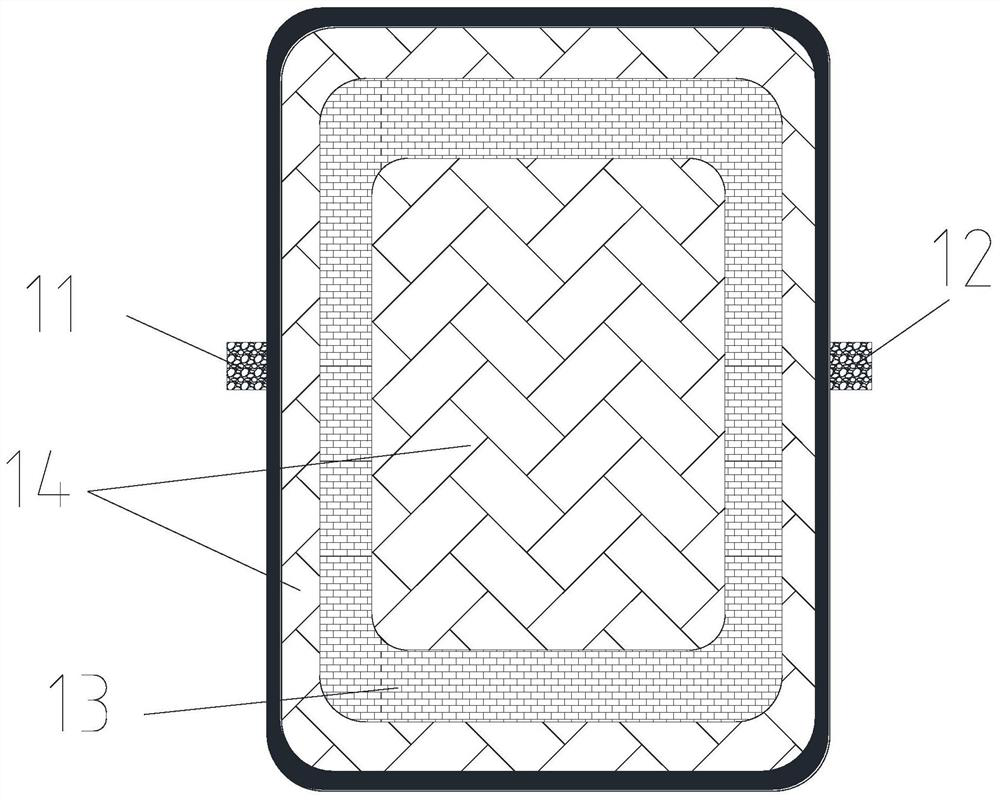

Plate-pipe composite heat-exchange-type evaporative condenser

ActiveCN105987622AIncrease the effective heat transfer areaIncrease the evaporation surface areaStationary conduit assembliesCoatingsThermal bondingEngineering

The invention discloses a plate-pipe composite heat-exchange-type evaporative condenser. The plate-pipe composite heat-exchange-type evaporative condenser comprises a fan, a water pump, a water distributor, and a water collection pond and further comprises a plate-pipe composite heat exchanger composed of connection among multiple plate-pipe composite heat-exchange sheets, a water inlet header and a water outlet header. The plate-pipe composite heat-exchange sheets comprise heat-transfer plate sheets and coil pipes formed by machining of a heat exchange pipe. Placement grooves are arranged in the heat-transfer plate sheets and matched with the coil pipes in terms of shapes. The coil pipes are arranged in the placement grooves. Heat conduction bonding layers are filled with the gaps between the coil pipes and the placement grooves. Compared with the prior art, the plate-pipe composite heat-exchange-type evaporative condenser has following beneficial effects: the heat conduction bonding layer enables the heat transfer plate sheets to be in full contact with the coil pipes such that the coil pipes have the finned effect through the heat transfer plate sheets and the effective heat exchange area can be effectively increased; the heat transfer plate sheets can introduce cooling water to form a continuous waterflow surface and increases the evaporation area of cooling water; and with an increased effective heat exchange area and an evaporation area of cooling water, heat exchange efficiency is raised and size of a condenser can be reduced.

Owner:GUANGZHOU WIDE IND

Extruded composite jerky and preparation method thereof

InactiveCN103404881AImprove product qualityQuality improvementFood preservationFood shapingFiberMeat cooking

The invention discloses an extruded composite jerky and a preparation method thereof. The extruded composite jerky is prepared from the following raw materials in parts by weight in an extruded manner by a screw bolt extruding machine: 100 parts of raw meat, 5-7 parts of hydrophilic colloid, 2-20 parts of condiment and 0-30 parts of food ingredients. The preparation method comprises the following steps: ingredient pretreatment: muscle fibers are used as main raw meat, and subjected to meat cooking and crushing; compounding: the cooked and crushed meat, the hydrophilic colloid and the food ingredients are mixed uniformly according to the composition, quality adjusting is performed and a wet basis water content of all materials is controlled within the range of 35-55 percent; extrusion molding: the materials with adjusted quality is formed through extrusion by the screw bolt extruding machine; drying for dehydration: the extruded composite jerky can be obtained after drying. According to the method, the condiment can be added in any one step or two or three steps. The extruded composite jerky is short in production period, low in low manufacturing cost and good in taste; as texture main bodies are mainly formed by the muscle fibers, the ingredients can be added within a wide range.

Owner:GUIZHOU UNIV

Fuel delivery system

InactiveUS7644705B2Increase the evaporation surface areaControl of transpirationElectrical controlInternal combustion piston enginesCombustionEngineering

Fuel delivery system for an internal combustion engine comprising a method and apparatus for generating and delivering a homogeneous charge with a variable fuel / air ratio which relies on fuel-absorbent, air-permeable evaporative wick membranes in a primary mixing region to which a portion of thermally-regulated air from an air dividing region has come. A single moving control element is used to control the quantity of in-rushing air in the primary mixing region, and therefore the amount of fuel rich air produced in this primary mixing region, and at the same time this single moving control element modulates both the quantity of fuel rich air and the quantity of regular fuel-free combustion air which are brought together in a secondary mixing region where they combine in the desired ratio to form a homogeneous charge with a variable fuel / air ratio. The use of a single moving control element allows extremely economical construction. A further advantage of this method is extremely rapid and accurate control of the fuel / fair ratio of the charge which is generated. The method can be used to safely and reliably generate clean-burning combustible mixtures for internal combustion engines, and to cool supercharged and turbocharged airstreams. Electronic control means are also provided to calculate the correct fuel / air ration under various engine operating and environmental conditions and so that spark plug timing and electromechanical valve timing can be adjusted in concert with adjustments to the fuel / fair ratio so that optimum fuel economy and emissions performance is obtained.

Owner:OZDEMIR PHILLIP NURI

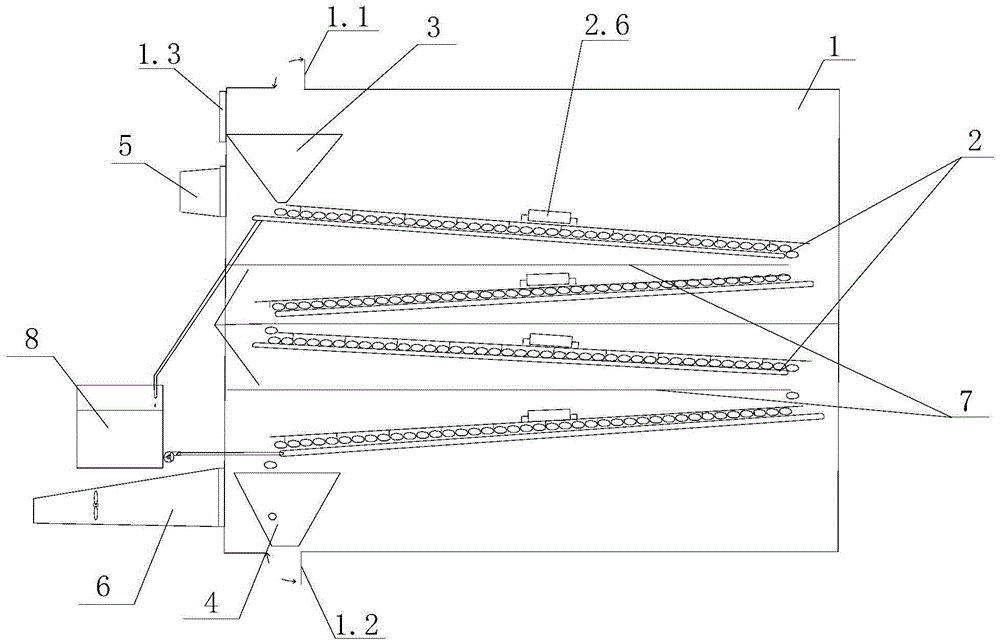

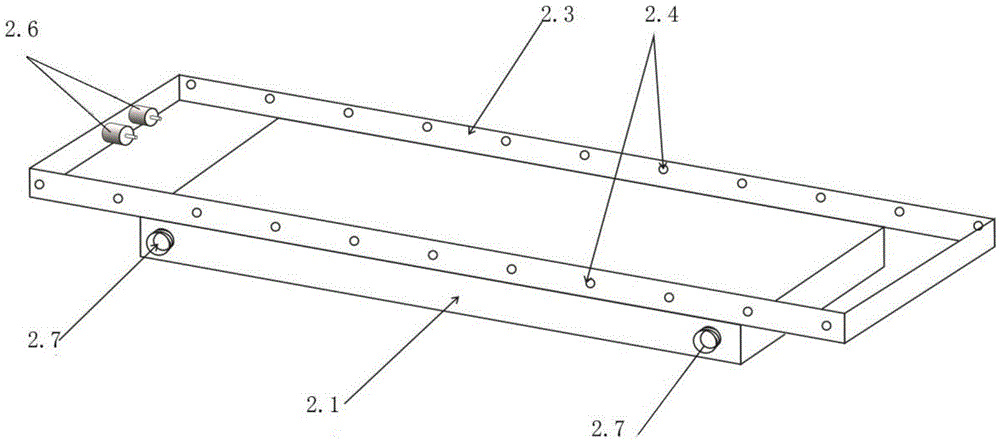

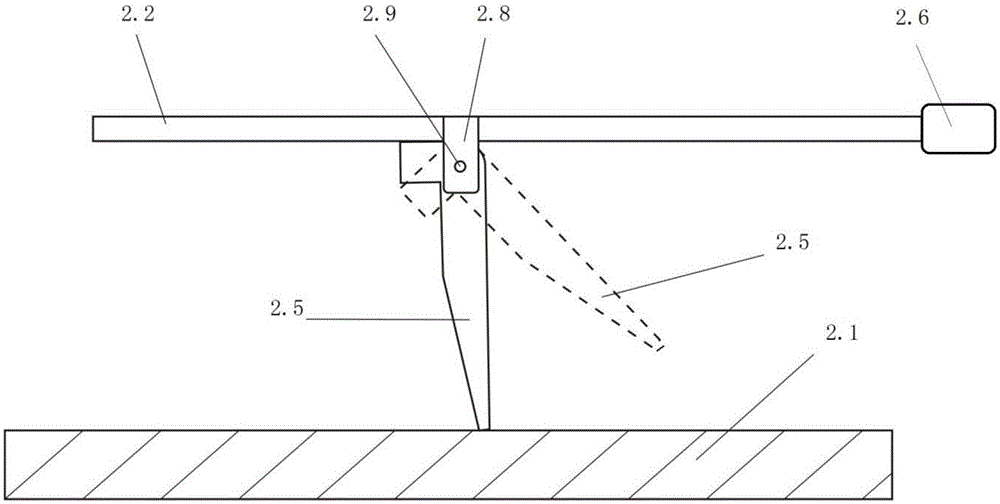

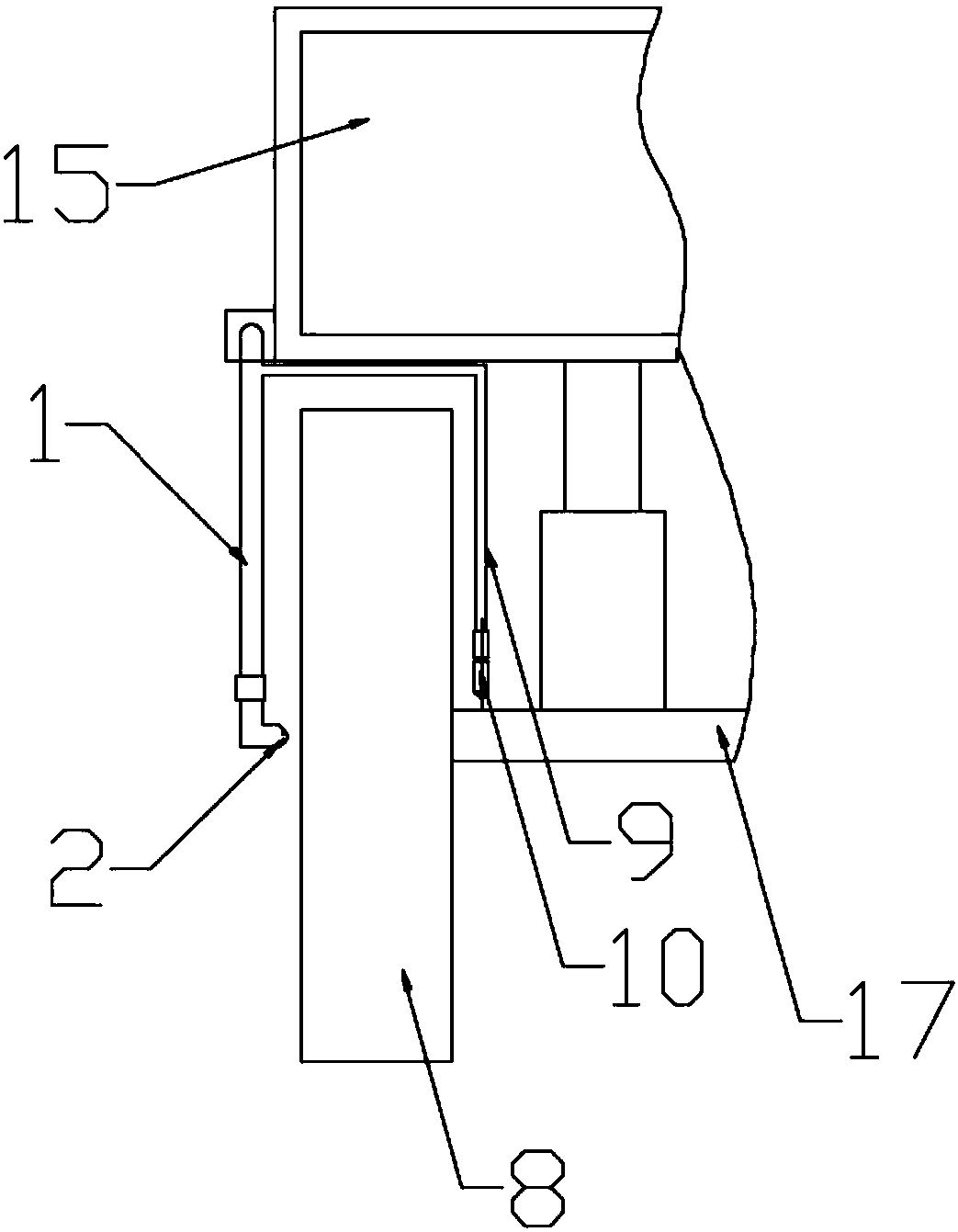

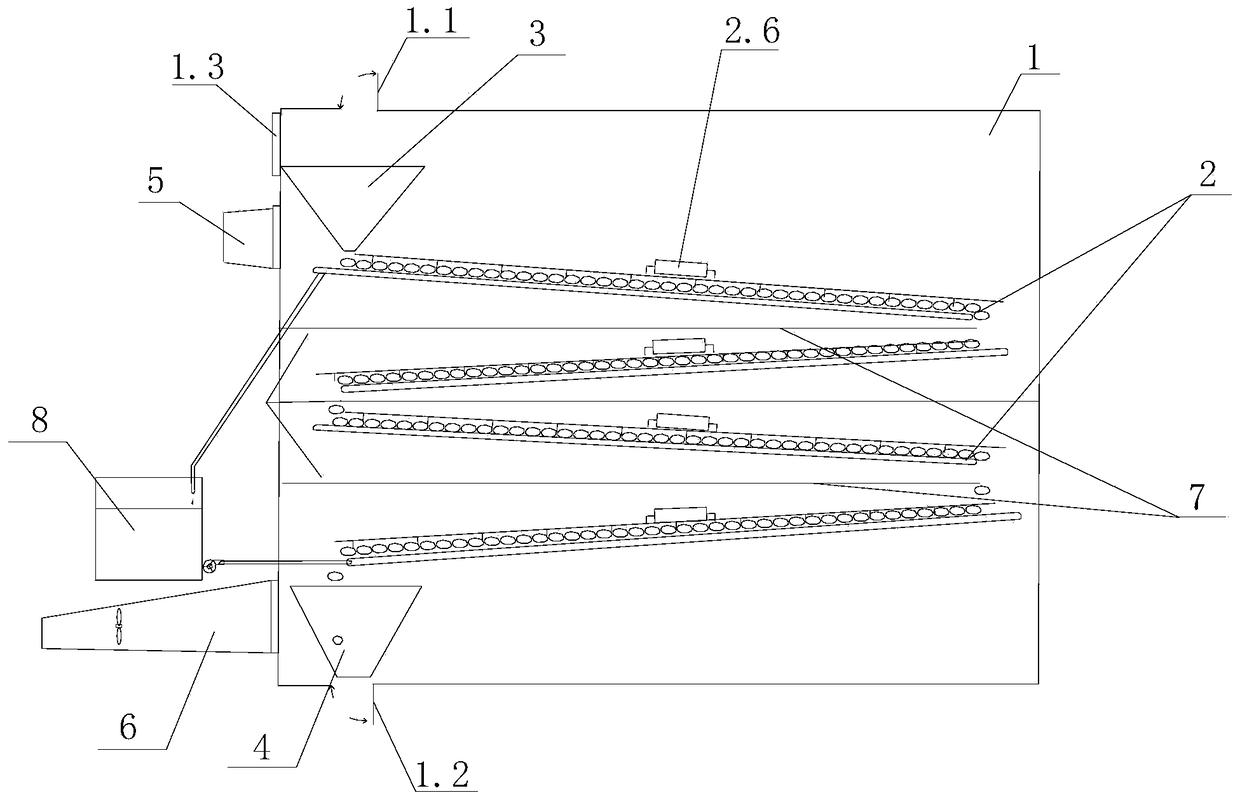

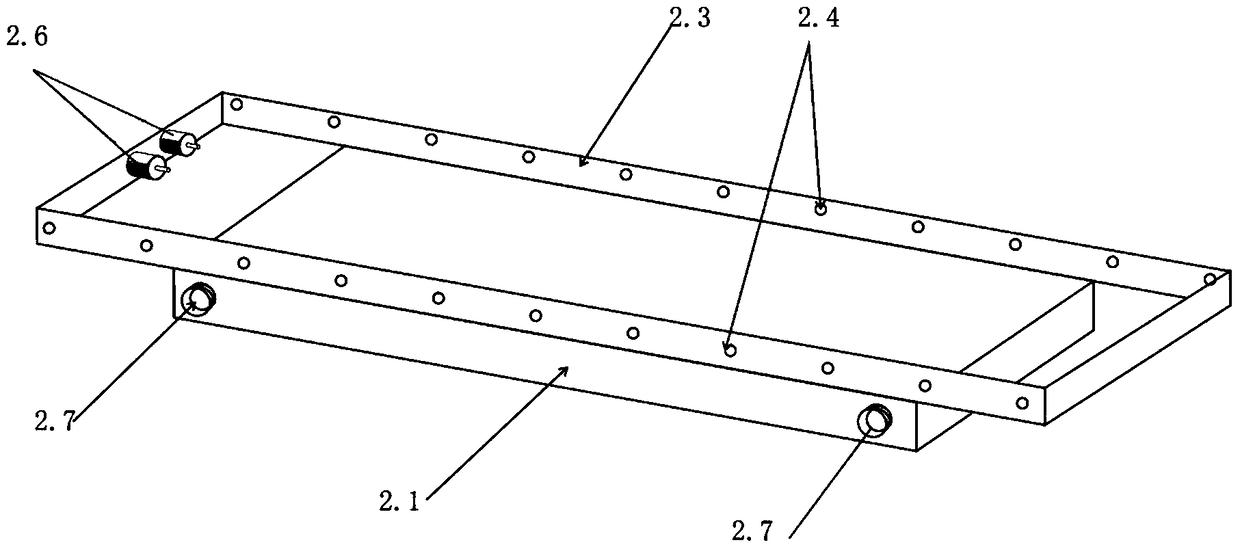

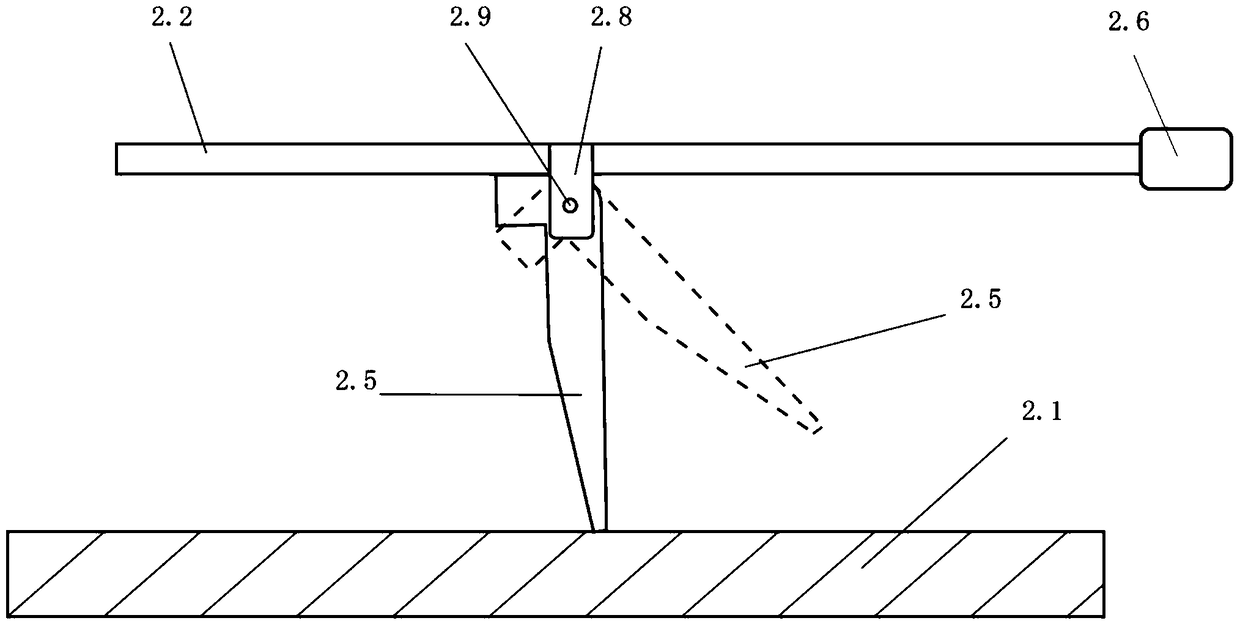

Coal slurry dewatering and drying device and method

ActiveCN105423731ASpeed up evaporationIncrease the evaporation surface areaGranular material dryingDrying gas arrangementsSmall footprintThermal water

The invention discloses a coal slurry dewatering and drying device and method. The device comprises a drying room and a coal slurry conveying device, a warm air machine and a negative pressure fan which are arranged inside the drying room. The coal slurry conveying device comprises a plurality of conveying belts arranged in a zigzag manner from top to bottom. A vibration feeder is arranged above the coal slurry inlet end of the uppermost conveying belt of the coal slurry conveying device. A feeding sealing door is formed in the top of the drying room. A discharging hopper is arranged below the coal slurry outlet end of the bottommost conveying belt of the coal slurry conveying device. A discharging sealing door is formed in the bottom of the drying room. The negative pressure fan and a warm air to atmosphere gate are arranged at the upper portion of the drying room. The hot air machine, a hot water inlet and outlet and the like are arranged at the lower portion of the drying room. The warm air to atmosphere gate is formed in the side wall of the upper portion of the drying room. The invention further discloses the coal slurry dewatering and drying method applied to the device. The device and method have the beneficial effects of saving energy and being environment-friendly, efficient, low in drying temperature, high in speed and efficiency, simple in structure and small in occupied area.

Owner:武汉汉缘新能源环保科技有限公司

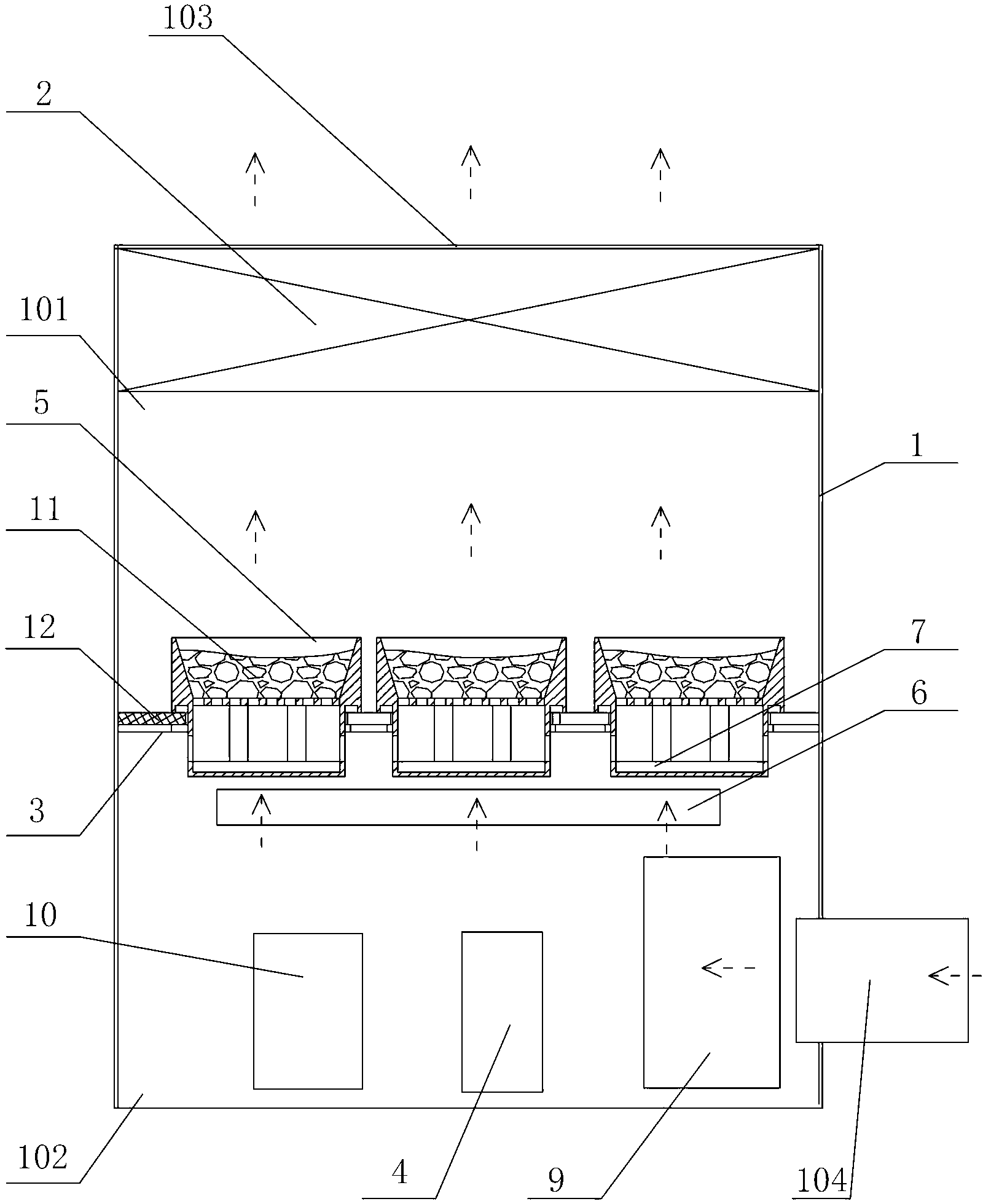

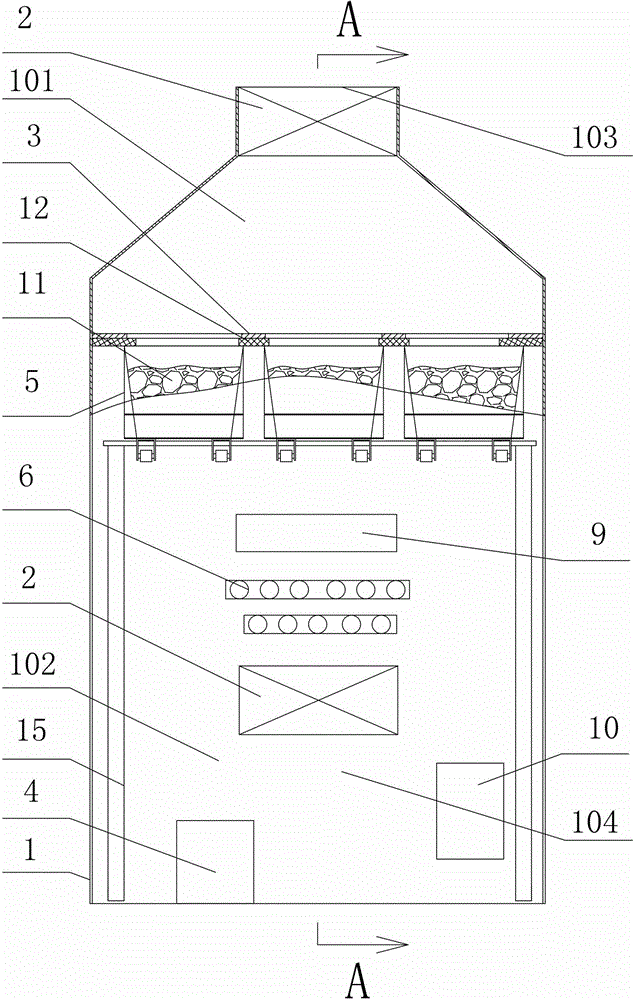

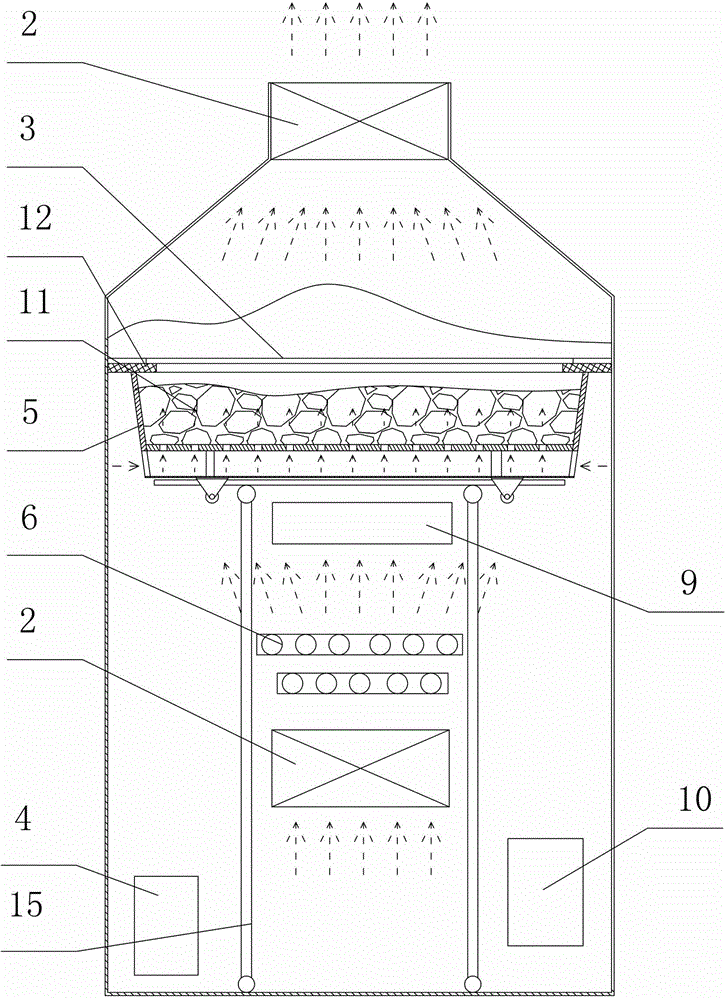

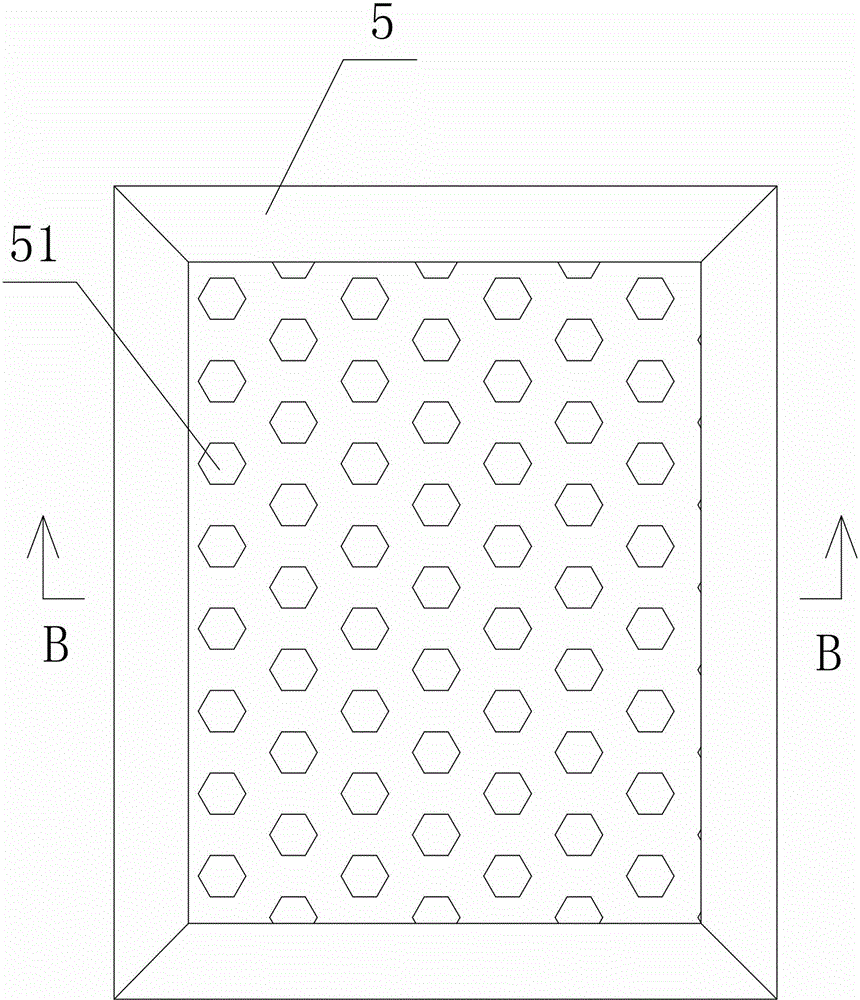

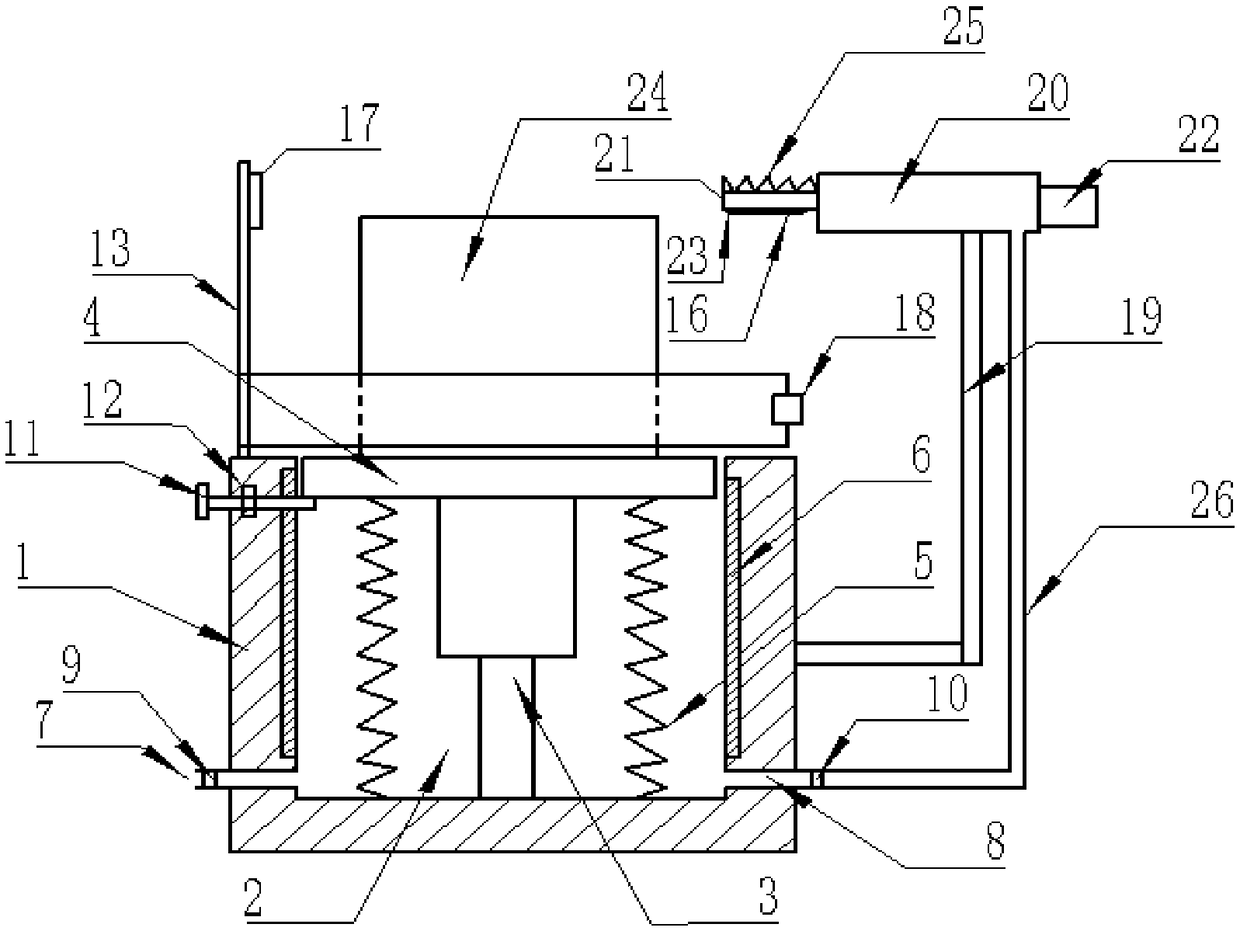

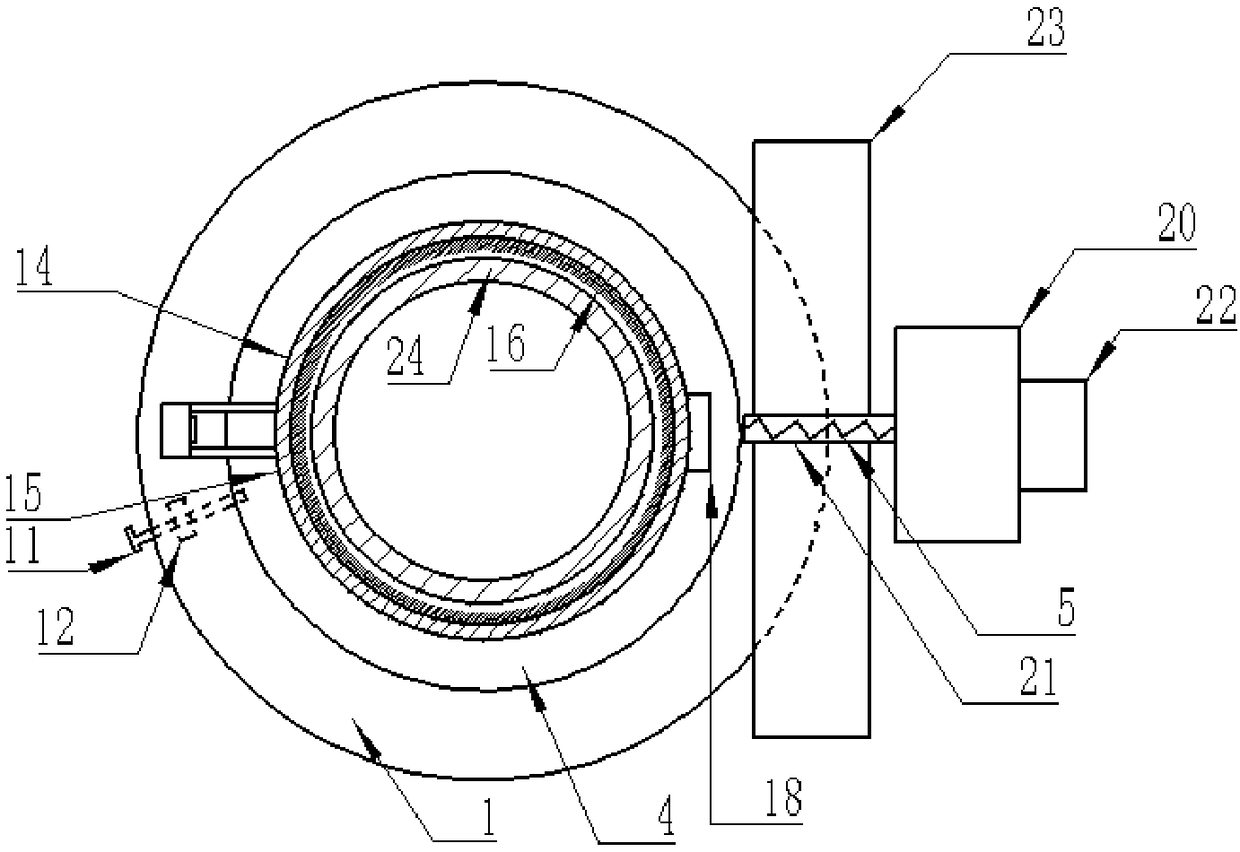

Hot air penetrating outer circulation type coal sample dehumidifying device

ActiveCN102937370AIncrease the evaporation surface areaIntegrity guaranteedDrying gas arrangementsDrying chambers/containersGas heaterEngineering

The invention discloses a hot air penetrating outer circulation type coal sample dehumidifying device. The hot air penetrating outer circulation type coal sample dehumidifying device comprises a box, a controller, a fan, a partition plate and a gas heater, wherein the fan, the partition plate and the gas heater are arranged in the closed box. The partition plate divides the box into an upper cavity and a lower cavity, the top or the side of the upper cavity is provided with an air outlet, the bottom or the side of the lower cavity is provided with an air inlet, the fan is located at the position inside the upper cavity close to the air outlet, and the gas heater is located in the lower cavity. More than one coal sample disc for accommodating coal samples is placed on the partition plate, the bottom of each coal sample disc is provided with more than one ventilation hole, and a coal sample support for collecting falling samples is arranged below the coal sample disc. The hot air penetrating outer circulation type coal sample dehumidifying device has the advantages of being simple in structure, convenient to operate, high in dehumidifying efficiency, low in energy consumption and capable of improving sample preparation accuracy and the like.

Owner:HUNAN SUNDY SCI & TECH DEV

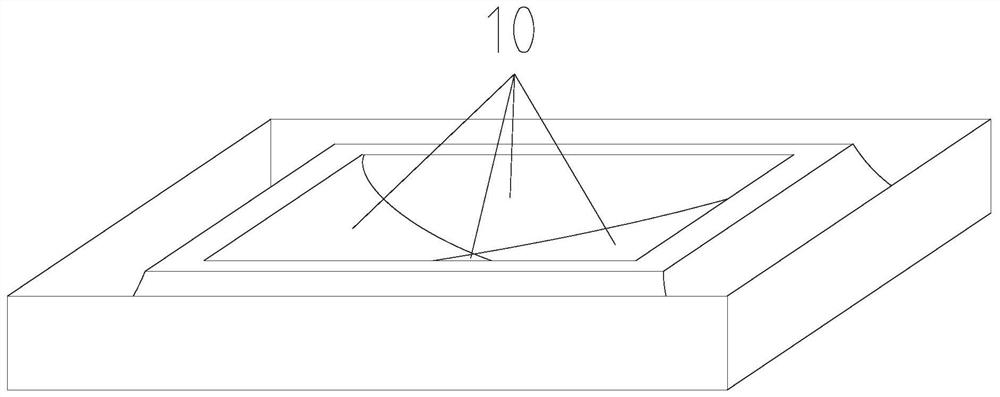

Micro-combustor for metal mesh heat storage and flame stabilization and combustion method thereof

ActiveCN104748111AHigh flame temperatureImprove stabilityLiquid fuel evaporation burnersLiquid fuel burnerCombustorPorous medium

The invention discloses a micro-combustor for metal mesh heat storage and flame stabilization and a combustion method thereof. The micro-combustor for the metal mesh heat storage and flame stabilization comprises a combustor outer barrel and an igniter arranged in the combustor outer barrel; a combustor comprises a hollow blunt body, a multi-hole medium disc and a metal mesh, wherein the longitudinal section of the hollow blunt body is in the shape of an inverted triangle, the multi-hole medium disc is arranged on the hollow blunt body, the metal mesh is arranged on the multi-hole medium disc, and the bottom of the hollow blunt body is connected with a fuel channel. By means of the multi-hole medium disc, it is guaranteed that fuel is dispersed evenly, the superficial area of the fuel is increased, and the evaporation rate is sped up. A high temperature low-velocity backflow zone is formed near an outlet of the hollow blunt body, the dwell time of the fuel is increased, the metal mesh is taken as a heat storage medium and has the functions of absorbing heat and releasing heat, and the flame temperature can be maintained at a certain level; compared with other combustors, by means of the micro-combustor for the metal mesh heat storage and flame stabilization, a flame can be made to be attached to the metal mesh stably, sharply swing or up and down fluctuation of the flame does not occur along with changes of working conditions, and the stability of combustion of liquid hydrocarbon under micro scale is greatly promoted.

Owner:SOUTH CHINA UNIV OF TECH

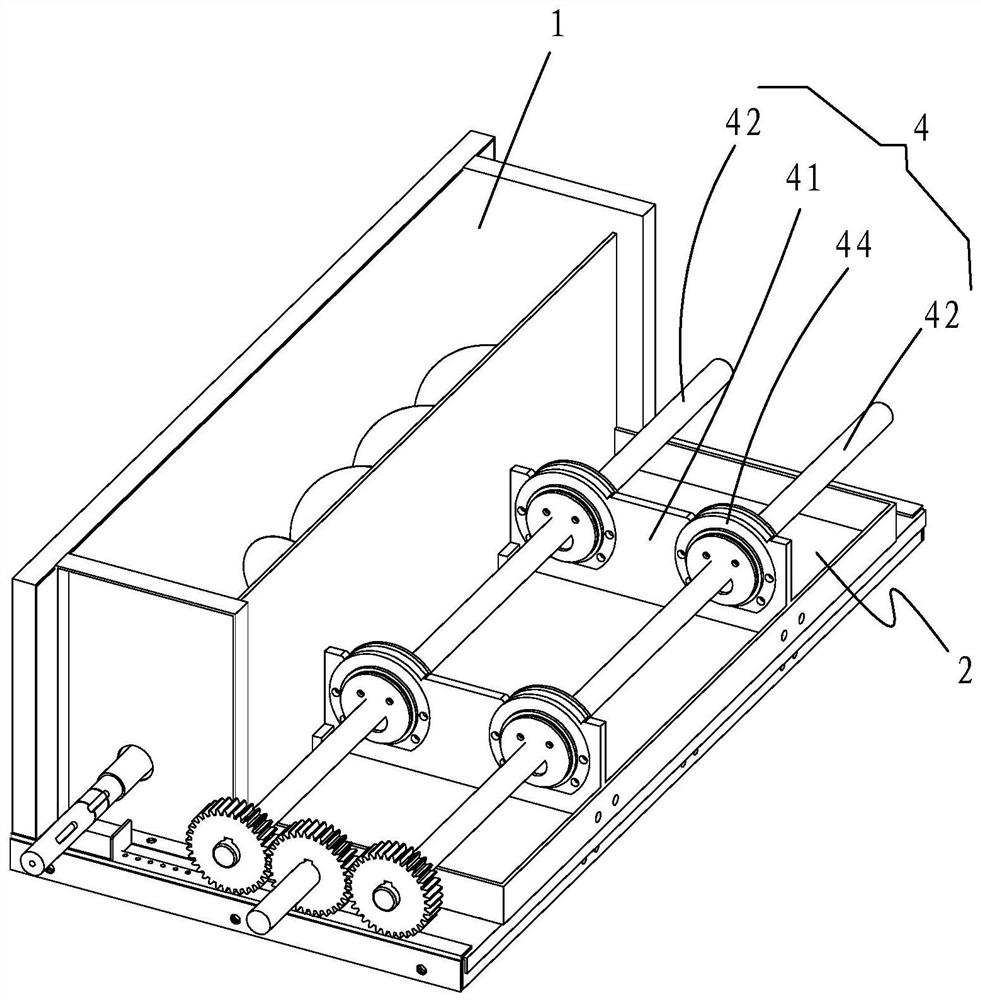

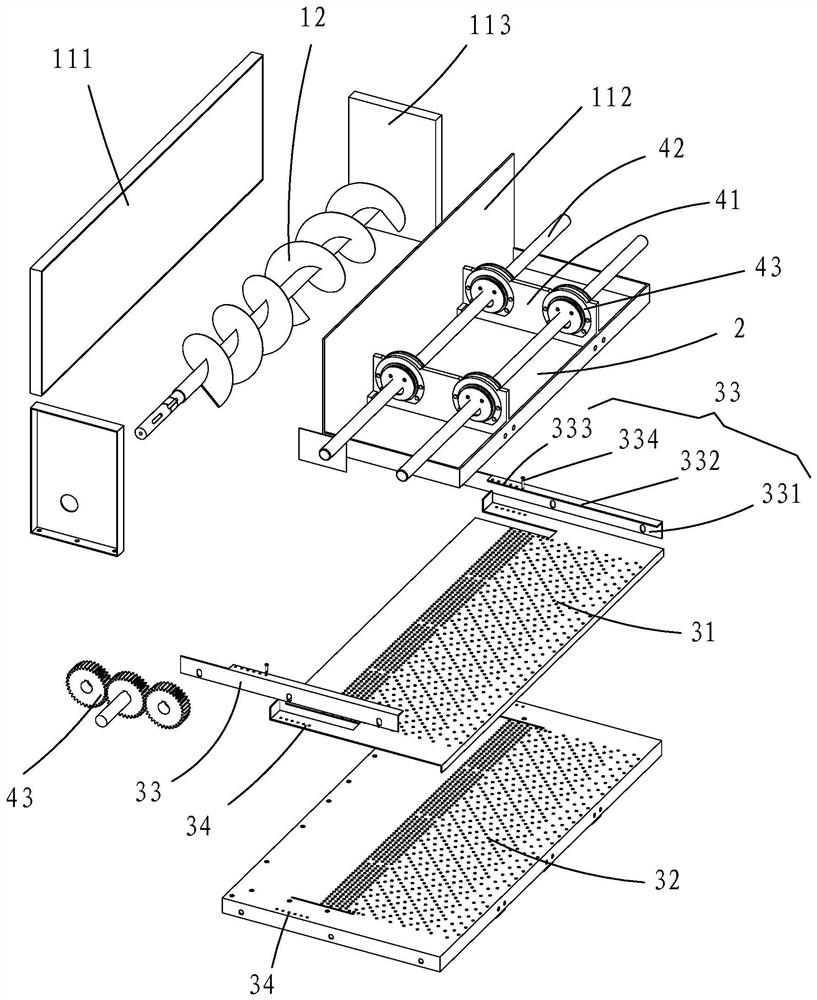

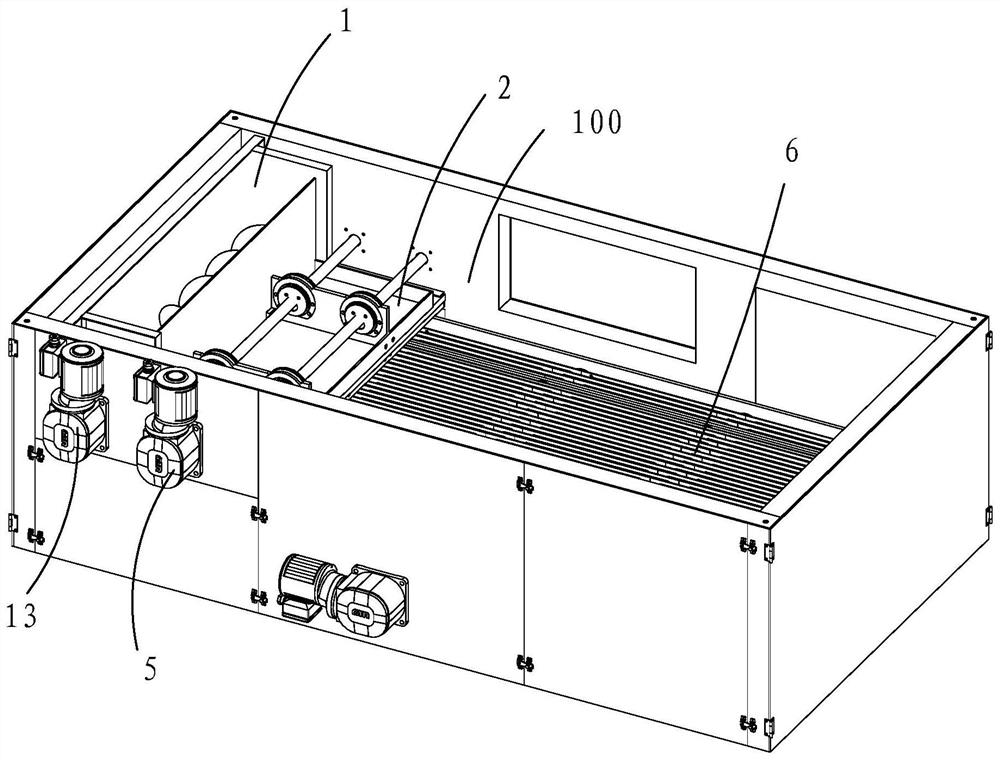

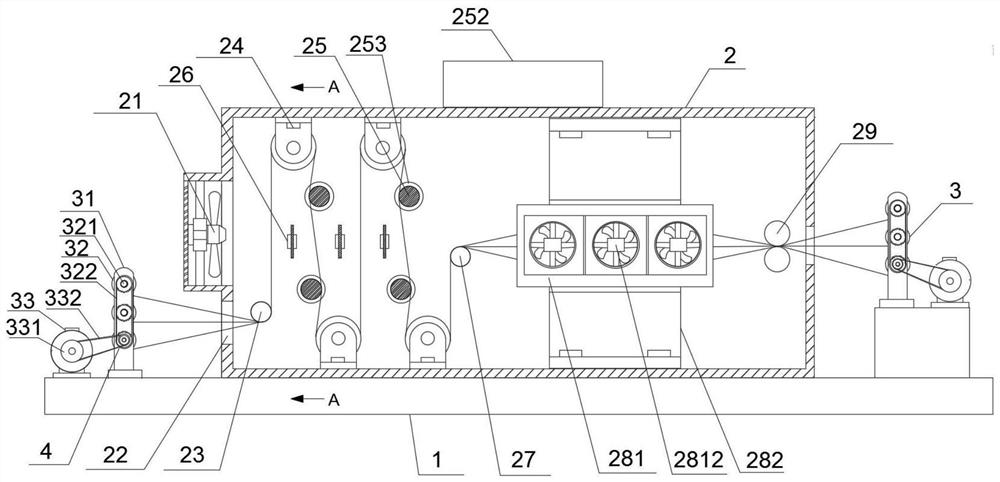

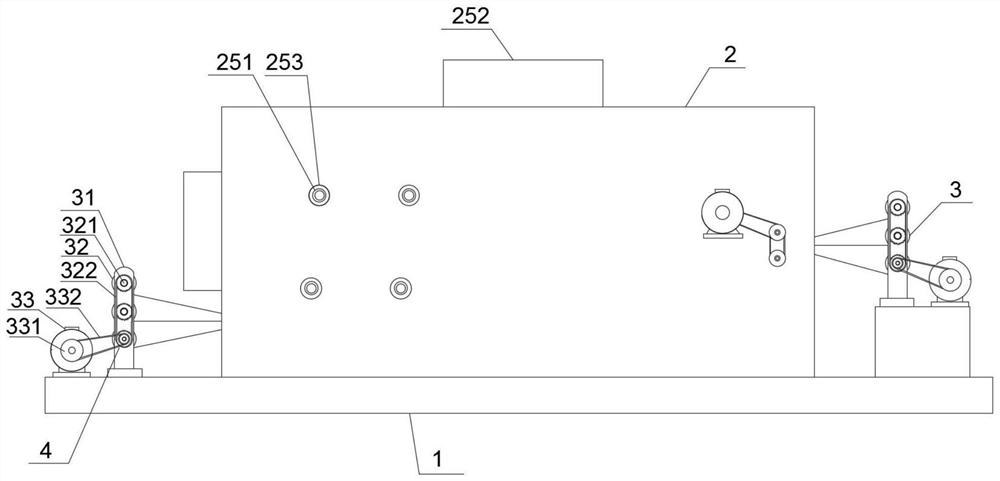

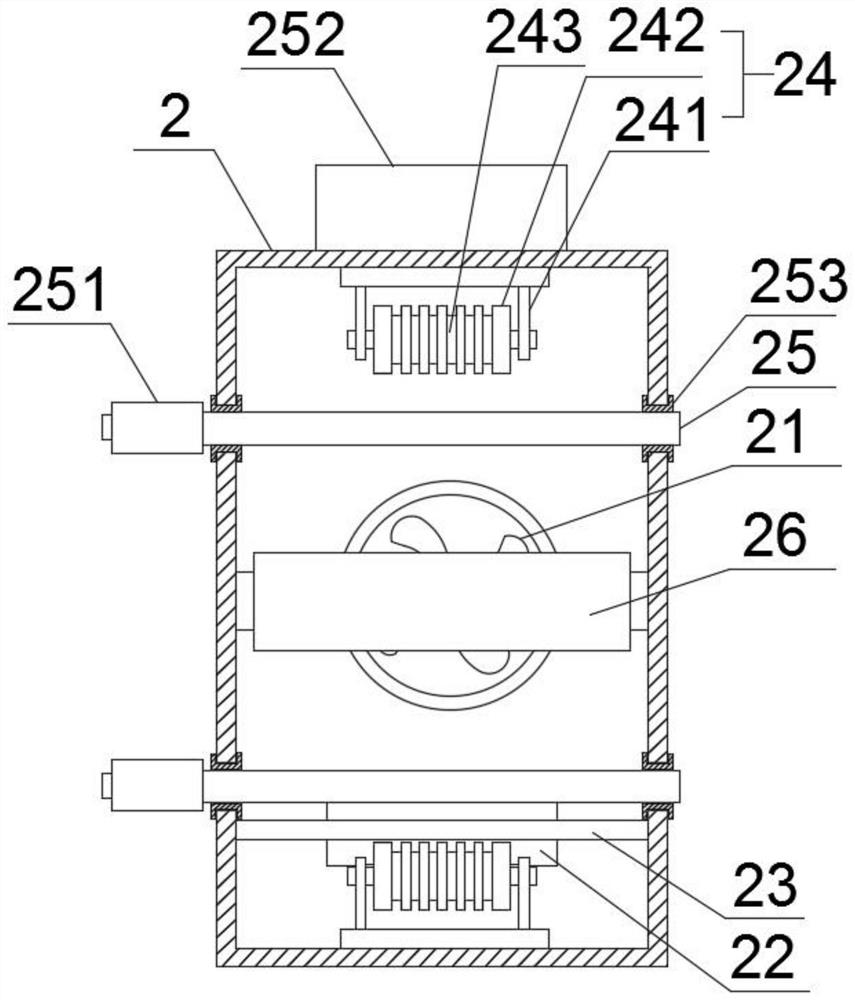

Reciprocating rolling material forming device

A reciprocating rolling material forming device comprises a feeding mechanism, a rolling plate and a bearing plate, wherein the rolling plate and the bearing plate are arranged in parallel, the bearing plate is located below the rolling plate, and a plurality of holes are formed in the bearing plate; the feeding mechanism is located at the same ends of the rolling plate and the bearing plate, andmaterials enter the gap between the rolling plate and the bearing plate from the feeding mechanism; at least one of the rolling plate and the bearing plate is connected with a driving mechanism, and the driving mechanism is connected with a first power source; and the first power source drives the driving mechanism to drive at least one of the rolling plate and the bearing plate to do reciprocating synchronous circular motion, so that the materials on the bearing plate are rolled and poked, and the materials are extruded and formed from the holes of the bearing plate located below. According to the device, the materials are periodically and intermittently rolled, so that the formed materials are short, accumulation is avoided, and the evaporation area can be enlarged.

Owner:AMCON FUJIAN ENVIRONMENT PROTECTION EQUIP CO LTD

Method for increasing salt field solarizing and evaporating rate by hydrophilic modified spheres

InactiveCN109305692AIncrease the evaporation surface areaIncrease evaporation rateEnergy inputAlkali metal chloridesChemistrySolar lamp

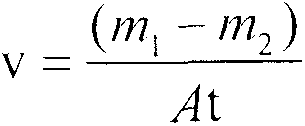

The invention discloses a method for increasing a salt field solarizing and evaporating rate by hydrophilic modified spheres. The method is characterized in that polymer spheres with different particle diameters are added into an evaporating tank filled with sodium chloride solutions of different concentrations, so that the spheres have different area proportions on solution evaporating surfaces;a salt field solarizing and evaporating test is stimulated by regulating air speed of a fan and an irradiation temperature of a solar lamp, and the evaporating rate is calculated through a formula. According to the results, under different conditions, the solution evaporating rate is greatly increased. By applying the method to salt field solarizing and evaporating, the salt field evaporating andvaporizing surface area can be effectively increased, and therefore, the evaporating rate can be increased, the site area for the salt field is reduced, the production period is shortened, the yield is increased, and has very important practical guiding significance.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

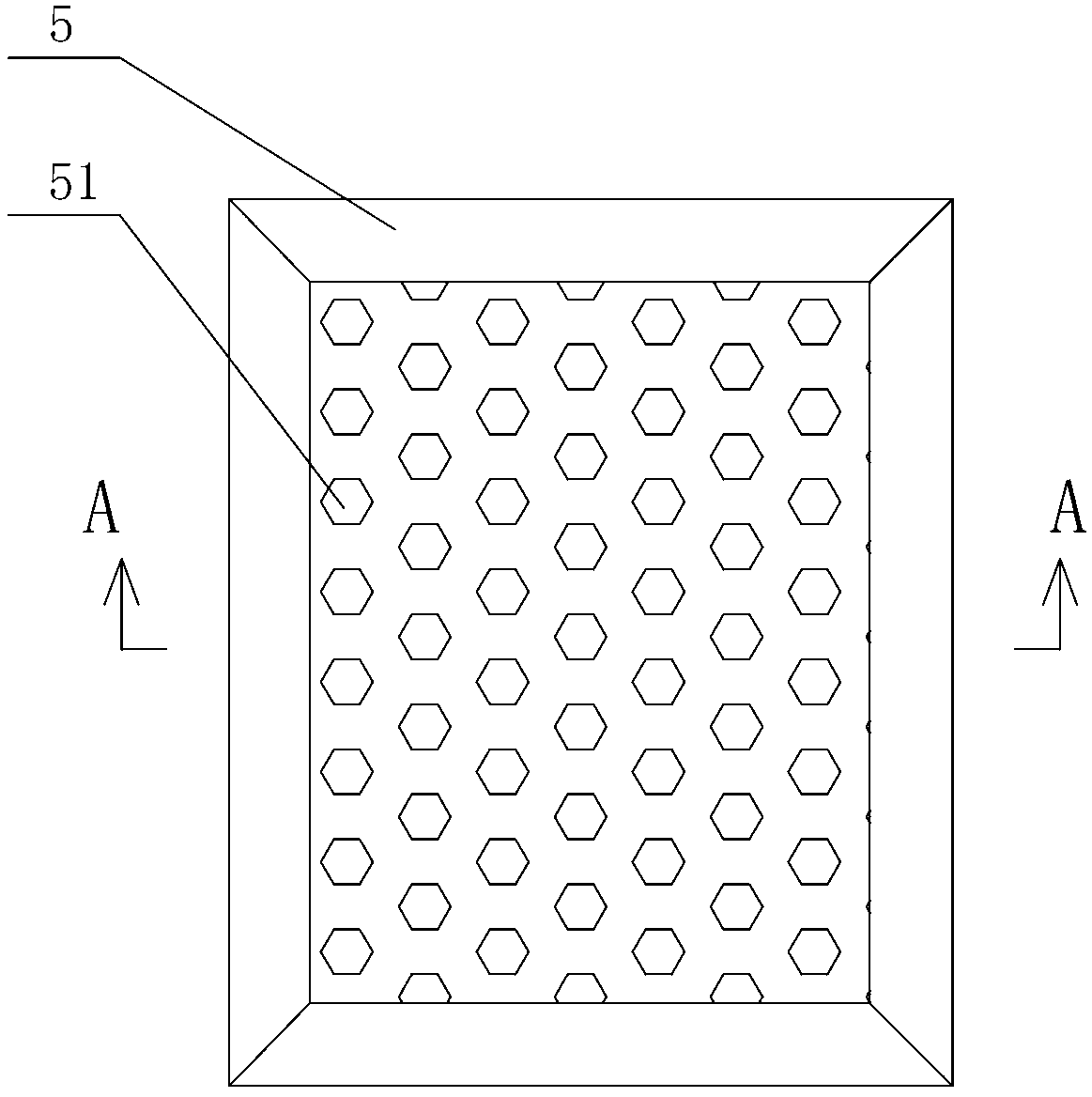

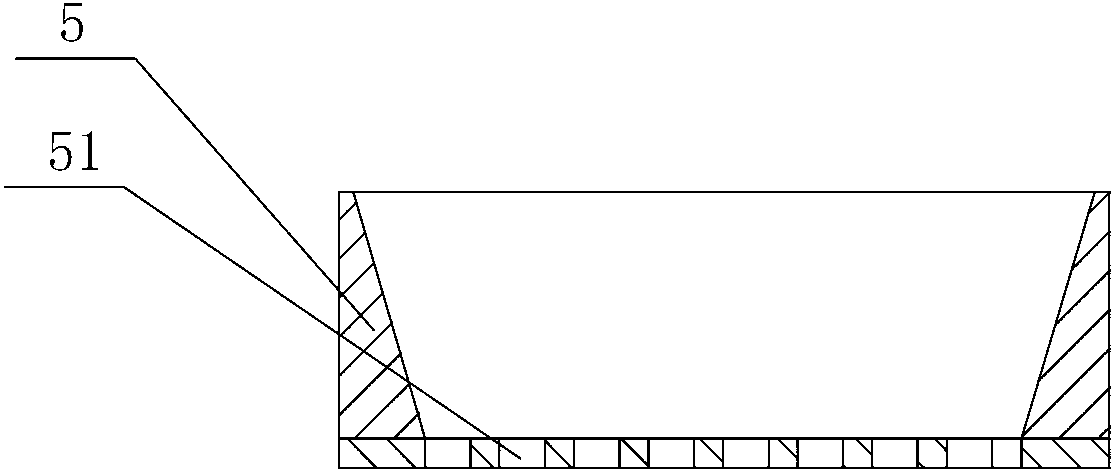

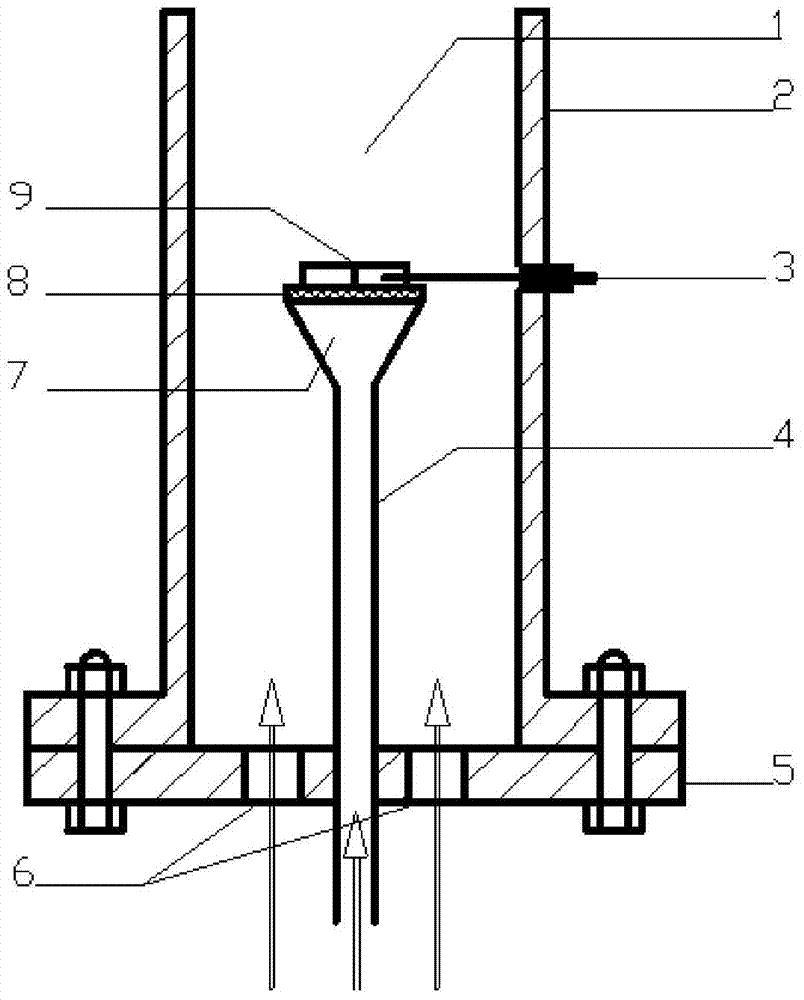

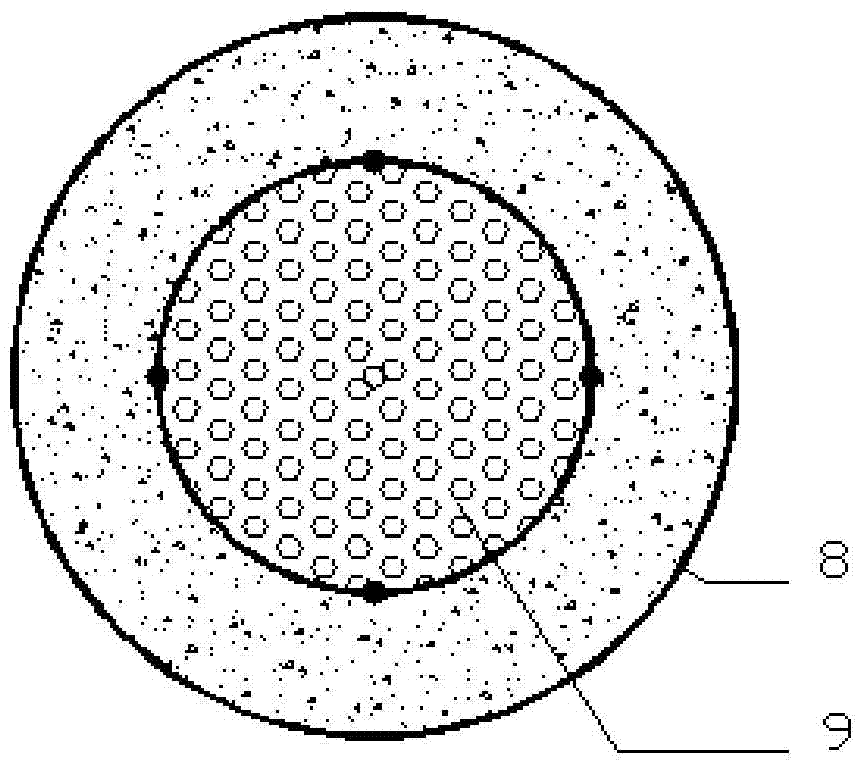

Water vapor generating device and method for SCR denitration catalyst performance detection

ActiveCN109268803AContinuous productionEfficient productionSteam generation heating methodsDispersed particle separationBuretteTemperature control

The invention relates to a water vapor generating device and method for SCR denitration catalyst performance detection, and belongs to the field of performance detection and evaluation of SCR denitration catalysts. How to quickly prepare water vapor and achieve good mixing of the water vapor and gas from a gas distribution system becomes an important part in the design of a denitration catalyst performance detection test stand. The water vapor generating device is characterized by comprising an intelligent temperature-controlled electric heating furnace system, a high-temperature evaporator system and a water vapor exporting system, wherein the high-temperature evaporator system comprises a high-temperature evaporator frame plate, a capillary burette fixing block, a capillary burette, a high-temperature evaporator body, a heat storage evaporation body, a packing tank and an air flow uniform distribution plate; an inlet of the capillary burette is exposed outside the high-temperature evaporator body, the heat storage evaporation body, the packing tank and the air flow uniform distribution plate are all fixed in an evaporation cavity of the high-temperature evaporator body, and the capillary burette is located directly above the heat storage evaporation body. The water vapor generating device and method for the SCR denitration catalyst performance detection have the advantages that the structural design is reasonable, the evaporation rate is fast, and the mixing effect is good.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Evaporating heat exchanger with moistened surface

InactiveCN1370973AEase of industrial productionQuality is easy to controlCondensate preventionStationary conduit assembliesSprayerEvaporation

The present invention relates to one kind of evaporating heat exchanger for air conditioner and other refrigerating equipment and aims at solving the problems of low heat efficiency and short servicelife of heat exchanger. The present invention includes blower, water sprayer, heat dissipating metal sheet, metal pipe passed through and fixed to the heat dissipating sheet, and non-woven cloth on the outer surface of the heat dissipating sheet. It has the advantages of high heat efficiency, large evaporation area, low power consumption, etc. and can make air conditioner and other refrigerating system run at low-pressure difference and low power consumption of compressor. The surface of the heat exchanger can maintain moisture for long time and the water sprayer may run intermittently.

Owner:张永锡 +1

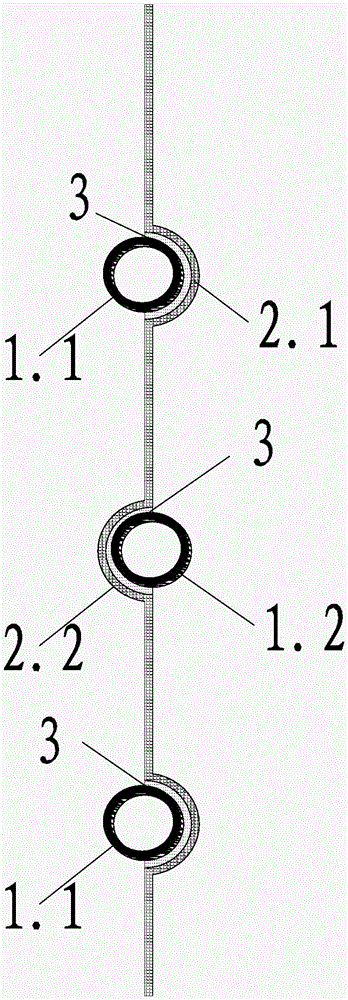

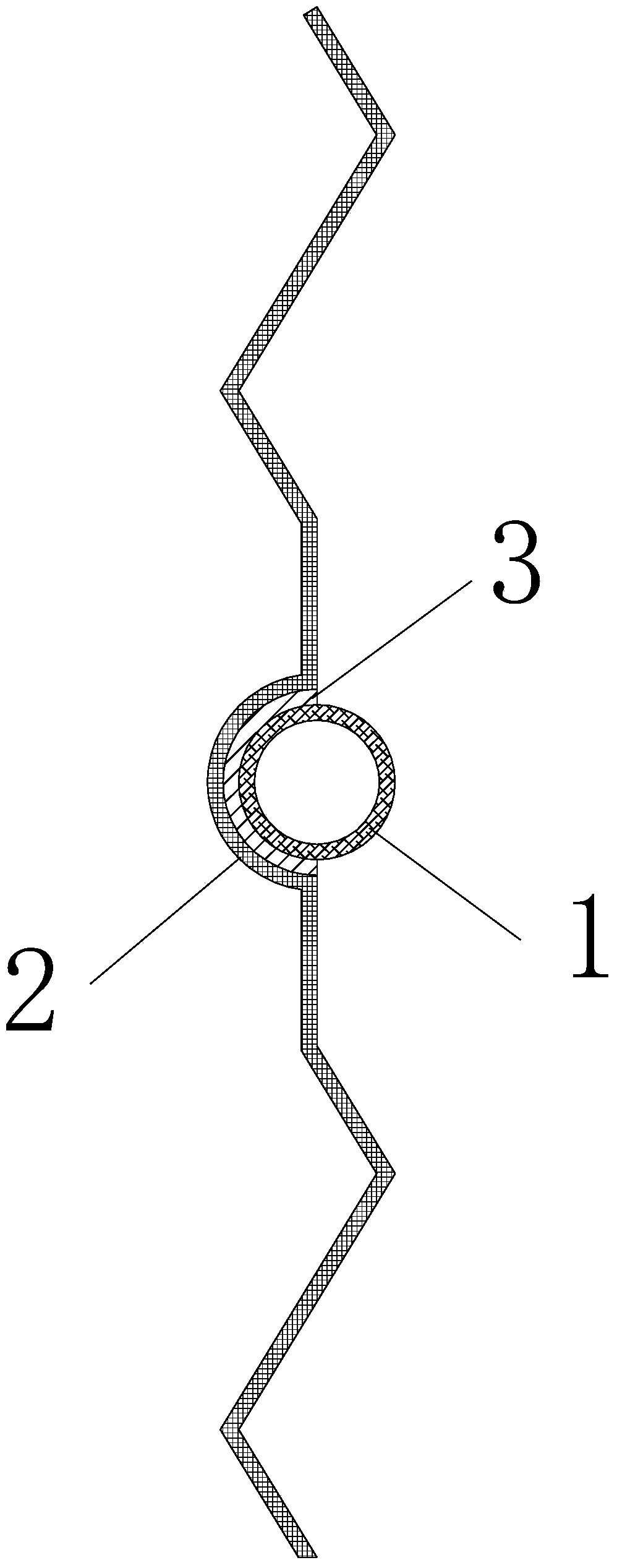

Negative pressure thermal evaporation equipment and technology of interventional activated carbon fiber boards

InactiveCN108355366ALower evaporation temperatureLarge specific surface areaEvaporator accessoriesSolution crystallizationFiberActivated carbon

The invention relates to negative pressure thermal evaporation equipment and technology of interventional activated carbon fiber boards. The negative pressure thermal evaporation equipment is formed by an evaporation assembly, a centrifugal cyclone gas-liquid separation assembly and a negative pressure gas exhaust assembly. The technology is characterized by immersing activated carbon fiber boardsin a raw material in need of heat evaporation and solid-liquid separation, adsorbing the heated raw material, exposing the raw material in negative-pressure space, evaporating the liquid raw material, and collecting the evaporated liquid in the centrifugal cyclone gas-liquid separation assembly. By adopting the activated carbon fiber boards as an evaporation surface basic material, the negative pressure thermal evaporation equipment provided by the invention has the advantage of large specific surface area, i.e., large evaporation surface area; the activated carbon fiber board is acid-resistant and alkali-resistant and can absorb water; the evaporation temperature of liquid can be reduced by adding negative pressure.

Owner:侯梦斌

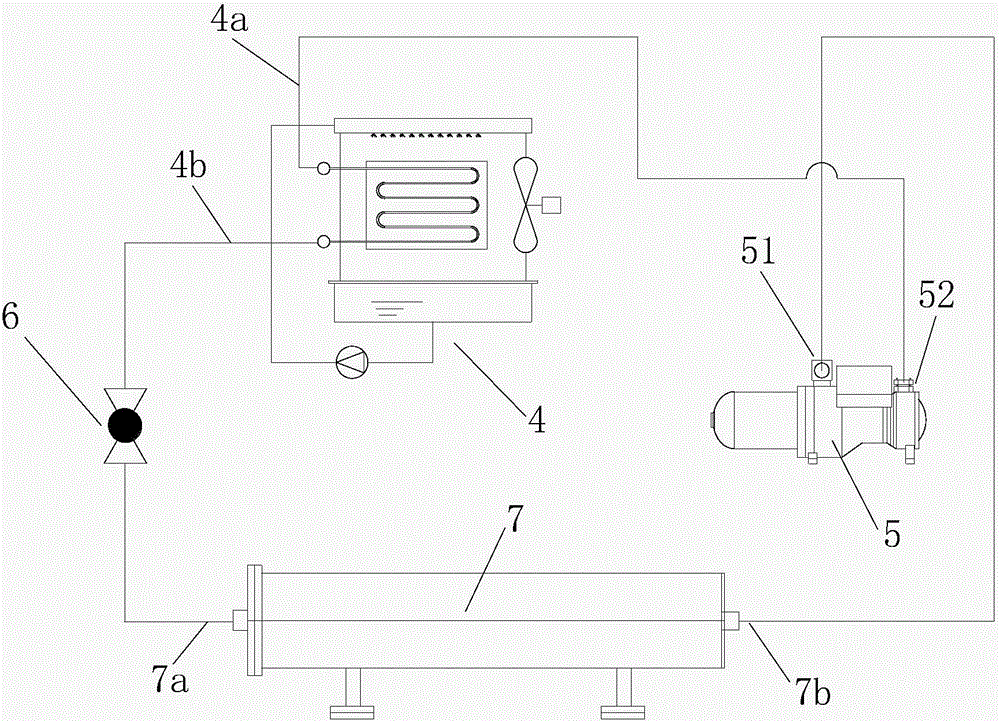

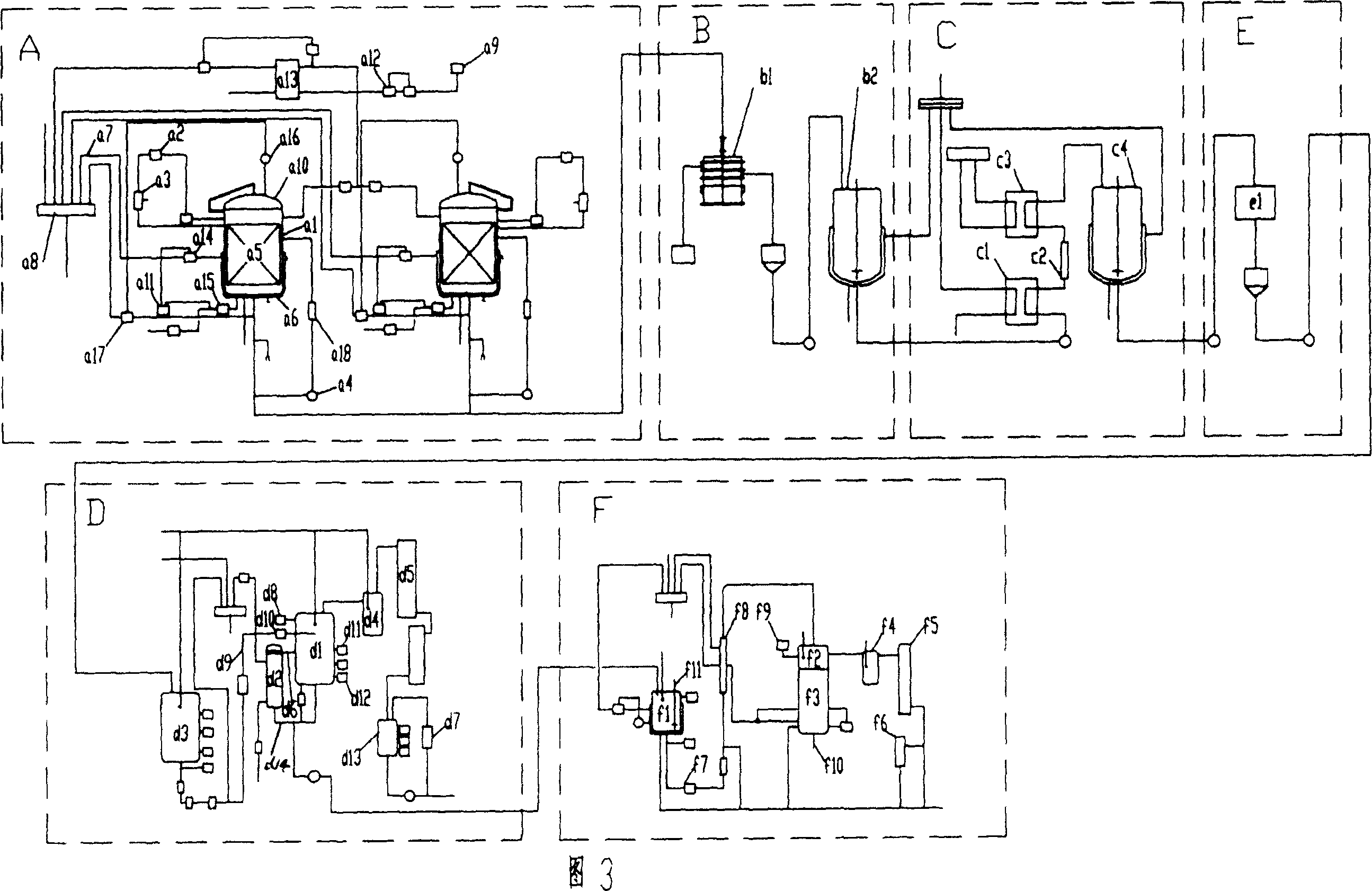

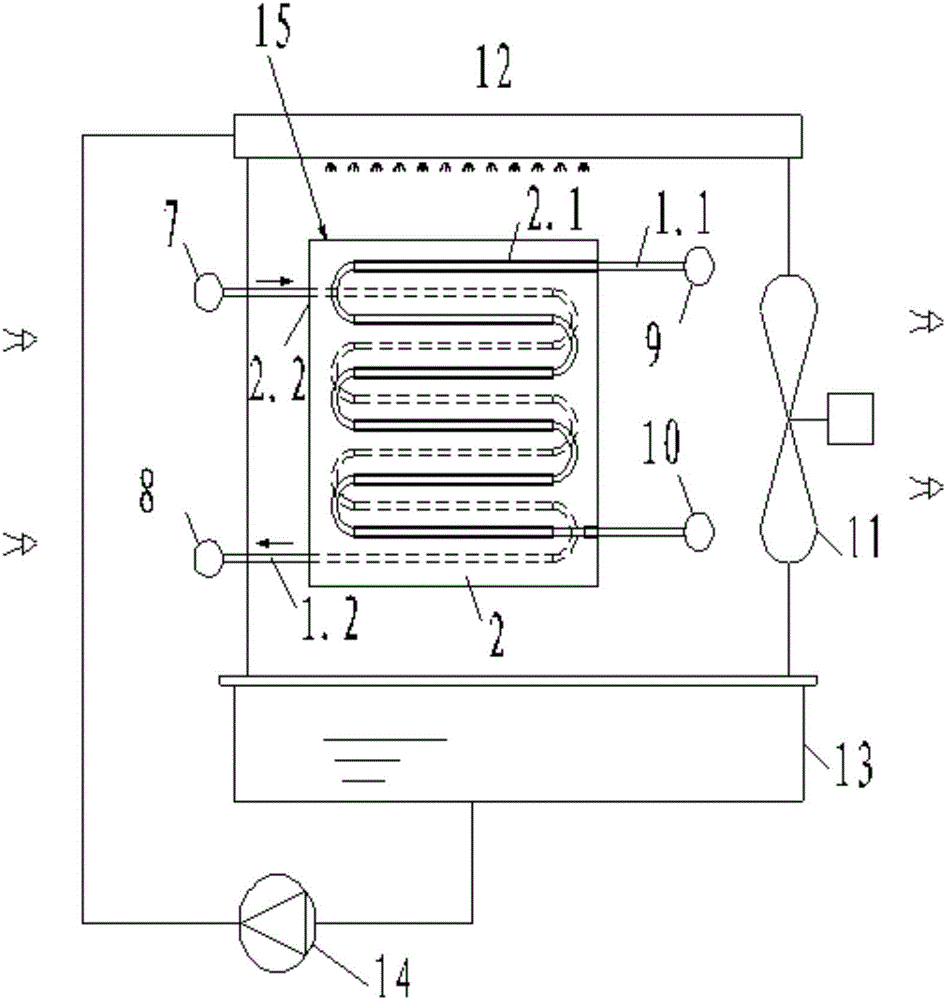

Cold-and-hot water unit with plate-pipe composite heat-exchange evaporative condenser

InactiveCN105987534AIncrease the effective heat transfer areaIncrease the evaporation surface areaMechanical apparatusEvaporators/condensersHeat conductingEvaporation

The invention discloses a cold-and-hot water unit with plate-pipe composite heat-exchange evaporative condenser. The cold-and-hot water unit comprises an air compressor, an evaporative condenser, a throttling device and an evaporator. The evaporative condenser comprises a fan, a water pump, a water distributor and a water collecting pond and further comprises a plate-pipe composite heat exchanger formed by connection of multiple plate-pipe composite heat-exchange sheets through a water inlet collection pipe and a water outlet collection pipe. The plate-pipe composite heat-exchange sheets comprise heat-transfer plate sheets and coil pipes formed by machining of heat-exchange pipes. The heat-transfer plate sheets are provided with placing grooves. The shapes of the placing grooves are matched with shapes of the coil pipes. The coil pipes are placed in the placing grooves. The gaps between the coil pipes and the placing grooves are filled with heat-conducting bonding layers. The cold-and-hot water unit with the plate-pipe composite heat-exchange evaporative condenser has following beneficial effects: the heat-conducting bonding layers enable the heat-transfer plate sheets to be in fully contact with the coil pipes such that the heat-exchange area is effectively enlarged; the heat-transfer plate sheets can drain cooling water to form a continuous waterflow surface; the evaporation superficial area of cooling water is enlarged; and heat transfer efficiency is increased while the size of the condenser is reduced.

Owner:GUANGZHOU WIDE IND

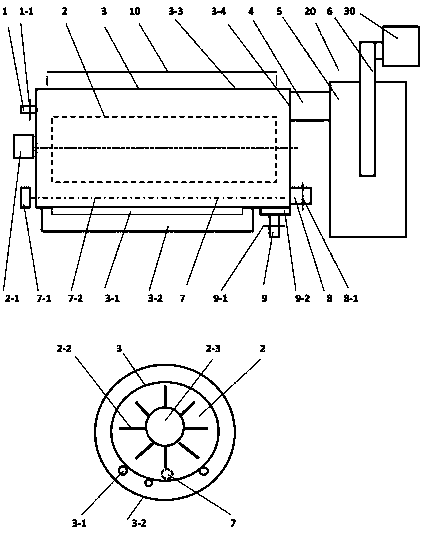

High-efficiency coil type heat exchange evaporator and heat exchange method

PendingCN109386994AImprove heat transfer efficiencySmall footprintEvaporators/condensersHollow cylinderWater pipe

The invention discloses a high-efficiency coil type heat exchange evaporator which comprises a hollow cylinder body; a tubular rotating shaft is installed in the center of the cylinder body, and the tubular rotating shaft is rotated by a variable frequency driving device. The upper and lower ends of the tubular rotating shaft are respectively provided with rotary joints communicating with the external fixed water pipe, and blocking plates are installed at the upper and lower ends of the tubular rotating shaft tube; a set of rotary vane device and a rotary tube device are respectively installedabove and below the tubular rotating shaft in the cylinder body, and the rotary tube device and the rotary vane device rotate together with the tubular rotating shaft; a liquid inlet pipe is radiallymounted on the inner wall of the cylinder between the rotary tube device and the rotary vane device, and an outlet pipe for evaporating gas is disposed at the top of the cylindrical body, and an insulating layer is further disposed outside the cylinder. The invention has high evaporation efficiency, high liquid cooling efficiency, low consumables, compact and reasonable structure, small volume ofthe same capacity equipment, especially the gas after heat exchange is dehydrated, and the discharged gas has no droplets or droplets.

Owner:沈阳天洁环保新能源有限公司 +1

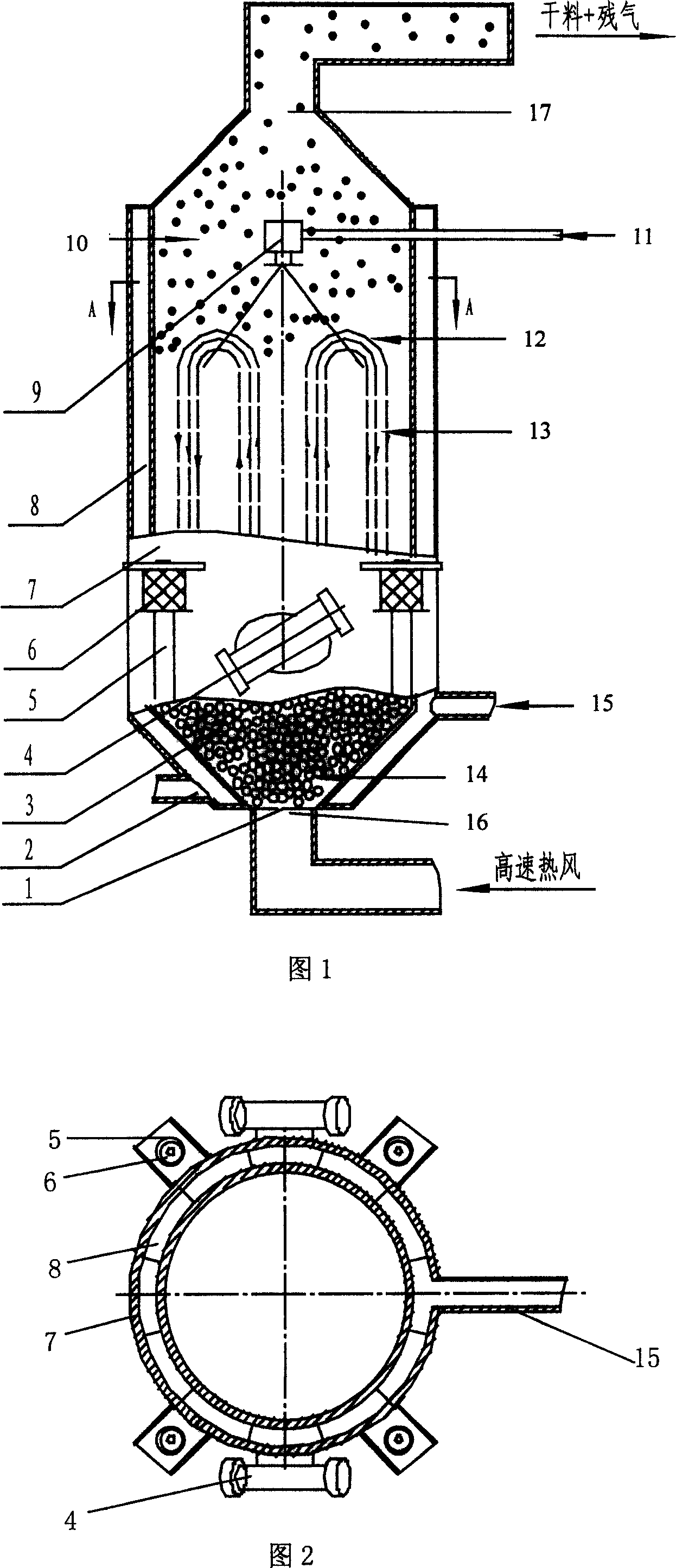

Inert medium spray-atomizing-drying machine by vibration

InactiveCN1936471AIncrease the evaporation surface areaIncrease the heat exchange areaDrying solid materials with heatHearth type furnacesElectric machineryEngineering

This invention relates to an atomized drying machine with vibrating inert medium, in which, the tower of which is a cylindrical drum, a fluid pipe and a pressure nozzle are mounted on top of inside of the drum, a hot air port is opened at the bottom of the drum and a discharge port is opened on the top characterizing the up and down ends of the drum are conic structure, two titled vibration motors in opposite direction are set at both sides of the drum, an isolation net is set at the lower taper drum with inert medium on it, which applies a double-vibration motor to avoid materials adhered on the wall and adds inert gas to increase drying degree and speed up the drying speed.

Owner:NORTHEASTERN UNIV

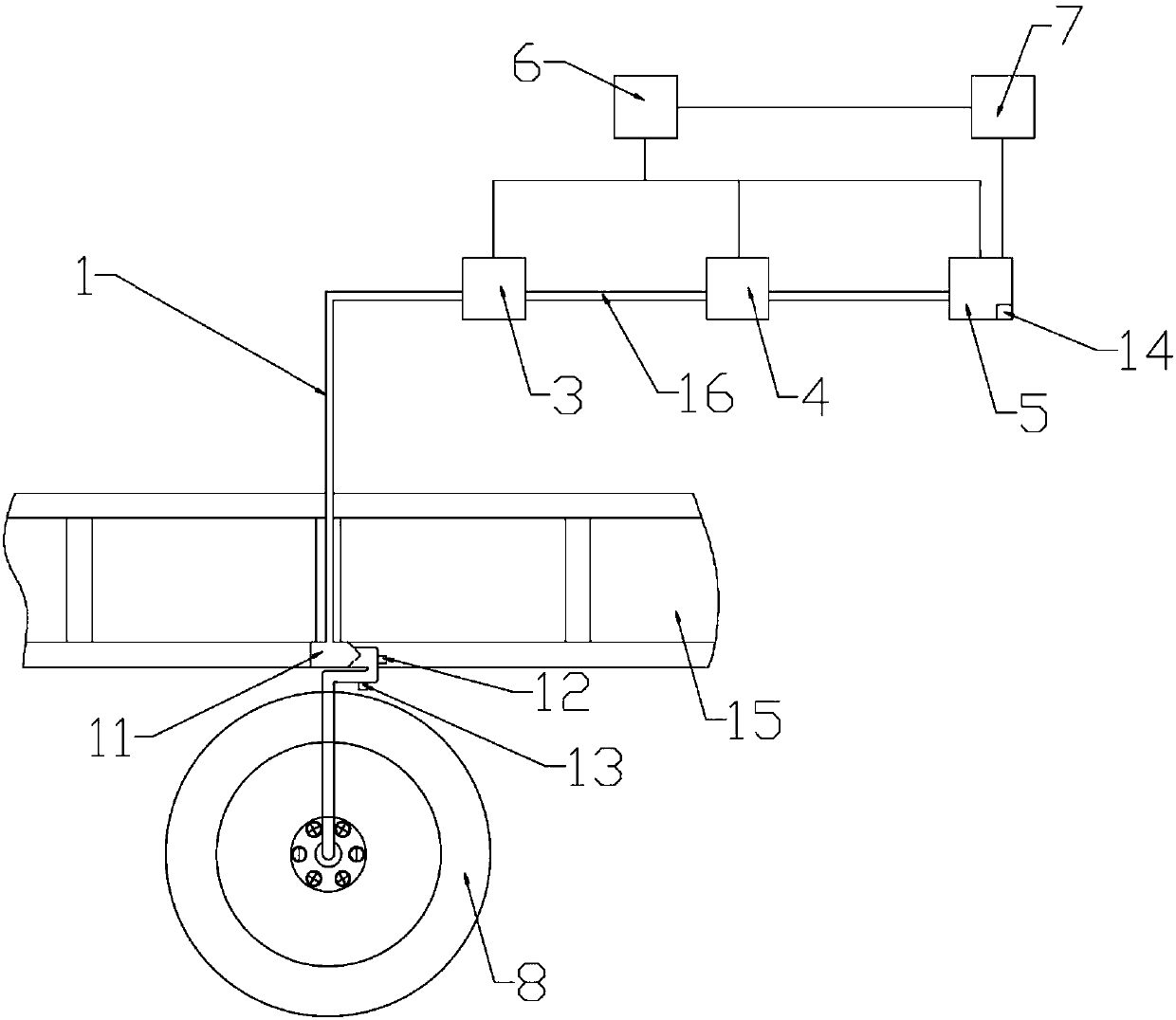

Brake heat-radiating and cooling device

The invention provides a brake heat-radiating and cooling device. The brake heat-radiating and cooling device comprises a first water spraying pipeline, a first atomizing nozzle, a compressing and cooling device, a water pump and a water tank; the water tank, the water pump, the compressing and cooling device and an inlet of the first water spraying pipeline are in communication with each other via pipelines in sequence; the water tank, the water pump and the compressing and cooling device are all positioned on a frame; the water pump and the compressing and cooling device are electrically connected with a power supply device; the first water spraying pipeline extends from the frame to the middle position of a wheel; the first atomizing nozzle is mounted in an outlet of the first water spraying pipeline; the compressing and cooling device cools the water and changes the liquid water into spray water by using the first atomizing nozzle to spray the spray water to a wheel hub to reduce the temperature of the wheel hub; due to the principle of heat conduction, the temperature of a brake pad can also be reduced, the safety and reliability of a brake are guaranteed and the water is saved; and as the evaporation velocity of the spray water is higher, the heat-radiating and cooling speed is further increased.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

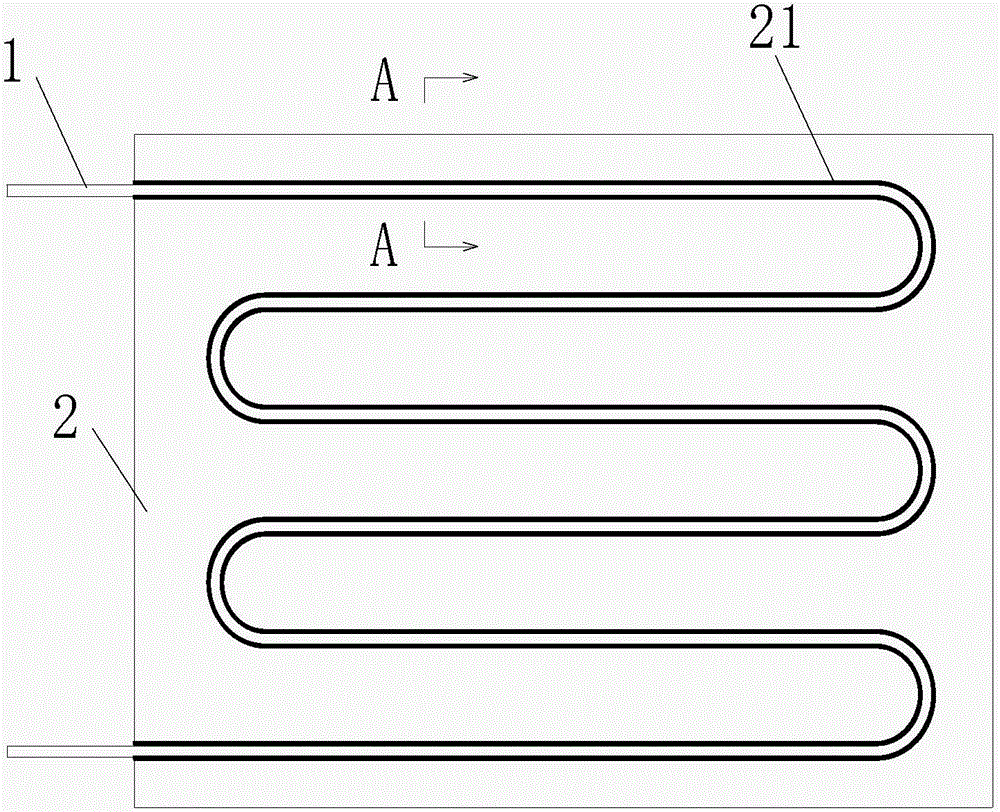

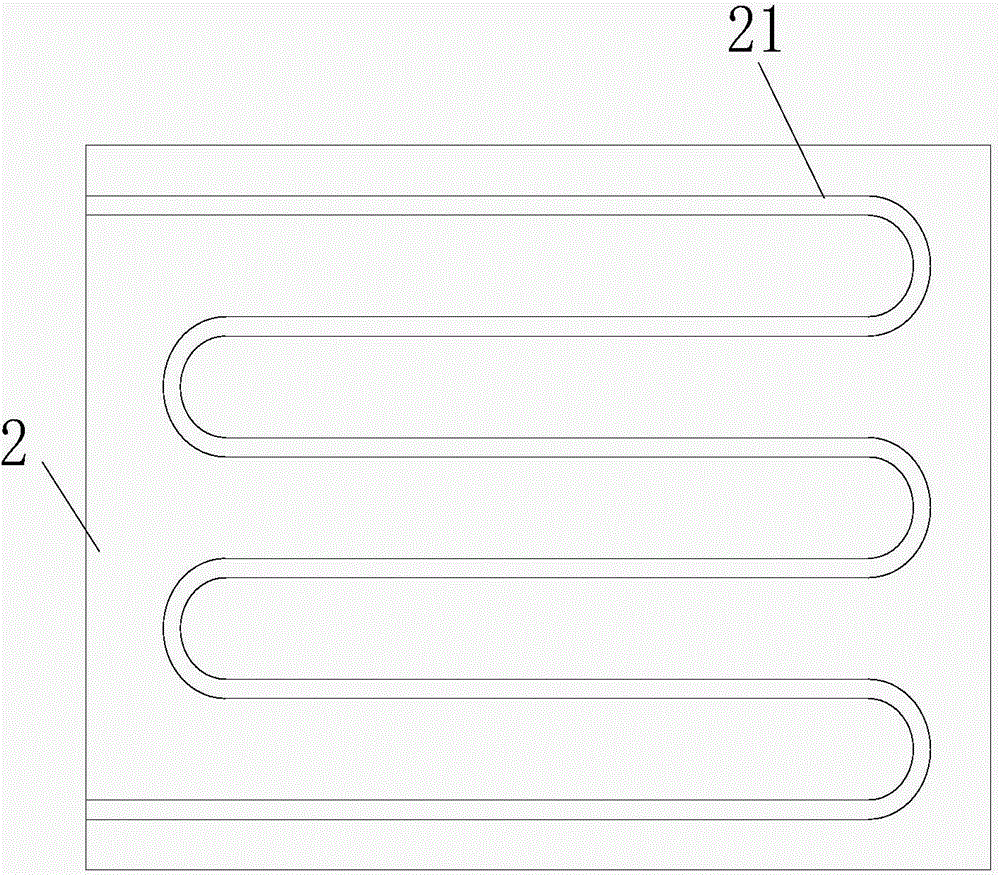

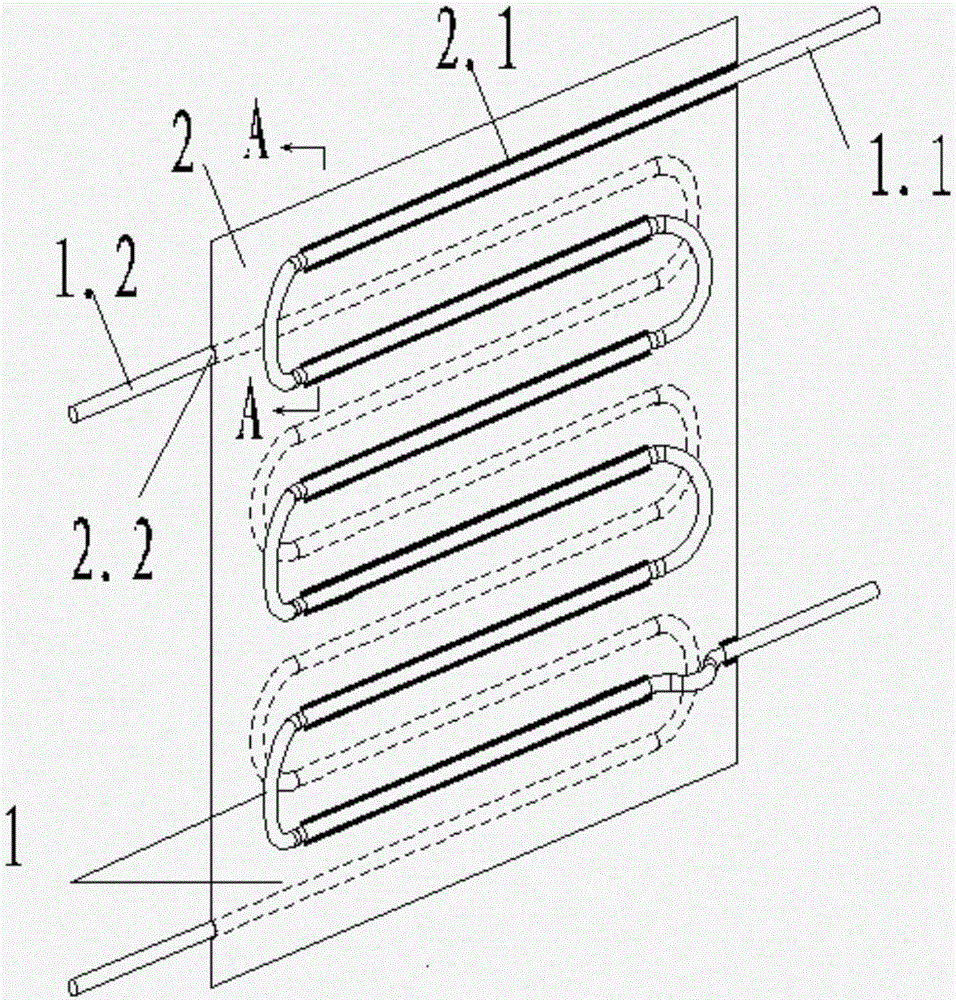

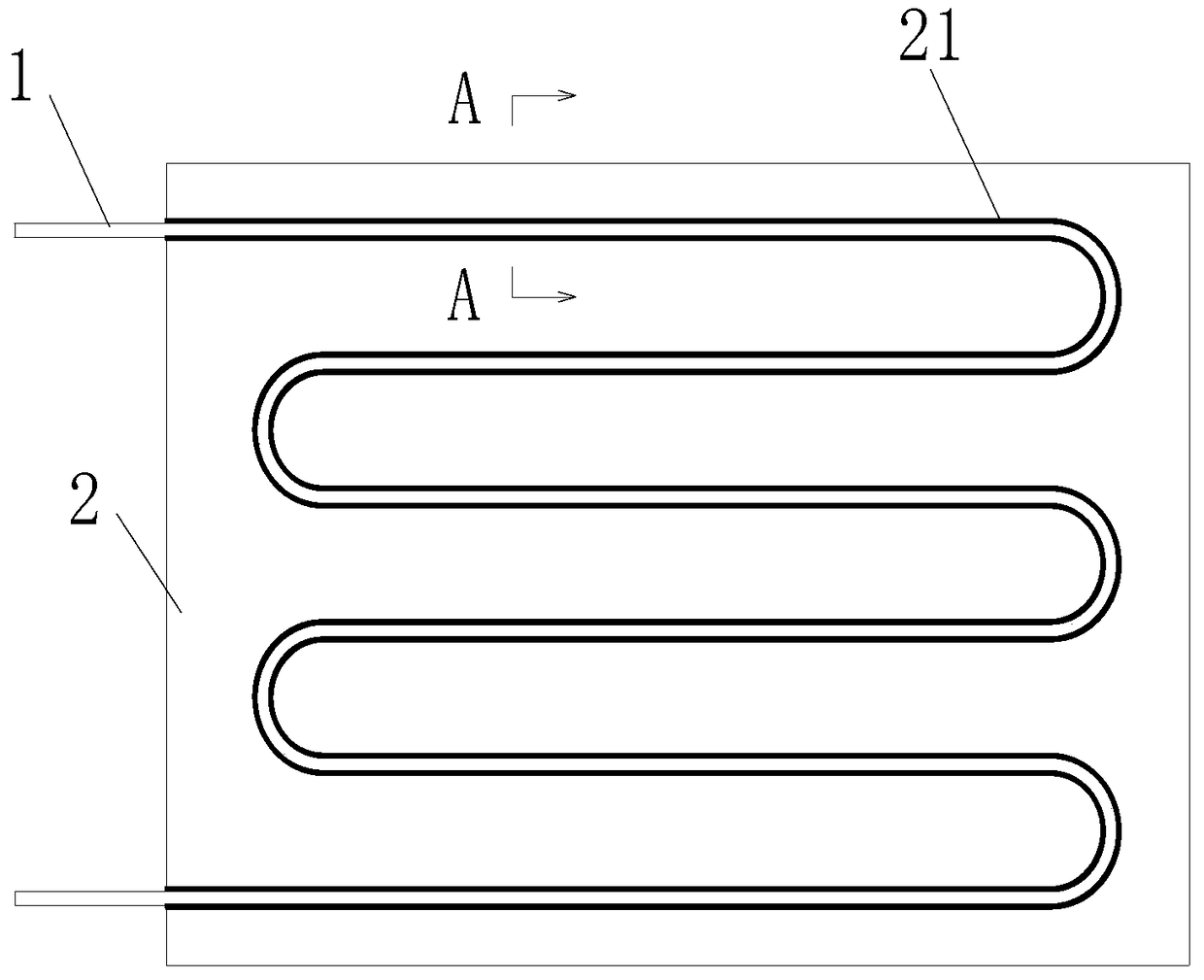

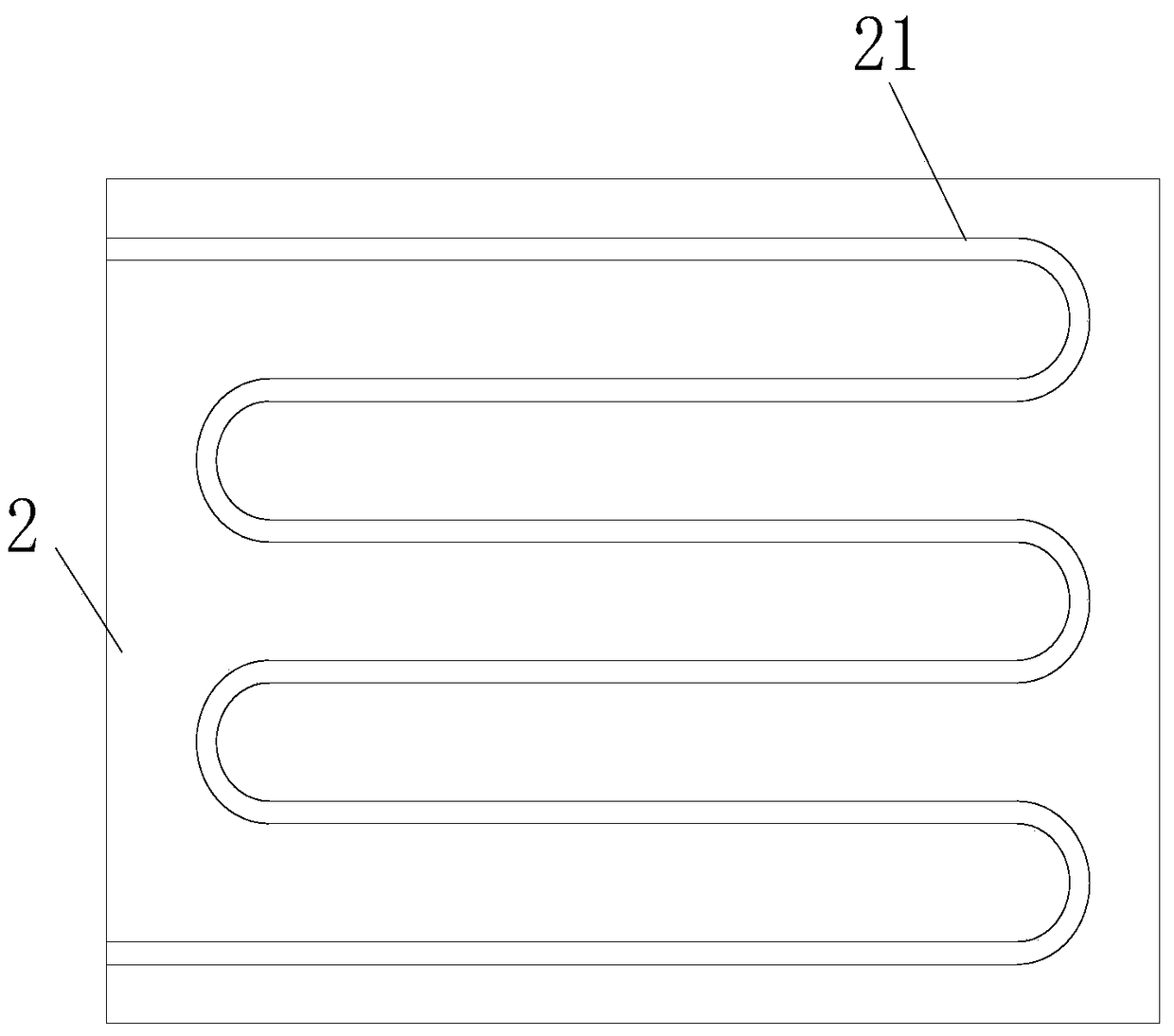

Plate-pipe composite heat-exchange fin and manufacturing method thereof

ActiveCN105987623AIncrease the effective heat transfer areaIncrease the evaporation surface areaEvaporators/condensersStationary conduit assembliesEvaporationEngineering

The invention discloses a plate-pipe composite heat-exchange fin. The plate-pipe composite heat-exchange fin comprises a coil pipe formed by machining of a heat exchange pipe and further comprises a heat transfer plate sheet. A placement groove is arranged in the heat transfer plate sheet. The shape of the placement groove is matched with that of the coil pipe. The coil pipe is placed in the placement groove. A gap between the coil pipe and the placement groove is filled with a heat conduction bonding layer. The invention further discloses a manufacturing method for the plate-pipe composite heat-exchange fin.Compared with the prior art, the plate-pipe composite heat-exchange fin has following beneficial effects: the heat conduction bonding layer enables the heat transfer plate sheet to be in full contact with the coil pipe such that the coil pipe has the finned effect through the heat transfer plate sheet and the effective heat exchange area can be effectively increased; the heat transfer plate sheet can introduce cooling water to form a continuous waterflow surface and increases the evaporation area of cooling water; and with an increased effective heat exchange area and an evaporation area of cooling water, heat exchange efficiency is raised and size of a condenser can be reduced.

Owner:GUANGZHOU WIDE IND

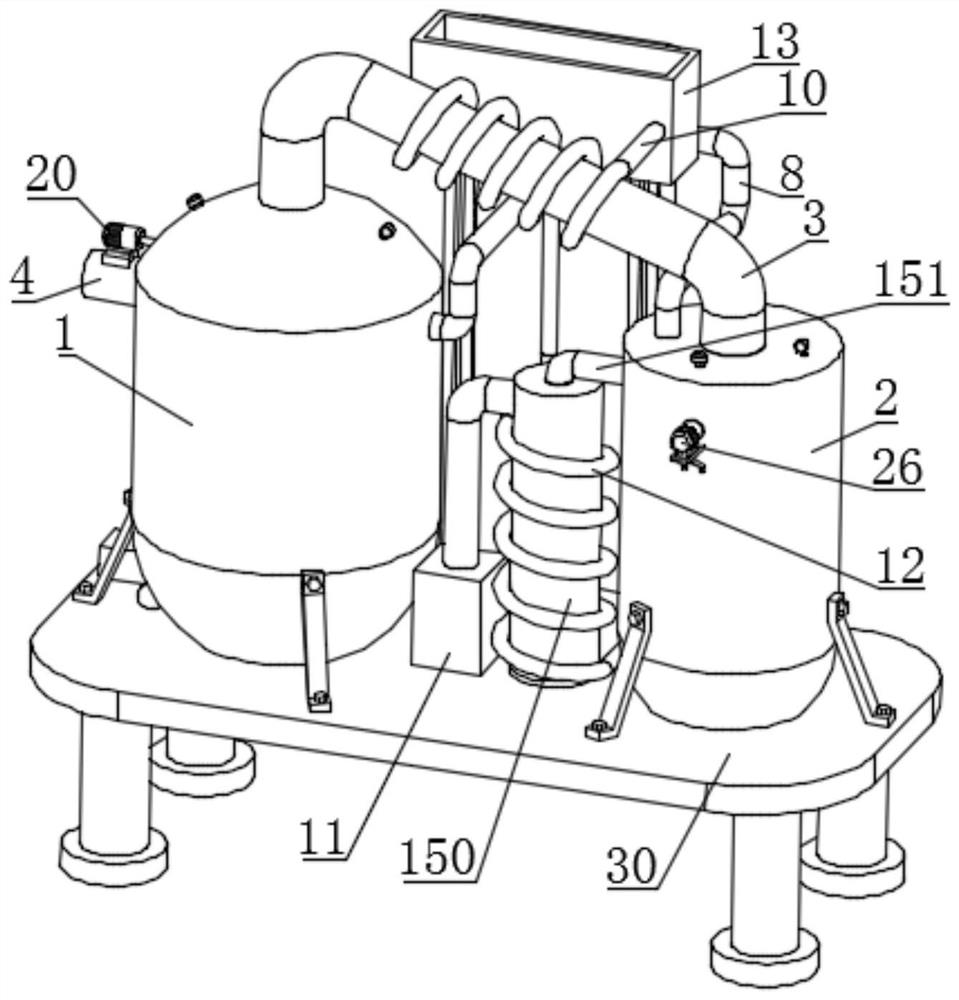

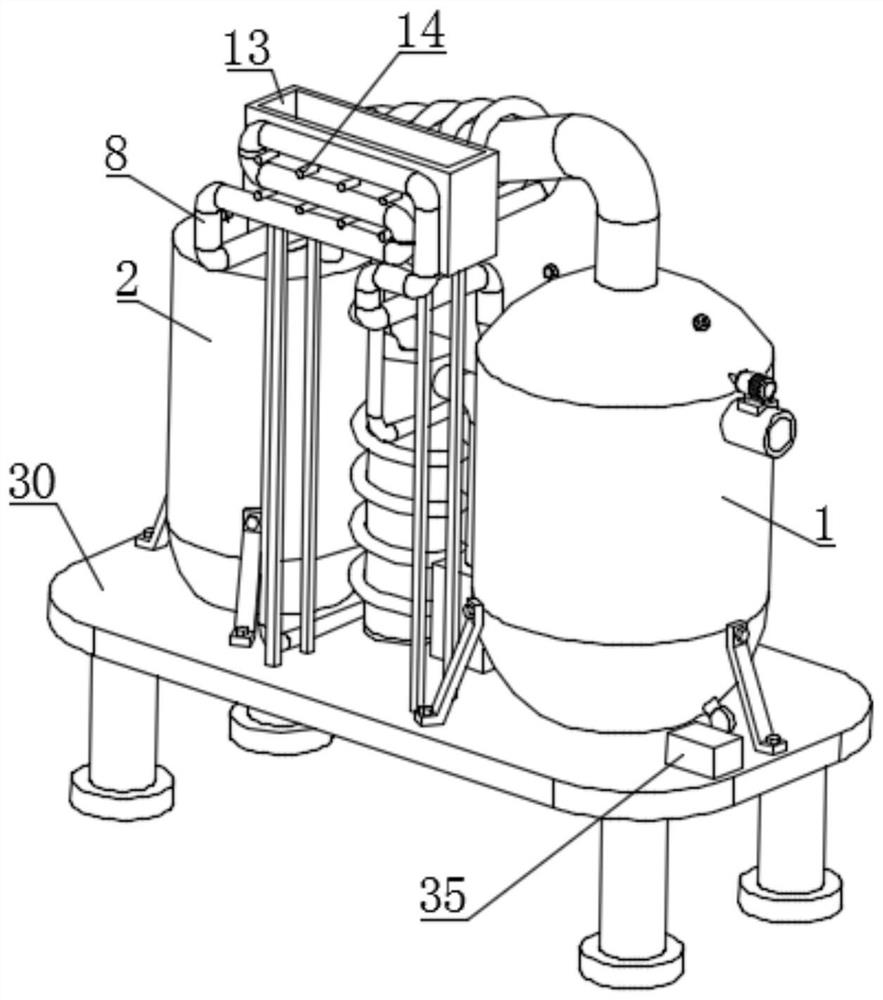

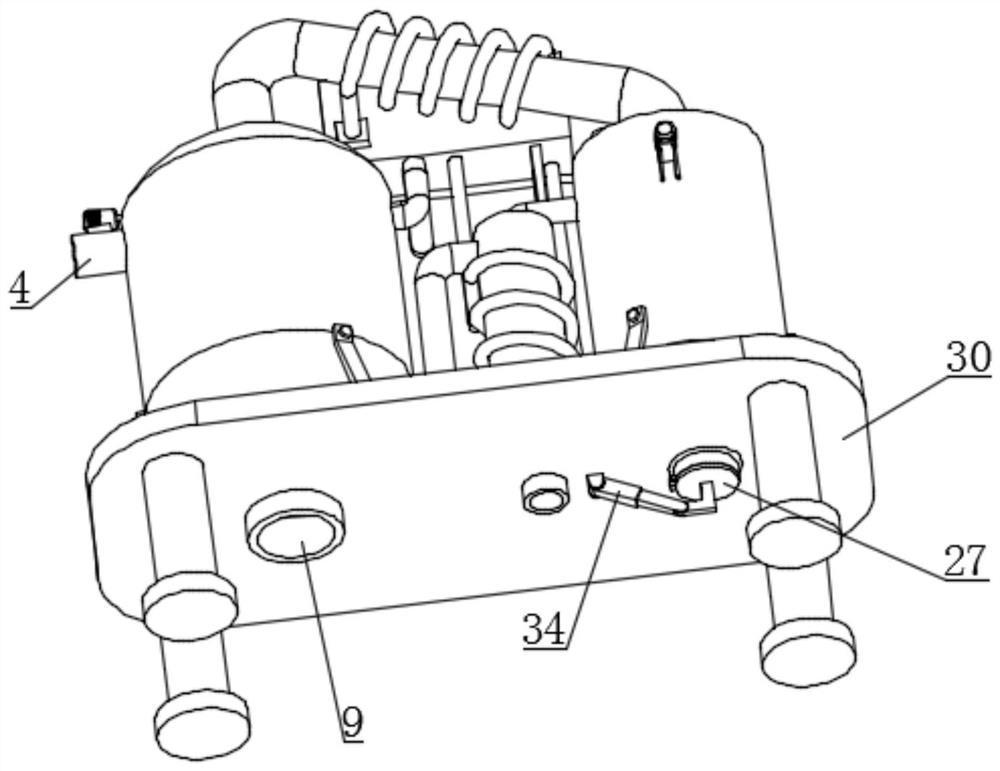

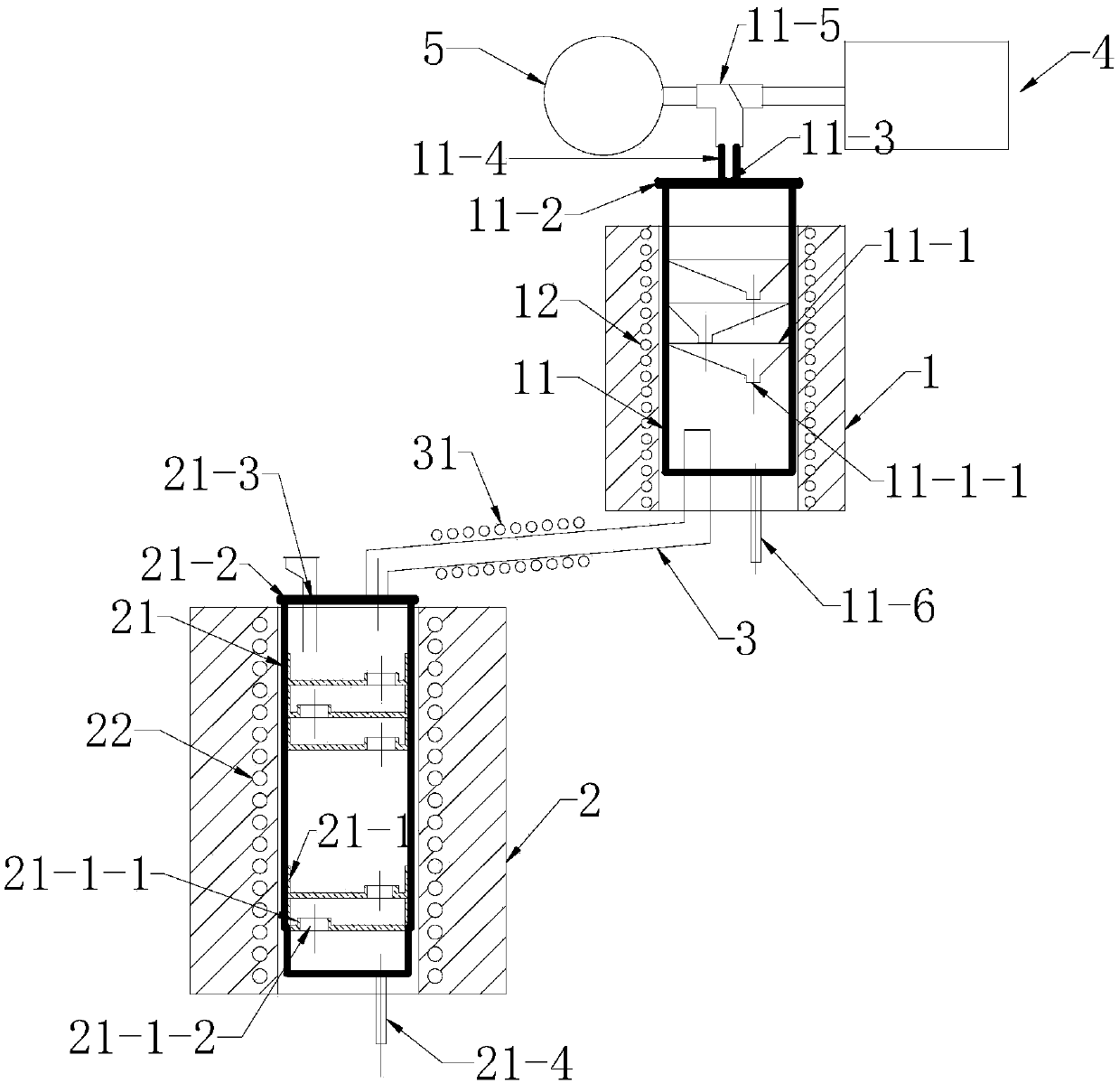

Circulating rare earth wastewater comprehensive treatment system

ActiveCN114031140APrevent evaporationAvoid damageWater treatment parameter controlSpecific water treatment objectivesThermodynamicsElectric machine

The invention discloses a circulating rare earth wastewater comprehensive treatment system, which comprises a distillation kettle and a collection tank, wherein a condensation pipe is connected between the distillation kettle and the collection tank, the distillation kettle is provided with a feeding pipe for feeding acidic wastewater and a discharging pipe for discharging distillation residual liquid, the inner side wall of the distillation kettle is provided with a plurality of electric heating wires, a rotating shaft is installed on the distillation kettle through a fixing frame fixedly connected to the interior of the distillation kettle, an air supply fan is installed at the upper end of the rotating shaft, the rotating shaft is driven by a first motor, a backflow pipe is further connected between the distillation kettle and the collecting tank, a discharging opening is formed in the lower end of the collecting tank, and the collecting tank is further connected with a vacuum pump. According to the invention, the evaporation loss of condensate can be well reduced, the evaporation treatment effect is improved, and the damage of the vacuum pump is avoided.

Owner:NANCHANG INST OF TECH

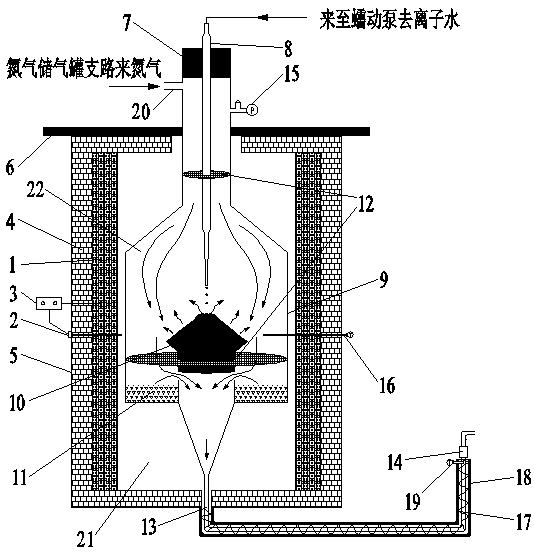

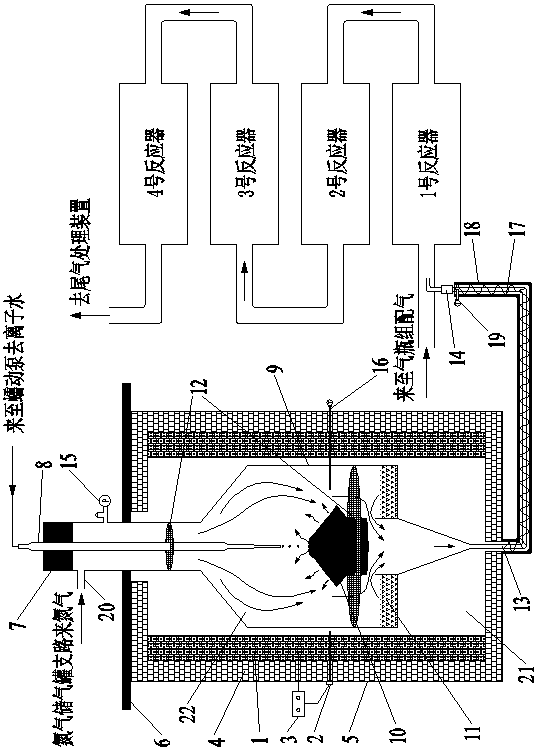

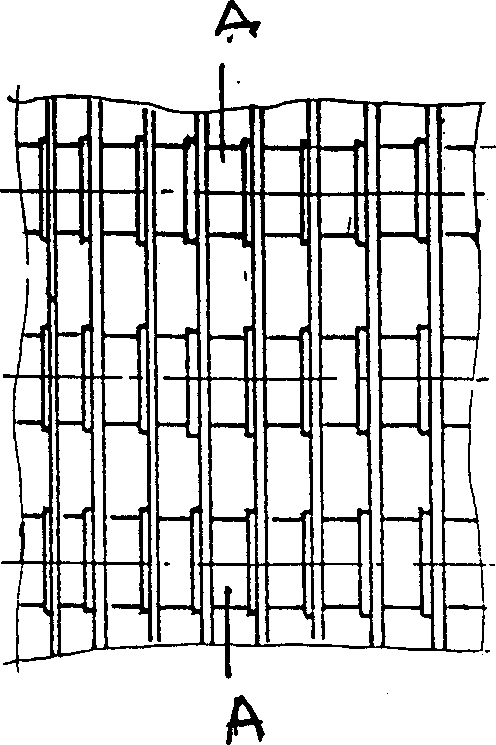

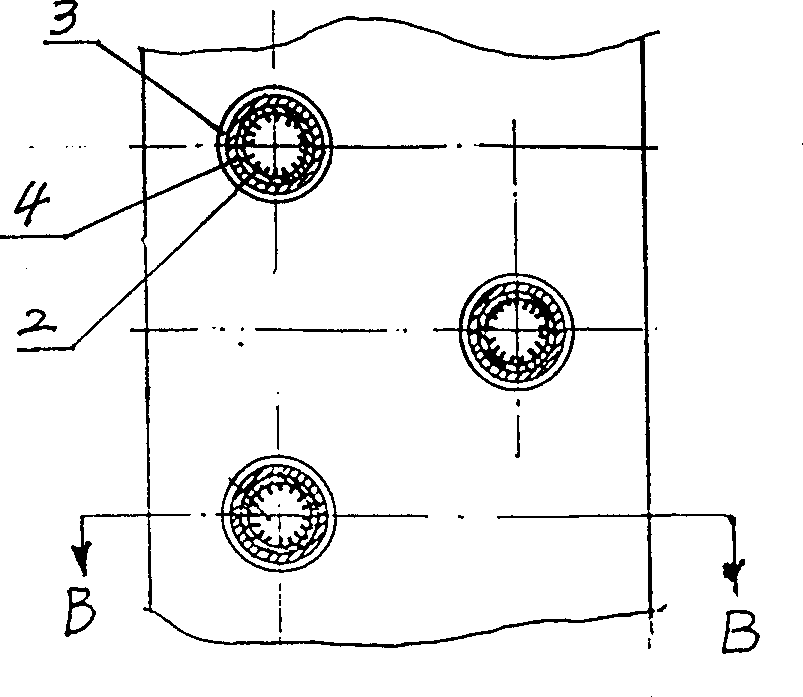

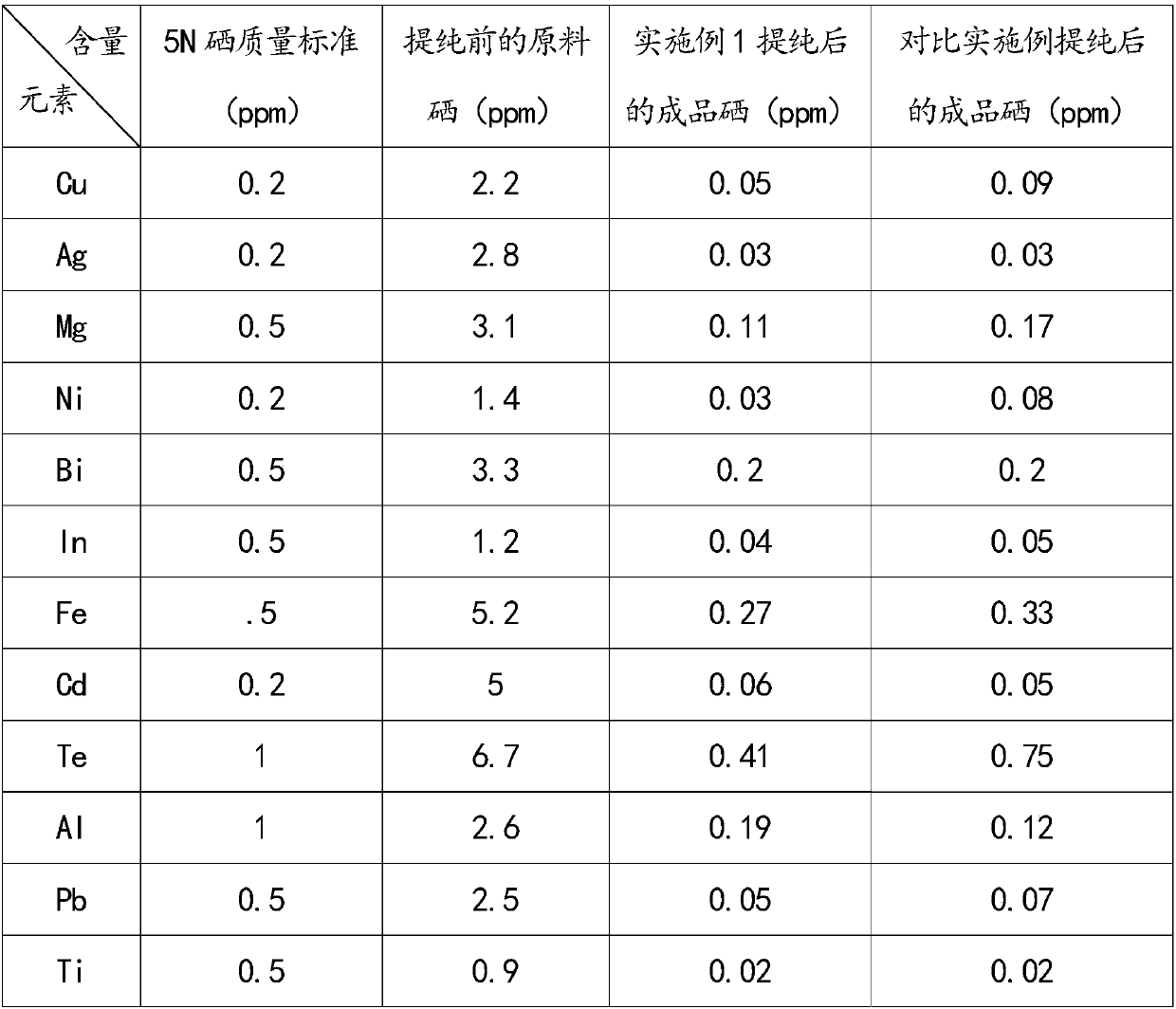

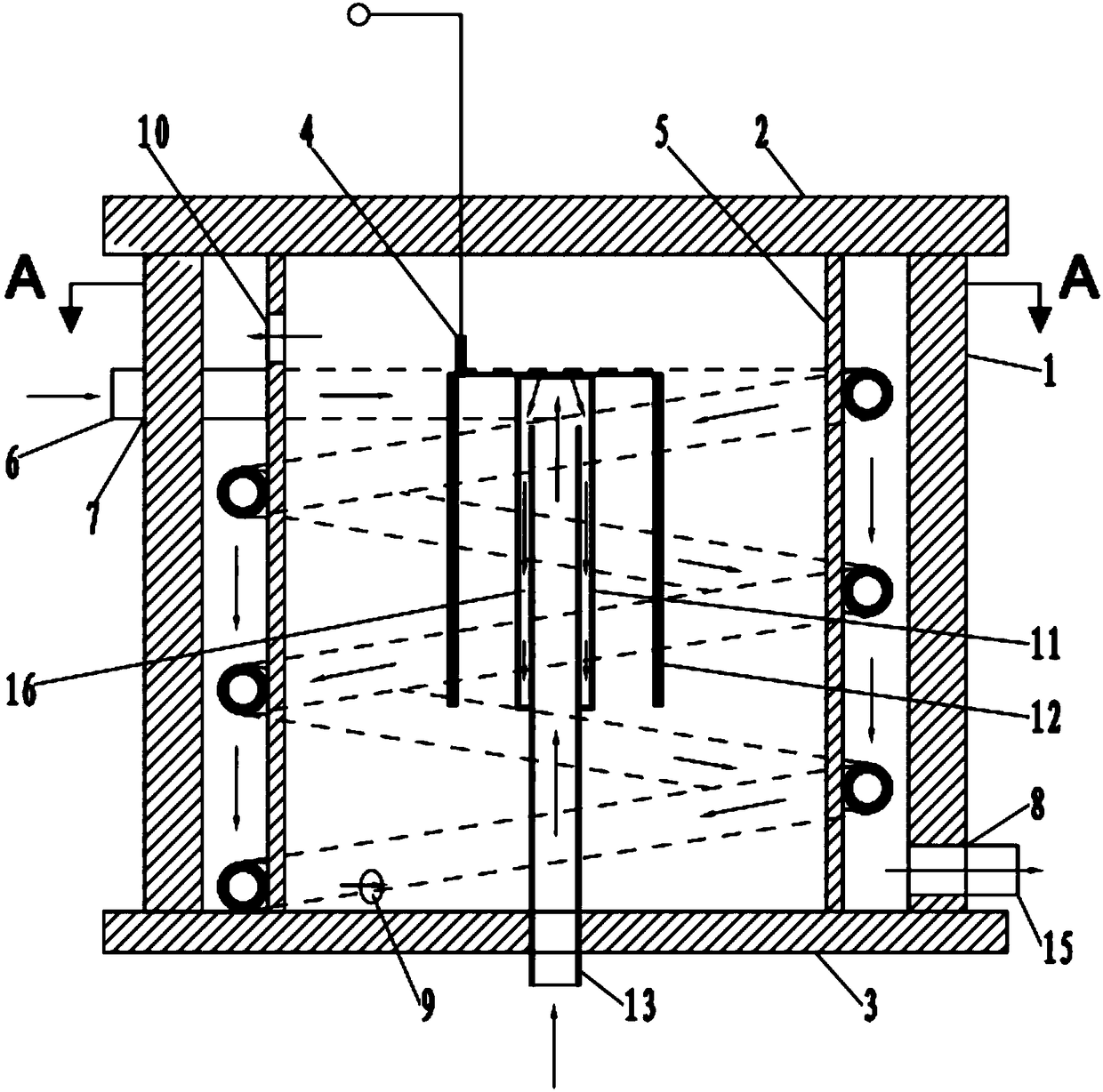

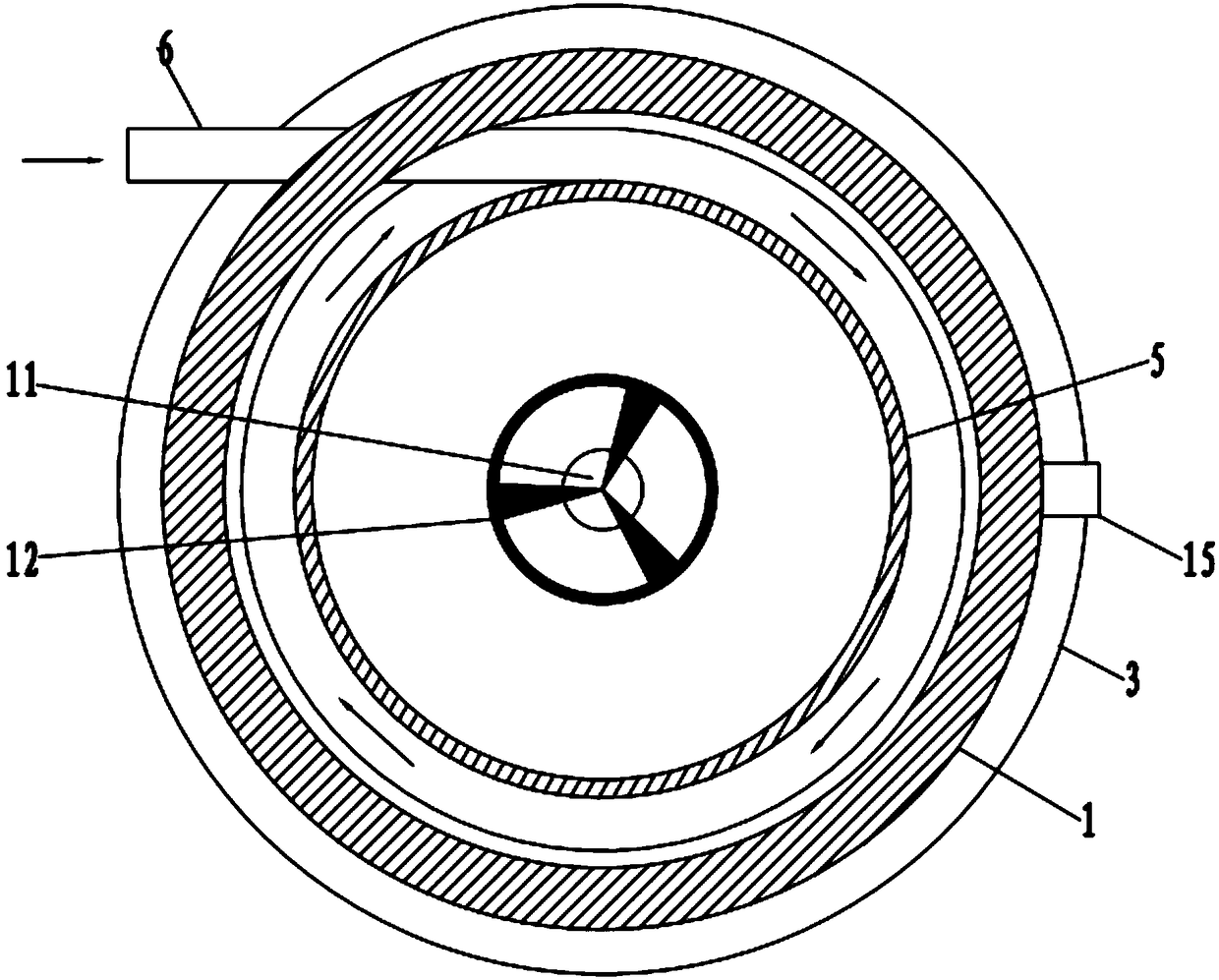

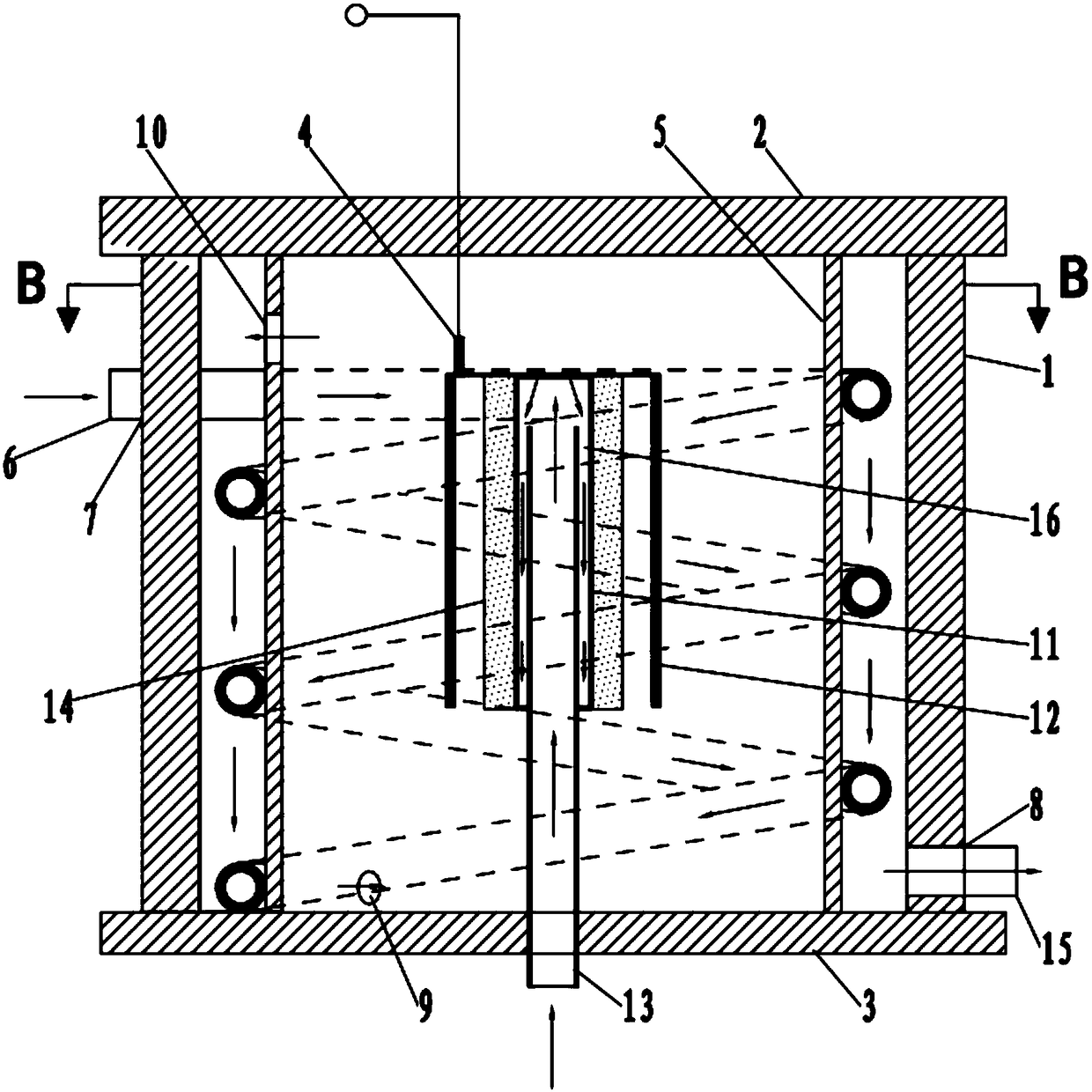

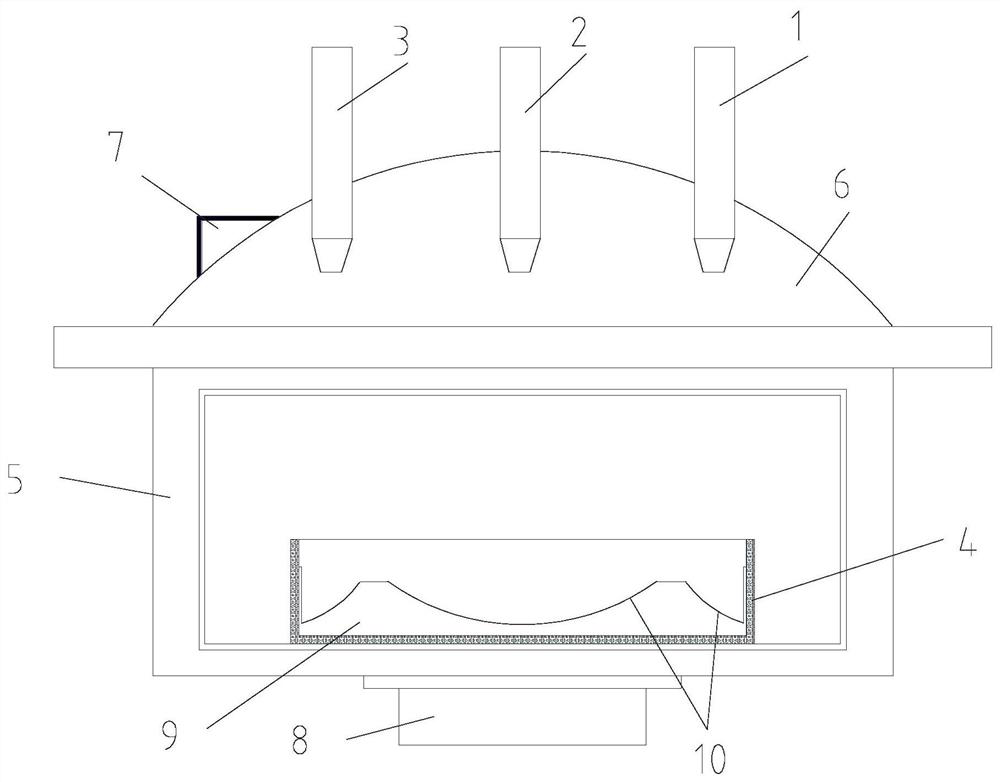

High-purity anaerobic selenium vacuum rectifying apparatus

ActiveCN109646979AIncrease productivityIncrease the evaporation surface areaVacuum distillation separationElemental selenium/telluriumEvaporationEngineering

The invention discloses a high-purity anaerobic selenium vacuum rectifying apparatus. The apparatus comprises an upper section furnace body and a lower section furnace body. A condensation chamber isarranged inside the upper section furnace body, a rectifying chamber is arranged inside the lower section furnace body, the condensation chamber and the rectifying chamber are connected through a steam pipe, the included angle between the steam pipe and the rectifying chamber is 5-10 degrees, and the condensation chamber, the rectifying chamber and the steam pipe are each wrapped by a heating device; a plurality of condensation discs are sequentially arranged inside the condensation chamber from top to bottom, and a plurality of evaporation discs are sequentially arranged inside the rectifyingchamber from top to bottom; a vacuumizing hole is formed in the upper end of the condensation chamber, and a finished product outlet is formed in the lower end of the condensation chamber; a materialinlet is formed in the upper end of the rectifying chamber, and a defective material outlet is formed in the lower end of the rectifying chamber; the condensation chamber and the rectifying chamber are made of quartz materials. The apparatus is simple in structure, convenient to manufacture, easy to maintain, high in production efficiency, high in purity and large in yield.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

Additive capable of improving combustion efficiency of diesel oil

InactiveCN106675677AIncrease the evaporation surface areaImprove combustion efficiencyLiquid carbonaceous fuelsCombustionManganese

The invention discloses an additive capable of improving the combustion efficiency of diesel oil. The additive comprises 10-20 parts of zinc naphthenate, 15-50 parts of calcium naphthenate, 30-50 parts of manganese naphthenate, 10-20 parts of iron naphthenate, 2-10 parts of calcium isooctanoate and 2-5 parts of cobalt naphthenate. In the process of preparation, the various raw materials are added into a mixing tank, and are evenly stirred and mixed. The raw materials of the product are easy to get, the formula is scientific, the property is high, the rate of fuel saving of the diesel oil reaches more than 10%, the functions of saving oil, abating smoke and maintaining are integrated, and the additive is convenient to use, is rapidly and evenly dispersed, and has a remarkable service efficiency.

Owner:王诗影

Cylindrical porous jetting-type miniature liquid combustor and combustion method thereof

The invention relates to a miniature liquid fuel combusting device, and discloses a cylindrical porous jetting-type miniature liquid combustor. The cylindrical porous jetting-type miniature liquid combustor comprises a combustion chamber, an upper sealing plate, a lower sealing plate and an air inlet pipeline, the upper sealing plate and the lower sealing plate are used for sealing the combustionchamber, the combustion chamber is provided with a first air inlet and a second air exhaust, and one end of the air inlet pipeline penetrates through the first air inlet and extends into the combustion chamber; the combustion chamber is internally provided with a feeding pipeline and a cumbustor body, one end of the feeding pipeline is located inside the combustor body, the bottom of the combustorbody is connected with the middle of the feeding pipeline, and the other end of the feeding pipeline penetrates through the lower sealing plate. The invention further provides a combustion method ofthe cylindrical porous jetting-type miniature liquid fuel combustor. The miniature liquid fuel combustor and the combustion method thereof have the advantages that the superficial area of liquid fuelis increased, so that the liquid fuel is sufficiently mixed with air, and meanwhile, evaporation of the liquid fuel is accelerated at the same time so that combustion can be stably and efficiently conducted.

Owner:SOUTH CHINA UNIV OF TECH

Polyglycolic acid drying equipment

InactiveCN111811238AIncrease the evaporation surface areaHigh frequencyDrying gas arrangementsDrying machines with progressive movementsGlycolic acidStructural engineering

The invention relates to polyglycolic acid drying equipment. The polyglycolic acid drying equipment comprises a base, a drying box, a winding device and an unwinding device. The winding device and theunwinding device are arranged at the two ends of the base correspondingly. The drying box is arranged in the middle of the base. A drying drum is arranged in the middle of an inner cavity of the drying box. The outer wall of the drying drum is provided with a locating seat. The two sides of the locating seat are provided with mounting grooves. Drying fans are mounted in the mounting grooves. Theupper and lower ends of each mounting groove are provided with heating wires. The drying drum is internally and horizontally provided with a plurality of heating chambers. The heating chambers communicate with the mounting grooves through a plurality of vent ports. The drying drum is internally provided with a plurality of electric heating bars. The electric heating bars are distributed in the periphery of each heating chamber. The end, close to the winding device, of the drying box is provided with a line outlet. The end, close to the line outlet, of the interior of the drying box is providedwith two line guide rolls. The two line guide rolls convey suture lines output from the drying drum to the winding device through the line outlet. Thus, the drying equipment can heat the multiple suture lines simultaneously and greatly improves the drying efficiency.

Owner:ZHONG HONG NANO FIBER TECH DANYANG

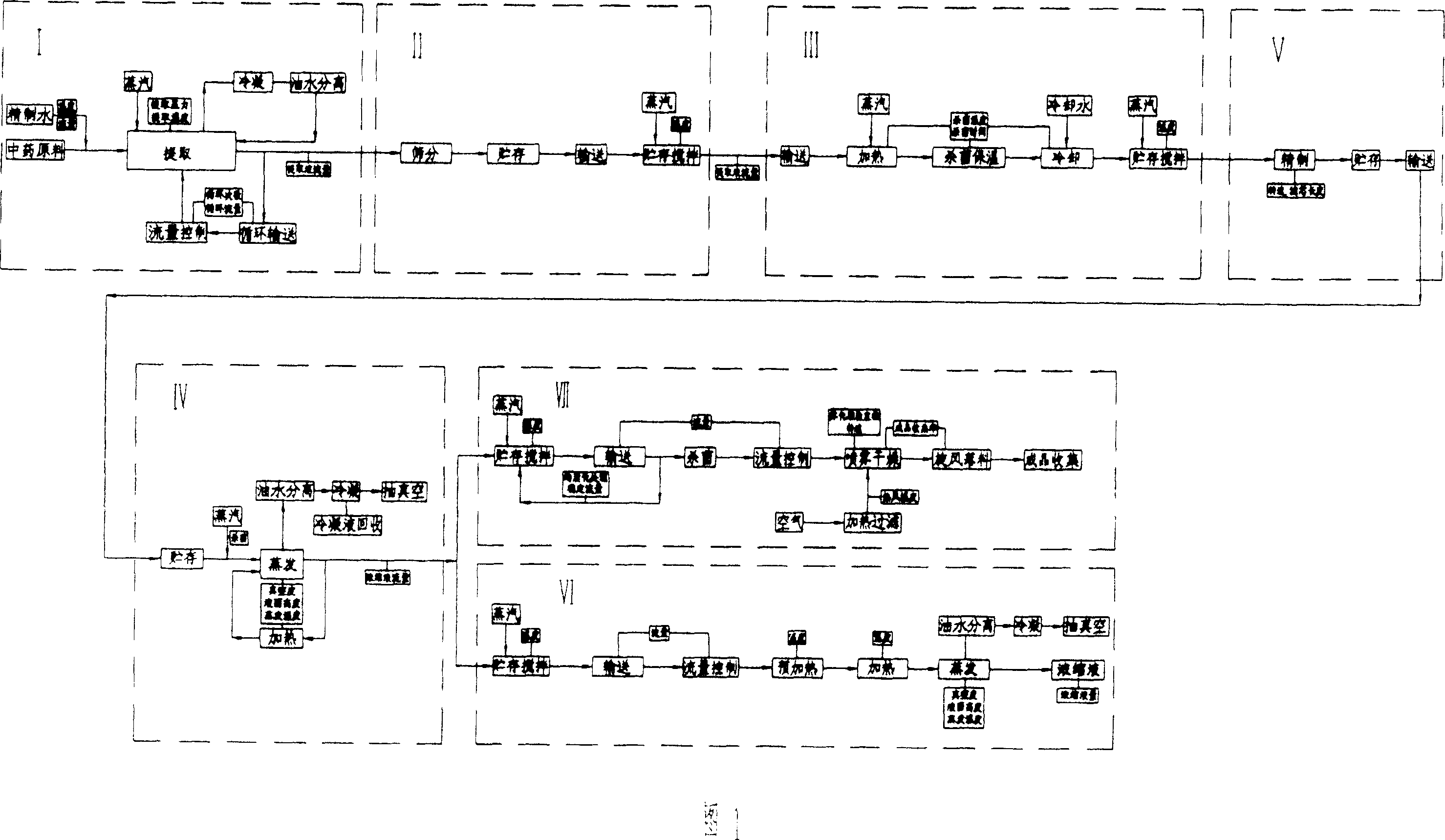

Chinese medicine preparation and set of apparatuses thereof

ActiveCN100342839CReduce heat gainSolve the blockageVapor condensationPharmaceutical product form changeProcess engineeringChinese drug

Owner:云南昆船电子设备有限公司

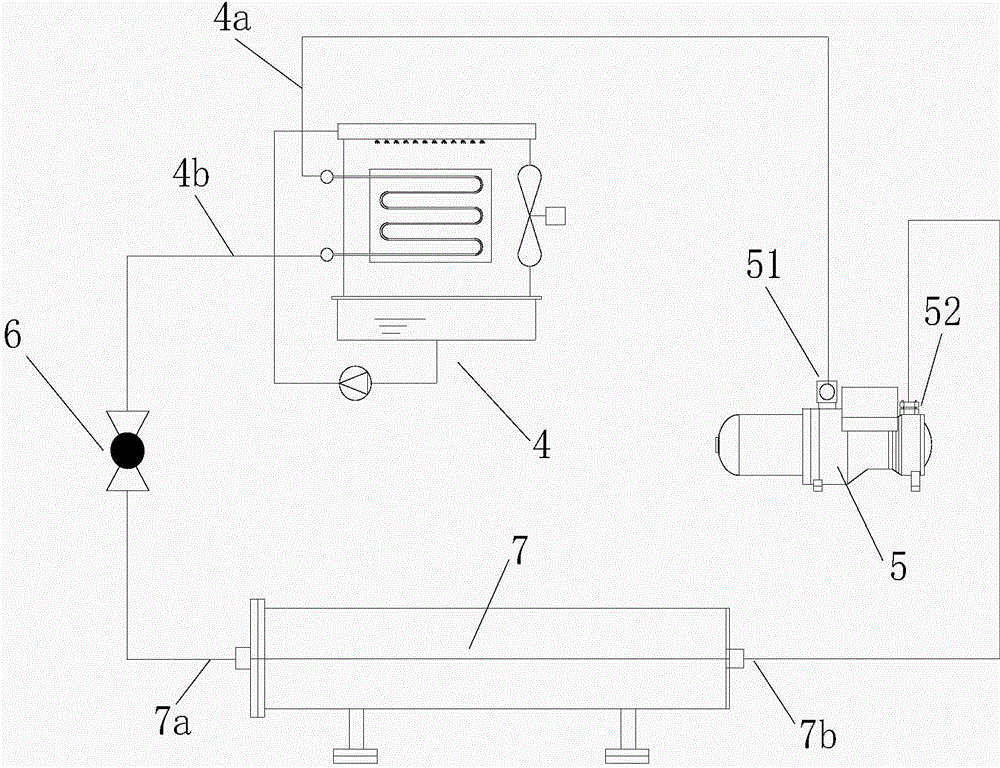

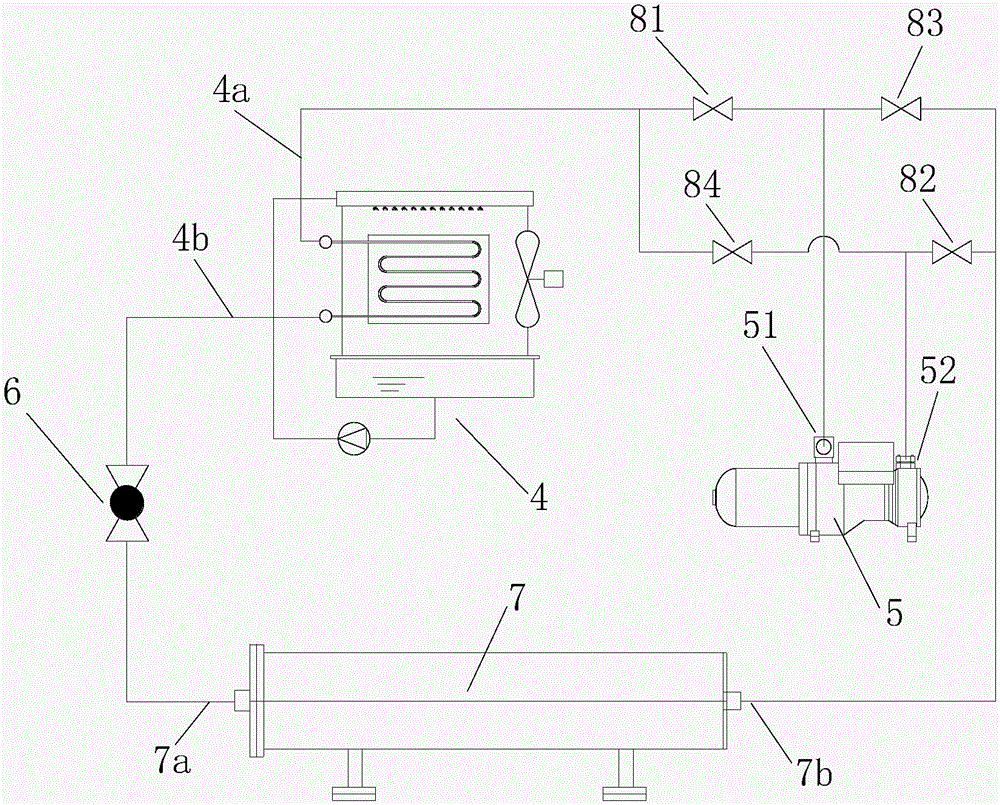

Natural cold source unit

ActiveCN106196667AImprove heat transfer efficiencyEfficient use ofCompression machines with non-reversible cycleEvaporators/condensersEvaporationEngineering

The invention discloses a natural cold source unit. The natural cold source unit comprises a compressor, an evaporation type condenser, a throttling device, a water-cooled type evaporator and a stopping device. The evaporation type condenser comprises a draught fan, a solution pump, a sprayer, a liquid trap and at least one heat exchange plate. Each heat exchange plate comprises a plate body. The two faces of the plate body are each provided with a heat exchange coiled pipe. According to the natural cold source unit, because the two faces of the plate body of each heat exchange plate of the evaporation type condenser are each provided with one heat exchange coiled pipe, the heat exchange efficiency is improved, and the effect that multiple working media conduct circulation at the same time can be achieved; and besides, the size of the natural cold source unit can be reduced under the condition that the same heat exchange efficiency is obtained, and the use demands of a user are met.

Owner:GUANGZHOU WIDE IND

A method and device for increasing the amount of volatile impurities removed during electron beam smelting

ActiveCN109850905BIncrease the evaporation surface areaAccelerate evaporationSilicon compoundsSmelting processCrucible

The invention discloses a method and device for increasing the impurity removal amount of volatile impurities in an electron beam smelting process. According to the invention, in an electron beam smelting process, the surface of a silicon melt can be fluctuated by changing the melting mode of an electron beam, so that the evaporation surface area is increased, the evaporation surface area of a melt interface is increased, and the evaporation amount of impurities in unit time is increased; a graphite substrate is placed at the bottom of a smelting crucible, and then the temperature distributionat the bottom of the silicon melt is changed, so that flowing of the silicon melt at the bottom of the smelting crucible is promoted, convection occurs in the silicon melt, and then melt exchange between the silicon melt at the bottom and the silicon melt at the top is accelerated. Through the change of the melting mode and the experimental device of the electron beam, the evaporation surface area of the melt is increased, the evaporation amount of the impurities in unit time is increased, and therefore, the problems that a silicon melt is low in impurity evaporation amount, long in melting time, large in silicon material loss and high in cost in an impurity removal process of volatile impurities are solved.

Owner:DALIAN UNIV OF TECH

Hot air-penetration external circulating-type coal sample dehumidification device having automatic sample feeding/taking function

ActiveCN102944452BIncrease the evaporation surface areaIntegrity guaranteedPreparing sample for investigationThermodynamicsGas heater

Owner:HUNAN SUNDY SCI & TECH DEV

Coal slime dehydration drying equipment and method

ActiveCN105423731BSpeed up evaporationIncrease the evaporation surface areaGranular material dryingDrying gas arrangementsEngineeringSmall footprint

The invention discloses a coal slime dehydration and drying equipment and method, which includes a drying room and a coal slime conveying device, a hot air fan and a negative pressure fan located in the drying room. The coal slime conveying device includes a plurality of coal slime conveying devices from top to bottom. The conveyor belt is arranged in a zigzag shape. There is a vibrating feeder above the slime inlet end of the uppermost conveyor belt of the coal slime conveying device. There is a feed sealing door on the top of the drying room; There is a discharging funnel below the slime outlet end of the conveyor belt at the bottom of the conveyor belt. There is a discharging sealing door at the bottom of the drying room. There is a negative pressure fan and a hot air ventilation air gate at the upper part of the drying room. The lower part of the drying room is equipped with a hot air fan, hot water inlet and outlet, etc., and the upper side wall of the drying room is equipped with a hot air ventilation airlock door, which also includes a slime dehydration and drying method applied to the above equipment. The invention has the beneficial effects of energy saving, environmental protection, high efficiency, low drying temperature, fast speed, high efficiency, simple structure and small floor space.

Owner:武汉汉缘新能源环保科技有限公司

Car accessory drying device

ActiveCN108469153AEasy to dryReduce manual work pressureDrying solid materials without heatHeating arrangementEngineeringElectric heating

The invention relates to a car accessory drying device. The car accessory drying device comprises a frame, wherein an annular electric heating plate is arranged in the frame, a main telescopic rod anda tray are arranged in a groove, the main telescopic rod is connected with the tray and the frame, a first support rod and a second support rod are fixed to both horizontal sides of the frame, the first support rod is located on the upper part of the frame, a rotating arm is movably connected to the first support rod, the rotating arm can be opened and closed, the rotating arm is used for dehumidifying a car accessory, a secondary telescopic rod is arranged on the second support rod, and a transverse block which is used for dehumidifying the car accessory is arranged on the secondary telescopic rod. By using the car accessory drying device, the defect of drying the surface of the accessory in the prior art is overcome, and the problems of no treatment of water drops before drying, watermarks after drying and low drying efficiency in the prior art are solved.

Owner:重庆广福科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com