Cold-and-hot water unit with plate-pipe composite heat-exchange evaporative condenser

An evaporative condenser, cold and hot water unit technology, applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc. Installation and disassembly are cumbersome and other problems, to achieve the effect of increasing the evaporation area of cooling water, reducing the volume of the condenser, and increasing the effective heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

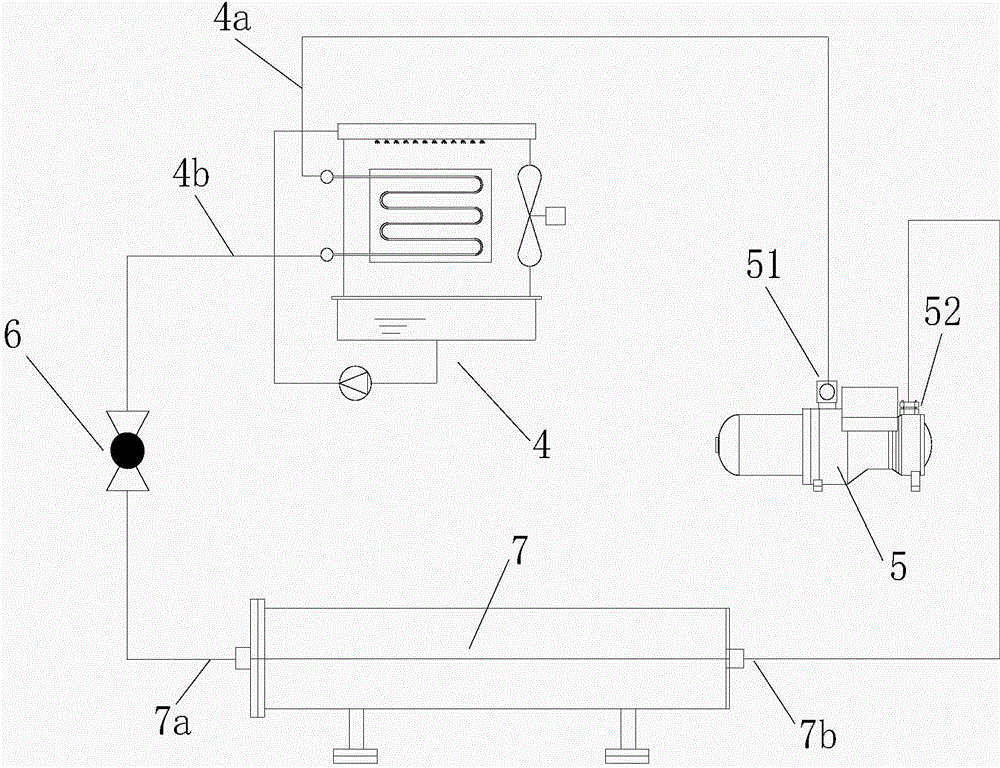

[0030] figure 1 It shows a schematic diagram of the principle of the refrigeration cycle mode of a cold and hot water unit with a plate-tube composite heat exchange type evaporative condenser according to the present invention. figure 1 It can be seen that the cold and hot water unit includes a compressor 5, an evaporative condenser 4, a throttling device 6 and an evaporator 7; the exhaust port 51 of the compressor 5 is connected with the gas pipe 4a of the evaporative condenser 4 to evaporate The liquid pipe 4b of the type condenser 4 is connected with the liquid pipe 7a of the evaporator 7 through the throttling device 6, and the gas pipe 7b of the evaporator 7 is connected with the suction port 52 of the compressor 5. The evaporative condenser 4 adopts plate-tube composite heat exchange fins, which will not be described in detail here.

[0031] Working principle: When the refrigerant is compressed by the compressor 5 and becomes a high-temperature and high-pressure gas, it...

Embodiment 2

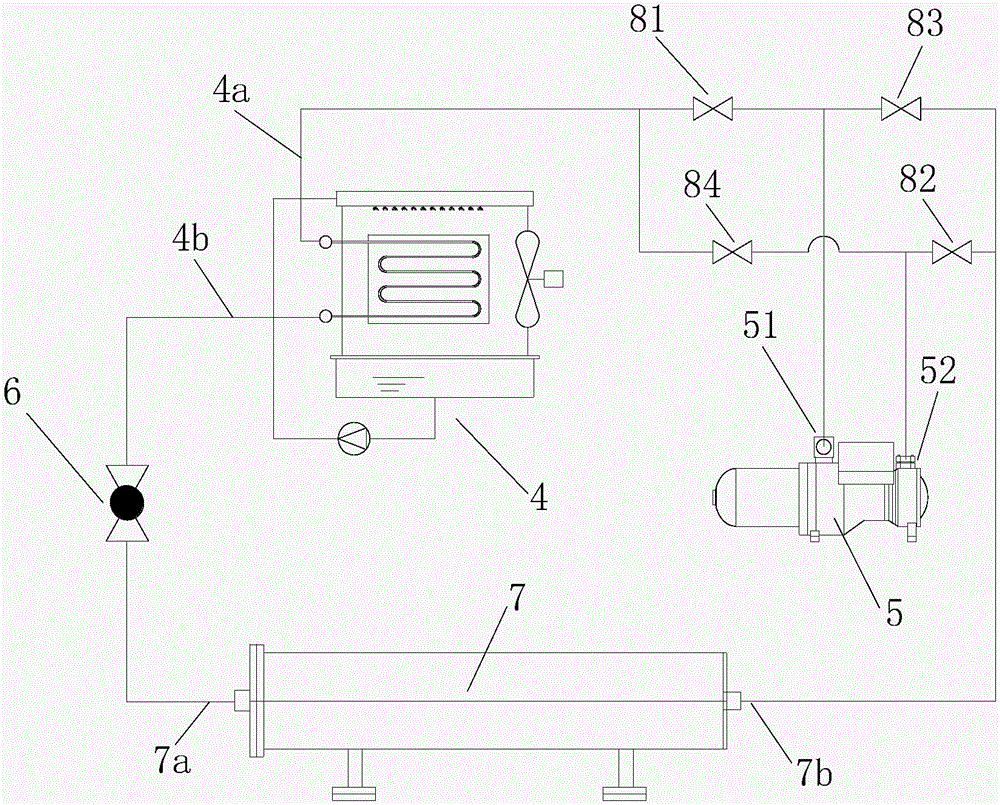

[0033] figure 2 It shows a schematic diagram of the principle of the cold and hot water unit of the present invention. Compared with Embodiment 1, the difference is that the cold and hot water unit is provided with a first refrigeration valve 81, a second refrigeration valve 82, a first heat pump Valve 83 and the second heat pump valve 84; the first refrigeration valve 81 is arranged on the connection pipeline between the exhaust port 51 of the compressor 5 and the gas pipe 4a of the evaporative condenser 4, and the second refrigeration valve 82 is arranged on the compressor 5 On the connecting pipeline between the suction port 52 of the compressor 5 and the gas pipe 7b of the evaporator 7, the first heat pump valve 83 is arranged on the connecting pipeline between the exhaust port 51 of the compressor 5 and the gas pipe 7b of the evaporator 7, and the second heat pump valve The pump valve 84 is arranged on the connection pipeline between the suction port 52 of the compressor...

Embodiment 3

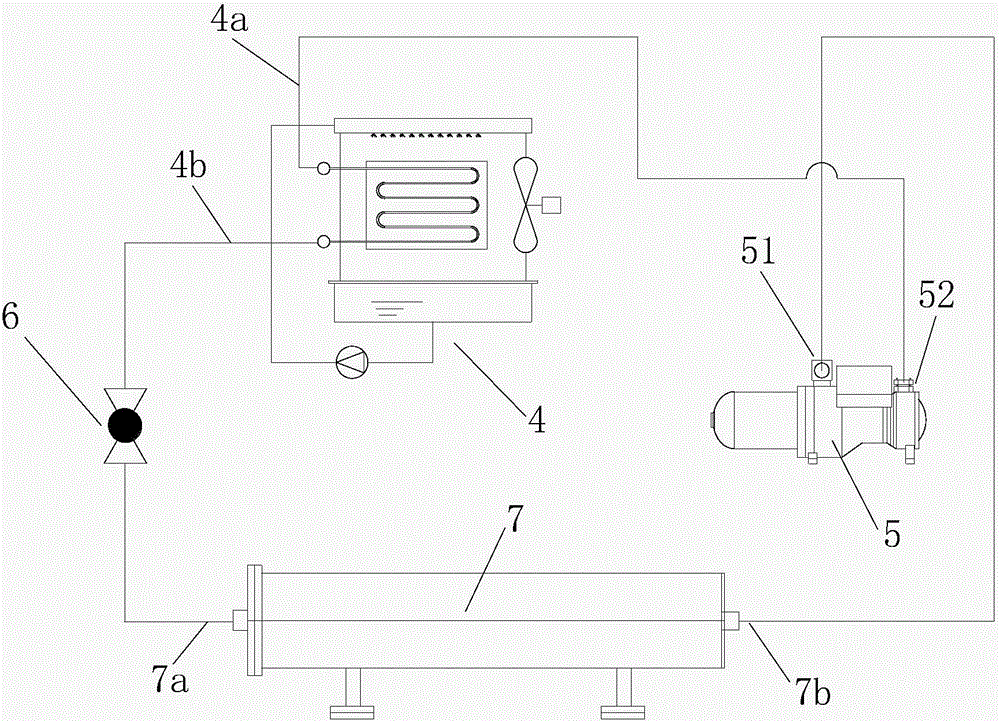

[0036] Figure 4 It shows the schematic diagram of the principle of the two-position three-way reversing valve used in the hot and cold water unit of the present invention. Compared with Embodiment 1, the difference is that the exhaust port 51 of the compressor 5 is provided with a first two-position Three-way reversing valve 85, the suction port 52 of the compressor is provided with the second two-position three-way reversing valve 86; 4a is connected to the gas pipe 7b of the evaporator, and the two inlets of the second two-position three-way reversing valve 86 are respectively connected to the gas pipe 4a of the evaporative condenser and the gas pipe 7b of the evaporator. Similarly, the evaporative condenser has 4 plate-tube composite heat exchange fins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com