Patents

Literature

460 results about "Exchange time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

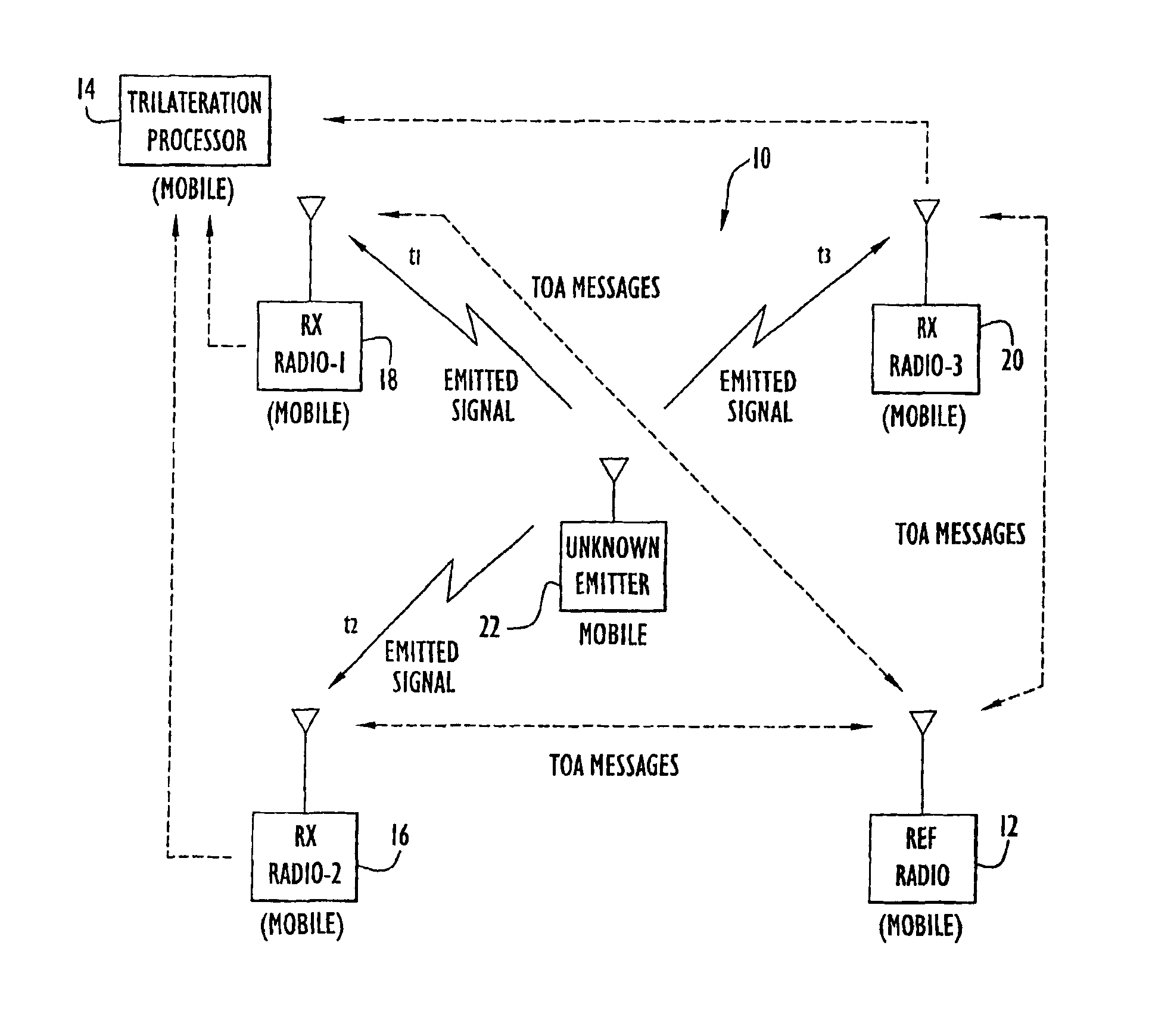

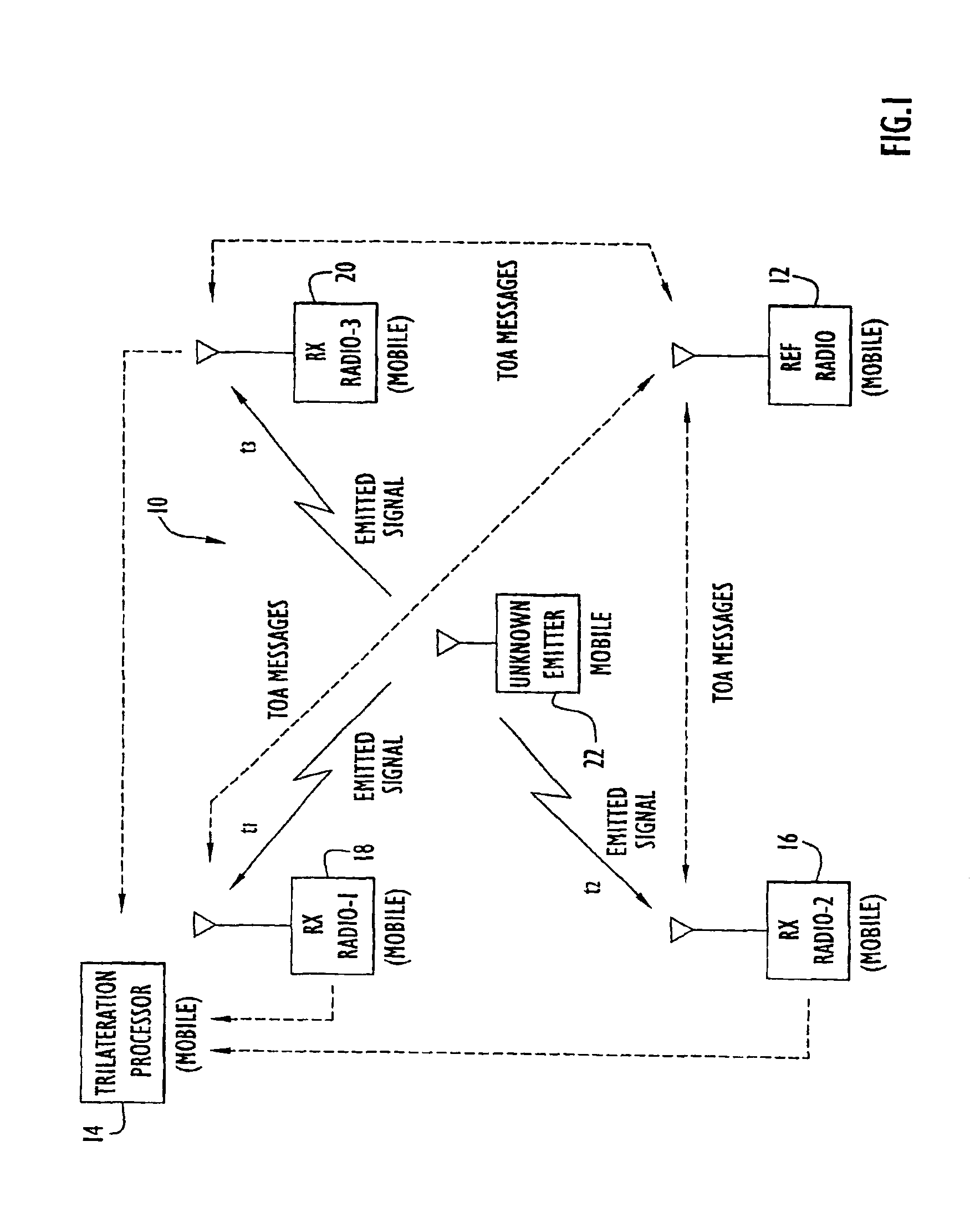

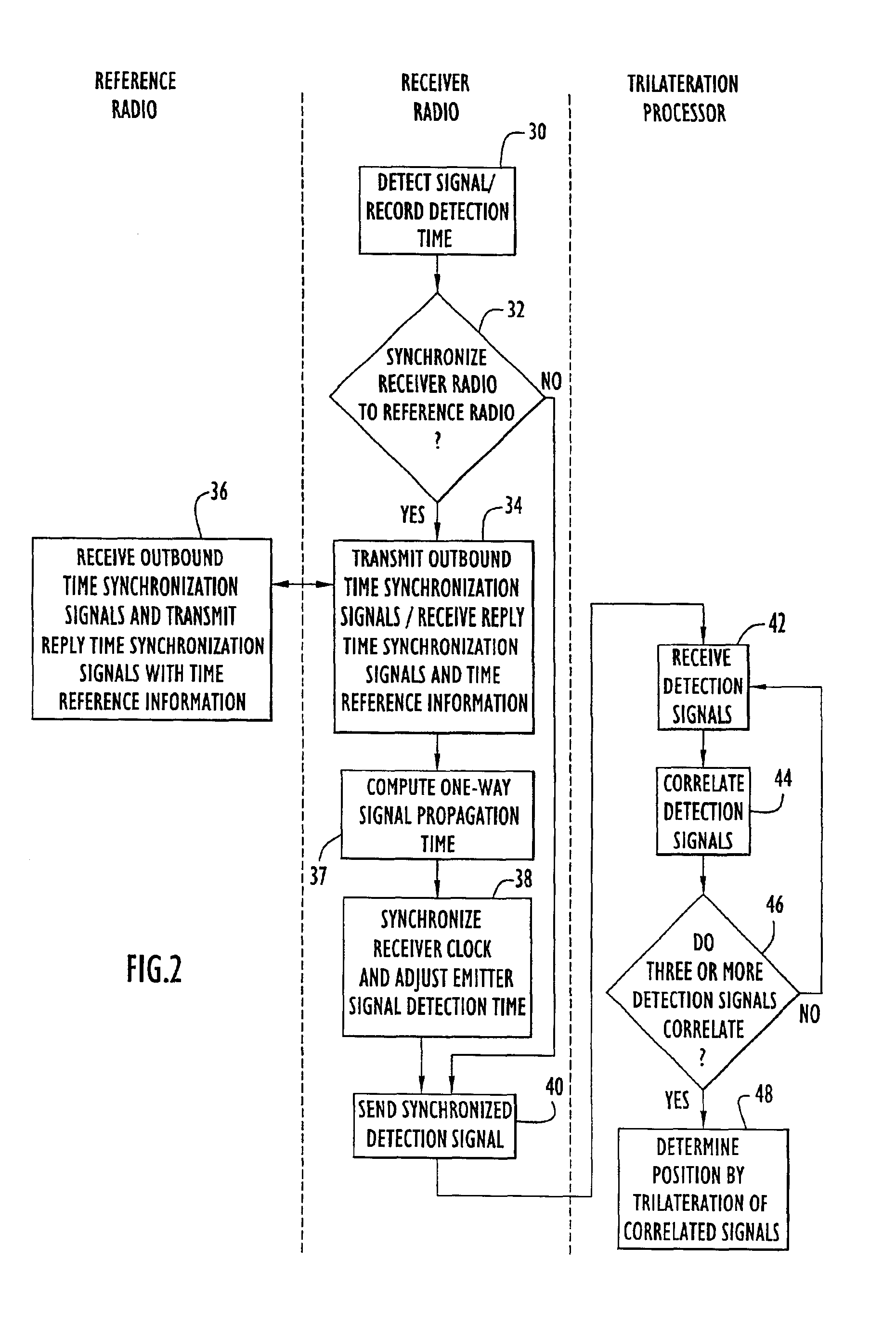

System for determining position of an emitter

InactiveUS6861982B2Improve accuracyMinimizes designDirection finders using radio wavesPosition fixationPropagation timeExchange time

The position of a non-cooperating emitter is determined by detecting a signal from the emitter at three or more receiver communication devices positioned at different locations. The receiver communication devices determine respective detection times of the emitted signal in respective local time reference frames. To establish a common time reference frame for the emitted signal detections, each receiver communication device exchanges time synchronization signals with a reference communication device. Since any of the receiver communication devices and the reference communication device may be mobile, the signal exchange allows each receiver communication device to accurately determine the signal propagation time between itself and the reference communication device and factor the signal propagation time into an accurate adjustment of the local time reference frame. Using trilateration, the position of the emitter is determined from known positions of the receiver communication devices and the emitted signal detection times from the receiver communication devices.

Owner:EXCELIS INC

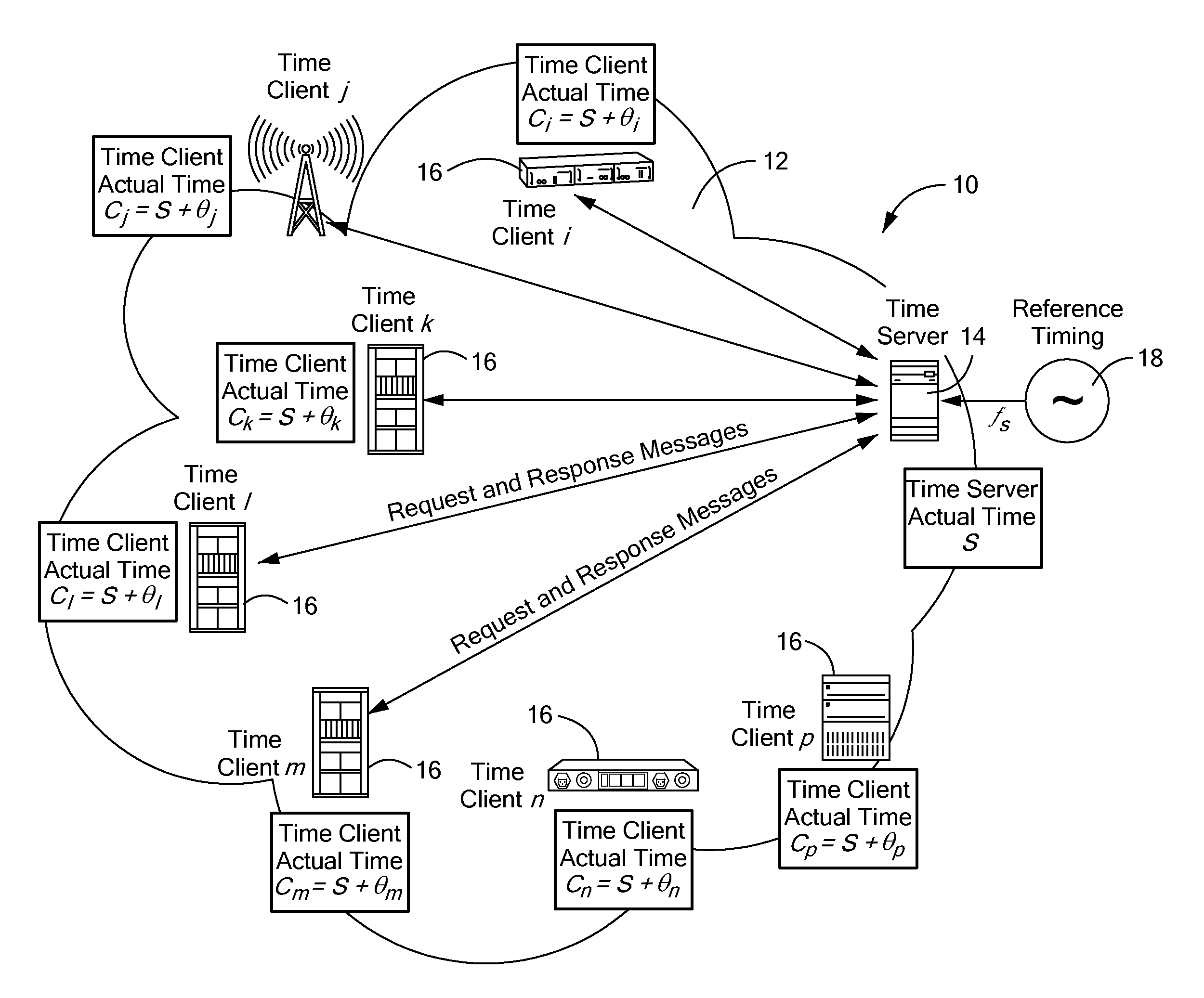

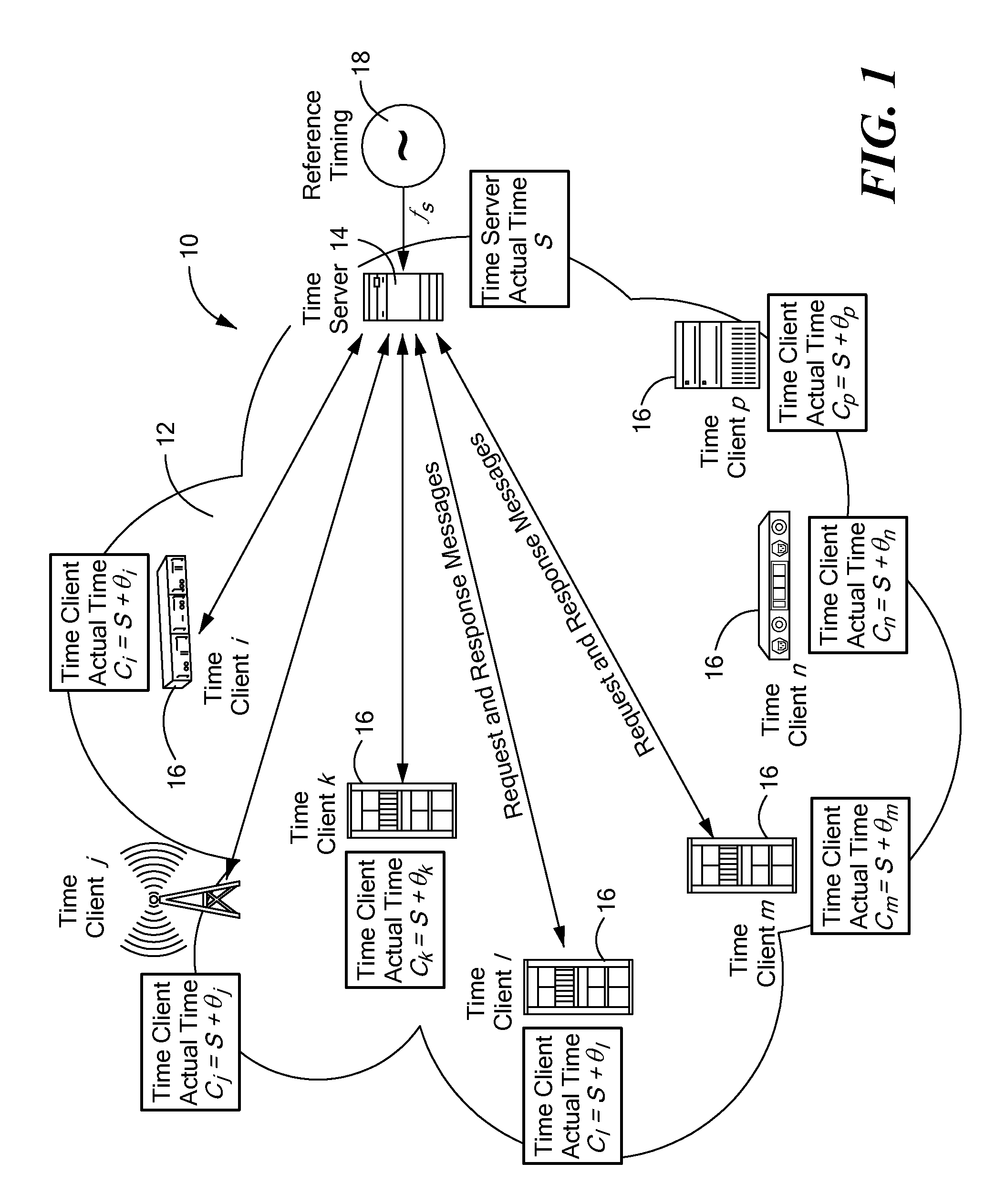

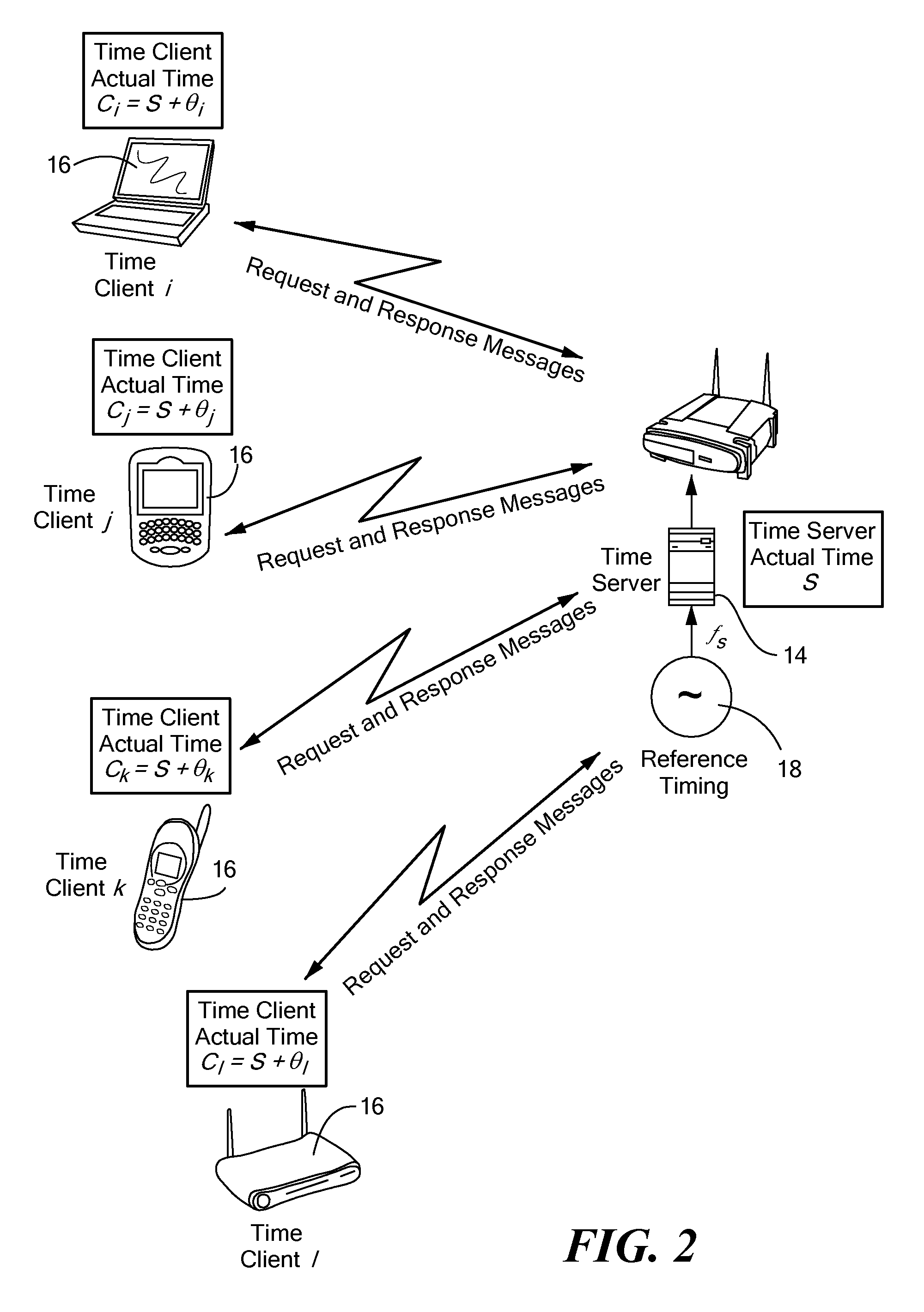

Method and apparatus for time and frequency transfer in communication networks

A timing system for time synchronization between a time server and a time client over a packet network. The timing system includes a time server for generating current timestamp information and a time client having a phase-locked loop driven client clock counter. The time client periodically exchanges time transfer protocol messages with the time server over the packet network, and calculates an estimated client time based on the timestamp information. The phase-locked loop in the time client receives periodic signals representing the estimated server time as its input and calculates a signal which represents the error difference between the estimated server time and the time indicated by the time client clock counter. The error difference eventually converges to zero or a given error range indicating the time presented by the client clock counter, which is driven by the phase-locked loop having locked onto the time of the time server.

Owner:RPX CLEARINGHOUSE +1

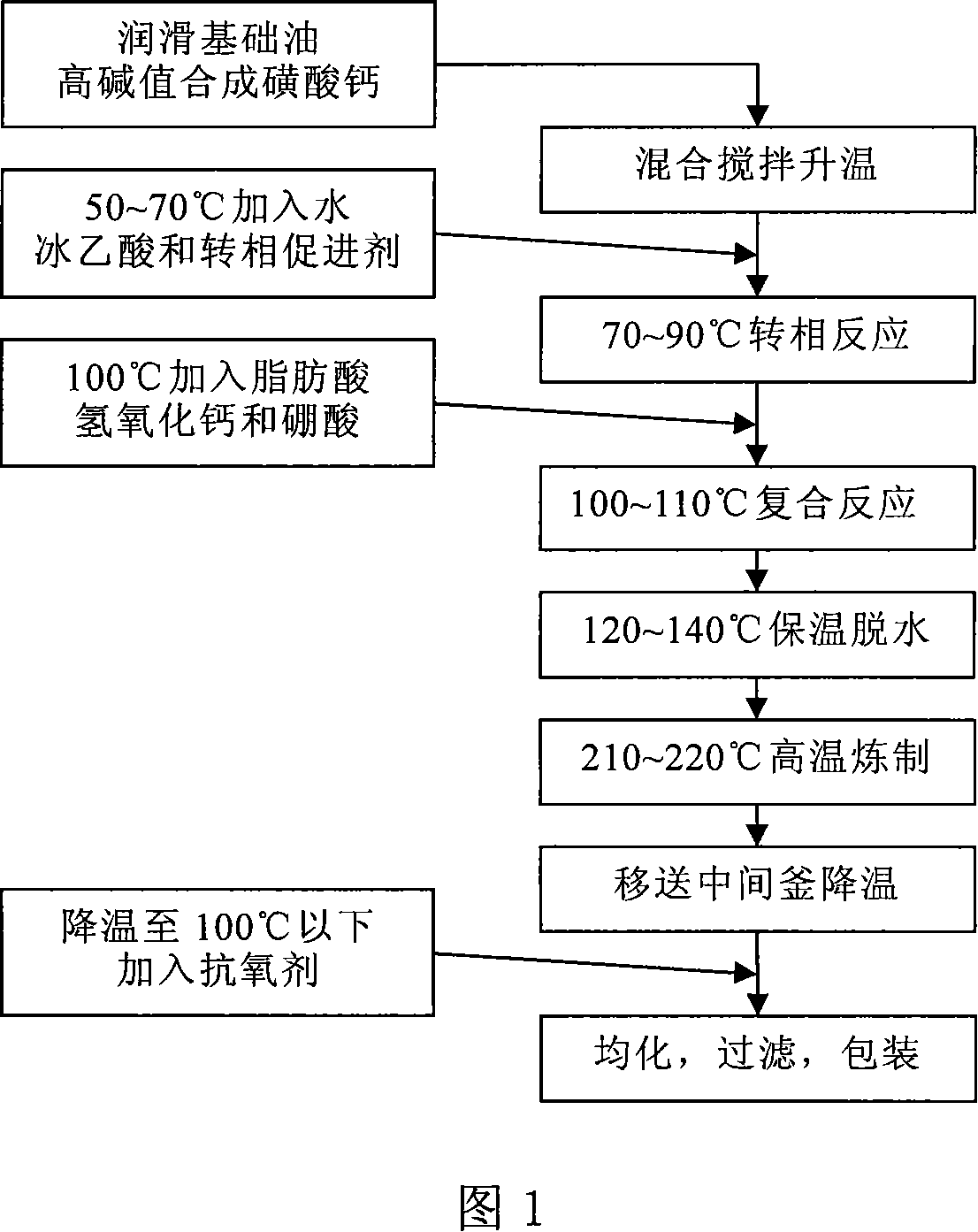

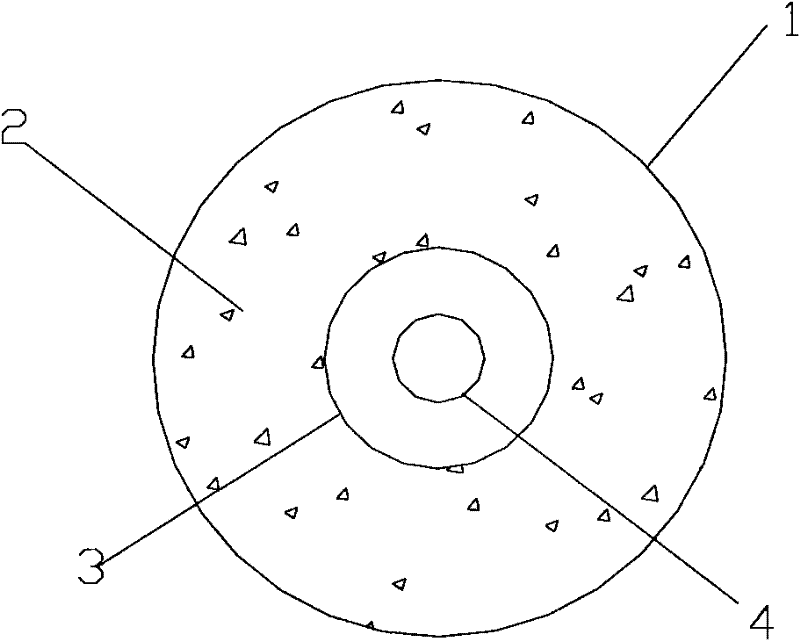

Compound sulphonic acid albany grease and method for producing the same

ActiveCN101153239AImprove performanceImprove water resistanceLubricant compositionAntioxidantManufacturing enterprises

The invention relates to calcium sulfonate complex grease and a manufacture method thereof, in particular to grease producing the thickening agent by synthetic reaction with super-high base value. At first, the lubricating base oil and the calcium sulfonate are added into an opening reaction kettle to be stirred, the phase inversion promoter, the glacial acetic acid and the water are added into the kettle to boost the temperature to make the insulating reaction until the materials are thickened, then the calcium hydroxide, the aliphatic acid and the boric acid are added into make an insulating reaction, a temperature rise, an insulating dehydration and a refining in turn, then the materials are moved into an intermediate kettle, the antioxidant is added to disperse and homogenize, and the finished product is produced after the filtering. The invention has excellent anti-spray performance, excellent high temperature performance, good extreme pressure anti-abrasion performance, prominent anti-shear performance, good pumping performance, anti-rust performance and water adding shear stability; has apparent phase inversion effect and good product performance, decreases the grease exchange times under the same working condition and increases the service life of the equipment, which is proved by the trial applications of a plurality of appliance manufacture enterprises, steel works, paper mills and so on.

Owner:无锡中石油润滑脂有限责任公司

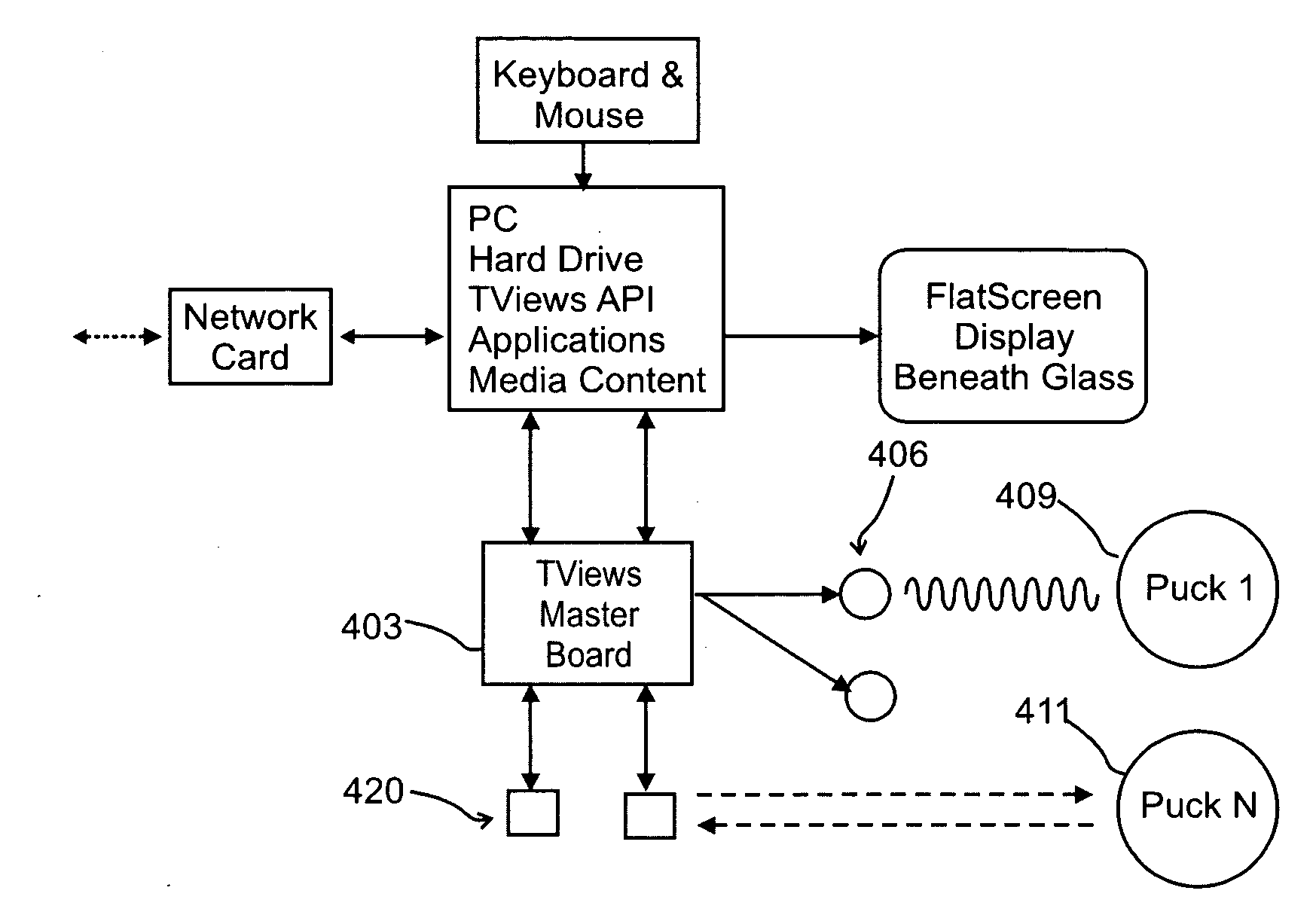

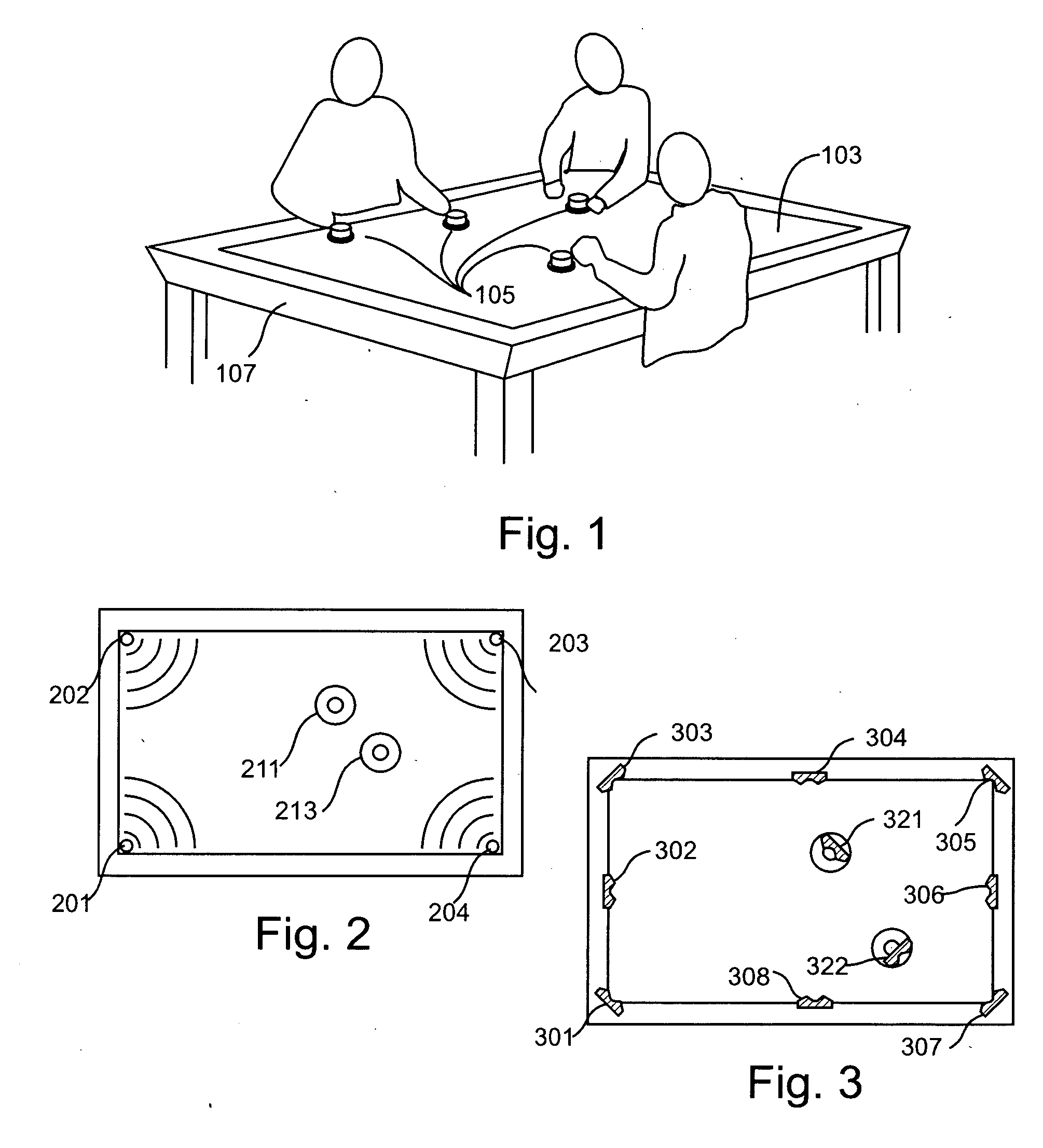

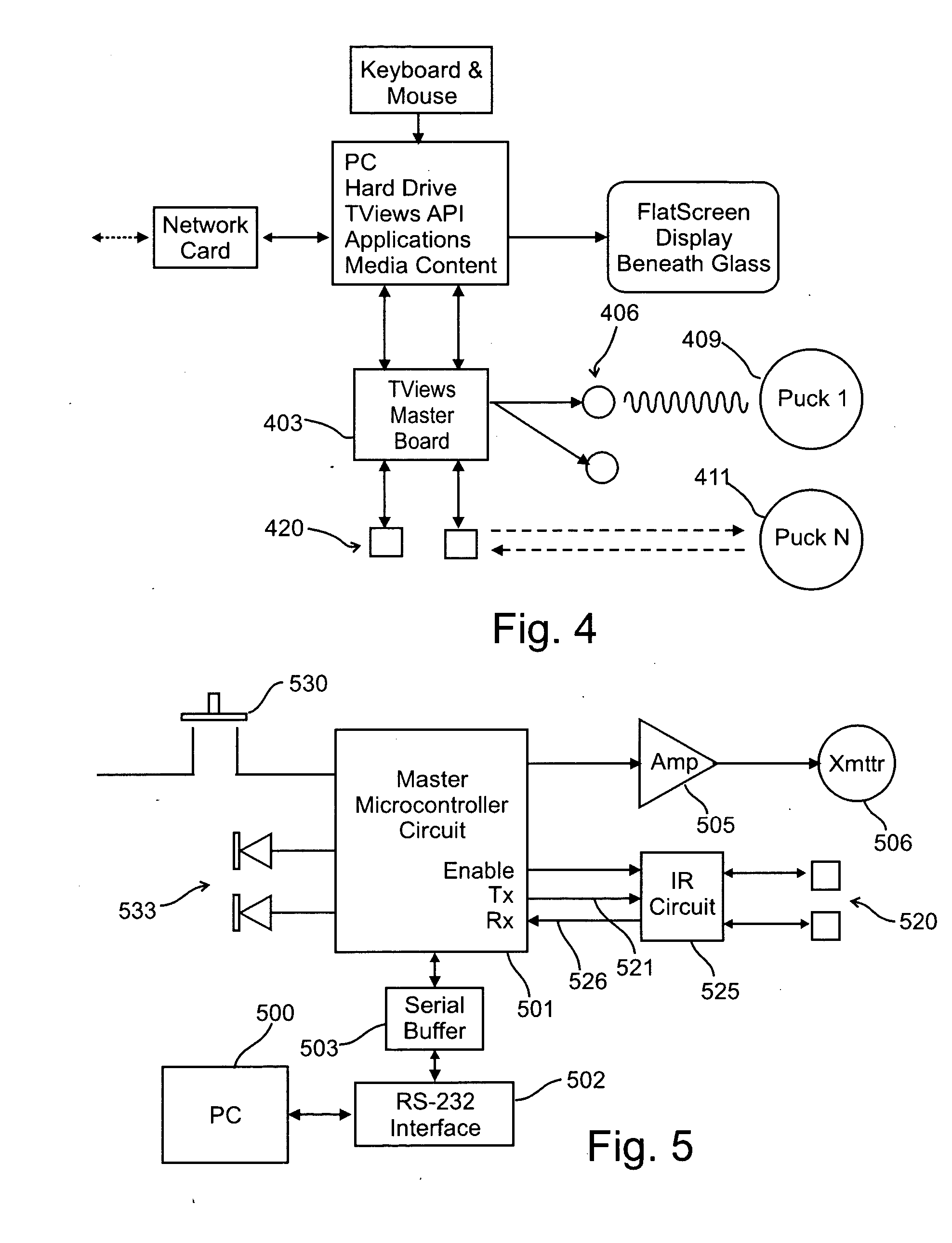

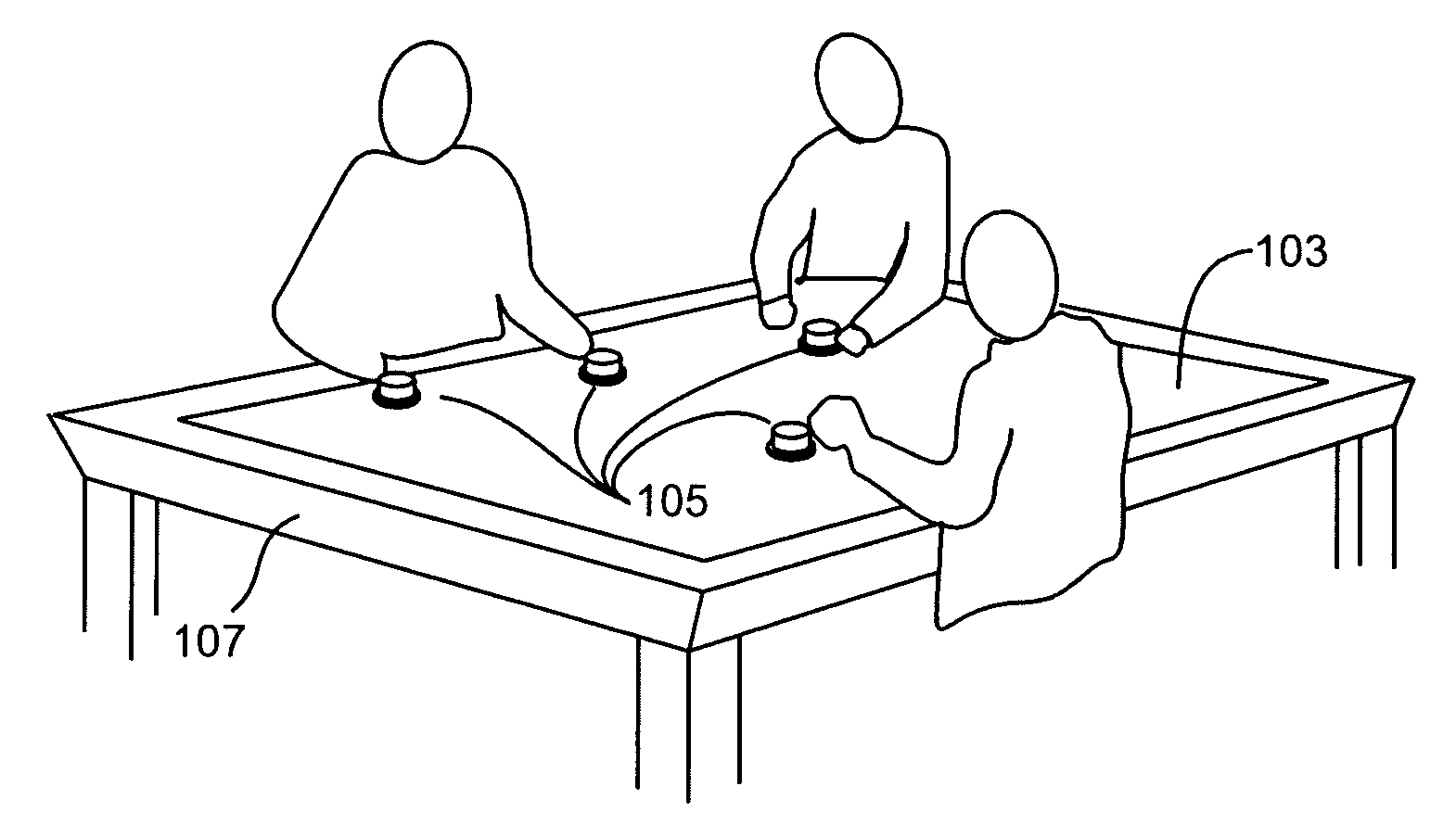

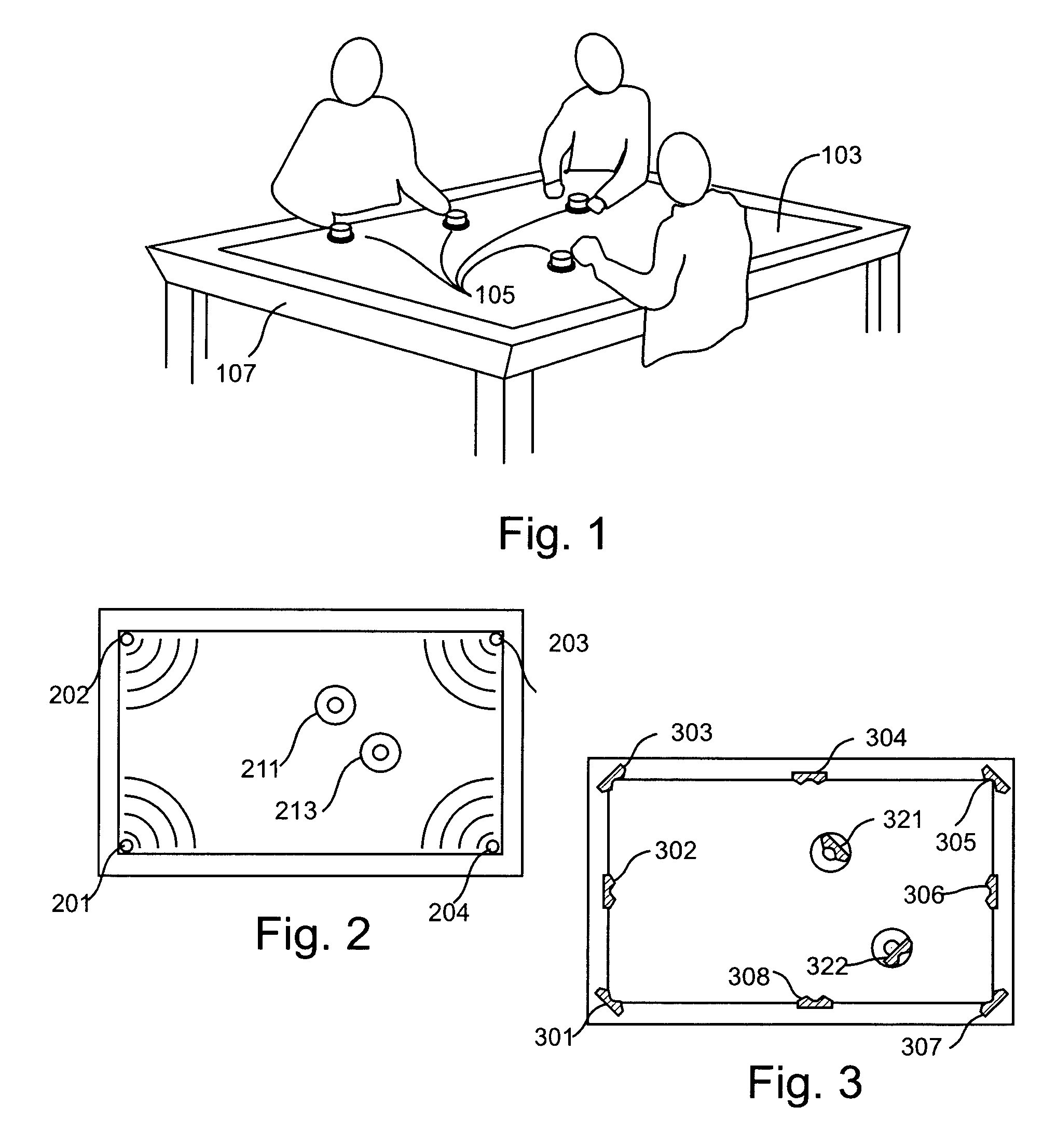

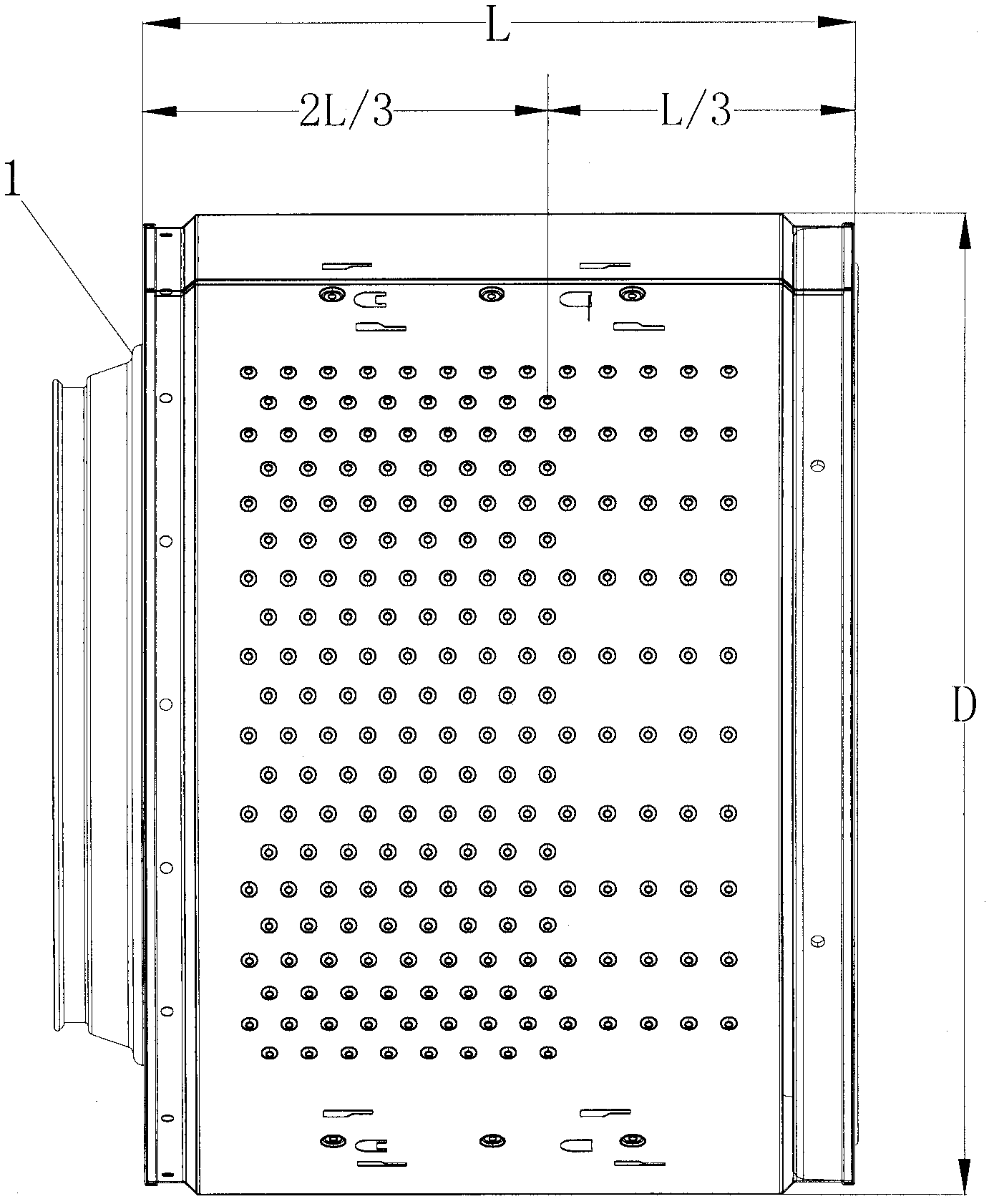

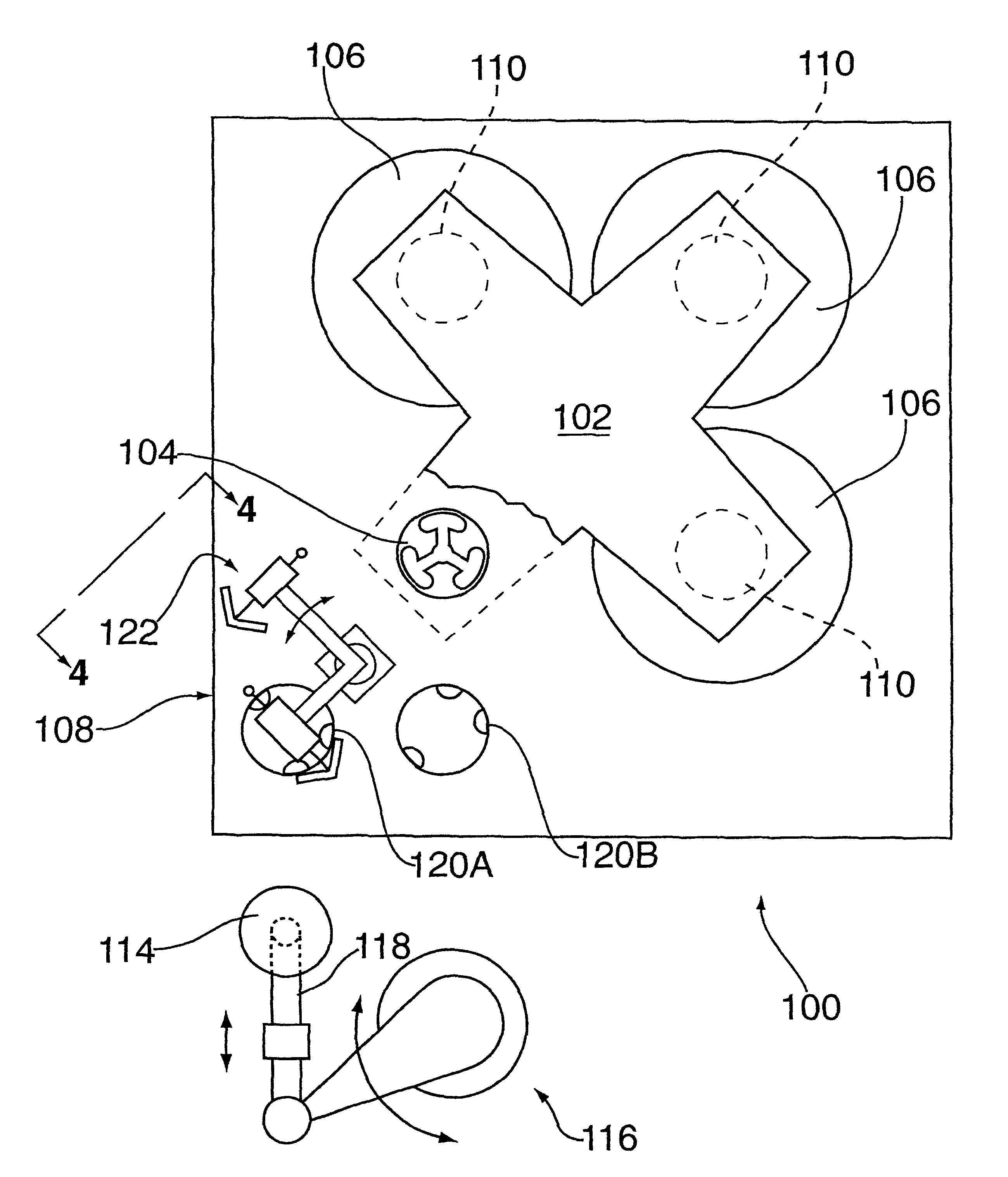

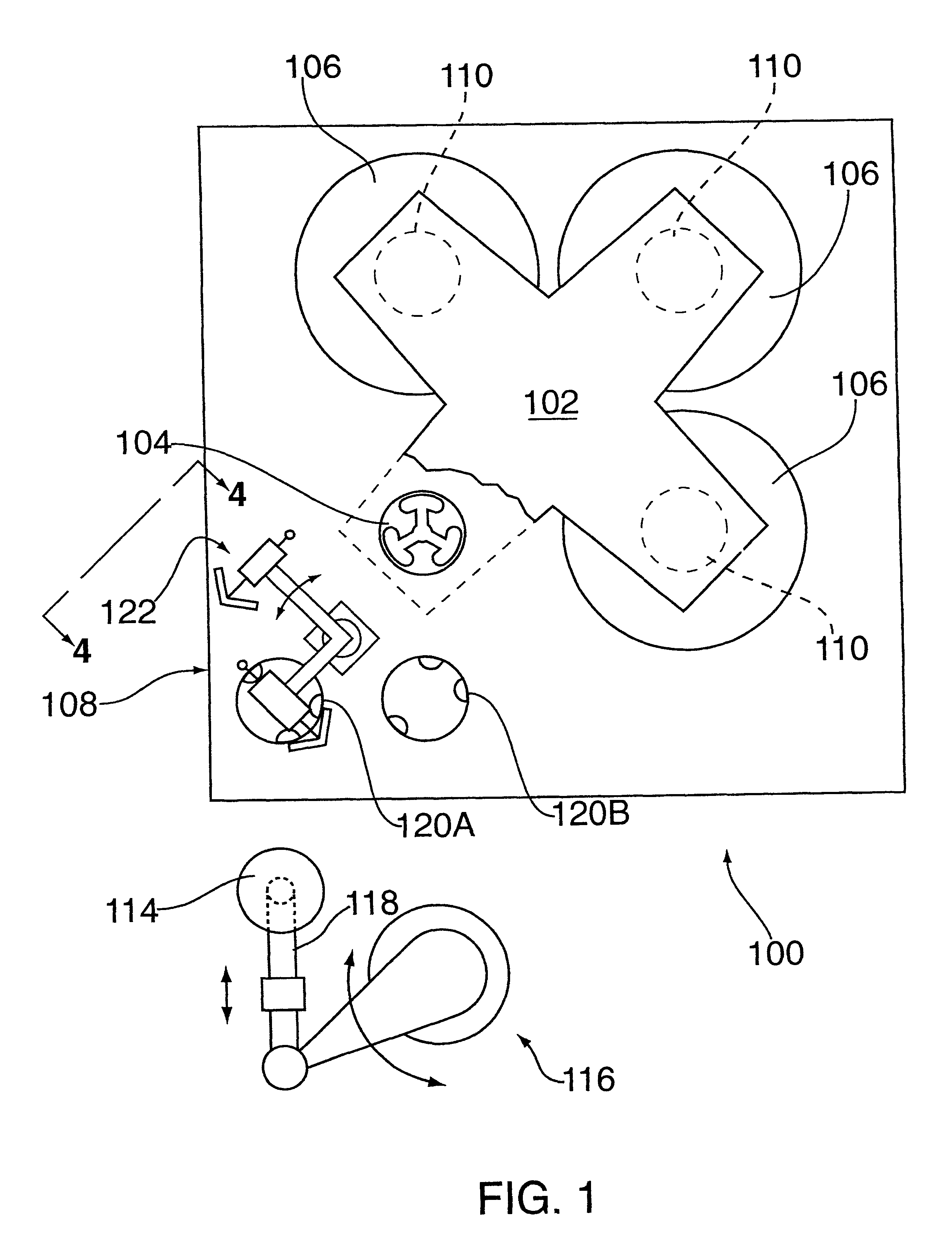

Method for object identification and sensing in a bounded interaction space

ActiveUS20060149495A1Avoid interferenceEasy to moveDigital computer detailsSpeed measurement using gyroscopic effectsData controlTriangulation

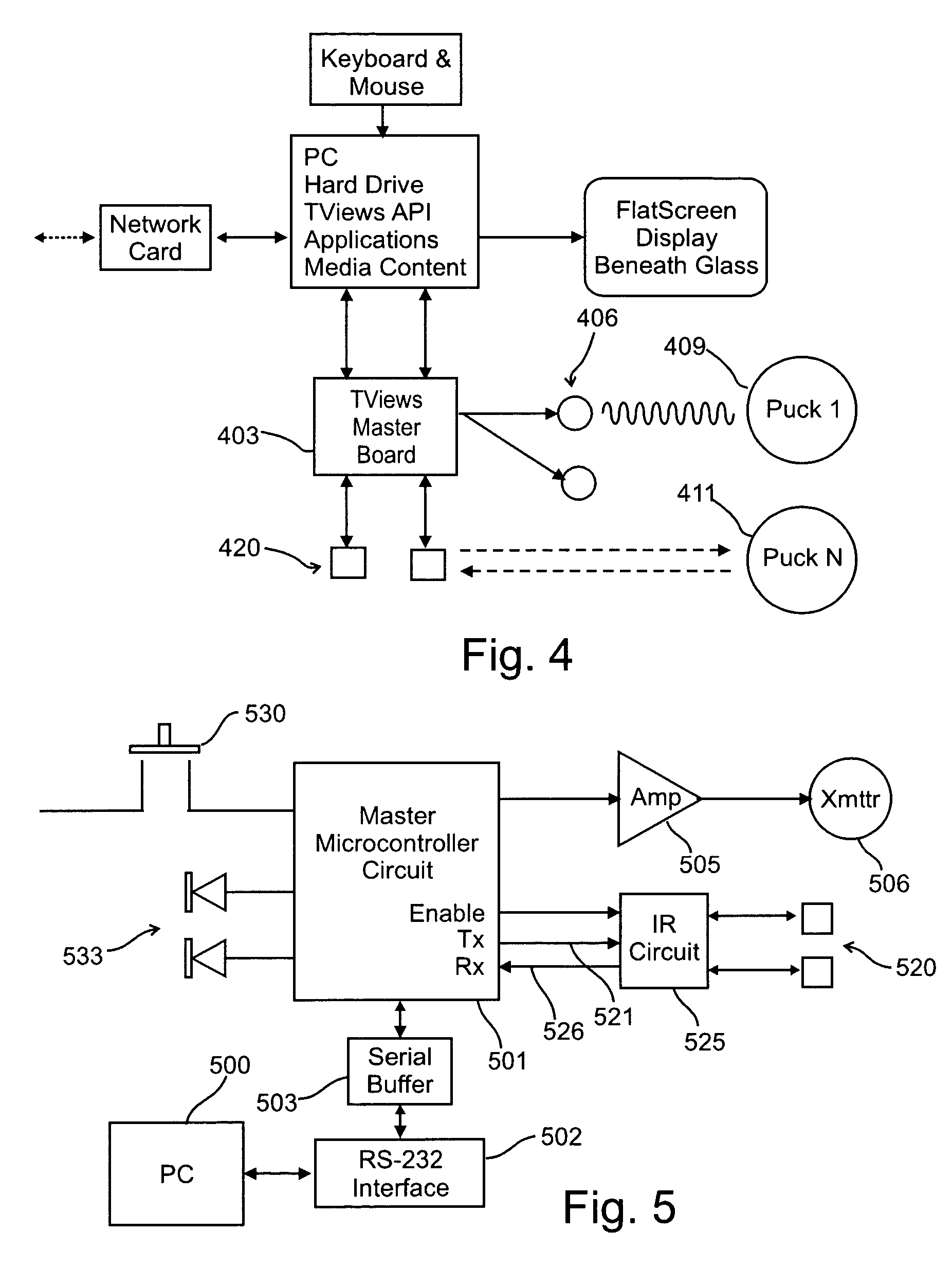

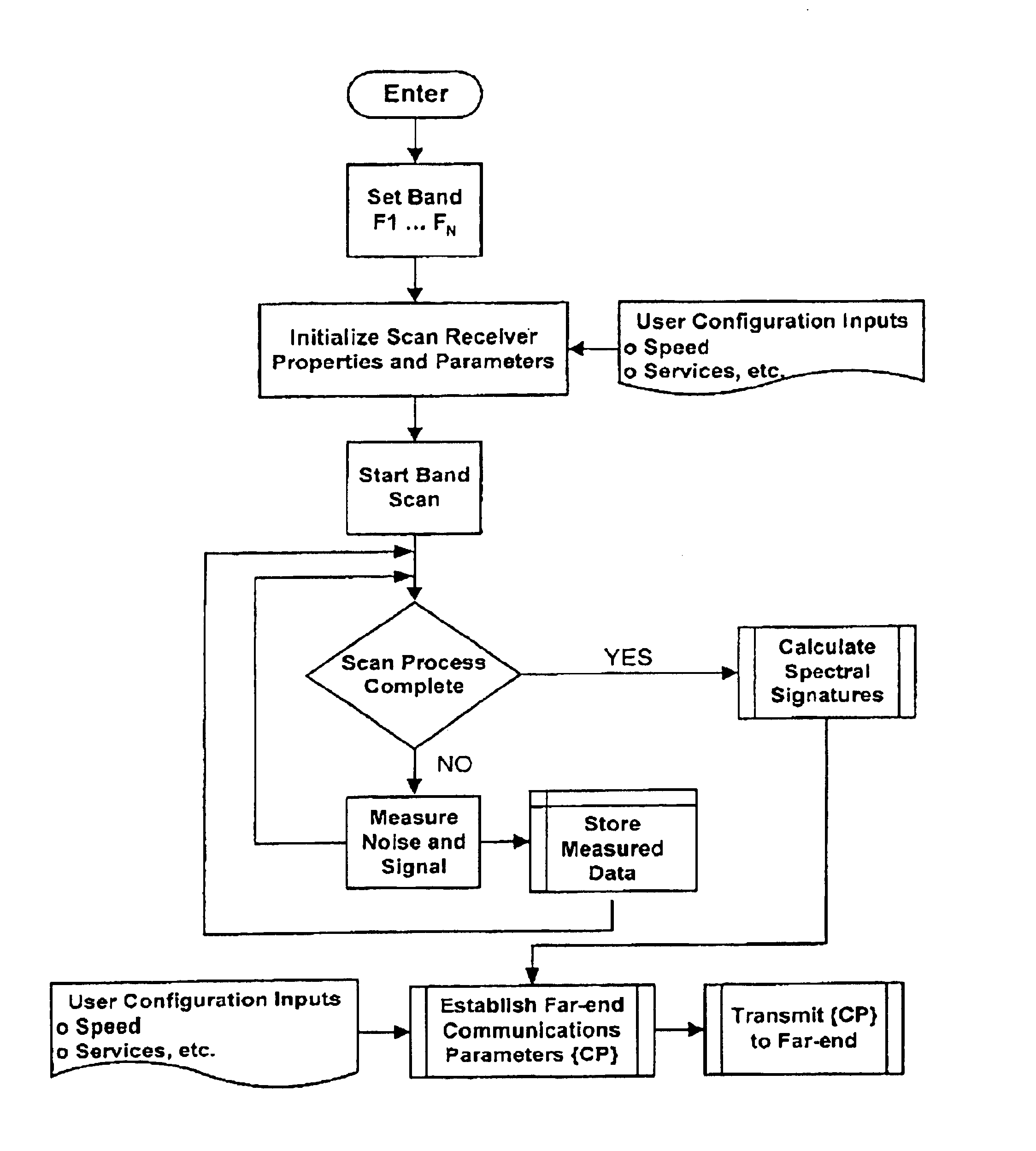

An interactive media table that includes a tabletop that supports of plurality of movable objects each of which is identified by a unique identification code and each of which can be moved from place to place on said tabletop surface by one or more media table users. A display unit produces a visual image on the surface of the tabletop surface and a position tracking system determines the current positions of each of said movable objects by transmitting timed acoustic signals to each movable object, sensing the timing of arrival of these signals using an acoustic pickup on each object, and estimating the location of the object by triangulation. An infrared communications network exchanges timing information, commands and data between the objects and a controller which provides an API to a personal computer which executes an application program that controls the display.

Owner:MASSACHUSETTS INST OF TECH

Method for object identification and sensing in a bounded interaction space

ActiveUS7474983B2Avoid interferenceEasy to moveDigital computer detailsSpeed measurement using gyroscopic effectsTriangulationComputer graphics (images)

An interactive media table that includes a tabletop that supports of plurality of movable objects each of which is identified by a unique identification code and each of which can be moved from place to place on said tabletop surface by one or more media table users. A display unit produces a visual image on the surface of the tabletop surface and a position tracking system determines the current positions of each of said movable objects by transmitting timed acoustic signals to each movable object, sensing the timing of arrival of these signals using an acoustic pickup on each object, and estimating the location of the object by triangulation. An infrared communications network exchanges timing information, commands and data between the objects and a controller which provides an API to a personal computer which executes an application program that controls the display.

Owner:MASSACHUSETTS INST OF TECH

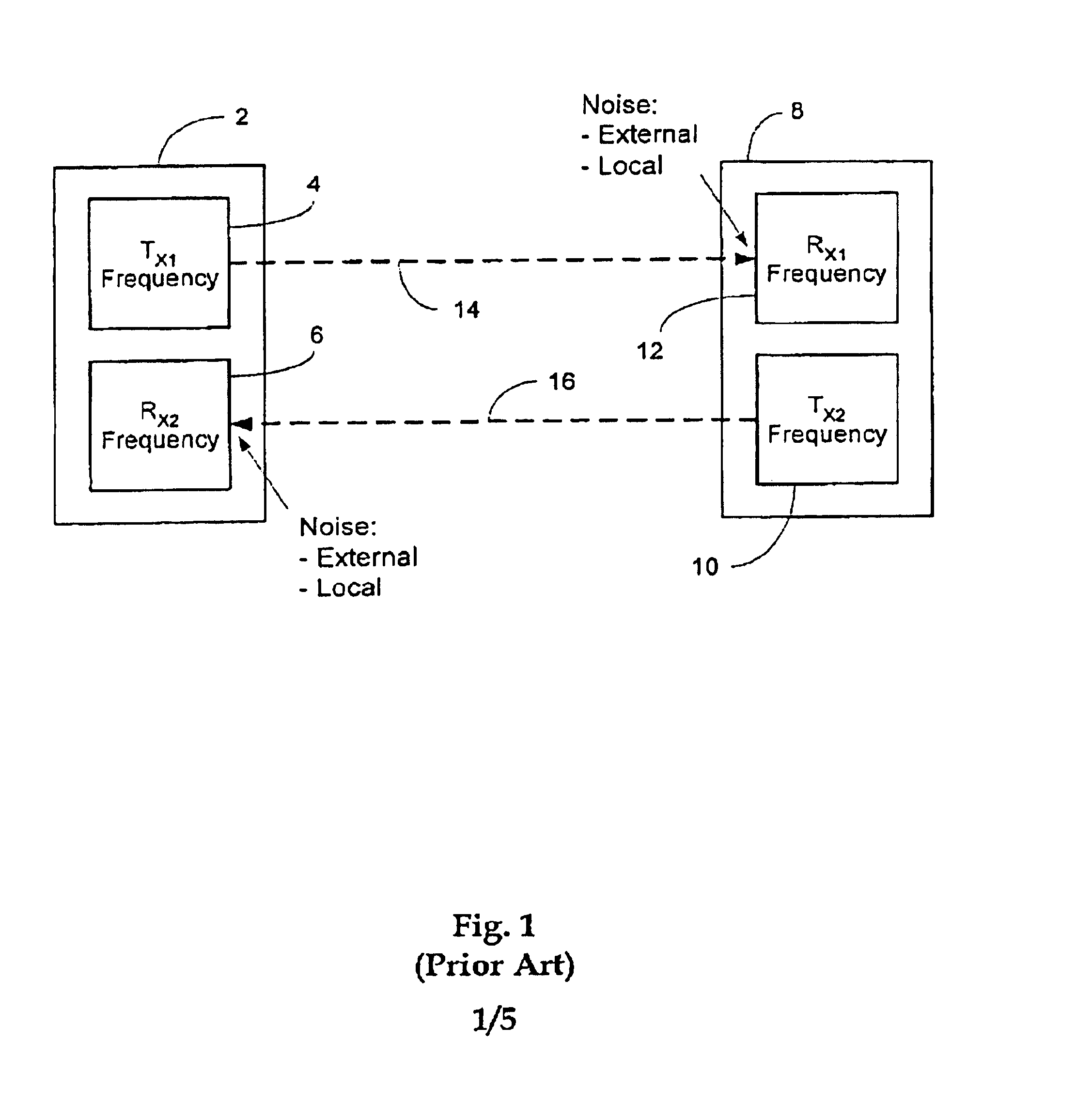

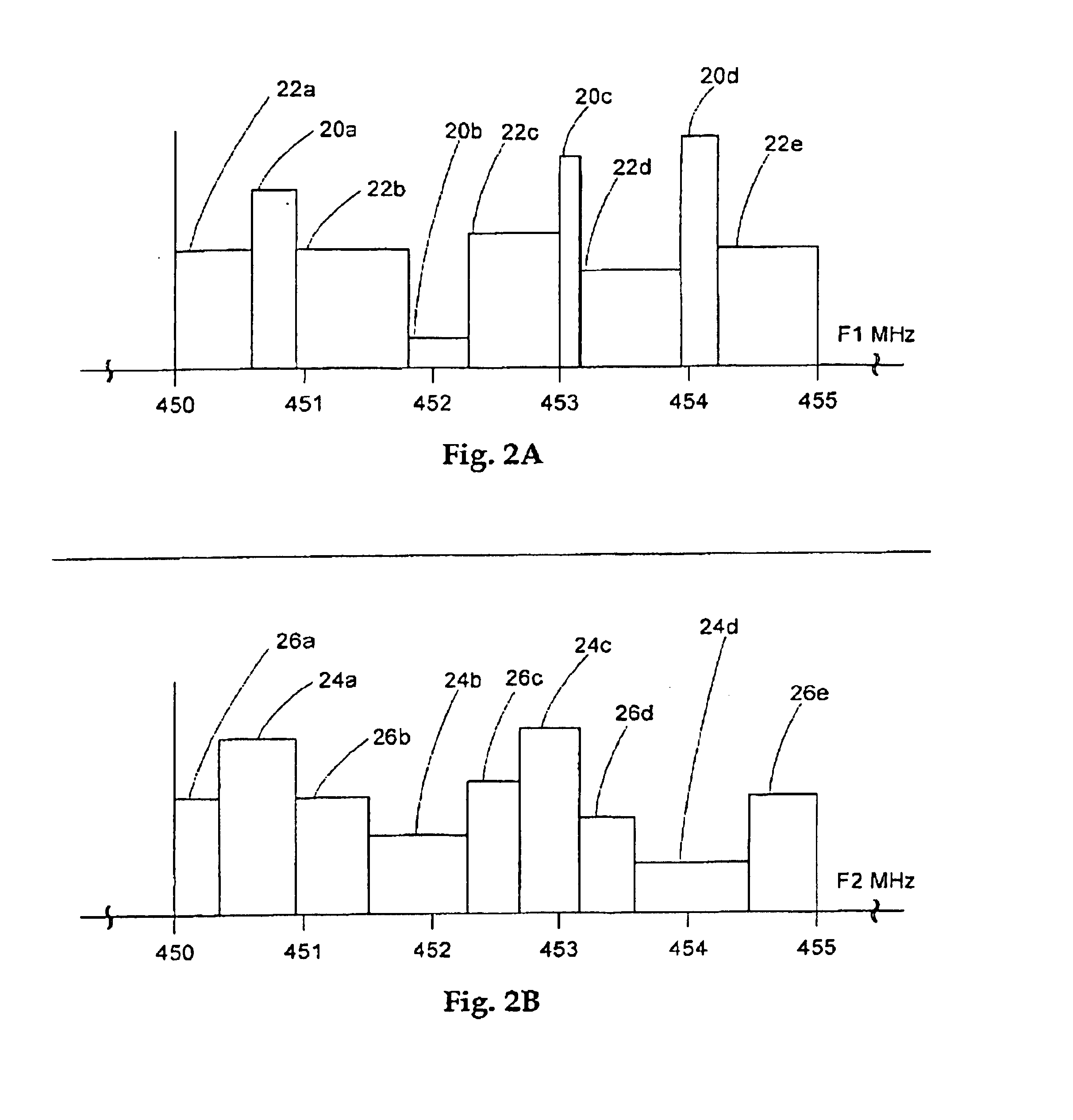

Method and apparatus for adaptively setting frequency channels in a multi-point wireless networking system

InactiveUS6952563B2Radio/inductive link selection arrangementsTransmission monitoringTelecommunicationsNetworked system

In a wireless network with point-to-point, multi-point or broadcast communications links, a method is provided for adaptively setting frequency channels for wireless devices within the network by dynamically exchanging time-varying spectral maps and communication parameters to utilize available frequency channels efficiently.

Owner:METRIC SYST

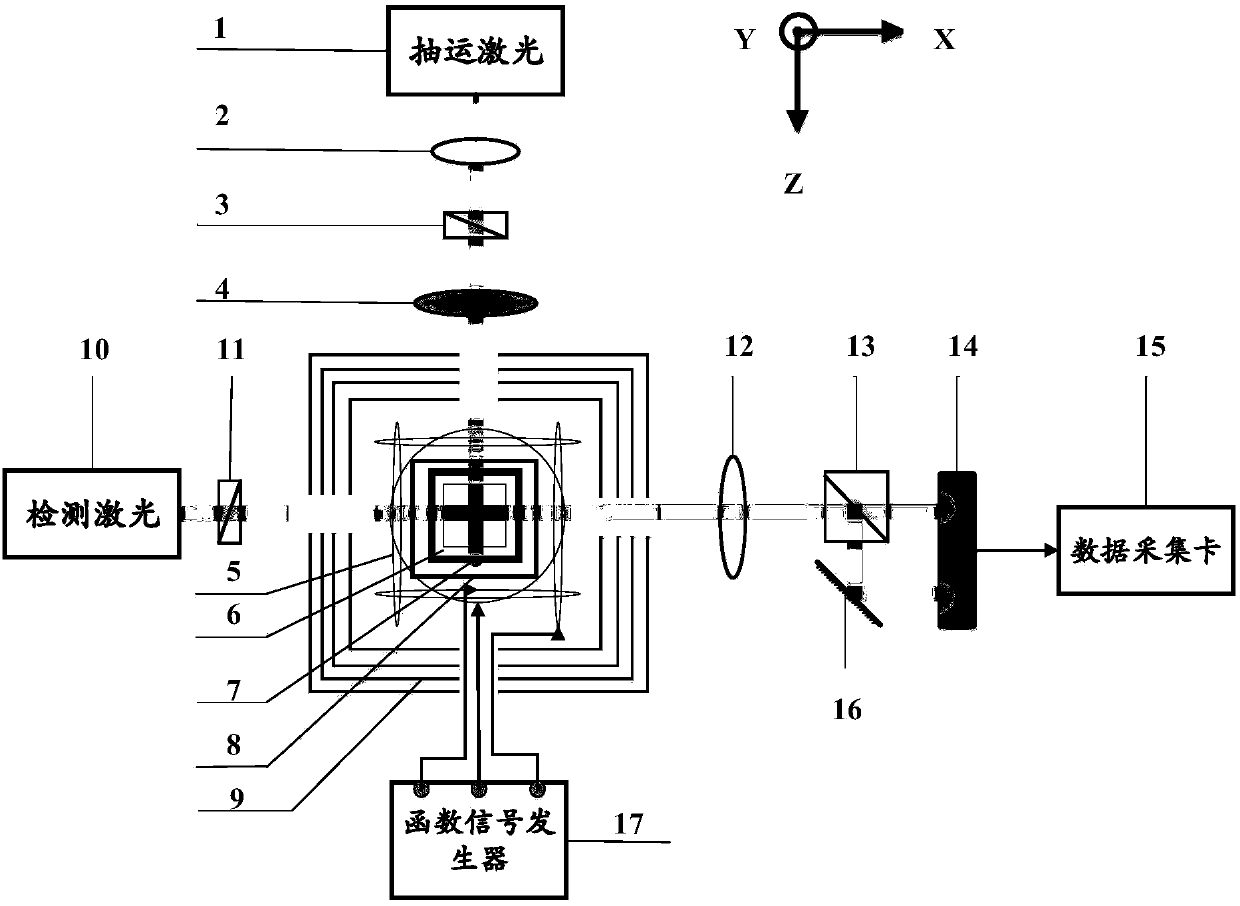

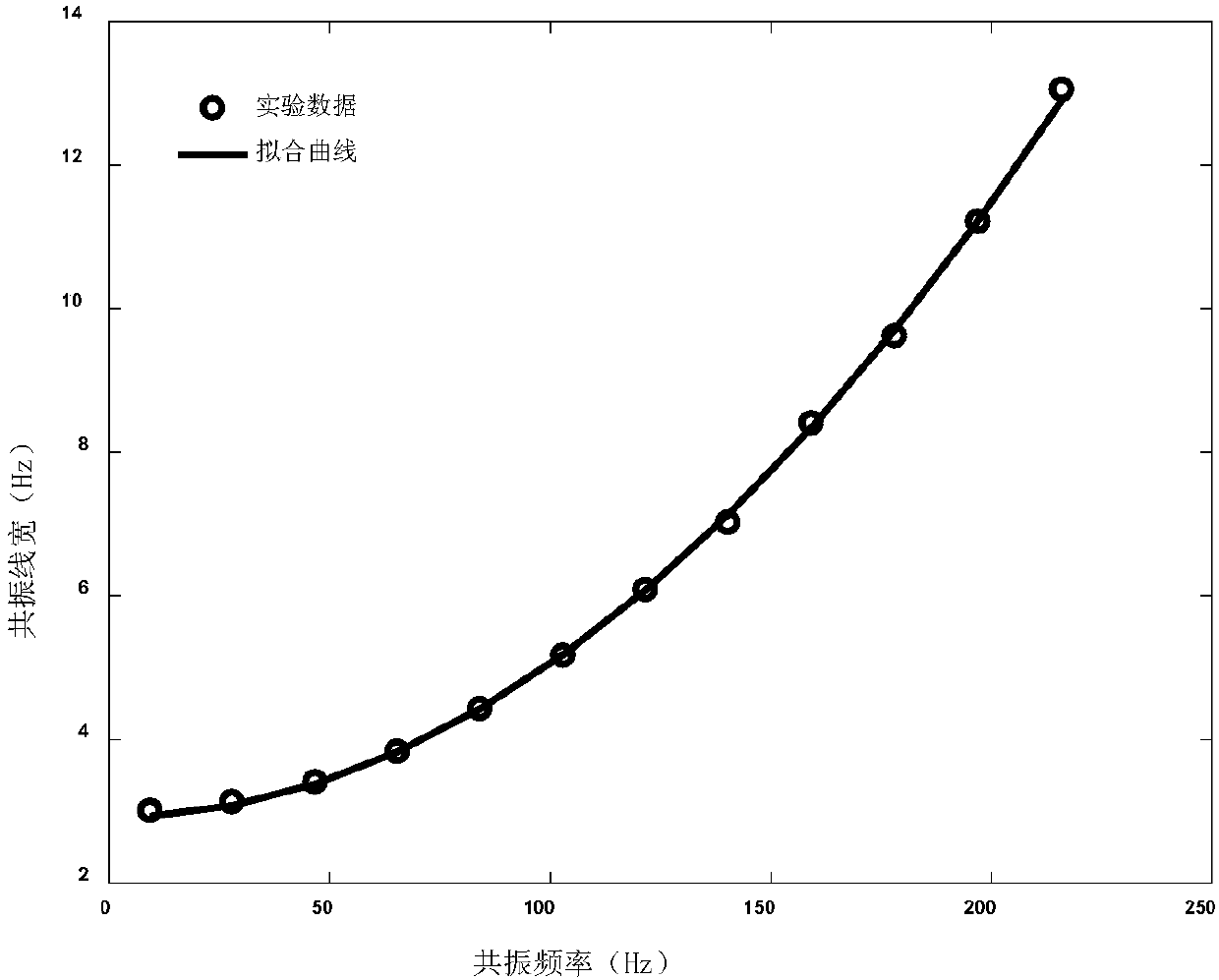

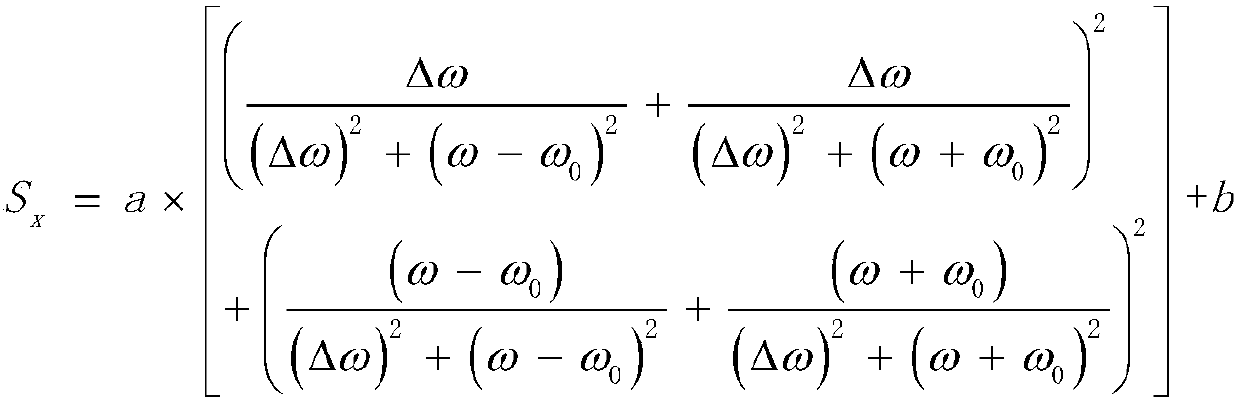

Method used for on-line measurement of density of alkali metal in atom magnetometer air chambers at SERF (spin-exchange relaxation free) states

InactiveCN107192633ARealize online density measurementRealize online measurementSpecific gravity measurementCurve fittingResonance line

The invention discloses a method used for on-line measurement of density of alkali metal in atom magnetometer air chambers at SERF (spin-exchange relaxation free) states. According to the method, an atom magnetometer is provided with a weak background magnetic field and low frequency stage horizontal linear frequency modulated signals, a data collecting card is used for collecting response signals of the atom magnetometer in frequency sweep time; fast Fourier transform is adopted so as to obtain a magnetic resonance curve in a frequency domain, the resonance line width and the resonant frequency of the magnetic resonance curve are obtained via calculation; the background magnetic field is changed so as to obtain a plurality of resonance line widths and resonant frequencies, quadratic curve fitting of the resonance line widths and the resonant frequencies is carried out so as to obtain spin exchange time; and at last the density of alkali metal in atom magnetometer air chambers at the current temperature can be obtained via calculation. The method can be performed at maintained SERF states, on-line measurement of the density of alkali metal in the air chambers can be realized only using the SERF magnetometer; excellent frequency resolution ratio of linear frequency signals can be achieved at low frequency range (1kHz or lower); and the method is suitable for low frequency scanning range required by SERF magnetometer weak magnetic field.

Owner:BEIHANG UNIV

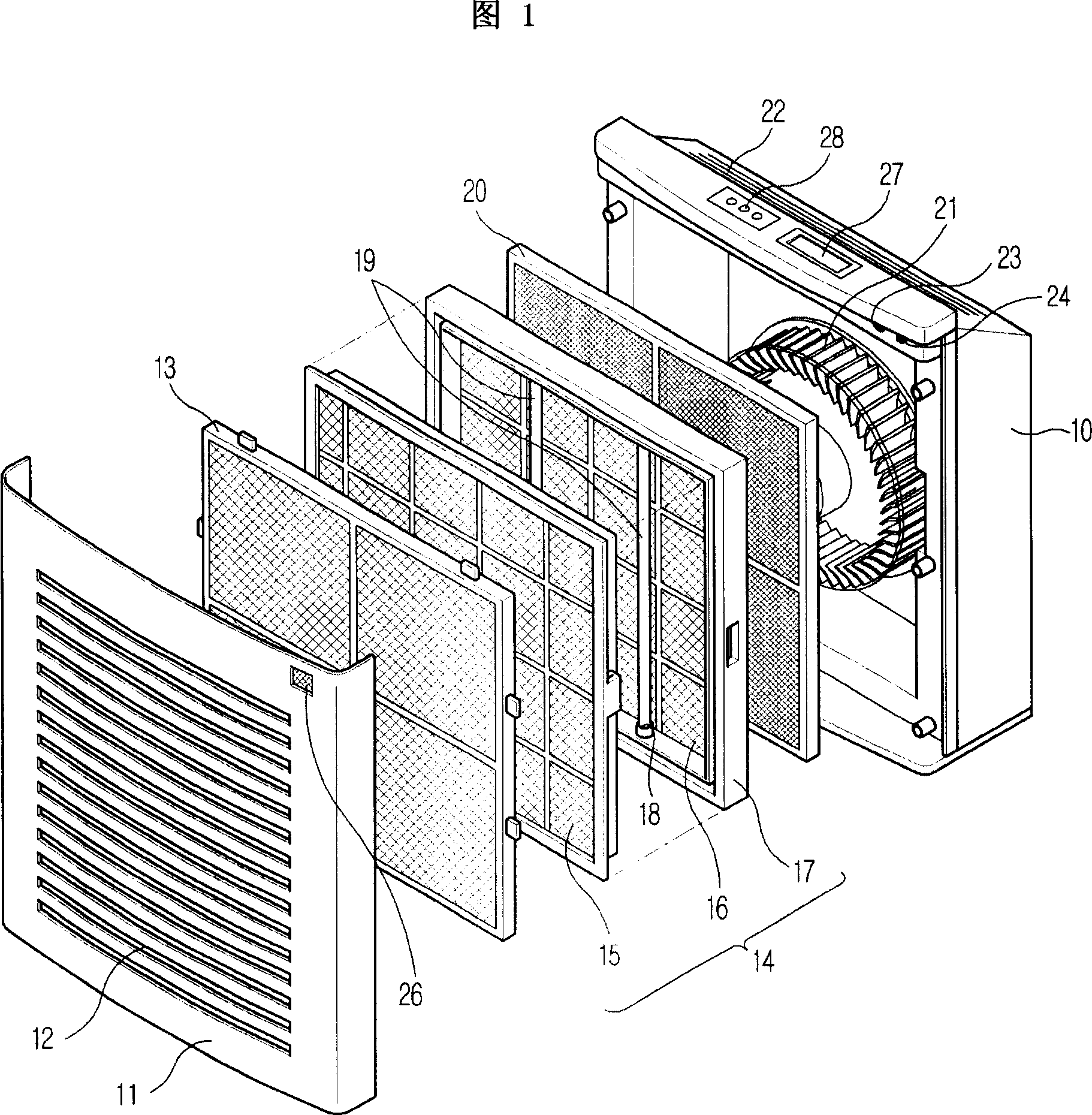

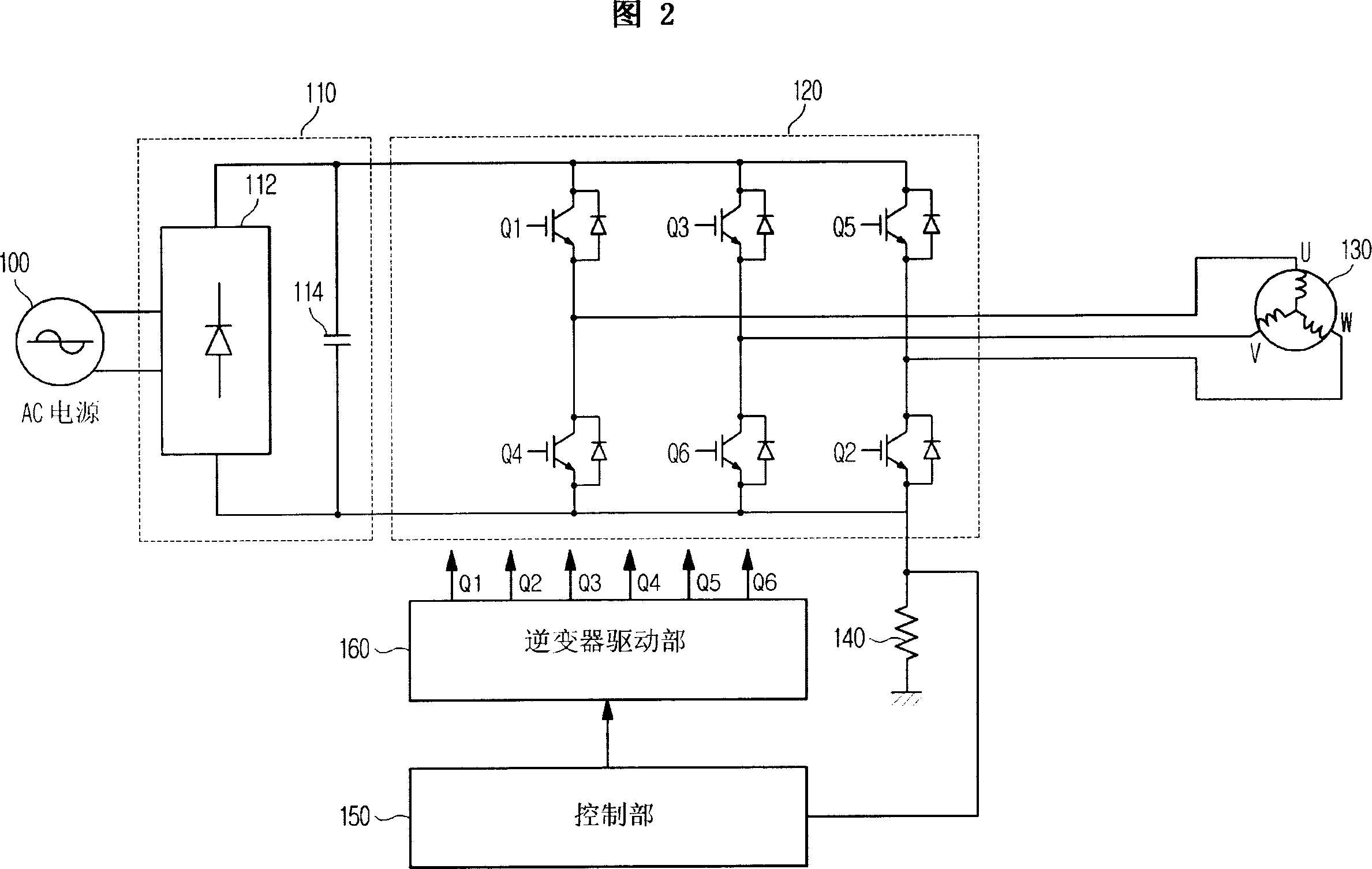

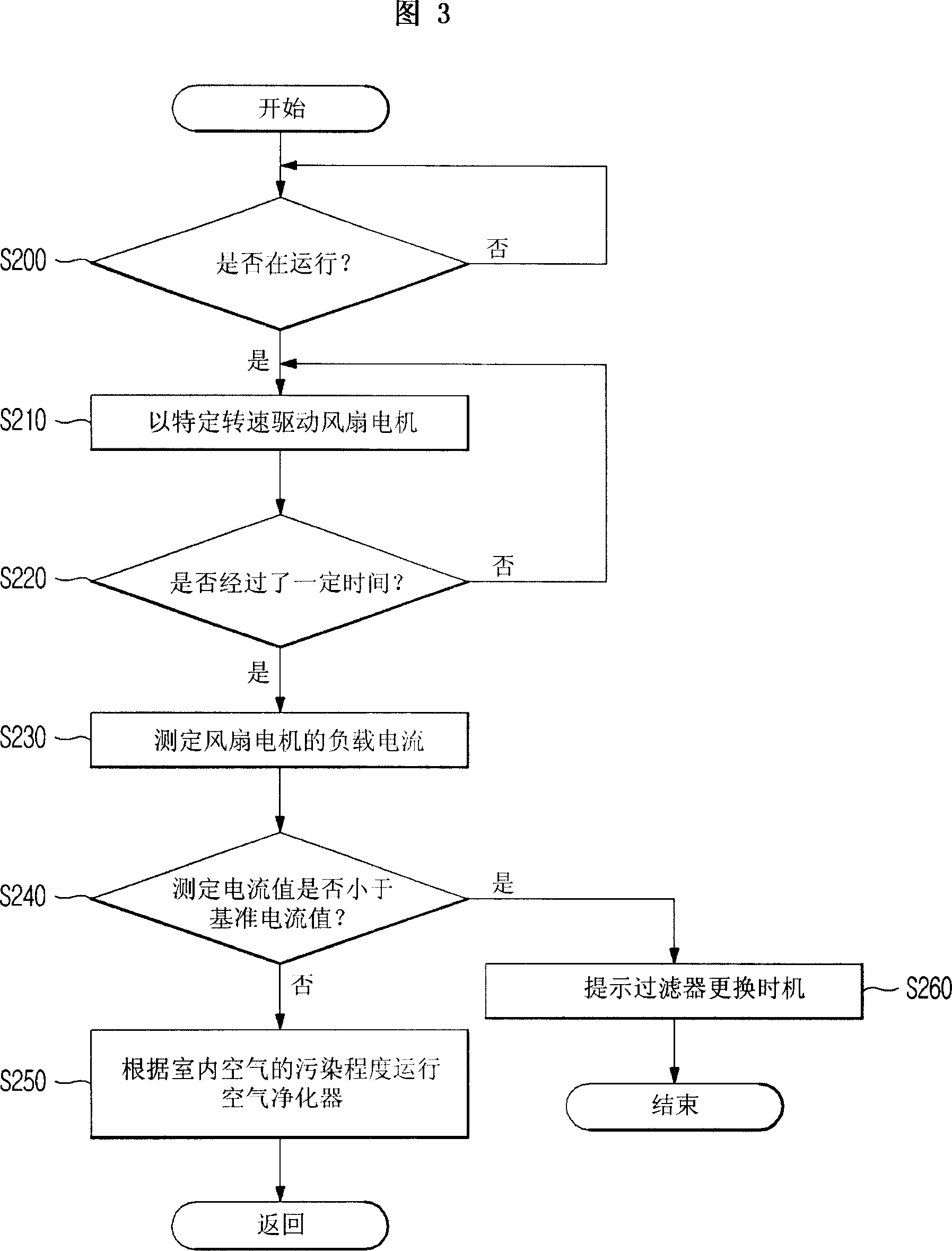

Filter replacing time prompt device for air purifier and its method

InactiveCN1994522ADispersed particle filtrationLighting and heating apparatusReference currentAir purifiers

The present invention relates to an apparatus for displaying filter exchange time of air cleaner and method thereof, the invention is to estimate practice degree of dust accumulated on the filter according to load state of fan motor, thereby more accurate filter exchange time is achieved. Therefore, the invention provides an apparatus for displaying filter exchange time of air cleaner, the air cleaner has a filter for eliminating dust and peculiar smell in the air, and a fan motor for driving air through said filter, the displaying device comprises a current monitor unit for measuring load current through the said fan motor; a control unit for comparing measured current value and predetermined reference current value, when the measured current value is less than reference current value, control signal for displaying said filter exchange time is output.

Owner:SAMSUNG ELECTRONICS CO LTD

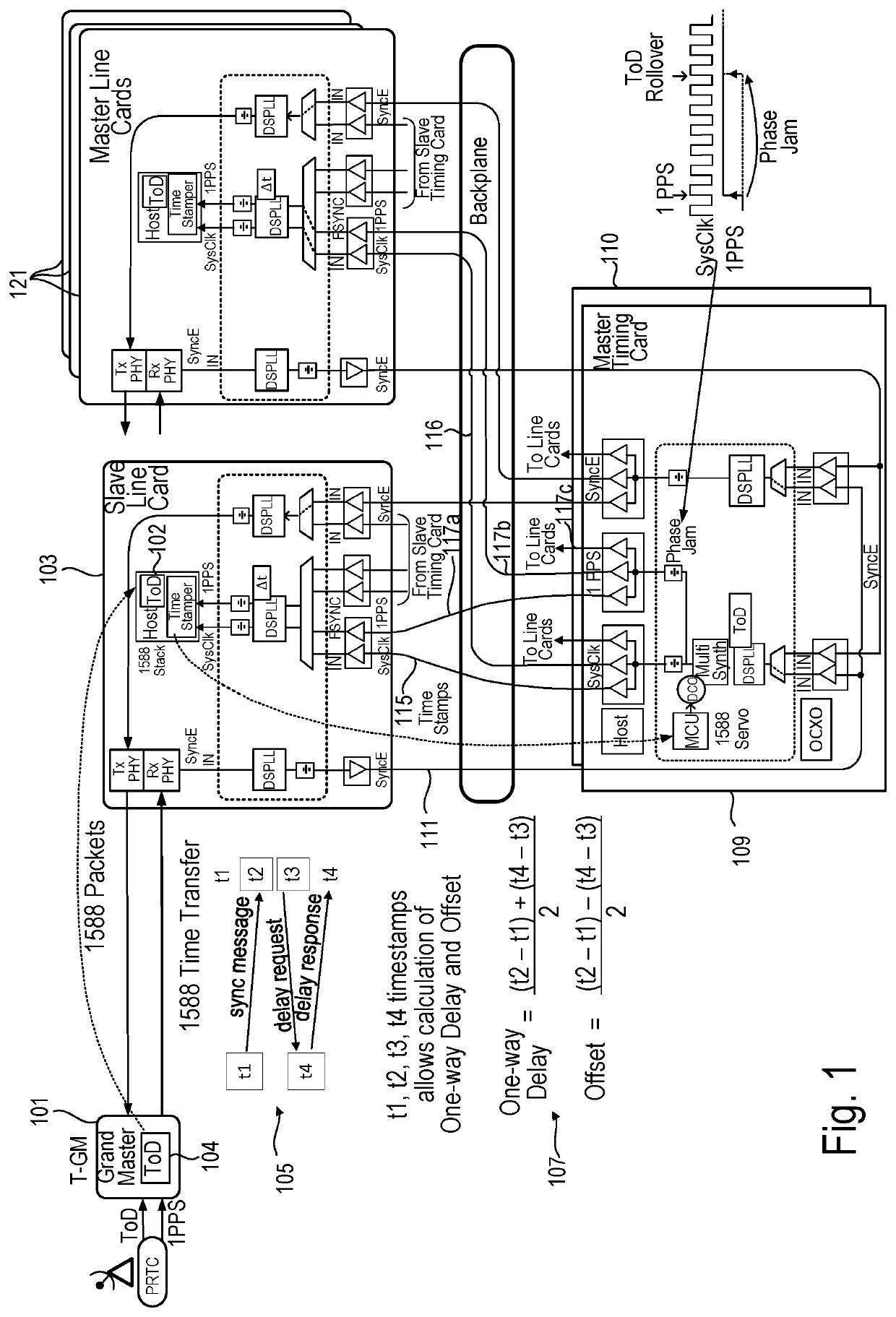

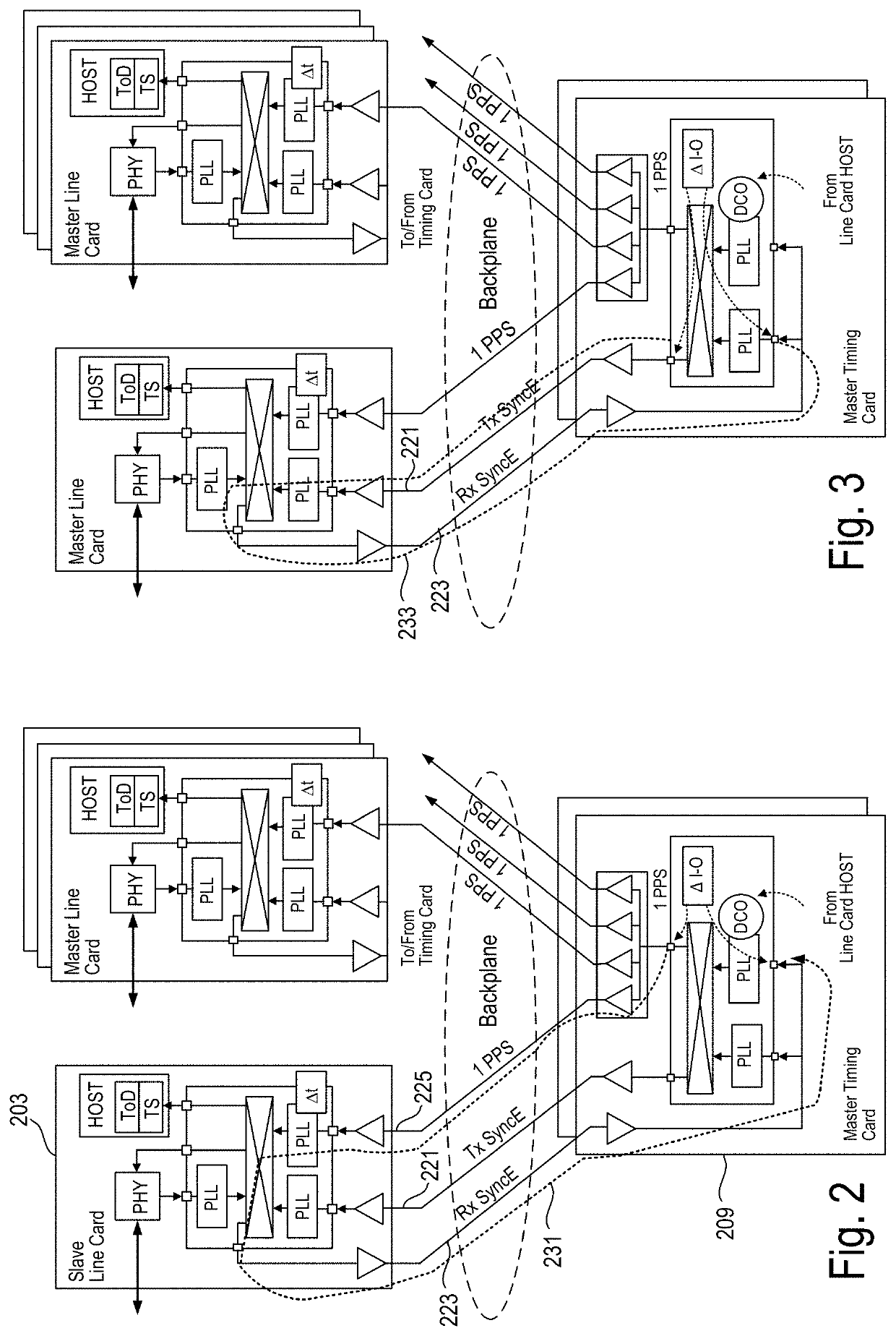

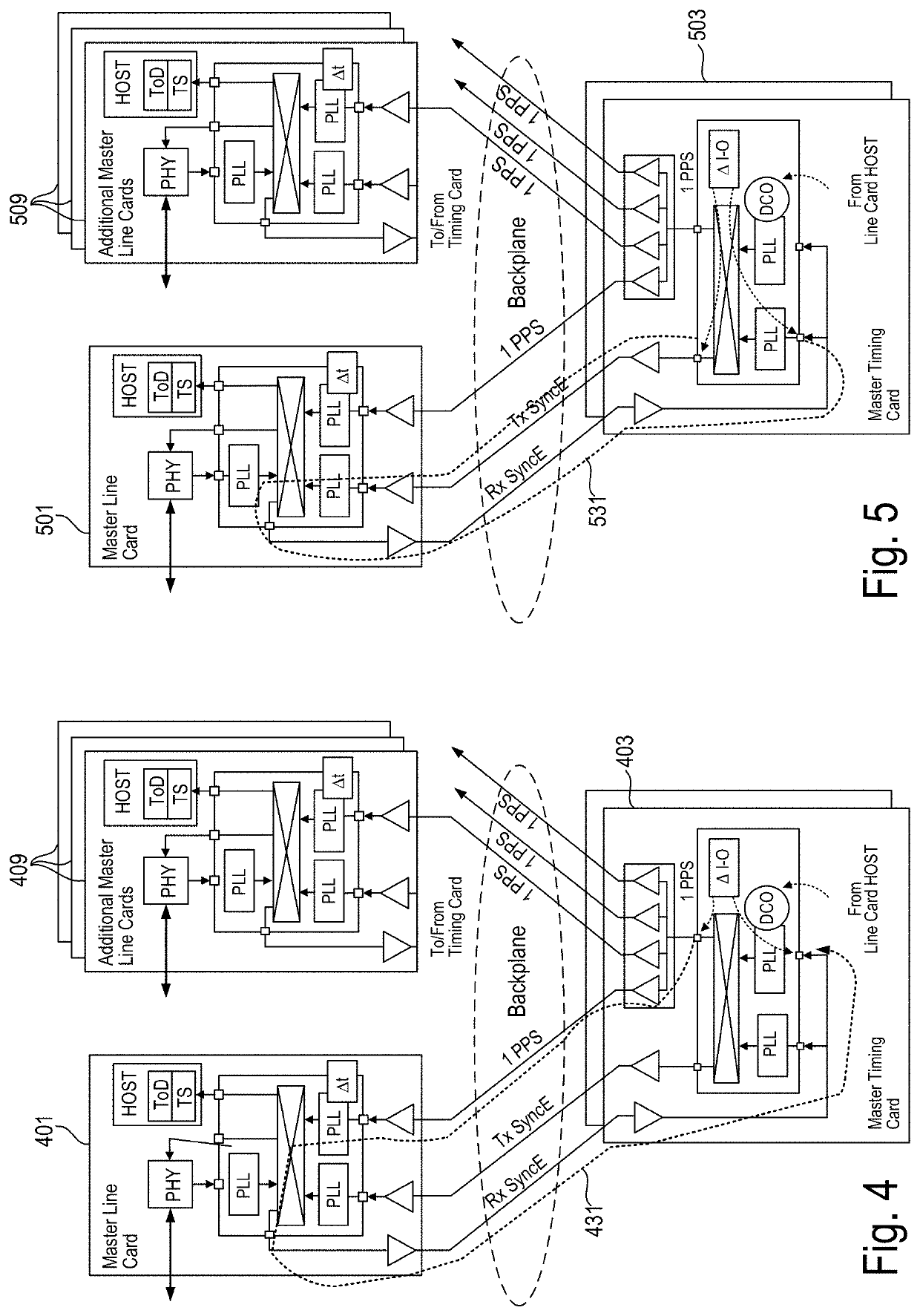

Synchronizing Update of Time of Day Counters Using Time Stamp Exchange Over A Control Plane

A control plane, available to all of the line cards in a system, is used to exchange time stamps to align the Time of Day counters in the master line cards. The master line cards are locked to a system clock distributed over the backplane by a timing card. The timing card is locked to timing of a slave line card that is synchronized with the grand master. Each master line card synchronizes updating its Time of Day counter based on a time stamp exchange and a local clock locked to the system clock and without the use of a 1 pulse per second signal.

Owner:SKYWORKS SOLUTIONS INC

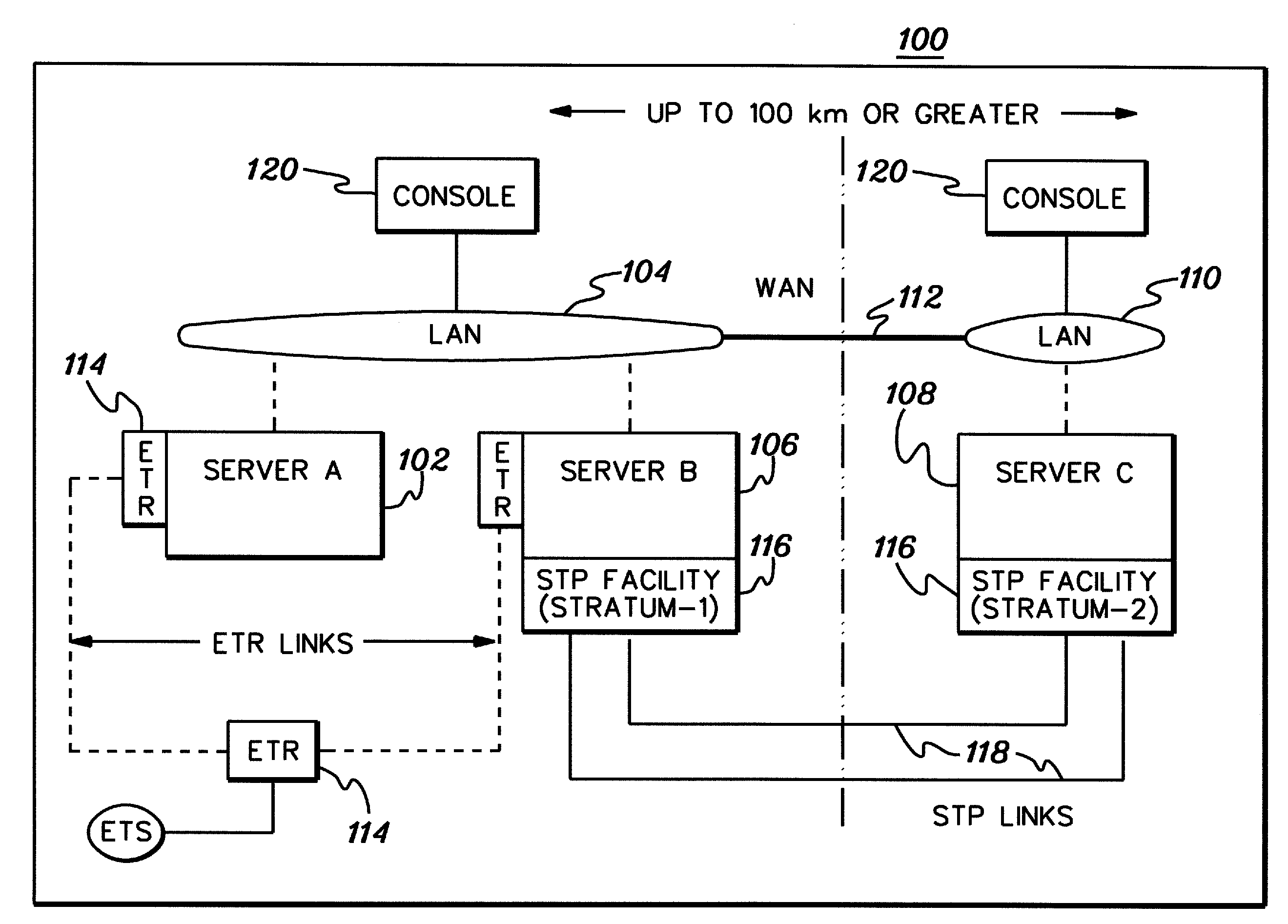

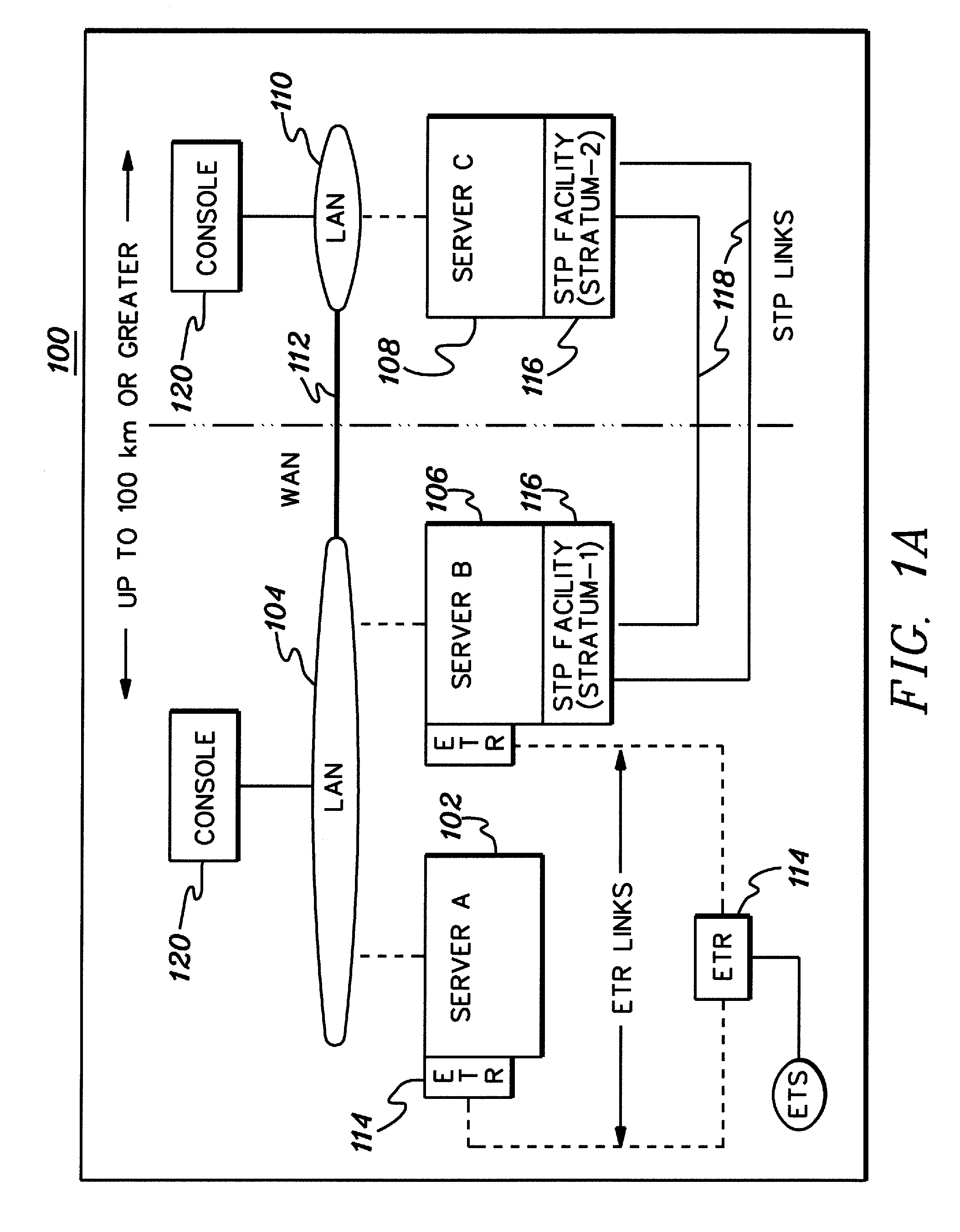

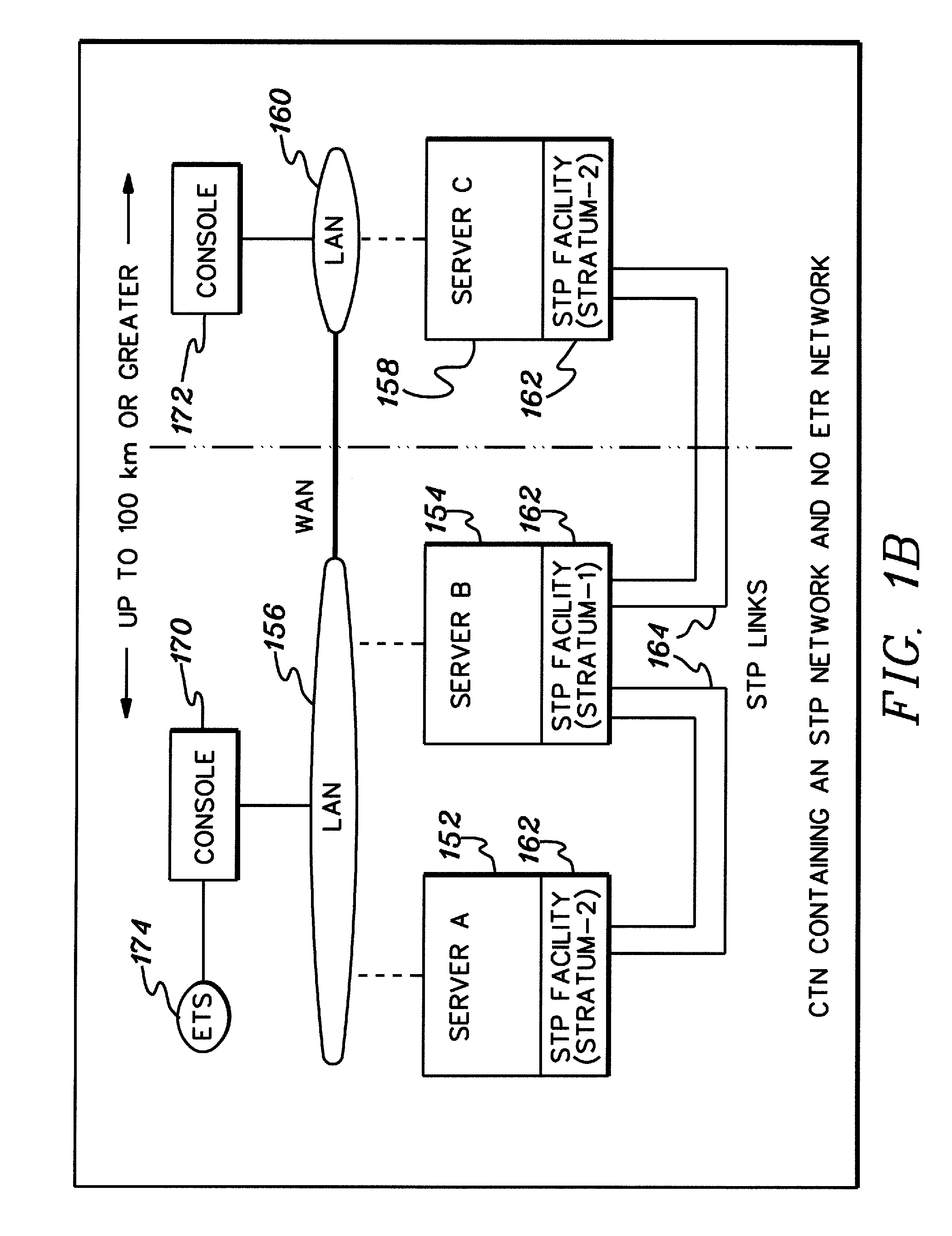

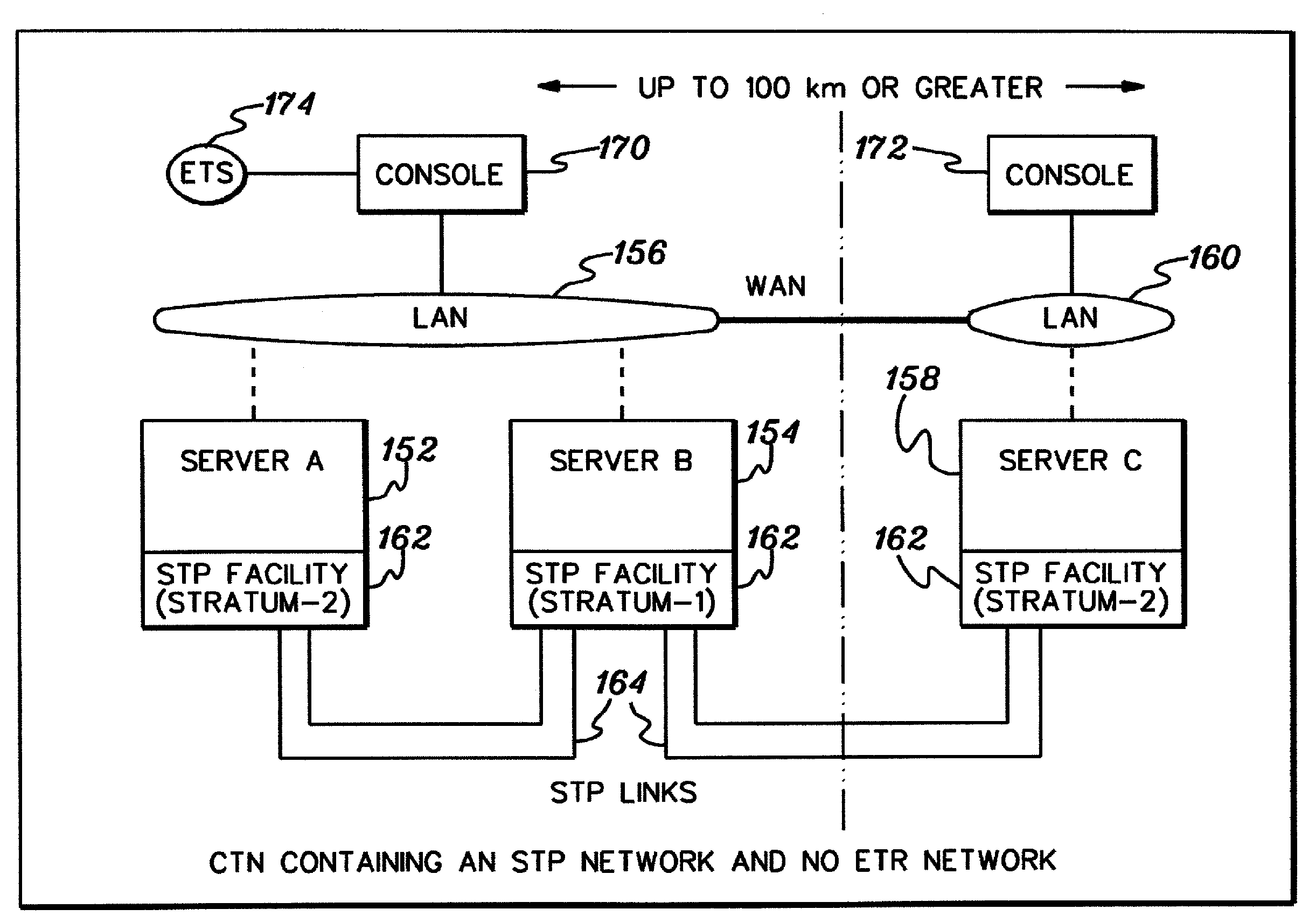

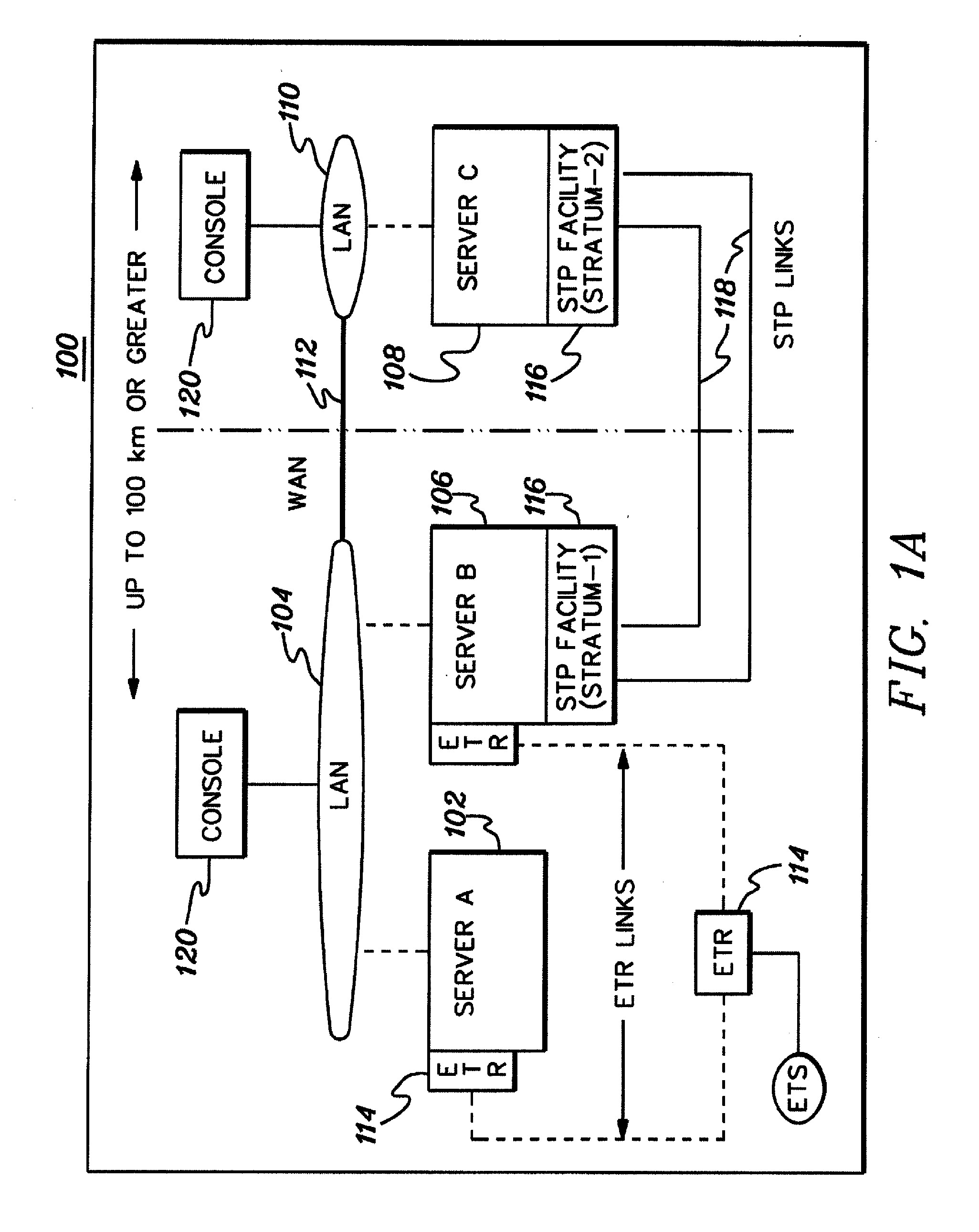

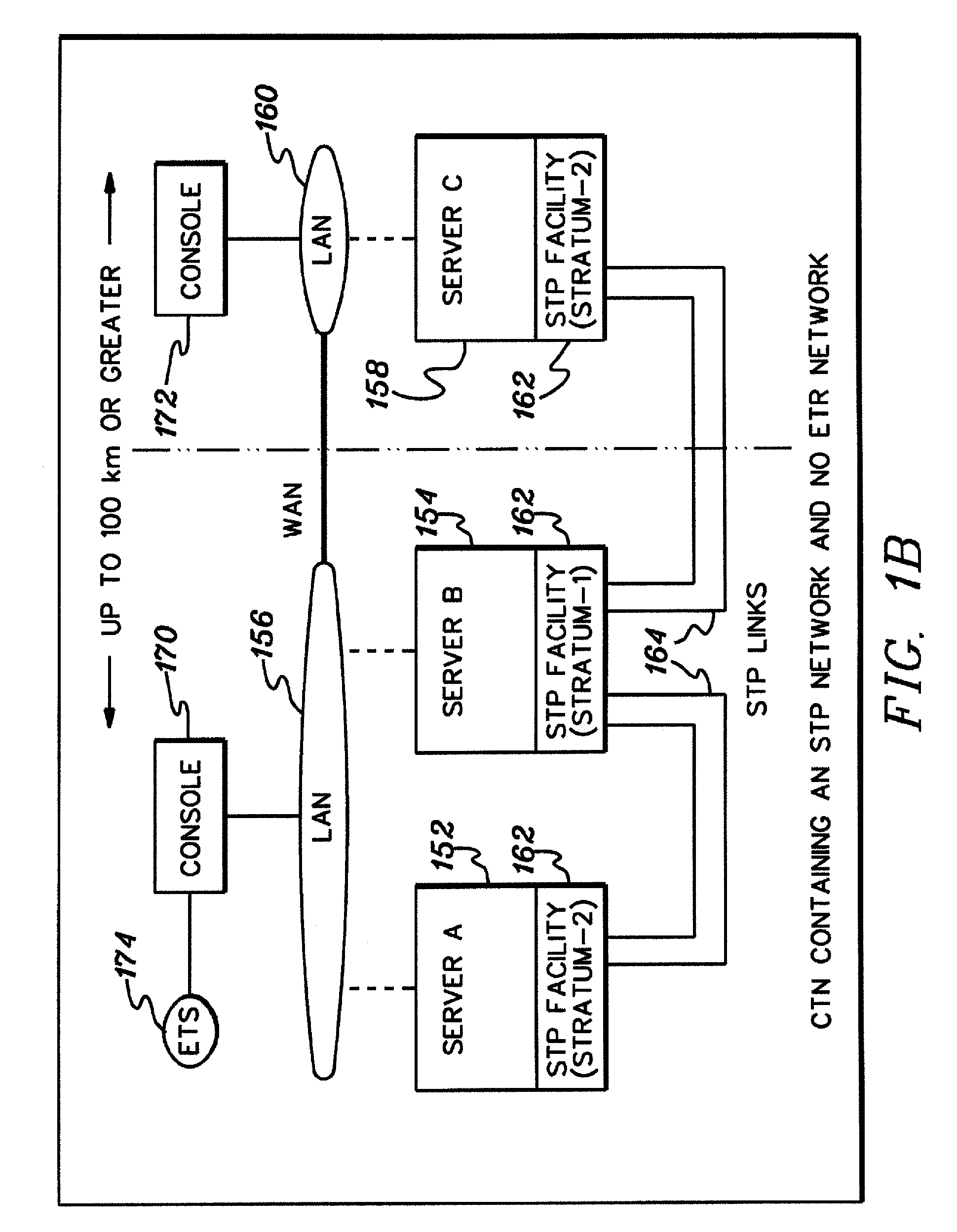

Server time protocol messages and methods

ActiveUS20080183899A1Easy to processOvercomes shortcomingTime-division multiplexMultiple digital computer combinationsTime ProtocolTimestamp

Server time protocol (STP) messages and methods of exchange thereof are provided for facilitating synchronization of processing units of a timing network. The STP messages include exchange time parameters (XTP) commands and responses, and STP control (STC) commands and responses. XTP message exchange processing includes: generating an XTP message command at a first processing unit including a command transmit timestamp field set by the first processing unit and a command receive timestamp field which is unset by the first processing unit; transmitting the XTP message command to a second processing unit; setting the command receive timestamp field in the XTP command with the time the XTP command is received at the second processing unit; and generating an XTP message response at the second processing unit, the message response including the command transmit timestamp set by the first processing unit and the command receive timestamp set by the second processing unit.

Owner:IBM CORP

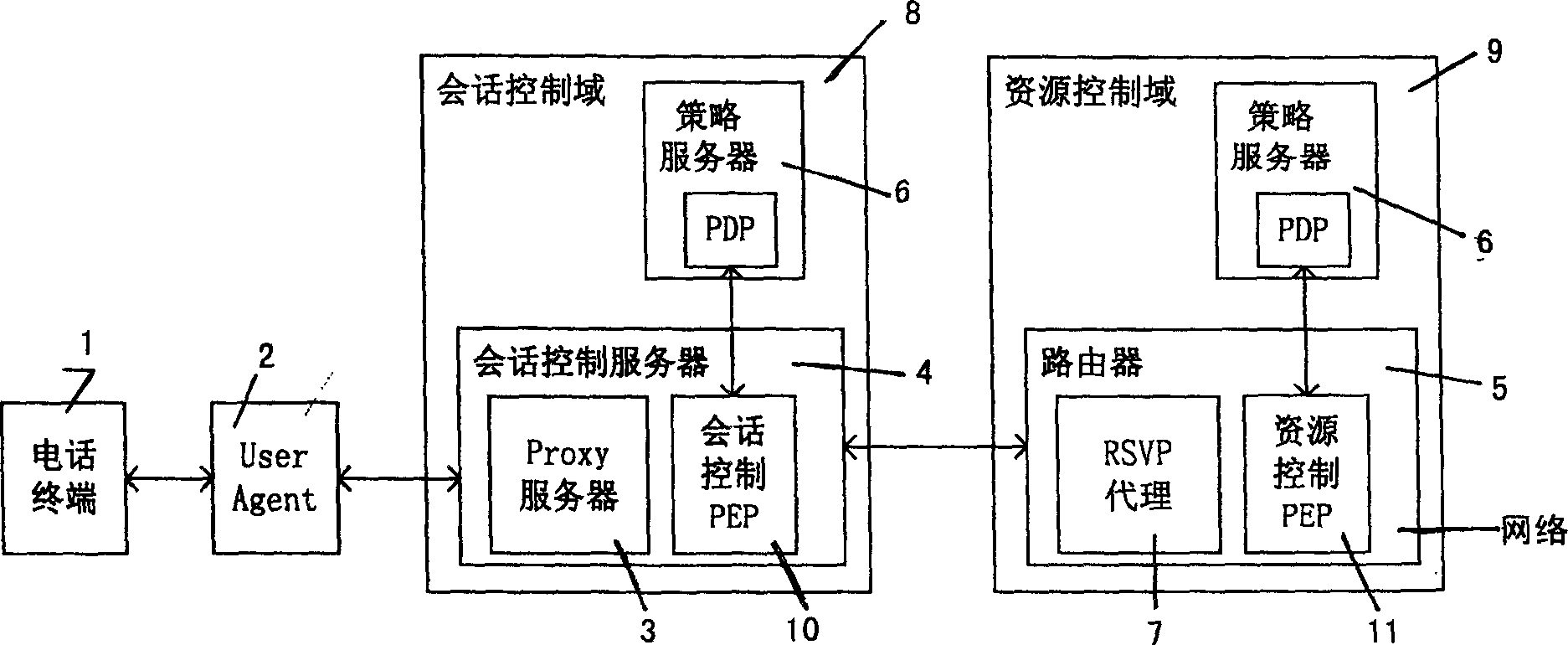

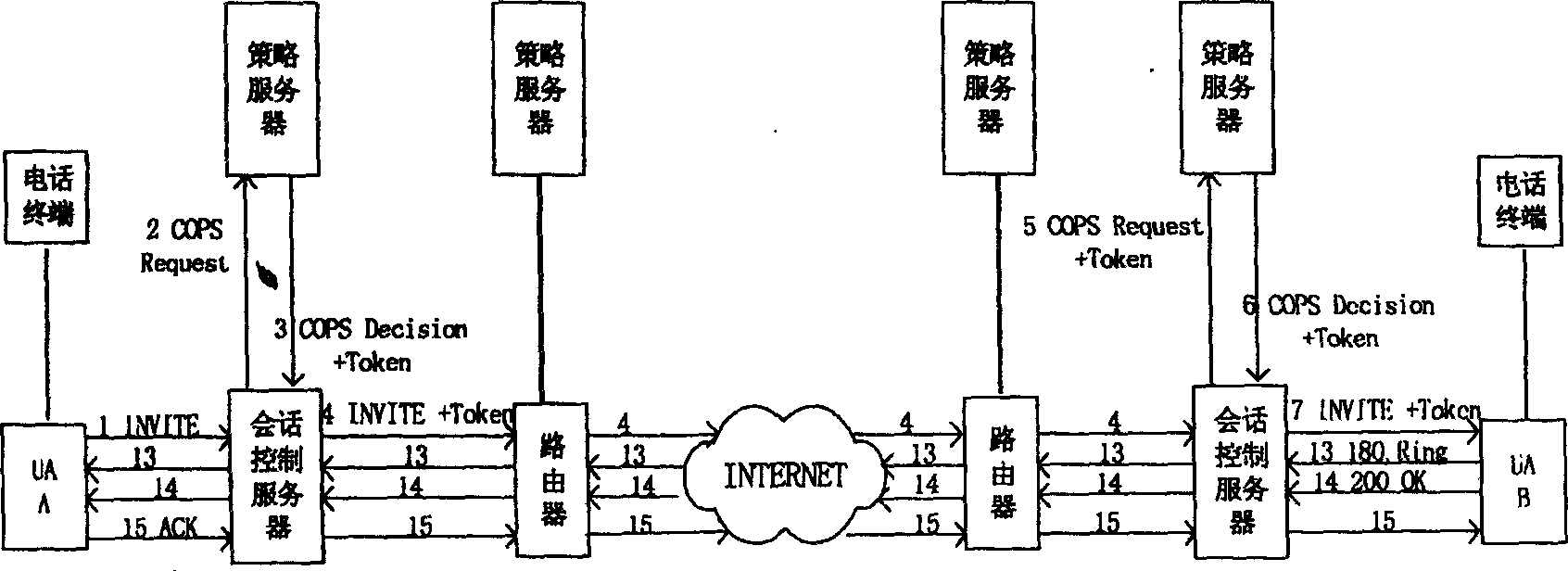

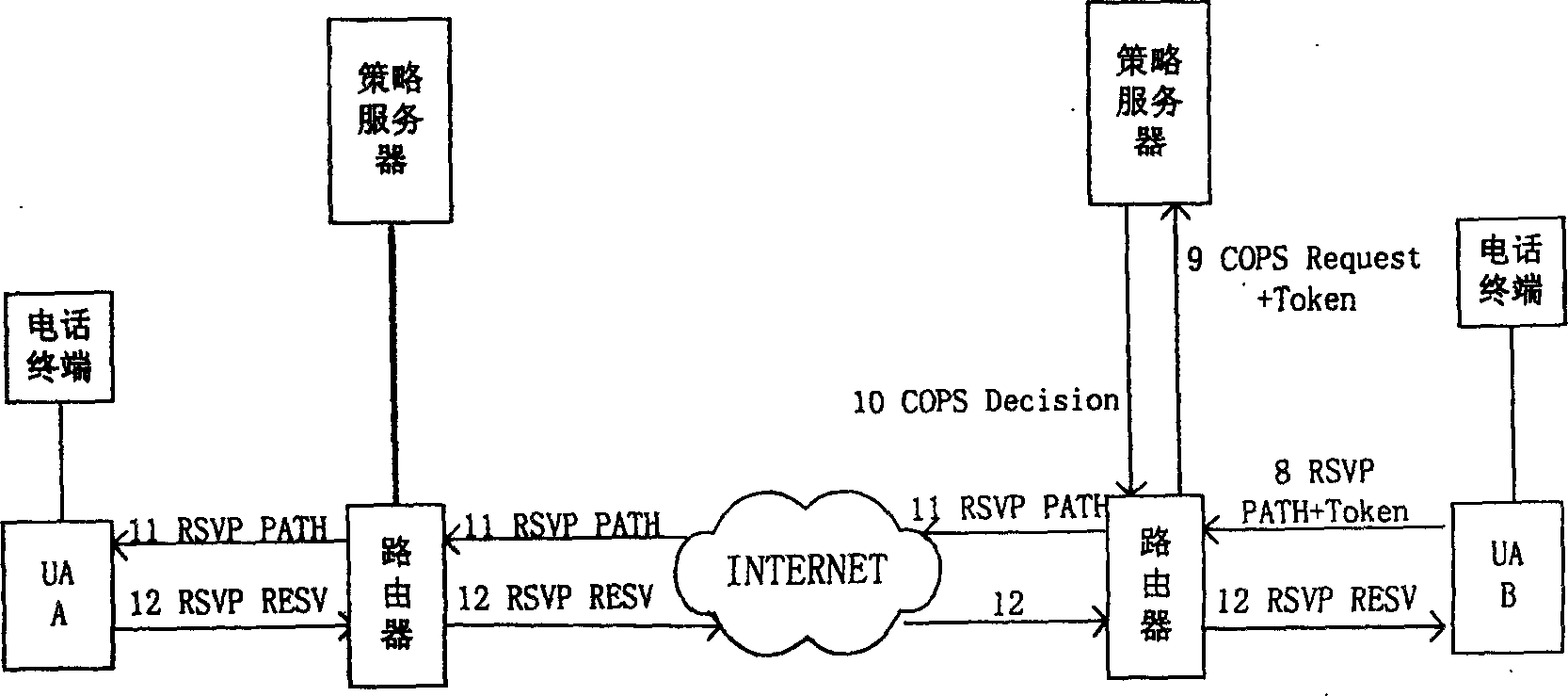

Session and medium authorization method in IP video telephone system based on session start protocol

InactiveCN1469585AEasy to manageReduce pre-trust relationshipsTelephonic communicationData switching networksSession controlNetwork management

The present invention relates to computer network management technology, and is one session and medium authorization method in IP video telephone system based on session initialization protocol. Thepresent invention adopts network management technology based on strategy in realizing session authorization, and one strategy server is used in generating management command to inform the session control server to execute management action. The present invention solves the session and medium authorization problem in IP video telephone system and can control effectively the session occupied network resource. The present invention features that during session course, all the network entities exchange authorization message via transmitting authorization token to reduce message exchange times, decrease the mutual independence between the network entities and obtain even more flexibility.

Owner:陈弟桂

Server time protocol control messages and methods

Server time protocol (STP) messages and methods of exchange thereof are provided for facilitating synchronization of processing units of a timing network. The STP messages include exchange time parameters (XTP) commands and responses, and STP control (STC) commands and responses. XTP message exchange processing includes: generating an XTP message command at a first processing unit including a command transmit timestamp field set by the first processing unit and a command receive timestamp field which is unset by the first processing unit; transmitting the XTP message command to a second processing unit; setting the command receive timestamp field in the XTP command with the time the XTP command is received at the second processing unit; and generating an XTP message response at the second processing unit, the message response including the command transmit timestamp set by the first processing unit and the command receive timestamp set by the second processing unit.

Owner:IBM CORP

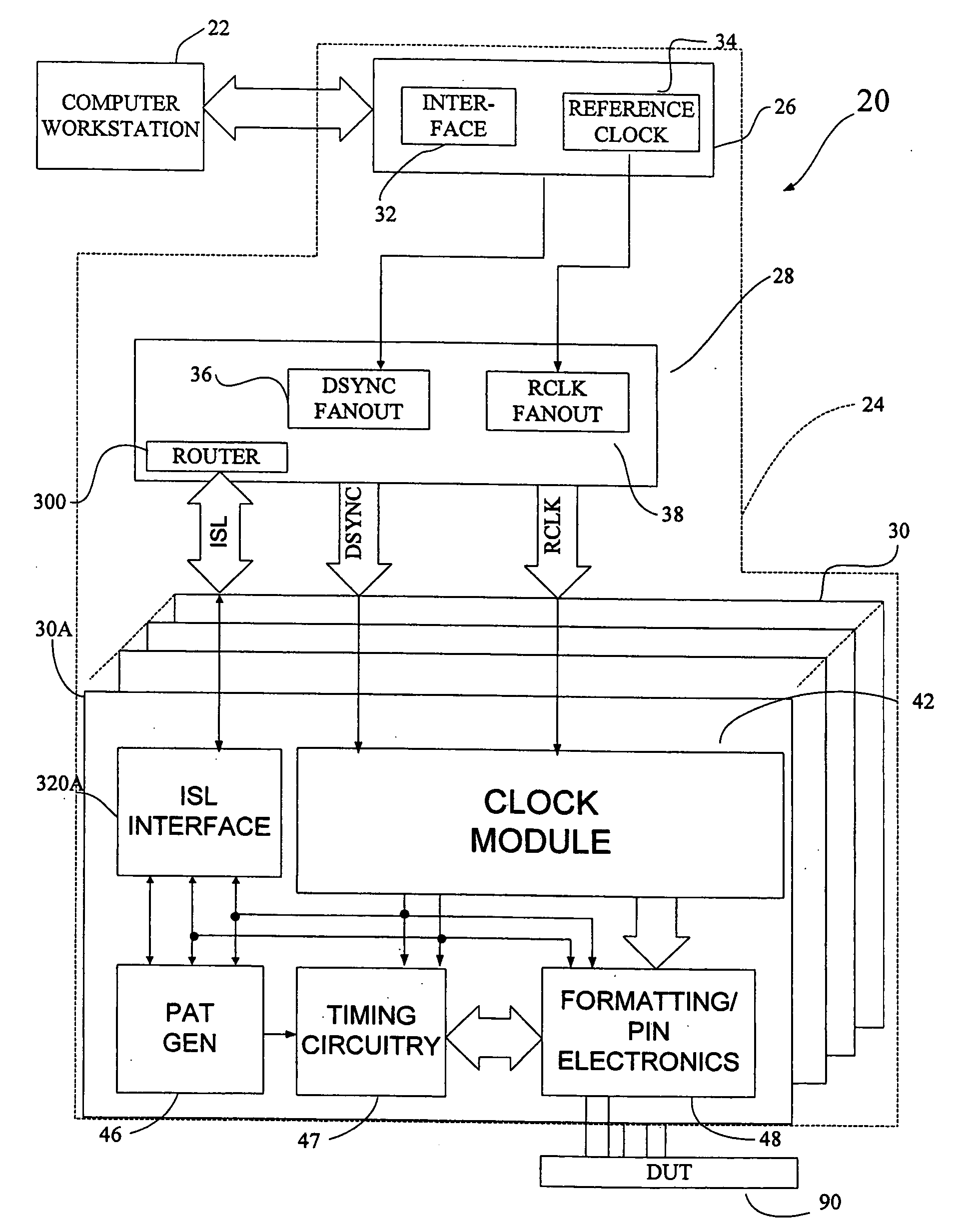

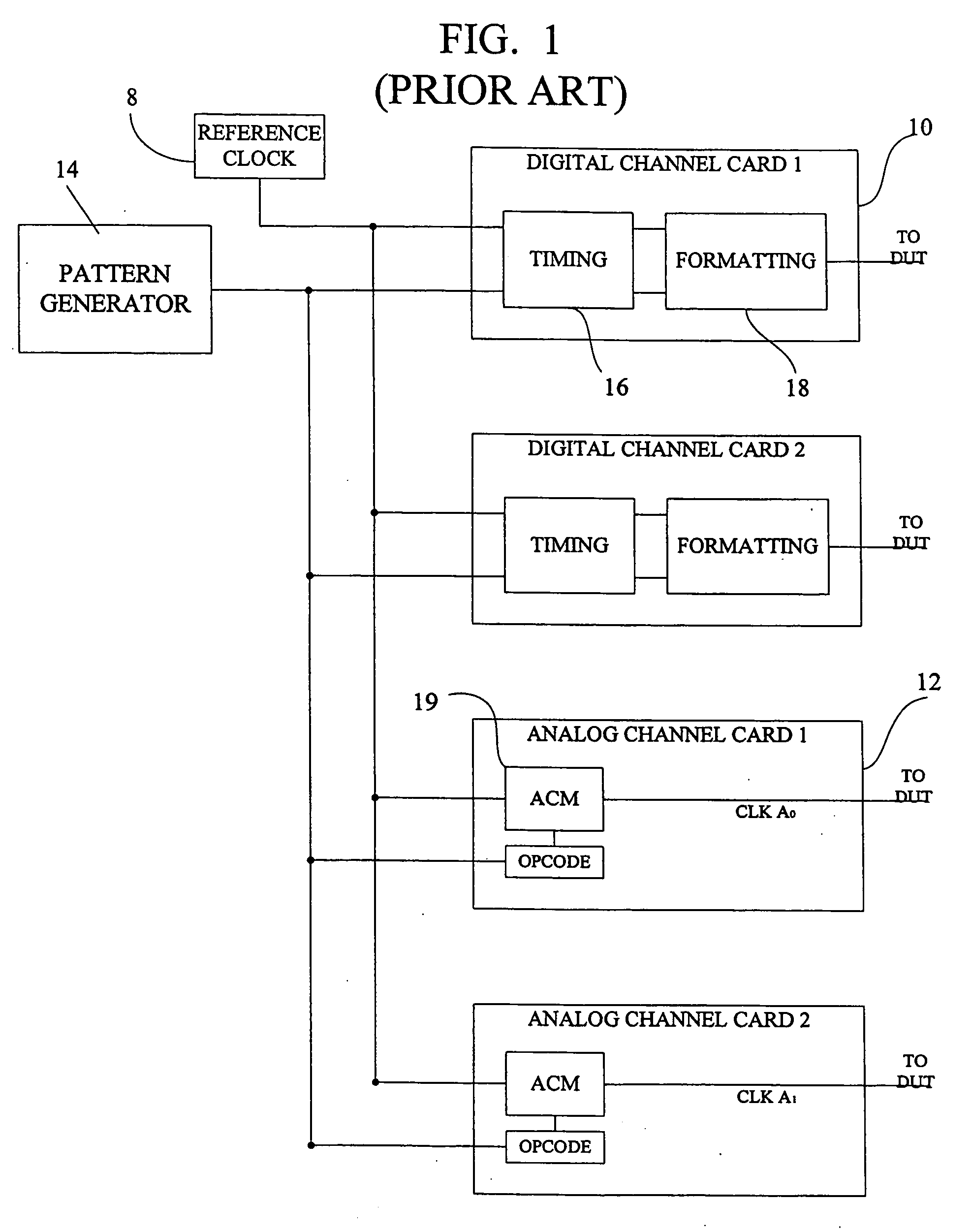

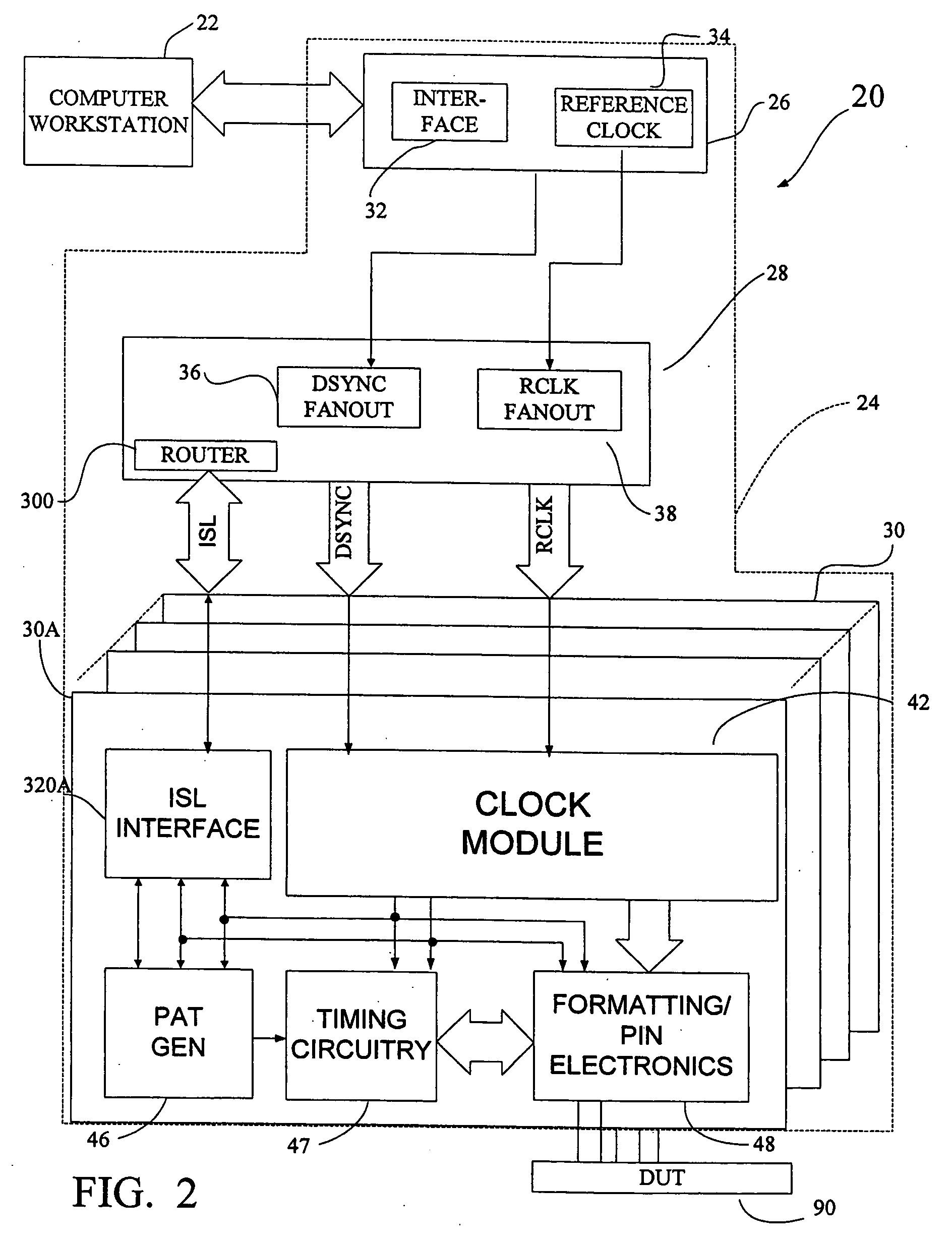

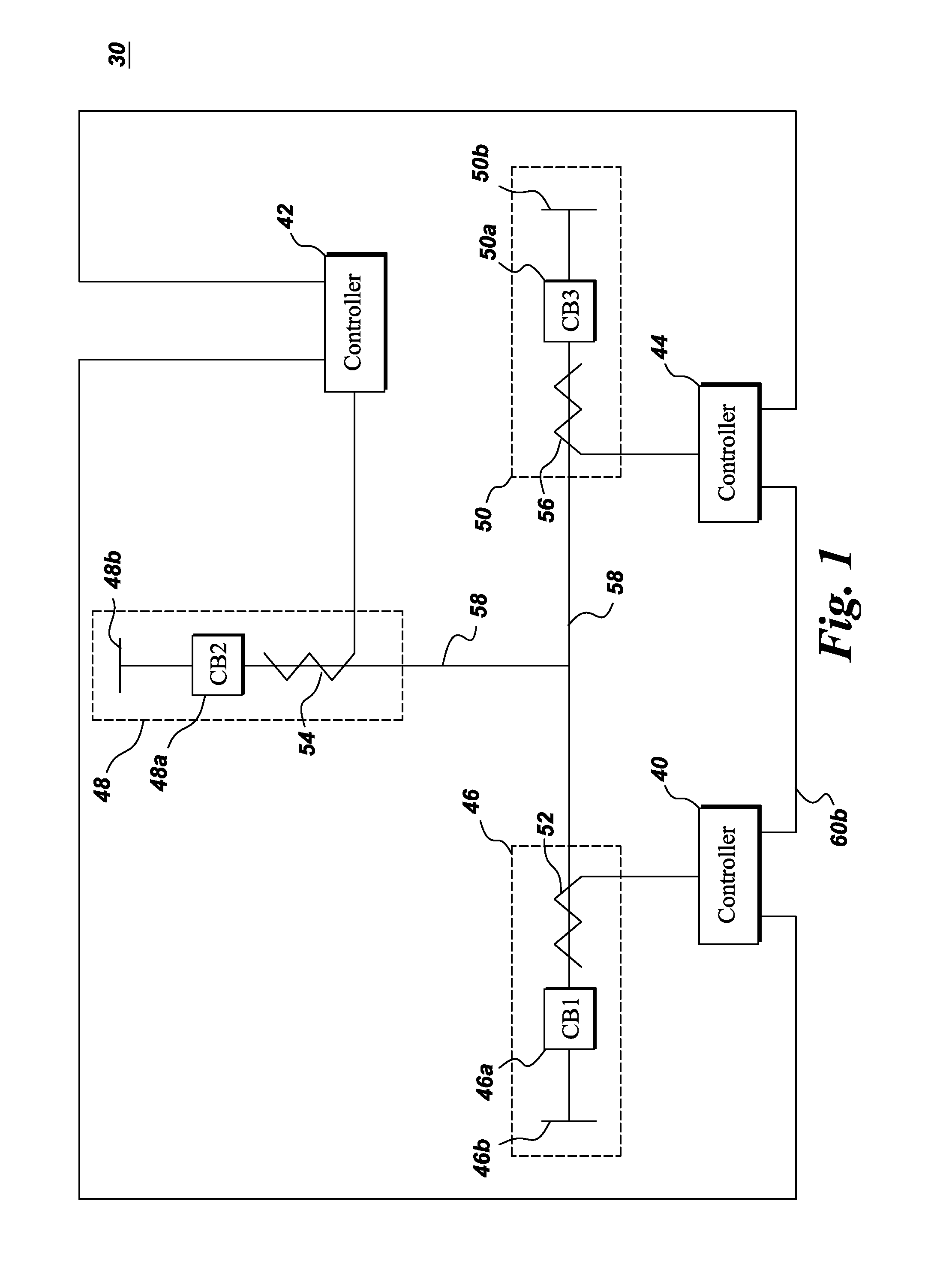

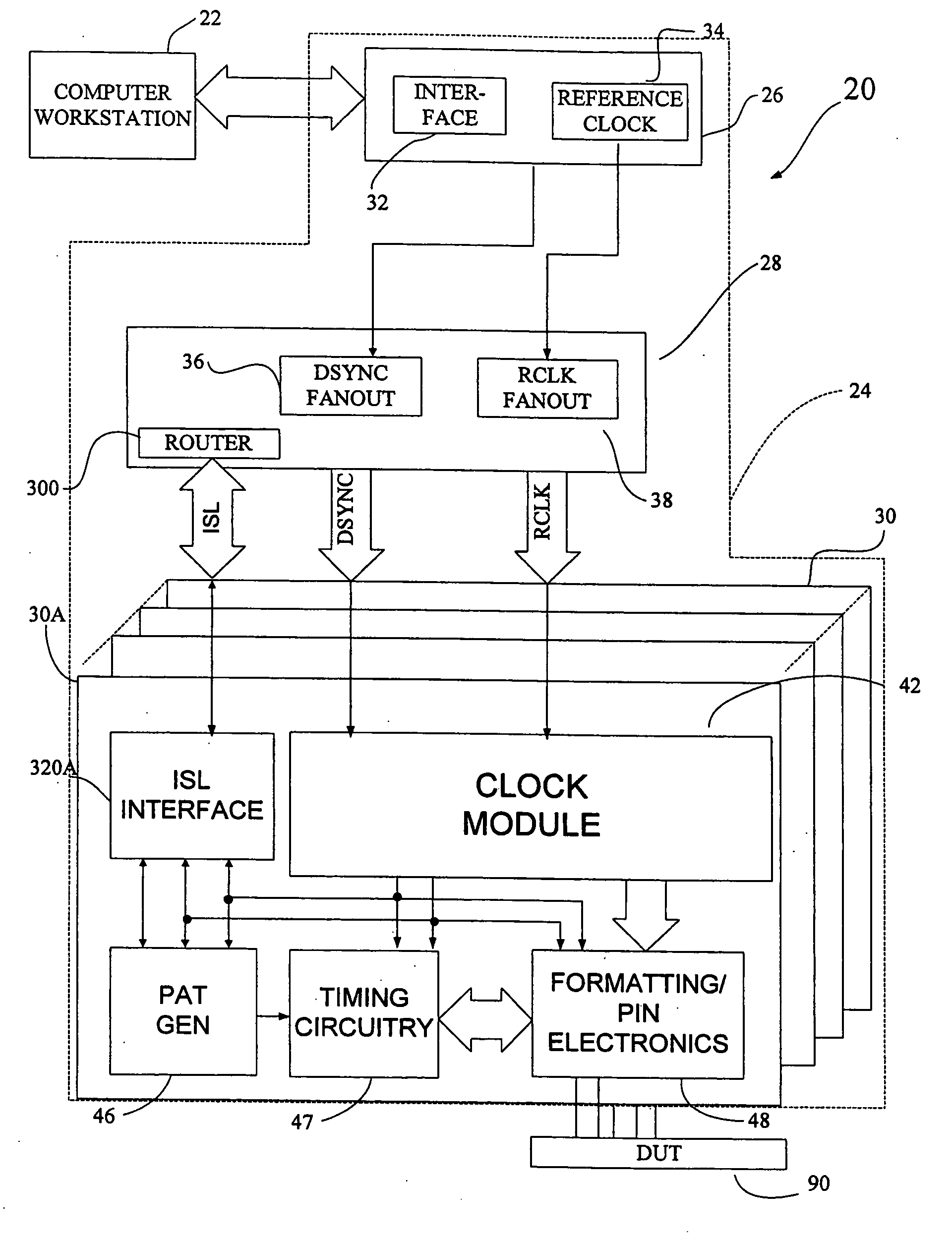

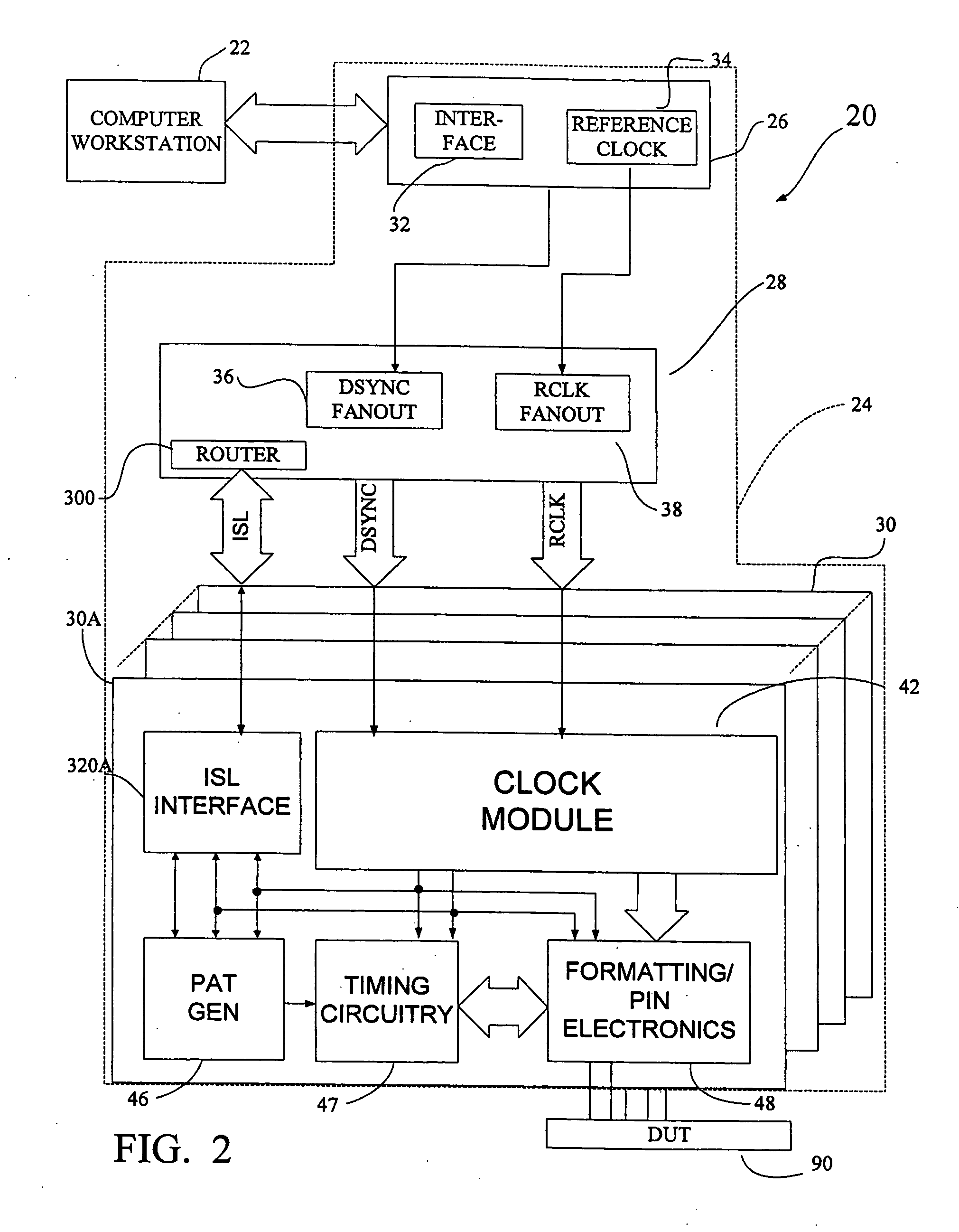

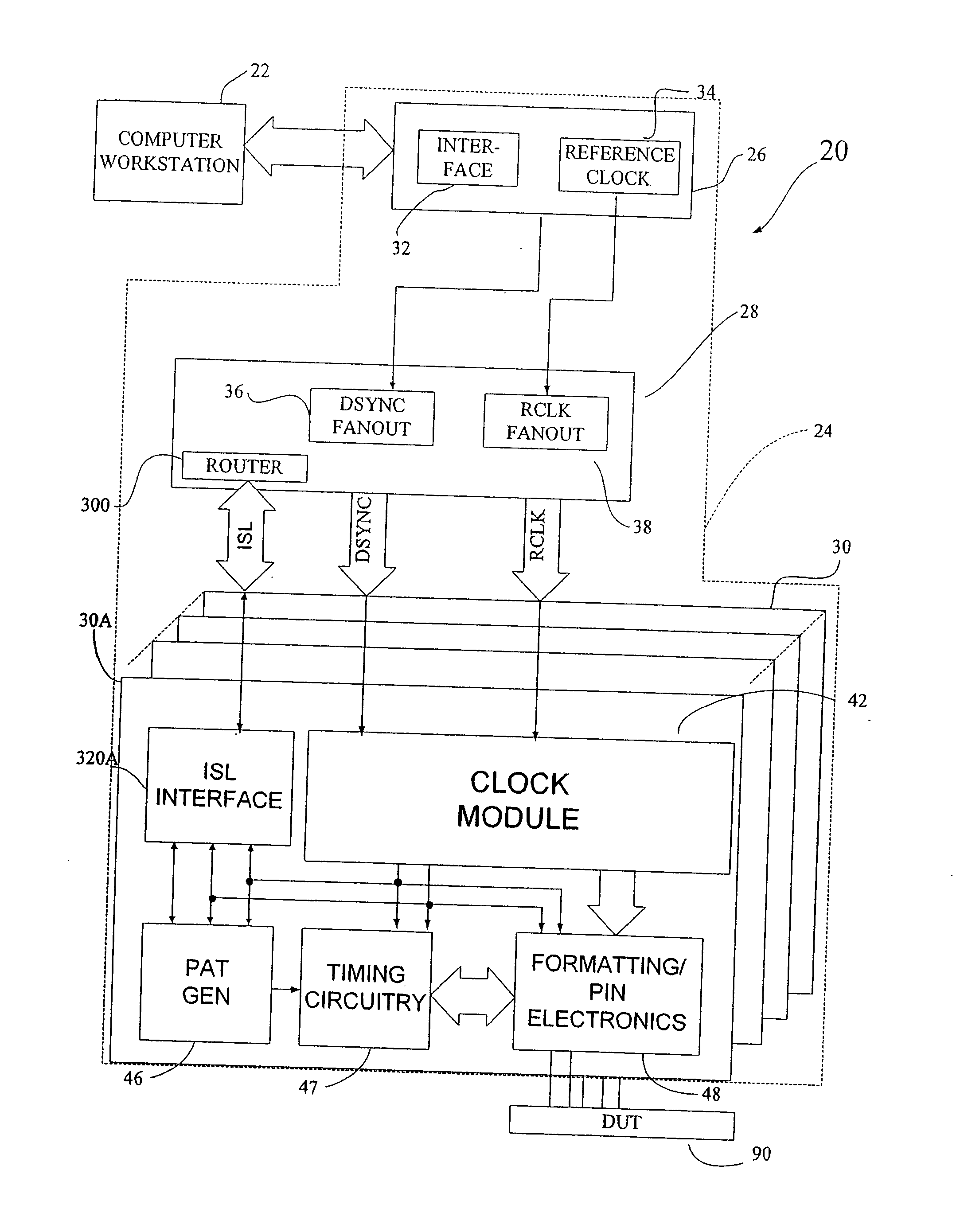

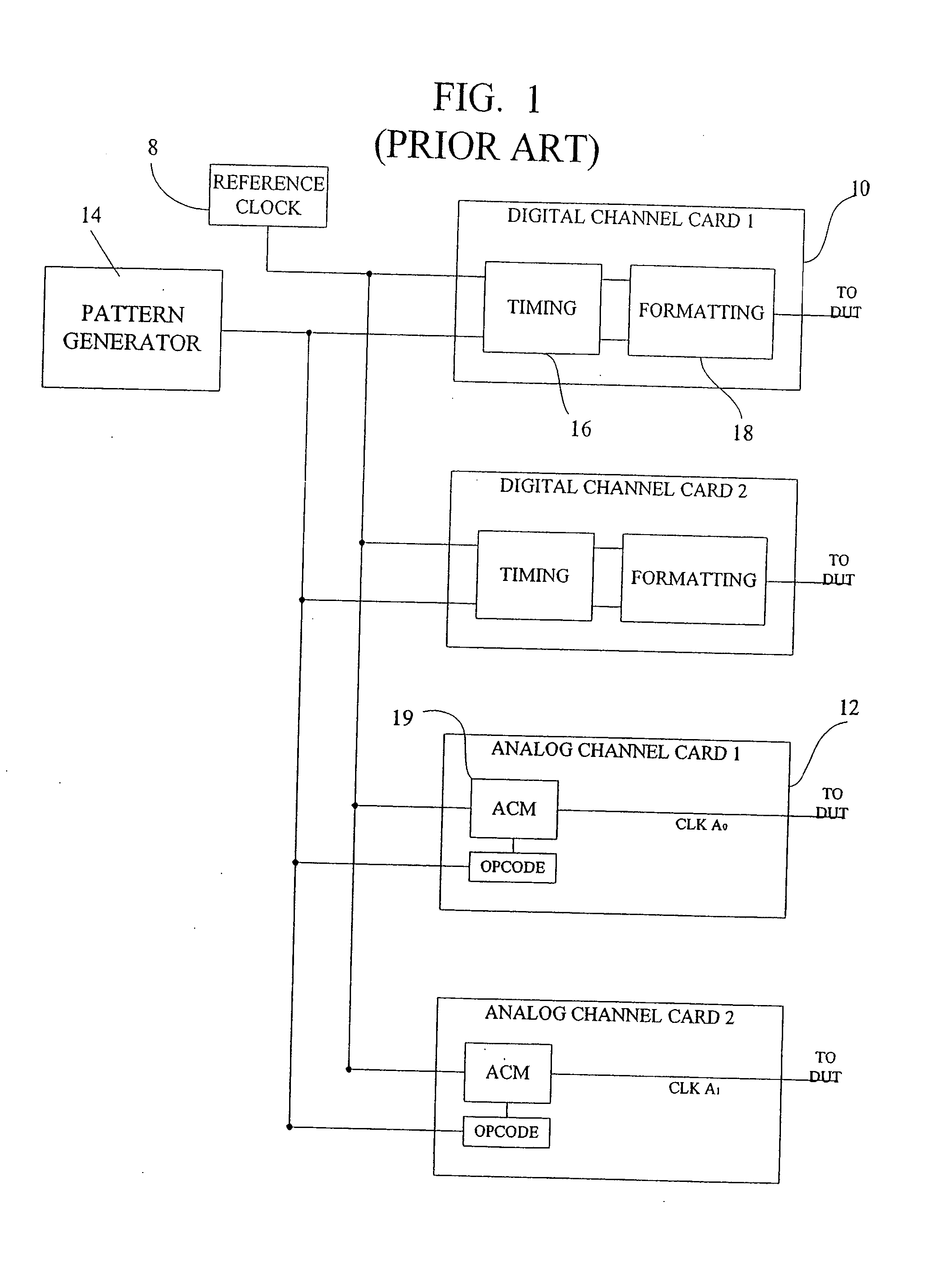

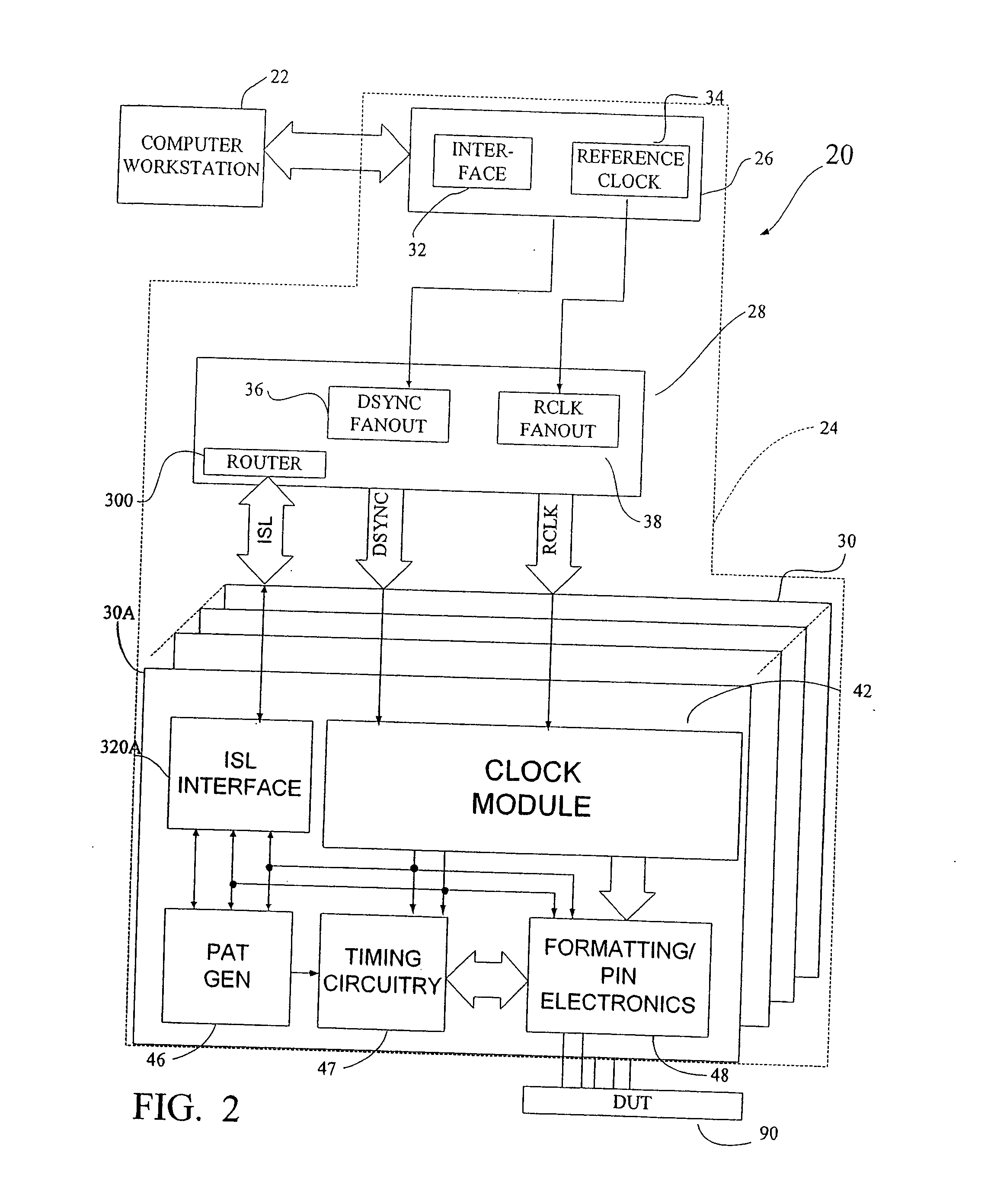

Automatic test system with synchronized instruments

ActiveUS20060123297A1Digital circuit testingSemiconductor/solid-state device testing/measurementAsynchronous communicationTelecommunications link

A test system with multiple instruments. Some instruments act as controller instruments and others act as controlled instruments. Each instrument includes a clock generator that synthesizes one or more local clocks from a reference clock. The reference clock is a relatively low frequency clock that can be inexpensively but accurately generated and distributed to all of the instruments. A communication link between instruments is provided. Timing circuits within instruments that are to exchange time information are synchronized to establish a common time reference. Thereafter, instruments communicate time dependent commands or status messages asynchronously over the communication link by appending to each message a time stamp reflecting a time expressed relative to the common time reference. The test system includes digital instruments that contain pattern generators that send command messages to analog instruments, which need not include pattern generators. The architecture simplifies design of analog instruments and avoids redesign of analog instrument as pattern rates of digital instruments change.

Owner:TERADYNE

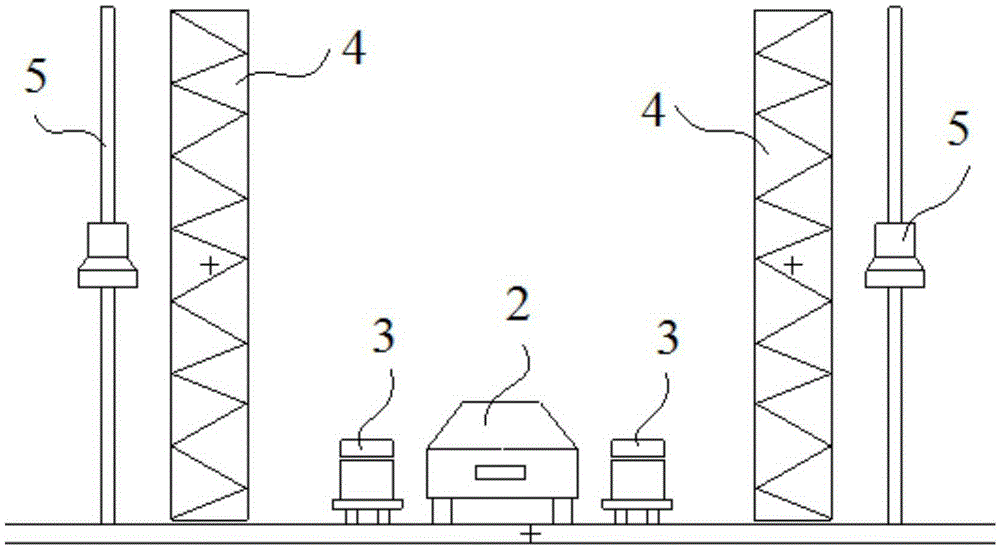

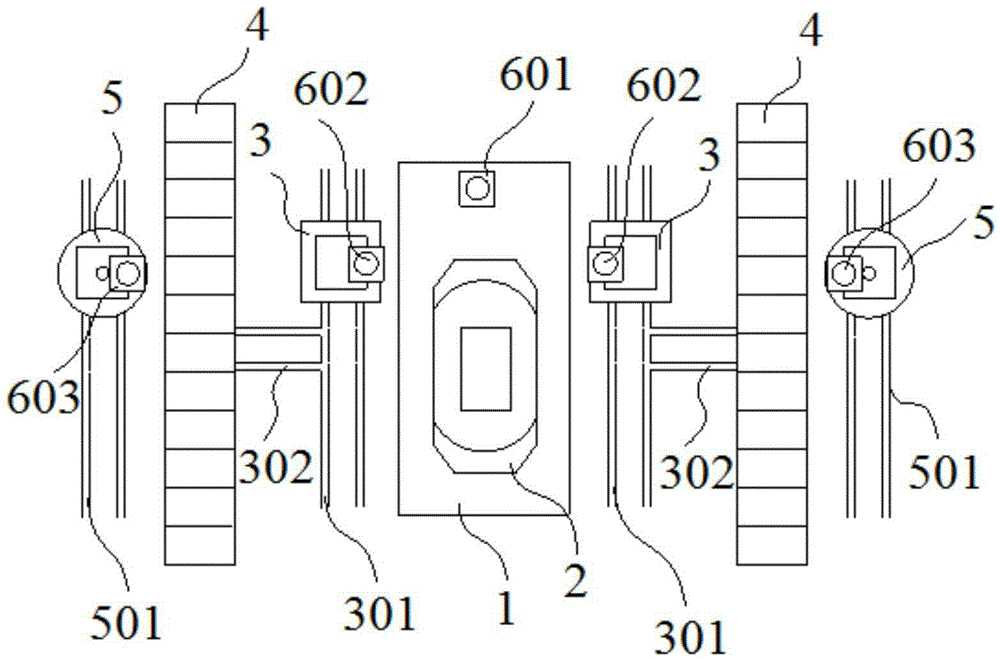

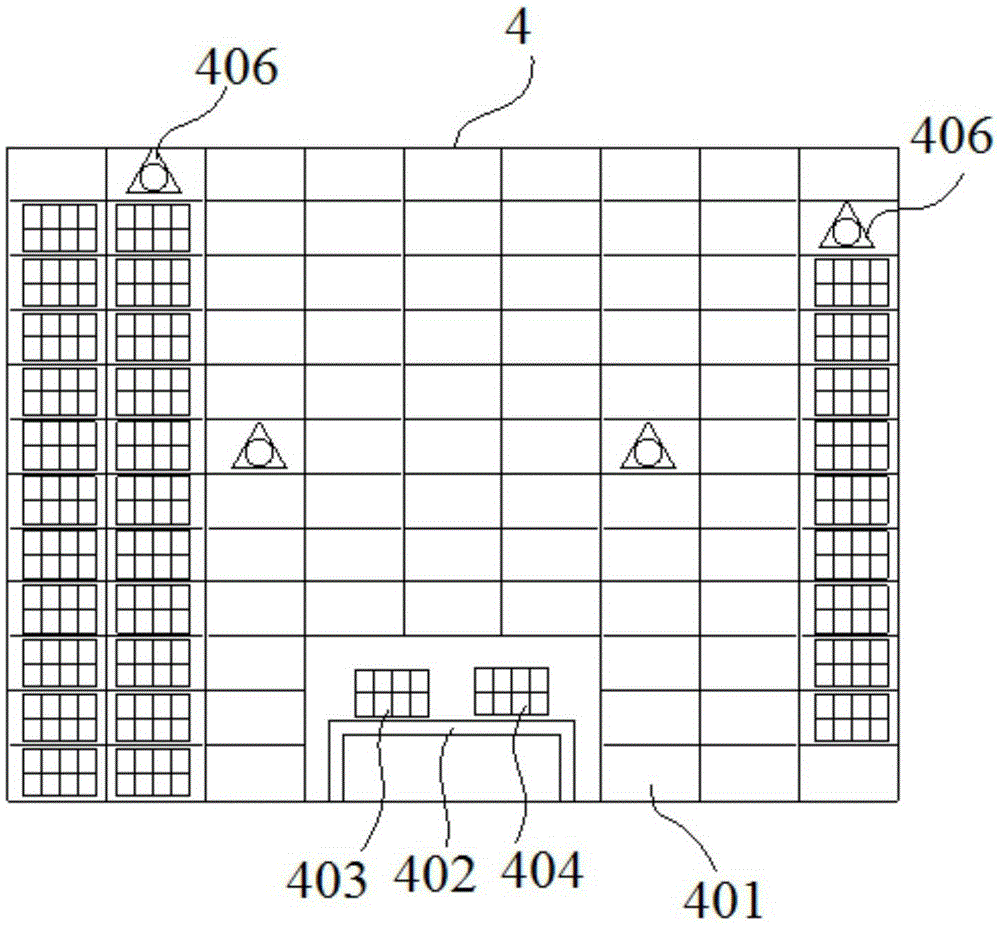

Electric vehicle battery pack rapid exchanging system

InactiveCN105235658AAutomatic and fast movementEasy to moveElectric propulsion mountingElectric/fluid circuitElectricityParking area

The invention discloses an electric vehicle battery pack rapid exchanging system, which comprises a vehicle parking area, an electricity exchanging device, a battery rack, a stacker and an image sensor, wherein the electricity exchanging device is moved on a first guide rail to a second guide rail to arrive at a battery pack position of an electric vehicle and take out a battery pack to be charged to delivery to the battery rack; the battery pack that is full charged is sent to the electric vehicle; the stacker is moved on a third guide rail for putting the battery pack to be charged into the battery rack for charging; and the battery pack that is full charged is put to a battery pack exchange platform for making preparations for the next battery exchange, thus automatically rapid exchange of the battery pack is realized, without manual carrying; the work efficiency is high; the exchange time is greatly shortened; through setting the image sensor on the vehicle parking area, the electricity exchange device and the stacker, the battery pack position can be acquired timely and the apparatus is conveniently moved; and through a smog sensor on the battery rack, the occurrence of safety accident of the battery pack during the charging process is timely monitored, thus improving the safety.

Owner:SUZHOU SIKABO COMM TECH

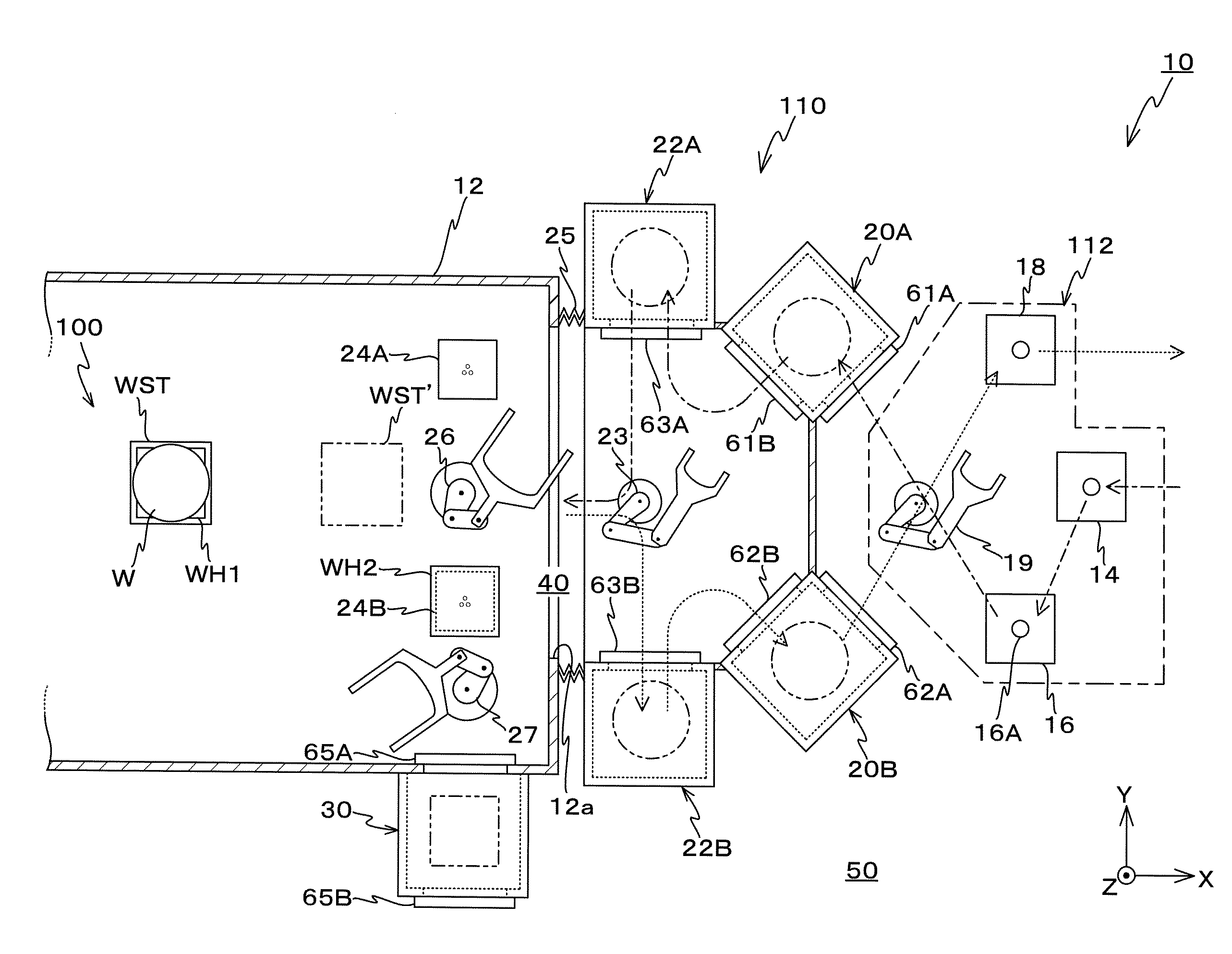

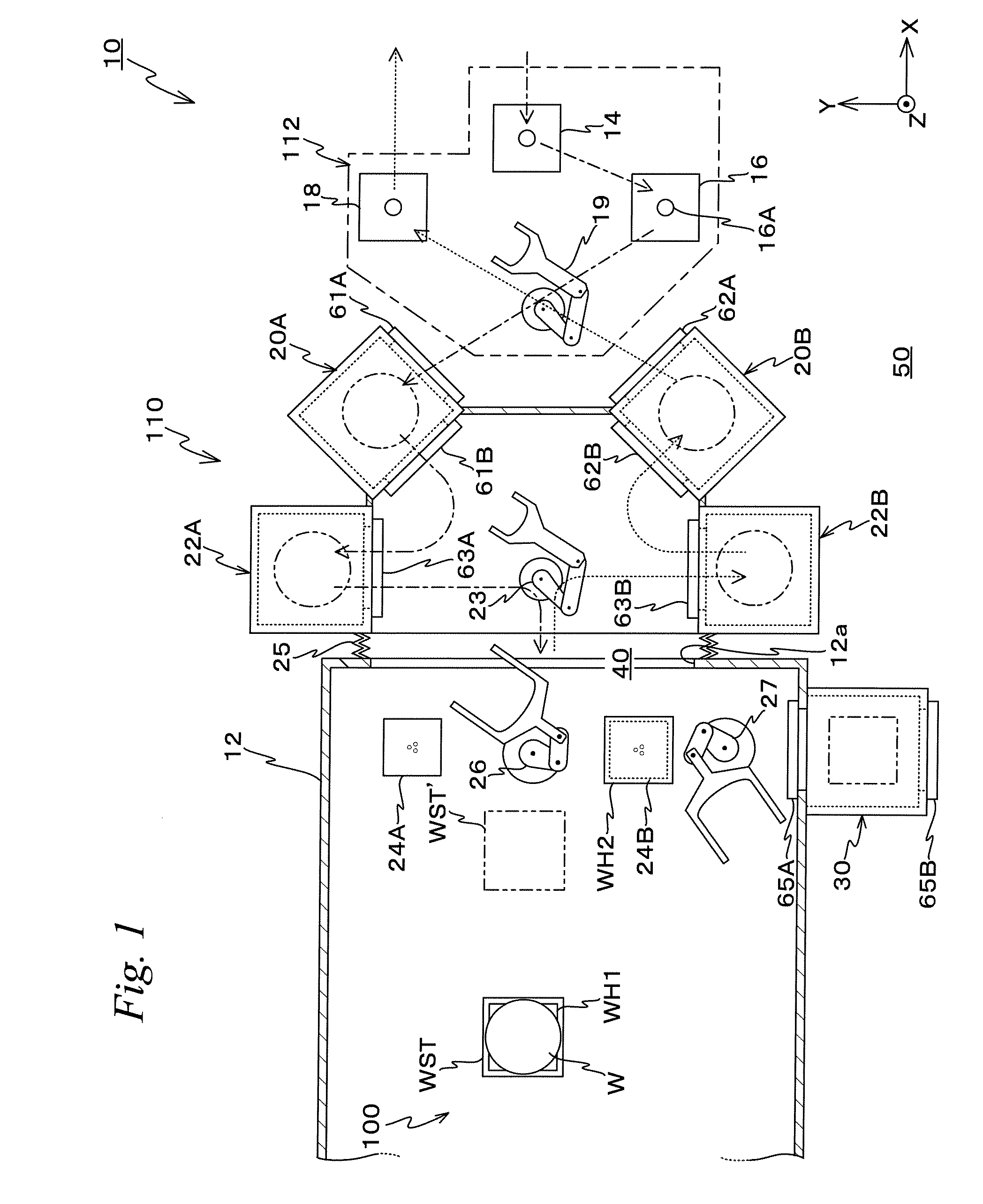

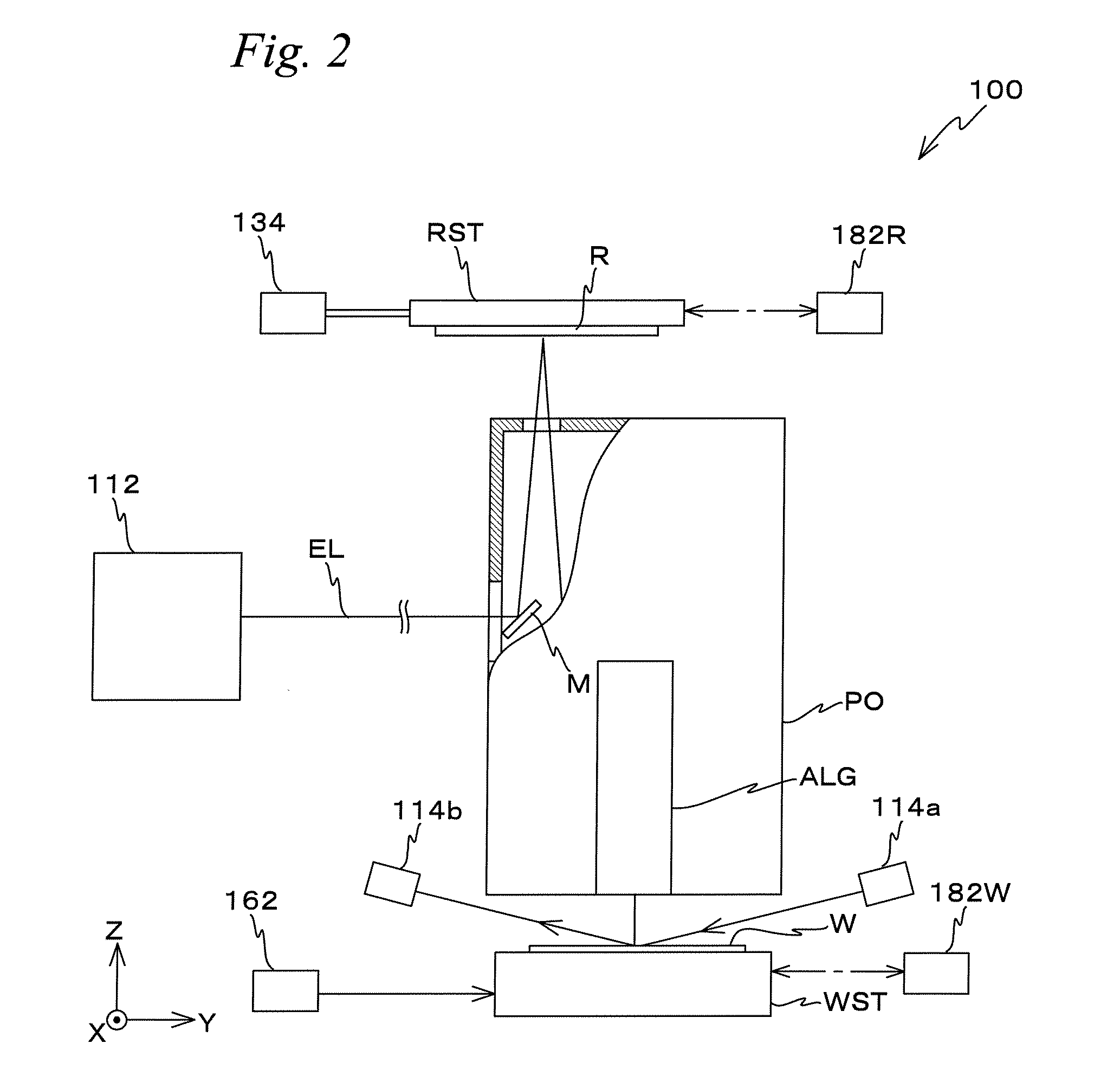

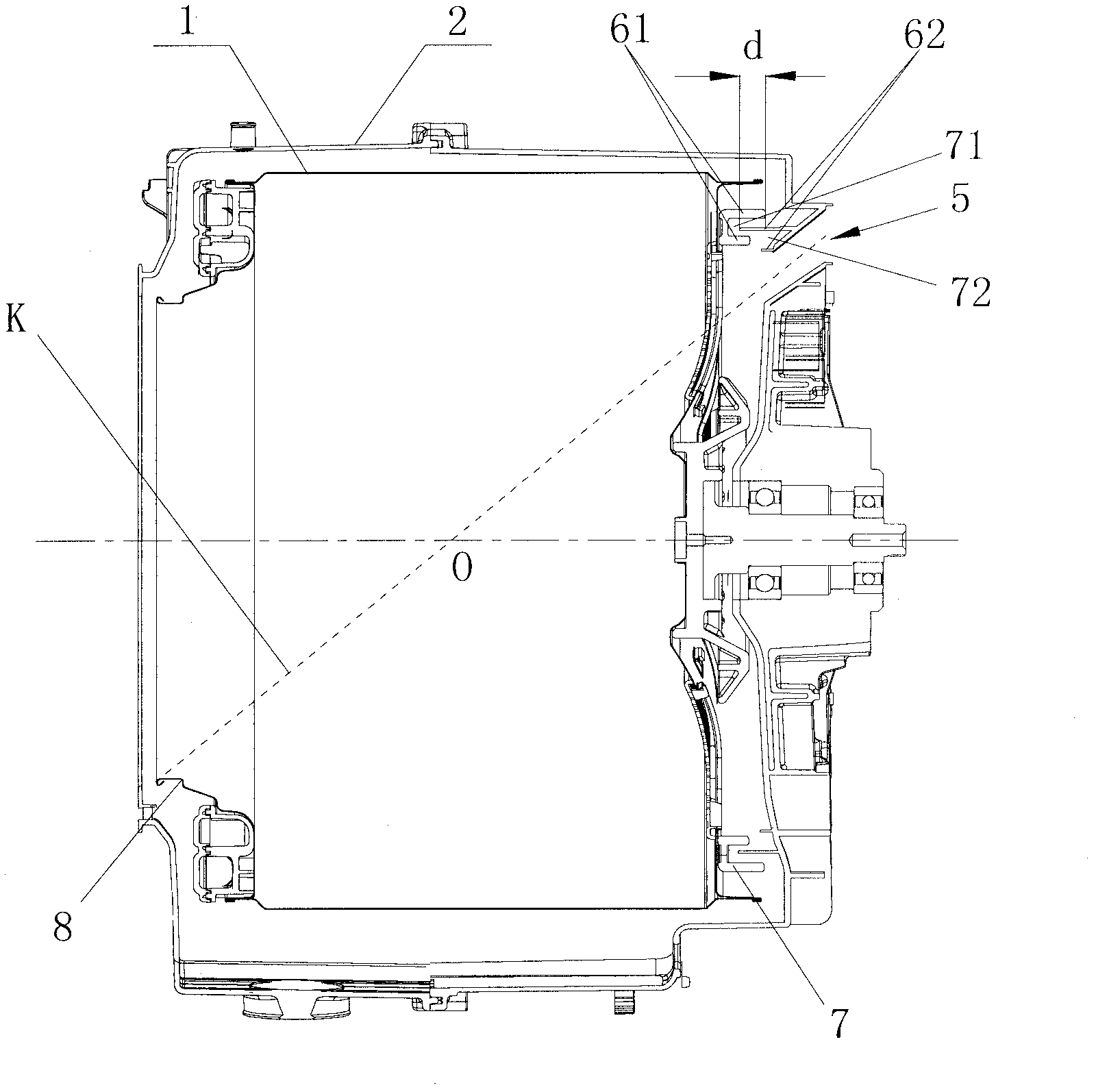

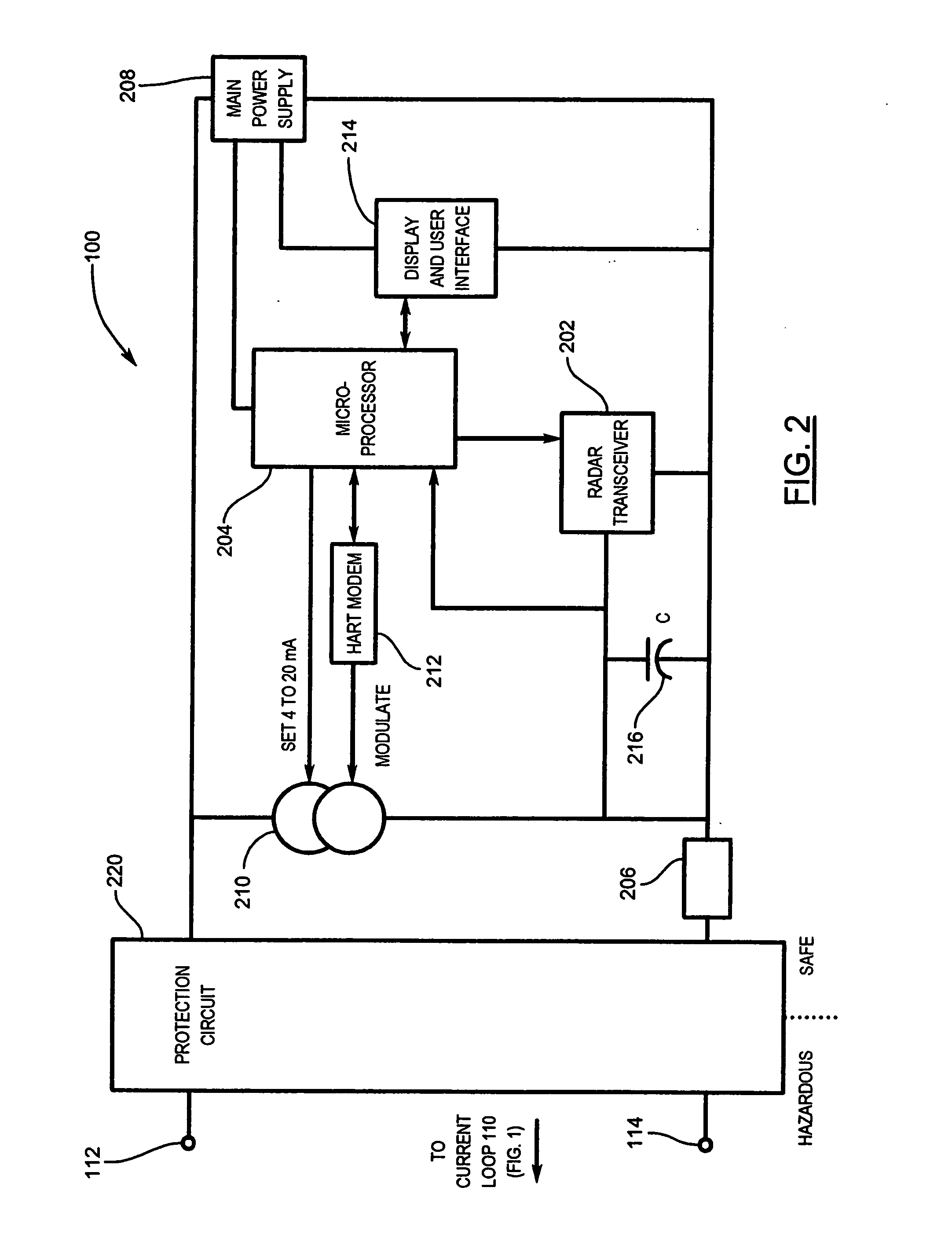

Exposure apparatus and device manufacturing method

InactiveUS20080225261A1Object exchange time has on throughput can be suppressedPhotomechanical apparatusSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringExchange time

An exposure apparatus is configured so that a wafer carrier robot can deliver a wafer to a wafer holder held by a holder carrier robot or can carry out a wafer from the wafer holder held by the holder carrier robot, under a reduced-pressure environment. According to the apparatus, even if it takes a relatively long time to replace the wafer on the wafer holder used inside the reduced pressure space, by performing the wafer exchange operation and a predetermined operation (the exposure apparatus main section operation) using the stage on which the wafer holder holding the wafer is mounted concurrently, the influence that the wafer exchange time has on the throughput can be suppressed.

Owner:NIKON CORP

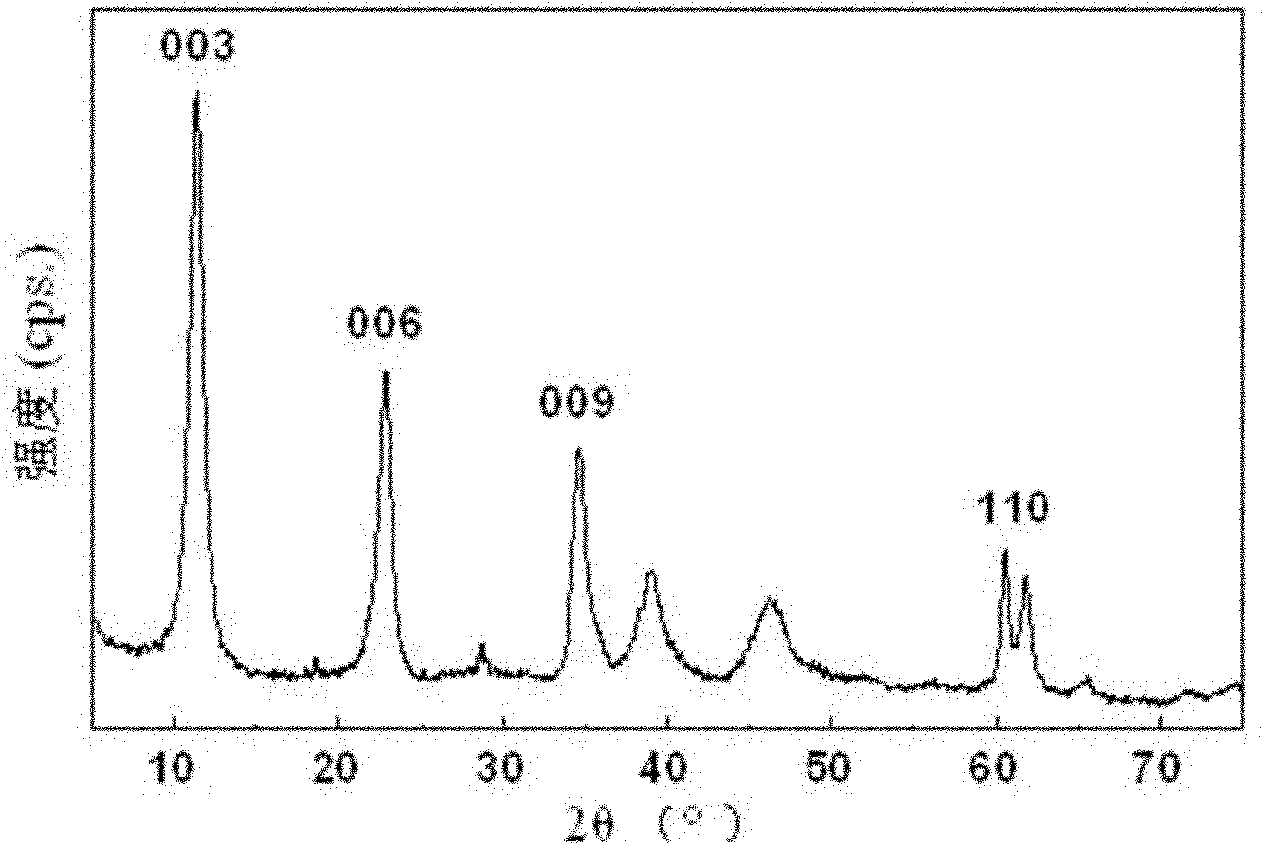

Pillared hydrotalcite and preparation method thereof

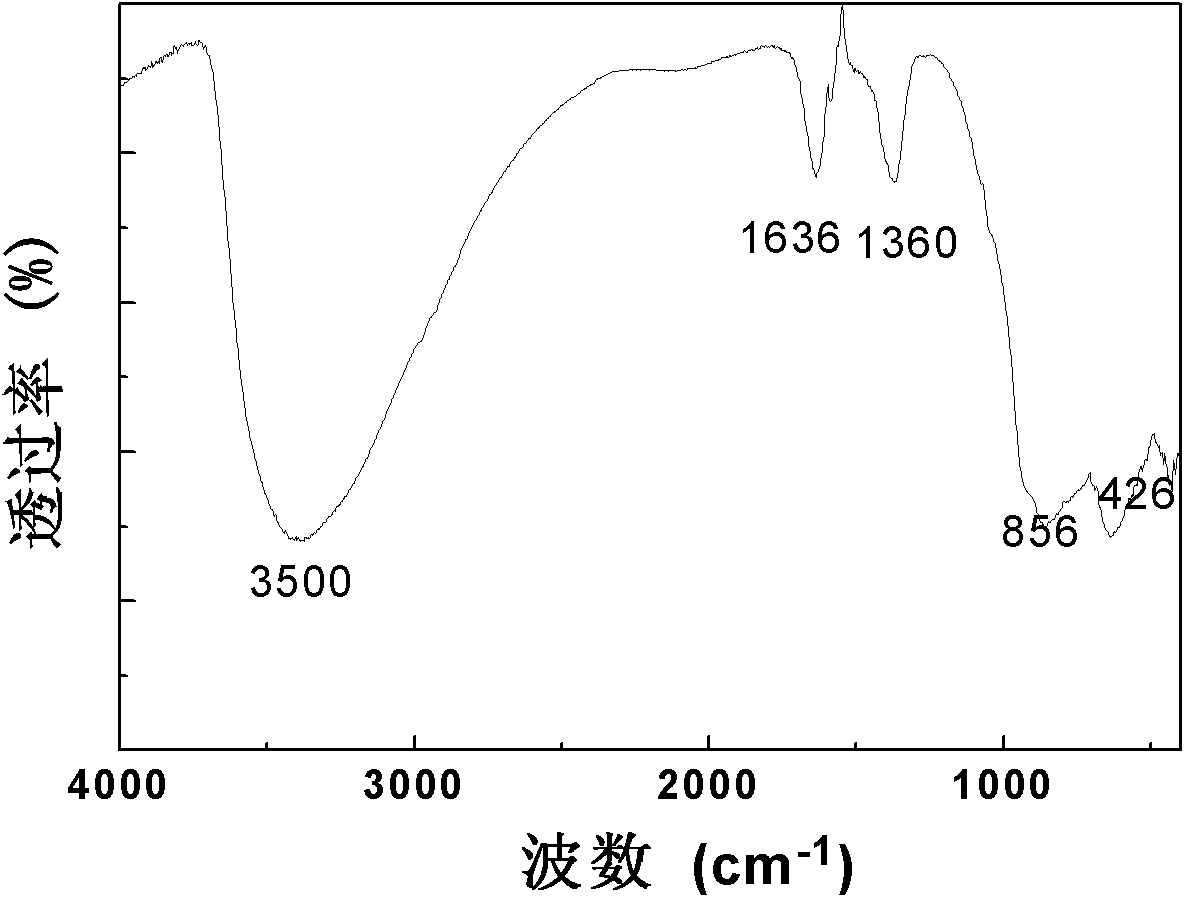

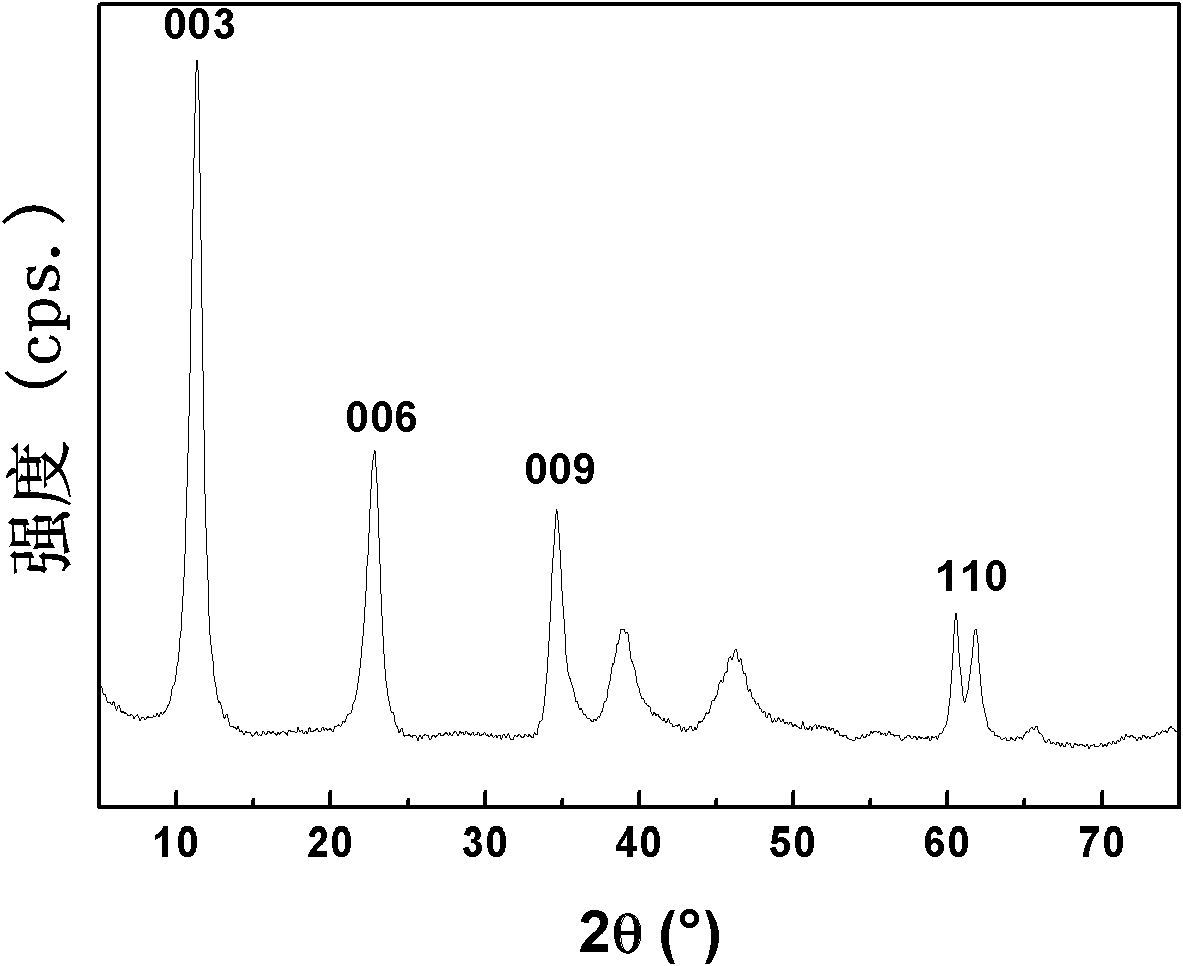

InactiveCN101913570AIncrease profitHigh crystallinityOxide/hydroxide preparationTungsten compoundsIon exchangeStructural formula

The invention discloses pillared hydrotalcite and a preparation method thereof, relates to hydrotalcite and a preparation method thereof, and solves the problems of easy agglomeration and long preparation time of the conventional pillared hydrotalcite. The structural formula of the pillared hydrotalcite is [M2+1-xM3+x(OH)2]x+[An-]x / n.zH2O, wherein M2+ and M3+ are laminar main body ions, An- is an interlayer ion, x is more than or equal to 0.20 and less than or equal to 0.34, and z is the number of crystal water. The method comprises the following steps of: dripping aqueous solution of mixed salt containing M2+ and M3+ and aqueous solution of alkali sodium carbonate into the stirring water, and obtaining a bimetallic composite oxide by microwave crystallization and sintering; and preparing reduction solution from the bimetallic composite oxide, sodium hydroxide and soluble salt of the interlayer ion An-, and performing microwave crystallization and sintering on the reduction solution to obtain the pillared hydrotalcite. The pillared hydrotalcite of the invention is difficult to agglomerate, the exchange time of the interlayer negative ions is only 10 to 20 minutes, and the pillared hydrotalcite can be used in the macromolecular flame-retardant field.

Owner:NORTHEAST FORESTRY UNIVERSITY

Phase change heat storage device based on gradient metal foam

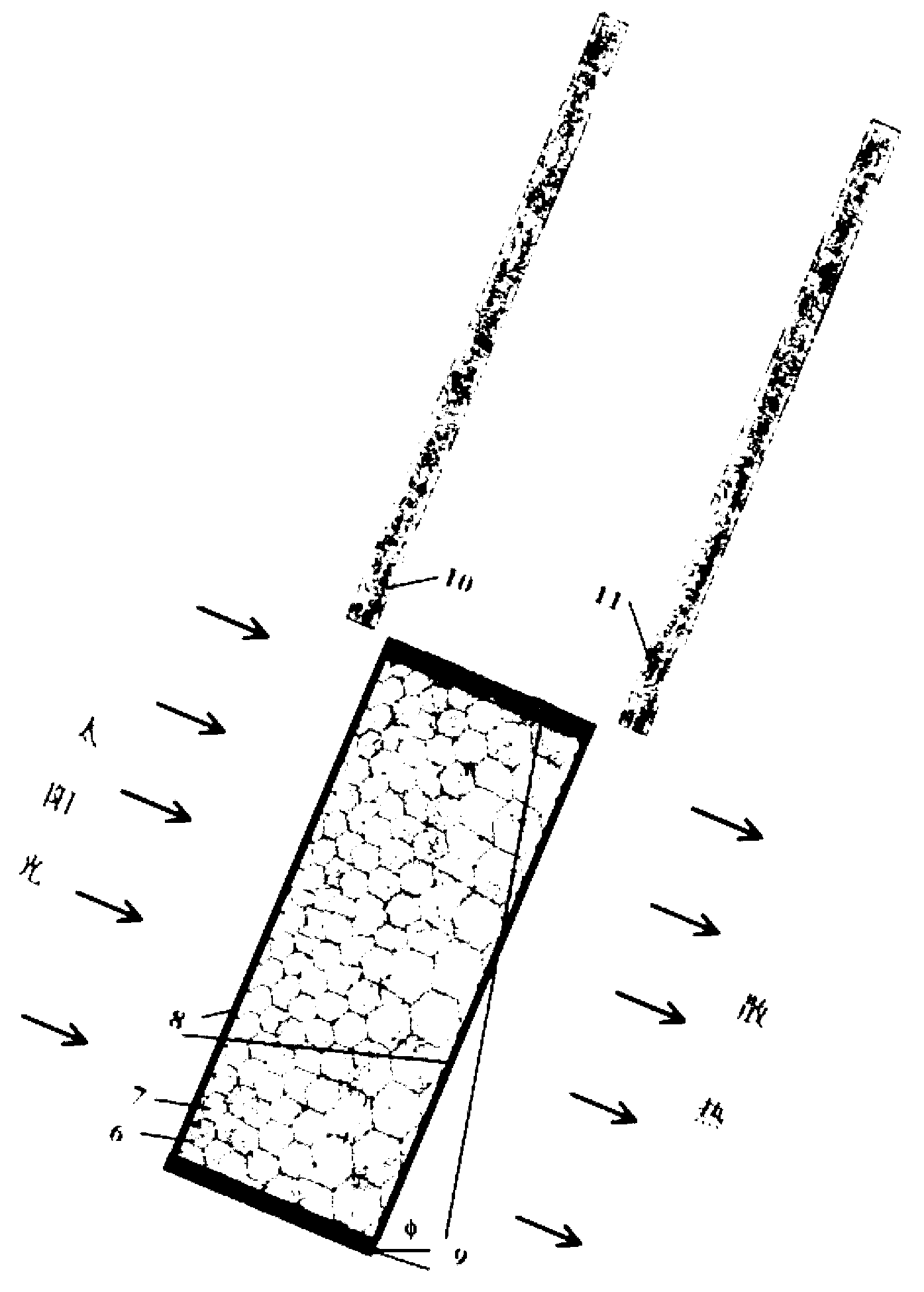

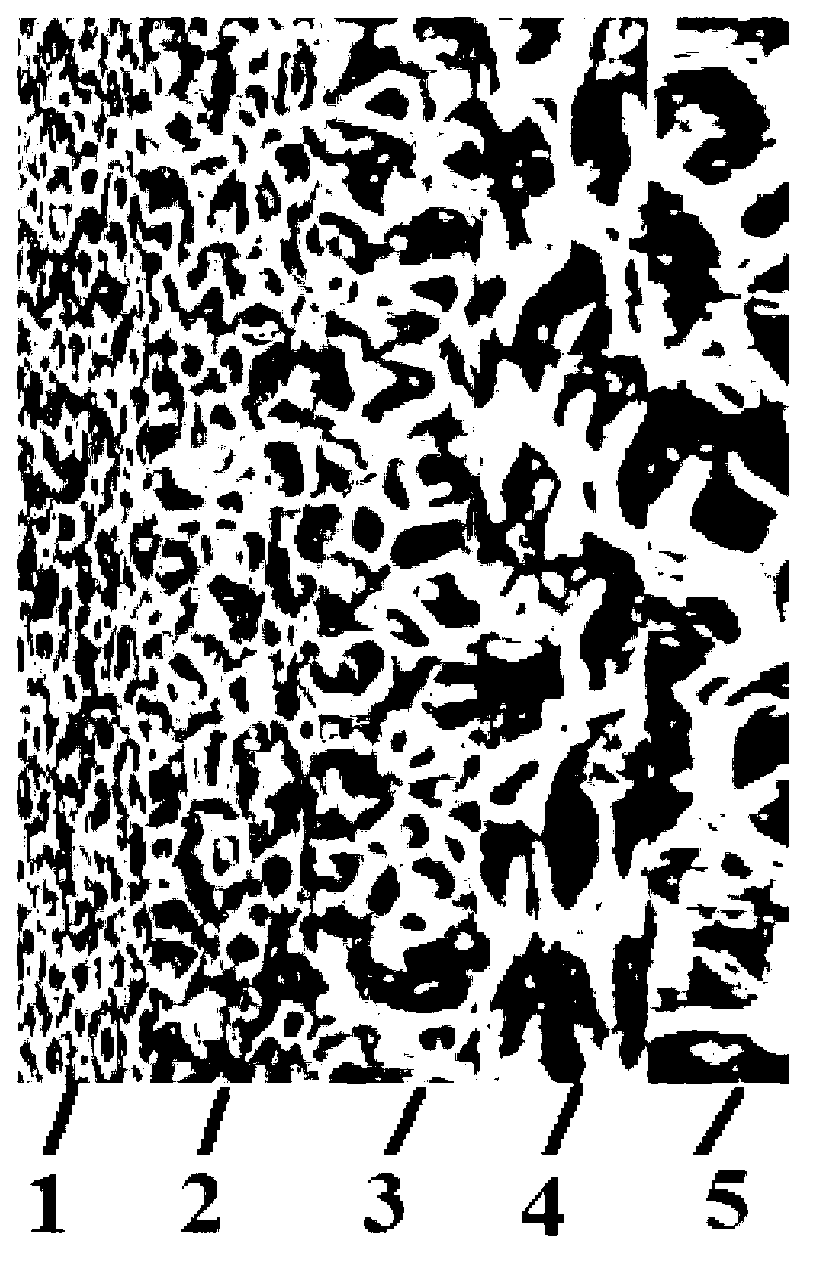

InactiveCN103234377AImprove heat storage capacityIncrease the heat transfer specific surface areaHeat storage plantsHeat exchange apparatusMaterial consumptionRelease time

A phase change heat storage device based on gradient metal foam is used for building insulation and utilizes the technical field of the rigid heat transfer bodies. The phase change heat storage device based on the gradient metal foam comprises two insulation plates, two heat exchange wall surfaces, two adiabatic wall surfaces, gradient metal foam with the gradually-changed denseness of inner through holes and a phase change portion prepared of phase change materials. The gradient metal foam is sintered between the two heat exchange wall surfaces, the denseness of the gradient metal foam gradually decreases from left to right in the vertical direction of the heat exchange wall surfaces, the left side portion faces the outdoor, the right side portion faced the indoor, the upper side portion and the lower side portion are respectively provided with an adiabatic wall surface. The phase change portion is filled in the gradient metal foam. Two insulation plates are arranged on the outside of the two heat exchange wall surfaces respectively. According to the phase change heat storage device based on the gradient metal foam, the heat storage and release time can be controlled by adjusting gradient feature parameters, the phase change heat exchange performance can be enhanced through the gradient metal foam, and the problems of poor heat exchange efficiency, great material consumption, large size and the like in existing heat exchange time are solved.

Owner:SHANGHAI JIAO TONG UNIV

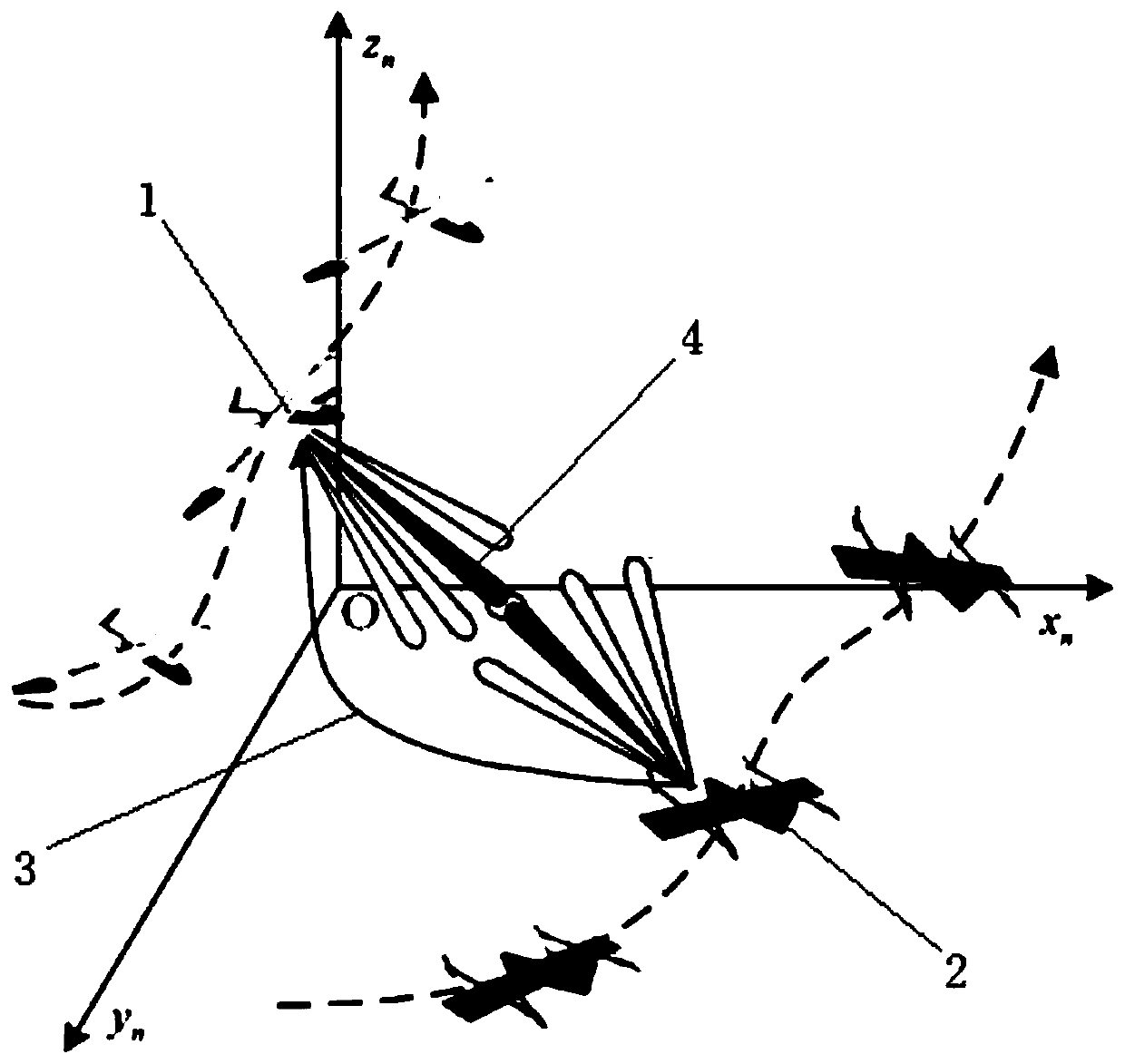

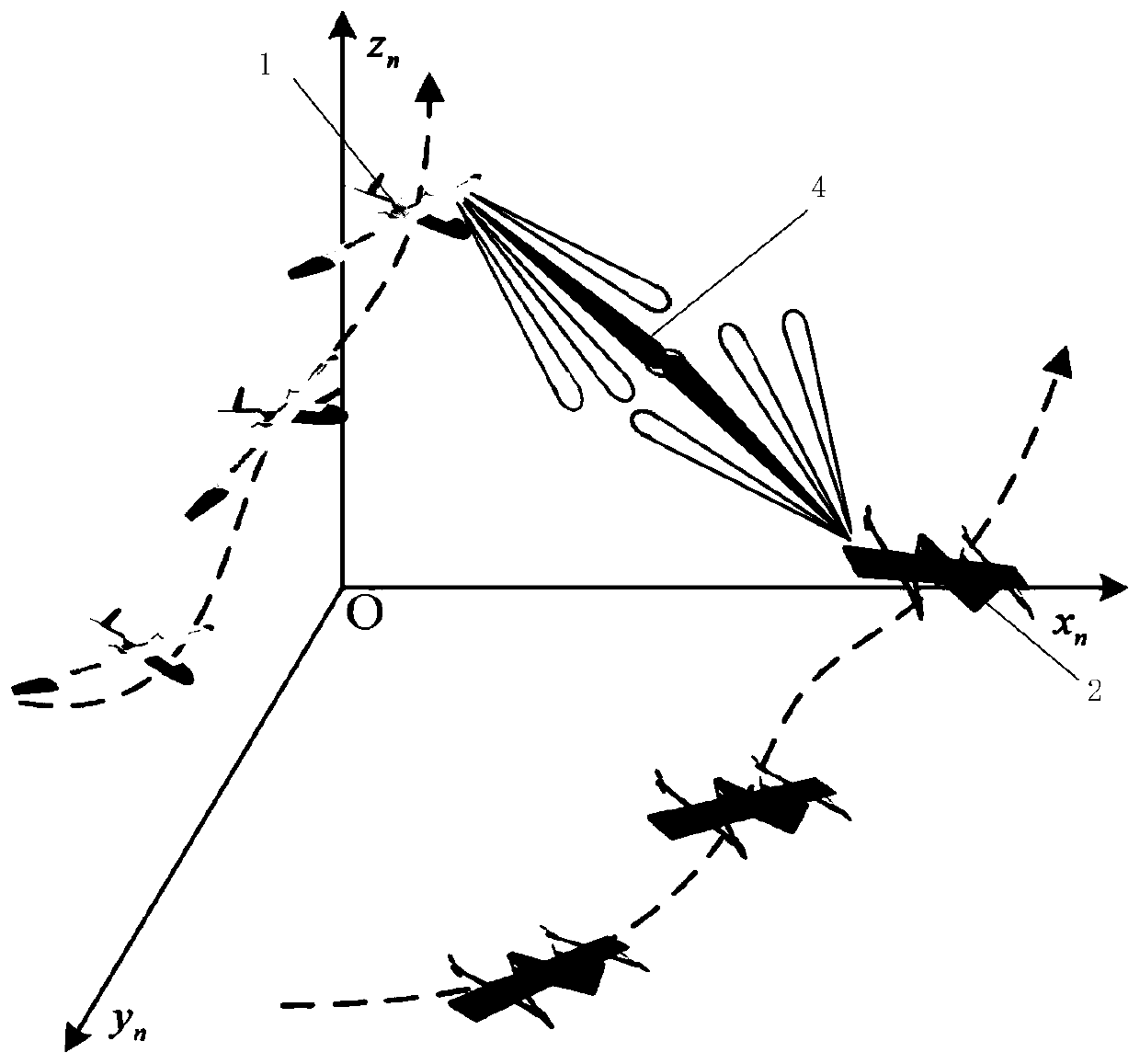

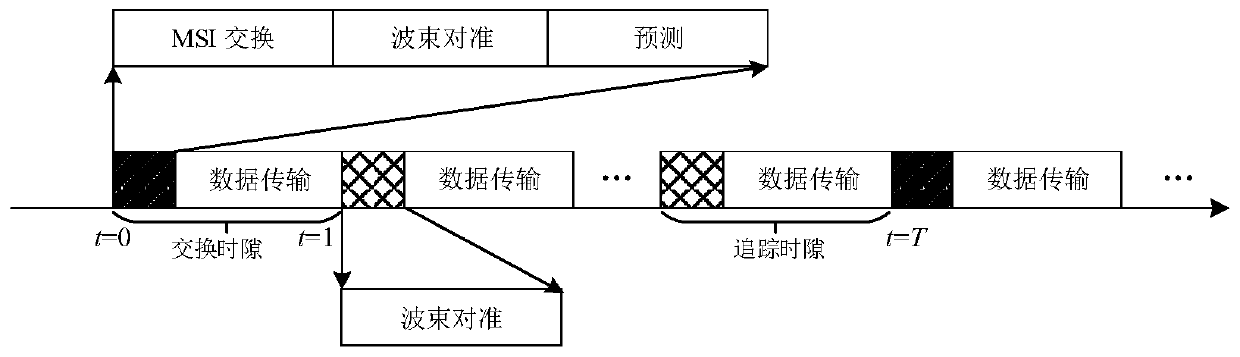

An unmanned aerial vehicle millimeter wave communication beam tracking method

ActiveCN109743093AImprove spectral efficiencyReduce delay errorSpatial transmit diversityUncrewed vehicleEngineering

The invention discloses an unmanned aerial vehicle millimeter wave communication beam tracking method. A time slot structure of unmanned aerial vehicle millimeter wave communication is designed into an exchange time slot and T tracking time slots, and the process in the exchange time slot comprises receiving MSI feedback; Calculating an actual beamforming vector according to the actual position and attitude information of the receiving-end unmanned aerial vehicle in MSI feedback, and predicting the position and attitude information of the receiving-end unmanned aerial vehicle in T tracking time slots in the future; Transmitting information through the actual beamforming vector, Wherein the process in the tracking time slot comprises the steps of calculating a predicted beam forming vectoraccording to a predicted position and attitude information; And transmitting information through the prediction beam forming vector. The position and the posture of the unmanned aerial vehicle are effectively tracked, the millimeter wave communication spectrum efficiency of the unmanned aerial vehicle can be improved under the condition that the unmanned aerial vehicle rapidly moves, channel stateinformation feedback of pilot frequency and a receiving end is not needed, and the time delay error difference between the unmanned aerial vehicle and the real motion state can be reduced.

Owner:BEIJING UNIV OF POSTS & TELECOMM

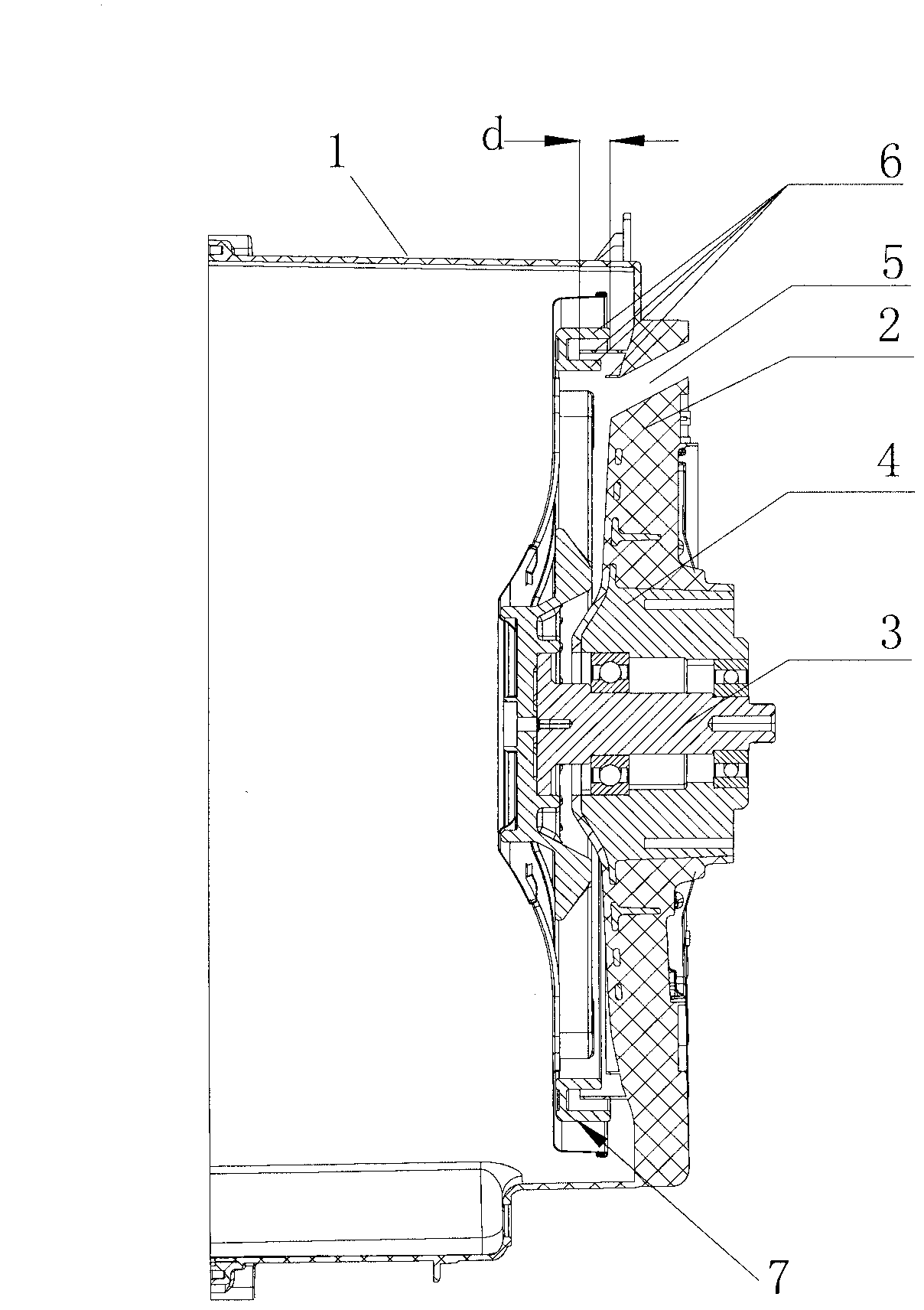

An inner and outer drum structure of a washing machine with drying function

ActiveCN102277708AExtended routeReduce lossOther washing machinesTextiles and paperEngineeringHeat losses

Owner:FOSHAN HAIER DRUM WASHING MACHINE

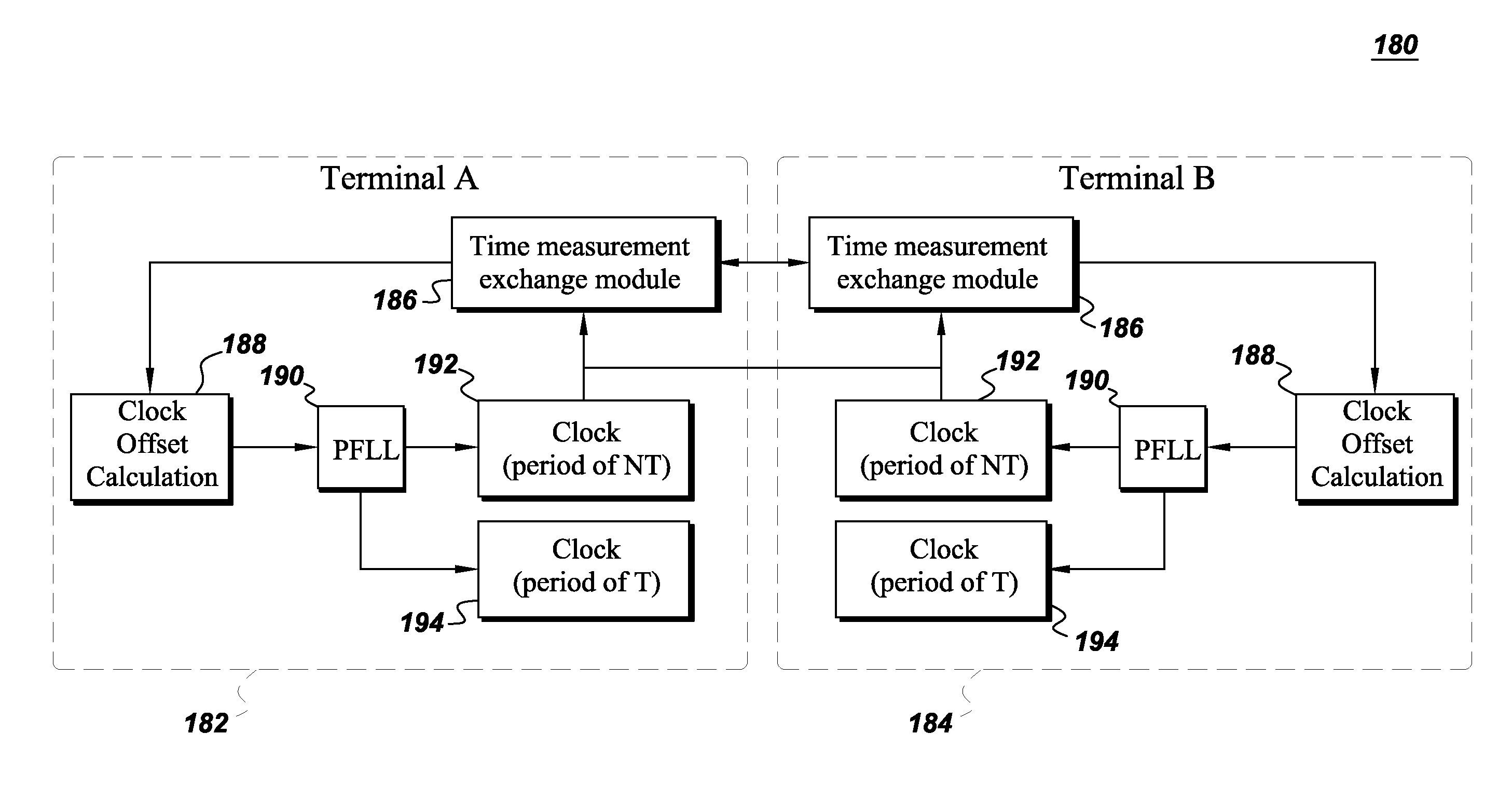

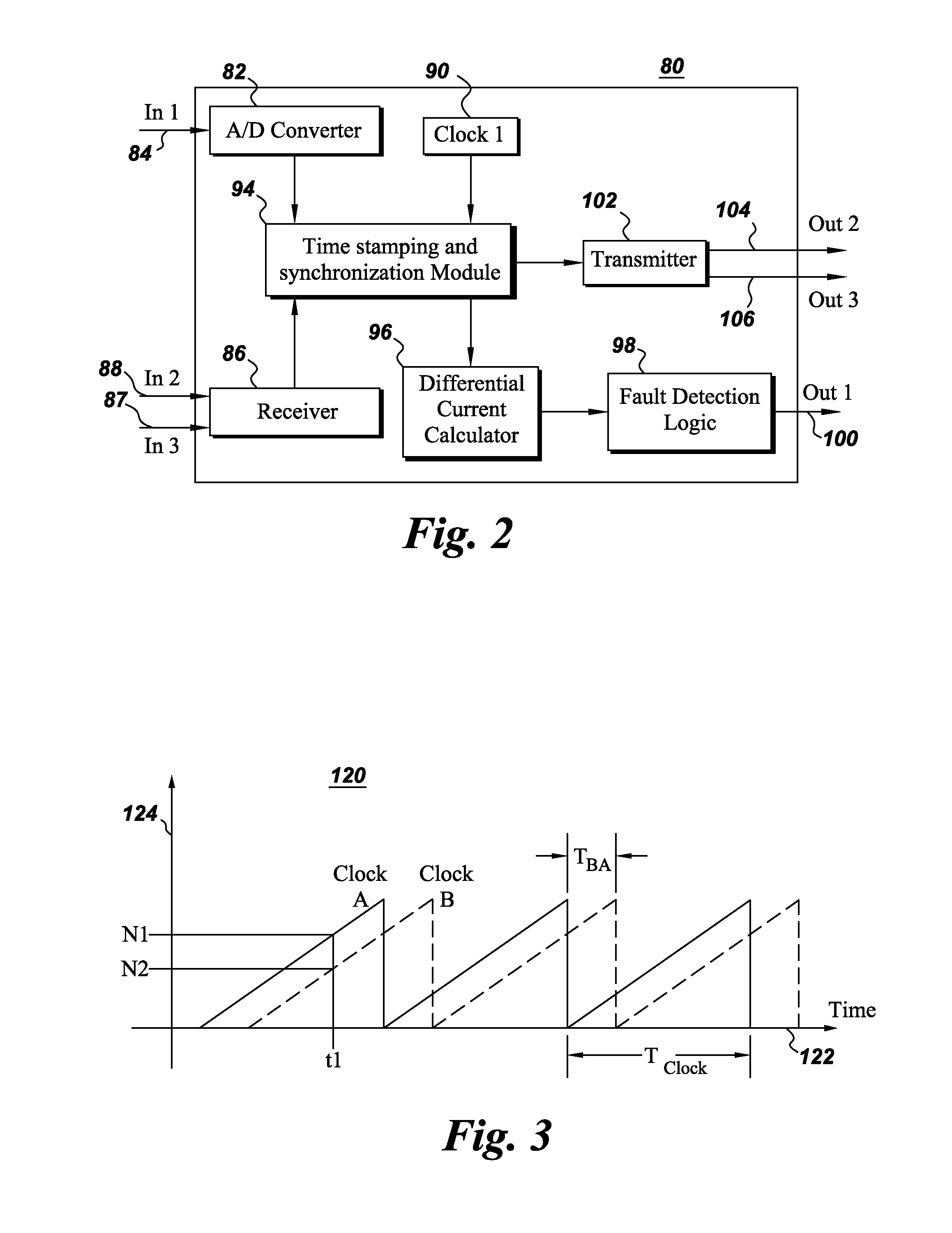

Current differential protection

ActiveUS20140118000A1Emergency protective arrangement detailsEmergency protective arrangements for automatic disconnectionCurrent sensorEngineering

A current differential protection system for a multi-terminal power line includes a current sensor for sensing a current at a local terminal, a controller for time synchronizing the local terminal and remote terminals, and a fault detection module to detect a fault in the multi-terminal power line if a differential current exceeds a threshold value. The controller includes a time measurement exchange module for exchanging time stamp data with remote terminals, an upper range clock for exchanging time stamp data with remote terminals and a lower range clock for indexing the current at the local terminal. A first time period of the upper range clock is N times a second time period of the lower range clock where N is a number of multi-terminals. The controller includes a clock offset calculation module for determining an average time offset based on time stamp data from remote terminals and the local terminal.

Owner:GENERAL ELECTRIC CO

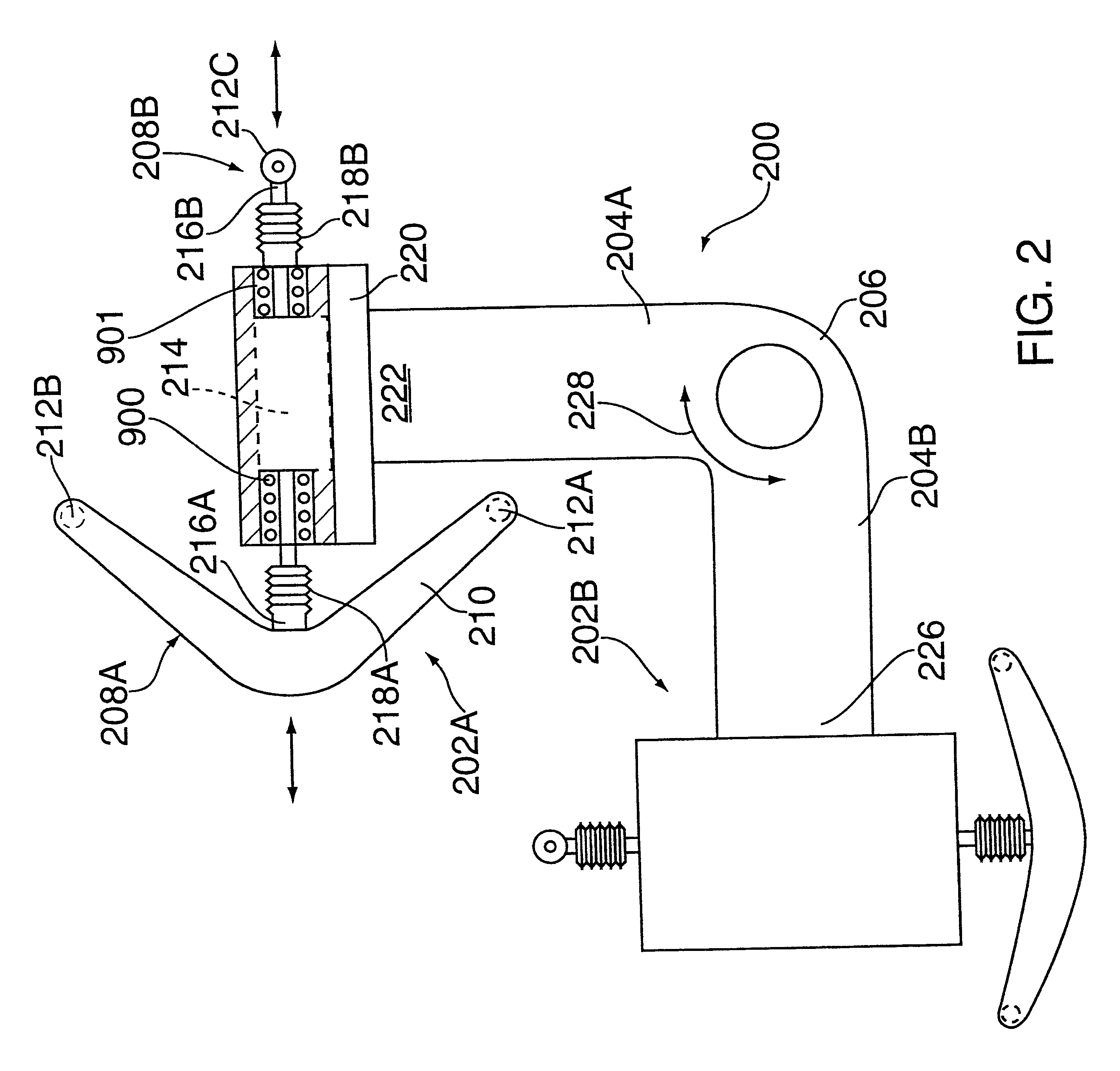

Wafer transfer station for a chemical mechanical polisher

InactiveUS6361648B1Precise positioningGripping headsSemiconductor/solid-state device manufacturingExchange timeControl theory

A transfer station and concomitant method for a chemical mechanical polishing system comprising a pair of buffer stations and a transport robot. The buffer stations and the ability to transport two wafers simultaneously with the transfer robot minimizes the exchange time for loading and unloading wafers into the chemical mechanical polishing system. The lowering of the exchange time improves the number of wafers processed per hour by the chemical mechanical polishing system. The transfer robot utilizes wafer edge grip features, adjustable wafer gripper force, minimum wafer contact points, fluid media for wafer present sensing, and mechanical interlocking mechanisms to protect both the wafer and the transfer station.

Owner:APPLIED MATERIALS INC

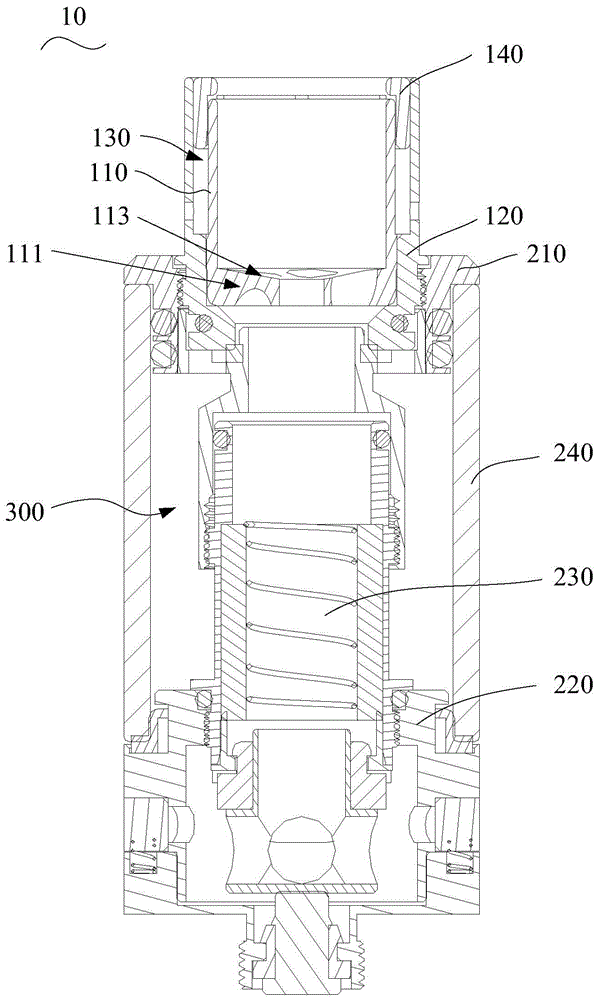

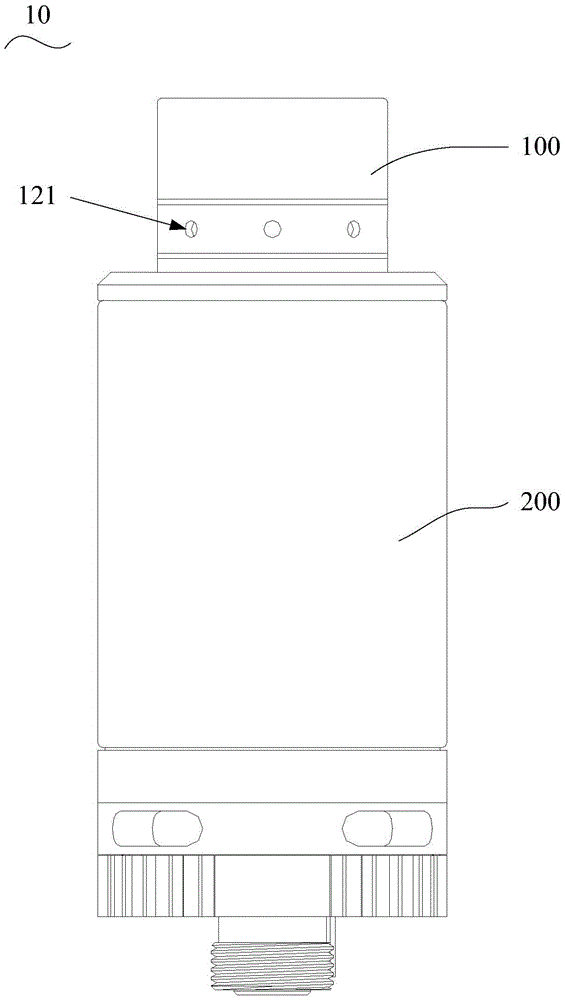

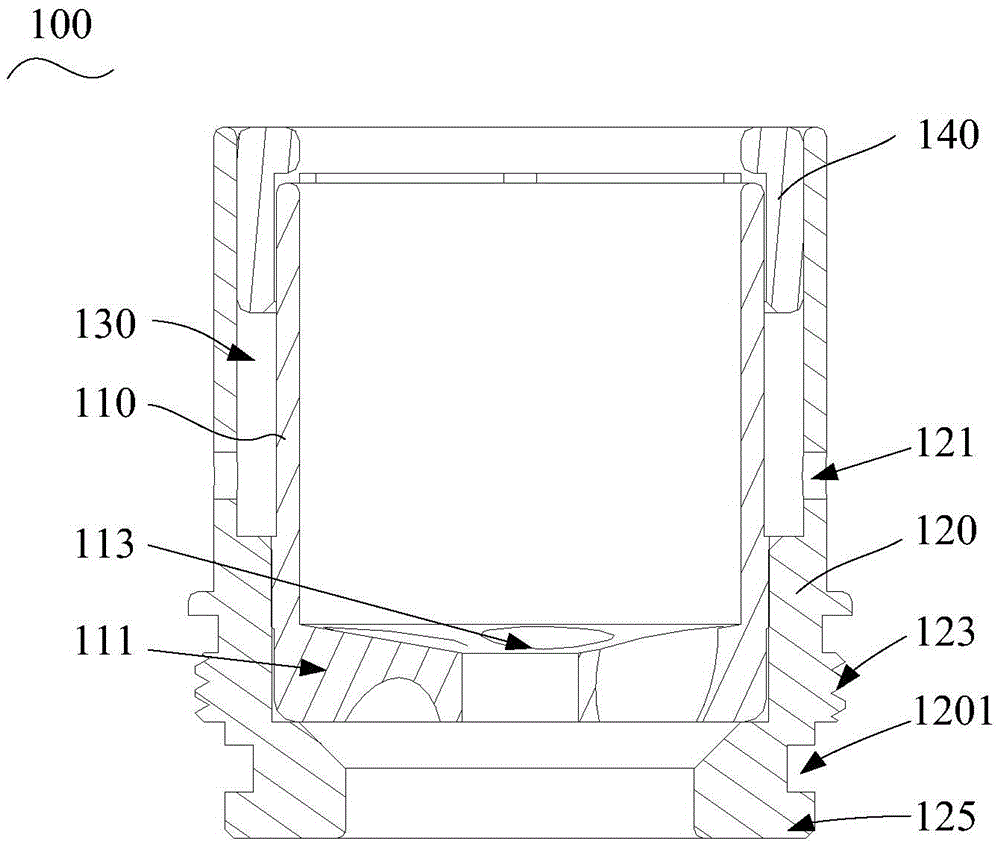

Electronic cigarette atomizer

The invention relates to an electronic cigarette atomizer, comprising a suction nozzle assembly and an atomization assembly connected with the suction nozzle assembly by airflow. The suction nozzle assembly comprises a suction nozzle base and a suction nozzle sleeve. The suction nozzle base is held in the suction nozzle sleeve. The bottom end of the suction nozzle base is provided with a slope-shaped venthole. The atomization assembly comprises an upper base, a lower base, an atomization core, and a sleeve housing. The sleeve housing is connected with the upper base and the lower base in an airtight manner. A tar storage cavity is formed among the upper base, the lower base, the atomization core, and the sleeve housing, and is used for storing tobacco tar. The atomization core is installed on the lower base. The atomization core is connected with the upper base by airflow. The suction nozzle sleeve is installed on the upper base. When smoke generated by the atomization core flows through the suction nozzle base, the smoke rotates and detours and rises in circles through the slope-shaped venthole, so that the smoke is mixed uniformly. The slope-shaped venthole can prolong heat exchange time of the smoke, the suction nozzle base, and the suction nozzle sleeve, so as to reduce temperature of the smoke, and reduce temperature of the electronic cigarette atomizer, and prolong service life.

Owner:SHENZHEN HANGSEN STAR TECH +1

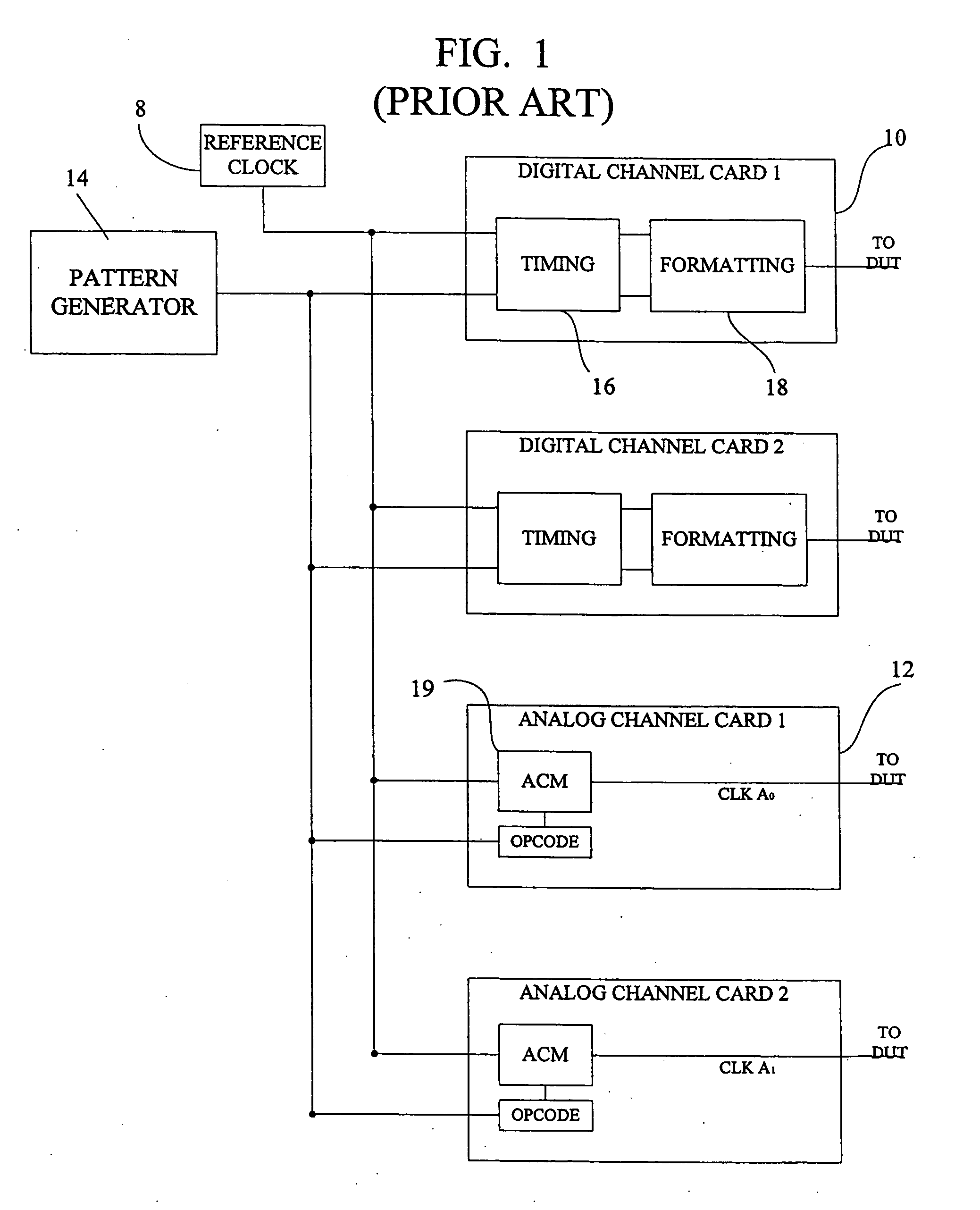

Instrument with interface for synchronization in automatic test equipment

ActiveUS20060123296A1Digital circuit testingSemiconductor/solid-state device testing/measurementAsynchronous communicationTelecommunications link

A test system with multiple instruments. Some instruments act as controller instruments and others act as controlled instruments. Each instrument includes a clock generator that synthesizes one or more local clocks from a reference clock. The reference clock is a relatively low frequency clock that can be inexpensively but accurately generated and distributed to all of the instruments. A communication link between instruments is provided. Timing circuits within instruments that are to exchange time information are synchronized to establish a common time reference. Thereafter, instruments communicate time dependent commands or status messages asynchronously over the communication link by appending to each message a time stamp reflecting a time expressed relative to the common time reference. The test system includes digital instruments that contain pattern generators that send command messages to analog instruments, which need not include pattern generators. The architecture simplifies design of analog instruments and avoids redesign of analog instrument as pattern rates of digital instruments change.

Owner:TERADYNE

Process for roasting waste sand into precoated sand material

InactiveCN102688982AHigh temperature heat exchange time is shortEvenly heatedMould handling/dressing devicesExchange timeMaterials science

The invention relates to a process for roasting waste sand into a precoated sand material. The process comprises the steps of shakeout, magnetic separation, crushing, screening, magnetic separation, roasting, dedusting, cooling and storage. When crushed and magnetically separated sand is roasted, the sand is required to be fed into a preheater for preheating, and then is fed into a roasting furnace for roasting. A passage for bearing the sand is stepped when the sand is in the preheater, the sand in the stepped passage is in a flocculated flow state, and when the sand is roasted, natural gas is jetted from three direction-adjustable jet tips in the roasting furnace to process the sand. Before being roasted, the sand is required to be preheated, so that the high-temperature heat exchange time of the sand in the roasting furnace is short, and the roasting efficiency and the roasting quality are improved. The sand is roasted at high temperature by the natural gas, so that the generation of an inert gas during the roasting is avoided. In addition, the three adjustable natural gas jet tips are adopted, so that the sand can be uniformly heated when roasted.

Owner:西峡县众德汽车部件有限公司

Lithography tool having a vacuum reticle library coupled to a vacuum chamber

InactiveUS20050057740A1Low costReduce exposureComputer controlSimulator controlAtmospheric pressureExchange time

A lithography tool includes an exposure chamber and a reticle handler that exchanges a reticle being exposed as prescribed by the user of the lithography tool. The reticle handler can include a vacuum-compatible robot, a vacuum chamber to house the robot, a load-lock to input reticles and transition them from atmospheric pressure to vacuum, a processing station for processing the reticle, and a reticle library for storing at least one extra reticle so that it is quickly available for exchange during an exposure process. The robot can have a two or more handed gripper to simultaneously hold multiple reticles. This allows a first reticle to be removed from the reticle stage with a first hand and a second reticle to be loaded onto the reticle stage with a second hand, and so on, which minimizes exchange time.

Owner:ASMI HLDG

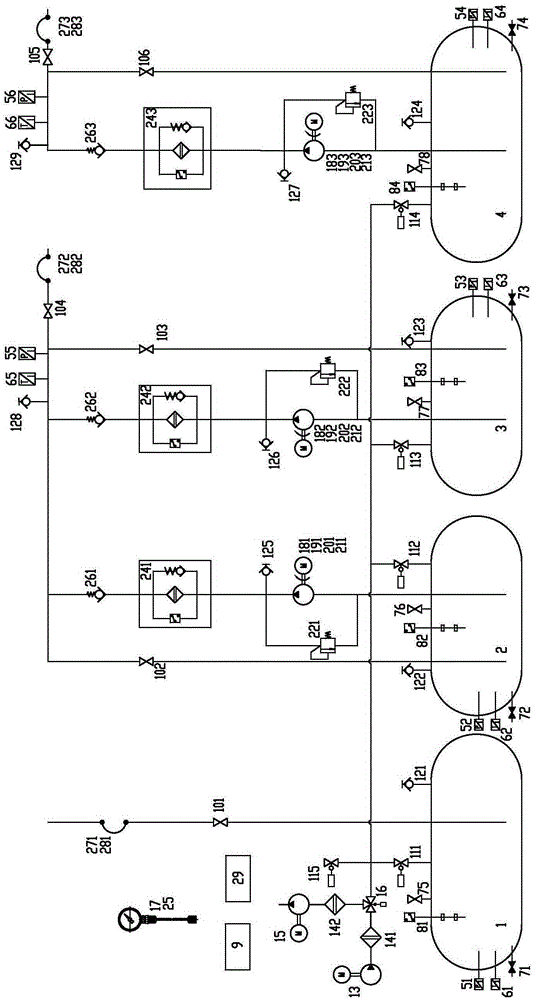

High-altitude oil exchange system for gearbox of wind driven generator and control method of high-altitude oil exchange system

ActiveCN105299202AGuaranteed cleanlinessImprove oil change efficiencyGear lubrication/coolingMachines/enginesWind drivenAutomatic control

The invention discloses a high-altitude oil exchange system for a gearbox of a wind driven generator and a control method of the high-altitude oil exchange system. The system comprises a waste oil discharging module, an oil flushing module, an oil cleaning module, a fresh oil module, an auxiliary power system and an electric control system. A four-step oil exchange manner is adopted, and the four steps include waste oil discharging, flushing, cleaning and fresh oil injecting, so that the cleanliness of an oil product obtained after oil exchange of the gearbox is thoroughly ensured, and a correct oil exchange manner is provided for the oil exchange work of the fan gearbox. The auxiliary power system is adopted so that pressurizing or vacuumizing can be conducted on an oil tank according to different working conditions, auxiliary oil exchange is conducted, and the oil exchange efficiency is improved, so that the oil exchange time is saved. A PLC processor is used for automatic control, multiple processes are controlled in a linkage manner, and one-key operation is adopted, so that the misoperation problem is eradicated; and meanwhile a set of completely-independent manual control device is arranged, so that manual control can be conducted in emergency, and the safety of the whole system is improved.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

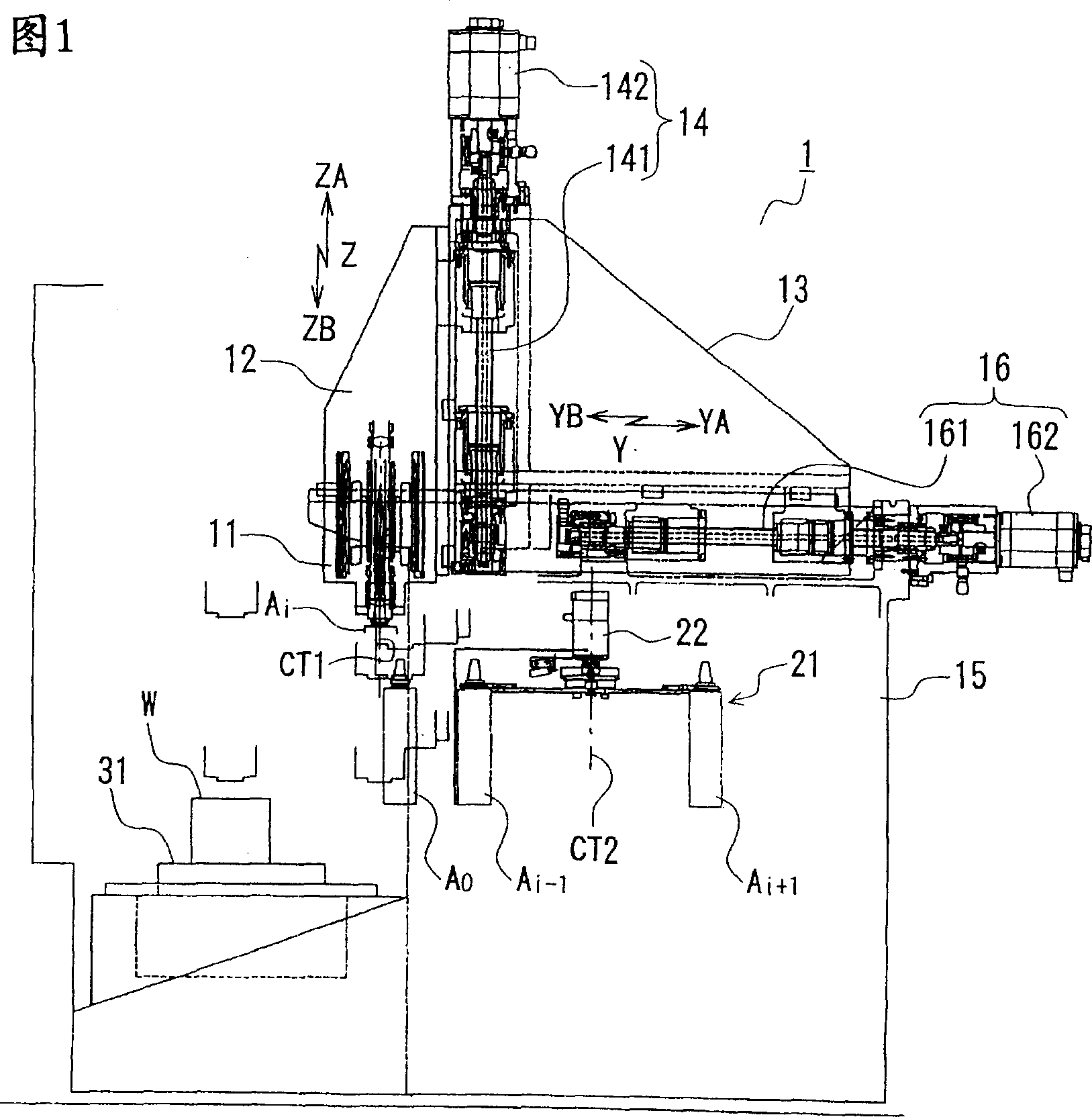

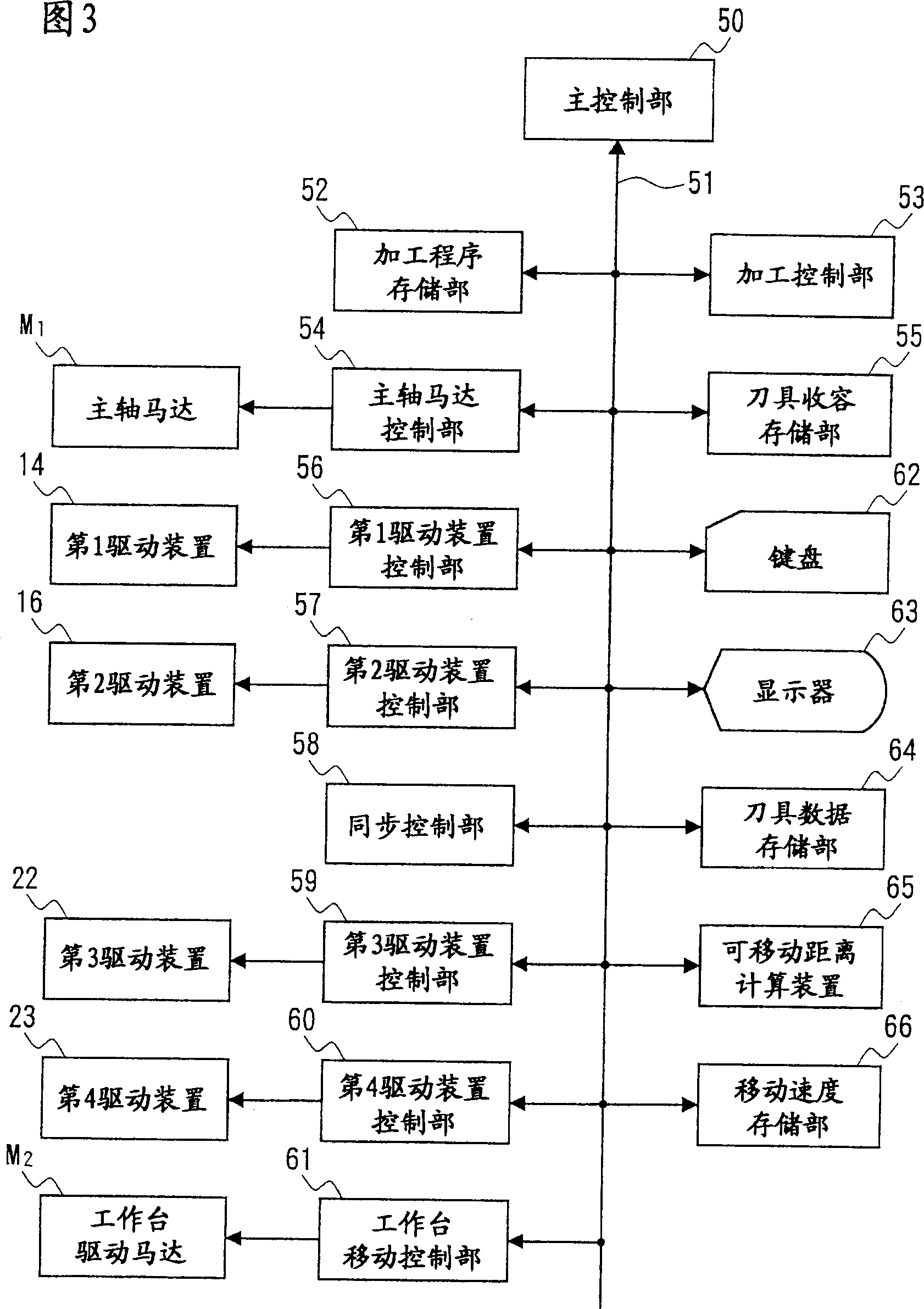

Machining centre

InactiveCN1597245AReduce replacement timeImprove productivityTool changing apparatusPositioning apparatusSynchronous controlExchange time

When exchanging a tool, a tool of a spindle is stored in an empty pocket of a tool magazine, and thereafter, upward movement of the spindle and rotation of the tool magazine are simultaneously executed. At this time, synchronous control is performed in order to prevent a collision between the spindle and the tool. When installing a next tool in the spindle, both downward movement of the spindle and rotation of the tool magazine are executed while synchronously controlling. The tool exchange time can be shortened with simultaneously executing the movements of the spindle and the tool magazine.

Owner:YAMAZAKI MAZAK KK

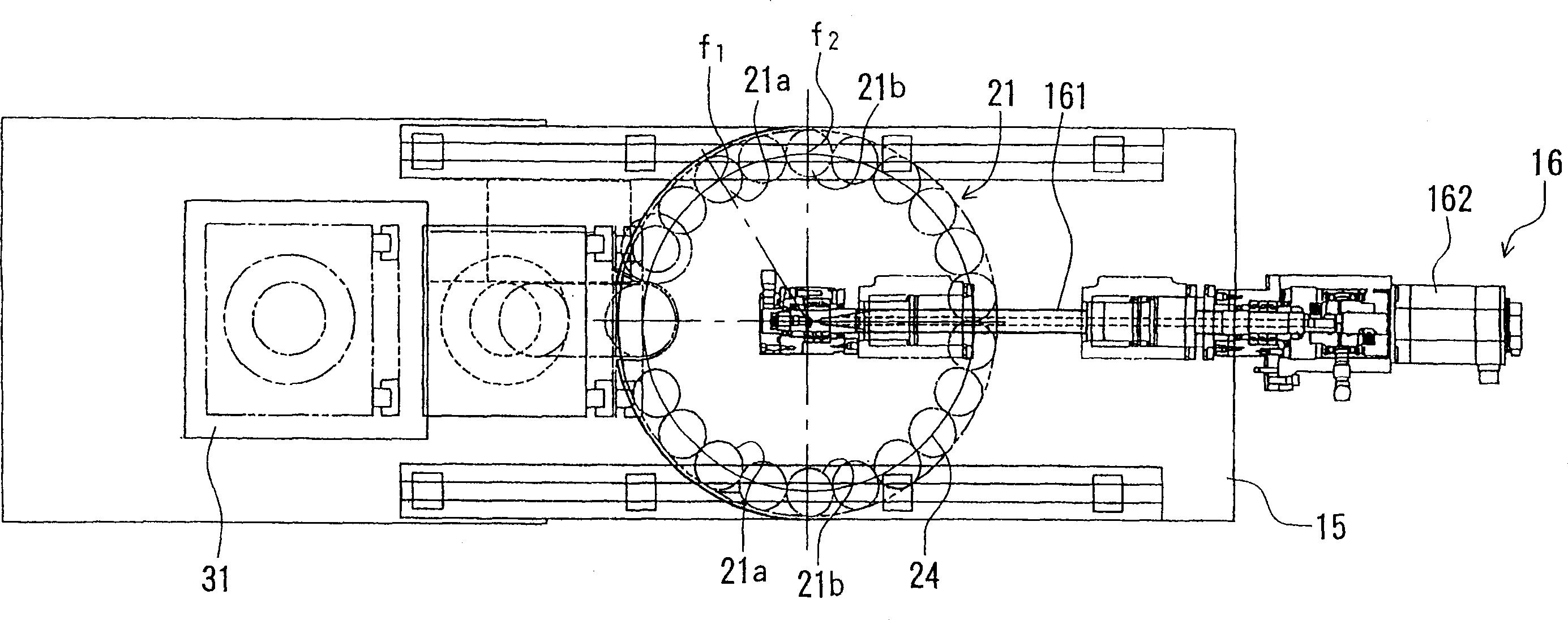

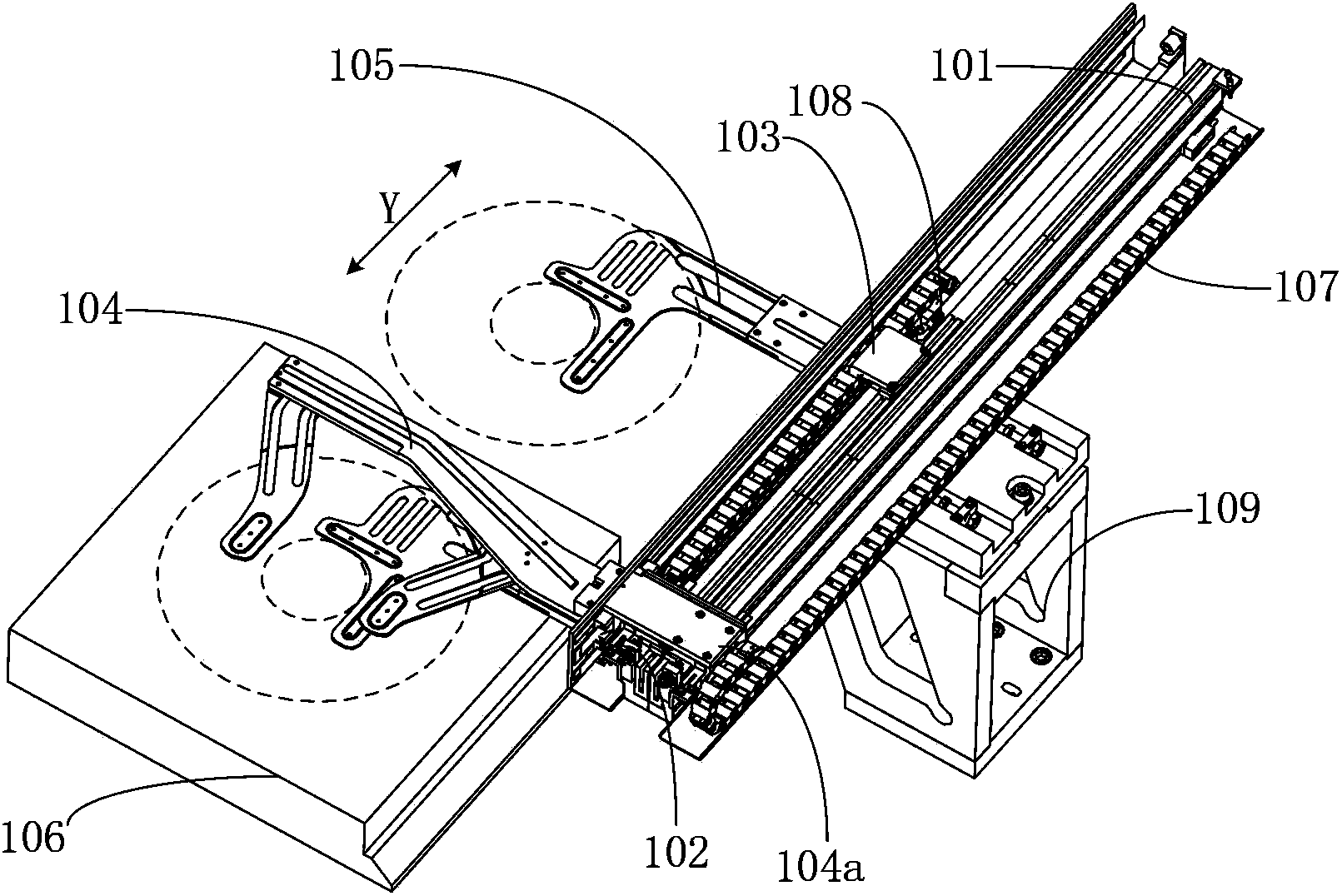

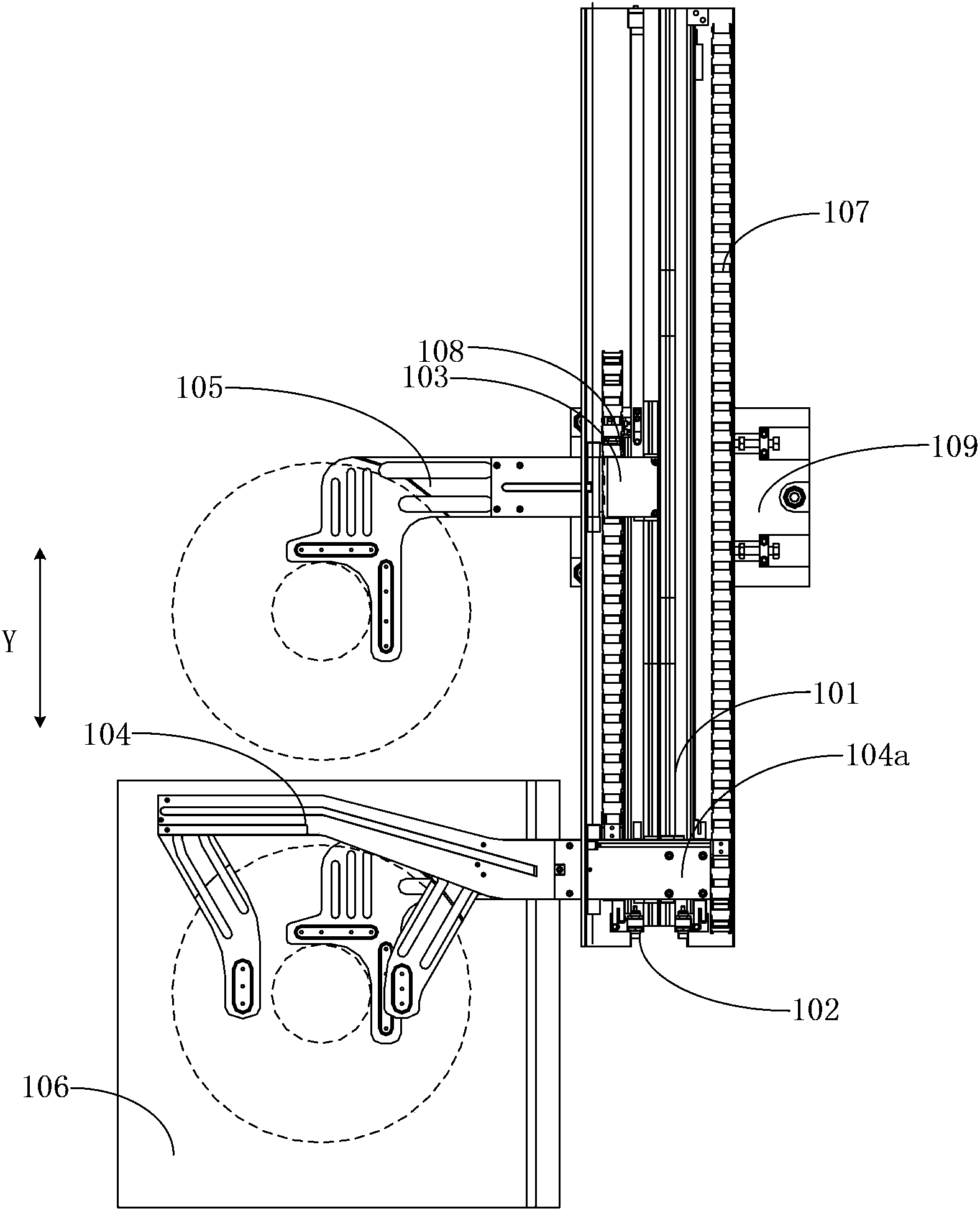

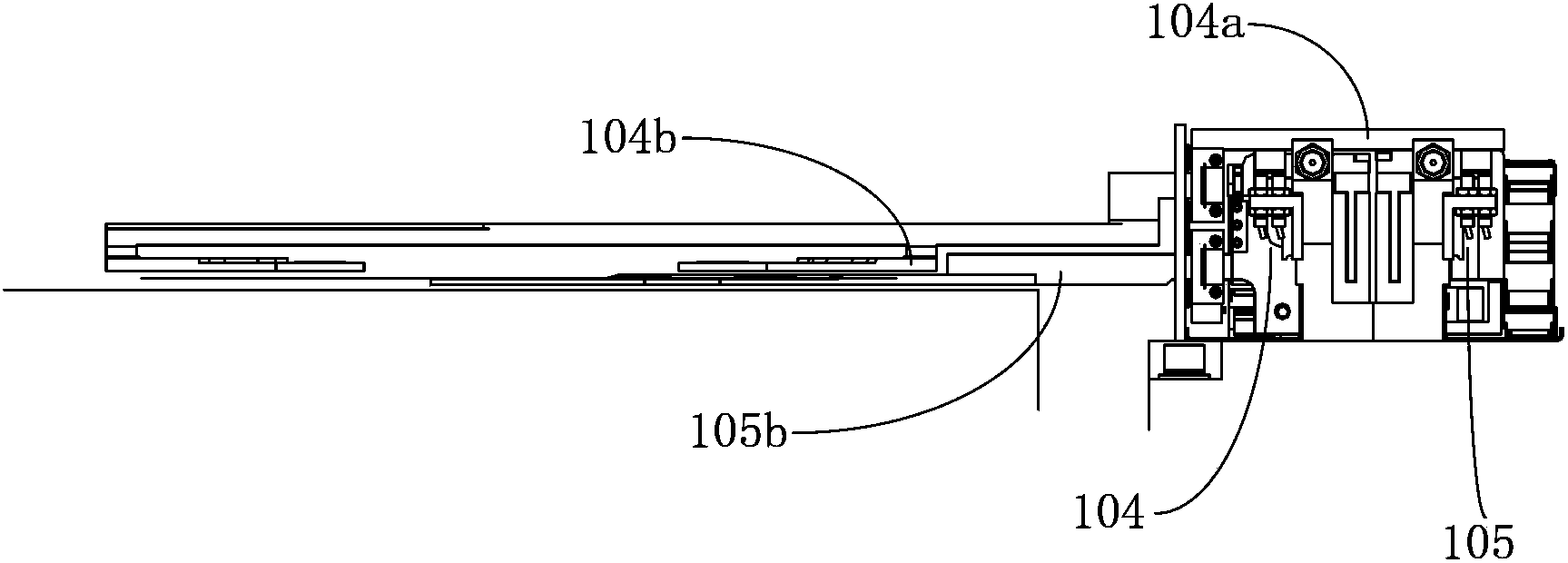

Silicon wafer linear exchange device and method

ActiveCN103424991AReduce movement handover timePhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistReciprocating motion

The invention relates to the field of lithography device, and especially relates to a silicon wafer linear exchange device and a method adopting the device. The method and device are used for delivering materials between a workbench and an external device. The device comprises a guide rail, a first slide block and a second slide block arranged on the guide rail, a first mechanical arm connected with the first slide block through a mechanical arm connection connector; and a second mechanical arm connected with the second slide block. The first and second slide blocks can perform staggered reciprocating movements along the guide rail. The first and second mechanical arms are positioned in two different movement planes which are parallel. The invention adopts an avoidance design, such that the first and second mechanical arms move in two parallel planes, such that the two sets of mechanical arms run from opposite directions. When the first mechanical arm exchange silicon wafer with the work bench, the second mechanical arm simultaneously carries out silicon wafer exchange with a manipulator. When the exchange is finished, the two sets of mechanical arms perform reverse movements simultaneously, and next exchange is carried out. Therefore, half of movement exchange time is reduced.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD +1

Instrument with interface for synchronization in automatic test equipment

ActiveUS20080077350A1Digital circuit testingSemiconductor/solid-state device testing/measurementAsynchronous communicationTelecommunications link

A test system with multiple instruments. Some instruments act as controller instruments and others act as controlled instruments. Each instrument includes a clock generator that synthesizes one or more local clocks from a reference clock. The reference clock is a relatively low frequency clock that can be inexpensively but accurately generated and distributed to all of the instruments. A communication link between instruments is provided. Timing circuits within instruments that are to exchange time information are synchronized to establish a common time reference. Thereafter, instruments communicate time dependent commands or status messages asynchronously over the communication link by appending to each message a time stamp reflecting a time expressed relative to the common time reference. The test system includes digital instruments that contain pattern generators that send command messages to analog instruments, which need not include pattern generators. The architecture simplifies design of analog instruments and avoids redesign of analog instrument as pattern rates of digital instruments change.

Owner:TERADYNE INC

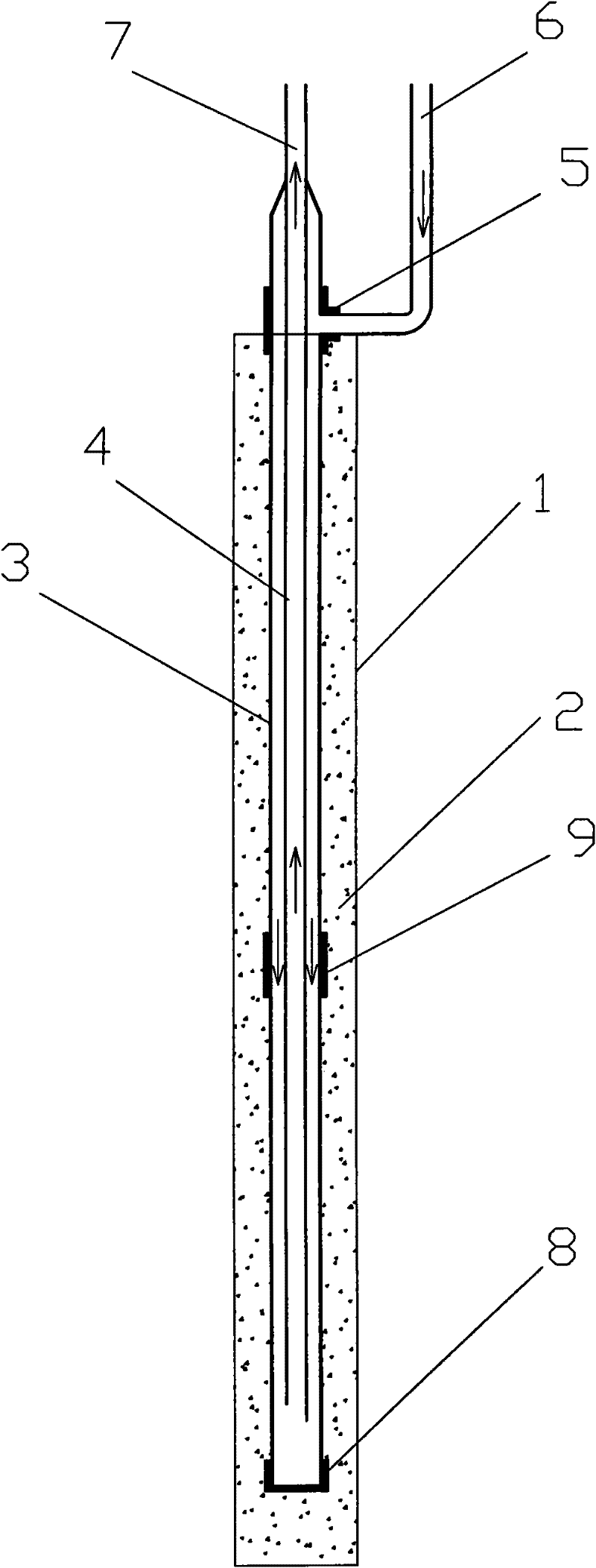

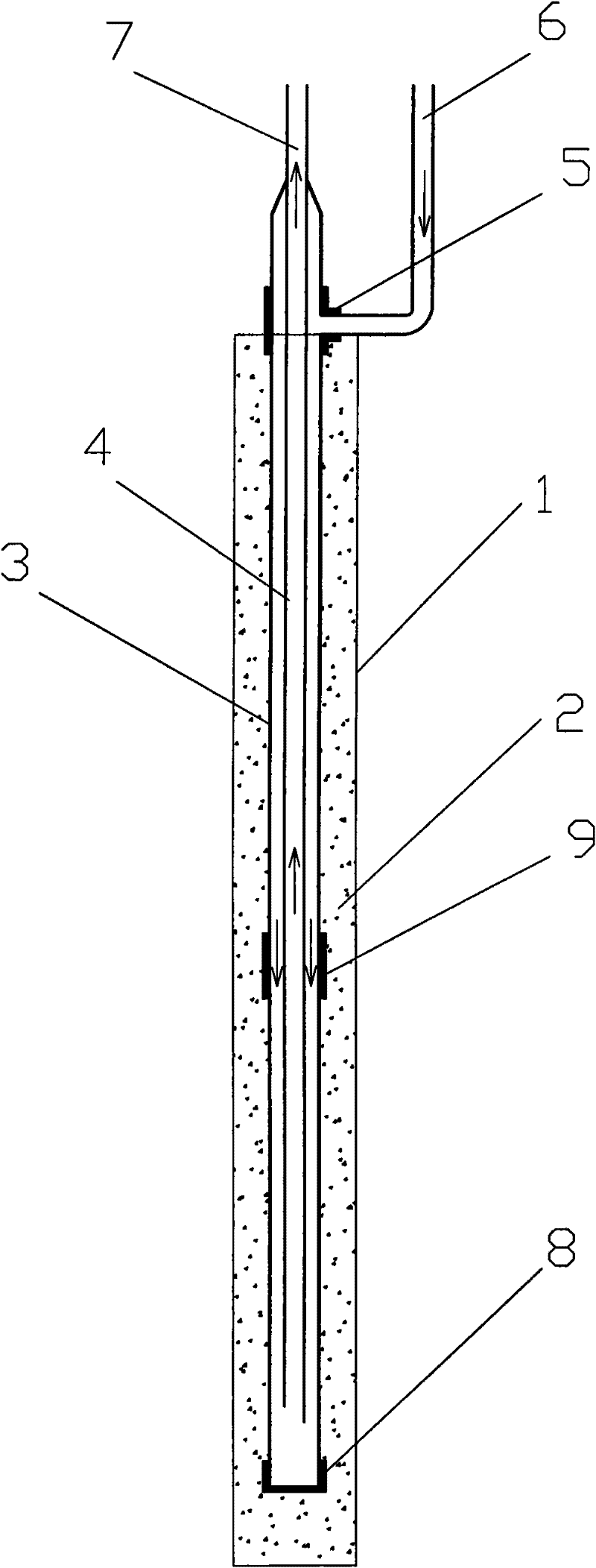

Tube heat exchange tube

InactiveCN102278901AExtend heat exchange timeReduce flow rateStationary tubular conduit assembliesAir conditioning systemsEngineeringExchange time

The invention discloses a casing type heat exchange tube, which comprises an inner tube and an outer tube, the inner tube is located in the outer tube, the upper end of the outer tube is connected with the medium inlet, the lower end of the outer tube is sealed, the upper end of the inner tube is connected with the medium The outlet is connected, and the lower end of the inner pipe is open. The sleeve-type heat exchange tube has the following advantages: 1) It increases the contact area with the surrounding filler or soil; 2) The flow velocity of the heat exchange medium in the outer tube is reduced, which increases the heat exchange time of the heat exchange medium; The heat exchange medium conducts heat exchange downwards by its own weight, and the flow distance of the heat exchange medium in the tube is shortened.

Owner:谢学军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com